Page 1

GT SoftGOT1000

Version 2

Operating Manual

SW2D5C-GTWK2-E

SW2D5C-GTD2-E

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "WARNING" and "CAUTION".

Note that the caution level may lead to a serious accident according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

[Test Operation Precautions]

WARNING

Before performing test operation (bit device on/off, word device's present value changing, timer/

counter's set value and present value changing, buffer memory's present value changing) for a

user-created monitor screen, system monitoring, special module monitoring or ladder monitoring,

read the manual carefully to fully understand how to operate the equipment.

During test operation, never change the data of the devices which are used to perform significant

operation for the system.

False output or malfunction can cause an accident.

A - 1

Page 4

CAUTIONS FOR USING THIS SOFTWARE

1. Required PC memory

The processing may be terminated by Microsoft Windows on a personal computer of which main memory

capacity is less than 128M bytes. Make sure to secure the capacity of 128M bytes or more.

2. Free capacity of hard disk

At least 100M bytes of free capacity of virtual memory should be secured within hard disk to run this software.

The processing may be terminated by Windows , if free space of 100M bytes or more cannot be secured

within hard disk while running GTSoftGOT1000.

Secure enough free capacity of virtual memory within hard disk space in order to run the software.

3. Display of GT SoftGOT1000 and GOT

Display of GT SoftGOT1000 may be different from display of GOT.

Confirm for actual display of GOT on the GOT.

A - 2

Page 5

REVISIONS

Partial corrections

* The manual number is given on the bottom left of the back cover

Print Date * Manual Number Revision

Jan., 2006 SH(NA)-080602 ENG-A First edition

Jun., 2006 SH(NA)-080602 ENG-B Compatible with the GT Designer2 Version2.32J.

Compatible with the GT SoftGOT1000 Version2.32J.

ABOUT MANUALS, ABBREVIATIONS AND GENERIC TERMS IN THIS

MANUAL, HOW TO READ THIS MANUAL, Section 1.1, 2.2, 2.3.1, 2.4.5, 3.2,

3.3.1, 4.1, 4.2, 4.3, 5.1, 5.7, 5.8, 5.9, 6.2.3, 6.4, 6.5.5, 6.7, 7.1, 7.2, 7.5, INDEX

Additions

Section 6.13, 6.14, 7.4, Appendix 3

Nov., 2006 SH(NA)-080602ENG-C Compatible with the GT Designer2 Version2.43V.

Compatible with the GT SoftGOT1000 Version2.43V.

Partial corrections

Section 1.1, 2.2, 2.3.4, 2.4, 2.4.2, 3.2, 3.3.1, 3.3.2, 4.1.2, 4.2, 5.2.1 to 5.2.4,

5.5.1, 5.6.1, 6.5.3, 6.5.5, 6.6.1, 6.7.2, 6.13.2, 7.1, 7.4, 7.5, Appendix 2,

Appendix 3

Additions

Section 6.9, Chapter 7, Section 8.6.2

Section 6.9 to 6.14 Section 6.10 to 6.15, Chapter 7 Chapter 8

Feb., 2007 SH(NA)-080602ENG-D Compatible with the GT Designer2 Version2.47Z.

Compatible with the GT SoftGOT1000 Version2.47Z.

Partial corrections

Section 1.1, 2.2, 2.3.2, 2.3.4, 2.5.1, 3.1.1, 4.1.1, 4.1.2, 4.2, 4.3, 5.8.1, 6.3, 6.9.2,

8.6.1, Appendix 3

Additions

Section 2.4, 2.4.8, 2.4.9, 5.5 to 5.7, 6.16, 6.17, 2.4 to 2.5 2.5 to 2.6, 5.5 to

5.12 5.8 to 5.15

A - 3

Page 6

Print Date * Manual Number Revision

Partial corrections

Additions

Partial corrections

Partial additions

May, 2007 SH(NA)-080602ENG-E Compatible with the GT Designer2 Version2.58L.

Compatible with the GT SoftGOT1000 Version2.58L.

Section 2.1, 2.2, 2.4, 3.1, 3.2, 5.5.2, 5.7.1, 5.8.1, 6.6, Appendix 3

Section 6.6.3

Section 6.6.3 Section 6.6.4

Aug., 2007 SH(NA)-080602ENG-F Compatible with the GT Designer2 Version2.63R.

Compatible with the GT SoftGOT1000 Version2.63R.

Partial corrections

Section 2.5.1, 4.2, 5.8.1, Appendix 3

Partial additions

Section 2.5.2, 3.2

Additions

Section 5.2.4, 6.18, 6.19

Section 5.2.4 Section 5.2.5

Dec., 2007 SH(NA)-080602ENG-G Compatible with the GT Designer2 Version2.73B.

Compatible with the GT SoftGOT1000 Version2.73B.

Partial corrections

Section 1.1, 2.2, 2.4, 3.1.1, 3.2, 5.8.1, 6.9.1, 6.18

Partial additions

Section 2.2, 2.5.1, 2.5.2, 5.8.1, 6.7.2, Appendix 3

Additions

Section 5.2.5

Section 5.2.5 Section 5.2.6

Feb., 2008 SH(NA)-080602ENG-H Compatible with the GT Designer2 Version2.77F.

Compatible with the GT SoftGOT1000 Version2.77F.

Section 1.1, 2.3.3, 2.4, 2.5.6, 3.1.1, 3.2, 5.7.1, 5.8.1, 6.2.3

Section 2.1, Appendix 3

A - 4

Page 7

Print Date * Manual Number Revision

Partial corrections

Additions

Partial additions

Jun., 2008 SH(NA)-080602ENG-I Compatible with the GT Designer2 Version2.82L.

Compatible with the GT SoftGOT1000 Version2.82L.

Section 2.3, 2.5, 8.1

Section 2.4.1 to 2.4.9

Section 2.3 Section 2.4

Section 2.4 Section 2.3

Section 5.2.6 Section 5.2.4

Section 5.4 to 5.6 Section 5.2.5 to 5.2.7

Section 5.7 to 5.14 Section 5.2 to 5.9

Oct., 2008 SH(NA)-080602ENG-J Compatible with the GT Designer2 Version2.90U.

Compatible with the GT SoftGOT1000 Version2.90U.

Partial corrections

Section 2.1, 2.2, 2.5.1, 2.5.7, 3.3.1, 4.1.2, 5.2.3, 5.3.1, 6.7.1, 6.7.2, 6.9.1,

Appendix 3

Dec., 2008 SH(NA)-080602ENG-K Compatible with the GT Designer2 Version2.91V.

Compatible with the GT SoftGOT1000 Version2.91V.

Partial corrections

Section 1.1, 2.5.1, 4.2, 5.3.1

Partial additions

Section 3.2, 3.3.1, Appendix 3

Additions

Section 6.5

Mar., 2009 SH(NA)-080602ENG-L Compatible with the GT Designer2 Version2.96A.

Compatible with the GT SoftGOT1000 Version2.96A.

Partial corrections

Section 3.2, 5.3.1, 6.5, 7.4

Partial additions

Section 3.3.1, 4.1.2, Appendix 3

Sep., 2012 SH(NA)-080602ENG-M

SAFETY PRECAUTIONS changed, Section 5.2.3

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

Japanese Manual Version SH-080598-R

© 2006 MITSUBISHI ELECTRIC CORPORATION

A - 5

Page 8

INTRODUCTION

Thank you for choosing Mitsubishi Graphic Operation Terminal (Mitsubishi GOT).

Read this manual and make sure you understand the functions and performance of the GOT thoroughly in

advance to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................A - 1

CAUTIONS FOR USING THIS SOFTWARE ....................................................................................................A - 2

REVISIONS....................................................................................................................................................... A - 3

INTRODUCTION...............................................................................................................................................A - 6

CONTENTS ......................................................................................................................................................A - 6

ABOUT MANUALS ......................................................................................................................................... A - 10

ABBREVIATIONS AND GENERIC TERMS....................................................................................................A - 11

HOW TO READ THIS MANUAL .....................................................................................................................A - 15

1. OVERVIEW 1 - 1 to 1 - 3

1.1 Features 1 - 2

2. SYSTEM CONFIGURATION 2 - 1 to 2 - 35

2.1 System Configuration 2 - 1

2.2 Operating Environment 2 - 4

2.3 Connection conditions 2 - 6

2.4 Connectable Modules 2 - 8

2.4.1 MITSUBISHI PLC ................................................................................................................. 2 - 8

2.4.2 Serial communication module, computer link module .......................................................... 2 - 8

2.4.3 Interface board, network module .......................................................................................... 2 - 9

2.4.4 Ethernet module, Ethernet board/card................................................................................ 2 - 10

2.4.5 CNC .................................................................................................................................... 2 - 11

2.4.6 Robot controller .................................................................................................................. 2 - 11

2.4.7 OMRON PLC ...................................................................................................................... 2 - 12

2.4.8 YASKAWA PLC .................................................................................................................. 2 - 12

2.4.9 YOKOGAWA PLC .............................................................................................................. 2 - 13

2.5 Connection Cable 2 - 14

2.5.1 Connecting to MITSUBISHI PLC ........................................................................................ 2 - 14

2.5.2 Connecting to serial communication module or computer link module............................... 2 - 21

2.5.3 Connecting to interface board or network module .............................................................. 2 - 27

2.5.4 Connecting to Ethernet module or Ethernet board/card ..................................................... 2 - 27

2.5.5 Connecting to CNC............................................................................................................. 2 - 28

2.5.6 Connecting to robot controller.............................................................................................2 - 29

2.5.7 Connecting to Omron PLC CPU ......................................................................................... 2 - 30

2.5.8 Connecting to YASKAWA PLC CPU .................................................................................. 2 - 31

2.5.9 Connecting to YOKOGAWA PLC ....................................................................................... 2 - 34

2.6 Access Range for Monitoring 2 - 35

A - 6

Page 9

3. SPECIFICATIONS 3 - 1 to 3 - 10

3.1 Specifications 3 - 1

3.1.1 Specifications of the GT SoftGOT1000 ................................................................................ 3 - 1

3.1.2 License key specifications .................................................................................................... 3 - 2

3.2 Functions that Cannot Be Used 3 - 3

3.3 Precautions 3 - 5

3.3.1 Precautions for using the GT Soft GOT1000........................................................................ 3 - 5

3.3.2 Precautions on license key.................................................................................................3 - 10

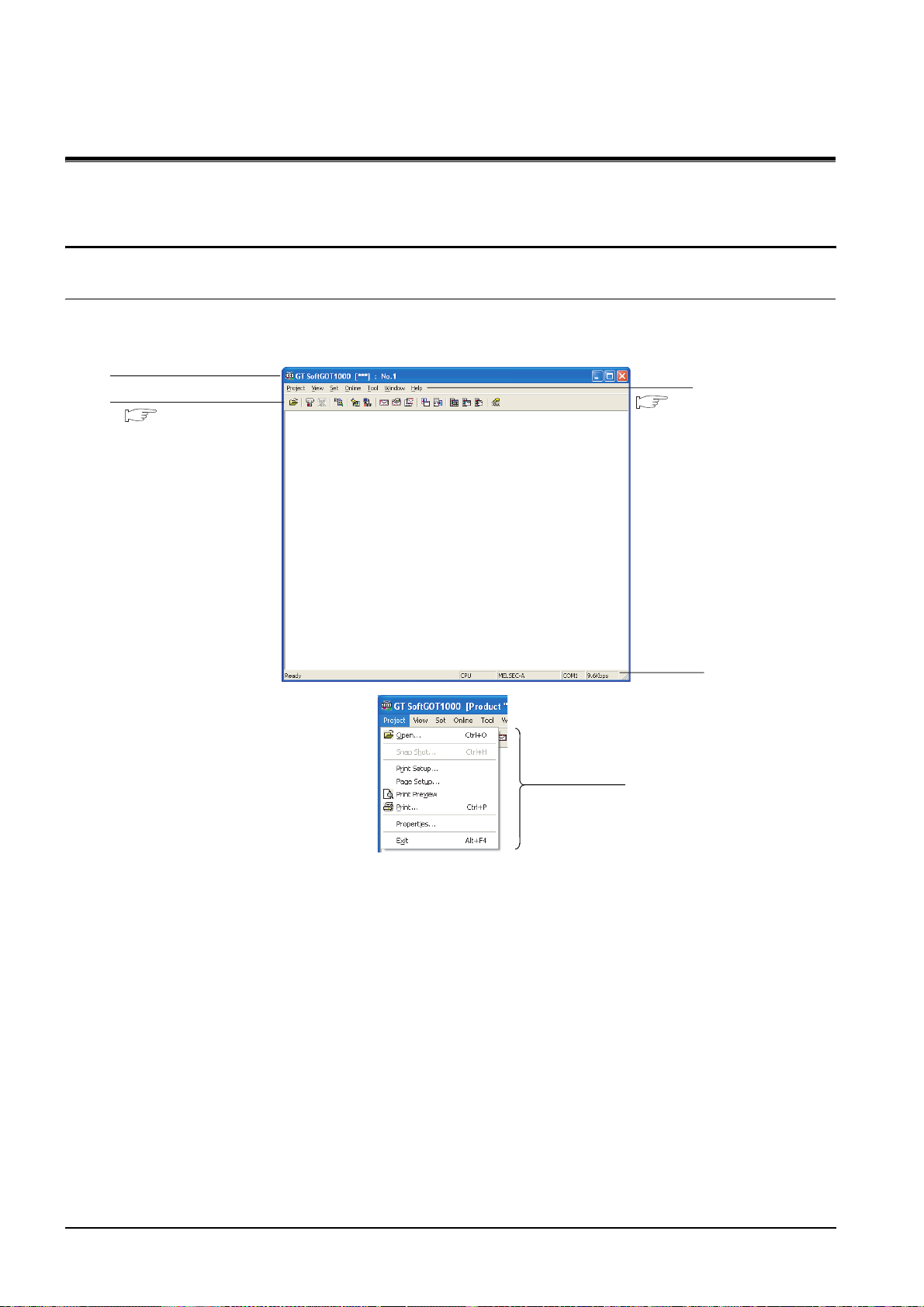

4. SCREEN CONFIGURATION 4 - 1 to 4 - 7

4.1 Screen Configuration and Basic Operation 4 - 1

4.1.1 Screen configuration............................................................................................................. 4 - 1

4.1.2 Basic operation..................................................................................................................... 4 - 2

4.2 Menu Bar 4 - 3

4.3 Tool bar 4 - 5

4.4 Help 4 - 6

5. OPERATING METHOD 5 - 1 to 5 - 65

5.1 Operating Procedure 5 - 1

5.2 Communication Setup 5 - 2

5.2.1 Communication setup dialog box ......................................................................................... 5 - 2

5.2.2 How to Set Up the Computer Link Connection ..................................................................... 5 - 5

5.2.3 How to Set Up the Ethernet Connection............................................................................... 5 - 9

5.2.4 Setting on GT Designer2 ....................................................................................................5 - 46

5.2.5 How to Set Up the OMRON PLC Connection .................................................................... 5 - 48

5.2.6 How to Set Up the YASKAWA PLC Connection ................................................................ 5 - 49

5.2.7 How to Set Up the YOKOGAWA PLC Connection ............................................................. 5 - 52

5.3 Environment Setup 5 - 54

5.3.1 Environment setup dialog box ............................................................................................ 5 - 54

5.4 Starting Monitoring 5 - 60

5.5 Opening the Project 5 - 61

5.6 Monitoring Operation 5 - 63

5.7 Monitor Stop 5 - 63

5.8 Exiting from GT SoftGOT1000 5 - 64

5.9 Automatic Startup 5 - 65

6. FUNCTIONS 6 - 1 to 6 - 53

6.1 Snap Shot 6 - 1

6.2 Print 6 - 2

6.2.1 Printing ................................................................................................................................. 6 - 2

6.2.2 Performing print preview....................................................................................................... 6 - 3

6.2.3 Performing page setup ......................................................................................................... 6 - 4

6.2.4 Performing print setup .......................................................................................................... 6 - 4

6.3 Property 6 - 5

A - 7

Page 10

6.4 Resource Data 6 - 6

6.5 Displaying File Information in PLC (QCPU, QSCPU Only) 6 - 8

6.5.1 Setting method...................................................................................................................... 6 - 8

6.5.2 Precautions for use............................................................................................................... 6 - 9

6.6 Mail Function 6 - 10

6.6.1 Mail function overview ........................................................................................................ 6 - 10

6.6.2 Operation flow when using the mail function ...................................................................... 6 - 12

6.6.3 How to set up the mail function........................................................................................... 6 - 13

6.6.4 Sending e-mail.................................................................................................................... 6 - 17

6.6.5 Mail history.......................................................................................................................... 6 - 19

6.7 Keyboard Input 6 - 20

6.7.1 Keyboard input enabling/disabling procedure..................................................................... 6 - 20

6.7.2 When operating the numerical input function or the ASCII input function from the

keyboard of a PC ................................................................................................................6 - 20

6.7.3 How to use function keys.................................................................................................... 6 - 21

6.7.4 Precautions......................................................................................................................... 6 - 22

6.8 Full Screen Mode 6 - 23

6.8.1 Full screen mode types....................................................................................................... 6 - 23

6.8.2 Setting method.................................................................................................................... 6 - 25

6.8.3 Precautions......................................................................................................................... 6 - 27

6.9 Popup Menu 6 - 28

6.9.1 Popup menu ineffective/effective........................................................................................ 6 - 28

6.9.2 Precautions......................................................................................................................... 6 - 28

6.10 Starting Up Multiple GT SoftGOT1000 Modules 6 - 29

6.10.1 Startup procedure ............................................................................................................... 6 - 29

6.10.2 Precautions for use............................................................................................................. 6 - 31

6.11 Moving the Window 6 - 32

6.11.1 Window movement types.................................................................................................... 6 - 32

6.11.2 Setting method.................................................................................................................... 6 - 33

6.12 System Alarm 6 - 34

6.13 Script Error 6 - 35

6.14 Object Script Error 6 - 36

6.15 Application Start-up 6 - 37

6.15.1 Setting method.................................................................................................................... 6 - 38

6.15.2 Application start-up history ................................................................................................. 6 - 42

6.15.3 Precautions......................................................................................................................... 6 - 43

6.16 Close Menu 6 - 44

6.16.1 Disabling/enabling the close menu ..................................................................................... 6 - 44

6.17 Interaction with PX Developer 6 - 45

6.17.1 Setting method.................................................................................................................... 6 - 46

6.17.2 PX Developer function call history ...................................................................................... 6 - 51

6.18 Back screen mode 6 - 52

6.18.1 Setting method.................................................................................................................... 6 - 52

6.19 Scroll Function 6 - 52

6.19.1 Setting method.................................................................................................................... 6 - 52

6.20 Exit Key 6 - 53

6.20.1 Disabling/enabling exit key ................................................................................................. 6 - 53

A - 8

Page 11

7. INTERNAL DEVICE INTERFACE FUNCTION 7 - 1 to 7 - 13

7.1 Development Environment 7 - 1

7.2 Accessible Devices 7 - 1

7.3 Internal Device Interface Function 7 - 2

7.3.1 GDev_OpenMapping (Opening and mapping the internal device shared memory)............. 7 - 4

7.3.2 GDev_Read (Reading from the internal device)................................................................... 7 - 5

7.3.3 GDev_Write (Writing to the internal device) ......................................................................... 7 - 7

7.3.4 GDev_CloseUnMapping (Unmapping and closing the internal device shared memory)...... 7 - 9

7.3.5 Precautions for the internal device interface function......................................................... 7 - 10

7.4 Sample Program 7 - 11

8. TROUBLESHOOTING 8 - 1 to 8 - 22

8.1 Error Message 8 - 1

8.2 Troubleshooting for License Key 8 - 5

8.3 Troubleshooting Related to Mail Transmission 8 - 7

8.4 Troubleshooting for Print 8 - 8

8.5 Troubleshooting for File Save Problems 8 - 8

8.6 Error Code and Error Message List 8 - 9

8.6.1 GOT error code list ............................................................................................................... 8 - 9

8.6.2 Error code list when using the internal device interface function........................................ 8 - 22

APPENDICES App - 1 to App - 3

Appendix 1 Applicable Project Data App - 1

Appendix 2 Unsupported Functions (Function Difference When Comparing GT SoftGOT1000 and GT

SoftGOT2) App - 2

Appendix 3 List of Functions Added by GT SoftGOT1000 Version Update App - 3

INDEX index - 1 to index - 3

A - 9

Page 12

ABOUT MANUALS

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Related Manuals

Manual Name

GT16 User's Manual

- Describes the GT16 hardware-relevant contents, including the specifications, part names, mounting, power

supply wiring, external dimensions, and option devices.

- Describes the GT16 functions, including the utility.

(Sold separately)

GT Designer2 Version2 Basic Operation/Data Transfer Manual (For GOT1000 Series)

Describes methods of the GT Designer2 installation operation, basic operation for drawing and transmitting data

to GOT1000 series.

(Sold separately)*

GT Designer2 Version2 Screen Design Manual (For GOT1000 Series) 1/3

GT Designer2 Version2 Screen Design Manual (For GOT1000 Series) 2/3

GT Designer2 Version2 Screen Design Manual (For GOT1000 Series) 3/3

Describes specifications and settings of each object function applicable to GOT1000 series.

(Sold separately)*

GOT1000 Series Connection Manual 1/3

GOT1000 Series Connection Manual 2/3

GOT1000 Series Connection Manual 3/3

Describes system configurations of the connection method applicable to GOT1000 series and cable creation

method.

(Sold separately)*

GOT1000 Series Extended/Option Functions Manual

Describes extended functions and option functions applicable to GOT series.

(Sold separately)*

1

1

1

1

Manual Number

(Model Code)

SH-080778ENG

(1D7M88)

SH-080529ENG

(1D7M24)

SH-080530ENG

(1D7M25)

SH-080532ENG

(1D7M26)

SH-080544ENG

(1D7M32)

A - 10

*1 The manual in PDF-format is included in the GT Works2 and GT Designer2 products.

Page 13

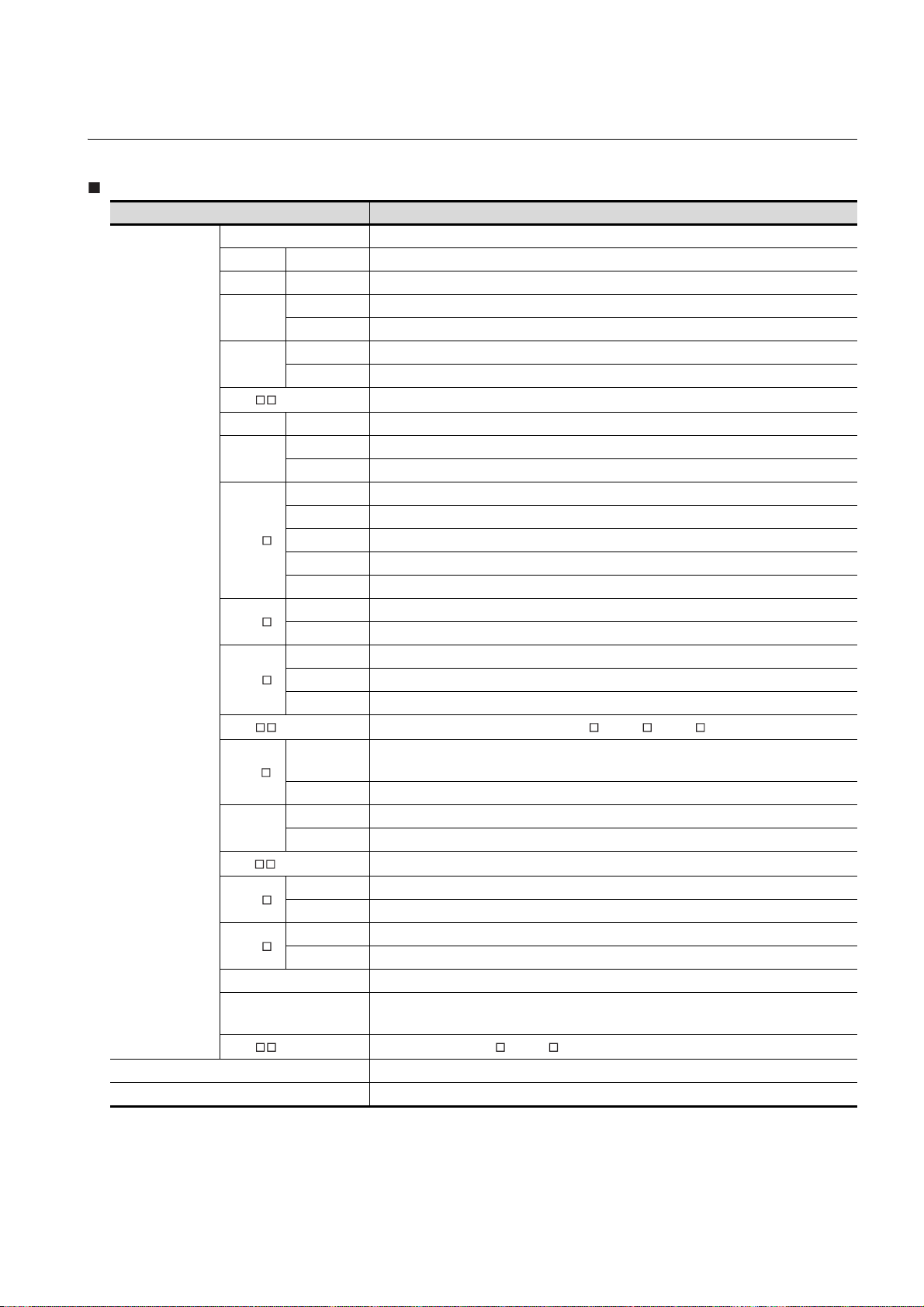

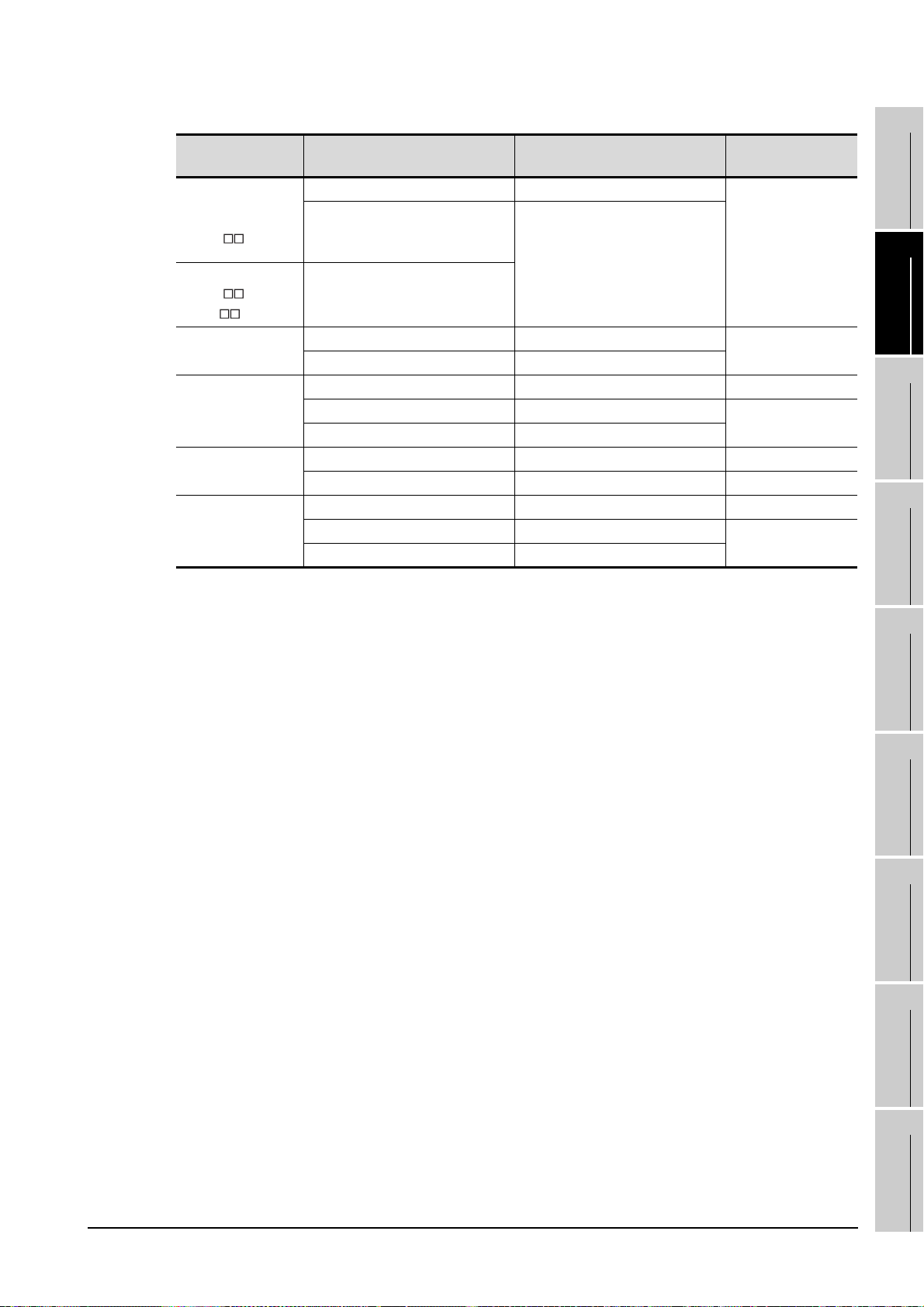

ABBREVIATIONS AND GENERIC TERMS

Abbreviations and generic terms used in this manual are as follows:

GOT

Abbreviations and generic terms Description

GT SoftGOT1000 Abbreviation of GT SoftGOT1000

GT1695 GT1695M-X Abbreviation of GT1695M-XTBA, GT1695M-XTBD

GT1685 GT1685M-S Abbreviation of GT1685M-STBA, GT1685M-STBD

GT1675

GT1665

GT16 , GT16

GT1595 GT1595-X Abbreviation of GT1595-XTBA, GT1595-XTBD

GT1585

GT157

GT156

GOT1000 Series

GT155

GT15 , GT15 Abbreviation of GT1595, GT1585, GT157 , GT156 , GT155

GT115

Handy

GOT

GT11 , GT11

GT105

GT104

GT1030 Abbreviation of GT1030-LBD, GT1030-LBD2, GT1030-LBDW, GT1030-LBDW2

GT1020

GT10 , GT10 Abbreviation of GT105 , GT104 , GT1030, GT1020

GOT900 Series Abbreviation of GOT-A900 series, GOT-F900 series

GOT800 Series Abbreviation of GOT-800 series

GT1675M-S Abbreviation of GT1675M-STBA, GT1675M-STBD

GT1675M-V Abbreviation of GT1675M-VTBA, GT1675M-VTBD

GT1665M-S Abbreviation of GT1665M-STBA, GT1665M-STBD

GT1665M-V Abbreviation of GT1665M-VTBA, GT1665M-VTBD

Abbreviation of GT1695,GT1685, GT1675, GT1665

GT1585V-S Abbreviation of GT1585V-STBA, GT1585V-STBD

GT1585-S Abbreviation of GT1585-STBA, GT1585-STBD

GT1575V-S Abbreviation of GT1575V-STBA, GT1575V-STBD

GT1575-S Abbreviation of GT1575-STBA, GT1575-STBD

GT1575-V Abbreviation of GT1575-VTBA, GT1575-VTBD

GT1575-VN Abbreviation of GT1575-VNBA, GT1575-VNBD

GT1572-VN Abbreviation of GT1572-VNBA, GT1572-VNBD

GT1565-V Abbreviation of GT1565-VTBA, GT1565-VTBD

GT1562-VN Abbreviation of GT1562-VNBA, GT1562-VNBD

GT1555-V Abbreviation of GT1555-VTBD

GT1555-Q Abbreviation of GT1555-QTBD, GT1555-QSBD

GT1550-Q Abbreviation of GT1550-QLBD

GT1155-Q

GT1150-Q Abbreviation of GT1150-QLBDQ, GT1150-QLBDA, GT1150-QLBD

GT1155HS-Q Abbreviation of GT1155HS-QSBD

GT1150HS-Q Abbreviation of GT1150HS-QLBD

GT1055-Q Abbreviation of GT1055-QSBD

GT1050-Q Abbreviation of GT1050-QBBD

GT1045-Q Abbreviation of GT1045-QSBD

GT1040-Q Abbreviation of GT1040-QBBD

Abbreviation of GT1155-QTBDQ, GT1155-QSBDQ, GT1155-QTBDA, GT1155-QSBDA,

GT1155-QTBD, GT1155-QSBD

Abbreviation of GT1155-Q, GT1150-Q, GT11 Handy GOT

Abbreviation of GT1020-LBD, GT1020-LBD2, GT1020-LBL, GT1020-LBDW,

GT1020-LBDW2, GT1020-LBLW

A - 11

Page 14

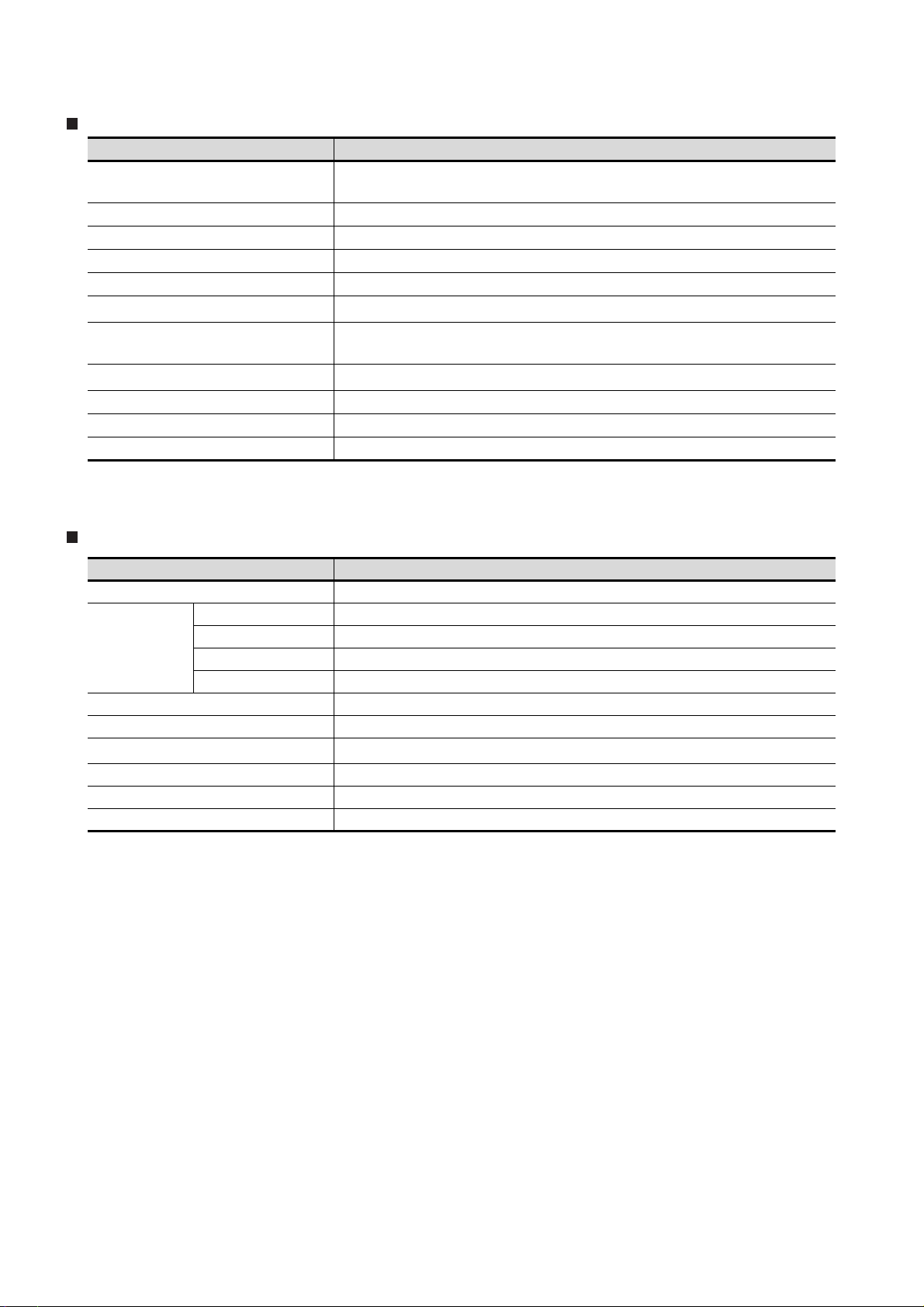

Communication unit

Abbreviations and generic terms Description

Bus connection unit

Serial communication unit GT15-RS2-9P, GT15-RS4-9S, GT15-RS4-TE

RS-422 conversion unit GT15-RS2T4-9P, GT15-RS2T4-25P

Ethernet communication unit GT15-J71E71-100

MELSECNET/H communication unit GT15-J71LP23-25, GT15-J71BR13

MELSECNET/10 communication unit

CC-Link IE controller network communication

unit

CC-Link communication unit

Interface converter unit GT15-75IF900

Serial multi-drop connection unit GT01-RS4-M

Connection Conversion Adapter GT10-9PT5S

GT15-QBUS, GT15-QBUS2, GT15-ABUS, GT15-ABUS2,

GT15-75QBUSL, GT15-75QBUS2L, GT15-75ABUSL, GT15-75ABUS2L

GT15-75J71LP23-Z*1, GT15-75J71BR13-Z

GT15-J71GP23-SX

GT15-J61BT13, GT15-75J61BT13-Z

*2

*3

*1 A9GT-QJ71LP23 + GT15-75IF900 set

*2 A9GT-QJ71BR13 + GT15-75IF900 set

*3 A8GT-J61BT13 + GT15-75IF900 set

Option unit

Abbreviations and generic terms Description

Printer unit GT15-PRN

Video input unit GT16M-V4, GT15V-75V4

Video/RGB unit

Multimedia unit GT16M-MMR

CF card unit GT15-CFCD

CF card extension unit

External I/O unit GT15-DIO, GT15-DIOR

Sound output unit GT15-SOUT

Fingerprint unit GT15-80FPA

RGB input unit GT16M-R2, GT15V-75R1

Video/RGB input unit GT16M-V4R1, GT15V-75V4R1

RGB output unit GT16M-ROUT, GT15V-75ROUT

*1

GT15-CFEX-C08SET

*1 GT15-CFEX + GT15-CFEXIF + GT15-C08CF set.

A - 12

Page 15

Option

Abbreviations and generic terms Description

Memory card CF card

Memory card adaptor GT05-MEM-ADPC

Option function board

Battery GT15-BAT, GT11-50BAT

Protective Sheet

Protective cover for oil

USB environmental protection cover GT16-UCOV, GT15-UCOV, GT11-50UCOV

Stan d

Attachment

Backlight

Multi-color display board GT15-XHNB, GT15-VHNB

Connector conversion box GT11H-CNB-37S

Emergency stop sw guard cover GT11H-50ESCOV

Memory loader GT10-LDR

Memory board GT10-50FMB

GT05-MEM-16MC, GT05-MEM-32MC, GT05-MEM-64MC, GT05-MEM-128MC,

GT05-MEM-256MC GT05-MEM-512MC, GT05-MEM-1GC, GT05-MEM-2GC

GT16-MESB, GT15-FNB, GT15-QFNB, GT15-QFNB16M,

GT15-QFNB32M, GT15-QFNB48M, GT15-MESB48M, GT11-50FNB

GT16-90PSCB, GT16-90PSGB, GT16-90PSCW, GT16-90PSGW,

For GT16

For GT15

For GT11

For GT10

GT05-90PCO, GT05-80PCO, GT05-70PCO, GT05-60PCO,

GT05-50PCO

GT15-90STAND, GT15-80STAND, GT15-70STAND, A9GT-50STAND,

GT05-50STAND

GT15-70ATT-98, GT15-70ATT-87, GT15-60ATT-97, GT15-60ATT-96,

GT15-60ATT-87, GT15-60ATT-77, GT15-50ATT-95W, GT15-50ATT-85

GT16-90XLTT, GT16-80SLTT, GT15-90XLTT, GT15-80SLTT,

GT16-70SLTT, GT16-70VLTT, GT16-60SLTT, GT16-60VLTT,

GT15-70SLTT, GT15-70VLTT, GT15-70VLTN, GT15-60VLTT,

GT15-60VLTN

GT16-80PSCB, GT16-80PSGB, GT16-80PSCW, GT16-80PSGW,

GT16-70PSCB, GT16-70PSGB, GT16-70PSCW, GT16-70PSGW,

GT16-60PSCB, GT16-60PSGB, GT16-60PSCW, GT16-60PSGW

GT15-90PSCB, GT15-90PSGB, GT15-90PSCW, GT15-90PSGW,

GT15-80PSCB, GT15-80PSGB, GT15-80PSCW, GT15-80PSGW,

GT15-70PSCB, GT15-70PSGB, GT15-70PSCW, GT15-70PSGW,

GT15-60PSCB, GT15-60PSGB, GT15-60PSCW, GT15-60PSGW,

GT15-50PSCB, GT15-50PSGB, GT15-50PSCW, GT15-50PSGW

GT11-50PSCB, GT11-50PSGB, GT11-50PSCW, GT11-50PSGW,

GT11H-50PSC

GT10-50PSCB, GT10-50PSGB, GT10-50PSCW, GT10-50PSGW,

GT10-40PSCB, GT10-40PSGB, GT10-40PSCW, GT10-40PSGW,

GT10-30PSCB, GT10-30PSGB, GT10-30PSCW, GT10-30PSGW,

GT10-20PSCB, GT10-20PSGB, GT10-20PSCW, GT10-20PSGW

Software

Abbreviations and generic terms Description

GT Works2 Version SW D5C-GTWK2-E, SW D5C-GTWK2-EV

GT Designer2 Version SW D5C-GTD2-E, SW D5C-GTD2-EV

GT Designer2 Abbreviation of screen drawing software GT Designer2 for GOT1000/GOT900 series

GT Converter2 Abbreviation of data conversion software GT Converter2 for GOT1000/GOT900 series

GT Simulator2 Abbreviation of screen simulator GT Simulator 2 for GOT1000 / GOT900 series

GT SoftGOT1000 Abbreviation of monitoring software GT SoftGOT1000

GT SoftGOT2 Abbreviation of monitoring software GT SoftGOT2

GX Developer

GX Simulator

Document Converter Abbreviation of document data conversion software Document Converter for GOT1000 series

PX Developer

Abbreviation of SW D5C-GPPW-E(-EV)/SW D5F-GPPW-E type software package

Abbreviation of SW D5C-LLT-E(-EV) type ladder logic test tool function software packages

(SW5D5C-LLT (-EV) or later versions)

Abbreviation of SW D5C-FBDQ-E type FBD software package for process control

A - 13

Page 16

License key (for GT SoftGOT1000)

Abbreviations and generic terms Description

License GT15-SGTKEY-U, GT15-SGTKEY-P

License key (for GT SoftGOT2)

Abbreviations and generic terms Description

License key A9GTSOFT-LKEY-P (For DOS/V PC)

License key FD SW5D5F-SGLKEY-J (For PC CPU module)

Others

Abbreviations and generic terms Description

OMRON PLC Abbreviation of PLC manufactured by OMRON Corporation

KEYENCE PLC Abbreviation of PLC manufactured by KEYENCE CORPORATION

KOYO EI PLC Abbreviation of PLC manufactured by KOYO ELECTRONICS INDUSTRIES CO., LTD.

SHARP PLC Abbreviation of PLC manufactured by Sharp Manufacturing Systems Corporation

JTEKT PLC Abbreviation of PLC manufactured by JTEKT Corporation

TOSHIBA PLC Abbreviation of PLC manufactured by TOSHIBA CORPORATION

TOSHIBA MACHINE PLC Abbreviation of PLC manufactured by TOSHIBA MACHINE CO., LTD.

HITACHI IES PLC Abbreviation of PLC manufactured by Hitachi Industrial Equipment Systems Co., Ltd.

HITACHI PLC Abbreviation of PLC manufactured by Hitachi, Ltd.

FUJI FA PLC Abbreviation of PLC manufactured by Fuji Electric FA Components & Systems Co., Ltd.

PANASONIC PLC Abbreviation of PLC manufactured by Panasonic Electric Works Co., Ltd.

YASKAWA PLC Abbreviation of PLC manufactured by YASKAWA Electric Corporation

YOKOGAWA PLC Abbreviation of PLC manufactured by Yokogawa Electric Corporation

ALLEN-BRADLEY PLC Abbreviation of Allen-Bradley PLC manufactured by Rockwell Automation, Inc.

GE FANUC PLC Abbreviation of PLC manufactured by GE Fanuc Automation Corporation

LS IS PLC Abbreviation of PLC manufactured by LS Industrial Systems Co., Ltd.

SCHNEIDER PLC Abbreviation of PLC manufactured by Schneider Electric SA

SIEMENS PLC Abbreviation of PLC manufactured by Siemens AG

OMRON temperature

controller

SHINKO indicating

controller

CHINO controller Abbreviation of temperature controller manufactured by CHINO CORPORATION

Temperature

controller

PC CPU module Abbreviation of PC CPU Unit manufactured by CONTEC CO., LTD

GOT (server) Abbreviation of GOTs that use the server function

GOT (client) Abbreviation of GOTs that use the client function

FUJI SYS temperature

controller

YAMATAKE temperature

controller

YOKOGAWA temperature

controller

RKC temperature

controller

Abbreviation of temperature controller manufactured by OMRON Corporation

Abbreviation of temperature controller manufactured by Shinko Technos Co., Ltd.

Abbreviation of temperature controller manufactured by Fuji Electric Systems Co., Ltd.

Abbreviation of temperature controller manufactured by Yamatake Corporation

Abbreviation of temperature controller manufactured by Yokogawa Electric Corporation

Abbreviation of temperature controller manufactured by RKC INSTRUMENT INC.

Windows font

Intelligent function module

MODBUS /TCP

A - 14

Abbreviation of TrueType font and OpenType font available for Windows

(Differs from the True Type fonts settable with GT Designer2)

Indicates the modules other than the PLC CPU, power supply module and I/O module that are

mounted to the base unit.

Generic term for the protocol designed to use MODBUS protocol messages on a TCP/IP

network.

Page 17

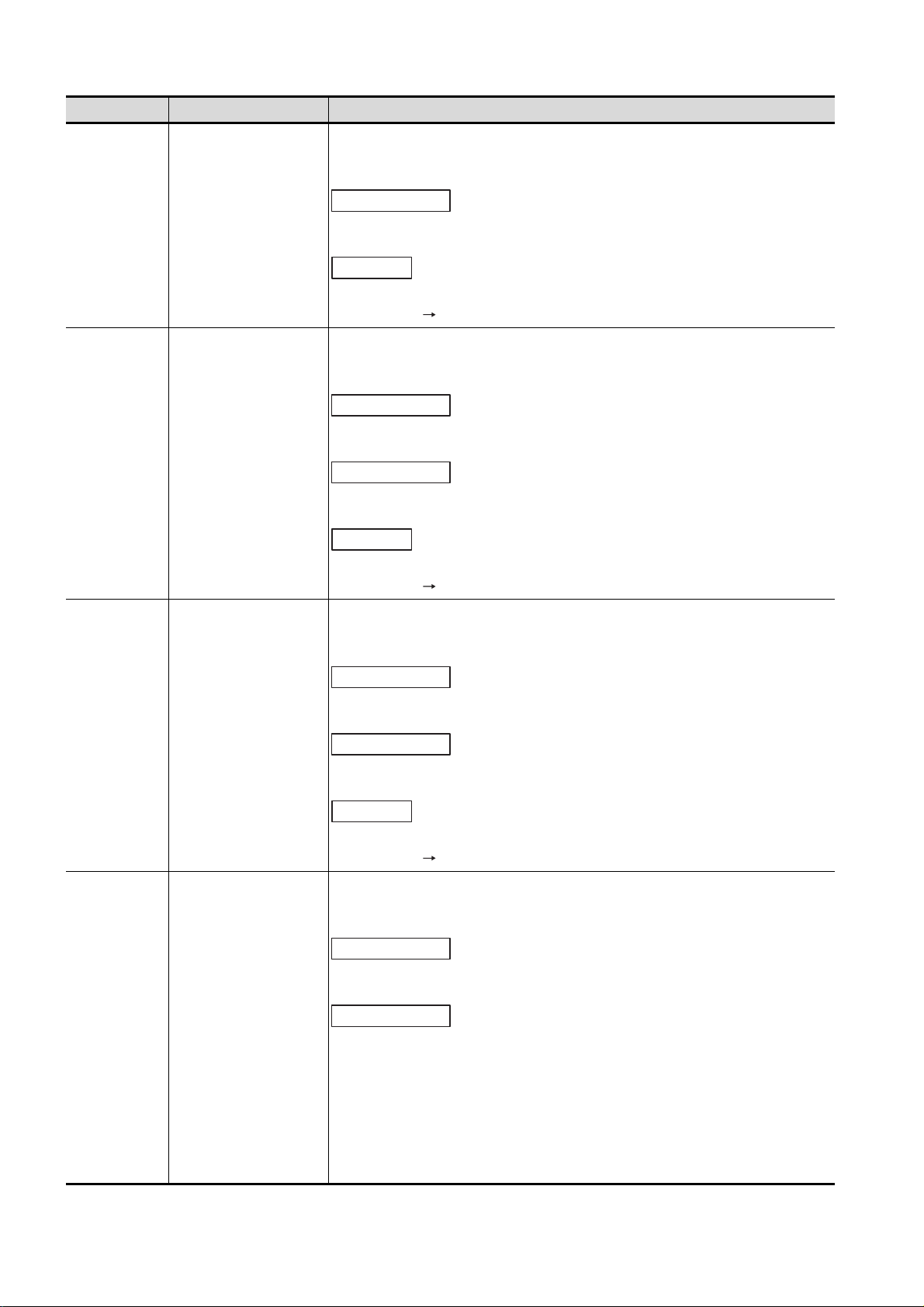

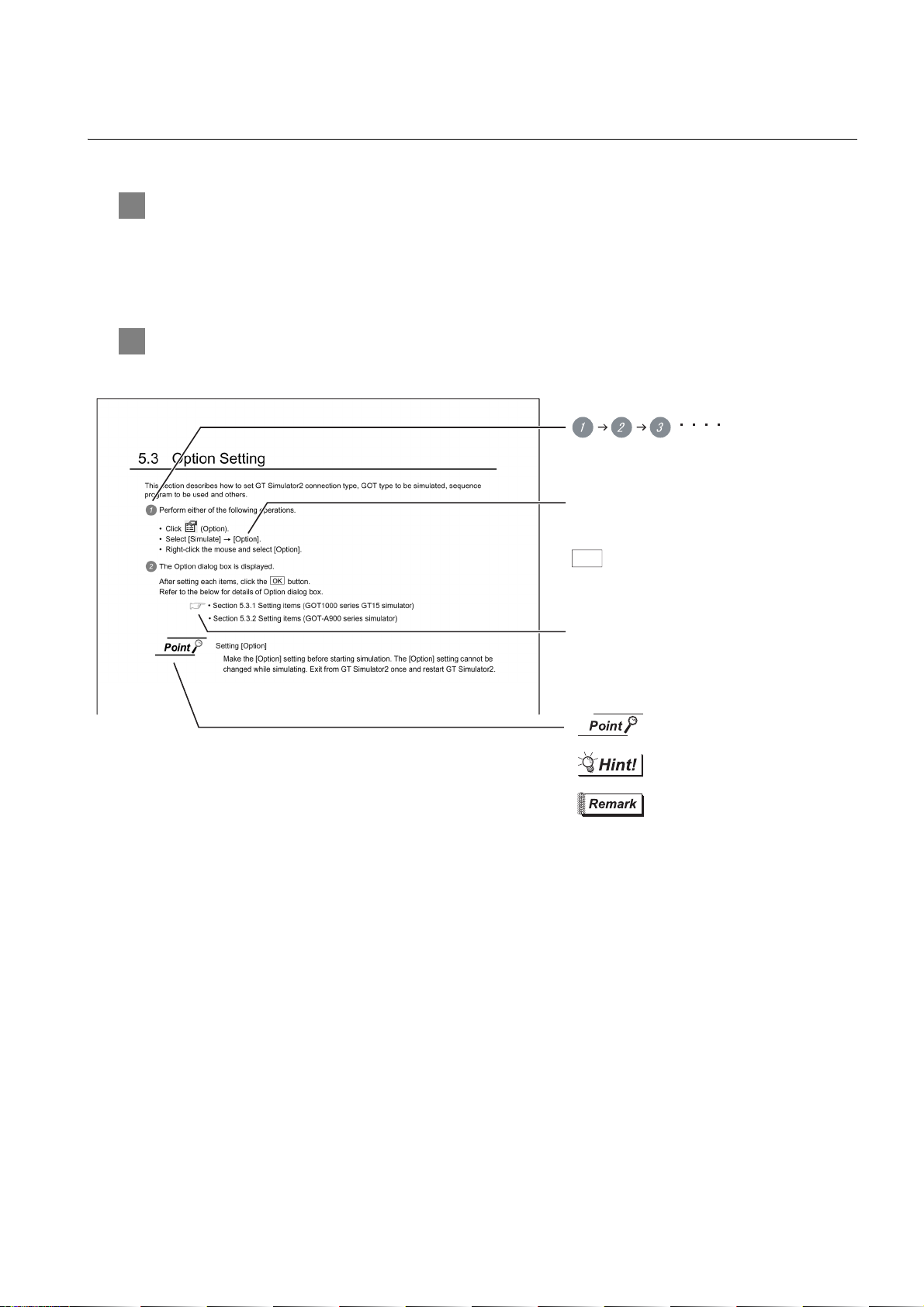

HOW TO READ THIS MANUAL

indicates the operation steps.

Refers to information required

for operation.

Refers to information useful

for operation.

Refers to supplementary

explanations for reference.

Indicates the location in which the detailed

explanation is given (manual, chapter section,

item of the manual).

Menu and items are differentiated with

parentheses.

[ ] refers to the menu of GOT utility.

: refers to dialog box buttons or keys

of PC keyboard.

1 Functions

This manual describes functions available for the GT SoftGOT1000 Version2.96A.

For the added functions by the product version upgrade, refer to the list of functions added by GT

SoftGOT1000 version upgrade in Appendices.

2 Symbols

Following symbols are used in this manual.

*Since the above page was created for explanation purpose, it differs from the actual page.L

A - 15

Page 18

1. OVERVIEW

This manual explains the system configuration, specifications, screen structure, and operating method of

monitoring software GT SoftGOT1000 (hereinafter abbreviated as GT SoftGOT1000).

GT SoftGOT1000 is the software that has the same functions as the GOT1000 series and is used to display

lamps, data, and messages on personal computers and panel controllers.

When applying the following program examples to the actual system, make sure to examine the applicability

and confirm that it will not cause system control problems.

Described contents in this manual

This manual describes the operation method for GT SoftGOT1000.

For other than operation method, refer to the following manuals.

(1) Installation method of GT SoftGOT1000

For the installation method of GT SoftGOT1000, refer to the following manuals.

GT Designer2 Version Basic Operation/Data Transfer Manual

(2.2 Installing the Software Programs)

(2) Project data creating method of GT Designer2

For the project data creating method of GT Designer2, refer to the following

manuals.

Designer2 Version Screen Design Manual

(3) Starting method of GT SoftGOT1000

For the starting method of GT SoftGOT1000, refer to the following manual.

GT Designer2 Version Basic Operation/Data Transfer Manual

(2.4 Starting the Software)

1 - 1

Page 19

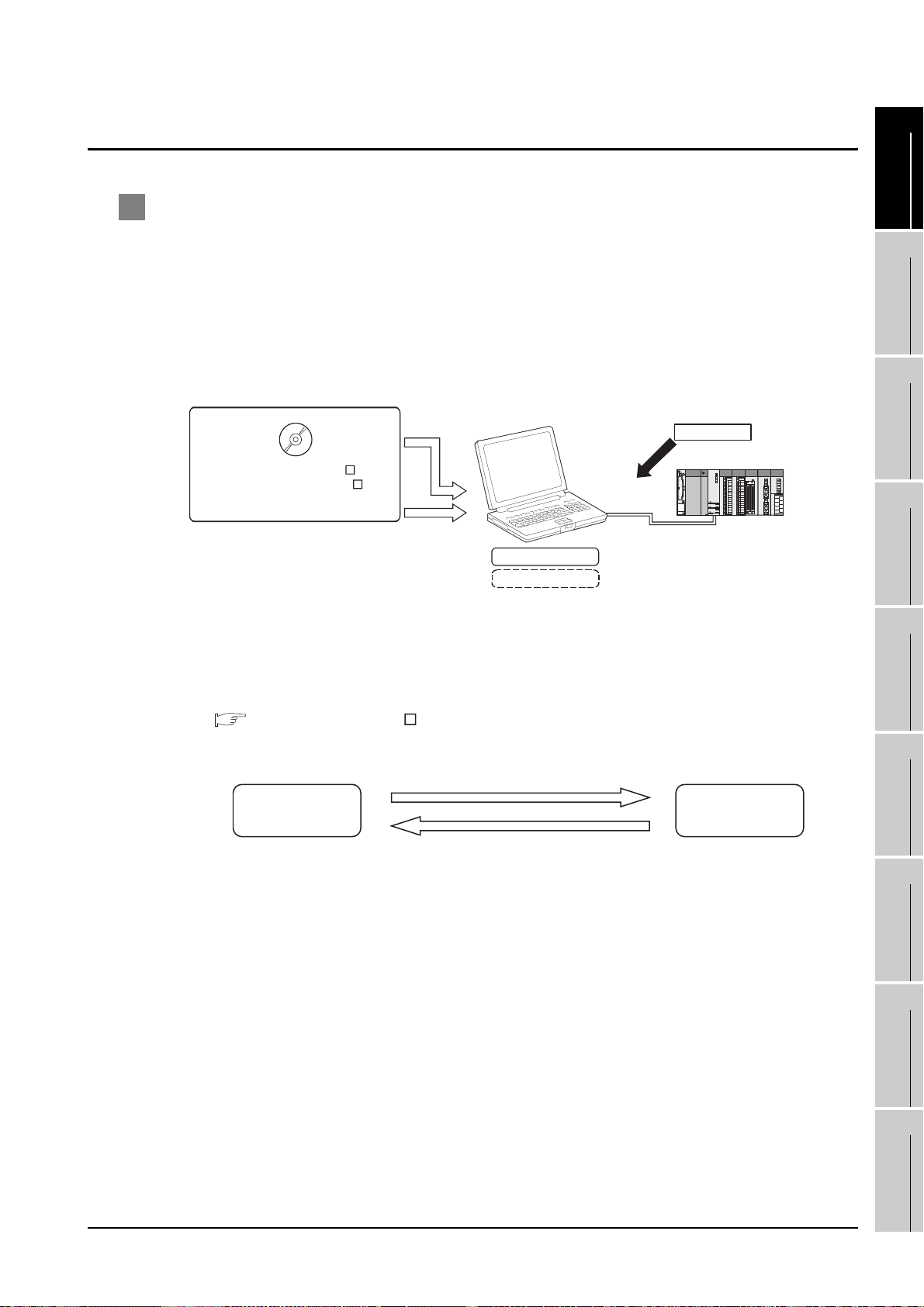

1.1 Features

Install

GT SoftGOT1000

GX Developer

GT Works2 Version

GT Designer2 Version

(GT Designer2, GT SoftGOT1000)

License key

CPU direct

connection

Attach

PX Developer

GT SoftGOT1000

Call a monitor tool function for in PX Developer

on GT SoftGOT1000.

Register GT SoftGOT1000 as a user graphic

screen of PX Developer, and start the registered

GT SoftGOT1000.

1

1 The features of the GOT series and advantages of personal computer and panel

computer are available

(1) Interactive use with applications (including MELSOFT)

(a) Interactive use with GT Designer2.

Installation of GT SoftGOT1000 and GT Designer2 on the same personal computer allows

operations from screen creation to monitoring to be supported by a single personal computer.

Immediately after creating or modifying a screen on GT Designer2, the screen can be

monitored on GT SoftGOT1000. Therefore, design efficiency is improved greatly.

(b) Interaction with PX Developer

With interaction between GT SoftGOT1000 and PX Developer, monitor tool functions for PX

Developer can be called on GT SoftGOT1000.

GT SoftGOT1000 can also be started on PX Developer, and the functions can be shared.

For the monitor tool of PX Developer, refer to the following manual.

PX Developer Version Operating Manual (Monitor Tool)

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

5

OPERATING

METHOD

1.1 Features

6

FUNCTIONS

7

INTERNAL DEVICE

INTERFACE

FUNCTION

8

TROUBLESHOOTING

APPENDICES

1 - 2

Page 20

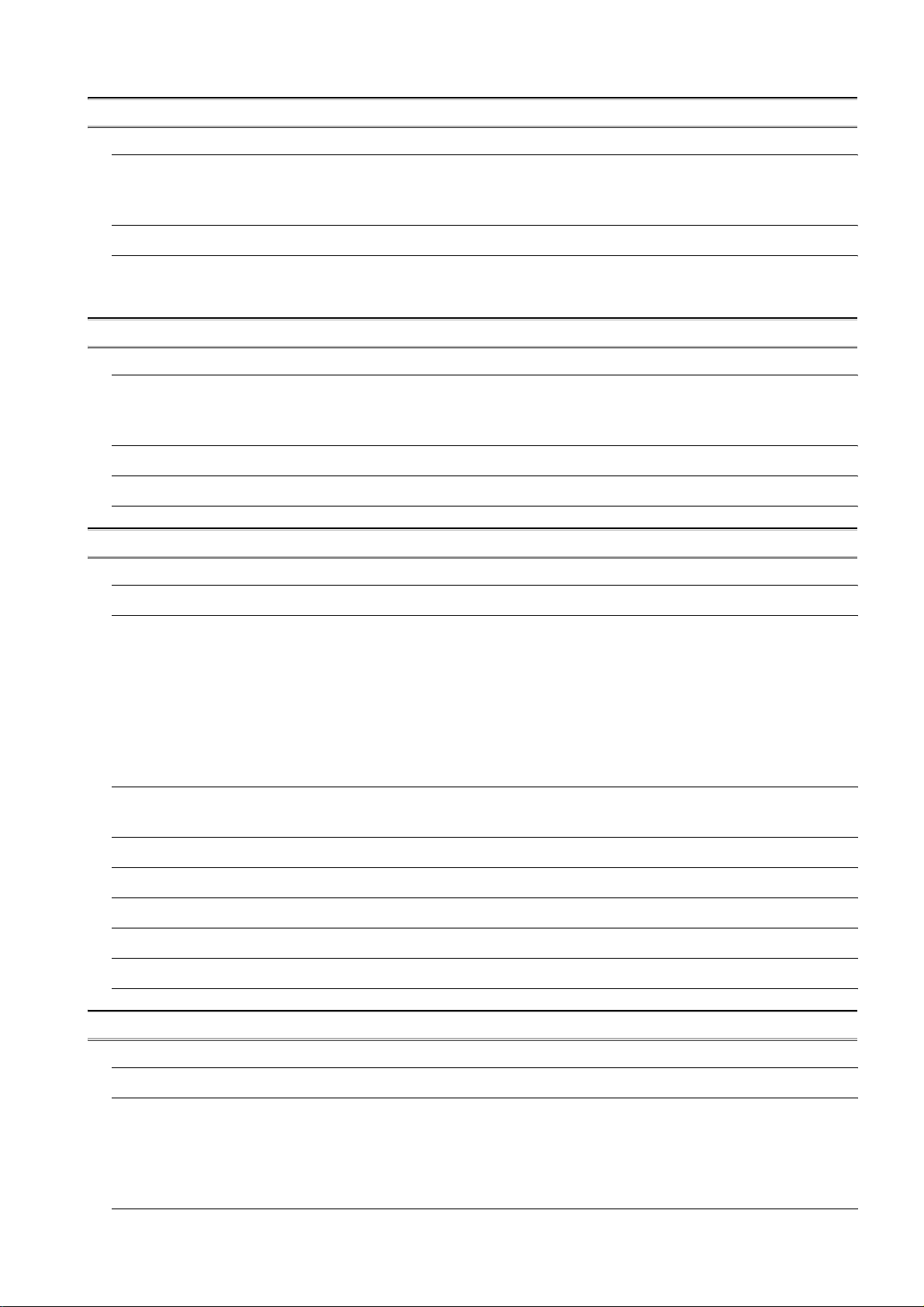

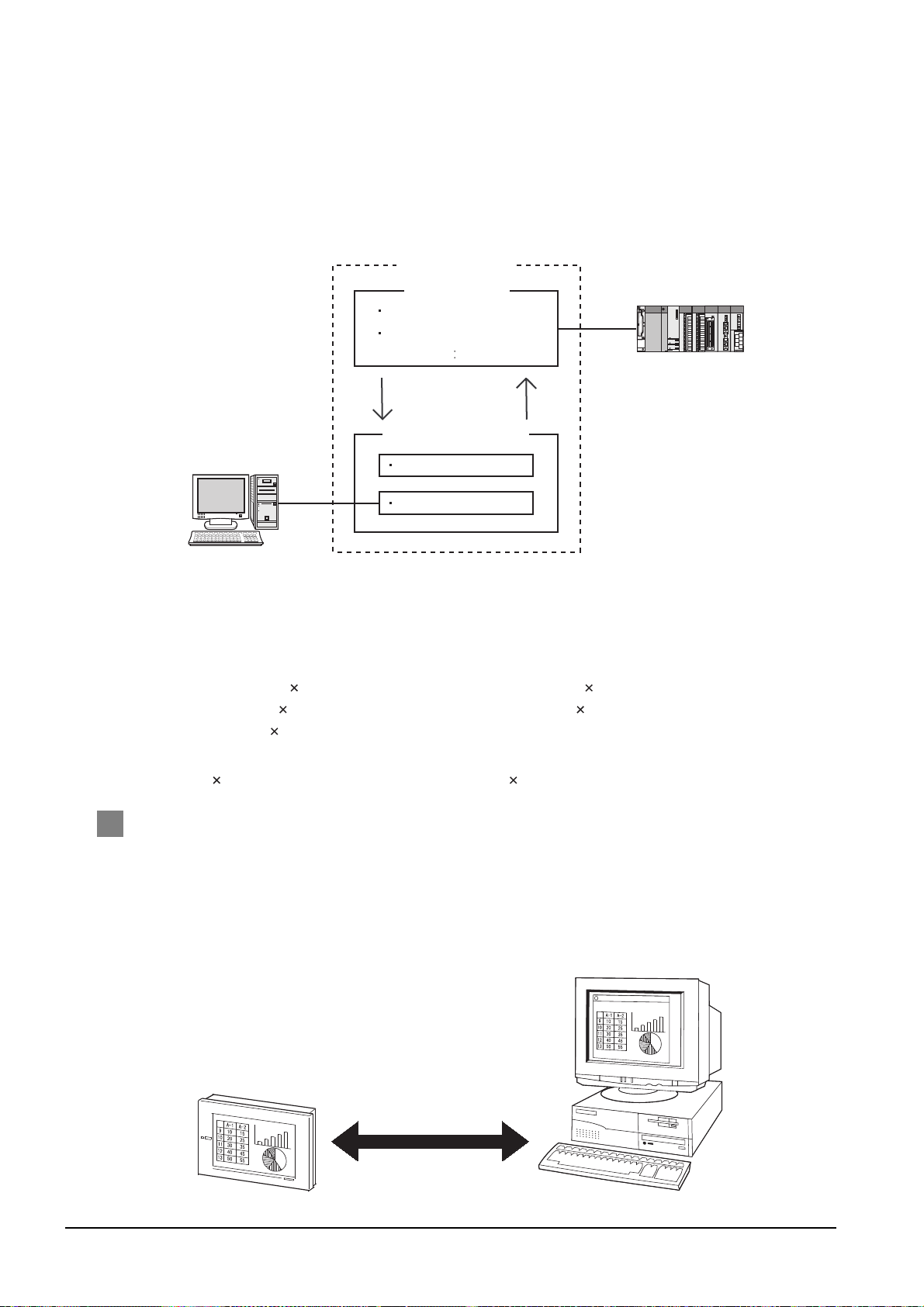

(c) Interactive use with Windows applications

Personal computer

GT SoftGOT1000

User-created application

PLC

Communication with PLC

Screen display (alarm etc.)

User's own data control

Server

Reading/writing

internal device value

User's own control

GOT GT SoftGOT1000

The monitor screen data is compatible.

A Windows application can be started up from GT SoftGOT1000.

Also, the data of GT SoftGOT1000 internal devices can be read/written from a user-created

application.

With interaction between GT SoftGOT1000 and a user-created application, the user can

control or manage data by own method.

(2) Flexible response to high-resolution

The user can select resolutions from UXGA to VGA and can set a resolution specification, which

sets a resolution dot by dot depending on applications.

GT SoftGOT1000 supports the following resolutions.

(a) Selectable resolutions

•UXGA (1600 1200 dots) • SXGA (1280 1024 dots)

•XGA (1024 768 dots) • SVGA (800 600 dots)

•VGA (640 480 dots)

(b) User setting

•X Y (Resolution specification) (1920 to 640 1200 to 480 dots)

2 The monitor screen data created for the GOT1000 series is applicable to GT

SoftGOT1000.

The GT SoftGOT1000 uses monitor screen data created with GT Designer2.

By converting the GOT type for GT SoftGOT1000, the monitor screen data used for the GOT1000

series can be used without modification.

GT SoftGOT1000 uses the same screens and operations as GOT.

Therefore, there will be no discomfort or confusion for the operators and maintenance personnel.

1 - 3

1.1 Features

Page 21

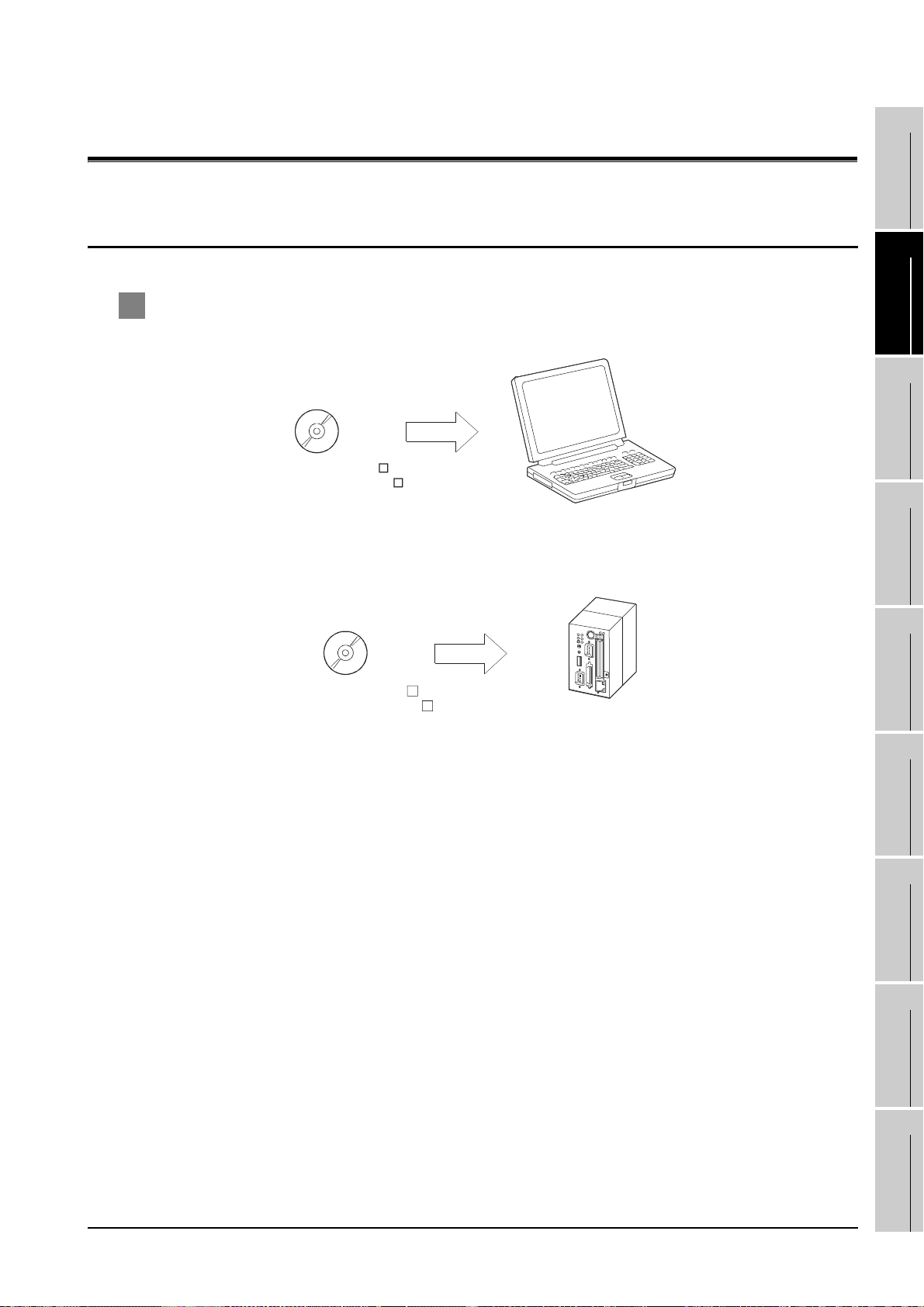

2. SYSTEM CONFIGURATION

DOS/V personal computer

GT Works2 Version

GT Designer2 Version

PC CPU module

GT Works2 Version

GT Designer2 Version

1

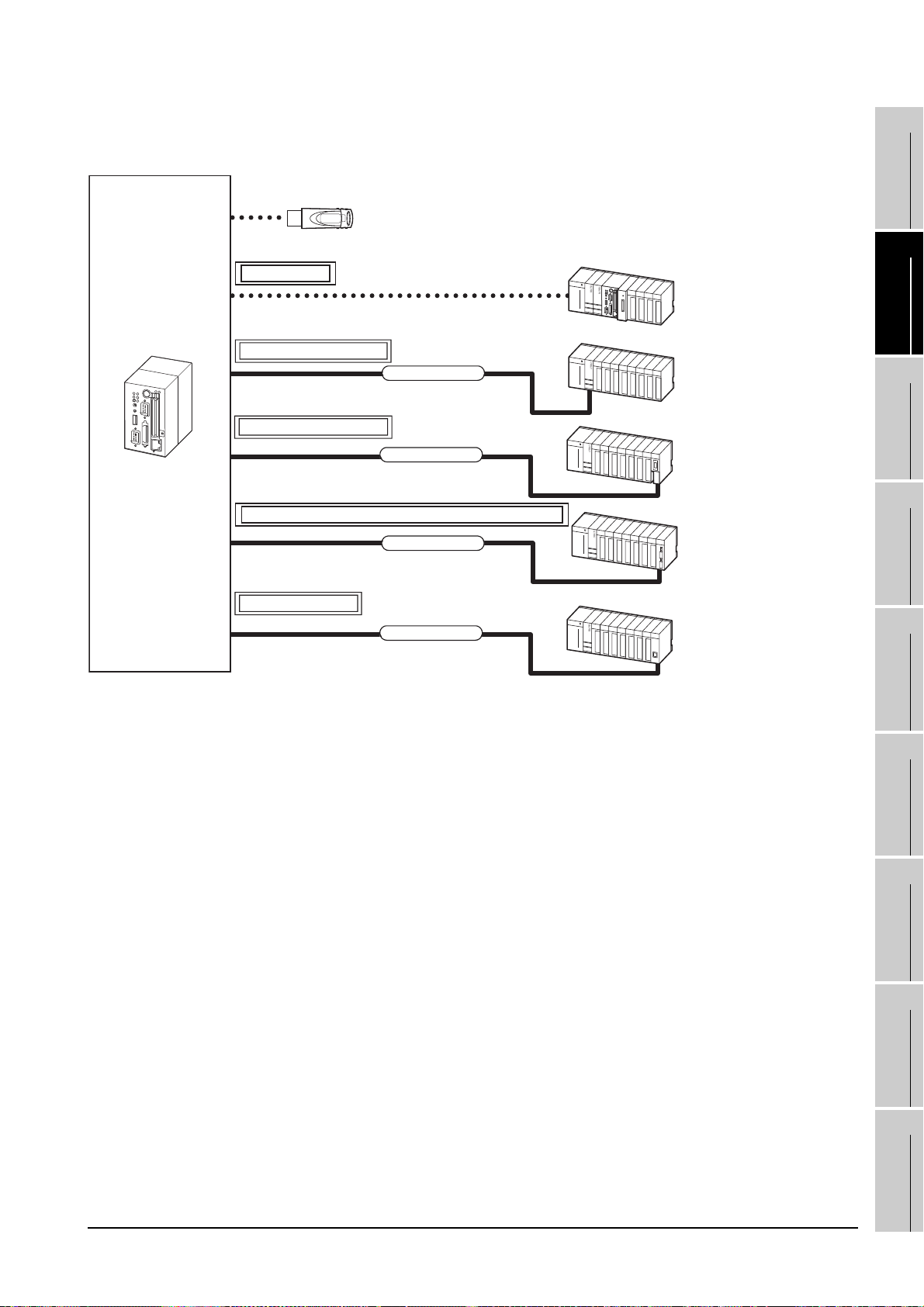

2.1 System Configuration

1 When installing GT SoftGOT1000

(1) When installing GT SoftGOT1000 on DOS/V personal computer

(2) When installing GT SoftGOT1000 on PC CPU module

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

5

INTERNAL DEVICE

OPERATING

6

7

INTERFACE

8

METHOD

FUNCTIONS

FUNCTION

TROUBLESHOOTING

2.1 System Configuration

APPENDICES

2 - 1

Page 22

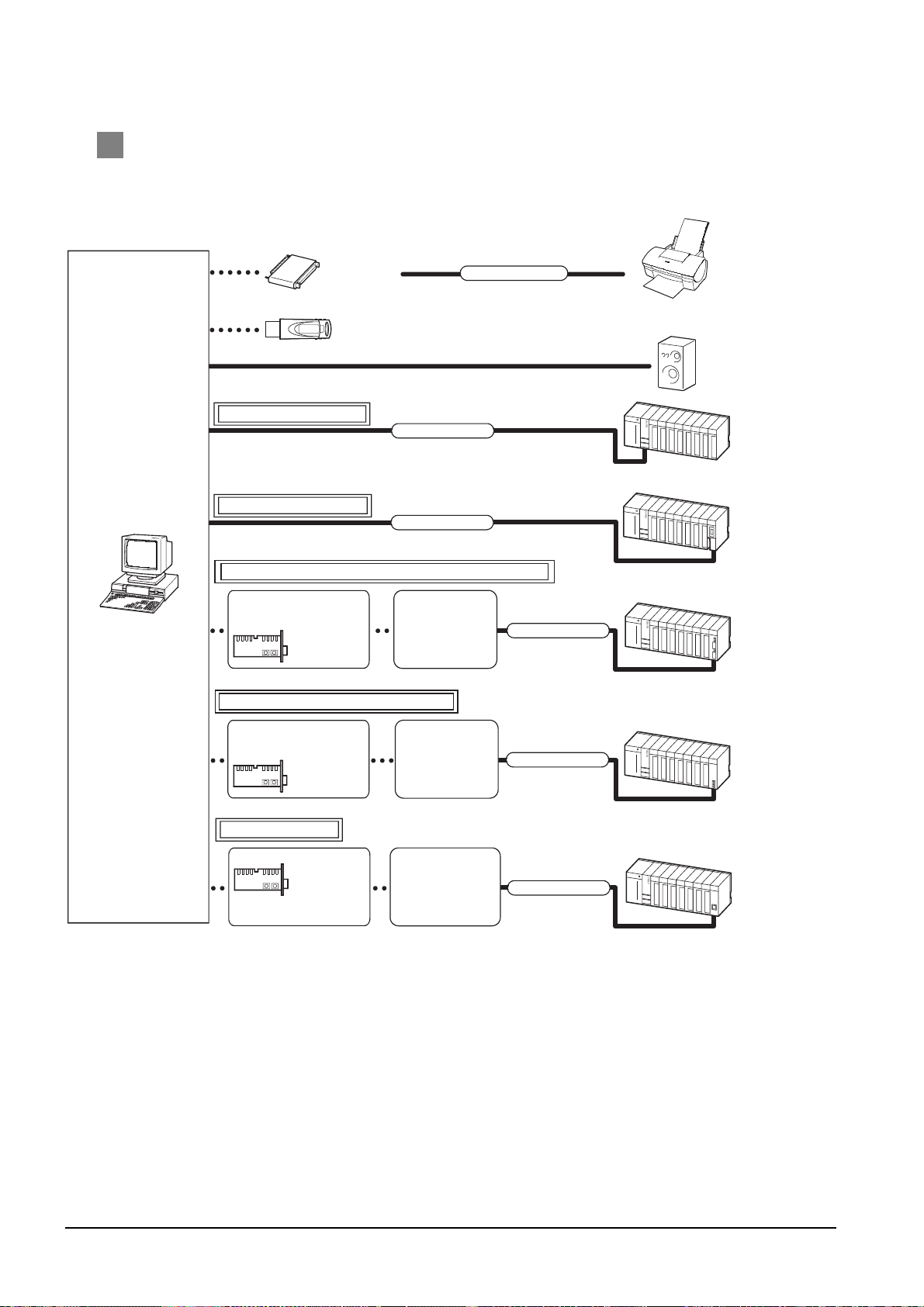

2 When executing GT SoftGOT1000

Direct connection to CPU

Printer cable

License key

(GT15-SGTKEY-P)

Printer

Sound output

device

Connection cable

PLC CPU

Ethernet connection

DOS/V personal computer

Ethernet

module

Computer link connection

Computer link

module, Serial

communication

module

Driver

MELSECNET/H connection, MELSECNET/10 connection

MELSECNET/H

network module,

MELSECNET/10

network module

MELSECNET/H board

Driver

Ethernet board

Driver supplied with

MELSECNET/H

board

Commercially available

Ethernet board

Driver supplied with

commercially available

Ethernet board

License key (GT15-SGTKEY-U)

Connection cable

Connection cable

Connection cable

CC-Link IE controller network connection

CC-Link IE

controller

network module

CC-Link IE controller

network interface board

Driver supplied with

CC-Link IE

controller network

interface board

Driver

Connection cable

(1) When using GT SoftGOT1000 on DOS/V personal computer

2 - 2

2.1 System Configuration

Page 23

(2) When using GT SoftGOT1000 with PC CPU module

1

GT SoftGOT1000

PC CPU module

License key (GT15-SGTKEY-U)

Bus connection

Direct connection to CPU

Connection cable

Computer link connection

Connection cable

MELSECNET/H connection, MELSECNET/10 connection

Connection cable

Ethernet connection

Connection cable

PLC CPU on the main

base unit that the PC CPU

module exists

PLC CPU on the main

base unit that the PC CPU

module does not exist

Computer link module, serial

communication module on

the main base unit that

the PC CPU module

does not exist

MELSECNET/H network

module, MELSECNET/10

network module on the main

base unit that the PC CPU

module does not exist

Ethernet module on the

main base unit that the PC CPU

module does not exist

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

5

INTERNAL DEVICE

OPERATING

6

7

INTERFACE

8

METHOD

FUNCTIONS

FUNCTION

TROUBLESHOOTING

2.1 System Configuration

APPENDICES

2 - 3

Page 24

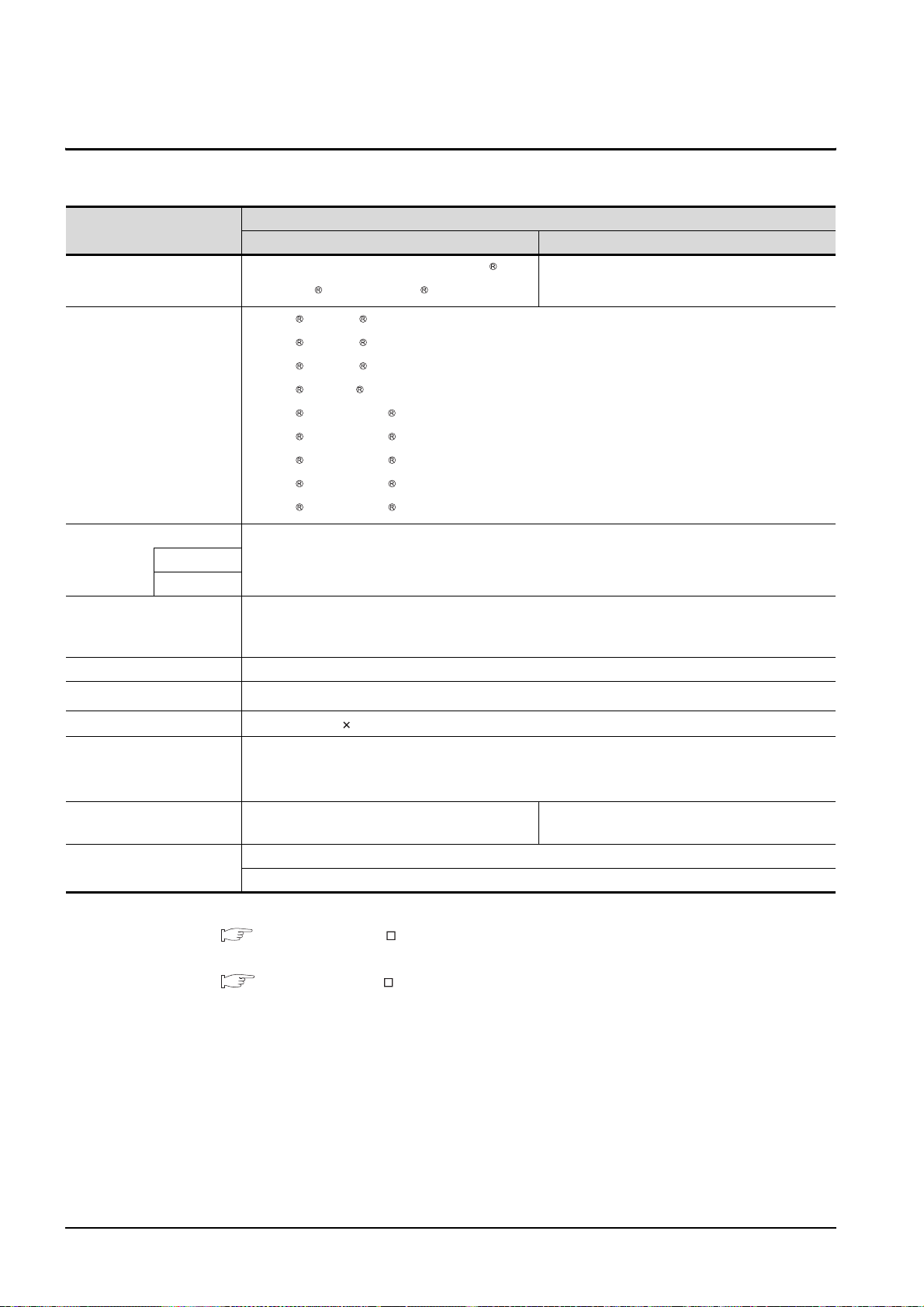

2.2 Operating Environment

The following shows the GT SoftGOT1000 operating environment.

Item

Personal computer

Operating system

Computer

Memory

Hard disk space*1

Disk drive CD-ROM drive

PC/AT compatible PC on which Windows 2000 ,

Windows XP or Windows Vista operates.

Microsoft Windows 2000 Professional Operating System Service Pack 4 or later [English version]

Microsoft Windows XP Professional Operating System Service Pack 2 or later [English version]

Microsoft Windows XP Home Edition Operating System Service Pack 2 or later [English version]

Microsoft Windows XP Embedded [English version]

Microsoft Windows Vista Ultimate Operating System [English version]

Microsoft Windows Vista Enterprise Operating System [English version]

Microsoft Windows Vista Business Operating System [English version]

Microsoft Windows Vista Home Premium Operating System [English version]

Microsoft Windows Vista Home Basic Operating System [English version]

Refer to "Applicable operating system and performance required for personal computer" on the next page.CPU

For installation (This product only) :600MB or more

For installation (This product and manuals) :850MB or more

For execution :100MB or more

With DOS/V personal computer With PC CPU module

Description

PPC-852-21B, PPC-852-21G, and PPC-852-22F

manufactured by CONTEC CO., LTD

*3*4*8

*3*4*9

*3*4*9

*3*4*9

*3*4*9

*3*4*9

*7

*2

*3*4*9

*3*4*9

Display color

Display

Software

Hardware*6

Others

65536 colors or more

Resolution of 640 480 dots or more

When creating or editing project data: GT Designer2

When using with PX Developer : PX Developer Version 1.14Q or later

GT Designer2 Version 2.47Z or later

GT15-SGTKEY-U (License key (for USB port) )

GT15-SGTKEY-P (License key (for parallel port) )

Installation of Internet Explorer 5.0 or later

The mouse, keyboard, printer, CD-ROM drive, sound card, and speakers must be compatible with the above OS.

*5

GT15-SGTKEY-U (License key (for USB port) )

*1 When using GT Designer2 or PX Developer, free space is required separately.

For the free space required when using GT Designer2, refer to the following manual.

GT Designer2 Version Basic Operation/Data Transfer Manual

For the available space required when using monitor tool functions of PX Developer, refer to the following

manual.

PX Developer Version Operating Manual (Monitor Tool)

When using a user-created application, free space is required separately.

*2 Administrator authority is required for installing GT SoftGOT1000.

*3 Administrator authority is required for installing and using GT SoftGOT1000.

*4 The following functions are not supported.

• "Compatibility mode" • "Fast user switching"

• "Change your desktop themes (fonts)" • "Remote desktop"

*5 Use GT Designer2 included in GT Works2/GT Designer2 that contains GT SoftGOT1000.

*6 When using GT15-SGTKEY-U, a USB port is required in the personal computer.

When using GT15-SGTKEY-P, a parallel port (Centronics/printer connecter) is required in the personal computer.

*7 Refer to the manual of the PC CPU module.

*8 For using the PPC-852-22F, GT SoftGOT1000 can be used on the PPC-852-22F with the OS preinstalled only.

*9 Only the 32-bit OS is available.

2 - 4

2.2 Operating Environment

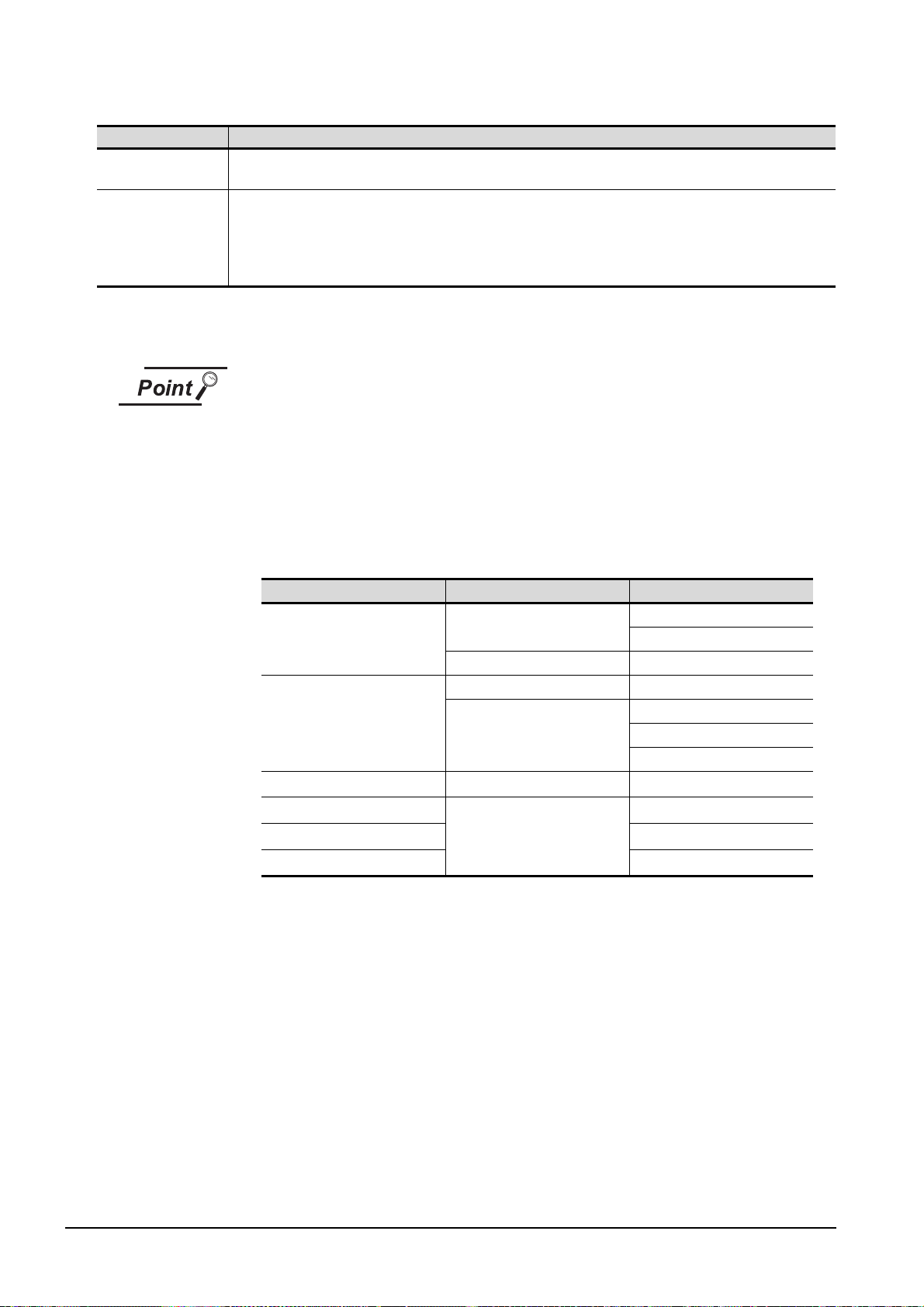

Page 25

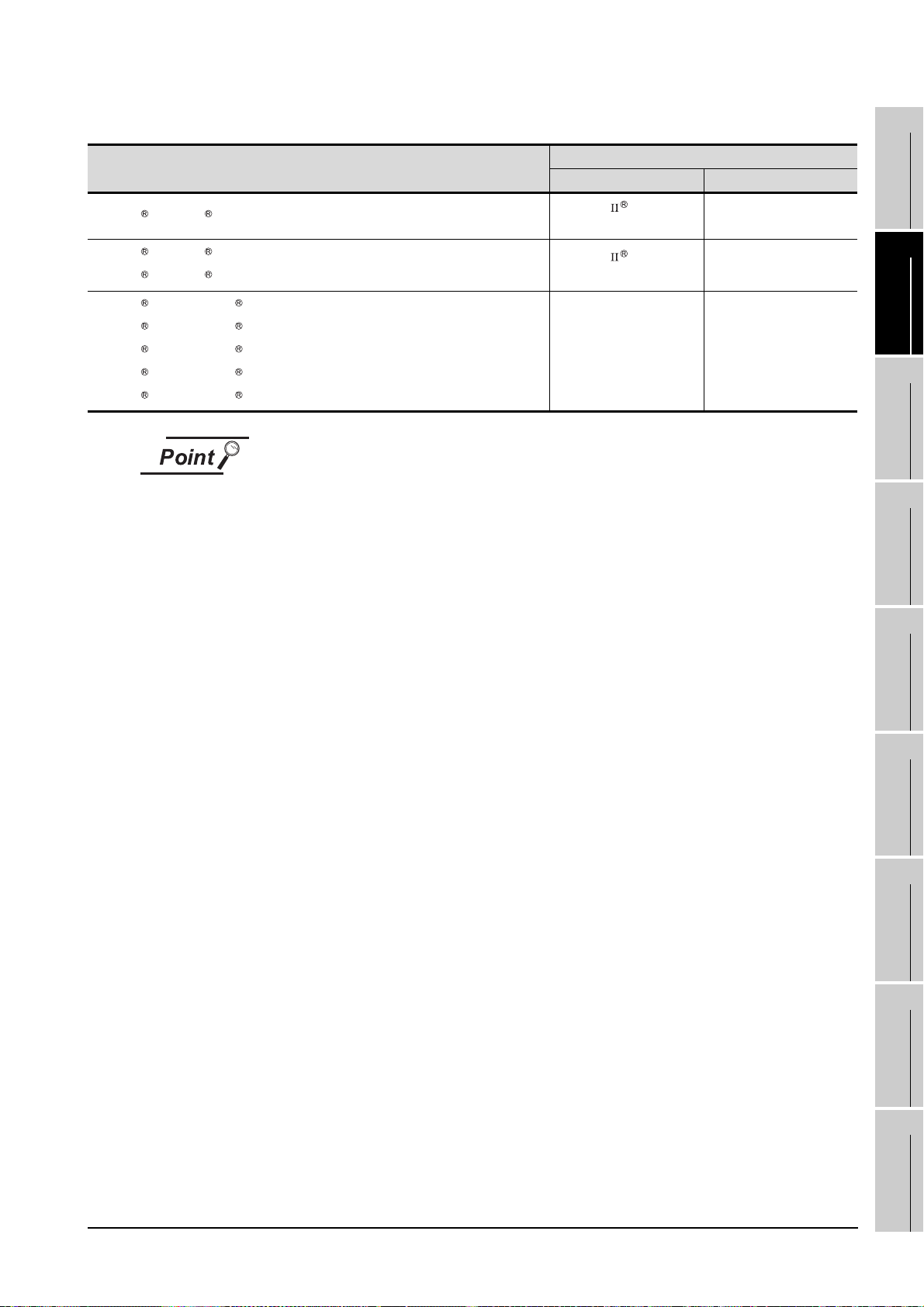

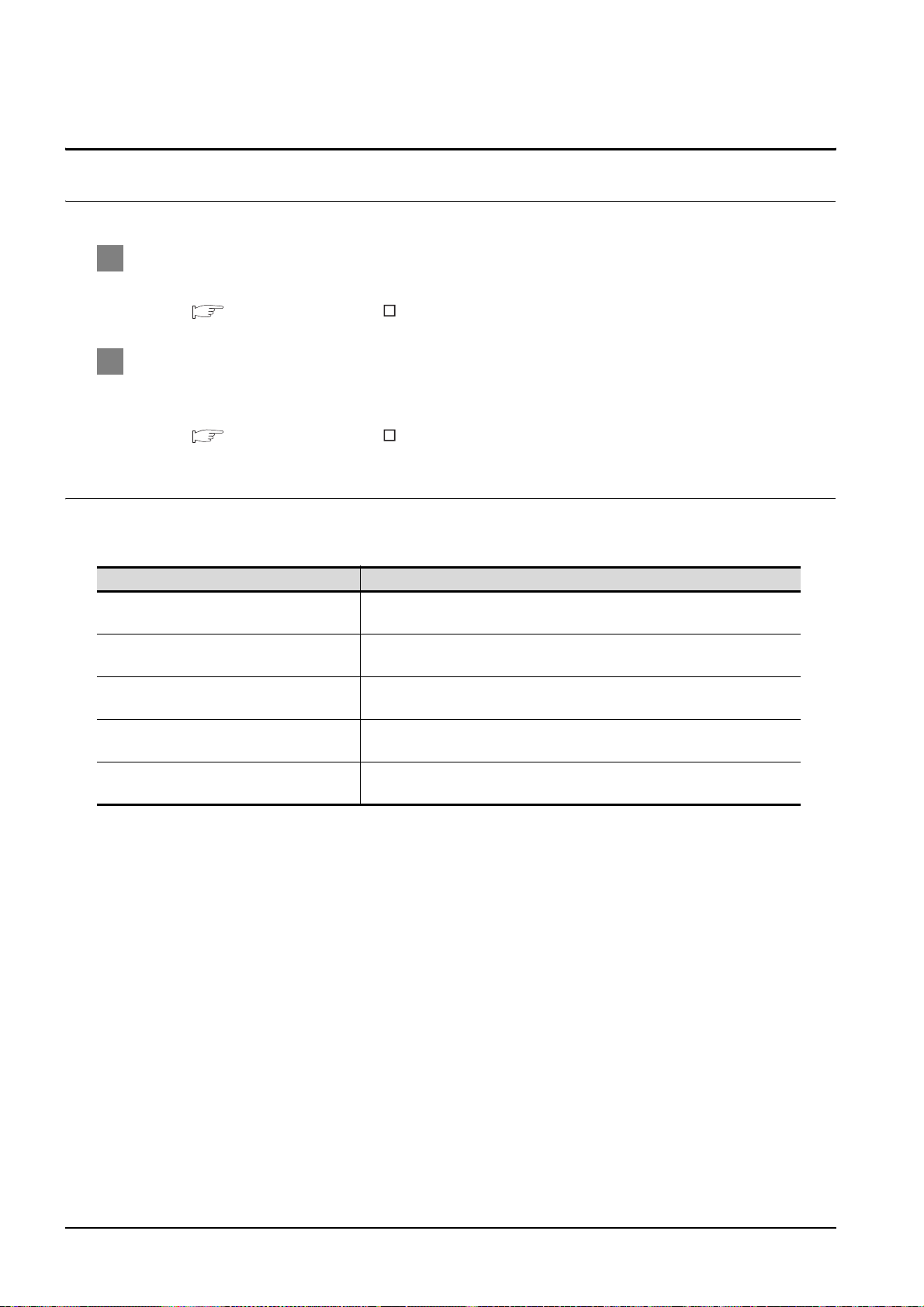

Applicable operating system and performance required for personal computer

1

Operating system

Microsoft Windows 2000 Professional Operating System [English version]

Microsoft Windows XP Professional Operating System [English version]

Microsoft Windows XP Home Edition Operating System [English version]

Microsoft Windows Vista Ultimate Operating System [English version]

Microsoft Windows Vista Enterprise Operating System [English version]

Microsoft Windows Vista Business Operating System [English version]

Microsoft Windows Vista Home Premium Operating System [English version]

Microsoft Windows Vista Home Basic Operating System [English version]

Operating environment when using a user-created application

A user-created application is used with GT SoftGOT1000.

When using a user-created application, therefore, prepare an operating environment

where both the user-created application and GT SoftGOT1000 can operate.

Performance required for personal computer

CPU Memory

Pentium 300MHz or

more

Pentium 300MHz or

more

800MHz or more

(Recommended: 1GHz or

more)

128MB or more

128MB or more

512MB or more

(Recommended: 1GB or

more)

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

INTERNAL DEVICE

5

OPERATING

6

7

INTERFACE

8

METHOD

FUNCTIONS

FUNCTION

2.2 Operating Environment

TROUBLESHOOTING

APPENDICES

2 - 5

Page 26

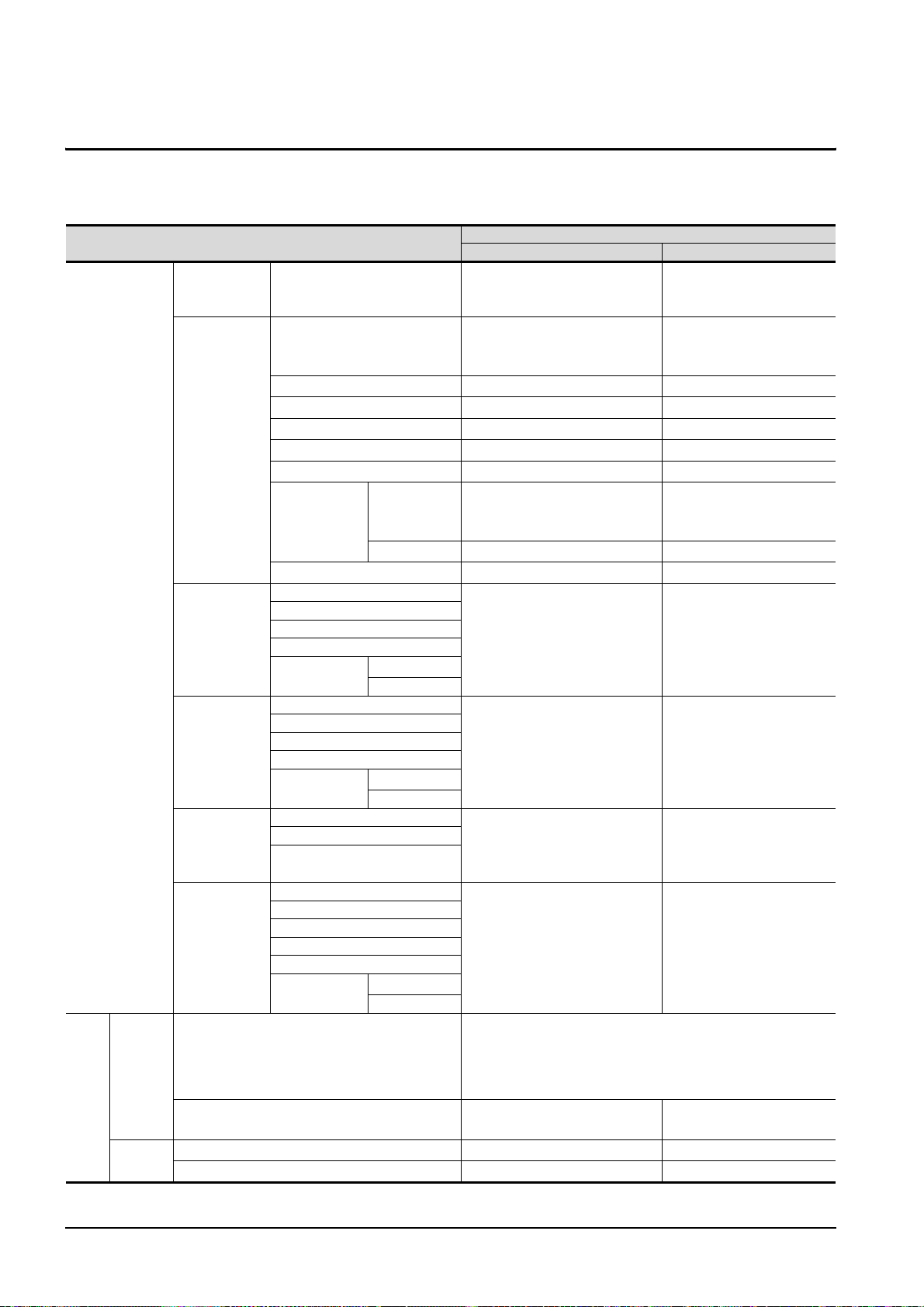

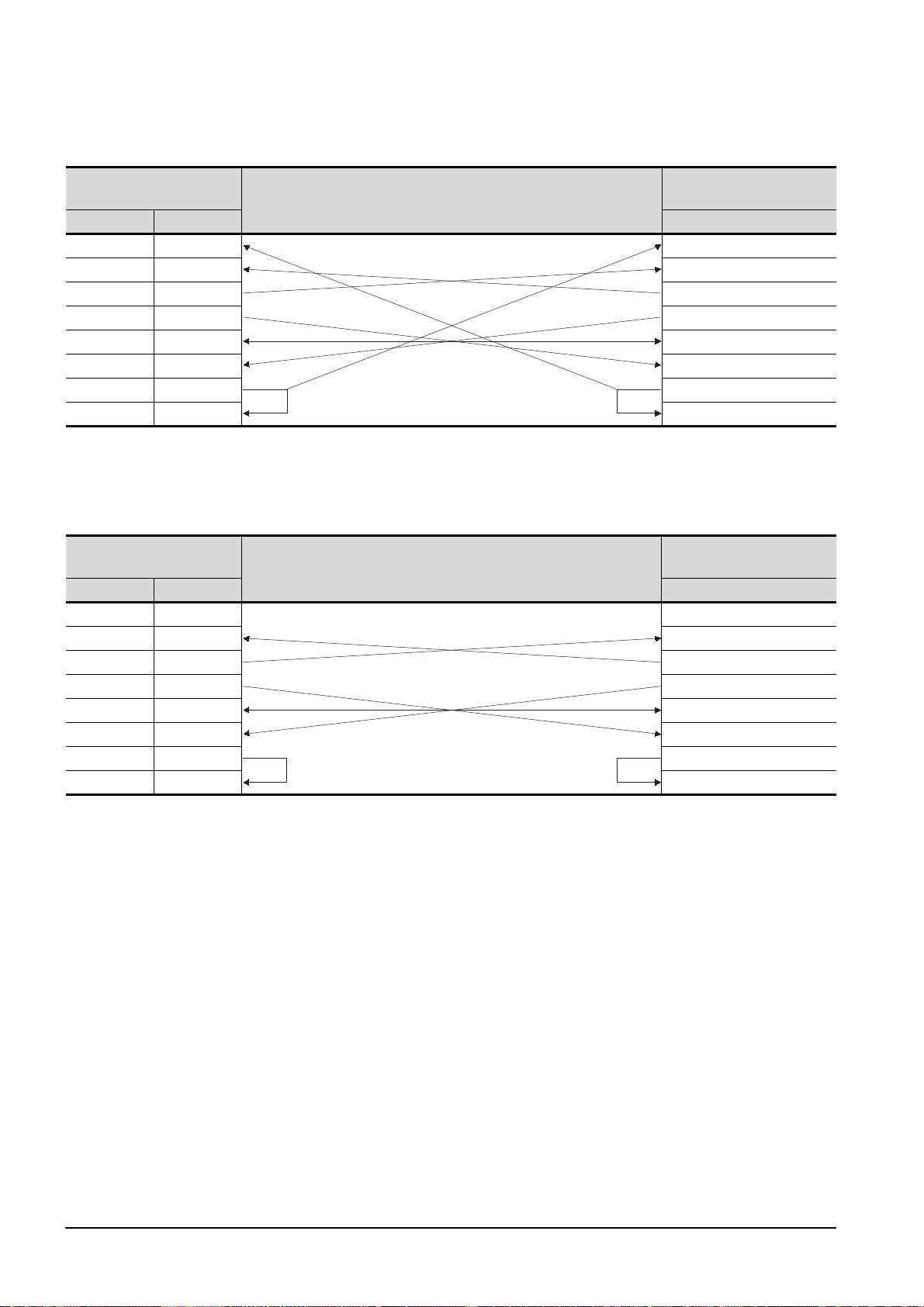

2.3 Connection conditions

The following table shows the connection distance between a controller and a personal computer and the

number of connectable personal computers when connecting GT SoftGOT1000 and a controller.

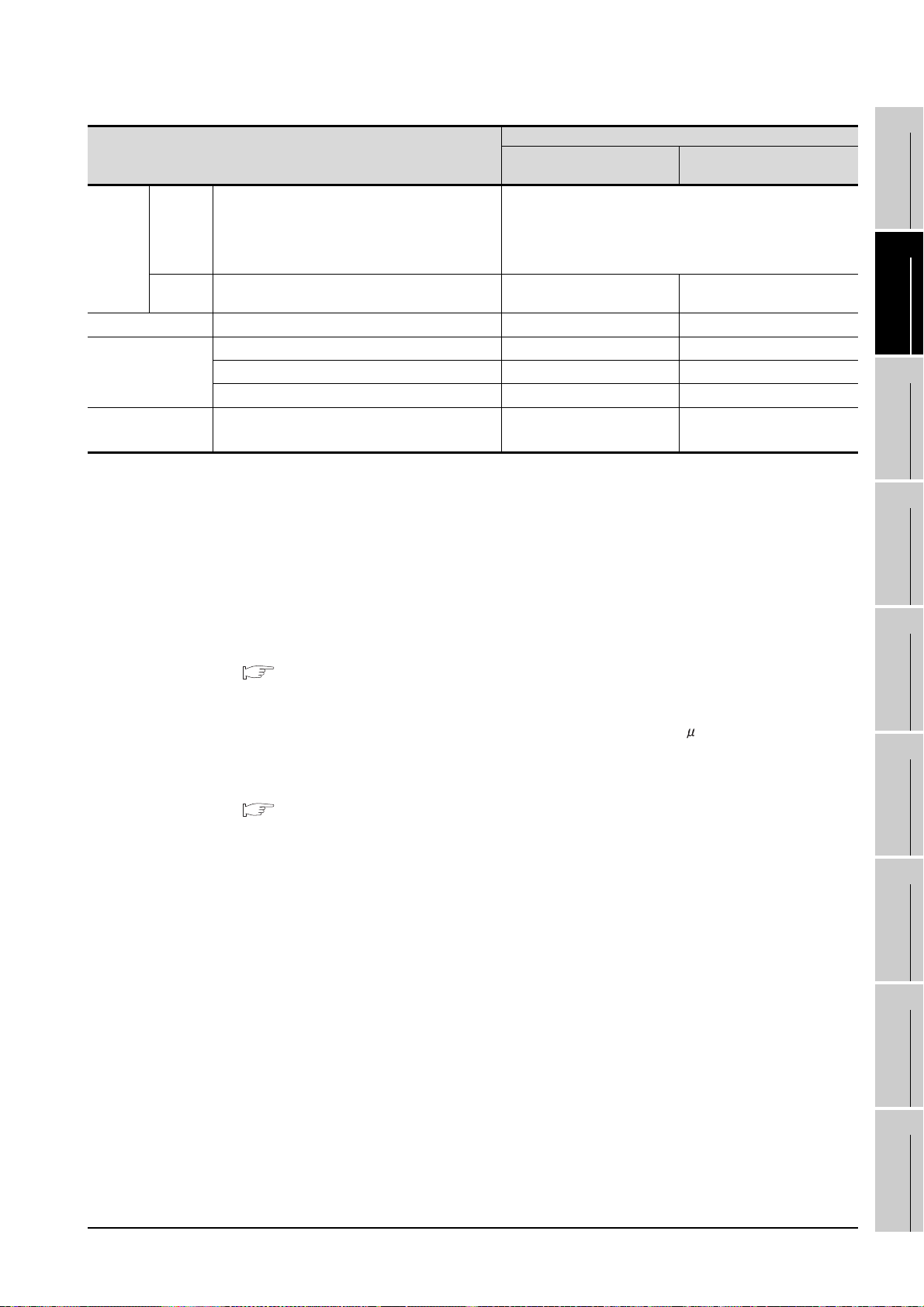

MITSUBISHI PLC

CNC C70

CNC

MELDAS

C6/C64

Connection type

Bus

connection

*8

QCPU (Q mode)

QCPU (Q mode)

Distance between controller and PC Number of connectable PCs

Connecting to the PLC CPU on the

main base unit that the PC CPU

module exists

RS-232 connection: 3m

USB connection: 3m

Connection conditions

QCPU (A mode) 15m

QSCPU 3m

Direct CPU

connection

QnACPU 15m

ACPU 15m

FXCPU 4.5m

Motion

controller CPU

Q series

*9

RS-232 connection: 3m

USB connection: 3m

A series 15m

MELSECNET/H remote I/O station 3m

QCPU (Q mode)

QCPU (A mode)

Computer link

connection

QnACPU

ACPU

Motion

controller CPU

Q series

A series

15m

*9

QCPU

MELSECNET/H

connection,

MELSECNET/

10 connection

CC-Link IE

controller

network

connection

QSCPU

QnACPU

ACPU

Motion

controller CPU

Q series

A series

*9

QCPU (Q mode)

QSCPU

Motion controller CPU (Q series)

Optical fiber cable: 1km

Coaxial cable: 500m

*7

550m

*9

*5

*5

QCPU (Q mode)

QCPU (A mode)

Ethernet

connection

QSCPU

QnACPU

ACPU

Motion

controller CPU

Q series

A series

100m (max. segment length)

*9

Direct CPU connection*2, Computer link connection*2,

MELSECNET/H connection*2, MELSECNET/10

Same as QCPU(Q mode)

connection*2, CC-Link IE controller network

connection

*2

Display I/F connection 100m (max. segment length)

Direct CPU connection 15m

Ethernet connection 100m (max. segment length)

*1

1

1 (2 units are connectable

when using both RS-232 and

USB connections.)

*1

1

*1

1

*1

1

*1

1

*1

1

*1

1 (2 units are connectable

when using both RS-232 and

USB connections.)

*1

1

*1

1

*1

1

Optical fiber cable: 64

Coaxial cable: 32

*1

120

*1

*1*6

*1*6

128 (recommended to 16 units

*1

or less)

128 (recommended to 16 units

*1

or less)

*1

1

*1

128

(Continued to next page)

2 - 6

2.3 Connection conditions

Page 27

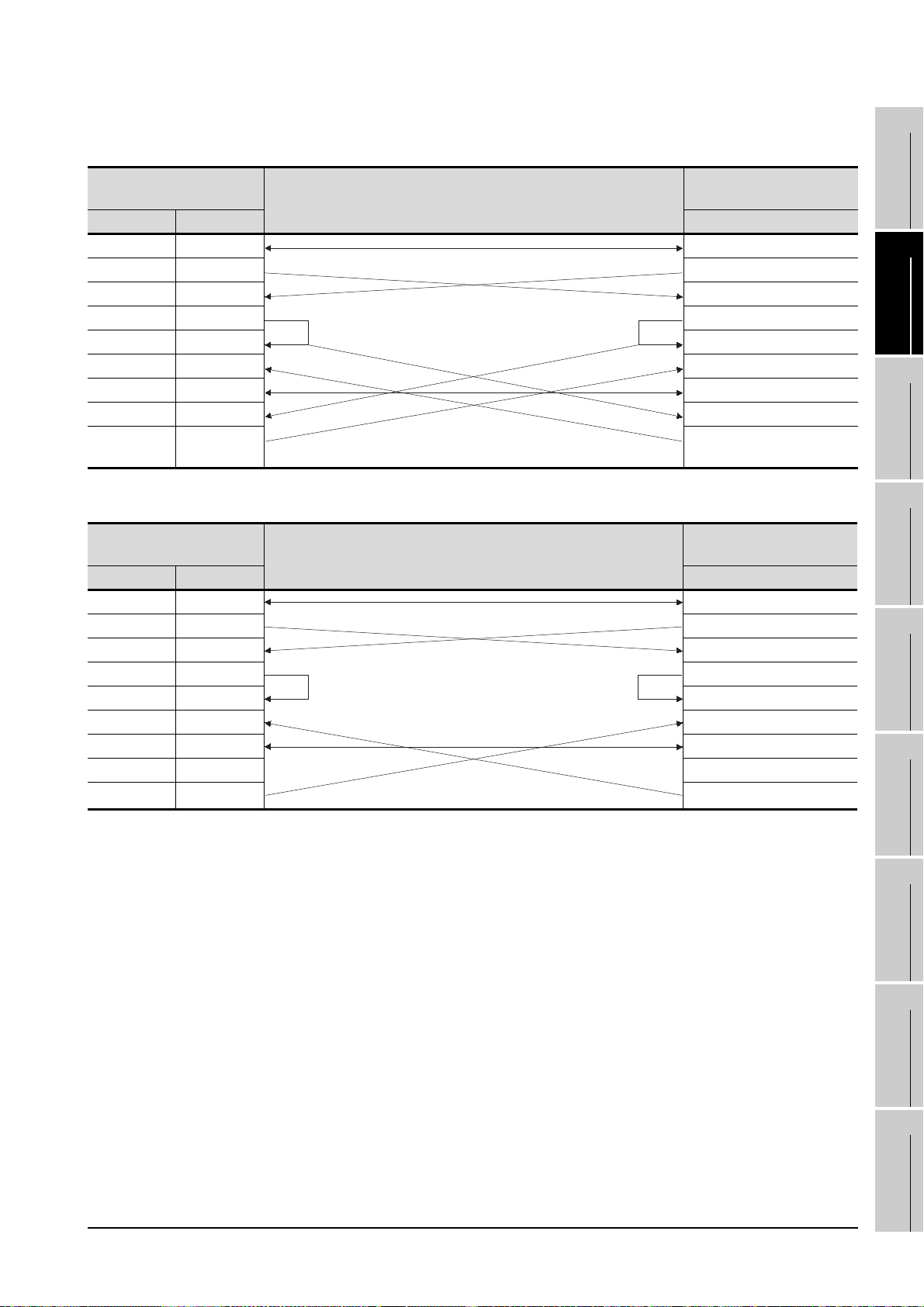

Connection conditions

Connection type

Direct CPU connection*2, Computer link connection*2,

CRnQ-

Robot

controller

OMRON PLC Direct CPU connection 15m

YASKAWA PLC

YOKOGAWA PLC Ethernet connection 100m (max. segment length)

700

CRnD-

700

MELSECNET/H connection*2, MELSECNET/10

connection*2, CC-Link IE controller network

connection*2, Ethernet connection

Ethernet connection 100m (max. segment length) 1

Direct CPU connection 15m

Computer link connection 15m

Ethernet connection 100m (max. segment length)

*1 When starting up multiple GT SoftGOT1000 modules, monitoring is enabled on the multiple screens.

*2 The multiple CPU system with the QCPU (Q mode) is mounted on.

*3 To use GT SoftGOT1000 module together with another GT SoftGOT1000 module or a different application, set

the different number for each port No.

If the port No. is the same, monitoring may not be available due to a communication timeout, or other causes.

*4 The number of connectable personal computers includes the number of total GT SoftGOT 1000 modules started

in a personal computer.

*5 Distance between stations for using QSI optical cable and 5C-2V coaxial cable.

The overall distance and distance between stations differs according to the type and the number of total stations

for the cable to be used.

For details on the cable, refer to the following manual.

Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC network)

*6 Applicable when using one MELSECNET/H board per personal computer.

Up to four MELSECNET/H boards can be mounted per personal computer.

*7 Distance between stations for using the fiber-optic cable (core/cladding = 50/125( m)

The overall distance and distance between stations differs according to the type and the number of total stations

for the cable to be used.

For details on the cable, refer to the following manual.

CC-Link IE Controller Network Reference Manual

*8 The connection type can be used only with the PC CPU module.

*9 For the motion controller CPU (Q series), only the PLC CPU area (CPU No.1) in the Q170MCPU can be

monitored. The PERIPHERAL I/F is unavailable for connecting the GOT.

*2

Distance between controller and

PC

Same as QCPU(Q mode)

Number of connectable PCs

*1

1

*1

1

*1

1

*3*4

10

UDP: 128

TCP: 8

*3

*3*4

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

5

OPERATING

METHOD

6

FUNCTIONS

7

2.3 Connection conditions

INTERNAL DEVICE

INTERFACE

FUNCTION

8

TROUBLESHOOTING

APPENDICES

2 - 7

Page 28

2.4 Connectable Modules

2.4.1 MITSUBISHI PLC

1 Applicable CPU

Refer to the following manual for PLC CPUs that can be monitored from GT SoftGOT1000.

GT Designer2 Version Screen Design Manual

2 Controllers that can be monitored in each connection type

Refer to the following manual for GT SoftGOT1000 connection types and PLC CPUs that can be

monitored in each connection type.

GT Designer2 Version Screen Design Manual

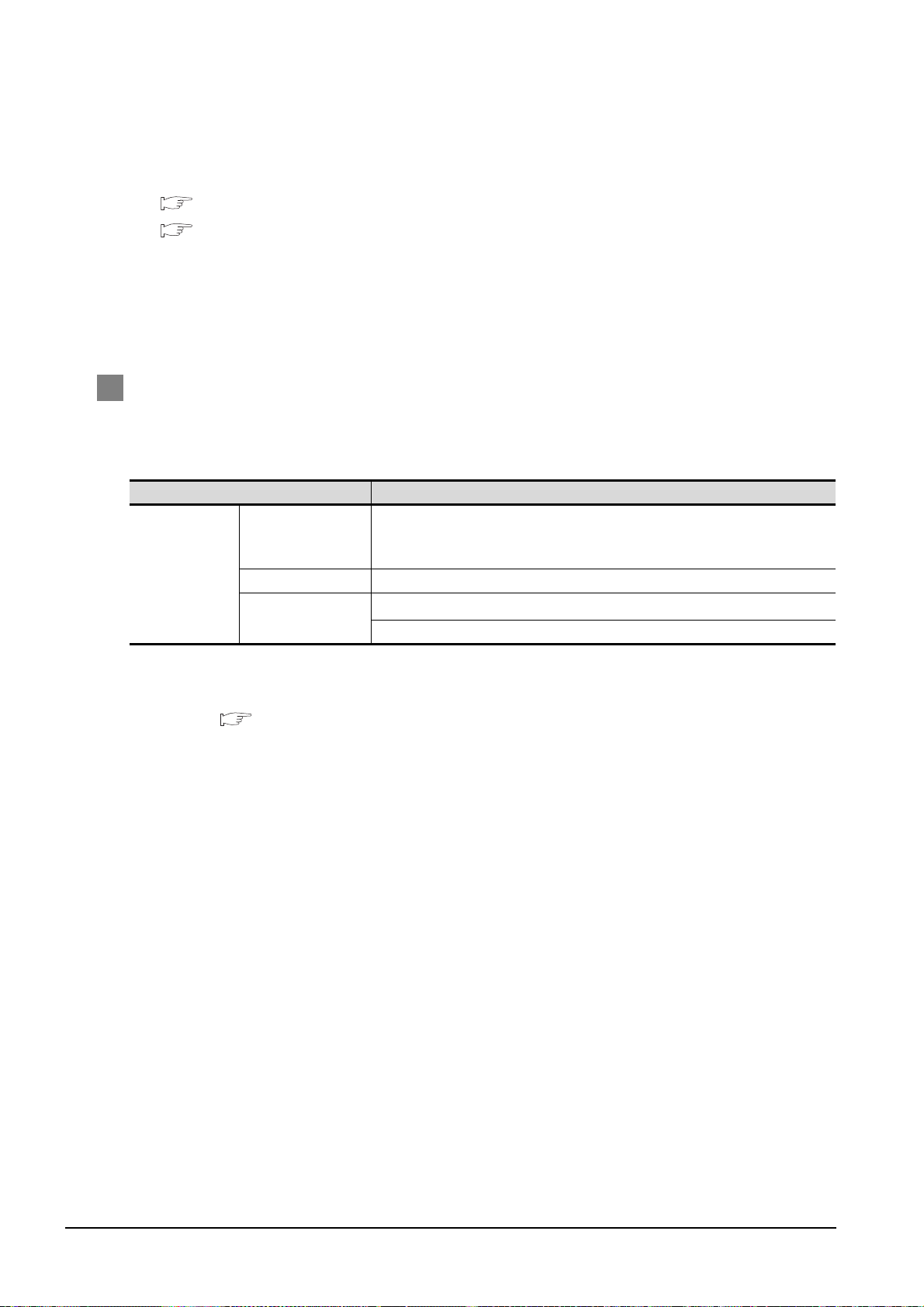

2.4.2 Serial communication module, computer link module

The following table shows connectable serial communication modules and computer link modules.

Connection via RS-422 communication cannot be used.

Item Model name

For QCPU (Q mode)

For QCPU (A mode)

For QnACPU

For ACPU or motion controller CPU (A series)

For motion controller CPU (Q series)

*1 For the motion controller CPU (Q series), only the PLC CPU area (CPU No.1) in the Q170MCPU can be

monitored.

*1

QJ71C24(-R2), QJ71C24N(-R2), QJ71CMO,

QJ71CMON

A1SJ71UC24-R2, A1SJ71UC24-PRF, A1SJ71C24-R2,

A1SJ71C24-PRF

AJ71QC24(-R2), AJ71QC24N(-R2), A1SJ71QC24(-R2),

A1SJ71QC24N(-R2)

AJ71C24-S8, AJ71UC24, A1SJ71C24-R2,

A1SJ71C24-PRF, A1SJ71UC24-R2, A1SJ71UC24-PRF

QJ71C24(-R2), QJ71C24N(-R2), QJ71CMO,

QJ71CMON

2 - 8

2.4 Connectable Modules

2.4.1 MITSUBISHI PLC

Page 29

2.4.3 Interface board, network module

When using PC CPU module

A interface board is not required.

For the system configuration of the PC CPU module, refer to the manual of the PC

CPU module .

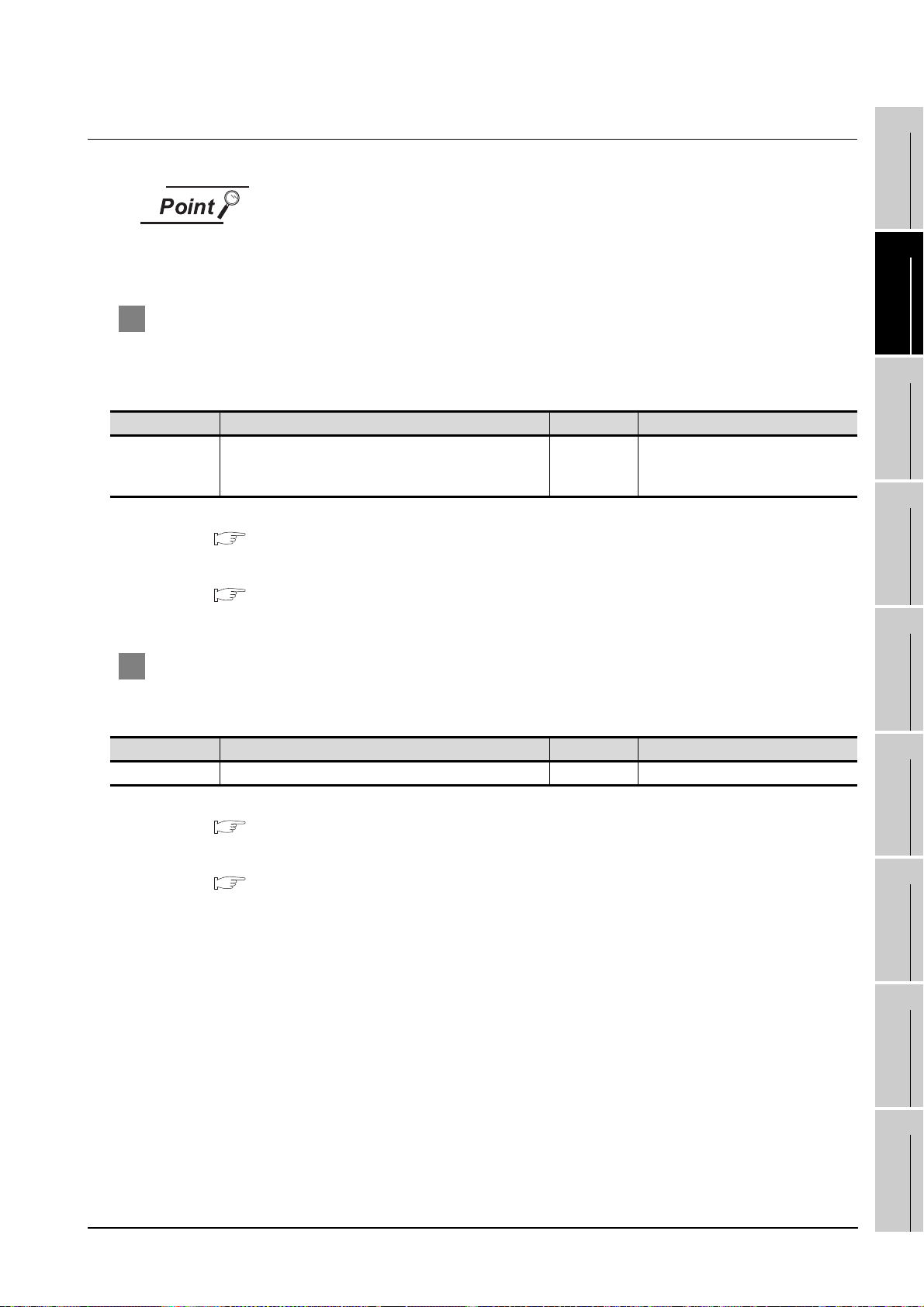

1 MELSECNET/H interface board/network module, MELSECNET/10 interface board/

network module

The following shows the required interface boards for GT SoftGOT1000 to configure a MELSECNET/H

network system and MELSECNET/10 network system.

Type Model name Bus format Driver

Q80BD-J71BR11 (Coaxial loop)

MELSECNET/H

Refer to the following manual for the settings of the interface board.

Refer to the following manual for the available network modules for each destination.

Q80BD-J71LP21-25 (Optical loop)

Q80BD-J71LP21G (Optical loop)

PCI SWODNC-MNETH-B

MELSECNET/H Interface Board User's Manual (For SW0DNC-MNETH-B)

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC

network)

2 CC-Link IE controller network interface board/network module

The following shows the required interface boards for GT SoftGOT1000 to configure a CC-Link IE

controller network.

Type Model name Bus format Driver

CC-Link IE Q80BD-J71GP21-SX, Q80BD-J71GP21S-SX PCI SW1DNC-MNETG-B

Refer to the following manual for the settings of the interface board.

CC-Link IE Controller Network Interface Board User's Manual (For SW1DNC-MNETG-B)

Refer to the following manual for the available network modules for each destination.

CC-Link IE Controller Network Reference Manual

INTERNAL DEVICE

SCREEN

5

OPERATING

6

7

INTERFACE

8

CONFIGURATION

METHOD

FUNCTIONS

FUNCTION

2.4 Connectable Modules

2.4.3 Interface board, network module

TROUBLESHOOTING

APPENDICES

2 - 9

Page 30

2.4.4 Ethernet module, Ethernet board/card

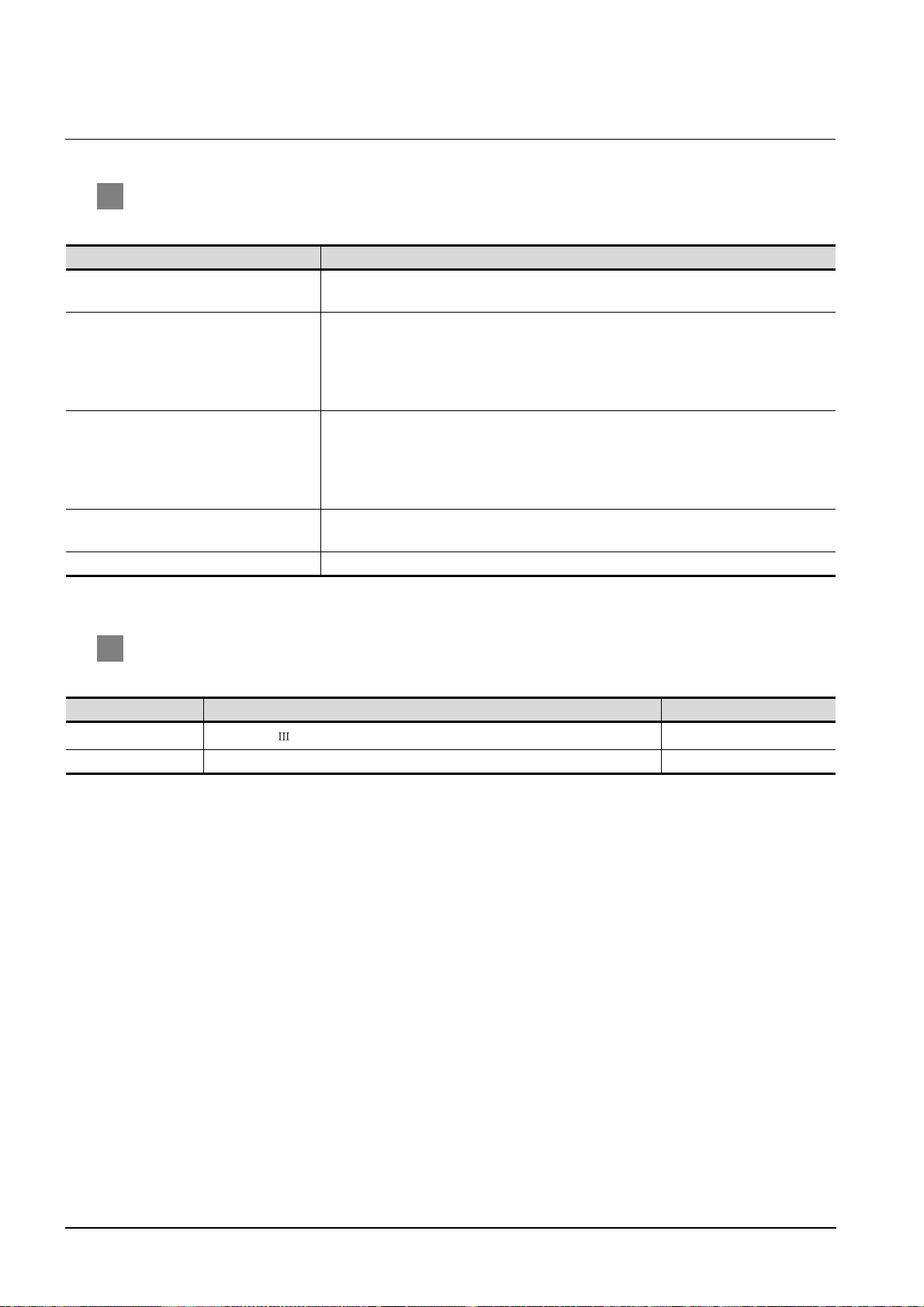

1 Ethernet module

Connectable Ethernet modules are shown in the following.

Item Model name

For QCPU

For QnACPU

For ACPU or motion controller CPU (A mode)

For motion controller CPU (Q series)

For MELDAS C6/C64 FCU6-EX875

*1 For the motion controller CPU (Q series), only the PLC CPU area (CPU No.1) in the Q170MCPU can be

*1

monitored. The PERIPHERAL I/F is unavailable for connecting the GOT.

QJ71E71, QJ71E71-B2, QJ71E71-B5,

QJ71E71-100

AJ71QE71, AJ71QE71-B5, AJ71QE71N-T,

AJ71QE71N-B2, AJ71QE71N-B5, AJ71QE71N-B5T,

AJ71QE71N3-T, A1SJ71QE71-B2, A1SJ71QE71-B5,

A1SJ71QE71N-T, A1SJ71QE71N-B2, A1SJ71QE71N-B5,

A1SJ71QE71N-B5T A1SJ71QE71N3-T

AJ71E71-S3, A1SJ71E71-B2-S3, A1SJ71E71-B5-S3,

AJ71E71N-T, AJ71E71N-B2, AJ71E71N-B5,

AJ71E71N3-T, AJ71E71N-B5T, A1SJ71E71N-T,

A1SJ71E71N-B2, A1SJ71E71N-B5, A1SJ71E71N-B5T,

A1SJ71E71N3-T

QJ71E71, QJ71E71-B2, QJ71E71-B5,

QJ71E71-100

2 Ethernet board/card

Applicable Ethernet bords/cards are shown in the following.

Manufacturer Model name Remarks

3COM

EthernetLink LAN PC Card

- Ethernet board built in the personal computer as standard Ethernet board

Ethernet board/card

2 - 10

2.4 Connectable Modules

2.4.4 Ethernet module, Ethernet board/card

Page 31

2.4.5 CNC

For CNCs that GT SoftGOT1000 can monitor and the applicable connection types, refer to the following

manual.

GT Designer2 Version Screen Design Manual

2.4.6 Robot controller

For robot controllers that GT SoftGOT1000 can monitor and the applicable connection types, refer to the following manual.

GT Designer2 Version Screen Design Manual

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

INTERNAL DEVICE

SCREEN

5

OPERATING

6

7

INTERFACE

8

CONFIGURATION

METHOD

FUNCTIONS

FUNCTION

2.4 Connectable Modules

2.4.5 CNC

TROUBLESHOOTING

APPENDICES

2 - 11

Page 32

2.4.7 OMRON PLC

For OMRON PLCs that GT SoftGOT1000 can monitor and the applicable connection types, refer to the following manual.

GT Designer2 Version Screen Design Manual

2.4.8 YASKAWA PLC

For YASKAWA PLCs that GT SoftGOT1000 can monitor and the applicable connection types, refer to the following manual.

GT Designer2 Version Screen Design Manual

1 Serial connection

The following table shows connectable MEMOBUS Modules and Communications Modules.

Connection via RS-422 communication cannot be used.

Item Model name

GL-60S, GL-60H, GL-70H JAMSC-IF60 JAMSC-IF61

MP920/NSC40 217IF

CP-9200SH CP-2171E

MP2200

JEPMC-MP2300 217IF-01

JEPMC-MP2200 218IF-01

2 Ethernet connection

(1) Communications Module

Item Model name

MP920 218IF

MP2200, MP2300 218IF-01

(2) Ethernet board/card

Use the same Ethernet board and card as those for connecting to MITSUBISHI PLC.

2 - 12

2.4 Connectable Modules

2.4.7 OMRON PLC

Page 33

2.4.9 YOKOGAWA PLC

For YOKOFGAWA PLCs that GT SoftGOT1000 can monitor and the applicable connection types, refer to

the following manual.

GT Designer2 Version Screen Design Manual

1 Ethernet connection

(1) Ethernet Interface Module

1

OVERVIEW

2

Item Model name

FA-M3 F3LE01-5T, F3LE11-0T, F3LE12-0T

(2) Ethernet board/card

Use the same Ethernet board and card as those for connecting to MITSUBISHI PLC.

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

5

OPERATING

METHOD

6

2.4 Connectable Modules

2.4.9 YOKOGAWA PLC

2 - 13

FUNCTIONS

7

INTERNAL DEVICE

INTERFACE

FUNCTION

8

TROUBLESHOOTING

APPENDICES

Page 34

2.5 Connection Cable

Remark

GT01-C30R2-6P (3m)

Personal computer: D-sub 9-pin Controller: MINI-DIN 6-pin

Personal computer: USB A type Controller: USB miniB type

MR-J3USBCBL3M (3m)

Personal computer: USB A type Controller: USB miniB type

GT09-C30USB-5P (3m)

USB-M53 (3m)

Personal computer: USB A type Controller: USB miniB type

USB2-30 (3m)

Personal computer: USB A type Controller: USB miniB type

AD-USBBFTM5M

+

This section provides the converter/cable whose operations has been checked by our company.

Converter/Cable used in GT SoftGOT1000

The converter/cable used for the GX Developer can be applied to the GT

SoftGOT1000.

2.5.1 Connecting to MITSUBISHI PLC

1 Connecting to QCPU or motion controller CPU (Q series)

(1) Connection via RS-232 cable

(a) When using MITSUBISHI SYSTEM & SERVICE product

*1 For the motion controller CPU (Q series), only the PLC CPU area (CPU No.1) in the Q170MCPU can be

monitored.

(2) Connection via USB cable

(a) With Universal model QCPU

• When using MITSUBISHI product

• When using product manufactured by Mitsubishi Electric System & Service Co., Ltd.

RS-232 cable

USB cable

USB cable

*1

• When using product manufactured by ELECOM CO.,LTD. (Recommended Product)

USB cable/USB conversion adapter

2 - 14

2.5 Connection Cable

2.5.1 Connecting to MITSUBISHI PLC

Page 35

• When using product manufactured by ARVEL CORP (Recommended Product)

AU2-30 (3m)

AUXUBM5

Personal computer: USB A type Controller: USB miniB type

+

Personal computer: USB A type Controller: USB miniB type

ZUM-430 (3m)

Personal computer: USB A type Controller: USB miniB type

USB2-30 (3m)

Personal computer: USB A type Controller: USB miniB type

AU2-30 (3m)

Personal computer: USB A type Controller: USB miniB type

USB2-30 (3m)

Personal computer: USB A type Controller: USB miniB type

AU2-30 (3m)

USB cable/USB conversion adapter

1

OVERVIEW

• When using product manufactured by LOAS CO., LTD. (Recommended Product)

USB cable

(b) With Basic model QCPU, High Performance model QCPU, Process CPU, Redundant CPU

• When using product manufactured by ELECOM CO.,LTD. (Recommended Product)

USB cable

• When using product manufactured by ARVEL CORP (Recommended Product)

USB cable

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

5

2 Connecting to QSCPU

(1) Connection with USB cable

(a) When using product manufactured by ELECOM CO.,LTD. (Recommended Product)

(b) When using product manufactured by ARVEL CORP (Recommended Product)

USB cable

USB cable

INTERNAL DEVICE

OPERATING

6

7

INTERFACE

8

METHOD

FUNCTIONS

FUNCTION

TROUBLESHOOTING

2.5.1 Connecting to MITSUBISHI PLC

2.5 Connection Cable

APPENDICES

2 - 15

Page 36

Precautions for using USB cable

QCPU (Q mode)

USB cable

QCPU (Q mode)

USB cable

Connecting from a personal computer with multiple USB ports to

multiple QCPUs (Qmode)

QCPU (Q mode)

USB cable

USB cable

QCPU (Q mode)

USB cable

Connecting from a personal computer to multiple QCPUs (Q mode)

through USB hub

USB hub

(1) Before using USB cable

The USB cable can be used with the USB driver already installed.

(2) Number of connectable programmable controllers when using USB cable

A single programmable controller can be connected when using the USB cable.

The following shows the system configurations, which do not meet the above

conditions.

(3) Precautions for connecting programmable controller

Connect or remove the USB cable, reset a programmable controller or turn the

power on/off after stop the monitor.

( 5.7 Monitor Stop)

If operated without stop, a communication timeout occurs, which cannot be fixed.

If not fixed, remove the USB cable completely. After 5 seconds or more, reconnect

the cable. (The error may occur at first communication after the above operation.

From the next time, the programmable controller functions normally.)

2 - 16

2.5 Connection Cable

2.5.1 Connecting to MITSUBISHI PLC

Page 37

3 Connecting to QnACPU, ACPU, motion controller CPU (A series), or FXCPU

F2-232CAB(3m)

*1*2

(For the 25-pin D-sub connector of the PC side)

FX-232AW

FX-232AWC

FX-232AWC-H

(FX series only)

FX-422CAB (0.3m), FX-422CAB-150 (1.5m)

(For connecting to QnACPU, ACPU, motion controller

CPU (A series), FX1CPU, FX2CPU, or FX2cCPU)

F2-232CAB-1(3m)

*2

(For the 9-pin D-sub connector of the PC side)

FX-422CAB0 (1.5m)

(For connecting to FX0/FX0S/FX0N/FX1S /FX1N/

FX2N/FX1NC/FX2NC/FX3UC/FX3U/FX3GCPU)

AC30N2A(3m)

*1

(For the 25-pin D-sub connector of the PC side)

FX-USB-AW

*4

(FX series only)

FX3U-USB-BD

*4

(FX3UC only)

(1) Using the product of Mitsubishi Electric make

1

PC side (RS-232 cable)

RS-232/RS-422

Converter

*3

PLC CPU Side(RS-422 cable)

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SCREEN

CONFIGURATION

5

(Use the cable included in the FX-USB-AW.)

(Use the cable included in the FX3U-USB-BD.)

*1 A straight cable for conversion between 9-pin D-sub and 25-pin D-sub is required separately.

*2 How to distinguish products compatible with QnACPU, ACPU.

Check the model name label of the cable.

Icompatible products Compatible products (with indication of F/FX/A)

F2-232CAB

Y990C*****

F2-232CAB-1

Y990C*****

*3 When connecting the FX-232AWC-H to the FX

bps is available.

When connecting the FX-232AWC or FX-232AW, either of transmission speed of 9600/19200bps is available.

*4 Drivers respectively stored in the CD-ROMs included in the FX-USB-AW and FX

the personal computer for using the converters. (The converters can be used by assigning the USB-serial

conversion driver to the COM number.)

F2-232CAB(F/FX/A)

Y990C*****

F2-232CAB-1(F/FX/A)

Y990C*****

3UCCPU, transmission speed of 9600/19200/38400/57600/115200

3U-USB-BD must be installed on

INTERNAL DEVICE

OPERATING

6

7

INTERFACE

8

METHOD

FUNCTIONS

FUNCTION

TROUBLESHOOTING

2.5 Connection Cable

2.5.1 Connecting to MITSUBISHI PLC

APPENDICES

2 - 17

Page 38

When connection to the function expansion board or function adaptor of FX1S/FX1N/FX2N/FX1NC/

GT01-C30R2-9S(3m)side)

GT01-C30R2-25P(3m)

FX

2NC/FX3UC/FX3U/FX3GCPU, the following cables are available.

RS-232 cable

*1*2

*1 The following system configurations are available in the GT01-C30R2-9S.

Model name

FX3U series,

FX3UC series

(FX3UC--LT)

FX3UC series

(FX3UC-/D,

FX3UC-/DSS)

FX3G series

FX2N series

FX1NC,

FX2NC series

FX1S, FX1N series

FX3U-232-BD -

FX3U-232-BD, FX3U-485-BD,

FX3U-422-BD, FX3U-USB-BD,

FX3U-CNV-BD

FX3G-232BD -

FX3G-CNV-ADP FX3U-232ADP

FX2N-232-BD -

FX2N-CNV-BD FX2NC-232ADP

FX1N-232-BD -

FX1N-CNV-BD FX2NC-232ADP

Function expansion

board

FX3U-232ADP

-

-FX2NC-232ADP 9-pin D-sub

Function adapter PC side connector

9-pin D-sub

9-pin D-sub

9-pin D-sub

9-pin D-sub

2 - 18

2.5 Connection Cable

2.5.1 Connecting to MITSUBISHI PLC

Page 39

*2 The following system configurations are available in the GT01-C30R2-25P.

Model name

FX3U series,

FX3UC series

(FX3UC--LT)

FX3UC series

(FX3UC-/D,

FX3UC-/DSS)

FX3G series

FX2N series

FX1NC,

FX2NC series

FX1S, FX1N series

FX3U-232-BD -

FX3U-232-BD, FX3U-485-BD,

FX3U-422-BD, FX3U-USB-BD,

FX3U-CNV-BD

FX3G-232BD -

FX3G-CNV-ADP FX3U-232ADP

FX2N-CNV-BD FX0N-232ADP 9-pin D-sub

FX2N-232-BD -

FX2N-CNV-BD FX2NC-232ADP

FX1N-CNV-BD FX0N-232ADP 9-pin D-sub

FX1N-232-BD -

FX1N-CNV-BD FX2NC-232ADP

Function expansion

board

-

-FX0N-232ADP 9-pin D-sub

-FX2NC-232ADP 25-pin D-sub

Function adapter PC side connector

FX3U-232ADP

25-pin D-sub

25-pin D-sub

25-pin D-sub

25-pin D-sub

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

INTERNAL DEVICE

SCREEN

5

OPERATING

6

7

INTERFACE

8

CONFIGURATION

METHOD

FUNCTIONS

FUNCTION

2.5 Connection Cable

2.5.1 Connecting to MITSUBISHI PLC

TROUBLESHOOTING

APPENDICES

2 - 19

Page 40

(1) Specifications and precautions for converters/cables

Refer to the following manual for the specifications and precautions for

converters/cables.

The manual for each product

(2) Inserting and removing a converter/cable that receives electricity from the 5VDC

power

Turn the PLC CPU side power OFF before inserting and removing the converter/

cable that receives electricity from the PLC CPU side 5VDC power.

(3) Inserting and removing a converter/cable that does not receive electricity from the

5VDC power

Refer to the following procedures when inserting and removing the peripheral

device or cable that does not receive electricity from the PLC CPU side 5VDC

power (receives from an external power supply).

1 Make sure to touch the static discharge wrist strap or grounded metal before

operation and discharge electrostatic from cables, human body or others.

2 Turn off the PC.

3 Turn off the converter.

Ground the FG terminal if provided.

4 Insert and remove the converter/cable connected to the PC and PLC.

5 Turn on the converter.

6 Turn on the PC.

7 Start the software package.

2 - 20

2.5 Connection Cable

2.5.1 Connecting to MITSUBISHI PLC

Page 41

2.5.2 Connecting to serial communication module or computer link module

1 Connecting to serial communication module communicating with QCPU

(1) When using an RS-232 cable

The user is required to make a RS-232 cable for connecting GT SoftGOT1000 to a module.

The cables connection diagram indicated below.

(a) Connector specifications

Pin No. Signal code Signal name

Q computible C24 GT SoftGOT1000

Signal direction

1

OVERVIEW

2

SYSTEM

CONFIGURATION

1 CD Receive carrier detection

2 RD(RXD) Receive data

3 SD(TXD) Send data

4 DTR(ER) Data terminal ready

5 SG Send ground

6 DSR(DR) Data set ready

7 RS(RTS) Request to send

8 CS(CTS) Clear to send

9 RI(CI) Call indication

(b) Connection diagram

1) Connection example which can turn ON/OFF CD signal (No. 1 pin)

Serial communication module

side

Signal code Pin No. Signal code

CD 1 CD

RD(RXD) 2 RD(RXD)

SD(TXD) 3 SD(TXD)

DTR(ER) 4 DTR(ER)

SG 5 SG

DSR(DR) 6 DSR(DR)

RS(RTS) 7 RS(RTS)

CS(CTS) 8 CS(CTS)

R1(CI) 9

(Connection example for full duplex/half duplex communication)

Cable Connection and Signal Direction

GT SoftGOT1000

(Personal computer) side

INTERNAL DEVICE

3

4

SCREEN

5

OPERATING

6

7

INTERFACE

SPECIFICATIONS

CONFIGURATION

METHOD

FUNCTIONS

FUNCTION

2.5 Connection Cable

2.5.2 Connecting to serial communication module or computer link module

8

TROUBLESHOOTING

APPENDICES

2 - 21

Page 42

2) Connection example which cannot turn ON/OFF CD signal (No. 1 pin)

Connection example for exercising DC code control or DTR/DSR control

Serial communication module

side

Signal code Pin No. Signal code

CD 1 CD

RD(RXD) 2 RD(RXD)

SD(TXD) 3 SD(TXD)

DTR(ER) 4 DTR(ER)

SG 5 SG

DSR(DR) 6 DSR(DR)

RS(RTS) 7 RS(RTS)

CS(CTS) 8 CS(CTS)

R1(CI) 9

Cable Connection and Signal Direction

(Connection example for full duplex communication)

GT SoftGOT1000 (Personal

computer) side

2 - 22

2.5 Connection Cable

2.5.2 Connecting to serial communication module or computer link module

Page 43

2 Connecting to serial communication module or computer link module communicating

AC30N2A

(For personal computer side 25 pin D-sub connector

with QnACPU, ACPU, or motion controller CPU (A series)

(1) When using an RS-232 cable

(a) Using the product of Mitsubishi Erectric make.

RS-232 cable

1

OVERVIEW

2

SYSTEM

CONFIGURATION

(b) When using an RS-232 cable prerared by user

The cable connection diagrams are indicated below.

For QnA Series (large-scale QC24(N))

1) Example of connection to an external device that allows the CD signal (No.8 pin) to be turned ON/OFF

Serial communication

module side

Signal code Pin No. Signal code

FG 1 FG

SD (TXD) 2 SD (TXD)

RD (RXD) 3 RD (RXD)

RS 4 RS

CS (CTS) 5 CS (CTS)

DSR (DR) 6 DSR (DR)

SG 7 SG

CD 8 CD

DTR (ER) 20 DTR (ER)

* DC code control or DTR/DSR control is enabled by connecting the QC24 (N) to an external device as shown

above.

(Connection example for full duplex/half duplex communication)

Cable Connection and Signal Direction

2) Example of connection to an external device that does not allow the CD signal (No. 8 pin) to be turned

ON/OFF

Serial communication

module side

Signal code Pin No. Signal code

FG 1 FG

SD (TXD) 2 SD (TXD)

RD (RXD) 3 RD (RXD)

RS 4 RS

CS (CTS) 5 CS (CTS)

DSR (DR) 6 DSR (DR)

SG 7 SG

CD 8 CD

DTR (ER) 20 DTR (ER)

* DC code control or DTR/DSR control is enabled by connecting the QC24 (N) to an external device as shown

above.

Cable Connection and Signal Direction

(Connection example for full duplex communication)

GT SoftGOT1000 (Personal

computer) side

GT SoftGOT1000 (Personal

computer) side

INTERNAL DEVICE

3

4

SCREEN

5

OPERATING

6

7

INTERFACE

8

SPECIFICATIONS

CONFIGURATION

METHOD

FUNCTIONS

FUNCTION

TROUBLESHOOTING

2.5.2 Connecting to serial communication module or computer link module

2.5 Connection Cable

APPENDICES

2 - 23

Page 44

1) Example of connection to an external device that allows the CD signal (No.1 pin) to be turned ON/OFF

For QnA Series (compact-scale QC24(N))1)

Serial communication

module side

Signal code Pin No. Signal code

CD 1 CD

RD (RXD) 2 RD (RXD)

SD (TXD) 3 SD (TXD)

DTR (ER) 4 DTR (ER)

SG 5 SG

DSR (DR) 6 DSR (DR)

RS (RTS) 7 RS (RTS)

CS (CTS) 8 CS (CTS)

(Connection example for full duplex/half duplex communication)

Cable Connection and Signal Direction

GT SoftGOT1000 (Personal

computer) side

* DC code control or DTR/DSR control is enabled by connecting the QC24 (N) to an external device as shown

above.

2) Example of connection to an external device that does not allow the CD signal (No. 1 pin) to be turned

ON/OFF

Serial communication

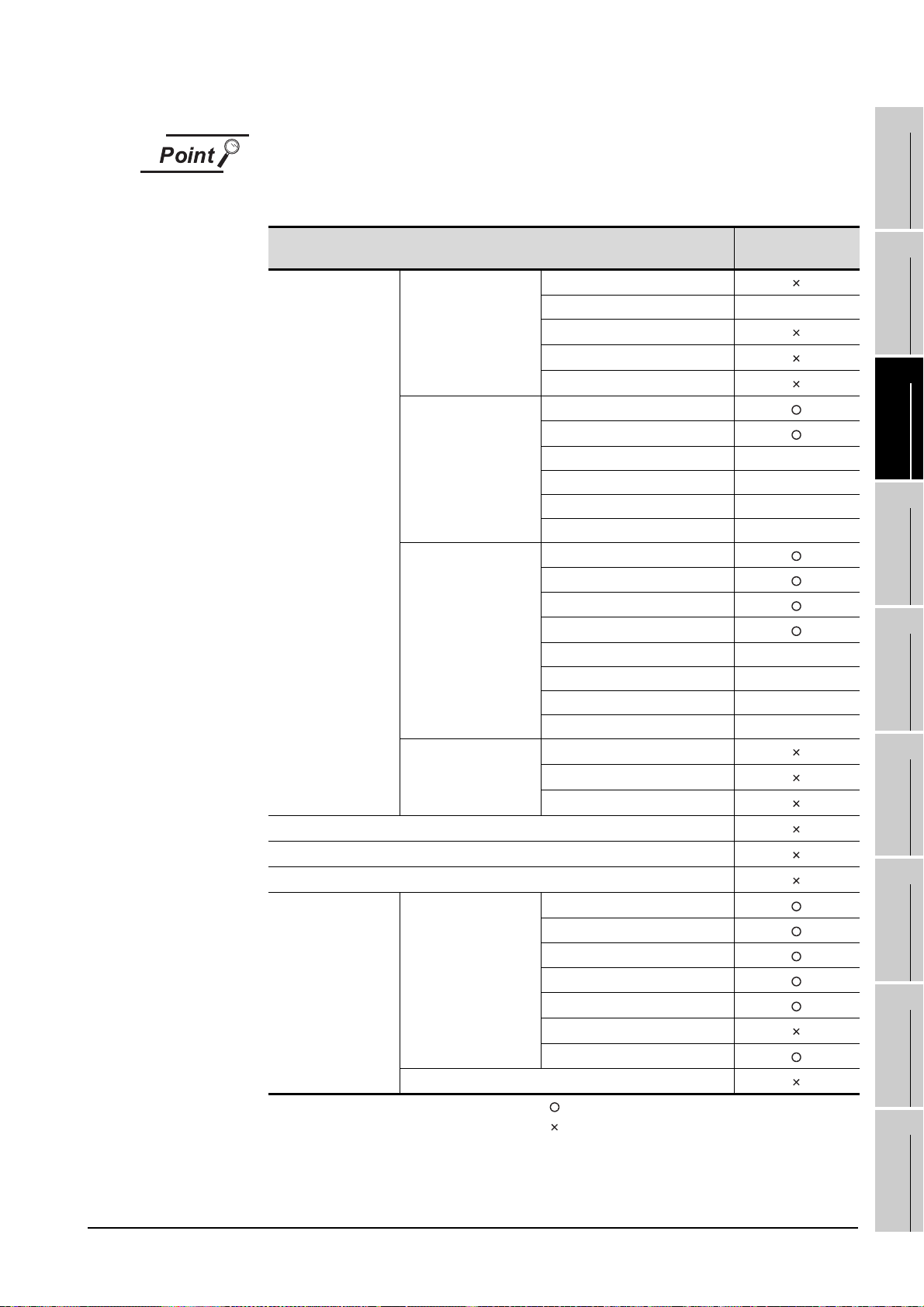

module side