Page 1

INSTALLATION / OPERATION

MANUAL

E35C CONVECTION OVEN

with Recipe Controller and

Graphical Display Screen

232107-12

Page 2

MANUFACTURED BY

Moffat Limited

Christchurch

New Zealand

INTERNATIONAL CONTACTS

AUSTRALIA

Moffat Pty Limited

Web: www.moffat.com.au

E.Mail: vsales@moffat.com.au

Main Office: (tel) +61 (03) 9518 3888

(fax) +61 (03) 9518 3833

Service: (tel): 1800 622 216

Spares: (tel): 1800 337 963

Customer Service: (tel): 1800 335 315

(fax): 1800 350 281

CANADA

Serve Canada

Web: www.servecanada.com

E.Mail: info@servecanada.com

Sales: (tel): 800 551 8795 (Toll Free)

Service: (tel): 800 263 1455 (Toll Free)

NEW ZEALAND

Moffat Limited

Web: www.moffat.co.nz

E.Mail: sales@moffat.co.nz

Main Office: (tel): 0800 663328

UNITED KINGDOM

Blue Seal

Web: www.blue-seal.co.uk

E.Mail: sales@blue-seal.co.uk

Sales: (tel): +44 121 327 5575

(fax): +44 121 327 9711

Spares: (tel): +44 121 322 6640

(fax): +44 121 327 9201

Service: (tel): +44 121 322 6644

(fax): +44 121 327 6257

UNITED STATES

Moffat

Web: www.moffat.com

Sales: (tel): 800 551 8795 (Toll Free)

(tel): +1 336 661 1556

(fax): +1 336 661 9546

Service: (tel): 800 858 4477 (Toll Free)

(tel): +1 336 661 1556

(fax): +1 336 661 1660

REST OF WORLD

Moffat Limited

Web: www.moffat.co.nz

E.Mail: export@moffat.co.nz

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless au thorized previously in

writing by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and

design without prior notice.

© Copyright Moffat Ltd. September 2011.

Page 3

Contents List

E35C Convection Oven

Introduction ............................................................................................. 3

Specifications ........................................................................................... 4

E35C Convection Oven (Single Oven on Stand)

E35C Convection Oven (Double Stacked)

Installation............................................................................................... 6

Installation Requirements

Before Connection to Power Supply

Location

Bench Mounting

Floor Mounting

Stand Mounting

Electrical Connection

Water Connection - Optional (not required for Main Oven Operation)

Before Use

Operation Guide ....................................................................................... 8

Description of Controls

Oven Pre-Heat Settings............................................................................ 9

Setting the Oven Pre-Heat Temperature

Changing the Oven Pre-Heat Temperature

Cooking with Programmed Recipes ....................................................... 10

Cooking with Programmed Recipes (Without Shelf Timer Function)

Cooking with Programmed Recipes (Using Shelf Timer Function)

Cooking in Manual Mode ........................................................................ 18

Cooking in Manual Mode

‘With NO Shelves / Timers Selected’

‘With Timers Selected’

‘With Shelves Selected’

Other Controller Functions..................................................................... 25

Door Open

Cool Down Feature

Service Support

Page 4

Contents List

Programming Recipes ............................................................................ 26

Editing Recipes

Editing Events

Controller Configuration......................................................................... 30

Entering the Service Mode

Service Parameters

Service Parameter Flow Chart

Oven Operation - General....................................................................... 35

Door Handle

Side Racks

Removal of Side Racks

Replacement of Side Racks

Cleaning and Maintenanc e ..................................................................... 36

General

Oven Cool-Down Mode

Daily Cleaning

Weekly Cleaning

Monthly Cleaning

Periodic Maintenance (6 Monthly)

Fault Finding........................................................................................... 39

Circuit Schematic.................................................................................... 40

Competency Check Lists......................................................................... 41

Turbofan E35C Convection Oven - Operation (Implement Safe Working Procedures)

Turbofan E35C Convection Oven - Daily Cleaning (Implement Essential Hygiene and Sanitation

Procedures)

Hazard Risk Assessment ........................................................................ 44

Replacement Parts List........................................................................... 45

Page 5

Introduction

We are confident that you will be delighted with your TURBOFAN OVEN, and it will become a most valued

appliance in your commercial kitchen.

A new oven can seem very complex and confusing at first glance. To ensure you receive the utmost

benefit from your new Turbofan, there are two important things you can do.

Firstly

Please read the instruction book carefully and follow the directions given. The time taken will be well

spent.

Secondly

If you are unsure of any aspect of the installation, instructions or performance of your oven, contact your

E35 dealer promptly. In many cases a phone call could answer your question.

Date Purchased........................................................... Serial No.....................................................

Dealer.............................................................................................................................................

Service Agent..................................................................................................................................

3

Page 6

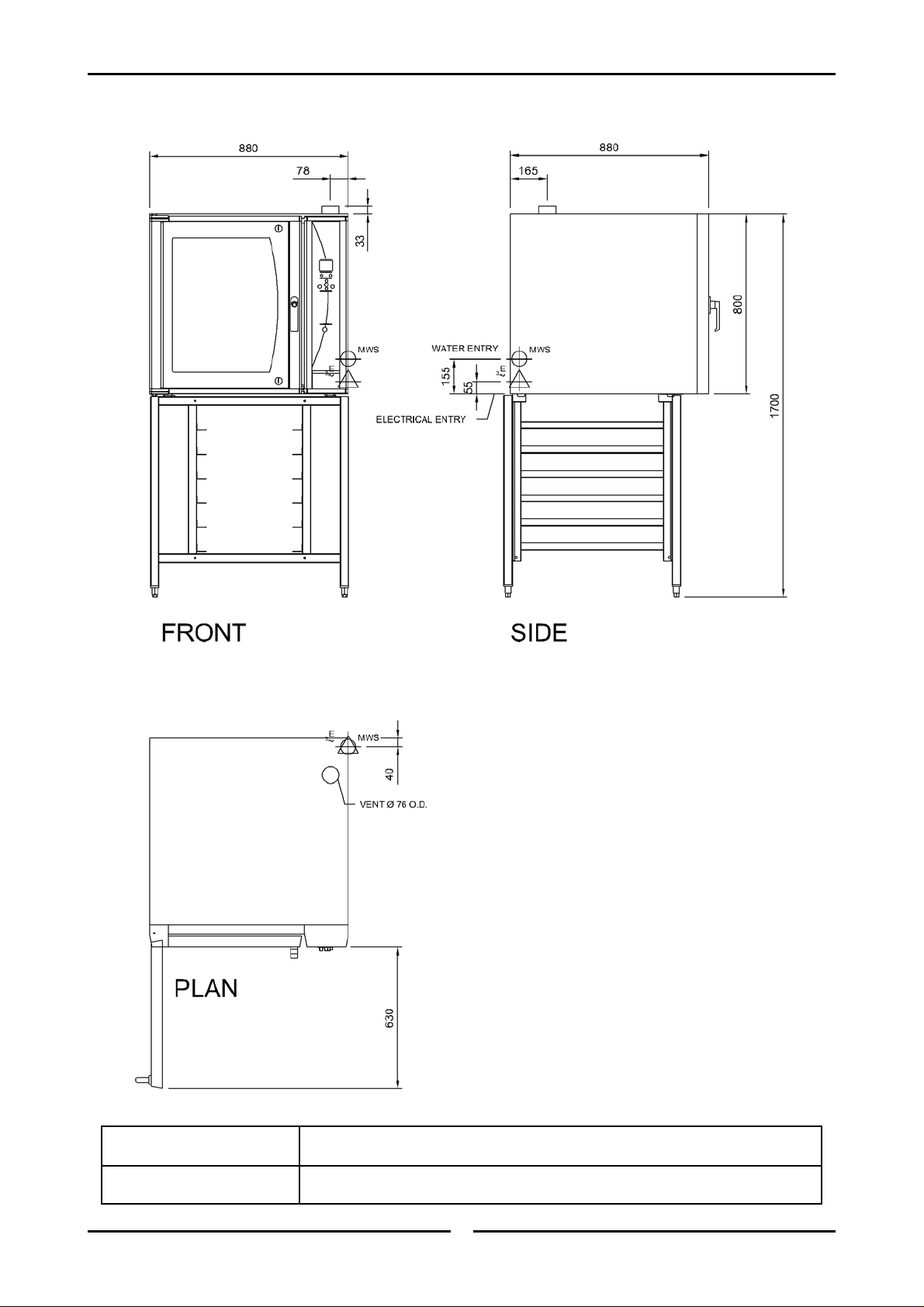

Specifications

E35C Single Oven on Stand

Electrical Connection Refer to Section 'Before Connecting to Power Supply' on Page 6.

Cold Water Connection ¾” B.S.P. or ½” ID hose (550 kPa / 80 psi maximum pressure).

4

Page 7

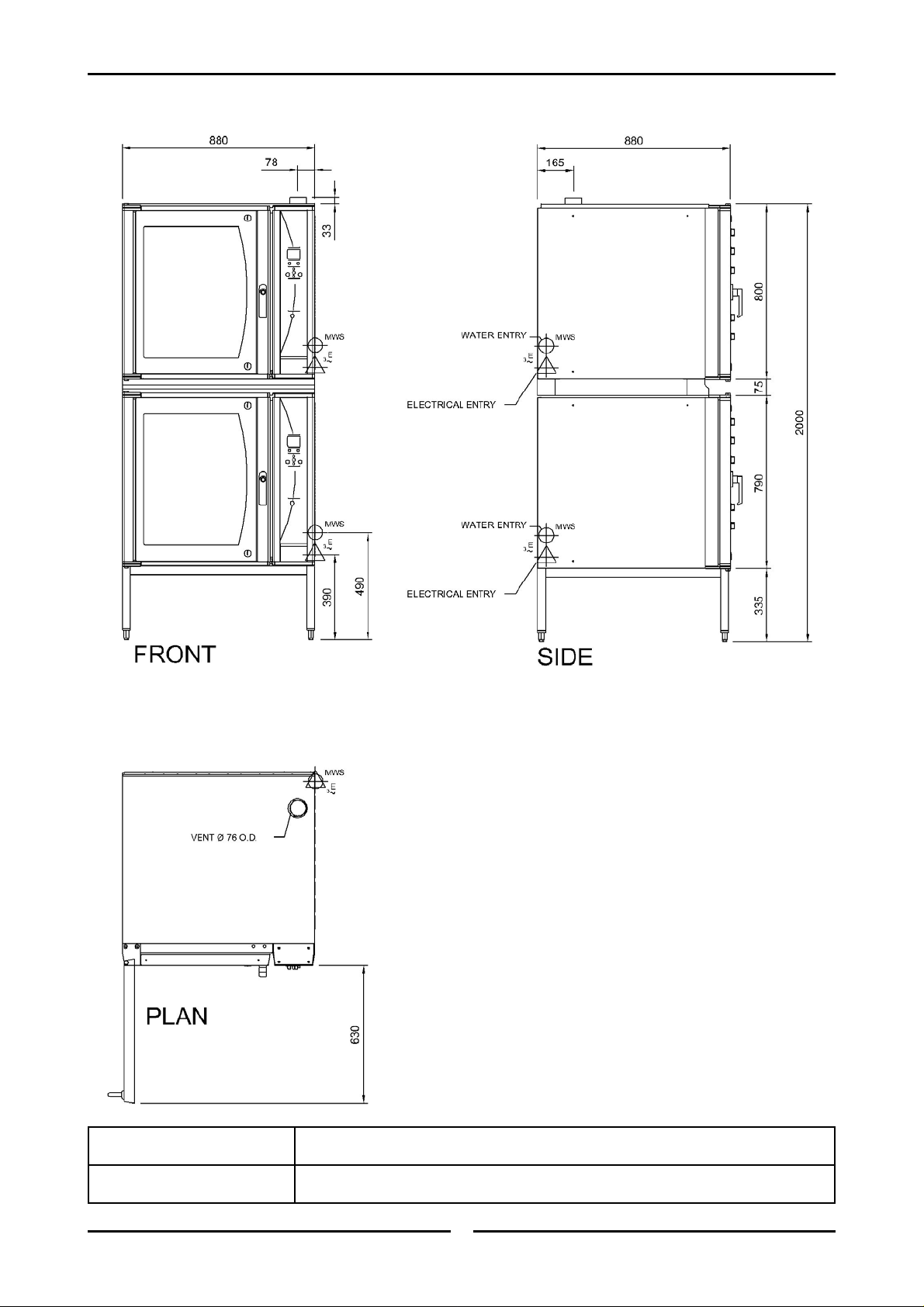

E35C Ovens - Double Stacked

Specifications

Electrical Connection Refer to Section 'Before Connecting to Power Supply' on Page 6.

Cold Water Connection ¾” B.S.P. or ½” ID hose (550 kPa / 80 psi maximum pressure).

5

Page 8

Installation

Installation Requirements

It is most important that this oven is installed correctly and that operation is correct

before use.

Installation shall comply with local electrical, health and safety requirements.

Before Connection to Power Supply

Remove all packing.

Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

Remove protective plastic coating from the side panels.

Check that the following parts have been supplied with your oven:

3 x Oven Racks.

Water Inlet Elbow.

Washer Rubber.

Report any deficiencies to the distributor who supplied the oven.

Fit the feet to the oven.

Check that the available power supply is correct to that shown on the rating plate located on the

right-hand side panel.

Location

Model Electrical Rating

E35C-xx-453 400-415 V a.c., 50 Hz, 3P+N+E, 12.5 kW @ 415 V

E35C8-xx-453 400-415 V a.c., 50 Hz, 3P+N+E, 8.0 kW @ 415 V

To ensure correct ventilation for the motor and controls the following minimum installation

clearances are to be adhered to:

Rear 0 mm / 0”.

Left-hand side 0 mm / 0”.

Right-hand side 75 mm / 3” (Fixed installations require at least 500 mm (20”) clearance at the

right hand side for service accessibility).

Position the oven in its working position.

Use a spirit level to ensure oven is level from side to side and front to back. (If this is not carried

out, uneven cooking could occur). The feet / legs used with bench / floor mounting or provided with

stands are adjustable and will require adjusting in levelling the unit.

The unit should be positioned such that the operating panel and oven shelves are easily reachable

for loading and unloading.

Important:

THE VENT LOCATED ON THE OVEN TOP MUST NEVER BE OBSTRUCTED.

6

Page 9

Installation

Bench Mounting

For bench mounted applications the oven must be fitted with 100 mm / 4” feet.

C

AUTION

To reduce the risk of fire, the appliance is to be installed over a non-combustible surface

only. Such surface shall extend not less than 12” (300 mm) beyond the appliance on all

sides.

Floor Mounting

For floor mounted applications the oven must be fitted with 150 mm / 6” legs.

NOTE: Four 100 mm / 4” adjustable or 150 mm / 6” legs are available separately from your

E35 dealer as an optional extra.

Stand Mounting

Ovens that are to be mounted on stands do not require feet or legs. Refer to instructions for

mounting on stand in instructions supplied with separately ordered stands.

Avoid having heat producing equipment such as fryers or steamers adjacent to the right-hand side of

oven.

Electrical Connection

:

Remove side cover panel to allow access to the terminal block and strain relief cable clamp.

The cable can be fitted through the entry grommet and secured from strain by tightening the fitted

strain relief bushing.

Connect cable to the terminals as marked.

Refit the cover panel.

Important:

• FIXED WIRING INSTALLATIONS MUST INCORPORATE AN ALL-POLE DISCONNECTION SWITCH.

THIS APPLIANCE MUST BE EARTHED / GROUNDED.

Water Connection

A cold water supply should be fitted to the water inlet (¾” BSP connection) which is located near the

rear of the right hand side of the unit.

Alternately, a connection elbow and sealing washer is supplied with this unit for direct connection of

a ½” ID hose, and is recommended for easy installation and service.

Connect water supply - Max inlet pressure 80 psi / 550 kPa.

Turn on water supply to check for leaks.

Before Use

Operate the oven for about 1 hour at 400°F (200°C) to remove any fumes or odours which may be

present.

7

Page 10

Operation Guide

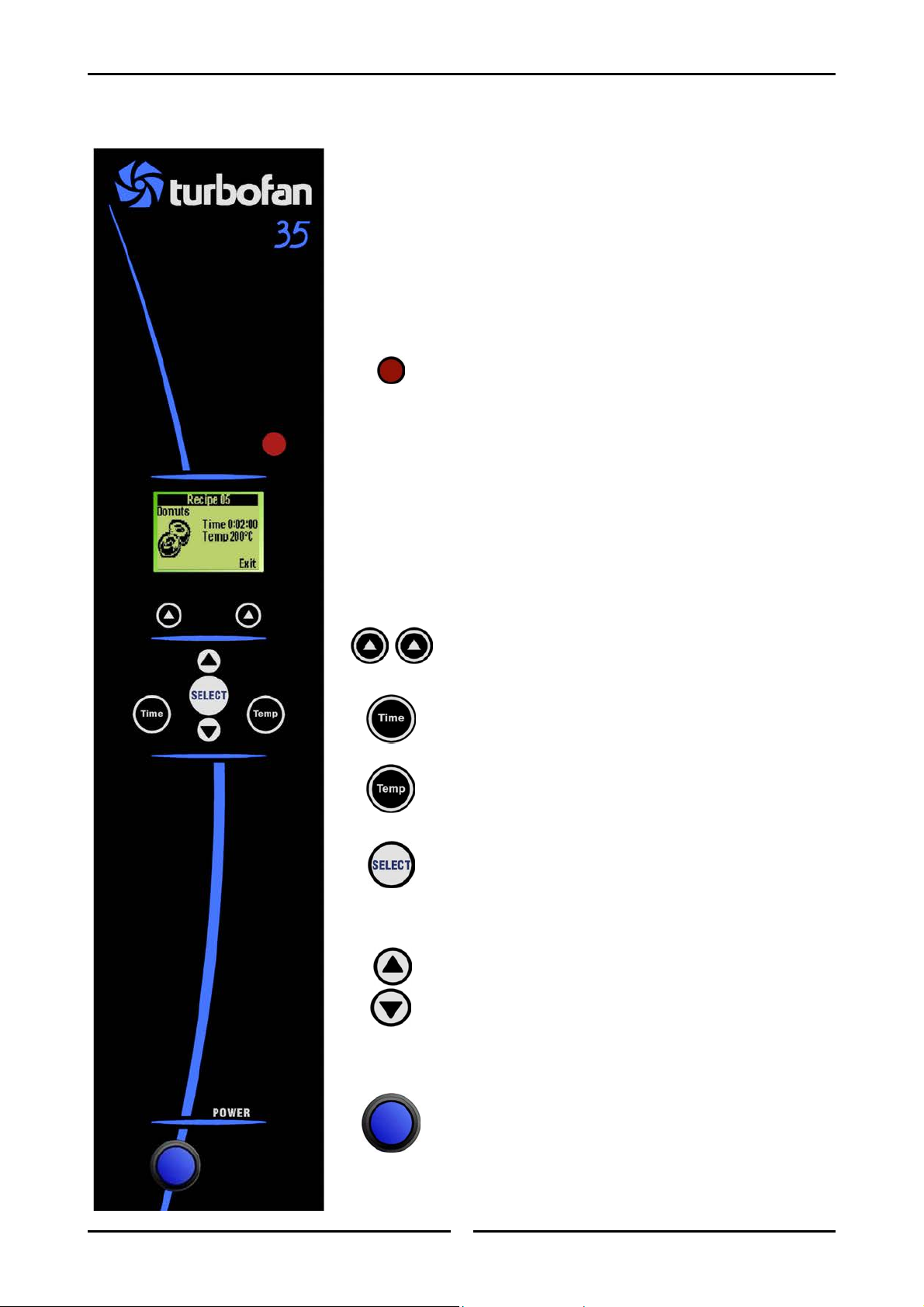

Description of Controls

KEY FEATURES

- Manual Recipe Mode.

- Program Recipes.

- Up to 5 Cooking Events (Stages) per Recipe.

- 12 Character Recipe Descriptions.

- Picture Display of Recipe Product.

IR Port

Infrared port, used with optional Palm recipe

programming software.

Display

Full graphical display, showing time / temp and recipe

information.

Function Keys (Left / Right)

Used for confirmation of screen bottom line text.

Time Key

Used for adjusting the time.

Temp Key

Used for adjusting the temperature.

Select Key

Used for confirming selection.

Select Up - Down Keys

Used for selecting programs / recipes.

Used for changing time and temperature values in

manual or programming modes.

Power

Depress to switch power 'On' or 'Off' (switch

illuminates when power is 'On').

8

Page 11

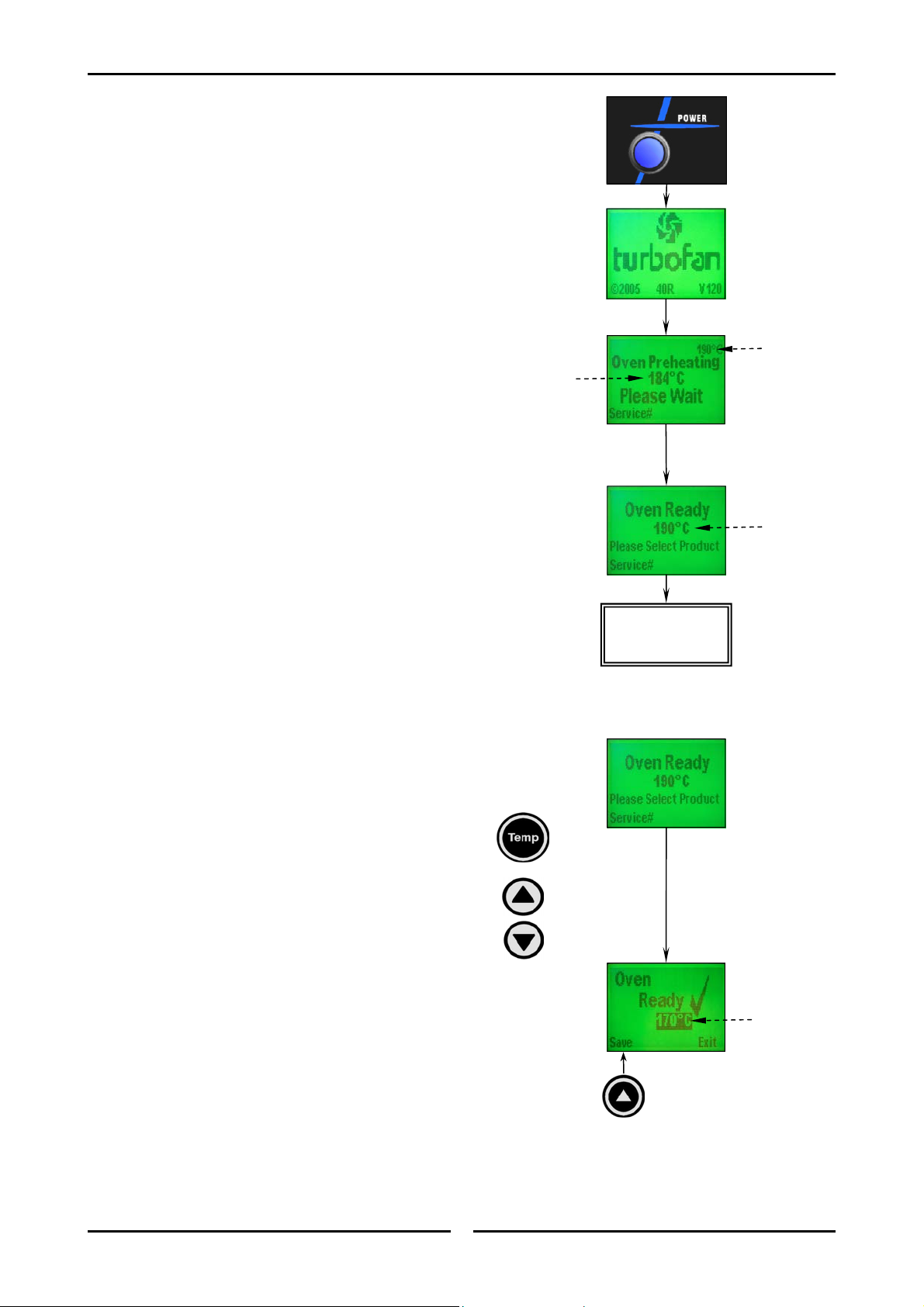

Setting the Oven Pre-Heat

Temperature

Turning the Oven ‘ON’

1. Depress the blue Power switch on the main

control panel to switch the oven ‘On’ /

‘Off’ (switch illuminates when power is ‘On’).

2. The ‘Turbofan’ start-up screen will appear for

10 seconds before being replaced by the ‘Oven

Preheating’ screen.

3. The display pre-heating screen will show Set

Temperature and Actual Temperature of

the oven.

Pre Heat and Oven Ready Mode

4. When Pre-Heat temperature is reached, an

Alarm prompt sounds and the ‘Oven Ready’

screen appears showing Pre Heat temperature.

5. Select the recipe required as shown in

‘Selecting a Recipe’ on the following pages.

Changing the Oven Pre-Heat

Temperature

Oven Pre-Heat Settings

Set Temp

Actual Temp

of Oven

Pre-Heat

Temp

Selecting Recipes

(Refer overleaf)

1. When in the ‘Oven Ready’ screen, the pre-heat

temperature of the oven can be adjusted to suit

requirements.

2. To change the pre-heat temperature, press the

‘Temp’ key.

3. Press the ‘Select Up - Down’ keys to change

the pre-heat temperature.

4. The new ‘Pre-Heat’ temperature will be

displayed on the screen.

5. Press the Save (Left function key) to save

the selected pre-heat temperature required.

New Pre-Heat

Temp

9

Page 12

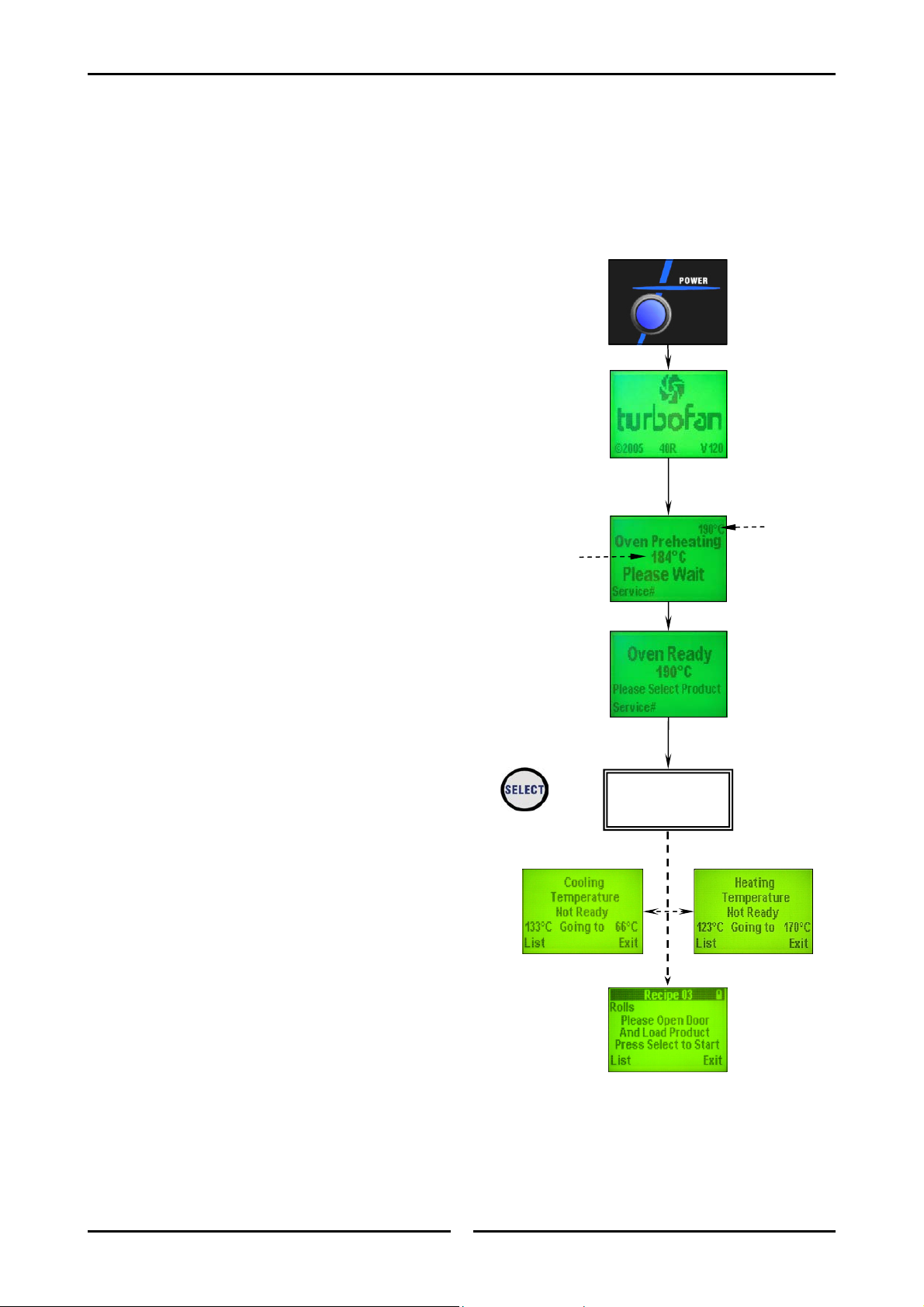

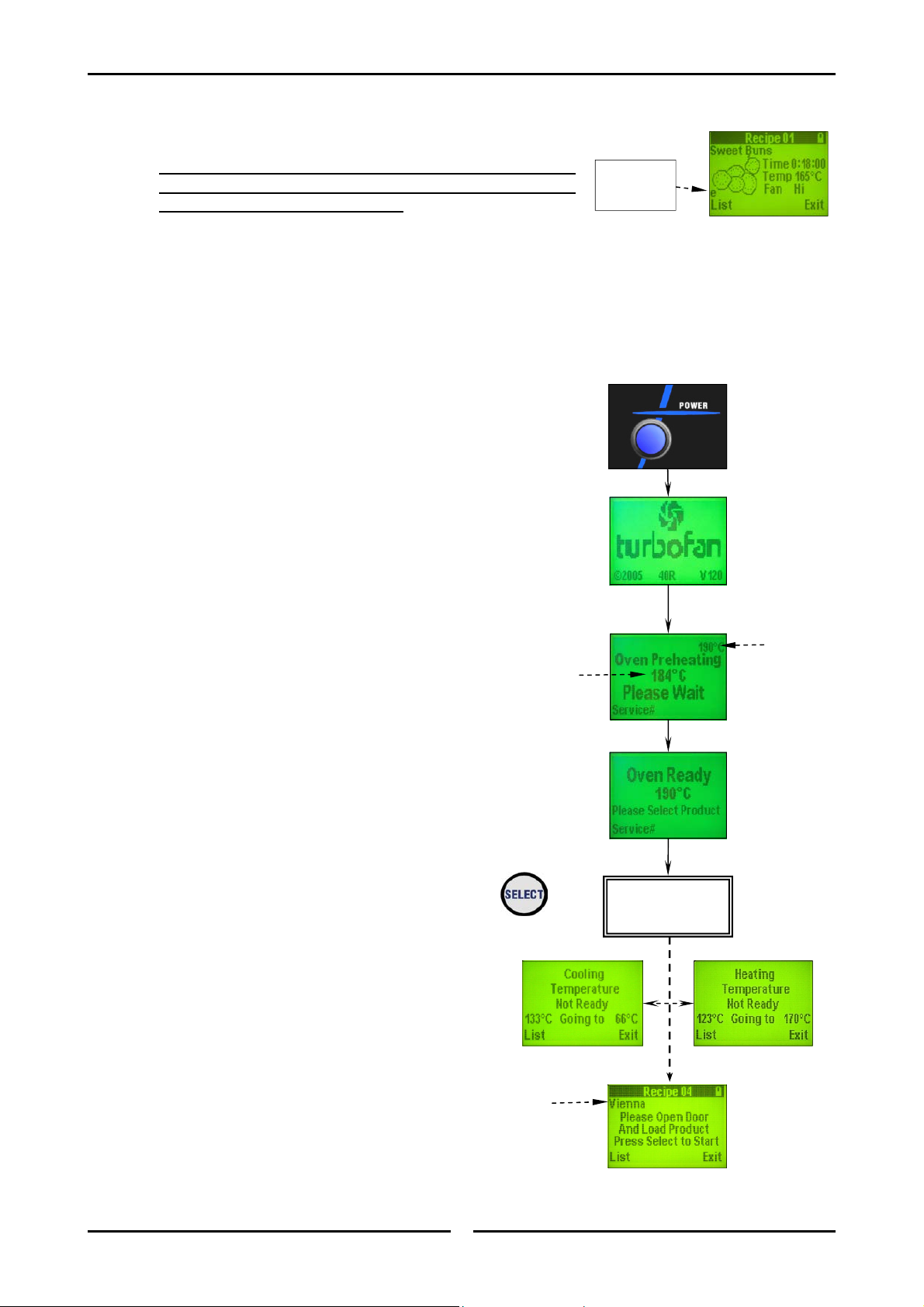

Cooking with Programmed Recipes

Cooking with Programmed Recipes (Without Shelf Timer Function)

NOTE:-

To turn ‘Off’ the ‘Shelf Timer’ function, refer to the Service Parameters section,

‘Controller Configuration’, Menu 2, Item 8 ‘Num of Shelves’. The ‘Number of Shelves’

setting must be set to ‘1’ to de-activate the ‘Shelf Timer’ function.

Turning Oven ON / OFF

1. Depress the blue Power switch on the main

control panel to switch the oven ‘On’ /

‘Off’ (switch illuminates when power is ‘On’).

2. The Turbofan Start Up Screen will appear for 10

seconds before being replaced by the ‘Oven

Pre-Heating’ screen. If the Pre-Heating

temperature needs to be adjusted, refer to

‘Changing the Oven Pre-Heat

Temperature’ on the previous page.

3. Pre-heat Screen will show ‘Set Temperature’

and ‘Actual Temperature’ of the oven.

4. When Pre-Heat temperature is reached, the

‘Oven Ready’ screen will show on the display.

5. Press ‘Select’ to select the recipe required as

shown in ‘Selecting a Recipe’ on the following

page.

6. The screen will show either the ‘Cooling Temp

Not Ready’ or ‘Heating Temp not Ready’

screens depending on the recipe temperature

and the temperature of the oven.

7. An alarm will sound when the oven is up to

temperature and the display will show ‘Open

Door - Load Product’.

8. Choose the recipe required from the options

shown at ‘Selecting a Recipe’, overleaf.

Actual Temp

of Oven

Selecting Recipes

(Refer overleaf)

Set Temp

10

Page 13

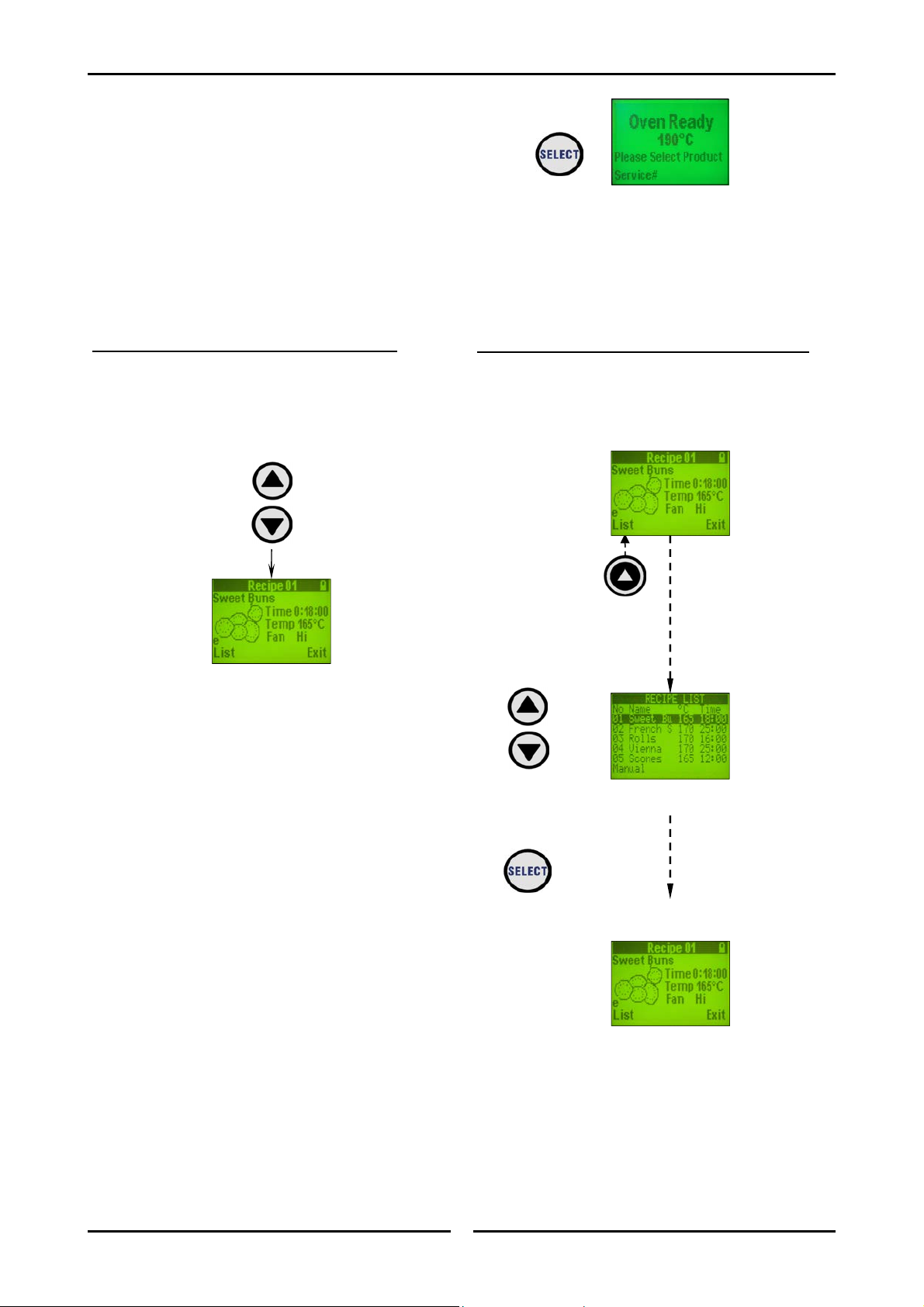

Cooking with Programmed Recipes

Selecting a Recipe

1. From the Oven Ready display, press the

‘Select’ key and a recipe screen will be shown

on the display.

2. The following Options are Available:-

METHOD A (Select ‘Up - Down’ Arrow Keys):

A. Press the ‘Select Up - Down’ keys to scroll

through the individual recipe selections and

select the recipe required.

B. Refer to 'Loading the Oven' on the following

page to commence the 'Cooking Cycle'.

METHOD B (Select the ‘List’ (Left Function Key):

A. Press the List (Left function key) below the

‘List’ logo will display the complete recipe list to

select the recipe required.

B. Scroll through the Recipe List shown using the

‘Select Up - Down’ keys until the desired

recipe is found.

C. Press the ‘Select’ key to select the recipe

required.

D. This recipe will be shown on the display.

E. Refer to 'Loading the Oven' on the following

page to commence the 'Cooking Cycle'.

11

Page 14

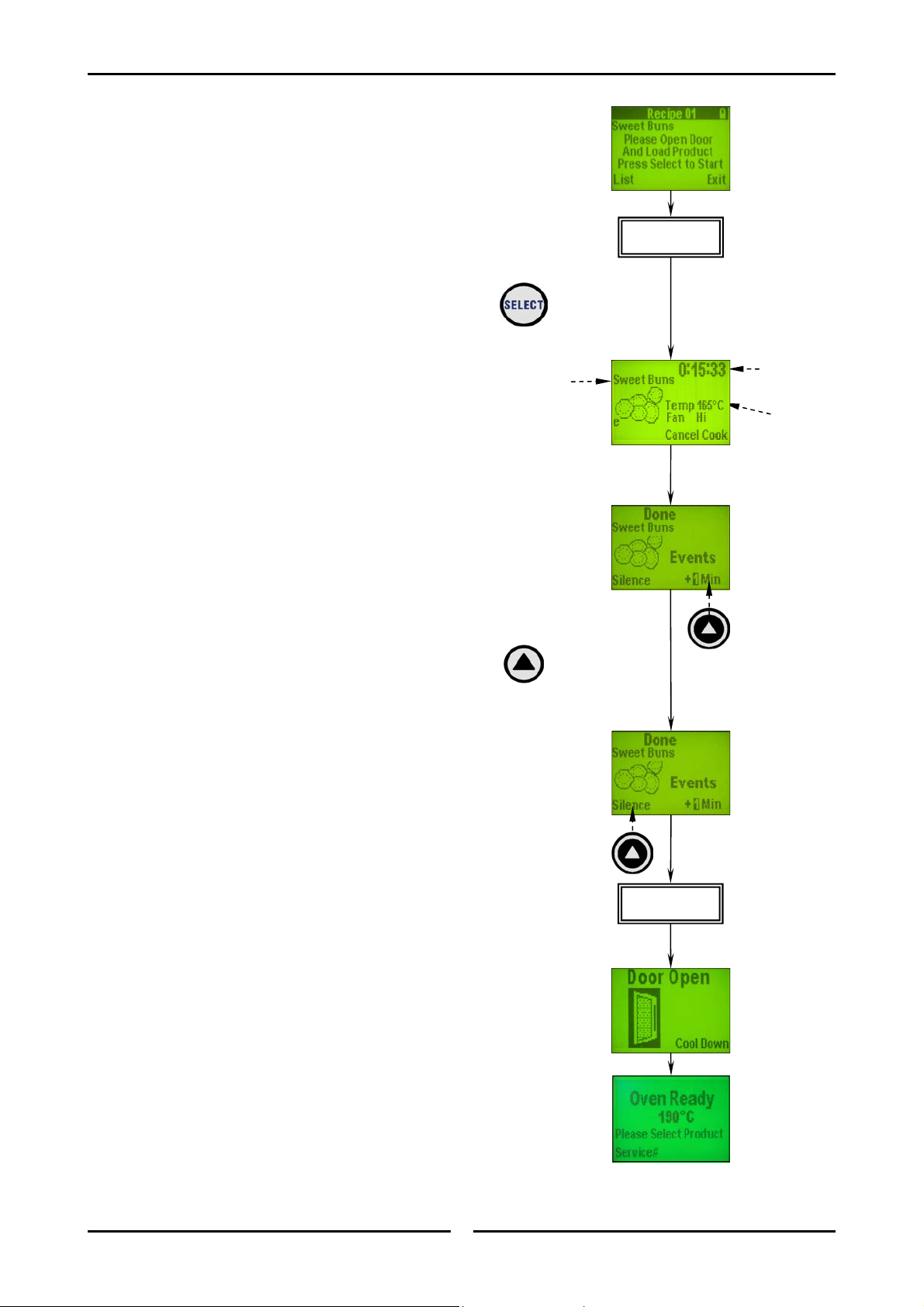

Cooking with Programmed Recipes

Loading the Oven

1. When the oven has reached the programmed

temperature the screen will display the

following screen and an alarm will sound.

2. Open the door and load the oven with the

product to be cooked.

3. Close the oven door and press the ‘SELECT’

key to start the cooking program.

4. The Time selection on the top right of the

display will commence counting down the cook

time.

Cooking Done

1. When cooking is completed, the 'Done' screen

will appear and a continuous alarm will sound.

2. To Increase Cooking Time by +1 Min -

If an additional minute of cooking time is

required, press the +1 Min - Right function

key.

3. To increase the cooking time by more

than 1 minute - Press the Select Up key in

increments of 1 minute.

automatically after approximately 3

seconds.

4. When cooking is completed, press the 'Silence'

- Left function key to stop the alarm.

5. Open the oven door and remove the cooked

product from the oven.

6. The display will show ‘Door Open’. Close the

oven door.

7. The display will revert to the ‘Oven Ready’

screen.

8. The oven can now be re-programmed as shown

at Loading the Oven above, to cook

additional items of the same temperature.

9. Continue cooking until all product is cooked.

Cooking will start

Recipe

Name

Open Door and

Load Oven

Time

Remaining

Set

Temperature

Open Door and

Unload Oven

12

Page 15

Cooking with Programmed Recipes

Cooking with Programmed Recipes (Using Shelf Timer Function)

NOTE:-

Recipes containing Programmed Events (shown by

an ‘e’ displayed on the screen) cannot be cooked

when using ‘Shelf Timer’ mode.

To use the ‘Shelf Timer’ mode, more than one shelf must be selected in the

Service Parameters. Refer to ‘Controller Configuration’, Menu 2, Item 8 ‘Num of

Shelves’. If ‘Number of Shelves’ is set to 1 then the ‘Shelf Timer’ function is

de-activated. Menu 1, Item 3 must be set to ‘Timer’.

Shelf timers are used to cook items that have the same cook temperatures. Shelves

can be loaded one at a time and an individual timer started for each shelf.

Turning Oven ON / OFF

1. Depress the blue Power switch on the main

control panel to switch the oven ‘On’ /

‘Off’ (switch illuminates when power is ‘On’).

2. The Turbofan Start Up Screen will appear for 10

seconds before being replaced by the ‘Oven

Pre-Heating’ screen. If the Pre-Heating

temperature needs to be adjusted, refer to

‘Changing the Oven Pre-Heat

Temperature’ on page 9.

3. Pre-heat Screen will show ‘Set Temperature’

and ‘Actual Temperature’ of the oven.

4. When the Pre-Heat temperature is reached, the

‘Oven Ready’ screen will show on the display.

5. Press ‘Select’ to select the recipe required as

shown in ‘Selecting a Recipe’ on the following

page.

6. The screen will show either the ‘Cooling Temp

Not Ready’ or ‘Heating Temp not Ready’

screens depending on the recipe

temperature and the temperature of the oven.

7. An alarm will sound when the oven is up to

temperature and the display will show the

product to be cooked and ‘Open Door - Load

Product’.

8. Choose the recipe required from the options

shown at ‘Selecting a Recipe’, overleaf.

Actual Temp

of Oven

Product to be

Cooked

‘e’ denotes

Programmed

Events.

Set Temp

Selecting Recipes

(Refer overleaf)

13

Page 16

Cooking with Programmed Recipes

Selecting a Recipe

1. From the Oven Ready display, press ‘Select’

key and a recipe screen will be shown on the

display.

2. The following Options are Available:-

METHOD A (Select ‘Up - Down’ Arrow Keys)

A. Pressing the ‘Select Up - Down’ keys and

scroll through the individual recipe selections

and select the recipe required.

:

METHOD B (Select the ‘List’ (Left Function Key):

A. Press the List (Left function key) below the

‘List’ logo will display the complete recipe list to

select the recipe required.

B. Refer to 'Loading the Oven' on the following

page to commence the 'Cooking Cycle'.

B. Scroll through the Recipe List shown using the

‘Select Up - Down’ keys until the desired

recipe is found.

C. Press the ‘Select’ key to select the recipe

required.

D. This recipe will now be shown on the display.

E. Refer to 'Loading the Oven' on the following

page to commence the 'Cooking Cycle'.

14

Page 17

Cooking with Programmed Recipes

Loading the Oven

1. When the oven is up to temperature for the

recipe selected, the display will show the screen

opposite.

2. Open the oven door and load the product into

the oven. The ‘Door Open’ logo will show in

the display.

3. Close the oven door and press the ‘Select’ key.

To Add a Timer Function

1. Press ‘Select’ to select the ‘Timer’ mode. The

display will show ‘Timer 1’.

2. Press the ‘Select Up - Down’ keys to select

the timer required.

3. Press ‘Select’ key and the timer selected will

start.

4. To alter the time of the timer selected, press

the ‘Time’ key to scroll through seconds /

minutes / hours.

5. Press the ‘Select Up - Down’ keys to change

the time.

6. Once the changes have been added, press

‘Select’ key to restart the timer selected.

Open Door and

Load Shelf

Timer 1 Time

Remaining

Minutes

Seconds

15

Page 18

Cooking with Programmed Recipes

To Add Further Timers

1. To add further timers, press ‘Select’, key

twice. ‘Timer 2’ will show on the display.

2. Load the shelf selected and close the door.

3. Press the Select Up - Down keys to select the

timer required.

4. Press ‘Select’ key, the selected timer will start.

5. To review the times remaining on all the timers

set, press ‘Review’ (Right function key) to

scroll through the timers.

6. To alter timers already programmed, refer to

Items 4 to 6 on the previous page and press

‘Select’ to restart the changed timer.

7. When scrolling through ‘Review’ mode, any

timers not running, timer number will flash and

‘Not Running’ will be shown on the display.

NOTE: Once times have been changed, the

display will always show the Timer

with the least time to completion.

Cooking Done

Open Door and

Load Shelf

1. When Timer Cooking is completed, the 'Done'

screen will appear and a continuous alarm will

sound.

2. To Increase Cooking Time by +1 Min -

If an additional minute of cooking time is

required, press the +1 Min - Right function

key.

3. To increase the cooking time by more than

1 minute - Press the Select Up key in increments of 1 minute.

matically after approximately 3 seconds.

Cooking will start auto-

4. When cooking is completed, press the 'Cancel'

- Left function key to stop the alarm and

complete the cooking cycle.

5. Open the oven door and remove the cooked

product from the oven.

6. The display will show ‘Door Open’. Close the

oven door.

Open Door and

Unload Shelf

16

Page 19

Cooking with Programmed Recipes

7. The display will show ‘Timer 1 Not Running’

and then will revert to the next timer with the

shortest time to run.

8. Repeat ‘Cooking Done’, Items 1 to 7 on the

previous page and above, for any further timers

that are in use.

9. The oven timers shown as ‘Not Running’ can

now be re-programmed as shown at Loading

the Oven on page 15, to cook additional items

of the same temperature.

10. Continue cooking until all product is cooked.

17

Page 20

Cooking in Manual Mode

Cooking in Manual Mode

1. Depress the blue Power switch on the main

control panel to switch the oven ‘On’ /

‘Off’ (switch illuminates when power is ‘On’).

2. The Turbofan Start Up Screen will appear for 10

seconds before being replaced by the ‘Oven

Pre-Heating’ screen.

3. Pre-Heat Screen will display Set Temperature

and Actual Temperature of oven.

4. When Pre-Heat temperature is reached, an

Alarm prompt sounds and the ‘Oven Ready’

screen appears showing the Pre Heat

temperature.

5. Press the ‘Select’ Key, and the ‘Recipe’ Screen

will appear.

6. Select List (Left function key), the ‘Recipe

List’ screen will display.

7. Select Manual (Left function key), the

‘Manual Cook’ screen will appear.

Set Temp

Actual Temp

of Oven

Pre Heat

Temp

18

Page 21

Enter Cook Temperature

1. Press the ‘Temp’ key to select the ‘Cook

Temperature’.

2. Adjust the temperature with the Select ‘Up Down arrow keys.

3. Press the SELECT key to enter new

temperature value.

Enter Cook Time

1. With the ‘Manual Cook’ screen showing on the

display.

2. To set the ‘Cook Time’ press the ‘Time’ key.

Adjust with the ‘Select Up - Down’ keys.

3. Press the ‘Time’ key again to move the cursor

between seconds, minutes and hours.

NOTE: The Cooking Compensation function

automatically compensates the time

when opening the door to add other

products to the oven.

4. To activate cooking compensation, from the

‘Manual Cook’ screen, select Cook Comp

(Left function key).

5. A small ‘c’ will appear in the display window

below the ‘Manual Cook’ logo.

6. Press the ‘Select’ key to save the new values.

The display will show new cook program.

7. The screen will show either the ‘Cooling Temp

Not Ready’ or ‘Heating Temp Not Ready’

screens depending on the recipe temperature

and the present temperature of the oven.

8. An alarm will sound when the oven is up to

temperature and the display will show ‘Open

Door - Load Product’.

NOTE: Select from the following, ‘With NO

Shelves / Timers Selected’ or ‘With

Timers Selected’, ‘With Shelves

Selected’ as shown on the following

pages to continue.

Cooking in Manual Mode

Cook Temp

Cook Time

Cooking Comp

Activated

19

Page 22

Cooking in Manual Mode

Cooking in Manual Mode - “with NO Shelves / Timers Selected”

NOTE:-

To cook in Manual Mode with NO Shelf or Timer function selected, Menu 2, Item 8

‘Num of Shelves’, in Service Parameters, must be set to ‘1’ to deactivate the shelf

function.

1. Open the oven door and load all shelves with

produce to be cooked.

2. Press ‘Select’ key to start the cooking mode.

3. While cooking is in progress, the screen on the

right will show on the display.

4. To cancel any cooking, press the Cancel (Left

function key).

Cooking Done

1. When cooking is completed, the screen to the

right is displayed. The alarm indicates the

product is done.

2. To Increase Cooking Time by +1 Min -

If an additional minute of cooking time is

required, press the +1 Min (Right function

key).

3. To increase the cooking time by more than

1 minute - Press the Select Up key in

increments of 1 minute.

automatically after approximately 3

seconds.

4. When cooking is completed, press the Cancel

(Left function key) to stop the alarm and

cancel the cooking program.

5. Open the oven door and remove the product

from the oven.

6. The display will show Door Open / Cool

Down.

7. Close the oven door and the display will return

to the ‘Oven Pre-Heating’ or ‘Oven Ready’

screens.

8. To continue cooking further items, return to

Item 1 at the top of this page.

Cooking will start

Open Door and

Unload Oven

Cook Time

Remaining

20

Page 23

Cooking in Manual Mode

Cooking in Manual Mode - “with Timers Selected”

NOTE:-

Recipes containing Programmed Events (shown by

an ‘e’ displayed on the screen) cannot be cooked

when using the ‘Timer’ mode.

To use the ‘Timer’ mode, more than one shelf must be selected in the Service

Parameters. ‘Controller Configuration’, Menu 2, Item 8 ‘Num of Shelves’, must be set

to the number of shelves being used. Menu 1, Item 3 must be set to ‘Shelf’. NOTE - If

‘Number of Shelves’ is set to ‘1’ then the ‘Shelf Timer’ mode is deactivated.

Shelf timers are used to cook items that have the same cook temperatures. Shelves

can be loaded one at a time and an Individual Timer started for each shelf.

1. Open the oven door and load the first shelf with

product to be cooked.

2. Press the ‘Select’ key to select one of the

timers.

3. Press the ‘Select Up - Down’ keys to select

the timer required. The timer selected will

show on the display.

4. Press ‘Select’ key to start the cooking mode for

this timer.

5. Press ‘Select’ key twice to return to ‘Timer’

mode, then continue as shown at Items 1 to

4 above to select and load any further timers.

6. When timers are activated, to review timers

during the cooking phase, press Review

(Right function key) to scroll through the

time remaining for each Timer selected.

7. When in ‘Review’ mode, timers that have not

been programmed will display the following

screen. This timer has not been programmed.

8. To cancel any cooking, select the timer

required by pressing the Review (Right

function key).

9. Press the Cancel (Left function key) to

cancel the timer option.

Timer Being

Reviewed

‘e’ denotes

Programmed

Events.

Shelf Timer

Time Remaining

to Cook

Completion

21

Page 24

Cooking in Manual Mode

Cooking Done

NOTE: The display will always revert to the

Timer with the least time left to cook

completion.

1. When cooking is completed, the screen to the

right is displayed. The alarm indicates the

product is done.

2. To Increase Cooking Time by +1 Min -

Press the +1 Min (Right function key), if an

additional minute of cooking time is required.

3. To increase the cooking time by more

than 1 minute - Press the Select Up key in

increments of 1 minute.

automatically after approximately 3

seconds.

4. When cooking is completed for that timer, press

the Cancel (Left function key) to stop the

alarm and cancel the cook program for this

timer.

5. Open the oven door and remove the product

from the oven shelf shown as ‘Done’.

6. The display will show ‘Door Open / Cool

Down’.

7. This shelf timer can now be re-programmed as

shown at Item 1 at the top of the previous

page to cook additional items of the same

temperature.

8. The display will revert to the next timer with the

least time to run. Continue cooking until all

timers are done.

Cooking will start

Open Door and

Unload Oven

22

Page 25

Cooking in Manual Mode

Cooking in Manual Mode - “with Shelves Selected”

NOTE:-

Recipes containing Programmed Events (shown by

an ‘e’ displayed on the screen) cannot be cooked

when using ‘Shelf’ mode.

To use the ‘Shelf’ mode, more than one shelf must be selected in the Service

Parameters. Refer to ‘Controller Configuration’, Menu 2, Item 8 ‘Num of Shelves’,

must be set to the number of shelves being used. Menu 1, Item 3 must be set to

‘Shelf’. NOTE - If ‘Number of Shelves’ is set to ‘1’ then the ‘Shelf Timer’ mode is

deactivated.

Shelves are used to cook items that have the same cook temperatures. Shelves can

be loaded one at a time and a cooking time set for each shelf.

1. Open the oven door and load the first shelf with

product to be cooked.

2. Press the ‘Select’ key to select one of the

shelves.

3. Press the ‘Select Up - Down’ keys to select

the shelf required.

4. The shelf selected will show on the display.

5. Press ‘Select’ key to start the cooking mode for

this shelf.

6. Press the ‘Select’ key twice to return to the

shelf mode, then continue as shown at Items 1

to 5 above to select and load any further

shelves.

7. When shelves are activated, to review the shelf

time at any time during the cooking phase,

press Review (Right function key) to scroll

through the time remaining for each Shelf

selected.

8. When in Review mode, shelves that have not

been programmed will display the following

screen. This shelf timer has not been

programmed.

9. To cancel any cooking, select the shelf required

by pressing the Review (Right function key).

10. Press the Cancel (Left function key) to

cancel the shelf option.

Shelf Being

Reviewed

‘e’ denotes

Programmed

Events.

Shelf Number

Time Remaining

to Cook

Completion

23

Page 26

Cooking in Manual Mode

Cooking Done

NOTE: The display will always revert to the

Shelf with the least time left to cook

completion.

1. When cooking is completed, the screen to the

right is displayed. The alarm indicates the

product is done.

2. To Increase Cooking Time by +1 Min -

Press the +1 Min (Right function key), if an

additional minute of cooking time is required.

3. To increase the cooking time by more

than 1 minute - Press the Select Up key in

increments of 1 minute.

automatically after approximately 3

seconds.

4. When cooking is completed for that shelf, press

the Cancel (Left function key) to stop the

alarm and cancel the cooking programme for

that shelf.

5. Open the oven and remove the product from

the oven shelf shown as ‘Done’.

6. The display will show ‘Door Open / Cool

Down’.

7. This shelf can now be re-programmed as shown

at Item 1 at the top of the previous Page,

to cook additional items of the same

temperature.

8. The controller will revert to the next shelf with

the least time to run. Continue cooking until all

shelves are done.

Cooking will start

Open Door and

Unload Oven

24

Page 27

Door Open

1. The screen on the right appears on the display

at any time the door is open.

Cool Down Feature

1. With the door open, press the Stop Cool

Down (Right function key) to turn on the

fan to cool down the oven.

2. The temperature is shown on the display screen

during cool down.

Service Support

1. When the Pre Heat or Oven Ready display is

shown, press Service # (Left function key)

to display the number to call for service help.

2. If the name and number of the service support

has not been programmed in, follow the steps

shown below to add these details to the on

screen prompt:-

To edit the name and number of the service

contact, from the For Service Call screen,

select Edit (Left function key) this will

take you to the EDIT NAME / NUMBER

screen.

Press Time or Temp to move the cursor

between Name and Number.

Press SELECT to move the cursor to the

right.

Editing Name

Other Controller Functions

Whilst in Name press Select Up - Down

keys to add name.

Press Select key to move cursor to the

right.

Editing Number

Whilst in Number press Select Up - Down

keys to add number.

Press Select key to move cursor to the

right.

3. On completion of editing, press Exit (Right

function key) to save the settings and exit to

the For Service Call screen.

4. In the For Service Call screen, press Select

key to return to the Oven Ready screen.

25

Page 28

Programming Recipes

Editing Recipes

Preset recipes can be programmed into the oven

controller. Each recipe can have up to 5 phases

with individual time and temperature settings.

The recipe may be changed when it is being

selected.

NOTE: If a recipe contains events “e”, the

time and temperature cannot be

changed in the ‘Programming

Recipes’ mode. To edit time and

temperature in ‘Events’, refer to

‘Editing Events’ on page 29.

1. From the ‘Oven Read y’ screen, press the

‘Select’ key to choose the recipe to be

changed.

2. Press the ‘Time’, ‘Temp’ and Left Function

Key to unlock the display. The ‘Unlock’

symbol will be displayed at the top right of the

display.

Edit Recipe Name:

Events Symbol

Unlock

Symbol

Recipe Name

1. With the display unlocked, press the ‘Time’ and

‘Temp’ keys to change the ‘Recipe Name’.

2. Use the Select Up - Down keys to change the

letters.

3. Use the ‘Select’ key to move across the letters.

4. Press the ‘Time’ and ‘Temp’ keys to move to

the recipe symbol.

5. Use the Select Up - Down keys to change the

symbol.

6. Press the ‘Save’ (Left function key) to save

the changes and revert back to the ‘Recipe’

screen.

Recipe Symbol

26

Page 29

Edit Recipe Time:

1. With the display unlocked, press the ‘Time’ key

to select the time to change.

2. Press the Select Up - Down keys to change

the time.

3. Press the ‘Time’ key again to move the cursor

between seconds, minutes and hours.

4. Press the ‘Select’ key to store the changes and

return to the recipe menu.

Cook Compensation – Automatically

compensates when opening the oven door to load

product into the oven.

5. Press Cook Comp (Left function key) to

enable the Cook Compensation feature whilst in

the ‘Edit Recipe Time’ mode.

NOTE: A “c” symbol will display in the

bottom left hand corner for all recipes

with Cook Compensation selected.

6. Press SELECT to store the Edit Recipe Time

and Cook Compensation setting changes.

Edit Recipe Temperature:

1. With the display unlocked, press the ‘Temp’

key to select the temperature.

2. Press the Select Up - Down keys to change

the temperature.

3. Press the ‘Temp’ key again to move the cursor

between seconds, minutes and hours.

4. Press the ‘Select’ key to store the changes.

Programming Recipes

Seconds Time

Symbol

Minutes Time

Symbol

Cook Comp

Symbol

Display

Unlocked

Temperature

Display

27

Page 30

Programming Recipes

Change Fan Settings:

1. Press the ‘Temp’ key to select the ‘Fan’ mode.

2. Press the Select Up - Down keys to select the fan

settings required, as shown below:-

Table of Fan Settings (E35 Ovens Only)

HI Fan - Fan speed Fast.

LO Fan - Fan speed Slow.

Hi H - Fan speed High when Heating.

Lo H - Fan speed Low when Heating.

Hi P - Fan speed High - Pulse to pre-set time.

(Refer ‘Edit Events’ for setting details).

Lo P - Fan speed Low - Pulse to pre-set time.

(Refer ‘Edit Events’ for setting details).

NOTE: Time settings for ‘Hi P’ and ‘Lo P’ are

programmed in the ‘Edit Events’ mode.

3. On completion of the fan settings, press the ‘Select’ key

to store the changes and return to the Recipe Menu.

28

Page 31

Programming Recipes

Editing Events

Each programmable recipe cooking period can be made up of the following:-

A straight time / temperature setting for the entire cooking period of the recipe. (Refer to ‘Edit Recipe

Time / Temperature’ on the previous pages).

Or

The cooking period can be programmed with a series of Events which will occur during the cooking

period. (Refer to the information below for details of how to program Events).

Each Event is a sequence of Time, Temperature, Steam and Fan operation which can be set as part of the

cooking process and influence the way a product is cooked.

A maximum of up to 5 Events can be programmed into each recipe.

The combination of all these Event settings added together will make up the overall cooking time for the

product being cooked.

Steam Setting

When a steam time setting is included as part of an Event, the setting relates to how many seconds of

steam will be activated at the start of the event, (i.e. If 5 seconds of steam is set for a 10 minute event,

then at the start of this event, 5 seconds of steam will be activated and then for 9 minutes 55 seconds the

product will cook at the temperature set for this event).

1. With the display unlocked in the Recipe select

screen, press both Select and Time keys

together to enter the EVENTS screen.

2. Press the ‘Time’ key to move the cursor to the

left

.

3. Press the ‘Temp’ key to move the cursor to the

right

.

4. Press the Select Up - Down arrow keys to

change the

highlighted number / time

.

5. Press the ‘Select’ key to save the highlighted

right

setting and move the cursor to the

.

6. Press Save (Left function key) to save the

programmed events and return to the Recipe

select screen.

7. Press Exit (Right function key) to e xit the

Recipe select screen without saving changes.

NOTE: If events are programmed into a

recipe, an ‘e’ will be displayed in the

recipe.

The ‘e’ denotes that

this Recipe has

Programmed Events

29

Page 32

Controller Configuration

Entering the Service Mode

To access the ‘Service Mode’, whilst in the PreHeat or Oven Ready screens, press the Time

and Right function key simultaneously for 3

seconds, Menu 1 will display.

Service Parameters

Service parameters are identified by a number,

shown on the left hand side of the display screen.

Use the ‘Select Up - Down’ keys to scroll to the

Service Mode Menu Number required.

Press the ‘Select’ key to enter the Recipe Menu

required.

Press 'Exit', 'Right' Function key to return to the

Menu Screen / Exit the Controller Configuration

Menu’s.

MENU 1

Parameter

Number

1. Set Temp Offset

Sometimes it is necessary to make a small

adjustment to the real temperature.

To carry out this function, place a digital

thermometer into the centre of the oven and

allow the oven temperature to stabilise.

The temperature display on the oven will

show the real temperature measured by the

temperature sensor without offset.

Press the ‘Select’ key to enter Item 1 ‘Set

Temp Offset’. The Offset Temp screen will

display.

Use the ‘Select Up - Down’ keys to enter

the actual difference that the digital

thermometer shows.

Press 'Save', 'Left' Function key to save the

settings and return to Menu 1.

Offset Temp Default – 005°C.

Offset

Temperature

Press the ‘Select - Down’ key to scroll to

the Item 2 - ‘Calibrate the Probes’.

30

Page 33

2. Calibrate the Probes

Press the ‘Select’ key to enter the

Parameters Screen.

Press 'Exit', 'Right' Function key to return

to the Menu Screen / Exit the Controller

Configuration Menu’s.

Used to Calibrate the Probes with the use of

a Calibration device with 1000 ohm RTD and

176°C.

The Probes are factory set and will not

require calibration.

Refer to Menu 1,

Item 1 to adjust the set temp offset.

Press the Select - Down key to scroll to

Item 3 - ‘Change to Timer / Change to

Shelf’.

3. Change to Timer / Change to Shelf

Determines whether to use ‘Timer’ or

‘Shelf’ identification on cooking screens.

Controller Configuration

Press the ‘Select’ key to change the options

from ‘Timer’ to ‘Shelf’.

Defaults to Shelf

.

NOTE: If the display shows ‘Chan ge to Shelf ’,

pressing the ‘Select’ button will

change to the ‘Shelf’ Mode. The

display will then show ‘Change to

Timer’ mode.

Press the Select - Down key to scroll to

Item 4 - ‘Change to Serial / Change to

IR’.

4. Change to Serial / Change to IR

Configures control for RS232 or IR recipe

exchange.

If ‘Change to Shelf’ is selected,

menu will show Shelf Symbol

here in Menu’s.

If ‘Change to Timer’ selected,

menu will show Timer

Symbol here in Menu’s.

Press the ‘Select’ key to change the options

from ‘Serial’ to ‘IR’.

Defaults to IR

.

Press the Select - Down key to scroll to

Item 5 - ‘Change to ºC / Change to ºF’.

31

Page 34

Controller Configuration

5. Change to ºC / Change to ºF

Temperatures can be displayed as either

Fahrenheit or Centigrade.

Press the ‘Select’ key to change the options

from ‘Timer’ to ‘Shelf’.

Defaults to Fahrenheit

Press the Select - Down key to scroll to

Item 6 - ‘Change to Lock / Change to

No Lock’..

6. Change to Lock / Change to No Lock

If all recipes require to be unlocked for

editing, the service setting can be changed

to the ‘No-Lock’ Mode.

Press the ‘Select’ key to change the options

from ‘Lock’ to ‘No Lock’.

To temporarily enable recipe editing while in

the Lock Mode, press Left function key +

Time + Temp keys simultaneously. The

locked padlock icon will be replaced with an

unlocked padlock icon in the title bar.

Recipes can be edited until the next oven

control power or until the time set at Item

10 - ‘Re-Lock Time’ is completed or until

the operator again presses Left function

key + Time + Temp keys simultaneously.

.

Recipe ‘Locked’ and

can NOT be edited.

Recipe ‘Unlocked’ and

can be edited.

Recipe editing will be disabled and a locked

padlock icon will appear in title bar. Refer to

Item 10 - ‘Re-Lock Time’.

Defaults to No Lock

.

Press 'Next', 'Left' Function key to return

to the Menu Screen / Exit the Controller

Configuration Menu’s.

MENU 2

7. Change to FAN /Change to NO FAN.

NOTE: The ‘FAN’ setting is to be used, i.e.

display shows ‘Change to No Fan’.

Press the ‘Select’ key to change the options

from ‘Change to Fan’ to ‘Change to No

Fan’.

Press the Select - Down key to scroll to

Item 8 - ‘Num of Shelves’.

32

Page 35

8. Num of Shelves

Determines the number of individual shelf

timers that can be used.

Can be set from

1 to 6. If set to 1, the shelf timers are

de-activated,

refer to ‘Cooking in Manual

Mode’ - ‘with NO Shelves / Timers

Selected

’.

Press the ‘Select’ key to change the shelf

options from ‘1’ to ‘6’.

Press the Select - Down key to scroll to

Item 9 - ‘Ld Tmp Drop’.

9. Load Temperature Drop - 150° (F)

Bypass.

Load Temperature drop from 25°F to 150°F,

in increments of 5°.

Defines allowable oven temperature drop

during oven loading (door open).

If oven temperature drop exceeds setting,

recipe will revert to the 'Heating

Temperature Not Ready' mode.

Load Temperature drop can also be by passed by setting the display to ‘Ld Tmp

Drop BP’.

Press the ‘Select’ key to scroll through the

Load Temperature drop options.

Press the Select - Down key to scroll to

Item 10 - ‘Re-Lock Time’.

Controller Configuration

From ’1’ to ’6’ Shelves can be selected. Press the

‘Select’ key to change number of shelves.

10. Re-Lock Time

Determines the duration time for the

controller to automatically return to the

‘Locked’ Mode during recipe editing. Can be

set from OFF to 60 secs in 10 second

increments.

Default Setting 10 Seconds.

Press the ‘Select’ key to scroll through the

Re-Lock Time options.

Press 'Exit', 'Right' Function key to return

to the Menu Screen / Exit the Controller

Configuration Menu’s.

NOTE: Menu 2 screen also shows the

present operating temperature of the

Controller board and the Max Board

Temp. These are not adjustable.

33

Current Board Temp.

Max Board Temp

Page 36

Controller Configuration

Service Parameter Flow Chart

MENU 1

NOTE: Factory Use Only - Do Not Change

MENU 2

Press 'Left' Function key to return to Menu 1,

OR

Press 'Right' Function key to Exit Service Mode.

34

Page 37

Oven Operation - General

Door Handle

Standard Door Catch Operation

A. To open the oven door, rotate the handle either

clockwise or anti-clockwise to the 'Open' position to

unlatch the door and pull the door open with the

door handle.

B. To close the door, push the door firmly closed and

the door will lock in the closed position. (there is no

need to turn the handle to the closed position as the

door self-latches in the closed position and the

handle will self-centre to the 'Closed' position.

Side Racks

1. The side racks can be fitted in one of two positions, in

order to take 16 or 18 inch trays.

2. To position racks for 16 inch trays, use the holes at the

rear of the rack.

3. Alternatively for 18 inch trays, use the holes nearest the

centre of the oven.

Removal of Side Racks

Open

Closed

Open

16 inch tray

locator

18 inch tray

locator

1. Lift the side rack off the bottom locating pins.

2. Move the bottom of the side rack toward the centre of the

oven.

3. Lower side rack to clear top locating pins, and remove.

Replacement of Side Racks

1. Insert rack into the oven, placing appropriate holes over

the top locating pins.

2. Lift the side rack over the bottom locating pins.

3. Lower side rack with the appropriate holes over the

bottom locating pins.

35

35

3

1

2

Page 38

Cleaning and Maintenance

General

C

AUTION

Always turn off the electrical power supply at the mains supply before

commencing oven cleaning.

This appliance is not water proof.

Do not use water jet spray to clean interior or exterior of this appliance.

Clean the oven regularly. A clean appliance looks better, will last longer and will perform better.

Carbonised grease on the oven will hinder the transfer of heat from the cooking surface to the food. This

will result in loss of cooking efficiency.

NOTE:

DO NOT use water on the oven while it is still hot as warping and cracking may occur.

Use the oven ‘Cool Down’ mode to cool the oven before commencing cleaning.

DO NOT use harsh abrasive scouring pads, abrasive detergents, strong solvents or

caustic detergents as they could corrode or damage the oven.

Ensure that any detergent or cleaning material has been completely removed after

each cleaning.

To keep your oven clean and operating at peak efficiency, follow the procedures shown below:-

Oven Cool-Down Mode

:

This Mode can be used to cool down the oven after cooking

operations have been completed and prior to cleaning, to

ensure that the oven is at an acceptable temperature before

commencing the cleaning operation.

1. Open the oven door. The following screen will be

displayed.

2. Press the Cool Down (Right function key) to turn ‘On’

the fan and cool down the oven.

3. The current temperature of the oven is shown on the right

hand side of the display screen during cool down.

4. When the correct oven temperature is reached, to stop

'Cool-Down', either close the oven door or press the

Stop Cool Down (Right function key). Cool down will

stop.

5. Press the blue Power switch on the main control panel to

switch ‘Off’ the oven (switch is illuminated when power is

‘On’).

Current Temp

of Oven.

36

Page 39

Cleaning and Maintenance

Daily Cleaning

Oven Control Panel - IMPORTANT

a. DO NOT use cleaning chemicals on control panel. Clean with damp cloth only. DO NOT apply

pressure on display screen.

b. Dry the control panel thoroughly with a dry cloth and polish with a soft dry cloth

Oven

a. Thoroughly clean the interior and exterior surfaces of the oven with a damp cloth moistened i n

hot water and a detergent solution and use a soft scrubbing brush if required.

b. Any carbon deposits within the oven should be removed using a wooden or plastic scraper tool

followed by wiping with a damp cloth to prevent accumulation of food deposits.

c. Dry the oven thoroughly with a dry cloth and polish with a soft dry cloth.

Oven Trays

a. Thoroughly clean the oven trays with a damp cloth moistened in hot water and a detergent

solution and use a soft scrubbing brush if required.

DO NOT use harsh abrasive scouring pads, abrasive detergents, strong solvents or

caustic detergents as they will damage the oven trays.

Oven Racks

a. To remove, follow instructions given in ‘Oven Operation - General’ section.

Weekly Cleaning

NOTE:

If the oven usage is very high, we recommend that the weekly cleaning procedure is

carried out on a more frequent basis.

DO NOT use water on the oven while the oven is still hot as warping may occur. Allow

the oven to cool before cleaning.

DO NOT use harsh abrasive scouring pads, abrasive detergents, strong solvents or

caustic detergents as they will damage the oven and oven seals.

Ensure that protective gloves are worn during the cleaning process.

Exterior

a. Clean with a good quality stainless steel cleaning compound. Harsh abrasive cleaners may

damage the surface.

Stainless Steel Surfaces

a. Clean the exterior surfaces of the oven with a damp cloth moistened with a mild detergent

solution, or a soft bristled brush.

b. Baked on deposits or discolouration may require a good quality stainless steel cleaner. Always

apply cleaner when the appliance is cold and rub in the direction of the grain.

c. Dry all components thoroughly with a dry cloth and polish with a soft dry cloth.

Oven Interior

a. Ensure that the oven chamber is cool. Do not use wire brushes, steel wool or other abrasive

materials to clean the oven interior.

b. Remove the oven racks and the fan baffle and clean any build up of grease from the oven

interior with a mild anti bacterial detergent and hot water solution using a soft bristled brush.

c. Take care not to damage the fan or the tube at the right side of the oven which controls the

thermostat.

d. Dry the oven thoroughly with a soft dry cloth.

37

Page 40

Cleaning and Maintenance

Oven Side Racks

a. Remove the RH and LH Side Racks by lifting the side racks off the bottom locating pins.

b. Move the bottom of the rack toward the centre of the oven.

c. Lower rack to clear top locating pins, and remove from the oven.

d. Clean the side racks with a mild anti bacterial detergent and hot water solution using a soft

bristled brush.

e. Dry the side racks thoroughly with a soft dry cloth before re-fitting.

f. Refit the side racks by inserting the racks into the oven, placing the appropriate holes over the

top locating pins.

g. Lift the side rack over the bottom locating pins.

h. Lower rack with appropriate holes over bottom locating pins.

Fan Baffle

a. To remove th e fan baffle, firstly remove the RH side rack as shown above

b. Undo the 4 screws (anti-clockwise) at the top and bottom of the baffle plate.

c. Remove the fan baffle from the right hand side of the oven.

d. Clean fan baffle with mild anti bacterial detergent, hot water solution and a soft bristled brush.

e. Dry the fan baffle thor oughly with a soft dry cloth before re-fitting.

f. Refit the fan baffle in reverse order and tighten the 4 securing screws to secure the fan baffle.

g. Refit the RH side rack as shown above.

Oven Door Cleaning

a. The oven door and glass can be cleaned with a mild anti bacterial

detergent and hot water solution using a damp cloth.

b. Dry the oven door thoroughly with a soft dry cloth.

c.

OUTER SURFACES: Clean door glass with a conventional glass cleaner.

INNER SURFACES: To clean between the inner and outer door glasses,

firstly ensure the door is locked shut. With a screwdriver, coin, or other

suitable device,

1

/4 turn the outer glass locks to release the outer glass

and allow it to be hinged open for cleaning access.

IMPORTANT: Always ensure outer glass is hinged closed and locked into position

before opening door.

Oven Seals

a. To remove, pull out the seal starting at each corner.

b. Check the seals for wear and damage and replace if damaged or worn.

c. Seals may be washed in a sink, take care not to cut or damage them.

d. Dry the oven seals thoroughly with a soft dry cloth before re-fitting.

e. To replace, fit the seal into the corners first, then push in rest of seal.

Monthly Cleaning

Top

Unlocked

Unlocked

Bottom

Locked

Locked

Oven Seals

a. Check the oven seals for wear and damage and replace if damaged or worn.

b. Clean the oven regularly with a good quality domestic oven cleaner.

Periodic Maintenance (6 Monthly)

1. To achieve the best results cleaning must be regular and thorough and all controls and mechanical parts

checked and adjusted periodically by a competent serviceman.

2. If any small faults occur, have them checked promptly. Don't wait until a complete breakdown occurs.

It is recommended that the appliance is serviced every 6 months.

38

Page 41

Fault Finding

C

AUTION

This appliance is;

For professional use and is to be used by qualified persons only.

Only authorised service persons are to carry out installation, and servicing

operations.

Components having adjustments protected (e.g. paint sealed) by the

manufacturer should not be adjusted by the user / operator.

This section provides an easy reference guide to the more common problems that may occur during the

operation of your equipment. The fault finding guide in this section is intended to help you correct, or at

least accurately diagnose problems with your equipment.

Although this section covers the most common problems reported, you may encounter a problem not

covered in this section. In such instances, please contact your local authorised service agent who will

make every effort to help you identify and resolve the problem. Please note that the service agent will

require the following information:-

Model Code and Serial Number of the appliance. (Both can be found on the Rating

Plate located on the appliance.

:

Fault Possible Cause Remedy

The oven does not operate /

start.

The mains isolating switch on the

wall, circuit breaker or fuses are

'Off' at the power board.

The power switch on the oven is

'Off'.

Overtemp safety thermostat

tripped.

Turn 'On'.

Depress switch. Switch will

illuminate.

Reset (Button located at bottom

RH side of RH side panel). If fault

re-occurs call for service.

Oven light illuminating but fan not

working and oven not heating.

Oven door not closed properly.

Door switch or door catch broken.

Close oven door properly.

Call for service.

Bake timer does not time down. Bake timer not set correctly. For settings less than 10 minutes,

first set to greater setting then turn

back to desired setting.

Oven light not illuminating. Blown bulb. Replace bulb.

No water injection / steam. Water not turned 'On'. Turn water 'On' at water supply.

39

Page 42

Circuit Schematic

380V, 3P+N+E

400-415V, 3P+N+E

40

Page 43

Competency Check Lists

Guide Sheets for Staff Training

The pages in the following section of this manual should be copied and used when training staff to operate

the E35C convection oven. It is suggested that the competency assessment checklists be completed,

signed, and a copy kept in the personnel files for future reference.

Supervisors to Ensure

Competency check lists are copied and completed as part of the training of staff.

Correct training of staff to the required competency expectations.

The verification section of the competency check list is signed off.

A copy of the completed and signed competency check list is placed in personnel records as evidence

of operator competence.

41

Page 44

Competency Check Lists

Turbofan E35C Convection Oven - Operation

Element

:

Implement Safe Work Procedures

Assessment Criteria

“Can the operator”

Identify the purpose and use of:

Warning signs.

Safety features.

Related to the Turbofan E35C Convection Oven?

Identify:

Machine-related health and safety risks of this equipment?

Emergency procedures to be used with this equipment?

Operate this equipment correctly in normal and emergency situations?

Identify:

OH&S reporting procedures related to hazard reporting for this machine?

Comments:

To gain competency in the use of the Turbofan E35C Convection Oven, the assessor must be satisfied

that the operator has consistently applied the knowledge and skills in all of the above elements.

— Use this form to train staff, and place a copy in personnel files.

SUGGESTION

This form should be signed off only when the assessor is satisfied that the employee / trainee

is competent to carry out all of the tasks described above.

Applicant’s signature

Assessor’s signature

Date / /

Date / /

42

Page 45

Competency Check Lists

Turbofan E35C Convection Oven - Daily Cleaning

Element

:

Implement essential hygiene and sanitation procedures

Assessment Criteria

“Can the operator”

Maintain sound personal hygiene at all times when working with the Turbofan E35C

Convection Oven?

Use appropriate protective and work clothing while working with the Turbofan E35C

Convection Oven?

Identify:

Product handling requirements during production process?

Critical points in the process where contamination can be introduced?

Why it is important to monitor hygiene and sanitation performance?

The effect of poorly maintained equipment on the control of contamination and spoilage?

Company policies and procedures regarding hygiene and sanitation?

Actual and potential contamination and spoilage hazards?

Solutions to rectify contamination and spoilage problems?

Use work practices and methods that reduce the risk of product contamination?

Remove contamination where appropriate in accordance with:

Workplace hygiene and sanitation procedures?

Procedures specific to the Turbofan E35C Convection Oven?

Comments:

To gain competency in the use of the Turbofan E35C Convection Oven, the assessor must be satisfied

that the operator has consistently applied the knowledge and skills in all of the above elements.

This form should be signed off only when the assessor is satisfied that the employee / trainee

is competent to carry out all of the tasks described above.

Applicant’s signature

Assessor’s signature

Date / /

Date / /

43

— Use this form to train staff, and place a copy in personnel files.

SUGGESTION

Page 46

Hazard Risk Assessment

The following risk assessment covers the reasonably foreseeable hazards to health and safety arising from

the Turbofan E35C Convection Oven and from systems of work associated with this machine.

Hazard Identified Existing Controls Consequences Likelihood Risk Rating

Cleaning the machine with

buckets of water or hoses is

extremely dangerous and may

lead to electrocution.

The machine must be cleaned

with a damp cloth only.

Electrical isolation switch

should be fully accessible to

the operator.

Recommend no more than 1.5

metres above the floor.

Service panels should not be

removed whilst the machine is

in operation.

The machine must not be

operated with any service

access panel removed.

The machine should never be

connected to alternative

power source other than that

which has been designed for

that machine by the store

designer.

Safe work cleaning practices

included in training manual

local workplace rules and

management.

Site supervision, inspection

and training as detailed in

this manual.

Dependent on store electrical

policy.

Machine designed to be

accessed by authorised

service technicians only.

Warning signs clearly evident.

Site supervision, inspection

and training as detailed in

this manual.

Direct connection to

switchboard only.

Catastrophic Rare High

Major injuries Rare High

Major injuries Unlikely High

Moderate injuries Rare Moderate

Exterior front surfaces and

interior surfaces can get

extremely hot - burn hazard.

Steam blow back burns from

opening door during oven

operation.

Glass viewing windows

become extremely hot.

Risk Rating Extreme Risk. Immediate action required.

High Risk. Senior management attention required.

Moderate Risk. Management responsibility must be specified.

Low Risk. Manage by routine procedures.

Warning signs.

Workplace standard operation

procedures.

Standard baking procedures

indicate how and when steam

is to be used.

Warning signs.

Workplace standard operation

procedures.

Minor injuries. Unlikely Low

Moderate injuries Unlikely Moderate

Minor injuries Unlikely Low

Owners and Operators Please Note:

The risk ratings and control measures as outlined in this manual must be incorporated into your safety

management systems and procedures. Ensure effective risk control by reinforcing these procedures with

staff. For example: never clean any electrical equipment with buckets of water or pressurised hoses.

44

Page 47

Replacement Parts List

Control Panel

026475 Oven Controller (100 Re cipe).

B26053 Control Panel.

026018 Overlay E35C.

B25926 Controller Cover Panel.

026506 Oven Control Relay Board.

026507 Oven Control Keypad.

232371 Operator Switch.

232394 Switch Contact 2N/O+Lamp.

025997 Temperature Probe PT1000.

025787 Transformer - 12Vac.

Electrical Gear

231739 Heating Contactor.

231742 Motor Contactor (3NO + 1NC).

231746 Suppressor (Heating Contactor).

231747 Suppressor ( Motor Contactors).

231743 Contactor Interlock.

232410 Shunt Trip.

232408 Circuit Breaker 3ø 25A.

232407 Circuit Breaker 1ø 6A.

232108 Lamp Hold er Complete (G9 Halogen).

231814 Light Bulb G9. 25W 230V - (G9 Halogen).

021352 Oven Lamp Glass.

021354 Lamp Gasket.

025400 Over Tem perature Thermostat.

021156 Cooling Fan.

024567 Motor Timer.

020774 Microswitch.

Motor & Elements

Replacement Parts List

020745K Motor Kit - 380 - 414V.

025396 Fan.

020896 Motor Shaft Seal.

020762 Elemen t - 230 - 240V, 2000W, - (E3 5 Standard Models).

022259 Elemen t - 230 - 240V, 1250W, - (E3 5C8, 8kW Models Only).

Steam System

020851 Water Sol enoid Valve.

020853 Spra y Adaptor Body.

020819 Vent O ver Pressure Spring.

020824 Vent Gasket.

021526 Water Inlet Elbow.

021527 Washer Rubber.

45

Page 48

Replacement Parts List

Replacement Parts List (continued)

Door

231438 Door Seal.

231804 Sin gle Step Locking Do g.

231803 Door Inner Glass.

232364 Door Glass Outer Spring .

231801 Door Inner Glass Buffer.

230745 Hinge Bush.

230741 Hinge Mounting Plate Top.

230742 Hinge Mounting Plate Bottom.

231494 Door Handle.

232134 Door O uter Glass Assembly.

Racks

020809 Side Rack L / Hand WA (E35-26 ”).

020810 Side Rack R / Hand WA (E35-26”).

020811 Side Rack L / Hand WA (E35-30 ”).

020812 Side Rack R / Hand WA (E35-30”).

015168 Oven Rack (E35-26”).

020993 Oven Rack (E35-30”).

Optional Extras

025916 Rack Run ner 4 Tray LH WA (E35-26”).

025917 Rack Run ner 4 Tray RH WA (E35-26”).

026127 Rack Run ner 5 Tray LH WA (E35-26”).

026128 Rack Run ner 5 Tray RH WA (E35-26”).

025089 Rack Run ner 8 Tray LH WA (E35-26”).

025090 Rack Run ner 8 Tray RH WA (E35-26”).

023118 Side Rack L / Hand WA 8 Tray (E35- 30”).

023119 Side Rack R / Hand WA 8 Tray (E35-30”).

026590 Rack Run ner 4 Tray L / Hand WA (E 35-30”).

026591 Rack Run ner 4 Tray R / Hand WA (E35-30 ”).

021236 Double Stack Kit (E35- 26”).

021237 Double Stack Kit (E35- 30”).

021348 Adj ustable Legs 4”.

230578 Leg Assy 150 mm ST/ST.

46

Page 49

Loading...

Loading...