Mitsubishi SEZ-KA35VA, SEZ-KA50VA, SEZ-KA60VA, SEZ-KA71VA Service Manual

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

ON/OFF

TEMP.

TECHNICAL & SERVICE MANUAL

Indoor unit

[Model names] [Service Ref.]

SEZ-KA35VA SEZ-KA35VA.TH

September 2006

No.OC321

REVISED EDITION-B

Revision:

•RoHS PARTS LIST is added

in REVISED EDITION-B.

•Some descriptions have

been modified.

•Please void OC321

REVISED EDITION-A.

SEZ-KA50VA SEZ-KA50VA.TH

SEZ-KA60VA SEZ-KA60VA.TH

SEZ-KA71VA SEZ-KA71VA.TH

CONTENTS

1. PART NAMES AND FUNCTIONS········2

2. SPECIFICATIONS·································4

Model name

indication

INDOOR UNIT

3. OUTLINES AND DIMENSIONS············9

4. WIRING DIAGRAM ·····························10

5.

REFRIGERANT SYSTEM DIAGRAM

6. TROUBLESHOOTING························12

7. DISASSEMBLY PROCEDURE ···········22

8. PARTS LIST········································25

9. RoHS PARTS LIST ·····························27

10. OPTIONAL PARTS·····························29

Note:

• This manual describes only

service data of the indoor

units.When servicing outdoor units, please refer to

the service manual

No.OC322, OC323 together

with this manual.

• RoHS compliant products

have <G> mark on the spec

name plate.

• For servicing of RoHS

compliant products, refer

to the RoHS Parts List.

·······11

WIRED REMOTE

CONTROLLER

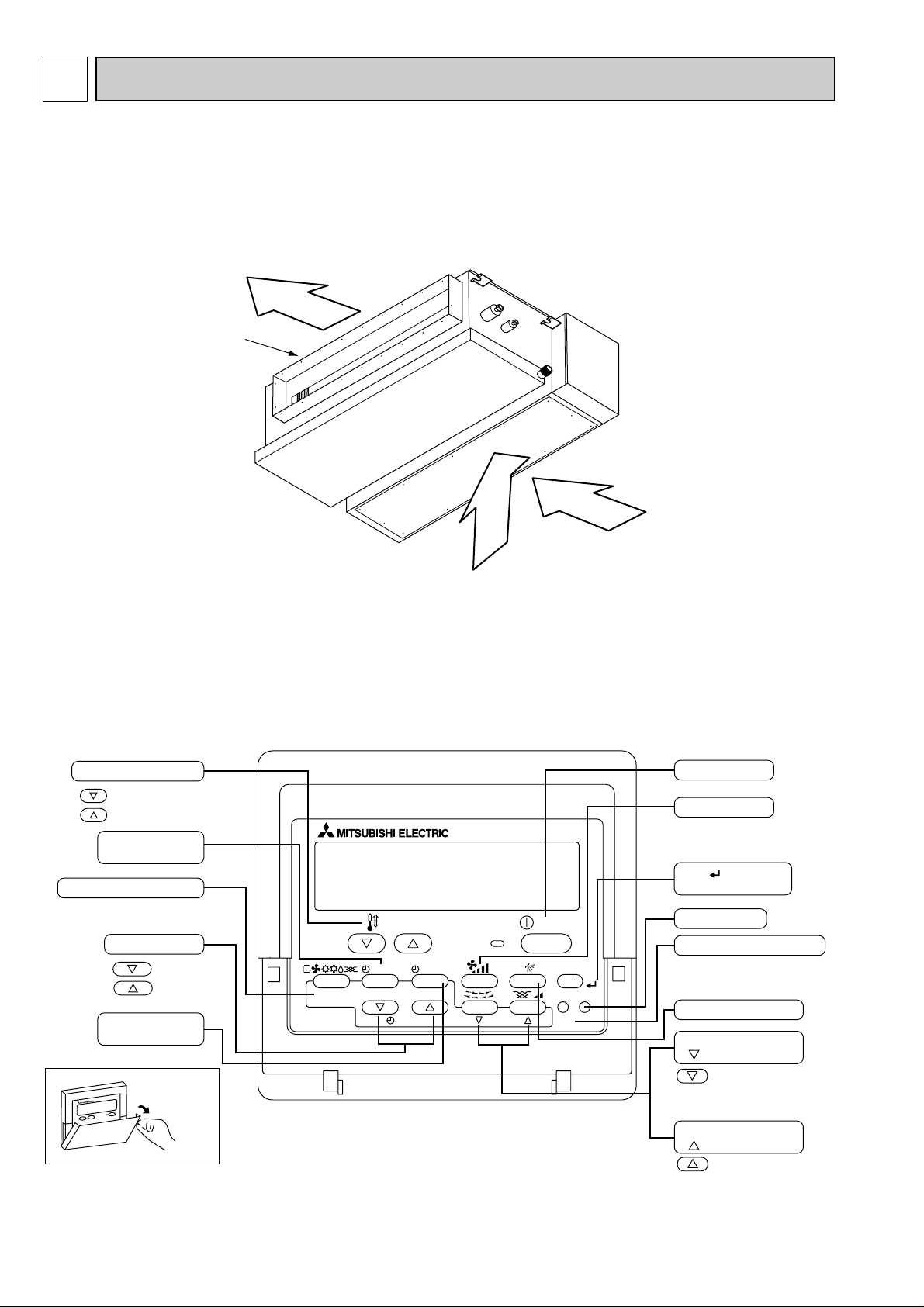

1

Air outlet duct flange

Air outlet

Air inlet

(Selecting the either back side or bottom side)

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door

Start/Stop button

Fan Speed button

Filter button

(<return sign> button)

Test Run button

Service button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To preceding operation

number

Ventilation button

(

Operation button)

To next operation number

PART NAMES AND FUNCTIONS

Indoor Unit

SEZ-KA35VA.TH

SEZ-KA50VA.TH

SEZ-KA60VA.TH

SEZ-KA71VA.TH

Wired remote controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

2

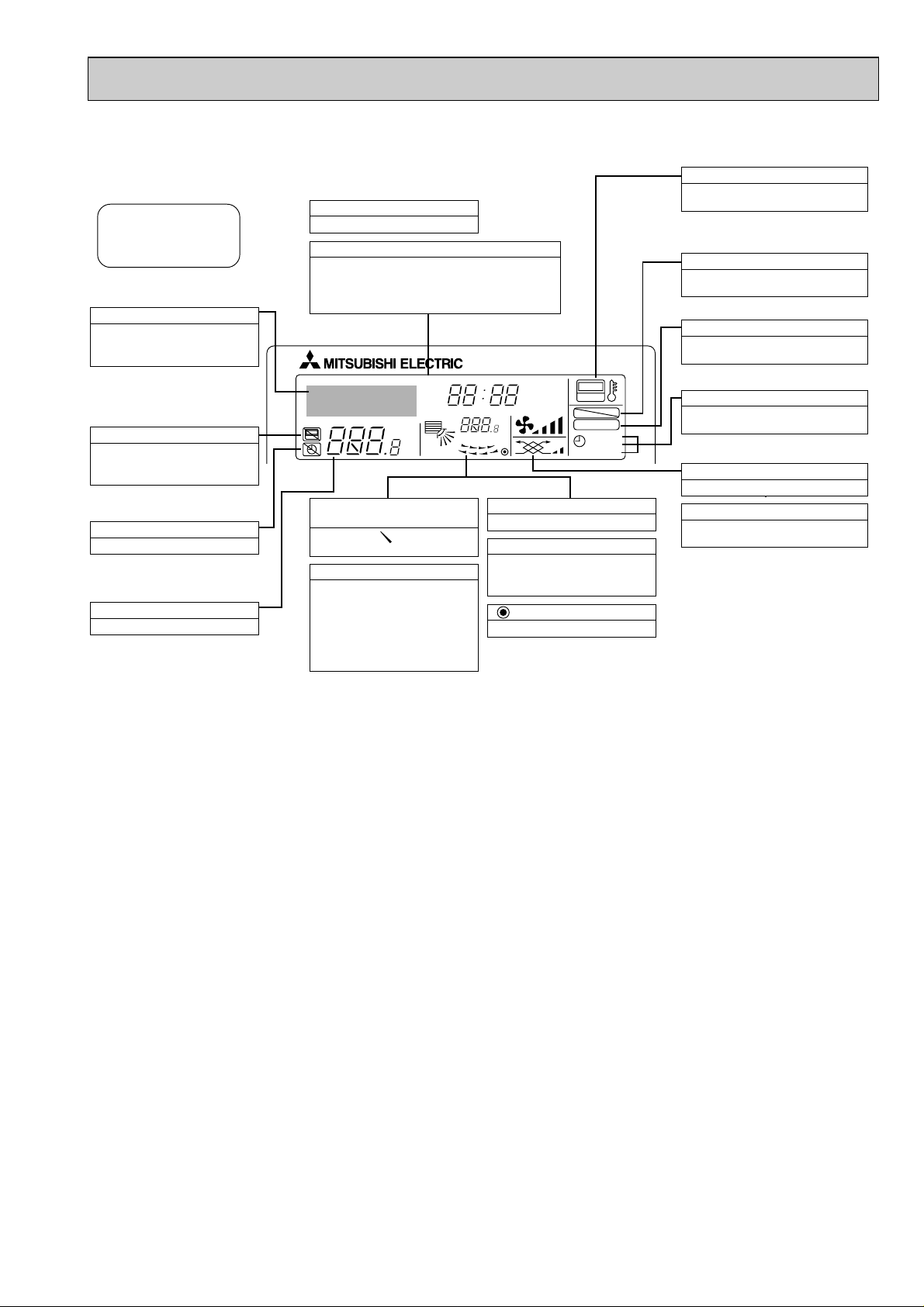

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

Low and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

● Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

● If you press a button for a feature that is not installed in the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to operate multiple indoor units, this message will appear only if the feature is not

present at the parent unit.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication (For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappears then start the operation.

3

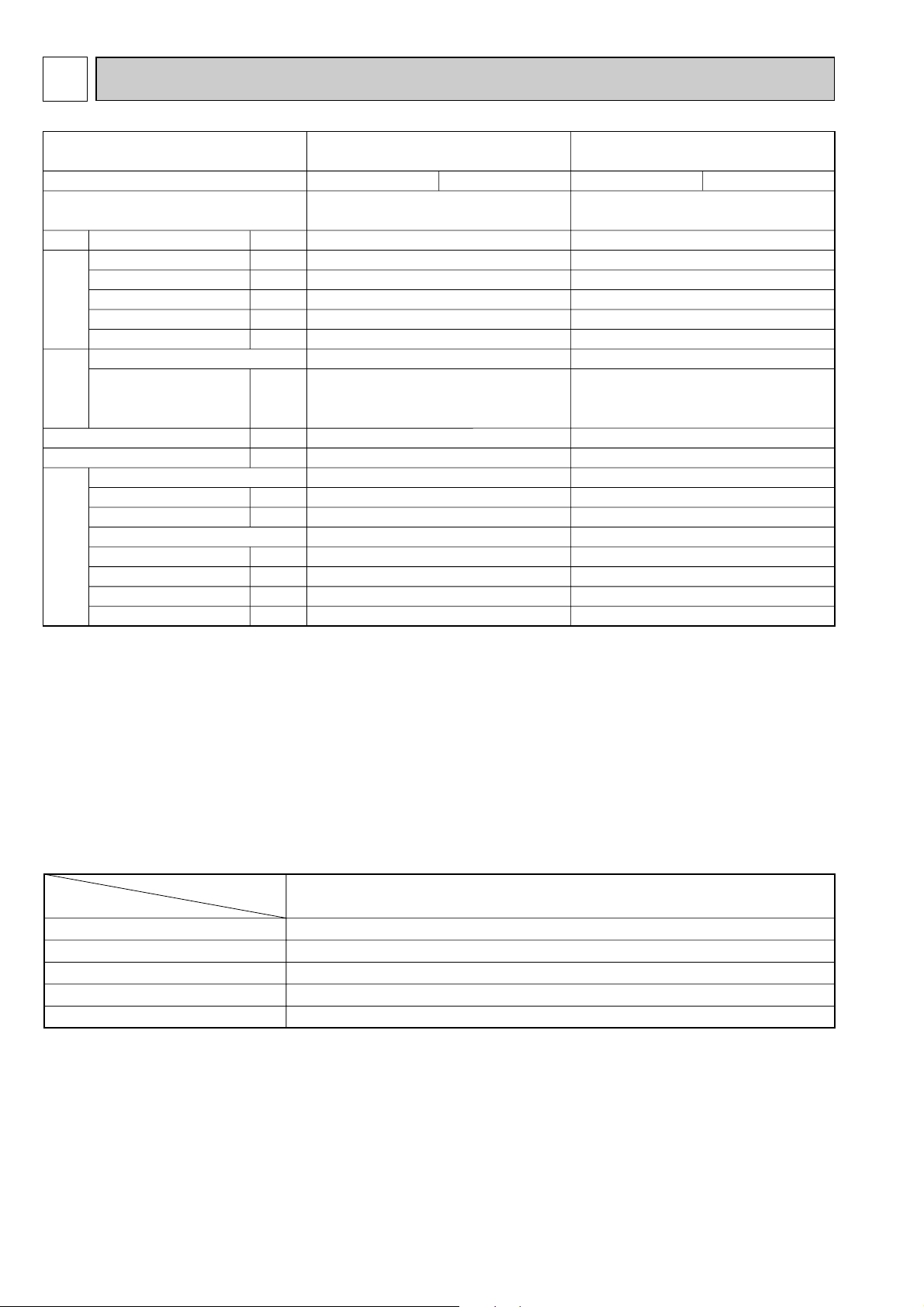

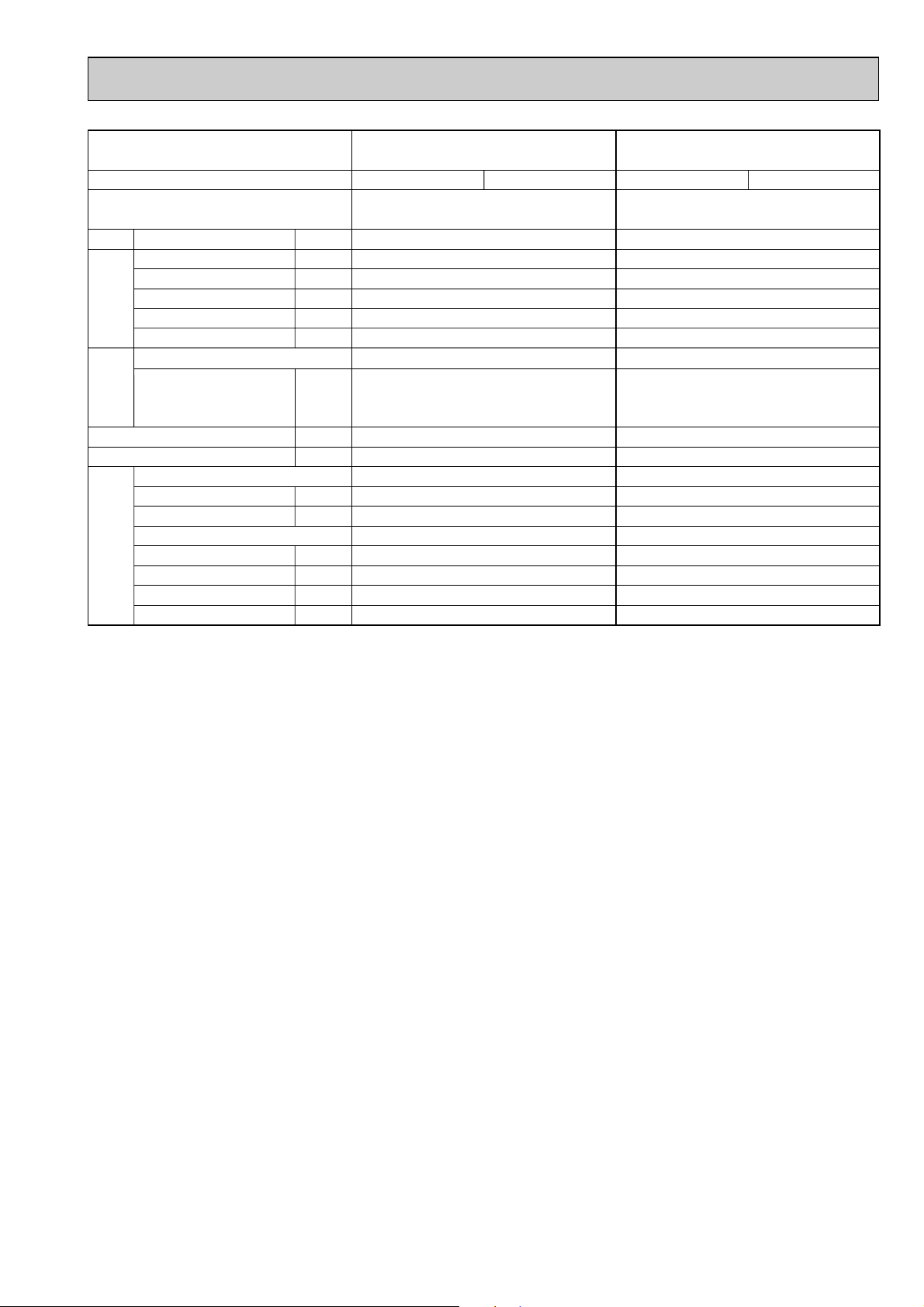

2

SEZ-KA35VA.TH SEZ-KA50VA.TH

Indoor model

Function

Power supply

Single phase

230V, 50Hz

780/600

10

0.40

60

—

0.22

PK6V19-EF

1100o270o700

33.5

1

35/30

770/630

3

Std : 30 Max : 50

10

10

10

Cooling Heating

Single phase

230V, 50Hz

1020/720

20

0.55

80

—

0.27

PK6V32-EF

1100o270o700

33.5

1

39/31

840/640

3

Std : 30 Max : 50

10

10

10

Cooling

Heating

Air flow (High/Low)

Power outlet

Running current ✽1

Power input Rated frequency

Auxiliary heater

Fan motor current ✽1

Model

Winding

resistance (at20:)

Dimensions WoHoD

Weight

Air direction

Sound level (High/Low)

Fan speed (High/Low)

Fan speed regulator

External satatic pressure

Thermistor TH1 (at 25:)

Thermistor TH2 (at 25:)

Thermistor TH5 (at 25:)

K /h

A

A

W

A(kW)

A

"

mm

kg

dB(A)

rpm

Pa

k"

k"

k"

Electrical

data

Fan

motor

Special remarks

Capacity

WHT-BLK : 257 BLK-BLU : 20

BLU-YLW : 27 YLW-BRN : 14

BRN-RED : 51(at 26:)

WHT-BLK : 166 BLK-BLU : 52

BLU-YLW : 19 YLW-BRN : 8

BRN-RED : 40(at 26:)

SEZ-KA35/50VA.TH : 2.5+ 440V SEZ-KA60VA.TH : 3.0+ 440V SEZ-KA71VA.TH : 4.0+ 440V

250V 6.3A

ERZV10D471

TO OUTDOOR UNIT : 3P TO WIRED REMOTE CONTROLLER : 2P

141:i3:

INDOOR UNIT

Item

Model

Indoor fan capacitor

Fuse

Varistor

Terminal block

Indoor fan motor thermal fuse

SEZ-KA35VA.TH SEZ-KA50VA.TH SEZ-KA60VA.TH SEZ-KA71VA.TH

(C1)

(FUSE)

(ZNR)

(TB)

SPECIFICATIONS

NOTE : Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27: W.B. 19:

Outdoor D.B. 35: W.B. 24:

Heating : Indoor D.B. 20: W.B. 15:

Outdoor D.B. 7: W.B. 6:

Refrigerant piping length (one way): 5m

✽1 Measured under rated operating frequency.

Specifications and rating conditions of main electric parts

4

Indoor model

SEZ-KA60VA.TH

SEZ-KA71VA.TH

Capacity

Air flow (High/Low)

Power outlet

Running current ✽1

Power input Rated frequency

data

Auxiliary heater

Electrical

Fan motor current ✽1

Model

Winding

Fan

motor

resistance

Dimensions WoHoD

Weight

Air direction

Sound level(High/Low)

Fan speed(High/Low)

Fan speed regulator

External satatic pressure

Thermistor TH1 (at 25:)

Thermistor TH2 (at 25:)

Special remarks

Thermistor TH5 (at 25:)

Function

Power supply

K /h

A

A

W

A(kW)

A

"

mm

kg

dB(A)

rpm

Pa

k"

k"

k"

Cooling Heating

Single phase

230V, 50Hz

1200/720

20

0.65

100

—

0.39

PK6V50-EF

WHT-BLK : 103 BLK-BLU : 57

BLU-YLW : 15 YLW-BRN : 7

BRN-RED : 29 (at 26:)

1100o270o700

33.5

1

43/32

890/660

3

Std : 30 Max : 50

10

10

10

Cooling Heating

Single phase

230V, 50Hz

1200/720

20

0.60

130

—

0.51

PK4V60-EA

WHT-BLK : 108 BLK-BLU : 29

BLU-YLW : 26 YLW-BRN : 14

at 26:

BRN-RED : 34 (

1100o270o700

35

1

43/32

1050/690

3

Std : 30 Max : 50

10

10

10

)

NOTE : Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27: W.B. 19:

Outdoor D.B. 35: W.B. 24:

Heating : Indoor D.B. 20: W.B. 15:

Outdoor D.B. 7: W.B. 6:

Refrigerant piping length (one way): 5m

✽1 Measured under rated operating frequency.

5

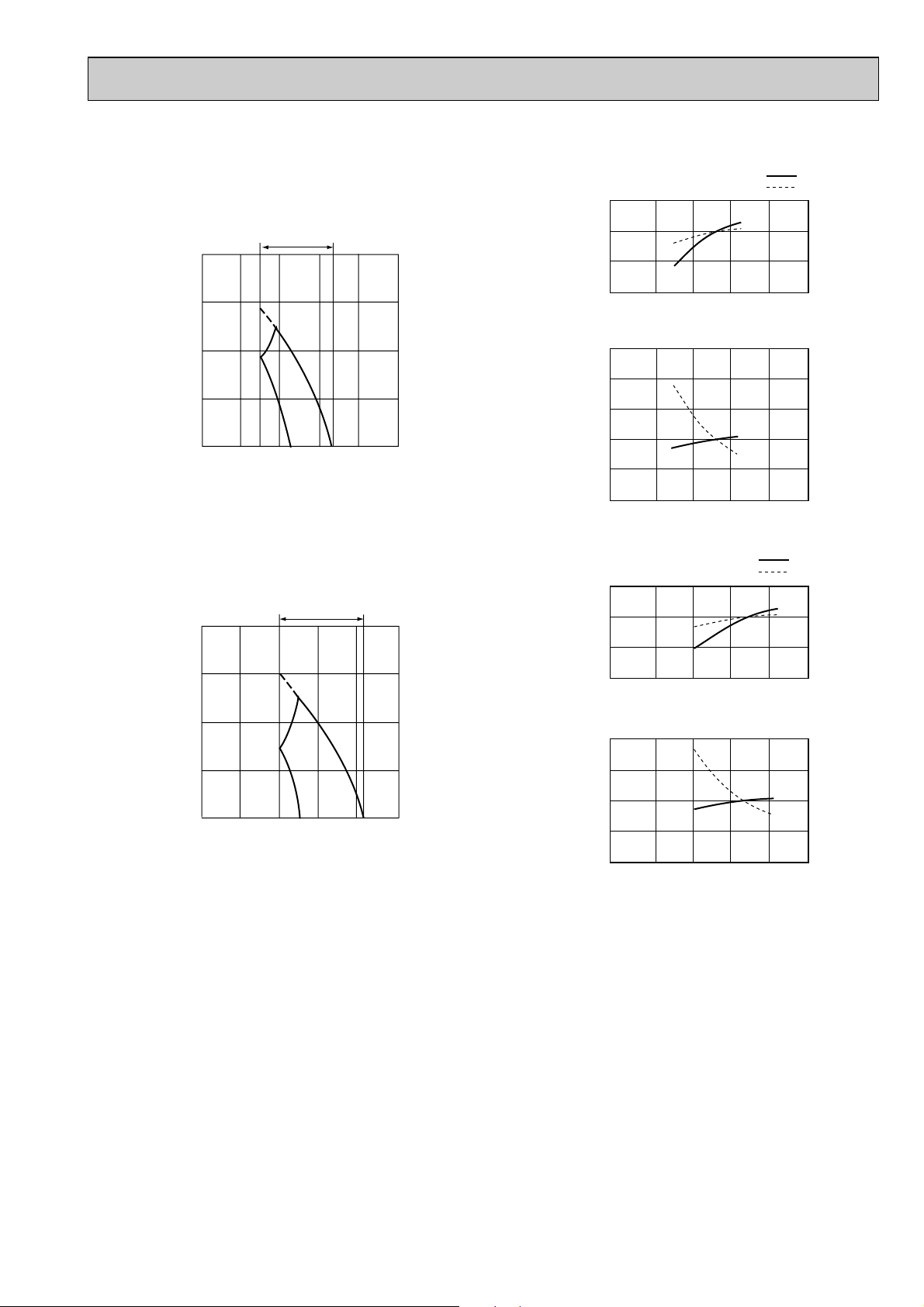

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SEZ-KA50VA.TH

High

Low

39

SPL(dB)

31

LINE

<50Hz>

NOTCH

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SEZ-KA35VA.TH

High

Low

35

SPL(dB)

30

LINE

<50Hz>

NOTCH

NOISE CRITERION CURVES

UNIT

External static

pressure 30Pa

1.5m

MICROPHONE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

SEZ-KA60VA.TH

SEZ-KA71VA.TH

High

Low

43

SPL(dB)

32

LINE

<50Hz>

NOTCH

NOTE: The sound level is measured in an anechoic room where echoes are few, when compressor stops. The sound

may be bigger than displayed level under actual installation condition by surrounding echoes. The sound level

can be higher by about 2 dB than the displayed level during cooling and heating operation.

6

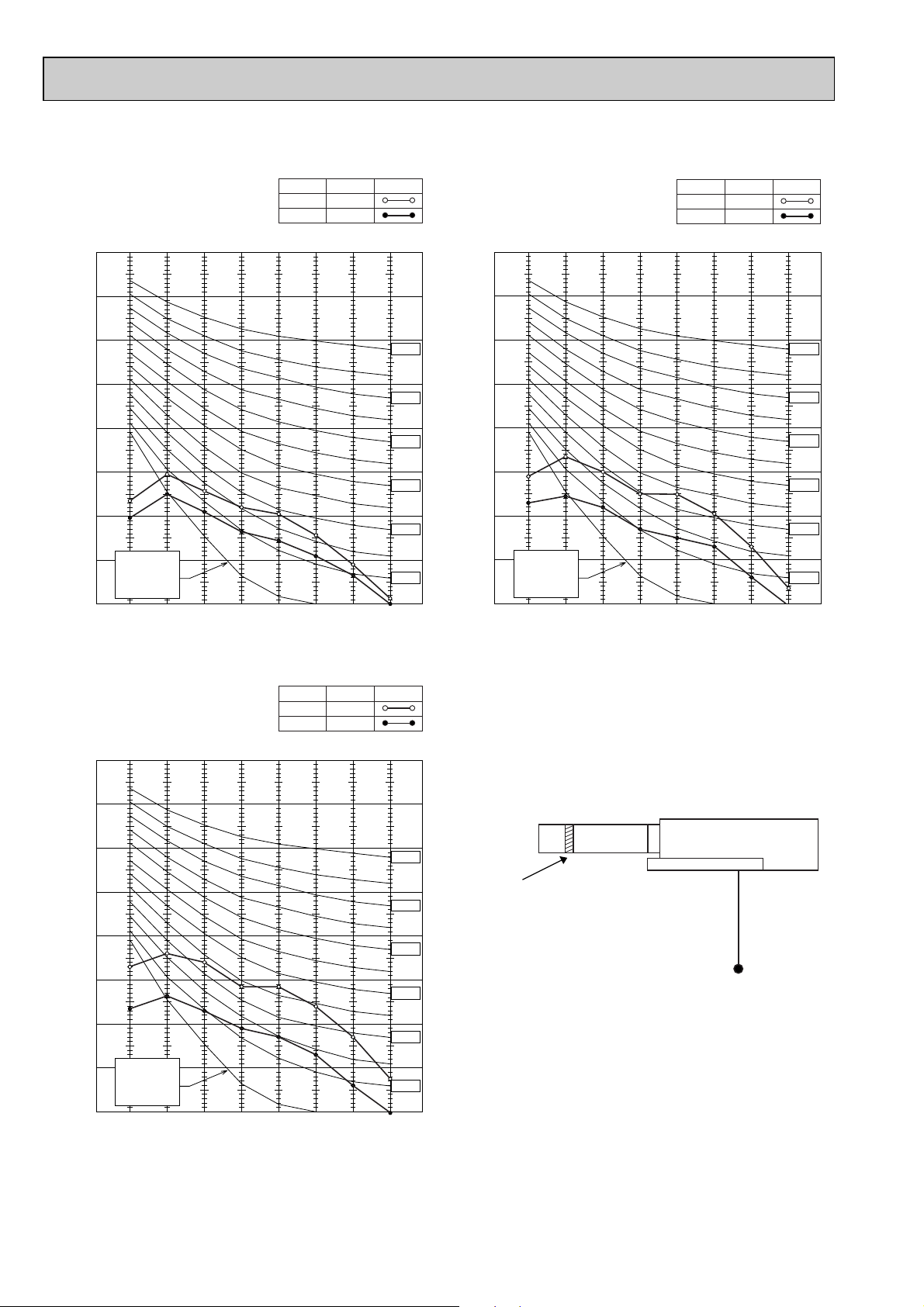

INDOOR FAN PERFORMANCE AND CORRECTED AIR FLOW

SEZ-KA35VA.TH

80

60

40

20

External static pressure(Pa)

(1Pa = 0.1mmAq)

0

SEZ-KA50VA.TH

80

60

40

Fan Performance

Recommended range

105 7 15 20 25

Air flow (K/X)

Fan Performance

Recommended range

Corrected Air flow

1.1

1.0

0.9

Correction factor

0.8

1.3

1.2

1.1

1.0

Correction factor

0.9

0.8

Corrected Airflow

1.1

1.0

0.9

Correction factor

0.8

1.2

Capacity

Cooling

1051520

Air flow (K/X)

Heating

5101520

Air flow (K/X)

Cooling

510152025

Air flow (K/X)

Heating

Input

25

25

Capacity

Input

20

External static pressure(Pa)

(1Pa = 0.1mmAq)

0

15510 2025

Air flow (K/X)

1.1

1.0

0.9

Correction factor

0.8

510152025

Air flow (K/X)

7

INDOOR FAN PERFORMANCE AND CORRECTED AIR FLOW

Air flow (K/X)

Recommended range

80

60

40

20

0

15510 2025

External static pressure(Pa)

(1Pa = 0.1mmAq)

Fan Performance

SEZ-KA60VA.TH

SEZ-KA71VA.TH

Corrected Air flow

1.1

0.9

1.0

0.8

10 15 20 25 30

Correction factor

Capacity

Input

Cooling

Air flow (K/X)

0.9

1.0

1.2

1.1

1.3

10 15 20 25 30

Correction factor

Heating

Air flow (K/X)

Air flow (K/X)

Recommended range

80

60

40

20

0

15510 2025

External static pressure(Pa)

(1Pa = 0.1mmAq)

Fan Performance

Corrected Air flow

1.1

0.9

1.0

0.8

10 15 20 25 30

Correction factor

Capacity

Input

Cooling

Air flow (K/X)

0.9

1.0

1.2

1.1

1.3

10 15 20 25 30

Correction factor

Heating

Air flow (K/X)

8

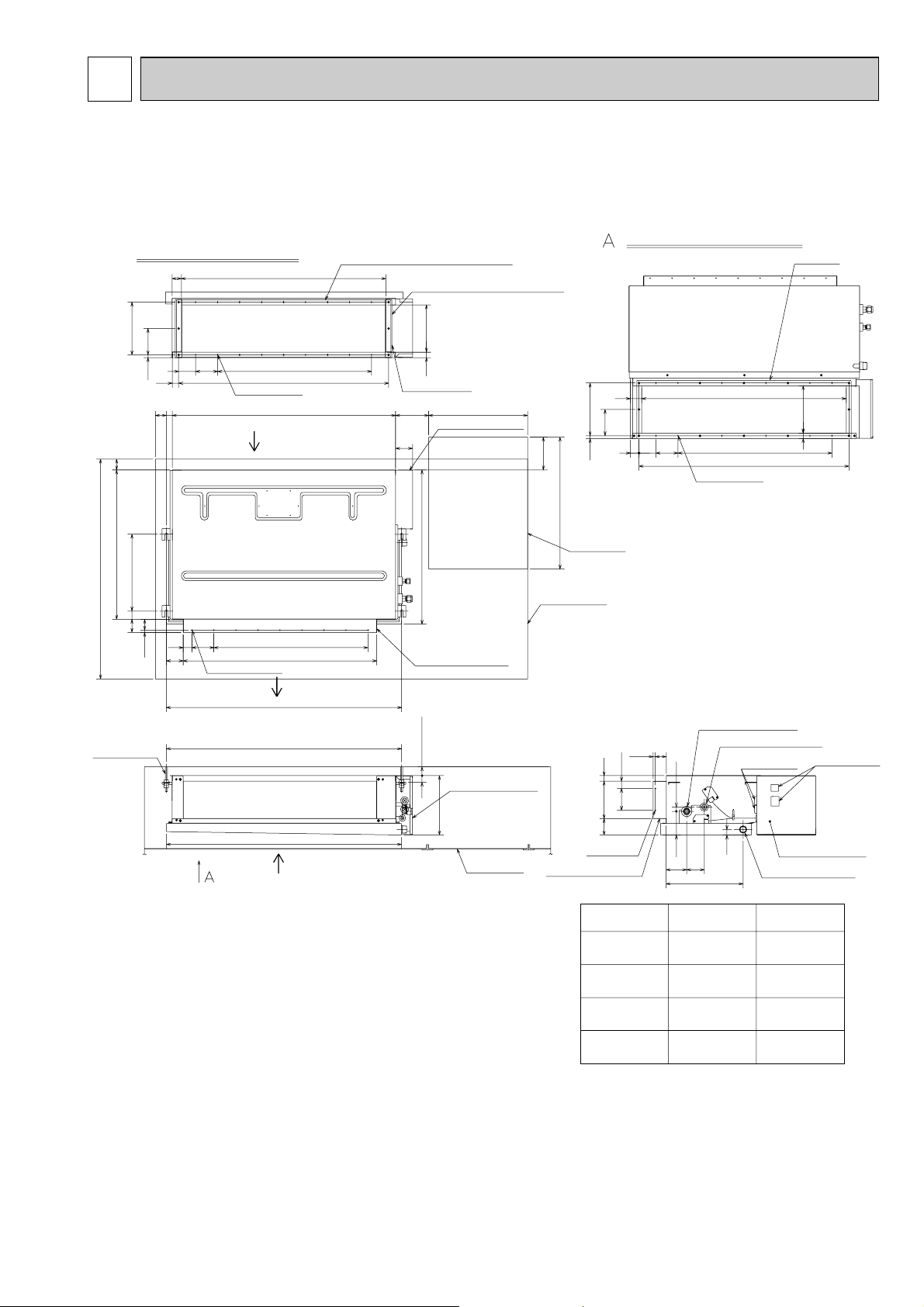

3

(10) 50

50

880

7

x100=700

100

40

9 x 2-{2.9 holes

1000

50

38

60

680

350

Suspension

bolt pitch

In case of bottom side suction,

mount the PLATE (A) on the rear side.

Air inlet (rear side) dimensions

240

1016

42

930

back side or bottom side.

29

955

7

x100=700

100

77.5

12012.5

(Inlet size)

24-

{2.9 holes

50

27

Air inlet

(rear side)

Air outlet duct flange

120

12.5 240

(It is necessary to maintain a working

service area from the ceiling.)

150

32.5

25

(10) 50

77

600

700

Access door

Service space

Air outlet

Suspension bolt pitch

1070

(Suspension bolt pitch)

Electrical parts box

(1070)

20 or more30

20

PLATE (B) x 2

After installation, remove the

transportation support PLATE (B).

25

(Inlet size)

215

450150

Electrical parts box

w Select the either

SEZ-KA60VA

SEZ-KA50VA

Terminal block

3/8F

flared connection

{9.52mm

{6.35mm

flared connection

1/4F

Air outlet duct flange

51

25

930

(Inlet size)

39

955

7

x100=700

100

77.5

(Inlet size)

215

Air inlet (bottom side) dimensions

24-{2.9 holes

flared connection

{6.35mm

Electrical parts box

2

x2-{2.9

holes

flared connection

{15.88mm

5/8F

flared connection

1/2F

{12.7mm

Refrigerent pipe

(gas)

Refrigerent pipe

(liquid)

1/4F

flared connection

{6.35mm

SEZ-KA35VA

Models

Wiring entry

Refrigerent pipe (liquid)

Refrigerent pipe (gas)

Drain plug R1 (male)

108

94 80

25

350

1/4F

SEZ-KA71VA

flared connection

{9.52mm

flared connection

5/8F

{15.88mm

3/8F

w Select the either back side or bottom side.

Air inlet

(bottom side)

100

75 170

Suspension bolt

M10 or 3/8

(procure locally)

1100

270

Access door

PLATE (A)

OUTLINES AND DIMENSIONS

SEZ-KA35VA.TH

SEZ-KA50VA.TH

SEZ-KA60VA.TH

SEZ-KA71VA.TH

Unit : mm

9

4

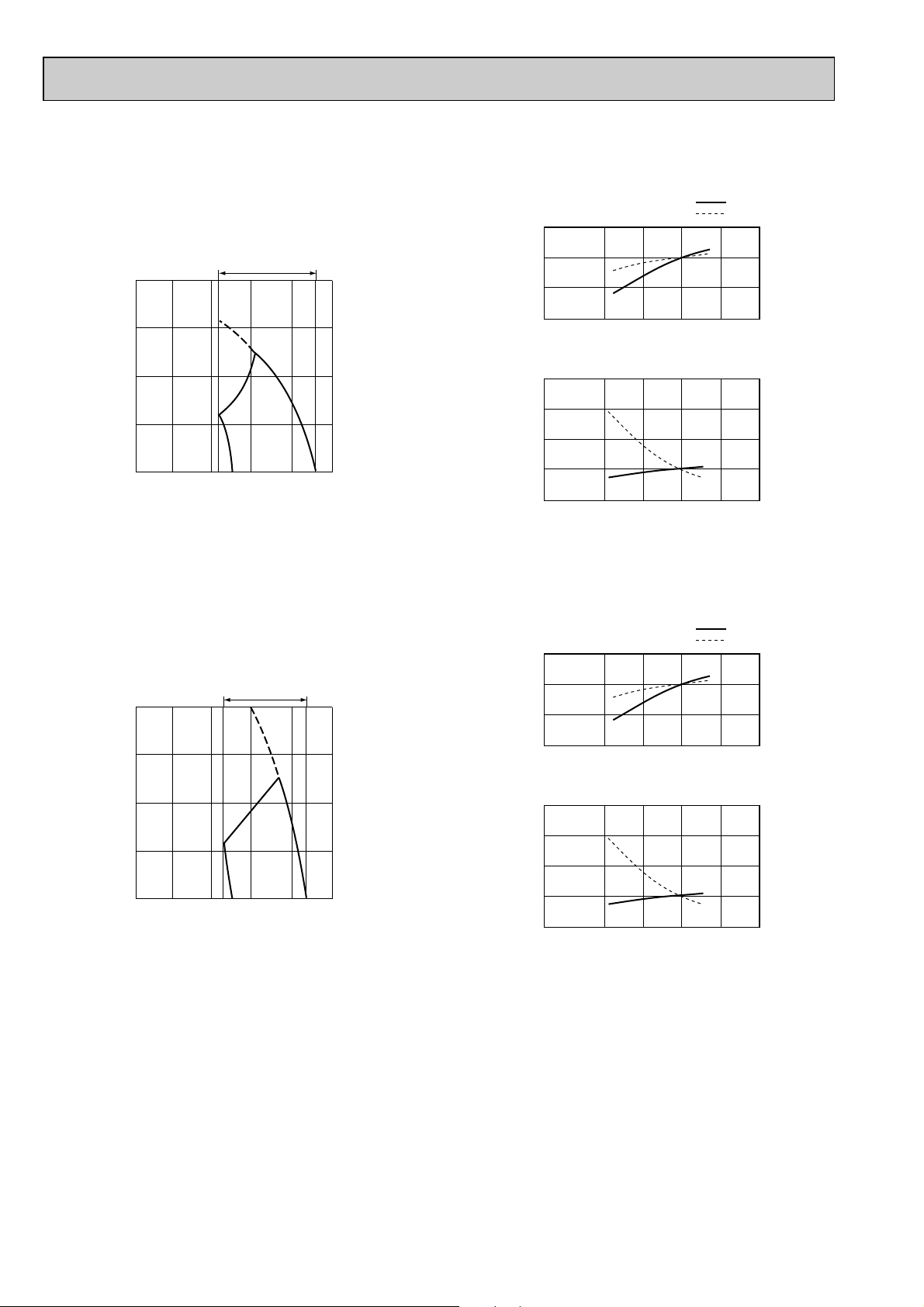

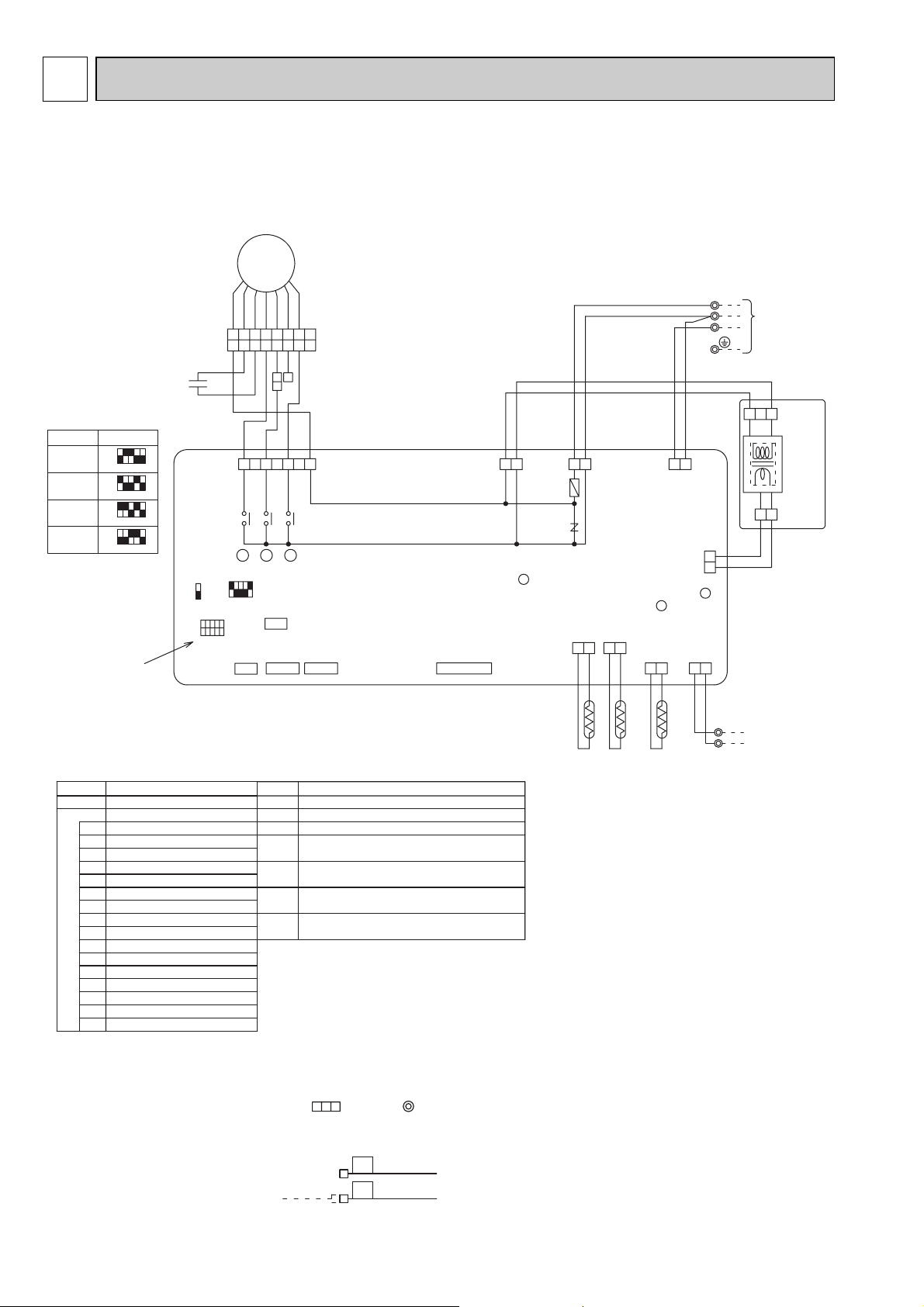

SWE

OFF

ON

SW3

OFF

54321

ON

SW2

OFF

54321

ON

(POWER

BOARD)

CNDK

RED

RED

WHT

ZNR

FUSE

RED

BLU

CND

(POWER)

ORN

BLU

YLW

WHT

BRN

BLU

BLK

1234567

87654321

BLU

BRN

YLW

ORN

87123456

RED

BLK

RED

WHT

C1

MF

ORN

WHT

FAN

(FAN)

CN90

BLU

BLU

(REMOCON)

BLU

TO OUTDOOR

UNIT

S3

P.B

123

TB4

S1

S2

TB15

1

2

TO MA-REMOTE

CONTROLLER

DC8.7-13V

}

I.B

12

CN22

12

WHT

RED

(INTAKE)

(LIQUID)

CN20

CN21

122

TH1 TH2

13

(CONTROL)

CN3C

BLU

3

LED1

12

TRANS

DC13.1V

CN2S(WHT)

AC220-240V

CNSK(RED)

WHT

BLK

2

1

(POWER

BOARD)

CN2D

WHT

LED2

ORN

BLU

LED3

CN2L

CN32

CN51

CN41

X5

X5 X4

X4X6

X6

(2 PHASE)

CN29

BLK

1

TH5

311

54321

OFF

ON

KA60

54321

OFF

ON

KA71

<fig:w1>

MODELS

KA35

KA50

ON

OFF

12345

ON

OFF

12345

SW2

See fig:w1

SYMBOL NAME

CONNECTOR(WIRELESS)

Indoor Fan Motor(MF)

for 60Hz

4.Since the indoor fan motor(MF) is connected with 50Hz power,

if 60Hz power is used, change the wiring connection shown in

fig:w2.

wFor details on how to operate self-diagnosis,

refer to the technical manuals etc.

CN90

MF

C1

TB4

TB15

TH1

TH2

TH5

FAN MOTOR

CAPACITOR(FAN MOTOR)

TERMINAL BLOCK(INDOOR/OUTDOOR CONNECTING LINE)

TERMINAL BLOCK(REMOTE CONTROLLER

TRANSMISSION LINE)

ROOM TEMP.THERMISTOR

(0°C/15kΩ,25°C/5.4kΩ DETECT)

PIPE TEMP.THERMISTOR/LIQUID

(0°C/15kΩ,25°C/5.4kΩ DETECT)

COND./EVA.TEMP.THERMISTOR

(0°C/15kΩ,25°C/5.4kΩ DETECT)

:Connector, :Terminal(block).

1.Since the outdoor side electric wiring may change be sure to

check the outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities,make

wiring matching terminal numbers(S1,S2,S3).

NOTES:

3.Symbols used in wiring diagram above are,

FUSE(T6.3AL250V)

X6

X5

X4

ZNR

RELAY(FAN MOTOR Hi)

RELAY(FAN MOTOR LL)

RELAY(FAN MOTOR Lo)

VARISTOR

SWITCH(CAPACITY CODE)

SW3

SW2

SWE SWITCH(EMERGENCY OPERATION)

SWITCH(MODE SELECTION)

TRANSMISSION(INDOOR-OUTDOOR)

LED1

LED2

LED3

POWER SUPPLY(I.B)

POWER SUPPLY(I.B)

CN51

CENTRALLY CONTROL

FUSE

P.B

CONNECTOR(HA TERMINAL-A)

CONNECTOR(REMOTE SWITCH)

CONNECTOR(LOSSNAY)

CN41

CN32

CN2L

INDOOR CONTROLLER BOARD

INDOOR POWER BOARD

I.B

NAMESYMBOL

YELLOW

BLUE

BLUE

<fig:w2>

50

60

[LEGEND]

WIRING DIAGRAM

SEZ-KA35VA.TH

SEZ-KA50VA.TH

SEZ-KA60VA.TH

SEZ-KA71VA.TH

10