Page 1

Operators’ Manual

Monroe Electronics, Inc.

Model 300

Charge Plate Monitor

P/N 0340193

Console Firmware Rev 1.05

Plate Assembly Firmware Rev 1.02

01302015

100 Housel Ave PO Box 535 Lyndonville NY 14098 1-800-821-6001 585-765-2254 fax: 585-765-9330 monroe-electronics.com

Page 2

CONTENTS

Section 1 Specifications Page

Specifications ................................................................................................................. 3

Accessories Included ..................................................................................................... 4

What this instrument does .............................................................................................. 5

Section 2 General Information

CAUTION – SHOCK HAZARD ....................................................................................... 6

Incoming Confidence Test .............................................................................................. 6

Section 3 Overview

Front Panel of the Console ............................................................................................. 7

Power Button and Power Indicator .......................................................................... 7

Charging the Battery ................................................................................................ 8

Rear Panel of the Console ............................................................................................. 8

AC Power Connection.............................................................................................. 8

USB Port .................................................................................................................. 8

CPM Plate ................................................................................................................ 8

Grounding the Model 300 ........................................................................................ 9

FM OUT / 1000 (Fieldmeter Analog Output) ........................................................... 9

Tripod Mounting ....................................................................................................... 10

Ion Collecting Plate Assembly ........................................................................................ 10

Ion Collecting Plate .................................................................................................. 10

Moving the Plate Assembly from the Storage Position ............................................ 10

Remote Placement of the Plate Assembly .............................................................. 12

Navigating the Front Panel ............................................................................................. 12

Programming (Customizing) the Model 300 for Testing .......................................... 13

Section 4 Operation

Performing Ionizer Tests ................................................................................................ 15

Recalling Ionizer Test Results ........................................................................................ 16

Section 5 Maintenance

Precautions ..................................................................................................................... 17

Cleaning ......................................................................................................................... 17

Battery ............................................................................................................................ 17

Calibration ...................................................................................................................... 17

Locating the Serial Numbers .......................................................................................... 17

Section 6 References ......................................................................................................... 18

Section 7 Appendices

Appendix I: Bad Battery Message and Resetting the Dead Battery Flag ...................... 19

Appendix II: CPA300 USB Driver Installation On Windows XP ..................................... 20

Appendix III: CPA300 USB Driver Installation On Windows 7 ....................................... 31

Appendix IV: CPA300 USB Driver Installation On Windows 8 ....................................... 40

Appendix V: Error Messages .......................................................................................... 47

Appendix VI: Operations Chart ....................................................................................... 49

WARRANTY ......................................................................................................................... 50

RETURN POLICIES AND PROCEDURES FOR FACTORY REPAIR ................................ 51

Copyright© 2013

Monroe Electronics, Inc.

Printed in USA

Specifications and procedures subject to change without notice

2

Page 3

Section 1

Specifications

All specifications are referred to plate voltage unless otherwise specified.

Charger ±1,100 volts (minimum), selectable polarity

Fieldmeter

Range: 0 to ±1,300 volts on display

0 to ±1,800 volts at analog output

1 volt resolution

Accuracy: ±2% of reading, ±2 volts, + zero offset, typical

Analog Output: 1/1000

Bandwidth: 6 Hz

Timer

Range: 0.1 second to 999.9 seconds

Accuracy: 0.1 second

Resolution: 0.1 second

Trip Points

Start Voltage: 1000 volts

Stop Voltage: Settable from 10 volts to 990 volts in 1-volt increments

Charge Plate

Size: 6 inches x 6 inches (15 cm x 15 cm)

Capacitance: 20 pF ±10%

Self-Discharge: Less than 100 volts within 5 minutes (<60% R.H.)

Power Requirements: 100 VAC to 220 VAC nominal line voltage; less than 5 watts

Battery Life: >8 hours per charge

Dimensions: 6-3/8” W x 6” H x 8-3/4” D (162mm x 152.4 mm x 223 mm)

Weight: 5.2 pounds (2.4 kg)

th

of the plate voltage, ±3%, typical

3

Page 4

Accessories Included:

CD containing: 300 Operator’s Manual

300 Data Sheet

300COM Software

300COM Software Operator’s Guide

Carrying Case

AC Adaptor w/international plug kit

6-inch-long Plate Cable

5-ft-long Plate Cable

Patch cord w/alligator clip & boot

USB cable

Stereo Phone Plug (analog output)

4

Page 5

What this instrument does —

This instrument is a charged-plate monitor for evaluating the performance of ionization

systems. As such, it performs positive and negative decay tests, and balance (offset voltage)

tests to determine if an ionization system is operating effectively. It can be used to test all

types of ionization systems as described in ESD Association Standard ANSI/ESD STM3.1

Ionization.

Over the years new technologies have placed new demands on both ionization systems and

on the capabilities and features of the charged-plate monitors used to evaluate them. Monroe

Electronics has responded to these needs by incorporating many additional and improved

features in the Model 300 Charged-Plate Monitor.

5

Page 6

Section 2

GENERAL INFORMATION

Model 300 performs manual or automatic decay and balance (offset voltage) tests for

qualification and periodic verification of ionization equipment. It then stores the results and

balance averages for manual tests and for a complete automatic test sequence, and saves

that data until the data is over-written by a subsequent manual test or automated test

sequence.

All instrument functions are controlled using six pushbuttons.

In DECAY mode, a built-in high-voltage generator charges the plate to a voltage greater than

1,000 volts. During the test the plate will discharge toward zero in the presence of ionization.

The elapsed time of decay between a 1000 volts and a selected stop voltage is displayed.

In the BALANCE (offset voltage) mode, the plate is first grounded, then disconnected from

ground and allowed to float to any voltage in response to air ion imbalances. It displays the

plate voltage, test duration, and minimum and maximum peak voltages. (Nearby charge

sources will also induce a voltage on the isolated plate.)

Memory is non-volatile. Setup and data are retained when the instrument is not in use.

CAUTION

When charged, the plate voltage can be in excess of 1000 volts with respect to ground.

Although the charges and potentials are below those that are normally detected by

human senses, A SHOCK HAZARD EXISTS.

If you are handling the plate assembly or conducting a test that involves

touching the plate, expect a shock

Do not charge large capacitors with this device.

.

Incoming Confidence Test

Plug the Model 300 into the AC power source. The display on the front panel of the Model

300 will indicate the battery voltage.

Turn on the Model 300 by pressing the Power button on the front panel. The Power indicator

above the Power button will illuminate. See also Power Switch and Power Indicator.

The display will indicate “CPA 300”, then will display the firmware revision numbers for both

the console and the ion-collecting plate assembly, and will then display the system prompt,

which is -.-.

Press the Bal button to start a balance test. Observe that the display counts up to 30

seconds and then scrolls through the minimum, maximum, and average plate voltages.

Press +Decay. Observe that the display indicates a voltage greater than +1000 volts.

Press -Decay. Observe that the display indicates a voltage greater than -1000 volts.

Press Shift/Cancel. Observe that the display indicates the system prompt, which is -.-.

6

Page 7

Section 3

OVERVIEW

The Model 300 is comprised of two major assembles: the ion collecting plate assembly and

the console.

ION COLLECTING

PLATE ASSEMBLY

CONSOLE

Figure 1. Front View and Major Assemblies

Front Panel of the Console

Power Button and Power Indicator

The Power button turns the instrument on and off.

If operating from the AC line

will display “CPA 300”, and then will display the firmware revision numbers of both the

console and the plate assembly, respectively. Then the Model 300 will display the system

prompt, which is “-.-“.

, press and release the Power button to turn on the Model 300. It

7

Page 8

If operating from battery, press the Power button for greater than 3 seconds to turn on the

Model 300. It will display “CPA 300” and then will display the firmware revision numbers of

both the console and the plate assembly, respectively. Then the Model 300 will display the

system prompt, which is “-.-“.

The Model 300 will run on either AC line or battery power. The internal, rechargeable battery

will supply up to 8 hours of operation.

The Power indicator presents one of three colors to indicate power conditions:

Green when the instrument is turned on and receiving power from the AC line.

Amber when the instrument is turned on and operating on battery power.

Red when the instrument is turned on, operating on battery power and the battery

needs to be re-charged.

NOTICE: When unplugging the AC adapter from the console, unplug the adapter from

the console unit before unplugging it from the wall outlet. Otherwise, the Model 300 will

turn off and will not continue to operate on battery power.

Charging the Battery

The Model 300 CPM is designed to be used on a regular basis. If it is not going to be used

for an extended period of time:

1. Leave unit connected to the charger. or

2. Recharge the battery every 60 days. or

3. Recharge the battery and remove one of the leads from the battery, then recharge

battery every 6 months.

Whenever the Model 300 is operated from an AC power source, it is charging the battery.

The display on the front panel of the Model 300 will indicate the battery voltage when the

Model 300 is plugged into an AC power source and is turned off.

The Power indicator is red when the battery needs to be recharged. Recharging the battery

may take up to ten (10) hours for a full charge.

Rear Panel of the Console

AC Power Connection

Connect the AC adaptor to the power jack on the rear panel of the Model 300. Use only the

AC adaptor provided by Monroe Electronics, Inc. for use with the Model 300.

USB Port

This connector is for control and data collection from a computer. Monroe Electronics offers a

program that can be installed on a computer for remote control and data collection.

8

Page 9

CPM Plate

Connect the ion-collecting plate assembly to this connector using a CAT 5 cable. A 6-inchlong cable is provided for making this connection when the ion-collecting plate assembly is

installed on the top of the console. A 5-foot-long cable is also provided to locate the ioncollecting plate farther from the console.

ION-COLLECTING PLATE CONNECTION

AC POWER CONNCTION

Figure 2. Rear View

Grounding the Model 300

ANALOG OUTPUT

USB PORT

A ground connection is essential for proper measurements of ionization systems. It is

essential to connect the chassis of the console to the facility ground conductor. The AC

adaptor does not provide a ground connection. Connect the Model 300 to ground via either

the banana jack or the green screw on the rear panel of the console.

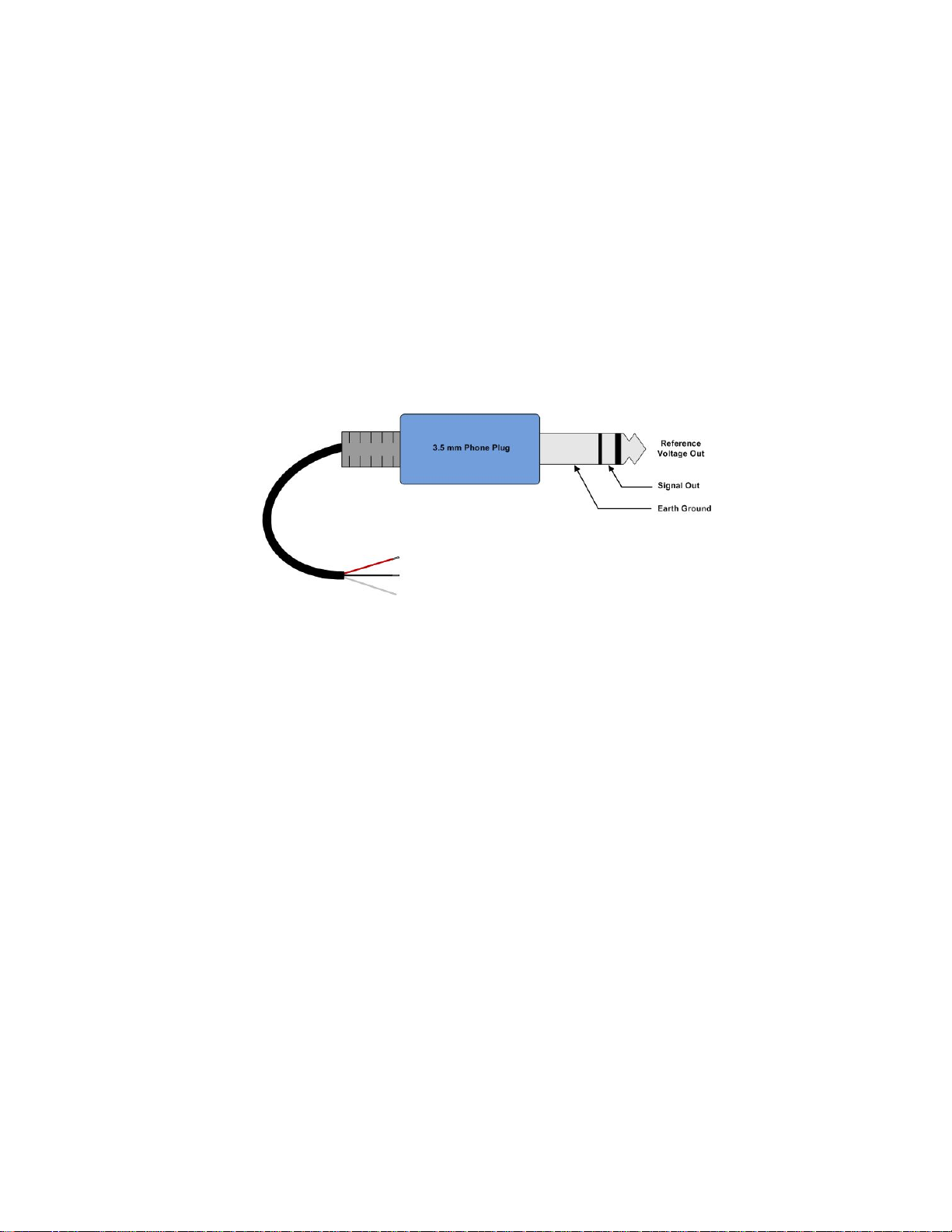

FM OUT ÷1000 (Fieldmeter Analog Output)

An analog output jack is provided on the rear panel of the console for connection to test

equipment such as chart recorders and oscilloscopes. The output signal is NOT a groundreferenced signal.

9

Page 10

A reference voltage representing zero volts on the ion-collecting plate is provided on one pin

of the connector. This reference voltage is in the range of 2.27V and 2.50V.

The analog output is a unipolar signal representing the plate voltage. The fieldmeter (plate

voltage sensor) output signal appears on another pin of the connector, and is in the range of

±1V from the reference voltage, wherein +1V with respect to the reference voltage

represents +1000V on the ion collecting plate, and -1V with respect to the reference voltage

represents -1000V on the ion collecting plate.

A stereo phone plug is provided. The third terminal is a ground connection.

If connecting the analog output of the Model 300 to an oscilloscope, we recommend

connecting the reference voltage output to one input of the oscilloscope and connecting the

signal output to another input of the oscilloscope, and subtracting the reference output from

the signal output using the math feature or add/invert features of the oscilloscope.

Figure 3. Analog Output Connections

Tripod Mounting

Both the bottom of the console and the bottom of the ion collecting plate are equipped with a

threaded insert for tripod mounting. Thus, either the entire instrument or just the ion

collecting plate can be tripod mounted, depending on your requirements.

Ion Collecting Plate Assembly

Ion Collecting Plate

The Model 300 has a 6 X 6 (15 cm x 15 cm) ion collecting plate assembly (plate assembly)

that can be used in an operational position on the top of the Model 300 console, or it can be

removed and located remotely for testing ionization systems. The plate assembly operational

position atop the console is different from the plate assembly storage position for shipment.

Moving the Plate Assembly from the Storage Position to the Operational Position

As received, the ion collecting plate assembly is stored in the console. (See Figure 4.) The

Model 300 cannot be operated properly when the plate assembly is in this storage position.

10

Page 11

Move the plate assembly from the storage position (See Figure 4.) to the operating position

atop the console unit (see Figure 5). Slide the plate assembly backwards to remove it from

Figure 4. Rear View Showing Plate Assembly Storage Position

11

Page 12

Figure 5. Rear View Showing Plate Assembly In Operational Position On Top of Console Unit

the console unit. Then slide it forward in the guide channel to insert it into the operational

position.

Connect the 6-inch CAT 5 cable between the plate assembly and the console unit.

NOTICE: The power should be off when connecting the plate assembly to

the console.

NOTICE: We recommend returning the plate assembly to the storage

position for transport.

Remote Placement of the Plate Assembly

Turn off the Model 300 before detaching the ion collecting plate from the console.

Disconnect the cable connecting the ion collecting plate to the console.

Slide the ion collecting plate backwards to remove it from the console.

Reconnect the ion collecting plate to the console using the 5-foot-long cable provided.

NOTE: When it is detached from the console, the ion collecting plate maintains a ground

connection via this cable.

NOTE: This cable is a standard CAT 5 cable. Longer cables can be purchased and used

when greater separations between the ion collecting plate and the console are needed.

Navigating the Front Panel

Three operations can be performed from the system prompt (-.-).

1. Perform ionizer tests- initiate tests directly from the system prompt, -.-.

2. Recall test results- press the Shift/Cancel button once to recall test results for the

Model 300.

3. Feature Set Up- press the Shift/Cancel button twice to set up features for the

Model 300.

12

Page 13

Programming (Customizing) the Model 300 for Testing

From the system prompt, -.-, press the Shift/Cancel button until the yellow SETUP indicator

is on, and “SET UP” is displayed.

The yellow button legend becomes the active legend to follow for the buttons.

Use the ↑ and ↓ buttons to scroll through the set up parameters. Once you have reached a

parameter that you want to change, press SELECT to edit its value. EDIT OPT is

momentarily displayed. Then use the ↑ and ↓ buttons to change the value. When done

changing the value, press SAVE to save the new value (SAVE OPT is momentarily

displayed) or CANCEL to exit without saving.

The set up parameters are as follows:

TDLY 0 Test Delay: Set a delay of 0 to 15 seconds after the button is pressed

(for a test) before the test begins. The factory default is 0 seconds.

GPLT DLY Choose an option for grounding the plate:

GPLT DLY ground the plate during the test delay

GPLT <DLY ground the plate prior to the test delay, but not

during the test delay

GPLT DLY> ground the plate after the test delay, but not during

the test delay

The factory default is to ground the plate during the test delay.

VSTP 100 Decay Stop Voltage: Set the desired stop voltage. The stop voltage

can be set to any value from 10V to 990V in 1V increments. The

factory default is 100V.

DLEN 30 Decay Test Length: Set the desired test length for a decay test before

test “times out” and ends the decay test. The decay test length can be

set to any value from 10 to 999 seconds in 1-second increments. The

factory default is 30 seconds.

BLEN 30 Balance (Offset Voltage) Test Length: Set the desired test length for a

balance test before the test “times out” and terminates the balance

test. The balance test length can be set to any value from 0 to 9999

seconds in 1-second increments. Choosing zero (0) as a test length

causes the balance test to run forever. The factory default is 30

seconds.

PKDL 3 Balance Peak Delay: Set the desired time delay after the start of a

balance test before the peak detectors begin to record peak offset

voltages. The balance peak delay can be set to any value from 10 to

300 seconds in 1-second increments. The Balance Peak Delay must

be less (shorter) than the balance test length. The factory default is 3

seconds.

PWR 300 DC Auto Power Off: Set the desired time that the Model 300 will

operate on battery before shutting off. The DC Auto Power Off can be

set to any value from 10 to 9999 seconds in 1-second increments.

Choosing zero (0) as a time causes the Model 300 not to automatically

shut off. The factory default is 300 seconds.

13

Page 14

+++ ---B Automated Test Sequence: Set the desired number and order of tests

for an automated sequence of tests. “+”represents a positive decay

test in the sequence. “-“ represents a negative decay test in the

sequence. “B” represents a balance (offset voltage) test in the

sequence. The choices for an automated test sequence are +-, +-+- +-,

+++---, +-B, +-+-+-B, and +++---B. The factory default is +++---B.

DEFT SET Use this set up option to restore all set up options to their factory

default settings. Press SELECT and then the ↑ and ↓ buttons to

choose “YES” or “NO” to restore the factory defaults edit the value

using. Once the desired value is displayed, press the SAVE button to

save the new value for the feature. SAVE OPT is displayed

momentarily.

CLR DATA Use this set up option to clear all saved test results. Press SELECT

and then the ↑and ↓ buttons to choose “YES” or “NO” to restore the

factory defaults edit the value using. Once the desired value is

displayed, press the SAVE button to save the new value for the

feature. SAVE OPT is displayed momentarily.

Press the Shift/Cancel button again to return to the system prompt, -.-.

14

Page 15

Section 4

OPERATION

Performing Ionizer Tests

Initiate automated test sequences and manual tests directly from the system prompt, -.-.

Selecting a Manual Test: Press +Decay to start a positive discharge test.

Press -Decay to start a negative discharge test.

Press Bal to start a balance (offset voltage) test.

The respective indicator is on and flashing while a test is in

progress.

The respective indicator is on and not flashing when the test is

complete and data is available.

Manual Zero for the Plate: In the event that the instrument does not indicate zero volts for

a balance test (when the ion collecting plate is hard-grounded),

the fieldmeter can be zeroed by pressing the Bal button for >2

seconds. This would be done from the system prompt, -.-.

Selecting an Automated

Test Sequence: Press Auto to run a sequence of discharge and balance tests.

Cancelling a Test: Press Shift/Cancel to cancel a test after it is started.

To View Test Results: Test results are displayed after each test.

For a Decay test, the Decay time is displayed until a new

button is pressed. In the instance when a decay test fails, such

as if there is no ionization to reduce the plate voltage, a failure

message is displayed: either +DCY DFAI or -DCY DFAI,

depending on the polarity of the decay test.

For a Balance test, the display scrolls through the negative

peak voltage (VMIN), the positive peak voltage (VMAX) and the

average voltage (AVG).

Press +Decay, -Decay, Bal or Auto to start a new test or

sequence of tests.

Press Shift/Cancel to return to the system prompt -.-.

Test data can also be viewed using the ReCall feature of the

Model 300.

15

Page 16

Recalling Ionizer Test Results

The test results are saved for the most recent of each positive decay, negative decay,

balance (offset voltage) and auto test. These test results can be recalled by pressing

Shift/Cancel until the green ReCall indicator is on, and RECALL is displayed.

The green button legend becomes the active legend to follow for the buttons.

The indicator corresponding to each type of test (+Decay, -Decay, Balance, and Auto) is on if

there is data available for viewing.

To view the data, press the corresponding button and the data is shown in the alpha-numeric

display.

For recalling balance data

display VMIN (most negative offset voltage), VMAX (most positive offset voltage), AVG

(average offset voltage for the balance test duration), and VSTP (final offset voltage at the

end of the balance test duration).

For recalling automated test sequence data

300 scrolls to display +1D (first +Decay time), +2D (second +Decay time), +3D (third +Decay

time), +AVG (average time for the three +Decay tests), -1D (first -Decay time), -2D (second Decay time), -3D (third -Decay time), -AVG (average time for the three -Decay tests), VMIN

(most negative offset voltage), VMAX (most positive offset voltage), BAVG (average offset

voltage for the balance test duration), and VSTP (final offset voltage at the end of the

balance test duration).

The test data is saved until overwritten by new test data, or until the data is cleared using

CLR DATA in the setup menu.

, each time the Bal button is pressed, the Model 300 scrolls to

, each time the Auto button is pressed, the Model

16

Page 17

Section 5

MAINTENANCE

Precautions

User maintenance should normally be limited to keeping the instrument clean and free from

physical damage. Store the instrument in its protective carrying pouch when not in use.

Cleaning

Fingerprints and other contaminants may be removed from the case with a clean lint-free

cloth dampened in a 70%/30% mix of clean technical grade isopropyl alcohol and de-ionized

water. DO NOT use soap or detergent.

Battery

Battery charge life depends on type of tests being run.

A complete re-charge cycle takes 10 hours with the power off. The battery voltage is

displayed on the console unit when the Model 300 is plugged into an AC power source and is

turned off.

The Model 300 CPM is designed to be used on a regular basis. If it is not going to be used

for an extended period of time:

1. Leave unit connected to the charger. or

2. Recharge the battery every 60 days. or

3. Recharge the battery and remove one of the leads from the battery, then recharge

battery every 6 months.

Calibration

Calibration is not a user function and is beyond the scope of this manual. Calibration

information is available from the factory. Monroe Electronics recommends annual calibration

and/or when the instrument is damaged or repaired or where called for more often by

contract. Monroe Electronics, Inc. offers repair and calibration services for a fee.

Locating the Serial Numbers

Serial number information is useful when consulting with Monroe Electronics or its

distributors for service.

The console and the plate assembly each have a serial number.

The serial number for the console is located on the rear panel.

The serial number for the plate assembly is located on the bottom of the assembly.

17

Page 18

REFERENCES

Documents associated with ionization:

ESD Association Standard — ANSI/ESD STM3.1 –Ionization

ESD Association Advisory – ESD ADV3.2 – Selection and Acceptance of Air Ionizers

ESD Association Standard – ANSI/ESD SP3.3 – Periodic Verification of Air Ionizers

ESD Association Advisory – ESD ADV1.0 – Glossary

These documents are available from:

ESD Association, Inc.

7900 Turin Rd.

Building 3, Suite 2

Rome, NY 13440-2069

Section 6

Phone (315) 339-6937

Fax (315) 339-6793

eosesd@aol.com

http://www.eosesd.org

Monroe Electronics, Inc. does not supply copies of standards or advisories.

18

Page 19

Section 7

APPENDIX I

Bad Battery Message and Resetting the Dead Battery Flag

When operating from the AC line, if the Model 300 has a bad battery, meaning that the Model

300 detects that the battery will not charge above 4 volts within 5 minutes, then a Bad

Battery flag is set and the battery charger will stop trying to charge the battery until the Bat

Battery flag is cleared.

When this condition occurs, the Model 300 displays a BAD BAT message on the front panel

for four (4) seconds. The Model 300 continues to operate properly from the AC line. In the

event that the operator does not see the BAD BAT message when it appears on the front

panel, this message is also displayed when the unit is turned on.

We recommend that the battery be replaced when this message is seen, although the unit

will continue to operate properly under AC power conditions.

Once the battery has been replaced, the Bad Battery flag can be reset by pressing

Shift/Cancel when BAD BAT is displayed during turn on. The Model 300 will display RSET

BATO to indicate that the Bad Battery flag is reset.

19

Page 20

APPENDIX II

CPA300 USB Driver Installation on Windows XP

1) Install the CPA300 pc software on to the PC. You may need to log onto the PC as

Administrator to install the software and the USB driver.

2) Turn on the Model 300. The display shows: [CPA 300], [V1.03 1.02] then the prompt:

[ -.-].

If all these are shown, then go on to Step 3.

If it shows [CPA 300], [COMM ERR], [V1.03 ???], then please check that the

plate cable on the back of the unit is properly connected to the plate assembly.

Power the Model 300 down then up again to see if it is connected. If the problem

persists, report it to Monroe Electronics.

3) Connect the Model 300 to the PC via the USB cable.

4) Run the CPA300 software. It will start searching available comports and list the

CPA300 with the comport if it is found. Selecting the port it will flash green and the

software is ready to communicate with the unit.

If the 300 device is not found, then go on to Windows Start - Control Panel, find the

device, and update the driver:

Control Panel.

It will lead to one of the two views.

Refer to screens below to see which

one apply to you.

Figure 1

20

Page 21

Printers and Other Hardware

Figure 2

System.

Then go on to

Figure 4.

Figure 2a

21

Page 22

System.

Then go on to

Figure 4.

Figure 3

22

Page 23

Hardware

Figure 4

23

Page 24

Device Manager

Figure 5

24

Page 25

Double click on the

SERIAL DEMO

(CPA300-USB), or

right click on it and

select Properties.

Figure 6

25

Page 26

Reinstall Driver

Figure 7

Install from a list or specific

location

Figure 8

26

Page 27

1) Click Include this location in the

search.

2) Then Browse to the 300 software and

USB location. By default, it is in:

C:\Monroe-Electronics\CPA300\USBDrivers

3) Click Next.

Figure 9

27

Page 28

Select USB to UART

Then click Next

Figure 10

Continue Anyway

Figure 11

28

Page 29

Well done if you get to this

page.

Click Finish to close it.

Figure 12

If the driver is updated successfully,

the Device Manager page will show

the USB to UART icon for the 300

USB. It is on Com11 in this example.

Figure 13

Power up the Model 300. You should see the system prompt, -.-, without showing “COMM

ERR”.

Run the 300 PC software, or click on the Connection. It will search for the comport and the

devices. Select the comport that labeled with CPA-300. Then click the [Select highlighted

comport and exit].

29

Page 30

Figure 14

The PC is now connected to the 300 via USB:

If it found the comport, but no CPA300 attached to it, then please try again from step 2.

30

Page 31

APPENDIX III

CPA300 USB Driver Installation on Windows 7

1) Install the CPA300 pc software on to the Win7 PC. You may need to log onto the PC as

Administrator to install the software and the USB driver.

2) Turn on the CPA300 unit, the display shows: [CPA 300], [V1.03 1.02], then the system

prompt, [-.-].

If all these are shown, then go on to Step 3.

If it shows [CPA 300], [COMM ERR], [V1.03 ???], then please check that the plate

cable on the back of the unit is properly connected to the plate assembly. Power the

Model 300 down and then up again to see if it is connected. If a problem persists,

report it to Monroe Electronics.

3) Connect the Model 300 to the PC via the USB cable.

4) Run the CPA300 software. It will start searching available comports and list the CPA300

with the comport if it is found. Selecting the port. It will flash green and the software is

ready to communicate with the unit.

If the 300 device is not found, then go on to Windows Start - Control Panel, find the

device, and update the driver:

Control Panel.

It may lead to one of the two pages.

Refer to the following screens to see

which one apply for you.

Figure 1

31

Page 32

View devices and printers

Figure 2

Double click on the

SERIAL DEMO

(CPA300-USB), or

right click on it and

select Properties. Go on

to Figure 5.

Figure 3

32

Page 33

Or from Windows – Start – Control Panel

Device Manager

Figure 4

Double click on the

SERIAL DEMO

(CPA300-USB), or

right click on it and

select Properties.

Figure 5

33

Page 34

Hardware

Properties

Figure 6

34

Page 35

Change settings

Figure 7

35

Page 36

Update Driver

Figure 8

Browse my computer for

driver software

Figure 9

36

Page 37

Browse to the 300 software and USB location.

By default, it is in:

C:\Monroe-Electronics\CPA300\USB-Drivers

Then click Next.

Figure 10

Install

Figure 11

37

Page 38

After the driver is updated successfully,

the Devices and Printers page will show

the USB to UART icon for the 300 USB.

It is on Com6 in this example.

Figure 12

Run the 300 PC software again, and the 300 is power up to the prompt, -.-, without showing

“COMM ERR”.

The Model 300 software will search for the comport and the devices. Select the comport with

CPA-300, then click the [Select highlighted comport and exit].

Figure 13

Now the PC is connected to the 300 via USB.

38

Page 39

If it found the comport, but no CPA300 attached to it, please try again from step 2.

39

Page 40

APPENDIX IV

CPA300 USB Driver Installation on Windows 8

1) Install the CPA300 pc software on to the PC. You may need to log on to the PC as

Administrator to install the software and the USB driver.

2) Turn on the CPA300 unit. The display shows: [CPA 300], [V1.03 1.02] then the prompt,

-.-.

If all these are shown, then go on to Step 3.

If it shows [CPA 300], [COMM ERR], [V1.03 ???], then please check that the plate cable

on the back of the unit is properly connected to the plate assembly. Power the Model 300

down, and then up again to see if it is connected. If the problem persists, report it to

Monroe Electronics.

3) Connect the Model 300 to the PC via the USB cable.

4) Run the CPA300 software. It will start searching available comports and list the CPA300

with the comport if it is found. Selecting the port it will flash green and the software is

ready to communicate with the unit.

If not found, then go on to Control Panel, find the device, and update the driver.

Click the down arrow

40

Page 41

Control Panel

Select Hardware and Sound:

Under Hardware and Sound,

click View devices and

printers

41

Page 42

Double click on the SERIAL DEMO

with the yellow mark. Or right click on it,

and select Properties.

Double click on the SERIAL DEMO, or right click on it select Properties

Hardware tab

42

Page 43

Properties

Properties:

Change settings

Change settings:

43

Page 44

Update Driver

Update Driver

Browse my computer:

Browse my computer

for driver software

44

Page 45

Browse to the 300 software and USB

location. By default, it is in: C:\MonroeElectronics\CPA300\USB-Drivers

Browse and enter the 300 USB-Driver location, then Next:

Install:

Install

45

Page 46

After the driver is updated successfully, the

Devices and Printers page will show the

USB to UART icon for the 300 USB. It is on

Com3 in this example.

Run the Model 300 PC software again. The Model 300 is powered up to the prompt, “-.-“,

without showing “COMM ERR”. The Model 300 software will search for the comport and the

devices. Select the comport with CPA-300, then click the [Select highlighted comport and

exit]. The PC is now connected to the Model 300 via USB.

46

Page 47

APPENDIX V

Error Messages

Error Messages on RECALL test data:

----------------------------------

+DCY CFAI +decay charge failed.

-DCY CFAI -decay charge failed.

The Model 300 charged for 30 seconds and the plate

voltage did not reach to 1100v.

+DCY DFAI +decay failed.

-DCY DFAI -decay failed.

It is caused by one of the following:

1) After charging to 1100v, the decay test ran for 1

minute without getting to 1000v, and the decay

timer did not start.

2) After the decay timer started at 1000v, the decay

test ran to the maximum decay length and the

voltage did not reached to the V stop setting

(timed out).

+AVG FAIL

-AVG FAIL The decay average fails to calculate on an auto

sequence test when one or more decay tests fails.

Error Message during operation:

-------------------------------

COMM ERR The plate isn't connected to the base unit. Check

connection.

CHRG CFAI Charge failed.

On a decay test, the Model 300 charged for 30

seconds without getting to 1100v.

DCAY DFAI Decay failed. Refer to above "DCY DFAI" for the

cause.

BAD BAT Bad battery

When the Model 300 is plugged in to AC power, the

battery charger starts. If charging for 5 minutes

and the battery voltage is still below 4v, then the

Bad Battery flag is set and the charger stops

charging until the flag is cleared. The device is

47

Page 48

still functional with AC supply. Replacing the

battery is recommended.

RSET BAT0 Reset Bad Battery Flag.

When the Model 300 is powered up and the Bad Battery

flag is set, it displays "BAD BAT" for 4 seconds.

During this time, pressing the Shift key will reset

the Bad Battery flag. If successful, it will show:

"RSET BAT0".

BAT LTMP Battery at low temperature <4c environment

BAT HTMP Battery at high temperature >50c environment

When in AC on power up, if the battery temperature

sensor detects that the temperature is below 4c or

above 50c, the Model 300 will not charge the battery

until the temperature is back to within 4c - 50c.

There is no need to take any action, the Model 300

continues to function as normal. The message will

not be shown when the temperature is back within

normal range, and then the charging resumes.

48

Page 49

APPENDIX VI

49

Page 50

WARRANTY

Monroe Electronics, Inc., warrants to the Owners, this instrument to be free from defects in

material and workmanship for a period of two years after shipment from the factory. This

warranty is applicable to the original purchaser only.

Liability under this warranty is limited to service, adjustment or replacement of defective parts

(other than tubes, fuses or batteries) on any instrument or sub-assembly returned to the

factory for this purpose, transportation prepaid.

This warranty does not apply to instruments or sub-assemblies subjected to abuse, abnormal

operating conditions, or unauthorized repair or modification.

Since Monroe Electronics, Inc. has no control over conditions of use, no warranty is made or

implied as to the suitability of our product for the customer’s intended use.

THIS WARRANTY SET FORTH IN THIS ARTICLE IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES AND REPRESENTATIONS, EXPRESS, IMPLIED OR STATUTORY

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS. Except for obligations expressly undertaken by Monroe Electronics, in this

Warranty, Owner hereby waives and releases all rights, claims and remedies with respect to

any and all guarantees, express, implied, or statutory (including without limitation, the implied

warranties of merchantability and fitness), and including but without being limited to any

obligation of Monroe Electronics with respect to incidental or consequential damages, or

damages for loss of use. No agreement or understanding varying or extending the warranty

will be binding upon Monroe Electronics unless in writing signed by a duly authorized

representative of Monroe Electronics.

In the event of a breach of the foregoing warranty, the liability of Monroe Electronics shall be

limited to repairing or replacing the non-conforming goods and/or defective work, and in

accordance with the foregoing, Monroe Electronics shall not be liable for any other damages,

either direct or consequential.

50

Page 51

RETURN POLICIES AND PROCEDURES FACTORY REPAIR

Return authorization is required for factory repair work. Material being returned to the factory

for repair must have a Return Material Authorization number. To obtain an RMA number,

call 585-765-2254 and ask for Customer Service.

Material returned to the factory for warranty repair should be accompanied by a copy of a

dated invoice or bill of sale, which serves as a proof of purchase for the material. Serial

numbers, date codes and tamper proof stickers on our products also serve to determine

warranty status. Removal of these labels or tags may result in voiding a product’s warranty.

Repairs will be returned promptly. Repairs are normally returned to the customer by UPS

within 10 to 15 working days after receipt by Monroe Electronics, Inc. Return (to the

customer) UPS charges will be paid by Monroe Electronics on warranty work. Return (to the

customer) UPS charges will be prepaid and added to invoice for out-of-warranty repair work.

RETURN OF REPAIRED ITEMS:

Factory repairs will be returned to the customer by the customer’s choice of FedEx, DHL or

UPS. Warranty repairs will be returned via UPS ground. The customer may request

accelerated shipping via the previous mentioned carriers for both warranty and non-warranty

repairs. NOTE: Accelerated transportation expenses for all factory repairs will always be at

the expense of the customer despite the warranty status of the equipment.

FACTORY REPAIRS TO MODIFIED EQUIPMENT:

Material returned to the factory for repair that has been modified will not be tested unless the

nature and purpose of the modification is understood by us and does not render the

equipment untestable at our repair facility. We will reserve the right to deny service to any

modified equipment returned to the factory for repair regardless of the warranty status of the

equipment.

51

Loading...

Loading...