Moffat E32D4 Service Manual

30DSERIES

E32D4

|

2 Speed |

Fan |

|

Moisture |

Mode |

|

Multi - Stage Cooking |

|

|

Optional |

Core Temp Probe |

Installation and Operation Manual

237456-1

MANUFACTURED BY

Moffat Limited

Christchurch

New Zealand

INTERNATIONAL CONTACTS

AUSTRALIA |

|

|

Moffat Pty Limited |

|

|

Web: |

www.moffat.com.au |

|

E.Mail: |

vsales@moffat.com.au |

|

Main Office: |

(tel) |

+61 (03) 9518 3888 |

Service: |

(fax) |

+61 (03 9518 3833 |

(tel): |

1800 622 216 |

|

Spares: |

(tel): |

1800 337 963 |

Customer Service: |

(tel): |

1800 335 315 |

|

(fax): |

1800 350 281 |

CANADA |

|

|

Serve Canada |

|

|

Web: |

www.servecanada.com |

|

E.Mail: |

info@servecanada.com |

|

Sales: |

(tel): |

800 551 8795 (Toll Free) |

Service: |

(tel): |

800 263 1455 (Toll Free) |

NEW ZEALAND |

|

|

Moffat Limited |

|

|

Web: |

www.moffat.co.nz |

|

E.Mail: |

sales@moffat.co.nz |

|

Main Office: |

(tel): |

0800 663328 |

UNITED KINGDOM |

|

|

Blue Seal |

|

|

Web: |

www.blue-seal.co.uk |

|

E.Mail: |

sales@blue-seal.co.uk |

|

Sales: |

(tel): |

+44 121 327 5575 |

Spares: |

(fax): |

+44 121 327 9711 |

(tel): |

+44 121 322 6640 |

|

Service: |

(fax): |

+44 121 327 9201 |

(tel): |

+44 121 322 6644 |

|

|

(fax): |

+44 121 327 6257 |

UNITED STATES |

|

|

Moffat |

|

|

Web: |

www.moffat.com |

|

Sales: |

(tel): |

800 551 8795 (Toll Free) |

|

(tel): |

+1 336 661 1556 |

Service: |

(fax): |

+1 336 661 9546 |

(tel): |

800 858 4477 (Toll Free) |

|

|

(tel): |

+1 336 661 1556 |

|

(fax): |

+1 336 661 1660 |

REST OF WORLD |

|

|

Moffat Limited |

|

|

Web: |

www.moffat.co.nz |

|

E.Mail: |

export@moffat.co.nz |

|

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in writing by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and design without prior notice.

© Copyright Moffat Ltd. July 2014.

Contents List

E32D4 Turbofan Convection Oven.

Introduction............................................................................................................ |

2 |

Safety Information |

|

Specifications.......................................................................................................... |

3 |

Installation ............................................................................................................. |

4 |

Installation Requirements |

|

Unpacking |

|

Location |

|

Clearances |

|

Stand Mounted Ovens |

|

Electrical Connection |

|

Water Connection |

|

Recommended Water Specifications |

|

Positioning and Levelling of Oven |

|

Initial Start-Up |

|

Commissioning |

|

Operation ................................................................................................................ |

6 |

Operation Guide |

|

Cooking in Manual Mode |

|

Cooking in Manual Mode using Core Temp Probe |

|

Cooking in Program Mode |

|

Programming ........................................................................................................ |

13 |

Controller - Operator Settings.............................................................................. |

16 |

Changing Operator Settings |

|

Operator Settings |

|

Cleaning and Maintenance ................................................................................... |

17 |

Cleaning Guidelines |

|

Oven Cleaning |

|

Periodic Maintenance |

|

Fault Finding ......................................................................................................... |

20 |

Electrical Schematics............................................................................................ |

21 |

Replacement Parts List......................................................................................... |

22 |

Appendix 1 - Reversing the Oven Door ................................................................ |

23 |

Introduction

Before using your new oven, please read this instruction manual carefully, pay particular attention to any information labelled

‘WARNING’, ‘CAUTION’, ‘IMPORTANT’ or ‘NOTE’ in this manual.

Warning

Caution

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, will result in minor or moderate injury.

If you are unsure of any aspect of the installation, instructions or performance of your oven, contact your TURBOFAN dealer promptly. In many cases a phone call could answer your question.

Should you contact your TURBOFAN dealer on any matter concerning this oven, please have the information provided opposite, readily available.

Safety Information

For your safety, please pay attention to the following symbols marked on the appliance.

- Risk of electric shock.

No user serviceable parts inside.

Qualified service person access only.

Disconnect from power before servicing.

This manual must be kept by the owner for future reference.

A record of Date of Purchase, Date of Installation and Serial Number of the oven should be recorded in the area provided below.

The serial number of this oven can be found on the Technical Data Plate located on the front right hand side panel, see diagram in ‘Installation Section’.

Model Number:

Serial Number:

Dealer:

Service Provider:

Date Purchased:

Date Installed:

2

Specifications

E32D4

Oven Power Ratings |

208 - 220V, 50/60Hz, 6.5 kW. |

||

|

|||

230 - 240V, 50/60Hz, 6.5 kW. |

|||

|

|

||

|

|

|

|

|

Tray Capacity |

4, 18” x 26” / 460 x 660 Full Size Sheet Pan Capacity. |

|

Oven Tray Details |

4, 600 x 400 Tray Capacity. |

||

|

|||

|

|

||

|

Tray Spacing |

110mm / 4⅜”. |

|

|

|

|

|

Water Connection |

Max Water Pressure |

80 psi / 550 kPa. |

|

|

|

||

Connection Size |

3/4” BSP. |

||

|

|||

NOTE: If the Moisture Mode cooking option is not required, the oven does not need to be connected to a water supply.

3

Installation

Installation Requirements

Important:

Installation shall comply with local electrical, health and safety requirements.

It is most important that this oven is installed correctly and that oven operation is correct before use.

If you have any questions regarding the proper installation and / or operation of this oven, please contact your local

Turbofan distributor.

Unpacking

1.Remove all packaging and transit protection including all protective plastic coating from the exterior stainless steel panels.

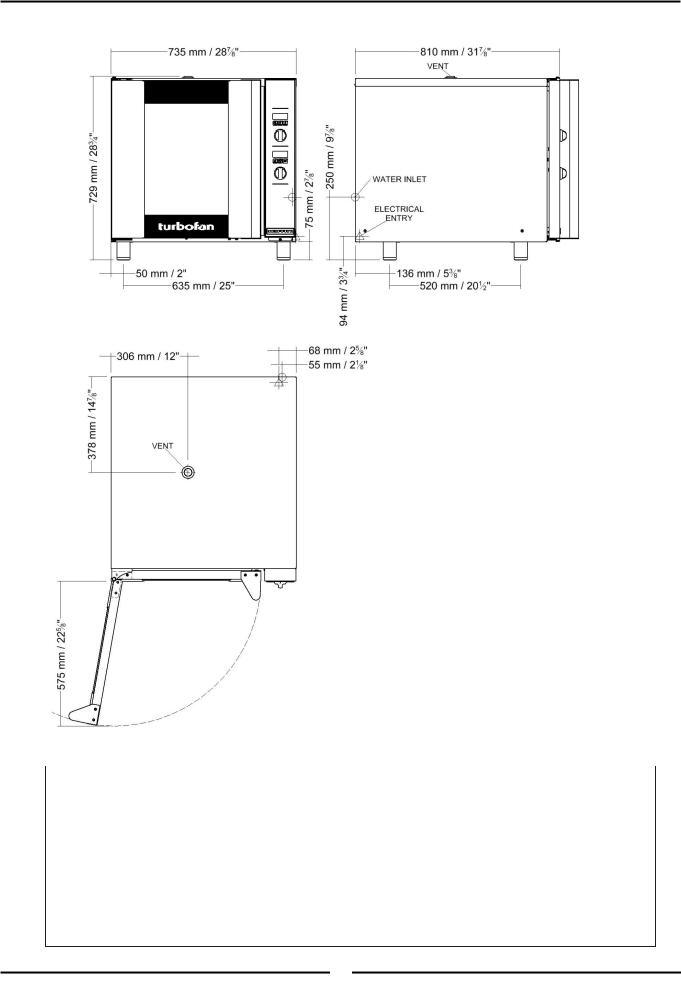

Clearances

To ensure correct ventilation for the motor and controls, the following minimum installation clearances are to be adhered to:-

2.Check the oven and supplied parts for damage. Report any damage immediately to the carrier and distributor.

3.Check that the following parts have been supplied with your oven:-

4 x Leg Adjustable.

4.Report any deficiencies to the distributor who supplied your oven.

5.Securely fit the 4 legs supplied with the oven.

6.Check that the available electrical supply is correct to that shown on the Technical Data Plate located on the front right hand side panel.

Technical Data Plate Location

Also refer to ‘Specifications’ section, ‘Oven

Specifications Tables’ for specifications details.

Top |

200mm / 8”. |

Rear |

50mm / 2”. |

Left-hand side |

50mm / 2”. |

Right-hand side |

75mm / 3”. |

CLEARANCE FROM SOURCE OF HEAT.

A minimum distance of 300mm (12”) from appliance sides is required.

NOTE: Fixed installations require at least 500mm - 20” clearance at the right hand side of oven for service access.

Important:

The vent located on the top of the oven must NOT be obstructed.

Oven Vent Location

Location

1.Position the oven in its approximate working position.

2.The unit should be positioned so that the control panel and oven shelves are easily reachable for loading and unloading.

NOTE: The oven door can be reversed to increase accessibility in certain locations. Refer to Appendix 1 at the rear of this Manual for door reversal details.

Stand Mounted Ovens

For stand mounted ovens, the oven feet are used to level the oven on the stand. Refer to the instructions supplied with separately ordered stands for mounting details.

4

Installation

Electrical Connection

Warning

This oven must be earthed / grounded.

Each oven should be connected to an adequately protected power supply with an appropriate three wire power cord. An isolation switch must be mounted adjacent to, but not behind the oven and must be readily accessible to the operator. This switch must be clearly marked and readily accessible in case of fire.

Check the electricity supply is correct to as shown on the Technical Data Plate on the front right hand corner of the oven side panel.

NOTE: All electrical connections must only be carried out by a suitably qualified person.

1.Remove oven right hand side panel.

2.Bring the supply cable up through the grommet at the back of oven and through the compression gland on the electrical switchgear panel.

3.Connect the mains supply to the appropriately marked terminals on the terminal block.

Water Connection

NOTE: If the Moisture Mode cooking option is not required, the oven does not need to be connected to a water supply.

1. |

Tighten the 2 screws securing the |

|

|

water connection to the rear of the |

|

|

oven. (These have purposely been |

|

|

left loose to prevent damage to the |

|

|

water connection during transit). |

|

2. |

Connect a cold water supply to the |

|

|

water inlet (R ¾” Connector) on the |

|

|

Tighten Screws. |

|

|

oven. |

|

|

|

|

|

|

-Max Inlet Pressure 80psi / 550kPa.

3.Turn ‘On’ the water supply and check for leaks.

Recommended Water Specifications

In order to prevent corrosion or scaling in the oven and water system due to supplying water that is either too soft or too hard, the following recommendations should be used as a guideline.

Hardness: |

Between 60 and 90ppm. |

PH: |

Greater than 7.5. |

Chlorides: |

Less than 30 ppm. |

Positioning and Levelling of Oven

1.Correctly locate the oven into its final operating position and, using a spirit level, adjust the oven feet so that the oven is level and at the correct height.

Initial Start-Up

Before using the new oven;

1.For first time use of the oven, operate the oven for about 1 hour at 200°C / 400°F to remove any fumes or odours which may be present.

2.Please refer to the Operation Section of this manual for details on how to correctly operate and shutdown the oven.

Commissioning

Before leaving the new installation;

1.Check the oven functions in accordance with the operating instructions specified in the ‘Operation’ section of this manual.

2.Ensure that the operator has been instructed in the areas of correct operation and shutdown procedure for the appliance.

NOTE: If it is not possible to get the appliance to operate correctly, turn ‘Off’ power supply at the mains supply and contact the supplier of this appliance.

5

Operation

Operation Guide

Warning

Some parts of this oven will become VERY HOT during use and could cause burns if touched.

Warning

Take care when opening the oven door during baking. Let the hot air and steam escape before removing or replacing food as the steam produced can cause steam burns.

This oven is intended for use in a commercial kitchen and must only be put to the use for which it was designed, i.e. cooking food product. To use this oven correctly please read the following sections carefully:-

Temperature Display -

Shows pre-set chamber temperature. When used with the ‘Temp’ key, display shows actual oven temperature for 5 seconds.

Shows cooking programs and error codes.

‘Steam’ Key and LED -

Used to set moisture level or to provide a manual injection of moisture when in Manual Moisture Mode.

LED is ‘On’ when automatic moisture injection is set or when moisture is manually injected.

Temperature Adjustment Control

Time Display -

Shows cook time in full minutes only from 180 - 10, and in minutes and seconds for the final 10 minutes.

NOTE:

In Core Temp Mode, time display alternates between ‘CP’ and set core probe temperature.

‘On-Off/Light’ Key and LED -

A dual-function key:

Press ‘On-Off/Light’ key once to turn the oven ‘On’

When oven is turned ‘On’, press ‘On-Off/Light’ key to switch oven light ‘On-Off’.

Press and hold ‘On-Off/Light’ key for 1.5 seconds to turn the oven ‘Off’.

Time Adjustment Control

NOTE: In Core Temp Mode, ‘Timer’ knob is used to set core probe temperature.

‘Program’ Key and LED -

Used to select cooking programs, and to set program parameters.

‘Temp’ Key and LED -

Displays actual oven temperature for 5 seconds on Temperature Display. LED ‘On’ when heating element is on (heating indicator).

LED flashes when Upper Display is showing actual temperature.

NOTE:

In Core Temp Mode, this key is used to display Actual Oven Temperature (Upper Display) and actual Core Probe Temperature (Lower Display).

‘Fan Lo’ Speed Key and LED -

Switches oven fan from high to low speed. LED is ‘On’ when fan is in Low Speed Mode. When LED is ‘Off’, fan is in High Speed Mode.

‘Timer-Start/Stop’ Key & LED -

The ‘Timer-Start/Stop’ key is used to control the following functions:-

Cancelling Alarm (All Modes).

Starting Core Temp Mode (Core Temp

Mode).

Starting Timer (Manual Mode).

Pausing (Manual / Program Modes).Re-Setting Timer (Manual Mode).Starting Program (Program Mode).

Cancelling and Re-Setting Program

(Program Mode).

Core Probe Connection Point.

6

Operation

Manual Mode

In Manual mode the ovens settings are.

- Temperature |

- 50-250C / 150-550F. |

- Timer setting |

- 0-180min or Infinite. |

- Fan Speed setting |

- Hi / Lo. |

- Moisture Mode settings |

- Off / On-Level. |

- Oven lights |

- Off / On. |

An Optional Core Probe can also be used in Manual Mode.

Program Mode

In Program Mode 20 Programs are able to be used. In each program the following settings are possible.

- Temperature |

- 50-250C / 150-550F. |

- Time |

- 0-180min or Infinite. |

- Fan Speed |

- Hi/ Lo. |

- Moisture Mode |

- Off / On-level. |

3 cooking stages can also be set in each of the 20 programs.

-All settings can be changed between cooking stages.

-At completion of each stage an end of stage alarm can also be set.

Optional Core Probe can also be used in Program Mode.

Changing between Manual to Program Modes

Press ‘Program’ key to select Program Mode. The LED will illuminate showing Program Mode now set.

Press ‘Program’ Key to return to Manual mode.

Fan Speed

This oven features a 2 speed fan.

Hi Speed - This is the default operating speed.

-Hi Fan should be used for most applications.

-Hi Fan provides the fastest cooking time and evenness

throughout oven.

Lo Speed - This is the optional setting.

-Lo Fan speed is selected using the Fan Lo key.

-Lo Fan provides slower cooking with less fan affect on the product.

-Lo Fan should be used on delicate products such as cake and muffin.

On start-up, the oven will always default to normal Hi speed fan. In Manual Mode, fan speed can be changed at any time during use.

In Program Mode, fan speed can be pre-set and each cooking stage can have a different fan speed.

Changing the Fan Speed

Press ‘FAN LO’ key to change to Lo Fan speed. LED will illuminate showing Lo Fan speed is now set.

Press ‘FAN LO’ key to change back to Hi Speed fan.

Moisture Mode

There are 6 levels of pre-set moisture injection.

Each level defines the number of moisture injection pulses per moisture cycle during oven operation.

H-0 Manual Moisture Mode. Automatic Moisture Injection is ‘Off’. Pressing ‘Steam’ key in this mode will inject 1 shot of steam into the oven, ie, no steam injection without user input.

H-1 Level 1. - Minimum automatic moisture injection setting. One moisture pulse per moisture cycle.

H-2 Level 2.

H-3 Level 3.

H-4 Level 4.

H-5 Level 5. - Maximum automatic moisture injection setting. Five moisture pulses per moisture cycle.

Selecting Moisture Mode

Press ‘Steam’ key to activate Moisture Mode. ‘Steam’ key LED will illuminate when Moisture Mode is ‘On’. Moisture Mode will operate at the preset level during the cooking cycle.

When Moisture Mode H-0 is selected, a shot of steam is available whenever the oven is running, by pressing the ‘Steam’ key.

When Moisture Mode H-1 to H-5 are selected, these moisture modes will only operate when a program is running, Core Temp Probe Mode has been selected or when a timer is running in Manual Mode.

When setting Moisture level, consider the Oven Set

Temperature. If set BELOW 100°C (212°F), water may pool in oven as temperature will be too low to create steam.

Changing Moisture Mode Level

Press and hold the ‘Steam’ Key until the ‘H-X’ level is displayed and flashing in the upper display.

Rotate the ‘Temp’ Knob -/+ to select Moisture Mode level required.

Press the STEAM Key to confirm setting.

The ‘Moisture’ Mode level can be changed at anytime during operation by following the setting method as described above.

Core Temp Cooking Mode - Optional

An Optional Core Temp Probe Kit #236060 is available for this oven.

This allows use of the Core Probe Cooking feature of this oven. When the core probe is fitted to the connection point on control panel side, the timer function and display becomes the core temp probe temperature setting and display. Cooking completion is then determined by the core temp probe reaching the set core probe temperature.

To enable Core Probe Cooking Mode plug in the Core Probe. The Timer Display will then change to 'CP' (Core Probe). The Timer Knob function will then be for Core Temp setting. To disable Core Probe Cooking Mode, unplug the Core Probe. The Timer Display and Knob will return to time function.

7

Loading...

Loading...