Page 1

C

MIT

SUBIS

C

MELFA

Industrial Robots

Specifications Manual

HI ELECTRI

Art. no.: 132309

05 07 2002

BFP-A8050-F

RV-1A/RV-2AJ Series

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

Page 2

CAUTION

CAUTION

WARNING

Safety Precautions

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

All teaching work must be carried out by an operator who has received special training.

(This also applies to maintenance work with the power source turned ON.)

→ Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures of oper

ating the robot, and to the measures to be taken when an error occurs or when restart

ing. Carry out work following this plan. (This also applies to maintenance work with the

power source turned ON.)

→ Preparation of work plan

Prepare a device that allows operation to be stopped immediately during teaching work.

(This also applies to maintenance work with the power source turned ON.)

→ Setting of emergency stop switch

-

-

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

During teaching work, place a sign indicating that teaching work is in progress on the

start switch, etc. (This also applies to maintenance work with the power source turned

ON.)

→ Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the operator and

robot.

→ Installation of safety fence

Establish a set signaling method to the related operators for starting work, and follow

this method.

→ Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign indicating that

maintenance work is in progress on the start switch, etc.

→ Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other related

devices, etc., and confirm that there are no errors.

→ Inspection before starting work

Page 3

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

Use the robot within the environment given in the specifications. Failure to do so could

lead to a drop or reliability or faults. (Temperature, humidity, atmosphere, noise environ

ment, etc.)

Transport the robot with the designated transportation posture. Transporting the robot

in a non-designated posture could lead to personal injuries or faults from dropping.

Always use the robot installed on a secure table. Use in an instable posture could lead

to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise source,

positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable. Failure to

observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the rated load

or tolerable torque. Exceeding these values could lead to alarms or faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to observe

this could lead to personal injuries or damage if the object comes off or flies off during

operation.

Securely ground the robot and controller. Failure to observe this could lead to malfunc

tioning by noise or to electric shock accidents.

-

-

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

Indicate the operation state during robot operation. Failure to indicate the state could

lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure the pri

ority right for the robot control. Failure to observe this could lead to personal injuries or

damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do so

could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with peripheral

devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic operation,

the door is locked or that the robot will automatically stop. Failure to do so could lead to

personal injuries.

Never carry out modifications based on personal judgments, or use non-designated

maintenance parts.

Failure to observe this could lead to faults or failures.

When the robot arm has to be moved by hand from an external area, do not place hands

or fingers in the openings. Failure to observe this could lead to hands or fingers catching

depending on the posture.

-

CAUTION

Do not stop the robot or apply emergency stop by turning the robot controller's main

power OFF.

If the robot controller main power is turned OFF during automatic operation, the robot

accuracy could be adversely affected.

Page 4

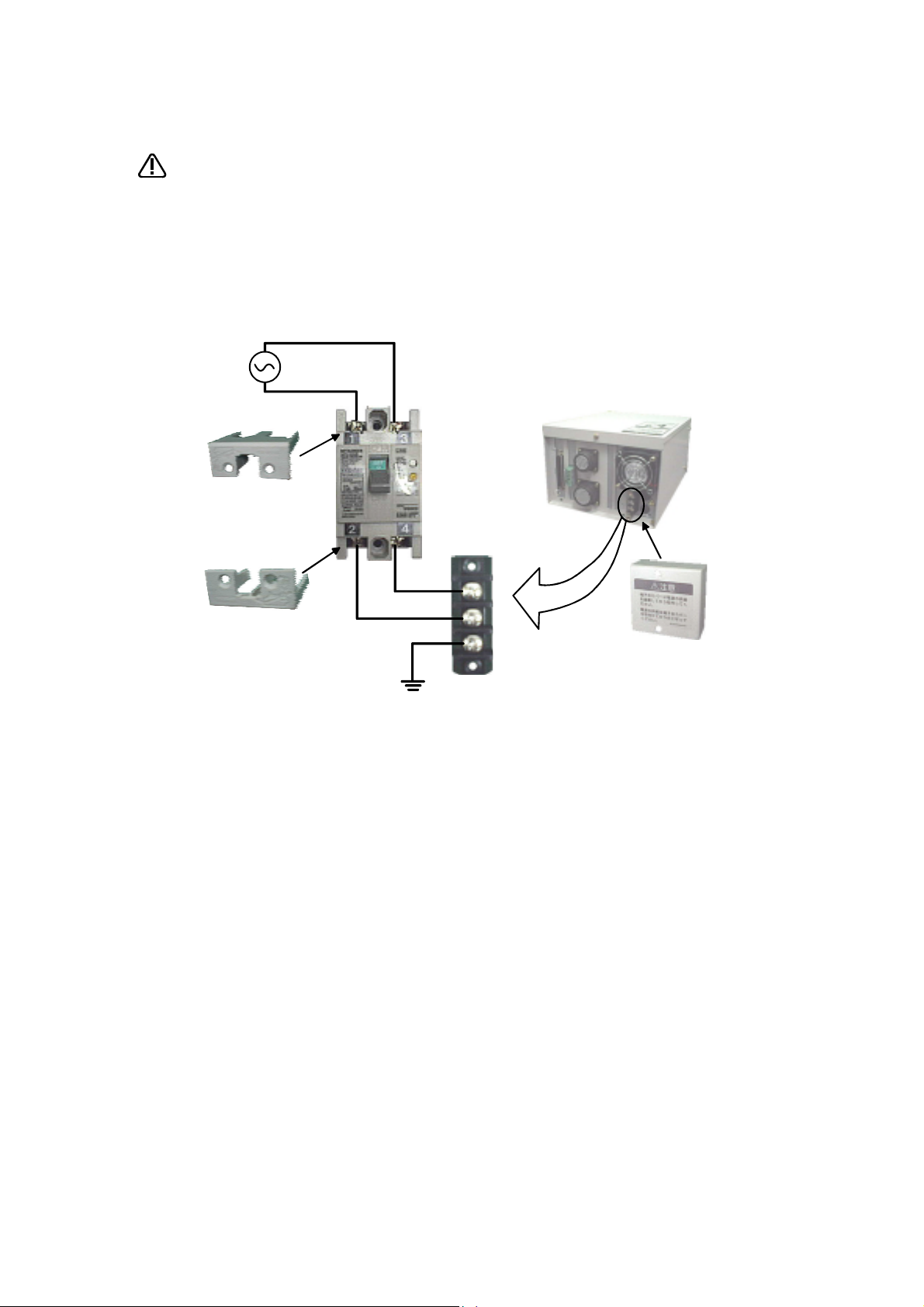

C.Precautions for the basic configuration are shown below.(When CR1-571 is used for the controller.)

CAUTION

Power supply *RV-1A/2AJ series and RP-1AH/3AH/5AH series: Single phase 90-132VAC, 180-253VAC.

Provide an earth leakage breaker that packed together on the primary power

supply of the controller as protection against electric leakage. Confirm the set

ting connector of the input power supply voltage of the controller, if the type

which more than one power supply voltage can be used. Then connect the

power supply.

Failure to do so could lead to electric shock accidents.

*Except the above: Single phase 180-253VAC.

Cover

Cover

Earth leakage

breaker

(NV)

Terminal

-

Rear side of controller

Protective earth

terminal

(PE)

Terminal cover

Page 5

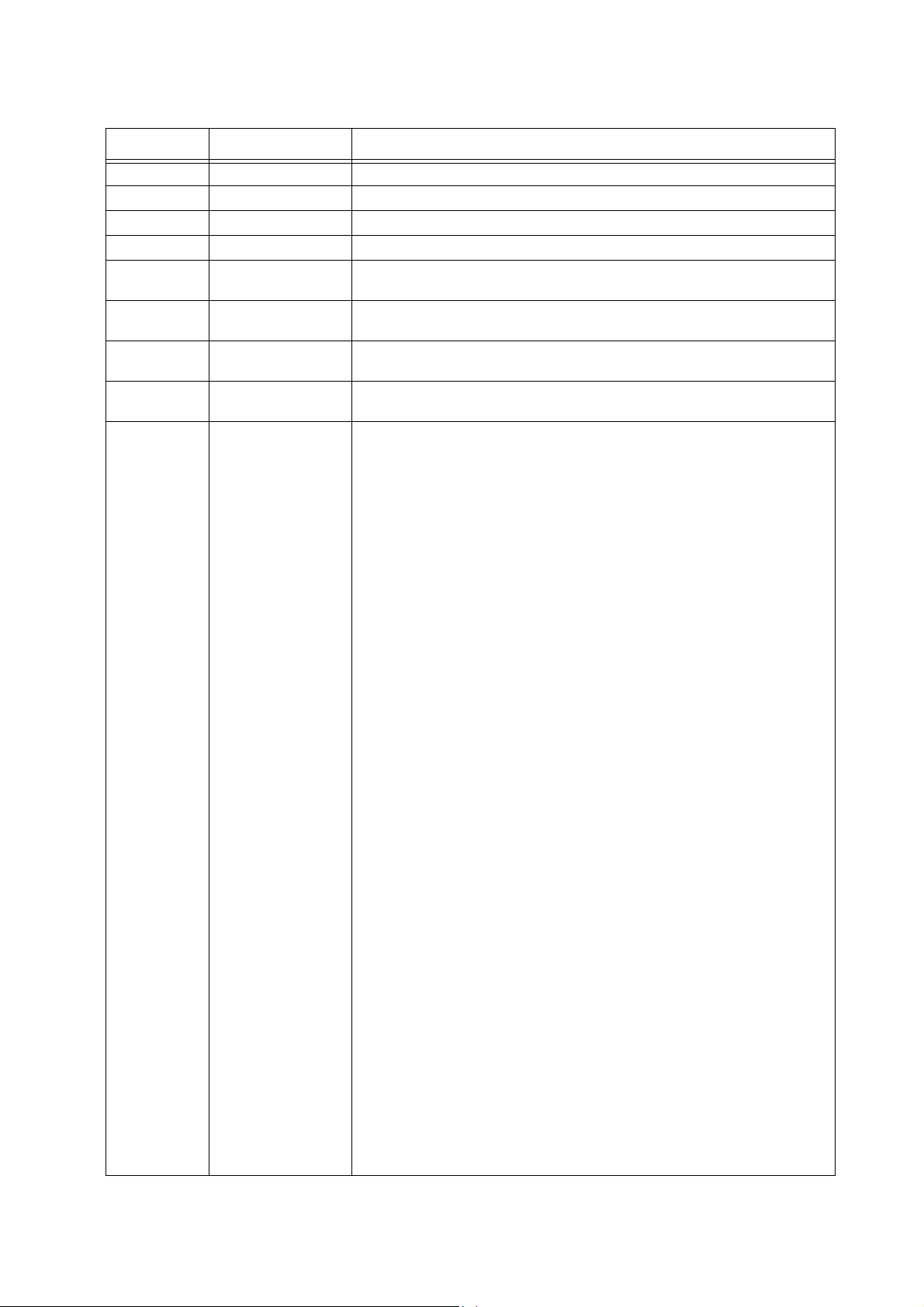

■ Revision history

Date of print Specifications No. Details of revisions

2000-02-08 BFP-A8050Z First print

2000-04-05 BFP-A8050 Formal style

2000-06-09 BFP-A8050-A The power supply voltage of CR1 controller was corrected

2001-03-12 BFP-A8050-B Error in writing correction.

2002-01-23 BFP-A8050-C LNG, RLNG and MESNGLSW parameters were added.

Error in writing correction.

2002-04-01 BFP-A8050-D CR1-MB (controller protction box) was added.

2002-06-03 BFP-A8050-E RV-1AC-SB, RV-2AJC-SB was added.

2002-07-05 BFP-A8050-F The description of input/output circuit terminal was corrected.

Error in writing correction.

Error in writing correction.

Error in writing correction.

Page 6

■ Introduction

The "RV-1A" and "RV-2AJ" are compact industrial robots developed with Mitsubishi's advanced technology.

These robots respond to users needs for compact and flexible production facilities generated due to the recent

diffusion of compact and highly accuracy products such as personal computer related devices, information termi

nal devices and compact electronic devices for mounting on vehicles, and due to shorter product life cycles.

However, to comply with the target application, a work system having a well-balanced robot arm, peripheral

devices or robot and hand section must be structured.

When creating these standard specifications, we have edited them so that the Mitsubishi robot's characteristics

and specifications can be easily understood by users considering the implementation of robots. However, if there

are any unclear points, please contact your nearest Mitsubishi branch or dealer.

Mitsubishi hopes that you will consider these standard specifications and use our robots.

In this manual, the specifications regarding the robot arm are given in Page 5, "2 Robot arm" and following, and the

specifications regarding the controller are given in Page 38, "3 Controller" and following. Refer to the correspond

ing sections for details on the specifications, options and maintenance parts, etc.

Note:

・ No part of this manual may be reproduced by any means or in any form, without prior consent from Mitsubishi.

・ The contents of this manual are subject to change without notice.

・ The specifications values are based on Mitsubishi standard testing methods.

・ The information contained in this document has been written to be accurate as much as possible. Please inter

pret that items not described in this document "cannot be performed.".

Please contact your nearest dealer if you find any doubtful, wrong or skipped point.

-

-

-

Page 7

Contents

1 General configuration .................................................................................................................................................................... 1-1

1.1 Structural equipment ............................................................................................................................................................. 1-1

1.1.1 Standard structural equipment .................................................................................................................................. 1-1

1.1.2 Shipping special specifications ................................................................................................................................... 1-1

1.1.3 Options ................................................................................................................................................................................. 1-1

1.1.4 Maintenance parts ........................................................................................................................................................... 1-1

1.2 Contents of the structural equipment ............................................................................................................................ 1-2

1.2.1 Robot arm ........................................................................................................................................................................... 1-2

1.3 Controller .................................................................................................................................................................................... 1-3

1.4 Contents of the Option equipment and special specification .............................................................................. 1-4

2 Robot arm ........................................................................................................................................................................................... 2-5

2.1 Standard specifications ........................................................................................................................................................ 2-5

2.2 Definition of specifications .................................................................................................................................................. 2-6

2.2.1 Pose repeatability and distance accuracy ............................................................................................................ 2-6

2.2.2 Rated load (mass capacity) ......................................................................................................................................... 2-7

2.2.3 Protection specifications and working environment ......................................................................................... 2-8

(1) Types of protection specifications ...................................................................................................................... 2-8

2.2.4 Clean specifications ........................................................................................................................................................ 2-9

(1) Types of clean specifications ................................................................................................................................. 2-9

2.3 Names of each part of the robot .................................................................................................................................... 2-10

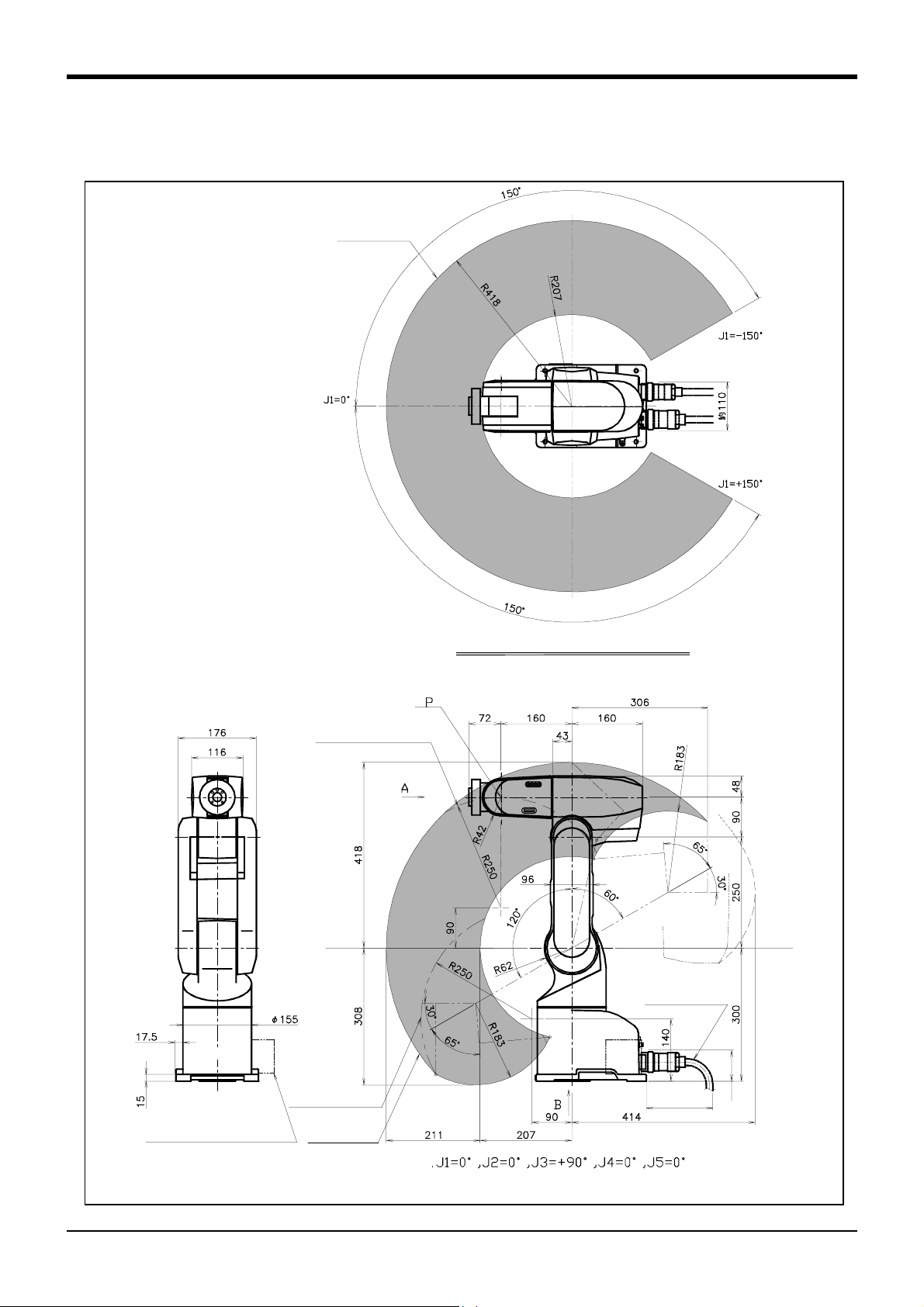

2.4 Outside dimensions ・ Operating range diagram ........................................................................................................ 2-11

(1) RV-1A/1AC-SB ........................................................................................................................................................ 2-11

(2) RV-2AJ/2AJC-SB ................................................................................................................................................... 2-12

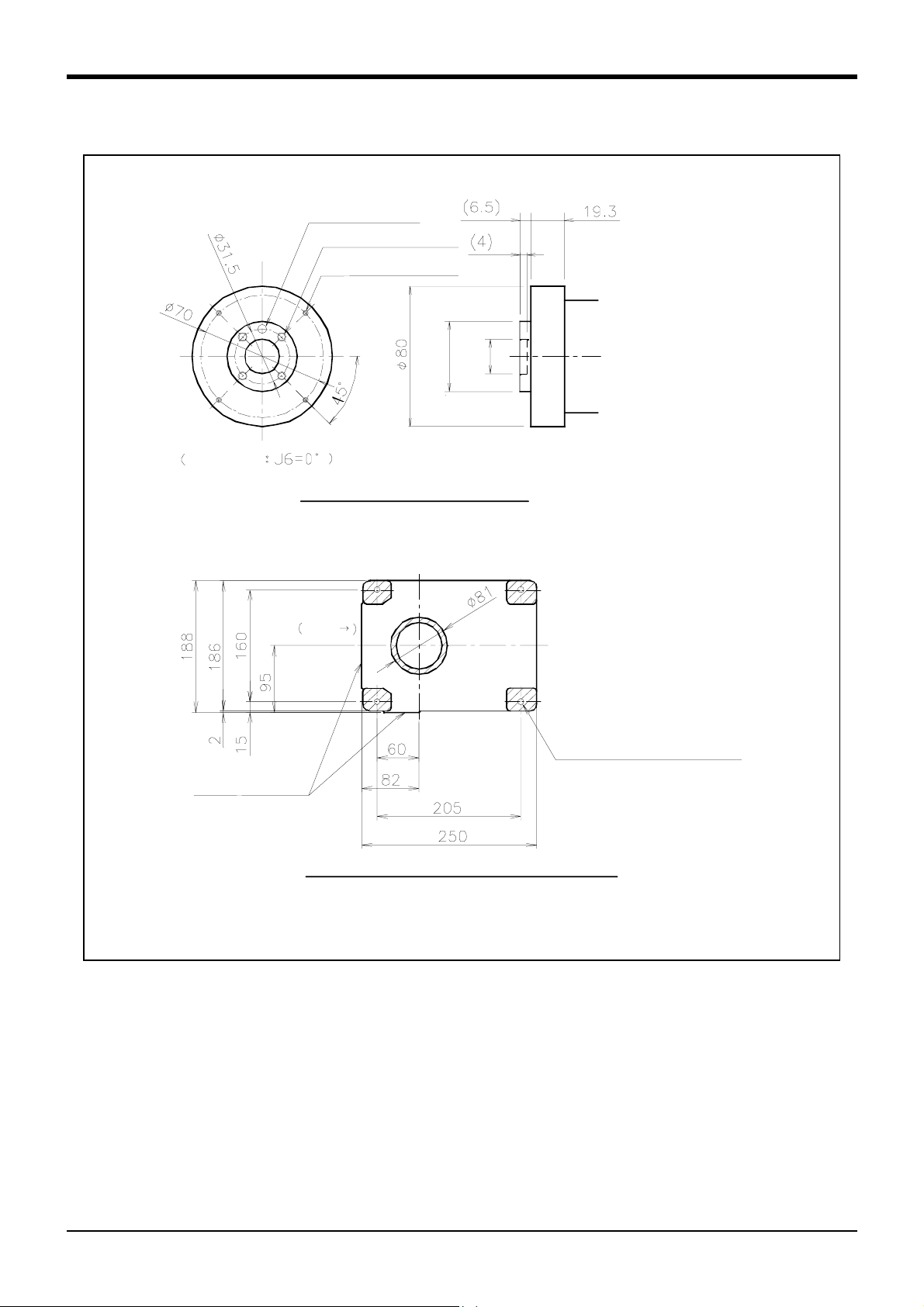

(3) Mechanical interface and Installation surface of RV-1A/2AJ, RV-1AC-SB/2AJC-SB .......... 2-13

2.5 Tooling ........................................................................................................................................................................................ 2-14

2.5.1 Wiring and piping for hand .......................................................................................................................................... 2-14

(1) RV-1A/2AJ (General environment) .................................................................................................................. 2-14

(2) RV-1AC-SB/2AJC-SB (Clean specification) .............................................................................................. 2-15

2.5.2 Internal air piping ............................................................................................................................................................ 2-16

2.5.3 Internal wiring for the pneumatic hand output cable ...................................................................................... 2-16

2.5.4 Internal wiring for the hand check input cable .................................................................................................. 2-16

2.5.5 Wiring and piping system diagram for hand ......................................................................................................... 2-17

(1) RV-1A/2AJ (General environment) .................................................................................................................. 2-17

(2) RV-1AC-SB/2AJC-SB (Clean specification) .............................................................................................. 2-19

2.5.6 Electrical specifications of hand input/output .................................................................................................. 2-21

2.5.7 Air supply circuit example for the hand ............................................................................................................... 2-22

2.6 Shipping special specifications, options, and maintenance parts ...................................................................... 2-23

2.6.1 Shipping special specifications ................................................................................................................................. 2-23

(1) Machine cable extension ........................................................................................................................................ 2-24

2.7 Options ....................................................................................................................................................................................... 2-26

(1) Motorized hand set ................................................................................................................................................... 2-27

(2) Pneumatic hand set .................................................................................................................................................. 2-29

(3) Solenoid valve set ..................................................................................................................................................... 2-31

(4) Hand input cable ........................................................................................................................................................ 2-33

(5) Hand output cable ..................................................................................................................................................... 2-34

(6) Hand curl tube ............................................................................................................................................................ 2-35

(7) Hand adapter ............................................................................................................................................................... 2-36

2.8 Maintenance parts ................................................................................................................................................................. 2-37

Page

3 Controller .......................................................................................................................................................................................... 3-38

3.1 Standard specifications ...................................................................................................................................................... 3-38

3.1.1 Standard specifications ............................................................................................................................................... 3-38

3.1.2 Protection specifications and operating supply ................................................................................................ 3-39

3.2 Names of each part .............................................................................................................................................................. 3-40

3.3 Outside dimensions/Installation dimensions .............................................................................................................. 3-42

i

Page 8

3.3.1 Outside dimensions ...................................................................................................................................................... 3-42

3.3.2 Installation dimensions ................................................................................................................................................ 3-43

3.4 External input/output ......................................................................................................................................................... 3-44

3.4.1 Types .................................................................................................................................................................................. 3-44

3.4.2 Explanation ....................................................................................................................................................................... 3-44

3.5 Dedicated input/output ...................................................................................................................................................... 3-45

3.6 Emergency stop input/output ......................................................................................................................................... 3-47

3.6.1 Connection of the external emergency stop ..................................................................................................... 3-47

3.6.2 Door switch function ................................................................................................................................................... 3-48

3.7 Parallel input/output unit .................................................................................................................................................. 3-49

3.8 Options ...................................................................................................................................................................................... 3-53

(1) Teaching pendant (T/B) ........................................................................................................................................ 3-54

(2) Pneumatic hand interface ..................................................................................................................................... 3-57

(3) Controller protection box ...................................................................................................................................... 3-59

(4) Expansion option box .............................................................................................................................................. 3-62

(5) Parallel I/O unit ......................................................................................................................................................... 3-64

(6) External I/O cable .................................................................................................................................................... 3-72

(7) Personal computer cable ....................................................................................................................................... 3-74

(8) Personal computer support software/Personal computer support software mini ....................... 3-76

3.9 Maintenance parts ................................................................................................................................................................ 3-78

4 Software ........................................................................................................................................................................................... 4-79

4.1 List of commands ................................................................................................................................................................. 4-79

(1) The procedure of robot language selection ................................................................................................... 4-79

(2) MELFA-BASIC Ⅳ commands ............................................................................................................................. 4-80

(3) MOVEMASTER commands ................................................................................................................................... 4-82

4.2 List of parameters ................................................................................................................................................................ 4-85

(1) List of parameters .................................................................................................................................................... 4-85

(2) Change the display language / 表示言語の切り 替え .............................................................................. 4-87

Page

5 Safety ................................................................................................................................................................................................ 5-88

5.1 Safety ........................................................................................................................................................................................ 5-88

5.1.1 Self-diagnosis stop functions .................................................................................................................................. 5-88

5.1.2 External input/output signals that can be used for safety protection measures ............................. 5-88

5.1.3 Precautions for using robot ...................................................................................................................................... 5-89

5.1.4 Safety measures for automatic operation .......................................................................................................... 5-89

5.1.5 Safety measures for teaching .................................................................................................................................. 5-89

5.1.6 Safety measures for maintenance and inspections, etc. ............................................................................. 5-89

5.1.7 Examples of safety measures .................................................................................................................................. 5-90

5.2 Working environment ........................................................................................................................................................... 5-91

5.3 Precautions for handling .................................................................................................................................................... 5-91

6Appendix ..............................................................................................................................................................................Appendix-92

Appendix 1 : Specifications discussion material ........................................................................................... Appendix-92

ii

Page 9

1General configuration

1 General configuration

1.1 Structural equipment

Structural equipment consists of the following types.

1.1.1 Standard structural equipment

The following items are enclosed as a standard.

(1) Robot arm

(2) Controller

(3) Machine cable

(4) Robot arm installation bolts

(5) Instruction manual, Safety manual

(6) Guarantee card

1.1.2 Shipping special specifications

Part of the standard structural equipment is changed at the time of factory shipment. Consequently, kindly con

firm the delivery date.

To make changes to the specifications after shipment, service work must be performed at the work site or the

robot must be returned for service.

1.1.3 Options

Installation is possible after shipment. Customer needs to perform the installation work.

-

1.1.4 Maintenance parts

Consumable parts and spare parts for maintenance use.

For items not listed, contact the dealer where you made your purchase.

Structural equipment

1-1

Page 10

1General configuration

1.2 Contents of the structural equipment

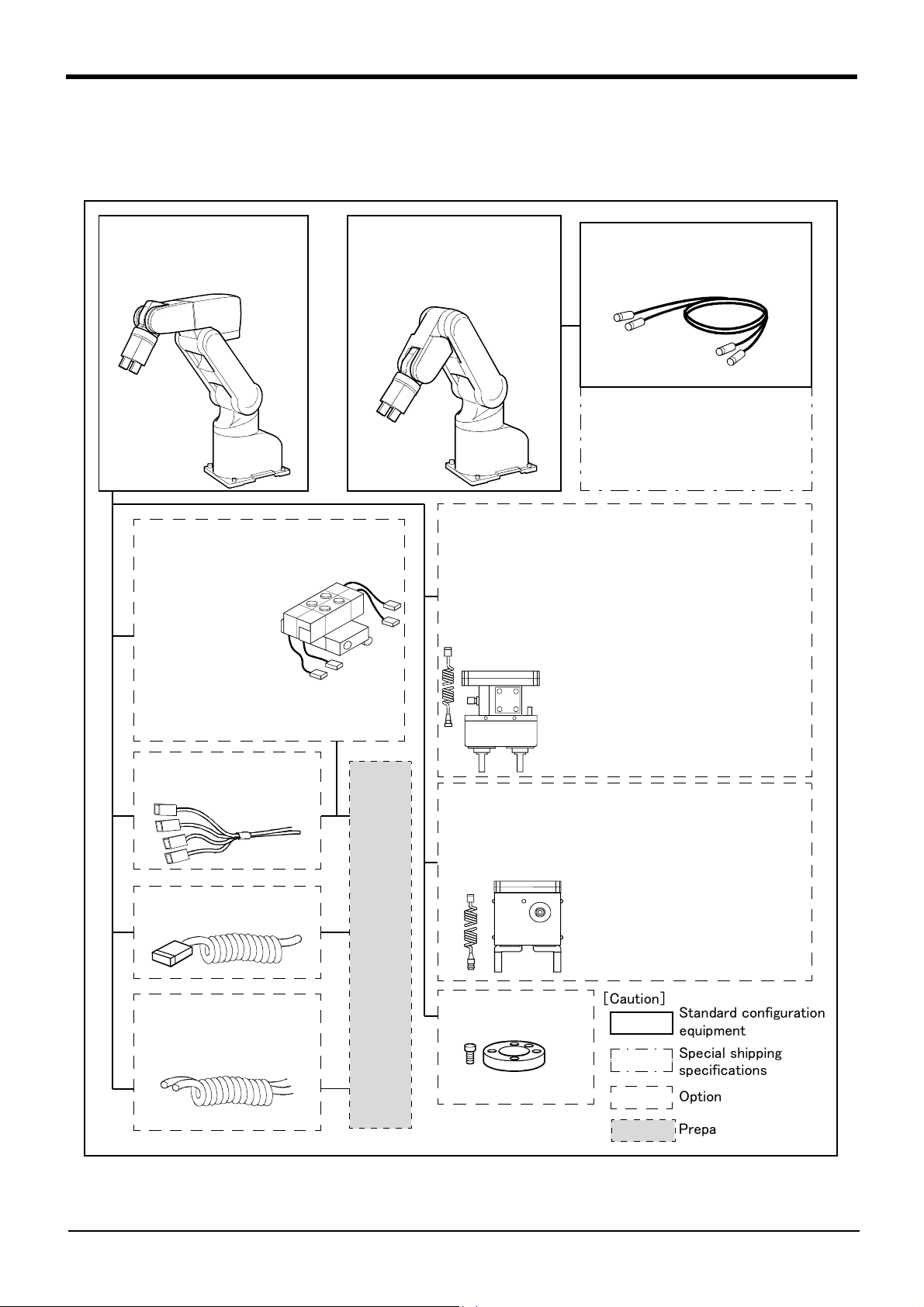

1.2.1 Robot arm

The list of structural equipment is shown in Fig. 1-1.

Vertical six-axis

RV-1A:

RV-1AC-SB:

General environment

Clean specification

Solenoid valve set

<sink type>

・1 set: 1E-VD01

・ 2 set: 1E-VD02

<source type>

・1 set: 1E-VD01E

・ 2 set: 1E-VD02E

Vertical five-axis

multiple-jointed type

RV-2AJ:

RV-2AJC-SB:

or

Machine cable fixed type 5m

General environment

Clean specification

・1A-5CBL-1

Machine cable

・ Fixed type:1A- □□ CBL-1

・ Flexed type:1A- □□ LCBL-1

Note) □□ refer the length.

Refer to section "1.4" for datails.

Pneumatic hand set

:

4A-HP01(sink type)/4A-HP01E (source type)

The set consists of the following parts.

Pneumatic hand

・

Solenoid valve set (1 pc.)

・

・ Curl cable :1A-GHCD/1A-GHCD

Hand curl tube

・

Pneumatic hand I/F

・

・ Hand adapter :1A-HA01/1A-HA01

:1A-HP01/1A-HP01E

:1E-VD01/1E-VD01E

:1A-ST0402C/1A-ST0402C

: 2A-RZ365/2A-RZ375

Note) Not

clean specification

Hand output cable

・1E-GR35S

Hand input cable

・1A-HC20

Hand curl tube

・

1 set, 2pc

・

2 set, 4pc

. :1E-ST0402C

. :1E-ST0404C

With installation bolts.

Pneumatic hand customer-manufactured parts

With installation bolts.

Note) Not

Motorized hand set : 4A-HM01

・ Motorized hand :1A-HM01

・ Curl cable :1A-GHCD

・ Motorized hand

・ Hand adapter :1A-HA01

I/F

clean specification

: 2A-RZ364

With installation bolts.

Note) Not

Hand adapter

:1A-HA01

clean specification

[Caution]

Standard configuration

equipment

Special shipping

specifications

With installation bolts.

Option

Prepared by customer

Fig.1-1:Structural equipment (Robot arm)

1-2

Contents of the structural equipment

Page 11

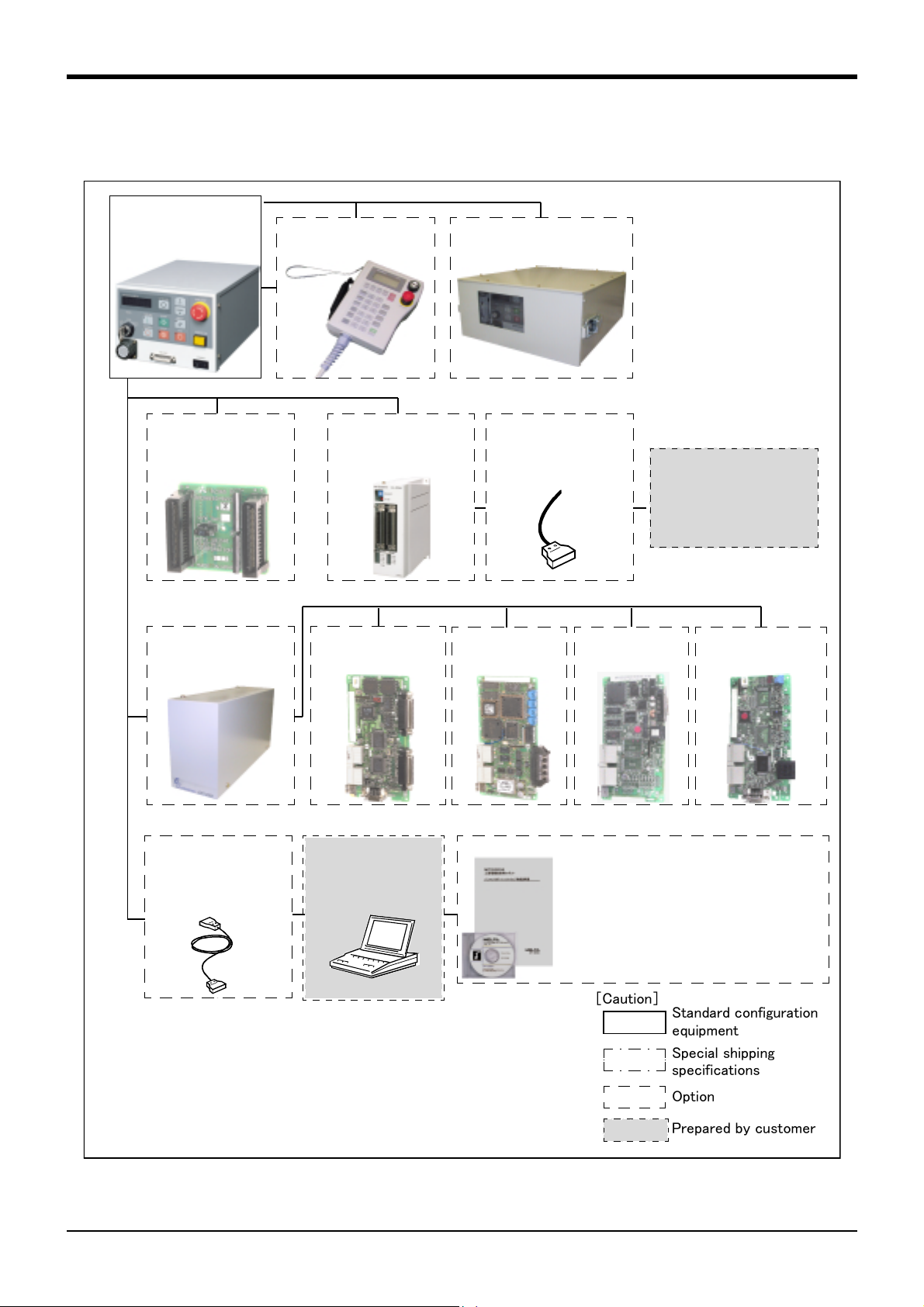

1.3 Controller

ETHERNET I/F

・ 2A-HR533E

The devices shown below can be installed on the controller.

Controller

・ CR1-571

Teaching pendant(T/B)

・ R28TB

Controller protection box

・ CR1-MB

1General configuration

Pneumatic I/F

・ 2A-RZ365 (Sink)

・ 2A-RZ375 (Source)

Expansion option box

・ CR1-EB3

Personal computer

cable

・ RS-MAXY-CBL

・ RS-AT-RCBL

Parallel I/O unit

・ 2A-RZ361 (Sink)

・ 2A-RZ371 (Source)

Extended serial I/F

・ 2A-RZ581E

Personal computer

Prepared

by customer

External I/O cable

・ 2A-CBL05(5m)

・ 2A-CBL15(15m)

CC-LINK I/F

・ 2A-HR575E

Personal computer support software

(MS-Windows95/98/NT4.0)

・ 3A-01C-WINE(CD-ROM)

Personal computer support software mini

(MS-Windows95/98/NT4.0)

・ 3A-02C-WINE(CD-ROM)

PLC(Programmable

Logic Controller)

External device

Prepared by customer

Additional axis I/F

・ 2A-RZ541E

Fig.1-2 : Structural equipment(Controller)

[Caution]

Standard configuration

equipment

Special shipping

specifications

Option

Prepared by customer

Controller

1-3

Page 12

1General configuration

1.4 Contents of the Option equipment and special specification

A list of all Optional equipments and special specifications are shown below.

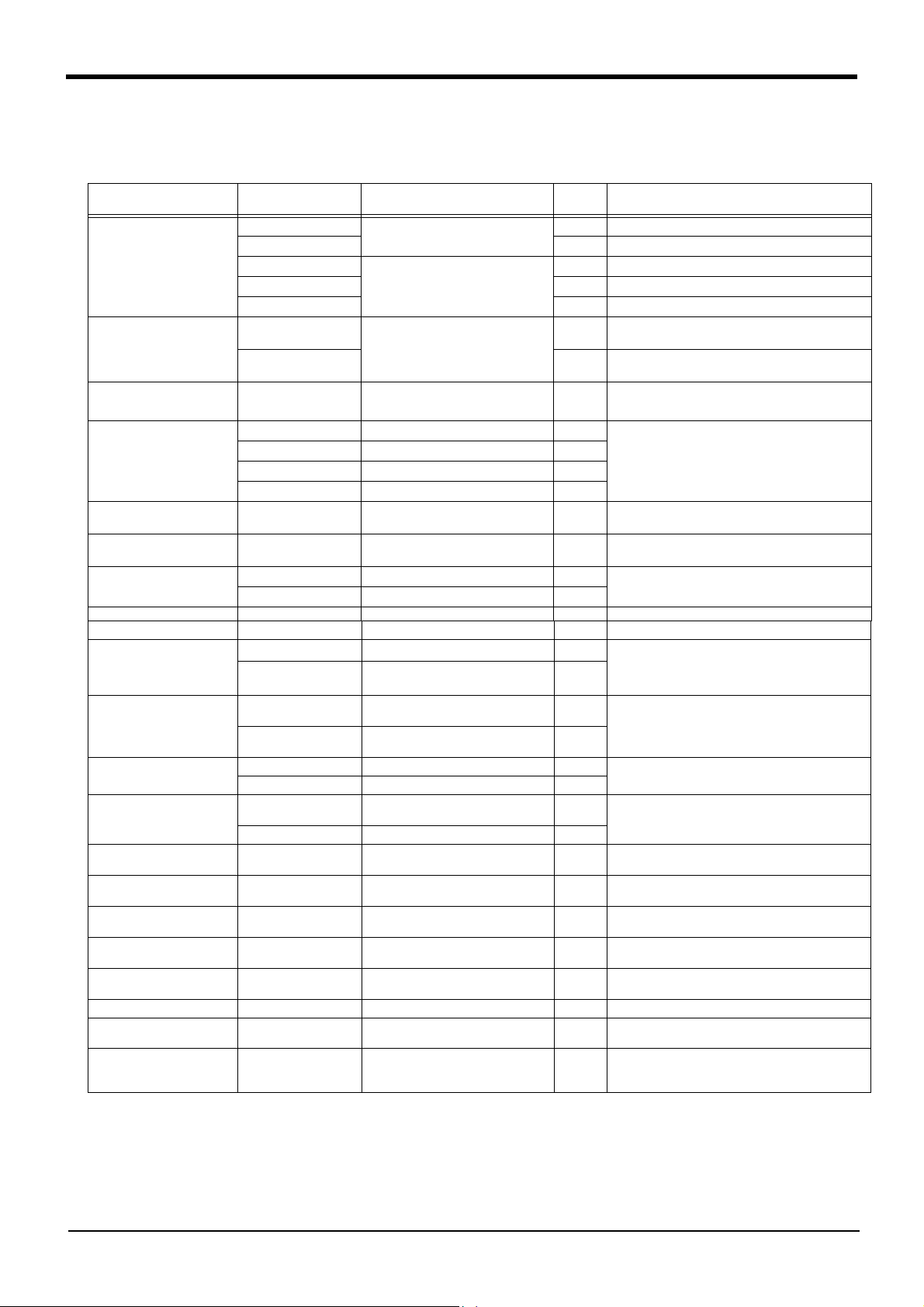

Table 1-1:The list of Option equipment and special specification

Item Type Specifications

Extended machine cables 1A-10CBL-1

1A-15CBL-1□15m

1A-05LCBL-1

1A-10LCBL-1□10m

1A-15LCBL-1□15m

Pneumatic hand set 4A-HP01

4A-HP01E

Motorized hand set 4A-HM01

Solenoid valve set 1E-VD011 set(Sink type) ○ A solenoid valve set for the pneumatic hand.

1E-VD02 2 set(Sink type) ○

1E-VD01E 1 set(Source type) ○

1E-VD02E 2 set(Source type) ○

Hand output cable 1E-GR35S Length 350mm with robot side con

Hand input cable 1A-HC20 Length 200mm with robot side con

Hand curl tube 1E-ST0402C For solenoid valve 1set.:Φ4x2 ○

1E-ST0404C For solenoid valve 2set.:Φ4x4 ○

Hand adapter 1A-HA01○

Teaching pendant R28TB Cable length 7m ○ With 3-position deadman switch/ IP 65

Pneumatic hand interface

Parallel I/O interface

External I/O cable 2A-CBL05 5m ○ Use to connect the external peripheral device to

Personal computer cable

Personal computer

Support software

Personal computer

Support software mini

Expansion option box CR1-EB3 Up to three option cards can be

Extended serial interface

CC-Link interface 2A-HR575E Local station (The local station

ETHERNET interface 2A-HR533E ETHERNET x 1○CR-EB3 is need.

Additional axis interface 2A-RZ541ESSC x 1

Controller protection box CR1-MB IP54 □

2A-RZ365

2A-RZ375

2A-RZ361

2A-RZ371

2A-CBL15 15m ○

RS-MAXY-CBL

RS-AT-RCBL ○

3A-01C-WINE CD-ROM ○

3A-02C-WINE CD-ROM ○

2A-RZ581E

For fixing

(Two sets for power and signal)

For flexed

(Two sets for power and signal)

Pneumatic hand, Solenoid valve set

(1 pc.), Curl tube(1 pc.), Pneumatic

hand I/F, Hand adapter, Installation

bolts

Motorized hand, Hand curl cable,

Motorized hand I/F, Hand adapter,

Installation bolts

nector. One terminal is not treated.

nector. One terminal is not treated.

DO: 8 point (Sink type)

DO: 8 point (Source type)

DO: 32 point (Sink type)/

DI : 32 point (Sink type)

DO: 32 point (Source type)/

DI : 32 point (Source type)

RS-232C cable 3m for PC-AT com

patible model

mounted

RS-232C x 1

RS-232C or RS-422 x 1

alone is supported.)

Up to 8 axises can be added

*1)

*1)

Note1) In the classification column, ○ refers to an option,and □ to a Sipping special specifications.

Note2) Use this option to protect the controller from the oil mist when the controller will be installed in the environ

ment such as the oil mist.

Classific

ation

□10m

□ 5m

The pneumatic hand and required parts are pre

○

pared in a set.(sink type)

The pneumatic hand and required parts are pre

○

pared in a set.(source type)

The motorized hand and required parts are pre

○

pared in a set.

-

-

-

The cable is connected to the hand output con

○

nector by the customer.

The cable is connected to the sensor by the cus

○

tomer.

Curl type air tube

For RV-M1 hand installation flange conversion.

It is necessary when the hand output signal of the

○

robot arm is used. (Integrated in the controller.)

*1)In RV-1A/2AJ type, even four points are

○

effective.

The unit for expansion the external input/output.

○

Electrical isolated Type

(100mA/Point)

○

the parallel input/output unit

Use RS-AT-RCBL for the connection from the

○

expansion option box.

MS-Windows95/98/NT4.0

(With the simulation function)

MS-Windows95/98/NT4.0

(Without the simulation function)

○ Install on the side of the controller

CR-EB3 is need.

○

for MELSEC PLC with CC-Link connection. CR-

○

EB3 is need.

MR-J2 servoAmplifer Unit connection. CR-EB3 is

○

need.

The controller protection box is used to protect

the controller from an oil mist or other operating

environment.

Descripsion

Note2)

-

-

-

-

-

-

1-4

Contents of the Option equipment and special specification

Page 13

2 Robot arm

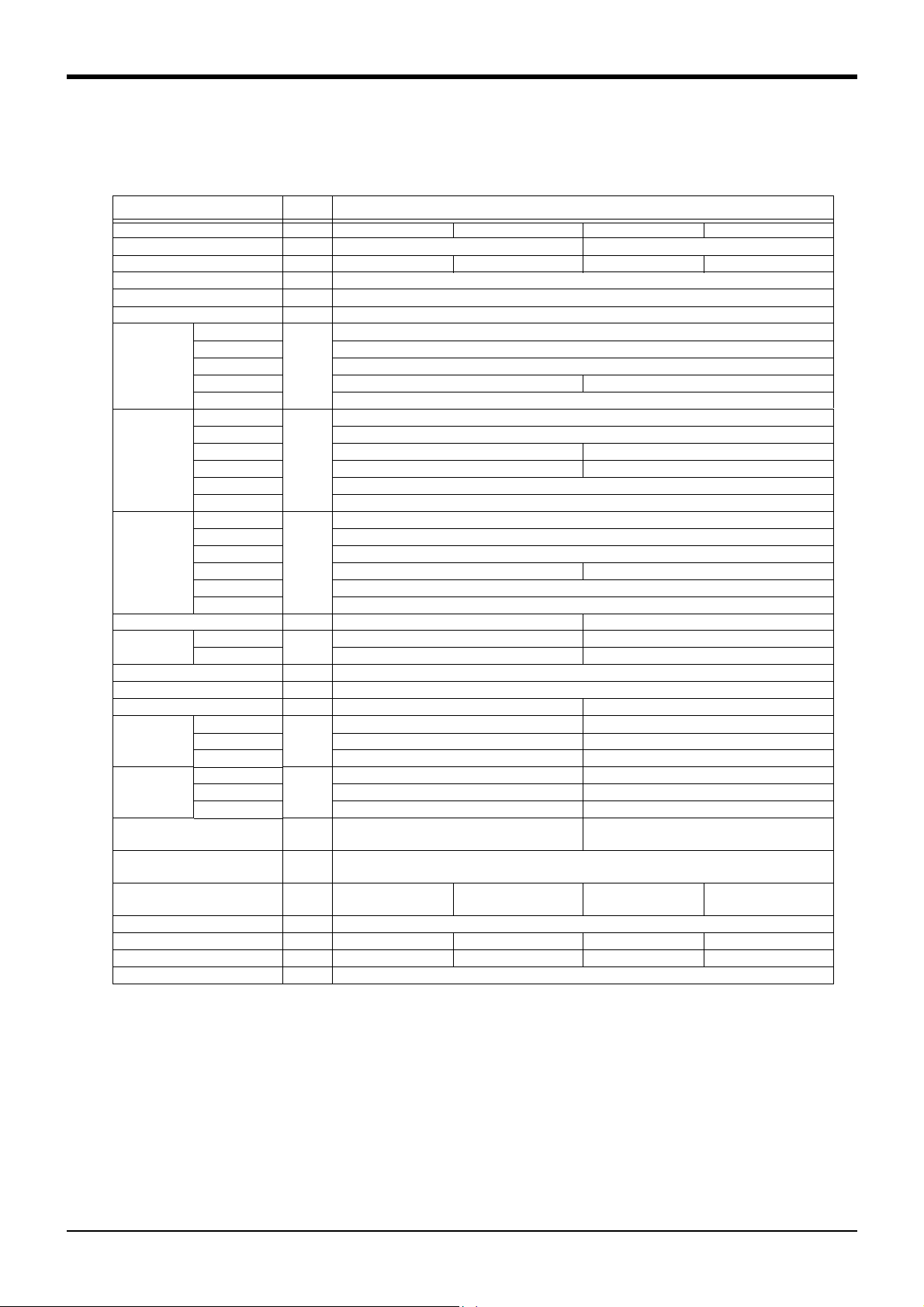

2.1 Standard specifications

2.1.1 Standard specifications

Table 2-1:Tab Standard specifications of robot

Item Unit Specifications

Type RV-1ARV-1AC-SB RV-2AJ RV-2AJC-SB

Degree of freedom 6 5

Installation posture On floor, hanging On floor On floor, hanging On floor

Structure Vertical, multiple-joint type

Drive system ACservo motor (J1 toJ3:50W with brake, J4,J6:15W no brake, J5:15Wwith brake)

Position detection method Absolute encoder

Shoulder shift

Upper arm 250

Arm length

Operating

range

Speed of

motion

Maximum resultant velocity mm/s Approx. 2200 Approx. 2100

Load

Pose repeatability

Ambient temperature ℃ 0 to 40

Mass kg Approx. 19 Approx. 17

Allowable

moment load

Allowable

inertia

Arm reachable radius

(front p-axis center point)

Tool wiring

Tool pneumatic pipes

Supply pressure MPa 0.5 ±10%

Protection specification

Degree of cleanliness

Paint color Light gray (Equivalent to Munsell: 7.65Y7.6/0.73)

Fore arm 160

Elbow shift 90 0

Wrist length 72

J1

J2 180(-60 to +120)

J3 95(+60 to +155) 230(-110 to +120)

J4 320(-160 to +160) -

J5 180(-90 to +90)

J6 400(-200 to +200)

J1

J2 90

J3 135

J4 180 -

J5 180

J6 210

Maximum

Rating 11.5

J4

J5 1.44 2.16

J6 0.73 1.10

J4

J5 2.16x10

J6 5.62x10

Note3)

Note1)

Note2)

Note4)

Note5)

mm

Degree

Degree/

s

kg

mm ± 0.02

N ・ m

2

kg ・m

mm 418410

Φ4x4 (Base to hand

Four input signals (Hand section), Four output signals (Base section),

section)

IP30 - IP30 -

-100(0.3μm) -100(0.3μm)

1.5 2

1.44 -

-2

2.16x10

-2

-3

Motorized hand output (Hand section)

Φ4x3 (Base to hand

section)

Note1)The maximum load capacity is the mass with the flange posture facing downword at the ±10 degree

limit.

Note2)The pose repeatability details are given in Page 6, "2.2.1 Pose repeatability and distance accuracy"

Note3)When using the 4-point hand output, the pneumatic hand interface (option) is required.

Note4)The protection specification details are given in Page 8, "2.2.3 Protection specifications and working

environment" .

Note5)The down flow (0.3m/s or more) in the clean room and the internal suction by using attached vacuum

generating valve are necessary conditions for the cleanliness.

0

300(-150 to +150)

180

Φ4x4 (Base to hand

section)

-

-2

3.24x10

-3

8.43x10

Φ4x3 (Base to hand

section)

2Robot arm

Standard specifications

2-5

Page 14

2 Robot arm

2.2 Definition of specifications

The accuracy of pose repeatability mentioned in catalogs and in the specification manual is defined as follows.

2.2.1 Pose repeatability and distance accuracy

This robot, the pose repeatability and distance accuracy are defined and calculated in Table 2-2.

(1) The pose accuracy in terms of coordinates (XYZ) for the standard point which is obtained repeatedly under

the same conditions and motions when the robot is on an operating course.

(2) The standard point is the intersection between the J6 axis and the flange surface for tooling installation.

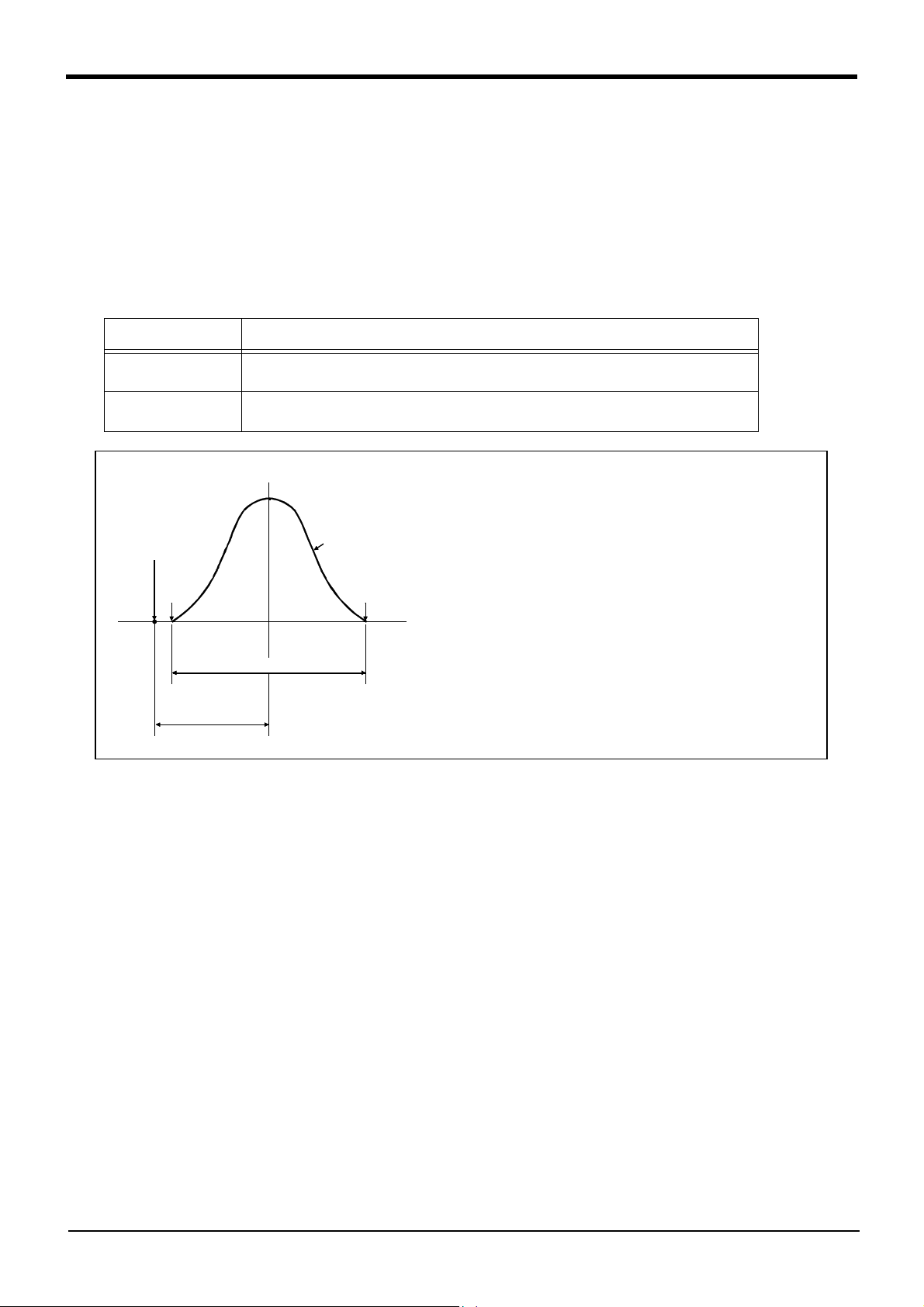

Table 2-2 : Specified accuracy

Item Specified conditionds

Pose repeatability The value equal to the average of the maximum value and the minimum value of the group of

attained poses, with (+) or (-) added.

Distance accuracy The distance from the teaching point to the point that is equal to the average of the maximum

value and the minimum value of the group of attained poses.

Group of attained poses

Programmed pose

Min.

(X, Y, Z)

Max.

Measuring conditions

Load ................................................................A load equal to the rated

load at the mass capacity

Double of pose repeatability

Distance

accuracy

The number of repitition and speed ..100 times at 100% speed

Measuring instrument ..............................Non-contact displace

reference point

-

ment meter

Fig.2-1:Specified accuracy

[Caution] The pose accuracy given in the specifications is the accuracy measured under the same conditions. It

does not include the effect of the robot working environment or conditions. Thus, even when used on

the same path, the repeatability according to the presence of a workpiece, or the repeatability when the

temperature changes will cause arm slack or expansion, so the accuracy will drop slightly. This also

applies to when the teaching speed and actual speed are different or when the coordinates set with val

ues.

-

2-6

Definition of specifications

Page 15

2 Robot arm

2.2.2 Rated load (mass capacity)

The robot's mass capacity is expressed solely in terms of mass, but even for tools and works of similar mass,

eccentric loads will have some restrictions. When designing the tooling or when selecting a robot, consider the fol

lowing issues.

(1) The tooling should have the value less or equal than the smaller of the tolerable inertia and the tolerable

moment found in Page 5, "Table 2-1: Tab Standard specifications of robot".

(2) Fig. 2-2 and Fig. 2-3shows the distribution dimensions for the center of gravity in the case where the vol

ume of the load is relatively small. Use this figure as a reference when designing the tooling.

(3) When the load is not mass, but force, you should design the tooling so that it does not exceed the value for

allowable moment described in Page 5, "Table 2-1: Tab Standard specifications of robot".

[Caution] The mass capacity is greatly influenced by the operating speed of the robot and the motion posture.

Even if you are within the allowable range mentioned previously, an overload or generate an overcurrnt

alarm could occur. In such cases, it will be necessary to change the time setting for acceleration/decel

eration, the operating speed, and the motion posture.

[Caution] The overhang amount of the load for the specified moment and inertia in this section is the dynamic limit

value determined by the motor driving each axis and by the capacity of the reduction gears. Conse

quently, accuracy cannot be guaranteed for the entire tooling area. Since accuracy is based on the cen

ter point of the mechanical interface surface, position accuracy can diminish as you go away from the

flange surface, or vibration can result, with tooling that is not rigid or that is long.

-

-

-

-

-

Maximum load capacity

Maximum load capacity

Maximum load capacity Maximum load capacity

with the flange posture facing downword

with the flange posture facing downword

with the flange posture facing downwordwith the flange posture facing downword

150

150

150150

136

136

136136

0.3kg

0.3kg

300

300

300300

0.3kg0.3kg

200

200

200200

250

250

250250

268

268 207

268268

207 147

207207

0.5kg

0.5kg

0.5kg0.5kg

1.0kg

1.0kg

1.0kg1.0kg

150

150150

147 97

147147

100

100

100100

1.5

1.5

1.51.5

kg

kg

kgkg

72

72

7272

97

9797

106

106

106106

100

100

100100

75

75

7575

50

50

5050

0000150

50

50

5050

Rotation center for J6 axis

Rotation center for J6 axis

75

75

7575

100

100

100100

106

106

106106

136

136

136136

150

150

150150

Rotation center for J6 axis Rotation center for J6 axis

Rotation center for J5 axis

Rotation center for J5 axis

Rotation center for J5 axis Rotation center for J5 axis

Fig.2-2 : Position of center of gravity for loads (for loads with comparatively small volume) : RV-1A/1AC-SB

Maximum load capacity

Maximum load capacity

Maximum load capacity Maximum load capacity

with the flange posture facing downword

with the flange posture facing downword

with the flange posture facing downwordwith the flange posture facing downword

150

150

150150

129

129

129129

0.5kg

0.5kg

0.5kg0.5kg

1.0kg

1.0kg

1.0kg1.0kg

1.5kg

1.5kg

1.5kg1.5kg

2kg

2kg

2kg2kg

100

100

100100

91

91

9191

75

75

7575

56

56

5656

72

72

110

110110

7272

0000

56

56

5656

75

75

7575

91

91

9191

100

100

100100

129

129

129129

150

150

150150

Rotation center for J6 axis

Rotation center for J6 axis

Rotation center for J6 axis Rotation center for J6 axis

Rotation center for J5 axis

Rotation center for J5 axis

Rotation center for J5 axis Rotation center for J5 axis

300

300

300300

250

250 200

200 150

250250

200200

254

254 180

254254

150 100

150150

180 147

147 110

180180

147147

100

100100

Fig.2-3 : Position of center of gravity for loads (for loads with comparatively small volume) : RV-2AJ/2AJC-SB

Definition of specifications

2-7

Page 16

2 Robot arm

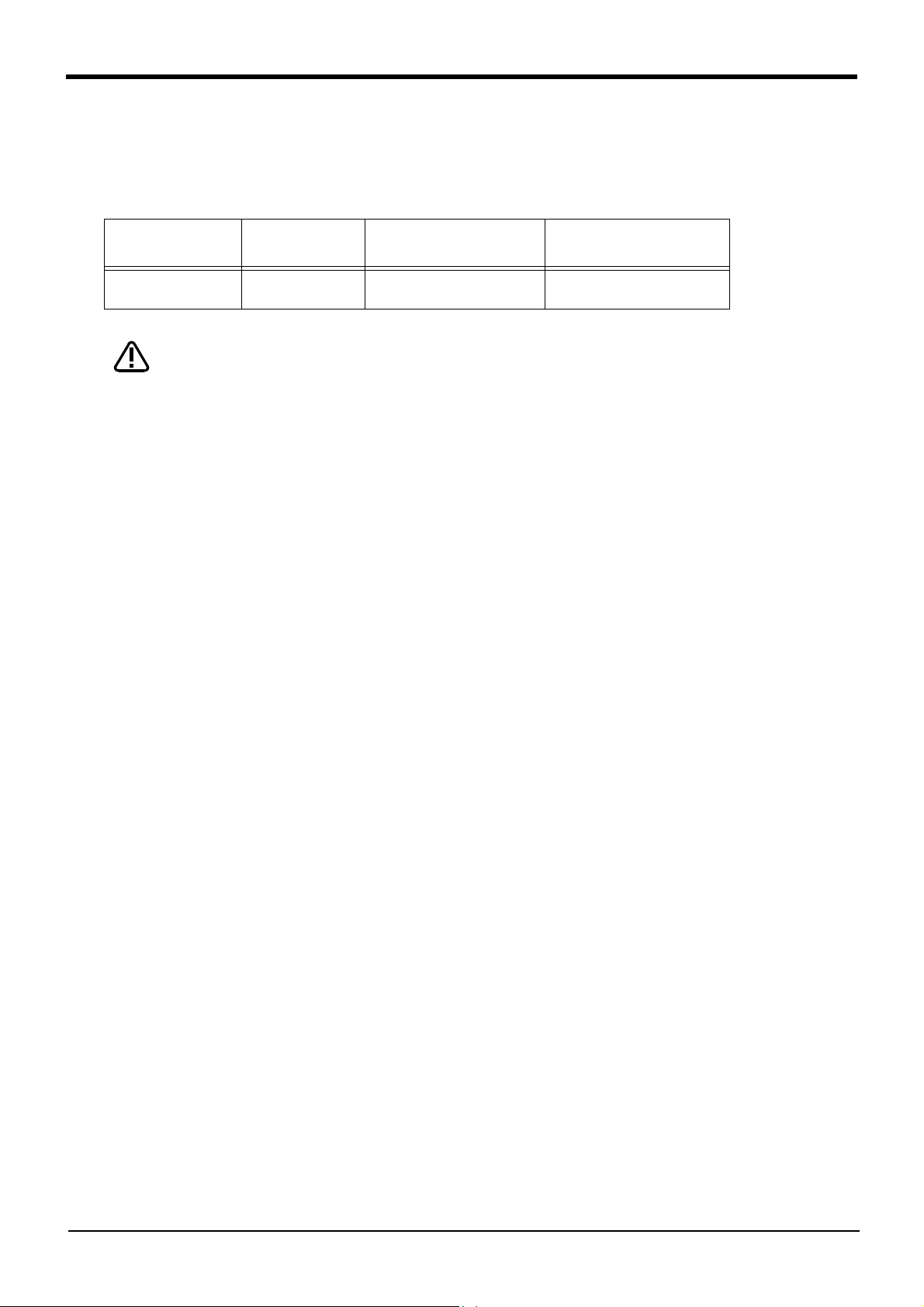

2.2.3 Protection specifications and working environment (1) Types of protection specifications

The robot arm has protection specifications that comply with the IEC Standards. The protection specifications

and applicable fields are shown in Table 2-3.

Table 2-3 : Protection specifications and applicable fields

Protection

specifications

General-purpose envi

ronment specifications

CAUTION

IEC Standards

value

-

IP30 General assembly

Slightly dusty environment

Use the controller protection box (CR1-MB) optional to protect the controller from

Applicable field Remarks

the environment when the controller will be used in the environment such as the oil

mist shown in the Table 2-3. Refer to the section Page 59, "(3) Controller protection

box" for details on the controller protection box.

【Information】

・ The IEC IP30

IP30 refers to a protective structure with which the tip of a solid object, such as a tool or wire, having a

diameter or thickness exceeding 2.5mm cannot enter. No particular protection is provided against the entry of

water.

The warranty is invalid for any faults that occur when the robot is used under the following conditions.

1) In surroundings that generate inflammable gases or corrosive gasses.

2) In surroundings where water, oil, and chips fall directly on the robot.

3) Mist atmosphere exceeding the specification.

2-8

Definition of specifications

Page 17

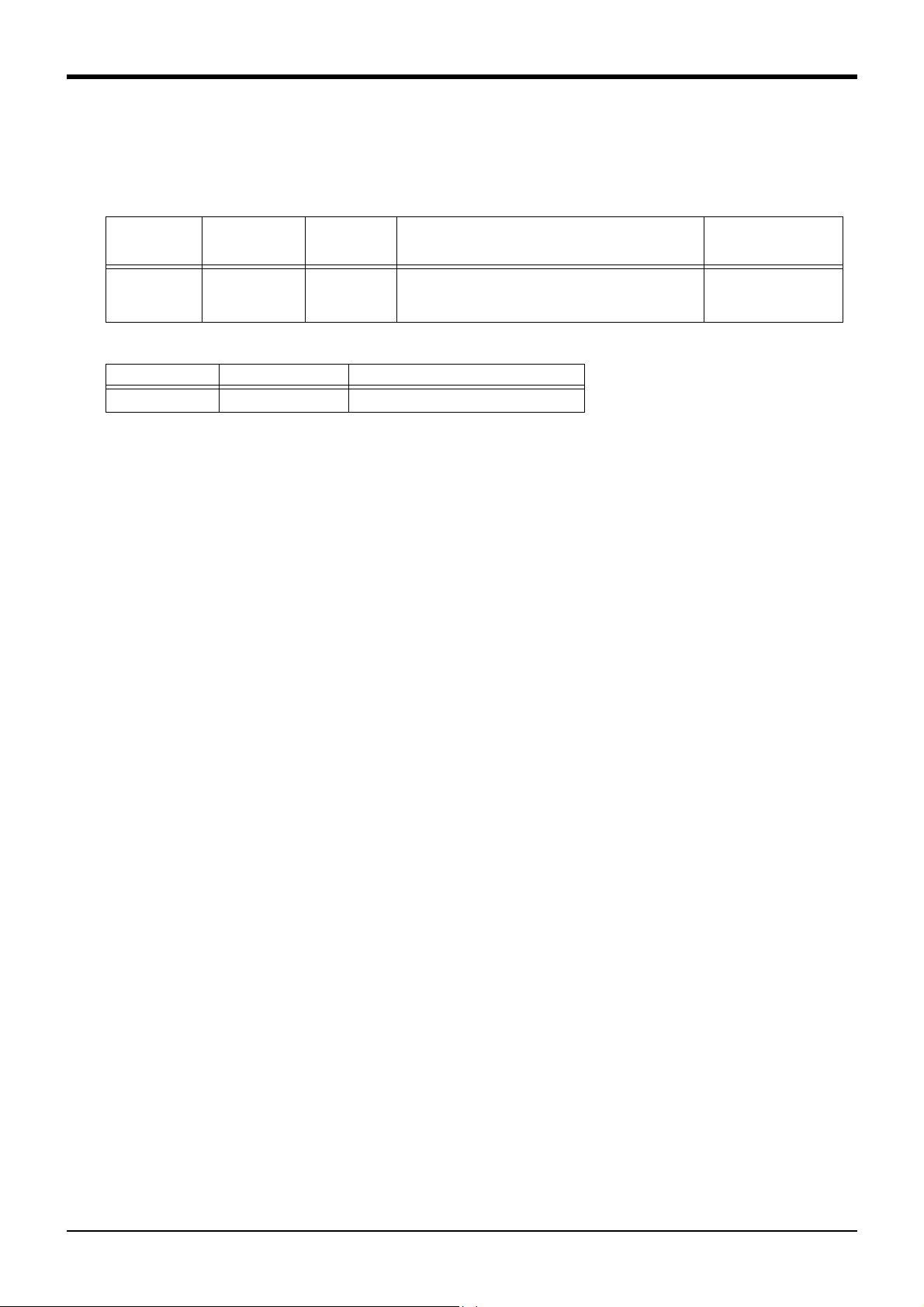

2.2.4 Clean specifications (1) Types of clean specifications

The clean specifications of robot arm shown in Table 2-4.

Please confirm the delivery date, because both are special specifications.

Table 2-4 : Clean specifications

2 Robot arm

Clean

specifications

Type SB RV-1AC-SB

Type

RV-2AJC-SB

Degree of

cleanliness

100(0.3μm) Internal suction with vaccum generating valve. A vacuum generating

Internal suction Remarks

valve (refer to Table 2-

5) is enclosed.

Table 2-5 : Specifications of vacuum generation valve

Type Maker Air pressure

MEDT 10 Koganei 0.2 to 0.6 MPa

■ Precautions for use

1) When using a device that moves or rotates the robot arm, the down flow may not be secured because of the

air flow. In this case, the degree of cleanliness cannot be ensured.

2) In the case of clean specification robot, the base side hoses are four and fore arm side hoses are three.

Prepare the hose of Φ4 x 2.5 and connect this joint to the appended vacuum generating valve or the vac

uum pump prepared by the customer.

* If the appended vacuum generating valve is used, connect the rear joint of the robot to the joint on the

"VACUUM" side of the vacuum generating valve. Moreover, in order to prevent the exhaust of the vacuum

generating valve from impairing the cleanness, install the vacuum generating valve on the downstream side

of the down flow or attach the filter to the exhaust section as possible.

Recommended filter: Exhaust filter EF300-02, Koganei Corporation

* If any vacuum pump is prepared by the customer, assure on the vacuum side flow rate 50 liters/min.(ANR)

or more .

-

Definition of specifications

2-9

Page 18

2 Robot arm

2.3 Names of each part of the robot

Fore arm

J5-axis

-

+

+

J6-axis

Mechanical interface

(Hand installation flange surface)

-

+

-

Shoulder

Note)

J4-axis

-

-

J1-axis

Elbow block

+

Upper arm

+

-

J3-axis

+

J2-axis

Base

Fig.2-4 : Names of each part of the robot

2-10

Names of each part of the robot

Note)J4-axis dosen't exist for 5-axis type.

Page 19

2.4 Outside dimensions ・ Operating range diagram

(1) RV-1A/1AC-SB

P point path

2 Robot arm

Operating range at section of X-X

Flange downward

limit line(dotted line)

XX

Machine cable

(Connect to

the controller)

(Front)

Flange downward

Solenoid valve (optional)

installation position

singular point path

P point path

150 or more

(Back projects)

Note 1) Refer to Fig. 2-7 for the hand installation flange section and installation base section dimensions.

Approx. 70

pose

Fig.2-5 : Outside dimensions for RV-1A/1AC-SB

Outside dimensions ・ Operating range diagram

2-11

Page 20

2 Robot arm

(2) RV-2AJ/2AJC-SB

P point path

(Front)

Solenoid valve (optional)

installation position

Operating range at section of X-X

Flange downward

limit line(dotted line)

P

XX

P point path

Machine cable

(Connect to

the controller)

150 or more

Back side limitations

(Two dotted line)

Approx. 70

Note 1) Refer to Fig. 2-7 for the hand installation flange section and installation base section dimensions.

Fig.2-6 : Outside dimensions for RV-2AJ/2AJC-SB

2-12

Outside dimensions ・ Operating range diagram

pose

Page 21

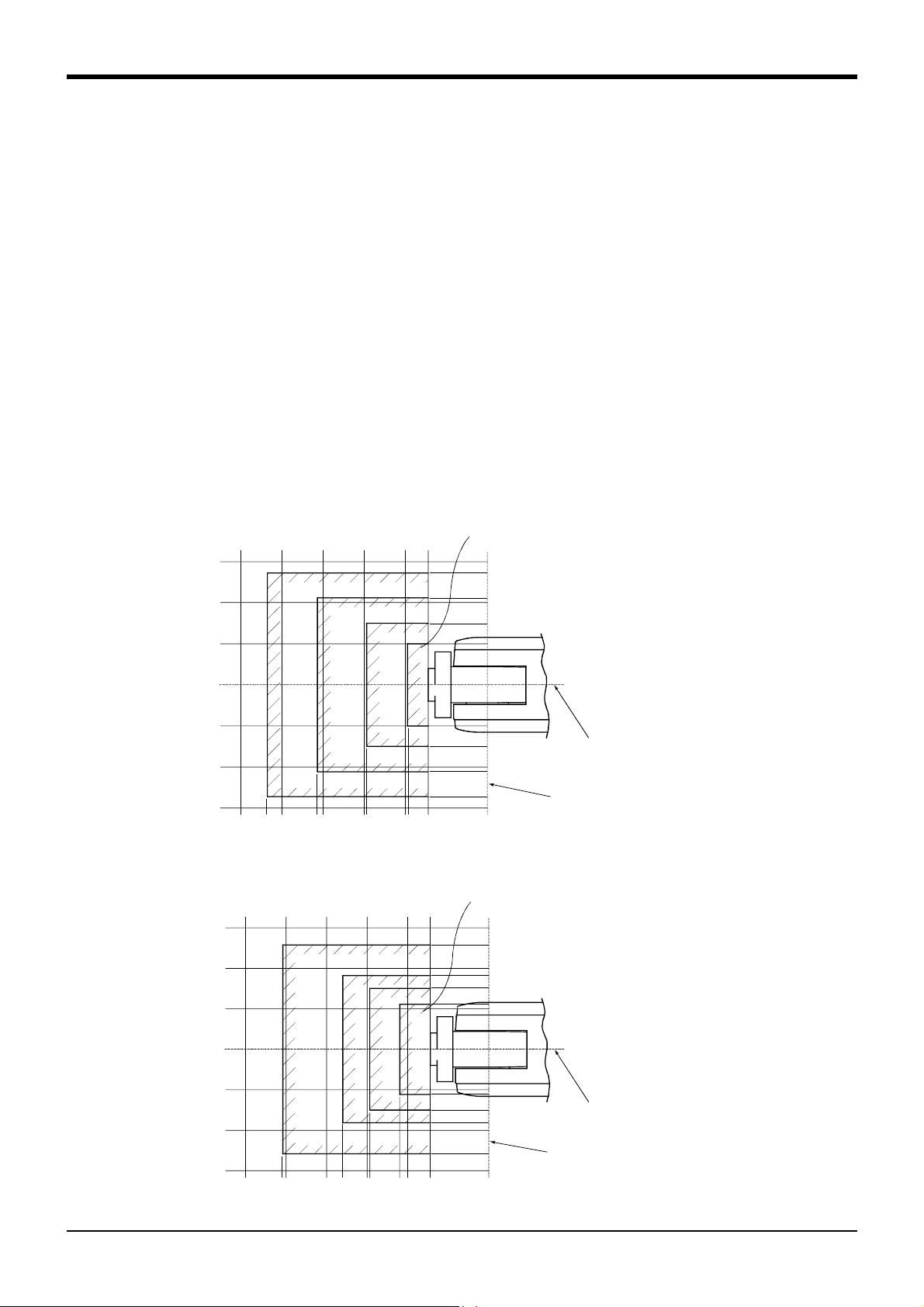

.

(3) Mechanical interface and Installation surface of RV-1A/2AJ, RV-1AC-SB/2AJC-SB

φ5H7, depth 8

reference hole

(

4-M5 screw,depth 8

4-M3 screw, depth 6

View from A

)

φ20H7,

φ40H8,

depth 4

depth 6.5

Detail of Mechanical interface

(ISO9409-1 )

2 Robot arm

Front

*

6.3a

Installation

reference surface

6.3a

4-φ9 hole

(Installation bolts for M8×35)

View from B : Installation dimension details

・The contact section shown with shading on the robot installation surface must be finished to 6.3a.

・The section marked with * must be contacted against the installation surface to ensure the robot rigidity

Fig.2-7 : Mechanical interface and Installation surface of RV-1A/2AJ, RV-1AC-SB/2AJC-SB

Outside dimensions ・ Operating range diagram

2-13

Page 22

2 Robot arm

2.5 Tooling

2.5.1 Wiring and piping for hand

Shows the wiring and piping configuration for a standard-equipped hand.

(1) RV-1A/2AJ (General environment)

Number of coupling for hand

AIR OUT

1 2 3 4

(1) Hand input signal or

motorized hand

connectors

(3) 1 to 4 : Secondary piping

couplings (φ4)

Note) This parts dosn't exist for 5-axis type

Note)

Solenoid valve set(optional)

installation section

a)

b)

9 8 7 6 5 4 3 2 1

CON1H

Hand connector pin assignment

Hand input signal and

motorized hand

cables

Secondary piping hoses

(φ4*4)

Note1)When using the hand output signal, it is necessary

to use the optional pneumatic hand interface

(2A-RZ365/2A-RZ375)

Note2)The user must prepare the φ4 and φ6

pneumatic hoses for connecting to the solenoid

valve set.

Secondary piping

pneumatic hoses(φ4)

Note2)

Magnification

GR1 GR2 GR3 GR4

Number of connector

for hand output.

Number of coupling for hand.

1 234

AIR IN

Connector and pneumatic coupling

Robot side(Robot arm side) Counter side (customer-prepared)

No Name Qty.

(1) Connector 1 SMP-09V-BC BHF-001GI-0.8BS SMP-09V-B BYM-001T-0.6 Japan solderless ter

(2) Connector 4 SMP-02V-BC BHF-001GI-0.8BS SMR-02V-B BYM-001T-0.6

(3) Coupling 4 TSH4-M5M ---Koganei

(4) Coupling 4 UKBL4 ---

Connectors,

couplings

Connector pins Connector Connector pins

GR1 to GR4 : Connect to the b)

Hand output connector

Primary piping

pneumatic hoses(φ6*1)

Note2)

CN2 CN1

Machine cable connector

(Power supply)

Machine cable connector

(Signals)

(2)GR1 to GR4:Connect to the b)

Hand output connector

(4) AIR IN 1 to 4:Connect to the a)

Secondary piping air coupling(φ4)

Manufacturer

minal MFG. Co.,LTD

-

Fig.2-8 : Wiring and piping for hand (RV-1A/2AJ)

2-14

Tooling

Page 23

(2) RV-1AC-SB/2AJC-SB (Clean specification)

Number of coupling for hand

AIR OUT

1 2 3 4

(1) Hand input signal or

motorized hand

connectors

Not use

(3) 1 to 3 : Secondary piping

couplings (φ4)

Note) This parts dosn't exist

for 5-axis type

Note3) Solenoid valve set

(optional, not clean secification)

installation section

a)

b)

2 Robot arm

9 8 7 6 5 4 3 2 1

Hand connector pin assignment

(φ4x4: One of those is used

for internal suction)

Note1)When using the hand output signal, it is necessary

to use the optional pneumatic hand interface.

(2A-RZ365/2A-RZ375)

Note2)The user must prepare the φ4 and φ6

pneumatic hoses for connecting to the solenoid

valve set.

Note3)The φ 6 pneumatic hose (for exhaust and

compressed air) and φ 4 pneumatic hose

(for suction) must be prepared by the user.

Note4)The vacuum solenoid valve must be fixed by

the user.

Note5)Suction is possible by connecting the vacuum pump

which is prepared by the user. In this case, select

a flow rate of 50 liters/min. as a guideline.

CON1H

Hand input signal and

motorized hand

cables

(Not use)

Secondary piping hoses

Internal suction (φ4)

Secondary piping

pneumatic hoses(φ4)

Note2)

Magnification

Number of connector

for hand output.

Number of coupling for hand.

GR1 GR2 GR3 GR4

1 234

AIR IN

GR1 to GR4 : Connect to the b)

Hand output connector

Primary piping

pneumatic hoses(φ6*1)

Note2)

CN2 CN1

Machine cable connector

(Power supply)

Machine cable connector

(Signals)

(2)GR1 to GR4:Connect to the b)

Hand output connector

Coupling for internal suction

(4) AIR IN 1 to 4:Connect to the a)

Secondary piping air coupling(φ4)

Vacuum solenoid valve Note4)

For suctionφ4 Note5)

Exhaustφ6 Note3)

Compressed airφ6 Note3)

Connector and pneumatic coupling

Robot side(Robot arm side) Counter side (customer-prepared)

No Name Qty.

(1) Connector 1 SMP-09V-BC BHF-001GI-0.8BS SMP-09V-B BYM-001T-0.6 Japan solderless ter

(2) Connector 4 SMP-02V-BC BHF-001GI-0.8BS SMR-02V-B BYM-001T-0.6

(3) Coupling 3 TSH4-M5M ---Koganei

(4) Coupling 4 UKBL4 ---

Connectors,

couplings

Connector pins Connector Connector pins

Manufacturer

minal MFG. Co.,LTD

-

Fig.2-9 : Wiring and piping for hand (RV-1AC-SB/2AJC-SB)

Tooling

2-15

Page 24

2 Robot arm

2.5.2 Internal air piping

(1) The robot has four φ4 x 2.5 urethane hoses from the pneumatic entrance on the base section to the foure

arm side.They are three in the case of clean specification.

(2) The hose end section has four coupling bridges for a φ4 hose on both the base and forearm side. In the case

of clean specification robot, the base side hoses are four and fore arm side hoses are three.

(3) The robot can have up to two pneumatic valve sets on the side of base (optional).

(4) Refer to Page 31, "Solenoid valve set" for details on the electronic valve set (optional).

2.5.3 Internal wiring for the pneumatic hand output cable

(1) The hand output cable extends from the connector of the base section to the side of the base section.

2

(AWG#24(0.2mm

connector names are GR1 to GR4.

) x 2 : 4 cables) The cable terminals have connector bridges for four hand outputs. The

2.5.4 Internal wiring for the hand check input cable

(1) The hand check input cable is wired to four points on the forearm side from the base.

-

2-16

Tooling

Page 25

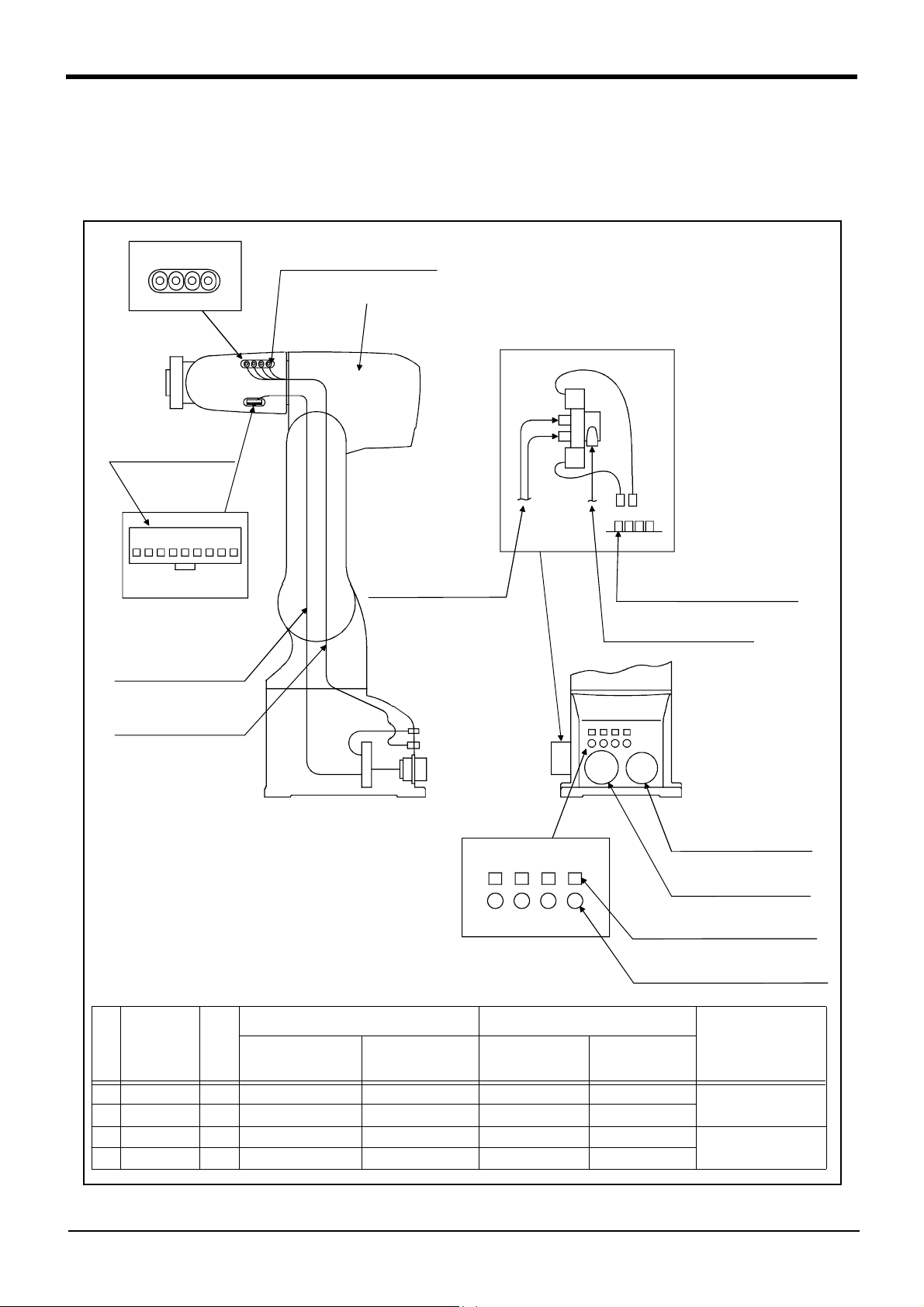

2.5.5 Wiring and piping system diagram for hand

Shows the wiring and piping configuration for a standard-equipped hand.

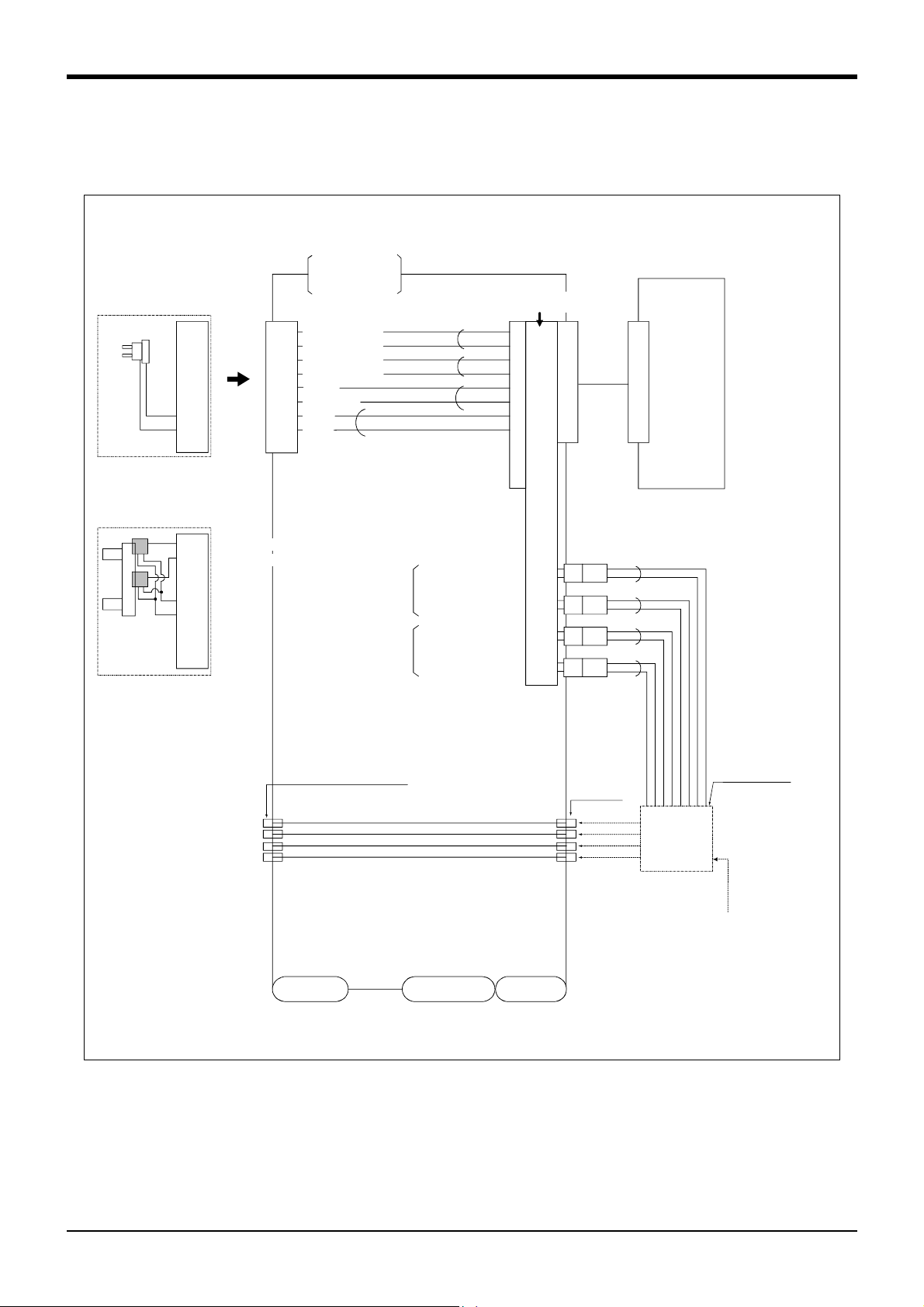

(1) RV-1A/2AJ (General environment)

<Sink type>

2 Robot arm

During use of

motorized

hand I/F(optional)

During use of

pneumatic

hand I/F(optional)

1

2

3

4

5

6

7

8

<Hand check 1>

1

2

<Hand check 1>

3

4

<+24V>

5

<0V(COM)>

6

7

8

9

1

<Hand check 1>

2

<Hand check 2>

3

<Hand check 3>

4

<Hand check 4>

5

<+24V>

6

<0V(COM)>

7

<DC+>

8

<DC->

99

Note1)

During use of

pneumatic

hand I/F.

White

Black

*1

*1

*1 is dedicated for the motorized

hand.

It is valid when the motorized

hand interface is installed.

General-purpose output

Hand 1

ON/OFF

Hand 2

ON/OFF

General-purpose output

General-purpose output

General-purpose output

White

Black

White

Black

White

Black

General-purpose

input No.

900

901

902

903

900

+24V

901

+24V

902

+24V

903

+24V

GR1

1

2

GR2

1

2

GR3

1

2

GR4

1

2

White

Black

White

Black

White

Black

White

Black

Robot

controller

Solenoid valve

section

Solenoid valve

manifold

Connect to the

primary air supply

(φ6 hose)

AIR OUT1

AIR OUT2

AIR OUT3

AIR OUT4

φ4 quick coupling bridge(1 to 4)

φ4 hose(4 hoses)

Wrist section

Shoulder section

Base section

φ4 quick

coupling

AIR IN1

AIR IN2

AIR IN3

AIR IN4

Solenoid valve

installation

section

(optional)

*Refer to Fig. 2-14 for air supply cir

cuit example.

Fig.2-10 : Wiring and piping system diagram for hand and example the solenoid valve installation(Sink type)

-

Tooling

2-17

Page 26

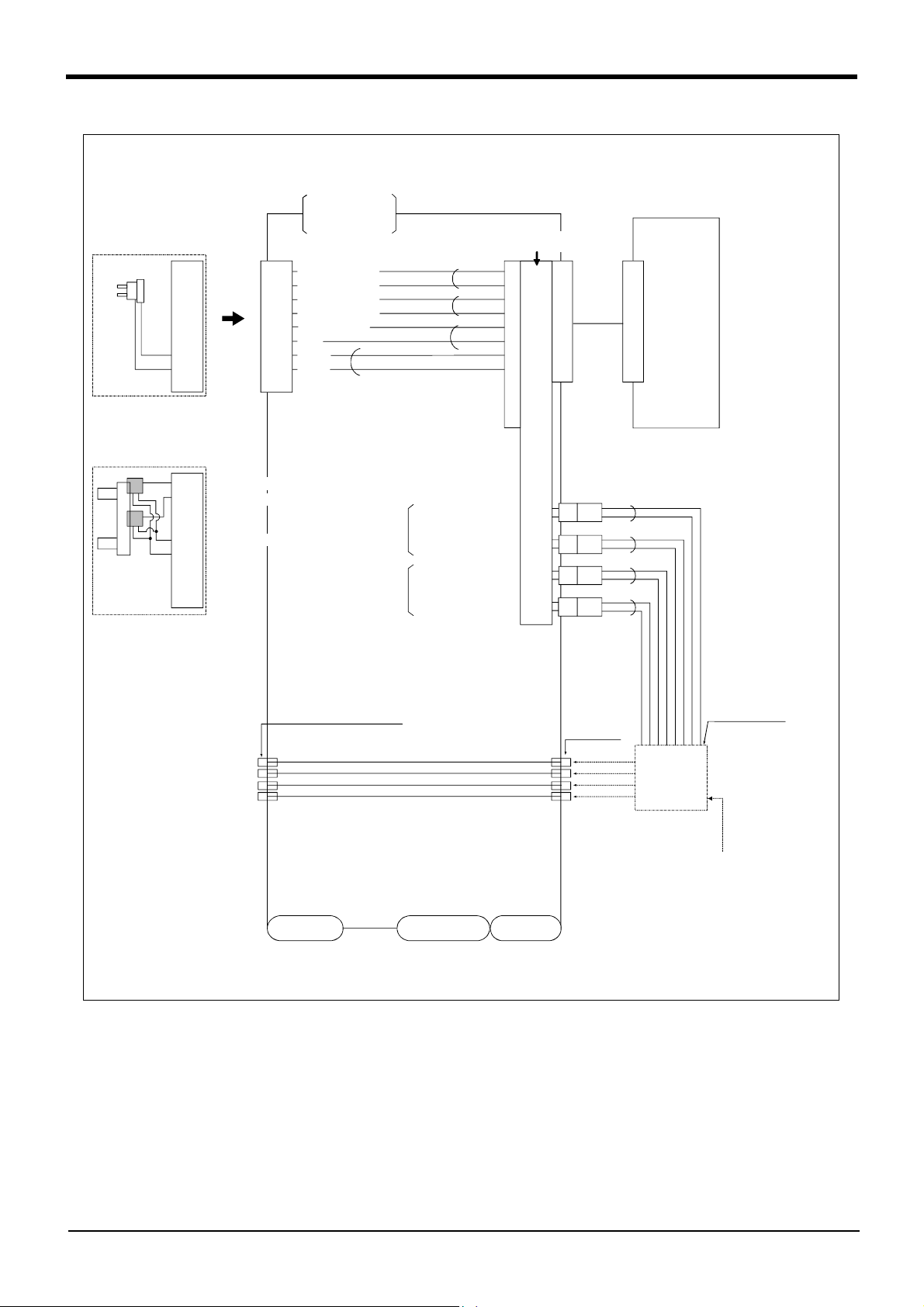

2 Robot arm

<Source type>

During use of

motorized

hand I/F(optional)

During use of

pneumatic

hand I/F(optional)

1

2

3

4

5

6

7

8

<Hand che ck 1>

1

2

<Hand che ck 1>

3

4

<+24V(COM)>

5

<0V>

6

7

8

9

1

<Hand check 1>

2

<Hand check 2>

3

<Hand check 3>

4

<Hand check 4>

5

<+24V(COM)>

6

<0V>

7

<DC+>

8

<DC->

99

Note1)

During use of

pneumatic

hand I/F.

White

Black

*1

*1

*1 is dedicated for the motorized

hand.

It is valid when the motorized

hand interface is installed.

General-purpose output

Hand 1

ON/OFF

Hand 2

ON/OFF

General-purpose output

General-purpose output

General-purpose output

White

Black

White

Black

White

Black

General-purpose

input No.

900

901

902

903

900

24G

901

24G

902

24G

903

24G

GR1

1

2

GR2

1

2

GR3

1

2

GR4

1

2

White

Black

White

Black

White

Black

White

Black

Robot

controller

Solenoid valve

section

Solenoid valve

manifold

Connect to the

primary air supply

(φ6 hose)

AIR OUT1

AIR OUT2

AIR OUT3

AIR OUT4

φ4 quick coupling bridge(1 to 4)

φ4 hose(4 hoses)

Wrist section

Shoulder section

Base section

φ4 quick

coupling

AIR IN1

AIR IN2

AIR IN3

AIR IN4

Solenoid valve

installation

section

(optional)

*Refer to Fig. 2-14 for air supply cir

cuit example.

Fig.2-11 : Wiring and piping system diagram for hand and example the solenoid valve installation(Source type)

-

2-18

Tooling

Page 27

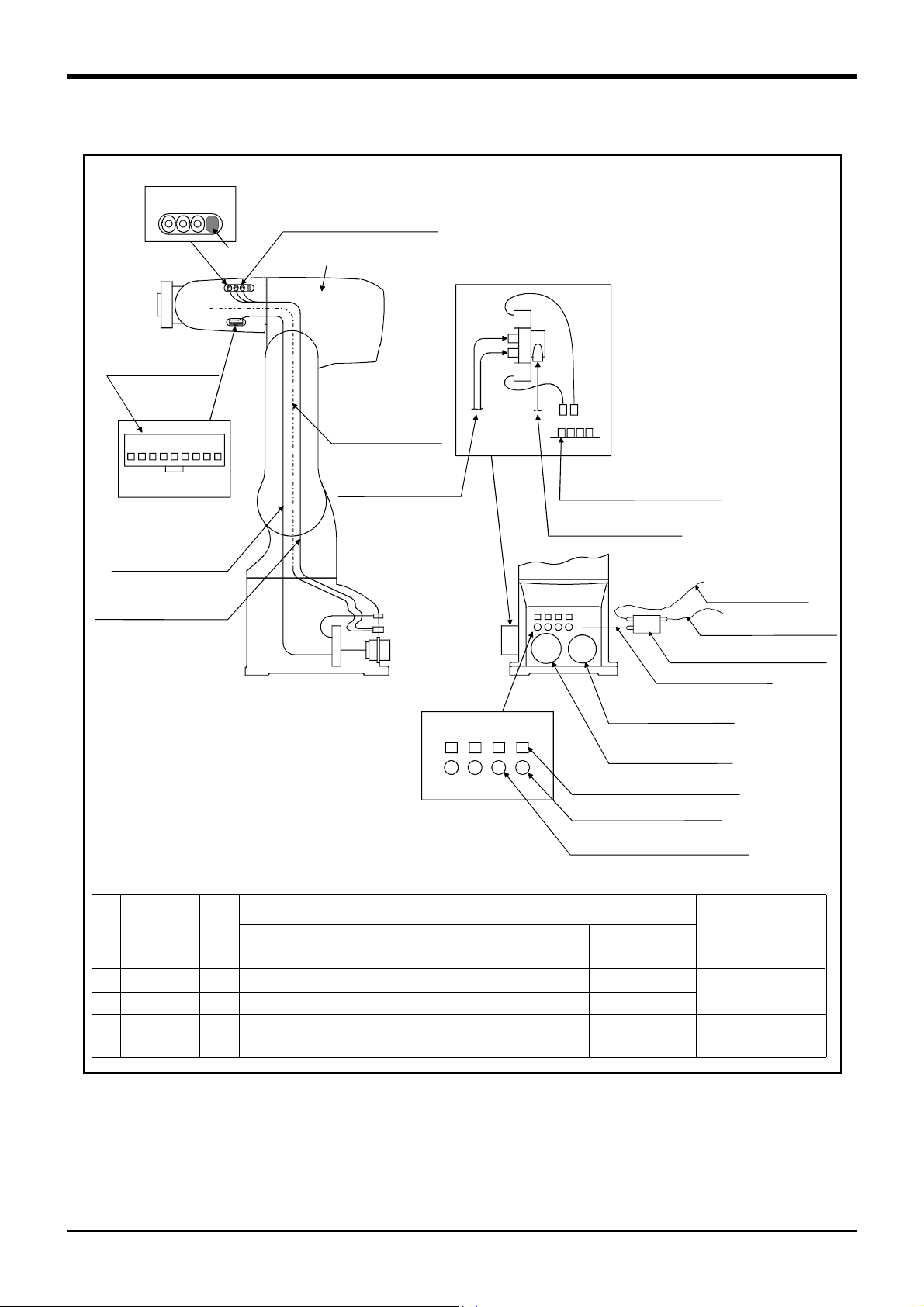

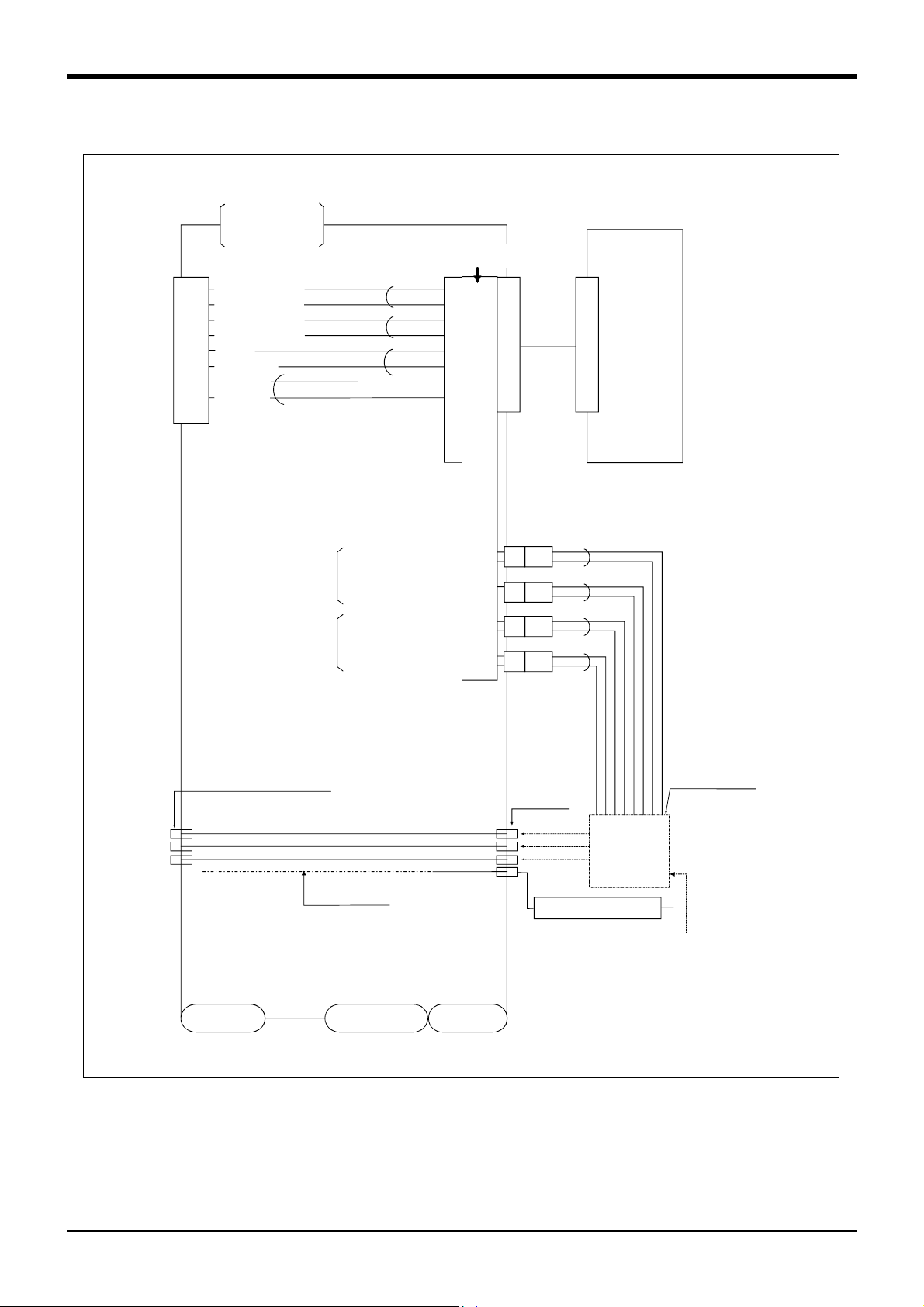

(2) RV-1AC-SB/2AJC-SB (Clean specification)

A

A

A

<Sink type>

2 Robot arm

During use of

pneumatic

hand I/F.

<Hand check 1>

1

<Hand check 2>

2

<Hand check 3>

3

<Hand check 4>

4

<+24V>

5

<0V(COM)>

6

<Not use>

7

<Not use>

8

9

White

Black

Hand 1

ON/OFF

Hand 2

ON/OFF

White

Black

White

Black

White

Black

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose

input No.

900

901

902

903

900

+24V

901

+24V

902

+24V

903

+24V

GR1

1

2

GR2

1

2

GR3

1

2

GR4

1

2

White

Black

White

Black

White

Black

White

Black

Robot

controller

Solenoid valve

section

Solenoid valve

manifold

Connect to the

primary air supply

(φ6 hose)

-

IR OUT1

IR OUT2

IR OUT3

φ4 quick coupling bridge(1 to 4)

φ4 hose(4 hoses)

Internal suction

Wrist section

Shoulder section

Base section

φ4 quick

coupling

AIR IN1

AIR IN2

AIR IN3

AIR IN4

Vacuum solenoid valve

Solenoid valve

installation

section

(optional)

*Refer to Fig. 2-14 for air supply cir

cuit example.

Fig.2-12 : Wiring and piping system diagram for hand and example the solenoid valve installation(Sink type)

Tooling

2-19

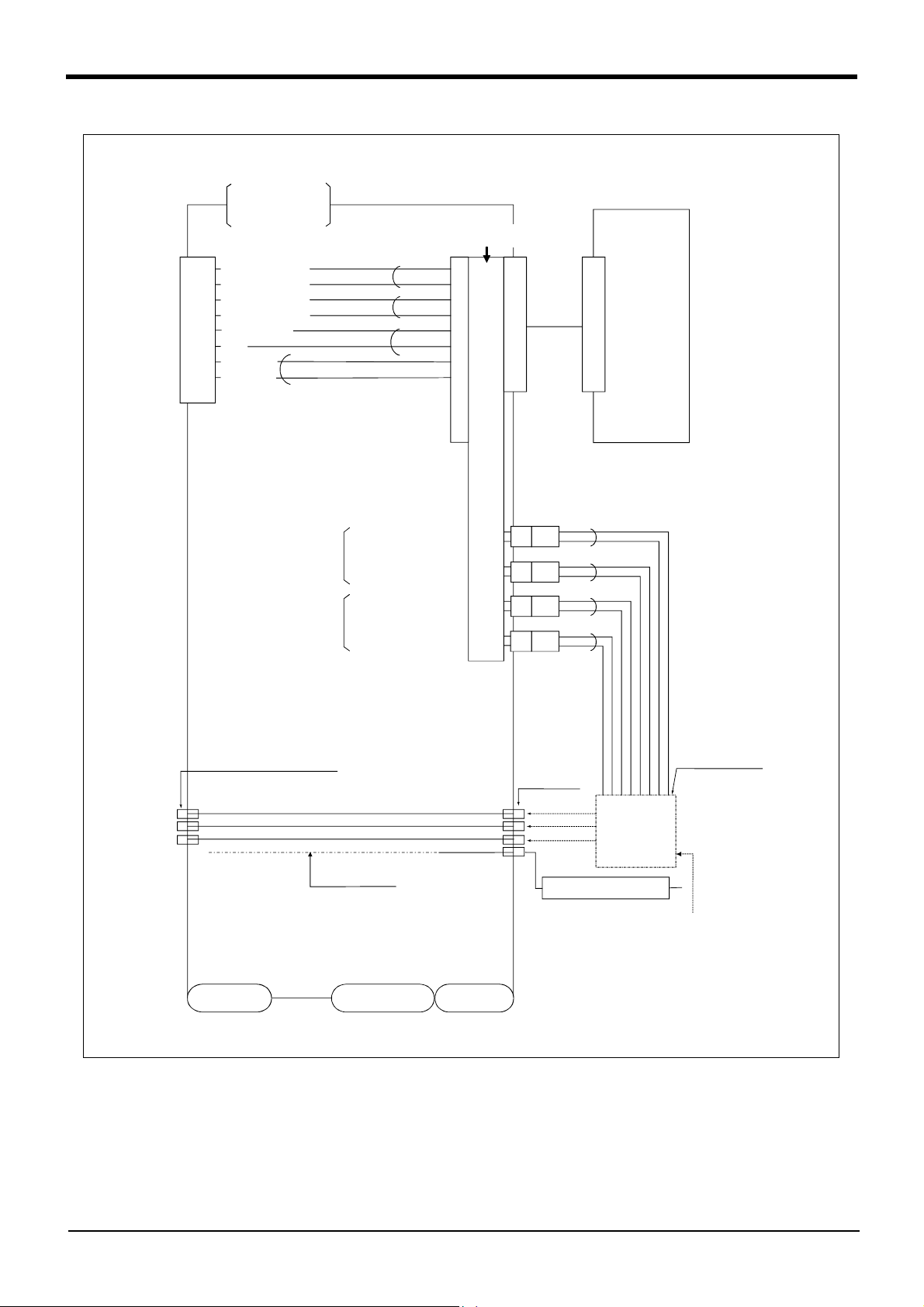

Page 28

2 Robot arm

A

A

A

<Source type>

During use of

pneumatic

hand I/F.

1

<Hand check 1>

2

<Hand check 2>

3

<Hand check 3>

4

<Hand check 4>

5

<24V(COM)>

6

<0V>

7

<Not use>

8

<Not use>

9

White

Black

Hand 1

ON/OFF

Hand 2

ON/OFF

White

Black

White

Black

White

Black

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose

input No.

900

901

902

903

900

24G

901

24G

902

24G

903

24G

GR1

1

2

GR2

1

2

GR3

1

2

GR4

1

2

White

Black

White

Black

White

Black

White

Black

Robot

controller

Solenoid valve

section

Solenoid valve

manifold

Connect to the

primary air supply

(φ6 hose)

-

IR OUT1

IR OUT2

IR OUT3

φ4 quick coupling bridge(1 to 4)

φ4 hose(4 hoses)

Internal suction

Wrist section

Shoulder section

Base section

φ4 quick

coupling

AIR IN1

AIR IN2

AIR IN3

AIR IN4

Vacuum solenoid valve

*Refer to Fig. 2-14 for air supply cir

Solenoid valve

installation

section

(optional)

cuit example.

Fig.2-13 : Wiring and piping system diagram for hand and example the solenoid valve installation(Source type)

2-20

Tooling

Page 29

2.5.6 Electrical specifications of hand input/output

3.3K

820

0V

24V

HCn

*

24V(COM)

24V

(Internal power supply)

*

GRn

Fuse

1.6A

0V

Fuse

1.6A

*

GRn

24V

0V

Table 2-6 : Electrical specifications of input circuit

Item Specifications Internal circuit

Type DC input

No. of input points 4

Insulation method Photo-coupler insulation

Rated input voltage 12VDC/24VDC

Rated input current Approx. 3mA/approx. 7mA

Working voltage range DC10.2 to 26.4V(ripple rate within 5%)

ON voltage/ON current 8VDC or more/2mA or more

OFF voltage/OFF current 4VDC or less/1mA or less

Input resistance Approx. 3.3kΩ

Response time

OFF-ON 10ms or less(DC24V)

ON-OFF 10ms or less(DC24V)

<Sink type>

<Source type>

820

3.3K

24V

24V

*

HCn

0V(COM)

2 Robot arm

Table 2-7 : Electrical specifications of output circuit

Item Specification Internal circuit

Type Transistor output

No. of output points 4

Insulation method Photo coupler insulation

Rated load voltage DC24V

Rated load voltage range DC21.6 to 26.4VDC

Max. current load 0.1A/ 1 point (100%)

Current leak with power OFF 0.1mA or less

Maximum voltage drop with power ON DC0.9V(TYP.)

Response time OFF-ON 2ms or less (hardware response time)

ON-OFF 2 ms or less (resistance load) (hardware response time)

Fuse rating 1.6A (each one common) Cannot be exchanged

* HCn = HC1~HC4

<Sink type>

<Source type>

Note) An optional air hand interface (2A-RZ365/RZ375) is required to use hand output.

* GRn = GR1~GR4

Tooling

2-21

Page 30

2 Robot arm

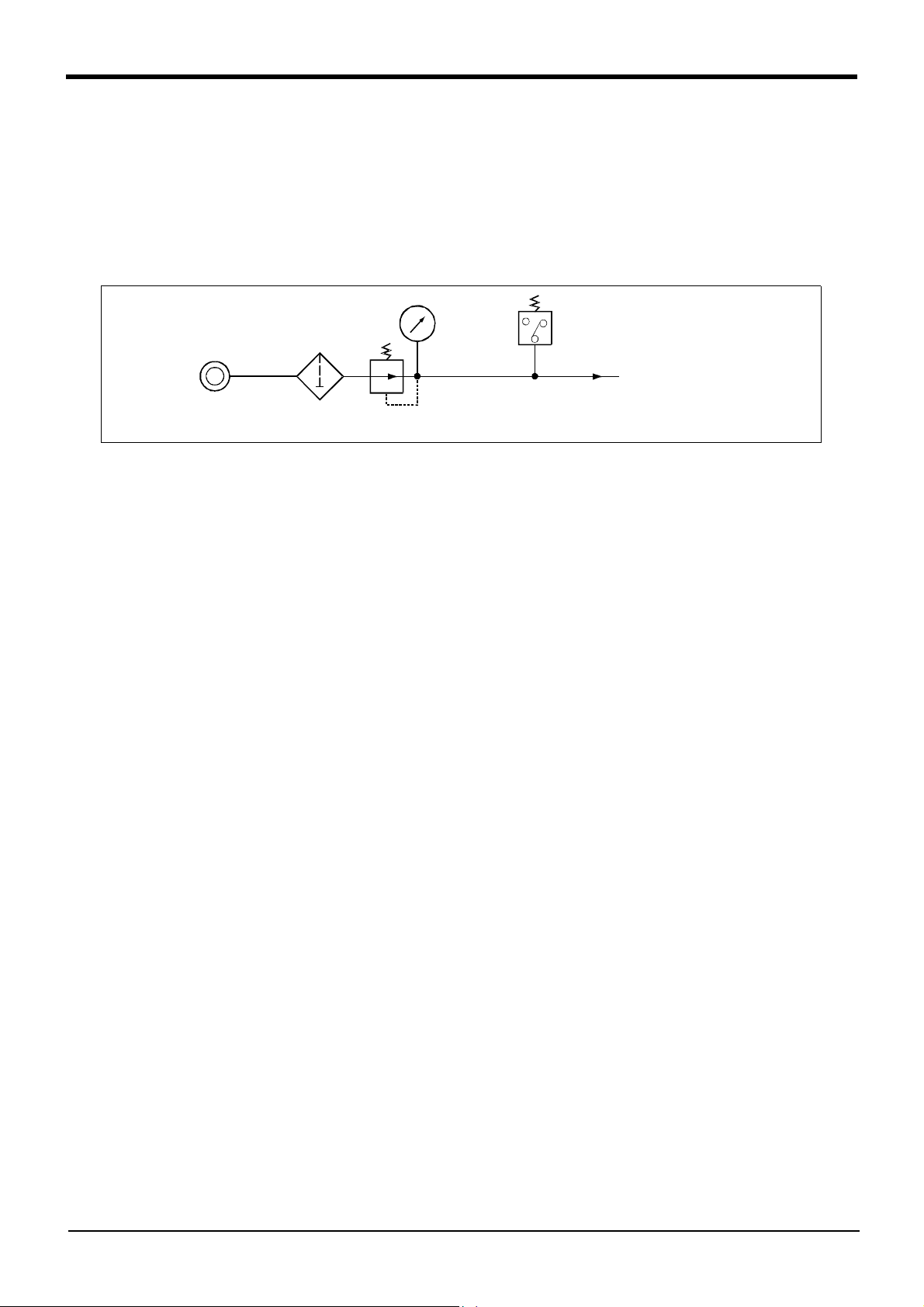

2.5.7 Air supply circuit example for the hand

Fig. 2-14 shows an example of pneumatic supply circuitry for the hand.

(1) Place diodes parallel to the solenoid coil.

(2) When the factory pneumatic pressure drops, as a result of the hand clamp strength weakening, there can be

damage to the work. To prevent it, install a pressure switch to the source of the air as shown in Fig. 2-14 and

use the circuit described so that the robot stops when pressure drops. Use a hand with a spring-pressure

clamp, or a mechanical lock-type hand, that can be used in cases where the pressure switch becomes dam

aged.

-

Pneumatic source

0.7MPa less

Filter

Regurater

Fig.2-14 : Air supply circuit example for the hand

Pressure switch

To the solenoid valve

primary air supply port

(0.5MPa

±10%)

2-22

Page 31

2.6 Shipping special specifications, options, and maintenance parts

2.6.1 Shipping special specifications

■ What are Sipping special specifications?

Shipping special specifications are changed at the time of shipment from the factory. Consequently, customer

need to confirm the delivery date.

To make changes to the specifications after shipment, service work must be performed at the work site or the

robot must be returned for service.

■ How to order

(1) Confirm beforehand when the Factory special specifications can be shipped, because they may not be

immediately available.

(2) Order before the factory shipping date.

(3) Specified method …… Specify the part name, model, and robot model type.

2 Robot arm

Shipping special specifications, options, and maintenance parts

2-23

Page 32

2 Robot arm

(1) Machine cable extension

■ Order type :●Fixed type(10m) :1A-10CBL-1

● Fixed type(15m) :1A-15CBL-1

● Flexed type(5m) :1A-05LCBL-1

● Flexed type(10m) :1A-10LCBL-1

● Flexed type(15m) :1A-15LCBL-1

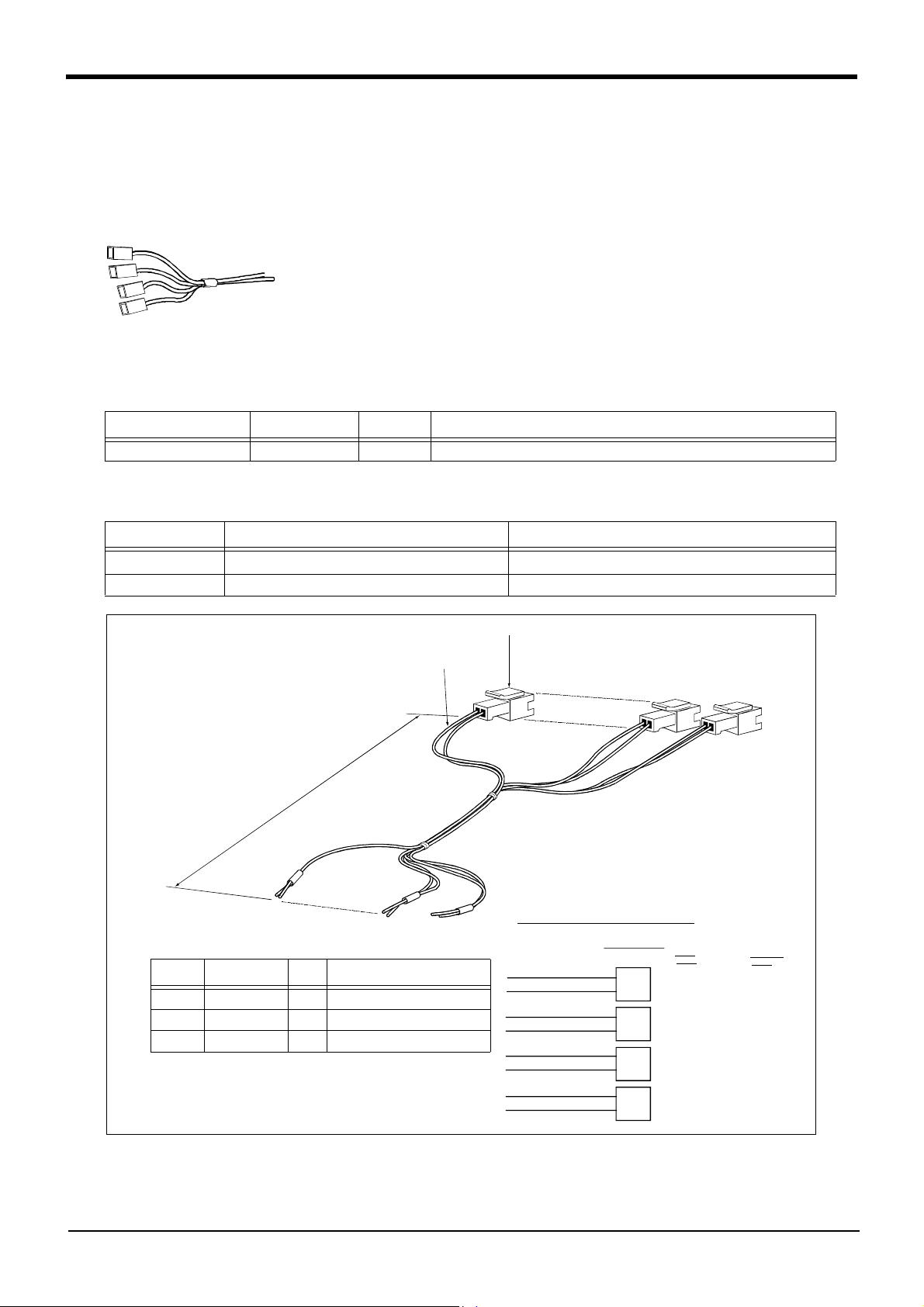

■ Outline

This cable is exchanged with the standard machine cable (5m) accessory to extend

the distance between the controller and the robot arm.

A fixed type and flexible type are available.

Exchanges after shipment will be charged (for packaging, shipping costs).

The fixing and flexible types are both configured of the motor signal cable and motor

power cable .

■ Configuration

Table 2-8 : Configuration equipments and types

Part name Type

Motor signal cable (for fixed type) 1E- □□ CBL(S)-N 1 cable - 10m, or 15m each

Motor power cable (for fixed type) 1A- □□ CBL(P)-11 cable - 10m, or 15m each

Motor signal cable (for flexed type) 1E- □□ LCBL(S)-N - 1 cable 5m, 10m, or 15m each

Motor power cable (for flexed type) 1A- □□ LCBL(P)-1- 1 cable 5m, 10m, or 15m each

Nylon clamp NK-18N - 2 pcs.

Nylon clamp NK-14N - 2 pcs.

Silicon rubber - 4 pcs.

Note) The numbers in the boxes □□ refer the length.

Qty.

Fixed Flexed

Remarks

■ Specifications

The specifications for the fixed type cables are the same as those for standard cables.

Shows usage conditions for flexed type cables in Table 2-9.

Table 2-9 : Conditions for the flexed type cables

Item Specifications

Minimum flexed radius 100R or more

Cable bare, etc., occupation rate 50% or less

Maximum movement speed 2000mm/s or less

Warranty life (no.) 7.5 million times

Environmental proof Oil-proof specification sheath

Cable configuration Motor power cable Φ6.5x10

Motor signal cable Φ7x6 and Φ1.7x1

(for silicon grease, cable sliding lubricant type)

[Caution] The warranty life may greatly differ according to the usage state (items related to Table 2-9 and to the

amount of silicon grease applied in the cable conduit.

[Caution] This option can be installed on clean-type, but its cleanliness is not under warranty.

2-24

Shipping special specifications, options, and maintenance parts

Page 33

■ Cable configuration

The configuration of the flexible cable is shown in Table 2-10. Refer to this table when selecting the cable bare.

Table 2-10 : Cable configuration

Item

No. of cores

Finish dimensions

No.of cables used 6 cables

No. in total 7 cables 10 cables

AWG#24(0.2mm

Approx.

Motor signal cable

1E- □□ LCBL(S)-N

2

) -4P AWG#18(0.75mm2)AWG#18(0.75mm2) -3C

φ7mm

Approx.

1

cable

φ1.7mm

Motor power cable

1A- □□ LCBL(P)-1

10

φ6.5mm

cables

Approx.

Note. The square in the cable name indicates the cable length.

■ Fixing the flexible cable

(1) Connect the connector to the robot arm and controller.

(2) Wind the silicon rubber around the cable at a position 300 to 400 mm from the robot arm and controller as

shown in Fig. 2-15, and fix with the nylon clamp to protect the cable from external stress.

2 Robot arm

300~400mm

Nylon clamp

NK-14N

Nylon clamp

NK-18N

Nylon clamp

Fig.2-15 : Fixing the flexible cable

300~400mm

1A-□□LCBL(P)-1

1E-□□LCBL(S)-N

Nylon clamp

NK-14N

Nylon clamp

NK-18N

Silicon rubber

Shipping special specifications, options, and maintenance parts

2-25

Page 34

2 Robot arm

2.7 Options

■ What are options?

There are a variety of options for the robot designed to make the setting up process easier for customer needs.

customer installation is required for the options. Options come in two types: "set options" and "single options".

1. Set options ...................................... A combination of single options and parts that together, from a set for serving

some purpose.

2. Single options ................................. That are configured from the fewest number of required units of a part.

Please choose customer's purpose additionally.

■ Precautions for optional of motorized hand, pneumatic hand and solenoid valve

(1) About clean specification robot

The motorized hand, solenoid valve set and pneumatic hand can be installed, but its cleanliness is not under war

ranty.

(2) About customer manufactured hand

Though the motorized hand can't be manufactured by customer, the pneumatic hand can be manufactured.

Put the precaution together in the following.

-

Item

Pneumatic hand set

Motorized hand set

Solenoid valve set

Pneumatic hand This can be manufactured by customer

Motorized hand This cannot be manufactured by customer

General environment specification

RV-1A/2AJ

Installation possible

But the cleanliness cannot be guaranteed.

Clean specification

RV-1AC-SB/2AJC-SB

Installation possible

2-26

Options

Page 35

)

)

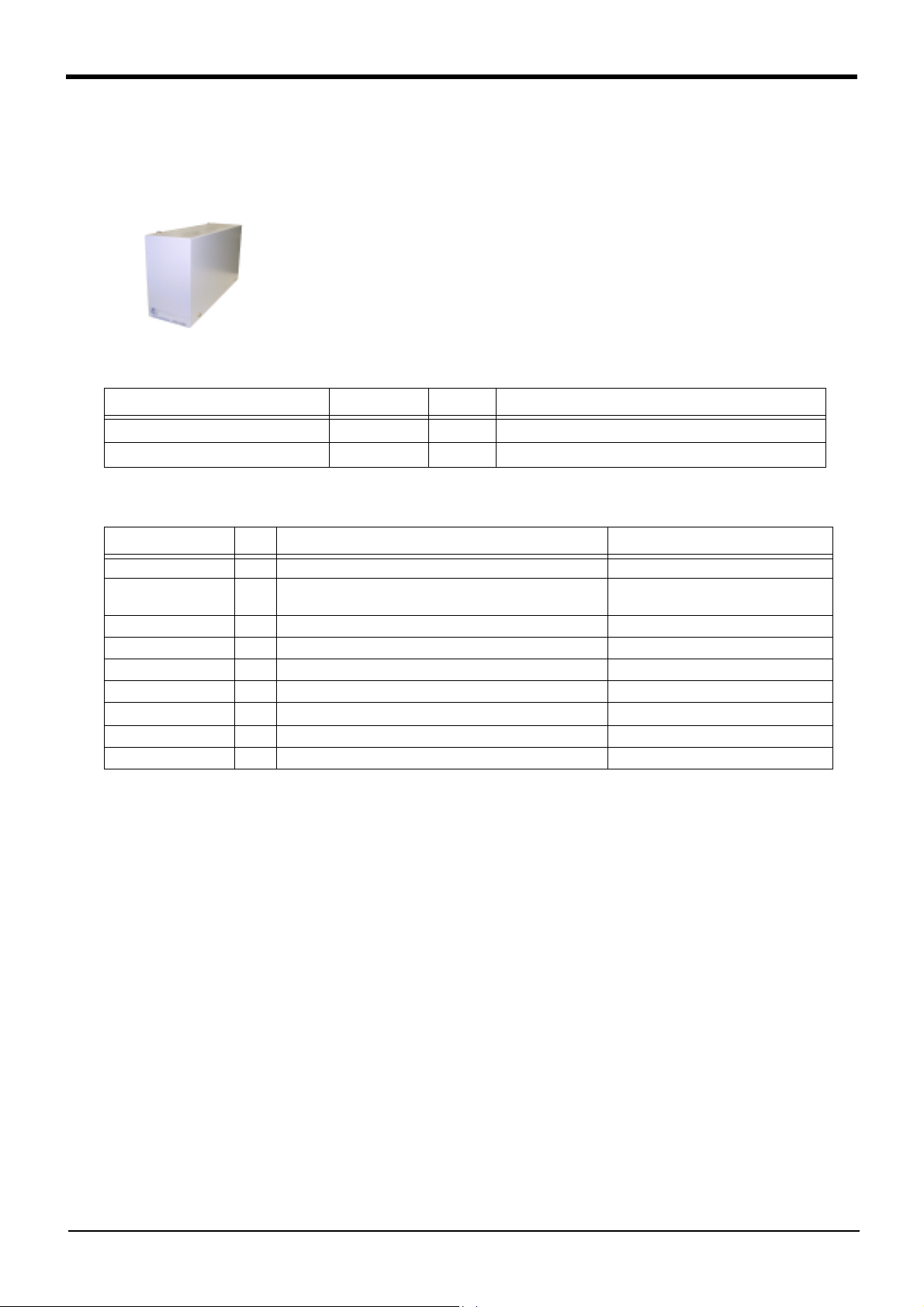

(1) Motorized hand set

■ Order type : 4A-HM01

■ Outline

・ Motorized hand and the required parts come in a set.

・ As air is not required, the hand can be used in laboratories.

・ The gripping force can be adjusted.

・ The life is 10,000,000 times at a 50% load. The 50% load refers to when the max. load

mass in Table 2-12 are all within 50%.

■ Configuration

Table 2-11 : Configuration equipment

Part name Type Qty. Remarks

Motorized hand 1A-HM011 pc.

Hand curl cable 1A-GHCD 1 pc.

Motorized hand I/F 2A-RZ364 1 pc.

Installation bolt (with hole) M3 × 84 bolts

M3 ×122 bolts

Hand adapter 1A-HA011 pc. The adapter for installing the motorized hand to the

robot's mechanical interface.

2 Robot arm

■ Specifications

Table 2-12 :

Drive method DC servo motor

Grip force 4.9 ~ 68.6N

Life 1,000,000 times cycle 100% load.

Repetition accuracy 0.03mm

Ambient temperature 0 to 40 ℃

Ambient humidity 45 to 85%

Atomosphere With no of oil mist, chip, powder dust.

Operation confirmation sensors None

Mass 0.59kg Including the adapter.

Maximum load per fin

ger

Motorized

hand specifications

Item Spacifications Remarks

(Each side grip is2.45 ~ 34.3N)

10,000,000 times cycle 50% load.

-

Radial 300N

Mpo moment 6.2N ・ m

Mro moment 10.8N ・ m

Myo moment 6.0N ・ m

RadialRadial

Radial

Radial

When installing the finger attachment, avoid

shock or excessive moment to the tips.

Others

Lp

LpLp

Lp

Mpo

Mpo

MpoMpo

Fp

Fp

FpFp

(=Lp*Fp)

(=Lp*Fp)

(=Lp*Fp)(=Lp*Fp)

Fr

Fr

FrFr

Mro

Mro

MroMro

(=Lr*Fr)

(=Lr*Fr)

(=Lr*Fr)(=Lr*Fr)

Lr

LrLr

Lr

The stroke cannot be adjusted.

Prepare the finger procured by the customer.

Ly

LyLy

Ly

Fy

Fy

FyFy

Myo

Myo

MyoMyo

(=Ly*Fy)

(=Ly*Fy

(=Ly*Fy)(=Ly*Fy

Options

2-27

Page 36

2 Robot arm

Motorized hand body

Adapter

1A-HA01

2-M3x12

(Hexagon socket bolt)

Approx. 70

4*2-M3

4-M3x8

(Hexagon socket bolt)

(From finger center)

4-Φ3.4 hole

(90 degree division)PCD70

(Φ6.5x4 spot facing on the

reverse side)

Hand body

Hand curl cable

Connector

160±10

Curl cable for bending

Fig.2-16 : Motorized hand outside dimensional drawing

(150)

φ11

40±10

Curl cable

Type 1A-GHCD

Connector

[Wiring system diagram]

Yellow

1

For

pneumatic

hand

DC+

DCReserve

Reserve

Reserve

Purple

2

Brown

5

Blue

6

Red

7

Black

8

3

4

9

6

5

4

3

1

2

2-28

Options

Page 37

)

)

(2) Pneumatic hand set

■ Order type: 4A-HP01 (Sink type)

4A-HP01E (Source type)

■ Outline

・ Pneumatic hand and the required parts come in a set.

・ The hand has a life of 10 million cycles.

・ There is a sensor at the open/close end.

■ Configuration

Table 2-13 : Configuration equipment

Part name Type

4A-HP01 4A-HP01E

Pneumatic hand 1A-HP011 pc. -

1A-HP01E-1 pc.

Hand curl tube (1 set: 2pc.) 1A-ST0402C 1 pc. 1 pc. Refer to the section on Page 35, "(6) Hand curl tube".

Curl cable 1A-GHCD 1 pc. 1 pc.