Page 1

OPERATION &

MAINTENANCE MANUAL

199405-A0120

The operator and supervisor are requested to read this Oper-

ation and Maintenance Manual carefully before operating the

engine or conducting inspection and maintenance.

Never operate the engine or conduct maintenance work with-

out completely understanding this manual.

October 2009

Pub. No. 99405-A0120

TP-6547 10/09

Page 2

INTRODUCTION

This operation and maintenance manual contains detailed operation, inspection

and maintenance information for engines from Mitsubishi Heavy Industries, Ltd.

Please read this manual thoroughly before proceeding with operation, inspection,

and maintenance work for correct use and servicing.

Please observe the contents of the emission controls which are applied in the

countries or areas where the engine is used.

Failure to follow directions in this manual may result in serious accidents.

i

Page 3

FOREWORD

LIMITED WARRANTY

Mitsubishi Heavy Industries, Ltd. will repair or replace parts returned to us when we judge that the parts are defec-

tive in material and/or workmanship after conducting inspection.

Mitsubishi Heavy Industries, Ltd.'s warranty is limited to the compensation work of repair or replacement of parts.

The warranty coverage is effective for the original purchaser only. Those to whom ownership is later transferred are

not provided with the warranty. However, that the warranty coverage is effective for the ultimate purchaser and each

subsequent purchaser for emission-related parts.

Mitsubishi Heavy Industries, Ltd. makes no warranties, either expressed or implied,

except as provided in this manual, including, but not limited to, warranties as to market-

ability, merchantability, fitness for a particular purpose or use, or against infringement of

any patent.

Mitsubishi Heavy Industries, Ltd. will not be liable for any damages or consequential

damages, including, but not limited to, damages or other costs resulting from any abuse,

misuse, misapplication of the engine and devices supplied from us.

Mitsubishi Heavy Industries, Ltd. will not be liable for any damages or personal injuries

resulting from any modification, without our written permission, of the engine and

devices supplied from us.

Mitsubishi Heavy Industries, Ltd. will not be liable for any damages or production losses

caused by the use of fuel, engine oil and/or long life coolant (LLC) that we are not recom-

mended.

The owner of the engine is responsible for the performance of the required maintenance

listed in this operation manual.

When performing the maintenance, follow the service manual published by Mitsubishi

Heavy Industries, Ltd.

Mitsubishi Heavy Industries, Ltd. may deny the warranty coverage if the engine or part

has failed due to inadequate or improper maintenance.

ii

Page 4

FOREWORD

EMISSION WARRANTY

The following warranty applies to the engines that are approved of the emission regulation of the U.S. Environ-

mental Protection Agency.

Warranty coverage

Mitsubishi Heavy Industries, Ltd. warrants to the first owner and each subsequent purchaser of a new non-road die-

sel engine that the emission control system of your engine:

is designed, built and equipped so as to conform at the time of sales with all applicable regulation of the U.S. Envi-

ronmental Protection Agency. If the vehicle in which the engine is installed is registered in the state of California, a

separate California emission regulation also applies.

is free from the defects in material and workmanship which will cause the engine to fail to meet these regulations

within the warranty period.

Warranty period

Then its warranty period is 5 years or 3000 hours, whichever comes first.

However, if your engine warranty period is longer than the emission warranty period, the emission warranty period

extends to same as the engine warranty period.

Below warranty period shall begin on the date the engine is delivered to the first owner.

Warranted parts

Mitsubishi Heavy Industries, Ltd. warrants the parts which will increase the emission of pollutants when they

become defective.

The followings are examples.

Inlet/Exhaust manifold

Crankcase ventilation system

Fuel system

Fuel injection nozzle

Limited warranty

Refer to "Limited warranty" (Page ii).

iii

Page 5

FOREWORD

CALIFORNIA EMISSION CONTROL WARRANTY STATE-

MENT YOUR WARRANTY RIGHTS AND OBLIGATIONS

The following warranty applies to the engines that are approved of the emission regulation of the California Air

Resources Board (CARB).

The California Air Resources Board (CARB) is pleased to explain the emission control system warranty on

you 2008 or later engine. In California, new heavy-duty off-road engines must be designed, built, and equipped to

meet the State's stringent anti-smog standards. Mitsubishi Heavy Industries, Ltd. must warrant the emission control

system on your engine for the periods of time listed below provided there has been no abuse, neglect or improper

maintenance of your engine.

Your emission control system may include parts such as the fuel-injection system and the air induction system. Also

included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Mitsubishi Heavy Industries, Ltd. will repair your heavy-duty off-road engine

at no cost to you including diagnosis, parts, and labor.

Manufacurer's warranty coverage:

The 2008 and later heavy-duty off-road engines are warranted for the warranty period. If any emission-related part

on your engine is defective, the part will be repaired or replaced by Mitsubishi Heavy Industries, Ltd.

Owner's warranty responsibilities:

As the heavy-duty off-road engine owner, you are responsible for the performance of the required maintenance

listed in your owner's manual. Mitsubishi Heavy Industries, Ltd. recommends that you retain all receipts covering

maintenance on your heavy-duty off-road engine, but Mitsubishi Heavy Industries, Ltd. cannot deny warranty

solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

As the heavy-duty off-road engine owner, you should however be aware that Mitsubishi Heavy Industries, Ltd. may

deny you warranty coverage if your heavy-duty off-road engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

Your engine is designed to operate on diesel fuel only. Use of any other fuel may result in your engine no longer

operating in compliance with California's emissions requirements.

You are responsible for initiating the warranty process. The Air Rexources Board suggests that you present your

heavy-duty off-road engine to a Mitsubishi Heavy Industries, Ltd. dealer or distributor dealer as soon as problem

exists. The warranty repairs should be completed by the dealer or distributor as expeditiously as possible.

If you have any questions regarding your warranty rights and responsibilities, you should contact Mitsubishi

Engine North America at 1-630-268-0750.

iv

Page 6

FOREWORD

Warranty coverage:

(a) The warranty period shall begin on the date the engine or equipment is delivered to an ultimate purchaser.

(b) Mitsubishi Heavy Industries, Ltd. warrants to the ultimate purchaser and each subsequent purchaser of the en-

gine registered in the state of California that the engine is:

(1) Designed, built and equipped so as to conform with all applicable regulations adopted by the Air Resources

Board.

(2) Free from defects in materials and workmanship which cause the failure of a warranted part to be identical

in all material respects to the parts as described in Mitsubishi Heavy Industries, Ltd.'s application for certifi-

cation for a period of 5 years or 3,000 hours of operation, whichever occurs first.In the absence of a device

to measure hours of use, the engine shall be warranted for a period of 5 years. For all engines rated less

than 19 kW, and for constant-speed engines rated under 37 kW with rated speeds higher than or equal to

-1

3,000 min

sence of a device to measure hours of use, the engine shall be warranted for a period of 2 years.

(c) The warranty on emission-related parts shall be interpreted as follows:

(1) Any warranted part which is not scheduled for replacement as required maintenance in the written instruc-

tions required by Subsection (e) shall be warranted for the warranty period defined in Subsection (b) (2). If

any such part fails during the period of warranty coverage, it shall be repaired or replaced by Mitsubishi

Heavy Industries, Ltd. according to Subsection (4) below. Any such part repaired or replaced under the war-

ranty shall be warranted for the remaining warranty period.

(2) Any warranted part which is scheduled only for regular inspection in the written instructions required by Sub-

section (e) shall be warranted for the warranty period defined in Subsection (b) (2). A statement in such writ-

ten instructions to the effect of "repair or replace as necessary" shall not reduce the period of warranty

coverage. Any such part repaired or replaced under the warranty shall be warranted for the remaining war-

ranty period.

(3) Any warranted part which is scheduled for replacement as required maintenance in the written instructions

required in Subsection (e) shall be warranted for the period of time prior to the first scheduled replacement

point for that part. If the part fails prior to the first scheduled replacement, the part shall be repaired or re-

placed by Mitsubishi Heavy Industries, Ltd. according to Subsection (4) below. Any such part repaired or

replaced under warranty shall be warranted for the remainder of the period prior to the first scheduled re-

placement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions shall be performed at no charge

to the owner at a warranty station.

(5) Notwithstanding the provisions of Subsection (4) above, warranty services or repairs shall be provided at all

Mitsubishi Heavy Industries, Ltd. distribution centers that are franchised to service the subject engines.

(6) The owner shall not be charged for diagnostic labor that leads to the determination that a warranted part is

in fact defective, provided that such diagnostic work is performed at a warranty station.

(7) Mitsubishi Heavy Industries, Ltd. shall be liable for damages to other engine components proximately caused

by failure under warranty of any warranted part.

(8) Throughout the engine's warranty period defined in Subsection (b) (2), Mitsubishi Heavy Industries, Ltd. shall

maintain a supply of warranted parts sufficient to meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of any maintenance or repairs and must be provided

without charge to the owner. Such use shall not reduce the warranty obligations of Mitsubishi Heavy Indus-

tries, Ltd.

, the period of 2 years or 1,500 hours of operation, whichever occurs first, shall apply. In the ab-

v

Page 7

FOREWORD

(10) Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of

any non-exempted add-on or modified parts shall be grounds for disallowing a warranty claim. Mitsubishi

Heavy Industries, Ltd. shall not be liable to warrant failures of warranted parts caused by the use of a non-

exempted add-on or modified part.

(11) The Air Resources Board may request and, in such case, Mitsubishi Heavy Industries, Ltd. shall provide,

any documents which describe that Mitsubishi Heavy Industries, Ltd.'s warranty procedures or policies.

(d) Warranted parts list.

(1) Fuel metering system

(A) Fuel injection system.

(B) Air/fuel ratio feedback and control system.

(C) Cold start enrichment system.

(2) Air induction system

(A) Controlled hot air intake system.

(B) Intake manifold.

(C) Heat riser valve and assembly.

(D) Turbocharger/supercharger systems.

(E) Charged air cooling systems.

(3) Exhaust gas recirculation (EGR) system

(A) EGR valve body, and carburetor spacer if applicable.

(B) EGR rate feedback and control system.

(4) Air injection system

(A) Air pump or pulse valve.

(B) Valves affecting distribution of flow.

(C) Distribution manifold.

(5) Catalyst or thermal reactor system

(A) Catalytic converter.

(B) Thermal reactor.

(C) Exhaust manifold.

(6) Particulate controls

(A) Traps, filters, precipitators, and any other devices used to capture particulate emissions.

(B) Regenerators, oxidizers, fuel additive devices, and any other device used to regenerate or aid in the

regeneration of the particulate control device.

(C) Control device enclosures and manifolding.

(D) Smoke puff limiters.

(7) Advances oxides of nitrogen (NOx) controls

(A) NOx absorbers.

(B) Lean NOx catalysts.

(C) Selective catalyst reduction.

(D) Reductant (urea/fuel) containers/dispensing systems.

(8) Positive crankcase ventilation (PCV) system

(A) PCV valve.

(B) Oil filler cap.

(9) Miscellaneous items used in above systems

(A) Vacuum, temperature, and time sensitive valves and switches.

(B) Electronic control units, sensors, solenoids, and wiring harnesses.

vi

Page 8

FOREWORD

(C) Hoses, belts, connectors, assemblies, clamps, fittings, tubing, sealing gaskets or devices, and mount-

ing hardware.

(D) Pulleys, belts and idlers.

(E) Emission control information labels.

(F) Any other part with the primary purpose of reducing emissions or that can increase emission during fail-

ure without significantly degrading engine performance.

(e) Mitsubishi Heavy Industries, Ltd. shall furnish with each new engine written instructions for the maintenance and

use of the engine by the owner.

Limited warranty:

Refer to "Limited warranty" (Page ii).

vii

Page 9

FOREWORD

IMPORTANT INFORMATION

To avoid the potential hazard, accident prevention

activities must be planned methodically and con-

ducted continually by considering all aspect of

engine operation, maintenance and inspection. All

related personnel, including managers and supervi-

sors, should actively participate, recognize their roles

and organize themselves and their work to ensure a

safe environment.

The foremost safety objective is to prevent accidents

which may result in injury or death, or equipment

damage.

Always observe laws or regulations of the local or

federal/national government.

Mitsubishi Heavy Industries, Ltd. cannot foresee all

potential dangers of the engine, potential danger

resulting from human error and other causes, or dan-

ger caused by a specific environment in which the

engine is used. Since there are many actions that

cannot be performed or must not be performed, it is

impossible to indicate every caution in this manual or

on warning labels. As such, it is extremely important

to follow directions in this manual and also to take

general safety measures when operating, maintain-

ing and inspecting the engine.

When the engine is used by individuals whose native

language is not English, the customer is requested to

provide thorough safety guidance to the operators.

Also add safety, caution and operating signs that

describe the original warning label statements in the

native language of the operators.

The engine must be operated, maintained and

inspected only by qualified persons who have thor-

ough knowledge of engines and their dangers and

who also have received risk avoidance training.

To prevent an accident, do not attempt to carry out

any operation other than those described in this man-

ual, and do not use the engine for any unapproved

purpose.

When the ownership of the engine is transferred, be

sure to provide this manual with the engine to the

new owner. Also inform Mitsubishi Heavy Industries,

Ltd. of the name and address of the new owner of the

engine.

This manual is copyrighted and all rights are

reserved.No part of this manual, including illustra-

tions and technical references, may be photocopied,

translated, or reproduced in any electronic medium

or machine readable form without prior written con-

sent from Mitsubishi Heavy Industries, Ltd.

The contents in this manual are subject to change at

any time without notice for improvement of the

engine.

Pictures or illustrations of the product in this manual

may differ from those of product you have. Please

note that, depending on specifications, items

described in this manual may differ from those on

your engine in shape, or may not be installed on your

engine.

Please contact a dealer of Mitsubishi Heavy Indus-

tries, Ltd. if you need more information or if you have

any questions.

If you lost or damaged this manual, obtain a new

copy at a dealer of Mitsubishi Heavy Industries, Ltd.

as soon as possible.

Mitsubishi Heavy Industries, Ltd. recommends the

engine owner to install an hour meter on the engine

due to monitor correct running intervals and to per-

form the maintenance at the appropriate timing.

viii

Page 10

FOREWORD

WARNING INDICATION

The following means are used to call the attention of the operators and maintenance personnel to potential dangers

of the engine.

Warning statements in the manual

Warning labels affixed on the engine

Warning statements

The warning statements in this manual describe potential danger in operating, inspecting or maintaining the engine,

using the following five classifications to indicate the degree of potential hazard.

Failure to follow these directions could lead to serious accidents which could result in personal injury, or death in

the worst case.

Understand the directions well, and handle engines with following directions.

Indicates an immediately hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in property

damage.

Note: Indicates important information or information which is useful for engine operation.

ix

Page 11

FOREWORD

UNITS OF MEASUREMENT

Measurements are based on the International System of Units (SI), and they are converted to the metric system

units in this manual using the following conversion rates.

Pressure :1 MPa = 10.197 kgf/cm

Torque:1 N•m = 0.10197 kgf•m

Force:1 N = 0.10197 kgf

Horsepower:1 kW = 1.341 HP = 1.3596 PS

Meter of mercury:1 kPa = 0.75 cmHg

Meter of water:1 kPa = 10.197 cmH

Rotational speed:1 min

Kinetic viscosity:1 mm

-1

= 1 rpm

2

/s = 1 cSt

2

2O (cmAq)

ABBREVIATIONS, STANDARD AND OTHERS

API = American Petroleum Institute

ASTM = American Society for Testing and Materials

ISO = International Organization for Standardization

JIS = Japanese Industrial Standards

LLC = Long Life Coolant

MIL = Military Specifications and Standards

MSDS = Material Safety Data Sheet

SAE = Society of Automotive Engineers

x

Page 12

CONTENTS

Chapter 1

BASIC SAFETY PRECAUTIONS

Fire and explosions .............................1-1

Keep flames away............................................ 1-1

Keep engine surrounding area tidy and clean.. 1-1

Ventilation of engine room ............................... 1-1

Do not open side cover until engine cools ....... 1-1

Care for fuel, oil and exhaust gas leakage....... 1-1

Use explosion-proof lighting apparatus............ 1-1

Prevent electrical wires from short-circuiting.... 1-1

Keep fire extinguishers and first-aid kit handy . 1-1

Stay clear of all rotating and moving

parts ....................................................1-2

Install protective covers around rotating parts . 1-2

Check work area for safety .............................. 1-2

Stay clear of moving parts while engine is

running ............................................................. 1-2

Lockout and tagout .......................................... 1-2

Keep engine stopped during servicing............. 1-2

Always restore engine turning tools after use .. 1-2

Be careful of exhaust fume poisoning .1-3

Operate engine in a well-ventilated area.......... 1-3

Protect ears from noise .......................1-3

Wear ear plugs................................................. 1-3

Be careful of falling down ....................1-3

Lift engine carefully .......................................... 1-3

Do not climb onto the engine ........................... 1-3

Always prepare stable scaffold ........................ 1-3

Be careful of burns ..............................1-4

Do not touch the engine during or immediately after

operation .......................................................... 1-4

Refill coolant only after the coolant temperature

dropped............................................................ 1-4

Never remove heat shields .............................. 1-4

Do not open the radiator filler cap when the engine

is hot ................................................................ 1-4

Do not touch high pressure injection fuel ......... 1-4

Be careful when handling fuel, engine oil or

LLC......................................................1-5

Use only specified fuel, engine oil and LLC ..... 1-5

Handle LLC carefully........................................ 1-5

Proper disposal of waste oil, LLC and coolant. 1-5

When abnormality occurs....................1-5

Do not add coolant immediately after a sudden stop

due to overheating ........................................... 1-5

Avoid immediate restart after abnormal stop ... 1-5

Avoid continuous engine operation at low oil

pressure ........................................................... 1-5

If belt breaks, stop engine immediately............ 1-5

Service battery .................................... 1-6

Handle the battery correctly ............................. 1-6

Other cautions..................................... 1-7

Never modify engine ........................................ 1-7

Observe safety rules at work site ..................... 1-7

Work clothing and protective gear.................... 1-7

Never break the seals ...................................... 1-7

Perform all specified pre-operation inspections and

periodic inspections.......................................... 1-7

Break-in the engine .......................................... 1-7

Warm-up the engine before use....................... 1-7

Never operate the engine in an overloaded

condition........................................................... 1-7

Conduct cooling operation before stopping the

engine .............................................................. 1-8

Protection of the engine against water entry.... 1-8

Conduct proper maintenance of air cleaner ..... 1-8

Use of tools optimum for each work................. 1-8

Avoidance of prolonged time of starter

operation .......................................................... 1-8

Do not turn off the battery switch during

operation .......................................................... 1-8

Cautionary instructions for transporting the

engine .............................................................. 1-8

Do not operate engine continuously under low

load .................................................................. 1-8

Warning labels .................................... 1-9

Maintenance of warning labels......................... 1-9

Chapter 2

NAME OF PARTS

Engine external diagrams ................... 2-1

Engine front...................................................... 2-1

Engine rear....................................................... 2-1

Left view ........................................................... 2-2

Right view......................................................... 2-2

Equipment and instrument .................. 2-3

Start and stop instrument ................................. 2-3

Instruments ...................................................... 2-3

Engine protection devices................... 2-4

Oil filter alarm switch ........................................ 2-4

Air cleaner indicator ......................................... 2-4

Using turning gear............................... 2-5

CONTENTS-1

Page 13

CONTENTS

Chapter 3

OPERATION

Operational environment .....................3-1

Preparation for operating new or

overhauled engine...............................3-1

Preparation of fuel system ............................... 3-1

Preparation of lubrication system..................... 3-4

Preparation of cooling system.......................... 3-5

Preparation of electrical system ....................... 3-6

Test operation .................................................. 3-6

Normal engine operation .....................3-7

Preparations for operation...................3-7

Engine external - Inspect ................................. 3-7

Fuel tank oil level - Check ................................ 3-8

Fuel tank - Drain water..................................... 3-8

Engine oil level - Check.................................... 3-9

Coolant level - Check ..................................... 3-10

Fuel control link - Check................................. 3-10

Air cleaner - Check......................................... 3-11

Temperature of damper - Check .................... 3-11

Starting ..............................................3-12

Warm-up operation............................3-12

Checking engine oil pressure......................... 3-12

External inspection during warm-up............... 3-12

Operation...........................................3-13

Cautions when operating ............................... 3-13

Inspection during operation............................ 3-13

Stopping ............................................3-14

Emergency stop ............................................. 3-14

Inspection after stopping................................ 3-14

Total base number ........................................... 5-3

Total acid number ............................................ 5-3

Water content................................................... 5-3

Flash point........................................................ 5-3

Insoluble........................................................... 5-3

Service limits of engine oil .................. 5-4

Engine oil analysis service.................. 5-4

Chapter 6

COOLANT

Recommended water for coolant ........ 6-1

Long life coolant (LLC)........................ 6-1

Genuine LLC....................................... 6-1

Other brand LLCs ............................... 6-2

Standard for other brand LLC ............. 6-2

General demands of LLC ................................. 6-2

LLC specification.............................................. 6-3

Maintenance of LLC............................ 6-5

Replacement intervals of LLC .......................... 6-5

LLC concentration ............................................ 6-5

Importance of LLC .............................. 6-6

Characteristics of LLC additive and

important notes ................................... 6-6

Examples of abnormalities caused by LLC

(amine type) ........................................ 6-6

Pitting of iron parts ........................................... 6-6

Corrosion of aluminum parts ............................ 6-6

Pitting and clogging of the radiator................... 6-6

Chapter 4

FUEL

Recommended fuel .............................4-1

Handling fuel........................................4-1

Chapter 5

ENGINE OIL

Recommended engine oil....................5-1

Selection of oil viscosity.......................5-1

Handling engine oil..............................5-1

Engine oil performance requirements..5-2

Engine oil deterioration mechanisms...5-2

Definition of properties of engine oil ....5-3

Kinetic viscosity................................................ 5-3

CONTENTS-2

Chapter 7

MAINTENANCE SCHEDULE

How to use the maintenance schedule7-1

General definition of engine ................ 7-1

Periodic maintenance chart for regular use

engine ................................................. 7-2

Periodic maintenance chart for emergency

engine ................................................. 7-4

Chapter 8

PERIODIC INSPECTION AND

MAINTENANCE PROCEDURES

Basic engine ....................................... 8-1

Engine external - Inspect ................................. 8-1

Belt and belt tension - Inspect and Adjust ........ 8-2

Page 14

CONTENTS

Damper - Inspect.............................................. 8-3

Fuel system .........................................8-5

Fuel system - Inspect ....................................... 8-5

Fuel tank - Clean.............................................. 8-5

Fuel tank - Drain water..................................... 8-5

Fuel control link ball joint - Inspect ................... 8-6

Gauze filter - Clean .......................................... 8-6

Fuel filter - Replace .......................................... 8-7

Fuel pipe - Inspect............................................ 8-8

Lubricating system...............................8-9

Engine oil, Oil filter and Bypass oil filter -

Replace............................................................ 8-9

Engine oil for mixing of fuel and water -

Inspect ........................................................... 8-12

Oil pipe - Inspect ............................................ 8-12

Cooling system..................................8-13

Coolant - Change ........................................... 8-13

Radiator fins - Check and Clean .................... 8-15

Inlet and exhaust systems.................8-16

Turbocharger - Inspect................................... 8-16

Draining water from the exhaust muffler ........ 8-16

Air cleaner element - Clean, Check and

Replace.......................................................... 8-17

Electrical system................................8-18

Starter - Inspect.............................................. 8-19

Alternator - Inspect......................................... 8-19

Chapter 11

TROUBLESHOOTING

General precautions.......................... 11-1

Contact a dealer of Mitsubishi Heavy Industries, Ltd.

for repair service ............................................ 11-1

Considerations before work ........................... 11-1

Cautions against contamination ..................... 11-1

Cautions regarding parts handling ................. 11-1

Work safety .................................................... 11-1

Troubleshooting ................................ 11-2

The starter does not crank or cranks slowly,

resulting in start failure ................................... 11-2

The starter cranks, but the engine does not

start ................................................................ 11-2

Output decrease............................................. 11-3

Exhaust smoke is white or blue...................... 11-4

Exhaust smoke is black or charcoal............... 11-5

Fuel consumption is high ............................... 11-6

Engine oil consumption is high....................... 11-7

Overheating.................................................... 11-7

Low engine oil pressure ................................. 11-8

When fuel has run out....................... 11-8

Chapter 12

MAIN SPECIFICATIONS

Main specifications............................ 12-1

Chapter 9

LONG-TERM STORAGE

Storing the engine in an inoperable

condition for 3 months or more............9-1

Preparation for storage .................................... 9-1

Maintenance during storage............................. 9-1

Using the engine after storage......................... 9-2

Storing the engine in an operable condition

for 3 months or more ...........................9-2

Operating the engine for maintenance............. 9-2

Chapter 10

TRANSPORTATION

Lifting the engine ...............................10-1

CONTENTS-3

Page 15

CONTENTS

List of Illustrations

Fig. 1-1 Warning labels...................................... 1-9

Fig. 2-1 Engine front view.................................. 2-1

Fig. 2-2 Engine rear view................................... 2-1

Fig. 2-3 Engine left view .................................... 2-2

Fig. 2-4 Engine right view .................................. 2-2

Fig. 2-5 Manual stop lever ................................. 2-3

Fig. 2-6 Stop solenoid........................................ 2-3

Fig. 2-7 Revolution detection pickup ................. 2-3

Fig. 2-8 Oil filter alarm switch ............................ 2-4

Fig. 2-9 Air cleaner indicator.............................. 2-4

Fig. 2-10 Turning gear position

(while engine is running) ...................... 2-5

Fig. 2-11 Turning gear position

(when pushing shaft in) ........................ 2-5

Fig. 2-12 Turning gear position

(when turning shaft).............................. 2-5

Fig. 3-1 Priming pump - Handle......................... 3-2

Fig. 3-2 Fuel filter - Bleed air ............................. 3-2

Fig. 3-3 Fuel injection pump - Bleed air............. 3-2

Fig. 3-4 Priming pump tightening method.......... 3-3

Fig. 3-5 Priming pump head packing................. 3-3

Fig. 3-6 Oil filler and Oil level gauge.................. 3-4

Fig. 3-7 Pouring engine oil on valve mechanisms

and chamber ........................................ 3-4

Fig. 3-8 Coolant drain cock (Engine) ................. 3-5

Fig. 3-9 Coolant drain cock (Water pump)......... 3-5

Fig. 3-10 Radiator coolant level........................... 3-5

Fig. 3-11 Reserve tank coolant level ................... 3-5

Fig. 3-12 Battery electrolyte level - Inspect ......... 3-6

Fig. 3-13 Valves for open/closed position - Check3-7

Fig. 3-14 Fuel tank - Drain water......................... 3-8

Fig. 3-15 Oil filler and Oil level gauge.................. 3-9

Fig. 3-16 Radiator filler cap ............................... 3-10

Fig. 3-17 Radiator coolant level......................... 3-10

Fig. 3-18 Reserve tank coolant level ................. 3-10

Fig. 3-19 Fuel control link - Check..................... 3-10

Fig. 3-20 Air cleaner - Check............................. 3-11

Fig. 3-21 Thermo label of damper ..................... 3-11

Fig. 3-22 Manual stop lever ............................... 3-14

Fig. 5-1 Recommended engine oil..................... 5-1

Fig. 5-2 Selection of oil viscosity ........................5-1

Fig. 6-1 GLASSY - LLC ......................................6-1

Fig. 8-1 Belt and belt tension - Inspect and Adjust8-

2

Fig. 8-2 Damper - Check visually .......................8-3

Fig. 8-3 Damper temperature management .......8-4

Fig. 8-4 Fuel tank - Drain water..........................8-5

Fig. 8-5 Ball joints for looseness - Inspect..........8-6

Fig. 8-6 Fuel control link - Remove.....................8-6

Fig. 8-7 Gauze filter - Clean ...............................8-6

Fig. 8-8 Fuel filter - Replace ...............................8-7

Fig. 8-9 Fuel filter ...............................................8-7

Fig. 8-10 High pressure fuel injection pipe and

Clamp seat - Inspect .............................8-8

Fig. 8-11 Low pressure fuel pipe and Clip -

Inspect...................................................8-8

Fig. 8-12 Oil filler and Oil level gauge ................8-10

Fig. 8-13 Oil filter and Bypass oil filter - Replace8-11

Fig. 8-14 Oil filter ................................................8-11

Fig. 8-15 Oil pipe and Clip - Inspect and Replace8-12

Fig. 8-16 Radiator filler cap ................................8-13

Fig. 8-17 Coolant drain cock (engine) ................8-13

Fig. 8-18 Coolant drain cock (water pump) ........8-14

Fig. 8-19 Radiator coolant level..........................8-14

Fig. 8-20 Reserve tank .......................................8-14

Fig. 8-21 Radiator fins - Clean ...........................8-15

Fig. 8-22 Turbocharger - Inspect........................8-16

Fig. 8-23 Draining water from the exhaust muffler8-16

Fig. 8-24 Air cleaner element - Remove.............8-17

Fig. 8-25 Air cleaner element - Clean and Check8-17

Fig. 8-26 Air cleaner - Check..............................8-17

Fig. 8-27 Battery electrolyte level - Inspect ........8-18

Fig. 8-28 Specific gravity of battery electrolyte -

Check ..................................................8-18

Fig. 8-29 Starter - Inspect...................................8-19

Fig. 8-30 Alternator - Inspect..............................8-19

Fig. 10-1 Hangers...............................................10-1

Fig. 10-2 Engine's center of gravity

(standard specification) .......................10-1

CONTENTS-4

Page 16

List of Tables

Table 3-1 Standard values at rated speed............ 3-13

Table 4-1 Recommended fuel ................................ 4-1

Table 4-2 Recommended limit and use limit of

fuel property............................................ 4-2

Table 5-1 Engine oil properties............................... 5-4

Table 6-1 Water quality standards.......................... 6-1

Table 6-2 LLC specification .................................... 6-3

Table 6-3 Recommended LLC concentration ......... 6-5

Table 7-1 Periodic maintenance chart for regular

use engine .............................................. 7-2

Table 7-2 Periodic maintenance chart for emergency

engine..................................................... 7-4

Table 8-1 Thermo label for temperature

management........................................... 8-4

Table 8-2 Specific gravity of electrolyte ................ 8-18

Table 9-1 Recommended rust-preventive oil and

corrosion inhibitor ................................... 9-1

Table 11-1 The starter does not crank or cranks slowly,

resulting in start failure ......................... 11-2

Table 11-2 The starter cranks, but the engine does

not start................................................. 11-2

Table 11-3 Output decrease................................... 11-3

Table 11-4 Exhaust smoke is white or blue ............ 11-4

Table 11-5 Exhaust smoke is black or charcoal ..... 11-5

Table 11-6 Fuel consumption is high...................... 11-6

Table 11-7 Engine oil consumption is high ............. 11-7

Table 11-8 Overheating .......................................... 11-7

Table 11-9 Low engine oil pressure........................ 11-8

Table 12-1 Main specifications ............................... 12-1

CONTENTS

CONTENTS-5

Page 17

Chapter 1 BASIC SAFETY PRECAUTIONS

Fire and explosions

Keep flames away

Do not use flames near the engine (in

the engine room). Fuel vapor or other

gas can catch fire and produce dan-

gerous situations.

Wipe off spilled fuel, oil and LLC

immediately and thoroughly. Spilled fuel, oil and LLC

may ignite and cause a fire.

Store fuel and engine oil in a well-ventilated area.

Make sure that the caps of fuel and engine oil contain-

ers are tightly closed.

Keep engine surrounding area

tidy and clean

Do not leave combustible or explosive materials, such

as fuel, engine oil and LLC, near the engine. Such

substances can cause fire or explosion.

Remove dust, dirt and other foreign materials accu-

mulated on the engine and surrounding parts thor-

oughly. Such materials can cause fire or the engine to

overheat. In particular, clean the top surface of the

battery thoroughly. Dust can cause a short-circuit.

Always operate the engine at a position at least 1 m

[3.28 ft.] away from buildings and other equipment to

prevent possible fire caused by engine heat.

Ventilation of engine room

Always provide adequate ventilation in the engine

room. Insufficient air in the room can cause an

increase in the engine temperature and a decrease in

the output power and performance. It is highly recom-

mended to calculate the required amount of air supply

to the engine and install an adequate ventilation sys-

tem before installing the engine.

Do not open side cover until

engine cools

Do not attempt to open the side cover of the crank-

case before the engine cools down. Wait at least 10

minutes after stopping the engine.

Opening the cover when the engine is hot allows fresh

air to flow into the crankcase, which can cause oil mist

to ignite and explode.

Care for fuel, oil and exhaust

gas leakage

If any fuel, oil or exhaust gas leakage is found, imme-

diately take corrective measures to stop it.

Such leakages, if left uncorrected, can cause fuel or

engine oil to reach hot engine surfaces or hot exhaust

gas to contact flammable materials, possibly leading

to personal injury and/or damage to equipment.

Use explosion-proof lighting

apparatus

When inspecting fuel, engine oil, coolant, battery elec-

trolyte, etc., use a flameproof light. An ordinary light-

ing apparatus may ignite gas and cause it to explode.

Prevent electrical wires from

short-circuiting

Avoid inspecting or servicing the electrical system with

the ground cable connected to the battery. Otherwise,

a fire could result from short-circuiting. Be sure to dis-

connect the battery cable from the negative (-) termi-

nal before beginning with the work procedure.

Short-circuits, possibly resulting in fire, may be

caused by a loose terminal or damaged cable/wire.

Inspect the terminals, cables and wires, and repair or

replace the faulty parts before beginning with the ser-

vice procedure.

Keep fire extinguishers and

first-aid kit handy

Keep fire extinguishers handy, and

become familiar with their usage.

Keep a first-aid kit at the designated

place where it is easily accessible by

anyone at any time.

Establish response procedures to follow in the event

of fire or accident. Provide an emergency evacuation

route and contact points and means of communication

in case of emergency.

1-1

Page 18

Chapter 1 BASIC SAFETY PRECAUTIONS

Stay clear of all rotating and moving parts

Install protective covers around

rotating parts

Make sure the protective covers of

the engine are correctly installed.

Repair any damaged or loose covers.

Never remove the covers protecting

the rotating parts while engine is run-

ning.

When the engine is coupled to the radiator or other

equipment, install protective covers around the

exposed connecting belt and coupling.

Never remove protective covers.

Check work area for safety

Before starting the engine, make sure no one is near

the engine and tools are not left on or near the engine.

Verbally notify persons within the immediate area

when starting the engine.

When the starter device is posted with a sign that pro-

hibits startup operation, do not operate the engine.

Stay clear of moving parts while

engine is running

Do not approach rotating or sliding

parts of the engine while the engine is

running. Keep objects likely to be

caught by rotating parts away from

such parts.

If any part of the clothing or outfitting is caught by a

rotating part, serious bodily injuries could result.

Lockout and tagout

Be sure to lockout and tagout before starting inspec-

tion and maintenance.

Lockout and tagout are effective methods of cutting off

machines and equipment from energy sources.

To accomplish the lockout/tagout, remove the starter

switch key, set the battery switch to OFF and attach a

"Do Not Run" or similar caution tag to the starter

switch.

The starter switch key must be kept by the person

who performs inspection and maintenance during the

work.

Keep engine stopped during

servicing

Be sure to stop the engine before proceeding to

inspection and service procedure. Never attempt to

make adjustments on the engine parts while the

engine is running.

Rotating parts such as belt can entangle your body

and cause serious injuries.

Always restore engine turning

tools after use

Be sure to remove all turning tools used during main-

tenance and inspection work. Remember also that the

turning gear shaft must be pulled out before starting

the engine.

Starting the engine with the turning tools inserted or

with the turning gear in engagement can lead to not

only engine damage but also personal injuries.

1-2

Page 19

Chapter 1 BASIC SAFETY PRECAUTIONS

Be careful of exhaust

fume poisoning

Operate engine in a well-ventilated area

Check the exhaust pipes and where

the pipes joint together for gas leaks.

Exhaust gas from the engine contains

carbon monoxide and other harmful

substances. Operating the engine in

an poorly-ventilated area can produce gas poisoning.

Protect ears from noise

Wear ear plugs

Always wear ear plugs when entering

the machine room (engine room).

Combustion sound and mechanical

noise generated by the engine can

cause hearing problems.

Be careful of falling down

Lift engine carefully

To lift the engine, use slings capable

of supporting the weight of the

engine.

Attach the wire rope to the hangers

provided on the engine using a cor-

rect sling.

During lifting process, keep the engine in a well-bal-

anced position by taking the center of gravity of the

engine into consideration.

The hangers equipped with the engine are designed

for lifting the engine only. Be careful not to affect the

hangers by added weight if installing the generator or

marine gear to the engine.

Keep the angle formed by slings attached to hangers

within 60°. If the angle exceeds this limit, excessive

load could be imposed on the hangers and this could

damage the hangers and result in a serious accident.

If the wire rope contacts the engine directly, place a

cloth or other soft padding to avoid damage to the

engine and wire rope.

Do not climb onto the engine

Do not climb onto the engine, nor step on any engine

parts located on the lateral sides.

To work on parts located on the upper section of

engine, use a ladder, stool, etc., that was firmly

secured.

Climbing on the engine may not only damage engine

parts but also cause falling down from the engine and

result in personal injuries.

Always prepare stable scaffold

When working on the upper part of

the engine and other hard-to-reach

places, use a stable work platform.

Standing on a decrepit stool or parts

box may result in personal injury.

Do not place any unnecessary objects on a work plat-

form.

1-3

Page 20

Chapter 1 BASIC SAFETY PRECAUTIONS

Be careful of burns

Do not touch the engine during

or immediately after operation

To avoid burns, do not touch the

engine during or immediately after

operation.

A hot engine can cause burns.

To conduct maintenance and inspec-

tion work, wait until the engine has cooled sufficiently

by checking the temperature gauge.

Refill coolant only after the

coolant temperature dropped

Do not add coolant immediately after the engine

stops. Wait until the coolant temperature lowers suffi-

ciently. Adding coolant immediately after the engine

stops cause burns.

Never remove heat shields

The exhaust system, which becomes extremely hot

while the engine is operating, is provided with various

heat shields. Do not remove these heat shields. If any

of these heat shields have been removed owing to

unavoidable circumstances during the work, be sure

to restore them after the work is completed.

Do not open the radiator filler

cap when the engine is hot

Never open the radiator filler cap while the engine is

running or immediately after the engine is stopped.

When opening the cap, stop the engine and allow the

coolant temperature to lower sufficiently.

When opening the radiator filler cap, open slowly to

discharge the pressure inside the tank. Also to avoid a

risk of getting scalded by steam, wear thick rubber

gloves or wrap a cloth around the cap.

When closing the cap, be sure to tighten securely.

The coolant is hot while engine is running and immedi-

ately after the engine stops. If the cap is opened when

the coolant is at operating temperature, steam and hot

coolant may blow out and result in burns.

Do not touch high pressure

injection fuel

If fuel leaks or sprays out from the high pressure injec-

tion pipe, do not touch the fuel.

Fuel in the fuel injection pipes is under high pressure

and if the fuel contact your skin, it goes into deep tis-

sues and may result gangrene.

1-4

Page 21

Chapter 1 BASIC SAFETY PRECAUTIONS

Be careful when handling

fuel, engine oil or LLC

Use only specified fuel, engine

oil and LLC

Use fuel, oil and LLC specified in this manual, and

handle them carefully.

Use of any other fuel, oil or LLC, or improper handling

may cause various engine problems and malfunc-

tions.

Obtain the MSDS issued by the fuel, oil and LLC sup-

pliers, and follow the directions in the MSDSs for

proper handling.

Handle LLC carefully

When handling LLC, always wear rubber gloves and a

protective face mask. If LLC or cooling water contain-

ing LLC comes into contact with your skin or eyes, or if

it is swallowed, you would suffer from inflammation,

irritation or poisoning.

Should LLC be accidentally swallowed, induce vomit-

ing immediately and seek medical attention. Should

LLC enter your eyes, flush them immediately with

plenty of water and seek medical attention. If LLC

splashes onto your skin or clothing, wash it away

immediately with plenty of water.

Keep flames away from LLC. The LLC can catch

flames, causing a fire. Coolant (containing LLC)

drained from the engine is toxic. Never dispose of

coolant into regular sewage. Abide by the applicable

law and regulations when discarding drained coolant.

Proper disposal of waste oil,

LLC and coolant

Do not discharge waste engine oil, LLC and coolant

into sewerage, river, lake or other similar places. Such

a way of disposal is strictly prohibited by laws and reg-

ulations.

Dispose of waste oil, LLC and coolant and other envi-

ronmentally hazardous waste in accordance with the

applicable law and regulations.

When abnormality occurs

Do not add coolant immediately

after a sudden stop due to overheating

If the engine stops suddenly or if you have no choice

but stop the engine suddenly due to overheating, do

not add coolant immediately.

Adding water while the engine is hot can damage

parts such as cylinder heads due to a sudden drop of

temperature. Add coolant gradually after the engine

has completely cooled.

Avoid immediate restart after

abnormal stop

If the engine stops abnormally, do not restart the

engine immediately. If the engine stops with an alarm,

check and remedy the cause of the problem before

restarting. Sustained use of the engine without any

remedy could result in serious engine problems.

Avoid continuous engine operation at low oil pressure

If an abnormal engine oil pressure drop is indicated,

stop the engine immediately, and inspect the lubrica-

tion system to locate the cause. Continuous engine

operation with low oil pressure could cause bearings

and other parts to seize.

If belt breaks, stop engine

immediately

If the belt breaks, stop the engine immediately and

replace the belt. Sustained use of the engine without

any remedy could cause defective charge and cooling

failure, and result in serious engine problems.

1-5

Page 22

Chapter 1 BASIC SAFETY PRECAUTIONS

Service battery

Handle the battery correctly

Never use flames or allow sparks to

generate near the battery. The bat-

tery releases flammable hydrogen

gas and oxygen gas. Any flames or

sparks in the vicinity could cause an

explosion.

Do not use the battery when the battery electrolyte

level of which is below the "LOWER LEVEL" line. Sus-

tained use of the battery could result in an explosion.

Do not short the battery terminals with a tool or other

metal object.

When removing battery, always remove the plug from

the negative (-) terminal first. When connecting bat-

tery, always connect the plug to the positive (+) termi-

nal first.

Remove all plugs, then charge the battery in a well-

ventilated area.

Make sure the cable clamps are securely installed on

the battery terminals. A loose cable clamp can cause

sparks that may result in an explosion.

Before servicing electrical components or conducting

electric welding, set the battery switch to [Open/OFF]

position or remove the plug from the negative (-) ter-

minal to cut off the electrical current.

Battery electrolyte contains dilute sulfuric acid. Care-

less handling of the battery can cause the loss of sight

and/or skin burns. Also, do not consume the battery

electrolyte.

Wear protective goggles and rubber gloves when

working with the battery (when adding water, charg-

ing, etc.)

If battery electrolyte is spilled onto the skin or clothing,

immediately wash it away with lots of water. Use soap

to thoroughly clean.

The battery electrolyte can cause the loss of sight if

splashing into the eyes. If it gets into the eyes, imme-

diately flush it away with plenty of clean water, and

seek immediate medical attention.

If the battery electrolyte is accidentally consumed,

gargle with plenty of water, then drink lots of water,

and seek immediate medical attention.

1-6

Page 23

Other cautions

Chapter 1 BASIC SAFETY PRECAUTIONS

Never modify engine

Unauthorized modification of the engine will void our

warranty.

Modification of the engine may not only cause engine

damage but also produce personal injuries.

If there is a need to modify the engine, contact a

dealer of Mitsubishi Heavy Industries, Ltd.

Observe safety rules at work

site

Observe the safety rules established at your work-

place when operating and maintaining the engine.

Do not operate the engine if you are feeling ill, inform

your supervisor of your condition. Operation of the

engine with reduced awareness may cause improper

operation that could result in accidents.

When working in a team for two or more people, use

specified hand signals to communicate among work-

ers.

Work clothing and protective

gear

Wear a hardhat, face shield, safety shoes, dust mask,

gloves and other protective gear as needed. When

handling compressed air, wear safety goggles, a hard-

hat, gloves and other necessary protective gear.

Works without wearing proper protective gear could

result in serious injuries.

Never break the seals

To ensure proper engine operation, the fuel control

links are sealed to prevent accidental change of the

injection volume and rotation speed settings. Operat-

ing the engine without these seals in place can cause

problems described below, and also invalidates the

warranty.

Rapid wear of moving and rotating parts

Engine troubles such as damage and seizure of en-

gine parts

Increased consumption of fuel and lubricating oil

Degradation of engine performance due to improper

balance between fuel injection volume and governor

operation or overrunning of the engine which could re-

sult in a serious accident

Perform all specified pre-operation inspections and periodic

inspections

Conduct the pre-operation inspections and periodic

inspections as described in this manual.

Failure to conduct the specified inspections may

cause various engine problems, damage to parts, and

serious accidents.

Break-in the engine

To break-in new engines or overhauled engines, oper-

ate the engine at a speed lower than the rated speed

in a light load condition during the first 50 hours of

operation.

Operating new engines or overhauled engines in a

severe condition during the break-in period shortens

the service life of the engine.

Warm-up the engine before use

After starting the engine, run the engine at low idling

speeds for 5 to 10 minutes for warming-up. Start the

work after this operation is completed. Warm-up oper-

ation circulates the lubricant through the engine.

Therefore, individual engine parts are well lubricated

before they are subjected to heavy loads.

Warm-up operation circulates lubricants in the engine

and contributes to a longer service life and economi-

cal operation.

Do not conduct warm-up operation for prolonged

period of time. Prolonged warm-up operation causes

carbon build-up in the cylinders that leads to incom-

plete combustion.

Never operate the engine in an

overloaded condition

If the engine shows an overloaded condition such as

black exhaust smoke, reduce the load immediately to

operate the engine at an appropriate output and load.

Overloading causes not only high fuel consumption

but also excessive carbon deposits inside the engine.

Carbon deposits cause various problems and will

shorten the service life of the engine.

1-7

Page 24

Chapter 1 BASIC SAFETY PRECAUTIONS

Conduct cooling operation

before stopping the engine

Before stopping the engine, idle the engine in low gear

for 5 to 6 minutes to cool down.

Stopping the engine immediately after high-load oper-

ation will cause engine parts to heat up and shorten

the service life of the engine.

During cooling operation, check the engine for abnor-

malities.

Protection of the engine against

water entry

Do not allow rainwater, etc. to enter the engine

through the air inlet or exhaust openings.

Do not wash the engine while it is operating. Cleaning

fluid (water) can be sucked into the engine.

Starting the engine with water inside the combustion

chambers can cause the water hammer action which

may result in internal engine damage and serious

accidents.

Conduct proper maintenance of

air cleaner

Maintain the engine with air cleaner according to the

following instructions.

Never service the air cleaner while the engine is run-

ning. The turbocharger may suck particles of foreign

materials into the engine and could result in serious

accidents.

Remove the air cleaner slowly to prevent foreign ma-

terials accumulated on the element from falling off. Af-

ter removing the air cleaner, immediately cover the air

inlet with plastic sheet or similar means to prevent for-

eign materials from entering the engine.

Use of tools optimum for each

work

Always keep in mind to select most appropriate tools

for the work to be performed and use them correctly. If

tools are damaged, replace them with new tools.

Avoidance of prolonged time of

starter operation

Do not use the starter for more than 10 seconds at a

time. If the engine does not start, wait for at least 1

minute before cranking again.

Continuous operation of the starter will drain the bat-

tery power and cause the starter to seize.

Do not turn off the battery

switch during operation

Do not turn off the battery switch during operation.

If the battery switch is turned OFF when the engine is

running, not only various meters will stop working but

also the alternator may have its diode and transistor

deteriorated.

Cautionary instructions for

transporting the engine

When transporting the engine on a truck, consider the

engine weight, width and height to ensure safety.

Abide by road traffic law, road vehicles act, vehicle

restriction ordinance and other pertinent laws.

Do not operate engine continuously under low load

When operating the engine with a 30 % of rated load

or lower, limit each operation to 10 minutes. Operating

the engine at low load tends to result in unburned fuel,

which can adhere on internal engine parts, and cause

malfunctions and shorten the engine service life.

1-8

Page 25

Chapter 1 BASIC SAFETY PRECAUTIONS

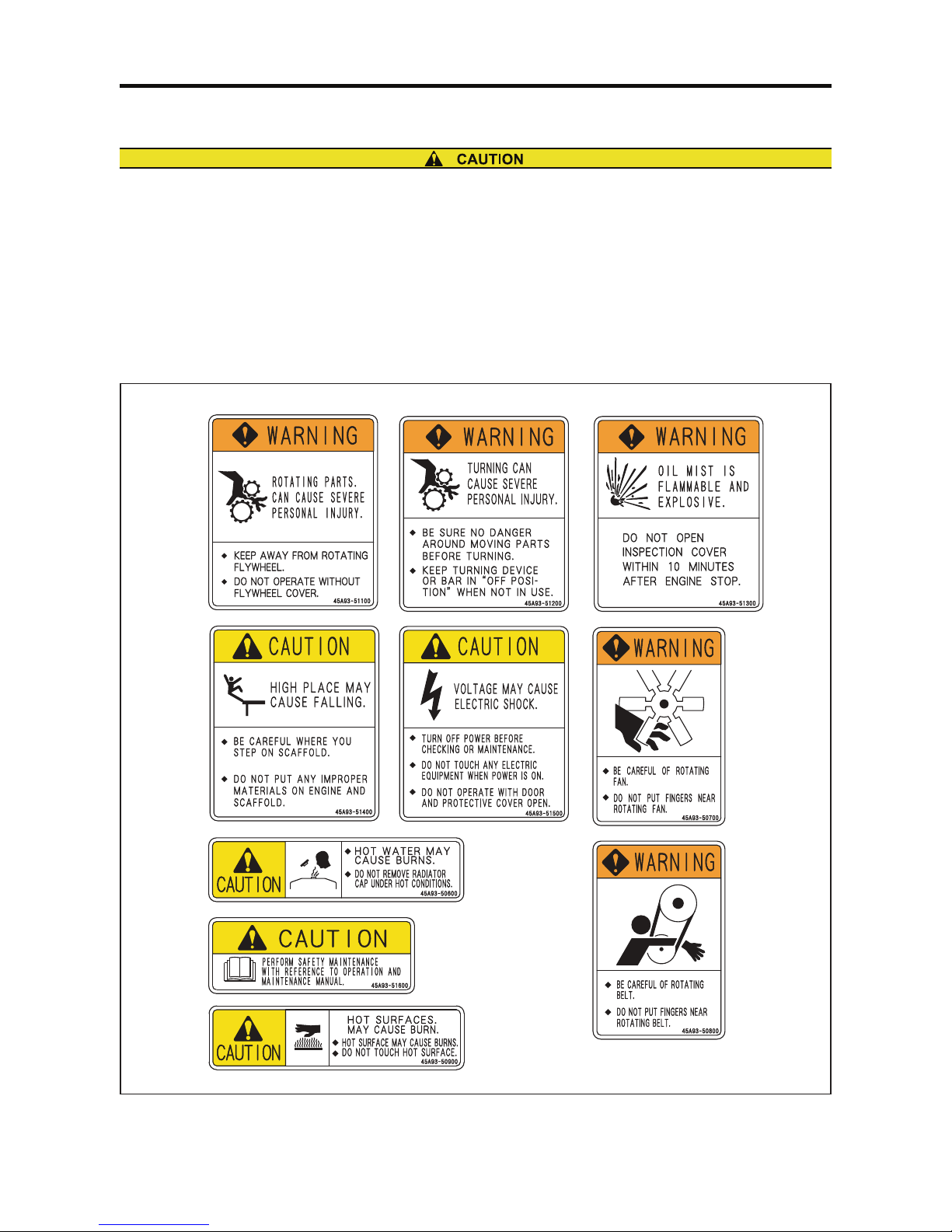

Warning labels

Maintenance of warning labels

Make sure all warning/caution labels are legible.

Clean or replace the warning/caution labels when the description and/or illustration are not clear to read.

For cleaning the warning/caution labels, use a cloth, water and soap. Do not use cleaning solvents, gasoline or

other chemicals to prevent the letters from getting blurred or the adhesion from being weakened.

Replace damaged or fractured labels with new ones.

If any engine part on which a warning label is attached is replaced with a new one, attach a new identical warning

label to the new part.

To obtain new warning labels, contact a dealer of Mitsubishi Heavy Industries, Ltd.

Fig. 1-1 Warning labels

1-9

Page 26

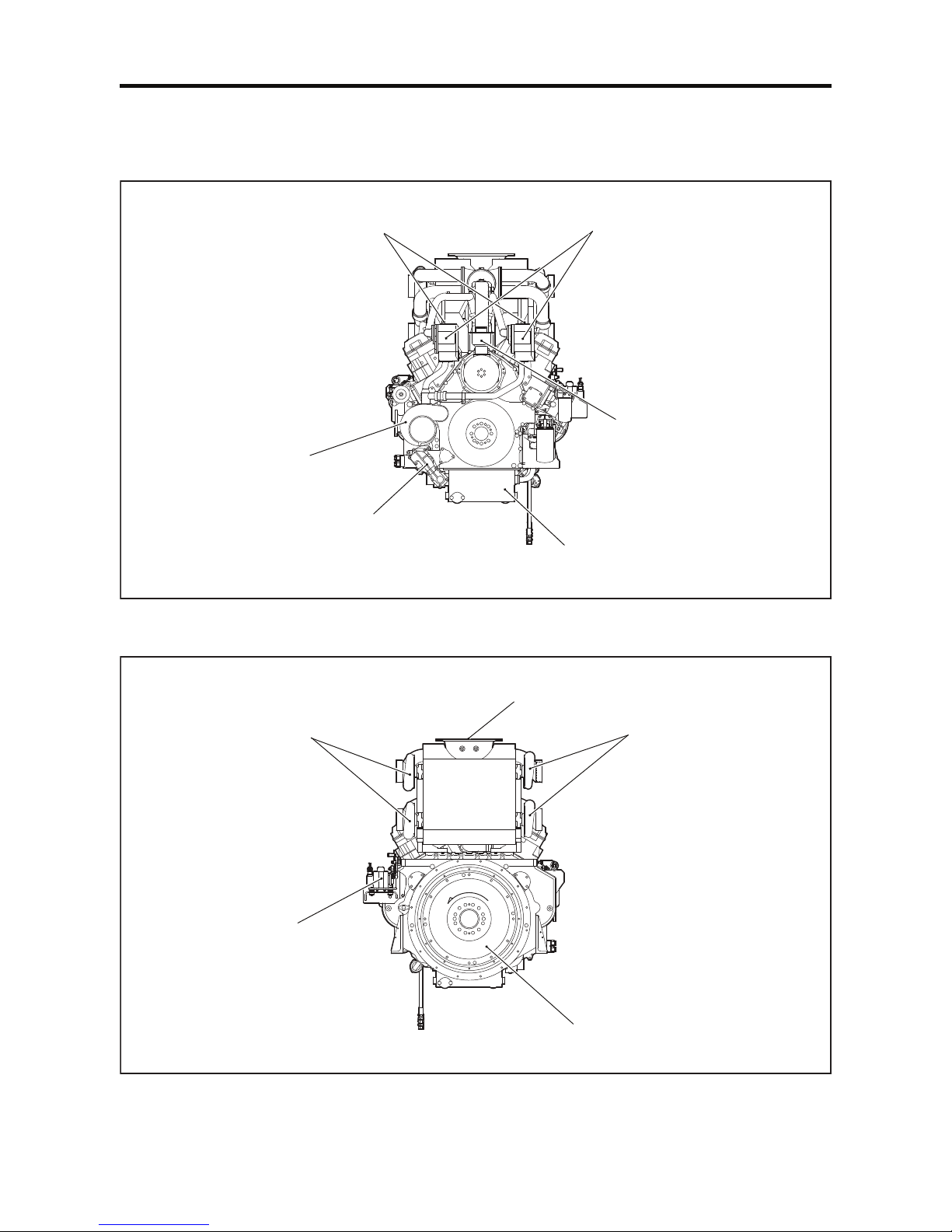

Chapter 2 NAME OF PARTS

Engine external diagrams

Engine front

Engine rear

Water pump

Coolant outlet

Oil pump

Thermostat

Breather

Oil pan

Fig. 2-1 Engine front view

Turbocharger

Governor actuator

Exhaust gas outlet

a

t

t

i

o

o

n

R

Fig. 2-2 Engine rear view

Turbocharger

Flywheel

2-1

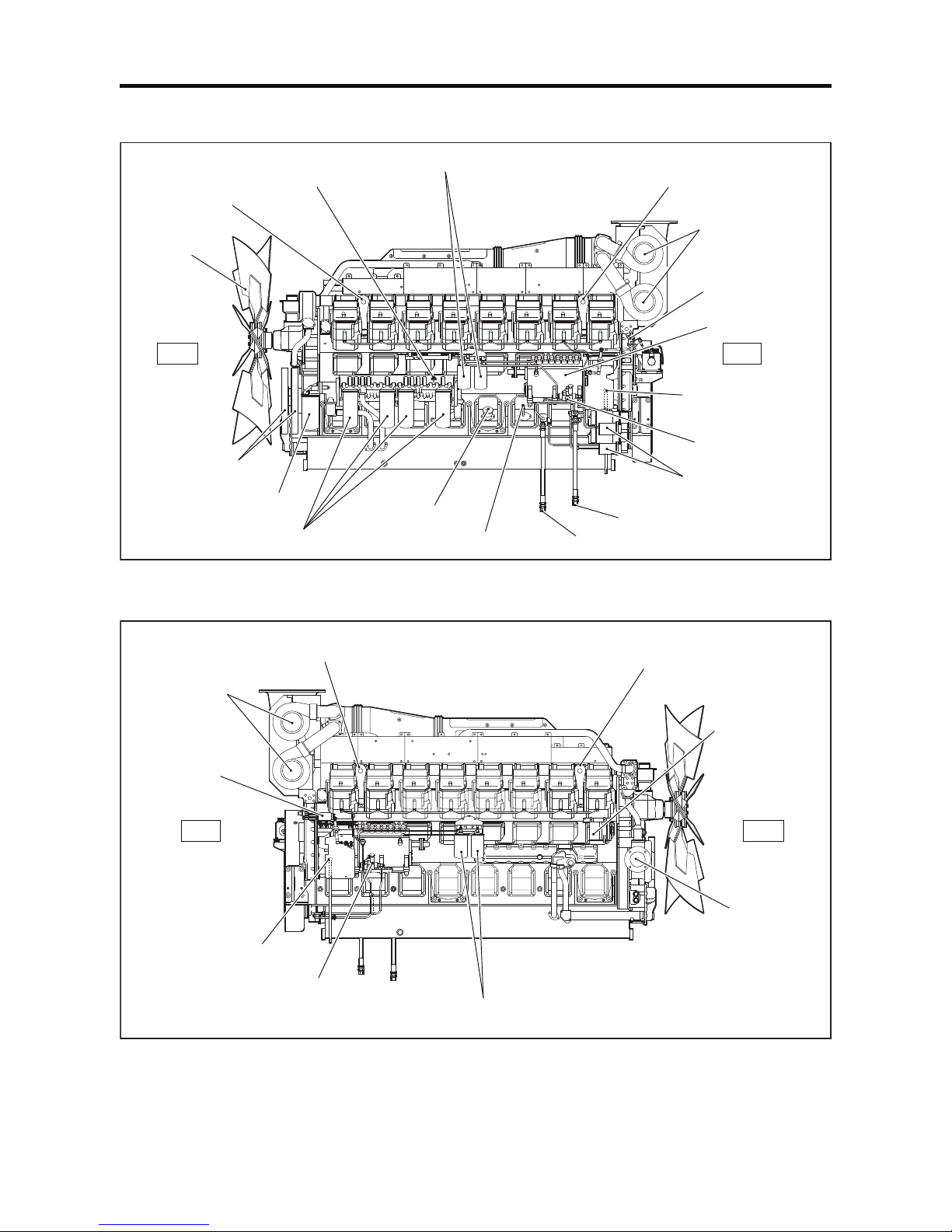

Page 27

Chapter 2 NAME OF PARTS

Left view

Oil filter

alarm switch

Front hanger

Fan

Front Rear

Damper

Bypass oil filter

Oil filter

Fuel filter

Oil filler

Oil level gauge

Fuel return port

Fuel inlet

Fig. 2-3 Engine left view

Right view

Rear hanger

Air inlet

Manual stop lever

Fuel injection pump

Engine coolant

drain cock

Fuel feed pump

Starter

Air inlet

Stop solenoid

Rear Front

Coolant drain cock

Rear hanger

Fuel feed pump

Front hanger

Alternator

Coolant inlet

Fuel filter

Fig. 2-4 Engine right view

2-2

Page 28

Equipment and instrument

The installed equipment and shapes differ on the engine type.

Start and stop instrument

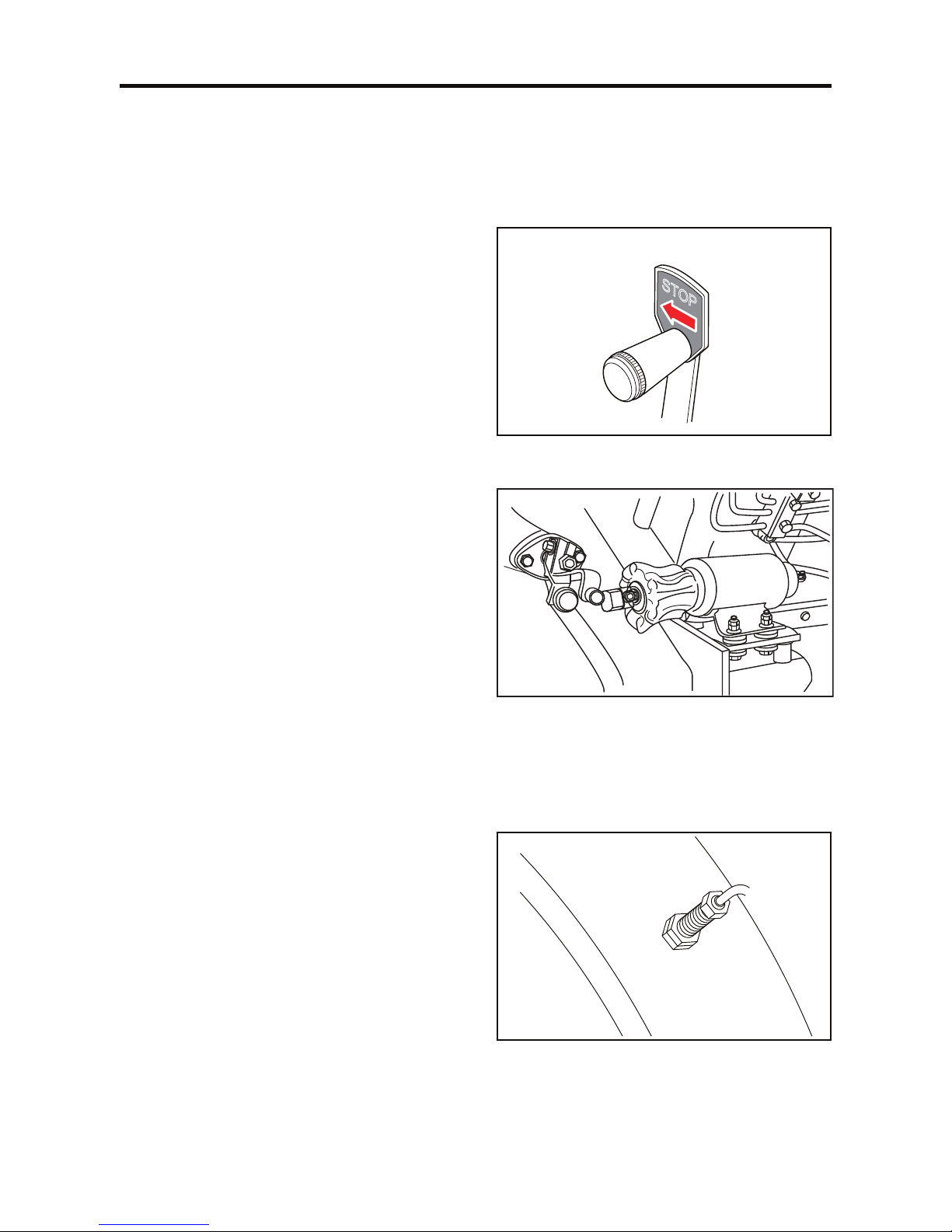

Manual stop lever

Use the manual stop lever to shut down the engine in

the event of an emergency. If the starter switch fails to

stop engine operation, use the manual stop lever.

When the manual stop lever, which is located in the

fuel control link, is moved in the "STOP" direction, the

engine stops.

If the engine continues to operate even after the man-

ual stop lever is moved in the "STOP" direction, cut off

the fuel supply to stop the engine.

Stop solenoid

The stop solenoid operates for normal shutdown of

engine operation.

The stop solenoid moves the rack of fuel injection

pump to cut the fuel, and consequently stops the

engine.

The RUN OFF type stop solenoid is equipped in this

engine. Not energized while the engine is running.

Energized by a stop signal to stop the engine.

Chapter 2 NAME OF PARTS

STOP

Fig. 2-5 Manual stop lever

Fig. 2-6 Stop solenoid

Instruments

This section describes about devices which transmit signals to necessary instruments of the engine operation.

Read carefully and understand functions of each device.

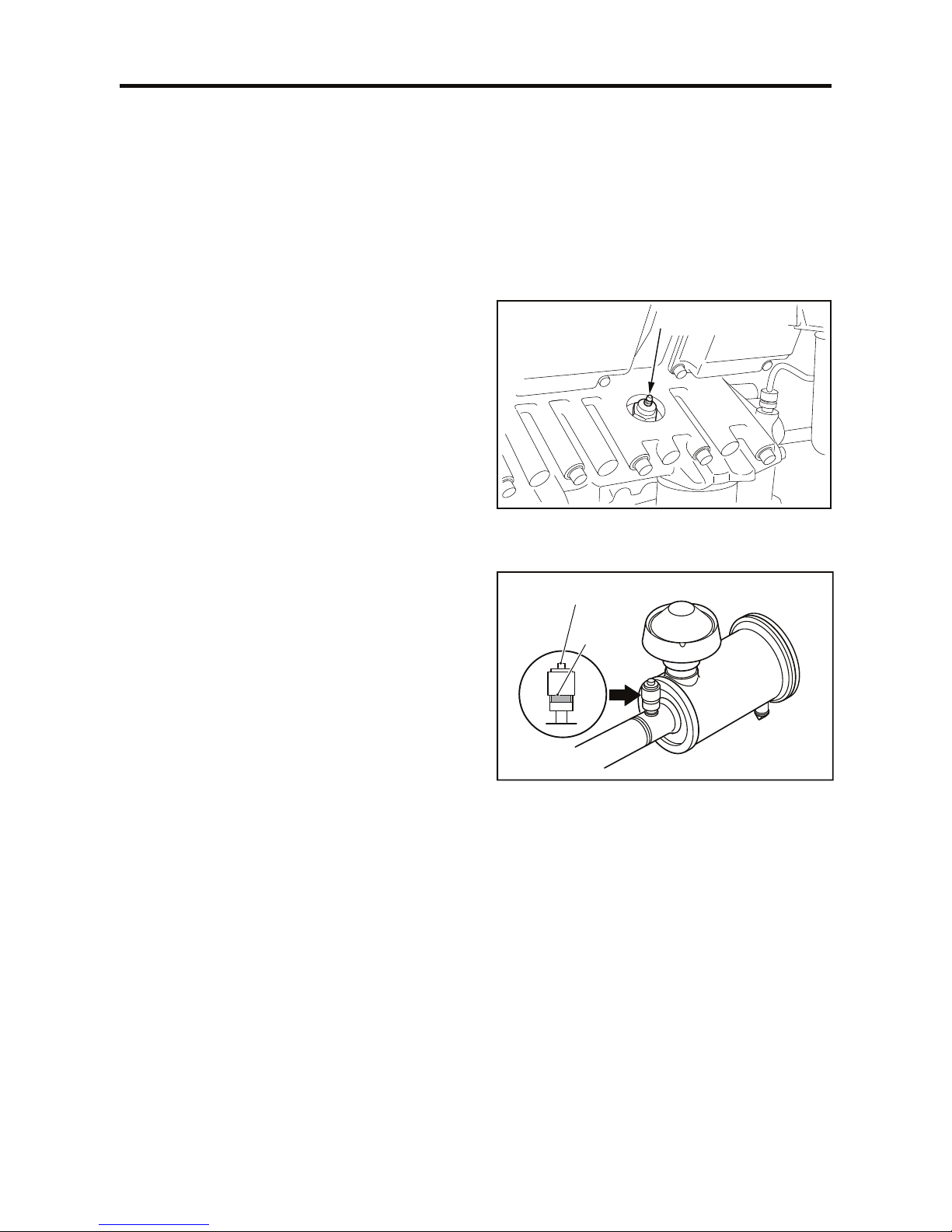

Revolution detection pickup

It is installed in the timing gear case, and always

detect engine speed.

Fig. 2-7 Revolution detection pickup

2-3

Page 29

Chapter 2 NAME OF PARTS

Engine protection devices

The engine protection devices activate an alarm when an abnormality occurs in the engine in order to protect the

engine and prevent serious problems and accidents. When a protection device is activated, stop the engine, exam-

ine the cause of the abnormality, and take corrective measures. If the cause of the problem is unknown, contact a

dealer of Mitsubishi Heavy Industries, Ltd. Protection devices installed on the engine and their types (setting values)

and shapes vary depending on the engine specifications.

Oil filter alarm switch

The oil filter alarm switch generates an alarm when oil

filters become clogged, the difference in pressure

between inlet and outlet of oil and reaches the speci-

fied value.

Oil filter alarm switch

Air cleaner indicator

The air cleaner indicator alarms with its red signal

when air cleaner elements become clogged, the differ-

ence in pressure between front air cleaner and rear air

cleaner, and reaches the specified value. The air

cleaner indicator indicates the signal only, and does

not generate an alarm. Therefore, the periodic visually

inspection is needed.

Press the reset button on the top of air cleaner indica-

tor and restore the signal after cleaned the air cleaner

indicator or replaced with a new one.

Fig. 2-8 Oil filter alarm switch

Reset button

Signal

(red)

Fig. 2-9 Air cleaner indicator

2-4

Page 30

Chapter 2 NAME OF PARTS

Using turning gear

Before starting the engine, make sure that the turning gear is pulled out in the original position. Starting the engine

with the turning gear pushed in not only damages the ring gear but also may result in personal injury.

1. Loosen the two bolts, and remove the plate from

the shaft groove.

Shaft

Bolt

2. Push in the shaft fully to engage it with the ring

gear.

3. Using a socket wrench and a ratchet handle, turn

the shaft.

4. After turning, pull out the shaft, insert the plate in

the shaft groove, and tighten the bolts.

Make sure the plate is securely installed in the shaft

groove.

Bolt

Fig. 2-10 Turning gear position

(while engine is running)

Fig. 2-11 Turning gear position (when pushing shaft in)

Socket

Plate

Ratchet handle

Fig. 2-12 Turning gear position (when turning shaft)

2-5

Page 31

Chapter 3 OPERATION

Operational environment

Check that the following contents are performed before the engine is operated. Failure to do so may cause various

problems and will shorten the service life of the engine.

Prevent from spreading water (especially, seawater or rainwater) and entering foreign materials to the air inlet

opening.

Prevent from entering foreign materials to the rotating parts.

Prevent from attaching water and dust to the electrical system.

Use the engine at 5 to 40 °C [41 to 104 °F].

Preparation for operating new or overhauled engine

Before proceeding with operation of a new overhauled engine, conduct the inspections described in this section.

For second operation onward, follow the instructions described in the "Normal engine operation" (3-7).

Preparation of fuel system

When handling fuel, make sure there are no open flames or other fire hazards near the engine.

Wipe off any spilled fuel completely. Spilled fuel can ignite and cause a fire.

Do not remove the strainer when filling the fuel tank.

For fuel to be used, refer to "FUEL" (4-1).

1. Make sure the insides of the fuel tank and fuel supply pipes to the engine are thoroughly clean.

2. Fill fuel tank with fuel.

3. Remove the fuel feed pipe and drain plug from the fuel inlet of engine, and check the discharged fuel for foreign

materials such as dust.

4. Reinstall the drain plug and the fuel feed pipe.

5. Refill fuel tank until fuel level gauge indicates "FULL" level line.

3-1

Page 32

Chapter 3 OPERATION

Fuel system - Bleed air

When fuel overflow from the air vent plug, wipe thor-

oughly. Spilled fuel causes fire hazard.

After bleeding, lock the priming pump securely. If the

cap is not locked tightly, the priming pump can be

damaged, causing a fuel leak that could lead to a

fire.

While feeding fuel with priming pump, bleed air from

the location closest to the fuel tank that are the water

separator, fuel filter, then the fuel injection pump.

Lock the priming pump according to "Priming pump

tightening method".

Fuel filter - Bleed air

If air vent plugs, the thread portion of the bracket, or

sealing washers are damaged, replace them with

new ones.

1. Loosen the air vent plug on the fuel filter about 1.5

turns.

2. Move the priming pump up and down, then feed fu-

el.

3. When the fuel from the air vent plug becomes free

from air bubbles, stop priming and tighten the air

vent plug to the specified torque.

[Unlock] [Priming] [Lock]

Turn left

Move up

and down

Fig. 3-1 Priming pump - Handle

Tightening torque

8.8 ± 1 N·m

{0.9 ± 0.1 kgf·m}

[6.4 ± 0.7 lbf·ft]

Air vent plug

Fig. 3-2 Fuel filter - Bleed air

Hold and

turn right

Fuel injection pump - Bleed air

1. Loosen the air vent plug on the fuel injection pump

by rotating about 1.5 turns.

2. Move the priming pump up and down until the fuel

flow from the air vent plug is free from air bubbles.

Push and turn the priming pump clockwise to lock

in the original position when the fuel flows is free

from bubbles.

3. Tighten the air vent plug on the fuel injection pump.

3-2

Air vent plug

15 ± 2 N·m

{1.5 ± 0.2 kgf·m}

[11.0 ± 1.4 lbf·ft]

Priming pump

Fig. 3-3 Fuel injection pump - Bleed air

Page 33

Priming pump tightening method

Chapter 3 OPERATION

Never fail to tighten the priming pump to the speci-

fied angle. If the priming pump is not firmly tightened,

internal thread will be worn due to engine vibration,

resulting in sudden ejection of the cap to cause fuel

flow-out. Or if the priming pump is excessively tight-

ened, the head of the priming pump can be dam-

aged.

1. Tighten the priming pump firmly by hand, and place

a mark on the priming pump.

2. Use a wrench or another appropriate tool to tighten

the priming pump 90±10°.

3. Check the mounting position of head packing.

Note: If the head packing has abnormality such as de-

formation or scratches, consult a dealer of Mit-

subishi Heavy Industries, Ltd., as the priming

pump needs to be changed.

90 ± 10°

Hand-tightening

becomes suddenly

heavy

Head section can be

damaged when

overtightened

(120° or more)

Fig. 3-4 Priming pump tightening method

Head packing

Fig. 3-5 Priming pump head packing

Priming pump

3-3

Page 34

Chapter 3 OPERATION

Preparation of lubrication system

Engine oil - Refill

Refilling engine oil must be specified level. If the

refilling oil goes over the high marks on the oil level

gauge, engine oil may blow out. And also, the engine

component parts are adversely affected by increas-

ing in oil temperature.

1. Remove the cap from the oil filler.

2. Fill the engine oil pan with specified engine oil to

the specified level.

Note: For engine oil, refer to "ENGINE OIL" (5-1). For

engine oil capacity, refer to "MAIN SPECIFICA-

TIONS" (12-1).

3. Remove the rocker cover, and pour engine oil to

the valve mechanism and camshaft oil bath. Pour

engine oil to camshaft oil bath from cylinder head

side.

Oil capacity per cylinder: 0.8 L [0.2 U.S. gal.]

4. Reinstall the rocker covers.

5. Check the oil level in the oil pan as follows:

6. Pull out the oil level gauge and wipe it clean with a

waste cloth.

7. Insert the oil level gauge fully into the oil level

gauge guide, then pull out the gauge again.

8. The proper oil level is between the high and low

marks on the oil level gauge.

If the oil level is low, add engine oil of the specified

type.

9. Check the oil pan and other area for oil leaks. Re-

pair the oil leakage if any.

10. While pulling the stop lever, rotate the crankshaft

for approx. 10 seconds to turn on the starter. Stop

the operation for 1 minute, then, repeat the opera-

tion two or three times. Circulate engine oil to each

engine parts.

Note: Prepare for the Cooling system.

11. Check the oil level with the oil level gauge again,

and add oil to the specified level.

Oil level gauge

Improper

H

High

Proper

L

Oil filler

Low

Oil level gauge

Improper

Fig. 3-6 Oil filler and Oil level gauge

Camshaft

oil bath

Fig. 3-7 Pouring engine oil on valve mechanisms and

chamber

3-4

Page 35

Preparation of cooling system

Coolant - Refill

Chapter 3 OPERATION

Always use the coolant with the same LLC concen-

tration.

1. Make sure the coolant drain cock of engine water

pump are closed securely.

2. Remove the radiator cap, and pour in undiluted

LLC.

Note: Determine the quantities of LLC based on the

coolant capacity and the LLC concentration

chart.

For the coolant, refer to "COOLANT" (6-1). For

the coolant capacity, refer to "MAIN SPECIFICA-

TIONS" (12-1).

3. Pour in water (soft water with minimal impurities,

such as tap water) slowly to the full level.

Note: For absolute air bleeding, loosen the air vent