Page 1

E35 CONVECTION OVEN

SERVICE

MANUAL

Revision 5/F3512

January, 2004

Manual P/N M0ME35

Page 2

CONTENTS

This manual is designed to take a more in depth look at the E35 convection oven for the purpose of making

the unit more understandable to service people.

There are settings explained in this manual that should never require to be adjusted, but for completeness

and those special cases where these settings are required to change, this manual gives a full explanation

as to how, and what effects will result.

SECTION PAGE NO.

1. SPECIFICATIONS.............................................................................................................................. 5

2. INSTALLATION.................................................................................................................................. 8

3. OPERATION....................................................................................................................................... 10

3.1 Description of Controls

3.2 Explanation of Control System

4. MAINTENANCE ................................................................................................................................. 15

4.1 Cleaning

4.2 Routine Procedures

5. TROUBLE SHOOTING GUIDE .......................................................................................................... 17

6. SERVICE PROCEDURES.................................................................................................................. 20

6.2 Access

6.3 Replacement

6.4 Adjustment / Calibration

7. ELECTRICAL SCHEMATICS ............................................................................................................ 36

8. ELECTRICAL WIRING DIAGRAMS .................................................................................................. 39

9. SPARE PARTS .................................................................................................................................. 42

10. ACCESSORIES / OPTIONS............................................................................................................... 45

IMPORTANT: MAKING ALTERATIONS MAY VOID WARRANTIES AND APPROVALS.

Revision 5/F3512

-3-

Page 3

PARTS DIAGRAMS ..................................................................................................................................... 46

11.1 Main Assembly

11.2 Control Panel Assembly

11.3 Gear Plate Assembly

11.4 Door Assembly

SERVICE CONTACTS ................................................................................................................................. 60

APPENDIX A. STACKING KIT INSTRUCTIONS........................................................................................ 62

APPENDIX B. STAND MOUNTING INSTRUCTIONS ................................................................................ 65

APPENDIX C. MOTOR CONTROL AND STEAM TIMER ADJUSTMENT GUIDE .................................... 66

Revision 5/F3512

-4-

Page 4

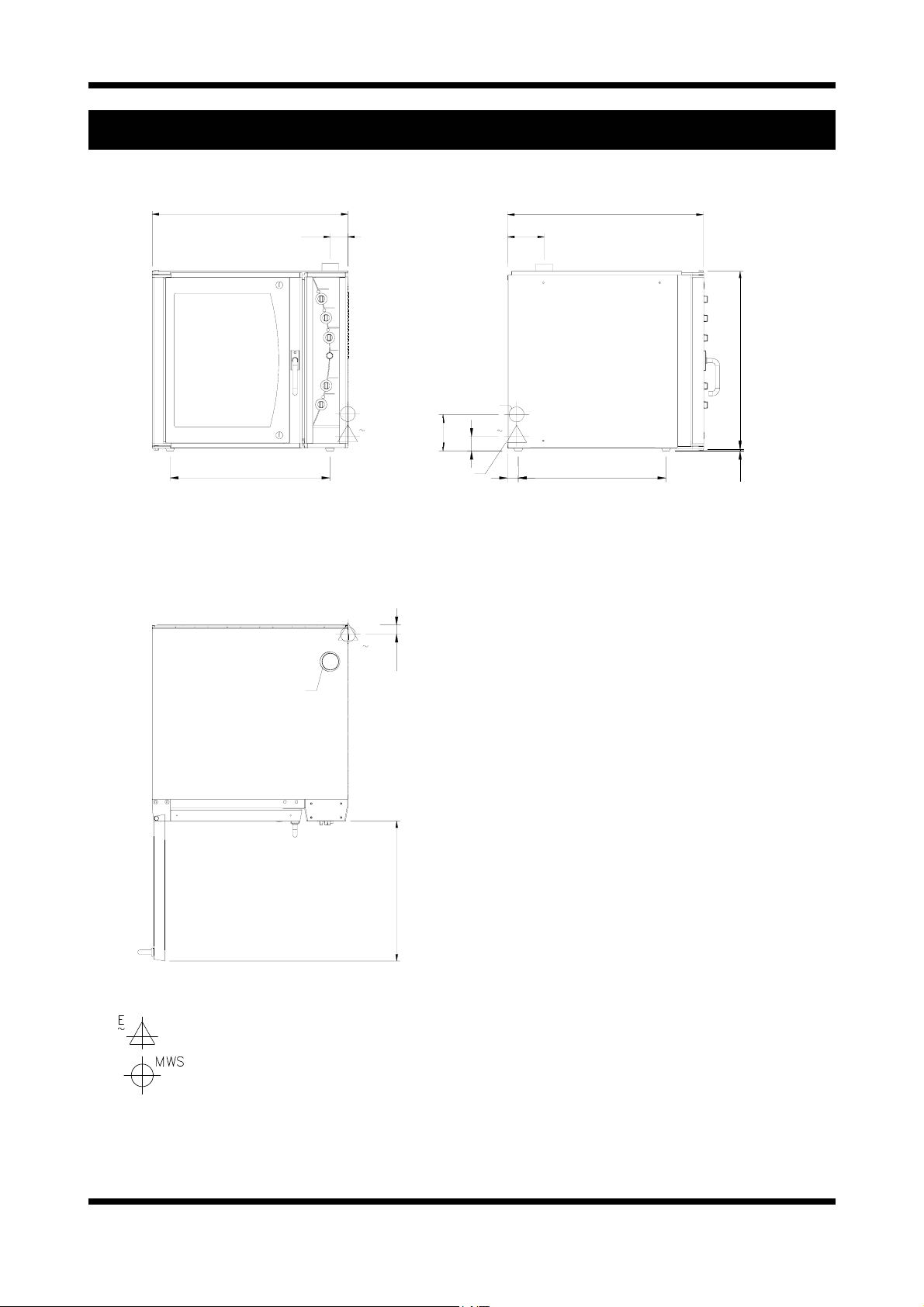

MODEL: E35-26

880

880

(34.6)

1. SPECIFICATIONS

78

78

(3.0)

165

165

(6.5)

880

880

(34.6)

800

800

(34.6)

FRONT

720

720

(28.3)

VENT Ø 76 O.D.

(3.0)

MWS

E

3

ELECTRICAL ENTRY

MWS

E

3

40

40

(1.6)

WATER ENTRY

55

(2.2)

155

165

(6.1)

0

3

E

(1.9)

48

MWS

SIDE

665

6650

(26.2)

9

12

(0.5)

PLAN

LEGEND

- Electrical connection entry point

- Water entry - 3/4” BSP hose connection

Dimensions shown in millimetres.

Dimensions in inches shown in brackets.

Revision 5/F3512

630

630

(24.8)

-5-

Page 5

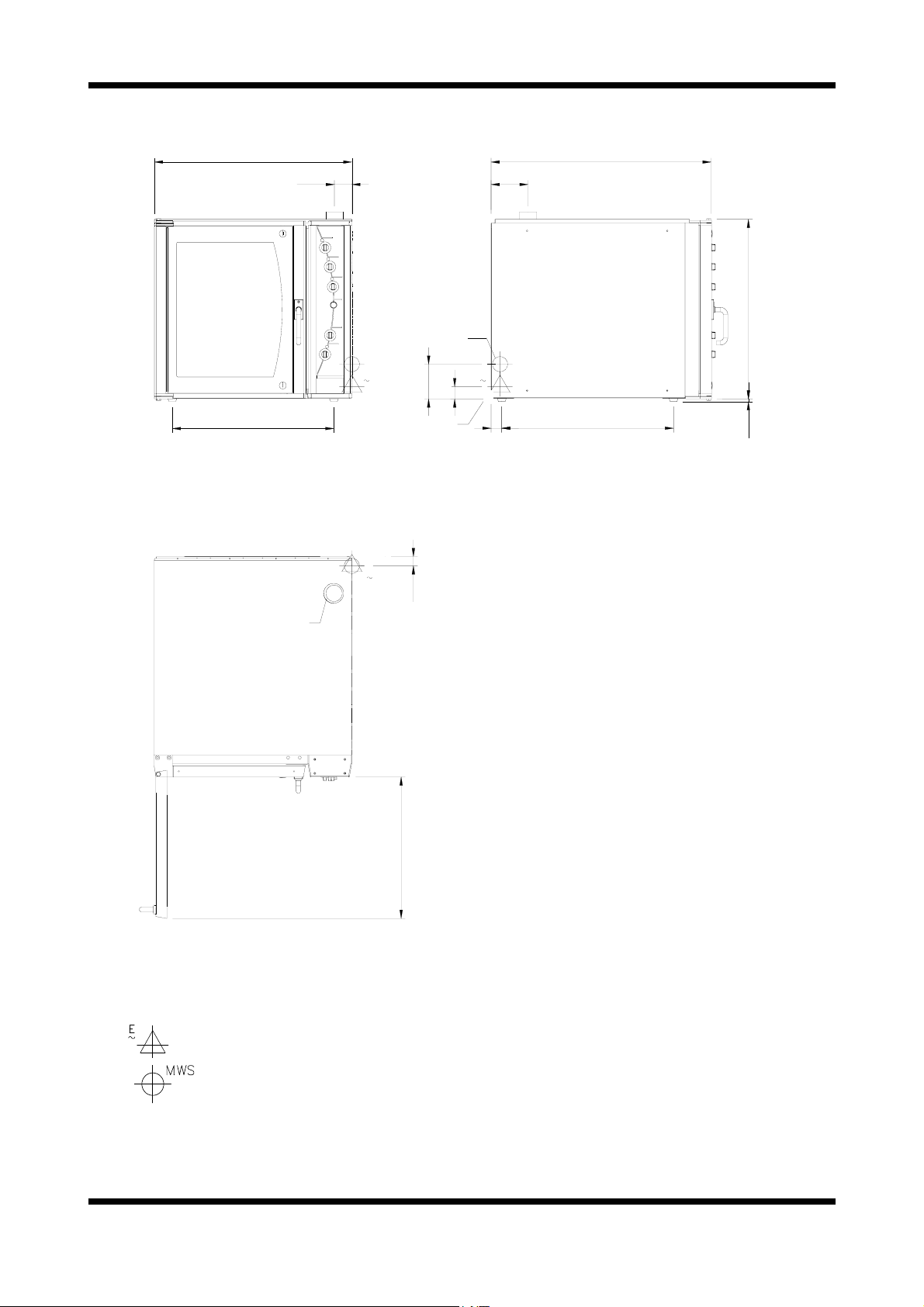

MODEL: E35-30

FRONT

880

880

(34.6)

720

(28.3)

VENT Ø 76 O.D.

(3.0)

78

78

(3.0)

WATER ENTRY

MWS

E

3

ELECTRICAL ENTRY

MWS

155

155

(6.1)

E

3

41

40

(1.6)

980

980

165

165

(6.5)

MWS

E

3

55

(2.2)

0

48

(1.9)

(38.6)

765

7650

(30.1)

800

800

12

12

(34.6)

(0.5)

SIDE

PLAN

LEGEND

- Electrical connection entry point

- Water entry - 3/4” BSP hose connection

Dimensions shown in millimetres.

Dimensions in inches shown in brackets.

Revision 5/F3512

630

630

(24.8)

-6-

Page 6

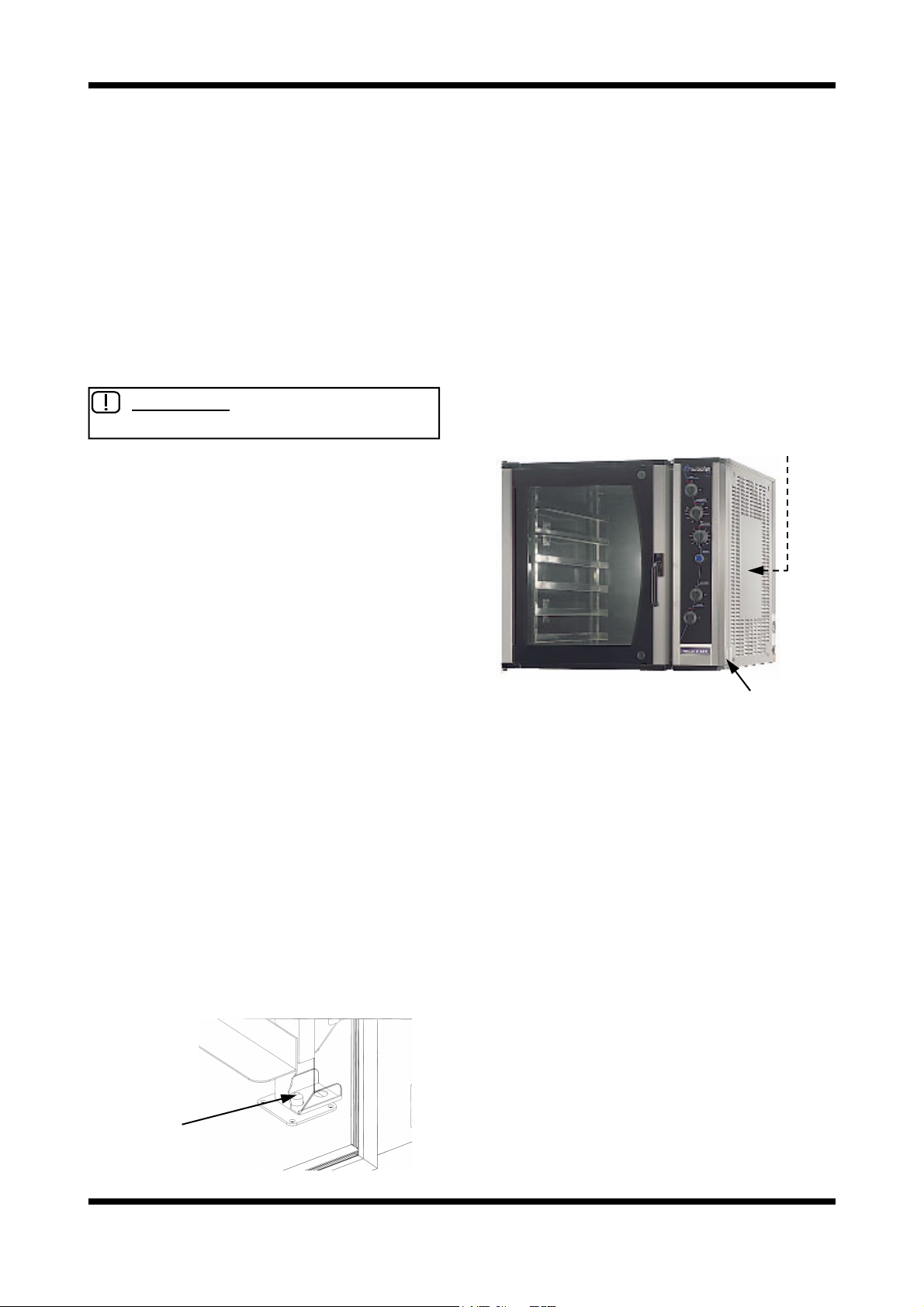

LOCATION

To ensure correct ventilation for the motor and

controls the following minimum installation

clearances are to be adhered to:

Rear 0mm / 0“

Left-hand side 0mm / 0”

Right-hand side 75mm / 3.0”

OVEN INTERNAL DIMENSIONS

E35-26

Width 465mm / 18

1

/4”

Height 685mm / 27”

Depth 760mm / 30”

Oven Volume 0.24m³ / 8.5ft³

E35-30

Width 465mm / 18

1

/4”

Height 685mm / 27”

Depth 860mm / 34”

Oven Volume 0.27m³ / 9.7ft³

OVEN RACK SIZE

Width 460mm / 18” or 405mm / 16”

(Adjustable shelf width)

Depth 660mm / 26” or 760mm / 30”

(Based on oven size model)

OVEN RACK SPACING

6 Tray (standard) 105 mm / 4

1

/8”

8 Tray (option) 78 mm / 3“

ELECTRICAL SUPPLY SPECIFICATION

OPTIONS

208V, 60Hz, 1P+N+E, 53.7A, 11.2 kW

220V, 50Hz, 1P+N+E, 56.8A, 12.5 kW

220-240V, 60Hz, 1P+N+E, 52.0A, 12.5 kW

230-240V, 50Hz, 1P+N+E, 52.0A, 12.5 kW

208V, 60Hz, 3P+E, 31A/Ph, 11.2 kW

220V, 50Hz, 3P+E, 33A/Ph, 12.5 kW

220-240V, 60Hz, 3P+E, 50.7A/Ph, 12.5 kW

220V, 60Hz, 3P+E, 32.8A/Ph, 12.5kW

380V, 60Hz, 3P+N+E, 18.9A/Ph, 12.5kW

380V, 50Hz, 3P+N+E, 18.9A/Ph, 12.5 kW

400-415V, 50Hz, 3P+N+E, 17.4A/Ph, 12.5 kW

400-415V, 50Hz, 3P+N+E, 11A/Ph, 8kW

ELECTRICAL CONNECTION WIRE

CONDUCTOR SIZES

1P+N+E/Gnd 6AWG/10mm² Copper T75 min

3P+E/Gnd 10AWG/6mm² Copper T75 min

3P+N+E/Gnd 12AWG/4mm² Copper T75 min

WATER SUPPLY CONNECTION

Max Pressure 550 kPa / 5.5 bar / 80 psi

Min Pressure 100 kPa / 1.0 bar / 15 psi

Revision 5/F3512

-7-

Page 7

2. INSTALLATION

WARNING: THIS APPLIANCE MUST BE GROUNDED.

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY

QUALIFIED PERSONS ONLY.

It is most important that the oven is installed

correctly and that the operation is correct

before use. Installation shall comply with local

electrical, health and safety requirements.

BEFORE CONNECTION TO POWER SUPPLY

Unpack and check unit for damage and report

any damage to the carrier and dealer. Report

any deficiencies to your dealer. Fit the feet which

are packed inside the oven. Check that the available power supply is correct to that shown on the

rating plate located on the right-hand side panel.

208V, 60Hz, 1P+N+E, 53.7A, 11.2 kW

220V, 50Hz, 1P+N+E, 56.8A, 12.5 kW

220-240V, 60Hz, 1P+N+E, 52.0A, 12.5 kW

230-240V, 50Hz, 1P+N+E, 52.0A, 12.5 kW

208V, 60Hz, 3P+E, 31A/Ph, 11.2 kW

220V, 50Hz, 3P+E, 33A/Ph, 12.5 kW

220-240V, 60Hz, 3P+E, 50.7A/Ph, 12.5 kW

220V, 60HZ, 3P+E, 32.8A/Ph, 12.5kW

380V, 60Hz, 3P+N+E, 18.9A/Ph, 12.5kW

380V, 50Hz, 3P+N+E, 18.9A/Ph, 12.5 kW

400-415V, 50Hz, 3P+N+E, 17.4A/Ph, 12.5 kW

400-415V, 50Hz, 3P+N+E, 11A/Ph, 8kW

LOCATION

To ensure correct ventilation for the motor and

controls the following minimum installation clearances are to be adhered to:

Rear 0mm / 0“

Left-hand side 0mm / 0”

Right-hand side 75mm / 3.0”

Position the oven in its allocated working position. Use a spirit level to ensure the oven is level

from side to side and front to back. (If this is not

carried out, uneven cooking could occur). The

feet/legs used with bench or floor mounting or

provided with stands are adjustable and will require adjusting in levelling the unit. It should be

positioned so the operating panel and oven

shelves are easily reachable for loading and

unloading.

Bench Mounting

For bench mounted applications the oven must

be fitted with 100mm / 4inch feet.

Floor Mounting

For floor mounted applications the oven must be

fitted with 150mm / 6 inch legs.

Note:

Four 100mm/4 inch or 150mm/6 inch adjustable legs are available separately from your

E35 dealer as an optional extra.

Stand Mounting

Ovens that are to be mounted on stands do not

require feet or legs. Refer to Appendix B for

stand mounting instructions.

Avoid having heat producing equipment such as

fryers or steamers adjacent to the right-hand side

of oven.

BEFORE USE

Operate the oven for about 1 hour at 200°C

(400°F) to remove any fumes or odours which

may be present.

ELECTRICAL CONNECTION

Remove side cover panel to allow access to the

terminal block and strain relief cable clamp. The

cable can be fitted through the entry grommet

and secured from strain by tightening the fitted

strain relief bushing. Connect cable to the

terminals as marked. Refit cover panel.

IMPORTANT: FIXED WIRING

INSTALLATIONS MUST INCLUDE AN

ALL-POLE DISCONNECTION SWITCH.

Refer to specifications section for wire

connections required, and supply connection

conductor sizes.

IMPORTANT: THE OVEN VENT

LOCATED ON THE CABINET TOP MUST

NEVER BE OBSTRUCTED.

Revision 5/F3512

-8-

Page 8

WATER CONNECTION

A cold water supply should be fitted to the water

3

inlet (

/4” BSP hose connection) which is located

on the rear of the right hand side of the unit.

Alternately, a connection elbow and sealing

washer is supplied with this unit for direct

connection of a

1

/2” ID hose, which is

recommended for easy installation and service.

Connect water supply - Max inlet pressure 80psi /

550kPa.

Turn on water supply to check for leaks.

IMPORTANT: MAXIMUM INLET WATER

PRESSURE IS 550 kPa / 80 psi.

DOUBLE STACKING UNITS

When it is desired to mount an E35 Turbofan

oven on an E85 prover, a double stacking kit

must be used. Available from your dealer or Turbofan distributor. (see Spare Parts).

When mounting one oven on top of another, a

double stacking kit is also required.

For stacking kit assembly instructions, refer to

Appendix A.

RACK WIDTH POSITIONS

The E35 models have an adjustable rack width

setting. This allows for the racking to be

configured for 405mm/16” or 460mm/18” wide

baking sheets/pans or racks.

Position the side racks in their innermost position

for 16” trays and in their outermost position for

18” trays.

Removal of Side Racks (as illustrated)

1) Lift the side rack off the bottom locating pins.

2) Move bottom of rack toward centre of oven.

3) Lower rack to clear top locating pins, and

remove.

Replacement of Side Racks

1) Insert rack into the oven, placing the

appropriate holes over the top locating pins.

2) Lift the side rack over the bottom locating

pins.

3) Lower rack with appropriate holes over bottom locating pins.

RATING PLATE LOCATION

The rating plate for the E35 convection oven is

located at the bottom left corner of the RH side

panel. An internal rating plate is also located

behind the RH side panel on the vertical dividing

panel behind the electrical contactors. (Units

manufactured from July 2002).

Internal Rating Plate

Figure 2.3

Rating Plate

Locating Stud

Revision 5/F3512

Figure 2.2

-9-

Page 9

3. OPERATION

NOTE: A full user’s operation manual is supplied with the product and can be used for further referencing

of installation, operation and service.

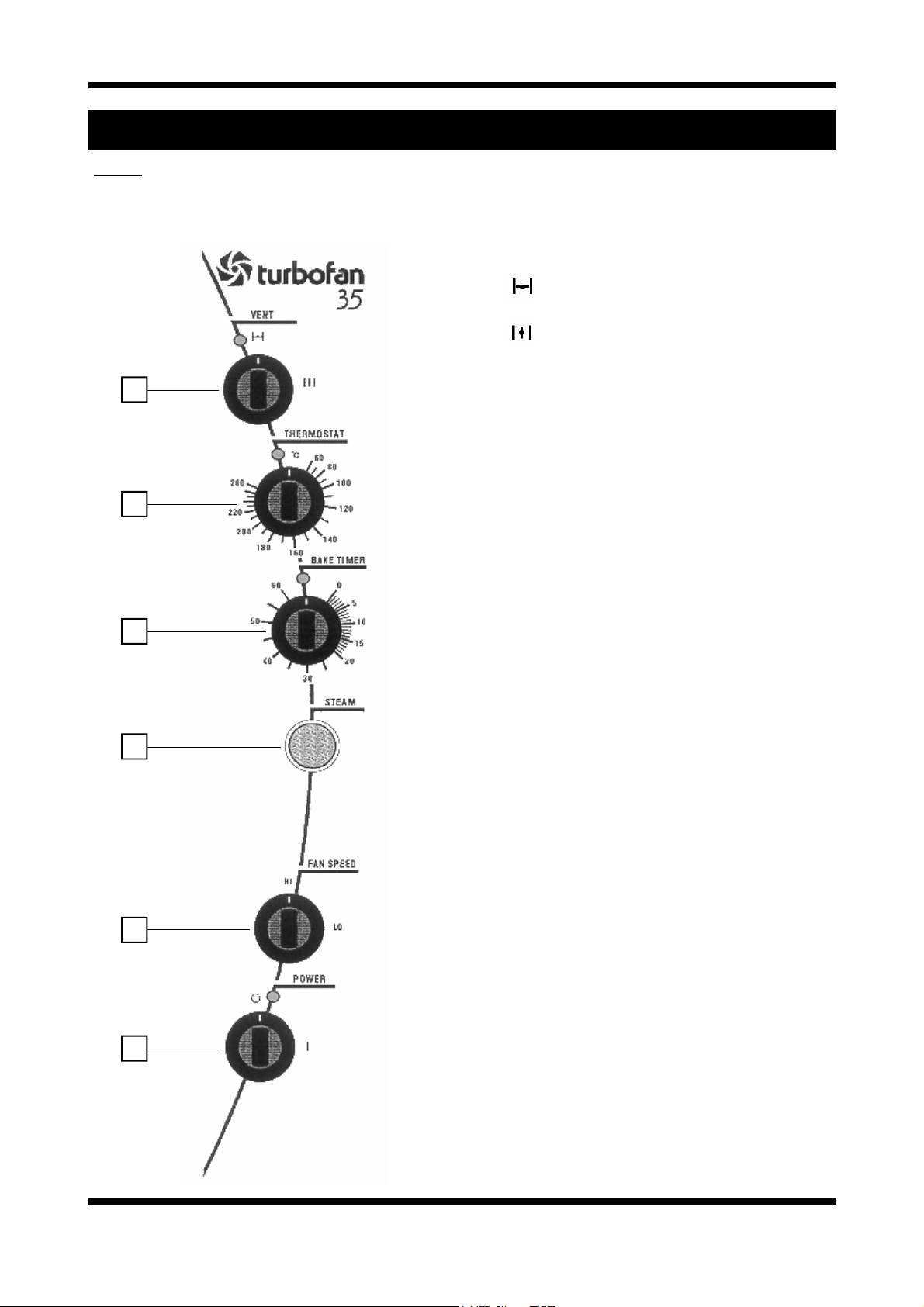

3.1 DESCRIPTION OF CONTROLS

1. VENT

Oven vent closed (incorporates over-

pressure relief when closed).

Oven vent open (light illuminates).

2. THERMOSTAT

1

2

3

4

Temperature range 60 - 280°C / 100 - 550°F.

(Light illuminates when elements are cycling ON

to maintain set temperature).

3. TIMER

1 Hour bake timer.

(Light illuminates when “time up” (0) reached, and

buzzer sounds).

4. STEAM BUTTON

Push button to activate automatic steam dose

into oven chamber.

(Light illuminates when button activated for

duration of steam cycle).

5. FAN SPEED

HI Full fan speed (Star point connection on

motor).

LO Half fan speed (Delta point connection

on motor).

6. POWER

O UNIT IS OFF

I UNIT IS ON (Light illuminates when

switched to this position).

Oven lights operate continuously.

Fan starts after 10 seconds when door

closed.

5

6

Revision 5/F3512

-10-

Page 10

3.2 EXPLANATION OF CONTROL

SYSTEM

The E35 Turbofan convection oven features

multi-function operator controls, and a combined

fan motor and steam control system.

A correct understanding of their operation is

required before carrying out any service or fault

repair work. The control device functions are

explained as follows:

Circuit Protection

All models are fitted with a 3 pole circuit breaker,

from which a control circuit is taken from L1

circuit breaker, and this control circuit is fitted with

a 6A circuit breaker. The 3 pole main circuit

breakers are rated 25A/pole for 3P+N+E/GND

and 1P+N+E/GND supply models, and 40A/pole

for 3P+E/GND (no neutral) models. These provide control circuit protection via the 6A circuit

breaker, and load circuit protection via the 3 pole

circuit breakers.

Additionally, the 3 pole circuit breaker is

mechanically connected to a Shunt Trip breaker,

which in the event of the oven fan motor

overheating will trip the 3 pole circuit breakers to

isolate power from the unit. The Shunt Trip is

directly connected to thermal limit switches in the

motor windings, and the supply Neutral (or L3 on

3 phase, no neutral models). A supply from the

6A control circuit breaker is connected to the

motor thermal switches. Should any of the motor

windings overheat, the thermal switches close

and supply power to the Shunt Trip, which in turn

trips (triggers) and mechanically trips the 3 pole

circuit breaker.

Accordingly, causes of circuit breakers tripping

can be ascertained with the above knowledge,

and this is covered in more detail in the Fault

Diagnosis section.

Power On/Off

A Power switch on the control panel isolates

power to the operator controls of the oven. With

the power switch OFF all functions of the oven

are inoperable.

An integral cooling fan, behind the control panel

used to keep the electrical controls of the oven

cool, is on continuously whenever the power

supply to the oven is on. Switching the oven

control panel Power switch off will leave the

cooling fan running.

With the Power switch ON (illuminated neon

indicator), power is supplied to all operator

controls.

Oven Lamps

The two oven lamps (12 volt halogen) are on

whenever the Power switch is on. The oven

lamps are supplied with 12 volts from an

electronic lamp transformer fitted on the

oven’s control switchgear assembly. The oven

lamps are on with the oven door open and

closed.

Bake Timer

The 60 minute bake timer is a mechanical timer

and can therefore be operated with the oven’s

power ON or OFF. However only with the oven’s

power switch On and the oven door closed will

the timer turn on the time-up buzzer and time-up

indicator neon on the control panel. The buzzer

and time-up indicator provide indication that the

time setting has run down to zero and at this point

will remain on continuously until the 60 minute

timer has been manually set back to the Off

(vertical) position. The 60 minute timer does not

control any other part of the oven’s operating

system as the timer is independent of the

temperature control, heating, fan, or steam

system.

Oven Vent

The oven vent is a manual operation by way of

the Vent knob on the control panel.

The vent knob directly rotates the vent shaft

through 90 degrees to open and close the vent.

The vent shaft passes through a rotary switch

mounted behind the control panel and this switch

is used to switch on or off the Vent indicating

neon. In the vent open position the indicator is

illuminated. The oven vent restricts venting of the

oven when in the closed position, however the

vent flap is fitted with a spring loaded

over-pressure flap which relieves excess

pressure created during oven steaming. This

avoids steam pressure escaping out of door seals

etc, if the oven is steamed with the vent closed.

The spring pressure on the over-pressure vent

flap ensures that only excess steam is lost out of

the vent.

Door Switch

The oven has a door switch, mechanical

micro-switch below oven opening, which breaks

the power supply to the oven fan, temperature,

and steam control circuits when the door is

opened. Additionally, opening the oven door will

remove power from the Bake Timer buzzer and

indicator, and the vent position indicator neon.

Revision 5/F3512

-11-

Page 11

This allows only the oven lights to be operational

if the oven door is opened.

Thermostat Control

Heating of the oven is controlled by an

electronic thermostat control, comprising of a

potentiometer dial and knob on the control panel,

a temperature sensing probe (thermistor type) in

the oven chamber, and the thermostat control

board behind the control panel. Power to the

electronic thermostat is supplied through an

over-temperature/hi limit thermostat. Accordingly

a failure of the electronic thermostat control

causing a temperature over-run will result in the

over-temperature thermostat switching and

removing power from the heating control circuit.

The over-temperature thermostat is able to be

manually reset, however a serviceman is required

to perform this function, as removal of the R/H

service panel is required to access this safety

protection device.

The electronic thermostat when set to a

temperature will illuminate the heating neon

indicator on the control panel whenever the oven

heating elements are on. When the indicator

neon goes out, the oven is up to the set

temperature.

Heating / Elements

The electronic thermostat when requiring heating

of the oven, switches power to the heating

contactor (referred to as C1 contactor in this

manual). The heating contactor closes to supply

power through to the heating elements in the

oven. In all ovens all 3 poles of the contactor are

used to supply L1, L2, and L3 phase circuits to

the 3 heating elements on each side of the oven

fan motor.

On 3 Phase + Neutral supply models, all 6

elements are looped to neutral, and the 3 Phase

power to the elements is to each set of three

elements in parallel connection. Hence each of

the elements is supplied with the Phase to

Neutral voltage.

On 3 Phase supply models (no neutral), the set

of three elements each of the fan motor are

connected in Delta configuration, which each

element being supplied the Phase to Phase

voltage.

On 1 Phase + Neutral supply models, all 6

elements are looped to neutral, and the 1 Phase

power to the elements is split into three poles at

the main circuit breakers on the oven, then feed

through the three poles of the heating contactor,

from where each pole is connected to two of the

six elements in parallel. Hence each of the

elements is supplied with the Phase to Neutral

voltage.

The heating elements are rated at 2000 Watts

each, therefore providing a total of 12000 Watts

or 12kW of heating.

In some cases special heating kilowatts may be

supplied to special request, so always check

rating plate information on the unit if in doubt.

The heating contactor cycles ON/OFF as

controlled by the thermostat to maintain set oven

temperature.

Fan / Motor

The E35 Turbofan ovens use a dual speed,

bi-directional oven fan circulation system, in order

to provide even heat distribution through the

oven, and fan speed control to suit different

product types.

To provide both dual fan speed and bi-direction, a

motor of 4pole/8pole configuration is used.

Fan / Motor Direction

The direction change is made by swapping two

phases to the motor through the motor contactors

C2 and C3. In one direction L1, L2, and L3 are

switched through motor contactor C2 with motor

contactor C3 open. In the alternate direction,

motor contactor C2 is open, and C3 is closed. L1

and L2 are reversed on the C3 contactor

connections. Motor contactors C2 and C3 are

mechanically interlocked (interlock fitted to rear of

contactors) to prevent any switching overlap.

Motor direction change is automatic, and the

duration of the direction cycle is factory set.

Additionally, a dwell period between at each

change of direction occurs to allow the motor to

restart in the opposite direction only after the

motor rotation has slowed down. This is

necessary to avoid motor overheating due to the

high current load that would be required to

change direction instantaneously.

Each direction cycle is 90 seconds long, at the

beginning of which is a preset 10 second dwell/

delay. As the dwell is at the beginning of the cycle, the fan always has a 10 second start delay

when the oven is first turned on, or when the door

is closed after opening.

The direction control timing is provided from three

electronic timers mounted below the motor

contactors on the electrical switchgear panel of

the oven. Timer T1 controls the direction cycle

time, timer T3 controls the dwell for one direction,

and timer T5 controls the dwell for the opposite

direction.

Revision 5/F3512

-12-

Page 12

When the door is closed and power is ON, cycle

timer T1 will switch power to dwell timer T3 for 90

seconds. Timer T3 will then switch power

through to motor direction contactor C2 after the

preset 10 second delay. The motor will then run

for the remainder of the 90 second cycle.

At the completion of the 90 second cycle,

cycle timer T1 will switch the power from T3 dwell

timer to T5 dwell timer. This T3 dwell timer will

then switch power through to the other motor

direction contactor (refer previous) after the

preset 10 second delay, and the motor will run in

the opposite direction for the remainder of that 90

second cycle. At the completion of that cycle the

cycle timer T1 switches power back to the other

dwell timer, and this continues until the oven door

is opened, or the power is turned off.

Fan / Motor Speed

For HI speed operation the motor is run as a 4

pole motor. (1420 rpm 50Hz/1750 rpm/60Hz) For

LO speed operation the motor is run as an 8 pole

motor. (715 rpm 50Hz/850 rpm/60Hz)

Selection of the pole configuration for run speed

is made though the motor contactors C4, C5 and

C6.

In HI speed setting the motor contactors C4 and

C6 close, C4 switching power to the motor on the

4 pole connection leads, and C6 binding 4 of the

8 motor poles to allow motor to run as a 4 pole

motor.

In LO speed setting the motor contactor C5

closes to switch power to the motor on the 8 pole

connections leads, with contactors C4 and C6

remaining open.

Motor contactors C5 and C6 are mechanically

interlocked (interlock fitted to rear of contactors)

to prevent any switching overlap between LO and

HI speed changes.

The motor speed control is by manual operation

of the Fan Speed switch on the control panel.

This rotary switch simply supplies power to either

motor contactors C4 and C6 for HI speed, or C5

for LO speed. The contactors stay closed in the

selected setting unless the oven door is opened.

Closing the oven door allows the contactors to

switch on again.

Fan / Motor - Single Phase Models

The operation of the fan motor on single phase

E35 models is the same as other three phase

models for two speed and bi-direction operation,

except for the electrical circuit required.

On single phase models the same motor is used

as on three phase models, but with capacitors in

the motor circuit to create an artificial phase lag,

that is normally part of the three phase supply on

three phase models. Use of the three phase

motor is required to retain the bi-direction

operation.

On single phase models the L1 supply to the

motor connects to the normal L1 connection of

the motor, and the Neutral supply connects to the

normal L2 (as connected on three phase models)

connection of the motor. A capacitor is then

connected to the normal L3 (as connected on the

three phase models) connection of the motor, and

this capacitor is supplied power from the L1/

Phase supply. This capacitor is referred to as the

Run capacitor as it is permanently in the circuit

during motor operation. Each motor on single

phase models has two run capacitors, one for the

LO speed operation (lower capacitance) and one

for the HI speed operation (higher capacitance).

Each Run capacitor is only used when the motor

is running at that speed setting.

Additionally a Start capacitor is also fitted on

single phase models, and is used for starting the

motor rotation at the beginning of each direction

change when in HI speed setting only. This

capacitor is switched on for approximately 7

seconds only at the beginning of each motor start

up, with a contactor C7 switching the Start

capacitor on and off, and with a timer T6

controlling the timing of the contactor C7.

Fan direction change in single phase models is

still controlled by motor contactors C2 and C3.

However unlike three phase models where C2

and C3 swap phases over to change motor start

rotation/direction, single phase models use C2

and C3 to switch the run capacitor form the L1

supply to the Neutral supply for direction change.

Control of the motor cycle timing and dwell timing

is the same as three phase models.

Motor Protection

Refer Circuit Protection at start of section.

Steam System

The E35 Turbofan ovens feature an

automatically timed oven chamber steaming

system, that allows operators to inject a 10

second period of steam into the oven at any

stage. The steam is generated when a solenoid

valve opens and supplies mains water to a

calibrated wide spray angle nozzle in the oven

that discharges the water as a fine spray into the

oven fan. The fine spray at a wide angle is then

immediately thrown by the fan circulation across

the oven heating elements either side of the fan.

The fine spray instantaneously turns to steam on

Revision 5/F3512

-13-

Page 13

the hot elements, which is supported by the hot

air of the oven also turning the water droplets into

steam.

The steam is initiated by depressing the Steam

switch on the control panel. When depressed the

steam switch provides power one of two Steam

timers which are preset to 10 seconds steam

cycle duration. These Steam timers are T2 and

T4.

T2 is associated with fan dwell timer T3 and is

used when steam is required during the fan

direction cycle that uses the T3 dwell timer.

T4 is associated with fan dwell timer T5 and is

used when steam is required during the fan

direction cycle that uses the T5 dwell timer.

This ensures that steam can be used in either fan

direction cycle, and additionally allows the fan to

be turned on as soon as steam is activated, even

if the fan was in a direction change dwell.

Ensuring that the fan is running when steam is

required is necessary to atomise the water

droplets by the mechanical action of the fan, and

by the fan throwing the water across the

elements.

The Steam switch on the control panel only

needs to be depressed momentarily as the

duration of the steam injection is automatically

timed by the steam timers. The Steam switch will

illuminate for the duration of the steam injection to

provide a visual confirmation of the steaming

process. The light in the steam switch is

independent of the switch contacts and is

powered by the electrical circuit to the water

solenoid valve. Therefore the switch is

illuminated for as long as the water solenoid is

open: 10 seconds.

Summary of Components

The electrical switchgear (not user controls)

components are summarised as follows:

C1 Heating contactor

Switches elements ON/OFF

C2 Motor direction contactor

Phases switched in line

C3 Motor direction contactor

Phases L1 and L2 swapped on 3 phase

models

Run capacitor swapped from L1 to

Neutral on 1 phase models

C4 Motor speed contactor

HI speed

C5 Motor speed contactor

LO speed

C6 Motor speed contactor

HI speed (changes motor from 8 pole

to 4 pole)

T1 Fan cycle timer

Direction cycle

T2 Steam timer

For T3 dwell direction

T3 Fan dwell timer

Alternate direction (always initial

direction dwell)

T4 Steam timer

For T5 dwell direction

T5 Fan dwell timer

Alternate direction (always 2

nd

direction

dwell)

C7 Motor start capacitor contactor.

(Single phase models only)

T6 Motor start capacitor timer

(Single phase models only)

Motor contactor interlocks fitted to C2+C3

(mounted on rear on contactors)

Motor contactor interlocks fitted to C5+C6

(mounted on rear on contactors)

The following Troubleshooting Guide should be

used to identify any incorrect oven operation. On

correct identification of the operating fault the

Troubleshooting guide will make reference to the

corrective action required, or refer to the Fault

Diagnosis section and/or Service section to assist

in correction of the fault.

Revision 5/F3512

-14-

Page 14

4. MAINTENANCE

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY

QUALIFIED PERSONS ONLY.

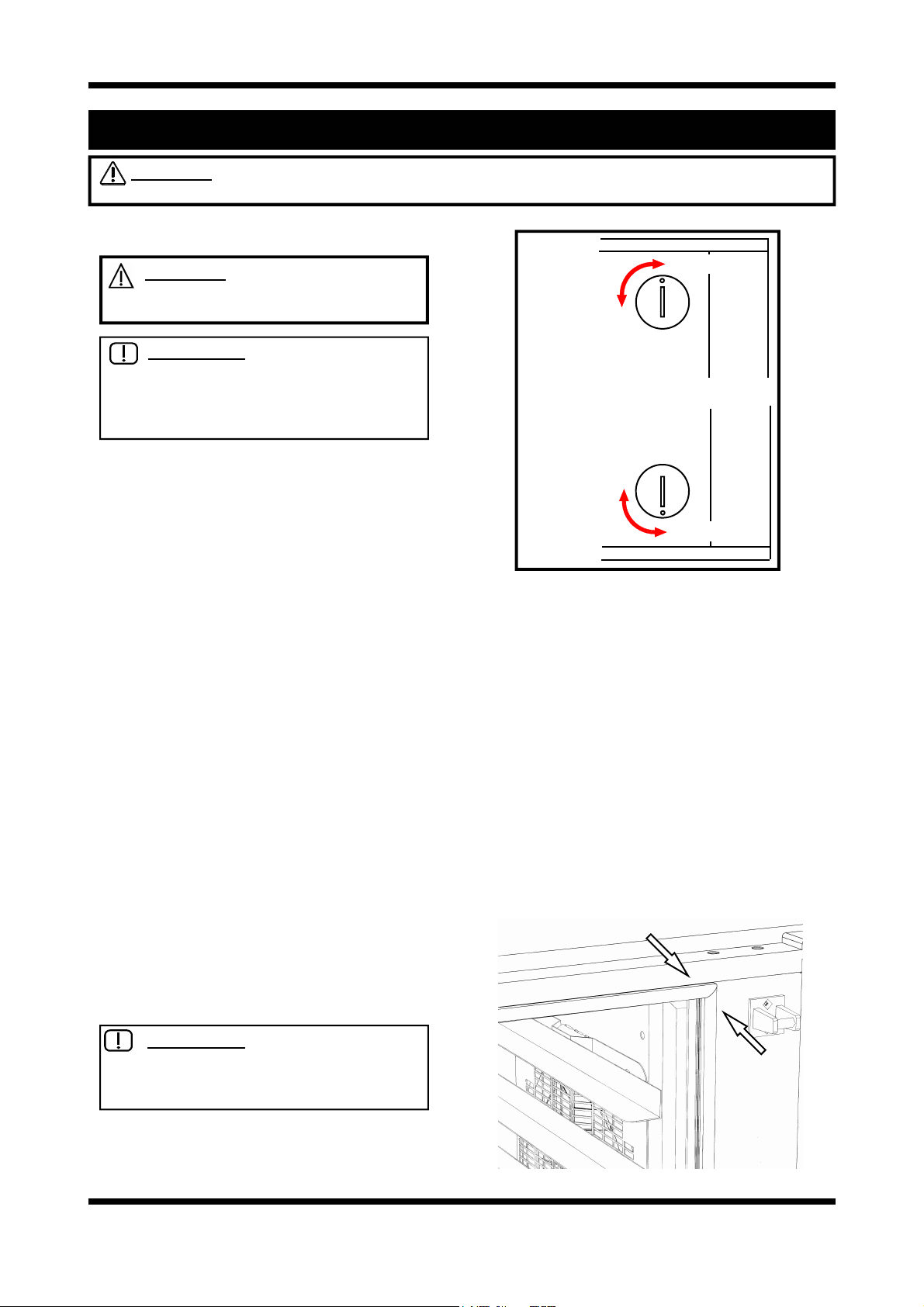

4.1 CLEANING

WARNING: ALWAYS TURN THE

POWER SUPPLY OFF BEFORE

CLEANING.

IMPORTANT: THIS UNIT IS NOT

WATER PROOF.

DO NOT USE A WATER JET SPRAY TO

CLEAN INTERIOR OR EXTERIOR OF THIS

UNIT.

EXTERIOR

Clean with a good quality stainless steel cleaning

compound. Harsh abrasive cleaners may damage the surface.

INTERIOR

Ensure that the oven chamber is cool. Do not use

wire brushes, steel wool or other abrasive materials. Clean the oven regularly with a good quality

oven cleaner. Take care not to damage the fan

or the tube at the right side of the oven which

controls the thermostat.

SIDE RACKS

To remove, follow instructions given in the

installation section.

OVEN DOOR (HINGED GLASS)

Outer surfaces: Clean with conventional glass

cleaners

Inner surfaces: To clean between the inner and

outer door glasses, firstly ensure the door is

locked shut. With a screwdriver, coin, or other

suitable device,

release the outer glass and allow it to be hinged

open for cleaning access (refer to figure 4.1 for

correct procedure).

IMPORTANT: ALWAYS ENSURE

THAT THE OUTER GLASS IS HINGED

CLOSED AND LOCKED INTO

POSITION BEFORE OPENING DOOR.

1

/4 turn the outer glass locks to

TOP

LOCKED

UN-LOCKED

UN-LOCKED

LOCKED

BOTTOM

Figure 4.1

OVEN DOOR (HINGED GLASS)

Outer surfaces: Clean stainless steel with quality

stainless steel cleaner.

Inner surfaces: Clean stainless steel with

quality stainless steel cleaner.

Door glass: Clean with conventional glass

cleaners.

OVEN SEALS

To remove, pull out the seal starting at each

corner. The seal may be washed in the sink, but

take care not to cut or damage it. To replace, fit

the seal in at the corners first, then push in the

rest of the seal.

Revision 5/F3512

Figure 4.2

-15-

Page 15

4.2 ROUTINE PROCEDURES

PROCEDURE INTERVAL

DOOR SEALS Check for deterioration. 12 months

DOOR PIVOT BUSHES Check for wear. 12 months

DOOR CATCH Ensure that catch is adjusted such that the door closes

properly.

ELEMENT Check that element resistance is correct to it’s rating (refer

6.3.12).

WATER NOZZLE Check for lime build-up in water nozzle. 12 months

12 months

12 months

Revision 5/F3512

-16-

Page 16

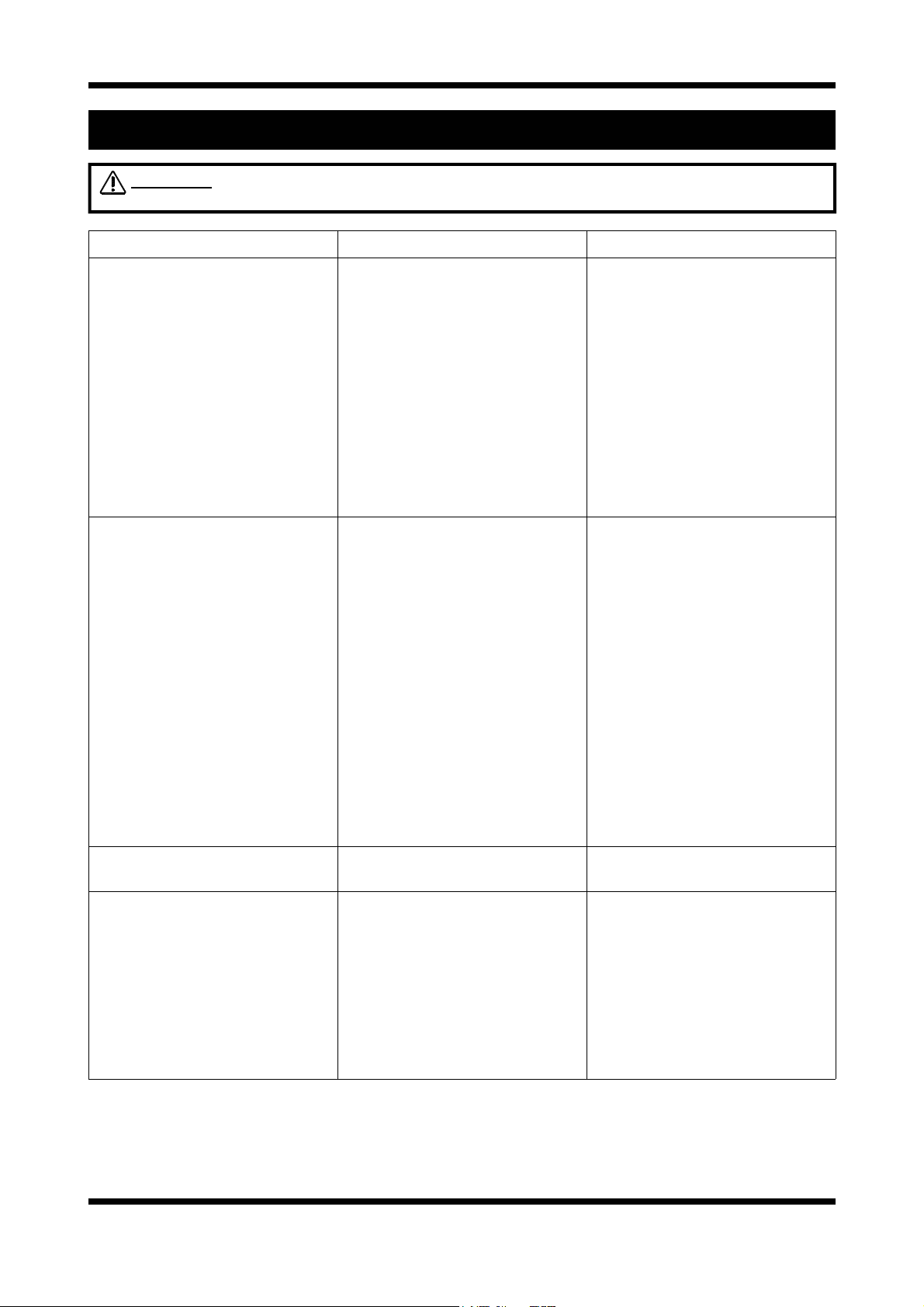

5. TROUBLE SHOOTING

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY

QUALIFIED PERSONS ONLY.

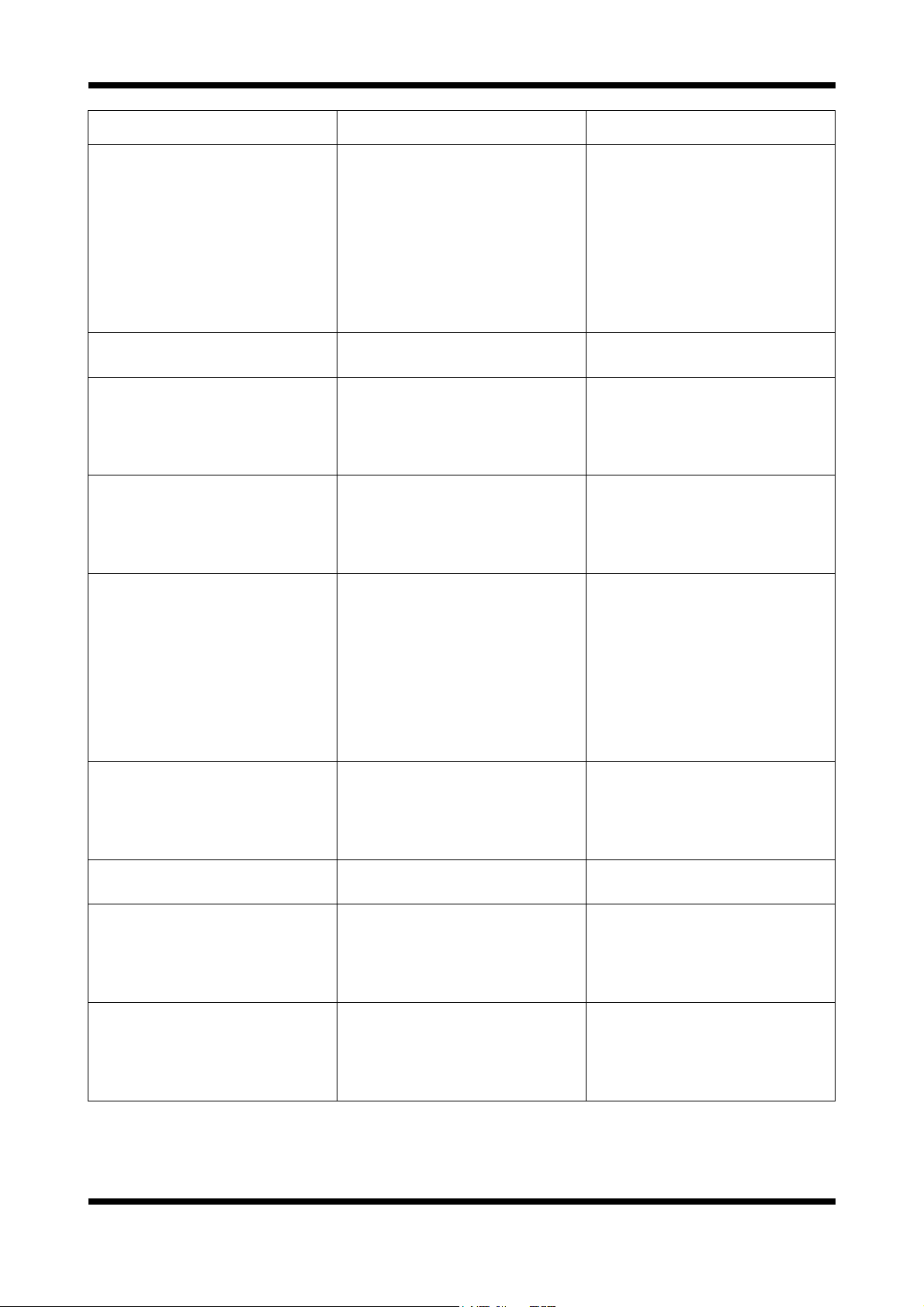

FAULT POSSIBLE CAUSE REMEDY

THE OVEN DOES NOT

OPERATE / START

FAN DOESN’T OPERATE Door not closed.

The mains isolating switch on the

wall, circuit breaker or fuses are

“off” at the power board.

The power switch on the oven is

off (‘0’).

Incorrect electrical supply.

Oven circuit breaker tripped.

Power switch on unit faulty.

(Fan only operates when the

door is closed).

Door microswitch out of

adjustment.

Door microswitch faulty.

Fan motor faulty.

Wiring.

Fan timers.

Turn on.

Turn switch to ‘I’ position.

Ensure electrical supply correct.

Identify fault.

Reset circuit breaker.

Replace.

(Refer service section 6.3.1)

Close door.

Adjust.

(Refer service section 6.4.1)

Replace.

(Refer service section 6.3.3)

Replace.

(Refer service section 6.3.21)

Check and tighten any loose

wiring.

Replace.

(Refer service section 6.3.11)

STEAM LIGHT DOES NOT

ILLUMINATE

NO STEAM

(continued next page)

Revision 5/F3512

Blown bulb. Replace bulb.

Water not turned on.

Blocked filter in water solenoid.

Nozzle blocked.

Check valve blocked/corroded.

-17-

Turn water on at isolating valve.

Clean filter.

Remove, clean or replace.

(Refer service section 6.3.16)

Remove check valve.

(Refer service section 6.3.15)

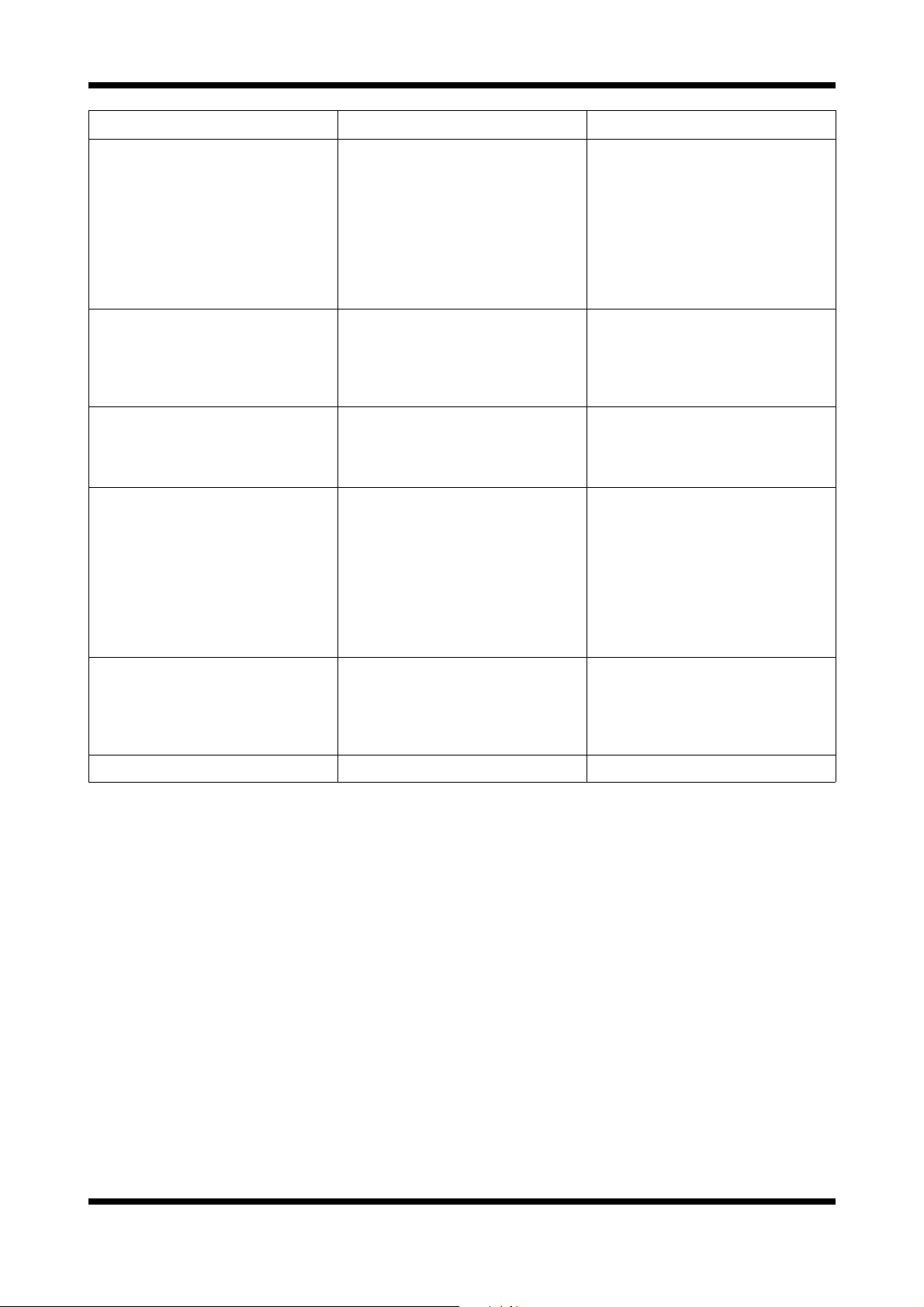

Page 17

FAULT POSSIBLE CAUSE REMEDY

NO STEAM

(continued)

STEAMS ONLY SOMETIMES Steam timer faulty.

NO HEAT Faulty contactor.

SLOW RECOVERY Faulty contactor.

NO TEMPERATURE

CONTROL

Steam tube blocked.

Faulty solenoid coil.

Steam switch faulty.

Timer faulty.

Thermostat faulty.

Element(s) blown.

Faulty door microswitch.

Faulty heating contactor.

Over-temperature control tripped.

Faulty thermostat controls.

Remove, clean or replace.

Replace.

(Refer service section 6.3.16)

Replace.

(Refer service section 6.3.14)

Adjust / Replace.

(Refer service section 6.3.11)

Replace.

(Refer service section 6.3.11)

Replace.

(Refer service section 6.3.11)

Replace.

(Refer service section 6.3.8)

Replace.

(Refer service section 6.3.11)

Replace.

(Refer service section 6.3.12)

Adjust or replace.

(Refer service section 6.3.3)

Replace.

(Refer service section 6.3.11)

Reset.

Replace.

(Refer service section 6.3.7)

OVER-TEMPERATURE

CONTROL TRIPS

TIMER WILL NOT TIME DOWN Faulty timer.

NO TIME UP ALARM

INDICATION

NO HIGH FAN SPEED

NO LOW FAN SPEED

Oven too hot, thermostat out of

calibration.

Over-temp out of calibration.

Faulty timer.

Faulty buzzer.

Fan selector switch faulty.

Fan selector switch faulty.

Replace.

(Refer service section 6.3.8)

Replace.

(Refer service section 6.3.13)

Replace.

(Refer service section 6.3.18)

Replace.

(Refer service section 6.3.18)

Replace.

(Refer service section 6.3.19)

Replace.

(Refer service section 6.3.22)

Replace.

(Refer service section 6.3.22)

Revision 5/F3512

-18-

Page 18

FAULT POSSIBLE CAUSE REMEDY

OVEN LIGHTS NOT

ILLUMINATING

Blown bulb(s).

Faulty lighting transformer.

NOTE: If both light bulbs have

blown then there will be no

output from the lighting

transformer.

OVEN VENT INDICATOR NOT

ILLUMINATING WHEN IN ‘OPEN’

POSITION

Indicator faulty.

Switch faulty.

OVER-PRESSURE VENT NOT

OPERATING DURING STEAM

CYCLE

Vent blocked.

Over-pressure vent mechanism

restricted.

DOOR DOES NOT CLOSE Tray in way of door.

Door seal obstruction.

Door handle in wrong position.

Door setting incorrect.

Replace.

(Refer service section 6.3.4)

Replace.

(Refer service section 6.3.6)

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.23)

Remove and clean blockage.

Remove and clean.

Correctly position tray in rack.

Correctly install door seal.

(Refer maintenance section)

Reposition door handle.

Adjust.

(Refer service section 6.4.3)

DOOR SEAL LEAKS Door seal damaged.

Door seal incorrectly fitted.

Replace.

(Refer maintenance section)

Correctly install door seal.

(Refer maintenance section)

RACKS DO NOT FIT Incorrect pin location. Relocate on correct pin.

Revision 5/F3512

-19-

Page 19

6. SERVICE PROCEDURES

WARNING: ENSURE POWER SUPPLY IS SWITCHED OFF BEFORE SERVICING.

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY

QUALIFIED PERSONS ONLY.

SECTION PAGE NO.

6.2 ACCESS ............................................................................................................................................. 22

6.2.1 Control Panel ...................................................................................................................... 22

6.2.2 Service Panel (RH Side Panel)........................................................................................... 22

6.2.3 Baffle................................................................................................................................... 22

6.2.4 Side Panel (LH Side) .......................................................................................................... 22

6.2.5 Control Panel Rear ............................................................................................................ 22

6.3 REPLACEMENT................................................................................................................................. 23

6.3.1 Power Switch ...................................................................................................................... 23

6.3.2 Indicator Neon Light............................................................................................................ 23

6.3.3 Door Microswitch ................................................................................................................ 23

6.3.4 Light Bulb / Glass................................................................................................................ 24

6.3.5 Light Fitting ......................................................................................................................... 24

6.3.6 Lighting Transformer........................................................................................................... 24

6.3.7 Thermostat Dial .................................................................................................................. 24

6.3.8 Thermostat Board ............................................................................................................... 25

6.3.9 Thermostat Probe ............................................................................................................... 25

6.3.10 Timer / Contactor ................................................................................................................ 26

6.3.11 Elements............................................................................................................................. 26

6.3.12 Over Temperature Thermostat ........................................................................................... 26

6.3.13 Steam Switch ...................................................................................................................... 27

6.3.14 Spray Nozzle ...................................................................................................................... 27

6.3.15 Check Valve........................................................................................................................ 27

6.3.16 Water Solenoid ................................................................................................................... 27

6.3.17 Cooling Fan ........................................................................................................................ 28

6.3.18 Bake Timer ......................................................................................................................... 28

6.3.19 Buzzer................................................................................................................................. 28

6.3.20 Oven Fan ............................................................................................................................ 28

6.3.21 Fan Motor ........................................................................................................................... 29

6.3.22 Fan Speed Selector Switch ................................................................................................ 29

6.3.23 Vent Switch ......................................................................................................................... 29

6.3.24 Vent / ‘Over Pressure’ Vent ................................................................................................ 29

6.3.25 Door Outer Glass ................................................................................................................ 30

6.3.26 Door Inner Glass................................................................................................................. 30

6.3.27 Door Catches ...................................................................................................................... 30

6.3.28 Door Handle........................................................................................................................ 30

6.3.29 Door Catch Mechanism ...................................................................................................... 30

6.3.30 Door Handle Mechanism .................................................................................................... 31

Revision 5/F3512

-20-

Page 20

6.4 ADJUSTMENT / CALIBRATION........................................................................................................ 31

6.4.1 Door Microswitch Adjustment ............................................................................................. 31

6.4.2 60 Minute Timer Zero Position Adjustment......................................................................... 31

6.4.3 Door Setting / Adjustment................................................................................................... 32

6.4.4 Door Reversal..................................................................................................................... 32

6.4.5 Fan and Steam Timer Operation / Adjustment ................................................................... 34

Fan / Steam Flow Chart...................................................................................................... 35

Revision 5/F3512

-21-

Page 21

6.2 ACCESS

6.2.4 SIDE PANEL (LH SIDE)

6.2.1 CONTROL PANEL

1) Remove vent knob by pulling straight off.

2) Remove screw above vent shaft.

One Screw

Figure 6.2.1

3) Panel is now free to hinge at bottom, take

care not to drop panel or pull wires out.

(support panel while working with panel

open).

6.2.2 SERVICE (RH SIDE) PANEL

1) Undo the 4 screws holding panel.

1) Undo the 4 screws holding panel.

2) Remove panel.

6.2.5 CONTROL PANEL—REAR

Vent Indicator

Heating Indicator

Thermostat

Bake Time Up

Indicator

Bake Timer

Four Screws

Figure 6.2.2

2) Remove panel.

6.2.3 BAFFLE

1) Remove racks, trays and RH side rack.

2) Undo the 4 nuts holding the baffle.

3) Pull panel off studs, pull bottom into middle of

oven and remove panel.

Four Nuts

Steam Switch

Fan Speed Selector

Switch

Power Indicator

Power Switch

Figure 6.2.4

Revision 5/F3512

Figure 6.2.3

-22-

Page 22

6.3 REPLACEMENT 6.3.3 DOOR MICROSWITCH

1) Open oven door.

2) Remove nut on front of micro-switch.

6.3.1 POWER SWITCH

1) Pull knob off front of switch.

2) Open control panel (refer 6.2.1) and undo 2

screws securing switch.

Figure 6.3.3

3) Remove 3 screws holding microswitch cover

Two Screws

Figure 6.3.1

3) Transfer wires to new switch.

4) Withdraw old switch and insert new switch,

securing with screws.

panel and drop panel down.

Microswitch

Nut

6.3.2 INDICATOR LIGHT

1) With control panel open (refer 6.2.1) remove

wires from the back of the indicator.

Indicator Wires

Figure 6.3.2

2) From back push indicator through front of

panel rotating clockwise.

3) Push new indicator in from front of panel, and

reconnect wires.

Three Screws

Figure 6.3.4

4) Remove 2nd nut on front of micro-switch, to

free micro-switch. (Loosen / remove 2 bolts

holding micro-switch bracket as required).

2nd Microswitch

Nut

Figure 6.3.5

5) Transfer wires to new the new switch and reassemble.

Common

Revision 5/F3512

Normally Open

Normally Closed

(Not used)

Figure 6.3.6

6) Adjust micro-switch (refer 6.4.1).

-23-

Page 23

6.3.4 LIGHT BULB / GLASS

6.3.6 LIGHTING TRANSFORMER

1) Remove LH side rack from oven.

2) Undo the four screws holding light face

surround on and remove the glass and

surround. Check the seal and replace if

necessary.

Four Screws

Figure 6.3.7

3) Pull bulb straight out of fitting, towards back

of oven (taking care not to break glass).

Replace bulb.

NOTE:

The bulb is a halogen lamp, so do not

touch the glass of the bulb while pushing

straight into light fitting (use an oil free cloth

or paper towel).

4) Replace seal, glass and surround, securing

with the screws (do not over tighten).

1) With R/H service panel removed (refer 6.2.2)

transfer wires to new transformer with the aid

of a screw-driver.

2) Remove one screw and loosen the second

screw securing the transformer.

Two Screws

Figure 6.3.9

3) Remove the old transformer and secure the

new transformer with the screws.

6.3.7 THERMOSTAT DIAL

1) Pull knob off front of thermostat.

2) Open control panel (refer 6.2.1) and undo two

screws securing thermostat bracket.

6.3.5 LIGHT FITTING

1) Remove glass and surround (refer 6.3.4).

2) Remove LH side panel (refer 6.2.).

2) Disconnect wires at connector block (inside

LH side panel).

Top Light Connector

Block

Bottom Light Connector

Block

Figure 6.3.8

3) Open fibreglass to expose lamp fitting.

4) Push in tabs at back of light fitting from

outside oven, pivot into oven and remove.

5) Re-assemble in reverse order.

Two Screws

Figure 6.3.10

3) Transfer wires to new thermostat.

4) Undo nut holding thermostat to bracket

Thermostat Nut

Figure 6.3.11

Revision 5/F3512

-24-

Page 24

5) Withdraw old thermostat and insert new

thermostat, securing with nut.

6) Re-assemble in reverse order.

e

P

u

g

n

r

p

a

l

r

e

O

Y

e

l

l

o

w

6.3.9 THERMOSTAT PROBE

1) Remove R/H service panel (refer 6.2.1) and

oven fan baffle (refer 6.2.3).

2) Remove bracket on steam line inside oven

cavity by undoing the two screws.

Thermostat Dial

n

w

o

r

B

B

r

o

w

n

Thermostat Board

Figure 6.3.12

Thermostat Dial Resistances

NOTE:

Dial must be disconnected from board for

testing.

O is orange wire, P is purple wire, Y is yellow

wire.

Resistance Between

Dial Position O-P P-Y O-Y

Off 900 Ω 900 Ω 0 Ω

Halfway 900 Ω 450 Ω 450 Ω

Maximum 900 Ω 0 Ω 900 Ω

6.3.8 THERMOSTAT BOARD

1) With control panel open (refer 6.2.1) transfer

wires to new board.

2) Squeeze legs together on plastic clips holding

board and extract.

3) Push new board onto clips.

Thermostat

Board

Two Screws

Figure 6.3.14

3) Undo the 2 bolts on the flange where the

probe enters the oven (inside oven).

NOTE:

Removal of probe and its mounting plate

will require breaking of the silicone sealant.

Two Bolts

Figure 6.3.15

4) With control panel open (6.2.1) remove wires

from thermostat board (2 brown wires at bottom left of board - refer figure 6.3.13).

5) Remove probe by drawing wires into oven.

6) Install the new probe in the reverse order.

NOTE:

Ensure probe mounting plate has RTV

silicone sealant applied to sealing face to

ensure a leak proof assembly. Remove

excess sealant after tightening securing

screws.

Thermostat Probe Resistances

NOTE:

Probe must be disconnected from board

for testing.

Temperature Resistance (kΩ)

Revision 5/F3512

Figure 6.3.13

0°C (32°F) 288

37°C (99°F) 56

100°C (212°F) 6.1

-25-

Page 25

6.3.10 CONTACTORS / TIMERS ETC

6.3.12 OVER-TEMP THERMOSTAT

1) With R/H service panel removed (refer 6.2.2),

remove the din rail mounted component.

2) Install the new component onto the din rail.

3) Transfer the wires from old component to new

one.

4) On contactors C2-C3, and C5-C6, ensure that

mechanical interlock (part number 020769) is

fitted as illustrated below.

Interlock fitted to

rear of contactors

Figure 6.3.16

1) Remove service panel (refer 6.2.2) and baffle

(refer 6.2.3).

2) Remove bracket on steam line inside oven

cavity by undoing the 2 screws (figure .3.15).

3) Undo the 2 bolts on the flange where the

probe enters the oven (inside oven).

NOTE:

Removal of the probe and mounting plate

will require breaking of the silicone sealant.

Two Bolts

Figure 6.3.17

4) Undo gland nut on bracket and extract the

probe from the bracket.

6.3.11 ELEMENTS

1) With service panel and baffle removed (refer

6.2.2 & 6.2.3) remove the wires from the

element.

2) With the use of an

11

/16” tube spanner, undo

the nuts on the outside at the element ends.

3) Pull element into oven and remove.

NOTE:

When replacing or refitting elements

ensure that the fibre sealing washers are

used.

Element Resistances

NOTE:

Element must be disconnected for

testing. Resistances are given at room

temperature.

208-220V 24.2 Ω

230-240V 28.8 Ω

Gland Nut

Figure 6.3.18

5) Undo the 2 screws holding the over-temp and

remove over-temp.

Two Screws

Figure 6.3.19

6) Transfer wires from old over-temp thermostat

to the new one.

7) Install the new over-temp and probe in the

reverse order of above.

NOTE:

Ensure probe mounting plate has RTV

silicone sealant applied to sealing face to

ensure a leak proof assembly. Remove

excess sealant after tightening securing

screws.

Revision 5/F3512

-26-

Page 26

6.3.13 STEAM SWITCH

6.3.15 CHECK VALVE - UP TO S/N 261984

1) Open control panel (refer 6.2.1).

2) Prise out or rotate the switch locking tab with

a small screwdriver, and withdraw the steam

switch assembly.

Prise out switch

locking tab

Steam switch

Figure 6.3.20

Rotate switch

locking tab

Steam switch

NOTE: If the check valve becomes blocked or

corroded, the recommended course of action is to

remove the internal parts of the valve, as it is not

required for operation of the oven. The procedure

for this is given below.

1) Remove the spray nozzle (refer 6.3.14).

2) Remove the check valve with

1

/2” and 5/8”

spanners.

Check

Valve

Figure 6.3.23

3) Dismantle the valve as illustrated, and discard

the ball and spring from the valve.

4) Reassemble the valve (without the ball and

spring) and refit to the unit.

Figure 6.3.21

3) Transfer wires to new steam switch, and

re-assemble in reverse order.

6.3.14 SPRAY NOZZLE

1) Remove the fan baffle (refer 6.2.3).

2) Unscrew the spray nozzle with

9

/16” and 5/8”

spanners.

3) Clean or replace as required, ensuring

debris free on re-assembly.

Spray

Nozzle

Figure 6.3.22

Ball Spring

Figure 6.3.24

6.3.16 WATER SOLENOID

1) Ensure water supply is turned off.

2) With the R/H service panel removed (refer

6.2.2) remove the wires from the solenoid.

3) Undo the compression fitting on the output

side of the solenoid (

4) Remove the hose fitting, inlet side, and

adapter (

13

/16”), outlet side.

1

/2” spanner).

5) Remove two screws (up under bracket) and

extract.

Solenoid

Wires

Revision 5/F3512

Two Screws

Figure 6.3.25

6) Secure new solenoid with screws, and

re-assemble.

-27-

Page 27

6.3.17 COOLING FAN

1) Remove R/H service panel (refer 6.2.2).

2) Remove the fan wires from the contactors.

Fan Wires

Figure 6.3.26

2) Remove the 4 screws securing the fan to it’s

mounting bracket and remove fan.

NOTE:

There is a nut on each screw, hold the

nut while undoing the screw.

Screws (4)

Two

Screws

Figure 6.3.29

3) Transfer wires to new timer.

4) Withdraw old timer and insert new timer, securing with screws.

5) Replace knob.

6) Check timer switches off at ‘0’ mark. If slight

adjustment required, loosen the mounting

screws and rotate timer in direction required.

6.3.19 BUZZER

1) Remove R/H service panel (refer 6.2.2).

2) Remove two screws holding buzzer bracket

to panel.

Figure 6.3.27

3) Replace and re-assemble in reverse order.

4) Ensure fan and flow direction is correct sucks air out of controls and into motor cavity.

Figure 6.3.28

6.3.18 BAKE TIMER

1) Remove bake timer knob by pulling it firmly

away from control panel.

2) Open control panel (refer 6.2.1) and undo two

screws securing timer.

Two Screws

Figure 6.3.30

3) Withdraw and transfer wires to new buzzer.

4) Remove old buzzer from bracket, and secure

new buzzer.

5) Reassemble in reverse order.

6.3.20 FAN

1) With service panel and oven fan baffle

removed (refer 6.2.2 & 6.2.3) undo the 6 bolts

holding the probes and steam line.

Revision 5/F3512

Six Bolts

Figure 6.3.31

-28-

Page 28

2) Undo the steam line compression fitting on

the outside of the oven nearest the oven.

Steam Line

Compression

Fitting

6.3.22 FAN SPEED SWITCH

1) Pull knob off front of switch.

2) Open control panel (refer 6.2.1) and undo 2

screws securing switch.

Two Screws

Figure 6.3.32

3) Pull assembly (steam nozzle etc) into the

oven (without damaging probe lines) and

support clear of the fan.

NOTE:

Removal of the probe and mounting plate

will require breaking of the silicone sealant.

4) Undo the bolt in the centre of the fan (use fan

blades and heat deflector to steady).

5) Use a gear puller if necessary to remove the

fan from the tapered shaft.

6) Replace and re-assemble in reverse order.

NOTE:

Ensure probe mounting plate has RTV

silicone sealant applied to sealing face to

ensure a leak proof assembly. Remove excess sealant after tightening securing screws.

6.3.21 MOTOR

1) Remove fan (refer 6.3.19).

2) Undo the 4 bolts holding the motor in place

(from the outside) and remove motor.

Figure 6.3.34

3) Transfer wires to new switch. Pull 2nd switch

off and transfer to new switch.

4) Withdraw old switch and insert new switch,

securing with screws.

6.3.23 VENT SWITCH

1) With control panel open (refer 6.2.1) remove

the four screws securing bracket and two

screws securing switch.

Bracket

Screws (4)

Switch Screws

(2)

Figure 6.3.35

2) Remove bracket (twist to clear frame and pull

forward), and switch (pull forward).

3) Transfer wires to the new switch and

re-assemble in reverse order.

6.3.24 VENT / ‘OVER-PRESSURE’ VENT

Four Bolts

Figure 6.3.33

3) Disconnect motor leads.

IMPORTANT:

Note wire colour and terminal

connections.

4) Replace and reassemble in reverse order.

Ensure wire leads are re-connected to correct

contactor terminals.

Revision 5/F3512

1) Remove vent switch (refer 6.3.23) and Baffle

(refer 6.2.3).

2) Rotate vent shaft 180° such that the spring is

facing into the oven.

3) With 3mm Allen key remove Allen screw

holding spring and vent assembly (inside top

back RHS of oven).

Allen Screw

Figure 6.3.36

4) Internal vent pressure relief and vent shaft

can now be removed and replaced.

-29-

Page 29

6.3.25 DOOR OUTER GLASS

6.3.27 DOOR CATCHES

1) Ensure the door is locked shut

2) With a screwdriver, coin, or other suitable

device, 1/4 turn the outer glass locks to

release the outer glass and allow it to be

hinged open.

Top

Locked

Unlocked

Unlocked

Locked

Bottom

Figure 6.3.37

3) Undo the two hinges (two screws per hinge)

and remove glass assembly.

1) Open the oven door.

2) Undo two screws and pull catch straight out.

Two Screws

Figure 6.3.40

6.3.28 DOOR HANDLE

1) Open the oven door.

2) Remove the two screw caps covering the

screws on the door handle.

3) Undo two screws securing handle, and pull

straight out.

Two

Screws

Figure 6.3.38

4) Replace and re-assemble in reverse order.

6.3.26 DOOR INNER GLASS

1) Open the oven door.

2) Remove the top door trim (two screws, one

each end of trim). Take care not to drop the

glass.

Two Screws

Figure 6.3.39

3) Lift and remove glass assembly. Replace

and re-assemble in reverse order.

Two

Screws

Figure 6.3.41

6.3.29 DOOR CATCH MECHANISM

1) Remove outer glass (refer 6.3.24) and door

handle (refer 6.3.27) leaving door open.

2) Drill out the six rivets (refer figure 6.3.36, E)

on the inside of the RH door trim (A) using a

3.5mm drill.

3) Remove four screws (F) on outside of RH

door trim (A).

4) Remove trim (rotate toward inside of door).

5) Remove four screws (J) from RH inner door

trim (B), and remove trim. (Loosen bottom

trim screw (K) if required).

6) Remove two split-pins (G) from the

connecting rod (H) on latch (C).

7) With handle in open position, push latch

mechanism (C1) away from connecting rod

(H) and remove the connecting rod.

8) Remove two screws (I) securing latching

mechanism (C), and remove.

9) Replace and reassemble in reverse order.

Revision 5/F3512

-30-

Page 30

6.3.30 DOOR HANDLE MECHANISM

1) Remove outer glass (refer 6.3.24), inner glass

(refer 6.3.25) and door handle (refer 6.3.27),

leaving door open.

2) Drill out the six rivets (refer figure 6.3.36, E)

on the inside of the RH outer door trim (A)

using a 3.5mm drill.

3) Remove four screws (F) on outside of RH

outer door trim (A).

4) Remove trim (rotate toward inside of door).

5) Remove four screws (J) from RH inner door

trim (B), and remove trim. (Loosen bottom

trim screw (K) if required).

6) Remove four split-pins (G) from the

connecting rods (H) on handle mechanism

(D).

7) With handle in open position, push latch

mechanism (C1) away from connecting rod

(H) and remove the connecting rods.

8) Remove two screws (L) securing handle

mechanism (D), and remove.

9) Re-assemble in reverse order.

6.4 ADJUSTMENT / CALIBRATION

6.4.1 DOOR MICROSWITCH ADJUSTMENT

1) Open oven door.

2) Loosen nut on front of microswitch, located at

bottom right of door frame.

Microswitch

Nut

Figure 6.4.1

3) Loosen two bolts securing microswitch

bracket from underside of oven.

Two Bolts

Figure 6.4.2

4) Adjust microswitch position and tighten bolts.

C

I

C1

H

G

L

D

B

E

NOTE:

Switch should operate when door handle

approximately

1

/2 engaged (45°).

5) Repeat steps 2-5 as required, then tighten the

front nut.

J

A

6.4.2 60 MINUTE TIMER ZERO POSITION

F

1) Remove 60 minute timer knob by pulling it

firmly away from control panel.

2) Open control panel (refer 6.2.1). Loosen two

screws on control panel holding 60 minute

timer.

J

E

Two

Screws

F

G

H

C

K

Revision 5/F3512

Figure 6.3.42

Figure 6.4.3

3) The timer can now be rotated as required to

ensure that the buzzer sounds at the zero

position.

-31-

Page 31

6.4.3 DOOR SETTING ADJUSTMENT

1) Open oven door.

2) Loosen the two bolts securing the top door

hinge plate to the oven.

Two Bolts

3) Undo the bolts securing the top hinge plate

and bottom hinge plate to the left hand side of

the oven door opening and remove.

Top Hinge Plate

Figure 6.4.4

3) Adjust oven door position and tighten two

bolts.

4) Check door operation. Repeat steps 2 and 3

as necessary to ensure that door closes and

latches evenly.

6.4.4 REVERSING THE DOOR

1) Open the oven door.

2) Undo the top and bottom door hinge pivot

pins (whilst supporting the door). Remove the

oven door.

Figure 6.4.6

4) Remove the bolt catches (secured by two

screws each) from the right hand side of the

door frame, and secure to the left hand side of

the door frame.

Bolt catch (top)

Figure 6.4.7

5) Remove the microswitch nut, and undo the

three screws securing the microswitch cover

panel to the bottom of the oven.

Revision 5/F3512

Figure 6.4.5

Three Screws

Figure 6.4.8

-32-

Page 32

6) Undo the screws securing the microswitch

mounting bracket to the cover panel, turn the

bracket around, and re-secure the switch

(facing the other way).

Figure 6.4.9

7) Refit the cover panel to the bottom of the

oven with the microswitch at the left hand side

of the oven.

8) Fit the top and bottom hinge plates (removed

in step 2) to the right hand side of the oven

door opening. (The plates should be turned

upside-down from their position on the left

hand side of the oven).

9) Turn the door over and refit the pivot pins to

the hinge plates to secure the door to the right

hand side of the door opening.

10) Check the operation of the door microswitch

and adjust as necessary.

NOTE:

The door handle mechanism will now

operate in the ‘up’ direction rather than down.

Revision 5/F3512

-33-

Page 33

6.4.5 FAN & STEAM TIMER OPERATION /

ADJUSTMENT

All the timers have a dial on the front that adjusts

the time the timer switches for when control

energised. All the timers have an LED on the

front that flashes when the timer is switched.

T1 Fan Cycle Timer

This timer switches power between the clockwise

and anti-clockwise fan direction circuits, the time

set is the duration on each fan direction.

Factory set to 1

1

/2 minute.

Refer to Appendix C for timer settings.

T2 & T4 Steam Timers (2)

These should be set the same and determine the

duration of the steam, one for clockwise fan

circuit and one for anti-clockwise fan circuit. If the

steam cycle is too long water will condense on

the product and oven chamber, and oven may

cool too much - it is usually better to have

multiple cycles than a long cycle.

Factory set to 10 seconds.

Refer to Appendix C for timer settings.

T3 & T5 Dwell Timers (2)

Once again these should be set the same, this is

the delay time between fan directions and after

steaming, when no power is applied to the fan

motor. One is for the clockwise fan circuit and

one is for the anti-clockwise fan circuit.

Factory set to 10 seconds.

Refer to Appendix C for timer settings.

Figure 6.4.5 shows the function of the timers on a

time line. The grey areas are when a timer is

switched (LED flashing) or where fan is rotating /

steam injecting. The dark lines show when the

steam button has been pressed, the first is most

common while the next two show the effect of

steaming at the beginning or end of a direction

cycle. Priority (power flow) is top to bottom on

the chart (cycle timer effects all others)

T1 C y cle timer

T2 Steam Clockwise

T4 Steam Anticlockwise

T3 Dwell Clockwise

T5 D well Anti c loc kwi s e

Fan rotation

Steaming

1 1/2 min 1 1/2 min 1 1/2 min 1 1/2 min 1 1/2 min 1 1/2 min 1 1/2 min

Steam injection activated

Steam injection activated

Steam injection activated

Figure 6.4.5

Revision 5/F3512

-34-

Page 34

Fan / Steam Flow Chart

This is a guide only, for accurate representation of all connections refer to the wiring chart.

Power In

via 6A breaker

Power Switch

Anti-Clockwise

Fan Rotation

Steam

Switch

T4

T5

C3

Steam Timer

(10sec)

Dwell timer

(10sec delay)

Fan Direction

Contactor

Door Switch

Cycle timer

1min 30sec

switching time

T1

Water Solenoid

3 Phase Power

phase

change

Clockwise

Fan Rotation

Steam

Switch

Steam Timer

(10sec)

Dwell timer

(10sec delay)

Fan Direction

Contactor

T2

T3

C2

C4 & C6

Steam switch on control panel - manual activation.

Timers T4 and T2 only operate when steaming (otherwise is direct connection).

Revision 5/F3512

Hi Speed

Contactors

Fan speed

switch selection

Motor

-35-

Low Speed

Contactor

C5

Page 35

7. ELECTRICAL CIRCUIT SCHEMATIC

7.1 380-415V, 3P+N+E

Revision 5/F3512

-36-

Page 36

7.2 208-240V, 3P+E

Revision 5/F3512

-37-

Page 37

7.3 208-240V, 1P+N+E

Revision 5/F3512

-38-

Page 38

8. ELECTRICAL WIRING DIAGRAM

8.1 380-415V, 3P+N+E

Revision 5/F3512

-39-

Page 39

8.2 208-240V, 3P+E

Revision 5/F3512

-40-

Page 40

8.3 208-240V, 1P+N+E

Revision 5/F3512

-41-

Page 41

9. SPARE PARTS

PART NO DESCRIPTION

CONTROL PANEL

020822 Power Switch

020849 Neon Indicator Lights

020985 Thermostat Potentiometer

011760 Timer - 60 Min

020893 Steam Switch Assembly

020882 Solid State Thermostat

020888 Fan Speed Switch (Rear half of fan switch assembly)

020822 Fan Speed Switch (Front half of fan switch assembly)

020883K Thermostat Probe Kit

020823 Control Panel Knobs

GEAR PLATE

015966 Heating Contactor 230-240V - 50Hz

020974 Heating Contactor 208-220V, 50Hz - E35-X253 only

020772 Heating Contactor 208-240V, 60Hz

020768 Motor Contactor

020769 Contactor Interlock (Used on C2 & C3, C5 & C6)

023059 Timer- Fan Direction (Cycle)

023058 Timer - Fan Direction (Dwell) / Steam Dose

020770 Shunt Trip (Vynkier) (50Hz to S/N 230810)

021345 Shunt Trip (AB) (50Hz from S/N 230811; 60Hz All)

020975 Circuit Breaker - 3ø 40A (AB) (3ø+E models)

020776 Circuit Breaker - 3ø 25A (Vynkier) (3ø+N+E models to S/N 230810)

021563 Circuit Breaker - 3 pole 25A (AB) (3ø+N+E models from S/N 230811; All 1ø+N+E models)

020777 Circuit Breaker - 1ø 6A (Vynkier) (50Hz to S/N 230810)

021344 Circuit Breaker - 1ø 6A (AB) (50Hz from S/N 230811; All 60Hz)

020213 Lighting Transformer

021351 Oven Lamp Complete

021350 Light Bulb G4/20W Halogen

021352 Oven Lamp Glass

021354 Gasket

019369K Over Temperature Control Kit

021156 Cooling Fan

021551 Capacitor 10µF (1ø models only) - 50Hz

021553 Capacitor 20µF (1ø models only) - 50 Hz

021554 Capacitor 30µF (1ø models only) - 50Hz

021552 Capacitor 12µF (1ø models only) - 60Hz

021555 Capacitor 35µF (1ø models only) - 60Hz

021560 Relay 10A (1ø models only) - Motor start capacitor switching

021561 Relay Socket Base (1ø models only) - Motor start capacitor switching

021562 Timer on Relay 1-30sec (1ø models only) - Motor start capacitor timing

011794 Buzzer

Revision 5/F3512

-42-

Page 42

PART NO DESCRIPTION

MOTOR & ELEMENTS

020745 Motor - 380-415V 50Hz 3ø

(E35-H453-xx, E35-N453-xx, E35-X353-xx only)

020885 Motor - 220-240V 50Hz 1ø/3ø

(E35-H251-xx, E35-X25x-xx only)

020886 Motor - 208-240V 60Hz 1ø/3ø

(E35-P26x-xx, E35-T26x-xx, E35-X263-xx only)

---------- Motor Front Bearing - SKF 6204-2Z/C3LHT23

---------- Motor Rear Bearing - NSK 6203Z

025396 Fan

020896 Motor Shaft Seal

020762 Element - 230-240V 2000W

(E35-Hxxx-xx, E35-Nxxx-xx, E35-Txxx-xx only)

020763 Element - 208-220V 2000W

(E35-Pxxx-xx, E35-Xxxx-xx only)

022259 Element - 208-220V 1250W

(E358-Nxxx-xx only)

STEAM SYSTEM

020851 Water Solenoid Valve

020853 Spray Adaptor Body

020854 Spray Nozzle Cap

020819 Vent Over Pressure Spring

020824 Vent Gasket

DOOR

025043 Door Seal

020738 Hinge Bush

020754 Bolt Catch

020750 Hinge Mounting Plate Bottom

023050 Hinge Mounting Plate Top

020753 Bolting Element

020833 Door Bolt Connecting Rod

020752 Handle Gear

020751 Door Handle

020774 Microswitch

020766 Latch Assembly (Hinged glass door only)

020713K Door Inner Glass (Hinged glass door only)

022308 Glass Clamp (Hinged glass door only)

021154 Door Outer Glass Assembly (Hinged glass door only)

024150 Door Glass Assembly - Complete (Stainless steel door only)

(NOTE:

Does not include inner and outer seals)

024094 Door Inner Glass (Stainless steel door only)

024095 Door Outer Glass (Stainless steel door only)

024104 Door Inner Glass Seal (Stainless steel door only)

024105 Door Outer Glass Seal (Stainless steel door only)

024087 Door Inner Glass Clamp Frame (Stainless steel door only)

Revision 5/F3512

-43-

Page 43

RACKS

020809 Side Rack LH WA (E35-xxxx-26 only)

020810 Side Rack RH WA (E35-xxxx-26 only)

020811 Side Rack LH WA (E35-xxxx-30 only)

020812 Side Rack RH WA (E35-xxxx-30 only)

025089 Side Rack 8 Tray LH WA (E35 –xxxx- 26)

025090 Side Rack 8 Tray RH WA (E35 –xxxx- 26)

023018 Side Rack 8 Tray LH WA (E35 –xxxx- 30)

023019 Side Rack 8 Tray RH WA (E35 –xxxx- 30)

015168 Oven Rack (E35-xxxx-26 only)

020993 Oven Rack (E35-xxxx-30 only)

Revision 5/F3512

-44-

Page 44

10. ACCESSORIES

OVEN RACKS

(PART NO 015168 - 26” / 020993 - 30”)

100 MM (FOUR INCH) LEG OPTION (PART

NO 021348 x4)

150 MM (SIX INCH) LEG OPTION (PART NO

018724 x4)

DOUBLE STACKING KIT (PART NO 021236

(26”) / 021237(30”))

STAINLESS STEEL DOOR OPTION

Stainless Steel Door Conversion Kit - Part

No 024150

A26 STAINLESS STEEL STAND

Revision 5/F3512

-45-

Page 45

11.1.1 MAIN ASSEMBLY

11. PARTS DIAGRAMS

Revision 5/F3512

-46-

Page 46

Pos Part No. Description

1 020788 SIDE PANEL RH (E35-xxx-26 only, to s/n 215839)

(Replace with 23971)

023971 SIDE PANEL RH (E35-xxx-26 only, from s/n 215840)

020790 SIDE PANEL RH (E35-xxx-30 only, to s/n 215839)

(Replace with 23972)

023972 SIDE PANEL RH (E35-xxx-30 only, from s/n 215840)

2 020792 SERVICE ENTRY PANEL

019213 CABLE ENTRY BUSH (Not illustrated - to s/n 205999)

3 020785 PANEL MOUNTING BRACKET

4 021526 WATER INLET ELBOW (Refer 11.1.3)

021527 WATER INLET WASHER

5 020745 MOTOR (380-415V 50Hz 3ø)

020885 MOTOR (220-240V 50Hz 1ø/3ø)

020886 MOTOR (208-240V 60Hz 1ø/3ø)

6 020860 WATER SUPPLY TUBE (E35-xxx-26 only) (Refer 11.1.3)

020862 WATER SUPPLY TUBE (E35-xxx-30 only) (Refer 11.1.3)

7 020851 WATER SOLENOID (Refer 11.1.3)

8 020869 CONNECTOR - 3/8"F x 1/4" COMPRESSION (Refer 11.1.3)

9 020991 MOUNTING BRACKET (Refer 11.1.3)

10 020897 MOTOR INSULATION PLATE

11 020778 MOTOR MOUNTING PLATE

12 020797 SIDE INSULATION PANEL (E35-xxx-26 only)

020798 SIDE INSULATION PANEL (E35-xxx-30 only)

13 021160 OVEN SIDE PLATE

14 090416 FIBREGLASS INSULATION 730x780x38

090417 FIBREGLASS INSULATION 730x880x38 (E35-xxx-30 only)

15 020762 ELEMENT - 220-240V 2000W (H,N,T only)

020763 ELEMENT - 208-220V 2000W (P,X only)

022259 ELEMENT - 208-220V 1250W (8kW units only - option)

015292 SEALING WASHER

16 020896 MOTOR SHAFT SEAL

17 020898 MOTOR SEAL HOUSING

18 025396 FAN

19 020780 CHASSIS HORIZONTAL SIDE (E35-xxx-26 only)