Page 1

MITSUBISHI ELECTRIC

2003/2004

™

own

HIGH SPEED TROUBLESHOOTING

V22/V24 & V23 CHASSIS

V22 Chassis

WS-48313 WS-55313 WS-65313

WS-48413 WS-55413 WS-65413

V24 Chassis

WS-48315 WS-55315 WS-65315

V23 Chassis

WS-48513 WS-65513 WS-73513

WS-48613 WS-65613 WS-73713

WS-55513 WS-65713

WS-55613 WS-65813

WS-55813

to

1

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2004 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

Page 3

Down To 1 - High Speed Troubleshooting

CONTENTS

INTRODUCTION ..................................................................................................................................................................................... 2

SAFETY PRECAUTIONS ......................................................................................................................................................................... 3

V22/V24 - PWB FUNCTIONS AND LOCATIONS ................................................................................................................................. 4

V23 - PWB FUNCTIONS AND LOCATIONS ......................................................................................................................................... 5

PWB PART NUMBERS ........................................................................................................................................................................... 6

TROUBLESHOOTING CHARTS

V22/V24 & V23 Audio .................................................................................................................................................................. 7

V22/V24 Video/Color ................................................................................................................................................................... 8

V23 Video/Color ........................................................................................................................................................................... 9

V22/V24 & V23 Power ............................................................................................................................................................... 10

V22/V24 & V23 Convergence .................................................................................................................................................... 12

Page 4

INTRODUCTION

DOWN to 1™ Goal: Isolate the faulty component 9 out of 10 times.

Required tools: Signal Generator such as Sencore VP300 or VP301

DOWN to 1™ High Speed Troubleshooting

The troubleshooting of any PTV chassis involves one of two methods. The first involves an exhaustive checking of all suspect DC and AC voltages,

waveforms, and the like. This is all possible given the necessary time and equipment. The second occurs most frequently in field service, where time is often

insufficient and equipment unavailable or impractical. It is then that all of a technician’s practical experience must be brought to bear in order to make an

educated guess as to where the product failure or difficulty may lie.

This second method is the focus of this publication and the DOWN to 1™ discipline.

Color, Pattern and Perception

Observation is key to an overall evaluation strategy. The details gathered from a precise observation can go a long way toward arriving at a repair solution in

a timely and efficient manner. With this understanding, MDEA has brought the combined technical expertise of its years to bear in creation of the DOWN to

1™ method. For simplicity and easy memorization, color, pattern and perception are employed as the primary tools.

Color

• Each component has its corresponding unique color.

Pattern

• For each troubleshooting case, the component to replace is identified by an oval color pad at the terminating end of its path.

Perception

• A perceived problem provides deductive reasoning clues to its solution.

Main Power Signal Terminal

Doubler

CRT(s) DM

Page 5

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard from the receiver's power supplies.

Work on the receiver should not be attempted by anyone who is not thoroughly familiar with the precautions necessary when working on

high voltage equipment.

2. Do not install, remove or handle the picture tubes in any manner unless shatterproof goggles are worn. People not so equipped should be

kept away while the picture tube is being handled. Keep the picture tube away from the body while handling.

3. When service is required, observe the original lead dress. Extra precaution should be taken to assure correct lead dress in the high voltage

area. Where a short-circuit has occurred, replace those components that indicate evidence of overheating.

X-Radiation warning

The surface of the cathode ray tubes (CRTs) may generate X-Radiation, so take proper precautions when servicing. It is recommended that a lead

apron be used for shielding while handling the CRT. Use this method if possible.

When replacing the CRTs, use only the designated replacement part since it is a critical component with regard to X-Radiation. High voltage must be

set as prescribed in the Service Manual under the section titled Electrical Adjustments.

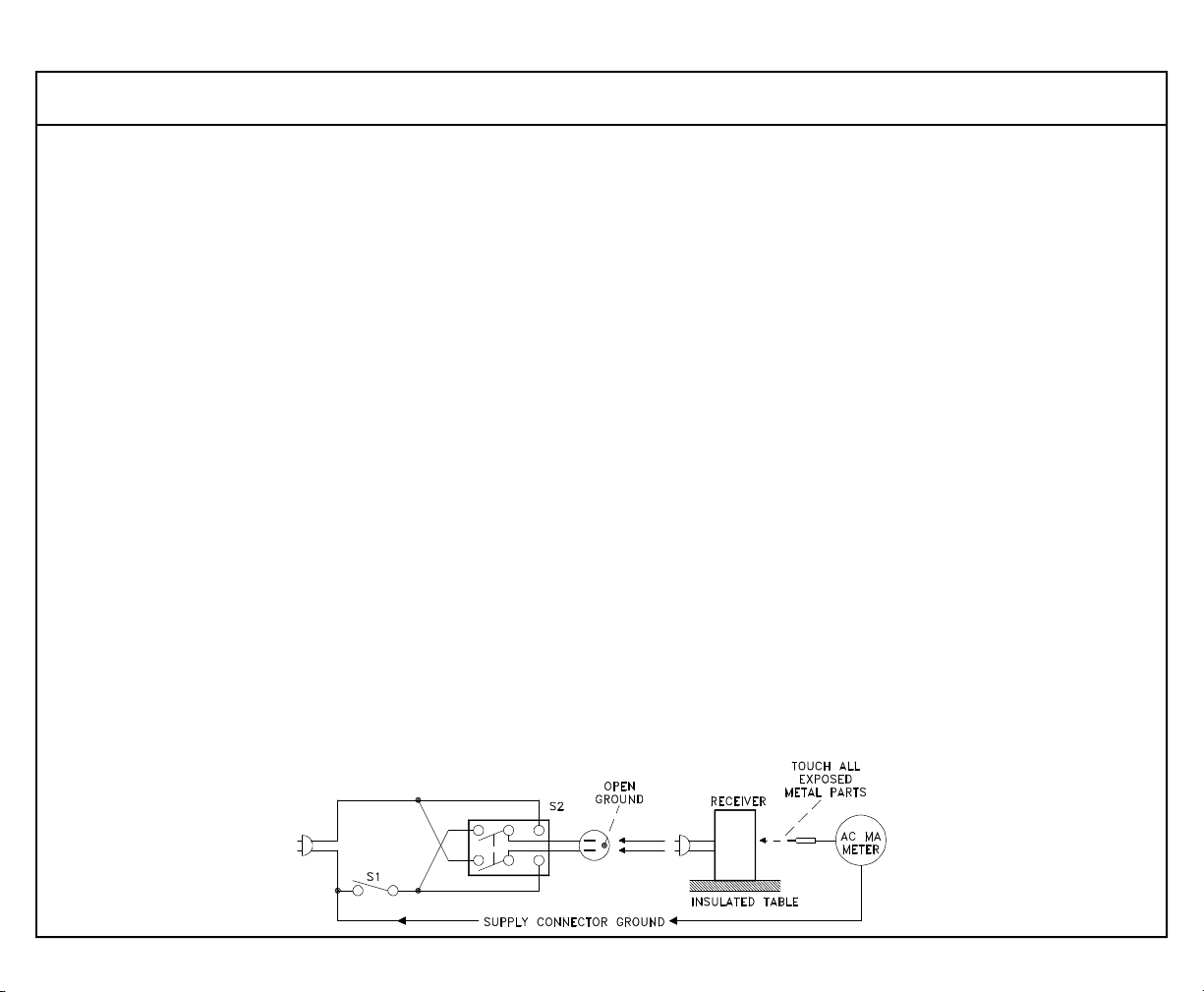

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the following methods.

Cold Check - With the AC plug removed, place a jumper across the two AC plug prongs. Connect one lead of an ohm meter to the AC plug

and touch the other lead to each exposed metal part (i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts,

(etc.), particularly any exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a return path

to the chassis should be a minimum of 1Mega Ohm. Any resistance below this value indicates an abnormal condition and requires

corrective action.

Hot Check... Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after connection, and with the switching devices of

the receiver in their operating positions, measure the leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the switching devices of the receiver in their

operating positions, measure the leakage current for both positions of switch S2. Repeat the current measurements of items 1 and 2 after

the receiver has reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

V22/V24 Chassis - PCB Functions and Locations

PWB-POWER

PWB-MAIN

PWB-SIGNAL

PWB-TERMINAL

PWB-DOUBLER

Convergence

NTSC Video

Line Double

PWB-Main PWB-Power PWB-Signal PWB-Terminal PWB-Doubler

Horizontal Defl. Power Supplies Control uPC A/V Inputs PIP-POP

Vertical Defl. High Voltage Tuning A/V Selection Picture Format

Audio Amp. SVM VCJ 3D-Y/C 3:2 Pull Down

Convergence Amps.

DBF Generator Decoders 480i to 480p

Page 7

V23 Chassis - PCB Functions and Locations

PWB-TERMINAL

PWB-DOUBLER

PWB-SIGNAL

PWB-POWER

PWB-MAIN

DM

PCB-Main PCB-Power PCB-Signal PCB-Terminal PCB-Doubler DM

Horizontal Defl. Power Supplies Control uPC A/V Inputs PIP-POP NetCommand

Vertical Defl. Audio Amp. Tuning A/V Selection Picture Format IEEE1394

High Voltage Convergence Amps. VCJ 3D-Y/C Line Double Card Viewer

Convergence NTSC Video 480i to 480p OSD-Menus

Generator Decoders Digital uPC Control

Page 8

V22/V23 Chassis - PWB Part Numbers

MODEL

PWB-MAIN

PWB-POWER

PWB-SIGNAL

PWB-TERMINAL

PWB-DOUBLER

DM

PWB Part Numbers

WS-48313 930B899003 930B900001 930B901001-48 930B902001 934C063001 WS-48413 930B899003 930B900001 930B901002-48 930B902001 934C063001 WS-55313 930B899003 930B900001 930B901001-55 930B902001 934C063001 -

V22

WS-55413 930B899001 930B900001 930B901002-55 930B902001 934C063001 WS-65313 930B899001 930B900001 930B901001-65 930B902001 934C063001 WS-65413 930B899001 930B900001 930B901002-65 930B902001 934C063001 -

WS-48315 930B899004 930B900002 930B901003-48 930B902001 934C063003 -

V24

WS-55315 930B899004 930B900002 930B901003-55 930B902001 934C063003 WS-65315 930B899005 930B900002 930B901003-65 930B902001 934C063003 -

WS-48513 930B903002 930B904001 930B905001-48 934C060001 934C063001 934C067001

WS-48613 930B903002 930B904001 930B905001-48 934C060001 934C063001 934C067001

WS-55513 930B903002 930B904001 930B905001-55 934C060001 934C063001 934C067001

WS-55613 930B903001 930B904001 930B905001-55 934C060001 934C063001 934C067001

WS-55813 930B903001 930B904001 930B905002-55 934C060002 934C063001 934C067002

V23

WS-65513 930B903001 930B904001 930B905001-65 934C060001 934C063001 934C067001

WS-65613 930B903001 930B904001 930B905001-65 934C060001 934C063001 934C067001

WS-65713 930B903001 930B904002 930B905002-65 934C060002 934C063001 934C067002

WS-65813 930B903004 930B904001 930B905002-65 934C060002 934C063001 934C067002

WS-73513 930B903004 930B904001 930B905001-73 934C060001 934C063001 934C067001

WS-73713 930B903004 930B904002 930B905002-73 934C060002 934C063001 934C067002

Page 9

V22/V24 & V23 Chassis - Audio Problem

Audio problem

Audio

problem any

or all NTSC

sources

Main

Supply

signal to

antenna

input.

PWB-Main

V22 Chassis

Power Signal Terminal

Check Monitor

Output. Good

YES

audio?

NO

PWB-Power

V23 Chassis

Doubler

Supply

signal to

different

line

inputs

CRT(s)

Have audio

to speakers?

NO

PWB-Terminal

YES

PWB-Signal

Page 10

V22/V24 Chassis - Video/Color Problem

NO

Is OSD good?PWB-Signal

YES

Supply a

signal and

test each

Input.

PWB-Terminal

Main

YES

Power Signal Terminal

Is any single

Input good?

NO

Doubler

PWB-Doubler

CRT(s)

Page 11

V23 Chassis - Video/Color Problem

Is OSD good?

NO

Is NTSC

Good?

YES

Make sure DM is

seated on the

PCB-DTV-TUNER.

Also check

connectors

between the PCBSIGNAL and PCB-

DTV-TUNER

PWB-Terminal

YES

Main

YES

Supply a

signal and

test each

Terminal

Input.

Is any single

Input good?

Power Signal Terminal

NO

NO

PWB-Signal

PWB-Doubler

Doubler

CRT(s)

Problem

Corrected?

NO

DM

DM

Page 12

V22/V24 & V23Chassis - Shut-Down Problem - (Pg 1 of 2)

Shut-Down Problem

While the set is in Shut-Down, press and hold the Front Panel "Device" and "Menu" buttons for five seconds.

Pause

Pause

Observe the flashing pattern of the front panel L.E.D. It will repeat 5 times.

No Fault

Detected

X-Ray

Protect

PWB-Main

V23 Chassis

Main Power Signal Terminal

Set powers up

then shuts down?

Arcing at CRTs

seen or heard?

NO

Doubler

YES

YES

PWB-Power

V22 Chassis

CRT(s)

PWB-Power

CRT(s)

Page 13

V22/V24 & V23Chassis - Shut-Down Problem - (Pg 2 of 2)

Shut-Down Problem (Continued)

Pause

V23 Chassis Only

Main Power Signal Terminal

Short-Circuit

Protect

Continuous

flashing

Press

RESET

on front

panel.

Doubler

PWB-Power

PWB-Main Pause Deflection

CRT(s)

Problem

Corrected?

DM

NO

Make sure DM is

properly seated on

the PCB-DTV-

TUNER. Also

check connectors

between the PCB-

SIGNAL and PCB-

DTV-TUNER

Problem

Corrected?

NO

DM

Page 14

V22/V24 & V23 Chassis - Convergence Problem

Enter

Convergence

Adjustment Mode

(MENU-0-3-5-9)

<4> Fine

<5> Coarse

PWB-Signal

YES

Does picture

respond to

adjustments?

NO

PWB-Main

V22 Chassis

PWB-Power

V23 Chassis

Main

Power Signal Terminal

Doubler

CRT(s)

Loading...

Loading...