Page 1

Projection Television

Technical Training &

Troubleshooting Manual

V23

V23

ECHNICAL

RAINING

T

2003

V23

WS-48513

WS-55513

WS-65513

WS-73513

V23+ V23++ V23+++

WS-48613 WS-65713 WS-55813

WS-55613 WS-73713 WS-65813

WS-65613

MITSUBISHI ELECTRIC

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

Page 2

Page 3

V23 Chassis

Projection Television

Technical Training &

Troubleshooting Manual

ECHNICAL

RAINING

T

2003

Copyright © 2003, Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 4

Page 5

V23 CHASSIS

TECHNICAL TRAINING AND TROUBLESHOOTING MANUAL

TABLE of CONTENTS

Introduction ... New Technologies

Models ............................................................................................................... 1

Features ............................................................................................................... 2

NetCommand™ 3.0 ............................................................................................. 3

Five Format Memory Card Reader ....................................................................... 4

PerfectColor™ ...................................................................................................... 5

MonitorLink™ ....................................................................................................... 6

Service Code Chart ............................................................................................ 12

Chapter1 ... Disassembly and Service

Disassembly Procedures ...................................................................................1-1

DM Replacement .............................................................................................. 1-2

PCB & Main Component Locations ................................................................... 1-4

Convergence Output IC Replacement .............................................................. 1-5

Composite Cabinet ............................................................................................ 1-6

Chapter 2 ... Alignment Procedures

Initial Setup .......................................................................................................2-1

Circuit Adjustment Mode ................................................................................... 2-3

ConvergenceAdjustment Mode ......................................................................... 2-5

Alignment Data Storage Locations ....................................................................2-6

Chapter 3 ... Power Supply

Low Energy Power Supply ................................................................................ 3-1

Standard Standby Power Supply ....................................................................... 3-4

Time Shift Recording Power Supply .................................................................. 3-2

Switched Supplies ............................................................................................. 3-7

Troubleshooting................................................................................................. 3-8

Chapter 4 ... Control Circuitry

Basic uPC Requirements .................................................................................. 4-1

Reset Circuitry ...................................................................................................4-2

Input Command Circuitry................................................................................... 4-3

Serial Data Lines ............................................................................................... 4-4

Parallel Input Lines ............................................................................................ 4-5

Parallel Outputs .................................................................................................4-7

I

Page 6

Chapter 5 ... Video/Color Circuitry

Overall Block Diagram ....................................................................................... 5-1

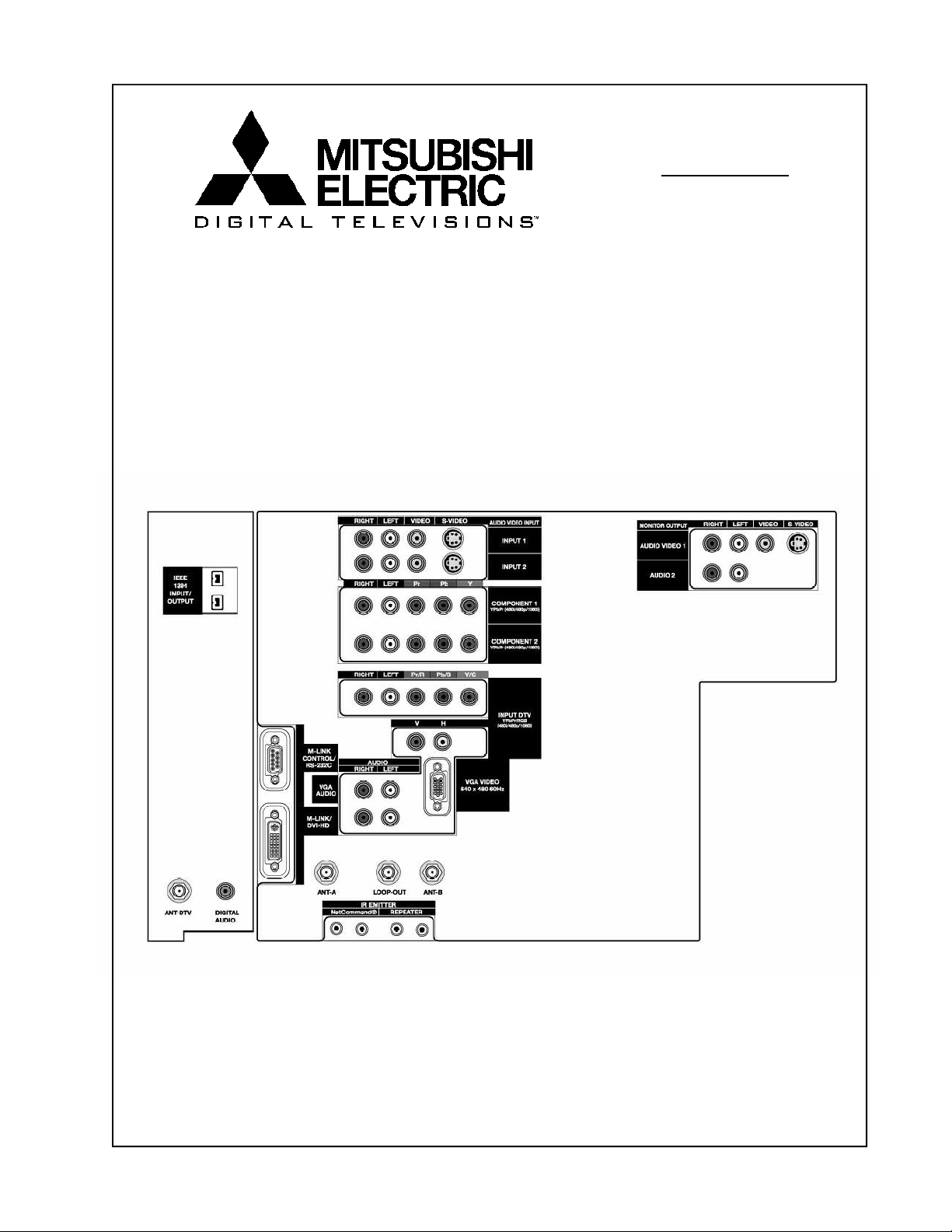

PCB-Terminal ....................................................................................................5-2

PCB-Signal ........................................................................................................ 5-3

RGB CRT Drive & Protect Circuitry ...................................................................5-4

Digital Signal Path .............................................................................................5-5

Monitor Out ....................................................................................................... 5-6

Chapter 6 ... Sync, Deflection and High Voltage

Overall Block Diagram ....................................................................................... 6-1

Sync Signal Path ............................................................................................... 6-2

Vertical Deflection ............................................................................................. 6-5

Horizontal Deflection ......................................................................................... 6-5

Deflection Loss Detection.................................................................................. 6-7

High Voltage & HV Regulation .......................................................................... 6-8

X-Ray Protect .................................................................................................... 6-9

Chapter 7... Convergence Circuitry

Overall Block Diagram ....................................................................................... 7-1

Waveform Generator and D/A Converter .......................................................... 7-2

LPF and Summing Amplifiers ............................................................................7-3

Convergence Output Circuitry ........................................................................... 7-4

Chapter 8 ... Sound Circuitry

Overall Block Diagram ....................................................................................... 8-1

Signal Path ........................................................................................................ 8-2

Chapter 9 ...Troubleshooting Tips

Using the Front Panel LED................................................................................ 9-1

II

Page 7

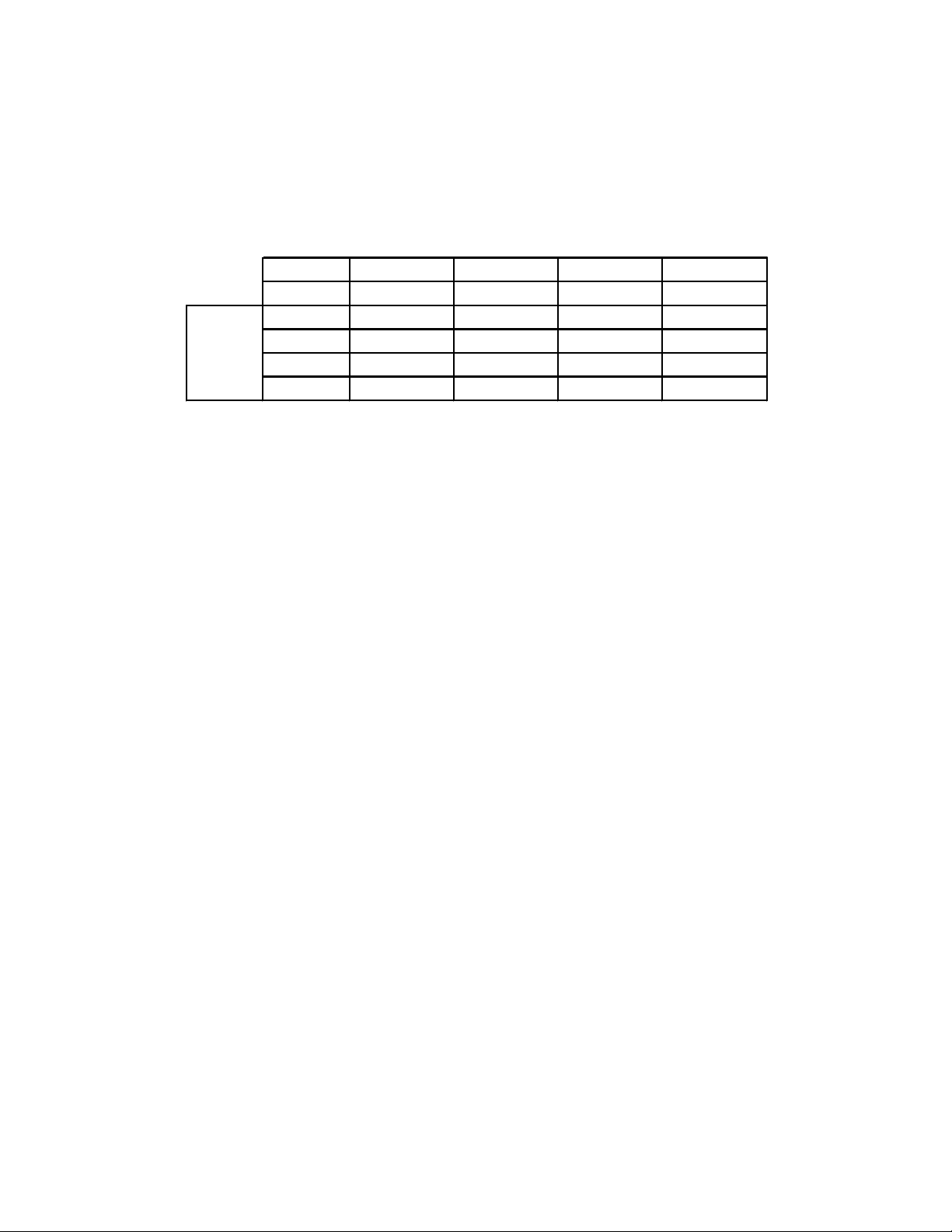

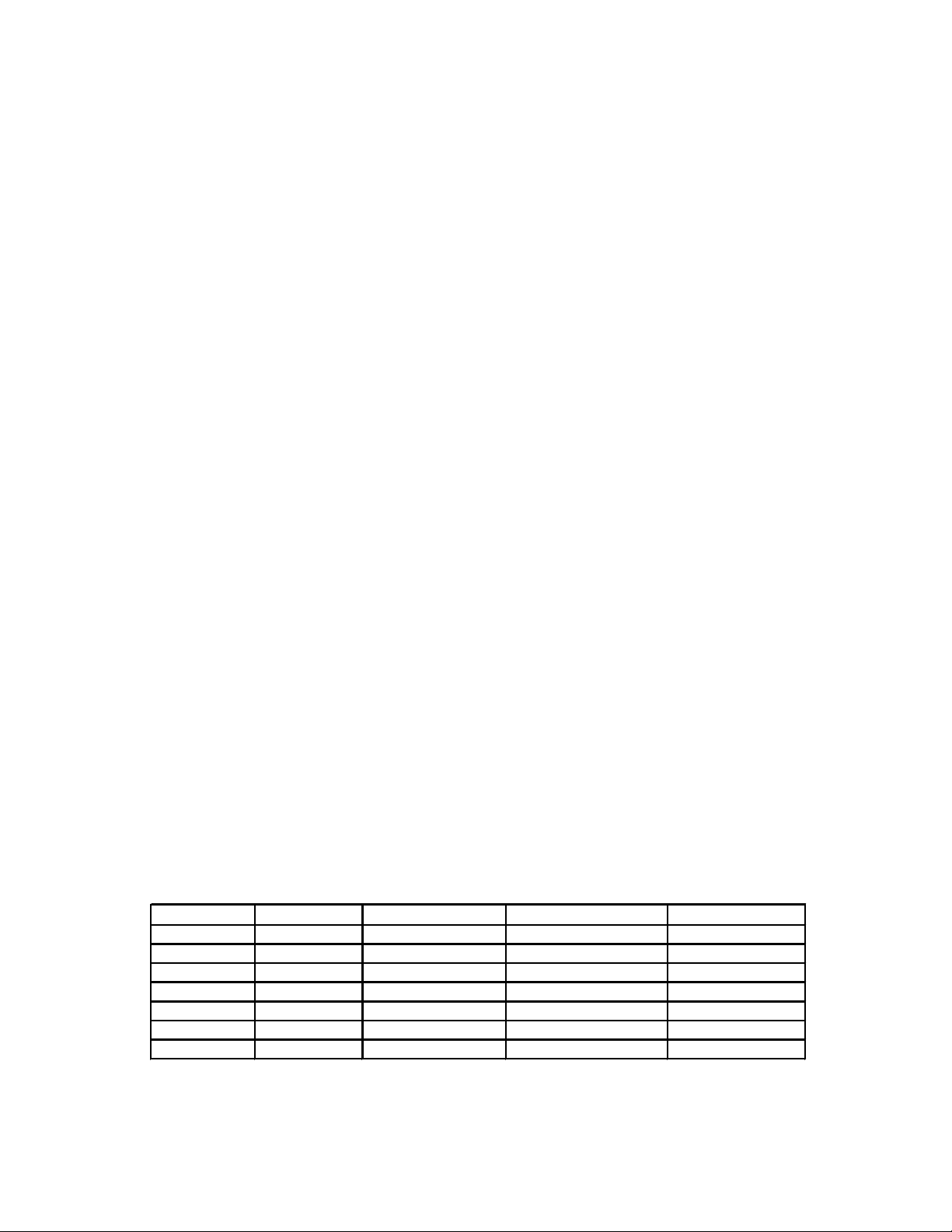

Screen

Size

Introduction

Series Gold Gold Plus Platinum Diamond

Chassis V23 V23+ V23++ V23+++

48" W WS-48513 WS-48613

55" W WS-55513 WS-55613 WS-55813

65" W WS-65513 WS-65613 WS-65713 WS-65813

73" W WS-73513 WS-73713

Table 1: V23 Models

The V23 Chassis is carried in the Gold, Gold Plus,

Platinum and Diamond series models for 2003 and

2004. This full featured, integrated HDTV chassis

represents the latest technologies in CRT based projection television. A breakdown of V23 models is

shown in Table 1.

Features

Table 2 shows some of the major features by model

category. Some of the features are carried over from

previous years, some have been improved upon and

some are totally new. In addition to all the user features, the V23 chassis includes many serviceability

features.

Carry Over Features

• IEEE1394, FireWire

• DTV Link

• VGA Input

• QuadField Focus

• TruFocus Lenses

• Gold Plated Jacks

• 2 Piece Cabinets (65" & 73")

• Fine Pitch Lenticular Screen

• Anti-glare DiamondShield

Improved Features

• 3rd Generation HDTV Receiver

• NetCommand 3.0 with IR Learning

• PerfectColor - All Inputs and Signal Types

• AMVP™ Improved Performance

• 9" CRTs now available in a 65" Model

• Coaxial and 2-way speaker systems

• Contemporary cabinet in a 55" Model

New Features

• 5 Format Memory Card Reader

• MonitorLink™ Input

• Low Energy Mode

Serviceability Features

• Modular design with "Light Box"

• Self Diagnostics

• Serviceable to Component or PCB level.

• ATSC Tuner/Decoder circuitry separated

from DM assembly.

• Reduction in number of stand-up PCBs.

• Service Adjustment Mode Data Reset.

This section will provide further explanation on the

following features that are either new or may have

the most impact on service:

1) NetCommand 3.0

2) 5 Format Memory Card Reader

3) PerfectColor

4) MonitorLink

1

Page 8

V23 Features

Feature Explaination

3rd Generation HDTV Receiver

NetCommand™ 3.0 Home Theater Control by Firewire or IR

Five-Format Memory Card Reader For viewing JPEG digital photos and listening to

AMVP (Advanced Multimedia Video

Processor)

FireWire/IEEE1394 Digital Home Networking Interface.

DTV-LINK Standard for future FireWire interfaces.

PerfectColor™ Individual Control of 6 Colors

Low Energy Mode Reduced Power Consumption in Standby

MonitorLink™ Input Digital Video Input

VGA Input 640x480 - 60HZ

QuadField Focus™ Magnetic Focus Assembly on CRT Neck.

Two-way Coaxial Speakers WS-55613 & WS-65613. Improved Audio.

ATSC and Unscrambled QAM Reception

Greater Sensitivity

MP3 or WMA audio recordings.

8 Screen Formats, Improved Line Doubling and

Noise Reduction

V23+ Features

(Additional Features)

Results in smaller electron beam.

V23++ Features

(Additional Features)

Tru-Focus™ Lenses Improved and more uniform focus.

Two-way Speaker System 6" Woofer & 1.5" Tweeter for improved audio.

Gold Plated Jacks Gives high quality connections.

V23+++ Features

(Additional Features)

Contemporary Cabinet

Fine-Pitch Lenticular Screen Best Horizontal Resolution

Anti-glare DiamondShield™ Reduction in Reflections

9" CRT (WS-65813) Improved Brightness and Resolution

9" CRTs in all 73" Models Improved Brightness and Resolution

2 Piece Cabinet (65" & 73" Models) Simplifies Delivery

High Gloss Black.

Composite Back has Reduced Weight

Other Features

Table 2: Features

2

Page 9

NetCommand 3.0

NetCommand allows most common

home theater products to be connected

and controlled by way of the TV's remote control by simply selecting onscreen icons. See Figure 1.

The control interface can be by one of

two means.

• IEEE1394/Firewire

• Infrared (IR Blaster)

The 3rd generation of NetCommand offers additional

functionality and a simplier user interface.

When using the Firewire, NetCommand is "plugand-play." For the end user, it makes all digital video,

audio and control connections with one cable (Fig-

ure 2).

All other configuration is automatic. For control, the

industry standard sofware supported includes:

• AV/C - Includes common functions such as

Stop, Play, FF, RWD, etc.

• HAVi - Includes AV/C but also allows a

higher level of sofware communication for a

more interactive interface.

Figure 1: NetCommand Icons

When using IR, an IR blaster must be connected to

the TV and placed in front of the device to be controlled. The TV must then be configured so the

proper IR codes will be used.

Like previous versions of NetCommand,

an "IR Library" is loaded in the TV's software so that most common devices can

be selected for immediate use. New for

NetCommand 3.0 is the "Learning" feature. For devices that are not included in

the IR Library, NetCommand can memorize the IR code from that devices remote.

A series of menus walks the customer

through the learning process. Once

loaded, the TV can then control the device using the IR blaster. This makes

NetCommand almost 100% compatable

with all other IR controlled devices.

Figure 2: FireWire Connection

Figure 3: IR Learning Menu

3

Page 10

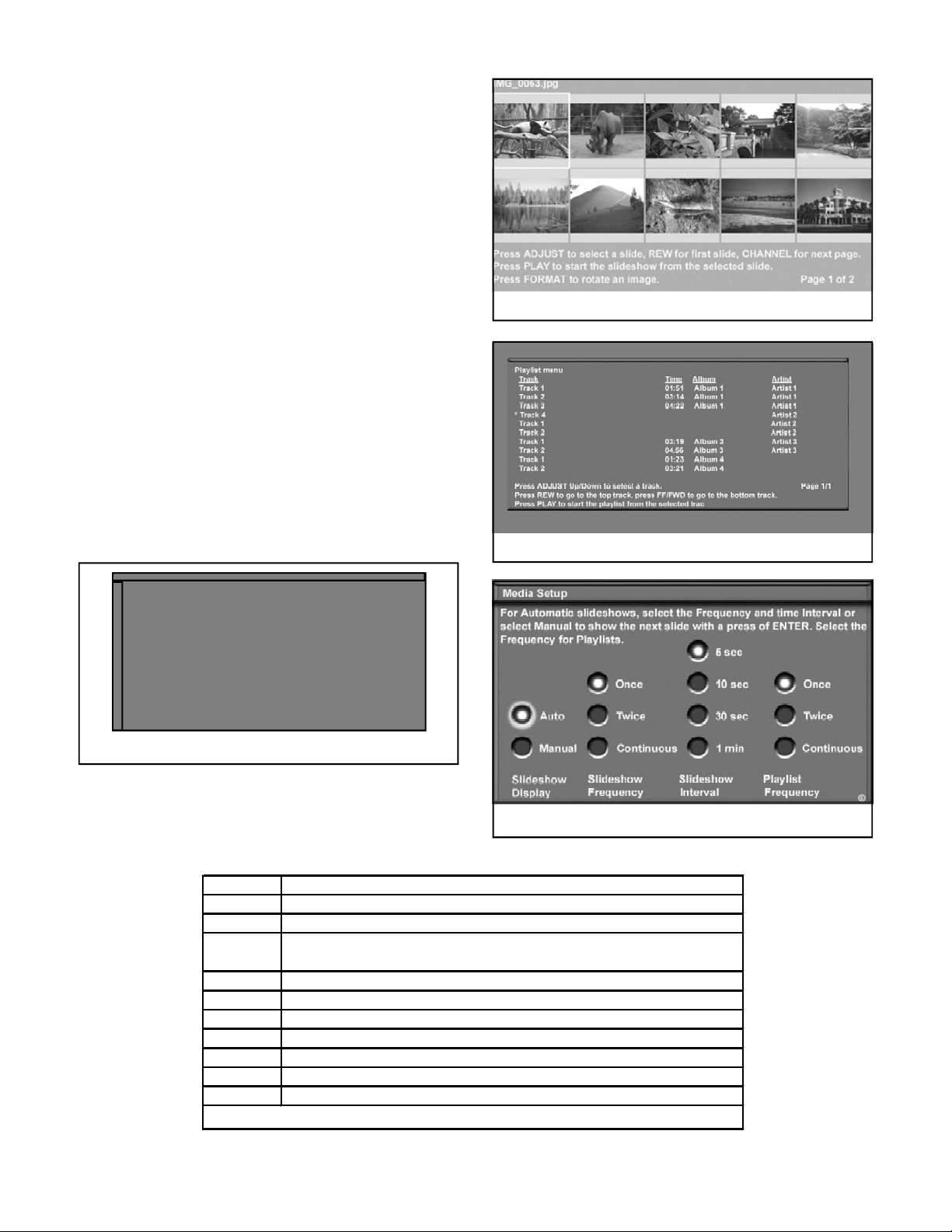

5 Format Memory Card Reader

BUTTON

FUNCTION

DEVICE

PAUSE

FF

REW

STOP

FORMAT

Rotates slide 90° each time it is pressed

Digital music and photography can now be enjoyed

in the home theater environment thanks to the

memory card reader featured in the V23 chassis.

When the user inserts a memory card into any one

of the four card reader slots on the front of the set,

NetCommand will take control, allowing a slide

show or giving a music play list.

The memory card formats supported are:

• Memory Stick™

• MultiMedia Card™

• SD (Secure Digital)

• SmartMedia™

• CompactFlash®

When a memory card is inserted into the correct slot,

an LED next to the slot will light up. Then, after the

slot is selected using the DEVICE button on the remote, the Memory Card Screen, Figure 4, will be

automatically displayed.

For Slideshow, press PLAY.

For Thumbnails, press GUIDE.

To redisplay this menu or to

setup, press DEVICE MENU.

For Playlist, press AUDIO

Figure 5: JPEG Thumbnails

Figure 6: Audio Playlist

Figure 4: Memory Card Screen

An overview of remote push buttons and their func-

tions is given in Table 3. Other remote functions are

explained within the menus. Full instructions are

included in the Owner's Guide.

VIDEO Switch from Audio Play List to JPEG Thumbnails (Figure 5)

AUDIO Switch from JPEG Thumbnails to Audio Playlist (Figure 6)

MENU

PLAY Start the Slideshow or play audio

GUIDE Return to the Thumbnail menu or the Audio Playlist while in Play

Display the Media Setup Menu (Figure 7 )

Pauses or resumes playback

Skips to the next slide or song

Returns to the previous slide or song

Stops slide show or play and returns to Memory Card Screen

Table 3: Remote Functions

Figure 7: Media Setup

4

Page 11

Compatibility

Users having difficulties with the memory card reader

should be aware of the following requirements:

For JPEG Pictures up to 128mb:

1. Still images recorded using the Exchangable

Image File Format (EXIF) for digital still cameras and Design Rules for Camera File Systems (DCF).

2. Standard digital images with a maximum size

of 5-megapixels (2560x1920).

3. File name maximum of 50 characters ending

with a .jpg extension.

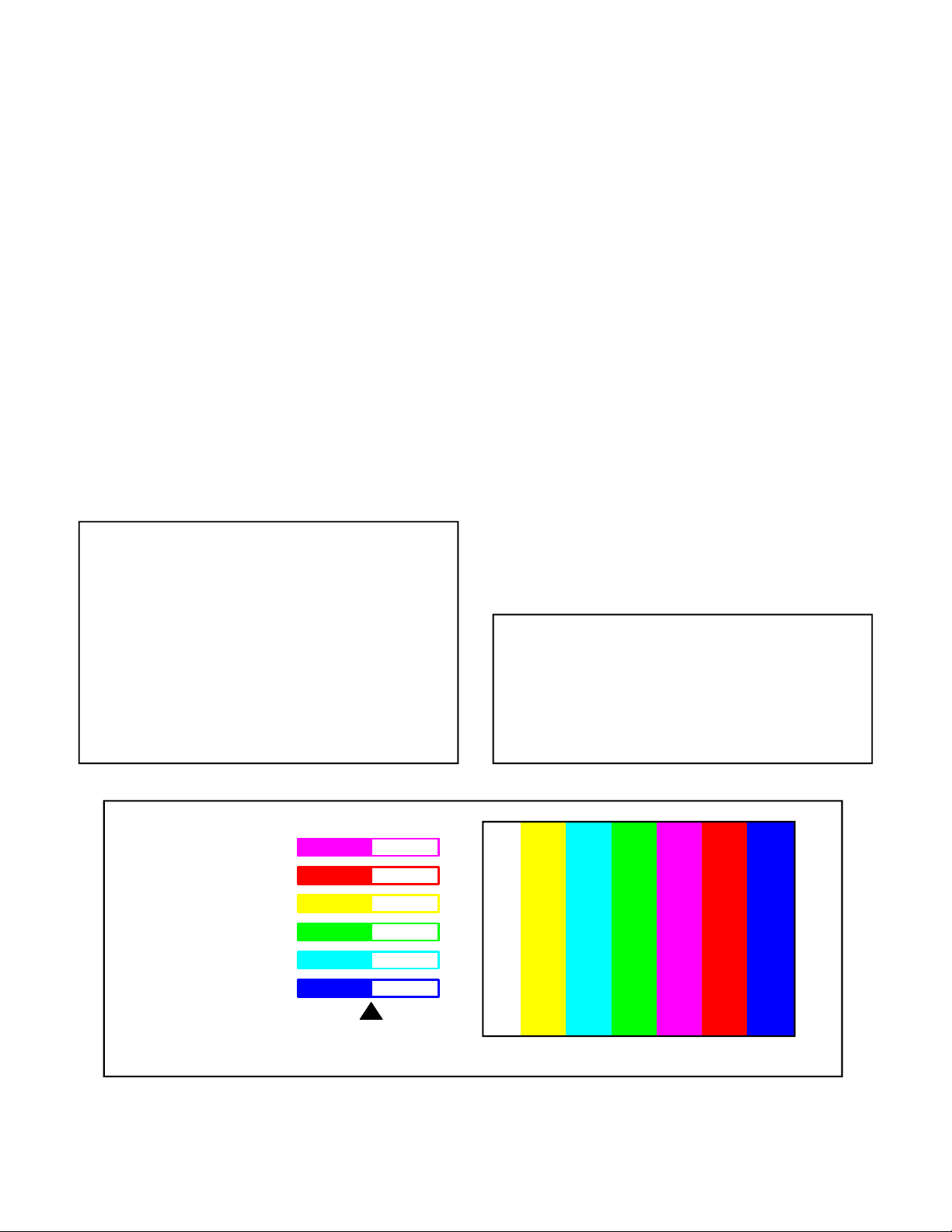

PerfectColor™

With conventional tint controls providing only a

tradeoff between red and green, PerfectColor was

developed to provide precise control over the 6 individual primary and secondary colors.

Introduced in the V20 Chassis, PerfectColor was

initially limited to 480i composite video sources only.

For the V22 and V23 chassis, PerfectColor can be

setup individually for each and every Input and is

compatible with all video source formats. (480i,

480p, 1080i)

For MP3 or WMA7 Audio files:

1. Files recorded with sampling rates of 32 KHz,

44.1 KHz or 48KHz.

2. Files recorded with fixed bit rates.

3. File names with .jpg or .wma extensions.

NOTES:

Images opened and resaved on a computer may

not playback or may not be able to display a

picture in the thumbnail list. This is because

the computer may change the file to an incompatible format.

For audio playback, the audio output from the

TV to the A/V receiver is analog. Digital audio output is not available.

Magenta (31):

Red (31):

Yellow (31):

Green (31):

Cyan (31):

Blue (31):

A colorbar chart with slider controls is provided in

the menu for easy reference. See Figure 8.

PerfectColor can also provide automatic color correction. Compared to conventional “Auto Color”

systems, it can better sense and correct for color differences when changing channels. It is specifically

designed for the customer that watches a wide range

of channels where no one setting can be used.

NOTE: Improperly set, PerfectColor can exhibit a wide variety of color symptoms. These

symptoms will not affect the on-screen menus

or a black and white picture. In such instances,

be sure to check the PerfectColor settings prior

to troubleshooting.

Y

C

G

E

L

L

O

W

Y

A

N

R

E

E

N

M

G

A

E

N

T

R

E

D

B

L

U

E

A

Figure 8: PerfectColor On-Screen Display

5

Page 12

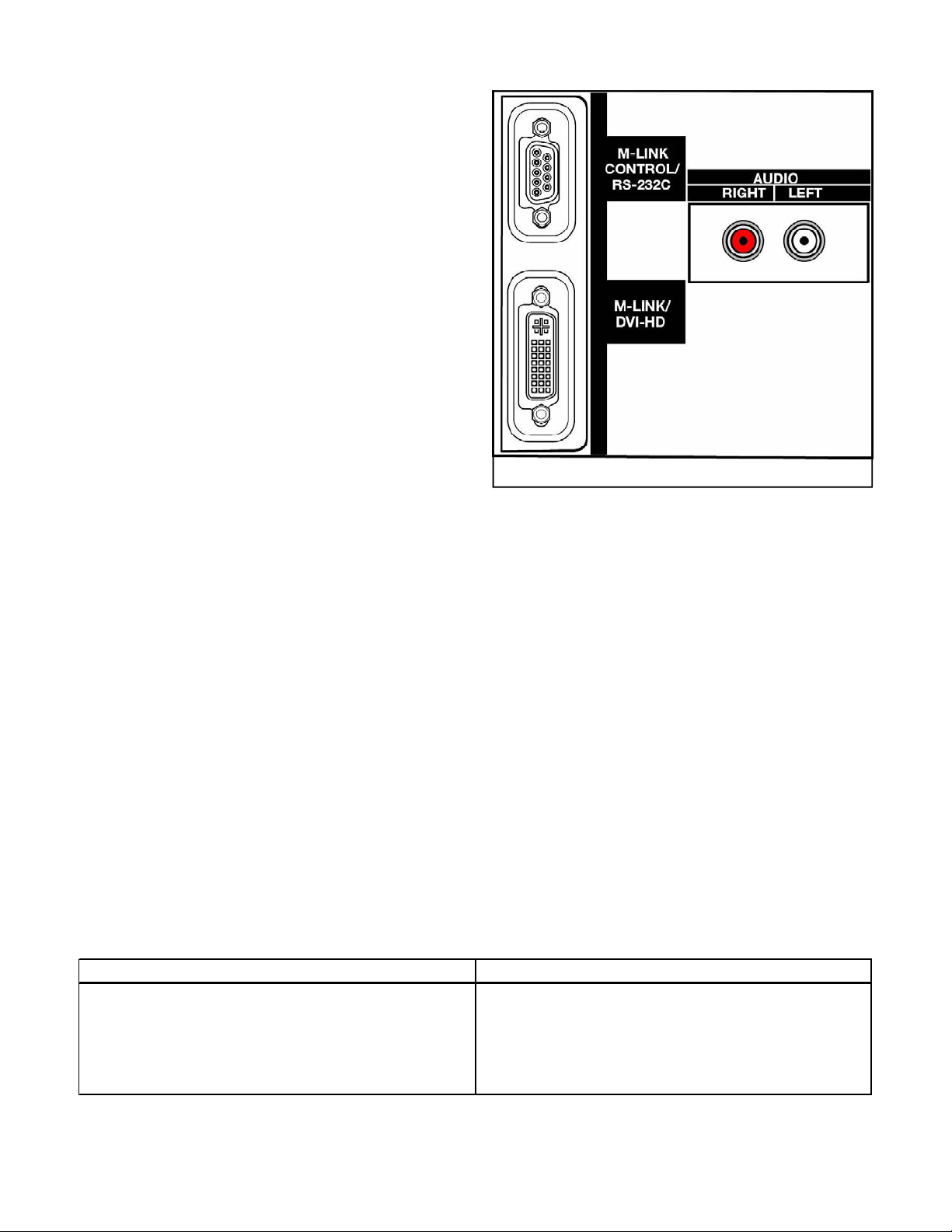

MonitorLink™

MonitorLink is a new digital interface introduced in

Mitsubishi's 2003-2004 model line, including the

V23 chassis.

MonitorLink provides a proprietary connection for

Mitsubishi's HD-5000, Monitor/Receiver, allowing

Mitsubishi's upgradeability promise to be fulfilled

using a digital, rather than analog, interface.

While MonitorLink is a proprietary connection, it

uses industry standard technologies that may provide even more versatility.

• RS-232C - Provides device communication

and control.

• Audio - Standard analog stereo connections.

• DVI - (Digital Visual Interface) Provides a

digital video connection.

RS-232C… The RS-232C connection interfaces

communications and control between the receiver/

controller and display. Commands such as Power

On, Input, Mute, etc., make the system operate as

one via the customer's remote control.

Audio… Analog Left and Right Audio connectors

are provided for the set's internal audio/speaker system. The V23 chassis has digital audio outputs and

IEEE1394 for more advanced connections with an

external A/V receiver.

Figure 9: MonitorLink Input

Digital Visual Interface (DVI)

DVI was originally designed by the Digital Display

Working Group (DDWG) to provide a universally

accepted digital connection between a PC and a display device.

At first glance, another digital interface would seem

unnecessary with the presence of IEEE1394,

Firewire. However, differences between IEEE1394

and DVI make them each suitable for different applications. A comparison of the two interfaces, as

applied to home theater, is provided in Table 4.

DVI… Technicians experienced with computer

monitors may already be familiar with DVI and its

features. However, because it is new to home theater, it will be covered here further.

IEEE1394 DVI

Bi-directional interface (Record and Playback) One direction interface (One way to a display)

Networkable between multiple devices Single point-to-point.

Distributes Compressed Data (MPEG2) Uncompressed Data (High bit rate HDTV)

Supports A/V Commands (AV/C & HAVi) No AV Control capability

Copy Protection (5C) Copy Protection (HDCP)

Table 4

Simply stated, 1394's bi-directional, compressed

data, and AV control capabilities make it suited for

recording and networking between various devices.

DVI's high speed, full bandwidth capabilities make

it most suitable to connect a display device.

6

Page 13

Acronyms

DDC Display Data Channel

DDWG Digital Display Working Group

DMPM Digital Monitor Power Management

DVI-A Digital Visual Interface - Analog

DVI-D Digital Visual Interface - Digital

DVI-I Digital Visual Interface - Integrated (Digital or Analog)

EDID Extended Display Identification Data

HDCP High-bandwidth Digital Content Protection

TMDS Transistion Minimized Differential Signaling

VESA Video Electronics Standards Association

Table 5

Used with its optional copy protection scheme, DVI

makes it possible to view full resolution signals without exposing the signal to copyright infringement.

It is the digital equivalent of component DTV connections (Y,Pr,Pb) that can be configured for use in

a copy protected environment.

The DVI standard supports the following…

• Analog only interface (DVI-A)

• Digital only interface (DVI-D)

• Analog or Digital interface (DVI-I)

• Transition Minimized Differential Signaling

(TMDS)

• Display Data Channel (DDC)

• Extended Display Identification Data

(EDID)

• High-bandwidth Digital Content Protection

(HDCP)

• Hot Plug Detect (HPD)

• Digital Monitor Power Management

(DMPM)

A glossary of acronyms is provided in Table 5.

DVI-A, DVI-D, DVI-I

DVI can provide an analog link, DVI-A, or a digital

link, DVI-D. The integrated link, DVI-I, was designed to support either. Each link has its own type

connector, covered later in this article. MonitorLink

uses digital only DVI, so the focus of the remainder

of this discussion will concentrate on the digital link.

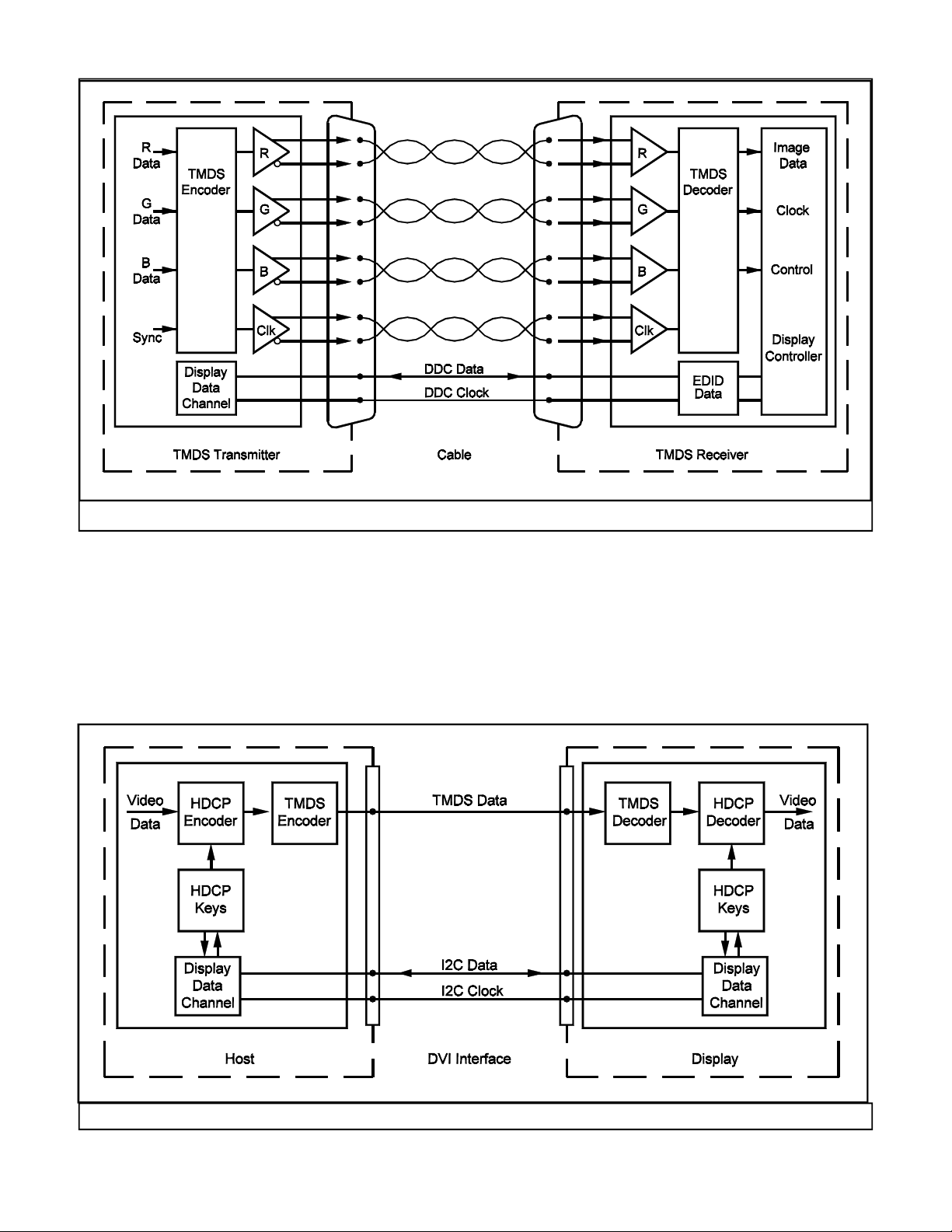

Transition Minimized Differential Signaling

(TMDS)

TMDS is a method used to transmit digital data that

reduces the number of bit transitions (high to low or

low to high) occurring in the serial bit stream. To

reduce the transitions, it uses an advanced formula

(algorithm) that converts 8 bit data into 10 bit data.

Differential circuitry is then used to output complimentary signals. The results are…

• Reduced Electromagnetic Interference

(EMI).

• Faster transfer rates with reduced errors.

• Ability to use twisted pair wire vs. coax.

A TMDS link consists of a TMDS Transmitter that

encodes and sends a data stream to a TMDS Receiver,

see Figure 10. Three sets of twisted pair wires carry

the Red, Green and Blue data. An additional twisted

pair carries the timing clock signal.

Because the bandwidth over copper wire is limited

to about 165 MHz, DVI can use up to two TMDS

links, or 6 channels sharing the same clock. DVI

with a dual-link TMDS has a bandwidth that is

doubled.

1080i HDTV, with a pixel rate of 1920 X 1080 at

30Hz can be supported by a DVI interface operating

in the single-link mode.

7

Page 14

Figure 10: Single-Link TMDS

Display Data Channel (DDC)

The VESA standard Display Data Channel, shown

in Figure 10, is part of the DVI specification. It is

an I2C bus used for data communications between

the two devices. The data can include information

specifying the type of display device connected and

can also be used to support copy protection.

Extended Display Identification Data (EDID)

EDID is the VESA standard protocol used over the

DDC so the display device can communicate identification about itself to the host device. The data,

stored in memory in the display device, can include

its resolution, sync timing and refresh rates, etc. It

is part of the plug and play package.

Figure 11: HDCP

8

Page 15

High-bandwidth Digital Content Protection

(HDCP)

HDCP is a system designed to protect the outputs of

a DVI device from being copied. The protection can

be applied in various ways.

• Unrestricted copies

• Limited number of copies

• Limited use of copies

• No copies

Since this is a optional element of DVI, both the host

device and the receiving device must be properly

equipped to function and provide the protected link

between them. There are three parts within the content protection scheme.

• Authentication… The host and receiver

exchange data to confirm the receiver is

authorized to receive the protected data.

• Encryption/Decryption… After the host

has verified the receiver, "keys" are provided

that will allow the receiver to decrypt the

data sent.

• Renewability… Each receiver is given both

a secret code and a non-secret identification

number. If the host determines the secret

keys have been tampered with, the receiver

is denied authentication.

the host know it is plugged in. When the host device detects a High condition greater than 2.4 VDC

(typically 5.0 VDC), it will read the EDID and start

operation. If the potential falls below 2.0 VDC the

TMDS transmitter is stopped.

Digital Monitor Power Management (DMPM)

DMPM allows several different levels of power management by detecting the presence of EDID and/or

TMDS activity. One pin on the DVI connector is

provided so the host can supply a 5 V source. The

display has the option to use this supply to keep the

DDC capable while the monitor is off.

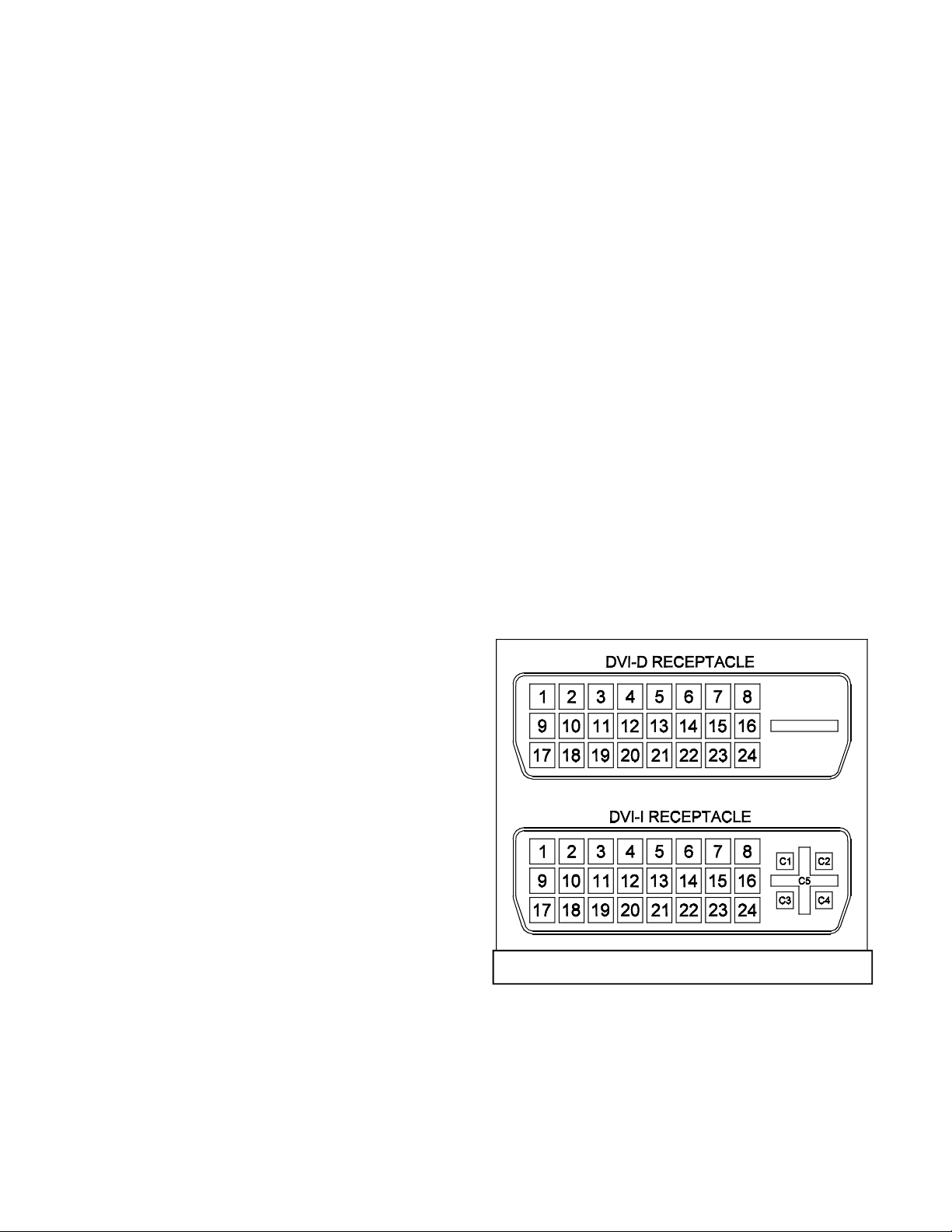

DVI Connectors

There two types of DVI receptacles shown in Figure 12, DVI-D and DVI-I. Pin assignments are de-

tailed in Table 6. It should be noted, the additional

pins, C1-C5, arranged in the + shape on the DVI-I

receptacle, are provided for analog signals. No DVIA connector is shown because DVI-A is generally

associated with adapting VGA connectors to DVI-I.

The authentication process occurs over the DDC I2C

bus shown in Figure 11. After authentication, the

encrypted video data is applied to the TMDS encoder.

The encrypted data sent over the DVI interface is

then immune to "eavesdropping." Only the authorized display device can reverse the encryption afterwards.

Hot Plug Detect (HPD)

Another part of the plug and play package is the

VESA standard Hot Plug Detect. A dedicated pin

on the DVI connector is used by the display to let

Figure 12: DVI Receptacles

9

Page 16

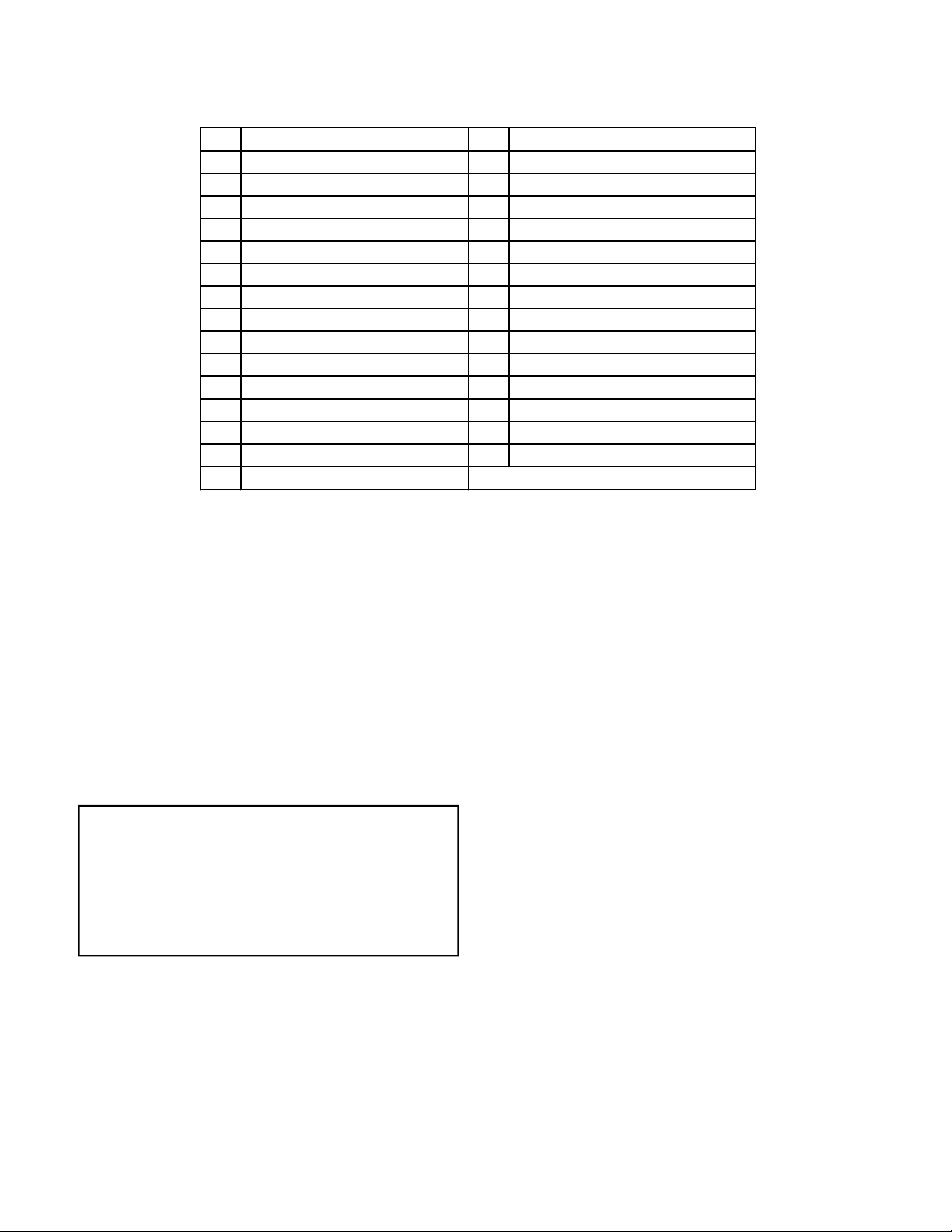

PIN SIGNAL PIN SIGNAL

1 TMDS Data 2- 16 Hot Plug Detect

2 TMDS Data 2+ 17 TMDS Data 03 TMDS 2&4 Shield 18 TMDS Data 0+

4 TMDS Data 4- (NA) 19 TMDS 0&5 Shield

5 TMDS Data 4+ (NA) 20 TMDS Data 5- (NA)

6 DDC Clock 21 TMDS Data 5+ (NA)

7 DDC Data 22 TMDS Clock Shield

8 Analog Vertical Sync (NA) 23 TMDS Clock+

9 TMDS Data 1- 24 TMDS Clock10 TMDS Data 1+ C1 Analog Red (NA)

11 TMDS 1&3 Shield C2 Analog Green (NA)

12 TMDS Data 3- (NA) C3 Analog Blue (NA)

13 TMDS Data 3+ (NA) C4 Analog Horizontal Sync (NA)

14 +5.0 VDC C5 Analog Ground (NA)

15 Ground

(NA) Not used by MonitorLink

Table 6

MonitorLink DVI Connector

Some manufacturers use DVI-I connectors for DVID only. This is the arrangement used by

MonitorLink. This configuration will not support

analog connections. Therefore, any attempt to interface analog signals, no matter what form of DVIA or DVI-I cables or adaptors used, will not be successful. Looking at the pin assignments in Table 6,

it should become obvious, the DVI-I connector used

by MonitorLink is a digital only, single-link TMDS

interface.

NOTE: V23 models are compliant with HDCP

and EIA861 standards for standard, extended

and high definition (480i, 480p, 1080i) video.

The DVI input is not intended for use with

personal computers or devices outputing video

signals with computer resolution.

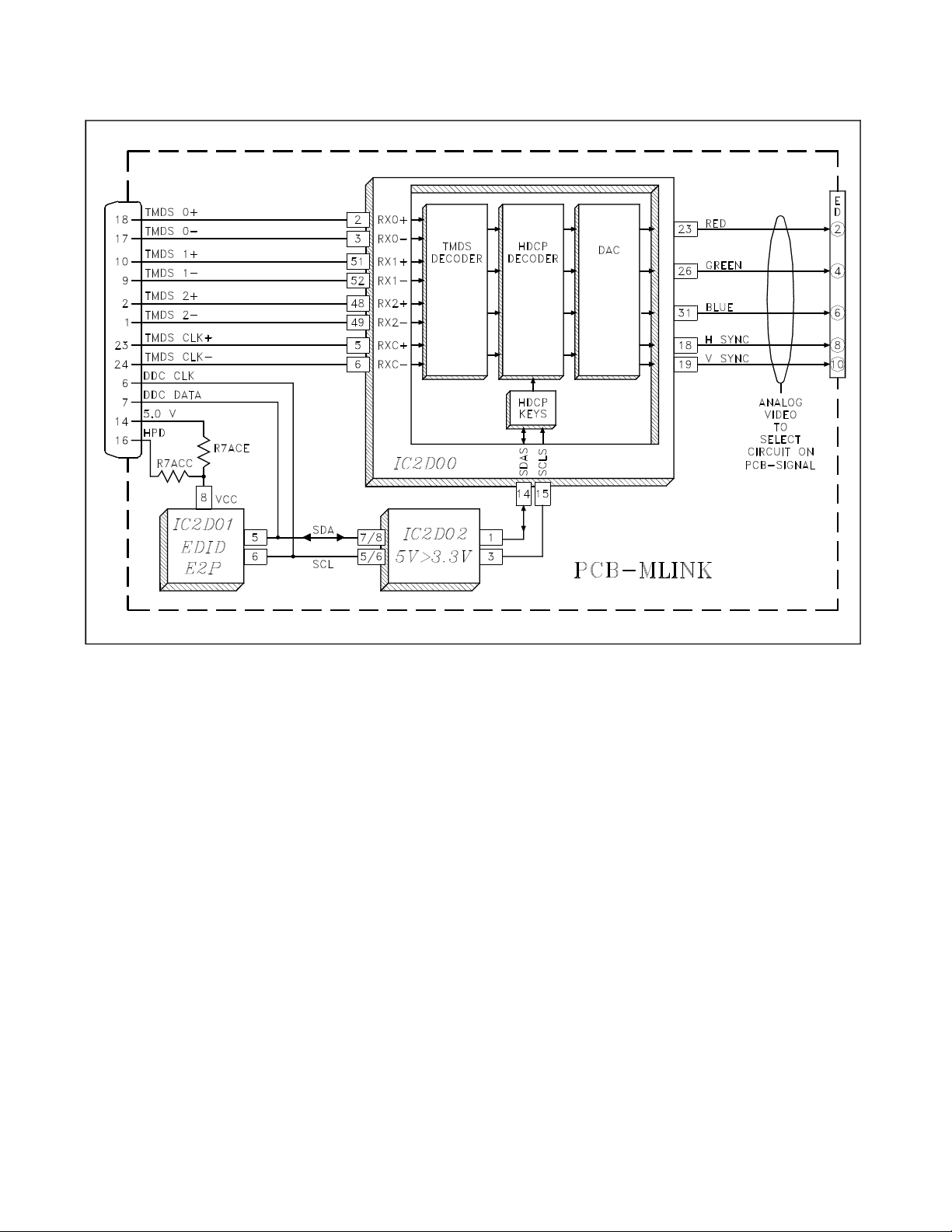

DVI Input Block Diagram

Figure 13 is a block diagram of the DVI input circuitry used on the V23 Chassis. The circuitry will

be similar in other models.

Single-link TMDS Data and Clock signals are applied directly to IC2D00. Vcc for the EEPROM,

IC7AAA, is supplied by the host device via the DVI

connector, pin 14. At the same time, this potential is

fed back to pin 16 for Hot Plug Detection. The host

device communicates over the DDC bus directly with

the EEPROM to retrieve the EDID. IC2D02 is used

to convert the 5V I2C to 3.3V logic for compatibility

with IC2D00 where HDCP data is exchanged.

IC2D00 decodes and outputs analog RGB/H/V signals for selection by the TV input select circuitry.

Firewire is a trademark of Apple Computer, Inc.

DVI is a trademark of the Digital Display Working Group.

VESA, DDC and EDID are trademarks of the Video Electronics Standard

Association.

TMDS is a trademark of Silicone Image, Inc.

HDCP is a trademark of Digital Content Protection, LLC.

10

Page 17

Figure 13: V23 Chassis DVI Input Block Diagram

11

Page 18

VZ5/VZ6/V15

VZ7/VZ8/V16

V17

VZ9/V18/V19

V20/VK20

V21

K20/V22/V23

Chassis Option Menu Adjustment Mode Convergence Mode OSD Position

1-3-7-0 2-3-5-7 2-3-5-9 <6><5><4> Adjust Mode

1-2-7-0 1-2-5-7 1-2-5-9 <6><5><4> Adjust Mode

8-2-7-0 8-2-5-7 8-2-5-9 <6><5><4> Adjust Mode

0-1-7-0 0-1-5-7 0-1-5-9 <6><5><4> Adj. Mode/0-1-8-8

2-2-7-0 2-2-5-7 2-2-5-9 <6><5><4> Adjust Mode

2-1-7-0 2-1-5-7 2-1-5-9 <6><5><4> 2-1-8-8

0-3-7-0 0-3-5-7 0-3-5-9 <6><5><4> Adj. Mode/0-3-8-8

Service Menu Access Codes

12

Page 19

Chapter 1

Disassembly and Service

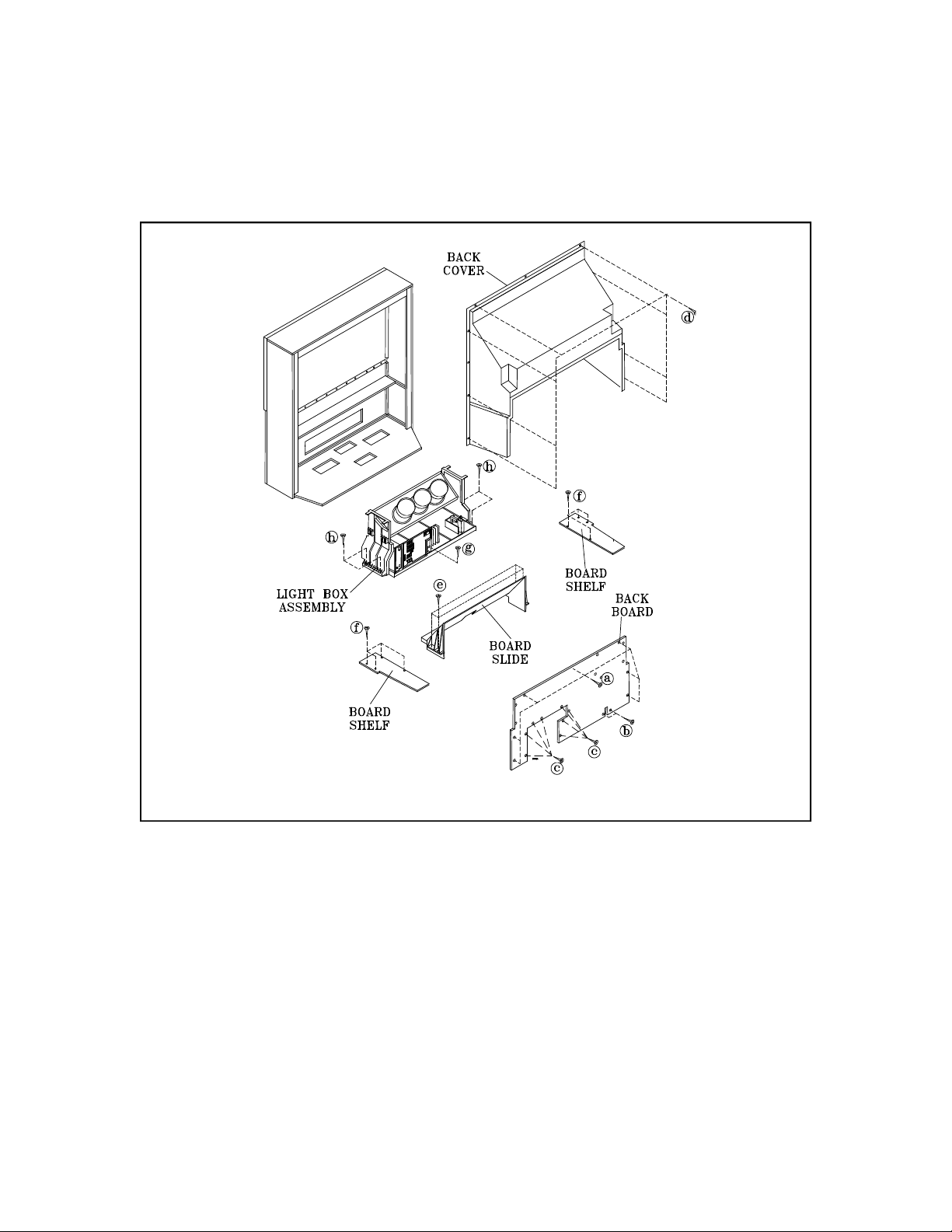

Figure 1-1: Lightbox Removal - 48” Models

With 11 different models, mechanical features and

disassembly procedures vary in the V23. Since all

features and disassembly procedures are in the Service Manual, this chapter will only provide a general discussion.

The V23 has the following mechanical features:

• Removable Lightbox

• Two piece cabinet (65” & 73” models)

• Customer Removable DiamondShield™

• Composite Cabinet Back (V23+++)

Lightbox

Like previous Mitsubishi projection TV chassis, the

V23 is based on a modular design that allows the

“lightbox” to be removed for service. Even without

the front control panel, card reader or front inputs, it

is still fully functional by use of the remote control.

This allows easier access to test points, etc. And,

when “shop service” becomes necessary, this design

has several more benefits.

• No lifting of heavy, bulky cabinets

• No cabinet or screen damage.

• Less customer inconvenience.

1-1

Page 20

The lightbox removal procedure for 48” V23 models is shown in Figure 1-1.

1. Remove the Back Board by removing 7

screws (a), 2 screws (b) and 8 screws (c).

2. Remove the Back Cover by removing 8

screws (d).

3 Remove 4 screws (e) to remove the Board

Slide.

4. Remove 8 screws (f) to remove the Board

Shelves.

5. Remove screw (g) holding the chassis.

6. Remove 4 screws (h) securing the Light Box

Assembly.

7. Be certain that all cables and connectors

between the Light Box Assembly and external items are disconnected (e.g. speaker

plugs, etc.), including the USB and IEE1394

connectors from the Card Reader to the DM.

8. Slide the Light Box Assembly from the

cabinet.

1) Apply AC power.

2) Press the remote Power button once.

3) Wait 90 seconds.

4) If no response, press the Power button again.

5) Wait 90 seconds.

Main Chassis Removal

Refer to Figure 1-2 to remove the Main Chassis.

1. Undo the cable wire ties to the Front Panel,

Speakers, CRTs, etc.

2. Unplug the Card Reader USB and 1394

cables from the DM module.

2. Remove screw (a) securing the Main Chassis

[and screws (b) in models WS-55813 and

WS-65813] .

3. Release the Chassis Locks on each side of

the chassis.

4. Slide the Chassis out the rear of the unit.

5. Tilt upward to access the bottom of the main

chassis.

The procedure is similar for all models. The 48” versions do not require the removal of the black plastic

Back Cover. Refer to the Service Manual for specific disassembly instructions on all models.

NOTE: When V19, V21 and V23 models are

first plugged in, the front panel LED will flash

for about 1 minute indicating the “boot time”

required before the Power On command will

be recognized. In addition, V23 models have

a “Energy Mode,” If set to Low, the 1 minute

boot time does not start until after the Power

on command is given. If the lightbox is being

serviced without the front panel, no indication

of these requirements will be present.

Although not required, for the reasons noted, it is

usually better to have the front panel connected when

servicing the lightbox. If this is not possible, the

following power up sequence should be used:

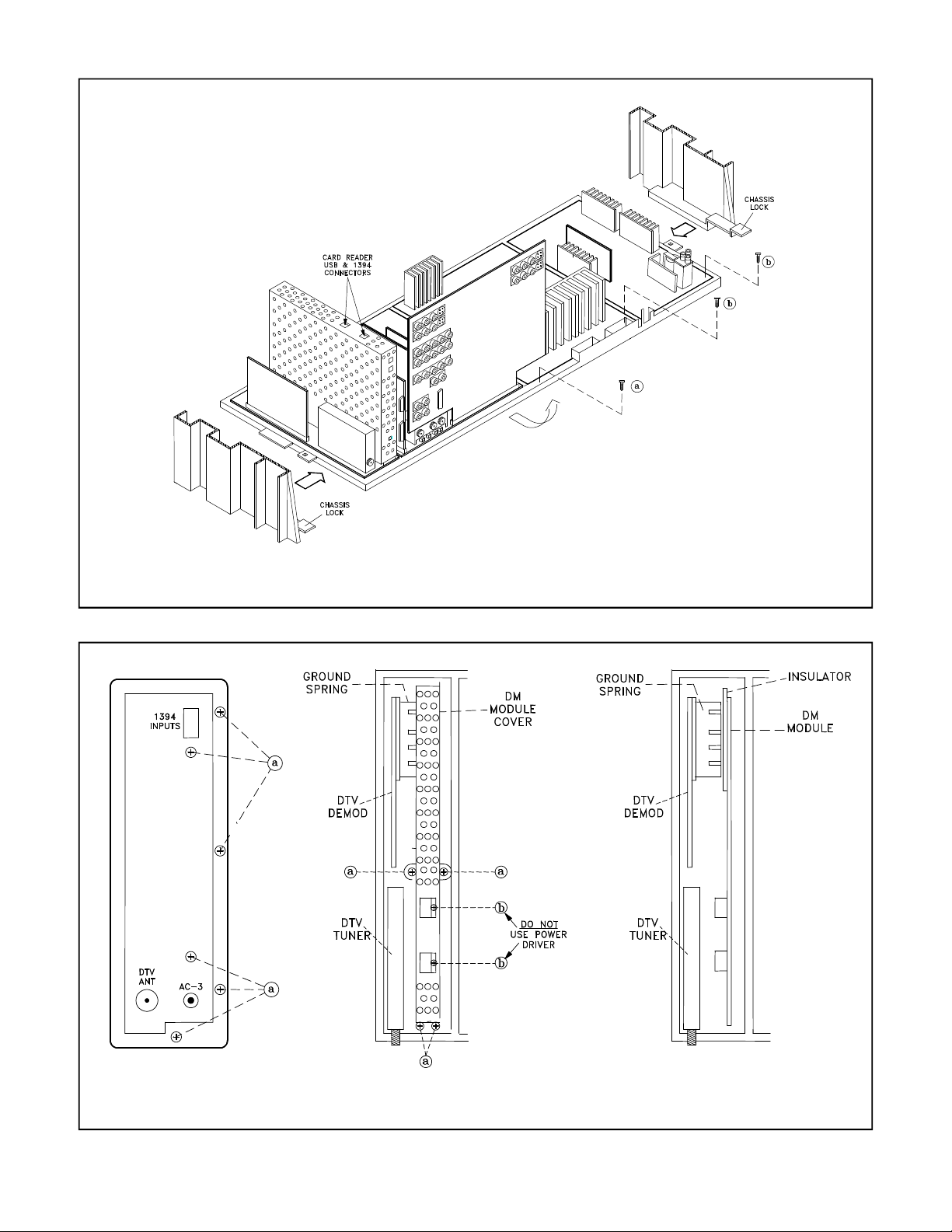

DM Replacement

Refer to Figure 1-3 to replace the DM assembly.

1. Unplug the Card Reader USB and 1394

cables from the DM module, and refer to the

Chassis Removal Procedure to slide the

chassis towards the rear of the set.

2. Remove screws (a), to remove the DM Rear

Panel, Step 1.

3. Remove screws (a) and (b) to remove the

DM Module Cover, Step 2.

3. Remove the E2P module from the original

DM and plug it into the replacement DM.

5. Plug the DM module securely into the PCBDTV-TUNER.

6. Check operation before installing the DM

Cover, Step 3.

• Insert insulation (cardboard) between the

Demodulator Ground Spring and the

DM.

• Plug the set in and check the operation.

• If O.K., unplug the set and install the

DM Cover.

1-2

Page 21

Figure 1-2: Main Chassis Removal

TOP VIEWREAR VIEW TOP VIEW

Step 1 Step 2 Step 3

Figure 1-3: DM Replacement

1-3

Page 22

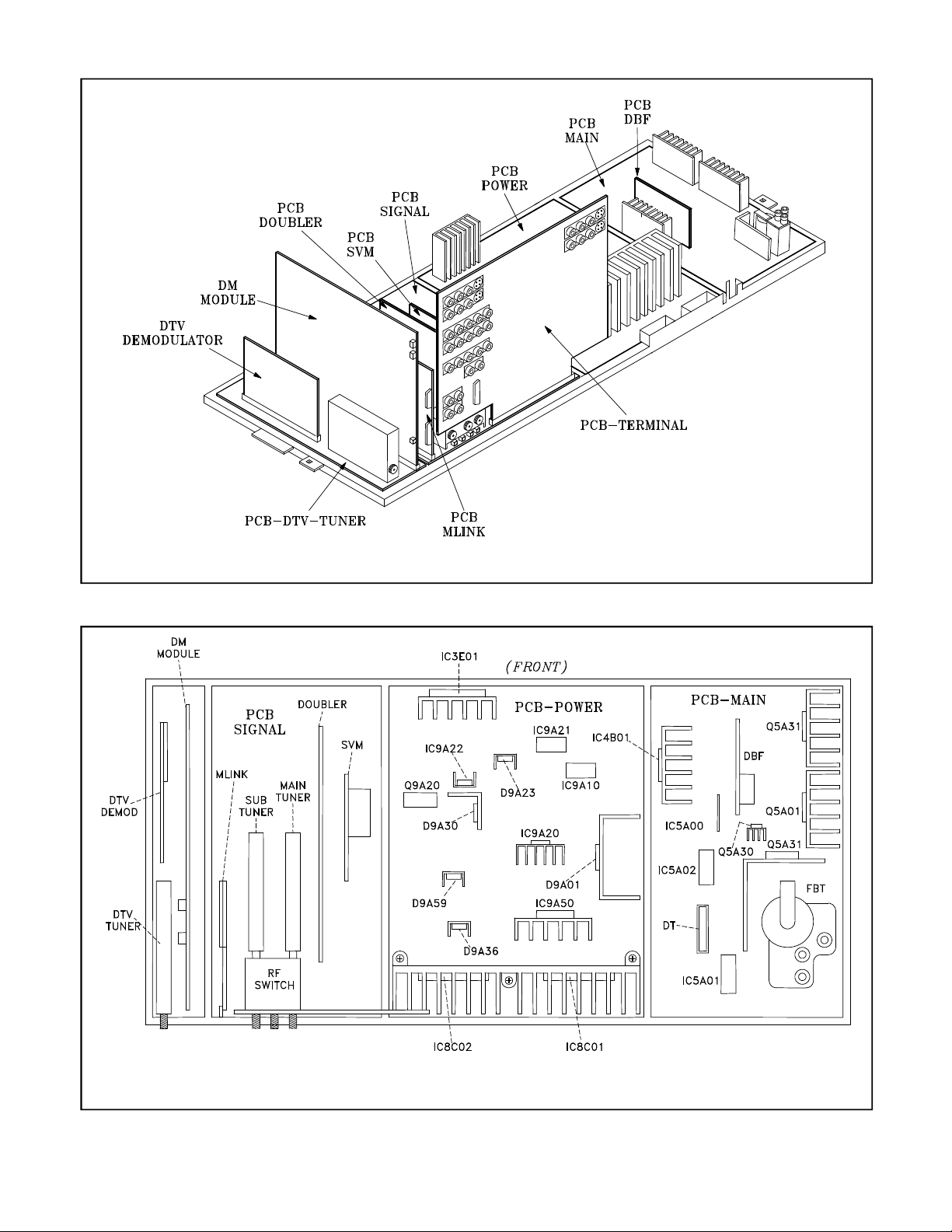

Figure 1-4: PCB Locations

Figure 1-5: Main Component Locations

1-4

Page 23

PCB-DTV Tuner DM PCB-MLINK PCB-Terminal PCB-Signal

IR Learning

NetCommand

DVI Decoder

A/V Inputs

Control uPC

NTSC Video

Convergence

Line Double

Enhancement)

(Corner Focus)

DM Interface IEEE1394 RS-232C Interface A/V Selection Tuning

DTV Tuner Card Viewer 3D-Y/C VCJ

& Demodulator OSD-Menus

Interface Digital uPC Control Decoders Generator

PCB-Doubler PCB-SVM PCB-Power PCB-Main PCB-DBF

PIP-POP Scan Velocity Power Supplies Horizontal Defl. Dynamic

Picture Format Modulation Audio Amp. Vertical Defl. Beam

3:2 Pull Down (Picture Edge Convergence Amps. High Voltage Forming

480i to 480p

Table 1-1: PCB Functions

PCB & Major Component Locations

PCB and major component locations are shown in

Figures 1-4 and 1-5. The major circuit functions

performed on each PCB is listed in Table 1-1.

Convergence IC Replacement

To maximize cooling efficiency, the Convergence

Amplifier ICs, IC8C01 & IC8C02, are mounted as

close to the back cover vents as possible. With the

heat sink fins over the top of the IC, access for replacement is restricted. To simplify replacement use

the following procedure to remove the heat sink.

1) Release the 2 spring clips from the rear

(towards the front of the set) of the heat sink.

2) Remove the 3 mounting screws shown in

Figure 1-6.

3) Remove the heat sink by gently prying the

IC’s loose.

When reinstalling, please note:

• Overtightening the screws can strip the

plastic threads in the chassis.

• Mounting clips should be firmly seated for

proper heat transfer.

Figure 1-6: Convergence IC Removal

1-5

Page 24

V23+++ Composite Cabinet Back

The WS-55813 and WS-65813 feature a unique cabinet similar to last year’s WS-65712. It has a composite cabinet back that offers several advantages.

• Rounded edges in the back have a modern

appearance.

• Unit construction gives it high strength.

• Low Weight - The 55” version is about 50

lbs lighter and the 65” version is about 100

lbs lighter than comparable models!

The disassembly procedure for the cabinet front differs from conventional cabinets. Note how the Cosmetic Front Panel is removed. Refer to Figure 1-7.

1. Remove the Speaker Grille by pulling

forward.

2. Remove 2 screws (a) securing the Cosmetic

Front Panel.

3. Slide the Cosmetic Front Panel 1 inch to the

right, then lift away from the TV.

4. Remove 6 screws (b) to remove the Board

Front.

5. Unplug the LF connector.

6. Remove the 4 screws (c) securing the Screen

Assembly.

7. Lift the Screen Assembly up and away from

the cabinet.

Figure 1-7: V23+++ Cabinet Front Disassembly

1-6

Page 25

Chapter 2

OPTION MENU

Alignment Procedures

With the exception of the Service Menu access codes,

the general alignment procedures for the V23 chassis remains the same as previous HD chassis. A chart

showing all recent Service Menu Access Codes is

provided on page 12 of the Introduction. This chapter will give an overview of the following alignment

procedures.

• Initial Setup - Option Menu

• Circuit Adjustment Mode

• Convergence Adjustment Mode

• Alignment Data Storage Locations

For specific alignments, refer to the Service Manual.

Initial Setup

Option Menu - Initial Setup

Prior to alignment, the procedures for initial setup

should be followed so that all customer Main Menu

and A/V settings are set to the factory defaults listed

in Table 2-1 and Table 2-2.

Follow the steps below for the initial set-up:

1) Select the "MENU" display by pressing the

"MENU" button once.

2) Press the number buttons "0", "3", "7", "0"

in sequence to select the "OPTION MENU"

display. See Figure 2-1.

3) Press the "ADJUST" button to select "INITIAL."

4) Press "ENTER."

NOTE: At this time, all Main Menu and A/

V settings will be set to the factory default

settings and channel 3 will be automatically

selected.

(MENU-0-3-7-0)

Initial

Power restore :OFF

DTV Port :Auto

Figure 2-1: Option Menu

2-1

Page 26

Audio

Edit Setup

Review

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

Video

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

(v) Enabled

Icon Position

(v) Enabled

(v) Enabled

Transport Menu

Energy Mode

Language

MAIN MENU DEFAULT SETTINGS

1/2/3

Compon.

1/2

1/2/3

1~4

Bass

Center

Center

Center

Center

Center

Center

Center

Center

Center

SETUP

Clock Setting Manual Volume 30%

Time 12:00 AM Bass 50%

Antenna A

Antenna B

Input DTV

Input 1

Input 2

Input 3

Component 1

Component 2

Antenna DTV

VGA

MonLink

Card 1

Card 2

Card 3

Card 4

As above V-Violence

Ant-A, Ant-B, Ant-DTV, ComFlash Program not Rated

MemStick, SmartMed, MMC& SD Movie Rating PG Video Mute On

Input-1, Input-2, Input-3, Comp-1, V-Chip Time Black Enhancement On

Comp-2, Input DTV, VGA, Start Time 12:00 AM

MonLink, Cards 1…4 Stop Time 12:00 AM Color Balance Manual

Standard Lock by Time Off

English Lock Time NA

ANTENNA

Antenna ANT A Front Button Lock Off PIP Position Lower Right

Memorize Channels Air POP Position Right Half

Channel Ch-3 A/V Memory Reset Ant-A PIP/POP Format 2 Window

Memory Deleted Format Stretched

Day Monday Treble 50%

Analog Captions With Mute Surround Off

Background Gray Listen to Stereo

Digital Captions With Mute Level Sound Off

Digital Settings TV Speakers On

Appearance Default Audio 2 Out Main

Digital Channel Guide Off

V-CHIP Off Brightness 50%

TV Rating TV-PG Sharpness 50%

FV-Fantasy Violence

D-Sexual Dialog

L-Adult Language

S-Sexual Situation

On PerfectColor™ Centered

Unlock Time NA Source Ant A Ch 3

AUDIO/VIDEO SETTINGS

TIME

CAPTIONS

V-CHIP LOCK

Lock By Time

Balance 50%

Contrast 100%

Color 50%

Tint 50%

Color Temp. High

Video Noise Standard

Image Type Video

VSM Sharpness On

Advanced

PIP/POP

Table 2-1: Main Menu Factory Defaults

A/V RESET DEFAULT SETTINGS (By Input)

A/V Memory Ant A/B Ant DTV Inp-DTV

Contrast Max. Max. Max. Max. Max. Max. Max. Max. Max.

Brightness Center Center Center Center Center Center Center Center Center

Sharpness Center Center Center Center Center N/A Center Center Center

Color Center Center Center Center Center Center Center Center Center

Tint Center Center Center Center Center Center Center Center Center

Color Temp. High High High High High High High High High

Video Noise Standard N/A Standard Standard Standard N/A N/A Standard N/A

Image Type Video N/A Video Video Video N/A N/A Video N/A

VSM Sharpness On On On On On On On On On

Treble Center Center Center Center Center Center Center Center Center

Balance Center Center Center Center Center Center Center Center Center

Surround OFF OFF OFF OFF OFF OFF OFF OFF OFF

Listen To Stereo English N/A N/A N/A N/A N/A N/A N/A

Level Sound OFF OFF OFF OFF OFF OFF OFF OFF OFF

INPUTS

VGA

1394

MonLink

Card

Table 2-2: A/V Default Settings

2-2

Page 27

Circuit Adjustment Mode

Most of the adjustments can only be performed using the remote hand unit. See Figure 2-2. Many of

the adjustments must be performed in both the 480i

and 1080i modes. Video/Color adjustments must

be performed in the 480i and 1080i modes, and data

must be preset in the 480P (DVD) and VGA modes.

Note: Set the Remote Operational Mode to

“NetCommand”. (Hold the “Power” button

and press “9-3-5” in sequence.) This slows

the remote’s response and makes adjustments

easier. When adjustments are complete, set

the Remote to its’ original Operational

Mode. (Hold the “Power” button and press

“0-0-0” in sequence)

Activating the Circuit Adjustment Mode

The current signal source determines if the activated

Adjustment Mode is 480i or 1080i.

1. Select the signal source (480i or 1080i).

2. Press the "MENU" button on the remote

control so the Main Menu is displayed.

3. Press the number buttons "0", "3", "5", "7"

in sequence. The screen will change to the

Circuit Adjustment Mode. See Figure 2-3.

Note: Repeat steps 2 and 3 if the circuit adjustment mode does not appear on screen.

Figure 2-2: Remote Control

CHASSIS V23

FUNCTION DECODER 1

ADJ ITEM 22 SCNT 16 480i SIGNAL

ABBREV. DATA

Figure 2-3: Circuit Adjustment Mode

2-3

Page 28

Selection of adjustment Functions and

CRT-VC

CRT-JNGL

DECODER 2

DECODER 1

DOUBLER

Adjustment Items

To select an adjustment item in the circuit

adjustment mode, first select the adjustment

function that includes the specific adjustment item to be selected. Then select the

adjustment item. Refer to the following

pages for the listing of adjustment functions

and adjustment items.

Adjustment Functions

Figure 2-4: Adjustment Functions

1) Press the "AUDIO" button on the remote

hand unit to select an adjustment function.

Each time the button is pressed, the Function changes in the sequence shown in

Figure 2-4.

2) Press the “VIDEO” button to select a specific Adjustment Item. The Item number

increases each time the “VIDEO” button is

pressed.

Changing Data

After selecting an adjustment Item, use the “ADJUST UP/DOWN” buttons to change data.

• Press “ADJUST DOWN” to decrease the

data value.

• Press “ADJUST UP” to increase the data

value.

Saving Adjustment Data

Press “ENTER” to save adjustment data in memory.

The character display turns red for approximately

one second in this step.

Note: If the circuit adjustment mode is terminated without pressing “ENTER”, changes

in adjustment data are not saved.

Terminating the Circuit Adjustment Mode

Press the “MENU” button on the remote hand unit

twice to terminate the adjustment mode.

Note: The circuit adjustment mode can also

be terminated by turning the power OFF.

Toggle Between Reception Modes

Pressing “3” when in the Adjustment Mode, CRTVC Function toggles between 480i, 480p, 1080i and

VGA. However, data changes are not automatically

saved. Press “ENTER” to save data before press-

ing “3”.

NEW FEATURE… Service Mode Reset

To reset items in the Service Mode to their original

factory adjusted values:

1) Press MENU-0-3-5-7 to enter the Service

Mode.

2) Press “0-1-2-3,” in sequence to Reset to the

Factory settings.

On Screen Display Position Adjustment Mode

Activation

1) Select 480i or 1080i source.

2) Press MENU-0-3-8-8

2-4

Page 29

Convergence Adjustment Mode

SD COARSE GREEN

0 HSTA

00

ITEM

ABREV

DATA

The Convergence mode is used to perform raster geometry correction and convergence adjustments.

These adjustments must be made in both the SD

(NTSC 480i) and HD (1080i) modes.

Note: Before activating the Convergence

mode, turn “Video Mute” Off. The internal

crosshatch pattern will not be displayed with

“Video Mute” On, only a blue background is

displayed.

Convergence Mode Activation

1. Press MENU-0-3-5-9

2. When the Convergence Mode is activated,

this display appears on a Green Crosshatch.

See Figure 2-5.

MODE FUNCTION SUB-FUNCTION

SD or HD

3. Activating the HD mode when no HD

signal is available

• Press the “DEVICE” button.

• Use the “UP-DOWN-RIGHT-LEFT”

direction buttons to select ANT-DTV,

then press “ENTER”.

• Press “MENU-0-3-9-5” in sequence to

activate the Coarse Green HD Convergence mode.

Convergence Mode Functions

In the Convergence Mode there are three main Functions (Categories).

• Pressing “6” activates CONV MISC

• Pressing “5” activates COARSE CONV

• Pressing “4” activates FINE CONV

CONV MISC (Press 6)

This mode is used to preset data values controlling

the Convergence Generator, and to perform the HV

Regulation adjustment.

1) Use the VIDEO button to select an item.

2) Use the ADJUST buttons to change data.

NO.

Figure 2-5: Convergence Mode

Selecting the HD or SD Mode

1. Select the Signal Source before entering the

Convergence Mode, either an NTSC or HD

source.

2. Enter the Convergence Mode

• If the signal source is NTSC, the SD mode

is activated.

• If the signal source is HD, the HD mode is

activated.

NOTE: When Item “1 HVOL” is selected the

screen goes black except for the data display.

This occurs since a black screen is required

when making the HV Regulation adjustment.

COARSE CONV (Press 5)

There are four Sub Functions in the Coarse mode,

COARSE GREEN, COARSE RED, COARSE

BLUE and DF.

• COARSE GREEN .... used to make Coarse

Raster Geometry Adjustments.

• COARSE RED ... used to make Coarse Red

Convergence Adjustments.

• COARSE BLUE ... used to make Coarse

Blue Convergence Adjustments.

• DF ... used to preset data values controlling

the Dynamic Beam Focus circuit drive

signal.

2-5

Page 30

1) Use AUDIO button to select a Sub

V23

CONV FINE

GREEN

V13

H-4

SD

VERTICAL

HORIZ.

Function

2) Use the VIDEO button to select an

Adjustment Item.

3) Use the ADJUST buttons to change

data.

FINE CONV (Press 4)

This mode is used to perform Fine Raster

Correction, and Fine Red and Blue Convergence Adjustments. There are three Sub

Adjustment Functions, selected with the

AUDIO button:

• FINE GREEN .... a Green Crosshatch is

displayed, to make Fine Raster Corrections.

• FINE RED .... a White Crosshatch is dis-

played, to make Fine Red Convergence

Adjustments.

• FINE BLUE .... a White Crosshatch is

displayed, to make Fine Blue Convergence

Adjustments.

Figure 2-6: Fine Convergence Mode

In the Fine mode a Cursor is added to the Crosshatch. See Figure 2-6. The ENTER button toggles

the Cursor between two modes:

• MOVE (blinking Cursor) .... use the AD-

JUST buttons to select any of 64 points on

the Crosshatch.

• ADJUST (Non blinking Cursor) .... the

ADJUST buttons adjust the active color at

the current Cursor position, horizontally or

vertically.

The on-screen display changes in the Fine mode, as

shown in Figure 2-7. The display shows the vertical and horizontal data for the current Cursor Position, and the horizontal and vertical coordinates for

that position.

Saving Data and Exiting the Convergence Mode

Press MENU twice to exit the Convergence mode.

Data is automatically saved at this time.

DATA

DATA

Figure 2-7: Fine Convergence

Alignment Data Storage Locations

Data accessed in the Convergence Adjustment Mode

is stored in IC8D01 located on the PCB-Signal. Replacement PCB’s are supplied pre-aligned so that

only fine adjustments should be necessary after replacement. All other service alignment data is stored

on the PCB-E2P located on the DM assembly. When

replacing the DM assembly, retaining the original

PCB-E2P will minimize the need for any realignment.

2-6

Page 31

Chapter 3

Power Supply

From the above diagram, it is apparent that the V23

Chassis has four Power Supply Operational Modes.

1) Low Energy Mode

2) Standard Standby Supply Mode.

3) Time Shift Recording Mode.

4) Conventional PTV On Mode.

Low Energy Mode

When the Low Energy Mode is activated the TV uses

less than 3 Watts while the set is Off. The Low Power

Standby Supply generates a 9VS supply. Three additional supplies are derived from the 9VS supply, 5VS,

3.3V-ES and 3.3VS-1.

These supplies furnish power for the PTV Control Circuitry. This is the only circuitry active in the Low Energy Mode when the PTV is Off.

In the Low Energy Mode the set is booted up each time

the TV is switched On. When switched On, the LED

will flash for approximately one minute before the TV

powers On.

Low Energy Mode Activation

The Low Energy Mode is activated from the user's Onscreen Menus. To activate the Low Energy Mode:

1) Press "MENU".

2) Select the Setup Menu (Shown in Figure 3-1).

3) Use the Remote Direction Keys to activate, or

deactivate the Low Energy Mode.

Low Energy Standby Regulator

Figure 3-2 illustrates the Low Energy Mode Regulator

Circuitry. IC9A10 is the same is the same type of regulator used in the V20.

3-1

Page 32

Figure 3-1: User Setup Menu

A 132 kHz internal Oscillator drives an internal Output

FET. The signal from the FET at pin 5 of IC9A10,

drives transformer T9A10. Signal from pin 10 of T9A10

is rectified, generating the 9VS supply.

The signal from pin 2 of the transformer is rectified and

takes two paths:

1) To pin 1 of IC9A10, adding to an internally

generated 6.3V supply.

2) Through R9A18 to the Standard Standby

Regulator circuit, serving as a start-up voltage

source.

For regulation a sample of the 9VS supply is fed back

to pin 4 of IC9A10, via D9A14 and PC9A20.

Regulation

IC9A10 does not regulate by controlling the PWM of

the oscillator signal. Under normal load, some of the

132 kHz cycles are removed and not applied to the

FET. Under light loads, more of the cycles are removed,

and during heavy loads few, if any cycles are removed.

This is illustrated in Figure 3-3.

3-2

Page 33

Low Energy Power Distribution

Figure 3-4 shows the Low Energy Mode Power Distribution. As stated earlier, the Low Energy 9VS is the

source for the 5VS, 3.3V-ES and 3.3VS-1. The 5VS

and 3.3VS-1 supplies power to the IC7A00 the PTV

Control µPC.

The 3.3V-ES supplies power to the PTV Control circuit E2PROM, now located on the PCB-TERMINAL.

The 9VS supply also provides power for the Antenna

Relay in the RF Switch.

3-3

Page 34

Standard Standby Supply

The Standard Standby Regulator circuit is shown in Figure 3-5.

• When oscillation starts, the signal from pin 2 of

T9A20 is rectified by D9A22 and added to the

start-up voltage to maintain oscillation.

Start-up

The Start-up Voltage Supply is from R9A18 in the Low

Energy Mode circuit, refer to Figure 3-2. The SUB-

POWER command from the Control Circuitry activates

the Standby Supply.

When SUB-POWER goes High:

• Q9A09 conducts, activating a Photo Coupler in

PC9A20.

• The Photo Coupler turns Q9A12 On, supplying

start-up voltage to pin 4 of IC9A20.

Regulation

The secondary 12VS supply is monitored for regulation. A sample of the 12VS is compared to a reference

in IC9A21. A correction voltage from IC9A21 controls a second Optical Coupler in PC9A20.

The output of the Optical Coupler is applied to pin 5 of

IC9A20, controlling the PWM of the oscillator's signal.

3-4

Page 35

Standard Standby Supplies

Two Standby supplies are generated directly from

T9A20, 12VS and 6VS. Both of these supplies are

directed to the DM module, and are denoted as 12VDM and 6V-DM.

A 30VS supply is derived from the 12VS source using

voltage doubler circuitry, comprised of D9A31, D9A32,

C9A32 and C9A27. The resulting 30VS is the source

for a 28V-DM supply.

Standby Power Distribution

Figure 3-6 illustrates the Standby Power Distribution.

As mentioned earlier, the 12VS is source for 12VDM,and through the Voltage Doubler circuitry is the

source for 30VS and 28-DM supplies. The 12VS is

also directed to Horizontal Drive Circuitry and is the

Start-up voltage source for the Switched Supply Regulator.

In addition to being the 6V-DM source, the 6VS supply supplies power for CRT Protect circuitry, and is the

source for the 3.3V-1 and 5V-2 supplies.

Time Shift Recording Power

Supplies.

The Time Shift Record Supplies are switched supplies

derived from the Standby 12VS supply. They are activated during Time Shift Recording and when the PTV is

switched On. The Time Shift Power Supply circuit is

shown if Figure 3-7.

The supply is activated by the PON-1 command from

the Control Circuitry. When Off, the PON-1 line is

low, holding Q921 On, which holds Q9A20 Off by pulling its Gate low.

3-5

Page 36

When PON-1 goes High, Q9A21 turns Off, allowing

Q9A20 to turn On. With Q9A20 conducting, the 12V

supply is generated from the 12VS supply. The 12V

supply enables IC9A22 and the 5V-1 supply is generated.

Time Shift Supply Power Distribution

Figure 3-8 illustrates the Power Distribution for the Time

Shift supplies. The 5V-1 supply is used by the MLink,

3DYC and Signal Select circuitry. It is also the source

for the 3.3V-2 supply, which is directed to the Conver-

3-6

Page 37

gence Generator, 3DYC and Signal Select circuitry, and

to IC2E65. IC2E65 generates 2.5 Volts for 3DYC.

The 12V supply provides power for Tuners and CRT

Protect circuitry. It also is the source of four additional

DC Supplies:

• 9V-1 for the Signal Select circuitry

• 5V-DECOD for the NTSC Decoders.

• 9V-2 for CRT Drive, MCS, Signal Select and

Doubler circuitry.

• 5V-DAC for the Convergence DAC circuits.

Switched Supplies Regulator

Figure 3-9 shows the Switched Supplies Regulator.

When the TV is switched On, both the PON-1 and

PON-2 lines go High. When PON-2 goes High Q9A51

conducts:

1) Closing relay K9A50, shorting out current

limiting resistor R9A02, refer to Figure 3-2.

2) Activating a Photo Coupler in PC9A50.

The Photo Coupler turns Q9A56 On, and start up voltage from the Standby Regulator is applied to pin 4 of

IC9A50.

Signal from pin 3 of T9A50 is rectified by D9A44 and

added to the start up voltage to maintain oscillation.

Regulation

Regulation is achieved by monitoring the 110V secondary supply, and through IC9A51 and PC9A50 a correction voltage is fed back to pin 1 of IC9A50. The

voltage at pin 1 determines the PWM (duty cycle) of

3-7

Page 38

the oscillator drive to the FET. The PWM is automatically changed to maintain a constant 110V source.

Five supplies are directly generated by signal from

T9A50, 210V, 110V, 17V, +24V and -24V.

Troubleshooting

The most common symptom due to Power Supply problems is "The TV Will Not Turn On". The Flow Chart in

Figure 3-11 may be of some help in isolating the cause

of a "Won't Turn On Problem".

Power Distributions

Figure 3-10 shows the Switched Supplies Power Distribution. The 110V supplies power to DBF, Horizontal Drive, HV and SVM circuitry.

The +24 source supplies power to the Vertical Output,

X-Protect and Convergence circuitry. It also generates

the 12V-MAIN supply that is dedicated to HV Drive

and Deflection Loss circuitry.

The -24V supply is used in the Convergence circuitry,

and is the source for the -20V supply used in the CRT

Drive circuitry. The 210V supply is also used in the

CRT Drive circuits.

If the LED flashes:

• For 1 minute before the TV turns On:

This is normal, it takes about 1 minute for the

circuitry to Boot Up. Boot Up occurs the first

time the TV is plugged, and if in the Low

Energy mode when the Power button is

pressed.

• Flashes Continuously

It indicates the TV µPC is not functioning.

• Flashes-Stops-Flashes-Stops-etc.

It indicates a loss of communication between

the TV µPC and the DM µPC.

3-8

Page 39

If the LED does not flash:

• Check that the DM board is seated properly.

• Check that there is Standby 9VS (Fig. 3-2).

• Check that the SUB-POWER command line

does not go High (Fig. 3-5).

• Chirping sound - check the Standby Regulator,

IC9A20 (Fig.3-5).

• If it Turns On then Off

-Check the ±24V fuses

-Check Horizontal Deflection Circuitry.

3-9

Page 40

3-10

Page 41

Chapter 4

Control Circuitry

As in the two earlier integrated HDTV chassis, V19

and V21, the V23 uses two Microprocessors in the

Control circuitry.

1) TV µPC … controlling the analog circuitry.

2) DM µPC … controlling the digital circuitry.

The two µPCs constantly communicate with each other.

User commands are input to the TV µPC. Digital commands are forwarded from the TV µPC to the DM µPC.

The TV µPC generates Control commands from two

sources.:

1) User commands from the front panel or remote

control

2) Commands from the DM µPC.

Even though circuitry is becoming more complex, the

same basic requirements must be met for a µPC to operate.

Basic µPC Requirements

Figure 4-1 illustrates the four basic requirements for

the TV µPC operation in the V23.

1) DC Supply … 3.3V-ES and 5VS.

2) Ground Returns … pins 8, 9 and 14.

3) Timing Signal … 15 mHz Clock Oscillator

4) Reset circuitry … sets the µPC to its nominal

starting point

There is similar circuitry for the DM µPC. Since the

DM Module is considered a replaceable component

4-1

Page 42

we are not showing the details of the DM circuitry. Fig-

ure 4-1 shows only the DC supplies and Reset signal

going to the DM module.

Reset Circuitry

Figure 4-2 illustrates the Reset circuitry in more detail.

The normal and Reset logic are shown in the diagram.

IC7C70 is the Reset IC. A Low from pin 1 resets the

TV µPC. IC7C70 is a Watch Dog type of Reset IC

that monitors the µPC’s operation. It has an internal

counter that is continually reset by pulses from the µPC,

input at pin 4 of the IC. If the µPC locks up, no pulses

are generated. The counter reaches its maximum count

and a reset pulse is output at pin 1 to reset the µPC.

4-2

Page 43

Both the µPCs have the ability to reset each other if

communication is lost. IC7C30 serves as a Reset interface between the two µPCs and the front panel Reset

button. If the TV µPC gets no response from the DM,

it outputs a High at pin 73 of IC7A00. The High is

routed through IC7C30 and drives the DM-RESET input at pin 15 of the TC connector High.

Conversely, if the DM µPC gets no response from

IC7A00, the DM outputs a Low at pin 18 of the VC

connector. The Low, through IC7C30 activates a TV

Reset pulse from IC7C70.

When the front panel recessed Reset button is pressed,

both µPCs are reset through IC7C30.

IC7A00 also outputs reset pulses for the Convergence

Generator, Audio Control, 3DYC and MLink circuitry.

Input Command Circuitry

Figure 4-3 illustrates the Command Input circuit. It is

basically the same as that in the V19 and V21 so an in

depth description is only necessary on those parts that

are different.

The front panel Buttons are in a conventional resistive

ladder configuration. Pressing a button changes the

voltage at the KSC0 or KSC1 input of the µPC. The

command is identified by the change in voltage at the

KSC input.

There are differences in the Remote input circuitry due

to the Remote Learning feature of the V23. As in previous models there are two Remote Preamps:

1) A conventional Mitsubishi Preamp.

2) A wideband Preamp amplifying the IR signals of

most manufacturers.

4-3

Page 44

IR signals from a Mitsubishi Remote are directed to the

RMC input of IC7A00. The signals are filtered, processed and directed over the IR-IN-BUSY line to the

SYS-5 µPC on PCB-DTV TUNER. If the SYS-5 circuitry is busy, it holds the IR-IN-BUSY line Low until it

is clear to receive data.

If it is a Mitsubishi command the SYS-5 µPC directs it

to the DM Module. The signal is processed and routed

back to the TV µPC over the DM-RXD line. If the

commands are for a System 5 component they are directed to the SYS-5 IR Blaster Outputs.

Other manufacturers IR signals are amplified by the Wide

Band Preamp, directed through IC7C50 to the Repeater

IR Blaster Outputs. If IR signals are being output at

that time the IR-OUT-EN line disables IC7C50 until

the current IR output has ended.

4-4

Page 45

Note that the output of the Wide Band Preamp (IR-IN)

is also directed to the SYS-5 µPC. This connection

was not used in the V19 and V21. It enables the Learning feature. The signals from the units Remote are memorized by the SYS-5 circuitry.

Serial Data Lines

Figure 4-4 shows the Serial Data lines and indicates

what circuits they control. ICs IC7B00~IC7B03 are

level shift ICs, changing the 3.3V data and clock lines

from IC7A00 to 5V lines.

In previous sets the TV Control circuitry used two

E2PROM Memory ICs, one on the PCB-SIGNAL and

one on the PCB-TERMINAL. Due to the changes in

design only one E2PROM is required, and for factory

alignment purposes it is located on PCB-TERMINAL.

In the V23 the DTV Tuner and Modulator are separate

from the DM Module. The DTV Tuner is controlled by

the TDAT and TCLK lines from the DM Module. The

DM Module also controls the MLink (DVI) circuitry,

through the DVI-RXD and DVI-TXD lines.

Figure 4-4 also shows that the DM Module receives

and processes the signals from the Card Reader.

µPC Parallel Inputs

The parallel inputs to the µPC are status inputs or signals inputs required for control purposes.

AC-OFF Input

Informs the µPC if AC Power is lost. The monitoring

circuit is shown in Figure 4-5. Samples of the input AC

are applied to the base of Q9A10. D9A16 removes

the negative half of the sine waves. The remaining positive half cycles keep Q9A10 conducting. With Q9A10

conducting PC9A10 conducts, turning Q7A20 On. The

conduction of Q7A20 holds the AC-OFF input to

IC7A00 Low.

If AC power is lost, Q9A10, PC9A10 and Q7A20 all

quit conducting, allowing pin 20 of IC7A00 to go High.

This informs the Control circuitry power has been lost.

The µPC responds by rapidly storing all user programming and service adjustments to memory. It also outputs a High on the Power Good line, informing the DM

of the power loss.

4-5

Page 46

SHORT Detect

IC7A00 Additional Inputs

Pin #

Name

Source

100

CV-IN-MAIN

Main Video (CCD, V-chip,etc)

The short Detect circuitry is shown in Figure 4-6 and is

the same as in the V19 and V21 chassis. If a short

occurs in the + or – 24V supplies, pin 46 on IC7A00

goes Low indicating a short and the TV shuts Off. With

-24V shorted, the 12VS supply turns Q9A53 On, pulling the SHORT line Low. If +24V is shorted D9A54 is

forward biased and the short line goes Low.

X-RAY Protect

Refer to Figure 4-7, the X-Ray input is at pin 47 of

IC7A00, and is normally High. The X-Ray Protect

circuit monitors:

• Excessive HV

• Excess CRT Beam Current

• Excess HV circuit Current

If any of the preceeding occurs, the X-Ray line goes

Low, and the TV shuts Off.

The monitoring circuits for X-ray Protect are described

in the detail in the Deflection and HV Section. Other

parallel inputs to the µPC, are listed in Table 4-1.

6 SD-SUB Sub Tuner Sync Detector

7 SD-MAIN Main Tuner Sync Detector

62 H-SYNC-IN ASIC Horizontal Sync

64 V-SYNC-IN ASIC Vertical Sync

92 AFT1 Main Tuner AFT voltage.

93 AFT2 Sub Tuner AFT voltage

94 VBLK Deflection Loss Detect circuit

97 CV-IN-SUB Sub Video (CCD, V-chip,etc)

Table 4-1: µPC Inputs

4-6

Page 47

Additional IC7A00 Outputs

Pin #

Name

Purpose

42 BLNK-CRT Blanks CRTs during Input &Channel changes.

87

SUB POWER

Activates/Deactivates the Economy Mode

49 PON-2 Power ON: (Defl, Conv, HV, etc. circuitry)

50 PON-1 Power ON: Signal Processing circuitry)

51 BWC Band Width Control for Doubler Output

52

56 F31K Decreases H-Defl DC supply for 31.5 kHz.

57 DEFL-MUTE Decreases H-Defl DC supply during freq. change.

71 BLK-EN Enables OSD Insertion

76 MUTE SUB Mutes Sub Picture Audio Output

80 MUTE SPKR Mutes the TV's Speakers

82 POWERGOOD Informs the DM that the DC Power is ok

86 MUTE MON Mutes Monitor Out Audio

F

Sets the Free Run Horizontal Frequency

Table 4-2: µPC Outputs

Parallel Outputs

Most of the parallel outputs are listed in Table 4-2. Most

of them have been used before and need no explanation. However, the function of two items should be described.

BWC (Band Width Control)

This line is directed to the Doubler circuitry, and automatically becomes active when the signal source is

NTSC. The Doubler circuit is designed to produce the

best possible picture for an HDTV signal. Due to this

design, artifacts may appear in the picture when the signal source is NTSC.

With an NTSC source, the BWC line automatically goes High. The High reduces some

of the high frequency output from the Doubler, removing the unwanted artifacts.

BLK-EN

Figure 4-8 illustrates the BLK-EN circuitry.

The BLK-EN selects the path for the OSD

insertion timing signal (DM-BLK). The OSD

signals and the DM-BLK timing signal are

generated in the DM Module.

directs the signal to the VCJ, and IC2V03 directs the

signal to the Doubler circuit. The path of the DM-BLK

signal is determined by BLK-EN from the TV µPC.

BLK-EN is applied directly to the OE (Output Enable)

input of IC2V03, and is inverted by Q2X04 and applied to the OE input of IC2V02. IC2V02 and IC2V03

are enabled when their OE input GOES Low.

When EN-BLK is High, IC2V02 is enabled and the

DM-BLK is directed to the VCJ. When EN-BLK is

Low, DM-BLK is directed to the Doubler. DM-BLK

is needed in Doubler, even though the OSD insertion

for a DM signal occurs in the DM Module.

If the source signal is not from the DTV Tuner

or a 1394 input, the OSD signal is inserted

in the main signal in the VCJ IC2V01. The

Timing Signal (DM-BLK) is applied to the

inputs of IC2V02 and ICSVO3. IC2V02

4-7

Page 48

The PerfectColor feature is performed in the Doubler

circuit, therefore all signal sources must pass through

the Doubler. With DM signal sources, any OSD is already inserted in the signal before it goes to the Doubler. The PerfectColor circuitry can cause incorrect color

in the OSD. The DM-BLK signal is directed to the

Doubler when the source is Digital, momentarily disabling the PerfectColor during the OSD.

Flash Circuit

Figure 4-9 shows the Flash Circuit in the V23. This

circuit is not controlled by the µPCs, but can be consid-

ered a status sensor. It prevents a momentary flash on

the screen:

• When the TV is switched Off (PON-1 goes

Low)

• If AC power is lost. (AC-OFF goes High)

• If the +24V supply is lost (Q7C11 conducts)

If any of the above occurs, drive to the HV circuit is

removed to prevent any flash on the screen. The Flash

line goes High, turns On Q2V41, which removes HV

Drive.

4-8

Page 49

Chapter 5

Video/Color Circuitry

The above block diagram illustrates the Video/Color

circuitry in the V23 chassis. Although initially it looks

the same as in the V21, there are differences. The A/V

Switch circuitry still selects main and sub picture signals

from NTSC signal sources. Although it’s not apparent

from the Block Diagram, the NTSC Decoders, Component Switch ICs, and the Doubler circuitry are different.

Note that all main picture sources, including the DTV

Tuner, are processed by the Doubler circuitry. In the

V21, 480p and DM signals only were processed by the

Doubler circuitry when a display other than Standard

format was selected, or when PIP/POP was activated.

The new improved Color Management (ColorPerfectTM)

circuitry is in the Doubler circuitry and it now processes

all signal sources. Therefore all signals must pass through

the Doubler. Two additional signal sources are shown in

the Block Diagram, MLink (DVI) Input, and a Memory

Card Reader located in the front of the TV.

Also the diagram indicates that the Sub Picture source

can only be from a NTSC source, an External Component Input or the DTV input.

5-1

Page 50

PCB-TERMINAL Video Path

Figure 5-1 illustrates the Video Signal Path on the PCBTERMINAL. The AV-Switch circuitry has not changed,

IC2L00 and IC2K00 are the same ICs used in the V21

chassis.

The 3DYC Motion Adaptive Come Filter provides a

clean separation of luminance (Y) and chroma (C) signals.

The Main and Sub Decoders are new, generic

#TA12440AF. Their functions include:

• Converting NTSC to YPbPr.

• Sync Separation

• Detecting signal format (480i, 480p, etc.)

• Converting RGB to YPbPr.

The Component Switch ICs are also new, generic #

MM1519XQ. There are two Component Switch ICs

on PCB-TERMINAL, and a third one on PCB-SIGNAL, not shown in Figure 5-1.

IC2A00 selects the Main and Sub picture sources from:

• Main Decoder output

• External Comp-1 Input

• External Comp-2 input

IC2B00 selects the Main and Sub picture sources from:

• The outputs of IC2A00

• The External DTV Inputs

• The VGA Input

The VGA Input cannot be selected as the Sub picture

source.

5-2

Page 51

The Sub picture signals from IC2B00 are directed to

IC2G00, the Sub Decoder. Switch circuitry in IC2G00

selects Sub picture signals from IC2B00 or the AVSW(2), IC2K00.

or the MLINK signal from the MLINK Decoder, or

the RGB signal from the DM Module. The output of

IC2H01 is applied to the Main Picture inputs to the

Doubler circuit.

As in previous chassis, the main and sub selected YPbPr

signal are direct to the PCB-SIGNAL.

PCB-SIGNAL Video Path

Figure 5-2 shows the PCB-SIGNAL Video Signal Path.

Sub picture signals from PCB-TERMINAL are routed

directly to the Sub YPbPr inputs of PCB-DOUBLER.

The main picture signals from PCB-TERMINAL are

routed to COMP SW-3, IC2H01. IC2H01 selects the

main signal from the PCB-TERMINAL main outputs,

Note that the OSD RGB signals from the DM Module

are also directed the VCJ, IC2V01.

On-Screen Display (OSD) signals are generated in the

DM Module, and when the signal source is not the DM,

OSD is inserted in the main picture in the VCJ. If the

source is from the DM, the DTV Tuner or 1394 inputs,

OSD insertion occurs in the DM module.

The diagram also shows that Convergence OSD signals are applied to the VCJ and inserted in the VCJ.

5-3

Page 52

The outputs of the Doubler circuit, ASIC-Y, ASIC-Pb

and ASIC-Pr are directed to the VCJ. The signals are

processed in the VCJ and CRT RGB drive signals are

output at pins 64, 63, and 62.

CRT Drive & Protect Circuitry

Figure 5-3 shows the CRT Drive circuitry. Since it is

the same as that in the V21, no explanation is necessary. The CRT Protection circuitry is also the same as

the V21, but a review may be in order.

When Q2W03 conducts, it turn On Q2W05, Q2W08

and Q2W11. The conduction of the three transistors

removes RGB drive to the CRTS.

The conduction of Q2W03 is controlled from two

sources:

1) The BLANK-CRT command from the µPC,

momentarily blanking the CRTs during channel

or input selection changes.

2) The VBLNK line. The logic on the VBLNK

line is controlled by Deflection Loss Detection

circuitry.

A High on VBLNK blanks the CRTs. The Deflection

Loss Detection circuitry is discussed in detail in the Section on Deflection and HV.

5-4

Page 53

Digital Signal Path

The basic Digital Signal path was shown in Figure 5-2.

Figure 5-4 shows the Digital Path in more detail. Digi-

tal signal sources are the DTV/AQM Tuner, 1394 Inputs and the front panel Card Reader. There are two

1394 inputs at the rear of the DM module. A third 1394

input is on the front of the Card Reader. The Card Reader

serves as a feed through for the 1394 signals and does

not process these signals at all.

The I.F. signal from the DTV/QAM Tuner is directed to

PCB-DEMODULATOR. The I.F. signal passes

through two SAW filters, and two I.F. amp ICs,

SF5200, IC5252, SF5201 and IC5253, in that order.

The (+) and (-) I.F. signals from IC5253 are directed to

pin 69 and 68 of the Demodulator, IC52A0. The out-

put of the Demodulator is the Transport data stream

used to modulate the carrier at the station.

The Transport Data Stream (TODATA) is directed to

the Digital Module. The signal is processed by the circuitry in the DM, and results in analog RGB signals output at pins 8, 4, and 6 of the VA connector.

Signals from the 1394 inputs are processed in the DM

Digital Signal Processing circuitry and are output as analog RGB signals at VA connector.

Signals from the Card Reader are send to the DM over

a USB cable. The DM also processes these signals

and outputs the resulting analog RGB signals.

5-5

Page 54

Monitor Out Circuit

Figure 5-5 shows that the Monitor Output signal source

is limited to an NTSC source, or the DM Module. The

NTSC Y and C signals from the 3DYC Comb Filter,

are directed back to IC2L00. IC2L00 directs the signals to the monitor Inputs of IC2K00. IC2K00 selects

the signal from IC2L00 or the DM signal input at pins

24 and 26 of IC2K00.

If the signal source is from a Component Input, the DTV

Input, VGA Input or MLINK Input, no signal is available at the Monitor Outputs.

5-6

Page 55

Chapter 6

Sync, Deflection & High Voltage

The Overall Sync, Deflection and Hign Voltage circuitry in the V23 is shown in the Block Diagram at