Page 1

MELSEC iQ-R High Speed Data Logger Module

User's Manual (Startup)

-RD81DL96

-SW1DNN-RDLUTL (High Speed Data Logger Module Tool)

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions for the programmable

controller system, refer to the user's manual for the module used and the MELSEC iQ-R Module Configuration Manual.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

2

Page 5

[Design Precautions]

WARNING

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Incorrect output or malfunction due to a

communication failure may result in an accident.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or do not reset the CPU module while the settings are

being written. Doing so will make the data in the flash ROM or SD memory card undefined. The values

need to be set in the buffer memory and written to the flash ROM or the SD memory card again. Doing

so may cause malfunction or failure of the module.

● When changing the operating status of the CPU module from external devices (such as remote RUN/

STOP functions), select "Do Not Open in Program" for "Open Method Setting" in the module

parameters. If "Open in Program" is selected, an execution of remote STOP causes the

communication line to close. Consequently, the CPU module cannot reopen the communication line,

and the external device cannot execute the remote RUN.

3

Page 6

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets general specifications written in Safety

Guidelines included in the base unit. Failure to do so may result in electric shock, fire, malfunction, or

damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module, and make sure to fix the module with screws since this module has no

module fixing hook. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of a CPU module. After

insertion, close the cassette cover and check that the cassette is inserted completely. Poor contact

may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, or connector. Doing so may cause malfunction or failure of the

module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact. Do not clamp the

extension cables with the jacket stripped. Doing so may change the characteristics of the cables,

resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

5

Page 8

[Wiring Precautions]

CAUTION

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for the module used. If not, normal data transmission is not guaranteed.

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury or fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit may cause

malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing so may

cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

7

Page 10

[Startup and Maintenance Precautions]

CAUTION

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM or SD memory card undefined. The values need to be set in the buffer memory and written

to the flash ROM or SD memory card again. Doing so can cause malfunction or failure of the module.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

9

Page 12

CONSIDERATIONS FOR USE

This section explains the following considerations.

Page 10 Considerations for network connection

Page 10 Considerations for performance/specifications

Page 11 Considerations for data logging, event logging, and report functions

Page 12 Considerations for other functions

Page 12 Considerations for accessing a high speed data logger module

Page 13 Considerations for security

Page 13 Considerations for using SD memory cards

Page 15 Considerations for the recipe function

Considerations for network connection

■Mail server and FTP server connections

When immediately powering ON after powering OFF, connection to mail servers or FTP servers may fail.

Power the programmable controller OFF, wait several minutes then power it ON.

Considerations for performance/specifications

■Sequence scan time of CPU module

When using the high speed data logger module, the CPU module sequence scan time may increase.

Design your system and programs keeping in mind this increase in sequence scan time of the CPU module.

■Network connection using Ethernet

• When connecting to Ethernet network, basically configure the communication route to the access target via Ethernet

(twisted pair) cables and hubs. Note that when accessing via wireless LAN (Wi-Fi) or router, an error such as timeout or

missing data occurs, and cannot be communicated properly depending on the status of the equipment (wireless LAN or

router) on the network or the access route.

• When the access to the high speed data logger module is overloaded, errors and missing data may occur. Creating logging

files, report files might take time, and communication with the module might not be possible. Reduce the load on the

Ethernet network which is connected to the high speed data logger module.

■Time handled on the high speed data logger module

Time handled on the high speed data logger module is the time on the CPU module.

For errors and the optimum timing for setting the time, refer to the following section.

Page 23 Performance Specifications

MELSEC iQ-R High Speed Data Logger Module User's Manual(Application)

■High speed sampling

The high speed sampling function is not supported by CPU modules on other stations via a network.

10

Page 13

Considerations for data logging, event logging, and report functions

■Data logging, event logging, and report functions

• The data logging, event logging, and report functions are best effort functions. Since the processing time of a module varies

depending on the setting and the status of other devices, these functions may not perform at the set sampling interval. Run

the system by fully verifying the processing time of each function when constructing it. For processing time, refer to the

following manual.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

• If data logging function, event logging function, or report function are used, they affect the sequence scan time of the

access target CPU module. Run the system by verifying how the sequence scan time is affected when configuring the

system.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

• If exponential format is selected for the data output format with the data logging, event logging, or report setting, rounding

errors will occur in the range of the number of digits that exceed the number of digits set for the decimal part.

• If the result of the linear function transformation with the scaling function exceeds the maximum or minimum range of the

specified output format, the maximum or minimum value will be output in binary format. Therefore, when outputting in the

binary format, errors may occur in the output values.

• The file transfer/e-mail transmission via the file transfer function/e-mail function may take from a few seconds to tens of

seconds depending on the network line or transmission size. Target files may be deleted before file transfer/e-mail

transmission completes depending on the settings. Review the file switching timing and the number of files saved setting

and lengthen the time until the file is deleted.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

• When a CSV file is opened with Excel, the date column format is displayed in the default setting of Excel. Set the cell format

as necessary.

• Since general sampling specified data and report current value data are sampled asynchronously with the sequence scan,

data separation may occur. If data separation must be prevented, set the number of device points sampled at one time to

less than the access units, or set the module to use high speed sampling.

■Data logging function

• Immediately after switching the programmable controller system ON, if a trigger occurs before sampling the number of lines

of data before the trigger, the data before the trigger may be a few lines less than the specified amount.

• When triggers continuously occur with the trigger logging function, triggers may not be detected or the number of lines of

data specified before the trigger may not be output. For operation when triggers continuously occur, refer to the following

manual.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

■Report function

• Immediately after switching the programmable controller system ON, if a creation trigger occurs when data does not exist in

the data logging file, an error occurs in the high speed data logger module. Configure and construct the system so that the

creation trigger occurs after data is saved in the data logging file.

• Report output takes time. Therefore, according to the data logging save setting, the data logging file including the data

when the creation trigger occurs, may be deleted before the report output is completed. In this situation, the data for the

specified number of records are not output, and an error occurs in the high speed data logger module. Check the Point in

the following manual when configuring and constructing the system.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

• When the creation triggers continuously occurred, they may not be detected. For operation when the creation trigger

continuously occurred, refer to the following manual.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

11

Page 14

• When using Microsoft Excel 2010 (32-bit version), Microsoft Excel 2013 (32-bit version), or Microsoft Excel 2016 (32-bit

version), install Visual Basic

is displayed when the "Layout setting" screen is started, and layout settings cannot be configured.

"This workbook has lost its VBA Project, ActiveX Controls and any other programmability-related features."

• The saving format of a report file output by the report function is the xls format. Some of the functions added to Microsoft

Excel 2007 and later cannot be used.

• Microsoft Excel 2010 (64-bit version) is not supported.

• Microsoft Excel 2013 (64-bit version) is not supported.

• Microsoft Excel 2016 (64-bit version) is not supported.

for Applications (abbreviated as VBA below). If VBA is not installed, the error message below

Considerations for other functions

■Access target CPU setting

• When rewriting the configuration tool settings, turning the power OFF to ON, or resetting the CPU module, the high speed

data logger module is prepared to communicate with the access target CPU module. Therefore, if a large number of access

target CPU modules are set, several minutes are required for this preparation.

• The following conditions may affect the general sampling, file transfer function, and e-mail function: when the CPU module

which does not exist in the access target CPU module is set, or the high speed data logger module cannot communicate

with the access target CPU module temporary because of the power interruption of access target CPU module or network

failure. Use the high speed data logger modules with the status that can communicate with the CPU module set as access

target CPU module.

■Time synchronization function

• If implementing the time synchronization with the CPU module, it will change the time of the high speed data logger

module. When the CPU module's time is changed, the high speed data logger module's time may be greatly changed.

• Since there is inaccuracy in the clock element of the CPU module and the high speed data logger module, the time may be

moved slightly forward or backward when the time is synchronized. Since changing the time of the high speed data logger

module affects the time stamp, as well as the following determination of the cycles and of the time: data logging, event

logging, and reports, configure the module to synchronize its time at the required minimum range.

Considerations for accessing a high speed data logger module

■Web browser operations and settings

• In the local area network (LAN) setting of the Web browser, do not set a proxy server for the local address.

(Page 53 Online startup)

■FTP server function

• Because of FTP client side application restrictions, if the user name or password is input incorrectly, end the FTP operation

and redo the FTP connection from the beginning. FTP may not operate correctly by reentering the correct user name or

password with the 'user' FTP command.

• The maximum number of simultaneous connections to the FTP server is 10. However, depending on the FTP client, it may

make multiple simultaneous connections, so an FTP client may not be able to login even if 10 clients are not connected. In

this situation, shutdown all the FTP clients, then restart and connect them.

• When transferring many files at once with FTP, a 426 error (data connection error) may occur. In this situation, split the files

into multiple parts then transfer them separately.

• When Internet Explorer is used for FTP access, the user authentication screen may not be displayed due to the Internet

Explorer specification. In such a case, enter the high speed data logger module's address in the following format.

ftp://<user name>:<password>@<high speed data logger module's address or hostname>/

12

Page 15

• When Internet Explorer is used for FTP access, data logging files, event logging files, report files, and recipe files may not

open directly due to the Internet Explorer specification. Make sure to open the files after saving them to a personal

computer.

• When Internet Explorer is used for FTP access, due to the Internet Explorer specification, errors may not be displayed even

if the transfer failed when files are transferred to the SD memory card which does not have enough free space. Update the

display and check if the files are transferred normally.

• When Internet Explorer is used for FTP access, a retry is performed at user authentication failure due to the Internet

Explorer specification. Note that unintentional repeated entry of wrong passwords may lock the module.

■Connecting GX LogViewer

• The maximum number of connections for GX LogViewer to access the high speed data logger modules simultaneously is 2.

■Connecting configuration tools

• Note that the module may be in an unintended status when operating it from multiple configuration tools at the same time.

Considerations for security

• Although the high speed data logger module supports basic authentication (account setting) using user names and

passwords, it does not completely protect the system from illegal access. Avoid accounts (user name, password) consisting

of simple alphanumeric characters only, and include some non-alphanumeric characters ($, &, ?) to create a complicated

user name and password.

Considerations for using SD memory cards

■SD memory card file/directory

• Do not create files (excluding module operating files and recipe files) or folders on the SD memory card with a personal

computer. If files or folders are created on the SD memory card with a personal computer, they may be deleted.

■SD memory card to be used

• Use SD memory cards manufactured by Mitsubishi Electric Corporation. If any other SD memory cards are used, a failure

such as data corruption on the SD memory card or a system shutdown (module major error (error code: 2450H) occurs in

the CPU module) may occur during an operation. (Page 71 Connection System Equipment)

■When turning OFF or resetting the CPU module

• When a CPU module is powered OFF or reset while writing data to an SD memory card, the processing to write data to the

SD memory card may not be completed. It may cause a loss of logging data during the processing, corruption of data in the

SD memory card that is being accessed, or occurrence of a file system error. The file is automatically recovered when the

high speed data logger module is powered ON again, but it will not succeed in some cases.

The operation, powering OFF or resetting the CPU module after stopping file access, should be considered. For the

important data, a periodic backup is recommended.

(Page 65 File access stop processing method)

13

Page 16

■When removing or replacing the SD memory card

• Make sure to stop file access before removing or replacing the SD memory card.

(Page 65 File access stop processing method)

• Not following the procedure may cause a loss of logging data during processing, corruption of data in the SD memory card

that is being accessed, a file system error, or false recognition of the mounting status of the SD memory card.

(Page 63 Operations for removing and reinserting SD memory card)

• If an error occurs on the SD memory card, refer to the following manual.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

• High speed data logger module settings are saved to the SD memory card. Therefore, the high speed data logger module's

IP address returns to the initial status (192.168.3.3) when the SD memory card is not inserted in the module or when the

power is turned OFF to ON or the CPU module is reset, without the settings written to the SD memory card. When

necessary, read the current settings before removing the SD memory card and after replacing the card, promptly write

those settings to the new card.

■SD memory card capacity

• Access speed to the SD memory card is affected by the amount of saved files. In particular, access speed becomes

extremely slow when files are saved up to the capacity limit of the SD memory card. Use the SD memory card maintaining

10% or more free space on the card.

• A minimum size occupied by the files on the hard disk varies depending on the SD memory card capacity. Therefore, the

actual file size and the occupied file size on the hard disk may differ.

■SD memory card diagnostic time

• The high speed data logger module performs diagnostics (file recovery, etc.) of the inserted SD memory card contents at

the times listed below.

When powering OFF to ON or resetting the CPU module

When inserting an SD memory card while the power is ON

• The SD memory card diagnostic time takes longer when there are more files on the card. 100 files takes approximately 5

seconds, and 1000 files takes approximately 10 seconds.

• When many files are saved on the SD memory card, the following operations require longer time. Delete unnecessary files.

'SD memory card status' (X1) startup time

Time before the high speed data logger module can start processing ('Module READY' (X0) or 'Module operating status'

(X5) startup time)

■Formatting SD memory card

• Use the format function of the configuration tool to format an SD memory card.

• Do not format an SD memory card using the format function of Windows.

• Do not reset the control CPU or turn the power OFF when formatting an SD memory card.

• High speed data logger module settings are saved to an SD memory card. Therefore, all settings are lost when formatting

the SD memory card. When necessary, read the current settings before formatting, and promptly write those settings after

formatting. The IP address of the high speed data logger module returns to the initial status (192.168.3.3) when turning the

power OFF to ON or when resetting the module without writing the settings to the SD memory card.

14

Page 17

■SD memory card life span (Limit on writing)

• An SD memory card has a limited life span (limit on writing). For details, refer to the following manual.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

■RECIPE folder

• The maximum number of recipe files that can be stored in the RECIPE folder is 256. Storing large numbers of files in the

RECIPE folder causes a longer processing time for the following operations. Delete unnecessary files.

Displaying or operating the file browser

Displaying a file list of recipe execution operation

Recipe execution operation

• Do not store any files other than recipe files in the RECIPE folder.

■Write protect switch

• Make sure that the write protect switch of the memory card is in the unlocked position. When the write protect switch is in

the locked position, no file can not be written on the SD memory card.

Considerations for the recipe function

■Recipe files

• For recipe file names, use the characters usable in file names and folder (directory) names only.

■Recipe execution operation

• Before performing the recipe execution operation, write the high speed data logger module settings using the configuration

tool, then set the module operating status to "In operation". The module operating status can be checked on the "Module

Diagnostic" screen.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

• The recipe execution operation can be performed to the control CPU only. It cannot be performed to a CPU module on

another station.

• Do not power OFF or reset the CPU module during the recipe execution operation. The recipe file being edited may be

damaged. Power OFF or reset the CPU module after confirming the completion of the recipe execution operation.

15

Page 18

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC iQ-R series programmable controllers.

This manual describes the performance specifications, procedures up to operation, wiring, and operation examples to use the

module listed below.

Before using the product, please read this manual and relevant manuals carefully and develop familiarity with the

performance of MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the example programs provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

The program examples shown in this manual are the examples in which the high speed data logger module

(RD81DL96) is assigned to the input/output No. X/Y0 to X/Y1F unless otherwise specified. To use the

program examples shown in this manual, the input/output number assignment is required. For details on the

assignment of input/output number, refer to the following manual.

MELSEC iQ-R Module Configuration Manual

Relevant product

RD81DL96

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated into other

machinery or equipment, certain measures may be necessary. Please refer to one of the following manuals.

• MELSEC iQ-R Module Configuration Manual

• Safety Guideline (included in Base unit)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage Directives.

Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to one of the following manuals.

• MELSEC iQ-R Module Configuration Manual

• Safety Guideline (included in Base unit)

16

Page 19

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CONSIDERATIONS FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

CHAPTER 1 PART NAMES 21

CHAPTER 2 SPECIFICATIONS 23

2.1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Transmission and interface specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2 Accessible Routes and Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Accessible CPU modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Accessible routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Accessible devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Bit specification/digit specification of devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Device specification with labels/comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Access units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.3 File Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Folder structure of the SD memory card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Folder structure at the time of file transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.4 Range of Values per Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

CONTENTS

CHAPTER 3 FUNCTION LIST 46

3.1 Function List of a High Speed Data Logger Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.2 Function List of Configuration Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CHAPTER 4 PROCEDURES PRIOR TO OPERATION 49

4.1 Start up of High Speed Data Logger Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Procedure to operate by installing the configuration tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Procedure to operate without installing the configuration tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configuration tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.2 SD Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Operations for inserting SD memory card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Operations for removing and reinserting SD memory card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Operations for replacing new SD memory card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

File access stop processing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

SD memory card insertion/removal method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

CHAPTER 5 SYSTEM CONFIGURATION 67

5.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Overall system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Software configuration of the high speed data logger module tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

System configuration when installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

17

Page 20

System configuration for the initial setup, maintenance, and inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

System configuration during operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.2 Connection System Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.3 Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.4 Considerations for System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Considerations for using C Controller module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.5 Supported Software Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

CHAPTER 6 WIRING 75

6.1 Wiring of an Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.2 Wiring considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

CHAPTER 7 INSTALLATION AND UNINSTALLATION 77

7.1 Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Environment after installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.2 Uninstallation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Environment after uninstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

CHAPTER 8 OPERATION EXAMPLE 79

8.1 Preparing for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Preparing equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

System construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2 Logging Data before and after Trigger Occurrence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Equipment figure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Operation flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Data logging settings (trigger logging). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Write settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Graphical display of data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.3 Creating Reports from Continuously Logged Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Equipment figure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Operation flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Data logging settings (continuous logging) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Report settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Write settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Checking created report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

18

APPENDIX 114

Appendix 1 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

INDEX 116

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Page 21

RELEVANT MANUALS

Manual name [manual number] Description Available form

MELSEC iQ-R High Speed Data Logger Module

User's Manual(Startup)

[SH-081561ENG] (this manual)

MELSEC iQ-R High Speed Data Logger Module

User's Manual(Application)

[SH-081562ENG]

This manual does not include detailed information on the following:

• General specifications

• Applicable CPU modules and the number of mountable modules

• Applicable remote head modules and the number of mountable modules

• Installation

For details, refer to the following manual.

MELSEC iQ-R Module Configuration Manual

e-Manual refers to the Mitsubishi FA electronic book manuals that can be browsed using a dedicated tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• Hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

Explains the specifications, procedures before operation, wiring, and operation

examples of high speed data logger modules.

Explains the functions, configuration tool, parameter setting, troubleshooting, I/

O signal, and buffer memory of high speed data logger modules.

Print book

e-Manual

PDF

Print book

e-Manual

PDF

19

Page 22

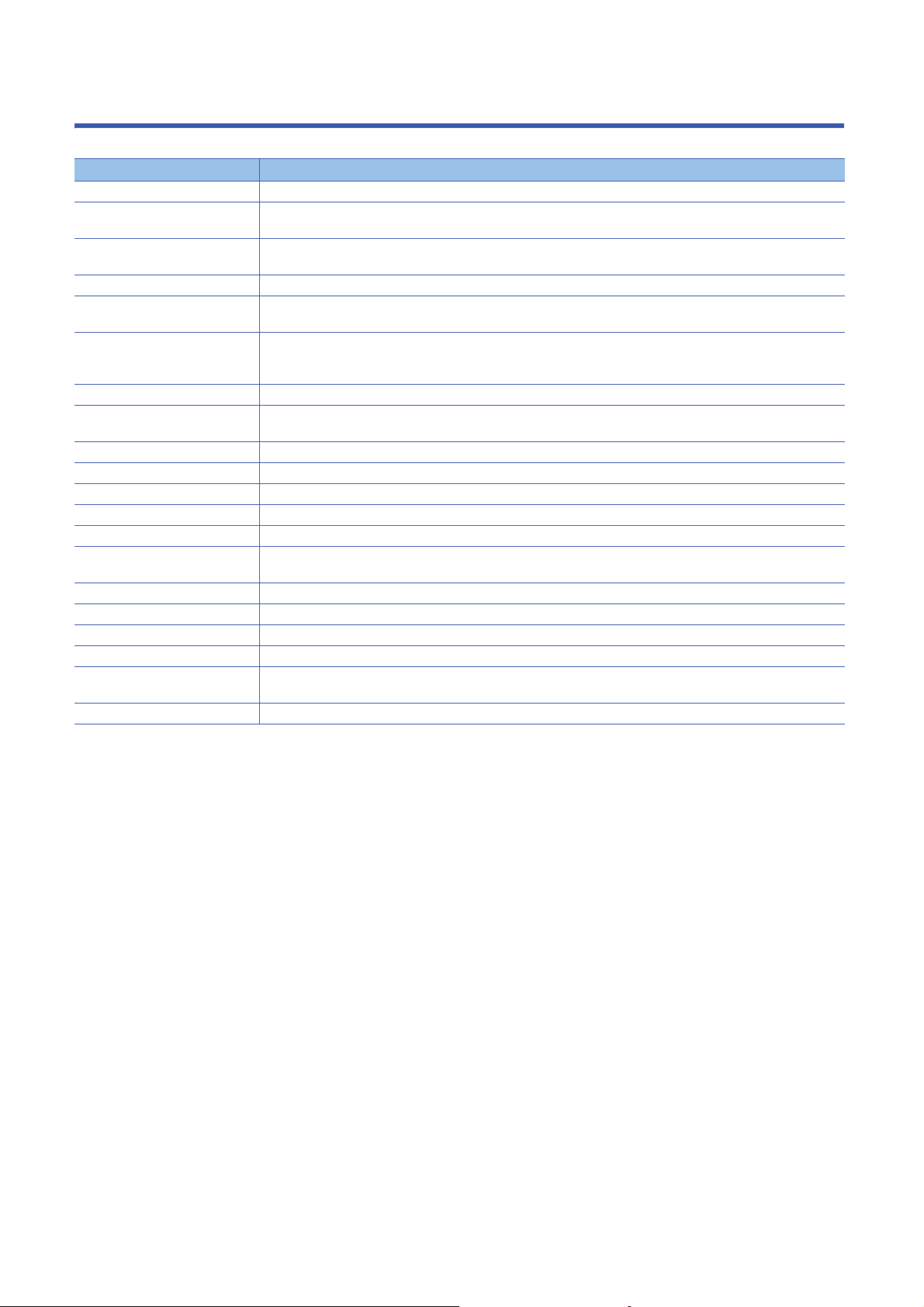

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

Account A right to use a high speed data logger module or an ID necessary when using the module.

Auto logging A function to automatically start logging when a SD memory card with the auto logging settings written to it in advance is

inserted in a running high speed data logger module.

Configuration tool An abbreviation for MELSEC iQ-R High Speed Data Logger Module Configuration Tool.

This tool configures and maintains the high speed data logger module.

Data logging A function to log CPU module device values at the specified data sampling interval.

Data logging file A file where the data sampled by the high speed data logger module is saved in the format specified with the

Engineering tool A tool for setting, programming, debugging, and maintaining programmable controllers.

Event logging A function to monitor device values sampled by a CPU module and to log occurred events.

Event logging file A file where the events sampled by a high speed data logger module are saved in the format specified with the

GX LogViewer An abbreviation for GX LogViewer Version 1.

High speed data logger module An abbreviation for MELSEC iQ-R series-compatible RD81DL96 high speed data logger module.

High speed data logger module tool An abbreviation for the high speed data logger module tool (SW1DNN-RDLUTL).

LCPU A generic term for MELSEC-L series CPU module.

Logging file A generic term for the data logging file and event logging file.

POP before SMTP One type of authorization method specified when sending e-mail. By accessing the specified POP3 server in advance

QCPU (Q mode) A generic term for the MELSEC-Q series CPU modules and MELSEC-Q series C Controller modules.

RCPU A generic term for the MELSEC iQ-R series CPU modules and MELSEC iQ-R series C Controller modules.

RnENCPU A generic term for R04ENCPU, R08ENCPU, R16ENCPU, R32ENCPU, and R120ENCPU.

RnPCPU A generic term for R08PCPU, R16PCPU, R32PCPU, and R120PCPU.

SMTP-Auth One type of authorization method specified when sending e-mail. The user's account and password are authenticated

Windows 8 or later A generic term for Windows 8, Windows 8.1, and Windows 10.

configuration tool.

For the supported tools, refer to the following manual.

MELSEC iQ-R Module Configuration Manual

configuration tool.

before sending an e-mail, this method grants permission to use the SMTP server.

between the SMTP server and user, and this method sends e-mail only if they are authenticated.

20

Page 23

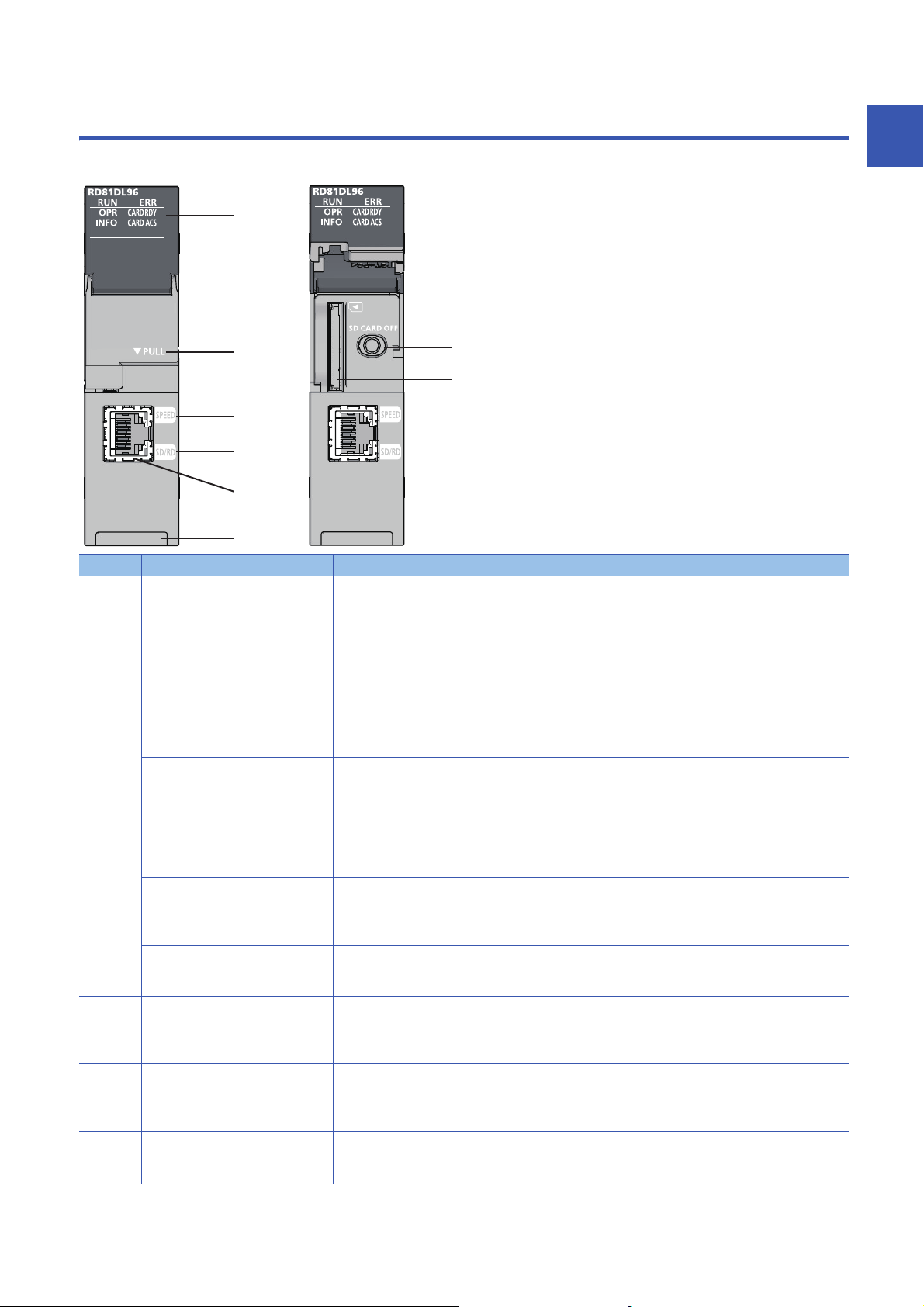

1 PART NAMES

(2)

(3)

(4)

(8)

(5)

(1)

(6)

(7)

This chapter shows the part names of a high speed data logger module.

1

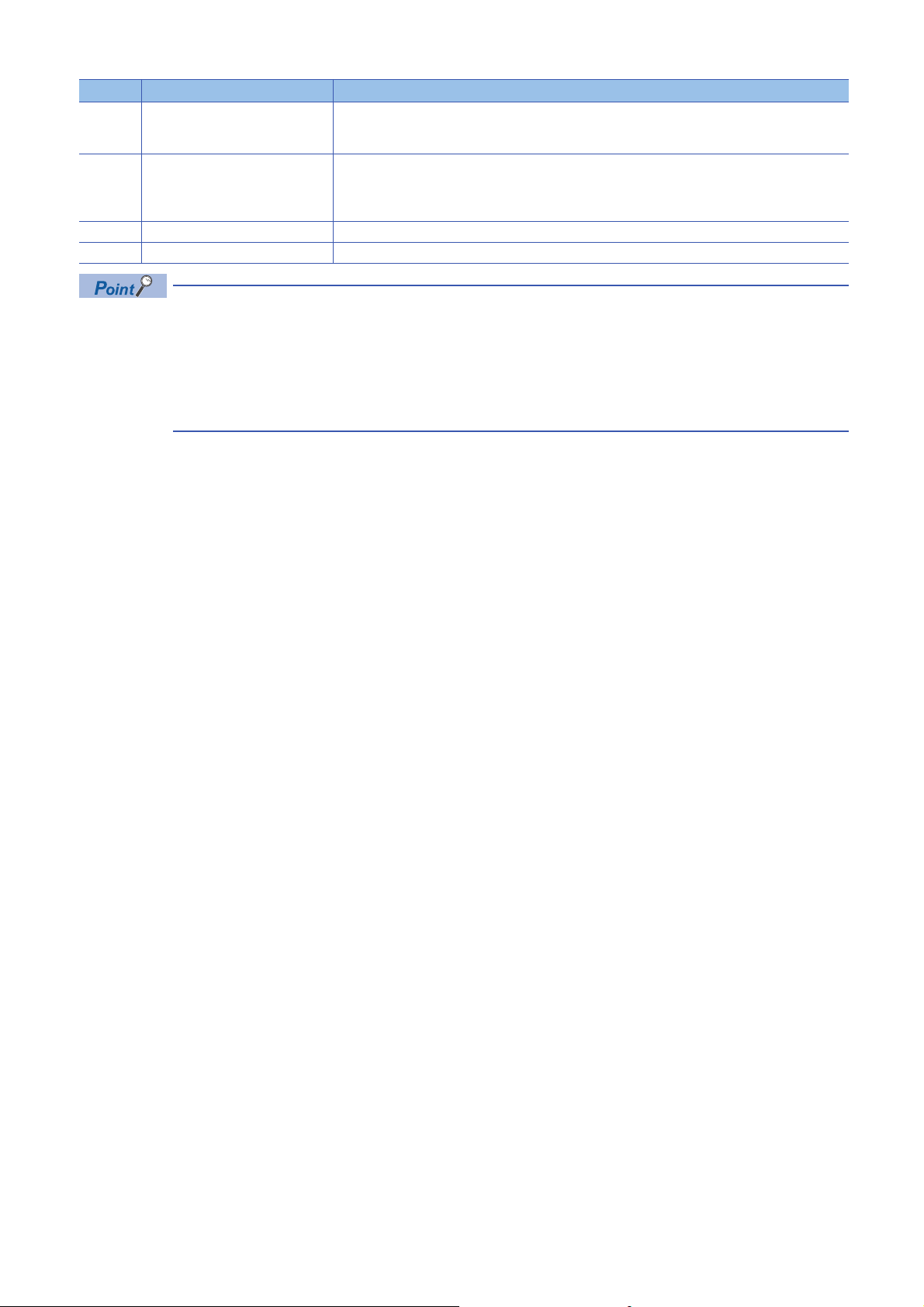

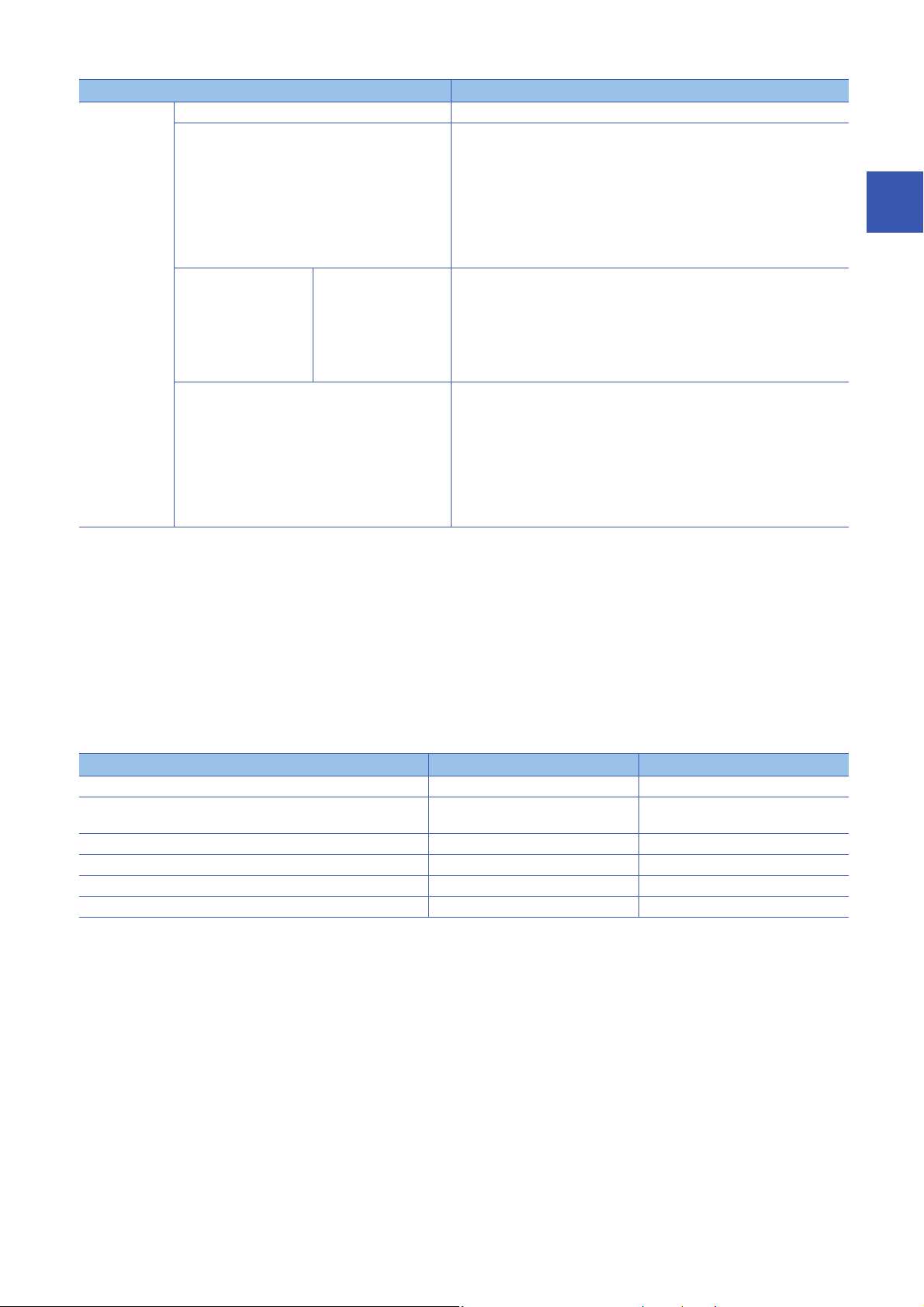

No. Name Description

(1) RUN LED Indicates the operating status.

ERR LED Indicates the error status.

OPR LED Indicates the module status.

INFO LED Indicates every information.

CARD RDY LED Indicates the availability of the SD memory card.

CARD ACS LED Indicates the access status of the SD memory card.

(2) Slot cover A cover of the SD memory card slot and the SD memory card lock switch.

(3) SPEED LED Indicates the communication speed and the link status for Ethernet.

(4) SD/RD LED Indicates the data sending/receiving status for Ethernet.

• ON: In operation

• Flashing: Checking module, selecting the module for online module change

(Flashes for 10 seconds in "Checking module" when the [Checking module] button is pressed on the

"Find High Speed Data Logger Module" screen of the configuration tool.)

• OFF: Watchdog timer error (hardware failure), module replacement allowed in the process of the online

module change

• ON: Minor error occurring/WDT error occurring (hardware error)

• Flashing: Moderate error or major error

• OFF: In normal status

• ON: Module operating status is in operation

• Flashing: Module operating status is initializing (update settings, etc.) and stopping

• OFF: Module operating status is stopped

• ON: Warning

• OFF: In normal status

• ON: SD memory card accessible status (mounted status)

• Flashing: SD memory card mounting/unmounting

• OFF: SD memory card inaccessible status (not installed/Unmounted)

• ON: Accessing SD memory card

• OFF: SD memory card not accessed

Open this cover to insert/remove an SD memory card or to operate the switch.

Close the cover unless inserting/removing an SD memory card or operating the switch to prevent foreign

material intrusion such as dust.

• ON (orange): Linking-up (1000 Mbps)

• Flashing (green): Linking-up (100 Mbps)

• OFF: Linking-down or linking-up (10 Mbps)

• ON: Sending/receiving data

• OFF: No data sending/reception

1 PART NAMES

21

Page 24

No. Name Description

(5) Ethernet port A port for connecting a high speed data logger module to 10BASE-T/100BASE-TX/1000BASE-T

(High speed data logger modules distinguish among 10BASE-T, 100BASE-TX, and 1000BASE-T

according to an external device.)

(6) SD memory card lock switch

(SD CARD OFF button)

(7) SD memory card slot A slot to insert an SD memory card.

(8) Product information marking Displays the product information (16 digits) of the module.

A switch for disabling access to an SD memory card to remove it.

Removing an SD memory card is prohibited while the CARD RDY LED is ON or flashing.

For inserting and removing an SD memory card, refer to the following section.

Page 62 SD Memory Card

• When checking the module at online module change, the RUN LED of the high speed data logger module

and the READY LED of the CPU module flash for more than 10 seconds at the same time.

Make sure to check not only the RUN LED also the READY LED of the CPU module.

• The cause of the INFO LED lightning can be checked with the INFO LED information on the "Module

Diagnostics" screen or buffer memory. Check the cause of LED lightning and take corrective actions.

(MELSEC iQ-R High Speed Data Logger Module User's Manual(Application))

22

1 PART NAMES

Page 25

2 SPECIFICATIONS

This chapter explains the performance specifications and accessible devices/device range of a high speed data logger

module.

2.1 Performance Specifications

The following table shows the performance specifications of a high speed data logger module.

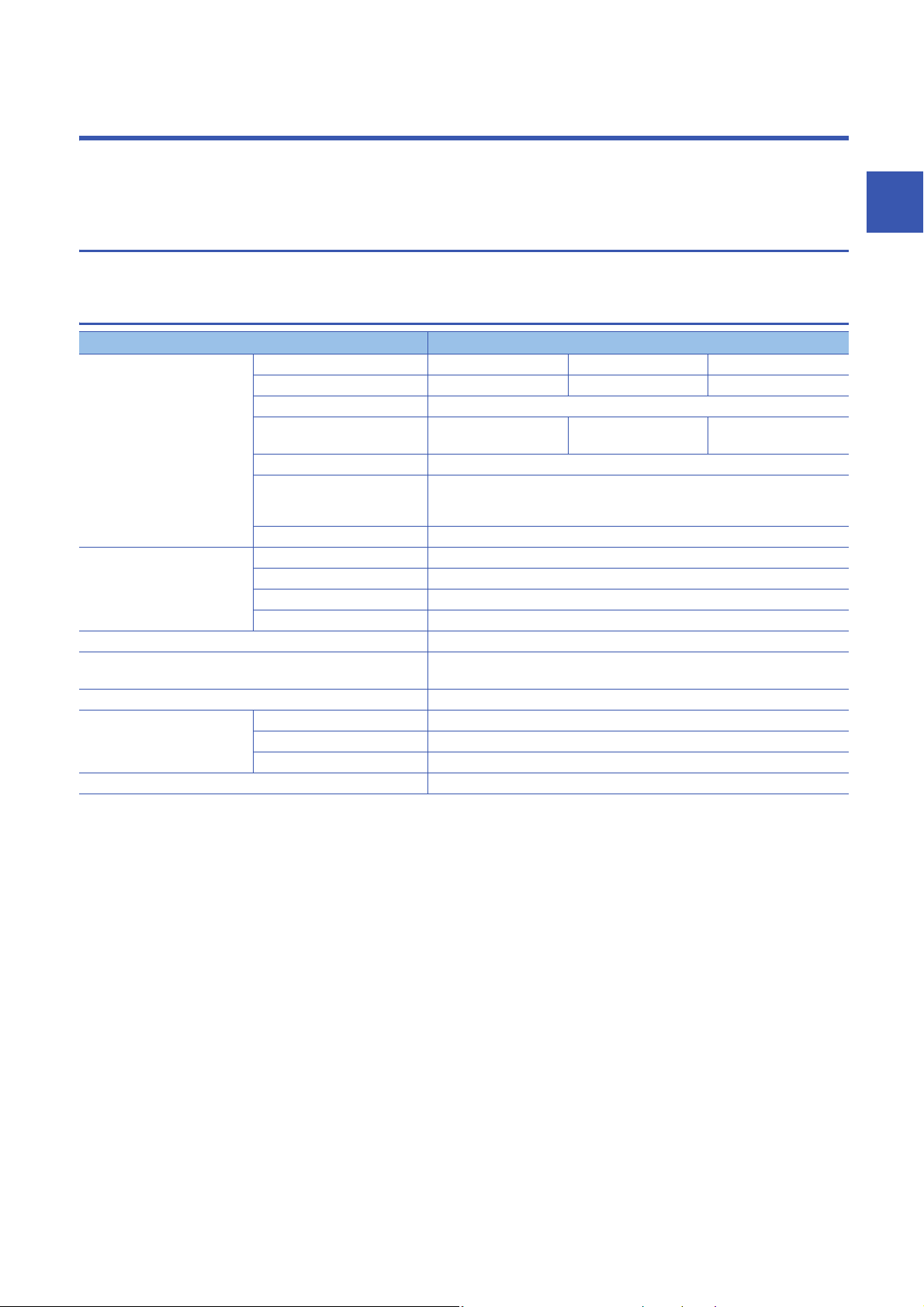

Transmission and interface specifications

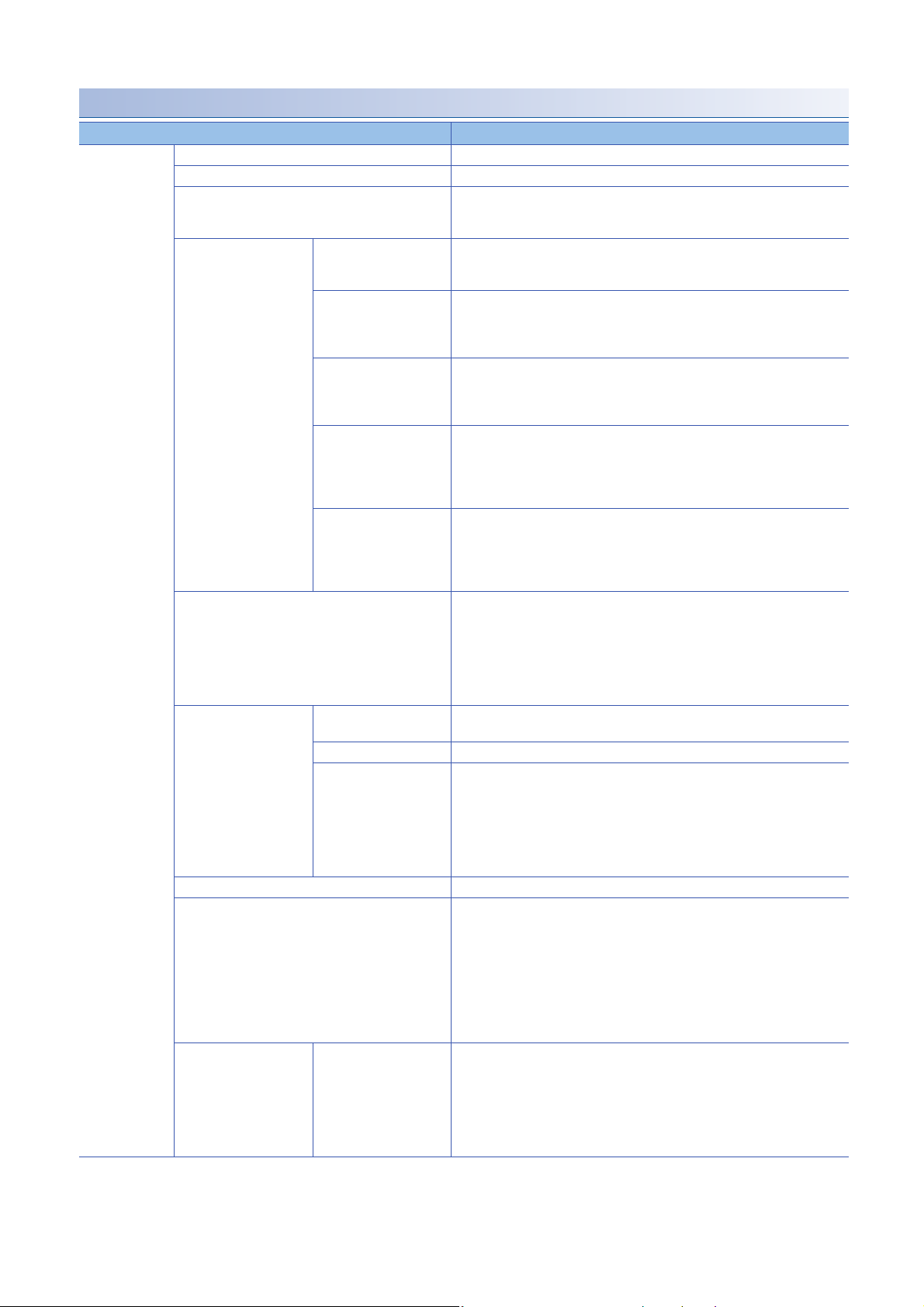

Item Specification

Ethernet Interface 1000BASE-T 100BASE-TX 10BASE-T

Data transmission rate 1 Gbps 100 Mbps 10 Mbps

Transmission method Base band

Number of cascade connections

(When using a repeater hub)

Maximum segment length 100 m (length between a hub and a node)

Supported function Auto-negotiation (automatic recognition of the communication speed/communication

IP version IPv4 supported

SD memory card slot Supply power voltage 3.3 VDC

Supply power capacity Up to 200 mA

Interface SD memory card/SDHC memory card

Number of insertable cards 1 card

Number of occupied I/O points 32 points (I/O assignment: Intelligent 32 points)

Clock Acquired from a CPU module (CPU No.1 in a multiple CPU system).

5 VDC internal current consumption 1.1 A

External dimensions Height 106 mm

Width 27.8 mm

Depth 110 mm

Weight 0.24 kg

Maximum 2 levels Maximum 4 levels

method)

Auto-MDI/MDI-X (automatic recognition of a straight/crossing cable)

Time accuracy after obtaining the time, daily error of ±9.504 seconds

2

2 SPECIFICATIONS

2.1 Performance Specifications

23

Page 26

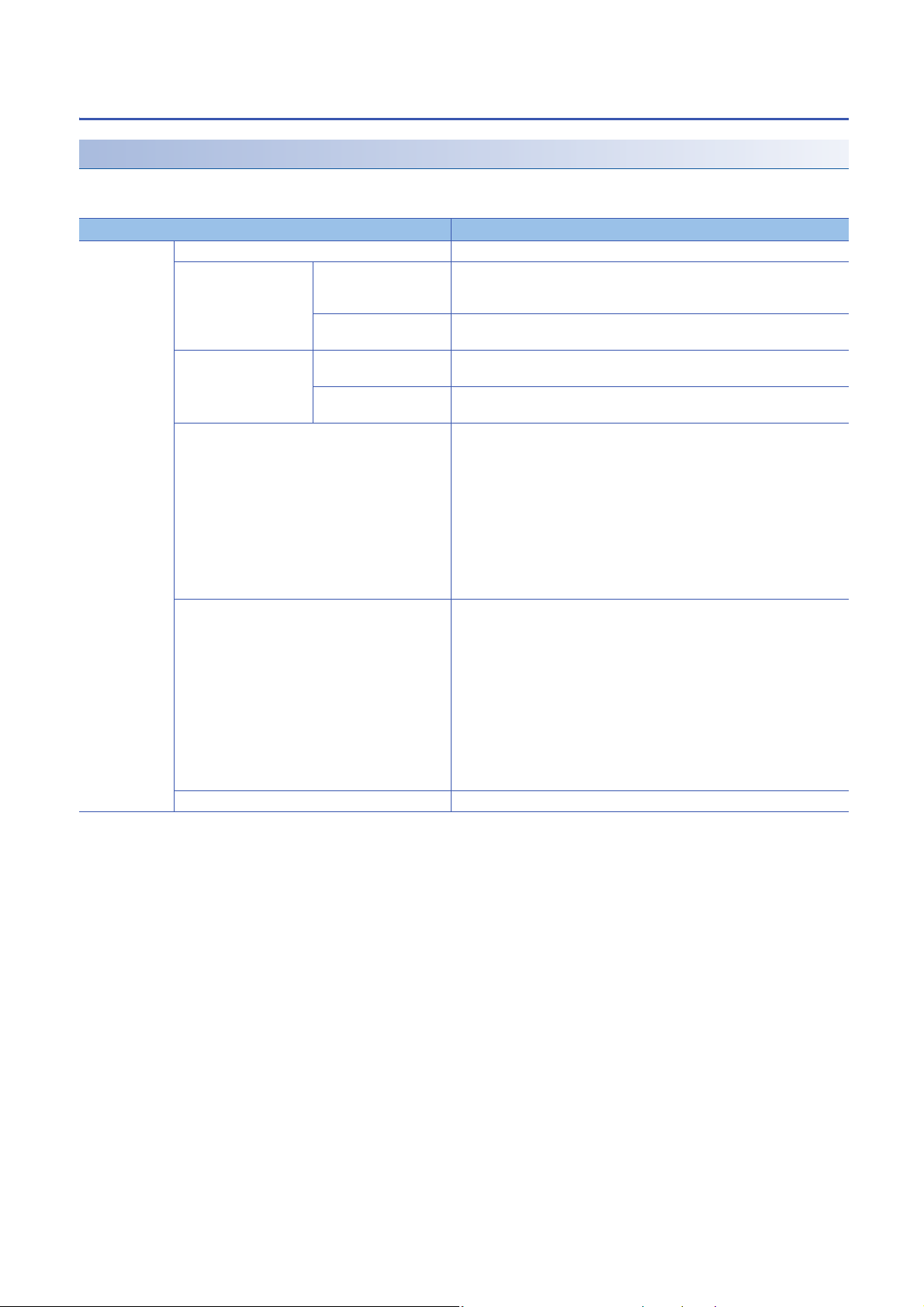

Functional specifications

Data sampling performance specifications

The following table lists the specifications for the data sampling used for the data logging function, the event logging function,

and the report function.

Item Specifications

Data sampling Number of access target CPUs Maximum 64 CPUs

Sampling interval High speed sampling • Sequence scan time synchronization

• 0.5 to 0.9 milliseconds, 1 to 32767 milliseconds (for trigger logging)

• 2 to 32767 milliseconds (for continuous logging)

Number of units of

sampled data

Data type

Data output format

(Unicode text file, CSV file)

Scaling

*1,*2,*3

*6

*8

*9

General sampling • 0.1 to 0.9 seconds, 1 to 32767 seconds

High speed sampling Total number of units of data: 32768 (per setting: 1024)

General sampling Total number of units of data: 65536 (per setting: 1024)

• Time interval specification (specify hour/minute/second)

*4,*5

Total number of device points: 32768

Total number of device points: 262144 (per setting: 4096)

•Bit

• Word [Signed]

• Double Word [Signed]

• Word [Unsigned]/Bit String [16-bit]

• Double Word [Unsigned]/Bit String [32-bit]

• FLOAT [Single Precision]

• FLOAT [Double Precision]

• 16bit BCD

• 32bit BCD

• String: 1 to 8192 characters

• Raw: 1 to 8192 bytes

•Bit

• Decimal format: 0 to 14 digits after the decimal point

• Exponential format: 0 to 14 digits after the decimal point

• Hexadecimal format

•String

•Raw

■For trigger logging (output only one line after triggering), following conditions

can be specified.

• Time/Total time

Decimal format: 0 to 4 digits after the decimal point

• Count/Total count

Decimal format: 0 digit after the decimal point

Basic arithmetic operations: calculations combining (×, ÷) and (+, -)

*7

(per setting: 4096)

24

2 SPECIFICATIONS

2.1 Performance Specifications

Page 27

*1 The number of device points available for a piece of data differs depending on the data type.

*2 The total number of sampling data of data logging, event logging, and report data.

*3 The total number of units of sampled data per setting is as follows only when the creation trigger and current value data are not

synchronized in the report setting.

Total number of units of data (per setting): 65535, device points (per setting): 65535

However, note that the number of device points per setting of data excluding the current value data is up to 4096.

*4 In high-speed sampling, target data is sampled by synchronizing with a sequence scan from a control CPU module by using the

sequence scan synchronization sampling function of a control CPU module.

When multiple intelligent function modules use the sequence scan synchronization sampling function, note the total number of points for

target data. If it exceeds the number of points that can be sampled, an error may occur in registration processing of an intelligent

function module registered later.

*5 If the number of device points for high speed sampling is increased, an error may occur when updating the settings. If an error occurred,

take the following corrective action.

⋅ Check the settings of other intelligent function modules controlled by the control CPU module, and adjust it so that the total number of

device points for the sequence scan synchronization sampling function does not exceed the number of points that can be sampled.

⋅ Power OFF to ON, or reset the control CPU.

⋅ Return the number of device points to the original settings.

*6 The data type when reading data from the device memory in the CPU module.

*7 The number of characters is determined by the specified size.

For Unicode text file and binary file format, the maximum number of characters is 4096 characters because one character contains two

bytes.

*8 The format when data is output to Unicode text file or CSV file with data logging or event logging.

Binary files are output in the binary format.

Reports are output in Excel cell format.

*9 A function to perform data scaling and offset calculations.

■Target sampling data

Type Data type

Data logging Logging target data, trigger condition data, period condition data, file switching condition data, saved file name data,

saved folder name data, e-mail transmission data

Event logging Monitoring data, period condition data, file switching condition data, saved file name data, saved folder name data, e-

mail transmission data

Report Current value data, creation trigger condition data, period condition data, saved file name data, saved folder name

data, e-mail transmission data

2

The data logging, event logging, and report functions are best effort functions.

Since module processing time changes according to the settings and status of other devices, it may not

operate with the set data sampling interval.

Run the system by fully verifying the processing time of each function when constructing it.

For processing time, refer to the following manual.

MELSEC iQ-R High Speed Data Logger Module User's Manual(Application)

2 SPECIFICATIONS

2.1 Performance Specifications

25

Page 28

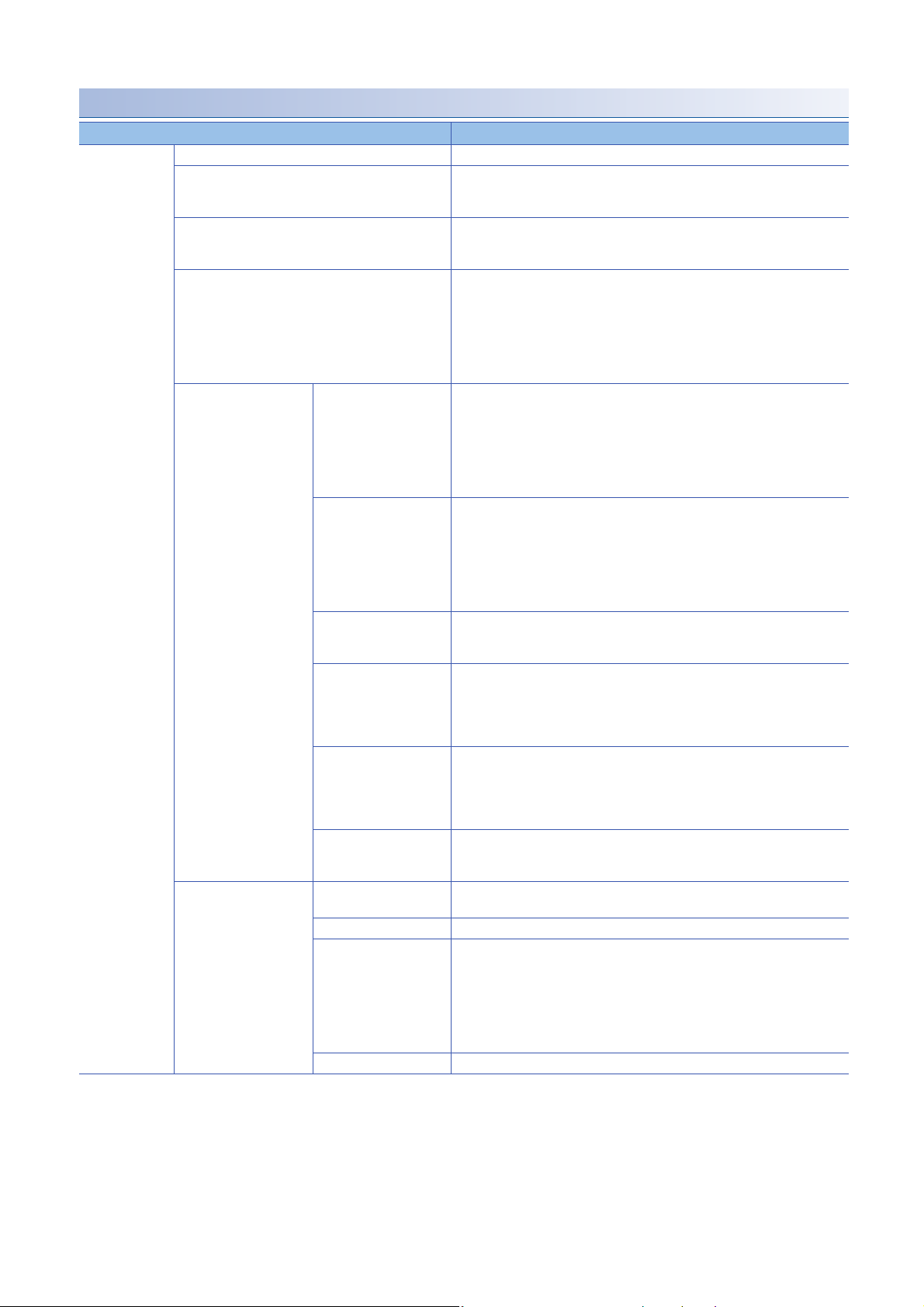

Data logging performance specifications

Item Specifications

Data logging Number of settings Up to 64

Logging type • Continuous logging

File format

Period Specify the applicable period or exclusion period.

Trigger logging Trigger condition

File switching timing Number of lines (number

*2

(Single condition)

Trigger condition

(Compound condition OR combine)

Trigger condition

(Compound condition AND combine)

Trigger condition

(Compound condition Number of times)

Trigger condition

(Compound condition Order)

Number of logging lines

of records) specification

File size specification 10 to 16384 KB

Condition specification • Data conditions (comparison): Bit ON/OFF, compare data to constant value,

Trigger logging unit At the time of trigger logging file output completion

*4

*1

• Trigger logging (output only one line after triggering)

• Trigger logging (output the lines before and after triggering)

• Unicode text file (extension: .TXT)

• CSV file (extension: .CSV)

• Binary file (extension: .BIN)

• Data condition: Bit ON/OFF, compare data to constant value, compare data to

data

• Date range: Specify the start and end in month and day

• Time range: Specify the start and end in hour, minute, and second

• Day of the week/Week of the month conditions: Specify the day of the week

and week

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (value change)

• Fixed cycle: 1 to 86400 seconds

• Time interval specification: Specify hour/minute/second

• Time specification: Specify month, day, hour, minute, second

• At module startup

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (value change)

• Fixed cycle: 1 to 86400 seconds

• Time interval specification: Specify hour/minute/second

• Time specification: Specify month, day, hour, minute, second

• At module startup

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

Specify the start condition, terminal condition, and count condition. (Up to 3

conditions)

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (value change)

Specify the start condition and order (1st condition, 2nd condition, or 3rd

condition). (Up to 4 conditions)

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (value change)

• Before trigger occurs: 0 to 65534 lines

• After trigger occurs: 1 to 65535 lines

The sum of lines of before and after trigger occurrence is up to 65535 lines.

100 to 100000 lines

compare data to data

• Data conditions (value change)

• Fixed cycle: 1 to 86400 seconds

• Time interval specification: Specify hour/minute/second

• Time specification: Specify month, day, hour, minute, second

• At module startup

*3

26

2 SPECIFICATIONS

2.1 Performance Specifications

Page 29

Item Specifications

Data logging Number of saved files

Saved file name ■Simple setting

Folder switching timing Condition specification • Data conditions (comparison): Bit ON/OFF, compare data to constant value,

Saved folder name ■Simple setting

*5

1 to 65535

• Add the name

• Add the date (4-digit year, month, day)

• Add the time (hour, minute, second)

• Add the sequential number

■Detailed setting

• 4-digit year/2-digit year, month, day, day of the week, hour, minute, second

• Device value (two types)

• Sequential number

compare data to data

• Data conditions (value change)

• Fixed cycle: 1 to 86400 seconds

• Time interval specification: Specify hour/minute/second

• Time specification: Specify month, day, hour, minute, second

• At module startup

• Add the name

• Add the date (4-digit year, month, day)

• Add the time (hour, minute, second)

• Add the sequential number

■Detailed setting

• 4-digit year/2-digit year, month, day, day of the week, hour, minute, second

• Device value (two types)

• Sequential number

*1 Up to 64 settings can be configured by combining data logging, event logging, and report function.

Of these, up to 32 settings can be configured for data logging, event logging, and report function when high speed sampling is specified.

*2 For the output file format, refer to the following manual.

MELSEC iQ-R High Speed Data Logger Module User's Manual(Application)

*3 By using the report function, data can be output again in Excel file format.

*4 The number of logging lines setting is affected by the amount of memory (trigger buffer) where sampled data is temporarily saved.

Since the amount of trigger buffer has an upper limit, there may be situations where the listed number of logging lines cannot be set.

Confirm the trigger buffer usage amount as given below. Do not exceed the upper limit.

MELSEC iQ-R High Speed Data Logger Module User's Manual(Application)

*5 When a subfolder is not created in the save folder, the number of saved files is in the range of 1 to 256.

2

■Restrictions on data logging

The restrictions on performance specifications of data logging are as follows.

Item High speed sampling General sampling

Total trigger buffer size Up to 20 MB in total using 32 settings*1Up to 20 MB in total using 64 settings

Total number of period condition, trigger condition, file switching

condition, and folder switching condition

Period condition Up to 4 conditions Up to 8 conditions

Trigger condition Up to 4 conditions Up to 8 conditions

File switching condition Up to 4 conditions Up to 8 conditions

Folder switching condition Up to 4 conditions Up to 8 conditions

*1 Size of the combined high speed sampling and general sampling.

When 20 MB is used for high speed sampling, trigger logging of general sampling cannot be added.

Up to combination of 5 conditions Up to combination of 10 conditions

*1

2 SPECIFICATIONS

2.1 Performance Specifications

27

Page 30

Event logging performance specifications

Item Specifications

Event logging Number of settings Up to 64

Number of events Up to 256 per event logging setting

File format

Event condition Event condition

Period Specify the applicable period or exclusion period.

File switching timing Number of lines (number

Number of saved files

Saved file name ■Simple setting

Folder switching timing Condition specification • Data conditions (comparison): Bit ON/OFF, compare data to constant value,

*2

(Single condition)

Event condition

(Compound condition Comparison - AND

combine)

Event condition

(Compound condition Comparison - OR

combine)

Event condition

(Compound condition Number of times)

Event condition

(Compound condition Order)

of records) specification

File size specification 10 to 16384 KB

Condition specification • Data conditions (comparison): Bit ON/OFF, compare data to constant value,

*3

*1

• Unicode text file (extension: .TXT)

• CSV file (extension: .CSV)

• Binary file (extension: .BIN)

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (value change)

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

Specify the start condition, terminal condition, and count condition. (Up to 3

conditions)

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (value change)

Specify the start condition and order (1st condition, 2nd condition, or 3rd

condition). (Up to 4 conditions)

• Data conditions (comparison): Bit ON/OFF, compare data to constant value,

compare data to data

• Data conditions (value change)

• Data condition: Bit ON/OFF, compare data to constant value, compare data to

data

• Date range: Specify the start and end in month and day

• Time range: Specify the start and end in hour, minute, and second

• Day of the week/Week of the month conditions: Specify the day of the week

and week

100 to 100000 lines

compare data to data

• Data conditions (value change)

• Fixed cycle: 1 to 86400 seconds

• Time interval specification: Specify hour/minute/second

• Time specification: Specify month, day, hour, minute, second