Page 1

TECHNICAL & SERVICE MANUAL

CONTENTS

1. PART NAMES AND FUNCTIONS········2

2. SPECIFICATIONS·································4

3. OUTLINES AND DIMENSIONS············6

4.WIRING DIAGRAM ·······························7

5.

REFRIGERANT SYSTEM DIAGRAM

·········8

6.TROUBLESHOOTING···························9

7. DISASSEMBLY PROCEDURE···········13

8. PARTS LIST········································18

9. OPTIONAL PARTS·····························21

INDOOR UNIT

Indoor unit

[Model names] [Service Ref.]

SEZ-KC25VA SEZ-KC25VA.W

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

WIRED REMOTE

CONTROLLER

ON/OFF

TEMP.

Ceiling Concealed

Series SEZ

R410A

Model name

indication

Note :

•This manual does not cover

outdoor units.When ser vicing

outdoor units, please refer

to the service manual

No.OC322 together with this

manual.

Page 2

2

1

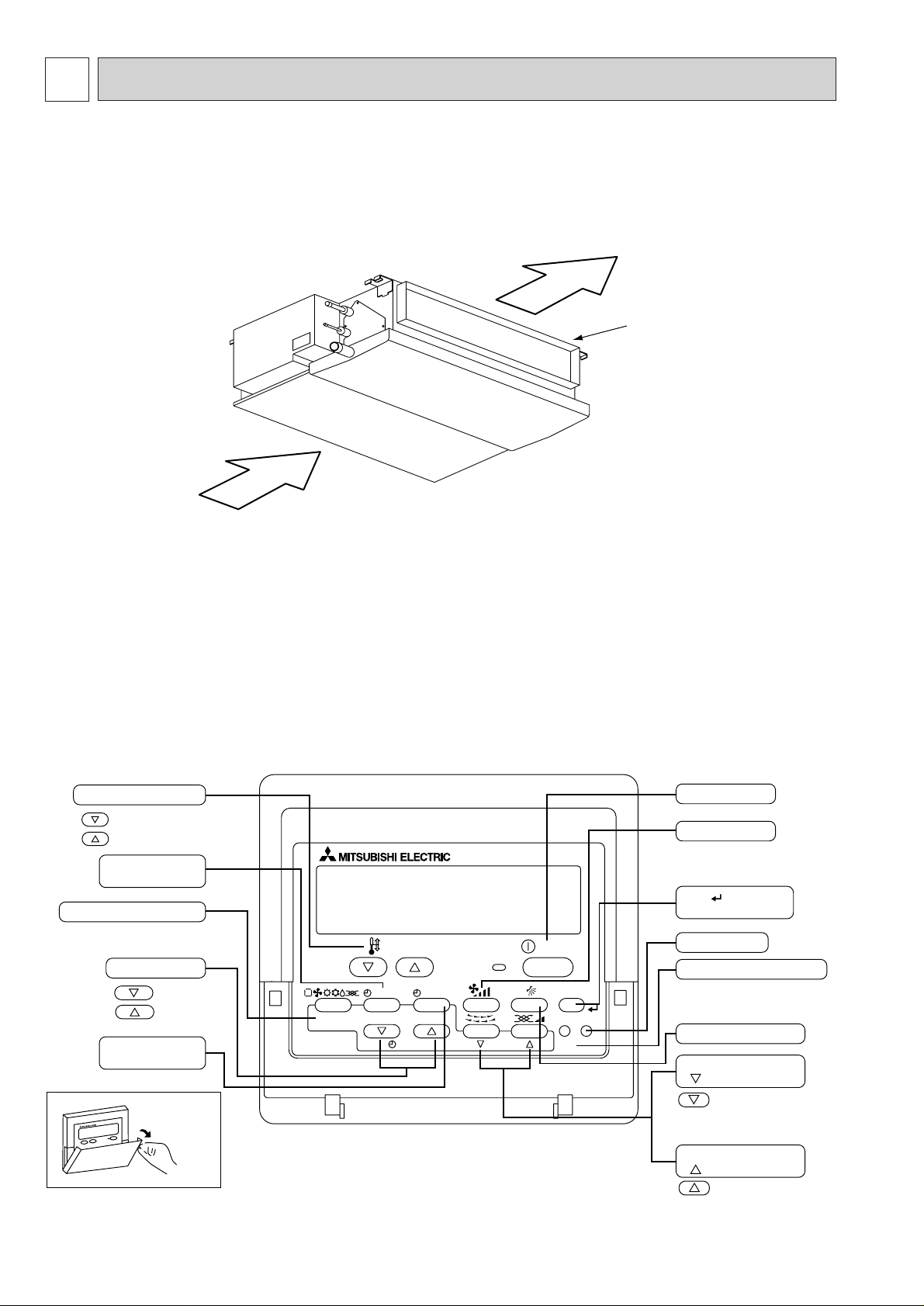

PART NAMES AND FUNCTIONS

Indoor Unit

SEZ-KC25VA.W

Air outlet duct flange

Air outlet

Air inlet

● Operation buttons

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

Start/Stop button

Fan Speed button

Filter button

(<return sign> button)

Test Run button

Service button (Clear button)

Airflow Up/Down button

Louver button

(

Operation button)

To preceding operation

number.

Ventilation button

(

Operation button)

To next operation number.

On the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

Wired remote controller

Page 3

3

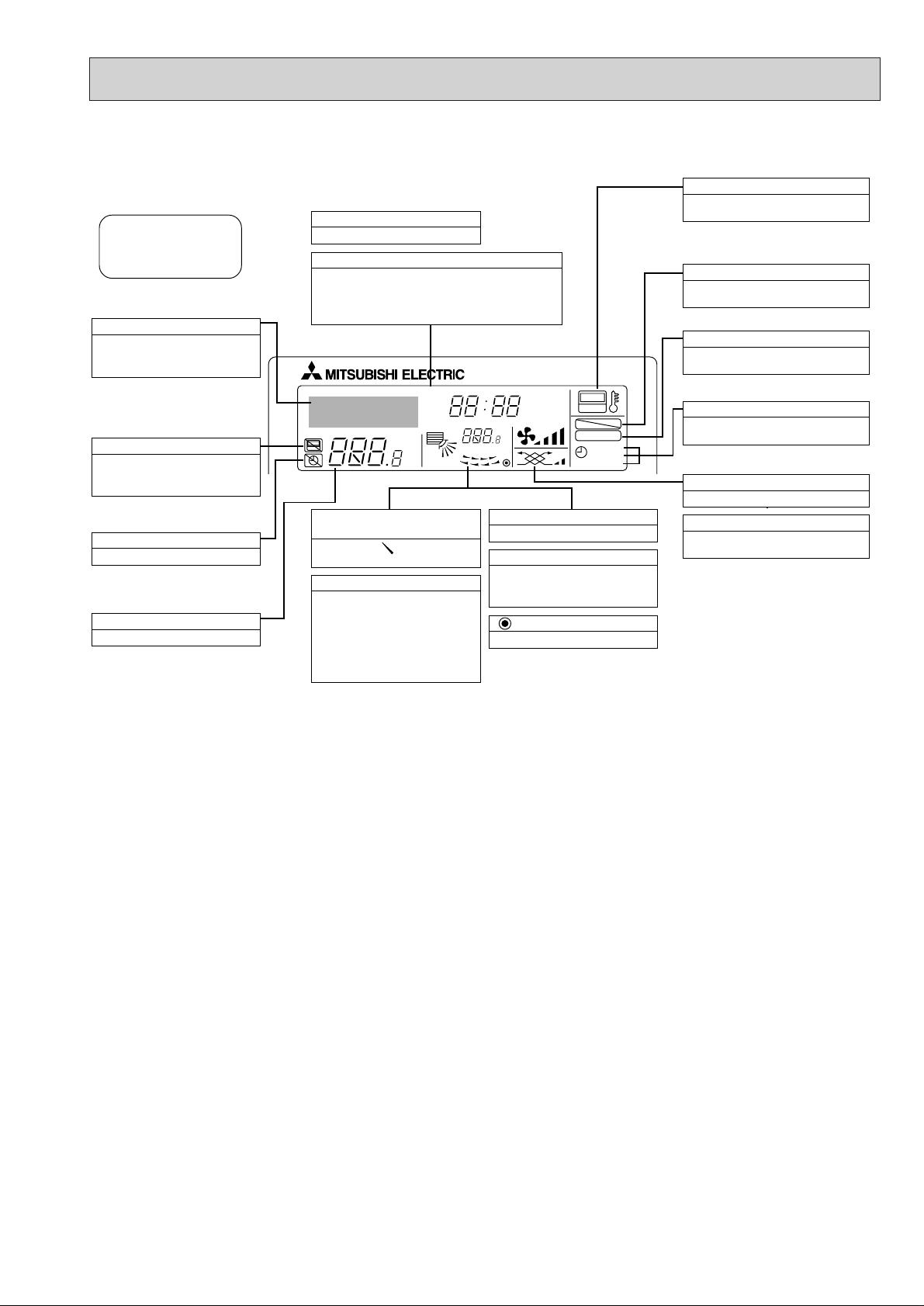

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When power is turned ON for the first time the (Centrally controlled) display appears to go off momentarily but this is not a

malfunction.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped with

the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication

(For max. 2minutes). Please wait until this “PLEASE W AIT”indication disappear then start the operation.

Page 4

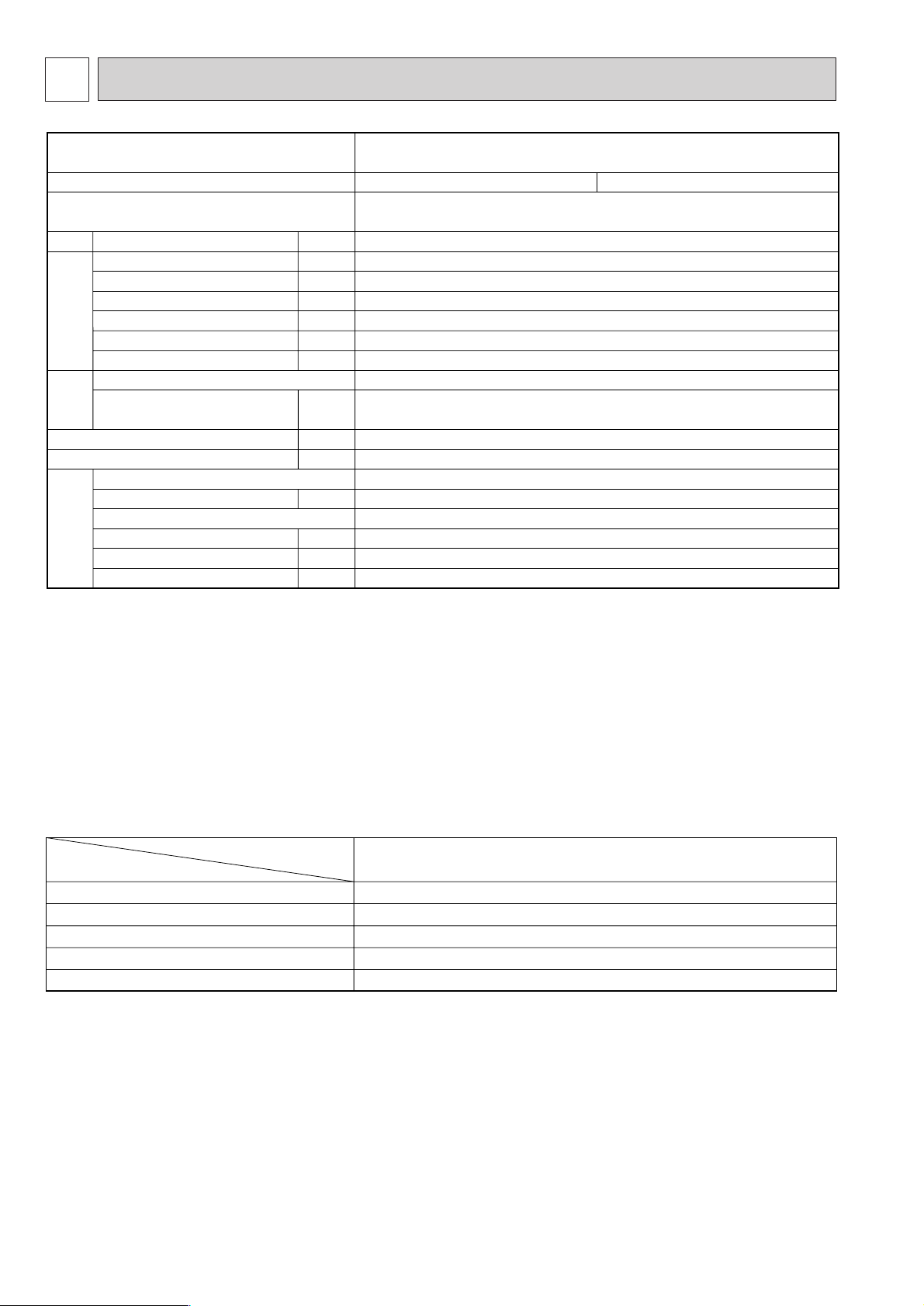

4

2

SPECIFICATIONS

SEZ-KC25VA.W

Indoor model

Function

Power supply

Single phase

230V , 50Hz

474/288

10

0.45

60

—

97

0.28

CRC4417BB

WHT-BLK : 261 BLK-BLU : 475

YLW-BRN : 294

790✕225✕550

19

1

36/25

2

10

10

10

Cooling

Heating

Air flow (High/Low)

Power outlet

Running current ✽1

Power input Rated frequency

Auxiliary heater

Power factor ✽1

Fan motor current ✽1

Model

Winding

resistance (at20:)

Dimensions W✕H✕D

Weight

Air direction

Sound level (High/Low)

Fan speed regulator

Thermistor RT11 (at 25:)

Thermistor RT12 (at 25:)

Thermistor RT13 (at 25:)

K /h

A

A

W

A(kW)

%

A

Ω

mm

kg

dB(A)

kΩ

kΩ

kΩ

Electrical

data

Fan

motor

Special remarks

Capacity

NOTE :Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27

: W.B. 19:

Outdoor D.B. 35: W.B. 24:

Heating : Indoor D.B. 20: W.B. 5:

Outdoor D.B. 7: W.B. 6:

Refrigerant piping length (one way): 5m

✽1 Measured under rated operating frequency.

1.5+ 440V

250V 6.3A

ERZV10D471

TO OUTDOOR UNIT : 3P TO WIRED REMOTE CONTROLLER : 2P

135:i5:

INDOOR UNIT

Item

Model

Indoor fan capacitor

Fuse

Varistor

Terminal block

Indoor fan motor thermal fuse

SEZ-KC25VA.W

(C)

(FUSE)

(ZNR)

(TB)

Specifications and rating conditions of main electric parts

Page 5

5

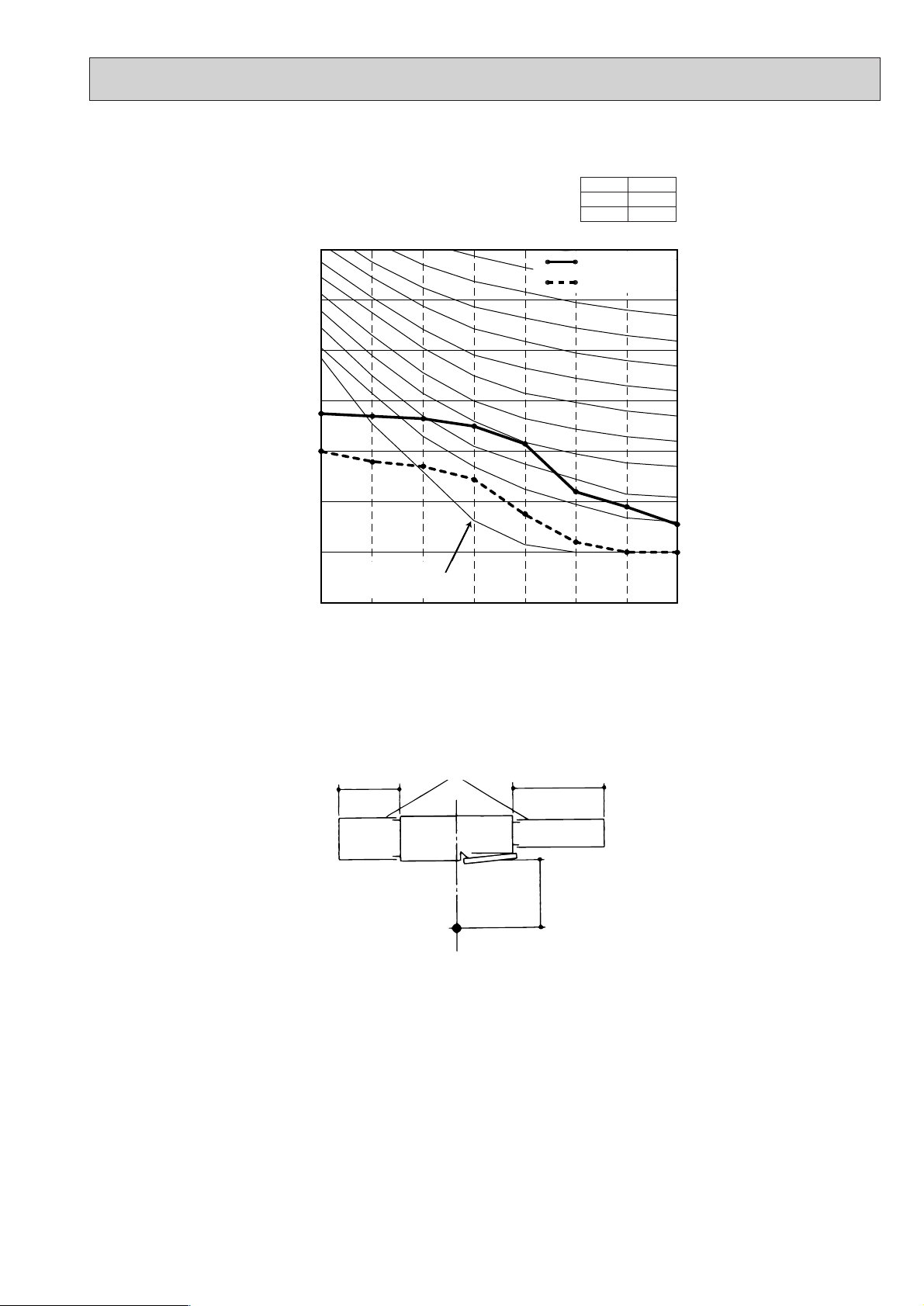

NOISE CRITERION CURVES

2m

Aux.duct

1m

1.5m

Measurement location

NOTE:The sound level is measured in an anechoic room where echoes are few, when compressor stops. The sound

may be bigger than displayed level under actual installation condition by surrounding echoes.The sound level

can be higher by about 2 dB than the displayed level during cooling and heating operation.

SEZ-KC25VA.W

NOTCH

Hi

Lo

<50Hz>

SPL(dB)

36

25

70

60

50

40

30

20

10

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

Appro

Approximate minimum

audible limit on continuous noise

0

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

NC60

NC50

NC40

NC30

NC20

Page 6

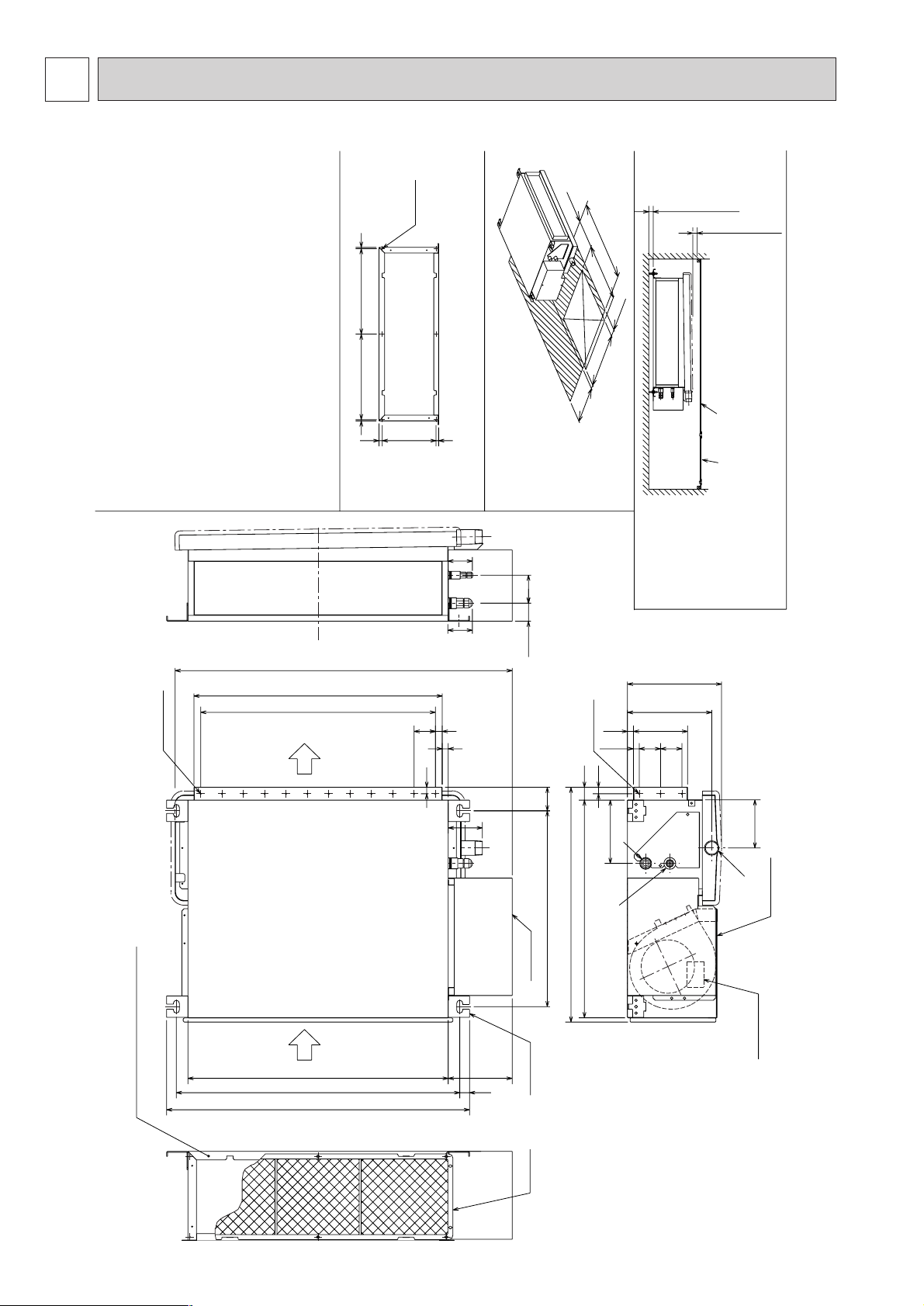

Make the access door at the appointed position properly

for service maintenance.

Ceiling surfaceAccess door

Required space for service and maintenance

Lifting plate

(4-14x30)

Air filter

80

Control box

T erminal bed

(Power source)

Bottom plate

23 664(Lifting bolt pitch)

710

The part air intake duct is attached.(✻3)

(When the air intake duct is used)

610

50

150

790

582

204.5

42.5

30

225(✻2)

15

148

13.55050

510

14127

56.5

(52)

(57)

129

55301 301

189

Detailed chart around the air intake duct frange(✻3)

(Duct and frange should be supplied in the field)

550(✻1)

More than 20mm

More than 20mm

6- ø 3hole

55

50X11=550

16

2X12- ø 3hole

14

459(Lifting bolt pitch)

15

113

Air outlet

Air inlet

450

50~150

300

450

2X3- ø 3hole

25

500

50~150

1

2

3

Note 1. Use M10 screw for the lifting bolt (field supply).

2. Keep the service space for the maintenance from the bottom

when the heat exchanger is cleaned.

3. The direction of air intake can be changed from the bottom to

the rear by attaching the bottom plate to the air intake side.

4. Drain Pan is changeable from right and left.

5. The dimension is changed, in case the optional long-life filter

is attached.

Rear Air-Intake spec. :Depth is increased by 30mm(✻1)

Bottom Air-Intake spec. :Height is increased by 30mm(✻2)

Refrigerant piping flare connection

(gas ø 9.52 copper tube):LP ········1

Refrigerant piping flare connection

(liquid ø 6.35 copper tube):HP ········2

Drain piping connection R1 (External thread) ········3

6

OUTLINES AND DIMENSIONS

3

SEZ-KC25VA.W

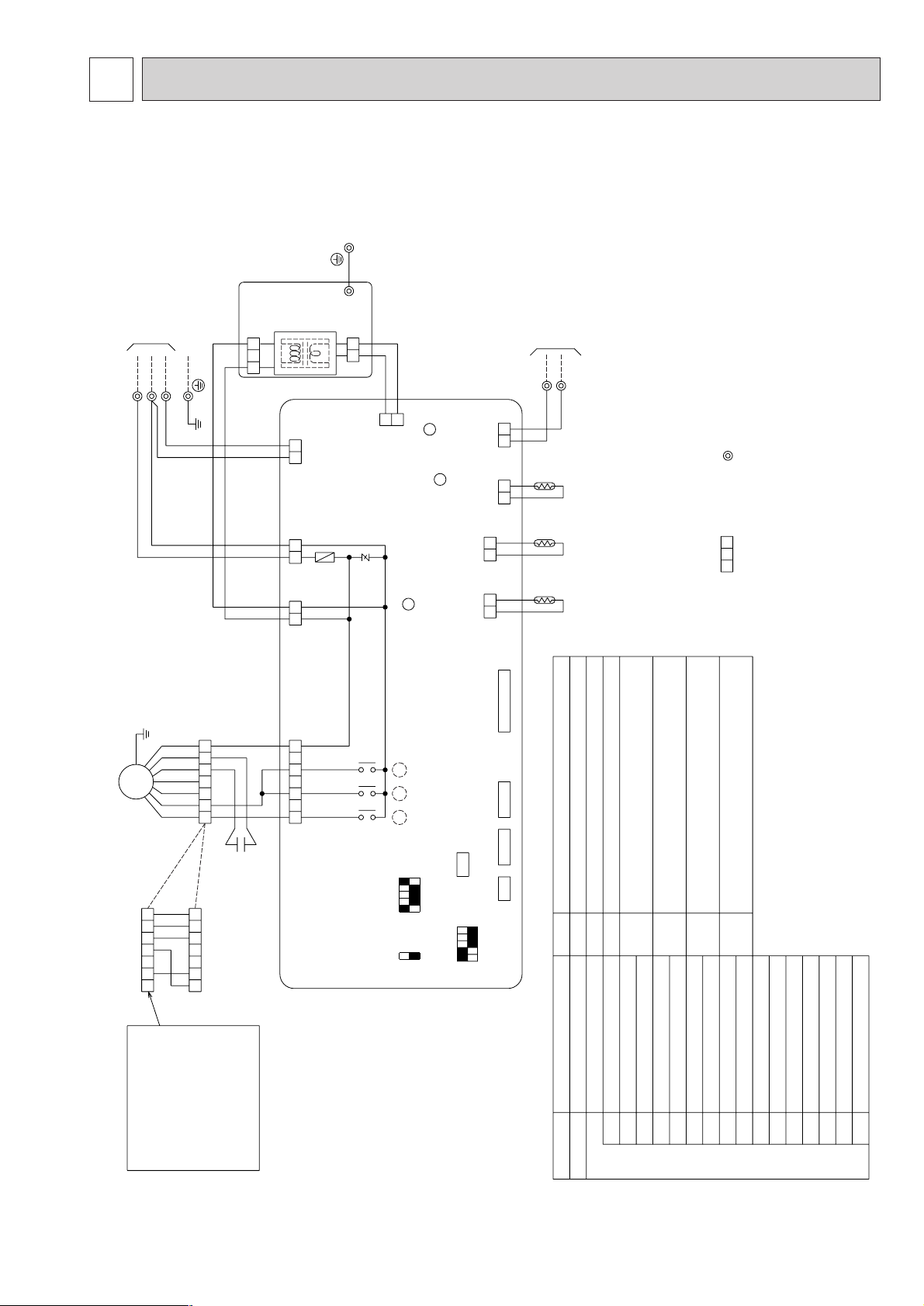

Page 7

7

4

WIRING DIAGRAM

SEZ-KC25VA.W

12

213

131313

1

2

312 4567

1234675

2121

2121

6457321

6457321

TO OUTDOOR UNIT

TH2

TRANS

AC220-240V

CNSK(RED)

DC13.1V

CN2S(WHT)

P.B.

BLU

(CONTROL)

CN3C

ORN

(POWER)

CND

RED

(POWER BOARD)

CNDK

S1S2S3

I.B.

TB4

FUSE

ZNR

X6 X5 X4

WHT

(POWER

BOARD)

CN2D

WHT

(FAN)

FAN

LED1

LED2

LED3

CN32

CN2L

CN51 CN41

CN90

BLK

(2 PHASE)

CN29

RED

(INTAKE)

CN20

WHT

(LIQUID)

CN21

BLU

(REMOCON)

CN22

X6 X5 X4

TH1TH5

1

2

SW2

12345

ON

OFF

5432

OFF

ON

1

SW3

OFF

ON

1

SWE

TB15

TO MA-REMOTE

CONTROLLER

DC8.7-13V

LED1

FUSE

CN90

ZNR

X6

X5

X4

VARISTOR

RELAY (FAN MOTOR HI)

RELAY (FAN MOTOR Lo)

SWE

SW3

RELAY (FAN MOTOR LL)

SWITCH (EMERGENCY OPERATION)

SWITCH (MODE SELECTION)

SW2

LED3

LED2

SWITCH (CAPACITY CODE)

TRANSMISSION (INDOOR-OUTDOOR)

POWER SUPPLY (I.B.)

POWER SUPPLY (I.B.)

FUSE (6.3A)

CN51

CN41

CN32

CN2L

CONNECTOR (WIRELESS)

CENTRALLY CONTROL

CONNECTOR (HA TERMINAL-A)

CONNECTOR (REMOTE SWITCH)

CONNECTOR (LOSSNAY)

I.B.

P.B.

SYMBOL

INDOOR CONTROLLER BOARD

NAME

INDOOR POWER BOARD

SYMBOL

C

MF FAN MOTOR

CAPACITOR (FAN MOTOR)

NAME

TB4

TERMINAL BLOCK (INDOOR/OUTDOOR CONNECTING LINE)

TB15

TERMINAL BLOCK (REMOTE CONTROLLER

TRANSMISSION LINE)

TH1

INT AKE AIR TEMP. THERMIST OR

(0˚C/15kΩ. 25˚C/5.2kΩ DETECT)

TH2

PIPE TEMP. THERMIST OR/LIQUID

(0

˚C/15kΩ. 25˚C/5.2kΩ DETECT)

TH5

COND./EVA. TEMP. THERMISTOR

(0

˚C/15kΩ. 25˚C/5.2kΩ DETECT)

C

MF

INSERT

BLU

The motor connector is

connected with 230V,240V

power at factory shipment.

If 220V power is used,

Insert the attachment.

Color/Power source

WHT/230,240V

BLU/220V

NOTES:1.Since the outdoor side electric wiring may change be sure to

check the outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities, make

wiring matching terminal numbers (S1,S2,S3).

3.Symbols used in wiring diagram above are,

: Connector, : Terminal.

4.The wiring between MA-REMOTE CONTROLLER and TB15 is

included in the package.

Page 8

REFRIGERANT SYSTEM DIAGRAM

5

8

Gas pipe

SEZ-KC25VA.W

ø 9.52<3/8>

mm<in>

Liquid pipe

ø 6.35<1/4>

Capacity

Item

Refrigerant flow in cooling

Refrigerant flow in heating

Pipe temperature

thermistor/liquid

(TH2)

Condenser/evaporator

temperature thermistor

(TH5)

Strainer (#50 mesh)

Heat exchanger

Intake air temperature thermistor TH1

Gas pipe

Flared joints

SEZ-KC25VA.W

Page 9

9

6

TROUBLESHOOTING

6-1. Cautions on troubleshooting

(1) Before troubleshooting, check the followings:

1 Check the power supply voltage.

2 Check the indoor/outdoor connecting wire for mis-wiring.

(2) Take care the followings during servicing.

1 Before servicing the air conditioner, be sure to first turn off the remote controller to stop the main unit, and then turn

off the breaker.

2 When removing the indoor controller board, hold the edge of the board with care NOT to apply stress on the

components.

3 When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

˚C

˚C

SIMPLE

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

B

C

A

E D

6-2. Self-check function

Wired remote controller

(1) Tur n on the power.

(2) Press the [CHECK] button twice.

(3) Set refrigerant address with [TEMP] button

if system control is used.

(4) Press the [ON/OFF] button to stop the

self-check.

AA

CHECK button

BB

Refrigerant address

CC

TEMP button

DD

IC : Indoor unit

OC : Outdoor unit

EE

Check code

1 Check code Symptom Remark

P1 Intake sensor error

P2 Pipe (TH2) sensor error

P9 Pipe (TH5) sensor error

E6,E7 Indoor/outdoor unit communication error

P4 Drain sensor error

P5 Drain pump error

P6 Freeing/Overheating safeguard operation

EE Communication error between indoor and outdoor units

P8 Pipe temperature error

E0, E3~E5 Remote controller transmission error

E1, E2 Remote controller control board error

Fb Indoor unit control system error (memory error, etc.)

E9 Indoor/outdoor unit communication error (Transmitting error) (Outdoor unit)

UP Compressor overcurrent interruption

U3,U4 Open/short of outdoor unit thermistors

UF Compressor overcurrent interruption (When compressor locked)

U2 Abnormal high discharging temperature/49C worked/insufficient refrigerant

U1,Ud Abnormal high pressure (63H worked)/Overheating safeguard operation

U5 Abnormal temperature of heat sink

U8 Outdoor unit fan safeguard stop

U6 Compressor overcurrent interruption/Abnormal of power module

U7 Abnormality of super heat due to low discharge temperature

U9,UH Abnormality such as overvoltage or voltage shortage and abnormal synchronous signal to main circuit

/Current sensor error

Others Other errors (Refer to the technical manual for the outdoor unit.)

For details, check the LED display

of the outdoor controller board.

As for outdoor unit, refer to

service manual OC322.

• On wired remote controller.

1 Check code displayed in the LCD.

• For description of each check code, refer to the following table.

Page 10

6-3.Test point diagram

6-3-1. Indoor power board

SEZ-KC25VA.W

10

CNSK

Connect to the indoor controller board

(CNDK)

Between

11

to 33220-240V AC

CN2S

Connect to the indoor controller board (CN2D)

Between

11

to

33

12.6-13.7V DC (Pin11(+))

Page 11

11

6-3.Test point diagram

6-3-2. Indoor controller board

SEZ-KC25VA.W

FAN

Fan motor output

CNDK

Connect to the indoor

power board (CNSK)

(220~240V AC)

FUSE

(6.3A 250V)

CND

Power

supply input

(220~240V AC)

SWE

Emergency operation

SW2

Capacity setting

Jumper connector

J11~J15

Unit setting

CN2L

Connector

(LOSSNAY)

CN51

Centrally control

CN29

Condenser/evaporator

temperature thermistor

(TH5)

CN21

Pipe temperature

thermistor/Liquid

(TH2)

CN20

Room temperature

thermistor (TH1)

CN22

Remote controller

connecting wire

(10.4~14.6V DC)

LED3

Transmission

(Indoor/outdoor)

LED2

Power supply

(R.B)

LED1

Power supply

(I.B)

CN2D

Connector to the indoor

power board (CN2S)

(12.5~13.7V DC)

CN3C

Transmission

(Indoor/outdoor)

(0~24V DC)

SW3

Mode selection

}

}

Non polarity

+

–

+

–

CN41

Connector

(HA terminal-A)

Page 12

12

6-4.Trouble criterion of main parts

SEZ-KC25VA.W

Intake air temperature

thermistor (TH1)

Condenser/evaporator

temperature thermistor (TH5)

Measure the resistance with a tester.

(Part temperature 10°C ~ 30°C)

Pipe temperature

thermistor/liquid (TH2)

Indoor fan motor

(MF)

Check method and criterion

Part name

Normal

8kΩ~20kΩ

Abnormal

Opened or short-circuited

Measure the resistance between the terminals using a tester. (at 20˚C)

Motor terminal

or

Relay connector

Normal Abnormal

Open or short

White-Black

261

Ω

White-Brown

White-Yellow

White-Blue

294

Ω

389

Ω

475

Ω

White

Orange

Red

Black

Brown

Yellow

Blue

1

2

4

7

5

6

Protector

Relay connector

3

Page 13

13

DISASSEMBLY PROCEDURE

7

7-1. CONTROL BOX

OPERATING PROCEDURE PHOTOS

1.Removing the control box cover

(1) Remove the fixing screws (two) of the control box (A), and

remove the cover. (Fig. 1)

*At this stage, the following servicing is possible.

1 Connection check of the lead wires (listed below) which

are connected to the controller board.

• Power supply (TB4) lead wire.

• Fan motor (MF) lead wire.

• Intake air sensor (TH1) lead wire

• Liquid

• Cond/Eva piping sensor (TH5) lead wire

piping sensor (TH2) lead wire

2

Control board (I.B.) exchange

3

4

Intake air sensor (TH1) exchange

Terminal block (TB4, TB15) exchange

Be careful on removing heavy parts.

fig.1

fig.2

(A)

Page 14

14

7-2. FAN and FAN MOTOR

OPERATING PROCEDURE PHOTOS

Be careful on removing heavy parts.

fig.3

fig.5

1.Removing the fan casing and sirocco fan.

(1) Remove the bottom plate B. (fixing screws : six) (Fig. 3)

(2) Remove the fixing screws (three) of the fan cover, and turn

it in direction of arrow. (Fig. 4)

(3) Remove the fixing screws (two) of the fan cover , and loosen

the set screw of the sirocco fan, and remove the fan cover

and sirocco fan. (Fig. 5)

2.Removing the fan motor.

(1) Remove the control box. (fixing screws : two) (Fig. 7)

(2) Move the control box to place that is not block operation.

(Fig. 8)

(3) Remove the fan motor cable connector in the control box,

and remove the screws of the fixing plate. (Fig. 9)

fig.7

fig.9

fig.4

fig.6

fig.8

Fan cover

Bottom plate B

Set screw

Fan motor

cable connector

Page 15

15

fig.10

fig.11

OPERATING PROCEDURE PHOTOS

1.Removing the drain pan.

(1) Remove the fixing screw (one) of the drain pan. (Fig. 10).

(2) Slide the drain pan in the order of arrow ①,➁,③, and remove

the drain pan. (Fig. 11)

Be careful on removing heavy parts.

7-3. DRAIN PAN

Drain pan

Drain pan

1

2

3

Page 16

16

OPERATING PROCEDURE PHOTOS

(1) Remove the drainpan with procedure 7-3.

(2) Remove the bottom plate A (fixing screws : six), and remove

the plate.(Fig. 12)

(3) Remove the thermistors from the thermistor holders which

are installed on the piping.(Fig. 13)

(liquid piping : fine piping )

fig.12

fig.13

Be careful on removing heavy parts.

1.Removing the thermistors.

7-4.THERMISTOR (Liquid piping temperature detection)

Bottom plate A

Thermistor

Page 17

17

7-5. HEAT EXCHANGER

OPERATING PROCEDURE PHOTOS

1.Removing the heat exchanger.

(1) Remove the drainpan with procedure 7-3.

(2) Remove the bottom plate A with procedure 7-4.

(3) Remove the heat exchanger cover.(fixing screws : four)

(Fig. 14)

(4) Remove the heat exchanger.(fixing screws : three)

(Fig. 15),(Fig. 16)

fig.14

fig15

fig.16

Be careful on removing heavy parts.

Heat exchanger cover

Page 18

18

101

R61 Y85 481 Heat exchanger ass'y 1 W273547

G06

102 R61 Y18 201 Thermistor (2phase) TH5 1 W848734G11

103 R61 Y19 201 Thermistor (liquid) TH2 1 W848734G10

104 R61 Y13 661 Bottom plate A 1 W635907G02

105 R61 Y14 661

Bottom plate B 1 W877415G02

106 R61 Y10 529 Drain pan 1 W877416G01

107 R61 Y06 501 Filter 1 W634781H01

108 R61 151 326 Lifting plate 4 W398770H02

Dwg. No. Price

No.

Part No. Part Name Spec.

-KC25VA

107

108

105

106

104

101.102.103

PARTS LIST

8

EXTERNAL PARTS

SEZ-KC25VA.W

Page 19

19

201

R61 Y14 140 Fan stand 1 W267214G01

202 R61 370 130 Motor support 1 W234925H06

203 R61 220 044 Rubber bush 2 W837244H01

204 R61 652 131 Fixing plate 2 W353715H01

205

R61 Y38 221

Motor P20L

CRC4417BB1ø23W<MF>

1 P714880X01

206

R61 Y16 118 Fan cover 1 W879404G03

207 R40 045 103 Sirocco fan ass'y 1 W234904G01

Dwg. No. Price

No.

Part No. Part Name Spec.

-KC25VA

BLOWER PARTS

SEZ-KC25VA.W

201

202

203

204203 205

206

207

Page 20

301

R61 Y08 715 Terminal bed <3P(S1,S2,S3)> 1 P436157X01

302 R61 435 246 Terminal bed <2P(1,2)>

440V 1.5µF

Intake air

1 A73S950H02

303 R61 Y65 281 Controller board ass'y

1 P785032X01

304 R61 R92 281 Power supply board ass'y 1 P785020X01

305 R61 Y01 287 Thermistor 1 W891304G16

306 R61 Y14 252 Capacitor 1 P412234X01

Dwg. No. Price

No.

Part No. Part Name Spec.

-KC25VA

306

303

304

305

301

302

S1

1

2

S2

S3

FAN

CNDK

CND

CN3C

CN2D

CN20

CN22

20

CONTROL BOX PARTS

SEZ-KC25VA.W

Page 21

21

Applied unit

SEZ-KC25VA.W

Models Pipe length

Pipe size O.D.mm (in.)

Cross-section A-Gas

9.52

(3/8)

6.35

(1/4)

27

21

B-liquid

Insulation

CD

3m

5m

7m

10m

MAC-440PI

MAC-441PI

MAC-442PI

MAC-443PI

9

OPTIONAL PARTS

9-1. REFRIGERANT PIPES

The air conditioner has flared connections.

Please use the optional extension pipe as follows.

Page 22

MEE04K350

Issued in Mar. 2005

Printed in Japan

New publication, effective Mar. 2005.

Specifications subject to change without notice.

TM

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Loading...

Loading...