Mitsubishi Electric PLA-SM100EA, SUZ-SA71VA3, SUZ-SA100VA2, PEAD-SM71JA(L), PLA-SM71EA Service Manual

...Page 1

TECHNICAL & SERVICE MANUAL

No.TCH030

R410A

Outdoor unit

[Model Name]

[Service Ref.]

SUZ-SA71VA3 SUZ-SA71VA3.TH

SUZ-SA100VA2 SUZ-SA100VA2.TH

CONTENTS

1.

COMBINATION OF INDOOR AND OUTDOOR UNITS

.....

2

2. TECHNICAL CHANGES

...................................

3

3. PARTS NAMES AND FUNCTIONS

..................

6

4. SPECIFICATION

................................................

7

5. NOISE CRITERIA CURVES

..............................

9

6. OUTLINES AND DIMENSIONS

......................

10

7. WIRING DIAGRAM

...........................................

11

8. REFRIGERANT SYSTEM DIAGRAM

.............

13

9. ACTUATOR CONTROL

...................................

14

10. SERVICE FUNCTIONS

....................................

15

11. TROUBLESHOOTING

.....................................

15

12. DISASSEMBLY INSTRUCTIONS

....................

31

Indication of

model name

Note:

•

This service manual describes

technical data of the outdoor

units only.

HFC

utilized

R410A

January 2018

PARTS CATALOG (TCB030)

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

Page 2

2

TCH030 TCH030

1

COMBINATION OF INDOOR AND OUTDOOR UNITS

Note: Please refer to the service manual of indoor unit or the technical data book for the combination data.

INDOOR UNIT SERVICE MANUAL

Model Name Service Ref. Service Manual No.

PLA-SM71/100EA PLA-SM71/100EA.UK

OCH683

OCB683

PEAD-SM71/100JA(L) PEAD-SM71/100JA(L) .UK

HWE17010

BWE017160

Page 3

3

2

TECHNICAL CHANGES

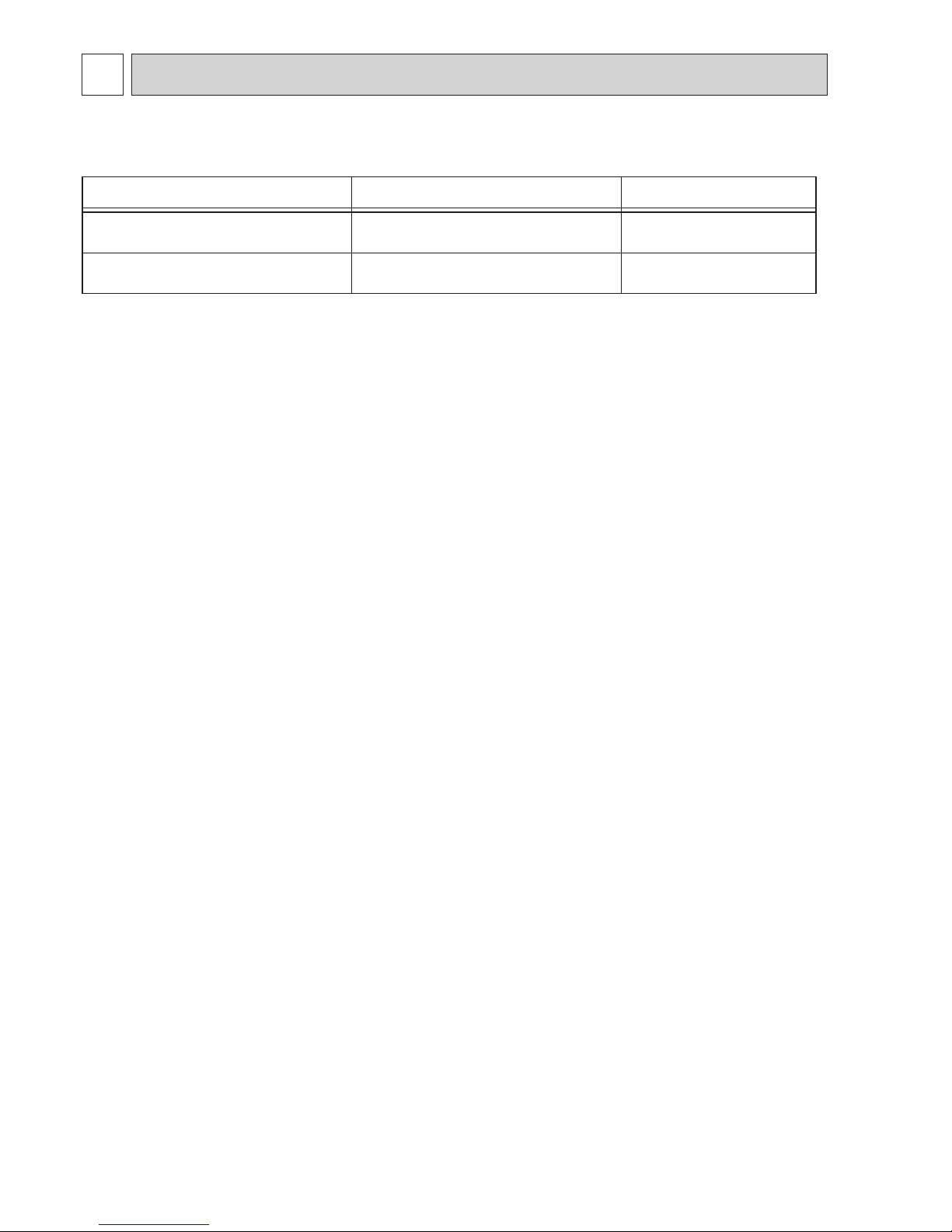

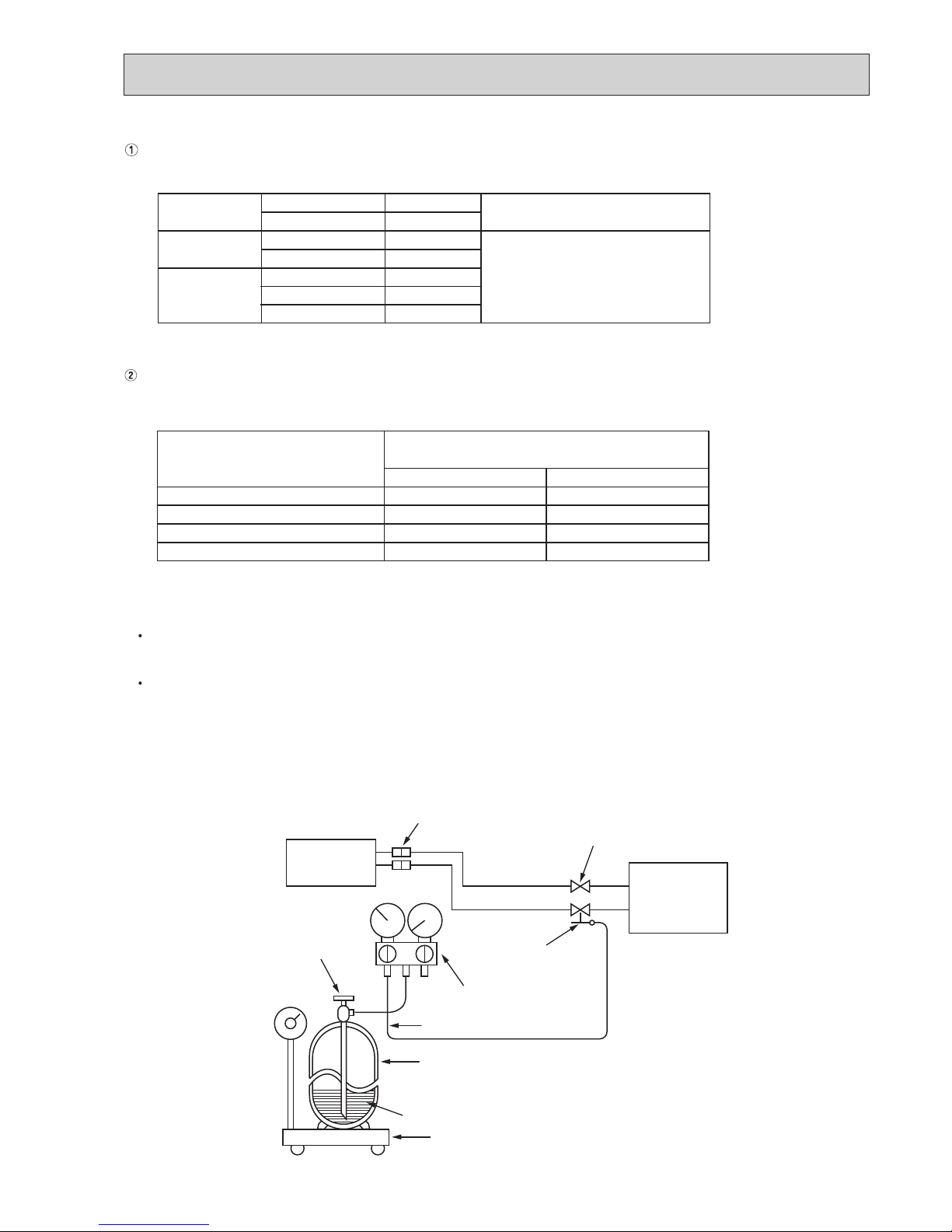

Refrigerant

oil

Refrigerant

New refrigerant

R410A

HFC-32: HFC-125 (50%:50%)

Pseudo-azeotropic refrigerant

Not included

A1/A1

72.6

−51.4

1.557

64

Non combustible

0

1730

From liquid phase in cylinder

Possible

Incompatible oil

None

None

Previous refrigerant

R22

R22 (100%)

Single refrigerant

Included

A1

86.5

−40.8

0.94

44.4

Non combustible

0.055

1700

Gas phase

Possible

Compatible oil

Light yellow

None

Refrigerant

Composition (Ratio)

Refrigerant handling

Chlorine

Safety group (ASHRAE)

Molecular weight

Boiling point (°C)

Steam pressure [25°C](Mpa)

Saturated steam density [25°C](Kg/K)

Combustibility

ODP *1

GWP *2

Refrigerant charge method

Additional charge on leakage

Kind

Color

Smell

*1: Ozone Depletion Potential : based on CFC-11

*2: Global Warming Potential : based on CO

2

INFORMATION FOR THE AIR CONDITIONER WITH R410A REFRIGERANT

• This room air conditioner adopts an HFC refrigerant (R410A) which never destroys the ozone layer.

• Pay particular attention to the following points, though the basic installation procedure is same as that for R22 conditioners.

As R410A has working pressure approximate 1.6 times as high as that of R22, some special tools and piping parts/materi-

als are required. Refer to the table below.

Take sufficient care not to allow water and other contaminations to enter the R410A refrigerant during storage and installa-

tion, since it is more susceptible to contaminations than R22.

For refrigerant piping, use clean, pressure-proof parts/materials specifically designed for R410A. (Refer to 2. Refrigerant

piping.)

Composition change may occur in R410A since it is a mixed refrigerant. When charging, charge liquid refrigerant to prevent

composition change.

NOTE : The unit of pressure has been changed to MPa on the international system of units (SI unit system).

The conversion factor is: 1 (MPa [Gauge]) =10.2 (kgf/cm

2

[Gauge])

New Specification Current Specification

The incompatible refrigerant oil easily separates from

refrigerant and is in the upper layer inside the suction muffler.

Raising position of the oil back hole enables to back the

refrigerant oil of the upper layer to flow back to the

compressor.

Since refrigerant and refrigerant oil are compatible with

each other, refrigerant oil backs to the compressor through

the lower position oil back hole.

Compressor

Suction muffler

Oil back hole

Refrigerant oil

Refrigerant

Compressor

Suction muffler

Oil back hole

Refrigerant oil /Refrigerant

Compressor

Page 4

4

TCH030 TCH030

R410A tools Can R22 tools be used?

Gas leak detector

R410A has high pressures beyond the measurement range of existing

gauges. Port diameters have been changed to prevent any other refrigerant

from being charged into the unit.

Hose material and cap size have been changed to improve the pressure

resistance.

Dedicated for HFC refrigerant.

6.35 mm and 9.52 mm

Description

Clamp bar hole has been enlarged to reinforce the spring strength in the tool.

Provided for flaring work (to be used with R22 flare tool).

Provided to prevent the back flow of oil. This adapter enables you to use

vacuum pumps.

It is difficult to measure R410A with a charging cylinder because the

refrigerant bubbles due to high pressure and high-speed vaporization

No

No

No

Yes

Yes

New

New

New

Gauge manifold

Charge hose

Torque wrench

Flare tool

Flare gauge

Vacuum pump

adapter

Electronic scale for

refrigerant charging

No: Not substitutable for R410A Yes: Substitutable for R410A

No 12.7 mm and 15.88 mm

1. Tools dedicated for the air conditioner with R410A refrigerant

The following tools are required for R410A refrigerant. Some R22 tools can be substituted for R410A tools.

The diameter of the service port on the stop valve in outdoor unit has been changed to prevent any other refrigerant being

charged into the unit. Cap size has been changed from 7/16 UNF with 20 threads to 1/2 UNF with 20 threads.

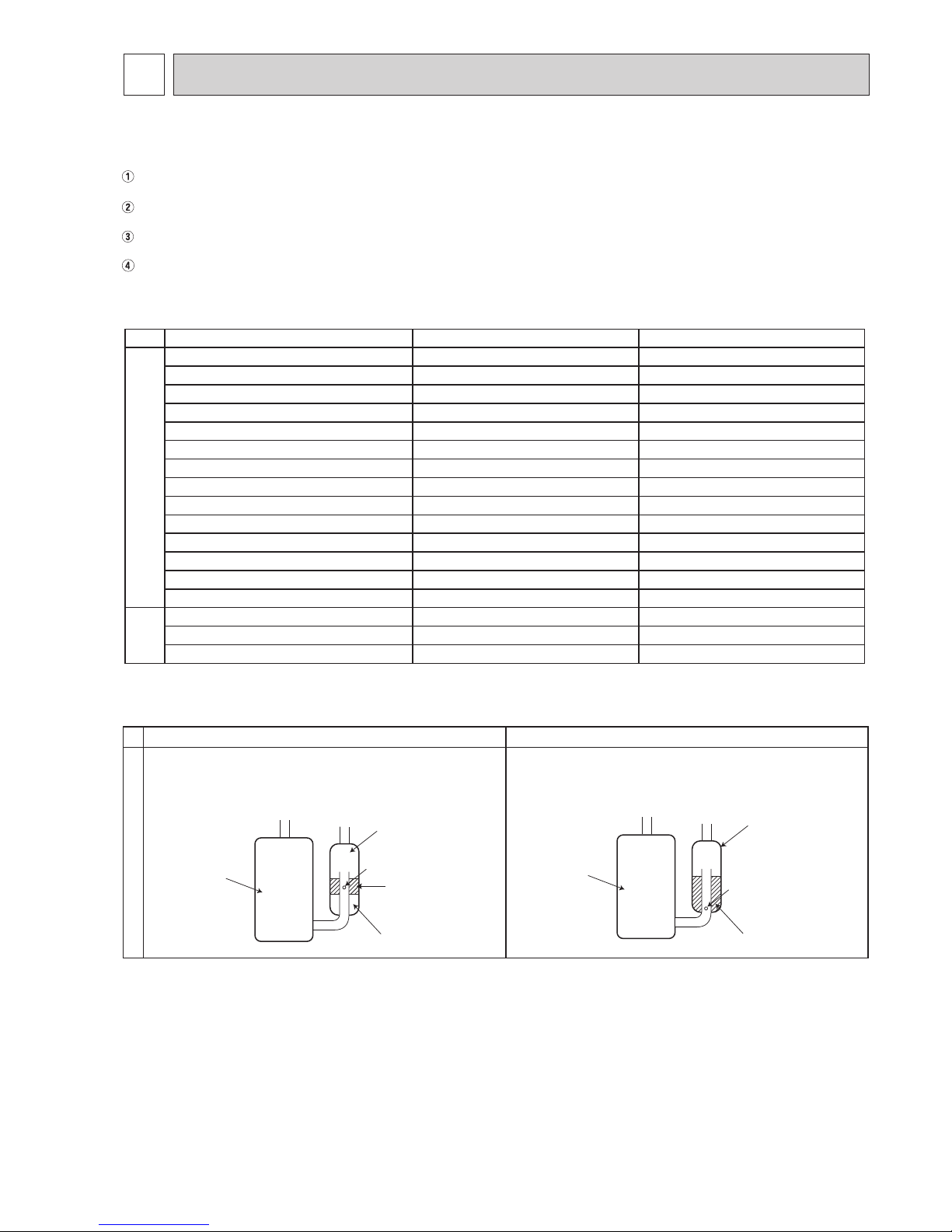

−30 −20 −10 0 10 20

30

40 50 60

−0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

(MPa [Gauge])

R410A

R22

Conversion chart of refrigerant temperature and pressure

Saturated liquid pressure

(:)

NOTE: The unit of pressure has been changed to MPa on the

international system of units (SI unit system).

The conversion factor is: 1 (MPa [Gauge]) =10.2 (kgf/cm

2

[Gauge])

Page 5

5

Electronic scale for refrigerant charging

Outdoor unit

Refrigerant gas

cylinder

operating valve

Refrigerant gas cylinder

for R410A with siphon

Refrigerant (liquid)

Service port

Gauge manifold

valve (for R410A)

Union

Liquid pipe

Gas pipe

Stop valve

Indoor unit

Charge hose (for R410A)

R410A

Pipe diameter (mm)

6.35

9.52

12.7

15.88

17

22

26

29

Dimension of flare nut (mm)

R22

17

22

24

27

• Use a copper pipe or a copper-alloy seamless pipe with a thickness of 0.8 mm. Never use any pipe with a thickness less

than 0.8 mm, as the pressure resistance is insufficient.

Flaring work and flare nut

Flaring work for R410A pipe differs from that for R22 pipe.

For details of flaring work, refer to Installation manual “FLARING WORK”.

3. Refrigerant oil

Apply the special refrigerant oil (accessories: packed with indoor unit) to the flare and the union seat surfaces.

4. Air purge

Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant

circuit.

Use the vacuum pump for air purging for the purpose of environmental protection.

5. Additional charge

For additional charging, charge the refrigerant from liquid phase of the gas cylinder.

If the refrigerant is charged from the gas phase, composition change may occur in the refrigerant inside the cylinder and

the outdoor unit. In this case, ability of the refrigerating cycle decreases or normal operation can be impossible. However,

charging the liquid refrigerant all at once may cause the compressor to be locked. Thus, charge the refrigerant slowly.

2. Refrigerant piping

Specifications

Use the refrigerant pipes that meet the following specifications.

Wall thicknessOutside diameter

Pipe

mm mm

For liquid

For gas

6.35

9.52

9.52

12.7

15.88

0.8

0.8

0.8

0.8

1.0

Heat resisting foam plastic

Specific gravity 0.045

Thickness 8 mm

Insulation material

Page 6

TCH030 TCH030

6

TCH030 TCH030

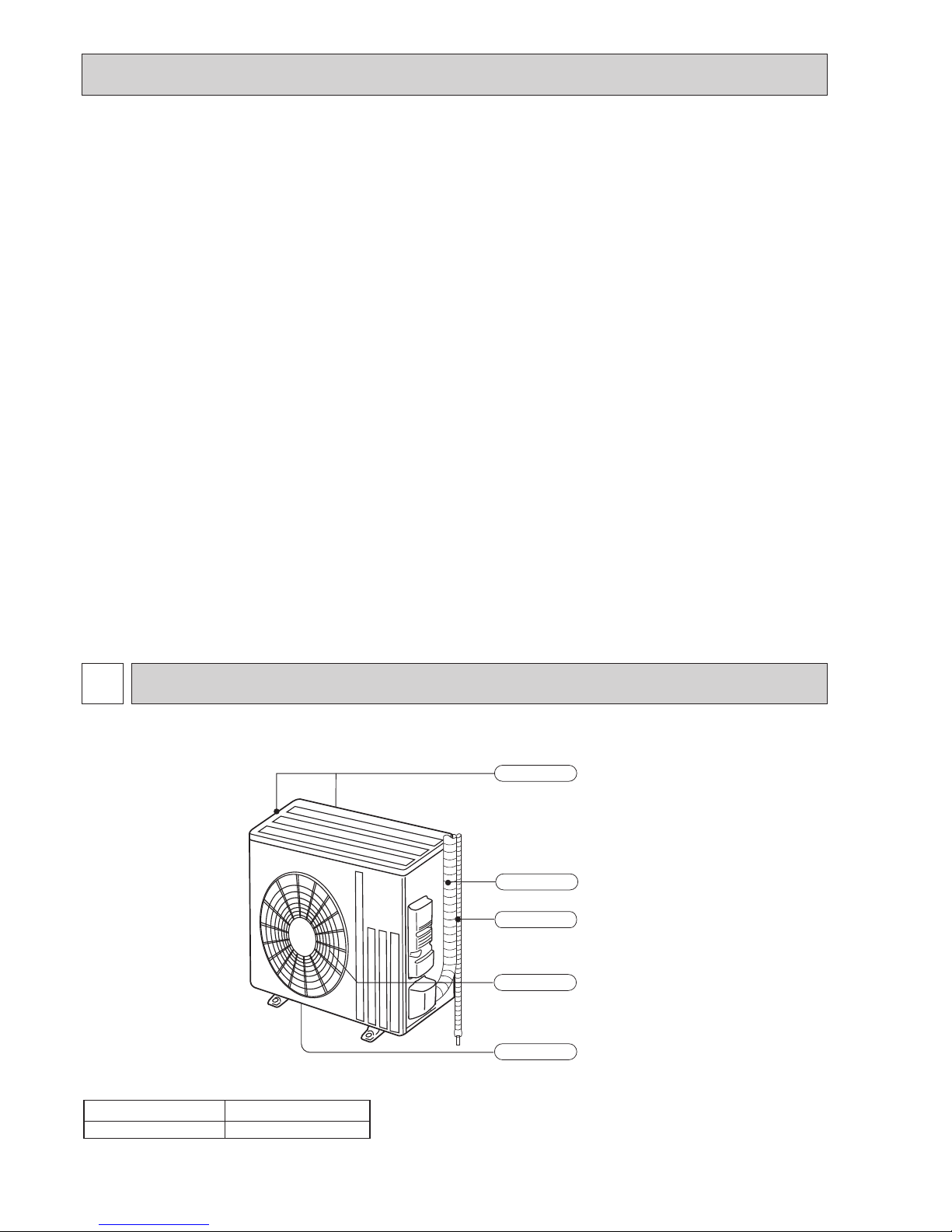

3

PARTS NAMES AND FUNCTIONS

SUZ-SA71VA3.TH

SUZ-SA100VA2.TH

Model SUZ-SA·VA2(3)

Drain socket 1

Piping

Air outlet

Drain outlet

Air inlet

(back and side)

Drain hose

Piping

Air outlet

Drain outlet

Air inlet

(back and side)

Drain hose

6. Pumping Down

When relocating or disposing of the air conditioner, pump down the system by following the procedure below so that no

refrigerant is released into the atmosphere.

1 Turn off the power supply (circuit breaker).

2 Connect the gauge manifold valve to the service port of the stop valve on the gas pipe side of the outdoor unit.

3 Fully close the stop valve on the liquid pipe side of the outdoor unit.

4 Supply power (circuit breaker).

5 Perform the refrigerant collecting operation (cooling test run).

•ForthePAR-31MAA,select“Service”→“Testrun”fromthemainmenutostartthetestrun,andthenselectthecooling

mode.

• For details or for other information about starting the test run when using remote controllers, refer to the installation manual

for the indoor unit or the remote controller.

6 Fully close the stop valve on the gas pipe side of the outdoor unit when the pressure gauge shows 0.05 to 0 MPa [Gauge]

(approx. 0.5 to 0 kgf/cm²) and quickly stop the air conditioner.

• Push the “ON/OFF” button on the remote controller to stop the air conditioner.

Notes:

1. When the extension piping is very long with a large refrigerant amount, it may not be possible to perform a pump down

operation. In this case, use refrigerant recovery equipment to collect all of the refrigerant in the system.

2. If the extension piping length for the SUZ-SA100VA is 20 m or longer, it will not be possible to perform a pump-down

operation because there is a large amount of refrigerant. In this case, collect the refrigerant in the system.

7 Turn off the power supply (circuit breaker), remove the gauge manifold valve, and then disconnect the refrigerant pipes.

.Warning: When pumping down the refrigerant, stop the compressor before disconnecting the refrigerant pipes.

• If the refrigerant pipes are disconnected while the compressor is operating and the stop valve (ball valve) is open,

the pressure in the refrigeration cycle could become extremely high if air is drawn in, causing the pipes to burst,

personal injury, etc.

Page 7

7

7

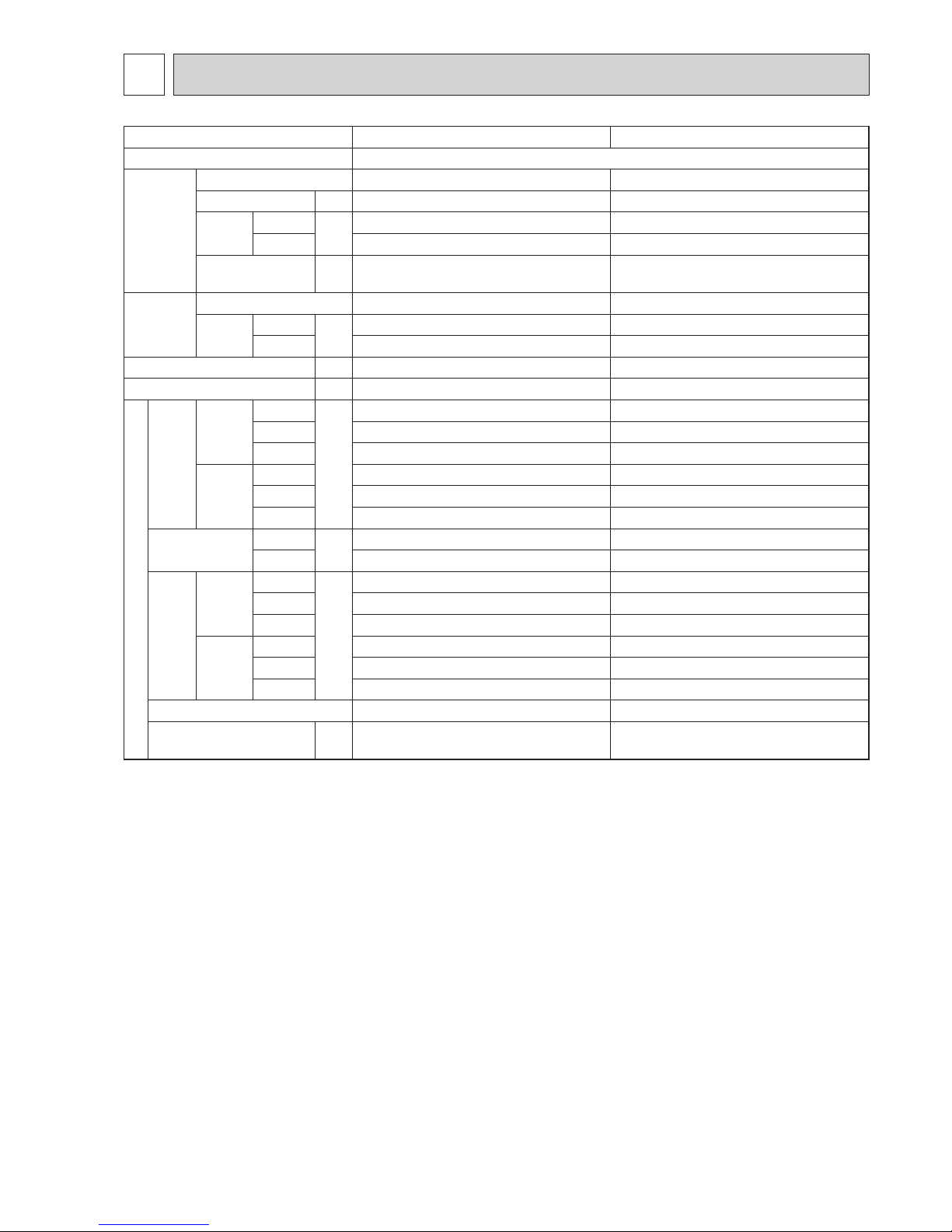

SPECIFICATION

4

NOTE: Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27°C W.B. 19°C

Outdoor D.B. 35°C

Heating : Indoor D.B. 20°C

Outdoor D.B. 7°C W.B. 6°C

Refrigerant piping length (one way): 5 m

*Measured under rated operating frequency.

Outdoor model

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Power supply Single phase 230V, 50Hz

Compressor

Model SNB140FRKMT SNB220FBGM1T

Output W 1,200 1,500

Current*

Cooling

A

8.30 11. 11

Heating 9.59 12.84

Refrigeration oil

(Model)

L 0.4 (FV50S) 0.46 (FV50S)

Fan motor

Model RC0J60-BC RC0J60-BC

Current*

Cooling

A

0.83 0.85

Heating 0.82 0.86

Dimensions W × H × D mm 840 × 880 × 330 840 × 880 × 330

Weight kg 52 56

Special remarks

Air

ow*

Cooling

High

m³/h

3,492 3,426

Med. 3,006 3,234

Low 2,226 2,394

Heating

High 2,952 3,276

Med. 2,952 3,276

Low 2,268 2,472

Sound level*

Cooling

dB(A)

55 55

Heating

55 55

Fan

speed

Cooling

High

rpm

950 950

Med. 840 900

Low 620 680

Heating

High 810 910

Med. 810 910

Low 630 700

Fan speed regulator

3 3

Refrigerantllingcapacity

(R410A)

kg 1.80 2.20

Page 8

TCH030 TCH030

8

TCH030 TCH030

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Specifications and rating conditions of main electric parts

Model

Item

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Smoothing

capacitor

(C61) —

(C62, C63) —

(CB1, 2, 3) 560μF450V

Diode module (DB61) —

Fuse

(F61) —

(F62) T20AL 250 V

(F701, F801, F901)

—

Intelligent power module

(IPM) —

(IC932) 5 A 600 V

IGBT module (IC700) 20 A 600V

Power factor

controller

(PFC) 20 A 600 V

(IC820) 20 A 600 V

Expansion valve coil (LEV) 12 V DC

Reactor

(L61) —

(L) 340μH20A

Current-Limiting

PTC thermistor

(PTC64, PTC65) 33Ω

Terminal block

(TB1, TB2) 3P

(TB) —

Relay

(X63) —

(X64) 20 A 250 V

(X601) 3 A 250 V

(X602) 3 A 250 V

R.V. coil (21S4) 220–240 V AC

Page 9

9

9

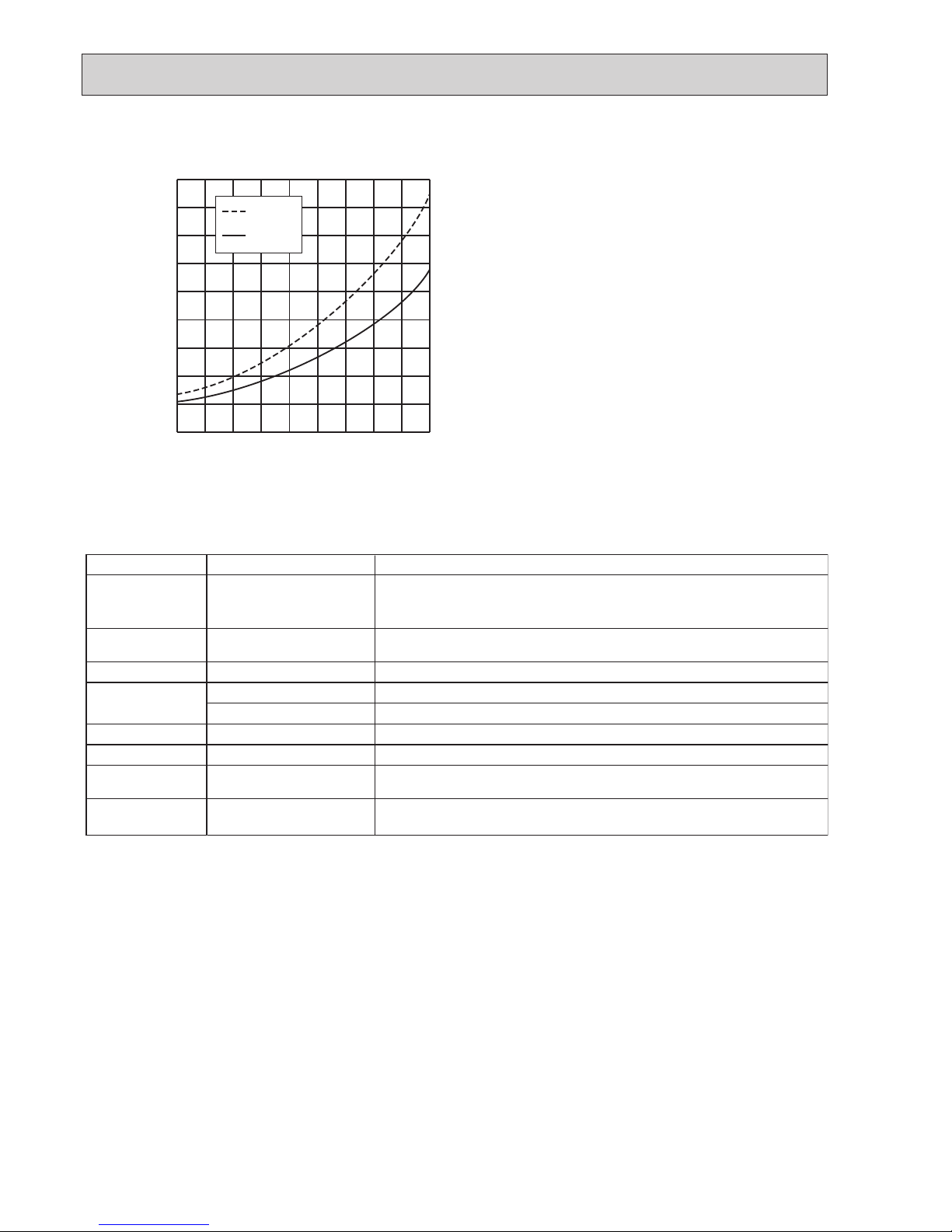

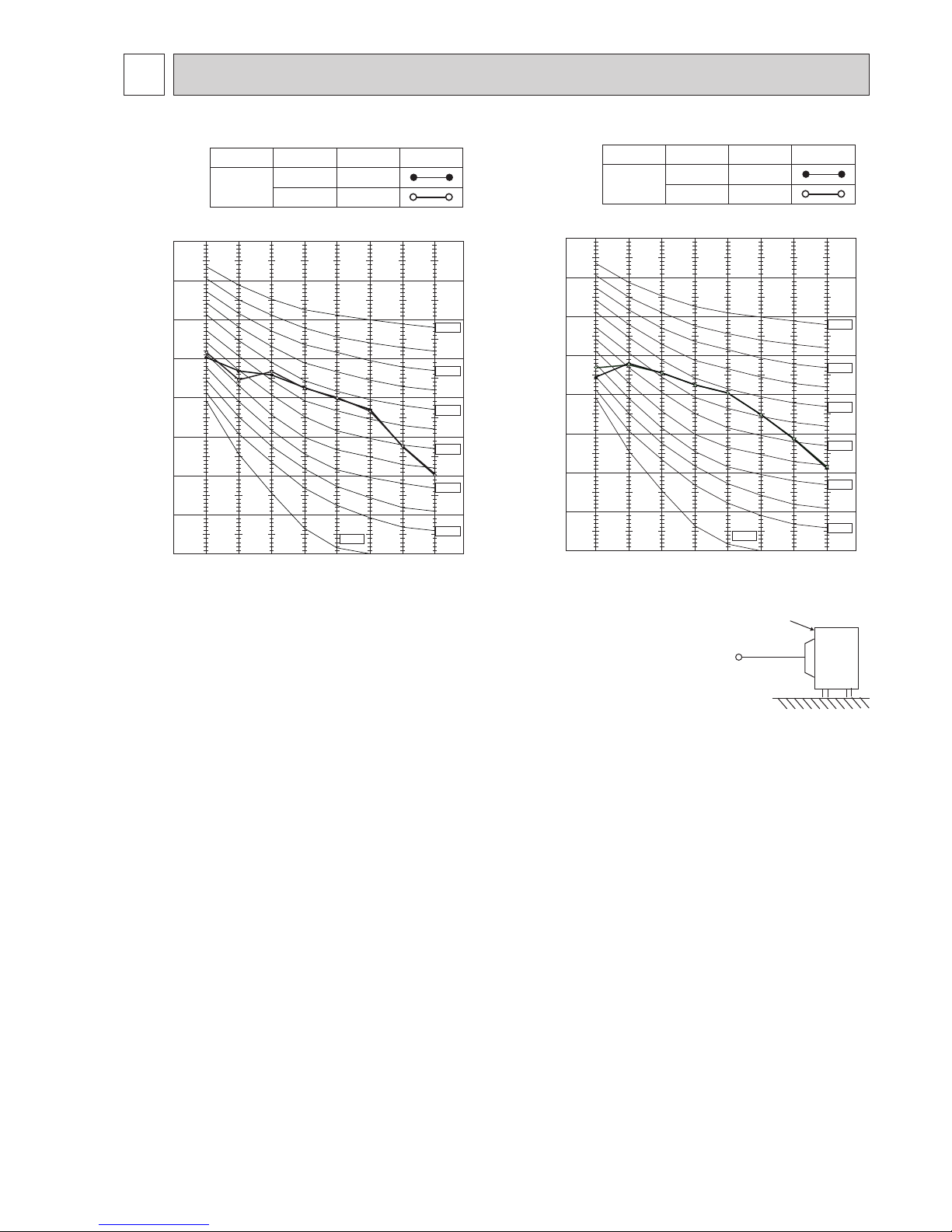

NOISE CRITERIA CURVES

5

Test conditions

Cooling: Dry-bulb temperature 35°C

Heating: Dry-bulb temperature 7°C

Wet-bulb temperature 6°C

OUTDOOR UNIT

MICROPHONE

1 m

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB re 0.0002 MICRO BAR

COOLING

FUNCTION

SPL(dB(A)) LINE

High

FAN SPEED

HEATING

55

55

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

NC-10

SUZ-SA71VA3.TH

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB re 0.0002 MICRO BAR

COOLING

FUNCTION

SPL(dB(A)) LINE

High

FAN SPEED

HEATING

55

55

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

NC-10

SUZ-SA100VA2.TH

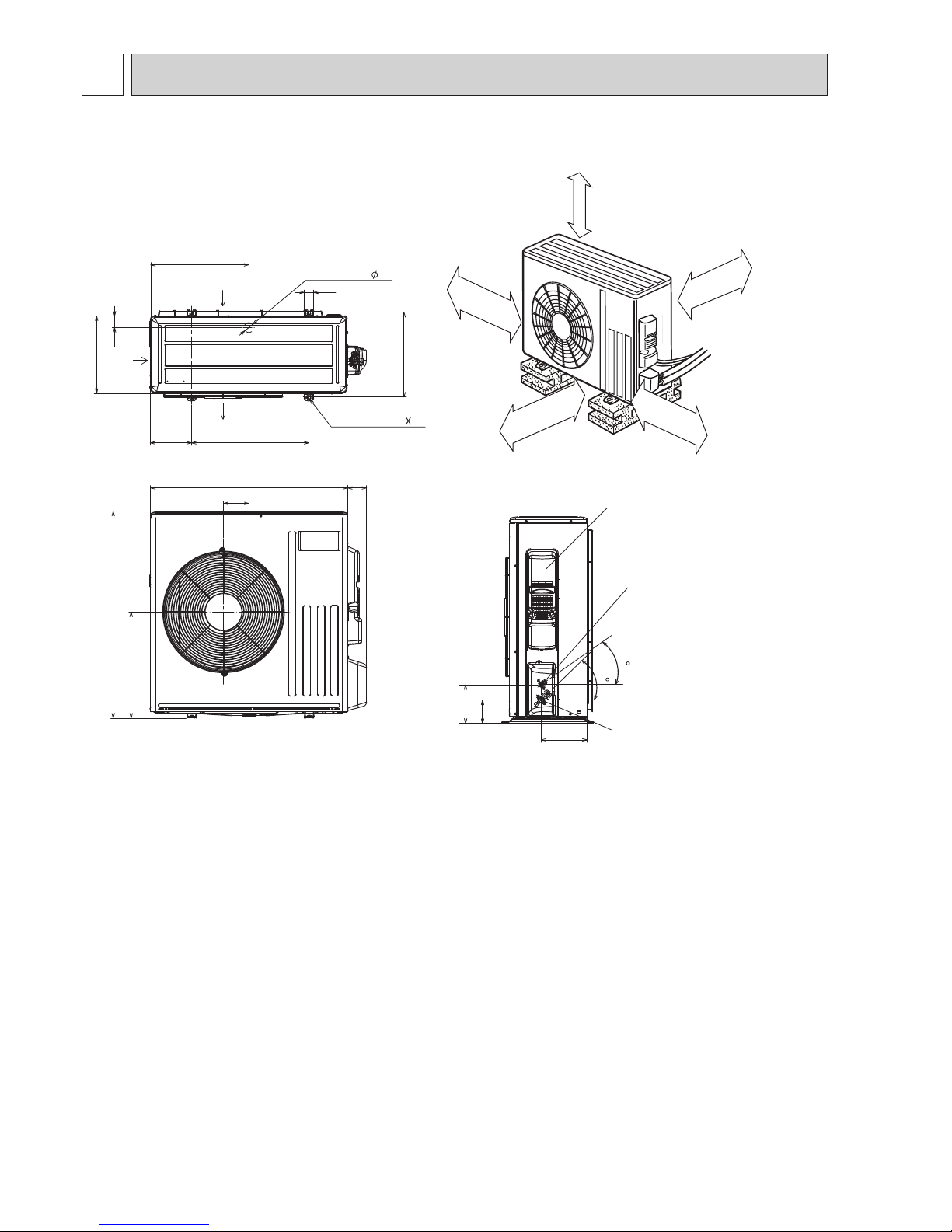

Page 10

10

TCH030 TCH030

6

OUTLINES AND DIMENSIONS

Unit: mm

417.5

40

42

Drain hole

175

500

330

50

Air in

Air out

2-Oval holes 10 21

840

109

81

880

452

Service panel

99.5

164.5

195

35

44

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared)

Ø 9.52

Gas refrigerant

pipe joint

Refrigerant pipe

(flared)

Ø 15.88

350 mm or more

100 mm or more

REQUIRED SPACE

Basically, leave this space open.

Only if front and both sides are open,

leave 500 mm at minimum.

100 mm or more

500 mm or more.

Leave any two sides

among right, left or rear open.

Air in

Bolt pitch for

installation

360

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

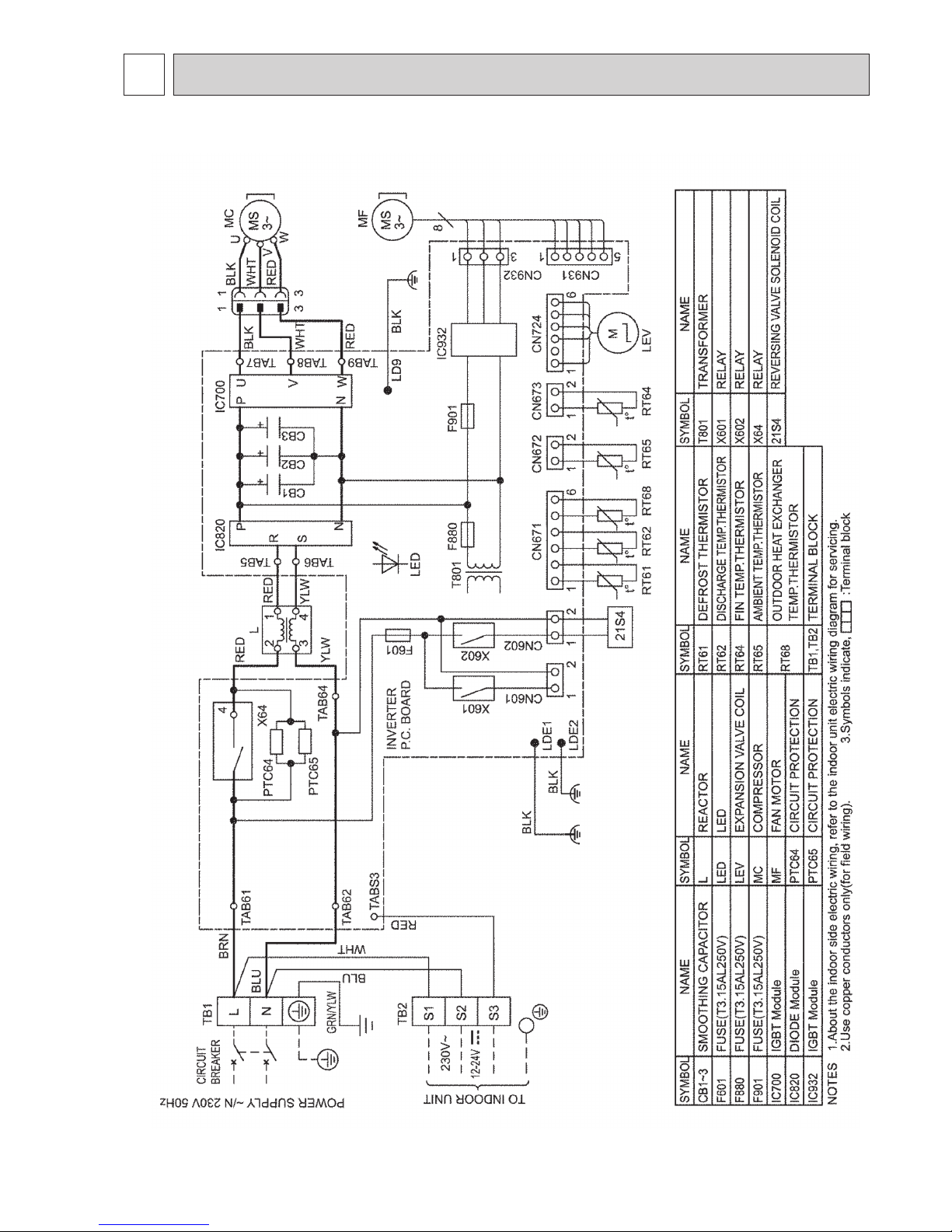

Page 11

11

7

WIRING DIAGRAM

SUZ-SA71VA3.TH

Page 12

TCH030 TCH030

12

TCH030 TCH030

SUZ-SA100VA2.TH

Page 13

13

13

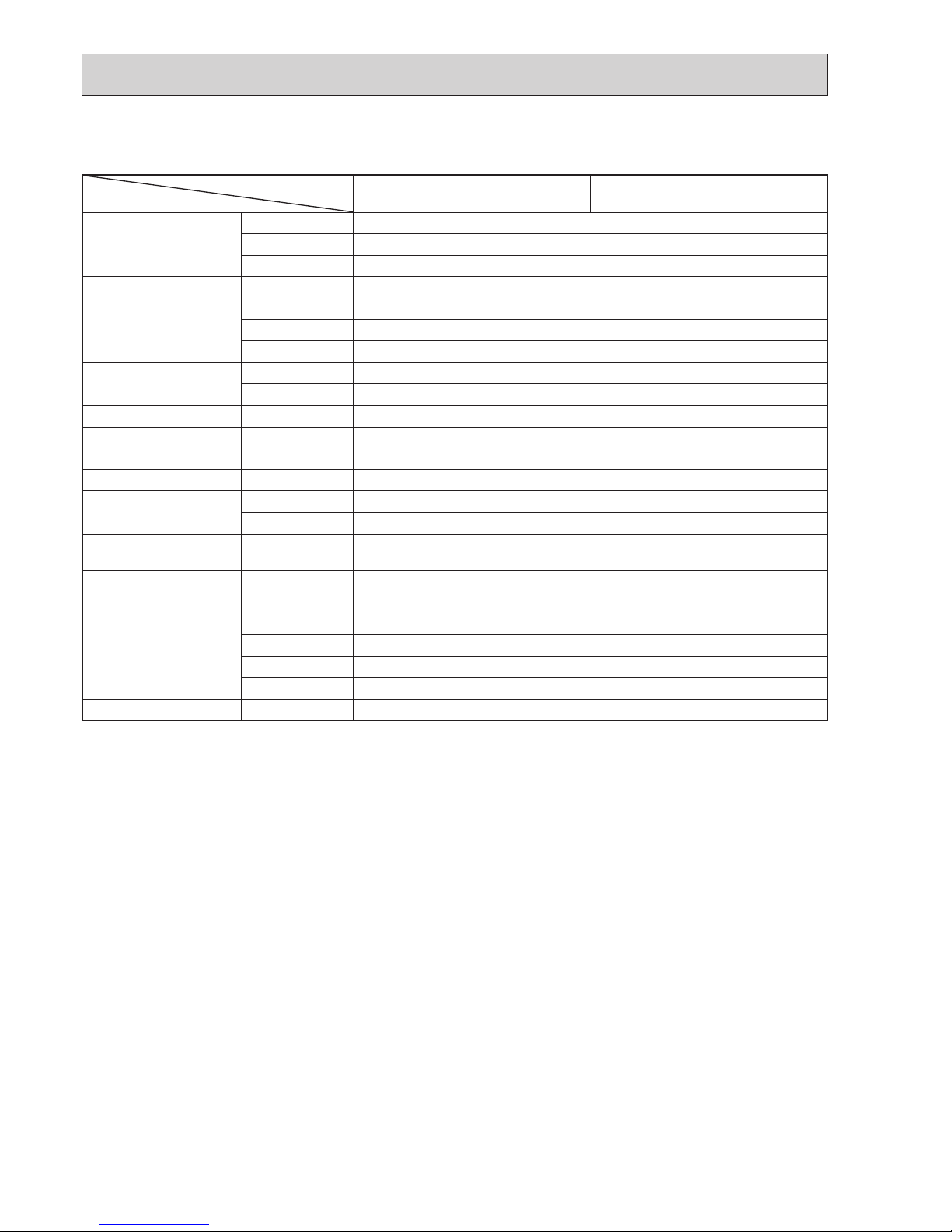

REFRIGERANT SYSTEM DIAGRAM

8

Unit: mm

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Outdoor

heat

exchanger

Flared connection

Defrost

thermistor

RT61

Discharge

temperature

thermistor

RT62

Flared connection

Stop valve

Stop valve

(with service port)

Capillary tube

ø

4.0

×

ø

2.4×100

Refrigerant flow in cooling

Compressor

4-way valve

Refrigerant flow in heating

Refrigerant pipe

(with heat insulator)

ø

15.88

Refrigerant pipe

(with heat insulator)

ø

9.52

LEV

R.V. coil

heating ON

cooling OFF

Muffler

#100

Strainer

#100

Outdoor heat

exchanger

temperature

thermistor

RT68

Ambient

temperature

thermistor

RT65

Strainer

#100

ADDITIONAL REFRIGERANT CHARGE (R410A: g)

MAX. REFRIGERANT PIPING LENGTH

Max. Length

A

* Height difference limitations are binding regardless of the height position at which either indoor or outdoor is placed higher.

* Max. Height

difference

B

Indoor

unit

Outdoor unit

MAX. HEIGHT DIFFERENCE

Model

Refrigerant piping: m Piping size O.D: mm

Max. Length A

Max. Height difference B

Gas Liquid

SUZ-SA71VA3.TH

SUZ-SA100VA2.TH

30

30

15.88 9.52

Calculation:Xg=50g/m×(Refrigerantpipinglength(m)−7)

Model

Outdoor unit

precharged

Refrigerant piping length (one way)

7 m 10 m 15 m 20 m 25 m 30 m

SUZ-SA71VA3.TH

SUZ-SA100VA2.TH

1,800 0 150 400 650 900 1,150

2,200 0 150 400 650 900 1,150

Page 14

14

TCH030 TCH030

ACTUATOR CONTROL

9

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

9-3. RELATION BETWEEN MAIN SENSOR AND ACTUATOR

9-2. R.V. COIL CONTROL

Heating

.................

ON

Cooling ................. OFF

Dry

....................

OFF

ON

OFF

ON

OFF

Outdoor fan

Compressor

5 seconds 15 seconds

ON

OFF

Compressor

Outdoor fan

motor

R.V.coil

ON

OFF

ON

OFF

<COOL>

5 seconds

<HEAT>

5 seconds

9-1. OUTDOOR FAN MOTOR CONTROL

The fan motor turns ON/OFF, interlocking with the compressor.

[ON] The fan motor turns ON 5 seconds before the compressor starts up.

[OFF] The fan motor turns OFF 15 seconds after the compressor has stopped running.

NOTE: The 4-way valve reverses for 5 seconds

right before start-up of the compressor.

Sensor Purpose

Actuator

Compressor

LEV

Outdoor fan

motor

R.V.coil

Indoor fan

motor

Discharge temperature

thermistor

Protection

○ ○

Indoor coil temperature

thermistor

Cooling: Coil frost prevention

○

Heating: High pressure protection

○ ○

Defrost thermistor Heating: Defrosting

○ ○ ○ ○ ○

Fin temperature thermistor Protection

○ ○

Ambient temperature

thermistor

Cooling: Low ambient temperature operation

○ ○ ○

Outdoor heat exchanger

temperature thermistor

Cooling: Low ambient temperature operation

○ ○ ○

Cooling: High pressure protection

○ ○ ○

Page 15

15

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

CHANGE IN DEFROST SETTING

Changing defrost finish temperature

<JS> To change the defrost finish temperature, cut/solder the JS wire of the outdoor inverter P.C. board. (Refer to "11-6. Test

point diagram and voltage".)

11

TROUBLESHOOTING

3. Troubleshooting procedure

1) Check if the OPERATION INDICATOR lamp on the outdoor P.C. board is blinking on and off to indicate an abnormality. To make sure, check how many times the abnormality indication is blinking on and off before starting service work.

2) Before servicing check that the connector and terminal are connected properly.

3) If the electronic control P.C. board is supposed to be defective, check the copper foil pattern for disconnection and the

components for bursting and discoloration.

4) When troubleshooting, refer to "11-2.TROUBLESHOOTING CHECK TABLE" and "11-3.HOW TO PROCEED "SELFDIAGNOSIS"".

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

11-1. CAUTIONS ON TROUBLESHOOTING

1. Before troubleshooting, check the following items:

1) Check the power supply voltage.

2) Check the indoor/outdoor connecting wire for miswiring.

2. Take care the following during servicing.

1)

Before servicing the air conditioner, be sure to turn OFF the main unit first with the remote controller, and turn off the breaker.

2) Be sure to turn OFF the power supply before removing the front panel, the cabinet, the top panel, and the electronic

control P.C. board.

3) When removing the electrical parts, be careful of the residual voltage of smoothing capacitor.

4) When removing the electronic control P.C. board, hold the edge of the board with care NOT to apply stress on the

components.

5) When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

Housing point

Lead wire

10

SERVICE FUNCTIONS

Jumper wire

Defrostnishtemperature(°C)

SUZ-SA71VA3.TH

SUZ-SA100VA2.TH

JS

Soldered (Initial setting) 10

None (cut) 18

Page 16

16

TCH030 TCH030

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

temperature thermistor, outdoor heat exchanger temperature

No. Symptoms

Abnormal point/

Condition

RemedyCondition

Outdoor unit

does not operate.

1-time flash

every

2.5 seconds

Outdoor power sys-

tem

Overcurrent protection cut-out operates 3 consecutive times

within 1 minute after the compressor gets started.

Reconnect connector of compressor.

Refer to 11-5. "How to check inverter/compressor".

Check stop valve.

•

•

•

Outdoor thermistors Discharge temperature thermistor shorts, or opens during

compressor running.

defrost thermistor, P.C. board

thermistor or ambient temperature thermistor shorts, or opens

during compressor running.

Refer to 11-5.F"Check of outdoor

thermistors".

•

Outdoor control system

Nonvolatile memory data cannot be read properly.

Replace inverter P.C. board. •

6-time flash

2.5 seconds

OFF

Serial signal The communication fails between the indoor and outdoor unit

for 3 minutes.

11-time flash Stop valve/

Closed valve

Closed valve is detected by compressor current. Check stop valve.

•

•

'Outdoor unit

stops and

restarts 3

minutes later'

is repeated.

2-time flash

2.5 seconds OFF

Overcurrent protection

Large current flows into intelligent power module.

Reconnect connector of compressor.

Refer to 11-5. "How to check inverter/compressor".

Check stop valve.

•

•

•

3-time flash

2.5 seconds OFF

Discharge temperature overheat protection

Temperature of discharge temperature thermistor exceeds

116°C, compressor stops. Compressor can restart if discharge

temperature thermistor reads 100°C or less 3 minutes later.

Check refrigerant circuit and refrigerant amount.

Refer to 11-5. "Check of LEV".

•

•

4-time flash

2.5 seconds OFF

Fin temperature

/P.C. board temperature thermistor

overheat protection

Temperature of fin temperature thermistor on the heat sink

exceeds 72 to 86 °C or temperature of P.C. board temperature

thermistor on the inverter P.C.board exceeds 72 to 85°C.

Check around outdoor unit.

Check outdoor unit air passage.

Refer to 11-5. "Check of outdoor

fan motor".

•

•

•

5-time flash

2.5 seconds OFF

High pressure protection

Indoor coil thermistor exceeds 70°C in HEAT mode. Defrost

thermistor exceeds 70°C in COOL mode.

Check refrigerant circuit and refrigerant amount.

Check stop valve.

•

•

8-time flash

2.5 seconds OFF

Compressor synchronous abnormality

The waveform of compressor current is distorted.

Reconnect connector of compressor.

Refer to 11-5. "How to check inverter/compressor".

•

•

10-time flash

2.5 seconds OFF

Outdoor fan motor Outdoor fan has stopped 3 times in a row within 30 seconds

after outdoor fan start-up.

Refer to 11-5. "Check of outdoor

fan motor.

Refer to 11-5. "Check of inverter

P.C. board.

•

•

12-time flash

2.5 seconds OFF

Each phase current

of compressor

Each phase current of compressor cannot be detected normally.

Refer to 11-5. "How to check inverter/compressor".

•

13-time flash

2.5 seconds OFF

DC voltage DC voltage of inverter cannot be detected normally. Refer to 11-5. "How to check in-

verter/compressor".

•

Outdoor unit

operates.

1-time flash

2.5 seconds OFF

Frequency drop by

current protection

When the input current exceeds approximately 16A, compressor

The unit is normal, but check the

following.

Check if indoor filters are clogged.

Check if refrigerant is short.

Check if indoor/outdoor unit air

circulation is short cycled.

•

•

•

3-time flash

2.5 seconds OFF

Frequency drop by

high pressure protection

Temperature of indoor coil thermistor exceeds 55°C in HEAT

mode, compressor frequency lowers.

Frequency drop by

defrosting in COOL

mode

Indoor coil thermistor reads 8°C or less in COOL mode, compressor frequency lowers.

4-time flash

2.5 seconds OFF

Frequency drop by

discharge temperature protection

Temperature of discharge temperature thermistor exceeds

111°C, compressor frequency lowers.

Check refrigerant circuit and refrigerant amount.

Refer to 11-5. "Check of LEV".

Refer to 11-5. "Check of outdoor

thermistors".

•

•

•

7-time flash

2.5 seconds OFF

Low discharge temperature protection

Temperature of discharge temperature thermistor has been

50°C or less for 20 minutes.

Refer to 11-5. "Check of LEV".

Check refrigerant circuit and refrig-

erant amount.

•

•

8-time flash

2.5 seconds OFF

This is not malfunction. PAM protection will be activated in the following cases:

1. Instantaneous power voltage

drop. (Short time power failure)

2. When the power supply voltage

is high.

9-time flash

2.5 seconds OFF

Inverter check mode The connector of compressor is disconnected, inverter check

mode starts.

Check if the connector of the compressor is correctly connected.

Refer to 11-5. "How to check

inverter/compressor".

•

Note: 1. The location of LED is illustrated at the right figure. Refer to “11-6. TEST POINT DIAGRAM AND VOLTAGE”.

2. LED is lighted during normal operation.

The flashing frequency shows the number of times the LED blinks after every 2.5-second OFF.

(Example) When the flashing frequency is “2”.

ON

OFF

2.5-second OFF

2.5-second OFF

0.5-second ON

0.5-second ON

LED

Flashing →

Inverter P.C. board

•

I

H

H

J

I

F

I

•

Check of indoor/outdoor connecting wire.

Replace indoor or outdoor P.C. board if

abnormality is displayed again.

Zero cross detecting

circuit

Zero cross signal for PAM control cannot be detected.

LED

indication

check

code

UP

U3

U4

FC

E8

E9

UE

Fin temperature thermistor,

/

frequency lowers.

PL

16-time flash

2.5 seconds OFF

Outdoor refrigerant

system abnormality

A closed valve and air trapped in the refrigerant circuit are detected

based on the temperature sensed by the indoor and outdoor thermistors

and the current of the compressor.

2.5 seconds OFF

•

Check for a gas leak in a connecting

piping, etc.

Check stop valve.

•

Refer to 11-5

.

L

refrigerant circuit”.

•

"Check of outdoor

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

11-2. TROUBLESHOOTING CHECK TABLE

Page 17

17

F1 F2 F3 F4

unem ecivreS

rosruC

:unem niaM

Test run

Input maintenance info.

Function setting

Check

Self check

kcehc fleS

:tceleS

Ref. address

sserddA

When there is no error history

Self check

Delete error history?

Ref. address

Cancel OK

kcehc fleS

Ref. address

Return:

teseR

Unt #Error

CI.prG

kcehc fleS

Ref. address

Return:

teseR

Unt #Error

.prG

--- --

Self check

Return:

Ref. address

Error history deleted

2

With theF1orF2button, enter the refrigerant address, and press the button.

Select "Self check" with the F1 or F2 button, and press the button.

1

Select "Service" from the Main menu, and press the button.

3

Check code, unit number, attribute will appear.

"-" will appear if no error history is available.

4

Resetting the error history.

Press the

F4

button (Reset) on the screen that shows the error history.

Aconrmationscreenwillappearaskingifyouwanttodeletetheerrorhistory.

Press the

F4

button (OK) to delete the error history.

If deletion fails, "Request rejected" will appear.

"Unit not exist" will appear if no indoor units that are correspond to the entered

address are found.

Navigating through the screens

• To go back to the Main menu ..........

button

• To return to the previous screen .......

button

11-3. HOW TO PROCEED "SELF-DIAGNOSIS"

11-3-1. Self-diagnosis <PAR-30MAA> <PAR-31MAA>

As this air conditioner has a function to memorize all the failures that had occurred, the latest failure detail can be recalled by

following the procedure below.

Use this function when the check code is not displayed with wired remote controller or the remote controller at use is wireless

type.

Page 18

18

TCH030 TCH030

If operations cannot be completed with the remote controller, diagnose the remote controller with this function.

F1 F2 F3 F4

unem ecivreS

rosruC

:unem niaM

Maintenance password

Remote controller check

F1 F2 F3 F4

Remote controller check

:nigeB

Start checking?

Remote controller check

:nigeB

Start checking?

1

Select "Service" from the Main menu, and press the button.

Select "Remote controller check" with the F1

or F2 button, and press

the

button.

2

Select "Remote controller check" from the Service menu, and press the button to start the remote controller check and see the check results.

To cancel the remote controller check and exit the Remote controller check

menu screen, press the

or the button.

The remote controller will not reboot itself.

Check the remote controller display and see if anything is displayed

(including lines). Nothing will appear on the remote controller display if

the correct voltage (8.5–12 V DC) is not supplied to the remote controller. If this is the case, check the remote controller wiring and indoor

units.

OK: No problems are found with the remote controller. Check other

parts for problems.

E3, 6832: There is noise on the transmission line, or the indoor unit or another

remote controller is faulty. Check the transmission line and the

other remote controllers.

NG (ALL0, ALL1):

Send-receive circuit fault. Remote controller needs replacing.

ERC:

The number of data errors is the discrepancy between the number of

bits in the data transmitted from the remote controller and that of the

data that was actually transmitted over the transmission line. If data

errors are found, check the transmission line for external noise inter

-

ference.

Remote controller check results screen

If the button is pressed after the remote controller check results are displayed, remote controller check will end, and the remote controller will automati-

cally reboot itself.

11-3-2. Remote controller check <PAR-30MAA> <PAR-31MAA>

3

Page 19

19

11-3-3. Self-diagnosis <PAC-YT52CRA>

Retrieve the error history of each unit using the Simple MA controller.

1 Switch to the self-diagnosis mode.

When the A button and the button are pressed for 5 seconds or longer, the

figure shown below is

2

Set the address or refrigerant address No. you want to self-diagnosis.

When the

B

and

C

are pressed, the address decreases and increases between 01 and 50 or 00 and 15.

Set it to the address No. or refrigerant address No. you want to self-diagnosis.

ON

OFF

.

. .

C

Self-diagnosis address

or self-diagnosis

refrigerant address

Approximately 3 seconds

after the change operation, the

self-diagnosis refrigerant

address changes from flashing

to a steady light and selfdiagnosis begins.

3

Self-diagnosis result display <error history>

the contents of the check code, refer to the indoor unit installation

Check code 4 digits or

check code 2 digits

Error detection attribute

Address 3 digits or

unit address No. 2 digits

<When there is no error history> <When opposite side does not exist>

(Alternate

display)

4

Error history reset

The error history is displayed in 3 self-diagnosis results display.

When the

D button is pressed two times successi

vely within 3 seconds, the self-

diagnosis object address

When the error history was reset, the display shown below appears.

When error history reset is failed, the error contents are displayed again.

5

Self-diagnosis reset

There are the following two ways of resetting self-diagnosis.

Press the

A button and the C button simultaneously for 5 seconds or longer.

→

Resets self-diagnosis and returns to the state before self-diagnosis.

Press the

A

button. → Self-diagnosis resets and indoor units stop.

prohibited, this operation is ineffective.)

ON

OFF

.

ON

OFF

displayed.

manual or service handbook.)

and refrigerant address flash.

(For

(When operation is

Page 20

20

TCH030 TCH030

11-3-4. Remote Controller Check <PAC-YT52CRA>

When the air conditioner cannot be controlled from the Simple MA controller, use this function

to check the remote controller.

1

First, check the power mark.

When normal voltage (12 V DC) is not applied to the remote controller, the power mark goes off.

When the power mark is off, check the remote controller wiring and the indoor unit.

2

Switch to the remote controller check mode.

When the B

button and

D

button are pressed simultaneously for 5 seconds or

longer, the figure

When the

A

button is pressed, remote controller check begins.

.

ON

OFF

Remote controller check result

<When remote controller is normal>

3

Since there is no problem at the remote controller, check for other causes.

<When remote controller is faulty>

(Error display 1) “NG” flashes →

Remote controller send/receive circuit abnormal

Remote controller switching is necessary.

When the problem is other than the checked remote controller

(Error display 2) “E3” “6833” “6832” flash

→

Cannot send

(Error display 3) “ERC” and data error count are displayed

→

Data error generation

There is noise on the transmission line, or the indoor unit or another remote controller is faulty.

Check the transmission line and the other remote controllers.

“Data error count” is the difference between the number of bits of remote controller send

data and the number of bits actually sent to the transmission line. In this case,

the send

data was disturbed by the noise, etc. Check the transmission line.

When data error count is 02

Remote controller send data

Send data on transmission line

4

Remote controller check reset

When the

B

button and

D

button are pressed simultaneously for 5 seconds or

longer, remote controller

and run lamp flash for a certain period of time, and then the remote controller returns to its

.

diagnosis is

reset, the [HO]

shown below is displayed.

Power mark

state before diagnosis.

Page 21

21

• "CHECK" lights, and refrigerant address

"00" flashes.

• Check that the remote controller's

display has stopped before continuing.

• Select the refrigerant address of the

indoor unit for the self-diagnosis.

Note: Set refrigerant address using the

outdoor unit’s DIP switch (SW1).

(For more information, see the

outdoor unit installation manual.)

• If an air conditioner error occurs, the

indoor unit's sensor emits an intermittent

buzzer sound, the operation light

flashes, and the check code is output.

(It takes 3 seconds at most for check

code to appear.)

• The check mode is cancelled.

[Procedure]

1. Press the CHECK button twice.

2. Press the TEMP buttons.

3. Point the remote controller at the

sensor on the indoor unit and

press the HOUR button.

4. Point the remote controller at the

sensor on the indoor unit and

press the ON/OFF button.

<Malfunction-diagnosis method at maintenance service>

11-3-5. Self-diagnosis <Wireless remote controller>

<In case of trouble during operation>

When a malfunction occurs to air conditioner, both indoor unit and outdoor unit will stop and operation lamp blinks to inform

unusual stop.

ON/OFF

TEMP

FAN

VANE

MODE

CHECK

LOUVER

TEST RUN

AUTO STOP

AUTO START

h

min

RESET

SET

CLOCK

CHECK

CHECK

display

Temperature

button

CHECK

button

Refrigerant

address

display

HOUR

button

ON/OFF

button

Page 22

22

TCH030 TCH030

[Output pattern A] Errors detected by indoor unit

[Output pattern B]

E9

1. If the beeper does not sound again after the initial

2 beeps to confirm the self-check start signal was received and

the OPERATION INDICATOR lamp does not come on,

there are no error records.

2. If the beeper sounds 3 times continuously “beep, beep, beep (0.4 + 0.4 + 0.4 seconds)” after the initial 2 beeps to confirm

the self-check start signal was received, the specified refrigerant address is incorrect.

OPERATION

INDICATOR

lamp flash

pattern

Beep Beep Beep Beep Beep

Beep Beep

Off

Approx. 2.5 sOnApprox. 3 sOn0.5 sOn0.5 sOn0.5 s

On

0.5 s

Off

Approx. 2.5 sOnApprox. 3 sOn0.5 sOn0.5 s

··· Repeated

Number of blinks/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “U2”)

Number of blinks/beeps in pattern indicates

the check code in the following table

n

th

1st2nd3

rd

1st2

nd

Self-check

starts

(Start signal

received)

Beeper sounds

[Output pattern B]

OPERATION

INDICATOR

lamp flash

pattern

Beep

Beep Beep Beep Beep Beep Beep

Off

Approx. 2.5 sOn0.5 sOn0.5 sOn0.5 s

On

0.5 s

Off

Approx. 2.5 sOn0.5 sOn0.5 s

··· Repeated

Number of blinks/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “P5”)

Number of blinks/beeps in pattern indicates

the check code in the following table

n

th

1st2nd3

rd

1st2

nd

Self-check

starts

(Start signal

received)

Beeper sounds

• Refer to the following tables for details on the check codes.

[Output pattern A]

Notes:

*The check code in the parenthesis indicates PAR-30/31MAA model.

Beeper sounds/OPERATION

INDICATOR lamp flashes Check code

Symptom Remark

(Number of times)

Wireless remote controller

Wired remote controller

Beeper sounds/OPERATION

INDICATOR lamp flashes Check code

(Number of times)

Wireless remote controller

Wired remote controller

1 P1

Intake sensor error

P9 Pipe (TH5) sensor error

2

P2 Pipe (TH2) sensor error

3 E6,E7

Indoor/outdoor unit communication error

4 P4 Drain sensor error/Float switch connector (CN4F) open

5

P5 Drain pump error

PA Forced compressor stop (due to water leakage abnormality)

6 P6 Freezing/Overheating protection operation

7 EE Communication error between indoor and outdoor units

9 E4, E5 Remote controller signal receiving error

Errors detected by unit other than indoor unit (outdoor unit, etc.)

Symptom

1

Indoor/outdoor unit communication error

2

(Transmitting error) (Outdoor unit)

3

Open/short of outdoor unit thermistors

UP

U3,U4

14

12

14

Fb (FB)*

PL

Indoor unit control system error (memory error, etc.)

–

E0, E3

– E1, E2 Remote controller control board error

Remote controller transmission error

Abnormality of refrigerant circuit

Compressor overcurrent interruption

As for indoor

unit, refer to

indoor unit's

service manual.

PL or others

Abnormality of refrigerant circuit or other errors (Refer to the technical manual for the outdoor unit.)

Page 23

23

11-4. TROUBLE CRITERION OF MAIN PARTS

Parts name

Figure

Check method and criterion

Outdoor fan motor

R.V. coil (21S4)

Expansion valve coil

(LEV)

Measure the resistance between terminals with a tester.

(Temperature: −10 to 40°C)

WHT - BLK

BLK - RED

RED - WHT

Normal

Measure the resistance between terminals with a tester.

(Temperature: −10 to 40°C)

Normal

Measure the resistance with a tester.

Refer to “11-6. TEST POINT DIAGRAM AND VOLTAGE” for the chart of thermistor.

Color of the lead wire

Discharge temperature

thermistor (RT62)

Measure the resistance with a tester.

Before measurement, hold the thermistor with your hands to warm it up.

Refer to “11-6. TEST POINT DIAGRAM AND VOLTAGE” for the chart of thermistor.

Defrost thermistor (RT61)

Fin temperature

thermistor (RT64)

Measure the resistance between terminals with a tester.

(Temperature: −10 to 40°C)

Compressor

U-V

U-W

V-W

Normal

W

U

V

WHT

RED BLK

W

U

V

WHT

RED BLK

Ambient temperature

thermistor (RT65)

Outdoor heat exchanger

temperature thermistor(RT68)

1.19 to 1.78 kΩ

12 to 17 Ω

LEV

WHT

RED

YLW

ORN

BLU

Measure the resistance with a tester.

(Temperature: −10 to 40°C)

RED - ORN

RED - WHT

RED - BLU

RED - YLW

Normal

37 to 54 Ω

Color of the lead wire

SUZ-SA71VA3.TH

0.91 to 1.13 Ω

SUZ-SA100VA2.TH

0.83 to 1.03 Ω

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Page 24

24

TCH030 TCH030

A How to check inverter/compressor

Are the voltages balanced?

Disconnect the connector between the

compressor and the intelligent power module

(SA71: IPM)

.

Replace the inverter P.C. board.

Check the voltage between terminals.

Check the compressor.

See 11-5. “Check of compressor”.

No

Yes

See 11-5. “Check of open phase”.

With the connector between the compressor and the intelligent power module disconnected, activate the inverter and check if

the inverter is normal by measuring the voltage balance between the terminals.

Output voltage is 50–130 V. (The voltage may differ according to the tester.)

<< Operation method (Test run operation)>>

•ForthePAR-31MAA,select“Service”→“Testrun”fromthemainmenutostartthetestrun,andthenselectthecooling

mode.

• For details or for other information about starting the test run when using remote controllers, refer to the installation manual

for the indoor unit or the remote controller.

<<Measurement point>>

At 3 points

BLK (U) - WHT (V)

BLK (U) - RED (W)

WHT (V) - RED (W)

Notes: 1. Output voltage varies according to power supply voltage.

2. Measure the voltage by analog type tester.

3.Duringthischeck,LEDoftheinverterP.C.boardashes9times.

(SA71: “11-6. TEST POINT DIAGRAM AND VOLTAGE”.)

Refer to 11-5. “Check of compressor

operation time”.

Does the compressor operate continuously?

OK

No

Yes

Refer to 11-5. “Check of compressor

winding”.

Is the compressor normal?

Replace the compressor.

No

Yes

C Check of compressor

B Check of open phase

11-5. TROUBLESHOOTING FLOW

Measure AC voltage between the lead wires at 3 points.

Is the compressor

operation time more than

10 seconds?

Replace the compressor.

No

Yes

Check the refrigerant circuit.

Page 25

25

D Check of compressor winding

Disconnect the connector between the compressor and intelligent power module, and measure the resistance between the

compressor terminals.

<<Measurement point>>

at 3 points

BLK-WHT

BLK-RED

WHT-RED

<<Judgement>>

Refer to "11-4. TROUBLE CRITERION OF MAIN PARTS".

0[Ω]················Abnormal[short]

Infinite[Ω]·······Abnormal[open]

NOTE: Be sure to zero the ohmmeter before measurement.

Measure the resistance between the lead wires at 3 points.

E Check of compressor operation time

Compressor starts

Abnormal

(IPM failure)

(Compressor winding short)

Abnormal

(Compressor lock out)

(Starting defect)

Abnormal

(Poor contact,)

(Outdoor P.C. board defect)

(Disconnected connector)

Abnormal

(Refrigerant circuit defect)

(Closed valve)

Normal

0 second

1 second

2 seconds

10 seconds

10 minutes

<<Judgement>>

Connect the compressor and activate the inverter. Then measure

the time until the inverter stops due to overcurrent.

<<Operation method>>

Start heating or cooling test run.

(TEST RUN OPERATION : Refer to 11-5

.)

<<Measurement>>

Measure the time from the start of compressor to the stop of

compressor due to overcurrent.

Is the resistance of thermistor normal?

(SA71: “11-6. TEST POINT DIAGRAM AND VOLTAGE”.)

Disconnect the connector of thermistor in the outdoor P.C. board (see

below table), and measure the resistance of thermistor.

Replace the thermistor except RT64.

When RT64 is abnormal, replace the inverter

P.C. board.

Reconnect the connector of thermistor.

Turn ON the power supply and press EMERGENCY OPERATION switch.

No

Yes

F Check of outdoor thermistors

Does the unit operate for 10 minutes or more

without showing thermistor abnormality?

Yes

OK

(Cause is poor contact.)

No

Replace the inverter P.C. board.

Thermistor Symbol

Connector, Pin No.

Board

SUZ-SA71VA3.TH

SUZ-SA100VA2.TH

Defrost RT61 Between CN671 pin1 and pin2

Inverter

P.C. board

Discharge temperature RT62 Between CN671 pin3 and pin4

Fin temperature RT64 Between CN673 pin1 and pin2

Ambient temperature RT65 Between CN672 pin1 and pin2

Outdoor heat exchanger temperature RT68 Between CN671 pin5 and pin6

Page 26

26

TCH030 TCH030

G Check of R.V. coil

First of all, measure the resistance of R.V. coil to check if the coil is defective. Refer to "11-4. TROUBLE CRITERION OF

MAIN PARTS".

In case CN602 (SA71) is not connected or R.V. coil is open, voltage is generated between the

terminal pins of the connector although any signal is not being transmitted to R.V. coil.

Check if CN602 (SA71) is connected.

Is there 230 VAC between CN602 (SA71)

and on the inverter P.C. board 3

minutes after the power supply is turned

ON?

No

Yes

Replace the inverter

P.C. board.

Replace the 4-way valve.

Unit operates COOL mode even if it is set to HEAT mode.

Is there 230 VAC between CN602 (SA71)

and on the inverter P.C. board 3

minutes after the power supply is turned

ON?

Yes

No

Replace the inverter

P.C. board.

Replace the 4-way valve.

Unit operates HEAT mode even if it is set to COOL mode.

Disconnect connector between

the compressor and the intelligent

power module.

Turn ON the power supply and start

heating test run.

(TEST RUN OPERATION: Refer to

11-5

)

Disconnect connector between

the compressor and the intelligent

power module.

Turn ON the power supply and start

cooling test run.

(TEST RUN OPERATION: Refer to

11-5

)

H Check of outdoor fan motor

Is the resistance between each terminal of outdoor fan motor normal?

(Refer

to "11-4. TROUBLE CRITERION OF MAIN PARTS".)

Disconnect the connectors CN931

and CN932 from the inverter P.C.

board. Check the connection between

the connector CN931 and CN932.

Disconnect CN932 from the inverter

P.C. board, and turn on the power sup-

ply.

Rotate the outdoor fan motor manually and measure the voltage of CN931.

Between1(+)and5(−)

Between2(+)and5(−)

Between3(+)and5(−)

Does the voltage between each terminal become 5 and 0 V

DC repeatedly?

Does the outdoor fan motor rotate smoothly?

Replace the outdoor fan motor.

Replace the inverter P.C. board.

Yes

Yes

No

(Fixed to either 5 or 0 V

DC)

No

No

Yes

Page 27

27

I Check of LEV

Turn on power supply to the outdoor unit after checking

LEVcoilisxedtotheLEVbodysecurely.

Yes

Disconnect the connector CN724. Is there normal resistance to LEV coil?

No

Replace the inverter P.C. board.

Replace the LEV coil.

No

Normal

Start

Is "click - click" sound heard?

Or, do you feel vibration of the LEV coil with a hand?

Yes

Check the outdoor fan motor.

(Refer to .)

Is the fuse (F901) blown on the inverter P.C. board?

Check the connection of the connectors

(CN931, CN932) of the outdoor fan motor.

If the connection is poor, make it correct.

Operate the outdoor unit by starting

EMERGENCY OPERATION.

Check the LED indication on the inverter P.C. board.

DoestheLEDash10times?

Replace the inverter P.C. board.

Check the corresponding parts

following LED indication.

(Refer to "11-2.TROUBLESHOOTING CHECK TABLE".)

Yes

No

Yes

(10-timeash)

No

J Check of inverter P.C. board

Page 28

28

TCH030 TCH030

Electromagnetic noise enters into TV sets or radios

Yes

Is the unit earthed?

No

Earth the unit.

Yes

Is the distance between the antennas

and the indoor unit within 3 m, or is the

distance between the antennas and the

outdoor unit within 3 m?

No

Extend the distance between the antennas and

the indoor unit, and/or the antennas and the

outdoor unit.

Is the distance between the TV sets or

radios and the indoor unit within 1 m, or

is the distance between the TV sets or

radios and the outdoor unit within 3 m?

Yes

Extend the distance between the TV sets and/or

radios and the indoor unit, or the TV sets or

radios and the outdoor unit.

Are the antennas damaged?

Is the coaxial cable damaged?

Is there any poor contact in the antenna wiring?

Yes

No

No

Replace or repair the antenna.

Replace or repair the coaxial cable.

Is the indoor/outdoor connecting wire

of the air conditioner and the wiring of

the antennas close?

Yes

Extend the distance between the indoor/outdoor

connecting wire of the air conditioner and the wiring of the antennas.

No

Evenifalloftheaboveconditionsarefullled,theelectromagneticnoisemayenter,dependingontheelectriceldstrength

ortheinstallationcondition(combinationofspecicconditionssuchasantennasorwiring).

Check the following before asking for service.

1. Devices affected by the electromagnetic noise

TV sets, radios (FM/AM broadcast, shortwave)

2. Channel, frequency, broadcast station affected by the electromagnetic noise

3. Channel, frequency, broadcast station unaffected by the electromagnetic noise

4. Layout of ;

indoor/outdoor unit of the air conditioner, indoor/outdoor wiring, earth wire, antennas, wiring from antennas, receiver

5.Electriceldintensityofthebroadcaststationaffectedbytheelectromagneticnoise

6.Presenceorabsenceofampliersuchasbooster

7. Operation condition of air conditioner when the electromagnetic noise enters in

1) Turn OFF the power supply once, and then turn ON the power supply. In this situation, check for the electromagnetic

noise.

2) Within 3 minutes after turning ON the power supply, press OPERATE/STOP (ON/OFF) button on the remote controller

for power ON, and check for the electromagnetic noise.

3) After a short time (3 minutes later after turning ON), the outdoor unit starts running. During operation, check for the

electromagnetic noise.

4) Press OPERATE/STOP (ON/OFF) button on the remote controller for power OFF, when the outdoor unit stops but the

indoor/outdoor communication still runs on. In this situation, check for the electromagnetic noise.

K

Page 29

29

Check of outdoor refrigerant circuit

L

The unit occasionally stops when the

stop valve is opened or closed during

operation. Open the stop valve and

start the cooling operation again.

No

Has the operation stopped

during pump down?

Yes

Was the operation started with

the stop valve closed, and was

it opened during operation?

Yes

The refrigerant gas amount may

be 60% or less than the normal

amount. Identify where the gas is

leakingfrom,andxtheleak.

No

CAUTION:

Do not start the operation again to

prevent hazards.

The operation has stopped to

prevent the diesel explosion caused

by air trapped in the refrigerant

circuit. Close the stop valve, and

disconnect the power plug or turn

the breaker OFF.

Note: If the abnormality can not be reset with remote controllers, it is

detected in the connected indoor unit. Please refer to the indoor

unit's service manual.

Page 30

TCH030 TCH030

30

TCH030 TCH030

11-6. TEST POINT DIAGRAM AND VOLTAGE

Inverter P.C. board

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

-20 -10 0 10 20 30 40

0

10

20

30

40

50

60

70

80

90

100

Temperature( )

Defrost thermistor(RT61)

Ambient temperature thermistor(RT65)

Outdoor heat exchanger temperature thermistor(RT68)

Temperature( )

Discharge temperature thermistor(RT62)

0 10 20 30 40 50 60 70 80 90 100 110 120

0

100

200

300

400

500

600

700

0 10 20 30 40 50 60 70 80

0

20

40

60

80

100

120

140

160

180

200

Temperature( )

Fin temperature thermistor(RT64)

Resistance(k )

Resistance(k )

Resistance(k )

CN673

Fin temperature

thermistor (RT64)

CN672

Ambient temperature

thermistor (RT65)

CN671

Discharge temperature

thermistor (RT62)

CN671

Defrost thermistor (RT61)

CN932

Output to

drive outdoor

fan motor

CN671

Outdoor heat exchanger temperature thermistor (RT68)

F901 Fuse

T3.15 A L250 V

F880 Fuse

T3.15 A L250 V

CN724

LEV connector

JS

Jumper wire for changing

defrost setting

F601

Fuse

T3.15 A L250 V

CN931

Signal of

outdoor fan

motor

CN602

R.V. coil

230 V AC

325–370 V DC

JP715 (+)

JP30(−)

LED

CN601

Heater

230 V AC

Page 31

31

31

12

DISASSEMBLY INSTRUCTIONS

(1) Slide the sleeve and check if there is a locking lever or not. (2) The terminal with this connector has the

locking mechanism.

1Slide the sleeve.

2Pull the terminal while

pushing the locking

lever.

1Hold the sleeve, and

pull out the terminal

slowly.

The terminal which has the locking mechanism can be detached as shown below.

There are two types ( Refer to (1) and (2)) of the terminal with locking mechanism.

The terminal without locking mechanism can be detached by pulling it out.

Check the shape of the terminal before detaching.

<"Terminal with locking mechanism" Detaching points>

Connector

Sleeve

Locking lever

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

NOTE: Turn OFF power supply before disassembling.

OPERATING PROCEDURE

PHOTOS

1. Removing the cabinet

(1) Remove the screws of the service panel.

(2) Remove the screws of the top panel.

(3) Remove the screw of the valve cover.

(4) Remove the service panel.

(5) Remove the top panel.

(6) Remove the valve cover.

(7) Disconnect the power supply and indoor/outdoor connect-

ing wire.

(8) Remove the screws of the cabinet.

(9) Remove the cabinet.

(10)

Remove the screws of the back panel.

(11)

Remove the back panel.

Photo 1

Screws of the

cabinet

Screws of the top panel

Screws of the top panel

Screw of the back panel

Screws of the

cabinet

Screws of the

cabinet

Screws of the

service panel

Screw of

the valve

cover

Screws

of the

cabinet

Screws of the

back panel

Photo 2

Page 32

32

TCH030 TCH030

OPERATING PROCEDURE

PHOTOS

2. Removing the inverter assembly, inverter P.C. board

(1) Remove the cabinet and panels. (Refer to procedure 1.)

(2) Disconnect the lead wire to the reactor and the following con-

nectors:

<Inverter P.C. board>

CN602 (R.V. coil)

CN931, CN932 (Fan motor)

CN671 (Defrost thermistor, discharge temperature thermistor

and outdoor heat exchanger temperature thermistor)

CN672 (Ambient temperature thermistor)

CN724 (LEV)

(3) Remove the compressor connector.

(4) Remove the screws fixing the relay panel.

(5) Remove the relay panel.

(6) Remove the earth wires and the lead wires of the inverter P.C.

board.

(7) Remove the screws of the PB support.

(8) Remove the inverter P.C. board from the relay panel.

Photo 3

Photo 4

3. Removing R.V. coil

(1) Remove the cabinet and panels. (Refer to procedure 1.)

(2) Disconnect the following connector:

<Inverter P.C. board>

CN602 (R.V. coil)

(3) Remove the R.V. coil.

Screws of the

PB support

Screws of

the relay

panel

Inverter P.C.

board

Earth wires

Screw of the

relay panel

Screws

of the PB

support

Welded parts of

4-way valve

Screw of the

R.V. coil

Page 33

33

OPERATING PROCEDURE PHOTOS

4. Removing the discharge temperature thermistor,

defrost thermistor, outdoor heat exchanger temperature thermistor and ambient temperature thermistor

(1) Remove the cabinet and panels. (Refer to procedure 1.)

(2) Disconnect the lead wire to the reactor and the following

connectors:

<Inverter P.C. board>

CN671 (Defrost thermistor, discharge temperature thermis-

tor and outdoor heat exchanger temperature thermistor)

CN672 (Ambient temperature thermistor)

(3) Pull out the discharge temperature thermistor from its hold-

er. (Photo 7)

(4) Pull out the defrost thermistor from its holder.

(5) Pull out the outdoor heat exchanger temperature thermistor

from its holder.

(6) Pull out the ambient temperature thermistor from its holder.

Photo 5

Photo 6

Photo 7

5. Removing outdoor fan motor

(1)

Remove the top panel, cabinet and service panel. (Refer to

procedure

1.)

(2) Disconnect the following connectors:

<Inverter P.C. board>

CN931 and CN932 (Fan motor)

(3) Remove the propeller.

(4) Remove the screws fixing the fan motor.

(5) Remove the fan motor.

6. Removing the compressor and 4-way valve

(1)

Remove the top panel, cabinet and service panel. (Refer to

procedure

1.)

(2) Remove the back panel. (Refer to procedure 1.)

(3) Remove the inverter assembly. (Refer to procedure 2.)

(4) Recover gas from the refrigerant circuit.

NOTE: Recover gas from the pipes until the pressure gauge

shows 0 kg/cm² (0 MPa).

(5) Detach the welded part of the suction and the discharge

pipe connected with compressor.

(6) Remove the compressor nuts.

(7) Remove the compressor.

(8) Detach the welded part of 4-way valve and pipe. (Photo 4)

Screws of the

outdoor fan motor

Welded part of the

discharge pipe

Welded part of the

suction pipe

Discharge temperature

thermistor

Outdoor heat

exchanger temperature thermistor

Ambient temperature

thermistor

Defrost thermistor

Page 34

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO100-8310, JAPAN

New publication, effective Jan. 2018

Specifications are subject to change without notice.

MITSUBISHI ELECTRIC CONSUMER PRODUCTS (THAILAND) CO., LTD.

AMATA NAKORN INDUSTRIAL ESTATE

700/406 MOO 7, TAMBON DON HUA ROH,

AMPHUR MUANG, CHONBURI 20000 THAILAND

Made in Thailand

Loading...

Loading...