Page 1

MODBUS Interface Module User's Manual

-QJ71MB91

-GX Configurator-MB (SW1D5C-QMBU-E)

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Always read these instructions before using this product.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the user's manual of the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[DESIGN PRECAUTIONS]

WARNING

For the operating status of each station after a communication failure, refer to relevant manuals for

each network.

Failure to do so may result in an accident due to an incorrect output or malfunction.

When connecting a peripheral with the CPU module or connecting an external device, such as a

personal computer, with an intelligent function module to modify data of a running programmable

controller, configure an interlock circuit in the program to ensure that the entire system will always

operate safely.

For other forms of control (such as program modification or operating status change) of a running

programmable controller, read the relevant manuals carefully and ensure that the operation is safe

before proceeding.

Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the sequence program, and determine

corrective actions to be taken between the external device and CPU module in case of a

communication failure.

Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the programmable controller

CPU to the intelligent function module.

Doing so may cause malfunction of the programmable controller system.

A - 1

Page 4

[DESIGN PRECAUTIONS]

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

[INSTALLATION PRECAUTIONS]

CAUTION

Use the programmable controller in an environment that meets the general specifications in the

user's manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module

with a screw.

Tighten the terminal screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may result in damage to the product.

Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

A - 2

Page 5

[WIRING PRECAUTIONS]

WARNING

Shut off the external power supply (all phases) used in the system before wiring.

Failure to do so may result in electric shock or damage to the product.

After wiring, attach the included terminal cover to the module before turning it on for operation.

Failure to do so may result in electric shock.

]

CAUTION

Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered.

Incomplete connections may cause short circuit, fire, or malfunction.

Securely connect the connector to the module.

Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

Check the interface type and correctly connect the cable.

Incorrect wiring (connecting the cable to an incorrect interface) may cause failure of the module and

external device.

Tighten the terminal screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable with connector, hold the connector part of the cable.

For the cable connected to the terminal block, loosen the terminal screw.

Failure to do so may result in damage to the module or cable or malfunction due to poor contact.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

A - 3

Page 6

[STARTUP AND MAINTENANCE PRECAUTIONS]

WARNING

Do not touch any terminal while power is on.

Doing so will cause electric shock.

Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may cause the module to fail or malfunction.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

CAUTION

Before performing online operations (especially, program modification, forced output or operating

status change) by connecting a peripheral device to a running CPU, read the manual carefully and

ensure the safety.

Improper operation may damage machines or cause accidents.

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller.

Failure to do so may cause malfunction.

Shut off the external power supply (all phases) used in the system before mounting or removing a

module.

Failure to do so may cause the module to fail or malfunction.

After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[DISPOSAL PRECAUTIONS]

CAUTION

When disposing of this product, treat is as an industrial waste.

A - 4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 5

Page 8

REVISIONS

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

Nov., 2005 SH(NA)-080578ENG-A First edition

Feb., 2006 SH(NA)-080578ENG-B Modifications

Section 2.1, 2.3, 10.1

Oct., 2006 SH(NA)-080578ENG-C Modifications

SAFETY PRECAUTIONS, Section 2.1, 6.6, 10.1

Jan., 2008 SH(NA)-080578ENG-D Modifications

SAFETY PRECAUTIONS, ABOUT THE GENERIC TERMS AND

ABBREVIATIONS, MEANINGS AND DEFINITIONS OF TERMS, Section 2.1,

2.4, 3.1, 3.2.1, 3.3.1, 3.3.2, 3.4.1, 4.1.6, 5.1, 5.2.1, 6.1, 6.3, 6.4.1, 6.4.2, 6.5.2,

6.6, 7.2.1, 7.3.1, 7.3.2, Chapter 8, 9.1.2, 9.3.1, 9.3.2, 10.2, 10.3, 11.1, 11.2,

11.4.1, 11.4.3, 11.5.1, Appendix 3

Added

Section 2.3

Section 2.3 changed to Section 2.4.

Mar., 2008 SH(NA)-080578ENG-E Modifications

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES, Section 2.1, 2.4,

4.16, 6.3, 6.4.1, 8.5, 8.6, Appendix 3

May, 2008 SH(NA)-080578ENG-F Change of a term

"PLC" was changed to "programmable controller".

Modifications

ABOUT THE GENERIC TERMS AND ABBREVIATIONS, Section 2.1, 4.16, 6.1,

6.6, 7.3.1, 8.2.1, 8.3.1, 8.3.3, 8.4, 8.5, 8.6, 10.2, 10.3, 11.4.3

Apr., 2009 SH(NA)-080578ENG-G Modifications

Section 1.1, 2.1, 2.4, 3.1, 3.4.1, 3.5.1, 4.16, 5.2.1, 8.2.1, 9.1.1 to 9.3.2,

10.1 to 10.3, 11.1, 11.4.3

Added

Section 10.4, Appendix 1

Appendix numbers 1 and 2 changed to 2 and 3.

Jan., 2013 SH(NA)-080578ENG-H Modifications

SAFETY PRECAUTIONS, COMPLIANCE WITH EMC AND LOW VOLTAGE

DIRECTIVES, ABOUT THE GENERIC TERMS AND ABBREVIATIONS,

Section 2.1, 2.3, 2.4, 3.3.2, 4.16, 7.1, 8.2.2, 11.4.3

Added

CONDITIONS OF USE FOR THE PRODUCT, Section 9.4

Sep., 2016 SH(NA)-080578ENG-I Modifications

SAFETYABOUT THE GENERIC TERMS AND ABBREVIATIONS, Section 1.1,

2.1, 2.2, 2.3, 2.4, 3.3.1, 4.2.1, 4.16, 5.2.1, 6.3, 9.2.1, 9.2.2, 9.2.3, 9.3.1, 9.3.2,

10.3, Appendix 3

Japanese Manual Version SH-080547-J

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

© 2005 MITSUBISHI ELECTRIC CORPORATION

A - 6

Page 9

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC-Q series programmable controllers.

Before using this product, please read this manual and the relevant manuals carefully and develop

familiarity with the functions and performance of the MELSEC-Q series programmable controller to handle

the product correctly.

When applying the program examples introduced in this manual to an actual system, ensure the

applicability and confirm that it will not cause system control problems.

CONTENTS

SAFETY PRECAUTIONS ................................................................................................................................. A - 1

CONDITIONS OF USE FOR THE PRODUCT..................................................................................................A - 5

REVISIONS....................................................................................................................................................... A - 6

INTRODUCTION...............................................................................................................................................A - 7

CONTENTS ...................................................................................................................................................... A - 7

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES................................................................... A - 12

THE MANUAL'S USAGE AND STRUCTURE ................................................................................................A - 13

ABOUT THE GENERIC TERMS AND ABBREVIATIONS ..............................................................................A - 15

MEANINGS AND DEFINITIONS OF TERM ................................................................................................... A - 16

PRODUCT CONFIGURATION ....................................................................................................................... A - 16

CHAPTER1 OVERVIEW 1 - 1 to 1 - 4

1.1 Features........................................................................................................................................... 1 - 1

CHAPTER2 SYSTEM CONFIGURATION 2 - 1 to 2 - 10

2.1 Applicable Systems ......................................................................................................................... 2 - 1

2.2 Network Configuration ..................................................................................................................... 2 - 3

2.3 Precautions for System Configuration ............................................................................................. 2 - 7

2.4 How to Check the Function Version/Software Version .................................................................... 2 - 8

CHAPTER3 SPECIFICATIONS 3 - 1 to 3 - 23

3.1 Performance Specifications............................................................................................................. 3 - 1

3.2 RS-232 Interface Specification ........................................................................................................ 3 - 3

3.2.1 RS-232 connector specification................................................................................................ 3 - 3

3.2.2 RS-232 cable specification ....................................................................................................... 3 - 5

3.3 RS-422/485 Interface Specification ................................................................................................. 3 - 6

3.3.1 RS-422/485 terminal block specification .................................................................................. 3 - 6

3.3.2 RS-422/485 cable specification ................................................................................................ 3 - 7

3.3.3 Precautions when transferring data using RS-422/485 line ..................................................... 3 - 8

3.4 I/O Signals for Programmable Controller CPU .............................................................................. 3 - 10

3.4.1 I/O signal list ........................................................................................................................... 3 - 10

3.5 Applications and Assignment of Buffer Memory ............................................................................ 3 - 13

A - 7

Page 10

3.5.1 Buffer memory list................................................................................................................... 3 - 13

CHAPTER4 MODBUS STANDARD FUNCTIONS 4 - 1 to 4 - 60

4.1 MODBUS Standard Function Support List ...................................................................................... 4 - 1

4.2 Frame Specifications ..................................................................................................................... 4 - 10

4.2.1 Frame mode ........................................................................................................................... 4 - 11

4.3 Protocol Data Unit Formats by Functions ......................................................................................4 - 15

4.4 Read Coils (FC: 01) ....................................................................................................................... 4 - 18

4.5 Read Discrete Inputs (FC: 02) ....................................................................................................... 4 - 19

4.6 Read Holding Registers (FC: 03)................................................................................................... 4 - 20

4.7 Read Input Registers (FC: 04) ....................................................................................................... 4 - 21

4.8 Write Single Coil (FC: 05) .............................................................................................................. 4 - 22

4.9 Write Single Register (FC: 06) ....................................................................................................... 4 - 23

4.10 Read Exception Status (FC: 07) .................................................................................................... 4 - 24

4.11 Diagnostics (FC: 08) ...................................................................................................................... 4 - 25

4.11.1 Return query data (sub-function code: 00) ............................................................................. 4 - 25

4.11.2 Restart communications option (sub-function code: 01)......................................................... 4 - 26

4.11.3 Return diagnostic register (sub-function code: 02) ................................................................. 4 - 28

4.11.4 Change ASCII input delimiter (sub-function code: 03)............................................................ 4 - 30

4.11.5 Force listen only mode (sub-function code: 04)...................................................................... 4 - 31

4.11.6 Clear counters and diagnostic register (sub-function code: 10) ............................................. 4 - 33

4.11.7 Return bus message count (sub-function code: 11)............................................................... 4 - 35

4.11.8 Return bus communication error count (sub-function code: 12) ............................................. 4 - 36

4.11.9 Return bus exception error count (sub-function code: 13)...................................................... 4 - 37

4.11.10 Return slave message count (sub-function code: 14) ............................................................ 4 - 38

4.11.11 Return slave no response count (sub-function code: 15) ....................................................... 4 - 39

4.11.12 Return slave NAK count (sub-function code: 16).................................................................... 4 - 40

4.11.13 Return slave busy count (sub-function code: 17) ................................................................... 4 - 41

4.11.14 Return bus character overrun count (sub-function code: 18) ................................................. 4 - 42

4.11.15 Return IOP overrun error count (sub-function code: 19) ........................................................ 4 - 43

4.11.16 Clear overrun counter and flag (sub-function code: 20) ......................................................... 4 - 44

4.12 Get Communications Event Counter (FC: 11) ............................................................................... 4 - 45

4.13 Get Communications Event Log (FC: 12) ...................................................................................... 4 - 47

4.14 Write Multiple Coils (FC: 15).......................................................................................................... 4 - 50

4.15 Write Multiple Registers (FC: 16)................................................................................................... 4 - 52

4.16 Report Slave ID (FC: 17) ............................................................................................................... 4 - 53

4.17 Read File Record (FC: 20) (SC: 06) .............................................................................................. 4 - 55

4.18 Write File Record (FC: 21) (SC: 06) .............................................................................................. 4 - 57

4.19 Mask Write Register (FC: 22) ........................................................................................................ 4 - 59

4.20 Read/Write Multiple Registers (FC: 23) ......................................................................................... 4 - 60

CHAPTER5 FUNCTIONS 5 - 1 to 5 - 22

5.1 Function List .................................................................................................................................... 5 - 1

A - 8

Page 11

5.2 Master Function ............................................................................................................................... 5 - 3

5.2.1 Automatic communication function ...........................................................................................5 - 3

5.2.2 Communication by dedicated instructions .............................................................................. 5 - 16

5.3 Slave Function ............................................................................................................................... 5 - 17

5.3.1 Automatic response function .................................................................................................. 5 - 17

5.3.2 MODBUS device assignment function ................................................................................... 5 - 18

5.3.3 Link operation function ........................................................................................................... 5 - 21

CHAPTER6 PRE-OPERATIONAL PROCEDURES AND SETTINGS 6 - 1 to 6 - 24

6.1 Handling Precautions....................................................................................................................... 6 - 1

6.2 Pre-Operational Procedures and Settings ....................................................................................... 6 - 2

6.3 Part Names...................................................................................................................................... 6 - 4

6.4 Unit Tests......................................................................................................................................... 6 - 6

6.4.1 Hardware test ........................................................................................................................... 6 - 6

6.4.2 Self-loopback test ..................................................................................................................... 6 - 8

6.5 Connection to a Target Device ...................................................................................................... 6 - 11

6.5.1 How to connect the RS-232 interface..................................................................................... 6 - 12

6.5.2 How to connect the RS-422/485 interface.............................................................................. 6 - 14

6.6 Intelligent Function Module Switch Setting .................................................................................... 6 - 19

6.7 Maintenance, Inspection ................................................................................................................ 6 - 24

6.7.1 Maintenance, inspection......................................................................................................... 6 - 24

6.7.2 When removing or installing the module ................................................................................ 6 - 24

CHAPTER7 PARAMETER SETTING 7 - 1 to 7 - 31

7.1 Parameter Settings and Setting Procedure .....................................................................................7 - 1

7.2 Automatic Communication Parameter ............................................................................................. 7 - 4

7.2.1 Automatic communication parameter details........................................................................... 7 - 4

7.3 MODBUS Device Assignment Parameter ..................................................................................... 7 - 11

7.3.1 MODBUS device assignment to the programmable controller CPU device memory ............. 7 - 13

7.3.2 MODBUS extended file register assignment to the programmable controller

CPU file register ..................................................................................................................... 7 - 23

7.3.3 QJ71MB91 buffer memory assignment .................................................................................. 7 - 24

7.3.4 Specifying the error status read device .................................................................................. 7 - 26

7.3.5 Specifying access target when mounted to MELSECNET/H remote I/O station .................... 7 - 29

7.3.6 Specifying the CPU response monitoring timer ...................................................................... 7 - 30

CHAPTER8 UTILITY PACKAGE (GX Configurator-MB) 8 - 1 to 8 - 37

8.1 Functions of the Utility Package ...................................................................................................... 8 - 1

8.2 Installing and Uninstalling the Utility Package ................................................................................. 8 - 2

8.2.1 Handling precautions ................................................................................................................ 8 - 2

8.2.2 Operating environment ............................................................................................................. 8 - 5

8.3 Utility Package Operation ................................................................................................................ 8 - 7

8.3.1 Common utility package operations ......................................................................................... 8 - 7

8.3.2 Operation overview................................................................................................................. 8 - 10

A - 9

Page 12

8.3.3 Starting the Intelligent function module utility ......................................................................... 8 - 12

8.4 Initial Setting .................................................................................................................................. 8 - 15

8.4.1 Automatic communication parameter ..................................................................................... 8 - 17

8.4.2 MODBUS device assignment parameter ................................................................................ 8 - 19

8.5 Auto Refresh Setting...................................................................................................................... 8 - 22

8.6 Monitor/Test ................................................................................................................................... 8 - 24

8.6.1 X/Y Monitor/test ...................................................................................................................... 8 - 29

8.6.2 MODBUS device assignment parameter status ..................................................................... 8 - 31

8.6.3 Automatic communication status ............................................................................................ 8 - 32

8.6.4 Error log .................................................................................................................................. 8 - 34

8.6.5 Communication status ............................................................................................................ 8 - 35

CHAPTER9 PROGRAMMING 9 - 1 to 9 - 45

9.1 Parameter Setting ............................................................................................................................ 9 - 1

9.1.1 Automatic communication parameters ..................................................................................... 9 - 1

9.1.2 MODBUS device assignment parameters ................................................................................ 9 - 4

9.2 Program Example for Normal System Configuration....................................................................... 9 - 8

9.2.1 Automatic communication parameters ..................................................................................... 9 - 8

9.2.2 MODBUS device assignment parameters .............................................................................. 9 - 14

9.2.3 When using the automatic communication function and the communication by dedicated

instructions on the same channel .......................................................................................... 9 - 18

9.3 Program Examples for Use in MELSECNET/H Remote I/O Network............................................ 9 - 25

9.3.1 Automatic communication parameters ................................................................................... 9 - 25

9.3.2 MODBUS device assignment parameters .............................................................................. 9 - 37

9.4 Program Examples for the Redundant System ............................................................................. 9 - 45

CHAPTER10 DEDICATED INSTRUCTIONS 10 - 1 to 10 - 32

10.1 Dedicated Instruction List and Available Devices .......................................................................... 10 - 1

10.2 Z(P).MBRW ................................................................................................................................... 10 - 2

10.3 Z(P).MBREQ................................................................................................................................ 10 - 14

10.4 ZP.UINI ........................................................................................................................................ 10 - 25

CHAPTER11 TROUBLESHOOTING 11 - 1 to 11 - 47

11.1 Troubleshooting ............................................................................................................................. 11 - 1

11.2 Checking QJ71MB91 Status........................................................................................................ 11 - 11

11.3 Checking the Communication Status of QJ71MB91.................................................................... 11 - 17

11.4 Error Codes ................................................................................................................................. 11 - 21

11.4.1 Error code storage area........................................................................................................ 11 - 21

11.4.2 Exception code list................................................................................................................ 11 - 28

11.4.3 Error code list........................................................................................................................ 11 - 30

11.5 Turning Off the ERR. LED ........................................................................................................... 11 - 41

11.5.1 Turning off the ERR. LED by GX Configurator-MB............................................................... 11 - 41

11.5.2 Turning off the ERR. LED by sequence program ................................................................. 11 - 45

11.5.3 Turning off the ERR. LED by request message from the master ......................................... 11 - 47

A - 10

Page 13

APPENDICES App - 1 to App - 13

Appendix 1 Function Upgrade of the QJ71MB91 ................................................................................ App - 1

Appendix 2 A Series Modules .............................................................................................................App - 2

Appendix 2.1 Comparisons in performance specifications.............................................................App - 2

Appendix 2.2 Functional comparisons ........................................................................................... App - 3

Appendix 2.3 Utilization of existing programs ................................................................................ App - 4

Appendix 3 Processing Time...............................................................................................................App - 7

Appendix 4 External Dimensions....................................................................................................... App - 13

INDEX Index - 1 to Index - 2

A - 11

Page 14

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage

Directives when incorporated into other machinery or equipment, certain measures

may be necessary. Please refer to one of the following manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance with

EMC and Low Voltage Directives.

(2) Additional measures

No additional measures are necessary for the compliance of this product with EMC

and Low Voltage Directives.

A - 12

Page 15

THE MANUAL'S USAGE AND STRUCTURE

This manual lists the process and functions up to systems operation using

the MODBUS interface module (QJ71MB91), divided into subjects.

Refer to the corresponding section when you need to know the following:

(1) Features ( CHAPTER 1)

CHAPTER 1 describes the features of the QJ71MB91.

(2) System Configuration ( CHAPTER 2)

Section 2.1 lists the applicable programmable controller CPU and corresponding

software package.

Section 2.2 lists network configuration example.

(3) Performance and Specifications ( CHAPTER 3)

Section 3.1 lists the performance specifications of the QJ71MB91.

Section 3.2 and 3.3 list the specifications of each interface.

Section 3.4 and 3.5 list the I/O signals and buffer memory of the QJ71MB91.

(4) MODBUS Standard Functions Supporting QJ71MB91 ( CHAPTER 4)

Section 4.1 lists the MODBUS standard functions supporting QJ71MB91.

Section 4.2 to 4.20 list the frame specifications of the MODBUS standard functions

supporting QJ71MB91.

(5) Usable Functions ( CHAPTER 5)

CHAPTER 5 describes the functions of the QJ71MB91.

(6) Settings and Procedures Necessary for System Operation

CHAPTER 6)

(

CHAPTER 6 describes the pre-operation settings and procedures.

(7) Parameter Settings of the QJ71MB91 ( CHAPTER 7)

CHAPTER 7 describes the parameter setting procedures and parameter details.

(8) Setting Parameters from the Utility Package ( CHAPTER 8)

CHAPTER 8 describes how to use the utility package.

(9) Setting Parameters from the Sequence Program ( CHAPTER 9)

CHAPTER 9 describes the I/O signals used for parameter settings, the I/O signal

timing charts, and program examples.

(10)Reading from/Writing to the MODBUS Device using the Sequence

Program ( CHAPTER 10)

CHAPTER 10 describes the dedicated instructions designed to read or write

MODBUS device data with sequence programs.

A - 13

Page 16

(11)Error Code and Corresponding Process Details (

Section 11.1 lists troubleshooting.

Section 11.2 lists the confirmation methods of the module conditions.

Section 11.3 lists the confirmation of the communication conditions.

Section 11.4 lists the storage location and details of the error codes.

Section 11.5 lists the methods to turn off the ERR. LED.

About the notation of the numerical values used in this manual

In this manual, the numerical values with the suffix "H" are displayed in

hexadecimal values.

(Example) 10......Decimal

H....Hexadecimal

10

CHAPTER 11)

A - 14

Page 17

ABOUT THE GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms

and abbreviations to explain the QJ71MB91 MODBUS interface module.

General term/Abbreviation Description

QJ71MB91 Abbreviation for the QJ71MB91 MODBUS interface module.

GX Developer

GX Works2

MODBUS Protocol Generic term for the protocol designed to use MODBUS protocol messages.

FC Abbreviation for the function code.

SC Abbreviation for the sub code.

Programmable controller

CPU

Basic model QCPU Generic term for the Q00JCPU, Q00CPU, and Q01CPU

Redundant CPU Generic term for the Q12PRHCPU and Q25PRHCPU

Universal model QCPU

C Controller module

Master The side from which a request is sent to execute a function.

Slave

Master function

Slave function

Request message

Response message The message with which the slave returns a function execution result to the master.

Target device

Personal computer Abbreviation for DOS/V personal computers of IBM PC/AT and compatible.

MELSECNET/H Abbreviation of the MELSECNET/H network system.

MBRW Abbreviation for Z.MBRW or ZP.MBRW.

MBREQ Abbreviation for Z.MBREQ or ZP.MBREQ.

UINI Abbreviation for ZP.UINI.

Windows 7

The product name of the software package for the MELSEC programmable controllers

Generic term for the Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU, Q25HCPU, Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU, Q12PRHCPU,

Q25PRHCPU, Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU, Q03UDVCPU,

Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU, Q06UDVCPU,

Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU, Q13UDVCPU,

Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU, Q26UDVCPU,

Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

Generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU,

Q03UDVCPU, Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU,

Q13UDVCPU, Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU,

Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

Generic term for the Q06CCPU-V-H01, Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-V,

Q24DHCCPU-V, Q24DHCCPU-VG, Q24DHCCPU-LS, and Q26DHCCPU-LS

The side where the execution request from the master is processed and its execution

result is sent.

The function that allows communication with the MODBUS compatible slave device as the

master of MODBUS.

The function that allows communication with the MODBUS compatible master device as the

slave of MODBUS.

The message used to give a function execution request to the slave In the MODBUS

protocol, a function execution request is given from the master to the slave.

A function execution request cannot be given from the slave to the master.

Abbreviation of the connected communication targets (devices corresponding to personal

computers, other QJ71MB91 MODBUS interface modules, MODBUS protocols) for data

communication.

Generic term for the following:

Microsoft Windows 7 Starter Operating System,

Microsoft Windows 7 Home Premium Operating System,

Microsoft Windows 7 Professional Operating System,

Microsoft Windows 7 Ultimate Operating System,

Microsoft Windows 7 Enterprise Operating System

A - 15

Page 18

General term/Abbreviation Description

Generic term for the following:

Windows Vista

Windows XP

Microsoft Windows

Microsoft Windows

Microsoft Windows

Microsoft Windows

Microsoft Windows

Generic term for the following:

Microsoft Windows XP Professional Operating System,

Microsoft Windows XP Home Edition Operating System

Vista Home Basic Operating System,

Vista Home Premium Operating System,

Vista Business Operating System,

Vista Ultimate Operating System,

Vista Enterprise Operating System

MEANINGS AND DEFINITIONS OF TERM

The following explains the meanings and definitions of the terms used in

this manual.

Ter m Description

MODBUS protocol

MODBUS device Device used for communication using the MODBUS protocol

Sequence program

Device memory

Listen only mode Mode detaching the slave station from the circuit.

Protocol used on an open MODBUS network which performs master-slave communications

over a serial bus or TCP/IP

Programming system devised to make a contact type sequence compatible with the

programmable controller language as-is. Draw two vertical control buses and describe

contacts, etc.

between the buses to perform programming.

Memory provided for the programmable controller CPU to record the data handled in

sequence program operation.

PRODUCT CONFIGURATION

The following indicates the product configuration of the QJ71MB91

MODBUS interface module.

Model Product name Quantity

QJ71MB91 MODBUS interface module 1

QJ71MB91

SW1D5C-QMBU-E GX Configurator-MB Version 1 (1-license product) (CD-ROM) 1

SW1D5C-QMBU-EA GX Configurator-MB Version 1 (Multiple-license product) (CD-ROM) 1

Terminal resistor 330 1/4 W (for RS-422 communication) 2

Terminal resistor 110 1/2 W (for RS-485 communication) 2

A - 16

Page 19

1

MODBUS slave device

(Third party sensor, etc)

MODBUS slave device

(Third party programmable

controller)

Device memory

MODBUS slave device

(Third party remote I/O, etc)

Holding register

Holding register

Holding register

RS-485

Programmable controller CPU

Device memory

Auto Refresh

QJ71MB91 (Master function)

Read

Read

Read

Write

Buffer memory

Automatically issues the

MODBUS device read/write

request message to Slave.

OVERVIEW

CHAPTER1 OVERVIEW

This manual explains the specifications, functions, programming, and troubleshooting of

the MELSEC-Q series QJ71MB91 MODBUS interface module (hereinafter referred to as

QJ71MB91).

The QJ71MB91 is used when a MELSEC-Q series programmable controller is connected

to the MODBUS protocol system.

1.1 Features

1

2

OVERVIEW

SYSTEM

CONFIGURATION

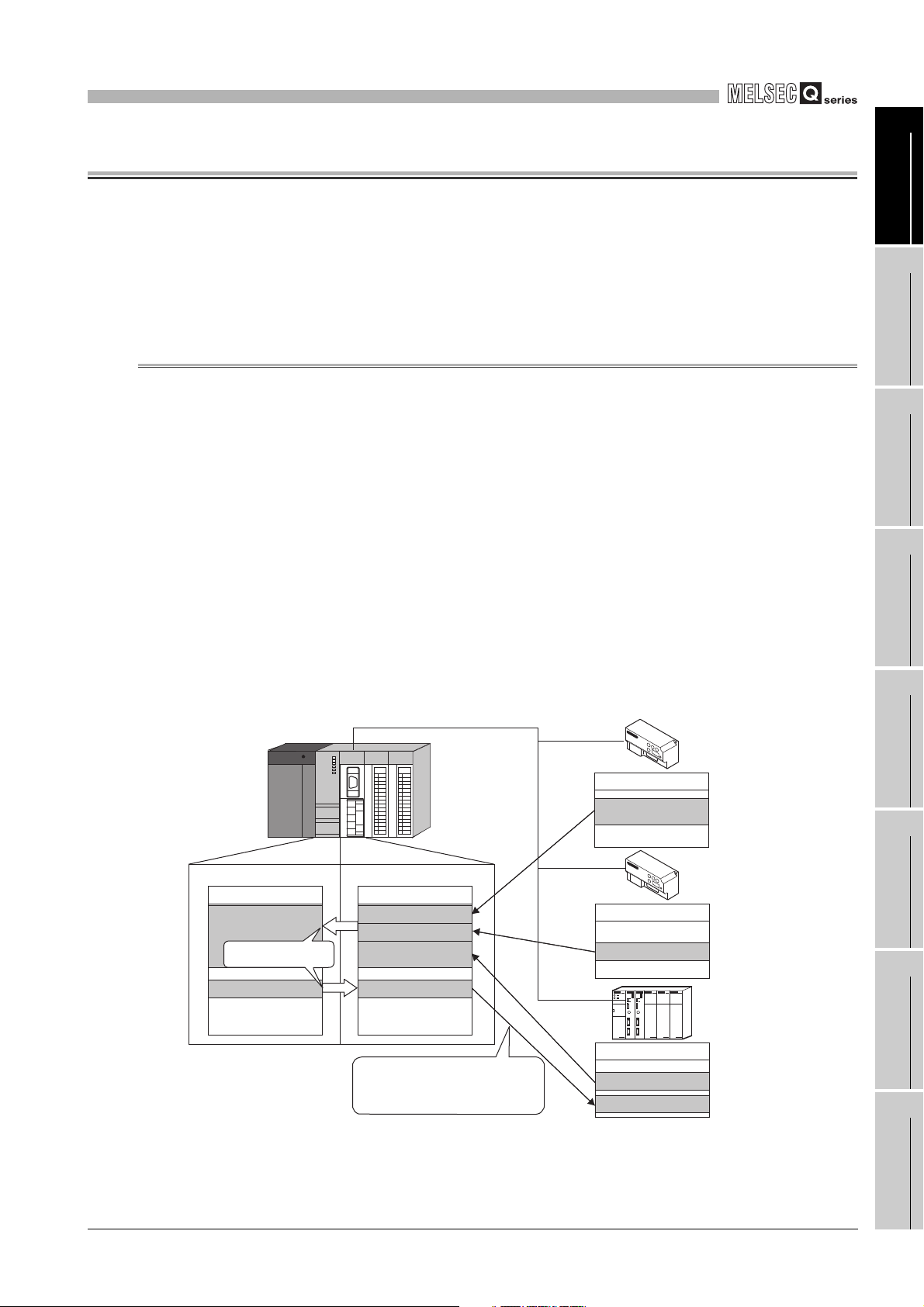

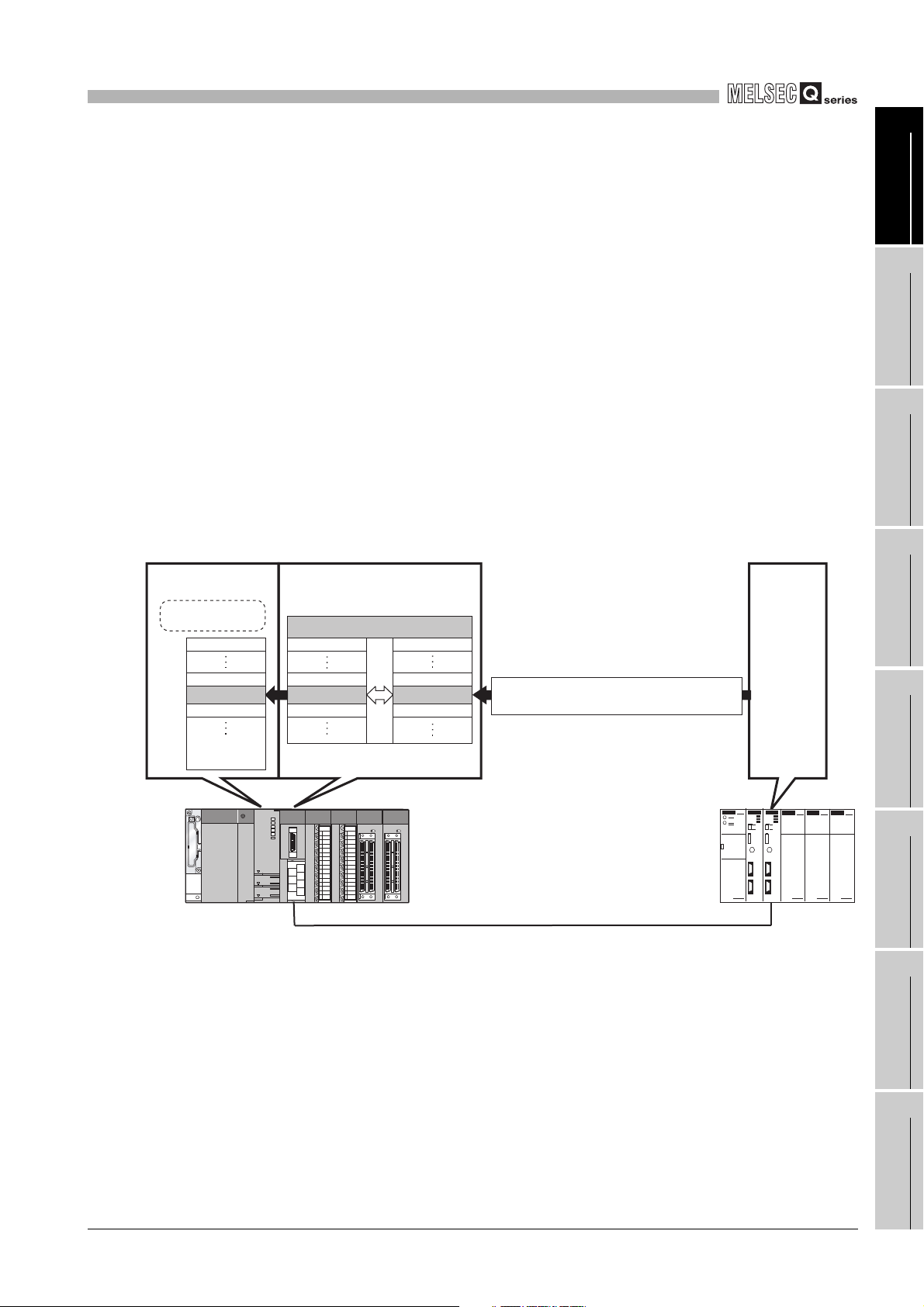

(1) Supporting the master function of MODBUS communication

The QJ71MB91 supports the master function of the MODBUS communication, which

is an open network system for factory automation, and thereby is compatible with

various MODBUS slave devices (hereinafter referred to as slave) of other

manufacturers.

The master function includes the following two functions.

(a) Automatic communication function

By setting the automatic communication parameters, MODBUS device data can

be automatically read from or written to the slaves at the specified intervals using

the QJ71MB91 buffer memory.

Data can be transferred between the QJ71MB91 buffer memory and

programmable controller CPU device memory by making the auto refresh setting

with the utility package (GX Configurator-MB) or by accessing any intelligent

function module device with a sequence program.

*1

3

SPECIFICATIONS

4

MODBUS STANDARD

FUNCTIONS

5

FUNCTION

6

Figure 1.1 Communication using the automatic communication function

* 1 The MODBUS device is defined as a device area of the slave where data can be read/written in

response to a request from the master.

1.1 Features

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

UTILITY PACKAGE

(GX Configurator-MB)

1 - 1

Page 20

1

[Z.MBRW ]

Command

QJ71MB91

(Master

function)

400500

Programmable

controller CPU

Device memory

1234H

Request message

(Read request for holding register 400500)

Response message

(Holding register 400500 = 1234H)

1234H

Holding register

MODBUS Slave device

RS-232, RS-422 or RS-485

OVERVIEW

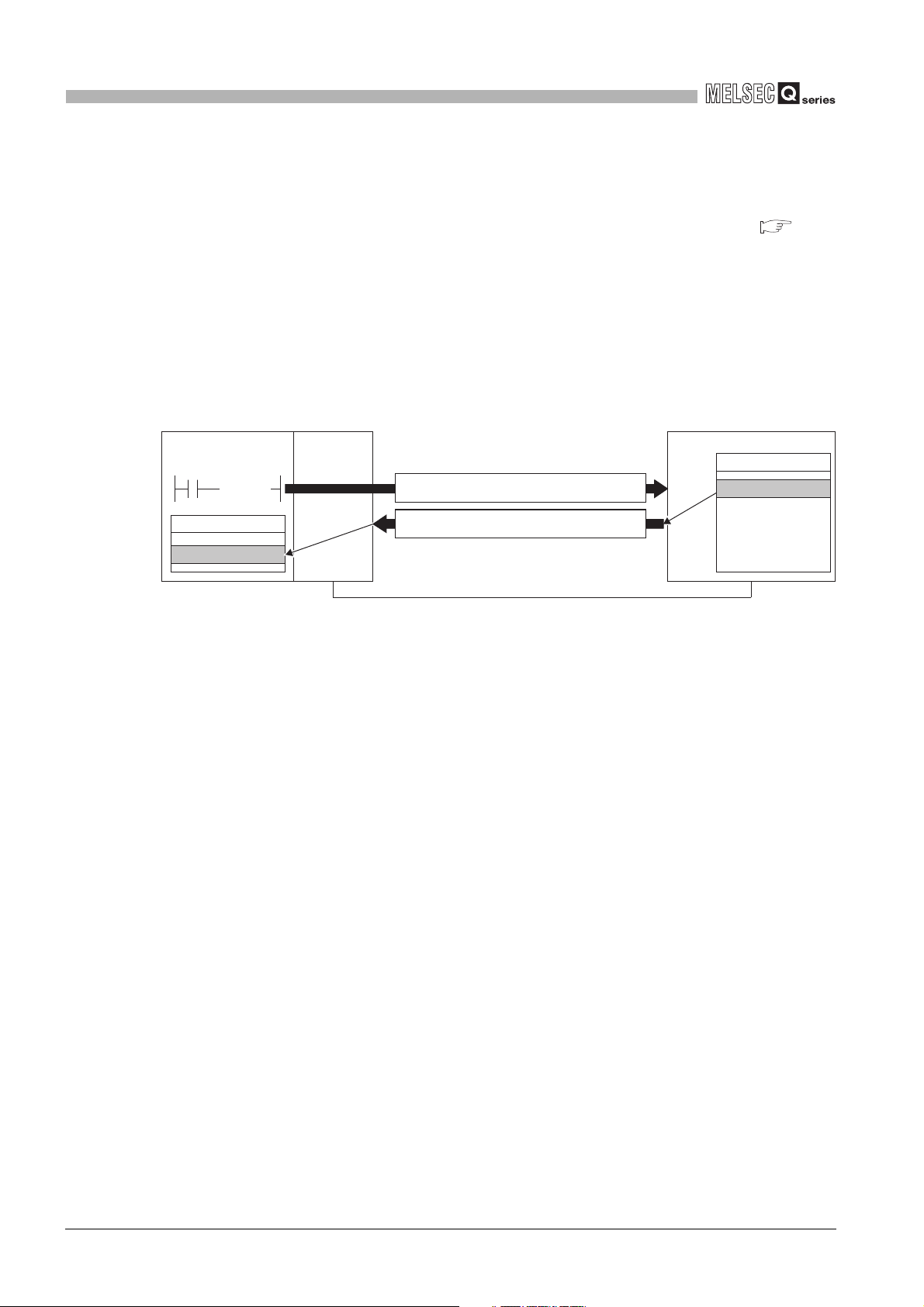

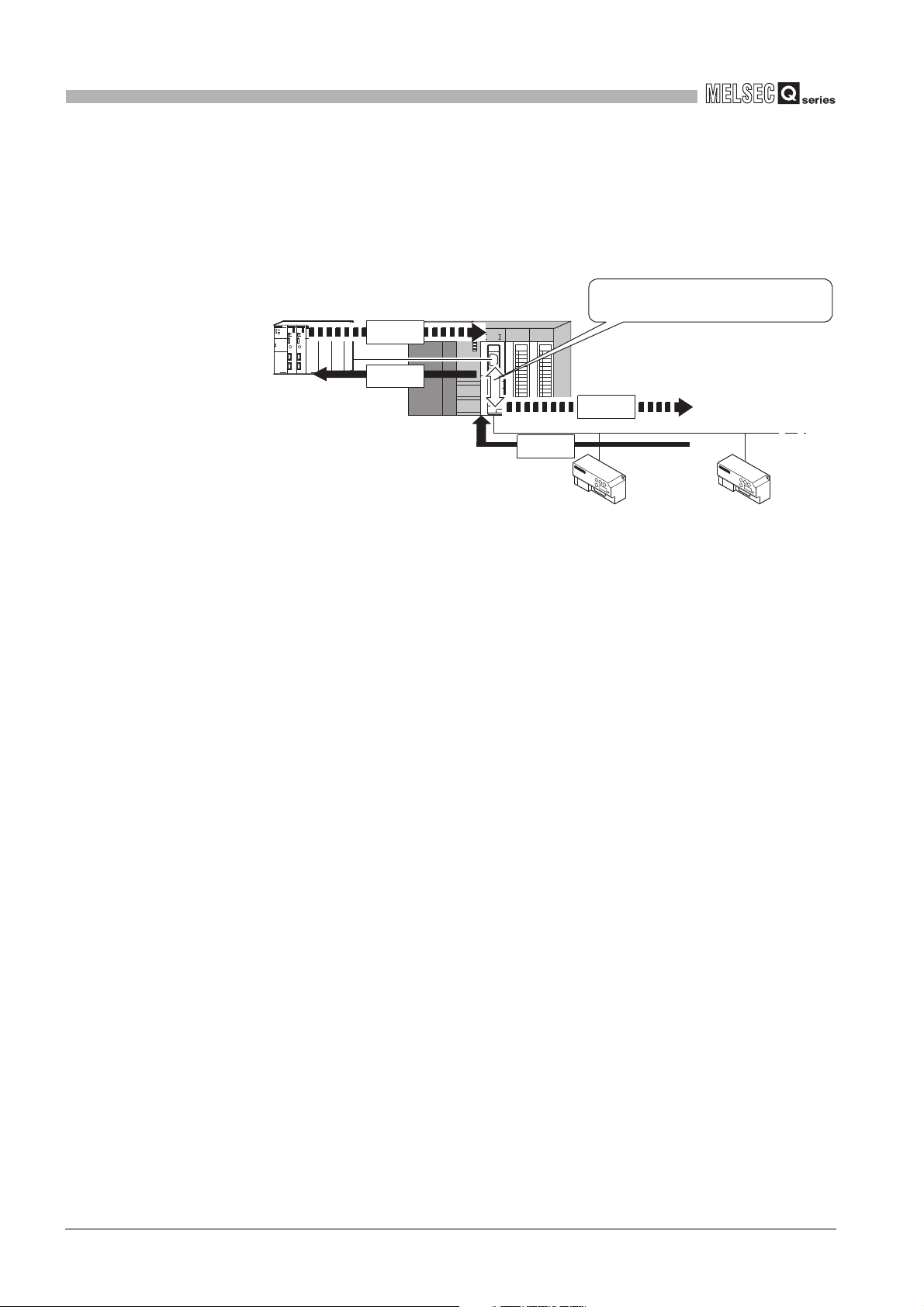

(b) Communication using dedicated instruction

Dedicated instructions can be used to make communication from sequence

programs at any timing.

The following dedicated instructions are available for the QJ71MB91. (

CHAPTER 10)

1) MBRW instruction

Reads or writes MODBUS device data from or to a slave.

This enables reading slave data to the programmable controller CPU device

memory or writing programmable controller CPU data to slaves.

2) MBREQ instruction

The user-determined request message format (function code + data unit) can

be issued to the slaves.

Figure 1.2 Communication using dedicated instruction

1 - 2

1.1 Features

Page 21

1

D300

D299

400499

D300

400500

D301

400501

1234H

Device memory

Device

Programmable

controller CPU

No sequence

program required

MODBUS device assignment parameter

QJ71MB91 (Slave function)

MODBUS device

RS-232, RS-422 or RS-485

Request message (Write 1234H to holding

register 400500)

MODBUS

Master device

OVERVIEW

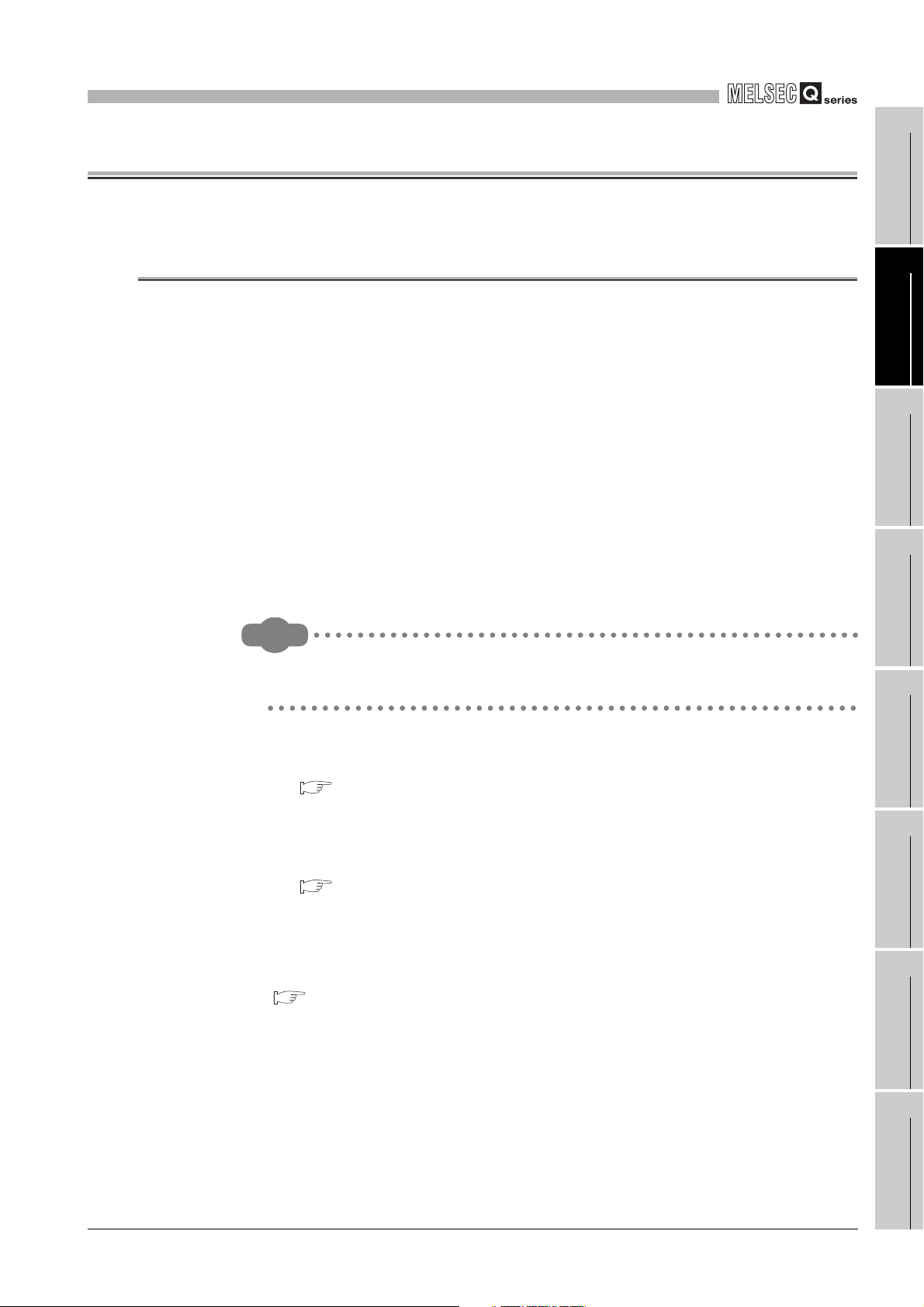

(2) Supporting the slave function of MODBUS communication

The QJ71MB91 supports the slave function of the MODBUS communication, which is

an open network system for factory automation, and thereby is compatible with

various MODBUS master devices (hereinafter referred to as master) of other

manufacturers.

The slave function includes the following two functions.

(a) Automatic response function

The QJ71MB91 can automatically respond to a request message received from

the master.

Any sequence program for the slave function is not needed.

(b) MODBUS device assignment function

Using MODBUS device assignment parameters, the MODBUS devices are

correlated with the programmable controller CPU device memory.

This enables direct access from the master to the programmable controller CPU

device memory.

Supporting the MODBUS devices of large capacity, the QJ71MB91 allows all

device memories of the programmable controller CPU to be assigned.

1

2

3

4

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

Figure 1.3 MODBUS device assignment function

MODBUS STANDARD

5

6

PRE-OPERATIONAL

PROCEDURES AND

7

8

FUNCTIONS

FUNCTION

SETTINGS

PARAMETER SETTING

1.1 Features

UTILITY PACKAGE

(GX Configurator-MB)

1 - 3

Page 22

1

OVERVIEW

(3) Link operation function

The master connected to the CH1 side (RS-232) can communicate with multiple

slaves connected to the CH2 side (RS-422/485) via the QJ71MB91.

This function allows the MODBUS master device with RS-232 interface (for one-onone communication) to communicate with multiple MODBUS slave devices.

The request message/response message

can be relayed between channel 1 and 2.

Request

message

RS-232

Response

Message

MODBUS master device

(Third party programmable

controller)

RS-485

Response

Message

Request

message

MODBUS slave device

(Third party remote I/O, etc)

Figure 1.4 Communication using the link operation function

MODBUS slave device

(Third party sensor, etc)

(4) Supporting high-speed communication of 115200 bps.

The total transmission speed of up to 115200bps is available for Channel 1 and 2.

(5) Easy setting by GX Configurator-MB

GX Configurator-MB, which is separately available, allows easy configuration of the

QJ71MB91.

It can reduce programing steps for sequence programs, and the setting and operating

states of each module can be checked easily.

Therefore, GX Configurator-MB is recommended to be used for the QJ71MB91.

By setting various parameters in GX Configurator-MB, the QJ71MB91 can

communicate without creating sequence programs.

1 - 4

1.1 Features

Page 23

2

Remark

SYSTEM CONFIGURATION

CHAPTER2 SYSTEM CONFIGURATION

This chapter explains the system configuration of the QJ71MB91.

1

OVERVIEW

2.1 Applicable Systems

This section describes the applicable systems.

(1) Applicable modules and base units, and number of mountable modules

(a) When mounted with a CPU module

Refer to the user’s manual of the CPU module used.

Observe the following:

• A shortage of the power capacity may result depending on the combination of

mounted modules or the number of mounted modules. When mounting

modules, consider the power capacity. If the power is insufficient, change the

combination of modules.

• Mount modules so that the total number of I/O points does not exceed the

point range of the CPU module. Modules can be mounted in any slot within

the applicable range.

When mounted with a C Controller module, refer to the user’s manual of the C

Controller module used.

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

MODBUS STANDARD

FUNCTIONS

5

(b) When mounted on a MELSECNET/H remote I/O station

Refer to the following.

Q Corresponding MELSECNET/H Network System Reference Manual

(Remote I/O network)

(c) When mounted on an RQ extension base unit

Refer to the following.

MELSEC iQ-R Module Configuration Manual

(2) Support of the multiple CPU system

Please refer to the following manual before using the QJ71MB91 in the multiple CPU

system.

QCPU User's Manual (Multiple CPU System)

FUNCTION

6

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

2.1 Applicable Systems

UTILITY PACKAGE

(GX Configurator-MB)

2 - 1

Page 24

2

SYSTEM CONFIGURATION

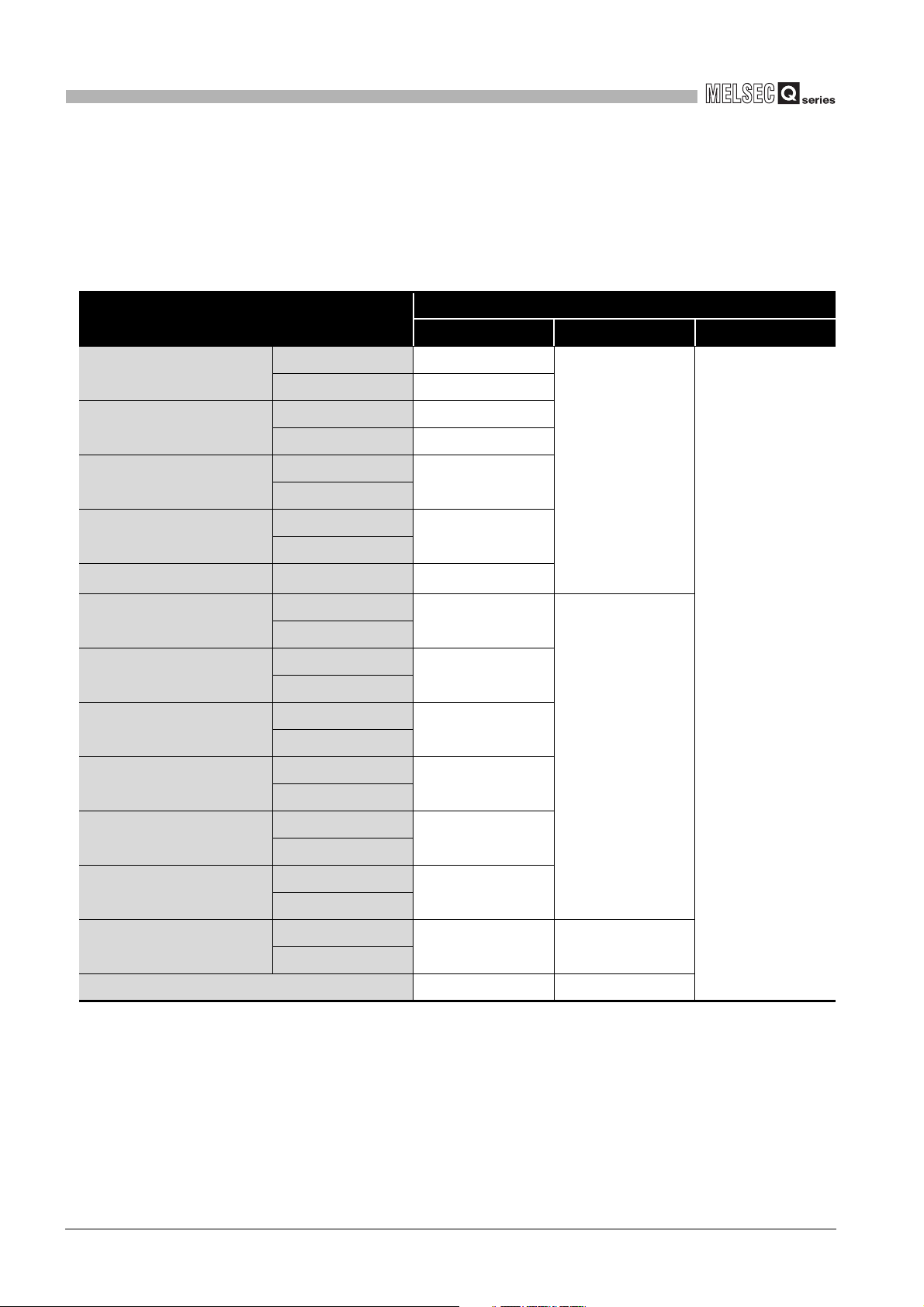

(3) Supported software package

Relation between the system containing the QJ71MB91 and software package is

shown in the following table.

GX Developer or GX Works2 is required to start up the system in which the

QJ71MB91 is used.

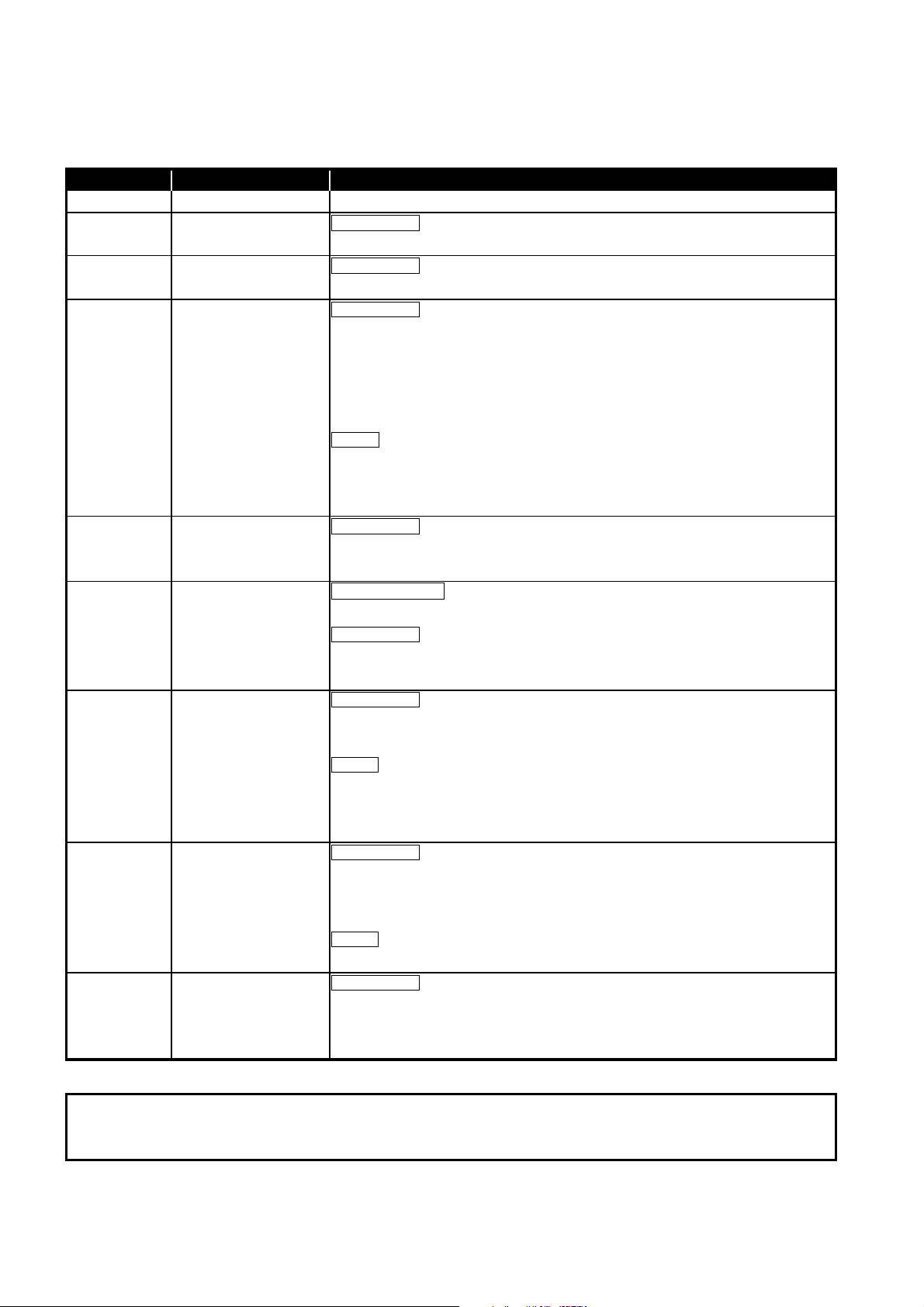

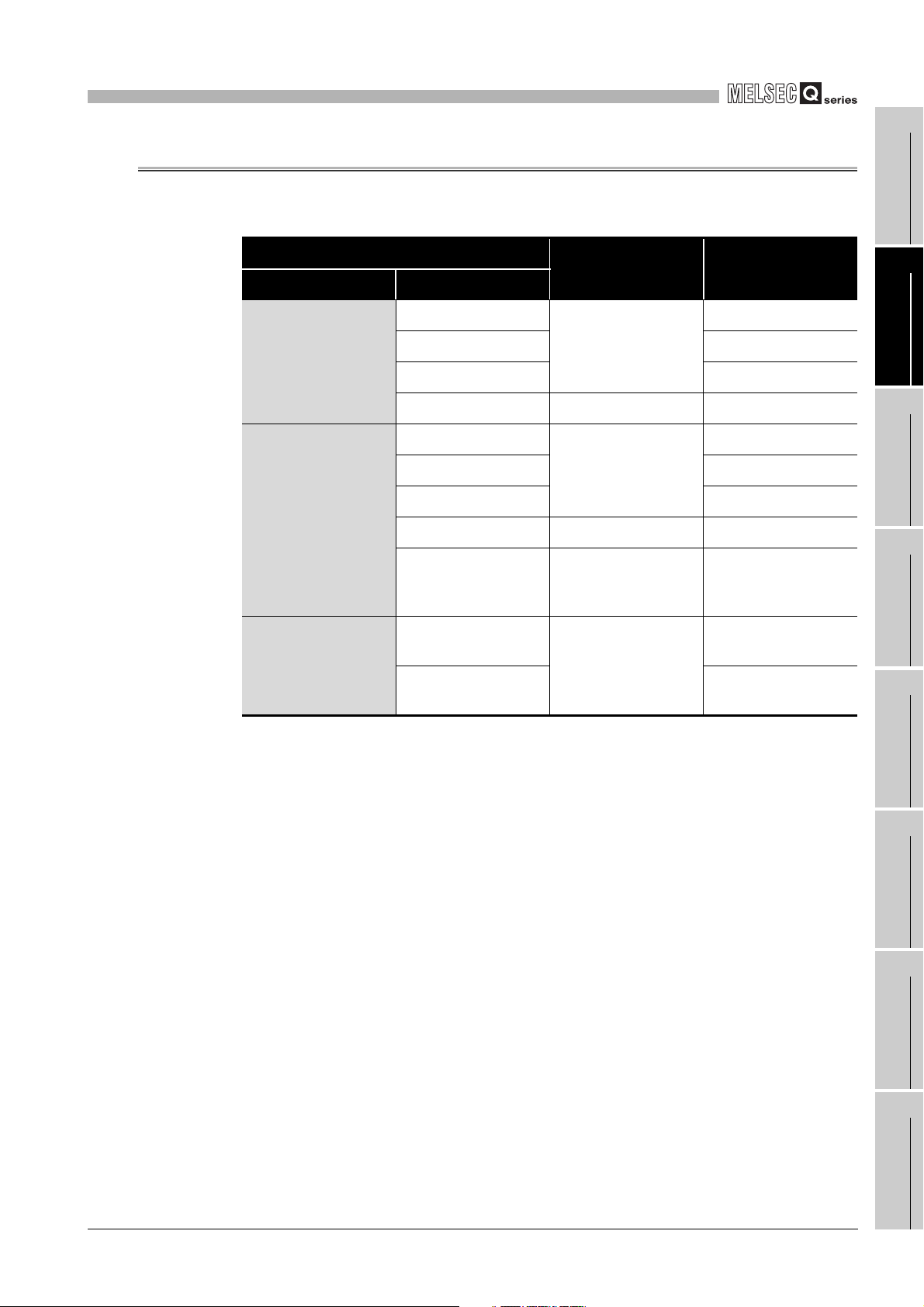

Table2.1 Supported software package

Software version

Item

GX Developer GX Configurator-MB GX Works2

Q00J/Q00/Q01CPU

Q02/Q02H/Q06H/

Q12H/Q25HCPU

Q02PH/Q06PHCPU

Q12PH/Q25PHCPU

Q12PRH/Q25PRHCPU Redundant system

Q00UJ/Q00U/Q01UCPU

Q02U/Q03UD/

Q04UDH/Q06UDHCPU

Q10UDH/Q20UDHCPU

Q13UDH/Q26UDHCPU

Single CPU system Version 7 or later

Multiple CPU system Version 8 or later

Single CPU system Version 4 or later

Multiple CPU system Version 6 or later

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Version 8.68W or later

Version 7.10L or later

Version 8.18U or later

Version 8.76E or later

Version 8.48A or later

Version 8.76E or later

Version 8.62Q or later

Version 1.05F or later

*1

Refer to the GX Works2

Version 1 Operating

Manual (Common).

Version 1.08J or later

Q03UDE/Q04UDEH/Q06UDEH/

Q13UDEH/Q26UDEHCPU

Q10UDEH/Q20UDEHCPU

CPU module other than those

listed above

When mounted to MELSECNET/H remote I/O station Version 6.01B or later Version 1.05F or later

2 - 2

2.1 Applicable Systems

Single CPU system

Version 8.68W or later

Multiple CPU system

Single CPU system

Version 8.76E or later

Multiple CPU system

Single CPU system

N/A N/A

Multiple CPU system

* 1 To use an extension base unit, use 8.45X or later.

Page 25

2

SYSTEM CONFIGURATION

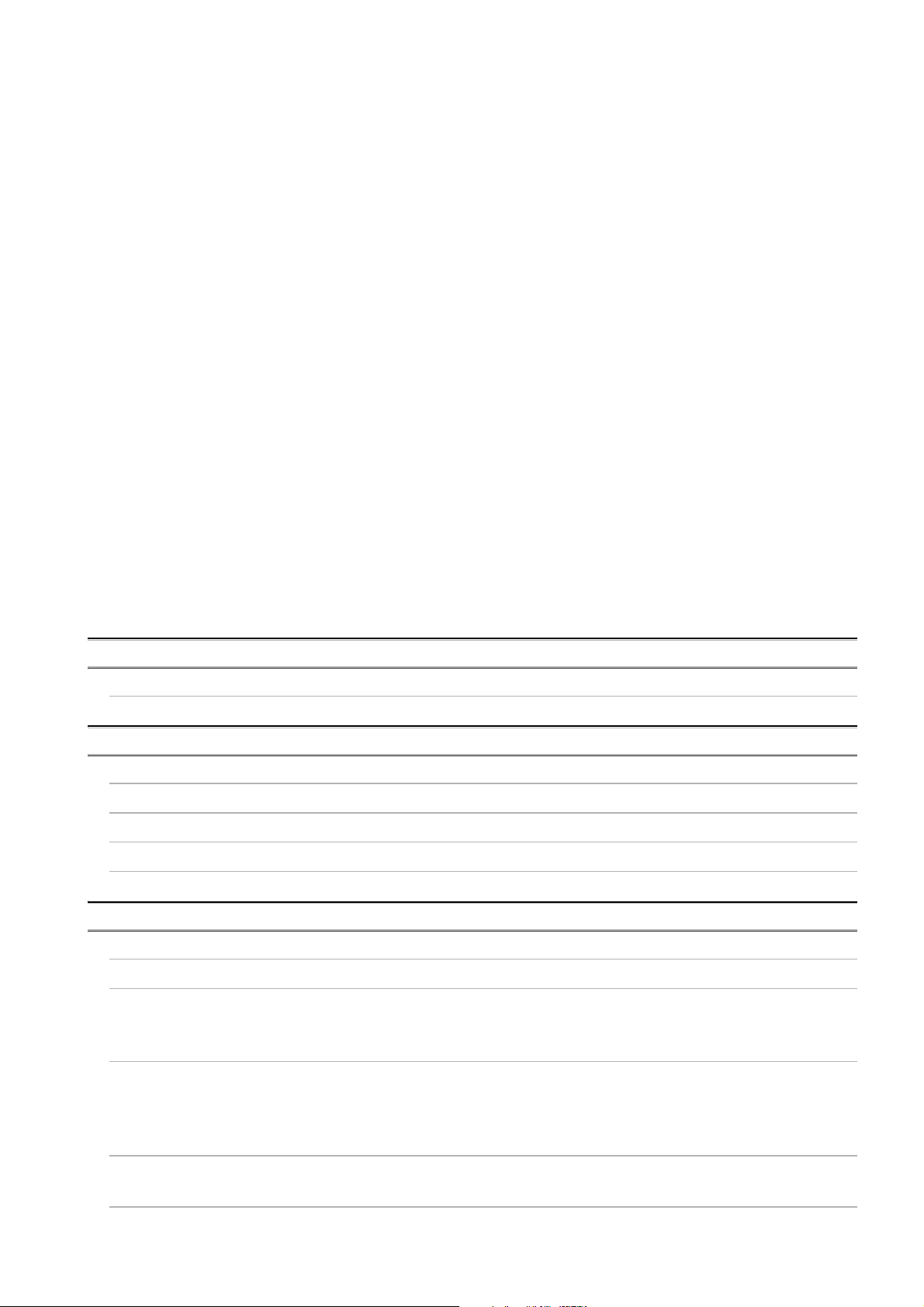

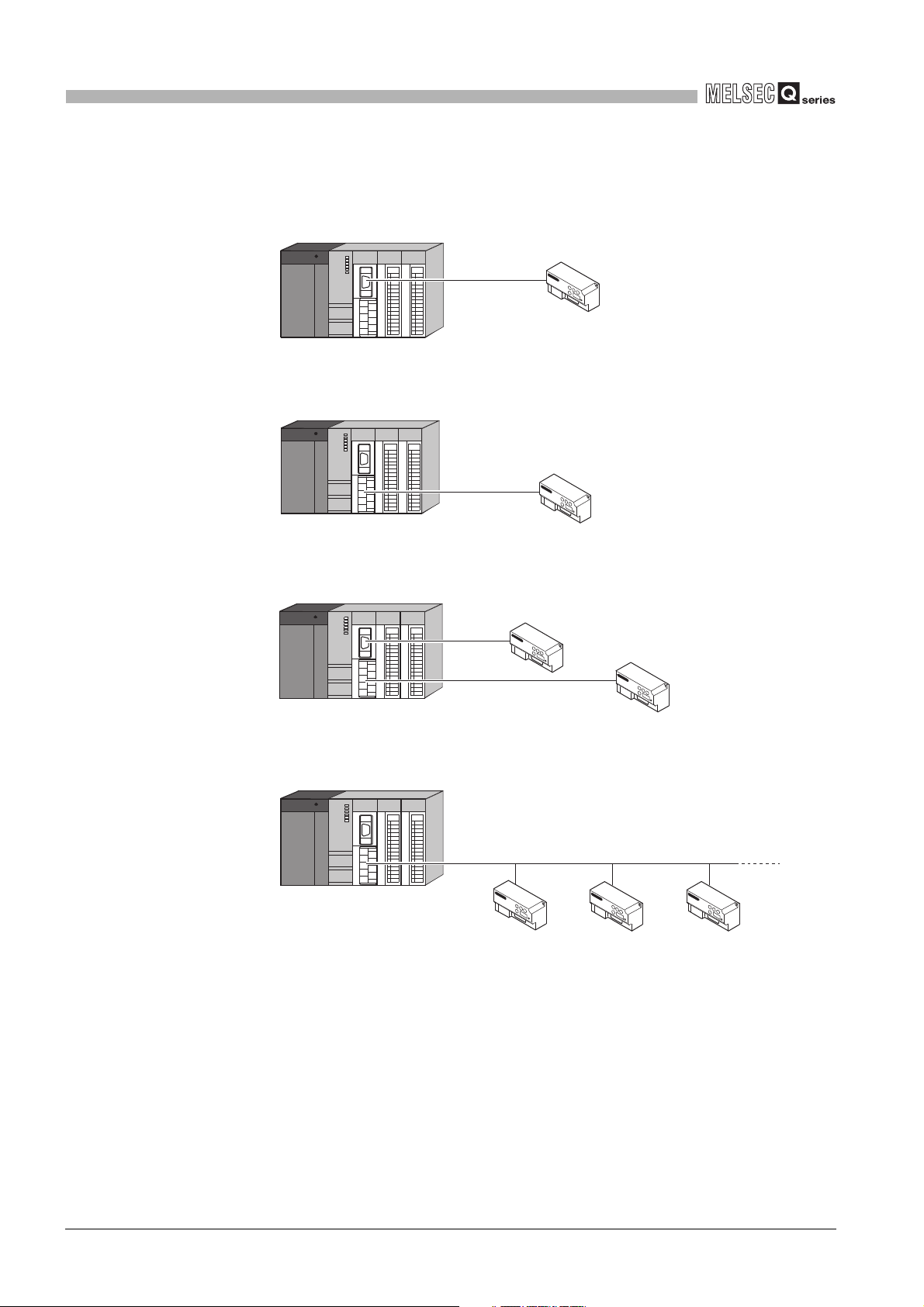

2.2 Network Configuration

The following shows MODBUS network configuration examples using the QJ71MB91.

Master/Slave Line Used

Table2.2 Network configuration using QJ71MB91

QJ71MB91

System Configuration Reference

1

OVERVIEW

2

Master

Slave

Master/Slave

RS-232

RS-422/485 This section (1) (b)

RS-232, RS-422/485 This section (1) (c)

RS-485 1:n This section (1) (d)

RS-232

RS-422/485 This section (2) (b)

RS-232, RS-422/485 This section (2) (c)

RS-485 1:n This section (2) (d)

RS-232, RS-485

(with link operation

function)

RS-232 (Master),

RS-485 (Slave)

RS-232 (Slave)

RS-485 (Master)

1:1

1:1

1:n This section (2) (e)

1:n

This section (1) (a)

This section (2) (a)

This section (3) (a)

This section (3) (b)

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

MODBUS STANDARD

FUNCTIONS

5

2.2 Network Configuration

FUNCTION

6

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

UTILITY PACKAGE

(GX Configurator-MB)

2 - 3

Page 26

2

RS-232

QJ71MB91 (Master function)

MODBUS slave device

RS-485

QJ71MB91 (Master function)

MODBUS

slave device

MODBUS

slave device

MODBUS

slave device

SYSTEM CONFIGURATION

(1) Using the QJ71MB91 as a master station

(a) Connecting to a slave station (1:1) with a RS-232 line

Figure 2.1 Connecting to a slave station (1:1) with a RS-232 line

(b) Connecting to a slave station (1:1) with a RS-422/485 line

QJ71MB91 (Master function)

MODBUS slave device

RS-422/485

Figure 2.2 Connecting to a slave station with a RS-422/485 line

(c) Connecting to slave stations (1:1) with RS-232 and RS-422/485 lines

QJ71MB91 (Master function)

MODBUS slave device

RS-232

MODBUS slave device

RS-422/485

Figure 2.3 Connecting to slave stations (1:1) with RS-232 and RS-422/485 lines

(d) Connecting to slave stations (1:n)

2 - 4

2.2 Network Configuration

Figure 2.4 Connecting to slave stations (1:n)

Page 27

2

RS-232

MODBUS master device

MODBUS master device

RS-422/485

QJ71MB91 (Slave function)

*1

SYSTEM CONFIGURATION

1

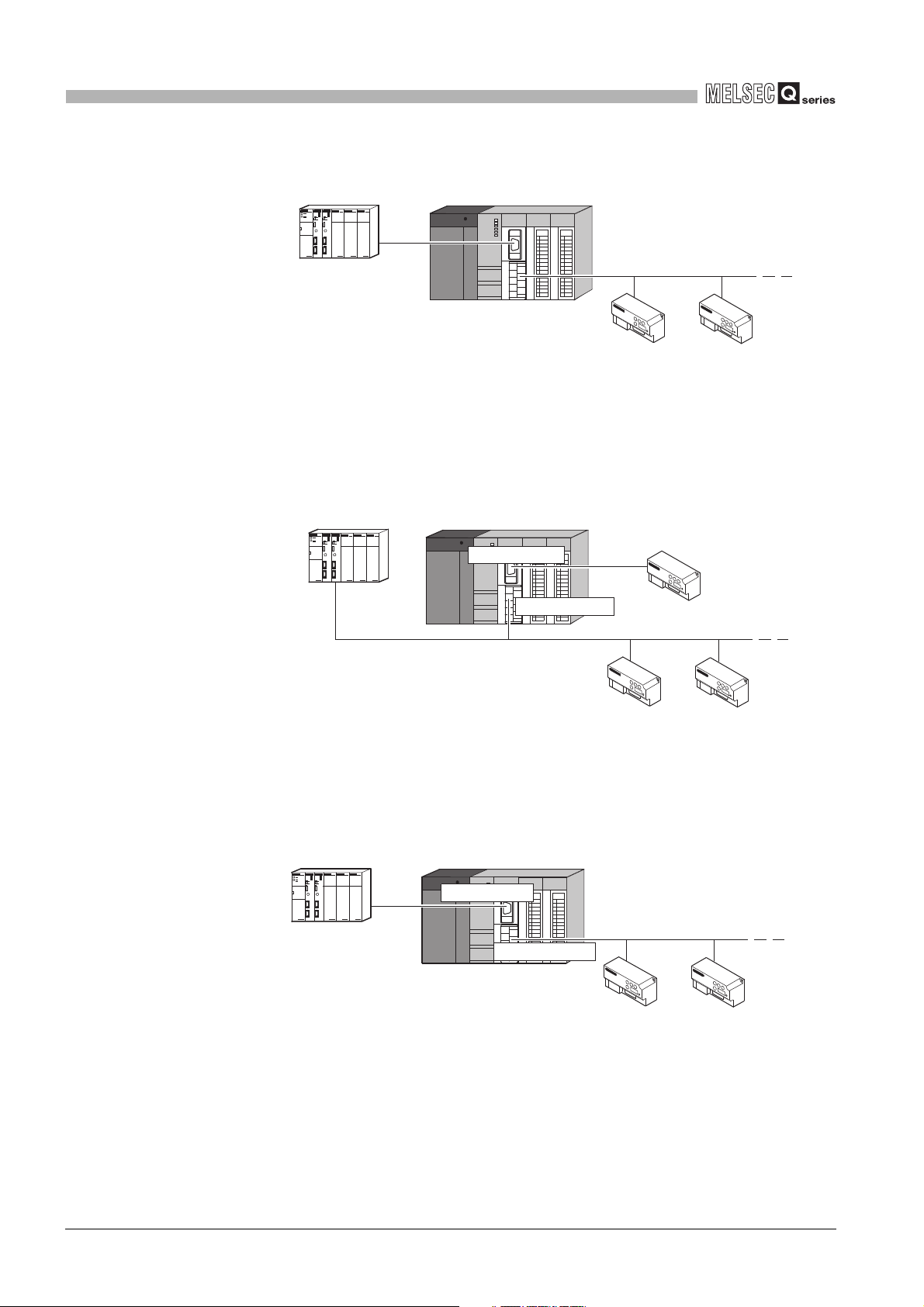

(2) Using the QJ71MB91 as a slave station

(a) Connecting to a master station (1:1) with a RS-232 line

MODBUS master device

RS-232

Figure 2.5 Connecting to a master station (1:1) with a RS-232 line

QJ71MB91 (Slave function)

(b) Connecting to a master station (1:1) with a RS-422/485 line

QJ71MB91 (Slave function)

MODBUS master device

RS-422/485

Figure 2.6 Connecting to a master station (1:1) with a RS-422/485 line

(c) Connecting to master stations (1:1) with RS-232 and RS-422/485 lines

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

MODBUS STANDARD

FUNCTIONS

Figure 2.7 Connecting to master stations with RS-232 and RS-422/485 lines

* 1 The same station number is used for both RS-232 and RS-422/485 interfaces.

(d) Connecting to a master station (1:n)

MODBUS master device

RS-485

MODBUS

slave device

QJ71MB91 (Slave function)

Figure 2.8 Connecting to a master station (1:n)

MODBUS slave

device

5

FUNCTION

6

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

UTILITY PACKAGE

(GX Configurator-MB)

2.2 Network Configuration

2 - 5

Page 28

2

RS-485

RS-232

MODBUS master device QJ71MB91 (Slave function)

MODBUS

slave device

MODBUS

slave device

QJ71MB91

RS-485

RS-232

MODBUS

MODBUS master device

(Master function)

(Slave function)

slave device

MODBUS

slave device

MODBUS

slave device

MODBUS master device

MODBUS

slave device

MODBUS

slave device

RS-232

QJ71MB91

(Slave function)

(Master function)

RS-485

SYSTEM CONFIGURATION

(e) Connecting to a master station (1:n) with the link operation function

Figure 2.9 Connecting to a master station (1:n) with the link operation function

(3) Connecting master and slave stations separately through each interface

(a) Using the RS-232 interface as the master station and the RS-422/485 interface as

the slave station

Figure 2.10 Using the RS-232 interface as the master station and the RS-422/485

(b) Using the RS-232 interface as the slave station and the RS-422/485 interface as

the master station

Figure 2.11 Using the RS-232 interface as the slave station and the RS-422/485 interface

interface as the slave station

as the master station

2 - 6

2.2 Network Configuration

Page 29

2

SYSTEM CONFIGURATION

2.3 Precautions for System Configuration

(1) When used with a Redundant CPU

For precautions, refer to the following.

QnPRHCPU User's Manual (Redundant System)

(2) When used with a C Controller module

For precautions, refer to the following.

User’s manual of the C Controller module used

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

4

MODBUS STANDARD

5

6

PRE-OPERATIONAL

PROCEDURES AND

7

FUNCTIONS

FUNCTION

SETTINGS

2.3 Precautions for System Configuration

PARAMETER SETTING

8

UTILITY PACKAGE

(GX Configurator-MB)

2 - 7

Page 30

2

10021

Relevant regulation standards

Function version

Serial number (first five digits)

Serial No.

Function version

SYSTEM CONFIGURATION

2.4 How to Check the Function Version/Software Version

Check the function version and serial No. of the QJ71MB91and the GX Configurator-MB

software version by the following methods.

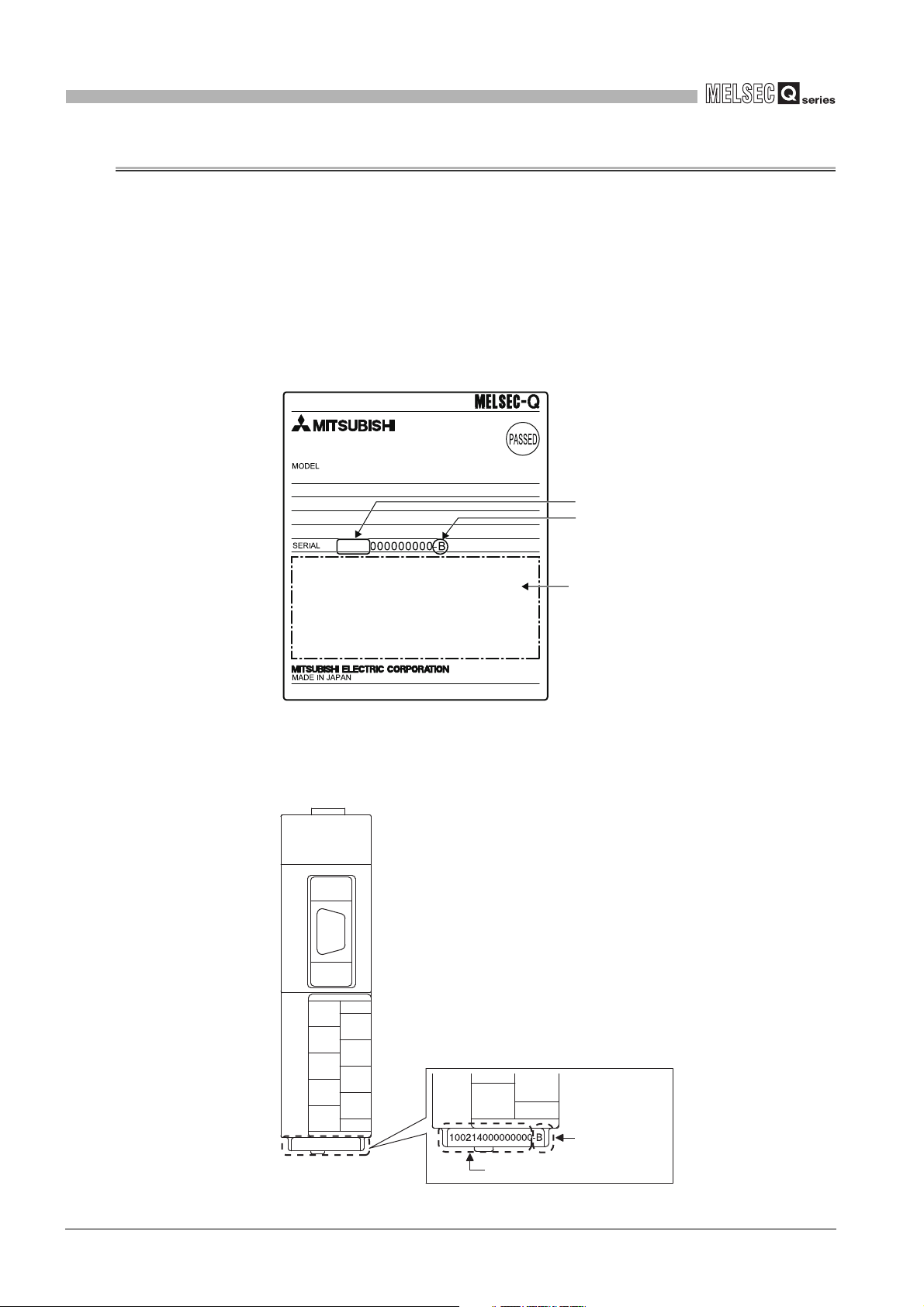

(1) Checking the version and serial No. of the QJ71MB91 functions

The serial No. and function version of the QJ71MB91 can be confirmed on the rating

plate and GX Developer's system monitor.

(a) Confirming the serial number on the rating plate

The rating plate is situated on the side face of the QJ71MB91.

Figure 2.12 Rating plate

(b) Checking on the front of the module

The serial No. and function version on the rating plate are also indicated on the

front of the module (lower part).

2 - 8

2.4 How to Check the Function Version/Software Version

Figure 2.13 Front face of QJ71MB91

Page 31

2

POINT

SYSTEM CONFIGURATION

1

(c) Confirming the serial number on the system monitor (Product Information List)

To display the system monitor, select [Diagnostics] [System monitor]

Product Inf. List

1) Production number display

Since the QJ71MB91 does not support the production number display, "-" is

displayed.

button of GX Developer.

Function version

Serial No. Production number

Figure 2.14 Product information list

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

MODBUS STANDARD

FUNCTIONS

5

The serial No. displayed in the Product Information List of GX Developer may be

different from the one on the rating plate and the front of the module.

• The serial No. on the rating plate and the front of the module indicates the

management information of the product.

• The serial No. in the Product Information List of GX Developer indicates

the functional information on the product, which is updated when a new

function is added.

2.4 How to Check the Function Version/Software Version

2 - 9

FUNCTION

6

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

UTILITY PACKAGE

(GX Configurator-MB)

Page 32

2

Software version

SYSTEM CONFIGURATION

(2) Checking the software version of GX Configurator-MB

The software version of GX Configurator-MB can be checked GX Developer’s

"Product information" screen.

[Operating Procedure]

GX Developer [Help] [Product information]

Figure 2.15 Product information

2 - 10

2.4 How to Check the Function Version/Software Version

Page 33

3

SPECIFICATIONS

CHAPTER3 SPECIFICATIONS

This chapter explains the performance specifications of the QJ71MB91, interface

specifications, I/O signals for communications with programmable controller CPU, and

buffer memory.

Please refer to the following manual for general specifications.

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

3.1 Performance Specifications

1

2

OVERVIEW

SYSTEM

CONFIGURATION

Transmission

specifications

This section provides the performance specifications of QJ71MB91.

Table3.1 Performance specifications

Item Specifications Reference

Number of interfaces

Transmission speed Section 6.6

Transmission

distance

(Overall distance)

Automatic

communication

function

RS-232 Max. 15m (49.2 ft.) -

RS-422/485 Max. 1200m (4592.4 ft.) (Overall distance) -

Number of slaves

Function (for send) 7 functions Section 7.2.1

Input area size 4k words

Output area size 4k words

*1

RS-232 1 channel, RS-422/485 1 channel

300 600 1200 2400

4800 9600 14400 19200

28800 38400 57600 115200 (bps)

Communication is available with total transmission

speed of two interfaces within 115200bps.

32 per channel -

-

Section 3.5.1

3

SPECIFICATIONS

4

MODBUS STANDARD

FUNCTIONS

5

FUNCTION

6

Master

function

Communication

by dedicated

instructions

(MBRW, MBREQ)

Number of instructions that

can be executed

concurrently

Function (for send)

Input area size Max. 253 bytes per instruction

Output area size Max. 253 bytes per instruction

*2

MBREQ instruction: 19 functions

1 per channel

MBRW instruction: 9 functions

(Continued on next page)

3.1 Performance Specifications

CHAPTER 10

3 - 1

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

UTILITY PACKAGE

(GX Configurator-MB)

Page 34

3

SPECIFICATIONS

Table3.1 Performance specifications (Continued)

Item Specifications Reference

Automatic

response function

MODBUS Device

Slave function

Number of occupied I/O points 32 points -

5VDC internal current consumption 0.31A -

External dimensions

Weight 0.20kg -

size

No. of simultaneously acceptable request

messages

Station No. 1 to 247 Section 6.6

Function (for receive) 17 functions CHAPTER 4

Coil 64k points

Input 64k points

Input register 64k points

Holding register 64k points

Extended file register Max. 4086k points

1 request per channel -

98 (3.86 in.) (H) 27.4 (1.08 in.) (W) 90 (3.54 in.)

(D) [mm]

* 1 Indicates the maximum number of slaves that can be communication targets.

* 2 Indicates the maximum number of dedicated instructions that can be executed simultaneously from

a sequence program.

Section 7.3.1

Appendix 4

3 - 2

3.1 Performance Specifications

Page 35

3

SPECIFICATIONS

3.2 RS-232 Interface Specification

This section explains RS-232 interface specifications.

3.2.1 RS-232 connector specification

This section provides the specifications of RS-232 connector that is connected to a target

device.

1

OVERVIEW

2

Pin

number

1

2 RD (RXD) Reception data

Signal code Signal name

(Use

prohibited)

(Use

prohibited)

QJ71MB91 Target device

Signal direction

-

3

SYSTEM

CONFIGURATION

1

2

3

4

6

7

8

9

5

3SD (TXD)

4

5 SG (GND) Signal ground

6

*1

7

*1

8

9

(Use

prohibited)

(Use

prohibited)

-

-

(Use

prohibited)

Transmission

data

(Use

prohibited)

(Use

prohibited)

Output for

cable

disconnection

detection

Input for cable

disconnection

detection

(Use

prohibited)

SPECIFICATIONS

-

-

4

MODBUS STANDARD

FUNCTIONS

5

FUNCTION

-

6

Figure 3.1 RS-232 connector specification

* 1 Connect Pin 8 to Pin 7.

Without connecting Pin 7 and 8, Pin 8 turns off and the CS signal may turn off (error code: 7403

(1) Descriptions of control signals

The following explains control signals. (The pin number of the connector is indicated

within the brackets.)

(a) RD signal (2)

Signal for receiving data.

(b) SD signal (3)

Signal for sending data.

3.2 RS-232 Interface Specification

3.2.1 RS-232 connector specification

H).

3 - 3

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

UTILITY PACKAGE

(GX Configurator-MB)

Page 36

3

SPECIFICATIONS

(2) ON/OFF status of each signal

The ON and OFF statuses of a signal are indicated below.

(Output side) (Input side)

ON ......................... 5V to 15VDC, 3V to 15VDC

OFF ......................... -5V to -15VDC, -3V to -15VDC

(3) Interface connector

For QJ71MB91 RS-232 interface connector, use a 9-pin D sub (female) screw type

connector.

Use metric screws.

3 - 4

3.2 RS-232 Interface Specification

3.2.1 RS-232 connector specification

Page 37

3

SPECIFICATIONS

3.2.2 RS-232 cable specification

The RS-232 cable should be based on RS-232 standards and used within 15m(49.2ft).

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

4

MODBUS STANDARD

5

6

PRE-OPERATIONAL

PROCEDURES AND

7

FUNCTIONS

FUNCTION

SETTINGS

3.2 RS-232 Interface Specification

3.2.2 RS-232 cable specification

3 - 5

8

PARAMETER SETTING

UTILITY PACKAGE

(GX Configurator-MB)

Page 38

3

+

+

+

+

+

+

+

SG

SDA

SDB

RDA

RDB

(FG)

(FG)

SPECIFICATIONS

3.3 RS-422/485 Interface Specification

This section explains RS-422/485 interface specifications.

3.3.1 RS-422/485 terminal block specification

This section provides the specifications of RS-422/485 terminal block that is connected to

a target device.

Signal

code

SDA Transmission data (+)

SDB Transmission data (-)

RDA Reception data (+)

RDB Reception data (-)

SG Signal ground

FG Frame ground

FG Frame ground

Figure 3.2 RS-422/485 terminal block specifications

Signal name

(1) The following explains control signals.

(a) SDA, SDB signal

Signal for QJ71MB91 to send data to a target device

(b) RDA, RDB signal

Signal for QJ71MB91 to receive data from a target device

Signal direction

QJ71MB91 Target device

3 - 6

(2) Terminating resistor

Connect the terminating resistor according to Section 6.5.2.

3.3 RS-422/485 Interface Specification

3.3.1 RS-422/485 terminal block specification

Page 39

3

SPECIFICATIONS

1

3.3.2 RS-422/485 cable specification

This section explains the specifications of RS-422/485 cable.

(1) RS-422/485 cable to be used

The RS-422/485 cable should meet the following specifications and used within

1200m(4592.4ft).

(2) When making a 1:n connection

When connecting to multiple devices (1:n), ensure that the overall distance is within

1200 m(4592.4ft).

(3) RS-422/485 cable specifications

Table3.2 RS-422/485 cable specifications

Item Description

Cable type Shielded cable

Number of pairs 3P

Conductor resistance (20°C) 88.0/km or less

Insulation resistance 10000M•km or more

Dielectric withstand voltage 500VDC, 1 minute

Electrostatic capacitance (1 kHz) 60nF/km or less by an average

Characteristic impedance (100 kHz) 110±10

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

MODBUS STANDARD

FUNCTIONS

5

Recommended conductor size

0.2 mm

2

to 0.75 mm

2

FUNCTION

6

PRE-OPERATIONAL

PROCEDURES AND

SETTINGS

7

PARAMETER SETTING

8

3.3 RS-422/485 Interface Specification

3.3.2 RS-422/485 cable specification

3 - 7

UTILITY PACKAGE

(GX Configurator-MB)

Page 40

3

POINT

Remark

+

-

Receive data

Target

device

Terminating

resistor

RDA

RDB

SPECIFICATIONS

3.3.3 Precautions when transferring data using RS-422/485 line

Note the following points when performing data communication with a target device

through the RS-422/485 interface of QJ71MB91.

For the target device side, pay attention to the following when sending/receiving data.

(1) Preventive measures against faulty data reception on the target device

side

If the target device receives error data, install a pull-up or pull-down resistor to the

target device as shown below.

Installing a pull-up or pull-down resistor (resistance value: approx. 4.7 k , 1/4 W) can

prevent the reception of error data.

Figure 3.3 Preventive measures against faulty data reception

Error data will not be received if a pull-up or pull-down resistor is connected on the

target device side.

The case where any pull-up or pull-down resistor is not connected on the target

device is described below.

When any station is not performing transmission, the transmission line is in a high

impedance status and the line status is not stable due to noises, and the target

device may receive error data.

In such a case, parity or framing error may have occurred. Skip data reading for

error data.

3 - 8

3.3 RS-422/485 Interface Specification

3.3.3 Precautions when transferring data using RS-422/485 line

Page 41

3

Data

Data

(Output control input)

(Output control input)

Target device side

QJ71MB91 side

Outputs a mark with

2 characters or more

Data transmission

time range

H/W gate OFF time

(Refer to explanation above)

OFF time range of

output control input

(High impedance status)

QJ71MB91 can receive data.

ON time range of output

control input

(Low impedance status)

QJ71MB91 can send data.

SPECIFICATIONS

(2) RS-422/485 interface operation

(a) RS-422/485 interface configuration

For RS-422/485 interface, the configuration of driver (send)/receiver (receive)

component of the QJ71MB91 is as shown in the following diagram.

SDR

SDB

Output Control Input (*

RDA

RDB

Figure 3.4 RS-422/485 interface configuration

* 1 The "output control input" (also referred to as send gate) of the driver (send) component

determines whether to output data externally from SDA, SDB.

Driver

Receiver

Send data

Receive data

1

OVERVIEW

2

1

)

SYSTEM

CONFIGURATION

3

(b) RS-422/485 interface operation

When the "output control input" in the above figure is ON, the impedance status is

low (data transmittable).

In addition, when the "output control input" is OFF, the impedance status is high

(data not transmitted).

(c) QJ71MB91 transmission start timing, transmission process complete timing

• Transmission start timing

After releasing the high impedance status indicated in above (a) and (b), and

outputting two or more character data during data transmission, output the

actual data.

• Transmission process complete timing

Data transmission time for data of 1 bit or less is required as the H/W gate

OFF time to complete the transmission process (high impedance status) after

finishing data transmission.

(Transmission speed set in the QJ71MB91 is targeted.)

4

MODBUS STANDARD

5

6

PRE-OPERATIONAL

PROCEDURES AND

SPECIFICATIONS

FUNCTIONS

FUNCTION

SETTINGS

3.3.3 Precautions when transferring data using RS-422/485 line

Figure 3.5 Transmission process complete timing

3.3 RS-422/485 Interface Specification

3 - 9

7

8

PARAMETER SETTING

UTILITY PACKAGE

(GX Configurator-MB)

Page 42

3

SPECIFICATIONS

3.4 I/O Signals for Programmable Controller CPU

This section explains the I/O signals for the programmable controller CPU of QJ71MB91.

3.4.1 I/O signal list

This section explains the I/O signals for the QJ71MB91.

The following I/O signal assignment is based on the case where the start I/O No. of the

QJ71MB91 is "0000" (installed to slot 0 of the main base unit).

Device X represents an input signal from the QJ71MB91 to the programmable controller