Page 1

1.INTRODUCTION

This manual provides instructions and procedures necessary to install,

operate and troubleshoot the Moog 641 Series Proportional Control Valve.

Troubleshooting instructions are outlined so that the specific component(s)

suspected of failure can be identified.

2. OPERATION

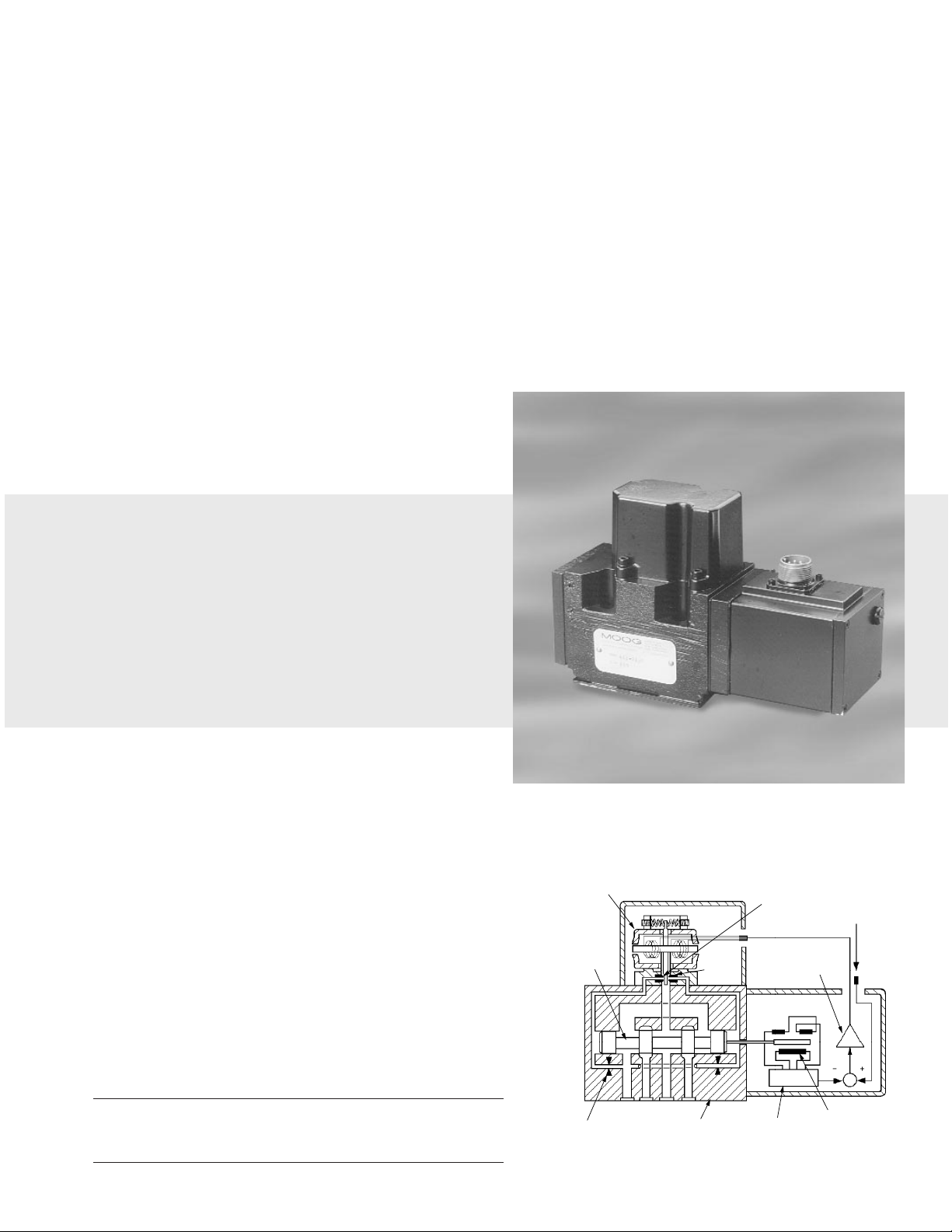

The Moog 641 Series proportional control valves are suitable for open

and closed loop position and velocity control systems where accelerations need

to be regulated.The 641 can be used like a directional solenoid valve or a

proportional valve while controlling ram or motor acceleration,deceleration

and velocity.

The 641 Series valves are two-stage devices consisting of a double nozzleflapper pilot stage and a sliding spool main stage.The position of the main stage

spool is measured by a non-contacting position transducer. On-board integrated

electronics provide closed-loop position control of the main stage spool.

The operation of the 641 Series valve is controlled by an electrical

command signal (VQS) provided to the integrated control electronics which

drives the pilot stage coils.The current sent from the electronics causes the

flapper to move toward one nozzle,diverting the pilot stage flow to one end of

the spool.The position transducer measures the position of the spool (VLI) and

produces a feedback voltage which is directed back to the control amplifier and

compared to the command voltage.The control amplifier then drives the pilot

stage until the command voltage and feedback voltage are equal,centering the

flapper between the nozzles which holds the spool at a position proportional to

the command signal.

m

641 Series Installation and

Operation Instruction

Proportional Control Valve

ELECTROHYDRA ULIC VAL VE CUT -A WA Y

CAUTION

DISASSEMBLY, MAINTENANCE, OR REPAIR OTHER THAN IN ACCORDANCE WITH THE

INSTRUCTIONS HEREIN OR OTHER SPECIFIC WRITTEN DIRECTIONS FROM MOOG WILL

INVALIDATE MOOG’S OBLIGATIONS UNDER ITS WARRANTY.

Figure 1 Moog Series 641

SINGLE STAGE

PILOT VALVE

SPOOL

PATB

INLET ORIFICE

NOZZLE

MAIN STAGE

FLAPPER

OSCILLATORDEMODULATOR

POSITION

CONTROL

AMPLIFIER

V

QS

V

LI

SPOOL POSITION

TRANSDUCER

(LVDT)

Page 2

3.HYDRAULIC SYSTEM PREPARATION

To prolong proportional control valve operational life and to reduce

hydraulic system maintenance,it is recommended that the hydraulic fluid be

kept at a cleanliness level of ISO Code 14/11 (NAS Class 5) or better.The most

effective filtration scheme incorporates the use of a kidney loop or “off-line”

filtration as one of the major filtration components. The filter for the “off-line”

filtration scheme should be a ß3≥75 filter for maximum effectiveness.

Upon system start-up,and prior to mounting the valve, the entire

hydraulic system should be purged of built-in contaminating particles by an

adequate flushing.The valve should be replaced by a flushing plate and the

hydraulic circuit powered up under conditions of fluid temperature and fluid

velocity reasonably simulating the normal operating conditions.Best possible

flushing is achieved if a 4 way/3 position directional control valve is fitted in

place of the proportional valve since,when the directional control valve is

actuated alternately,the downstream actuators are also flushed.New system

filters are installed during the flushing process whenever the pressure drop

across the filter element becomes excessive.The flushing processes should turn

over the fluid in the reservoir between fifty to one hundred times.

To maintain a clean hydraulic system, the filters must be replaced on a

periodic basis. It is best to monitor the pressure drop across the filter assembly

and replace the filter element when the pressure drop becomes excessive.In

addition to other filters installed in the hydraulic circuit,it is recommended that

a large capacity,low pressure ß3≥75 filter be installed in the return line.This

filter will increase the interval between filter element replacements and greatly

reduce system contamination.

4.INSTALLATION

The Moog 641 Series Proportional Control Valves may be mounted in any

position,provided the valve pressure,control,and return ports match respective

manifold ports.The mounting pattern and port location of the valve are shown

on Installation Drawing No.G2785. Apply a light film of oil to the mounting

screw threads and torque the screws to 90 inch-pounds.

Wire mating connector for desired coil configuration and polarity. Thread

connector to valve.

5.ELECTRICAL NULL ADJUSTMENT

It may be desirable to adjust the proportional valve for flow null

independent of other system parameters.The electrical null adjustment permits

convenient control set-ups.The electrical null adjust is a 4-turn potentiometer

located behind the pan head screw in the electronics housing.When turned,it

provides control of the spool position to obtain the desired flow null.

Adjustment Procedure

1. Verify that ±15 vdc power is supplied to the valve,and that the input signal

(pin D or E) is zero or grounded.

2. Using a flat blade screwdriver, remove the pan head screw (see Figure 2)

to permit adjustment of the potentiometer.

3. Using a flat blade screwdriver, adjust the potentiometer to obtain the

desired flow null. Note: Clockwise rotation of the potentiometer p

reduces flow out of control port A.

4. Replace the pan head screw.

5. Restore the input signal wiring for system operation.

Tools and Equipment:

a. Flat blade screwdriver

b. Allen wrench set (21/2,3,4,5 mm;3/16,7/32inch )

c. Volt-ohm-milliammeter

d. Torque wrenches,various,to meet reassembly requirements

6.GENERAL SERVICING RECOMMENDATIONS

a. Disconnect the electrical lead to the control valve.

b. Relieve the hydraulic system of residual pressure.

c. Remove the valve.

Table 1. Replacement Parts

Part Description Qty. Part Number

641 Series Filter Replacement Kit 1 B52555RK90K1

Base O-Rings 5 42082-4

Base O-Rings 2 42082-11

Filter O-Ring (1) 1 G2140-13-15

Filter Retainer Plate O-Ring (1) 1 G2140-17-20

Filter (1) 1 G2196-100

(1) Included in Filter Replacement Kit

Figure 2

Electrical Null Adjustment

Page 3

P otential Tr ouble

Proportional valve does not respond to

command signal

Output flow obtained from one control

port only. Limited or no response to

command signal.

High null bias (actuator drifts or hydraulic

motor slowly rotates when controller

returns to neutral).

Poor response (valve delays in returning to

neutral after controller is returned to

neutral).

Non-repeatability (valve fails to return to

neutral each time controller is returned to

neutral).

Probable Cause

1 Controller does not function

2.Open or miswired controller cable

3.Open connector lead or damaged

electronics board

4.Jammed spool

5.Filter completely plugged

1.Controller not functioning properly

2.Filter silted with contamination

3.Plugged inlet orifice assembly

4.Plugged torque motor

5.Jammed spool

6.Electrical null adjust adjusted hardover

1.Incorrect null adjustment

2.Filter silted with contamination

3.Partially plugged inlet orifice assembly

4.Partially plugged torque motor

5.Damaged electronics

1.Filter silted with contamination

2.Contamination in spool bore

1.Controller not functioning properly

2.Contamination in spool bore

3.Partially plugged torque motor assembly

Remedy

1.Replace controller

2.Replace/repair controller cable

3.Return to factory

4.Return to factory

5.Replace filter

1.Replace controller

2.Replace filter

3.Return to factory

4.Return to factory

5.Return ot factory

6.Readjust electrical null

1.Readjust electrical null

2.Replace filter

3.Return to factory

4.Return to factory

5.Return ot factory

1.Replace filter

2.Return to factory

1.Replace controller

2.Return to factory

3.Return to factory

7. TROUBLESHOOTING CHART

The following troubleshooting chart list potential troubles encountered,probable causes,and remedies.

8.FIL TER ASSEMBL Y REPLACEMENT

a. Using a 3 mm Allen wrench,remove the four (4) socket head capscrews

and lockwashers. Remove filter plate.

b. Remove,inspect and discard filter disc. Remove O-Ring from filter cavity

and retainer plate.

c. Install new O-Rings and filter. Install filter retainer using 4 socket head

capscrews.torque to 36 inch pounds.

9.FUNCTIONAL CHECKOUT AND CENTERING

a. Install the control valve in your hydraulic system or test fixture,but do not

connect electrical lead.

b. Apply required system pressure to the control valve and visually examine

for evidence of external leakage.If leakage is present and cannot be

rectified by replacing O-Rings,remove the discrepant component and

return for repair or replacement.

Note: If the system components are drifting or hardover,adjust

the electrical null of the control valve.

c. Connect electrical lead to control valve and check phasing in accordance

with system requirements.

10.AUTHORIZED REPAIR FACILITIES

Moog does not authorize any facilities other than Moog or Moog subsidiaries to

repair its servovalves.It is recommended you contact Moog at (716)655-3000

to locate your closest Moog repair facility.Repair by an independent

(unauthorized) repair house will result in voiding the Moog warranty and could

lead to performance degradation or safety problems.

Figure 3

Filter O-Ring

Filter

Filter Retainer Plate

Page 4

[54.00]

2.126

PIN E

PIN D

PIN C

PIN B

PIN A

PIN F

INSTALL SEAL WASHER

AND SCREW FOR

INTERNAL PILOT SUPPLY

8.74 MAX

[222.0]

2.75 MAX

[69.9]

[27.00]

1.063

3.85

[97.8]

[46.02]

1.812

[23.01]

.906

4.17

[105.9]

1.42

[36.1]

2.84

[72.1]

3.27

[83.1]

2.09 REF

[53.1]

5.11

[129.8]

3.00

[76.2]

SEAL WASHER AND SCREW SHOWN

INSTALLED FOR EXTERNAL PILOT SUPPLY

1.66

[42.2]

4 PLACES

ELECTRICAL NULL

ADJUSTMENT

2.36

[60.0]

1.52

[38.6]

3.28

[83.3]

.79

[20.0]

REMOVABLE

FILTER

COVER

.270 [6.86] DIA THRU

CBORE .437 [11.10] DIA

TO DEPTH SHOWN (1.66 REF)

4 PLACES

.008

M

ELECTRICAL

CONNECTOR

641 SERIES INSTALLATION AND OPERATION INSTRUCTION

CDS6381 REV B 500-314 1199

Moog Inc.,East Aurora,NY 14052-0018

Telephone: 716/655-3000

Fax:716/655-1803

Toll Free: 1- 800-272-MOOG

NOTES

STANDARD ELECTRICAL

CONFIGURATION

The products described herein are subject to change at any time without notice, including, but not limited to, product features, specifications, and designs.

1 Fluid:

Industrial type petroleum base hydraulic

fluid,maintained to ISO DIS 4406 Code

14/11 recommended.

2 Operating Temperature Range:

-4˚F to 175˚F (-20˚C to 80˚C)

3 Surface:

Surface to which valve is mounted

requires 63[ ] finish,flat within .002

[0.05] TIR.

4 Null Adjust:

Remove coverscrew.Clockwise rotation

of potentiometer increases flow out

port A.

T

63

A

PRESSURE PORT

CONTROL PORT B

CONTROL PORT A

1.94

.38

.38

5.00

2.12

3.51

2.13

5.00

4.250

4.250

VALVE MOUNTS ON THIS

MANIFOLD SURFACE

NOTE: CONTROL

PORT 'B' FARSIDE

PORT PER SAE J1926

1.3125-12 UN-2B DASH 16

STR THD O-RING BOSS

(1.00 OD TUBE REF)

4 PLACES

PORT PER SAE J1926

.4375-20 UNF-2B DASH 4

STR THD O-RING BOSS

(.25 OD TUBE REF)

.438 DIA

4 PLACES

.406 DIA THRU

CBORE .609 DIA x .62 DEEP

4 MOUNTING HOLES

.970

5 PL

2.126

1.063

.406

.406

2.190

.437

.552

.937

.250-20 UNC-2B THD

4 VALVE MTG HOLES

.007

M

.002

1.480

2.125

.594

.843

1.812

RETURN (TANK)

PORT

NOTE: SUPPLY PRESSURE

PORT FARSIDE

.125 DIA PILOT

PRESSURE PORT

[LOCATION NOT PER

ISO 4401 PATTERN]

.014

M

.014

M

∆∆

Figure 4

+3V (200mA MAX)

A

-3V (200mA MAX)

B

COMMON

C

INPUT SIGNAL (±10V)

D

E

SPOOL POSITION OUTPUT (±1.5VDC)

F

POSITIVE SIGNAL AT PIN 'D' RESULTS IN FLOW OUT PORT 'A'.

}

POWER

SUPPLY

+15V (200mA MAX)

A

-15V (200mA MAX)

B

COMMON

C

D

INPUT SIGNAL (±10V)

E

SPOOL POSITION OUTPUT (±1.5VDC)

F

POSITIVE SIGNAL AT PIN 'E' RESULTS IN FLOW OUT PORT 'B'.

}

POWER

SUPPLY

Industrial Controls Division

Loading...

Loading...