Moffat E27-2 Service Manual

E27 CONVECTION OVEN

SERVICE

MANUAL

Revision 1/F3563

September, 2001

Manual P/N M0ME27

CONTENTS

This manual is designed to take a more in depth look at the E27 convection oven for the purpose of

making the unit more understandable to service people.

There are settings explained in this manual that should never require to be adjusted, but for

completeness and those special cases where these settings are required to change, this manual

gives a full explanation as to how, and what effects will result.

SECTION PAGE NO.

1. SPECIFICATIONS .........................................................................................................5

2. INSTALLATION .............................................................................................................7

3. OPERATION ...................................................................................................................8

3.1 Description of Controls

3.2 Explanation of Control System

4. MAINTENANCE .............................................................................................................10

4.1 Cleaning

4.2 Routine Procedures

5. TROUBLE SHOOTING GUIDE .....................................................................................11

6. SERVICE PROCEDURES ..............................................................................................14

6.1 Fault Diagnosis

6.2 Access

6.3 Replacement

6.4 Adjustment / Calibration

7. ELECTRICAL SCHEMATICS ........................................................................................27

8. ELECTRICAL WIRING DIAGRAMS ..............................................................................28

9. SPARE PARTS ..............................................................................................................29

10. ACCESSORIES / OPTIONS ..........................................................................................30

IMPORTANT: MAKING ALTERATIONS MAY VOID WARRANTIES AND APPROVALS.

Revision 1/F3563

-3-

11. PARTS DIAGRAM .........................................................................................................31

11.1 Main Assembly

11.2 Control Panel Assembly

12. SERVICE CONTACTS ..................................................................................................35

APPENDIX A. DOUBLE STACKING KIT ...............................................................................37

Revision 1/F3563

-4-

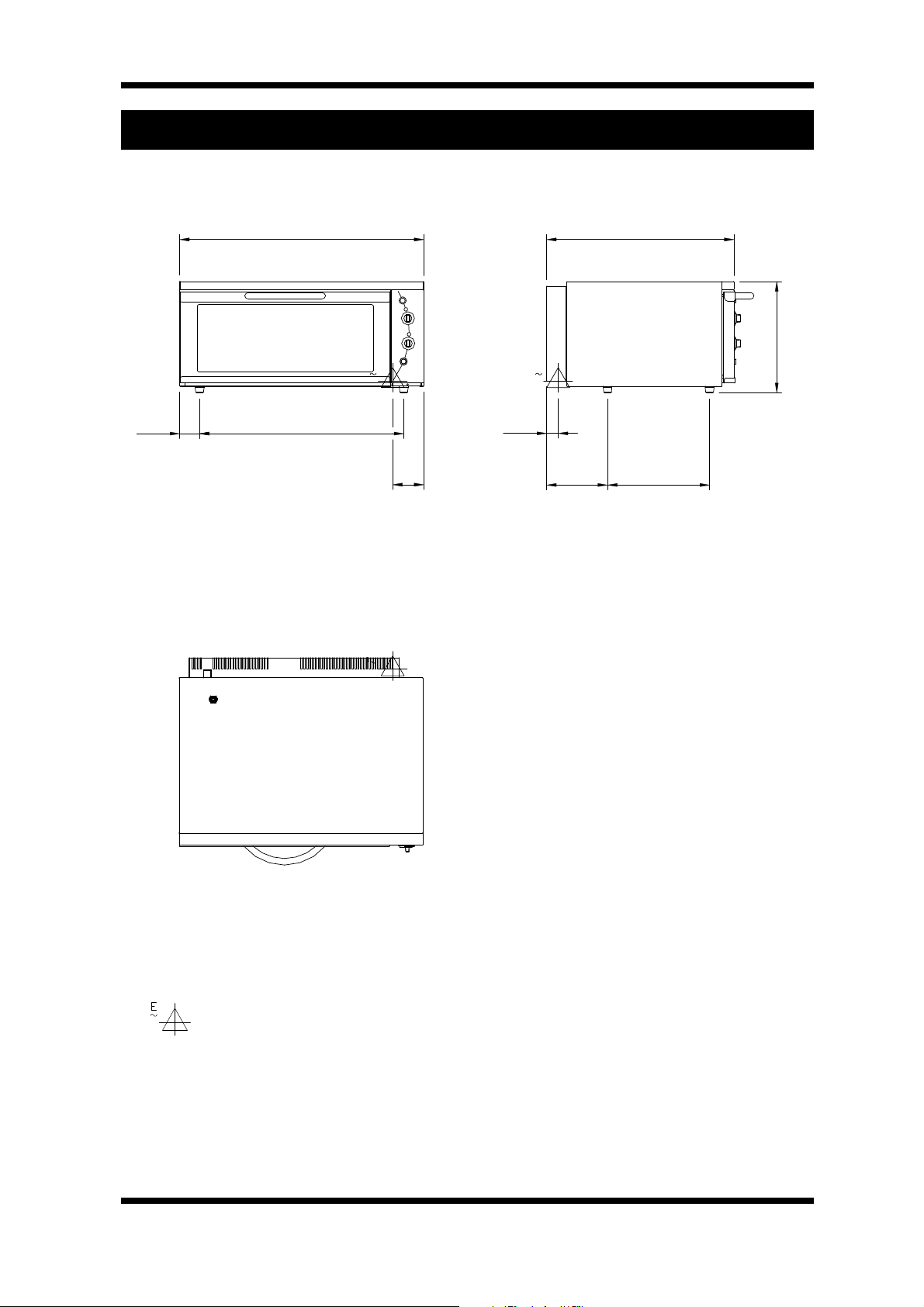

MODEL: E27

1. SPECIFICATIONS

77

FRONT

945

(37.2)

791

(31.1)(3.0)

725

(28.5)

430

E

1

120

(4.7)

45

(1.75)

E

1

236

(9.3) (15.6)

395

(16.9)

SIDE

E

1

PLAN

LEGEND

- Electrical connection entry point

Dimensions shown in millimetres.

Dimensions in inches shown in brackets.

Revision 1/F3563

-5-

LOCATION

To ensure correct ventilation for the motor and

controls the following minimum installation

clearances are to be adhered to:

Rear 25mm / 1”

Left-hand side 25mm / 1”

Right-hand side 25mm / 1”

OVEN INTERNAL DIMENSIONS

Width 695 mm / 27 3/8”

Height 285 mm / 11 1/4”

Depth 505 mm / 19 7/8”

Oven Volume 0.10 m³ / 3.5 ft³

OVEN RACK SIZE

Width 660 mm / 26”

Depth: 460 mm / 18”

ELECTRICAL SUPPLY SPECIFICATION

OPTIONS

208-220V ac, 50/60Hz, 14.4A, 3.0kW @ 208V

230-240V ac, 50/60Hz, 12.5A, 3.0kW @ 240V

ELECTRICAL PLUG SPECIFICATION

REQUIREMENTS

Australia 3-pin 250V 15A, AS/NZ 3112

Canada 3-pin 250V 15A, NEMA 6-15

New Zealand 3-pin 250V 15A, AS/NZ 3112

United Kingdom 3-pin 250V 13A fused, BS

1363A

United States 3-pin 250V 15A, NEMA 6-15

Other Countries 3-pin 250V 13A minimum,

type to meet country stan-

dards

Revision 1/F3563

-6-

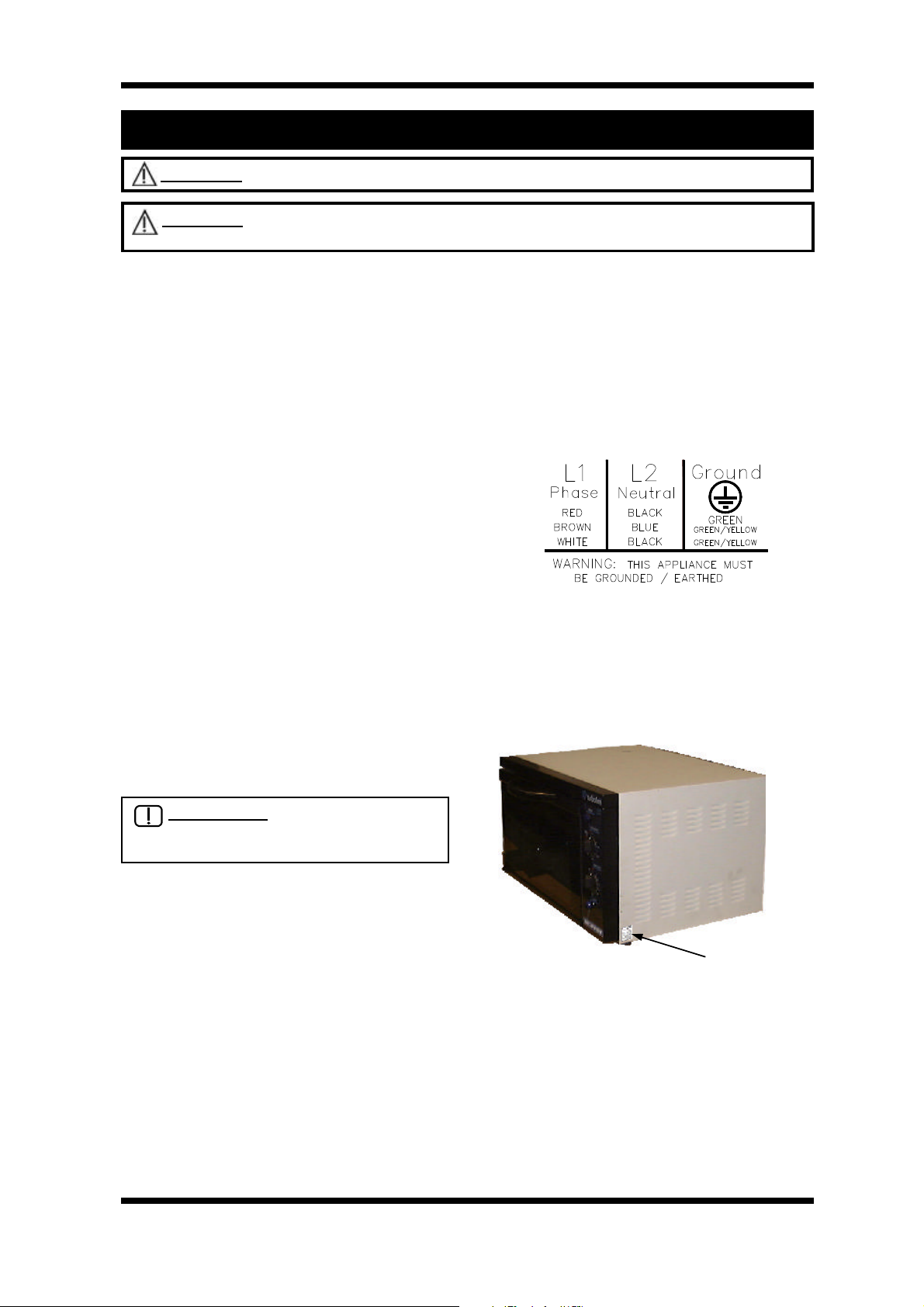

2. INSTALLATION

WARNING: THIS APPLIANCE MUST BE GROUNDED.

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

It is most important that the oven is installed

correctly and that the operation is correct

before use. Installation shall comply with local

electrical, health and safety requirements.

BEFORE CONNECTION TO POWER

SUPPLY

Unpack and check unit for damage and report

any damage to the carrier and dealer. Report

any deficiencies to your dealer. Check that

the available power supply is correct to that

shown on the rating plate located on the righthand side panel.

208-220V ac, 50/60Hz, 14.4A, 3.0kW @ 208V

230-240V ac, 50/60Hz, 12.5A, 3.0kW @ 240V

LOCATION

To ensure correct ventilation for the motor,

and controls the following minimum

installation clearances are to be adhered to:

Rear 25mm / 1”

Left-hand side 25mm / 1”

Right-hand side 25mm / 1”

ELECTRICAL CONNECTION

E27 convection ovens are supplied with

pre-fitted cords. Ensure unit is fitted with the

correct cord and plug for the installation.

Refer specifications section.

Should changing of the cord be necessary,

gain access to the electrical connection

terminal block, grounding lug, and strain relief

by removing the back panel (four screws).

Figure 2.1

RATING PLATE LOCATION

The rating plate for the E27 convection oven

is located at the bottom left corner of the RH

side panel.

IMPORTANT: THE OVEN VENT

LOCATED ON THE CABINET TOP

MUST NEVER BE OBSTRUCTED.

Position the oven in its allocated working

position. Use a spirit level to ensure the oven

is level from side to side and front to back. (If

this is not carried out, uneven cooking could

occur). The feet used with bench mounting or

provided with stands are adjustable and will

require adjusting in levelling the unit. It should

be positioned so the operating panel and oven

shelves are easily reachable for loading and

unloading.

BEFORE USE

Operate the oven for about 1 hour at 200°C

(400°F) to remove any fumes or odours which

may be present.

Revision 1/F3563

Rating Plate

Figure 2.2

-7-

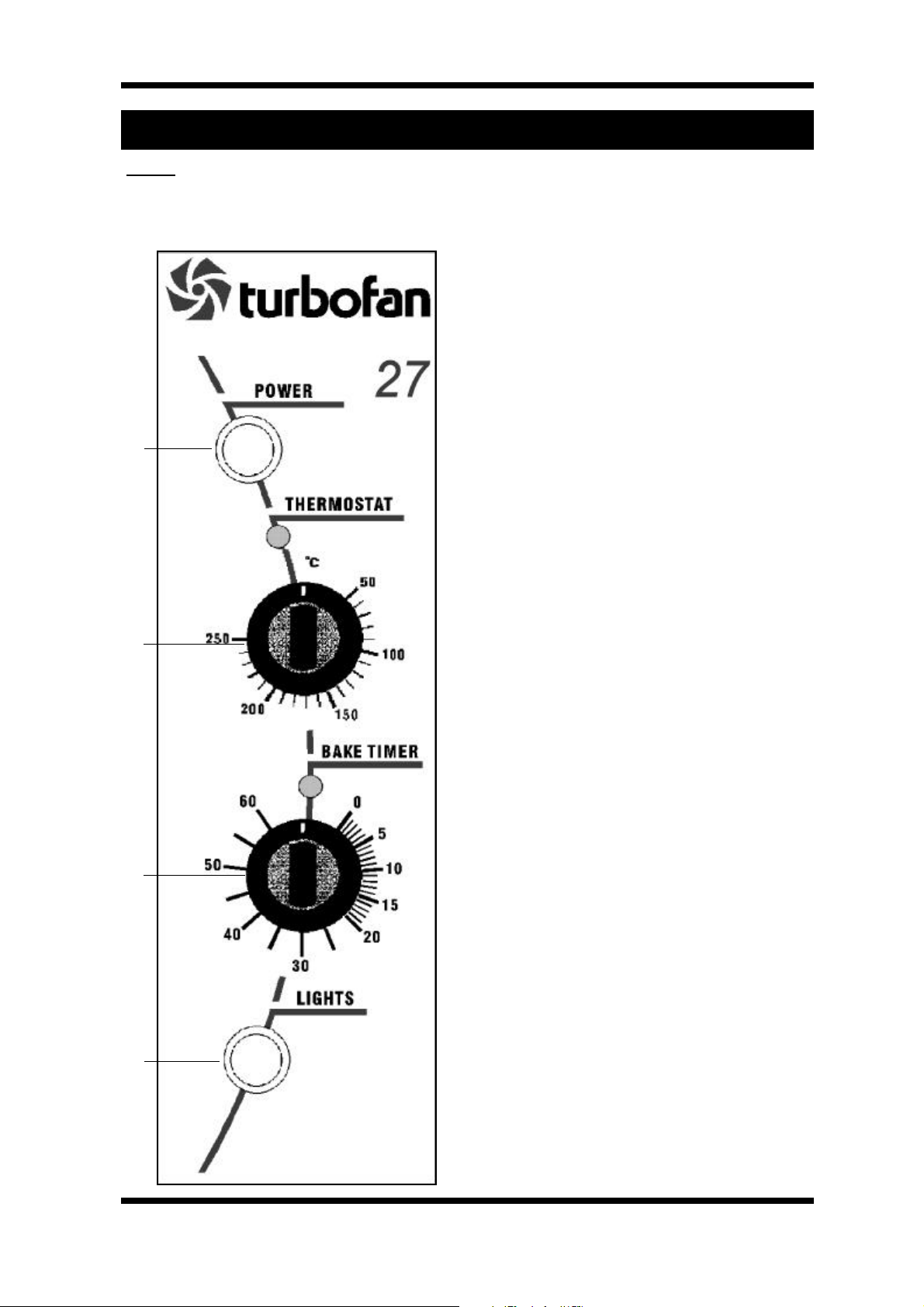

3. OPERATION

NOTE: A full user’s operation manual is supplied with the product and can be used for further

referencing of installation, operation and service.

3.1 DESCRIPTION OF CONTROLS

1. POWER

Depress to switch power on or off (switch

illuminates when power is on).

2. THERMOSTAT

Temperature range 50 - 250°C (120 - 480°F).

Indicator illuminates when elements are cycling

ON to maintain set temperature.

3. BAKE TIMER

1

1 Hour bake timer.

(Indicator illuminates when “time up” (0)

reached, and buzzer sounds).

4. LIGHT SWITCH

Push switch to activate light.

(Oven light illuminates while button depressed).

2

3

4

Revision 1/F3563

-8-

3.2 EXPLANATION OF CONTROL

SYSTEM

The E27 Turbofan convection ovens feature

multi-function operator controls for which a

correct understanding of their operation is

required before carrying out any service or

fault repair work. The control device functions

are explained as follows:

A power switch on the control panel isolates

power to all the controls of the oven. With the

power switch Off all functions of the oven are

inoperable.

NOTE: The supply voltage is fed to the input

side of the heating element power relay

whenever the electrical supply is on.

With the power switch On (illuminated) power

is directly supplied to the 60 minute bake

timer, door microswitch, and the light switch.

The light switch will turn the oven light on

when the door is closed, but only whilst the

light switch is held in.

The door microswitch on the E27 oven

controls the light, the circulation fan, and the

fan element. Hence, opening the door on the

E27 oven causes the circulation fan and fan

element to switch off, as well as causing the

oven light to come on.

The 60 minute timer is a mechanical timer and

can therefore be operated with the oven’s

power switch On or Off. However, only with

the oven’s power switch On will the switch

contacts of the 60 minute timer turn on the

time-up buzzer and illuminate the time-up

indicator on the control panel. The buzzer

and time-up indicator provide indication that

the time setting has run down to zero and at

this point will remain On continuously until the

60 minute timer has been manually set back

to the Off (vertical) position. The 60 minute

timer does not control any other part of the

oven’s operating system as this timer is

independent of the temperature control and

heating system.

The temperature control of these ovens is with

a capillary type thermostat which can be set to

a required cooking temperature.

The E27 has an element coiled around the

circulation fan in the rear of the oven. Power

to the element is provided via a heating power

relay located at the rear of the oven. When

the thermostat calls for heat, it energises this

relay, which switches power to the fan

element. The control panel indicator light

above the thermostat knob cycles on and off

with the thermostat to indicate when the

element is on and the oven is heating. In the

‘Off’ position, the element relies on the

thermostatic control to prevent it switching on.

Accordingly, if the oven temperature drops

below approximately 20°C the thermostat and

element may cycle on at this setting.

The circulation fan on the E27 oven reverses

direction every 90 seconds for a 50Hz supply

(every 75 seconds for 60Hz). Prior to a

change of direction the fan motor is switched

off for 10 seconds (8½ seconds for 60Hz) to

allow the motor/fan to slow down. Cycling of

the fan motor is controlled by a continuous

cam timer with electric motor. The timer has

two cams and switches which supply power

alternately to one of two motor supply wires,

causing the motor to alternate direction.

During the fan motor slow down periods, both

cam switches are open and power is not

supplied to either of the motor supply wires.

When the oven door is opened or the power is

switched off the cams will stop. When the

oven door is closed or the power switched

back on the cam timer will resume its cycle

from the point where it stopped.

The fan motor is a split phase continuous

capacitor motor with the capacitor externally

connected across the motor supply leads.

The motor also incorporates an internal

thermal trip switch for overheat protection

which is auto resetting.

The following Troubleshooting Guide (section

5) should be used to identify any incorrect

oven operation. On correct identification of

the operating fault the Troubleshooting Guide

will make reference to the corrective action

required, or refer to the Fault Diagnosis

section and/or Service section to assist in

correction of the fault.

Revision 1/F3563

-9-

4. MAINTENANCE

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

4.1 CLEANING

WARNING: ALWAYS TURN THE

POWER SUPPLY OFF BEFORE

CLEANING.

IMPORTANT: THIS UNIT IS NOT

WATER PROOF.

DO NOT USE A WATER JET SPRAY TO

CLEAN INTERIOR OR EXTERIOR OF

THIS UNIT.

EXTERIOR

Clean with a good quality stainless steel

cleaning compound. Harsh abrasive cleaners

may damage the surface.

INTERIOR

Ensure that the oven chamber is cool. Do not

use wire brushes, steel wool or other abrasive

materials. Clean the oven regularly with a

good quality oven cleaner. Take care not to

damage the fan or the tube at the right side of

the oven which controls the thermostat.

OVEN RACKS

To remove, slide out to the stop position, raise

the front edge up, and lift out.

SIDE RACKS

Undo the thumbscrew (anti-clockwise rotation)

securing rack to oven wall, swing rack

towards centre of oven to disengage location

pin at front of side, and pull rack forward to

remove. To replace, engage rack in rear

holes, swing towards side of oven to engage

in front hole, and replace thumbscrew.

FAN BAFFLE

To remove, loosen thumbscrews (anticlockwise rotation) at top of baffle. Lift baffle

to disengage from locating studs and thumbscrews then pull forward to remove. Replace

in reverse order.

OVEN SEALS

To remove, hold at their centre point and pull

forward until they unclip. Remove side seals

first, then top and bottom. The seals may be

washed in the sink, but take care not to cut or

damage them. To replace the top seal,

ensure that the lip is facing the oven opening.

The left, right and bottom seals have the lip

facing out. Fit the top and bottom seals first,

then the side seals.

OVEN DOOR GLASS

Clean with conventional glass cleaners

4.2 ROUTINE PROCEDURES

DOOR SEALS

Check for deterioration 12 months

ELEMENTS

Check that element resistances 12 months

are correct to their ratings (refer

6.3.9)

Revision 1/F3563

-10-

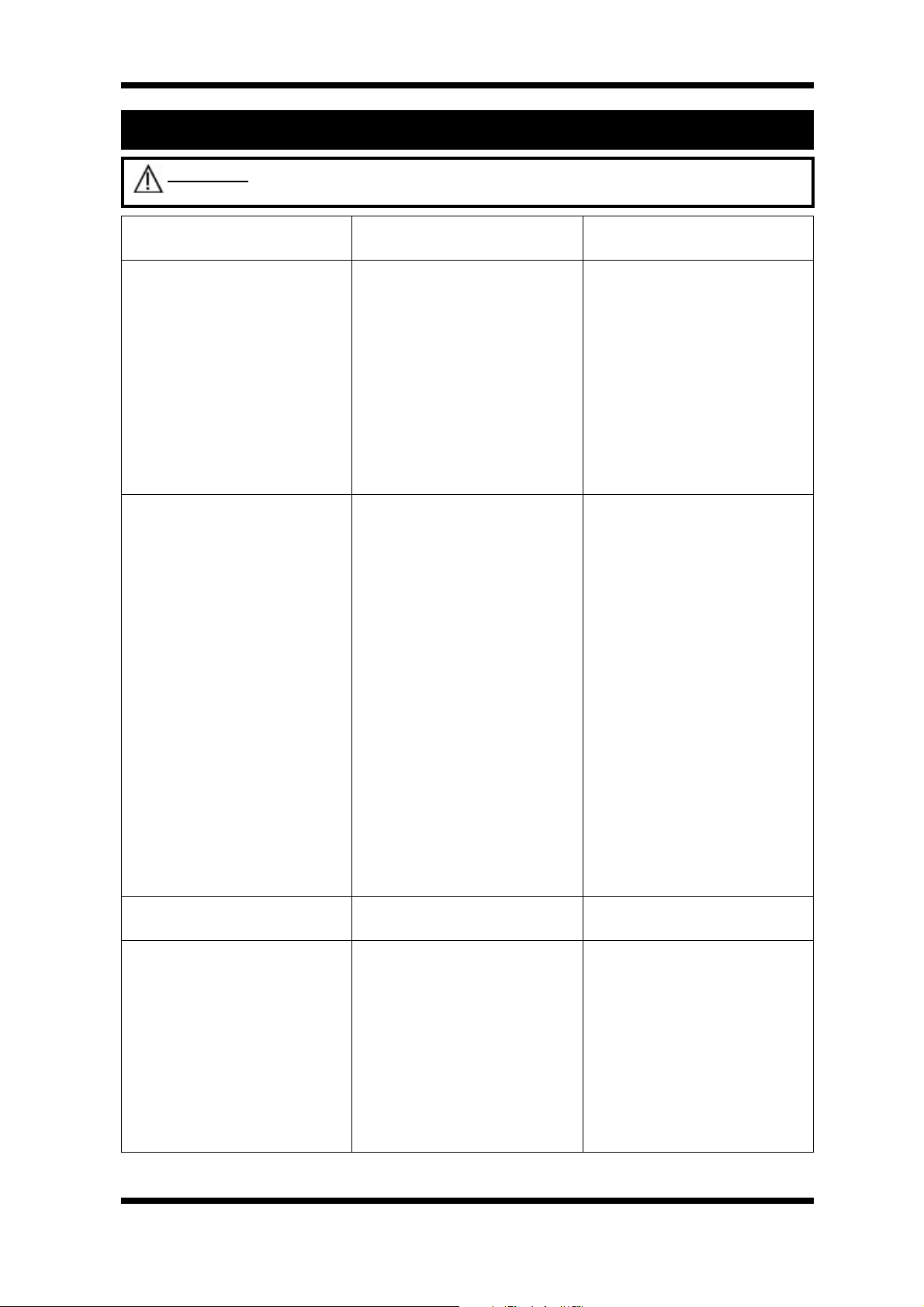

5. TROUBLE SHOOTING

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

FAULT POSSIBLE CAUSE REMEDY

THE OVEN DOES NOT

OPERATE / START

FAN DOESN’T OPERATE Door not closed.

FAN ONLY OPERATES IN

ONE DIRECTION

OVEN LIGHT NOT

ILLUMINATING - DOOR OPEN

OVEN LIGHT NOT

ILLUMINATING - DOOR

CLOSED

The mains isolating switch on

the wall, circuit breaker or fuses

are “off” at the power board.

The power switch on the oven is

off.

Incorrect electrical supply.

(Refer fault diagnosis 6.1.1)

Power switch on unit faulty.

(Refer fault diagnosis 6.1.1)

Fan obstructed.

Door microswitch is out of

adjustment.

(Refer fault diagnosis 6.1.2)

Door microswitch faulty.

(Refer fault diagnosis 6.1.2)

Fan motor faulty.

(Refer fault diagnosis 6.1.2)

Motor timer faulty.

(Refer fault diagnosis 6.1.2)

Motor capacitor faulty.

(Refer fault diagnosis 6.1.2)

Wiring.

Motor timer faulty.

(Refer fault diagnosis 6.1.2)

Blown bulb.

No power to light.

(Refer fault diagnosis 6.1.3)

Blown bulb.

Light switch faulty.

(Refer fault diagnosis 6.1.4)

Turn on.

Depress switch. Switch will

illuminate.

Ensure electrical supply correct.

Replace.

(Refer service section 6.3.4)

Close door.

Clear obstruction.

Adjust.

(Refer service section 6.4.2)

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.11)

Replace.

(Refer service section 6.3.12)

Replace.

(Refer service section 6.3.13)

Check and tighten any loose

wiring.

Replace.

(Refer service section 6.3.13)

Replace.

(Refer service section 6.3.1)

Correct fault.

Replace.

(Refer service section 6.3.1)

Replace.

(Refer service section 6.3.4)

Revision 1/F3563

-11-

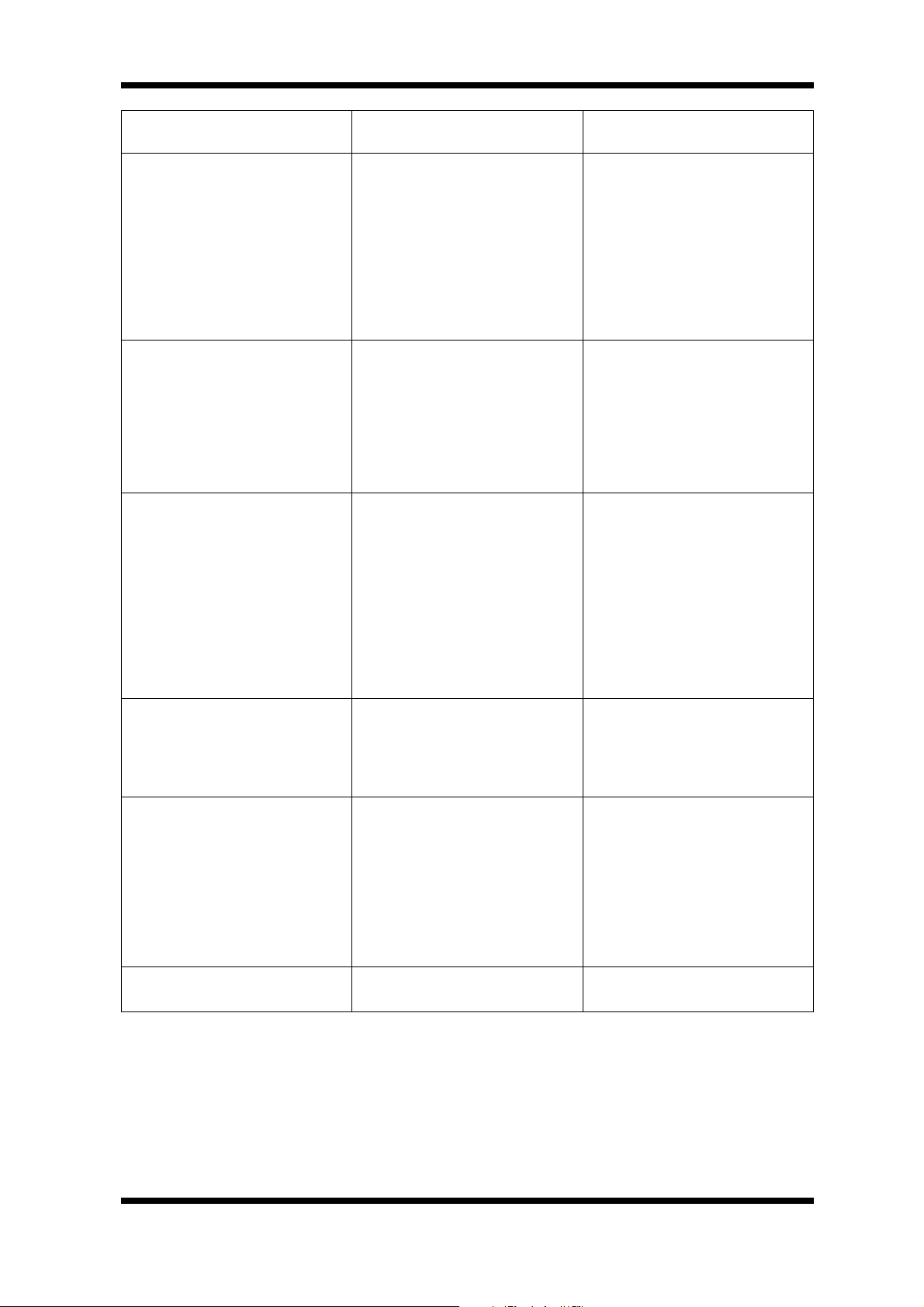

FAULT POSSIBLE CAUSE REMEDY

60 MINUTE TIMER WILL NOT

TIME DOWN

60 MINUTE TIMER

INACCURATE BELOW 20

MINUTES

60 MINUTE TIMER NO TIME

UP BUZZER

60 MINUTE TIMER NO TIME

UP INDICATOR

NO HEAT - FAN ELEMENT

NOT WORKING

NO TEMPERATURE

CONTROL

Timer faulty.

Timer not set correctly.

Zero (time up) position not set

correctly.

Buzzer faulty.

(Refer fault diagnosis 6.1.5)

Timer not switching on buzzer.

(Refer fault diagnosis 6.1.5)

Indicator faulty.

(Refer fault diagnosis 6.1.6)

No power to thermostat.

(Refer fault diagnosis 6.1.7)

Thermostat faulty.

(Refer fault diagnosis 6.1.7)

Fan element not working.

(Refer fault diagnosis 6.1.7)

Heating power relay faulty.

(Refer fault diagnosis 6.1.7)

Thermostat faulty.

(Refer fault diagnosis 6.1.8)

Heating relay faulty.

(Refer fault diagnosis 6.1.8)

Replace.

(Refer service section 6.3.6)

For timer settings below 20

minutes, always rotate past 20

minutes, then back to desired

time.

(Refer service section 6.4.3)

Replace.

(Refer service section 6.3.5)

Replace timer.

(Refer service section 6.3.6)

Replace.

(Refer service section 6.3.3)

Identify fault and correct.

Replace.

(Refer service section 6.3.7)

Replace.

(Refer service section 6.3.9)

Replace.

(Refer service section 6.3.8)

Replace.

(Refer service section 6.3.7)

Replace.

(Refer service section 6.3.8)

SLOW RECOVERY Overloading of oven.

Electrical supply incorrect.

Fan not working.

Thermostat calibration.

(Refer fault diagnosis 6.1.9)

NO THERMOSTAT HEATING

INDICATOR LIGHT

Revision 1/F3563

Indicator faulty.

(Refer fault diagnosis 6.1.10)

-12-

Reduce oven loading.

Check supply voltage is as per

rating plate voltage.

Check fan operation.

Correct calibration.

(Refer service section 6.4.1)

Replace.

(Refer service section 6.3.3)

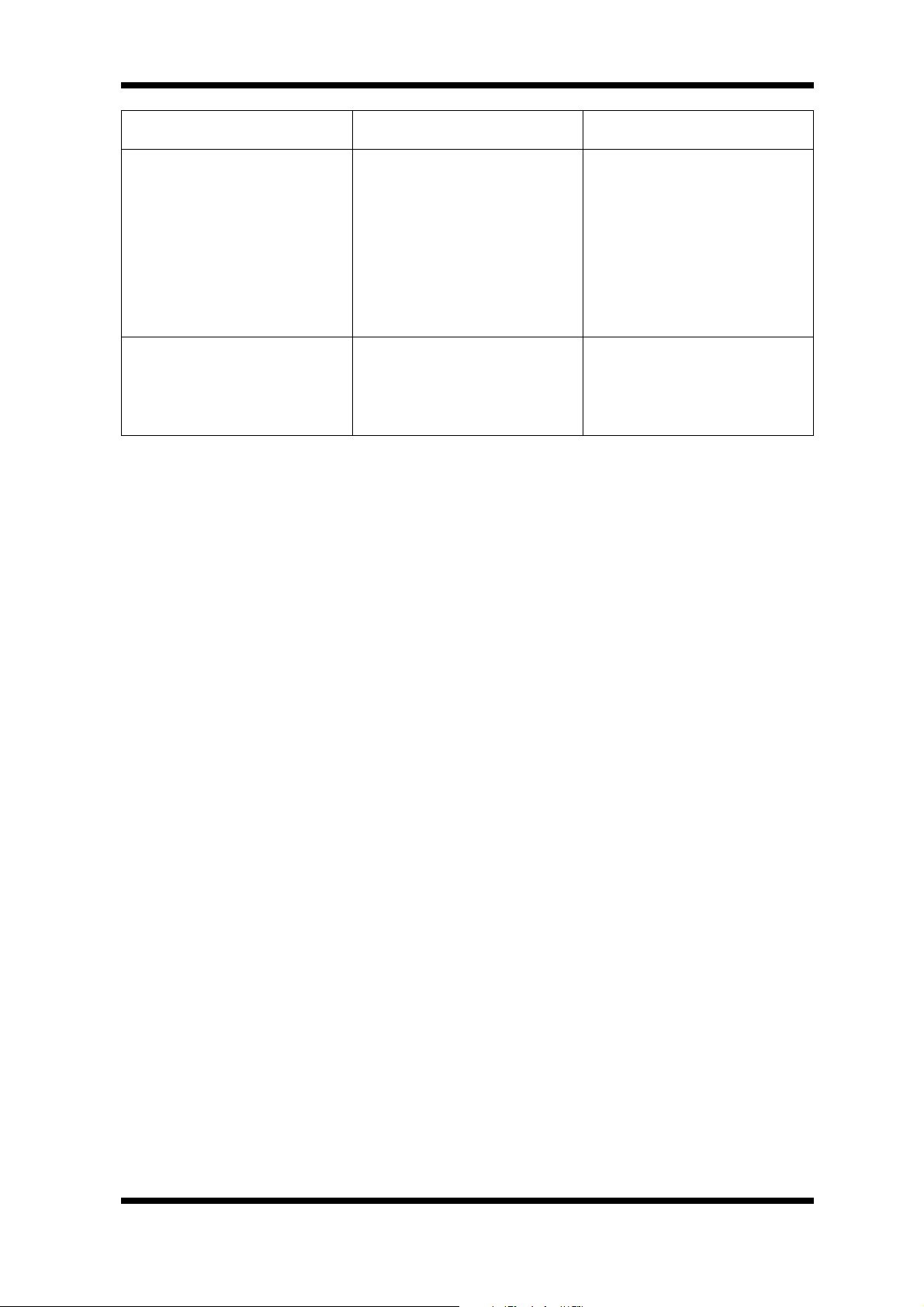

FAULT POSSIBLE CAUSE REMEDY

DOOR DOES NOT CLOSE Tray in way of door.

Door seal obstruction.

Door hinges worn.

Door hinge counter brackets

worn.

DOOR SEAL LEAKS Door seal damaged.

Door seal incorrectly fitted.

Correctly position tray in rack.

Correctly install door seal.

(Refer service section 6.3.16)

Replace.

(Refer service section 6.3.18)

Replace.

(Refer service section 6.3.19)

Replace.

(Refer service section 6.3.16)

Correctly install door seal.

(Refer service section 6.3.16)

Revision 1/F3563

-13-

Loading...

Loading...