Page 1

Page 2

V

RF system

VRF stands for Variable Refrigerant Flow.

A VRF air conditioning system modulates the

flow of refrigerant depending upon the capacity

requirements of the building. In its simplest

form, a VRF system comprises an air-cooled

outdoor unit and a series of indoor units that

regulate the air temperature inside an internal

space.

I

nverter driven technology

At Mitsubishi Electric we strive to continually

meet the increasing demands of our customers,

being the first in the industry to offer highly

advanced ‘inverter driven’ systems. Using

inverter technology our systems produce just

the right amount of output to match the exact

requirement of any building. These systems

work so efficiently that they don’t waste

valuable energy by over-heating or

over-cooling, resulting in greatly reduced

running costs. Alternative systems that may

appear cheaper, can often cost substantially

more to run, making us the most cost effective

choice all round.

I

ntelligent Power Module (IPM)

technology

The CITY MULTI range from Mitsubishi Electric

provides precise control of energy input,

through utilization of its Intelligent Power

Module (IPM) technology. By employing this

technology, highly efficient operation is possible

with compact units closely matching building

requirements.

R

410A refrigerant

As scientific evidence points to man-made

chemicals for the damage caused to the ozone

layer, we only use chlorine-free refrigerants

that are safe with zero ODP (Ozone Depletion

Potential). Accordingly, our systems require

less energy to run, and have a significantly

lower indirect global warming potential. In

short, we produce the most efficient equipment

possible, while helping to protect the environ-

ment.

Known the world over, the name

Mitsubishi is a trusted household

name associated with a variety of

products and services. Founded in

1920, the company known today as

Mitsubishi Electric, quickly rose to the

forefront of the air conditioning

industry - a position we still enjoy

today. We pride ourselves on offering

some of the most energy efficient

systems available on the market.

Our Latest Technologies

Unsurpassed air conditioning

from Mitsubishi Electric

Air conditioning is an ideal way of controlling the temperature, movement and

cleanliness of air inside any building, large or small. With today's buildings being so

well insulated and increasingly full of electronic equipment, the need for effective

climate control is greater than ever. Not only does it cool in the summer months, but

air conditioning can also heat, doing away with the need for separate heating systems

altogether. More and more people today are enjoying the benefits of comfortable

working and living environments made possible with air conditioning.

Features of Mitsubishi Electric

air conditioners

Page 1-16

Remote Controller Page 17-36

Indoor unit Page 37-79

Outdoor unit Page 80-135

Optional parts Page 137-140

Contents

Known the world over, the name

Mitsubishi is a trusted household

name associated with a variety of

products and services. Founded in

1920, the company known today as

Mitsubishi Electric, quickly rose to the

forefront of the air conditioning

industry - a position we still enjoy

today. We pride ourselves on offering

some of the most energy efficient

systems available on the market.

Unsurpassed air conditioning

from Mitsubishi Electric

Features of Mitsubishi Electric

air conditioners

Page 1-16

Remote Controller Page 17-36

Indoor unit Page 37-79

Outdoor unit Page 80-135

Optional parts Page 137-140

Contents

Page 1

Page 2

Page 3

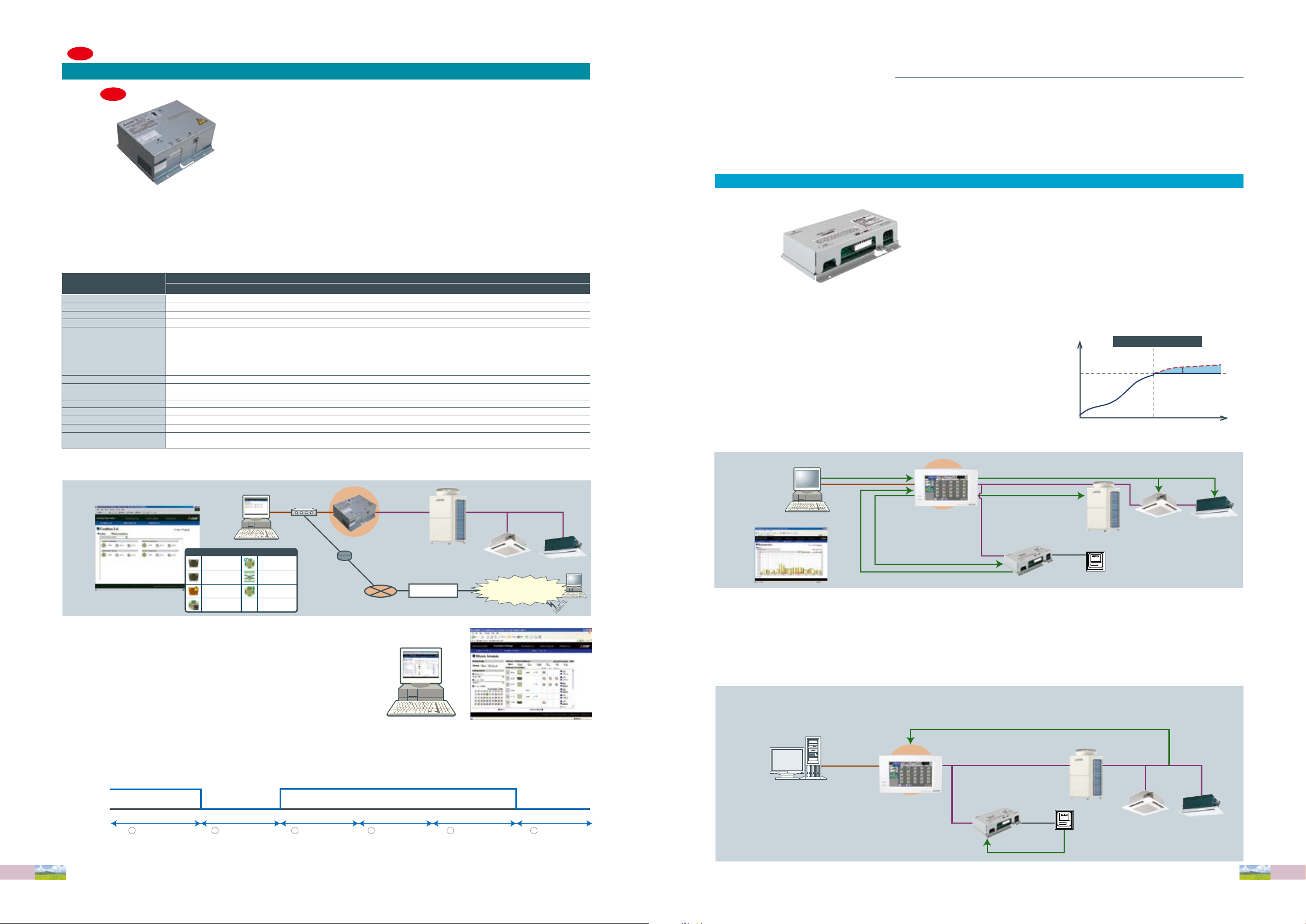

VRF system

Our answer to VRF

Designed and manufactured to the highest standards, the

CITY MULTI range offers one of the most reliable air

conditioning systems available. Simple to install and easy to

maintain, this range provides ideal solutions you can trust to

protect your investment.

Reliable

>All the CITY MULTI outdoor units are made in Japan under stringent control.

Mitsubishi Electric sets the boundaries of VRF technology with the CITY MULTI range, which is available using

R410A refrigerant with zero ODP (Ozone Depletion Potential). The range has been specifically designed for

today’s building requirements and addresses key market issues such as energy efficiency, adaptability and

reliability. With user friendly control systems utilizing internet technology and integrated cooling and ventilation

indoor units, CITY MULTI is the benchmark and market leader in VRF technology.

VRF is a multi and direct expansion type air conditioning system where by one outdoor unit can be connected with

multiples indoor units. The amount of refrigerant can be regulated freely according to the load on the indoor unit by

the inverter driven compressor in the outdoor unit. Zoning in a small office is possible with a small capacity indoor

unit. Energy conservation is easily handled because individual indoor units can stop and start their operation as

needed. There are various indoor units available in order to suit various interior design needs.

Outdoor unit

Joint

Header

Inverter driven compressor

PEFY-VMS1

PEFY-VMR

ON 27°c

ON 25°c

ON 25°c

OFF

OFF

ON 23°c

ON 26°c

Controller

Indoor unit

PFFY-VKM

Sophisticated

yet simple technology

V

RF system

Our answer to VRF

Mitsubishi Electric sets the boundaries of VRF technology with the CITY MULTI range, which is available using

R410A refrigerant with zero ODP (Ozone Depletion Potential). The range has been specifically designed for

today’s building requirements and addresses key market issues such as energy efficiency, adaptability and

reliability. With user friendly control systems utilizing internet technology and integrated cooling and ventilation

indoor units, CITY MULTI is the benchmark and market leader in VRF technology.

VRF is a multi and direct expansion type air conditioning system where by one outdoor unit can be connected with

multiples indoor units. The amount of refrigerant can be regulated freely according to the load on the indoor unit by

the inverter driven compressor in the outdoor unit. Zoning in a small office is possible with a small capacity indoor

unit. Energy conservation is easily handled because individual indoor units can stop and start their operation as

needed. There are various indoor units available in order to suit various interior design needs.

Outdoor unit

Joint

Header

Inverter driven compressor

ON 27°c

ON 25°c

ON 25°c

OFF

OFF

ON 23°c

ON 26°c

Controller

Indoor unit

Page 3

Page 4

Page 4

I

nverter Driven Compressor

Technology - now up to 50HP

Using inverter driven technology

saves energy for several reasons:

The unique Heat Interchange Circuit (HIC) enhances efficiency by providing additional sub-cooling and allows the

expansion device to effectively control the refrigerant distribution, thereby increasing the operating efficiency and

reducing the volume of refrigerant in each system.

Heat Interchange Circuit

The compressor varies its speed to match the indoor cooling or heating demand and therefore only consumes the

energy that is required.

When an inverter driven system is operating at partial load, the energy

efficiency of the system is significantly higher than that of a standard fixed

speed, non inverter system.

The fixed speed system can only operate at 100%, however, partial load

conditions prevail for the majority of the time. Therefore fixed speed

systems cannot match the annual efficiencies of inverter driven systems.

Using proven single inverter driven compressor technology, the CITY

MULTI range is favored by the industry for low starting currents (only 8 amps

for a 16HP YJM-A outdoor unit), and smooth transition across the range of

compressor frequencies.

100%

15%

15Hz Cooling:74Hz

Heating:81Hz

Heating / Cooling Capacity

Linear Capacity

Control

Compressor Frequency

* image

Low

Starting

Currents

Low

Starting

Currents

CIT Y MULT I Refr igera n t Cir cuit

Condenser

High temperature

Supercooled

heat exchanger

Low temperature

LEV

Medium temperature

Bypass

LEV

Heat exchanger

Compressor

Accumulator

Evaporator

Common Refrigerant Circuit

Condenser

LEV

Compressor

Accumulator

Evaporator

All CITY MULTI compressors are inverter-driven type.

-Capable of precisely matching a building's cooling and heating demands.

The outdoor unit combinations comprise 1 unit for 8-18HP systems (for Y and R2 series), 2 units for 20-36HP

systems (for R2, 18-36HP) and 3 units for 38-50HP systems (Y series only). Each unit carries one inverter

compressor making simple and highly reliable control possible.

Not only does it allow low starting currents, the inverter-driven compressor also provides precise indoor comfort

and adapts to the air conditioning load.

Inverter

capacity

load load load

100%

capacity

100%

capacity

100%

1 inverter compressor

Y series 8-18HP

R2 series 8-18HP

Y series 20-36HP

Y series 38-50HP

R2 series 18-36HP

2 inverter compressors

No1

No1

No2

3 inverter compressors

No1

No1

No1

No2

No2

No3

Stable and smooth operation

Unbeatable Efficiency

I

nverter Driven Compressor

Technology - now up to 50HP

Using inverter driven technology

saves energy for several reasons:

The compressor varies its speed to match the indoor cooling or heating demand and therefore only consumes the

energy that is required.

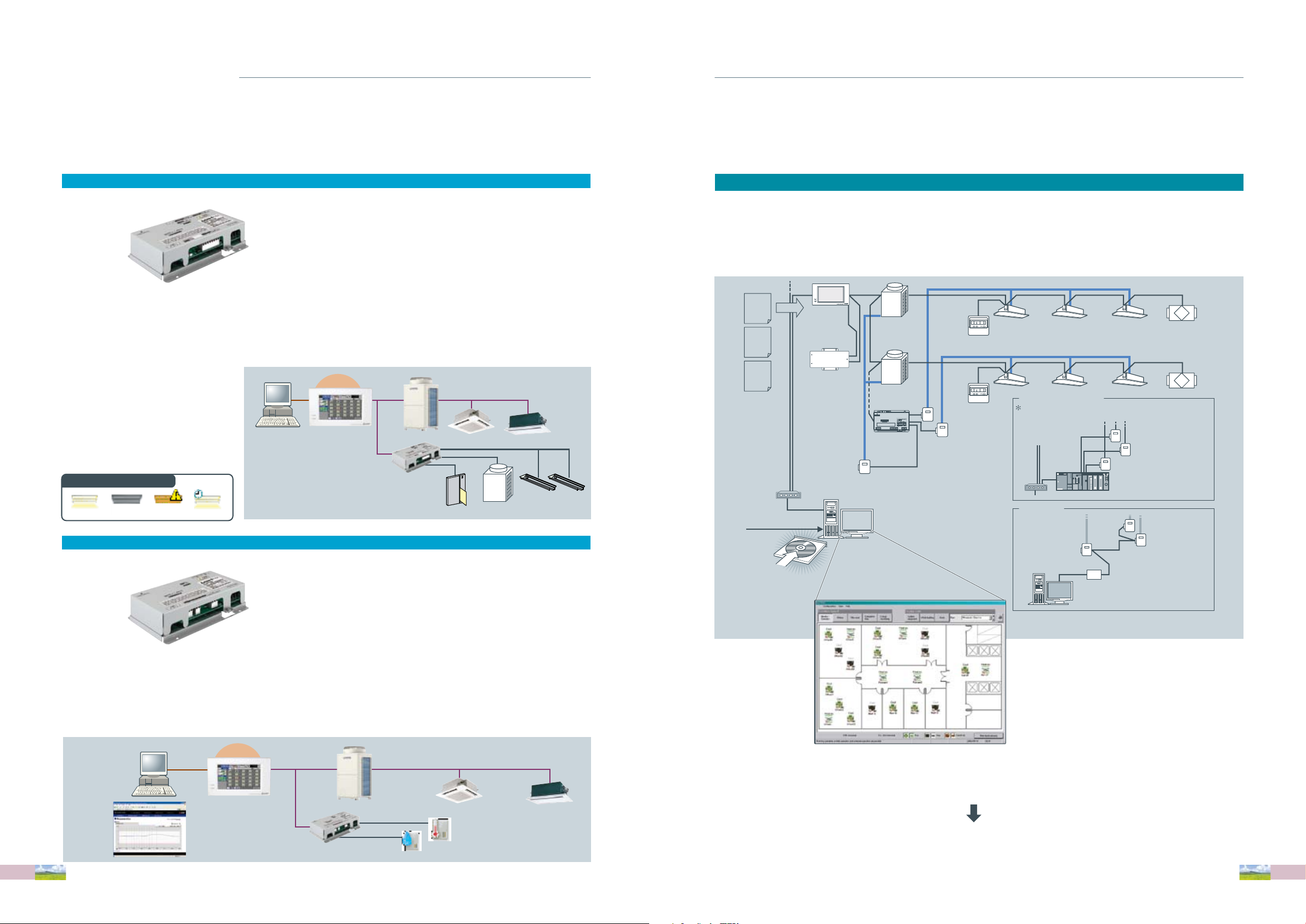

When an inverter driven system is operating at partial load, the energy

efficiency of the system is significantly higher than that of a standard fixed

speed, non inverter system.

The fixed speed system can only operate at 100%, however, partial load

conditions prevail for the majority of the time. Therefore fixed speed

systems cannot match the annual efficiencies of inverter driven systems.

Using proven single inverter driven compressor technology, the CITY

MULTI range is favored by the industry for low starting currents (only 8 amps

for a 16HP YJM-A outdoor unit), and smooth transition across the range of

compressor frequencies.

100%

15%

15Hz Cooling:74Hz

Heating:81Hz

Heating / Cooling Capacity

Linear Capacity

Control

Compressor Frequency

* image

Low

Starting

Currents

Low

Starting

Currents

All CITY MULTI compressors are inverter-driven type.

-Capable of precisely matching a building's cooling and heating demands.

The outdoor unit combinations comprise 1 unit for 8-18HP systems (for Y and R2 series), 2 units for 20-36HP

systems (for R2, 18-36HP) and 3 units for 38-50HP systems (Y series only). Each unit carries one inverter

compressor making simple and highly reliable control possible.

Not only does it allow low starting currents, the inverter-driven compressor also provides precise indoor comfort

and adapts to the air conditioning load.

Inverter

capacity

load load load

100%

capacity

100%

capacity

100%

1 inverter compressor

Y series 8-18HP

R2 series 8-18HP

Y series 20-36HP

Y series 38-50HP

R2 series 18-36HP

2 inverter compressors

No1

No1

No2

3 inverter compressors

No1

No1

No1

No2

No2

No3

Stable and smooth operation

Page 5

Page 6

Page 5

Comparison of COP (energy efficiency) – 8HP system

The difference between YJM-A and previous

Mitsubishi Electric models

Technology is key when increased efficiency is demanded.

The CITY MULTI YJM-A range is able to deliver this in simple ways.

The importance of COP

The YHM-A range from Mitsubishi Electric provides precise control of energy input, through utilization of its

Intelligent Power Module (IPM) technology. By employing this technology it is possible to closely match the

building requirements, achieving more accurate control of the occupied space. By using incremental 1Hz steps of

capacity control, the amount of power input required is significantly reduced, resulting in greatly improved COP’s.

In addition, IPM technology ensures effective performance under partial load conditions, a condition that most

systems will be in for the majority of the normal working life cycle. By taking account the efficiency at both part

load, and peak load conditions, R410A CITY MULTI is designed to provide unbeatable year round/seasonal

efficiency.

A highly efficient R410A scroll compressor design results in less friction losses at the motor. A simplified refrigerant

circuit (low pressure loss) including a new accumulator design also adds a few more points to the efficiency scale.

Enhancements to the heat interchange circuit, an inverter driven fan motor and a heat exchanger design again add

vital increases to overall system efficiencies and COPs.

COP stands for “Coefficient of Performance”. It is a measure of the useful energy a system can deliver compared

to the energy it consumes. It is calculated by dividing the energy output by the energy input of a system. The

higher the figure then the more efficient the system is deemed to be. Mitsubishi Electric VRF models, the world's

highest energy-efficient air-conditioners, will undoubtedly reduce millions of tons of CO2 emissions.

I

ntelligent Power Module (IPM)

Technology

4.05

0

R22

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Our equivalent product

10 years ago, PUHY-200YMF

*

Average COP of cooling / heating

29%

Energy Saving

COP

2.87

4.35

34%

Energy

Saving

High COP (Coefficient of Performance)

is realized

Standard model High COP model

Total Energy Conservation

The difference between YJM-A and previous

Mitsubishi Electric models

Technology is key when increased efficiency is demanded.

The CITY MULTI YJM-A range is able to deliver this in simple ways.

The importance of COP

The YHM-A range from Mitsubishi Electric provides precise control of energy input, through utilization of its

Intelligent Power Module (IPM) technology. By employing this technology it is possible to closely match the

building requirements, achieving more accurate control of the occupied space. By using incremental 1Hz steps of

capacity control, the amount of power input required is significantly reduced, resulting in greatly improved COP’s.

In addition, IPM technology ensures effective performance under partial load conditions, a condition that most

systems will be in for the majority of the normal working life cycle. By taking account the efficiency at both part

load, and peak load conditions, R410A CITY MULTI is designed to provide unbeatable year round/seasonal

efficiency.

A highly efficient R410A scroll compressor design results in less friction losses at the motor. A simplified refrigerant

circuit (low pressure loss) including a new accumulator design also adds a few more points to the efficiency scale.

Enhancements to the heat interchange circuit, an inverter driven fan motor and a heat exchanger design again add

vital increases to overall system efficiencies and COPs.

COP stands for “Coefficient of Performance”. It is a measure of the useful energy a system can deliver compared

to the energy it consumes. It is calculated by dividing the energy output by the energy input of a system. The

higher the figure then the more efficient the system is deemed to be. Mitsubishi Electric VRF models, the world's

highest energy-efficient air-conditioners, will undoubtedly reduce millions of tons of CO2 emissions.

I

ntelligent Power Module (IPM)

Technology

Page 7

Page 8

Page 6

For the Environment

History of refrigerant

R22, an HCFC-based refrigerant, has been a popular choice for most chillers. R22 has been targeted by the

Montreal Protocol to be phased out in new equipment. Additionally, governments in many countries are enforcing a

ban of HCFC-based refrigerants for new installations.

Because of these restrictions, R410A refrigerants are desirable. R410A is a blend of HFCs, which do not deplete

the ozone.

Technical aspects of refrigerant

New Design

R410A is a more efficient refrigerant as it has a higher specific heat capacity when compared to R407C or R22.

This higher energy carrying capacity allows for smaller pipe sizes, longer pipe runs and reduces the volume of

refrigerant within a system. This is a major factor when concerning safety and environmental requirements in the

design, manufacture, installation, operation, maintenance and disposal or refrigerating systems.

Enhancing environmental care (measures for the RoHS Directive and the refrigerant reduction)

Every unit is in compliance with the RoHS Directive,* which stands for the Restriction of Hazardous Substances:

Lead-free soldering is used to avoid Lead Groundwater Contamination on the print board. The amount of

refrigerant on the unit has also been reduced to enhance environmental care.

* RoHS Directive: the restriction of the use of certain hazardous substances in electrical and electronic equipment that has been sold in EU since July 2006

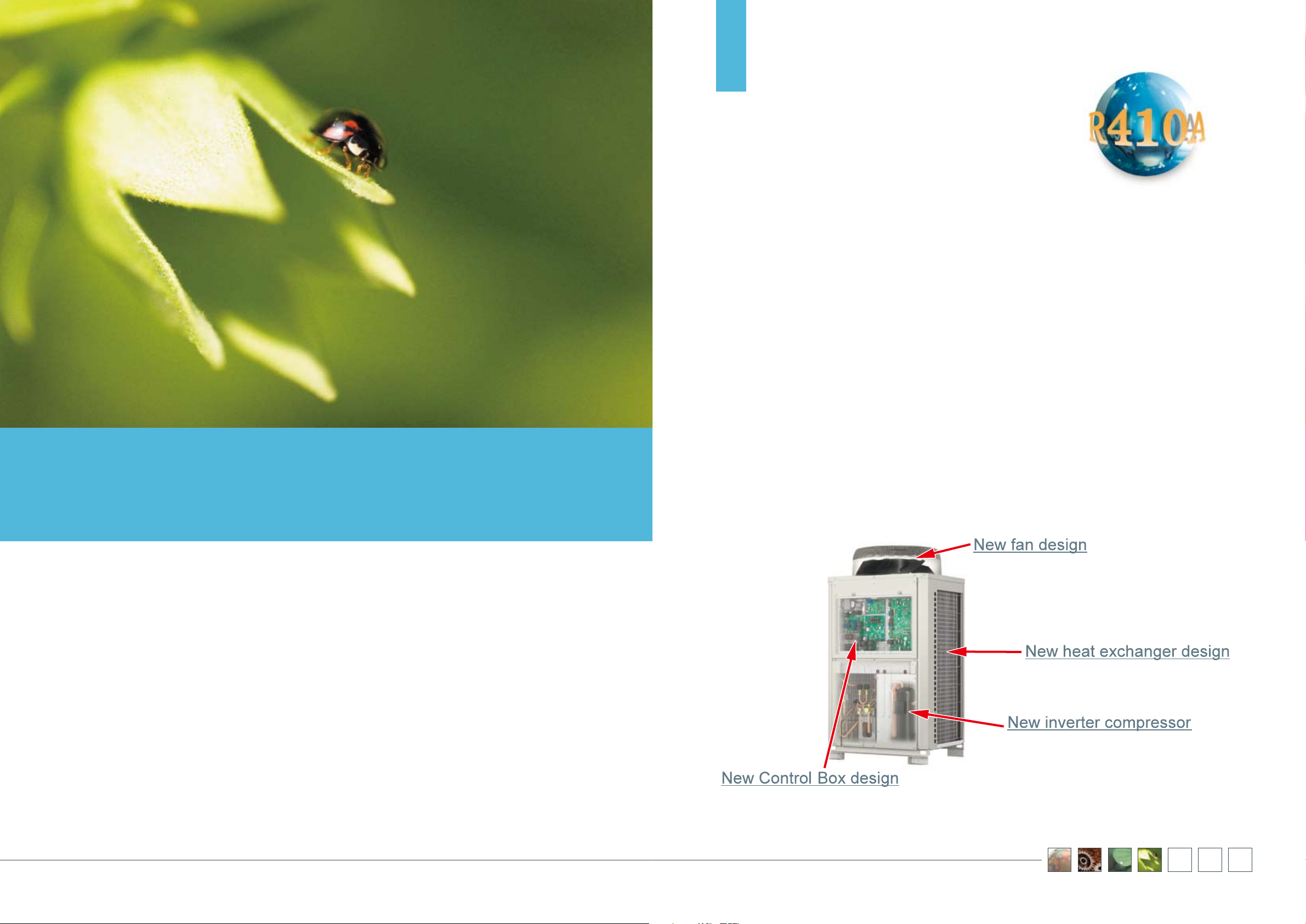

E

fficient R410A refrigerant

Reduction of operation noise

Improvement of COP

Improvement of COP

Improvement of reliability and

easy maintenance

Photo : Y series

History of refrigerant

R22, an HCFC-based refrigerant, has been a popular choice for most chillers. R22 has been targeted by the

Montreal Protocol to be phased out in new equipment. Additionally, governments in many countries are enforcing a

ban of HCFC-based refrigerants for new installations.

Because of these restrictions, R410A refrigerants are desirable. R410A is a blend of HFCs, which do not deplete

the ozone.

Technical aspects of refrigerant

New Design

R410A is a more efficient refrigerant as it has a higher specific heat capacity when compared to R407C or R22.

This higher energy carrying capacity allows for smaller pipe sizes, longer pipe runs and reduces the volume of

refrigerant within a system. This is a major factor when concerning safety and environmental requirements in the

design, manufacture, installation, operation, maintenance and disposal or refrigerating systems.

E

fficient R410A refrigerant

Reduction of operation noise

Improvement of COP

Improvement of COP

Improvement of reliability and

easy maintenance

Photo : Y series

Page 9

Page 10

Page 7

Equipment room

Office compartment

Office

Office

Meeting room

BC controller

Outdoor unit

Refrigerant piping: 2-pipe type

Meeting room

Cooling

Cooling

Cooling

Heating

Heating

Heating

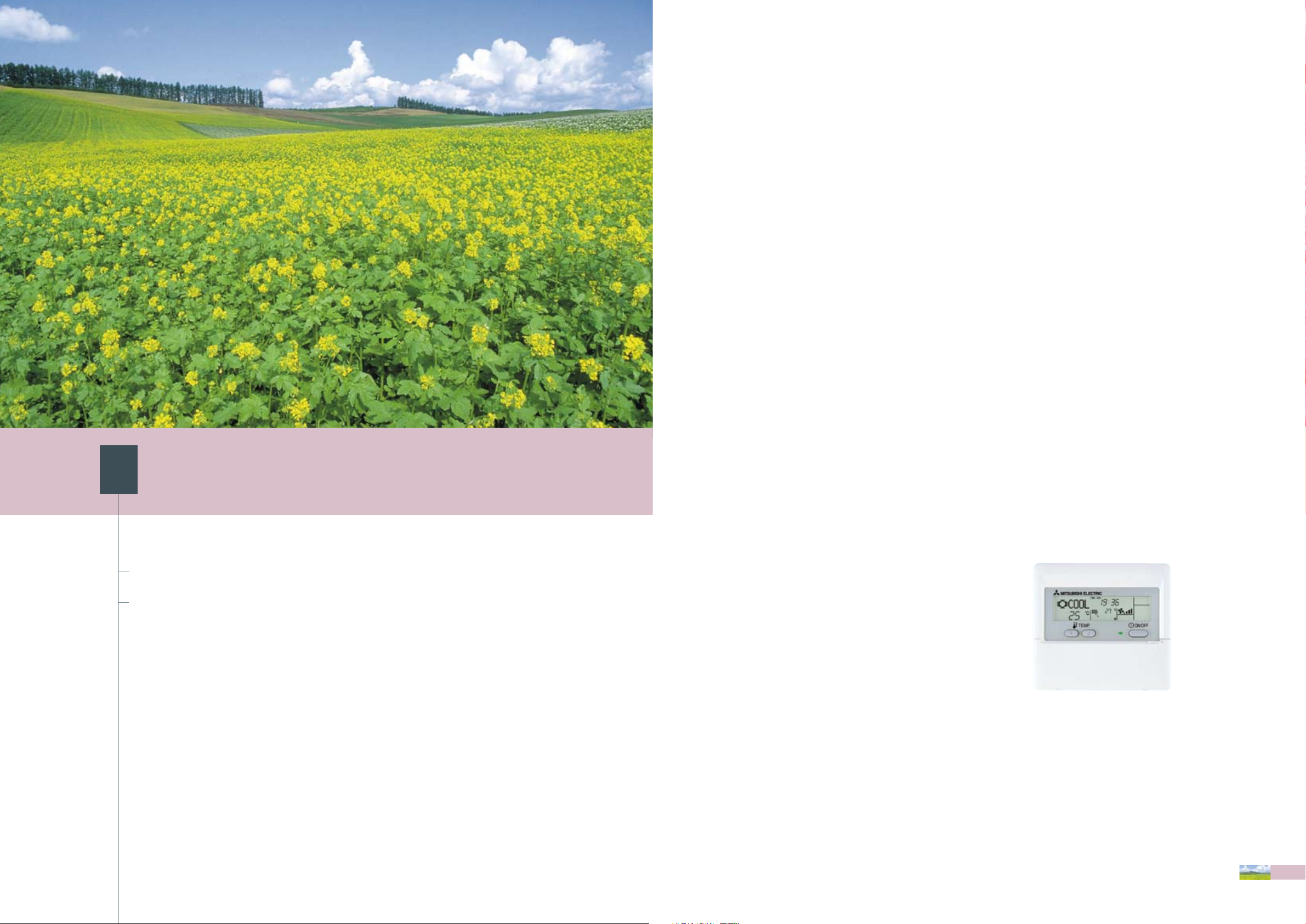

Why Heat Recovery?

Flexibility and efficiency are key factors when selecting a heat recovery system. For example, while a heat pump

system is adequate for a large open-plan office, an office that has a more partitioned structure will require the need

to simultaneously heat or cool different sections of the office according to each user's individual preferences. The

efficiency of this type of system comes from the ability to use the by-products of cooling and heating to transfer

energy where it is required, thus acting as a balanced heat exchanger achieving up to 20% cost savings over a

conventional heat pump system. The number of connection sites needed for a R2 / WR2 system are also signifi-

cantly lower than those needed for a three pipe version. This helps to reduce installation costs, further increasing

the savings associated with CITY MULTI.

U

nique technology

By the heat recovery system, the more frequently cooling and heating simultaneous

operation is carried out, the higher energy-saving effect becomes.

Unique to Mitsubishi Electric, our heat recovery technology uses just two pipes,

as opposed to the market conventional three. Designed for effective simultaneous

heating and cooling our R2 and WR2 systems offer substantial savings on

installation and annual running costs.

A

B

C

15HP

10HP

7.5HP

5HP

5HP 7.5HP 10HP

Mainly heating operation

Cooling indoor unit

Heating indoor unit

15HP

Total heat recovery operation

( )

Total 15HP indoor unit is connected

with 10HP outdoor unit.

SystemOperation pattern of

Affordable & Effective

air conditioning you can rely on

Equipment room

Office compartment

Office

Office

Meeting room

BC controller

Outdoor unit

Refrigerant piping: 2-pipe type

Meeting room

Cooling

Cooling

Cooling

Heating

Heating

Heating

Why Heat Recovery?

Flexibility and efficiency are key factors when selecting a heat recovery system. For example, while a heat pump

system is adequate for a large open-plan office, an office that has a more partitioned structure will require the need

to simultaneously heat or cool different sections of the office according to each user's individual preferences. The

efficiency of this type of system comes from the ability to use the by-products of cooling and heating to transfer

energy where it is required, thus acting as a balanced heat exchanger achieving up to 20% cost savings over a

conventional heat pump system. The number of connection sites needed for a R2 / WR2 system are also signifi-

cantly lower than those needed for a three pipe version. This helps to reduce installation costs, further increasing

the savings associated with CITY MULTI.

U

nique technology

Unique to Mitsubishi Electric, our heat recovery technology uses just two pipes,

as opposed to the market conventional three. Designed for effective simultaneous

heating and cooling our R2 and WR2 systems offer substantial savings on

installation and annual running costs.

Page 11

Page 12

Page 8

“2-pipe” system provides

Better Efficiency and Performance

How does the R2/WR2 Heat Recovery System

operate on 2 Pipe’s?

The secret of CITY MULTI heat recov-

ery systems lies in the

The BC Controller houses a liquid/gas separator,

allowing the outdoor unit to deliver a mixture (2

phase) of hot gas for heating and liquid for cooling,

all through the same pipe. Three pipe systems

allocate a pipe to each of these phases. When this

mixture arrives at the BC Controller, it is separated

and the correct phase delivered to each indoor unit

depending on the individual requirement of either

heating or cooling.

BC Controller

Comparison example of piping connection sites

T

he world’s first and

the only “2-pipe” system

Heating=gas refrigerant

Cooling=liquid refrigerant

Meet the demand of

cooling / heating flexibly.

Indoor unit

2

1

R2/WR2 refrigerant circuit

3

High pressure and low pressure

decides the compressor frequency

and the mode of heat exchanger,

and control the amounts of heat

exchange.

Adjust the refrigerant flow by temperature

difference between inlet and outlet.

Gas-liquid 2-phase refrigerant from outdoor unit into

gas refrigerant and liquid refrigerant is divided by

gas-liquid separator in BC controller.

BC controller divides refrigerant to each indoor unit

properly in compliance with the operation mode of

each indoor unit.

High pressure

gas-liquid 2 phase

refrigerant

Outdoor unit

BC controller

Gas refrigerant

Gas

refrigerant

Liquid refrigerant

Heating Heating Cooling Cooling

Liquid

refrigerant

25°C 26°C 22°C 24°C

Outdoor Unit Outdoor Unit

Indoor Units Indoor Units

Solenoid Box

MITSUBISHI ELECTRIC OTHER MANUFACTURERS

BC Controller

CITY MULTI R2 3 Pipe System

= 2 sites = 3 sites

How does the R2/WR2 Heat Recovery System

operate on 2 Pipe’s?

The secret of CITY MULTI heat recovery systems lies in the

The BC Controller houses a liquid/gas separator,

allowing the outdoor unit to deliver a mixture (2

phase) of hot gas for heating and liquid for cooling,

all through the same pipe. Three pipe systems

allocate a pipe to each of these phases. When this

mixture arrives at the BC Controller, it is separated

and the correct phase delivered to each indoor unit

depending on the individual requirement of either

heating or cooling.

BC Controller

T

he world’s first and

the only “2-pipe” system

Heating=gas refrigerant

Cooling=liquid refrigerant

Meet the demand of

cooling / heating flexibly.

Indoor unit

2

1

R2/WR2 refrigerant circuit

3

High pressure and low pressure

decides the compressor frequency

and the mode of heat exchanger,

and control the amounts of heat

exchange.

Adjust the refrigerant flow by temperature

difference between inlet and outlet.

Gas-liquid 2-phase refrigerant from outdoor unit into

gas refrigerant and liquid refrigerant is divided by

gas-liquid separator in BC controller.

BC controller divides refrigerant to each indoor unit

properly in compliance with the operation mode of

each indoor unit.

High pressure

gas-liquid 2 phase

refrigerant

Outdoor unit

BC controller

Gas refrigerant

Gas

refrigerant

Liquid refrigerant

Heating Heating Cooling Cooling

Liquid

refrigerant

25°C 26°C 22°C 24°C

Page 13

Page 14

Page 9

What is Water-Cooled?

It is possible now to combine the features of VRF with a water circuit using CITY

MULTI WR2/WY. In this case the heat is rejected to a water source rather than to

the outside air.

The advantages of water cooled systems are that the water can be delivered at

optimised temperatures and volumes, which allows even greater flexibility and

increased COP.

WR2(Heat recovery type)

>A unique offering from Mitsubishi Electric

Mitsubishi Electric now offers double heat recovery operation.

The first heat recovery is within the refrigerant system. Simultaneous cooling and heating operation is available

with heat recovery performed between indoor units.

The second heat recovery is within the water loop, where heat recovery is performed between the PQRY units.

This double heat recovery operation substantially improves energy efficiency and makes the system the ideal

solution to the requirements of modern office buldings, where some areas require cooling even in winter.

Water cooled systems can be used even in buildings

that are taller than 50m by running a main water pipe

through each floor.

Any heat source system that can supply heat source

water between 10°C~45°C can be used.

Simultaneous heating and cooling operation is available.

(WR2 series)

It is suggested that Water-Cooled systems are used in the

buildings in which there are heating and cooling needs as follows.

Buildings that require all year cooling

Example,

Tenant buildings in which kitchens and offices exist together

Buildings in which equipment rooms and offices exist together

Buildings in which there are large room temperature

differences between sunny and unsunny rooms

Hotels in which there are a lot of individual operation needs

E

nergy Saving Technology

Director's room

Heat source unit

Meeting room

BC controller

Meeting room

Equipment room

Water piping

Heat

source

unit

Water cooled systems are ideally suited for use in temperate and

cooler climates since heat exchange with the outside air is not

required.

Indoor units

Indoor units

Heat source unit

BC controller

Double heat recovery (WR2)

Heat recovery

Heat recovery

Heat recovery

Water

circuit

Refrigerant Circuit

Heating

Cooling

Heating

Cooling

Equipment room

CoolingHeating

Heating

Water Cooled CITY MULTI Benefits

What is Water-Cooled?

It is possible now to combine the features of VRF with a water circuit using CITY

MULTI WR2/WY. In this case the heat is rejected to a water source rather than to

the outside air.

The advantages of water cooled systems are that the water can be delivered at

optimised temperatures and volumes, which allows even greater flexibility and

increased COP.

WR2(Heat recovery type)

>A unique offering from Mitsubishi Electric

Mitsubishi Electric now offers double heat recovery operation.

The first heat recovery is within the refrigerant system. Simultaneous cooling and heating operation is available

with heat recovery performed between indoor units.

The second heat recovery is within the water loop, where heat recovery is performed between the PQRY units.

This double heat recovery operation substantially improves energy efficiency and makes the system the ideal

solution to the requirements of modern office buldings, where some areas require cooling even in winter.

E

nergy Saving Technology

Director's room

Heat source unit

Meeting room

BC controller

Meeting room

Equipment room

Water piping

Heat

source

unit

Indoor units

Indoor units

Heat source unit

BC controller

Double heat recovery (WR2)

Heat recovery

Heat recovery

Heat recovery

Water

circuit

Refrigerant Circuit

Heating

Cooling

Heating

Cooling

Equipment room

CoolingHeating

Heating

Page 15

Page 16

Page 10

Remote Controller

Individual Remote Controller

Centralized Remote Controller

The need for control is paramount in order

to optimise the performance of any air

conditioning system and minimize its

running costs. Mitsubishi Electric offers a

wide range of control options designed to

meet such needs.

Operating an air conditioning system without

the right control can prove costly. It's therefore

important to ensure that every system is

correctly specified to the degree of control it

requires. Mitsubishi Electric have a wide range

of controls available 'off-the-shelf' and

individual control systems can be specifically

designed to match.

Good controls will benefit any application,

large or small. Air conditioning products need

to react to a variety of factors: different room

sizes, usage and staff levels; changes in the

climate; electronic equipment and lighting ...the

list goes on. So whatever the application,

optimum control of air conditioning systems is

essential and will result in a constant,

comfortable environment, which in turn is both

energy and cost efficient.

A degree of difference

When an air conditioning system is not

properly controlled, it will not run as efficiently

as it should. For every degree that the system

deviates from the required temperature,

energy costs can rise by up to 5%. Specify one

of the many control options from Mitsubishi

Electric to ensure air conditioning works as

intended, whilst giving the optimum amount of

control.

The simpler, the better

With the array of comprehensive control

systems available from Mitsubishi Electric, it

becomes simple to design and install air

conditioning systems. From a simple

hand-held controller to a AG-150A system -

you are in control.

The importance of control

Remote Controller

Page 17 Page 18

Page 11

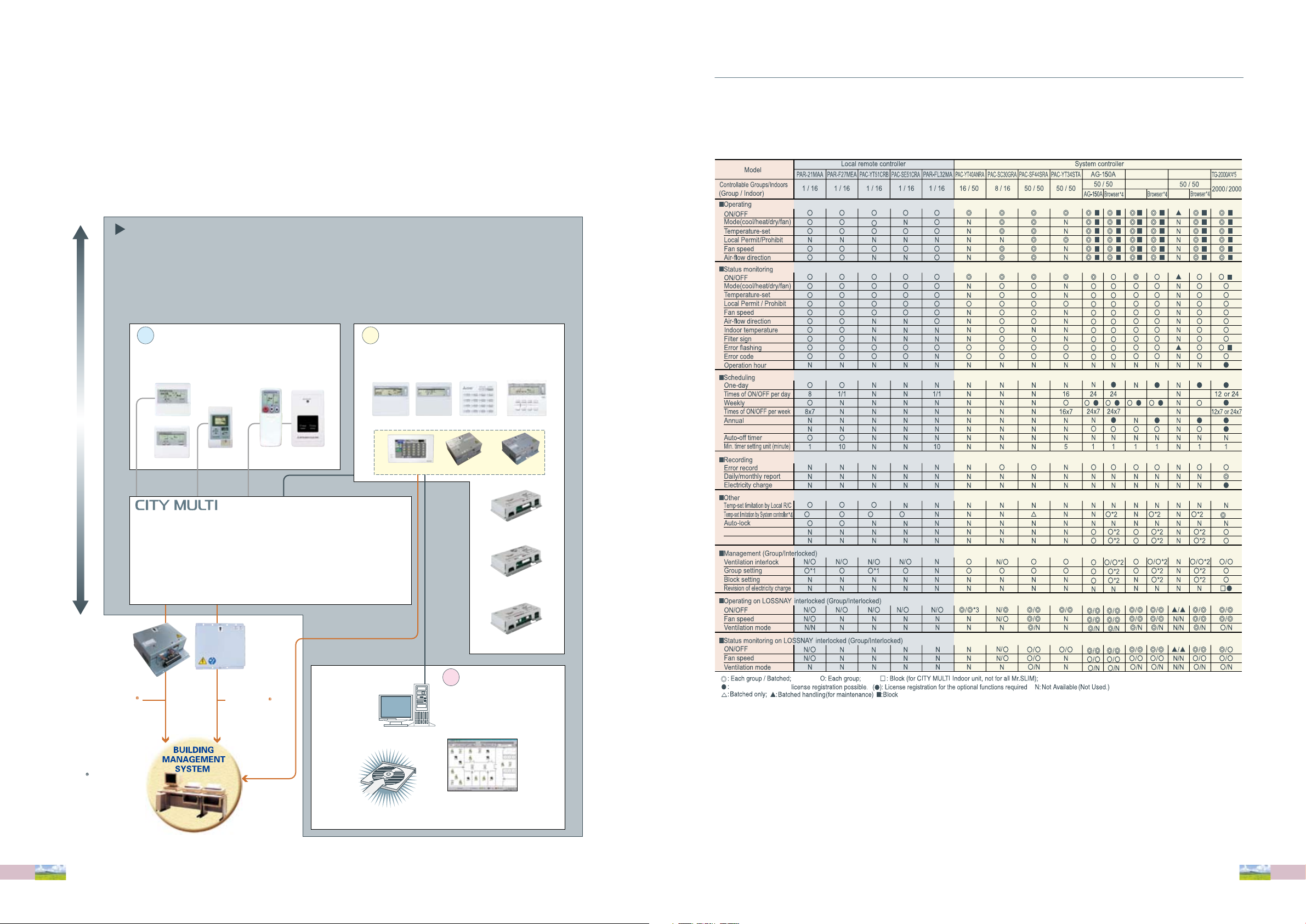

System Controller

MELANS

Use of our MELANS products enhances EFFICIENCY and QUALITY of air-conditioning, contributing to

ENERGY SAVING and reduction in running cost. We offer a wide variety of MELANS products to meet all

requirements - from the smallest and simplest to the largest and most complex.

We have individual remote controllers, various centralized controllers, and centralized integrated software, as

well as BMS interface hardware and software etc. Above all, with AG-150A/GB-50ADA, PC browser and long

distance remote control (monitoring and operating) via communication Network is possible and easy.

C entralized Remote ControllerI ndividual Remote Controller

LMAP02

Interface

LONWORKS

transmission line

Ethernet

Integrated centralized

control software TG-2000A

M-NET

MITSUBISHI ELECTRIC's Air-conditioner Network System (MELANS) leads air conditioner management a PC

browser and Network era.

System

Remote

Controller

Schedule

Timer

All of the local remote controllers feature liquid

crystal and LED displays and easy to operate.

Remote

Controller

Simple

Remote

Controller

Wireless

Remote

Controller

PAR-F27MEA

PAR-FA32MA

PAC-SE51CRA

PAC-YT51CRB

PAR-FL32MA

PAR-21MAA

OUTDOOR UNIT

S :PUMY

Y :PUHY

ZUBADAN:PUHY-HP

WY:PQHY

R2 :PURY

WR2:PQRY

INDOOR UNIT

PLFY-VBM/VCM

PLFY-VLMD

PMFY-VBM

PEFY-VMR

PEFY-VMS1

PEFY-VMA

PEFY-VMH

PCFY-VKM

PKFY-VBM / VHM / VKM

PFFY-VLEM

PFFY-VKM

PFFY-VLRM

PFFY-VLRMM

Fresh Air Intake type

A ir-Conditioning

Control System

This is a specialized air conditioning management system, in which

up to 2000 indoor units can be

centrally controlled.

ON/OFF

Remote

Controller

PAC-YT40ANRAPAC-SF44SRA PAC-YT34STA

Group

Remote

Controller

PAC-SC30GRA

PAC-YG60MCA

PAC-YG66DCA

PAC-YG63MCA

AI Controller

DIDO Controller

PI Controller

MITSUBISHI ELECTRIC's

CITY MULTI can be easily

connected to the building

managementsystem through

BACnet .

AG-150A GB-50ADA

PAC-YG50ECA

BAC-HD150

Interface

BACnet

transmission line

(Ethernet)

Integrated centralized

control software

TG-2000A

*Some controllers cannot be used in combination with certain models of devices.

Integrated Communications Control

with Mitsubishi's Unique Transmission Network (M-NET)

*9

*6 *7*6

*6 *6 *6 *6

*8

AG-150A+

PAC-YG50ECA

150/150

AG-150A

AG-150A / GB-50ADA

24 24

24x7 24x7

24

24x7

Optimized start-up

Night setback

Sliding temperature control

*10 *10

*11

( ) ( ) ( ) ( )

*1. Group setting via wiring between Indoor units with cross-over cable;

*2. Installation possible at Initial setting web browser;

*3. Inter-lock is set at Local remote controller.

*4. AG-150A/GB-50ADA license registration to AG-150A/GB-50ADA is required to monitor and operate the units by browser and TG-2000A.

*5. AG-150A connected with PAC-YG50ECA is compatible with TG-2000A Ver.6.1* or later.

*6. This function can be set only on the ME/Simple ME remote controller. This function cannot be used with the MA/Simple MA remote controller.

(But, the validity of this function with the MA/Simple MA remote controller depends on the indoor unit model, and there are possibilities that this function can be used with them.)

*7. This function is available only when applying together with TG-2000A, AG-150A and GB-50ADA.

*8. Inter-lock is set from system controller. (Except PAC-YT40ANRA)

*9. The maximum number of controllable units decreases depending on the indoor unit model.

*10. For indoor use only.

*11.It is planned that GB-50ADA will be supported on TG-2000A Ver. 6.3* or later.

GB-50ADA

GB-50ADA

Remote Controller

Page 19

Remote Controller

Page 20

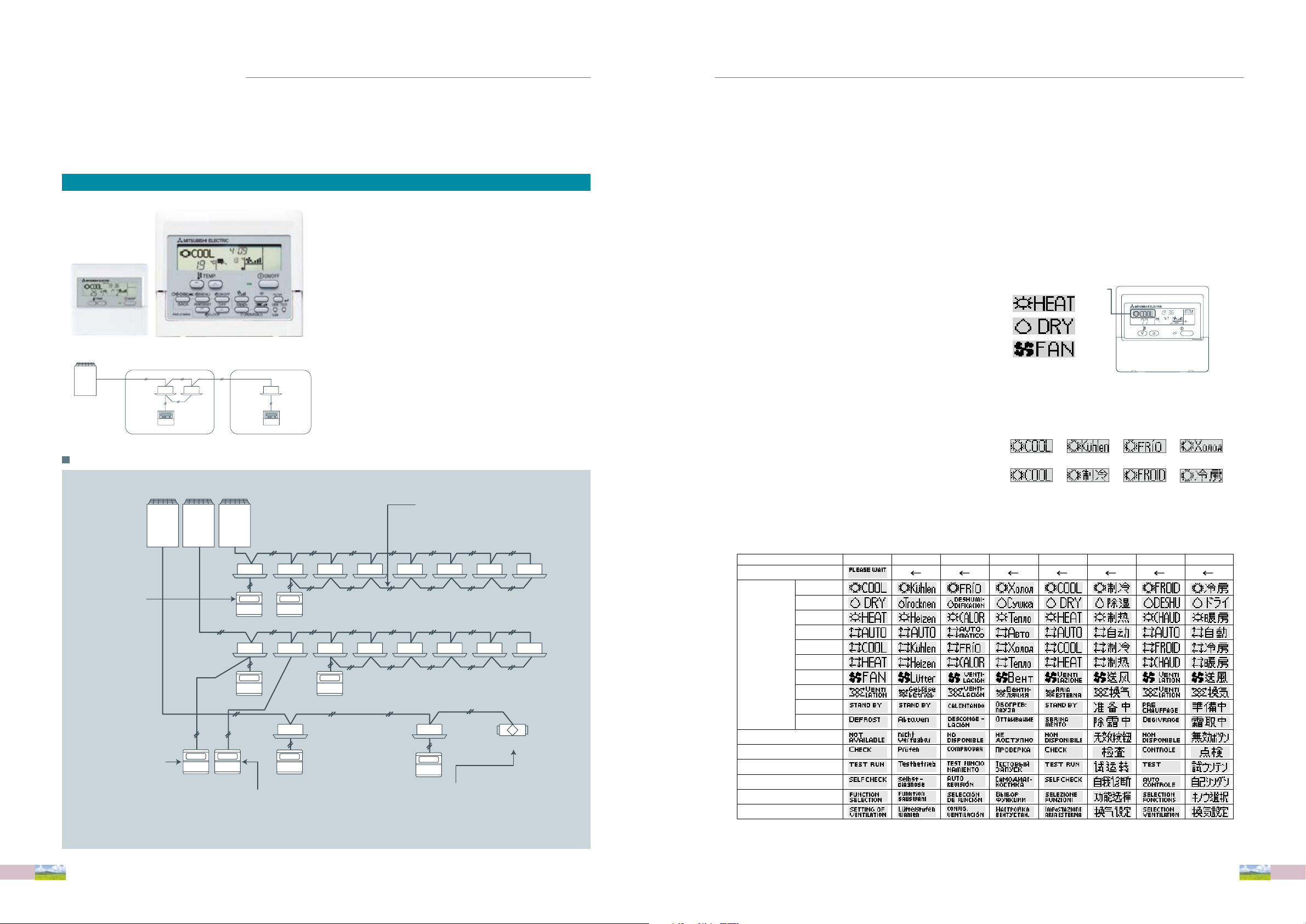

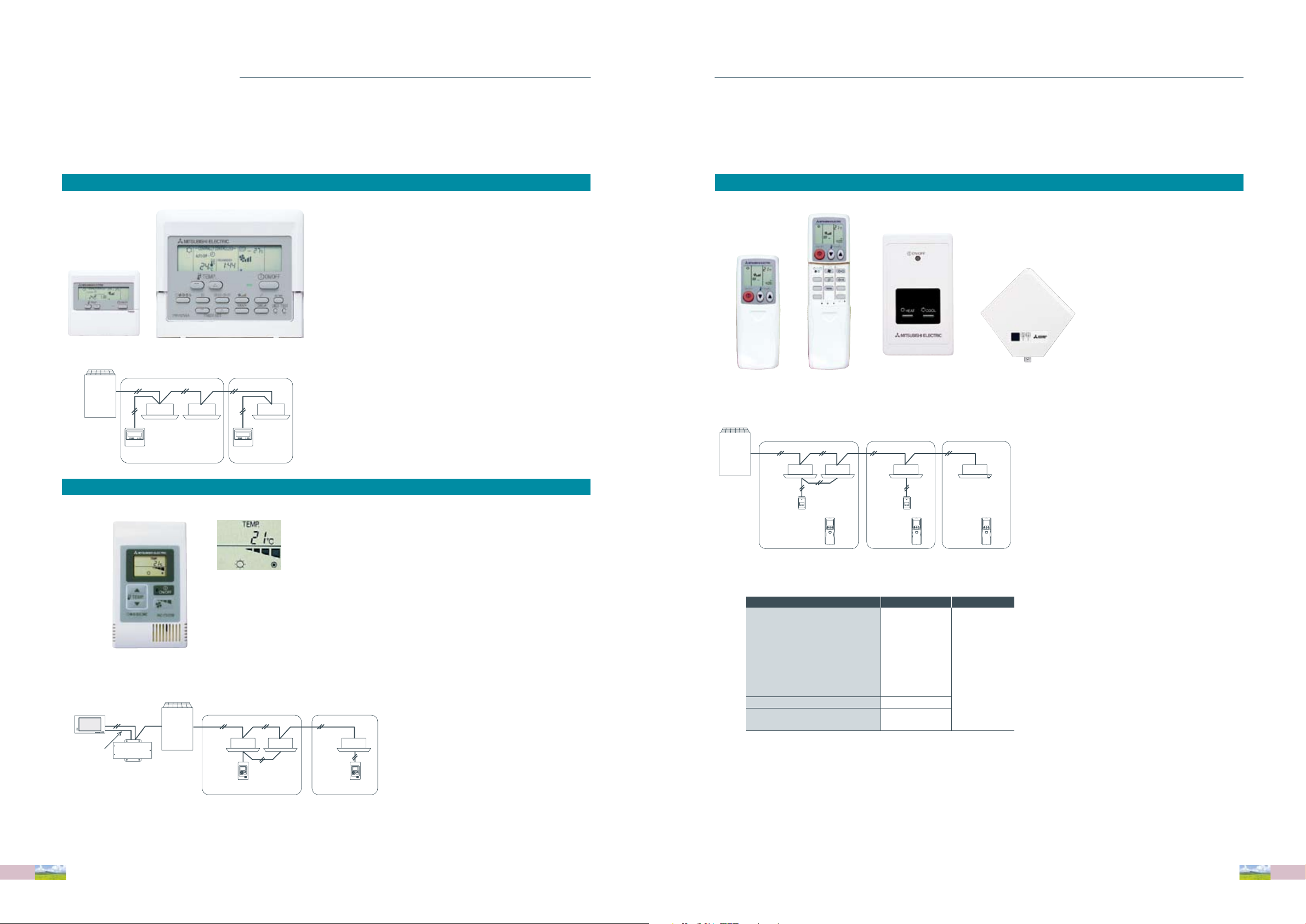

Page 12

Individual

Remote Controller

MA remote controller

Non-polarized

2-wire

Non-polarized

2-wire

MA remote controller

Example of system configuration

M-NET

Wired MA remote controller PAR-21MAA

• Dot matrix liquid crystal screen

• Set temperature in 1°C/°F increment

• Weekly timer

Up to 8 ON/OFF/temperature setting per day in 1 minute

increment. Setting kept in nonvolatile memory. No need to

worry about re-setting at power failure.

• Room temperature control with thermostat sensor inside the

unit

• Limit set temperature (upper/lower)

• Restrict setting changes (all changes/all except ON/OFF)

• Self-diagnosis function immediately informs error code in case

of malfunction

• Dimensions: 130(W) x 120(H) x 19(D) mm

: 5-1/8(W) x 4-23/32(H) x 3/4(D) in.

Various control systems can be offered with indoor unit remote controller.

Lossnay

Remote

controller

Outdoor unit

Indoor unit

Cooling/Heating

mode switch control

Cooling/Heating mode of

the outdoor unit can be

switched with the remote

controller for indoor unit.

Two-remote-controller

control

By connecting with two remote

controllers, an outdoor unit can

be controlled freely either from

the one in the room or from the

one in the control room. (Last

setting overrides any previous

ones)

Group control is possible by

using two remote controllers.

Remote control

Remote controller wiring can be extended up

to 200m, which makes it possible for the

indoor unit remote controllers to be installed at

one place without being separated.

Interlocking control

Heat recovery ventilator (Lossnay)

can be operated and controlled with

indoor unit remote controller.

Group control

A remote controller can control up to 16

indoor units at the same time.

(Automatic address setting)

New display-Larger,easier-to-see characters

Dot liquid crystal display

●Display example [Operation mode]

●Display example [Cool mode]

ON/OFF

TEMP.

°F

°F

TIME SUN

WEEKLY

SIMPLE

AUTO OFF

[Japanese]

[Russian][English]

[Italian]

[German]

[Chinese]

[Spanish]

[French]

Various information is displayed and conveyed clearly, enabling more accurate operation of the air conditioner.

Dot Liquid Crystal Display (LCD)

The dot liquid crystal display enables quick understanding

of the operation state.

Multi-language Display

In addition to English, contents can be displayed in seven

other languages.

Multi-language Display Example

[Dot display table]

Waiting for start-up

Operation mode Cool

Dry

Heat

Auto

Auto(Cool)

Auto(Heat)

Fan

Ventilation

Stand by

(Hot adjust)

Defrost

Not use button

Check (Error)

Test run

Self check

Unit function selection

Setting of ventilation

Language

English German Spanish Russian Italian Chinese French Japanese

Page 21

Remote Controller

Remote Controller

Page 22

Page 13

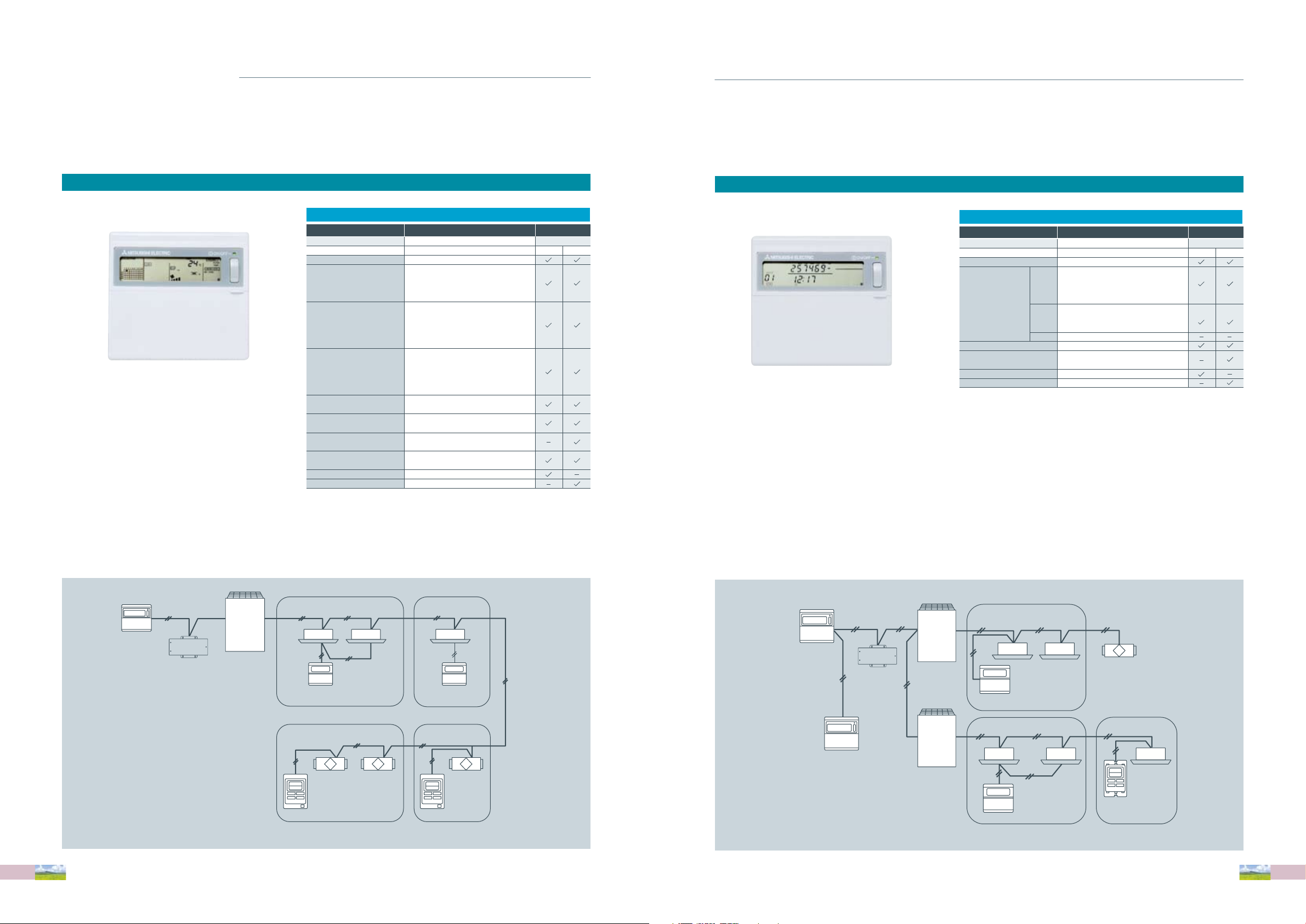

PAC-YT51CRB

Simple remote controller PAC-YT51CRB (MA)

Wired ME remote controller PAR-F27MEA

Example of system configuration

• This remote control requires non-polar wiring to only one

indoor unit.

• Group operation over multiple outdoor units is possible.

Grouping can be changed without re-wiring, which makes

dividing rooms for tenants easier.

• Timer operation

*Daily timer operation of one ON/OFF setting everyday

*Auto-off timer : 0:30, 1:00, 1:30, 2:00...4:00

*The setting is kept in nonvolatile memory.

• Function lock

All functions or all functions except ON / OFF can be selected.

• Set temperature range limit

• Interlock setting and operation of LOSSNAY

• Dimensions:130(W) x 120(H) x 19(D) mm

:5-1/8(W) x 4-23/32(H) x 3/4(D) in.

• LCD temperature setting and display in 2°F increments.

• Control: START/STOP, room temperature, fan speed, and

operation mode

• The only wiring required is cross-over wiring based on

two-wire signal lines.

• Room temperature sensors are built-in.

• LCD temperature setting and display in 1°C /1°F increments.

• Set temperature range limit

• Can operate all types of indoor units

*Since this controller has limited functions, it should always be

used in conjunction with standard controller or centralized

controller.

• Dimensions:70(W) x 120(H) x 41(D) mm

:2-3/4(W) x 4-23/32(H) x 1-5/8(D) in.

Individual

Remote Controller

ME R/C ME R/C

Simple

MA R/C

Simple

MA R/C

Example of system configuration

Centralized

controller

24VDC

Power supply unit

(PAC-SC51KUA)

PAR-FL32MA PAR-FA32MA PAR-SA9FA

(4-way Cassette signal receiver)

Wireless remote controller PAR-FL32MA / PAR-FA32MA

Example of system configuration

Correspondence table

• No need to configure addresses for group

operation.

• Lit LED keeps you informed of operation blinking even gives you the error code via

the number of blinks.

• Can be used with the MA remote controller.

*When used in group configurations, wiring

between indoor units is required.

*Combining ME remote controller and/or

LOSSNAY remote controller in a group is not

possible.

• LCD temperature setting and display in 1°C

/1°F increments.

• Dimensions:58(W) x 159(H) x 19(D) mm

:2-5/16(W) x 6-5/16(H) x 3/4(D) in.

Signal

receiving

unit

Non-polarized

2-wire

Nonpolarized

2-wire

Wireless

remote

controller

Signal

receiving

unit

Wireless

remote

controller

PMFY-P VBM

PLFY-P VCM/ VLMD

PCFY-P VKM

PFFY-P VKM

PEFY-P VMR-E-L/R/ VMH

PFFY-P VLEM/VKM/VLRM/VLRMM

PEFY-P VMS1(L)

PEFY-VMA(L)

PLFY-P VBM-E

PKFY-P VBM-E

PKFY-P VHM/VKM

PAR-FA32MA PAR-FA32MA PAR-SA9FA

PAR-FL32MA

receiver transmitter

PAR-FA32MA

PAR-SA9FA-E

Built-in

Signal

receiving

unit

PAR-SA9FA

Wireless

remote

controller

Page 23

Remote Controller

Remote Controller

Page 24

Page 14

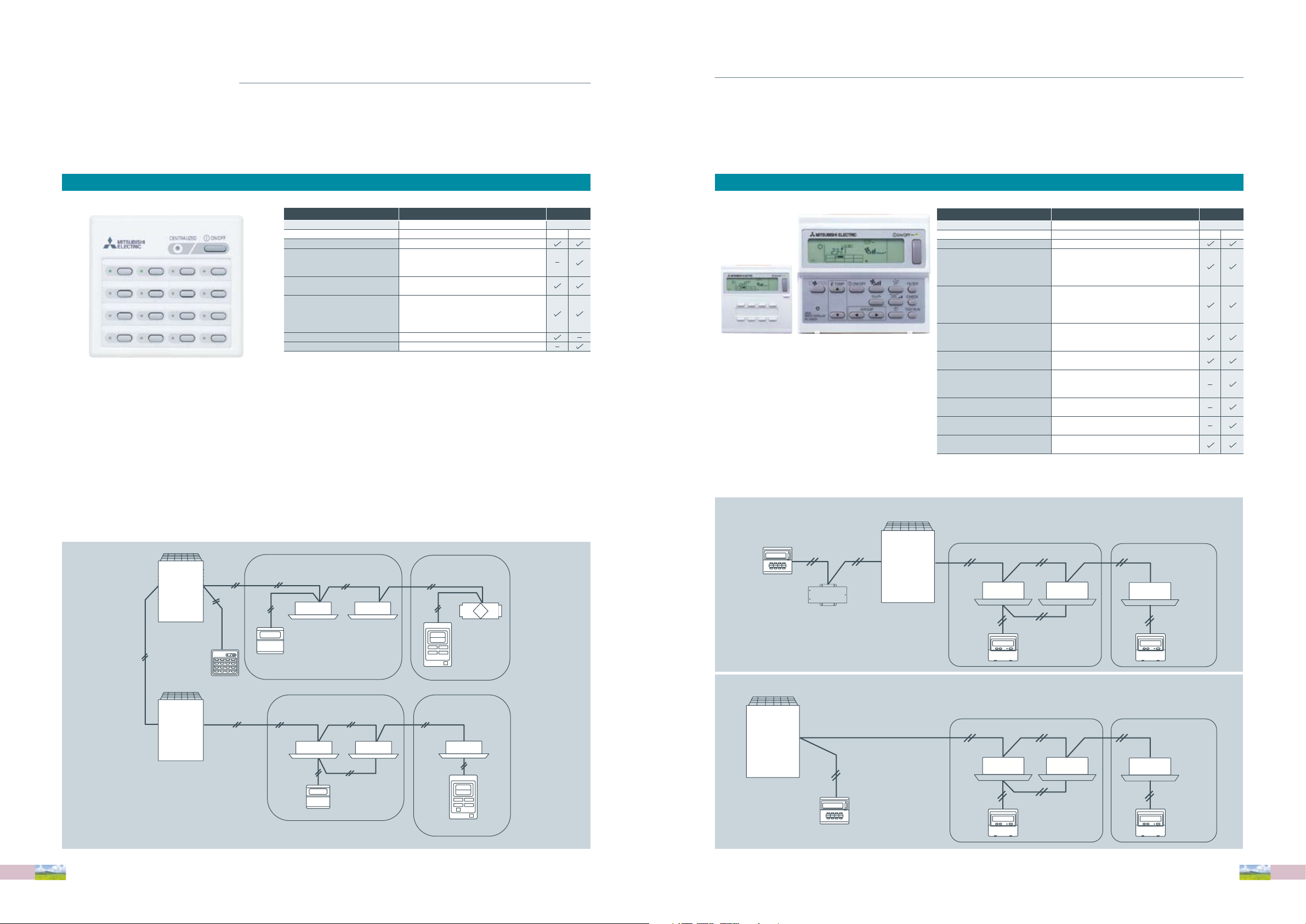

Centralized

Remote Controller

System example

System

remote

controller

PZ-52SFPZ-52SF

LOSSNAY

Power supply

unit

LOSSNAYLOSSNAY

PAR-21MAA

PAR-21MAA

System remote controller PAC-SF44SRA

FUNCTION

UNITS

ON/OFF

MODE SELECTION

TEMPERATURE SETTING

FAN SPEED SETTINGS

AIR FLOW DIRECTION SETTING

PERMIT/PROHIBIT FUNCTION

ERROR INDICATION

VENTILATION INTERLOCK

EXTERNAL INPUT

EXTERNAL OUTPUT

DESCRIPTION

PAC-SF44SRA

50 units/50 groupMax No.Units

Run and stop operation

Switches between Cool/Dry/Auto/Fan/Heat.

Operation Mode will vary depending on the

indoor unit. Auto mode is available with only

R2 and WR2 systems

Sets the groups temperature control.

Values in

parentheses are for the medium-temperature indoor unit.

Cool/Dry:19-30°C [14-30°C] / 67-87°F [57-87°F]

Heat :17-28°C [17-28°C] / 63-83°F [63-83°F]

Auto :19-28°C [17-28°C] / 67-83°F [63-83°F]

Models with 4 air flow speed settings: Hi/Mid-2/Mid-1/Low

Models with 3 air flow speed settings: Hi/Mid/Low

Models with 2 air flow speed settings: Hi/Low

Fan speed setting (including Auto) varies depending

on the model.

Air flow angles: 4-angle or 5-angle, Swing, Auto,

Louver ON/OFF

Run/Stop,Temperature Setting,Mode Selection

and Filter Reset functions can be prohibited.

Displays a 4 digit code and the affected

unit address

Allows the group to be interlocked with a heat

recovery Lossnay unit

On/Off/Fire Alarm

On/Off/Faults

• The group setting is kept in nonvolatile memory.

No need to worry about re-setting at power

failure.

• No individual AC power supply is needed.

The power can be supplied from one outdoor unit

(R410A) or Power supply unit.

On e syste m con troller can control up to fif ty in door units from o ne lo cation. The PAC-SF44SR A also has

hardwired connection available (On/Off input, fire alarm input, run output, fault output).

System Controller

Displays

Operation

• Dimensions:130(W) x 120(H) x 19(D) mm

:5-1/8(W) x 4-23/32(H) x 3/4(D) in.

System example

System

remote

controller

Schedule timer

Power supply

unit

Simple

PAC-SE51CRA

PAR-F27MEA

PAR-21MAA

LOSSNAY

Schedule timer PAC-YT34STA

• The schedule group setting is kept in nonvolatile

memory. No need to worry about re-setting at

power failure.

• No individual AC power supply is needed.

The power can be supplied from one outdoor unit

(R410A) or Power supply unit.

Mitsubishi Electric controllers are complimented by a weekly programmable timer, being able to control up

to fifty indoor units. The PAC-YT34STA also has hardwired connection available (On/Off input, fire alarm

input, run output, fault output).

FUNCTION

UNITS

ON/OFF

SCHEDULE

FUNCTION

CURRENT TIME

ERROR INDICATION

EXTERNAL INPUT

EXTERNAL OUTPUT

DESCRIPTION

PAC-YT34STA

50 units/50 groupMax No.Units

Run and stop operation

On/Off

Mode:Cool/Heat/Auto

Set temperature:19°C to 28°C

Operation Prohibit: On/Off, Mode, Set temperature

Weekly timer for each group

9 setting patterns + no setting

16 operations per day

5 minutes

Set the time

Displays a 4 digit code and the affected

unit address

On/Off/Fire Alarm

On/Off/Faults

Programmable Timer

Operation

Displays

• Dimensions:130(W) x 120(H) x 19(D) mm

:5-1/8(W) x 4-23/32(H) x 3/4(D) in.

Content

Number

Unit

Remote Controller

Remote Controller

Page 25

Page 26

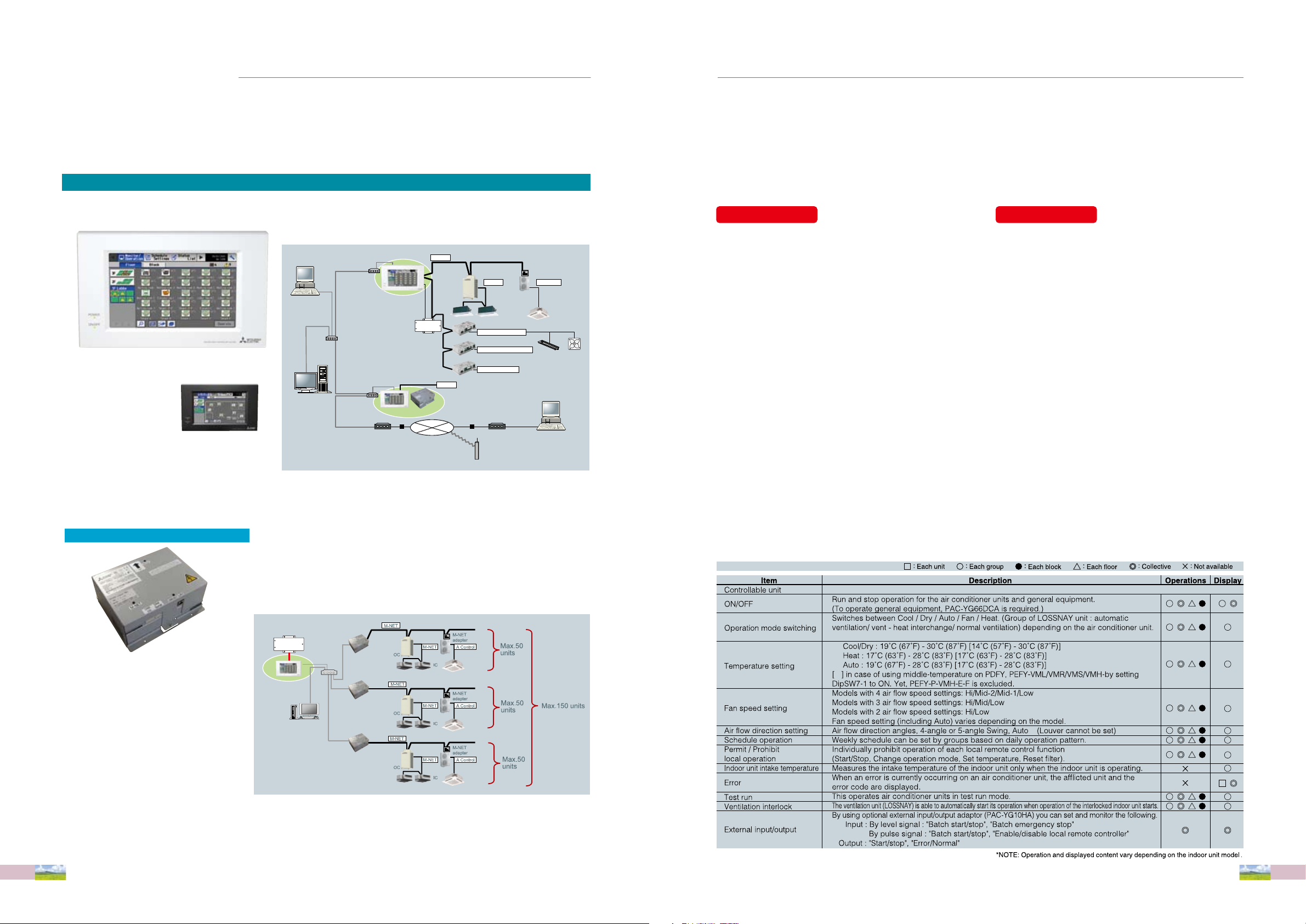

Page 15

System example

ON/OFF

remote

controller

LOSSNAY

PZ-52SF

PAC-YT51CRB

PAR-F27MEA

PAR-21MAA

ON/OFF remote controller PAC-YT40ANRA

Centralized

Remote Controller

FUNCTION

UNITS

ON/OFF

ERROR INDICATION

VENTILATION OPERATION

(INDEPENDENT)

VENTILATION OPERATION

(INTERLOCKED)

EXTERNAL INPUT

EXTERNAL OUTPUT

DESCRIPTION

Max No.Units

Run and stop operation

LED flashes during failure.

(The error code can be confirmed by removing

the cover.)

Group operation of only LOSSNAY units possible.

*Only ON/OFF of group.

The LOSSNAY will run in interlock with the

operation of indoor unit.

*The fan rate and mode cannot be changed.

The LED will turn ON only during operation after interlocking.

On/Off/Fire Alarm

On/Off/Faults

Just press a switch to start. All of the units can be On/Off by pressing the main switch, and each unit in

the gro up can be On/Off with individual sw itch. The PAC-YT40A NR A also has hardwired connection

available (On/Off input, fire alarm input, run output, fault output).

• Dimensions:130(W) x 120(H) x 19(D) mm

:5-1/8(W) x 4-23/32(H) x 3/4(D) in.

PAC-YT40ANRA

OPERATIONS

50 units/16 groups

DISPLAY

• The group setting is kept in nonvolatile

memory. No need to worry about re-setting at

power failure.

• No individual AC power supply is needed.

The power can be supplied from one outdoor

unit (R410A) or Power supply unit.

Group remote controller PAC-SC30GRA

System example

Connect to the centralized transmission line

Power supply

unit

Group remote

controller

PAR-21MAA PAR-21MAA

Connect to the indoor/outdoor transmission line

Group remote

controller

PAR-21MAA PAR-21MAA

• The group setting is kept in nonvolatile

memory. No need to worry about re-setting at

power failure.

• No individual AC power supply is needed.

The power can be supplied from one outdoor

unit (R410A) or Power supply unit.

Up to 8 groups can be operated (maximum of 16 units). Just by pressing PAC-SC30GRA switches, groups can

be On/Off as a batch.

Suitable for small office and residential project.

• Dimensions:130(W) x 120(H) x 19(D) mm

:5-1/8(W) x 4-23/32(H) x 3/4(D) in.

FUNCTION

UNITS

ON/OFF

MODE SELECTION

TEMPERATURE SETTING

FAN SPEED SETTINGS

AIR FLOW DIRECTION SETTING

PERMIT/PROHIBIT FUNCTION

INDOOR RETURN AIR TEMPERATURE

ERROR INDICATION

VENTILATION INTERLOCK

DESCRIPTION

Max No.Units

Run and stop operation

Switches between Cool/Dry/Auto/Fan/Heat.

Operation Mode will vary depending on the

indoor unit. Auto mode is available with only

R2 and WR2 systems

Sets the groups temperature control.

Cool/Dry:19-30°C

Heat:17-28°C

Auto:19-28°C

4 speed – Hi-Mid2-Mid1-Low, Auto

3 speed – Hi-Mid-Low, Auto

2 speed – Hi-Low

Air flow angles: 4-angle or 5-angle, Swing, Auto,

Louver ON/OFF

Run/Stop,Temperature Setting, Mode Selection

and Filter Reset functions can be prohibited

via main system controller

Measures the intake temperature of the

master unit within the group

Displays a 4 digit code and the affected

unit address

Allows the group to be interlocked with a heat

recovery Lossnay unit

PAC-SC30GRA

OPERATIONS

16 units / 8 groups

DISPLAY

Page 27

Remote Controller

Remote Controller

Page 28

Page 16

System structure

System structure

Centralized controller AG-150A

With a new colore d touch panel, and continuation of all th e G-50A functions, AG -150A visualizes its

functions from basic control to advanced operations and bringing an ultimate controller to reality.

Option : Black surface cover

PAC-YG71CBL

Internet

Switching Hub

Hub

LAN

(100BASE-TX)

A Control

Central Control PC

(TG-2000A)

*Ver. 6.10 or later

Remote

Monitoring PC

Hub

DIDO Controller (PAC-YG66DCA)

General Equipment

Temp/Humidity sensor

Watt hour meter

AI Controller (PAC-YG63MCA)

PI Controller (PAC-YG60MCA)

Note : Use a security device such as a VPN router when connecting the

AG-150A/GB-50ADA to the Internet to prevent unauthorized access.

AG-150A / GB-50ADA

M-NET

M-NET

Service company

/Sales office

Mobile phone

of service person

Remote

monitoring PC

M-NET

AG-

150

A

Remote monitoring

via a Web browser

Remote monitoring

via a Web browser

VPN

Router

VPN

Router

Modem

Power supply unit

(PAC-SC51KUA)

Lights Ventilation

Modem

M-NET

adapter

Centralized

Remote Controller

Centralized

Remote Controller

Dimensions: 250(W) x 217(H) x 97.2(D) mm

: 9-7/8(W) x 8-9/16(H) x 3-7/8(D) in.

Dimensions: 300(W) x 185(H) x 70.3(D) mm

: 11-13/16(W) x 7-5/16(H) x 2-13/16(D) in.

With a connection of a Expansion Controller, maximum of 150 units/groups

can be connected to AG-150A.

*Do not connect PAC-YG50ECA to TB3 of the outdoor unit.

*Use a security device such as a VPN router when connecting the AG-150A etc. to the Internet

to prevent unauthorized access.

Expansion Controller PAC-YG50ECA

PAC-YG50ECA

PAC-YG50ECA

PAC-YG50ECA

Power supply unit

(PAC-SC51KUA)

AG-

150

A

Central Control PC

(TG-2000A)

LAN

(100BASE-TX)

Backlight color liquid crystal

Backlight makes it easy to see and control units.

One can identify whether a unit is ON or OFF from a

distance.

Control in the night with no lights is possible.

Touch panel

9 inch wide, high-resolution

Touch panel enables operation of units by touching with

index finger.

When object unit is touched, orange box appears around

the unit icon indicating the unit selected.

Flat back

Easy installation

Allows for an installation of the unit either directly to the

wall surface or using the installation hole in the wall.

USB memory compatible

All measurement/initial setting CSV data extractable with

USB memory.

Can save and overwrite setting data.

New Design

New Design New Functions

Controllable units/groups

Controls up to 50 units/groups (including indoor units,

LOSSNAY, DIDO/AI/PI controller)

Up to 150 units can be controlled via expansion

controller;PAC-YG50ECA (AG-150A software needs to be

upgraded)

Monitoring functions

Temperature/Humidity (using AI controller with WEB

browser) *

1

General equipment such as lights on LCD (using DIDO

controller)

Interlock function from AI controller, DIDO controller to

indoor units and between DIDO units are available.

AG-150A interlock with DIDO controller or free contact on

an indoor unit available.

* Ver. 2.30 or later

Energy saving functions

Seasonal scheduling and automatic switch over *

1

Yearly scheduling on LCD *

1

Scheduling fan speed and airflow direction

Optimized Start up *

1

External temperature interlock control *

1

Night setback control *

1

*1 License required.

Functions

New Functions

New Functions

♦Future release schedule is subject to change without notice.

50 units/groups or 150 units/groups via expansion controller; PAC-YG50ECA.

Auto mode is for CITY MULTI R2 and WR2 series only.

Remote Controller

Remote Controller

Page 29

Page 30

Page 17

Annual / Weekly Schedule

Enables Weekly and Annual scheduling with a registering

license

• ON/OFF, operation mode, temperature setting, prohibit remote

controller operation can be set.

• For annual schedule, it is possible to set 50 day-long settings up to

24 months into the future.

System Structure

GB-50ADA

M-NETLAN

HUB

Remote monitoring via a

Web browser

Web license

Operation

Example of display icons (air conditioner icons)

Stop

Occurrence of

abnormality

Operation/

Occurrence of a filter sign

In timer operation

Lossnay on

Under energy-saving

control

ON

8:00

(Start)

12:00

(Lunchtime)

13:00

(Energy saving)

15:00 17:00

(Overtime)

22:00

OFF

1 42 63 5

Public telephone

line

Provider

Router

Transmits abnormality mail.

Scheduling example in the office

27°C [81°F] Cooling

Up to 12 operation settings per day in 1-minute increment

29°C [84°F] Cooling

All operations

permitted

All operations

permitted

All operations

prohibited

All operations

prohibited

Temperature

adjustment

prohibited

Temperature

adjustment

prohibited

Centralized controller GB-50ADA

The Web Server Function enables Remote Operation or Scheduling

Via a Web Browser on a Personal Computer!

Up to 50 indoor units can be controlled!

Web Browser

Enables monitoring and operation of indoor units using a PC

with Microsoft® Internet Explorer (Ver.6 or 7 or 8) (Web browser

function is an optional and needs license registration for -J type.)

*When connecting to the Internet, please use the VPN (Virtual Private

Network).

Using “Dial-up Connection”

• Enables monitoring and operation from a remote place

• Enables error notification by e-mails to a PC or to a mobile phone

• Dimensions:250 (W) x 217 (H) x 97.2 (D) mm

:9-7/8 (W) x 8-9/16 (H) x 3-7/8 (D) in.

GB-50ADA (without display)

New

New

Function

Description

GB-50ADA (web browser)

*NOTE: Operation and displayed content vary depending on the indoor unit model.

Up to 50 units/groups.

250 (9-7/8) x 217 (8-9/16) x 97.2 (3-7/8) mm (in)

Run and stop operation for the air conditioner units

Switches between Cool / Dry / Auto / Fan / Heat.

Range of temperature setting

Cool/Dry :19-30°C [14-30°C] / 67-87°F [57-87°F]

Heat :17-28°C [17-28°C] / 63-83°F [63-83°F]

Auto :19-28°C [17-28°C] / 67-83°F [63-83°F]

( ) in case of using middle-temperature on PEFY, PEFY-VML/VMR/VMS/VMH-by setting DipSW7-1 to ON. Yet, PEFY-P-VMH-E-F is excluded.

*Range of temperature settings vary depending on model.

Air flow direction angles, 4-angle or 5-angle Swing, Auto (Louver cannot be set)

Annaul/Weekly (2 types)/today schedule can be set for each group of air conditioning units.

Optimized startup setting is also available.

Individually prohibit operation of each local remote control function

Measures the intake temperature of the indoor unit only when the indoor unit is operating.

When an error is currently occurring on an air conditioner unit, the afflicted unit and the error code are displayed.

Operation of indoor groups or general equipment can be interlocked by the change of state (ON/OFF, mode, error of indoor groups

and general equipment).

Controllable unit

Dimensions W x H x D

ON / OFF

Mode selection

Temperature setting

Air flow direction setting

Timer operation / Schedule

Permit / Prohibit function

Indoor unit intake temperature

Error

Test run

Ventilation interlock

Energy Saving Control

Enables Energy Saving Control with the use of our new PI controller.

(Registration of “Energy Save” licence is required.)

To perform energy saving, the capacity of the outdoor unit is

controlled.

Charge Calculation

Enables charge calculation for each tenant and output as CSV file

Dimension: 200(W) x 120(H) x 45(D) mm

: 7-7/8(W) x 4-3/4(H) x 1-13/16(D) in.

No more PLCs are needed!

Our new PI controller makes it possible to perform energy

saving without PLC, which is cost saving.

Maximum of 4 measurement meter (WHM, gas meter, water

meter, calorie meter) can be connected to the PI controller

and can be used also for charge calculation.

*24 VDC power needs to be provided on site.

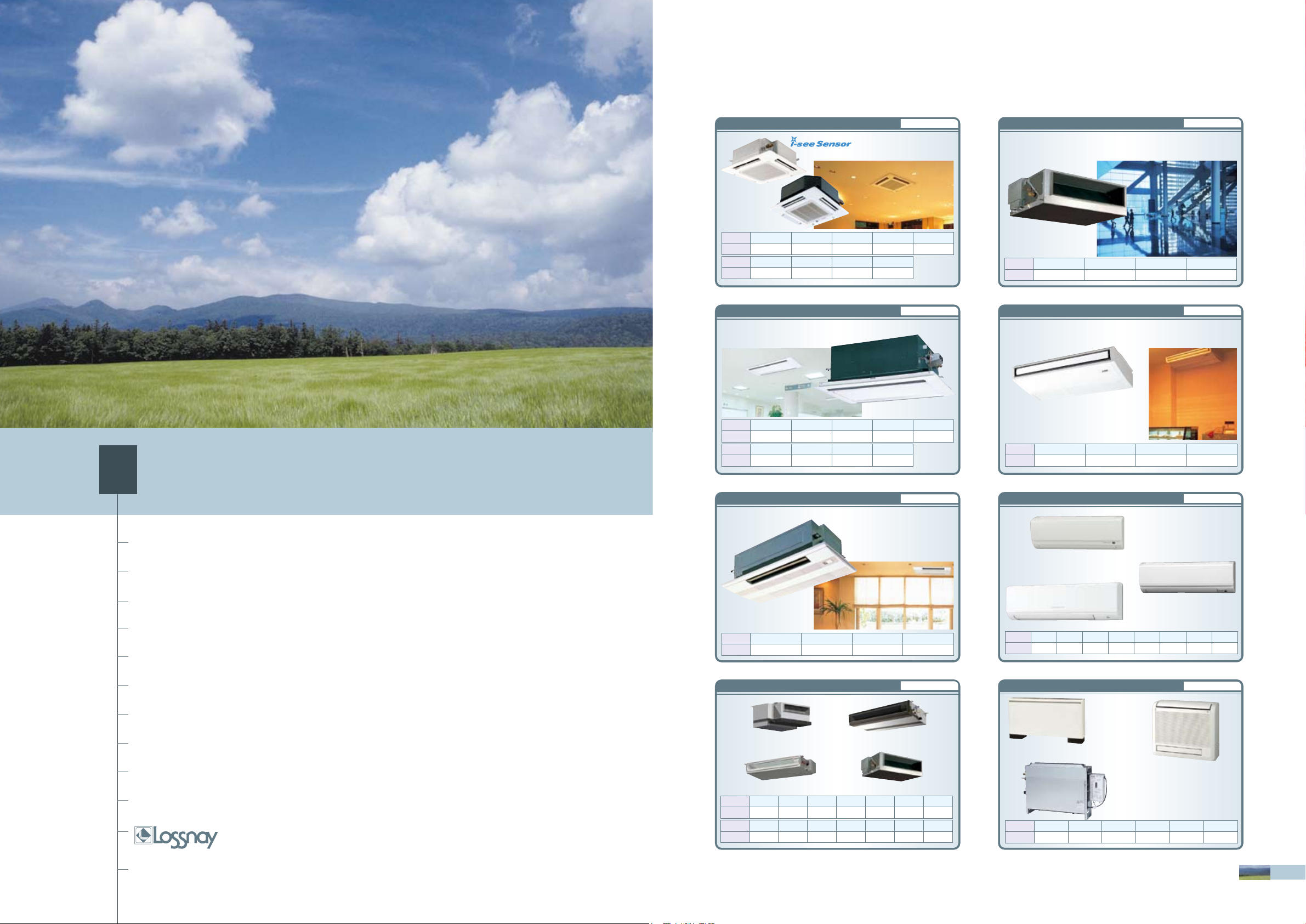

System Structure

Remote monitoring via a

Web browser

PI Controller PAC-YG60MCA

System Structure

Maximum Capacity at 80%

Capacity

Capacity

Value

With energy-savining effectsNo energy-saving

effects

80%

Time

Amount of saved energy

.

Control level setting

.

Monitors current state

.

Monitors demand level

.

Monitors electric power

Registration of

“Energy Save” license

.

Outdoor unit control

- Capacity control

(60/70/80/90%)

.

Indoor unit control

- ± 2°C control

- Fan control

- Stop control

TG-2000A collects operation

and electric power data from

AG-150A and PI controller and

does apportion calculation.

AG-150A monitors every minute and

stores operation data necessary for

charging.

PI controller counts pulse output from

the watt-hour meter.

Watt-hour meter

Max. 4

PI controller

M-NETLAN

M-NET

LAN

Watt-hour meter

PI controller

Centralized

Remote Controller

*Please note that when using an energy saving control,

there are no warranties to failures such as usage over the contracted electricity.

AG-150A

Registration of

“Charge Calculation” license

AG-150A

Page 31

Remote Controller

Remote Controller

Page 32

Page 18

Dimension: 200(W) x 120(H) x 45(D) mm

: 7-7/8(W) x 4-3/4(H) x 1-13/16(D) in.

No more PLCs are needed!

Our new DIDO controller makes it possible to control

general-purpose equipment without PLC, which is cost saving.

Up to 6 general-purpose equipment can be connected to

the DIDO controller.

*24 VDC power needs to be provided on site.

Centralized

Remote Controller

System Structure

DIDO Controller PAC-YG66DCA

DIDO controller

Security card reader

AC of other companies

Lights

Dimension: 200(W) x 120(H) x 45(D) mm

: 7-7/8(W) x 4-3/4(H) x 1-13/16(D) in.

Our new AI controller makes it possible to monitor the values

measured by the temperature/humidity sensor connected to

the AI controller.

The AI controller has two input and two output channels.

*24 VDC power needs to be provided on site.

System Structure

Remote monitoring via a

Web browser

AI Controller PAC-YG63MCA

AI controller

Temperature sensor

Humidity sensor

General-purpose equipment Control

Enables to control and monitor equipment other than air-conditioners (air-conditioners of other companies,

lights, ventilators, etc.)

• In addition to above, the

air-conditioners can be interlocked

with general-purpose equipment.

E.g. Interlock between indoor units

and security system.

• The indoor units can be turned

ON/OFF when the security system

is activated/deactivated.

Temperature/Humidity Monitoring

Monitors the values measured by the temperature/humidity

sensor connected to the AI controller

• Trend displays of measurement data can be shown on a Web browser.

• An alarm can be output by e-mail when measurement data exceeds a preset upper or lower limit.

M-NETLAN

M-NETLAN

Temperature : Pt100, 4 to 20mA DC, 1 to 5 VDC, 0 to 10 VDC

Humidity : 4 to 20mA DC, 1 to 5 VDC, 0 to 10 VDC

Icon display (Lights)

ON OFF Error

Schedule set

AG-150A

AG-150A

Up to 150 units can be controlled by AG-150A.*

*Expansion controller is required.

Effective use of TG-2000A

Multiple air conditioning charges in multiple buildings can be calculated. The power apportionment percentage

data and apportioned power rate can be calculated for each unit, and can be output as a CSV file.

For example, installing TG-2000A to the system in the headquarters makes it possible to control AG-150A/GB-50ADA*

units that are used in branch offices.

*It is planned that GB-50ADA will be supported on TG-2000A Ver. 6.3* or later.

Integrated centralized control software TG-2000A

etc.

Input

AG-150A

M-NET

24VDC

3-phase 208/230V

(3-wire)

Indoor unit system

watt-hour meter

Outdoor unit system

watt-hour meter

PI Controller

(PAC-YG60MCA)

Uninterruptive

power supply (UPS)

Integrated

centralized control

software installation

Indoor unit

watt-hour meter

power source

Indoor unit system watt-hour meter

Outdoor unit system watt-hour meter

PLC (with electric amount count software)

Indoor unit watt-hour meter

RS-232C

RS-485

Indoor unit system

watt-hour meter

Outdoor unit system

watt-hour meter

Personal computer for

TG-2000A

Indoor unit

watt-hour meter

Power

source

Converter

PLC (PAC-YG21CDA)

RS-485WHM

The electric amount count software or separately

procured parts must be used with the designated PLC.

harmful interference, and (2)this device must accept any interference

received, including interference that may cause undesired operation.

subject to the following two conditions: (1)this device may not cause

This device complies with Part15 of the FCC Rules.Operation is

[ 24 VDC Power Supply]

Example of Basic System Configuration

The air-conditioning layout can be displayed

on the screen, making control and operation

easier.

Power supply unit

PA

C-SC51KU

A

*1

Energy

management

Schedule

license

monitor

license

Web

Single-phase 208/230V

Single-phase 208/230V

Personal computer for

TG-2000A

*1 GB-50A can be used.

Remote Controller

Page 33

Remote Controller

Page 34

Page 19

LMAP

LMAP

M-NET

LMAP 02

LMAP

CITY MULTI

LMAP

Example of System Configuration

System design made simple through integration of

various devices into a total control configuration.

Outdoor unit

M-NET

LONWORKS

(78kbps)

Remote

controller

Indoor units

Remote

controller

Indoor units

Remote

controller

Indoor units

Remote

controller

Indoor units

Remote

controller

Lighting

Security

Center

control device

CITY MULTI System

Outdoor unit

Indoor units

Max. 50 indoor units

LONWORKS

The building management system is connected to the CITY MULTI air conditioning system using LONWORKS , which is widely used on field

networks, allowing for an open network and savings in construction to face.

LONWORKS

Protocol converter

between LONWORKS

and M-NET

LONWORKS (LMAP02)

LON, LONWORKS and the Echelon logo are trademarks of Echelon Corporation registered in the United

States and other countries.

CITY MULTI can easily combine into a Building Management System (BMS) via the LONWORKS and M-NET adapter LMAP02.

LONWORKS is an opened transmission protocol widely used at BMS, and related equipment control.

CITY MULTI is therefore compatible with large-scaled BMS management via LONWORKS .

One LM ADAPTER unit can connect up to 50 Groups/50 indoor units.

Using a single LONWORKS adapter (LM ADAPTER), you can connect up to a maximum of 50 indoor units.

FUNCTION

CONTENT

Run/Stop

Cooling/Drying/Heating/Auto/Fan

Cooling 19-30°C,Heating 17-28°C,Auto 19-28°C

Lo-Mi1-Mi2-Hi

On/Off,Mode,Setpoint

-

Run/Stop

Cooling/Drying/Heating/Auto/Fan

Cooling 19-30°C,Heating 17-28°C,Auto 19-28°C

Lo-Mi1-Mi2-Hi

On/Off,Mode,Setpoint

-

-10°C~50°C

On/Off

ON/OFF

MODE OPERATION

SETPOINT ADJUSTMENT

FAN SPEED CONTROL

PERMIT / PROHIBIT

EMERGENCY STOP

ON/OFF

MODE

SETPOINT

FAN SPEED

PERMIT / PROHIBIT

ALARM STATE

ROOM TEMPERATURE

THERMO ON/OFF

LONWORKS INTERFACE

Control

Monitoring

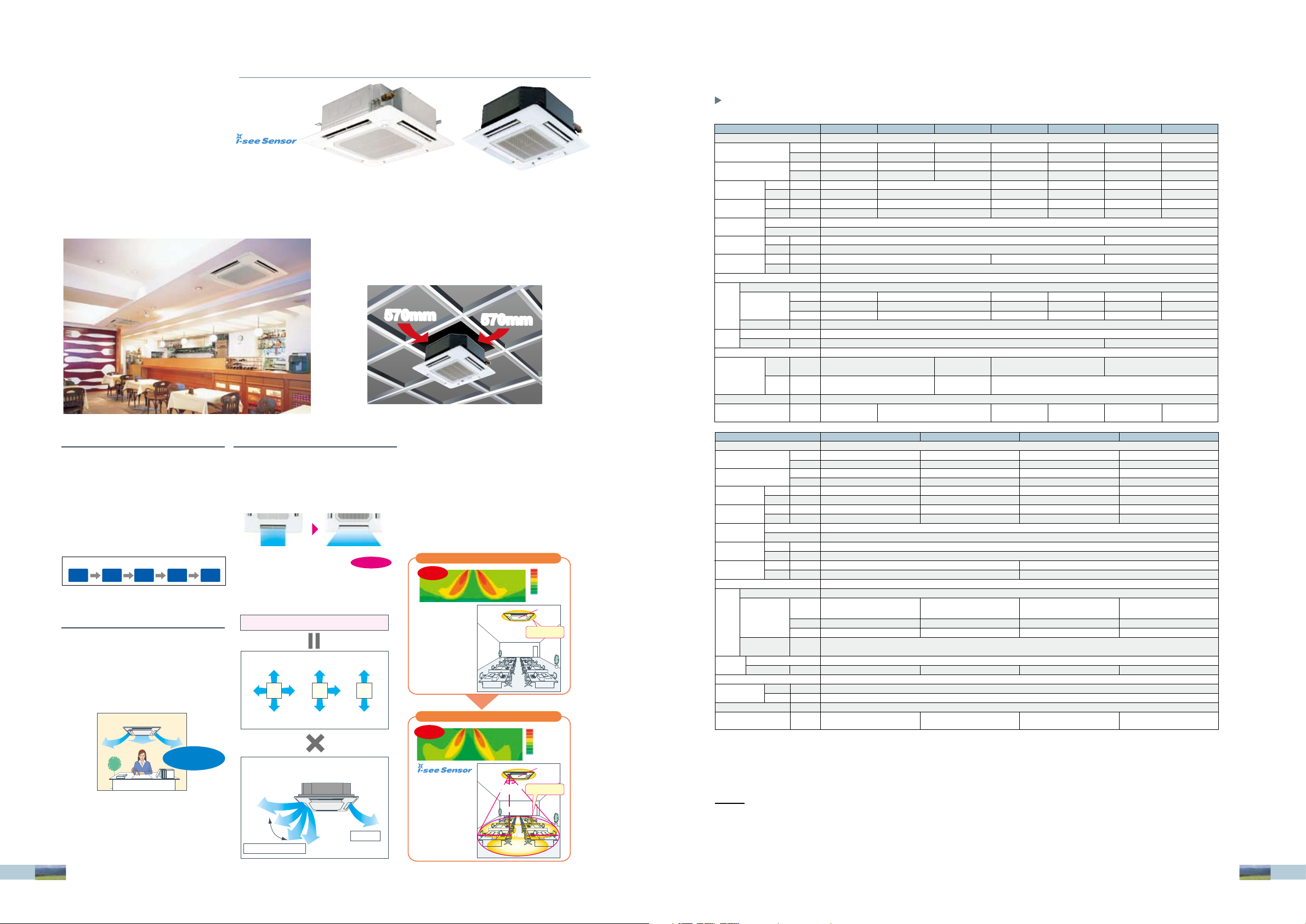

BACnet® and M-NET adapter (BAC-HD150)

System example (Connection of 150 units / groups with PAC-YG50ECA)

CITY MULTI can easily combine into a Building Management System (BMS) via the BACnet® and M-NET adapter BAC-HD150. BACnet

is an opened transmission protocol widely used at BMS, and related equipment control. CITY MULTI is therefore compatible with

large-scaled BMS management via BACnet.

BAC-HD150 can control up to 50 units/groups (including LOSSNAY).

Up to 150 units/groups (including LOSSNAY) can be controlled from one BAC-HD150 with three expansion controllers

PAC-YG50ECA. (50 units/PAC-YG50ECA)

M-NET

M-NET

M-NET

ME remote

controller

ME remote

controller

PZ-52SF

LOSSNAY

unit

ME remote

controller

M-NET

M-NET

ME remote

controller

ME remote

controller

PZ-52SF

LOSSNAY

unit

ME remote

controller

M-NET

Central

monitor

BMS

BACnet® /IP

BACnet® /IP

HUB

AG-150A

LAN1

LAN

LAN2

PAC-YG50ECA

M-NET

PAC-YG50ECA

M-NET

PAC-YG50ECA

BAC-HD150

PAC-SC51KUA

FUNCTION

CONTENT

ON/OFF

Mode

Fan Speed

Airflow Direction

Set Temperature

Filter Sign reset

Permit/ Prohibit

Forced OFF

ON/OFF

Mode

Fan Speed

Air direction

Set Temperature

Filter sign

Permit/ Prohibit

Indoor temperature

Alarm signal

Error code

Communication state

BACnet® and M-NET adapter

Operation

Monitoring

Run/ Stop

Cool/ Dry/ Heat/ Auto/ Fan

Low-Mid1-Mid2-Hi

Horizontal- 60°-80°-100°swing

Cooling 19-30°C [67-87°F], Heating 17-28°C [63-83°F], Auto 19-28°C [67-83°F]

Normal/ Reset

ON/OFF, Mode, Filter sign reset, Set temp.

Release/ Effective

Run/ Stop

Cool/ Dry/ Heat/ Auto/ Fan

Low-Mid1-Mid2-Hi

Horizontal- 60°-80°-100°swing

Cooling 19-30°C [67-87°F], Heating 17-28°C [63-83°F], Auto 19-28°C [67-83°F]

Normal/ Reset

ON/OFF, Mode, Filter sign reset, Set temp.

Normal/ Abnormal

2 Character code- Indicates all unit alarms

Normal/ Abnormal

Page 35

Remote Controller

Remote Controller

Page 36

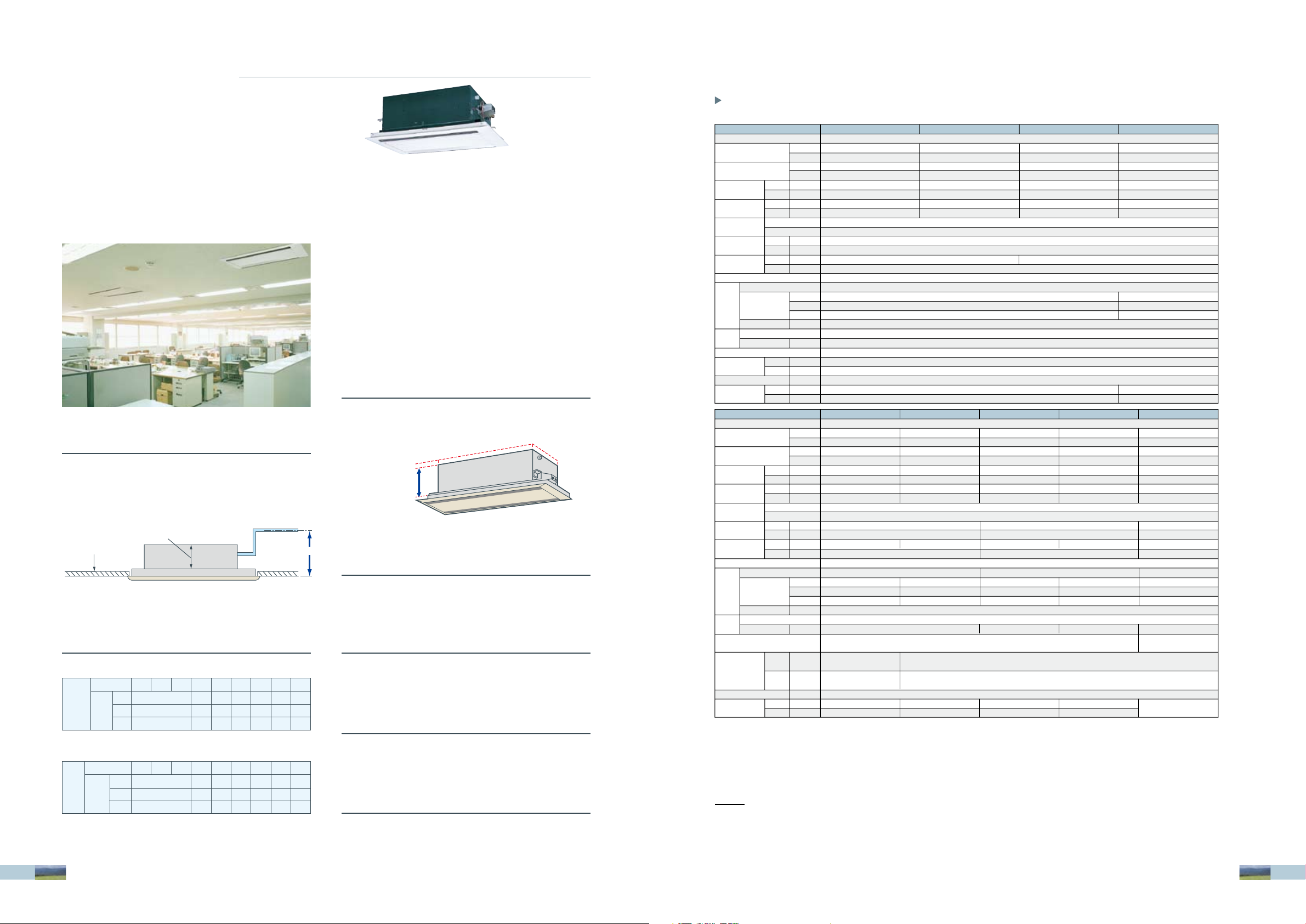

Page 20

I ndoor unit

Ceiling cassette type 4-way airflow

Ceiling cassette type 2-way airflow

Ceiling cassette type 1-way airflow

Ceiling concealed type

Fresh Air Intake type

Ceiling suspended type

Wall mounted type

Floor mounted concealed type

Floor standing exposed

BC controller

OA Processing Units

Ceiling cassette (4-way air flow)

Ceiling concealed

Ceiling cassette (2-way air flow)

Ceiling cassette (1-way air flow)

Ceiling suspended

Wall mounted

Floor standing / Floor mounted concealed

PKFY-P VBM-E

PFFY-P VLRMM-E

PFFY-P VLRM-E

PFFY-P VKM-E

Wide selection of indoor units

PLFY-P VBM-E

PLFY-P VCM-E

PFFY-P VLEM-E

Model

Capacity

P20 P25 P32 P40 P50

2.2kW 2.8kW 3.6kW 4.5kW 5.6kW

Model

Capacity

P63 P80 P100 P125

7.1kW 9.0kW 11.2kW 14.0kW

Model

Capacity

P20 P25 P32 P40 P50

2.2kW 2.8kW 3.6kW 4.5kW 5.6kW

Model

Capacity

P63 P80 P100 P125

7.1kW 9.0kW 11.2kW 14.0kW

Model

Capacity

P15 P20 P25 P32 P40 P50 P63

1.7kW 2.2kW 2.8kW 3.6kW 4.5kW 5.6kW 7.1kW

Model

Capacity

P71 P80 P100 P125 P140 P200 P250

8.0kW 9.0kW 11.2kW 14.0kW 16.0kW 22.4kW 28.0kW

Model

Capacity

P15 P20 P25 P32 P40 P50 P63 P100

1.7kW 2.2kW 2.8kW 3.6kW 4.5kW 5.6kW 7.1kW 11.2kW

Model

Capacity

P20 P25 P32 P40 P50 P63

2.2kW 2.8kW 3.6kW 4.5kW 5.6kW 7.1kW

Model

Capacity

P20 P25 P32 P40

2.2kW 2.8kW 3.6kW 4.5kW

Model

Capacity

P80 P140 P200 P250

9.0kW 16.0kW 22.4kW 28.0kW

Model

Capacity

P40 P63 P100 P125

4.5kW 7.1kW 11.2kW 14.0kW

PEFY-P VMH-E-F

PLFY-P VLMD-E

PMFY-P VBM-E

PCFY-P VKM-E

Fresh Air Intake

Page39 - Page40

Page55 - Page56

Page

41 -

Page

42

Page57 - Page58

Page43 - Page44

Page59 - Page64

Page45 - Page52

Page53 - Page54

PKFY-P VHM-E

PKFY-P VKM-E

PEFY-P VMR-E-L/R

PEFY-P VMH-EPEFY-P VMS1(L)-E

PEFY-P VMA(L)-E

Page 37 Page 38

Indoor Unit

Page 21

PLFY-P VBM-E

PLFY-P VCM-E

INDOOR UNIT

Ceiling cassette type

4-way airflow

The new 4-way cassette VBM offers 72 different airflow patterns, making

it ideal for applications with ceilings up to 4.2 m (13-13/16ft) in height.

Compact body to match with 2 feets

(600mm) x 2 feets (600mm) ceiling

design (VCM)

570mm

570mm

570mm

570mm

PLFY-P VBM PLFY-P VCM

Auto-fan-speed mode enables speedy and

comfortable heating during heating startup.

The Auto-fan-speed mode is added to the

usual four steps “Low, Mid1, Mid2, High.”

The Auto-fan-speed mode enables speedy

and comfortable air conditioning because the

air flow speeds up when starting, and air flow

slows down when the air conditioning

becomes stable. (PLFY-P VBM-E ONLY)

Low

High AutoMid2Mid1

* When using a wireless remote controller, initial settings are

required.

* Optional parts air outlet shutter plate (PLFY-P VBM-E

ONLY) is required for 2 or 3 way outlet selection.

*Default

*The ceiling may be smudged at a spot where the supplied

airflow is seriously disturbed.

Discharge air reaches wider area and the fan

speed is decreased by 20% thanks to the new

wide shape air outlet.

Cooling softly with Wide Air Flow

Co nve nti ona l m odel

Ne w m ode l

72 patterns of airflow to accommodate

any room layout are available.

First in the industry

The number of outlet can be set to 4, 3, or 2. Flexible airflow is

available by fixing the up-down airflow direction of the outlet

with a wired remote controller (or manually).

72 airflow patterns

4-, 3-, or 2- way outlet selection*

Setting the air direction for each

outlet with wired remote controller

Down blow

Horizontal blow

Remote controller setting

Fixed

*On the commercial air

conditioners (According to the

survey by Mitsubishi Electric)

Auto-fan-speed mode of

4-way Cassette with

“i-see sensor” heats the

floor well and decreases

the temperature

difference at the top and

bottom in a room.

Preset temperature is

tended to be higher

than we need,

because heated air

rises to the ceiling.

Feeling temperature

at 20°C (Bottom17°C)

Feeling temperature

at 20°C (Bottom 20°C)

37°C

25°C

13°C

37°C

25°C

13°C

New 4-way Cassette PLFY-VBM controls the

temperature difference at the top and bottom in

a room by checking the floor temperature with

“i-see sensor”. Comfortable air conditioning can

be realized smoothly with “sensible temperature

control.” (Option PAC-SA1ME-E, PLFY-VBM-E

ONLY)

“i-see sensor” can be used with

ceiling cassette type 4-way airflow

unit. (Option PAC-SA1ME-E, PLFYVBM-E ONLY)

Prevents overcooling/overheating, and

improves comfort/energy-efficiency

Without i-see sensor: preset temperature at 23°C

With i-see sensor+Auto fan speed: pr eset t emperature at 20

°C

In heating

In heating