Page 1

G77X/77X Series Installation

and Operation Instruction

1. INTRODUCTION

This manual provides instructions and procedures necessary

to install, operate and troubleshoot the Moog Inc.Series G771/G772/G773

(simplified as G77X) and 771/772/773 (simplified as 77X) Electrohydraulic

Industrial Servovalve.Troubleshooting instructions are outlined to permit the

identification of the specific component(s) suspected of failure.

2. OPERATION

The Moog G77X/77X Series Industrial Servovalve consists of a polarized

electrical torque motor and two stages of hydraulic power amplification.The

motor armature extends into the air gaps of the magnetic flux circuit and is

supported in this position by a flexure tube member.The flexure tube acts as a

seal between the electromagnetic and hydraulic sections of the valve.The two

motor coils surround the armature, one on each side of the flexure tube.

Electrohydraulic Servovalve

The flapper of the first stage hydraulic amplifier is rigidly attached to the

midpoint of the armature.The flapper extends through the flexure tube and

passes between two nozzles, creating two variable orifices between the nozzle

tips and the flapper.The pressure controlled by the flapper and nozzle variable

orifice is fed to the end areas of the second stage spool.

The second stage is a conventional four-way spool design in which output

flow from the valve, at a fixed valve pressure drop, is proportional to spool

displacement from the null position. A cantilever feedback spring is fixed to the

flapper and engages a slot at the center of the spool. Displacement of the spool

deflects the feedback spring which creates a force on the armature/flapper

assembly.

Input signal induces a magnetic charge in the armature and causes a

deflection of the armature and flapper.This assembly pivots about the flexure

tube and increases the size of one nozzle orifice and decreases the size of the

other.

This action creates a differential pressure from one end of the spool to

the other and results in spool displacement.The spool displacement transmits a

force to the feedback wire which opposes the original input signal torque. Spool

movement continues until the feedback wire force equals the input signal force.

CAUTION

DISASSEMBLY, MAINTENANCE, OR REPAIR OTHER THAN IN ACCORDANCE WITH THE

INSTRUCTIONS HEREIN OR OTHER SPECIFIC WRITTEN DIRECTIONS FROM MOOG WILL

INVALIDATE MOOG’S OBLIGATIONS UNDER ITS WARRANTY.

ELECTROHYDRAULIC VALVE CUT-AWAY

Magnet

(not shown)

Coil

Armature

Nozzle

Spool

Filter

PB T A

Figure 1 Moog Series G77X/77X

Upper Polepiece

Flexure Sleeve

Lower Polepiece

Flapper

Feedback Wire

Inlet Orifice

Page 2

3. HYDRAULIC SYSTEM PREPARATION

To prolong servovalve operational life and to reduce hydraulic system

maintenance, it is recommended that the hydraulic fluid be kept at a cleanliness

level of ISO DIS 4406 Code 16/13 maximum, 14/11 recommended.The most

effective filtration scheme incorporates the use of a kidney loop or “off-line”

filtration as one of the major filtration components.The filter for the “off-line”

filtration scheme should be a ß3≥75 filter for maximum effectiveness.

Upon system startup and prior to mounting the servovalve, the entire

hydraulic system should be purged of built-in contaminating particles by an

adequate flushing.The servovalve should be replaced by a flushing manifold and

the hydraulic circuit powered up under conditions of fluid temperature and fluid

velocity, reasonably simulating normal operating conditions. New system filters

are installed during the flushing process whenever the pressure drop across the

filter element becomes excessive.The flushing processes should turn over the

fluid in the reservoir between fifty to one hundred times.

To maintain a clean hydraulic system, the filters must be replaced on a

periodic basis. It is best to monitor the pressure drop across the filter assembly

and replace the filter element when the pressure drop becomes excessive. In

addition to other filters that are installed in the hydraulic circuit, it is

recommended that a large capacity, low pressure ß3≥75 filter be installed in the

return line. This filter will increase the interval between filter element

replacements and greatly reduce the system contamination level.

4. INSTALLATION

The Moog G77X/77X Series Industrial Servovalve may be mounted in any

position, provided the servovalve pressure, piston and return ports match

respective manifold ports.

The mounting pattern, port location and mounting bolts of the servovalve

are shown on Figure 4. Apply a light film of oil to the screw threads and torque

to 57 inch-pounds.

Wire mating connector for desired coil configuration and polarity.

Thread connector to valve.

Adjustment Procedure

Using a 3/8inch offset box wrench, loosen the self-locking fitting until the

null adjustor pin can be rotated. (This should usually be less than 1/2 turn).

DO NOT remove self-locking fitting. Insert a 3/32inch Allen wrench in null

adjustor pin. Use the 3/32Allen wrench to rotate the mechanical null adjustor

pin to obtain desired flow null.Torque self-locking fitting to 57 inch lbs.

Note:

Clockwise rotation of null adjustor pin produces open loop flow from port B to port A.

Table 1. Replacement Parts

Part Description Qty. Part Number

G77X/77X Series Filter

Replacement Kit 1 B52555RK054K001

Inlet Orifice End Cap O-Rings (1) 2 42082-001

Inlet Orifice O-Rings (1) 2 42082-189

End Cap - Bushing O-Rings (1) 2 42082-042

Filter Tube (1) 1 C39486-005-060

End Cap - O-Rings (1) 2 42082-001

Base O-Rings

G771/771 4 42082-007

G772/772 4 42082-013

G773/773 4 42082-022

(1) Included in Filter Replacement Kit.

5. MECHANICAL NULL ADJUSTMENT

It is often desirable to adjust the flow null of a servovalve independent of

other system parameters.The “mechanical null adjustment” on the Moog

G77X/77X Series servovalve allows at least ±20% adjustment of flow null. The

“mechanical null adjustor” is an eccentric bushing retainer pin located above the

port designation on the valve body (see Figure 2) which, when rotated, provides

control of the bushing position. Mechanical feedback elements position the

spool relative to the valve body for a given input signal.Therefore, a movement

of the bushing relative to the body changes the flow null.

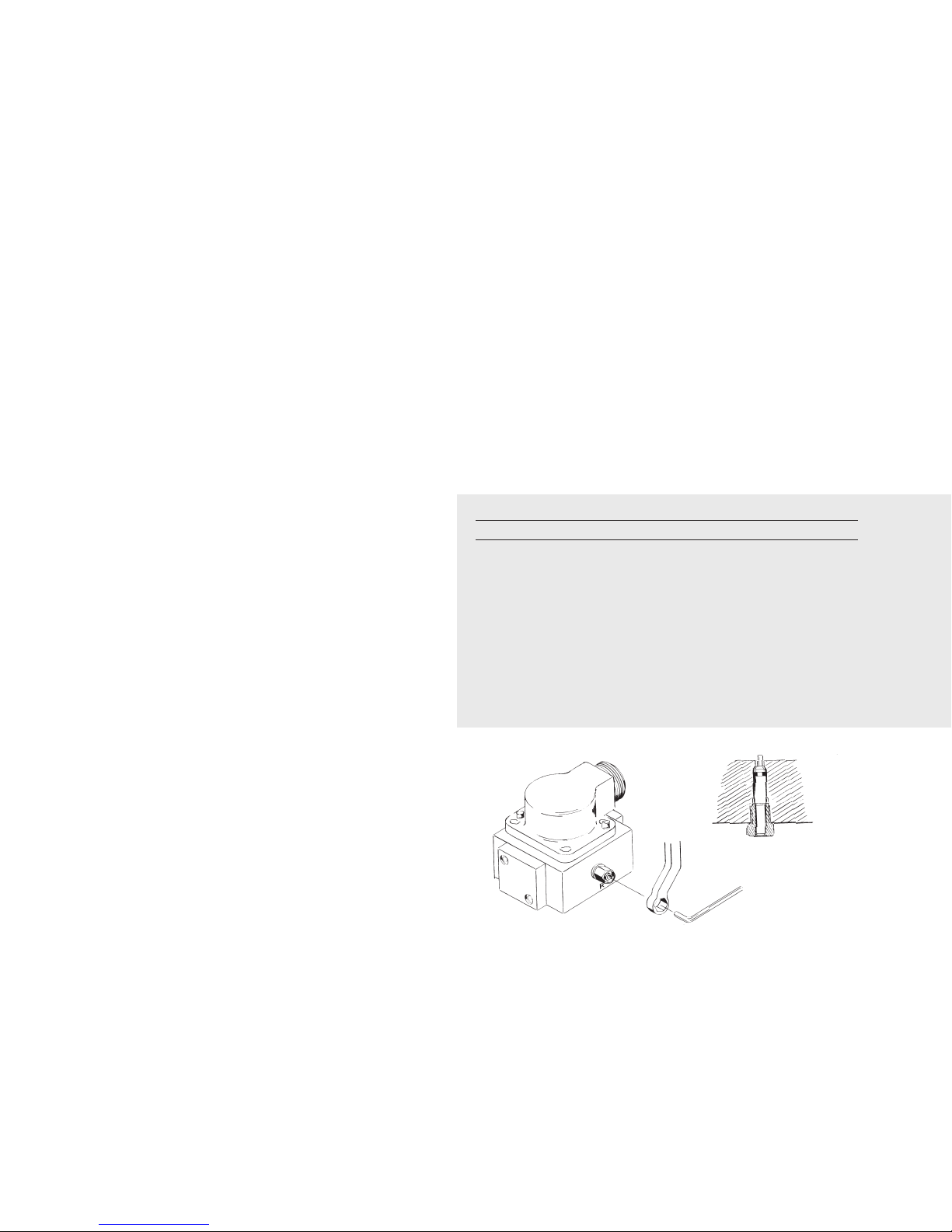

Figure 2

Mechanical Null Adjustment

6. GENERAL SERVICING RECOMMENDATIONS

a. Disconnect electrical lead to servovalve.

b. Relieve hydraulic system of residual pressure.

c. Remove servovalve.

Page 3

7.TROUBLESHOOTING CHART

The following troubleshooting chart list potential troubles encountered,probable causes, and remedies.

Potential Trouble

Servovalve does not follow input command

signal. (Actuator or components are

stationary or creeping slowly.)

High threshold. (Jerky,possible oscillatory

or “hunting” motion in closed loop system.)

Poor response. (Servovalve output lags

electrical command signal).

High Null Bias. (High input current required

to maintain hydraulic cylinder or motor

stationary.)

Figure 3

Inlet Orifice O-Rings (two at each end cap)

Probable Cause

Plugged inlet filter element.

Plugged filter element.

Partially plugged filter element.

1. Incorrect null adjustment

2. Partially plugged filter element.

Filter

End cap

End Cap O-Rings

Remedy

Replace filter element.

Replace filter element.

Replace filter element and check for dirty

hydraulic fluid in system.

1. Readjust null

2. Replace filter element and check for dirty

hydraulic fluid in system.

Tools and Equipment

a. Blade screwdriver

16

b.3/

Allen wrench

c. No. 2-56 NC by 11/2inch screw

d. Torque wrenches

8. FILTER ASSEMBLY REPLACEMENT

a. Remove four socket head cap screws and lockwashers using a 3/16inch

Allen wrench. Remove end caps. (See Figure 3).

b. Remove O-Rings from end caps.

c. Remove inlet orifice assembly from both sides of body.

Note: 2-56 screw threads into the filter plug and inlet orifice assembly.

Remove filter.The inlet orifice assemblies are matched to each other and

are therefore interchangeable.

Note: These assemblies seat in body and cannot go through bore

during removal.

d. Remove O-Rings from inlet orifice assemblies.

e. Visually inspect orifice assemblies for damage or foreign material.

f. Discard O-Rings and filters.

g. Install O-Rings on inlet orifices.

h. Install filter and inlet orifice assembly in body.Inlet orifice assembly pilots

into filter. Install the other inlet orifice assembly into other end of filter.

Inlet orifice assemblies are interchangeable.

i. Install O-Rings on end caps.

j. Install end caps on body and install four socket head cap screws and

lockwashers.Torque the screws to 85 inch-pounds.

9. FUNCTIONAL CHECKOUT AND CENTERING

a. Install servovalve on hydraulic system or test fixture,but do not connect

electrical lead.

b. Apply required system pressure to servovalve and visually examine for evi-

dence of external leakage. If leakage is present and cannot be rectified by

replacing O-Rings, remove the discrepant component and return for

repair or replacement.

Note: If the system components are drifting or hardover, adjust

the mechanical null of the servovalve.

c. Connect electrical lead to servovalve and check phasing in accordance

with system requirements.

10.AUTHORIZED REPAIR FACILITIES

If servovalve continues to malfunction after all recommended corrective

action procedures are performed,defective valve should be returned to Moog

for repair. Moog does not authorize any facilities other than Moog or Moog

subsidiaries to repair its servovalves. It is recommended you contact Moog at

(716) 652-2000 to locate your closest Moog repair facility.Repair by an

independent (unauthorized) repair house will result in voiding the Moog

warranty and could lead to performance degradation or safety problems.

Page 4

P A B T G F1 F2 F3 F4

4.85 4.85 4.85 4.85 2.39 M5 M5 M5 M5

X 21.3 13.5 29.5 21.3 11.4 0 42.9 42.9 0

Y 9.1 17.0 17.0 24.9 4.3 0 0 34.0 34.0

P A B T G F1 F2 F3 F4

6.6 6.6 6.6 6.6 2.39 M5 M5 M5 M5

X 21.3 11.4 31.2 21.3 11.4 0 42.9 42.9 0

Y 7.2 17.0 17.0 27.0 4.3 0 0 34.0 34.0

P A B T G F1 F2 F3 F4

7.92 7.92 7.92 7.92 2.39 M6 M6 M6 M6

X 21.3 9.7 33.3 21.3 11.4 0 42.9 42.9 0

Y 5.1 17.0 17.0 29.0 4.3 0 0 34.0 34.0

G77X/77X SERIES INSTALLATION AND OPERATION INSTRUCTION

47.8

1.57

44.5

MAX

47.8

1.343

35.3

64.77

26.2

P

3.0

OR

[28.4]

1.75

1.275

.844

1.06

MAX

PIN C

1.00

2.12

2.18

2.81

17.04

.014

1.688

34.11

1.56

1.88

PIN D

1.88

.12

.007

(OPTION)

21.44

25.4

26.9

1.39

39.6

1.12 MAX

1.03

MTG HGT

PIN B

.671

53.8

55.4

71.4

PIN A

32.39

2.550

42.88

ELECTRICAL CONNECTOR

LOCATING PIN

Ø.062

EXTERNAL NULL ADJUST

3/32 IN. HEX SOCKET

4X Ø.221(5.61) THRU (G771 AND G772)

4X Ø.265(6.73) THRU (G773)

P A B T G F1 F2 F3 F4

Ø .191 Ø .191 Ø .191 Ø .191 Ø .094 .190-32 .190-32 .190-32 .190-32

X 0.84 0.53 1.16 0.84 0.45 0 1.69 1.69 0

Y 0.36 0.67 0.67 0.98 0.17 0 0 1.34 1.34

P A B T G F1 F2 F3 F4

Ø .260 Ø .260 Ø .260 Ø .260 Ø .094 .190-32 .190-32 .190-32 .190-32

X 0.84 0.45 1.23 0.84 0.45 0 1.69 1.69 0

Y 0.28 0.67 0.67 1.06 0.17 0 0 1.34 1.34

P A B T G F1 F2 F3 F4

Ø .312 Ø .312 Ø .312 Ø .312 Ø .094 .250-20 .250-20 .250-20 .250-20

X 0.84 0.38 1.31 0.84 0.45 0 1.69 1.69 0

Y 0.20 0.67 0.67 1.14 0.17 0 0 1.34 1.34

Y

X

T

BA

P

F2

F3

F4

F1

T

G

6

NOTES

1 Fluid:

Industrial type petroleum base hydraulic

fluid, maintained to ISO DIS 4406 Code

14/11 recommended.

2 Operating Temperature Range:

-20°F [-29°C] to +275°F [+135°C]

3 Valve Phasing:

Flow out port B results when Series

coils: B & C connected,A+, D-;

Parallel coils:A & C connected, B & D

connected; Single coil:A+, B-, or C+, D-.

4 Ports:

See table below left.

5 Surface:

Surface to which valve is mounted

requires 32[ ] finish, flat within 0.002

[0.05] TIR.

6 Null Adjust:

Flow out port B results with clockwise

rotation of null adjust screw (3/32 hex key).

Flow bias is continually varied for a given

port as the null adjust is rotated.

∆∆

G771/771 U.S. METRIC

G772/772 U.S. METRIC

G773/773 U.S. METRIC

Figure 4

4 Three standard designs are available.

Model Diameter Diameter Manifold O-Rings Mounting Bolt Size

Number in mm in mm Moog MS (socket head cap screws)

G771/771 .625 15.8 .191 4.85 -007 -010 .190-32 NF x 2.0 long

G772/772 .780 19.8 .260 6.60 -013 -012 .190-32 NF x 2.0 long

G773/773 .937 23.8 .312 7.93 -022 -013 .250-20 NF x 2.25 long

The products described herein are subject to change at any time without notice, including, but not limited to, product features, specifications, and designs.

Port Circle Port

TYPICAL WIRING SCHEMATIC

ABCD

3

Moog Inc., East Aurora, NY 14052-0018

Telephone:+1-716-652-2000

Fax: +1-716-687-7910

Toll Free:+1-800 -272-MOOG

www.moog.com/industrial

©2007 Moog Inc. All changes are reserved.

CDS6674 REV C 500-380 807

Loading...

Loading...