Page 1

Page 2

Thank you for your purchase of Mitsubishi Transistor inverter FREQ,ROL-2200.

r

r

r--

This inverter is a variable frequency power supply unit used to control a squirrelcage induction motor.

IMPORTANT NOTE

This instruction manual describes handling, installation, operation and maintenance

of the inverter.

.Although it is easy to use the inverter,

cause unforeseen trouble. Before operating the inverter,

Your inverter is built to a high standard of quality and reliability.

Correct application and regular inspection,

operation.

-C 0 N T E N T S-

- INVERTER

HANDLING GUIDANCE

Q 1. CONSTRUCTICN

9 2. UNPACKING AND CHECKING

Q 3. INSTALLATION

3.1 Handling during transfer and installation

3.2 Environment

3.3 Mounting position and clearances

3.4 Inverter housed in enclosure

§ 4, WIRING

4.1 Main circuit

4.2 Control circuit

4.3 Terminals for wiring

4.4 Field wiring reference table

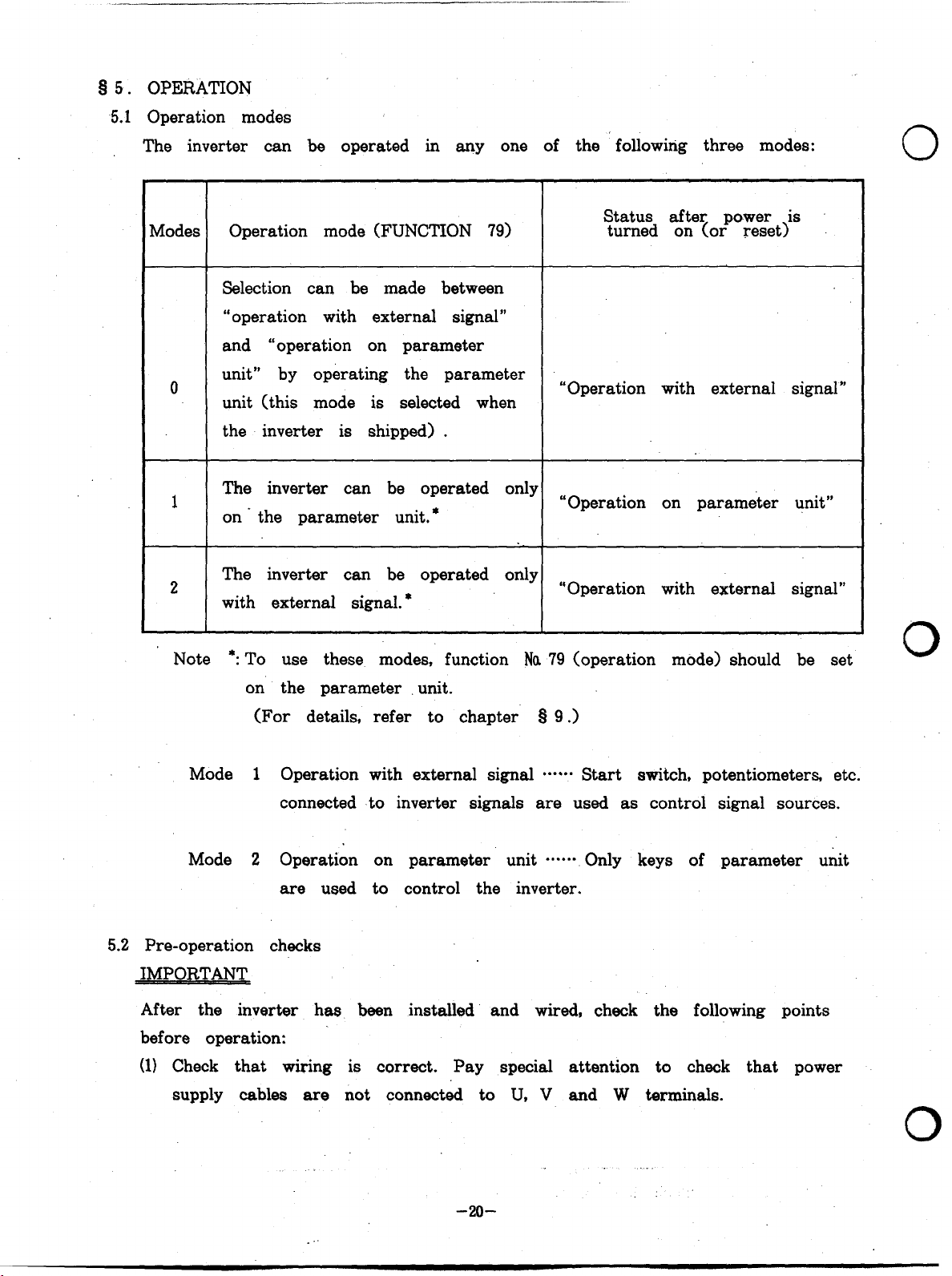

8 5. OPERATION

5.1 Operation modes

5.2 Pre-operation checks

5.3 Pre-operation settings and adjustments

5.4 Check points at test operation

8 6.

MAINTENANCE AND. INSPECTION

6.1 Caution for maintenance and inspection

6.2 Inspection points

improper

should give you long, trouble free,

use and mis-operation might

read this manual carefully.

\

...............

...............

...............

...............

...............

...............

...............

...............

...............

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

...............

...............

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

...............

...............

6

6

6’

7

8

8

12

15

17

20

20

20

21

24

27

27

27

Page 3

_--

.._-*

--.

.’

6.3 Method of measuring main circuit voltage;

current and output power

6.4 Measuring instrument, selection and usage

6.5 Transistor modules and diode modules

6.6 Parts replacement

Q 7. TROUBLESHOOTING

7.1 Troubleshooting

7.2 Protective functions

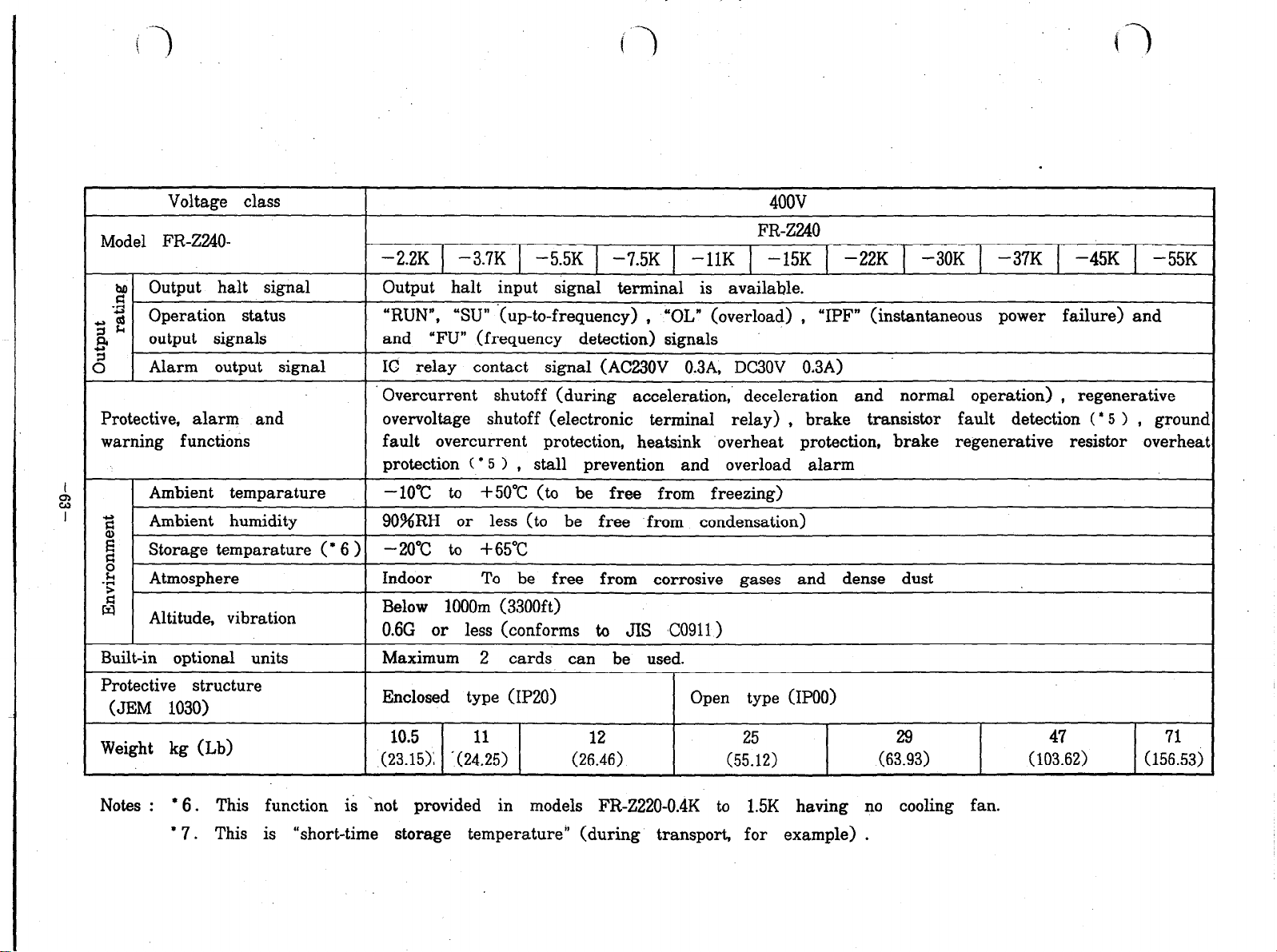

Q 8: SPECIFICATIONS

8.1 Block diagram

8.2 Terminals

8.3 Standard specifications

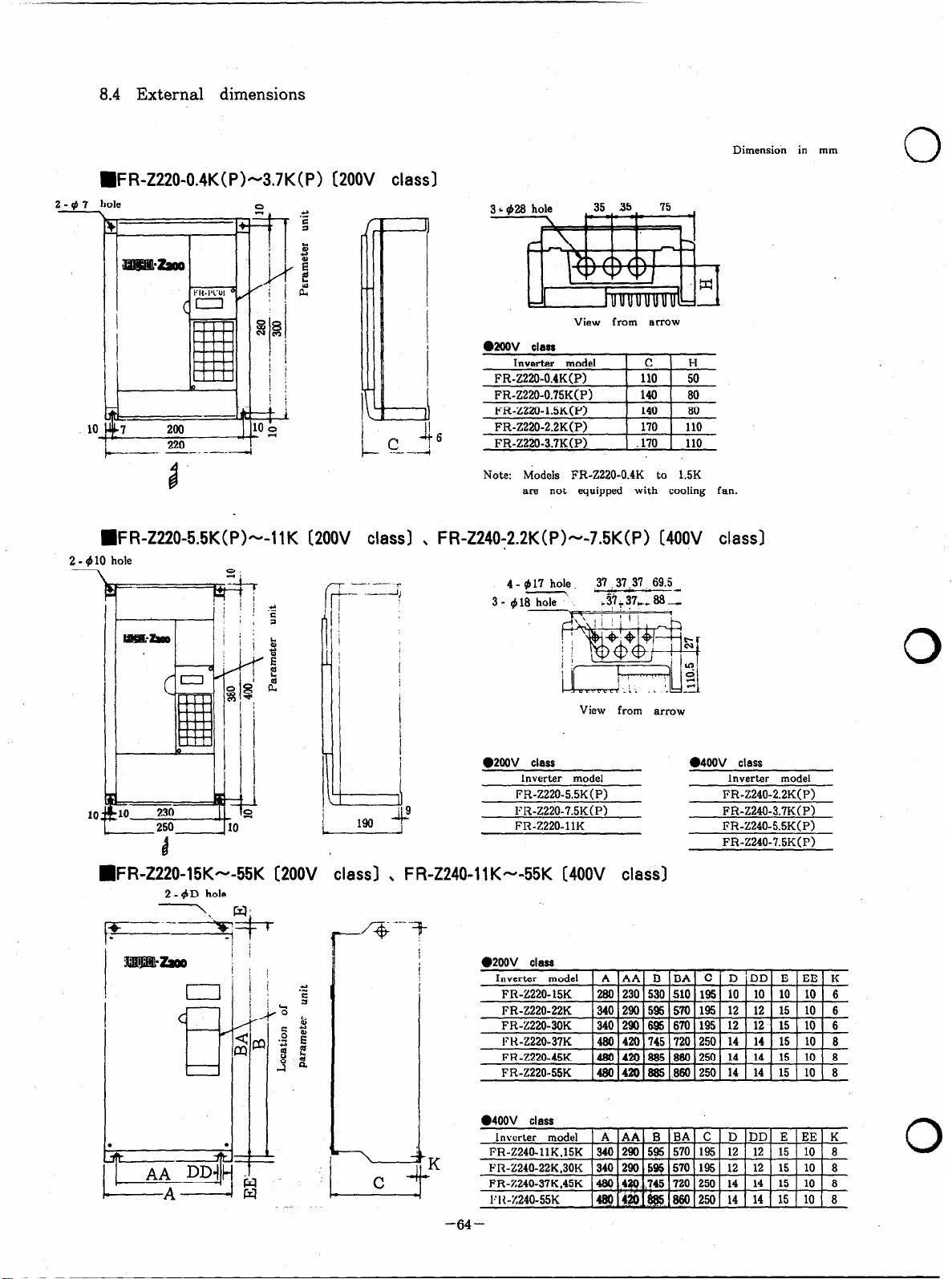

8.4 External dimensions

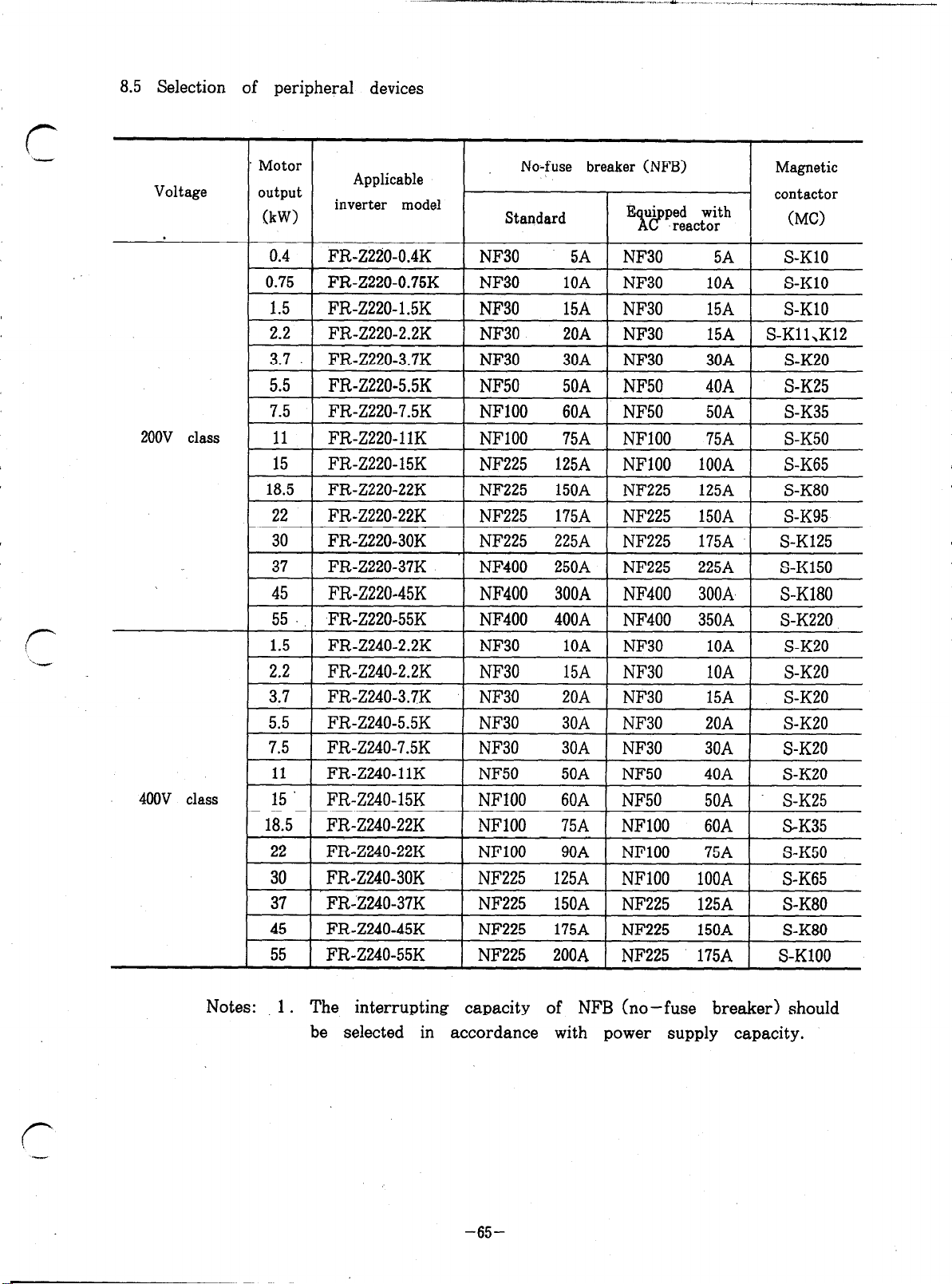

8.5 Selection of peripheral devices

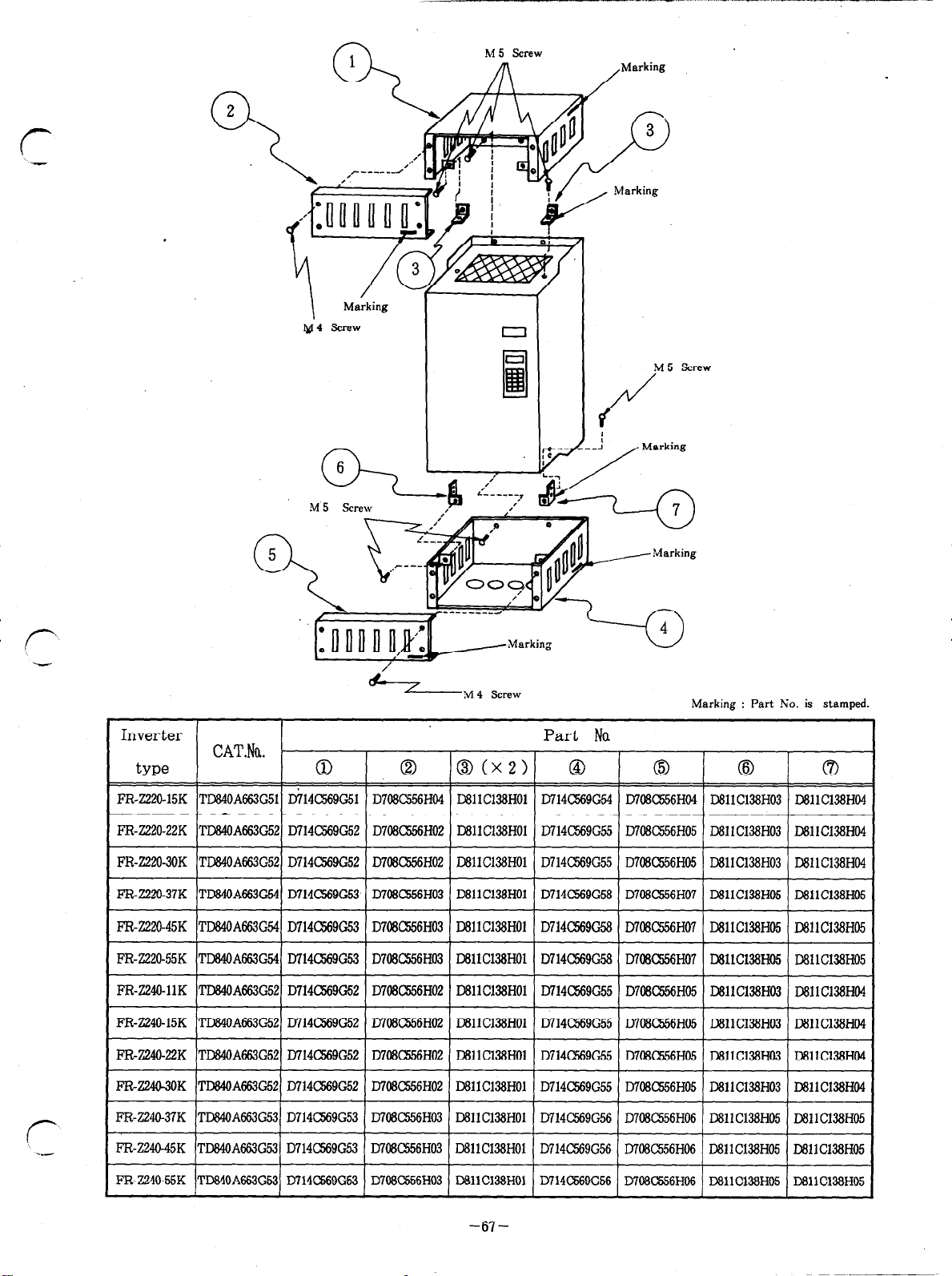

8.6 Drip shield kit

. .

8.7 Overload protection

.................. 51

................ 51

...

..... . ... . ... ..... ‘31

...............

............... 36

............... 38 -’

............... 46

.... ..*........ 46

...............

................ 53

............... 58

...............

............... 65

.

.

...............

............... 68

34

44

64

66

0

r PARAMETER UNIT

Q 1.. INSTALLATION

8 2. OUTLINE OF FUNCTIONS

1 Q 3. FUNCTION KEY DESCRIPTIONS

Q 4. OPERATION

4.1 Operation modes

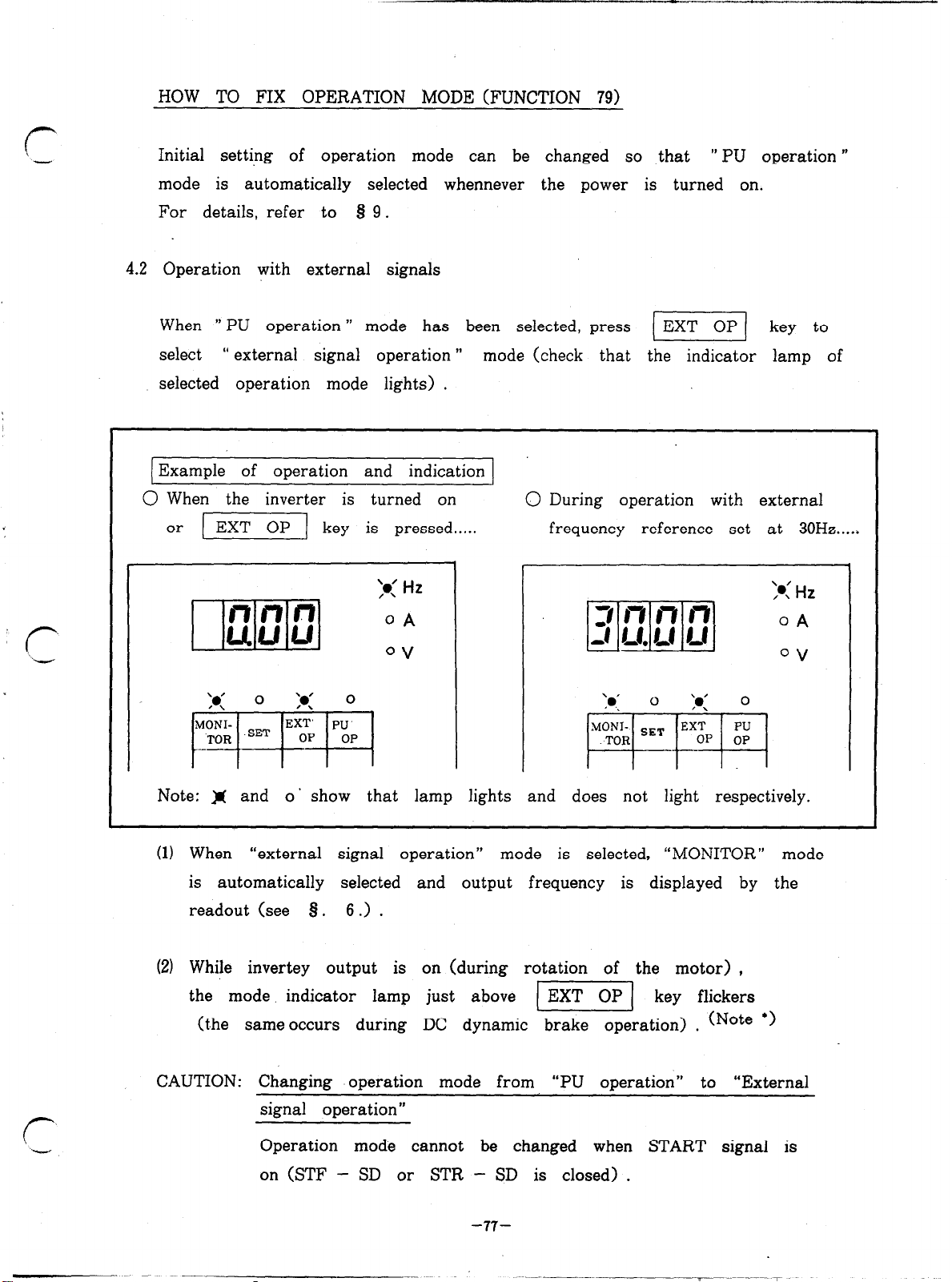

4.2 Operation with external signals

4.3 Operation with PU

4.4 Common setting errors

see also Page 92

Q 5. SETTINGS OF CONTROL VARIABLES (PARAMETERS)

5.1 Control functions and setting method

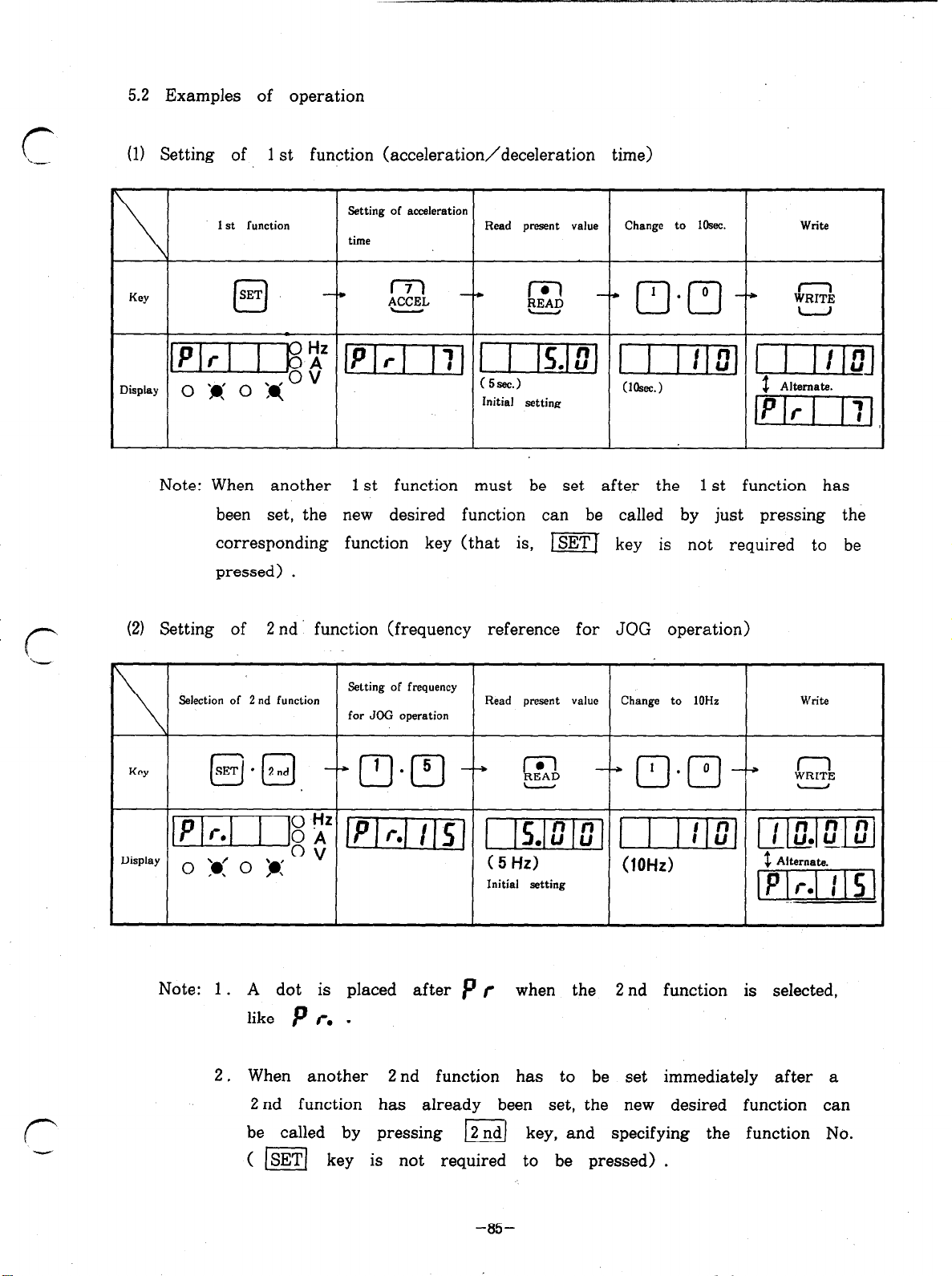

5.2 Examples of operation

. .

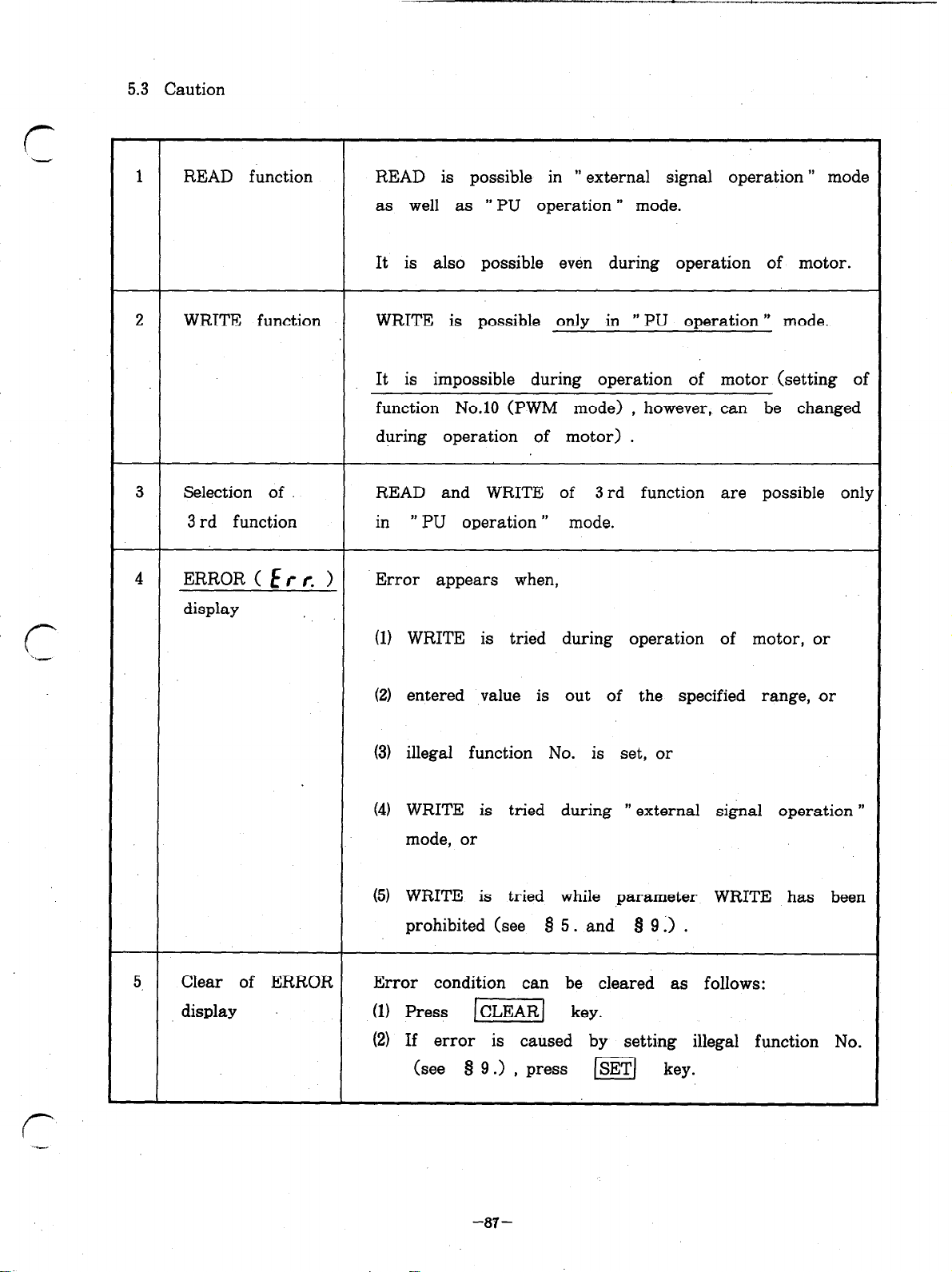

5.3 Caution (iIlega1 settings)

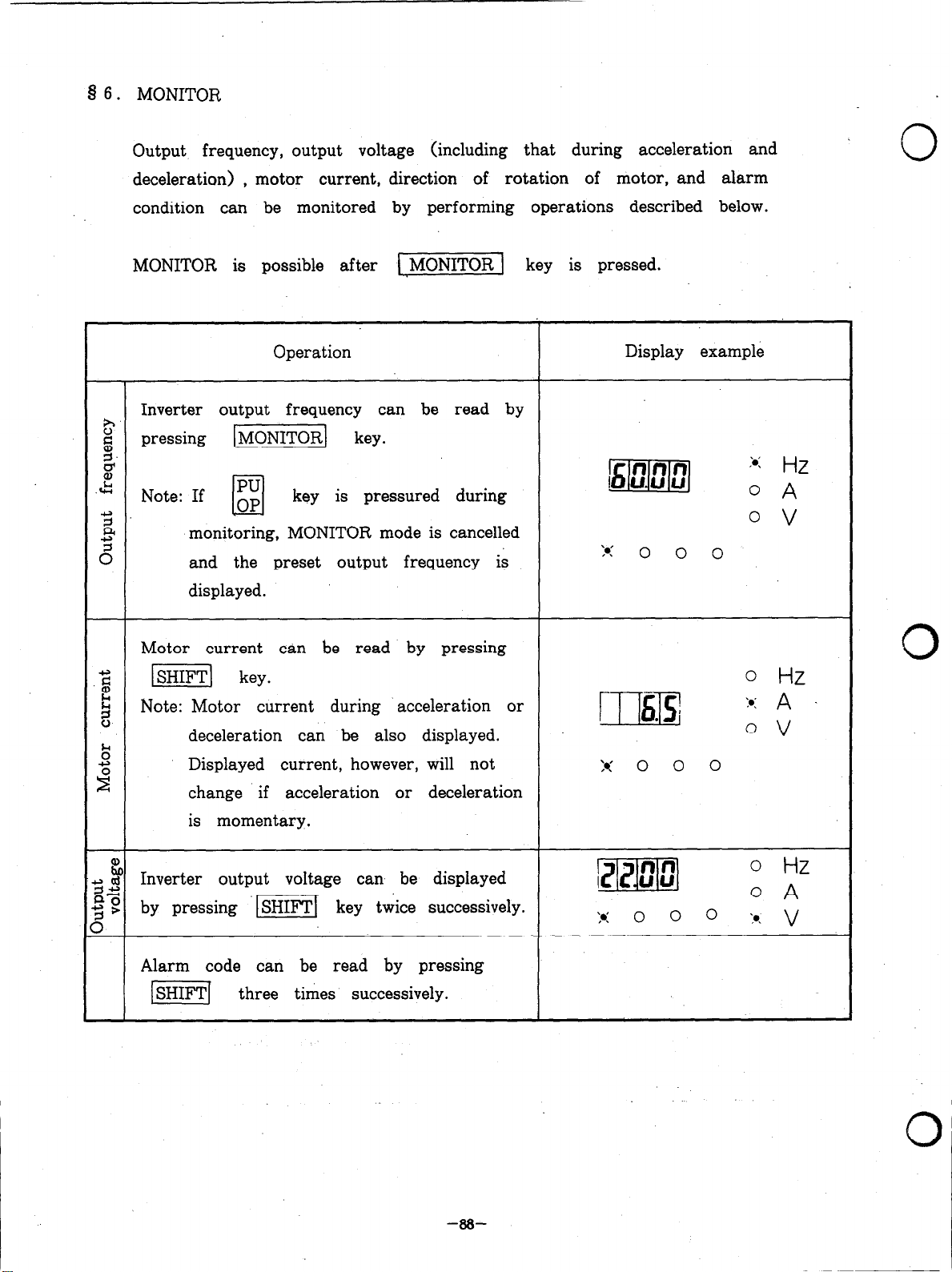

8 6. MONITOR

$3 7. DISPLAY

7.1 Alarm display

7.2 Indicator lamps

7.3 Characters appearing in readout

9 8. LIST OF FUNCTIONS NUMBERS

..I

. .

. .

‘,

.,.’

.I

. . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . 72

. . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . 76

....... . ....... 76

............... 77

............... 78

. . . . . . . . . . . . . . .

: . . . . . . . . . . . . . . 83

.: . . . . . . . . . . . . . 83

. . . . . . .i. . . . . . .

. . . . . . . . . . . . . . . 87

.’

. . . . . . . . . . . . . . .

. . . . . . ...*. :...

. . . . . . . . . . . . . . .

. . . . . . * . . . . 1.;.

,,..,..........

. . . . . . . . . . . . . . .

I

Q

81

85

88

92

92

93

93

0

94

Page 4

(-

‘-was-

g 9. DETAILS OF EACH FUNCTION

8 10. PARAMETER UNIT SPECIFICATIONS

§ll. EXTERNAL DIMENSIONS AND CABLE DETAILS

. . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

112

113

Page 5

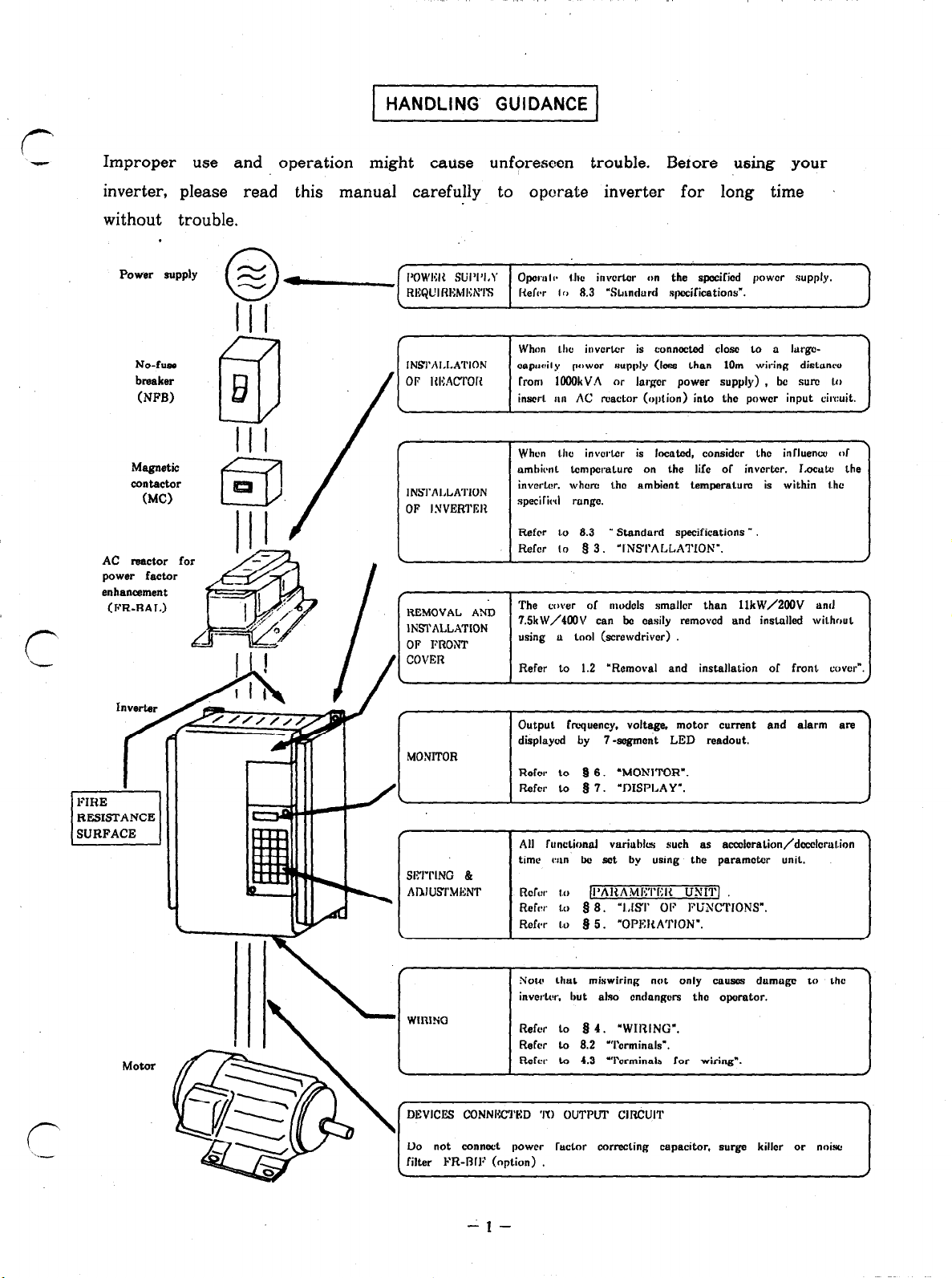

1 HANDLING GUIDANCE 1

Improper use and operation might cause unforeseen trouble. Betore using your

inverter, please read this manual carefully to operate inverter for long time

without trouble.

No-fuse

breaker

(NPB)

Magnetic

contactor

(MC)

AC reactor for

power factor

enhancement

,

INSI’ALLATION

OF I.VVERTRIZ

Rl?MOVAL AND

INSI’ALLATION

OF PRONT

MONITOR

When the icvcrtcr is connected close LO a lurgc-

capwily lwwcr supply (Ins than 1Om wiring distonw

lrom IOOOkVA or lorgcr power supply) , bc sure 1.0

inscrl. an AC reactor (option) inlo Lhc power input ciwuit.

When the invortcr is located, coasidcr the in&mu, 111

ambirnt temperature on the life of invcrtcr. I.ocutc the

invcrlcr. whcrc the ambient temperaturn is within l.hc

speGic~d range.

Refer

I -

1.0 8.3

Refer lo 93. ‘lNSThLLA1’ION”.

The cover of models smallcr than llkW/2OOV and

7SkW/4OOV can be easily removed and installed without

using u LOOI (screwdriver)

Refer to 1.2 ‘Removal and installation of front cover”.

Output frequency, voltage, motor current and alarm are

dbplaycd by 7-segment LED readout.

Rdcr LO 9 6. ‘MONlTOR”.

Rofcr to 8 7. “DISPLAY”.

” Standard specifications .

/

7

J

A

Mom

time wn bc set by using the paramctcr unit.

Not+ that mixwiring not only ~1~80s damogc to the

invcrtrr, but also cndongers the operator.

Refer lo I) 4. ‘WIRING”.

Refer LO 8.2 “Terminals’.

Refer to 4.3 “Terminals Ior wiring”.

‘DEVICES CONNlGI’I’E:D ‘I’0 OUTPUT CIRCUIT

Do not connect power Tactor correcting capacitor, surbw killer or n&c

filter FR-RIP (oplion) .

\.

\

J

Page 6

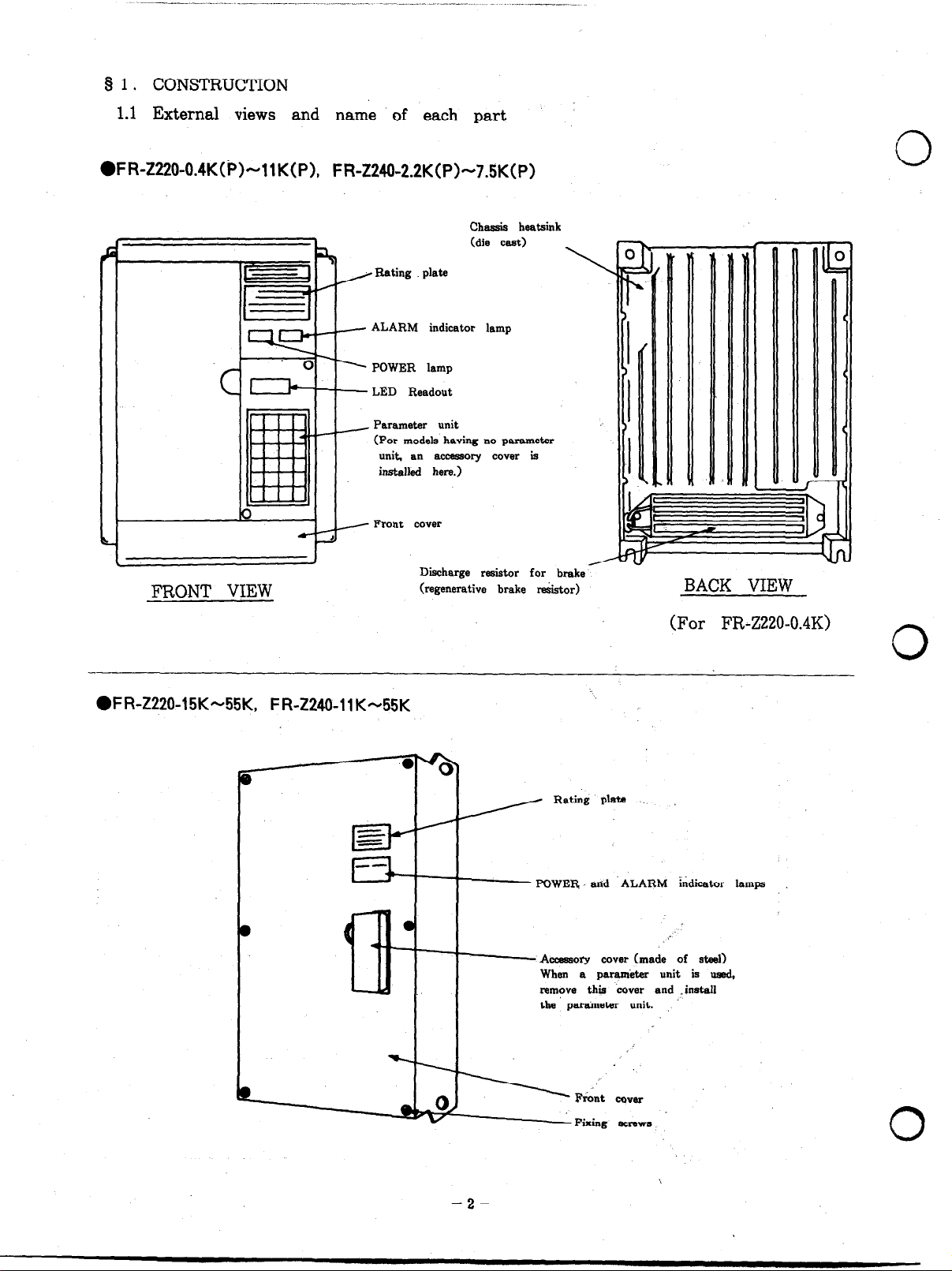

8 1. CONSTRUCTION

1.1 External views and name of each part

.FR-2220-0.4K(~)-11K0, FR-Z240-2.2K(P)-7.5KCP)

Chassis heatsink

(die cast)

, Rating plate

- ALARM indicator lamp

. POWER lamp

- LED Readout

- Parameter unit

(For models having no parameter

unit. an accessory cov*r is

installed hem.)

~~ -

FRONT VIEW

Discharge resistor for brake

(regenerative brake r&i&or)

0

\f--

BACK VIEW

l

FR-Z220-15K-55K, FR-Z240-llK-55K

(For FR-Z220-0.4K)

3

- POWER. atid ALARM indicator lamps

- A-ory cover (made of steel)

When a parameter unit is used,

remove this cover and .instaU

the paraineter unit.

0

Page 7

f-

/

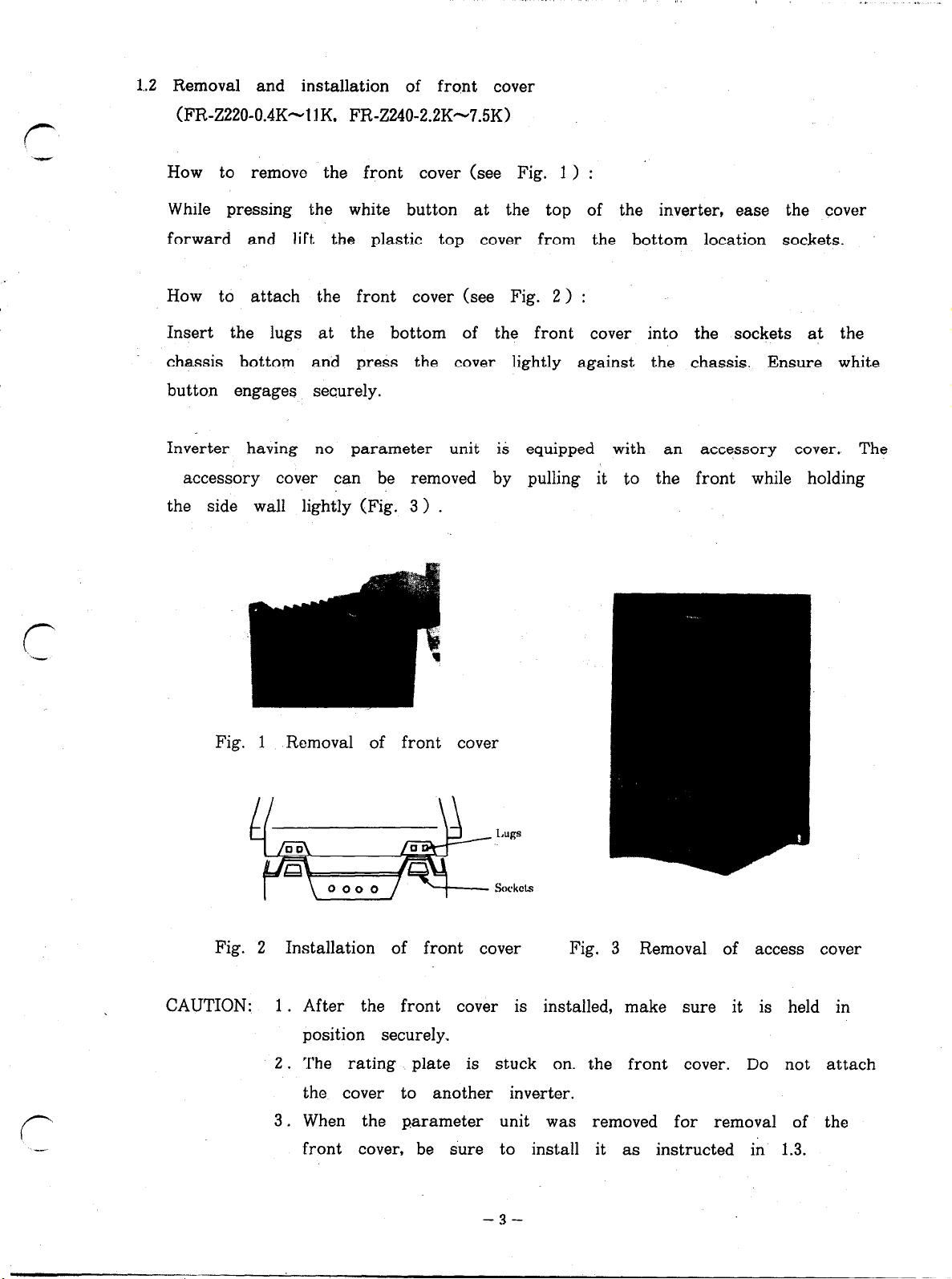

1..2 Removal and installation of front cover

(FR-Z220-0.4K--11 K, FR-Z240-2.2K-7.5K)

How to remove the front cover (see Fig. 1 ) :

While pressing the white button at the top of the inverter, ease the cover

. . . ..3 .

forward and lift the plastic top cover

from the bottom location sockets.

How to attach the front cover (see Fig. 2 ) :

Insert the lugs at the bottom of the front cover into the sockets at the

chassis bottom and press the cover lightly against the chassis. Ensure white

button engages securely.

Inverter having no parameter unit is

equipped with an accessory cover. The

accessory cover can be removed by pulling it to the front while holding

the side wall lightly (Fig. 3 ) .

Fig. 1 Removal of front cover

Fig.

2 Installation of front cover

Fig. 3 Removal of access cover

CAUTION: 1 . After the front cover is installed, make sure it is held in

position securely,

2, The rating plate is stuck on. the front cover. Do not attach

the cover to another invertor.

3. When the parameter unit was removed for removal of the

r

--.

front cover, be sure to install it as instructed in 1.3.

-3-

Page 8

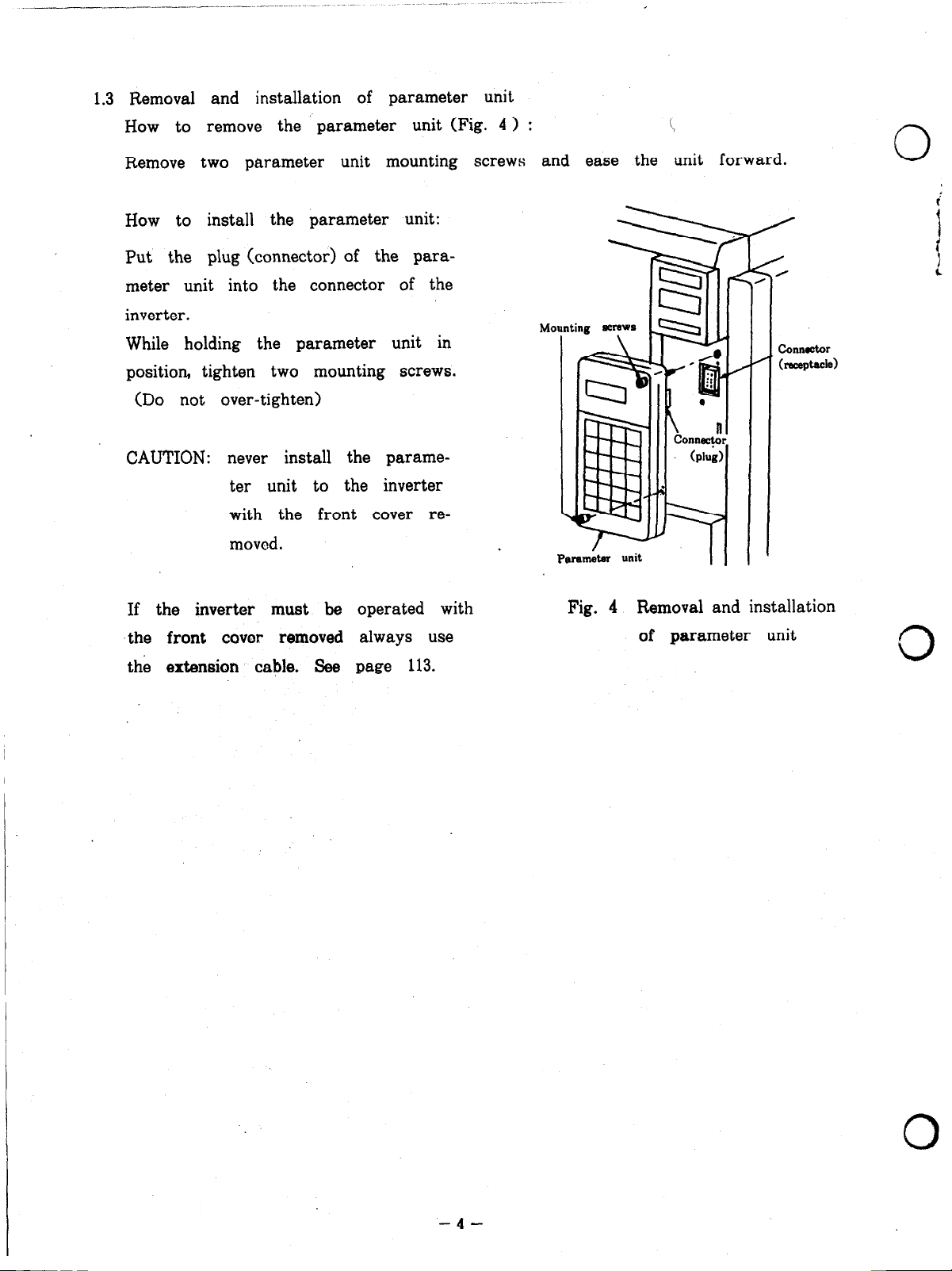

1.3 Removal and installation of parameter unit

How to remove the parameter unit (Fig. 4 > : i

Remove two parameter unit mounting screws and ease the unit forward.

How to install the parameter unit:

Put the plug (connector) of the para-

meter unit into the connector of the

inverter.

While holding the parameter unit in

position, tighten two mounting screws.

(Do not over-tighten)

CAUTION: never install the parame-

ter unit to the inverter

with the front cover removed.

If the inverter must be operated with

‘the front covw removed always use

the extension cable. See page 113.

Connector

hc%ptacle)

Fig. 4 Removal and installation

of parameter unit

0

-4-

0

Page 9

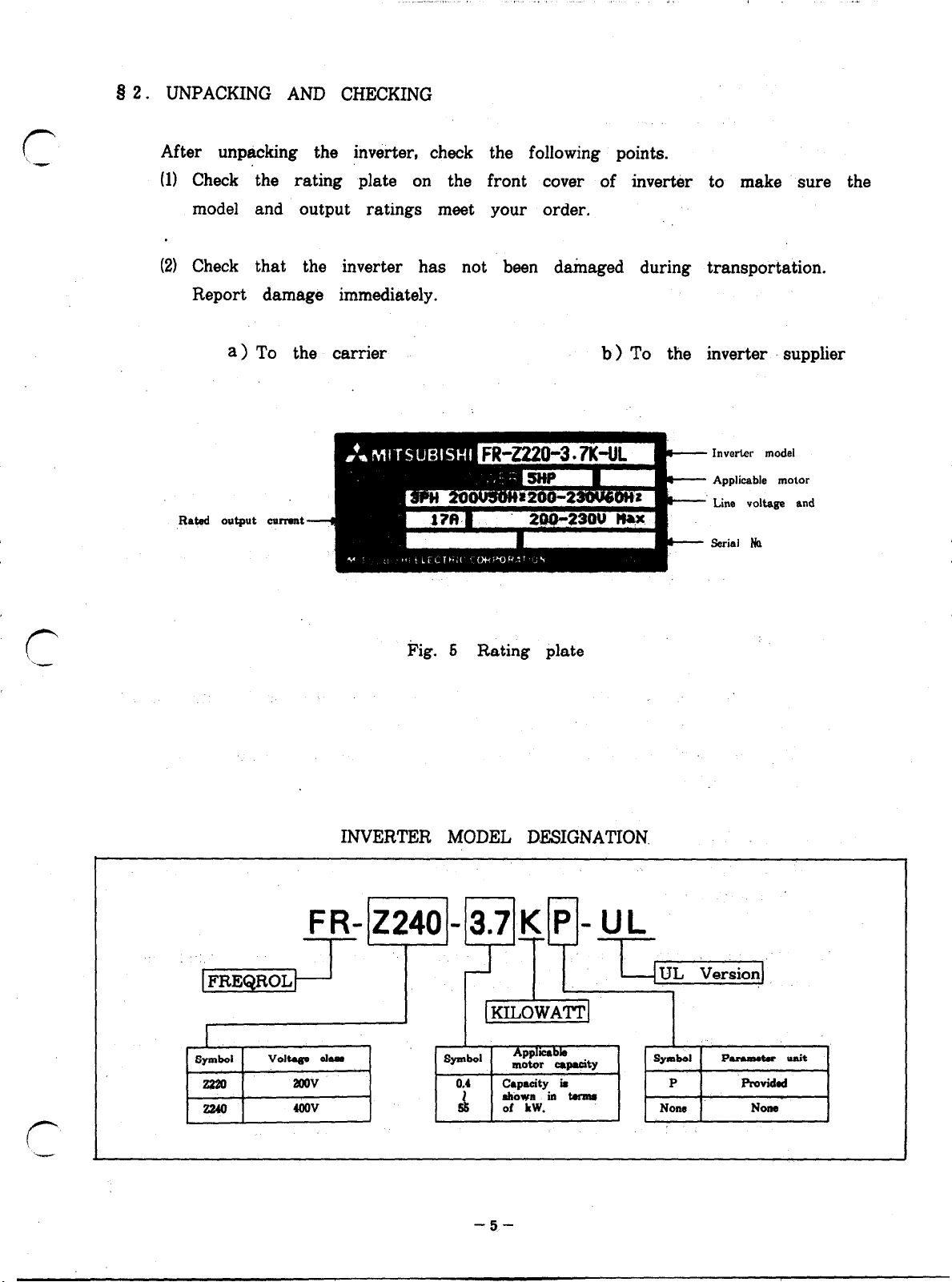

b 2. UNPACKING AND CHECKING

After unpacking the inverter, check the following points.

(11 Check the rating plate on the front cover of inverter to make sure the

model and output ratings meet your order.

(21 Check that the inverter has not been damaged during transportation.

Report damage immediately.

a > To the carrier b > To the inverter supplier

Invc&r model

Applicable motor

Line voltage and

Serial k

pcz@iJ-

I

SylllbOl

zm

2240

Volta@ clam

2OOV 0.4

4OOV 55 of LW. NOM

Pig. 5 Rating plate

INVERTER MODEL DESIGNATION.

FR-224003.7KP-UL

L < yI+-%q

KILOWATT

SpllbOl

Appl=bb

motor c8pacity

capacity k

akoun in Wnm

SyUlbOI

P Providad

ParalMtw unit

Nona

-5-

Page 10

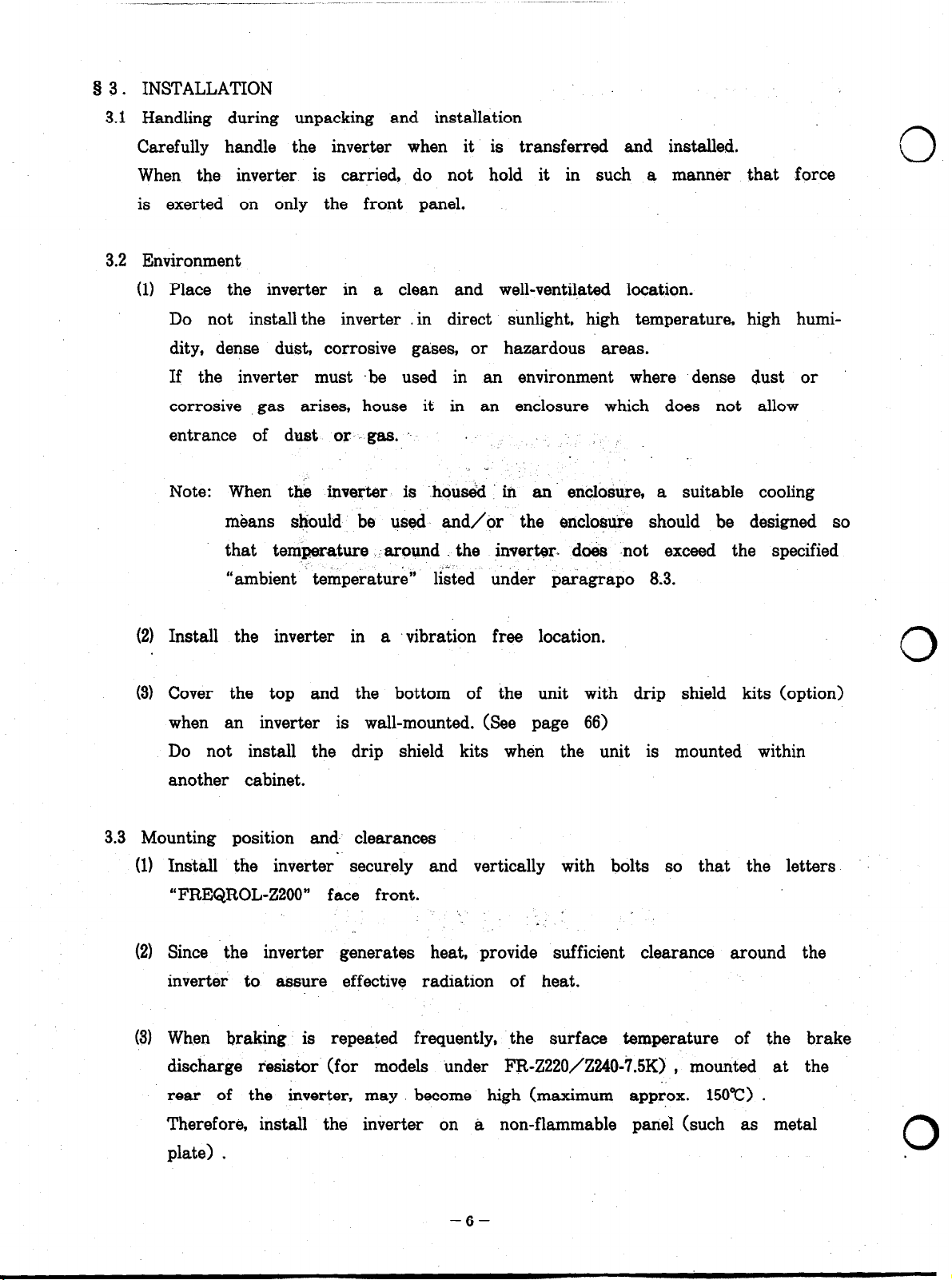

8 3. INSTALLATION

3.1 Handling during unpacking and installation

Carefully handle the inverter when it is transferred and installed.

When the inverter is carried, do not hold it in such a manner that force

is exerted on only the front panel.

3.2 Environment

(1) Place the inverter in a clean and well-ventilated location.

Do not install the inverter . in direct sunlight, high temperature, high humidity, dense dust, corrosive gases, or hazardous areas.

If the inverter must .be used in an environment where dense dust or

corrosive gas arises, house it in an enclosure which does not allow

entrance of dust or gas. ..

Note: When the inverter is ..hous&d : in an enclosure, a suitable cooling

means should be used and/or the enclosure should be designed so

that temperature . around the inverter. do& not exceed the specified

“ambient t temperature“ listed under paragrapo 8.3.

(2) Install

(31 Cover the top and the bottom of the unit with drip shield kits (option)

when an inverter is wall-mounted. (See page 66)

Do not install the drip shield kits when the unit is mounted within

another cabinet.

3.3 Mounting position and- clearances

(1) Install

“FREQROL-Z200” face front.

th e inverter in a vibration free location.

th e inverter securely and vertically with bolts so that the letters

.

0

(2) Since the inverter generates heat, provide sufficient clearance around the

inverter to assure effective radiation of heat.

(31 When braking is repeated frequently, the surface temperature of the brake

discharge resistor (for models under FR-Z220/Z240-?.5K) , mounted at the

rear of the inverter, may become high (maximum approx. 150°C) .

Therefore, install the inverter on a non-flammable panel (such as metal

plate) .

-6-

.,

p

Page 11

.,-

r

‘W

--- ----

1Wmm ( 4 ‘1 or mGre

0

FREQROL-2200

1OOmm (4”) or more 1OOmm (4”) or more

Fig. 6 Minimum clearance around inverter

CONSIDERATION FOR AMBIENT TEMPERATURE

The life time of the inverter depends on

I?

or mot-c

spaces to aaun spaces to aaun

good cooling effect. good cooling effect.

I

i

In*lw* In*lw*

Air stream r Air stream r

2 2

AA,: AA,:

1: / 1: /

/ /

0 0

/ /

/ /

/ /

I I

/ /

the ambient temperature. The ambient

temperature should not exceed the permissive value.

50mm (2’ 1

5Omm

(2’

)

Moamwing point

Measure the ambient temperature at the

positions shown in figure A.

Fig. A

Permissive ambient temperature: +5O”c (+ 122°F)

3.4 Inverter housed in enclosure

When two or more. inverters are housed in an enclosure equipped with a

fan, locate each inverter and fan so that the maximum cooling efficiency

can be achieved.

I--"1

i

Iawtter 1

II

lpeD i

r‘

(GOOD) (WRONG)

Two or more inverters housed in an enclosure

-?-

(GOOD)

(WRONG)

Location of ventilating fan

Page 12

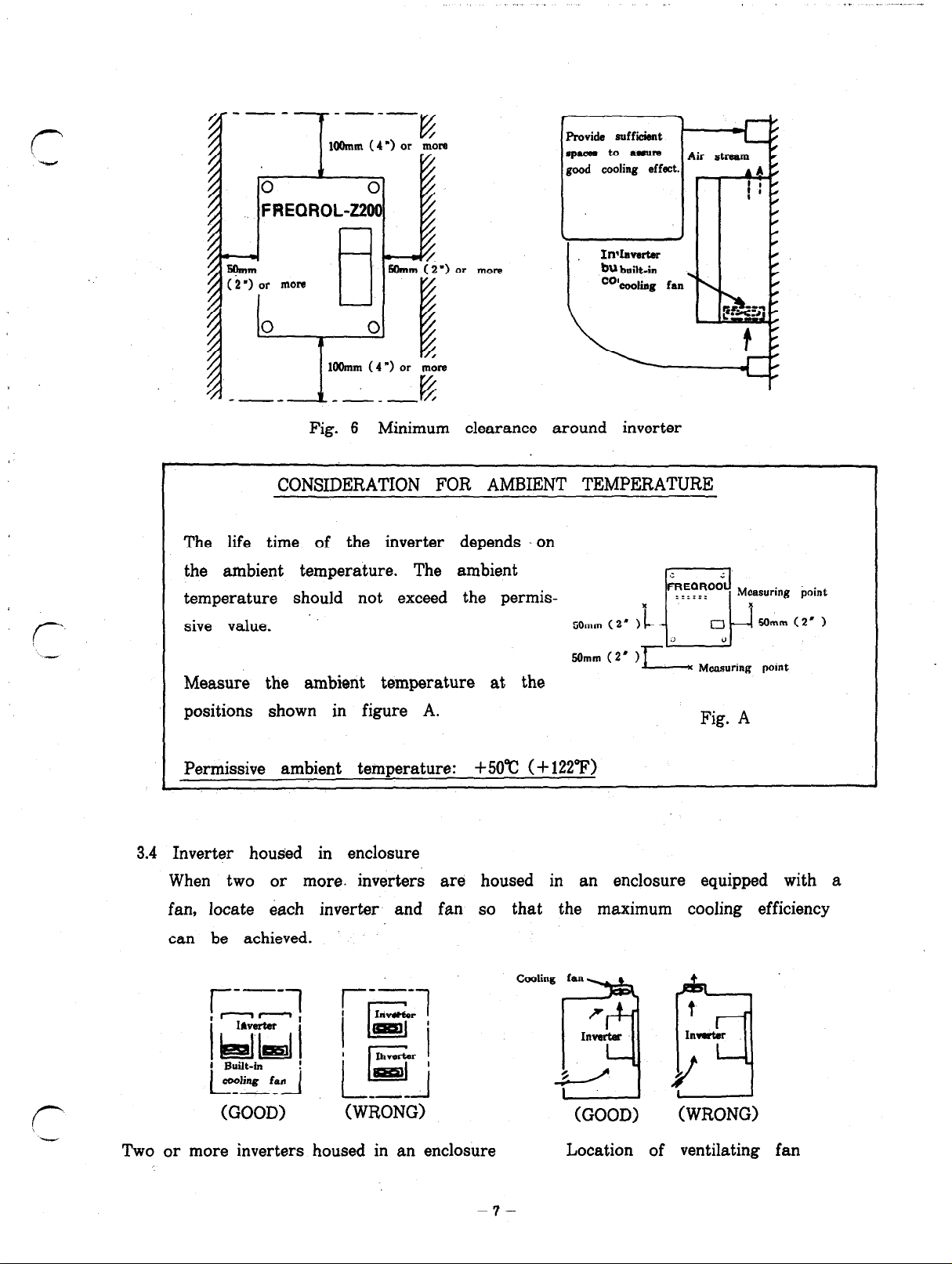

Q 4. WIRING

4.1 Main circuit.

(1) Connection to power source and motor

For models FR-%220-0.4K to 1.5K

For models larger than

PR-Z220-2.2K and Z240-2.2K

I I I

Power supply

* When the inverter is connected as

clockwise, as viewed from the load side, with “forward” (normal) command

signal.

shown above, the motor runs counber-

Power supply

0

IMPORTANT

Notes: 1 .

-._ _ ..-

--.- _ . --

------

2. The inverter is not equipped with a” means to. protect persons

-from .acci&nts due to leakage. ‘. .

DCJ not

directly because such miswiring n~ay cause not only damage

the inverter, but also danger to the operator.

The same danger ..may be caused by backflow of current if the

invorter is connected as shown below. To prevent backflow, MC 1

and MC 2 .should be interlocked with each other (electrically as

well as m&hanically) .

Pay attention so that cables do not touch the. chassis, etc.

‘connect power supply to the output terminals (II, V, W)

L __...____. _. ..__ ---. .-- ---- .--

Lo

-._ . _._.- -

-..-_

:’

_ .-

0

‘Be’ sure to earth the inverter with the earth terminal.

- 8 --

0

Page 13

r

3. If magnetic contactor (MC) is not inserted on the inverter primary

side and a power failure occurs for a short time (instantaneous

power failure) ,

time as the power source is restored.

If it is likbly that this automatic restart may cause damage to

the machine or persinnel, connect .(MC> so that restart is possible

only after’ safety is verified.

For a better understanding, refer to the following diagrams and

descriptions:

Para. 4.3 “Wiring diagram”

Para. 8.2 “Terminals for wiring”

Para: 8.1 “Block diagram”

the inverter will restart automatically at the same

(-

-.I

- CAUTION FOR WIRING OF PERIPHERAL DEVICES

When MC, NFB and other peripheral devices are being connected to the

inverter, cover the inverter to prevent wire chips, screws and other foreign

matter from entering into the inverter through slits and other openings of

the inverter.

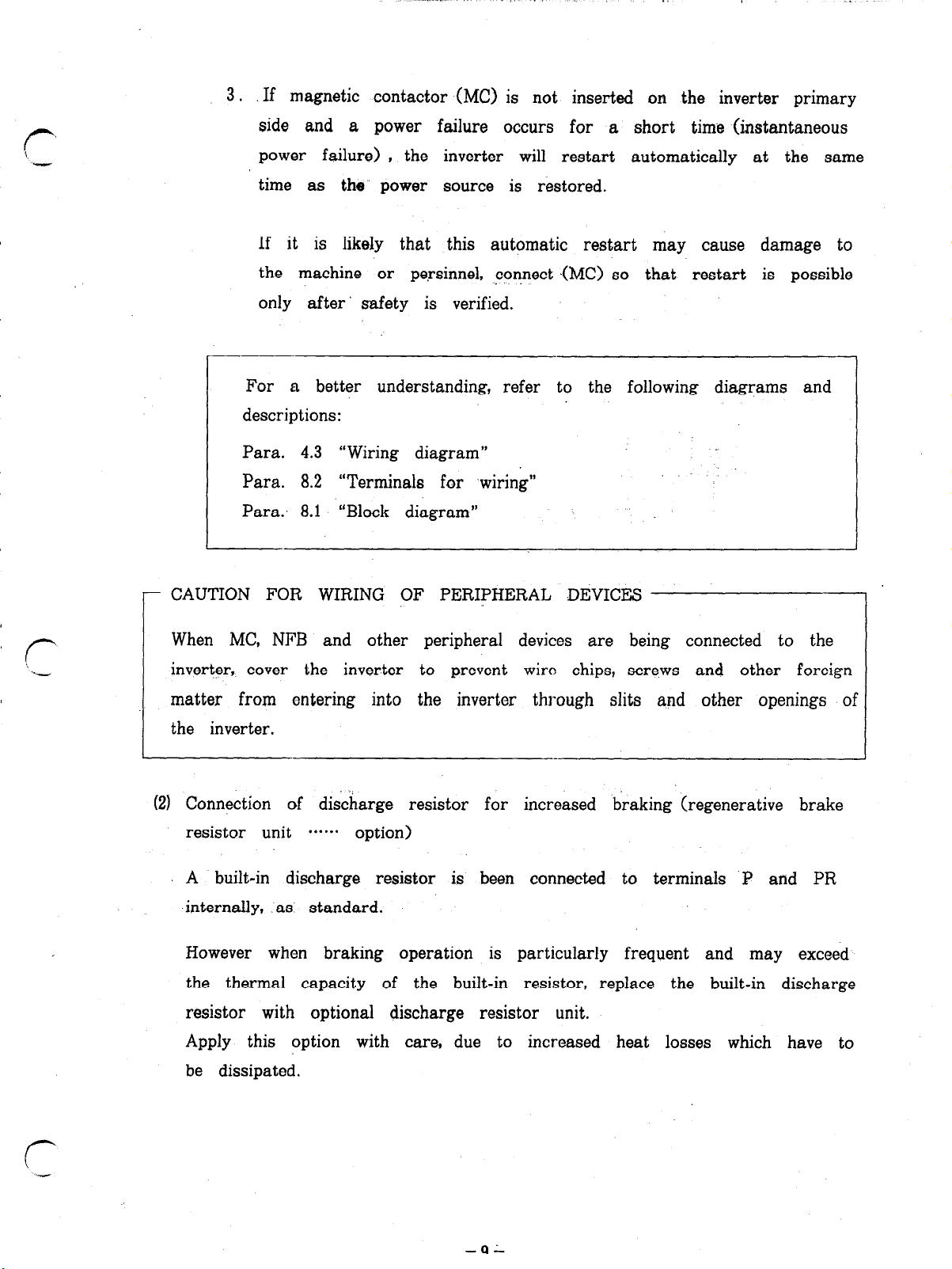

(21 Connection of discharge resistor for increased braking (regenerative brake

resistor unit ****** option)

A built-in discharge resistor is been connected to terminals P and PR

-internally, .as standard. ’

However when braking operation is particularly frequent and may exceed

the thermal capacity of the built-in resistor, replace the built-in discharge

resistor with optional discharge resistor unit.

Apply this option with care, due to increased heat losses which have to

be dissipated.

- 9.’

Page 14

Do not connect any resistor other than those specified by us, to

terminals P and PR.

-

--* I3

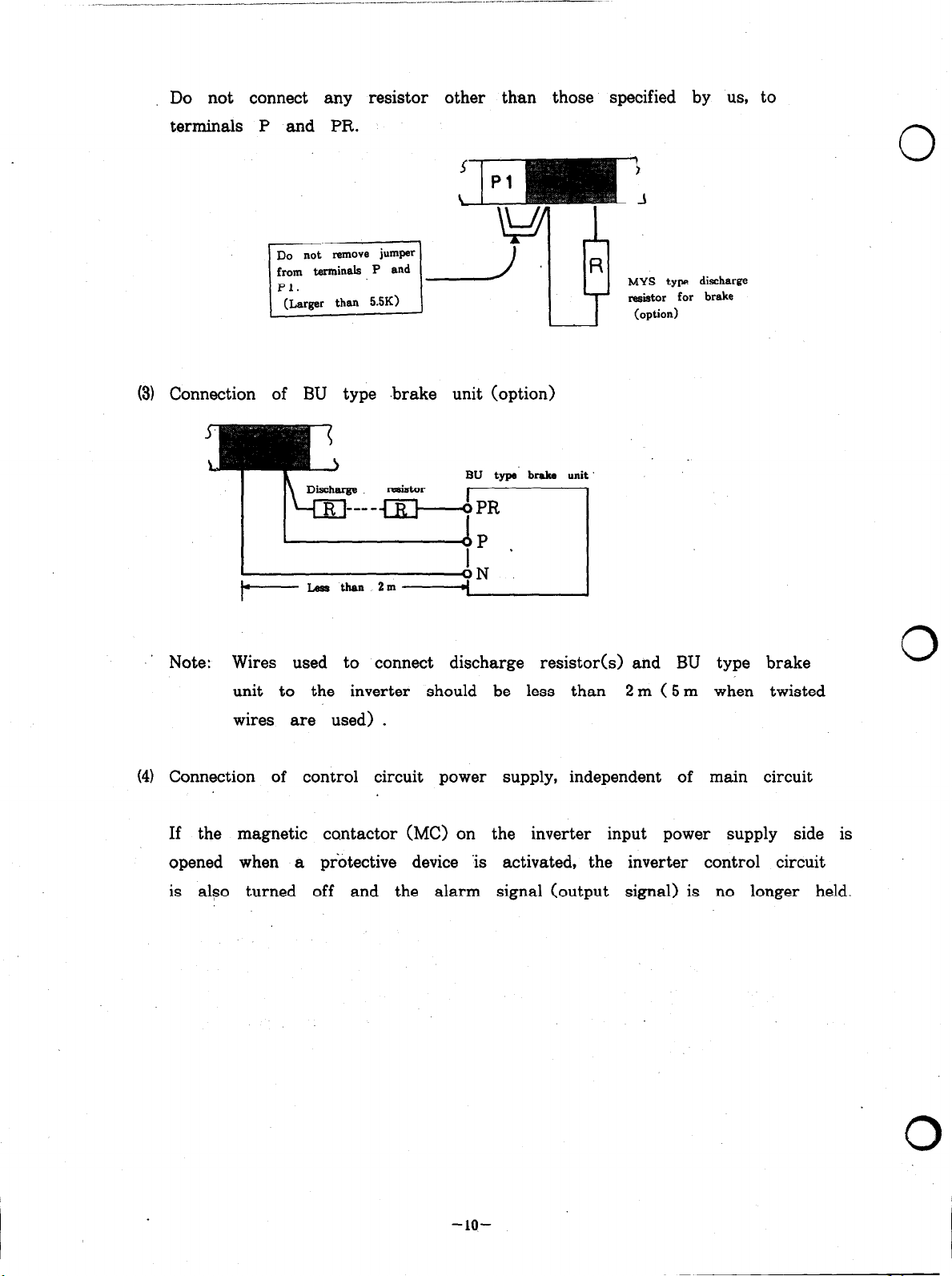

(3)

Connection of BU type .brake unit (option)

BU type braka unit

\

Yh

LT

?

>

-J

MYS

type

resistor for

(option)

0

discharge

brake

.’ Note: Wires used to connect discharge resistor(s) and BU type brake

unit to the inverter should be less than 2 m (5 m when twisted

wires are used) .

(41 Connection of control circuit power supply, independent of main circuit

If the magnetic contactor (MC) on the inverter input power supply side is

opened when a protective device is activated, the inverter control circuit

is also turned off and the alarm signal (output signal) is no longer held.

0

I

0

-lO-

Page 15

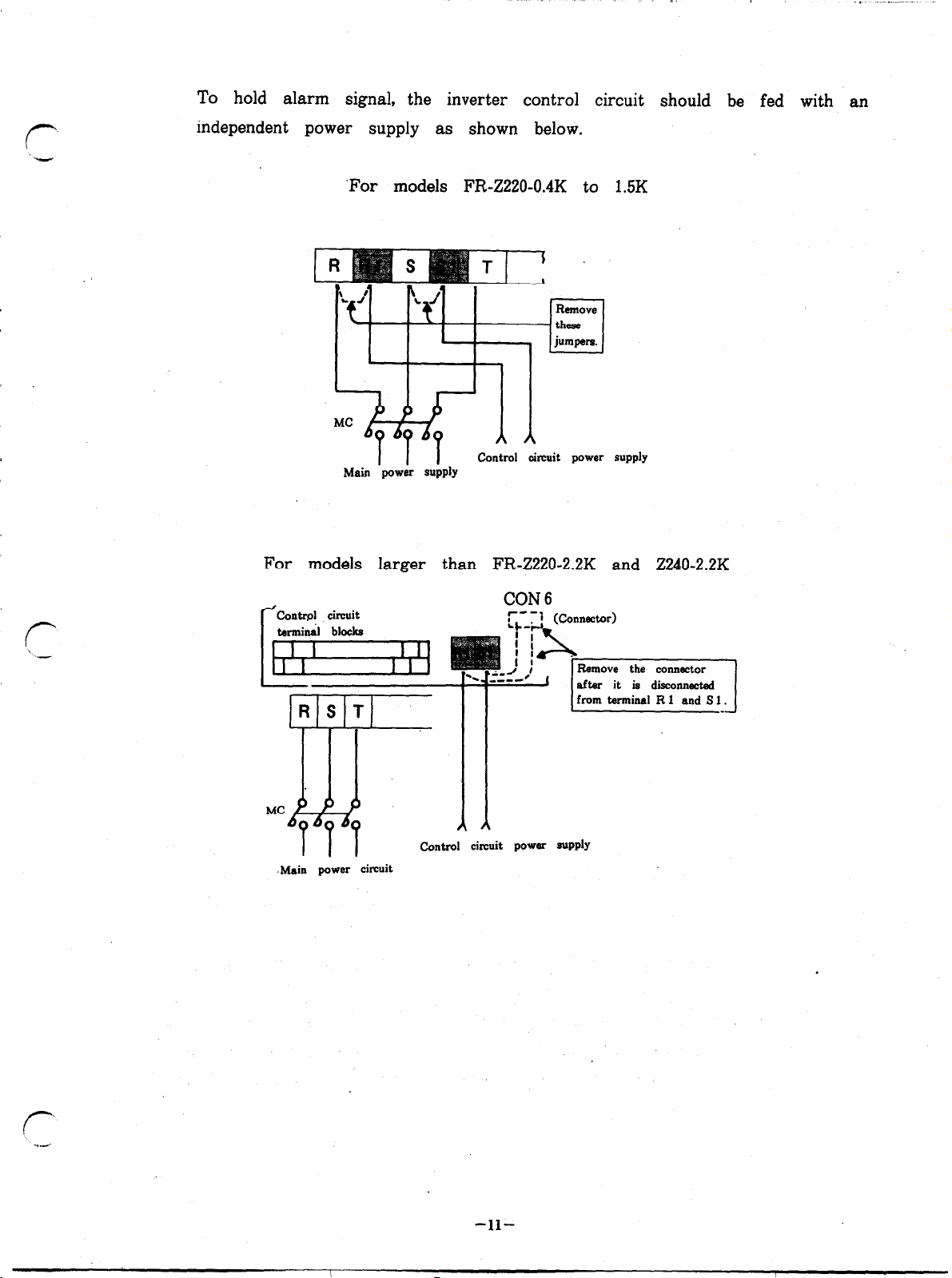

To hold alarm signal, the inverter control circuit should be fed with an

independent power supply as shown below.

r

‘v

‘For models FR-Z220-0.4K to 1.5K

RrmOW

these

jumpers.

Main ‘povJk

control oircuit

power supply

For models larger than FR-Z220-2.2K and Z240-2.2K

CON

6

from

tennina RI and Sl.

Control circuit power

.Main power circuit

SuPPlY

-ll-

Page 16

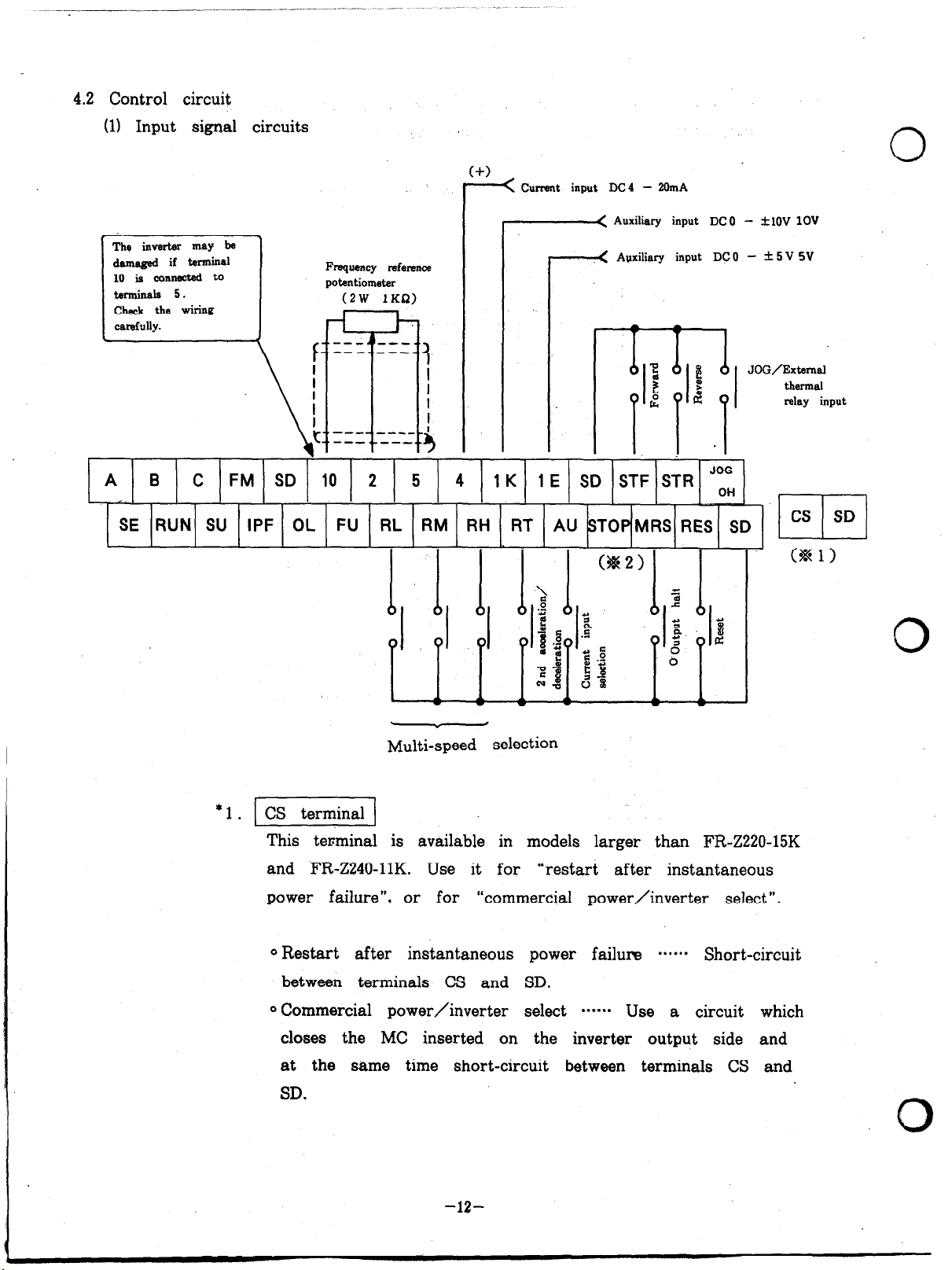

4.2 Control circuit

(1) Input signal circuits

0

c_( Current input DC4 - 20mA

-< Auxiliary input DC 0 - +lOV 1OV

darn4 if terminal

10 is connected to

Check the wiring

A B C FM SD 10 2 5 4

SE RUN SU IPF OL FU RL RM RH RT AU STOPMRS RES SD

Frequency reference

(2W 1KQ)

1 K 1 E SD STF STR JoG

___( Apxiliary input DC0 - f 5 V SV

CS SD

uzl

Multi-speed selection

This terminal is available in models larger than FR-Z220-15K

and FR-Z240-11K. Use it for

power failure”, or for

0 Restart after instantaneous power failure ****** Short-circuit

between terminals CS and SD.

0 Commercial power/inverter select ***-** Use a circuit which

closes the MC inserted on the inverter output side and

at the same time short-circuit between terminals CS and

SD.

“commercial power/inverter select “.

-12-

“restart after instantaneous

.O

Page 17

For details, refer to the technical information.

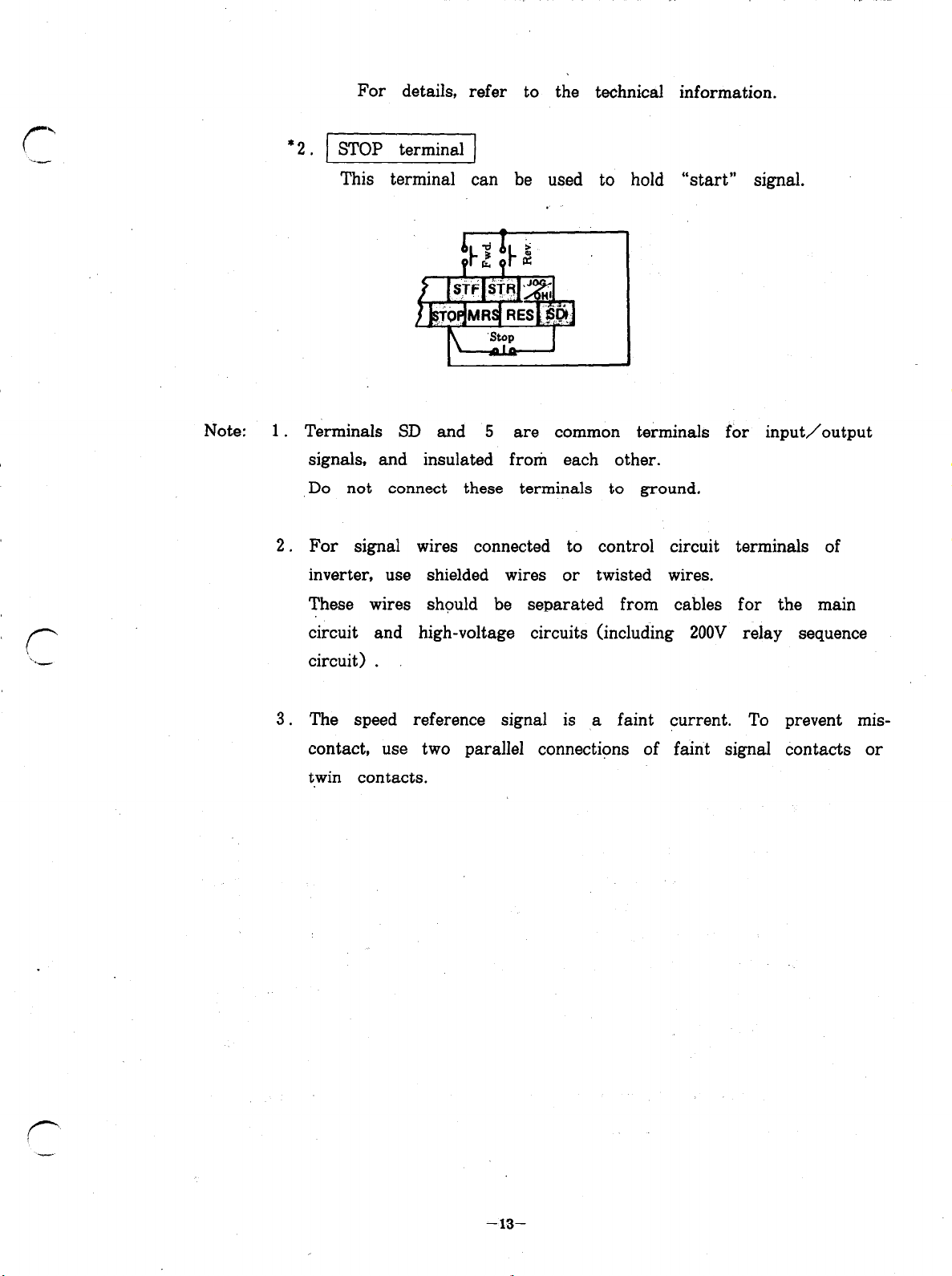

*2. STOP terminal

This terminal can be used to hold “start” signal.

1

’ f-

Note:

1 . Terminals SD and 5 are common terminals for input/output

signals, and insulated from each other.

,Do not connect these terminals to ground.

2. For signal wires connected to control circuit terminals of

inverter, use shielded wires or twisted wires.

These wires should be separated from cables for the main

circuit and high-voltage circuits (including 200V relay sequence

circuit) .

3. The speed reference signal is a faint current. To prevent miscontact, use two parallel connections of faint signal contacts or

twin contacts.

-13-

Page 18

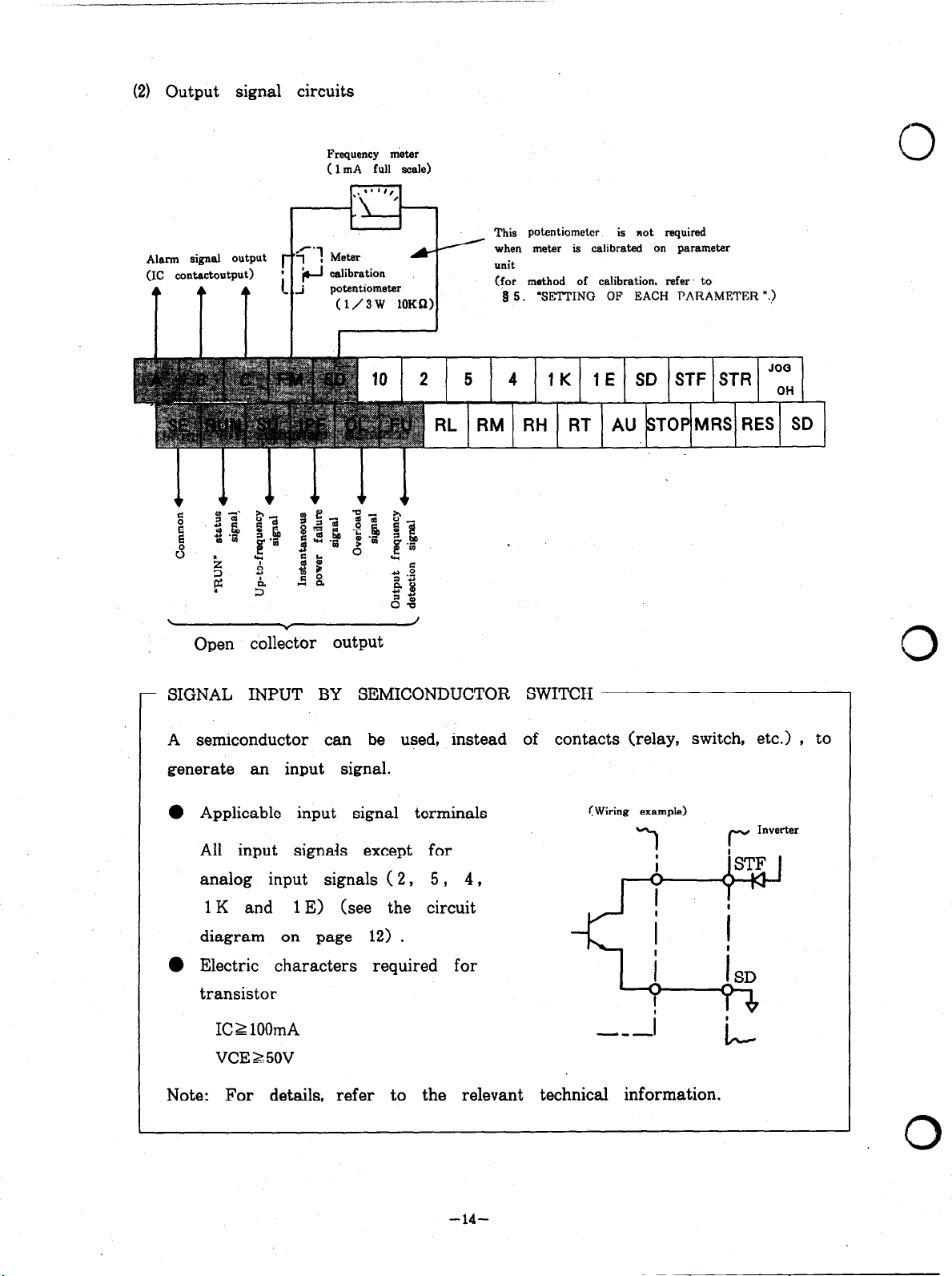

(21 Output signal circuits

Alarm signal output

(IC contactoutput)

.

Open collector output

Frequency nieter

( 1 mA full scale)

(1/3W lOKn>

Y

0

This potentiometer

when meter ie calibrated on parameter

(for method of calibration. refer. to

8 5. ‘SETTING OF EACH PARAMETER “.>

/

is not required

0

- SIGNAL INPUT BY SEMICONDUCTOR SWITCH

A semiconductor can be used, instead of contacts (relay, switch, etc.) , to

generate an input signal.

0 Applicable input signal terminals

All input signals except for

analog input signals ( 2, 5 , 4,

1 K and 1 E) (see the circuit

diagram on page 12) .

l

Electric characters required for

transistor

IC1 lOOmA

VCEZ 50V

Note: For details, refer to the relevant technical information.

(Wiring example)

A--

0

-14-

Page 19

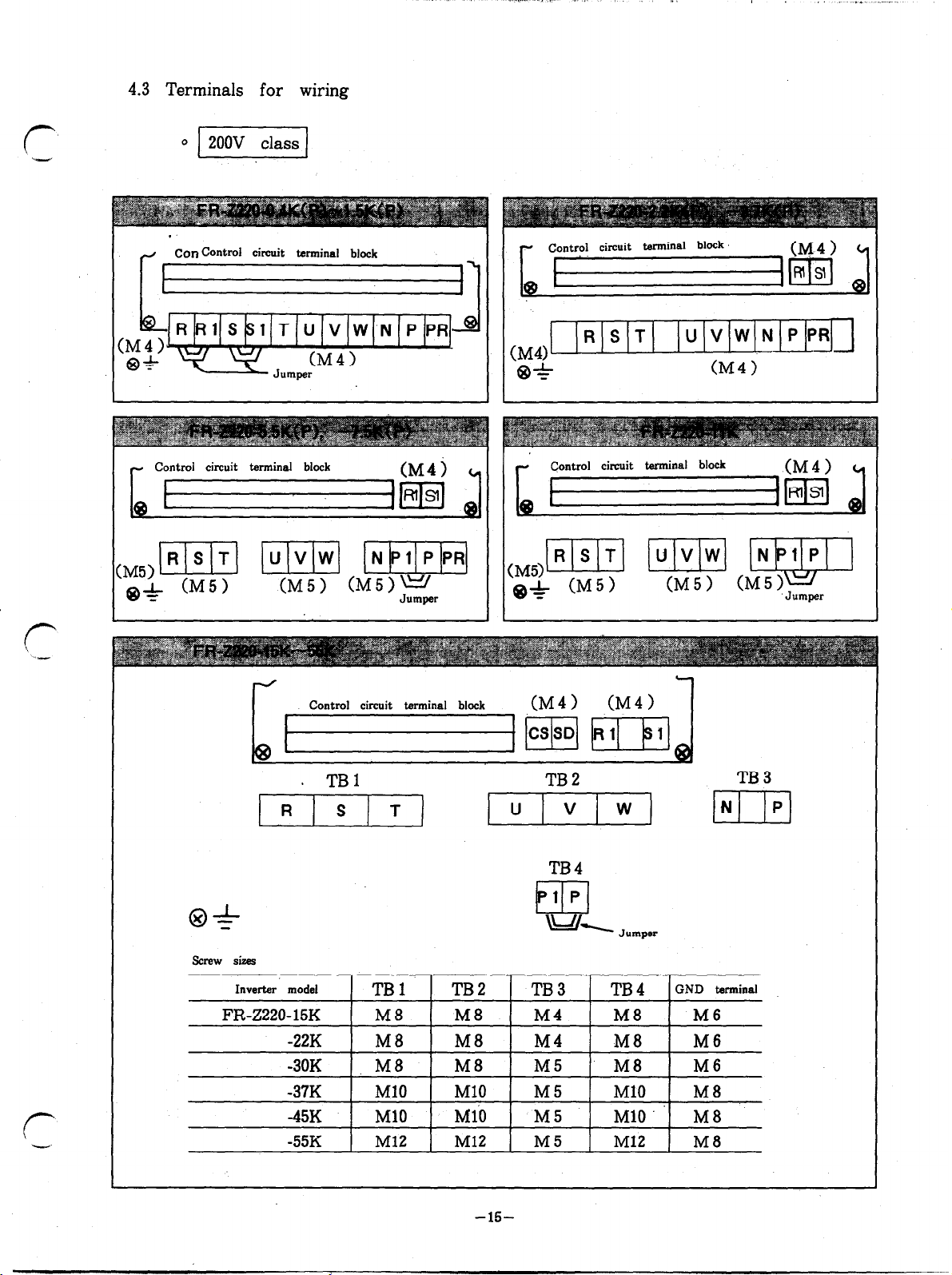

4.3 Terminals for wiring

Concontrd circuit terminal block

U VW N PPR

- Control circuit terminal block

Screw sizes

rc/

f=====jpqm

. TBl

Control circuit terminal block

(M51m w ,Mp

e+ CM51

v

(M4) (M4)

TB2

TB3

TB4

‘Jumper

Page 20

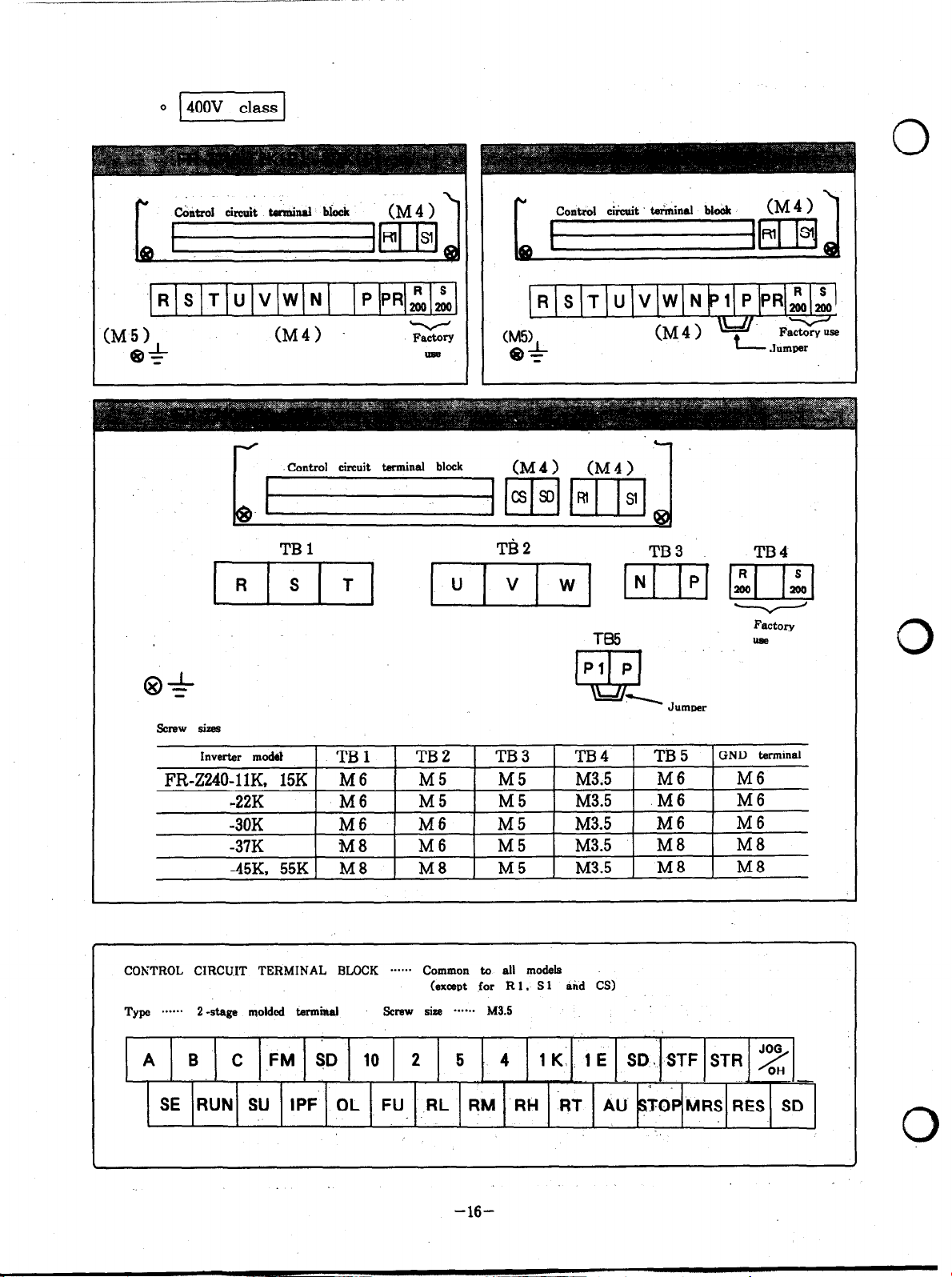

.RSTUVWN

PPRZA

R S ‘T U V W N 1 PPRz;i

CM51

e+

(M4)

J

-Control circuit tanninal block

TBl Tti2

screw sizes

Inverter model

TBl TB2 TB3

FR-Z240-llK, 15K M6

-22K M6 M5 M5

-3OK

-37K M8 M6 M5

-45K, 55K M8 M8 MS

Factory

use

(M5>

e+

(M4) (M4)

M 5

MS

M6 M6 MS

(M4)

c1

wc Faxse

TB3

TB4

TB5

M3.5 M6

M3.5 M6

M3.5 M 6

M3.5 M 8

GND terminal

M6

M6

M6

M8

M3.5 M8 M8

Jumper

TB4

Factory

ua?

0

CONTROL CIRCWT TERMINAL BLOCK ****+* Common to all models

(except

for Rl. Sl aid CS)

SE RUN SU IPF OL FU RL qM -RH -RT AU STOP

-16-

MRS RES SD

Page 21

(+-

-

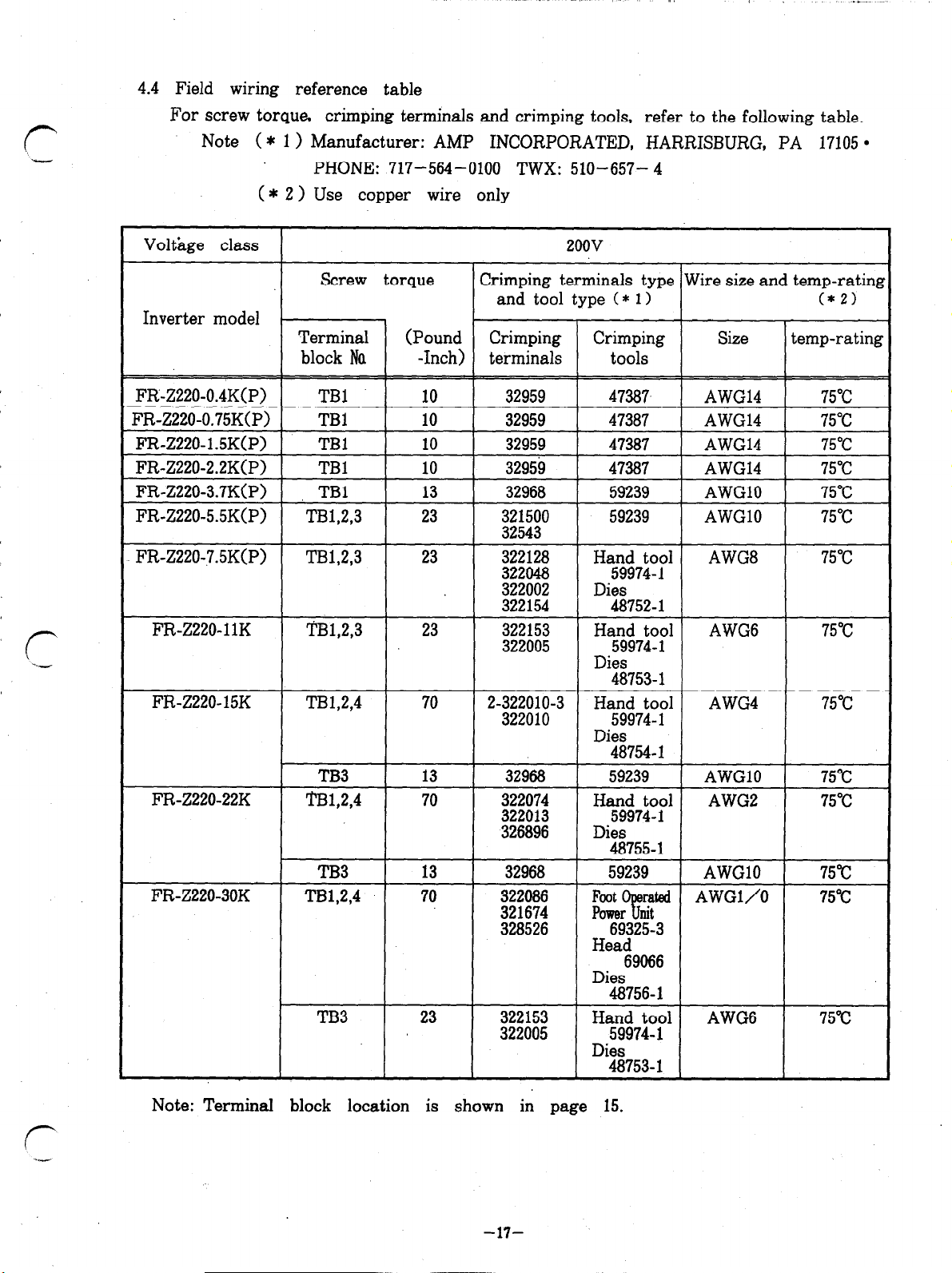

4.4 Field wiring reference table

For screw torque, crimping terminals and crimping tools, refer to the following table.

Note ( * 1) Manufacturer: AMP INCORPORATED, HARRISBURG, PA 17105

PHONE: 717-564-0100 TWX: 510-657- 4

( * 2 > Use copper wire only

Inverter model

l

FR-2220-15K

FR-2220-22K

FR-Z220-30K

Note: Terminal block location is shown in page 15.

TB1,2,4 70

TB3 13 32968 59239 AWGlO 75°C

TB1,2,4 70

TB3 13 32968 59239 AWGlO 75°C

TB1,2,4 70 EY: ;rr& 9 r$d AWGl/O 75°C

TB3 23 322153

2-;;;%;;-3 Hy9i70pl AWG4 75°C

48754- 1

E;; H%:7??

48755-l

328526 69325-3

Head

Dies

48756- 1

Hyg;70;l

322005

Dies

48753- 1

- Dies

AWG2 75°C

- 326896 Dies

69066

AWG6 75°C

-17-

Page 22

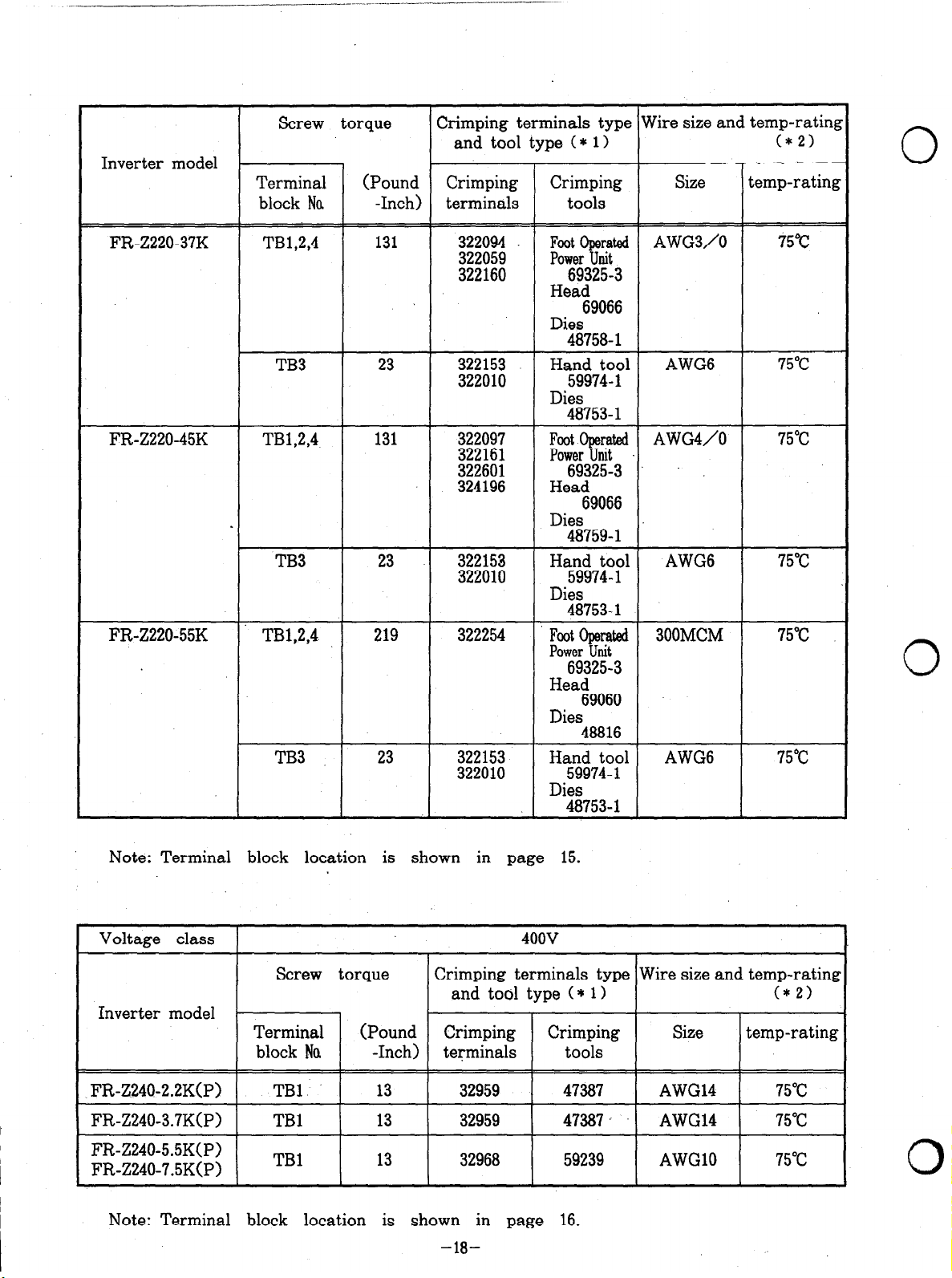

Inverter model

Screw torque

Terminal (Pound Crimping Crimping

block

Na

-Inch) terminals tools

Crimping terminals type Wire size and temp-rating

and tool type ( *

1)

(* 2)

0

Size temp-rating

FR-2220-37K

FR-Z220-45K TB1,2,4 131

FR-Z220-55K TB1,2,4 219

TB1,2,4

TB3 23

TB3 23

TB3

131

23

322094 Foot Operated AWGS/O 75°C

;E!

322153 AWG6 75°C

322010

Ei

322601 69325-3

324196 Head

E;

322254 Foot Operated 300MCM 75°C

Ei

Power Unit

69325-3

Head

69066

Dies

48758-l

Hygi70p1

Dies

48753- 1

Foot Operated AWG4/0

Power Unit

69066

Dies

48759-l

Hygi70y1 AWG6 75°C

Dies -

48753-l

Power Unit

69325-3

Head

69060

Dies

48816

Hygi70;l AWG6

Dies -

48753- 1

75°C

75°C

0

Note: Terminal block location is shown in page 15.

Inverter model

Note: Terminal block location is shown in page 16.

-18-

Page 23

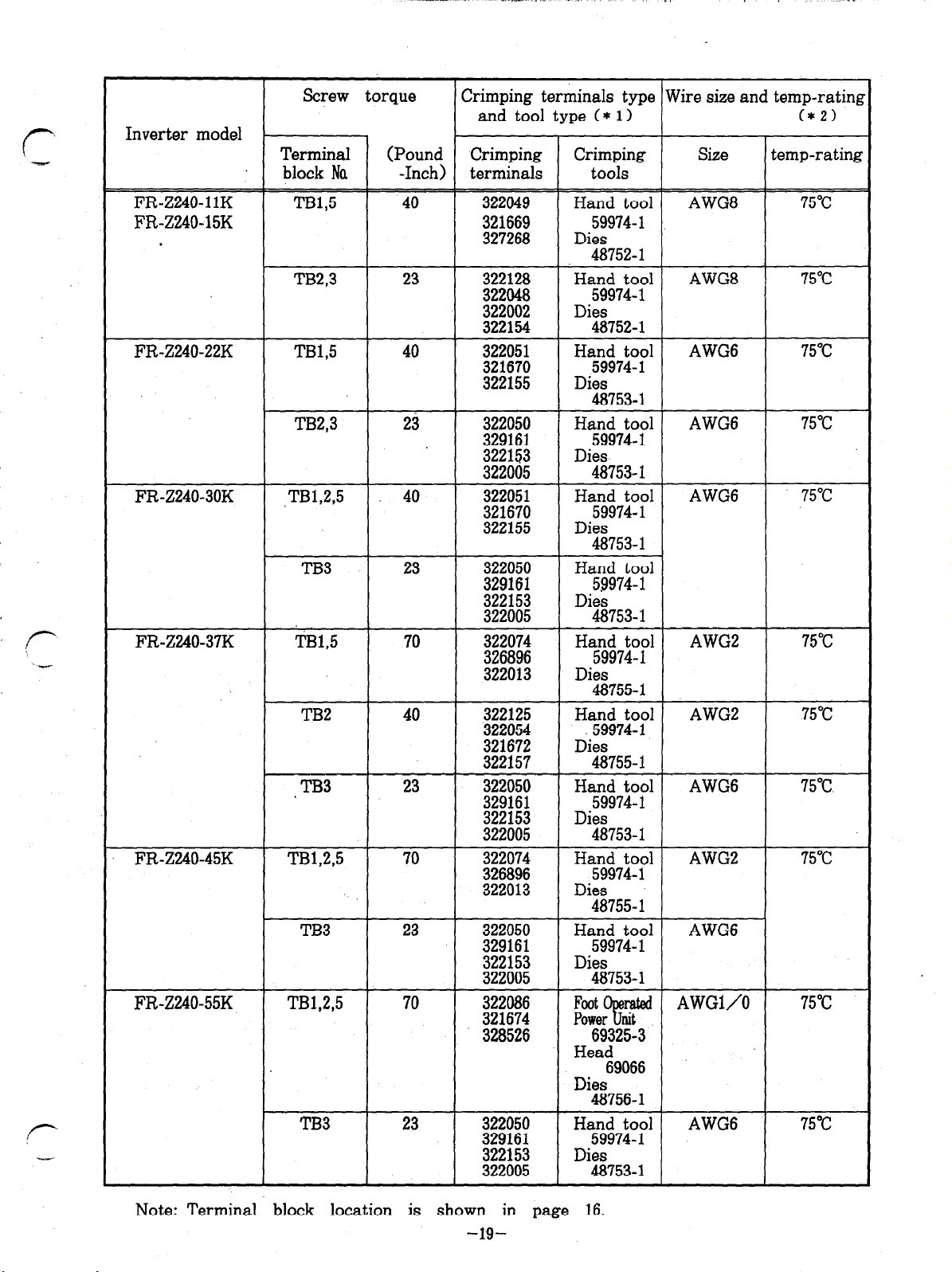

Inverter model

Screw torque

Crimping terminals type Wire size and temp-ratink

and tool type (*

Terminal (Pound Crimping

block

Na

-Inch) terminals tools

1)

(*2>

Crimping Size temp-rating

FR-Z240-11K TB1,5

40 322049 Hand tool AWG8

FR-ZZQO-15K

23

FR-Z240-22K

TB2,3

TB1,5 40

TB2,3 23

FR-Z240-30K ,TB1,2,5 40

TB3

FR-Z240-37K

TB1,5 70

TB2

?3

FR-Z240-45K TB1,2,5

TB3

FR-Z240-55K TB1,2,5

TB3

23

40

23

70

23

70

23

59974- 1

%E

Dies

48752- 1

Hand tool AWG8

Et!

59974-l

322002 Dies

322154

322051

48752-l

H”5”g&f;’

w Dies

48753-l

Hygi70~l AWG6

;I%

Dies

3;

322051

48753- 1

Hagngdg7F;l AWG6

%2 Dies -

48753-l

E%!

H”5”9d97;P’

Dies

;Ei;

E;i

48753- 1

Hyg;7~p1

322013 Dies

48755-l

EfE

7%7?P’

Dies -

x;

EE!i

322153

48755-l

“%$72’

Dies -

322005 48753-l

Ha;lgdgorl AWGZ

;;;:;;

322013 Dies -

48755- 1

Hsgngdg70yl AWG6

Ei!!

Dies

EE

48753-l

Foot rated AWGl/O

EE

77

Power nit

328526 69325-3

Head

69066

Dies

48756-l

Hand tool AWG6 75°C

!Ei!l

322153

322005

59974-l

Dies

48753-l

AWG6

AWG2

AWG2

AWG6

75°C

75°C

75°C

75°C

75°C

75°C

75°C

75°C

75°C

75°C

Note: Terminal block location is shown in page 16.

-19-

Page 24

Page 25

(2) Check that

(31 Check that h t s or -circuit and earth fault do not exist in the output circuit.

(4) Check that all screws, terminals and other fasteners. are tight.

CAUTION FOR INSULATION RESISTANCE TEST WITH MEGGER

th

ere is no short-circuit due to wire offcut, etc.

r

0 For insulation resistance test with megger, refer to Q 6 . 6.2, (3).

0 Never apply the test voltage to the control circuit terminals and across

the inverter terminals.

5.3 Pi-e-operation settings and adjustments

The inverter itself does not have control devices to set or adjust by operator,

(-

--

such as select switch and potentiometer. (As with previous models of FREQROL)

When settings (accelation/deceleration time, electronic thermal relay setting, etc.)

must be changed, the parameter unit (FR-PUO 1 > is used (for the initial settings,

refer to chapter

For methods of changing parameter setting, refer to the description “HANDLING

AND OPERATIGN OF PARAMETER UNIT”. (p. 69 - p. 113)

98.1.

r

-

-2l-

Page 26

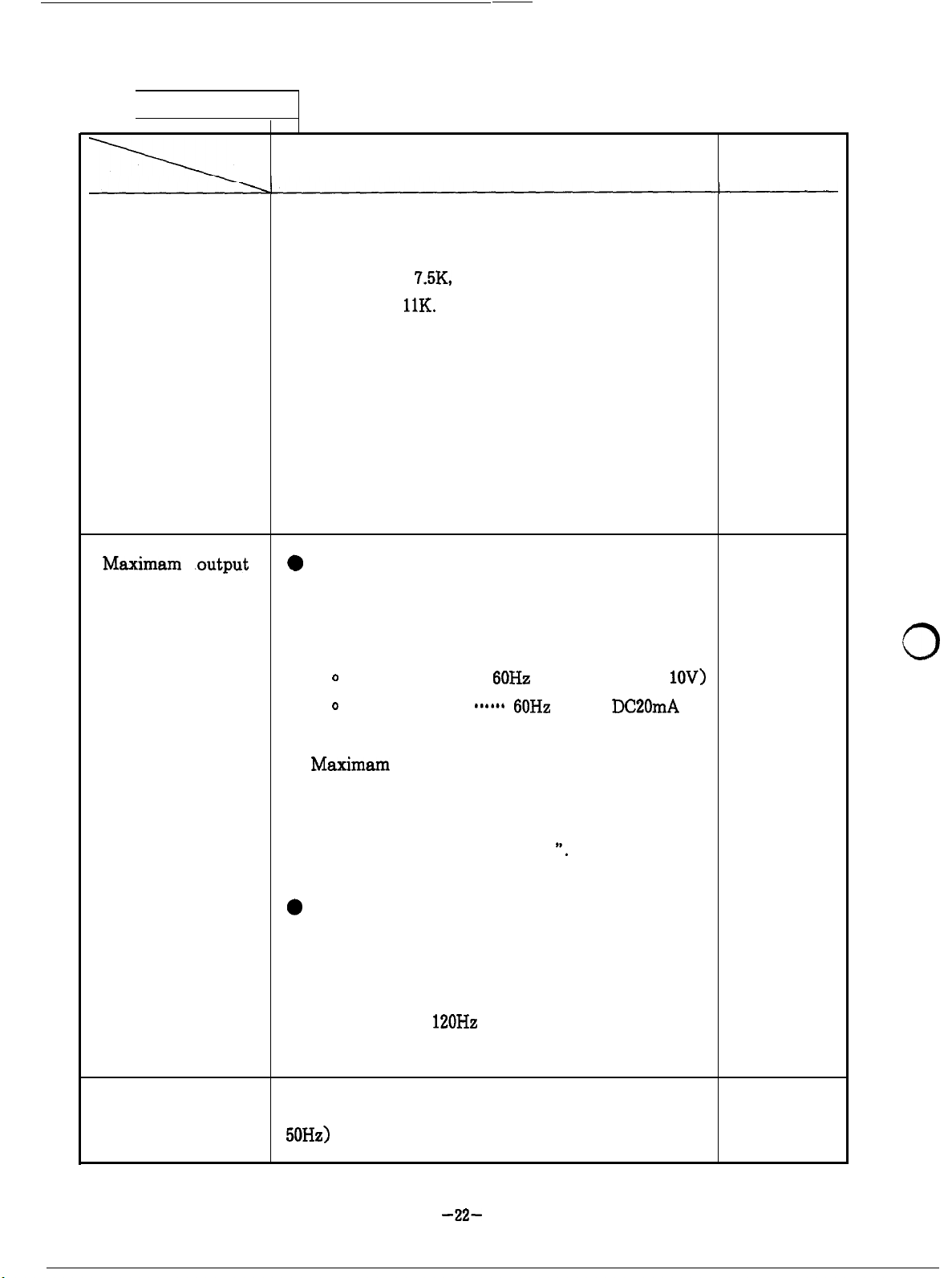

SETTING TABLE

Acceleration/

deceleration

time

Maximam .output

frequency

Description

When the inverter is shipped, acceleration/

deceleration time is set to 5 sec. for models P. 99

smaller than

larger than

The time setting can be changed on the

parameter unit.

Acceleration/deceleration time is the time in

which the inverter output frequency becomes

equal to the frequency at

reference signal voltage.

0

For operation with external signals

When the inverter is shipped, the maximum

7.5K,

and to 15 sec. for models

11K.

5 V of frequency

Refer to

P. 83

P. 83

P. 97

0

Electronic

thermal relay

inverter output frequency is set as follows:

---

6OHz

0

Voltage signal

0

Current signal

Maximam

changed by changing “frequency at 5 V

frequency reference input signal (or at 20mA

frequency reference signal)

0

For operation with parameter unit

The maximum output frequency can be

increased up to the maximum frequency

limit (set to

shipped) .

Setting should be based on current ‘value (at

50Hz)

indicated on the nameplate of the motor.

output frequency setting can be

--+-*- 60Hz

120Hz

when the inverter is

at DC 5 V (or

at

“.

DC20mA

lOV>

P. 83

P. 97

0

0

-22-

Page 27

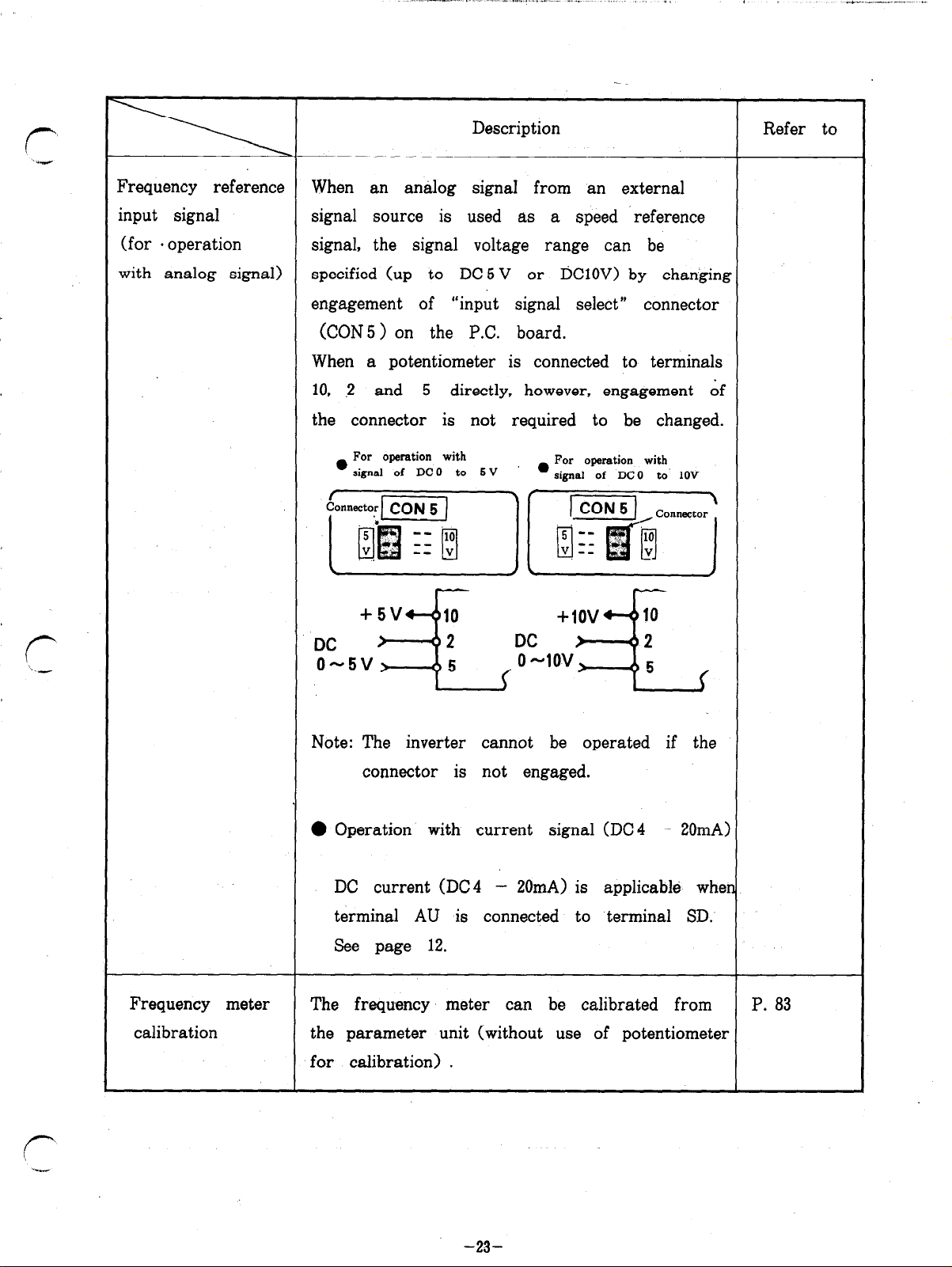

--..-.. ,.. .-. I. -.. . . . . . . . . - “._. I.. ., ,,

Description Refer to

4

*“c -...... --- .-

Frequency reference

input signal signal source is

When an analog signa from an external

used as a speed ‘reference

(for . operation signal, the signal voltage range can be

with analog signal)

specified (up to DC 5 V or DClOV) by changing

engagement of “input signal select” connector

(CON5 > on the P.C. board.

When a potentiometer is connected to terminals

10, 2 and 5 directly, however, engagement of

the connector is not required to be changed.

. 1”’ operation with

SIgnal Of DC O

;/f (;:,;yf (

tO

S V

For operation with

l

sipa] of DC0 b. 1OV

Frequency meter

calibration

Note: The inverter cannot be operated if the

connector is not engaged.

0 Operation with current signal (DC4 - 20mA)

DC current (DC4

- 20mA) is applicable when

terminal AU is connected to terminal SD.

See page 12.

The frequency meter can be calibrated from P. 83

the parameter unit (without use of potentiometer

for calibration) .

-23-

Page 28

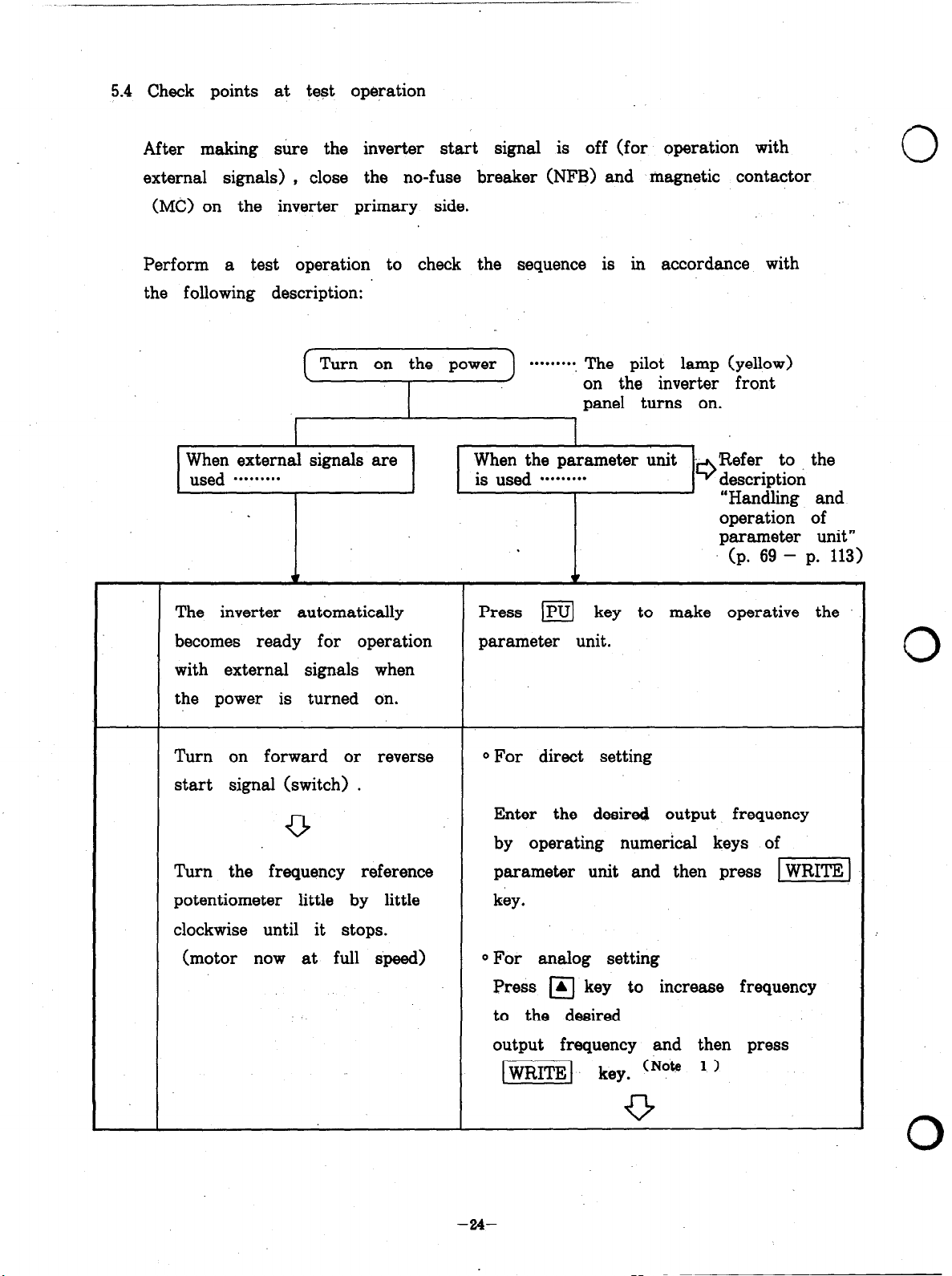

5.4 Check points at test operation

After making sure the inverter start signal is off (for operation with

external signals) ,

(MC) on the inverter primary side.

Perform a test operation to check the sequence is in accordance with

the following description:

When external signals are

. . . . . . . . .

used

The inverter automatically

close the no-fuse breaker (NFB) and magnetic contactor

Turn on the power

When the parameter unit Refer to the

is used

w

Press m key to make operative the

********‘. The pilot lamp (yellow)

on the inverter front

panel turns on.

. . . . . . . . . 9

‘I

description

“Handling and

operation of

parameter unit”

(p. 69 - p. 113)

0

becomes ready for operation

with external signals when

the power is turned on.

Turn on forward or reverse

start signal (switch) .

0

Turn the frequency reference

potentiometer little by little

clockwise until it stops.

(motor now at full speed)

parameter unit.

0 For direct setting

Enter the desired output frequency

by operating numerical keys of

parameter unit and then press

key.

0 For analog setting

Press m key to increase frequency

to the desired

output frequency and then press

-1 key. (Note * ’

pizeiq

0

-24-

-0

0

Page 29

Press I[ or @%$ key

(“MONITOR” function becomes

applicable automatically) .

.$g*

8-r:

ad

s

4

6

Turn the frequency reference Press -1 key. (Note 2,

potentiometer little by little

counter-clockwise to “zero”

position. (motor now stopped)

Change of frequency is not displayed if the parameter unit is not set

in “MONITOR” mode.

(Note 1) As the frequency displayed by the readout of parameter unit

increases, the motor speed increases.

(Note 2 > As the frequency displayed by the readout of parameter unit

decreases, the motor speed decreases.

When the output frequency reaches the “DC brake operating

1

:

L*

frequency”, the DC dynamic brake is activated and the motor

is stopped immediately (refer to “CAUTION” described below) .

f-

Check points:

(1) Check that the motor rotates in correct direction (for relationship

between motor phase sequence and direction of rotatiom, refer to

chapter 8 4. WIRING.)

(2)

Check that the motor does not generate unusual hums or vibration.

(3) Check that change of output frequency is displayed correctly.

(4) Check if “ALARM” lamp lights during acceleration or deceleration

(inverter trip) . If it lights, perform the following check:

l

Check if load is too heavy.

0 Increase acceleration/deceleration time.

-

l

Reduce amount of boost.

-25-

Page 30

CAUTION:

(11 If the forward (STF) and reverse (STR) start signals turn on at the same ’

time, the inverter will not start. If these signals turn on simultaneously

during operation, the motor is decelerated (the inverter output frequency

decreases) to a stop. _ .

(2) Durpng deceleration, the DC dynamic brake is actuated for 0.5 seconds when

the inverter output frequency decreases to less than the DC brake frequency

(below the start frequency, when speed reference signal voltage (or current)

is reduced gradually) .

During this DC dynamic braking period, the motor may generate a high-

pitched hum, but this is not a failure, nor a sign of trouble. This is

normal during DC braking.

(31, If “ALARM” lamp lights and the motor stops after coasting, check that the

motor has stopped completely and then reset the inveyter to shut off the

power, using the reset terminal.

0

0

.:

-26-

r

0

Page 31

8 6. MAINTENANCE AND INSPECTION

f-

%me-

The inverter is a piece of static equipment consisting mainly of semiconduct-

or elements.

To prevemt trouble with the inverter, due to high temperature, humidity, dust,

intense vibration, component deterioration, etc., it is very important to perform

periodic inspection.

6.1 Caution for maintenance and inspection

(1) Operator must check whether, power supply is ON or OFF by himself

to prevent misoperation by others.

(2) After the power

voltage for a while.

Before making an pnspection, check that the CHARGE lamp on the P.C.

board is off, and voltage across the inverter main circuit terminals P

is switched ’ off, the capacitor remains charged at high

and N is below DC30V, using a multimeter, etc.

6.2 Inspection points

This invertey is equipped with the power pilot lamp and error (alarm)

display function. .

It is advisable that you familiarize yourself with the error display definitions.

Also note the normal settings of the electronic thermal relay, acceleration/

deceleration time, etc.

(1) Daily inspection

During daily operation, check the following:

(a) The motor operates properly.

(b) The environment is normal.

(cl The cooling system is normal.

(d) There is no unusual vibration and noise.

r

i-l

(e) There is no overheat and discoloration in any component of the

inverter .

-n-

Page 32

During operation, check inverter input/output voltage with a multimeter.

(2) Periodic inspection

Check the followings periodically with the inverter stopped:

(a) Check that the cooling system is in good condition.

Clean air filters, etc.

(b) Screws, bolts, nuts and other fasteners may become loose with time,

due to vibration, thermal expansion/retraction, etc.

Retighten loose screws or other fasteners.

(c) Check if conductors and insulators are not corroded. or damaged.

(d) Measure insukation resistances.

(e) Check the cooling fan, smoothing capacitor, contactors and relays for

condition.

0

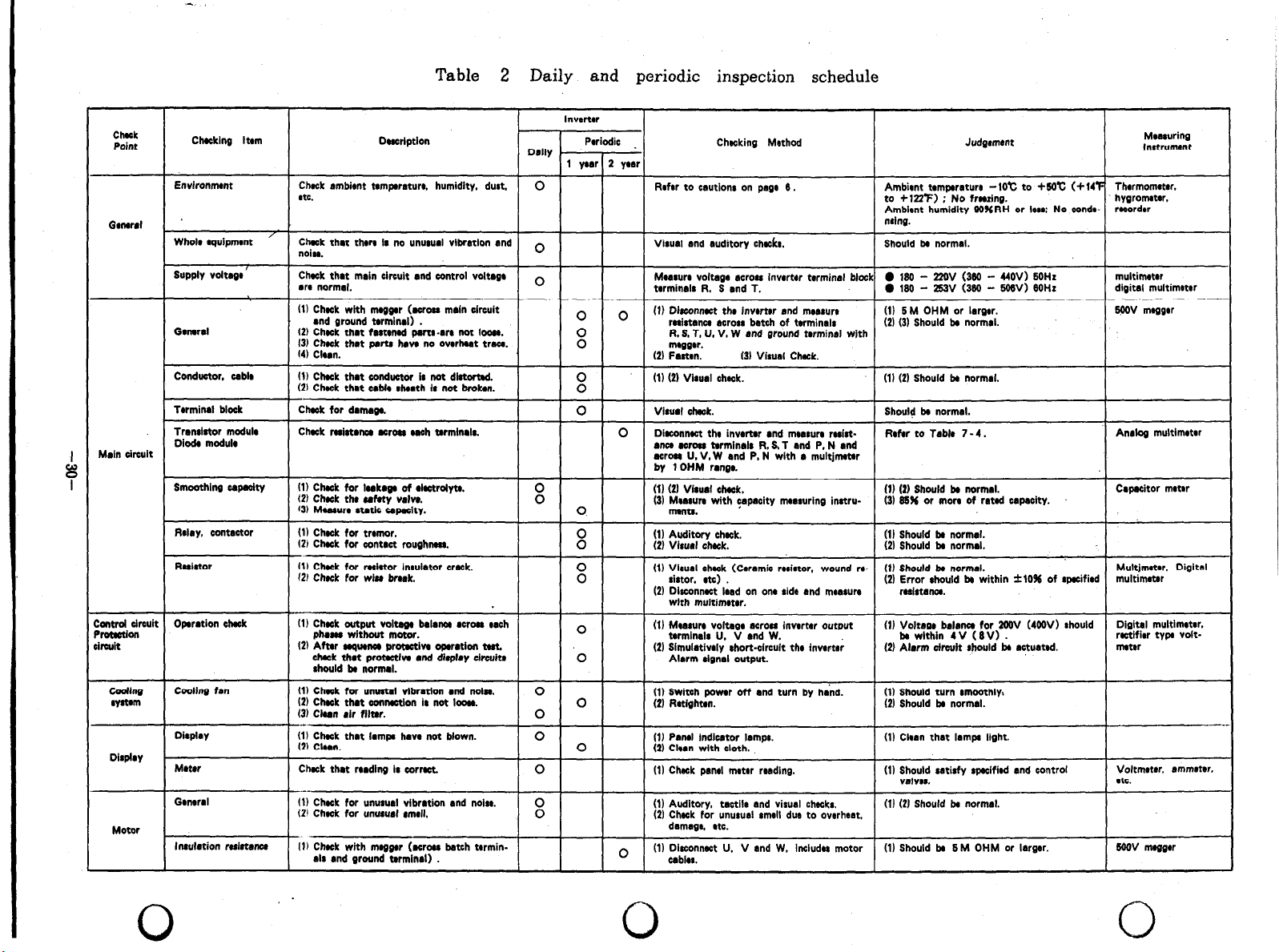

Table 2 shows the standard daily and periodic inspection schedule.

(3) Insulation resistance test with megger

(a) Before checking insulation resistances of the external circuits with a

megger, disconnect wires (cables) from all inverter terminals so that

test voltage is not applied to the inverter circuits.

(b) Conduct the insulation resistance test on the inverter main circuit

only, as shown in Fig. 7.

Do not conduct the test on the control circuit of inverter.

(c) To check the control circuits for continuity, use a multimeter (high

resistance range> .

Do not use a megger or buzzer to check.

,

0

-28-

I

Page 33

Ground trrminsl

-m-m-)

---VW

Motor

Fig. 7

Insulation resistance test with megger

Page 34

Check

ammeter.

Point

Environnlwt

Gwwr*l ’

Whole rquipmont

supply voltage

Gmwd

Conductor. ublr

Tarmind block

Trrndstor module

Main circuit

t

:antrol circuit Operation chtok

WOtUtiW

:imuit

phi

mm

Dirplry

Motor

Diode module

Smoothing

AaIry. contactor

Rrirtor

CodInS fan

Dirplay

Meter

Guwral

Insulation rrrirtatwa

Checking Item

I

rpwity

Table 2 Daily and periodic inspection schedule

Dwcrlption

Check ambient temperature, humidity, dust.

etc.

/

Chmk that thrra ir no unutud vibration and O

noita.

Check that main circuit and control voltaS*

ore normal.

(11 Check with meggw (across main circuit

and ground tbrminal) .

(2) Chock that fastenad parts.rre not loom.

13) Chock that porta hrw no owrhut trau.

14) Clwn.

(1) Check that conductor is not dietort&.

(21 Chack that cable rhuth i# not broken.

Chnk for damago.

Check mist~nce acroa ah orminrls.

(1) Chack tar lukap of rlactrdytt.

(2) chuk

thr

‘3) Mwwn notit copuity.

(1) Chock for tramor.

(2i Cheek for contact roughen.

(1) Check for resistor insulator crack.

12) Check for wlrr break.

(1) Chrck output voltaga balmtea across wch

phases without motor.

(2) After nquana prouetiw operation tact.

chuk that protutlw and die& chita

should k normal.

(1) Cheek for unwtal vibration and noln.

(2)

Chuk that wmutlon h not loon.

(3) Ghan rlr flltar.

{:I Eh$ that Iamy have not blown.

Chack that wading Is corract. 0

(1) Check for unusual vibration and noisr.

(21 Chrcl: for unusurf rmrll.

(1) Check with nuggw (-roes batch trrmin-

elr and ground terminal) .

wfety VdW.

Inwrter

Dally .

0

O

8

0

0

0 (1) Panel indicator Iampc. (1) Clean that lamp light.

Periodic

1 ywr 2 year

Rnhr to cautions on paga 6. Ambirnt temperature -1O’c to +SaC (+14f Thrrmomrar.

Visual and auditory chock@. Should k normal.

Measure voltage (Iwo* inwrtrr terminal Mock 0 180 - 220; l:E 1 440:; ZO:

torminrlr R. 8 and T.

0 0

8

8

0

0 ment8.

8

8

0

0

0 (2) Should b normal.

0 (2) Clrrn with cloth.

HI Dlmomwct tha invutrr and mnrrure (1) 6M OHM or larger.

(2) Fasttm.

(1) (2) Visual ahack. (1) (21 should bb normal.

Viruel &ask. Should k normal.

0

Di@connect thr inwrtw and mratun resistanca mron hrmlnals R.S.T and P. N and

awon U. V. W and P. N with a multjmrtw

by 1 OHM ron~r

(1) (21 Vi8ual thack.

(3) Mea~un with capacity measuring instru- (3) 85% or man of rated wpacity.

(1) Auditory check. (II Should br normal.

(2) Visual c&k.

(1) Vl8url ahack (Ceramic rrsictor. wound R(2) Disconnect lrad on one sldr and measure

(1) Mearun volteg* acrow inwrtw output

(2) Simulativaly rhort-clreult the lnv&

(1) Switch poww off and turn by h&d. (1) Should turn wnwthly8

(2) Ratighan.

(II Chak panel meter reading.

(1) Auditory. tactile and visual checks. (1) (2J Should k normal.

(21 Check for unusual #mrll due to overheat,

(1) Clbl,nnwt U. V and W. Includrc motor

0

Chocking Method

to +122’F) ; No frnxing.

Ambirnt humidity SOURH or lass: No con&nrlng.

l 180 -

rrlstana across batch of terminals (2) (3) Should k normal.

R. S. T, LJ. V, W and around terminal with

mwg9.r.

sirtor. 9tc) .

with multim#rr.

twmlnalo U. V and W.

Alarm rlgnal output.

dsmsgr etc.

(3) Visual Chock.

Refer to Table 7-4.

(1) 0) Should k normal.

(21 Should k normal.

(1) Should k normal.

(2) ;~ti;~uld k within f10% of sceified multimater

(1) Voltage balona for 2OSV (4OOV) should

br wlthin 4V (8V) .

(2) Alarm &cult rhould k actuated.

(1) Should satisfy specified and control

VSIVU.

(1) Should ba 6M OHM or larger. MH)V mm

Judgment

Meaalurinp

lnstrumrnt

hygrometer.

rnordrr

multimeter

digital multimater

WOV mwgtr

An&S multimeter

Capwitor meter

Multjmmr. Digital

Digital multimrtrr.

rutlfior typ voltmeter

-

Voltmeter,

etc.

-_

0

.

0

Page 35

/ . 1.x. . ..^.

i..____-

_

-

6.3 Method of measuring main circuit voltage, current and output power

(1) Method of measuring voltage and current

Since the inverter power supply (input) , output voltage and current include

* high-harmonic components, date (measurement results) depend on instrument

and circuit used in measurement.

To measure voltafe and current with an instrument for commercial

frequency application, use the instrument in accordance with Table 3, and

the circuit shown .in Fig. 8.

3 -phase

power

SUPPlY

Input

VOltage

VwAi

Av

1 )

1

To

Output

voltage

output

current

motor

Fig. 8 Measuring points and instruments

Page 36

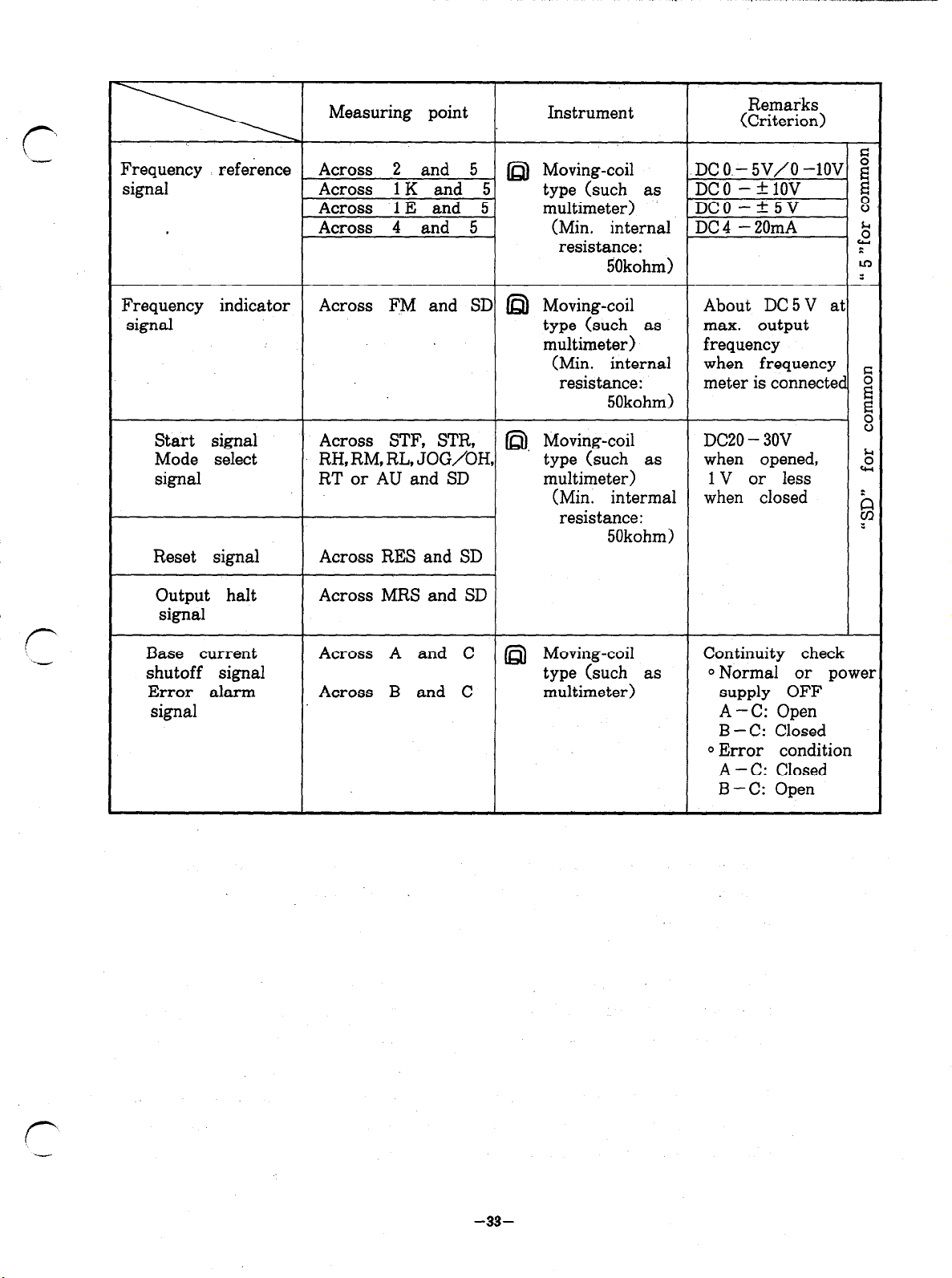

Table 3 Measuring points and measuring instruments

Measuring point Instrument

Line voltage

VI

Input current

11

Input power

P*

Input power

factor .

Pf,

Output voltage Across U and V,

VZ

Across R and S,

S and T, and T

and R

R, S and T line - Moving-iron

current

On R, S and T,

and across R and

S, and S and T

To be calculated from the equation shown below. after

line voltage, input current and input power and measured.

Pf, = &P1* I, X 100%

I

V and W, and W (moving-iron phases is * 1% or

and U

Remarks

(Criterion)

Moving-iron

c

type

c

type

Electrodynamic P*=W,, + WI?

8

type

’ Rectifier type Difference between

t

type is not less of maximum

acceptable) output voltage.

Commercial voltage

0 180 - 22OV

(360 --i 44OV)

50Hz

0 180 - 253V

(360 - 506V)

60Hz

0

0

Output current U, V and W line

I* current

Output power

PZ

Output power

factor

Converter output Across P and N

and across U

and V, and ,V

and W

: To be calculated from the equation shown below

Pf, = &IZ. I* X 100%

Moving-iron Current should be

c

type

type .

a Moving-coil

type (suoh

as multimeter)

equal to or less

than inverter rated

current.

Difference between

phases is 10% or

less.

Pz = wn + wtr On .U, V and W, e Electrodynamic

POWER lamp should

light.

1.35 X VI

Max. voltage during

regenerative braking

380v (73OV)

0

-32-

Page 37

r

-

Measuring point

Frequency reference

signal Across 1 K and 5.

Across 2 and 5 _ n Moving-coil DC O.- 5V/O -lOV G E

Across 1 E and 5 multimeter) DC0

Across 4 and 5 (Min. internal DC 4 - 20mA

Instrument

type (such as

resistance:

5Okohm)

Remarks

(Criterion)

,DCO -klOV E

-+5v

8

5

:

m

:

Frequency indicator

signal

Start signal Across STF, STR,

Mode select

signal RT or AU and SD

Reset signal Across RES and SD

Output halt

signal

Base current

shutoff signal

Error alarm

signal

Across FM and SD D Moving-coil

RH, RM, RL, JOG/OH,

Across MRS and SD

Across A and C @) Moving-coil Continuity check

Across B and C

About DC5V at

type (such as max. output

multimeter)

(Min. internal when frequency

resistance: meter is connected 5

50kohm)

@), Moving-coil DC20 - 30V

type (such as when opened, k

multimeter) 1 V or less cy

(Min: intermal when closed

resistance:

50kohm)

type (such as ~Normal or power

multimeter)

frequency

supply OFF

A-C: Open

B - C: Closed

0 Error condition

A - C: Closed

B-C: Open

b

1

g

8

f-

-

-33-

Page 38

6.4 Mesuring instrument selection and usage

To observe the condition of insulation, voltage, current, signal level, waveform,

etc., select an adequate instrument and use it in accordance with the

following description:

(1) Measurements on main circuit

The measurements include power supply and output voltages and

current measurements, load (motor) continuity check, insulation check,

voltage and current waveform observation.

The followings are particularly important to be checked carefully with

the specified instrument(s):

0 Multfmeter

For continuity check with a multimeter, be careful of sneak path

0

circuit. Do not make continuity check for the inverter circuit transistor

module with the motor connected, and for the converter circuit diode

module with the power connected.

Make continuity check only for components to be checked with the

wiring to other components disconnected.

@ Voltmeter and ammeter

The input power supply voltage is sine-wave of the commercial

frequency. To measure the input voltage, any appropriate instrument

may be used.

Since the input and output current waveforms include various highharmonic components, use a moving-iron type ammeter, as it indicates

values in r.m.s., to measure the input and output currents.

0

To measure the output voltage, use a rectifier type voltmeter because

it reads nearly the basic wave

which is used as the reference value of torque generated by the motor.

component of the voltage waveform

0

Page 39

-_l__l___- II ..-..--- “.--“” ._..* - -..-... .._, ,.,..,_ ., ,

, . I...+

Anyway, it is important’ to record the instruments used and measurement

results, and to always use the same instruments at inspection.

0 Oscilloscope

To measure high voltage (4OOV or higher) , insulate the power supply

of oscilloscope and use a high-voltage probe or insulate the point to

be measured with a potential transformer or current transformer.

In the latter case, the potential transformer or current transformer

should have a capacity large enough to prevent magnetic saturation.

(21 Measurements on control circuits

The measurements on control circuits include measurements of frequency

reference signal, inverter

control voltage and observation of waveforms.

For accurate measurement, note the followings:

@ Voltage measurement and waveform observation

Since the currents of these signals are

faint and the impedances of

the circuits are high, use an instrument, input resistance of which is

as high as possible (lOOkohm to

1 Megohm) .

It is recommended to use a digital multimeter or oscilloscope in the

measurements.

Since input resistance of multimeter set in a low range is significantly

low, value read by multimeter may be lower than the true value.

0 Common line connection

f-

“,-

Connect the common terminal of instrument to an optimum point of

circuit (i.e. the common point nearest to the point measured) .

@ Instrument characteristics

For waveform observation, use’ an oscilloscope which has characteristics

that meet the waveform to be observed.

-35-

Page 40

The inverter base drive waveform can be observed, for example, with,

Instruments

5ooV megger

Multimeter

Voltmster

Ammeter

a 10MHz oscilloscope.

To measure transient waveform at rise of

signal (dv/dt or di/dt) , however, an oscilloscope of 200MHz or

larger frequency is required.

._

Table 4 Instruments and points to be measured

Measuring point

Main

..

circuit circuit ductivity

Control insulation Con- Voltage Current W aveform

0

0 0

?

0 ‘0

0

Measuring item

0 0

t

Description

Measure across batch of main circuit

terminals and ground.

(This does not apply to control circuit.)

Judges whether semiconductor element

is proper or not. Used to know

conductivity or resistance value.

0

Measure line and inverter output voltage.

Use a rectifier type.

Measure line and output current.

Use a moving-iron type.

0

Oscilloscope

Digital multimeter 0

0

0 0

1 ’ 1 ’ 1 ’ 1 transient voltage and current.

Used to observe waveform and measure

Used to measure circuit voltage instead

of multimeter.

6.5 Transistor modules and diode modules

To check transistor modules and diode modules, follow the procedure

described below.

(1) Preparation .

0 Disconnect the power supply cables (R, S, T) and motor ‘cables (II, V, W> .

l

Prepare a multimeter (set the multimeter to “ 1 OHM” resistance

measurement range) .

(21 Checking method

0

Alternate polarity of multimeter with the multimeter probes connected to

inverter terminals R, S, T, U, V, W; P and N and check for continuity

as listed in Table 5.

-36.-

0

Page 41

__~___.I.____----._-.lr--_ .-*,-. I ,, .r b (. , __,.._ -.~_l”ll_l-._----

Table 5 Checking the transistor modules and

diode modules

Normal conditidns Normal conditions

Notes: 1. Before measurement, check that the smoothing capacitor

been discharged.

2. “Discontinuity” means that the multimeter reading is almost

infinite. Due to electricity remaining in smqothing capacitor,

the multimeter may indicate “continuity” momentarily.

“Continuity” means that the multimeter reading is about

1 - lOOohm, depending on number of total modules, number

of modules connected in parallel, type of- modules, etc.

If all measurement results are almost same, the modules

are in good condition.

have

-37-

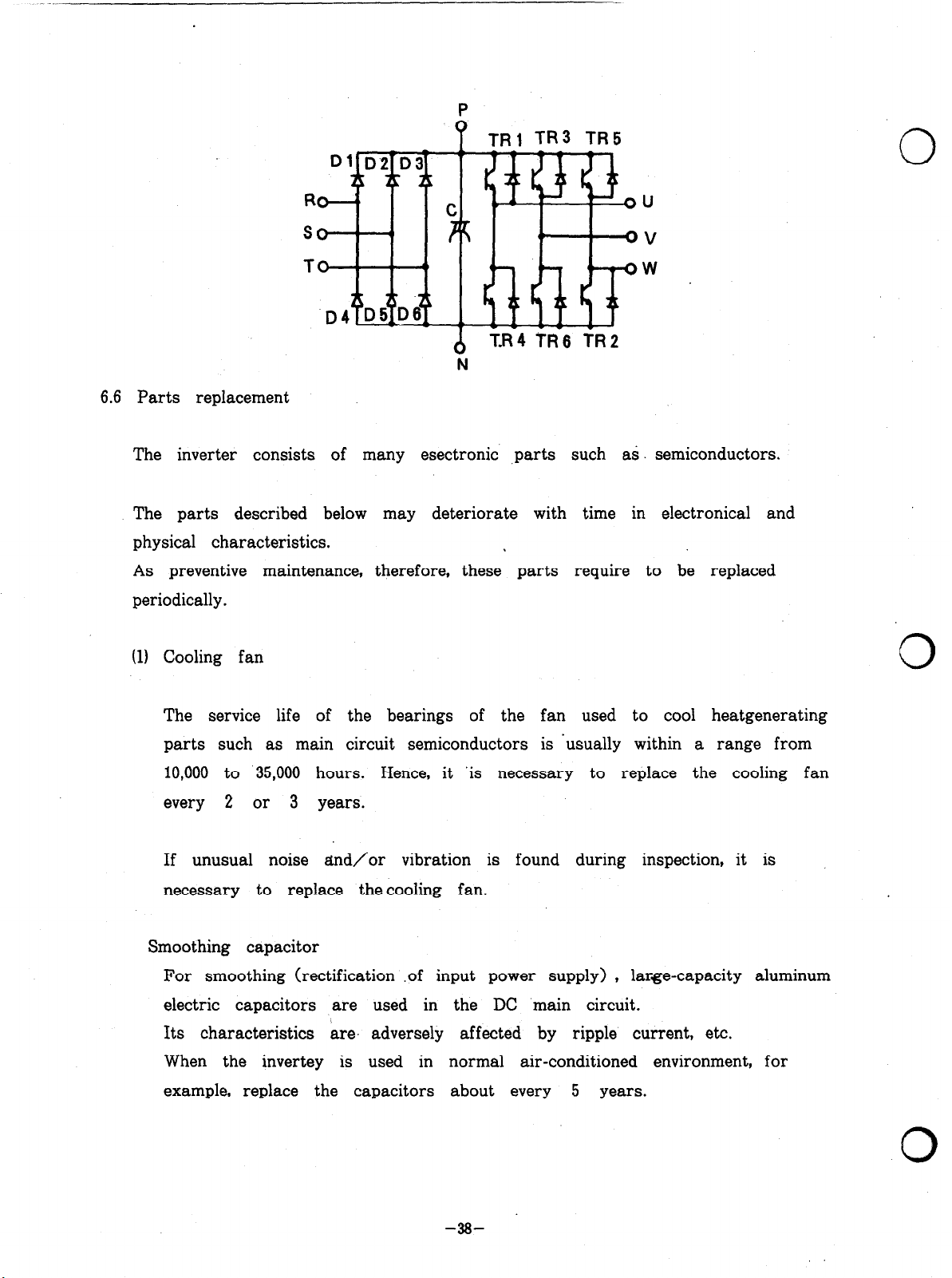

Page 42

P

TRl TR3 TR5

P

Dim

v

W

id6 TR 2

N

6.6 Parts replacement

The inverter consists of many esectronic ,parts such as. semiconductors.

The parts described below may deteriorate with time in electronical and

physical characteristics.

As preventive maintenance, therefore, these parts require to be replaced

0

periodically.

(11 Cooling fan

The service life of the bearings of the fan used to cool heatgenerating

parts such as main circuit semiconductors is ‘usually within a range from

10,000 to 35,000 hours. Hence, it ‘is necessary to replace the cooling fan

every 2 or 3 years.

If unusual noise and/or vibration is found during inspection, it is

necessary to replace thecooling fan.

Smoothing capacitor

For smoothing (rectification .of input power supply) , large-capacity aluminum

electric capacitors are used in the DC main circuit.

Its characteristics are, adversely affected by ripple current, etc.

When the invertey is used in normal air-conditioned environment, for

0

example, replace the capacitors about every 5 years.

0

Page 43

- ,_-. -.-.“*-*, .,._ < _ 4. . _. ._i .,_..___ ___I_-. I

When a capacitor is used for the period specified as life, it may

deteriorate suddenly.

It is necessary to check all smoothing capacitors yearly (several months

if life ‘is about to expire) .

.

Check the followings:

.

0 Case

. Side walls and bottom for deformation

0 Sealing plate

@ Pressure relief valve :

: For unusual warp and cracks

For excessive valve expansion and

operation

@ Appearance, crack in case, discoloration and leakage:

When capacitance of a capacitor is reduced below 85% of rated

capacitance, replace that capacitor.

To measure capacitance, use an

instrument available commercially.

(3) Relays

To prevent miscontact, it is necessary to replace relays in accordance

with the acumulated switching times.

For approximate interver parts replacement, refer to Table 6.

Other parts , having a relatively short service life, such as lamps. Replace

when deemed necessary as periodic inspection result will reveal.

Table 6 Inverter replacement parts

Part uame

Cooling fan

Standard interval 1

2 to 3 years

Replace (determine

Description

after checking)

Smoothing capacitor

5 years

Replace (determine

after checking)

Relays

Determine after checking

-39-

I

Page 44

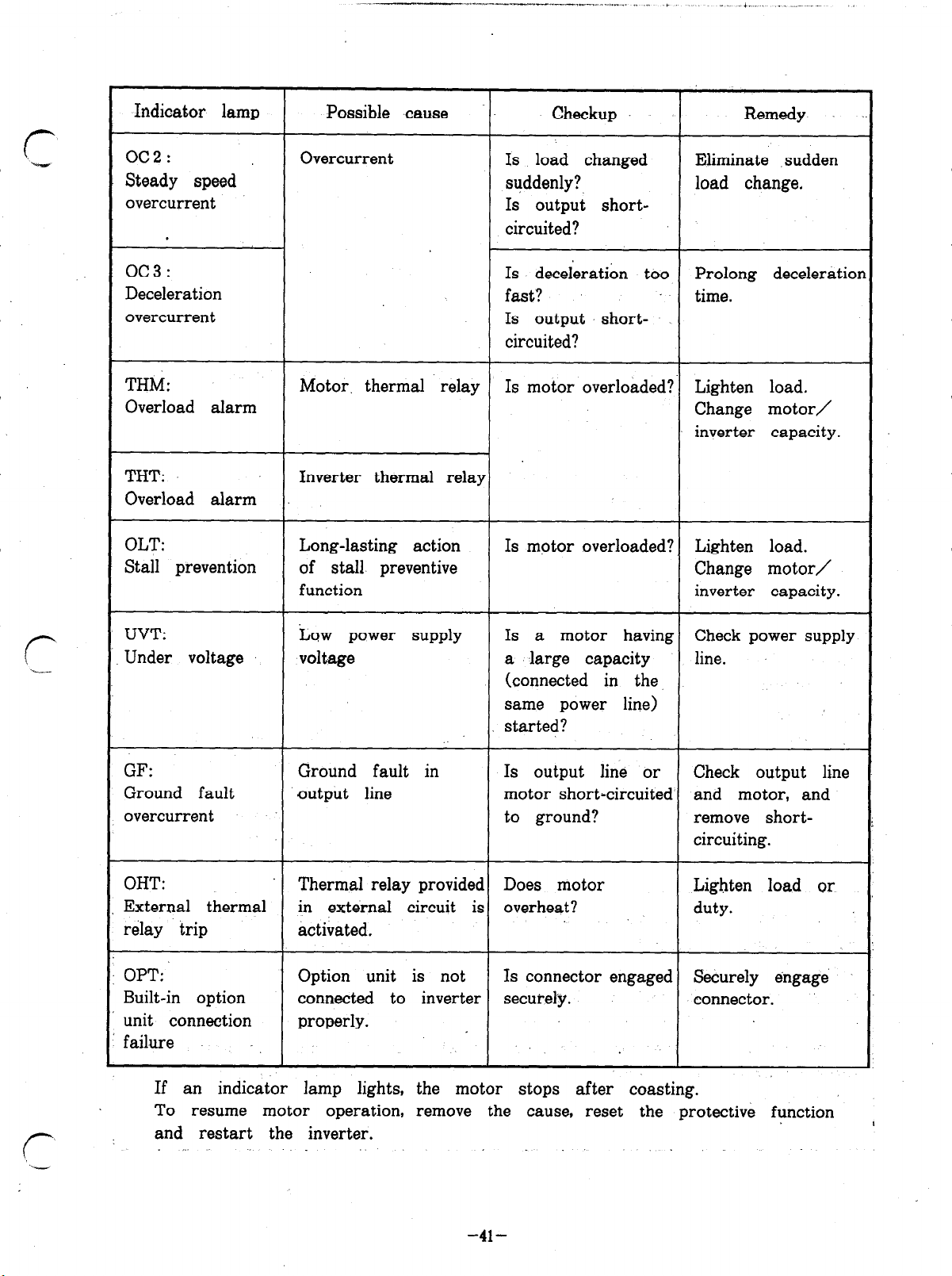

Q 7. TROIJBLESHOOTING

If a fault occurs and the mverter does not work properly,, determine the

cause referring to the following troubleshooting list and apply the remedy.

If the cause cannot be determined in accordance with the list, the inverter

or its part(s) ,is likely to be defective.

For remedy of serious trouble or any inquiry, contact the nearest service

representative.

7.1 Troubleshooting

(1) Troubleshooting by indicator lamps’ of parameter unit

Indicator lamp. Possible cause Checkup Remedy

OVT: Overvoltage in DC

Regenerative output circuit fast? time (it should meet

overvoltage (across terminals load GDP (WK*) **a

shut off P and N) inertia) ‘.

(deceleration time

set improperly)

IPF:

Instantaneous failure of instantaneous

power failure power failure.

FIN: Heatsinks are Is cooling fan Replace cooling fan

Heatsink overheat overheated.

BE: ‘Brake transistor is Is brake operating Reduce load GD*

Brake transistor, defective. duty proper? (WK’) .

fault Reduce brake

Instantaneous power Determine the cause

.

Is ’ deceleration too Increase deceleration

stopped (for models

larger than 2.2K) ? Reduce. ambient

temperature.

Is ambient temperature too high?

. . .

‘operating duty.

‘0

OCl:

Acceleration ‘.- -

overcurrent Is outptt short-

Overcurrent Is acceleration too Prolong acceleration

ftist? --. : ,time.

circuited?

-4o-

0

Page 45

Indicator lamp

Possible cause

Checkup

Remedy

oc2:

Steady speed

overcurrent

oc3:

Deceleration

overcurrent

THM:

Overload alarm

THT:

Overload alarm

OLT:

Stall prevention

Overcurrent

Motor. thermal relay Is motor overloaded? Lighten load.

Inverter thermal relay

Long-lasting action

of stall preventive Change motor/

function inverter capacity.

Is load changed

suddenly?, load change,

Is output shortcircuited?

Is deceleration too

fast? time.

Is output shortcircuited?

Is motor overloaded? Lighten load.

Eliminate sudden

Prolong deceleratior

Change motor/

inverter capacity.

r

r‘

UVT:

Under voltage

GF:

Ground fault

overcurrent

OHT:

External thermal in external circuit is overheat?

relay trip activated.

OPT: Option unit is not

Built-in option connected to inverter securely. connector.

unit connection properly.

failure

If an indicator lamp lights, the motor stops after coasting.

To resume motor operation,

and restart the inverter.

,..

Low power supply Is a motor having Check power supply

voltage

Ground fault in

output line

Thermal relay provided Does motor Lighten load or

remove the cause, reset the protective function

a large capacity

(connected in the,

same power line)

started?

Is output line or Check output line

motor short-circuited and motor, and

to ground? remove short-

Is connector engaged Securely engage

.

line.

circuiting.

duty.

‘

-41-

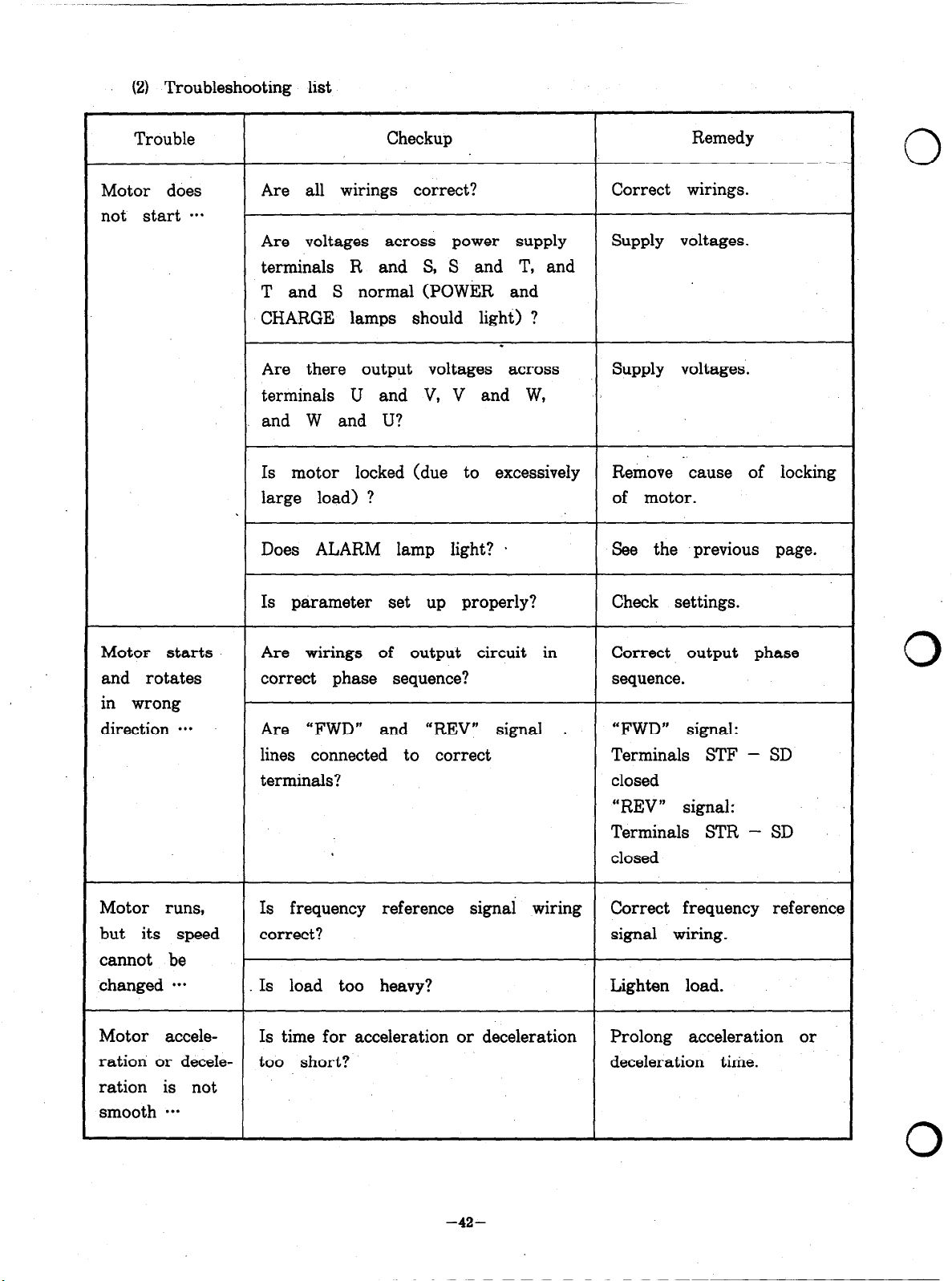

Page 46

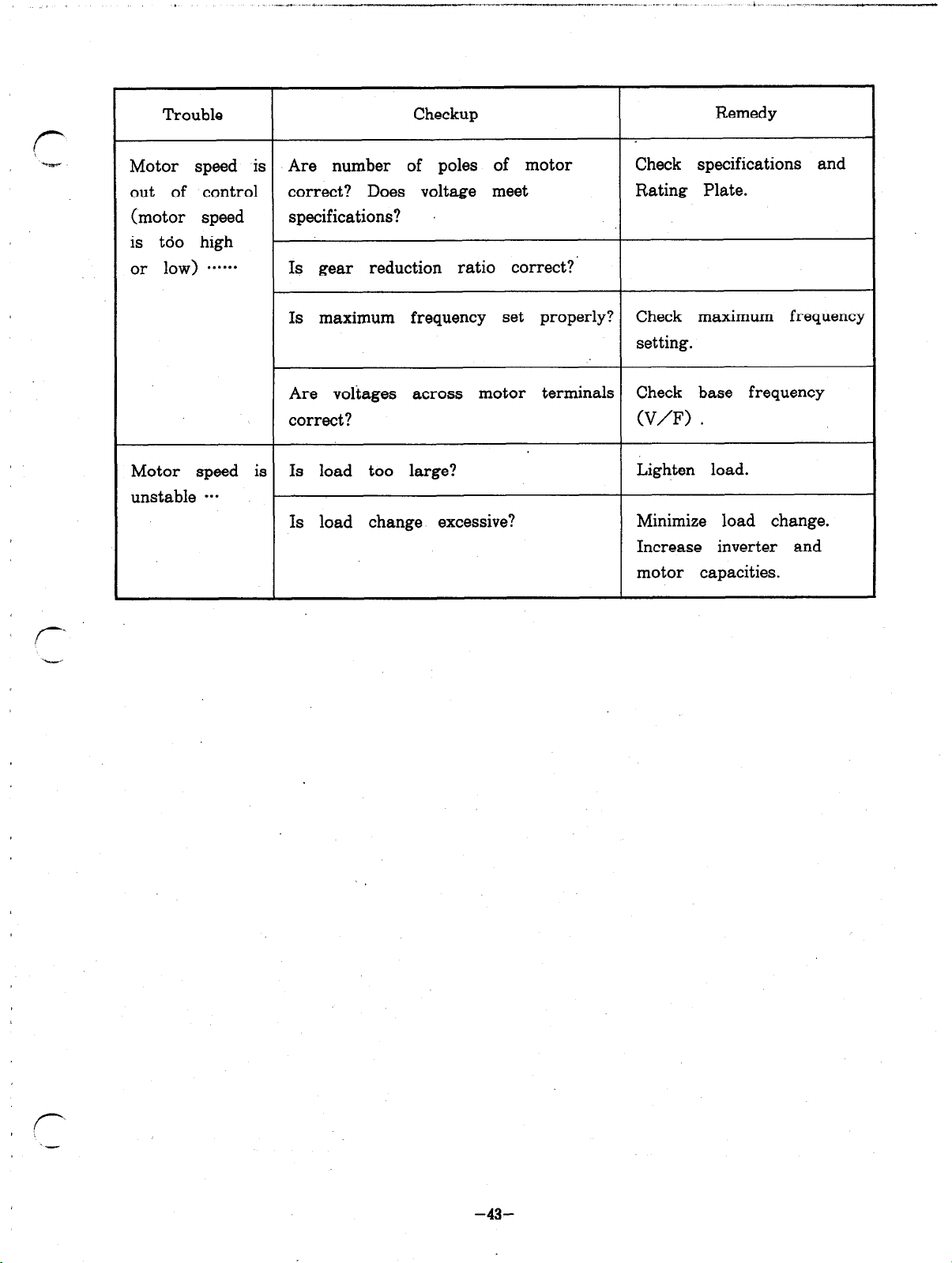

(2) Troubleshooting list

Trouble

Motor does

not start ***

Checkup

Are all wirings correct?

Are voltages across power supply

terminals R and S, S and T, and

T and S normal (POWER and

CHARGE lamps should light) ?

.

Are there output voltages across

terminals U and V, V and W,

and W and U?

Is motor locked (due to excessively

large load) ?

Does ALARM lamp light? *

Is parameter set up properly?

Remedy

0

Correct wirings.

Supply voltages.

Supply voltages.

Remove cause of locking

of motor.

See the previous page.

Check settings.

Motor starts

and rotates

in wrong

direction a*.

Motor runs,

but its speed

cannot be

changed ***

Motor accele-

ration or deceleration is not

smooth a**

Are wirings of output circuit in

correct phase sequence?

Are “FWD” and “REV” signal .

lines connected to correct

terminals?

Is frequency reference signai wiring

correct?

Is load too heavy?

Is time for acceleration or deceleration

too short?

Correct output phase

sequence.

“FWD” signal:

Terminals STF - SD

closed

“REV” signal:

Terminals STR - SD

closed

Correct frequency reference

signal wiring.

Lighten load.

Prolong acceleration or

deceleration time.

0

-42-

0

Page 47

. -.e

. . d._ __-,- .---.

.--I-- “ll__ ,. .I.. e... - 1.

* .-. - .---

Trouble Checkup

Remedy

Motor speed is Are number of poles of motor Check specifications and

out of control correct? Does voltage meet Rating Plate.

(motor speed

specifications?

is too high

or low)

. . . . . .

Is gear reduction ratio correct?

Is maximum frequency set properly? Check maximum frequency

setting.

Are voltages across motor terminals Check base frequency

correct?

(V/F) .

Motor speed is Is load too large? Lighten load.

unstable *..

Is load change excessive? Minimize load change.

Increase inverter and

motor capacities.

-43-

Page 48

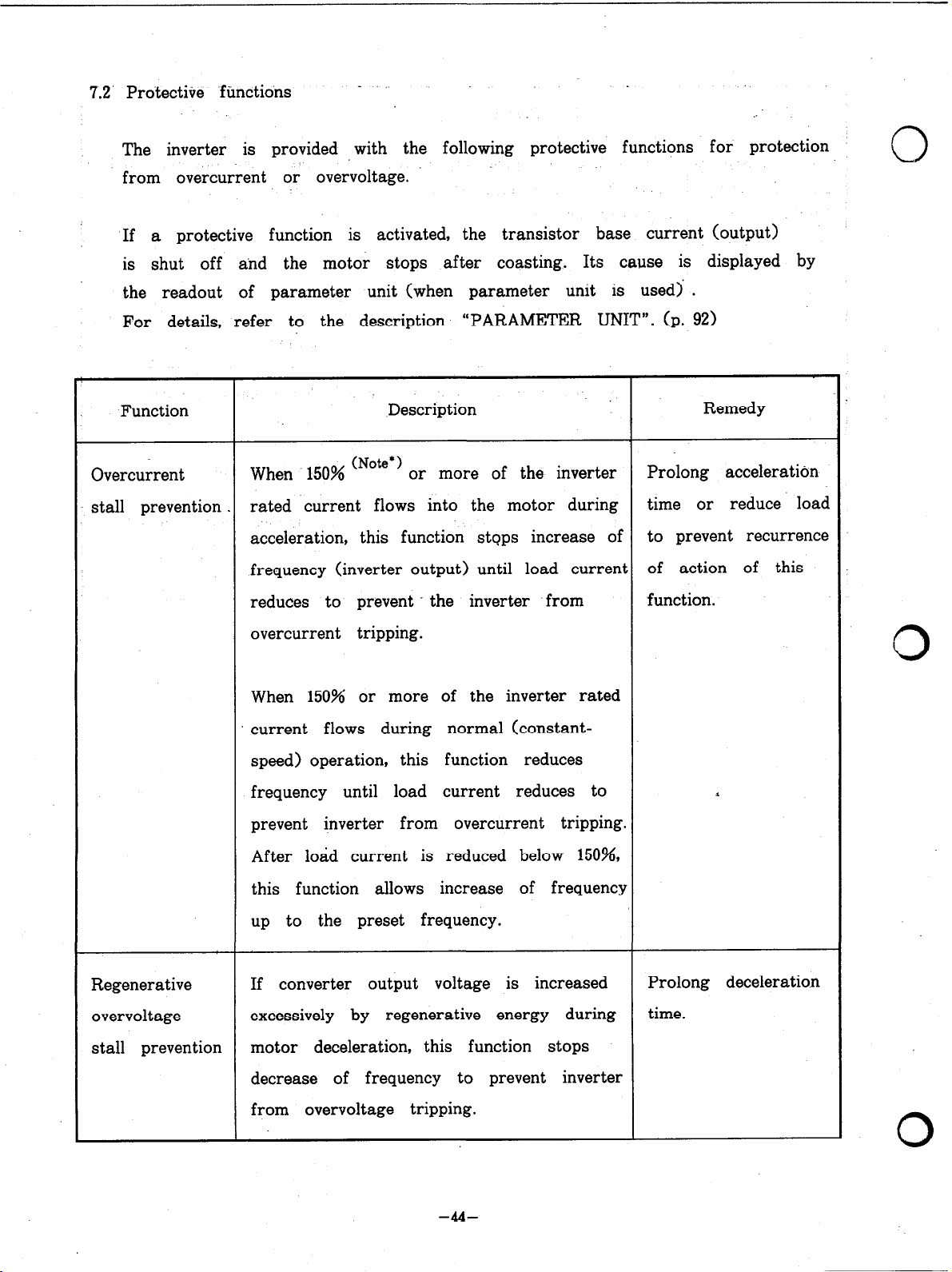

7.2’ Protective functions

The inverter is provided with the following protective functions for protection

from overcurrent or overvoltage.

. .

If a protective function is

is shut off and the motor stops after coasting. Its cause is displayed by

the readout of parameter unit (when parameter unit is used) .

For details, refer to the description “PARAMETER UNIT”. (p. 92)

Function Description

Overcurrent

stall prevention . rated current flows into the motor during

When 150% (Note*)

acceleration, this function stops increase of to prevent recurrence

frequency (inverter output) until load current of action of this

reduces to prevent - the inverter from

overcurrent tripping.

When 150% or more of the inverter rated

activated, the transistor base current (output)

Remedy

or more of the inverter

Prolong acceleration

time or reduce load

function.

0

current flows during normal (constantspeed) operation, this function reduces

frequency until load current reduces to

prevent inverter from overcurrent tripping.

After load current is reduced below 150%,

this function allows increase of frequency

up to the preset frequency.

Regenerative If converter output voltage is increased

overvoltage excessively by regenerative energy during

stall prevention motor deceleration, this function stops

decrease of frequency to prevent inverter

from overvoltage tripping.

Prolong deceleration

time.

0

-44-

Page 49

-._. . . . ..- -.,...... ^.l_l-- -,__,__-. _1 ,--,- ,,, ,,.--. +

.- ” .i< _... * ._._” _-____

Function

Overcurrent

shutoff

(OCl)

(OC2)

(OC3)

Description

Remarks

As soon as regenerative energy has

reduced, this function decreases frequency

again to allow deceleration to continue.

When 200% or more of the inverter

rated output current flows, this protective

The most possible

causes of overcurrent

function is activated to stop the inverter. shutoff include invertel

output short-circuit,

ground fault, excessivt

load inertia (GD’) ,

extremely short setting

of acceleration/

deceleration time,

Regenerative

overvoltage

shutoff :

(OVT)

When converter output voltage becomes

excessive, ‘due to regenerative energy from

the motor, this protective function is

activated to stop and hold transistor

start during motor

coasting, start of

special motor or

motor of capacity

larger than inverter

rating.

Restart after

examinating and

removing the cause.

This function is

activated mainly due

to short deceleration

time or negative

base current off.

load.

-ai-

Page 50

Function

Description

Remarks

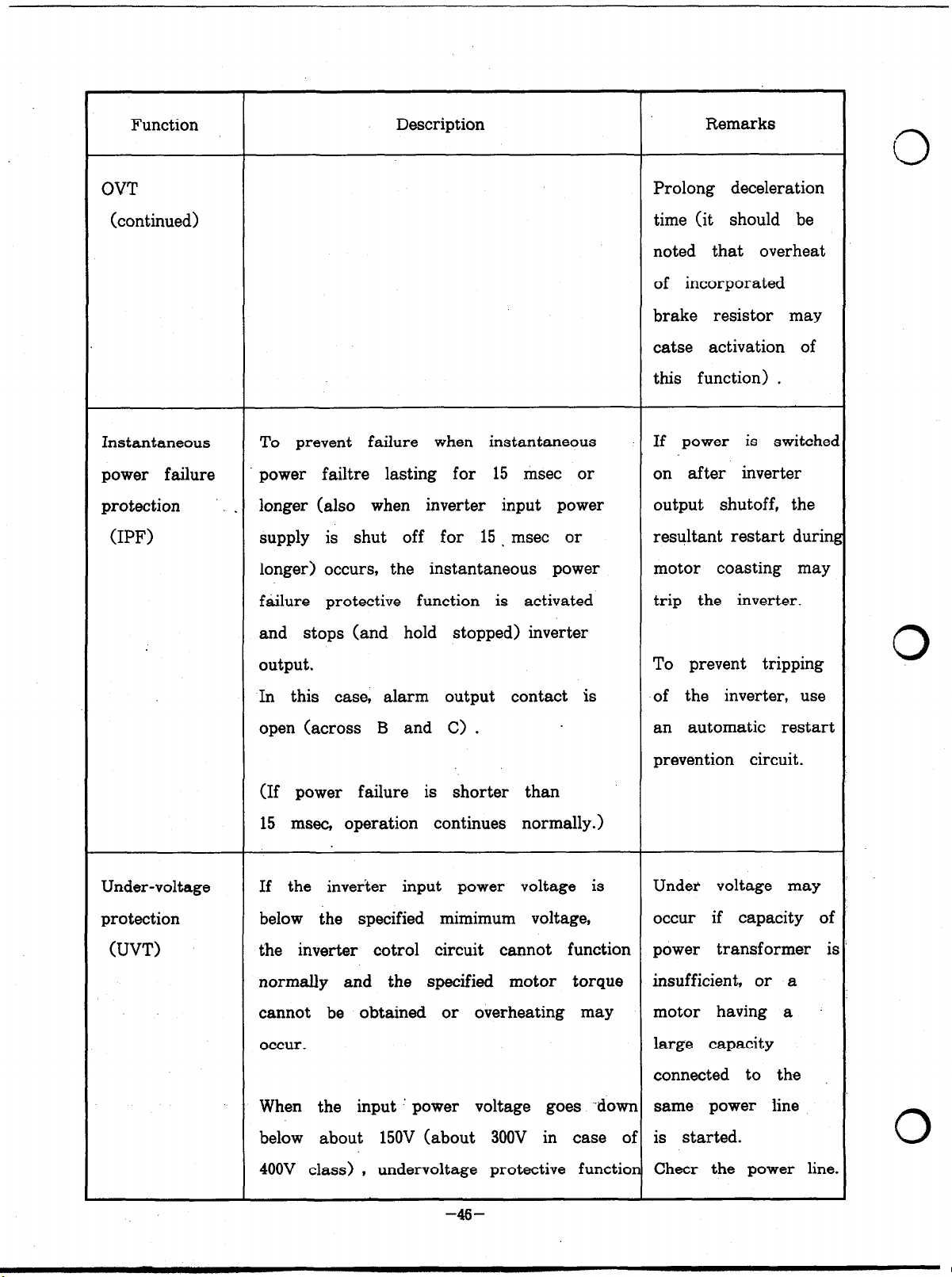

OVT

(continued)

Instantaneous

power failure

protection .

(IPF)

Prolong deceleration

time (it should be

noted that overheat

of incorporated

brake resistor may

catse activation of

this function) .

To prevent failure when instantaneous If power is switchec

power failtre lasting for 15 msec or

longer (also when inverter input power

supply is shut off for 15 . msec or

longer) occurs, the instantaneous power

failure protective function is activated

and stops (and hold stopped) inverter

on after inverter

output shutoff, the

resultant restart durini

motor coasting may

trip the inverter.

Under-voltage

protection

(UVT)

output.

In this case, alarm output contact is

open (across B and C> .

(If power failure is shorter than

15 msec, operation continues normally.)

If the inverter input power voltage is

below the specified mimimum voltage,

the inverter cotrol circuit cannot function power transformer ir

normally and the specified motor torque

cannot be obtained or overheating may

occur.

When the input ’ power voltage goes -down same power line

To prevent tripping

of the inverter, use

an automatic restart

prevention circuit.

Under voltage may

occur if capacity of

insufficient, or a

motor having a

large capacity

connected to the

below about 150V (about 300V in case of is started.

400V class) , undervoltage protective function Cheer the power line

-46-

Page 51

f-

Function

Description

is activated and stops (and holds stopped)

inverter output.

Remarks

Brake transistor If trouble occurs with brake transistor,

fault detection

(BE)

Overload shutoff Electronic thermal relay in the inverter

(Electronic

thermal relay) under rated conditions, or motor over-

(THT)

(THM)

this function detects it and shuts off

inverter output.

detects overload of motor during operation of overload, and

heating at low speed, and activates this

protective function which stops (holds

stopped) inverter output.

Examine thermal

capacity of brake

resistor and regene-

rative braking duty

(%ED) and use

inverter having a

larger capacity, if

necessary.

Examine the cause

lighten load, change

operation pattern,

or use inverter

having a larger

r--

CkUTION

External overload protection must be

provided to protect the motor in

accordance with UL508 Par.144.3.

Heatsink overheat Models larger than 2.2K are equipped

protection with cooling far&) .

(FIN)

If the fan fails and the semiconductor

heatsinks overheat, temperature sensor is

activated to shut off (hold shut off)

inverter output.

capacity if necessary

Examine cooling fan

operation and ambient

temperature.

Page 52

Function

Description Remarks

0

Brake resistor

overheat exceeds the specified value, the brake

protection operation is stopped to protect the

Ground fault If ground fault occurs on the inverter Check if ground

current protectior output side (load side) and ground fault

(GF)

If regenerative brake energy from motor Prolong deceleration

time or change

operati-on sequence

brake resistor .from overheating.

When the brake resistor is cooled, the

brake operation restarts automatically.

_ current flows, the inverter output is

shut off.

to reduce. braking

duty.

fault occurs on the

load side (motor

power circuit) .

After removal of

the cause, restart

operation.

0

External thermal If externallyinstalled thermal relay for

relay trip protection of motor from overheat

(OHT)

Built-in option When an inverter built-in option unit Check connection

unit connection is used and not connected properly (connector engage-

failure

(OPT)

(or motor built-in thermal relay) is

activated (relay contact is opened) , the

inverter output is shut off and held

shut off.

This function is applicable when

,“external thermal signal input” function

is selected. (FUNCTION 46)

(misengagement

the inverter is shut off.

of conector, for example) , men0 of option unit.

Examine load and

motor duty to

determine the cause

of overheat.

_’

Page 53

-- “. ,..,.i-.“--

--- ,-,- -- _-._._ .,. . .._- _..* .I.. _ , I _, .~ . . __.~l__l

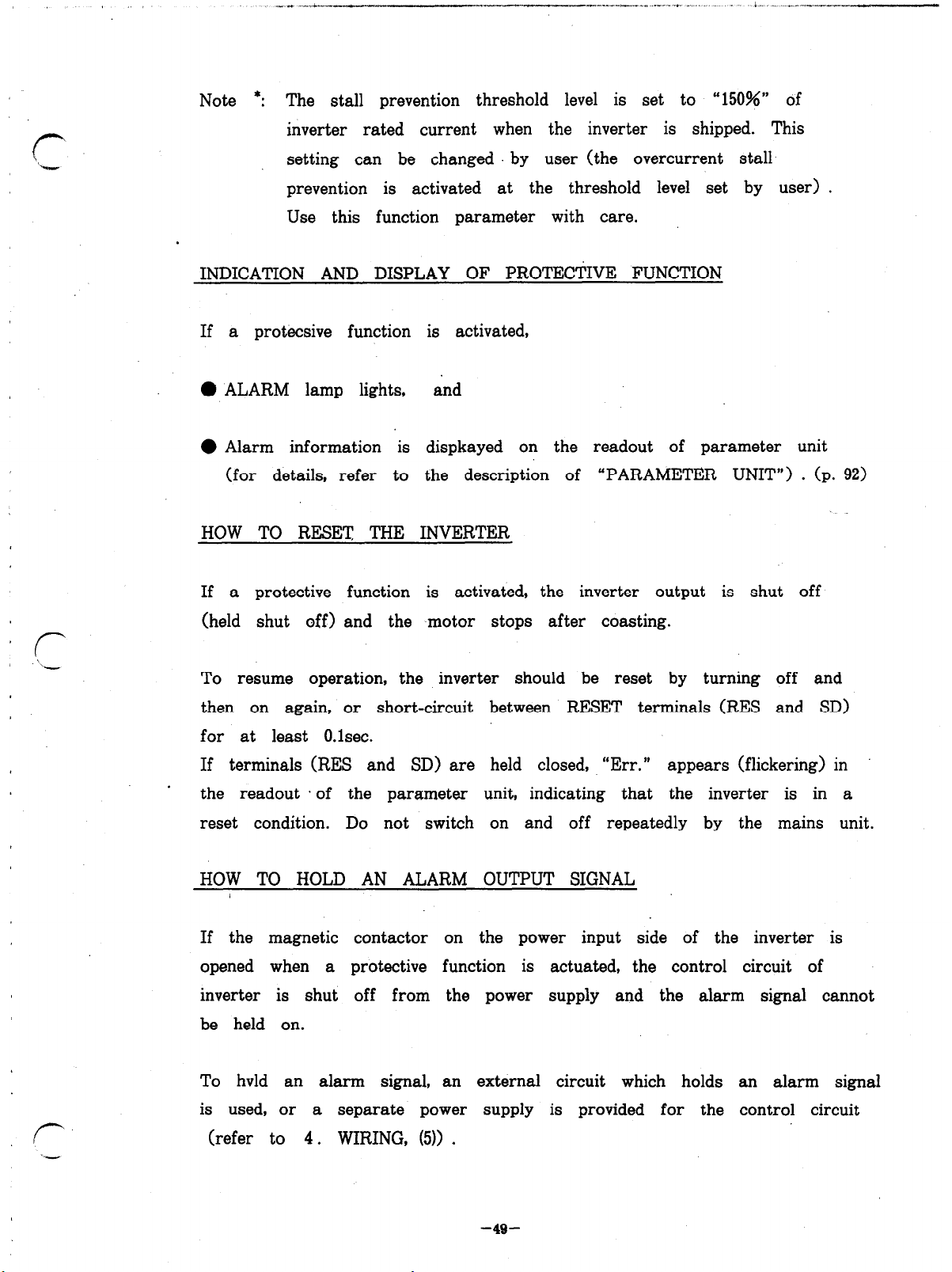

Note *: The stall prevention threshold level is set to “150%” of

inverter rated current when the inverter is shipped. This

setting can be changed by user (the overcurrent stall

prevention is activated at the threshold level set by user) .

Use this function parameter with care.

INDICATION AND DISPLAY OF PROTECTIVE FUNCTION

If a protecsive function is activated,

0 ALARM lamp lights,

and

0 Alarm information is dispkayed on the readout of parameter unit

(for details, refer to the description of

“PARAMETER UNIT”) . (p. 92)

HOW TO RESET THE INVERTER

If a protective function is activated, the inverter output is shut off

(held shut off) and the -motor stops after coasting.

To resume operation, the inverter should be reset by turning off and

then on again, or short-circuit between RESET terminals (RES and SD>

for at least O.lsec.

If terminals (RES and SD) are held closed, “Err.” appears (flickering) in

the readout * of the parameter unit, indicating that the inverter is in a

reset condition. Do not switch on and off repeatedly by the mains unit.

HOW TO HOLD AN ALARM OUTPUT SIGNAL

/

If the magnetic contactor on the power input side of the inverter is

opened when a protective function is actuated, the control circuit of

inverter is shut off from the power supply and the alarm signal cannot

be held on.

To hvld an alarm signal, an external circuit which holds an alarm signal

is used, or a separate power supply is provided for the control circuit

r

‘1

(refer to 4. WIRING, (5)) .

-4Q-

Page 54

ALARM HISTORY

The alarm information is stored In the memory (E’ROM) of inverter, and

not erased even when the power is turned off.

Since a maximum of 4 alarms can be stored in the memory, they can

be read one by one to identify the cause (for details, refer to the

description’ of “PARAMETER UNIT”) . (p. 89)

0

0

-5o-

0

Page 55

_x_

,*

..*-_..-

_IL_~~-_*--_--l-_II

,._-_

1. . .

..^

.c

--

..--

--

§ 8. SPECIFICATIONS

8.1 Block diagram

Factory use

Provided only

in 400V class

Forward run

Reverse run

stop

Multi- speed

selection

JOG/OH

select

2nd accel./

decel.

Output halt

Current

input

common

Reset

0

B..

t ATT

(Note 2 )

CPU

(Note 1)

PR.

I I

I ,I

G3

LSI

Custom -

made)

ALARM

-3

i

,

RA

s

(Note 3)

ii Jjg/y’

Common dr

DC 4 -2OmA >

DCOm+lOV>

DCOmk5V

> ‘lE

Notes:

-J

+1ov

Y

:onnector

14

T -

il K

Y

Parameter unit

FR-PUOl

1

--

1 . Terminal PR is provided in FR-Z220-0.4K to 7.5K,

and FR-Z24+2.2K to 7.5K.

-51-

-I

RUN

su

OL

IPF

FU

SE

i

Ground

Page 56

2. Terminal P 1 is provided in FR-Z220-5.5K to 55K, and

FR-Z240-5.5K to 55K.

3. Terminal CS is provided in models larger than FR-Z220-15K

and FR-Z240-11K.

*4 . For models larger than llK, built-in regenerative brake resistor

and brake transistor are not installed in the inverter. Fit

” BU ” brake option externally. on these larger models.

See page 53. P, P 1, PR, N.

0

0

-52-

0

Page 57

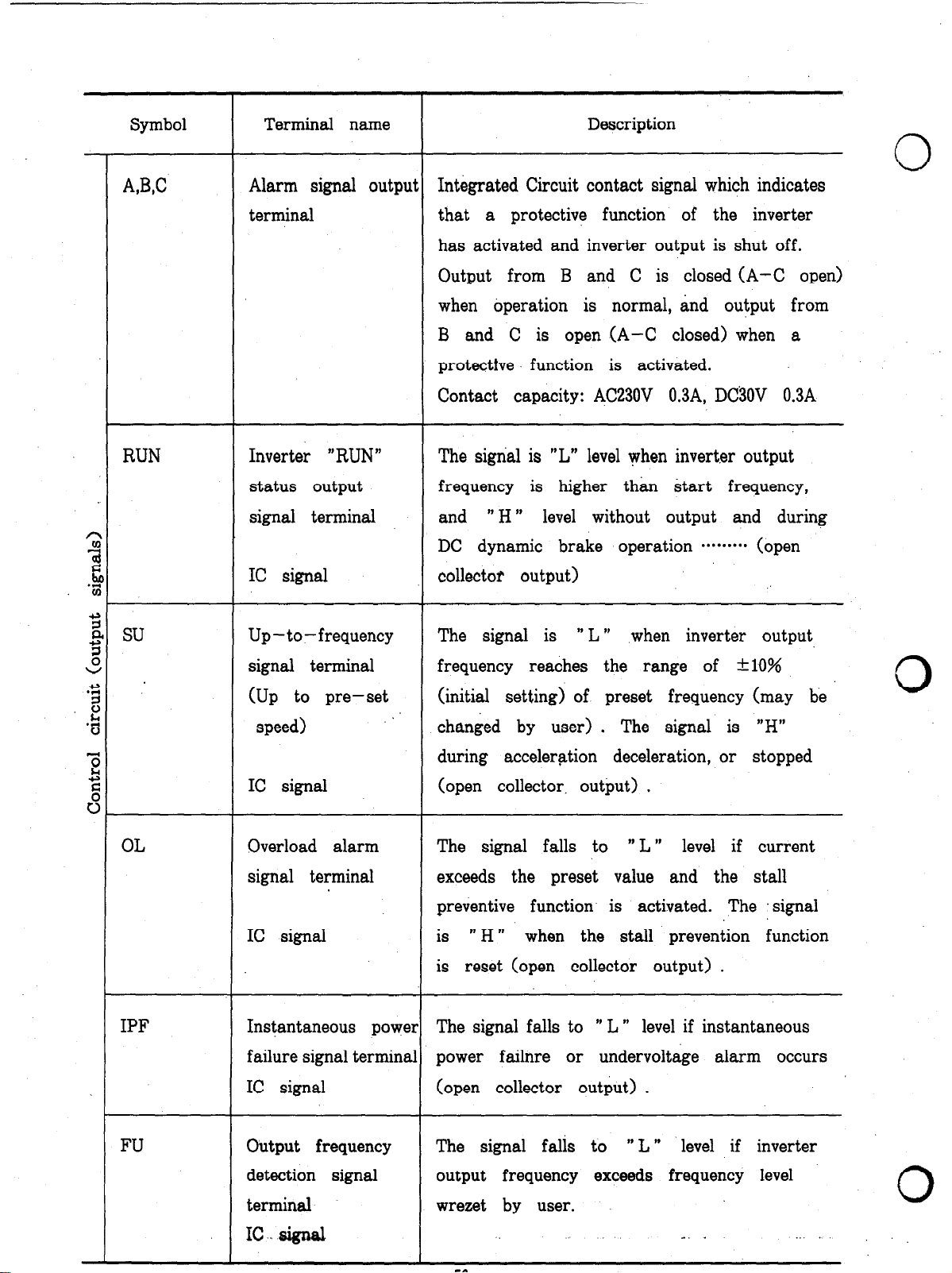

8.2 Terminals

. .-

__,....-_ .___ j. ,. _I” .-... c.“---....” __,-.-”

Symbol

STF

L

STR

Terminal name

AC power supply

input terminals

Inverter output

terminals

Converter output

terminals

Control power

supply terminals

Ground terminal

Forward

start input signal

terminal

Reverse

start input signal

terminal

Description

Connected to commercial power supply

Connected to three-phase squirrel-cage motor

Connected to optional BU type brake unit

(terminals P and N) or external regenerative

brake resistor (terminals P and PR)

Connected to power supply terminals (R and

S) in the inverter. When it is desirous to

hold alarm display, remove jumper wire from

terminals R and S and connect external

power supply to these terminals.

Inverter chassis grounding terminals

Motor starts rotating in forward

direction (normal run) when ,STF and SD

are short-circuited.

Motor starts rotating in reverse direction

when STR and SD are short-circuited.

STOP

RH,RM,RL

JOG/OH

Start signal selfhold terminal

Multi-speed

select terminals

JOG mode select or

external thermal

Start signal can be self-held ,when STOP

and SD are short-circuited. (p. 13)

A speed range can be selected from 7

different preset speed ranges. (p. 103)

JOG operation mode is selected when JOG

and SD are short-circuited.

To start and stop in JOG, use. signals

STF and SIR. (p. 106)

-53-

Page 58

Symbol

Terminal name

Description

JOG/OH

Continued)

RT

MRS

RES

AU

With external relay, it is possible to stop

inverter operation by a thermal contact

input signal.

2 nd acceleration/ 2 nd acceleration/deceleration time can be

deceleration time selected by short-circuiting, between RT and

select terminal SD.

Inverter output

shutoff, input

terminal

Reset signal, input

terminal

Current frequency

reference signal

select terminal

Shuts off transistor base current (inverter

output) to stop motor by. means of

magnetic brake, etc.

Inverter output is shut off when MRS and

SD are short-circuited.

To reset inverter after tripping, RES and

SD are* short-circuited for ‘more than O.lsec,

When AU and SD are short-circuited, DC

current ranging from 4 mA to 20mA can

be used as frequency reference signal.

0

0

SD

10

2

Instantaneous stop,

restart select

terminal

Common terminal .foi

contact input

Power supply

terminal for

frequency reference

Frequency reference

input signal

When CS and SD are held short-circuited,

operation is restarted automatically after

restoration following a power failure. (p. 12)

Common to contact input signal and

frequency indication

Insulated from common’ circuit of inverter

control circuit

DC 5 V or DClOV (selestabble by changing

position of connector) . See p. 23.

Permissible maximum load current: 1OmA

When 0 to 5 V signal ‘(or 0 to lOV> is

input, the output frequency is at a maximum

at 5 V (or lOV> of input voltage.

0

-54-

Page 59

..-...--- .s .I .-,-A.. .-. .- .-.. “.A..” “_. . ..,&.--

If-

1/ -

-‘w

Symbol

2

IContinued)

5

Terminal name

Common terminal fol

frequency reference

Description

The output frequency is directly proportional

to the input frequency reference signal

voltage. The frequency reference signal

voltage is within range from

ov to 5v

when connector (CON 5 > is engaged to m 5 V “,

and within range from

engaged to

” 1ov ” .

0 V to 1OV when

See p.23.

Input resistance : 1Okohm

Common to frequency reference input signal

Not insulated from common circuit of the

control circuit

Do not ground this terminal.

.K

1E

4

Auxiliary frequency

reference input signal

terminal

Auxiliary frequency

reference input signal

terminal

Current frequency

When DC0 to +lOV is input, the output

frequency becomes

-lOV*) .

The output frequency is proportional

maximum at +lOV (or

to the input frequency reference signal voltage.

The signal is added to signal on terminal 2.

Input resistance: 1Okohm

When DC0 to + 5 V is input, the output

frequency reaches a maximum at + 5 V (or

- 5 V * > . The output frequency is proportional

to the frequency reference signal voltage.

The signal is added to reference on terminal 2.

Input resistance: 1Okohm

Current signal ranging from DC4 mA to

r

-a.-.-

reference input

signal terminal

20mA is input.

Input rezistance: 2500hm

-55-

Page 60

Symbol

-56-

A,W

Terminal name

Alarm signal outpui

terminal

Description

0

Integrated Circuit contact signal which indicates

that a protective function of the inverter

has activated and inverter output is shut off.

Output from B and C is closed (A-C open)

when operation is normal, and output from

B and C is open (A-C closed) when a

protectfve function is activated.

Contact capacity: AC230V 0.3A, DC3OV 0.3A

RUN

Inverter “RUN”

status output

signal terminal

IC signal

Up-to-frequency

signal terminal

(Up to pre-set

speed)

IC signal

Overload alarm

signal terminal

The signal is “L” level when invert.er output

frequency is higher than start frequency,

and ” H ” level without output and during

DC dynamic brake operation ********. (open

collector output)

The signal is ” L ”

frequency reaches the range of -tlO%

(initial setting) of preset frequency (may be

changed by user) . The signal is “H”

during acceleration deceleration, or stopped

(open collector, output) .

The signal falls to ” L ” level if current

exceeds the preset value and the stall

preventive function is activated. The signal