Mitsubishi Electric SEZ-KD25VA, SEZ-KD35VA, SEZ-KD50VA, SEZ-KD60VA, SEZ-KD71VA INSTALLATION MANUAL

Air-Conditioners

SEZ-KD25,KD35,KD50,KD60,KD71VA

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner

unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimaanlage das Installationshandbuch gründlich

durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous

assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de

aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore

d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner

installeert.

INSTALLATIONSMANUAL

Läs denna installationsmanual noga för säkert och korrekt bruk innan luftkonditioneringen installeras.

INSTALLATIONSMANUAL

Læs venligst denne installationsmanual grundigt, før De installerer airconditionanlægget, af hensyn til sikker og

korrekt anvendelse.

FOR INSTALLER

FÜR INSTALLATEURE

POUR L’INSTALLATEUR

PARA EL INSTALADOR

PER L’INSTALLATORE

VOOR DE INSTALLATEUR

FÖR INSTALLATÖREN

TIL INSTALLATØREN

English

Deutsch

Français

Español

Italiano

Nederlands

Svenska

Dansk

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade

de ar condicionado.

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜

ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным

руководством по установке до выполнения установки кондиционера.

MONTAJ ELK‹TABI

Emniyetli ve do¤ru biçimde nas›l kullan›laca¤›n› ö¤renmek için lütfen klima cihaz›n› monte etmeden önce bu

elkitab›n› dikkatle okuyunuz.

PARA O INSTALADOR

°π∞ ∞À∆√¡ ¶√À ∫∞¡∂π ∆∏¡ ∂°∫∞∆∞™∆∞™∏

ДЛЯ УСТАНОВИТЕЛЯ

MONTÖR ‹Ç‹N

Português

∂ППЛУИО¿

Русский

Türkçe

3

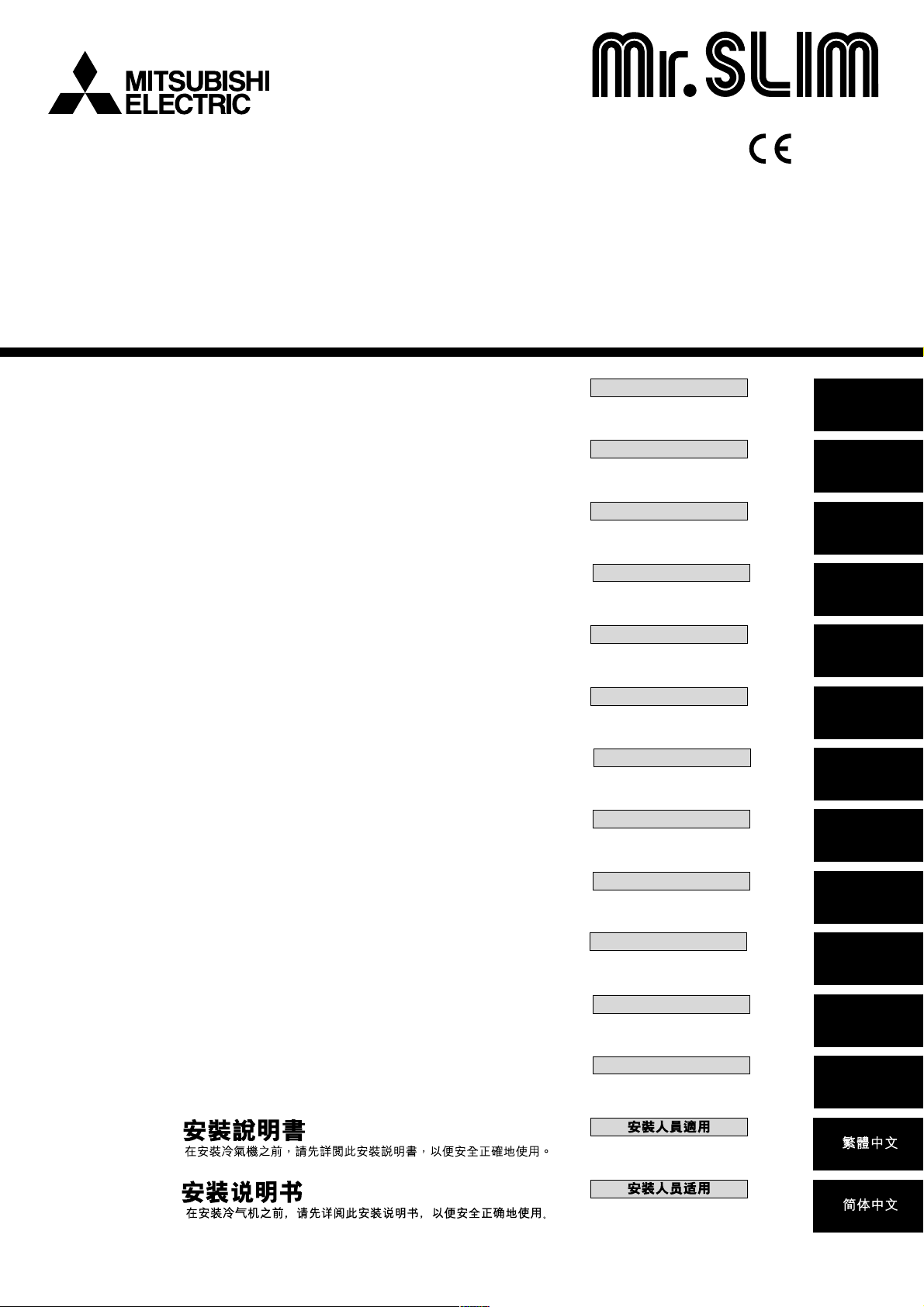

A

3.1

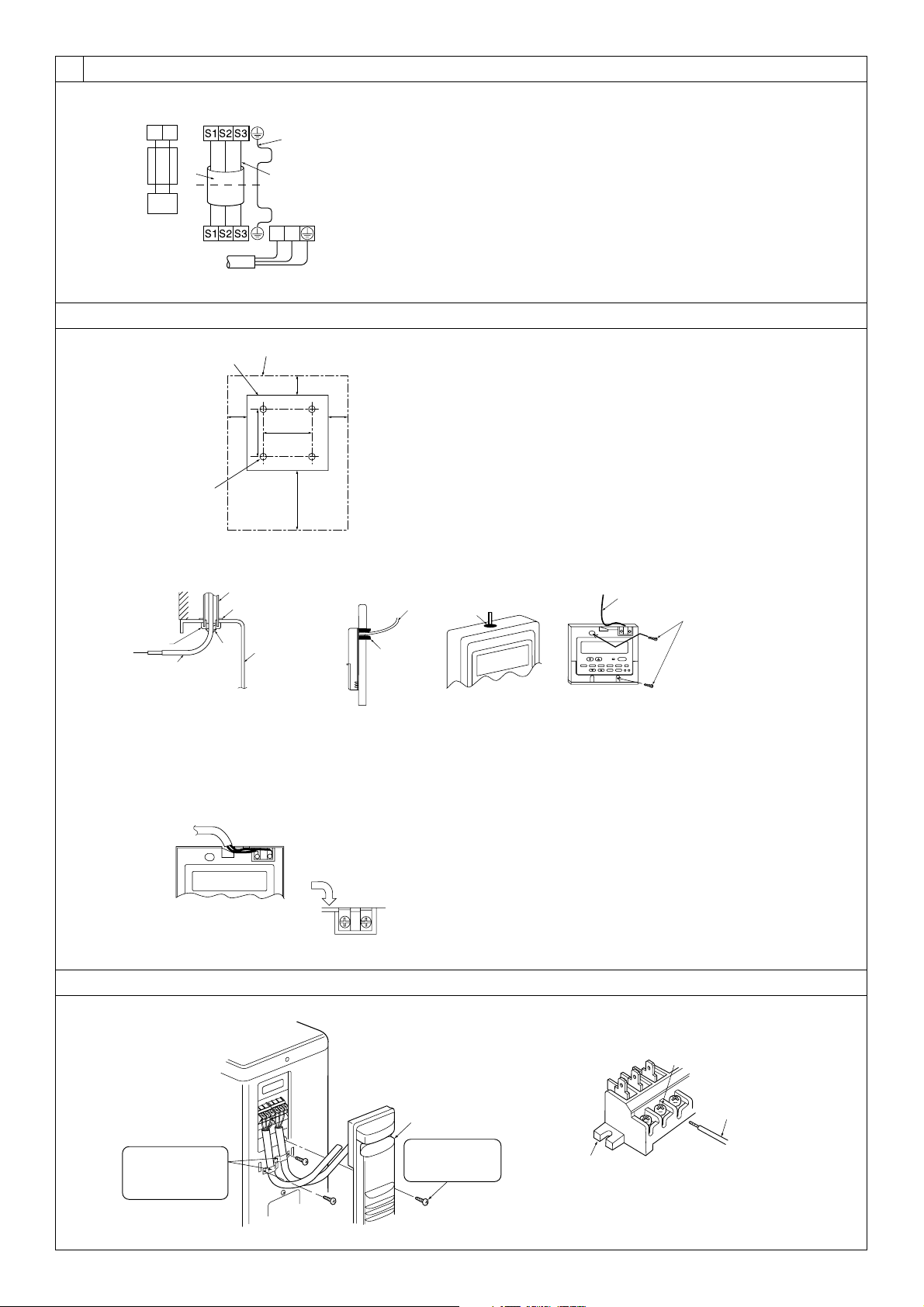

[Fig. 3-1]

D

C

G

50~150 450

23

90

B

57

20

200

A

777

A

1

450

A Access door

B Electrical parts box

C Air inlet

D Air outlet

E Ceiling surface

F Service space (viewed from the side)

E

G Service space (viewed from the direction of arrow)

Model

SEZ-KD25

SEZ-KD35, 50

SEZ-KD60, 71

1 600 mm or more

2 100 mm or more

3 10 mm or more

4 300 mm or more

A

B

700

752

900

952

1100

1152

C

798

998

1198

D

660

860

1060

(mm)

E

800

1000

1200

C

4

625

49

2

B

A

D

B

3

F

E

3.3

[Fig. 3-2]

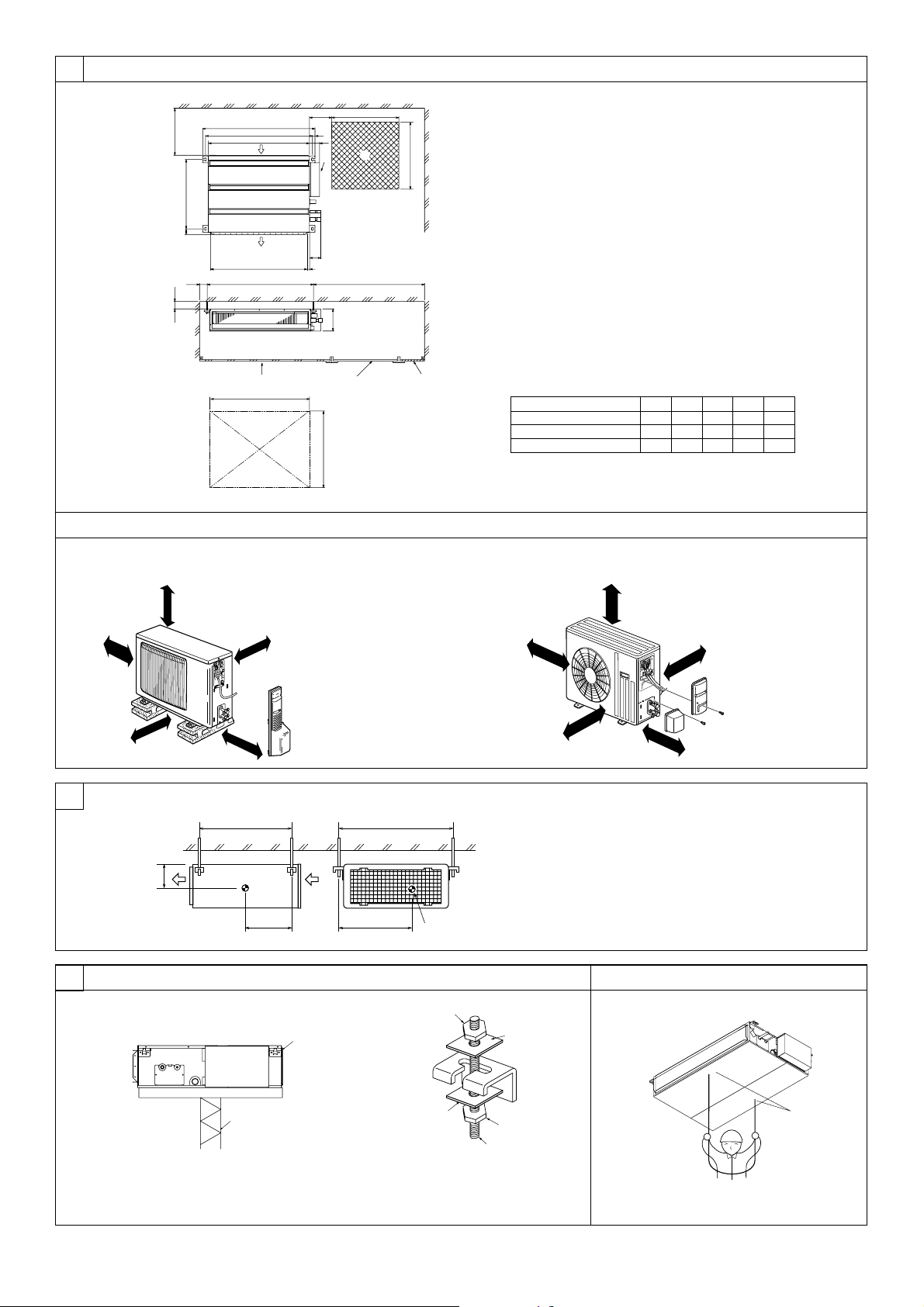

■ SUZ-KA25/35VA

A

D

C

A

A 100 mm or more

B 350 mm or more

C Basically open 100 mm or more without

only obstruction in front and on both

B

sides of the unit.

D 200 mm or more (Open two sides of

left, right, or rear side.)

■ SUZ-KA50/60/71VA

A

C

4

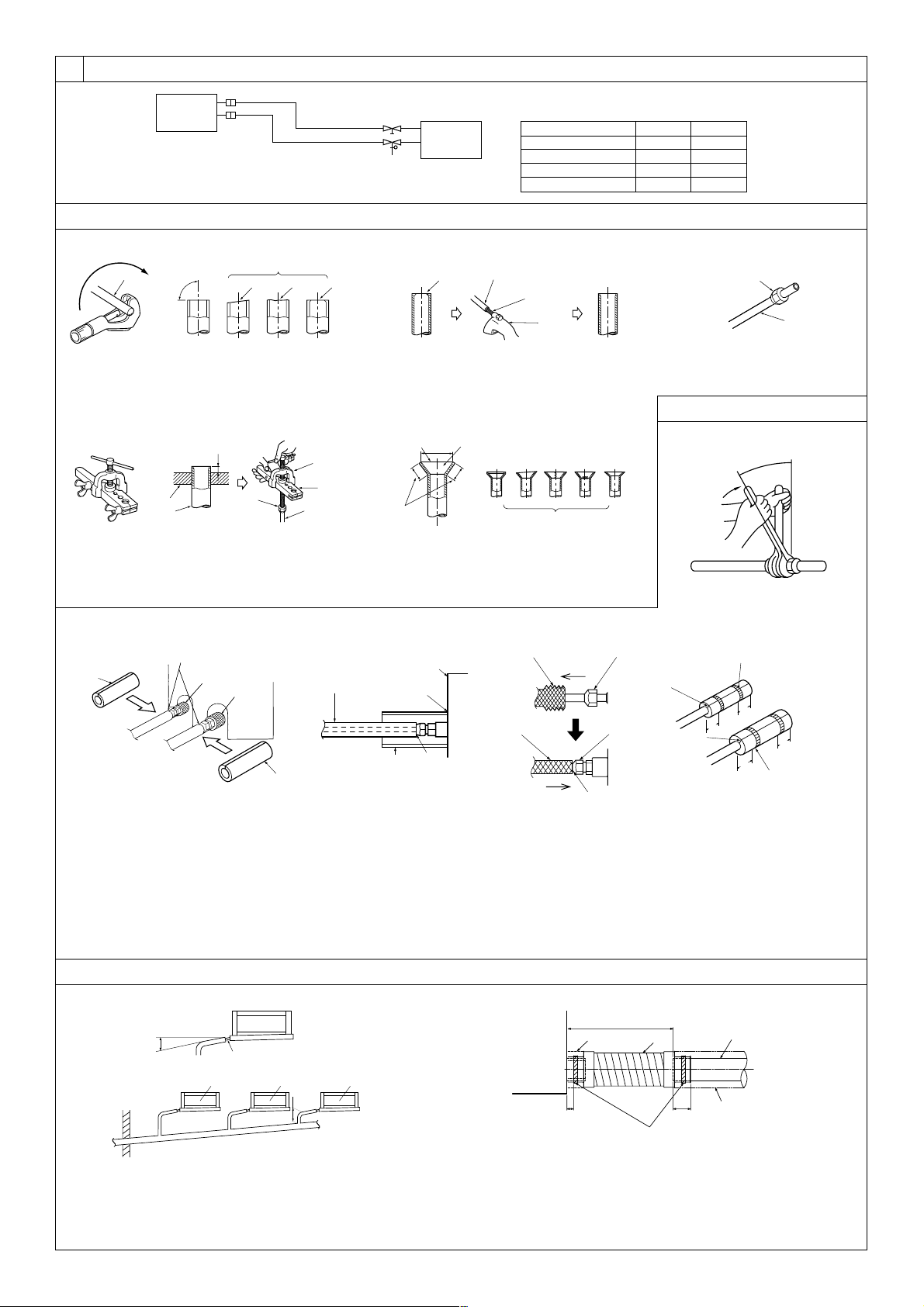

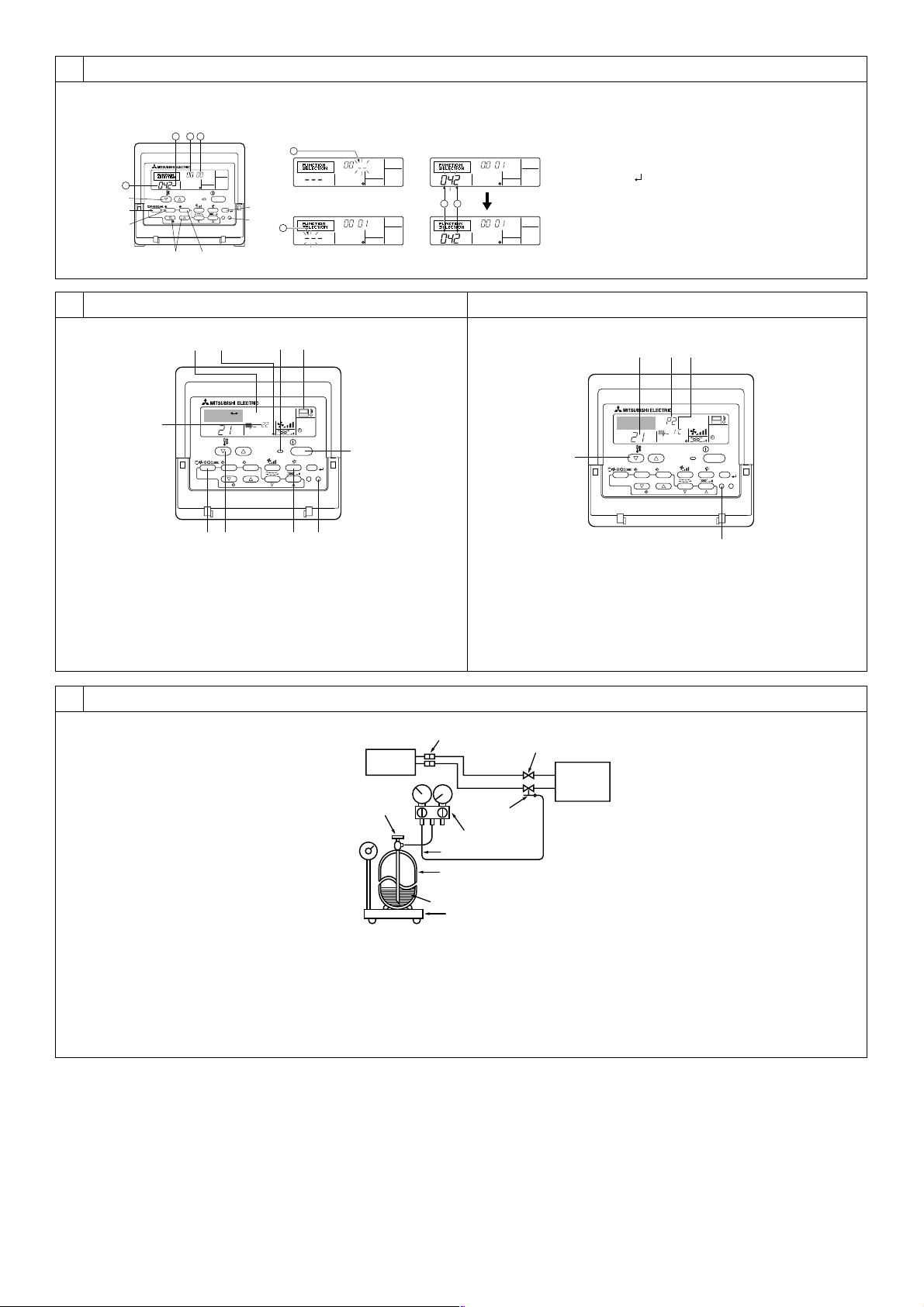

[Fig. 4-1]

Z

LW

YX

A

A Center of gravity

5

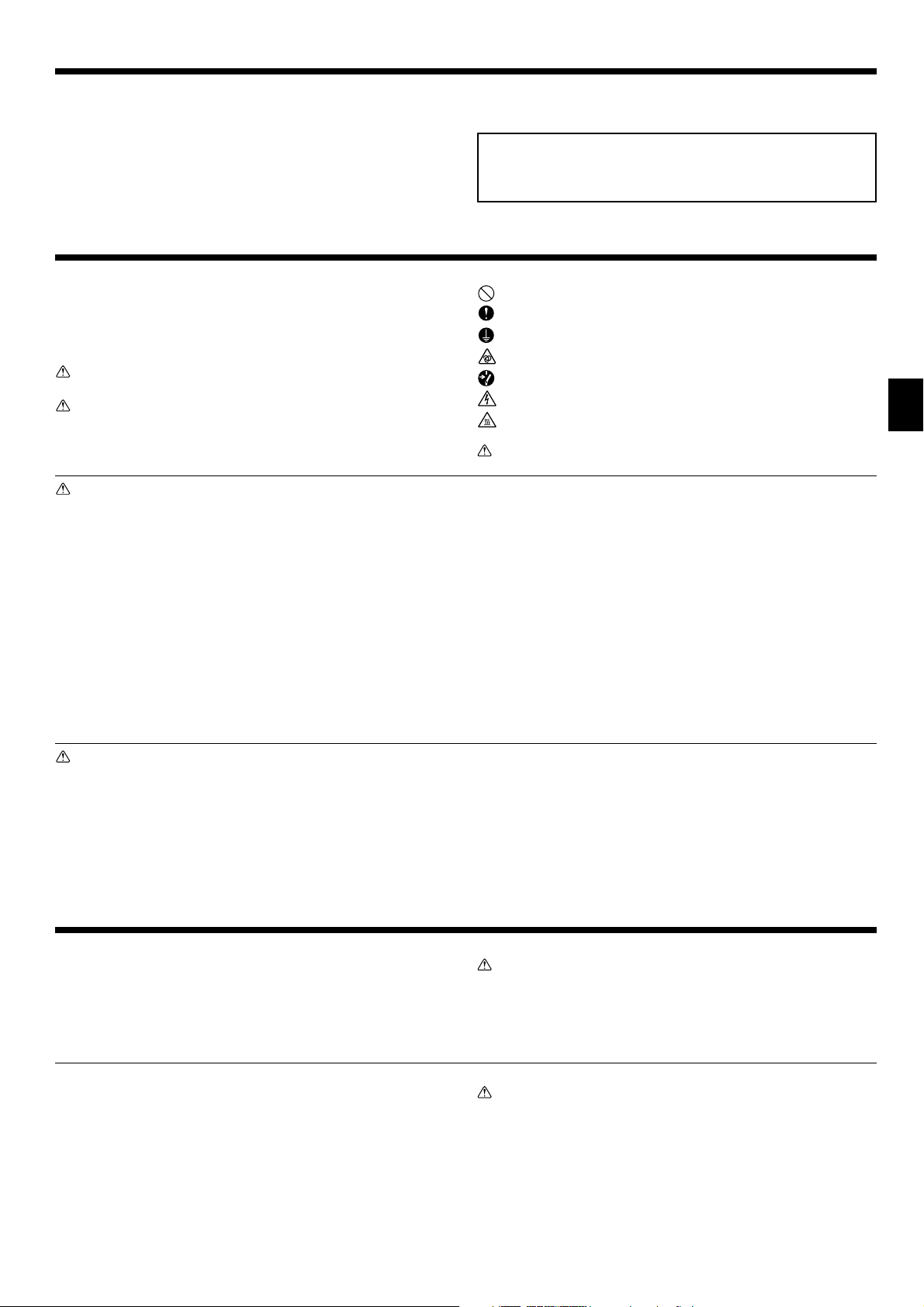

[Fig. 5-1] [Fig. 5-2] [Fig. 5-3]

A

C

D

C

A

A 100 mm or more

B

B 350 mm or more

C 500 mm or more

5.25.1

B

D

C

E

A Unit body

B Lifting machine

C Nuts (field supply)

D Washers (accessory)

E M10 hanging bolt (field supply)

A Indoor unit’s bottom surface

2

6

C C C

[Fig. 6-1]

[Fig. 6-3]

6.1

a

øA

øB

b

a Indoor unit

b Outdoor unit

Model

SEZ-KD25, 35

SEZ-KD50

SEZ-KD60

SEZ-KD71

A

9.52

12.7

15.88

15.88

B

6.35

6.35

6.35

9.52

6.2

[Fig. 6-4] [Fig. 6-5]

a

a Copper tubes

b Good

90°

c No good

d Tilted

dcbef

e Uneven

f Burred

[Fig. 6-6]

a

b

A

d

c

a Flaring tool

b Die

c Copper tube

d Flare nut

e Yo k e

[Fig. 6-9]

B

A

C

D

F

E

G

A Pipe cover (small) (accessory)

B Caution:

Pull out the thermal insulation on the refrigerant piping at the

site, insert the flare nut to flare the end, and replace the insulation in its original position.

Take care to ensure that condensation does not form on exposed copper piping.

C Liquid end of refrigerant piping

e

b

c

a Smooth all around

b Inside is shining without

c Even length all around

E

a

a Burr

b Copper tube/pipe

[Fig. 6-7]

b

a

c

any scratches

M

L

F

L

AG

D Gas end of refrigerant piping

E Site refrigerant piping

F Main body

G Pipe cover (large) (accessory)

H Thermal insulation (field supply)

I Pull

J Flare nut

K Return to original position

b

c

d

c Spare reamer

d Pipe cutter

defgh

i

d Too much

e Tilted

f Scratch on

flared plane

H

H

g Cracked

h Uneven

i Bad examples

I

J

L

K

L Ensure that there is no gap here

M Plate on main body

N Band (accessory)

O Ensure that there is no gap here. Place join upwards.

a

b

a Flare nut

b Copper tube

6.3

[Fig. 6-8]

J

O

N

20

20

O

20

20

N

[Fig. 6-10]

A

D 2

A Downward slope 1/100 or more

B Connection dia. R1 external thread

C Indoor unit

D Collective piping

E Maximize this length to approx. 10 cm

B 1

6.5

[Fig. 6-11]

I

A

E

B

525

D

F

E

G

H

C

A Indoor unit

B Pipe cover (short) (accessory)

C Tie band (accessory)

D Band fixing part

E Insertion margin

F Drain hose (accessory)

G Drain pipe (O.D. ø32 PVC TUBE,

field supply)

H Insulating material (field supply)

I Max.145 ± 5 mm

3

A

B

C

S3

S2

S1

12

S1 S2 S3

K

J

M

L

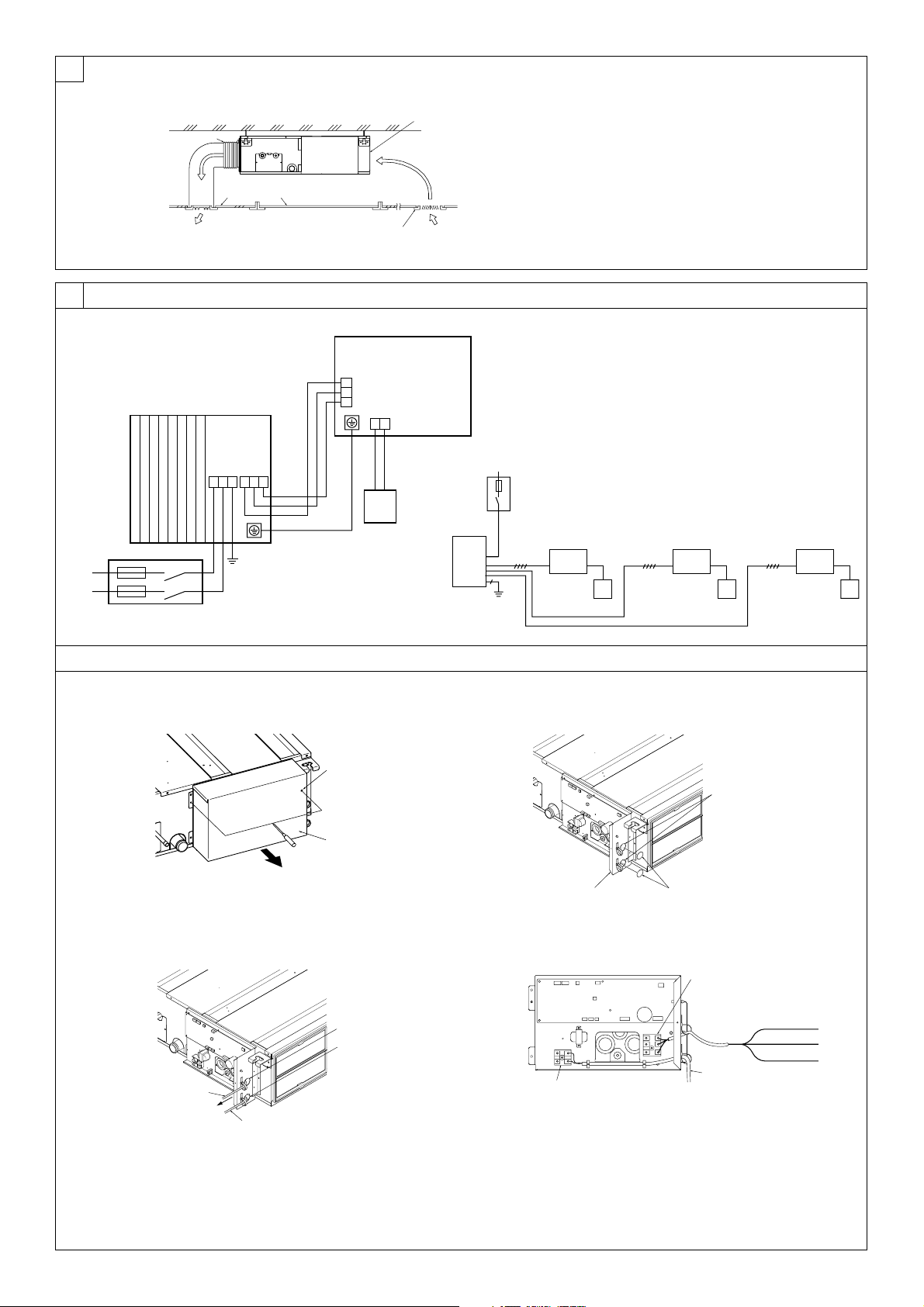

7

8

[Fig. 7-1]

[Fig. 8-1]

F

E

DC

BA

G

A Air inlet

B Air outlet

C Access door

D Ceiling surface

E Canvas duct

F Air filter

G Inlet grille

8.1

A Indoor unit

S1

S2

S3

A

21

B Outdoor unit

C Wired remote controller

D Main switch/fuse

E Grounding

B

S3

S2S1

C

D

For Power

supply

B

E

For Power supply

D

8.2

[Fig. 8-2-1] [Fig. 8-2-2]

A

B

A Screw holding cover (2pcs)

B Cover

[Fig. 8-2-3] [Fig. 8-2-4]

A A

C C

A

C

A Terminal bed box

B Knockout hole

C Remove

E

H

F

G

I

E Use PG bushing to keep the weight of the cable and external force from being applied to

the power supply terminal connector. Use a cable tie to secure the cable.

F Power source wiring

G Tensile force

H Use ordinary bushing

I Transmission wiring

4

J Terminal bed for power source and indoor transmission

K Terminal bed for remote controller

L To 1-phase power source

M Transmission line to the remote controller

B

C

A

F

A

H

C

D

E

G

I

8

8.2

[Fig. 8-3]

[Fig. 8-4]

A Indoor terminal block

2

12

5

1

6

3

D Outdoor terminal block

7

E Power supply cord : 2.0 mm2 or more

A

30

C

B Earth wire (green/yellow)

4

C Indoor/outdoor unit

connecting wire

3-core 1.5 mm2 or

more

L

N

B

30120

46

83.5

A Indoor terminal block

B Earth wire (green/yellow)

C Indoor/outdoor unit connecting wire 3-

core 1.5 mm2 or more

D Outdoor terminal block

E Power supply cord : 2.0 mm2 or more

1 Connecting cable

Cable 3-core 1.5 mm2, in conformity

with Design 245 IEC 57.

2 Indoor terminal block

3 Outdoor terminal block

4 Always install an earth wire (1-core 1.5 mm2)

longer than other cables

5 Remote controller cable

Wire No × size (mm2) : Cable 2C × 0.3

This wire accessory of remote controller

(wire length : 10m, non-polar. Max. 500m)

6 Wired remote controller

7 Power supply cord

Cable 3-core 2.0 mm2 or more, in conformity with Design 245 IEC 57.

8.3

30

A Remote controller profile

B Required clearances surrounding the remote controller

C Installation pitch

[Fig. 8-5]

B-1. B-2.

B

H

I

I

A For installation in the switch box:

B For direct installation on the wall select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run the remote controller cord from

the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cut-out notch with putty similarly as

above.

[Fig. 8-6]

A

A To the terminal block on the indoor unit

B TB6 (No polarity)

AB TB6

B

8.4

[Fig. 8-7] [Fig. 8-8]

H

J

C Wall

D Conduit

E Lock nut

F Bushing

G Switch box

H Remote controller cord

I Seal with putty

J Wood screw

Service panel

Be sure to fix the

indoor/outdoor unit

connecting wire using

this cord clamp.

Remove one fixing

screw to open the

service panel.

A Loosen terminal screw

B Terminal block

C Lead wire

5

8

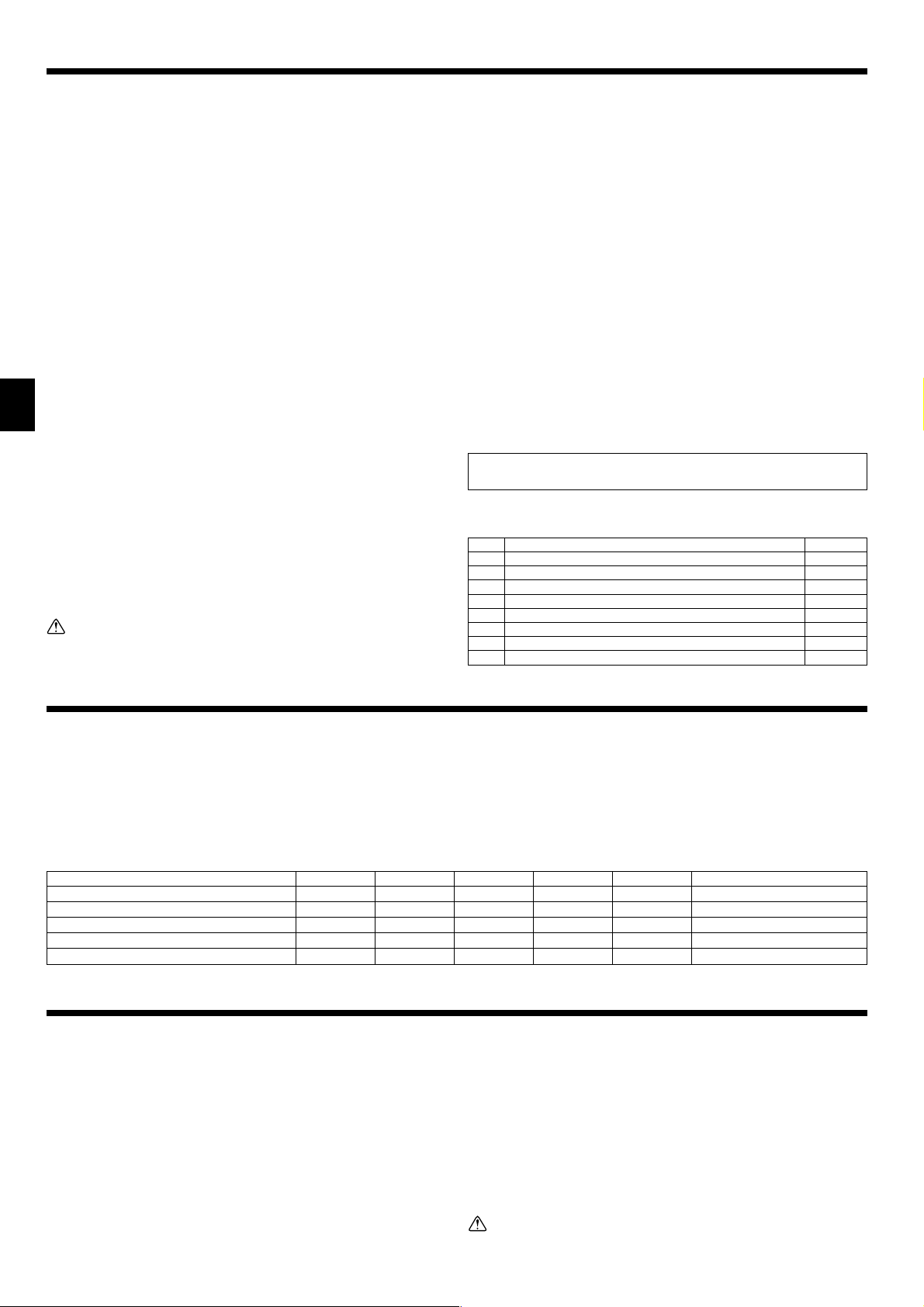

[Fig. 8-9]

8.5

1

⁄ Mode number

213 4

1

F

E

G

MONITOR/SET

BACK DAY

PAR-21MAA

TEMP.

MENU

ON/OFF

ON/OFF

FILTER

CHECK

OPERATION

DC

TEST

CLEAR

CLOCK

4

A

B

1 2

2

⁄ Setting number

3

⁄ Refrigerant address

4

⁄ Unit number

A Filter button (<Enter> button)

B TEST button

C Set Time button

D Timer On/Off button (Set Day button)

E Mode selection button

F Set temperature button

G Timer Menu button (Monitor/Set button)

9

[Fig. 9-1] [Fig. 9-2]

A ON/OFF button

B Test run display

C Indoor temperature liquid line

temperature display

D ON/OFF lamp

E Power display

10

[Fig. 10-1]

FCEDB

TEST RUN

COOL, HEAT

MONITOR/SET

BACK DAY

PAR-21MAA

MENU

˚C

˚C

TEMP.

ON/OFF

CLOCK

OPERATION

F Error code display

G Set temperature button

H Mode selection button

I Fan speed button

M TEST button

SIMPLE

ON/OFF

FILTER

CHECK

TEST

CLEAR

M

IH G

Test run remaining time display

A

10.1

B

A

C

D

9.39.2

B

E D

˚C

C

TEMP.

MENU

MONITOR/SET

BACK DAY

PAR-21MAA

˚C

ON/OFF

CLOCK

OPERATION

SIMPLE

ON/OFF

CHECK

CLEAR

FILTER

TEST

A

A CHECK button

B Refrigerant address

C TEMP. button

D IC: Indoor unit

OC: Outdoor unit

E Check code

E

F

G

K

H

I

J

A Indoor unit

B Union

C Liquid pipe

D Gas pipe

E Stop valve

F Outdoor unit

G Refrigerant gas cylinder operating valve

M

L

H Refrigerant gas cylinder for R410A with

siphon

I Refrigerant (liquid)

J Electronic scale for refrigerant charging

K Charge hose (for R410A)

L Gauge manifold valve (for R410A)

M Service port

6

Contents

1. Safety precautions ................................................................................... 7

2. Selecting the installation location ............................................................. 7

3. Selecting an installation site & Accessories ............................................. 8

4. Fixing hanging bolts ................................................................................. 8

5. Installing the unit ...................................................................................... 8

6. Refrigerant piping work ............................................................................ 9

7. Duct work ............................................................................................... 11

8. Electrical work ........................................................................................ 11

1. Safety precautions

• Please report to or take consent by the supply authority before connection

to the system.

• Be sure to read “The following should always be observed for safety” before

installing the air conditioner.

• Be sure to observe the cautions specified here as they include important

items related to safety.

• The indications and meanings are as follows.

Warning:

Could lead to death, serious injury, etc.

Caution:

Could lead to serious injury in particular environments when operated incorrectly.

• After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer’s site.

Warning:

• Do not install it by yourself (customer).

Incomplete installation could cause injury due to fire, electric shock, the unit

falling or leakage of water. Consult the dealer from whom you purchased the

unit or special installer.

• Install the unit securely in a place which can bear the weight of the unit.

When installed in an insufficient strong place, the unit could fall causing injured.

• Use the specified wires to connect the indoor and outdoor units securely and

attach the wires firmly to the terminal board connecting sections so the stress

of the wires is not applied to the sections.

Incomplete connecting and fixing could cause fire.

• Do not use intermediate connection of the power cord or the extension cord

and do not connect many devices to one AC outlet.

It could cause a fire or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

• Check that the refrigerant gas does not leak after installation has completed.

9. Test run .................................................................................................. 13

10. Maintenance .......................................................................................... 14

This Installation Manual describes only for the indoor unit and the connected

outdoor unit of SUZ series.

If the connected outdoor unit is MXZ series, refer to the Installation Manual for

MXZ series.

Symbols put on the unit

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts.

: Indicates that the main switch must be turned off before servicing.

: Beware of electric shock.

: Beware of hot surface.

Warning:

Carefully read the labels affixed to the main unit.

• Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to fire, electric shock,

the unit falling or leakage of water.

• Perform electrical work according to the installation manual and be sure to

use an exclusive circuit.

If the capacity of the power circuit is insufficient or there is incomplete electrical work, it could result in a fire or an electric shock.

• Attach the electrical part cover to the indoor unit and the service panel to the

outdoor unit securely.

If the electrical part cover in the indoor unit and/or the service panel in the

outdoor unit are not attached securely, it could result in a fire or an electric

shock due to dust, water, etc.

• Be sure to use the part provided or specified parts for the installation work.

The use of defective parts could cause an injury or leakage of water due to a

fire, an electric shock, the unit falling, etc.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a flame, poisonous gases will be released.

Caution:

• Perform grounding.

Do not connect the ground wire to a gas pipe, water pipe arrester or telephone

ground wire. Defective grounding could cause an electric shock.

• Do not install the unit in a place where an inflammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it could cause

an explosion.

• Install a ground leakage breaker depending on the installation place (where it

is humid).

If a ground leakage breaker is not installed, it could cause an electric shock.

2. Selecting the installation location

2.1. Indoor unit

• Where airflow is not blocked.

• Where cool air spreads over the entire room.

• Where it is not exposed to direct sunshine.

• At a distance 1 m or more away from your TV and radio (to prevent picture from

being distorted or noise from being generated).

• In a place as far away as possible from fluorescent and incandescent lights (so the

infrared remote control can operate the air conditioner normally).

2.2. Outdoor unit

• Where it is not exposed to strong wind.

• Where airflow is good and dustless.

• Where it is not exposed to rain and direct sunshine.

• Where neighbours are not annoyed by operation sound or hot air.

• Where rigid wall or support is available to prevent the increase of operation sound

or vibration.

• Where there is no risk of combustible gas leakage.

• When installing the unit at a high level, be sure to fix the unit legs.

• Where it is at least 3 m away from the antenna of TV set or radio. (Otherwise,

images would be disturbed or noise would be generated.)

• Perform the drainage/piping work securely according to the installation

manual.

If there is a defect in the drainage/piping work, water could drop from the unit

and household goods could be wet and damaged.

• Fasten a flare nut with a torque wrench as specified in this manual.

When fastened too tight, a flare nut may broken after a long period and cause

a leakage of refrigerant.

• Where the air filter can be removed and replaced easily.

Warning:

Mount the indoor unit into a ceiling strong enough to withstand the weight of

the unit.

• Install the unit horizontally.

Caution:

Avoid the following places for installation where air conditioner trouble is liable to occur.

• Where there is too much machine oil.

• Salty environment as seaside areas.

• Hot-spring areas.

• Where sulfide gas exists.

• Other special atmospheric areas.

7

3. Selecting an installation site & Accessories

• Select a site with sturdy fixed surface sufficiently durable against the weight of unit.

• Before installing unit, the routing to carry in unit to the installation site should be

determined.

• Select a site where the unit is not affected by entering air.

• Select a site where the flow of supply and return air is not blocked.

• Select a site where refrigerant piping can easily be led to the outside.

• Select a site which allows the supply air to be distributed fully in room.

• Do not install unit at a site with oil splashing or steam in much quantity.

• Do not install unit at a site where combustible gas may generate, flow in, stagnate

or leak.

• Do not install unit at a site where equipment generating high frequency waves (a

high frequency wave welder for example) is provided.

• Do not install unit at a site where fire detector is located at the supply air side. (Fire

detector may operate erroneously due to the heated air supplied during heating

operation.)

• When special chemical product may scatter around such as site chemical plants

and hospitals, full investigation is required before installing unit. (The plastic components may be damaged depending on the chemical product applied.)

• If the unit is run for long hours when the air above the ceiling is at high temperature/

high humidity (due point above 26 °C), due condensation may be produced in the

indoor unit. When operating the units in this condition, add insulation material (1020 mm) to the entire surface of the indoor unit to avoid due condensation.

3.1. Install the indoor unit on a ceiling strong enough

to sustain its weight

[Fig. 3-1] (P.2)

A Access door B Electrical parts box

C Air inlet D Air outlet

E Ceiling surface F Service space (viewed from the side)

G Service space (viewed from the direction of arrow)

1 600 mm or more 2 100 mm or more

3 10 mm or more 4 300 mm or more

* If the optional long-life filter is installed, the dimensions of the air conditioner

increase.

Rear inlet: Depth increases by 30 mm (*1)

Bottom inlet: Height increases by 30 mm (*2)

Warning:

The unit must be securely installed on a structure that can sustain its weight. If

the unit is mounted on an unstable structure, it may fall down causing injuries.

3.2. Securing installation and service space

• Select the optimum direction of supply airflow according to the configuration of the

room and the installation position.

• As the piping and wiring are connected at the bottom and side surfaces, and the

maintenance is made at the same surfaces, allow a proper space properly. For the

efficient suspension work and safety, provide a space as much as possible.

3.3. Outdoor unit

Ventilation and service space

[Fig. 3-2] (P.2)

■ SUZ-KA25/35VA

A 100 mm or more

B 350 mm or more

C Basically open 100 mm or more without only obstruction in front and on both sides of the

unit.

D 200 mm or more (Open two sides of left, right, or rear side.)

■ SUZ-KA50/60/71VA

A 100 mm or more

B 350 mm or more

C 500 mm or more

When the piping is to be attached to a wall containing metals (tin plated) or metal

netting, use a chemically treated wooden piece 20 mm or thicker between the wall

and the piping or wrap 7 to 8 turns of insulation vinyl tape around the piping.

Units should be installed by licensed contractor accordingly to local code requirement.

3.4. Indoor unit accessories

The unit is provided with the following accessories:

No. Name Quantity

1 Pipe cover (for refrigerant piping joint) Small diameter 1

2 Pipe cover (for refrigerant piping joint) Large diameter 1

3 Bands for temporary tightening of pipe cover and drain hose 6

4 Remote controller parts 1

5 Remote controller cable 1

6 Washer 8

7 Drain hose 1

8 Pipe cover (for Drain hose) short 1

4. Fixing hanging bolts

4.1. Fixing hanging bolts

[Fig. 4-1] (P.2)

A Center of gravity

(Give site of suspension strong structure.)

Hanging structure

• Ceiling: The ceiling structure varies from building to one another. For detailed information, consult your construction company.

Center of gravity and Product Weight

Model name

SEZ-KD25

SEZ-KD35

SEZ-KD50

SEZ-KD60

SEZ-KD71

W

625

625

625

625

625

L

752

952

952

1152

1152

5. Installing the unit

5.1. Hanging the unit body

ss

s Bring the indoor unit to an installation site as it is packed.

ss

ss

s To hang the indoor unit, use a lifting machine to lift and pass through the

ss

hanging bolts.

[Fig. 5-1] (P.2)

A Unit body

B Lifting machine

[Fig. 5-2] (P.2)

C Nuts (field supply)

D Washers (accessory)

E M10 hanging bolt (field supply)

• If necessary, reinforce the hanging bolts with anti-quake supporting members as

countermeasures against earthquakes.

* Use M10 for hanging bolts and anti-quake supporting members (field supply).

1 Reinforcing the ceiling with additional members (edge beam, etc.) must be re-

quired to keep the ceiling at level and to prevent the ceiling from vibrations.

2 Cut and remove the ceiling members.

3 Reinforce the ceiling members, and add other members for fixing the ceiling boards.

X

263

286

280

285

285

Y

351

448

437

527

527

Z

106

104

104

104

104

Product Weight (kg)

18

21

24

28

28

5.2. Confirming the unit’s position and fixing hanging

bolts

ss

s Use the gage supplied with the panel to confirm that the unit body and

ss

hanging bolts are positioned in place. If they are not positioned in place, it

may result in dew drops due to wind leak. Be sure to check the positional

relationship.

ss

s Use a level to check that the surface indicated by

ss

the hanging bolt nuts are tightened to fix the hanging bolts.

ss

s To ensure that drain is discharged, be sure to hang the unit at level using a

ss

level.

[Fig. 5-3] (P.2)

A Indoor unit’s bottom surface

AA

A is at level. Ensure that

AA

Caution:

Be sure to install the unit body at level.

8

Loading...

Loading...