Mitsubishi SLH-1AR(1).TH, SLH-1.6AR(1).TH, SLH-2AR(1).TH, SL-1AR.TH, SL-1.6AR.TH Service Manual

...Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

COOL

DRYFAN

FAN

VANE

SELECT

TIME

h

SPLIT-TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

No. OC280

REVISED EDITION-B

Series SLH/SL

Ceiling Cassettes

Indoor unit

[Model names] [Service Ref.]

SLH-1AR SLH-1AR.TH

SLH-1AR

SLH-1.6AR SLH-1.6AR.TH

SLH-1.6AR

SLH-2AR SLH-2AR.TH

SLH-2AR

SL-1AR SL-1AR.TH

SL-1AR.TH-T

SL-1.6AR SL-1.6AR.TH

SL-1.6AR.TH-T

SL-2AR SL-2AR.TH

SL-2AR.TH-T

1.TH

1.TH

1.TH

Revision:

•SLH-1AR1.TH, SLH-1.6AR1.TH and

SLH-2AR1.TH are added in REVISED

EDITION-B.

•Please void OC280 REVISED

EDITION-A.

•This manual does not cover the

following outdoor units. When

servicing them, please refer to the

service manual No.OC282 REVISED

EDITION-B and this manual in a set.

SUH-1VR.TH, SUH-1.6VR2.TH,

SUH-2VR1.TH, SUH-2VR2.TH,

SU-1VR.TH, SU-1.6VR2.TH,

SU-2VR1.TH, SU-1VR.TH-T,

SU-1.6VR2.TH-T, SU-2VR1.TH-T

[For SLH- • AR1.TH]

NOTE:

This service manual descrides only for

the indoor unit and the connected outdoor

unit of SUH series. In PUMY series, refer

to the service manual outdoor unit and

“R-CONVERTER UNIT” for PUMY series.

CONTENTS

1. TECHNICAL CHANGE ·························2

2. PART NAMES AND FUNCTIONS ········2

3. SPECIFICATIONS·································4

4. OUTLINES AND DIMENSIONS··········34

5. WIRING DIAGRAM·····························36

6.

REFRIGERANT SYSTEM DIAGRAM

INDOOR UNIT

7. DATA ···················································43

8. MICROPROCESSOR CONTROL·······47

9. TROUBLESHOOTING ························56

10. 4-WAY AIR FLOW SYSTEM ··············63

11. DISASSEMBLY PROCEDURE···········65

12. PARTS LIST·······································68

REMOTE CONTROLLER

SLH-1AR

SLH-1.6AR

SLH-2AR

SL-1AR

SL-1.6AR

SL-2AR

·······39

Page 2

1

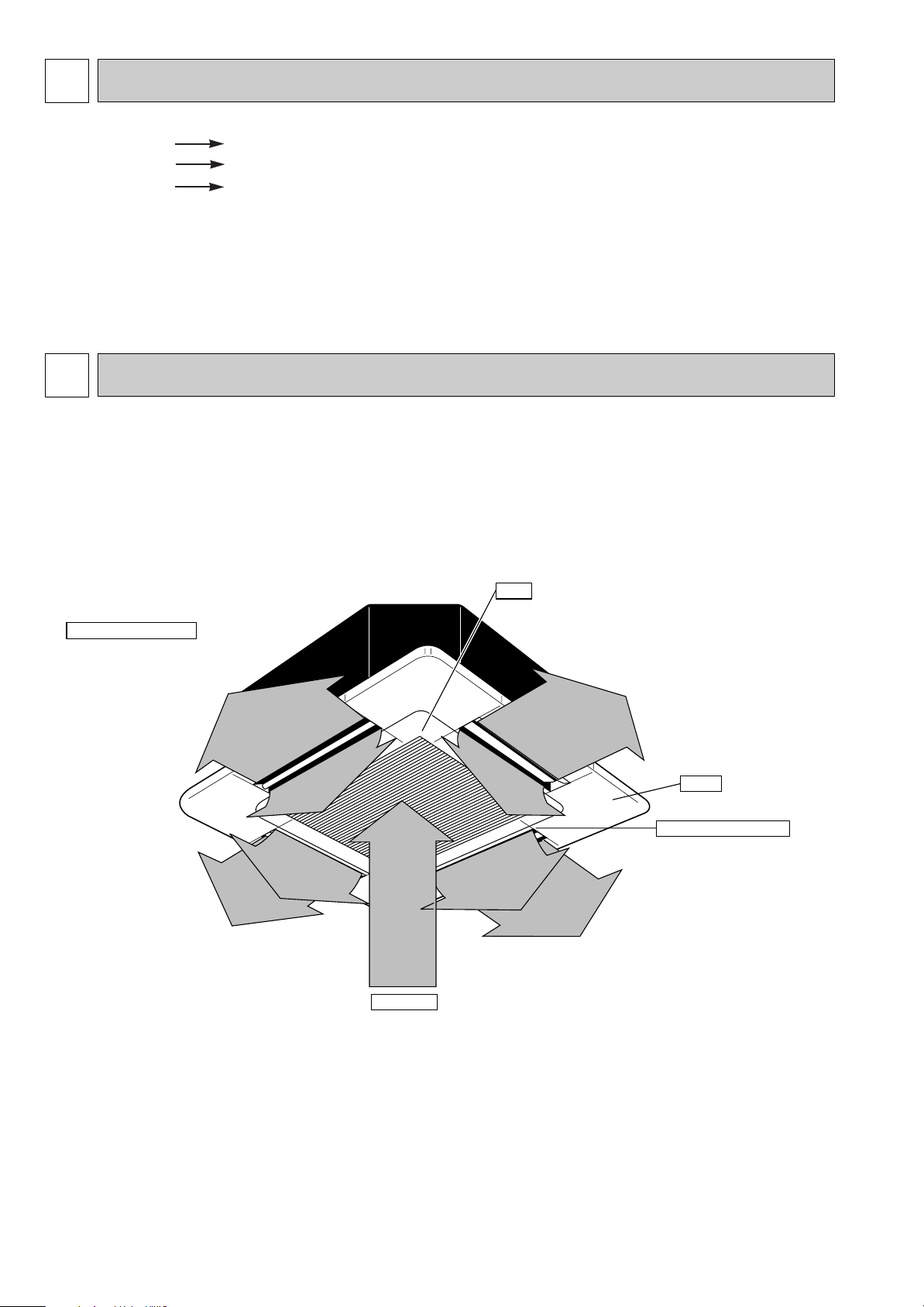

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Grille

Filter

Remove dust and pollutants

from inhaled air

Horizontal Air Outlet

Sets airflow horizontal automatically

during cooling or dehumidifying.

Air Intake

Inhales air from room.

TECHNICAL CHANGE

SLH-1AR.TH SLH-1AR1.TH

SLH-1.6AR.TH SLH-1.6AR1.TH

SLH-2AR.TH SLH-2AR1.TH

1. The indoor controller board changed in order to connect with R-CONVERTER UNIT.

2. Outdoor units of the PUMY series are cnnectable via R-CONVERTER UNIT.

2

PART NAMES AND FUNCTIONS

● Indoor (Main) Unit

SLH-1AR.TH SL-1AR.TH SL-1AR.TH-T

SLH-1.6AR.TH SL-1.6AR.TH SL-1.6AR.TH-T

SLH-2AR.TH SL-2AR.TH SL-2AR.TH-T

SLH-1AR

SLH-1.6AR

SLH-2AR

1.TH

1.TH

1.TH

2

Page 3

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

COOL

DRYFAN

FAN

VANE

SELECT

TIME

h

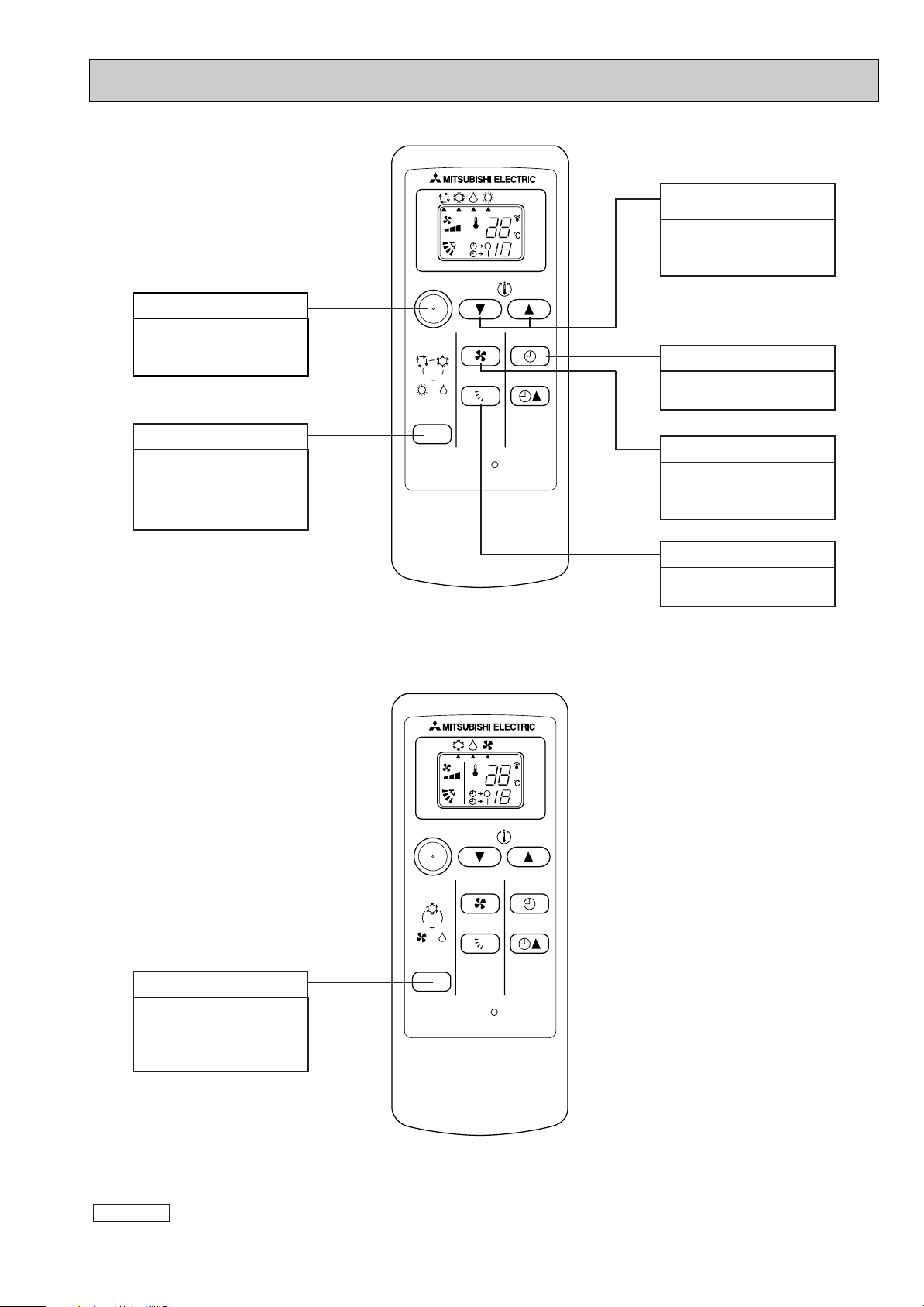

● Remote controller

ON / OFF button

Pushing button starts

operation. Pushing again

stops operation.

MODE SELECT button

This button is used to change

between auto, cooling,

heating and drying operation

modes. (SLH)

h

ON/OFF

AUTO COOL

HEAT

MODE

DRY

TOO

WARM

FAN

VANE

TOO

COOL

SELECT

TIME

RESET

SLH-1AR.TH SLH-1AR1.TH

SLH-1.6AR.TH SLH-1.6AR

SLH-2AR.TH SLH-2AR

1.TH

1.TH

SET TEMPERATURE

button

SET TEMPERATURE

button sets and any

desired room temperature.

TIMER SELECT button

Used for selecting timed

starting or stopping.

FAN SPEED button

This button is used to set

fan speed to low, medium

or high.

VANE CONTROL button

Used to change the airflow

direction.

MODE SELECT button

This button is used to

change between cooling,

drying and fan operation

modes. (SL)

SL-1AR.TH SL-1AR.TH-T

SL-1.6AR.TH SL-1.6AR.TH-T

SL-2AR.TH SL-2AR.TH-T

Attention :

● Avoid operation of buttons with fingernails or other sharp objects. Sharp objects may scratch remote controller.

3

Page 4

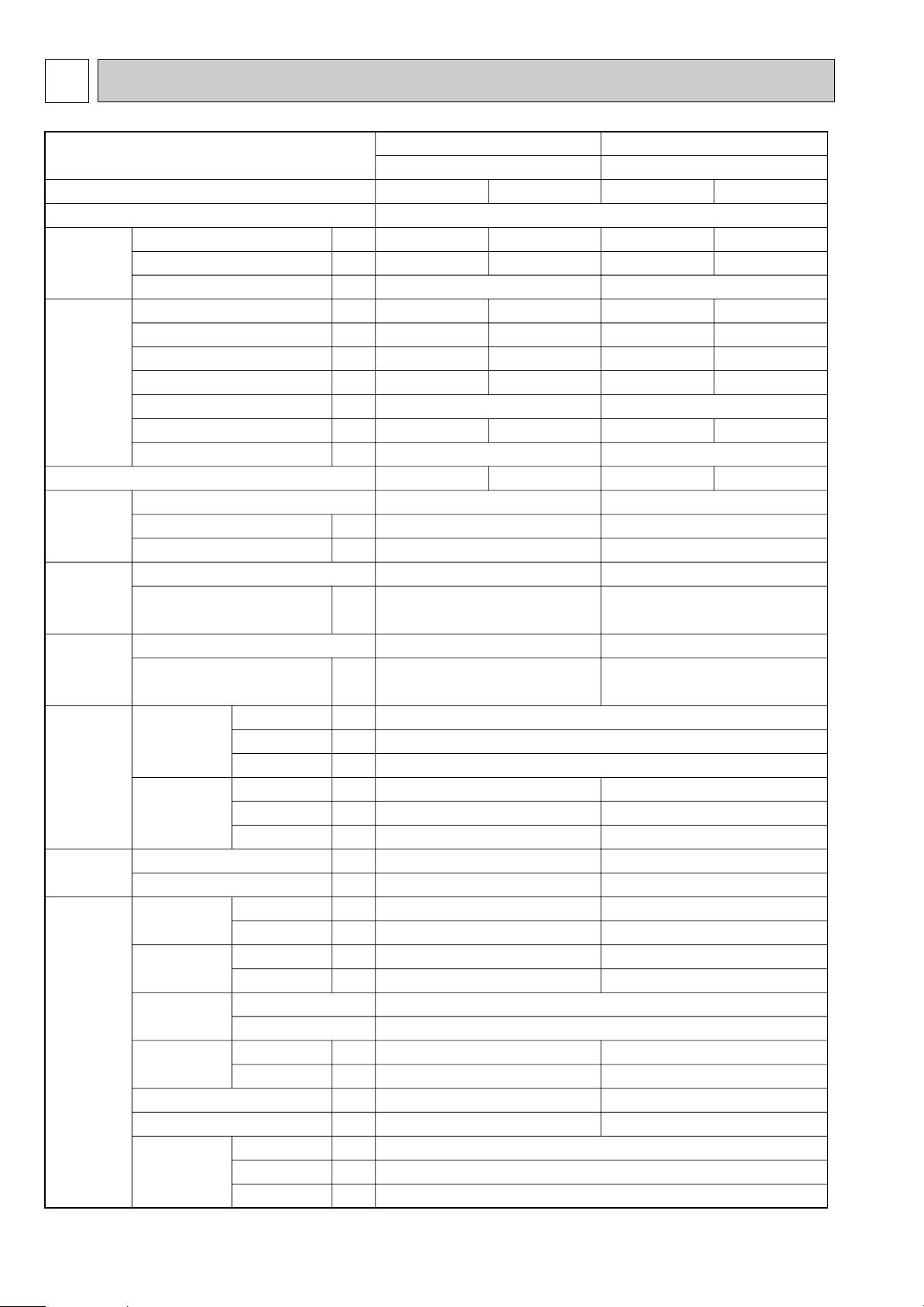

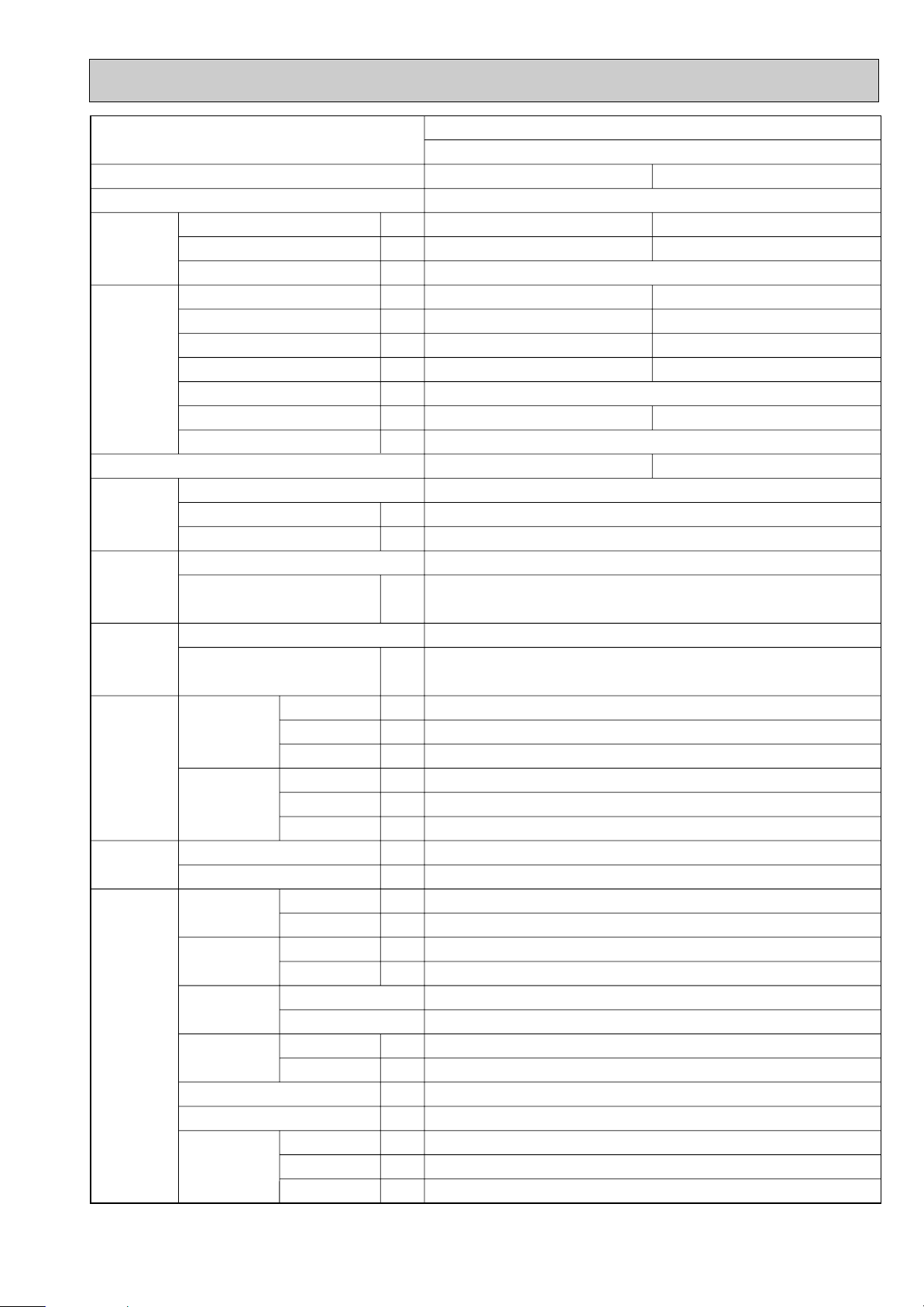

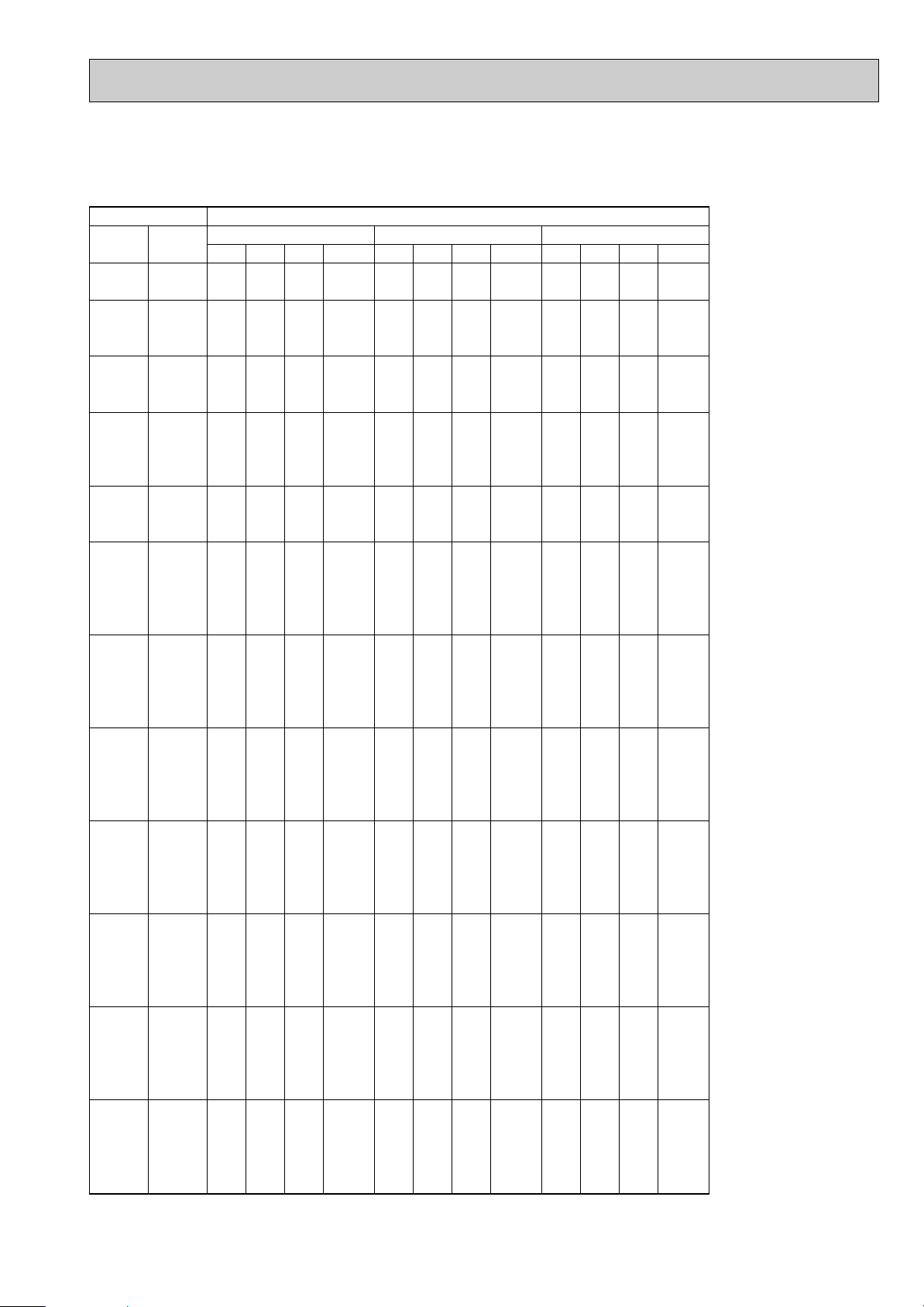

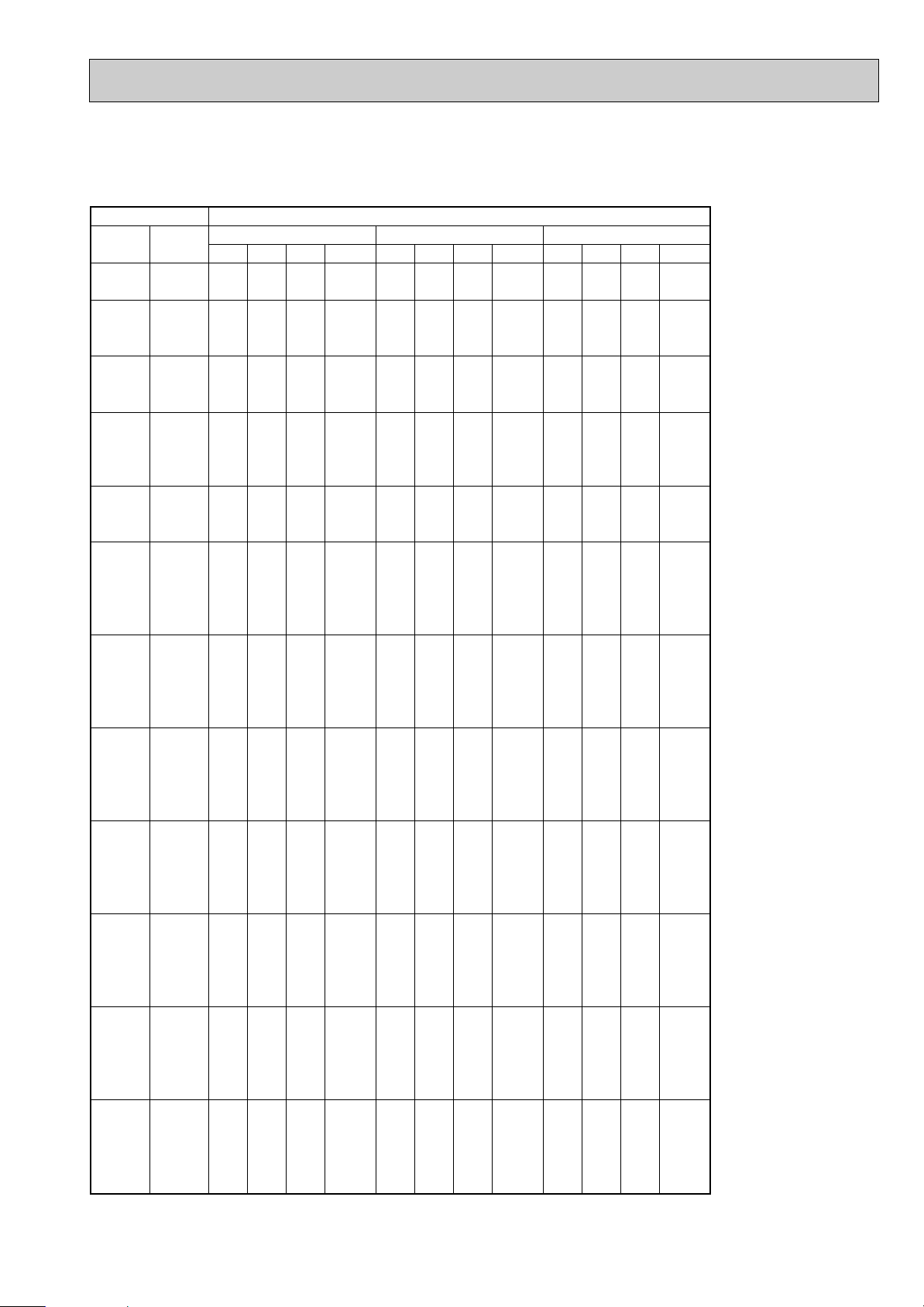

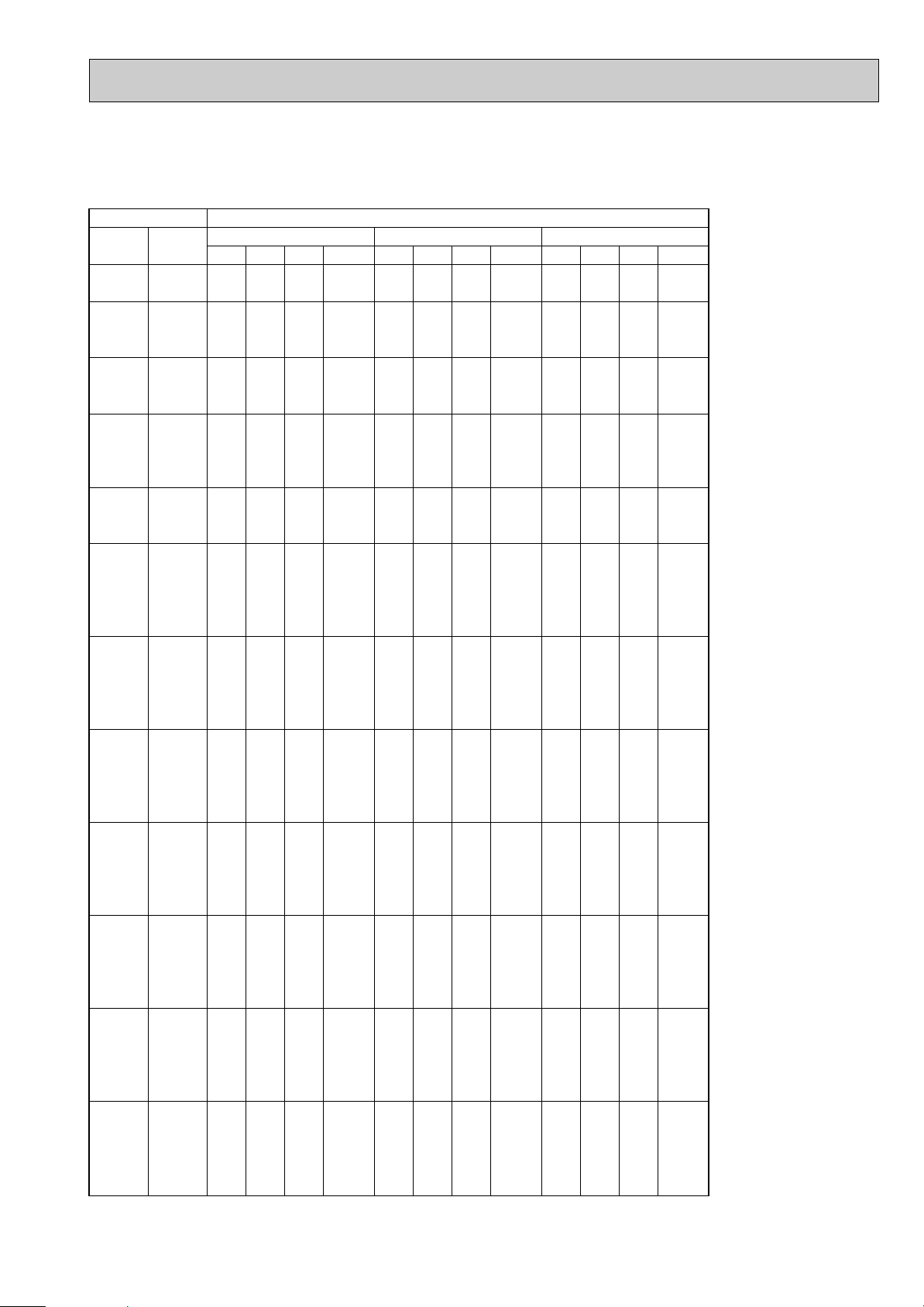

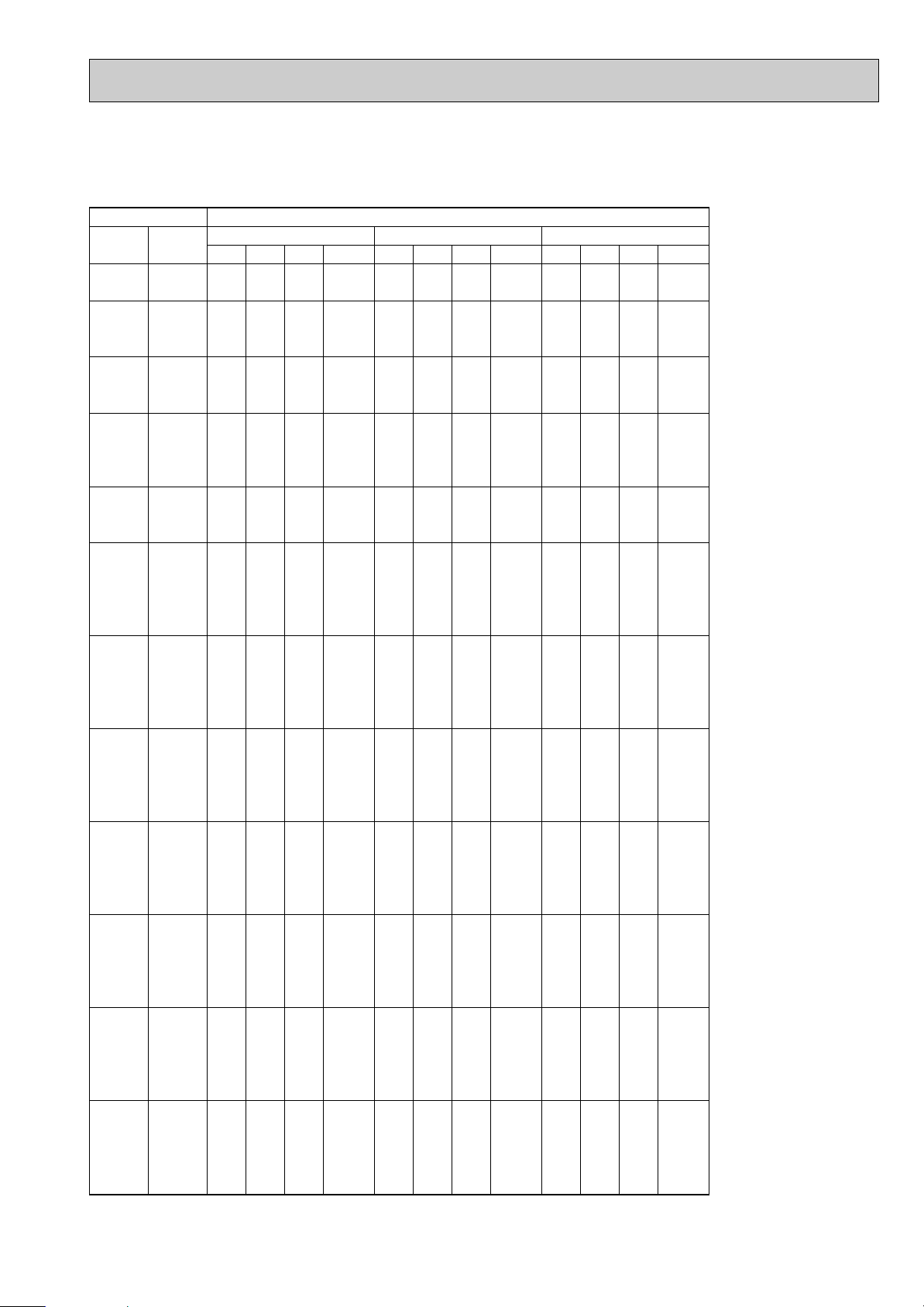

3

Function

Power supply

Service Ref.

Capacity

Dehumidification

Air flow

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

kW

R/h

K/h

A

W

A(kW)

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

m/W

m

kg

L

k"

k"

k"

Capacity

Electrical

data

Coefficient of performance (C.O.P)

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Indoor unit

[Grille]

Indoor unit [Grille]

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Air speed

Coverage range

RT11(at 25:)

RT12(at 25:)

RT61(at 0:)

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Outlet air speed

and coverage range

Outdoor unit

Outdoor unit

Refrigerant filling capacity(R-22)

Thermistor

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

SUH-1VR.TH

Single phase, 220-240V, 50Hz

Cooling

SUH-1.6VR2.TH

SLH-1AR.TH SLH-1AR

1.TH SLH-1.6AR.TH SLH-1.6AR1.TH

2.5-2.5

0.9

4.5-4.3

970-1010

—

98-98

4.10-3.88

2.58-2.48

Heating

3.0-3.1

—

4.7-4.5

1010-1050

—

98-97

4.30-4.08

2.97-2.95

33

36

47

580-620

710-760

3.4

3.7

0.8

MS56 O 0.30

RH-174VGHT

800

C-R: 3.30 C-S: 5.80

PK6V11-LA

WHT-BLK : 308 BLK-BLU : 57

BLU-YLW : 35 YLW-BRN : 39

BRN-RED : 271

PN6V23-UA

WHT-BLK : 353

BLK-RED : 321

780

540

255

15 [3]

43

39

50

670-700

780-820

3.7

4.1

1.4

MS56 O 0.52

570 [650]

208 [20]

570 [650]

3

1

10

10

33.18

600

Cooling

4.0-4.1

1.8

7.5-7.5

1600-1700

—

97-94

6.91-6.88

2.50-2.41

Heating

4.5-4.6

—

7.1-7.1

1510-1610

—

97-94

6.51-6.48

2.98-2.86

RH-277VHAT

1300

C-R: 1.80 C-S: 3.00

PK6V21-LA

WHT-BLK : 384 BLK-BLU : 111

BLU-YLW : 49 YLW-BRN : 46

BRN-RED : 311

RA6V40-EE

WHT-BLK : 130

BLK-RED : 135

850

605

290

16.5 [3]

660

21-23 33-36

0.40-0.42 0.59-0.62

Refrigerant oil

SPECIFICATIONS

NOTE:Test conditions

Cooling : Indoor D.B. 27°C W.B. 19°C Outdoor D.B. 35°C W.B. 24°C

Heating : Indoor D.B. 20°C W.B. — Outdoor D.B. 7°C W.B. 6°C

4

Page 5

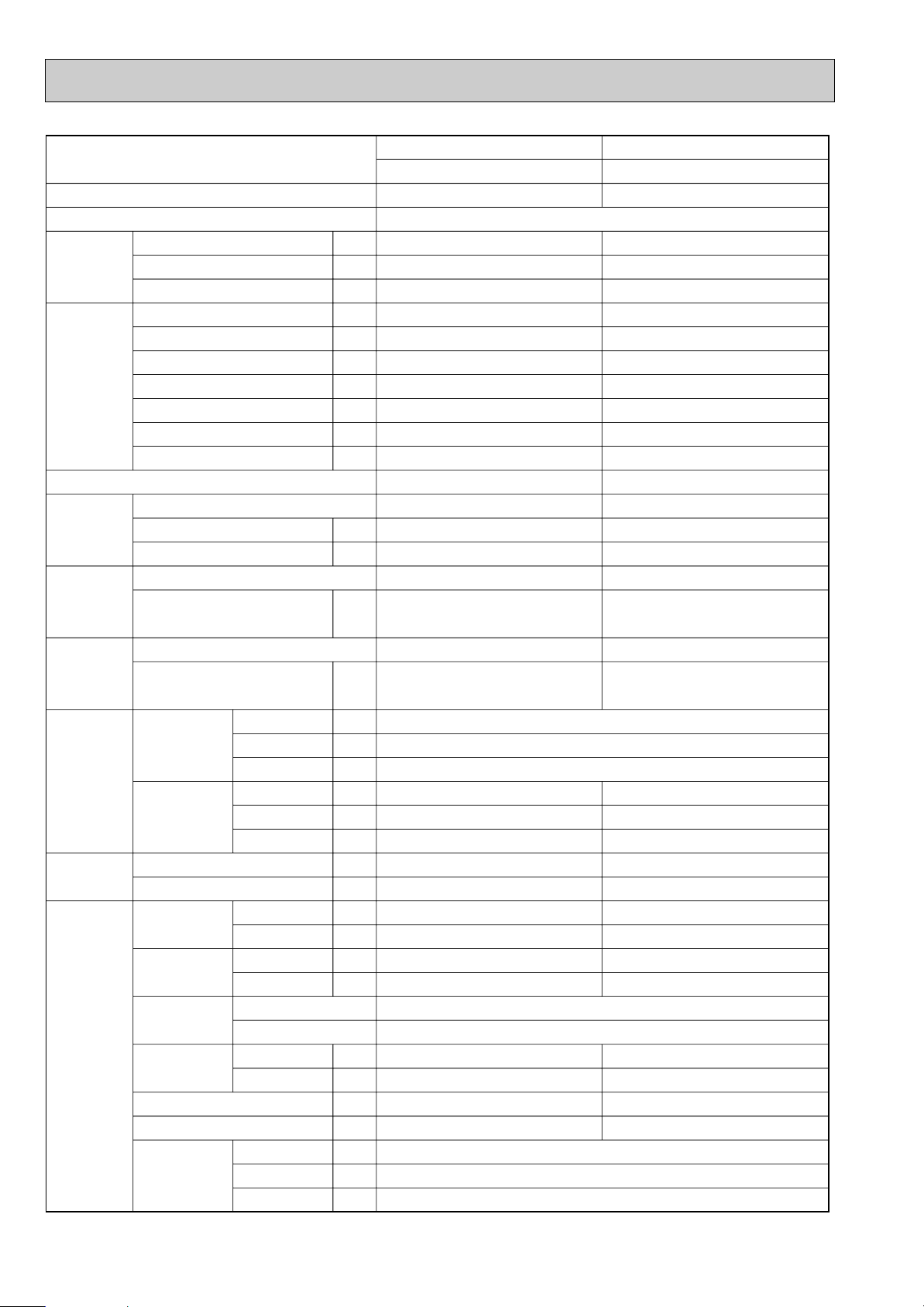

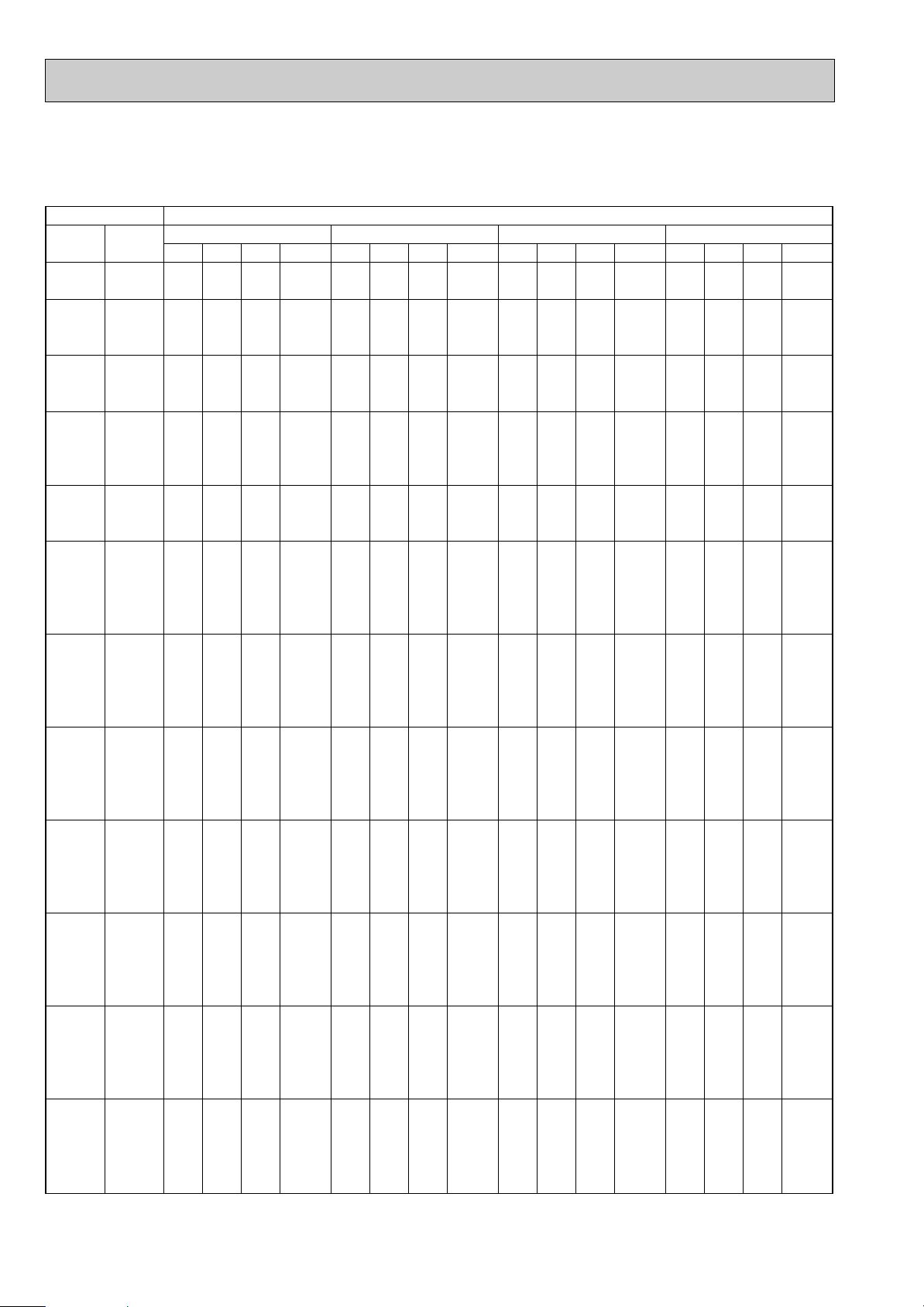

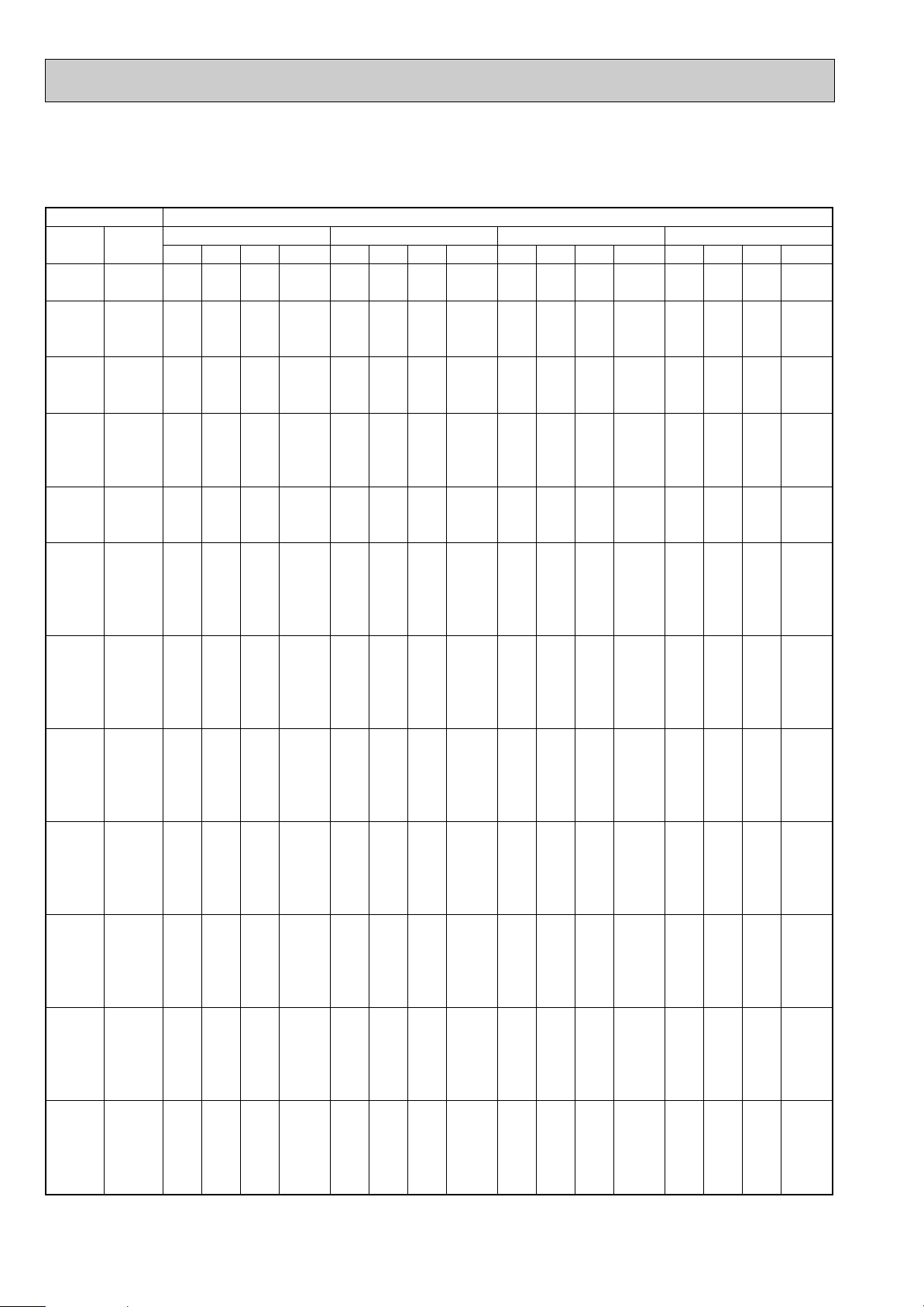

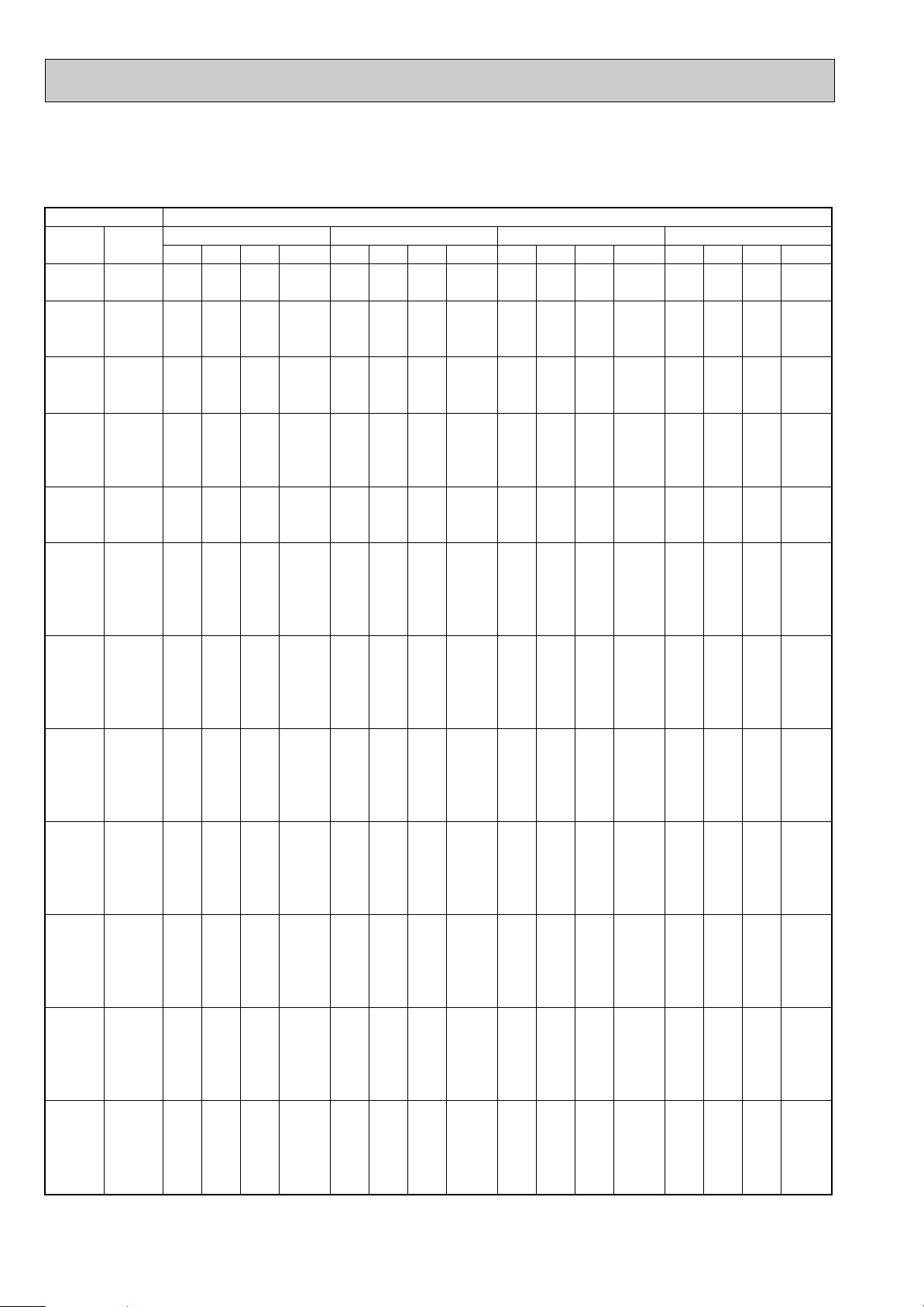

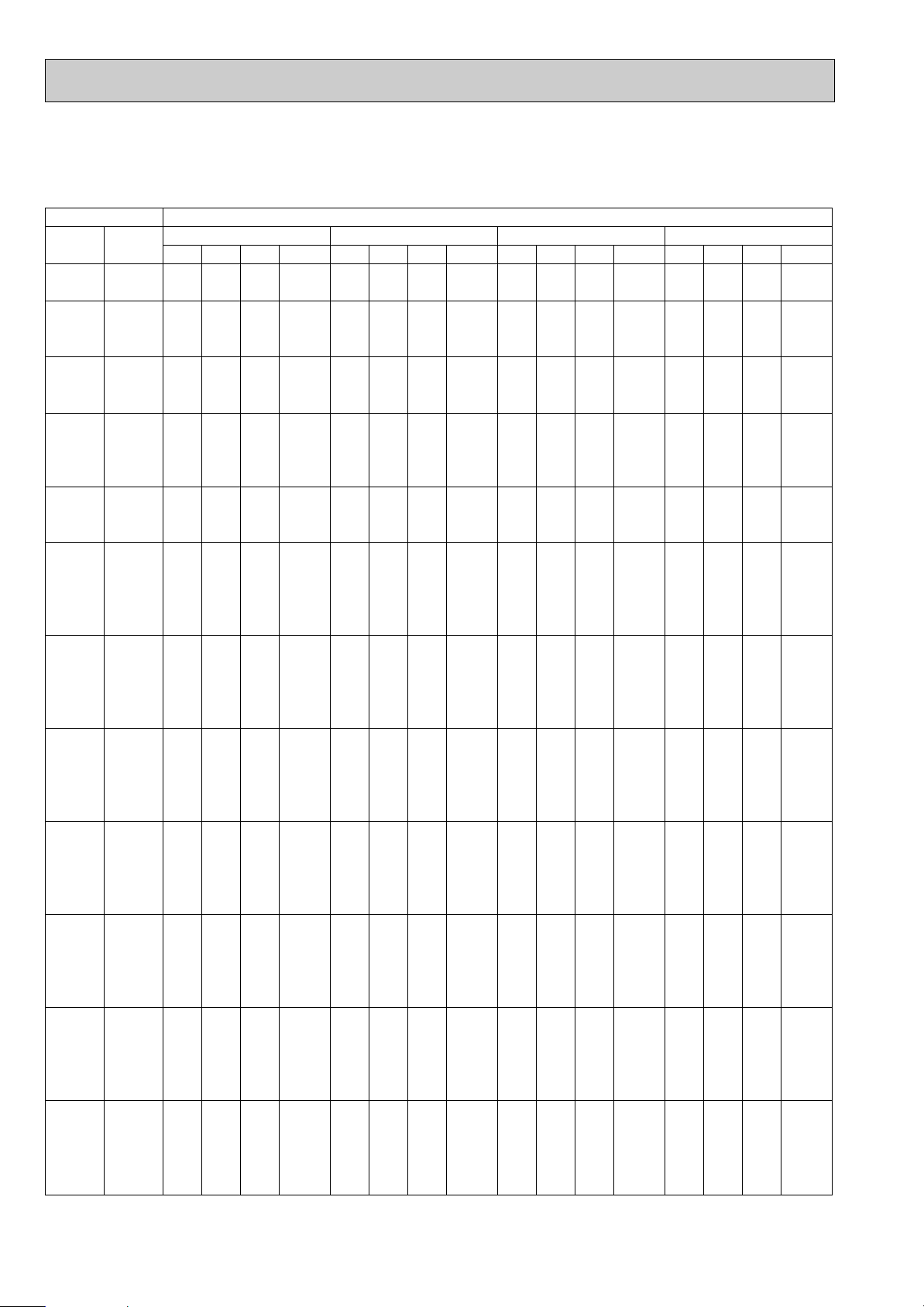

Service Ref.

Function

Power supply

Capacity

Capacity

Electrical

data

Coefficient of performance (C.O.P)

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Weight

Special

remarks

NOTE:Test conditions

Cooling : Indoor D.B. 27°C W.B. 19°C Outdoor D.B. 35°C W.B. 24°C

Heating : Indoor D.B. 20°C W.B. — Outdoor D.B. 7°C W.B. 6°C

Dehumidification

Air flow

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Width

Indoor unit

[Grille]

Outdoor unit

Indoor unit [Grille]

Outdoor unit

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Outlet air speed

and coverage range

Refrigerant filling capacity(R-22)

Refrigerant oil

Thermistor

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Air speed

Coverage range

RT11(at 25:)

RT12(at 25:)

RT61(at 0:)

kW

R/h

K/h

A

W

A(kW)

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

m/W

m

kg

L

k"

k"

k"

Cooling

5.0-5.1

10.2-9.8

2230-2310

99-98

9.58-9.15

2.24-2.21

SLH-2AR.TH SLH-2AR1.TH

SUH-2VR1.TH

SUH-2VR

Single phase, 220-240V, 50Hz

2.6

—

NH38VMDT

C-R : 1.07 C-S : 2.26

PK6V21-LB

WHT-BLK : 317 BLK-BLU : 88

BLU-YLW : 52 YLW-BRN : 45

BRN-RED : 301

RA6V50-OF

WHT-BLK : 116

BLK-RED : 111

MS32(N-1) O 1.2

2.TH

660

52-58

0.62-0.65

1700

570 [650]

208 [20]

570 [650]

850

605

290

16.5 [3]

59

40

52

700-730

810-845

3

1

3.7

4.1

1.8

10

10

33.18

Heating

5.4-5.5

—

10.0-9.4

2180-2220

—

99-98

9.38-8.75

2.48-2.48

5

Page 6

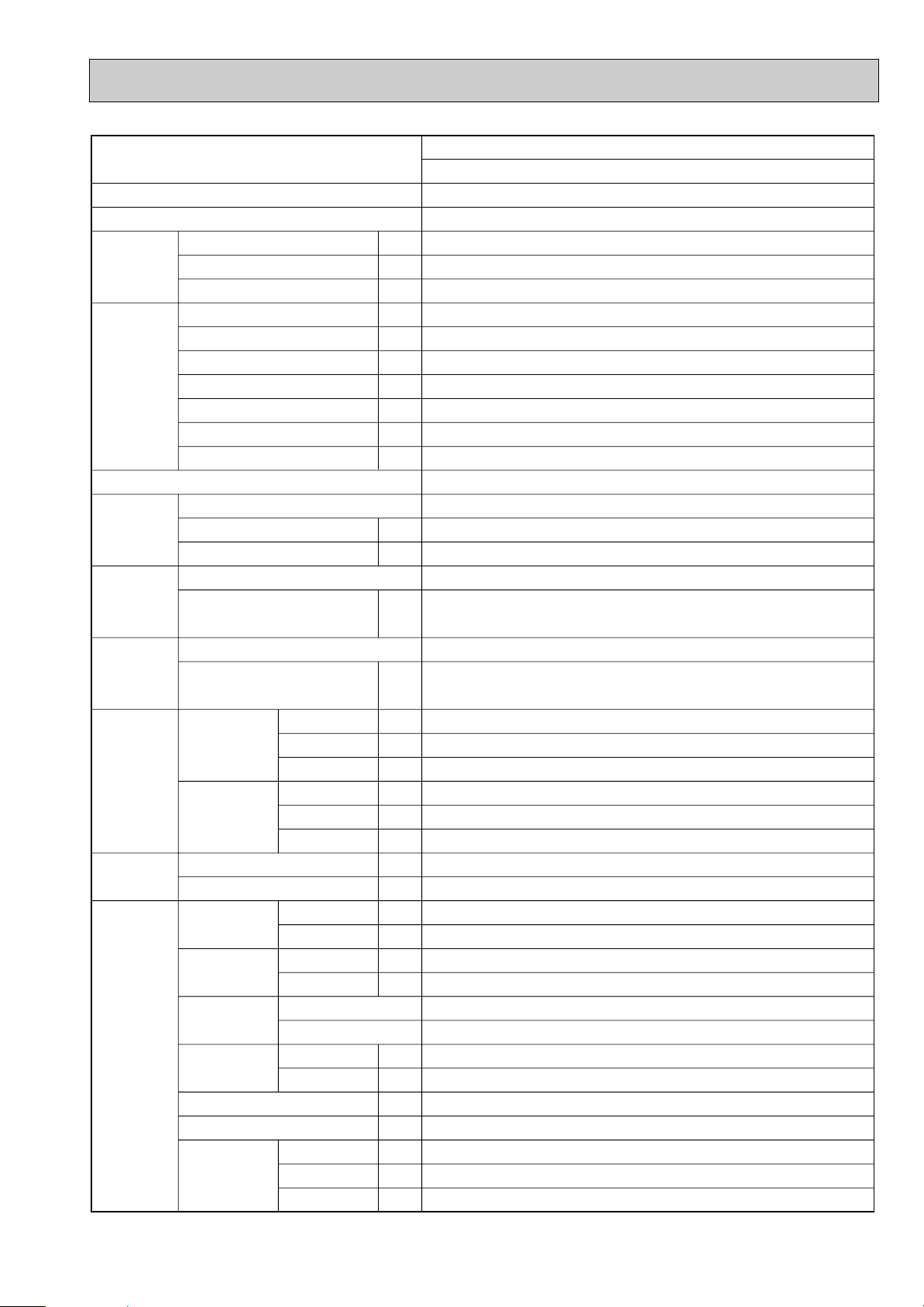

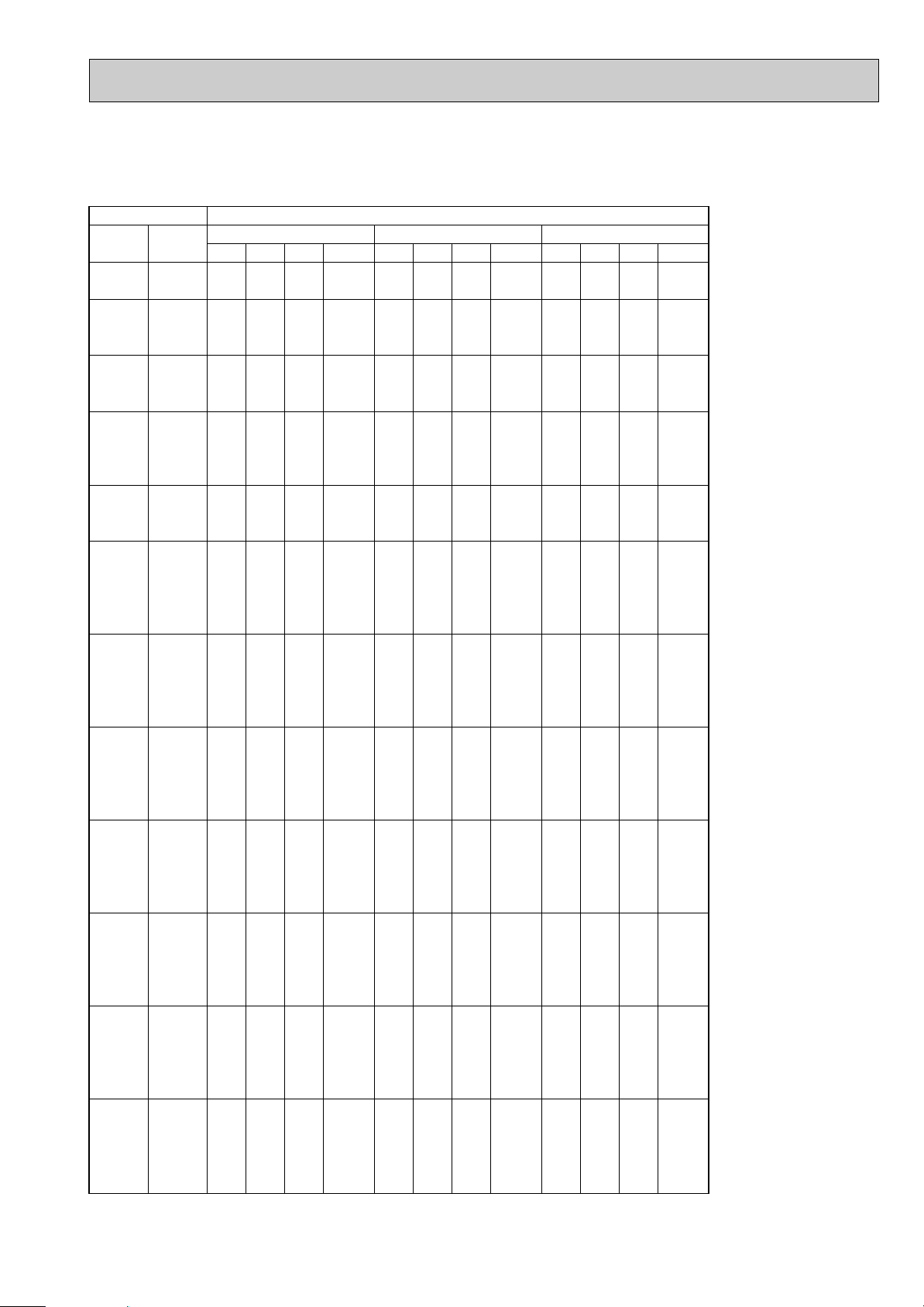

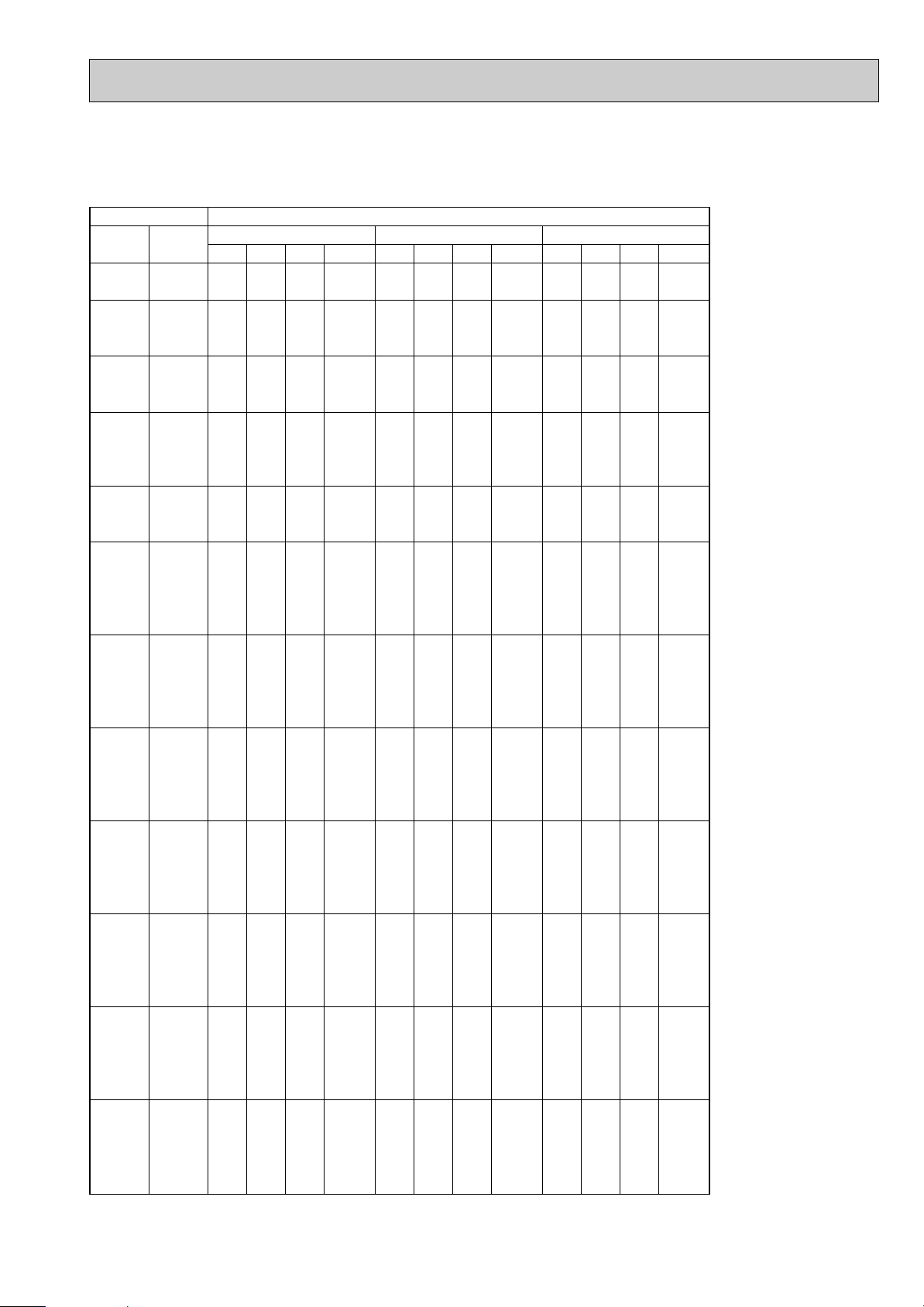

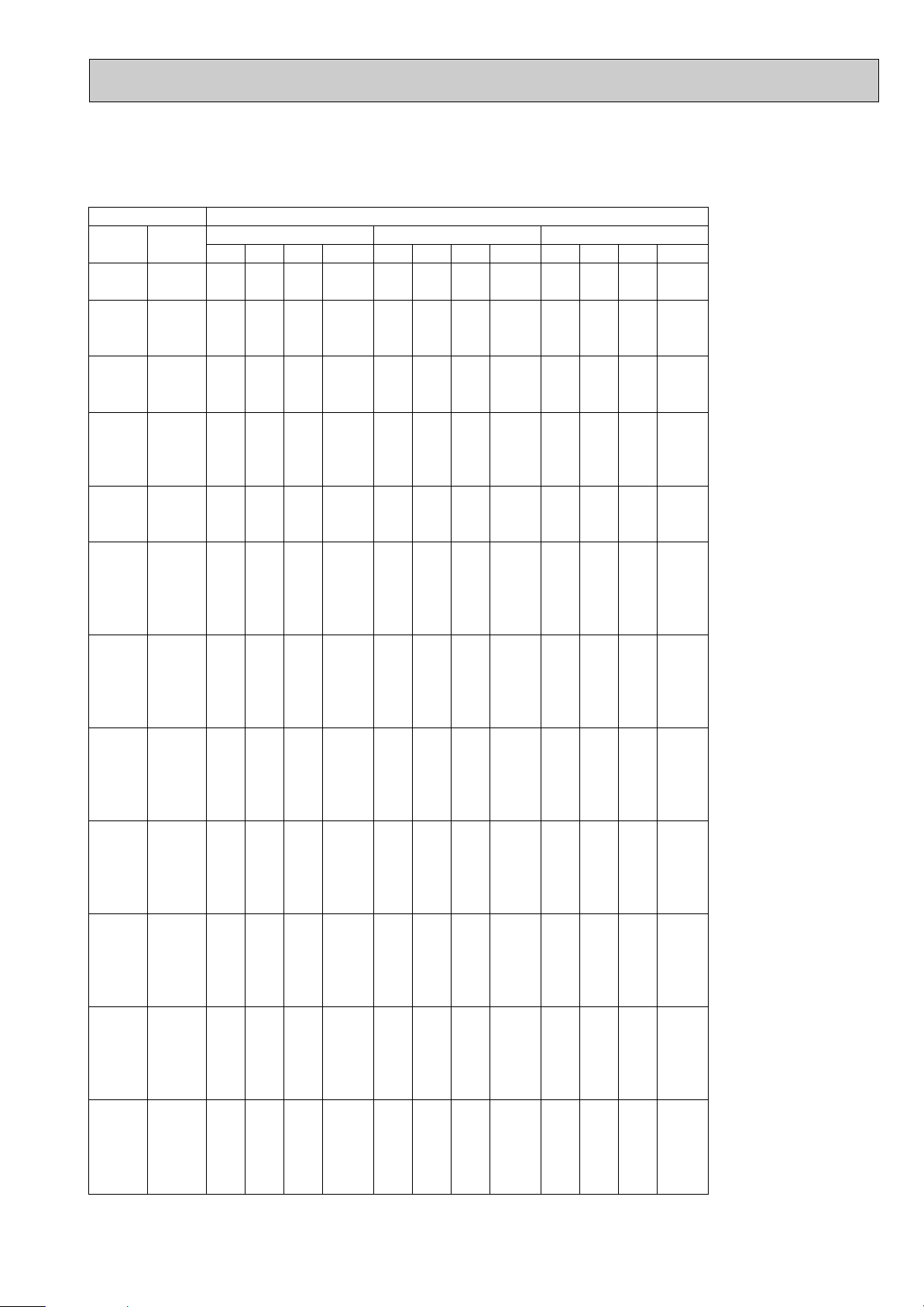

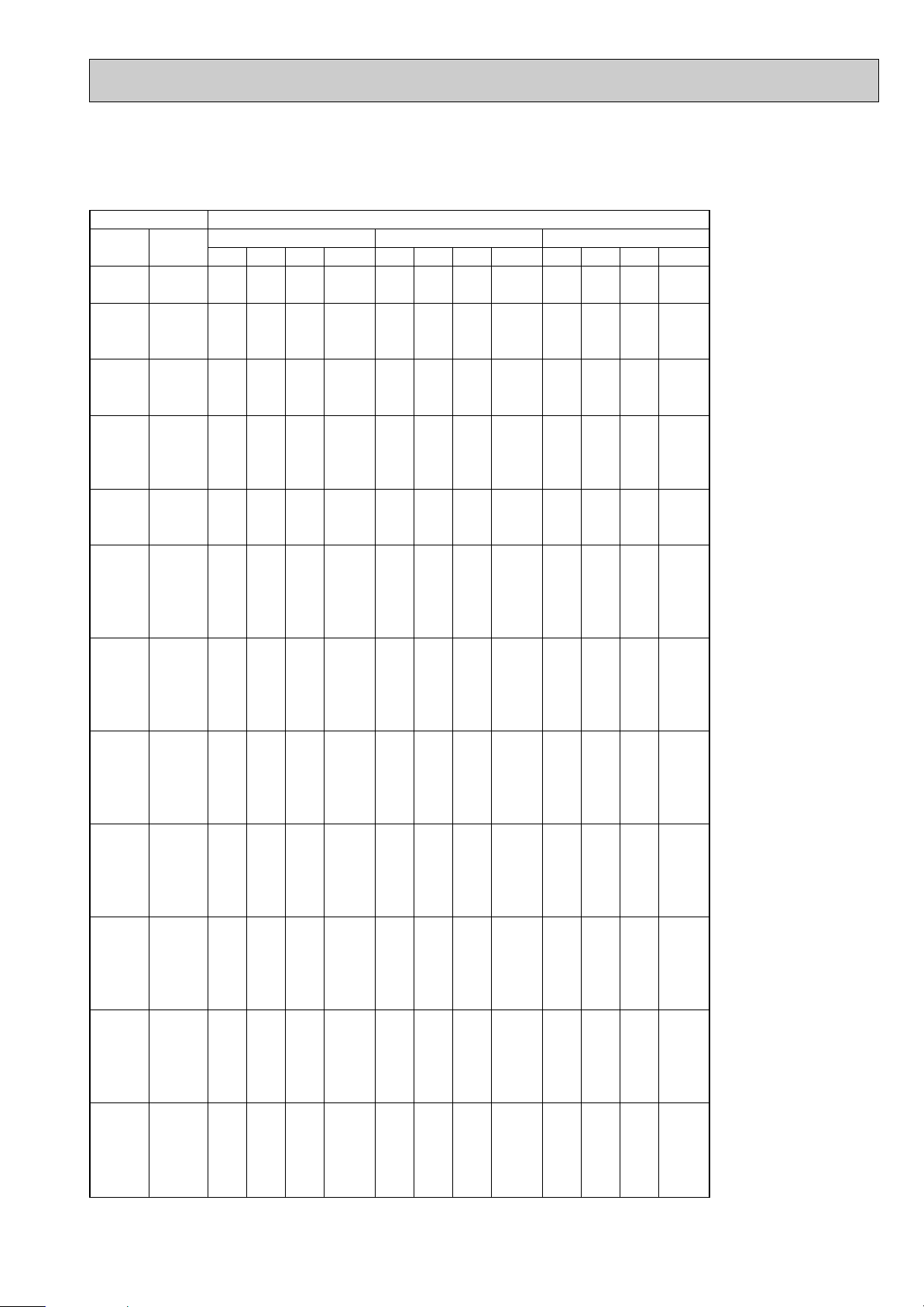

Function

Power supply

Service Ref.

Capacity

Dehumidification

Air flow

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

kW

R/h

K/h

A

W

A(kW)

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

m/W

m

kg

L

k"

k"

k"

Capacity

Electrical

data

Coefficient of performance (C.O.P)

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Indoor unit

[Grille]

Indoor unit [Grille]

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Air speed

Coverage range

RT11(at 25:)

RT12(at 25:)

RT61(at 0:)

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Outlet air speed

and coverage range

Outdoor unit

Outdoor unit

Refrigerant filling capacity(R-22)

Thermistor

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

SU-1VR.TH

SU-1VR.TH-T

Single phase, 220-240V, 50Hz

Cooling

SU-1.6VR2.TH

SU-1.6VR2.TH-T

SL-1AR.TH

SL-1AR.TH-T

SL-1.6AR.TH

SL-1.6AR.TH-T

2.6-2.6

1.0

600

4.6-4.4

990-1030

—

98-98

21-23

4.20-3.98

0.40-0.42

2.63-2.52

RH-174VGHT

800

C-R: 3.30 C-S: 5.80

PK6V11-LA

RA6V23-FC

WHT-BLK : 353

BLK-RED : 321

780

540

255

15 [3]

32

36

45

580-620

710-760

3.4

3.7

0.8

MS56 O 0.30

570 [650]

208 [20]

570 [650]

3

1

10

10

33.18

Cooling

4.0-4.1

1.8

660

7.7-7.7

1640-1740

—

97-94

33-36

7.11-7.08

0.59-0.62

2.44-2.36

RH-277VHAT

1300

C-R: 1.80 C-S: 3.00

PK6V21-LA

RA6V40-EE

WHT-BLK : 130

BLK-RED : 135

850

605

290

16.5 [3]

38

39

50

670-700

780-820

3.7

4.1

0.9

MS56 O 0.52

WHT-BLK : 308 BLK-BLU : 57

BLU-YLW : 35 YLW-BRN : 39

BRN-RED : 271

WHT-BLK : 384 BLK-BLU : 111

BLU-YLW : 49 YLW-BRN : 46

BRN-RED : 311

Refrigerant oil

NOTE:Test conditions

Cooling : Indoor D.B. 27°C W.B. 19°C Outdoor D.B. 35°C W.B. 24°C

Heating : Indoor D.B. 20°C W.B. — Outdoor D.B. 7°C W.B. 6°C

6

Page 7

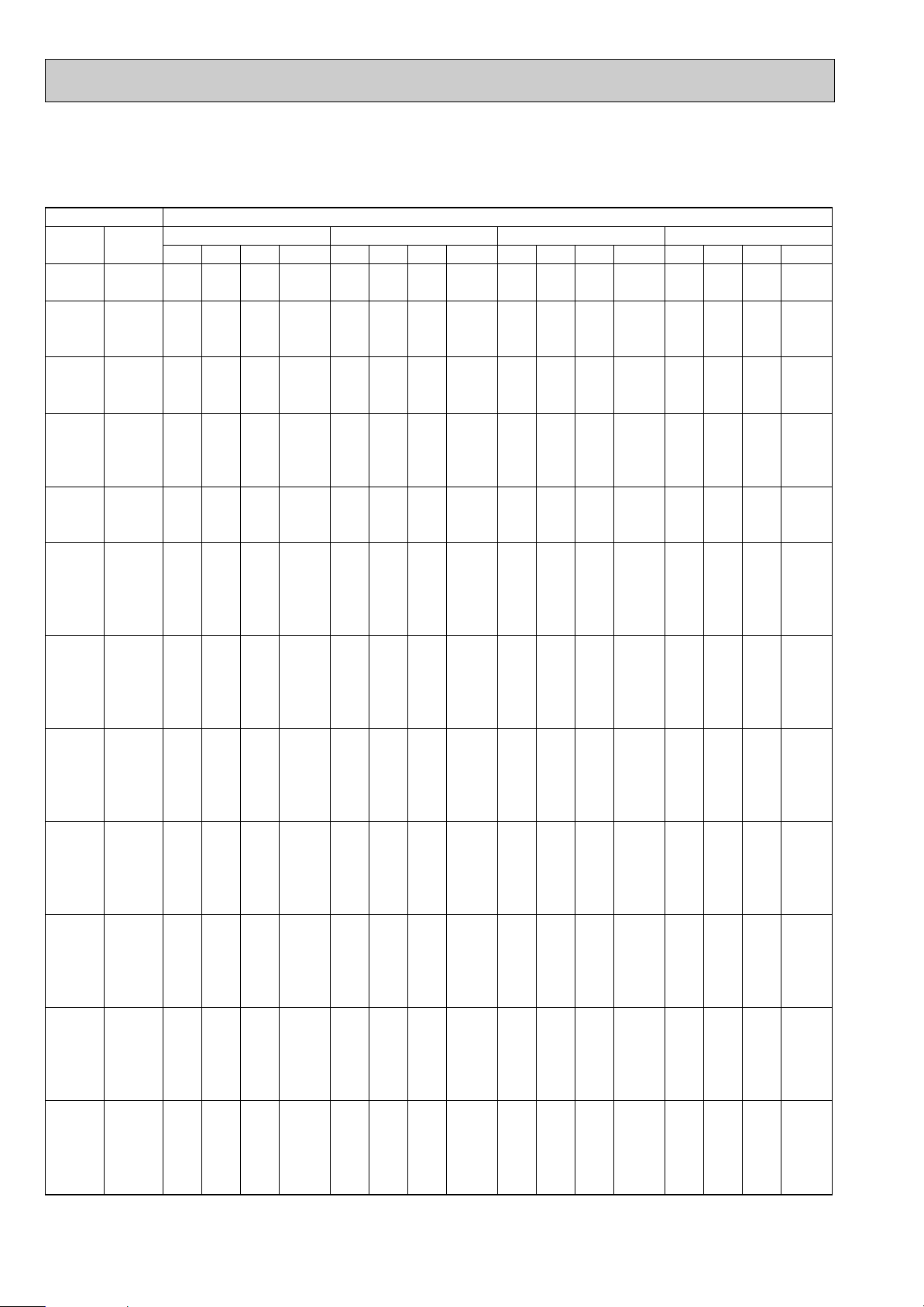

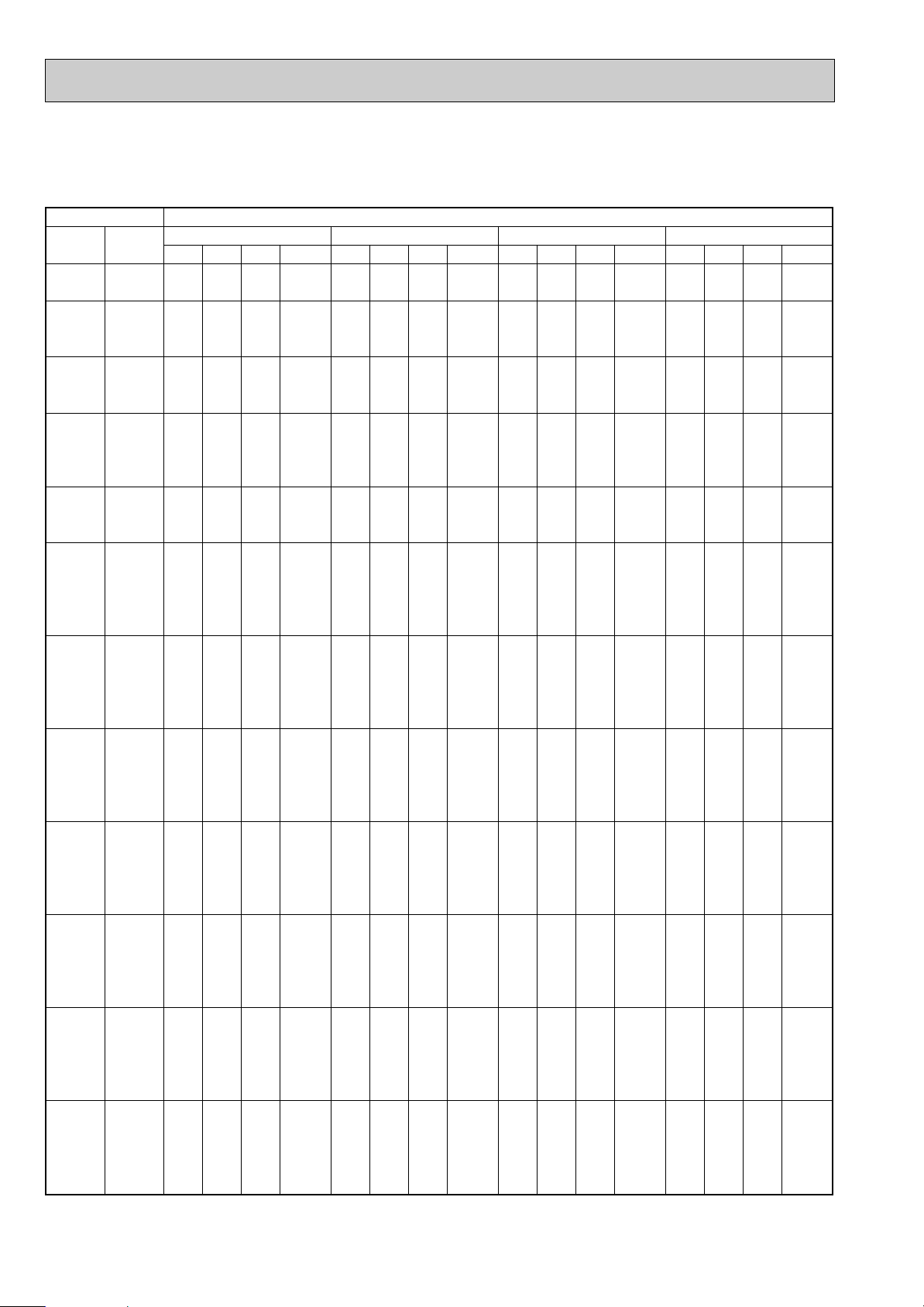

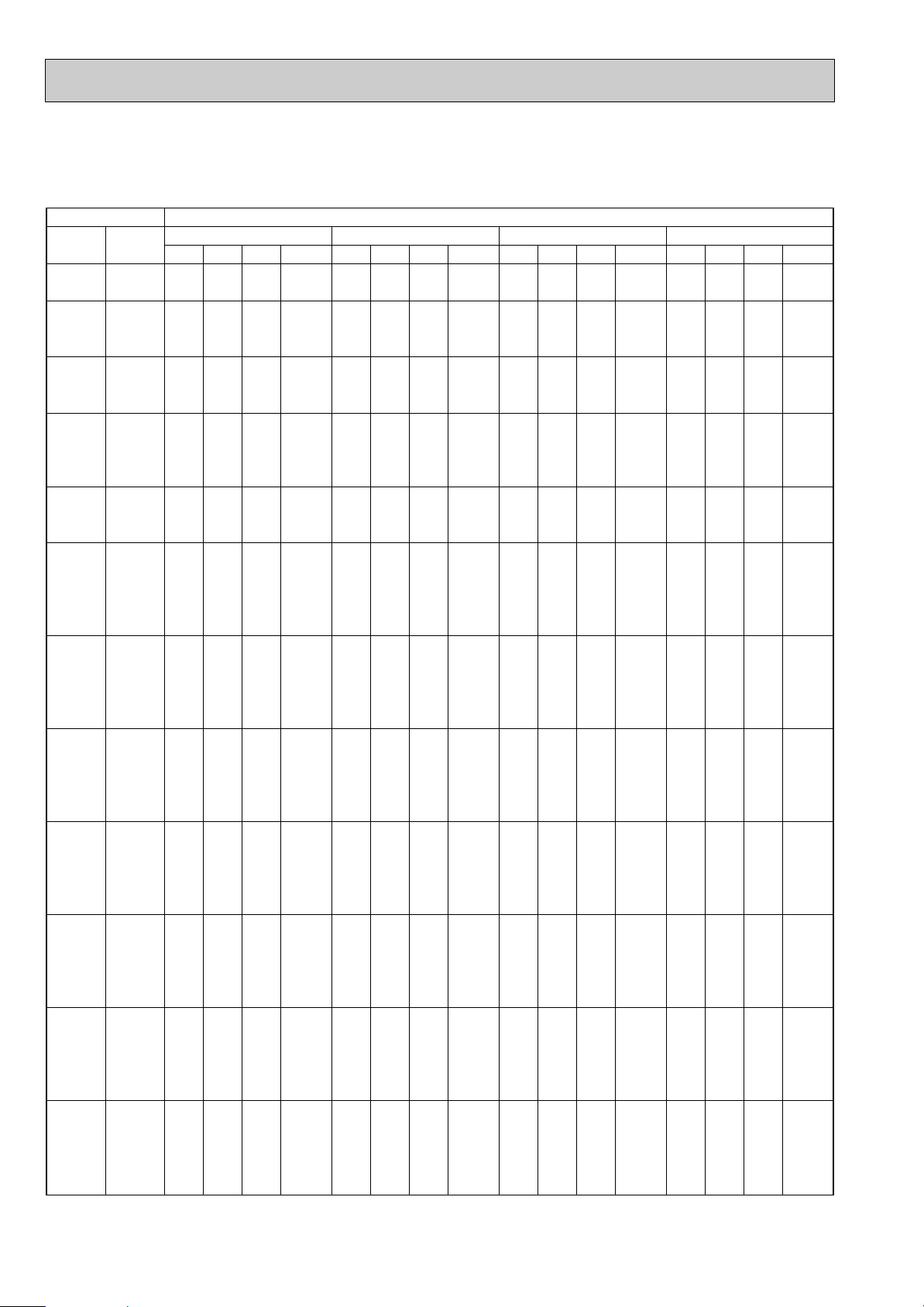

Service Ref.

Function

Power supply

Capacity

Electrical

data

Capacity

Dehumidification

Air flow

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

kW

R/h

K/h

A

W

A(kW)

%

A

A

A

Coefficient of performance (C.O.P)

Model

Compressor

Output

Winding resistance (at 20:)

W

"

Model

Indoor

fan motor

Winding resistance (at 20:)

"

Model

Outdoor

fan motor

Dimensions

Weight

Special

remarks

Winding resistance (at 20:)

Width

Indoor unit

[Grille]

Height

Depth

Width

Outdoor unit

Height

Depth

Indoor unit [Grille]

Outdoor unit

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Outlet air speed

and coverage range

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Air speed

Coverage range

Refrigerant filling capacity(R-22)

Refrigerant oil

RT11(at 25:)

Thermistor

RT12(at 25:)

RT61(at 0:)

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

m/W

m

kg

L

k"

k"

k"

NOTE:Test conditions

Cooling : Indoor D.B. 27°C W.B. 19°C Outdoor D.B. 35°C W.B. 24°C

Heating : Indoor D.B. 20°C W.B. — Outdoor D.B. 7°C W.B. 6°C

7

SL-2AR.TH

SL-2AR.TH-T

SU-2VR1.TH

SU-2VR

1.TH-T

Cooling

Single phase, 220-240V, 50Hz

5.1-5.2

2.7

660

10.6-10.0

2300-2360

—

99-98

35-38

9.73-9.51

0.62-0.65

2.22-2.20

NH38VMDT

1700

C-R : 1.07 C-S : 2.26

PK6V21-LB

WHT-BLK : 317 BLK-BLU : 88

BLU-YLW : 52 YLW-BRN : 45

BRN-RED : 301

RA6V50-OF

WHT-BLK : 116

BLK-RED : 111

570 [650]

208 [20]

570 [650]

850

605

290

16.5 [3]

55

40

52

700-730

810-845

3

1

3.7

4.1

1.6

MS32(N-1) O 1.2

10

10

33.18

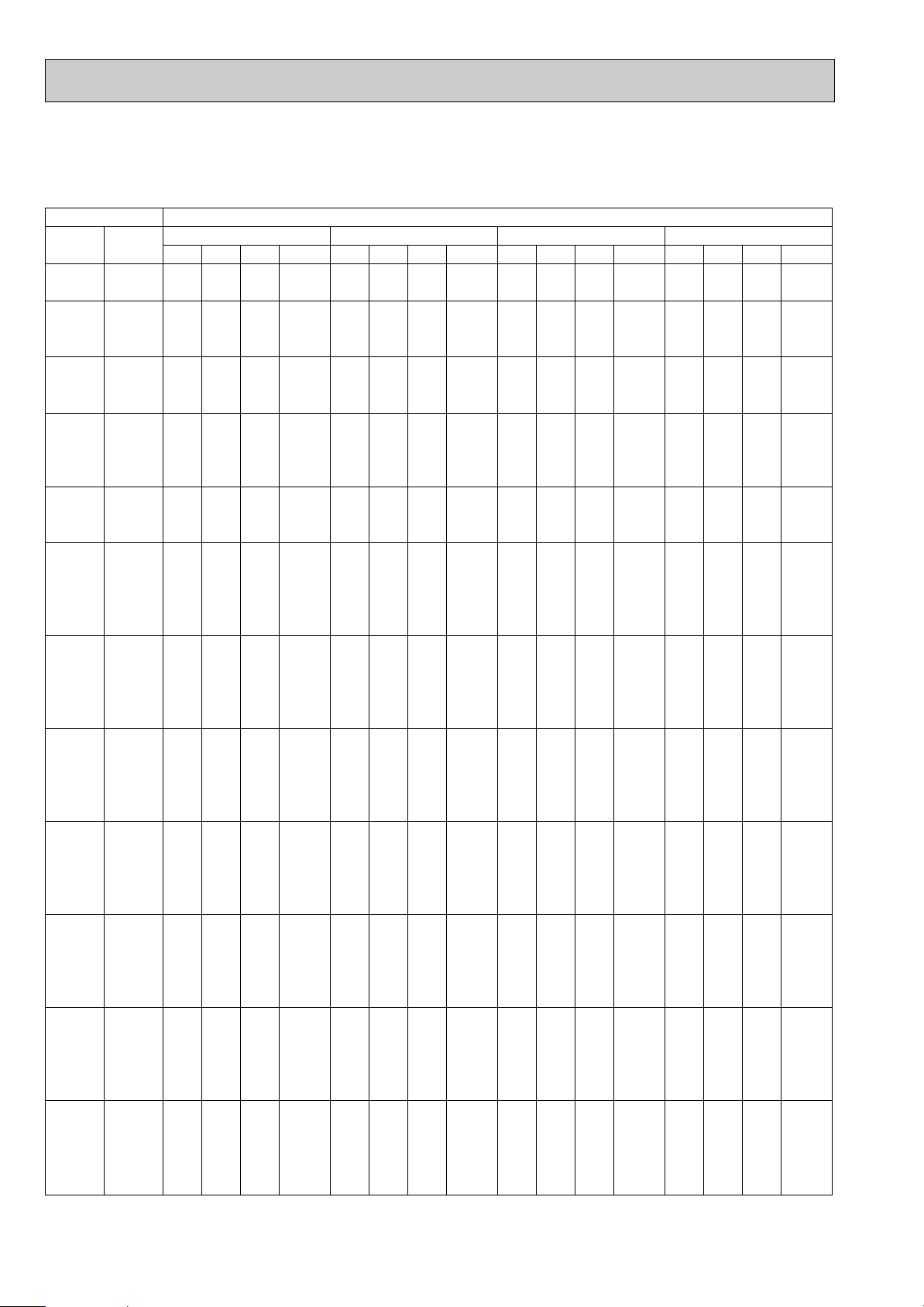

Page 8

OUTDOOR D.B.(;)

INDOOR INDOOR

21 25 27 30

D.B.(;) W.B.(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21

21

22

22

22

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

27

27

28

28

28

28

28

29

29

29

29

29

30

30

30

30

30

31

31

31

31

31

32

32

32

32

32

18

20

18

20

22

18

20

22

18

20

22

24

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

2.59

2.70

2.59

2.70

2.81

2.59

2.70

2.81

2.59

2.70

2.81

2.95

2.70

2.81

2.95

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

776

815

776

815

844

776

815

844

776

815

844

883

815

844

883

776

815

844

883

931

776

815

844

883

931

776

815

844

883

931

776

815

844

883

931

776

815

844

883

931

776

815

844

883

931

776

815

844

883

931

1.67

1.38

1.79

1.50

1.18

1.91

1.62

1.31

2.03

1.75

1.43

1.11

1.87

1.56

1.24

2.26

1.99

1.69

1.37

1.00

2.38

2.11

1.82

1.51

1.14

2.50

2.24

1.94

1.64

1.28

2.61

2.36

2.07

1.78

1.41

2.73

2.48

2.20

1.91

1.55

2.85

2.60

2.33

2.04

1.69

2.97

2.73

2.45

2.18

1.83

2.81

2.94

2.81

2.94

3.08

2.81

2.94

3.08

2.81

2.94

3.08

3.23

2.94

3.04

3.23

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

815

863

815

863

897

815

863

897

815

863

897

931

815

863

897

815

863

897

931

980

815

863

897

931

980

815

863

897

931

980

815

863

897

931

980

815

863

897

931

980

815

863

897

931

980

815

863

897

931

980

1.60

1.32

1.72

1.44

1.14

1.83

1.56

1.26

1.94

1.67

1.38

1.06

1.79

1.51

1.19

2.17

1.91

1.63

1.32

0.97

2.28

2.03

1.75

1.45

1.11

2.39

2.14

1.88

1.58

1.24

2.50

2.26

2.00

1.71

1.37

2.62

2.38

2.12

1.84

1.51

2.73

2.50

2.24

1.97

1.64

2.84

2.61

2.37

2.10

1.78

2.70

2.85

2.70

2.85

3.00

2.70

2.85

3.00

2.70

2.85

3.00

3.15

2.85

3.00

3.15

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

854

883

854

883

922

854

883

922

854

883

922

960

883

922

960

854

883

922

960

1009

854

883

922

960

1009

854

883

922

960

1009

854

883

922

960

1009

854

883

922

960

1009

854

883

922

960

1009

854

883

922

960

1009

1.54

1.28

1.65

1.40

1.11

1.76

1.51

1.23

1.86

1.62

1.35

1.04

1.74

1.47

1.17

2.08

1.85

1.59

1.29

0.96

2.19

1.97

1.71

1.42

1.09

2.30

2.08

1.83

1.54

1.22

2.40

2.19

1.95

1.67

1.35

2.51

2.31

2.07

1.80

1.49

2.62

2.42

2.19

1.92

1.62

2.73

2.54

2.31

2.05

1.75

2.60

2.75

2.60

2.75

2.88

2.60

2.75

2.88

2.60

2.75

2.88

3.05

2.75

2.88

3.05

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

892

922

892

922

960

892

922

960

892

922

960

1009

922

960

1009

892

922

960

1009

1038

892

922

960

1009

1038

892

922

960

1009

1038

892

922

960

1009

1038

892

922

960

1009

1038

892

922

960

1009

1038

892

922

960

1009

1038

1.48

1.24

1.59

1.35

1.06

1.69

1.46

1.18

1.79

1.57

1.29

1.01

1.68

1.41

1.13

2.00

1.79

1.52

1.25

0.93

2.11

1.90

1.64

1.37

1.06

2.21

2.01

1.75

1.49

1.18

2.31

2.12

1.87

1.62

1.31

2.42

2.23

1.98

1.74

1.44

2.52

2.34

2.10

1.86

1.57

2.63

2.45

2.21

1.98

1.70

PERFORMANCE DATA

COOLING operation(220V)

SLH-1AR

CAPACITY : 2.5 kW INPUT : 970 W SHF : 0.75

8

Page 9

PERFORMANCE DATA

COOLING operation(220V)

SLH-1AR

CAPACITY : 2.5 kW INPUT : 970 W SHF : 0.75

INDOOR INDOOR

D.B.(;) W.B.(;)

21

21

22

22

22

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

27

27

28

28

28

28

28

29

29

29

29

29

30

30

30

30

30

31

31

31

31

31

32

32

32

32

32

18

20

18

20

22

18

20

22

18

20

22

24

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

2.45

2.58

2.45

2.58

2.73

2.45

2.58

2.73

2.45

2.58

2.73

2.88

2.58

2.73

2.88

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

35 40 46

1.40

1.16

1.49

1.26

1.01

1.59

1.36

1.12

1.69

1.47

1.23

0.95

1.57

1.34

1.06

1.89

1.67

1.44

1.18

0.88

1.98

1.78

1.55

1.29

1.00

2.08

1.88

1.66

1.41

1.12

2.18

1.98

1.77

1.52

1.24

2.28

2.09

1.88

1.64

1.36

2.38

2.19

1.99

1.75

1.48

2.47

2.29

2.10

1.87

1.60

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

1028

1028

1028

1067

1028

1067

1028

1067

1106

1028

1067

1106

1028

1067

1106

1028

1067

1106

1028

1067

1106

1028

1067

1106

1028

1067

1106

951

989

951

989

951

989

951

989

989

951

989

951

989

951

989

951

989

951

989

951

989

951

989

2.25

2.40

2.25

2.40

2.55

2.25

2.40

2.55

2.25

2.40

2.55

2.70

2.40

2.55

2.70

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

OUTDOOR D.B.(;)

1.28

1.08

1.37

1.18

0.94

1.46

1.27

1.05

1.55

1.37

1.15

0.89

1.46

1.25

1.00

1.73

1.56

1.35

1.11

0.83

1.82

1.66

1.45

1.22

0.94

1.91

1.75

1.56

1.32

1.05

2.00

1.85

1.66

1.43

1.17

2.09

1.94

1.76

1.54

1.28

2.18

2.04

1.86

1.65

1.40

2.27

2.14

1.96

1.76

1.51

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

1009

1038

1009

1038

1086

1009

1038

1086

1009

1038

1086

1116

1038

1086

1116

1009

1038

1086

1116

1154

1009

1038

1086

1116

1154

1009

1038

1086

1116

1154

1009

1038

1086

1116

1154

1009

1038

1086

1116

1154

1009

1038

1086

1116

1154

1009

1038

1086

1116

1154

2.08

2.23

2.08

2.23

2.38

2.08

2.23

2.38

2.08

2.23

2.38

2.55

2.23

2.38

2.55

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

1.18

1.00

1.27

1.09

0.88

1.35

1.18

0.97

1.43

1.27

1.07

0.84

1.36

1.16

0.94

1.60

1.45

1.26

1.05

0.78

1.68

1.54

1.35

1.15

0.88

1.76

1.62

1.45

1.25

0.99

1.85

1.71

1.54

1.35

1.10

1.93

1.80

1.64

1.45

1.20

2.01

1.89

1.73

1.56

1.31

2.10

1.98

1.83

1.66

1.42

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

1048

1096

1048

1096

1125

1048

1096

1125

1048

1096

1125

1164

1096

1125

1164

1048

1096

1125

1164

1203

1048

1096

1125

1164

1203

1048

1096

1125

1164

1203

1048

1096

1125

1164

1203

1048

1096

1125

1164

1203

1048

1096

1125

1164

1203

1048

1096

1125

1164

1203

9

Page 10

OUTDOOR D.B.(;)

INDOOR INDOOR

21 25 27 30

D.B.(;) W.B.(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21

21

22

22

22

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

27

27

28

28

28

28

28

29

29

29

29

29

30

30

30

30

30

31

31

31

31

31

32

32

32

32

32

18

20

18

20

22

18

20

22

18

20

22

24

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

2.94

3.06

2.94

3.06

3.19

2.94

3.06

3.19

2.94

3.06

3.19

3.35

3.06

3.19

3.35

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

808

848

808

848

879

808

848

879

808

848

879

919

848

879

919

808

848

879

919

970

808

848

879

919

970

808

848

879

919

970

808

848

879

919

970

808

848

879

919

970

808

848

879

919

970

808

848

879

919

970

1.67

1.38

1.79

1.50

1.18

1.91

1.62

1.31

2.03

1.75

1.43

1.11

1.87

1.56

1.24

2.26

1.99

1.69

1.37

1.00

2.38

2.11

1.82

1.51

1.14

2.50

2.24

1.94

1.64

1.28

2.61

2.36

2.07

1.78

1.41

2.73

2.48

2.20

1.91

1.55

2.85

2.60

2.33

2.04

1.69

2.97

2.73

2.45

2.18

1.83

2.81

2.94

2.81

2.94

3.08

2.81

2.94

3.08

2.81

2.94

3.08

3.23

2.94

3.08

3.23

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

848

899

848

899

934

848

899

934

848

899

934

970

899

934

970

848

899

934

970

1020

848

899

934

970

1020

848

899

934

970

1020

848

899

934

970

1020

848

899

934

970

1020

848

899

934

970

1020

848

899

934

970

1020

1.60

1.32

1.72

1.44

1.14

1.83

1.56

1.26

1.94

1.67

1.38

1.06

1.79

1.51

1.19

2.17

1.91

1.63

1.32

0.97

2.28

2.03

1.75

1.45

1.11

2.39

2.14

1.88

1.58

1.24

2.50

2.26

2.00

1.71

1.37

2.62

2.38

2.12

1.84

1.51

2.73

2.50

2.24

1.97

1.64

2.84

2.61

2.37

2.10

1.78

2.70

2.85

2.70

2.85

3.00

2.70

2.85

3.00

2.70

2.85

3.00

3.15

2.85

3.00

3.15

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

889

919

889

919

960

889

919

960

889

919

960

1000

919

960

1000

889

919

960

1000

1050

889

919

960

1000

1050

889

919

960

1000

1050

889

919

960

1000

1050

889

919

960

1000

1050

889

919

960

1000

1050

889

919

960

1000

1050

1.54

1.28

1.65

1.40

1.11

1.76

1.51

1.23

1.86

1.62

1.35

1.04

1.74

1.47

1.17

2.08

1.85

1.59

1.29

0.96

2.19

1.97

1.71

1.42

1.09

2.30

2.08

1.83

1.54

1.22

2.40

2.19

1.95

1.67

1.35

2.51

2.31

2.07

1.80

1.49

2.62

2.42

2.19

1.92

1.62

2.73

2.54

2.31

2.05

1.75

2.60

2.75

2.60

2.75

2.88

2.60

2.75

2.88

2.60

2.75

2.88

3.05

2.75

2.88

3.05

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

929

960

929

960

1000

929

960

1000

929

960

1000

1050

960

1000

1050

929

960

1000

1050

1081

929

960

1000

1050

1081

929

960

1000

1050

1081

929

960

1000

1050

1081

929

960

1000

1050

1081

929

960

1000

1050

1081

929

960

1000

1050

1081

1.48

1.24

1.59

1.35

1.06

1.69

1.46

1.18

1.79

1.57

1.29

1.01

1.68

1.41

1.13

2.00

1.79

1.52

1.25

0.93

2.11

1.90

1.64

1.37

1.06

2.21

2.01

1.75

1.49

1.18

2.31

2.12

1.87

1.62

1.31

2.42

2.23

1.98

1.74

1.44

2.52

2.34

2.10

1.86

1.57

2.63

2.45

2.21

1.98

1.70

PERFORMANCE DATA

COOLING operation(240V)

SLH-1AR

CAPACITY : 2.5 kW INPUT : 1010 W SHF : 0.75

10

Page 11

PERFORMANCE DATA

COOLING operation(240V)

SLH-1AR

CAPACITY : 2.5 kW INPUT : 1010 W SHF : 0.75

INDOOR INDOOR

D.B.(;) W.B.(;)

21

21

22

22

22

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

27

27

28

28

28

28

28

29

29

29

29

29

30

30

30

30

30

31

31

31

31

31

32

32

32

32

32

18

20

18

20

22

18

20

22

18

20

22

24

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

2.45

2.58

2.45

2.58

2.73

2.45

2.58

2.73

2.45

2.58

2.73

2.88

2.58

2.73

2.88

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

35 40 46

1.40

1.16

1.49

1.26

1.01

1.59

1.36

1.12

1.69

1.47

1.23

0.95

1.57

1.34

1.06

1.89

1.67

1.44

1.18

0.88

1.98

1.78

1.55

1.29

1.00

2.08

1.88

1.66

1.41

1.12

2.18

1.98

1.77

1.52

1.24

2.28

2.09

1.88

1.64

1.36

2.38

2.19

1.99

1.75

1.48

2.47

2.29

2.10

1.87

1.60

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

990

1030

990

1030

1071

990

1030

1071

990

1030

1071

1111

1030

1071

1111

990

1030

1071

1111

1151

990

1030

1071

1111

1151

990

1030

1071

1111

1151

990

1030

1071

1111

1151

990

1030

1071

1111

1151

990

1030

1071

1111

1151

990

1030

1071

1111

1151

2.25

2.40

2.25

2.40

2.55

2.25

2.40

2.55

2.25

2.40

2.55

2.70

2.40

2.55

2.70

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

OUTDOOR D.B.(;)

1.28

1.08

1.37

1.18

0.94

1.46

1.27

1.05

1.55

1.37

1.15

0.89

1.46

1.25

1.00

1.73

1.56

1.35

1.11

0.83

1.82

1.66

1.45

1.22

0.94

1.91

1.75

1.56

1.32

1.05

2.00

1.85

1.66

1.43

1.17

2.09

1.94

1.76

1.54

1.28

2.18

2.04

1.86

1.65

1.40

2.27

2.14

1.96

1.76

1.51

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

1050

1081

1050

1081

1131

1050

1081

1131

1050

1081

1131

1162

1081

1131

1162

1050

1081

1131

1162

1202

1050

1081

1131

1162

1202

1050

1081

1131

1162

1202

1050

1081

1131

1162

1202

1050

1081

1131

1162

1202

1050

1081

1131

1162

1202

1050

1081

1131

1162

1202

2.08

2.23

2.08

2.23

2.38

2.08

2.23

2.38

2.08

2.23

2.38

2.55

2.23

2.38

2.55

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

1.18

1.00

1.27

1.09

0.88

1.35

1.18

0.97

1.43

1.27

1.07

0.84

1.36

1.16

0.94

1.60

1.45

1.26

1.05

0.78

1.68

1.54

1.35

1.15

0.88

1.76

1.62

1.45

1.25

0.99

1.85

1.71

1.54

1.35

1.10

1.93

1.80

1.64

1.45

1.20

2.01

1.89

1.73

1.56

1.31

2.10

1.98

1.83

1.66

1.42

0.57

0.45

0.61

0.49

0.37

0.65

0.53

0.41

0.69

0.57

0.45

0.33

0.61

0.49

0.37

0.77

0.65

0.53

0.41

0.29

0.81

0.69

0.57

0.45

0.33

0.85

0.73

0.61

0.49

0.37

0.89

0.77

0.65

0.53

0.41

0.93

0.81

0.69

0.57

0.45

0.97

0.85

0.73

0.61

0.49

1.01

0.89

0.77

0.65

0.53

1091

1141

1091

1141

1172

1091

1141

1172

1091

1141

1172

1212

1141

1172

1212

1091

1141

1172

1212

1252

1091

1141

1172

1212

1252

1091

1141

1172

1212

1252

1091

1141

1172

1212

1252

1091

1141

1172

1212

1252

1091

1141

1172

1212

1252

1091

1141

1172

1212

1252

11

Page 12

OUTDOOR D.B.(;)

INDOOR INDOOR

21 25 27 30

D.B.(;) W.B.(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21

21

22

22

22

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

27

27

28

28

28

28

28

29

29

29

29

29

30

30

30

30

30

31

31

31

31

31

32

32

32

32

32

18

20

18

20

22

18

20

22

18

20

22

24

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

4.70

4.90

4.70

4.90

5.10

4.70

4.90

5.10

4.70

4.90

5.10

5.36

4.90

5.10

5.36

4.70

4.90

5.10

5.36

5.52

4.70

4.90

5.10

5.36

5.52

4.70

4.90

5.10

5.36

5.52

4.70

4.90

5.10

5.36

5.52

4.70

4.90

5.10

5.36

5.52

4.70

4.90

5.10

5.36

5.52

4.70

4.90

5.10

5.36

5.52

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1280

1344

1280

1344

1392

1280

1344

1392

1280

1344

1392

1456

1344

1392

1456

1280

1344

1392

1456

1536

1280

1344

1392

1456

1536

1280

1344

1392

1456

1536

1280

1344

1392

1456

1536

1280

1344

1392

1456

1536

1280

1344

1392

1456

1536

1280

1344

1392

1456

1536

2.40

1.91

2.59

2.11

1.58

2.77

2.30

1.79

2.96

2.50

1.99

1.45

2.70

2.19

1.66

3.34

2.89

2.40

1.88

1.27

3.53

3.09

2.60

2.09

1.49

3.71

3.28

2.81

2.30

1.71

3.90

3.48

3.01

2.52

1.93

4.09

3.68

3.21

2.73

2.15

4.28

3.87

3.42

2.95

2.37

4.47

4.07

3.62

3.16

2.59

4.50

4.70

4.50

4.70

4.92

4.50

4.70

4.92

4.50

4.70

4.92

5.16

4.70

4.92

5.16

4.50

4.70

4.92

5.16

5.36

4.50

4.70

4.92

5.16

5.36

4.50

4.70

4.92

5.16

5.36

4.50

4.70

4.92

5.16

5.36

4.50

4.70

4.92

5.16

5.36

4.50

4.70

4.92

5.16

5.36

4.50

4.70

4.92

5.16

5.36

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1344

1424

1344

1424

1480

1344

1424

1480

1344

1424

1480

1536

1424

1480

1536

1344

1424

1480

1536

1616

1344

1424

1480

1536

1616

1344

1424

1480

1536

1616

1344

1424

1480

1536

1616

1344

1424

1480

1536

1616

1344

1424

1480

1536

1616

1344

1424

1480

1536

1616

2.30

1.83

2.48

2.02

1.53

2.66

2.21

1.72

2.84

2.40

1.92

1.39

2.59

2.12

1.60

3.20

2.77

2.31

1.81

1.23

3.38

2.96

2.51

2.01

1.45

3.56

3.15

2.71

2.22

1.66

3.74

3.34

2.90

2.43

1.88

3.92

3.53

3.10

2.63

2.09

4.10

3.71

3.30

2.84

2.30

4.28

3.90

3.49

3.04

2.52

4.32

4.56

4.32

4.56

4.80

4.32

4.56

4.80

4.32

4.56

4.80

5.04

4.56

4.80

5.04

4.32

4.56

4.80

5.04

5.28

4.32

4.56

4.80

5.04

5.28

4.32

4.56

4.80

5.04

5.28

4.32

4.56

4.80

5.04

5.28

4.32

4.56

4.80

5.04

5.28

4.32

4.56

4.80

5.04

5.28

4.32

4.56

4.80

5.04

5.28

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1408

1456

1408

1456

1520

1408

1456

1520

1408

1456

1520

1584

1456

1520

1584

1408

1456

1520

1584

1664

1408

1456

1520

1584

1664

1408

1456

1520

1584

1664

1408

1456

1520

1584

1664

1408

1456

1520

1584

1664

1408

1456

1520

1584

1664

1408

1456

1520

1584

1664

2.20

1.78

2.38

1.96

1.49

2.55

2.14

1.68

2.72

2.33

1.87

1.36

2.51

2.06

1.56

3.07

2.69

2.26

1.76

1.21

3.24

2.87

2.45

1.97

1.43

3.41

3.06

2.64

2.17

1.64

3.59

3.24

2.83

2.37

1.85

3.76

3.42

3.02

2.57

2.06

3.93

3.60

3.22

2.77

2.27

4.10

3.78

3.41

2.97

2.48

4.16

4.40

4.16

4.40

4.60

4.16

4.40

4.60

4.16

4.40

4.60

4.88

4.40

4.60

4.88

4.16

4.40

4.60

4.88

5.12

4.16

4.40

4.60

4.88

5.12

4.16

4.40

4.60

4.88

5.12

4.16

4.40

4.60

4.88

5.12

4.16

4.40

4.60

4.88

5.12

4.16

4.40

4.60

4.88

5.12

4.16

4.40

4.60

4.88

5.12

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1472

1520

1472

1520

1584

1472

1520

1584

1472

1520

1584

1664

1520

1584

1664

1472

1520

1584

1664

1712

1472

1520

1584

1664

1712

1472

1520

1584

1664

1712

1472

1520

1584

1664

1712

1472

1520

1584

1664

1712

1472

1520

1584

1664

1712

1472

1520

1584

1664

1712

2.12

1.72

2.29

1.89

1.43

2.45

2.07

1.61

2.62

2.24

1.79

1.32

2.42

1.98

1.51

2.95

2.60

2.16

1.71

1.18

3.12

2.77

2.35

1.90

1.38

3.29

2.95

2.53

2.10

1.59

3.45

3.12

2.71

2.29

1.79

3.62

3.30

2.90

2.49

2.00

3.79

3.48

3.08

2.68

2.20

3.95

3.65

3.27

2.88

2.41

PERFORMANCE DATA

COOLING operation(220V)

SLH-1.6AR

CAPACITY : 4.0 kW INPUT : 1600 W SHF : 0.69

12

Page 13

PERFORMANCE DATA

COOLING operation(220V)

SLH-1.6AR

CAPACITY : 4.0 kW INPUT : 1600 W SHF : 0.69

INDOOR INDOOR

D.B.(;) W.B.(;)

21

21

22

22

22

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

27

27

28

28

28

28

28

29

29

29

29

29

30

30

30

30

30

31

31

31

31

31

32

32

32

32

32

18

20

18

20

22

18

20

22

18

20

22

24

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

3.92

4.12

3.92

4.12

4.36

3.92

4.12

4.36

3.92

4.12

4.36

4.60

4.12

4.36

4.60

3.92

4.12

4.36

4.60

4.84

3.92

4.12

4.36

4.60

4.84

3.92

4.12

4.36

4.60

4.84

3.92

4.12

4.36

4.60

4.84

3.92

4.12

4.36

4.60

4.84

3.92

4.12

4.36

4.60

4.84

3.92

4.12

4.36

4.60

4.84

35 40 46

2.00

1.61

2.16

1.77

1.35

2.31

1.94

1.53

2.47

2.10

1.70

1.24

2.27

1.87

1.43

2.78

2.43

2.05

1.61

1.11

2.94

2.60

2.22

1.79

1.31

3.10

2.76

2.40

1.98

1.50

3.25

2.93

2.57

2.16

1.69

3.41

3.09

2.75

2.35

1.89

3.57

3.25

2.92

2.53

2.08

3.72

3.42

3.10

2.71

2.27

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1568

1632

1568

1632

1696

1568

1632

1696

1568

1632

1696

1760

1632

1696

1760

1568

1632

1696

1760

1824

1568

1632

1696

1760

1824

1568

1632

1696

1760

1824

1568

1632

1696

1760

1824

1568

1632

1696

1760

1824

1568

1632

1696

1760

1824

1568

1632

1696

1760

1824

3.60

3.84

3.60

3.84

4.08

3.60

3.84

4.08

3.60

3.84

4.08

4.32

3.84

4.08

4.32

3.60

3.84

4.08

4.32

4.56

3.60

3.84

4.08

4.32

4.56

3.60

3.84

4.08

4.32

4.56

3.60

3.84

4.08

4.32

4.56

3.60

3.84

4.08

4.32

4.56

3.60

3.84

4.08

4.32

4.56

3.60

3.84

4.08

4.32

4.56

OUTDOOR D.B.(;)

1.84

1.50

1.98

1.65

1.26

2.12

1.80

1.43

2.27

1.96

1.59

1.17

2.11

1.75

1.34

2.56

2.27

1.92

1.51

1.05

2.70

2.42

2.08

1.68

1.23

2.84

2.57

2.24

1.86

1.41

2.99

2.73

2.41

2.03

1.60

3.13

2.88

2.57

2.20

1.78

3.28

3.03

2.73

2.38

1.96

3.42

3.19

2.90

2.55

2.14

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1664

1712

1664

1712

1792

1664

1712

1792

1664

1712

1792

1840

1712

1792

1840

1664

1712

1792

1840

1904

1664

1712

1792

1840

1904

1664

1712

1792

1840

1904

1664

1712

1792

1840

1904

1664

1712

1792

1840

1904

1664

1712

1792

1840

1904

1664

1712

1792

1840

1904

3.32

3.56

3.32

3.56

3.80

3.32

3.56

3.80

3.32

3.56

3.80

4.08

3.56

3.80

4.08

3.32

3.56

3.80

4.08

4.28

3.32

3.56

3.80

4.08

4.28

3.32

3.56

3.80

4.08

4.28

3.32

3.56

3.80

4.08

4.28

3.32

3.56

3.80

4.08

4.28

3.32

3.56

3.80

4.08

4.28

3.32

3.56

3.80

4.08

4.28

1.69

1.39

1.83

1.53

1.18

1.96

1.67

1.33

2.09

1.82

1.48

1.10

1.96

1.63

1.26

2.36

2.10

1.79

1.43

0.98

2.49

2.24

1.94

1.59

1.16

2.62

2.39

2.09

1.75

1.33

2.76

2.53

2.24

1.92

1.50

2.89

2.67

2.39

2.08

1.67

3.02

2.81

2.55

2.24

1.84

3.15

2.95

2.70

2.41

2.01

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1728

1808

1728

1808

1856

1728

1808

1856

1728

1808

1856

1920

1808

1856

1920

1728

1808

1856

1920

1984

1728

1808

1856

1920

1984

1728

1808

1856

1920

1984

1728

1808

1856

1920

1984

1728

1808

1856

1920

1984

1728

1808

1856

1920

1984

1728

1808

1856

1920

1984

13

Page 14

OUTDOOR D.B.(;)

INDOOR INDOOR

21 25 27 30

D.B.(;) W.B.(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21

21

22

22

22

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

27

27

28

28

28

28

28

29

29

29

29

29

30

30

30

30

30

31

31

31

31

31

32

32

32

32

32

18

20

18

20

22

18

20

22

18

20

22

24

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

4.82

5.02

4.82

5.02

5.23

4.82

5.02

5.23

4.82

5.02

5.23

5.49

5.02

5.23

5.49

4.82

5.02

5.23

5.49

5.66

4.82

5.02

5.23

5.49

5.66

4.82

5.02

5.23

5.49

5.66

4.82

5.02

5.23

5.49

5.66

4.82

5.02

5.23

5.49

5.66

4.82

5.02

5.23

5.49

5.66

4.82

5.02

5.23

5.49

5.66

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1360

1428

1360

1428

1479

1360

1428

1479

1360

1428

1479

1547

1428

1479

1547

1360

1428

1479

1547

1632

1360

1428

1479

1547

1632

1360

1428

1479

1547

1632

1360

1428

1479

1547

1632

1360

1428

1479

1547

1632

1360

1428

1479

1547

1632

1360

1428

1479

1547

1632

2.46

1.96

2.65

2.16

1.62

2.84

2.36

1.83

3.04

2.56

2.04

1.48

2.76

2.25

1.70

3.42

2.96

2.46

1.92

1.30

3.61

3.16

2.67

2.14

1.53

3.81

3.37

2.88

2.36

1.75

4.00

3.57

3.08

2.58

1.98

4.19

3.77

3.29

2.80

2.21

4.38

3.97

3.50

3.02

2.43

4.58

4.17

3.71

3.24

2.66

4.61

4.82

4.61

4.82

5.04

4.61

4.82

5.04

4.61

4.82

5.04

5.29

4.82

5.04

5.29

4.61

4.82

5.04

5.29

5.49

4.61

4.82

5.04

5.29

5.49

4.61

4.82

5.04

5.29

5.49

4.61

4.82

5.04

5.29

5.49

4.61

4.82

5.04

5.29

5.49

4.61

4.82

5.04

5.29

5.49

4.61

4.82

5.04

5.29

5.49

0.51

0.39

0.55

0.43

0.31

0.59

0.47

0.35

0.63

0.51

0.39

0.27

0.55

0.43

0.31

0.71

0.59

0.47

0.35

0.23

0.75

0.63

0.51

0.39

0.27

0.79

0.67

0.55

0.43

0.31

0.83

0.71

0.59

0.47

0.35

0.87

0.75

0.63

0.51

0.39

0.91

0.79

0.67

0.55

0.43

0.95

0.83

0.71

0.59

0.47

1428

1513

1428

1513

1573

1428

1513

1573

1428

1513

1573

1632

1513

1573

1632

1428

1513

1573

1632

1717

1428

1513

1573

1632

1717

1428

1513

1573

1632

1717

1428

1513

1573

1632

1717

1428

1513

1573

1632

1717

1428

1513

1573

1632

1717

1428

1513

1573

1632

1717

2.35

1.88

2.54

2.07

1.56

2.72

2.26

1.77

2.91

2.46

1.97

1.43

2.65

2.17

1.64

3.27

2.84

2.37

1.85

1.26

3.46

3.04

2.57

2.06

1.48

3.64

3.23

2.77

2.27

1.70

3.83

3.42

2.98

2.49

1.92

4.01

3.61

3.18

2.70

2.14

4.20

3.81

3.38

2.91

2.36

4.38

4.00

3.58

3.12

2.58

4.43

4.67

4.43

4.67

4.92

4.43

4.67

4.92

4.43

4.67

4.92

5.17

4.67

4.92

5.17

4.43

4.67

4.92

5.17

5.41

4.43

4.67

4.92

5.17