Page 1

Analog Input/Output Module

User's Manual

-Q64AD2DA

-GX Configurator-AD (SW2D5C-QADU-E)

-GX Configurator-DA (SW2D5C-QDAU-E)

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only.

programmable controller system, refer to the user’s manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

For the safety precautions of the

[Design Precautions]

WARNING

Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the programmable controller CPU

to the intelligent function module.

Doing so may cause malfunction of the programmable controller system.

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

A - 1

Page 4

[Installation Precautions]

CAUTION

Use the programmable controller in an environment that meets the general specifications in the

user’s manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

To mount the module, while pressing the module mounting lever located in the lower part of the module,

fully insert the module fixing projection(s) into the hole(s) in the base unit and press the module until it

snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module

with a screw.

Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Shut off the external power supply for the system in all phases before mounting or removing the module.

Failure to do so may result in damage to the product.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in the

system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant chapter in this manual.

Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

A - 2

Page 5

[Wiring Precautions]

CAUTION

Ground the FG terminal to the protective ground conductor dedicated to the programmable

controller.

Failure to do so may result in electric shock or malfunction.

After wiring, attach the included terminal cover to the module before turning it on for operation.

Failure to do so may result in electric shock.

Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when the terminal screw comes loose,

resulting in failure.

Tighten the terminal screw within the specified torque range.

Undertightening the terminal screws can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in short circuit or malfunction.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

A - 3

Page 6

[Wiring Precautions]

CAUTION

A protective film is attached to the top of the module to prevent foreign matter, such as wire chips, from

entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

[Startup and Maintenance Precautions]

CAUTION

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Shut off the external power supply for the system in all phases before mounting or removing the module.

Failure to do so may cause the module to fail or malfunction.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in the

system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant chapter in this manual.

After the first use of the product, do not mount/remove the module to/from the base unit, and the terminal

block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

Do not touch any terminal while power is on.

Doing so may cause malfunction.

Shut off the external power supply for the system in all phases before cleaning the module or retightening

the terminal screws or module fixing screws.

Failure to do so may cause the module to fail or malfunction.

Undertightening the screws can cause drop, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Before handling the module, touch a grounded metal object to discharge the static electricity from the

human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

When disposing of this product, treat it as industrial waste.

A - 4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 5

Page 8

REVISIONS

Addition

Correction

Correction

Correction

Addition

Correction

*The manual number is given on the bottom left of the back cover.

Print date *Manual number Revision

May, 2009 SH(NA)-080793ENG-A First edition

Dec., 2010 SH(NA)-080793ENG-B

CONDITIONS OF USE FOR THE PRODUCT

SAFETY PRECAUTIONS, Relevant Manuals, GENERIC TERMS AND

ABBREVIATIONS, Section 1.1, 2.1, 2.3, 3.1, 4.2.5, 4.2.7, 5.2.1, 6.17, 6.22, 7.4.1,

7.4.2, 7.4.3, 8.2.1, 8.3.1, 8.7, 10.1, Warranty

May., 2015 SH(NA)-080793ENG-C

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES, GENERIC

TERMS AND ABBREVIATIONS, Section 2.1, 3.1, 4.3.3, 7.3, 7.4.3, 8.2.1, 8.2.2,

9.2.1, 9.2.3

Oct., 2015 SH(NA)-080793ENG-D

Section 5.2.1, 7.5.1

Nov., 2016 SH(NA)-080793ENG-E

Section 11.2.7

SAFETY PRECAUTIONS, Section 3.1, 4.2.5, 4.2.7, 6.23, 7.4.1, 9.2.1, 9.2.3,

9.3.3, 11.2.1, 11.2.4, Appendix 1

Japanese Manual Version SH-080792-G

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

2009 MITSUBISHI ELECTRIC CORPORATION

A - 6

Page 9

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC-Q series programmable controllers.

Before using the product, please read this manual carefully to develop full familiarity with the functions and

performance of the Q series programmable controllers to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................A - 1

CONDITIONS OF USE FOR THE PRODUCT..................................................................................................A - 5

REVISIONS.......................................................................................................................................................A - 6

INTRODUCTION...............................................................................................................................................A - 7

CONTENTS ......................................................................................................................................................A - 7

ABOUT MANUALS ......................................................................................................................................... A - 12

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES...........................................................A - 12

GENERIC TERMS AND ABBREVIATIONS.................................................................................................... A - 13

PACKING LIST ...............................................................................................................................................A - 14

CHAPTER1 OVERVIEW 1 - 1 to 1 - 2

1.1 Features........................................................................................................................................... 1 - 1

CHAPTER2 SYSTEM CONFIGURATION 2 - 1 to 2 - 7

2.1 Applicable Systems ......................................................................................................................... 2 - 1

2.2 Using the Q64AD2DA with Redundant CPU ................................................................................... 2 - 4

2.3 Checking Function Version, Serial Number, and Software Version ................................................ 2 - 5

CHAPTER3 SPECIFICATIONS 3 - 1 to 3 - 11

3.1 Performance Specifications ............................................................................................................. 3 - 1

3.2 I/O Conversion Characteristic .......................................................................................................... 3 - 4

3.2.1 I/O conversion characteristic of A/D conversion ....................................................................... 3 - 4

3.2.2 I/O conversion characteristic of D/A conversion ....................................................................... 3 - 9

CHAPTER4 FUNCTION 4 - 1 to 4 - 33

4.1 Function List .................................................................................................................................... 4 - 1

4.2 Function Details of A/D Conversion................................................................................................. 4 - 3

4.2.1 A/D conversion methods .......................................................................................................... 4 - 3

4.2.2 Maximum and minimum values hold function........................................................................... 4 - 6

4.2.3 Scaling function (A/D conversion) ............................................................................................ 4 - 6

4.2.4 Shifting function (A/D conversion) ............................................................................................ 4 - 9

4.2.5 Input signal error detection function ....................................................................................... 4 - 11

4.2.6 Input range extended mode function ...................................................................................... 4 - 16

4.2.7 Logging function ..................................................................................................................... 4 - 18

A - 7

Page 10

4.3 Function Details of D/A Conversion............................................................................................... 4 - 25

4.3.1 D/A output enable/disable function .........................................................................................4 - 25

4.3.2 Analog output HOLD/CLEAR function .................................................................................... 4 - 25

4.3.3 Analog output test during a CPU module STOP..................................................................... 4 - 27

4.3.4 Scaling function (D/A conversion)........................................................................................... 4 - 28

4.3.5 Shifting function (D/A conversion) .......................................................................................... 4 - 31

4.4 Details of Common Function ......................................................................................................... 4 - 33

4.4.1 Analog conversion enable/disable setting .............................................................................. 4 - 33

CHAPTER5 I/O SIGNALS FOR THE CPU MODULE 5 - 1 to 5 - 10

5.1 List of I/O Signals............................................................................................................................. 5 - 1

5.2 Details of I/O Signals ....................................................................................................................... 5 - 2

5.2.1 Input signals.............................................................................................................................. 5 - 2

5.2.2 Output signals........................................................................................................................... 5 - 9

CHAPTER6 BUFFER MEMORY 6 - 1 to 6 - 38

6.1 Buffer Memory Assignment ............................................................................................................. 6 - 1

6.2 CH1 A/D Conversion Enable/Disable Setting (Un\G0) .................................................................. 6 - 10

6.3 CH1 Averaging Process Method Setting (Un\G1) ......................................................................... 6 - 10

6.4 CH1 Averaging Process (Time/Number of Times) Setting (Un\G2)............................................... 6 - 11

6.5 CH1 A/D Conversion Scaling Enable/Disable Setting (Un\G10) ................................................... 6 - 11

6.6 CH1 A/D Conversion Scaling Lower Limit Value (Un\G11) and CH1 A/D Conversion Scaling Upper

Limit Value (Un\G12) ..................................................................................................................... 6 - 12

6.7 CH1 Shifting Amount to Conversion Value (Un\G13) .................................................................... 6 - 13

6.8 CH1 Input Signal Error Detection Setting (Un\G20) ...................................................................... 6 - 13

6.9 CH1 Input Signal Error Detection Setting Value (Un\G21) ............................................................ 6 - 14

6.10 CH1 Logging Enable/Disable Setting (Un\G30)............................................................................. 6 - 14

6.11 CH1 Logging Cycle Setting Value (Un\G31) and CH1 Logging Cycle Unit Setting (Un\G32) ....... 6 - 15

6.12 CH1 Logging Data Setting (Un\G33) ............................................................................................. 6 - 16

6.13 CH1 Logging Points After Trigger (Un\G34) .................................................................................. 6 - 16

6.14 CH1 Level Trigger Condition Setting (Un\G35) ............................................................................. 6 - 17

6.15 CH1 Trigger Data (Un\G36) ........................................................................................................... 6 - 19

6.16 CH1 Trigger Setting Value (Un\G37) ............................................................................................. 6 - 19

6.17 CH1 Digital Output Value (Un\G100, Un\G1700) .......................................................................... 6 - 20

6.18 CH1 Scaling Value (Un\G102, Un\G1710) .................................................................................... 6 - 21

6.19 CH1 Maximum Digital Output Value (Un\G104, Un\G1720) and CH1 Minimum Digital Output Value

(Un\G106, Un\G1721).................................................................................................................... 6 - 22

6.20 CH1 Maximum Scaling Value (Un\G108, Un\G1740) and CH1 Minimum Scaling Value

(Un\G110, Un\G1741).................................................................................................................... 6 - 23

6.21 CH1 Setting Range (Un\G112) ...................................................................................................... 6 - 24

6.22 CH1 A/D Conversion Completed Flag (Un\G113) ......................................................................... 6 - 24

A - 8

Page 11

6.23 CH1 Input Signal Error Detection Flag (Un\G114)......................................................................... 6 - 25

6.24 CH1 Oldest Pointer (Un\G120) ...................................................................................................... 6 - 26

6.25 CH1 Latest Pointer (Un\G121)....................................................................................................... 6 - 27

6.26 CH1 Logging Data Points (Un\G122) ............................................................................................ 6 - 28

6.27 CH1 Trigger Pointer (Un\G123) ..................................................................................................... 6 - 28

6.28 CH1 Latest Error Code (Un\G190), CH1 Error Time (Un\G191 to Un\G194), Latest Error Code

(Un\G1790), and Error Time (Un\G1791 to Un\G1794) ................................................................. 6 - 29

6.29 CH5 D/A Conversion Enable/Disable Setting (Un\G800) .............................................................. 6 - 30

6.30 CH5 Digital Input Value (Un\G802)................................................................................................ 6 - 31

6.31 CH5 D/A Conversion Scaling Enable/Disable Setting (Un\G810) ................................................. 6 - 32

6.32 CH5 D/A Conversion Scaling Lower Limit Value (Un\G811) and CH5 D/A Conversion Scaling Upper

Limit Value (Un\G812) ................................................................................................................... 6 - 33

6.33 CH5 Shifting Amount to Input Value (Un\G813) ............................................................................ 6 - 33

6.34 CH5 Set Value Check Code (Un\G900, Un\G1764) ...................................................................... 6 - 34

6.35 CH5 Real Conversion Digital Value (Un\G902, Un\G1774)........................................................... 6 - 35

6.36 CH5 Setting Range (Un\G912) ...................................................................................................... 6 - 35

6.37 CH5 HOLD/CLEAR Function Setting (Un\G913)........................................................................... 6 - 35

6.38 Level Data (Un\G1600 to Un\G1609) ............................................................................................ 6 - 36

6.39 Latest Address of Error History (Un\G1800)..................................................................................6 - 37

6.40 Error History (Un\G1810 to Un\G1964) ......................................................................................... 6 - 37

6.41 CH1 Logging Data Storage Area (Un\G5000 to Un\G14999)........................................................ 6 - 38

CHAPTER7 PREPARATORY PROCEDURES AND SETTING 7 - 1 to 7 - 20

7.1 Handling Precautions....................................................................................................................... 7 - 1

7.2 Preparatory Procedures and Setting ............................................................................................... 7 - 2

7.3 Part Names...................................................................................................................................... 7 - 3

7.4 Wiring............................................................................................................................................... 7 - 5

7.4.1 Wiring precautions .................................................................................................................... 7 - 5

7.4.2 External wiring .......................................................................................................................... 7 - 8

7.4.3 Wiring of external power supply connector............................................................................... 7 - 9

7.5 Setting from GX Developer ............................................................................................................ 7 - 12

7.5.1 Intelligent function module detailed setting............................................................................. 7 - 12

7.5.2 Intelligent function module switch setting ............................................................................... 7 - 14

7.6 Offset/Gain Correction ................................................................................................................... 7 - 16

CHAPTER8 UTILITY PACKAGE (GX Configurator-AD/GX Configurator-DA)

8 - 1 to 8 - 26

8.1 Utility Package Functions ................................................................................................................ 8 - 1

8.2 Installing and Uninstalling the Utility Package ................................................................................. 8 - 2

8.2.1 Precautions for use................................................................................................................... 8 - 2

8.2.2 Operating environment ............................................................................................................. 8 - 5

A - 9

Page 12

8.3 Operating the Utility Package .......................................................................................................... 8 - 7

8.3.1 Common operations ................................................................................................................. 8 - 7

8.3.2 Operation overview................................................................................................................... 8 - 9

8.3.3 Starting Intelligent function module utility ...............................................................................8 - 11

8.4 Initial Setting .................................................................................................................................. 8 - 14

8.5 Auto Refresh Setting...................................................................................................................... 8 - 16

8.6 Monitor/Test ................................................................................................................................... 8 - 18

8.6.1 Monitor/Test window............................................................................................................... 8 - 18

8.7 FB Conversion of Initial Setting/Auto Refresh ............................................................................... 8 - 21

8.8 Usage of FB................................................................................................................................... 8 - 23

8.8.1 Overview................................................................................................................................. 8 - 23

8.8.2 Pasting an FB to a sequence program ................................................................................... 8 - 25

8.8.3 Converting (compiling) a sequence program.......................................................................... 8 - 26

CHAPTER9 PROGRAMMING 9 - 1 to 9 - 34

9.1 Programming Procedures ................................................................................................................ 9 - 2

9.2 Programming for Normal System Configuration .............................................................................. 9 - 4

9.2.1 Before program creation ........................................................................................................... 9 - 6

9.2.2 Program example using the utility package .............................................................................. 9 - 9

9.2.3 Program example without using the utility package................................................................ 9 - 15

9.3 Programming for Remote I/O Network .......................................................................................... 9 - 19

9.3.1 Before program creation ......................................................................................................... 9 - 21

9.3.2 Program example using the utility package ............................................................................ 9 - 22

9.3.3 Program example without using the utility package................................................................ 9 - 27

CHAPTER10 ONLINE MODULE CHANGE 10 - 1 to 10 - 15

10.1 Execution Condition of Online Module Change ............................................................................. 10 - 2

10.2 Operations During Online Module Change .................................................................................... 10 - 3

10.3 Procedures of Online Module Change........................................................................................... 10 - 4

10.3.1 When the initial setting has been configured with GX Configurator-AD or GX Configurator-DA

................................................................................................................................................ 10 - 4

10.3.2 When the initial setting has been configured with sequence program.................................. 10 - 10

CHAPTER11 TROUBLESHOOTING 11 - 1 to 11 - 12

11.1 Error Code List............................................................................................................................... 11 - 1

11.2 Troubleshooting ............................................................................................................................. 11 - 5

11.2.1 When "RUN" LED turns off ..................................................................................................... 11 - 5

11.2.2 When "ERR" LED turns on or blinks....................................................................................... 11 - 5

11.2.3 When "ALM" LED blinks ......................................................................................................... 11 - 5

11.2.4 When digital output values cannot be read............................................................................. 11 - 6

11.2.5 When A/D conversion completed flag does not turn on during use in normal mode .............. 11 - 7

11.2.6 When an analog output value is not output ............................................................................ 11 - 7

11.2.7 When External power off flag (X6) turns on............................................................................ 11 - 8

11.2.8 Checking the Q64AD2DA status ............................................................................................ 11 - 9

A - 10

Page 13

APPENDIX App - 1 to App - 2

Appendix 1 External Dimensions......................................................................................................... App - 1

INDEX Index - 1 to Index - 2

A - 11

Page 14

ABOUT MANUALS

Remark

Relevant Manuals

The following manuals are also related to this product.

Order each manual as needed, referring to the following list.

Manual name

GX Developer Version 8 Operating Manual

Describes the methods for creating, printing, monitoring, and debugging programs with GX

Developer.

(Sold separately.)

GX Developer Version 8 Operating Manual (Function Block)

Describes the methods for creating and printing function blocks with GX Developer.

(Sold separately.)

GX Works2 Version1 Operating Manual (Common)

System configuration, parameter settings, and online operations (common to Simple project and

Structured project) of GX Works2

(Sold separately)

The manuals are included on the CD-ROM for the software package in PDF

format.

The printed manuals are sold separately. When obtaining a manual individually,

order it by quoting the manual number (model code) in the table above.

Manual number

(model code)

SH-080373E

(13JU41)

SH-080376E

(13JU44)

SH-080779ENG

(13JU63)

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES

(1) For programmable controller system

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage

Directives when incorporated into other machinery or equipment, certain measures

may be necessary. Please refer to one of the following manuals.

• QCPU User’s Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance with

EMC and Low Voltage Directives.

(2) For the product

For the compliance of this product with the EMC and Low Voltage Directives, refer to

Section 7.4.1 Wiring precautions.

A - 12

Page 15

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and

abbreviations.

Generic term/

abbreviation

Q64AD2DA Abbreviation for the Q64AD2DA analog input/output module

GX Developer

GX Works2

GX Configurator-AD

GX Configurator-DA

QCPU (Q mode)

Basic model QCPU Generic term for the Q00JCPU, Q00CPU, and Q01CPU

High Performance

model QCPU

Process CPU Generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Redundant CPU Generic term for the Q12PRHCPU and Q25PRHCPU

Universal model QCPU

Personal computer

Factory default setting

FB Abbreviation for function block

Product name of the software package for the MELSEC programmable controllers

Abbreviation for analog-digital converter module setting and monitor tool, GX ConfiguratorAD (SW2D5C-QADU-E)

Abbreviation for digital-analog converter module setting and monitor tool, GX-ConfiguratorDA (SW2D5C-QDAU-E)

Generic term for the Basic model QCPU, High Performance model QCPU, Process CPU,

Redundant CPU, and Universal model QCPU

Generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU,

Q03UDVCPU, Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU,

Q13UDVCPU, Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU,

Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

IBM-PC/AT -compatible personal computer

Generic term for analog input ranges of 0 to 10V, 0 to 5V, 1 to 5V, -10 to 10V, 0 to 20mA, and

4 to 20mA, and for analog output ranges of 0 to 5V, 1 to 5V, -10 to 10V, 0 to 20mA, and 4 to

20mA

Generic term for the following:

Description

Windows Vista

Windows XP

Microsoft Windows Vista Home Basic Operating System,

Microsoft Windows Vista Home Premium Operating System,

Microsoft Windows Vista Business Operating System,

Microsoft Windows Vista Ultimate Operating System,

Microsoft Windows Vista Enterprise Operating System

Generic term for the following:

Microsoft Windows XP Professional Operating System,

Microsoft Windows XP Home Edition Operating System

A - 13

Page 16

Generic term/

abbreviation

Windows 7

Generic term for the following:

Microsoft Windows 7 Starter Operating System,

Microsoft Windows 7 Home Premium Operating System,

Microsoft Windows 7 Professional Operating System,

Microsoft Windows 7 Ultimate Operating System,

Microsoft Windows 7 Enterprise Operating System

Note that the description "Windows 7 (32-bit version)" indicates the 32-bit version only and

"Windows 7 (64-bit version)" indicates the 64-bit version only.

Description

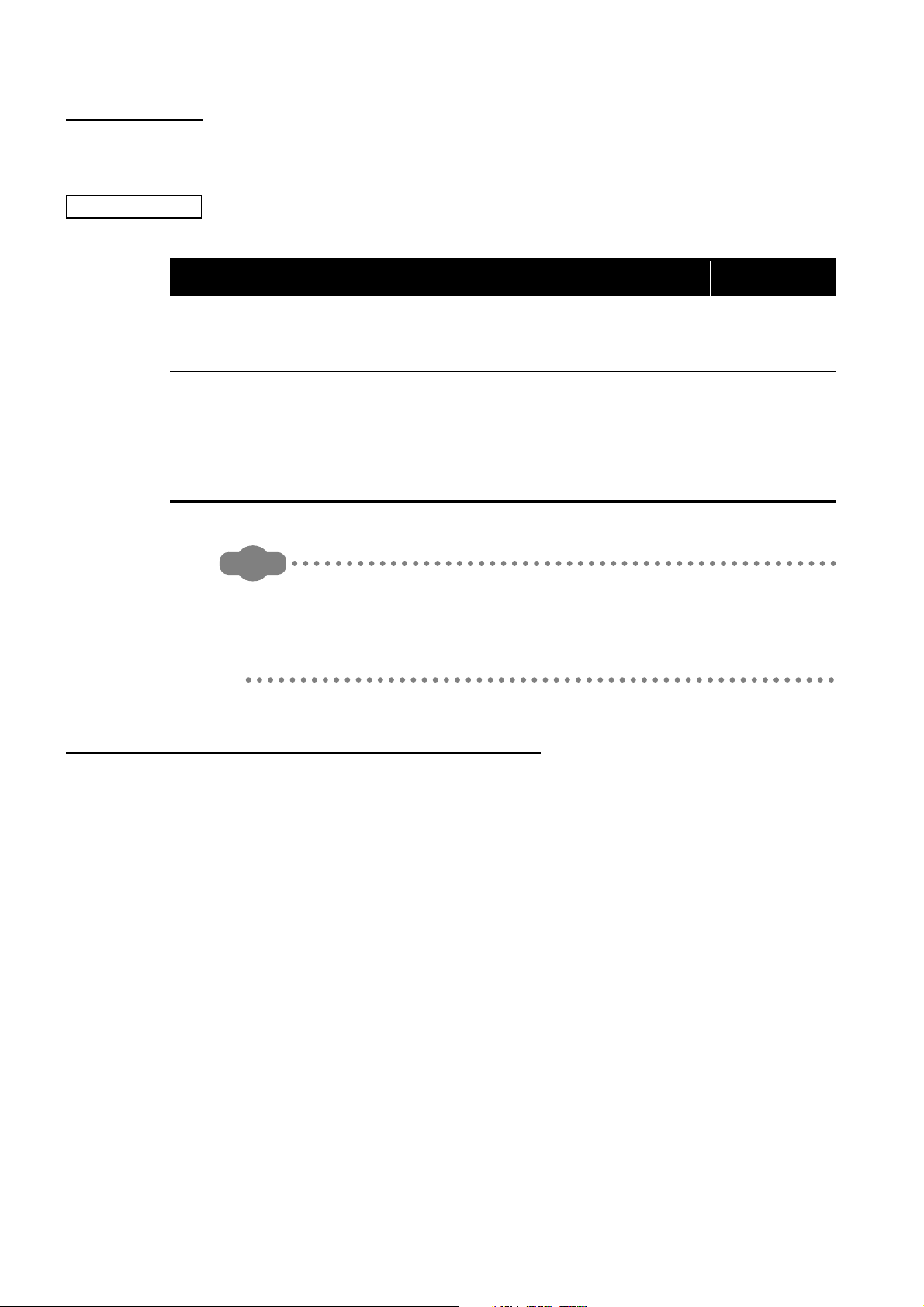

PACKING LIST

The following is included in the package.

Model Product name Quantity

Q64AD2DA

SW2D5C-QADU-E GX Configurator-AD Version 2 (Single license product) (CD-ROM) 1

SW2D5C-QADU-EA GX Configurator-AD Version 2 (Volume license product) (CD-ROM) 1

SW2D5C-QDAU-E GX Configurator-DA Version 2 (Single license product) (CD-ROM) 1

SW2D5C-QDAU-EA GX Configurator-DA Version 2 (Volume license product) (CD-ROM) 1

Q64AD2DA analog input/output module 1

External power supply connector 1

A - 14

Page 17

1

OVERVIEW

CHAPTER1 OVERVIEW

This user's manual provides the specifications, handling instructions, programming

procedures, and other information of the Q64AD2DA analog input/output module

(hereinafter the "Q64AD2DA"), which is designed to use with the MELSEC-Q series CPU

module.

1.1 Features

(1) Analog input and output using a module

The Q64AD2DA can perform both A/D conversion using four channels and D/A

conversion using two channels.

(2) Ranges can be set for each channel

Various voltage or current range can be set for each channel.

Also, the ranges can be switched by using GX Developer.

* 1 Set in Switch setting for I/O and intelligent function module dialog box.

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

*1

SPECIFICATIONS

4

(3) Switching resolution mode

A resolution can be selected from a normal resolution mode (1/4000) and high

resolution mode (1/12000 or 1/16000).

* 2 Set in Switch setting for I/O and intelligent function module dialog box.

*2

(4) Scaling function

Digital output values can be converted to scaling values (ratio (%)) and the converted

values can be stored into buffer memory.

In D/A conversion, an input range of digital input values can be changed to a setting

range and the analog output can be performed.

(5) Shifting function

In A/D conversion, a given value is added to an A/D converted digital output value.

In D/A conversion, a given value is added to a digital input value and an analog value

is output.

Changing a shifting quantity reflects the output value in real time. Therefore, the

output value can be adjusted with the shifting function when the CPU is powered on.

(6) Input range extended mode function

The analog input range, 4 to 20mA and 1 to 5V can be increased to the input range of

0 to 22mA and 0 to 5.5V, respectively.

A/D conversion can be performed even if the input range falls below 4mA or 1V, when

sensors do not measure concrete values.

Combining the input range extended mode function and input signal error detection

function detects a disconnection.

* 3 Set in Switch setting for I/O and intelligent function module dialog box.

*3

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

1.1 Features

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

1 - 1

Page 18

1

OVERVIEW

(7) Logging facility

The A/D converted digital output values can be stored into buffer memory.

Logging data can be stored up to 10000th data point storage area for a channel.

The logging facility logs data every sampling periods in the shortest period.

In addition, the logging facility logs large volumes of data at high speeds, resulting in

improving efficiency of debugging.

(8) Online module change

Modules can be changed without the system being stopped.

(9) Easy setting using GX Configurator-AD or GX Configurator-DA

The number of sequence programs can be reduced since GX Configurator-AD or GX

Configurator-DA

Also, GX Configurator-AD or GX Configurator-DA simplifies checking of the module

settings and operation status.

In addition, FB

parameters set in advance to use them in a sequence program.

*1

(sold separately) allows the Q64AD2DA settings on the dialog box.

*2

can be automatically created from intelligent function module

* 1 Either GX Configurator-AD or GX Configurator-DA checks the intelligent function module

parameter setting and the setting status or operation status of the Q64AD2DA.

In addition, the setting and status can be checked by installing both GX Configurator-AD and GX

Configurator-DA.

* 2 FB is the function for making a circuit block used in a sequence program repeatedly a part (FB) to

use it in the sequence program.

This function can improve the efficiency of program development and minimize program bugs to

improve program qualities.

For the details of FB, refer to GX Developer Version 8 Operating Manual (Function

Block).

1 - 2

1.1 Features

Page 19

2

Remark

SYSTEM CONFIGURATION

CHAPTER2 SYSTEM CONFIGURATION

This chapter explains the system configuration of the Q64AD2DA.

2.1 Applicable Systems

This section describes the applicable systems.

(1) Applicable modules and base units, and number of modules

(a) When mounted with CPU module

For the applicable modules, the number of modules, and base units applicable to

the Q64AD2DA, refer to the user’s manual for the CPU module used.

Note the following when the Q64AD2DA is mounted with a CPU module.

• Depending on the combination with other modules or the number of mounted

modules, power supply capacity may be insufficient. Pay attention to the

power supply capacity before mounting modules, and if the power supply

capacity is insufficient, change the combination of modules.

• Mount a module within the number of I/O points for the CPU module. If the

number of slots is within the available range, the module can be mounted on

any slot.

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

When the module is used with a C Controller module, refer to the user’s manual

for the C Controller module.

(b) When mounted with MELSECNET/H remote I/O station

For the MELSECNET/H remote I/O station, the number of modules, and base

units applicable to the Q64AD2DA, refer to the Q Corresponding MELSECNET/H

Network System Reference Manual (Remote I/O network).

(2) Support of multiple CPU system

When using the Q64AD2DA in a multiple CPU system, refer to the following manual

first.

• QCPU User's Manual (Multiple CPU System)

(3) Support of online module change

The function version of the Q64AD2DA has been "C" from the first release, supporting

online module change.

For details, refer to CHAPTER 10.

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

2.1 Applicable Systems

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

2 - 1

Page 20

2

SYSTEM CONFIGURATION

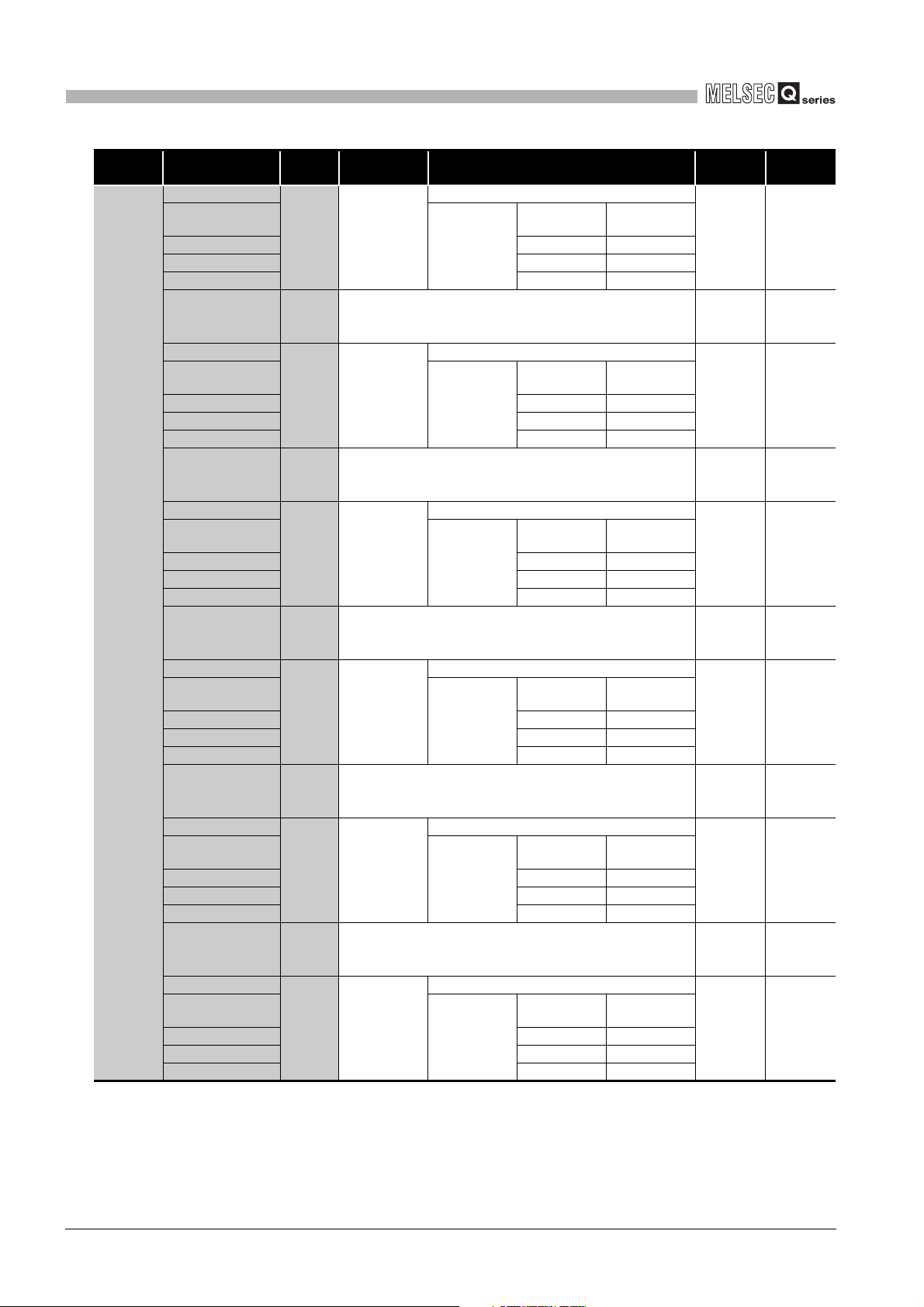

(4) Supported software packages

Operating the Q64AD2DA requires GX developer or GX Works2 with a software

version that is compatible with the CPU system used.

The software packages, GX Configurator-AD and GX Configurator-DA

required. The intelligent function module parameter setting, setting status, and

operating status can be checked easily by using the packages.

The software versions compatible with GX Developer, GX Configurator-AD, GX

Configurator-DA, and GX Works2 are listed in the Table 2.1.

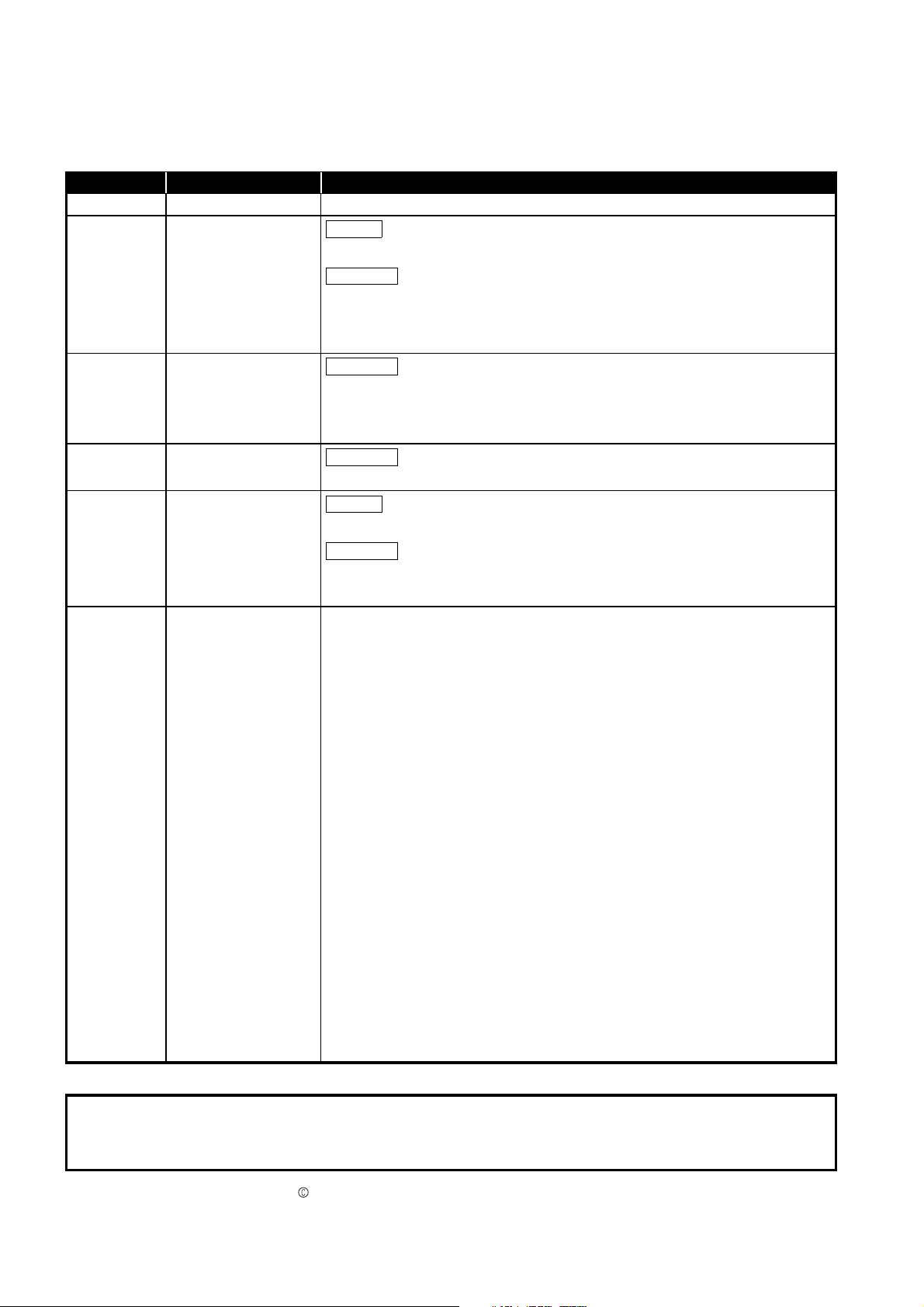

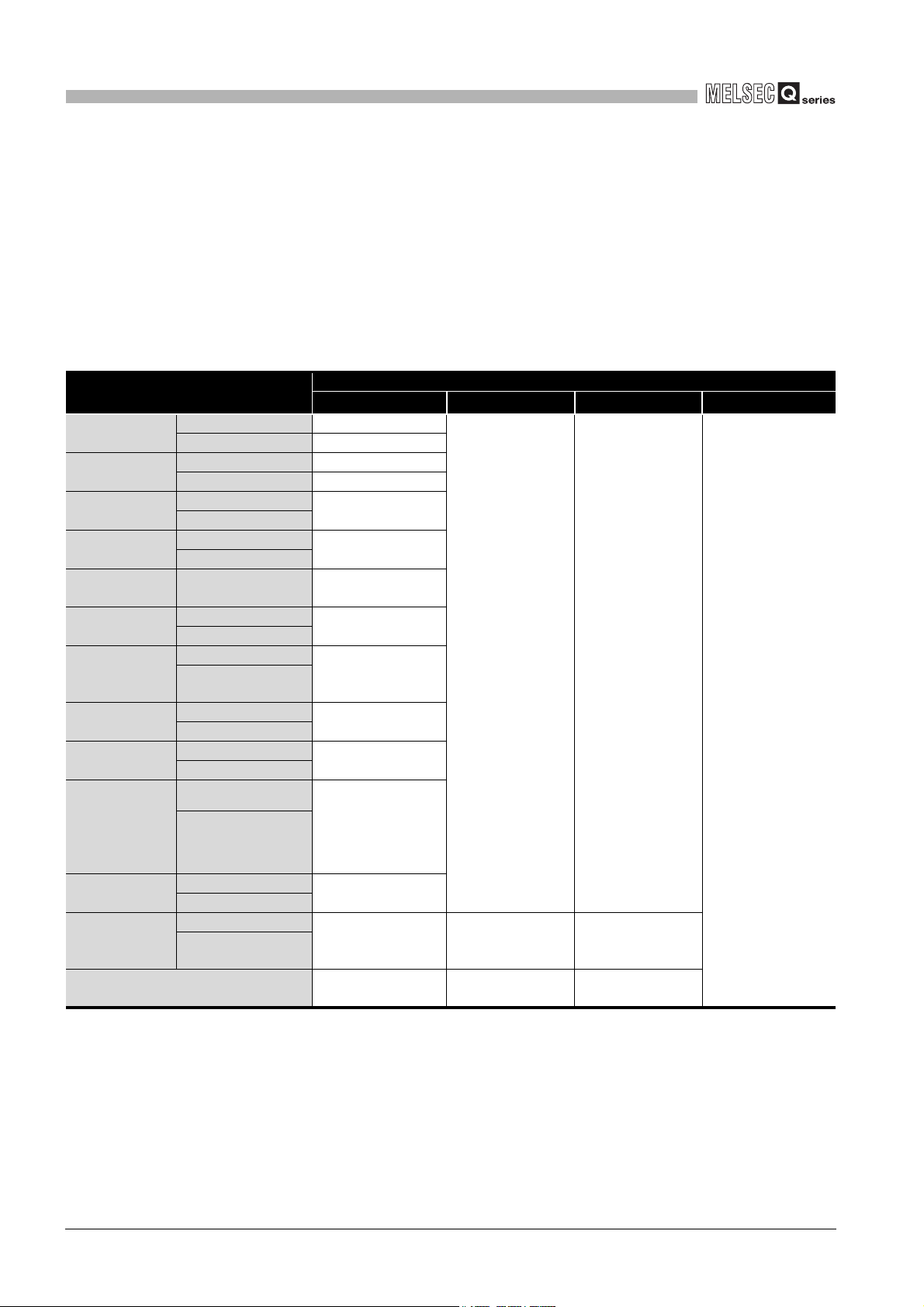

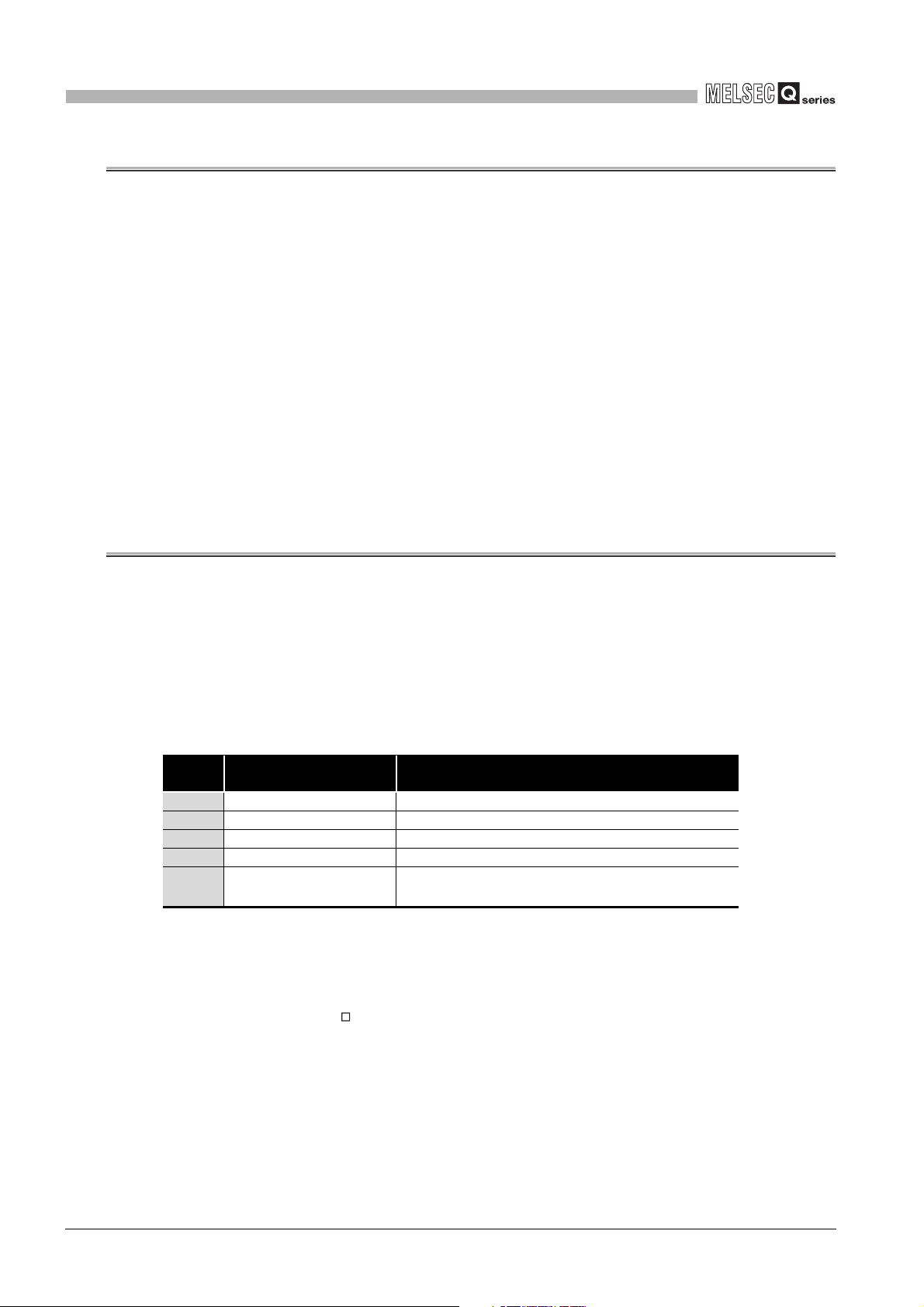

Table 2.1 Compatible software package and software version

System

Q00J/Q00/

Q01CPU

Q02/Q02H/Q06H/

Q12H/Q25HCPU

Q02PH/

Q06PHCPU

Q12PH/

Q25PHCPU

Q12PRH/

Q25PRHCPU

Q00UJ/Q00U/

Q01UCPU

Q02U/Q03UD/

Q04UDH/

Q06UDHCPU

Q10UDH/

Q20UDHCPU

Q13UDH/

Q26UDHCPU

Q03UDE/

Q04UDEH/

Q06UDEH/

Q13UDEH/

Q26UDEHCPU

Q10UDEH/

Q20UDEHCPU

CPU modules

other than the

above

When mounted to MELSECNET/H remote

I/O station

Single CPU system Version 7 or later

Multiple CPU system Version 8 or later

Single CPU system Version 4 or later

Multiple CPU system Version 6 or later

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Redundant CPU

system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

* 1 The setting of intelligent function module parameters for A/D conversion and D/A conversion, the

* 2 For the FB conversion function, use GX Developer 8 or later.

*1

, are not

Software version

*2

GX Developer

Version 8.68W or later

Version 7.10L or later

Version 8.45X or later

Version 8.76E or later

Version 8.48A or later

Version 8.76E or later

Version 8.62Q or later

Version 8.68W or later

Version 8.76E or later

Cannot be used Cannot be used Cannot be used

Version 6 or later Version 2.10L or later Version 2.10L or later

setting status, and operating status can be checked by installing either GX Configurator-AD or GX

Configurator-DA.

The setting and setting states can be checked with the installed GX Configurator-AD and GX

Configurator-DA.

GX Configurator-AD GX Configurator-DA GX Works2

Version 2.10L or later Version 2.10L or later

Refer to the GX

Works2 Version 1

Operating Manual

(Common).

2 - 2

2.1 Applicable Systems

Page 21

2

POINT

SYSTEM CONFIGURATION

(1) Depending on the version of GX Configurator-AD or GX Configurator-DA,

supported systems and CPU modules, and available functions of the

Q64AD2DA vary.

(2) When using GX Works2, refer to the following:

• GX Works2 Version 1 Operating Manual (Common)

• GX Works2 Version 1 Operating Manual (Intelligent Function Module)

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

2.1 Applicable Systems

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

2 - 3

Page 22

2

Main base unit

Extension base unit

12

1

Connecting directly to a programmable controller CPU

2

Connecting to a programmable controller CPU via an intelligent function module

(Ethernet module, MELSECNET/H module, or CC-Link module) on the main base unit

(GX Configurator-AD or GX Configurator-DA

cannot be used.)

SYSTEM CONFIGURATION

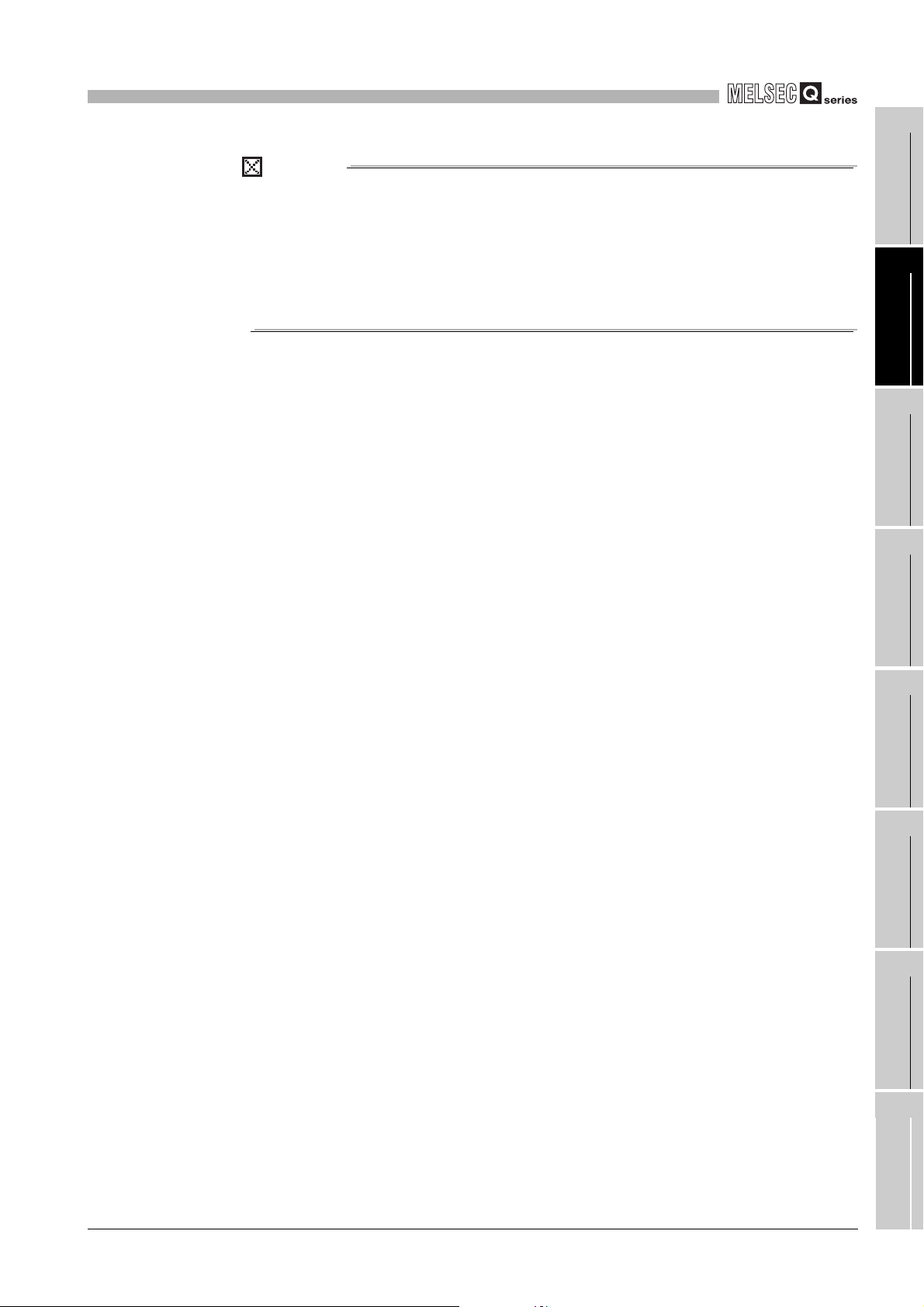

2.2 Using the Q64AD2DA with Redundant CPU

(1) GX Configurator-AD and GX Configurator-DA

GX Configurator-AD and GX Configurator-DA cannot be used when accessing the

Redundant CPU via an intelligent function module on an extension base unit from GX

Developer.

Connect a personal computer to the Redundant CPU with a communication path

indicated below.

Figure 2.1 Communication path for GX Configurator-AD and GX Configurator-DA

2 - 4

2.2 Using the Q64AD2DA with Redundant CPU

Page 23

2

Function version

Relevant regulation

standards

Serial No.

Function version

SYSTEM CONFIGURATION

2.3 Checking Function Version, Serial Number, and Software

Version

1

This section describes how to check the function version of the Q64AD2DA and the

software version of GX Configurator-AD or GX Configurator-DA.

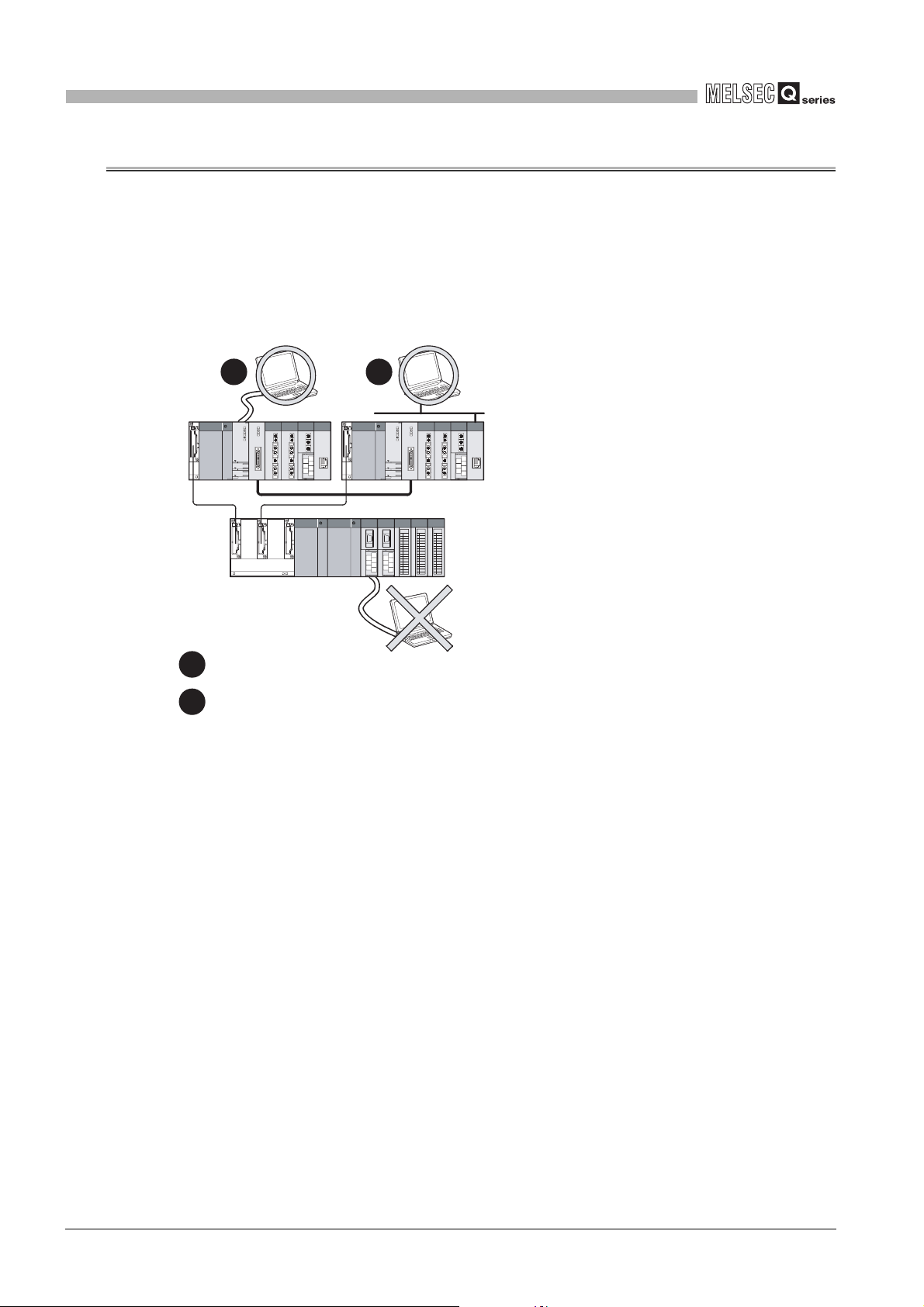

(1) Checking the function version and serial number of the Q64AD2DA

The serial number and function version of the Q64AD2DA are described in the rating

plate, on the front part of the module, or displayed in the System monitor dialog box of

GX Developer.

(a) Checking on the rating plate on the side of the Q64AD2DA

Figure 2.2 Rating plate on the side of module

(b) Checking on the front of the module

The serial number and function version on the rating plate is shown on the front

(at the bottom) of the module.

2

SYSTEM

3

4

5

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTION

Figure 2.3 Description on the front part of module

2.3 Checking Function Version, Serial Number, and Software Version

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

2 - 5

Page 24

2

POINT

Product Information List

Serial No.

Function version

Product No.

SYSTEM CONFIGURATION

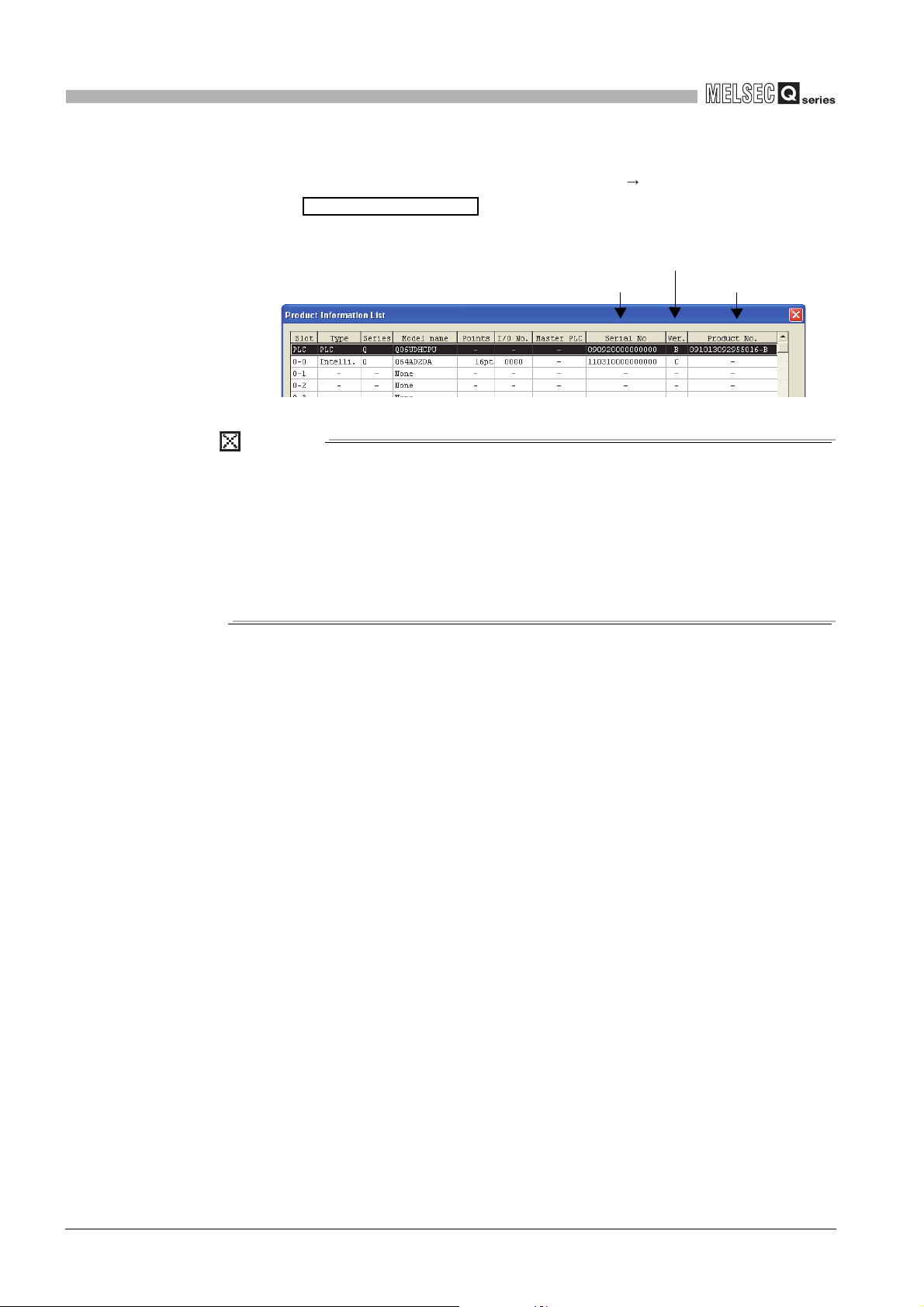

(c) Checking on the System monitor dialog box (Product Information List)

To display the system monitor, select [Diagnostics] [System monitor] and click

the button of GX Developer.

Figure 2.4 Checking the serial number and function version

The serial number displayed on the Product information list dialog box of GX

Developer may differ from that on the rating plate and on the front of the module.

• The serial number on the rating plate and front part of the module

indicates the management information of the product.

• The serial number displayed on the Product information list dialog box of

GX Developer indicates the function information of the product.

The function information of the product is updated when a new function is added.

2 - 6

2.3 Checking Function Version, Serial Number, and Software Version

Page 25

2

SYSTEM CONFIGURATION

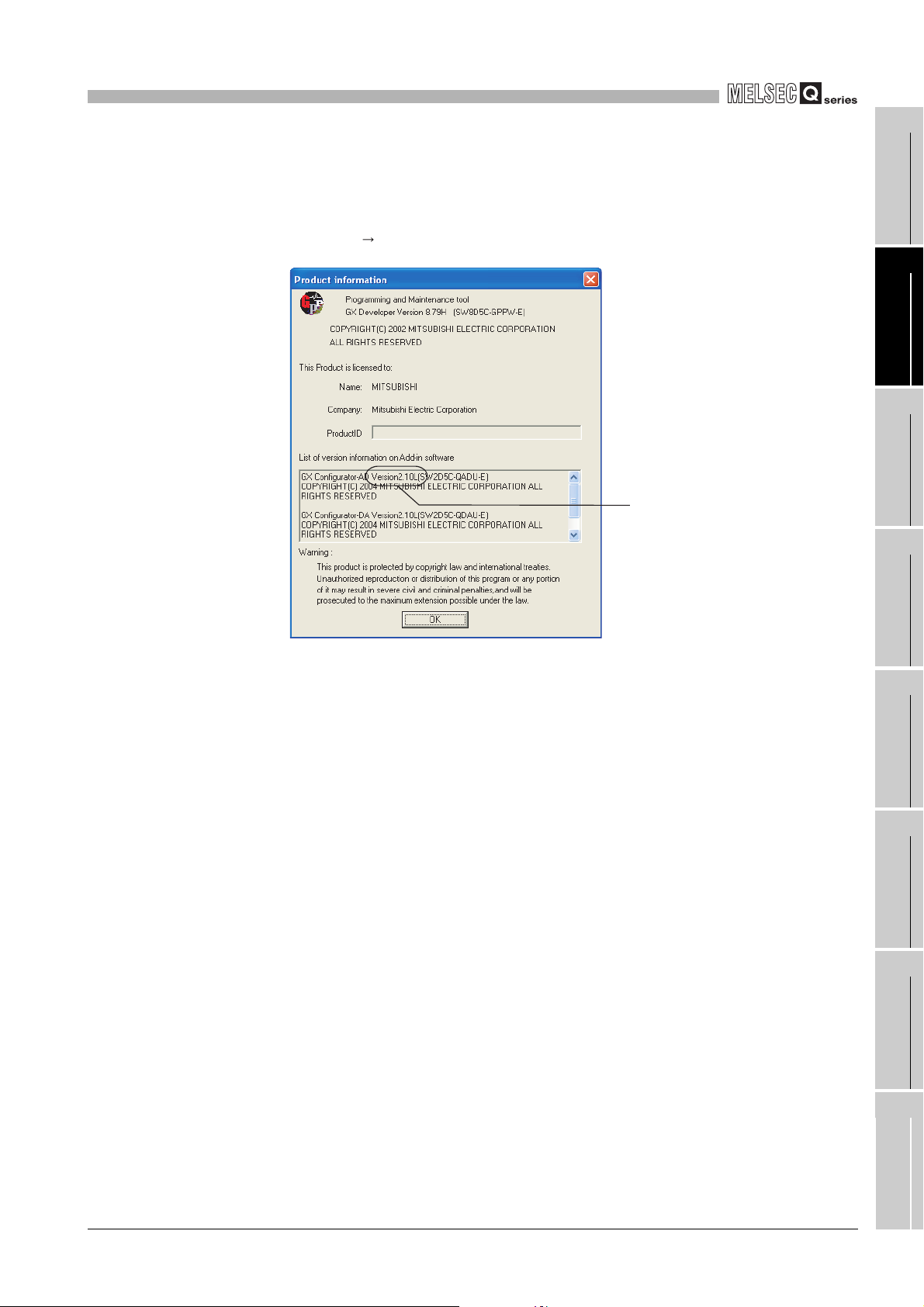

(2) Checking the software version of GX Configurator-AD and GX

Configurator-DA

To check the software version of GX Configurator-AD and GX Configurator-DA,

select [Help] [Product information] of GX Developer.

Software version

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

("Product information" dialog box of GX Developer Version 8)

Figure 2.5 Product information dialog box

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

2.3 Checking Function Version, Serial Number, and Software Version

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

2 - 7

Page 26

3

SPECIFICATIONS

CHAPTER3 SPECIFICATIONS

3.1 Performance Specifications

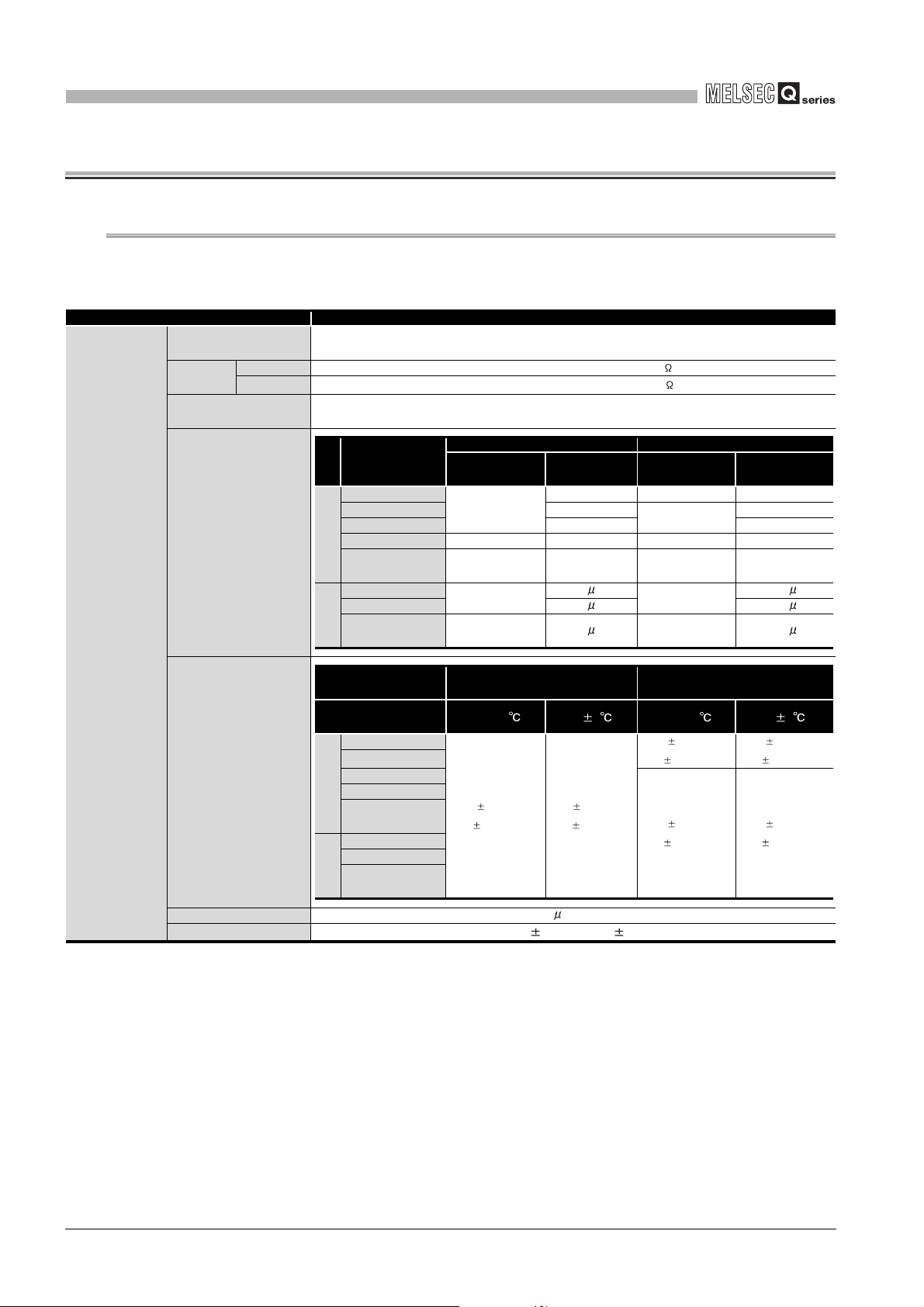

The following table shows the performance specifications of the Q64AD2DA.

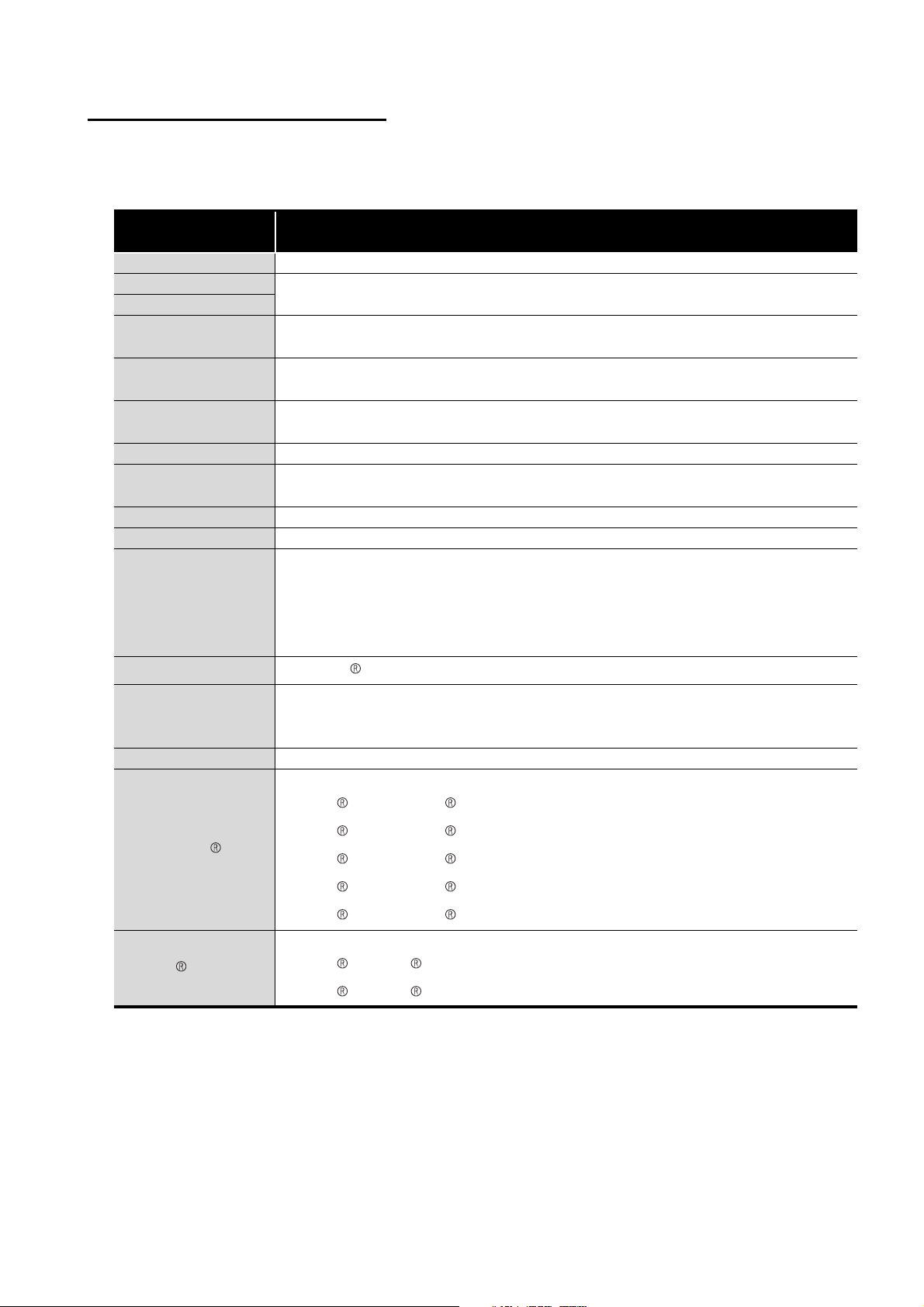

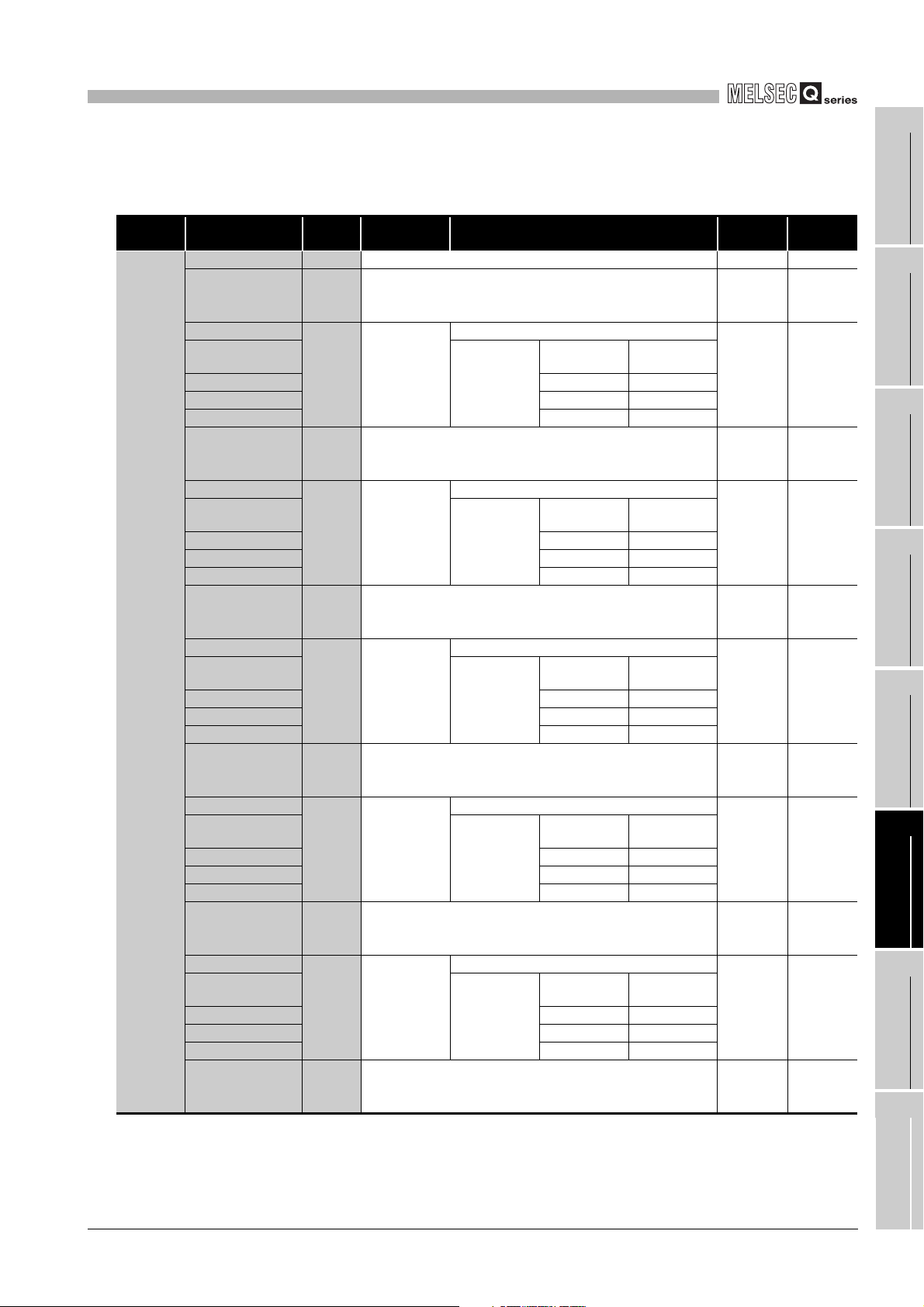

Table 3.1 Performance specifications of the Q64AD2DA (1/2)

Item Specifications

Number of analog input

points

Analog

input

Digital output

I/O characteristics and

maximum resolution*

A/D

conversion area

Voltage -10 to 10VDC (Input resistance: 1M )

Current 0 to 20mADC (Input resistance: 250 )

Normal resolution mode:-96 to 4095, -4096 to 4095, -1096 to 4595

High resolution mode:-384 to 16383, -288 to 12287, -16384 to 16383, -3288 to 13787

Analog

input range

Input

0 to 10V

0 to 5V 1.25mV

1 to 5V 1.0mV 0.333mV

1

-10 to 10V -4000 to 4000 2.5mV -16000 to 16000 0.625mV

Voltage

1 to 5V

(Extended mode)

0 to 20mA

4 to 20mA 4 A 1.33 A

4 to 20mA

Current

(Extended mode)

Digital output

-1000 to 4500 1.0mV -3000 to 13500 0.333mV

-1000 to 4500 4 A -3000 to 13500 1.33 A

4 channels

Normal resolution mode High resolution mode

value

0 to 4000

0 to 4000

Maximum

resolution

2.5mV 0 to 16000 0.625mV

5A

Digital output

value

0 to 12000

0 to 12000

Maximum

resolution

0.416mV

1.66 A

Analog

input range

Ambient

temperature

0 to 10V

Accuracy (Accuracy

relative to maximum

digital output value)

Conversion speed 500 s/channel

Absolute maximum input

-10 to 10V

0 to 5V

1 to 5V

Voltage

1 to 5V

(Extended mode)

0 to 20mA

4 to 20mA

4 to 20mA

Current

(Extended mode)

Normal resolution mode High resolution mode

0 to 55

0.4%

( 16digit)

Voltage: 15V Current: 30mA

25 5 0 to 55 25 5

0.1%

( 4digit)

0.4%

( 64digit)

0.4%

( 48digit)

*2

0.1%

( 16digit)

0.1%

( 12digit)

3 - 1

3.1 Performance Specifications

Page 27

3

SPECIFICATIONS

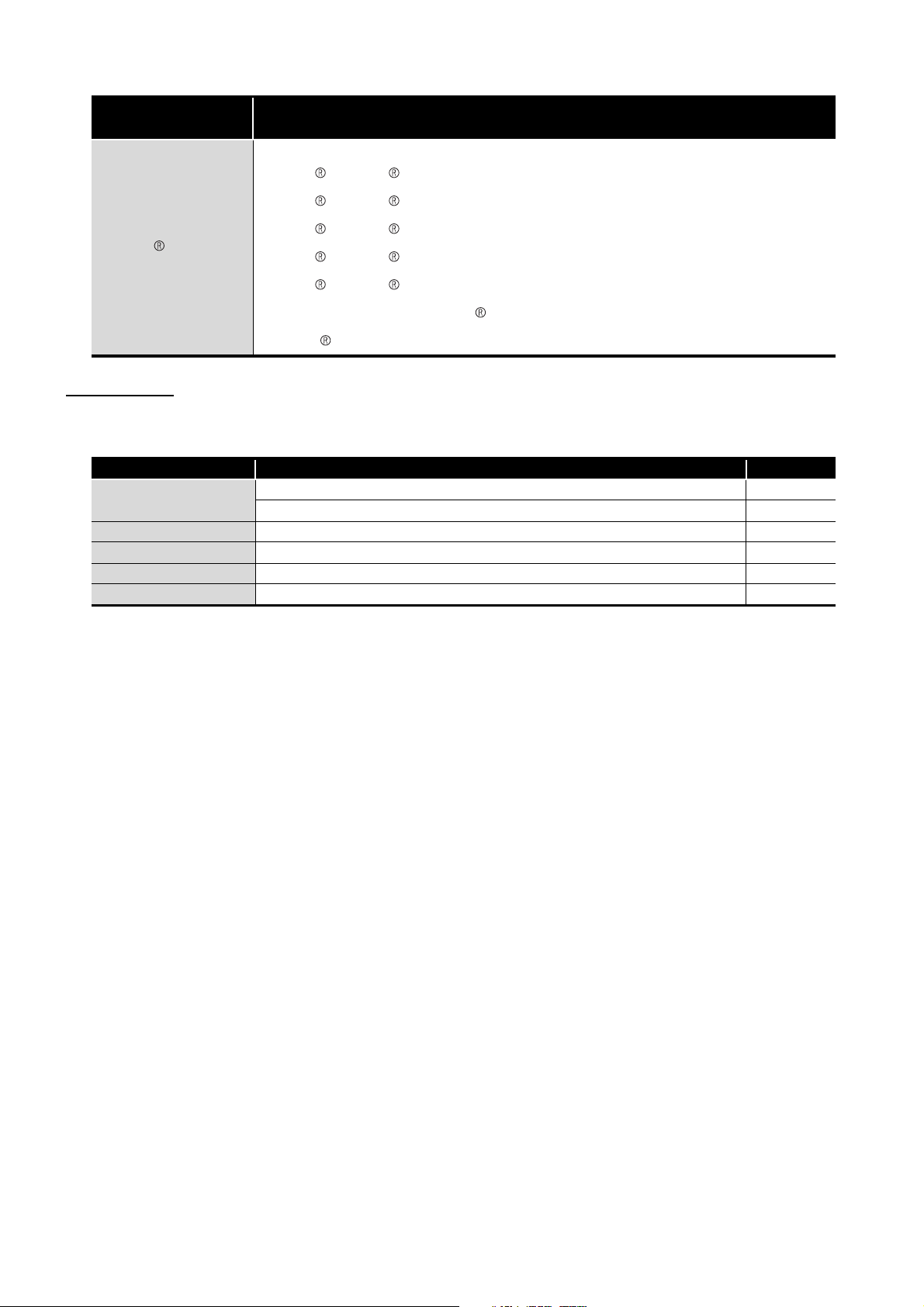

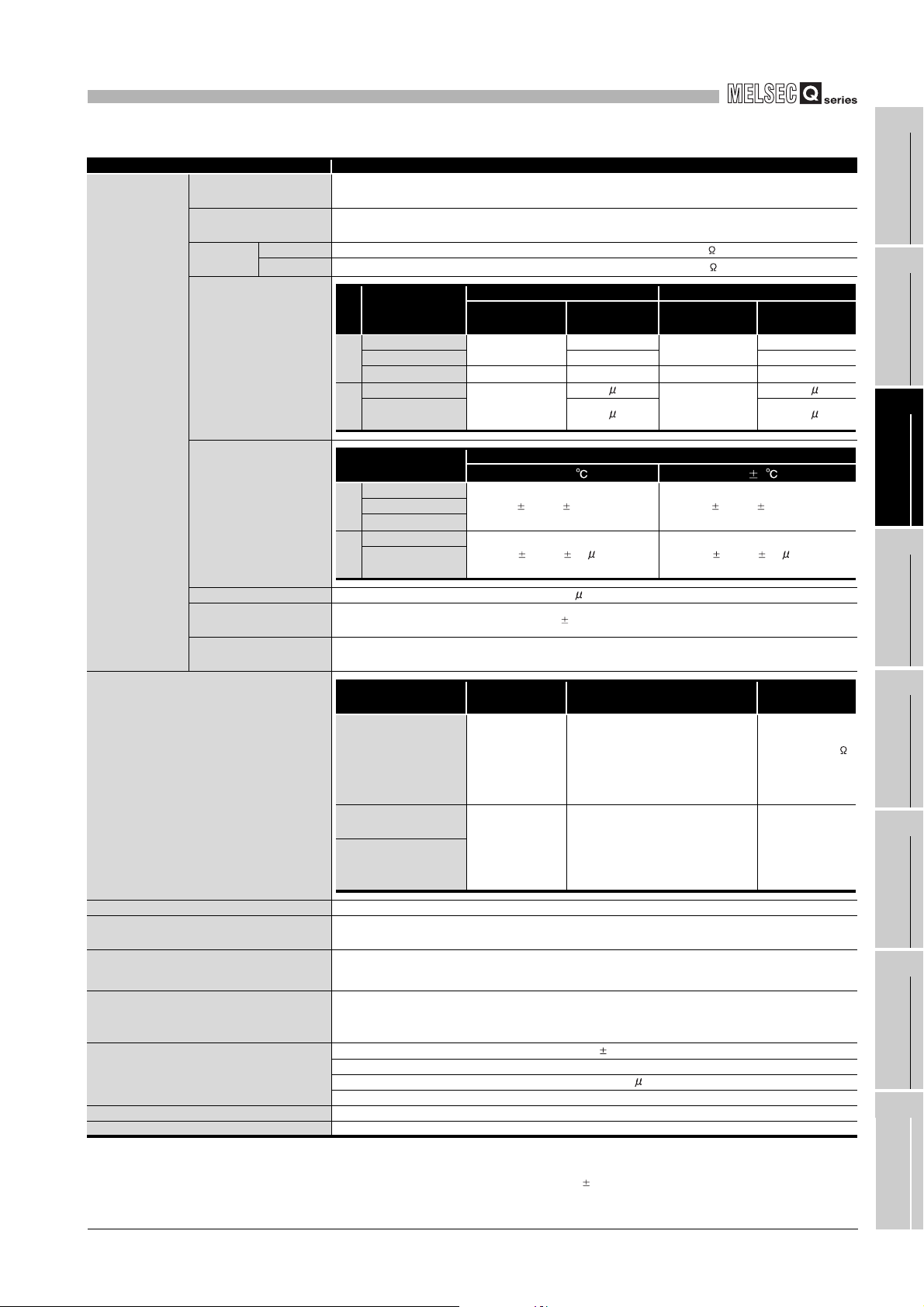

Table 3.1 Performance specifications of the Q64AD2DA (2/2)

Item Specifications

Number of analog output

points

Digital input

Analog

output

I/O characteristics

and maximum resolution

D/A

conversion area

Accuracy (Accuracy

relative to maximum

analog output value)

Conversion speed 500 s/channel

Absolute maximum

output

Output short-circuit

protection

Insulation specifications

Number of I/O occupied points 16 points (I/O assignment: Intelligent 16 points)

External connection system

Applicable cable size

Applicable solderless terminals

External power supply

Internal current consumption (5VDC) 0.17A

Weight 0.23kg

Voltage -10 to 10VDC (External load resistance: 1M )

Current 0 to 20mADC (External load resistance: 600 )

Analog

output range

Output

0 to 5V

1 to 5V 1.0mV 0.333mV

-10 to 10V -4000 to 4000 2.5mV -16000 to 16000 0.625mV

Voltage

0 to 20mA

4 to 20mA 4 A 1.33 A

Current

Analog

output range

0 to 5V

1 to 5V

-10 to 10V

Vol tag e

0 to 20mA

4 to 20mA

Current

Specific isolated

area

Between input

terminal and

programmable

controller power

supply

Between input/output

channels

Between external

power supply and

analog input/output

External power supply 24VDC, FG terminal connection: External power supply connector

External power supply 24VDC, FG terminal connection: Refer to Table 3.2.

A/D conversion area, D/A conversion area: R1.25-3 (Solderless terminals with sleeves are

External power supply 24VDC, FG terminal connection: Not available

* 1 For the details of the I/O conversion characteristic, refer to Section 3.2.1.

* 2 Indicates the value of the instant input current that does not break module inner electrical

resistance. The maximum input current value is 24mA when the current is impressed steadily.

Normal resolution mode: -96 to 4095, -4096 to 4095

High resolution mode: -288 to 12287, -16384 to 16383

Normal resolution mode High resolution mode

Digital input

value

0 to 4000

0 to 4000

Voltage: 12V Current: 21mA

Isolation

method

Photocoupler

isolation

--- --- ---

A/D conversion area, D/A conversion area:18 points terminal block

A/D conversion area, D/A conversion area: 0.3 to 0.75mm

Ripple, spike 500mV

Inrush current: 2.5A 150 s or less

Current consumption: 0.19A

2 channels

Maximum

resolution

1.25mV

5A

Ambient temperature

0 to 55 25 5

0.3% ( 30mV) 0.1% ( 10mV)

0.3% (60A) 0.1% (20A)

Available

Dielectric withstand voltage

500VACrms, 1min

unavailable.)

24VDC 15%

P-P or less

Digital input

value

0 to 12000

0 to 12000

Maximum

resolution

0.416mV

1.66 A

Insulation

resistance

500VDC 20M

or more

2

*3

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

3.1 Performance Specifications

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

3 - 2

Page 28

3

Remark

External power supply

connector (accessory)

SPECIFICATIONS

* 3 The following shows the specifications of the cable applicable to an external power supply

connector.

Figure 3.1 When inserting two cables into one terminal

Table 3.2 Cable applicable to external power supply connector

Item Specifications

Applicable cable size

Size when inserting two

cables into one terminal

Screw tightening torque 0.5 to 0.6N m

0.2 to 3.3mm

Single wire: 0.2 to 0.8mm2 2

Stranded wire: 0.2 to 0.8mm

2

(AWG 24 to 12)

2

2

For general specifications of the Q64AD2DA, refer to the user's manual for the

CPU module used.

3 - 3

3.1 Performance Specifications

Page 29

3

SPECIFICATIONS

3.2 I/O Conversion Characteristic

3.2.1 I/O conversion characteristic of A/D conversion

The I/O conversion characteristic of A/D conversion represents the angle formed by a

straight line connecting the "offset value" and "gain value" when the analog signals

(voltage or current input) from outside the programmable controller are converted to digital

values.

1

OVERVIEW

2

[Offset value]

The offset value refers to the analog input value (voltage or current) that makes the

digital output value be 0.

[Gain value]

The gain value refers to the analog input value (voltage or current) that makes the

digital output value be:

• 4000 (in normal resolution mode)

• 16000 or 12000 (in high resolution mode)

SYSTEM

3

4

5

I/O SIGNALS FOR

6

CONFIGURATION

SPECIFICATIONS

FUNCTION

THE CPU MODULE

3.2 I/O Conversion Characteristic

3.2.1 I/O conversion characteristic of A/D conversion

3 - 4

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

Page 30

3

0

0

0

5

12287

4000

12000

4095

-288

-96

Practical analog input range

Digital output value

Normal resolution

mode

High resolution

mode

2) 0 to 5V

Analog input voltage (V)

0

0

-10

0

10

16383

4000

16000

-16000

4095

-4096

-4000

-16384

High resolution mode

Practical analog input range

Digital output value

Normal resolution mode

3) -10 to 10V

Analog input voltage (V)

0

0

0

10

16383

4000

16000

4095

-384

-96

High resolution mode

Practical analog input range

Digital output value

Normal resolution mode

4) 0 to 10V

Analog input voltage (V)

0

0105.5

13787

4500

13500

4595

-1096

-3288

-1000

-3000

Practical analog input range

Digital output value

Normal resolution

mode

High resolution mode

5) 1 to 5V (Extended mode)

Analog input voltage (V)

1) 1 to 5V

12287

12000

4095

4000

-288

Digital output value

SPECIFICATIONS

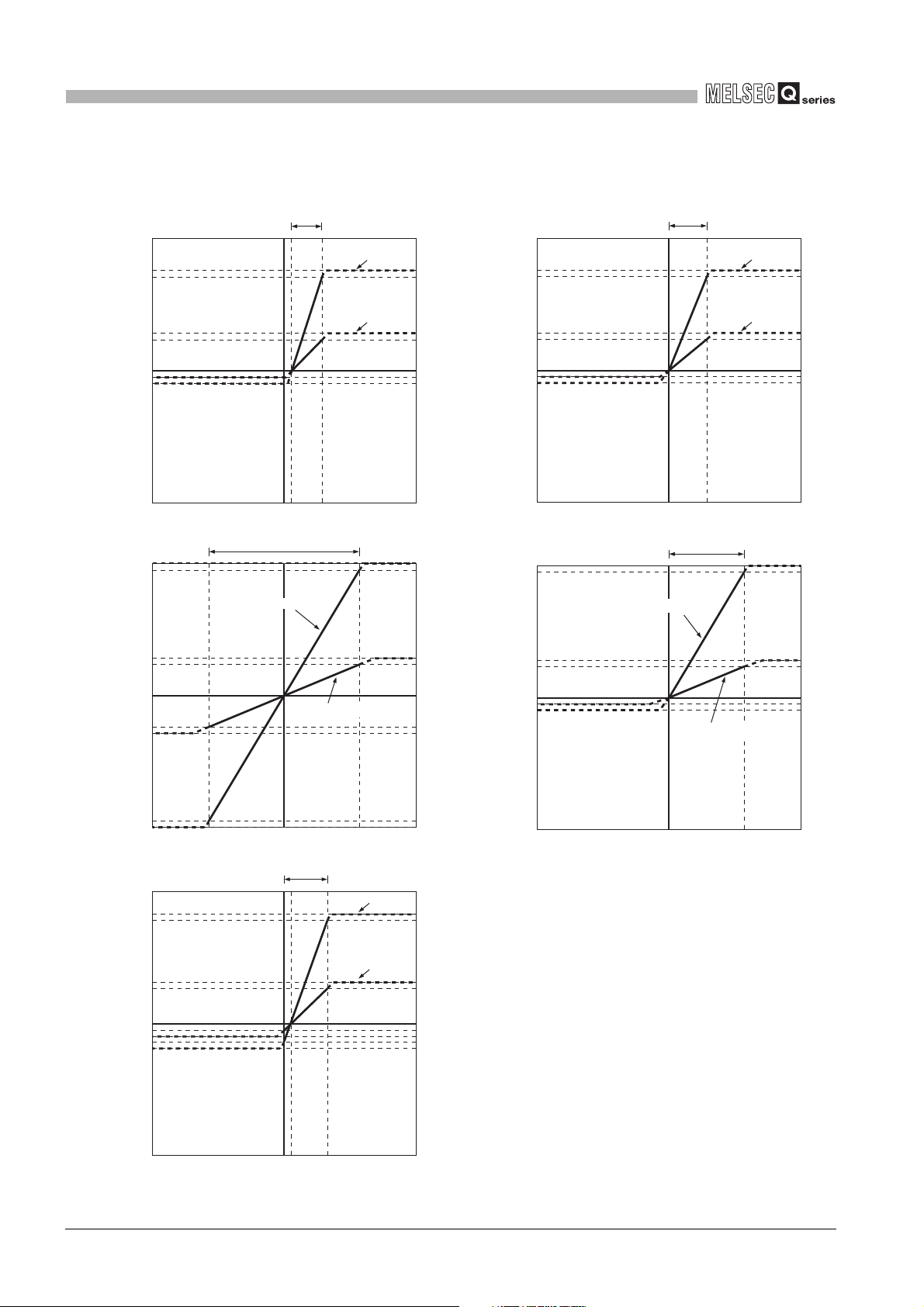

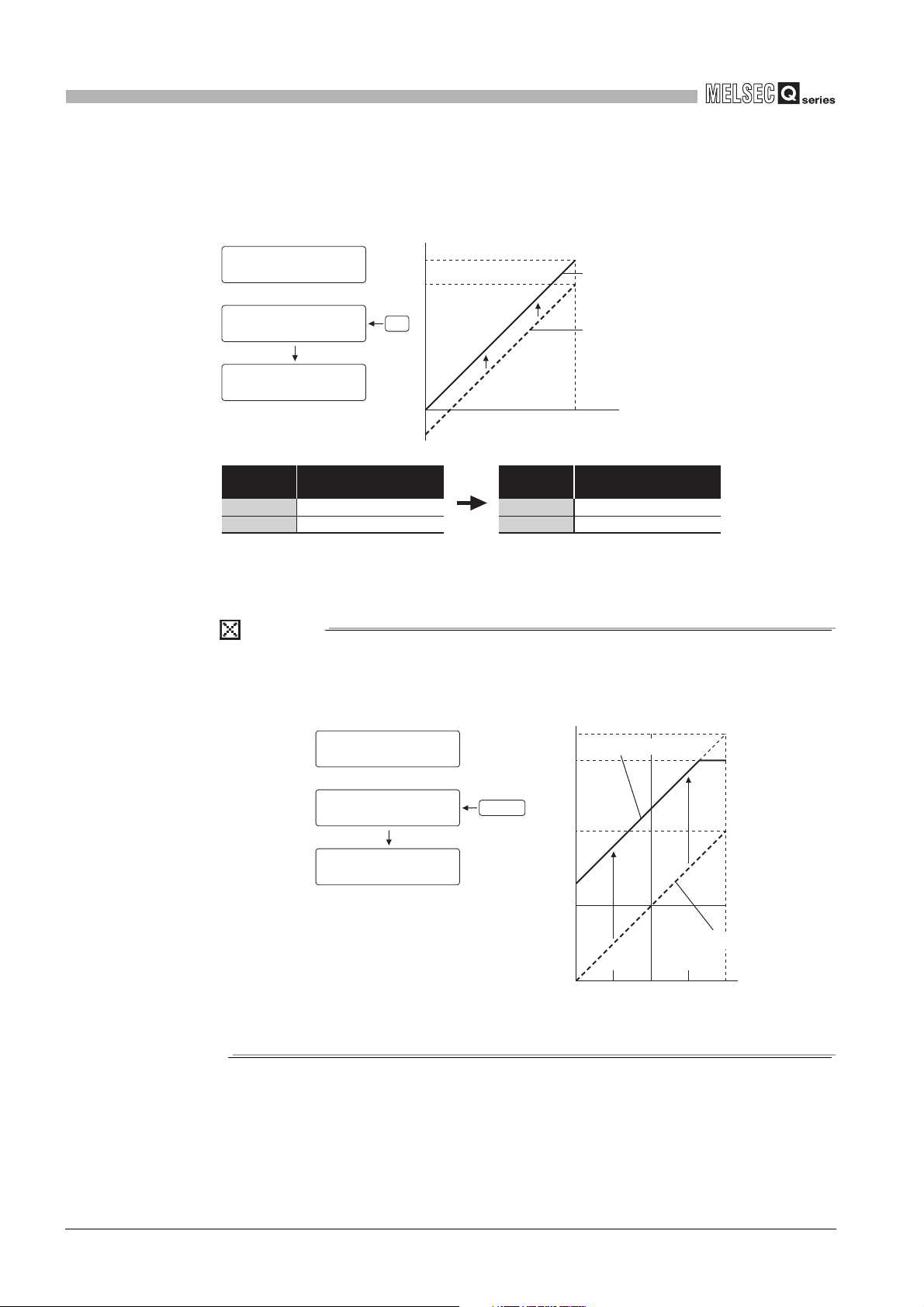

(1) Voltage input characteristic

Figure 3.2 shows voltage input characteristics.

Practical analog input range

0

-96

0105

Analog input voltage (V)

High resolution

mode

Normal resolution

mode

3 - 5

Figure 3.2 Voltage input characteristic

3.2 I/O Conversion Characteristic

3.2.1 I/O conversion characteristic of A/D conversion

Page 31

3

POINT

SPECIFICATIONS

(1) Set each input range within the practical analog input range and digital output

range. If these ranges are exceeded, the maximum resolution and accuracy

may not fall within the performance specifications. (Avoid using the dotted line

area shown in Figure 3.2.)

(2) Do not input an analog input voltage of 15 V or more. The input element

may be damaged.

(3) If an analog value that exceeds the range for the digital output value is

entered, the digital output value will be fixed at the maximum or minimum

value.

Table 3.3 Digital output values in the case of an analog value, exceeding the range

for the digital output value, being entered

Analog input range

setting

1 to 5V

0 to 5V

-10 to 10V -4096 -16384

0 to 10V -96 -384

1 to 5V

(Extended mode)

Digital output value

(normal resolution mode)

Minimum Maximum Minimum Maximum

-96

4095

-1096 4595 -3288 13787

Digital output value

(high resolution mode)

-288 12287

16383

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

3.2 I/O Conversion Characteristic

3.2.1 I/O conversion characteristic of A/D conversion

3 - 6

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

Page 32

3

0

04

0

20

12287

4000

12000

4095

-288

-96

Practical analog input range

Digital output value

Normal resolution

mode

High resolution

mode

1) 4 to 20mA

Analog input current (mA)

0

0

0

20

12287

4000

12000

4095

-288

-96

Practical analog input range

Digital output value

Normal resolution

mode

High resolution

mode

2) 0 to 20mA

Analog input current (mA)

0

04

0

22

13787

4500

13500

4595

-1096

-1000

-3288

-3000

Practical analog input range

Digital output value

3) 4 to 20mA (Extended mode)

Analog input current (mA)

High resolution

mode

Normal resolution

mode

SPECIFICATIONS

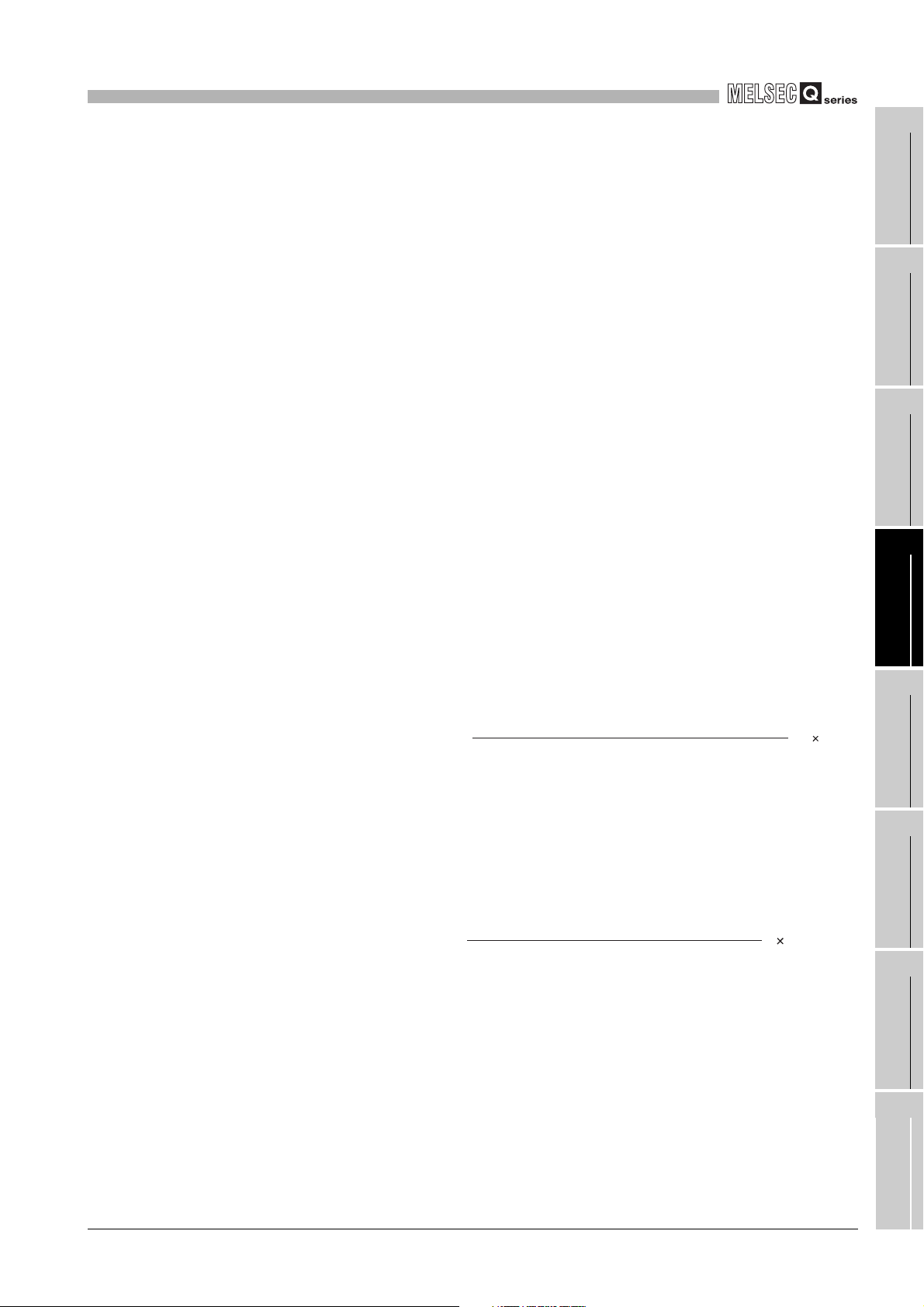

(2) Current input characteristic

Figure 3.3 shows current input characteristics.

3 - 7

Figure 3.3 Current input characteristic

3.2 I/O Conversion Characteristic

3.2.1 I/O conversion characteristic of A/D conversion

Page 33

3

POINT

SPECIFICATIONS

(1) Set each input range within the practical analog input range and digital output

range.

If these ranges are exceeded, the maximum resolution and accuracy may not

fall within the performance specifications. (Avoid using the dotted line area

shown in Figure 3.3.)

(2) Do not input an analog input current of 30 mA or more. The input elements

may be damaged.

(3) If an analog value that exceeds the range of the digital output value is

entered, the digital output value will be fixed at the maximum or minimum

value.

Table 3.4 Digital output values in the case of an analog value, exceeding the range

for the digital output value, being entered

Analog input range

setting

4 to 20mA

0 to 20mA

4 to 20mA

(Extended mode)

Digital output value

(normal resolution mode)

Minimum Maximum Minimum Maximum

-96 4095 -288 12287

-1096 4595 -3288 13787

Digital output value

(high resolution mode)

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

3.2 I/O Conversion Characteristic

3.2.1 I/O conversion characteristic of A/D conversion

3 - 8

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

Page 34

3

SPECIFICATIONS

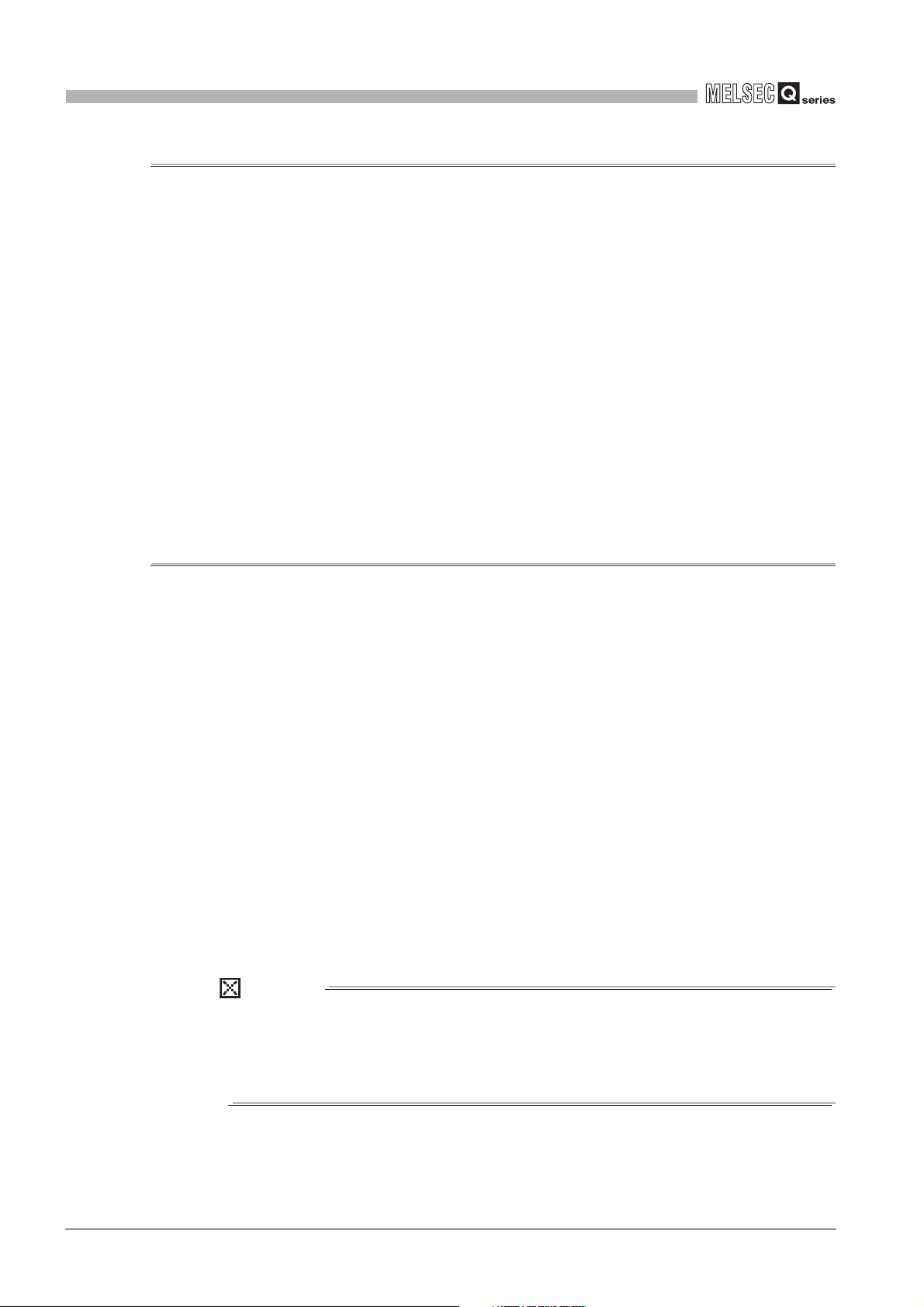

3.2.2 I/O conversion characteristic of D/A conversion

The I/O conversion characteristic of D/A conversion represents the angle formed by a

straight line connecting the "offset value" and "gain value" when converting the digital input

value written from the CPU module to an analog output value (voltage or current output).

[Offset value]

The offset value refers to the analog output value (voltage or current) when the digital

input value set from the CPU module is 0.

[Gain value]

The gain value is the analog output value (voltage or current) when the digital input

value set from the CPU module is:

• 4000 (in normal resolution mode)

• 12000 (when 1 to 5V, 0 to 5V, 4 to 20mA, or 0 to 20mA selected in high resolution

mode)

• 16000 (when -10 to 10V is selected in high resolution mode)

3 - 9

3.2 I/O Conversion Characteristic

3.2.2 I/O conversion characteristic of D/A conversion

Page 35

3

POINT

0 4000 4095 1200012287

0

1

5

0

-288 -96

Analog output voltage (V)

Practical analog output range

1) 1 to 5V

Digital input value

High resolution

mode

Normal resolution

mode

0 4000 4095 16000 16383-4096 -4000-16384 -16000

0

10

-10

0

Analog output voltage (V)

Practical analog output range

3) -10 to 10V

Digital input value

High resolution

mode

Normal resolution

mode

SPECIFICATIONS

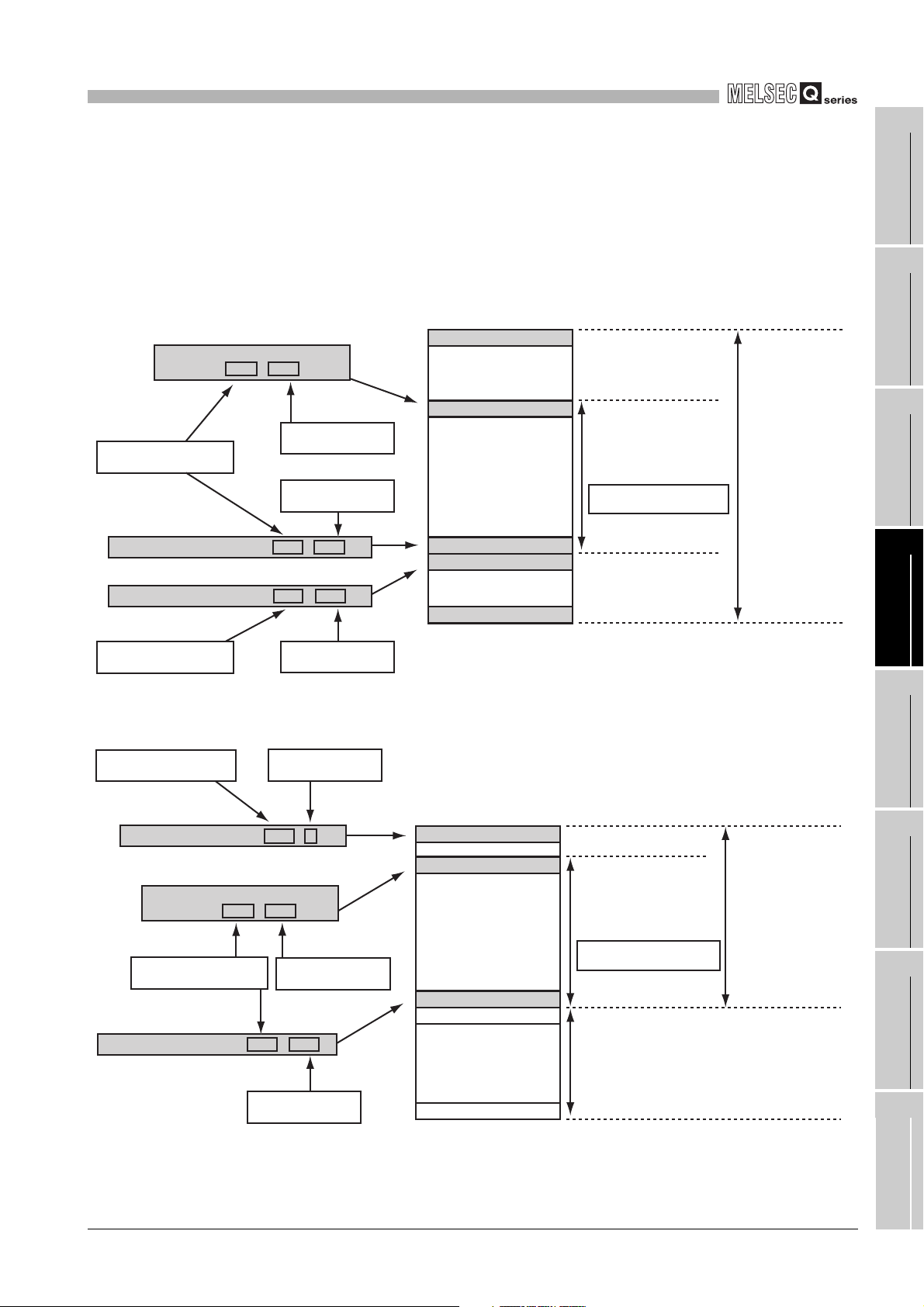

(1) Voltage output characteristic

Figure 3.4 shows voltage output characteristics.

2) 0 to 5V

5

Normal resolution

mode

1

OVERVIEW

2

0

Analog output voltage (V)

0

0 4000 4095 12000 12287

-288 -96

Digital input value

High resolution

mode

SYSTEM

Practical analog output range

CONFIGURATION

3

SPECIFICATIONS

4

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

Figure 3.4 Voltage output characteristic

Set each output range within the practical digital input range and analog output

range.

If these ranges are exceeded, the maximum resolution and accuracy may not fall

within the performance specifications. (Avoid using the dotted line area shown in

Figure 3.4.)

3.2 I/O Conversion Characteristic

3.2.2 I/O conversion characteristic of D/A conversion

3 - 10

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

Page 36

3

POINT

0 4000 4095-288 -96 12000 12287

0

4

20

0

Analog output current (mA)

Practical analog output range

1) 4 to 20mA

Digital input value

High resolution

mode

Normal resolution

mode

SPECIFICATIONS

(2) Current output characteristic

Figure 3.5 shows current output characteristics.

2) 0 to 20mA

20

Normal resolution

mode

0

Analog output current (mA)

Figure 3.5 Current output characteristic

0

0 4000 4095 12000 12287

-288 -96

Digital input value

High resolution

mode

Practical analog output range

Set each output range within the practical digital input range and analog output

range.

If these ranges are exceeded, the maximum resolution and accuracy may not fall

within the performance specifications. (Avoid using the dotted line area shown in

Figure 3.5.)

3 - 11

3.2 I/O Conversion Characteristic

3.2.2 I/O conversion characteristic of D/A conversion

Page 37

4

FUNCTION

CHAPTER4 FUNCTION

The device numbers (X or Y) and buffer memory addresses described in this chapter are

used for CH1. (The device numbers and buffer memory addresses specified in D/A

conversion are used for CH5.)

For the device numbers and buffer memory addresses used for other channels, refer to

Section 5.1 and Section 6.1.

4.1 Function List

Table 4.1 lists the functions of the Q64AD2DA.

Item Function

(1) Sampling processing

The A/D conversion for analog input values is performed successively

for each channel, and the digital output value is output upon each

conversion. The value is stored in buffer memory.

(2) Averaging processing

The digital output value is averaged on a channel basis and the

averaged value is stored in buffer memory.

The averaging processing has three methods as follows:

(a) Time average

(b) Count average

(c) Moving average

(1) This function retains the maximum and minimum values of the digital

output values and scaling values in the module.

(2) The retained values can be reset in any timing.

This function converts digital output values to scaling values and stores the

converted values into buffer memory.

Time to configure a program for scaling can be decreased.

The digital output value can be adjusted easily with the shifting function when

the CPU is powered on.

The shifting function adds a setting quantity to a digital output value and

stores the value into buffer memory.

This function detects voltage or current input values exceeding the setting

ranges.

A channel set to averaging processing can be checked every sampling

processing.

This function increases input ranges.

Combining the input range extended mode function and input signal error

detection function detects a disconnection.

This function performs logging of the digital values that A/D conversion is

performed.

Logging data can be stored up to 10000th data point and time-series data that

A/D conversion is performed can be referred and stored easily.

A/D

conversion

function

A/D conversion method

Maximum and minimum values

hold function

Scaling function (A/D

conversion)

Shifting function (A/D

conversion)

Input signal error detection

function

Input range extended mode

function

Logging facility

Table 4.1 Function list

Reference

section

Section

4.2.1

Section

4.2.2

Section

4.2.3

Section

4.2.4

Section

4.2.5

Section

4.2.6

Section

4.2.7

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

FUNCTION

5

I/O SIGNALS FOR

THE CPU MODULE

6

BUFFER MEMORY

7

PREPARATORY

PROCEDURES AND

SETTING

8

4.1 Function List

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

4 - 1

Page 38

4

D/A

conversion

function

Common

function

FUNCTION

Table 4.1 Function list

Item Function

(1)

This function sets whether D/A conversion values are output or offset

D/A output enable/disable

function

Analog output HOLD/CLEAR

function

Analog output test during a CPU

module STOP

Scaling function (D/A

conversion)

Shifting function (D/A

conversion)

Analog conversion enable/

disable setting

Resolution mode

Online module change Modules can be changed without the system being stopped.

values are output for each channel.

(2) The conversion speed does not change regardless of whether CH5

Output enable/disable flag (Y5) is enabled (ON) or disabled (OFF).

This function retains an output analog value for the case where the CPU

module is placed in STOP or in a stop error status.

When CH5 Output enable/disable flag (Y5) is set to on forcibly while the CPU

module is placed in STOP status, the analog value that D/A conversion is

performed is output.

This function changes an input range of digital input values to a given range

between -32000 and 32000.

Time to configure a program for scaling can be decreased.

The digital input value can be adjusted easily with the shifting function when

the CPU is powered on.

The shifting function adds a setting quantity to a digital input value and stores

the value into buffer memory.

(1)

This function sets whether A/D or D/A conversion for each channel is

enabled or disabled.

(2)

Setting the channels not to be used to be disabled decreases sampling

periods.

(3) The analog conversion enable/disable setting is set to be disabled for all

channels conversion in default configuration.

(1)

A resolution can be selected from a normal resolution mode (1/4000)

and high resolution mode (1/12000 or 1/16000).

(2) Setting a resolution mode is performed for all the channels at once.

(3) For details of a digital output value, digital input value, and a maximum

resolution in normal resolution mode or high resolution mode, refer to

Section 3.1.

Reference

section

Section

4.3.1

Section

4.3.2

Section

4.3.3

Section

4.3.4

Section

4.3.5

Section

4.4.1

Section

3.1

Section

7.5

CHAPTER

10

4 - 2

4.1 Function List

Page 39

4

= 7.5 (times) The figures after the decimal fractions are omit.

Seven times conversion processing are performed

and the average value is output.

(7 4 0.5 = 14(ms) The average value is output every 14(ms).)

15

(4 0.5)

FUNCTION

4.2 Function Details of A/D Conversion

4.2.1 A/D conversion methods

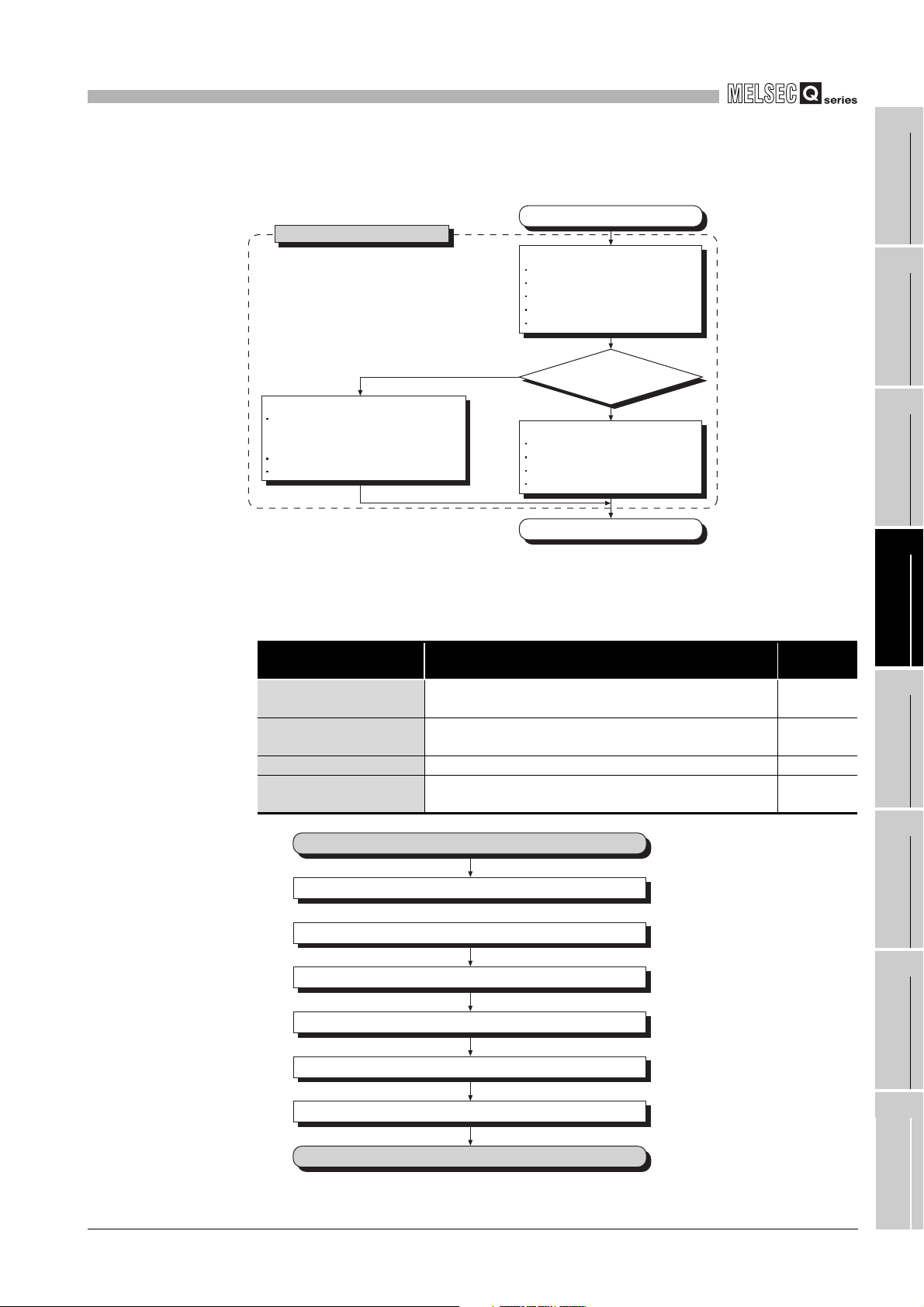

(1) Sampling period of the Q64AD2DA

A/D conversion is performed from CH1 to CH4 and D/A conversion is performed from

CH5 to CH6 in series in 500 s per channel for the Q64AD2DA.

Sampling period is the period of renewing digital output values.

The period of renewing digital output values varies depending on the total number of

channels enable A/D conversion and D/A conversion.

(2) Sampling processing

A/D conversion is made successively for analog input values, and the converted

digital output values are stored in buffer memory.

(3) Averaging processing

Averaging processing requires at least two times of conversion processing excluding

the maximum and the minimum values.

After the first averaging processing is completed, A/D conversion completed flag (XE)

is set to on.

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

(a) Time average

A/D conversion is made for the preset period of time, and the sum of values

excluding maximum and minimum values is averaged, resulting in storing into the

buffer memory.

The processing times within the set time varies depending on the number of

channels used (total number of channels enable A/D conversion and D/A

conversion).

The processing times within the set time is shown below.

Processing times

(Times)

[Example] Processing times under the following setting

• Number of channels used 4CH

A/D conversion: CH1, CH2, and CH3

D/A conversion: CH5

• Setting time 15ms

=

(Numbers of channels to be used 0.5)

Setting time

5

I/O SIGNALS FOR

6

7

FUNCTION

THE CPU MODULE

BUFFER MEMORY

4.2 Function Details of A/D Conversion

4.2.1 A/D conversion methods

4 - 3

PREPARATORY

PROCEDURES AND

SETTING

8

UTILITY PACKAGE

(GX Configurator-AD/GX

Configurator-DA)

Page 40

4

POINT

POINT

FUNCTION

Set the setting time that meets the following condition for time averaging

processing. If the setting time does not meet the following condition, an error

(error code: 202) occurs and the digital output value changes to 0.

• Setting time Minimum processing times 4 (times) 0.5(ms) Number

of channels to be used (total number of A/D conversion and D/A

conversion)

[Example] Number of channels to be used: Six channels

• Setting time (4 6 0.5)

Set the setting time to 12ms or higher.

(b) Count average

A/D conversion is made the preset number of times, and the sum of values

excluding the maximum and minimum values is averaged, resulting in storing into

the buffer memory.

The time required for the count-based average value to be stored into the buffer