Page 1

1

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

PUMY-71VM, PUMY-125VM

CONTENTS

1. Specifications

2. Capacity Tables

2-1 Correction by temperature

2-2 Correction by total indoor

2-3 Correction by refrigerant piping length

2-4 Correction at frosting and defrosting

2-5 Operation limit

3. Sound Levels

4. External Dimensions

5. Electrical Wiring Diagram

6. Refrigerant Circuit Diagram

·································································

······························································

············································

·············································

·······························································

··································································

····················································

··············································

·········································

And Thermal Sensor

···························

····························

2

4

4

6

8

9

9

10

11

13

15

Page 2

2

PUMY

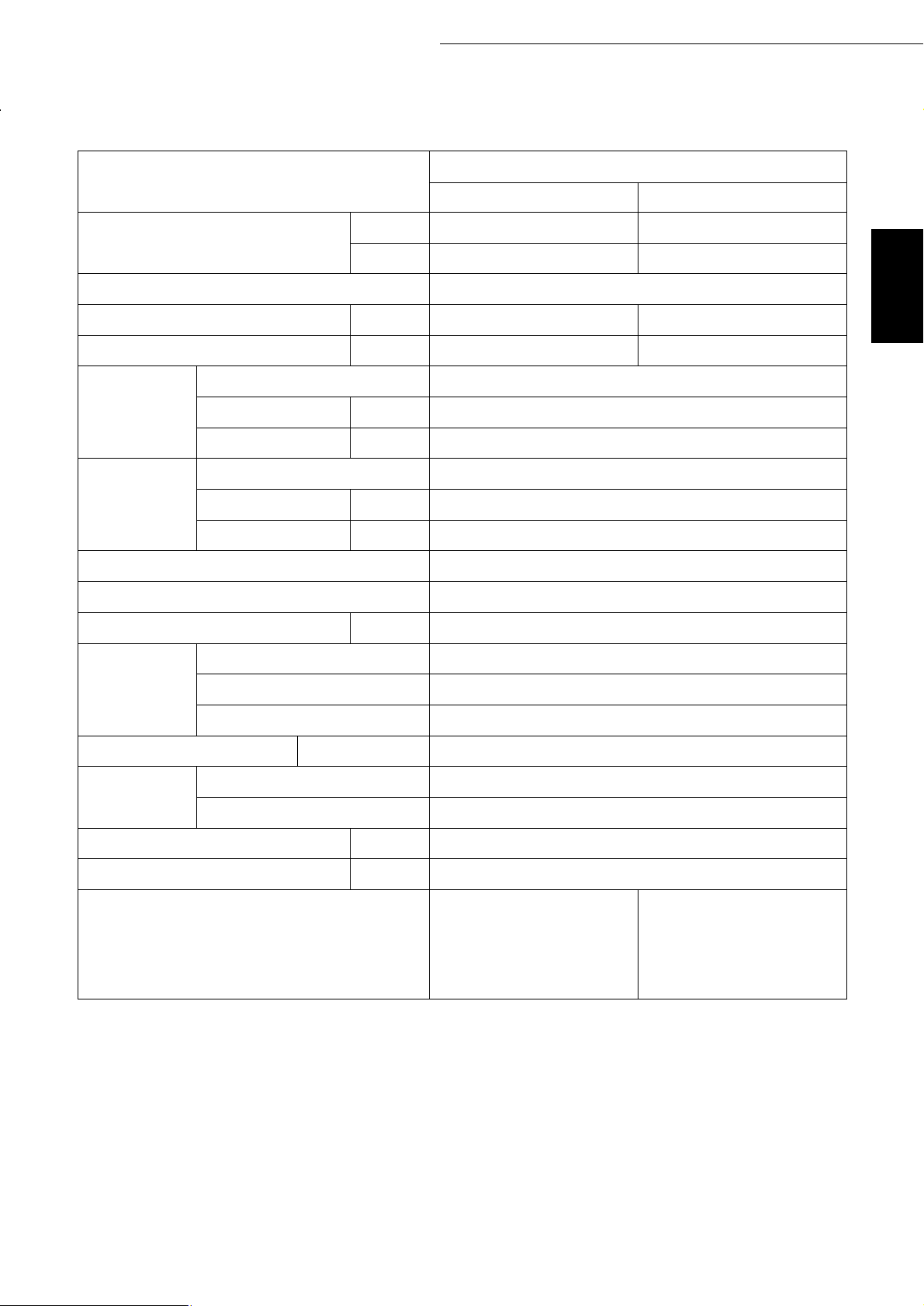

1. Specifications

Model name

Capacity

Power source

Power input

Current

Type ✕ Quantity

Fan

Compressor

Refrigerant / Lubricant

External finish

External dimension mm

Airflow rate

Motor output

Type

Motor output

Crankcase heater

kW ✻1

kcal/h

kW

A

3

m

/min

kW

kW

kW

PUMY-71VM

Cooling Heating

8.0 9.0

✻2

7,100 -

~/N 220-230-240V 50Hz / 208-23

3.50/3.63 3.65/3.53

17.5-16.7-16.0/18.1 18.2-17.4-16.0/17.6

Propeller fan ✕ 2

95

0.04 ✕ 2

Hermetic

2.6

-

R22/MS56

Steel plate painting with polyester powder

<MUNSELL 5Y8/1>

1200(H)✕900(W)✕320(+30)(D)

0V 60Hz

High pressure protection

Protection

devices

Refrigerant piping diameter Liquid / Gas

Indoor unit

Noise level

Net weight

Operating temperature range

Note: 1.Cooling/heating capacity indicates the maximum value at operation under the following condition.

Cooling ✻1 Indoor : 27˚CDB/19˚CWB Outdoor : 35˚CDB

Heating Indoor : 20˚CDB Outdoor : 7˚CDB/6˚CWB

Compressor / Fan

Inverter

Total capacity

Model / Quantity

dB<A>

kg

Indoor:15˚CWB ~ 24˚CWB

Outdoor:-5˚CDB ~ 46˚CDB

Pipe length : 7.5m Height difference : 0m

Internal thermal switch / Internal thermal switch

Over current protection, Overheat protection

50 ~ 130% of outdoor unit capacity

Model 20 ~ 80 / 1 ~ 4

Cooling ✻2 Indoor : 27˚CDB/19.5˚CWB Outdoor : 35˚CDB

Pipe length : 5m Height difference : 0m

3.0MPa

ø9.52 /ø15.88 (Flare)

52

93

Indoor:15˚CDB ~ 27˚CDB

Outdoor:-15˚CWB ~ 15.5˚CWB

2.Works not included : Installation/foundation work, electrical connection work, duct work, insulation work, power

source switch and other items not specified in this specification.

Page 3

3

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

Model name

Capacity

Power source

Power input

Current

Type ✕ Quantity

Fan

Compressor

Refrigerant / Lubricant

External finish

External dimension mm

Airflow rate

Motor output

Type

Motor output

Crankcase heater

kW ✻1

kcal/h

kW

A

3

m

/min

kW

kW

kW

PUMY-125VM

Cooling Heating

14.0 16.0

✻2

12,500 -

~/N 220-230-240V 50Hz / 208-230V 60Hz

6.57/6.43 6.10/6.03

34.9-33.5-32.2/33.6 32.6-31.2-29.9/31.5

Propeller fan ✕ 2

90

0.06 ✕ 2

Hermetic

3.5

-

R22/MS32(N-1)

Steel plate painting with polyester powder

<MUNSELL 5Y8/1>

1280(H)✕1020(W)✕350(+30)(D)

High pressure protection

Protection

devices

Refrigerant piping diameter Liquid / Gas

Indoor unit

Noise level

Net weight

Operating temperature range

Note: 1.Cooling/heating capacity indicates the maximum value at operation under the following condition.

Cooling ✻1 Indoor : 27˚CDB/19˚CWB Outdoor : 35˚CDB

Heating Indoor : 20˚CDB Outdoor : 7˚CDB/6˚CWB

Compressor / Fan

Inverter

Total capacity

Model / Quantity

dB<A>

kg

Indoor:15˚CWB ~ 24˚CWB

Outdoor:-5˚CDB ~ 46˚CDB

Pipe length : 7.5m Height difference : 0m

Internal thermal switch / Internal thermal switch

Over current protection, Overheat protection

50 ~ 130% of outdoor unit capacity

Model 20 ~ 125 / 1 ~ 8

Cooling ✻2 Indoor : 27˚CDB/19.5˚CWB Outdoor : 35˚CDB

Pipe length : 5m Height difference : 0m

3.0MPa

ø9.52 /ø19.05

54

130

Indoor:15˚CDB ~ 27˚CDB

Outdoor:-15˚CWB ~ 15.5˚CWB

2.Works not included : Installation/foundation work, electrical connection work, duct work, insulation work, power

source switch and other items not specified in this specification.

Page 4

4

PUMY

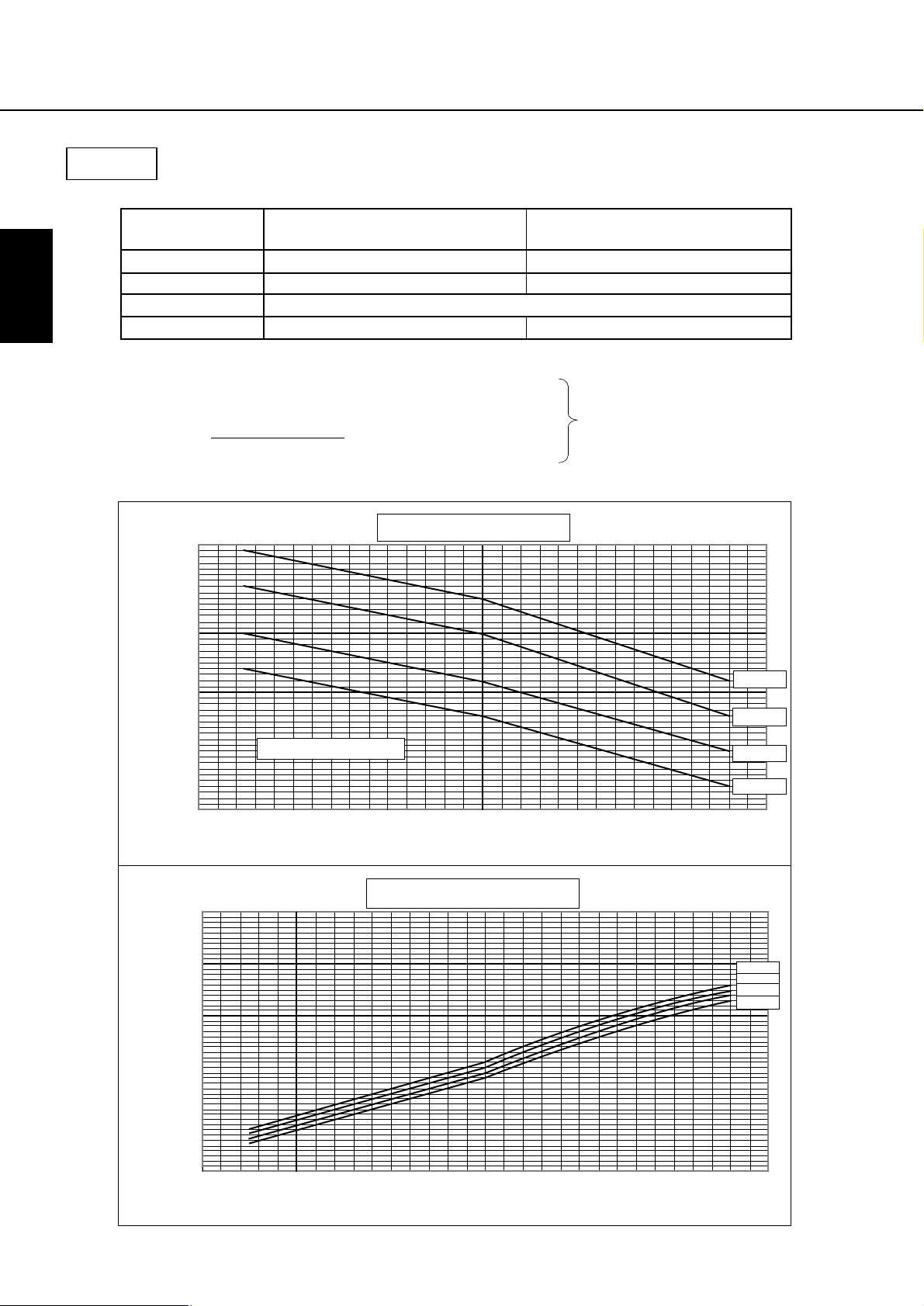

2-1. Correction by temperature

2. Capacity table

Cooling

• Standard Specifications

• Calculation

Capacity

Input

Source

kW

kW

V

Current A

Capacity' Capacity Ratio= ✕

Input Input Ratio'= ✕

Current'

Input'

=

✕✕1000

Source

1.20

1.10

Ratio

1.00

PUMY-71VM

8.0

3.50/3.63

17.5-16.7-16.0/18.1

❇ Capacity'

Input'

0.91 (:PUMY-71VM)

Current'

0.85 (:PUMY-125VM)

The Ratio of Cooling Capacity

PUMY-125VM

14.0

6.57/6.43

208-230V

34.9-33.5-32.2/33.6

After correction

22˚CWB

20˚CWB

0.90

0.80

-1001020304050

1.40

1.20

1.00

Ratio

0.80

0.60

0.40

-100 1020304050

Indoor Temperature(˚CWB)

The Ratio of Cooling Power Input

Outdoor Temperature (˚CDB)

Outdoor Temperature (˚CDB)

18˚CWB

16˚CWB

22˚CWB

20˚CWB

18˚CWB

16˚CWB

Page 5

Heating

5

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

• Standard Specifications

Capacity

Input

Source

Current A

• Calculation

Capacity' Capacity Ratio= ✕

Input Input Ratio'= ✕

Current'

=

1.30

1.20

1.10

1.00

kW

kW

V

Input'

Source

PUMY-71VM

9.0

3.65/3.53

18.2-17.4-16.0/17.6

✕✕1000

0.91 (:PUMY-71VM)

0.85 (:PUMY-125VM)

The Ratio of Heating Capacity

Indoor Temperature(˚CDB)

220-230-240/220V

❇Capacity'

Input'

Current'

PUMY-125VM

16.0

6.10/6.03

32.6-31.2-29.9/31.5

After correction

15˚CDB

20˚CDB

25˚CDB

Ratio

0.90

0.80

0.70

0.60

-15 -10 -5 0 5 10 15 20

Outdoor Temperature (˚CWB)

The Ratio of Heating Power Input

1.20

1.10

1.00

0.90

Ratio

0.80

0.70

Indoor Temperature(˚CDB)

20˚CDB

15˚CDB

25˚CDB

0.60

-15 -10 -5 0 5 10 15 20

Outdoor Temperature (˚CWB)

Page 6

6

PUMY

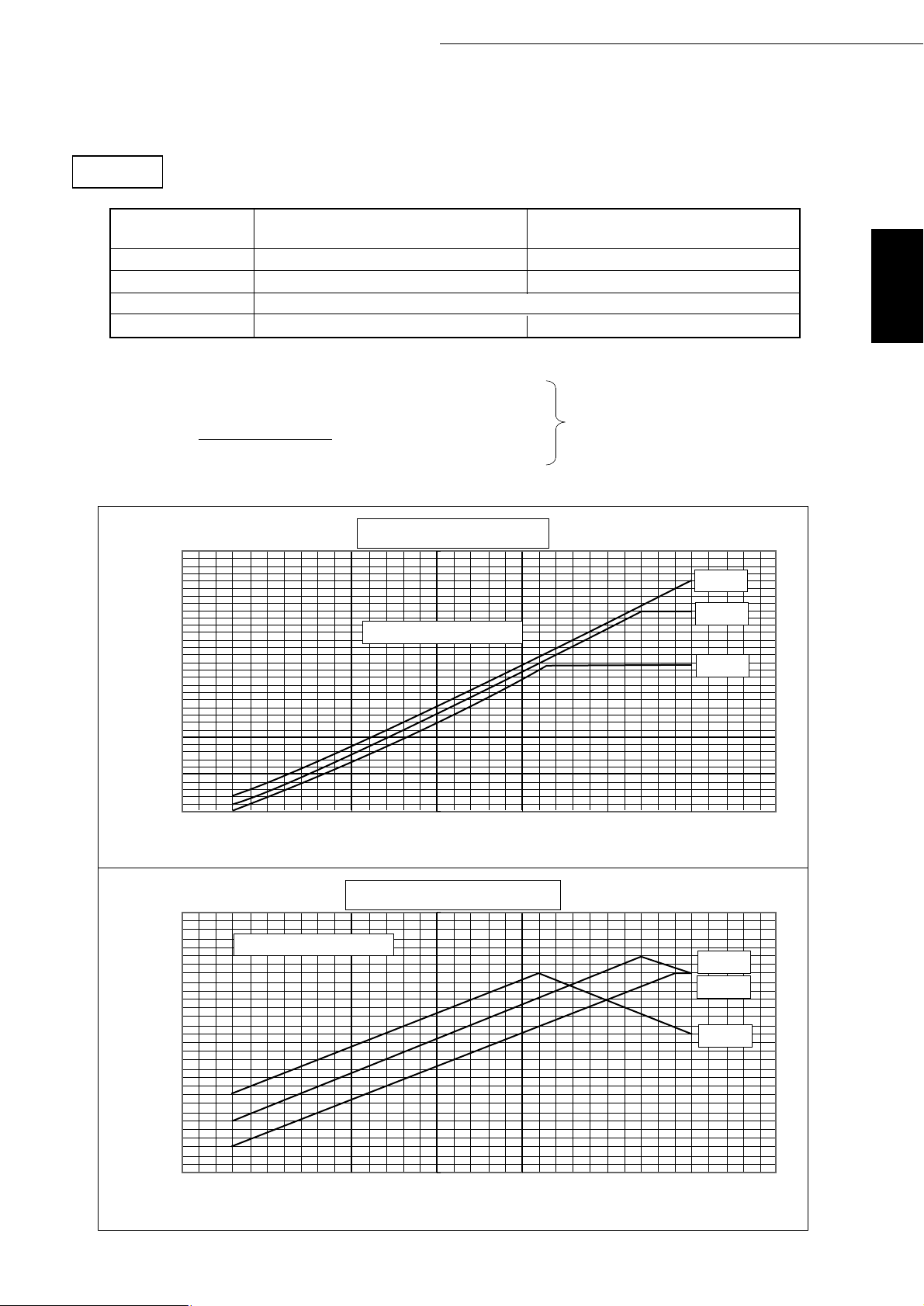

2-2. Correction by total indoor

PUMY-71VM

1) Capacity

10.0

9.0

8.0

7.0

Capacity(kW)

6.0

5.0

4.0

40 50 60 70 80 90 100

Heating

Cooling

Total capacity of indoor units

2) Input

4.00

3.50

3.00

Input(kW)

2.50

2.00

3) Current

20.0

18.0

16.0

Current(A)

14.0

Cooling

Heating

40 50 60 70 80 90 100

Total capacity of indoor units

Cooling

Heating

220V 60Hz

220V 50Hz

220V 50Hz

220V 60Hz

220V 50Hz

220V 60Hz

220V 50Hz

220V 60Hz

12.0

10.0

40 50 60 70 80 90 100

Total capacity of indoor units

Page 7

PUMY-125VM

7

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

1) Capacity

17.0

15.0

13.0

11.0

Capacity(kW)

9.0

7.0

60 80 100 120 140 160 180

2) Input

7.00

6.00

5.00

Input(kW)

4.00

Total capacity of indoor units

Heating

Cooling

50Hz

60Hz

50Hz

60Hz

Cooling

Heating

3.00

2.00

3) Current

36.0

34.0

32.0

30.0

28.0

26.0

Current(A)

24.0

22.0

20.0

18.0

16.0

14.0

60 80 100 120 140 160 180

Total capacity of indoor units

220V 50Hz

Cooling

Heating

60 80 100 120 140 160 180

Total capacity of indoor units

220V 60Hz

220V 50Hz

220V 60Hz

Page 8

8

PUMY

2-3 Correction by refrigerant piping length

To obtain a decrease in cooling/heating capacity due to refrigerant piping extension, multiply by the capacity

correction factor based on the refrigerant piping equivalent length in the table below.

• Cooling capacity correction

PUMY-71VM

Cooling capacity

1.0

0.9

0.8

correction factor

0.7

1002030405060

• Heating capacity correction

PUMY-71VM

1.0

Total capacity of indoor unit

35

53

71

93

Piping equivalent length (m)

PUMY-125VM

1.0

0.9

0.8

Cooling capacity

correction factor

0.7

10520304050607075

PUMY-125VM

1.0

Total capacity of indoor unit

63

94

125

163

Piping equivalent length (m)

0.9

0.8

Heating capacity

correction factor

0.7

10020304050 60

Piping equivalent length (m)

0.9

0.8

Heating capacity

correction factor

0.7

10020304050 60

Piping equivalent length (m)

• How to obtain piping equivalent length

➀ PUMY-71VM

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.3 ✕ number of bent on the piping)m

➁ PUMY-125VM

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.35 ✕ number of bent on the piping)m

Page 9

9

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

2-4 Correction at frosting and defrosting

When a decrease in heating capacity due to frosted and defrosting operations is considered, the value multiplied by the correction factor in the table below represents the heating capacity.

2-5 Operation limit

Correction factor table

Outdoor inlet air temp

(˚CWB)

6 4 2 0 -2 -4 -6 -8 -10

Correction factor

• Cooling

30

25

20

15

Indoor temperature (˚CWB)

10

-5 0 5 10 15 20 25 30 35 40 45 50

• Heating

30

25

1.0 0.98 0.89 0.88 0.89 0.9 0.95 0.95 0.95

Outdoor temperature (˚CDB)

20

15

Indoor temperature (˚CDB)

10

-15 -10 -5 0 5 10 15 20

Outdoor temperature (˚CDB)

Page 10

10

PUMY

3. Sound levels

PUMY-71VM

Measurement condition

70

1m

A

1m

Sound pressure level in anechoic room

57 dB (A)

60

NC60

50

B

40

30

20

Approximate minimum

OCTAVE BAND PRESSURE LEVEL< dB> 0dB = 0.0002µbar

audible limit on

continuous noise

NC50

NC40

NC30

NC20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES<Hz>

PUMY-125VM

Measurement condition

1m

A

1m

B

Sound pressure level in anechoic room

58 dB (A)

70

60

50

40

30

20

Approximate minimum

OCTAVE BAND PRESSURE LEVEL< dB> 0dB = 0.0002µbar

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES<Hz>

NC60

NC50

NC40

NC30

NC20

Page 11

11

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

4. External dimensions

PUMY-71VM

Terminal block for transmission

Terminal block for central remote control

Optional parts

(base branching

Terminal block for Power source

pipe) installation

hole

ø15.88(5/8F)

ø9.52(3/8F)

Gos refrigerant-pipe

connection

Liquid refrigerant-pipe

connection

Knock out hole for right piping

Unit : mm

Knock out holes fo power line 2-ø27

ø27

shaped notched holes

(standard bolt M10)

Air intake

Air intake

Air outlet

Optional parts

installation hole

Side air intake

Service panel

Handle for

moving

Rear air intake

Handing for moving

Knock out holes for

power line 2-

Knock out hole

for front piping

Piping cover

Oval holes

(standard bolt M10)

Bottom piping hole

Drain hole

(3-ø33 hole)

Handle for moving

Rear piping hole

when a piping cover is used for aesthetic reasons.

✻1...Indicates the dimensions of the cutoff valve connector.

✻2...Make sure that the panel can be easily removed for maintenance

Page 12

12

PUMY

PUMY-125VM

Optional parts

(base branching

pipe) installation

hole

Unit : mm

ø9.52 (3/8F)

Knock out holes for power line 2-ø 29

Air intake

Teminal block for transmission

Teminal block for central remote control

Terminal block for power source

Air outlet

Optional parts

installation hole

Handle for

moving

Liquid refrigerant pipe

connection

Gos refrigerant-pipe

connection ø19.05 (3/4F)

Knock out hole for right piping

Knock out holes for

power line 2-ø27

Knock out hole for

front piping

Piping cover

Oval holes

(standard bolt M10)

Bottom piping hole

shaped dotched holes

(standard bolt M10)

Drain hole

(3-ø33 hole)

Handle for moving

Side air intake

Rear air intake

Rear piping hole

when a piping cover is used for aesthetic reasons.

✻1...Indicates the dimensions of the cutoff valve connector.

✻2...Make sure that the panel can be easily removed for maintenance

Page 13

13

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

5. Electrical Wiring Diagram

PUMY-71VM

SYMBOL

AC,CT

CH

CNA

CND

CNS1

CNS2

CN1

CN2

CN3

CN4

CN5

CN6

CN40

CN41

CN51

CN3D

CNCT

C1,2

C3

C5

DS

D1

DCL

POWER SUPPLY

Single-phase 220-240V 50Hz

Single-phase 208-230V 60Hz

Current detection

Crankcase heater

Connector <Power supply>

Connector <DC Power supply>

Connector <Multi system>

Connector <Centralized control>

Connector <Controller drive control>

Connector <Power sync signal, protection>

Connector <Power supply 30V, 12V, 5V>

Connector <Inverter signal 5V>

Connector <IPM power supply>

Connector <IPM power supply, trouble output>

Connector <Centralized control power supply>

Connector <For storing jumper connector>

Connector <Compressor drive signal output>

Connector <Demand signal, silent mode input>

Connector <Current detection>

Fan motor capacitor

Capacitor <Smoothing>

Capacitor <Power factor improvement>

Diode stack

Diode <Power factor improvement>

Reactor

TO INDOOR UNIT

CONNECTING WIRES

DC 30V (Non-polar)

FOR CENTRALIZED

CONTROL

DC 30V (Non-polar)

NAME NAME

M1

M2

S

M1

M2

S

L1

L2

TB3

BRN

BRN

TB7

ORN

ORN

TB1

RED

WHT

GRN/YLW

FUSE(30A)

SYMBOL SYMBOL

F.C

FUSE1

FUSE2

FUSE

IPM

LD1

Fan control

Fuse(2A)

Fuse(6A)

Fuse(30A)

Intelligent power module

Digital indication LED

<Operation inspection indication>

NF1

RED

1

2

MC

MF1,2

NF1

R1

R2

SLEV

SV1

SW1

SW2

SW3

SW4

SW5

SWU1

SWU2

SWU3

TB1

1

CNCT

Compressor

Fan motor (Inner thermostat)

Noise filter

Resistor <Rush current protect>

Resistor <Discharge>

Expansion valve

Solenoid valve <Hot gas bypass>

Switch <Display selection selfdiagnosis>

Switch <Function selection>

Switch <Test run>

Switch <Model selection>

Switch <Function selection>

Switch <Unit address selection,1st digit>

Switch <Unit address selection,2nd digit>

Switch <Unit address selection,3rd digit>

Terminal block <Power supply>

1234

CN41

CN51

CN40

(WHT)

(WHT)

CNS2

1

(YLW)

2

0

1

(3rd digit)

X1

CNA

31

WHT

WHT

CH

PUMY-71VM

Only

DS

9

8

7

6

SWU3

CH

WHT

4

5

CNS1

1

(RED)

2

<MULTI CONTROLLER BOARD>

<POWER SUPPLY BOARD>

FUSE2

(6A)

1

3

RED

RED

3

2

WHT

4

LD1

2

3

SWU2

(2nd digit)

1

3

BLK

RED

RED

WHT

(WHT)

0

1

9

9

2

8

8

3

7

7

4

6

6

5

SWU1

(1st digit)

X2

52C 21S4

31

BLK

RED

R1

RED

52C

ZNR

CN3D

(WHT)

0

1

2

4

5

X3

RED

C5

3

3

RED

SV152C 21S4

DCL

1

321543214321

SV1

2

CNCT

(WHT)

RED

MF1

C1

D1

3

WHT

RED

1

1

MF1

F.C

BLU

ORN

3

MF2

C2

RED

R2

THHS

THHS

(BLK)

OFF

ON

OFF

CN1

6

6

FUSE1

MF2

1

WHT

RED

TB3

TB7

THHS

TH1

TH2

TH5

TH6

X1

X2

X3

ZNR

21S4

26C

52C

63HS

TH6 TH5

TH6

(WHT)

ON

SW3

12 321

(RED)

3

21

3

CN1

(RED)

CND

BLU

ORN

RED

+

C3

Terminal block <Transmission>

NAME

Terminal block

<Transmission> (Centralized control)

Thermistor

<IPM Radiator panel temperatuer detection>

Thermistor <Discharge temperatuer detection>

Thermistor

<Low pressure saturated temperatuer detection>

Thermistor

<Pipe temperatuer detection, judging defrost>

Thermistor <Outdoor temperatuer detection>

Relay

<Crankcase heater, magnetic contactor>

Relay <4-way valve>

Relay <Solenoid valve>

Varistor

4-Way valve

Thermal switch <Compressor>

Magnetic contactor

<Inverter main circuit>

High pressure sensor

<Discharge pressure detection>

TH2 TH1

63HS

SLEV

6

3

2123

453

AC,CT

(YLW)

CN4

7

6

67

W

SLEV

(YLW)

5

4123

5

CN4

(YLW)

6

2

1

RED

1234

11231121321

TH1

TH5

(GRN)

(GRN)

SW1

ON

OFF

34567821

SW4

ON

OFF

4

(YLW)

CN2

43

21

5

6

645

26C

6

12

4321

5

CN2

(YLW)

(2A)

1

2

RED

WHT

(YLW)

3

WHT

(BLK)

(WHT)

CN5

1

P(+)

CN5

(WHT)

<GATE AMP BOARD>

N(-)

63HS

TH2

(WHT)

(WHT) (WHT)

SW2

12345678910

SW5

87654321

(WHT)

CN3

1263

7

YLW

YLW

21

3621

7

26C

CN3

(WHT)

(WHT)

CN6

10

321

9652

63 7

96521

10

321

CN6

(WHT)

V

U

WHT

P(+)

RED

U

W

V

BLU

WHT

AC.CT

V

W

MC

1.Refer to the wiring boards of the indoor units for details on wiring of each indoor unit.

N(-)

<IPM>

U

2.The transmission line is two-wire type and has no polarity.

3.Mark shows the terminal board,mark the connector .Symbols in parentheses () show the colors of connectors.

4.Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch(SW1) and LD1(LED indication)

found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

Page 14

14

PUMY

PUMY-125VM

SYMBOL

AC,CT

AR

CB

CH

CNA

CND

CNS1

CNS2

CN1

CN2

CN3

CN4

CN5

CN6

CN40

CN41

CN51

CN3D

C1,2

C3,4

C5,6

C7

D

DB1,DB2

TO INDOOR UNIT

CONNECTING WIRES

DC 30V (Non-polar)

FOR CENTRALIZED

CONTROL

DC 30V (Non-polar)

POWER SUPPLY

Single-phase 220-240V 50Hz

Single-phase 208 -230 60Hz

Current detection

Surge absorber

Smoothing capacitor

Crankcase heater

Connector <Power supply>

Connector <DC Power supply

Connector <Multi system>

Connector <Centralized control>

Connector <Controller drive control>

Connector <Power sync signal, protection>

Connector <Power supply 30V, 12V, 5V>

Connector <Inverter signal 5V>

Connector <IPM Power supply>

Connector <IPM Power supply, trouble output>

Connector <Centralized control power supply>

Connector <For storing jumper connector>

Connector <Compressor drive signal output>

Connector <Demand signal, silent mode input>

Fan motor capacitor

Capacitor <Power factor improvement>

Capacitor

Capacitor <Filter>

Diode <Power factor improvement>

Diode stack

NAME NAME

SYMBOL

DCL

F.C

FUSE1

FUSE2

FUSE

IPM

LD1

Reactor

Fan control

Fuse(2A)

Fuse(6A)

Fuse(60A)

Intelligent power module

Digital indication LED

<Operatioin inspection indication>

Compressor

Fan motor (Inner thermostat)

Noise filter

Resistor <Discharge>

Resistor <Rush current protect>

Expansion valve

Solenoid valve <Hot gas bypass>

Switch <Display selection selfdiagnosis>

Switch <Function selection>

Switch <Test run>

Switch <Model selection>

Switch <Function selection>

Switch <Unit addres selection , 1st digit>

Switch <Unit address selection 2nd digit>

Switch <Unit address selection 3rd digit>

Terminal block <Power supply>

0

9

8

7

6

1

1

2

4

5

FUSE2

(6A)

3

RED

CN41

(WHT)

LD1

0

1

9

8

3

7

4

6

5

SWU2

(2nd digit)(3rd digit)

CNA

1

3

BLU

WHT

CH

PUMY-125VM

Only

YLW

4321

2

8

3

7

SWU1

(1st digit)

CH

WHT

CH

DB1 DB2

2

3

1

X4

8

CN40 CN51 CN3D

(WHT) (WHT)(WHT)

CNS2

1

(YLW)

2

CNS1

1

(RED)

2

SWU3

<MULTI CONTROLLER BOARD>

<POWER SUPPLY BOARD>

NF

RED

143

BLK

2

GRN/YLW

M1

M2

M1

M2

TB3

S

TB7

S

TB1

L

N

BRN

BRN

ORN

ORN

RED

RED

BLK

BLK

GRN

GRN/YLW

RED

C5

C6

MC

MF1,2

NF

RB

RS

SLEV

SV1

SW1

SW2

SW3

SW4

SW5

SWU1

SWU2

SWU3

TB1

AR

RED

FUSE(60A)

321543214321

0

1

9

2

3

4

6

5

X2X1X3

21S4

52C

1

3

1

3

YLW

YLW

RED

RED

21S4

52C SV1

BLK

RED

2

ZNR

3

52C

1

BLK

X4

RS

BRN

BRN

3

YLW

7

3

RED

RED

C3

1

DCL

C4

5

SV1

RED

WHT

BLU

3

MF1

C1

BLK

BLK

BRN

1

WHT

RED

1

3

RB

F.C

MF1

BLU

ORN

D

BLU

SYMBOL

TB3

TB7

THHS

TH1

TH2

TH5

TH6

X1

X2

X3

X4

ZNR

21S4

26C

52C

63HS

THHS

CN1

3

6

3

6

CN1

(RED)

MF2

1

3

BLU

WHT

MF2

RED

ORN

C2

2

RED

RED

+

2

6

-

BLK

Terminal block <Transmission>

NAME

Terminal block

<Transmission> (Centralized control)

Thermistor

<IPM radiator panel temperature detection>

Thermistor <Discharge temperature detection>

Thermistor

<Low pressure saturated temperature detection>

Thermistor

<Pipe temperature detection, judging defrost>

Thermistor

<Outdoor temperature detection>

Relay

<Crankcase heater, magnetic contactor>

Relay<4-way valve>

Relay<Solenoid valve>

Relay

Varistor

4-way valve

Thermal switch <Compressor>

Magnetic contactor

<Inverter main circuit>

High pressure sensor

<Discharge pressure detection>

TH1

TH2TH5TH6

63HS

SLEV

3

6

THHS

(RED)

2

2132311

TH6

TH5

(WHT)

(GRN)

(BLK)

SW1

ON

OFF

12 876543

SW3

SW4

ON

OFF

12 4321 12345678

(YLW)

CN2

1

3

2

4

6

1

5

26C

1

2

(YLW)

CND

1

RED

CB

4

5

6

(YLW)

CN2

FUSE1

(2A)

CN5

2

3

BLK

RED

P(+)

C7

BLK

N(-)

<IPM>

1

3

2

2

5

1

2

1

CN5 CN6

(WHT) (WHT)

3121

TH2

TH1

(WHT)(GRN)

ON

OFF

SW5

ON

OFF

CN3

7

YLW

YLW

21

7

CN3

26C

(BLK)

(WHT)

CN6

10

9

6

1

6

1

965

10

<GATE AMP BOARD>

WVX4U

BLU

RED

WHT

V

U

W

MC

63HS

SW2

(WHT)

3

6

(WHT)

(WHT)

2

2

AC.CT

(WHT)

263

546

2

3

3

3

456

123

321

SLEV

(WHT)

10987654321

1

1

CN4

657

AC.CT

(YLW)

(YLW)

213

4

2

1

7

54362

1

7

CN4

(YLW)

RED

WHT

1.Refer to the wiring boards of the indoor units for details on wiring of each indoor unit.

2.The transmission line is two-wire type and has no polarity.

3.Mark shows the terminal board,mark the connector.Symbols in parentheses() show the colors of connectors.

4.Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch(SW1) and LD1(LED indication)

found on the multi-controller of the outdoor unit.

LED indication:Set all contacts of SW1 to OFF.

Page 15

15

PUMY

11

Outdoor units / Y series / PUMY-71·125VM

6. Refrigerant circuit diagram and Thermal sensor

PUMY-71, 125VM

Thermistor TH6

(outdoor air

temperature sensor)

Cooling

Heating

(Refrigerant flow)

High-pressure sensor

discharge pressure sensor

(63HS)

4-way

valve

Strainer

Service port

Strainer

Oil

separator

Flare

Thermistor

Check valve

(High prssure)

Check valve

(low pressure)

Capillary

Thermistor TH5

(pipng temperature

monitoring and

determination)

Electromag-

netic valve

(SV1)

TH1 (discharge

temperature

sensor)

Capillary

tube 1

Strainer

tube 3

Outdoor heat exchanger

Thermistor THHS

(Radiator panel

temperature sensor)

Compressor

(MC)

Strainer

Accumulator

Electronic expansion valve (SLEV)

Capillary

tube 2

Flare

Overcooling heat exchanger

Strainer

Strainer

Service port

Connector

Gas pipe

Flare

Thermistor TH23

for monitoring gas

pipe temperature

Indoor heat

exchanger

Thermistor

TH21 (intake

temperature

detection)

Thermistor TH2

(Saturation temperature

of suction pressure)

Thermistor

TH22 (piping

temperature

detection)

Connector

Liquid pipe

Indoor unit Outdoor unit

Flare

Linear expansion

valve (LEV)

Page 16

16

PUMY

Loading...

Loading...