Page 1

MITSUBISHI ELECTRIC

2003

Service

Manual

PROJECTION TELEVISION

V22 / V22+ CHASSIS

V22 Chassis

MODELS

WS-48313

WS-55313

WS-65313

V22+ Chassis

MODELS

WS-48413

WS-55413

WS-65413

WS-48313

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

Power : AC 120V, 60Hz

240W

Frequency : VHF 54 ~ 470MHz

Range UHF 470 ~ 806MHz

Antenna Input : VHF/UHF 75Ω unbalanced

CRT Size : 7 inches

High Voltage : 30.8KV

• Speakers : [WS-48313 / WS-48413]

Two 5" round, full range (8Ω 10W)

: [WS-55313 / WS-55413 / WS-65313/

WS-65413]

Two 6" round, full range (8Ω 10W)

• Input Level : VIDEO IN JACK (RCA Type)

1.0Vp-p 75Ω unbalanced

: AUDIO IN JACK (RCA T ype)

-4.7dBm 43kΩ unbalanced

: S-VIDEO IN JACK (Y/C separate)

Y=1.0 Vp-p C=0.286Vp-p(BURST)

75Ω unbalanced

: COMP / Y, Cr , Cb (RCA T ype)

Y=1.0 Vp-p. Cr , Cb=700mVp-p

: DTV / Y(G), Pr(R), Pb(B), H, V

Y 1.0Vp-p with sync 75Ω (RCA Type)

Pr, Pb: 700mV 75Ω

H, V: 3.0Vp-p 75Ω

• Digital Inputs

:MonitorLink

:MonitorLinkTM Control/RS-232C

TM

/DVI

Weight / Cabinet Demensions

Model Weight Height Width Depth

WS-48313

WS-48413 172lbs 49" 44.5" 24"

WS-55313 213 lbs 50.4" 50.5" 25.4"

WS-55413 221 lbs 50.4" 50.5" 27.8"

WS-65313

WS-65413 327 lbs 62" 59" 28"

Weight and dimensions shown are approximate.

Design specifications are subject to change without notice.

172 lbs 49" 44.5" 24"

327 lbs 62" 59" 28"

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2003 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

• Output Level : VIDEO OUT JACK (RCA T ype)

1.0Vp-p 75Ω unbalanced

: AUDIO OUT JACK (RCA

-4.7dBm 4.7kΩ unbalanced

Type)

Page 2

Page 3

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

CONTENTS

INTRODUCTION ............................................................................................................................... 5

PRODUCT SAFETY NOTICE ...........................................................................................................5

SAFETY PRECAUTIONS ................................................................................................................. 6

DISASSEMBLY PROCEDURES ......................................................................................................... 7

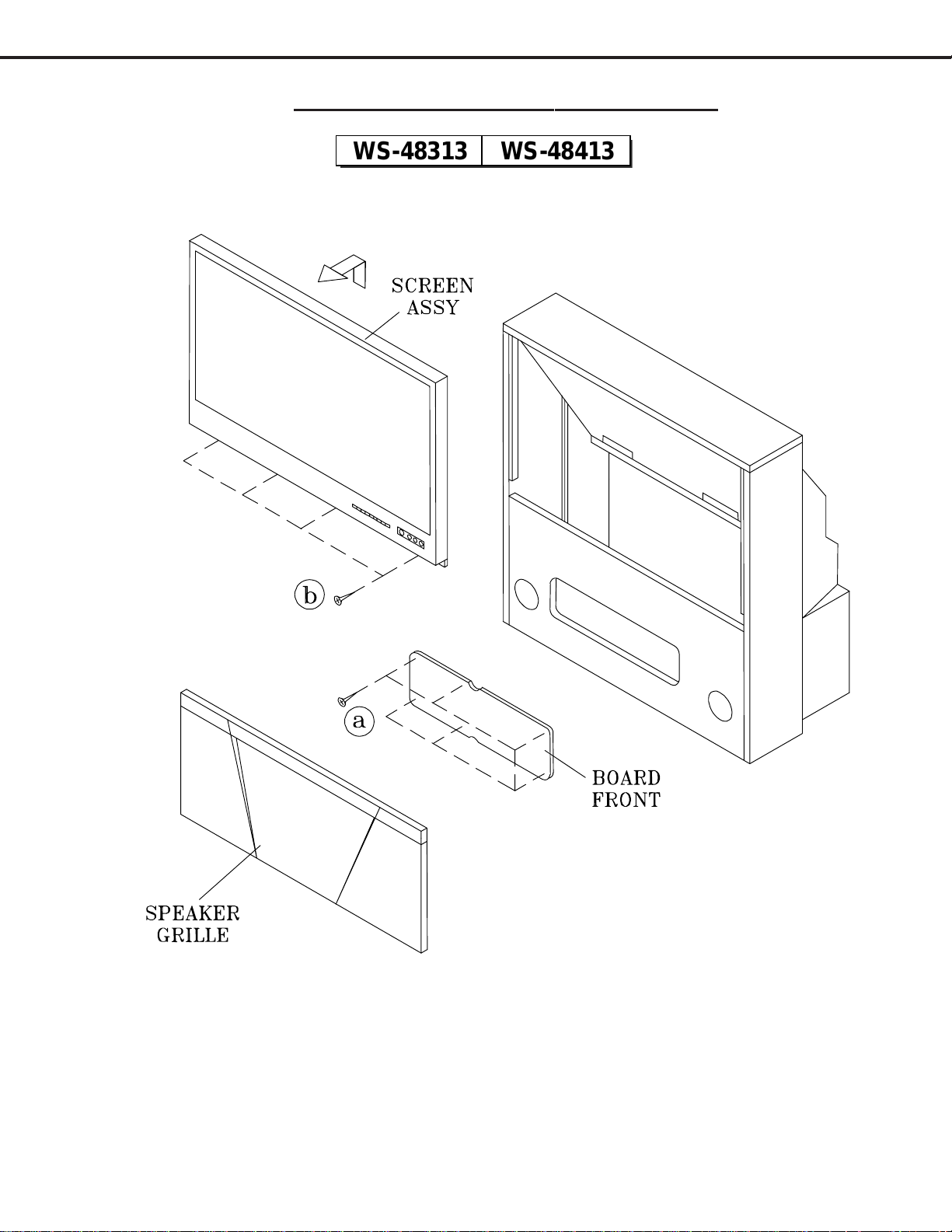

WS-48313 / WS-48413

Front Cabinet Components .................................................................................................... 7

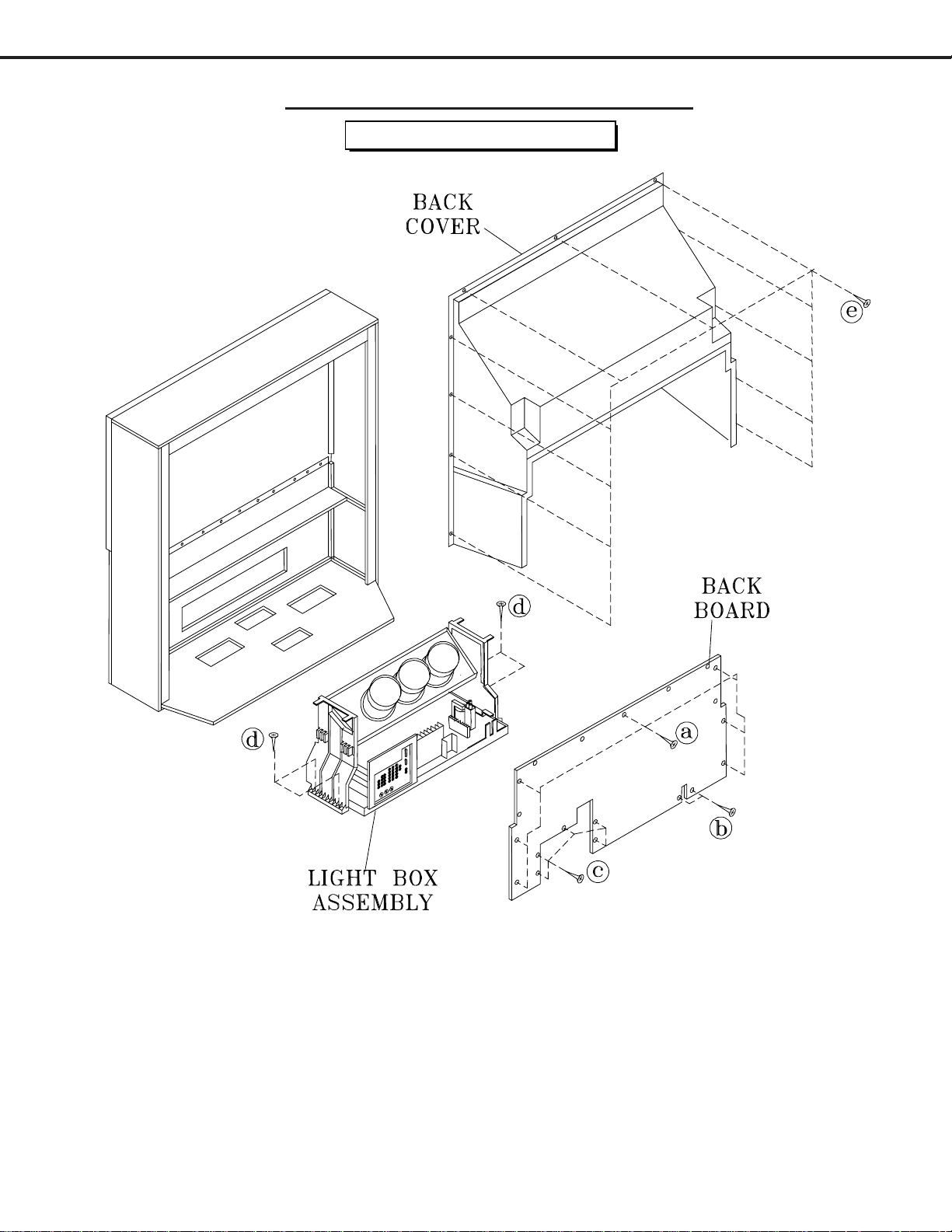

Rear Cabinet Components ..................................................................................................... 8

WS-55313 / WS-55413 / WS-65313 / WS-65413

Front Cabinet Components .................................................................................................... 9

Rear Cabinet Components ................................................................................................... 10

SERVICING THE LENTICULAR LENS AND FRESNEL SCREEN ................................................ 11

WS-48313 / WS-48413

Removal of the Lenticular Screen and Fresnel Lens .......................................................... 11

WS-55313 / WS-55413 / WS-65313 / WS-65413

Removal of the Lenticular Screen and Fresnel Lens .......................................................... 12

All Models

Installation of the Lenticular Screen and Fresnel Lens ....................................................... 13

CABINET SEPARATION PROCEDURES .......................................................................................... 14

WS-65313 / WS-65413 ................................................................................................................. 14

SERVICING THE DIAMONDSHIELDS

DiamondShields TM Removal ......................................................................................................... 15

DiamondShields TM Installation ...................................................................................................... 15

SERVICING PCBs ............................................................................................................................ 16

Chassis Removal .......................................................................................................................... 16

PCB Locations .............................................................................................................................. 16

Major Parts Locations ................................................................................................................... 16

ANODE LEAD REMOVAL ................................................................................................................. 17

CRT REPLACEMENT ....................................................................................................................... 17

CRT Removal ................................................................................................................................17

CRT Installation ............................................................................................................................ 18

ELECTRICAL ADJUSTMENTS ...................................................................................................... 20

Equipment .................................................................................................................................... 20

Initial Setup ................................................................................................................................... 21

LED Indicator Diagnostics ............................................................................................................. 22

Circuit Adjustment Mode ............................................................................................................... 23

Convergence Adjustment Mode ..................................................................................................... 24

Adjustment Items List ................................................................................................................... 26

Adjustment Procedures ................................................................................................................ 29

Test Point Locations ............................................................................................................29

HV Regulation ...................................................................................................................... 30

Main / Sub Y Level ............................................................................................................... 30

Main / Sub Color Level ......................................................................................................... 31

CRT Cutoff ........................................................................................................................... 31

White Balance (NTSC) ......................................................................................................... 32

TM

r ........................................................................................ 15

Page 3

Page 4

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

White Balance (HD) ............................................................................................................. 32

Black Level .......................................................................................................................... 33

Sub Contrast ....................................................................................................................... 33

Dynamic Focus Presets ...................................................................................................... 34

Lens Focus.......................................................................................................................... 34

Alignment Magnet & Electrostatic Focus ............................................................................. 35

Charactrer Position .............................................................................................................. 35

Geometry Presets ............................................................................................................... 36

Deflection Geometry Adjustments ........................................................................................ 37

Convergence Geometry Adjustments ................................................................................... 38

Centering & Static Convergence ........................................................................................... 39

Coarse Convergence Adjustments ........................................................................................ 40

Fine Convergence Adjustments ............................................................................................ 41

CHIP PARTS REPLACEMENT ......................................................................................................... 42

REPLACEMENT PARTS .................................................................................................................. 43

Parts Ordering .............................................................................................................................. 43

Critical and Warranty Parts Designation........................................................................................ 43

Parts Tolerance Codes .................................................................................................................. 43

Quick Reference List .................................................................................................................... 44

SERVICE PARTS LIST .................................................................................................................... 45

SCREEN ASSEMBLY PARTS LIST.................................................................................................. 57

CIRCUITRY BLOCK DIAGRAMS ..................................................................................................... 60

Part 2

Schematic Diagrams

CONTENTS Page

SCHEMATIC DIAGRAMS

PCB Interconnect Diagram.............................................................................................................. 1

PCB-MAIN ...................................................................................................................................... 2

PCB-POWER ................................................................................................................................. 3

PCB-SIGNAL-1 (TUNER I/O) ........................................................................................................... 4

PCB-SIGNAL-2 (MICRO) ................................................................................................................. 5

PCB-SIGNAL-3 (VIDEO / CHROMA) ............................................................................................... 6

PCB-SIGNAL-4 (CONVERGENCE GENERATOR) .......................................................................... 7

PCB-DOUBLER-1 ........................................................................................................................... 8

PCB-DOUBLER-2 ........................................................................................................................... 9

PCB-DOUBLER-3 ......................................................................................................................... 10

PCB-TERMINAL-1 (A/V I/O) .......................................................................................................... 11

PCB-TERMINAL-2 (MonLink) ........................................................................................................ 12

PCBsCRT, CONTROL, FRONT and PREAMP .............................................................................. 13

PCB LAYOUT DIAGRAMS ............................................................................................................... 14

Page 4

Page 5

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

INTRODUCTION

This service manual provides service instructions for the PTV Models listed below. Service personnel should read this

manual thoroughly before servicing these chassis.

V22 Chassis V22+ Chassis

WS-48313 WS-48413

WS-55313 WS-55413

WS-65313 WS-65413

This service manual includes:

1. Assembly and disassembly instructions for the front and rear cabinet components.

2. Servicing of the Lenticular Screen and Fresnel Lens.

3. Servicing printed circuit boards (PCBs).

4. CRT replacement procedure.

5. Electrical adjustments.

6. Chip parts replacement procedures.

7. Circuit path diagrams.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Schematic and block diagrams of the above listed models are included in this service manual for better understanding of the circuitry. PCB drawings are also included for easy location of parts and test points.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be

obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagram and by bold

type in the parts list of this service manual. The replacement for any safety part should be identical in value

and characteristics.

Page 5

Page 6

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. Do not install, remove or handle the picture tubes in any manner unless shatterproof goggles are

worn. People not so equipped should be kept away while the picture tube is being handled. Keep

the picture tube away from the body while handling.

3. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

X-Radiation warning

The surface of the cathode ray tubes (CRTs) may generate X-Radiation, so take proper precautions when servicing. It is recommended that a lead apron be used for shielding while handling the CRT. Use this method if

possible.

When replacing the CRTs, use only the designated replacement part since it is a critical component with regard to

X-Radiation. High voltage must be set as prescribed under the section titled Electrical Adjustments.

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to

the following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal

part (i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts, etc.), particularly any exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts

having a return path to the chassis should be a minimum of 1Mega Ohm. Any resistance below this value

indicates an abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure

the leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

Page 7

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

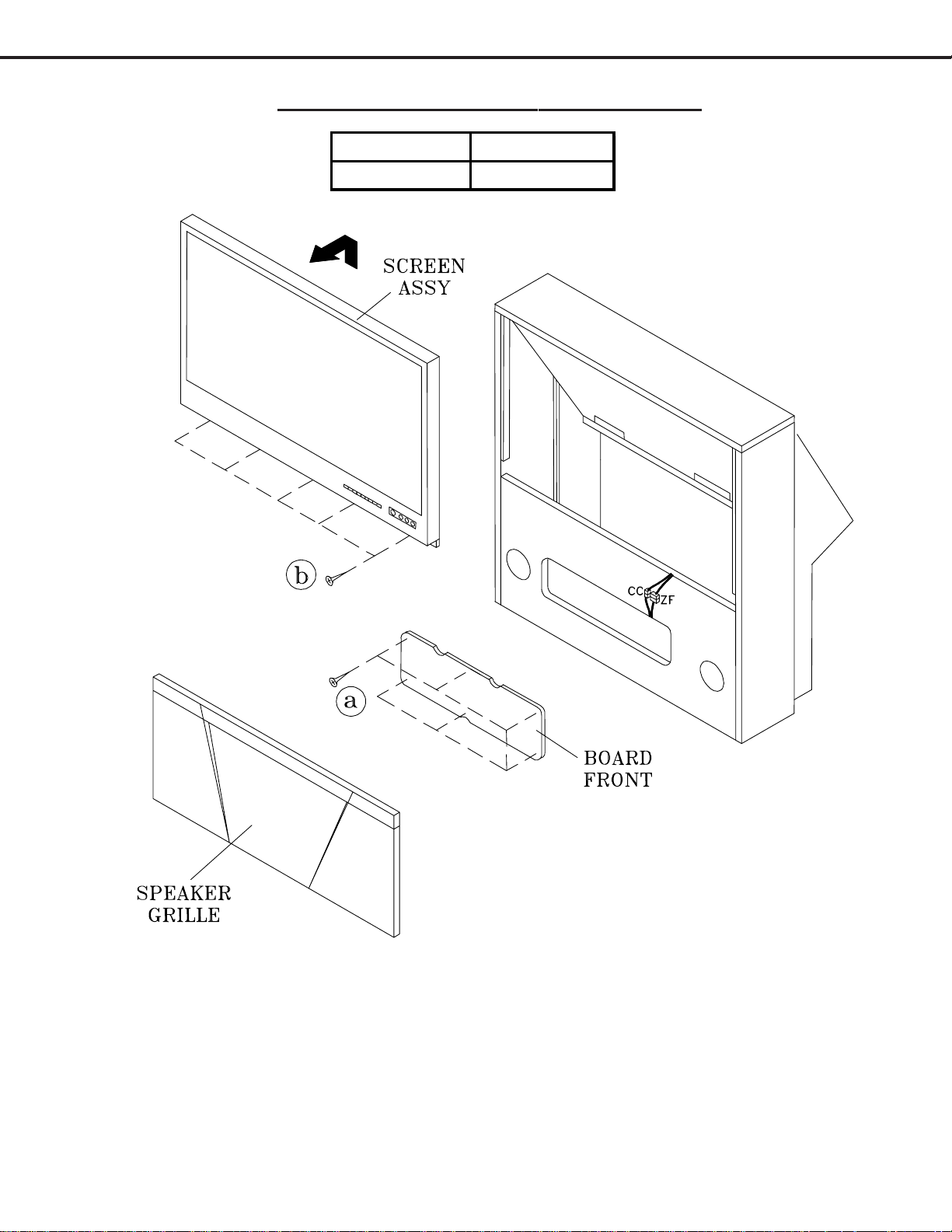

CABINET DISASSEMBLY (FRONT VIEW)

WS-48313 WS-48413

*Refer to PARTS LIST for Part Numbers

Front Cabinet Disassembly

1. Remove the Speaker Grille by pulling forward.

2. Remove the Board-Front by removing six screws "a".

3. Remove the Screen Assembly by removing four screws "b". Disconnect all cable harnesses between the

Screen Assembly and the PCB-Signal.

4. Lift the Screen Assembly and pull up and away from the cabinet as shown.

Page 7

Page 8

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

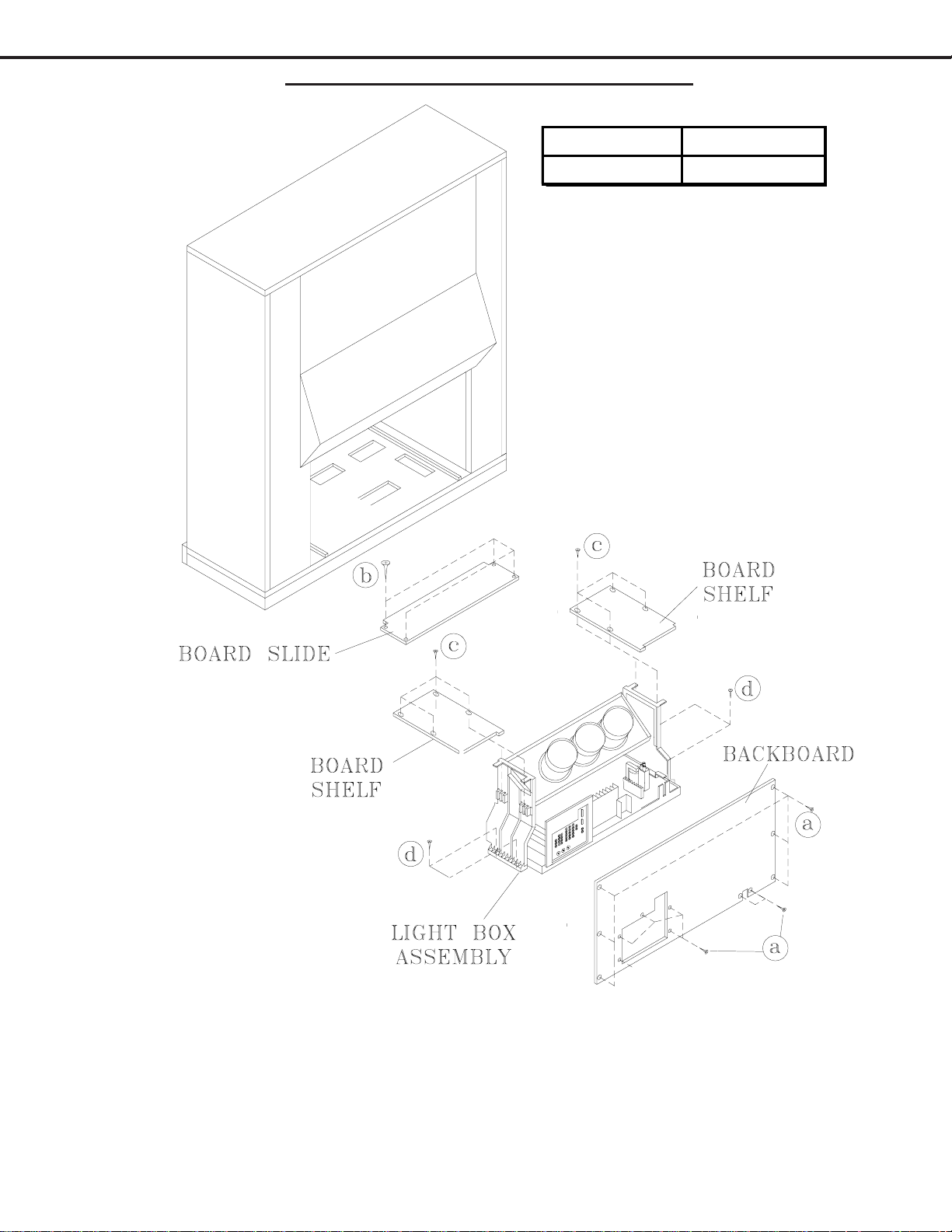

CABINET DISASSEMBLY (REAR VIEW)

WS-48313 / WS-48413

Rear Cabinet Disassembly

1. Remove the Back Board by removing 14 screws "a", b and c.

2. Remove the Back Cover by removing screws "e".

3. Remove 4 screws "d" securing the Light Box Assembly.

4. Be certain that all cables and connectors between the Light Box Assembly and external items are disconnected (e.g. speaker plugs).

5. Slide the Light Box Assembly out of the cabinet.

Page 8

Page 9

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

CABINET DISASSEMBLY (FRONT VIEW)

WS-55313 WS-55413

WS-65313 WS-65413

Front Cabinet Disassembly

1. Remove the Speaker Grille by pulling forward.

2. Remove the Front-Board by removing screws "a".

3. Remove the Screen Assembly by removing 5 screws "b". Disconnect connectors CC and ZF between the

Screen Assembly and the PCB-Signal.

4. Lift the Screen Assembly and pull up and away from the cabinet as shown.

Page 9

Page 10

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

CABINET DISASSEMBLY (REAR VIEW)

WS-55313 WS-55413

WS-65313 WS-65413

Rear Cabinet Disassembly

1. Remove the Back Board by removing 13 screws "a" (15 screws a in 65 inch models).

2. Remove the Board Slide by removing four screws b.

3. Remove the two Board Shelves by removing 8 screws c.

4. Remove 4 screws "d" securing the Light Box Assembly.

5. Be certain that all cables and connectors between the Light Box Assembly and external items are disconnected (connectors CC, ZF and EJ)).

6. Slide the Light Box Assembly out of the cabinet.

Page 10

Page 11

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

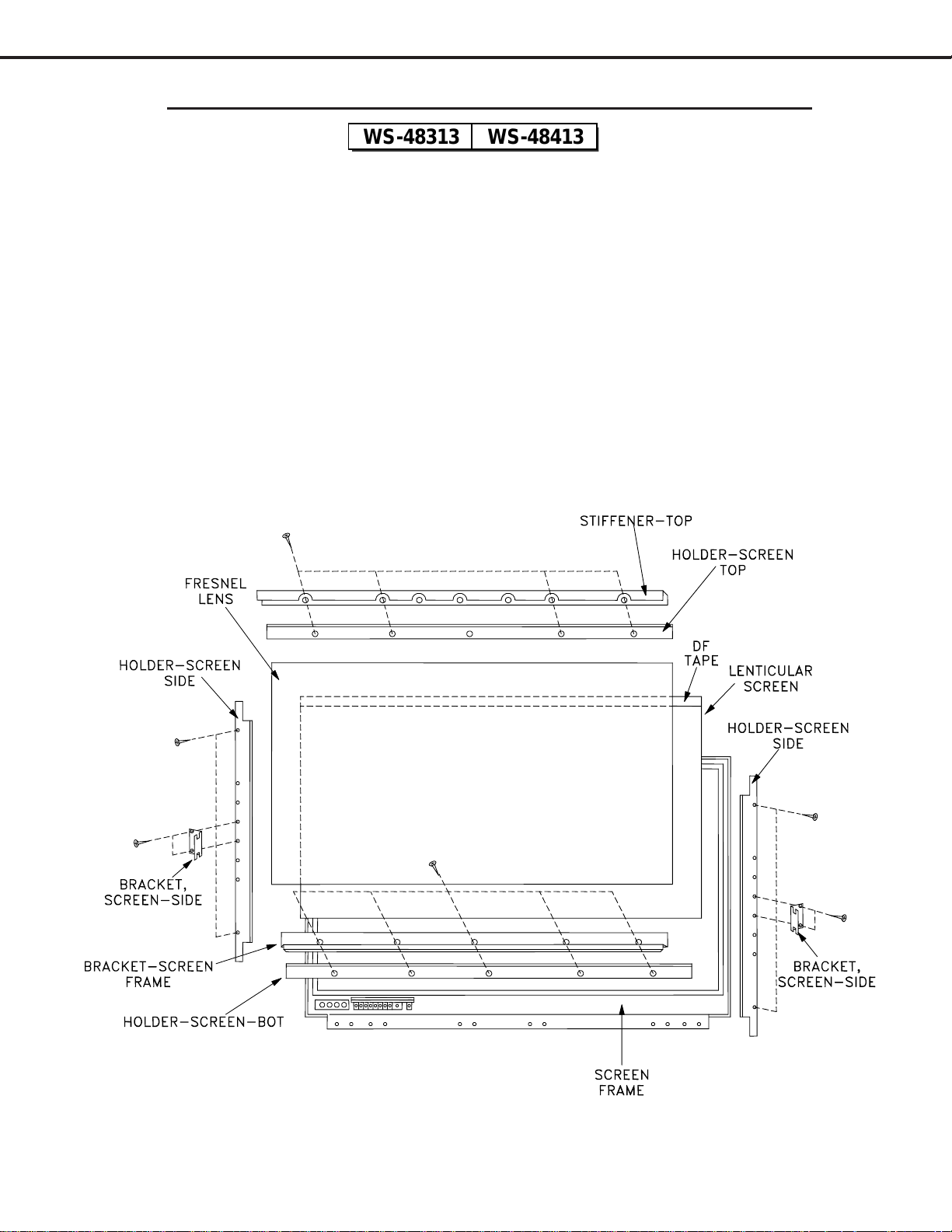

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

WS-48313 WS-48413

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

1a. Lenticular Screen and Fresnel Lens Removal

1. Remove the screen assembly as shown in the Cabinet Disassembly procedure.

2. Remove the Top, Bottom and Side Holder Screens..

3. Carefully lift the Lenticular Screen and Fresnel Lens combination from the Screen Frame Assembly.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

Page 11

Page 12

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

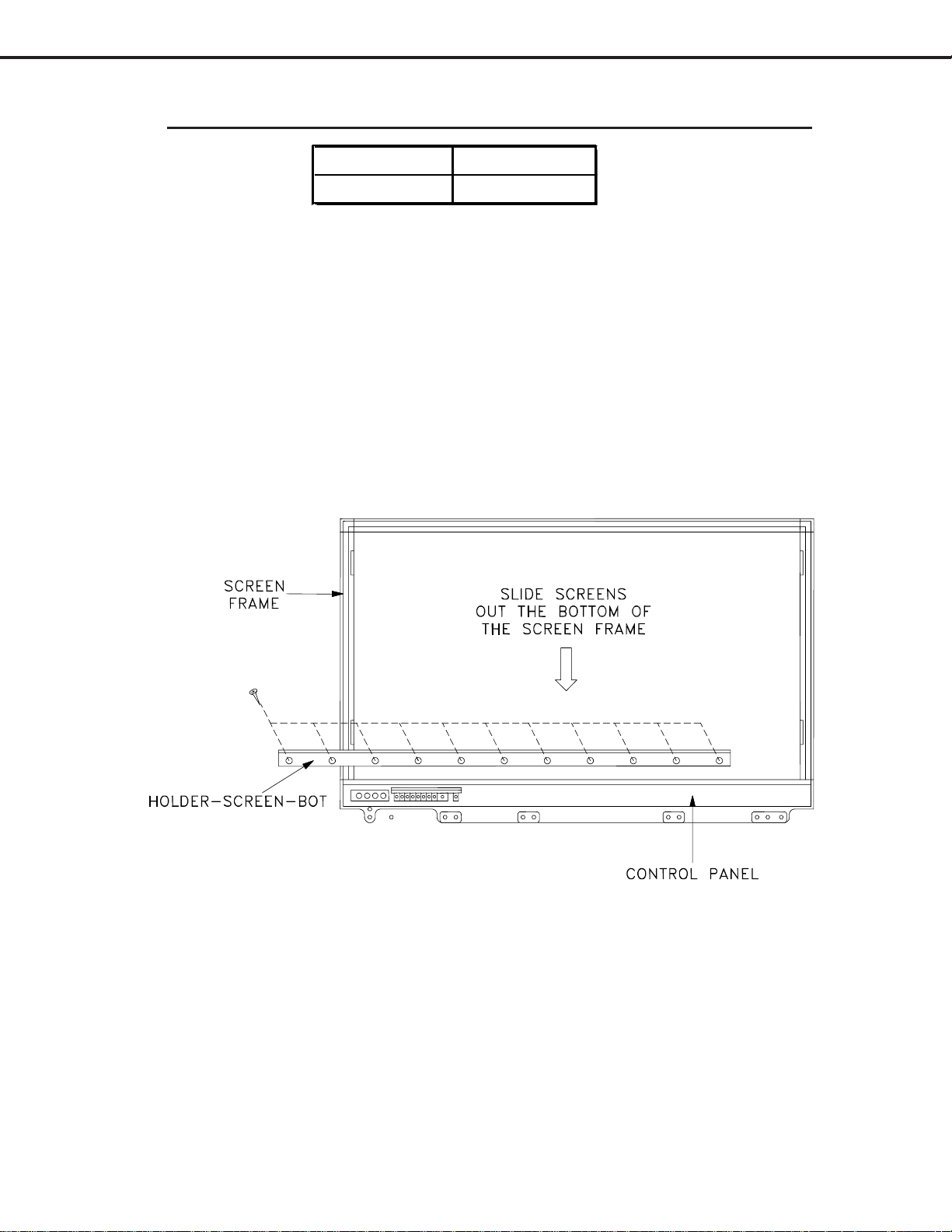

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

WS-55313 WS-55413

WS-65313 WS-65413

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

1b. Lenticular Screen and Fresnel Lens Removal

1. Remove the screen assembly as shown in the Cabinet Disassembly procedure.

2. Remove the HOLDER-SCREEN-BOTTOM.

3. Carefully slide the Lenticular Screen and Fresnel Lens combination from the upper Screen Frame Assembly.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

1b. Installing the Fresnel Lens and Lenticular Screen

1. Insert the Lenticular Screen and Fresnel Lens combination into the upper Screen Frame.

2. Install the HOLDER-SCREEN-BOTTOM, install the end screws first. .

Page 12

Page 13

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

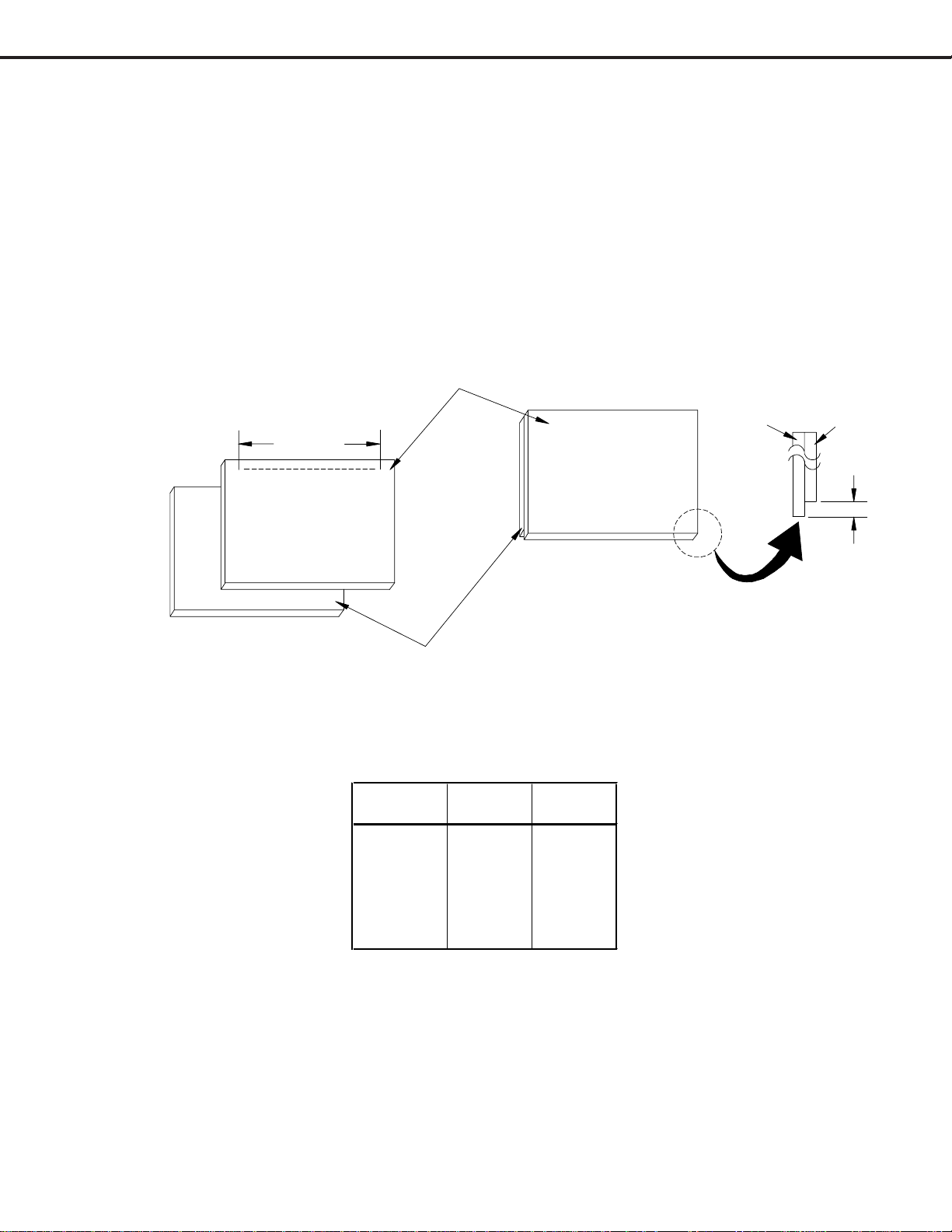

2. Installation of the Lenticular Screen and Fresnel Lens

Note: Store the Lenticular Screen and Fresnel Lens in a cool dry place. High humidity may

deform the Lenticular Screen and Fresnel Lens.

1. Apply double coated tape (Part # LENS-TAPE) along the top front edge of the Fresnel Lens

as shown in Figure 2-2. Refer to Table B for proper tape length.

2. Place the Fresnel Lens on top of the Lenticular Screen and apply pressure at the top edge to

bond them together as shown in Figure 2-2.

3. Reverse the disassembly procedure for that model to install the screens in the screen frame.

Fresnel Lens

To p

To p

( * X ) inch

Double Sided Tape

(Part# LENS-TAPE)

Fresnel

Lens

Lenticular

Screen

Bottom

Lenticular Screen

Figure 2-2

Model

Screen

Size

Tape

Length

WS-48313 48" 41.76

WS-48413 48" 41.76

WS-55313 55" 47.85

WS-55413 55" 47.85

WS-65313 65" 56.55

WS-65413 65" 56.55

Table A

Bottom

0.16 inch

Page 13

Page 14

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

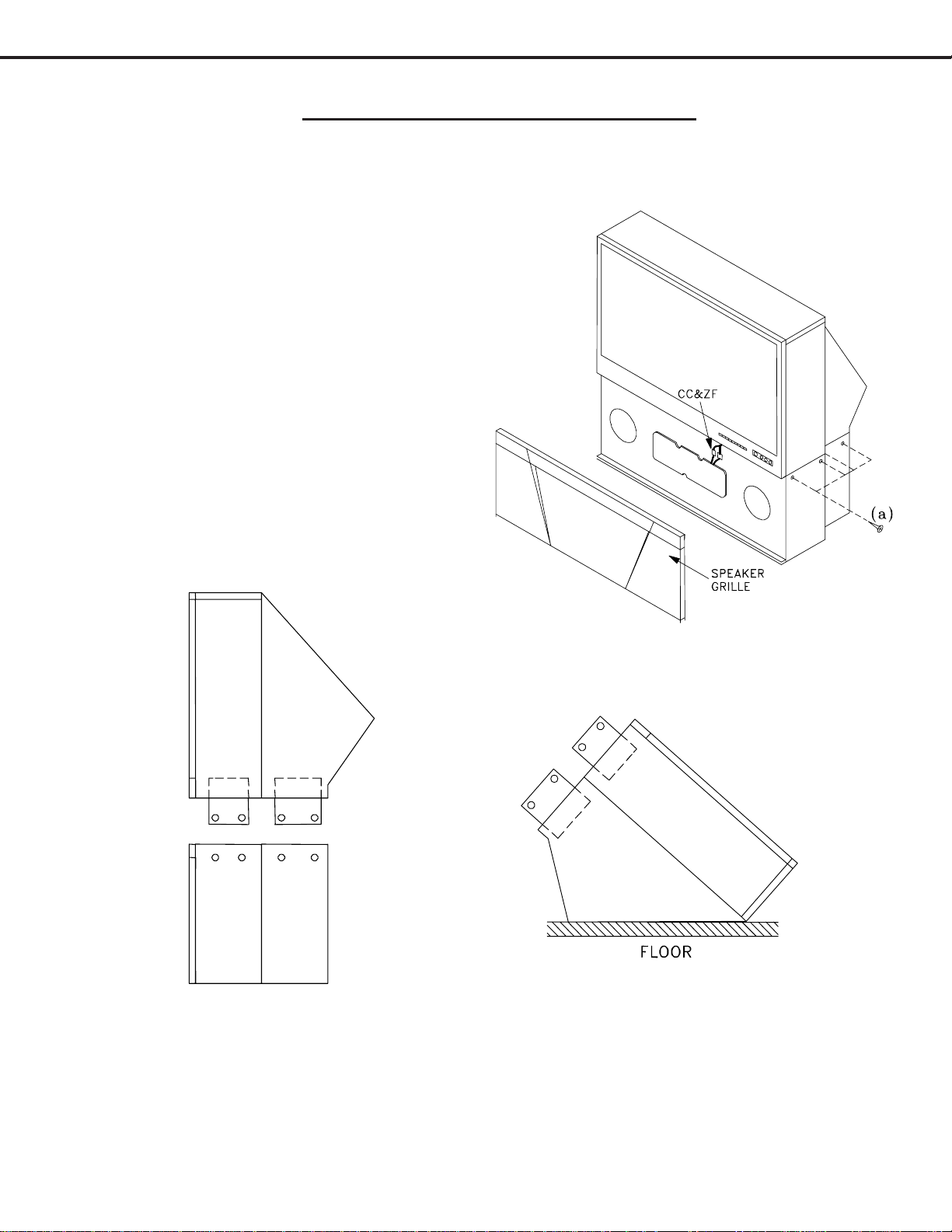

CABINET SEPARATION PROCEDURE

(WS-65313 / WS-65413)

Models WS-65313, and WS-65413 cabinets are assembled in two pieces. These two pieces may be separated to

allow easier delivery and setup.

Cabinet Separation Precedure

(Figure 1)

1. Pull the Speaker Grille off.

2. Unplug connectors CC and ZF.

3. Remove 4 screws a on both sides of the

cabinet.

(Figure 2)

4. Carefully lift the cabinet top until the support

tabs clear the bottom cabinet.

(Figure 3)

5. Carefully rotate the cabinet top and place it on

the floor.

6. Reverse the procedure and mount the cabinet

top on the cabinet bottom.

Figure 1

Figure 3

Figure 2

Page 14

Page 15

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

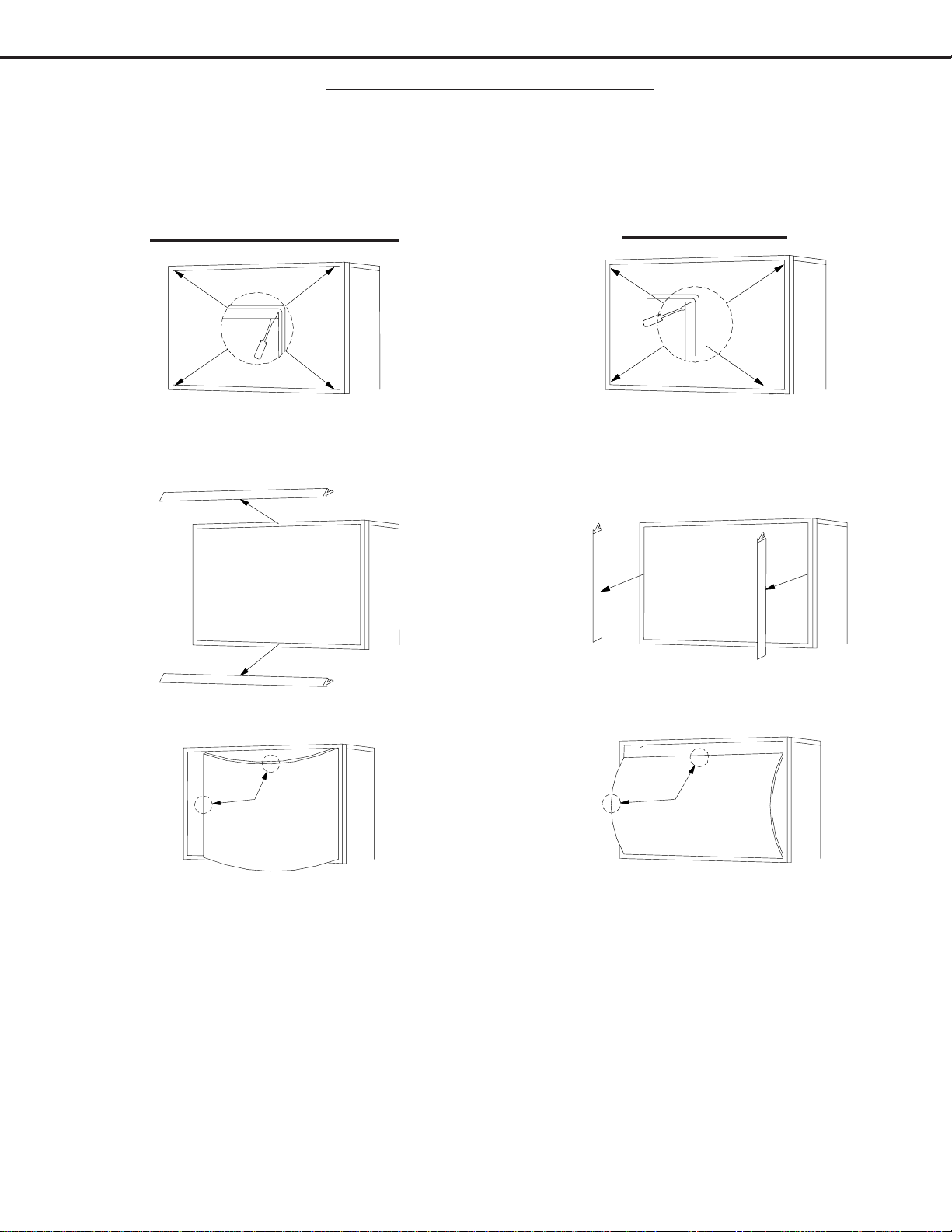

SERVICING THE DIAMONDSHIELD

1. DiamondShield Removal Procedure

The location of the DiamondShieldTM molding clips may vary between models, top and bottom, or sides. Use

the appropriate disassembly procedure given below.

Note: Wear gloves when handling the DiamondShield to prevent finger prints.

Top & Bottom Molding Clips

1. Gently insert a small screwdriver between the

DiamondShield and one end of the clip to pry

the clip loose.

Side Molding Clips

1. Gently insert a small screwdriver between the

DiamondShield and one end of the clip to pry

the clip loose.

2. Remove both clips by pulling them toward you.

3. Carefully insert a small screwdriver into the gap

at the top/center point of the Shield and pull the

Shield slightly away from the unit. Place your

hands at the points shown and gently bow the

Shield toward you and remove from the unit.

Then re-install the two clips.

2. DiamondShield Installation Procedure

*(See the Parts List for DiamondShield part numbers)

To install the DiamondShieldTM, reverse the above Removal Procedure.

2. Remove both clips by pulling them toward you.

3. Carefully insert a small screwdriver into the gap

at the side/center point of the Shield and pull the

Shield slightly away from the unit. Place your

hands at the points shown and gently bow the

Shield toward you and remove from the unit.

Then re-install the two clips.

Page 15

Page 16

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

SERVICING PCBs

Chassis Removal and PCB Locations

Chassis Removal

1) Remove screw a from the Main Chassis.

2) Raise the two chassis locks on the inner sides of the

Lightbox Assembly and slide the chassis towards the

rear.

Major Parts Locations

Page 16

Page 17

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

ANODE LEAD REMOVAL

CAUTION: To prevent damage, the following procedure must be used when removing an

Anode Lead from the Flyback Transformer.

1) Push the Anode Lead down.

3) Carefully remove the Anode Lead

1. Removal of the CRT

Caution! High voltage should be completely discharged prior to CRT removal.

Since the CRTs receive high voltage from the Flyback transformer, discharge

by shorting the open end of the respective high voltage cable to chassis ground.

from the Flyback Transformer.

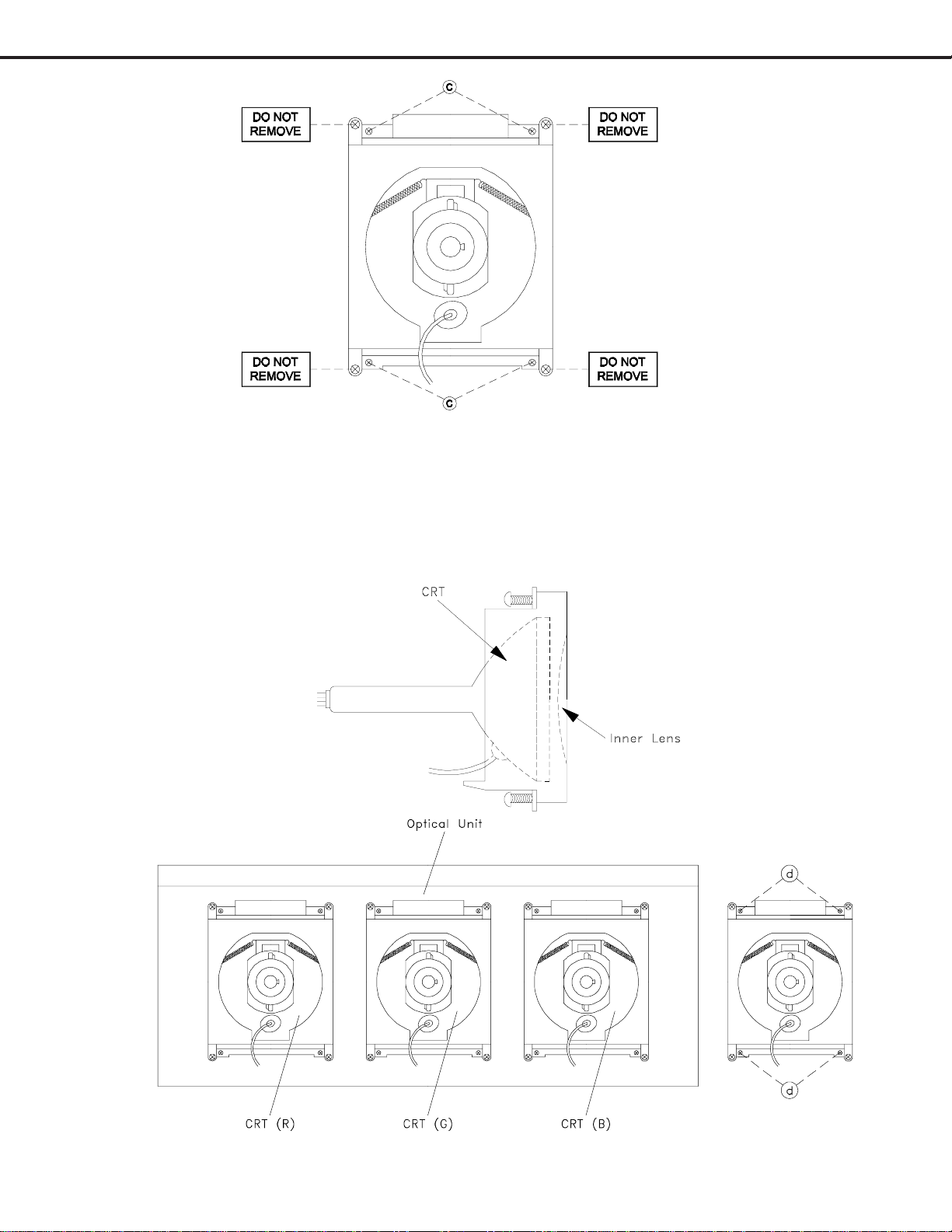

CRT REPLACEMENT

2) While holding the lead down rotate

the lead 90º counter clockwise.

Note: Refer to Cabinet Disassembly when performing steps 1 through 2.

1. Remove the Speaker Grille, Front Board, and Screen Assy.

2. Remove the Back Board.

3. Remove the Anode Lead Wire from the Flyback transformer. (Use the above procedure)

4. Remove the PCB-CRT.

5. Remove 4 hex-screws "a" retaining the Optical Unit. [Figure 5-1]

6. Remove 4 screws "b" retaining the Lens.

Note: DO NOT loosen the RED screws. Doing so will break the seal between the

C-Element and the # 6 Lens, causing leakage of the CRT Coolant.

7. Remove 4 screws "c" retaining the CRT. [Figure 5-2]

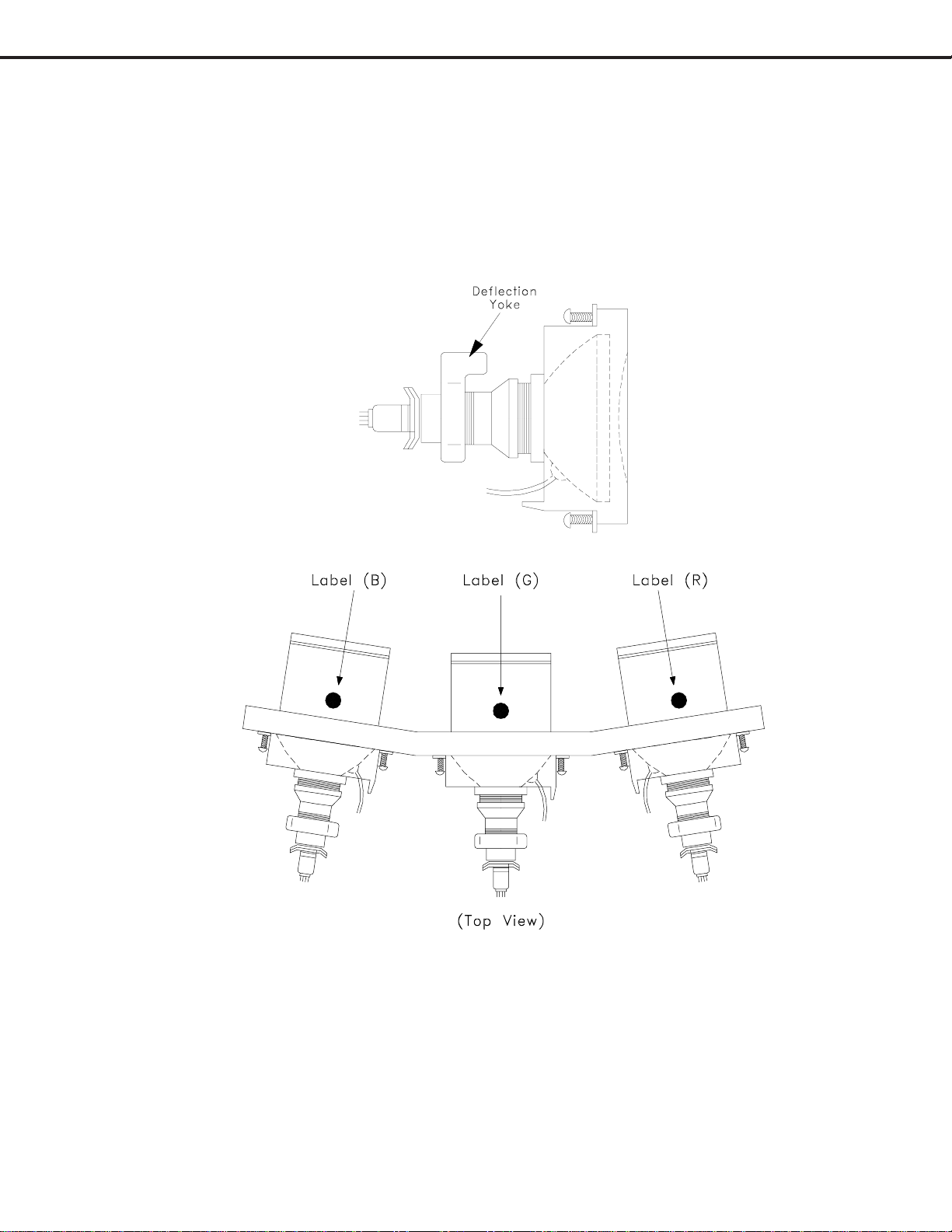

8. Remove the Deflection Yoke and other CRT components from the neck of the CRT. [Figure 5-6]

Figure 5-1

Page 17

Page 18

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

2. Installation of the CRT

Note: The 4 spring-loaded screws shown

in Fig 5-2 and labeled as "DO NOT

REMOVE", should not be loosened

under any circumstance. Doing so

will break the seal between the

CRT and the CRT-Spacer, causing

leakage of the CRT Coolant.

Figure 5-2

Note: The replacement CRT is supplied as an assembly comprised of the CRT and the

Inner Lens with the space between them filled with ethylene glycol. Care should

be taken during handling and installation to prevent shock from disrupting the seal

or alignment between the CRT and Inner Lens. [Figure 5-3]

Figure 5-3

Figure 5-4

Page 18

Figure 5-5

Page 19

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

1. Carefully position the replacement CRT and fasten in place using 4 screws "d". [Figure 5-5]

2. Install the Deflection Yoke and other CRT components back in there original position on the CRT neck.

[Figure 5-6]

3. Install the Lens that was removed in step6 of Removal Of The CRT. [ Figures 5-1 and 5-2 ]

a) Position the Lens so that the Label faces the direction shown in Figure 5-7

b) Install the mounting screws b. [Figure 5-1]

4. Insert the Optical Unit into the Light Box Assembly.

5. Install the PCB-CRT.

6. Insert the Anode Lead Wire into the Flyback Transformer.

7. Re-clamp the Lead Wire in its original position.

Figure 5-6

Figure 5-7

Adjustment procedures after replacing the CRT(s)

CRT Cut Off / White Balance Adjustment

Static Convergence Adjustment

Dynamic Convergence Adjustment

Page 19

Page 20

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

ELECTRICAL ADJUSTMENTS

Note: Perform only the adjustments required.

Do not attempt an alignment if proper equipment is not available.

1. Test Equipment

Oscilloscope (Unless otherwise specified, use 10:1 probes)

Signal Generator (both SD and HD capable)

Frequency Counter

Direct Current Voltmeter

Direct Current Power Supply

Multiplex Audio Signal Generator

Direct Current Ampere Meter

2. Test Signal

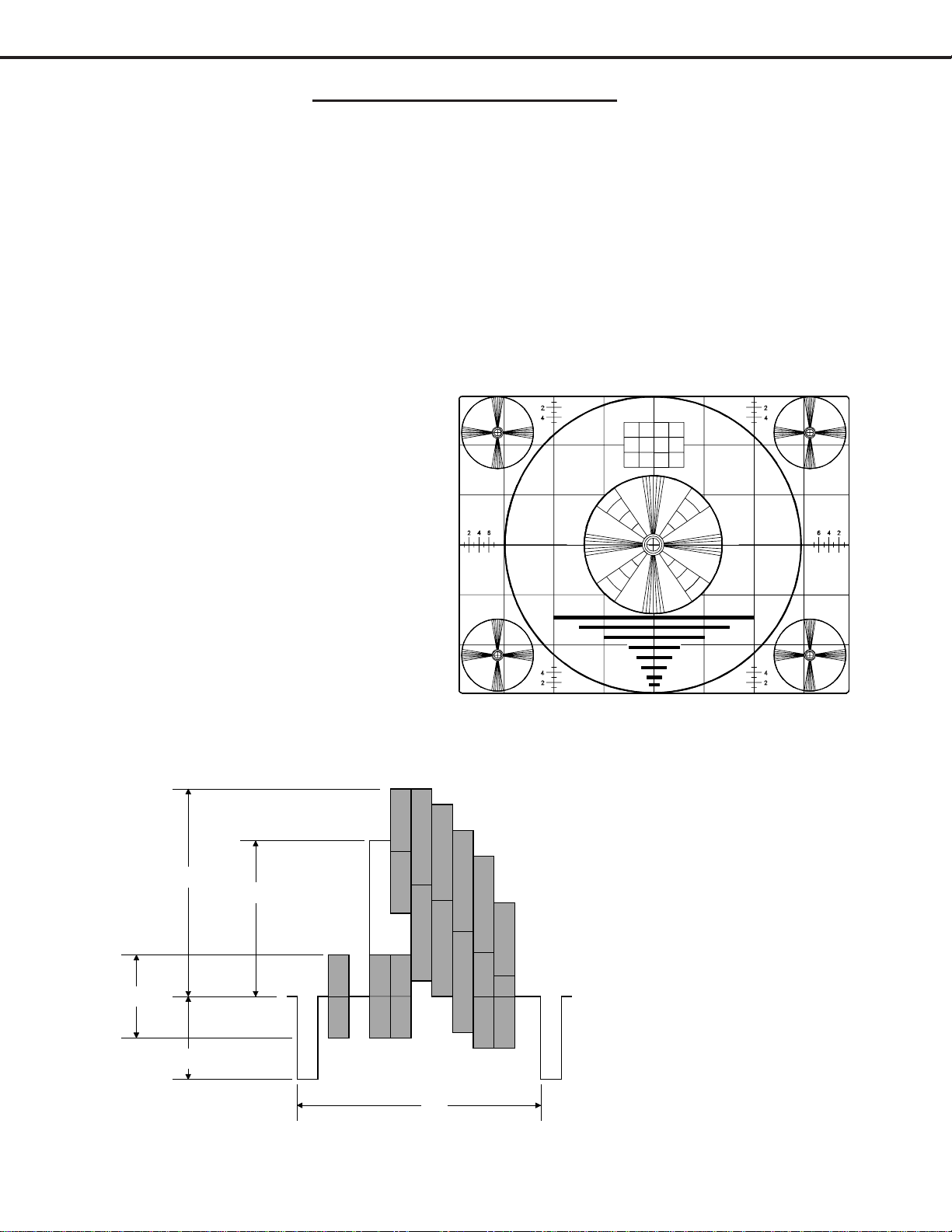

A. Monoscope Signal

Note: If you do not have

a monoscope signal source,

connect the unit to a VCR

and play a Monoscope

*alignment tape.

(* Part Number: 859C568060)

B. Color Bar Signal

Use the color bar signal shown

below, unless otherwise specified

in this manual.

100%

75%

40%

40%

Monoscope Signal

1H

Split-Field Color Bars (100% window)

Page 20

Page 21

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

®

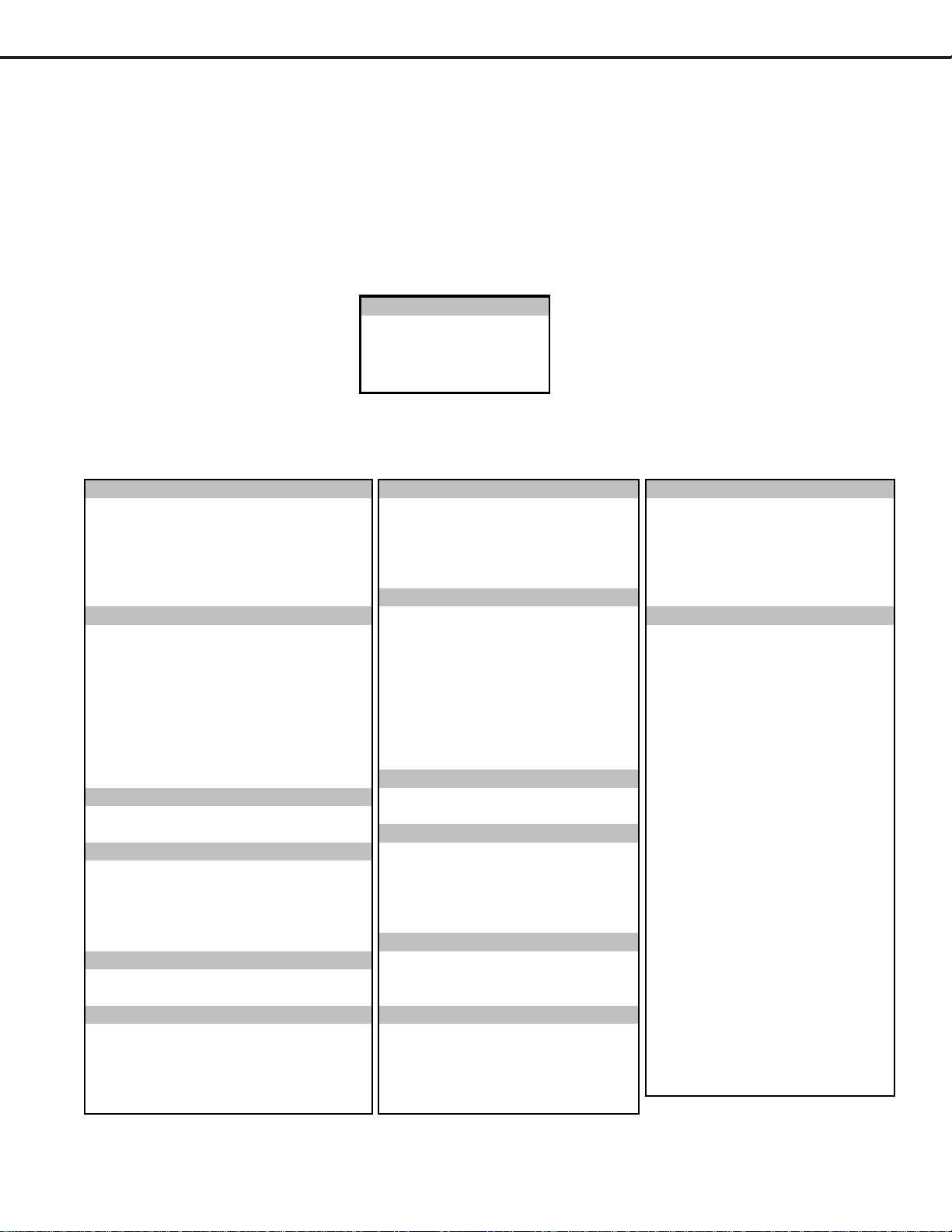

3. Initial Setup

A. Option Menu Setup

Follow the steps below for the initial set-up:

1. Select the "MENU" display by pressing the "MENU" button once.

2. Press the number buttons "0", "3", "7", "0" in sequence to select the "OPTION MENU" display.

3. Press the "ADJUST" button to select "INITIAL."

4. Press "ENTER."

NOTE: At this time channel 3 is automatically selected.

MENU-0-3-7-0

OPTION MENU

Initial

Power Restore :OFF

DTV Port :Auto

Direct Key Mod :OFF

B. Default Settings

MAIN MENU DEFAULT SETTINGS

SETUP Menu

Memorize Channels Ant-A Air Lock by Time Off Magenta 50%

Input Assignment (V22) Lock Time N/A Red 50%

NetCommand® IR Setup (V22+) Unlock Time N/A Yell o w 50%

Clock Front Button Lock Off Green 50%

Language English V-Chip Cyan 50%

Energy Mode Low Blue 50%

INPUT ASSIGNMENT Menu (V2 2)

Antenna-A On TV Rating TV-PG A/V Memory Reset Ant A

Antenna-B On FV-Fantasy Violence Allow TV Speakers (Internal) On

DTV YPrPb D-Sexual Dialog Allow Audio Output Variable

Component-1 Comp-1 L-Adult Language Allow

Component-2 C omp-2 S-Sexual Situati o n Allow TV Bass 50%

Input-1 Input-1 V-Violence Allow TV Treble 50%

Input-2 Input-2 Movie Rating PG TV Balance 50%

Input-3 Input-3 Programs Not Rated Allow TV Surround Off

MonLink M onLink TV Listen To Stereo

Welcome to NetCommand® IR (V22+)

Language English V-Chip Stop Time 12:00am VIDEO SETTINGS

NetCommand

Clock Setting Manual Timer TV Sharpness 50%

Clock Time --:-- Convergence TV Color 50%

Set Day Sunday Video Mute On TV Tint 50%

Time Zone N/A Black Enhancement On TV Color Temp High

Daylig ht Savings Time N /A TV Video Noise Standard

CAPTIONS Menu Ant-A Auto Color Correction Off TV Film Mode (Auto) On

Closed Captions In Mute PerfectColor™ TV VSM (V22+ Only) On

CC Background Gray Reset Color for Ant-A TV Volume 30%

CHANNEL EDIT Menu TIMER Menu PIP Source Ant A Ch 3

Antenna ANT-A Timer Off PIP Position Lower Right

Channel 003 Set Time 12:00 am POP Position Right Half

Memory Deleted Set Day Everyd ay

Name N/A Input Ant-A PIP/POP Format Dble Win

SQV N/A Channel 003

IR Setup

CLOCK M enu Color Balance TV Brightness 50%

V-Chip Off

V-Chip Start Time 12:00am TV Level Sound Off

V-CHIP LOCK Menu

V-CHIP Menu

V-CHIP Hours

ADVANCED FEATURES Menu

COLOR BALANCE Menu

AUDIO/VIDEO SETTINGS Menu

AUDIO SETTINGS

TV Contrast 100%

Format

PerfectColor™

Stretch

Page 21

Page 22

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Items in the table below are set to following after Initalization.

AV Memory Initial Settings

A/V Memory

TV Contrast

TV Brightness

TV Sharpness Center Center Center Center Center

TV Color Center Center Center Center Center

TV Ti nt Center Center Center Center Center

TV Color Temp. High High High High High

Video Noise Standard Standard Standard Standard Standard

TV Image Type Video Video Video Video Video

TV SVM

Sharpness

TV Bass Center Center Center Center Center

TV Treb le Center Center Center Center Center

TV Balance Center Center Center Center Center

TV Surrond Off Off Off Off Off

TV Listen To Stereo Stereo Stereo Stereo Stereo

TV Level Sound

Ant-A

Ant-B

Max Max Max Max Max

Center Center Center Center Center

On On On On On

Off Off Off Off Off

DTV

NTSC

1/2/3

COMP

1/2

MonLink

4. LED Indicator Diagnostics

The Power ON LED provides an indication of the sets operation, and the possible cause of a malfunction.

A. Initial Control Circuitry Check

Immediately after the TV is connected to an AC power source:

The LED flashes three times ... indicating the Microprocessor has initialized and is functioning

properly.

If the LED does not flash ... the Microprocessor is NOT functioning.

B. Error Code Operational Check

Note: The TV must be in Shut Down and not heve been switched Off, to perform the Error Code Opera-

tional Check. When the TV is switched Off, the code automatically resets to 12 No Error.

Pressing the front panel INPUT and MENU buttons at the same time, and holding for 5 seconds,

activates the Error Code Mode. The LED flashes denoting a two digit Error Code, or indicating no problem

has occured since the last Initalization.

Note: The front panel buttons must be used, NOT those on the Remote Control.

The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

The flashing then pauses for approximately 1/2 second.

The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

The Error Code is repeated a total of 5 times.

Example: If the Error Code is 23, the LED will flash two times, pause, and then flashes three

times.

C. Error Codes

The Error Code designations indicating a malfunction, or no malfunction, are listed below:

Error Co d e De scrip tion

12 No e rror h as oc curre d.

21 X-Ray P rotect c ircuit.

22 S hort P rotect circuit.

23 De flect ion failure.

Page 22

Page 23

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

1

2

3

5

6

789

0

SQV

QV

4

POWER

HOME

PAUSE

REC

FF/FWDREW/REV

PLAY

STOP

VOLUME

INFO

CANCEL

MENU

PIP/POP

PIP SIZE

PIP CH

INPUT

SLEEP

VIDEO

AUDIO

MUTE

CHANNEL

ENTER

PIP INPUT

EXCH

GUIDE

TV

AUDIO

CABLE/DBS

DVD

VCR

g

5. Circuit Adjustment Mode

Except for the following, all adjustment items must be performed

using the remote hand unit.

CRT Cutoff

Lens Focus

Electrostatic Focus

FUNCTION CHASSIS

Video Chr V 22

A. Activating the Circuit Adjustment Mode

1. Press the "MENU" button on a remote hand unit.

2. Press the number buttons "0", 3", "5", "7" in sequence.

The screen will change to the Adjustment Mode.

Note: Repeat steps 1 and 2 if the circuit

adjustment mode display does not appear

on screen

B. Selection of adjustment Functions and

Adjustment Items

To select an adjustment item in the circuit adjustment mode,

first select the adjustment function that includes the specific

adjustment item to be selected. Then, select the adjustment

item.

Refer to the following pages for the listing of adjustment

functions and adjustment items.

1. Press the "AUDIO" button on a remote hand unit to

select an adjustment function. Each time the button

is pressed, the Function changes in the following

sequence:

MODE

ITEM#

Mode 0 NTSC

SIGNAL

1SCT55

ABBREV. DATA

VIDEO

AUDIO

Video Chr Defl Jun

FUNCTIONS

HR Sub Matr Main Matr

2. Press the VIDEO button to select a specific

Adjustment Item. The Item number increases each

time the VIDEO button is pressed.

C. Changing Data

After selecting an adjustment Item, use the ADJUST

UP/DOWN button to change data.

Press ADJUST DOWN to decrease the data value.

Press ADJUST UP to increase the data value.

Page 23

ENTER

ADJUST

UP/DN

MENU

Page 24

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

D. Saving Adjustment Data

Press ENTER to save adjustment data in memory. The character display turns red for

approximately one second in this step.

Note: If the circuit adjustment mode is terminated without pressing ENTER, changes

in adjustment data are not saved.

E. Terminating the Circuit Adjustment Mode

Press the MENU button on the remote hand unit twice to terminate the adjustment mode.

Note: The circuit adjustment mode can also be terminated by turning power OFF.

F. Service Mode Reset

To reset items in the service mode to their factory values:

1. Press MENU-0-3-5-7 to enter the Service Mode.

2. Press the INPUT or DEVICE button, on the front panel or the remote, and hold for 2 seconds.

6. Convergence Adjustment Mode

The Convergence mode is used to perform raster geometry correction, and convergence adjustments as

specified in Adjustment Procedures 15 through 18.

A. Convergence Mode Activation

1. Press MENU-0-3-5-9

2. When the Convergence Mode is activated, the display at

the right appears on a Green Crosshatch.

SD Coarse GREEN

1HSTA -50

Coars e Conv. Di s play

B. Selecting the HD or SD Mode

1. Select the Signal Source before entering the Convergence Mode, either an NTSC or HD source.

2. Enter the Convergence Mode (MENU-0-3-5-9)

If the signal source is NTSC, the SD mode is activated.

If the signal source is HD 1080i, the HD mode is activated.

3. Activating the HD mode when no HD signal is available.

Activate the Factory Option Menu (MENU-0-3-7-0)

Use the Adjust keys to select DTV Port and press Enter to change the setting to 1080i.

Sequence = Auto-480i-480p-1080i. Ignore any loss of sync while changing modes.

Exit the Option Menu (Press MENU twice).

Select the DTV Inputs as the signal source (INPUT or DEVICE button).

Activate the Convergence Mode ... the Convergence mode will be in the HD mode and the internal

crosshatch is displayed.

4. After adjusting Convergence, be sure to set the DTV Port back to AUTO.

Select an analog input as the signal source (INPUT or DEVICE button).

Activate the Option Menu (MENU-0-3-7-0).

Use the Adjust keys to select DTV Port and press Enter to change the setting from 1080i to

AUTO.

Exit the Option Menu (Press MENU twice).

C. Convergence Mode Functions

In the Convergence Mode there are three main Functions (Categories).

Pressing 6 activates CONV MISC

Pressing 5 activates COARSE CONV

Pressing 4 activates FINE CONV

Page 24

Page 25

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

D. CONV MISC (Press 6)

This mode is used to preset data values controlling the Convergence Generator, and to perform the HV

Regulation adjustment.

1. Use the VIDEO button to select an item.

2. Use the ADJUST buttons to change data.

Note: When Item 1 HVOL is selected the screen goes black except for the data display.

This occurs since a black screen is required when making the HV Regulation adjustment.

E. COARSE CONV (Press 5)

There are four Sub Functions in the Coarse mode, COARSE GREEN, RED and BLUE, and DF.

COARSE GREEN .... used to make Coarse Raster Geometry Adjustments.

COARSE RED ... used to make Coarse Red Convergence Adjustments.

COARSE BLUE ... used to make Coarse Blue Convergence Adjustments.

DF ... used to preset data values controlling the Dynamic Beam Focus circuit drive signal.

1. Use AUDIO button to select a Sub Function

2. Use the VIDEO button to select an Adjustment Item.

3. Use the ADJUST buttons to change data.

F. FINE CONV (Press 4)

Sub Functions

This mode is used to perform Fine Raster Correction, and Fine Red and Blue Convergence Adjustments.

There are three Sub Adjustment Functions, selected with the AUDIO button:

FINE GREEN .... a Green Crosshatch is displayed, for Fine Raster Corrections.

FINE RED .... a White Crosshatch is displayed, for Fine Red Convergence Adjustments.

FINE BLUE .... a White Crosshatch is displayed, for Fine Blue Convergence Adjustments.

Cursor

In the Fine mode a Cursor is added to the Crosshatch. The ENTER button toggles the Cursor between two

modes:

MOVE (blinking Cursor) .... use the ADJUST buttons to select any of 64 points on the Crosshatch.

ADJUST (Non blinking Cursor) .... the ADJUST buttons adjust the active color at the current Cursor

position, horizontally or vertically.

Page 25

Page 26

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Cursor Coordinates

Specific intersections in the Crosshatch are assigned vertical and horizontal coordinates.

These are shown in the preceeding diagram. The Cursor can only be moved to those positions that

have coordinates assigned. If the Cursor is at coordinates outside the screen area, the Cursor will not be

visible. Use the ADJUST buttons to move the Cursor to an intersection on the screen.

Display

The on-screen display changes in the Fine mode, as shown below.

The display shows the vertical and horizontal data for the current

Cursor Position, and the horizontal and vertical coordinates for

that position.

Horiz. H Coor d. V Coor d. Vert.

Data Data

SD Fine RED

13 H1 V3 -32

F. Saving Data and Exiting the Convergence Mode

Press MENU twice to exit the Convergence mode, data is automatically saved.

Note: If power is interrupted, or the CANCEL button is presssed prior to properly exiting the Convergence

Mode, changes in adjustment data will not be saved. The data is restored to the last saved previous

values.

ADJUSTMENT ITEMS LIST

Video Chroma Function

Data

Item# Abbrev. Description Range 480i 480p 1080i Adjustment

1 SCT Picture Gain control 0~63 42 42 42 Sub Contrast

2 SBRT Sub Brightness 0~63 20 20 20 Black Level

3 SCON Sub Contrast 0~15 7 7 7 Preset

4 RDRH R Drive (H temp) 0~63 31 31 31 White Balance

5 GDRH G Drive (H temp) 0~63 41 41 41 Preset

6 BDRH B Drive (H temp) 0~63 31 31 31 White Balance

7 CTRH R Cutoff (H temp) 0~63 31 31 31 "

8 CTGH G Cutoff (H temp) 0~63 31 31 31 Preset

9 CTBH B Cutoff (H temp) 0~63 31 31 31 White Balance

10 RDRL R Drive (L temp) 0~63 31 31 31 "

11 GDRL G Drive (L temp) 0~63 41 41 41 Preset

12 BDRL B Drive (L temp) 0~63 31 31 31 White Balance

13 CTRL R Cutoff (L temp) 0~63 31 31 31 "

14 CTGL G Cutoff (L temp) 0~63 31 31 31 Preset

15 CTBL B Cutoff (L temp) 0~63 31 31 31 White Balance

16 GMMA RGB Gamma Correction 0~3 2 2 2 Preset

17 GAML Gamma Differential Corr. Switch 0~1 0 0 0 "

18 BRT Brightness 0~63 31 31 31 "

19 COL Color 0~63 38 34 33 White Balance

20 TINT Tint 0~63 29** 30 29 Preset

21 SHRP Sharpness 0~63 31 31 31 "

22 CBOF Cb DC Offset 0~63 31 31 31 "

23 CROF Cr DC Offset 0~63 31 31 31 "

31 VMLE VM Output Level 0~3 1 1 2 "

40 AGIW White output aging mode switch 0~1 0 0 0 "

55 ABLT Threshold Adjust for ABL input 0~15 4* 4* 4* "

* For models WS-55413, WS-65313 & WS-65413 set data to 0

**For models WS-48313 and WS-48413 set #20 TINT data to 29

For models WS-55313 and WS-55413 set #20 TINT to 28

For models WS-65313 and WS-65413 set #20 TINT data to 30

Page 26

Page 27

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Deflection Jungle

WS-65413WS-65313WS-48313 WS-48413 WS-55313 WS-55413

Item Abbrev. Description Range NTSC HD NTSC HD NTSC HD NTSC HD NTSC HD NTSC HD

1 HWID Width 0~63 30 29 30 29 23 22 25 25 32 32 30 28

2 HKEY Horiz. Keystone 0~63 24 25 24 25 24 25 24 25 24 25 24 25

7 VHGT Height 0~63 18 16 18 16 14 13 28 28 36 31 33 31

8 VLIN Vert. Linearity 0~15 5 5 5 5 5 5 5 5 7 7 7 7

9 VSCN Vert. S Corr. 0~15 0 0 0 0 0 0 0 0 0 0 0 0

18 VPOS Vert. Position 0~63 31 31 31 31 31 31 31 31 31 31 31 31

36 PINA Pincushion Comp. 0~63 10 8 10 8 10 8 10 8 10 8 10 8

MAIN MATRIX MENU-0-3-5-7

Data

Item# Abbrev. Description Range Initial

39 SCNT Main Y-Out 0~31 16

41 SCLR CbCr Amp 0~31 16

SUB MATRIX MENU-0-3-5-7

Data

Item# Abbrev. Description Range Initial

39 SCNT Main Y-Out 0~31 16

41 SCLR CbCr Amp 0~31 16

HR MENU-0-3-5-7

Item# Abbrev. Description Initial

1 HR NTSC Disp.Pos. 29

CONVERGENCE MODE ITEMS

CONV M IS C. MENU-0-3-5-9-6

Da ta

Item# Abbrev. De scrip tio n Ra n ge SD HD

1 HVO L HV A djus t 0~352 150 150

2 VC NT V-s aw am plitude 0~127 29 29

3 VSTR V-s aw s t art tim er 0~127 0 10

4 VO FS V-s aw offset 0~ 127 10 8

5 S TLN St art line 0~ 127 38 26

6 FP HS F ine phase 0~ 352 303 294

7 CPHS Coarse phas e 0~ 31 15 15

8 HOFS H-saw offset 0~ 127 22 22

9 DPHS DF coars e horiz phas e 0~ 31 1 1

10 DOF S DF offs et 0~ 127 34 34

11 TPHS Test P att ern phase 0~352 43 39

12 TPV D Test P att ern Vert. P os ition 0~127 23 39

13 O DE V Odd/ E ven detec ti on 0~ 352 24 42

14 HRTC H-s aw ret race 0~ 3 1 1

15 DRTC DF retrac e 0~3 1 1

16 DA C E x ternal DA C s elec tion 0~ 1 1 1

17 E P WP EE P RO M write protec tion 0~1 0 0

Page 27

Page 28

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

y

COARS E CONV GREEN MENU 0-3-9-5

# Abbrev. Description WS-55313 WS-65413

WS-48413

WS-55413 WS-65313WS-48313

SD HD SD HD SD HD SD HD SD HD SD HD

1HSTAHoriz. Position 000000000000

2VSTAVert. Position 000000000000

3 SKEW Skew (Y axis) 0 00000000000

4TILTTilt (X axis) 000000000000

5 HWID Width 20 20 20 20 20 20 20 20 20 20 20 20

6 H LIN Horiz. Linearity 0 00000000000

7SPCCSide PC Corr. 000000000000

8HKEYHoriz. Keystone23202320151020200000

9 TBPC Top/Bottom PC -180 -160 -180 -160 -190 -165 -190 -180 -200 -175 -200 -175

10VKEYVert. Keystone 000000-480000

11 VWID Height 30 20 30 20 30 20 30 20 30 20 30 20

12 VLIN Vert. Linearit

000000000000

COARS E CO NV RED MENU 0-3-9-5

# Abbrev. Description WS-55313 WS-65413

WS-48313 WS-48413 WS-55413 WS-65313

SD HD SD HD SD HD SD HD SD HD SD HD

1 HSTA Horiz. Position 50 50 50 50 50 50 50 50 50 50 50 50

2VSTAVert. Position 000000000000

3 SKEW Skew (Y axis) 5 50000550000

4TILTTilt (X axis) 000000000000

5 HLIN Horiz. Linearity -220 -200 -220 -200 -215 -195 -195 -18 0 -170 -150 -170 -150

6HWIDWidth 000000-10-510101010

7 VKEY Vert. Keystone -90 -90 -90 -90 -75 -75 -90 -70 -90 -75 -90 -75

8VWIDHeight 0000000000010

9VLINVert. Linearity 000000000000

10 TBPC Top/Bottom PC 20 20 20 20 20 20 20 20 20 20 20 20

11SDBWSide Bow 303030303030303030303030

COARS E CO NV BLUE MENU 0-3-9-5

# Abbrev. Description WS-55313 WS-65413

WS-48313 WS-48413 WS-55413 WS-65313

SD HD SD HD SD HD SD HD SD HD SD HD

1 HSTA Horiz. Position -50 -50 -50 -50 -50 -50 -50 -50 -50 -50 -50 -50

2VSTAVert. Position 000000000000

3 SKEW Skew (Y axis) 0 -5 0 0 0 -5 000000

4TILTTilt (X axis) 000000000000

5 HLIN Horiz. Linearity 220 200 220 20 0 220 205 195 180 175 160 175 160

6 HWID Width 0 0 0 -15 0 0 -10 -15 10 10 10 10

7 VKEY Vert. Keystone 90 90 90 90 90 70 90 70 80 75 80 75

8VWIDHeight 000000000000

9VLINVert. Linearity 000000000000

10 TBPC Top/Bottom PC 0 0 -20 0 0 0 -20 0 -20 0 -20 0

11 SDBW Side Bow -30 -30 -30 -30 -30 -30 -30 -30 -30 -30 -30 -30

DF MENU-0-3-5-9-5

WS-48313 / WS-48413

Item Abbr.

0 DFH -220 -220 -280 -250

1 DFV -100 -100 -110 -95

WS-55313

SD Data HD Data SD Data HD Data

WS-55413 / WS-65313

WS-65413

Page 28

Page 29

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Adjustment Test Point Location

DT pin 3 - HV Adjust

DT pin 6 - Ground

DT pin 7 - 12 Volts

DT pin 8 - ACL

JA pin 22 - Main Picture (Y)

JA pin 20 - Main Color (Pr)

JB pin 3 - Sub Picture (Y)

JB pin 5 - Sub Picture (Cr)

TP6(R, G or B) - CRT Cathode

Page 29

Test Points

Page 30

[HV Circuit]

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Purpose:

To set the CRT Anode voltage.

1. HV Regulation

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

DC Voltmeter

DT connector pins 3 & 6

------

-------

Video Signal

Monoscope

Video Input

Symptom:

Note: This adjustment must be rechecked following Adjustment 9 CRT Cutoff.

1. Supply a video monoscope signal.

2. Set Contrast to maximum, and Brightness to mid position.

3. Connect a DC volt meter between pins 3 and 6 of the DT connector.

(Positive lead to pin 3)

4. Activate the Conv-Misc Mode.

5. Select Item 1 HVOL (screen goes black).

6. Adjust Item 1 HVOL for 15.4V ±0.02V on the meter.

7. Save data and exit the Conv-Misc mode.

8. Confirm that the voltage does not change more than 0.15V.

Note: This adjustment must be performed if E2RESET or Convergence E2RESET

are activated.

Dark Picture

CONVERGENCE MODE

Activate ……..MENU-0-3-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G or B)……AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

[Video Circuit]

2. Main/Sub Y Level

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

JA Connector pin 22

JB Connector pin 3

------

-----Color Bars

Video Input

Purpose

Symptom:

1. Supply a color bar signal to a Video Input (not an RF input).

2. Select the color bar signal for both the main and sub pictures.

3. Connect the oscilloscope to connector JA pin 22 (Main-Y).

4. Activate the Adjustment Mode

5. Select Item 39 SCNT in the Main Matrix function.

6. Adjust the data so the Main-Y signal is between 0.71 Vp-p max. and 0.66 Vp-p

min. at JA pin 22.

(If it cannot be adjusted within this range, set to the lower value)

7. Move the oscilloscope to connector JB pin 3 (Sub-Y).

8. Select Item 39 SCNT in the Sub Matrix function.

9. Adjust the data to equal the MAIN-Y Gain (+0.0V -0.05V).

10. Press ENTER to save data.

To set picture luminance

Excess or insufficient brightness.

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Page 30

Page 31

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Video Circuit]

Purpose:

To match the sub picture color to that of the main picture.

3. Main/Sub Color Level

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Oscilloscope

JA pin 22

JB pin 5

------

------

Color Bars

Video

Symptom:

1. Supply an NTSC signal to an External Video Input.

2. Select the NTSC signal as the source for both the main and sub pictures.

3. Connect an oscilloscope to connector JA pin 20 (Main PR).

4. Activate the Adjustment mode.

5. Select Item 41 SCLR in the Main Matrix Function.

6. Adjust data so the PR signal is 0.71 Vp-p max. - 0.66 Vp-p min

(If it cannot be adjusted within this range, set to the lower value)

When using a Leader 480, set to 0.585±0.02Vp-p.

7. Connect an oscilloscope to connector JB pin 5 (Sub PR).

8. Select item 41 SCLR in the Sub Matrix Function.

9. Adjust so Sub PR = Main PR (+0.0V -0.05V)

10. Press ENTER to save data.

Main and sub pictures colors differ.

[CRT Circuit]

4. CRT Cutoff

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Oscilloscope

TP6R, TP6G, TP6B

------

50V/Div. 2msec/Div.

None

Video Input

Purpose

Symptom:

Note: Use the Expand mode (full screen)

1. Select an External Input with no signal.

2. Enter the Adjustment Mode, Video Chroma Function.

3. Press 1, automatically blanks the screen and sets COL to 0.

4. Set the data to the values given in the table below.

5. Connect the oscilloscope to TP6R.

6. Adjust the Red Screen VR so the black level is 170V, as shown below, or

178V ±1VDC using an DC Voltmeter.

7. Repeat Steps 4 and 5 to set the Blue and Green Screen VRs, using

TP6G and TP6B.

Note: White Balance must be performed after this adjustment.

VC Preset Data

Item Abbr Data

1SCT42

2SBRT20

3SCON7

4 RDRH 31

5GDRH41

6BDRH31

7CTRH31

8 CRGH 31

9CTBH31

To set the cutoff point for all three CRTs.

Monochrome has a color tint, or incorrect brightness.

Page 31

Page 32

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[CRT Circuit]

Purpose:

To set the CRTs white level in the NTSC mode.

5. White Balance (NTSC)

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

DC Voltmeter

------

------

------

NTSC White Raster

RF or Video

CIRCUIT ADJUST MODE

Symptom:

Monochrome has a color tint.

Note: Use the FORMAT button to activate the Expand mode (full screen).

1. Supply a full White Raster Signal

2. Activate the Service Mode, Video Chroma Function.

3. Set the data for Item 19 COL to 0.

4. Adjust Items 4 RDRH and 6 BDRH for optimum white at the center of

the screen.

5. Reduce the input luminance level to 25%.

6. Adjust Items 7 CTRH and 9 CTBH for optimum white.

7. Insert a Milliammeter in series with each CRT Cathode. The maximum

allowable current for each CRT is given in the table below.

8. Set the white raster to 100% and adjust Items 10 RDRL and 12 BDRL for

optimum white at the center of the screen.

9. Reduce the luminance level to 25%.

10. Adjust Item 13 CTRL and 15 CTBL for optimum white.

11. Set the data for Item 19 COL back to 31.

12. Press ENTER to save data.

Max CRT Current

CRT ALL

Red 580 ua

Green 580 ua

Blue 580 ua

[CRT Circuit]

6. White Balance (HD)

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

-----

-----

------

-----

HD White Raster

DTV Inputs

CIRCUIT ADJUST MODE

Purpose

Symptom:

To set the CRTs white level in the HD mode.

Monchrome pictures have a color tint.

1. Supply an HD Full White Raster signal to the DTV Inputs.

2. Select the DTV Inputs (Input button)

3. Activate the Adjustment mode, Video Chroma Function.

4. Set Item 19 COL to 0.

5. Adjust Items 4 RDRH and 6 BDRH for optimum white at the center of the

screen.

6. Reduce the input signal luminance to 25%.

7. Adjust Items 7 CTRH and 9 CTBH for optimum white.

8. Set the white raster to 100% and adjust Items 10 RDRL and 12 BDRL for

optimum white at the center of the screen.

9. Reduce the luminance level to 25%.

10. Adjust Item 13 CTRL and 15 CTBL for optimum white.

11. Set the data for Item 19 COL back to 31.

12. Press ENTER to save data.

Page 32

Page 33

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Video Circuit]

7. Black Level

Purpose:

Symptom:

To set the black level of the picture.

Excess or insufficient brightness.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

-----

-----

------

------

Monoscope

Video Input

1. Supply a Monoscope signal to a Video Input.

2. Activate the Adjust Mode, Video Chroma Function.

3. Adjust Item 2 SBRT so the 0% and 10% black levels on the gradation scale

are the same.

4. Press ENTER to save data.

7. Exit the Service Mode.

NOTE: Item 2 SBRT should be no more the 21.

40% 30% 20% 10%

50% 0% 0% 0%

60% 70% 80% 90%

GRADATION SCALE

[Video Circuit]

8. Sub Contrast

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

DC ma meter

DT connector pins 7 & 8

------

-----

Grayscale

RF Input

Sub Contrast Current Alignment

Purpose

Symptom:

Note: Activate the Expand mode (full screen).

1. Supply a Grayscale signal to a RF Input.

2. Activate the Adjust Mode, Video Chroma Function.

3. Select Item 1 SCT, signal level automatically reduces.

4. Connect a 3ma DC meter between DT connector pins 7 and 8. Positive lead to

pin 7.

5. Adjust Item 1 SCT for the current given in the table below.

6. Remove the meter.

7. Press ENTER to save data.

8. Exit the Service Mode.

WS-48313 / WS-48413

WS-55413 / WS-65313

WS-55313

520 ±10ua 550 ±10ua

To set overall beam current to its optimum level.

Excess or insufficient contrast.

WS-65413

Page 33

Page 34

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Focus Circuit]

Purpose:

To improve edge focus.

9. Dynamic Focus Preset

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate ……..MENU-0-3-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G or B)……AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

-----

------

-----

Monoscope

Video Input

CONVERGENCE MODE

Symptom:

Poor focus at the edges of the screen.

1. Supply a Monoscope signal to a Video Input

2. Activate the Convergence Mode.

3. Select the DF Function under the Conv. Coarse Mode.

4. Set Items 0 DFH and 1 DFV to the data values given in the DF Table.

5. Press 6 to activate CONV-MISC

6. Set 0 FPHS and 1 DPHS to data values given in the CONV-MISC Table.

7. Press ENTER to save data.

8. Exit the Conv. Mode.

DF MENU-0-3-5-9-5

Item Abbr.

WS-48313 / WS-48413

WS-55313

WS-55413 / WS-65313

WS-65413

SD Data HD Data SD Data HD Data

1 DFH -220 -220 -280 -250

2 DFV -100 -100 -110 -95

CONV MISC

(MENU-0-3-5-9-6)

Item Abbr. SD & HD

9DPHS 1

10 DOFS 34

[Video Circuit]

10. Lens Focus

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

------

------

-----

Monoscope

Video Input

Purpose

Symptom:

To set the Lens position for optimum focus.

Poor focus

Note: This adjustment must be done before Electrostatic Focus. Perform this

adjustment for RED, GREEN, and BLUE monochrome pictures.

1. Supply a VIDEO signal (Monoscope).

2. Cover the Red and Blue Lens (producing a green raster).

3. Adjust the Green Lens for best focus at the center of the Monoscope pattern.

Note: Attach a white paper to the

screen center. During adjustment,

observe the picture on the screen

from inside for easier adjustment.

4. Repeat Steps 2 and 3 for the Red

and Blue monochrome pictures.

Page 34

Page 35

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[CRT Circuit]

11. Electrostatic Focus &

(Alignment Magnet)

Purpose:

Symptom:

To set electrostatic focus to the optimum point.

Poor focus.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

-----

------

------

Monscope & Crosshatch

Video Input

Note: This adjustment must be performed after the Sub Contrast adjustment.

Alignment Magnet Adjustment (WS-48413, WS-55413 and WS-65413 Only)

This adjustment must be performed before Static Focus Adjustment

1. Set the display to the Standard mode (Format button)

2. Supply a Crosshatch with Center Dot signal to a Video Input.

3. Select a Green raster using the table below.

4. Roughly adjust Green Focus VR.

5. Rotate Green Focus VR CCW so the center dot is about 10mm diameter.

6. Adjust the Green 4 Pole Magnet for the roundest center dot.

7. Set the Green Focus VR for optimum focus.

8. Repeat the procedure with a Red raster and adjust the Red 4 Pole Magnet.

9. Use silicon to lock the magnets in place.

Static Focus Adjustment (All Models)

1. Supply a Monoscope signal to a Video Input

2. Activate A/V Reset

3. Select Red, Green or Blue rasters using the table below.

3. Set the Red, Green and Blue Focus VRs for optimum focus at the top center of

the picture..

Raster Color Se le ction

Color Rast er Activation Code

Red MENU-0-3-5-9-1

Green ME NU-0-3-5-9-2

Blue ME NU-0-3-5-9-3

[On Screen Display]

12.Character Position

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

-----

------

------

Video Signal (HD/NTSC)

ANT-A/DTV

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Purpose

Symptom:

To position the character display horizontally.

Incorrect display position

1. Supply a Monoscope signal to the Video or RF Input.

2. Select the Monoscope as the source for the main picture (Input button).

3. Activate the Service Mode, HR Function.

4. Use the Adjust Right/Left buttons to center the display horizontally.

(A = B)

5. Save data and exit the Service Mode..

Page 35

Page 36

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Conv/Defl]

13. Geometry Preset

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

------

------

-----

NTSC & HD

Video & DTV Inputs

Deflection Jungle Menu-0-3-5-7

Item Abbr. NTSCHDNTSCHDNTSCHDNTSCHDNTSC HD

Purpose:

Symptom:

To preset data controlling raster geometry

Raster distortion.

Note: This procedure is usually only necessary if an E2PROM is replaced in the TV

Control or Convergence circuits.

Procedure

In the Circuit Adjustment and Coarse Convergence Modes pre-set the data to the

values given in the Tables below.

# Abbrev.

WS-48313

WS-48413

WS-55313 WS-55413 WS-65313

WS-65413

1 HWID 30292322252532323028

2 HKEY24252425242524252425

7 VHGT18161413282833313331

8VLIN5555557777

9VSCN0000000000

18VPOS31313131313131313131

36PINA108108108108108

COARSE CONV GREEN (MENU-0-3-5-9-5)

#Abbrev.

WS-48313

WS-48413

WS-55313

SD HD SD HD SD HD SD HD

1HSTA00000000

2VSTA00000000

3 SKEW 0 0 0 0 0 0 0 0

4TILT00000000

5HWID2020202020202020

6HLIN0 0 0 010100 0

7SPCC00000000

8 HKEY 23 20 15 10 20 20 0 0

9 TBPC -180 -160 -190 -165 -190 -180 -200 -175

10 VKEY 0 0 0 0 -4 8 0 0

11 VWID 30 20 30 20 30 20 30 20

12VLIN00000000

COARSE CONV RED (MENU-0-3-5-9-5)

# Abbrev.

1HSTA5050505050505050

2VSTA00000000

3 SKEW 5 5 5 5 5 5 0 0

4TILT00000000

5 HLIN -220 -200 -215 -195 -195 -180 -170 -150

6 HWID 0 0 0 0 -10 -5 10 10

7 VKEY -90 -90 -75 -75 -90 -70 -90 -75

8VWID000000010

9VLIN00000000

10 TBPC 20 20 20 20 20 20 20 20

11 SDBW 30 30 30 30 30 30 30 30

WS-48313

WS-48413

SD HD SD HD SD HD SD HD

WS-55313 WS-55413

WS-65313

WS-65413

WS-55413

COARSE CONV BLUE (MENU-0-3-5-9-5)

#Abbrev.

1 HSTA -50 -50 -50 -50 -50 -50 -50 -50

2VSTA00000000

3SKEW 0 -5 0 -5 0 0 0 0

4TILT00000000

5 HLIN 220 200 220 205 195 180 175 160

6HWID 0 0 0 0 -10-15 10 10

7VKEY9090907090708075

8VWID00000000

9VLIN00000000

10 TBPC 0 0 0 0 -20 0 -20 0

11SDBW-30-30-30-30-30-30-30-30

WS-65313

WS-65413

WS-48313

WS-48413

SD HD SD HD SD HD SD HD

WS-55313

WS-55413

WS-65313

WS-65413

Page 36

Page 37

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Deflection Circuit]

14: Deflection Geometry

Height & Width Adjustment

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

-----

-----

------

-----

Monoscope (NTSC & HD)

Video & DTV Inputs

Purpose:

Symptom:

To set the height, width and linearity of the raster.

Incorrect height, width and/or linearity.

Preliminary:

DO NOT change the initial values for #8 VLIN in the Defl. Jungle Function.

1.

2.

DO NOT exceed the following VHGT adjustment ranges:

NTSC ... from -4 to +10

HD ... from -10 TO +5

NTSC Mode

1. Supply an NTSC Monoscope signal to a Video Input.

2. Select the Monoscope as the signal source.

3. Activate the Adjustment Mode, JNGL Function.

4. Select and adjust each of the following items.

7 VHGT ... so the vertical marker sum = 4

1 HWD ... so the horizontal marker sum = 7

5. Save data and Exit the Service Mode.

HD Mode

1. Supply an HD Monoscope signal to the DTV HD Inputs.

2. Select the DTV Inputs as the signal source (Input button)

3. Activate the Service Mode, Defl. Jungle Function.

4. Select and adjust each of the following items.

7 VHGT ... so the vertical marker sum = 2

1 HWD ... so the horizontal marker sum = 5

5. Save data and Exit the Service Mode.

Page 37

Page 38

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Convergence Circuit]

15. Convergence Geometry

Adjustment

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

------

------

-----

NTSC -- None

HD -- HD sync

Video & DTV Inputs

CONVERGENCE MODE

Activate ……..MENU-0-3-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G or B)……AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

Purpose:

Symptom:

Note: Deflection Circuit Geometry must be performed before this adjustment.

NTSC mode

1. Select a Video Input with no signal.

2. Activate the Convergence Mode, Coarse Green.

3. Adjust the Coarse Green Items shown below for straight crosshatch lines.

4. Select the Fine Green Mode, a Cursor is displayed on the crosshatch.

5. Use the Cursor to adjust for straight crosshatch lines.

6. Exit the Convergence Mode.

HD mode

1. Supply horizontal and vertical HD sync to the DTV Inputs and select the DTV

Inputs as the source.

Note: If an HD signal is not available, use the Conv. HD with No Signal

2. Enter the Convergence Mode, Coarse Green.

3. Repeat NTSC Steps 3 through 6 in the HD mode.

To set the Convergence circuit geometry adjustments.

Raster distortion at the top, bottom or sides of the picture.

Procedure

CONV. HD WIT H NO S IG NAL

1. M E NU-0-3-7-0

2. Set DTV Port to 1080i

3. MENU (Twice)

4. INPUT s elec t DTV input s

5. M E NU-0-3-5-9

Afte r Ad j u stin g , set th e

DTV Port to AUTO

Page 38

Page 39

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Convergence Circuit]

16. Centering and Static

Convergence

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate ……..MENU-0-3-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G or B)……AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

-----

------

-----

NTSC -- Monoscope

HD -- Monoscope

Video & DTV Inputs

CONVERGENCE MODE

Purpose:

Symptom:

To converge red, green and blue at the center of the screen

Color edging over the entire picture.

Preliminary

Degauss the shield cover and bracket unit of the CRT assembly and chassis.

DO NOT degauss the CPM Assemblies.

CAUTION: On models WS-48413, WS-55413 and WS-65413, Do Not adjust the

Alignment Magnets instead of the Centering Magnets.

HD mode

1. Supply an HD Monoscope signal to the DTV Inputs.

2. Select the DTV Inputs as the signal source (Input button).

3. Enter the Convergence Coarse mode.

4. Set the data for the HSTA and VSTA items to:

GREEN RED BLUE

HSTA = 0 HSTA = 50 HSTA = -50

VSTA = 0 VSTA = 0 VSTA = 0

5. In the Coarse Green mode:

Center the Green Raster using the Green Centering Magnet.

Rotate the Green Deflection Yoke to correct any tilt.

6. In the Coarse Red mode, use the Red Centering Magnet to converge

red on the green at the center of screen. Correct any red tilt with the Red

Deflection Yoke.

7. In the Coarse Blue mode, repeat Step 6 using the Blue Centering magnet and

the Blue Deflection Yoke.

8. Exit the Convergence mode.

SD mode

1. Supply an NTSC Monoscope signal to a Video Input.

2. Select the Monoscope as the signal source (Input button).

3. Enter the Convergence Coarse Green mode.

4. If needed, center the green raster using 1 HSTA and 2 VSTA adjustments.

5. In the Coarse Red mode, use 1 HSTA and 2 VSTA adjustments to converge

the red on the green at the center of the screen.

6. In the Coarse Blue mode, repeat step 5 to converge the blue of the green.

7. Exit the Convergence Mode

Page 39

Page 40

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Convergence Circuit]

17. Coarse Convergence

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CONVERGENCE MODE

Activate ……..MENU-0-3-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G or B)……AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

------

------

-----

NTSC -- None

HD -- HD sync

Video & HD Inputs

Purpose:

To converge red and blue on green at the edges of the

screen.

Symptom:

SD mode

1. Select an External Input with no signal.

2. Activate the Convergence Mode, Coarse Red.

3. Adjust the Items shown below to converge the red on the green.

4. Select Coarse Blue mode.

5. Adjust the Items shown below to converge the blue on the green.

Note: If center convergence shifts, use red and blue Items 0 HSTA and

6. Exit the Convergence Mode.

HD mode

1. Supply horizontal and vertical HD sync to the DTV Inputs and select the DTV

Inputs as the source.

Note: If an HD signal is not available, use the Conv. HD with No Signal

2. Repeat SD Steps 2 through 5 in the HD mode.

3. Exit the Convergence mode.

Color edging at the top, bottom and sides of the screen.

1 VSTA to correct the shift.

Procedure.

CONV. HD WITH NO SIGNAL

1. MENU-0-3-7-0

2. Set DTV Port to 1080i

3. MENU (Twice)

4. INPUT select DTV inputs

5. MENU-0-3-5-9

After Adjusting, set the

DTV Port to AUTO

Page 40

Page 41

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

[Convergence Circuit]

18. Fine Convergence

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate ……..MENU-0-3-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G or B)……AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

-----

------

-----

NTSC -- None

HD -- HD sync

Video & DTV Inputs

CONVERGENCE MODE