Page 1

Page 2

Page 3

SAFETY PRECAUTIONS

(Always read these instructions before using this product.)

Before using this product, thoroughly read this manual and the relevant manuals introduced in this manual

and pay careful attention to safety and handle the products properly.

The precautions given in this manual are concerned with this product. For the safety precautions of the

programmable controller system, refer to the User’s Manual for the CPU module.

In this manual, the safety precautions are ranked as " WARNING" and " CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to serious consequences according to the circumstances.

Always follow the precautions of both levels because they are important for personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

[Design Instructions]

WARNING

● When data change, program change, or status control is performed from a personal computer to a running

programmable controller, create an interlock circuit outside the programmable controller to ensure that the whole

system always operates safely.

Furthermore, for the online operations performed from a personal computer to a programmable controller CPU, the

corrective actions against a communication error due to such as a cable connection fault should be predetermined as

a system.

[Startup and Maintenance Instructions]

CAUTION

● The online operations performed from a personal computer to a running programmable controller CPU (Program

change when a programmable controller CPU is RUN, operating status changes such as forced input/output

operation and RUN-STOP switching, and remote control operation) must be executed after the manual has been

carefully read and the safety has been ensured.

When changing a program while a programmable controller CPU is RUN, it may cause a program corruption in some

operating conditions. Fully understand the precautions described in GX Works2 Version 1 Operating Manual

(Common) before use.

● The positioning test functions of OPR, JOG, inching or positioning data for QD75/LD75 positioning module must be

executed with the programmable controller set to STOP after the manual has been carefully read and the safety has

been ensured. Specially when executing the function on the network system, ensure the safety thoroughly since the

machinery whose operation cannot be checked by an operator may be activated. The operation failure may cause the

injury or machine damage.

A - 1

Page 4

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi representative

in your region.

A - 2

Page 5

REVISIONS

The manual number is written at the bottom left of the back cover.

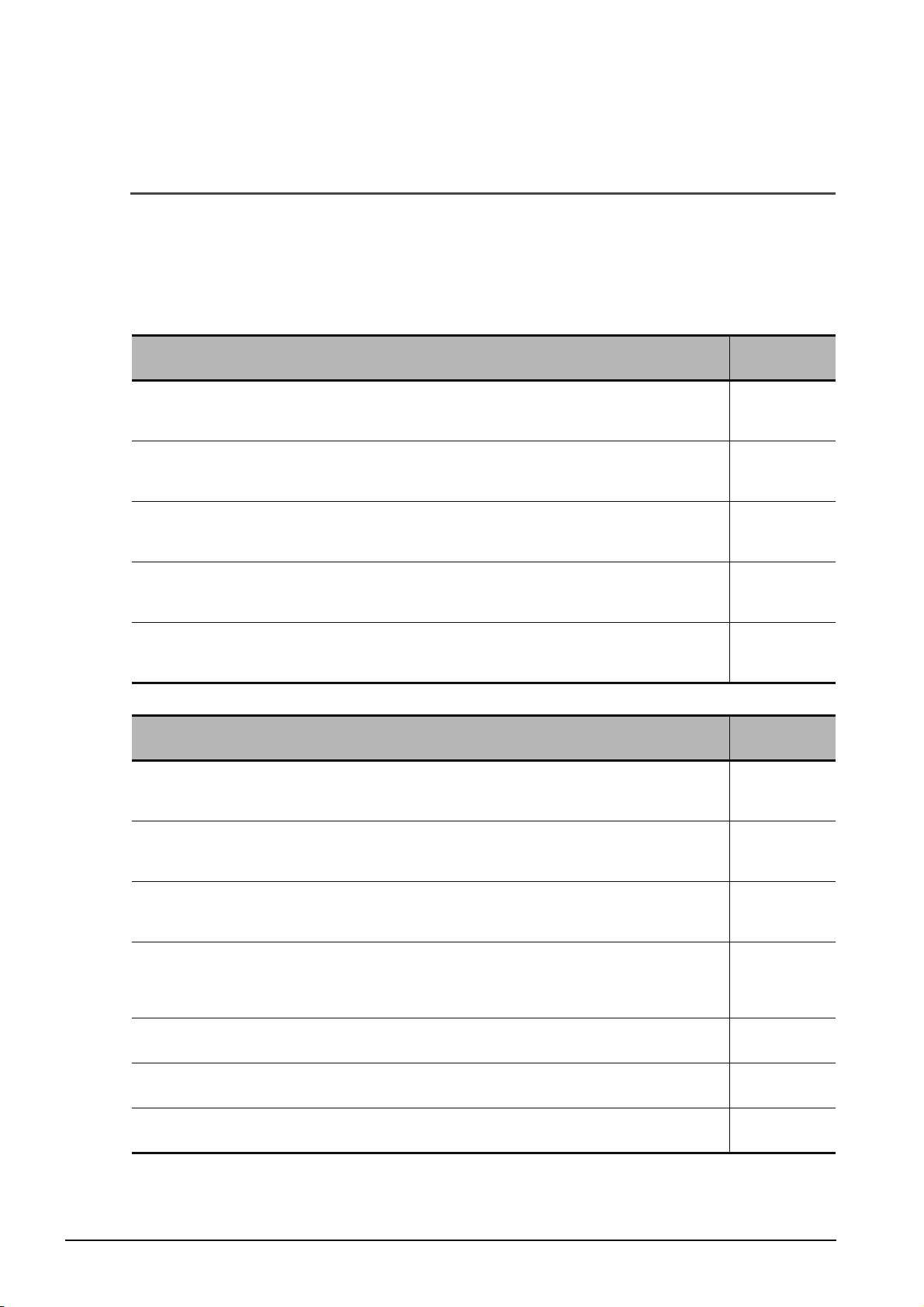

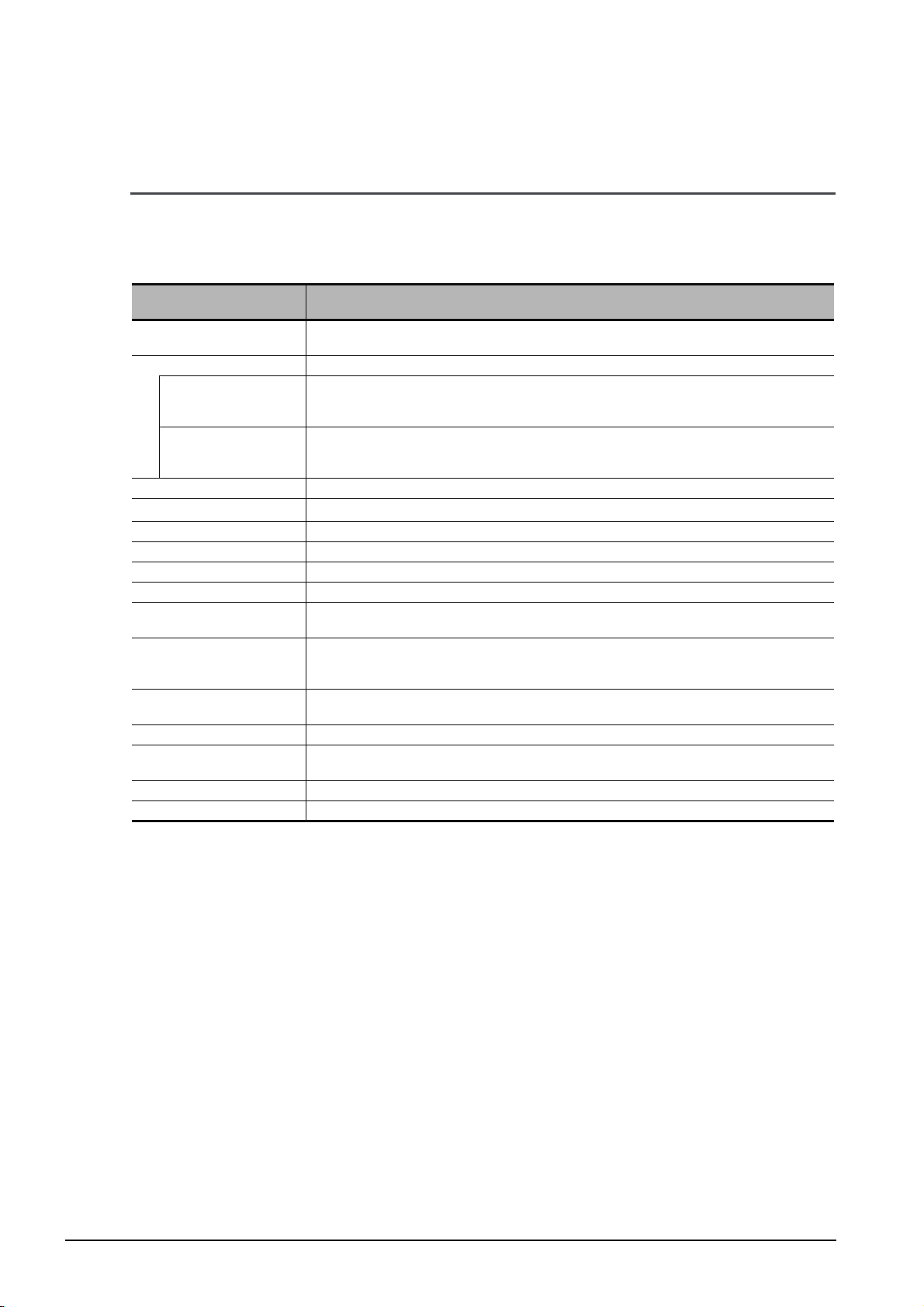

Print date Manual number Revision

Jul., 2008 SH(NA)-080788ENG-A First edition

Jan., 2009 SH(NA)-080788ENG-B

Jul., 2009 SH(NA)-080788ENG-C

Oct., 2009 SH(NA)-080788ENG-D

Model Addition

Q00UJ, Q00U, Q01U, Q10UDH, Q10UDEH, Q20UDH, Q20UDEH, FXCPU

Addition

MANUALS, Section 1.1, Section 3.6

Correction

GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL, Section 1,

Section 2.2, Section 3, Section 3.2.1, Section 3.2.2, Section 3.2.3, Section 3.2.5,

Section 3.2.6, Section 3.2.7, Section 3.3.1, Section 3.3.2, Section 3.4.1,

Section 3.4.2, Section 3.7.2, Section 4, Section 4.2.6, Section 4.4.1, Section 4.7,

Section 5, Section 5.2.5, Section 5.2.6, Section 5.4.1, Section 5.7

Model Addition

Q00J, Q00, Q01

Addition

MANUALS, Section 1.1

Correction

MANUALS, Section 3.1, Section 3.2, Section 3.3, Section 3.4, Section 3.5,

Section 3.6, Section 3.7, Section 3.8, Section 3.9, Section 4.1, Section 4.2,

Section 4.4, Section 4.7, Section 5.1, Section 5.2, Section 5.4, Section 5.7

Correction

SAFETY PRECAUTIONS, Section 1.2, Section 3.2.2, Section 3.2.3, Section 3.2.5,

Section 3.2.6, Section 3.7.1, Section 3.7.2, Section 3.7.3, Section 3.8, Section 4.9,

Section 5.2.6, Section 5.9

Jan., 2010 SH(NA)-080788ENG-E

Apr., 2010 SH(NA)-080788ENG-F

Model Addition

L02, L26-BT

Addition

CONDITIONS OF USE FOR THE PRODUCT

Correction

MANUALS, GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL,

Section 3.2.1, Section 3.2.2, Section 3.2.3, Section 3.2.4, Section 3.2.5,

Section 3.2.6, Section 3.2.7, Section 3.3.2, Section 3.4.1, Section 3.4.2,

Section 3.5, Section 3.6, Section 3.7.2, Section 3.7.4, Section 4.2.5, Section 4.2.6,

Section 4.4.1, Section 5.2.5, Section 5.2.6, Section 5.2.7, Section 5.4.1

Correction

SAFETY PRECAUTIONS, MANUALS, GENERIC TERMS AND ABBREVIATIONS

IN THIS MANUAL, Section 3.2.1, Section 3.2.2, Section 3.2.3, Section 3.2.7,

Section 3.3.1, Section 3.3.2, Section 3.4.1, Section 3.4.2, Section 3.5, Section 3.9,

Section 4.2.6, Section 4.4.1, Section 5.4.1

A - 3

Page 6

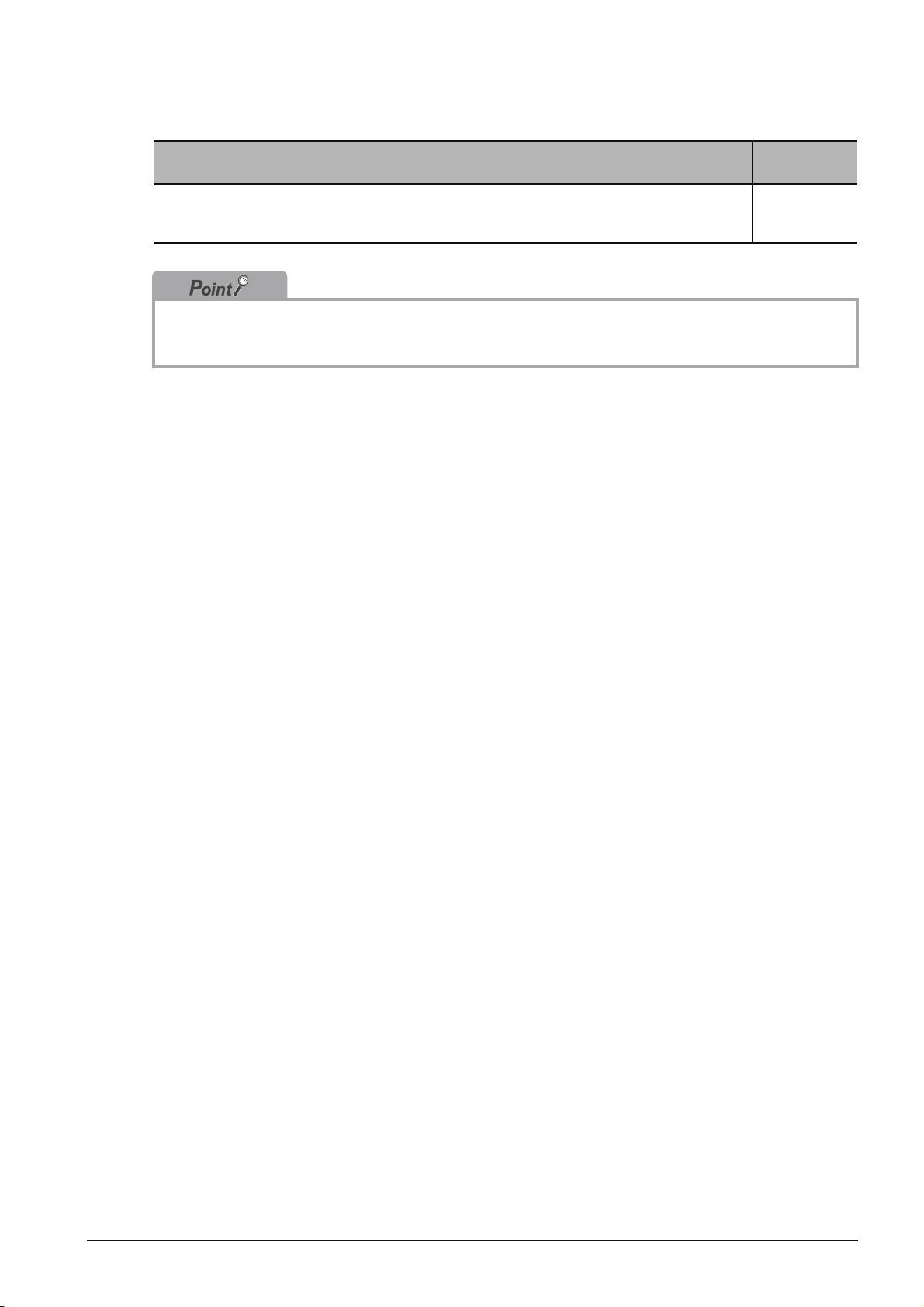

Print date Manual number Revision

Sep., 2010 SH(NA)-080788ENG-G

Jan., 2011 SH(NA)-080788ENG-H

Jul., 2011 SH(NA)-080788ENG-I

Correction

GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL, Section 3.2.3,

Section 3.2.6, Section 3.3.1, Section 3.3.2, Section 3.5, Section 3.6

Correction

MANUALS, Section 2.1, Section 3.2.1, Section 3.2.2, Section 3.2.3, Section 3.2.4,

Section 3.2.5, Section 3.2.6, Section 3.2.7, Section 3.3.1, Section 3.3.2,

Section 3.4.1, Section 3.4.2, Section 3.5, Section 3.6, Section 3.7.2, Section 3.7.4,

Section 3.8, Section 4.2.6, Section 4.4.1, Section 5.2.5, Section 5.2.7, Section 5.4.1

Addition

Section 3.2.8

Correction

MANUALS, Section 1.1, Section 2.2, Section 3.1.2, Section 3.2.1, Section 3.2.2,

Section 3.2.3, Section 3.2.6, Section 3.3.2, Section 3.4.1, Section 3.4.2, Section 3.6,

Section 3.7.1, Section 3.7.2, Section 3.7.3, Section 3.8, Section 3.9, Section 4.2.6,

Section 4.4.1, Section 5.1.2, Section 5.2.5, Section 5.2.7, Section 5.4.1

Japanese Manual Version SH-080734-K

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may occur

as a result of using the contents noted in this manual.

© 2008 MITSUBISHI ELECTRIC CORPORATION

A - 4

Page 7

INTRODUCTION

Thank you for purchasing the Mitsubishi integrated FA software, MELSOFT series.

Before using the product, thoroughly read this manual to develop full familiarity with the functions and performance

to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS ...................................................................................................................... A - 1

CONDITIONS OF USE FOR THE PRODUCT ...................................................................................... A - 2

REVISIONS ........................................................................................................................................... A - 3

INTRODUCTION ................................................................................................................................... A - 5

CONTENTS ........................................................................................................................................... A - 5

MANUALS.............................................................................................................................................. A - 8

GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL........................................................... A - 16

1OVERVIEW 1 - 1 to 1 - 6

1.1 Simple Project and Structured Project 1 - 2

1.2 Program Creation Procedure 1 - 4

2 CREATED PROGRAM AND SYSTEM CONFIGURATION 2 - 1 to 2 - 4

2.1 System Configuration 2 - 2

2.2 Overview of Program Creation 2 - 2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE 3 - 1 to 3 - 48

3.1 Created Program 3 - 2

3.1.1 Operations of program..................................................................................................................3 - 2

3.1.2 Created program ..........................................................................................................................3 - 2

3.2 Creating a Project 3 - 3

3.2.1 Starting GX Works2......................................................................................................................3 - 3

3.2.2 Screen configuration in GX Works2 .............................................................................................3 - 4

3.2.3 Creating a new project..................................................................................................................3 - 5

3.2.4 Setting parameters .......................................................................................................................3 - 7

3.2.5 Setting labels ................................................................................................................................3 - 8

3.2.6 Creating a program.....................................................................................................................3 - 11

3.2.7 Compiling a program .................................................................................................................. 3 - 19

3.2.8 Creating an FBD program ..........................................................................................................3 - 20

3.3 Writing a Project to the programmable controller 3 - 21

3.3.1 Connecting the personal computer to the programmable controller........................................... 3 - 21

3.3.2 Writing a project to the programmable controller........................................................................3 - 26

3.4 Monitoring Operations 3 - 29

3.4.1 Monitoring a program .................................................................................................................3 - 29

3.4.2 Batch monitoring of device values.............................................................................................. 3 - 34

A - 5

Page 8

3.5 Diagnosing the programmable controller 3 - 38

3.6 Reading a Project from programmable controller 3 - 39

3.7 Printing 3 - 41

3.7.1 Setting the printer....................................................................................................................... 3 - 41

3.7.2 Previewing a program ................................................................................................................ 3 - 42

3.7.3 Printing a program...................................................................................................................... 3 - 44

3.7.4 Previewing a PLC Parameter..................................................................................................... 3 - 45

3.7.5 Printing a PLC Parameter .......................................................................................................... 3 - 46

3.8 Saving a Project 3 - 47

3.9 Exiting GX Works2 3 - 48

4 CREATING PROGRAM IN ST LANGUAGE 4 - 1 to 4 - 12

4.1 Created Program 4 - 2

4.1.1 Operations of program ................................................................................................................. 4 - 2

4.1.2 Created program .......................................................................................................................... 4 - 2

4.2 Creating a Project 4 - 3

4.2.1 Starting GX Works2 ..................................................................................................................... 4 - 3

4.2.2 Screen configuration in GX Works2 ............................................................................................. 4 - 3

4.2.3 Creating a new project ................................................................................................................. 4 - 3

4.2.4 Setting parameters....................................................................................................................... 4 - 3

4.2.5 Setting labels................................................................................................................................ 4 - 3

4.2.6 Creating a program ...................................................................................................................... 4 - 4

4.2.7 Compiling a program.................................................................................................................... 4 - 6

4.3 Writing a Project to the programmable controller 4 - 7

4.4 Monitoring Operations 4 - 7

4.4.1 Monitoring a program ................................................................................................................... 4 - 7

4.4.2 Batch monitoring of device values ............................................................................................. 4 - 10

4.5 Diagnosing the programmable controller 4 - 11

4.6 Reading a Project from programmable controller 4 - 11

4.7 Printing 4 - 11

4.8 Saving a Project 4 - 11

4.9 Exiting GX Works2 4 - 11

5 CREATING TWO OR MORE PROGRAM BLOCKS 5 - 1 to 5 - 19

5.1 Created Program 5 - 2

5.1.1 Operations of program ................................................................................................................. 5 - 2

5.1.2 Created program .......................................................................................................................... 5 - 3

5.2 Creating a Project 5 - 4

5.2.1 Starting GX Works2 ..................................................................................................................... 5 - 4

5.2.2 Screen configuration in GX Works2 ............................................................................................. 5 - 4

5.2.3 Creating a new project ................................................................................................................. 5 - 4

5.2.4 Setting parameters....................................................................................................................... 5 - 4

A - 6

Page 9

5.2.5 Preparing (creating) the program configuration............................................................................5 - 5

5.2.6 Setting labels ................................................................................................................................5 - 8

5.2.7 Creating a program.......................................................................................................................5 - 9

5.2.8 Compiling a program .................................................................................................................. 5 - 11

5.3 Writing a Project to the programmable controller 5 - 12

5.4 Monitoring Operations 5 - 12

5.4.1 Monitoring a program .................................................................................................................5 - 12

5.4.2 Batch monitoring of device values.............................................................................................. 5 - 18

5.5 Diagnosing the programmable controller 5 - 18

5.6 Reading a Project from programmable controller 5 - 18

5.7 Printing 5 - 19

5.8 Saving a Project 5 - 19

5.9 Exiting GX Works2 5 - 19

A - 7

Page 10

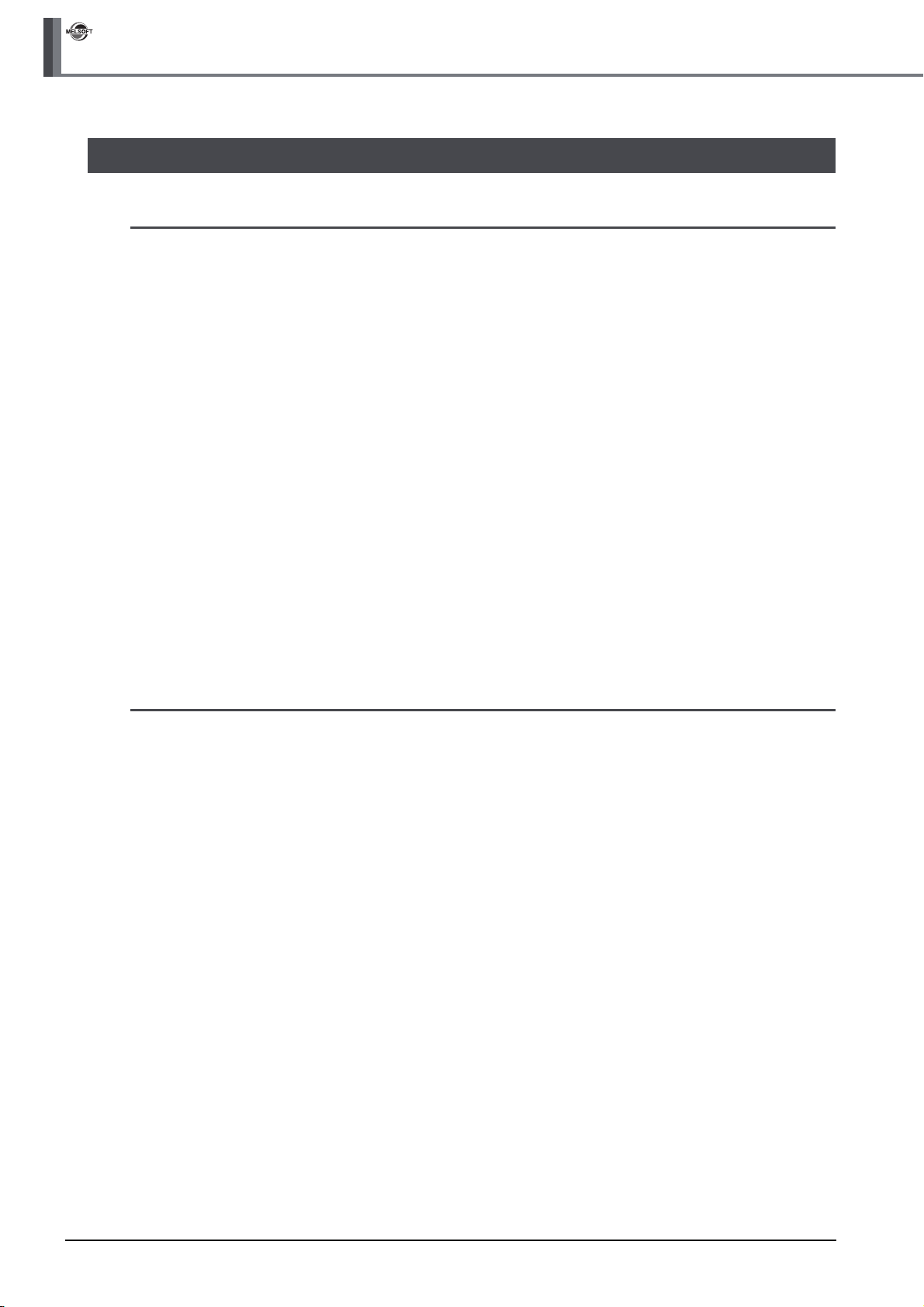

■ MANUALS

Related manuals are separately issued according to the purpose of their functions in GX Works2.

● Related manuals

The manuals related to this product are shown below.

Refer to the following tables when ordering required manuals.

1) Operation of GX Works2

Manual name

GX Works2 Version 1 Operating Manual (Common)

Explains the system configuration of GX Works2 and the functions common to a Simple project and

Structured project such as parameter setting, operation method for the online function. (Sold separately)

GX Works2 Version 1 Operating Manual (Simple Project)

Explains operation methods such as creating and monitoring programs in Simple project of GX Works2.

(Sold separately)

GX Works2 Version 1 Operating Manual (Structured Project)

Explains operation methods such as creating and monitoring programs in Structured project of GX Works2.

(Sold separately)

GX Works2 Version 1 Operating Manual (Intelligent Function Module)

Explains operation methods of intelligent function module such as parameter setting, monitoring programs,

and predefined protocol support function in GX Works2. (Sold separately)

GX Works2 Beginner’s Manual (Simple Project)

Explains fundamental operation methods such as creating, editing, and monitoring programs in Simple

project for users inexperienced with GX Works2. (Sold separately)

2) Structured Programming

Manual name

MELSEC-Q/L/F Structured Programming Manual (Fundamentals)

Explains the programming method, types of programming languages and other information required to

create structured programs. (Sold separately)

Manual number

(Manual code)

SH-080779ENG

(13JU63)

SH-080780ENG

(13JU64)

SH-080781ENG

(13JU65)

SH-080921ENG

(13JU69)

SH-080787ENG

(13JZ22)

Manual number

(Manual code)

SH-080782ENG

(13JW06)

A - 8

MELSEC-Q/L Structured Programming Manual (Common Instructions)

Explains the specifications and functions of common instructions such as sequence instructions, basic

instructions, and application instructions, that can be used in structured programs. (Sold separately)

MELSEC-Q/L Structured Programming Manual (Application Functions)

Explains the specifications and functions of application functions that can be used in structured programs.

(Sold separately)

MELSEC-Q/L Structured Programming Manual (Special Instructions)

Explains the specifications and functions of special instructions such as module dedicated instruction, PID

control instruction, and built-in I/O function dedicated instruction, that can be used in structured programs.

(Sold separately)

FXCPU Structured Programming Manual (Device & Common)

Explains the devices and parameters provided in GX Works2 for structured programming. (Sold separately)

FXCPU Structured Programming Manual (Basic & Applied Instruction)

Explains the sequence instructions provided in GX Works2 for structured programming. (Sold separately)

FXCPU Structured Programming Manual (Application Functions)

Explains the application functions provided in GX Works2 for structured programming. (Sold separately)

SH-080783ENG

(13JW07)

SH-080784ENG

(13JW08)

SH-080785ENG

(13JW09)

JY997D26001

(09R925)

JY997D34701

(09R926)

JY997D34801

(09R927)

Page 11

3) Operation of iQ Works

Manual name

iQ Works Beginner's Manual

Explains fundamental operation methods such as managing the system using MELSOFT Navigator and

using system labels for users inexperienced with GX Works2. (Sold separately)

The Operating Manuals are included on the CD-ROM of the software package in a PDF file format.

Manuals in printed form are sold separately for single purchase. Order a manual by quoting the manual

number (model code) listed in the table above.

Manual number

(Manual code)

SH-080902ENG

(13JZ44)

A - 9

Page 12

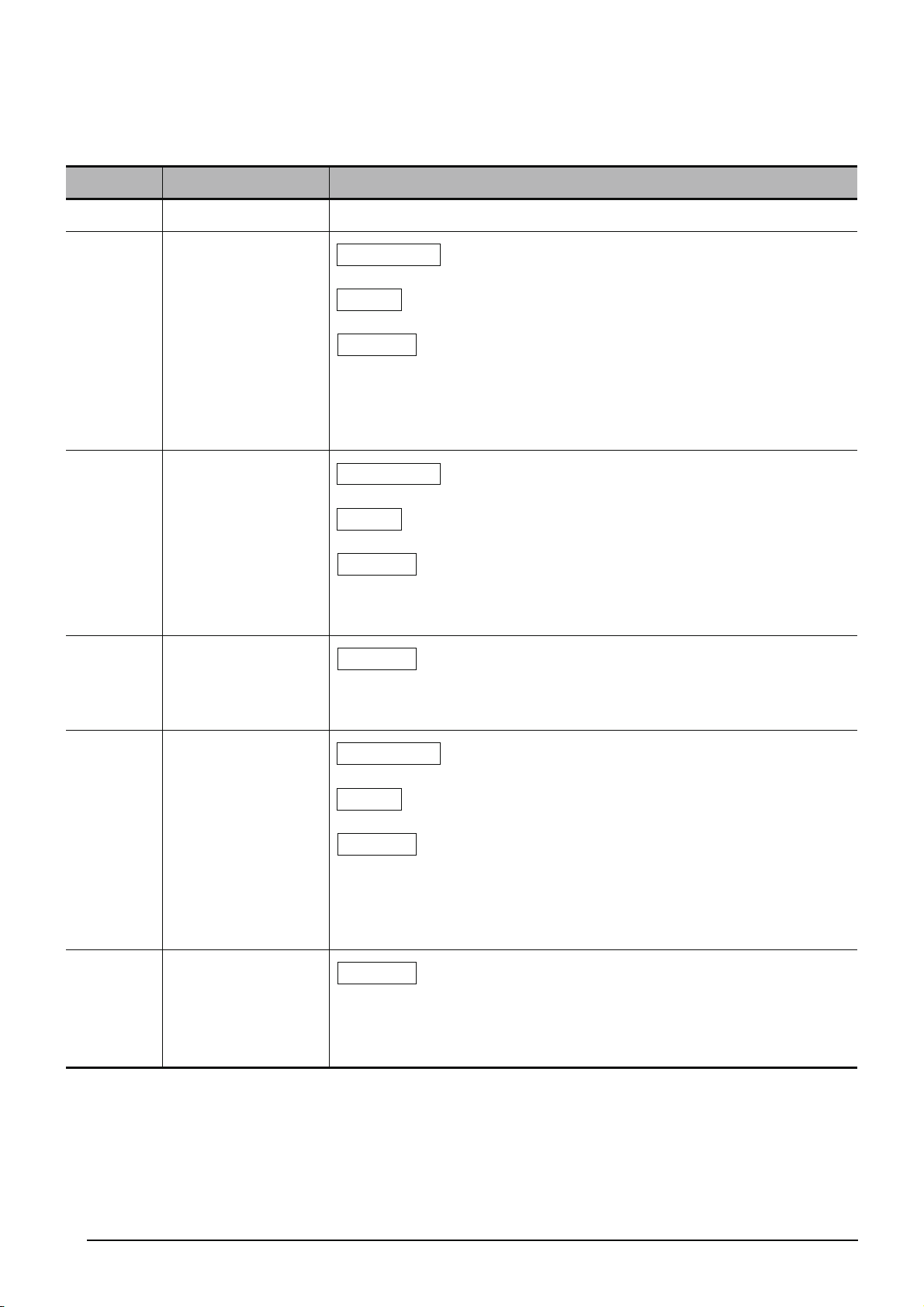

● Purpose of this manual

This manual explains the operation for creating sequence programs in Structured project, one of the

functions supported with GX Works2.

Manuals for reference are listed in the following table according to their purpose.

For information such as the contents and manual number of each manual, refer to the list of 'Related

manuals'.

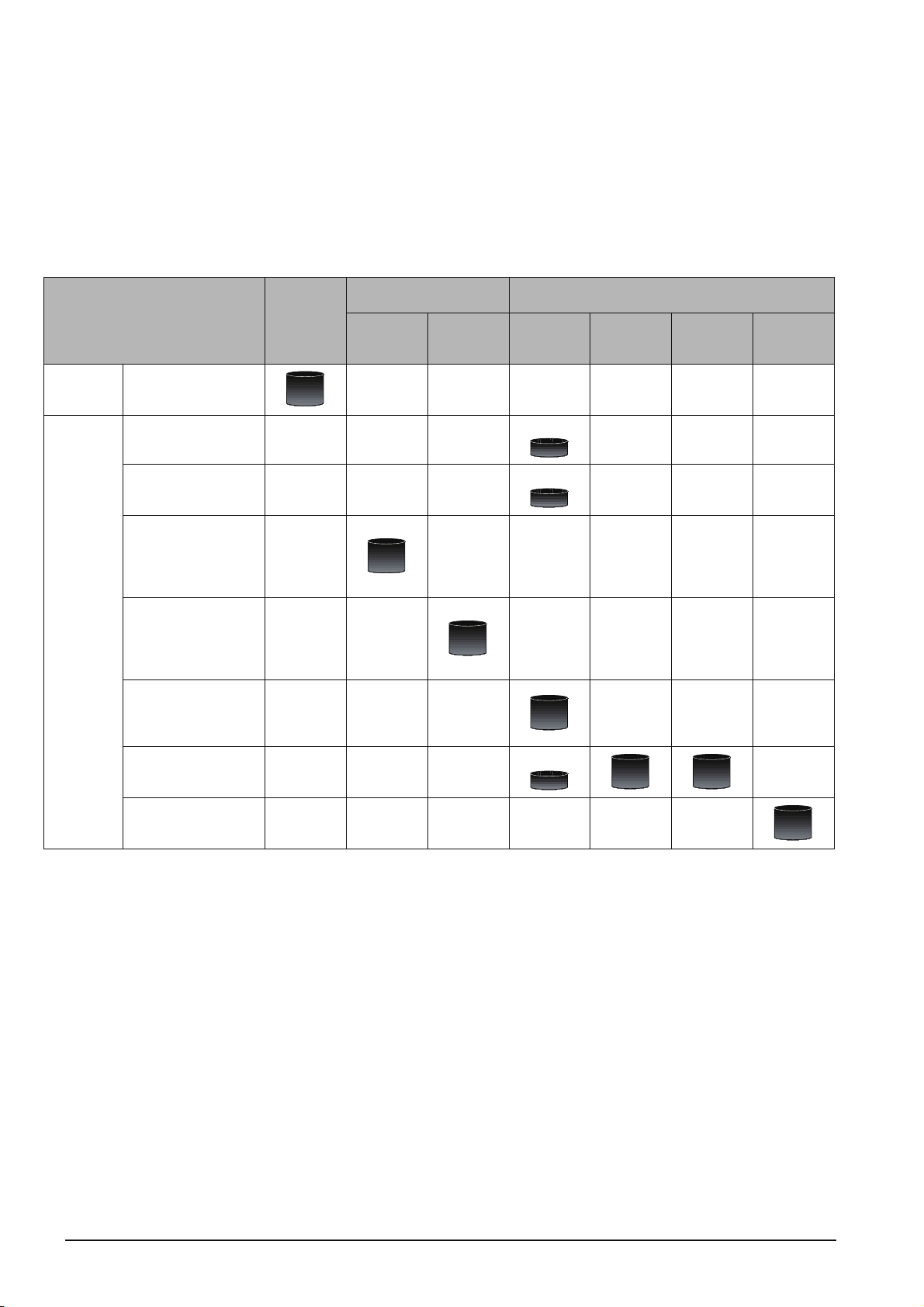

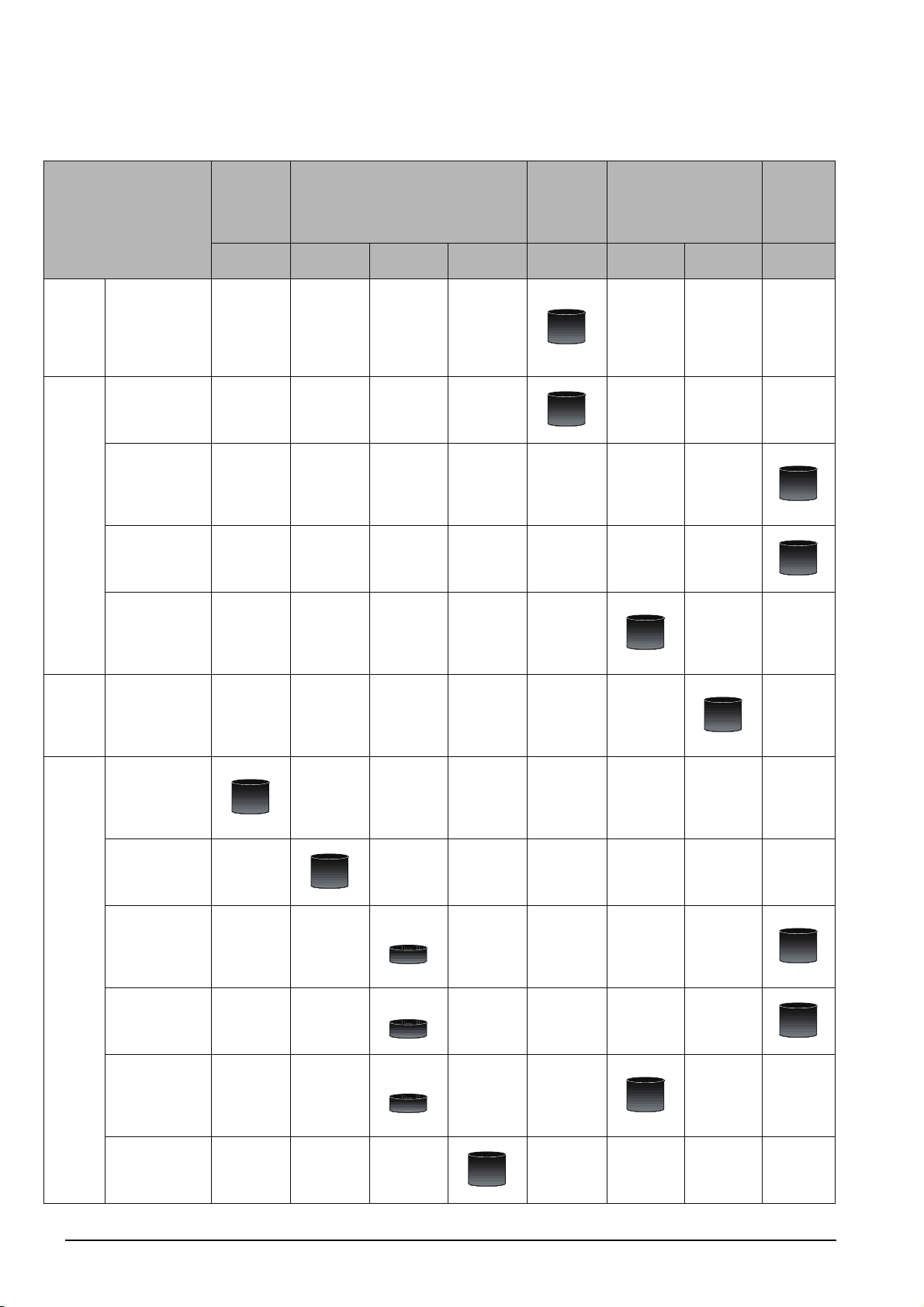

1) Operation of GX Works2

Installation

Operation of

GX Works2

Purpose

Learning the operating

environment and

installation method

Learning all functions of

GX Works2

Learning the project

types and available

languages in GX Works2

Learning the basic

operations and operating

procedures when

creating a simple project

for the first time

Learning the basic

operations and operating

procedures when

creating a structured

project for the first time

Learning the operations

of available functions

regardless of project

type.

Learning the functions

and operation methods

for programming

Learning data setting

methods for intelligent

function module

GX Works2

Installation

Instructions

Details

GX Works2

Beginner’s Manual

Simple

Project

Details

Structured

Project

Details

Common

Outline

Outline

Details

Outline

GX Works2 Version 1

Operating Manual

Simple

Project

Details Details

Structured

Project

Intelligent

Function

Module

Details

A - 10

Page 13

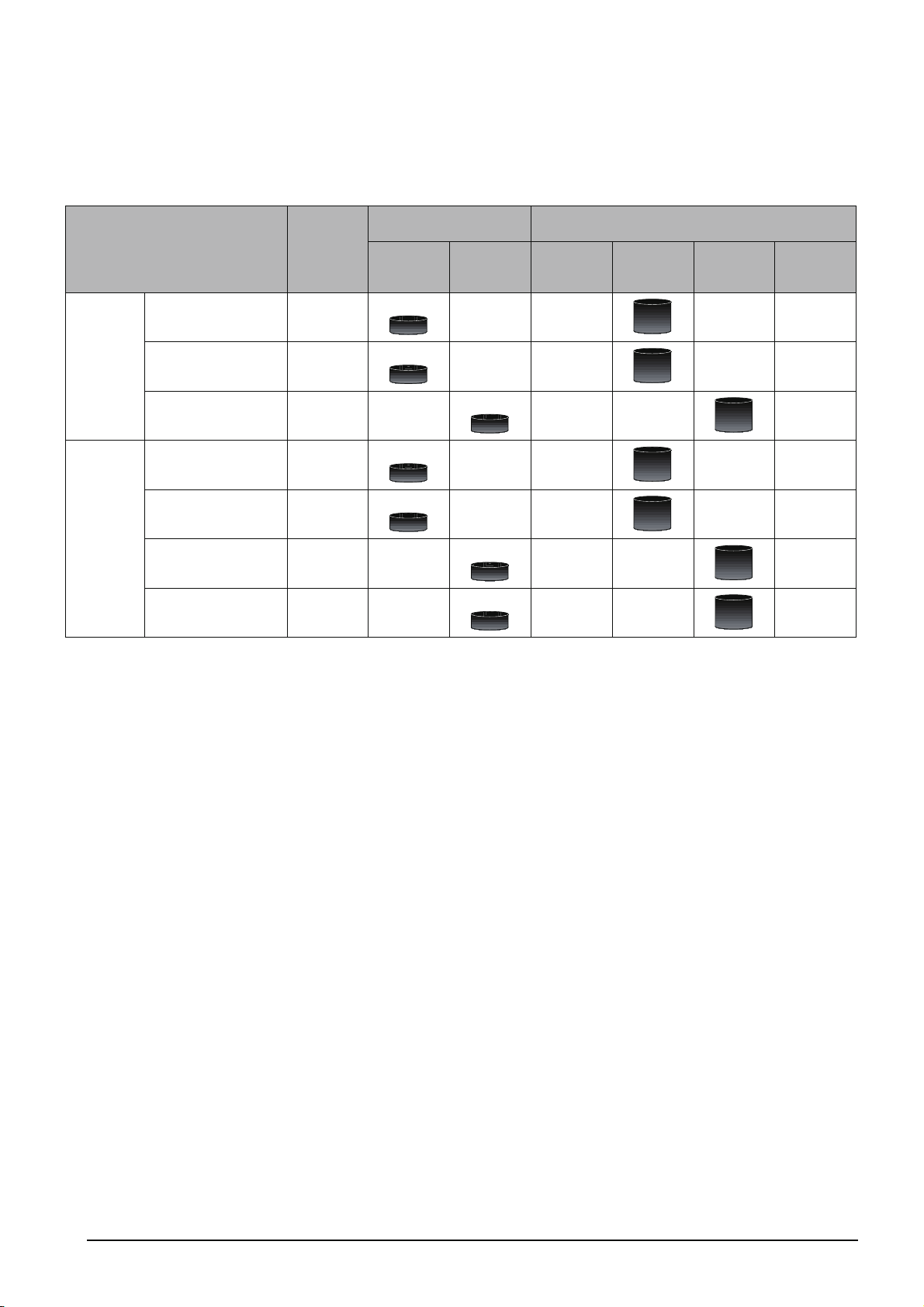

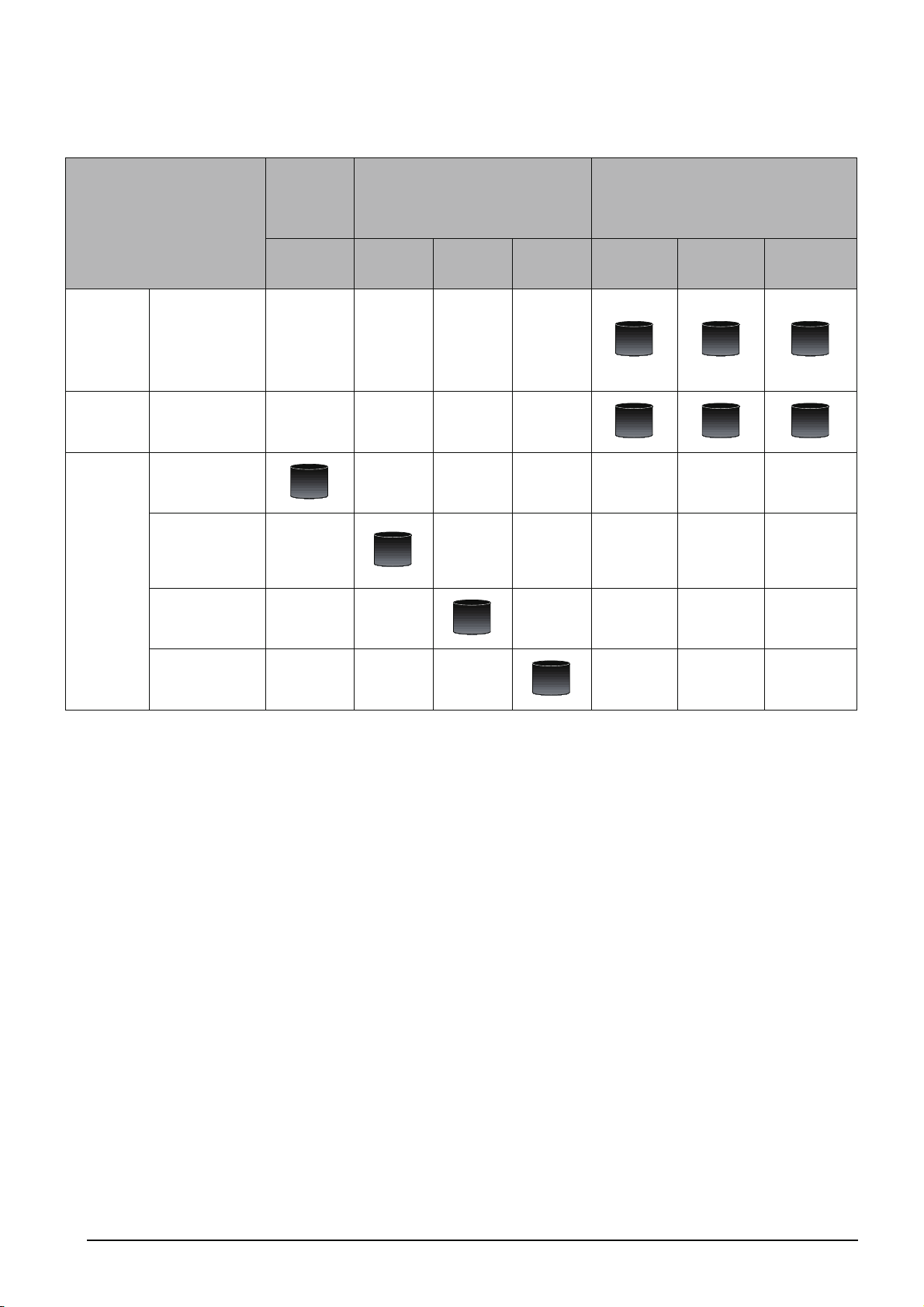

2) Operation of GX Works2

For details of instructions used in each programming language, refer to the section 3 on the next

page.

Purpose

Ladder

Simple

Project

SFC

ST

Ladder

SFC

Structured

Project

Structured Ladder/FBD

ST

*1: MELSAP3 and FX series SFC only

GX Works2

Installation

Instructions

GX Works2

Beginner’s Manual

Simple

Project

Outline

*1

Outline

Outline

*1

Outline

Structured

Project

Outline

Outline

Outline

Common

GX Works2 Version 1

Operating Manual

Simple

Project

Details

Details

Details

Details

Structured

Project

Details

Details

Details

Intelligent

Function

Module

A - 11

Page 14

3) Details of instructions in each programming language (for QCPU (Q mode)/LCPU)

All

languages

Using

ladder

language

Using

SFC

language

Using

Structured

Ladder/

FBD or ST

language

Purpose

Learning details of

programmable

controller CPU

error codes,

special relays, and

special registers

Learning the types

and details of

common

instructions

Learning the types

and details of

instructions for

intelligent function

modules

Learning the types

and details of

instructions for

network modules

Learning the types

and details of

instructions for the

PID control

function

Learning details of

specifications,

functions, and

instructions of

SFC (MELSAP3)

Learning the

fundamentals for

creating a

structured

program

Learning the types

and details of

common

instructions

Learning the types

and details of

instructions for

intelligent function

modules

Learning the types

and details of

instructions for

network modules

Learning the types

and details of

instructions for the

PID control

function

Learning the types

and details of

application

functions

MELSEC-

Q/L/F

Structured

Programming

Manual

Fundamentals

Details

MELSEC-Q/L Structured

Programming Manual

Common

Instructions

Details

Instructions

Special

Outline

Outline

Outline

Application

Functions

Details

MELSEC-

Q/L

Programming

Manual

Common

Instructions

Details

Details

MELSEC-Q/L/QnA

Programming Manual

PID Control

Instructions

Details

Details

SFC -

Details

Manual for

module to

be used

Details

Details

Details

Details

A - 12

Page 15

Using ladder

language

Using SFC

language

Using

Structure d

Ladder/FBD

or ST

language

4) Details of instructions in each programming language (for FXCPU)

MELSEC-

Q/L/F

Purpose

Learning the types

and details of

basic/application

instructions,

descriptions of

devices and

parameters

Learning details of

specifications,

functions, and

instructions of SFC

Learning the

fundamentals for

creating a

structured program

Learning the

descriptions of

devices,

parameters, and

error codes

Learning the types

and details of

sequence

instructions

Learning the types

and details of

application

instructions

Structured

Programming

Manual

Fundamentals

Details

FXCPU Structured Programming Manual

Device &

Common

Details

Basic &

Applied

Instruction

Details

Application

Functions

Details

FXCPU Programming Manual

FX0, FX0S,

FX

0N, FX1,

FX

U, FX2C

Details Details Details

Details Details Details

FX1S, FX1N,

FX

2N, FX1NC,

FX

2NC

FX3G, FX3U,

FX

3UC

A - 13

Page 16

● How to read this manual

Section title

Clarifies the section of currently

opened page.

Chapter heading

Index on the right of the page

number clarifies the chapter of

currently opened page.

Reference location

leads to the reference

location and reference manuals.

Section title

Clarifies the section of currently

opened page.

* Since the above page was created for explanation purpose, it differs from the actual page.

A - 14

Page 17

This manual also uses the following columns:

This explains notes for requiring attention or useful functions relating to the information given on the

same page.

Restrictions

This explains restrictions relating to the information given on the same page.

● Symbols used in this manual

The following shows the symbols used in this manual with descriptions and examples.

No. Symbol Description Example

(1) [ ] Menu name on a menu bar [Project]

(2) Toolbar icon

(3) << >> Tab name in a screen <<PLC System>>

(4) Button on a screen

(5) " " Item name in a screen "Timer Limit Setting"

− Keyboard key

button

A - 15

Page 18

■ GENERIC TERMS AND ABBREVIATIONS IN THIS MANUAL

This manual uses the generic terms and abbreviations listed in the following table to discuss the

software packages and programmable controller CPUs. Corresponding module model names are also

listed if needed.

Generic terms and

Abbreviations

GX Works2

Existing application -

GX Developer

GX Simulator

iQ Works Abbreviation for iQ platform supporting engineering environment MELSOFT iQ Works

Personal computer

Q series Abbreviation for Mitsubishi programmable controller MELSEC-Q series

L series Abbreviation for Mitsubishi programmable controller MELSEC-L series

FX series Abbreviation for Mitsubishi programmable controller MELSEC-F series

Basic model QCPU Generic term for Q00J, Q00, Q01

High Performance model

QCPU

Universal model QCPU

QCPU (Q mode)

LCPU Generic term for L02, L02-P, L26-BT and L26-PBT

FXCPU

CPU module Generic term for QCPU (Q mode), LCPU, and FXCPU

SFC Generic term for MELSAP3, MELSAP-L, and FX series SFC

Generic product name for SWnDNC-GXW2-E model

(n: version)

Generic product name for SWnD5C-GPPW-E, SWnD5C-GPPW-EA, SWnD5C-GPPW-EV, and

SWnD5C-GPPW-EVA

(n: version)

Generic product name for SWnD5C-GPPW-E, SWnD5C-GPPW-EA, SWnD5C-GPPW-EV, and

SWnD5C-GPPW-EVA

(n: version)

Generic term for personal computers on which Windows

Generic term for Q02, Q02H, Q06H, Q12H, and Q25H

Generic term for Q00UJ, Q00U, Q01U, Q02U, Q03UD, Q03UDE, Q04UDH, Q04UDEH,

Q06UDH, Q06UDEH, Q10UDH, Q10UDEH, Q13UDH, Q13UDEH, Q20UDH, Q20UDEH,

Q26UDH, Q26UDEH, Q50UDEH, and Q100UDEH

Generic term for Basic model QCPU, High Performance model QCPU, and Universal model

QCPU

Generic term for FX

and FX

3UC

0, FX0S, FX0N, FXU, FX2C, FX1S, FX1N, FX1NC, FX2N, FX2NC, FX3G, FX3U,

Description

®

operates

A - 16

Page 19

1

OVERVIEW

1OVERVIEW

This manual explains the procedures to actually create a program (Structured Project) using GX Works2 and

operate the programmable controller using the created program.

If this is your first time creating a Structured Project using GX Works2, you are recommended to read this

manual first, and then use GX Works2.

Refer to the following manual for Simple Projects:

GX Works2 Beginner’s Manual (Simple Project)

1.1 Simple Project and Structured Project . . . . . . . . . . . . . . . . . . . 1-2

1.2 Program Creation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

1 - 1

Page 20

GX Works2

1 OVERVIEW

1.1 Simple Project and Structured Project

■ Simple Project

In a Simple Project, you can create sequence programs using instructions for the Mitsubishi

programmable controller CPU.

The Simple Project offers the same operability for program creation as the conventional GX Developer.

You can create sequence programs using the following programming languages:

● Graphic languages

• Ladder

Use this graphic language to describe programs as ladders consisting of contacts, coils, etc.,

using the same operating procedures as the conventional GX Developer.

•SFC

Use this graphic language to describe sequence control in a way easy to understand.

Describe steps which specify the processing and transition conditions which specify conditions

for proceeding to the next step.

You can describe steps and transition conditions using the ladder language.

● Text language

• ST (Structured Text)

This text language allows you to describe controls by syntax including alternative sequences

offered by conditional sentences and repetition offered by repetition sentences in the same way

as high-level languages such as the C language. Accordingly, you can briefly create programs

easy to look at.

■ Structured Project

In a Structured Project, you can create programs by structured program.

By dividing controls into small portions and making parts of common contents, you can create programs

easy to understand and applicable to many cases (by structured program.)

You can create sequence programs using the following programming languages:

● Graphic languages

• Ladder

Use this graphic language to describe programs as ladders consisting of contacts, coils, etc.,

using the same operating procedures as the conventional GX Developer.

• Structured Ladder/FBD

Structured Ladder is created based on the relay circuit design technology. Because this

language is easy to understand intuitively, it is used generally for sequence programs.

Every ladder always starts from a base line on the left.

Structured Ladder consists of contacts, coils, function blocks and functions which are connected

each other with vertical lines and horizontal lines.

FBD connects functions and function blocks with ruled lines to describe ladders.

•SFC

Use this graphic language to describe sequence control in a way easy to understand.

Describe steps which specify the processing and transition conditions which specify conditions

for proceeding to the next step.

You can describe steps and transition conditions using the ladder language.

1 - 2

Page 21

1.1 Simple Project and Structured Project

● Text language

• ST (Structured Text)

This text language allows you to describe controls by syntax including alternative sequences

offered by conditional sentences and repetition offered by repetition sentences in the same way

as high-level languages such as the C language. Accordingly, you can briefly create programs

easy to look at.

Restrictions

The FXCPU does not support the ST language in Simple Project, and does not support the ladder language

and SFC language in Structured Project.

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

1 - 3

Page 22

GX Works2

1 OVERVIEW

1.2 Program Creation Procedure

The figure below shows how to create a program with a Structured Project and execute it in a programmable

controller CPU.

1. Opening a project

Procedure Reference

Start GX Works2. 3.2.1

Create a new Structured Project. Or open an existing Structured Project. 3.2.3

2. Setting parameters

Procedure Reference

Set the parameters. 3.2.4

3. Creating the program configuration

Procedure Reference

Create Program File. --

Create Task in Program File. --

Create POU.

Register program block of POU to Task in Program File.

5.2.5

4. Setting labels

Procedure Reference

Define global labels. 3.2.5

Define local labels. --

5. Editing the program

Procedure Reference

3.2.6

Edit the program in each POU.

4.2.6

5.2.7

1 - 4

(To the next page)

Page 23

6. Conversion

1.2 Program Creation Procedure

1

Procedure Reference

Compile the program. 3.2.7

7. Connecting the programmable controller CPU

Procedure Reference

Connect the personal computer to the programmable controller CPU.

Set the connection destination.

3.3.1

8. Writing to the programmable controller

Procedure Reference

Write the parameters to the programmable controller CPU.

Write the program to the programmable controller CPU.

3.3.2

9. Checking operations

Procedure Reference

3.4

Monitor the sequence program execution status, and check operations.

Check for errors in the programmable controller. 3.5

4.4

5.4

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

10.Printing

Procedure Reference

Print the program and parameters.

11.Exiting GX Works2

Procedure Reference

Save the project. 3.8

Exiting GX Works2. 3.9

3.7

4.7

5.7

CREATING TWO OR

MORE PROGRAM

BLOCKS

1 - 5

Page 24

GX Works2

1 OVERVIEW

MEMO

1 - 6

Page 25

1

OVERVIEW

2 CREATED PROGRAM AND

SYSTEM CONFIGURATION

This chapter explains the system configuration and gives an overview of the program created by using this

manual.

2.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Overview of Program Creation. . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

2 - 1

Page 26

GX Works2

2 CREATED PROGRAM AND SYSTEM CONFIGURATION

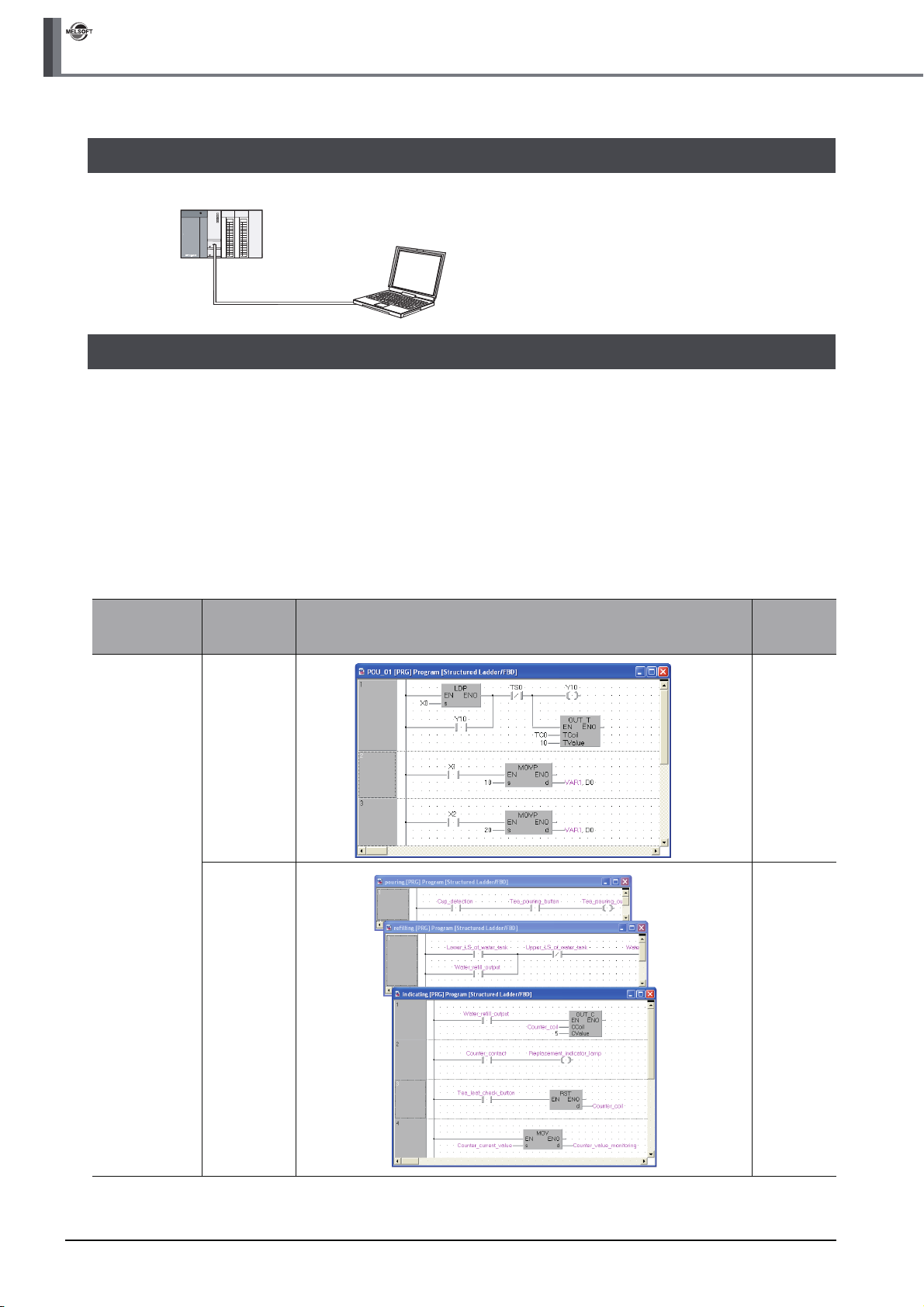

2.1 System Configuration

This manual uses GX Works2 and the Q Series programmable controller for explanation.

Programmable controller (QCPU)

GX Works2

USB cable

2.2 Overview of Program Creation

This manual explains the following program creation procedures using the simple example program shown in

the table below.

• Creating a new project

• Setting parameters

• Setting labels

• Creating a program (inputting contacts and application instructions, converting ladder blocks and compiling

the program)

• Writing to the programmable controller

• Monitoring ladder, etc.

• Preview, Printing

Program

language

Number of

program

blocks

Table 2.1 Overview of created program

Operation overview Reference

Structured

Ladder

1 Chapter 3

3 Chapter 5

2 - 2

Page 27

2.2 Overview of Program Creation

Table 2.1 Overview of created program

Program

language

FBD 1 Chapter 3

ST 1 Chapter 4

Number of

program

blocks

Operation overview Reference

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

Ladder

SFC

Refer to the following manual.

GX Works2 Beginner's Manual (Simple Project)

You can create the Inline ST Box that displays ST language programs in the Ladder Editor, and edit

and monitor ST language programs.

Refer to the following manual for the details.

GX Works2 Version 1 Operating Manual (Simple Project)

Refer to the following manual.

GX Works2 Beginner's Manual (Simple Project)

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

2 - 3

Page 28

GX Works2

2 CREATED PROGRAM AND SYSTEM CONFIGURATION

MEMO

2 - 4

Page 29

1

OVERVIEW

3 CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

This chapter explains how to create a program in the Structured Ladder/FBD language with a Structured

Project using a simple Structured Ladder program.

Refer to the following manuals for the details on structured programs including programming languages,

labels, data types and functions (instructions):

MELSEC-Q/L/F Structured Programming Manual (Fundamentals)

Structured Programming Manual of the programmable controller CPU

3.1 Created Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Creating a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Writing a Project to the programmable controller . . . . . . . . . 3-21

3.4 Monitoring Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.5 Diagnosing the programmable controller. . . . . . . . . . . . . . . . 3-38

3.6 Reading a Project from programmable controller . . . . . . . . . 3-39

3.7 Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.8 Saving a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

3.9 Exiting GX Works2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

3 - 1

Page 30

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

3.1 Created Program

This section explains the operations of the program to be created and ladder programs.

3.1.1 Operations of program

● When X0 turns ON, the programmable controller turns ON Y10, and then turns OFF Y10 1 second

later.

● When X1 turns ON, the programmable controller transfers K10 to D0 (which is defined with the

LABEL "VAR1").

● When X2 turns ON, the programmable controller transfers K20 to D0 (which is defined with the

LABEL "VAR1").

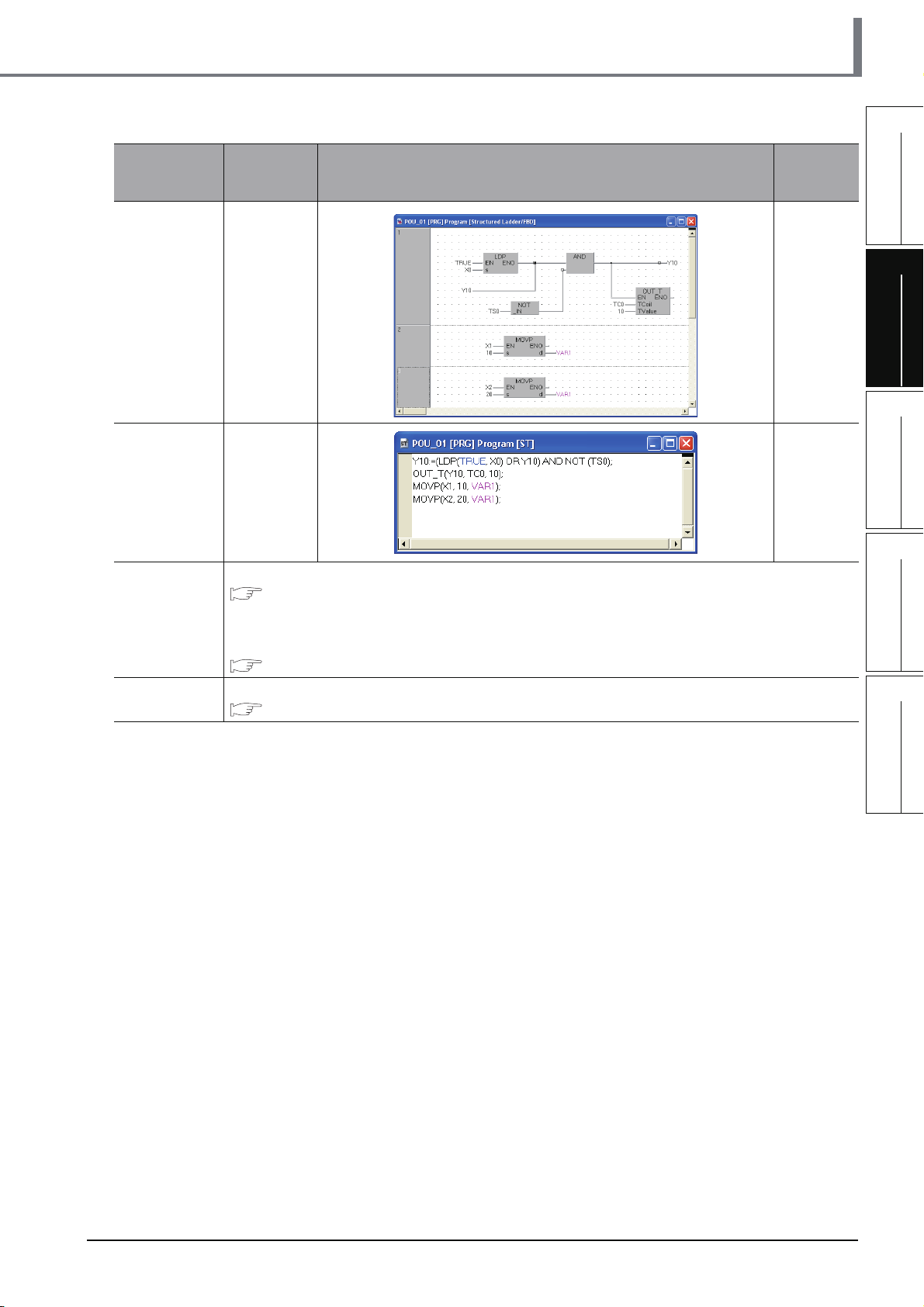

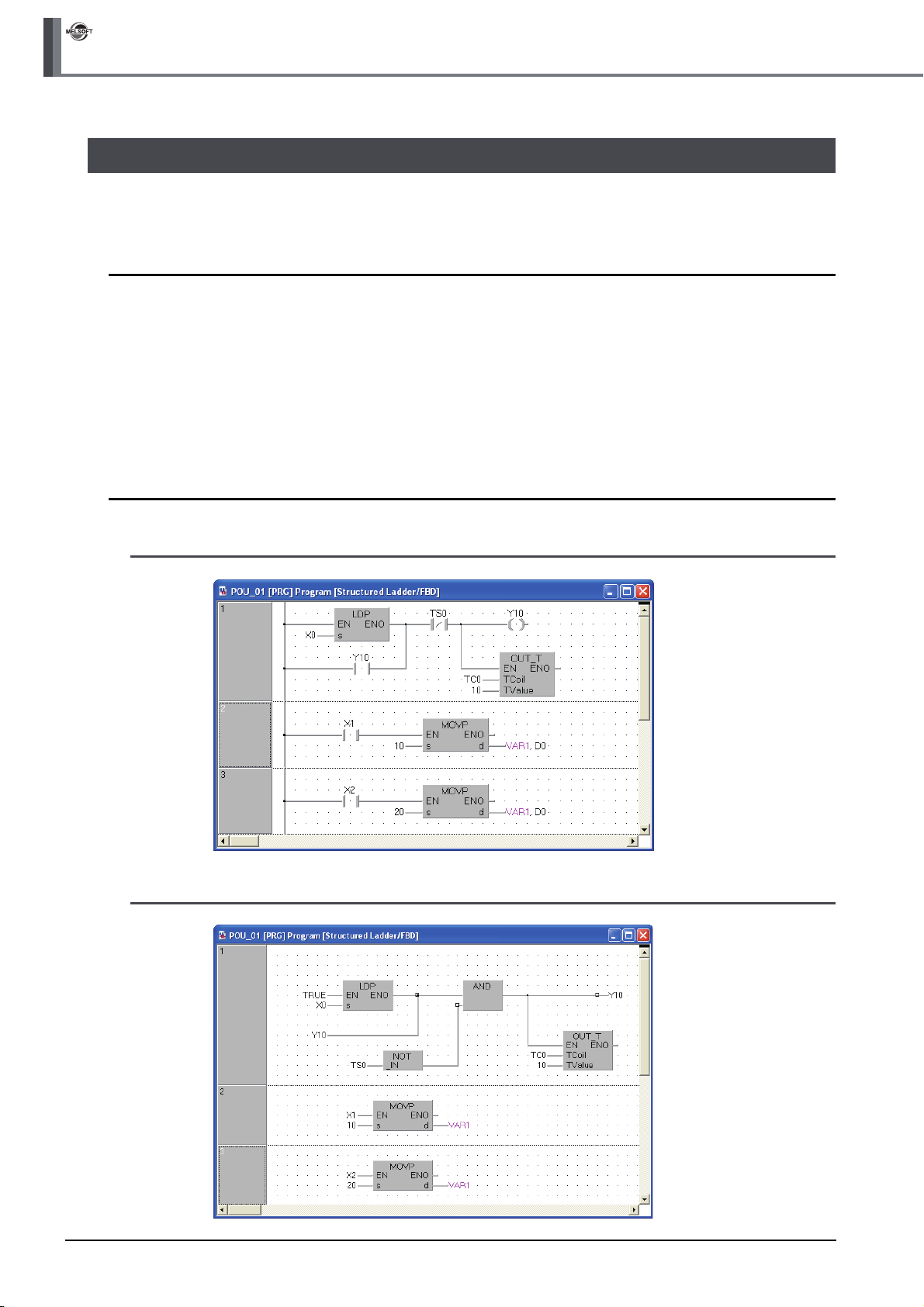

3.1.2 Created program

■ In the case of Structured Ladder

■ In the case of FBD

3 - 2

3.1.1 Operations of program

Page 31

3.2 Creating a Project

Create a project using Structured Ladder programs.

Refer to Section 3.2.8 for creating an FBD program.

3.2 Creating a Project

1

OVERVIEW

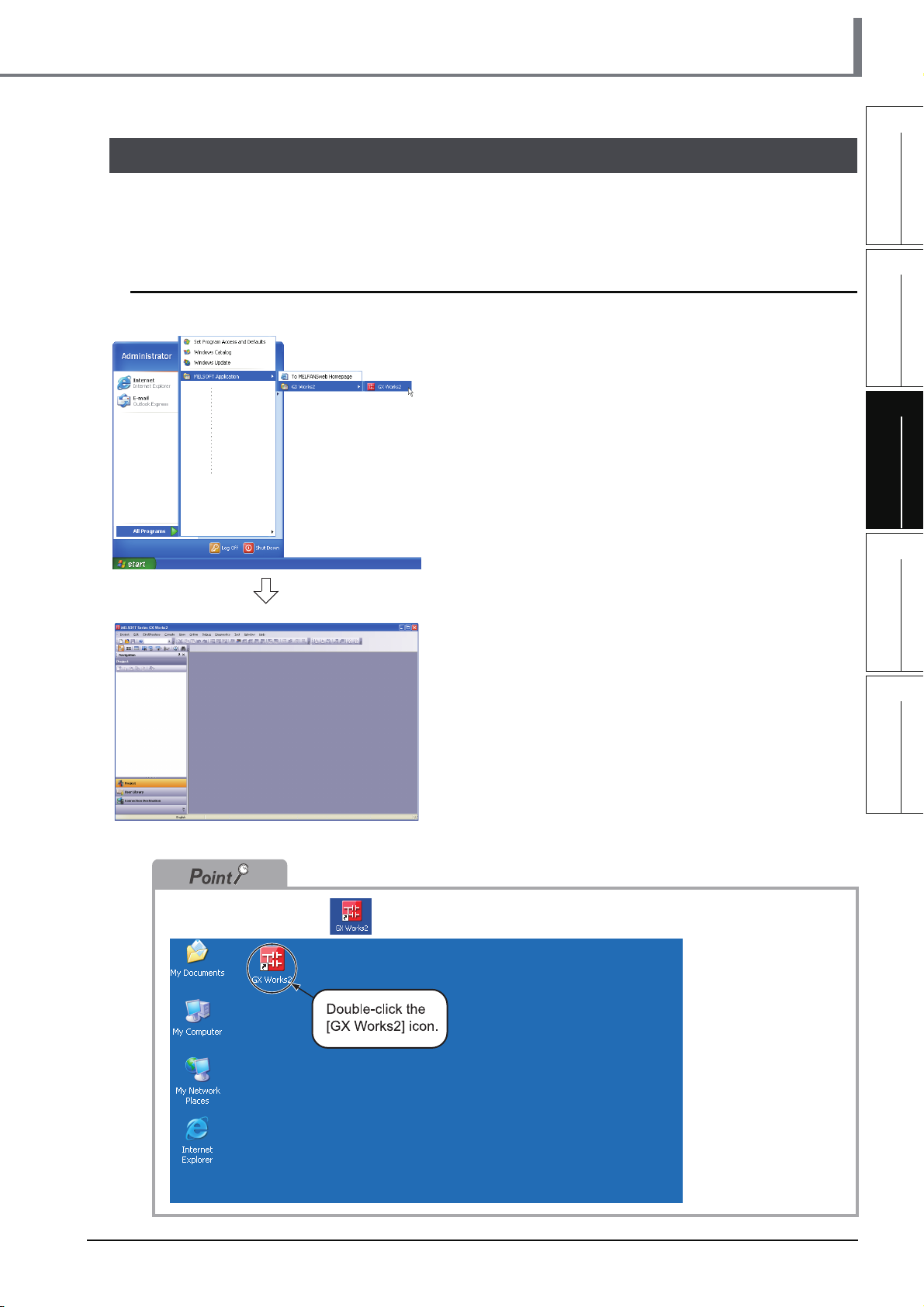

3.2.1 Starting GX Works2

1. Select the software package menu to be

started.

2. The selected software package is started.

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

You can double-click the icon on the desktop to start the software package.

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.2.1 Starting GX Works2

3 - 3

Page 32

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

3.2.2 Screen configuration in GX Works2

The GX Works2 screen has the following configuration.

Select "View" or "Hide" in the [View] menu for each of the Toolbar, Status bar, Navigation Window,

Function Block Selection window and Output window.

Refer to the following manual for the details on the GX Works2 screen configuration:

Title bar

Menu bar

Toolbar

Navigation Window

GX Works2 Version 1 Operating Manual (Common)

Function Block selection

window

Displays the list of

function blocks available

to program creation.

View contents display area

Displays the contents of

the currently selected view.

View selection area

Allows selection of the

view to be displayed.

Work window

Used for programming,

parameter setting,

monitoring, etc.

Output window

Displays the compile

result, error information

and warning information.

Status bar

3 - 4

3.2.2 Screen configuration in GX Works2

Page 33

3.2.3 Creating a new project

At first, create a project.

3.2 Creating a Project

1. Perform either procedure below to display the

New Project screen.

• Select [Project] [New].

• Click (New).

2. Select the "Project Type", "PLC Series", "PLC

Type" and "Language" from the list boxes for

the new project to be created.

After the setting, click the button.

Settings

• Project Type : Structured Project

• PLC Series : QCPU (Q mode)

• PLC Type : Q02/Q02H

• Language : Structured Ladder/FBD

*1: Labels are always available in structured

projects. You do not have to check "Use Label".

*1

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

3. GX Works2 creates a new project.

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.2.3 Creating a new project

3 - 5

Page 34

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

Opening an existing project

Refer to the following manual for the details on the existing project opening procedure:

GX Works2 Version 1 Operating Manual (Common)

1. Perform either operation below.

• Select [Project] [Open].

• Click (Open).

2. The Open Project screen appears.

Select an existing project to be opened in the "Workspace Location" and "Workspace/

Project List".

Specify the existing

project to be opened.

The selected project

is displayed in

"Project Name".

3. Click the button to open the selected project.

Specify the "Workspace

Location" saving an

existing project to be

opened. The selected

folder is displayed in

"Workspace Name".

3 - 6

3.2.3 Creating a new project

Page 35

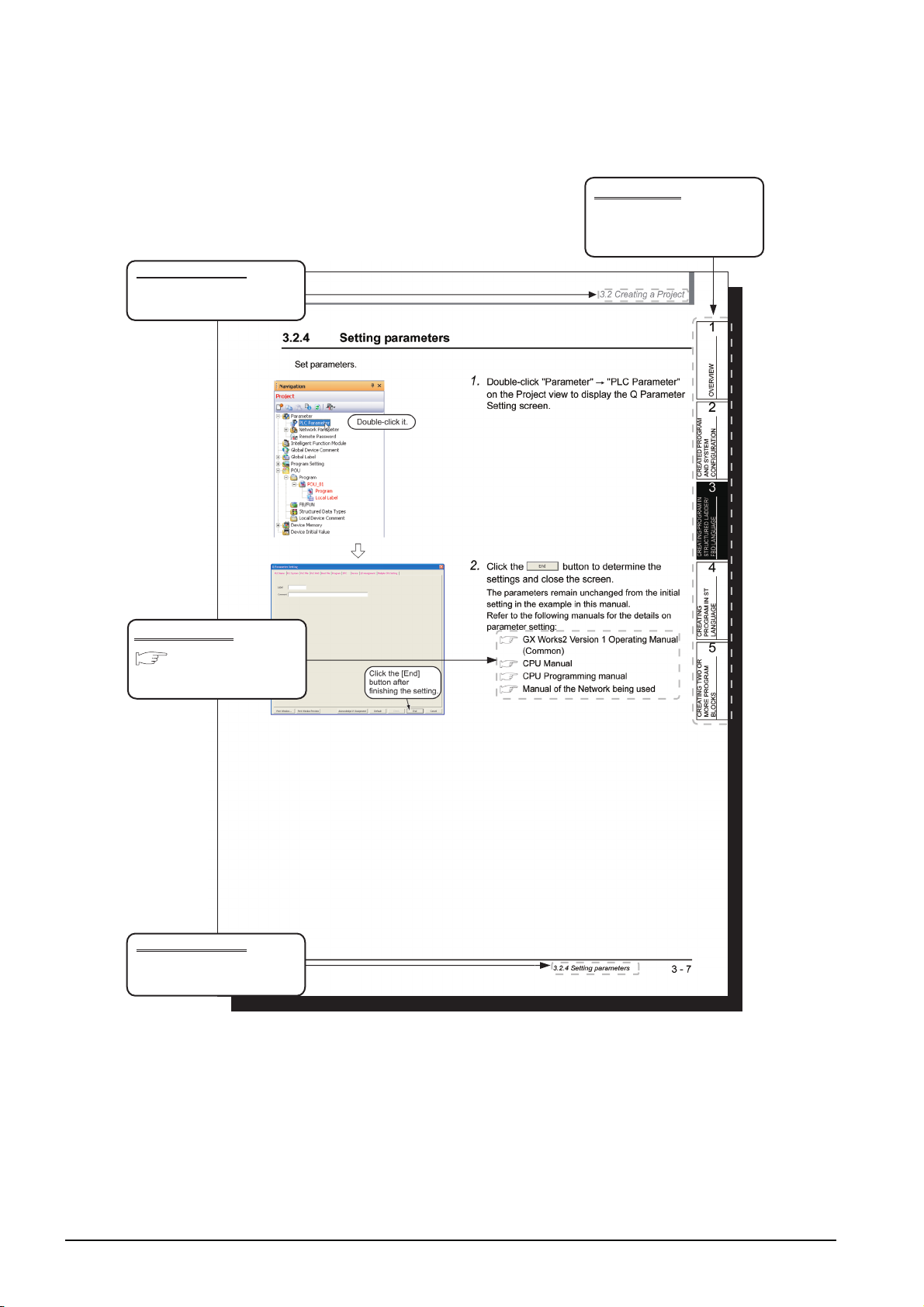

3.2.4 Setting parameters

Set parameters.

Double-click it.

3.2 Creating a Project

1. Double-click "Parameter" "PLC Parameter"

on the Project view to display the Q Parameter

Setting screen.

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

Click the [End]

button after

finishing the setting.

2. Click the button to determine the

settings and close the screen.

The parameters remain unchanged from the initial

setting in the example in this manual.

Refer to the following manuals for the details on

parameter setting:

GX Works2 Version 1 Operating Manual

(Common)

CPU Manual

CPU Programming manual

Manual of the Network being used

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.2.4 Setting parameters

3 - 7

Page 36

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

3.2.5 Setting labels

Set Global Labels.

1. Double-click "Global Label" "Global1" on the

Project view to display the Global Label Setting

screen.

2. Select the "Class" from the list box on the

Global Label Setting screen.

Settings

• Class: VAR_GLOBAL

3. Directly input the "Label Name" on the Global

Label Setting screen.

Settings

• Label Name: VAR1

3 - 8

Restrictions

● Characters available for the label name

You can enter up to 32 characters as the label name.

However, note that the following label name will cause a compile error.

• Label name which contains space

• Label name whose first character is a number

• Label name equivalent to a device name

For other characters unavailable for the label name, refer to the following manual.

GX Works2 Version 1 Operating Manual (Common)

(To the next page)

3.2.5 Setting labels

Page 37

3.2 Creating a Project

4. Directly input the "Date Type" on the Global

Label Setting screen.

Settings

• Date Type: Word [Signed]

You can click to display the Type Selection screen, and then select the Types on this screen.

Settings

1) Libraries : ALL

2) Type Class : Simple Types

3) Types : Word [Signed]

4) Array Element : Not checked

*1: Set "Libraries", "Type Class", "Types" and "Array

*1

Element" in this order.

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

(To the next page)

After completing the setting, click the button.

5. Directly input the "Device" on the Global Label

Setting screen.

Inputting "Device" in GX Works2 automatically sets

"Address".

In the same way, inputting "Address" automatically

sets "Device".

Settings

• Device: D0

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.2.5 Setting labels

3 - 9

Page 38

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

6. Set the "Constant", "Comment" and "Remark"

on the Global Label Setting screen.

"Relation with System Label", "System Label Name"

and "Attribute" are not used in examples shown in

this manual.

Settings

• Constant : When the label class is

"VAR_GLOBAL", you cannot set or

change the initial value.

• Comment : No setting

• Remark : No setting

Refer to the following manual for the details on the global label/local label setting procedure:

GX Works2 Version 1 Operating Manual (Structured Project)

Refer to the following manual for the details on the programming of global labels and labels:

MELSEC-Q/L/F Structured Programming Manual (Fundamentals)

3 - 10

3.2.5 Setting labels

Page 39

3.2.6 Creating a program

Create the Structured ladder/FBD program shown in Section 3.1.2.

1. Double-click "POU" "Program"

"POU_01" "Program" on the Project view to

display the POU_01 [PRG] Program [Structured

Ladder/FBD] screen.

Double-click it.

3.2 Creating a Project

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

2. Drag "Function" "LDP" from the Function

Block Selection window, and drop it on the

POU_01 [PRG] Program [Structured Ladder/

FBD] screen to position it there.

Position "LDP".

Positioning Function and Function block using the Function Block Selection window

You can easily position Function and Function block by dragging them from the Function Block Selection

window.

Perform the following procedure to display the Function Block Selection Window:

Select "View" "Docking window" "Function Block Selection Window".

In the example below, drag the Function "LDP" from the Function Block Selection window, and drop it on the

POU_01 [PRG] Program [Structured Ladder/FBD] screen to position it there.

Refer to the following manual for the details:

GX Works2 Version 1 Operating Manual (Structured Project)

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

2) Drop it.

1) Drag it.

Using ladder symbols instead of the Function "LDP (Rising Edge)"

Click (Rising Edge) on the structured ladder/FBD toolbar, and then click a desired location to position the

Rising Edge there.

(To the next page)

3.2.6 Creating a program

3 - 11

Page 40

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

Start Point End Point

Connection with grid line

Connect ladder symbols such as contacts, coils, Function and Function block with grid lines.

Click (Interconnect Mode), and draw a grid line.

Turn ON the Auto Connect function in the interconnect mode to easily draw a grid line only by specifying the

start point and end point using the mouse.

Refer to the following manual for the details:

GX Works2 Version 1 Operating Manual (Structured Project)

Start Point End Point

3. Click (Interconnect Mode) on the Structured

Ladder/FBD toolbar to specify the Interconnect

mode.

Click the start point and end point in this order to

draw a grid line as shown left.

(GX Works2 is using the Auto Connect function

described in "Point".)

Perform either of the following procedures to turn ON the Auto Connect function.

● Select [Edit] [Auto Connect] to put a check mark.

● Right-click the Structured Ladder/FBD work window to display the menu, and select "Auto Connect" to put a check

mark.

Click it.

4. Click (Select Mode) on the Structured

Ladder/FBD toolbar to specify the Select mode.

3 - 12

(To the next page)

3.2.6 Creating a program

Page 41

3.2 Creating a Project

5. Set the function "LDP".

Click the input variable "?" of "s", and set the input

variable.

Input Variable

Referring to the data type of input/output labels in a Function or Function block

Double-click a positioned function or function block to display the Function/FB Label Setting screen where you

can refer to the data type of labels.

Refer to the following manual for the details:

GX Works2 Version 1 Operating Manual (Structured Project)

Double-click it to

display the screen.

Settings

•s: X0

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

6. Click (Open Contact) on the Structured

Ladder/FBD toolbar, and then move the cursor

to a desired position to display an open contact

there. Click the open contact to connect it with

the left bus line and enable setting of a variable.

(GX Works2 is using the Auto Connect function

described in "Point".)

Settings

• Variable: Y10

Automatic connection with grid lines

While the Auto Connect function is ON, you can easily connect network elements such as contacts and coils

with connection points on the right side of left bus lines, vertical grid lines, contacts, coils, functions and

function blocks.

Refer to the following manual for the details.

GX Works2 Version 1 Operating Manual (Structured Project)

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

(To the next page)

Select a connection point by moving the cursor, and click there

to automatically connect the connection point.

For avoiding automatic connection, lay out network elements

while pressing and holding the button.

3.2.6 Creating a program

3 - 13

Page 42

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

7. Click (Close contact) on the Structured

Ladder/FBD toolbar, and then move the cursor

to a desired position to display a close contact

there.

Click the close contact to connect it with a

function of the LDP and enable setting of a

variable.

Settings

• Variable: TS0

*1: "TS0" indicates a contact of the timer T0.

*1

8. Draw a grid line on the left figure (position 1)

using the procedure described in the step 3.

1)

After drawing grid lines, click (Select Mode) on

the Structured Ladder/FBD toolbar to specify the

Select mode.

9. Click (Coil) on the Structured Ladder/FBD

toolbar, and then move the cursor to a desired

position to display a coil there.

Click the coil to connect it with the close contact

"TS0" and enable setting of a variable.

After drawing grid lines, click (Select Mode) on

the Structured Ladder/FBD toolbar to specify the

Select mode.

Settings

• Variable: Y10

10.Select "Function" "OUT_T" on the Function

Block Selection window, drag it, and drop it in a

desired position to position "OUT_T" there.

3 - 14

Input variables

TCoil and TValue

(To the next page)

3.2.6 Creating a program

Click "?" of "TCoil*1" and "TValue*2", and set the

input variables.

Settings

• TCoil : TC0

•TValue: 10

*1: Set a coil of the timer to "TCoil".

*2: Set the set value of the timer to "TValue".

*3: "TC0" indicates a coil of the timer T0.

*3

Page 43

3.2 Creating a Project

11.Draw a grid line (1) using the procedure

described in the step 3.

1

1)

12.Select a ladder block, and click (New

Select a ladder block.

Create a one Structured Ladder program in one ladder block.

13.Click (Open Contact) on the Structured

Variable

• After drawing a grid line, click (Select Mode)

on the Structured Ladder/FBD toolbar to specify

the Select mode.

Ladder Block After) on the Structured Ladder/

FBD toolbar to add a ladder block.

Ladder/FBD toolbar, and then move the cursor

to a desired position to display an open contact

there.

Click the open contact to connect it with the left bus

line and enable setting of a variable.

Settings

• Variable: X1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

1)

Input variable "s"

(To the next page)

Output variable "d"

14.Select "Function" "MOVP" on the Function

Block Selection window, drag it, and drop it in a

desired position to position "MOVP" there.

Draw a grid line on the left figure (position 1) using

the procedure described in the step 3.

Click "?" of "s" and "d", and set the input and output

variables.

Settings

•s: 10

•d: VAR1

*1: The label VAR1 is set in Section 3.2.5.

*1

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.2.6 Creating a program

3 - 15

Page 44

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

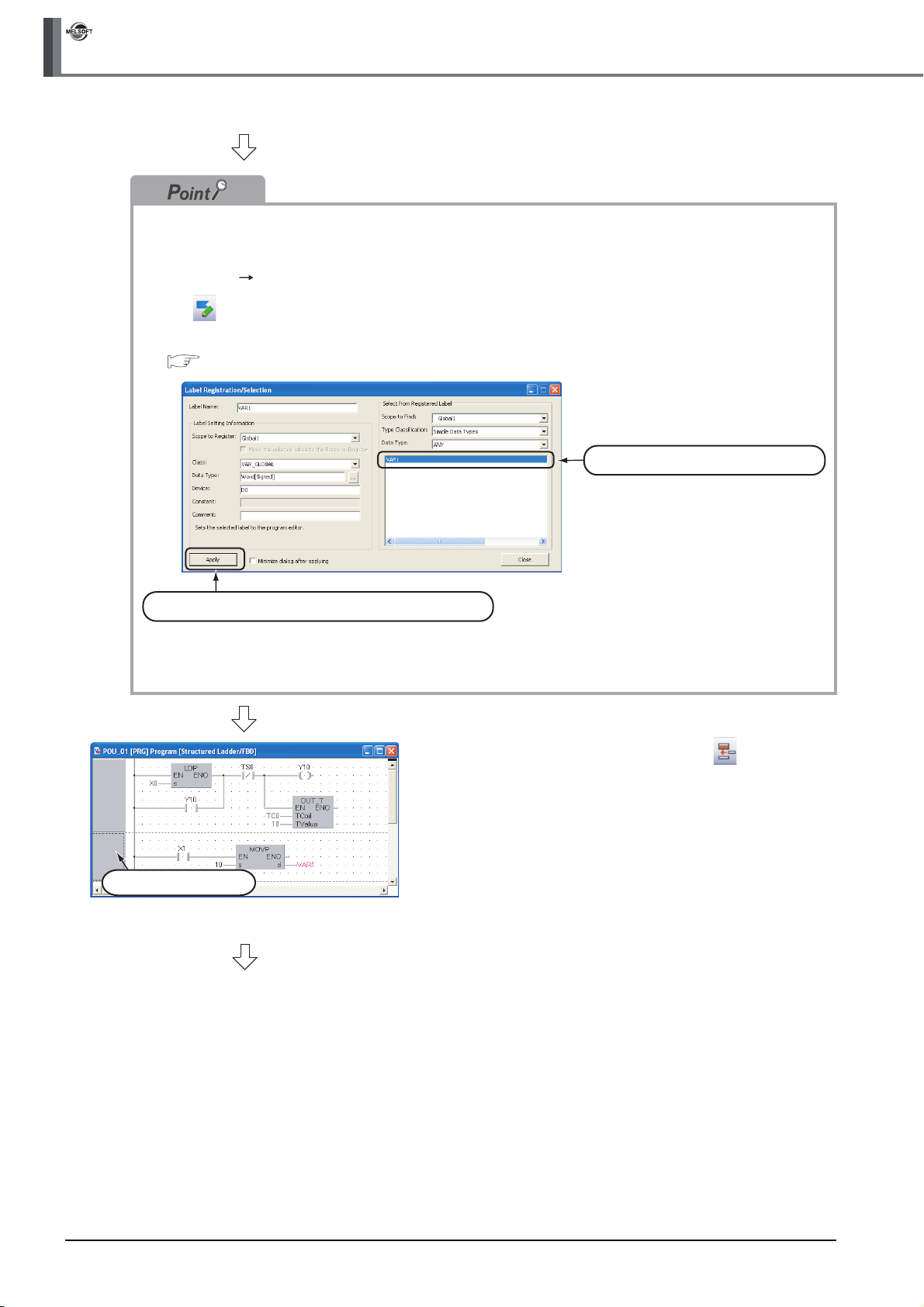

Selecting a label from the Label Registration/Selection screen

You can input a label also by selecting it from the Label Registration/Selection screen.

Perform the following procedure to display the Label Registration/Selection screen.

● Select "Edit" "List Operands".

● Click (List Operands).

Refer to the following manual for the details on the Label Registration/Selection screen:

GX Works2 Version 1 Operating Manual (Structured Project)

1) Select a label to be used.

2) Click the Apply button to set the selected.

Select a ladder block.

(To the next page)

15.Select a ladder block, and click (ADD

Ladder Block After) on the Structured Ladder/

FBD toolbar to add a ladder block.

3 - 16

3.2.6 Creating a program

Page 45

1)

Input variable "s" Output variable "d"

3.2 Creating a Project

16.Click (Open Contact) on the Structured

Ladder/FBD toolbar, and then move the cursor

to a desired position to display an open contact

there.

Click the open contact to connect it with the left bus

line and enable setting of a variable.

Settings

• Variable: X2

17.Select "Function" "MOVP" on the Function

Block Selection window, drag it, and drop it in a

desired position to position "MOVP" there.

Draw a grid line on the left figure (position 1) using

the procedure described in the step 3.

Click "?" of "s" and "d", and set the input and output

variables.

Settings

•s: 20

•d: VAR1

*1

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

(To the next page)

*1: The label VAR1 is set in Section 3.2.5.

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.2.6 Creating a program

3 - 17

Page 46

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

Copying a ladder block by drag & drop

When there is a similar ladder block, you can create a new ladder block efficiently by copying the existing

similar ladder block and editing necessary portions.

Drag an existing ladder block, and drop it while pressing the key to copy the existing ladder block.

Drag it, and drop it while pressing .

Change "X1" to "X2" in this example.

Change "10" to "20" in this example.

Changing over the device display format

You can check a program by changing over the device display format between "Device" and "Address".

Switch the device display format after performing compiling or compiling all when using local labels.

Refer to the following section for compiling:

3.2.7 Compiling a program

● Procedure to display Device

Select [View] [View Mode] [Device].

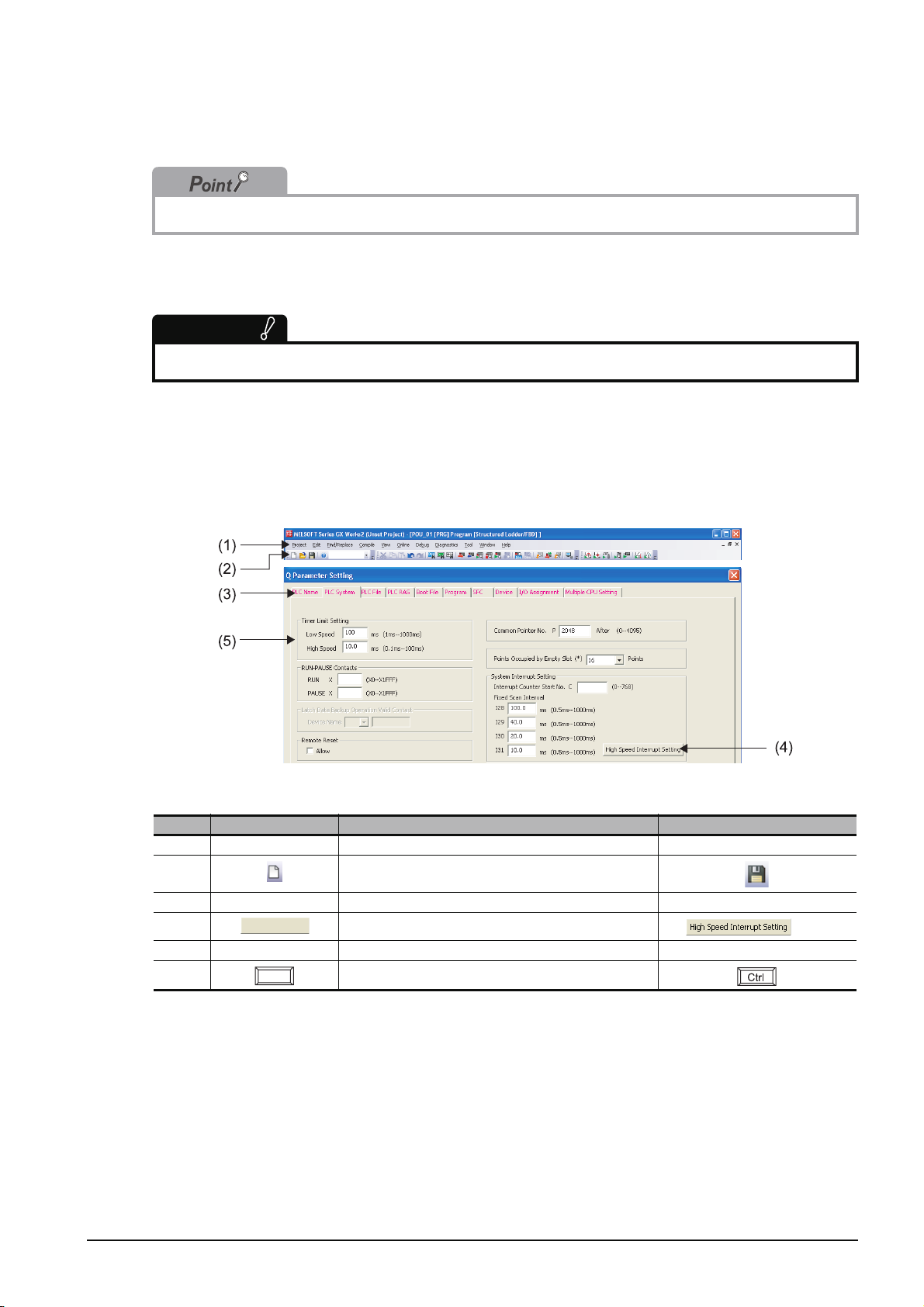

● Procedure to display Address

Select [View] [View Mode] [Address].

< Device mode> < Address mode >

Displaying labels and devices at the same time

You can display devices also in the label display mode by adding an optional setting.

Select [Tool] [Options] to display the Options screen.

On the Options screen, select "Program Editor" "Structured Ladder/FBD " "Label", and check "Display

label and devices".

In the example below, "X1" and " D0" are labels.

< Display Label mode > < Display label and devices mode >

3 - 18

3.2.6 Creating a program

Page 47

3.2 Creating a Project

3.2.7 Compiling a program

There are two types of compiling shown below. The compile target is different between the two types.

Select "Rebuild All" here.

The "Rebuild All" procedure is described below.

Refer to the following manual for compiling:

GX Works2 Version 1 Operating Manual (Structured Project)

Table 3.1 Compiling type and target program

Target program to be compiled

Build

Rebuild All

Converts non-compiled program blocks among program blocks registered in the task into

sequence program. (Does not compile already compiled program blocks.)

Converts all program blocks registered in the task into sequence program.

(Compiles already compiled program blocks also.)

1. Select [Compile] [Rebuild All] to execute

"Rebuild All".

You can click (Rebuild All) to execute "Rebuild

All".

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

2. The screen shown on the left appears.

Click the button to execute "Rebuild All".

If an error is detected, the Output window is

displayed.

• Make sure to compile the created or edited program to make it a sequence program executable in the

programmable controller CPU.

• "Warning C9062" is compiled correctly as a program, and can be monitored.

• Compile status checking method

You can check the compile status on the Project view.

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

Each non-compiled portion is displayed in red.

3.2.7 Compiling a program

3 - 19

Page 48

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

3.2.8 Creating an FBD program

Create an FBD program using the same procedure for Structured Ladder programs without using left

power rail on the left for Structured Ladder.

Display or hide left power rail by selecting [Edit] on the menu bar, selecting [Ladder Symbol], and

clicking [Left Power Rail].

Or hide Left Power Rail by clicking on the Structured Ladder/FBD tool bar.

Refer to 3.1.2 for an FBD program.

Displaying or hiding left power rail

● Even while left power rail are displayed, you can create an FBD program by ignoring left power rail.

● If you try to delete a left power rail to which a function, etc. is already connected, the left power rail is not

deleted.

Delete a connection to the left power rail first, and then delete the left power rail.

● It is not possible to create programs in the symbolic expression using FBD.

When using FBD, create programs in the functional expression using functions and operators.

Creating two or more ladders in one ladder block

When creating an FBD program, you can create two or more ladders in one ladder block. In this case, a

warning is displayed during compiling.

It is possible to hide this warning by adding an optional setting.

Select [Tool] [Options] to display the Options screen.

On the Options screen, select "Compile" "Output Result" "Disable Warning Codes", enter "C2034",

and click the

button button.

3 - 20

3.2.8 Creating an FBD program

Page 49

3.3 Writing a Project to the programmable controller

3.3 Writing a Project to the programmable controller

Write a project to the programmable controller CPU.

1

3.3.1 Connecting the personal computer to the programmable

controller

Connect the personal computer and a programmable controller with a cable, and set the connection

channel.

■ Connecting the personal computer to the programmable controller

Make sure to turn OFF the power of all units before connecting the personal computer to the

programmable controller CPU.

Refer to the following manual for the details on setting when using another channel or using the FXCPU

for connection.

Notebook personal computer

USB Cable

■ Setting the Transfer Setup

Programmable controller

(Q02HCPU)

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

Set the channel to connect the personal computer to the programmable controller CPU (Q02HCPU)

with a USB cable.

Refer to the following manual for the details on setting when using another channel or using the FX

CPU for connection.

GX Works2 Version 1 Operating Manual (Common)

1. Click "Connection Destination" in the view

selection area on the Navigation window to

display the Connection Destination view.

Click it.

2. Double-click "Connection1" in the Current

Connection on the Connection Destination view

to display the Transfer Setup screen.

Double-click it.

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

(To the next page)

3.3.1 Connecting the personal computer to the programmable controller

3 - 21

Page 50

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

3. Double-click (Serial USB) in "PC side I/F" to

display the PC side I/F Serial setting screen.

Double-click it.

Click it.

4. Set the PC side I/F.

After the setting, click the button to

complete the setting and close the screen.

Settings

• Select "USB".

5. Click (PLC Module) in "PLC side I/F" to

select the interface to be used.

3 - 22

(To the next page)

3.3.1 Connecting the personal computer to the programmable controller

Page 51

Click it.

3.3 Writing a Project to the programmable controller

6. Click the button to execute

a communication test with the programmable

controller through the specified connection

channel.

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

7. When communication with the programmable

controller is finished normally, the left screen

appears, and the "PLC Type" field screen the

programmable controller CPU model name.

Click the button to close the screen.

If communication with the programmable controller

has failed, the screen below appears.

Check the connection destination, connection cable,

etc.

8. Click the button to finish "Transfer

Setup" and close the screen.

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.3.1 Connecting the personal computer to the programmable controller

3 - 23

Page 52

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

● You can set two or more connection destinations and change them over if there are two or more

connection destinations.

1. Select "Connection1" in the Current

Connection on the Connection

Destination view, right-click it, and then

select the menu item "Add New Data".

The Add New Data screen will appear.

2. Set "Data Name", and uncheck "Set as

Default Connection".

Click the button to display the

newly created connection destination in

"All Connections" on the Connection

Destination view.

Settings

• Data Name : Connection2

• Set as Default Connection: Unchecked

3. Set the connection destination.

Double-click "Connection2" in "All

Connections" to display the Transfer

Setup screen.

3.3.1 Step3 in the Setting the

Transfer Setup

3 - 24

Newly created connection destination

3.3.1 Connecting the personal computer to the programmable controller

Page 53

3.3 Writing a Project to the programmable controller

● For selecting the newly created connection destination, check "Set as Default Connection " while creating

the data, or set the newly created connection destination as the default connection destination as described

below.

Then, the newly created connection destination will be selected as the connection destination for

communication with the programmable controller CPU (for "Read from PLC", "Write to PLC", etc).

1. Select "Connection2" in the All

Connections on the Connection

Destination view, right-click it, and then

select the menu item "Set as Default

Connection".

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

Default Connection

2. The connection destination set as the

default connection destination is

displayed in "Current Connection" on the

Connection Destination view.

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

3.3.1 Connecting the personal computer to the programmable controller

3 - 25

Page 54

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

3.3.2 Writing a project to the programmable controller

Write the project data to the programmable controller CPU set as the connection destination in Section

3.3.1.

1. Select "Online" "Write to PLC" to display the

Online Data Operation screen.

You can click (Write to PLC) to display the Online

Data Operation screen.

2. Set the "Target module" and "Target project" on

the Online Data Operation screen.

Setting of the target module

Click it.

Setting of the project

Setting of the target module

• Target module: Select <<PLC Module>>

Setting of the project

• Symbolic Information : Select "Program Memory/Device Memory" in "Target Memory", and

check "Symbolic Information" in "Target".

"Program (Program File)" and "MAIN" are checked in "PLC Data", and

change into gray.

"Symbolic Information" contains program files and variables.

• PLC Data : Select "Program Memory/Device Memory" in "Target Memory", and

check "PLC/Network/Remote Password/Switch Setting" in "Target". Do

not check "Global Device Comment" or "Device Memory".

After the setting, click the button.

3 - 26

(To the next page)

3.3.2 Writing a project to the programmable controller

Page 55

3.3 Writing a Project to the programmable controller

Restrictions

In the case of FXCPU

• The symbolic information is displayed only in the FX

• In the case of structured project, data can be read from the FXCPU only in the FX

3.00 or later.

When data cannot be read from the FXCPU, carefully store projects written in the programmable controller.

3U and FX3UC Series version 3.00 or later.

3U and FX3UC Series version

3. The left screen is displayed.

Click the button to write

the project (program).

If a program or parameters already exist in the programmable controller, the following screen appears.

Click the or button to overwrite the existing program or parameters.

When you click the button, GX Works2 overwrite the existing program or parameters without

displaying the overwrites confirmation screen for other data.

1

OVERVIEW

2

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

When parameters already exist When a program already exists

4. The left screen is displayed during

writing.

When writing is finished, "Write to

PLC: Completed" appears.

Click the button to close the

Write to PLC screen.

Writing Completed

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

(To the next page)

3.3.2 Writing a project to the programmable controller

3 - 27

Page 56

GX Works2

3 CREATING PROGRAM IN STRUCTURED LADDER/FBD LANGUAGE

5. Click the button to close the

Online Data Operation screen.

3 - 28

3.3.2 Writing a project to the programmable controller

Page 57

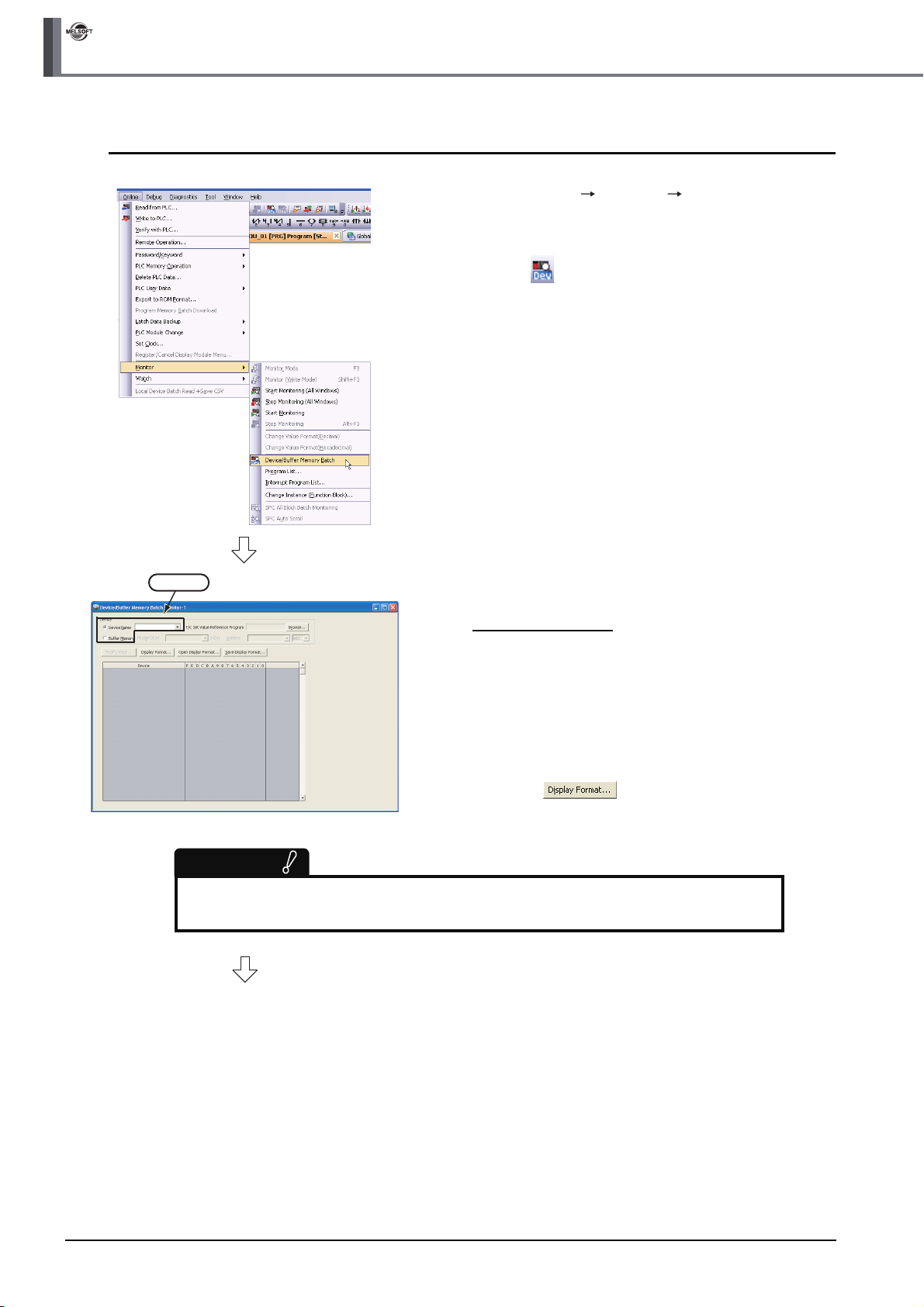

3.4 Monitoring Operations

3.4 Monitoring Operations

Execute "Monitor" to check the operations.

In some monitor screen display examples, colors are changed for the convenience of printing.

GX Works2 has the function to simulate programmable controller operations in the offline mode.

Refer to the following manual for the simulation function:

GX Works2 Version 1 Operating Manual (Common)

3.4.1 Monitoring a program

1

OVERVIEW

2

Double-click it.

Click it.

1. Click "Project" in the view selection area on the

Navigation window to display the Project view.

2. Double-click "POU" "Program"

"POU_01" "Program" on the Project view to

display the POU_01 [PRG] Program [Structured

Ladder/FBD] screen.

CREATED PROGRAM

AND SYSTEM

CONFIGURATION

3

CREATING PROGRAM IN

STRUCTURED LADDER/

FBD LANGUAGE

4

CREATING

PROGRAM IN ST

LANGUAGE

5

CREATING TWO OR

MORE PROGRAM

BLOCKS

(To the next page)

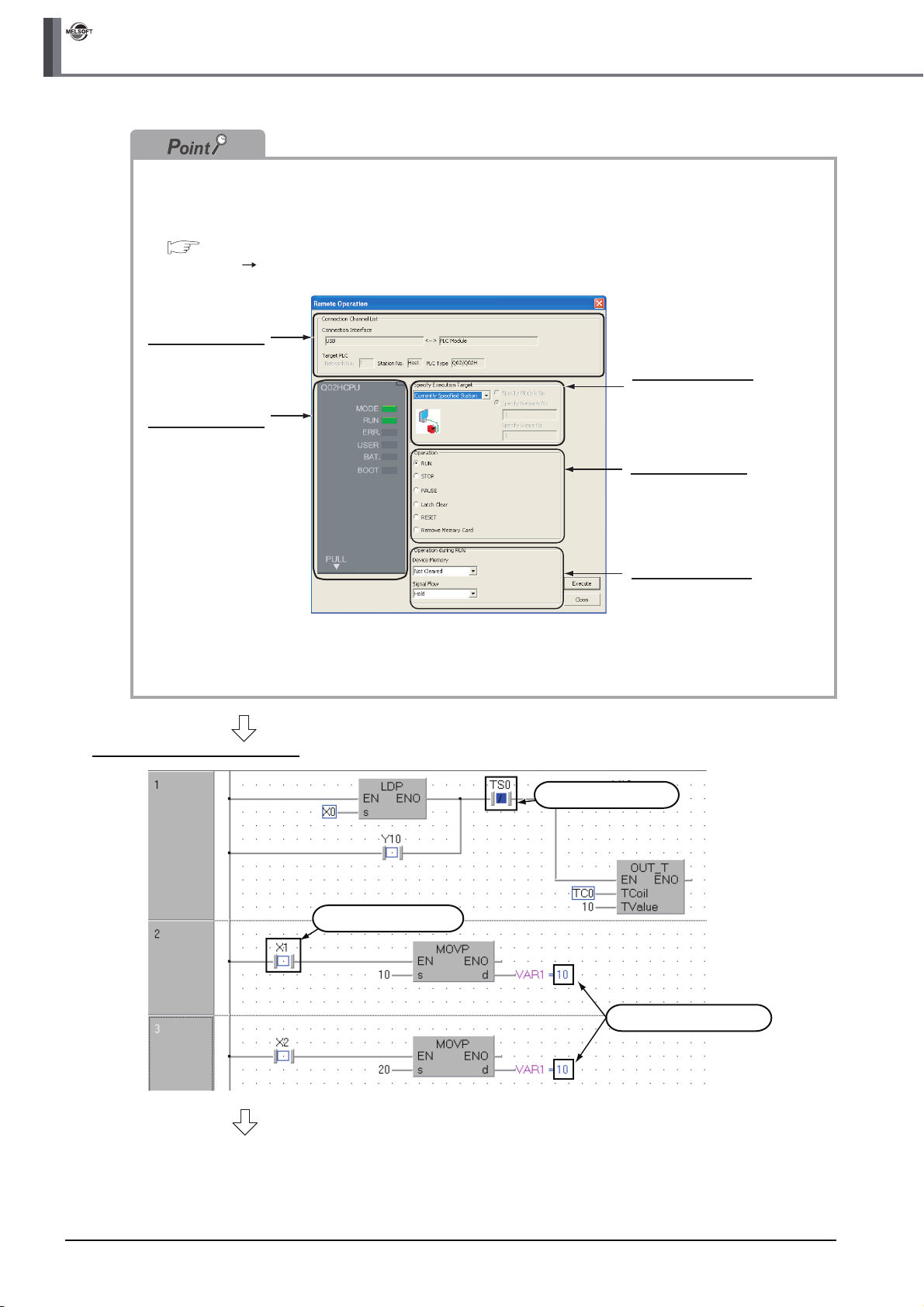

3. Select [Online] [Monitor] [Start

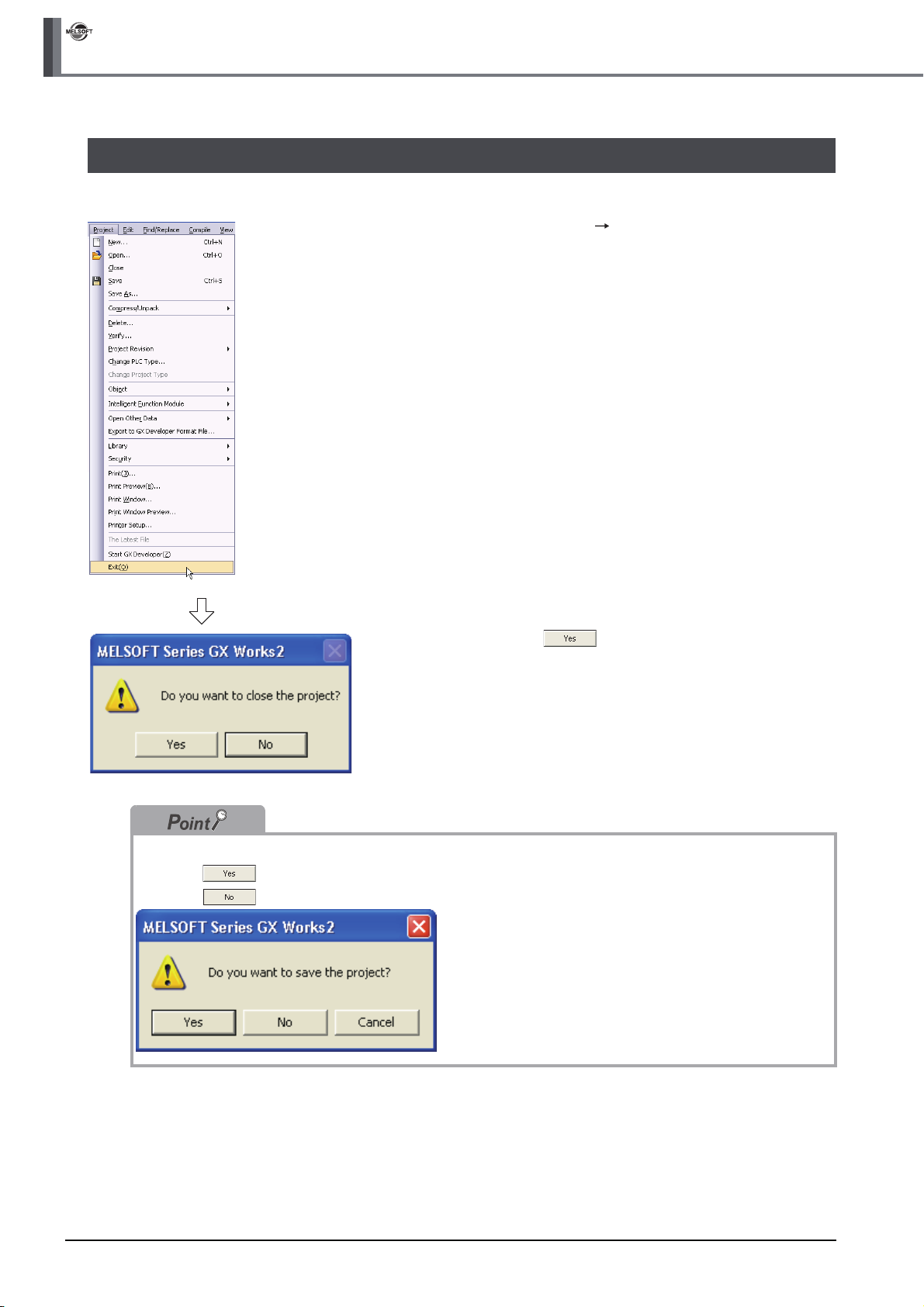

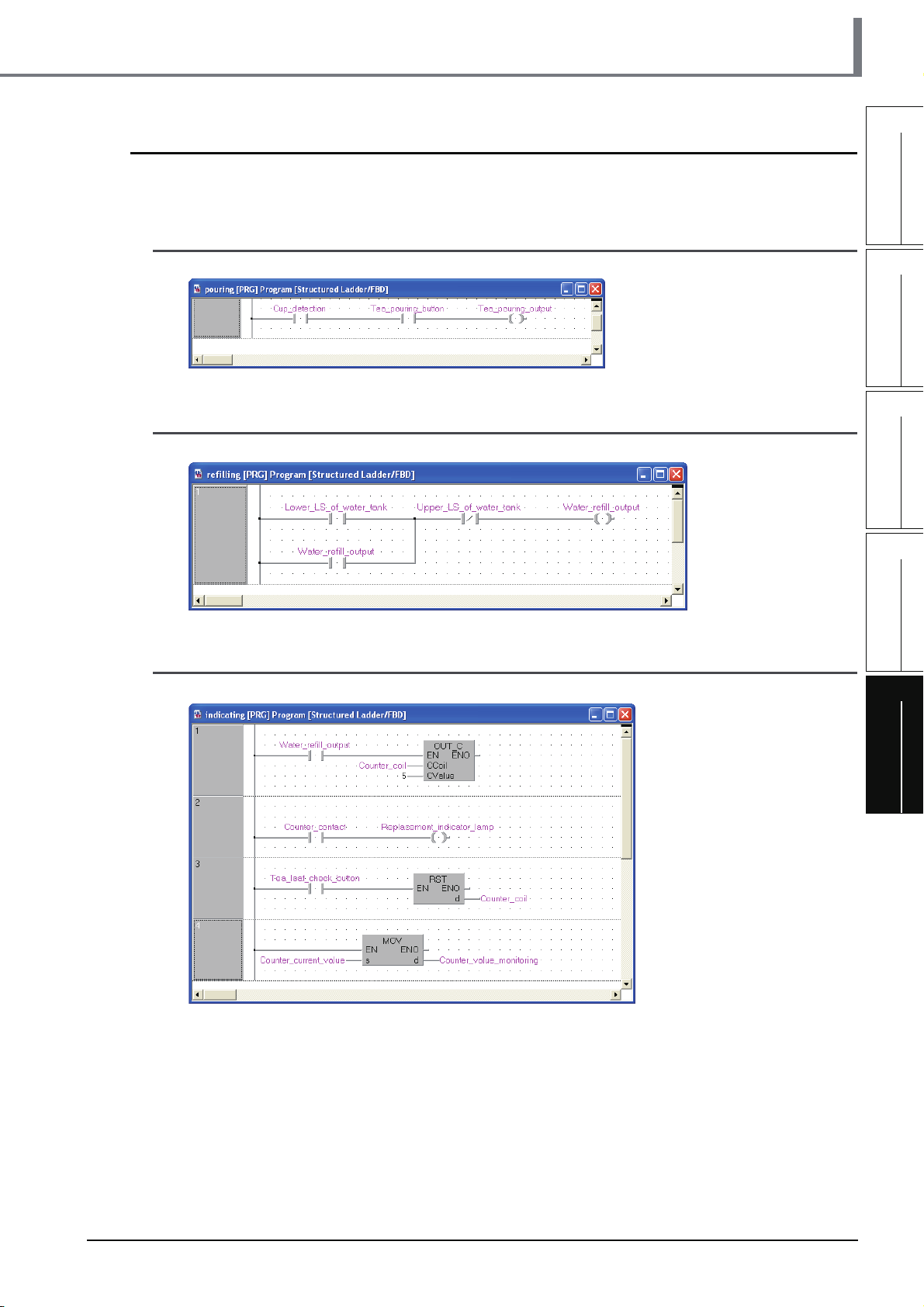

Monitoring] to switch the POU_01 [PRG]