Page 1

Page 2

Page 3

SAFETY PRECAUTIONS

(Always read these instructions before using this product.)

Before using this product, thoroughly read this manual and the relevant manuals introduced in this manual

and pay careful attention to safety and handle the products properly.

The precautions given in this manual are concerned with this product. For the safety precautions of the

system, refer to the User's Manual for each controller.

In this manual, the safety precautions are ranked as " WARNING" and " CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to serious consequences according to the circumstances.

Always follow the precautions of both levels because they are important for personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in miner or moderate injury or property damage.

[Design Instructions]

WARNING

● When data change, program change, or status control is performed from a personal computer to a running controller,

create an interlock circuit outside the programmable controller to ensure that the whole system always operates safely.

Furthermore, for the online operations performed from a personal computer to a controller, the corrective actions against a

communication error due to such as a cable connection fault should be predetermined as a system.

[Startup/Maintenance Instructions]

CAUTION

● The online operations performed from a personal computer to a running controller (Program change, operating status

change such as RUN-STOP switching, and remote control operation) have to be executed after the manual has been

carefully read and the safety has been ensured.

When changing a program while a controller is RUN, it may cause a program corruption in some operating conditions.

Fully understand the precautions described in the manuals and Help function of each controller before use.

A - 1

Page 4

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi representative

in your region.

A - 2

Page 5

REVISIONS

The manual number is written at the bottom left of the back cover.

Print date Manual number

Oct., 2009 SH-080902ENG-A First edition

Apr., 2010 SH-080902ENG-B

Sep., 2010 SH-080902ENG-C

Model Addition

MELSEC-L series

Addition

CONDITIONS OF USE FOR THE PRODUCT, Section 3.4, Section 3.10

Correction

MANUALS, GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL,

Section 1.1, Section 1.2, Section 2.1, Section 3.3, Section 3.4, Section 3.5,

Section 3.6, Section 3.7, Section 3.8, Section 3.9, Section 3.10, Section 3.12,

Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 5.1, Section 5.2,

Section 6.2

Model Addition

MELSEC-FX series

Addition

Section 3.4, Section 3.10

Correction

GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL,

Section 1.1, Section 1.2, Section 2.1, Section 3.1, Section 3.3, Section 3.4,

Section 3.5, Section 3.6, Section 3.7, Section 3.8, Section 3.9, Section 3.11,

Section 3.13, Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 5.1,

Section 5.2, Section 6.2

Revision

Apr., 2011 SH-080902ENG-D

Nov., 2011 SH-080902ENG-E

Jun., 2012 SH-080902ENG-F

Nov., 2012 SH-080902ENG-G

Addition

GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL

Correction

HOW TO READ THIS MANUAL, Section 1.1, Section 1.2, Section 2.1, Section 3.1,

Section 3.3, Section 3.4, Section 3.5, Section 3.6, Section 3.7, Section 3.8,

Section 4.1, Section 4.2, Section 4.4, Section 5.1, Section 5.2, Section 6.2

Addition

MANUALS, GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL,

Section 3.4.4

Correction

Section 1.1, Section 1.2, Section 2.1, Section 3.1, Section 3.2, Section 3.3,

Section 3.4, Section 3.5, Section 3.8, Section 3.9, Section 3.11, Section 3.13,

Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 5.2, Section 6.1,

Section 6.2

Correction

Section 1.1, Section 1.2, Section 2.1, Section 3.4, Section 3.5, Section 3.8,

Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 6.2

Correction

Section 1.2, Section 3.2, Section 3.4, Section 3.11, Section 5.2

A - 3

Page 6

Print date Manual number

Revision

Jun., 2013 SH-080902ENG-H

Dec., 2013 SH-080902ENG-I

Addition

Section 3.4.5

Correction

Section 2.1, Section 3.4.1, Section 3.4.4, Section 3.11

Addition

Section 3.4.6, Section 3.4.7

Correction

MANUALS, GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL,

Section 3.4.2, Section 3.4.3, Section 3.4.4, Section 3.5.1, Section 3.6, Section 3.7,

Section 3.9, Section 3.11, Section 5.2

Japanese Manual Version SH-080763-J

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may occur

as a result of using the contents noted in this manual.

© 2009 MITSUBISHI ELECTRIC CORPORATION

A - 4

Page 7

INTRODUCTION

Thank you for purchasing the Mitsubishi integrated FA software, MELSOFT series.

Before using the product, thoroughly read this manual to develop full familiarity with the functions and performance

to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS ...................................................................................................................... A - 1

REVISIONS ........................................................................................................................................... A - 3

INTRODUCTION ................................................................................................................................... A - 5

CONTENTS ........................................................................................................................................... A - 5

MANUALS.............................................................................................................................................. A - 7

HOW TO READ THIS MANUAL .......................................................................................................... A - 11

GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL........................................................... A - 13

1OVERVIEW 1 - 1 to 1 - 10

1.1 MELSOFT iQ Works 1 - 2

1.2 Features 1 - 3

2 SCREEN CONFIGURATION 2 - 1 to 2 - 4

2.1 Screen Configuration 2 - 2

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR 3 - 1 to 3 - 60

3.1 Procedure of MELSOFT Navigator from Start to End 3 - 2

3.2 Starting MELSOFT Navigator 3 - 3

3.3 Creating Workspaces 3 - 4

3.4 Creating System Configuration Diagram 3 - 8

3.4.1 System configuration to be created.............................................................................................. 3 - 8

3.4.2 Creating module configuration diagrams......................................................................................3 - 9

3.4.3 Creating network configuration diagrams...................................................................................3 - 20

3.4.4 Creating CC-Link configuration diagrams...................................................................................3 - 22

3.4.5 Creating AnyWireASLINK configuration diagrams .....................................................................3 - 24

3.4.6 Creating Ethernet configuration diagrams ..................................................................................3 - 26

3.4.7 Creating CC IE Field configuration diagrams .............................................................................3 - 28

3.5 Creating Projects 3 - 30

3.5.1 Creating new projects.................................................................................................................3 - 30

3.5.2 Allocating projects to controllers................................................................................................. 3 - 35

3.6 Setting Parameters 3 - 38

3.7 Checking System Configuration 3 - 47

A - 5

Page 8

3.7.1 Checking system configuration .................................................................................................. 3 - 47

3.7.2 Checking power supply capacity and I/O points ........................................................................ 3 - 48

3.8 Editing Projects 3 - 49

3.8.1 Editing projects........................................................................................................................... 3 - 49

3.8.2 Utilizing existing projects (import) .............................................................................................. 3 - 50

3.9 Reading/Writing/Verifying Controller Data 3 - 53

3.10 Saving Workspaces 3 - 56

3.10.1 Saving workspaces with specified names .................................................................................. 3 - 56

3.10.2 Overwriting workspaces ............................................................................................................. 3 - 57

3.11 Printing Workspaces 3 - 58

3.12 Closing Workspaces 3 - 59

3.13 Exiting MELSOFT Navigator 3 - 60

4 USING SYSTEM LABELS 4 - 1 to 4 - 20

4.1 Registering System Labels in MELSOFT Navigator 4 - 2

4.1.1 Registering system labels in MELSOFT Navigator ...................................................................... 4 - 3

4.1.2 Assigning devices to system labels.............................................................................................. 4 - 5

4.1.3 Using system labels in GT Designer3 .......................................................................................... 4 - 8

4.2 Utilizing Existing Labels as System Labels 4 - 11

4.2.1 Registering labels as system labels ........................................................................................... 4 - 12

4.2.2 Using system labels in motion controller projects ...................................................................... 4 - 15

4.3 Using System Labels on another personal computer 4 - 17

4.4 Checking System Labels 4 - 19

5 CREATING SYSTEM BACKUP DATA 5 - 1 to 5 - 6

5.1 Setting Batch Read Password 5 - 2

5.2 Executing Batch Read Function 5 - 4

6 USING PROGRAM JUMP FUNCTION 6 - 1 to 6 - 5

6.1 Example of System Configuration 6 - 2

6.2 Program Jump Function 6 - 3

A - 6

Page 9

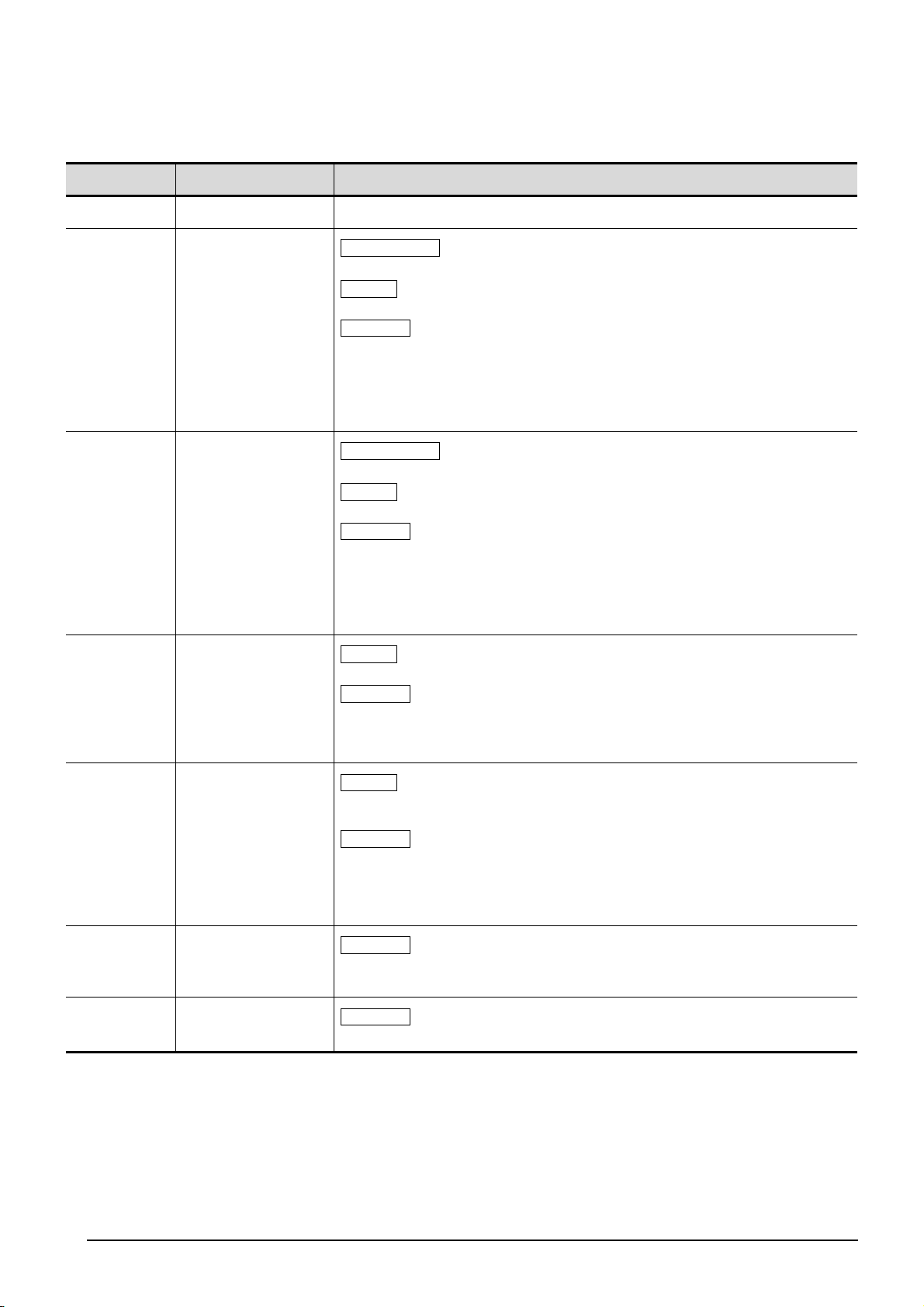

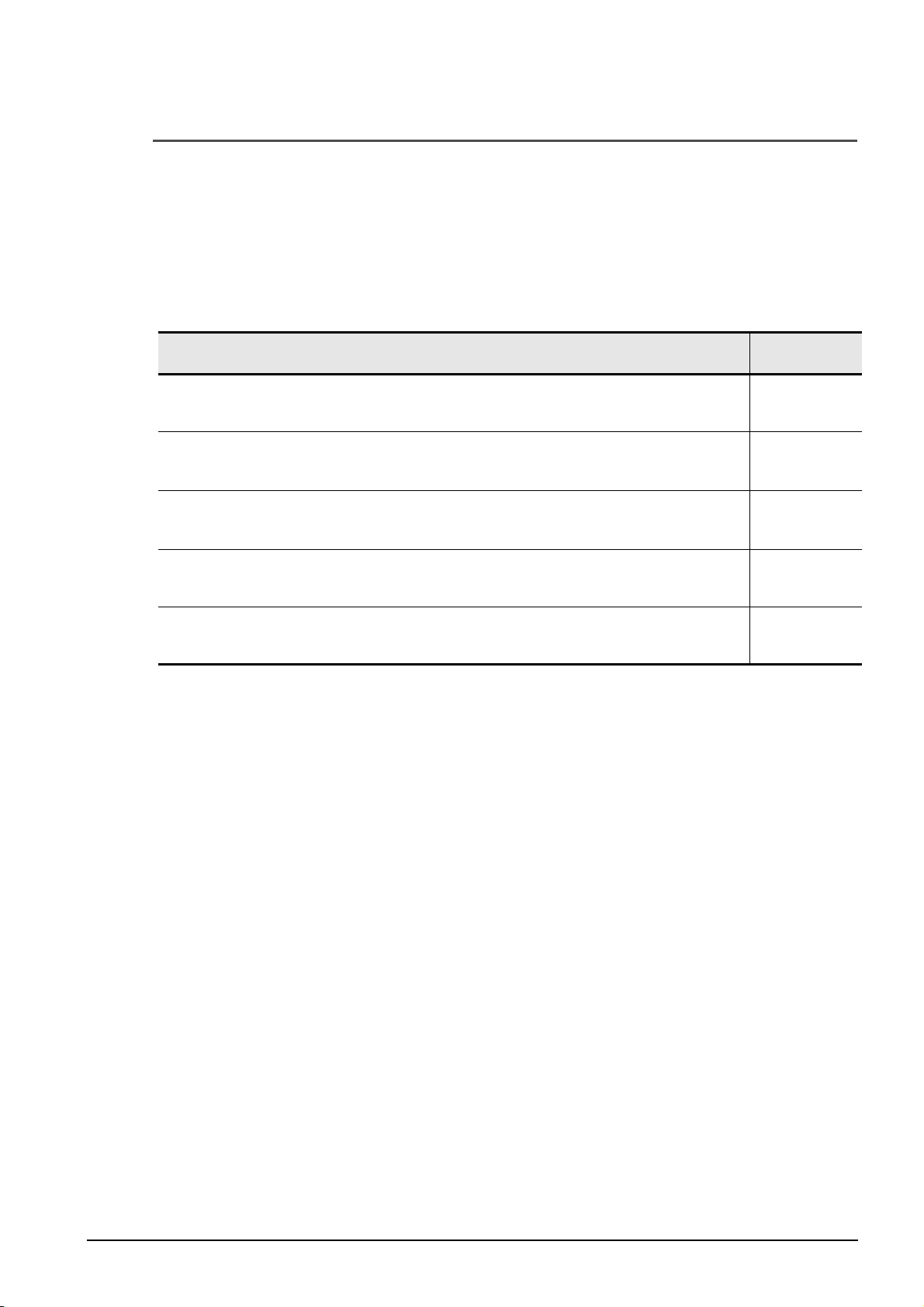

■ MANUALS

The manuals related to this product are shown below.

Refer to the following tables when ordering required manuals.

Related manuals

1) MELSOFT Navigator

For details of operations, refer to the Help function of MELSOFT Navigator.

2) GX Works2

Manual name

GX Works2 Version 1 Operating Manual (Common)

Explains the system configuration of GX Works2 and the functions common to a Simple project and

Structured project such as parameter setting, operation method for the online function. (Sold separately)

GX Works2 Version 1 Operating Manual (Simple Project)

Explains operation methods such as creating and monitoring programs in Simple project of GX Works2.

(Sold separately)

GX Works2 Version 1 Operating Manual (Structured Project)

Explains operation methods such as creating and monitoring programs in Structured project of GX

Works2. (Sold separately)

GX Works2 Beginner's Manual (Simple Project)

Explains fundamental operation methods such as creating, editing, and monitoring programs in Simple

project for users inexperienced with GX Works2. (Sold separately)

GX Works2 Beginner's Manual (Structured Project)

Explains fundamental operation methods such as creating, editing, and monitoring programs in

Structured project for users inexperienced with GX Works2. (Sold separately)

Manual number

(Model code)

SH-080779ENG

(13JU63)

SH-080780ENG

(13JU64)

SH-080781ENG

(13JU65)

SH-080787ENG

(13JZ22)

SH-080788ENG

(13JZ23)

A - 7

Page 10

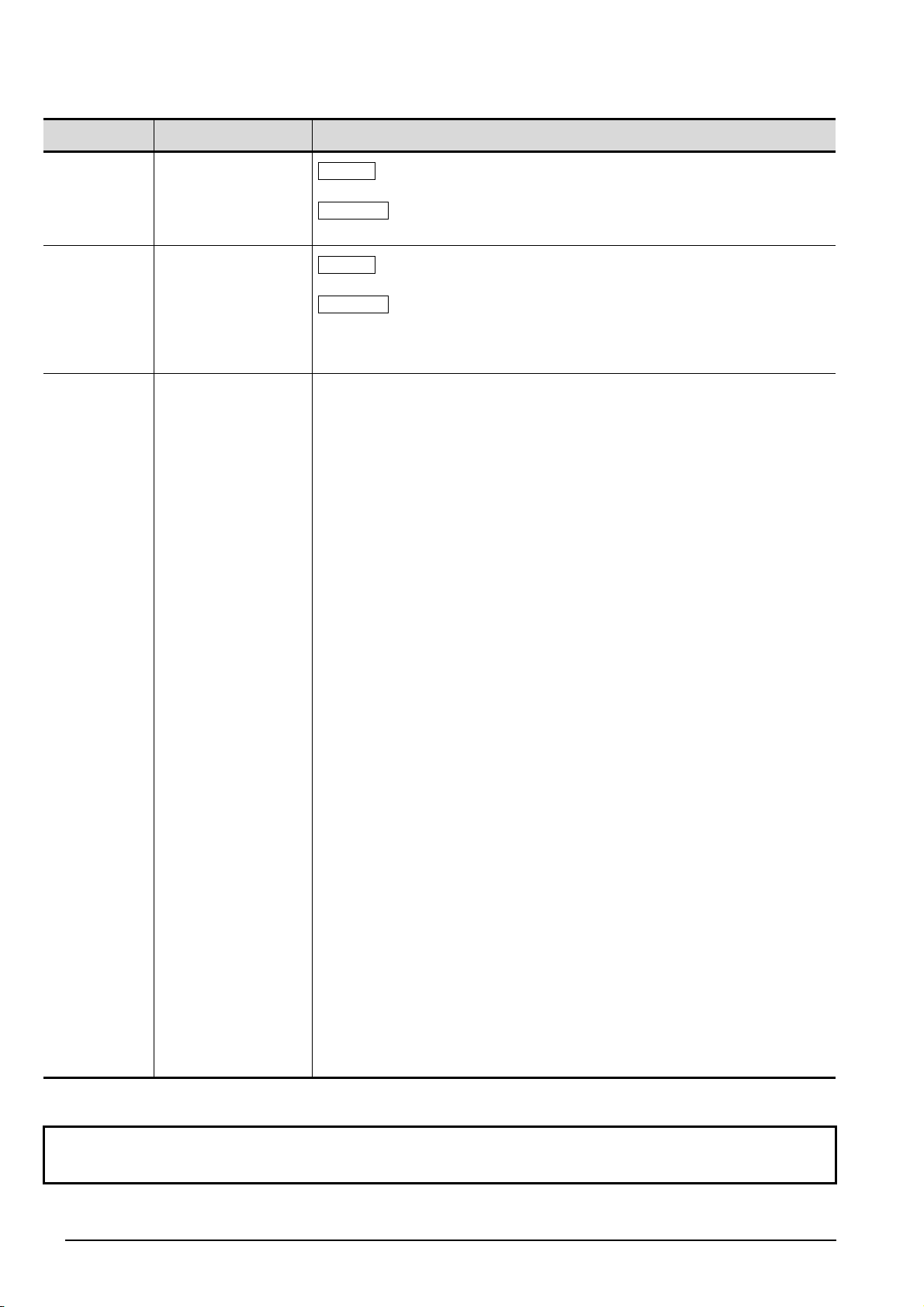

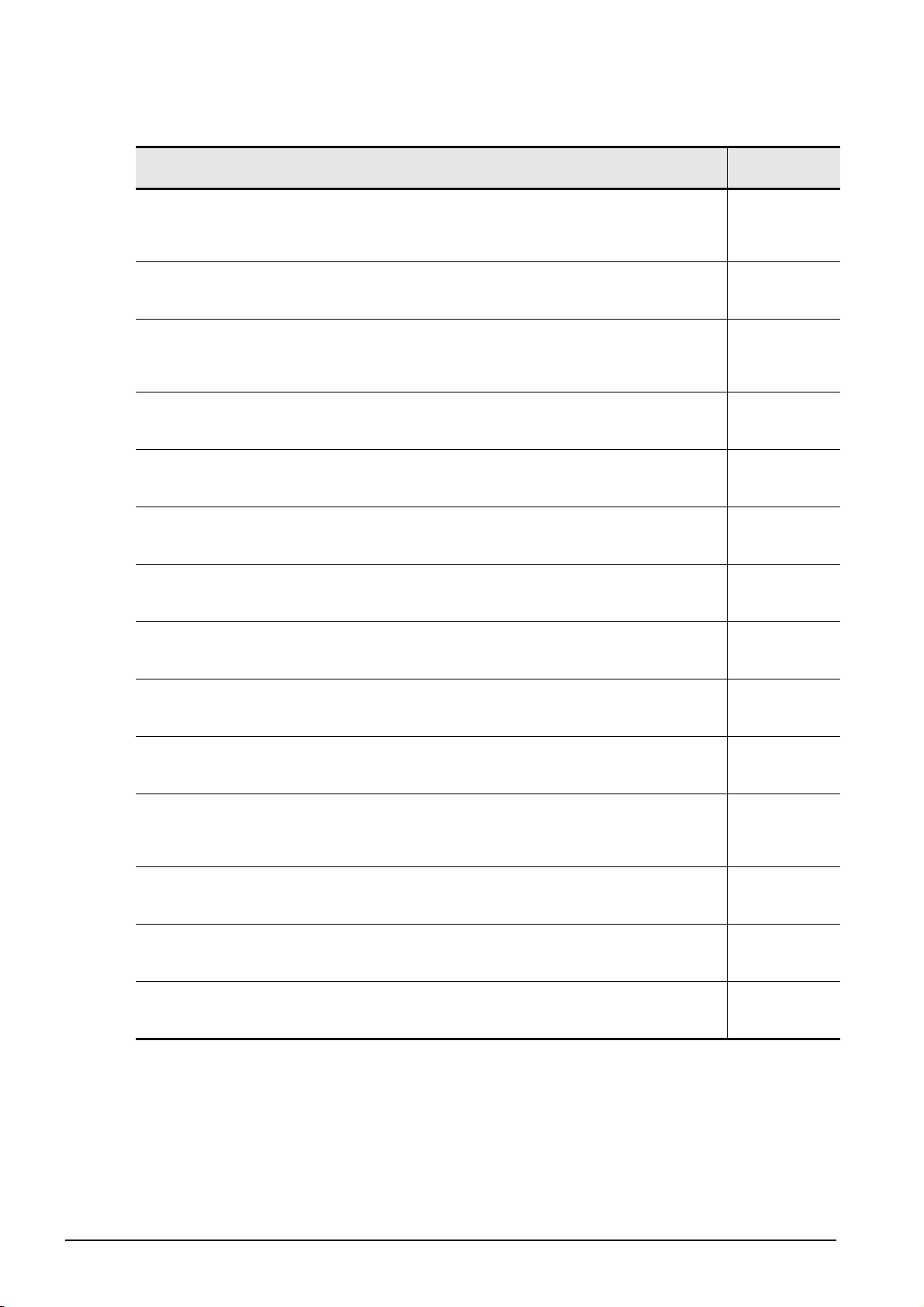

3) GT Designer3

Manual name

GT Designer3 Version 1 Screen Design Manual (Fundamentals)

Explains the system configuration, screen configuration, basic operations for dialog boxes, methods

such as creating new project and transferring data to GOT, and convenient screen editing operations of

GT Designer3. (Sold separately)

GT Designer3 Version 1 Screen Design Manual (Functions) (1/2, 2/2)

Explains common settings, object function specifications, setting methods, and arranging methods of GT

Designer3. (Sold separately)

GT Designer3 (GOT2000) Screen Design Manual

Explains the system configuration, screen configuration, basic operations for dialog boxes, methods

such as creating new project and transferring data to GOT, and convenient screen editing operations of

GT Designer3. (Sold separately)

GOT1000 Series Connection Manual (Mitsubishi Products) for GT Works3

Explains Mitsubishi products that can be connected to GOT and their connection method.

(Sold separately)

GOT1000 Series Connection Manual (Non-Mitsubishi Products 1) for GT Works3

Explains non-Mitsubishi products that can be connected to GOT and their connection method.

(Sold separately)

GOT1000 Series Connection Manual (Non-Mitsubishi Products 2) for GT Works3

Explains non-Mitsubishi products that can be connected to GOT and their connection method.

(Sold separately)

GOT1000 Series Connection Manual (Microcomputer, MODBUS Products, Peripherals) for GT Works3

Explains the connection method between GOT and peripherals such as a bar code reader.

(Sold separately)

Manual number

(Model code)

SH-080866ENG

(1D7MB9)

SH-080867ENG

(1D7MC1)

SH-081220ENG

(1D7ML9)

SH-080868ENG

(1D7MC2)

SH-080869ENG

(1D7MC3)

SH-080870ENG

(1D7MC4)

SH-080871ENG

(1D7MC5)

GOT2000 Series Connection Manual (Mitsubishi Product) For GT Works3 Version1

Explains Mitsubishi products that can be connected to GOT and their connection method.

(Sold separately)

GOT2000 Series Connection Manual (Non Mitsubishi Product 1) For GT Works3 Version1

Explains non-Mitsubishi products that can be connected to GOT and their connection method.

(Sold separately)

GOT2000 Series Connection Manual (Non Mitsubishi Product 2) For GT Works3 Version1

Explains non-Mitsubishi products that can be connected to GOT and their connection method.

(Sold separately)

GOT2000 Series Connection Manual (Microcomputer, MODBUS Products, Peripherals) For GT Works3

Version1

Explains the connection method between GOT and peripherals such as a bar code reader.

(Sold separately)

GT Simulator3 Version 1 Operating Manual

Explains the system configuration, screen configuration, and operation methods of GT Simulator3 used

in GOT1000 series (GT16/GT15/GT11) and GOT-A900 series. (Sold separately)

GT SoftGOT1000 Version 3 Operating Manual for GT Works3

Explains the system configuration, screen configuration, and operation methods of monitoring software

GT Soft GOT1000. (Sold separately)

GT SoftGOT2000 Version1 Operating Manual

Explains the system configuration, screen configuration, and operation methods of monitoring software

GT Soft GOT2000. (Sold separately)

4) MT Developer2

Refer to the Help function of MT Developer2.

SH-081197ENG

(1D7MJ8)

SH-081198ENG

(1D7MJ9)

SH-081199ENG

(1D7MK1)

SH-081200ENG

(1D7MK2)

SH-080861ENG

(1D7MB1)

SH-080860ENG

(1D7MA9)

SH-081201ENG

(1D7MK3)

A - 8

Page 11

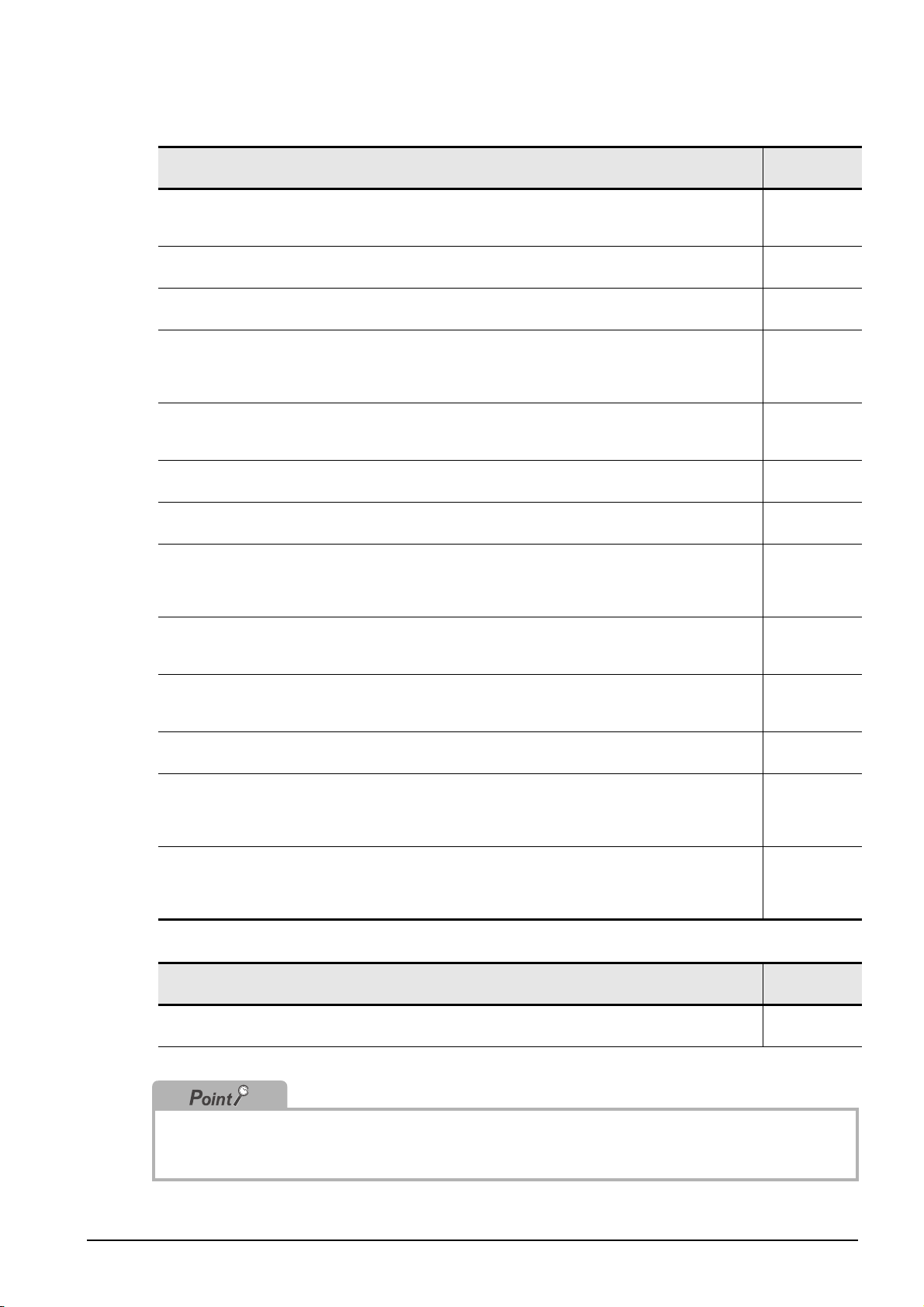

5) Motion Controllers

Manual name

Q173DCPU/Q172DCPU Motion controller Programming Manual (COMMON)

Explains the Multiple CPU system configuration, performance specifications, common parameters,

auxiliary/applied functions, and error lists. (Optional)

Q173DCPU/Q172DCPU Motion controller (SV13/SV22) Programming Manual (Motion SFC)

Explains the functions, programming, debugging, and error lists of Motion SFC. (Optional)

Q173DCPU/Q172DCPU Motion controller (SV13/SV22) Programming Manual (REAL MODE)

Explains the servo parameters, positioning instructions, device lists, and error lists. (Optional)

Q173DCPU/Q172DCPU Motion controller (SV22) Programming Manual (VIRTUAL MODE)

Explains the dedicated instructions, servo parameters, positioning instructions for mechanical system

program comprised of a virtual main shaft or mechanical module required to execute the synchronous

control, device lists, and error lists. (Optional)

Q173HCPU/Q172HCPU Motion controller Programming Manual (COMMON)

Explains the Multiple CPU system configuration, performance specifications, common parameters,

auxiliary/applied functions and error lists. (Optional)

Q173HCPU/Q172HCPU Motion controller (SV13/SV22) Programming Manual (Motion SFC)

Explains the functions, programming, debugging, and error lists of Motion SFC. (Optional)

Q173HCPU/Q172HCPU Motion controller (SV13/SV22) Programming Manual (REAL MODE)

Explains the servo parameters, positioning instructions, device list, and error lists. (Optional)

Q173HCPU/Q172HCPU Motion controller (SV22) Programming Manual (VIRTUAL MODE)

Explains the dedicated instructions, servo parameters, positioning instructions for mechanical system

program comprised of a virtual main shaft or mechanical module required to execute the synchronous

control, device lists, and error lists. (Optional)

Manual number

(Model code)

IB-0300134

(1XB928)

IB-0300135

(1XB929)

IB-0300136

(1XB930)

IB-0300137

(1XB931)

IB-0300111

(1XB911)

IB-0300112

(1XB912)

IB-0300113

(1XB913)

IB-0300114

(1XB914)

Q173HCPU/Q172HCPU Motion controller (SV43) Programming Manual

Explains the dedicated instructions to execute the positioning control by Motion program of EIA language

(G-code), servo parameters, positioning instructions, device list, and error lists. (Optional)

Q173CPU(N)/Q172CPU(N) Motion controller (SV13/SV22) Programming Manual (Motion SFC)

Explains the Multiple CPU system configuration, performance specifications, functions, programming,

and error codes of the Motion SFC. (Optional)

Q173CPU(N)/Q172CPU(N) Motion controller (SV13/SV22) Programming Manual (REAL MODE)

Explains the servo parameters, positioning instructions, device list, and error lists. (Optional)

Q173CPU(N)/Q172CPU(N) Motion controller (SV22) Programming Manual (VIRTUAL MODE)

Explains the dedicated instructions, servo parameters, positioning instructions for mechanical system

program comprised of a virtual main shaft or mechanical module required to execute the synchronous

control, device lists, and error lists. (Optional)

Q173CPU(N)/Q172CPU(N) Motion controller (SV43) Programming Manual

Explains the dedicated instructions to execute the positioning control by Motion program of EIA language

(G-code), Multiple CPU system configuration, performance specifications, functions, programming,

debugging, servo parameters, positioning instructions, device list, and error lists. (Optional)

6) RT ToolBox2

Manual name

CR750/700/500 series RT ToolBox2 / RT ToolBox2 mini User's Manual

Explains operation methods such as creating and monitoring programs, and connecting with robots.

IB-0300115

(1XB915)

IB-0300042

(1XB781)

IB-0300043

(1XB782)

IB-0300044

(1XB783)

IB-0300070

(1CT784)

Manual number

(Model code)

BFP-A8618

The Operating Manual is included on the DVD-ROM/CD-ROM of the software package in PDF file format.

Manuals in printed form are sold separately for single purchase. Order a manual by quoting the manual number

(model code) listed in the table above.

A - 9

Page 12

● Purpose of this manual

This manual explains the features and operations of iQ Platform supporting engineering environment

MELSOFT iQ Works.

Manuals and the Help function for reference are listed in the following table according to their

purpose.

For information such as the contents and number of each manual, refer to the list of 'Related

manuals'.

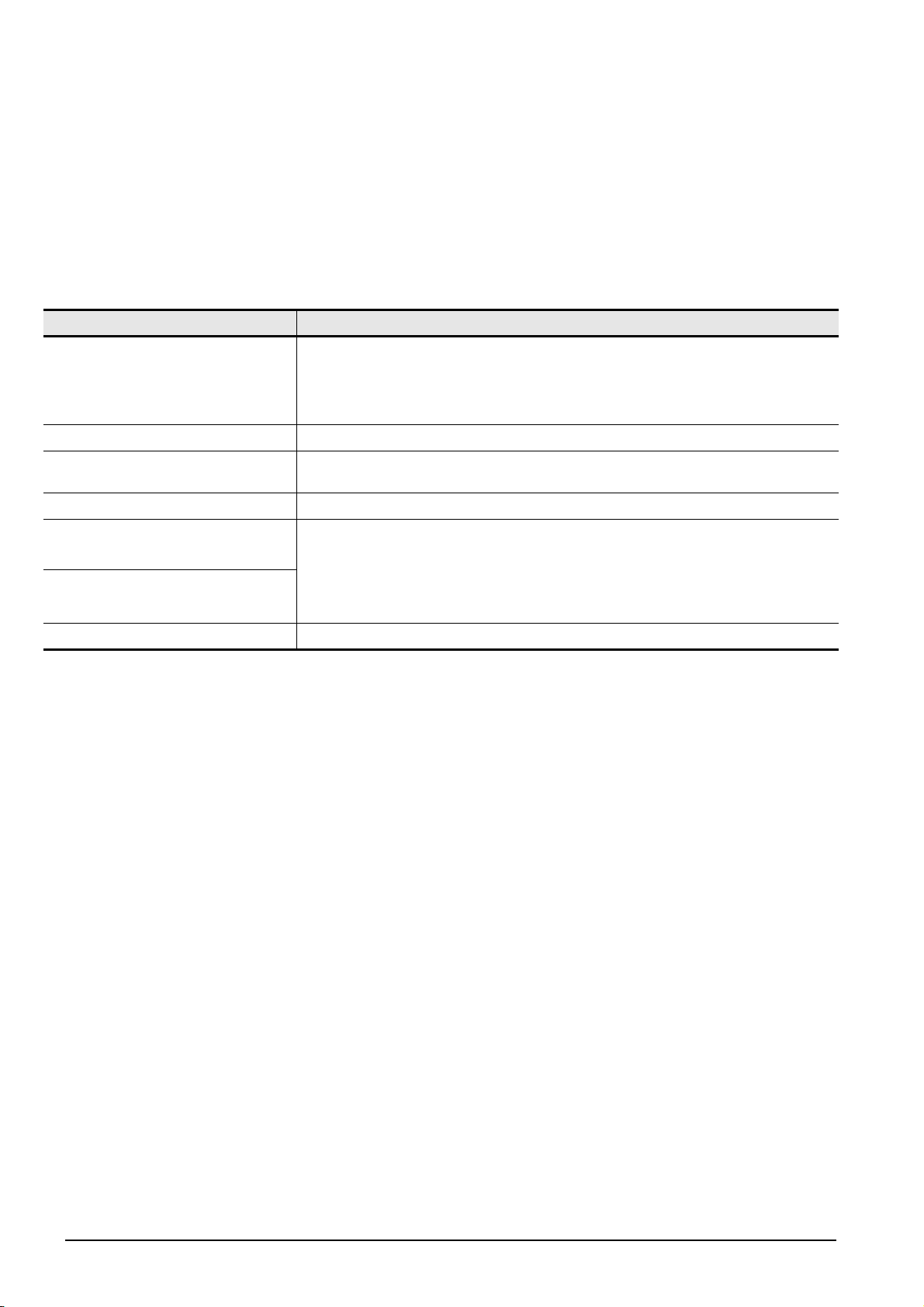

Purpose Manuals and HELP function for reference

GX Works2 Version 1 Operating Manual (Common)

GX Works2 Version 1 Operating Manual (Simple Project)

Creating GX Works2 projects

Creating MT Developer2 projects Help function of MT Developer2

Creating GT Designer3 projects

Creating RT ToolBox2 projects CR750/700/500 series RT ToolBox2 / RT ToolBox2 mini User's Manual

GX Works2 Version 1 Operating Manual (Structured Project)

GX Works2 Beginner's Manual (Simple Project)

GX Works2 Beginner's Manual (Structured Project)

GT Designer3 Version 1 Screen Design Manual (For GOT 1000 Series)

GT Designer3 (GOT2000) Screen Design Manual

Using system labels

Using data backup function

Using program jump function Motion controller programming manual of Q173D/Q172D, Q173H/Q172H, Q173/Q172

GX Works2 Version 1 Operating Manual (Common)

GX Works2 Version 1 Operating Manual (Simple Project)

GX Works2 Version 1 Operating Manual (Structured Project)

GX Works2 Beginner's Manual (Simple Project)

GX Works2 Beginner's Manual (Structured Project)

Help function of MT Developer2

A - 10

Page 13

■ HOW TO READ THIS MANUAL

This section explains how to read this manual according to your purpose when using MELSOFT iQ

Works.

Please use this manual with referring to the following descriptions.

1) To learn about the overview of MELSOFT iQ Works

Chapter 1 OVERVIEW

Chapter 1 explains the features of MELSOFT iQ Works.

2) To learn about the screen configuration of MELSOFT iQ Works

Chapter 2 SCREEN CONFIGURATION

Chapter 2 explains the screen configuration of MELSOFT Navigator.

3) To learn about the operating procedures of MELSOFT Navigator

Chapter 3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

Chapter 3 explains a sequence of the basic operation from start-up to creating and saving methods

of workspaces and projects.

4) To learn about the system labels

Chapter 4 USING SYSTEM LABELS

Chapter 4 explains the functions to utilize labels used in a project for controller projects in a

workspace.

5) To learn about the data backup

Chapter 5 CREATING SYSTEM BACKUP DATA

Chapter 5 explains the functions to read programmable controller projects, motion controller

projects, and GOT projects from respective controllers in batch and create their backup data using

MELSOFT Navigator.

6) To learn about the program jump function

Chapter 6 USING PROGRAM JUMP FUNCTION

Chapter 6 explains the function which can start motion SFC programs/servo programs, that are

linked with motion controller programs, using the SFCS and SVST instructions of ladder programs.

A - 11

Page 14

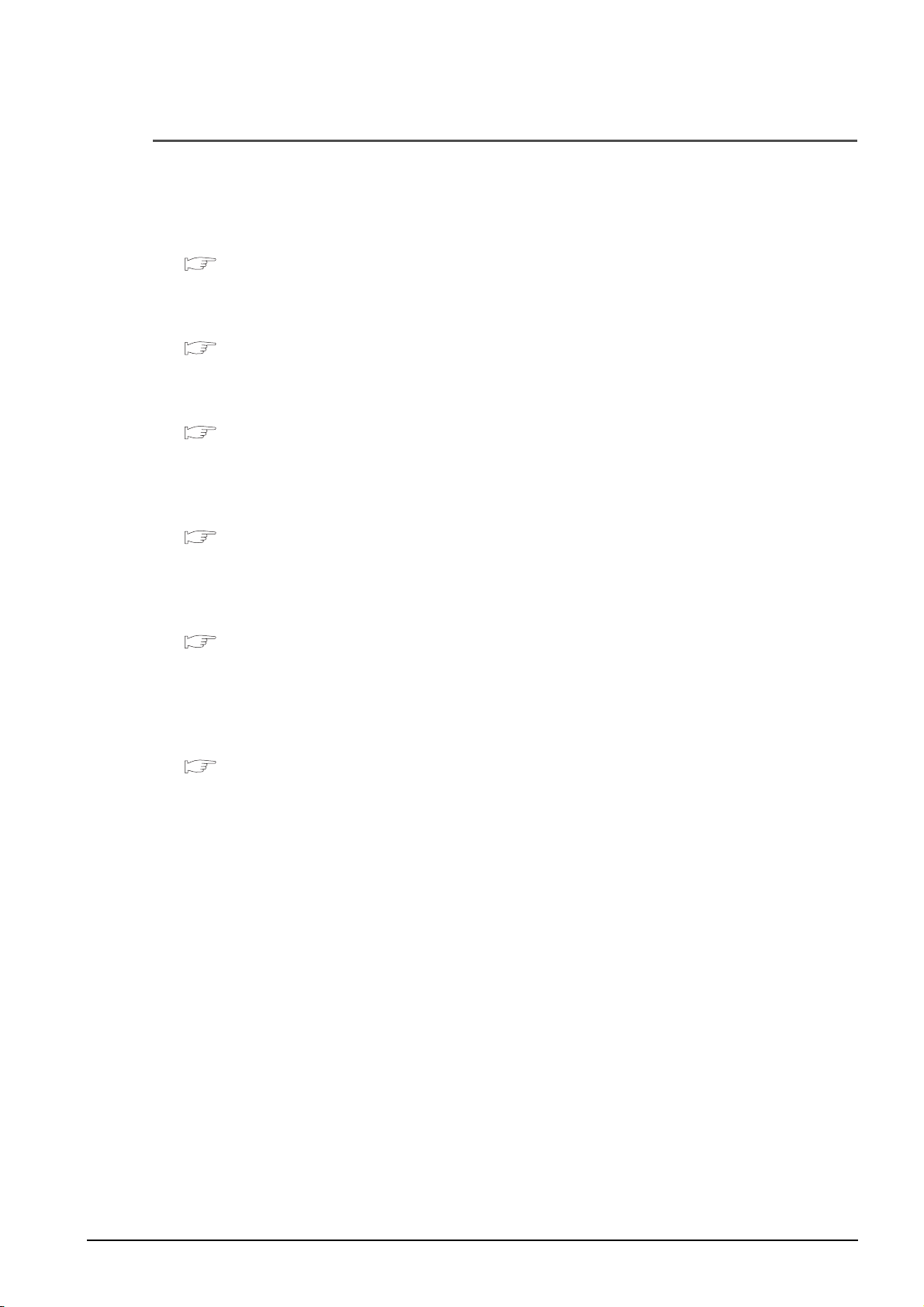

This explains notes requiring attention or useful functions relating to the information given on the

same page.

● Symbols used in this manual

The following shows the symbols used in this manual with descriptions and examples.

No. Symbol Description Example

[ ] Menu name on a menu bar [Workspace]

Toolbar icon

" " Item name in a workspace "Configuration diagram B"

" " Item name in a screen "Open Startup Screen at Start"

Button on a screen

- Keyboard key

Ctrl

A - 12

Page 15

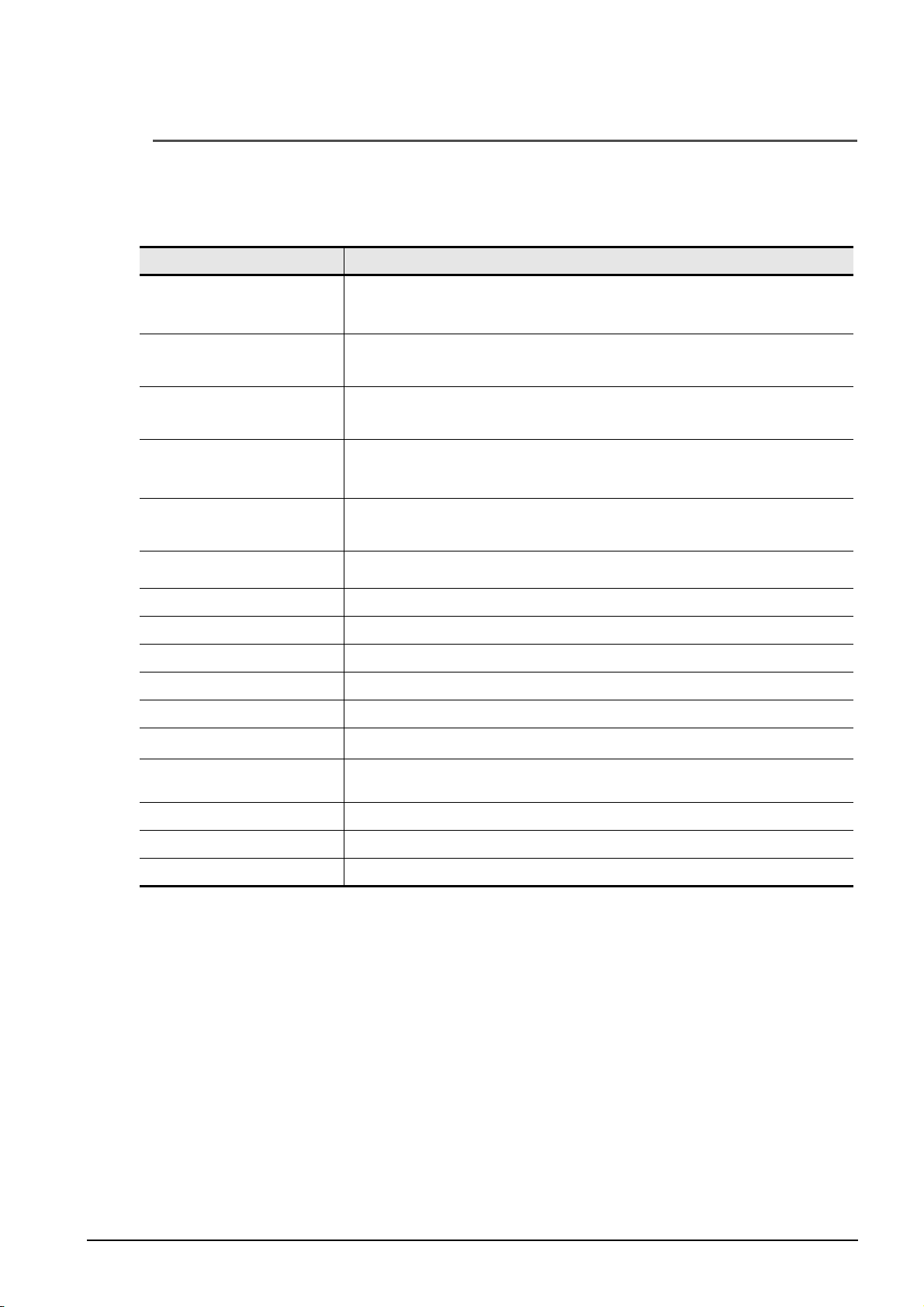

■ GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL

This manual uses the generic terms and abbreviations listed in the following table to discuss the

software packages and programmable controller CPUs. Corresponding module models are also listed if

needed.

Generic term and abbreviation Description

Generic product name of the integrated development environment for SWnDND-IQWK-E/

MELSOFT Navigator

GX Works2

MT Developer2

GT Designer3

GX Developer

RT ToolBox2

Q series Generic term for MELSEC-Q series

SWnDNC-IQWK-E (iQ Platform supporting engineering environment MELSOFT iQ Works)

(n: version)

Generic product name for SWnDNC-GXW2-E

(n: version)

MELSOFT Navigator compatible GX Works2 is GX Works2Version 1.15R or later.

Generic product name for SWnDNC-MTW2-E

(n: version)

MELSOFT Navigator compatible MT Developer2 is MT Developer2 Version 1.09K or later.

Generic product name for SWnD5C-GTWK3-E

(n: version)

MELSOFT Navigator compatible GT Designer3 is GT Designer3 Version 1.05F or later.

Generic product name for SWnD5C-GPPW-E

(n: version)

MELSOFT Navigator compatible GX Developer is GX Developer Version 8.95Z or later.

Generic product name for 3D-11C-WINE/3D-12C-WINE

MELSOFT Navigator compatible RT ToolBox2 is RT ToolBox2 Version 2.00A or later.

L series Generic term for MELSEC-L series

FX series Generic term for MELSEC-F series

Controller Generic terms for programmable controller, motion controller, and GOT

Network Generic terms for CC-Link IE controller network, MELSECNET/H, and Ethernet

Personal computer

GOT

System configuration diagram Generic terms for network configuration and module configuration

GX Works2 project Projects that created/saved with GX Works2 (GX Works2 format project)

GX Developer project Projects that created/saved with GX Developer (GX Developer format project)

Generic term for personal computers on which Windows

Generic term for Mitsubishi Graphic Operation Terminal GOT1000 series and GOT2000

Series

®

operates

A - 13

Page 16

MEMO

A - 14

Page 17

1OVERVIEW

This chapter explains the features of MELSOFT iQ Works.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

1.1 MELSOFT iQ Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

1 - 1

Page 18

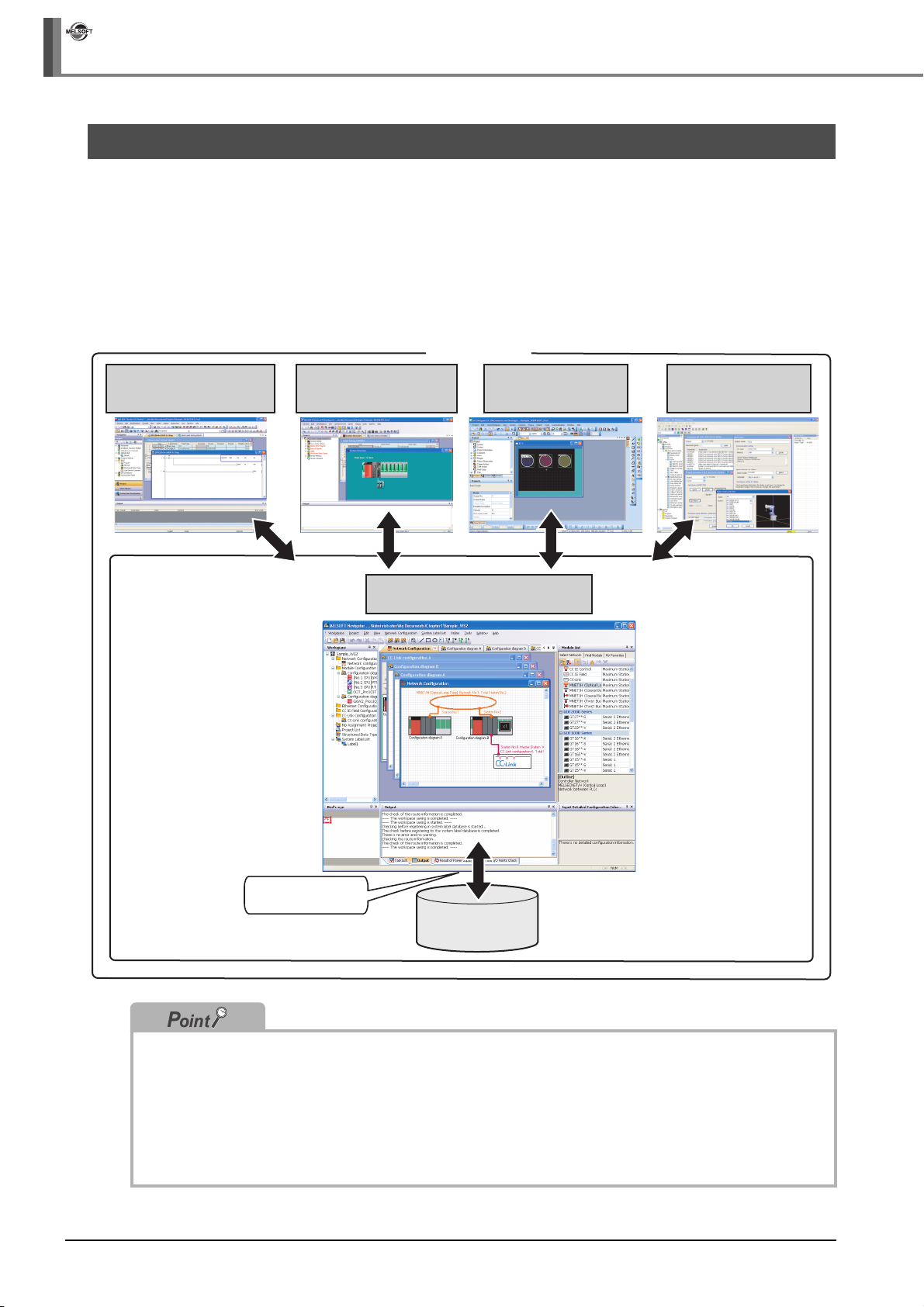

iQ Works

1 OVERVIEW

1.1 MELSOFT iQ Works

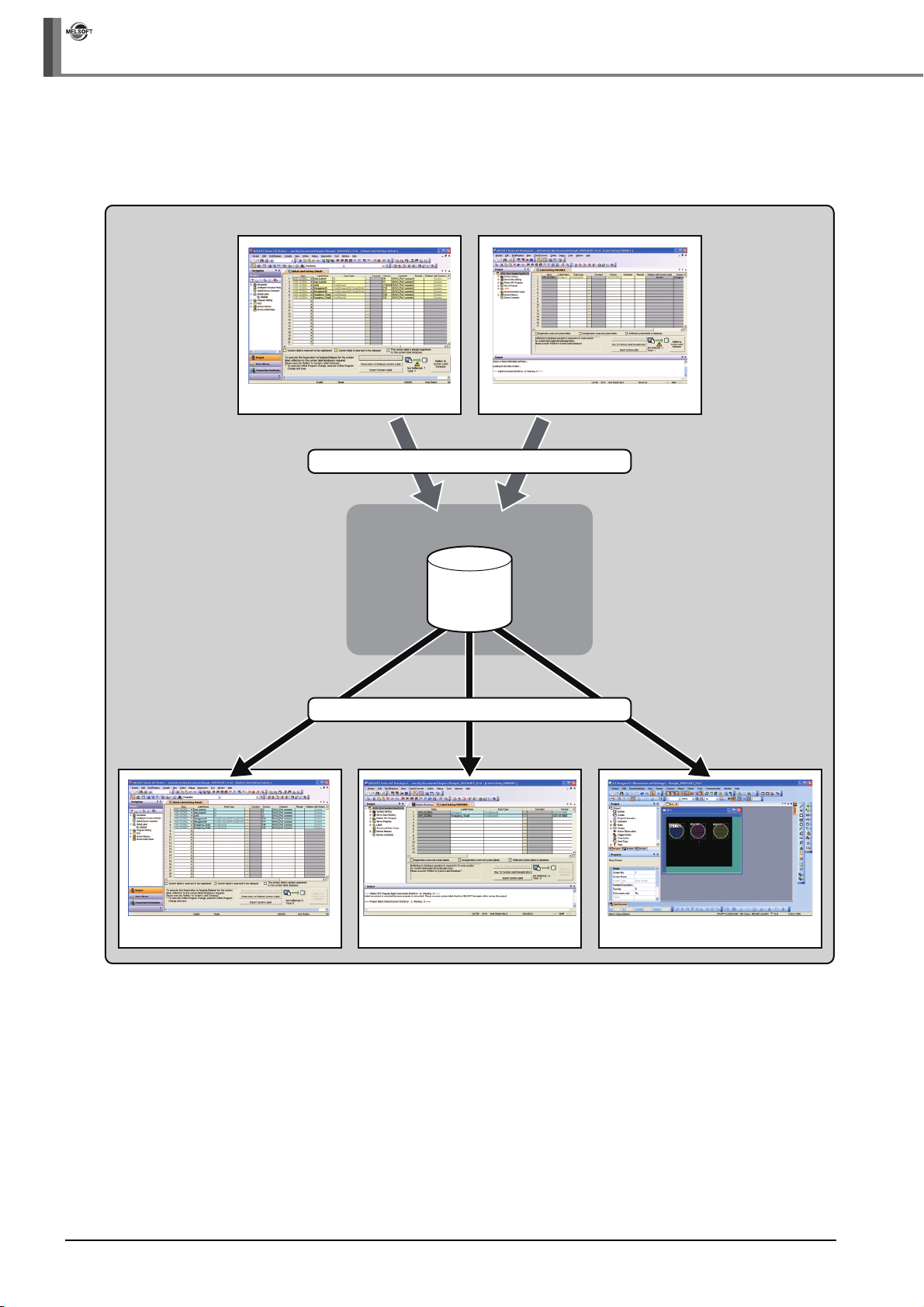

MELSOFT iQ Works is an integrated engineering software product which includes GX Works2, MT Developer2, GT

Designer3, and RT ToolBox2.

While sharing design information such as system designs and programming in the whole control system, the

system designing efficiency and the programming efficiency are improved, and thus the total programming cost is

reduced.

This manual explains the system management method using MELSOFT Navigator.

Q series, L series, and FX series are supported in MELSOFT Navigator, however, this manual explains the

operations of Q series.

MELSOFT iQ Works

GX Works2

(PLC programming and

maintenance software)

MT Developer2

(Motion programming and

maintenance software)

GT Designer3

(HMI screen creation software)

RT ToolBox2

(Robot total engineering

support software)

Share design information

among software products

MELSOFT Navigator

(System management software)

Design information

database

1 - 2

To start MELSOFT Navigator and engineering software products, select an item registered in the start menu by

following the procedures below.

• MELSOFT Navigator : Select [MELSOFT Application]

• GX Works2 : Select [MELSOFT Application]

• MT Developer2 : Select [MELSOFT Application]

• GT Designer3 : Select [MELSOFT Application]

• RT ToolBox2 : Select [MELSOFT Application]

⇒ [MELSOFT iQ Works] ⇒ [MELSOFT Navigator].

⇒ [GX Works2] ⇒ [GX Works2].

⇒ [MT Works2] ⇒ [MT Developer2].

⇒ [GT Works3] ⇒ [GT Designer3].

⇒ [RT ToolBox2] ⇒ [RT ToolBox2].

Page 19

1.2 Features

This section explains the features of MELSOFT iQ Works.

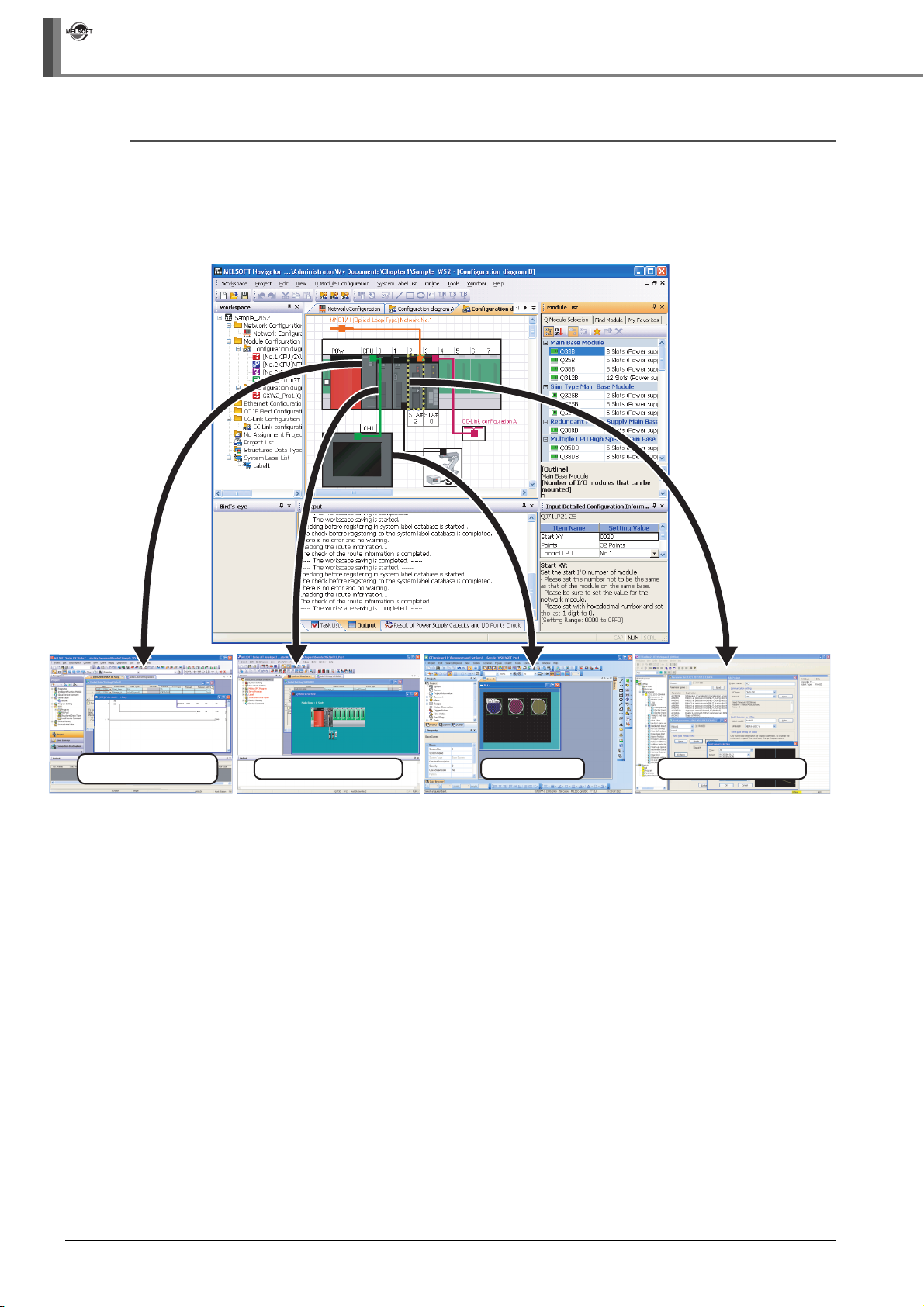

■ Project management using graphical system configuration diagrams

Projects are managed by using graphically displayed diagrams of the actual hardware equipment

configuration of the whole system, linking each equipment and the project.

1.2 Features

SCREEN

1

OVERVIEW

2

CONFIGURATION

Activate the Module Configuration

window by double-clicking a module

configuration diagram on the

Network Configuration window.

Activate the project linked

to the respective module by

double clicking a module on

the Module Configuration

window.

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

GOT project

Programmable controller project

1 - 3

USING PROGRAM

JUMP FUNCTION

Page 20

iQ Works

1 OVERVIEW

■ Improved project management efficiency

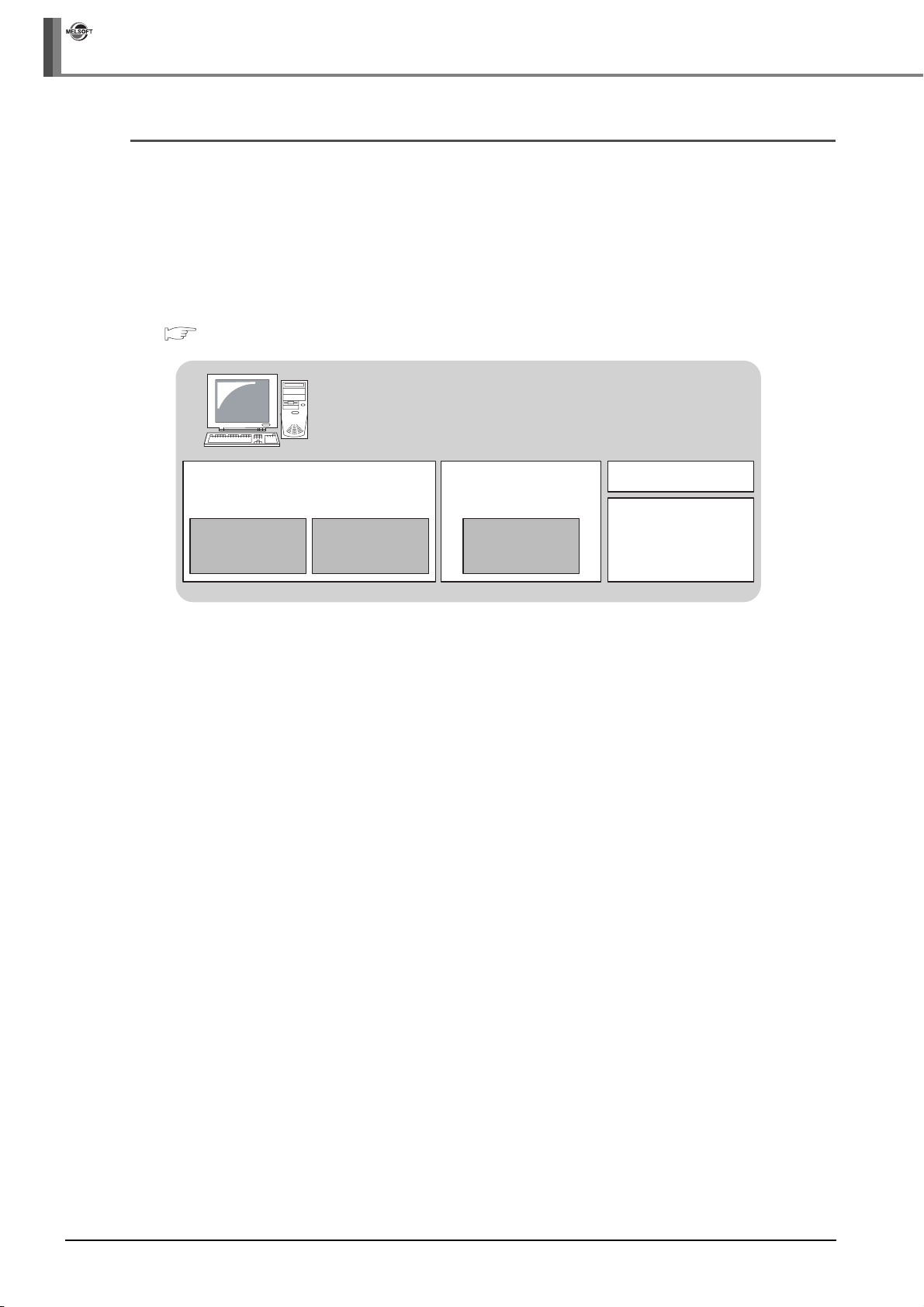

● Multiple project management using a workspace

Multiple project data (programmable controller projects, motion controller projects, GOT projects,

and robot controller projects) can be managed totally using a workspace.

Created date and modified date of each project can be confirmed with the project list.

Programmable controller

project

Motion controller project

GOT project

Robot controller project

1 - 4

Page 21

1.2 Features

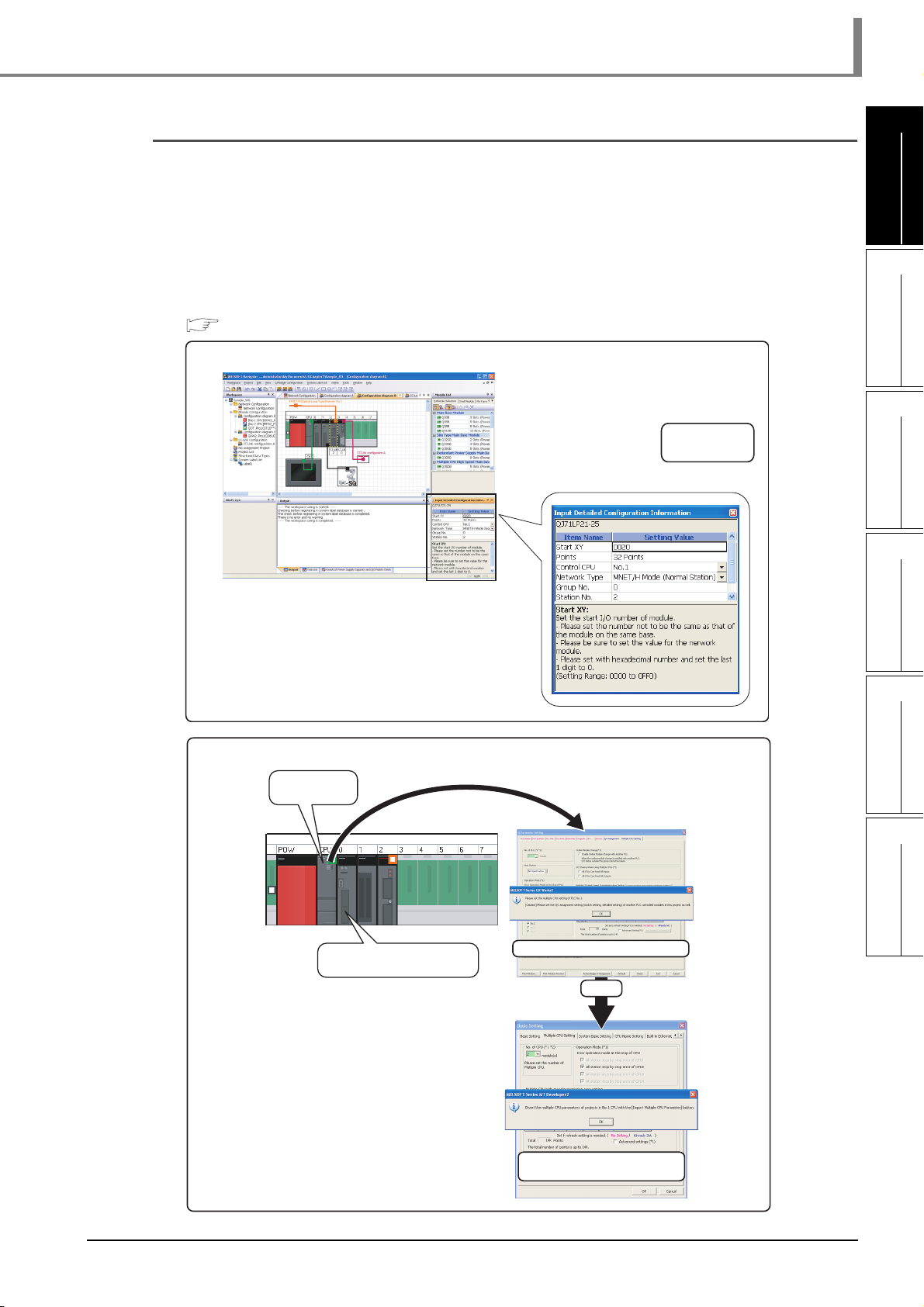

■ Simplified parameter settings

Parameters, such as I/O assignment and network parameters, which require consistencies can be

set without opening related projects of each engineering software (GX Works2, MT Developer2,

and GT Designer3).

Parameters set to the project on CPU No. 1 can be utilized for the project on CPU No. 2 when

configuring multiple CPU system.

For the parameter setting function, refer to the following chapter.

Chapter 3

< I/O assignment/Network parameter >

Parameters are set

by reflecting them

to the project.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

< Multiple CPU parameter >

QCPU

(CPU No. 1)

Motion controller (CPU No. 2)

Multiple CPU parameter of CPU No. 1

Utilize

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

Multiple CPU parameter of CPU

No. 2 and other CPUs

1 - 5

Page 22

iQ Works

1 OVERVIEW

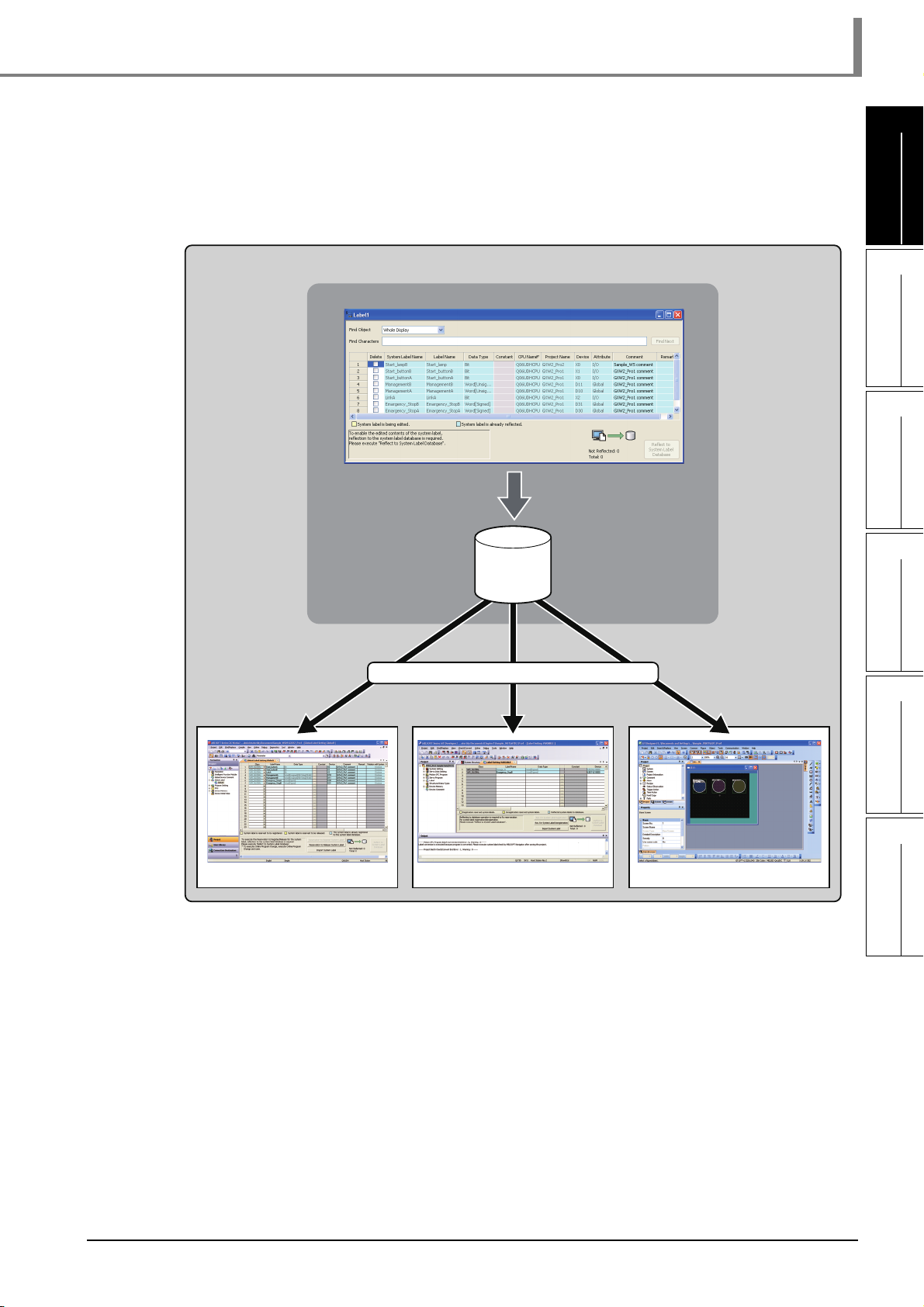

■ Improved programming efficiency using system labels

System labels are labels that can be used in any project within the workspace (within the

equipment configured in the network configuration diagram or module configuration diagram).

Programming (drawing) efficiency is improved by opening devices of programmable controller

projects and motion controller projects as system labels, and sharing them with multiple projects.

As the device assignment settings are changed in batch, device assignment changes are not

necessary on other projects or graphics.

For using system labels, refer to the following chapter.

Chapter 4

< Workspace >

System labels

(Valid within workspace)

< Programmable controller project >

Global labels

(Valid within project)

[Program (MAIN)]

Local labels

(Valid within program)

[Program (SUB)]

Local labels

(Valid within program)

< Programmable controller project >

Global labels

(Valid within project)

[Program (MAIN)]

Local labels

(Valid within program)

< GOT project >

< Motion controller project >

Labels

(Valid within project)

To use system labels in iQ Platform supporting engineering environment MELSOFT iQ Works,

utilize system labels registered in MELSOFT Navigator from projects (Top-down design method),

or register global labels defined in projects as system labels (Bottom-up design method).

1 - 6

Page 23

1.2 Features

● Top-down design method

Design system labels for accessing GOT or communicating between equipment after designing

network configuration in the upstream design.

In top-down design method, register system labels using MELSOFT Navigator, import them to

global labels of controller projects, and assign devices.

< Workspace >

MELSOFT Navigator

Register system labels

System label

database

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

Programmable controller project

Use system labels in controller projects

Motion controller project GOT project

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

1 - 7

Page 24

iQ Works

1 OVERVIEW

● Bottom-up design method

Design system labels for accessing GOT by using global labels which are registered in controller

projects as system labels, for a such case when configuring system by utilizing existing projects.

< Workspace >

Programmable controller project Motion controller project

Register global labels as system labels

Programmable controller project

MELSOFT Navigator

System label

database

Utilize system labels

Motion controller project GOT project

1 - 8

Page 25

1.2 Features

■ Simplified data backup operation

All controller projects in the workspace can be read and saved in batch without activating

respective engineering software (GX Works2, MT Developer2, and GT Designer3).

For the batch read function, refer to the following chapter.

Chapter 5

Programmable controller

GOT project

project

Motion controller project

MELSECNET/H

Programmable controller

project

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

Create backup data in batch

MELSOFT Navigator

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

1 - 9

Page 26

iQ Works

1 OVERVIEW

■ Improved programming efficiency by linking with motion controller programs

A motion controller program, which corresponds to the motion dedicated programmable controller

instruction selected in the sequence program, can be activated by a simple mouse operation. This

function significantly improves programming efficiency.

For the program jump function, refer to the following chapter.

Chapter 6

Activate the programmable

controller project

The motion controller project

corresponds to the selected

motion dedicated programmable

controller instruction is activated.

1 - 10

Page 27

2 SCREEN CONFIGURATION

This chapter explains the screen configuration of MELSOFT Navigator.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

2.1 Screen Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

2 - 1

Page 28

iQ Works

2 SCREEN CONFIGURATION

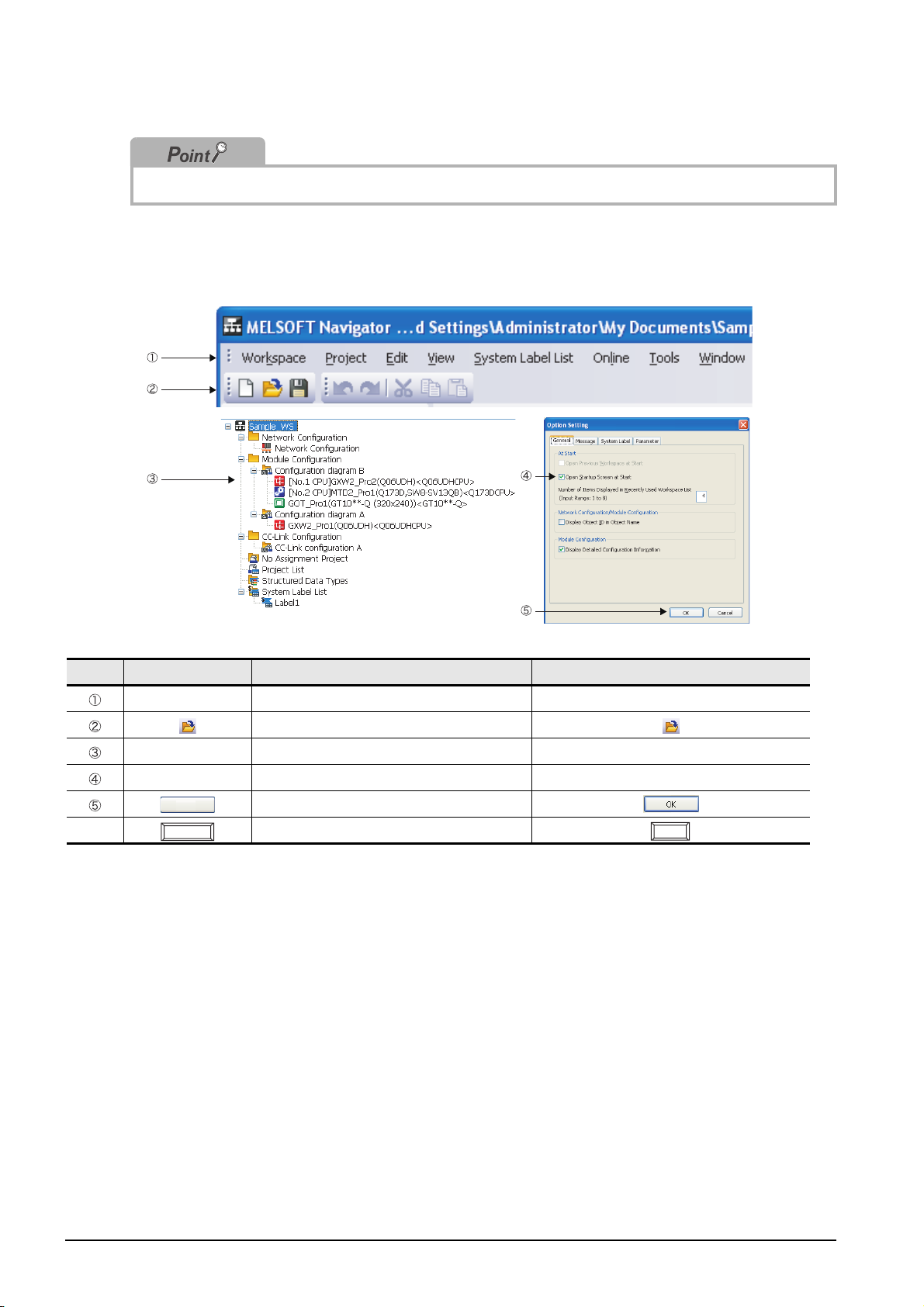

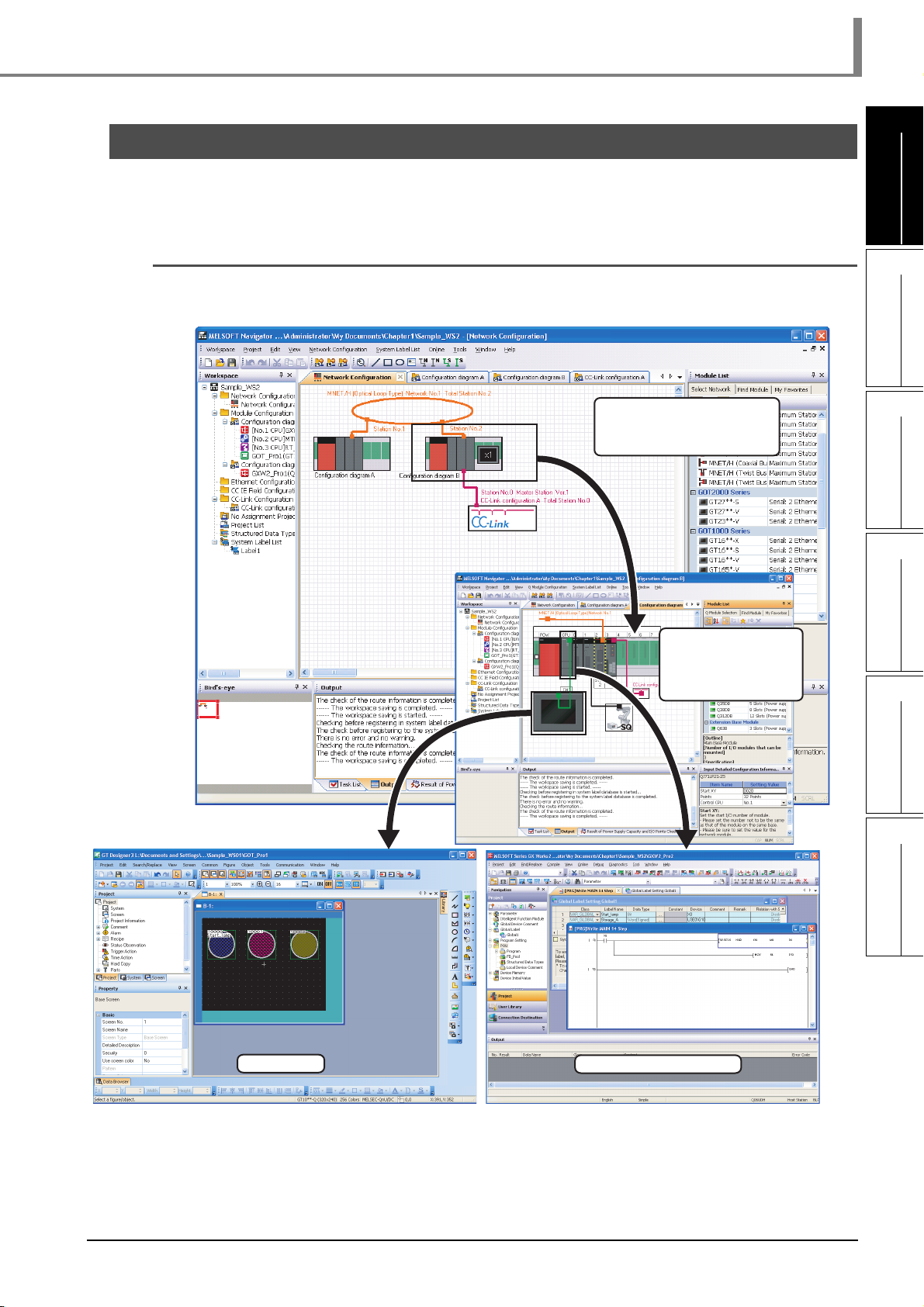

2.1 Screen Configuration

The following explains the screen configuration.

Screen display

Title bar

Menu bar

Toolbar

Workspace

window

Configuration window

Bird's-eye

window

Status bar

Module Configuration

window

Output window

Task List window

Network Configuration

window

Module List

window

Input Detailed

Configuration

Information

window

Result of Power Supply Capacity and I/O Points Check window

Display contents

Name Description

Title bar Displays a title of product name, workspace path, and active window.

Menu bar Displays items of the basic menu.

Toolbar Displays tool buttons for functions executed frequently.

Workspace window Displays objects managed in a workspace in tree format.

Bird’s-eye window Displays a bird’s-eye view of the Network Configuration window.

Module Configuration window

Network Configuration window Set graphical network configuration.

Configuration window Set configurations and display them graphically.

Module List window Displays modules used in Q series/L series/FX series in list form.

Input Detailed Configuration

Information window

Output window

Task List window

Result of Power Supply Capacity

and I/O Points Check window

Status bar Displays information about the selected project.

Set details of graphical Q series/L series/FX series module configurations which are

allocated in the network configuration diagram.

Set I/O assignment and network parameters required in MELSOFT Navigator.

Displays messages and log outputs being processed in the parameter reflection process in

list form.

Displays a result of system configuration check, power supply capacity and I/O points

check or system label consistency check in list form.

Displays a result of power supply capacity and I/O points check.

2 - 2

Page 29

Help information of MELSOFT iQ Works can be displayed by pressing the key.

2.1 Screen Configuration

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

2 - 3

Page 30

iQ Works

2 SCREEN CONFIGURATION

MEMO

2 - 4

Page 31

3 OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

1

OVERVIEW

2

This chapter explains the methods for creating workspaces and system configurations using MELSOFT

Navigator.

3.1 Procedure of MELSOFT Navigator from Start to End . . . . . . 3-2

3.2 Starting MELSOFT Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Creating Workspaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Creating System Configuration Diagram . . . . . . . . . . . . . . . . 3-8

3.5 Creating Projects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.6 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.7 Checking System Configuration . . . . . . . . . . . . . . . . . . . . . . 3-47

3.8 Editing Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3.9 Reading/Writing/Verifying Controller Data . . . . . . . . . . . . . . 3-53

3.10 Saving Workspaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

3.11 Printing Workspaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

3.12 Closing Workspaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

3.13 Exiting MELSOFT Navigator. . . . . . . . . . . . . . . . . . . . . . . . . 3-60

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

3 - 1

USING PROGRAM

JUMP FUNCTION

Page 32

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.1 Procedure of MELSOFT Navigator from Start to End

This section explains the procedure of MELSOFT Navigator from start to end.

Start

Start MELSOFT Navigator

Create a workspace

Create a system configuration diagram

Create module configuration diagrams

Create a network configuration diagram

Create a CC-Link configuration

Create projects

Create new projects

Allocate the projects to the controllers

Set parameters

Check the system configuration

Check the system configuration

Check the power supply capacity and I/O points

Save the created workspace

Print the project

Close the workspace

*1

Edit the created projects

Edit the projects

Utilize an existing project

Perform controller data read/write/verification

3 - 2

Exit MELSOFT Navigator

Complete

*1 : Not supported by FXCPU.

Do not change the storage location and names of folders/files of a created workspace/project using the application

such as Windows

®

Explorer.

Page 33

3.2 Starting MELSOFT Navigator

This section explains a method for starting MELSOFT Navigator.

3.2 Starting MELSOFT Navigator

1

Select

1. Start MELSOFT Navigator from

Windows [Start] menu.

2. MELSOFT Navigator is activated.

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

●Double-clicking the icon on the desktop can also start MELSOFT Navigator.

Double-click the MELSOFT

Navigator icon.

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3 - 3

Page 34

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.3 Creating Workspaces

This section explains a method for creating a new workspace.

Select

1. Select [Workspace] ⇒ [New] ( ) in the

menu bar to display the "New

(Workspace)" dialog box.

2. Set "Save Folder Path", "Workspace

Name", and "Title" for the new

workspace.

After setting the items, click the

button.

Setting example

• Save Folder Path : C:\Documents and

Settings\

Administrator\

My Documents

• Workspace Name: Sample_WS

• Title (option) : Sample Data

(To the next page)

3. The "Choose a Default Configuration"

dialog box is displayed.

Select "Create Module Configuration" and

click the button.

Setting example

• Configuration : Q Series

Module Configuration

4. The message shown on the left is

displayed.

Read the message and click the

button.

3 - 4

Page 35

3.3 Creating Workspaces

(From the previous page)

● Opening existing workspaces

Open an existing workspace by following the procedure below.

Select

5. The new workspace is created.

1. Select [Workspace] ⇒ [Open] ( )

in the menu bar to display the

"Open (Workspace)" dialog box.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

2. Select "Save Folder Path" and

"Workspace" for the workspace to

be opened.

The workspace folder copied by the

®

application such as Windows

can be selected.

After selecting the items, click the

button to open the workspace.

Setting example

• Save Folder Path : C:\Documents and

Settings\

Administrator\

My Documents

• Workspace Name: Sample_WS

Explorer

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3 - 5

Page 36

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

● Creating workspaces for motion system using templates

Workspaces for motion system can be created from templates consist of a combination of programmable controller

CPU and motion controller, which are used for multiple CPU system configuration.

The following shows the procedure to create a workspace for motion system using a template.

Select

1. Select [Tools] ⇒ [Motion Dedicated

Device Setting Support] in the menu

bar to display the "Select Motion

System Template" dialog box.

2. The message shown on the left is

displayed.

Read the message and click the

button to display the "Select

Motion System Template" dialog box.

3. Select a workspace name in "Select

Template Workspace", and click the

button.

The "Motion Dedicated Device Setting

Support" dialog box is displayed.

Click

4. Set "Save folder path" and

"Workspace name" for the template

workspace.

After setting the items, click the

button.

Setting example

• Save Folder Path : C:\Documents and

Settings\

Administrator\

My Documents

• Workspace Name: WS_tmp1

3 - 6

(To the next page)

Page 37

(From the previous page)

3.3 Creating Workspaces

1

5. The workspace for motion system is

displayed.

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3 - 7

Page 38

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

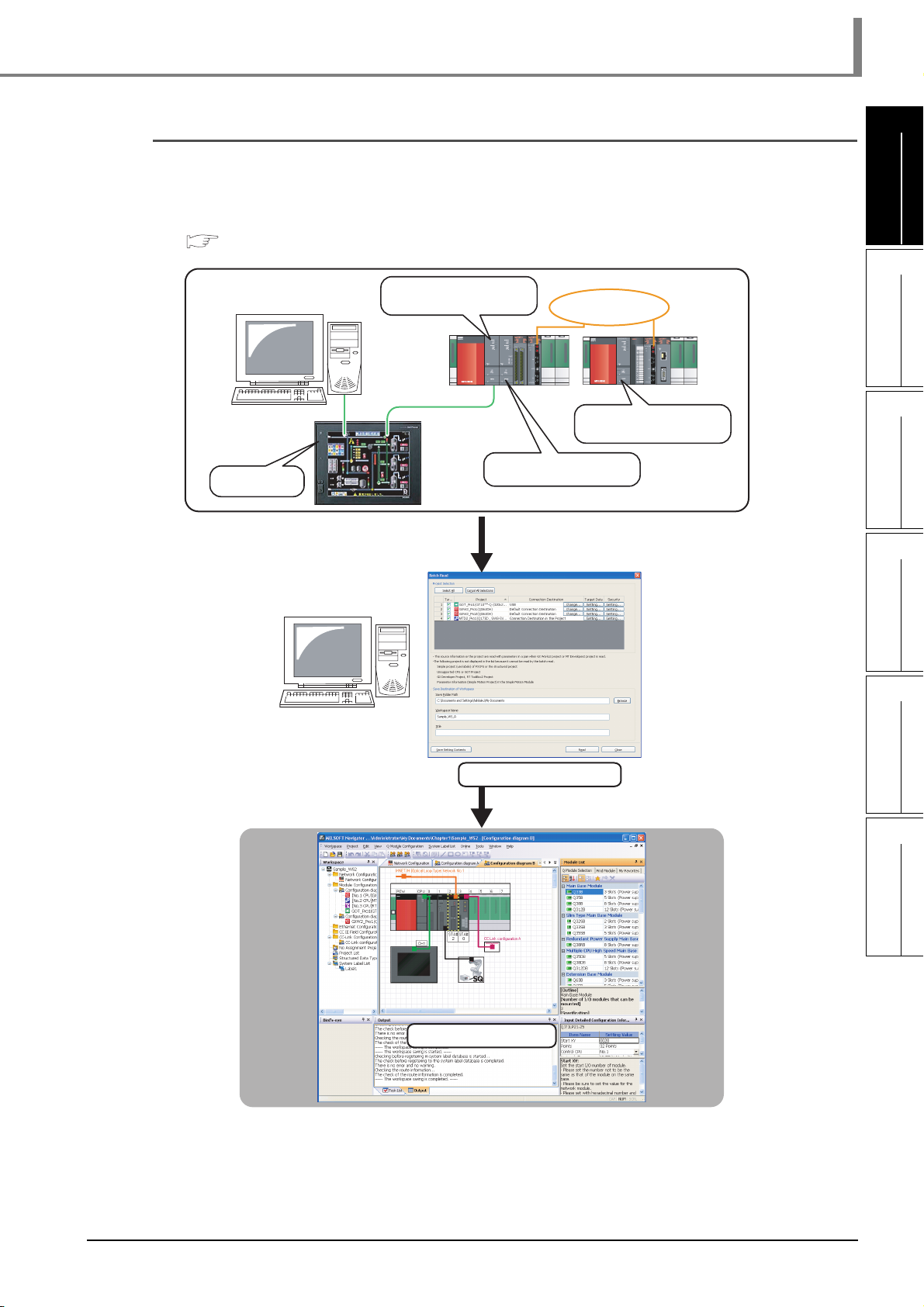

3.4 Creating System Configuration Diagram

This section explains a method for creating a system configuration diagram.

Created module configuration diagrams are reflected to the network configuration diagram.

3.4.1 System configuration to be created

Create the following system configuration diagram.

< Configuration diagram A >

Base unit (Q35B)

QCPU

(Q62P)

Power supply

< Configuration diagram B >

Power supply

GOT

(GOT1000)

(Q06UDHCPU)

Base unit (Q38DB)

QCPU

(Q64P)

(Q06UDHCPU)

<CC-Link configuration A>

(QX40)

Input module

(QJ71LP21-25)

Network module

MELSECNET/H

(QH42P)

I/O module

Motion CPU

(Q173DCPU)

(Empty)

(Empty)

(Empty)

Station No. 1: Control station

Station No. 2: Normal station

(Empty)

(Empty)

(QJ61BT11N)

Master module

(QJ71LP21-25)

Network module

(Empty)

Module configuration diagrams

(Empty)

(AJ65SBTB1-8D)

CC-Link configuration

3 - 8

Remote I/O

station

3.4.1 System configuration to be created

Remote device

station

(AJ65BT-64DAV)

Remote device

(FR-A720-0.4K)

station

Network configuration diagram

Page 39

3.4 Creating System Configuration Diagram

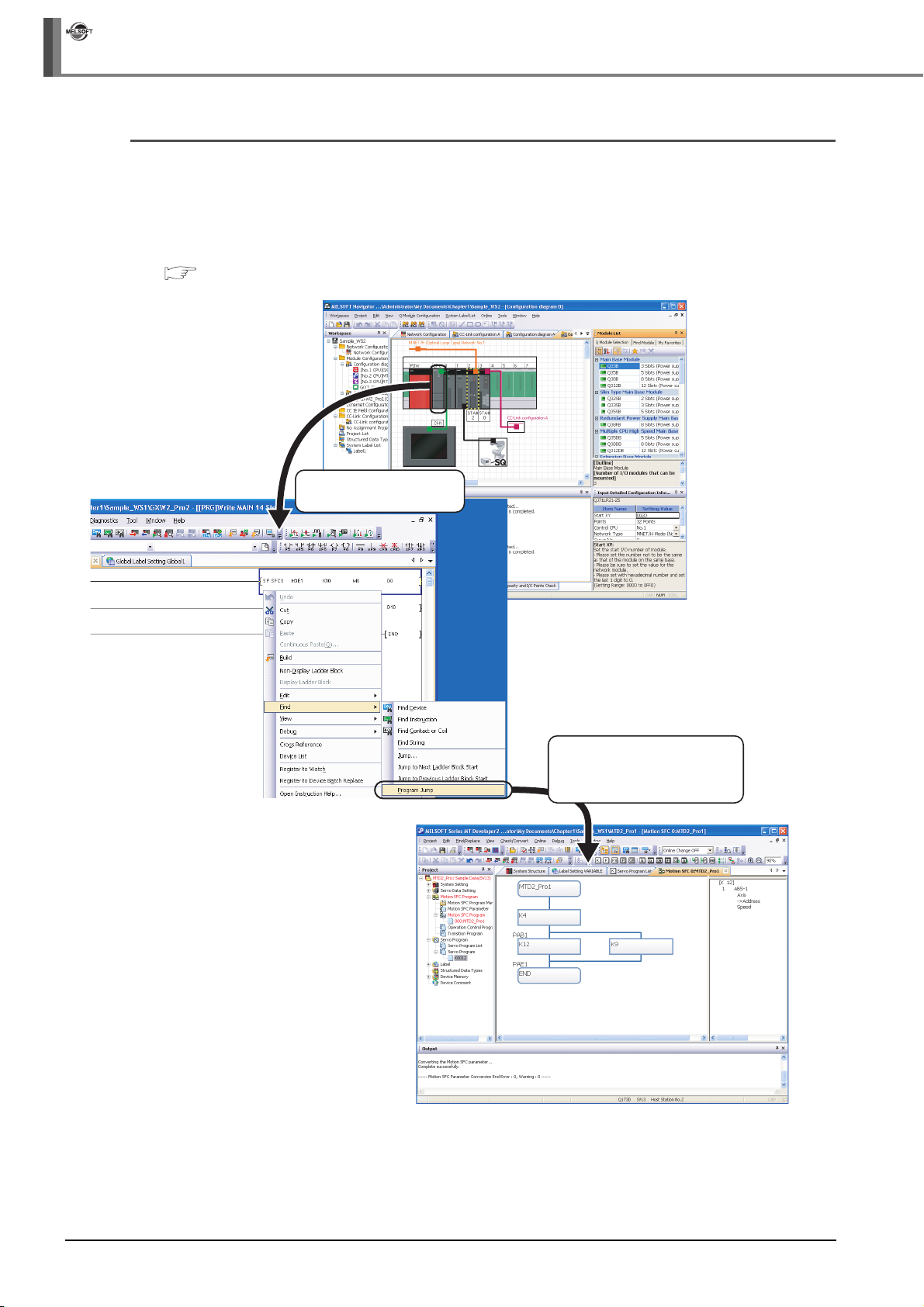

3.4.2 Creating module configuration diagrams

Create module configuration diagrams by placing modules on the Module Configuration window.

1. Right-click "Q Module Configuration"

on the Workspace window, and select

[Module Configuration] ⇒ [Rename] in

the shortcut menu.

Select

2. Enter "Configuration diagram A" to

change the module configuration

diagram name.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

Drag & drop

Drag & drop

3. Select the base unit ( ) from the

Module List window, and drag and drop

it onto the Module Configuration

window.

4. Select the power supply module

( ) from the Module List window,

and drag and drop it onto the base unit.

5. Select modules from the Module List

window, and drag and drop them onto

the base unit following the same

procedure in the step 4, and complete

the creation of "Configuration diagram

A".

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

(To the next page)

3.4.2 Creating module configuration diagrams

3 - 9

Page 40

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

(From the previous page)

6. Select [Workspace] ⇒ [System

Configuration] ⇒ [New] ⇒ [Q Series

Module Configuration], and create a

Select

new module configuration diagram.

7. Change the module configuration name

to "Configuration diagram B" following

the same procedure in the step 1 and

step 2.

Drag & drop

8. Select modules from the Module List

window, and drag and drop them onto

the base unit following the same

procedure in the step 3 and step 4.

9. Select the GOT unit ( ) from

the Module List window, and drag and

drop it onto the Module Configuration

window.

10. The message shown on the left is

displayed.

Read the message and click the

button.

3 - 10

(To the next page)

3.4.2 Creating module configuration diagrams

Page 41

(From the previous page)

Drag & drop

Drag & drop

3.4 Creating System Configuration Diagram

11. Select Serial Cable ( ) from

the Module List window, and drag and

drop it onto the connection port of the

GOT unit.

12. Drag and drop the edge of connection

line to the connection port of the

connection target CPU module.

The GOT unit is connected to the CPU

module.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.2 Creating module configuration diagrams

3 - 11

Page 42

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

● Mounting modules

• When a module is dragged onto the base unit, the mountable area of the base unit is displayed in light green as

shown below.

Mountable slots

• If a module is not mounted properly, the whole module is displayed in pink as shown below.

● Connection lines

When a connection line is dragged and dropped onto the Module Configuration window, the connectable ports of

each controller are displayed as shown below.

Connectable ports

Drag & drop

● Connection points of GOT unit

By setting parameters on the Input Detailed Configuration Information window, I/F type and number of

connectable points of GOT unit can be changed.

3 - 12

3.4.2 Creating module configuration diagrams

Page 43

3.4 Creating System Configuration Diagram

■ Creating module configuration diagrams for L series

For L series, create module configuration diagrams refer to this section.

Basically, L series module configurations can be created in a similar way to Q series.

For operations that differ from Q series, refer to the Point in this section.

● System configuration to be created

Create the following system configuration.

<L module configuration diagram A>

(L61P)

Power supply

Ethernet (Network No.1)

LCPU

(L02CPU)

IP address :192.168.3.38

Input module

er (L6EC)

(LX40C6)

END cov

Module configuration diagrams

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

<L module configuration diagram B>

(L61P)

Power supply

GOT

(GOT1000)

(L6ADP-R2)

RS-232 adaptor

IP address :192.168.3.39

LCPU

(L02CPU)

L6EC)

(LX40C6)

Input module

END cover (

Network configuration diagram

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.2 Creating module configuration diagrams

3 - 13

Page 44

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

● Creating module configuration diagrams

Create module configuration diagrams by placing modules on the Module Configuration window.

1. Right-click "Module Configuration" on

the Workspace window, and select

[Module Configuration] ⇒ [New] ⇒

[L Series Module Configuration] in the

Select

shortcut menu.

2. Right-click "L Module Configuration "

on the Workspace window, and select

[Module Configuration] ⇒ [Rename] in

the shortcut menu.

Drag & drop

Select

3. Enter "L module configuration diagram

A" to change the module configuration

diagram name.

4. Select modules from the Module List

window, and drag and drop them onto

the Module Configuration window

following the same procedure in the

step 4 through step11 in section 3.4.2.

3 - 14

3.4.2 Creating module configuration diagrams

Page 45

3.4 Creating System Configuration Diagram

● Creating L series module configurations

When creating workspaces, select "L Series Module Configuration" in the "Choose a Default Configuration" dialog

box.

For creating workspaces, refer to the following section.

3.3 Creating Workspaces

● Mounting modules

When a module is dragged onto the Module Configuration window, the mountable areas are displayed in light blue

as shown below.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

Mountable areas

● Deleting modules

When a module is deleted from the Module Configuration window, the modules next to the deleted module are

connected automatically as shown below.

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

Delete

3.4.2 Creating module configuration diagrams

3 - 15

Page 46

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

● Mounting display module

Display module can be mounted on L series CPU modules.

Mount display module by following procedure below.

1. Right click the controller on the

Module Configuration window, and

select [Property] in the shortcut

menu.

Select

2. The "Properties" dialog box is

displayed.

Select "Installed" in the Display Module

tab and select the model name to be

mounted from "Select Model Name"

Setting example

• Select Model Name :L6DSPU

3. Click the button.

Display module is mounted on the

controller.

3 - 16

3.4.2 Creating module configuration diagrams

Page 47

3.4 Creating System Configuration Diagram

■ Creating module configuration diagrams for FX series

For FX series, create module configuration diagrams refer to this section.

Basically, FX series module configurations can be created in a similar way to Q series.

For operations that differ from Q series, and for main units, special blocks, and special adapters that

can be used in FX series, refer to the Point in this section.

● System configuration to be created

Create the following system configuration.

<FX Module configuration diagramA>

3UCPU)

FXCPU

(FX

IP address :192.168.3.38

Ethernet

special function block

Module configuration diagram

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

Ethernet (Network No.1)

<FX Module configuration diagramB>

FXCPU

(FX3UCPU)

IP address :192.168.3.39

GOT

(GOT1000)

Ethernet

special function block

Network configuration diagram

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.2 Creating module configuration diagrams

3 - 17

Page 48

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

● Creating module configuration diagrams

Create module configuration diagrams by placing modules on the Module Configuration window.

1. Right-click "Module Configuration" on

the Workspace window, and select

[Module Configuration] ⇒ [New] ⇒

[FX Series Module Configuration] in the

Select

shortcut menu.

2. Right-click "FX Module Configuration"

on the Workspace window, and select

[Module Configuration] ⇒ [Rename] in

the shortcut menu.

Select

Drag & drop

3. Enter "FX module configuration

diagramA" to change the module

configuration diagram name.

4. Select modules from the Module List

window, and drag and drop them onto

the Module Configuration window

following the same procedure in the

step 4 through step11 in section 3.4.2.

3 - 18

3.4.2 Creating module configuration diagrams

Page 49

3.4 Creating System Configuration Diagram

● Creating FX series module configurations

When creating workspaces, select "FX Series Module Configuration" in the "Choose a Default Configuration"

dialog box.

For creating workspaces, refer to the following section.

3.3 Creating Workspaces

● Mounting modules

When a module is dragged onto the Module Configuration window, the mountable areas are displayed in light blue

as shown below.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

Mountable area

● Supported CPU modules of FX series in MELSOFT Navigator

The following CPU modules of FX series are supported in MELSOFT Navigator.

• Main units

FX

3S, FX3G, FX3GC, FX3U, FX3UC

• Special block

Ethernet special function block (FX-ENET series)

• Special adapter

Ethernet communication special adapter (FX

For FX series, special blocks and special adapters are mounted to a main unit which combines power supply,

CPU, and I/O module. However, the following blocks and units can not be mounted: special blocks and special

units which do not contain related project or configuration software, and extension blocks which do not support a

function to check power supply capacity and I/O points.

● Parameters of special adapters

The parameters of special adapters can be set on the Input Detailed Configuration Information window.

The setting content is reflected to the parameter of a programmable controller project by performing parameter

reflection. For details of the parameter settings, refer to the following section.

Section 3.6 Setting Parameters

● Displaying module list window

The model name of special blocks of FX series compatible with MELSOFT Navigator are displayed on the Module

List window when the related software

When using special blocks install the related software

*1: The related software of FX-ENET series may be downloaded from MITSUBISHI ELECTRIC FA Global Website.

For the method of obtaining the related software, contact the store where you purchased the product.

are installed.

3U-ENET-ADP)

*1

of each module in advance.

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.2 Creating module configuration diagrams

3 - 19

Page 50

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.4.3 Creating network configuration diagrams

Create a network configuration diagram by placing and connecting the module configuration diagrams

on the Network Configuration window.

Double click

Drag & drop

1. Double-click "Network Configuration"

on the Workspace window to open the

Network Configuration window.

All module configuration diagrams created

on the Module Configuration windows are

displayed.

2. Drag and drop the module

configuration diagrams to desired

positions.

Drag & drop

3. Select MNET/H (Optical Loop Type)

( ) from the Module

List window, and drag and drop it onto

the Network Configuration window.

Drag & drop

(To the next page)

4. Select CC-Link ( ) from the

Module List window, and drag and drop

it onto the Network Configuration

window.

CC-Link configuration is added on the

Workspace window.

3 - 20

3.4.3 Creating network configuration diagrams

Page 51

3.4 Creating System Configuration Diagram

(From the previous page)

Drag & drop

Drag & drop

5. Select Network Cable ( )

from the Module List window, and drag

and drop it onto the Network

Configuration window.

6. Drag and drop the edge of connection

line to the connection point of the

connection target module configuration

diagram.

CC-Link configuration is connected to the

module configuration diagram.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

● Adding Ethernet configuration

When adding Ethernet configuration by dragging and dropping from Module Configuration window onto the

Network Configuration window, select an Ethernet configuration from "Component Device"

Drag & drop

● Network Configuration window

• A Module Configuration window opens by double-clicking the module configuration diagram/CC-Link

configuration on the Network Configuration window/CC-Link configuration window.

For Ethernet/CC IE Field, each configuration window can be opened with the same operation as above.

• The whole system created on the Network Configuration window can be reviewed on the Bird’s-eye window.

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.3 Creating network configuration diagrams

3 - 21

Page 52

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.4.4 Creating CC-Link configuration diagrams

Create a configuration by placing modules on the CC-Link Configuration window.

1. Double-click "CC-Link Configuration"

on the Workspace window to open the

CC-Link Configuration window.

Double click

2. Right-click "CC-Link Configuration" on

the Workspace window, and select

[CC-Link Configuration] ⇒ [Rename] in

the shortcut menu.

Select

Drag & drop

3. Enter "CC-Link configuration A" to

change the CC-Link configuration

name.

4. Select AJ65SBTB1-8D ( )

from the Module List window, and drag

and drop it onto the CC-Link

Configuration window.

CC-Link configuration is added on the

Module configuration window.

5. Select modules to be connected from

the Module List window, and drag and

drop them onto the CC-Link

Configuration window following the

same procedure in the step 4.

3 - 22

3.4.4 Creating CC-Link configuration diagrams

Page 53

3.4 Creating System Configuration Diagram

● Module display on configuration window

Check that the network modules on the Module Configuration window are connected to the network. If not, the

modules are not displayed on the configuration window.

● Detecting actual system configuration

The actual system configuration can be reflected to the CC-Link Configuration window by performing one of the

following operations.

• Click the button on the CC-Link Configuration window.

• Select [Online] ⇒ [Detect Now].

For the automatic detection of connected devices, refer to the following manual.

iQ Sensor Solution Reference Manual

● Verifying CC-Link configuration against the actual system configuration

The CC-Link configuration can be verified against the actual system configuration by performing one of the

following operations.

• Click the button on the CC-Link Configuration window.

• Select [Online] ⇒ [Verification of the Configuration with the Connected Module].

For the verification of the configuration with the connected modules, refer to the following manual.

iQ Sensor Solution Reference Manual

● Deleting CC-Link modules

The following shows a method for deleting CC-Link modules from CC-Link Configuration window.

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

Select

Select

1. Select "Station No." or "Model

Name" of the CC-Link module to be

deleted.

2. Select [Edit] ⇒ [Delete] in the menu

bar to delete CC-Link module.

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.4 Creating CC-Link configuration diagrams

3 - 23

Page 54

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.4.5 Creating AnyWireASLINK configuration diagrams

Create a configuration by placing modules on the AnyWireASLINK Configuration window.

1. Select AnyWireASLINK master module

(QJ51AW12AL) from the Module List

window, and drag and drop it onto the

Module Configuration window.

The AnyWireASLINK configuration

Drag & drop

diagram is created.

2. Double-click "AnyWireASLINK

Configuration" on the Workspace

window to open the AnyWireASLINK

Configuration window.

Double click

3. Select the AnyWireASLINK slave

Drag & drop

4. Set the address to the added slave

*1: The address of the slave module can be set automatically.

For the address auto-input, refer to the following manual.

GX Works2 Version 1 Operating Manual (Intelligent Function Module)

module (B281PB-02U-CC20) from the

Module List window, and drag and drop

it onto the AnyWireASLINK

Configuration window.

The slave module is added on the "list of

modules", and the added slave module is

displayed on the "device map area".

module.

For the general-purpose AnyWireASLINK

module, set the I/O type, address, and

number of occupied I/O points.

*1

3 - 24

3.4.5 Creating AnyWireASLINK configuration diagrams

Page 55

3.4 Creating System Configuration Diagram

● Detecting actual system configuration

The actual system configuration can be reflected to the AnyWireASLINK Configuration window by performing one

of the following operations.

• Click the button on the AnyWireASLINK Configuration window.

• Select [Online] ⇒ [Detect Now].

For the automatic detection of connected devices, refer to the following manual.

iQ Sensor Solution Reference Manual

● Verifying AnyWireASLINK configuration against the actual system configuration

The AnyWireASLINK configuration can be verified against the actual system configuration by performing one of

the following operations.

• Click the button on the AnyWireASLINK Configuration window.

• Select [Online] ⇒ [Verification of the Configuration with the Connected Module].

For the verification of the configuration with the connected modules, refer to the following manual.

iQ Sensor Solution Reference Manual

● Deleting AnyWireASLINK slave modules

The following shows a method for deleting AnyWireASLINK slave modules from AnyWireASLINK Configuration

window.

1. Select the row of the

AnyWireASLINK slave module to be

deleted. (Multiple rows can be

Select

selected.)

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

Select

2. Select [Edit] ⇒ [Delete] in the menu

bar to delete AnyWireASLINK slave

module.

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.5 Creating AnyWireASLINK configuration diagrams

3 - 25

Page 56

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.4.6 Creating Ethernet configuration diagrams

Create a configuration by placing modules on the Ethernet Configuration window.

1. Right-click "Ethernet Configuration" on

the Workspace window, and select

[Ethernet Configuration] ⇒ [Rename] in

the shortcut menu.

Select

2. Enter "Ethernet configuration A" to

change the Ethernet configuration

name.

Double click

Drag & drop

3. Select an Ethernet built-in CPU to be

set as an own station and IP address of

Ethernet module.

4. Double-click "Ethernet Configuration"

on the Workspace window to open the

Ethernet Configuration window.

5. Select an Ethernet device

Module List window, and drag and drop

it onto the Ethernet Configuration

window.

*1

from the

3 - 26

*1: For the parameter processing of Ethernet devices, refer to the following manual.

iQ Sensor Solution Reference Manual

3.4.6 Creating Ethernet configuration diagrams

Page 57

3.4 Creating System Configuration Diagram

● Module display on the configuration window

Check that the network modules on the Module Configuration window are connected to the network. If not, the

modules are not displayed on the configuration window.

● Detecting actual system configuration

The actual system configuration can be reflected to the Ethernet Configuration window by performing one of the

following operations.

• Click the button on the Ethernet Configuration window.

• Select [Online] ⇒ [Detect Now]

For the automatic detection of connected devices, refer to the following manual.

iQ Sensor Solution Reference Manual

● Reflecting communication settings of Ethernet devices

The communication settings of Ethernet devices can be reflected by performing the following operation.

• Select [Online] ⇒ [Communication Setting Reflection of Ethernet Device]

For the Communication Setting Reflection of Ethernet Device function, refer to the following manual.

iQ Sensor Solution Reference Manual

● Deleting Ethernet devices

The following shows a method for deleting Ethernet devices from Ethernet Configuration window.

1. Select the row of the Ethernet

device to be deleted. (Multiple rows

Select

can be selected.)

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

Select

2. Select [Edit] ⇒ [Delete] in the menu

bar to delete Ethernet device.

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.6 Creating Ethernet configuration diagrams

3 - 27

Page 58

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.4.7 Creating CC IE Field configuration diagrams

Create a configuration by placing modules on the CC IE Field Configuration window.

1. Double-click "CC IE Field

Configuration" on the Workspace

window to open the CC IE Field

Configuration window.

Double click

Select

CC IE Field configuration diagram

created.

*1

is

2. Right-click "CC IE Field Configuration"

on the Workspace window, and select

[CC IE Field Configuration] ⇒

[Rename] in the shortcut menu .

3. Enter "CC IE Field configuration A" to

change the CC IE Field configuration

name.

4. Select a slave station

*1

from the

Module List window, and drag and drop

it onto the CC IE Field Configuration

Drag & drop

*1: For the parameter processing of slave station, refer to the following manual.

GX Works2 Version 1 Operating Manual (Common)

● Module display on configuration window

Check that the network modules on the Module Configuration window are connected to the network. If not, the

modules are not displayed on the configuration window.

window.

3 - 28

3.4.7 Creating CC IE Field configuration diagrams

Page 59

3.4 Creating System Configuration Diagram

● Deleting slave stations of CC IE Field

The following shows a method for deleting slave stations from CC IE Field Configuration window.

1. Select the row of the slave station to

Select

be deleted. (Multiple rows can be

selected.)

2. Select [Edit] ⇒ [Delete] in the menu

bar to delete the slave station.

Select

1

OVERVIEW

2

SCREEN

CONFIGURATION

3

OPERATING PROCEDURE

OF MELSOFT NAVIGATOR

4

USING SYSTEM

LABELS

5

CREATING SYSTEM

BACKUP DATA

6

USING PROGRAM

JUMP FUNCTION

3.4.7 Creating CC IE Field configuration diagrams

3 - 29

Page 60

iQ Works

3 OPERATING PROCEDURE OF MELSOFT NAVIGATOR

3.5 Creating Projects

This section explains the methods for creating project data (programmable controller projects, motion

controller projects, GOT projects).

3.5.1 Creating new projects

■ Programmable controller projects

Create a new programmable controller project.

Select

1. Select [Project] ⇒ [New] ⇒ [GX

Works2 Project] in the menu bar to

display the "New (GX Works2 Project)"

dialog box.

2. Set "Project Name", "Title", "Project

Type", "PLC Series", "PLC Type", and

"Language" for the new project.

After setting the items, click the

button.

Setting example

• Project Name : GXW2_Pro1

• Title (option) : Sample Data

•Project Type

• Use Labels : Yes

• PLC Series : QCPU (Q mode)

• PLC Type : Q06UDH