Page 1

Outdoor-Air Processing unit

GUF-50/100RD3

GUF-50/100RDH3

Page 2

CONTENTS

CHAPTER 1 Product Section

1. Summary .......................................................................................................................................... 2

2. Main Functions of OA Processing Unit.............................................................................................. 3

3. Model Line-Up .................................................................................................................................. 4

4. Summary of Types ............................................................................................................................ 4

5. Specifications .................................................................................................................................... 5

6. Outline Drawings .............................................................................................................................. 7

7. Electric Wiring Diagrams .................................................................................................................. 8

8. Characteristic Curves ........................................................................................................................ 10

9. Construction and Principle of Heat Recovery Unit (Lossnay Core) .................................................. 11

10. Total Heat Recovery Characteristics ................................................................................................ 13

11. Principle and Features of Permeable Film Humidifier ...................................................................... 14

12. Cooling and Heating Characteristics ................................................................................................ 18

13. Filter Characteristics.......................................................................................................................... 33

14. Noise Characteristics ........................................................................................................................ 35

15. Reference Documents ...................................................................................................................... 36

CHAPTER 2 Air Conditioning System Design Section

1. Guide to a Comfortable Air Conditioning System.............................................................................. 48

2. Features of the OA Processing Unit.................................................................................................. 49

3. Air Conditioning and Ventilation ........................................................................................................ 50

4. Characteristics .................................................................................................................................. 61

5. Lossnay Core Effect .......................................................................................................................... 64

6. Humidifying........................................................................................................................................ 70

7. Humidifying Effect of the OA Processing Unit ..................................................................................72

8. Water Quality and Service Life of Humidifier .................................................................................... 75

9. Dust Removal.................................................................................................................................... 77

10. Sound ................................................................................................................................................ 82

11. Precautions when Using.................................................................................................................... 87

CHAPTER 3 Control System Design Section

1. System Selection .............................................................................................................................. 92

2. Precautions when Designing Systems .............................................................................................. 99

3. Cable Installation .............................................................................................................................. 100

4. System Designs ................................................................................................................................ 104

5. Control of OA Processing Unit .......................................................................................................... 106

6. Automatic Ventilation Switching ........................................................................................................ 107

7. Operation with Cooling/Heating ........................................................................................................ 110

8. Feature Settings ................................................................................................................................ 115

9. How to Operate ................................................................................................................................ 120

10. System Component .......................................................................................................................... 126

11.Troubleshooting ................................................................................................................................ 129

12. Remote Controller Check Code List.................................................................................................. 130

13. Circuit Test Point................................................................................................................................ 131

Page 3

CHAPTER 1

Product Section

Page 4

2

CHAPTER 1 ● Product Section

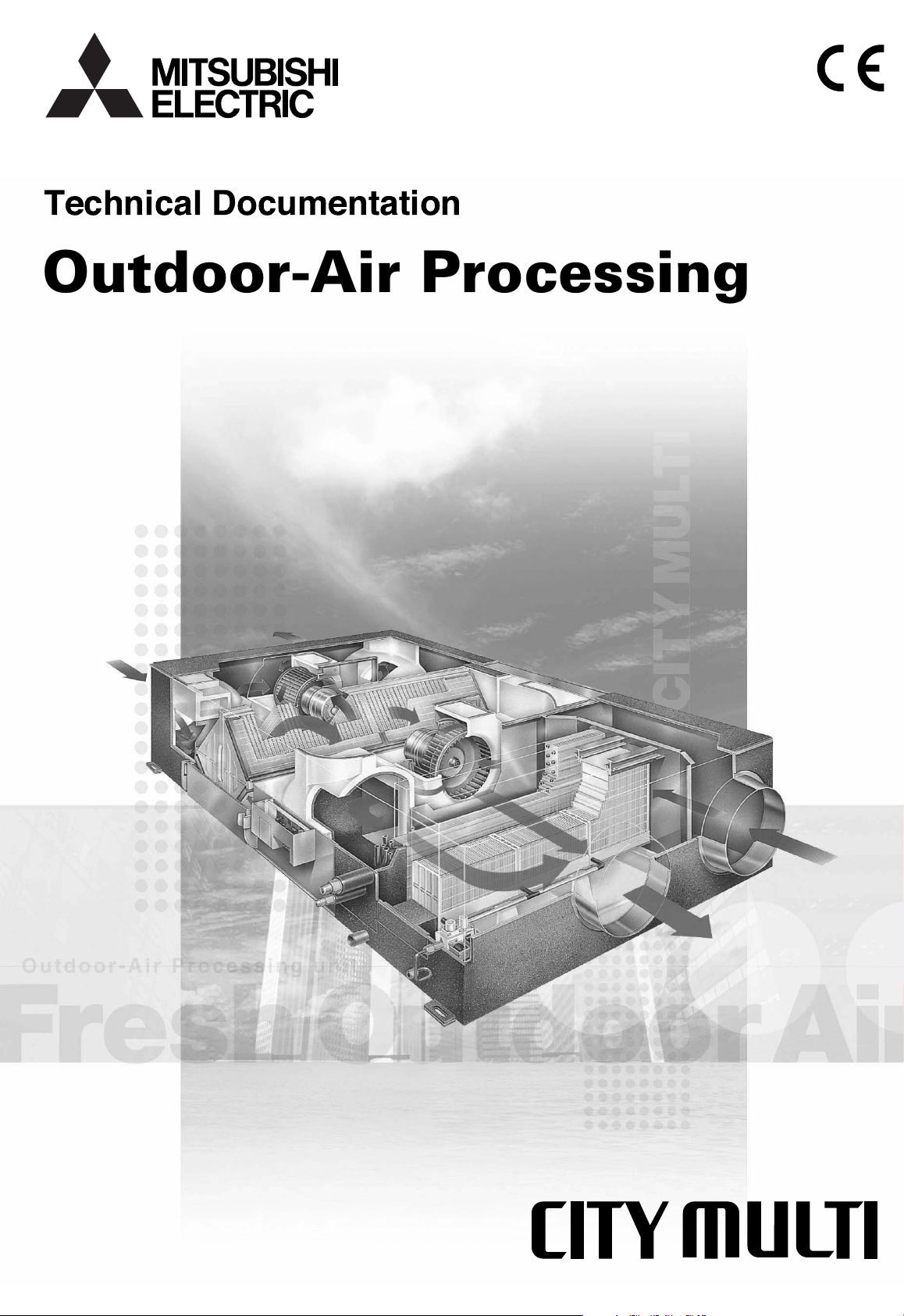

1. Summary

Introducing state-of-the-art comprehensive air conditioning that provides precise control for individual

rooms.

RDH3 series : Lossnay Ventilation and efficient humiditying.

RD3 series : Lossnay Ventilation and the Air conditioner.

(1)When the load is light. → Main Air conditioner.

(2)When the load is heavy. → Supplemental Air conditioner.

Introducing the latest advancement for total air conditioning comfort – the Outdoor Air processing unit (hereafter

OA processing unit). It uses the latest technology to provide comprehensive air conditioning control including

ventilation, heat recovery, humidifying, heat processing and dust removal*. Control can be performed for each

room, giving the flexibility to create the best comfort for each type of living space.

Note: (Dust removal) ......This function is enabled by using the optional high-efficiency filter.

The exhaust fan

High-efficiency filters (Option)

The supply fan

Maintenance cover

EA (Exhaust air)

The heat of room air is recovered

(sensible and latent heat) by

Lossnay Core, and exhausted to

the outside of the room by the

exhaust fan.

OA (Outdoor air)

Fresh outdoor air in a

quantity corresponding to

the required ventilation

rare is taken in by the

supply fan.

Lossnay Core

Temperature and humidity are

recovered between supply air

and exhaust air.

Air filter

Prevents clogs in the

Lossnay Core.

Direct Expansion coil

The outdoor air taken in is cooled or

heated by Direct Expansion coil.

Permeable-film humidifier

Outdoor air taken in is humidified by the permeable film

humidifier as required for more comfortable air conditioning.

Not available on GUF-50/100RD3.

SA (Supply air)

The fresh outdoor air processed is supplied to

the inside of rooms.

RA (Return air)

Contaminated room

air is sucked by the

exhaust fan.

Page 5

3

CHAPTER 1 ● Product Section

2. Main Functions of OA Processing Unit

2.1 Common Functions of Humidifying/Non-Humidifying Type

(GUF-RDH3/RD3)

●

Ventilation

Ensures proper ventilation by simultaneous forced air induction and exhaust.

Dual intake fans are used to simultaneously force both supply air diffuser and exhaust. This means that even

sealed buildings will be ensured of proper ventilation.

●

Heat recovery

Heat recovery system that provides energy-saving operation.

The unit has a built-in static type total heat recovery unit Lossnay Core. There is no mixing of the intake and

exhaust air as they pass through the Lossnay Core. Recover of both temperature (sensible heat) and humidity

(latent heat) – in other words total heat recovery – is performed with minimal loss to the heating or cooling effect,

ensuring energy-saving operation.

●

Dust removal*

High-efficiency filter provides 65% filtration using colorimetric method (Optional parts)

The high-efficiency filter provides up to 3,000 hours of maintenance free operation and is capable of 65% filtration

(colorimetric method). It can be installed inside of the OA processing unit itself, so no additional installation space

is required. In addition, the high-efficiency filter can be installed after the OA processing unit has been installed.

Note: This function is enabled by using the optional high-efficiency filter.

●

Free Cooling

When the air conditioning system is operating in its cooling mode and the temperature of the air outdoors drops

below the temperature indoors (e.g.a summer night), the OA processing unit detects this and automatically

switches to a mode of operation which bypasses the heat-exchange element. Bringing in cool air from outside

serves to help reduce the air conditioner’s cooling load.

2.2 Functions of Humidifying Type (GUF-RDH3)

●

Humidifier

Total introduction of permeable-film humidifier that functions using natural evaporation.

The humidifier installed in the OA processing unit was designed exclusively by Mitsubishi Electric. It is the

permeable-film humidifier that functions using natural evaporation. This design total eliminates the spreading of

impurities such as breaching powder and silicon dioxide. This means that this system can provide a clean supply

air diffuser free of white exhaust.

●

Heat processing

Efficient heat processing and compact design allows for design freedom.

By including the direct expansion coil, approximately 25% of the air conditioning load can be heat processed by

the OA processing unit. This means that the air conditioning unit itself can be more compact. And since it totally

processes the outdoor air loads, it is possible to separate outdoor air loads and indoor air loads, allowing the

freedom for easier installation designs. In addition, air passes through the permeable film humidifier that

increases its heat and ensures proper humidity content.

2.3 Functions of Non-Humidifying Type (GUF-RD3)

●

Air conditioning

The high-performance direct-expansion coil and the air conditioning and Lossnay Core allow a single OA

processing unit to provide low-energy heating and cooling ventilation.

Page 6

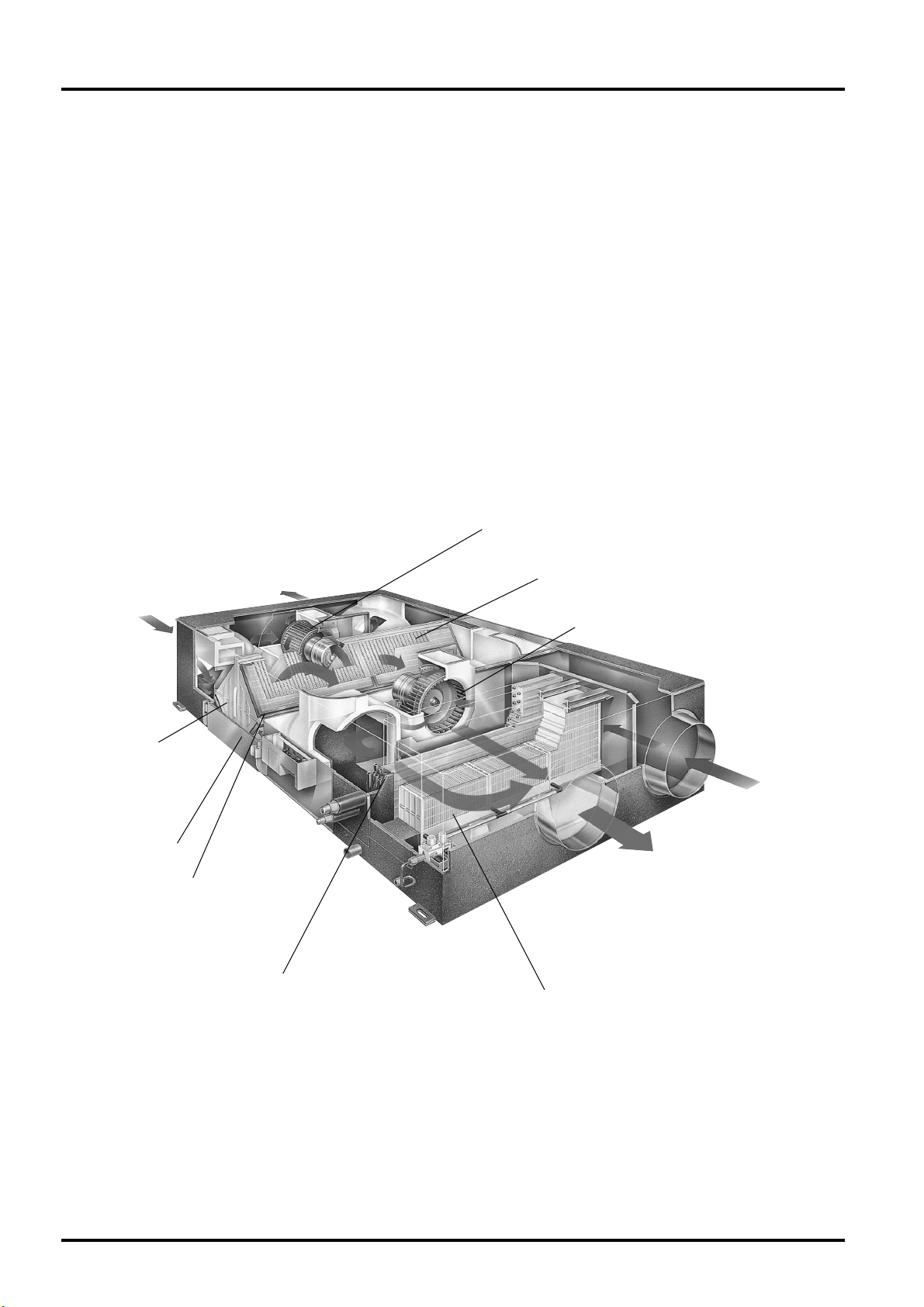

Model 50

Rated air flow volume

500 m3/h

4

CHAPTER 1 ● Product Section

3. Model Line-Up

4. Summary of Types

Outdoor Air

processing unit

H: with humidifier

D: with direct-expansion coil

R: Ceiling recessed

Air volume

50: 500 m

3

/h

100:1,000 m3/h

GUF

–

50 R D H

Humidifying type

Direct-expansion coil and

permeable-film humidifier

Non-humidifying type

Direct-expansion coil

Model 100

Rated air flow volume

1,000 m3/h

Ventilation, Heat recovery,

Humidifying, Heat processing

and (Dust removal)

Ventilation, Heat recovery,

Air conditioning and

(Dust removal)

GUF-50RD3

Ventilation, Heat recovery,

Humidifying, Heat processing

and (Dust removal)

GUF-100RDH3

Ventilation, Heat recovery and

(Dust removal)

GUF-100RD3

Note: (Dust removal) ......This function is enabled by using the optional high-efficiency filter.

GUF-50RDH3

3

3: Development Version

Page 7

GUF-50RDH3 GUF-100RDH3

Lossnay ventilation By-pass ventilation Lossnay ventilation By-pass ventila

tion

High Low High Low High Low High Low

Single phase 220 V - 240 V 50 Hz Single phase 220 V - 240 V 50 Hz

1.15 0.70 1.15 0.70 2.20 1.76 2.25 1.77

235-265 150-165 235-265 150-165 480-505 385-400 490-515 385-410

(P)32 (P)63

5.29 (DX coil:3.63, Lossnay:1.66) 10.81 (DX coil:7.32, Lossnay:3.49)

6.42 (DX coil:4.17, Lossnay:2.25) 13.00 (DX coil:8.30, Lossnay:4.70)

2.7 (heating) 5.4 (heating)

Supply air: Centrifugal fan [Sirocco fan] × 1 Exhaust air: Centrifugal fan [Sirocco fan] × 1

500 400 500 400 1,000 800 1,000 800

125 80 125 80 135 86 135 86

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

33.5-34.5 29.5-30.5 35-36 29.5-30.5 38-39 34-35 38-39 35-36

317 398

1,016 1,231

1,288 1,580

57 (filled with water 61) 98 (filled with water 106)

LEV control

12.7 15.88

6.35 9.52

VP25

Permeable film humidifier

Minimum pressure: 2.0 × 10

4

Pa Maximum pressure: 49.0 × 104Pa

R1/2 of External thread

Non-woven fabrics filter: Gravitational method 82%

+

High-efficiency filter: Colorimetric method 65% (optional parts)

Non-woven fabrics filter: Gravitational method 82%

5

CHAPTER 1 ● Product Section

5. Specifications

5.1 Humidifying Type

Fan

EA

OA

SA

RA

Lossnay Core Direct Expansion coil Humidifier

High-efficiency filter

(Optional parts)

Air filter

Ventilation

Heat

recovery

Humidifying

Heat

processing

(

Dust removal

)*

Model

Items

Power source

Current

Input

Capacity equivalent to the indoor unit

Cooling capacity

Heating capacity

Humidifying capacity

Fan

Fan motor

Noise level

Maximum

dimensions

Weight

Refrigerant control

Refrigerant pipe

dimensions

Drain pipe dimension

Type of humidifier

Water supply pressure

Water supply pipe dimension

Filter

Width

Height

Depth

Gas

Liquid

A

W

kW

kW

kg/h

m

3

/h

Pa

dB (A)

mm

mm

mm

kg

ø mm

ø mm

Note: (Dust removal) ......This function is enabled by using the optional high-efficiency filter.

Supply air

Type × No. of fans

Air volume

External static pressure

Exhaust air

Page 8

6

CHAPTER 1 ● Product Section

GUF-50RD3 GUF-100RD3

Lossnay ventilation By-pass ventilation Lossnay ventilation By-pass ventilation

High Low High Low High Low High Low

Single phase 220 V - 240 V 50 Hz Single phase 220 V - 240 V 50 Hz

1.15 0.70 1.15 0.70 2.20 1.73 2.25 1.77

235-265 150-165 235-265 150-165 480-505 370-395 490-515 385-410

(P)32 (P)63

5.29 (DX coil:3.63, Lossnay:1.66) 10.81 (DX coil:7.32, Lossnay:3.49)

6.42 (DX coil:4.17, Lossnay:2.25) 13.00 (DX coil:8.30, Lossnay:4.70)

Supply air diffuser: Centrifugal fan [Sirocco fan] × 1 Exhaust air: Centrifugal fan [Sirocco fan] × 1

500 400 500 400 1,000 800 1,000 800

140 90 140 90 140 90 140 90

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

33.5-34.5 29.5-30.5

35-36

29.5-30.5 38-39 34-35

38-39

35-36

317 398

1,016 1,231

1,288 1,580

54 92

LEV control

12.7 15.88

6.35 9.52

VP25

Non-woven fabrics filter: Gravitational method 82%

+

High-efficiency filter: Colorimetric method 65% (optional parts)

Non-woven fabrics filter: Gravitational method 82%

5.2 Non-Humidifying Type

Ventilation

Heat

recovery

Air

conditioning

(

Dust removal

)*

Model

Items

Power source

Current

Input

Capacity equivalent to the indoor unit

Cooling capacity

Heating capacity

Fan

Fan motor

Noise level

Maximum

dimensions

Weight

Refrigerant control

Refrigerant pipe

dimensions

Drain pipe dimension

Filter

Width

Height

Depth

Gas

Liquid

A

W

kW

kW

m

3

/h

Pa

dB(A)

mm

mm

mm

kg

ø mm

ø mm

Note: (Dust removal) ......This function is enabled by using the optional high-efficiency filter.

Supply air

Type × No. of fans

Exhaust air

Fan

EA

OA

SA

RA

Lossnay Core Direct Expansion coil

High-efficiency filter

(Optional parts)

Air filter

Air volume

External static pressure

Page 9

!

!

"#$

% &'

% &(

)*

+

,

)

,

-

-

,

. /

)

,

%!

)

0

+

"

12

324

5

622

#2

7

8989

6$2:#$2

322

/

;

&

&

7

CHAPTER 1 ● Product Section

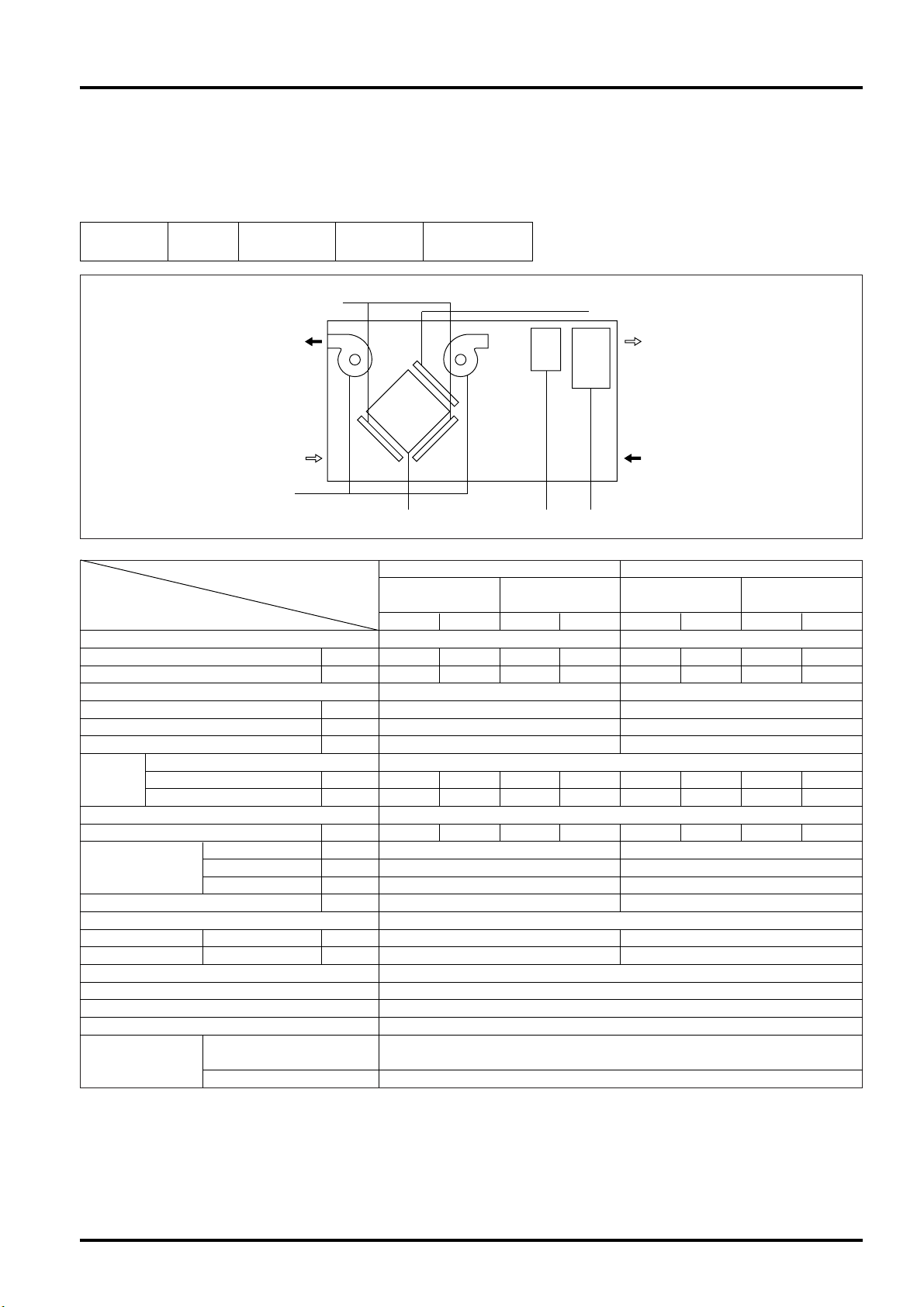

6. Outline Drawings

6.1 Humidifying Type GUF-50/100RDH3

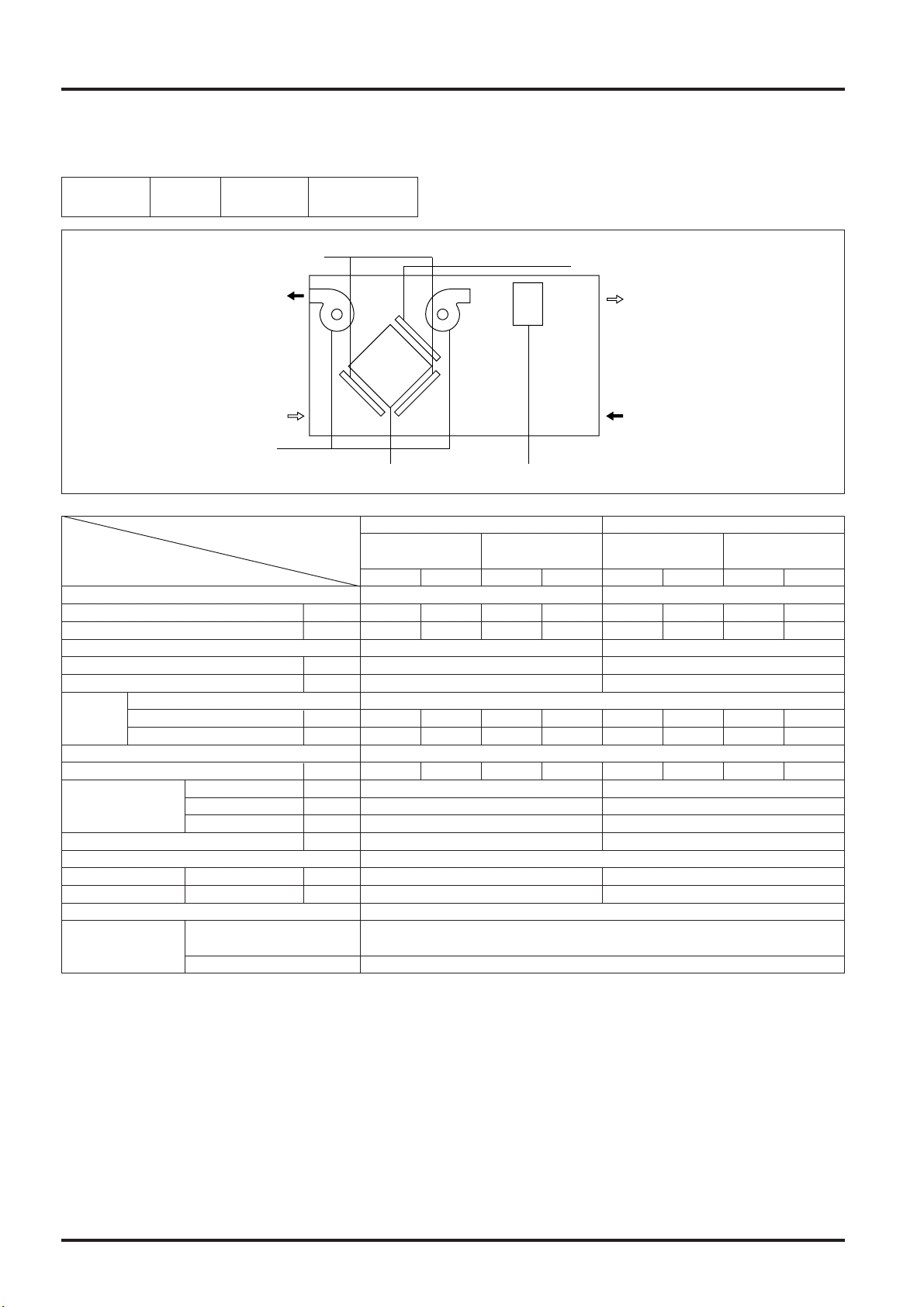

6.2 Non-Humidifying Type GUF-50/100RD3

Unit (mm)

! "

#

$

%

% $

&

%

#

$

'()

* +

,)-

#. / 01

2 / 03

&

% $

4

4

.

$$

*

56

7

86

,

9: ;

'66

'-6<)-6

#

/

2

"

866

0

0

9:9: =

%

>

)6 ?

Unit (mm)

Model A

GUF-50RDH3

745

1,016

124

1,185

1,048 22 124 450 372.5 435 158.5

GUF-100RDH3

920

1,231

149

1,465

1,271 16 149 600 460 670 199

BCDEFGHJ KL

Model M

GUF-50RDH3

317

1,288

124 266 192 208 12.7 6.35 347 99 135

GUF-100RDH3

398

1,580

149 280 242 258 15.88 9.52 361 110 169

NPQRSTUVWX

Model A

GUF-50RD3

745

1,016

124

1,185

1,048 22 124 450 372.5 435 158.5

GUF-100RD3

920

1,231

149

1,465

1,271 16 149 600 460 670 199

BCDEFGHJ KL

Model M

GUF-50RD3

317

1,288

124 266 192 208 12.7 6.35 347 135

GUF-100RD3

398

1,580

149 280 242 258 15.88 9.52 361 169

NPQRSTUVW

Page 10

LED3

SW4

SW5

BROWN

S

B

A

2

1

7

8

9

10

11

12

BROWN

BROWN

BLUE

RED

BLUE

BROWN

/ YELLOW

PURPLE

FAN1

FAN4

TR

CN3TCNT

CND1 CND2

GREEN

BLACK

YELLOW

YELLOW

TH4 (RA)

TH1 (OA)

YELLOW

YELLOW

WHITE

WHITE

RED

PINK

PINK

YELLOW

GREY

GREY

YELLOW

YELLOW

ORANGE

ORANGE

RED

WHITE

WHITE

ORANGE

PURPLE

ORANGE

BLUE

WHITE

RED

BLACK

PINK

GREEN/ YELLOW

GREEN/ YELLOW

BLACK

PINK

ORANGE

WHITE

RED

GREEN/ YELLOW

CN22

CN29

CN21

SW1

SW2

SW3

SW12

LED1

LED2

SW11

SW14

CN20

SV1

SV2

L S

W. S

GM

M1

M2

RED

RED

PURPLE

PURPLE

BROWN

RED

PURPLE

ORANGE

PINK

WHITE

CN60

CN70

CNL

CN27

CN4D

RED

RED

FAN2

FAN3

FUSE1

PAR-F27MEA

PAR-20MAA

Remote Controller

Uncharged a-contact

Humidistat

240VAC more than

10mA

31

Operation monitor output

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

MAX MIN

Malfunction monitor output

MAX MIN

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

Shield wire

M-NET Remote controller

Fresh Master

To Outdoor Unit , BC Controller

X09

X08

M-NET transmissiion cable

DB901

1

6

7

1

5

5

1

ZNR901ZNR902

DSA1

X05

X04

X07

X06

X03

X02

BREAKER (16A)

RSV (1kΩ)

pipe

Liquid

TH2

pipe

Gas

TH3

SUPPLY FAN

EXHAUST FAN

PINK

PINK

C

C

TM2

TM3

TM1

LEV

1

220-240V ~50Hz

POWER SUPPLY

N

L

PE

N

L

MARK : indicates terminal block, : connector

: board insertion connector or fastening connector of control board.

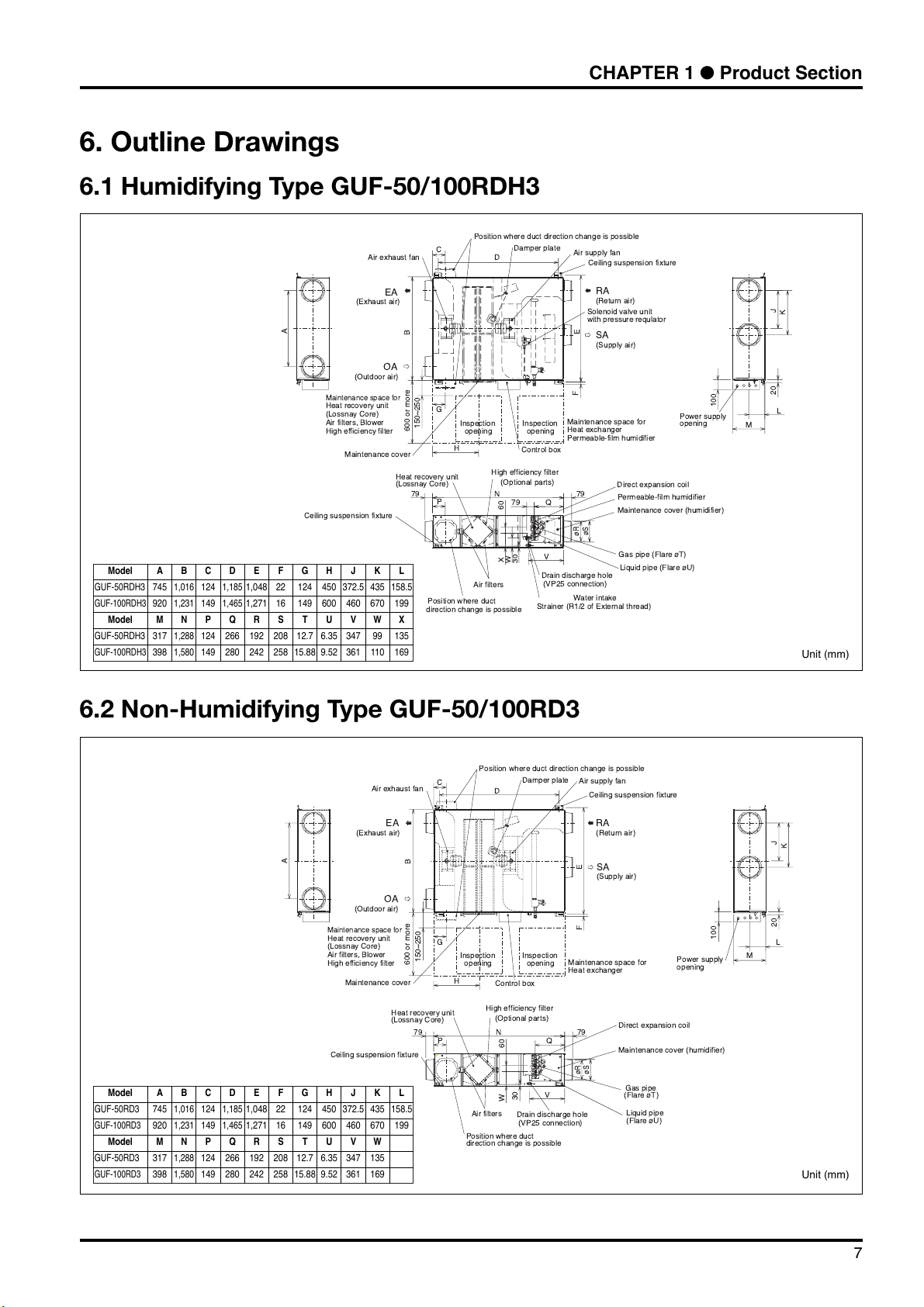

Symbol Explanation

M1

M2

C

W. S

SV1

SV2

TH1

TH2

TH3

TH4

LEV

RSV

Fan motor (exhaust)

Fan motor (supply)

Capacitor

Water sensor

Solenoid valve (pressure regulator)

Solenoid valve (exhaust)

Thermistor (outdoor air temp. detection)

Thermistor (pipe temp. detection/liquid)

Thermistor (pipe temp. detection/gas)

Thermistor (room air temp. detection)

Electronic linear expansion valve

Resistance (solenoid valve)

TM1

TM2

TM3

SW1

SW2

SW3

SW4

SW5

SW11

SW12

SW14

Terminal block (power supply)

Terminal block (transmission)

Terminal block (humidistat, monitor)

Switch (function selection)

Switch (capacity code setting)

Switch (function selection)

Switch

Switch

Switch (1st digit address set)

Switch (2nd digit address set)

Switch (branch NO. set)

1, 2

A, B

S

CND1, CND2

X02-X09

TR

GM

LS

LED1

LED2

LED3

Remote controller terminal

M-NET transmission terminal

Shield

Connector (power supply)

Relay

Transformer

Damper motor

Limit switch

Power supply monitor

MA remote controller

Power supply monitor

M-NET Power supply monitor

Symbol Name Symbol Name Symbol Name

250V 6.3A

8

CHAPTER 1 ● Product Section

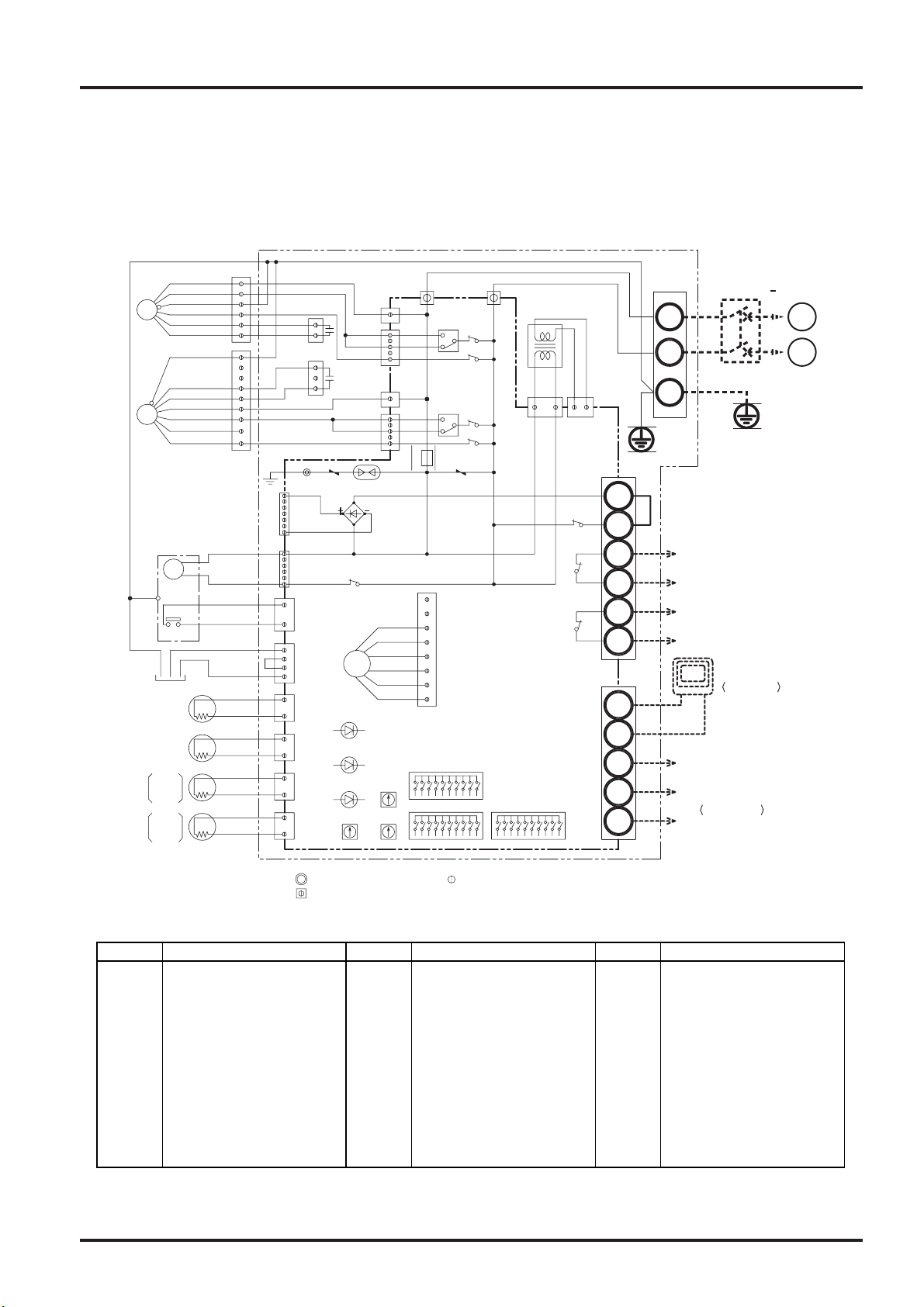

7. Electric Wiring Diagrams

7.1 Humidifying Type GUF-50/100RDH3

●

TM1, TM2, TM3 shown in dotted lines are field work.

●

Be sure to connect the grounding wire.

●

Breakers and controller switches should be provided by the customer.

Page 11

9

CHAPTER 1 ● Product Section

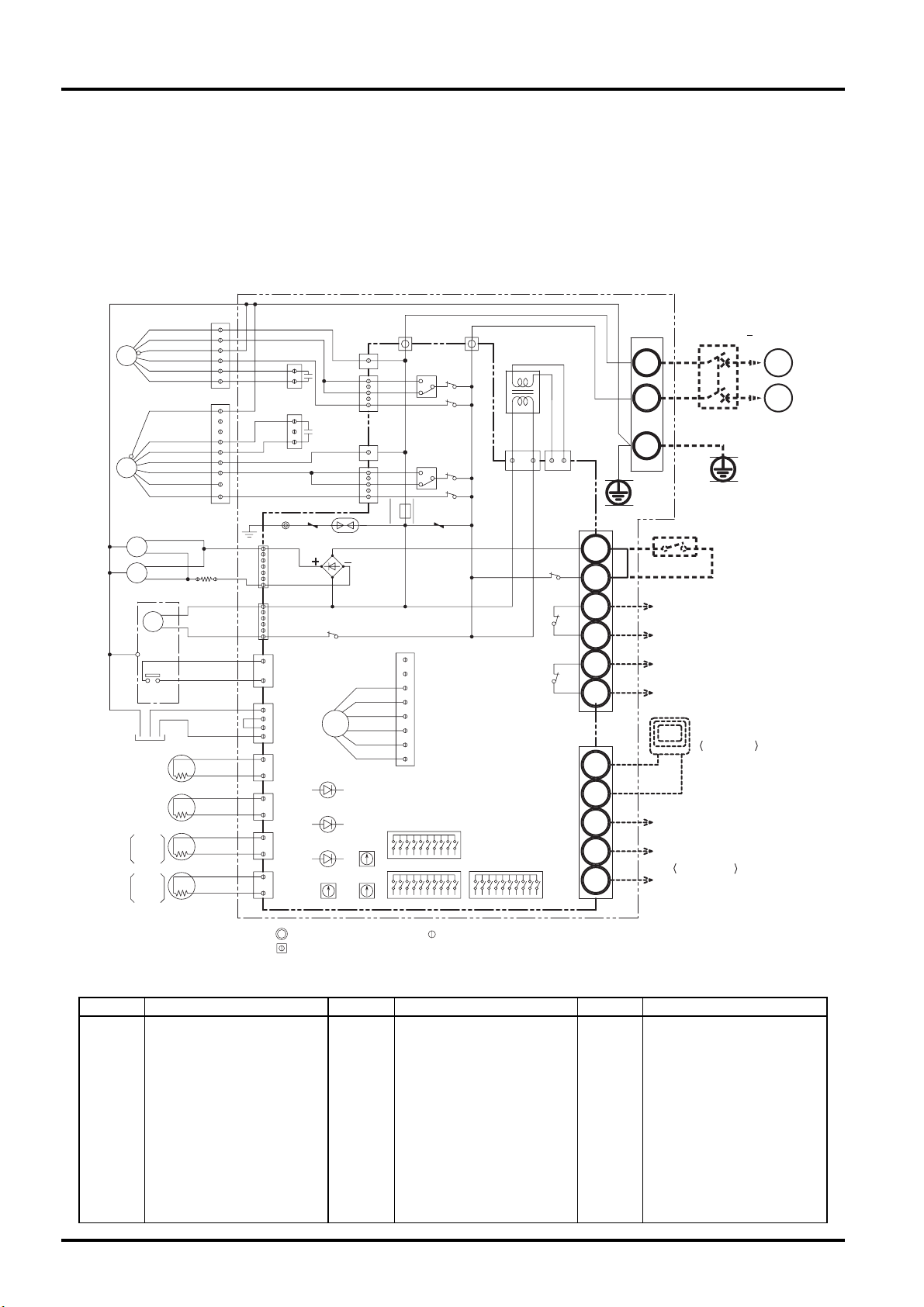

7.2 Non-Humidifying Type GUF-50/100RD3

●

TM1, TM2 shown in dotted lines are field work.

●

Be sure to connect the grounding wire.

●

Breakers and controller switches should be provided by the customer.

Symbol Explanation

M1

M2

C

W.S

TH1

TH2

TH3

TH4

LEV

Fan motor (exhaust

)

Fan motor (supply)

Capacitor

Water sensor

Thermistor (outdoor air temp. detection

)

Thermistor (pipe temp. detection/liquid)

Thermistor (pipe temp. detection/gas)

Thermistor (room air temp. detection

)

Electronic linear expansion valve

TM1

TM2

TM3

SW1

SW2

SW3

SW4

SW5

SW11

SW12

SW14

Terminal block (power supply)

Terminal block (transmission)

Terminal block (humidistat, monitor)

Switch (function selection)

Switch (capacity code setting)

Switch (function selection)

Switch

Switch

Switch (1st digit address set)

Switch (2nd digit address set)

Switch (branch NO. set)

1, 2

A, B

S

CND1, CND2

X02-X09

TR

GM

LS

LED1

LED2

LED3

Remote controller terminal

M-NET transmission terminal

Shield

Connector (power supply)

Relay

Transformer

Damper motor

Limit switch

Power supply monitor

MA remote controller

Power supply monitor

M-NET Power supply monitor

Symbol Name Symbol Name Symbol Name

PINK

PINK

C

C

FUSE1

PAR-F27MEA

PAR-20MAA

Remote Controller

N

L

PE

N

1

Operation monitor output

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

MAX MIN

Malfunction monitor output

MAX MIN

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

Shield wire

M-NET Remote controller

Fresh Master

To Outdoor Unit , BC Controller

X09

X08

M-NET transmission cable

DB901

7

5

1

5

1

ZNR901

ZNR902

DSA1

X05

X04

X07

X06

X03

X02

BREAKER (16A)

220-240V ~50Hz

POWER SUPPLY

L

pipe

Liquid

TH2

pipe

Gas

TH3

SUPPLY FAN

EXHAUST FAN

MARK : indicates terminal block, : connector

: board insertion connector or fastening connector of control board.

LED3

SW4

SW5

BROWN

S

B

A

2

7

8

9

10

11

BROWN

BROWN

BLUE

RED

BLUE

BROWN

/YELLOW

PURPLE

FAN1

FAN4

TR

CN3TCNT

CND1 CND2

GREEN

1

12

BLACK

YELLOW

YELLOW

TH4 (RA)

TH1 (OA)

YELLOW

YELLOW

WHITE

WHITE

RED

PINK

PINK

YELLOW

GREY

GREY

YELLOW

YELLOW

ORANGE

ORANGE

RED

WHITE

WHITE

ORANGE

PURPLE

ORANGE

BLUE

WHITE

RED

BLACK

PINK

GREEN/ YELLOW

GREEN/ YELLOW

BLACK

PINK

ORANGE

WHITE

RED

GREEN/ YELLOW

CN22

CN29

CN21

SW1

SW2

SW3

SW12

LED1

LED2

SW11

SW14

CN20

L S

W. S

GM

M1

M2

BROWN

RED

PURPLE

ORANGE

PINK

WHITE

LEV

CN60

CN70

CNL

CN27

CN4D

FAN2

FAN3

3

1

6

1

TM3

TM1

TM2

250V 6.3A

Page 12

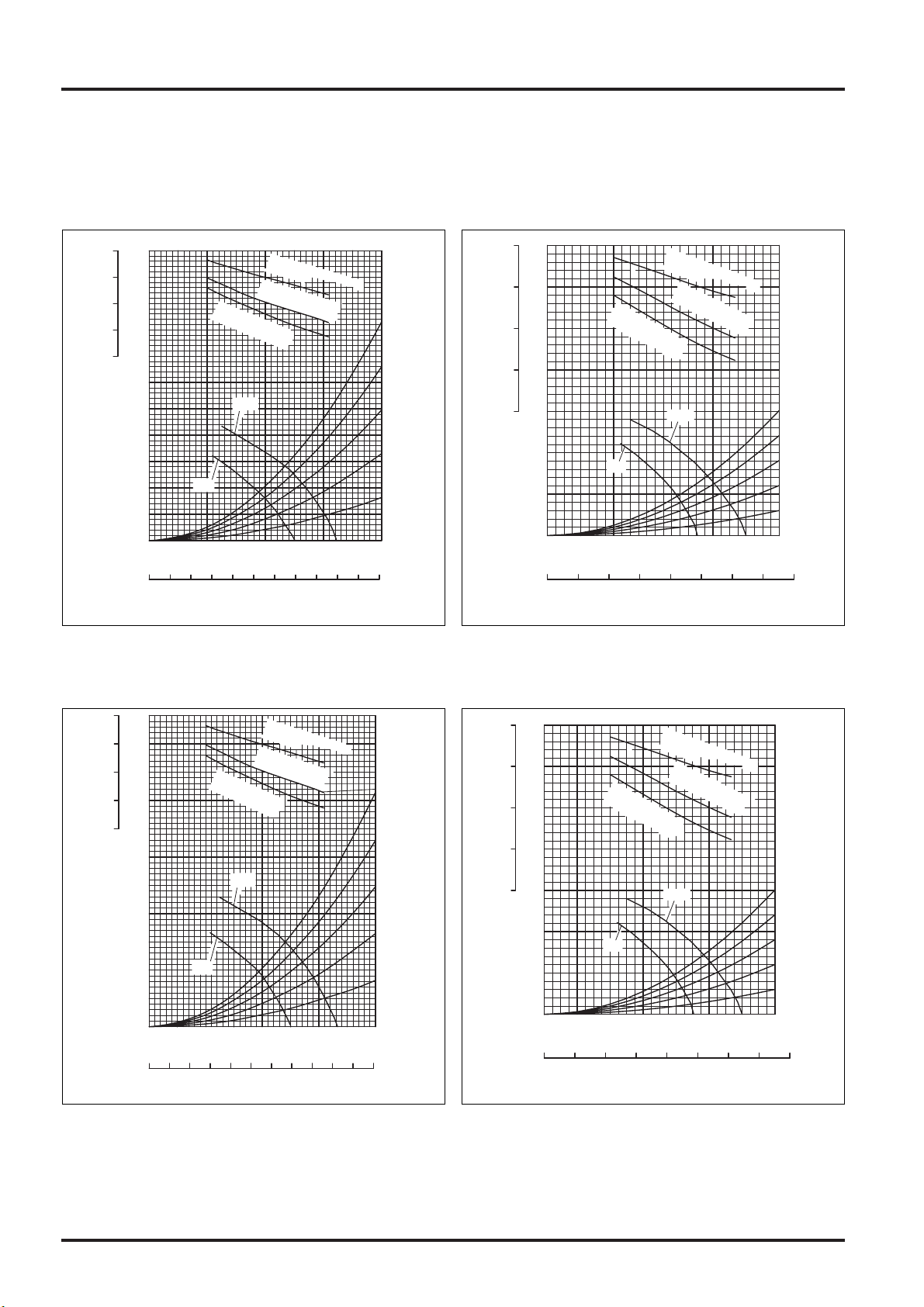

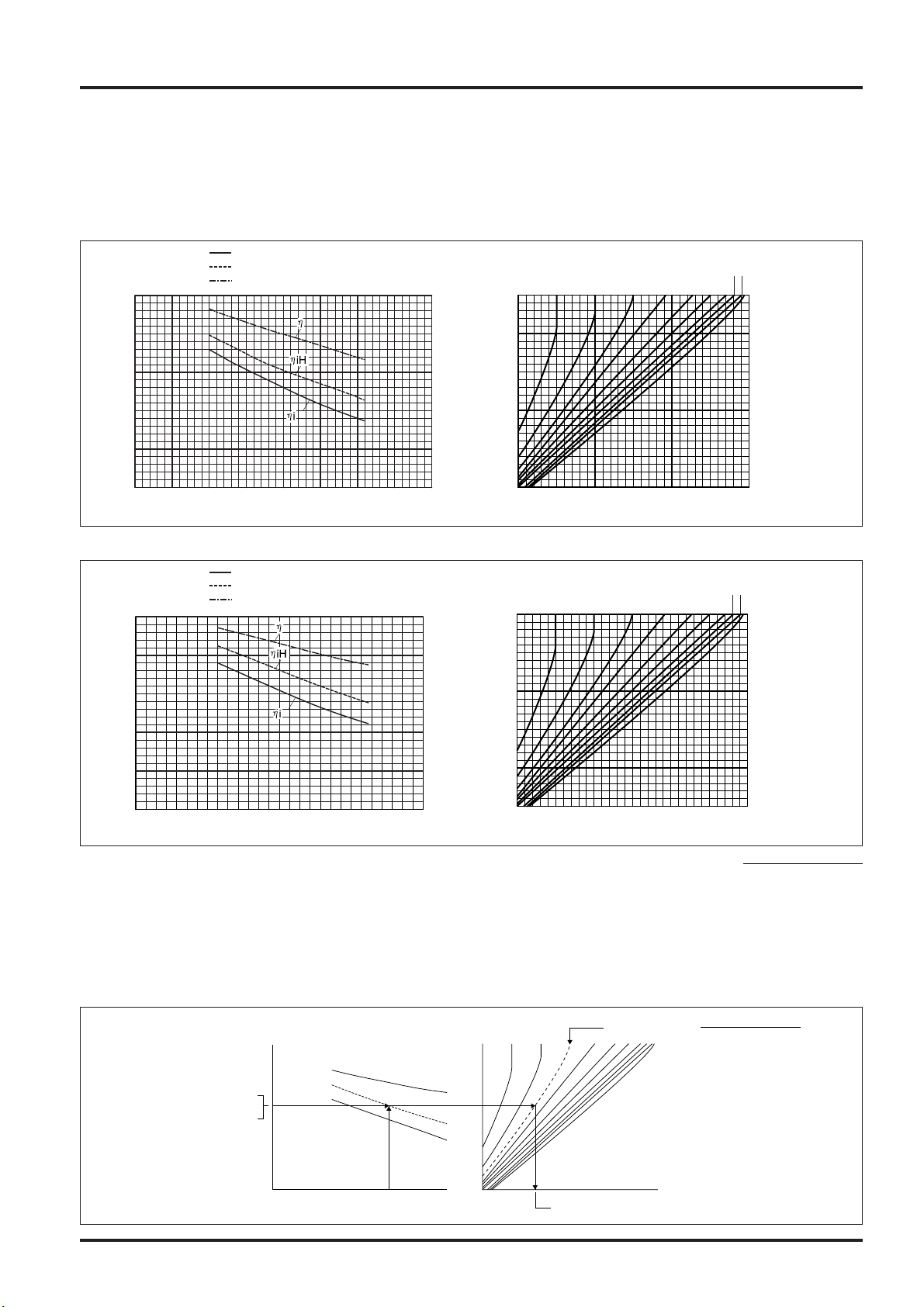

10

CHAPTER 1 ● Product Section

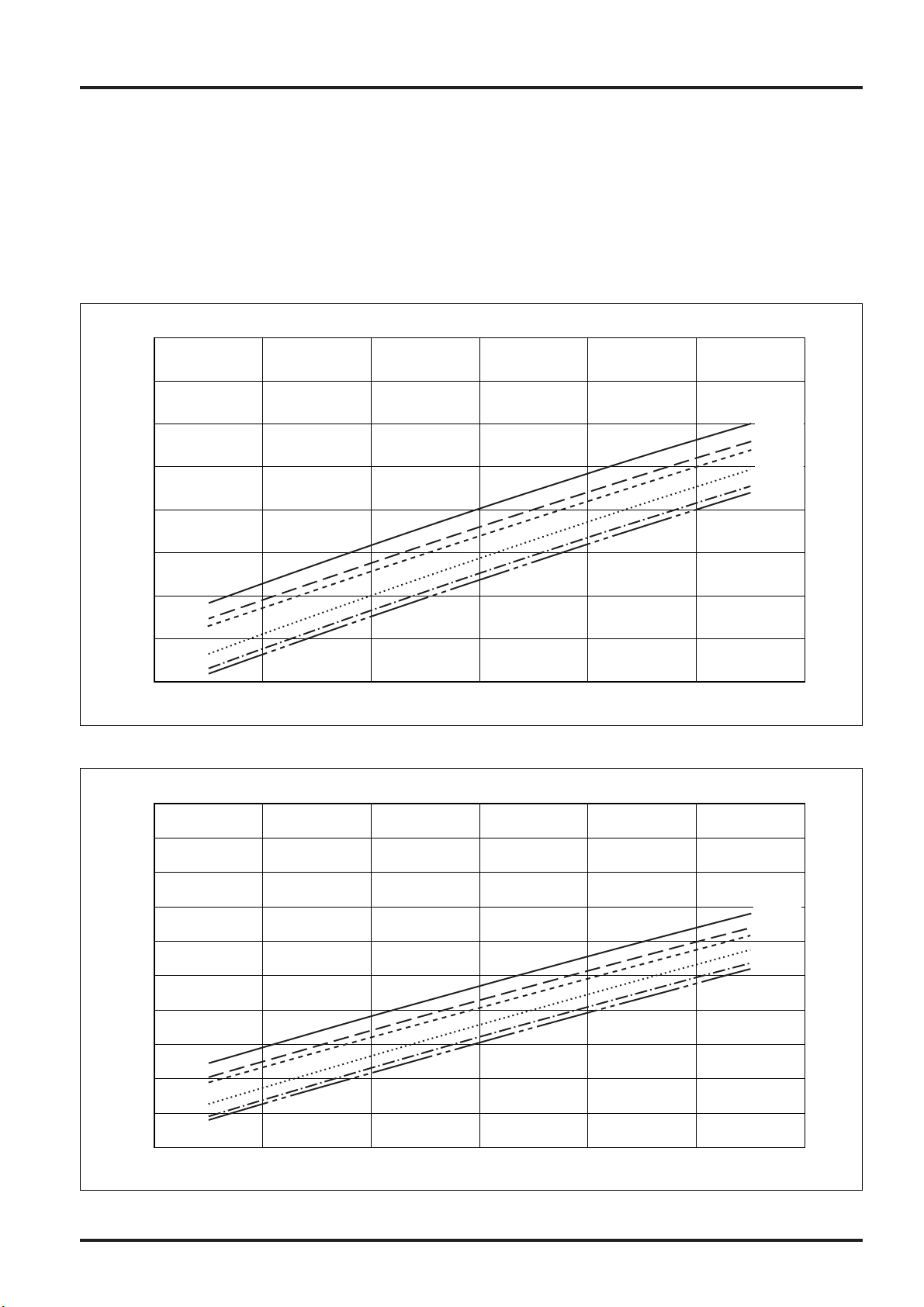

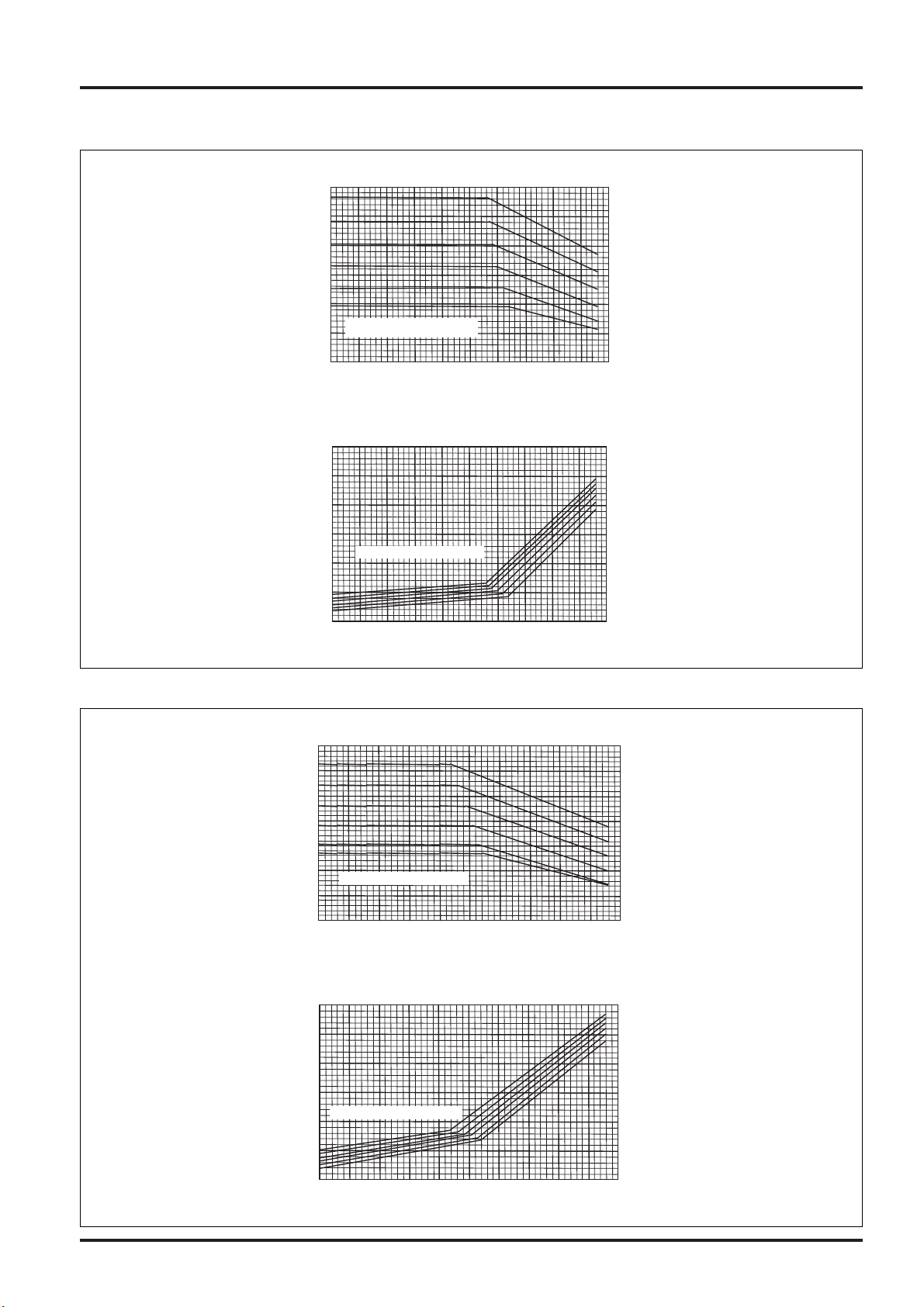

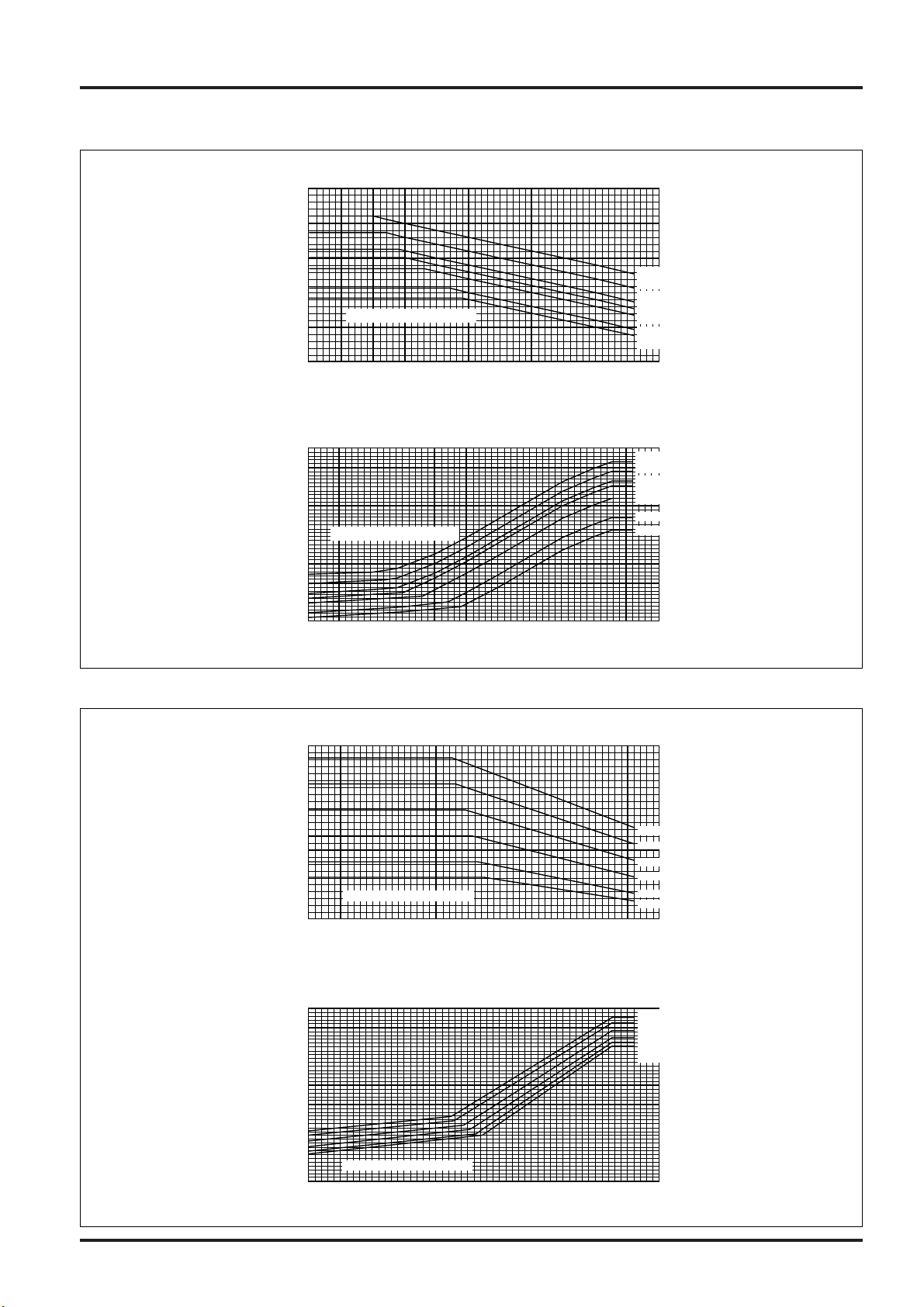

8. Characteristic Curves

8.1 Humidifying Type

8.2 Non-Humidifying Type

Low

High

Enthalpy exchange

efficiency (Cooling)

Enthalpy exchange

efficiency (Heating)

Temperature exchange

efficiency

300

0

(Pa)

External static pressure

Exchange efficiency

500

200

400

50

60

70

80

90

400

Air volume (L/s)

35025020015010050 3000

1400

(m

3

/h)

12001000800600400200

100m

80m

60m

40m

20m

250mm dia

pipe length

100

(%)

Low

High

Enthalpy exchange

efficiency (Cooling)

Enthalpy exchange

efficiency (Heating)

Temperature exchange

efficiency

020 220180 2006040 80 100 120 140 160

Air volume (L/s)

(m

3

/h)

200mm dia

pipe length

(Pa)

External static pressure

90

50

60

70

80

Exchange efficiency

3

2

1

4

m06

001

m

m04

m02

00

00

00

m08

060040020 080

00

0

(%)

GUF-100RDH3GUF-50RDH3

Low

High

Enthalpy exchange

efficiency (Cooling)

Enthalpy exchange

efficiency (Heating)

Temperature exchange

efficiency

300

0

(Pa)

External static pressure

Exchange efficiency

500

100

200

400

50

60

70

80

90

400

Air volume (L/s)

35025020015010050 3000

1400

(m

3

/h)

12001000800600400200

100m

80m

60m

40m

20m

pipe length

250mm dia.

(%)

Low

High

Enthalpy exchange

efficiency (Cooling)

Enthalpy exchange

efficiency (Heating)

Temperature exchange

efficiency

Air volume (L/s)

220160140120100802004060 200180

(m

3

/h)

060

00

00

00

00

External static pressure

(Pa)

4

08

07

06

05

09

Exchange efficiency

0

080020 040

80m

20m

40m

m

100

60m

1

2

3

pipe length

200mm dia.

(%)

GUF-100RD3GUF-50RD3

Page 13

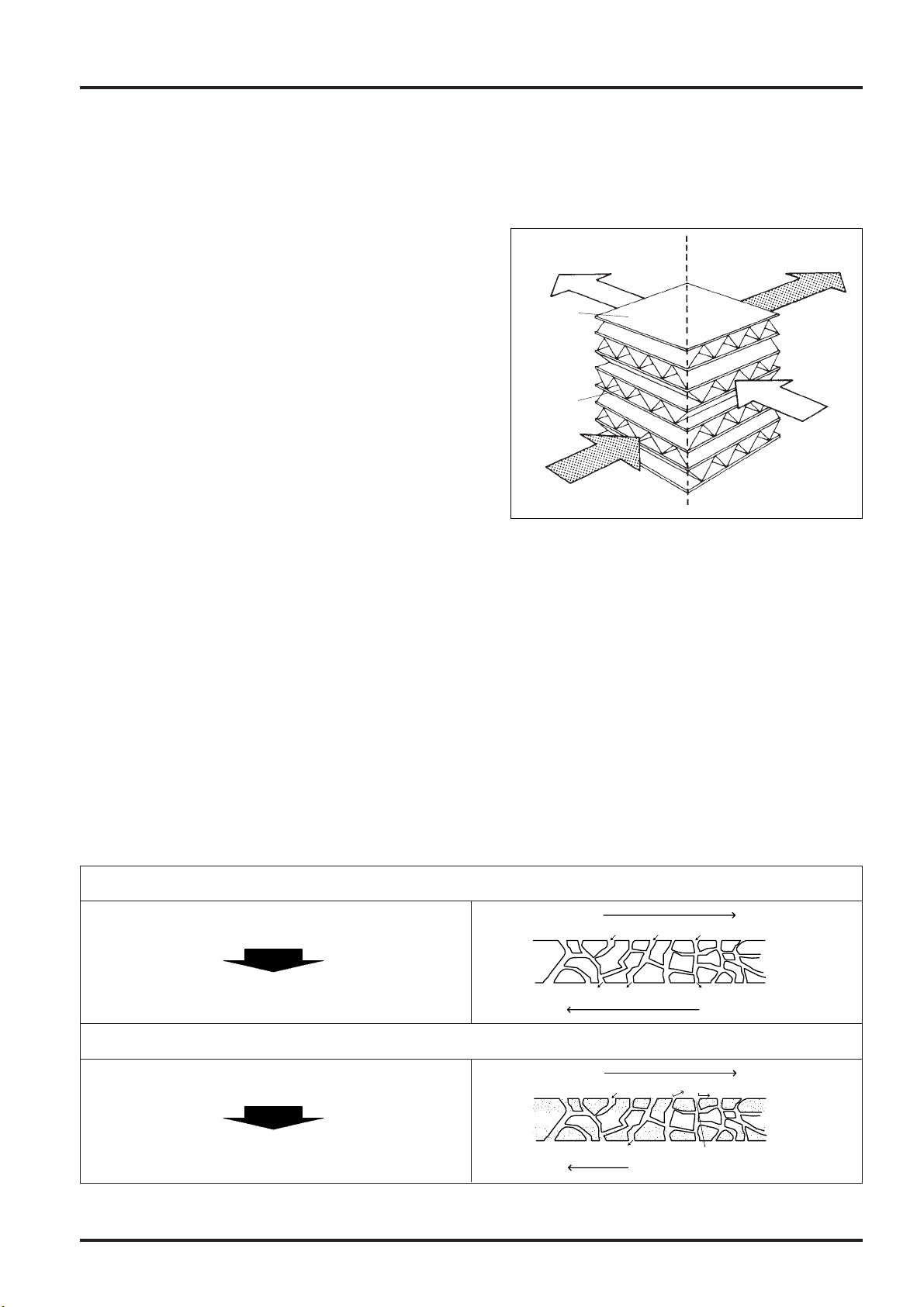

11

CHAPTER 1 ● Product Section

9. Construction and Principle of Heat Recovery Unit (Lossnay Core)

●

Simple construction

The Lossnay Core is a cross-flow total heat recovery unit

constructed of plates and fins made of treated paper.

The fresh air and exhaust air passages are completely

separated allowing the fresh air to be introduced without

mixing with the exhaust air.

●

Principle

The Lossnay Core uses the heat transfer properties and

moisture permeability of the treated paper. Total heat

(sensible heat plus latent heat) is transferred from the stale

exhaust air to the fresh air being introduced into the system

when they pass through the Lossnay Core.

Try this simple experiment. Roll a piece of paper into a tube

and blow through it. Your hand holding the paper will

immediately feel warm. If cold air is blown through the tube,

your hand will immediately feel cool. This means heat is

transferred through paper. Lossnay Core is a total heat

recovery unit that utilizes these special properties of paper.

●

Treated paper

The paper partition plates are specially treated so that the Lossnay Core is an appropriate heat recovery unit for

the ventilator. This paper differs from ordinary paper, and has the following unique properties.

(1) The paper is incombustible and is strong.

(2) The paper has selective hydroscopicity and moisture permeability that permits the passage of water vapor

only (including some water-soluble gases).

(3) The paper has gas barrier properties that does not pass gases such as CO

2

.

A comparison of the ordinary paper and the Lossnay Core plates is as shown in the table.

Ordinary paper

Water vapor is transferred, but gas elements that are easily

dissolved in water such as CO2, NO2 are also transferred.

The contaminated air passes through the plates during

ventilation and returns to the room.

Treated paper

Water vapor is transferred, but gas elements such as CO

2, NO2

are not transferred.

The contaminated air does not return to the room when

ventilated.

SA

Supply air diffuser

(Fresh cold or warm air)

Partition

plate

(Treated

paper)

Spacer plate

(Treated paper)

RA

Return air

(Stale cold or warm air)

Indoors Outdoors

EA

Exhaust air

(Stale air)

OA

Outdoor air

(Fresh air)

Highly humid air

Water vapor

Water vapor

CO

2 NO2

CO2 NO2

CO2 NO2Water vapor

Water vapor

Treatment

(Selective permeable film)

(Incombustible specifications)

Low humid air

Highly humid air

Cellulose

fibers

Low humid air

Page 14

12

CHAPTER 1 ● Product Section

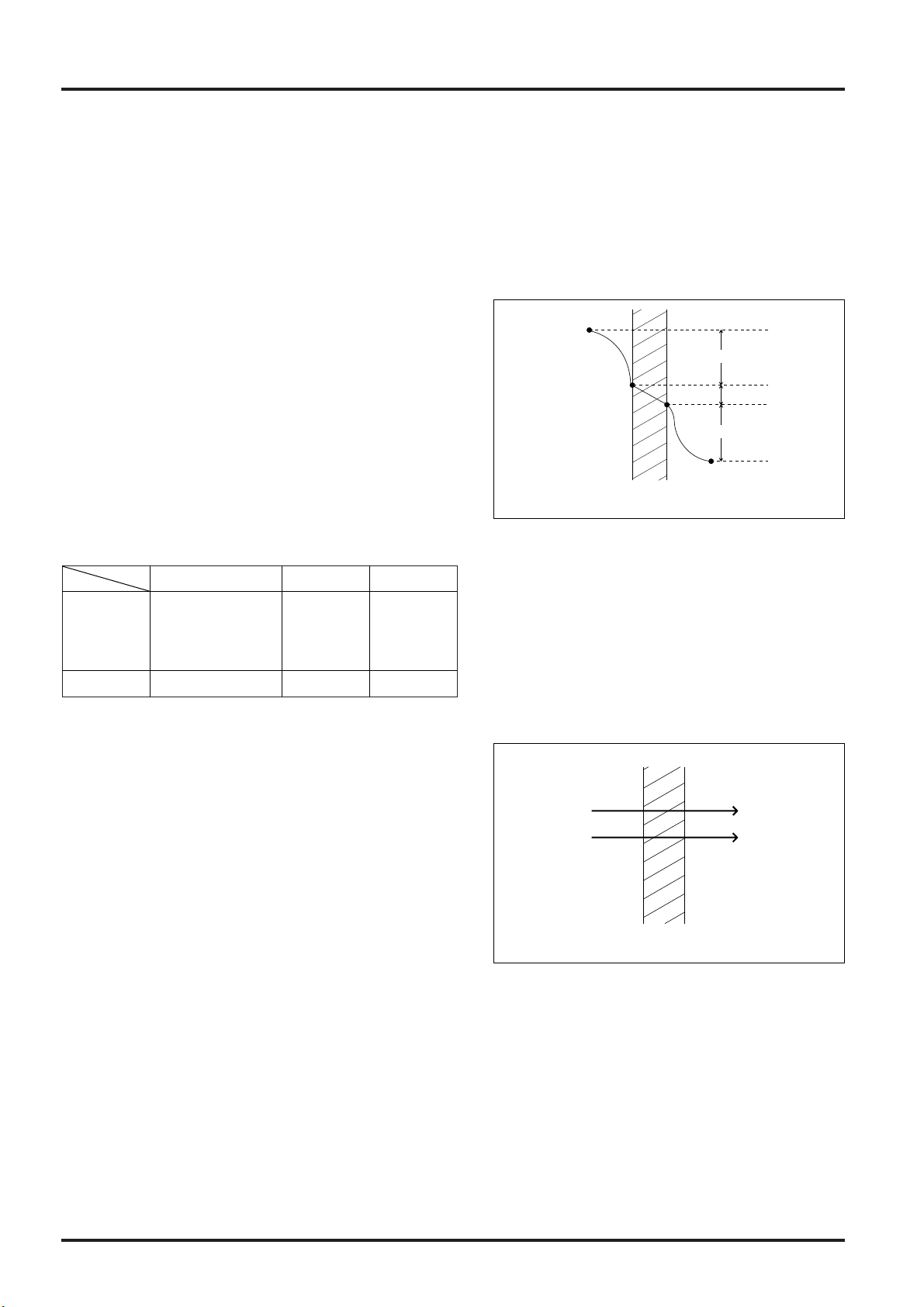

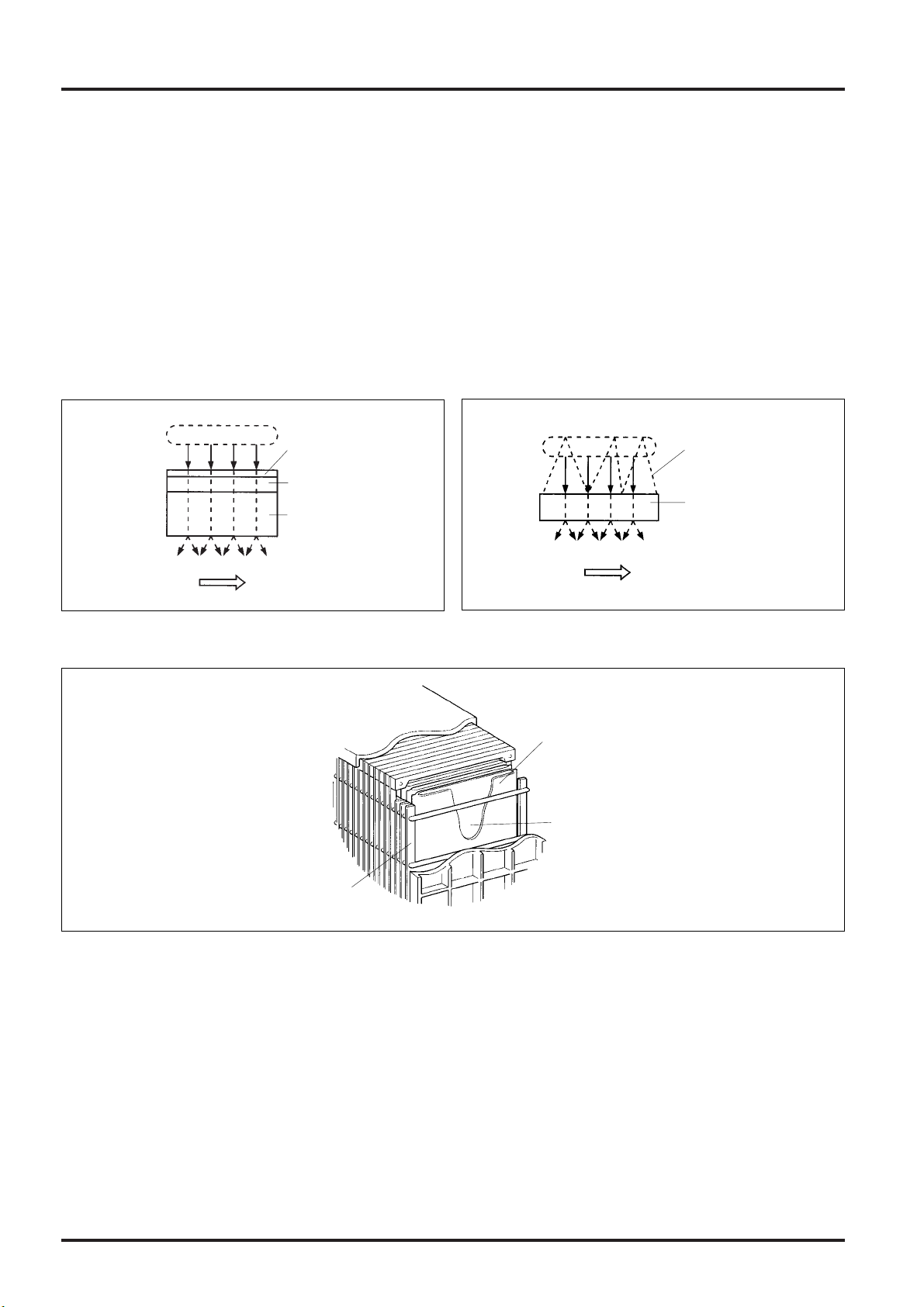

●

Total heat recovery mechanism

Sensible heat and latent heat

The heat that enters and leaves in accordance with changing temperature (rise or drop) is called sensible heat.

The heat that enters and leaves due to the changes in the physical properties of the matter (evaporation,

condensation) is called latent heat.

(1) Heat (sensible heat) exchange

1) Heat conduction and heat passage is performed

through a partition plate from the high temperature to

low temperature side.

2) As shown on the right, the heat exchange efficiency is

affected by the resistance of the boundary layer, and for

the Lossnay Core there is little difference when

compared to materials such as copper or aluminium

which also have high thermal conductivity.

Heat resistance coefficients

Treated paper Cu Al

Ra1 10 10 10

Rp 1 0.00036 0.0006

Ra2 10 10 10

Total 21 20.00036 20.0006

(2) Humidity (latent heat) exchange

●

Water vapor is moved through the partition plate from

the high humidity to the low humidity side by means

of the differential pressure in the vapor.

t1

t2

Ra1

Ra2

Rp

Partition plate

Ra1+Ra2

»Rp

High humidity side

Low humidity side

Partition plate

Page 15

13

CHAPTER 1 ● Product Section

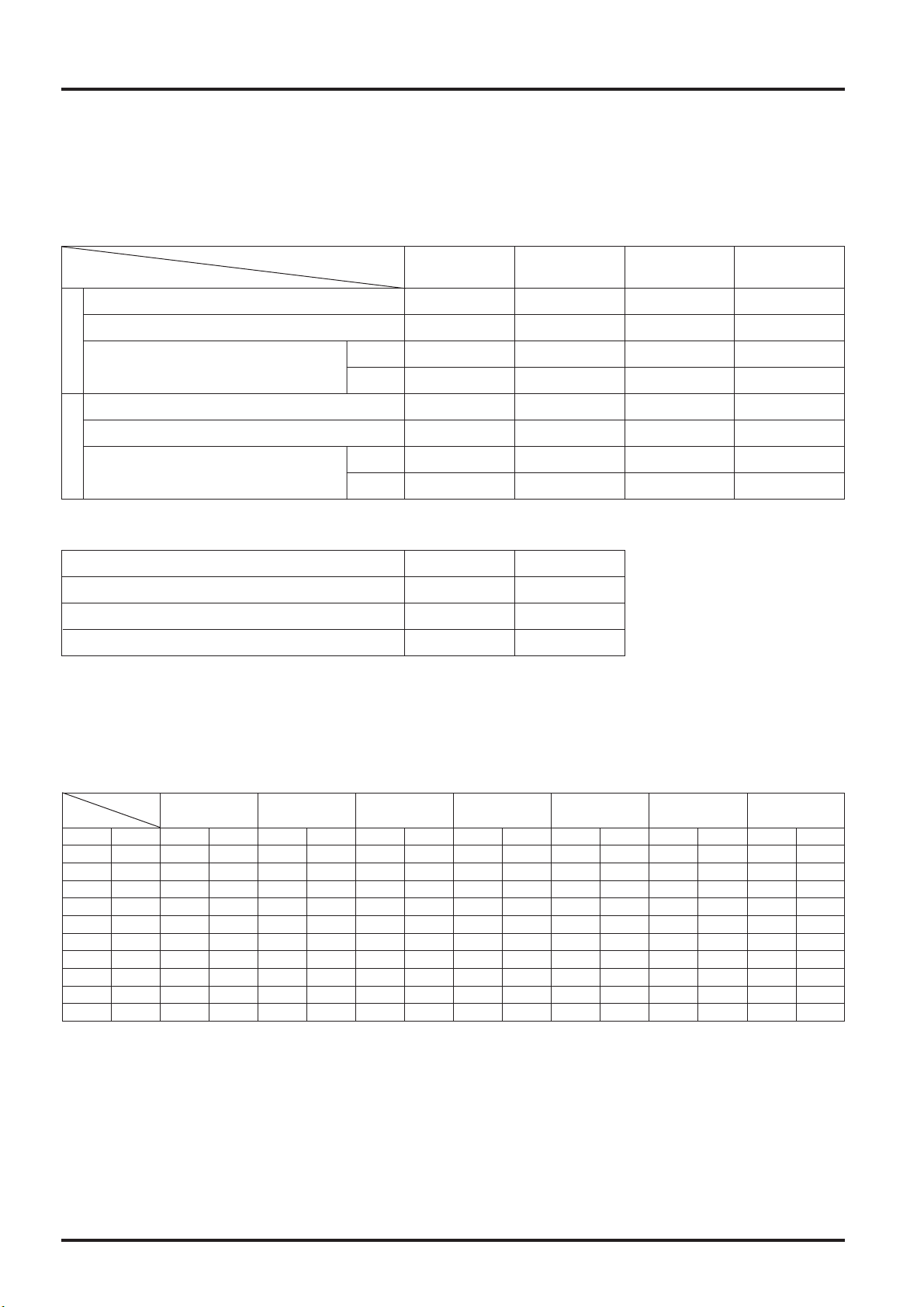

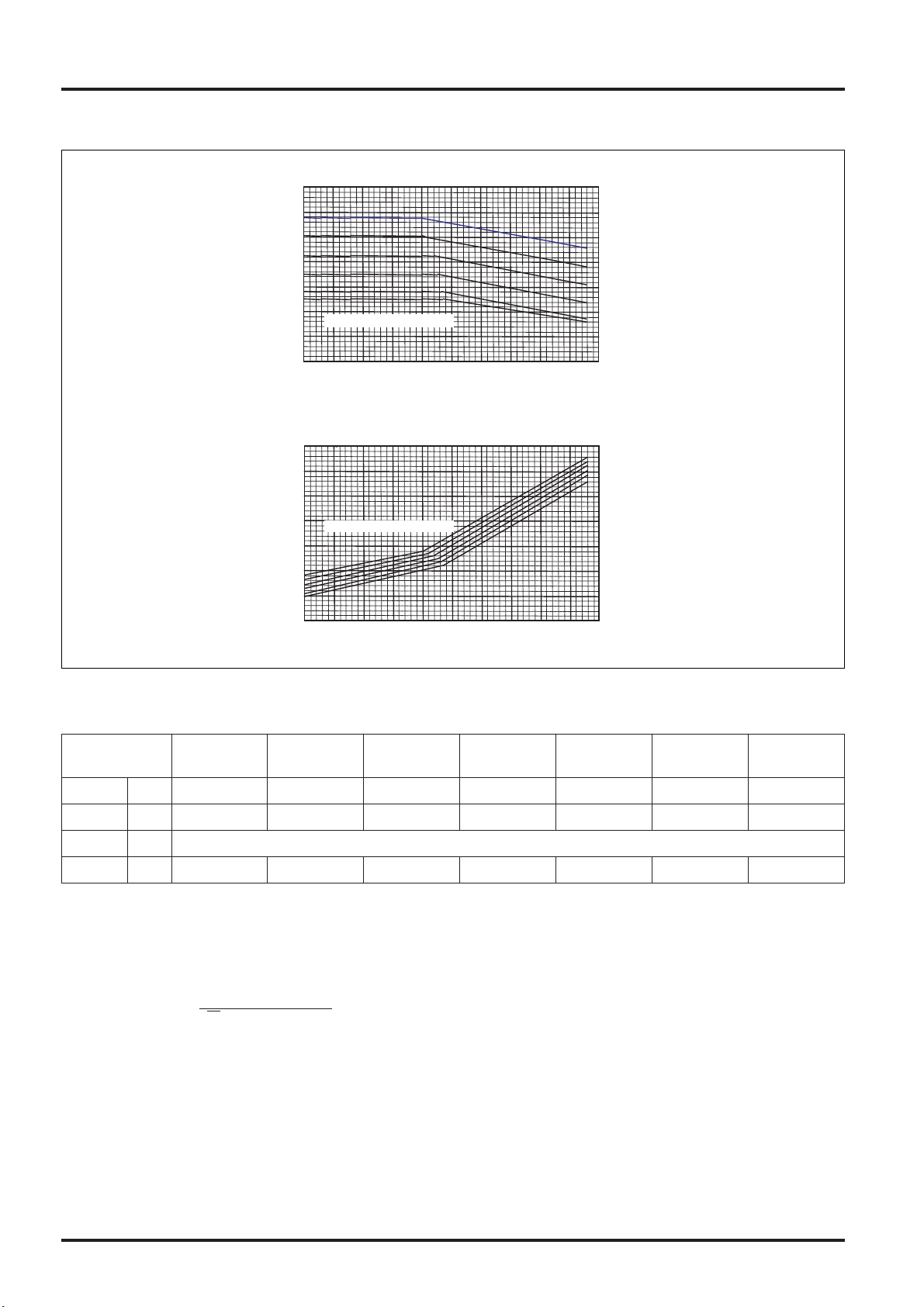

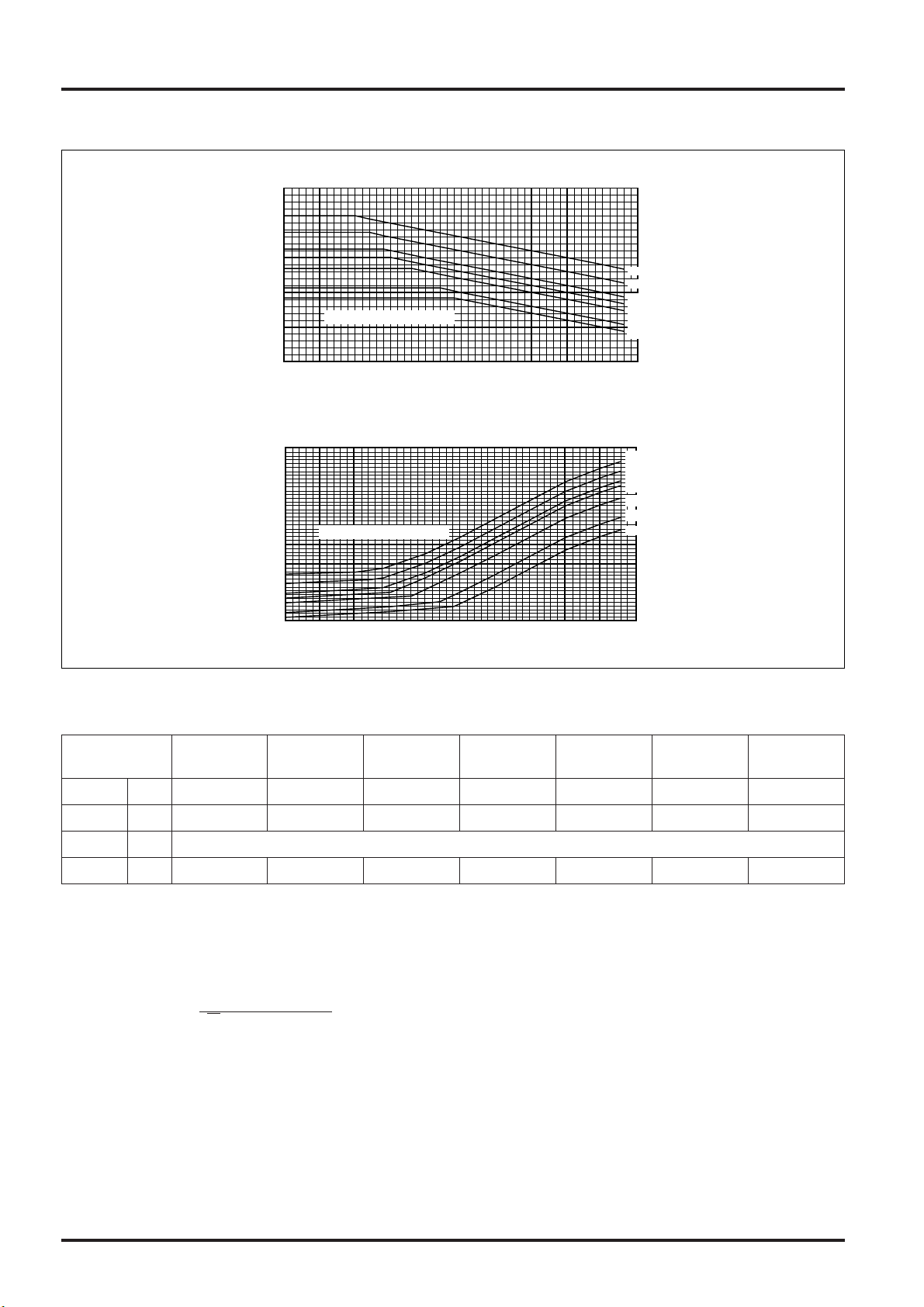

10. Total Heat Recovery Characteristics

10.1 Lossnay Core Heat Recovery Characteristic

90

50 60 70 80 90 100

80

70

60

50

40

Exchange efficiency (%)

0

800

200 400 600

90

50

40

60

70

80

tt

cc

Exchange efficiency (%)

SA Air volume (m3/h)

1400120010008006004002000

tt

90

50

40

60

70

80

cc

90

50 60 70 80 90 100

80

70

60

50

40

Exchange efficiency (%)

SA Air volume (m3/h)

*Air volume ratio =

Exhaust air flow volume

Suplly air flow volume

●

Obtaining the efficiency when supply air and exhaust air volumes differ

The efficiency obtained from the intake side air volume in each characteristic curve can be corrected with the air

volume ratio in the chart on the right.

If the intake side and exhaust side duct lengths differ greatly or if a differential air volume is required, obtain the

intake side efficiency from the chart on the right.

Efficiency when there is

no air volume difference

between exhaust side

and supply side.

Efficiency of supply air flow after correction

Air volume ratio =

Exhaust air volume

Supply air volume

GUF-50RDH3/50RD3

GUF-100RDH3/100RD3

0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.4

1.2 1.3

Exchange efficiency (%)

ηt : Heat exchange efficiency after correction (%)

ηt : Heat exchange efficiency after correction (%)

0.5 0.6 0.7 0.8 0.9 1.01.1 1.4

1.2 1.3

Enthalpy exchange efficiency (Cooling) : ηic

Characteristics curve Enthalpy exchange efficiency (Heating) : ηiH

Temperature exchange efficiency : ηt

Enthalpy exchange efficiency (Cooling) : ηic

Characteristics curve Enthalpy exchange efficiency (Heating) : ηiH

Temperature exchange efficiency : ηt

Efficiency correction curve

Efficiency correction curve

← Air volume ratio*

← Air volume ratio*

Page 16

14

CHAPTER 1 ● Product Section

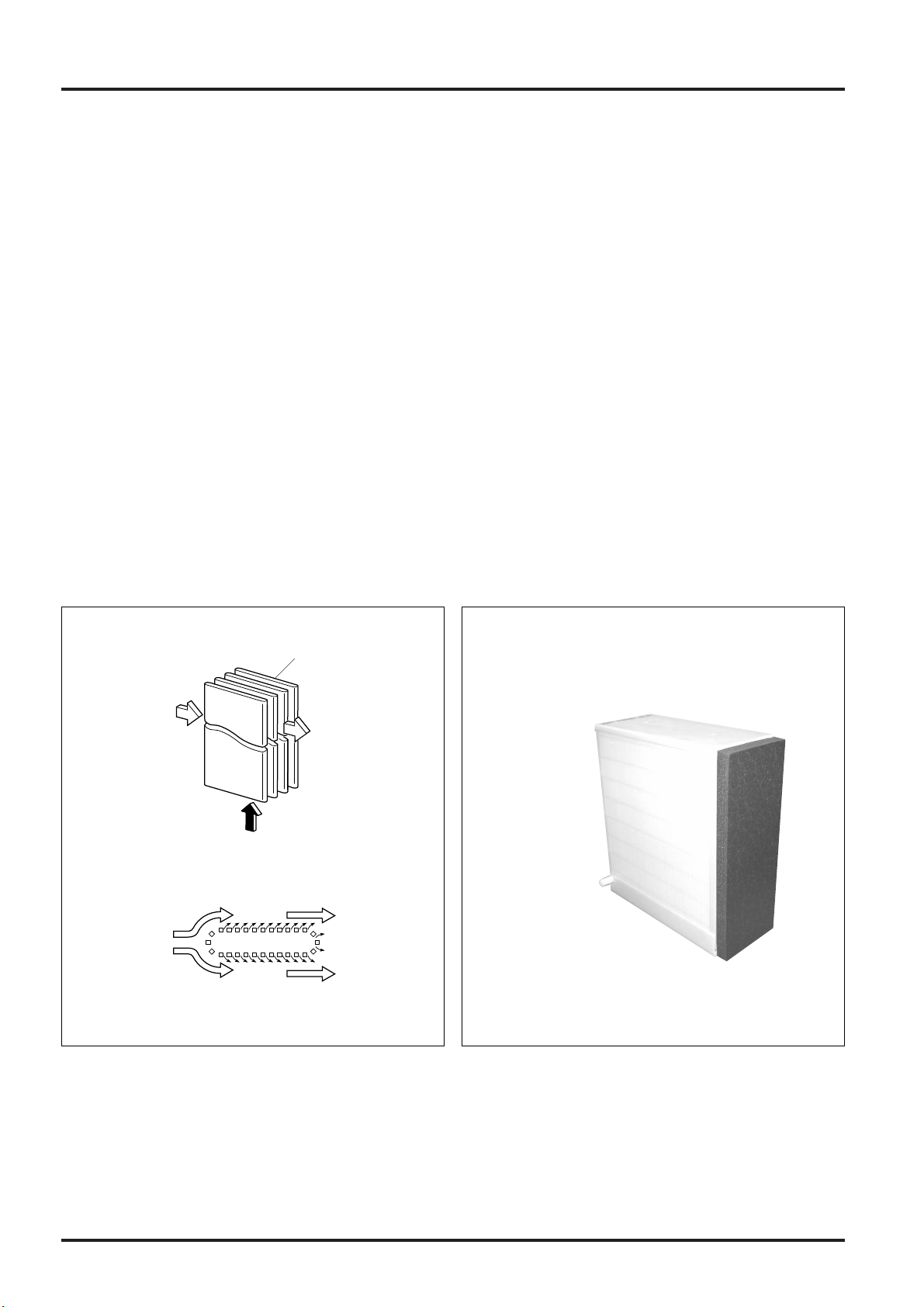

11. Principle and Features of Permeable Film Humidifier

11.1 Principles and Construction of Permeable Film Humidifier

Basic

A permeable film type humidifier uses the basic characteristics of natural evaporation. In this model, those

characteristics have been dramatically improved. The main points of the improvement are that the water is

wrapped in an ultra-water-repellant porous film (the permeable film) that forms a surface for releasing the water

vapor and that the surface are of this evaporating surface has been dramatically increased.

Principle

As shown in Fig. 1, there are tubes filled with water. Space is provided between these tubes for air to pass

through, forming a “layered strip” design that ensures rectangular- shaped flow passages. Since the permeable

film of the tube (ultra-water repellant porous film) allows water moisture to pass through in an evaporated state,

the water in the tube is released from the surface of the tube in an evaporated state and is included with the

passing air as shown in Fig. 1 (b). As can be seen by looking Fig. 2, spacers have been placed between the

tubes of permeable film to form layered openings for air to pass through. This provides an extremely large

humidifying surface area – 8.5 times larger than natural evaporation type humidifiers of the same size and offering

an increase of humidifying performance that is 6 times greater.

Fig. 1 Principles behind permeable film humidifier Fig. 2 Humidifying module

Output air from

Lossnay Core

Output air from

Lossnay Core

Permeable film

Humidified air

outlet

Water

Water

Humidified air outlet

(a) Water cross section of layered humidifying section.

(b) Cross section of layered humidifying section.

Water supply by pressure

reduction solenoid valve

Water supply port

Humidifier element

Page 17

15

CHAPTER 1 ● Product Section

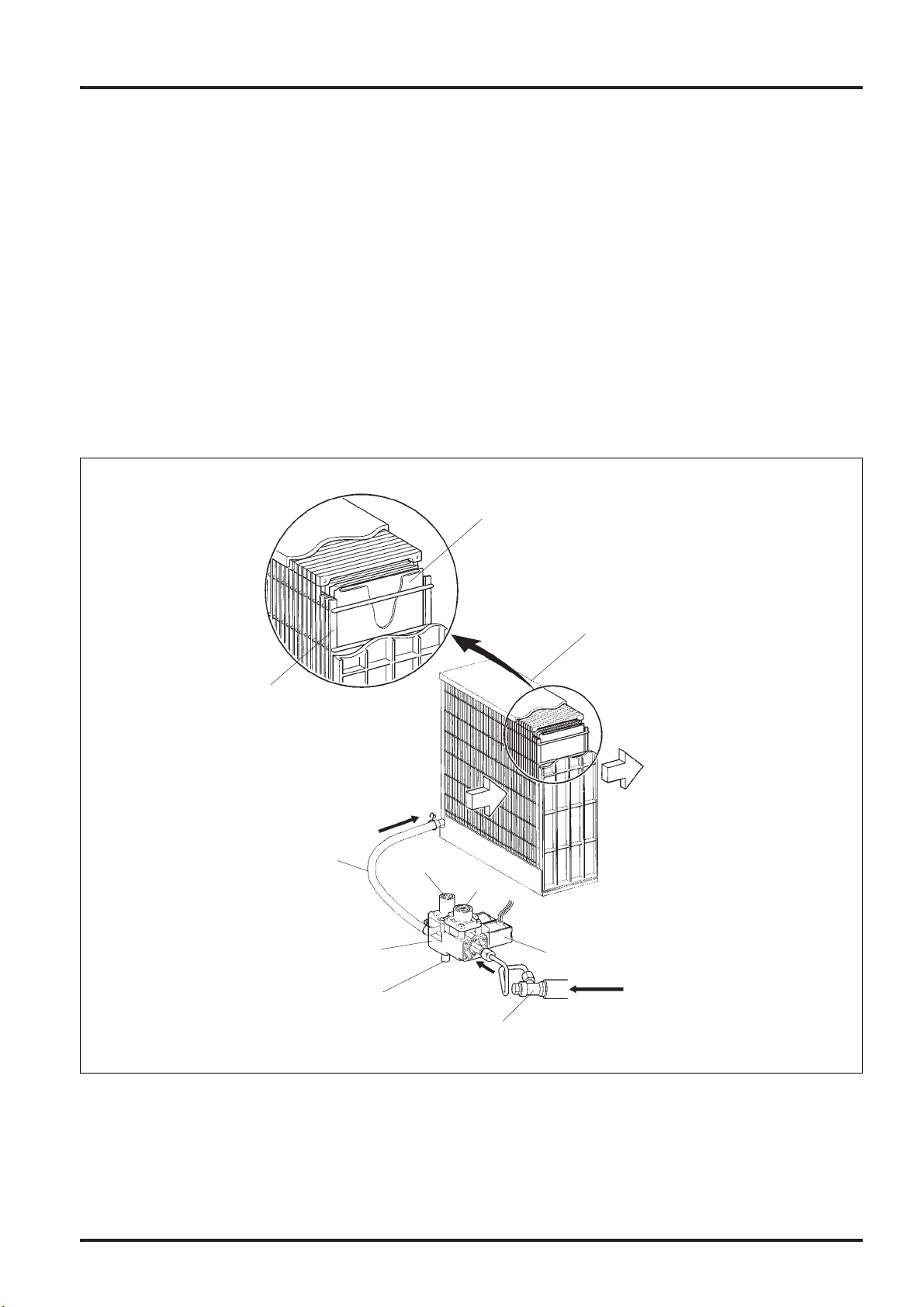

Construction

1) The water supply unit is comprised of strainer, pressure reduction solenoid valve and supply pipe. This

design ensures stable water pressure and water volume are supplied to the humidifier unit.

The strainer removes foreign material as water passes through the water supply piping. The solenoid valve

opens to allow the water to be supplied while the pressure reduction valve ensures that water pressure is

maintained at 7 kPa or less as water is supplied to the humidifier unit.

(If the water pressure exceeds 7 kPa, the safety valve opens and the water is discharged to a drain.)

2) As explained in the operating principles for the humidifying unit, the tube-shaped permeable film is arranged

in a layered construction and spacers have been provided to create opening for the air to pass through.

Water is supplied to these tubes and then evaporates from their surfaces into the air.

Note that any impurities in the water settle to the bottom of the tube and, due to the extremely large surface

area of the permeable film, have almost no affect on the creation of humidity.

Basic design of a permeable film humidifier

Spacer

Permeable film tube

Humidifier unit

Humidified air outlet

Supply air diffuser

from Lossnay Core

Water supply piping

Pressure reduction solenoid valve

Drain port

Safety

valve

Pressure

reduction valve

Solenoid valve

Strainer

Water

Page 18

16

CHAPTER 1 ● Product Section

11.2 Features of Permeable Film Humidifier

Design of the new type permeable film type humidifier

The previous type of permeable film had a selective-type permeable layer that only allowed water vapor to pass

through surfaces in contact with water and base cloth with a layer of porous PTFE with extremely fine pores with

1/20,000 water droplets and 1,000 times water vapor (0.1 to 1 µm) that allowed evaporation without air or water

passing through. The new type permeable film does not have the base cloth used in the previous permeable

membrane. Instead, it has an ultra water-resistant porous permeable film that reduces the resistance to

permeation by 1/2 when compared with the previous type and a 3-dimensional fabric that ensures water passages

inside the permeable film tube, dramatically improving the ability for water vapor only to permeate.

●

New type permeable film type

●

New unit

●

3-dimensional fabric

The 3-dimensional fabric inside the new type of permeable film tube is comprised of spiral-like threads that are

attached upright in the tube. These act as a type of reinforcing material for ensuring the passage of water inside

the permeable film tubes.

This 3-dimensional fabric used in the new type permeable film type humidifier keep the permeable film tubes from

collapsing and ensure that the water supplied at a constant pressure from the water supply port at the base of the

humidifier seeps to the ends of the humidifying surface.

Water

Selective-type

permeable layer

PTFE layer

Base cloth

Water vapor

Air

Water

3-dimentional fabric

Water-resistant porous

permeable film

Water vapor

Air

Permeaable film tube

3-dimentional fabric

Spacer

●

Previous permeable film

Page 19

17

CHAPTER 1 ● Product Section

0246–6

6

5.8

5.6

5.4

5.2

5

4.8

4.6

4.4

4.2

4

–4 –2

RA 22°C40%

RA 21°C40%

RA 21°C50%

RA 20°C40%

RA 20°C50%

RA 22°C50%

0246–6

3

2.9

2.8

2.7

2.6

2.5

2.4

2.3

2.2

–4 –2

RA 22°C40%

RA 21°C40%

RA 22°C50%

RA 21°C50%

RA 20°C40%

RA 20°C50%

Reference

Quick reference graph for amount of humidifying

Conditions:

●

The air flow is the rated air flow (GUF-50RDH3: 500 m3/h GUF-100RDH3: 1,000 m3/h )

●

The connections to the outdoor unit are an OA processing unit and indoor unit for a total capacity of 100%.

●

The relative humidity of the outdoor air is 50%.

Amount of humidifying (kg/h)

Outdoor Air temperature (°C)

GUF-50RDH3

GUF-100RDH3

Amount of humidifying (kg/h)

Outdoor Air temperature (°C)

Page 20

18

CHAPTER 1 ● Product Section

Note: When using a combination of City Multi and Air Multi units, there is a need to calculate the total value of

performance capacity of the indoor units connected to each outdoor unit as a parameter. This information

can be found in the technical documentation for the units. Refer to the City Multi Data Book for details.

Dry bulb Wet bulb Relative

Enthalpy

temperature temperature humidity

Outdoor air 35°CDB 24°CWB 40% 71.6kJ/kg

Indoor air 27°CDB 19.5°CWB 50% 55.7kJ/kg

Heat exchange inlet air

50 28.8°CDB 21.3°CWB 51.7% 61.7kJ/kg

(Lossnay Core outlet temperature)

100 28.7°CDB 21.2°CWB 51.4% 61.2kJ/kg

Outdoor air 7°CDB 6°CWB 85% 20.5kJ/kg

Indoor air 21°CDB 14.6°CWB 50% 40.6kJ/kg

Heat exchange inlet air

50 17.8°CDB 12.0°CWB 49.9% 33.9kJ/kg

(Lossnay Core outlet temperature)

100 18.1°CDB 12.3°CWB 50.5% 34.7kJ/kg

CoolingHeating

Model number Model 50 Model 100

City Multi indoor unit equivalent 32 63

Cooling capacity 3.63kW 7.32kW

Heating capacity 4.17kW 8.30kW

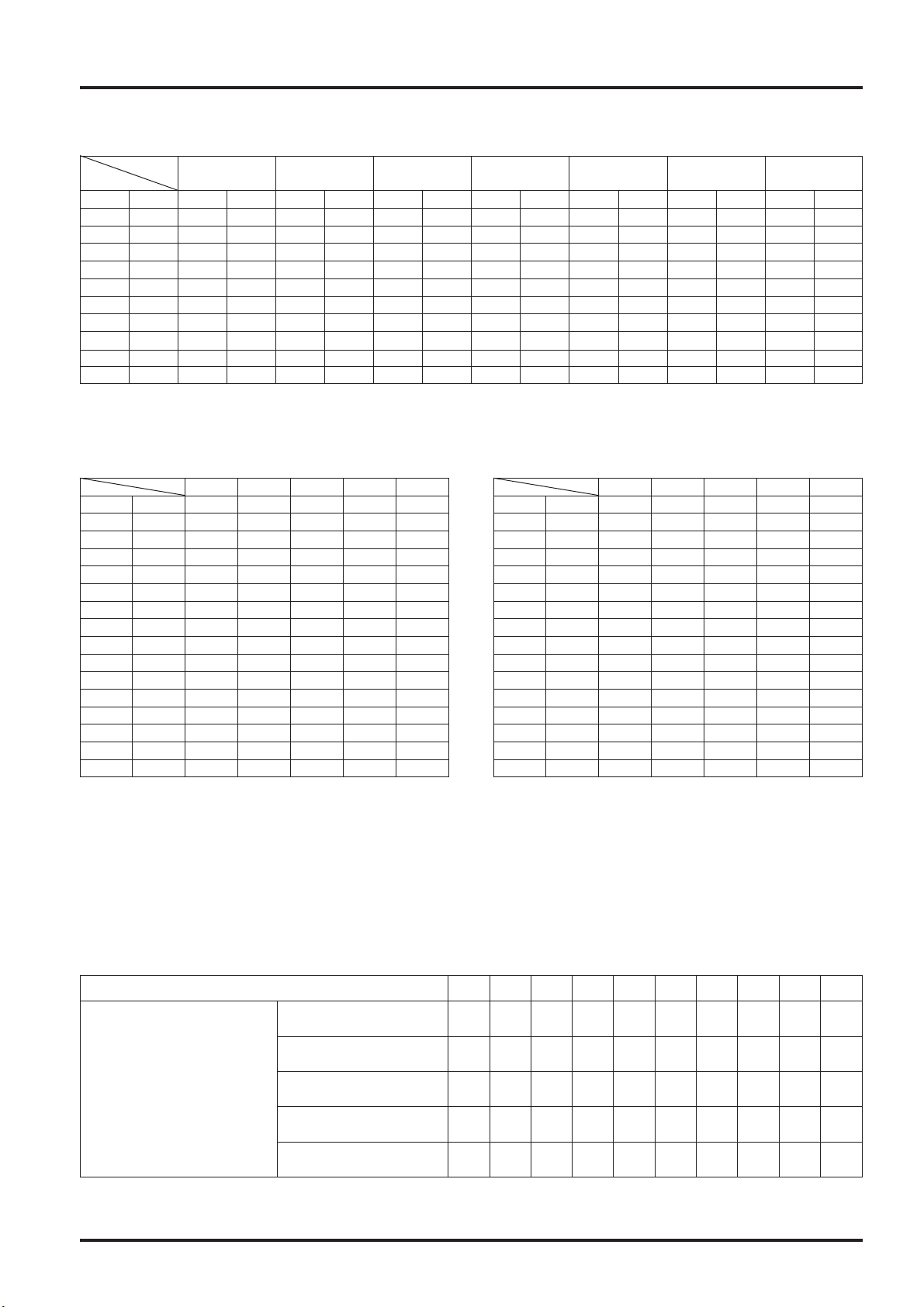

12. Cooling and Heating Characteristics

12.1 Direct Expansion Coil Characteristics

12.1.1 Rated operating conditions <At rated air flow>

12.1.2 Standard cooling and heating performance

12.1.3 Cooling Capacity (In combination with PUHY, PURY)

GUF-50RD3

CA:Capacity (kW)

SHC:Sensible heat capacity (kW)

21.5°CDB

15°CWB

23°CDB

16°CWB

25°CDB

18°CWB

27°CDB

19.5°CWB

28°CDB

20°CWB

30°CDB

22°CWB

32°CDB

24°CWB

DB

OA

20.0 12.0 3.3 2.0 3.4 2.1 3.4 2.1 3.5 2.1 3.6 2.2 3.7 2.3 3.8 2.3

22.5 14.0 3.3 2.0 3.4 2.1 3.5 2.1 3.6 2.2 3.6 2.2 3.7 2.3 3.8 2.3

25.0 16.0 3.3 2.0 3.4 2.1 3.5 2.1 3.5 2.1 3.6 2.2 3.8 2.3 3.8 2.3

27.5 18.0 3.3 2.0 3.4 2.1 3.5 2.1 3.5 2.1 3.6 2.3 3.7 2.2 3.8 2.2

30.0 20.0 3.4 2.1 3.4 2.1 3.5 2.1 3.5 2.1 3.6 2.2 3.7 2.2 3.8 2.2

32.5 22.0 3.4 2.0 3.4 2.0 3.4 2.1 3.5 2.1 3.7 2.2 3.7 2.2 3.8 2.2

35.0 24.0 3.3 1.9 3.4 2.0 3.4 2.1 3.6 2.2 3.6 2.2 3.7 2.1 3.8 2.2

37.5 26.0 3.3 1.9 3.4 2.0 3.4 2.1 3.6 2.1 3.6 2.1 3.7 2.1 3.7 2.1

40.0 28.0 3.3 1.9 3.3 1.9 3.5 2.0 3.6 2.1 3.5 2.0 3.7 2.1 3.7 2.1

43.0 30.0 3.3 1.9 3.3 1.9 3.5 2.0 3.6 2.0 3.5 1.9 3.6 2.0 3.6 2.0

WBRACA SHC CA SHC CA SHC CA SHC CA SHC CA SHC CA SHC

Page 21

19

CHAPTER 1 ● Product Section

GUF-100RD3

CA:Capacity (kW)

SHC:Sensible heat capacity (kW)

21.5°CDB

15°CWB

23°CDB

16°CWB

25°CDB

18°CWB

27°CDB

19.5°CWB

28°CDB

20°CWB

30°CDB

22°CWB

32°CDB

24°CWB

DB

20.0 12.0 6.9 4.3 7.0 4.5 7.0 4.5 7.3 4.6 7.4 4.6 7.6 4.9 7.9 4.9

22.5 14.0 6.9 4.3 7.0 4.4 7.2 4.4 7.4 4.5 7.4 4.5 7.6 4.9 7.8 4.8

25.0 16.0 6.9 4.3 7.1 4.4 7.2 4.4 7.3 4.5 7.3 4.5 7.7 4.7 7.8 4.8

27.5 18.0 6.9 4.3 7.1 4.4 7.2 4.4 7.2 4.4 7.3 4.6 7.6 4.7 7.9 4.7

30.0 20.0 6.9 4.2 7.0 4.2 7.1 4.3 7.2 4.5 7.3 4.5 7.6 4.7 7.9 4.7

32.5 22.0 6.9 4.2 7.0 4.2 7.1 4.3 7.2 4.4 7.4 4.5 7.6 4.6 7.8 4.6

35.0 24.0 6.9 4.2 7.0 4.2 7.0 4.2 7.3 4.4 7.4 4.5 7.7 4.5 7.7 4.4

37.5 26.0 6.8 4.0 6.9 4.2 7.1 4.3 7.4 4.5 7.4 4.5 7.6 4.4 7.6 4.4

40.0 28.0 6.8 4.0 6.9 4.1 7.2 4.3 7.3 4.4 7.3 4.4 7.6 4.4 7.6 4.4

43.0 30.0 6.8 4.0 6.9 4.1 7.2 4.2 7.2 4.2 7.3 4.2 7.5 4.3 7.5 4.3

WB CA SHC CA SHC CA SHC CA SHC CA SHC CA SHC CA SHC

12.1.4 Heating Capacity (In combination with PUHY, PURY)

GUF-50RD3

OA

RA

15

SHC20SHC21SHC25SHC27SHC

-14.6 -15.0

DB WB

2.8 2.8 2.8 2.8 2.8

-11.5 -12.0 3.0 3.0 3.0 3.0 3.0

-9.5 -10.0 3.2 3.2 3.2 3.1 3.1

-6.9 -7.5 3.4 3.4 3.4 3.3 3.3

-4.3 -5.0 3.6 3.6 3.6 3.5 3.5

-1.8 -2.5 3.8 3.8 3.8 3.7 3.7

1.0 0 4.0 4.0 4.0 3.9 3.9

3.5 2.5 4.2 4.2 4.2 4.1 4.0

6.0 5.0 4.2 4.2 4.2 4.2 4.0

7.0 6.0 4.2 4.2 4.2 4.0 4.0

8.8 7.5 4.4 4.4 4.4 4.0 4.0

11.5 10.0 4.7 4.2 4.2 4.0 4.0

14.0 12.5 5.0 4.2 4.2 4.0 3.3

16.5 15.0 5.0 4.2 4.2 3.3 3.3

17.0 15.5 5.0 4.2 4.2 3.3 3.3

GUF-100RD3

15

SHC20SHC21SHC25SHC27SHC

-14.6 -15.0 5.6 5.6

-11.5 -12.0 6.0 6.0

-9.5 -10.0 6.3 6.3

-6.9 -7.5 6.7 6.7

-4.3 -5.0 7.1 7.1

-1.8 -2.5 7.5 7.5

1.0 0 7.9 7.9

3.5 2.5 8.3 8.3

6.0 5.0 8.3 8.3

7.0 6.0 8.3 8.3

8.8 7.5 8.7 8.7

11.5 10.0 9.3 8.3

14.0 12.5 9.9 8.3

16.5 15.0 10.0 8.3

17.0 15.5 10.0 8.3

5.6

6.0

6.3

6.7

7.1

7.5

7.9

8.3

8.3

8.3

8.7

8.3

8.3

8.3

8.3

5.6

6.0

6.3

6.7

7.1

7.5

7.8

8.2

8.3

8.0

8.0

8.0

8.0

6.5

6.5

5.6

5.9

6.3

6.7

7.1

7.5

7.8

8.0

8.0

8.0

8.0

8.0

6.5

6.5

6.5

*The above data shows an assumed value obtained by calculation.

*The above data shows an assumed value obtained by calculation.

OA

RA

OA

RA

DB WB

Outdoor inlet air temp (°C)

Correction factor

PUHY-P200/P250YGM-A

PURY-P200/P250YGM-A

PUHY-P300YGM-A

PURY-P300YGM-A

PUHY-P350YGM-A

PURY-P350YGM-A

PUHY-P400YGM-A

PURY-P400YGM-A

PUHY-P450/P500YGM-A

PURY-P450/P500YGM-A

64210-2-4-6-8-10

1.0 0.95 0.84 0.83 0.83 0.87 0.90 0.95 0.95 0.95

1.0 0.93 0.82 0.80 0.82 0.86 0.90 0.90 0.95 0.95

1.0 0.93 0.85 0.83 0.84 0.86 0.90 0.90 0.95 0.95

1.0 0.95 0.90 0.87 0.88 0.89 0.90 0.95 0.95 0.95

1.0 0.98 0.89 0.86 0.89 0.90 0.92 0.95 0.95 0.95

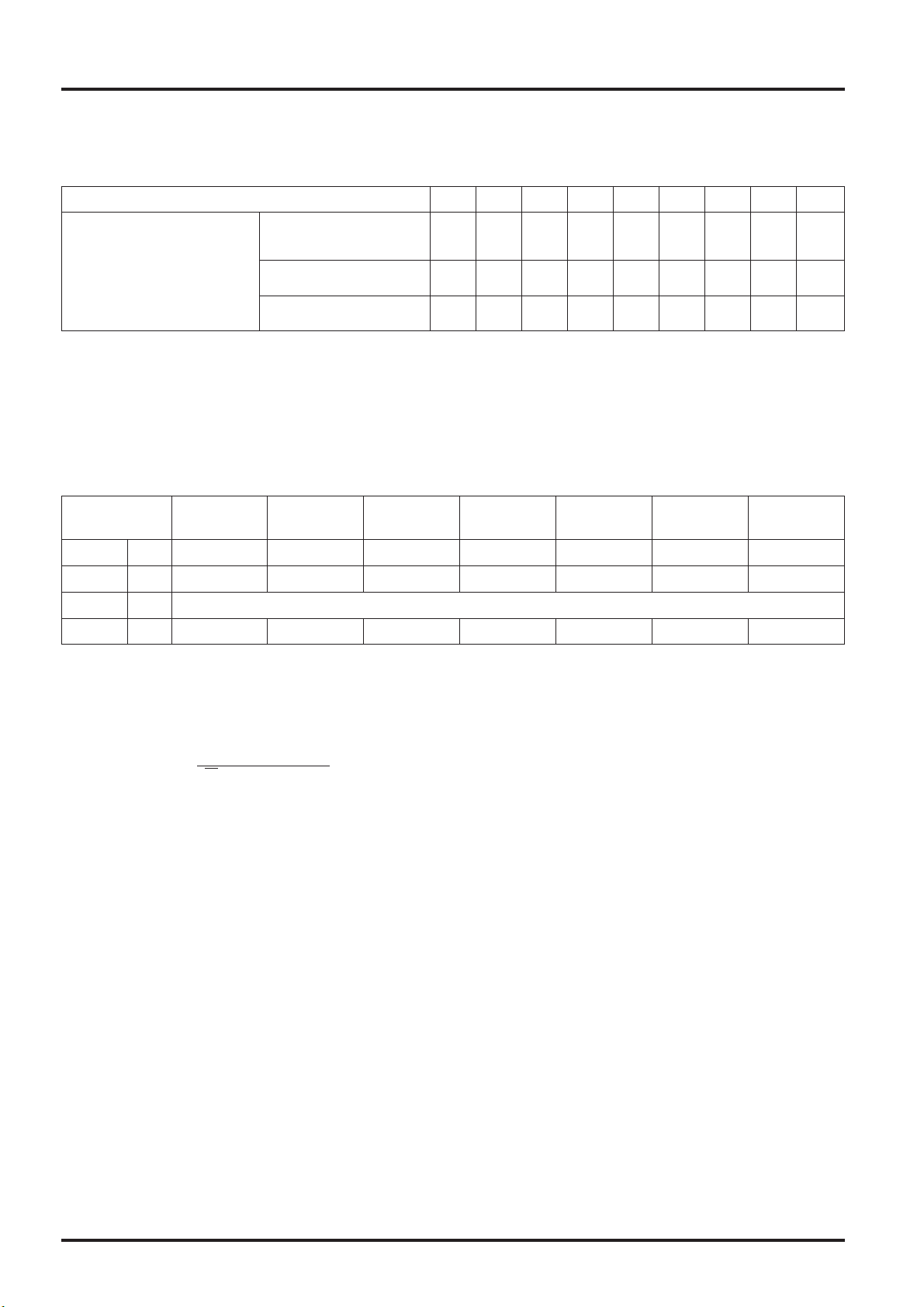

12.2 Correction at frosting and defrosting

When a decrease in heating capacity due to frosted and defrosting operations is considered, the value multiplied

by the correction factor in the table below represents the heating capacity. Refer to the City Multi Data Book for

details.

12.2.1

R410A refrigerant unit

Correction factor table

Page 22

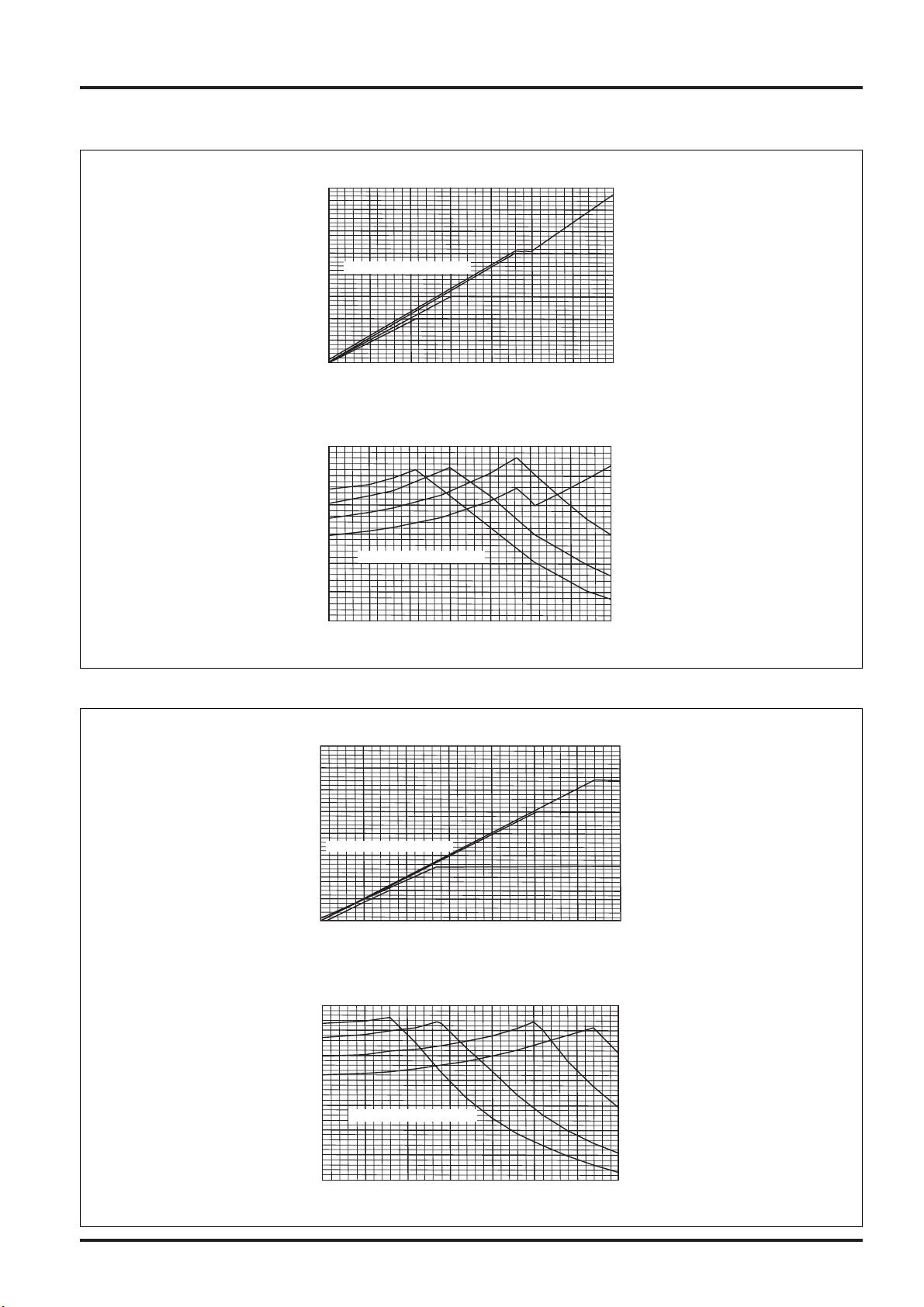

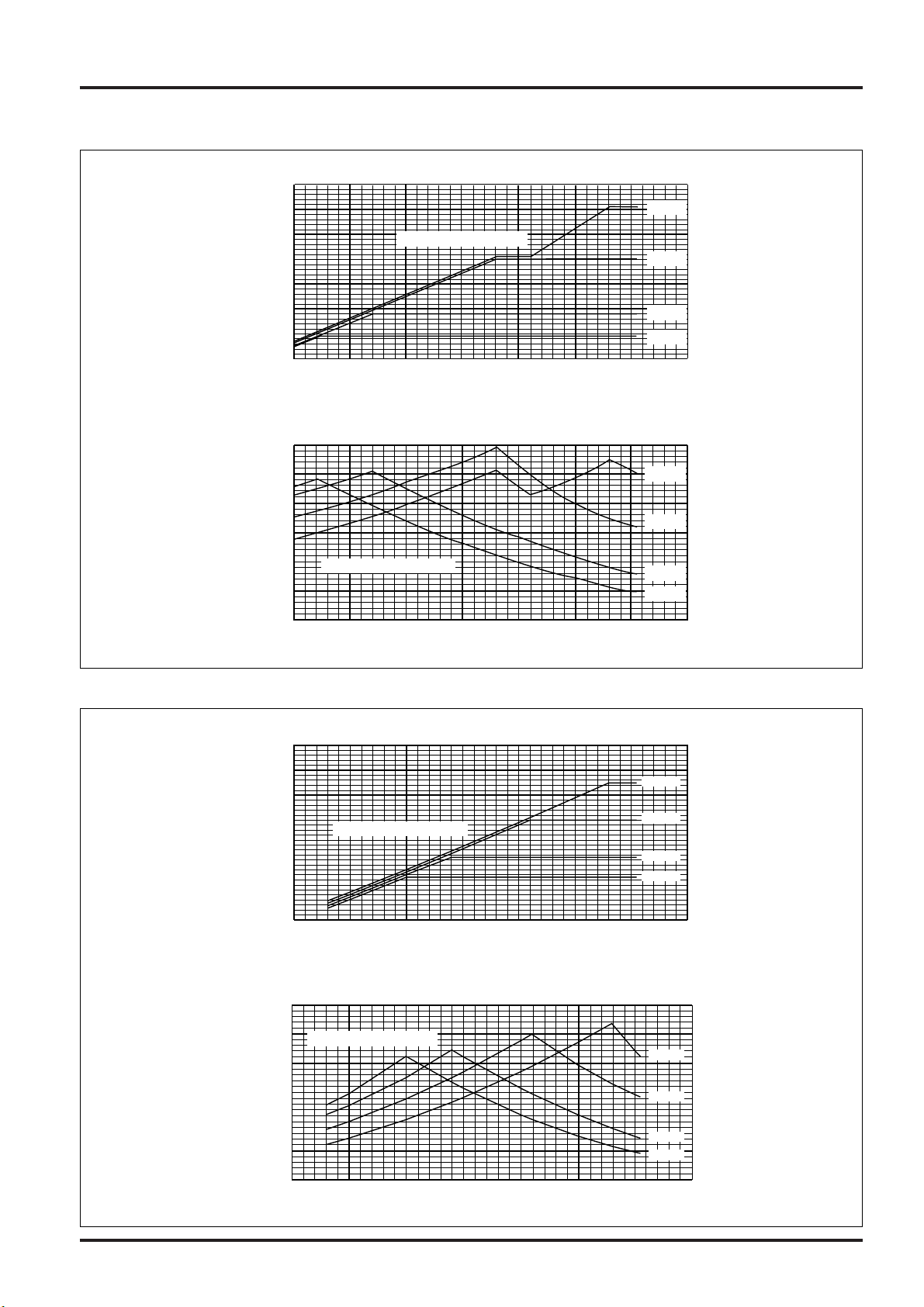

12.3 Correction by temperature

12.3.1

R410A refrigerant unit

(1) Cooling

Standard specifications

●

Calculation

Capacity’ = Capacity × Ratio

Input’ = Input × Ratio

Current’ =

Input’ × 1,000

3 × Source × 0.91

* Capacity’

Input’ After correction

Current’

√

}

PUHY-

P200YGM-A

PUHY-

P250YGM-A

PUHY-

P300YGM-A

PUHY-

P350YGM-A

PUHY-

P400YGM-A

PUHY-

P450YGM-A

PUHY-

P500YGM-A

Capacity

6.14

380/400/415

10.3/9.8/9.4

22.4

7.72

13.0/12.3/11.9

28.0

9.57

16.1/15.3/14.7

33.5

11.39

19.2/18.2/17.6

40.0

13.42

22.6/21.5/20.7

45.0

13.61

22.9/21.8/21.0

50.0

15.59

26.3/25.0/24.0

56.0

kW

kW

V

A

Input

Source

Current

20

CHAPTER 1 ● Product Section

12.2.2 R22

refrigerant unit

Corection factor table

Outdoor inlet air temp (°C)

Correction factor

PUHY-200/250YEM-A

PUHY-200/250YEMC-A

PURY-200/250YEMC-A

PUHY-315YEM-A

PUHY-315YEMC-A

PUHY-400/500YEM-A

PUHY-400/500YEMC-A

6420-2-4 -6 -8 -10

1.0 0.95 0.84 0.83 0.87 0.90 0.95 0.95 0.95

1.0 0.93 0.82 0.82 0.86 0.90 0.90 0.95 0.95

1.0 0.98 0.89 0.89 0.86 0.90 0.92 0.95 0.95

Page 23

21

CHAPTER 1 ● Product Section

The ratio of cooling power input

PUHY-P200/P250YGM-A

The ratio of cooling capacity

The ratio of cooling power input

PUHY-P300/P350/P400YGM-A

The ratio of cooling capacity

0.8

0.7

0.9

1.0

1.1

1.2

1.3

-5 0 5 10 15 20 25 30 35 40 45

Ratio

Indoor Temperature (˚CWB)

Outdoor Temperature (˚CDB)

24˚CWB

16˚CWB

18˚CWB

20˚CWB

22˚CWB

15˚CWB

0.8

0.7

0.9

1.0

1.1

1.2

1.3

-5 0 5 10 15 20 25 30 35 40 45

Ratio

Indoor Temperature (˚CWB)

Outdoor Temperature (˚CDB)

24˚CWB

16˚CWB

18˚CWB

20˚CWB

22˚CWB

15˚CWB

Ratio

Outdoor Temperature (˚CDB)

Indoor Temperature (˚CWB)

0.8

0.7

0.9

1.0

1.1

1.2

1.4

1.3

-5 0 5 10 15 20 25 30 35 40 45

24˚CWB

16˚CWB

18˚CWB

20˚CWB

22˚CWB

15˚CWB

0.8

0.7

0.6

0.9

1.0

1.1

1.2

Ratio

Indoor Temperature (˚CWB)

Outdoor Temperature (˚CDB)

24˚CWB

16˚CWB

18˚CWB

20˚CWB

22˚CWB

15˚CWB

-5 0 5 10 15 20 25 30 35 40 45

Page 24

22

CHAPTER 1 ● Product Section

(2) Heating

Standard specifications

●

Calculation

Capacity’ = Capacity × Ratio

Input’ = Input × Ratio

Current’ =

Input’ × 1,000

3 × Source × 0.91

* Capacity’

Input’ After correction

Current’

√

}

PUHY-

P200YGM-A

PUHY-

P250YGM-A

PUHY-

P300YGM-A

PUHY-

P350YGM-A

PUHY-

P400YGM-A

PUHY-

P450YGM-A

PUHY-

P500YGM-A

Capacity

5.98

380/400/415

10.0/9.5/9.2

25.0

7.62

12.8/12.2/11.7

31.5

9.10

15.3/14.5/14.0

37.5

11.02

18.6/17.6/17.0

45.0

12.43

20.9/19.9/19.2

50.0

13.86

23.3/22.2/21.4

56.0

15.89

26.8/25.4/24.5

63.0

kW

kW

V

A

Input

Source

Current

The ratio of cooling power input

PUHY-P450/P500YGM-A

The ratio of cooling capacity

0.8

0.7

0.9

1.0

1.1

1.2

1.3

1.4

Ratio

Indoor Temperature (˚CWB)

Outdoor Temperature (˚CDB)

24˚CWB

16˚CWB

18˚CWB

20˚CWB

22˚CWB

15˚CWB

-5 0 5 10 15 20 25 30 35 40 45

0.8

0.7

0.5

0.6

0.9

1.0

1.1

1.2

Ratio

Indoor Temperature (˚CWB)

Outdoor Temperature (˚CDB)

24˚CWB

16˚CWB

18˚CWB

20˚CWB

22˚CWB

15˚CWB

-5 501015202530354045

Page 25

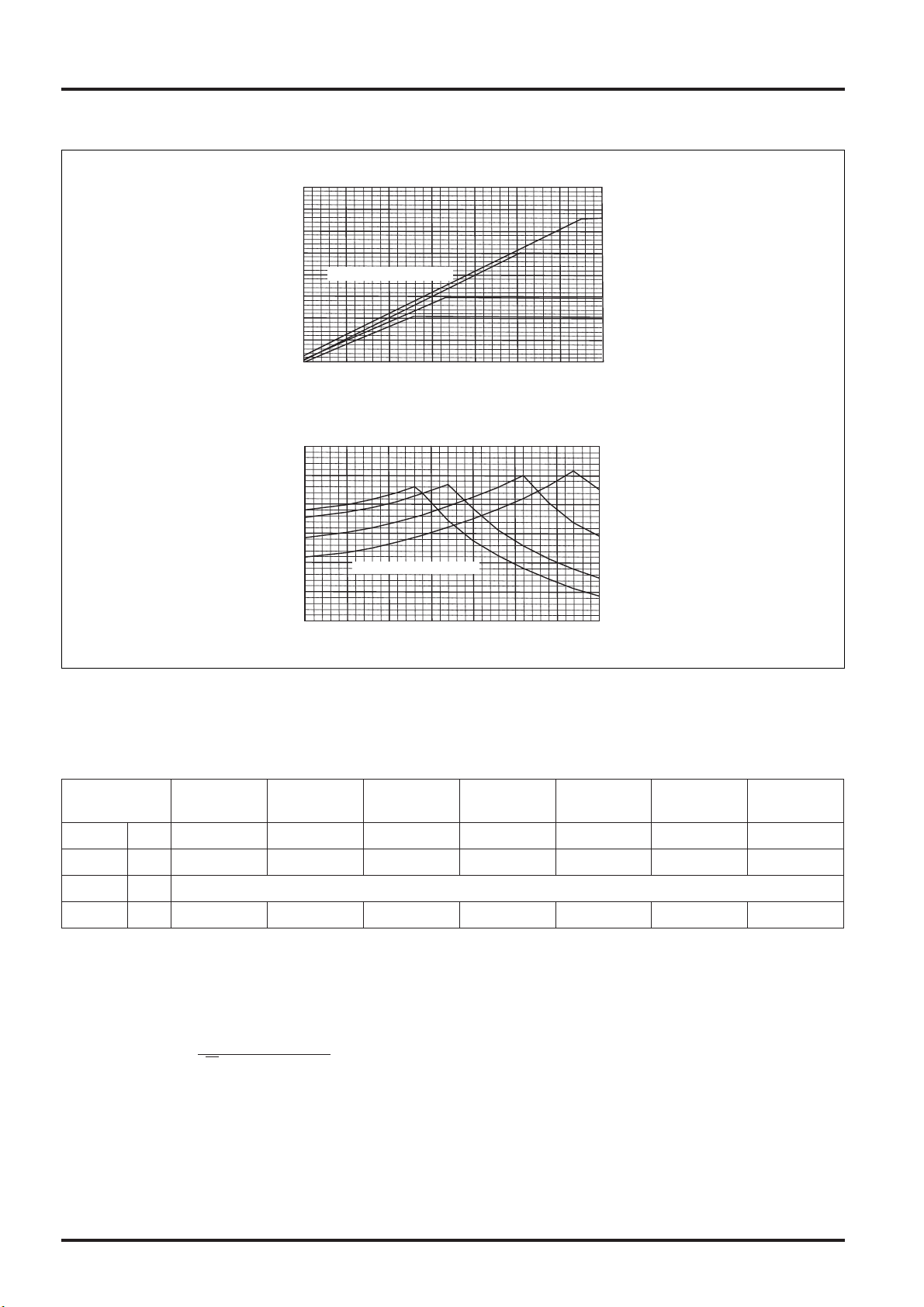

23

CHAPTER 1 ● Product Section

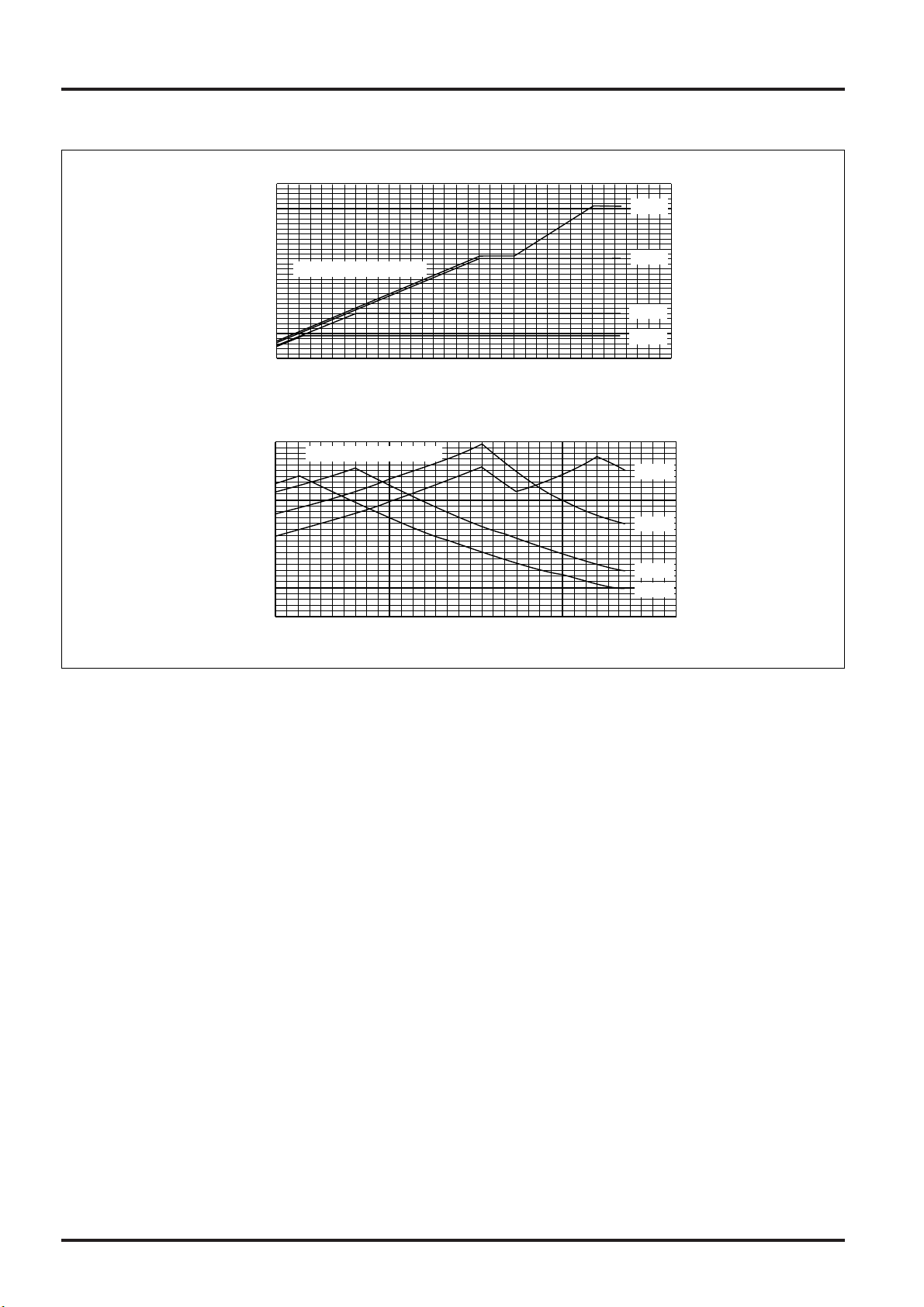

The ratio of heating power input

PUHY-P200/P250YGM-A

The ratio of heating capacity

The ratio of heating power input

PUHY-P300/P350/P400YGM-A

The ratio of heating capacity

0.6

0.7

0.5

0.8

0.9

1.0

1.1

1.2

1.3

-20 -15 -10 -5 0 5 10 15

Ratio

Outdoor Temperature (˚CWB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Indoor Temperature (˚CDB)

0.6

0.7

0.5

0.8

0.9

1.0

1.1

-20 -15 -10 -5 0 5 10 15

Ratio

Outdoor Temperature (˚CWB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Indoor Temperature (˚CDB)

0.8

0.9

0.7

1.0

1.1

1.2

1.3

0.6

0.5

-20 -15 -10 -5 0 5 10 15

Ratio

Outdoor Temperature (˚CWB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Indoor Temperature (˚CDB)

0.8

0.9

0.7

1.0

1.1

0.6

0.5

0.4

-20 -15 -10 -5 0 5 10 15

Ratio

Outdoor Temperature (˚CWB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Indoor Temperature (˚CDB)

Page 26

24

CHAPTER 1 ● Product Section

●

Calculation

Capacity’ = Capacity × Ratio

Input’ = Input × Ratio

Current’ =

Input’ × 1,000

3 × Source × 0.91

* Capacity’

Input’ After correction

Current’

√

}

12.3.2 R22 refrigerant unit

(1) Cooling

Standard specifications

PUHY-

200YEMC-A

PUHY-

250YEMC-A

PUHY-

315YEMC-A

PUHY-

400YEMC-A

PUHY-

500YEMC-A

PURY-

200YEMC-A

PURY-

250YEMC-A

Capacity

7.13

380/400/415

12.0/11.4/11.0

24.6

8.37

14.1/13.4/12.9

28.0

12.05

19.9/18.9/18.2

35.5

15.87

26.7/25.4/24.5

45.0

18.98

32.0/30.4/29.3

56.0

9.65

16.2/15.4/14.9

24.6

10.56

17.8/16.9/16.3

28.0

kW

kW

V

A

Input

Source

Current

The ratio of heating power input

PUHY-P450/P500YGM-A

The ratio of heating capacity

0.8

0.9

0.7

1.0

1.1

1.2

1.3

0.6

0.5

-20 -15 -10 -5 0 5 10 15

Ratio

Outdoor Temperature (˚CWB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Indoor Temperature (˚CDB)

0.8

0.9

0.7

1.0

1.1

0.6

0.5

-20 -15 -10 -5 0 5 10 15

Ratio

Outdoor Temperature (˚CWB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Indoor Temperature (˚CDB)

Page 27

25

CHAPTER 1 ● Product Section

The ratio of cooling power input

PUHY-200/250/315YEMC-A

The ratio of cooling capacity

The ratio of cooling power input

PUHY-400/500YEMC-A

The ratio of cooling capacity

Ratio

Outdoor Temperature (˚CDB)

0.80

0.90

1.00

1.10

1.20

1.30

-5 5 15 25 35 45 50010203040

Indoor Temperature (˚CWB)

16˚CWB

18˚CWB

19˚CWB

20˚CWB

22˚CWB

24˚CWB

15˚CWB

Outdoor Temperature (˚CDB)

Ratio

0.50

0.70

0.90

1.10

1.30

0.40

0.60

0.80

1.00

1.20

-5 0 5 10 15 20 25 30 35 45 5040

Indoor Temperature (˚CWB)

19˚CWB

20˚CWB

22˚CWB

24˚CWB

15˚CWB

16˚CWB

18˚CWB

Ratio

Outdoor Temperature (˚CDB)

0.80

0.90

1.00

1.10

1.20

1.30

-5 5 15 25 35

45 50010203040

Indoor Temperature (˚CWB)

16˚CWB

18˚CWB

20˚CWB

22˚CWB

24˚CWB

15˚CWB

0.50

0.70

0.90

1.10

1.30

0.40

0.60

0.80

1.00

1.20

-5 0 5 10 15 20 25 30 35 40 45 50

Outdoor Temperature (˚CDB)

Ratio

Indoor Temperature (˚CWB)

24˚CWB

22˚CWB

20˚CWB

18˚CWB

16˚CWB

15˚CWB

Page 28

26

CHAPTER 1 ● Product Section

●

Calculation

Capacity’ = Capacity × Ratio

Input’ = Input × Ratio

Current’ =

Input’ × 1,000

3 × Source × 0.91

* Capacity’

Input’ After correction

Current’

√

}

(2) Heating

Standard specifications

PUHY-

200YEMC-A

PUHY-

250YEMC-A

PUHY-

315YEMC-A

PUHY-

400YEMC-A

PUHY-

500YEMC-A

PURY-

200YEMC-A

PURY-

250YEMC-A

Capacity

6.66

380/400/415

11.2/10.6/10.2

25.0

8.77

14.8/14.0/13.5

31.5

10.91

18.2/17.3/16.6

39.1

14.31

24.1/22.9/22.1

50.0

17.92

30.2/28.7/27.7

63.0

7.66

12.9/12.2/11.8

25.0

9.74

16.4/15.6/15.0

31.5

kW

kW

V

A

Input

Source

Current

The ratio of cooling power input

PURY-200/250YEMC-A

The ratio of cooling capacity

0.80

0.90

1.00

1.10

1.20

1.30

-5 5 15 25 35 45010203040

Ratio

Indoor Temperature (˚CWB)

Outdoor Temperature (˚CDB)

16˚CWB

18˚CWB

19˚CWB

20˚CWB

22˚CWB

24˚CWB

15˚CWB

0.50

0.70

0.90

1.10

1.30

0.40

0.60

0.80

1.00

1.20

-5 0 5 10 15 20 25 30 35 40 45

Outdoor Temperature (˚CDB)

Ratio

19˚CWB

20˚CWB

22˚CWB

24˚CWB

15˚CWB

16˚CWB

18˚CWB

Indoor Temperature (˚CWB)

Page 29

27

CHAPTER 1 ● Product Section

The ratio of heating power input

PUHY-200/250/315YEMC-A

The ratio of heating capacity

The ratio of heating power input

PUHY-400/500YEMC-A

The ratio of heating capacity

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

-15 -10 -5 0 5 10 15 20

Ratio

Indoor Temperature (˚CDB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Outdoor Temperature (˚CWB)

Outdoor Temperature (˚CWB)

Ratio

0.50

0.60

0.70

0.80

0.90

1.00

1.10

-15 -10 -5 0 5 10 15 20

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Indoor Temperature (˚CDB)

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

-15 -10 -5 0 5 10 15 20

Outdoor Temperature (˚CWB)

Ratio

Indoor Temperature (˚CDB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

0.50

0.60

0.70

0.80

0.90

1.00

1.10

-15 -10 -5 0 5 10 15 20

Ratio

Indoor Temperature (˚CDB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Outdoor Temperature (˚CWB)

Page 30

28

CHAPTER 1 ● Product Section

The ratio of heating power input

PURY-200/250YEMC-A

The ratio of heating capacity

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

-15 -10 -5 0 5 10 15 20

Ratio

Outdoor Temperature (˚CWB)

Indoor Temperature (˚CDB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

0.50

0.60

0.70

0.80

0.90

1.00

1.10

-15 -10 -5 0 5 10 15 20

Ratio

Outdoor Temperature (˚CWB)

Indoor Temperature (˚CDB)

15˚CDB

20˚CDB

25˚CDB

27˚CDB

Page 31

29

CHAPTER 1 ● Product Section

12.4 Correction by Refrigerant Piping Length

12.4.1 R410A refrigerant unit

To obtain a decrease in cooling/heating capacity due to refrigerant piping extension, multiply by the capacity

correction factor based on the refrigerant piping equivalent length in the table below.

0.65

0.7

0.75

0.8

0.85

0.9

0.95

0204060 80100 120 140 160

Pinping equivalent length (m)

Cooling capacity

correction factor

100

150

200

260

Total capacity of indoor unit

(1) Cooling capacity correction

0.65

0.7

0.75

0.8

0.85

0.9

0.95

0204060 80100 120 140 160

Pinping equivalent length (m)

Cooling capacity

correction factor

150

225

300

390

Total capacity of indoor unit

PUHY-P300YGM-A, PURY-P300YGM-A

PUHY-P200YGM-A, PURY-P200YGM-A

0.7

0.75

0.8

0.85

0.9

0.95

0204060 80100 120 140 160

Pinping equivalent length (m)

Cooling capacity

correction factor

125

188

250

325

Total capacity of indoor unit

0.7

0.75

0.8

0.85

0.9

0.95

0204060 80100 120 140 160

Pinping equivalent length (m)

Cooling capacity

correction factor

175

263

350

455

Total capacity of indoor unit

PUHY-P350YGM-A, PURY-P350YGM-A

PUHY-P250YGM-A, PURY-P250YGM-A

0.75

0.8

0.85

0.9

0.95

Cooling capacity

correction factor

020406080100 120 140 160

Pinping equivalent length (m)

200

300

400

520

Total capacity of indoor unit

0.7

0.75

0.8

0.85

0.9

0.95

0204060 80100 120 140 160

Pinping equivalent length (m)

Cooling capacity

correction factor

250

375

500

650

Total capacity of indoor unit

PUHY-P500YGM-A, PURY-P500YGM-A

PUHY-P400YGM-A, PURY-P400YGM-A

0.75

0.8

0.85

0.9

0.95

Cooling capacity

correction factor

0204060 80100 120 140 160

Pinping equivalent length (m)

225

338

450

585

Total capacity of indoor unit

PUHY-P450YGM-A, PURY-P450YGM-A

Page 32

30

CHAPTER 1 ● Product Section

0.9

0.95

1

020406080100 120

Pinping equivalent length (m)

Heating capacity

correction factor

(2) Heating capacity correction

0.8

0.82

0.84

0.86

0.88

0.9

0.92

0.94

0.96

0.98

1

020406080100 120 140 160

Pinping equivalent length (m)

Heating capacity

correction factor

PURY-P200YGM-A, PURY-P250YGM-A

PURY-P300YGM-A

PUHY-P200YGM-A, PUHY-P250YGM-A

0.9

0.95

1

020406080100 120

Pinping equivalent length (m)

Heating capacity

correction factor

0.8

0.82

0.84

0.86

0.88

0.9

0.92

0.94

0.96

0.98

1

020406080100 120 140 160

Pinping equivalent length (m)

Heating capacity

correction factor

PURY-P350YGM-A, PURY-P400YGM-A

PUHY-P300YGM-A, PUHY-P350YGM-A

PUHY-P400YGM-A, PUHY-P450YGM-A

PUHY-P500YGM-A

0.8

0.82

0.84

0.86

0.88

0.9

0.92

0.94

0.96

0.98

1

020406080100 120 140 160

Pinping equivalent length (m)

Heating capacity

correction factor

PURY-P450YGM-A, PURY-P500YGM-A

●

How to obtain piping equivalent length

1) PUHY-P200YGM-A, PURY-P200YGM-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.35 × number of bent on the piping) m

2) PUHY-P250/P300YGM-A, PURY-P250/P300YGM-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.42 × number of bent on the piping) m

3) PUHY-P350YGM-A, PURY-P350YGM-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.47 × number of bent on the piping) m

4) PUHY-P400/P450/P500YGM-A, PURY-P400/P450/P500YGM-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.50 × number of bent on the piping) m

Page 33

31

CHAPTER 1 ● Product Section

12.4.2 R22

refrigerant unit

Total capacity of indoor unit

Cooling capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

100

150

200

260

(1) Cooling capacity correction

Cooling capacity

correction factor

1.0

0.9

0.8

200406080 100 120

Piping equivalent length (m)

158

237

315

410

Total capacity of indoor unit

PUHY-315YEM-A/315YEMC-A

PUHY-200YEM-A/200YEMC-A

Total capacity of indoor unit

Cooling capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

125

188

250

325

200

300

400

520

Total capacity of indoor unit

Cooling capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

PUHY-400YEM-A/400YEMC-A

PUHY-250YEM-A/250YEMC-A

250

375

500

650

Total capacity of indoor unit

0

Cooling capacity

correction factor

1.0

0.9

0.8

0.7

20 40

60

80 100 120

Piping equivalent length (m)

Total capacity of indoor unit

Cooling capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

125

188

250

375

PURY-250YEMC-A

PUHY-500YEM-A/500YEMC-A

Total capacity of indoor unit

Cooling capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

100

150

200

300

PURY-200YEMC-A

Page 34

32

CHAPTER 1 ● Product Section

Heating capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

(2) Heating capacity correction

Heating capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

PUHY-200YEM-A/200YEMC-A PUHY-250YEM-A/250YEMC-A

Heating capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

Piping equivqlent length (m)

0

Heating capacity

correction factor

1.0

0.9

20 40

60

80 100 120

PUHY-315YEM-A/315YEMC-A

Total capacity of indoor unit

Heating capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

100

150

200 or more

PURY-200YEMC-A

Total capacity of indoor unit

Heating capacity

correction factor

1.0

0.9

0.8

0.7

200406080 100 120

Piping equivalent length (m)

125

188

250 or more

PURY-250YEMC-A

PUHY-400YEM-A/400YEMC-A

PUHY-500YEM-A/500YEMC-A

●

How to obtain piping equivalent length

1) PUHY-200YEM-A/200YEMC-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.47 × number of bent on the piping) m

2) PUHY-250YEM-A/250YEMC-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.50 × number of bent on the piping) m

3) PUHY-315YEM-A/315YEMC-A/400YEM-A/400YEMC-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.70 × number of bent on the piping) m

4) PUHY-500YEM-A/500YEMC-A

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.80 × number of bent on the piping) m

Page 35

33

CHAPTER 1 ● Product Section

100

50

0 200 400 600

100

50

0 200 400 600 800 1000 1200

PZ-50RFM 466 174 2 GUF-50RDH3/50RD3

PZ-100RFM 561 236 2 GUF-100RDH3/100RD3

Dimension (mm)

AB

Tested

dust

Measurement method

Filter type

Applicable

model

GUF-50RDH3

GUF-100RDH3

GUF-50RD3

GUF-100RD3

Protection of heat

exchange element

Assurance of sanitary

environment

AFI

Gravitational

method

Compound

dust

ASHRAE

Colorimetric

method

Atomspheric

dust

Countingh method

(DOP method)

Application

JIS 14 types

DOP 0.8 µm

DOP 0.3 µm

82% 8% - 12% 5% - 9% 2% - 5%

99% 65% 60% 25%

Pre-filter NP/400 (EU3)

High Model PZ-50RFM

efficiency PZ-100RFM

filter

(EU7)(Optional parts)

Note: This is one set per main body.

PZ-50RFM PZ-100RFM

External static pressure (Pa)

External static pressure (Pa)

Air volume (m3/h) Air volume (m3/h)

13. Filter Characteristics

13.1 Filter Types

13.2 High-Efficiency Filter (Optional Parts)

13.3 Pressure Loss

Pressure loss characteristics

A

B

25

AIR

FLOW

Model

Number of

filters per set

Applicable model *

Page 36

34

CHAPTER 1 ● Product Section

The ability of the filters used within the OA processing units are shown below, expressed in terms of collection

ratio (%).

20

40

60

80

100

Collection

ratio (%)

High efficiency

filter

NP/400

0.2 0.3 0.4 0.6 0.8 1.0 2.0 3.0 4.0 6.0 8.0 10.0

20 30

40 60 80 100

Particle diameter (µm)

Dust removal retention characteristics (NP/400 + High efficiency filter)

GUF-50RDH3/50RD3

0

0 100 200 300 350

400

50 150 250

20

40

60

80

100

140

120

Presure

loss (Pa)

Dust removal volume (g/set)

GUF-100RDH3/100RD3

0

0

100 200 300 400 500 600 700

20

40

60

80

100

180

200

160

140

120

Presure

loss (Pa)

Dust removal volume (g/set)

Page 37

35

CHAPTER 1 ● Product Section

14. Noise Characteristics

14.1 GUF-50RDH3/50RD3

14.2 GUF-100RDH3/100RD3

●

Measurement Condition

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

NC-10

Directly below (Measurement point A)

Octave band sound level (dB)

Octave band central frequency (Hz)

<Ceiling recessed type>

Supply/

Exhaust air

Main unit

To indoor unit

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

NC-10

Outlet (Measurement point B)

Octave band sound level (dB)

Octave band central frequency (Hz)

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

NC-10

Directly below (Measurement point A)

Octave band sound level (dB)

Overall

Octave band central frequency (Hz)

62.5 125 250 500 1K 2K 4K 8K Overall 62.5 125 250 500 1K 2K 4K 8K

Overall 62.5 125 250 500 1K 2K 4K 8K Overall 62.5 125 250 500 1K 2K 4K 8K

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

NC-10

Outlet (Measurement point B)

Octave band sound level (dB)

Octave band central frequency (Hz)

Measurement site:

Mitsubishi Electric Co.,

Nakatsugawa Works

Anechoic chamber

A

B

1.5 m

1.5 m

High

Low

High

Low

Page 38

36

CHAPTER 1 ● Product Section

Test report

This document reports the result that there is no bacterial cross contamination for the Lossnay Core.

(1) Object

The object of this test is to verify that there is no bacterial cross contamination from the outlet air to the

inlet air of the Lossnay Core in the heat exchange process.

(2) Client

MITSUBISHI ELECTRIC CO. NAKATSUGAWA WORKS.

(3) Test period

April 26, 1999 - May 28, 1999

(4) Test method

The configuration of the test equipment is shown below. The test bacteria suspension is sprayed in the

outlet duct at a pressure of 1.5 kg/cm2with a sprayer whose dominant particle size is 0.3 - 0.5 µm. The

air sampling tubes are installed at the each center of the locations of A, B, C, D, in the Lossnay Core

inlet/outlet ducts so that their openings are directly against the air flow, and then connected to the

impinger outside the duct. The impinger is filled with 100 mL physiological salt solution. The airborne

bacteria in the duct air are sampled at the rate of 10L air/minute for three minutes.

(5) Test bacteria

The bacteria used in this test are as followed;

Bacillus subtilis IFO 3134

Pseudomonas diminuta IFO14213 (JIS K 3835 Method of testing bacteria trapping capability of

precision filtration film elements and modules; applicable to precision filtration film, etc. applied to air

or liquid)

(6) Test result

The result of the test with Bacillus subtilis is shown in Table 1.

The result of the test with Pseudomonas diminuita is shown in Table 2.

Sprayer

Impinger

Impinger

Impinger

Fan

Fan

Safety cabinet

Impinger

LOSSNAY Core

HEPA filter

15. Reference Documents

15.1 The Result of No Bacterial Cross Contamination for the

Lossnay Core and Determining Resistance of the Lossnay

Core to Molds

Page 39

37

CHAPTER 1 ● Product Section

Table 1 Test result with bacillus subtilis (CFU/30L air)

No. ABCD

1 5.4 × 10

4

5.6 × 10

4

<10

3

<10

3

2 8.5 × 10

3

7.5 × 10

3

<10

3

<10

3

3 7.5 × 10

3

<10

3

<10

3

<10

3

4 1.2 × 10

4

1.2 × 10

4

<10

3

<10

3

5 1.8 × 10

4

1.5 × 10

3

<10

3

<10

3

Average 2.0 × 10

4

1.5 × 10

4

<10

3

<10

3

Table 2 Test result with pseudomonas diminuita (CFU/30L air)

No. ABCD

1 3.6 × 10

5

2.9 × 10

5

<10

3

<10

3

2 2.5 × 10

5

1.2 × 10

5

<10

3

<10

3

3 2.4 × 10

5

7.2 × 10

5

<10

3

<10

3

4 3.4 × 10

5

8.4 × 10

5

<10

3

<10

3

5 1.7 × 10

5

3.8 × 10

5

<10

3

<10

3

Average 2.7 × 10

5

4.7 × 10

5

<10

3

<10

3

(7) Considerations

Bacillus subtilis is commonly detected in the air and resistant to dry. Pseudomonas diminuita is