Page 1

Installation and Operation Manual

30T

E33T C-Store

Convection Oven

SERIES

238681-1

Page 2

Australia

www.moffat.com.au

New Zealand

www.moffat.co.nz

www.turbofanoven.com

Australia

Moffat Pty Limited

740 Springvale Road

Mulgrave, Victoria 3170

Telephone 03-9518 3888

Facsimile 03-9518 3833

nsw@moffat.com.au

New Zealand

Moffat Limited

16 Osborne Street

Christchurch 8011

Telephone 03-389 1007

Facsimile 03-389 1276

sales@moffat.co.nz

Designed and manufactured by

ISO9001

All Turbofan products are designed and

manufactured by Moffat using the

internationally recognised ISO9001

quality management system, covering

design, manufacture and final inspection,

Ensuring consistent high quality at all

times.

In line with policy to continually develop

and improve its products, Moffat Limited

reserves the right to change specifications

and design without notice.

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in writing

by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and design

without prior notice.

© Copyright Moffat Ltd. April 2015.

Page 3

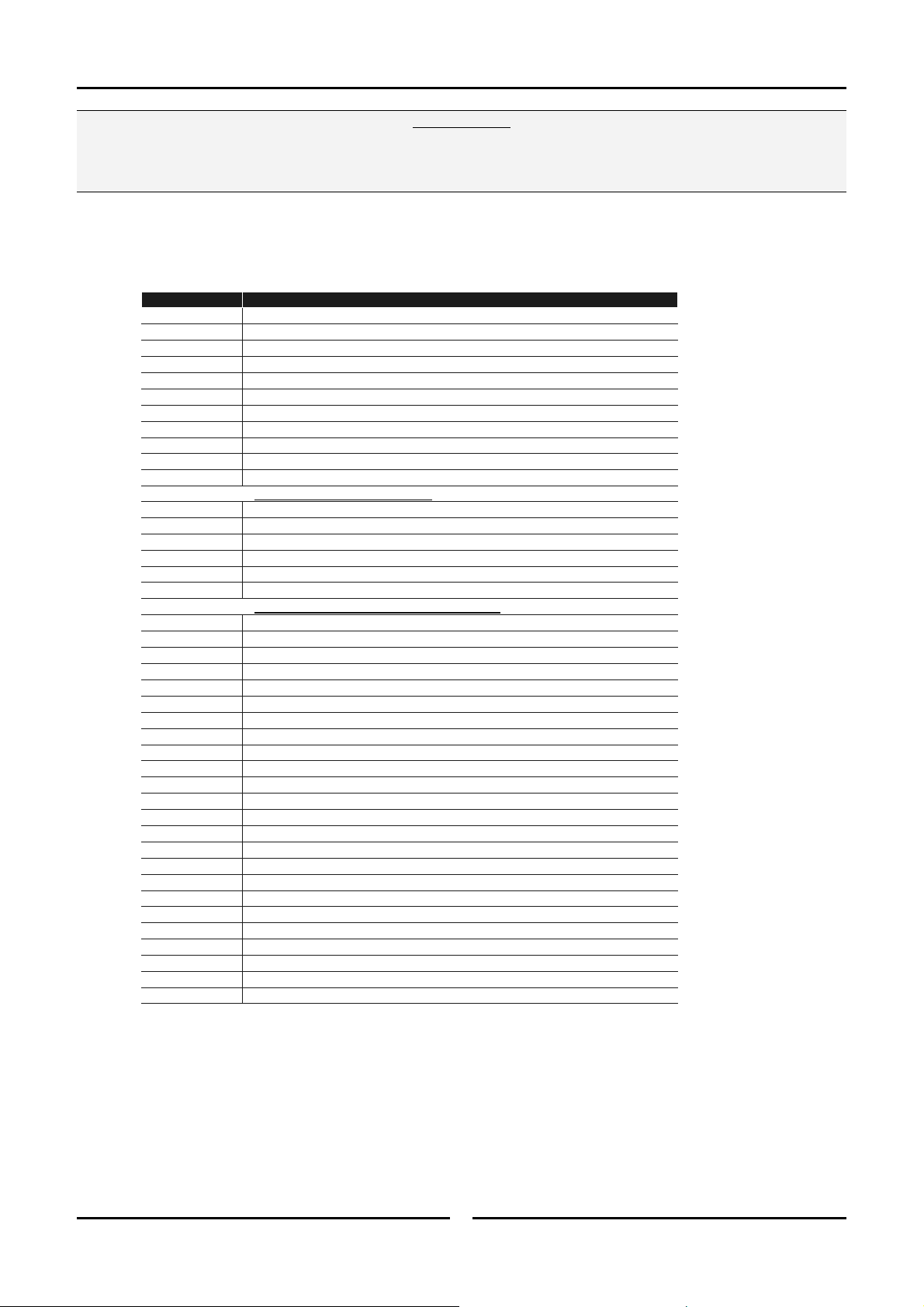

Contents List

E33T Turbofan Convection Oven.

E33T C-Store Convection Oven

Introductio n ............................................................................................................................... 3

Safety Information

Specificati ons ............................................................................................................................. 4

Installation ................................................................................................................................. 5

Installation Requirements

Unpacking

Location

Clearances

Stand Mounted Ovens

Electrical Connection

Water Connection

Recommended Water Specifications

Positioning and Levelling of Oven

Initial Start-Up

Commissioning

Operation - Oven Mode .............................................................................................................. 7

Oven Mode

Control OFF

Control ON

Pre-Heating

Select Shelf

Select Product

Load Tray(s)

Program Start

Done - Time Up

Return to Step 4

Manager Mode - Recipe Programming .................................................................................... 9

Entering Recipe Programming

Enter Manager Mode

Enter Passcode

Enter Recipe Programming

Recipe Editing

Recipe Naming

Recipe Image

Recipe Category

Set Number of Shelves

Set Recipe Time and Temperature

Page 4

Contents List

Manager Mode - Settings ......................................................................................................... 13

Selecting Manager Mode

Control ON

Enter Passcode

Manager Screen #1

Recipe Programming

Copy Recipes to USB

Copy Recipes from USB

Preheat Options

Manager Screen #2

Piezo Volume Adjustment

Cook Done Beep On/Off Setting

Ready Beep On/Off Setting

Keypress Feedback Enable/Disable

Manager Screen #3

Manager Passcode Enable/Disable

Screen Brightness Adjust

Screen Auto Dim Setting

Recipe Image Maintenance

Manager Screen #4

Change Passcode

Energy Saving Temperature Setback Options

Auto Start Setting Options

System Information

Manager Screen #5

Real Time Setting

Date Settings

Language Selection

Temperature Unit Selections °C / °F

Manager Screen #6

Touch Screen Calibration

Cleaning and Maintenance ..................................................................................................... 18

Cleaning Guidelines

Oven Cleaning

Periodic Maintenance

Electrical Schematics ............................................................................................................. 20

Electrical Schematic E33T C-Store (High Speed Option - 2 Speed Fan Motor)

Electrical Schematic E33T C-Store (Standard 2 Speed Fan Motor)

Replacement Parts List .......................................................................................................... 22

Page 5

Introduction

Before using your new oven, please read this instruction manual

carefully, pay particular attention to any information labelled

‘WARNING’, ‘CAUTION’, ‘IMPORTANT’ or ‘NOTE’ in this

manual.

Warning

Caution

If you are unsure of any aspect of the installation, instructions or

performance of your oven, contact your TURBOFAN dealer promptly.

In many cases a phone call could answer your question.

Should you contact your TURBOFAN dealer on any matter concerning this oven, please have the information provided opposite, readily

available.

I

NDICATES A HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED, WILL RESULT IN

DEATH OR SERIOUS INJURY.

I

NDICATES A HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED, WILL RESULT IN

MINOR OR MODERATE INJURY.

This manual must be kept by the owner for future reference.

A record of

Number of the oven

below.

Date of Purchase, Date of Installation

should be recorded in the area provided

and

Serial

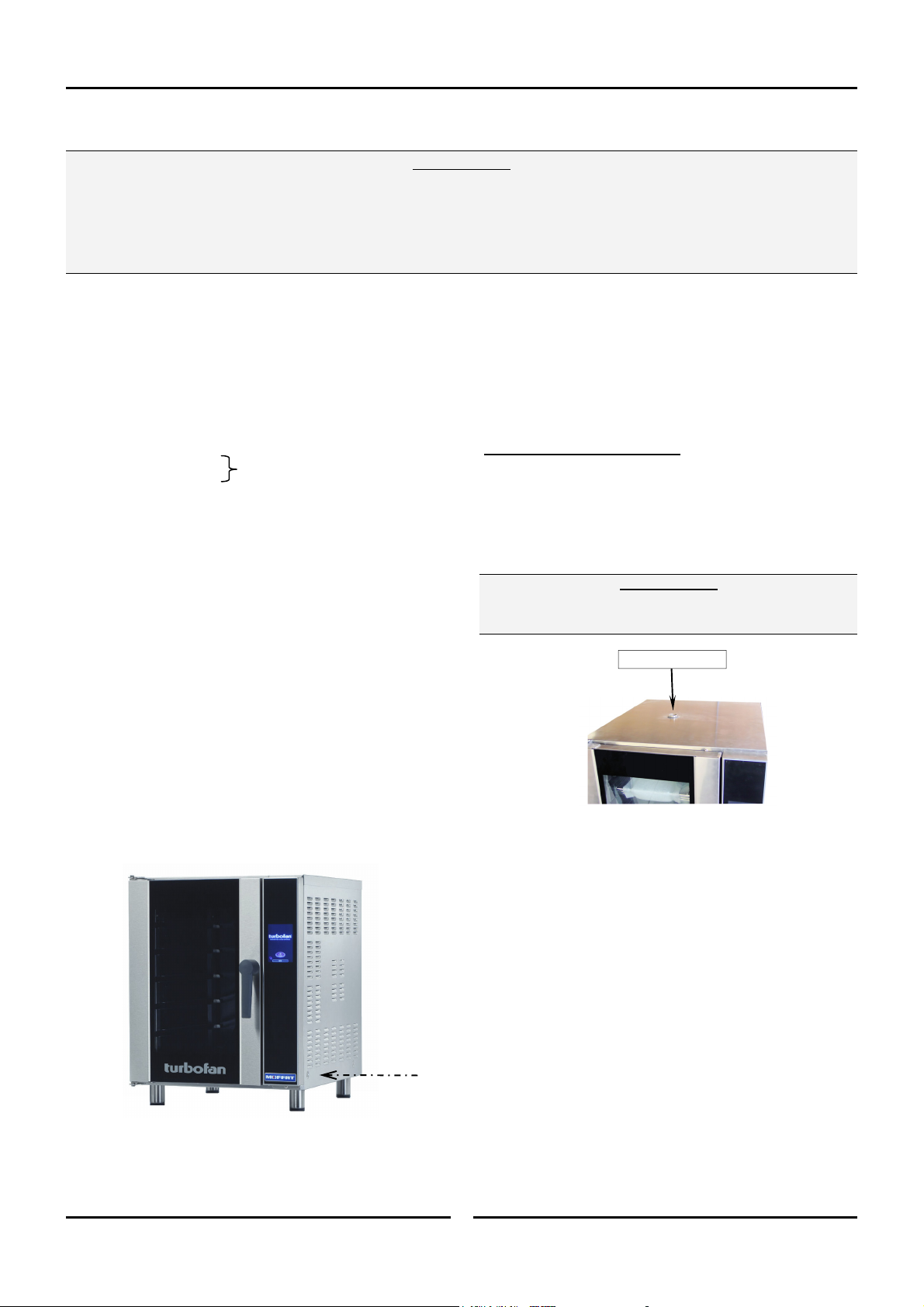

The serial number of this oven can be found on the

Technical Data Plate located on the front right hand side

panel, see diagram in ‘Installation Section’.

Model Number:

Serial Number:

Dealer:

Service Provider:

Date Purchased:

Date Installed:

Safety Information

For your safety, please pay attention to the following symbols

marked on the appliance.

- R

ISK OF ELECTRIC SHOCK.

NO USER SERVICEABLE PARTS INSIDE.

UALIFIED SERVICE PERSON ACCESS ONLY.

Q

DISCONNECT FROM POWER BEFORE SERVICING.

3

Page 6

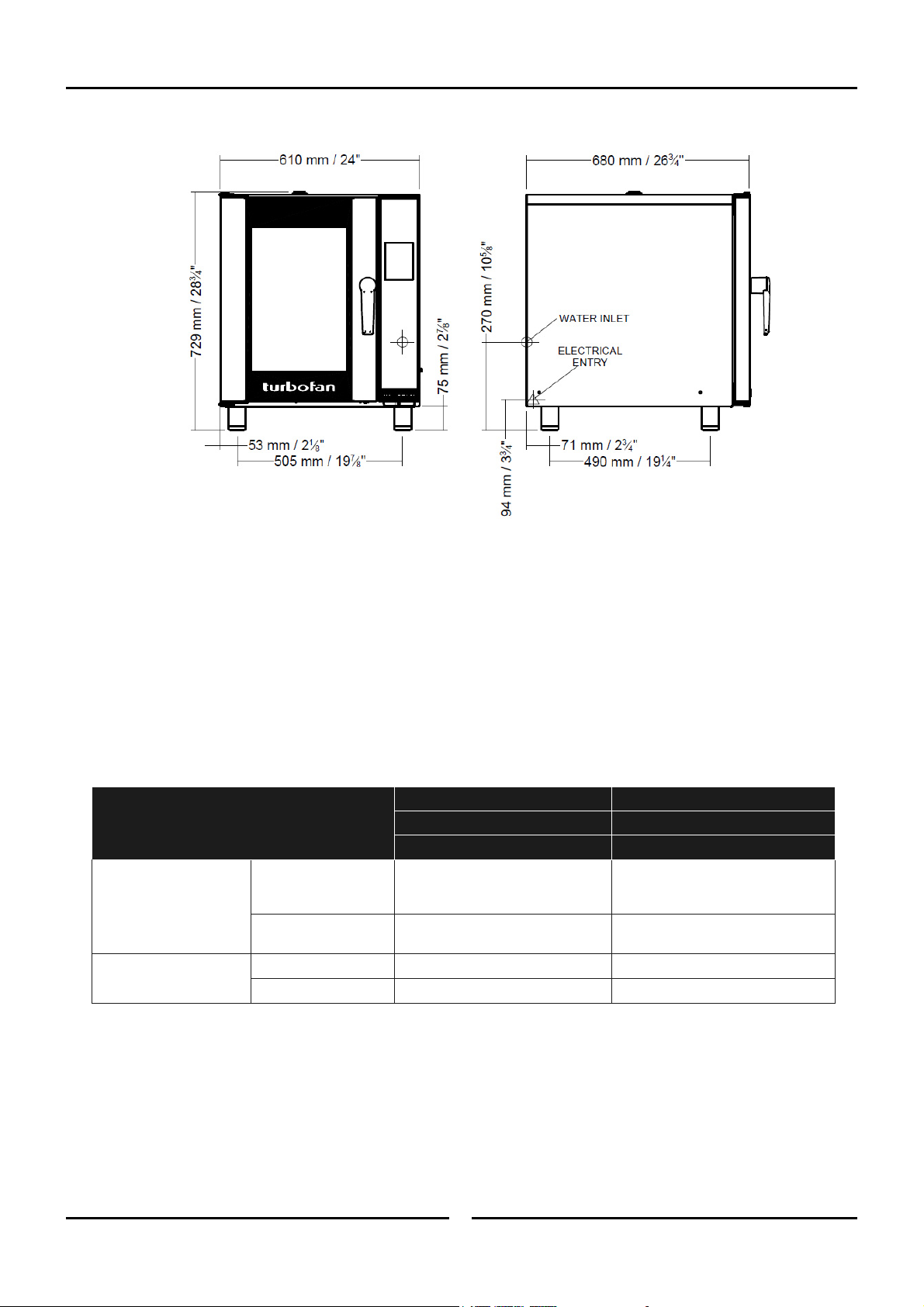

E33T

Specifications

Oven Power Ratings

Oven Tray Details

Water Connection

USA / Canada

208V, 60Hz, 5.4kW.

220 - 240V, 60Hz, 6.0kW.

5 Shelf - 13” x 18” Bun Pan.

Tray Capacity

12” x 20” Steam Pan.

(Optional, 4 Shelf).

Tray Spacing

5 Shelf - 3

4 Shelf - 113mm / 4

1

/3” / 85mm.

Max Water Pressure 80psi / 550kPa.

3

Connection Size

/4” GHT.

4

1

/2”.

Other Markets

220V, 50Hz or 60Hz, 6.0kW.

230 - 240V, 50Hz or 60Hz, 6.0kW.

5 Shelf, 1/1 GN Pan.

(Optional, 4 Shelf).

5 Shelf - 85mm / 3

4 Shelf - 113mm / 4

1

/3”.

1

/2”.

80psi / 550kPa.

3

/4” BSP.

Page 7

Installation Requirements

Installation

Important:

Installation shall comply with local electrical, health and safety requirements.

It is most important that this oven is installed correctly and that oven operation is correct before use.

If you have any questions regarding the proper installation and / or operation of this oven, please contact your local

Turbofan distributor.

Unpacking

1. Remove all packaging and transit protection including all

protective plastic coating from the exterior stainless steel

panels.

2. Check the oven and supplied parts for damage. Report any

damage immediately to the carrier and distributor.

3. Check that the following parts have been supplied with your

oven:-

4 x Leg Adjustable.

Adaptor Brass.

Washer Rubber.

4. Report any deficiencies to the distributor who supplied your

oven.

5. Securely fit the 4 legs supplied with the oven.

6. Check that the available electrical supply is correct to that

shown on the Technical Data Plate located on the front right

hand side panel.

Refer to ‘Specifications’ section, ‘Oven Specifications

Table’ on previous page.

Location

1. Position the oven in its approximate working position.

2. The unit should be positioned so that the control panel and

oven shelves are easily reachable for loading and unloading.

USA / Canada Only.

Clearances

To ensure correct ventilation for the motor and controls, the

following minimum installation clearances are to be adhered to:-

Clearance From Source of Heat.

A minimum distance of 300mm (12”) from the appliance

sides is required.

NOTE: Fixed installations require at least 500mm (20”)

The vent located on the top of the oven must NOT be

obstructed.

Top 200mm / 8”

Rear 50mm / 2”.

Left-hand side 50mm / 2”.

Right-hand side 75mm / 3”.

clearance for service access.

Important:

Oven Vent Location

Stand Mounted Oven

For stand mounted ovens, the oven feet are used to level the oven

on the stand. Refer to the instructions supplied with separately

ordered stands for mounting details.

Technical Data Plate - Data and Location

5

Page 8

Installation

Electrical Connection

T

HIS OVEN MUST BE EARTHED / GROUNDED.

Each oven should be connected to an adequately protected power

supply with an appropriate three wire power cord.

An isolation switch must be mounted adjacent to, but not behind

the oven and must be readily accessible to the operator. This

switch must be clearly marked and readily accessible in case of

fire.

Check the electricity supply is correct to as shown on the

Technical Data Plate on the front right hand corner of the oven

side panel.

NOTE: All electrical connections must only be carried out

1. Remove oven right hand side panel.

2. Bring the supply cable up through the grommet at the back

3. Connect the mains supply to the appropriately marked

Water Connection - Optional

by a suitably qualified person.

of oven and through the compression gland on the electrical

switchgear panel.

terminals on the terminal block.

(Not required for Main Oven Operation)

Warning

Positioning and Levelling of Oven

1. Correctly locate the oven into its final operating position and

using a spirit level, adjust the oven feet so that the oven is

level and at the correct height.

Initial Start-Up

Before using the new oven;

1. When using the oven for the first time, operate oven for

about 1 hour at 200°C / 400°F to remove any fumes or

odours which may be present.

2. Please refer to the Operation Section of this manual for

details on how to correctly operate and shutdown the oven.

Commissioning

Before leaving the new installation;

Check the oven functions in accordance with the operating

instructions specified in the ‘Operation’ section of this manual.

Ensure that the operator has been instructed in the areas of

correct operation and shutdown procedure for the appliance.

NOTE: If it is not possible to get appliance to operate

correctly, turn ‘Off’ power at the mains supply and

contact supplier of this appliance.

1. If the manual addition of water into the oven for

humidification or steaming effect on baked product is

required, the unit’s water connection can be used.

2. Tighten the 2 screws securing the

water connection to the rear of

the oven. (These have

purposely been left loose to

prevent damage to the water

connection during transit).

3. Connect a cold water supply to the

water inlet (R ¾” Connector) on

the rear, right hand side of the

oven. (USA / Canada only, supplied with ¾” GHT adaptor).

- Max Inlet Pressure 80psi / 550kPa.

4. Turn ‘On’ the water supply and check for leaks.

Recommended Water Specifications

In order to prevent corrosion or scaling in the oven and water

system due to supplying water that is either too soft or too hard,

the following recommendations should be used as a guideline.

Hardness: Between 60 and 90ppm.

PH: Greater than 7.5.

Chlorides: Less than 30ppm.

Tighten Screws.

6

Page 9

Operation - Oven Mode

Oven Mode

1. CONTROLOFF

Press key to turn control ON.

2. CONTROLON

Press OVEN to start using oven.

3. PRE‐HEATING

Press to show HELP screen.

(All screens)

Press to turn oven light On/Off.

Press to cool down oven.

Press to turn OFF controller.

Press to show HELP screen.

Press to return to previous screen.

Oven Pre-Heating will occur

automatically.

Shelves cannot be selected until

oven has completed ‘pre-heating’.

4. SELECTSHELF

Always select empty shelves nearest

top of oven first.

Once Pre-Heating has completed.

Press to select shelf.

Up to 5 shelves can be selected.

Heat ‘On’ symbol will illuminate when

oven is heating.

Press to show HELP screen.

Press to return to previous screen.

7

Page 10

Operation - Oven Mode

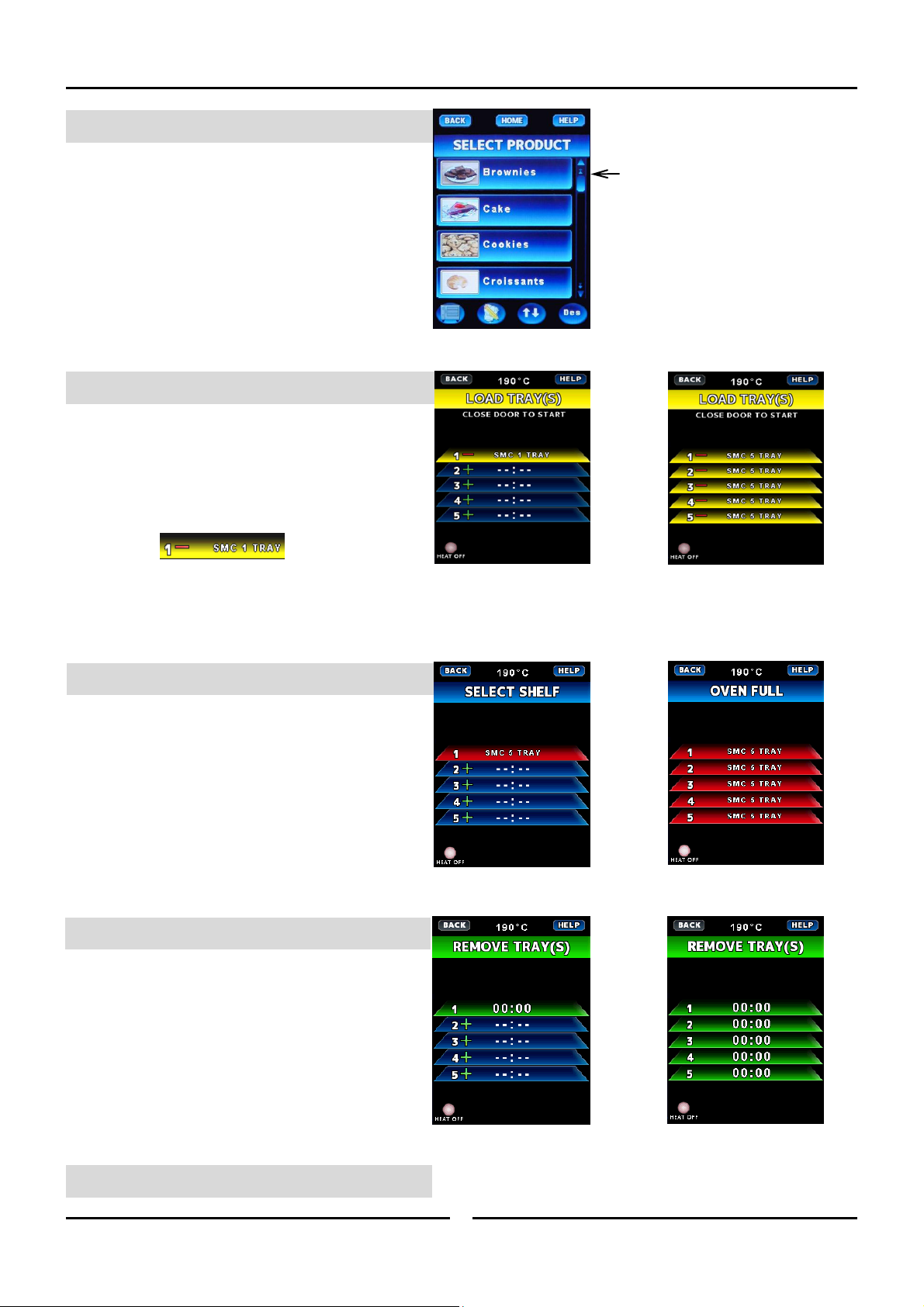

5. SELECTPRODUCT

SELECT product from list.

Alarm will sound when oven is ready to

load.

6. LOADTRAY(S)

LOAD TRAY(S) to selected shelf or shelves.

Always select empty shelves nearest

top of oven first.

Press to cancel a shelf.

Close oven door after loading trays, the

program will start cooking automatically.

7. PROGRAMSTART

When tray shelf is running, it is

coloured RED.

Recipe name and countdown time

alternate in the shelf display.

Press scroll bar to scroll up/down

recipes.

Part Oven Load Full Oven Load

Part Oven Load Full Oven Load

Part Oven Load Full Oven Load

8. DONE‐TIMEUP

Alarm will sound.

OPEN OVEN DOOR.

REMOVE TRAY(s).

Oven alarm and shelf selected will self

cancel when the oven door is closed.

CLOSE OVEN DOOR

9. RETURNTOSTEP4.

8

Page 11

Manager Mode - Recipe Programming

Entering Recipe Programming

1. ENTERMANAGERMODE

Press MANAGER to enter Manager

Mode.

2. ENTERPASSCODE

ENTER passcode (4500).

Press to confirm.

Press to cancel.

3. ENTERRECIPEPROGRAMMING

Press to show HELP screen.

Press to show HELP screen.

Press to exit.

Press to select

4. RECIPEEDITING

Select recipe to edit.

Press for next MANAGER screen.

Press to show HELP screen.

Press to return to previous screen.

Press to select Product Category.

Press to scroll through Recipes.

Press to create a new Recipe.

Press and the Recipe to be deleted,

to remove a recipe.

9

Page 12

Manager Mode - Recipe Programming

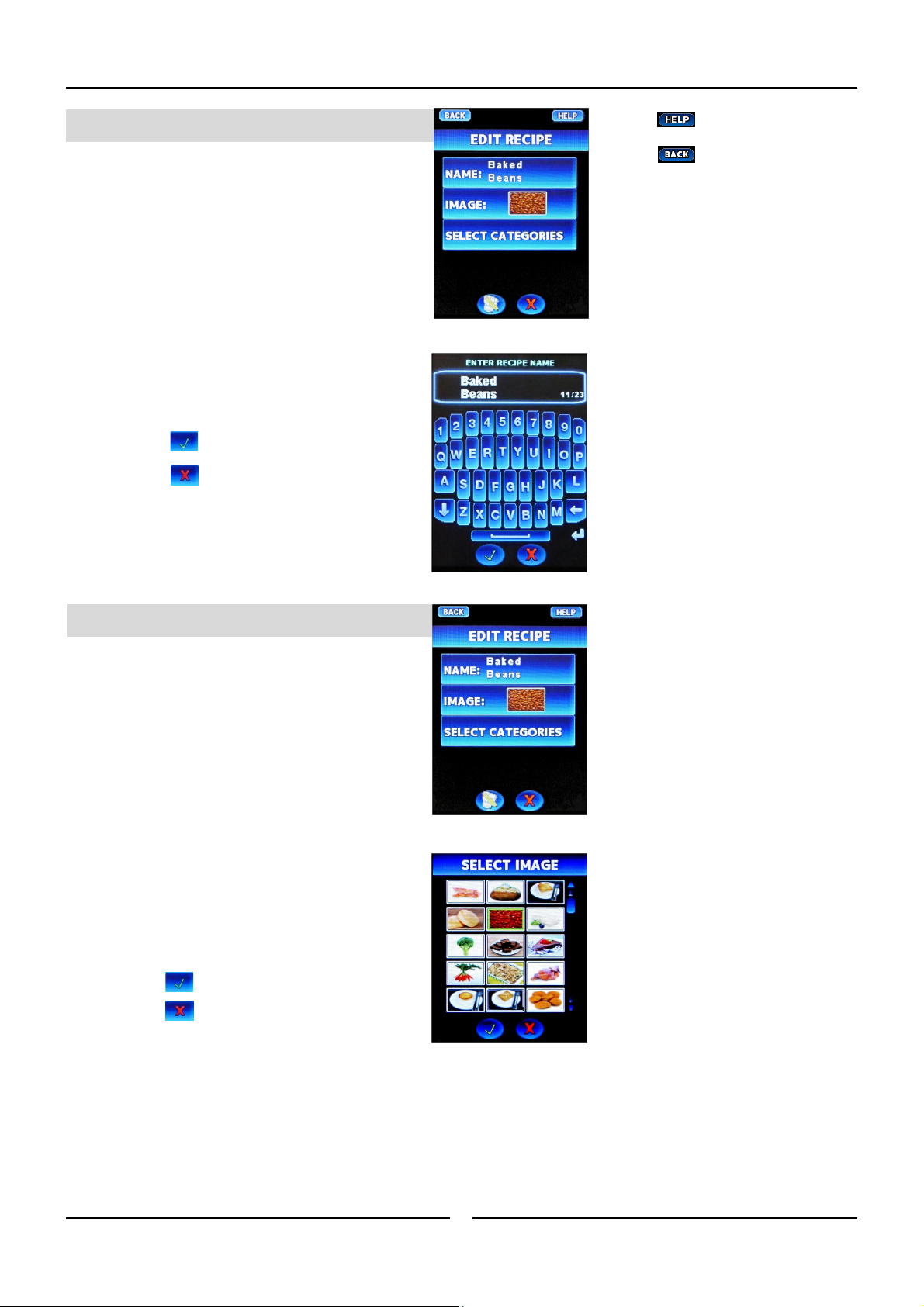

5. RECIPENAMING

In the Edit Recipe screen.

Press recipe name to edit name.

Edit / add recipe name using keypad.

Press to confirm.

Press to cancel.

Display will return to Edit Recipe

screen.

Press to show HELP screen.

Press to return to previous screen.

6. RECIPEIMAGE

Press Image in Edit Recipe screen.

Image gallery will display.

Select image required from Image

gallery.

Press to confirm.

Press to cancel.

Display will return to Edit Recipe

screen.

10

Page 13

Manager Mode - Recipe Programming

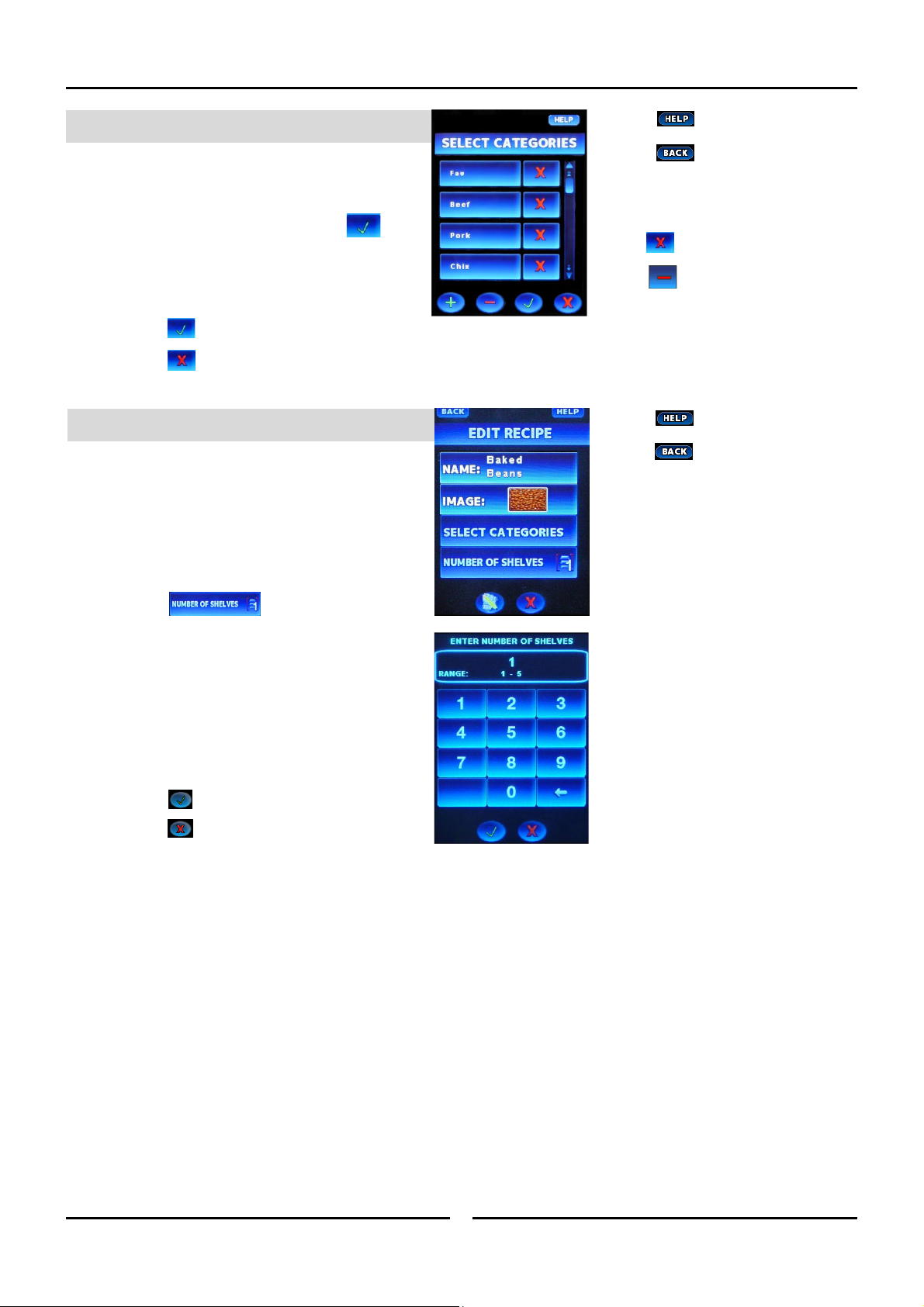

7. RECIPECATEGORY

Press Select Categories in Edit Recipe

screen.

Choose a category and press to

add a recipe to a category.

NOTE: Recipes can be added to more than

one category.

Press to confirm.

Press to cancel.

8. SETNUMBEROFSHELVES

Display will return to Edit Recipe

screen.

Press to select number of

shelves that will be loaded together

when this recipe is selected.

Enter number of shelves on the keypad.

Range 1 to 6.

Press to confirm.

Press to cancel.

Press to show HELP screen.

Press to return to previous screen.

Press to create a new Category.

Press and the Category to be deleted,

to remove a category.

Press to show HELP screen.

Press to return to previous screen.

11

Page 14

Manager Mode - Recipe Programming

9. SETRECIPETIMEANDTEMP

Press to enter recipe settings

Press to set stage temperature

Press to set stage time.

Press to select fan speed.

Press to set time to count Down.

Press to set FLEX time to No.

Select to add a new cooking stage.

Select to delete a cooking stage.

Press to confirm.

Press to cancel.

Press to show HELP screen.

Press to return to previous screen.

12

Page 15

Manager Mode - Settings

Selecting Manager Mode

1. CONTROLON

Select MANAGER.

2. ENTERPASSCODE

ENTER Passcode (4500).

Press to confirm.

Press to cancel.

3. MANAGERSCREEN#1

Press to show HELP screen.

Press to show HELP screen.

Press to exit MANAGER screens.

Press to select . Refer

to previous section, ‘Manager Mode -

Recipe Programming’.

Press to .

Press to .

Press to select .

ONFIGURE PREHEAT SCREEN.

C

Press to set Preheat

Temperature. Enter temperature on

keypad.

Press to confirm.

Press to cancel.

Press for next MANAGER screen.

Press to show HELP screen.

Press to return to previous screen.

13

Page 16

Manager Mode - Settings

4. MANAGERSCREEN#2

Press to adjust.

Press to turn On / Off.

Press to turn On / Off.

Press to enable / disable

key press beep.

5. MANAGERSCREEN#3

Press to enable /

disable MANAGER passcode protection.

Press to adjust screen

brightness.

Press to enter AUTO

DIM SETTINGS.

Press .

Select and follow ‘On-

Screen’ prompts.

Select and follow ‘OnScreen’ prompts.

AUTO DIM SETTINGS SCREEN.

Press Time to adjust

automatic screen dimming time.

Press Brightness to adjust

screen dim percentage.

Press to confirm.

Press to cancel.

Press to show HELP screen.

Press to exit MANAGER screens.

Press for next / previous

MANAGER screen.

Press to show HELP screen.

Press to exit MANAGER screens.

Press for next / previous

MANAGER screens.

Press to show HELP screen.

6. MANAGERSCREEN#4

Press to .

Press to enter oven

temperature Setback (stand-by)

settings.

Press to enter .

Press to view System

Software version.

Press to show HELP screen.

Press to exit MANAGER screens.

Press for next / previous

MANAGER screens.

14

Page 17

Manager Mode - Settings

CHANGE PASSCODE SCREEN.

Press to change

passcode.

Press , numeric key

pad will display. Enter passcode.

Press , numeric key

pad will display. Verify passcode.

Press to confirm.

Press to cancel.

SETBACK OPTIONS SCREEN.

Press to enable /

disable Setback mode.

Press to change

setback time. Enter time on keypad.

Press to change

setback temperature. Enter

temperature on keypad.

AUTOSTART SCREEN.

Press to set Autostart

temperature. Enter temperature on

keypad.

Press to set Autostart

time. Enter time on keypad.

Press to enable /

disable Autostart Mode.

SYSTEM SCREEN.

Screen displays controller system

information.

Press to show HELP screen.

Press to return to previous screen.

Press to show HELP screen.

Press to return to previous screen.

Press to show HELP screen.

Press to return to previous screen.

Press to change from AM to PM.

Press to return to previous screen.

Press to exit MANAGER screens.

15

Page 18

Manager Mode - Settings

7. MANAGERSCREEN#5

Press to enter /

change real time settings.

Press to enter / change

date settings.

Press to enter

Language selection.

Press to change

Temperature Unit settings, °C / °F.

IME ENTRY SCREEN.

T

Enter time.

Press to confirm.

Press to cancel.

ATE ENTRY SCREEN.

D

To change the Day, press ,

numeric key pad will display.

To change the Month, press ,

numeric key pad will display.

To change the Year, press ,

numeric key pad will display.

To change the Day Shown,

press to toggle through.

Press to confirm.

Press to cancel.

SELECT LANGUAGE SCREEN.

Press to select

language required.

Press to confirm.

Press to cancel.

Press to show HELP screen.

Press to exit MANAGER screens.

Press to change from AM to PM.

Press for next / previous

MANAGER screen.

Press to show HELP screen.

Press to return to previous screen.

Press to show HELP screen.

Press to return to previous screen.

16

Page 19

Manager Mode - Settings

8. MANAGERSCREEN#6

E-CALIBRATE TOUCH SCREEN.

R

Press to Re-Calibrate the Touch

Screen.

NOTE; This should only be done if the touch positions

on the screen become difficult to operate.

Warning Reboot Unit? screen will appear.

Press to confirm.

Press to cancel.

Follow the On-Screen prompts.

Press to show HELP screen.

Press to exit MANAGER screens.

Press for previous MANAGER screen.

17

Page 20

Cleaning and Maintenance

Cleaning Guidelines

Caution

Always turn off electrical power at the

mains supply before commencing cleaning.

This oven is not water proof. Do not use

water jet spray to clean interior or exterior

of the appliance.

To achieve the best results, cleaning must be regular and

thorough. If any small faults occur, have them looked at promptly.

Don't wait until they cause a complete breakdown.

NOTE:

Carefully read and follow the safety instructions on

the label of the cleaning product to be used.

DO NOT use harsh abrasive scouring pads or

abrasive detergents as they could damage the

oven.

Ensure that any detergent or cleaning material has

been completely removed after each cleaning.

To keep your oven clean and operating at peak efficiency, follow

the procedures shown below:-

Oven Cleaning

NOTE:

If oven usage is very high, the cleaning procedure

should be carried out more frequently.

Allow the oven interior to cool to approx 50˚C /

120˚F before commencing cleaning.

NOTE: Clean interior of Oven first. This prevents build-up

of soil and fingerprints on exterior of oven whilst

cleaning the interior of each unit.

Activate oven cool-down

function on the controller.

Open oven door.

When the oven temperature

reaches 50°C, the oven will

shut down.

Stainless Steel Surfaces

a. Thoroughly clean the exterior surfaces of the oven

with, a damp cloth moistened with a mild detergent

solution, or a soft bristled brush.

b. Baked on deposits or discoloration may require a

good quality stainless steel cleaner. Always apply

cleaner when the oven is cold and rub in the

direction of the grain.

Side Racks Removal

Right Rack / Fan Baffle

a. Lift up and unhook RH side rack from locating pegs

on RH side of oven. The fan baffle is an integral part

of the RH Side Rack.

R/Hand Front

Locating Peg

b. Tilt top of rack inwards and lift off lower mounting

brackets.

R/Hand Rear

Locating Peg

c. Tilt top of rack inwards and lift off lower mounting

brackets.

Left Rack

a. Lift the LH rack off the front locating peg.

L/Hand Front

Locating Peg

b. Pull rack forward to disengage rear of rack from rear

location peg and remove rack from oven.

L/Hand Rear

Locating Peg

c. Clean the racks with a mild anti bacterial detergent

and hot water, using a soft bristled brush.

d. Dry the racks thoroughly with a dry cloth.

18

Page 21

Cleaning and Maintenance

Side Racks Re-Fitting

Right Rack

a. Align the bottom of the rack with the 2 brackets in

the bottom RH side of the oven.

RH Lower Mounting Brackets

b. Tilt the rack upwards and hook the top of the rack

onto the locating pegs in the top of the oven.

R/Hand Rear

Locating Peg

Oven Lamp

a. Remove the LH side rack as shown previously.

b. Wash the glass lens with a soft sponge using warm

water and a detergent solution. Rinse with clean,

warm water.

R/Hand Front

Locating Peg

Left Rack

a. Locate the top rear of the rack onto the locating peg

at the top rear LH side of the oven.

L/Hand Rear

Locating Peg

b. Locate the top front of the rack over the locating peg

at the top front LH side of the oven.

c. Dry the glass lens thoroughly with a dry cloth.

d. Refit LH side rack as shown previously.

19

Page 22

Cleaning and Maintenance

Door Seal

a. To remove the door seal, pull the 1 piece seal

forward until it pulls out of the location groove

around the oven. Note the way the seal is fitted

to the oven, with the lip facing inwards.

b. Check the door seal for wear and damage and

replace as required.

c. Wash the door seal in a sink, taking care not to cut

or damage the seal.

d. Dry the door seal thoroughly.

e. Refit the door seal with lip facing into centre of the

oven.

Push Seal carefully into

locating channel

Door Glass Cleaning

Ensure that the oven door is cool before

cleaning the oven door glass.

a. Open the oven door.

b. Lift up the bottom of the inner glass at the centre of

the door to unlock from the inner glass retaining

catches and swing the glass inwards towards the

oven.

Top Locking Catches

f. Press the door seal into the locating groove in the

front face of the oven until the seal is properly

located all around the oven.

Oven Interior

Allow the oven interior to cool to approx 50˚C /

120˚F before commencing cleaning.

a. Remove the oven racks as shown previously.

b. Clean any build up of grease from the oven interior,

using a soft bristled brush with a solution of hot

water and a mild anti bacterial detergent.

c. Dry the oven thoroughly with a soft dry cloth.

d. Clean the oven regularly with a good quality oven

cleaner.

c. Clean both sides of the inner glass and the inner side

of the outer door glass with a conventional glass

cleaner.

d. Dry the oven door thoroughly with a soft dry cloth.

e. Swing the inner glass back towards the outer door.

f. Whilst holding the outer door, lift the inner glass

back onto the locking catches until the inner glass is

securely held.

Periodic Maintenance

NOTE: All maintenance operations should only be carried

out by a qualified service person.

Controls and mechanical parts should be checked and adjusted

periodically by a qualified service person. It is recommended that

the appliance is serviced every 6 months.

20

Page 23

Electrical Schematics

Electrical Schematic E33T C-Store - (High Speed Option - 2 Speed Fan Motor).

21

Page 24

Electrical Schematics

Electrical Schematic E33T C-Store - (Standard 2 Speed fan Motor).

22

Page 25

Replacement Parts List

Only genuine authorized replacement parts should be used for the servicing and repair of this oven. The instructions

supplied with the parts should be followed when replacing components.

For further information and servicing instructions, contact your nearest authorized service provider or Turbofan Dealer.

When ordering replacement parts, please quote the part number and the description as listed below. If the part required is not listed

below, request the part by description and quote model number and serial number which is shown on the Technical Data Plate.

Item Description

235657 Control Panel Laminated E33T.

236258 Touch Screen Controller Kit.

235700 USB Cable Panel Mount Type A, 0.3m.

235701 USB Protective Cap, Type A.

235848 Reed Switch

235698 Transformer 208 / 240V x 24V, 40VA.

236713 Cooling Fan, 24VDC.

236202 Oven Temperature Probe - T Series.

234821 Overtemp Thermostat 355°C / 670°F.

308155 Contactor (Heating), 24VDC, 20A (Eaton).

Standard 2 Speed Fan Motor

235625 Fan Motor 208-240V, 50/60Hz, 4/8 Pole.

234138 Fan 220mm (50/60Hz).

236054 Motor Capacitor 8uF (50Hz).

236053 Motor Capacitor 6.3uF (60Hz).

236217 Contactor Mini 3P+1NC, 24VDC.

High Speed Option - 2 Speed Fan Motor

237335 Fan Motor 208-240V, 50/60Hz, 2/4 Pole.

234138 Fan 220mm (50Hz).

234625 Fan 200mm (60Hz).

234252 Motor Capacitor 10uF.

234875 Motor Capacitor 3uF.

235610 Motor Shaft Seal.

235420 Fan Puller / Tightener.

235696 Relay Single Pole, Double Throw, 20A, 24VDC.

235695 Relay Single Pole, Single Throw, 20A, 24VDC.

236109K Oven Element, 5800W, 230 - 240V.

236110K Oven Element, 5800W, 208 - 220V.

236264 Element Gasket.

021353 Support Frame

021352 Oven Glass Lens.

236214 Lampholder (231814 25W lamp included).

231814 Lamp Bulb G9 25W, Halogen, 230V.

021354 Oven Lamp Gasket.

234803 Fuse 10A, 250V.

234802 Fuse Holder.

020851 Water Solenoid.

021057 Spray Nozzle Assembly.

Important:

23

Page 26

Replacement Parts List

Replacement Parts List (Cont.d)

Item Description

235615 Oven Seal - E33T.

236203 Door Outer Glass Assembly E33.

237167

234752 Hinge Pivot Kit (Includes Door Hinge Pivot Pin, Pivot Bush, Washer M8 Nord-Lock).

235652 Door Inner Glass Assembly

234779 Inner Glass Retaining Clip

234767 Door Pivot Spacer

235859 Door Handle Assembly E33T

231804 Single Step Locking Dog

236014 Door Locking Dog Escutcheon

235015 Door Strike Escutcheon Washer

235849 Door Actuator Magnet

232379 Leg Adjustable 73-80mm

232380 O-Ring

237020 Side Rack LH, 5 Tray - 1/1GN.

237015 Side Rack RH, 5 Tray - 1/1GN.

238676 Side Rack LH, 4 Tray - 1/1GN.

238678 Side Rack RH, 4 Tray - 1/1GN.

238727 Side Rack LH, 4 Tray 238728 Side Rack RH, 4 Tray -

Door Hinge Kit ( includes Door Hinge Set Bottom, Door Hinge Set Top, Door Hinge Pivot Pin,

Pivot Bush, Washer M8 Nord-Lock, Gaskets and Screws).

1

/2 US Pan (USA / Canada Only).

1

/2 US Pan (USA / Canada Only).

24

Page 27

Loading...

Loading...