Mitsubishi MOTORS Laser 1993, Talon 1993 Service Manual

Partial

BACKUP

Service Manual

.i’

GROUP INDEX

NOSAl

LASER

TALON

1993

Volume-l

Engine, Chassis

& Body

FOREWORD

This Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any

servicrng

necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

This

BACKUP DSM

manual IS

to be used

ONLY

as a BACKUP. Please DO

NOT REDISTRIBUTE

WHOLE SECTIONS. This

BACKUP

was

sold to you

under the fact that

you do

indeed OWN

a GENUINE

DSM MANUAL. It

CANNOT

BE

considered a

REPLACEMENT

(Unless your orlglnal

manual was

lost or

destroyed.)

Please See

README.N

or

README.HTML for additional Information.

Thank you.

G~mm~emymanual@hotma~l.com

CHRYSLER

CORPORATION

Chrysler Corporation

reserves the right to make

changes in

design or

to

make additions to or improvements in

its

products

without

imposing

any

obligations

upon

itself to

install

them on

its

products previously

manufactured.

Introduction and

Master

Troubleshooting

.-I

. . . . . . . . . . . . . . . . . .

i

Lubrication and Maintenance . . . . . . . .El

Front Suspension

. . . . . . . . . . . . . . . . . . . . . . . . . . .

..A..

t

i

Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..~...

Service

’ Brakes- Parking

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..~.....

Cooling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..~.....~~..

Engine

. . . . . . . . . . . . . . . . . . . . . . . . ..*..............................

Intake and Exhaust

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System

‘,,, .*

. . . . . . . . . . . . . . . . . . ..*........................

4

Propeller Shaft

..,.....,....,.................m.......

Rear Suspension

.*........s........................

Manual

Steering-po,er

.h

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..$\

Manual

i

Transaxle-Automatic

:

. . . . . , . . . . . . . . . . . . . .

r+:,

Wheels

and Tires

_. .;,:.;*&i

. .

. . . . . . . . . . . . . . . . . . . . .

.&......

j 8 .A$

: >

Body

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*...**...

Heater & Air

CondjtJoning ..,.. ,.,.

. . ...’

Emission

Control

Systems

1

. . . . . . . . . . . . . .

0

1992

Mitsubishi)

L-.”

:

Printed in U.S.A.

BRAKES

SERVICE AND PARKING

CONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING

.........................

9

BRAKE BOOSTER

..............................

71

BRAKE LINE

....................................

73

BRAKE PEDAL

..................................

63

ELECTRONIC CONTROL UNIT

<VEHICLES WITH

ABS>

...................

102

FRONT DISC BRAKE

..........................

76

G-SENSOR

<AWD-ABS>

...................

101

HYDRAULIC UNIT

<VEHICLES WITH

ABS>

...................

92

MASTER CYLINDER

........................... 67

PARKING BRAKES

.............................

103

REAR DISC BRAKE

............................

65

SERVICE ADJUSTMENT PROCEDURES

..a

47

ABS Power Relay Check ....................

62

Bleeding

.......................................

50

Brake Booster Operating

Inspection

.......

49

Brake Fluid Level Sensor Check ...........

48

Brake Pedal Inspection and Adjustment

...

47

Check Valve Operation Check ..............

49

Flat Battery Remedy .........................

62

Front Disc Brake Pad Check and

Replacement

..................................

51

Front Disc Brake Rotor Inspection

.........

53

Inspection of Hydraulic Unit

.................

59

Measurement of Wheel Speed Sensor

Output Voltage

................................

57

Parking Brake Lever Stroke Check

.........

48

Parking Brake Switch Check

................

49

Proportioning Valve Function Test

..........

50

Rear Brake Disc Run-out Check

............

57

Rear Brake Disc Run-out Correction

.......

57

Rear Brake Disc Thickness Check

..........

56

Rear Disc Brake Pad Check and

Replacement

..................................

55

Run-out Check

................................

54

Run-out Correction

...........................

54

Thickness Check

..............................

55

SPECIAL TOOLS

...............................

6

SPECIFICATIONS

...............................

2

General Specifications

........................

2

Lubricants

.....................................

5

Service Specifications

........................

4

Torque Specifications

..................

.:.

...

4

TROUBLESHOOTING

..........................

7

WHEEL

SPEED SENSOR

<VEHICLES WITH

ABS>

....................

95

CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake

parts

with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many

brake components contain asbestos fibers which can become air-borne if dust

is.created

during

service operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

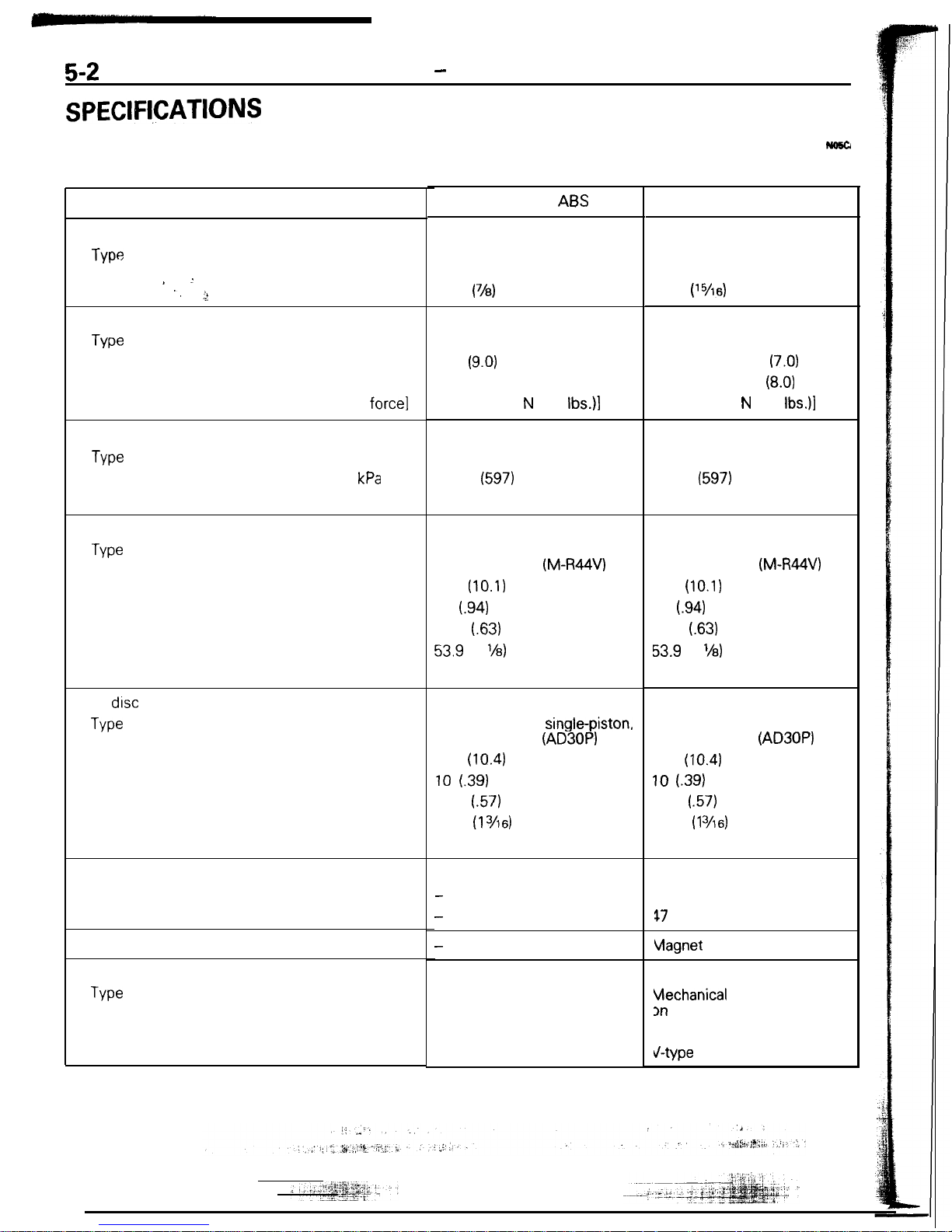

5-2

BRAKES

-

Specifications

SPECIFl,CATIONS

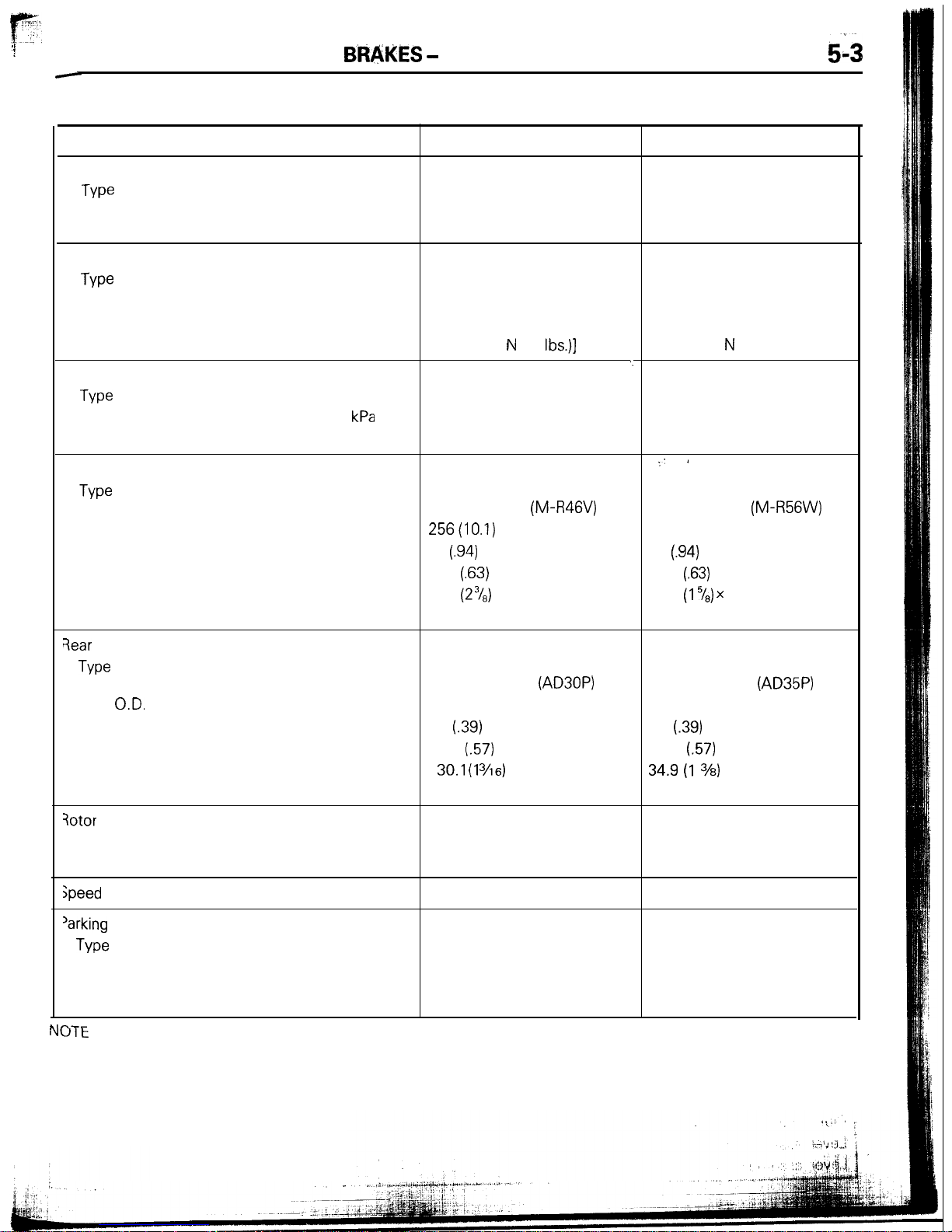

GENERAL SPECIFICATIONS

<Non-Turbo>

Items

Master cylinder

J-w

I.D. ’ ,, ’

,;!

mm (in.)

Brake booster

Tvw

Effective dia. of power cylinder mm (in.)

Boosting ratio [Brake pedal depressing

force]

5.0 [at 220 N (48

Ibs.)l

Proportioning valve

Type

Split point

Decompression ratio

kPa

(psi)

Front brakes

Type

Disc O.D.

Disc thickness

Pad thickness

Wheel cylinder I.D.

Clearance adjustment

mm (in.)

mm (in.)

mm (in.)

mm (in.)

Rear

drsc

brakes

Type

Disc O.D.

Disc thickness

Pad thickness

Wheel cylinder I.D.

Clearance adjustment

mm (in.)

mm (in.)

mm (in.)

mm (in.)

Rotor teeth

Front wheel side

Rear wheel side

Speed sensor

-

Parking brakes’

Tvw

Brake lever type

Cable arrangement

Vehicles without

ABS

Vehicles with ABS

Tandem type

(with level sensor)

22.2

(78)

Tandem type

(with level sensor)

23.8

P5/1d

Vacuum type

230

(9.0)

Vacuum type

Front side: 180

(7.0)

Rear side: 205

(8.0)

5.5 [at 220 N (48

Ibs.)l

Dual type

4,200

(597)

0.3

Dual type

4,200

(597)

3.3

Floating caliper, single-piston,

ventilated disc

(M-R44V)

256

(10.1)

24

i.94)

16.0

(.63)

53.9

(2

l/8)

Automatic

Floating caliper, single-piston,

ventilated disc

(M-R44V)

256

(10.1)

24

i.94)

16.0

(.63)

53.9

(2

%)

Automatic

Floating caliper,

single-piston,

ventilated disc

(AD30P)

265

(10.43

10

(39)

14.5

(.57)

30.1 (1

Yl6)

Automatic

Floating caliper, single-piston,

ventilated. disc

(AD30P)

265

(10.4)

10 l.39)

14.5

(.57)

30.1

(1

3/6)

Automatic

-

-

47

47

vlagnet

coil type

Mechanical brake acting

Vlechanical

brake acting

on rear wheels

3n

rear wheels

Lever type

-ever type

V-type

V-type

! y+

fr

. .

‘i

BR&gES -

Specifications

513

-

<Turbo>

Items

FWD

AWD

Master cylinder

Type

Tandem type

Tandem type

(with level sensor) (with level sensor)

I.D.

mm (in.) 25.4 (1)

25.4 (1)

Brake booster

Type

Vacuum type Vacuum type

Effective dia. of power cylinder

mm (in.) Front side: 188 (7.4)

Front side: 188 (7.4)

Rear side: 215 (8.5) Rear side: 215 (8.5)

Boosting ratio [Brake pedal depressing force]

6.0 [at 220 N (48

Ibs.)]

6.0 [at 220 N (48 Ibs.)]

‘.

Proportioning valve

Type

Dual type Dual type

Split point

kPa

(psi) 2,500 (363)

3,500 (508)

Decompression ratio

0.25

0.25

Front brakes

,,’ I

Type

Floating caliper, single-piston,

Floating caliper, double-piston

ventilated disc

(M-R46V)

ventilated disc

(M-R56W)

Disc O.D.

mm (in.)

256(10.1)

276 (10.9)

Disc thickness

mm (in.) 24

(94)

24

(.94)

Pad thickness

mm (in.) 16.0

(63)

16.0

(63)

Wheel cylinder I.D.

mm (in.) 60.3

(2?,)

41.3

(l”/*) x

2

Clearance adjustment

Automatic

Automatic

?ear

disc brakes

Type

Floating caliper, single-piston, Floating caliper, single-piston,

ventilated disc

(AD30P)

ventilated disc

(AD35P)

Disc

O.D.

mm (in.) 265 (10.4)

265 (10.4)

Disc thickness

mm (in.) 10 (39)

10

f.39)

Pad thickness

mm (in.) 14.5

(.57)

14.5

(.57)

Wheel cylinder I.D.

mm (in.)

30.1

(1

3/16)

34.9 (1

3h)

Clearance adjustment

Automatic Automatic

3otor

teeth*

Front wheel side

47

47

Rear wheel side

47

47

speed

sensor*

Magnet coil type Magnet coil type

‘arking

brakes

We

Mechanical brake acting Mechanical brake acting

on rear wheels

on rear wheels

Brake lever type

Lever type

Lever type

Cable arrangement

V-type

V-type

k ,.-YT--

Nult

The *symbol

indicates vehicles with ABS.

-

5-4

BRAKES

-

Specifications

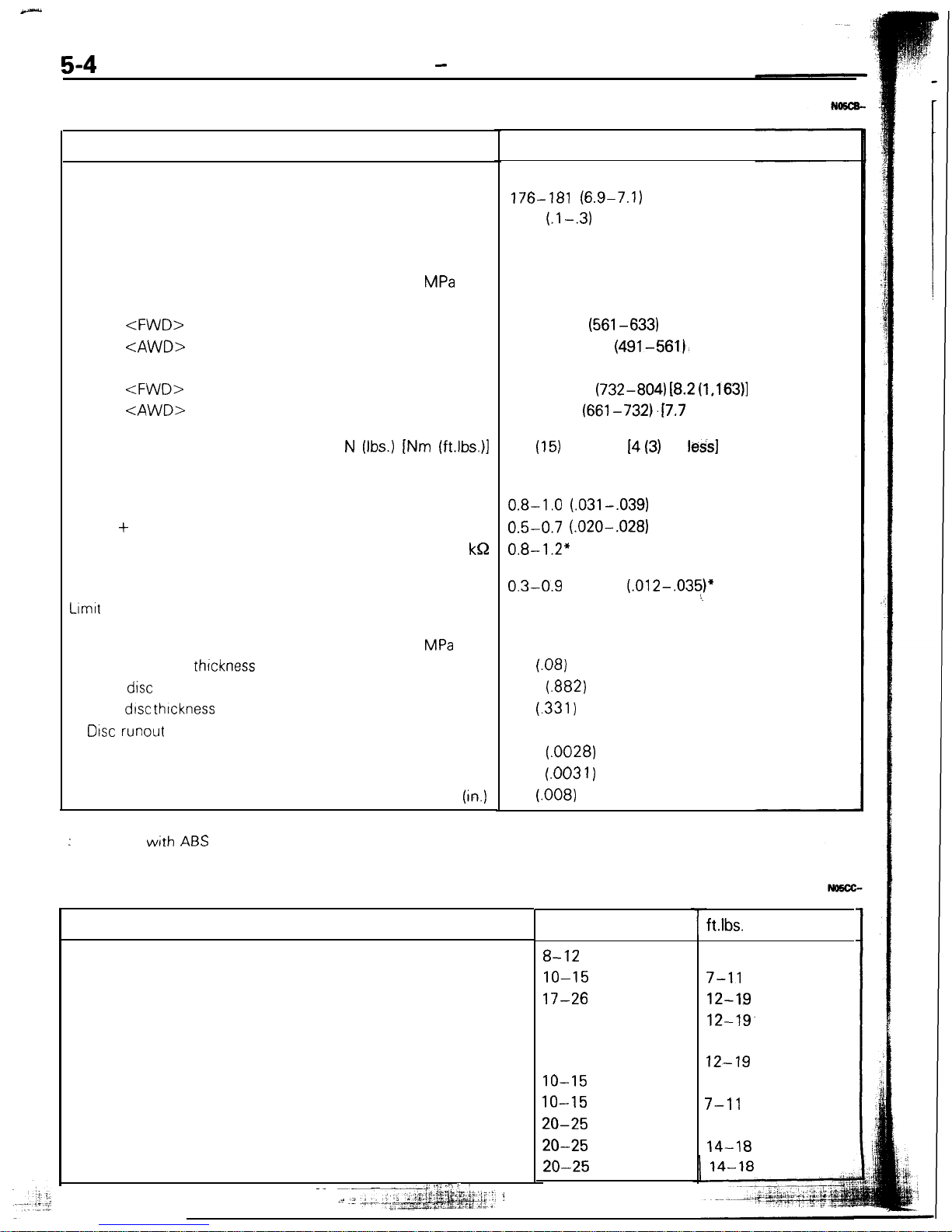

SERVICE SPECIFICATIONS

Items

Standard value

Brake pedal height

mm (in.)

Brake pedal free play

mm (in.)

Brake pedal to floorboard clearance

mm (in.)

Parking brake lever stroke.

Output pressure proportioning valve

MPa

(psi)

Split point

<FWD>

<AWD>

Output pressure [input pressure]

<FWD>

<AWD>

DISC brake dragging force at hub bolt

N (Ibs.) [Nm (ft.lbs.)l

Booster push rod to master cylinder piston clearance

mm (in.)

9 inch brake booster

7 + 8 inch brake booster

Speed sensor’s internal resistance

k&

Clearance between the speed pole piece and

the toothed rotor mm (in.)

Lrmtt

Left/right proportioning valve out pressure difference

MPa

(psi)

DISC brake pad

thrckness

mm (in.)

Front

drsc

thickness

mm (in.)

Rear

dtsc thrckness

mm (in.)

DISC runout

mm (in.)

Front

Rear

Hub end play

mm

(In.)

NOTE

l

:

Vehicles

with ABS

TORQUE SPECIFICATIONS

Specifications

176-181 (6.9-7.1)

3-8

(.l-.3)

80 (3.1) or more

5-7 notches

3.95-4.45 (561-633)

3.45-3.95 (491-561).

5.15-5.65 (732-804) i8.2

(1,163)1

4.65-5.15 (661-732j.17.7 (1,095))

70

(15)

or less I4

(3)

or

less]

0.8-1.0

(.031-,039)

0.5-0.7

(.020-.028)

0.8-1.2"

0.3-0.9

(.012-,035)"

6

0.4 (57)

2.0

(.08)

22.4

(.882)

8.4

(.331)

0.07

(.0028)

0.08 l.0031)

0.2

(.008)

Items

Pedal support bracket installation bolts

Pedal support bracket installation nut

Pedal rod to pedal support bracket

Pedal rod to clutch pedal bracket

Clutch pedal bracket installation bolt

Turn-over spring mounting bolt

Stop lamp switch mounting nut

Clutch master cylinder installation nuts

Clutch pedal installation nut

Lever assembly (A) installation nut

Lever assembly (B) installation nut

I

:: ::I .:‘i j ,:

~~ -__

j

.

-, .‘- ‘+‘+gg&p.~j:

;.;1--?.+.k

Nm

8-12

IO-15

17-26

17-26

8-12

17-26

10-15

10-15

20-25

20-25

20-25

T

ft.lbs.

6-9

7-11

12-19

12-19.

6-9

12-19

7-11

7-11

14-18

14-18

-

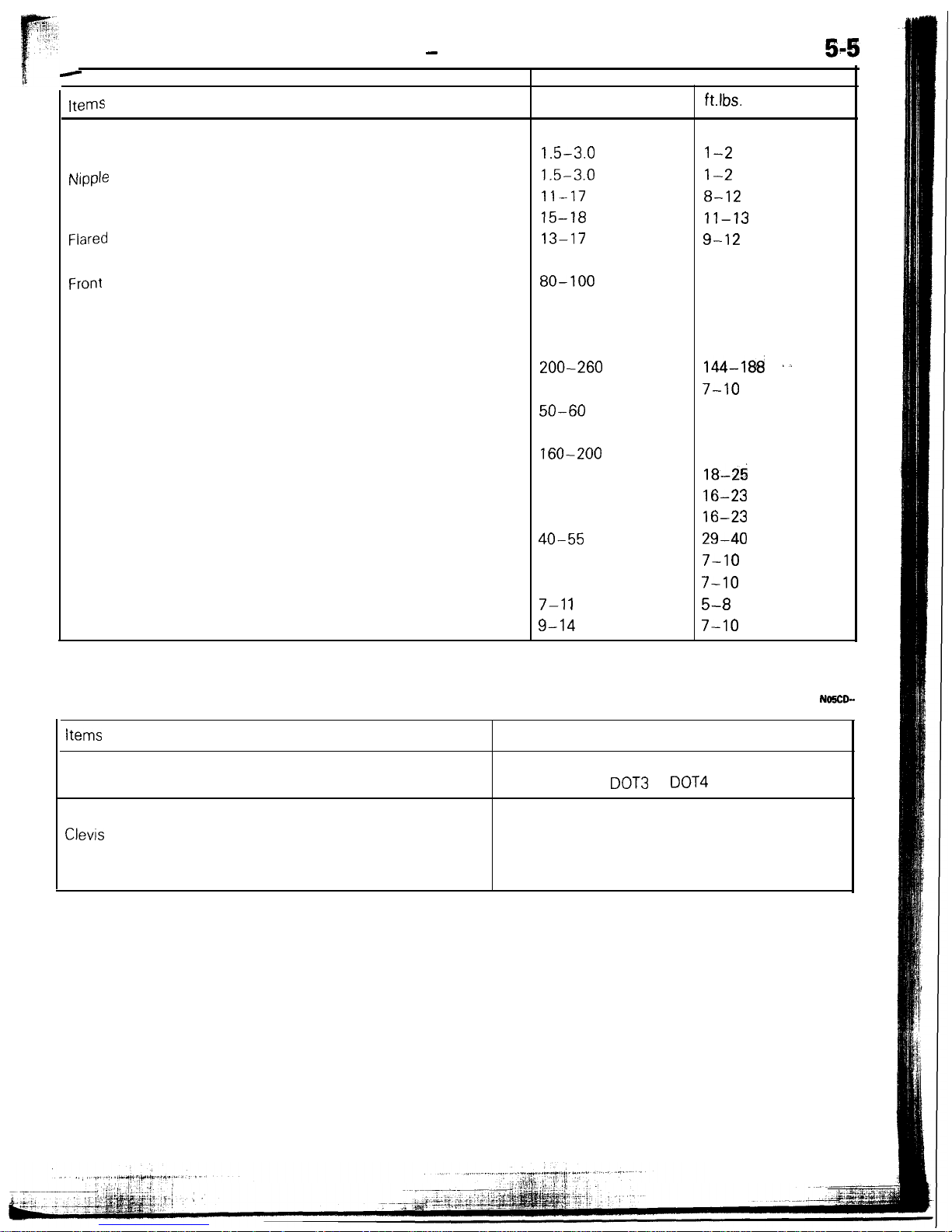

BRAKES - Specifications

Items

Master cylinder to brake booster

Piston stopper bolt

Nipple

installation screw

Brake booster installation nuts

Fitting

Flared

brake line nuts

Brake hose bracket installation bolts

Front

disc brake assembly installation bolts

Lock pin (front)

Guide pin (front)

Bleeder screw

Wheel bearing nut

Dust shield to axle beam

Rear disc brake assembly installation bolts

Drive shaft to companion flange

Companion flange to rear axle shaft

Brake hose to caliper body (rear)

Lock pin (rear)

Guide pin (rear)

Spindle lever to parking brake lever

Rear speed sensor installation bolt

Speed sensor bracket installation bolt

Rotor to front hub

Rotor to rear hub

Nm

8-12

1.5-3.0

1.5-3.0

11-17

15-18

13-17

17-26

80-100

64-86

64-86

7-9

200-260

9-14

50-60

55-65

160-200

25-35

22-32

22-32

40-55

9-14

9-14

7-l 1

9-14

ft.lbs.

6-9

l-2

l-2

8-12

11-13

9-12

12-19

58-72

46-62

46-62

5-7

144-188

”

7-10

36-43

39-47

116-159

18-25

16-23

16-23

29-40

7-10

7-10

5-a

7-10

LUBRICANTS

No!xD-

Items

Brake fluid

Specified lubricant

MOPAR Brake Fluid/

Conforming to

DOT3

or

DOT4

Brake pedal bushing inner surface

Clevls

pin and washer

Parking brake lever sliding parts

Bushing inner surface

MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

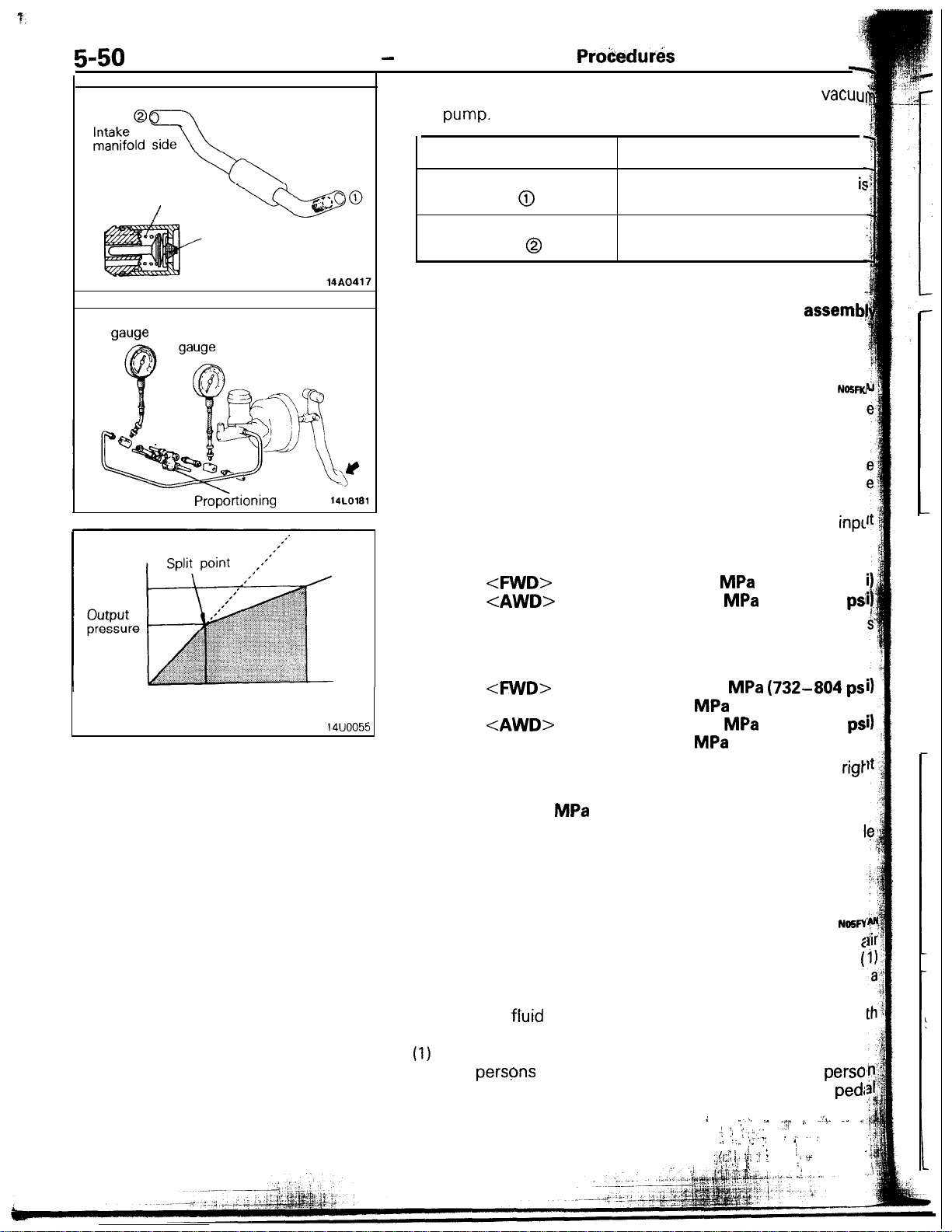

5-50

BRAKES

-

Service Adjustment

Proi?edur&

Brake

booster

side

Spring

’

/

Valve

Pressure

gauge

Pressure

PropGtioning

valve

14LO181

input pressure

14uoo55

2.

Check the operation of the check valve by using a

vacuul

pump.

Vacuum pump connection Accept/reject criteria

Connection at the brake A negative pressure (vacuum)

is

booster side

@

created and held.

Connection at the -intake

manifold side

@

A negative pressure (vacuum) is not

created.

Caution

If the check valve is defective, replace it as an

assemb!

unit together with the vacuum hose.

PROPORTIONING VALVE FUNCTION TEST

NO!iR(r

1.

Connect two pressure gauges, one each to the input sid

and output side of the proportioning valve, as shown,

2. Air bleed the brake line and the pressure gauge.

3. While gradually depressing the brake pedal, make th

following measurements and check to be sure that th

measured values are within the allowable range.

(1) Output pressure begins to drop relative to inpl

pressure (split point).

Standard value:

<PWD>

3.95-4.45

MPa

(561-633 psi

<AWD>

3.45-3.95

MPa

(491-561

ps

(2) Output fluid pressure when input fluid pressure are a

follows.

Standard value:

<PWD>

5.15-5.65

MPa (732-804 ps

[at 8.2

MPa

(1,163 psi))

<AWD>

4.65-5.15

MPa

(661-732

ps

[at 7.7

MPa

(1,095 psi)]

(3) Output pressure difference between left and

rig1

brake lines

Limit: 0.4

MPa

(57 psi)

4. If the measured pressures are not within the permissibl

ranges, replace the proportioning valve.

BLEEDING

No5FY

When the master cylinder is empty of brake fluid, bleed i

from the master cylinder by proceeding with procedures

(

thru (6). (Because this master cylinder is not equipped with

check valve.)

When brake fluid remains in the master cylinder, proceed wi

step (6).

(1)

Disconnect the brake tube from the master cylinder.

(2) Two

persqs

should conduct the air bleeding, one

perso

slowly depressing the brake pedal and holding the

ped:

depressed.

i .I.

.[ j,

‘I

- .~ j, Z’:. ~. jl

2;:‘,.

Y .‘.:

./ ‘:” ‘: ,,

.

8,

, .

.;$y; ii; :: 1

. .

i;, d

BRAKES

-

Service Adjustment Procedures

5-51

2

3

14A0454

When new

When worn

14G0017

1

14

LO169

check the sliding co

WsTm~

3

..“.W% ,Y :

sleeve and guide pin

-~

I

.

_. ;;

:i

‘.

(3) In this condition, the other person should use a finger to

close the outlet part of the, master cylinder, and then the

first person should release the brake pedal.

(4) Steps (2) and (3) should be repeated three or four times,

and then the master cylinder should be filled with brake

fluid to the specified level.

NOTE

The air is completely bled from the master cylinder by steps

(1) to

(4).

(5) Connect the brake tube to the master cylinder.

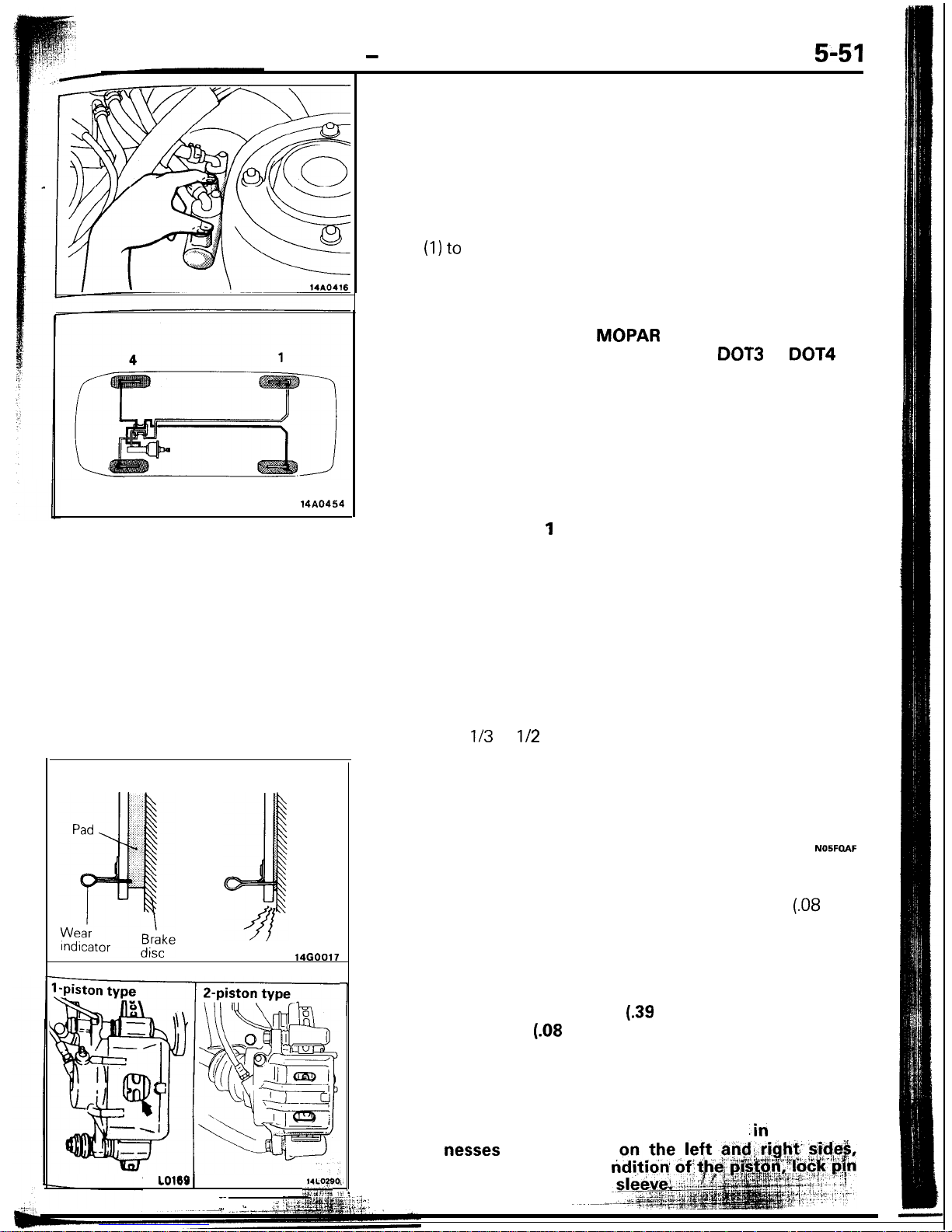

(6) Start the engine; then, in the sequence shown in the

illustration, bleed the air from each wheel cylinder.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to

DOT3

or DOT4

Caution

1.

Use the specified brake fluid. Avoid using a mixture

of the specified brake fluid and other fluid.

2. If brake fluid is exposed to the air, it will absorb

moisture; as water is absorbed from the atmosphere, the boiling point of the brake fluid will

decrease and the braking performance will be

seriously impaired. For this reason, use a hermeti-

cally sealed 1 lit. (1.06 qt.) or 0.5 lit. (0.52 qt.) brake

fluid container.

3. Firmly close the cap of the brake fluid container

after use.

4. For vehicles with the anti-lock braking system, be

sure to install a filter to the master cylinder

reservoir tank when supplying brake fluid.

ORDINARY AIR-BLEEDING PROCEDURES

(1) Depress the brake pedal several times until resistance is

felt; then, with the pedal depressed, loosen the bleeder

screw

l/3

to

l/2

turn and then tighten it before the fluid

pressure is all gone.

(2) Release the brake pedal. Repeat this procedure until there

are no more air bubbles in the brake fluid.

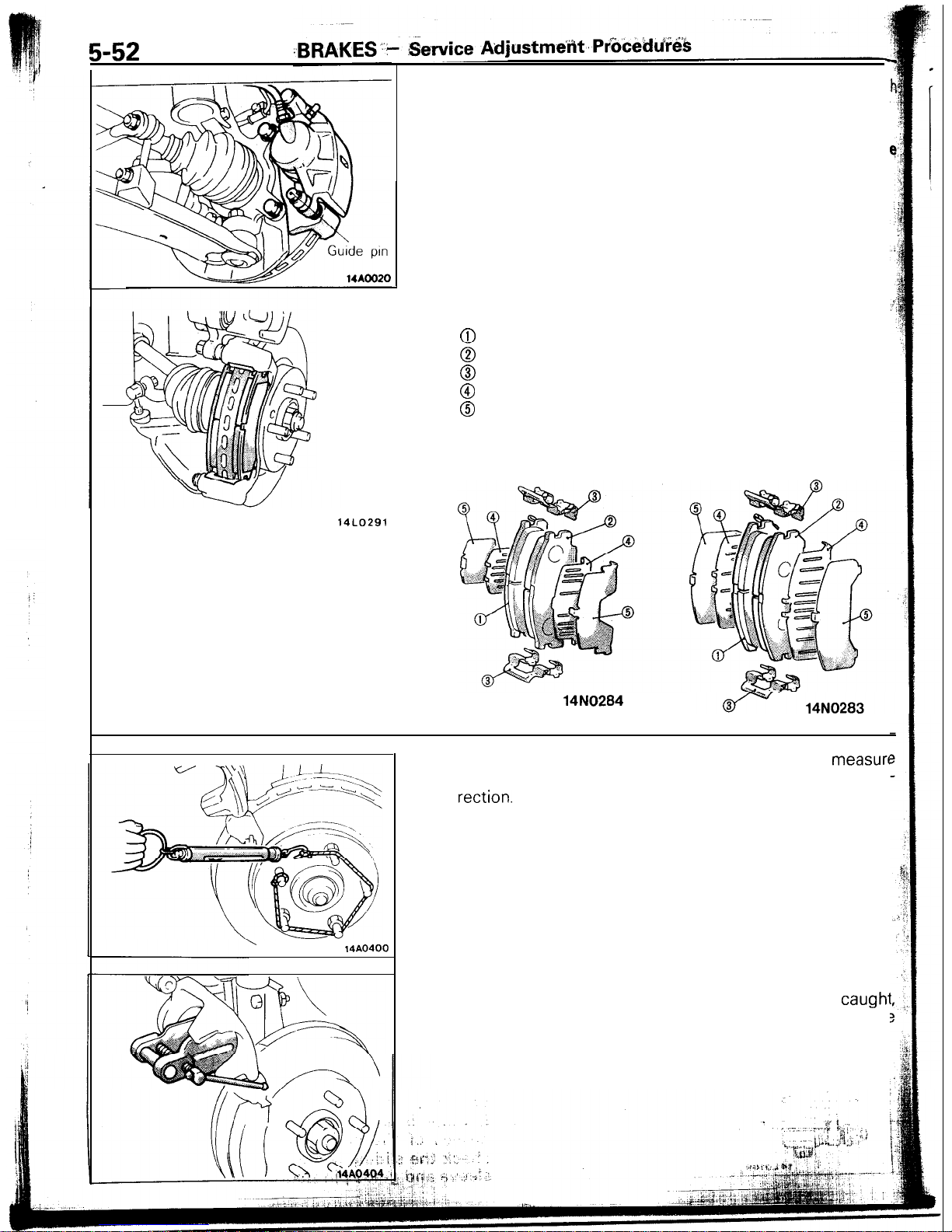

FRONT DISC BRAKE PAD CHECK AND

REPLACEMENT

N05FOAF

NOTE

The brake pads have wear indicators that contact the brake

disc when the brake pad thickness becomes 2 mm

(.08

in.),

and emit a squealing sound to warn the driver.

1. Check brake pad thickness through caliper body check

port.

Standard value: 10.0 mm

(.39

in.)

Limit: 2.0 mm

(.08

in.)

Caution

1. When the limit is exceeded, replace the pads at

both sides, and also the brake pads for the wheels

on the opposite side at the same time.

2. If there is a

significant difference

.in

the thick-

nesses

of the pads

5-52

14LO291

2. Remove guide pin. Lift caliper assembly and retain wit

wires.

Caution

Do not wipe off the special grease that is on the guid

pin or allow it to contaminate the guide pin.

3.

Remove the following parts from caliper support.

0

Pad &wear indicator assembly

0

Pad assembly

@

Clip

@I

Inner shim

@

Outer shim

1 -piston type

14N0284

P-piston type

\

14AO400

4. With the pad removed, use a spring balance to

measure

the rotation sliding resistance of the hub in the forward di

rection.

NOTE

Tighten the nuts in order to secure the disc to the hub.

5.

Securely attach the pad clip to the caliper support.

6.

Clean piston and insert into cylinder with tool.

7. Be careful that the piston boot does not become

caughl

when lowering the caliper assembly and install the guidt

pin.

gui

isur

dd

lght

clidc

Pad assembly

luter shim

nner

shim

43l

a

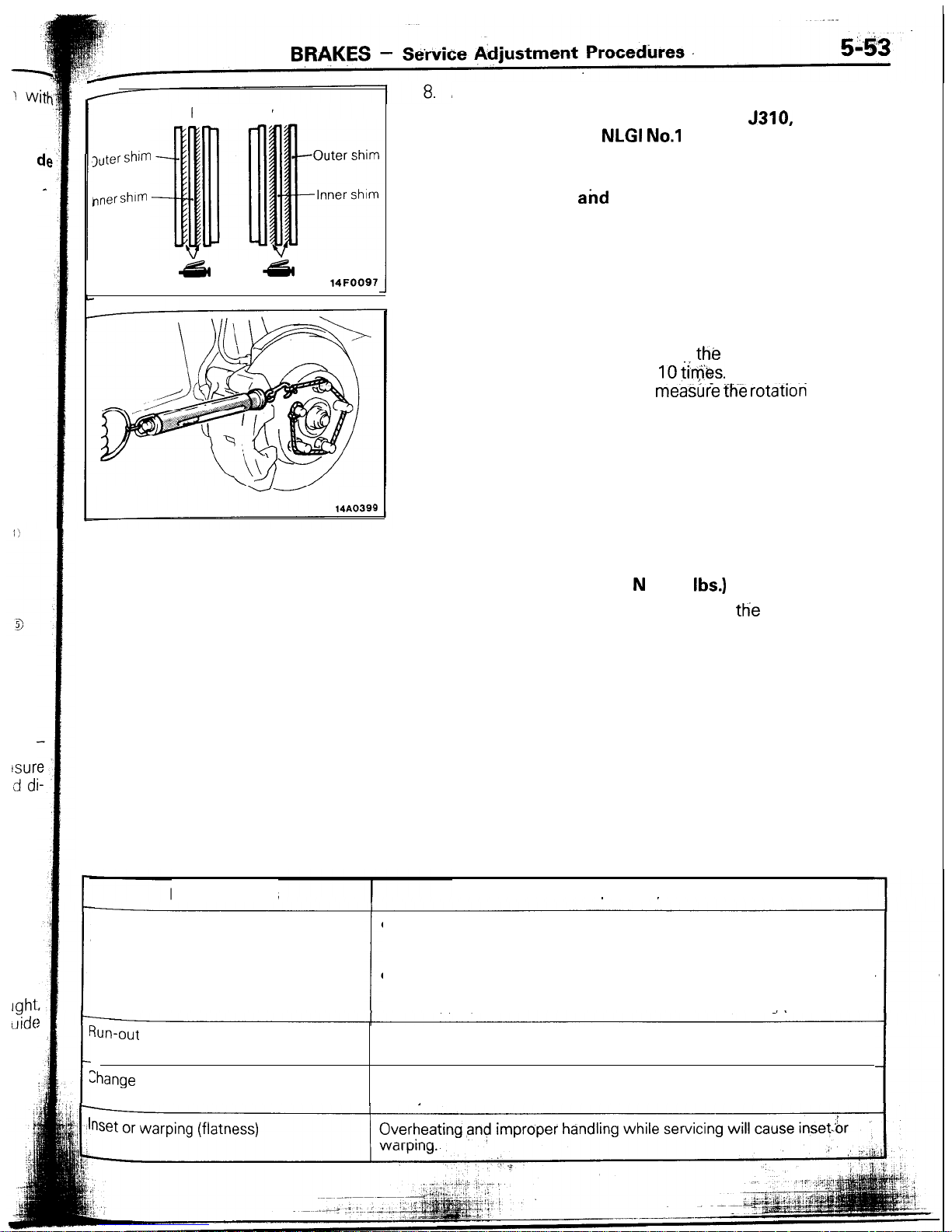

14FOO97

14A0399

Apply repair kit grease to both sides of the inner shims.

Specified grease: Brake grease SAE 5310,

NLGI No.1

Caution

1. Make sure that the friction surfaces of pads and

brake discs and free of grease and other contaminants.

2.

The grease should never squeeze out from around

the shim.

9.

Check the disc brake drag force as follows.

(1) Start the engine, and after depressing the brake pedal

hard two or three times, stop the

(2) Turn brake disc forward 10

tie&.

engine.

(3) Use a spring balance to

meastiie fh-e

rotation Sliding re-

sistance of the hub in the forward direction.

(4) Calculate the drag torque of the disc brake (difference

between measured values in 3 and 4).

Standard value: 70 N (15.4

Ibs.)

or less

10. If the disc brake drag force exceeds

tlie

standard value,

disassemble piston and clean the piston. Check for corrosion or worn piston seal, and check the sliding condition of

the lock pin and guide pin.

FRONT DISC BRAKE ROTOR INSPECTION

CAUTION

When servicing disc brakes, it is necessary to exercise caution to keep the disc brakes within the

allowable service values in order to maintain normal brake operation.

Before re-finishing or re-processing the brake disc surface, the following conditions should be checked.

Inspection items

Remarks

Scratches, rust, saturated lining materials

and wear

l If the vehicle is not driven for a certain period, the sections of the discs

that are not in contact with lining will become rusty, causing

noise and

shuddering.

l

If grooves resulting from excessive disc wear and scratches are not removed prior to installing a new pad assembly, there will momentarily

be

inappropriate

contact between the disc and the

lining

(pad).

Run-out

or drift

Ehange

in thickness (parallelism)

Excessive run-out or drift of the discs will increase the pedal depression

resistance due to piston knock-back.

If the thickness of the disc changes, this will cause pedal pulsation, shud-

dering and surging.

14A0391

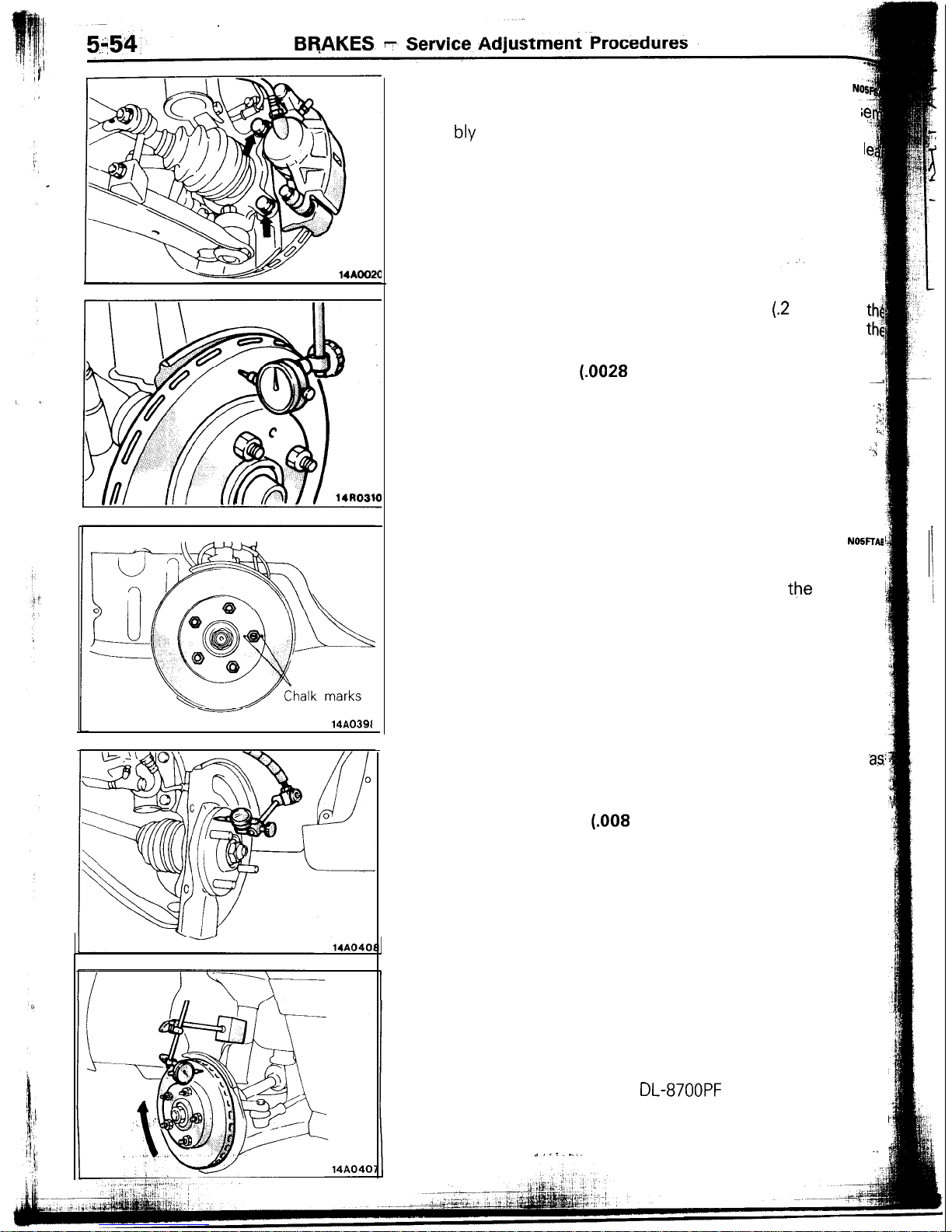

RUN-OUT CHECK

1.

Remove the caliper support; then raise the caliper ass

bly

upward and secure by using wire.

2.

Inspect the disc surface for grooves, cracks, and rust. Cl

the disc throughly and remove all rust.

3. Place a dial gauge approximately 5 mm

(.2

in.) from

thi

outer circumference of the brake disc, and measure

tt$

run-out of the disc.

_i

Limit: 0.07 mm

(.0028

in.)

-2

NOTE

Tighten the nuts in order to secure the disc to the hub..

‘l;

i,!

..,;

RUN-OUT CORRECTION

NOSFTAB

1.

If the run-out of the brake disc is equivalent to or exceeds

the limit specification, change the phase of

the

disc and

hub, and then measure the run-out again.

(1) Before removing the brake disc, chalk both sides of the

wheel stud on the side at which run-out is greatest.

(2) Remove the brake disc, and then place a dial gauge

2s

shown in the illustration; then move the hub in the axial

direction and measure the play.

Limit: 0.2 mm

(.008

in.)

If the play is equivalent to or exceeds the limit, disassemble the hub knuckle and check each part.

2.

(3) If the play does not exceed the limit specification, and

then check the run-out of the brake disc once again.

Mount the brake disc on the position dislocated from

the chalk mark.

If the run-out cannot be corrected by changing the phase

of the brake disc, replace the disc or turn rotor with on the

car type brake lathe (MAD

DL-8700PF

or equivalent).’

.,

“, . . . -..

: : :.. t

,:...!b

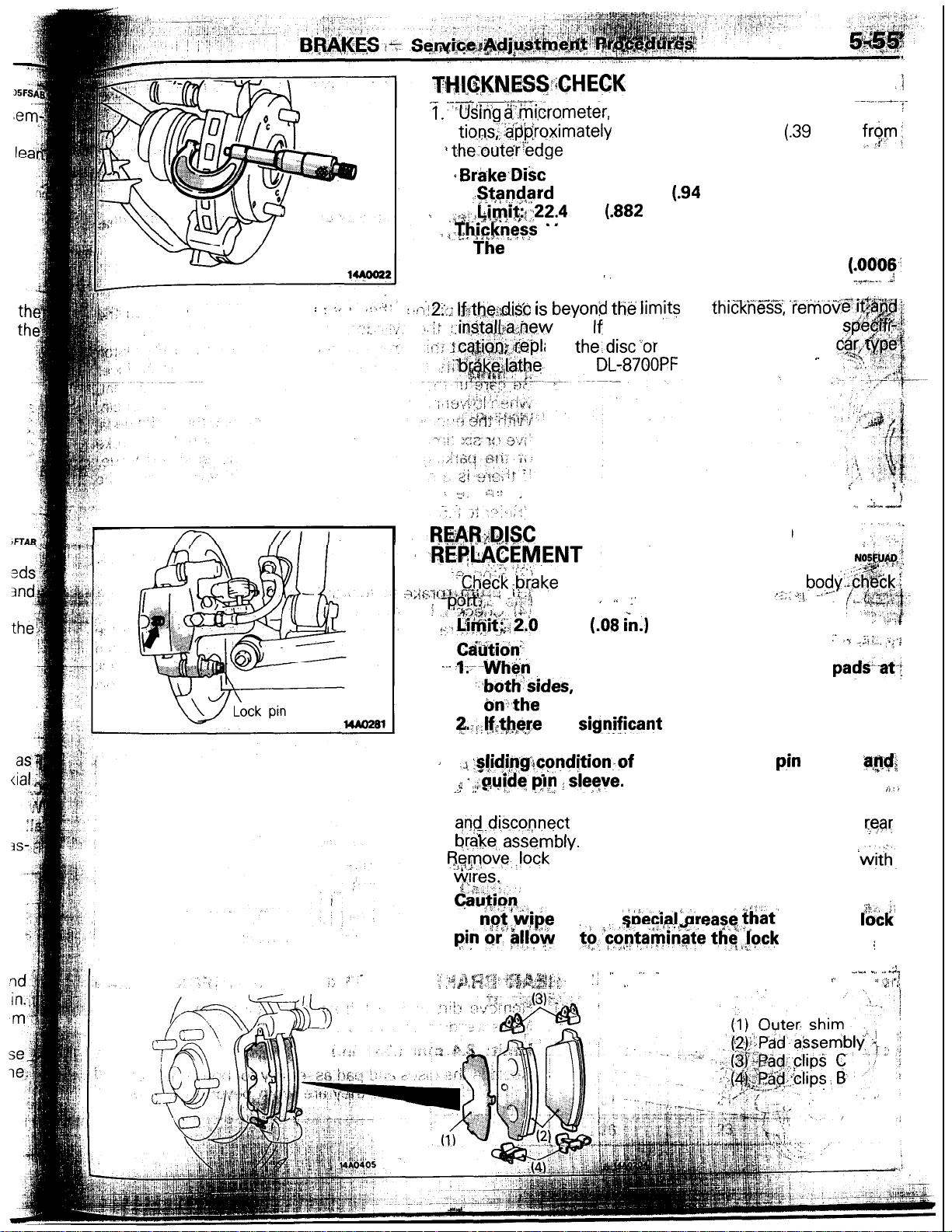

THl,~,KNES~i;CHECK

,

.‘i

.- _d

--.-.--.

1:

‘Using $.$i,crometer, measure disc thickness at eight posi-

I

tions;:‘.@‘proximately

45” apart and 10 mm

(.39

in.) in

f,r$,m;,

i theouter’edge

of the disc.

‘I

+

Brbke.Disc Thickness

..!+@Card value: 24 mm

(94

in.)

i

,,~~~:-~4!-~~~t;:22.4

mm

(.882

in.)

: ,aThrckness

Variation (At least 8 position)

_

The ‘*difference between any thickness. measure-

ments should not be more than 0.015 mm

(.0006:

in.).

,,

7.9’-,... .J

.

: .A12fi: If~thei;di& is

beyond

t&

Jim@

for

thickneT.%, ‘ie’mdv

.,.

one. If thickness variation exceeds the

ace the:disc”or turn. rotor with on the.

(MAD,

DL-87OOPF

or equivalent).

-

;

_:.j ::

!

‘_,

I

i

..;, ‘I

t&;&C

BRAKE PAD CHECK AND

.,

.

.:L”” cn:

,.,

1.

~:“ch&ii -brake

pad thickness through, caliper body$%ck.~

:?;{&:?p., d ii,; ,i..i

; I&+# ~4:

‘ ” :’

/I..: “j.

. .

~~Tl$$$‘~&b

mm

(08 cn.)

-.‘-‘: (~~#&q

,,I,.

:: y;.

/.

C&&ion”

,- ‘-, -,

iii,,,

I.“‘?

,t

--. +-When

the limit is exceeded, replace the pad&at-:

,--both&sides,

and also the brake pads for the wheels

onth-e

opposite side at the same time.

&.Jf,tb@re is a

signjfjcant

difference in the thicknesses

of the pads on the left and right sides, check the

A

.J. :%!idi,~g!~ondStion.of

the piston, ‘lock

p,in

sleeve

;a,$$

f * ,midq py I sleye.

_, ,: .’ i.

. .

ii’.

2.

Loosen the parking brake cable (from the vehicle interior),

an$dis.co-nnect

the parking brake end installed to the

rear

I I

I I

orake,. assemory.

3.

f5$_move.,lock

pin. Lift caliper assembly and retain

‘&h,

yps..

,

(y&on,

DO

r$$v$e

off. the

stiecial!.grease.

that’ is on the

&ck

pi”

cii’@!fow

it

to..c,ontait;inate tl;<jock

pin.

j

4. Remove. the- following parts from caliper support.

,,

f :.

,3-

:: ” ,, ” -

_.__ _, .“_,.

/

‘7

,

.< :$, ~

. .

6

BRAKES

-

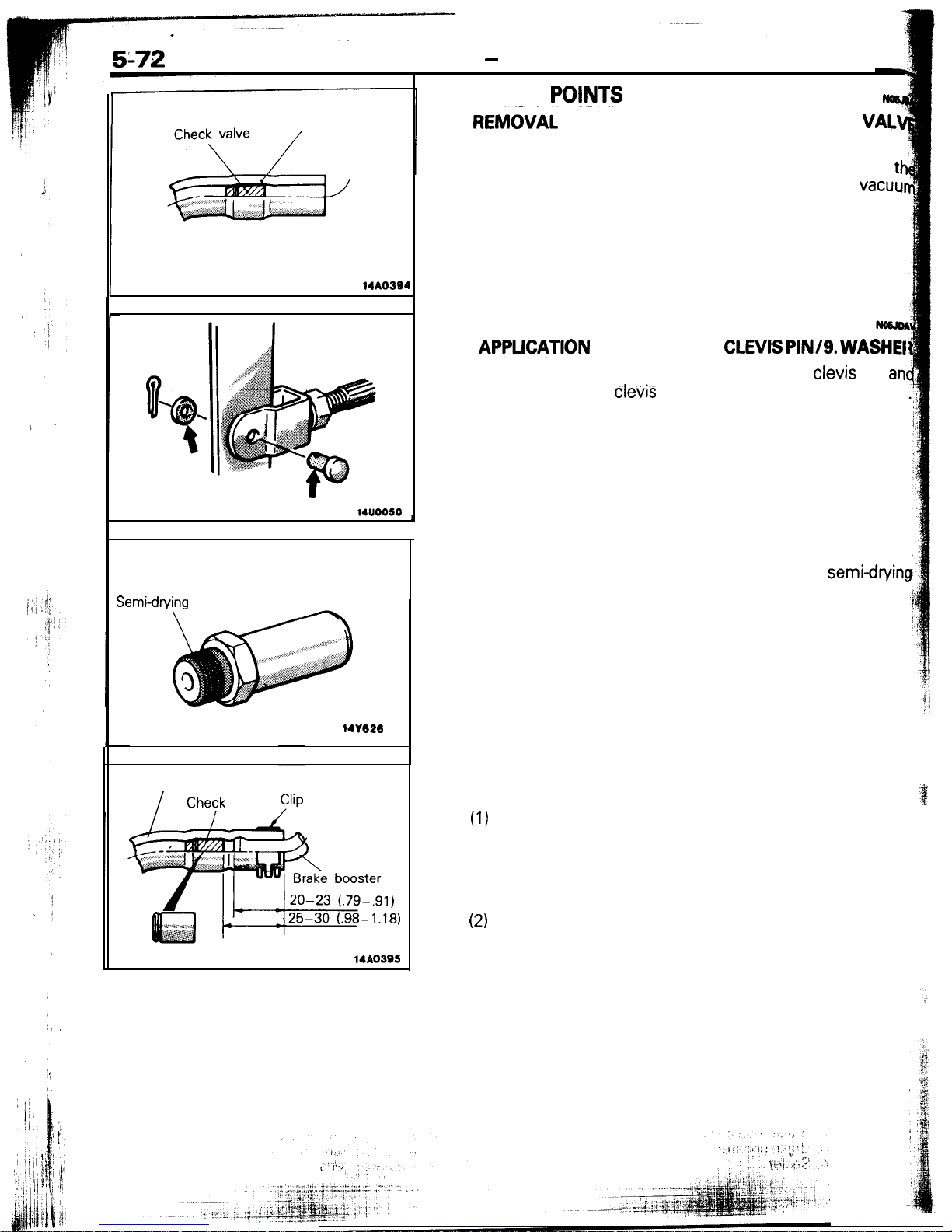

Brake Booster

Vacuum hose

14AO394

14u0050

Semidrvina sealant

141626

Vacuum hose

I

Chevk

valve

mm (in.)

14AO395

SERVICE

PO@JTS

OF REMOVAL

Nocm

6.

REM&AL

OF VACUUM HOSE WITH CHECK

VA+

NOTE

Since the check valve is fit to the vacuum hose, replace

th

check valve as an assembly unit together with the

vacuur

hose if the check valve is defective.

SERVICE POINTS OF INSTALLATION

10.

APPLDJTION

OF GREASE TO CLEVIS

PIN/g.

WASHEI

After applying the specified grease to the

clevis

pin

an

washer, insert the

cievis

pin and bend the cotter pin tightly

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

7. APPLICATION OF SEALANT TO FITTING

When installing the vacuum hose fitting, apply

semi-cfryin!

sealant to its threaded portion.

6. INSTALLATION OF VACUUM HOSE WITH CHECK

VALVE

(1)

Attach the vacuum hose so that it may be inserted to a

dimension illustrated.

Caution

Prevent interference between the check valve and

brake booster.

(2)

The vacuum hose at the engine should be securely

connected until it contacts the hexagonal edge of the

fitting, and then should be secured by the hose clip.

N0sJa

4LVI

:e

the

cuu<

‘=JD4\

;HER

and

!htly.

Wg

CK

3a

nd

3ly

he

P.

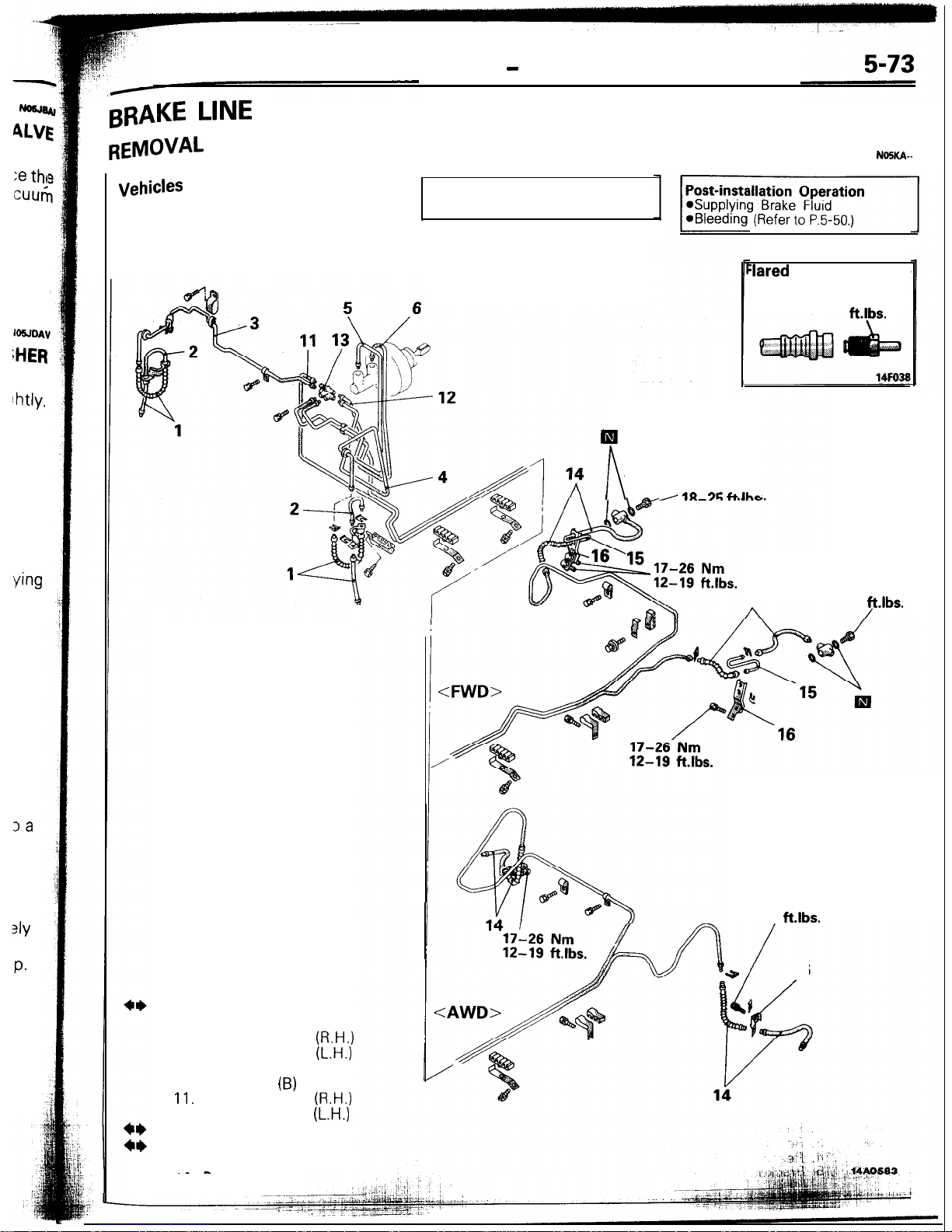

BRAKES

-

Brake Line

BRAKE LINE

REMOVAL

AND INSTALLATION

NOSKA--

1. Front brake hose

2. Strut brake tube

3. Front brake tube

(R.H.)

4. Front brake tube

(L.H.)

5. Brake tube (A)

6. Brake tube

(B)

11.

Main brake tube

(R.H.)

12. Main brake tube

(L.H.)

13. Proportioning valve

14. Rear brake hose

15. Rear axle brake tube

._-

Ill

n

25-35 Nm

I

111-7G f-t Ihr

:lared brake line nuts

13-17 Nm

9-12

ftlbs.

vehicles

without ABS

Pre-removal Operation

*Draining of Brake Fluid

14

25-35 Nm

18-25

ft.lbs.

17-26 Nm

12-19

ft.lbs.

+

16

16. Bracket

a-.

i

.-J

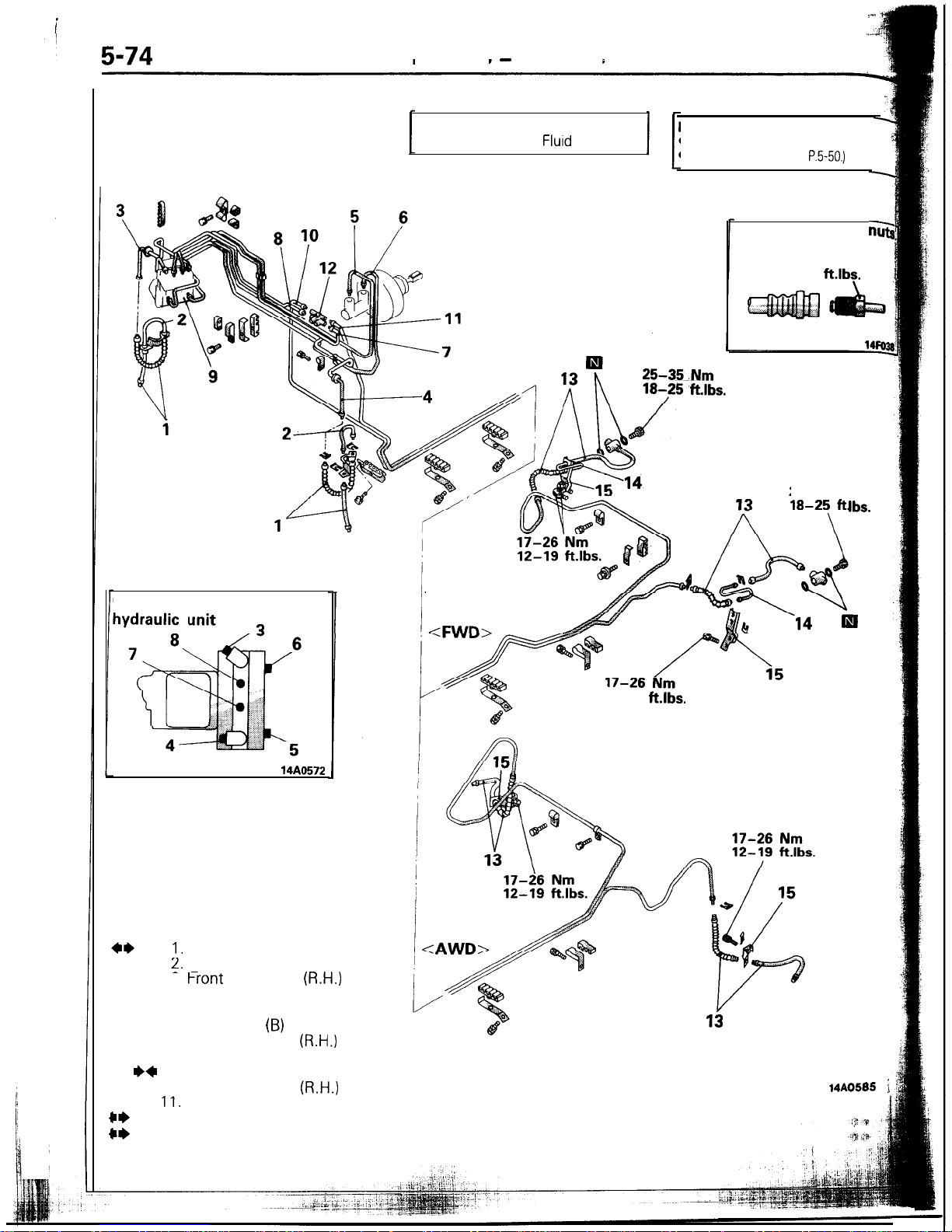

5-74

BRAKES

-

Brake tine

Vehicles with ABS

Pre-removal Operation

*Draining of Brake

Fluid

,“i

Post-installation Operation

A

@Supplying Brake Fluid

1

l

Bleeding (Refer to

P.5-50.)

-

Connecting part of

14AO572

I.

Front brake hose

2.

Strut brake tube

- -

25-35 Nm

Ibs.

12-19

ft.lbs.

Flared brake line

ns

13-17 Nm

9-12

ftlbs.

15. Bracket

3.

f-ront

brake tube

(R.H.)

4. Front brake tube (L.H.)

5. Brake tube (A)

6. Brake tube

(B)

7. Rear brake tube

(R.H.)

8. Rear brake tube (L.H.)

I)+

9. Hydraulic unit

10. Main brake tube

(R.H.)

11.

Main brake tube (L.H.)

::

12. Proportioning valve

13. Rear brake hose

14. Rear axle brake tube

14AO585

;

SERVICE POINTS OF REMOVAL

14w593

Brake hose

woo07

s 4

6

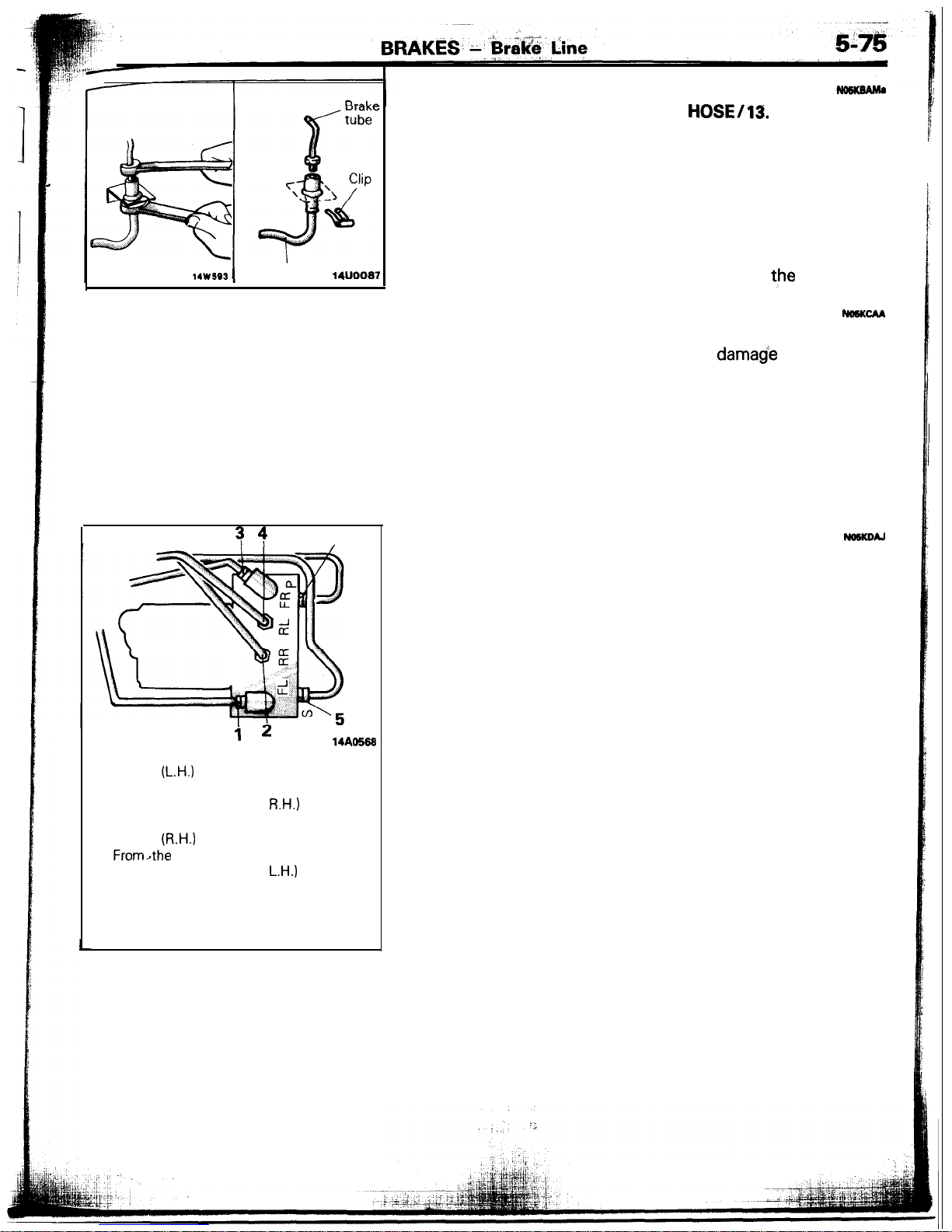

1. REMOVAL OF FRONT BRAKE

HOSE/13.

REAR BRAKE

HOSE

(1) Holding the lock nut on the brake hose side, loosen the

flared brake line nut.

(2) Pull off the brake hose clip and remove the brake hose

from the bracket.

12. REMOVAL OF PROPORTIONING

VALVE

Do not disassemble the proportioning valve because its

performance depends on the set load of the spring.

INSPECTION

No6KcM

l Check the brake tubes for cracks, crimps and corrosion.

l Check the brake hoses for cracks,

damade

and leakage.

l

Check the flared brake line nuts for damage and leakage.

SERVICE POINTS OF INSTALLATION

NOSKOAJ

9. CONNECTION OF TUBE TO HYDRAULIC UNIT

Connect the tubes to the hydraulic ‘unit as shown in the

illustration.

i 2

14AO568

1.

From the hydraulic unit to the front

brake

(L.H.)

2. From the hydraulic unit to the proportioning valve (Rear,

R.H.)

3. From the hydraulic unit to the front

brake

(R.H.)

4. From,the hydraulic unit to the proportioning valve (Rear,

L.H.)

5. From the master cylinder

(for left front and right rear)

6. From the master cylinder

(for right front and left rear)

!

-;-

596

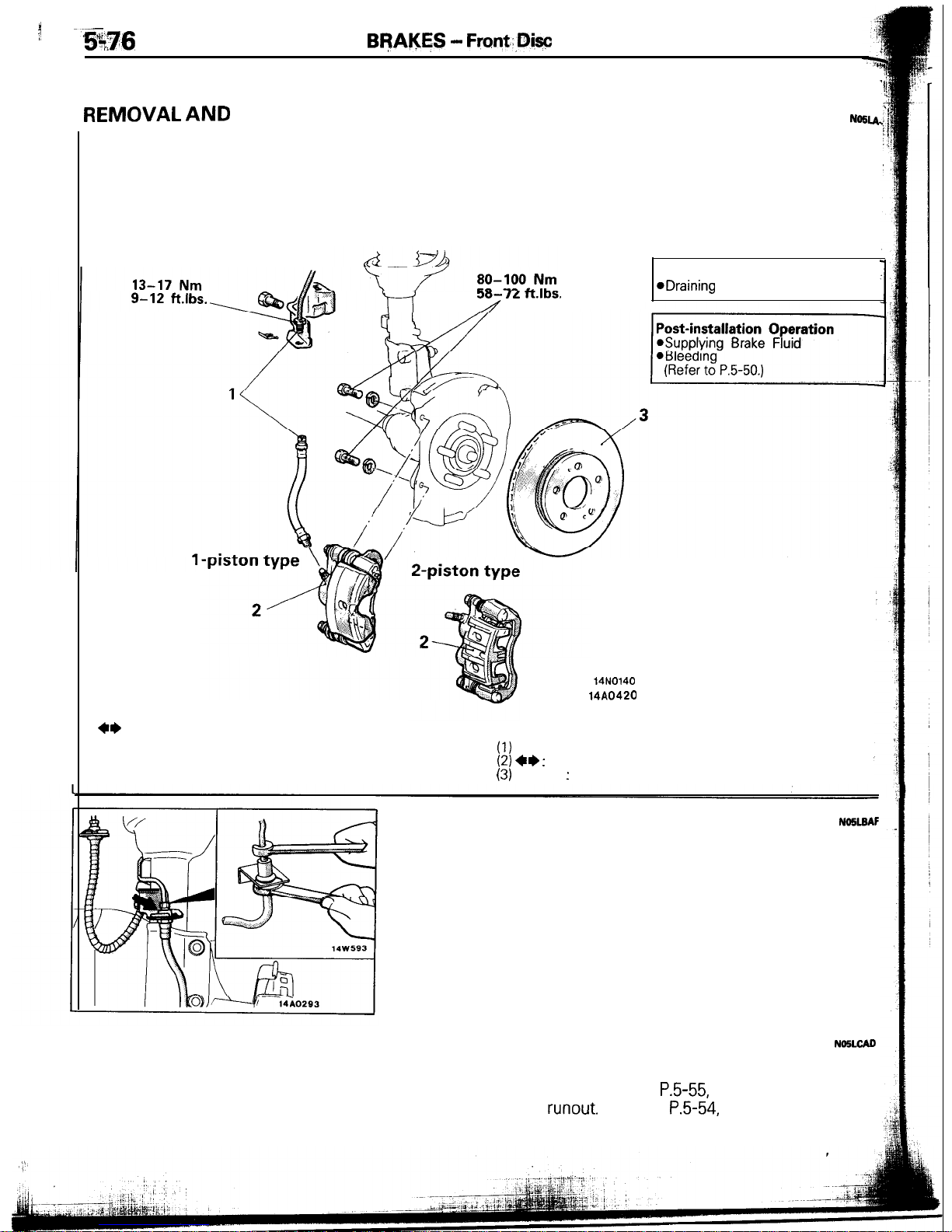

FRONT DISC BRAKE

Bf?Al$ES - Front.:,Diw

Brake

REMOVAL

AND INSTALLATION

N=U.

3U- IL l-LIDS.

Y-i

A

14N0140

14A0420

Pre-removal Operation

eDraining

of Brake Fluid

Removal steps

+e

l

1. Connection for the brake hose and the

brake tube

NOTE

l

+

2. Front brake assembly

(1)

Reverse the removal procedures to reinstall.

3. Brake disc

(2) ++ :

Refer to “Service Points of Removal”.

(3)

l +

:

Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

No5LsAF

1. DISCONNECTION OF BRAKE HOSE

Holding the nut on the brake hose side. Loosen the flared

brake line nut.

INSPECTION

NNiLCID

INSPECTION OF BRAKE DISC

l

Check disc for wear. (Refer to

P.5-55,

Thickness Check.)

l

Check disc for

runout.

(Refer to

P.5-54,

Run-out Check.)

l Check disc for damage.

Loading...

Loading...