Mitsubishi SEZ-KD18NA4, SEZ-KD12NA4, SEZ-KD15NA, SEZ-KD15NA4, SEZ-KD09NA Installation Guide

...Page 1

4F1k EL.ECTRIC

Air-Conditioners

SEZ-KD09,KD12,KD15,KD18NA

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner

unit.

MANUEL D'INSTALLATION

Veuillez life le manuel d'installation en entier avant d'installer ce climatiseur pour eviter tout accident et vous

assurer d'une utilisation correcte.

Page 2

3

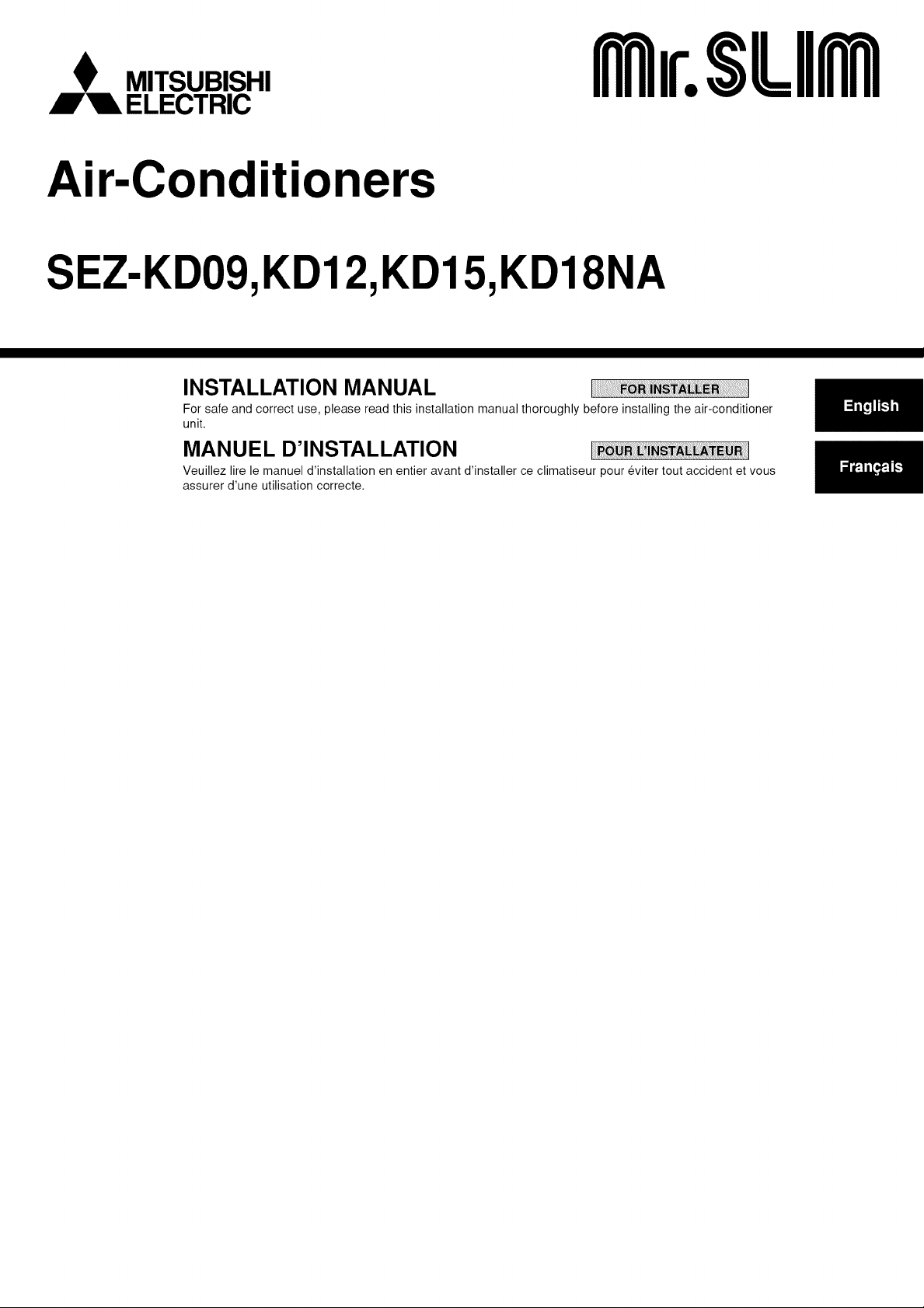

[Fig. 3-1]

3.1

(Unit: mm [in])

41

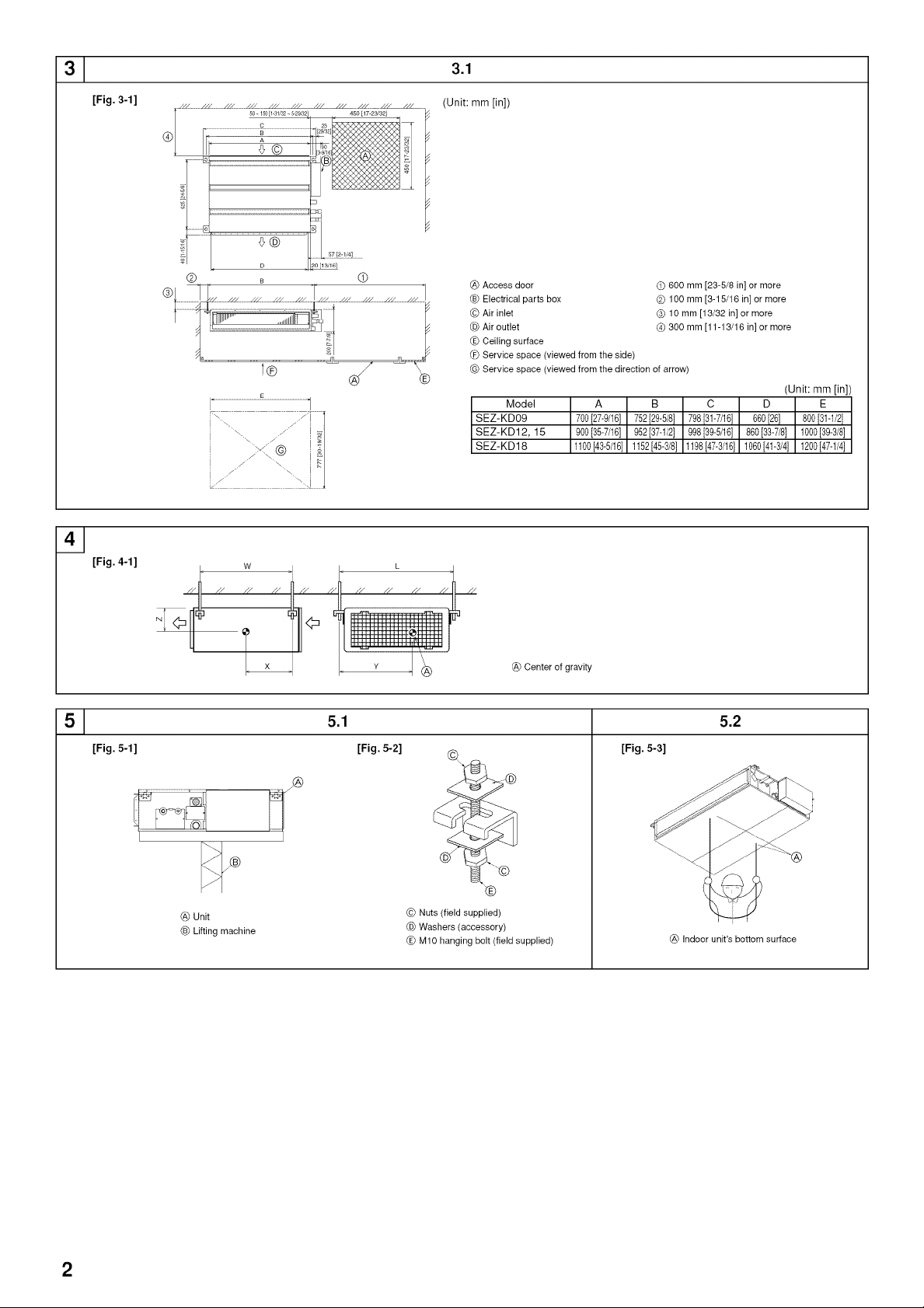

[Fig. 4-1]

@

D

5712-1/4 ]

@

(_ Access door

(_ Electrical parts box

(_©Air inlet

(_) Air outlet

(_) Ceiling surface

(F_)Service space (viewed from the side)

G(G)Service space (viewed from the direction of arrow)

Model A B C D E

SEZ-KD09 700[27-9/16] 752[29-5/8] 798[31-7/16] 660[26] 800[31-1/2]

SEZ-KD12,15 900135-7/16] 952137-1/2] 998139-5/16] 860133-7/8] 1000139-3/8]

SEZ-KD18 1100143-5/16]1152145-3/8]1198147-3/16]1060141-3/4]1200147q/4]

(_ Center of gravity

G 600 mm [23-5/8 in] or more

Q 100 mm [3-15/16 in] or more

@ 10 mm [13/32 in] or more

@ 300 mm [11-13/16 in] or more

(Unit: mm [in])

5__ 5.1 5.2

[Fig. 5-1] [Fig. 5-2]

©

[Fig. 5-3]

®

@ Unit © Nuts (field supplied)

(B_Lifting machine @ Washers (accessory)

(E_ M10 hanging bolt (field supplied)

(_ Indoor unit's bottom surface

2

Page 3

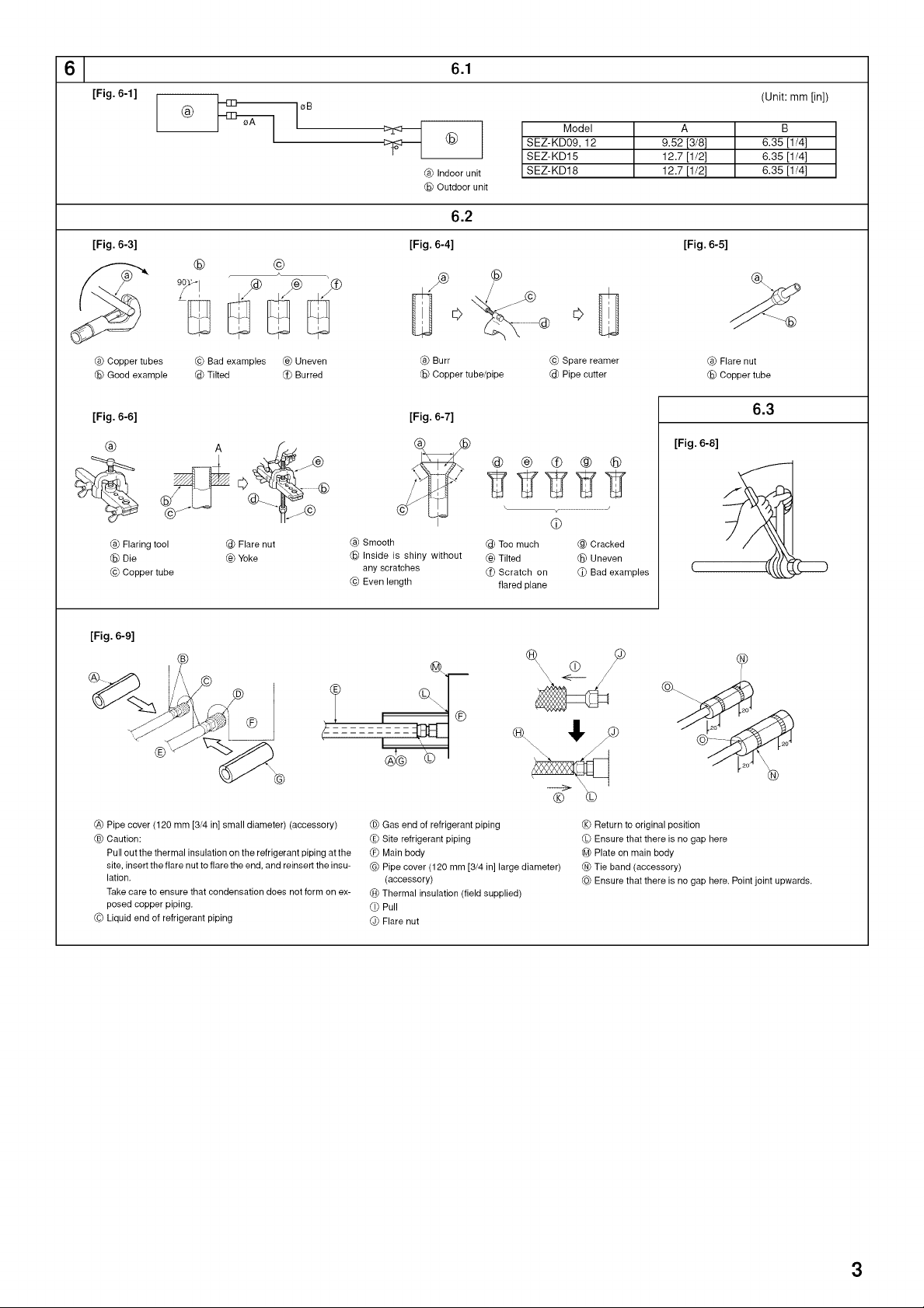

1 6.1

(Unit: mm [in])

[Fig. 6-1] _ _ 1_B

[Fig. 6-3]

@ Copper tubes @ Bad examples @ Uneven

@ Good example @ Tilted (_ Burred

[Fig. 6-6]

®

Ca_Flaring tool @ Flare nut

(_ Die Ce_Yoke

_ Copper tube

_) Indoor unit

@ Outdoor unit

[Fig. 6-4]

@ Burr @ Spare reamer

@ Copper tube/pipe @ Pipe cutter

[Fig. 6-7]

_) Smooth

@ Inside is shiny without

any scratches

@ Even length

SEZ-KD09, 12 9.52 [3/8] 6.35 [1/4]

SEZ-KD15 12.7 [1/2] 6.35 [1/4]

SEZ-KD18 12.7 [1/2] 6.35 [1/4]

6.2

@

@ @ O @ ®

g' ggg

_ .........................................J

@

@ Too much @ Cracked

Ce_Tilted @ Uneven

(_ Scratch on _ Bad examples

flared plane

Model A B

[Fig. 6-5]

®

@ Flare nut

@ Copper tube

6.3

[Fig. 6-8]

[Fig. 6-9]

®

(_ Pipe cover (120 mm [3/4 in] small diameter) (accessory)

C_ Caution:

Pull out the thermal insulation on the refrigerant piping at the

site, insert the flare nut to flare the end, and reinsert the insu-

lation.

Take care to ensure that condensation does not form on ex-

posed copper piping.

Cc_Liquid end of refrigerant piping

@ Gas end of refrigerant piping

_E_Site refrigerant piping

_ Main body

@ Pipe cover (120 mm [3/4 in] large diameter)

(accessory)

(_ Thermal insulation (field supplied)

_) Pull

@ Flare nut

® ©

(_ Return to original position

CL_Ensure that there is no gap here

@ Plate on main body

Tie band (accessory)

@ Ensure that there is no gap here. Point joint upwards.

3

Page 4

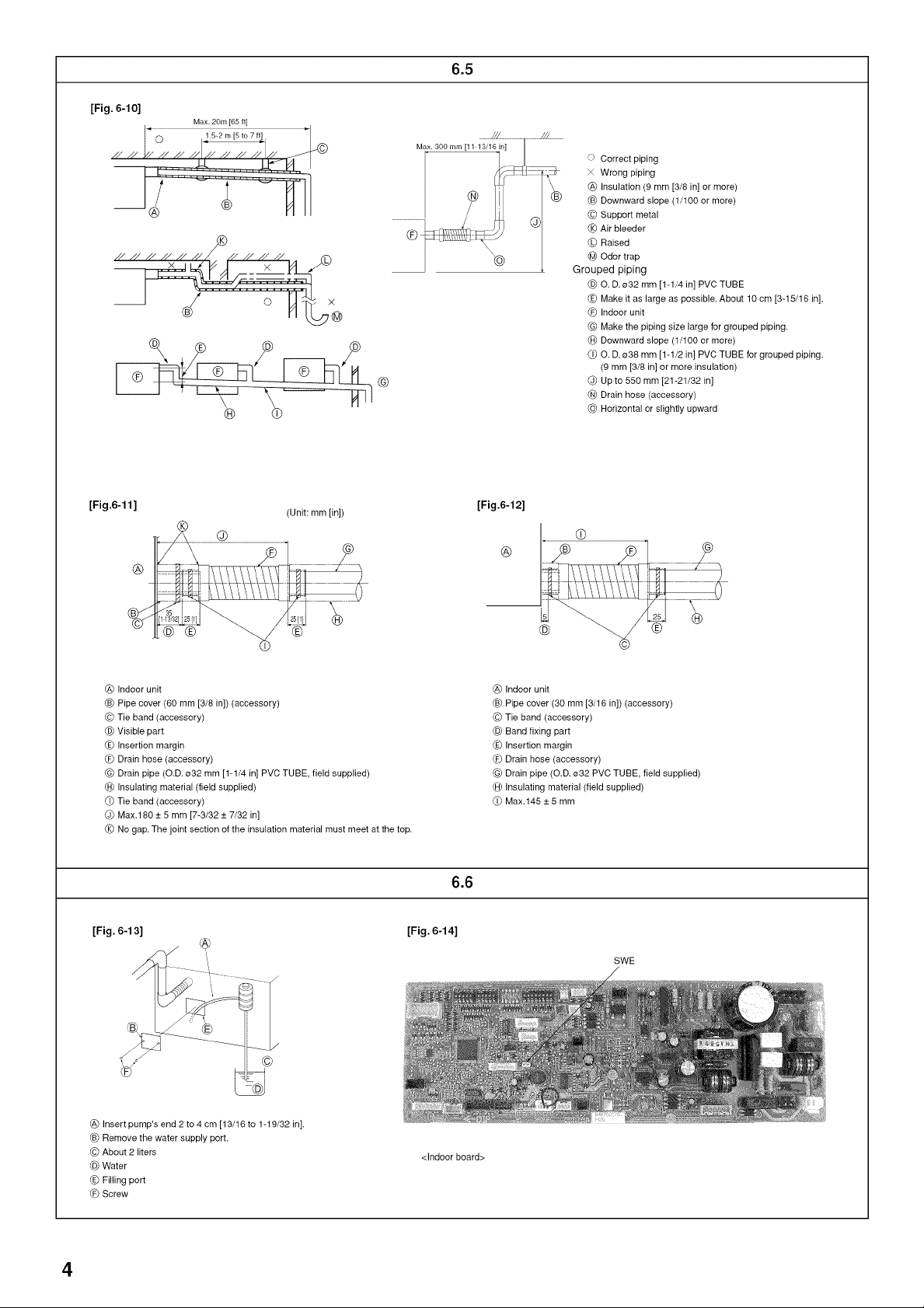

6.5

[Fig. 6-10]

140 1.5_2m [5to 7ft] _L_C_

////Y/// ////1_// _v

////////////J //////// _

Max. 20m [65 ft]

x ,_ _x _'_

[Fig.6-11]

@

®

(Unit: mm [in])

b Correct piping

>4 Wrong piping

@ Insulation (9 mm [3/8 in] or more)

Downward slope (1/100 or more)

© Support metal

(_ Air bleeder

(_ Raised

@ Odor trap

Grouped piping

@ O. D. e32 mm [1-1/4 in] PVC TUBE

(E_Make it as large as possible. About 10 cm [3-15/16 in].

@DIndoor unit

(_ Make the piping size large for grouped piping.

(_ Downward slope (1/100 or more)

O. D.038 mm [1-1/2 in] PVC TUBE for grouped piping.

(9 mm [3/8 in] or more insulation)

@ Up to 550 mm [21-21/32 in]

(_) Drain hose (accessory)

@ Horizontal or slightly upward

[Fig.6-12]

®

@ Indoor unit

Pipe cover (60 mm [3/8 in]) (accessory)

© Tie band (accessory)

@ Visible part

(E_ Insertion margin

@DDrain hose (accessory)

(_ Drain pipe (O.D. 032 mm [1-1/4 in] PVC TUBE, field supplied)

(_ Insulating material (field supplied)

(_ Tie band (accessory)

(_J)Max.180 + 5 mm [7-3/32 + 7/32 in]

(_ No gap. The joint section of the insulation material must meet at the top.

[Fig. 6-13] [Fig. 6-14]

©

_) Insert pump's end 2 to 4 cm [13/16 to 1-19/32 in].

(_ Remove the water supply port.

(© About 2 liters

(_) Water

(_, Filling port

@_ Screw

<Indoor board>

(_) Indoor unit

(_ Pipe cover (30 mm [3/16 in]) (accessory)

© Tie band (accessory)

(_) Band fixing part

C_,Insertion margin

@_Drain hose (accessory)

Drain pipe (O.D. 032 PVC TUBE, field supplied)

(€1_Insulating material (field supplied)

Ci_Max.145 + 5 mm

6.6

SWE

4

Page 5

71

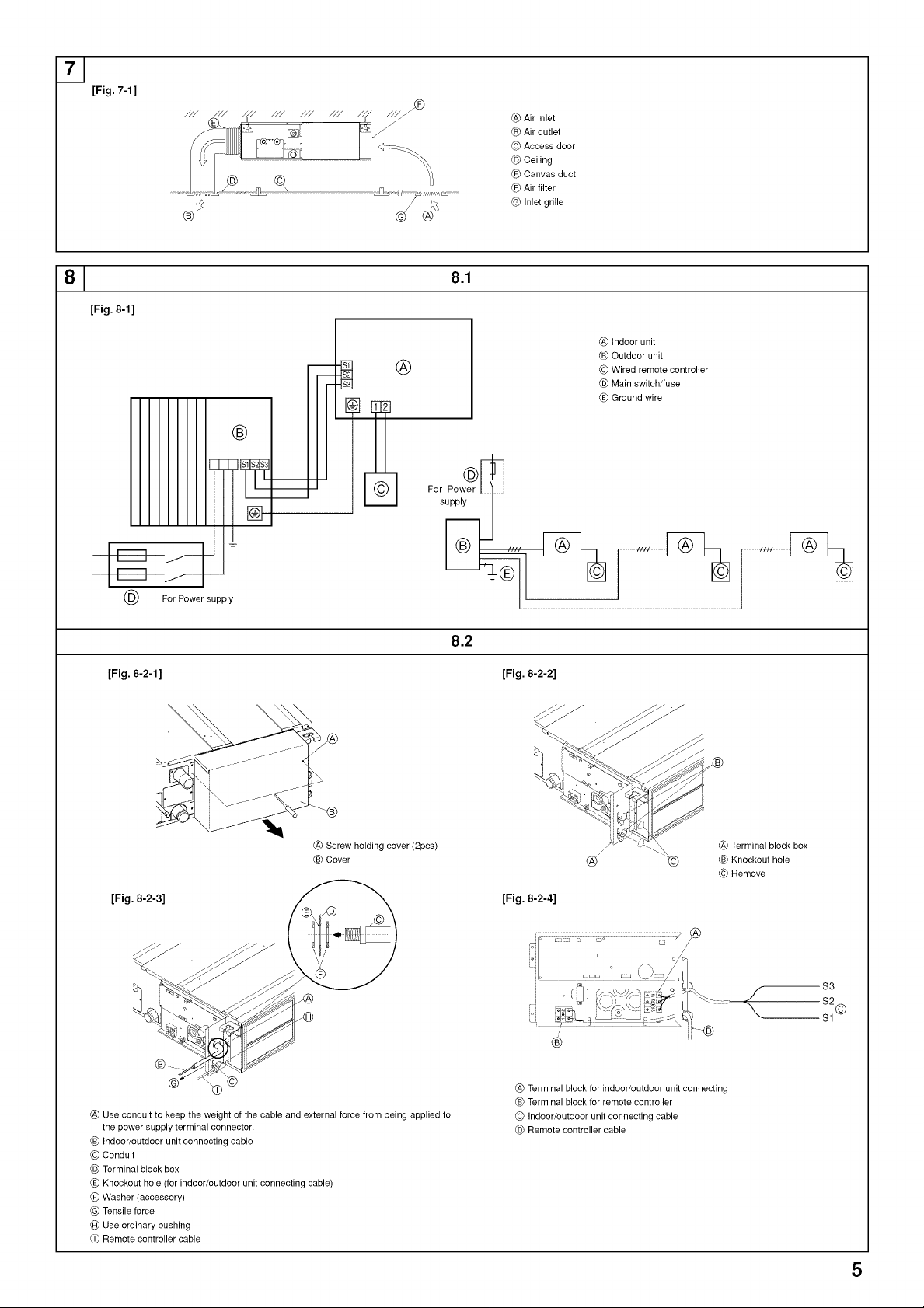

[Fig. 7-1]

®

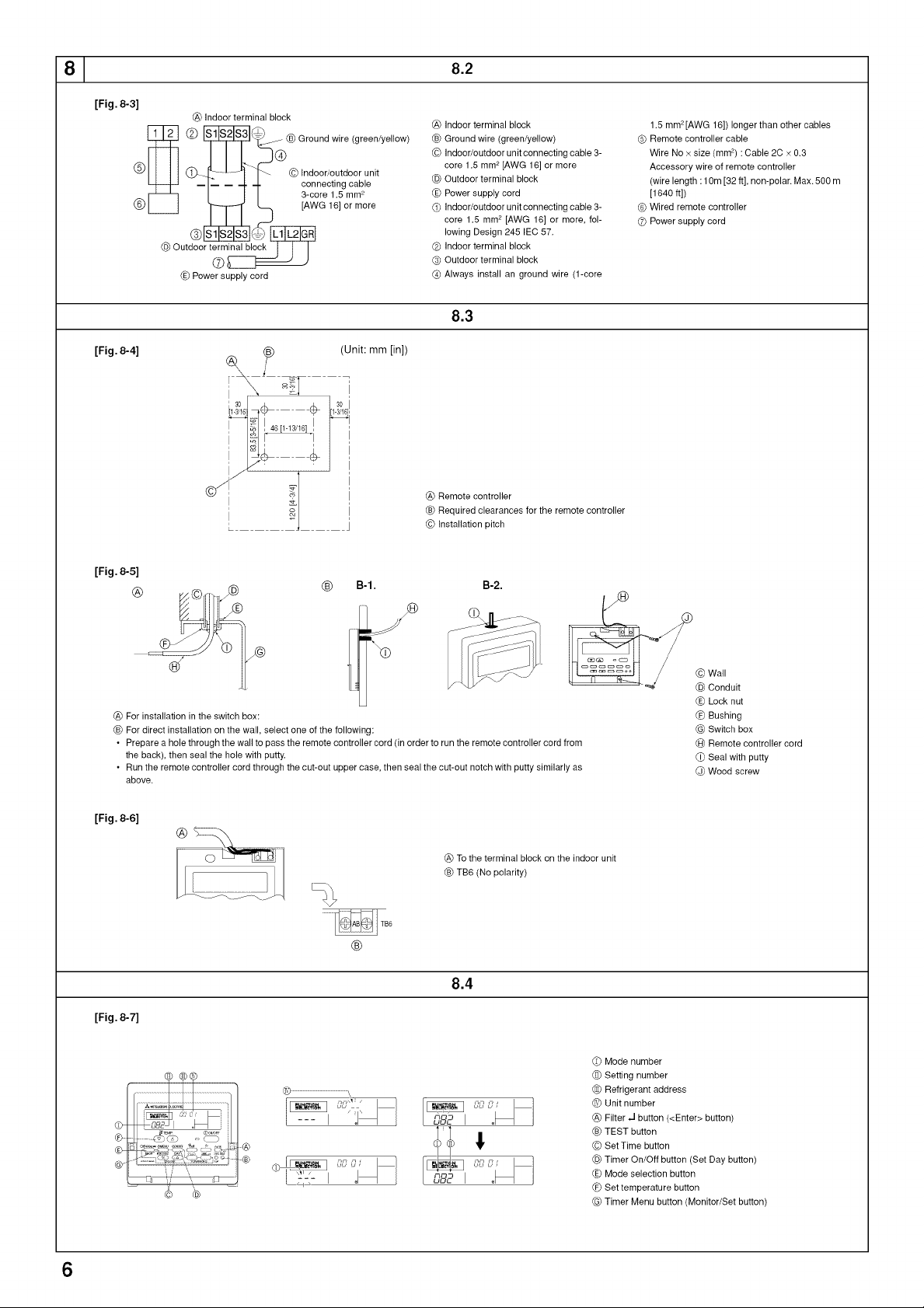

8 8.1

[Fig. 8-1]

®

(_ Air inlet

C_ Air outlet

C©Access door

(_) Ceiling

C_,Canvas duct

_ Air filter

G_ Inlet grille

@ Indoor unit

Outdoor unit

© Wired remote controller

@ Main switch/fuse

_E_Ground wire

For Power supply

8.2

[Fig. 8-2-1] [Fig. 8-2-2]

(8) Screw holding cover (2pcs) __ _ Terminal block box

C_ Cover (_ _ _ Knockout hole

[Fig. 8-2-3]

[Fig. 8-2-4]

_ i _ _ /_S _

© Remove

$3

®

(8) Use conduit to keep the weight of the cable and external force from being applied to

the power supply terminal connector.

C_ Indoor/outdoor unit connecting cable

© Conduit

(_) Terminal block box

C_,Knockout hole (for indoor/outdoor unit connecting cable)

_ Washer (accessory)

Tensile force

CH_Use ordinary bushing

Ci_Remote controller cable

(_ Terminal block for indoor/outdoor unit connecting

C_ Terminal block for remote controller

© Indoor/outdoor unit connecting cable

(_) Remote controller cable

5

Page 6

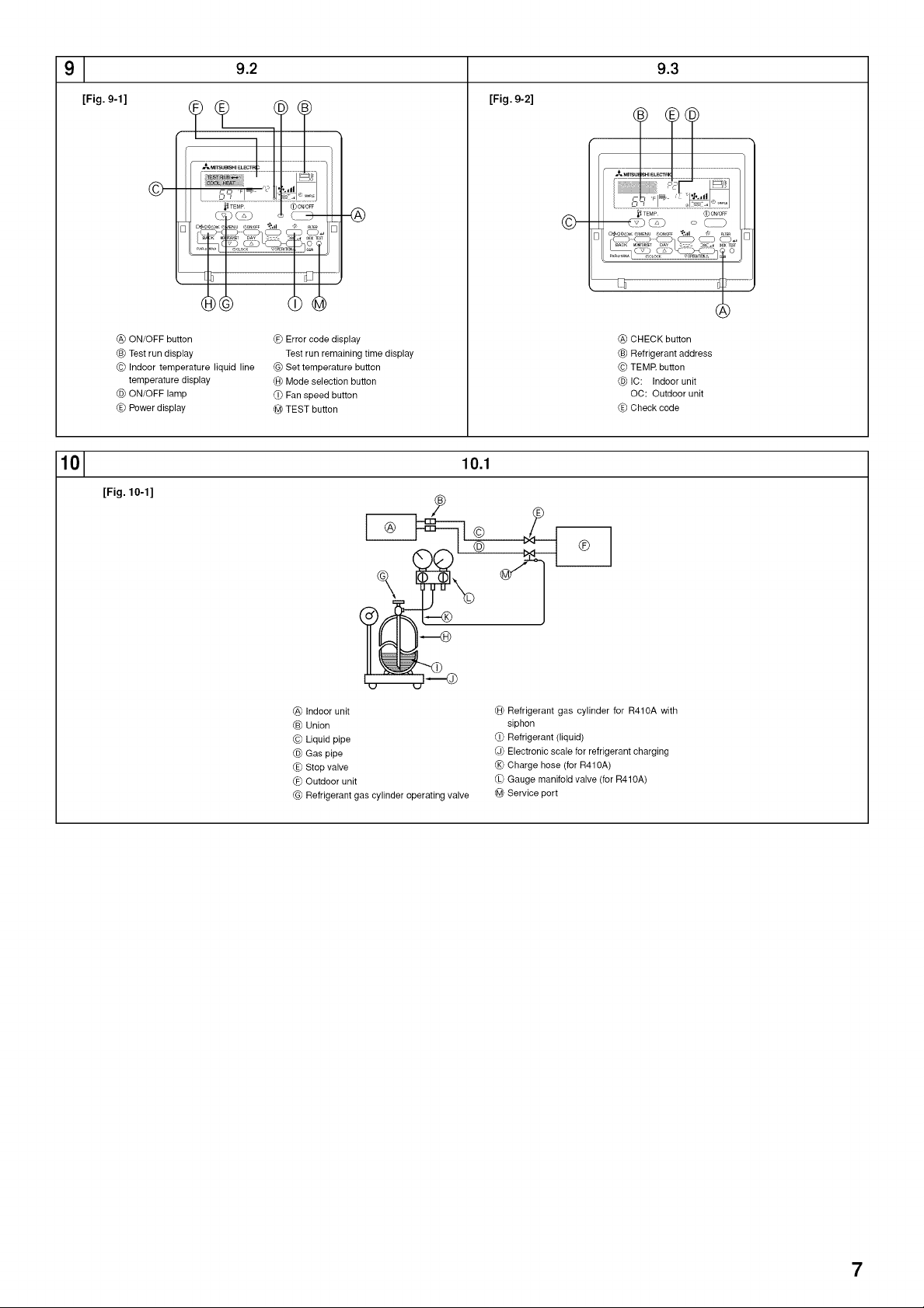

8 8.2

[Fig. 8-3]

@L-----J L_ b [AWG16] or more

(_ Indoor terminal block

Outdo o

@ Power supply cord

[Fig. 8-4]

__ CE;_ iUnit: mm [in])

(8) Indoor terminal block

C_ Ground wire (green/yellow)

Cc_Indoor/outdoor unit connecting cable 3-

core 1.5 mm 2 [AWG 16] or more

(_) Outdoor terminal block

C_,Power supply cord

O Indoor/outdoor unit connecting cable 3-

core 1.5 mm2 [AWG 16] or more, fol-

lowing Design 245 IEC 57.

(D Indoor terminal block

@ Outdoor terminal block

@ Always install an ground wire (1-core

8.3

(8) Remote controller

C_ Required clearances for the remote controller

Cc_Installation pitch

1.5 mm 2[AWG 16]) longer than other cables

@ Remote controller cable

Wire No x size (mm2) : Cable 2C × 0.3

Accessory wire of remote controller

(wire length : 10m [32 ft], non-polar. Max. 500 m

[1640 ft])

O Wired remote controller

(_ Power supply cord

[Fig. 8-5]

@ B-1.

®

@ For installation in the switch box:

CB_For direct installation on the wall, select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run the remote controller cord from

the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cut-out notch with putty similarly as

above.

[Fig. 8-6]

(_ To the terminal block on the indoor unit

C_ TB6 (No polarity)

®

8.4

[Fig. 8-7]

C©Wall

(_) Conduit

C_,Lock nut

@_Bushing

Switch box

CA_Remote controller cord

Ci_Seal with putty

CJ_Wood screw

(_ Mode number

(_ Setting number

(_ Refrigerant address

(_ Unit number

(_ Filter .I button (<Enter> button)

C_ TEST button

&,

"_-',-_-I

6 4_

C©Set Time button

(_) Timer On/Off button (Set Day button)

C_,Mode selection button

_ Set temperature button

Timer Menu button (Monitor/Set button)

6

Page 7

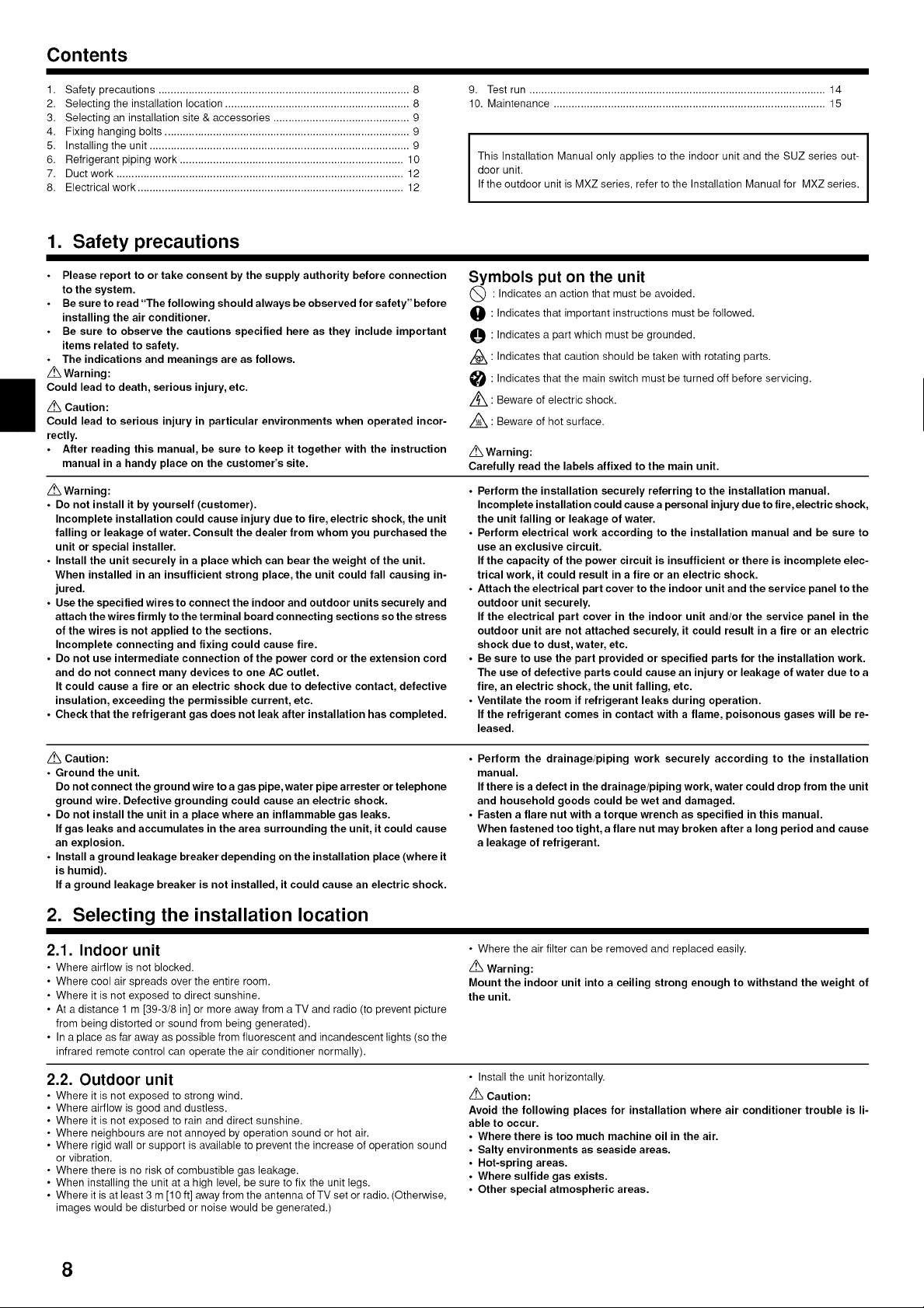

91

[Fig. 9-1]

9.2 9.3

[Fig. 9-2]

©

_TEMP

@ ON/OFF button

Test run display

© Indoor temperature liquid line

temperature display

@ ON/OFF lamp

(E_ Power display

_ Error code display

Test run remaining time display

(_ Set temperature button

(_ Mode selection button

_) Fan speed button

@ TEST button

10 lO.1

[Fig. lO-1]

©

@ Indoor unit

Union

© Liquid pipe

@ Gas pipe

(E_ Stop valve

_ Outdoor unit

CG_Refrigerant gas cylinder operating valve

@ CHECK button

Refrigerant address

© TEME button

@ IC: Indoor unit

OC: Outdoor unit

(E_ Check code

(H_Refrigerant gas cylinder for R410A with

siphon

(i_ Refrigerant (liquid)

(J_)Electronic scale for refrigerant charging

(_ Charge hose (for R410A)

(L_Gauge manifold valve (for R410A)

@ Service port

7

Page 8

Contents

1. Safety precautions ................................................................................... 8

2. Selecting the installation location ............................................................. 8

3. Selecting an installation site & accessories ............................................. 9

4. Fixing hanging bolts ................................................................................. 9

5. Installing the unit ...................................................................................... 9

6. Refrigerant piping work .......................................................................... 10

7. Duct work ............................................................................................... 12

8. Electrical work ........................................................................................ 12

1. Safety precautions

Please report to or take consent by the supply authority before connection

to the system.

Be sure to read "The following should always be observed for safety" before

installing the air conditioner.

Be sure to observe the cautions specified here as they include important

items related to safety.

• The indications and meanings are as follows.

/_ Warning:

Could lead to death, serious injury, etc.

Z_ Caution:

Could lead to serious injury in particular environments when operated incor-

rectly.

After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer's site.

z_ Warning:

• Do not install it by yourself (customer).

Incomplete installation could cause injury due to fire, electric shock, the unit

falling or leakage of water. Consult the dealer from whom you purchased the

unit or special installer.

• Install the unit securely in a place which can bear the weight of the unit.

When installed in an insufficient strong place, the unit could fall causing in-

jured.

• Use the specified wires to connect the indoor and outdoor units securely and

attach the wires firmly to the terminal board connecting sections so the stress

of the wires is not applied to the sections.

Incomplete connecting and fixing could cause fire.

• Do not use intermediate connection of the power cord or the extension cord

and do not connect many devices to one AC outlet.

It could cause a fire or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

• Check that the refrigerant gas does not leak after installation has completed.

9. Test run .................................................................................................. 14

10. Maintenance .......................................................................................... 15

This Installation Manual only applies to the indoor unit and the SUZ series out-

door unit.

If the outdoor unit is MXZ series, refer to the Installation Manual for MXZ series.

Symbols put on the unit

: Indicates an action that must be avoided.

O: Indicates that important instructions must be followed.

O : Indicates a part which must be grounded.

z_: Indicates that caution should be taken with rotating parts.

: Indicates that the main switch must be turned off before servicing.

Z_ : Beware of electric shock.

z_ : Beware of hot surface.

Z_ Warning:

Carefully read the labels affixed to the main unit.

• Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to fire, electric shock,

the unit falling or leakage of water.

• Perform electrical work according to the installation manual and be sure to

use an exclusive circuit.

If the capacity of the power circuit is insufficient or there is incomplete elec-

trical work, it could result in a fire or an electric shock.

• Attach the electrical part cover to the indoor unit and the service panel to the

outdoor unit securely.

If the electrical part cover in the indoor unit and/or the service panel in the

outdoor unit are not attached securely, it could result in a fire or an electric

shock due to dust, water, etc.

• Be sure to use the part provided or specified parts for the installation work.

The use of defective parts could cause an injury or leakage of water due to a

fire, an electric shock, the unit falling, etc.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a flame, poisonous gases will be re-

leased.

/_, Caution:

• Ground the unit.

Do not connect the ground wire to a gas pipe, water pipe arrester or telephone

ground wire. Defective grounding could cause an electric shock.

• Do not install the unit in a place where an inflammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it could cause

an explosion.

• Install a ground leakage breaker depending on the installation place (where it

is humid).

If a ground leakage breaker is not installed, it could cause an electric shock.

2. Selecting the installation location

2.1. Indoor unit

• Where airflow is not blocked.

• Where cool air spreads over the entire room.

• Where it is not exposed to direct sunshine.

• At a distance 1 m [39-3/8 in] or more away from aTV and radio (to prevent picture

from being distorted or sound from being generated).

• In a place as far away as possible from fluorescent and incandescent lights (so the

infrared remote control can operate the air conditioner normally).

2.2. Outdoor unit

• Where it is not exposed to strong wind.

• Where airflow is good and dustless.

• Where it is not exposed to rain and direct sunshine.

• Where neighbours are not annoyed by operation sound or hot air.

• Where rigid wall or support is available to prevent the increase of operation sound

or vibration.

• Where there is no risk of combustible gas leakage.

• When installing the unit at a high level, be sure to fix the unit legs.

• Where it is at least 3m [10 ft] away from the antenna of TV set or radio. (Otherwise,

images would be disturbed or noise would be generated.)

• Perform the drainage/piping work securely according to the installation

manual,

If there is a defect in the drainage/piping work, water could drop from the unit

and household goods could be wet and damaged,

• Fasten a flare nut with a torque wrench as specified in this manual,

When fastened too tight, a flare nut may broken after a long period and cause

a leakage of refrigerant,

• Where the air filter can be removed and replaced easily.

Warning:

Mount the indoor unit into a ceiling strong enough to withstand the weight of

the unit.

• Install the unit horizontally.

Z_ Caution:

Avoid the following places for installation where air conditioner trouble is li-

able to occur.

• Where there is too much machine oil in the air.

• Salty environments as seaside areas.

• Hot-spring areas.

• Where sulfide gas exists.

• Other special atmospheric areas.

8

Page 9

3. Selecting an installation site & accessories

• Select a site with sturdy fixed surface that is strong enough to support the weight of

unit.

• Before installing unit, the routing to carry in unit to the installation site should be

determined.

• Select a site where the unit is not affected by entering air.

• Select a site where the flow of supply and return air is not blocked.

• Select a site where refrigerant piping can easily be installed to the outside.

• Select a site which allows the supply air to be fully distributed in a room.

• Do not install unit at a site near a lot of oil or steam.

• Do not install unit at a site where combustible gas may generate, flow in, stagnate

or leak.

• Do not install unit at a site where there is equipment generating high frequency

waves (a high frequency wave welder for example).

• Do not install unit at a site where fire detector is located at the supply air side. (Fire

detector may operate erroneously due to the heated air supplied during heating

operation.)

• If there are chemicals in the area, such as chemical plants and hospitals, full inves-

tigation is required before installing unit. (The plastic components may be dam-

aged depending on the chemical product applied.)

• If the unit runs for long hours when the air above the ceiling is at high temperature/

high humidity (due point above 79 °F [26 °C]), condensation may be produced in

the indoor unit. Add insulation material (10-20 mm [13/32 to 13/16 in]) to the entire

surface of the indoor unit to avoid condensation.

3.1. Install the indoor unit on a ceiling strong enough

to sustain its weight

[Fig. 3-1] (P.2)

@ Access door (_ Electrical parts box

© Air inlet (_)Air outlet

(E_Ceiling surface @_Service space (viewed from the side)

(_ Servicespace (viewed from the direction of arrow)

(_ 600 mm[23-5/8 in] or more (D 100mm [3-15/16 in] or more

Q 10 mm [13/32 in] or more @ 300mm [11-13/16 in] or more

/_ Warning:

The unit must be securely installed on a structure that can sustain its weight. If

the unit is mounted on an unstable structure, it may fall down, causing injuries.

3.2. Securing installation and service space

• Select the optimum direction of supply airflow according to the configuration of the

room and the installation position.

• As the piping and wiring are connected at the bottom and side surfaces, and the

maintenance is made at the same surfaces, allow a proper space properly. For the

efficient suspension work and safety, provide a space as much as possible.

3.3. Outdoor unit

Ventilation and service space

Units should be installed by licensed contractor accordingly to local code require-

ments.

For outdoor units to be connected, refer to the Installation Manual that comes with

the units.

3.4. Indoor unit accessories

The unit is provided with the following accessories:

No. Name Quantity

Q Pipecover (forrefrigerant pipingjoint) 120 mm [3/4 in] Small diameter 1

Q Pipecover (forrefrigerant pipingjoint) 120 mm [3/4 in] Large diameter 1

Q Tie band 7

(_ Remote controller parts 1

@ Remote controller cable 1

@ Washer (for hanging) 8

Q Drain hose 1

Q Pipe cover (for Drain hose) 60 mm [3/8 in] 1

@ Pipe cover (for Drain hose) 30 mm [3/16 in] 1

@ Washer (for power source wiring) 2

4. Fixing hanging bolts

4.1. Fixing hanging bolts

[Fig. 4-1] (P.2)

@ Centerof gravity

Hanging structure

• Ceiling:The ceiling structure varies from building to one another. For detailed infor-

mation, consult the construction company.

Center of gravity and Product Weight

Model name

SEZ-KD09

SEZ-KD12

SEZ-KD15

SEZ-KD18

W (mm [in]) L (mm [in]) X (mm [in]) Y (mm [in]) Z (mm [in]) Product Weight (kg [Ib])

625 [24-5/8] 752 [29-5/8] 263 [10-3/8] 351 [13-27/32] 106 [4-3/16] 19 [42]

625 [24-5/8] 952 [37-1/2] 286 [11-9/32] 448 [17-21/32] 104 [4-1/8] 22 [50]

625 [24-5/8] 952 [37-1/2] 280 [11-1/32] 437 [17-7/32] 104 [4-1/8] 24 [54]

625 [24-5/8] 1152 [45-3/8] 285 [11-1/4] 527 [20-3/4] 104 [4-1/8] 28 [62]

5. Installing the unit

5.1.

Hanging the unit

I,

Transport the indoor unit to the site in its original packing material.

I,

To hang the indoor unit, use a lifting machine to lift and pass through the

hanging bolts.

[Fig. 5-1] (P.2)

@ Unit

@ Lifting machine

[Fig. 5-2] (P.2)

© Nuts (field supplied)

@ Washers (accessory)

(E_M10hanging bolt (fieldsupplied)

• If necessary, reinforce the hanging bolts to protect against earthquakes.

* Use M10 for hanging bolts and reinforcements to protect against earthquake

(field supplied).

(_) Ceiling reinforcement (edge beam, etc.) must be required to keep the ceiling level

and to prevent it from vibrating.

(D Cut and remove the ceiling beams.

(_ Reinforce the ceiling, and add other beams for fixing the ceiling boards.

5.2. Confirming the unit's position and attaching hang-

ing bolts

Use the gauge supplied with the panel to confirm that the unit and hanging

bolts are positioned in place. If they are not positioned in place, it may

condensated due to drafts. Be sure to check the position.

Use a level to check that the surface indicated by @ is straight. Ensure that

the hanging bolt nuts are tightened to fix the hanging bolts.

To ensure that drain is discharging properly, be sure to hang the unit is

straight using a level.

[Fig. 5-3] (P.2)

_) Indoorunit's bottomsurface

Z_ Caution:

Be sure to install the unit level.

9

Page 10

6. Refrigerant piping work

6.1. Refrigerant pipe

[Fig. 6-1] (P.3)

Ca_Indoorunit

@ Outdoor unit

Refer to the outdoor unit Instruction Manual for restrictions on

the height difference between units and for the amount of additional refrigerant

charge.

Avoid the following places for installation where the air conditioner malfunction is

liable to occur.

Where there is too much oil in the air such as for machines or cooking.

Salty environments as seaside areas.

Hot-spring areas.

Where sulfide gas exists.

Other special atmospheric areas.

This unit has flared connections on both indoor and outdoor sides. (Fig. 6-1)

Refrigerant pipes are used to connect the indoor and outdoor units as shown inthe

figure below.

• Insulate both refrigerant and drainage piping completely to prevent condensation.

Piping preparation

• Refrigerantpipes 3, 5, 7, 10 and 15 m [5 ft] are availableas optional items.

(1) The specifications of commercially available pipes.

Model Pipe

SEZ- For liquid 6.35 1/4 0.8rnm[1/16in] 8mm[11/32in]

KD09 For gas 9.52 3/8 0.8rnm[1/16in] 8mm[11/32in]

SEZ- For liquid 6.35 1/4 0.8rnm[1/16in] 8mm[11/32in]

KD 12 For gas 9.52 3/8 0.8rnm[1/16in] 8mm[11/32in]

SEZ- For liquid 6.35 1/4 0.8rnm[1/16in] 8mm[11/32in]

KD15 For gas 12.7 1/2 0.8rnm[1/16in] 8mm[11/32in]

SEZ- For liquid 6.35 1/4 0.8rnm[1/16in] 8mm[11/32in]

KD 18 For gas 12.7 5/8 1.0rnm[1/16in] 8mm[11/32in]

Outside diameter Min wall Insulation

mm inch thickness thickness

Insulation

material

Heat-resistant

foam plastic,

0.045 specific

gravity

6.2.3. Putting nut on

[Fig. 6-5] (P.3)

Ca_Flare nut

@ Copper tube

• Remove flare nuts attached to indoor and outdoor unit, then attach them on pipe/

tube after burr removal.

(not possible to attach them on after flaring work)

6.2.4. Flaring work

[Fig. 6-6] (P.3)

Ca_Flaringtool

(_ Die

_ Copper tube

@ Flare nut

Yoke

• Carry out flaring work using flaring tool as shown below.

Dimension

Pipe diameter

(mm [in]) B -+°4[-u32](mm [in])

6.35 [1/4] 9.1 [3/8]

9.52 [3/8] 13.2 [17/32]

12.7 [1/2] 16.6 [21/32]

15.88 [5/8] 19.7 [25/32]

Firmly hold copper tube in a die in the dimension shown in the table at above.

6.2.5. Check

[Fig. 6-7] (P.3)

(_ Smooth (_ Scratch on flared plane

@ Insideis shiny withoutany scratches @ Cracked

@ Even length @ Uneven

@ Toe much (D Badexamples

@_Tilted

• If flare is defective, cut off the flared section and repeat.

When the tool for R410A is used

A (ram [in])

Clutch type

0 to 0.5 [0 to 1/32]

0 to 0.5 [0 to 1/32]

0 to 0.5 [0 to 1/32]

0 to 0.5 [0 to 1/32]

(2) Ensure that the two refrigerant pipes are well insulated to prevent condensation.

(3) Refrigerant pipe bending radius must be 10 cm [3-15/16 in] or more.

/_, Caution:

Use insulation of specified thickness. Excessive thickness prevents storage

behind the indoor unit and smaller thickness causes condensation.

6.2. Flaring work

• Main cause of gas leakage is defect in flaring work.

Carry out correct flaring work in the following procedure.

6.2.1. Cutting the pipes

[Fig. 6-3] (P.3)

Ca_Copper tubes

(_)Goodexample

_ Badexamples

@ Tilted

_e_Uneven

(_ Burred

• Use a pipe cutter cut the copper tube correctly.

6.2.2. Burr removal

[Fig. 6-4] (P.3)

Ca_Burr

(_)Coppertube/pipe

_ Spare reamer

@ Pipecutter

• Completely remove all burrs from the cut section of pipe/tube.

• Point the end of the copper tube/pipe to downward direction as you remove burrs in

order to avoid burrs drop in the tubing.

6.3. Pipe connection

[Fig. 6-8] (P.3)

• Apply a thin coat of refrigeration oil on the surface of pipe.

• When connecting, first align the center, then tighten the flare nut 3 to 4 turns.

• Use tightening torque table below as a guideline for indoor unit side union joint section,

and tighten using two wrenches. Excessive tightening damages the flare section.

Copper pipe O.D.

(mm [in])

66.35 [1/4]

69.52 [3/8]

612.7 [1/2]

615.88 [5/8]

Z_ Warning:

Be careful of removing the flare nut! (Internally pressurize can cause them to

burst off.)

Remove the flare nut as follows:

1. Loosen the nut until you hear a hissing noise.

2. Do not remove the nut until the gas has been completely released (i.e., hiss-

ing noise stops).

3. Check that the gas has been completely released, and then remove the nut.

Outdoor unit connection

Connect pipes to stop valve pipe joint of the outdoor unit following the same proce-

dure as the indoor unit.

• For tightening, use a torque wrench or spanner, and use the same tightening torque

procedure for indoor unit.

Flare nut O.D. Tightening torque

(mm [in]) (N.m)

17 [11/16] 14- 18

22 [7/8] 34- 42

26 [1-1/32] 49- 61

29 [1-5/32] 68- 82

10

Page 11

6. Refrigerant piping work

Refrigerant pipe insulation

• After connecting refrigerant piping, insulate the joints (flared joints) with thermal

insulation tubing as shown below.

[Fig. 6-9] (P.3)

@ Pipecover (120 mm [3/4 in]small diameter) (accessory)

_B_Caution:

Pullout thethermal insulationon the refrigerant pipingat the site,insertthe flarenut toflare

the end,and reinsertthe insulation.

Takecare to ensure thatcondensation does notform on exposed copper piping.

© Liquidend of refrigerant piping

@ Gasend of refrigerant piping

(E_Site refrigerant piping

@_Mainbody

(_ Pipecover (120 mm [3/4 in] large diameter) (accessory)

(_ Thermal insulation (fieldsupplied)

(_ Pull

@ Flare nut

(_ Returnto original position

(_ Ensurethat there is no gap here

@ Plate on mainbody

(_) Tie band (accessory)

@ Ensurethat there is no gap here. Point joint upwards.

1.Remove and discard the rubber bung which is inserted in the end of the unit piping.

2.Flare the end of the refrigerant piping.

3.Remove the thermal insulation on the site refrigerant piping and replace the insula-

tion in its original position.

Cautions On Refrigerant Piping

Be sure to use non-oxidized brazing for brazing to ensure that foreign mat-

ter or moisture do not enter into the pipe.

Be sure to apply refrigerating machine oil over the flare connection seating

surface and tighten the connection using a double spanner.

Provide a metal brace to support the refrigerant pipe so that no load is

imparted to the indoor unit end pipe.This metal brace should be provided

50 cm [19-11/16 in] away from the indoor unit's flare connection.

6.4. Purging procedures leak test

( PURGING PROCEDURES 1

*Close

Stop valve

*Open

Hexagonal wrench *4 to 5 turns

-0.10IMPs Compound pressure gauge

Stop valve (-760 mmHg) (for R410A)

_ , Pressure gauge

,F_S_ "_ / (for R410A)

Ill[ _ _ _ Gauge manifold

./

IIL ,,_ _valve (for R410A)

II Ij,_ffJ-'_ Handle2, Handle High

_ll_,__-_k Low ///7 _ Charge hose (for

_" \X Stop /j/ _,.=.. R410A)

. ./ \\valve J/ / ' va_u_ (or the vacuum

Service _ / i_'"1 numn wth th_

oft -- • - _ r-...r .......

P ,,7 Wmaow f'b'rrrz¢_7" function to prevent

Charge hose Ada)ter for the back flow)

(for R410A) preventing the

back flow

l

['Remove the gage manifold valve quickly from the service port of the stop valve.

l

After refrigerant pipes are connected and evacuated, fully open all stop valves on']

gas and liquid pipe sides. |

Operating without fully opening lowers the performance and causes trouble. )

1

7 m [23 ft] maximum Charge the prescribed

I Pipe length : 1 [ Pipe length exceeding 7 m [23 ft] l

No gas charge is needed, amount of gas.

1

Connect the refrigerant pipes (both the liquid and gas pipes) between the indoor"

and the outdoor units.

l

Remove the service port cap of the stop valve on the side of the outdoor unit gas pipe."

(The stop valve will not work in its initial state fresh out of the factory (totally closed

with cap on).) .,

l

Connect the gage manifold valve and the vacuum pump to the service port of the"

stop valve on the gas pipe side of the outdoor unit.

l

(Run the vacuum pump. (Vacuumize for more than 15 minutes.)

!

Check the vacuum with the gage manifold valve, then close the gage manifold valve,_

and stop the vacuum pump. )

1

Leave it as is for one or two minutes. Make sure the pointer of the gage manifold']

valve remains in the same position. Confirm that the pressure gage show -0.101 MPa|

(-760 mmHg). J

l

4,

(

(

(

6.5. Drain piping work

• Ensure that the drain piping is downward (pitch of more than 1/100) to the outdoor

• Ensure that any cross drain piping is less than 20 m [65 ft] (excluding the differ-

• Use a hard vinyl chloride pipe O.D. e32 mm [1-1/4 in] for drain piping.

• Ensure that collected pipes are 10 cm [3-15/16 in] lower than the unit body's drain

• Do not provide any odor trap at the drain discharge port.

• Place the end of the drain piping in a position where odor is not generated.

• Do not put the end of the drain piping in any drain where ionic gases are generated.

Grouped piping

Tighten the cap to the service port to obtain the initial status. )

Retighten the cap )

Leak test )

(discharge) side. Do not add a trap.

ence of elevation). If the drain piping is long, add metal braces to prevent it from

shaking. Never provide an air vent pipe, otherwise drain may be ejected.

port.

[Fig. 6-10] (P.4)

c Correct piping

x Wrong piping

@ Insulation (9 mm [3/8in] or more)

Downward slope (1/100 or more)

© Support metal

(_ Air bleeder

(_ Raised

@ Odor trap

@ O. D. o32 mm [1-1/4 in] PVC TUBE

(E_Make itas large as possible. About 10 cm [3-15/18 in].

@_Indoorunit

(_ Makethe pipingsize largefor grouped piping.

(_ Downward slope (1/100 or more)

O. D.038 mm[1-1/2 in] PVC TUBEfor groupedpiping.

(9 mm [3/8 in] or more insulation)

@ Up to 550 mm [21-21/32 in]

(_)Drain hose (accessory)

@ Horizontal or slightly upward

11

Page 12

6. Refrigerant piping work

1. Insert the drain hose (accessory) into the drain port (insertion margin: 25 mm

[1 in]).

(The drain hose must not be bent more than 45 ° to prevent the hose from break-

ing or clogging.)

(Attach the hose with glue for the hard vinyl chloride pipe, and fix it with the band

(accessory).)

2. Attach the drain pipe (O.D. o32 mm [1-1/4 in] PVC TUBE, field supplied).

(Attach the pipe with glue for the hard vinyl chloride pipe, and fix it with the band

(accessory).)

3. Perform insulation work on the drain pipe (O.D. 032 mm [1-1/4 in] PVC TUBE)

and on the socket (including elbow).

4. Check the drainage. (Refer to [Fig. 6-13])

5. Attach the insulating material (accessory), and fix it with the band (accessory) to

insulate the drain port.

[Fig. 6-11] (R4)

_) Indoorunit

(_ Pipecover (60 mm [3/8 in]) (accessory)

(© Tie band(accessory)

(_)Visiblepart

_, insertion margin

@_Drain hose (accessory)

G(_Drain pipe (O.D.032 mm [1-1/4 in] PVC TUBE, field supplied)

(€1_Insulating material (field supplied)

(i_ Tie band(accessory)

(J_)Max.180+ 5 mm[7-3/32 + 7/32 in]

(_ Nogap.The joint of the insulation material must meet atthe top.

[Drainage by gravity]

1. Insert the drain hose (accessory) into the drain port.

(The drain hose must not be bent more than 45 ° to prevent the hose from breaking

or clogging.)

The connecting part between the indoor unit and the drain hose may be discon-

nected at the maintenance. Fix the part with the accessory band, not be adhered.

2. Attach the drain pipe (O.D. e32 PVC TUBE, field supplied).

(Attach the pipe with glue for the hard vinyl chloride pipe, and fix it with the band

(accessory).)

3. Perform insulation work on the drain pipe (O.D. e32 PVC TUBE) and on the socket

(including elbow).

7. Duct work

[Fig. 6-12] (P.4) * Drainage by gravity

(_) Indoor unit

(_ Pipe cover (30 mm [3/16 in]) (accessory)

© Tie band (accessory)

(_) Band fixing part

<_, Insertion margin

@_ Drain hose (accessory)

G(_Drain pipe (O.D. 032 PVC TUBE, field supplied)

(€1_Insulating material (field supplied)

(i_ Max. 145+ 5 mm

6.6. Confirming drain discharge

b' Make sure that the drain-up mechanism operates normally for discharge

and that there is no water leakage from the connections.

• Be sure to confirm the above when in heating operation.

• Be sure to confirm the above before ceiling work is done in the case of a new

construction.

1. Remove the water supply port cover on the same side as the indoor unit piping.

2. Fill water into the feed water pump using a feed water tank. Be sure to put the end

of the pump or tank in a drain pan. (If the insertion is incomplete, water may flow

over the machine.)

3. Perform the test run in cooling mode, or turn on the switch SWE on the controller

circuit board. (The drain pump and the fan are forced to operate without any re-

mote controller operation.) Make sure using a transparent hose that drain is dis-

charged. SWE SWE

ON OFF ON OFF

4. After confirmation, cancel the test run mode, and turn off the main power. When

the switch SWE has been turned on, turn it off, and attach the water supply port

cover into its original position.

[Fig. 6-13] (P.4)

(_ Insertpump's end 2to 4 cm [13/16 to 1-19/32 in].

_ Removethe water supply port.

© About 2000 liters

(_)Water

<_,Filling port

@_Screw

[Fig. 6-14] (P.4)

<Indoor board>

SWE SWE

liTir-I ---. I-lilil

ON OFF ON OFF

• When connecting ducts, insert a canvas duct between the main body and the duct.

• Use non-combustible duct components.

/_ Caution:

The sound from the intake will increase dramatically if intake (_) is fitted

directly beneath the main body. Intake @ should therefore be installed as

far away from the main body as possible.

Particular care is required when using it with bottom inlet specifications.

Install sufficient thermal insulation to prevent condensation forming on

outlet duct flanges and outlet ducts.

To connect the air conditioner main body and the duct for potential equali-

zation.

8. Electrical work

8.1. Power supply

Electrical specification Input capacity Main Switch/Fuse (A)

Power supply SEZ-KD09 SEZ-KD12 SEZ-KD15 SEZ-KD18

(1 phase _/N, 208/230V, 60Hz 10 10 20 20

Z_ Warning:

• The compressor will not operate unless the power supply phase connection

is correct.

• Ground protection with a no-fuse breaker (ground leakage breaker) is usu-

ally installed for (!_).

• The connection wiring between the outdoor and indoor units can be extended

up to a maximum of 50 m [164 ft], and the total extension including the crosso-

ver wiring between rooms is a maximum of 80 m [262 ft].

Provide switch with at least 3 mm [1/8 in] contact separation in each pole.

* Label each breaker according to purpose (heater, unit etc.).

[Fig. 8-1] (P.5)

(_ Indoorunit _B_Outdoorunit

(© Wired remote controller @ Mainswitch/fuse

(_)Groundwire

The distance between the inlet grille and the fan should be at least over 850

mm [33-15/32 in] or more.

If it is less than 850 mm [33-15/32 in], install a safety guard so the fan can-

not be easily accessed.

[Fig. 7-1] (P.5)

(_) Air inlet

(_ Air outlet

© Access door

(_) Ceiling

<_,Canvas duct

@_Air filter

G(_Inlet grille

8.2. Indoor wire connection

Work procedure

1. Remove two screws to detach the electric component cover.

2. Route each cable through the wiring intake into the electric component box. (Pro-

cure power cable and in-out connecting cable locally and use remote control cable

supplied with the unit.)

3. Securely connect the power cable and the in-out connecting cable and the remote

control cable to the terminal blocks.

4. Secure the cables with clamps inside the electric component box.

5. Reattach the electric component cover.

• Attach power supply cable and indoor/outdoor cable to control box by using buffer

bushing for tensile force. (PG connection or the like.)

Warning:

• Attach the electrical part cover securely. If it is attached incorrectly, it could

result in a fire or electric shock due to dust, water, etc.

• Use the specified indoor/outdoor unit connecting wire to connect the indoor

and outdoor units. Attach the wire to the terminal block securely so that stress

is not applied to the terminal block connection. Incomplete connection or

fixing of the wire could result in a fire.

12

Page 13

8. Electrical work

[Fig. 8-2-1] (P.5)

@ Screw holding cover (2pcs)

_B_Cover

[Fig. 8-2-2] (P.5)

@ Terminal block box

Knockout hole

© Remove

[Fig. 8-2-3] (P.5)

@ Use conduit to keep the weight of the cable and external force from being applied to the

power supply terminal connector.

Indoor/outdoor unit connecting cable

© Conduit

@ Terminal block box

(E_ Knockout hole (for indoor/outdoor unit connecting cable)

@_ Washer (accessory)

(_ Tensile force

O Use ordinary bushing

Remote controller cable

[Fig. 8-2-4] (P.5)

@ Terminal block for indoor/outdoor unit connecting

Terminal block for remote controller

© Indoor/outdoor unit connecting cable

@ Remote controller cable

• Perform wiring as shown in the diagram to the lower left. (Procure the cable lo-

cally.)

Make sure to use cables of the correct polarity only.

[Fig. 8-3] (P.6)

@ Indoor terminal block

Ground wire (green/yellow)

© Indoor/outdoor unit connecting cable 3-core 1.5 mm 2 [AWG 16] or more

@ Outdoor terminal block

(E_ Power supply cord

(_ Indoor/outdoor unit connecting cable 3-core 1.5 mm 2[AWG 16] or more, following Design

245 IEC 57.

(_ Indoor terminal block

@ Outdoor terminal block

@ Always install an ground wire (1-core 1.5 mm 2 [AWG 16]) longer than other cables

(_ Remote controller cable

Wire No × size (mm 2) : Cable 2C x 0.3

Accessory wire of remote controller

(wire length : 10 m [32 ft], non-polar. Max. 500 m [1640 ft])

G Wired remote controller

G Power supply cord

• Connect the terminal blocks as shown in the diagram below.

Z_ Caution:

• Conduct electrical work properly.

• Firmly tighten the terminal screws to prevent them from loosening.

• After tightening, pull the wires lightly to confirm that they do not move.

8.3. Remote controller

8.3.1. For wired remote controller

1) Installing procedures

(1) Select an installing position for the remote controller.

The temperature sensors are located on both remote controller and indoor unit.

Procure the following parts locally:

Two piece switch box

Thin copper conduit tube

Lock nuts and bushings

[Fig. 8-4] (P.6)

@ Remotecontroller

Required clearancesfor the remote controller

© Installationpitch

(2) Seal the service entrance for the remote controller cord with putty to prevent pos-

sible invasion of dew drops, water, cockroaches or worms.

[Fig. 8-5] (P.6)

@ Forinstallation inthe switch box:

_B_For direct installationon the wall,select oneof the following:

• Preparea holethrough the wallto passthe remotecontrollercord (in orderto run the remote

controller cord from the back), then seal the hole withputty,

• Run the remote controller cord through the cut-out upper case, thenseal the cut-out notch

with putty similarly as above.

© Wall G(_Switch box

@ Conduit (A_Remote controller cord

(E_Locknut (i_ Seal with putty

@_Bushing (3pWoodscrew

B-1. To lead the remote controller cord from the back of the controller:

B-2. To run the remote controller cord through the upper portion:

(3) For direct installation on the wall

2) Connecting procedures

(_) Connect the remote controller cord to the terminal block.

[Fig. 8-6] (P.6)

@ Tothe terminal block on the indoor unit

(B_TB6 (Nopolarity)

(D Set the dip switch No.1 shown below when using two remote controller's for the

same group.

3) Selecting the remote controller function

If two remote controllers are connected, set one to "Main" and the other to "Sub". For

setting procedures, refer to "Function selection of remote controller" in the operation

manual for the indoor unit.

8.4. Function settings (Function selection via the re-

mote controller)

Refer to the manual that came with the remote controller for setting procedure and

operation method.

8.4.1 Function setting on the unit (Selecting the unit functions)

1) Changing the external static pressure setting [Fig. 8-7] (P.6)

• Be sure to change the external static pressure setting depending on the duct and

the grill used.

(_) Go to the function setting mode.

Switch OFF the remote controller.

Press the @ and (_) buttons simultaneously and hold them for at least 2

seconds. FUNCTION will start to flash.

(D Use the © button to set the refrigerant address (HI) to 00.

(_ Press @ and [--] will start to flash in the unit number (IV) display.

(_ Use the © button to set the unit number (_T) to 01-04 or AL.

O Press the (_ MODE button to designate the refrigerant address/unit number.

[--] will flash in the mode number ( [ ) display momentarily.

O Press the (_ buttons to set the mode number ( _ ) to 08.

(_ Press the @ button and the current set setting number ([J[) will flash.

Use the (_ button to switch the setting number in response to the external static

3ressure to be used.

External static Setting no. of mode Setting no. of mode

pressure no. 08 no. 10

5 Pa (0.02 in.WG) 1 2

15 Pa (0.06 in.WG) 1 1

(before shipment)

35 Pa (0.14 in.WG) 2 1

50 Pa (0.20 in.WG) 3 1

O Press the MODE button (_ and mode and the setting number ( _ ) and ( L[ ) will

change to being on constantly and the contents of the setting can be confirmed.

@ Press the FILTER @ and TEST RUN (_) buttons simultaneously for at least two

seconds. The function selection screen will disappear momentarily and the air

conditioner OFF display will appear.

O To set the static pressure at 5Pa (0.02 in.WG), repeat steps (_ to @. (Set the

mode number to 10 for step O.)

2) Other functions

(_) Select unit number 00 for the settings. (Settings for all indoor units)

Refer to Function table 1.

(D Select unit number 01 to 04 or AL for the settings. (Settings for each indoor unit)

To set the indoor unit in the individual system, select unit number 01.

To set each indoor unit of two, three or four indoor units, which are connected

when these units are simultaneously in operation, select unit number 01 to 04.

To set all indoor units of two, three or four indoor units which are connected when

these units are simultaneously in operation, select AL.

Refer to Function table 2.

13

Page 14

8. Electrical work

Function table 1

Select unit number 00

Mode

Power failure automatic recovery*l

(AUTO RESTART FUNCTION)

Indoor temperature detecting

LOSSNAY connectivity

Function table 2

Select unit numbers 01 to 04 or all units (AL [wired remote controller]/07 [wireless remote controller])

Mode Settings

Filter sign 100 Hr

External static pressure 15 Pa (0.06 in.WG)

"1 When the power supply returns, the air conditioner will start 3 minutes later.

Note: When the function of an indoor unit were changed by function selection after the end of installation, always indicate the contents by

appropriate check filed of the tables.

Settings Mode no.

Not available 01

Available "1

Indoor unit operating average

Set by indoor unit's remote controller 02

Remote controller's internal sensor

Not Supported

Supported (indoor unit is not equipped with outdoor-air intake) 03

Supported (indoor unit is equipped with outdoor-air intake)

Mode no. Setting no. Initial setting

2500 Hr

No filter sign indicator

35 Pa (0.14 in.WG)

50 Pa (0.20 in.WG)

The same as setting of mode no.08

5 Pa (0.02 in.WG) (set mode no. 08 to 1)

O7 2

08 2

10

Setting no. Initial setting

1

Check

2 O

1 O

2

3

1 O

2

3

Check

1

3 O

1 O

3

1 O

2

entering a O or other mark in the

9. Test run

9.1. Before test run

After completing installation and the wiring and piping of the indoor and outdoor

units, check for refrigerant leakage, looseness in the power supply or control

wiring, wrong polarity, and no disconnection of one phase in the supply.

Use a 5OO-volt megohmmeter to check that the resistance between the power

supply terminals and ground is at least 1.0 M_.

Do not carry out this test on the control wiring (low voltage circuit) termi-

nals.

//_ Warning:

Do not use the air conditioner if the insulation resistance is less than 1.0 MQ.

Insulation resistance

After installation or after the power source to the unit has been cut for an extended

period, the insulation resistance will drop below 1 M_Qdue to refrigerant accumulat-

ing in the compressor.This is not a malfunction. Perform the following procedures.

1. Remove the wires from the compressor and measure the insulation resistance of

the compressor.

2. If the insulation resistance is below 1 M£_, the compressor is faulty or the resist-

ance dropped due the accumulation of refrigerant in the compressor.

3. After connecting the wires to the compressor, the compressor will start to warm

up after power is supplied. After supplying power for the times indicated below,

measure the insulation resistance again.

• The insulation resistance drops due to accumulation of refrigerant in the com-

pressor. The resistance will rise above 1M_Qafter the compressor is warmed

up for two to three hours.

(The time necessary to warm up the compressor varies according to atmos-

pheric conditions and refrigerant accumulation.)

• To operate the compressor with refrigerant accumulated in the compressor,

the compressor must be warmed up at least 12 hours to prevent breakdown.

4. If the insulation resistance rises above 1 M_Q,the compressor is not faulty.

Z_ Caution:

• The compressor will not operate unless the power supply phase connection

is correct.

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can result in

severe damage to internal parts. Keep the power switch turned on during the op-

erational season.

9.2. Test run

9.2.1. Using wired remote controller

Q Turn on the power at least 12 hours before the test run.

@ Press the [TEST] button twice. -_ "TEST RUN" liquid crystal display

Q Press the [Mode selection] button. -_ Make sure that wind is blown out.

(_ Press the [Mode selection] button and switch to the cooling (or heating) mode.

-_ Make sure that cold (or warm) wind is blown out.

@ Press the [Fan speed] button. -_ Make sure that the wind speed is switched.

@ Check operation of the outdoor unit fan.

Q Release test run by pressing the [ON/OFF] button. -_ Stop

Q Register a telephone number.

The telephone number of the repair shop, sales office, etc., to contact if an error

occurs can be registered in the remote controller. The telephone number will be

displayed when an error occurs. For registration procedures, refer to the operation

manual for the indoor unit.

[Fig. 9-1] (P.7)

(_)ON/OFF button

C_Test rundisplay

(© Indoor temperature liquid line temperaturedisplay

(_)ON/OFF lamp

(_, Powerdisplay

@_Errorcode display

Test run remaining time display

G(_Set temperature button

(A_Modeselection button

(i_ Fanspeed button

@ TEST button

14

Page 15

9. Test run

9.3. Self-check

9.3.1. Wired remote controller

(_ Turn on the power.

(D Press the [CHECK] button twice.

(_ Set refrigerant address with [TEMP] button if system control is used.

(_ Press the [ON/OFF] button to stop the self-check.

• For description of

Q Check code

P1

P2, P9

E6, E7

P4

P5

PA

P6

EE

P8

E4

Fb

E0, E3

El, E2

E9

UP

U3, U4

UF

U2

U1, Ud

U5

U8

U6

U7

U9, UH

Others Other errors (Refer to the technical manual for the outdoor unit.)

On wired remote controller

(_) Check code displayed in the LCD.

each check code, refer to the following table.

Intake sensor error

Pipe (Liquid or 2-phase pipe) sensor error

Indoor/outdoor unit communication error

Drain sensor error

Drain pump error

Forced compressor error

Freezing/Overheating safeguard operation

Communication error between indoor and outdoor units

Pipe temperature error

Remote controller signal receiving error

Indoor unit control system error (memory error, etc.)

Remote controller transmission error

Remote controller control board error

Indoor/outdoor unit communication error (Transmitting error) (Outdoor unit)

Compressor overcurrent interruption

Open/short of outdoor unit thermistors

Compressor overcurrent interruption (When compressor locked)

Abnormal high discharging temperature/49C worked/insufficient refrigerant

Abnormal high pressure (63H worked)/Overheating safeguard operation For details, check the LED display

Abnormal temperature of heat sink of the outdoor controller board.

Outdoor unit fan safeguard stop

Compressor overcurrent interruption/Abnormal of power module

Abnormality of super heat due to low discharge temperature

Abnormality such as overvoltage or voltage shortage and abnormal synchronous signal to main circuit/

Current sensor error

Symptom Remark

[Fig. 9-2] (P.7)

_} CHECK button

Refrigerant address

© TEMR button

IC: Indoor unit

OC: Outdoor unit

(E_Check code

10. Maintenance

10.1. Gas charge

[Fig. 10-1] (P.7)

_A}Indoorunit

Union

© Liquidpipe

@ Gaspipe

(E_Stopvalve

@DOutdoor unit

(_ Refrigerant gas cylinder operatingvalve

(_ Refrigerant gas cylinder forR410A with siphon

(_) Refrigerant(liquid)

@ Electronic scalefor refrigerant charging

(_ Charge hose (for R410A)

(_ Gaugemanifold valve (for R410A)

@ Serviceport

1. Connect gas cylinder to the service port of stop valve (3-way).

2. Execute air purge of the pipe (or hose) coming from refrigerant gas cylinder.

3. Replenish specified amount of refrigerant, while running the air conditioner

for cooling.

Note:

In case of adding refrigerant, comply with the quantity specified for the refrigerating

cycle.

_, Caution:

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installa-

tion, reinstallation, or repairs to the refrigerant circuit.

• For additional charging, charge the refrigerant from liquid phase of the gas

cylinder.

If the refrigerant is charged from the gas phase, composition change may

occur in the refrigerant inside the cylinder and the outdoor unit. In this case,

ability of the refrigerating cycle decreases or normal operation can be impos-

sible. However, charging the liquid refrigerant all at once may cause the com-

pressor to be locked. Thus, charge the refrigerant slowly.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with warm

water (under 104 °F [40 °C]) during cold season. But never use naked fire or steam.

15

Page 16

Index

1. Consignes de securite ........................................................................... 16

2. Choisir I'emplacement de Hnstallation ................................................... 16

3. Selection de I'emplacement d'installation et accessoires ...................... 17

4. Fixation des boulons de suspension ...................................................... 17

5. Installation de I'appareil ......................................................................... 18

6. Mise en place des tuyaux de r6frig6rant ................................................ 18

7. Travaux de conduites ............................................................................. 20

8. Installations electriques ......................................................................... 21

1. Consignes de securite

Avant la connexion au systeme, le signaler au distributeur d'electricite ou

demander son accord.

• Veuillez lire en entier "Les mesures de securite suivantes doivent toujours

6tre respectees" avant d'installer le climatiseur.

Comme ces mesures sont tres importantes pour votre securite, veuillez les

respecter.

• Les symboles signifient.

/_ Avertissement:

pourrait resulter en un deces, une blessure grave, etc.

Z_ Attention:

pourrait resulter en une blessure grave, selon les circonstances, si I'appareil

est incorrectement utilis&

Lorsque vous aurez lu le manuel en entier, veuillez le garder dans un en-

droit pratique, chez le client, avec le manuel d'utilisation.

/_ Avertissement:

• Ne pas installer I'appareil vous-m6me (client).

Toute mauvaise installation pourrait resulter en une blessure due a un incen-

die, un choc electrique, ou une fuite d'eau ou si I'appareil tombait. Consulter

votre distributeur ou technicien specialise.

• Vous assurer que I'appareil est installe dans un endroit assez solide pour en

supporter le poids.

Autrement, il pourrait tomber et par consequent blesser quelqu'un.

• Utiliser les c&bles specifies pour connecter les appareils interieur et exte-

rieur en toute securite, et attacher les fils fermement au bloc de sorties pour

qu'aucune force venant des fils ne soit exercee sur les bornes.

Toute connexion ou attachement defectueux pourrait resulter en un incen-

die.

• N'utilisez pas de rallonge et ne branchez pas plusieurs appareils a la m6me

prise de courant CA.

II y aurait risque d'incendie ou de decharge electrique a cause d'un contact

ou d'une isolation defectueux, ou a cause d'un exces de courant etc.

• Verifier que le gaz refrigerant ne fuit pas Iorsque I'installation est terminee.

• Veuillez suivre ce manuel durant I'installation.

Toute installation defectueuse pourrait 6tre la cause d'une blessure due a un

incendie, une decharge electrique, si I'appareil tombait ou une fuite d'eau.

Z_ Attention:

• Mettre I'appareil a la terre.

Ne pas relier le c_ble de terre au tuyau de gaz, d'eau, un parafoudre ou un

c&ble de terre telephonique. Toute mise a la terre defectueuse pourrait 6tre la

cause d'un choc electrique.

• Ne pas installer I'appareil dans un endroit o=3il sera expose a des gaz inflam-

mables.

Tout gaz accumule autour de I'appareil pourrait exploser.

• Installer un disjoncteur differentiel si necessaire (Iorsque I'endroit de I'instal-

lation est humide.)

Sans disjoncteur differentiel, il y aura risque de decharge electrique.

9. Marche d'essai ....................................................................................... 23

10. Entretien ................................................................................................ 24

Le manuel d'installation ne concerne que I'unite int@ieure et I'unit6 ext@ieure de

la s@ie SUZ.

Si I'appareil exterieur fait partie de la s@ie MXZ, consulter le manuel d'installa-

tion de cette s@ie MXZ.

Symboles sur rappareil

: Indique une action qui dolt _tre evitee.

O : Indique que des instructions importantes doivent _tre prises en consid@ation.

: Indique un element qui dolt _tre mis & la terre.

Z_ : Indique des precautions & prendre Iors du maniement de pieces tournantes.

_ : Indique que I'interrupteur principal dolt _tre desactive avant d'effectuer tout

travail d'entretien.

z_ : Danger d'electrocuition.

Z_: Attention, surface chaude.

Z_ Avertissement:

Prendre soin de lire les etiquettes se trouvant sur I'appareil principal.

• Veuillez suivre ce manuel durant I'installation electrique et veuillez utiliser un

circuit exclusif pour cette installation electrique.

Tout manque de capacite de circuit ou toute installation defectueuse pourrait

resulter en un incendie ou une decharge electrique.

• Veuillez fermement attacher les couvercles de la partie electrique de I'appa-

reil interieur et le panneau de service de I'appareil exterieur.

Tout attachement defectueux du couvercle de I'appareil interieur et/ou le pan-

neau de service de I'appareil exterieur pourrait resulter en un incendie ou un

choc electrique a cause de la poussiere, de I'eau, etc, pouvant s'infiltrer.

• Veuillez vous assurer d'utiliser la piece fournie ou les pieces specifiees pour

I'installation.

Toute piece defectueuse utilisee pourrait 6tre la cause d'un incendie, d'un

choc electrique, de I'appareil tombant de sa position, etc, ce qui resulterait

en une blessure ou une fuite d'eau.

• Aerez le local en cas de fuite de liquide frigorigene en cours de fonctionne-

ment.

Tout contact du liquide frigorigene avec une flamme libere des gaz toxiques.

• Veuillez suivre les instructions de ce manuel pour I'installation de la tuyaute-

rie et du systeme d'evacuation.

Si cette installation n'est pas faite correctement, il est possible que I'appareil

fuie et par consequent mouille ou abime vos meubles.

• Serrer I'ecrou evase avec une cle dynamometrique en respectant les indica-

tions du present manuel.

Un ecrou evase trop serre peut en effet casser apres un certain temps et

provoquer une fuite de refrigerant.

2. Choisir I'emplacement de I'installation

2.1. Appareil interieur

• Emplacement ne favorisant pas la circulation d'air.

• Emplacement favorisant une bonne repartition de I'air froid darts la piece.

• Emplacement ne favorisant pas une exposition directe au soleil.

• A une distance au moins egale b.1 m [39-3/8 in] d'un televiseur ou d'une radio

(pour eviter que I'image ne soit d_formee ou que des sons ne soient produits).

2.2. Appareil exterieur

• Emplacement ne favorisant pas une exposition aux rafales de vent.

• Emplacement favorisant une bonne circulation d'air sans poussiere.

• Emplacement ne favorisant pas une exposition directe & la pluie et au soleil.

• Emplacement ne suscitant pas une nuisance par le bruit de fonctionnement de

I'appareil et la pulsion d'air chaud pour le voisinage.

• Emplacement avec un mur solide ou un support ferme emp_chant la propagation

du bruit de fonctionnement et de vibrations.

16

• Emplacement permettant d'obtenir un eloignement suffisant d'une lampe fiuores-

cente ou de tout autre dispositif d'eclairage b.ampoule (la proximite de ces disposi-

tifs entravent la reception des signaux de commande du boitier de tel_commande

et emp_che le climatiseur de fonctionner normalement).

• Emplacement permettant de retirer facilement le filtre & air vers le bas.

,/_ Avertissement:

Fixer I'appareil interieur dans un plafond suffisamment resistant pour suppor-

ter son poids.

• Emplacement ot_ il n'y a aucun risque de fuites de gaz combustibles.

• Lorsque I'appareil est installe en hauteur, les pieds de support doivent _tre instal-

I_s.

• A 3 m [10 ft] au moins de I'antenne d'un t_leviseur ou d'une radio. (Autrement il

pourrait y avoir du brouillage sonore ou visuel.)

• Installer I'appareil & I'horizontale.

Page 17

2. Choisir I'emplacement de I'installation

Z_ Attention:

Les emplacements sousmentionnes doivent _tre evites pour effectuer rinstal-

lation s'il existe un risque de panne pour le climatiseur.

• Si rair a une teneur trop elevee en huile machine.

• Sites salins.

• Stations thermales.

• En presence de gaz sulfurique.

• Autres types de conditions climatiques speciales.

3. Selection de I'emplacement d'installation et accessoires

Choisir un endroit avec une surface suffisamment solide pour supporter le poids de

I'appareil.

Avant d'installer I'appareil, d_terminer la maniere de I'acheminer au lieu d'installa-

tion.

Choisir un endroit or) le bon fonctionnement de I'appareil ne peut pas _tre affect6

par un courant d'air.

Selectionner un endroit cO le debit d'alimentation en air et de retour d'air n'est pas

perturb&

Selectionner un endroit cO les tuyaux de refrig@ant peuvent facilement _tre instal-

les & I'ext@ieur.

Selectionner un emplacement qui permet de repartir I'air enti@ement dans toute la

piece.

Ne pas installer I'appareil dans un endroit sujet a des eclaboussures de graisse ou

de vapeur.

Ne pas installer I'appareil dans un endroit avec arriv6e de gaz combustible, entre-

p6t de gaz ou sujet a des fuites de gaz.

Ne pas installer I'appareil dans un endroit contenant des equipements qui produi-

sent des ondes de haute frequence (comme une machine b. souder fonctionnant

par ondes de haute fr6quence).

• Ne pas installer I'appareil dans un endroit cO le d_tecteur incendie est situe du c6te

de I'arrivee d'air. (Le detecteur d'incendie risque de se d6clencher par erreur suite

b.I'alimentation en air chaud pendant le fonctionnement du chauffage.)

• En cas de pr6sence de produits chimiques sur les lieux, comme dans des usines

chimiques ou des h6pitaux, une etude approfondie s'av@e necessaire avant de

proc6der a Hnstallation de I'appareil. (Certains produits chimiques peuvent en effet

endommager les composants plastiques du climatiseur.)

• Si I'appareil dolt fonctionner pendant Iongtemps quand Fair au-dessus du plafond

est a haute temp@ature/haute humidite (point de condensation sup@ieur & 79 °F

[26 °C]), la condensation d'humidite est possible dans I'appareil int@ieur. Couvrir la

totalite de la surface de I'unit6 int@ieure d'un mat@iau isolant (10-20 mm [13/32 b.

13/16 in]) de fagon a interdire la formation de condensation.

3.1. Fixer I'appareil interieur a un plafond suffisamment

resistant pour supporter son poids

[Fig. 3-1] (P.2)

@ Porte d'acces (_ Boftier des elements _lectriques

© Arriveed'air (_)Sortie d'air

(E_Surfacedu plafond _ Espace pour I'entretien (vue de c6t_)

(_ Espacepour I'entretien (vue du sens de la fl_che)

(_ 600 mm[23-5/8 in] ou plus (D 100 mm [3-15/16 in] ou plus

Q 10 mm [13/32 in] ou plus @ 300 mm[11-13/16 in] ou plus

/_ Avertissement:

L'appareil doit 6tre fermement installe sur une structure capable de supporter

son poids. Si le climatiseur est monte sur une structure trop fragile, il risque de

tomber et de blesser quelqu'un.

3.2. Prevoir I'espace necessaire pour I'installation et

rentretien

• Selectionner le meilleur sens pour I'arrivee d'air en fonction de la configuration de

la piece et du lieu d'installation.

• Pr6voir un espace suffisant pour le raccordement des c&bles et des tuyaux, ainsi

que pour I'entretien, sur les panneaux inf@ieur et lat6raux. Pour faciliter les travaux

de suspension et pour plus de s6curite, veuillez prevoir un maximum d'espace.

3.3. Appareil exterieur

Espace pour la ventilation et le service

Les appareils doivent _tre installes par un technicien qualifie suivant les regle-

mentations locales en vigueur.

Pour le raccordement des appareils ext@ieurs, reportez-vous au manuel d'instal-

lation fourni avec les appareils.

3.4. Elements qui accompagnent I'appareil interieur

I'appareil est livr6 avec les el6ments suivants:

No Nom Quantite

Q C0uvercledetuyau(pourlejointdestuyauxderefrigerant)petitdiametre120rnrn[3/4in] 1

Q C0uvercledetuyau(pourlejointdestuyauxder_frigerant)granddiametre120rnrn[3/4in] 1

Q Sangle 7

(_ Pieces de la tel_commande 1

@ C&ble de I'unit_ recevant le signal 1

@ Rondelle (pour la suspension) 8

Q Tuyau d'evacuation 1

Couvre-tube (pour tuyau d'evacuation) 60 mm [3/8 in] 1

@ Couvre-tube (pour tuyau d'evacuation) 30 mm [3/16 in] 1

@ Rondelle (pour le fil d'alimentation) 2

4. Fixation des boulons de suspension

4.1 Fixation des boulons de suspension

[Fig. 4-1] (P.2)

@ Centrede gravit_

Cadre de suspension

• Plafond: La structure du plafond varie d'un edifice b.un autre. Pour plus d'informa-

tions, veuillez prendre contact avec la societ_ de construction de I'immeuble.

Centre de gravite et poids du produit

Nom du modele

SEZ-KD09

SEZ-KD12

SEZ-KD15

SEZ-KD18

W (mm [in]) L (mm [in]) X (mm [in]) Y (mm [in]) Z (mm [in]) Poids du produit (kg [Ib])

625 [24-5/8] 752 [29-5/8] 263 [10-3/8] 351 [13-27/32] 106 [4-3/16] 19 [42]

625 [24-5/8] 952 [37-1/2] 286 [11-9/32] 448 [17-21/32] 104 [4-1/8] 22 [50]

625 [24-5/8] 952 [37-1/2] 280 [11-1/32] 437 [17-7/32] 104 [4-1/8] 24 [54]

625 [24-5/8] 1152 [45-3/8] 285 [11-1/4] 527 [20-3/4] 104 [4-1/8] 28 [62]

• Le cas echeant, renforcer les boulons de suspension pour assurer la protection en

cas de tremblement de terre.

* Utilisez M10 pour les boulons de suspension et les supports antisismiques

(fourni sur place).

(_) Renfort du plafond avec des elements supplementaires (poutres sur champ, etc)

n_cessaire pour maintenir le plafond a niveau et pour eviter qu'il vibre.

(_ Couper et retirer les elements de construction du plafond.

(_ Renforcer les elements de construction du plafond et ajouter d'autres elements

pour y fixer les planches du plafond.

17

Page 18

5. Installation de I'appareil

5.1. Suspension de I'appareil

Transporter I'appareil interieure jusqu'au site en la conservant dans son

emballage d'origine.

Pour le suspendre, utiliser une poulie de levage pour le soulever et le faire

passer par les boulons de suspension.

[Fig. 5-1] (P.2)

(_ Appareil

(_ Pouliede levage

[Fig. 5-2] (R2)

© Boulons (fourni sur place)

(_)Rondelles(accessoire)

([) Boulon desuspension M10 (fourni sur place)

6. Mise en place des tuyaux de refrigerant

6.1. Tuyaux de refrigerant

[Fig. 6-1] (P.3)

(a_Appareil interieur

@ Appareil exterieur

Reportez-vous au mode d'emploi de I'appareil ext@ieure pour les hauteurs limites

entre les appareils et pour la quantite de refrig@ant b. charger.

Eviter d'installer I'appareil dans les endroits suivants, pour eviter toute complication :

Eair contient trop d'huile provenant de machine ou de cuisson.

Dans un environnement sale, par exemple pres de lamer.

Pres de sources naturelles d'eau chaude.

Pres de gaz sulfurique.

Tout autre zone atmosph@ique inhabituelle.

Cet appareil a des connexions _vas_es sur les c6tes ext@ieurs et int@ieurs. (Fig. 6-1 )

Les tuyaux b.r6frig_rant sont utilis6s pour connecter les appareils int6rieur et exte-

rieur comme I'indique le croquis ci-dessous.

• Isoler entierement les tuyaux & refrig@ant et d'evacuation pour eviter toute con-

densation.

Pre,paration des tuyaux

• Des tuyaux de 3, 5, 7, 10 et 15 metres [5 ft] sont disponibles en option.

(1) Specifications des tuyaux disponibles dans le commerce.

Modele Tuyau Diametre ext@ieur Epaisseur Epaisseur Isolant

SEZ- A liquide 6,35 1/4 0.8mm[1/16in] 8mm[11/32in]

KD09 ,_,gaz 9,52 3/8 0.8mm[1/16in] 8mm[11/32in]

SEZ- Aliquide 6,35 1/4 0.Smrn[l/16in] 8mm[11/32in] Plastiquemousse

KD12 A gaz 9,52 3/8 0.8mm[1/16in] 8mm[11/32in] r6sistantala

SEZ- A liquide 6,35 1/4 0.Smrn[l/16in] 8mm[11/32in] chaleurgravit_

KD15 Agaz 12,7 1/2 0.Smrn[l/16in] 8mm[11/32in] ;p@ifiquede 0,045

SEZ- A liquide 6,35 1/4 0.Smrn[l/16in] 8mm[11/32in]

KD18 Agaz 12,7 5/8 1.0mrn[1/16in] 8mm[11/32in]

(2) Vous assurer que les deux tuyaux & r6frig@ant sont bien isol6s contre la conden-

sation.

(3) Le rayon du coude du tuyau b. r6frig@ant doit mesurer au moins 10 cm

[3-15/16 in].

Z_ Attention:

Utiliser risolant ayant repaisseur prescrite.Trop d'epaisseur emp6chera le stoc-

kage derriere rappareil interieur et un isolant trop mince ne pourra eviter le

suintage de condensation.

6.2. Evasement

• La cause principale de fuite de gaz est un evasement defectueux.

Veuillez effectuer I'evasement selon la methode suivante.

mm inch min.du mur del'isolant

5.2. Assurer I'emplacement de I'appareil et monter les

boulons de suspension

Utiliser le calibre livre avec le panneau pour verifier si I'appareil et les bou-

Ions de suspension sont places a rendroit indique. Si ce n'est pas le cas,

de la condensation peut se former en raison des courants d'air. Verifier

soigneusement les differents emplacements.

Utiliser un niveau pour verifier si la surface reperee 1_)est bien a niveau.

Veiller a ce que les ecrous des boulons de fixation soient bien serres avant

de fixer les boulons eux-m_mes.

Pour s'assurer d'une bonne vidange, suspendre soigneusement I'appareil

rhorizontale en se servant d'un niveau.

[Fig. 5-3] (P.2)

(_ Basde I'appareil int@ieur

/_ Attention:

Ne pas omettre de s'assurer que I'appareil est de niveau.

6.2.1. Couper le tuyau

[Fig. 6-3] (P.3)

(a_Tubes en cuivre

(_) Bonexemple

_ Mauvaisexemple

@ Penche

(e) Inegal

(_) Bavure

• Utiliser un coupe-tuyaux pour couper le tube en cuivre correctement.

6.2.2. Enlever les bavures

[Fig. 6-4] (P.3)

(a_Bavure

(_)Tuyau/tubeen cuivre

@ Al_soir suppl_mentaire

@ Coupe-tuyaux

• t_barber soigneusement la coupe de la section de tuyau/tube.

• Diriger vers le bas I'extr_mite de la section de tuyau/tube b.ebarber de mani@e que

les copeaux ne p_netrent pas dans le tuyau/tube.

6.2.3. Mettre I'ecrou en place

[Fig. 6-5] (P.3)

(a_)Ecrou _vas_

(6_Tube en cuivre

• Retirer les raccords coniques fixes sur les appareils int@ieure et exterieure et les

poser sur les tuyau/tube apres ebarbage.

(il est impossible de les fixer apres mise en forme conique)

6.2.4. Le fraisage

[Fig. 6-6] (P.3)

(a_Fraise

(_) Etau

_ Tubeen cuivre

d@Ecrou_vas_

(e_Serrage

• Effectuez I'evasement a I'aide de I'alesoir selon la m@hode suivante.

Dimensions

Diametre de tuyau

(mm [in]) B -+04[-1,'32](mm [in])

6,35 [1/4] 9,1 [3/8]

9,52 [3/8] 13,2 [17/32]

12,7 [1/2] 16,6 [21/32]

15,88 [5/8] 19,7 [25/32]

Coincer fermement le tube en cuivre dans un etau aux dimensions indiquees ci-

dessus.

L0rsdeI'utilisati0ndeI'0utilpourleR410A

A (ram [in])

Type d'embrayage

0 a 0,5 [0 b.1/32]

0 a 0,5 [0 b.1/32]

0 a 0,5 [0 b.1/32]

0 a 0,5 [0 b.1/32]

18

6.2.5. Verification

[Fig. 6-7] (P.3)

(a_Lisse (_ Rayuresur la surfaceevasee

(_) Eint@ieurbrille et n'est pas raye @ Craqu_

c_)Longueur egale @ Inegal

@ Trop (i_ Exemples de mauvais specimens

(._ Penche

• Si la section conique est defectueuse, la supprimer et r_peter les op@ations.

Page 19

6. Mise en place des tuyaux de refrigerant

6.3. Connexion des tuyaux

[Fig. 6-8] (P.3)

• Appliquer une fine couche d'huile de r6frig@ant sur la surface de conduite.

• Lors du raccordement, aligner le centre puis serrer le raccord conique de 3 b. 4

tours.

• Appliquer les couples de serrage sp6cifi_s dans letableau ci-dessous comme moyen

de r6f@ence pour les raccords de tuyauterie de I'appareil int@ieur et serrer avec

deux cles. Un serrage endommage la partie evas6e.

Diam. ext. Tuyau en cuivre

(mm [in])

e6,35 [1/4]

e9,52 [3/8]

el 2,7 [1/2]

e15,88 [5/8]

z_ Avertissement:

II faut veiller a ne pas retirer le raccord conique ! (La pression interne peut

provoquer leur echappement.)

Retirer recrou evase en procedant comme suit:

1. Desserrer I'ecrou jusqu'a ce qu'un sifflement se fasse entendre.

2. Ne jamais retirer I'ecrou tant que tout le gaz ne s'est pas echappe (c'est-a-

dire Iorsque le sifflement s'arr6te).

3. Verifier si tout le gaz s'est echappe avant de retirer I'ecrou.

Connexion de I'appareil exterieur

Connecter les tuyaux au raccord de vanne d'arr_t de I'appareil ext@ieur en proce-

dant comme pour I'appareil int@ieure.

• Pour le serrage, utiliser une cle dynamom@rique et serrer au m6me couple que

pour I'appareil int@ieure.