Mitsui MTV-DV05 Schematic

FILE NO. SM-CTV-O-228

TV/DVD COMBO

SERVICE MANUAL

MODEL NO. MTV-DV05

CHASSIS NO. CN-12DV

Please read this manual carefully before service.

TABLE OF CONTENTS

SERVICE SAFETY INSTRUCTIONS

ADJUSTMENTS

...................................................................................................................5

......................................................................2

STRUCTURE AND CHASSIS FUNCTION DESCRIPTION

SERVICE DATA

TROUBLESHOOTING FLOW CHARTS

APPENDIX

....................................................................................................................21

..............................................................65

.....................15

SERVICE MANUAL

SERVICE SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RA Y RADIATION PRECAUTION”,

“

SAFETY PRECAUTIONS”AND “PRODUCT SAFETY NOTICE”INSTRUCTION BELOW.

X-RAY RADIATION PRECAUTION

1. The EHT must be checked every time the TV is serviced to ensure that the CRT does not emit X-ray

radiation as result of excessive EHT voltage. The maximum EHT voltage permissible in any operating

circumstances must not exceed the rated value. When checking the EHT, use the High Voltage Check

procedure in this manual using an accurate EHT voltmeter.

2. The only source of X-RAY radiation in this TV is the CRT. The TV minimizes X-RAY radiation, which

ensures safety during normal operation. To prevent X-ray radiation, the replacement CRT must be

identical to the original fitted as specified in the parts list.

3. Some components used in this TV have safety related characteristics preventing the CRT from emitting

X-ray radiation. For continued safety, replacement component should be made after referring the

PRODUCT SAFETY NOTICE below.

4. Service and adjustment of the TV may result in changes in the nominal EHT voltage of the CRT anode.

So ensure that the maximum EHT voltage does not exceed the rated value after service and

adjustment.

SAFETY PRECAUTION

WARNING: REFER SERVICING TO QUALIFIED SERVICE PERSONNEL ONLY.

1. The TV has a nominal working EHT voltage. Extreme caution should be exercised when working on the

TV with the back removed.

1.1 Do not attempt to service this TV if you are not conversant with the precautions and procedures for

working on high voltage equipment.

1.2 When handling or working on the CRT, always discharge the anode to the TV chassis before removing

the anode cap in case of electric shock.

1.3 The CRT, if broken, will violently expel glass fragments. Use shatterproof goggles and take extreme care

while handling.

1.4 Do not hold the CRT by the neck as this is a very dangerous practice.

2. It is essential that to maintain the safety of the customer all power cord forms be replaced exactly as

supplied from factory.

3. Voltage exists between the hot and cold ground when the TV is in operation. Install a suitable isolating

transformer of beyond rated overall power when servicing or connecting any test equipment for the sake

of safety.

4. When replacing ICs, use specific tools or a static-proof electric iron with small power (below 35W).

5. Do not use a magnetized screwdriver when tightening or loosing the deflection yoke assembly to avoid

electronic gun magnetized and decrement in convergence of the CRT.

6. When remounting the TV chassis, ensure that all guard devices, such as nonmetal control buttons,

switch, insulating sleeve, shielding cover, isolating resistors and capacitors, are installed on the original

2

SERVICE MANUAL

place.

7. Replace blown fuses within the TV with the fuse specified in the parts list.

8. When replacing wires or components to terminals or tags, wind the leads around the terminal before

soldering. When replacing safety components identified by the international hazard symbols on the

circuit diagram and parts list, it must be the company-approved type and must be mounted as the

original.

9. Keep wires away from high temperature components.

PRODUCT SAFETY NOTICE

CAUTION: FOR YOUR PROTECTION, THE FOLLOWING PRODUCT SAFETY NOTICE SHOULD BE

READ CAREFULLY BEFORE OPERATING AND SERVICING THIS TV SET.

1. Do not slap or beat the cabinet or CRT, since this may result in fire or explosion.

2. Never allow the TV sharing a plug or socket with other large-power equipment. Doing so may result in

too large load, thus causing fire.

3. Do not allow anything to rest on or roll over the power cord. Protect the power cord from being walked

on, modified, cut or pinched, particularly at plugs.

4. Do not place any objects, especially heavy objects and lightings, on top of the TV set. Do not install the

TV near any heat sources such as radiators, heat registers, stove, or other apparatus that produce heat.

5. Service personnel should observe the SAFETY INSTRUCTIONS in this manual during use and

servicing of this TV set. Otherwise, the resulted damage is not protected by the manufacturer.

6. Many electrical and mechanical components in this chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the X-ray radiation

protection afforded by them cannot necessarily be obtained by using replacements rated at higher

voltages or wattage, etc. Components which have these special safety characteristics in this manual

and its supplements are identified by the international hazard symbols on the circuit diagram and parts

list. Before replacing any of these components read the parts list in this manual carefully. Substitute

replacement components which do not have the same safety characteristics as specified in the parts list

may create X-ray radiation.

SAFETY SYMBOL DESCRIPTION

The lightning symbol in the triangle tells you that the voltage inside this product may be strong

enough to cause an electric shock. Extreme caution should be exercised when working on the

TV with the back removed.

This is an international hazard symbol, telling you that the components identified by the symbol

have special safety-related characteristics.

FDA This symbol tells you that the critical components identified by the FDA marking have special

safety-related characteristics.

UL This symbol tells you that the critical components identified by the UL marking have special

safety-related characteristics.

3

SERVICE MANUAL

SERVICE SAFETY INSTRUCTIONS FOR DVD UNIT

1. Never allow unqualified personnel to remove and service the DVD130A modules.

2. The unit will generate static. Extreme care should be taken when servicing the modules DVD130A

modules.

3. Never touch the laser pickup head.

4. When this unit is connected to the mains, do not bring your eyes into the laser pickup head or try to look

into the disc tray of any of the opening. Looking into a laser may cause eyes damaged.

5. Ensure that leads of DVD130A are connected correctly.

6. When the unit is powered on, do not connect or disconnect the leads of DVD130A

7. Before power on, ensure each operating voltage coincides with the marking on the PCB and make sure

no short circuit exits on PCB.

8. Do not use scratched, warped or repaired discs.

MAINTENANCE

1. Place the unit on a stable stand or base that is of adequate size and strength to prevent the is from

being accidentally tipped over, pushed off, or pulled off. Do not place the set near or over a radiator or

heat register, or where it is exposed to direct sunlight.

2. Do not install the unit set in a place exposed to rain, water, excessive dust, mechanical vibrations or

impacts.

3. Allow enough space (at least 10cm) between the unit and wall or enclosures for proper ventilation.

4. Slots and openings in the cabinet should never be blocked by clothes or other objects.

5. Please power off the unit set and disconnect it from the wall immediately if any abnormal phenomenon

occurs, such as bad smell, belching smoke, sparkling, abnormal sound, no picture/sound/raster. Hold

the plug firmly when disconnecting the power cord.

6. Unplug the unit set from the wall outlet before cleaning or polishing it. Use a dry soft cloth for cleaning

the exterior of the unit set or CRT screen. Do not use liquid cleaners or aerosol cleaners.

4

SERVICE MANUAL

ADJUSTMENTS

SET-UP ADJUSTMENTS

The following adjustments should be made when a complete realignment is required or a new picture tube is

installed.

Perform the adjustments in the following order:

1. Color purity

2. Convergence

3. White balance

Notes:

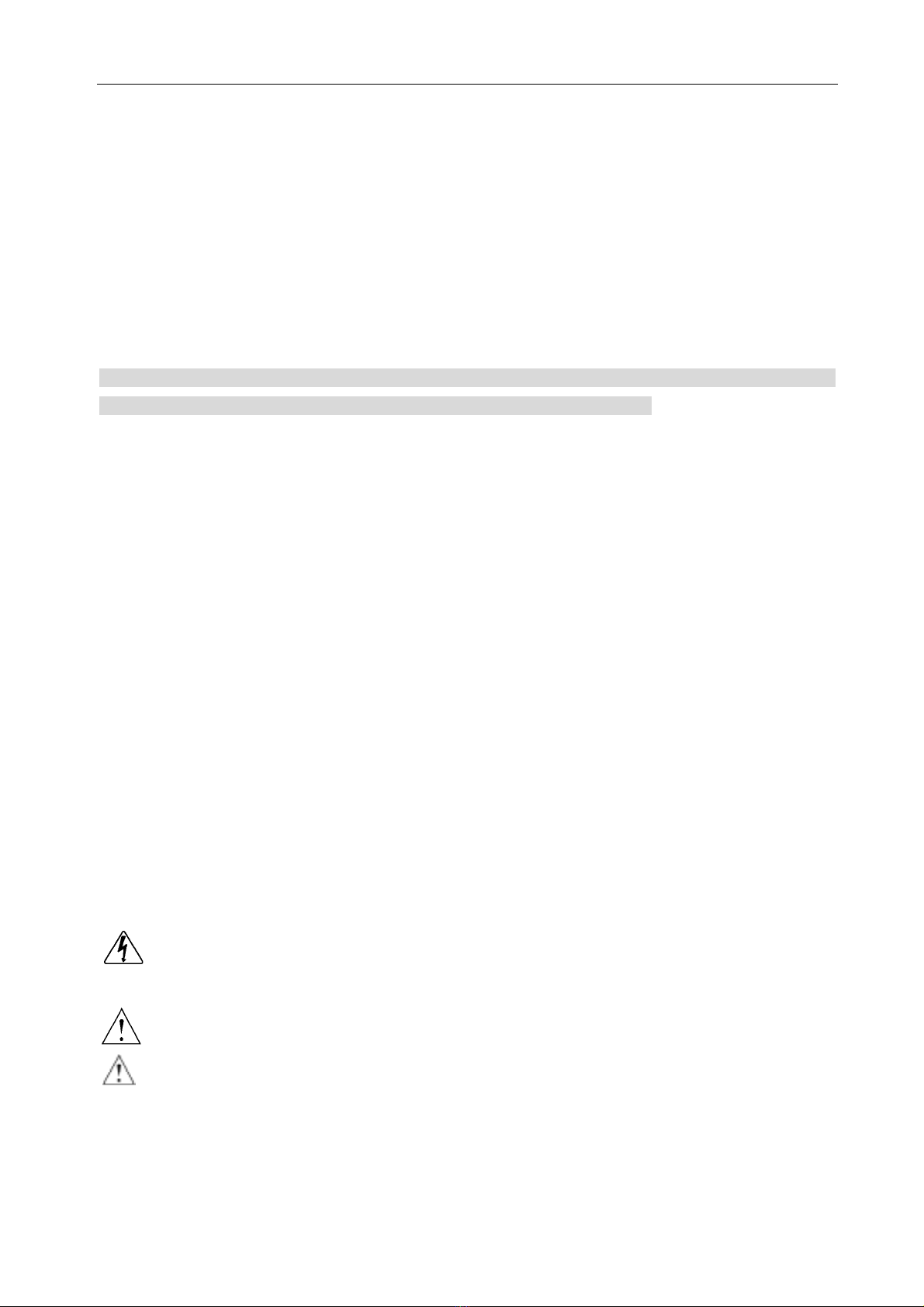

① The purity/convergence magnet assembly and rubber wedges need mechanical positioning.

② For some picture tubes, purity/convergence adjustments are not required.

1. Color Purity Adjustment

Preparation:

Before starting this adjustment, adjust the vertical sync, horizontal sync, vertical amplitude and focus.

1.1 Face the TV set north or south.

1.2 Connect the power plug into the wall outlet and turn on the main power switch of the TV set.

1.3 Operate the TV for at least 15 minutes.

1.4 Degauss the TV set using a specific degaussing coil.

1.5 Set the brightness and contrast to maximum.

1.6 Counter clockwise rotate the R/B low brightness potentiometers to the end and rotate the green low

brightness potentiometer to center.

1.7 Receive green raster pattern signals.

1.8 Loosen the clamp screw holding the deflection yoke assembly and slide it forward or backward to

display a vertical green zone on the screen. Rotate and spread the tabs of the purity magnet around the

neck of the CRT until the green zone is located vertically at the center of the screen.

1.9 Slowly move the deflection yoke assembly forward or backward until a uniform green screen is

obtained.

1.10 Tighten the clamp screw of the assembly temporarily. Check purity of the red raster and blue raster until

purity of the three rasters meets the requirements.

5

SERVICE MANUAL

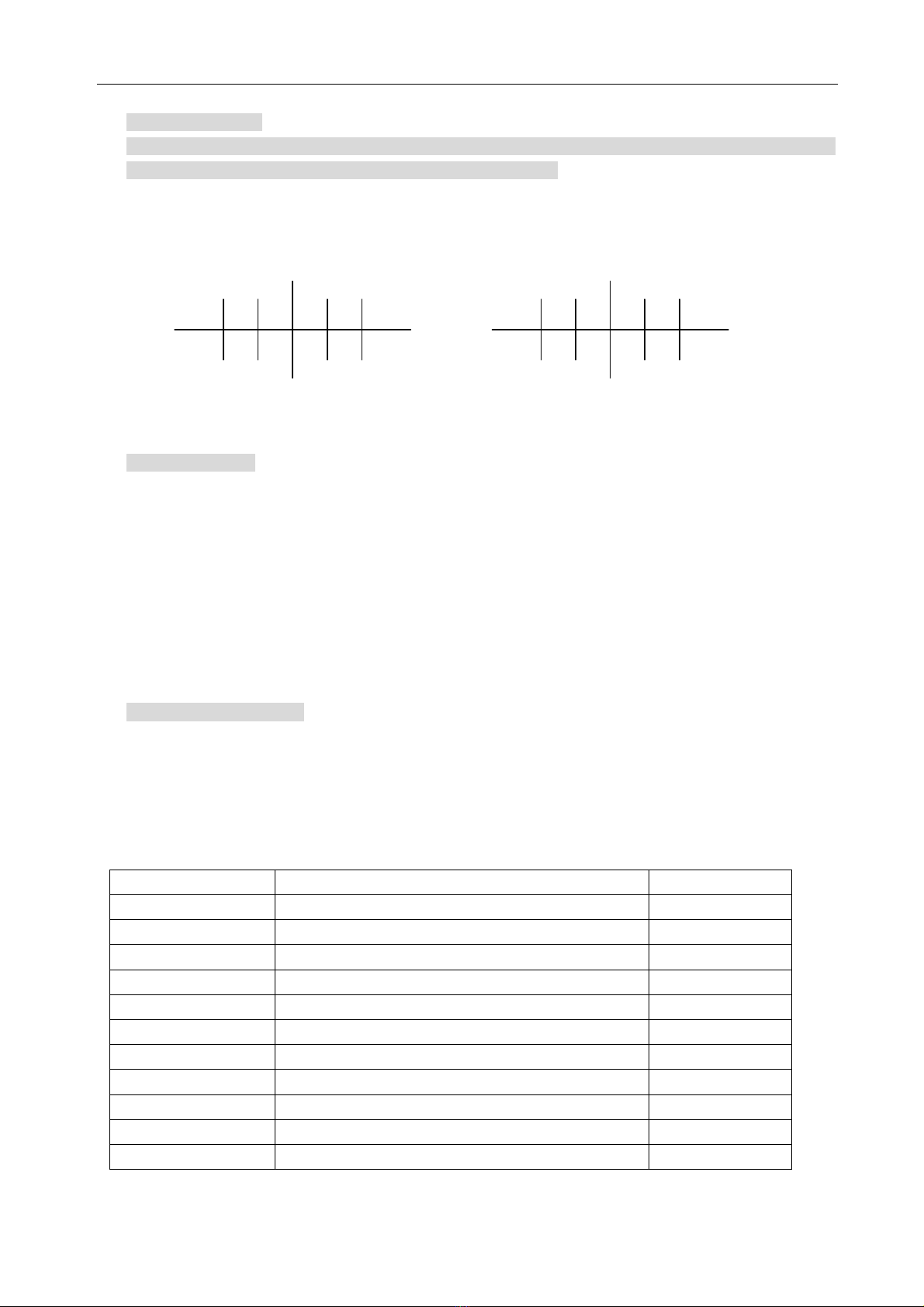

Yoke

Fig. 1

Fig. 2

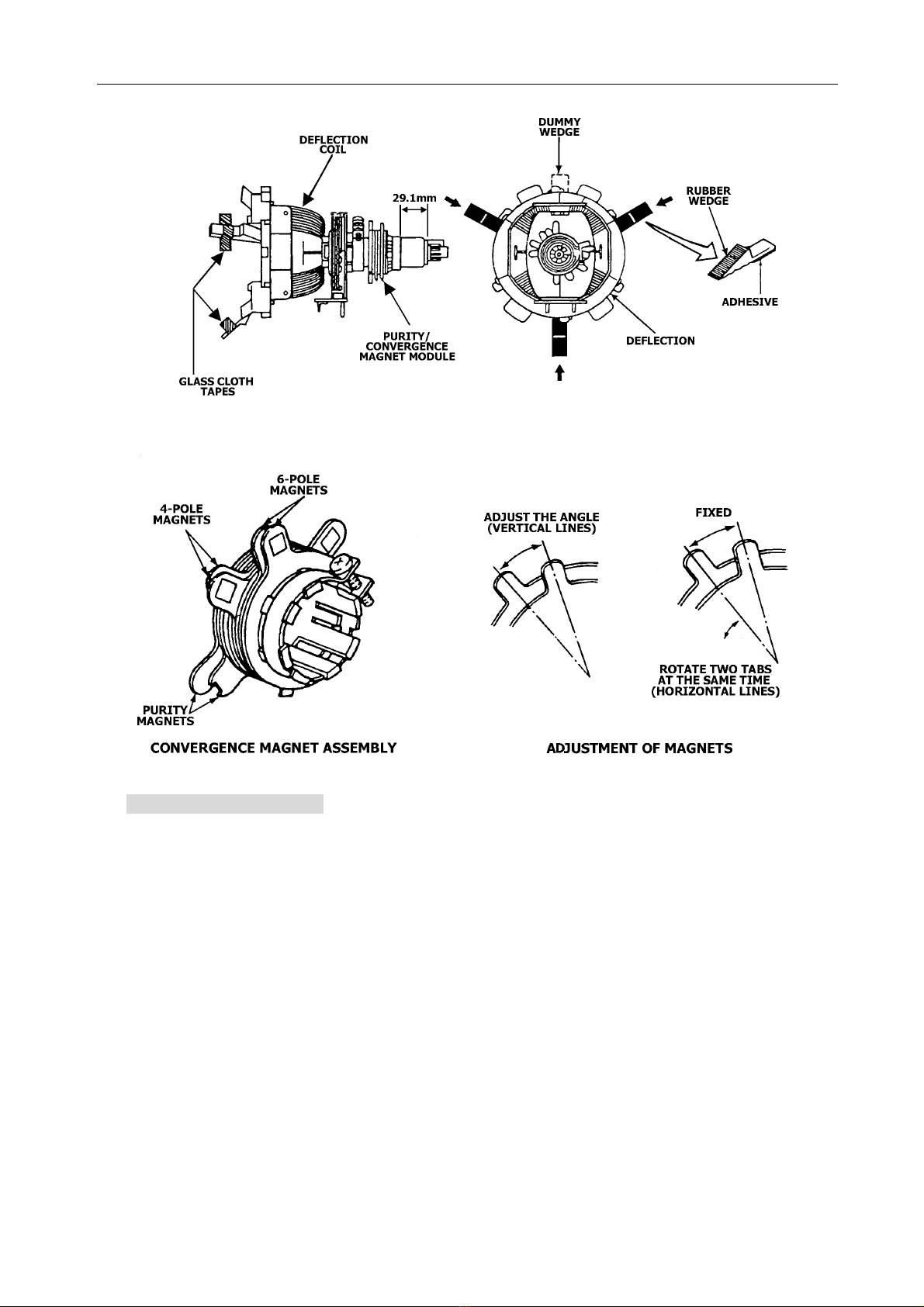

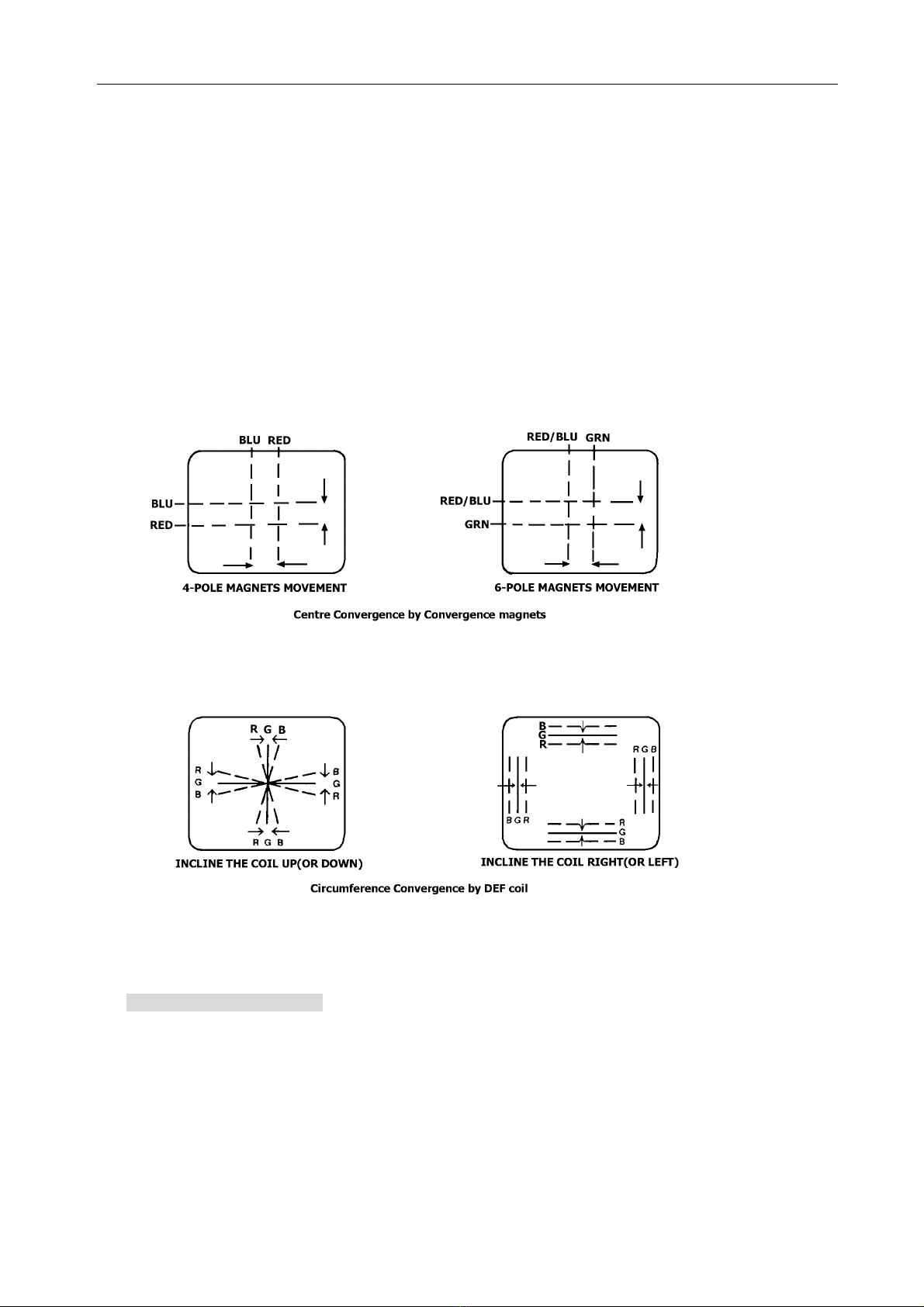

2. Convergence Adjustment

Preparation:

Before attempting any convergence adjustment, the TV should be operated for at least 15 minutes.

2.1 Center convergence adjustment

2.1.1 Receive dot pattern.

2.1.2 Adjust the brightness/contrast controls to obtain a sharp picture.

2.1.3 Adjust two tabs of the 4-pole magnet to change the angle between them and red and blue vertical

lines are superimposed each other on the center of the screen.

2.1.4 Turn both tabs at the same time keeping the angle constant to superimpose red and blue horizontal

on the center of the screen.

2.1.5 Adjust two tabs of the 6-pole magnet to superimpose red/blue line and green line.

2.1.6 Remember red and blue movement. Repeat steps 2.1.3~2.1.5 until optimal convergence is

obtained.

2.2 Circumference convergence adjustment

2.2.1 Loosen the clamp screw holding the deflection yoke assembly and allow it tilting.

6

SERVICE MANUAL

2.2.2 Temporarily put the first wedge between the picture tube and deflection yoke assembly. Move front

of the deflection yoke up or down to obtain better convergence in circumference. Push the mounted

wedge in to fix the yoke temporarily.

2.2.3 Put the second wedge into bottom.

2.2.4 Move front of the deflection yoke to the left or right to obtain better convergence in circumference.

2.2.5 Fix the deflection yoke position and put the third wedge in either upper space. Fasten the deflection

yoke assembly on the picture tube.

2.2.6 Detach the temporarily mounted wedge and put it in either upper space. Fasten the deflection yoke

assembly on the picture tube.

2.2.7 After fastening the three wedges, recheck overall convergence and ensure to get optimal

convergence. Tighten the lamp screw holding the deflection yoke assembly.

4-pole Magnet Movement 6-pole Magnet Movement

Center Convergence by Convergence Magnets

Incline the Yoke Up (or Down) Incline the Yoke Right (or Left)

Circumference Convergence by DEF Yoke

Fig.3

3. White Balance Adjustment

Generally, white balance adjustment is made with professional equipment. It’s not practical to get good

white balance only through manual adjustment. For TVs with I

2

C bus control, change the bus data to

adjust white balance.

7

SERVICE MANUAL

CIRCUIT ADJUSTMENTS

Preparation:

Circuit adjustments should be made only after completion of set-up adjustments.

Circuit adjustments can be performed using the adjustable components inside the TV set. For TVs with

2

I

C bus control, first change the bus data.

1. Degaussing

A degaussing coil is built inside he TV set. Each time the TV is powered on, the degaussing coil will

automatically degauss the TV. If the TV is magnetized by external strong magnetic field, causing color

spot on the screen, use a specific degausser to demagnetize the TV in the following ways. Otherwise,

color distortion will be exist on the screen.

1.1 Power on the TV set and operate it for at least 15 minutes.

1.2 Receive red full-field pattern.

1.3 Power on the specific degausser and face it to the TV screen.

1.4 Turn on the degausser. Slowly move it around the screen and slowly take it away from the TV.

1.5 Repeat the above steps until the TV is degaussed completely.

2. Supply Voltage Adjustment

Caution: +B voltage has close relation to high voltage. To prevent X-ray radiation, set +B voltage

to the rated voltage.

2.1 Make sure that the supply voltage is within the range of the rated value.

2.2 Connect a digital voltmeter to the +B voltage output terminal VD891 of the TV set. Power on the TV and

set the brightness and sub-brightness to minimum.

2.3 Regulate voltage adjustment components on the power PCB to make the voltmeter read 115±1V .

3. High V oltage Inspection

Caution: No high voltage adjustment components inside the chassis. Please perform high

voltage inspection in the following ways.

3.1 Connect a precise static high voltmeter to the second anode (inside the high voltage cap) of the picture

tube.

3.2 Plug in the supply socket (120V, AC) and turn on the TV. Set the brightness and contrast to minimum (0

μA).

3.3 The high voltage reading should be less than the EHT limitation.

3.4 Change the brightness from minimum to maximum, and ensure high voltage not beyond the limitation in

any case.

Nominal EHT voltage: 22±1KV Limited EHT voltage: 25KV

8

SERVICE MANUAL

4. Focus Adjustment

Caution: Dangerously high voltages are present inside the TV. Extreme caution should be

exercised when working on the TV with the back removed.

4.1 After removing the back cover, look for the FBT on the main PCB. There should be a FCB on the FBT.

4.2 Power on the TV and preheat it for 15 min.

4.3 Receive a normal TV signal. Rotate knob of the FCB until you get a sharp picture.

Before Adjusting After Adjusting

5. Safety Inspection

5.1 Inspection for insulation and voltage-resistant

Perform safety test for all naked metal of the TV. Supply high voltage of 3000V AC, 50Hz (limit current of

10mA) between all naked metal and cold ground. Test every point for 3 seconds. and ensure no arcing

and sparking.

5.2 Requirements for insulation resistance

Measure resistance between naked metal of the TV and feed end of the power cord to be infinity with a

DC-500 high resistance meter and insulation resistance between the naked metal and degaussing coil

to be over 20MΩ.

6. DESIGN/SERVICE mode

6.1 To enter the DESIGN/USER SERVICE (S) mode

Set the volume to 0. Then press the MUTE key on the remote control and on the TV at the same time

for over 2 seconds. In the S mode, press the POWER key to quit the S mode.

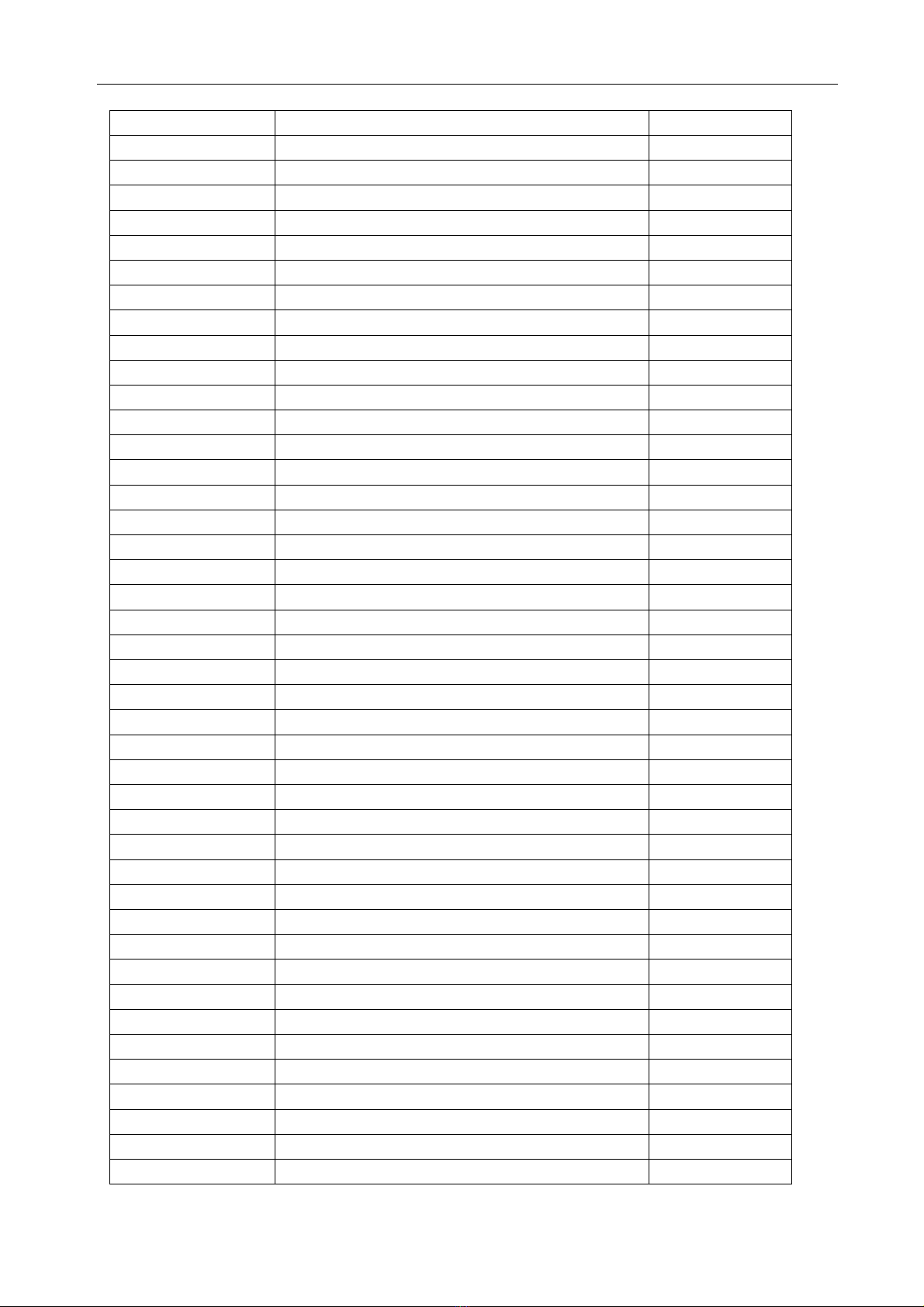

6.2 Adjustments and bus data

Table 1 Bus Data

Item Symbol Description Bus Data

MENU.00

V.POSITION VERTICAL POSITION 40

H.PHASE HORIZONTAL PHASE 15

V.SIZE VERTICAL SIZE 60

V.SC VERTICAL S-CORRECTION 18

V.LINE VERTICAL LINE 19

V.SIZE CMP VERTICAL SIZE COMPENSATION 7

MENU.01

SUB.BIAS SUB-BRIGHT 63

SUB.CONT SUB-CONTRAST 31

V.KILL VERTICAL KILL 0

(continued)

9

SERVICE MANUAL

RF.AGC RF AGC 20

R.BIAS RED BIAS 130

G.BIAS GREEN BIAS 130

B.BIAS BLUE BIAS 130

R.DRIVE RED DRIVE 75

G.DRIVE GREEN DRIVE 15

B.DRIVE BLUE DRIVE 75

MENU.02

SECAM B DC SECAM B-Y 0

SECAM R DC SECAM R-Y 0

H.APC GAIN HORIZONTAL APC GAIN 0

SYNC.KIL SYNC KILL 0

H.BLK.L HORIZONTAL BLANKING LEFT 4

H.BLK.R HORIZONTAL BLANKING RIGHT 4

CROS.B/W CROSSHATCH BLACK/WHITE 0

VIDEO.LVL VIDEO LEVEL 7

FM.LEVEL FM LEVEL 16

MENU.03

FM.MUTE FM MUTE 0

AUDIO.MUTE AUDIO MUIE 0

VIDEO.MUTE VIDEO MUTE 0

DEEM.TC DE-EMPHASIS TIME CONSTANT 0

SND.TRAP SOUND TRAP 0

MENU.04

SUB.COLOR SUB COLOR 63

SUB.TINT SUB TINT 32

SUB.SHARP SUB SHARP 63

AUTO FLESH AUTOMATIC FLESH 0

CORING.GAN CORING GAIN 1

C.EXT EXTERNAL CHROMA 0

C.BYPASS CHROMA BAND-PASS BYPASS 0

C.KILL ON COLOR KILL ON 0

MENU.05

FIL.SYS

FILTER SYSTEM:SELECT Y/C FILTER MODE

1

COLOR.SYS COLOR SYSTEM 5

VOL.FIL VOLUME FILTER 0

VIF.SYS VIF SYSTEM 0

SIF.SYS.SW SIF SYSTEM SWITCH 0

VIDEO.SW VIDEO SWITCH 1

MENU.06

R/B G.BAL R-Y/B-Y GAIN BALANCE 7

R/B ANGLE R-Y/B-Y ANGLE 9

CD MODE VERTICAL COUNTDOWN MODE 0

(continued)

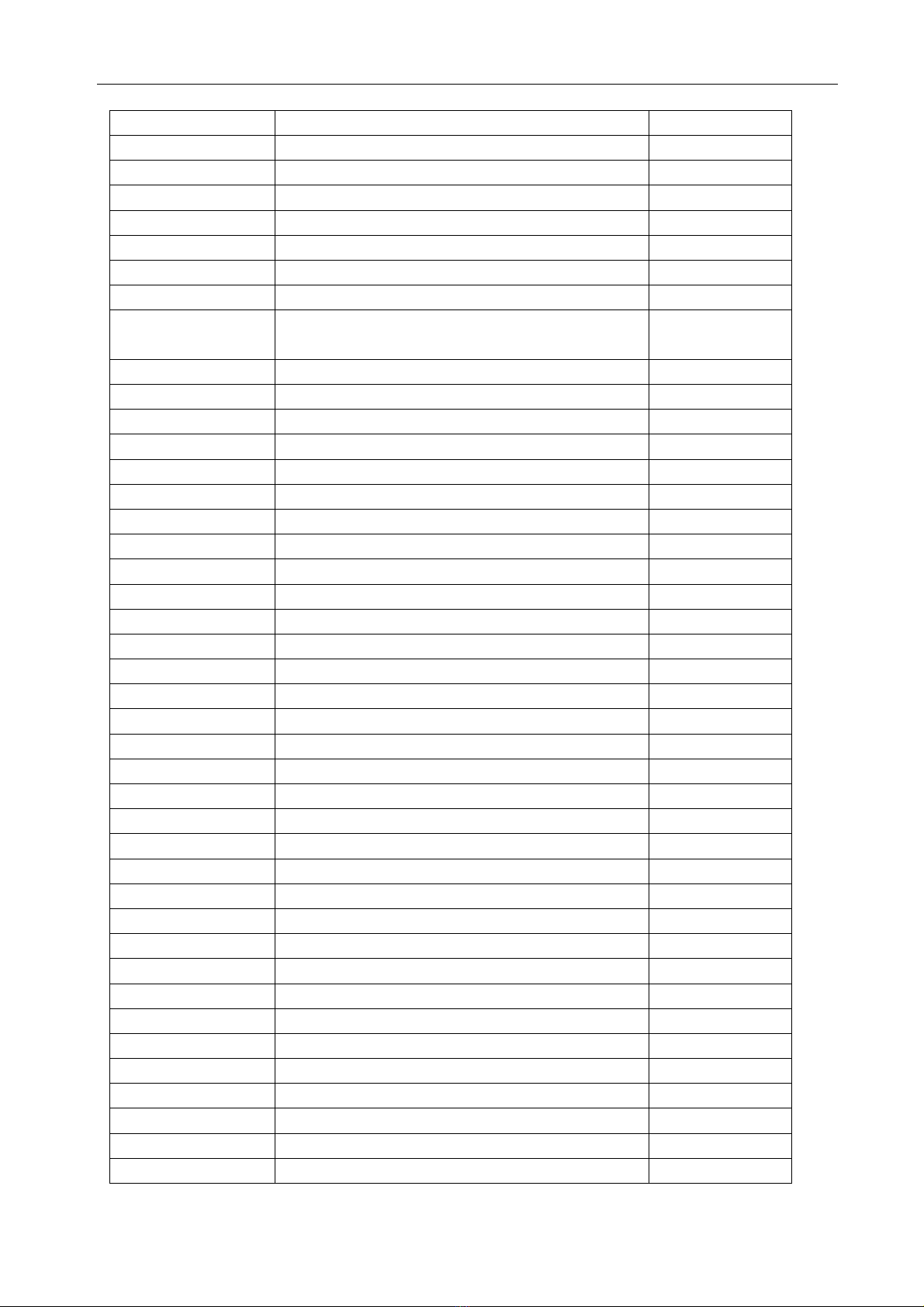

10

SERVICE MANUAL

GREY MODE GREY MODE 0

V.SETUP VERTICAL SETUP 1

MENU.07

BLANK.DEF BLANK DEFEAT 0

BRT.ABL.TH BRIGHT ABL THRESHOLD 7

RGB TEMP RGB TEMPERATURE SWITCH 1

BRT.ABL.DF BRIGHT ABL DEFEAT 0

MID.STP.DF BRIGHT MID STOP DEFEAT 0

FBP.BLK.SW

FLYBACK PULSES (HORIZONTAL)BLANKING

0

SWITCH

MENU.08

DIGITAL.OSD DIGITAL OSD MODE 0

OSD.CONT OSD CONTRAST CONTROL 10

OSD.CONTST OSD CONTRAST TEST 0

OSD.H.POS OSD HORIZONTAL POSITION 22

MENU.09

H.FREQ HORIZONTAL FREQUENCY 46

FM.GAIN FM GAIN 0

C.KILL.OFF COLOR KILL OFF 0

AUDIO.SW AUDIO SWITCH 0

T.DISBLE TEST MODE SWITCH DISABLE 1

MENU.10

G/Y ANGLE G/Y ANGLE 0

COL KIL OP COLOR KILLER OPERATIONAL LEVEL 5

CBCR-IN YCBCR INPUT 1

Y-APF

YC

MODE,ALL PASS FILTER MODE

BCR

0

PRE SHOOT PRE-SHOOT WIDTH 0

WPL OPE WHITE PEAK LIMITER LEVEL OPERATE 0

DC REST LUMA DC RESTORATION 0

BK STR STA BLACK STRETCH START POINT 1

BK STR GAN BLACK STRETCH START GAIN 1

MENU.11

OVER MD SW 1

Y GAMMA Y GAMMA START POINT 0

FSC C.SYNC fSC C-SYNC OUTPUT 1

VBLK SW VERTICAL BLANKING CONTROL SWITCH 0

SND TRAP SOUND TRAP 1

HALF TONE HALF TONE LEVEL 3

HALF T SW HALF TONE ON/OFF SWITCH 1

TST VERSET 0

MENU.12

E/W DC

E/W(EAST/WEST)

32

E/W AMP E/W 32

(continued)

11

SERVICE MANUAL

E/W TILT E/W 32

E/W C TOP E/W 5

E/W C BOTM E/W 5

MENU.13

E/W TEST E/W TEST 7

HSIZE COMP HORIZONTAL SIZE COMPENSATION 7

IF TEST 3B 3dB IF TEST 0

V.LEV ADJ VIDEO LEVEL ADJUSTMENT 0

OV MOD LEV 5

PRE/OVER PRE/OVER-SHOOT ADJUSTMENT 0

C.VCO SW CHROMA VCO(VOLTAGE CONTROLLED OSCILLATOR)SWITCH 0

C.VCO ADJ CHROMA VCO ADJUSTMENT 0

MENU.14

VNSYNC 0

TINT.THROU TINT THROUGH 0

HLOCK.VDET 0

MENU.15

OPT.1CHIP OPTION 1CHIP 1

OPT.VIDEO OPTION VIDEO 1

OPT.DVD OPTION DVD 1

OPT.AV1AV2 OPTION AV1/AV2 1

OPT.AV3 OPTION AV3 0

OPT.S-VHS OPTION S-VHS 1

OPT.YUV OPTION YUV 0

OPT.COMB OPTION COMB 0

OPT.BYPASS OPTION BYPASS 0

MENU.16

OPT . VM OPTION VM 0

OPT.BLUEBK OPTION BLUEBK 1

OPT.V-CHIP OPTION V-CHIP 1

OPT.CCD OPTION CCD 1

OPT.CLOCK OPTION CLOCK 1

OPT.P-ON OPTION 0

SRCH.SPEED SEARCH SPEED 0

ROM .CORREC ROM CORRECTION 0

MENU.17

OPT.BTSC OPTION BTSC 1

OPT.AV-INP OPTION AV-INP 0

OPT.BBE OPTION BBE 0

OPT. DVD-IN

SUB.BASS SUB BASS 3

SUB.TREBLE SUB TREBLE 3

OPTION DVD-IN 0

(continued)

12

SERVICE MANUAL

MENU.18

LOUNDNESS LOUDNESS 9

FM/AM.PRES FM/AM PRESETTING 63

SCART.PRES SCART PRESETTING SCART VOLUME 39

SCART.VOL SCART VOLUME 117

OPT.AVC OPTION AVC 1

AVC.DECAY 2

BBE.BASS BBE BASS 32

BBE.TREBLE BBE TREBLE 32

Notes:

① The data sheet may differ dependent on different models.

② The data sheet may differ dependent on different CRTs for the same model.

13

SERVICE MANUAL

ADJUSTMENTS FOR DVD UNIT

1. Power on the unit only after ensuring DVD130A modules is connected correctly in accordance with the

wiring diagram.

2. If the unit fails to play after power-on, repair the DVD130A according to the service illustration until it can

read discs and has corresponding AV output.

3. Inspect audio output of the DVD130A in the following ways.

a. Inspect digital audio output: When playing a disc, connect a signal cable to the coaxial output

terminal. Press the SETUP button on the remote control and set “AUDIO OUT” in the SETUP

menu to “SPDIF/SOURCE CODE”. Then start playback with the PLAY button and the following

diagram will be displayed with waveform amplitude of 0.75±0.25Vpp on the oscilloscope. After

inspection, set “AUDIO OUT”to “ANALOG”.

b. Connect the OUT terminal on the DVD130A to the IN terminal on the TV and shift the TV to the DVD

mode. After power-on for several seconds, the TV should display the preset LOGO picture on the

screen, which should be smooth and distort-free with normal color. Press the OPEN/CLOSE button

on the remote control to open the disc tray. Place the disc on the disc tray. Press the PLAY button

and play should begin after several seconds. The color and sound should be normal, and picture

should be smooth and distortionless.

c. With a CD disc played, the TV should display the preset LOGO picture on the screen. The color

and sound should be normal, and picture should be smooth and distortionless.

14

SERVICE MANUAL

STRUCTURE AND CHASSIS FUNCTION DESCRIPTION

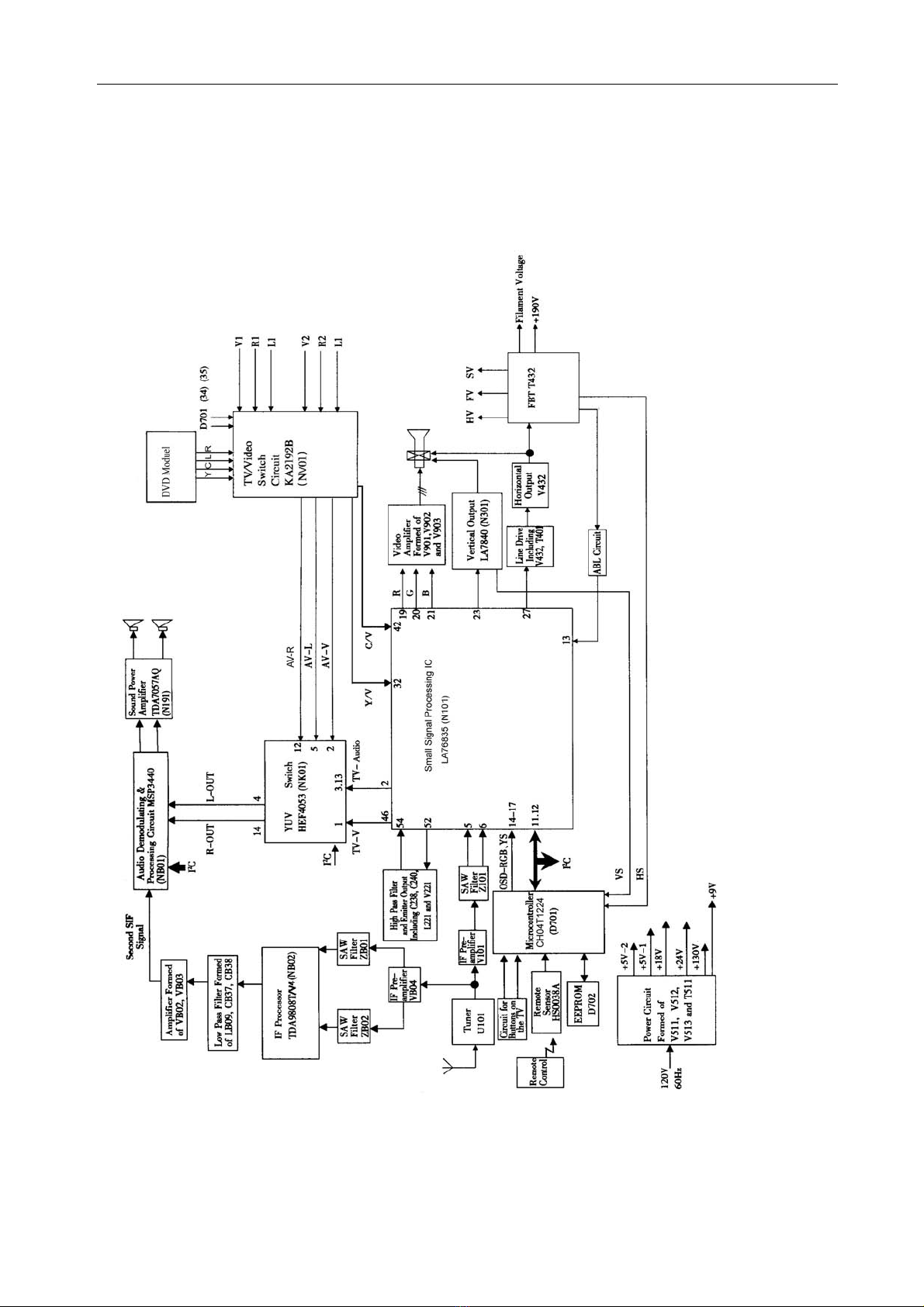

1. STRUCTURE BLOCK DIAGRAM (For CPU CH04T1224 Only)

15

Fig. 4 Structure Block Diagram for CN-12DV Chassis

SERVICE MANUAL

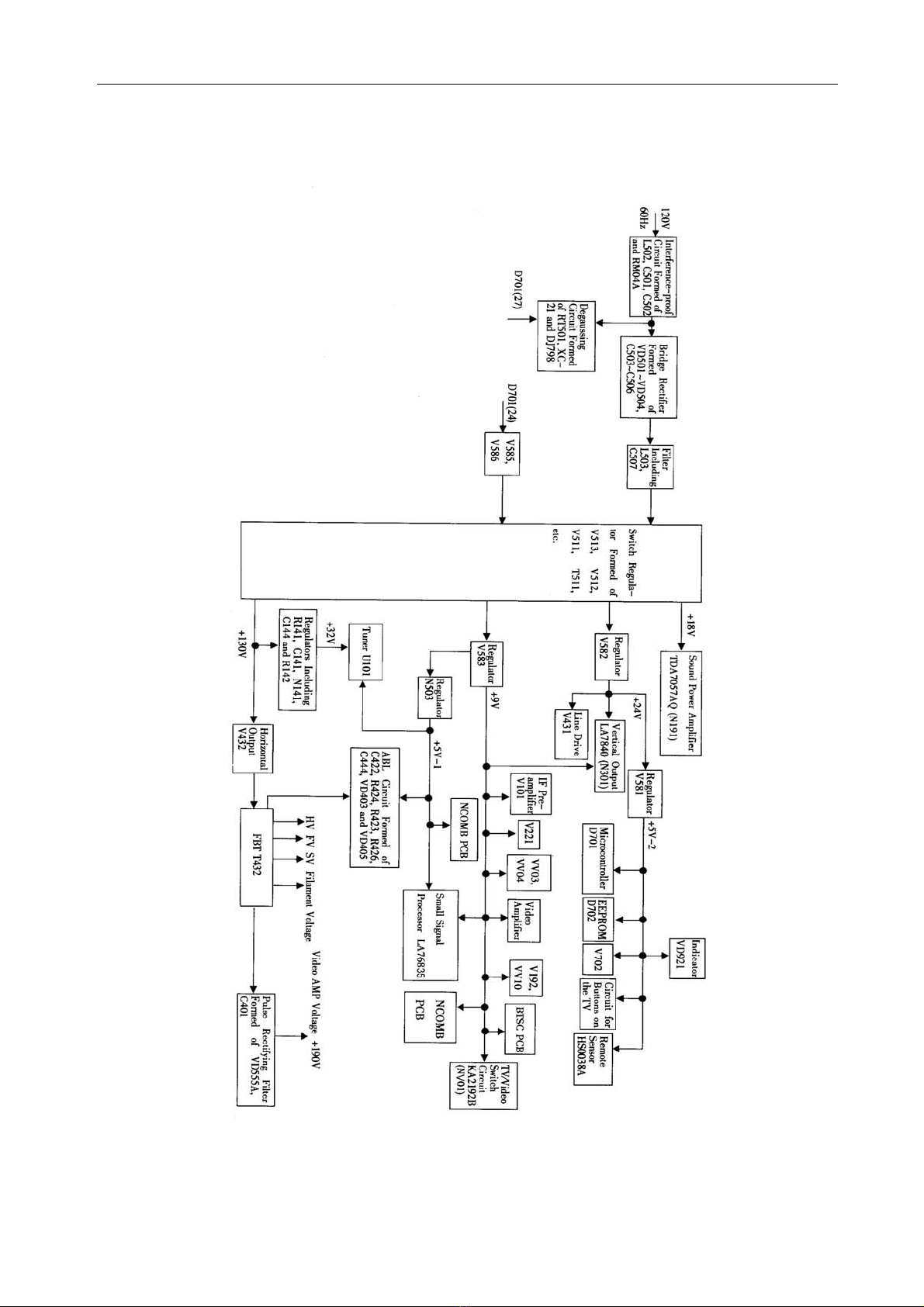

3.BLOCK DIAGRAM OF SUPPLY VOLTAGE SYSTEM

Fig. 6 Block Diagram for CN-12DV Supply Voltage System

16

SERVICE MANUAL

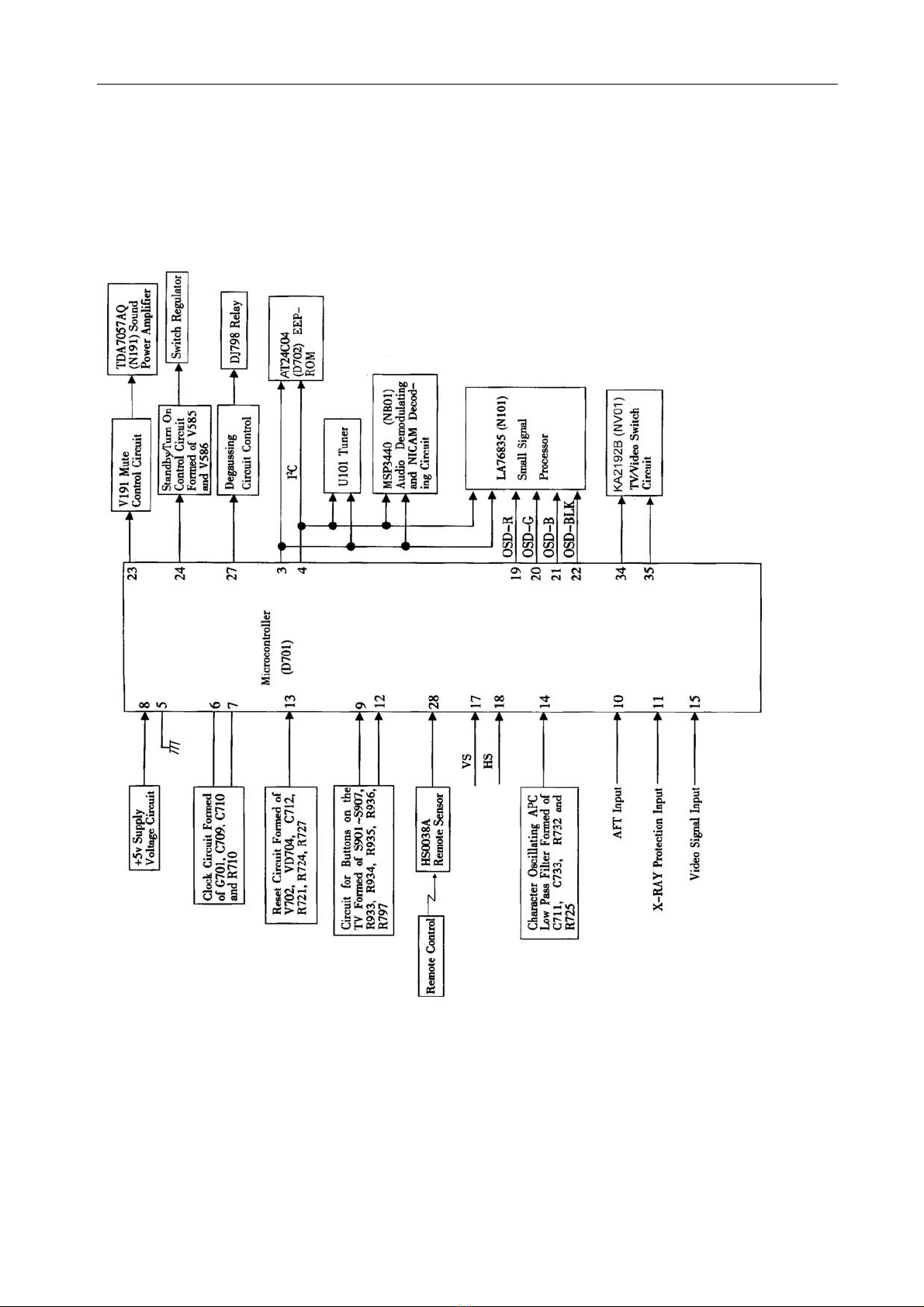

4. BLOCK DIAGRAM OF REMOTE CONTROL SYSTEM

Fig. 7 Block Diagram for CN-12DV Remote Control Structure

17

SERVICE MANUAL

4.STRUCTURE BLOCK DIAGRAM FOR DVD130A

DVD130A MODULE

EEPROM

24C01

2X16M SDRAM

CS4955-CD

Sanyo

MT1336E

+DJ-100

Pickup head

BA5954

MT1369AE

8M FLASH

L

74HCU04

CS4340

Audio DAC

R

NJM4558M

Audio Amp

S-VIDEO

SPDIF

L-out

R-out

TV

Power Supply

Fig.

8 Structure Block Diagram for DVD130A

18

SERVICE MANUAL

5.CHASSIS FUNCTION DESCRIPTION

5.1. General Description

MTV-DV05 TV/DVD combo has combined function of TV signal reception and DVD discs playback, of

which TV unit uses CN-12C2 chassis and DVD unit uses loader DVD 130A.

CN-12C2 chassis applies a single chip IC LA76835 of Japan-based Sanyo for small signal processing,

featuring multi system reception. The applied I

control the TV for much convenience of operation and servicing. Refer to Fig.4 about the chassis’

structure block diagram.

Compatible with DVD, CD, VCD, SVCD, MP3, and KODAR Picture CD, DVD130A, high-quality modules

with various functions, features multi angle, multilingual and multi captions. With Dolby dual channel

amplifying and DTS coaxial cable, the DVD audio system offers astonishingly high-quality audio output.

DVD130A consists of a disc tray (including DJ-100 assembly and small loader DV-33FS) and analog

signal processor/servo control/MPEG decoding board MT1369AE+MT1336E. The servo control/MPEG

decoding board MT1369AE, developed by MEDIATEK, is designed for use in signal control, decoding,

data processing, etc., featuring servo control, AV decoding, analog front end, DPU (DATA PATH UNIT),

2

C bus control technology can automatically adjust and

main axis control, CSS/CPPM module, system analysis program, video output unit, audio terminals and

system control. MT1336E, also

developed by MEDIATEK, is a high-performance CMOS analog signal processor with servo amplifying

and DPD tracking error signal for use in CD-ROM drive and DVD-RAM. For DVD-RAM, MT1336E also

uses DPP for developing tracking signal and DAD for processing focus signal. Meanwhile, the IC,

programmable, is equipped with a separate DVD-ROM, CD-ROM two-way automatic laser power

control circuit and reference voltage generator.

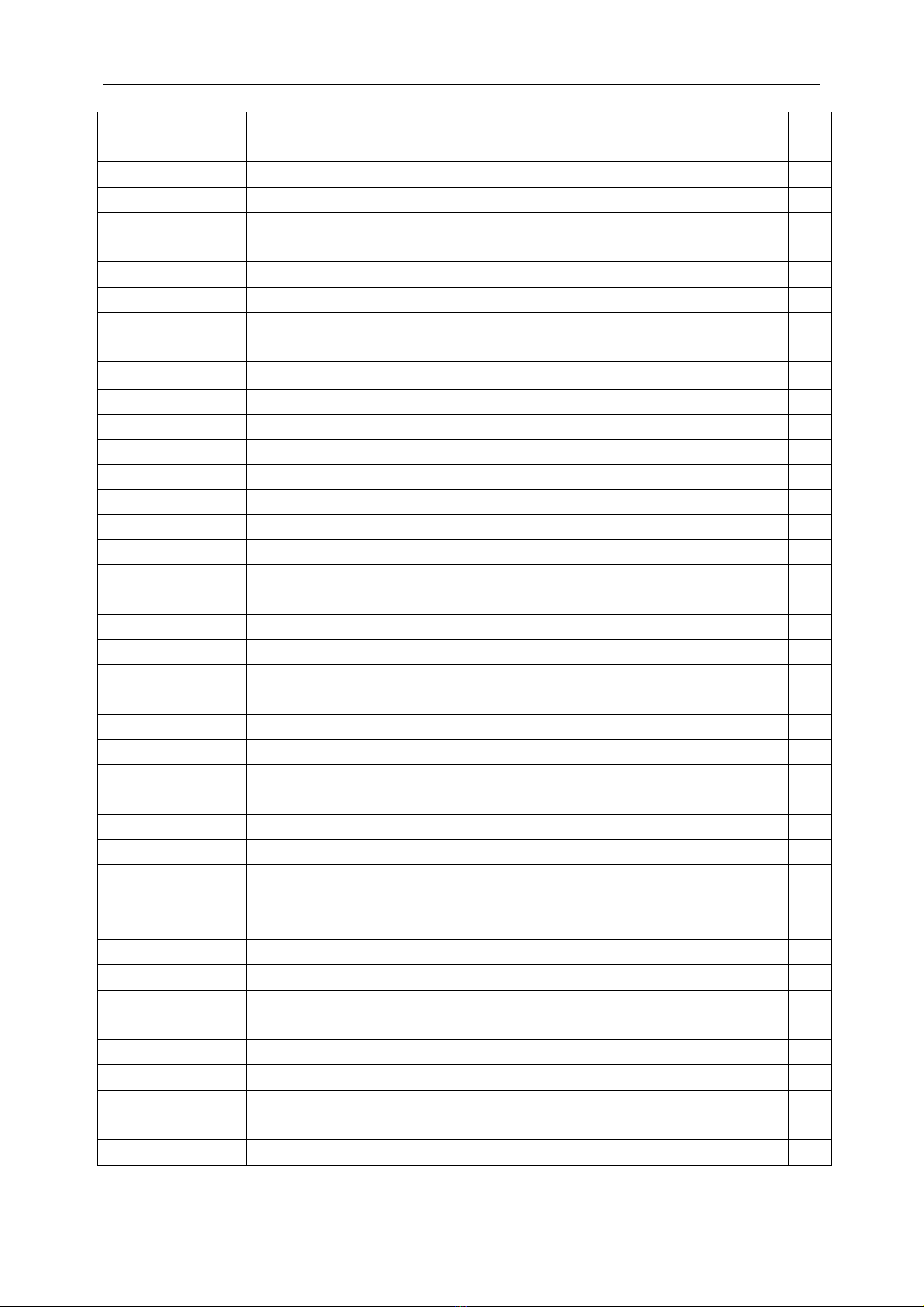

5.2 Key ICs and Assemblies

5.2.1 The CN-12C2 chassis mainly uses the following ICs and assemblies.

Table 2 Key ICs and Assemblies of CN-12C2 Chassis

Serial No. Position Type Function Description

1 D701

2 D702 AT24C08

3 N101 LA76835

4 NV01 KA2192B

5 N301 LA7840

6 N191 TDA7057AQ

CH04T1227

Microcontroller

EEPROM

Small signal processor

TV/Video switch circuit

Vertical output circuit

Sound power amplifier

7 NN01 TDA9808T Audio IF demodulator

8 NN02 MSP3410G NICAM audio processor

9 N503 LM7805

10 NK01 HEF4053

11 U101 TDQ-3B8/136

Tri-pin regulator

Electronic switch circuit

Tuner

19

SERVICE MANUAL

5.2.2. The DVD130A mainly uses the following ICs and assemblies.

Table 3 Key ICs and Assemblies of DVD130A

Serial No. Position Type Function Description

MPEG board Drawing No. JUV2.033.071-1MX

1 U1 MT1336E RF amplifier

2 U2 BA5954FM Focus/tracking coil and feed motor drive

3 U3 MT1369AE MPEG decoder

4 U5 74HCU04 Enhancement drive

5 U7 8M FLASH Flash memory

6 U9 NJM4558M Sound amplifier

7 U10 24C01 1K EEPOM

8 U13 CS4340 Audio D/A controller

9 U14 CS4955-CD Video encoder

10 U17 16M SDRAM Dynamic EEPROM

DJ-100 Disc tray assembly

20

SERVICE MANUAL

SERVICE DATA

SERVICE DATA FOR TV UNIT

TECHNICAL DATA OF KEY ICS

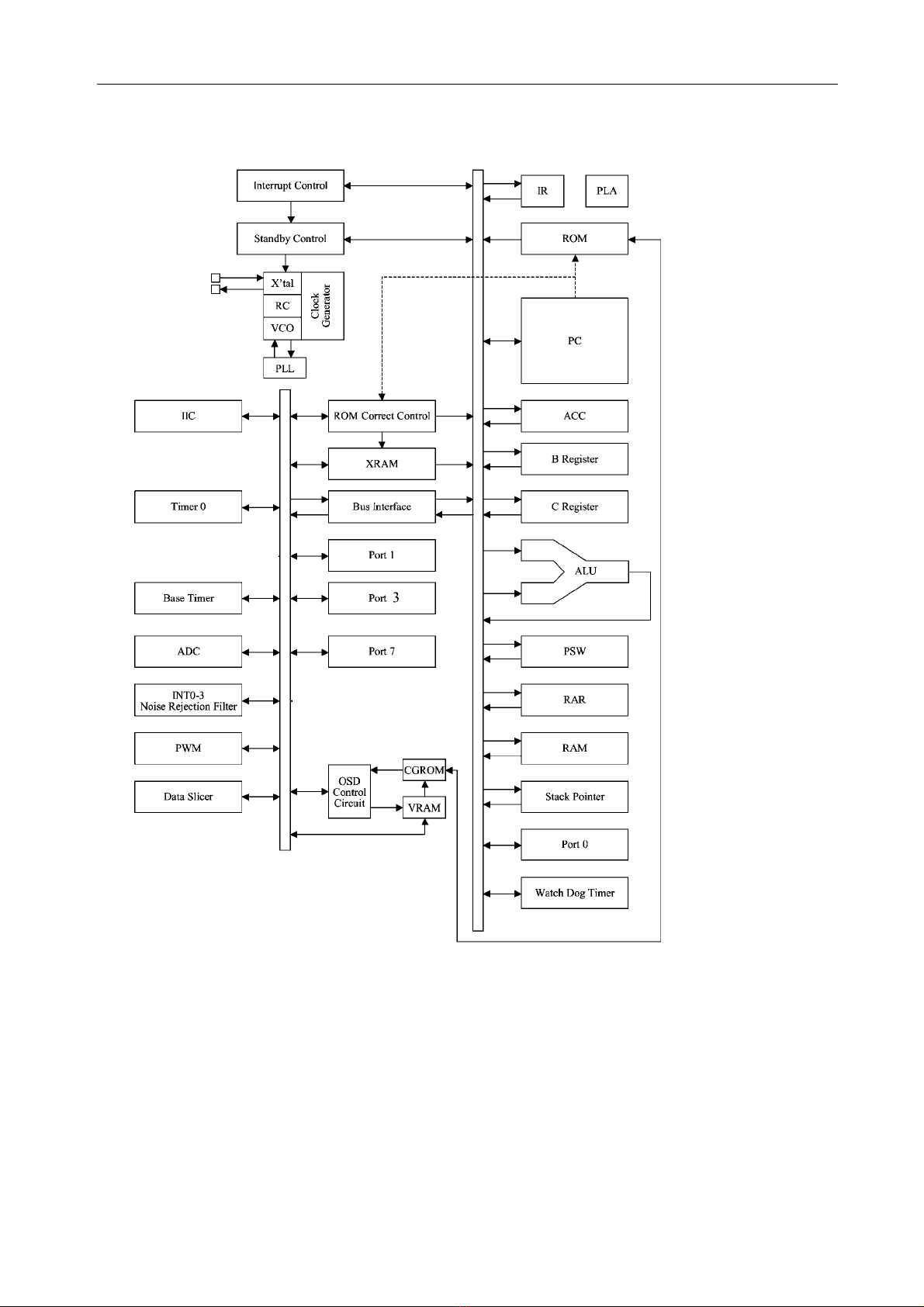

CH04T1227 (D701)

8-Bit Single Chip Microcontroller

1. Overview

The LC86F344BA are 8-bit single chip microcontrollers with the following on-chip functional blocks:

-CPU:Operable at a minimum bus cycle time of 0.424µs

-On-chip ROM capacity

Program ROM:32K/28K/24K/20K/16K bytes

CGROM:16K bytes

-On-chip ROM capacity: 512 bytes

-OSD RAM: 352×9 bits

-Closed-Caption TV controller and the on-screen display controller

-Closed-Caption data slicer

-Four channels×6-bit AD Converter

-Three channels×7-bit PWM

-16-bit timer/counter,14-bit base timer

-IIC-bus compliant serial interface circuit (Multi-master type)

-ROM correction function

-11-source 8-vectored interrupt system

-Integrated system clock generator and display clock generator

Only one X’tal oscillator (32.768kHz) for PLL reference is used for both generators

TV control and the Closed Caption function

All of the above functions are fabricated on a single chip.

21

2. System Block Diagram

SERVICE MANUAL

Fig. 9

3. Refer to Table 4 about Functions and Service Data of the IC’s Pins.

22

SERVICE MANUAL

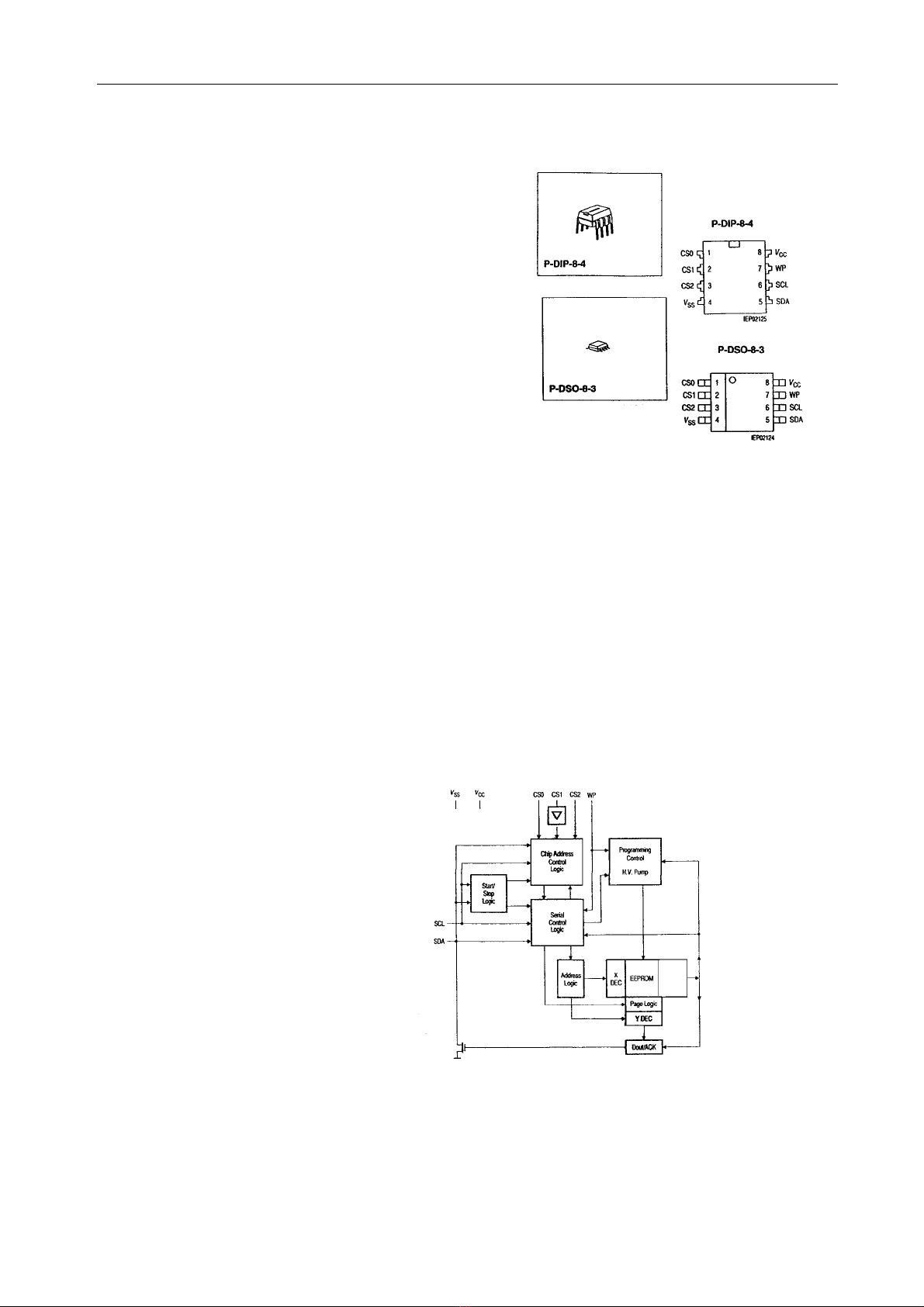

AT24C08 (D702)

EEPROM

1. Features

·Data EEPROM internally organized as 1024/2048 bytes

and 64/128 pages×16 bytes

·Page protection mode, flexible page-by-page hardware

write protection

- Additional protection EEPROM of 64/128 bits, 1 bit per

data page

- Protection setting for each data page by writing its

protection bit

- Protection management without switching WP pin

·Low power CMOS

·Vcc=2.7 to 5.5V operation

·Two wire serial interface bus, I

·Filtered inputs for noise suppression with Schmitt trigger

·Clock frequency up to 400 kHz

·High programming flexibility

- Internal programming voltage

- Self timed programming cycle including erase

- Byte-write and page-write programming, between 1 and 16 bytes

- Typical programming time 6 ms(<10ms) for up to 16 bytes

·High reliability

- Endurance 10

- Data retention 40 years

6

cycles1)

1)

- ESD protection 4000 V on all pins

·8 pin DIP/DSO packages

·Available for extended temperature ranges

- Industrial: -40℃ to +85℃

- Automotive: -40℃ to +125℃

3. Block Diagram

2

C-Bus compatible

2. Pin Configuration

Fig.10

4. Refer to Table 5 about Functions and Service Data of AT24C08’s Pins.

23

SERVICE MANUAL

KA2192B (NV01)

TV/Video Switch Circuit

1. Features

The TV/Video switch circuit KA2192B (NY01) is an electronic switch circuit controlling four sets of audio

signal inputs, three sets of video signal inputs, two sets of Y/C separation signals inputs, one set of video

signal output, one set of Y/C separation signal output and one set of audio signal output.

2. Block Diagram

Fig.11

3. Value Table

Level for Control Terminal

(15) (16)

H H TV

H L AV1

L H SVHS

L L AV2

4. Refer to Table 6 about Functions and Service Data of KA2192B’s Pins.

Switchover Mode

24

SERVICE MANUAL

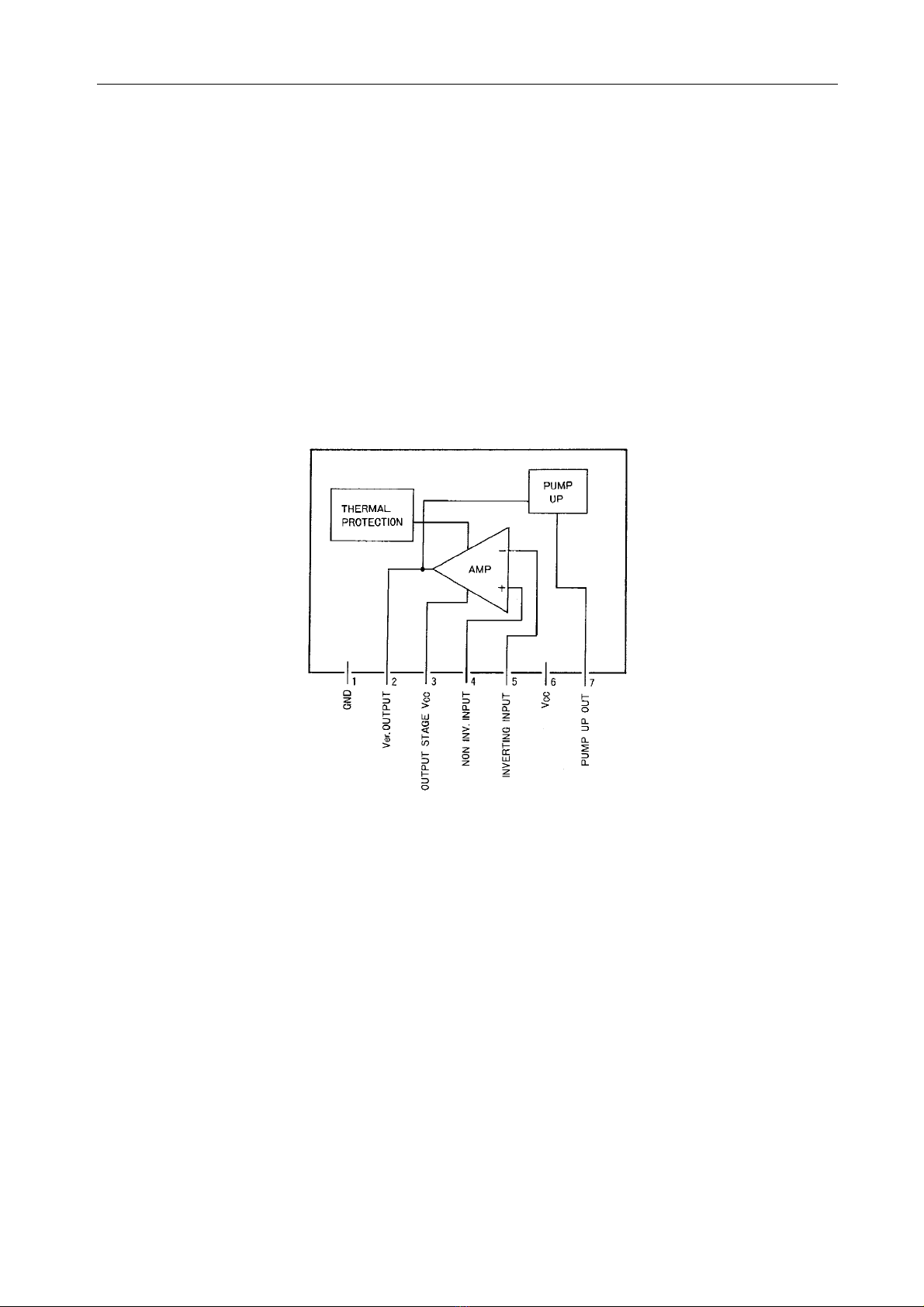

LA7840 (N301)

Vertical Deflection Output Circuit

1. Features

·Low power dissipation due to built-in pump-up circuit

·Vertical output circuit

·Thermal protection circuit built in

·Excellent crossover characteristics

·DC coupling possible

2. Block Diagram

Fig. 12

3. Refer to Table 7 about Functions and Service Data of LA7840’s Pins.

25

Loading...

Loading...