Mitsubishi Electric t-NEXT DF DX 011 P1 S, t-NEXT DF DX 016 P1 S, t-NEXT DF DX 014 P1 S, t-NEXT DF DX 020 P1 S, t-NEXT DF DX 022 P1 S User Manual

Page 1

The picture of the unit is indicative and may vary depending on the model

• PERIMETER INSTALLATION

• FULLY HERMETIC ON/OFF COMPRESSORS

• DUAL FLUID SYSTEM WITH ADDITIONAL COIL

• SINGLE OR DOUBLE REFRIGERANT CIRCUIT

• AIR DELIVERY FROM THE BOTTOM (UNDER) OR FROM THE TOP (OVER)

• PLUG FANS WITH EC ELECTRIC MOTOR

• ELECTRONIC EXPANSION VALVE

• AIR SUCTION TEMPERATURE UP TO 40°C

t-NEXT DF DX

10 – 149 kW

Air conditioners for IT Cooling with Dual Fluid system.

To be matched with remote air-cooled condenser.

Data Book: T_tNEXTDFDX_0719_EN

CLOSE CONTROL AIR CONDITIONERS

rcitcooling.com

Page 2

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

2

MEHITS S.p.A.

DATA BOOK

INDEX

MEHITS CERTIFICATIONS ........................................................................................................................................................................................................... 4

GENERAL CHARACTERISTICS ................................................................................................................................................................................................... 5

INSTALLATION .............................................................................................................................................................................................................................. 6

PRODUCT FEATURES AND BENEFITS ...................................................................................................................................................................................... 6

F-GAS DIRECTIVE ........................................................................................................................................................................................................................ 6

MODEL IDENTIFICATION ............................................................................................................................................................................................................. 7

TRANSPORT AND STORAGE TEMPERATURE .......................................................................................................................................................................... 7

WORKING LIMITS ......................................................................................................................................................................................................................... 8

MAIN COMPONENTS .................................................................................................................................................................................................................... 9

REMOTE AIR-COOLED CONDENSERS .................................................................................................................................................................................... 11

OPTIONAL ACCESSORIES ........................................................................................................................................................................................................ 11

TECHNICAL DATA ...................................................................................................................................................................................................................... 14

DUAL FLUID SYSTEM ................................................................................................................................................................................................................. 18

2-WAY BALL VALVE FOR CHILLED WATER FLOW CONTROL .............................................................................................................................................. 19

WATER QUALITY OF THE HYDRAULIC CIRCUITS .................................................................................................................................................................. 20

ANTIFREEZE MIXTURES ........................................................................................................................................................................................................... 20

REFRIGERANT CHARGE ........................................................................................................................................................................................................... 21

PRESSURE RELIEF VALVE ....................................................................................................................................................................................................... 22

REFRIGERANT CIRCUIT ............................................................................................................................................................................................................ 23

RECOMMENDED REFRIGERANT LINES .................................................................................................................................................................................. 25

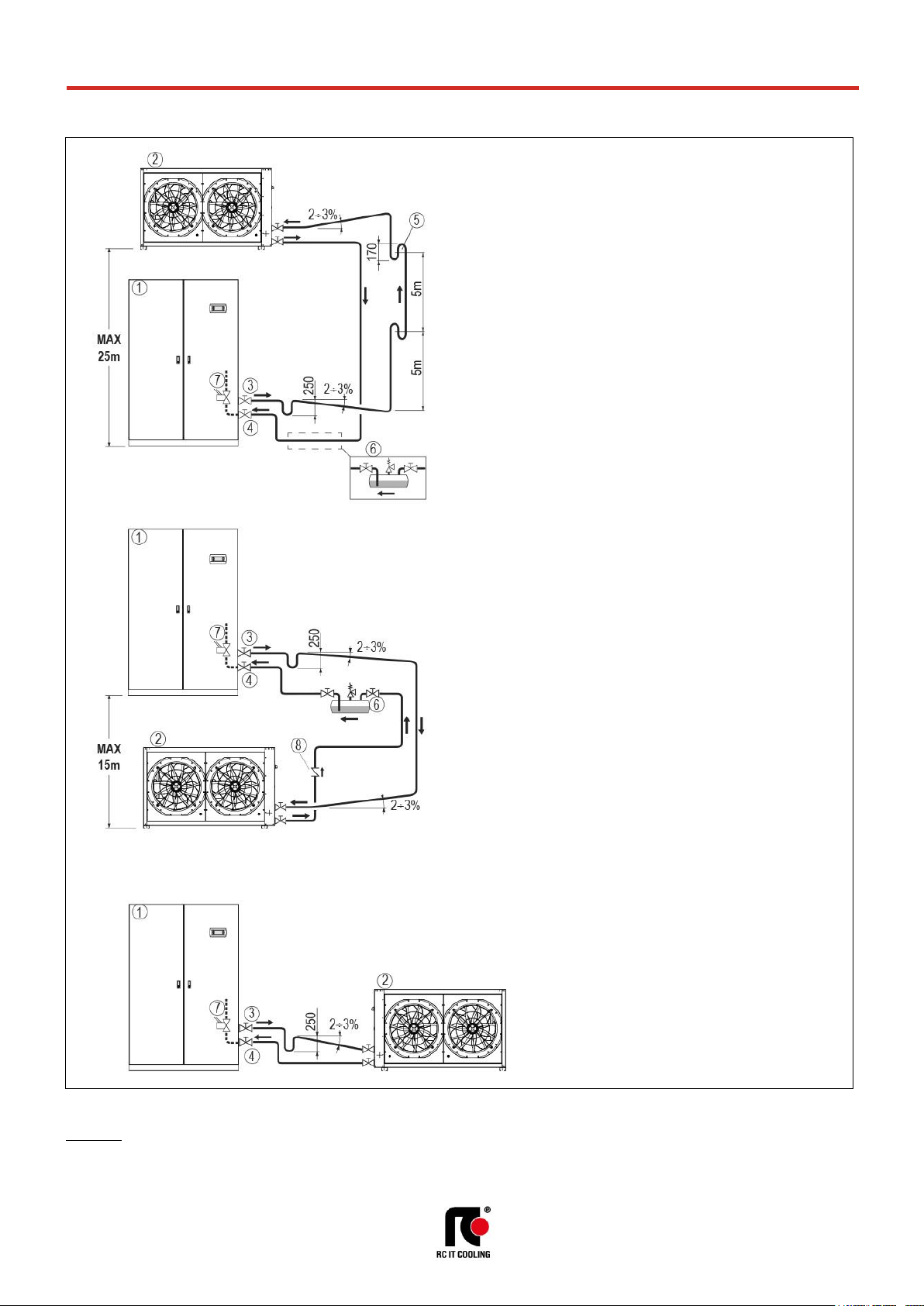

INSTALLATION DIAGRAM .......................................................................................................................................................................................................... 26

ACOUSTIC DATA ........................................................................................................................................................................................................................ 27

ELECTRICAL DATA ..................................................................................................................................................................................................................... 28

MICROPROCESSOR CONTROL SYSTEM ................................................................................................................................................................................ 29

DEMAND LIMIT ............................................................................................................................................................................................................................ 31

TEMPERATURE PROBE ON AIR RETURN / DELIVERY .......................................................................................................................................................... 31

CLOGGED FILTERS SENSOR ................................................................................................................................................................................................... 31

FLOOD SENSOR ......................................................................................................................................................................................................................... 31

POSSIBLE AIR INTAKE FOR OVER VERSIONS ....................................................................................................................................................................... 32

REMOTE AIR-COOLED CONDENSER ....................................................................................................................................................................................... 33

OPTIONAL ACCESSORIES: P121 – FRONT AIR INTAKE+BOTTOM PANEL .......................................................................................................................... 35

OPTIONAL ACCESSORIES: 601 – SOLENOID VALVE ON LIQUID LINE ................................................................................................................................ 35

OPTIONAL ACCESSORIES: A548 - CONSTANT PREVALENCE ............................................................................................................................................. 35

OPTIONAL ACCESSORIES: P091 - BACK-UP MODULE CONTROLLER ................................................................................................................................ 35

OPTIONAL ACCESSORIES: P171 – KIT FOR AIR -45°C MCH AXIAL AC ............................................................................................................................... 36

OPTIONAL ACCESSORIES: P172 – KIT FOR AIR -45°C AXIAL AC ........................................................................................................................................ 36

OPTIONAL ACCESSORIES: A492 – WATER LEACKAGE DETECTOR + ADDITIONAL DETECTOR..................................................................................... 37

OPTIONAL ACCESSORIES: A511 - SMOKE DETECTORS ...................................................................................................................................................... 37

OPTIONAL ACCESSORIES: A512 – FIRE DETECTORS .......................................................................................................................................................... 37

ACCESSORI: P181 – ANALIZZATORE DI RETE ....................................................................................................................................................................... 38

ACCESSORI: P182 – ANALIZZATORE DI RETE+OPTIONAL ................................................................................................................................................... 38

ACCESSORI: P183 – KIT ANALIZZATORE DI RETE ................................................................................................................................................................. 38

ACCESSORI: P184 – KIT ANALIZZATORE DI RETE+ OPTIONAL ........................................................................................................................................... 38

OPTIONAL ACCESSORIES: P021 – 2-WAY BALL BY-PASS VALVE ....................................................................................................................................... 39

OPTIONAL ACCESSORIES: A431 – ELECTRIC HEATERS ...................................................................................................................................................... 41

OPTIONAL ACCESSORIES: A432 – EXTRA POWER ELECTRIC HEATERS .......................................................................................................................... 41

OPTIONAL ACCESSORIES: 4301 – STEAM HUMIDIFIER 3KG/H ............................................................................................................................................ 43

OPTIONAL ACCESSORIES: 4303 – STEAM HUMIDIFIER 8KG/H ............................................................................................................................................ 43

OPTIONAL ACCESSORIES: 4305 – STEAM HUMIDIFIER 15KG/H .......................................................................................................................................... 43

OPTIONAL ACCESSORIES : P051 – DEHUMIDIFICATION FUNCTION .................................................................................................................................. 46

OPTIONAL ACCESSORIES: P161 - T/RH AIR INTAKE SENSOR ............................................................................................................................................. 46

Page 3

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

3

MEHITS S.p.A.

DATA BOOK

OPTIONAL ACCESSORIES: P071 - REMOTE T/RH PROBE .................................................................................................................................................... 46

OPTIONAL ACCESSORIES: 4666 – EXTERNAL AIR PROBE .................................................................................................................................................. 46

OPTIONAL ACCESSORIES: P111 – DUAL POWER SUPPLY .................................................................................................................................................. 47

OPTIONAL ACCESSORIES: P112 – DUAL POWER SUPPLY + OPTIONAL ............................................................................................................................ 47

OPTIONAL ACCESSORIES: P113 – KIT DUAL POWER SUPPLY ........................................................................................................................................... 47

OPTIONAL ACCESSORIES: P114 – KIT DUAL POWER SUPPLY + OPTIONAL ..................................................................................................................... 47

OPTIONAL ACCESSORIES: A381 - DRAIN PUMP .................................................................................................................................................................... 48

OPTIONAL ACCESSORIES: P084 – AIR FILTER EPM

10

50% .................................................................................................................................................. 49

OPTIONAL ACCESSORIES: A531 – ON-OFF DAMPER ........................................................................................................................................................... 50

OPTIONAL ACCESSORIES: P011 - EMPTY PLENUM .............................................................................................................................................................. 52

OPTIONAL ACCESSORIES: P012 - EMPTY PLENUM CL.A1 ................................................................................................................................................... 52

OPTIONAL ACCESSORIES: P031 - EMPTY INTAKE PLENUM ................................................................................................................................................ 52

OPTIONAL ACCESSORIES: P032 - EMPTY INTAKE PLENUM CL.A1 ..................................................................................................................................... 52

OPTIONAL ACCESSORIES: P013 - PLENUM + 3 GRILLES ..................................................................................................................................................... 52

OPTIONAL ACCESSORIES: P014 - PLENUM + 3 GRILLES CL.A1 .......................................................................................................................................... 52

OPTIONAL ACCESSORIES: P015 - SILENCED PLENUM ........................................................................................................................................................ 52

OPTIONAL ACCESSORIES: P016 - SILENCED PLENUM + 1 GRILLE .................................................................................................................................... 52

OPTIONAL ACCESSORIES: P017 - PLENUM + FILTER EPM2.5 50% ..................................................................................................................................... 52

OPTIONAL ACCESSORIES: P018 - PLENUM + FILTER EPM1 50% ........................................................................................................................................ 52

OPTIONAL ACCESSORIES: P019 - PLENUM + FILTER EPM1 85% ........................................................................................................................................ 52

OPTIONAL ACCESSORIES: P034 – INTAKE FREE-COOLING PLENUM ................................................................................................................................ 59

OPTIONAL ACCESSORIES: P041 – SUPPORT FRAME H 255-350MM ................................................................................................................................... 63

OPTIONAL ACCESSORIES: P042 – SUPPORT FRAME H 355-450MM ................................................................................................................................... 63

OPTIONAL ACCESSORIES: P043 – SUPPORT FRAME H 400-510MM ................................................................................................................................... 63

OPTIONAL ACCESSORIES: 1511 – SOFT STARTER ............................................................................................................................................................... 64

OPTIONAL ACCESSORIES: A272 – CL.0 OR A1 (EN13501-1) INSULATION .......................................................................................................................... 65

MACHINE DRAWINGS ................................................................................................................................................................................................................ 66

HOLE IN THE RAISED FLOOR FOR DOWNFLOW VERSION .................................................................................................................................................. 83

EXAMPLE FOR MACHINES NOISE EMISSION CALCULATION............................................................................................................................................... 84

VALVE PRESSURE DROP CALCULATION AS FUNCTION OF WATER FLOW RATE ............................................................................................................ 86

AIR FILTERS REPLACEMENT .................................................................................................................................................................................................... 87

SHIPMENT: PACKING DIMENSIONS ......................................................................................................................................................................................... 88

SHIPMENT: SHIPPING WEIGHT ................................................................................................................................................................................................ 88

SHIPMENT: OPTIONALS PACKING DIMENSIONS AND SHIPPING WEIGHT ......................................................................................................................... 89

Page 4

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

4

MEHITS S.p.A.

DATA BOOK

MEHITS CERTIFICATIONS

SYSTEM CERTIFICATIONS

ISO 9001 CERTIFICATION – MEHITS S.p.A.

Quality Management System

ISO 14001 CERTIFICATION – MEHITS S.p.A.

Environmental Management System

BS OHSAS 18001 CERTIFICATION – MEHITS S.p.A.

Occupational Health and Safety Management System

PRODUCT CERTIFICATIONS BY COUNTRY

CE MARKING

MEHITS units are in compliance with the European Directives in force.

CCC – CQC CERTIFICATION

(People’s Republic of China)

EAC CERTIFICATION

(Russian Federation, Belarus, Kazakhstan)

Page 5

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

5

MEHITS S.p.A.

DATA BOOK

GENERAL CHARACTERISTICS

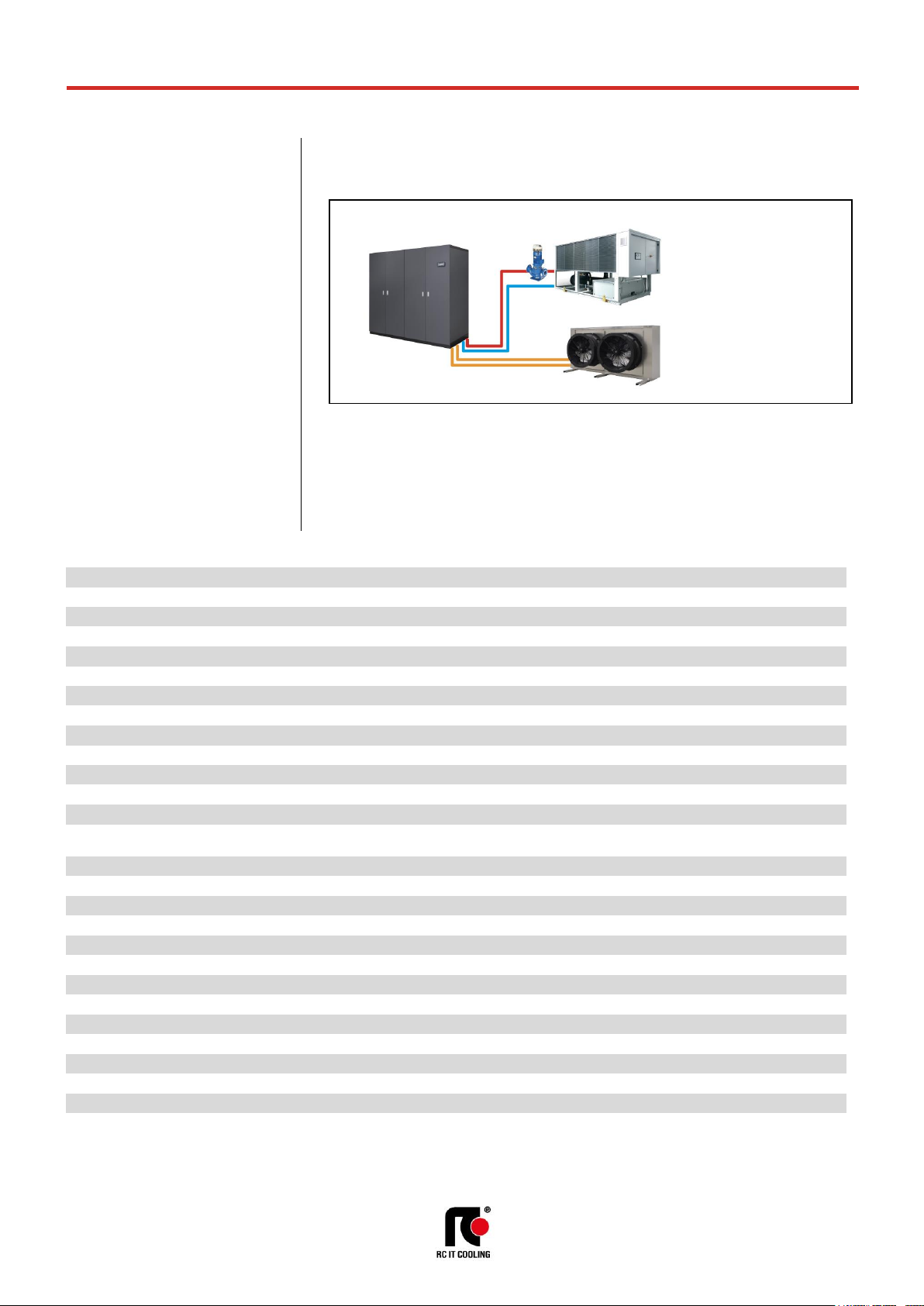

Air Conditioners for IT Cooling with Dual Fluid system.

• Direct expansion, air cooled.

For matching with remote air-cooled condenser;

• Two independent cooling systems:

Direct expansion coil; Chilled water coil;

• Plug fans with EC electric motors;

• Rotary or scroll on/off compressors;

• Single or double refrigerant circuit.

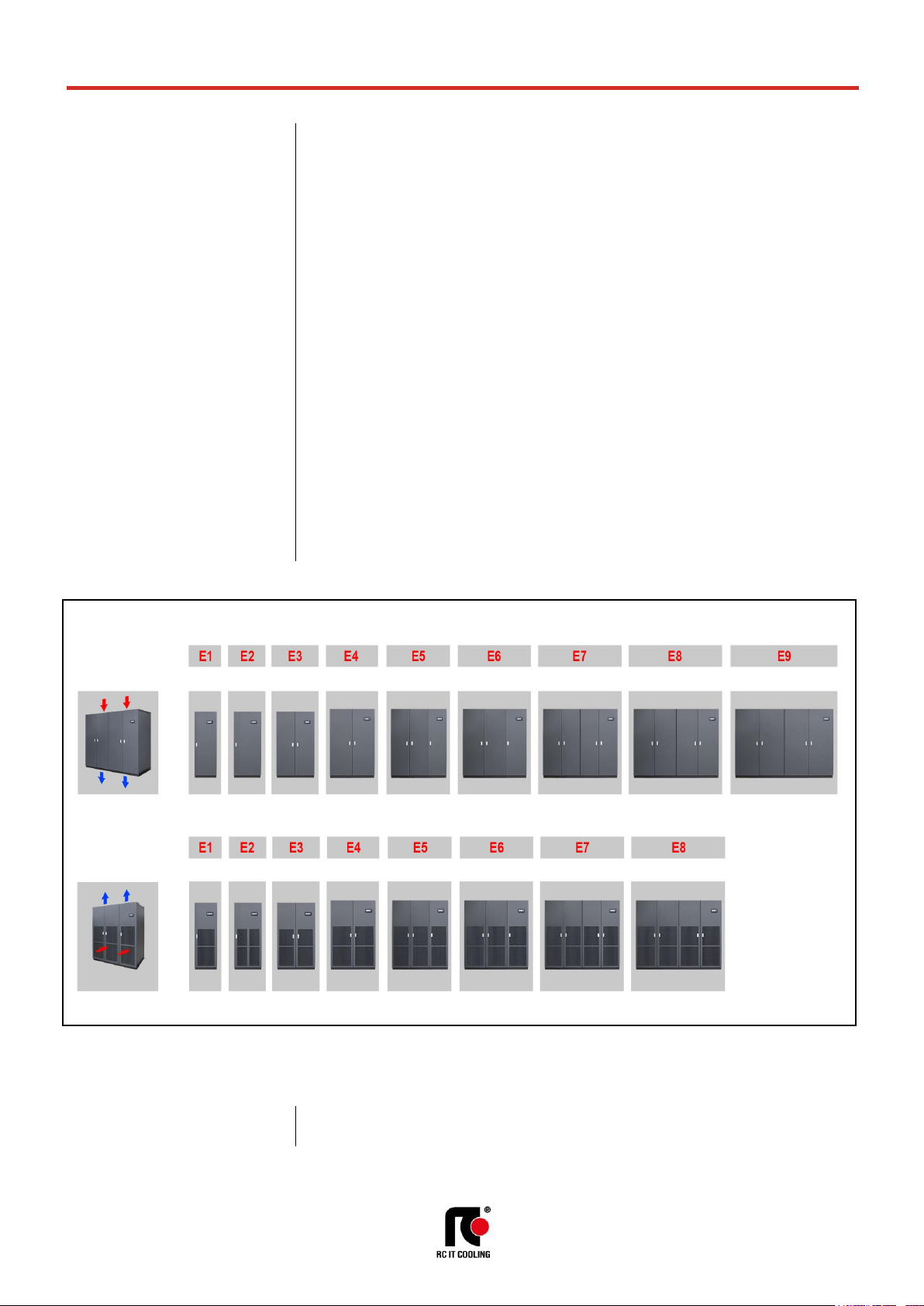

This series is offered in 20 models available in the following versions:

• The upflow version (Over) is characterized by air intake from the front through honeycomb grille

and air delivery from the top of the unit.

• The downflow version (Under) is characterized by air intake from the top and air delivery from

the bottom of the unit.

Cooling capacity: 10 ÷ 149 kW

The machines are made for indoor installation.

The constructive solutions and the internal lay-out allow high application flexibility and the frontal access to

the main components for the inspection and routine maintenance.

The installation requires refrigerant charge, electrical and hydraulic connections.

Final assembly on all machines before shipment including running test, reading and monitoring of operating

parameters, alarms simulation and visual check.

UNDER

Downflow air delivery

OVER

Upflow air delivery

UNDER

Downflow air delivery

OVER

Upflow air delivery

Air conditioner

Remote

condenser

Liquid chiller

Page 6

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

6

MEHITS S.p.A.

DATA BOOK

INSTALLATION

The series is particularly suitable for installation in Data Centre of medium / small size with constant load.

DOWNFLOW VERSION (Under)

Typical installation is on the perimeter.

The units are placed along the perimeter of the Data Center. Air suction from the top of the unit and air

delivery in the underfloor void.

The air distribution is achieved by special tiles placed in front of the racks row, forming cold aisle for air

diffusion. On the rear of the racks is expelled the hot then aspirated by the unit.

For an optimal installation is advisable to provide the cold aisle containment.

Some solutions provide a service corridor around the server rooms where to place the units. In this case, it

is necessary to provide the air intake plenum for each unit. With this solution, all the space in the Data

Center is available for the installation of racks.

UPFLOW VERSION (Over)

The type of installation is practically similar to the previous. The only difference is that for the air distribution

in the Data Center is not used the raised floor but ducts in the ceiling.

The series is also suitable for installation in UPS, Batteries, Distribution rooms and in all service areas of

the Data Center that need a service of conditioning.

OPTIONAL

An extensive list of accessories allows the unit to adapt effectively to the real needs of the system, reducing

the time and cost of installation.

PRODUCT FEATURES AND BENEFITS

• Dual Fluid System: Two independent cooling systems: Chilled water coil; Direct expansion coil

• Electronic expansion valve;

• New plug fans with EC electric motors and impeller in composite material, which guarantees a

reduction of power consumption;

• New fans electric motor that do not require maintenance;

• Improvement of the control software with advanced control logic;

• Single or double refrigerant circuit;

• Air suction temperature up to 40°C

F-GAS DIRECTIVE

The units highlighted in this publication contain <HFC R410A [GWP

100

2088]> fluorinated

greenhouse gases.

Page 7

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

7

MEHITS S.p.A.

DATA BOOK

MODEL IDENTIFICATION

Air conditioners for IT Cooling

model: t-NEXT DF DX O 041 P1 S E4

t-NEXT Series

DF DX Unit type

DF – with dual fluid system

Two independent cooling systems:

Direct expansion coil, chilled water coil,

DX – direct expansion, air cooled

O Air delivery

O = over – upflow air delivery

U = under – downflow air delivery

041 Model / Cooling capacity (kW) at nominal conditions

P1 Compressor type and number

P = scroll compressor for R410A

1 = number of compressors

S Refrigerant circuit

S = single

D = double

E4 Size

TRANSPORT AND STORAGE TEMPERATURE

During transport and if the machine is not installed at the reception, do not remove the packaging and place

the machine in an enclosed, dry and protected from sunlight site at temperatures ranging between -30°C

and 50°C in absence of superficial condensation.

THE RANGE

UNDER

OVER

Page 8

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

8

MEHITS S.p.A.

DATA BOOK

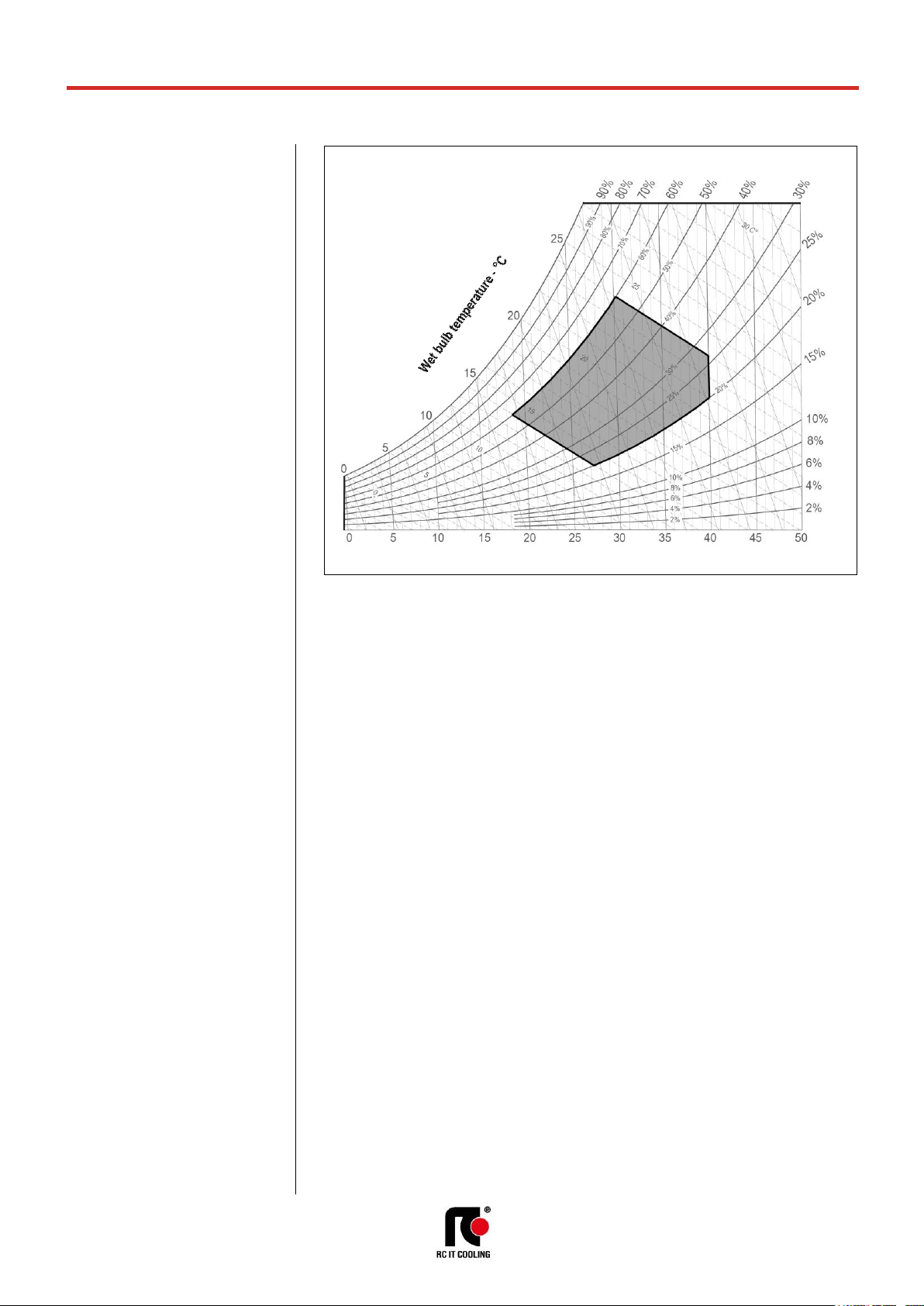

WORKING LIMITS

ROOM AIR CONDITIONS

Room air temperature:

14°C minimum temperature with wet bulb.

24°C maximum temperature with wet bulb.

18°C minimum temperature with dry bulb

40°C maximum temperature with dry bulb.

AREA “A”. Machine operating envelope.

Room air humidity:

20%RH minimum relative humidity.

60%RH maximum relative humidity.

AMBIENT AIR TEMPERATURE

45°C Maximum ambient air temperature

-20°C Minimum ambient air temperature

With “Kit for air -45°C” for low ambient temperature operation (optional)

-45°C minimum ambient air temperature with remote condensers with AC fans

CHILLED WATER TEMPERATURE (Dual Fluid circuit)

6-25°C temperature range of the water entering the coil

ΔT 3°C Minimum temperature difference between water inlet and outlet

ΔT 10°C Maximum temperature difference between water inlet and outlet

All the values are indicative. The working temperatures are influenced by a series of variables as:

• Working conditions;

• Thermal load;

• Set of the microprocessor control.

HYDRAULIC CIRCUIT (Dual Fluid circuit)

ΔP 5-150kPa Pressure drop range of the hydraulic circuit.

10 Bar Maximum working pressure of the hydraulic circuit

POWER SUPPLY

± 10% Maximum tolerance of the supply voltage (V)

± 2% Maximum unbalancing of the phases.

A

Relative humidity

- %

Relative humidity - %

Dry bulb temperature - °C

Page 9

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

9

MEHITS S.p.A.

DATA BOOK

MAIN COMPONENTS

FRAMEWORK

• Base in aluminium extrusion, painted with epoxy powders. Colour RAL 9005;

• Frame in aluminium profile, painted with epoxy powders. The inner frame is provided with

seals for the panels. Colour RAL 9005;

• Panels in galvanized steel sheet with protective surfaces treatment in compliance with UNI

ISO 9227/ASTMB117 and ISO 7253, and painted with epoxy powders. Colour RAL 7016

hammered;

• Panels insulated with polyurethane foam and seals to ensure air tight.

• Hinged front panels with quick release removal system.

• Total front access for routine maintenance.

• Removable lateral and back side panels.

• Air flow OVER version:

- Air intake from the front through honeycomb type grille and air delivery from the top.

• Air flow UNDER version:

- Air intake from the top and air delivery from the bottom.

• Compartment for electrical panel on unit front for direct access to control and regulation

devices;

FILTER SECTION

• Washable air filters with COARSE 60% efficiency (according to ISO EN 16890), with cells in

synthetic fibre and metallic frame.

• Air filters access:

OVER version

- Frontal access for all machines

UNDER version

- For machines size E1 – E2 – E3 frontal access

- For machine size E4 – E5 – E6 – E7 – E8 – E9 access from upper side

• Clogged filters sensor with differential pressure switch on air side.

ON / OFF COMPRESSORS SECTION

Units size E1 and E2:

• Rotary vane compressors for R410A refrigerant

• 2-pole 3-phase electric motor with direct on line starting.

• Crankcase heater.

• Rubber supports.

Units size E3, E4, E5, E6, E7, E8 and E9

• Scroll rotary compressors with spiral profile optimized for R410A refrigerant.

• 2-pole 3-phase electric motor with direct on line starting.

• Crankcase heater.

• Rubber supports.

FANS SECTION

The fan section is contained within the machine and includes:

• Centrifugal fans with backward curved blades with wing profile, single suction and without

scroll housings (Plug-fans), directly coupled to external rotor electric motor.

• Impeller in composite material exempt from rust formation.

• Brushless type synchronous EC motor with integrated electronic commutated system and

continuous variation of the rotation speed. The motor rotation control is obtained with the EC

system (Electronic Commutation) that manage the motor according to the signal coming from

the microprocessor control.

• Fans control through ModBus. In case of failure, the control stops the interested fan indicating

the type of fault. The machine with more than one fan is not stopped.

• Adjustable External Static Pressure (ESP).

• Fan guard with rubber support (UNDER version)

Page 10

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

10

MEHITS S.p.A.

DATA BOOK

COOLING SECTION – DIRECT EXPANSION COIL

• Heat exchanger coil with internally corrugated copper tubes and high efficiency aluminium

fins, specifically developed to provide high heat transfer and lower pressure drops.

• Frame in galvanized steel or peraluman.

• Condensate tray in peraluman with PVC flexible discharge pipe.

• Temperature sensor on air intake with control and regulation functions.

• Temperature sensor on air delivery with function of temperature display.

• Under floor water alarm through sensor to be placed on the floor.

COOLING SECTION – CHILLED WATER COIL

• Chilled water 4 rows cooling coil with copper tubes, aluminium fins and galvanized steel

frame.

• 2-way motorized valve with 0÷10 VDC control actuator and emergency manual control.

• Temperature probe on water inlet.

• Hydraulic pipes in copper with anticondensate insulation

REFRIGERANT CIRCUIT

The air conditioner is supplied with a minimum R410A refrigerant charge.

Components for each refrigerant circuit:

• Electronic expansion valve. The valve allows high performance and system efficiency thanks

to a timely and accurate response to changes in temperature and pressure.

• Sight glass.

• Filter dryer on liquid line.

• Pressure transducers with indication, control and protection functions, on low and high

refrigerant pressure.

• High pressure safety switch with manual reset.

• Liquid receiver.

• Pressure relief valve on liquid receiver for models 041 P1, 045 P1, 075 P2, 082 P2,

092 P2, 102 P2, 117 P4, 146 P4.

• Refrigerant circuit with copper tubing with anticondensate insulation of the suction line.

• Lubricant oil charge.

• Valves on gas delivery and liquid return for coupling to remote air-cooled condenser.

• 0÷10V proportional signal to manage the condensing control system of the remote air-cooled

condenser.

• Condensing control by continuous variation of remote condenser fan rotation speed for

operations with ambient temperature down to -20°C.

ELECTRICAL PANEL

In accordance with EN60204-1 norms, suitable for indoor installation, complete with:

• Main switch with door lock safety on frontal panel.

• Magnetothermic switches for each compressor.

• Magnetothermic switches for supply fans.

• Contactors for each load. The supply fans equipped with EC electric motor don’t require

contactors.

• Transformer for auxiliary circuit and microprocessor supply.

• Numbered wirings.

• Terminals:

OUTLETS

- Voltage free deviating contact for General Alarm 1-2

- Voltage free contact for supply fans status.

- Voltage free contact for smoke / fire sensor (the sensors are accessory)

INLETS

- External enabling.

• Power supply 400/3+N/50.

CONTROL SYSTEM

Microprocessor control system with graphic display for control and monitor of operating and alarms

status. The system includes:

• Built-in clock for alarms date and time displaying and storing;

• Built-in memory for the storing of the intervened events (up to 200 events recorded);

• Predisposition for additional connectivity board housing (MODBUS, LON,

BACNET MS/TP RS485, BACNET OVER IP). The electronic cards are optional accessories.

• Main components hour-meter;

• Non-volatile “Flash” memory for data storage in case of power supply faulty;

• Menu with protection password;

• Demand Limit function;

• LAN connection (max 10 units).

Page 11

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

11

MEHITS S.p.A.

DATA BOOK

REMOTE AIR-COOLED CONDENSERS

The descriptions of these series can be found in Chapter REMOTE AIR-COOLED CONDENSERS.

............................................ Remote air-cooled condenser: Remote air-cooled condenser in

PERALUMAN aluminium alloy with microchannel condensing coil:

P821 - with AC axial fans and standard acoustic version

series GR-Z A B 50;

P831 - with AC axial fans and low noise acoustic version

series GR-Z A L 50;

P841 - with EC axial fans and standard acoustic version

series GR-Z E B 50;

P851 - with EC axial fans and low noise acoustic version

series GR-Z E L 50.

Remote air-cooled condenser with condensing coil with copper tubes and

aluminium fins:

- with AC axial fans series T-MATE DX-A;

- with EC axial fans series T-MATE DX-E;

- with EC plug-fans series T-MATE DX-PF-E.

OPTIONAL ACCESSORIES

The descriptions of these additional components can be found in Chapter OPTIONAL ACCESSORIES.

P121 .................................... Front air intake + bottom panel. Unit base noise insulation with special

bottom panel for OVER version. Restriction: Non-compatible with “P122

Bottom air intake + blind panels” for OVER version.

P122 .................................... Bottom air intake+blind panels. Blind frontal panel for OVER version. The

accessory allows the intake air from the bottom of the machine. Restriction:

Not compatible with “P121 Front air intake + bottom panel” for OVER

version.

601 ...................................... Solenoid valve on liquid line.

A548 .................................... Constant prevalence. Automatic system for the air pressure control in the

aisle. The system controls the supply fans rotation speed to keep constant

the air pressure via a differential pressure transmitter connected to the

microprocessor control.

P091 .................................... Back-up module controller. The system guarantees the microprocessor

power supply for a few minutes, in case of supply voltage failure. (size E1

excluded).

P171 .................................... Kit for air -45°C MCH axial AC (condenser series GR). Kit for operations

with low ambient air temperature down to -45°C. For machine start up and

operation with very low ambient air temperatures (between -20°C and 45°C).

P172 (1) .............................. Kit for air -45°C axial AC (condenser series T-MATE). Kit for operations

with low ambient air temperature down to -45°C. For machine start up and

operation with very low ambient air temperatures (between -20°C and 45°C).

P191 .................................... Power supply for condenser. Electrical power supply for remote

condenser from the indoor machine electrical board. The optional includes

magneto-thermic switches for condenser fans and the control/alarm signals.

383 ...................................... Numbered wirings + UK requests;

4181 / 4182 / 4184 / 4185 ... Serial cards:

4181 – Serial card MODBUS;

4182 – Serial card LON;

4184 – Serial card BACNET MS/TP RS485;

4185 – Serial card BACNET OVER IP.

A492 .................................... Water leakage detector + additional sensor. Supplied in mounting kit.

A511 .................................... Smoke detector. Supplied in mounting kit.

A521 .................................... Fire detector. Supplied in mounting kit.

P141 .................................... Analogue set-point compensation. - Analogue set point compensation

according to an external analogue signal at Customer care.

The microprocessor control, through the additional module “expansion

card”, can manage a compensation signal of the return air setpoint by

analogue input (0...1V; 0...5V; 0,5...4,5V; 4...20mA; 0...20mA). The

compensation curve allows to assign a temperature setpoint offset

respectively to the minimum and maximum signal managed by the input.

Page 12

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

12

MEHITS S.p.A.

DATA BOOK

P181 .................................... Network analyser (standard machine) Multifunction utility for calculating and

displaying the machine electrical measurements.

P182 .................................... Network analyser+optional (full optional machine) Multifunction utility for

calculating and displaying the machine electrical measurements.

P183 .................................... Kit network analyser (standard machine) Multifunction utility for calculating

and displaying the machine electrical measurements. Supplied in mounting

kit.

P184 .................................... Kit network analyser+optional (full optional machine) Multifunction utility

for calculating and displaying the machine electrical measurements. Supplied

in mounting kit.

A812 (2) .............................. Free-cooling direct control.

P021 .................................... 2 way 0-10V modulating water valve.2-way motorized valve with 0÷10

VDC control actuator and emergency manual control for the third way (bypass) of the chilled water hydraulic circuit. The valve is in combination with

the main water flow control valve

A431 .................................... Electric heater. Heating with electric heaters.

A432 .................................... Extra power electric heater. Size E1, E2 excluded.

4301 / 4303 / 4305 (3) ......... Humidification: Modulating steam humidifier with immersed electrodes

with electronic control.

4301 - Steam humidifier 3kg/h

4303 - Steam humidifier 8kg/h

4305 - Steam humidifier 15kg/h

P051 (4) .............................. Dehumidification function.

P161 .................................... T/rH air intake sensor. Combined Temperature / Humidity sensor on air

intake. The optional replace the standard temperature sensor on machine

air intake.

4666 .................................... External air probe. External air temperature probe.

P071 .................................... Remote T/rH probe. Combined Temperature / Humidity sensor for remote

installation. The optional is added to the standard temperature sensor on

machine air intake.

P111 / P112 / P113 / P114 . Dual power supply. Dual power supply with automatic change-over.

P111 - Dual power supply.

P112 - Dual power supply + optional.

P113 - Dual power supply kit. Supplied in mounting kit

P114 - Dual power supply kit + optional. Supplied in mounting kit

A381 .................................... Drain pump. Supplied in mounting kit. The system includes pump with

activation float and 10 linear meters long discharge pipe.

P084 .................................... Air filter ePM10 50%. Washable high efficiency air filter (according to ISO

EN 16890). Not compatible with “P017 / P018 / P019 Plenum + filter ePM

2.5

50%, ePM1 50%, ePM1 85% (according to ISO EN 16890)”.

A531 (5) .............................. On-off damper. Non-return air damper with frame driven by electric

servomotor installed on the machine air delivery.

P011 .................................... Empty plenum.

P012 .................................... Empty plenum CL.A1. Plenum with fire reaction in class “0” or “A1”.

P013 .................................... Plenum + 3 grilles on three sides with double adjustable row.

P014 .................................... Plenum + 3 grilles CL.A1. Plenum with grilles on three sides with double

adjustable row, with fire reaction in class “0” or “A1”.

P015 .................................... Silenced plenum. Not compatible with “P084 Air filter ePM10 50%.”.

P016 .................................... Silenced plenum + 1 grille. Grille with double adjustable row on front side

and sound absorbers.

P017 .................................... Plenum + filter ePM

2,5

50%. Plenum with high efficiency air filter (according

to ISO EN 16890). Not compatible with “P084 Air filter ePM10 50%.”.

P018 .................................... Plenum + filter ePM1 50%. Plenum with high efficiency air filter (according

to ISO EN 16890). Not compatible with “P084 Air filter ePM10 50%.”.

P019 .................................... Plenum + filter ePM1 85%. Plenum with high efficiency air filter (according

to ISO EN 16890). Not compatible with “P084 Air filter ePM10 50%.”.

P031 (6) .............................. Empty intake plenum.

P032 (6) .............................. Empty intake plenum CL.A1. Plenum with fire reaction in class “0” or “A1”.

(size E0 excluded).

P034 (7) .............................. Intake free-cooling plenum.

P041 / P042 / P043 ............. Support frame with height adjusting rubber holders. Supplied in mounting

kit. It is not possible to match the support frame with plenum installed under

the machine.

P041 – Support frame h 255-350mm

P042 – Support frame h 355-450mm

P043 – Support frame h 400-510mm

3601 .................................... Compressor operating signal contact. Voltage free contact for

compressor status signalling.

Page 13

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

13

MEHITS S.p.A.

DATA BOOK

2411 .................................... Phase sequence relay. Phases sequence control relay for the machine.

The system checks that the phase sequence of the power supply is correct

to prevent the opposite rotation of the three phase electric motors of the

machine as compressors. The optional is installed in the electrical box

downstream the main switch with door lock safety and in case of wrong

phase sequence prevents starting the machine;

1511 .................................... Soft starter. Compressor motors soft-starter system (size E1, E2

excluded).

3301 .................................... Compressor rephasing. Compressors capacitor for power factor - cosφ

0,9 (sizes E1, E2 excluded).

A181 .................................... Compressor soundproof jacket. Compressor soundproof jacket for a

sound level reduction of 2 dB(A).

A272 .................................... CL. 0 or A1 (EN 13501-1) insulation: Panelling with fire reaction in class

“0” or “A1;

P151 .................................... Lowered display for Under – for UNDER units equipped with plenum

under the unit.

9973 .................................... Wooden cage packing. The machines are delivered on wooden pallet,

covered with shrink wrap and packaged in wooden cage.

7387012600 ........................ Remote terminal. Graphic display for remote installation, the optional is

added to the standard graphic display placed on machine frontal panel.

WARNING

The Manufacturers reserves the right to accept the matching of the optional installed on the

machine.

MANDATORY COMBINATIONS OF ACCESSORIES

1. When optional accessory “P172 Kit for air -45°C axial AC” is present, it requires mandatory

accessory “P191 Power supply for condenser”.

2. When optional accessory “A812 Free cooling direct control” is present, it requires mandatory

accessories “P161 T/rH air intake sensor“ and “4666 External air probe”.

3. When optional accessories “4301 / 4303 / 4305 Steam humidifier” are present, they require

mandatory accessory “P161 T/rH air intake sensor“.

4. When optional accessory “P051 Dehumidification function” is present, it requires mandatory

accessory “P161 T/rH air intake sensor“.

5. When optional accessory “A531 On-off damper” is present, it requires mandatory accessory

“9973 Wooden cage packing”.

6. When optional accessories “P031 Empty intake plenum, for OVER version” and “P032 Empty

intake plenum CL.A1, for OVER version” are present, they require mandatory accessory “P122

Bottom air intake+blind panels, for OVER version only”

7. When optional accessory “P034 Intake free-cooling plenum” is present, it requires mandatory

accessories “P161 T/rH air intake sensor“, “4666 External air probe”, “A812 Free-cooling direct

control” and “P122 Bottom air intake+blind panels, for OVER version only”

Page 14

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

14

MEHITS S.p.A.

DATA BOOK

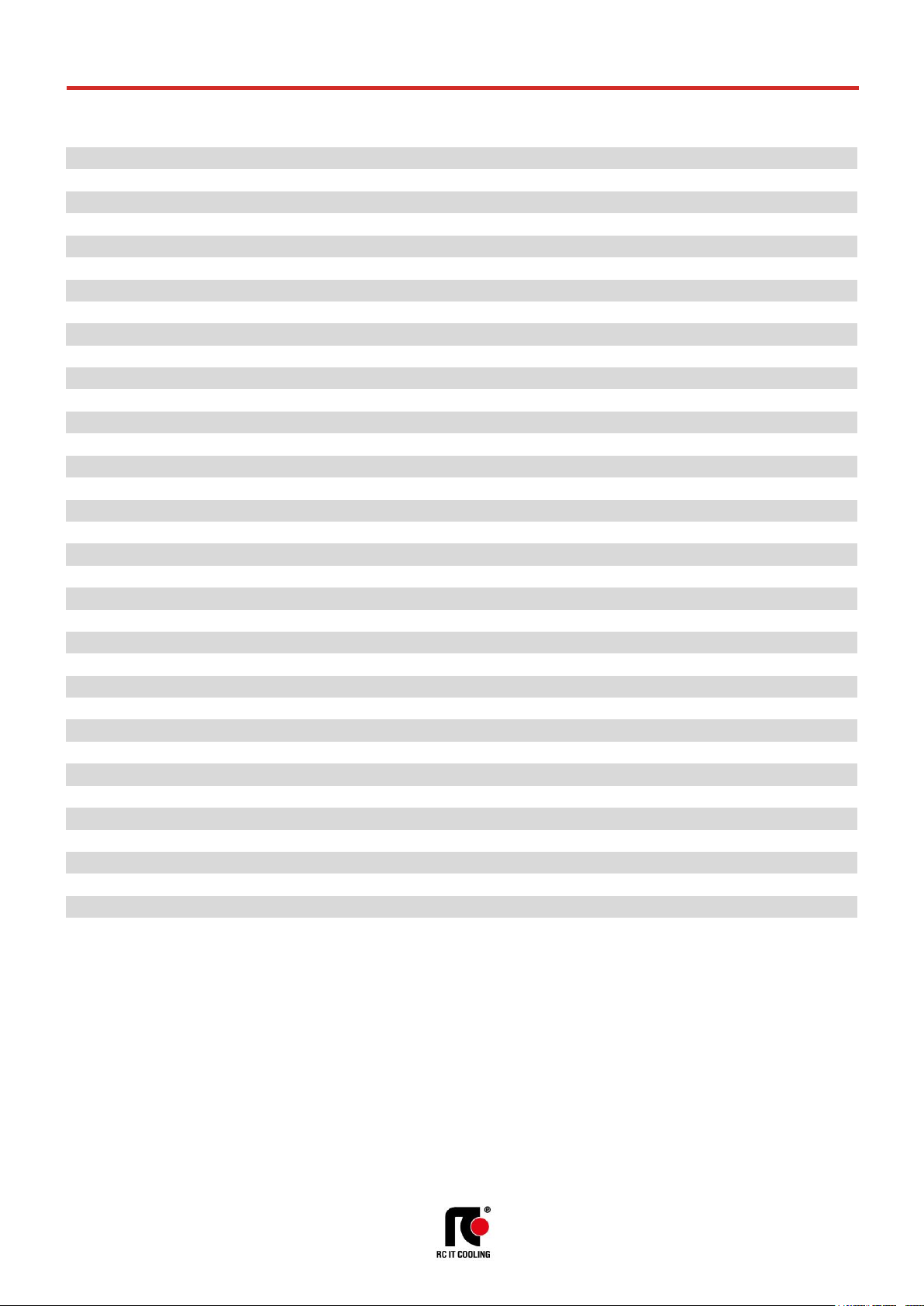

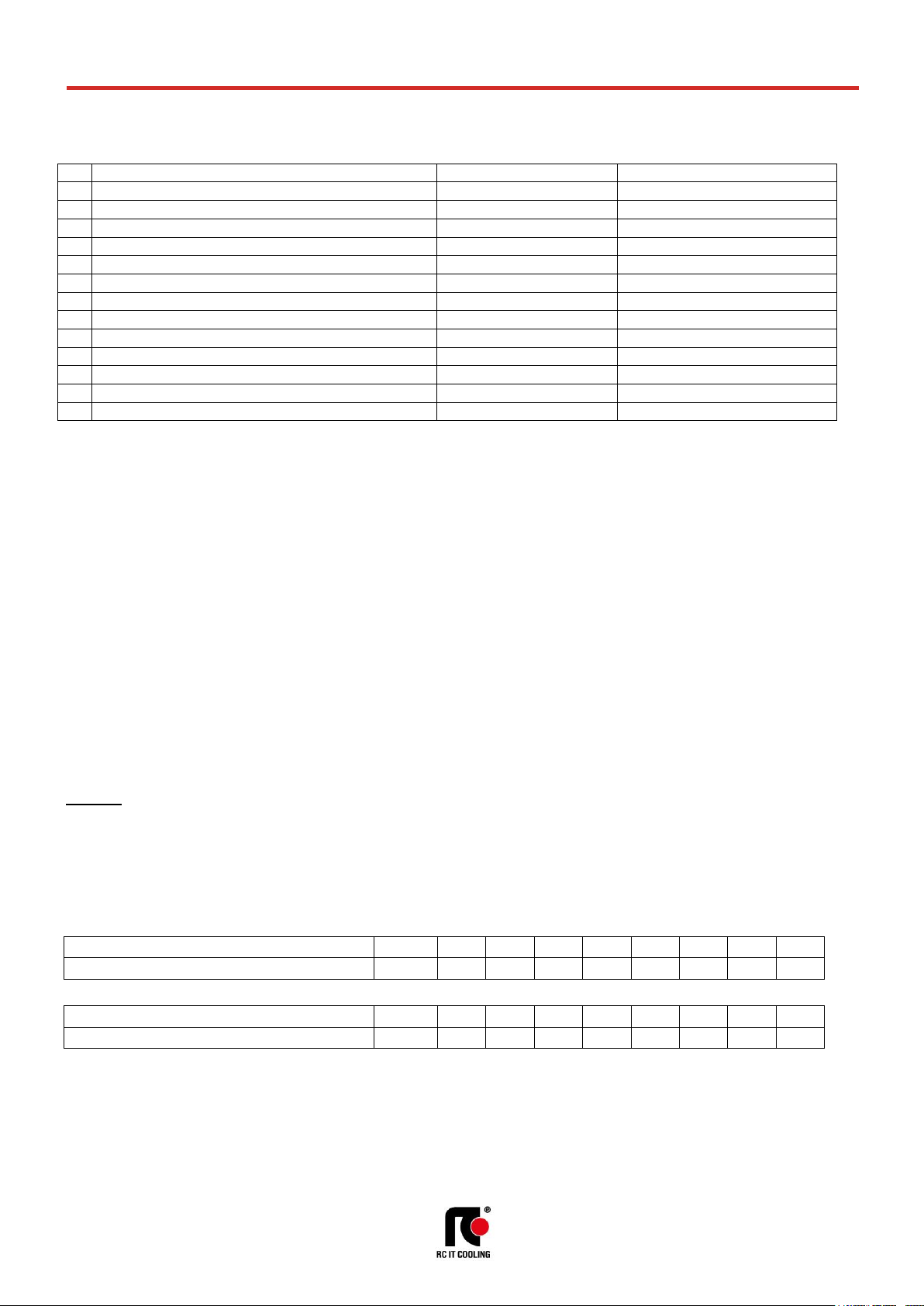

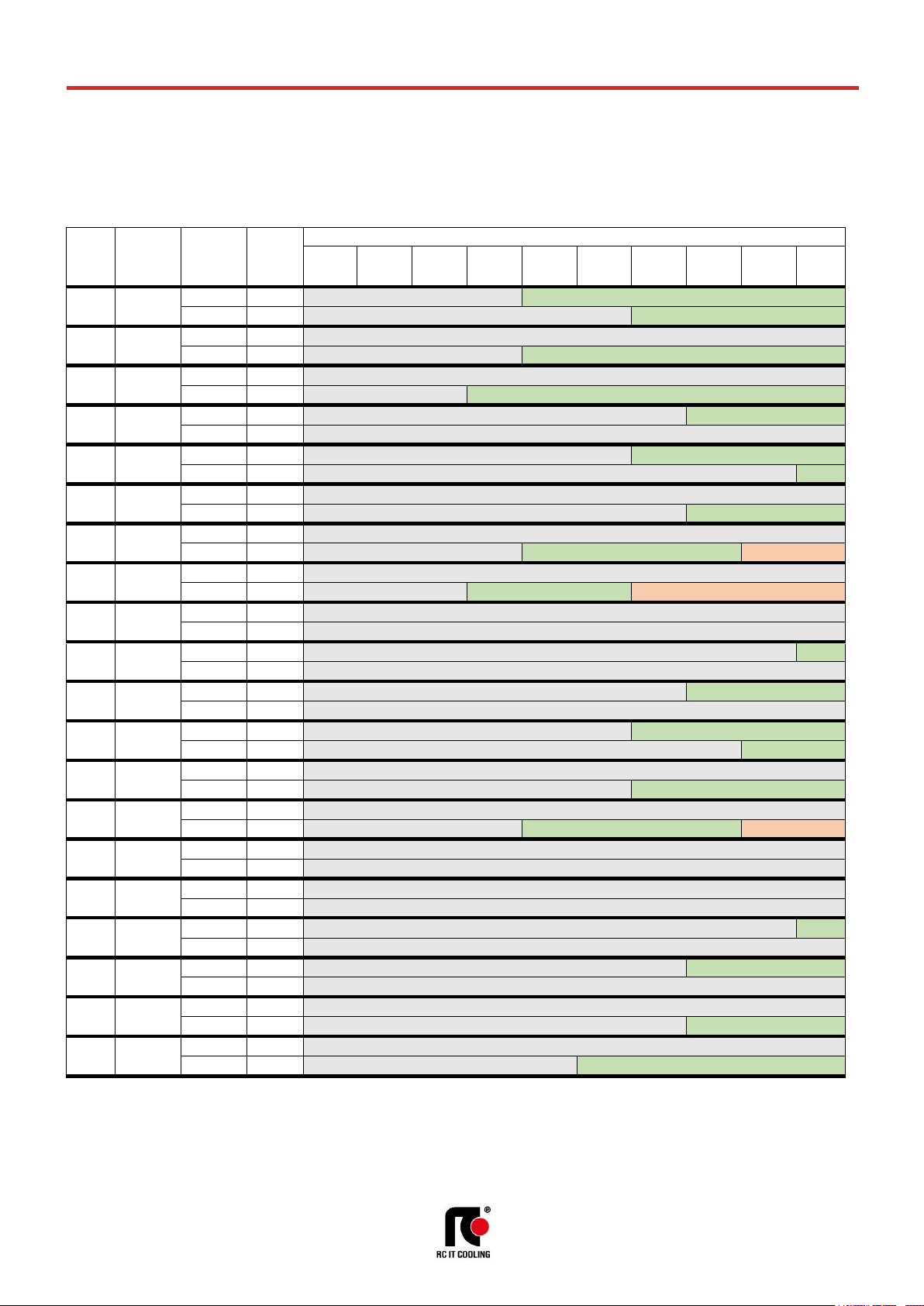

TECHNICAL DATA

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 011 P1 S

014 P1 S

016 P1 S

020 P1 S

022 P1 S

SIZE E1

E2

E2

E3

E3

COOLING CAPACITY (2)

Total

kW

10,3

13,8

16

20,3

22,1

Sensible

kW

10,2

13,8

14,8

20,3

22,1

SHR (3) 0,99 1 0,92 1 1

Total power input (Comp. + Fans)

kW

2,64

3,27

3,74

4,54

5,5

"EC" SUPPLY FANS

n. 1 1 1 1

1

Air flow

m³/h

2800

4000

4200

5700

6100

Nominal external static pressure

Pa

20

20

20

20

20

Maximum external static pressure

Pa

29

329

276

803

729

Fans power input (4)

kW

0,35

0,5

0,57

0,85

1,04

ON/OFF COMPRESSORS

rotary vane

rotary vane

rotary vane

scroll

scroll

Compressors number

n. 1 1 1 1

1

Capacity steps

n. 1 1 1 1

1

Compressors power input

kW

2,29

2,77

3,16

3,69

4,46

AIR FILTERS

n. 1 1 1 2

2

Filter area

m2

0,61

0,78

0,78

1,24

1,24

Efficiency (ISO EN 16890)

COARSE

60%

60%

60%

60%

60%

REFRIGERANT CIRCUITS

n. 1 1 1 1

1

POWER SUPPLY

V/Ph/Hz

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

ENERGY EFFICIENCY INDEX (2) (5)

EER Energy Efficiency Ratio

kW/kW

3,90

4,22

4,28

4,47

4,02

DIMENSIONS

Length

mm

650

785

785

1085

1085

Width

mm

675

675

675

775

775

Height

mm

1925

1925

1925

1925

1925

NET WEIGHT OVER

kg

248

283

288

333

338

NET WEIGHT UNDER

kg

258

293

298

353

358

REFRIGERANT CONNECTIONS

Gas delivery

ODS Ø

12

16

16

16

16

Liquid return

ODS Ø

12

12

12

16

16

HYDRAULIC CONNECTIONS

CONDENSATE DISCHARGE

Rubber pipe – internal diameter

Ø mm

19

19

19

19

19

THE COOLING CAPACITY DOES NOT CONSIDER THE SUPPLY FAN MOTOR THERMAL LOAD

1. U = Under, downflow / O = Over, upflow

2. Gross value. Characteristics referred to entering air at 26°C-40%RH; condensing temperature 45°C. ESP=20Pa.

3. SHR = Sensible cooling capacity / Total cooling capacity.

4. Corresponding to the nominal external static pressure

5. The Energy Efficiency Index does not consider the remote air-cooled condenser.

The units highlighted in this publication contain <HFC R410A [GWP

100

2088]> fluorinated greenhouse gas

Page 15

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

15

MEHITS S.p.A.

DATA BOOK

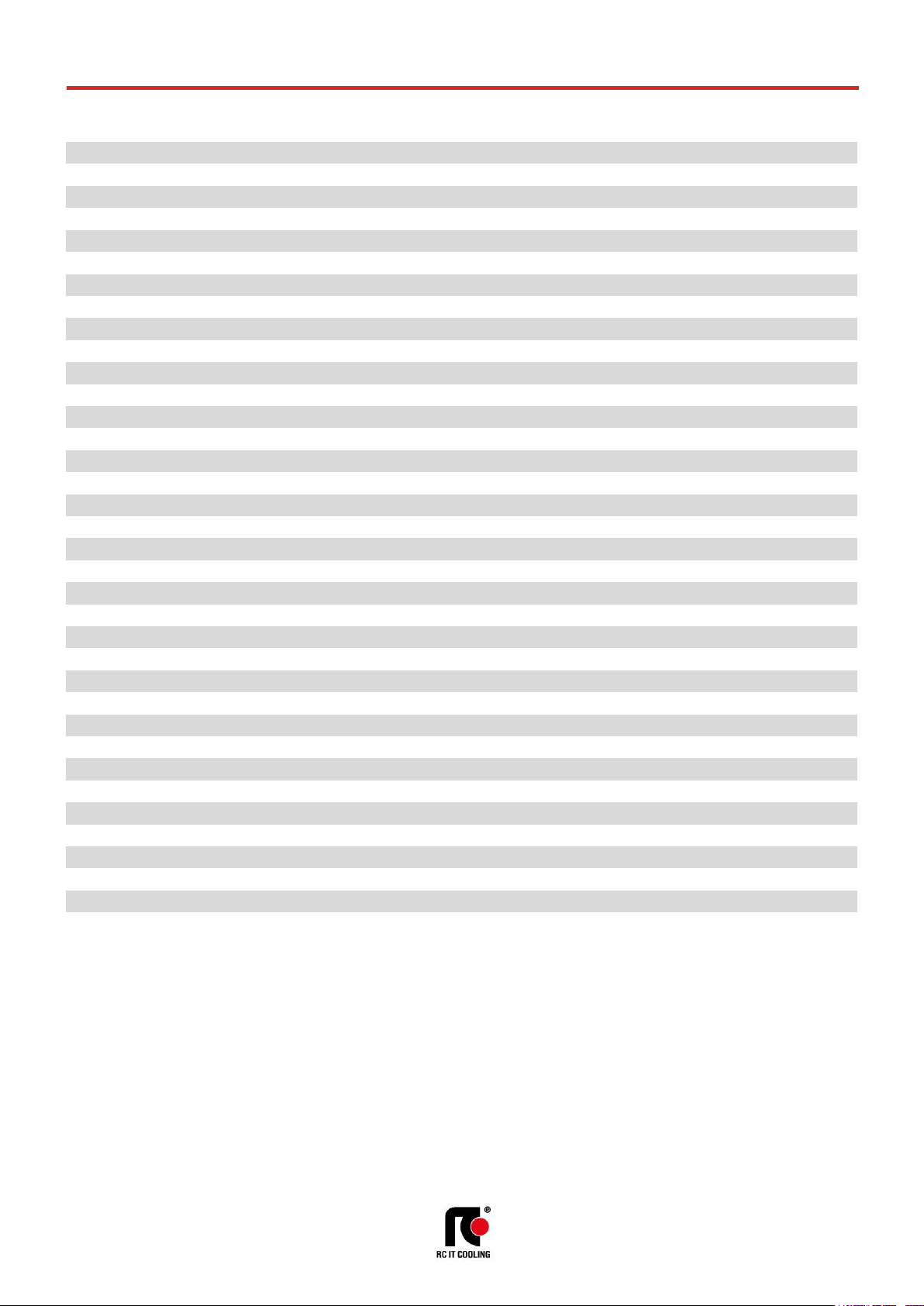

TECHNICAL DATA

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 026 P1 S

032 P1 S

037 P1 S

041 P1 S

045 P1 S

SIZE E3

E4

E4

E4

E4

COOLING CAPACITY (2)

Total

kW

26,2

32,5

37,6

41,4

45,4

Sensible

kW

25,3

32,5

37,6

41,2

43,4

SHR (3) 0,97 1 1 1 0,96

Total power input (Comp. + Fans)

kW

6,74

7,62

9,25

10,2

11,2

"EC" SUPPLY FANS

n. 1 1 1 1

1

Air flow

m³/h

6400

8700

10000

10800

10800

Nominal external static pressure

Pa

20

20

20

20

20

Maximum external static pressure

Pa

665

512

175

332

332

Fans power input (4)

kW

1,19

1,42

2,1

2,08

2,08

ON/OFF COMPRESSORS

scroll

scroll

scroll

scroll

scroll

Compressors number

n. 1 1 1 1

1

Capacity steps

n. 1 1 1 1

1

Compressors power input

kW

5,55

6,2

7,16

8,1

9,13

AIR FILTERS

n. 2 2 2 2

2

Filter area

m2

1,24

2,07

2,07

2,07

2,07

Efficiency (ISO EN 16890)

COARSE

60%

60%

60%

60%

60%

REFRIGERANT CIRCUITS

n. 1 1 1 1

1

POWER SUPPLY

V/Ph/Hz

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

ENERGY EFFICIENCY INDEX (2) (5)

EER Energy Efficiency Ratio

kW/kW

3,89

4,27

4,06

4,06

4,05

DIMENSIONS

Length

mm

1085

1305

1305

1305

1305

Width

mm

775

930

930

930

930

Height

mm

1925

1980

1980

1980

1980

NET WEIGHT OVER

kg

338

462

467

479

487

NET WEIGHT UNDER

kg

358

472

477

489

497

REFRIGERANT CONNECTIONS

Gas delivery

ODS Ø

22

22

22

22

22

Liquid return

ODS Ø

16

16

16

22

22

HYDRAULIC CONNECTIONS

CONDENSATE DISCHARGE

Rubber pipe – internal diameter

Ø mm

19

19

19

19

19

THE COOLING CAPACITY DOES NOT CONSIDER THE SUPPLY FAN MOTOR THERMAL LOAD

1. U = Under, downflow / O = Over, upflow

2. Gross value. Characteristics referred to entering air at 26°C-40%RH; condensing temperature 45°C. ESP=20Pa.

3. SHR = Sensible cooling capacity / Total cooling capacity.

4. Corresponding to the nominal external static pressure

5. The Energy Efficiency Index does not consider the remote air-cooled condenser.

The units highlighted in this publication contain <HFC R410A [GWP

100

2088]> fluorinated greenhouse gas

Page 16

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

16

MEHITS S.p.A.

DATA BOOK

TECHNICAL DATA

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 039 P2 D

048 P2 D

055 P2 D

062 P2 D

075 P2 D

SIZE E5

E5

E6

E6

E7

COOLING CAPACITY (2)

Total

kW

38,1

48,6

55,1

61,9

75,4

Sensible

kW

38,1

47,4

55,1

60,6

75,4

SHR (3) 1

0,98 1 0,98

1

Total power input (Comp. + Fans)

kW

9,21

12,5

13,5

15,1

17,9

"EC" SUPPLY FANS

n. 1 1 2 2

2

Air flow

m³/h

10000

12000

15000

15600

20000

Nominal external static pressure

Pa

20

20

20

20

20

Maximum external static pressure

Pa

259

206

654

592

438

Fans power input (4)

kW

1,82

2,31

2,4

2,68

3,6

ON/OFF COMPRESSORS

scroll

scroll

scroll

scroll

scroll

Compressors number

n. 2 2 2 2

2

Capacity steps

n. 2 2 2 2

2

Compressors power input

kW

7,39

10,2

11,1

12,4

14,3

AIR FILTERS

n. 3 3 3 3

4

Filter area

m2

2,59

2,59

3,16

3,16

3,82

Efficiency (ISO EN 16890)

COARSE

60%

60%

60%

60%

60%

REFRIGERANT CIRCUITS

n. 2 2 2 2

2

POWER SUPPLY

V/Ph/Hz

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

ENERGY EFFICIENCY INDEX (2) (5)

EER Energy Efficiency Ratio

kW/kW

4,14

3,89

4,08

4,10

4,21

DIMENSIONS

Length

mm

1630

1630

1875

1875

2175

Width

mm

930

930

930

930

930

Height

mm

1980

1980

1980

1980

1980

NET WEIGHT OVER

kg

584

594

684

704

777

NET WEIGHT UNDER

kg

594

604

694

714

834

REFRIGERANT CONNECTIONS

Gas delivery

ODS Ø

2x16

2x16

2x22

2x22

2x22

Liquid return

ODS Ø

2x16

2x16

2x16

2x16

2x22

HYDRAULIC CONNECTIONS

CONDENSATE DISCHARGE

Rubber pipe – internal diameter

Ø mm

19

19

19

19

19

THE COOLING CAPACITY DOES NOT CONSIDER THE SUPPLY FAN MOTOR THERMAL LOAD

1. U = Under, downflow / O = Over, upflow

2. Gross value. Characteristics referred to entering air at 26°C-40%RH; condensing temperature 45°C. ESP=20Pa.

3. SHR = Sensible cooling capacity / Total cooling capacity.

4. Corresponding to the nominal external static pressure

5. The Energy Efficiency Index does not consider the remote air-cooled condenser.

The units highlighted in this publication contain <HFC R410A [GWP

100

2088]> fluorinated greenhouse gas

Page 17

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

17

MEHITS S.p.A.

DATA BOOK

TECHNICAL DATA

VERSION (1)

U / O

U / O

U / O U U

MODEL 082 P2 D

092 P2 D

102 P2 D

117 P4 D

146 P4 D

SIZE E7

E8

E8

E9

E9

COOLING CAPACITY (2)

Total

kW

82,5

92

104

122

147

Sensible

kW

79,5

88,1

94,9

122

140

SHR (3) 0,96

0,96

0,91 1 0,95

Total power input (Comp. + Fans)

kW

19,8

22,6

26,4

31,5

39

"EC" SUPPLY FANS

n. 2 2 2 3

3

Air flow

m³/h

20000

22000

22000

32000

32000

Nominal external static pressure

Pa

20

20

20

20

20

Maximum external static pressure

Pa

438

295

295

298

298

Fans power input (4)

kW

3,6

4,37

4,37

6,65

6,65

ON/OFF COMPRESSORS

scroll

scroll

scroll

scroll

scroll

Compressors number

n. 2 2 2 4

4

Capacity steps

n. 2 2 2 4

4

Compressors power input

kW

16,2

18,3

22

24,8

32,4

AIR FILTERS

n. 4 5 5 5

5

Filter area

m2

3,82

4,46

4,46

5,24

5,24

Efficiency (ISO EN 16890)

COARSE

60%

60%

60%

60%

60%

REFRIGERANT CIRCUITS

n. 2 2 2 2

2

POWER SUPPLY

V/Ph/Hz

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

400/3+N/50

ENERGY EFFICIENCY INDEX (2) (5)

EER Energy Efficiency Ratio

kW/kW

4,17

4,07

3,94

3,87

3,77

DIMENSIONS

Length

mm

2175

2499

2499

2899

2899

Width

mm

930

930

930

930

930

Height

mm

1980

1980

1980

1980

1980

NET WEIGHT OVER

kg

784

886

886

--

--

NET WEIGHT UNDER

kg

839

946

946

1150

1210

REFRIGERANT CONNECTIONS

Gas delivery

ODS Ø

2x22

2x22

2x22

2x28

2x28

Liquid return

ODS Ø

2x22

2x22

2x22

2x22

2x22

HYDRAULIC CONNECTIONS

CONDENSATE DISCHARGE

Rubber pipe – internal diameter

Ø mm

19

19

19

19

19

THE COOLING CAPACITY DOES NOT CONSIDER THE SUPPLY FAN MOTOR THERMAL LOAD

1. U = Under, downflow / O = Over, upflow

2. Gross value. Characteristics referred to entering air at 26°C-40%RH; condensing temperature 45°C. ESP=20Pa.

3. SHR = Sensible cooling capacity / Total cooling capacity.

4. Corresponding to the nominal external static pressure

5. The Energy Efficiency Index does not consider the remote air-cooled condenser.

The units highlighted in this publication contain <HFC R410A [GWP

100

2088]> fluorinated greenhouse gas

Page 18

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

18

MEHITS S.p.A.

DATA BOOK

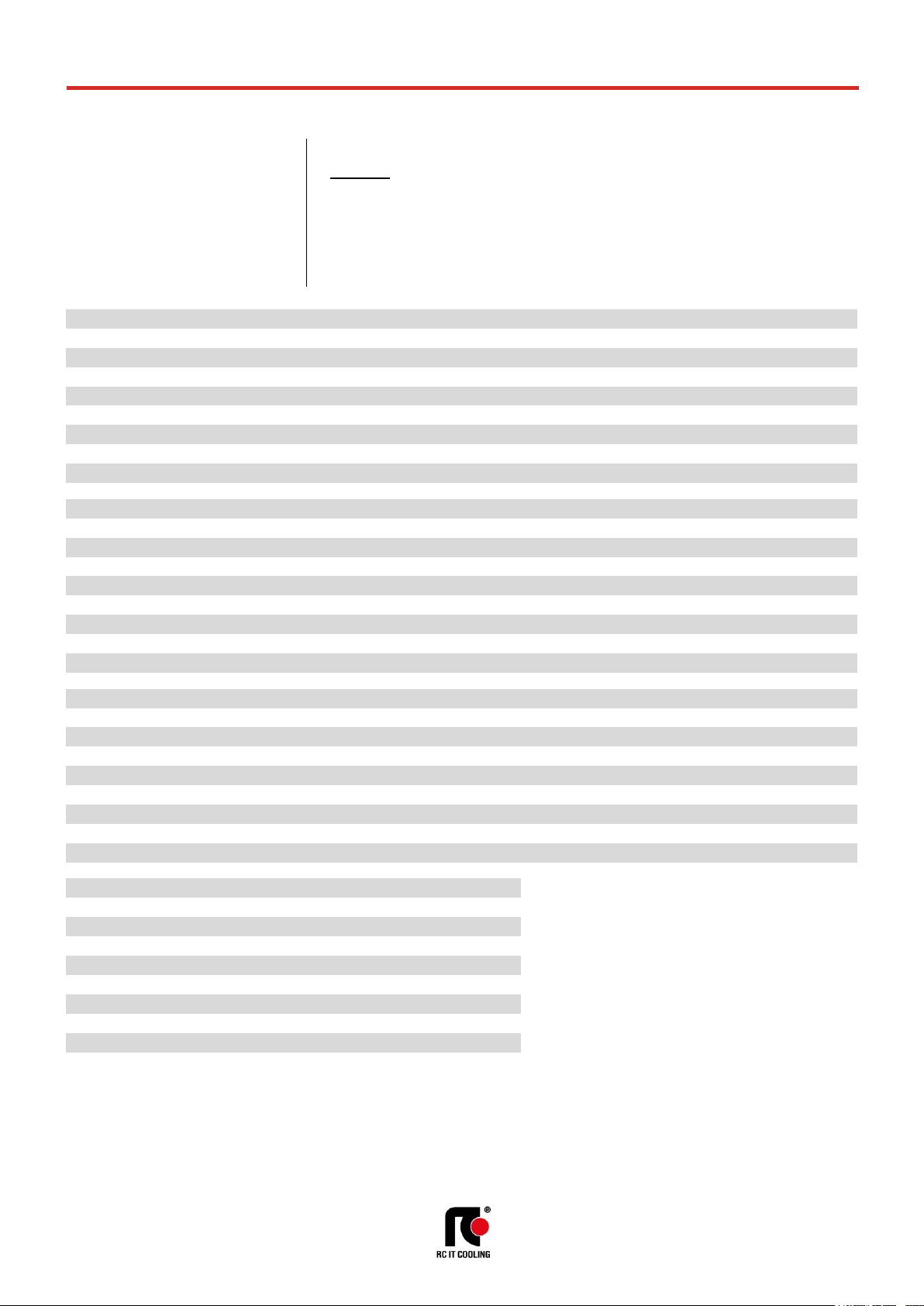

DUAL FLUID SYSTEM

DUAL FLUID system on the machine allows to obtain two independent cooling systems:

• Chilled water coil

• Direct expansion coil

The microprocessor control system automatically manages the system, by activating the cooling circuit

more convenient according to the parameters set.

With this system, it is possible, with a limited use of space, to solve several plant problems such as:

• Chilled water coil fed with chilled water or mains water as a stand-by of the main cooling

circuit.

• Double chilled water feeding with two independent circuit. This solution is used when you

need to ensure redundancy of the cooling system.

The temperature control is performed with the same logic of the main coil.

TECHNICAL DATA

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 011 P1 S

014 P1 S

016 P1 S

020 P1 S

022 P1 S

SIZE E1

E2

E2

E3

E3

COOLING CAPACITY (2)

Total

kW

12,2

17,8

18,4

25,4

26,5

Sensible

kW

11,8

17,2

18

24,6

25,6

SHR (3) 0,97

0,97

0,98

0,97

0,97

COOLING COIL

Water flow rate (2)

m3/h

2,12

3,06

3,16

4,35

4,57

dP coil + valve (2)

kPa

15

33,5

35,6

24,7

26,6

Water volume

l

4,2

5,3

5,3

7,8

7,8

HYDRAULIC CONNECTIONS

WATER INLET / OUTLET ISO 7/1 - R

Ø

1"

1"

1"

1+1/4"

1+1/4"

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 026 P1 S

032 P1 S

037 P1 S

041 P1 S

045 P1 S

SIZE E3

E4

E4

E4

E4

COOLING CAPACITY (2)

Total

kW

27,4

39

43,4

46

46

Sensible

kW

26,8

38,3

42

44,9

44,9

SHR (3) 0,98

0,98

0,97

0,98

0,98

COOLING COIL

Water flow rate (2)

m3/h

4,71

6,69

7,45

7,92

7,92

dP coil + valve (2)

kPa

28,3

14,2

17,1

19

19

Water volume

l

7,8

13,8

13,8

13,8

13,8

HYDRAULIC CONNECTIONS

WATER INLET / OUTLET ISO 7/1 - R

Ø

1+1/4"

1+1/2"

1+1/2"

1+1/2"

1+1/2"

THE COOLING CAPACITY DOES NOT CONSIDER THE SUPPLY FAN MOTOR THERMAL LOAD

1. U = Under, downflow / O = Over, upflow

2. Characteristics referred to entering air at 26°C-40%RH with chilled water temperature 7-12°C - 0% glycol

3. SHR = Sensible cooling capacity / Total cooling capacity.

Air conditioner

Remote

condenser

Liquid chiller

Page 19

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

19

MEHITS S.p.A.

DATA BOOK

TECHNICAL DATA

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 039 P2 D

048 P2 D

055 P2 D

062 P2 D

075 P2 D

SIZE E5

E5

E6

E6

E7

COOLING CAPACITY (2)

Total

kW

48,8

55,5

65,3

67,3

101

Sensible

kW

48,8

55,2

63,2

65,4

95,3

SHR (3) 1

0,99

0,97

0,97

0,94

COOLING COIL

Water flow rate (2)

m3/h

8,38

9,54

11,23

11,59

17,42

dP coil + valve (2)

kPa

26,3

33,1

15,7

16,6

38,8

Water volume

l

18,1

18,1

18,1

18,1

24,6

HYDRAULIC CONNECTIONS

WATER INLET / OUTLET ISO 7/1 - R

Ø

2"

2"

2"

2"

2+1/2"

VERSION (1)

U / O

U / O

U / O U U

MODEL 082 P2 D

092 P2 D

102 P2 D

117 P4 D

146 P4 D

SIZE E7

E8

E8

E9

E9

COOLING CAPACITY (2)

Total

kW

101

116

116

136

136

Sensible

kW

95,3

108

108

136

136

SHR (3) 0,94

0,93

0,93 1 1

COOLING COIL

Water flow rate (2)

m3/h

17,42

19,9

19,9

23,43

23,43

dP coil + valve (2)

kPa

38,8

49,3

49,3

39,9

39,9

Water volume

l

24,6

28,5

28,5

33,8

33,8

HYDRAULIC CONNECTIONS

WATER INLET / OUTLET ISO 7/1 - R

Ø

2+1/2"

2+1/2"

2+1/2"

3”

3”

THE COOLING CAPACITY DOES NOT CONSIDER THE SUPPLY FAN MOTOR THERMAL LOAD

1. U = Under, downflow / O = Over, upflow

2. Characteristics referred to entering air at 26°C-40%RH with chilled water temperature 7-12°C - 0% glycol

3. SHR = Sensible cooling capacity / Total cooling capacity.

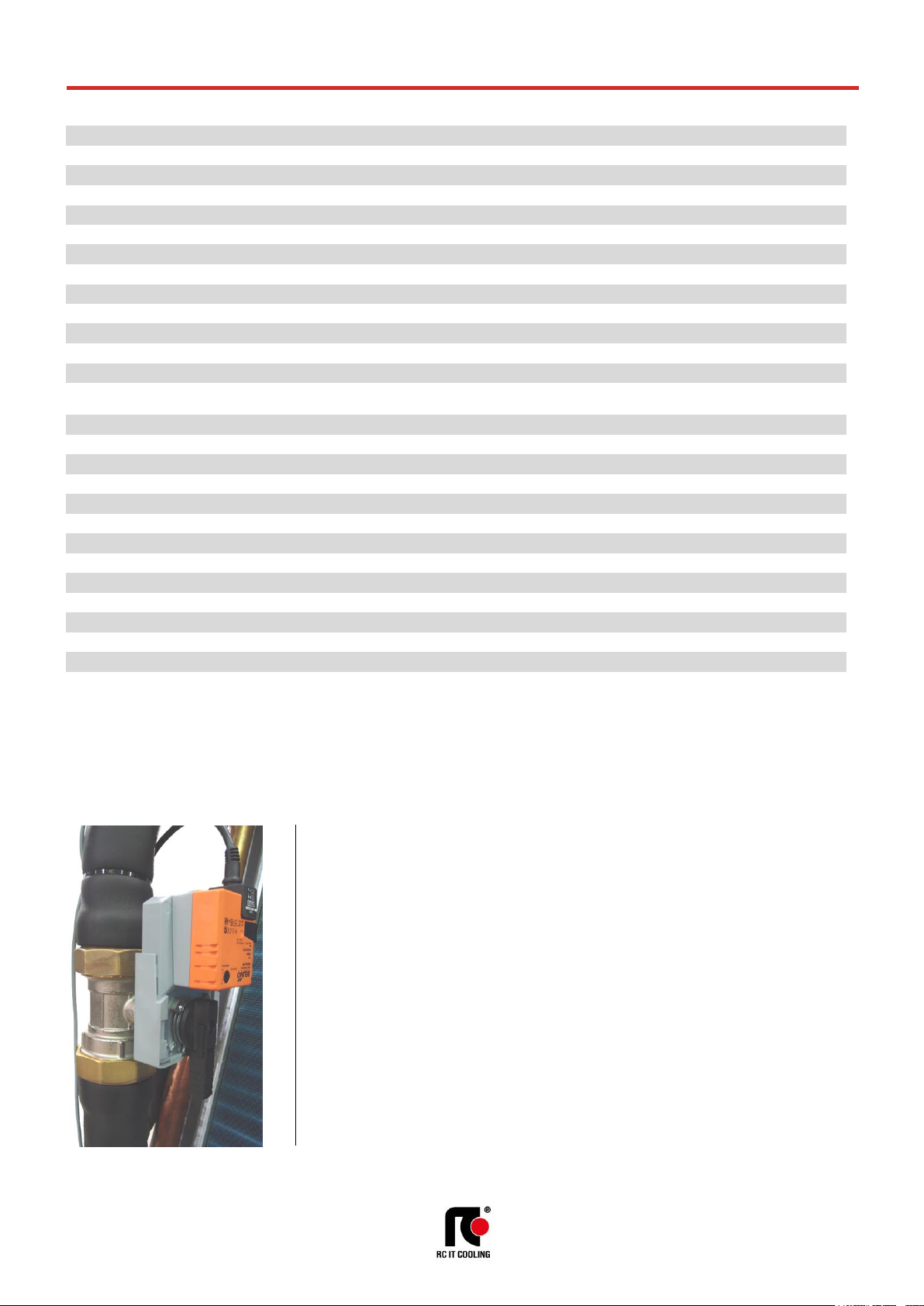

2-WAY BALL VALVE FOR CHILLED WATER FLOW CONTROL

The water flow control in the finned coil is acieved through a 2-way modulating ball valve with equal

percentage flow control ensured by the integrated characterizing disc.

This type of valve offers the following series of benefits:

• Equal percentage flow control.

• No peaks initial flow.

• Excellent stability control thanks to the integrated characterizing disc.

• Excellent characteristic in partialisation.

• Stability in control.

• Maintenance free.

• Self-cleaning.

CHARACTERISTICS OF THE 2-WAY BALL VALVE

• Closing seal with leakage rate in Class A (EN 12266-1)

• Maximum fluid pressure Ps=1600kPa

• Maximum closing pressure (Close-off) ∆Ps=1400kPa

The rotative actuator is controlled by a signal 0 … 10VDC from the microprocessor controller. The

actuator is equipped with an emergency button for manual operation and is maintenance-free.

Page 20

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

20

MEHITS S.p.A.

DATA BOOK

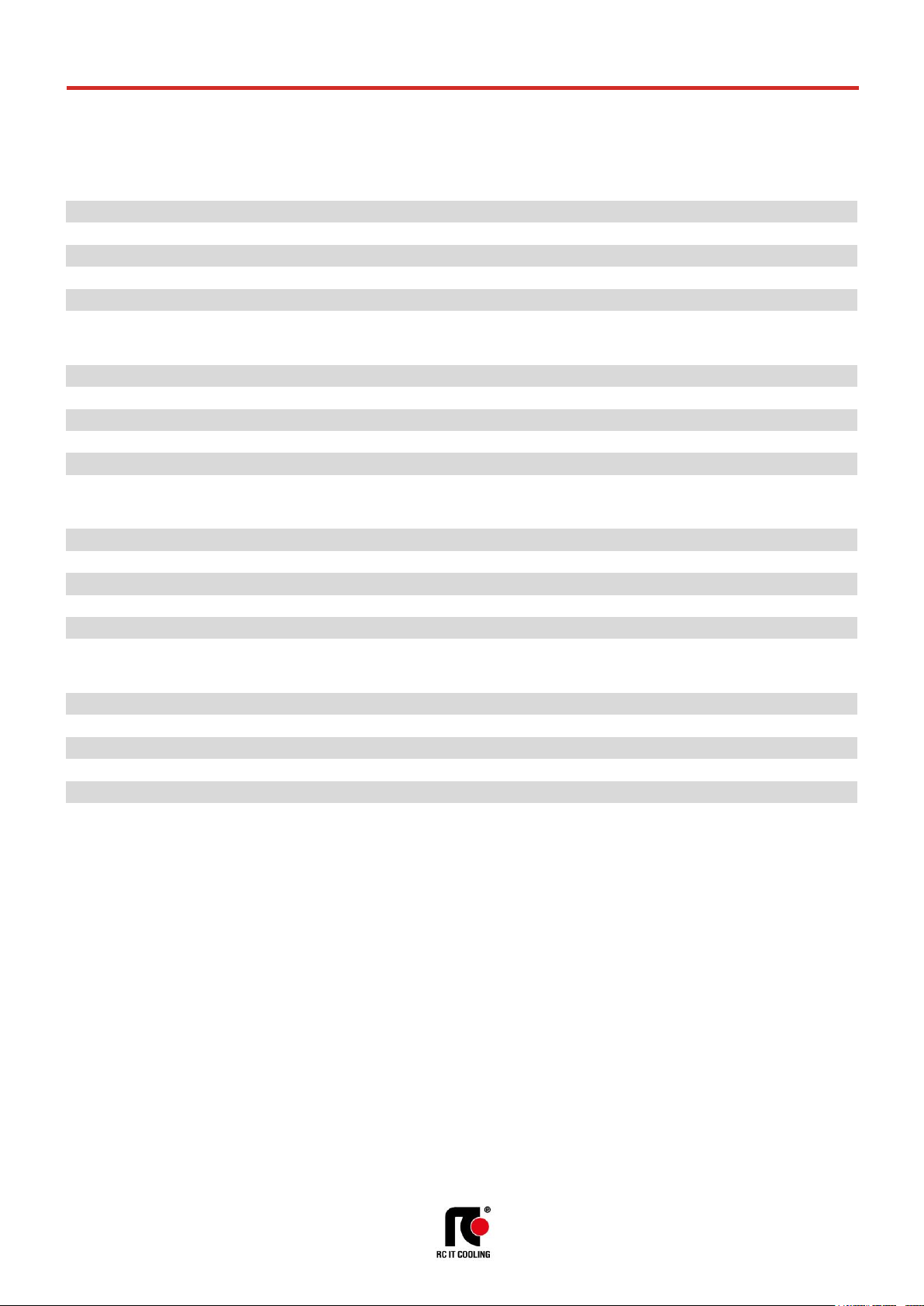

WATER QUALITY OF THE HYDRAULIC CIRCUITS

The values shown in the table must be guaranteed during the entire life cycle of the machine.

Description

Symbol

Range 1 Hydrogen Ions

pH

7.5 ÷ 9

2

Presence of calcium (Ca) and magnesium (Mg)

Hardness

4 ÷ 8.5 °D

3

Chlorine ions

Cl-

< 150 ppm

4

Iron Ions

Fe3+

< 0.5 ppm 5 Manganese Ions

Mn2+

< 0.05 ppm 6 Carbon dioxide

CO2

< 10 ppm

7

Hydrogen sulphide

H2S

< 50 ppb

8

Oxygen

O2

< 0.1 ppm 9 Chlorine

Cl2

< 0.5 ppm

10

Ammonia

NH3

< 0.5 ppm

11

Ratio between carbonates and sulphates

HCO3-/SO

4

2-

> 1

12

Sulphate ions

SO

4

--

< 100 ppm

13

Phosphate ions

PO

4

3-

< 2.0 ppm

where: 1/1.78°D = 1°Fr with 1°Fr = 10 gr CaCO3 / m3

ppm = parts for millions

ppb = part for billion

Explanatory notes:

ref.1: A greater concentration of hydrogen ions (pH) than 9 implies a high risk of deposits, whereas a lower pH than 7 implies a high risk of

corrosion.

ref.2: The hardness measures the amount of Ca and Mg carbonate dissolved in the water with a temperature lower than 100°C (temporary

hardness). A high hardness implies a high risk of deposits.

ref.3: The concentration of chloride ions with higher values than those indicated causes corrosion.

ref. 4 - 5 - 8: The presence of iron and manganese ions and oxygen leads to corrosion.

ref.6 - 7: Carbon dioxide and hydrogen sulphide are impurities that promote corrosion.

ref.9: Usually in water from the waterworks it is a value of between 0.2 and 0.3 ppm. High values cause corrosion.

ref.10: The presence of ammonia reinforces the oxidising power of oxygen

ref.11: Below the value shown in the table, there is a risk of corrosion due to the trigger of galvanic currents between copper and other less noble

metals.

ref.12: The presence of sulphates ions triggers corrosion phenomenon.

ref.13: The presence of phosphates ions triggers corrosion phenomenon.

It is necessary to carry out periodic checks, with withdrawals at different points of the hydraulic system. During the first year of operation, checks are

recommended every 4 months which can be reduced every 6 months starting from the second year of operation.

WARNING:

It is necessary that, in the presence of dirty and / or aggressive waters, an intermediate heat exchanger is installed upstream of the heat

exchangers

ANTIFREEZE MIXTURES

In plants that are not adequately protected by heating cables, protect the hydraulic circuit with an anti-freeze mixture when the ambient air temperature can

drop below 5°C.

The values are indicative and may significantly vary depending on the glycol manufacturer. Refer to your glycol supplier for detail.

The values consider a precautionary difference of 5°C between the minimum ambient air temperature and the freezing temperature of the mixture.

In the hydraulic circuit do not send fluids other than water or mixtures with ethylene / propylene glycol.

If other products are provided, in addition to mixtures of water and ethylene or propylene glycol, contact the Manufacturer to check the compatibility with the

machine components.

Minimum ambient air temperature

°C 5 0

-5

-10

-15

-20

-25

-30

ETHYLENE GLYCOL (suggested % in weight)

% 0 12

20

30

35

40

45

50

Minimum ambient air temperature

°C 5 2

-3

-9

-13

-17

-23

-29

PROPYLENE GLYCOL (suggested % in weight)

% 0 10

20

30

35

40

45

50

Page 21

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

21

MEHITS S.p.A.

DATA BOOK

REFRIGERANT CHARGE

The air conditioner is supplied with a minimum R410A refrigerant charge. Refrigerant must be charged. The following table shows the refrigerant charge that

must be introduced for the air conditioner only. Remote condenser, connections pipes and optional are excluded.

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 011 P1 S

014 P1 S

016 P1 S

020 P1 S

022 P1 S

SIZE E1

E2

E2

E3

E3

REFRIGERANT

R410A

R410A

R410A

R410A

R410A

Refrigerant circuits x Refrigerant charge (2)

n x kg

1 x 3,2

1 x 3,4

1 x 3,4

1 x 4,0

1 x 4,0

HFC R410A - F Gas - CO2 equivalent

t

6,68

7,10

7,10

8,35

8,35

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 026 P1 S

032 P1 S

037 P1 S

041 P1 S

045 P1 S

SIZE E3

E4

E4

E4

E4

REFRIGERANT

R410A

R410A

R410A

R410A

R410A

Refrigerant circuits x Refrigerant charge (2)

n x kg

1 x 4,0

1 x 5,7

1 x 5,7

1 x 8,6

1 x 8,6

HFC R410A - F Gas - CO2 equivalent

t

8,35

11,90

11,90

17,96

17,96

VERSION (1)

U / O

U / O

U / O

U / O

U / O

MODEL 039 P2 D

048 P2 D

055 P2 D

062 P2 D

075 P2 D

SIZE E5

E5

E6

E6

E7

REFRIGERANT

R410A

R410A

R410A

R410A

R410A

Refrigerant circuits x Refrigerant charge (2)

n x kg

2 x 4,5

2 x 4,5

2 x 4,9

2 x 4,9

2 x 8,1

HFC R410A - F Gas - CO2 equivalent

t

18,79

18,79

20,46

20,46

33,83

VERSION (1)

U / O

U / O

U / O U U

MODEL 082 P2 D

092 P2 D

102 P2 D

117 P4 D

146 P4 D

SIZE E7

E8

E8

E9

E9

REFRIGERANT

R410A

R410A

R410A

R410A

R410A

Refrigerant circuits x Refrigerant charge (2)

n x kg

2 x 8,1

2 x 8,7

2 x 8,7

2 x 10,8

2 x 10,8

HFC R410A - F Gas - CO2 equivalent

t

33,83

36,33

36,33

45,1

45,1

1. U = Under, downflow / O = Over, upflow

2. Refrigerant charge required for the air conditioner only operation. Remote condenser, connections pipes and optional are excluded.

For air conditioners with double refrigerant circuit is indicated the number of circuits x the charge of a single circuit.

Page 22

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

22

MEHITS S.p.A.

DATA BOOK

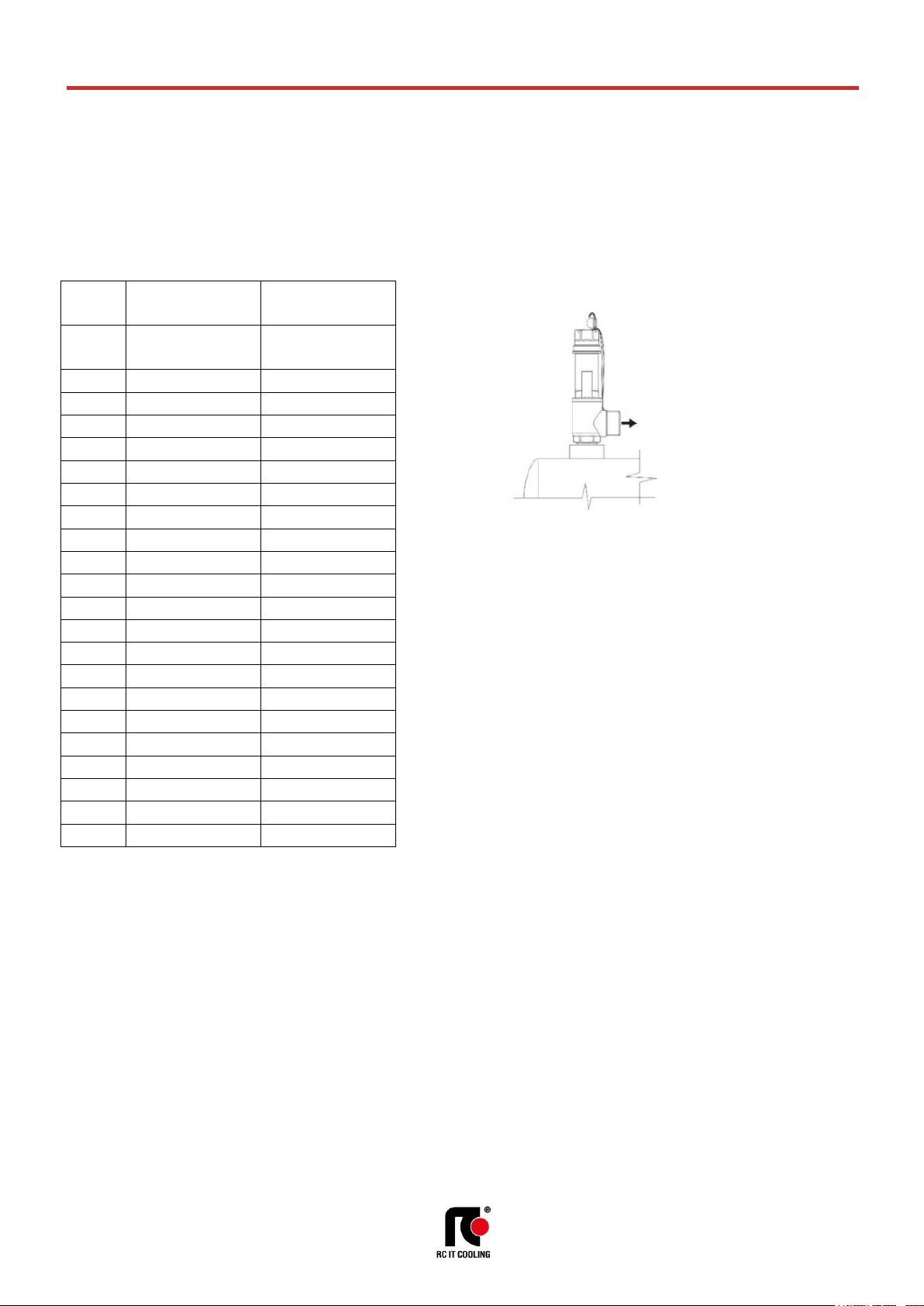

PRESSURE RELIEF VALVE

The pressure relief valve of the refrigerant circuit is installed in the machines when required by Directive 2014/68/EU.

The valve is installed on liquid receiver of each refrigerant circuit of the machine with the purpose to protect the circuit from overpressure.

It is up to the installer to check whether the system complies with the 2014/68 / EU standard regarding the installation of the pressure relief valve.

By plant we mean the complete system that includes the internal machine, the remote condenser and the connecting pipes

The installer must calculate the amount of refrigerant contained in the system and, if the refrigerant charge is higher than 10 kg, he must install the pressure

relief valve.

Factory installed

components

At Installer care

Pressure relief valve on

liquid receiver

Possible pressure relief

valve

Model

[bar]

[bar]

011 P1 S

---

41,5

014 P1 S

---

41,5

016 P1 S

---

41,5

020 P1 S

---

45,0

022 P1 S

---

45,0

026 P1 S

---

45,0

032 P1 S

---

45,0

037 P1 S

---

45,0

041 P1 S

45,0

---

045 P1 S

45,0

---

039 P2 D

---

45,0

048 P2 D

---

45,0

055 P2 D

---

45,0

062 P2 D

---

45,0

075 P2 D

45,0

---

082 P2 D

45,0

---

092 P2 D

45,0

---

102 P2 D

45,0

---

117 P4 D

45,0

---

146 P4 D

45,0

---

Exhaust flow

CONNECTION Ø 3/4” G – M

Page 23

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

23

MEHITS S.p.A.

DATA BOOK

R1

EVP

RU

C1

SPH1

BPH1

BPL1

IP

FG

VE

IP

FG

VE1

T1

RL

VS

CND1

RU

RU

RU

M1

DF

T2

Tin

R1

EVP

RU

C1

SPH1

BPH1

BPL1

IP

FG

VE

IP

FG

VE1

T1

RL

VS

CND1

RU

RU

RU

M1

DF

T2

Tin

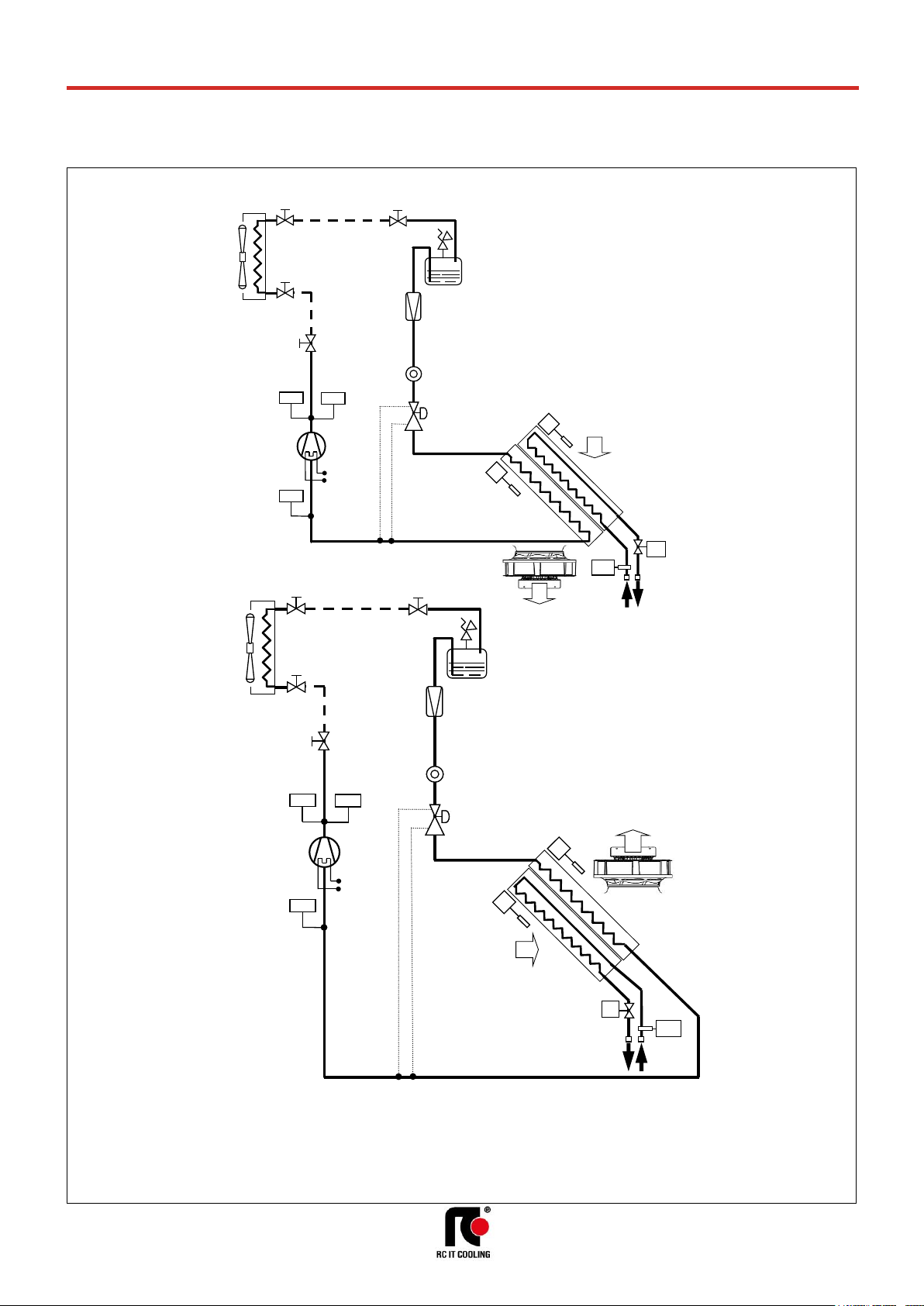

REFRIGERANT CIRCUIT

Below refrigerant diagrams for version with single or double refrigerant circuit. The diagrams refer to the standard configuration, without optional.

UNDER - SINGLE REFRIGERANT CIRCUIT

OVER - SINGLE REFRIGERANT CIRCUIT

LEGENDA

C1 Compressor

R1 Crankcase heater

CND Condenser.

EVP Evaporator

EC Dual fluid

Chilled water coil

BPH High pressure transducer.

BPL Low pressure transducer.

SPH High pressure switch

M1 Dual-Fluid 2-way valve

VS Pressure relief valve.

FG Refrigerant filter.

IP Sight glass.

VE Expansion valve.

T Temperature probes.

RU Valves

RL Liquid receiver

VS = Pressure relief valve

Only models 041 P1, 045 P1

VS = Pressure relief valve

Only models 041 P1, 045 P1

Page 24

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

24

MEHITS S.p.A.

DATA BOOK

R1

R2

IP

EVP

FG

RU

VE

C1

SPH1

BPH1

BPL1

VS

C2

SPH2

BPH2

BPL2

IP

FG

VE2

IP

FG

RU

VE

IP

FG

VE1

RL

RL

VS

CND1

RU

RU

CND2

RU

RU

RU

RU

T1

M1

DF

T2

Tin

R1

R2

IP

EVP

FG

RU

VE

C1

SPH1

BPH1

BPL1

VS

C2

SPH2

BPH2

BPL2

IP

FG

VE2

IP

FG

RU

VE

IP

FG

VE1

T1

RL

RL

VS

CND1

RU

RU

CND2

RU

RU

RU

RU

M1

DF

T2

Tin

R2

R1

C2

C1

R2

R1

C2

C1

UNDER - DOUBLE REFRIGERANT CIRCUIT

OVER - DOUBLE REFRIGERANT CIRCUIT

LEGENDA

C1 Compressor

R1 Crankcase heater

CND Condenser.

EVP Evaporator

EC Dual fluid

Chilled water coil

BPH High pressure transducer.

BPL Low pressure transducer.

SPH High pressure switch

M1 Dual-Fluid 2-way valve

VS Pressure relief valve.

FG Refrigerant filter.

IP Sight glass.

VE Expansion valve.

T Temperature probes.

RU Valves

RL Liquid receiver

VS = Pressure relief valve

Only models 075 P2, 082 P2,

092 P2, 102 P2, 117 P4, 146 P4

VS = Pressure relief valve

Only models 075 P2, 082 P2,

092 P2, 102 P2

SIZE E9

Page 25

t-NEXT DF DX

T_tNEXTDFDX_0719_EN

25

MEHITS S.p.A.

DATA BOOK

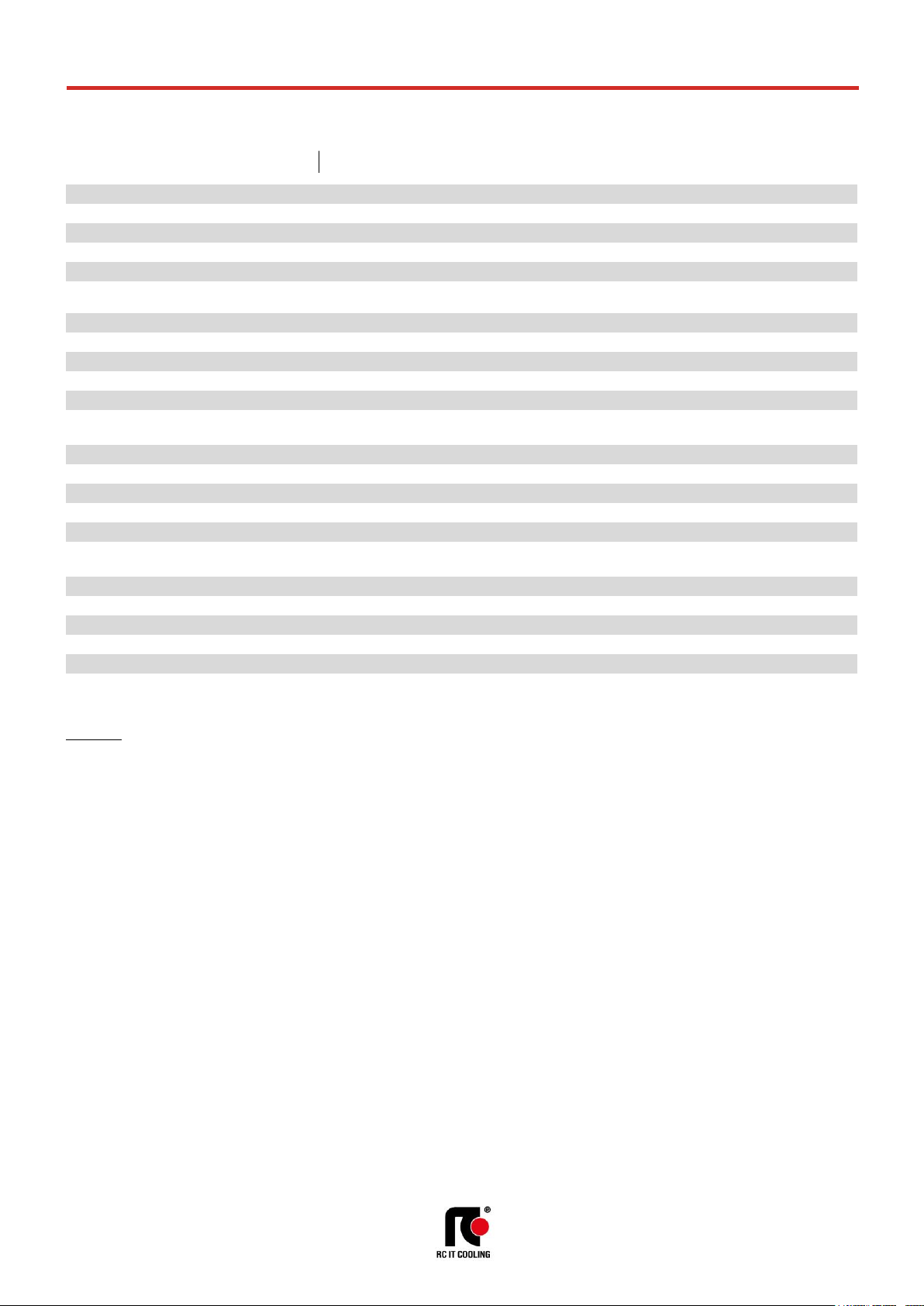

RECOMMENDED REFRIGERANT LINES

Values are referred to “EQUIVALENT LENGTH” of the piping.

You are kindly requested to always refer to the “INSTALLATION DIAGRAM” for the allowable height difference and to properly select all necessary

components. Verify the need to use pressure limiting devices (pressure relief valves) where not already provided for by Directive 2014/68 / EU.

In some cases, the diameter of the refrigerant lines may not correspond with the diameter of the cooling taps.

This is completely normal. It is enough to provide a reduction fitting to adjust the diameter.

Model

Capacity

for single

circuit

[kW]

Line

Nominal

Ø [mm]

EQUIVALENT LENGHT [m] FOR ON / OFF COMPRESSORS R410A

5

10

15

20

25

30

35

40

45

50

011

P1 S

11

Gas

12

12 mm

16 mm

Liquid

12

12 mm

16 mm

014

P1 S

14

Gas

16

16 mm

Liquid

12

12 mm

16 mm

016

P1 S

16

Gas

16

16 mm

Liquid

12

12 mm

16 mm

020

P1 S

20

Gas

16

16 mm

18 mm

Liquid

16

16 mm

022

P1 S

22

Gas

16

16 mm

18 mm

Liquid

16

16 mm

18 mm

026

P1 S

26

Gas

22

22 mm

Liquid

16

16 mm

18 mm

032

P1 S

32

Gas

22

22 mm

Liquid

16

16 mm

18 mm

22 mm

037

P1 S

37