Page 1

INSTRUCTION MANUAL

ISOPROBE® ELECTROSTATIC VOLTMETER

MODEL 279L

110309

P/N 0340177

Accessories Included:

Manual

Line Cord

Probe Cover Plug

100 Housel Ave PO Box 535 Lyndonville NY 14098 1-800-821-6001 585-765-2254 fax: 585-765-9330 monroe-electronics.com

Page 2

PRODUCT WARRANTY

Monroe Electronics, Inc., warrants to the Owners, this instrument to be free from defects in material and

workmanship for a period of two years after shipment from the factory. This warranty is applicable to the original

purchaser only.

Liability under this warranty is limited to service, adjustment or replacement of defective parts (other than tubes,

fuses or batteries) on any instrument or sub-assembly returned to the factory for this purpose, transportation

prepaid.

This warranty does not apply to instruments or sub-assemblies subjected to abuse, abnormal operating conditions,

or unauthorized repair or modification.

Since Monroe Electronics, Inc. has no control over conditions of use, no warranty is made or implied as to the

suitability of our product for the customer’s intended use.

THIS WARRANTY SET FORTH IN THIS ARTICLE IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES

AND REPRESENTATIONS, EXPRESS, IMPLIED OR STATUTORY INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS. Except for obligations expressly undertaken by

Monroe Electronics, in this Warranty, Owner hereby waives and releases all rights, claims and remedies with

respect to any and all guarantees, express, implied, or statutory (including without limitation, the implied warranties

of merchantability and fitness), and including but without being limited to any obligation of Monroe Electronics with

respect to incidental or consequential damages, or damages for loss of use. No agreement or understanding

varying or extending the warranty will be binding upon Monroe Electronics unless in writing signed by a duly

authorized representative of Monroe Electronics.

In the event of a breach of the foregoing warranty, the liability of Monroe Electronics shall be limited to repairing or

replacing the non-conforming goods and/or defective work, and in accordance with the foregoing, Monroe

Electronics shall not be liable for any other damages, either direct or consequential.

RETURN POLICIES AND PROCEDURES FACTORY REPAIR

Return authorization is required for factory repair work. Material being returned to the factory for repair must have a

Return Material Authorization number. To obtain an RMA number, call 585-765-2254 and ask for Customer

Service.

Material returned to the factory for warranty repair should be accompanied by a copy of a dated invoice or bill of

sale, which serves as a proof of purchase for the material. Serial numbers and date codes on our products also

serve to determine warranty status. Removal of these labels or tags may result in voiding a product’s warranty.

Repairs will be returned promptly. Repairs are normally returned to the customer by UPS within 10 to 15 working

days after receipt by Monroe Electronics, Inc. Return (to the customer) UPS charges will be paid by Monroe

Electronics on warranty work. Return (to the customer) UPS charges will be prepaid and added to invoice for outof-warranty repair work.

RETURN OF REPAIRED ITEMS:

Factory repairs will be returned to the customer by the customer’s choice of FedEx, DHL or UPS. Warranty repairs

will be returned via UPS ground. The customer may request accelerated shipping via the previous mentioned

carriers for both warranty and non-warranty repairs.

repairs will always be at the expense of the customer despite the warranty status of the equipment.

FACTORY REPAIRS TO MODIFIED EQUIPMENT:

Material returned to the factory for repair that has been modified will not be tested unless the nature and purpose of

the modification is understood by us and does not render the equipment untestable at our repair facility. We will

reserve the right to deny service to any modified equipment returned to the factory for repair regardless of the

warranty status of the equipment.

NOTE: Accelerated transportation expenses for all factory

website: www.monroe-electronics.com e-mail: electrostatics@monroe-electronics.com

Page 3

MODEL 279L

ISOPROBE® ELECTROSTATIC VOLTMETER

TABLE OF CONTENTS

I. SPECIFICATIONS ..........................................................................PAGE 1

II. INSTALLATION .............................................................................. PAGE 3

III. CONTROLS AND INDICATORS ....................................................PAGE 5

IV. OPERATION................................................................................... PAGE 7

V. THEORY .........................................................................................PAGE 8

VI. ADJUSTMENT..............................................................................PAGE 10

VII. TROUBLESHOOTING.................................................................. PAGE 14

APPENDIXES:

MODEL 1034 PROBE MOUNTING..... APPENDIX I……………………….Page 16

POWER ENTRY MODULE..... APPENDIX II………………………………..Page 18

HV BREAKDOWN CONSIDERATIONS.....APPENDIX III………………...Page 20

ACHIEVING SPACING INDEPENDENCE ....APPENDIX IV……………...Page 21

iii

Page 4

SECTION 1

SPECIFICATIONS

A. Applications:

Model 279L ISOPROBE®ELECTROSTATIC VOLTMETER takes advantage of Monroe’s years of experience in

design of reliable instruments for

modern semiconductor technology. A full spectrum of proven-design interchangeable probes exposes broad new

areas for exploratory research as well as providing a precision instrument for routine applications in electrostatic

measurements. Some typical and potential applications include:

Disk media research

IC manufacturing and handling

Materials evaluation

Contact potential measurements

Bioelectric field studies

Process monitoring and control

B. Features:

Low profile half rack size for multi-channel applications

NON-CONTACTING measurement of electrostatic potential combined with

Full complement of interchangeable probes

Analog recorder output

LED meter with “blackout switch” for darkroom applications

C. Range:

0 to ±300 volts DC

D. Accuracy:*

0.1% of full scale or 10mV, whichever is greater, 0.003%/C over +20 to +40C range (at recorder

output). Useable to +50

E. Meter resolution:

100mV (4 ½ digit LCD)

F. Speed of response:*

3ms, 10% to 90%, achievable at probe to surface spacing up to 0.1” with low resolution probe.

G. Settling time:

<6½ms to 1% of final value.

C.

H. Frequency response:

Small signal frequency response typically 3db to >300Hz.

Page 1

Page 5

I. Drift:*

<0.01V/hr after 1 hr stabilization (0.003V/hr typical). Not measurably affected by 10C temperature

variation or changes between 10% and 90% relative humidity.

J. Noise:*

<90mV rms referred to input, typical.

K. Surface resolution:

Determined by probe aperture size and surface-probe separation. Standard type 1034E & S probes

with 0.07” (1.75mm) aperture will resolve a 0.10” (2.5mm) spot at 0.02” (0.5mm) separation.

L. Recorder output:

100:1, 3 volts full-scale

M. Output filter:

Bessel low pass filter with 1.2ms constant delay.

N. Size:

1.7 x 8.2 x 15.1 inches (44 x 208 x 384mm), 1.75” rack mounting available (1 or 2 per rack).

Weight 4 lb. (1.8kg).

O. Power requirement:

100, 120, 230 or 240 VAC, 10%, 50/60Hz, 15 watts.

1

/4A SB for 100 & 120 V (Littelfuse 313.250 or equiv.)

Fuse

1

/8A 5x2mm for 230 & 240 V (Littelfuse 217.125 or equiv.)

Fuse

* Dependent on specific probe model, probe-to-surface separation and environment. Specifications shown are for

standard Type 1034E or S probes in a normal laboratory atmosphere. Separation for accuracy and response speed

tests is

environments and may be degraded under exceptionally dirty or dusty conditions or in ambiance of unstable

gaseous constituents.

1

/8” (3mm) and for noise and drift tests, 0.005” (0.13mm). Performance generally improves in controlled

PROBES:

Monroe Electronics Type 1034E (end viewing) or 1034S (side-viewing) probes are 0.35” (9mm) x 0.35” (9mm) x

3.25” (82.6mm) in length. Add 0.8” (20mm) length for cable at minimum bend radius. Contains 1kHz tuning fork

chopping driver and onboard hybrid microcircuit preamp. Useable from -50

configurations are available for high or low resolution and transparent probes for light decay measurements. Length

of probe cable is 10 ft. (3.05 meters). Provision has been made for air or inert gas purging of probe. Standard basic

instrument package includes Model 279L electrostatic voltmeter, line cord and instruction manual. Rear mounted

connector on instrument is standard; front panel connector is optional. Unit is calibrated independent of probe and

includes certificate of NIST traceability. Interchangeable Model 1034 probe (type specified by customer) is sold

separately.

C to +80C. Optional probe

Page 2

Page 6

SECTION 2

INSTALLATION

CAUTION:

Before plugging instrument in, make certain that it is matched to local power line voltage. The factory set line

voltage may be determined by the position of the voltage selector indicator pin in the power entry module. All units

are shipped configured for 120 VAC unless otherwise specified. In the event that it is necessary to change the

operating voltage of the instrument (or inspect or replace the fuses), see Appendix II for more information.

NOTE:

Wire Color Code for Line Cord Provided.

HIGH SIDE OF LINE - BLACK or BROWN

LOW SIDE OF LINE - WHITE or LIGHT BLUE

SAFETY GROUND - GREEN or GREEN/YELLOW

A. Probe mounting:

The 1034 and all other compatible probes must be mounted with the sensitive aperture facing the surface to be

measured.

The probe must be electrically isolated for up to about 400V, since the probe acquires the potential of the surface

being measured.

Further probe mounting information is given in Appendix I.

B. Probe-to-surface spacing:

CAUTION:

When operating at very close probe-to-surface spacing -- BEWARE OF PROBE-TO-SURFACE ARC-OVER and

possible accidental physical contact. Refer to Appendix III for further information.

Probe to surface spacing should be maintained as close as physically reasonable for best performance. Typical

spacing range is from .005” (0.1mm) for unknown voltages below 500 volts to over .125” (3mm) for unknown

voltages up to 3000 volts.

As probe to surface spacing increases instrument performance will suffer:

1. Decreased Accuracy

2. Decreased Speed-of-Response

3. Decreased Surface Resolution

4. Increased Noise

5. Increased Drift

C. System grounding:

The instrument is normally grounded via power cord and the potential measured is referenced to ground. A rear

panel ground connection is provided.

D. Output circuitry:

The output connector is a BNC connector mounted to the rear panel. The output voltage unless otherwise specified

is the measured voltage divided by 100. Normal useable output range is ±3V.

Page 3

Page 7

E. Probe purging:

Probe purging improves instrument performance especially with regard to zero stability, noise and sensitivity to

variations in probe-to-surface spacing. An optional purge kit Model 1017/22G available from Monroe Electronics

maintains an even airflow, reduces temperature variations and filters out dust and other particles.

Contact potential is a function of these variables and should be considered when making any changes in the purging

techniques. Care should be taken to maintain the purged air as free from chemical vapor contamination as

possible.

Probes may also be purged using clean, dry oil-free air from a local source or through the use of dry nitrogen or

other inert gas. Pressure needs only be sufficient to maintain a positive flow of gas out of the sensitive aperture to

prevent foreign materials from entering and, in no case should it exceed ½ psi (14” w.c.). All materials used should

have low out-gassing properties.

For best results, leave purge in continuous operation. For long term storage, cover the end of the probe with the

plastic cap supplied or with aluminum foil to seal against contamination.

Page 4

Page 8

SECTION 3

CONTROLS AND INDICATORS

FRONT PANEL - Figure 3-1

A. STBY/OPER Switch:

This push-push switch controls the operating condition of the unit. So long as power is applied, the following is true:

STANDBY Starts the probe oscillating but leaves the high voltage disabled.

OPERATE Activates high voltage only if the probe is plugged in and the tuning fork is oscillating.

B. Display:

The 4½-digit LED display is normally illuminated when power is applied to the unit and acts in a secondary capacity

as a power indicator.

A minus (-) sign at the left side of the display indicates that a negative voltage is being measured and is displayed

approximately 50% of the time (a polarity indecision) when the instrument is properly zeroed while measuring an

input signal of zero. No sign is displayed for a positive input.

The display may be turned off for darkroom use by actuating the push-push display switch through the access hole

in the panel with a suitable tool such as the point of a pen.

C. ZERO 1:

Balances internal probe contact potential to obtain probe to surface spacing insensitivity. This adjustment

procedure is described in Section 4A. ZERO 1 may also be used for large zero offset when spacing insensitivity is

not needed.

D. GAIN:

Closed loop system gain varies with probe to surface spacing. Excessive gain at close spacing causes instability

and insufficient gain at large spacing produces sluggish response and static error.

E. ZERO 2:

Compensates for unwanted system offsets over a range of approximately ±4 volts and does not affect probe to

surface spacing insensitivity. Adjustment procedure is outlined in Section 4. Once set, this operator accessible

adjustment usually does not require further attention except in critical applications.

F. Probe receptacle:

Mates with Model 1034 series probes manufactured by Monroe Electronics. An appropriate and functional probe

must be connected for the instrument to operate.

To connect the probe to the instrument, hold the plug (on probe cable) so that the two arrows are on top. Align with

the receptacle and push straight in until a “click” is heard.

To disconnect, hold the part with the two arrows and pull straight out. This will release the locking device.

Do not connect or disconnect the probe with power applied.

Page 5

Page 9

REAR PANEL - Figure 3-2

G. Power Entry Module:

The Power Entry Module combines power inlet, switch and fusing system. Power supply voltage is usually factory

preset for local conditions.

When in doubt, check! See Appendix II for details.

H. Ground jack:

Instrument ground - the reference point for measurement. The instrument is normally grounded through the power

cord. This jack accepts a standard size banana plug (0.175” [4.4mm] across flats).

I. Recorder output:

The signal at this BNC jack is a low voltage representation of the input. The output voltage is equal to the measured

voltage measured divided by 1000 or 0 to ±3 volts for full scale (±17 volts full scale typical for ÷200 option and ±19

volts full scale typical for ÷100 option). Representative uses include observation or recording of waveforms or levels

seen by the input, monitoring of safe/unsafe electrostatic operating conditions in equipment and low level process

control in electrostatic feedback loops.

J. Probe receptacle:

Duplicate of (F) provides the option of a probe connection at the rear of the instrument. Only one or the other may

be used. Model 279 will not support two probes simultaneously.

Page 6

Page 10

SECTION 4

OPERATION

CAUTION:

Verify that instrument operating voltage matches local power line voltage. See Section 2 and Appendix II.

PRECAUTIONARY NOTE

Model 279 is a non-contacting voltmeter. The potential of the probe will attempt to follow the potential of any object

within the field of view of the sensitive electrode (up to

of operator safety and also to reduce high voltage stress within the instrument, it should be left in the STANDBY

mode whenever it is not being used and particularly when the probe will not be “looking” at a surface potential of

less than 3000V.

A. Initial setup:

As shipped from the factory, the instrument is set up to make general-purpose electrostatic measurements except

for zero adjustment.

1. Position probe approximately

2. Switch into OPERATE mode.

3. Adjust ZERO 1 for an indication of 0000 on meter.

1

/8” from a grounded surface.

3400 volts) when the instrument is operating. In the interest

4. Proceed with measurements.

B. Restoration of factory settings:

The following steps are necessary only if the factory settings of ZERO 2 and/or GAIN controls have been disturbed

as evidenced by a constant zero offset or unstable performance at close probe to surface spacing.

ZERO 2

1. With the probe positioned as above, switch into STANDBY mode.

2. Adjust ZERO 2 for an indication of 0000 with approximately 50% polarity indecision.

GAIN

This adjustment requires a metallic test surface at least 3- 4 inches (50-75mm) square and a means of applying

repetitive pulses or square waves to it. Amplitude should be in the order of 100-300 volts with a rise time

significantly better than 2 milliseconds. An oscilloscope is also required.

1. Set GAIN to maximum counterclockwise (CCW ) rotation.

2. Position probe 0.005” (0.13mm) from the test surface.

3. Apply repetitive pulses to the test surface while observing the output of the 279.

4. Adjust GAIN for optimized transient response (fastest rise time with minimum overshoot and no oscillatory

tendency).

Page 7

Page 11

SECTION 5

THEORY

A. General: Principle of Operation (See Figure 5-1)

The electrostatic electrode "looks" at the surface under measurement through a small hole at the base of the probe

assembly. The chopped AC signal induced on this electrode is proportional to the differential voltage between the

surface under measurement and the probe assembly. Its phase is dictated by the DC polarity.

The reference voltage and this mechanically modulated signal, conditioned by the high input impedance preamplifier

and signal amplifier are fed to a phase sensitive detector whose output DC magnitude and polarity are dictated by

the amplitude and phase of the electrostatically induced signal relative to the reference signal. The output of the

phase sensitive detector feeds a DC integrating amplifier. Its output polarity is inverted to that of the unknown. The

output of this amplifier is used to drive a high voltage amplifier, which in turn drives the probe to the same potential

as that of the surface under measurement.

The probe is driven to a DC voltage typically within 0.1% of the potential of the unknown for a 2-3mm probe-tosurface spacing. By simply metering the output of the H.V. amplifier, one has an accurate indication of the unknown

potential.

Figure 5-1

B. Null balance: (ZERO 1)

This instrument's basic operating principle, i.e., "field-nulling" provides a high degree of immunity to errors in

measurement caused by variations in probe-to-surface separation. As long as the probe and the surface under

measurement are at the same potential the electrical field between them is zero, neglecting fringing, regardless of

the probe-to-surface distance.

Page 8

Page 12

If, however there exist voltage sources in the vicinity of the sensitive electrode which are independent of the

unknown to be measured, the offsets produced will detrimentally affect the spacing independence. Such voltage

sources include contact potential differences among the internal probes parts, small specks of charged dust

particles, etc.

The null balance circuitry is provided to neutralize such offsets by applying a voltage directly to the sensitive

electrode.

C. Zero: (ZERO 2)

The instrument's zero control is a voltage source connected in the metering circuitry. It is used to overcome offsets

produced by voltage sources external to the probe.

D. Gain:

The instrument functions as a closed loop unity gain voltage follower. Its open loop gain from probe to integrator is

determined by the gain of various amplifiers. The exact gain required for optimum transient responses during a

specific measurement is determined by the probe-to-surface spacing used. In order to accommodate

measurements at various probe-to-surface separations, a front panel gain control is provided which controls the

gain of the signal amplifier.

Page 9

Page 13

SECTION 6

ADJUSTMENT

A. General:

The following procedure sequence is such that it will aid in troubleshooting the unit. The circuit board layout is

illustrated in 3570/22. All test points and reference numbers used in this section are indicated on schematic 279L/1,

assembly drawing 3570/22 and are identified in Table 6-2 at the end of this section.

The procedure should be followed in the order given to prevent possible interaction of controls.

A phase-compensated (normal) Monroe Electronics, Inc. Model 1034E or 1034S miniature probe must be used

wherever the use of a probe is indicated.

B. Recommended Equipment:

Oscilloscope – 50kHz bandwidth, 0.1mV/div sensitivity

Compensated high voltage probe for oscilloscope (optional)

High voltage source –

Digital voltmeter – five-digit, 0.1mV resolution

High voltage probe – 1000:1,

Shorting plug, ME P/N 9232301, Keystone P/N 1463 (used at JP8)

500V, Stanford Research Systems Model PS350 or equivalent

0.01% (for DVM)

C. Initial Setup and Adjustments:

1. Insure that available nominal power line voltage and frequency match those shown of the back panel of the

unit and that the line voltage selector is properly configured. (See Section 2, INSTALLATION).

apply power at this time.

2. Remove cover from unit.

3. Consult Table 6-2. Make the following potentiometer adjustments: Set R53, R54, R108 and R111 to

midrange. Set R55 and R56 counterclockwise. Set R107 clockwise.

4. Connect a probe to the rear panel connector and fixture it to look at a metal test plate at least six inches

(150mm) square at a distance of 0.005 inch (0,13mm).

5. Connect a high voltage source to the test plate and set its output for zero volts.

6. Install a shorting plug at JP8 and disconnect P300. Jumpers JP1, JP3, JP4, JP6, and JP7 should be

installed.

7. On the front panel, put the OPER/STBY switch in STBY and turn on the display.

Do not

8. Connect the 279 to the appropriate source of power and turn on the rear panel power switch.

D. Low Voltage Power Supply Check:

Check the following test points with a digital voltmeter between the test point and chassis.

Test Point D.V.M. Reading

TP15

TP16

TP18

TP20

-15 VDC 0.5 V

+15 VDC 0.5 V

+15 VDC 0.5 V

-15 VDC 0.5 V

Table 6-1

Page 10

Page 14

E. Probe Oscillator Adjustment:

Connect an oscilloscope probe to TP5 and adjust R53 for a 6 Vp-p sine wave.

F. Demodulator Phase Adjustment:

1. Move the oscilloscope probe to TP3 and adjust the ZERO 1 pot on the front panel for a null (straight line) on

the oscilloscope.

2. Apply +10V to the test plate and adjust R65 for the best representation of a negative going half-wave

rectified sine wave with an amplitude of about 0.2V.

3. Switch the test plate voltage to –10V and the oscilloscope should display a positive going half wave.

G. FET String Bias Adjustment:

1. Switch off the rear panel power switch.

2. Remove JP4.

3. Tie TP8 to TP6.

4. Connect a DVM acrossR309 of the 279L/71 board.

5. Connect P300.

rectifier.

6. Switch on the rear panel power switch.

7. Adjust R55 for 40mV on the DVM.

8. Move the DVM from R309 to R311.

9. Adjust R56 to match the N-FET bias reading. Switch off the rear panel power switch.

WARNING! When the power is on, high voltage will be present on the high voltage

H. High Voltage Adjustment:

1. Remove the ground from TP8.

2. Remove the jumper at JP8.

3. Replace jumper JP4.

4. Connect the DVM from chassis ground to end of R303 nearest the edge of the 279L/71 board and the DVM

should read about +390V.

5. Move the DVM input lead to the end of R314 nearest the edge of the 279L/71 board and DVM should read

about -390V.

6. Remove the DVM.

I. Speed of Response:

1. Set the gain pot, front panel recessed, for about midrange.

2. Connect the oscilloscope to the rear panel output connector.

3. With the 279L in standby, STBY/OPER switch out, check the range of the ZERO 2 pot on the front panel

meter. It should swing plus and minus with a total of about 10V. Zero the front panel meter with ZERO 2.

4. Push the operate switch and then zero the front panel meter with the ZERO 1 pot on the front panel.

5. Apply a repetitive +300V pulse to the test plate.

6. Adjust the gain pot, the integrator gain pot (R54) and the oscilloscope controls until a critically damped step

response between 0% and 100% is observed. Rise and fall times from 10% to 90% should be typically

5ms.

Page 11

Page 15

7. Check the response to negative steps in a similar manner.

8. Switch to standby.

J. Noise Check:

1. Replace the oscilloscope with an rms voltmeter. Noise is typically 0.6mV rms.

K. Output Calibration:

1. Connect the rear panel output connector to a DVM

2. Adjust ZERO 1 for zero volts on the DVM and the front panel meter.

3. Slowly apply voltage to the test plate until it is precisely +300V.

4. The DVM at the output should +3.00V

5. The front panel meter should indicate +300.0

6. Repeat steps 3 through 5 using –300v.

7. Remove the test equipment and replace the cover. This completes the adjustment procedure.

0.1%. Adjust R5 if necessary to meet this condition.

0.1% LSD.

Page 12

Page 16

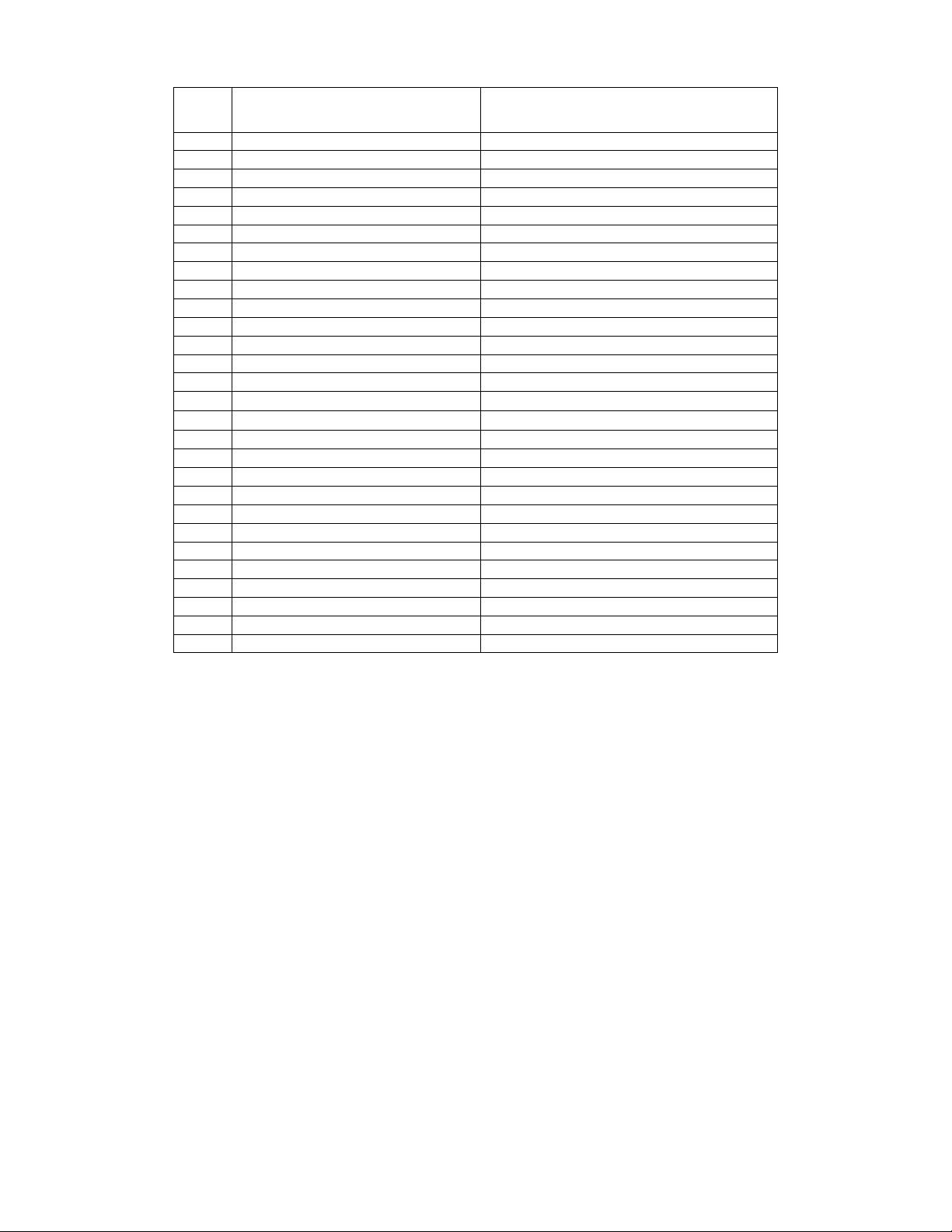

ID Description NOTE

JP1 HV TEST

JP3 VM OPTion

JP4 Driver link

JP6 Standard output option selector

JP7 Standard output option selector

JP8 HV JUMPER Shorting plug, ME P/N 9231029

JP13 3KV Red wire

R5 1/1000 cal.

R8 SET 37 VDC

R53 OSCillator LEVEL

R54 INTegrator GAIN

R55 +BIAS

R56 -BIAS

R65 DEMODulator PHASE

R107

R108

R111

TP1 *Located on FET boards

TP3 DEMODULATOR SIGnal

TP5 CARRIER REFerence OSCillator

TP6 Common

TP8 Set bias

TP10 37 V+

TP11 37 VTP15 -15 VDC Chassis referenced power supply

TP16 +15 VDC Chassis referenced power supply

TP18 +15 VDC Floating power supply

TP20 -15 VDC Floating power supply

GAIN

ZERO 1

ZERO 2

Recessed through front panel

10 turn pot on front panel with knob

Recessed through front panel

Table 6-2

Page 13

Page 17

SECTION 7

TROUBLESHOOTING

PRECAUTIONARY NOTE

Model 279 is a non-contacting voltmeter. The potential of the probe will attempt to follow the potential

of any object within the field of view of the sensitive electrode (up to

is operating. In the interest of operator safety and also to reduce high voltage stress within the

instrument, it should be left in the STANDBY mode whenever it is not being used and particularly when

the probe will not be “looking” at a surface potential of less than 3000V.

A. General:

BEFORE ATTEMPTING TROUBLE-SHOOTING TECHNIQUES, CONSIDER THE FOLLOWING:

1. Attempt to determine mode and cause of failure. If you broke it you probably have some idea

how. If someone else did, try to get as many details as possible.

2. Check control settings. Review the CONTROLS and INDICATORS section of this manual.

3. Check power line voltage. Be sure that VOLTAGE SELECTOR is in the correct position.

Check fuse.

4. Look for obvious physical damage (charred parts, loose connections, broken solder joints,

broken circuit board, etc.)

3400 volts) when the instrument

5. Check calibration. If it appears that the instrument is uncalibrated, review the ADJUSTMENT

section of this manual.

6. Always rectify the cause of the problem.

B. User checklist:

1. INDICATION—Power switch at rear of instrument is ON—no display illumination.

a) Check display button recessed behind front panel. Should be latched in to turn display

on. See Paragraph 3B.

b) Check fuse(s) and line voltage settings. See Appendix II.

INDICATION—Power switch is ON—no sound from probe. NOTE: A faint 1kHZ tone should

2.

normally be heard emanating from the tuning fork chopper in the probe.

a) Check to be sure that the probe connector is firmly locked in its receptacle.

b) Check for physical damage to probe (dents in case, cut cable, dirt or dust inside of

aperture) that would prevent the tuning fork from operating.

INDICATION—Arcing between probe and surface under test.

3.

a) GAIN too high at close spacing—system unstable.

b) GAIN too low at close spacing—system cannot follow fast high voltage transient

c) Surface voltage beyond range of instrument.

INDICATION—Operator receives shock from probe.

4.

a) DO NOT TOUCH metal body of probe while in operation.

b) Check for frayed or damaged insulation.

INDICATION—Unit does not seem “calibrated”.

5.

a) There is no “calibration” necessary from an operator standpoint. The instrument is

factory calibrated and certified so. Otherwise, calibration is recommended following

repairs to the instrument or annually unless more frequent calibration is required by

contract.

b) Probes are not calibrated; they either work or they don’t work.

c) Review the steps in the OPERATION Section, Section 4.

Page 14

Page 18

C. Detailed Troubleshooting – Initial Setup:

1. Follow instructions given in Section 6-C; Initial Setup and Adjustments leaving out Step 3

(potentiometer adjustments).

OPER/STBY switch in STBY.

NOTE: The following steps are done with the front panel

D. Low Voltage Power Supplies:

1. With a DVM, check between chassis ground and TP-16 and TP-15 for plus and minus 15

volts. These are the ground referenced (non-floating) supplies for some of the output

circuitry. Incorrect readings could indicate trouble at A-1 or A-2 or their associated circuitry or

trouble with the supplies themselves, A-9 and A-10 and their associated circuitry.

2. With a DVM, check for plus and minus 15 volts at TP-18 and TP-20. These are the floating

supplies for the signal and reference circuits and are supplied from PS300 on the 279L/71

card.

E. Reference and Signal Section:

1. With floating common still tied to ground with JP-8 (Section 6-C-6), connect an oscilloscope

probe to TP-5. There should be a 6V p-p sine wave of about 1kHz present. The amplitude

should be adjustable with R-53. Trouble here usually indicates a defective probe.

2. Move the oscilloscope probe to TP-3. Turn the front panel GAIN pot (R-107) clockwise and

zero the display with ZERO 1 pot (R-108). Apply +100 volts to the test plate and the

oscilloscope should display a negative-going half wave rectified signal of about 1V p-p. Minus

10 volts on the test plate should produce a positive-going half wave rectified signal of about

1V p-p.

3. If the demodulator signal is incorrect, check for a +15 volt square wave at TP-4 and a 15 volt

p-p sine wave at the carrier signal test point TP-2 when 100VDC is applied to the test plate.

Page 15

Page 19

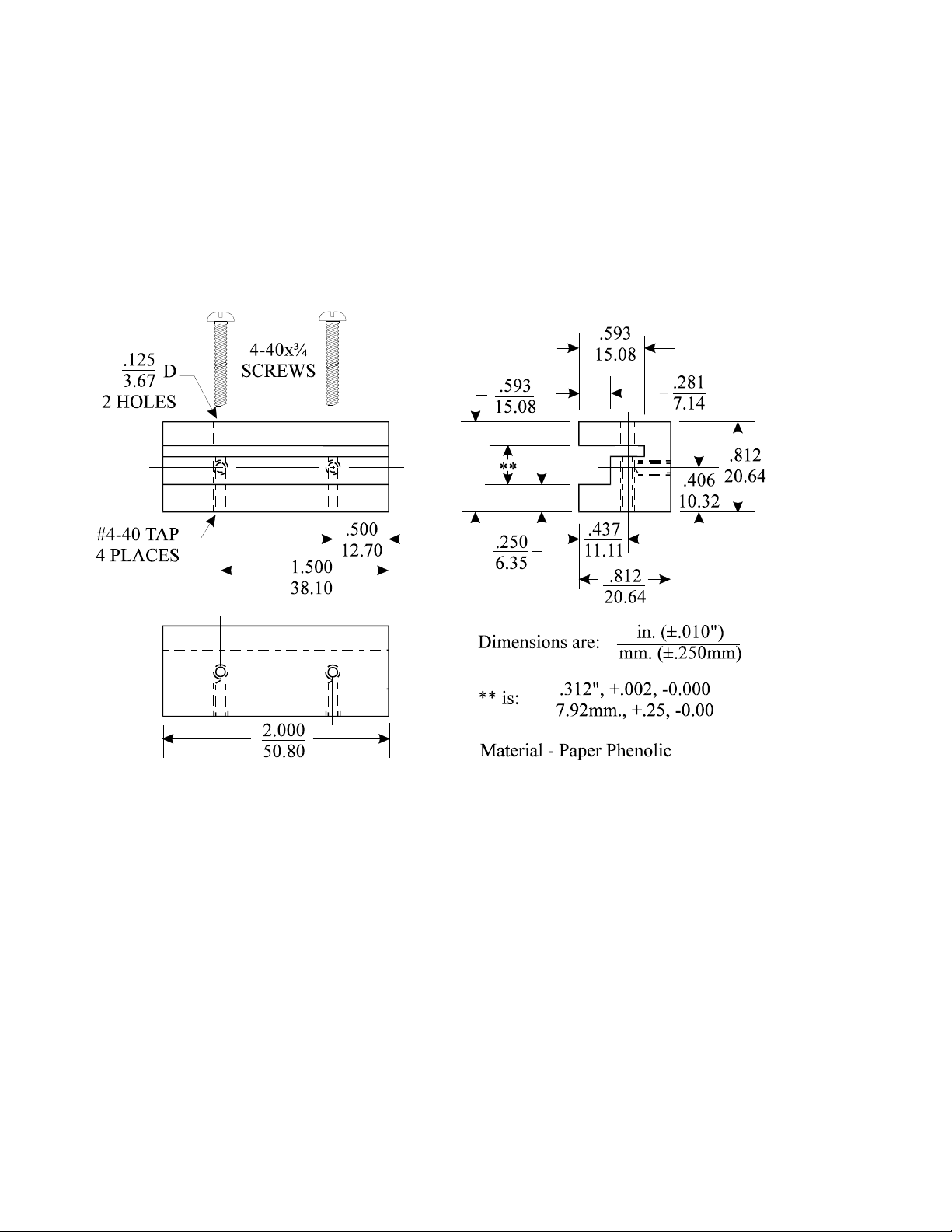

APPENDIX I

MODEL 1034 PROBE MOUNTING

The Monroe Electronics, Inc. Model 1034 Miniature Probe is intentionally constructed with no mounting

devices, as any such mounting device would serve only to enlarge the physical dimensions. It is,

therefore, left to the user to devise a method of mounting the probe to suit his individual needs and to

realize the fullest potential of the inherently small size.

As supplied, the probe is partially jacketed by a length of irradiated polyolefin shrinkable tubing. This

jacket provides insulation of sufficient dielectric strength that the probe may be hand-held or clamped

using light pressure for use within the operating range of the Model 279 ISOPROBE

Voltmeter.

This tubing is otherwise not essential to the operation of the probe. IT MAY BE REMOVED AND

DISCARDED, IF DESIRED. It must, in fact, be removed if the probe is to be disassembled for any

purpose such as cleaning (in those procedures involving removal of the case). A sharp model maker's

knife may be used to slit the tubing using CAUTION to assure that the cable jacket is not nicked or slit.

5

If replacement is required, a 2

/8-inch length of ALPHA FIT221-3/8 or equivalent is recommended.

Apply heat only long enough to shrink the tubing in place as damage to the sensitive electronics and

adhesives within the probe may result from prolonged elevated temperature on the outside of the case.

®

Electrostatic

When devising fixturing for the Model 1034 probe, consideration must be given to the fact that the

normal operating range of the Model 279 ISOPROBE

®

Electrostatic Voltmeter is 3000 volts and that

the probe assumes the potential of the surface under measurement within these limits. The probe,

therefore, must be insulated from other parts of the system.

Choice of insulating materials, although not critical in many applications, should be limited, if possible,

to "leaky" dielectric materials with relatively low volume resistivities (in the general order of 10

10

ohmcm) as opposed to those such as polystyrene, which is a very good insulator. Example of "leaky"

insulators are the phenolics. The primary purpose in this is to provide a discharge path for the

insulator which has a short relaxation time. This is especially important in the vicinity of the sensitive

aperture.

The Model 279 is capable of driving a capacitive load of several hundred picofarads without severe

degradation in performance. It is possible, therefore, to attach the probe to some fixed portion of the

apparatus via a metal clamp, so long as the metal clamp is insulated from the remainder of the

apparatus.

In any friction clamp design, the pressure (unit force) on the probe case should be kept low, thus over

as large an area of the case as possible as distortion of the gold plated brass may otherwise occur.

One possible configuration is illustrated in Figure A-I-1.

For general bench use burette or utility clamps attached to a ringstand or similar support may prove

adequate. These are available from scientific supply houses.

An attractive alternative to clamping is the use of double sided adhesive tape or fast-setting

polymerizing adhesives such as LOCTITE* SuperBonder 495 cyanoacrylate adhesive or equivalent

which does not require long setting or curing time and provides a relatively permanent bond.

LOCTITE* is a registered trademark of and is available from:

*LOCTITE CORPORATION

Newington, CT 06111

(208) 278-1280

279L-0401-RCA Page 16

Page 20

Figure A-I-1

Page 17

Page 21

APPENDIX II

POWER ENTRY MODULE

This instrument uses a Corcom, Inc. M Series Power Entry Module that combines a power inlet, switch and fusing

system in one compact unit. The IEC 320 power inlet accepts any suitably terminated cordset. The ON/OFF switch

is DPST and has international I/O markings. The selectable fuseholder allows use of single or dual European fuses

or a single North American fuse. A voltage selector provides a convenient means to change transformer primary

connections to interface with worldwide power sources.

An exploded view of the power entry module with its components identified is shown below in Figure A-II-1:

Figure A-II-1

Voltage selection:

The nominal voltage to which the power entry module is set is indicated by the indicator pin visible in one of the

holes adjacent the voltage markings.

To change selected voltage: open cover using a small blade screwdriver or similar tool; set aside cover/fuse block

assembly; pull voltage selector card straight out of housing using indicator pin; orient selector card so that desired

voltage is readable at the bottom; orient indicator pin to point up when desired voltage is readable at the bottom

(note that when the indicator pin is fixed; successive voltages are selected by rotating the card 90

voltage selector card into housing,

voltage first; replace cover and verify that the indicator pin shows the desired voltage.

Voltage selector card orientation is shown in Figure A-II-2.

printed side of card facing toward IEC connector and edge containing the desired

clockwise); insert

Figure A-II-2

279L-0401-RCA Page 18

Page 22

Fuse changing:

Figure A-II-3a

European fusing arrangement

North American fusing arrangement

Figure A-II-3b

Figure A-II-4

Fuse block/cover assembly

To change from North American to European fusing: open cover using a small blade screwdriver or similar tool;

loosen Phillips screw 2 turns; remove fuse block by sliding up, then away from Phillips screw and lifting up from

pedestal; change fuses (note that

neutral [lower] holder); invert fuse block and slide back onto Phillips screw and pedestal; tighten Phillips screw and

replace cover (note that the fuse[s] that go into the housing first are the active set.)

See SPECIFICATIONS for recommended fuses.

two European fuses are required, although a dummy fuse may be used in the

279L-0401-RCA Page 19

Page 23

APPENDIX III

HV BREAKDOWN CONSIDERATIONS

Air is subject to dielectric breakdown when the probe-to-surface spacing is small and the difference in voltage

between the probe and the surface under test is high. A destructive arc-over can occur damaging the surface under

test and/or the sensitive circuitry of the probe. Under normal operating conditions this is usually not a problem as

the probe housing is driven to a voltage essentially identical to the unknown and the difference in voltage is very

close to zero.

®

Under normal circumstances the Model 279 ISOPROBE

to its high voltage amplifier limits — a few hundred volts above its specified range of ±3000 volts.

Electrostatic Voltmeter can follow the unknown voltage up

Figure A-III-1

279L-0401-RCA Page 20

Page 24

APPENDIX IV

ACHIEVING SPACING INDEPENDENCE

Eliminating Zero Shift Over a Large Probe-to-Surface Spacing Range

This instrument’s basic operating principle is to null the electric field between a surface under measurement and the

sensitive electrode in the probe. When the potential of the surface under measurement is zero, the instrument

drives the sensitive electrode and the probe housing (a reference surface) to zero potential, thereby nulling the

electric field between the probe and the surface under measurement.

Ideally, only the surface under measurement contributes to this process. However, if other voltage sources exist in

the vicinity of the sensitive electrode, which are independent of the unknown to be measured, offsets are produced.

Such voltage sources include contact potential differences among internal probe parts, small specs of charged dust,

etc. The ZERO1 control is provided to counter such offsets by applying a voltage directly to the sensitive electrode.

The influence of these voltage sources is usually not the same at all probe-to-surface separations. Their influence

will vary in proportion to the probe-to-surface separation and will cause the instrument zero offset voltage to vary

with probe-to-surface spacing changes. This effect can be minimized to afford a high degree of zero stability over a

range of spacing changes. This is known as spacing independence.

The following procedure is used to optimize the spacing independence of the instrument:

1. Position the probe at the minimum spacing to the surface under test. Apply zero volts to the surface under

test.

2. Switch the instrument to the OPERATE mode and adjust the GAIN for a critically damped or somewhat

over-damped condition.

3. Adjust the ZERO2 control for a zero output voltage from the instrument.

4. Re-position the probe to the maximum spacing from the surface under test.

5. Adjust the ZERO1 control for a zero output voltage from the instrument.

6. Return the probe to the minimum spacing to the surface under test.

7. Repeat steps 3 through 7 until the zero shift is minimized to the desired level.

279L-0401-RCA Page 21

Loading...

Loading...