Page 1

MITSUBISHI

Mitsubishi Industrial Robot

RV-1A/2AJ Series

ROBOT ARM SETUP & MAINTENANCE

INSTRUCTION MANUAL

BFP-A8052-D

Page 2

CAUTION

CAUTION

WARNING

Safety Precautions

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

All teaching work must be carried out by an operator who has received special training.

(This also applies to maintenance work with the power source turned ON.)

→ Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures of operating the robot, and to the measures to be taken when an error occurs or when restarting. Carry out work following this plan. (This also applies to maintenance work with the

power source turned ON.)

→ Preparation of work plan

Prepare a device that allows operation to be stopped immediately during teaching work.

(This also applies to maintenance work with the power source turned ON.)

→ Setting of emergency stop switch

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

During teaching work, place a sign indicating that teaching work is in progress on the

start switch, etc. (This also applies to maintenance work with the power source turned

ON.)

→ Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the operator and

robot.

→ Installation of safety fence

Establish a set signaling method to the related operators for starting work, and follow

this method.

→ Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign indicating that

maintenance work is in progress on the start switch, etc.

→ Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other related

devices, etc., and confirm that there are no errors.

→ Inspection before starting work

Page 3

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

Use the robot within the environment given in the specifications. Failure to do so could

lead to a drop or reliability or faults. (Temperature, humidity, atmosphere, noise environment, etc.)

Transport the robot with the designated transportation posture. Transporting the robot

in a non-designated posture could lead to personal injuries or faults from dropping.

Always use the robot installed on a secure table. Use in an instable posture could lead

to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise source,

positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable. Failure to

observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the rated load

or tolerable torque. Exceeding these values could lead to alarms or faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to observe

this could lead to personal injuries or damage if the object comes off or flies off during

operation.

Securely ground the robot and controller. Failure to observe this could lead to malfunctioning by noise or to electric shock accidents.

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

Indicate the operation state during robot operation. Failure to indicate the state could

lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure the priority right for the robot control. Failure to observe this could lead to personal injuries or

damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do so

could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with peripheral

devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic operation,

the door is locked or that the robot will automatically stop. Failure to do so could lead to

personal injuries.

Never carry out modifications based on personal judgments, or use non-designated

maintenance parts.

Failure to observe this could lead to faults or failures.

When the robot arm has to be moved by hand from an external area, do not place hands

or fingers in the openings. Failure to observe this could lead to hands or fingers catching

depending on the posture.

CAUTION

Do not stop the robot or apply emergency stop by turning the robot controller's main

power OFF.

If the robot controller main power is turned OFF during automatic operation, the robot

accuracy could be adversely affected.

Page 4

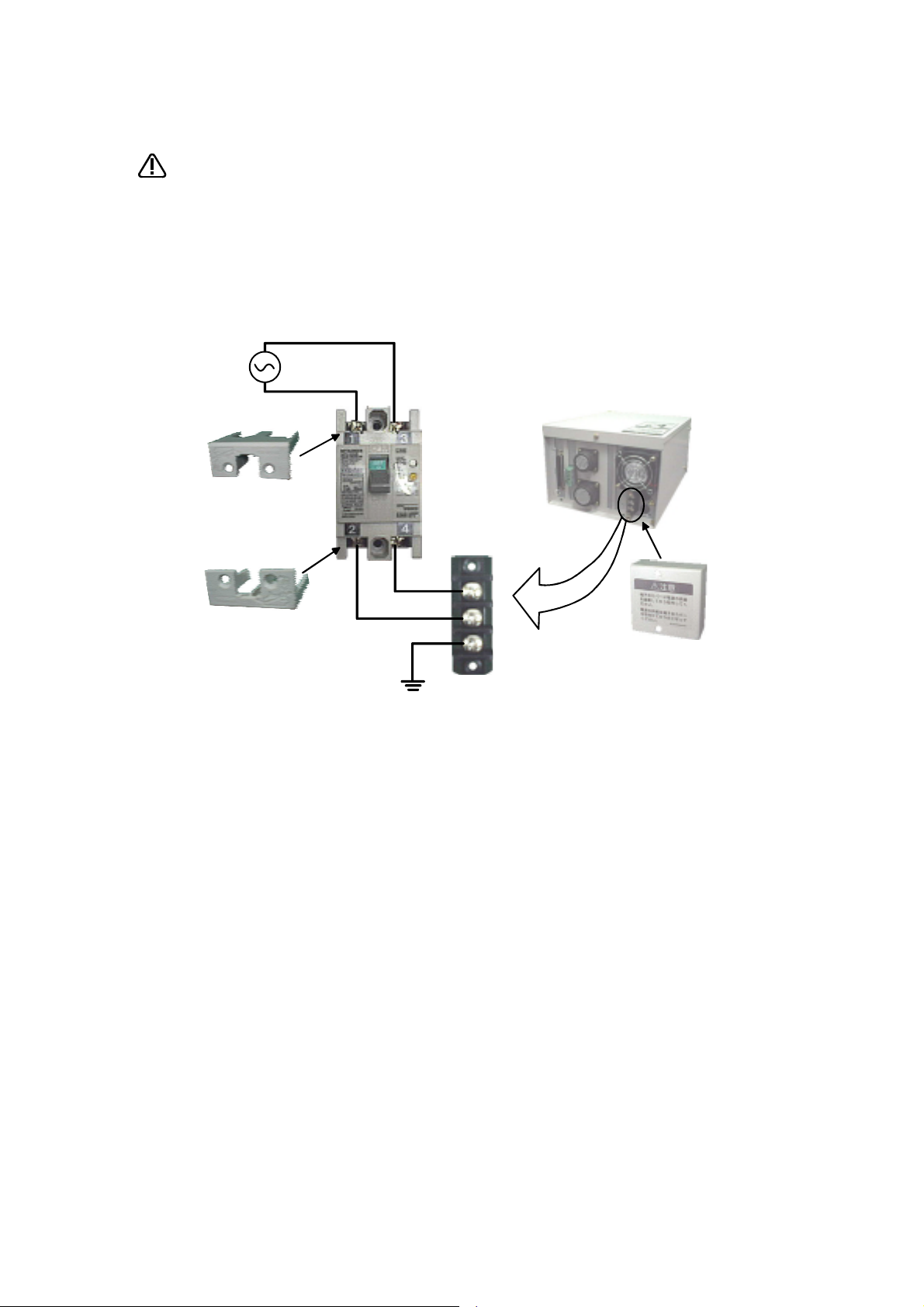

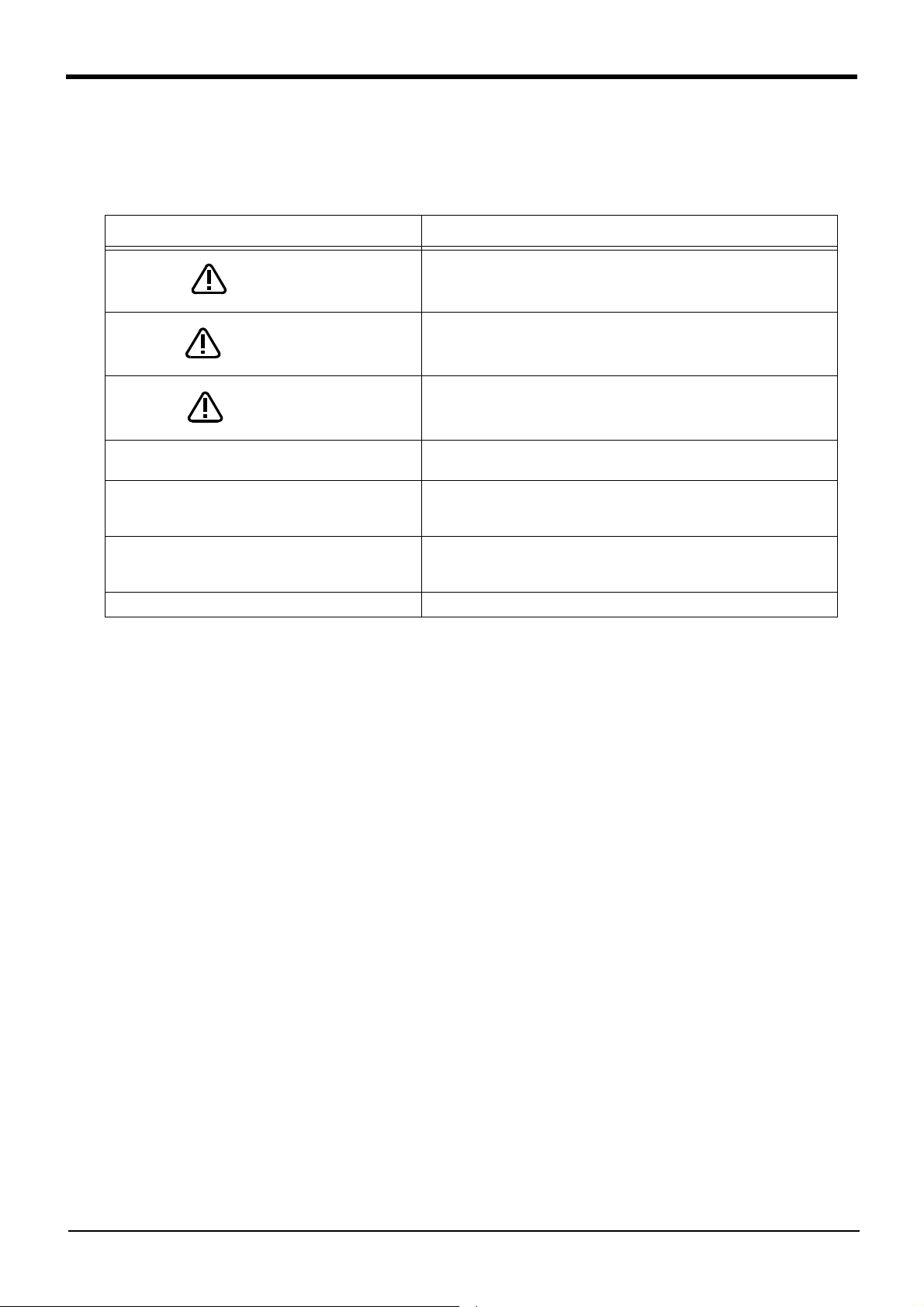

C.Precautions for the basic configuration are shown below.(When CR1-571 is used for the controller.)

CAUTION

Power supply *RV-1A/2AJ series and RP-1AH/3AH/5AH series: Single phase 90-132VAC, 180-253VAC.

Provide an earth leakage breaker that packed together on the primary power

supply of the controller as protection against electric leakage. Confirm the setting connector of the input power supply voltage of the controller, if the type

which more than one power supply voltage can be used. Then connect the

power supply.

Failure to do so could lead to electric shock accidents.

*Except the above: Single phase 180-253VAC.

Cover

Cover

Earth leakage

breaker

(NV)

Terminal

Rear side of controller

Protective earth

terminal

(PE)

Terminal cover

Page 5

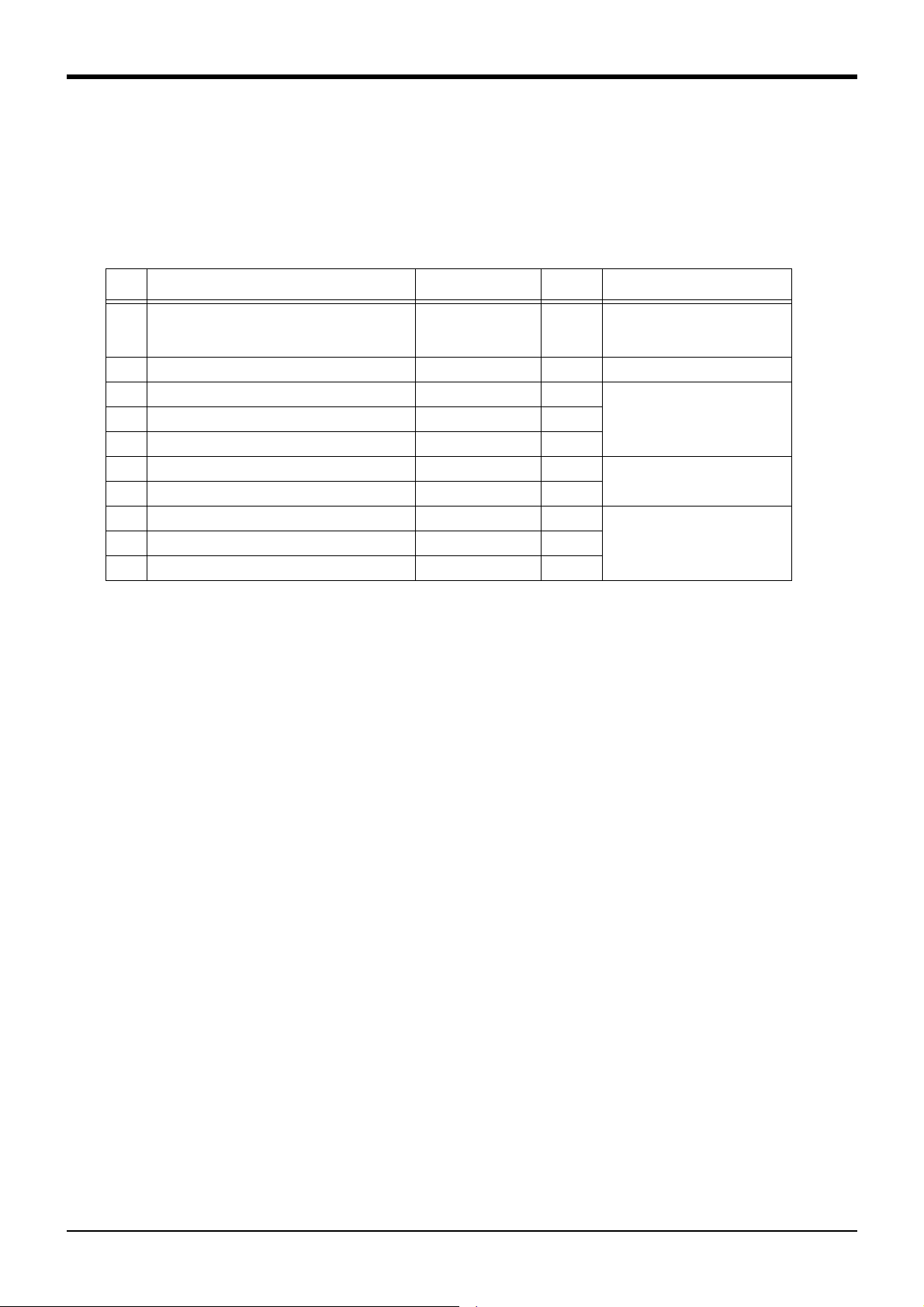

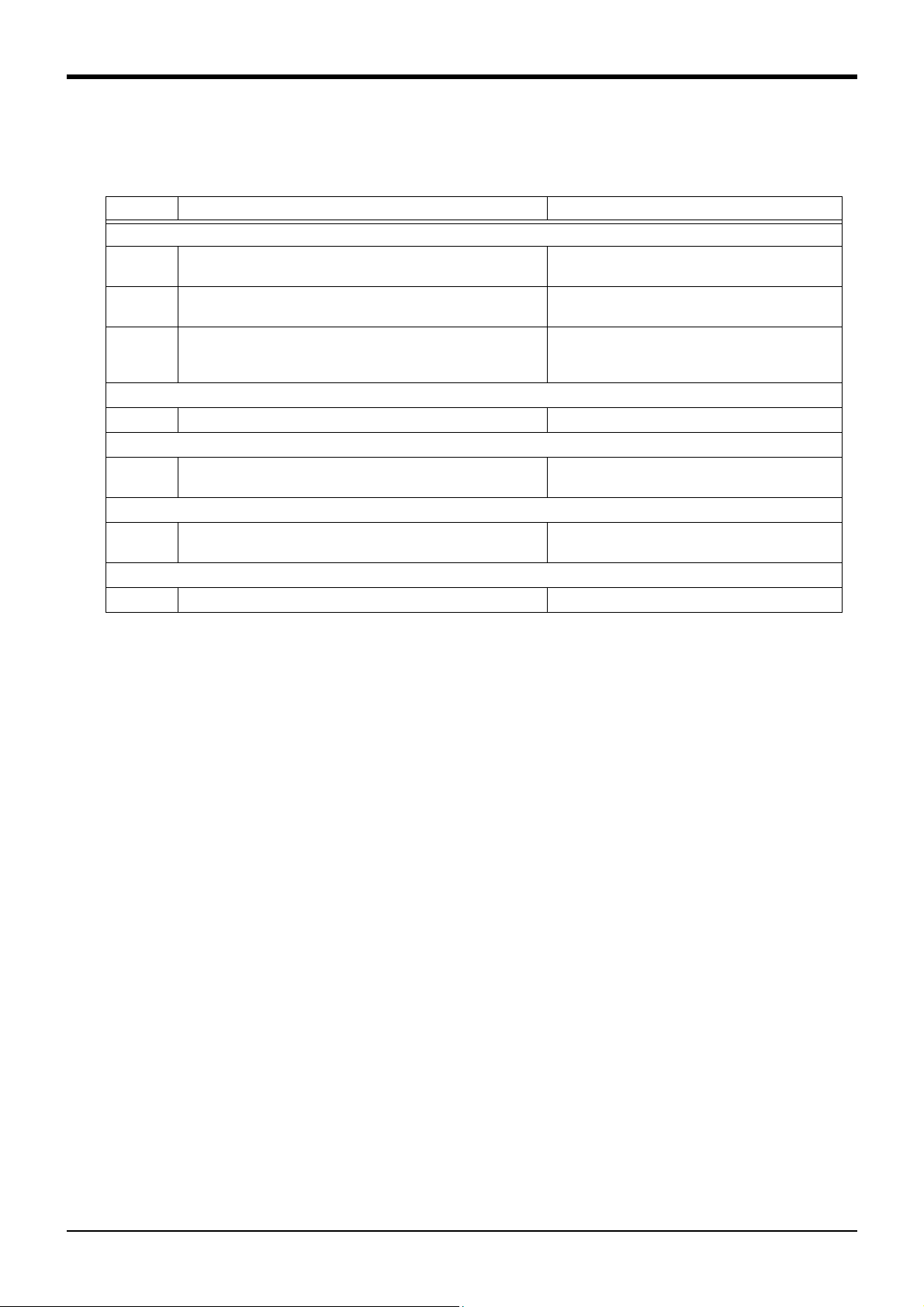

Revision history

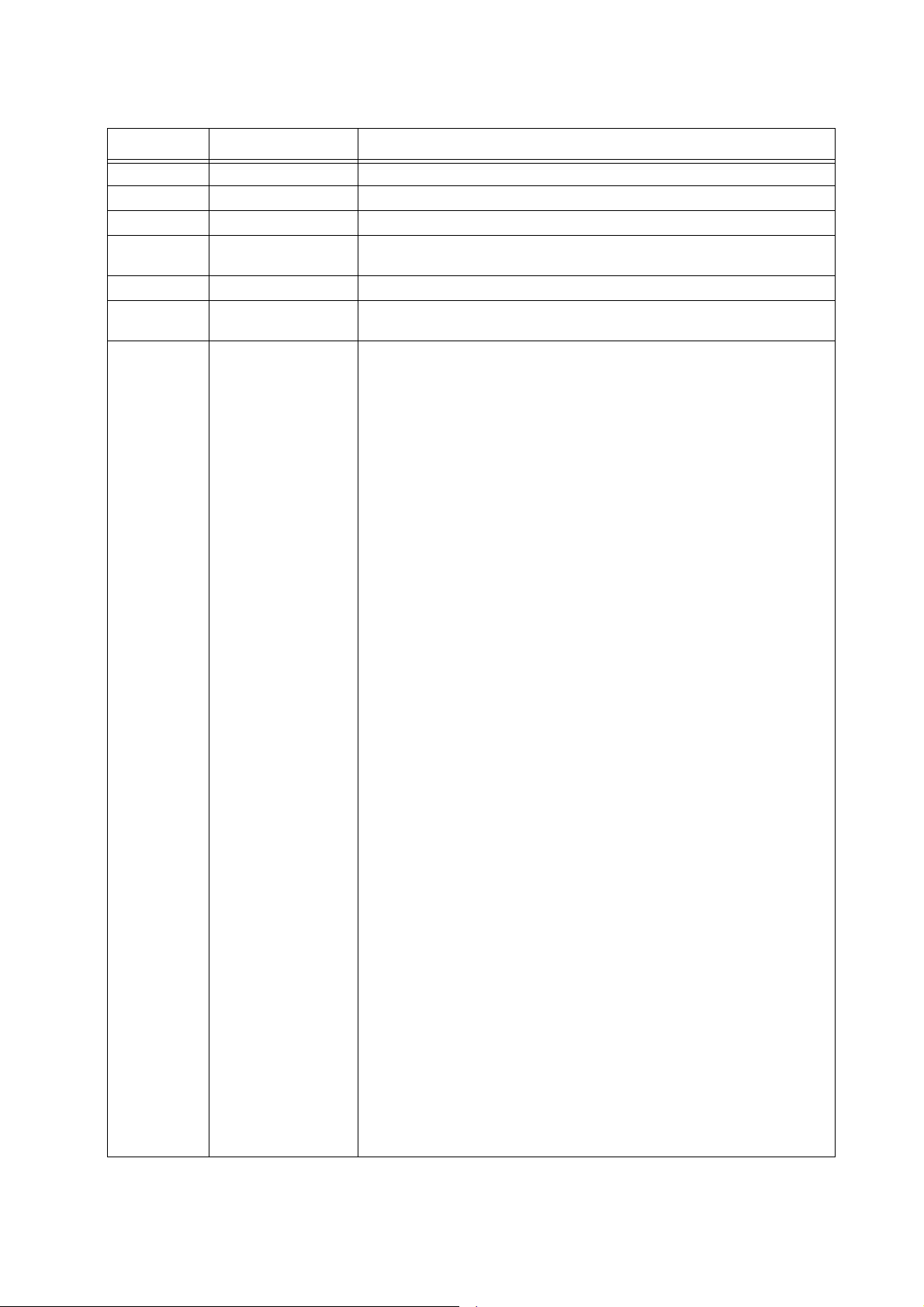

Date of Point Instruction Manual No. Revision Details

2000-02-17 BFP-A8052Z First print

2000-04-05 BFP-A8052 Formal style

2000-05-10 BFP-A8052-A Error in writing correction.

2000-07-12 BFP-A8052-B Spare parts (option) list was added.

2001-03-21 BFP-A8052-C Error in writing correction.

2002-06-05 BFP-A8052-D RV-1AC-SB, RV-2AJC-SB (Clean specification) was added.

Error in writing correction.

Error in writing correction.

Page 6

■ Introduction

Thank you for purchasing the Mitsubishi industrial robot.

This instruction manual explains procedures to be taken for unpacking, installing, servicing and inspecting the

robot arm.

Always read through this manual before starting use to ensure correct usage of the robot.

・ No part of this manual may be reproduced by any means or in any form, without prior consent from

Mitsubishi.

・ The details of this manual are subject to change without notice.

・ An effort has been made to make full descriptions in this manual. However, if any discrepancies or

unclear points are found, please contact your dealer.

・ The information contained in this document has been written to be accurate as much as possible.

Please interpret that items not described in this document "cannot be performed.".

Please contact your nearest dealer if you find any doubtful, wrong or skipped point.

Copyright(C) 2001 MITSUBISHI ELECTRIC CORPORATION

Page 7

CONTENTS

1 Before starting use ......................................................................................................................................................................... 1-1

1.1 Using the instruction manuals ............................................................................................................................................ 1-1

1.1.1 The details of each instruction manuals ................................................................................................................ 1-1

1.1.2 Symbols used in instruction manual ........................................................................................................................ 1-2

1.2 Safety Precautions ................................................................................................................................................................. 1-3

1.2.1 Precautions given in the separate Safety Manual ............................................................................................. 1-4

2 Unpacking to Installation .............................................................................................................................................................. 2-5

2.1 Confirming the product ......................................................................................................................................................... 2-5

2.2 Installation .................................................................................................................................................................................. 2-6

2.2.1 Unpacking ............................................................................................................................................................................ 2-6

2.2.2 Transportation procedures .......................................................................................................................................... 2-7

2.2.3 Installation procedures .................................................................................................................................................. 2-8

2.2.4 Grounding procedures .................................................................................................................................................... 2-9

(1) Grounding methods ..................................................................................................................................................... 2-9

(2) Grounding procedures ............................................................................................................................................... 2-9

2.2.5 Connecting with the controller ................................................................................................................................ 2-10

2.3 Setting the origin ................................................................................................................................................................... 2-11

2.3.1 Installing the teaching pendant (T/B) ................................................................................................................... 2-11

(1) Installing with the control power OFF .............................................................................................................. 2-11

2.3.2 Setting the origin with the origin data input method ...................................................................................... 2-12

(1) Confirming the origin data ..................................................................................................................................... 2-12

(2) Turning ON the control power ............................................................................................................................. 2-12

(3) Preparing the T/B ..................................................................................................................................................... 2-13

(4) Selecting the origin setting method ................................................................................................................... 2-14

(5) Inputting the origin data ......................................................................................................................................... 2-15

(6) Installing the connector box cover .................................................................................................................... 2-16

2.4 Confirming the operation .................................................................................................................................................... 2-17

(1) JOINT jog operation ................................................................................................................................................. 2-20

(2) XYZ jog operation ...................................................................................................................................................... 2-22

(3) TOOL jog operation .................................................................................................................................................. 2-24

(4) 3-axis XYZ jog operation ....................................................................................................................................... 2-26

(5) CYLNDER jog operation ......................................................................................................................................... 2-28

Page

3 Installing the option devices ..................................................................................................................................................... 3-31

3.1 Installing the solenoid valve set (1E-VD01/VD01E/VD02/VD02E) ................................................................ 3-31

3.2 Installation the pneumatic hand set (4A-HP01/HP01E) ................................................................................... 3-33

3.3 Installation the motorized hand set (4A-HM01) .................................................................................................... 3-35

3.4 Hand output cable (1E-GR35S) ...................................................................................................................................... 3-36

3.5 Installing the hand input cable (1A-HC20) and hand curl tube (1A-ST040*C) .......................................... 3-36

3.6 Installing the hand adaptor (1A-HA01) ........................................................................................................................ 3-36

4 Basic operations ............................................................................................................................................................................ 4-37

5 Maintenance and Inspection ..................................................................................................................................................... 5-39

5.1 Maintenance and inspection interval ............................................................................................................................. 5-39

5.2 Inspection items ..................................................................................................................................................................... 5-40

5.2.1 Daily inspection items .................................................................................................................................................. 5-40

5.2.2 Periodic inspection ........................................................................................................................................................ 5-41

5.3 Maintenance and inspection procedures ..................................................................................................................... 5-42

5.3.1 Robot arm structure ..................................................................................................................................................... 5-42

5.3.2 Installing/removing the cover ................................................................................................................................... 5-44

5.3.3 Inspection, maintenance and replacement of timing belt .............................................................................. 5-46

(1) Timing belt replacement period ......................................................................................................................... 5-46

(2) Inspection, maintenance and replacement of J2-axis timing belt ........................................................ 5-47

(3) Inspection, maintenance and replacement of J3-axis timing belt ........................................................ 5-48

i

Page 8

(4) Inspection, maintenance and replacement of J4-axis timing belt ........................................................ 5-49

(5) Inspection, maintenance and replacement of J5-axis timing belt ........................................................ 5-50

(6) Timing belt tension ................................................................................................................................................... 5-51

5.3.4 Lubrication ........................................................................................................................................................................ 5-52

(1) Lubrication position and specifications ............................................................................................................ 5-52

(2) Lubrication method ................................................................................................................................................... 5-53

5.3.5 Replacing the backup battery ................................................................................................................................... 5-54

(1) Replacing the robot arm battery ......................................................................................................................... 5-54

5.4 Maintenance parts ................................................................................................................................................................. 5-55

5.5 Resetting the origin .............................................................................................................................................................. 5-56

5.5.1 Mechanical stopper method ...................................................................................................................................... 5-57

(1) Select the T/B ........................................................................................................................................................... 5-57

(2) J1 axis origin setting ................................................................................................................................................ 5-58

(3) J2 axis origin setting ................................................................................................................................................ 5-59

(4) J3 axis origin setting ................................................................................................................................................ 5-60

(5) J4 axis origin setting (Only 6-axis type) ......................................................................................................... 5-62

(6) J5 axis origin setting ................................................................................................................................................ 5-64

(7) J6 axis origin setting ................................................................................................................................................ 5-65

(8) All axis origin setting ................................................................................................................................................ 5-67

5.5.2 User origin method ........................................................................................................................................................ 5-69

5.5.3 Recording the origin data ........................................................................................................................................... 5-70

(1) Confirming the origin data label ........................................................................................................................... 5-70

(2) Confirming the origin data ..................................................................................................................................... 5-70

(3) Recording the origin data ....................................................................................................................................... 5-70

(4) Installing the cover ................................................................................................................................................... 5-70

6Appendix ...............................................................................................................................................................................Appendix-71

Appendix 1 : Configuration flag ............................................................................................................................ Appendix-71

Page

ii

Page 9

1Before starting use

1 Before starting use

This chapter explains the details and usage methods of the instruction manuals, the basic terminology and the

safety precautions.

1.1 Using the instruction manuals

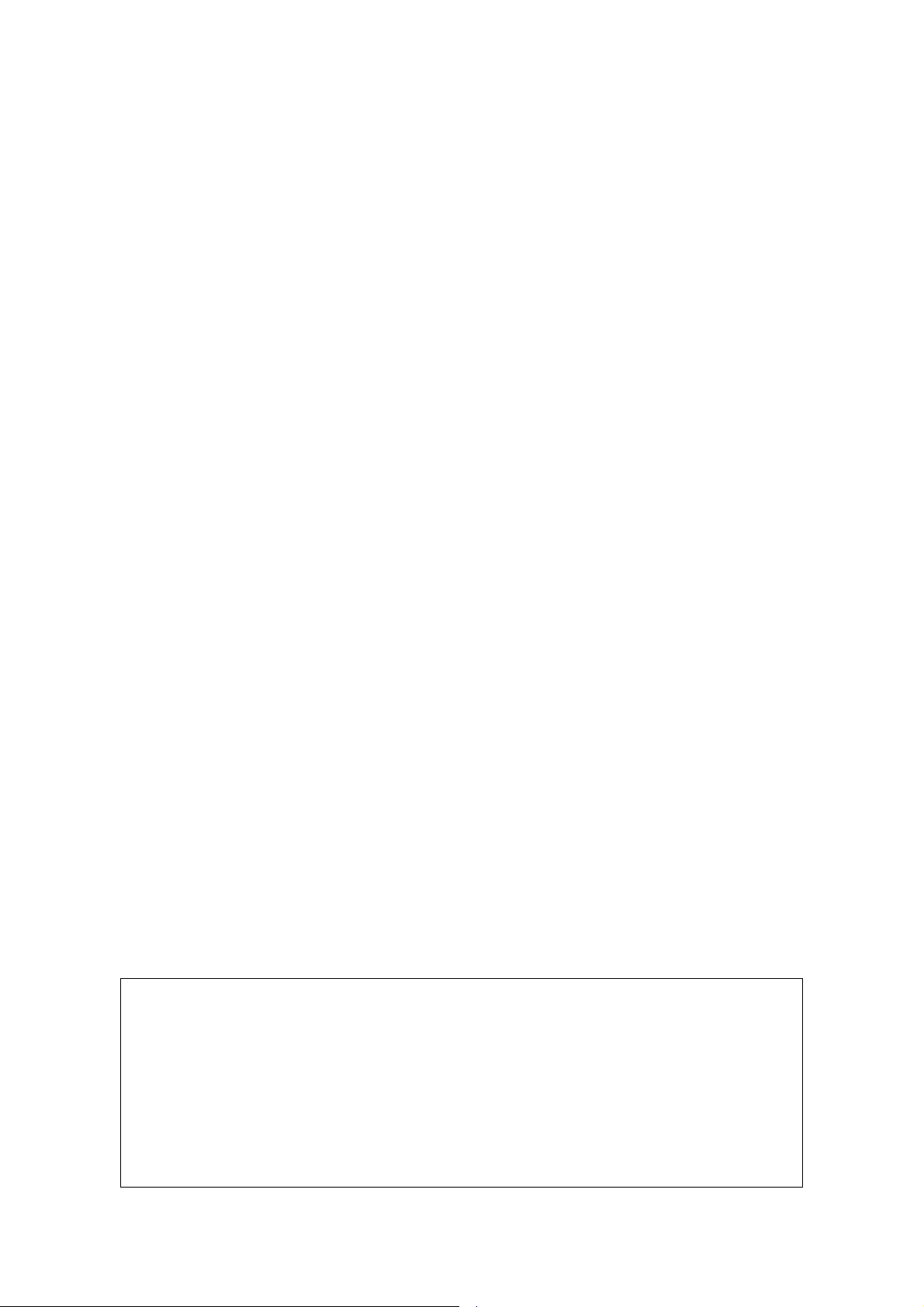

1.1.1 The details of each instruction manuals

The contents and purposes of the documents enclosed with this product are shown below. Use these documents

according to the application.

For special specifications, a separate instruction manual describing the special section may be enclosed.

Safety Manual

Standard

Specifications

Robot Arm

Setup &

Maintenance

Controller

Setup, Basic

Operation and

Maintenance

Explains the common precautions and safety measures to be taken for robot handling,

system design and manufacture to ensure safety of the operators involved with the

robot.

Explains the product's standard specifications, factory-set special specifications, option

configuration and maintenance parts, etc. Precautions for safety and technology, when

incorporating the robot, are also explained.

Explains the procedures required to operate the robot arm (unpacking, transportation,

installation, confirmation of operation), and the maintenance and inspection procedures.

Explains the procedures required to operate the controller (unpacking, transportation,

installation, confirmation of operation), basic operation from creating the program to

automatic operation, and the maintenance and inspection procedures.

Detailed

Explanation of

Functions and

Operations

Explanations of

MOVEMASTER

COMMANDS

Troubleshooting

Explains details on the functions and operations such as each function and operation,

commands used in the program, connection with the external input/output device, and

parameters, etc.

Explains details on the MOVEMASTER commands used in the program.

(For RV-1A/2AJ and RV-2A/3AJ series)

Explains the causes and remedies to be taken when an error occurs. Explanations are

given for each error No.

Using the instruction manuals

1-1

Page 10

1Before starting use

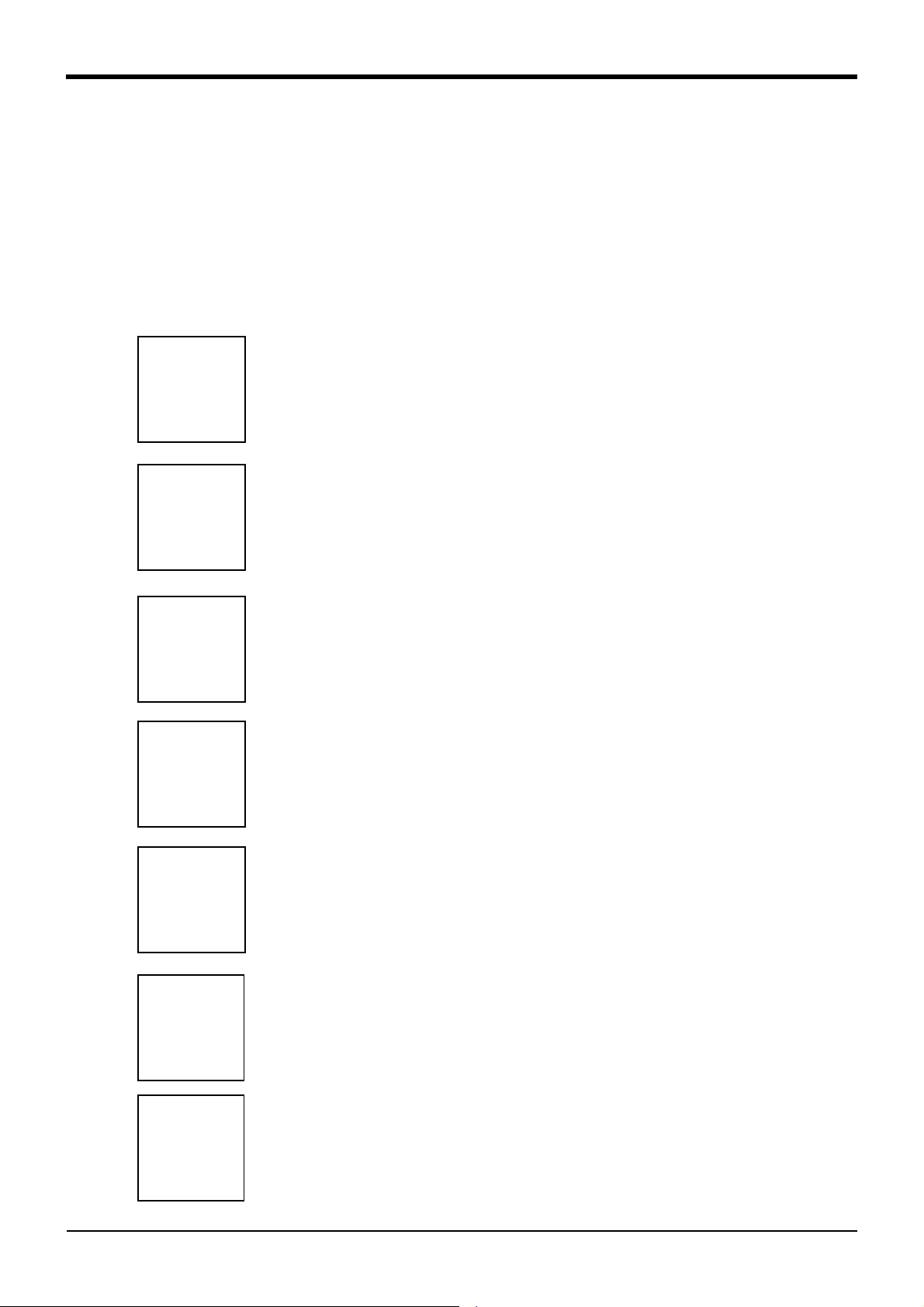

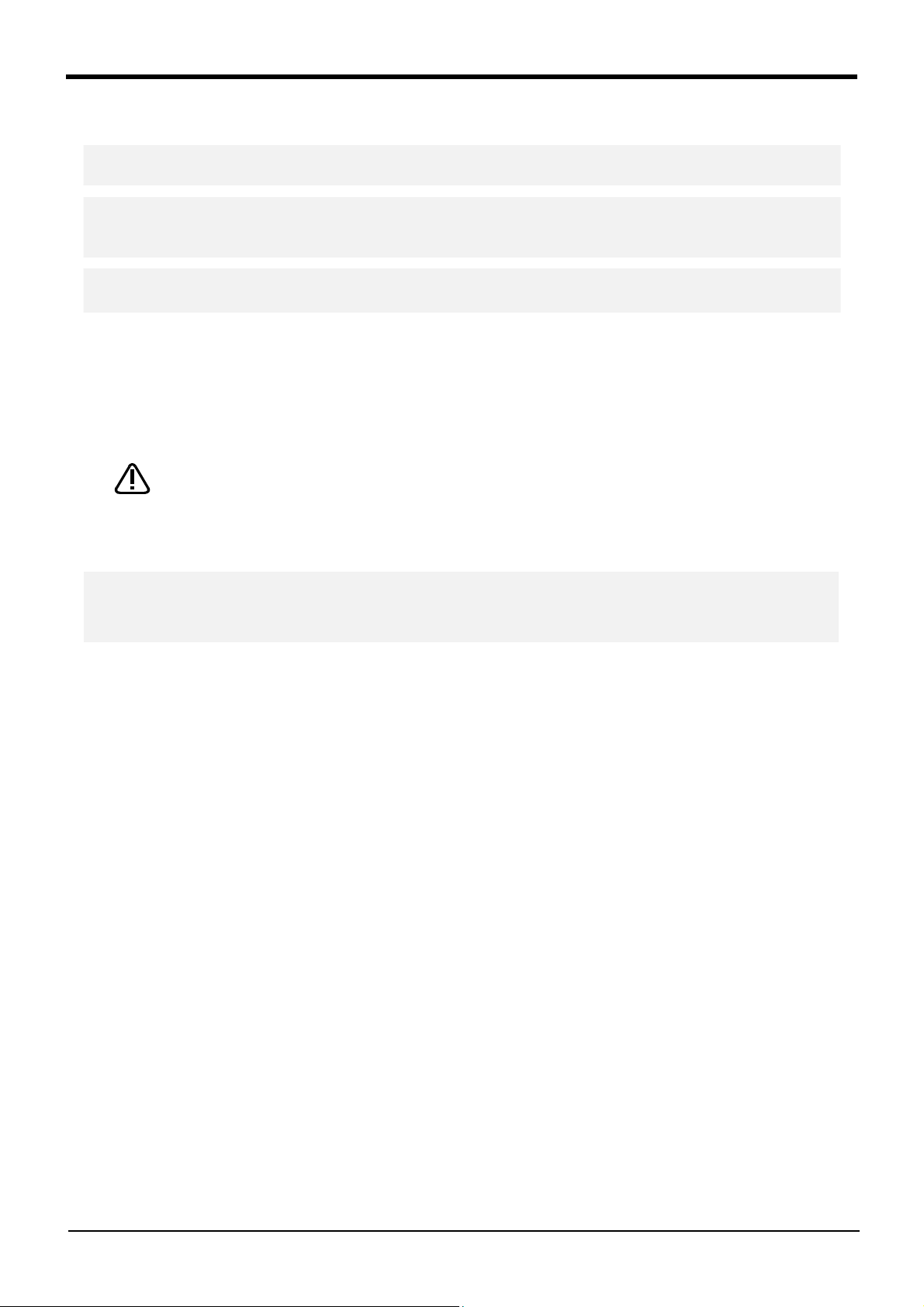

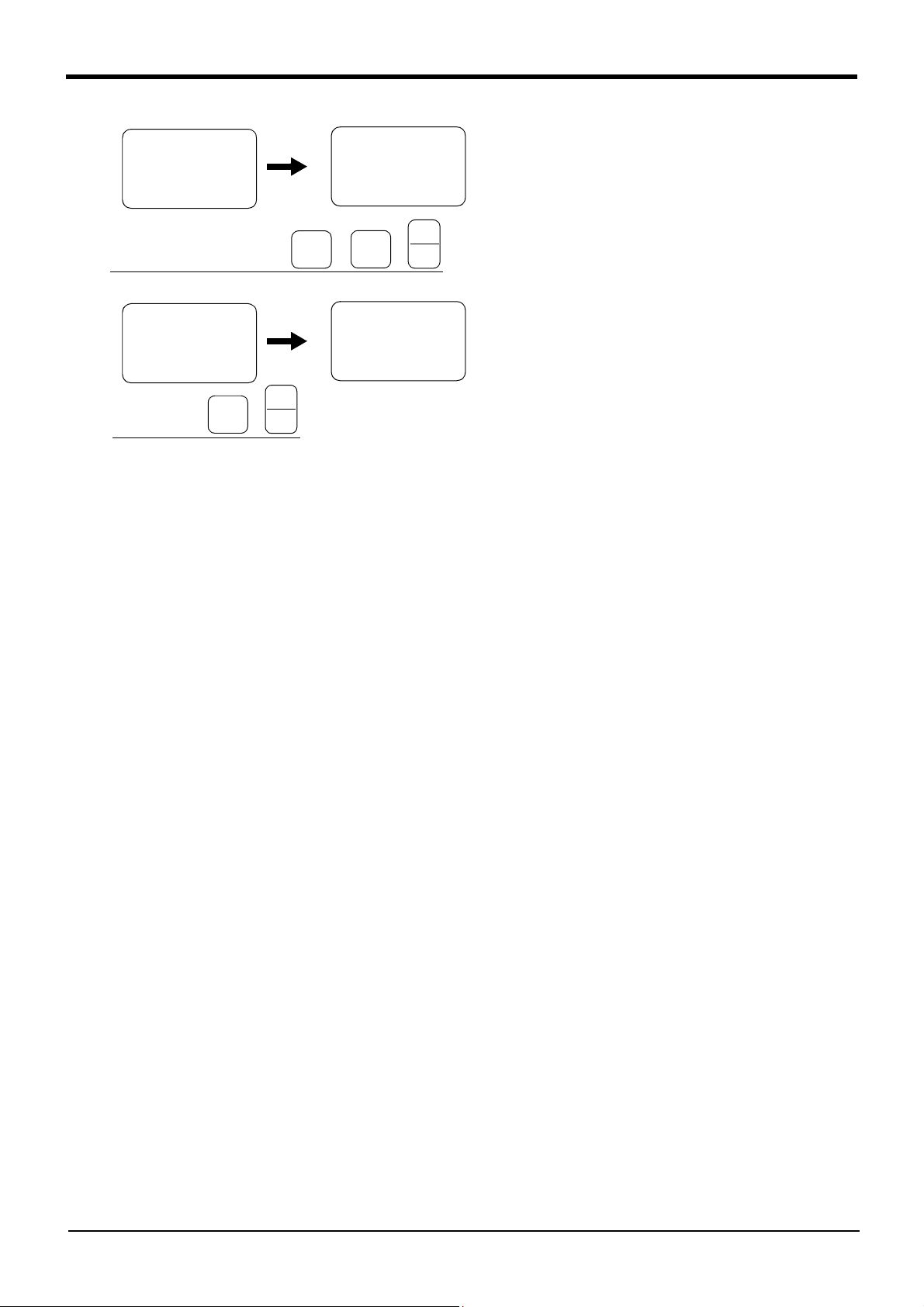

1.1.2 Symbols used in instruction manual

The symbols and expressions shown in Table 1-1 are used throughout this Instruction Manual. Learn the meaning

of these symbols before reading this instruction manual.

Table 1-1:Symbols in instruction manual

Symbol Meaning

DANGER

WARNING

CAUTION

[ JOINT ]

[+/ F O R W D ] + [+ X ]

(A) (B)

[S T E P / MO V E] + ([ COND] → [ RPL ↓ ])

(A) (B) (C)

T/B This indicates the teaching pendant.

Precaution indicating cases where there is a risk of operator fatality or seri

ous injury if handling is mistaken. Always observe these precautions to safely

use the robot.

Precaution indicating cases where the operator could be subject to fatalities

or serious injuries if handling is mistaken. Always observe these precautions to

safely use the robot.

Precaution indicating cases where operator could be subject to injury or

physical damage could occur if handling is mistaken. Always observe these

precautions to safely use the robot.

If a word is enclosed in brackets or a box in the text, this refers to a key on

the teaching pendant.

This indicates to press the (B) key while holding down the (A) key.

In this example, the [+/Forward] key is pressed while holding down the [+X/

+Y] key.

This indicates to hold down the (A) key, press and release the (B) key, and

then press the (C) key. In this example, the [Step/Move] key is held down, the

[Condition] key is pressed and released, and the [Replace ↓ key is pressed.

-

1-2

Using the instruction manuals

Page 11

1Before starting use

1.2 Safety Precautions

Always read the following precautions and the separate "Safety Manual" before starting use of the robot to learn

the required measures to be taken.

CAUTION

CAUTION

WARNING

All teaching work must be carried out by an operator who has received special training.

(This also applies to maintenance work with the power source turned ON.)

→ Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures of operating the robot, and to the measures to be taken when an error occurs or when restarting. Carry out work following this plan. (This also applies to maintenance work with the

power source turned ON.)

→ Preparation of work plan

Prepare a device that allows operation to be stopped immediately during teaching work.

(This also applies to maintenance work with the power source turned ON.)

→ Setting of emergency stop switch

CAUTION

DANGER

CAUTION

CAUTION

CAUTION

During teaching work, place a sign indicating that teaching work is in progress on the

start switch, etc. (This also applies to maintenance work with the power source turned

ON.)

→ Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the operator and

robot.

→ Installation of safety fence

Establish a set signaling method to the related operators for starting work, and follow

this method.

→ Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign indicating that

maintenance work is in progress on the start switch, etc.

→ Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other related

devices, etc., and confirm that there are no errors.

→ Inspection before starting work

Safety Precautions

1-3

Page 12

1Before starting use

1.2.1 Precautions given in the separate Safety Manual

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

Use the robot within the environment given in the specifications. Failure to do so could

lead to a drop or reliability or faults. (Temperature, humidity, atmosphere, noise environment, etc.)

Transport the robot with the designated transportation posture. Transporting the

robot in a non-designated posture could lead to personal injuries or faults from dropping.

Always use the robot installed on a secure table. Use in an instable posture could lead

to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise

source, positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable. Failure

to observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the rated

load or tolerable torque. Exceeding these values could lead to alarms or faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to

observe this could lead to personal injuries or damage if the object comes off or flies

off during operation.

Securely ground the robot and controller. Failure to observe this could lead to malfunctioning by noise or to electric shock accidents.

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

Indicate the operation state during robot operation. Failure to indicate the state could

lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure the

priority right for the robot control. Failure to observe this could lead to personal injuries or damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do so

could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with peripheral devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic operation, the door is locked or that the robot will automatically stop. Failure to do so could

lead to personal injuries.

Never carry out modifications based on personal judgments, or use non-designated

maintenance parts.

Failure to observe this could lead to faults or failures.

When the robot arm has to be moved by hand from an external area, do not place

hands or fingers in the openings. Failure to observe this could lead to hands or fingers

catching depending on the posture.

1-4

Safety Precautions

CAUTION

Do not stop the robot or apply emergency stop by turning the robot controller's main

power OFF.

If the robot controller main power is turned OFF during automatic operation, the robot

accuracy could be adversely affected.

Page 13

2Unpacking to Installation

2 Unpacking to Installation

2.1 Confirming the product

The standard configuration of the robot arm, part of the purchased product, is shown in Table 2-1.

Confirm the parts.

Users who have purchased optional products should refer to the separate "Standard Specifications".

Table 2-1:Standard configuration

No. Part name Type Qty. Remarks

1 Robot arm RV-1A, RV-2AJ,

RV-1AC-SB or

RV-2AJC-SB

2 Guarantee card 1 copy

3 Installation bolts M8x30 4 pcs.

5 Plain washer for installation bolts For M8 4 pcs.

6 Suspension fitting 1 pcs.

7 Suspension fitting installation bolt M5x104 pcs.

8 Nylon clamp (Three kinds one each) 3 pcs.

9 Nylon clamp installation bolts M3x22 1 pcs.

10 Plain washer for Nylon clamp installation bolts For M3 1 pcs.

Either

1 unit

For robot arm installation4 Spring washer for installation bolts For M8 4 pcs.

For robot arm transportation

For wiring and piping for optional

hand

Note) The number 3 - 5, 8-10 are in the plastic bag of the robot arm attachment.

Confirming the product

2-5

Page 14

2Unpacking to Installation

2.2 Installation

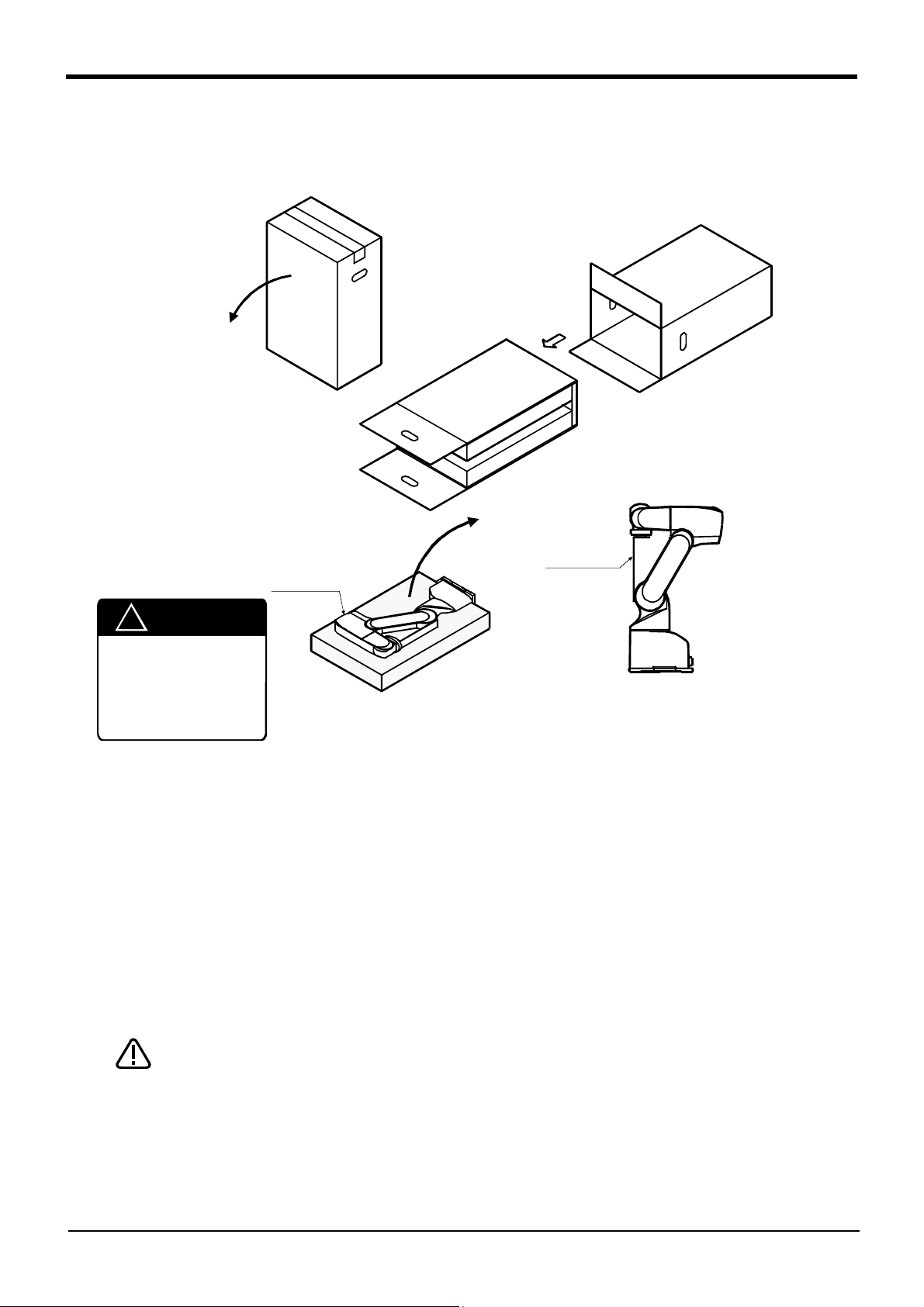

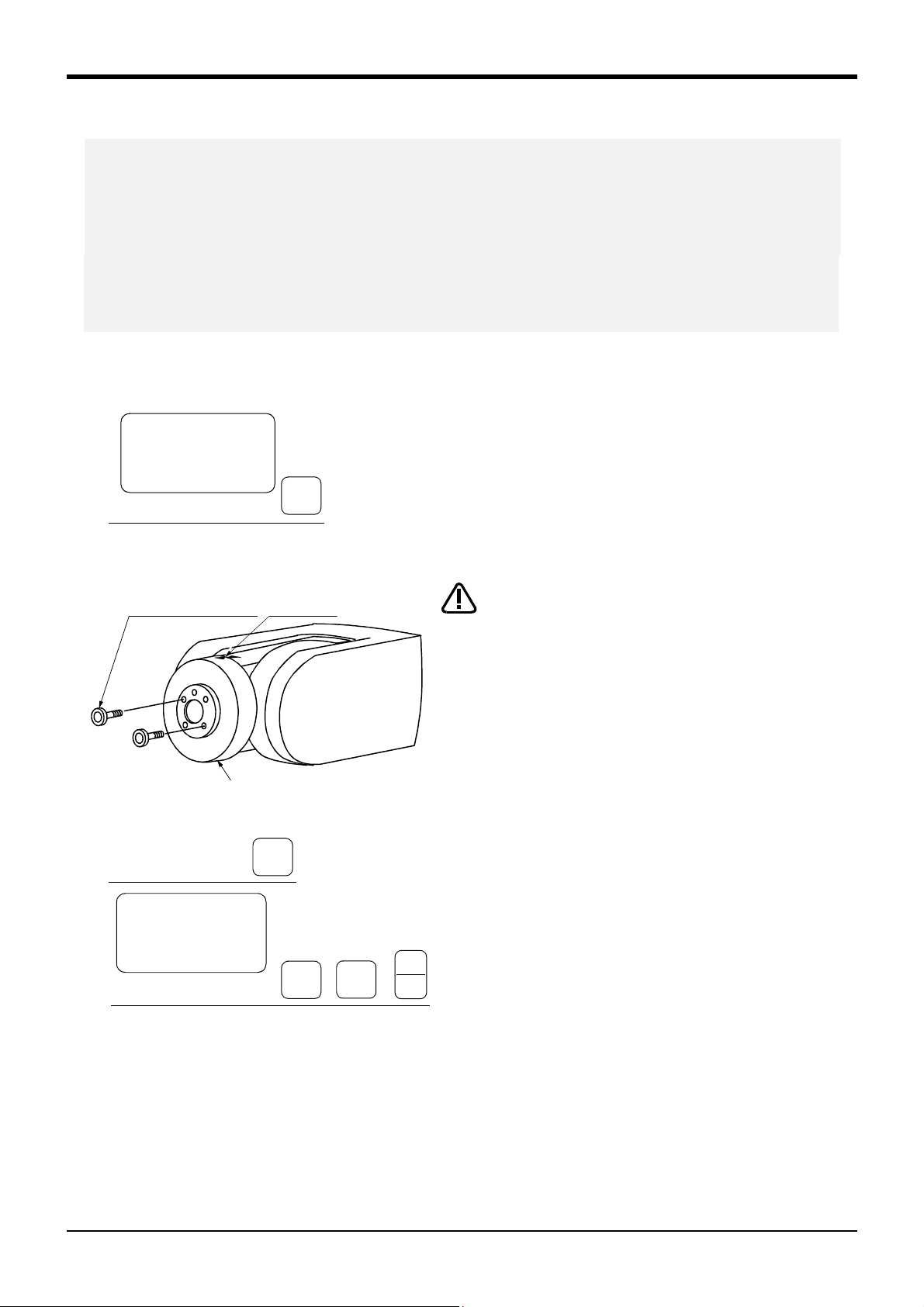

2.2.1 Unpacking

Lays

( a )

Stand up

Robot arm

!

CAUTION

Always unpack the

robot at a flat place.

The robot could tilt

over if unpacked at an

unstable place.

Note) The cushioning material will be required if the robot is transported again , so save it in a safe place.

!

( d )

Pull out

( b )

( c )

Arm fixing

plate

( e )

Fig.2-1:Unpacking the robot arm

The robot is shipped from the factory in cardboard packing. Always refer to Fig. 2-1 and unpack the robot.

Handle the robot arm according to"2.2.2 Transportation procedures"

The unpacking process is shown below.

1) Carefully lay the cardboard box on its side while taking care not to apply impacts. (Fig. 2-1 (a))

2) Using a knife, cut the tape fixing the opening of the cardboard box. (Fig. 2-1 (b))

3) Horizontally pull out the inner box onto the floor. (Fig. 2-1 (c))

4) Remove the inner box and upper cushioning material. (Fig. 2-1 (d))

5) Pull up the robot arm together with the lower cushioning material. (Fig. 2-1 (e))

CAUTION

2-6

Installation

When repackaging the robot in the cardboard box, always use the fixing plates.

Page 15

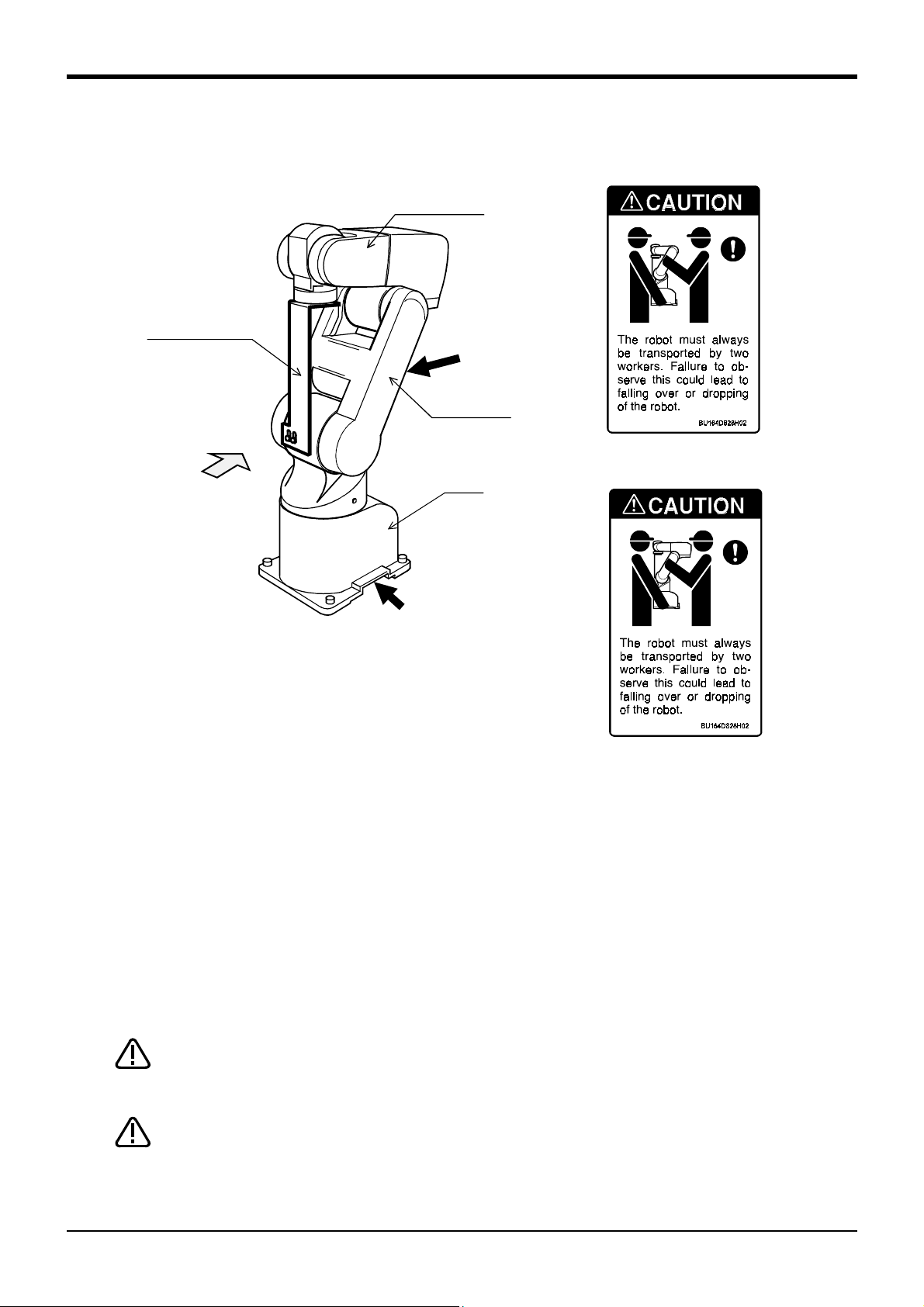

2.2.2 Transportation procedures

Forearm

2Unpacking to Installation

Arm fixing plate

B

Upper arm

Front

Base

A

Note) The figure shows the 6-axis type, but this also applies for the

5-axis type.

6-axis type

5-axis type

Fig.2-2 : Transportation of robot arm

1) The robot must be transported by two workers. Place the robot on a dolly, etc., and move it to near the

installation place. Transporting the robot with the following grips should be limited to placing the robot on

the frame or dolly, and to positioning.

2) When transporting with the grips, one worker should hold the grip (A) at the base, and support the arm from

the front with his body. The other worker should support the back of the upper arm (B). If the robot is held

from the left/right sides or if a cover is held, the robot could tilt over, the cover could be damaged, or

accidents such as dropping could occur.

3) When transporting the robot, do not apply force on the cover, or apply a strong impact on the robot

4) Remove the fixing plates after installing the robot.

CAUTION

CAUTION

To prevent accidents, do not hold the robot from the left/right sides, or hold

covers that have no grips.

When installing the fixing plates again, set each axis of the robot to J1=0 degree,

J2=-30 degree, J3=120 degree, J4=0 degree (6-axis type only), J5=90 degree, and

J6=0 degree.

Installation

2-7

Page 16

2Unpacking to Installation

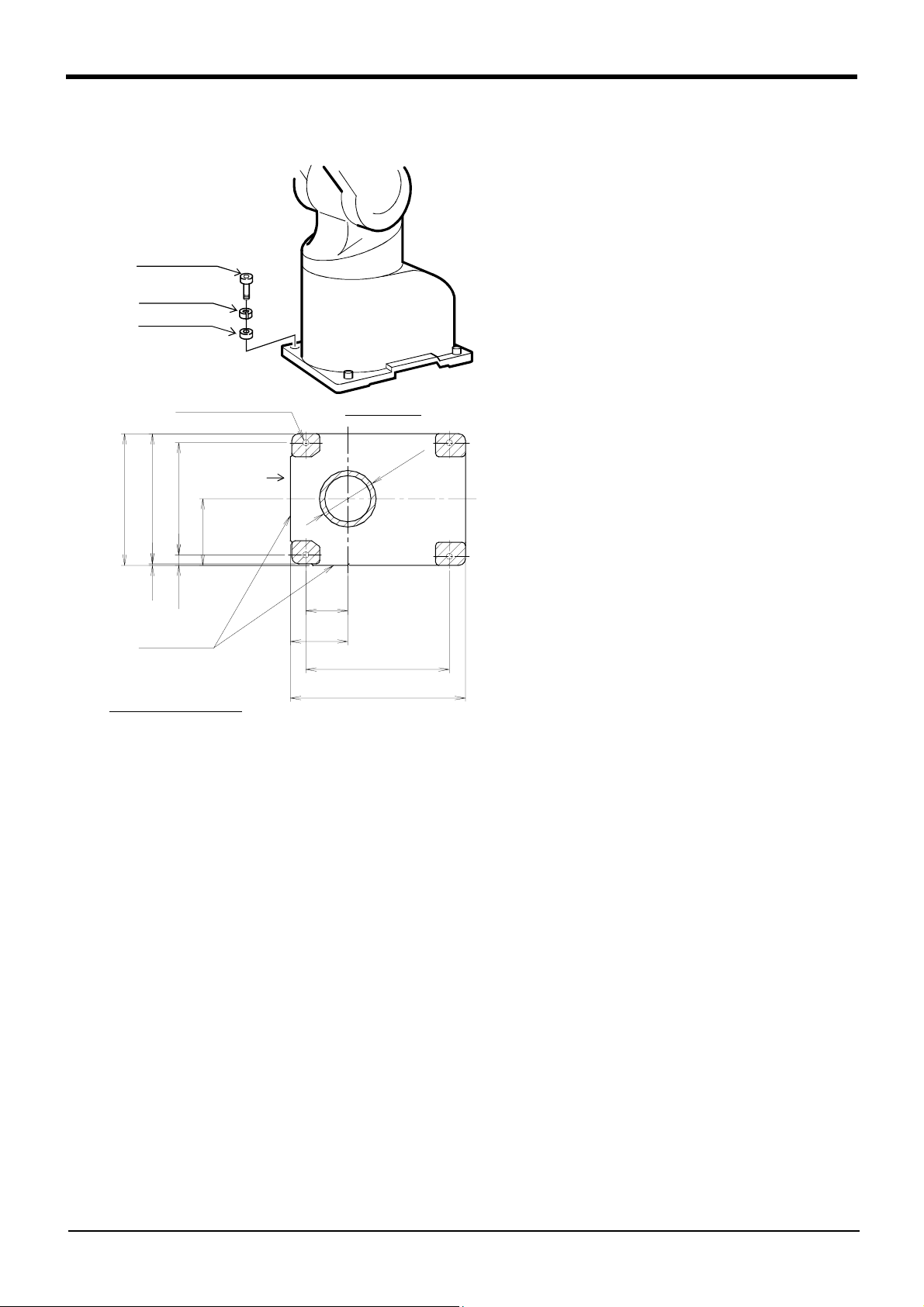

2.2.3 Installation procedures

4-M8×30

(Four positions)

Spring washer

Plain washer

(4-Φ9 installation hole )

(installation bolt M8×35)

Base bottom

1) The robot installation surface has been machine

finished. Use the installation holes (4-φ18 holes)

opened at the four corners of the base, and

securely fix the robot with the enclosed installation bolts (M8 x 30 hexagon socket bolts).

2) Install the robot on a level surface.

3) It is recommended that the surface roughness of

the table onto which the robot is to be installed

by 6.3a or more. If the installation surface is

rough, the contact with the table will be poor, and

positional deviation could occur when the robot

moves.

81

φ

(Front of robot )

188

186

160

95

6.3a

2

15

Installation

reference surface

Installation dimension details

・ The contact section shown with shading on the robot installation surface

must be finished to 6.3a.

・ The section marked with *1 must be contacted against the installation surface

to ensure the robot rigidity.

60

82

6.3a

*1

205

250

Fig.2-3 : Installation dimensions

4) When installing, use a common table to prevent

the position of the devices and jigs subject to

robot work from deviating.

5) The installation surface must have sufficient

strength to withstand the arm reaction during

operation, and resistance against deformation and

vibration caused by the static (dynamic) load of

the robot arm and peripheral devices, etc.

6) When installing on the ceiling, use the ceiling suspension jig available from Mitsubishi. Contact Mitsubishi or your dealer for the ceiling suspension

jig.

7) Remove the fixing plates after installing the robot.

2-8

Installation

Page 17

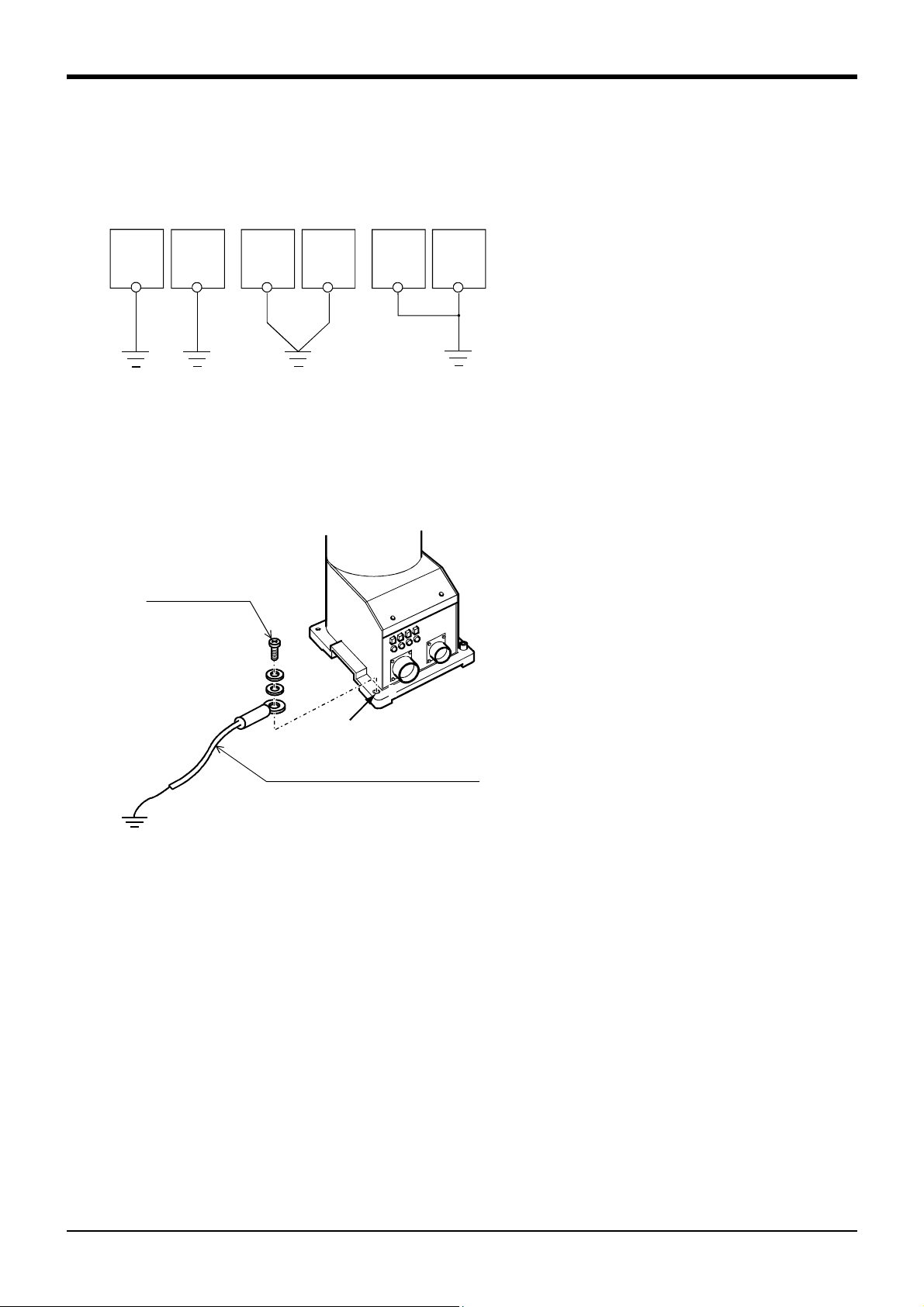

2.2.4 Grounding procedures (1) Grounding methods

Controller

(Optimum)

and

personal

computer

Robot arm

(a) Dedicated grounding

Robot arm

(b) Common grounding

Fig.2-4 : Grounding methods

(2) Grounding procedures

(Good)

Controller

and

personal

computer

(Normal)

Controller

personal

computer

Robot arm

(c) Common grounding

and

2Unpacking to Installation

1) There are three grounding methods as shown in

Fig. 2-4, but the dedicated grounding (Fig. 2-4 (a))

should be used for the robot arm and controller

when possible. (Refer to the separate " Controller

Setup, Basic Operation and Maintenance" for

details on the controller grounding.)

2) Use Class D grounding (grounding resistance

100Ω or less).

Dedicated grounding separated from the other

devices should be used.

3) Use a AWG#14(2mm

2

) or more stranded wire for

the grounding wire. The grounding point should be

as close to the robot arm and controller as possible, and the length of the grounding wire should

be short.

Robot arm

M4×10, SW, PW

A

Robot grounding cable

(AWG#14(2mm

(Prepared by customer)

Fig.2-5 : Connecting the grounding cable

2

) or more)

1) Prepare the grounding cable (AWG#14(2mm2) or

more) and robot side installation screw and

washer.

2) If there is rust or paint on the grounding screw

section (A), remove it with a file, etc.

3) Connect the grounding cable to the grounding

screw section.

Installation

2-9

Page 18

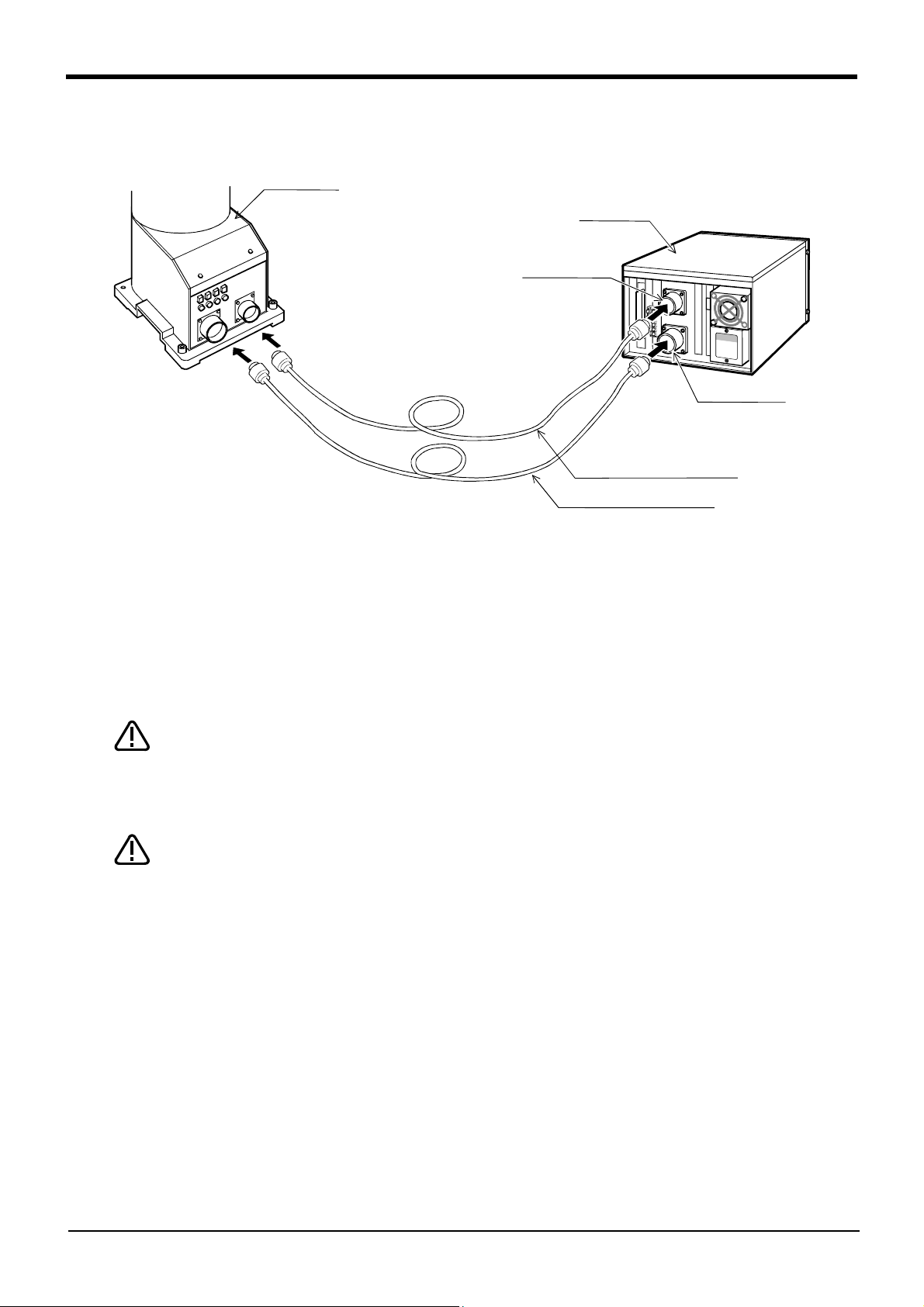

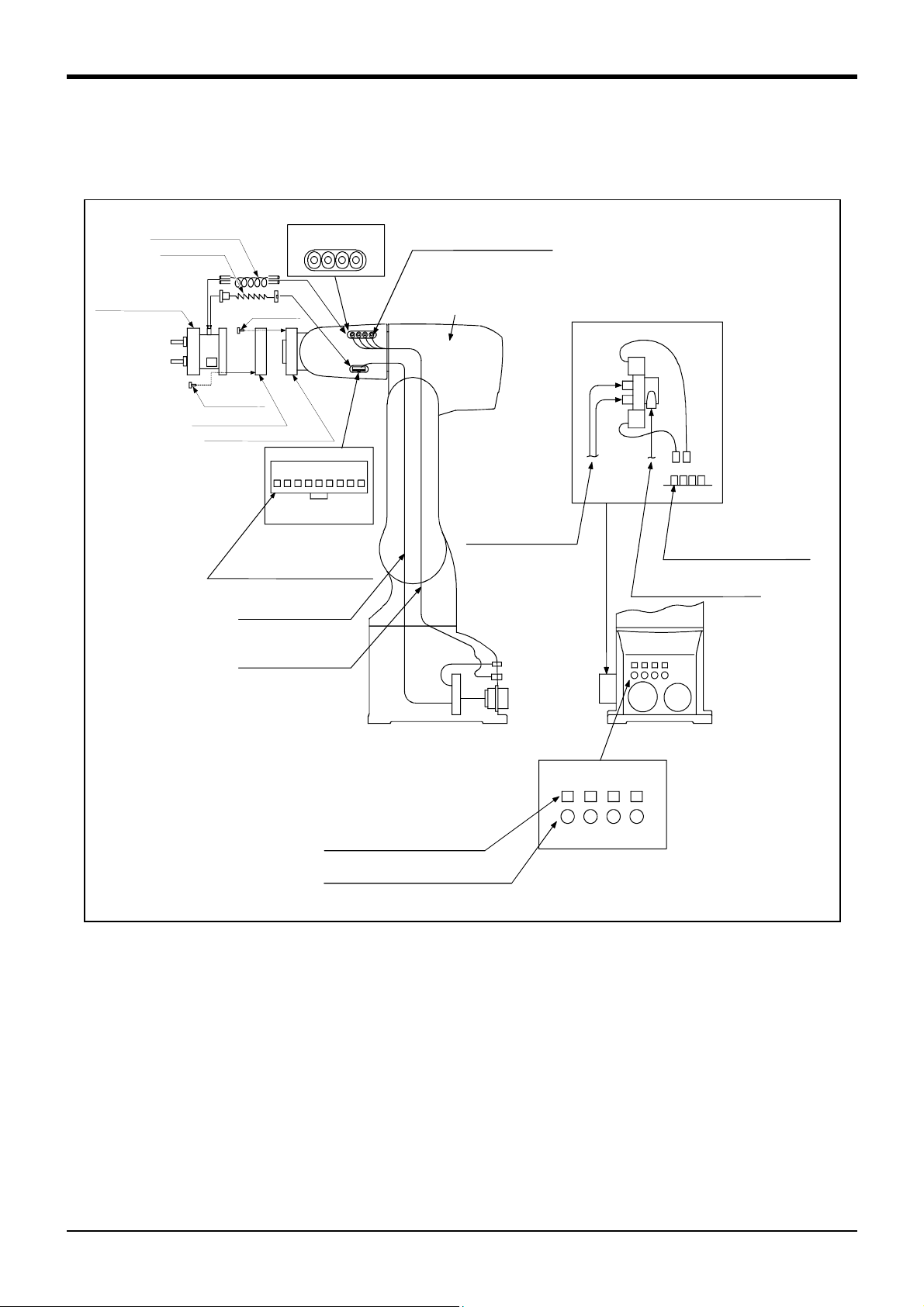

2Unpacking to Installation

2.2.5 Connecting with the controller

Robot arm

CN2

Controller

Motor power

(CN1)

CN1

Motor signal

(CN2)

Motor power cable(5m)

Motor signal cable(5m)

Fig.2-6 : Connecting the machine cables

Carry out the following procedure after installing the controller referring to the separate "Controller Setup, Basic

Operation and Maintenance" manual.

1) Make sure that the power switch on the front of the controller is turned OFF.

2) Connect the machine cable to the robot arm and the corresponding connector on the controller

CAUTION

CAUTION

The machine cable connectors are dedicated for the controller side and robot arm

side, so take special care when connecting.

If connected incorrectly, the connector pins could bend or break. Thus, even if

connected correctly, the robot will not operate correctly, creating a dangerous

situation.

Take special care to the leading of the connection cable. If the cable is pulled with

force or bent excessively, wires could break or the connector could be damaged.

2-10

Installation

Page 19

2Unpacking to Installation

2.3 Setting the origin

The origin is set so that the robot can be used with a high accuracy. After purchasing the robot, always carry out

this step before starting work. This step must also be carried out if the combination of robot and controller being

used is changed.

There are several methods for setting the origin, but the origin data input method will be explained here. Refer to

"5.5 Resetting the origin" on page 56 for the other methods.

The teaching pendant is required for this operation.

2.3.1 Installing the teaching pendant (T/B)

By using the "REMOVE T/B" switch, the T/B can be installed and removed while the controller's control power is

ON. However, in this procedure, the teaching pendant will be installed with the control power OFF.

Refer to the separate "Controller setup, basic operation, and maintenance" for details on installing the teaching

pendant with the control power ON.

(1) Installing with the control power OFF

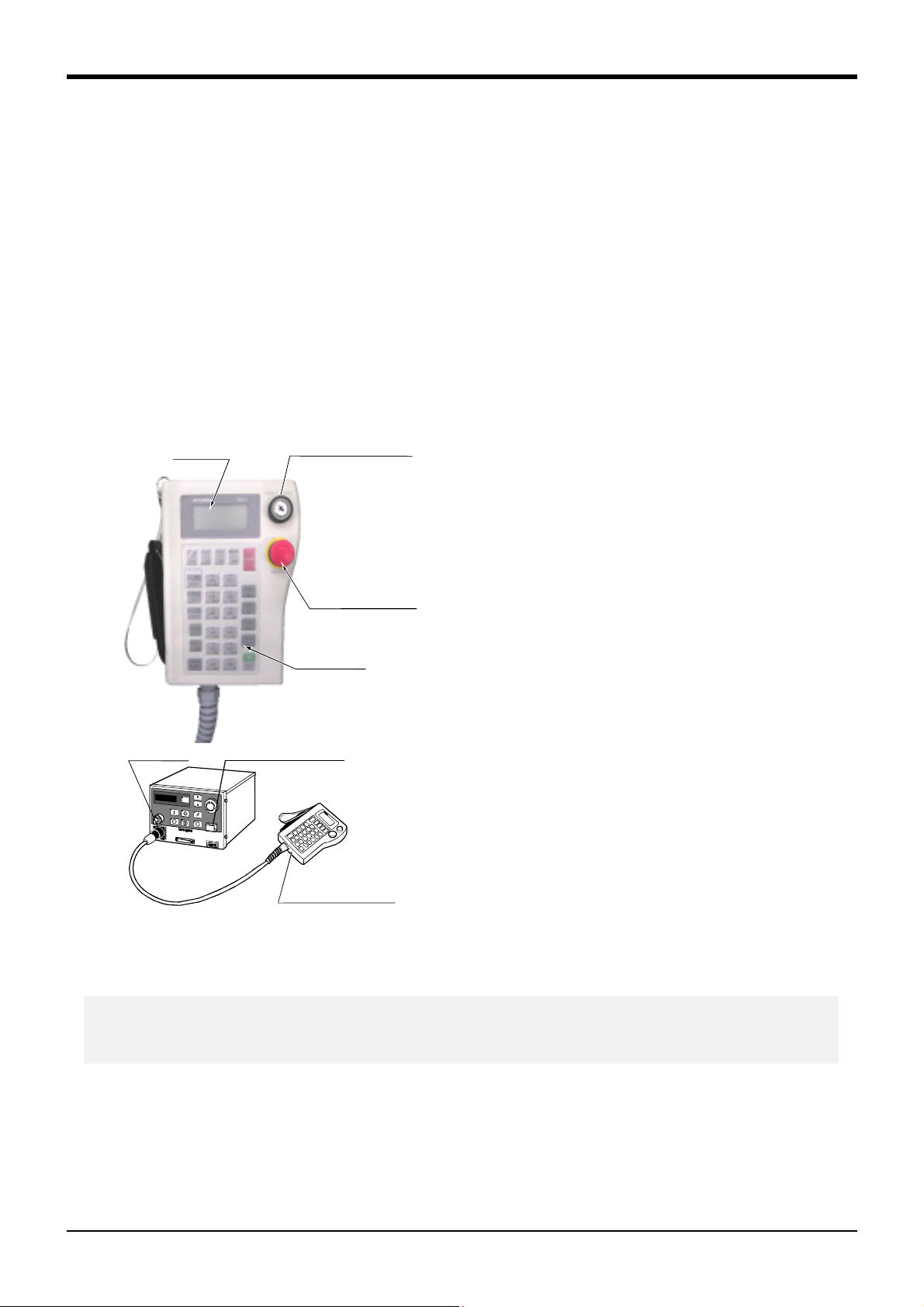

Displ ay LCD

ENABLE/DISABLE switch

1) Confirm that the controller's power supply switch is OFF.

2) Connect the T/B connector to the RS-422 (T/B) connector

on the controller.

3) Do not pull the cable with force or bend it excessively, as

the cable could break or the connector could be damaged.

Emergency stop switch

4) Confirm that the [REMOVE T/B] switch on the side of the

controller is not depressed (is projected).

Connector

Appearance of teaching pendant

REMOVE T/B switch

Operation keys

Teaching pendant

(T/B)

5) Set the T/B [ENABLE/DISABLE] switch to "DISABLE".

Fig.2-7 : Installing the T/B (control power OFF)

◇◆◇ [REMOVE T/B] switch ◇◆◇

When using the robot with the T/B, this switch is used to invalidate the emergency stop from the T/B. This is

also used to install the T/B with turning the controller's power supply ON.

Setting the origin

2-11

Page 20

2Unpacking to Installation

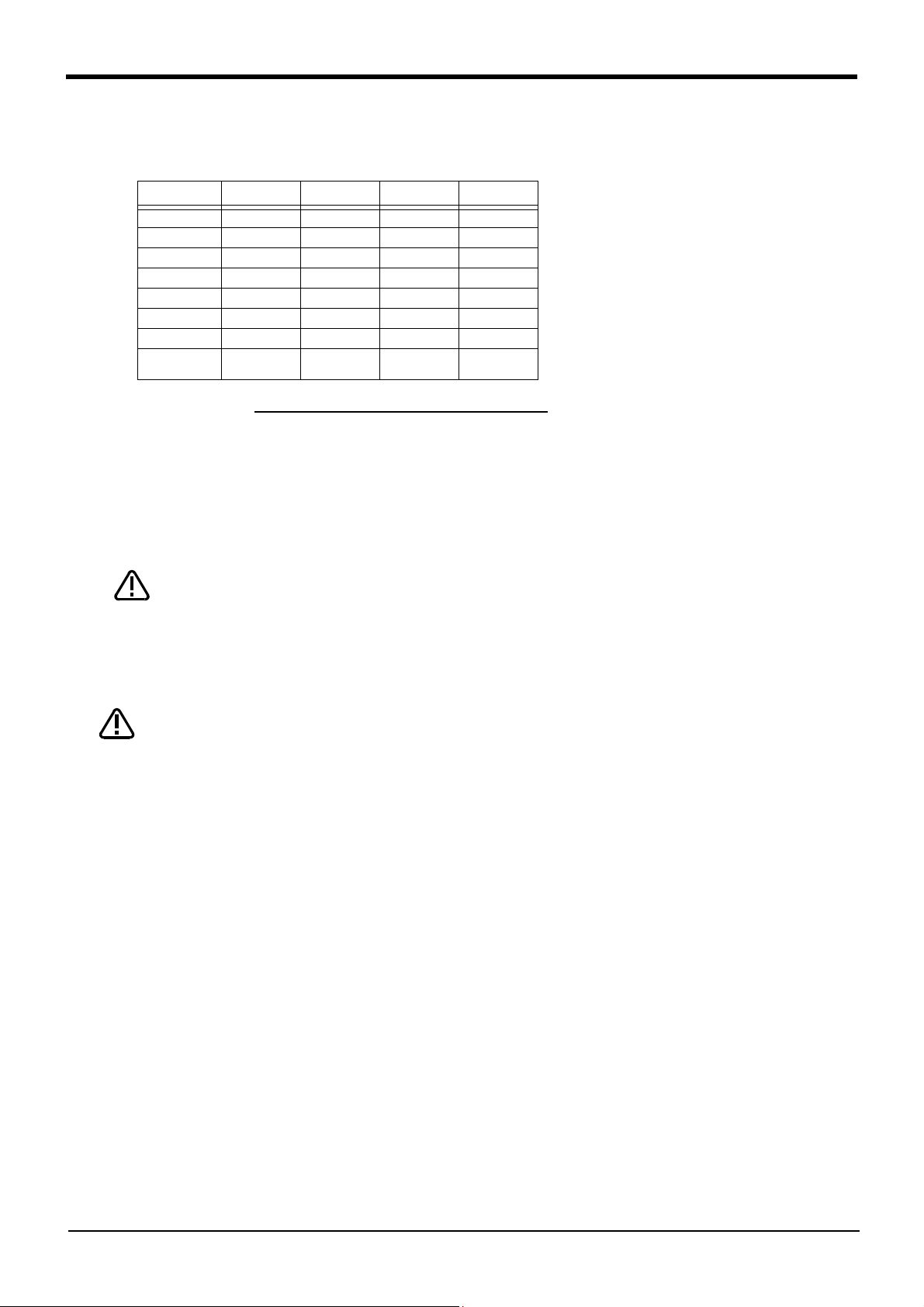

2.3.2 Setting the origin with the origin data input method (1) Confirming the origin data

● Origin data history table (Origin Data History) Serial No.ES804008

Date Default . . . . . . . . .

D V!#S29

J1 06DTYY

J2 2?HL9X

J3 1CP55V

J4 T6!M$Y

J5 Z2IJ%Z0

J6 A12%Z0

Method E E・N・SP E・N・SPE・N・SP

(O: AlphabetO, 0: Zero)

Note) Meanings of symbols in method column

E: Jig method

N: Not used

SP: Not used

Fig.2-8 : Origin data label (an example)

The origin data to be input is noted in the

origin data sheet enclosed with the arm,

or on the origin data history table

attached to the back side of the connector box cover. (Refer to Fig. 2-8).

Referring to "5.3.2 Installing/removing

the cover" on page 44, remove the con-

nector box cover, and confirm the value.

The value given in the default setting

column is the origin settings set with the

calibration jig before shipment.

Note that the 5-axis type does not have

the J4 axis.

WARNING

Always install/remove the cover with the controller control power turned OFF.

Failure to do so could lead to physical damage or personal injury should the robot

start moving due to incorrect operations.

(2) Turning ON the control power

CAUTION

1) Turn the controller [POWER] switch ON.

The control power will be turned ON, and " □ . 100" will appear on the STATUS NUMBER display on the

front of the controller.

Confirm that there are no operators near the robot before turning the power ON.

2-12

Setting the origin

Page 21

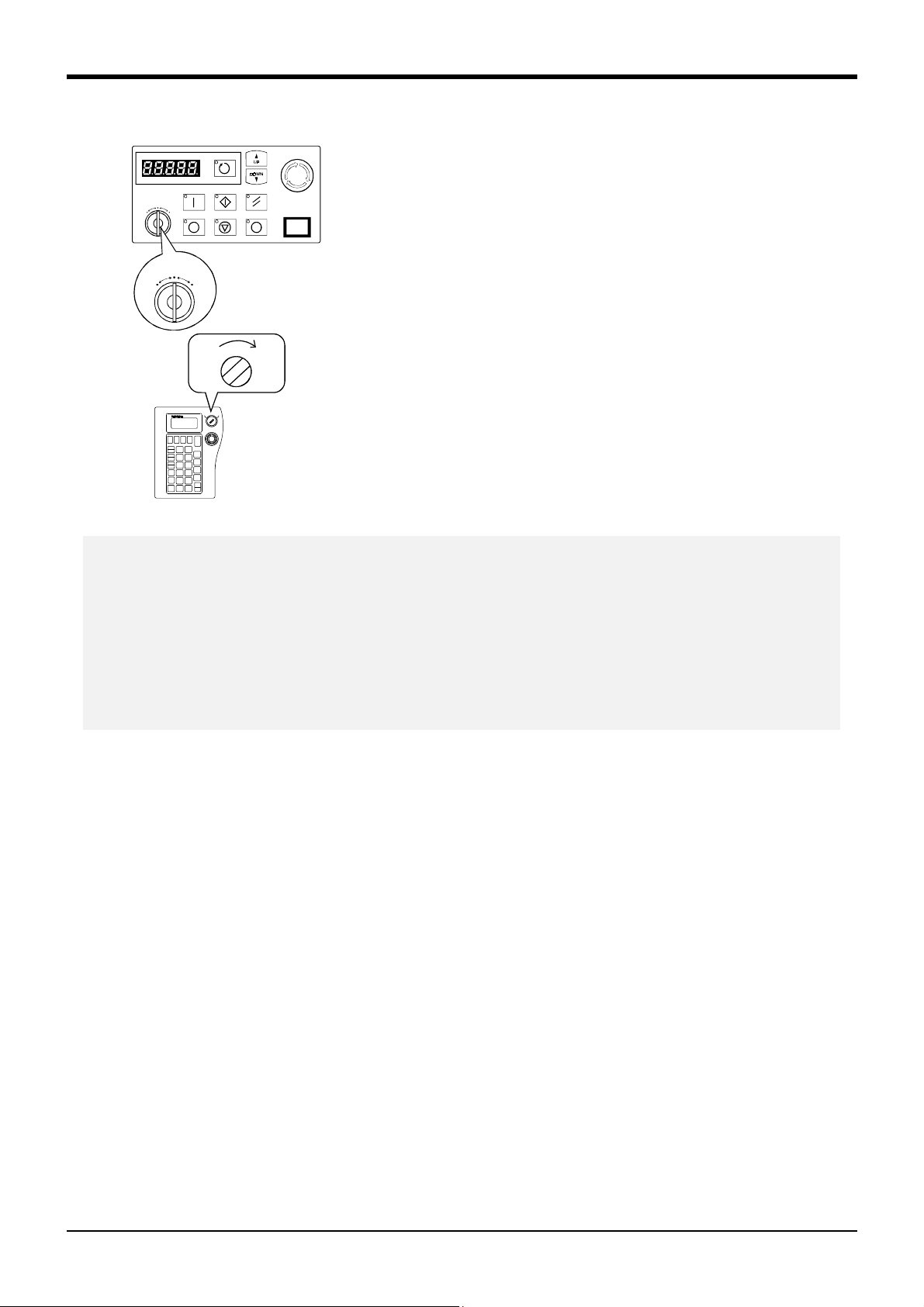

(3) Preparing the T/B

STATUS NUMBER

AUTO

(Op.)

AUTO

(Op.)

TEACH

MODE

TEACH

SVO ONMODE

AUTO

(Ext.)

SVO OFF STOP

AUTO

(Ext.)

CHANG DISP

START

RESET

EMG.STOP

Next, prepare to use the T/B

2Unpacking to Installation

1) Set the [MODE] switch on the front of the controller to "TEACH".

REMOVE T/B

END

DISABLE

ENABLE

2) Set the T/B [ENABLE/DISABLE] switch to "ENABLE". The menu

selection screen will appear.

The following operations are carried out with the T/B.

DISABLE ENABLE

P8TB‑TE

EMG.STOP

◇◆◇ Operating from the T/B ◇◆◇

Always set the [MODE] switch (mode selection key switch) on the front of the controller to "TEACH", and then

set the T/B [ENABLE/DISABLE] switch to "ENABLE".

When the T/B is valid, only operations from the T/B are possible. Operations from the controller or external

signals will not be accepted.

◇◆◇ When T/B operations are mistaken ◇◆◇

The displayed screen will return to the "menu selection screen" when the [MENU] key is pressed. Carry out the

operations again from this screen. Operations can also be carried out again by setting the T/B [ENABLE/

DISABLE] switch to "DISABLE" once and then setting to "ENABLE".

Setting the origin

2-13

Page 22

2Unpacking to Installation

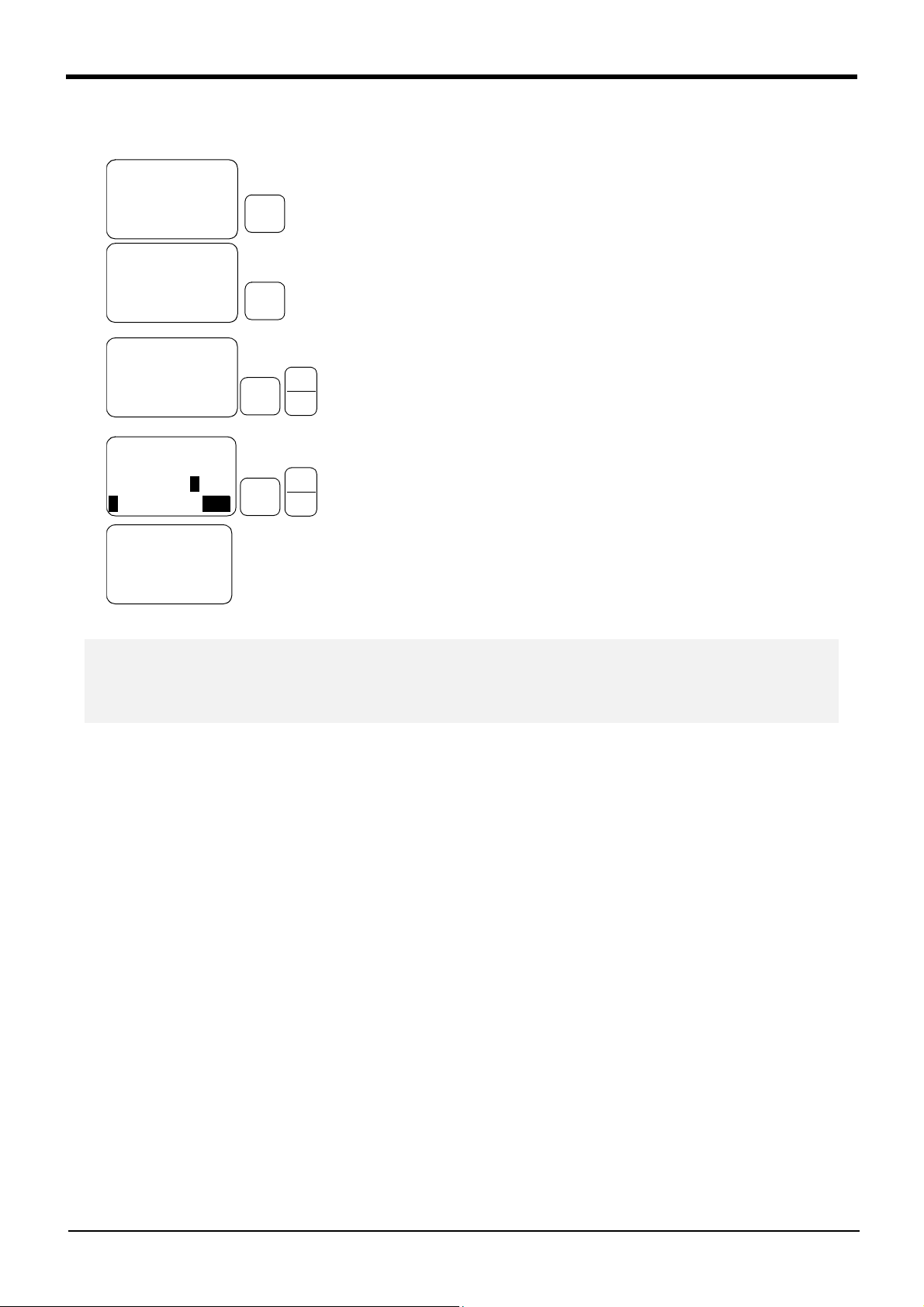

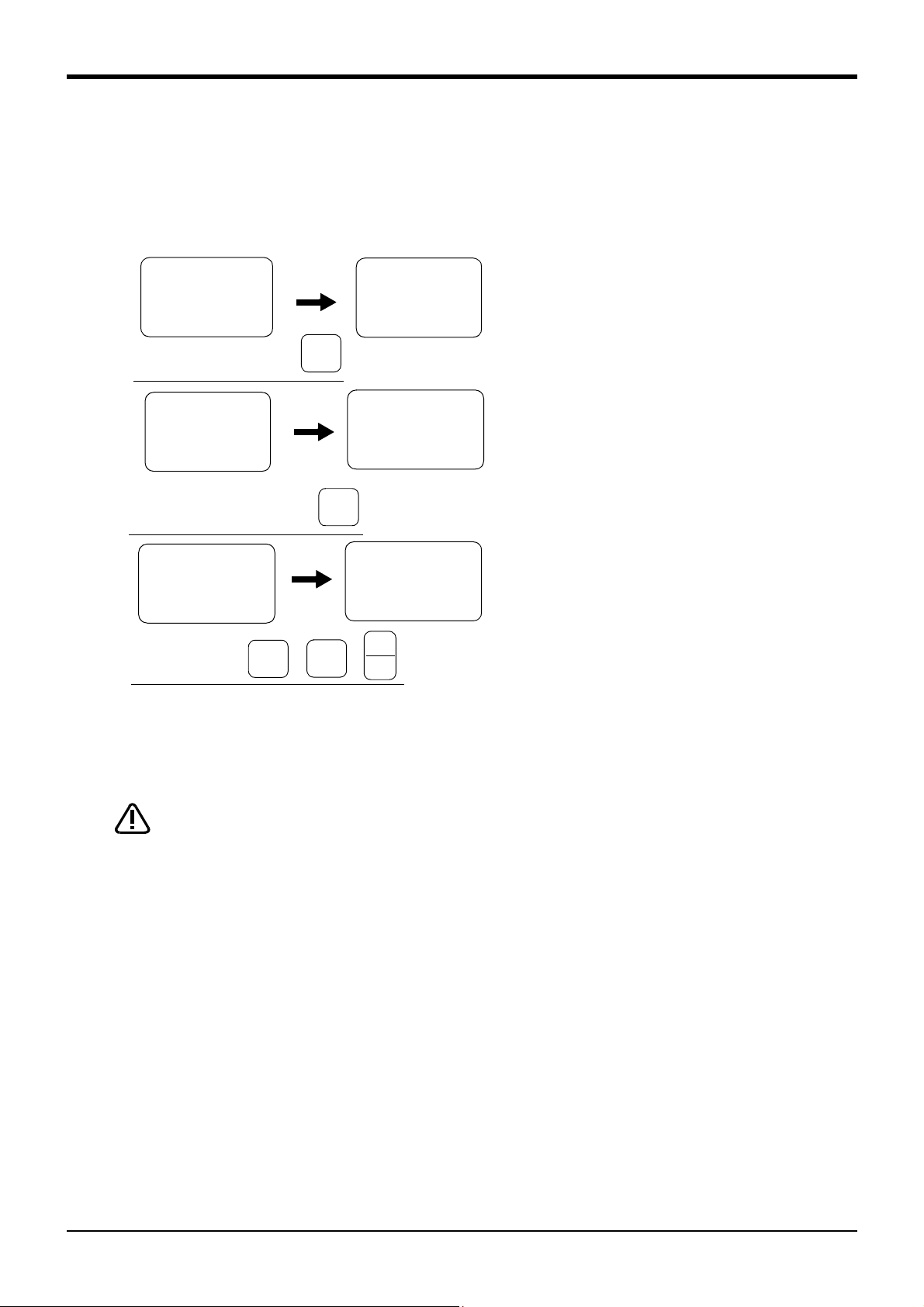

(4) Selecting the origin setting method

<T/B screen> [Keys used]

<MENU>

1.TEACH 2.RUN

3.FILE 4.MONI

5.MAINT 6.SET

5

+C

(J6)

STU

1) Press the [5] key on the menu screen, and display the maintenance screen.

<MAINT>

1.

PARAM2.INIT

3.

BRAKE4.ORIGIN

5.

POWER

<ORIGIN>

1.DATA 2.MECH

3.JIG 4.ABS

5.USER

<ORIGIN>

SERVO OFF

OK?(1)

1:EXECUTE

<

DATA>D(000000)

1

1

4

(J2)

-B

(J5)

-B

(J5)

-Y

MNO

DEF

DEF

2) Press the [4] key on the maintenance screen, and display the origin setting

method selection screen.

3) Press the [1] key on the origin setting method selection screen, and select

INP

EXE

the data input method.

The origin data input method will be selected, and the screen for turning

OFF the servo power will appear.

4) Press the [1] and [INP] keys to turn OFF the servo power. The screen for

INP

EXE

inputting the origin data will appear.

1:000000 000000

3:000000 000000

5:000000 000000

◇◆◇ Selecting a menu ◇◆◇

The menu can be selected with one of the following methods.

A: Press the numeral key for the No. of the item to be selected.

B: Using the [ ↓ ] and [ ↑ ] keys, etc., move the cursor to the item to be selected, and then press the [INP] key.

2-14

Setting the origin

Page 23

(5) Inputting the origin data

2Unpacking to Installation

Input the value confirmed in section "(1) Confirming the origin

T/B screen

<DATA> D( D

1: J1

J2

Origin data label

(D,J1,J2,J3,J4,J5,J6)

)

data" on page 12.

The correspondence of the origin data label value and axis to be

input is shown in Fig. 2-9.(For the 5-axis robot, the J4 axis is

meaningless.)

3: J3 J4

5: J5 J6

Fig.2-9 : Correspondence of origin data label and axis

The method for inputting the origin data is explained below. The value shown in Fig. 2-8will be input as an example.

<T/B screen> [Keys used]

<

DATA>D(000000)

1:000000 000000

3:000000 000000

1) Confirm that the cursor is at the "D" position on the T/B display

screen.

5:000000 000000

<

DATA

>D(V00000)

1:000000 000000

3:000000 000000

5:000000 000000

POS

CHAR

+

+B

(J5)

6

VWX

2) Input the D value V!%S29.

Inputting "V"

Press the [VWX] key once while holding down the [CHAR] key. "V" will

appear, so release the [CHAR] key. "V" will be set.

<

DATA

>D(V!0000)

1:000000 000000

3:000000 000000

5:000000 000000

<

DATA

>D(V!0000)

1:000000 000000

3:000000 000000

5:000000 000000

<

DATA

>D(V!%S29)

1:000000 000000

3:000000 000000

5:000000 000000

<

DATA

>D(V!%S29)

1:A@B&8F G#$Y5#

3:H+7%2H B="!1L

5:59A37! K8#&6P

POS

POS

POS

2

CHAR

CHAR

CHAR

-A

(J4)

RPL

↓

INP

EXE

GHI

+

+

+

5

9

SPD

#%!

SPD

#%!

+C

(J6)

+Y

(J2)

Inputting "!"

Press the [#%!] key three times while holding down the [CHAR] key. "!"

will appear, so release the [CHAR] key. "!" will be set.

In the same manner, while holding down the [CHAR] key, press the

["%"] key twice, and the [STU] key once (input "S").

Release the [CHAR] key, and press the [2] key (input "2") and then

the [9] key (input "9").

V!%S29 will appear at the "D" data on the teaching pendant screen.

STU

&<>

3) Press the [ ↓ ] key, and move the cursor to the J1 input position.

4) Input the J1 value in the same manner as above.

5) Input the J2, J3, J4, J5 and J6 values in the same manner. Note

that the J4 axis is not required for the 5-axis type.

6) After inputting all of the values, press the [INP] key. The origin

setting confirmation screen will appear.

<

DATA

>D(V!%S29)

CHANGES TO ORIGIN

OK? (1)

1:EXECUTE

1

-B

(J5)

DEF

INP

EXE

7) Press [1] (-B/-P) and [INP] key to end the origin setting

Setting the origin

2-15

Page 24

2Unpacking to Installation

i

◆◇ Moving the cursor ◇◆◇

Press the [ ↑ ], [ ↓ ], [ ← ] and [ → ] keys.

◆◇ Inputting characters ◇◆◇

Hold down the [CHAR] key and press the key with the character to be input on the lower right. Three characters w

scroll each time the character key is pressed.

◇◆◇ Correcting an input ◇◆◇

After returning one character by pressing the [DEL] key, input the character again.

(6) Installing the connector box cover

Return the connector box cover, removed in section "(1) Confirming the origin data" on page 12 to its original

position.

This completes the setting of the origin with the origin data input method.

Always remove and install the cover with the controller power turned OFF. Failure

WARNING

to do so could lead to the robot moving because of incorrect operations, or to

physical damage or personal injury.

◇◆◇ If the origin input data is incorrect ◇◆◇

If the origin input data is incorrect, the alarm No. 1760 (origin setting data illegal) will occur when origin data input.

In this case, reconfirm the value input for the origin data.

2-16

Setting the origin

Page 25

2Unpacking to Installation

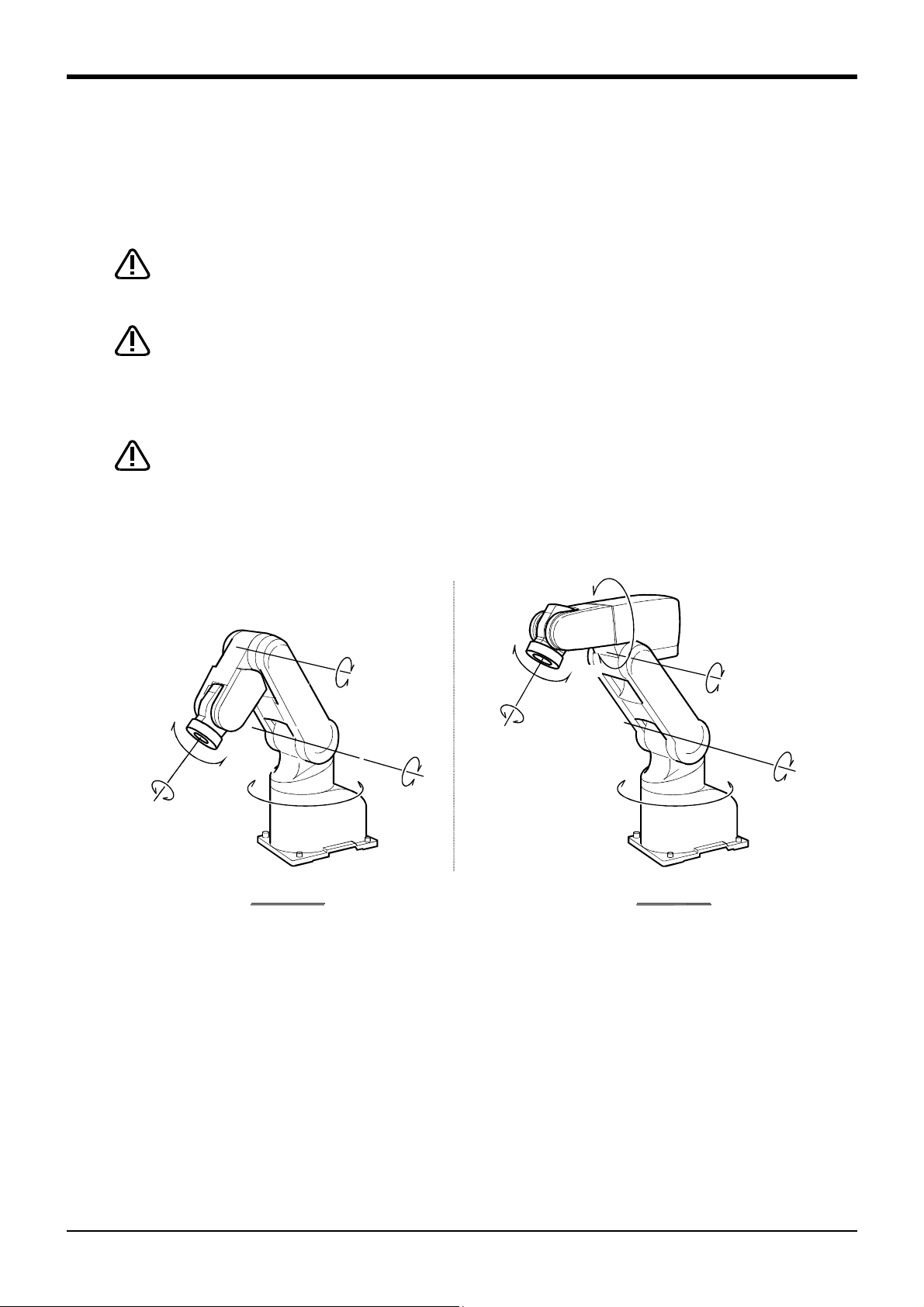

2.4 Confirming the operation

In this section, the robot will be moved manually using the T/B to confirm that the operation is correct.

Moving the robot manually is called "jog operation". This operation includes the JOINT jog that moves each axis,

the XYZ jog that moves along the base coordinate system, the TOOL jog that moves along the tool coordinate

system, and the CYLNDER jog that moves along the circular arc.

This operation is carried out while pressing the deadman switch on the back of the T/B.

CAUTION

CAUTION

CAUTION

The robot will move during this operation. Make sure that there are no operators

near the robot, and that there are no obstacles, such as tools, in the robot operation

range.

To immediately stop the robot, release the deadman switch on the back of the T/B.

The servo power will turn OFF, and the robot will stop.

The robot will also stop if the [EMG.STOP] switch (emergency stop switch) on the

front of the T/B or the [EMG.STOP] switch (emergency stop) on the front of the

controller is pressed.

Confirm that the origin has been set. If the origin has not been set, "****" will

appear at the current position display on the teaching pendant, the JOINT jog operation will take place in any jog mode selected.

Refer to "2.3 Setting the origin" on page 11 for details on setting the origin.

-

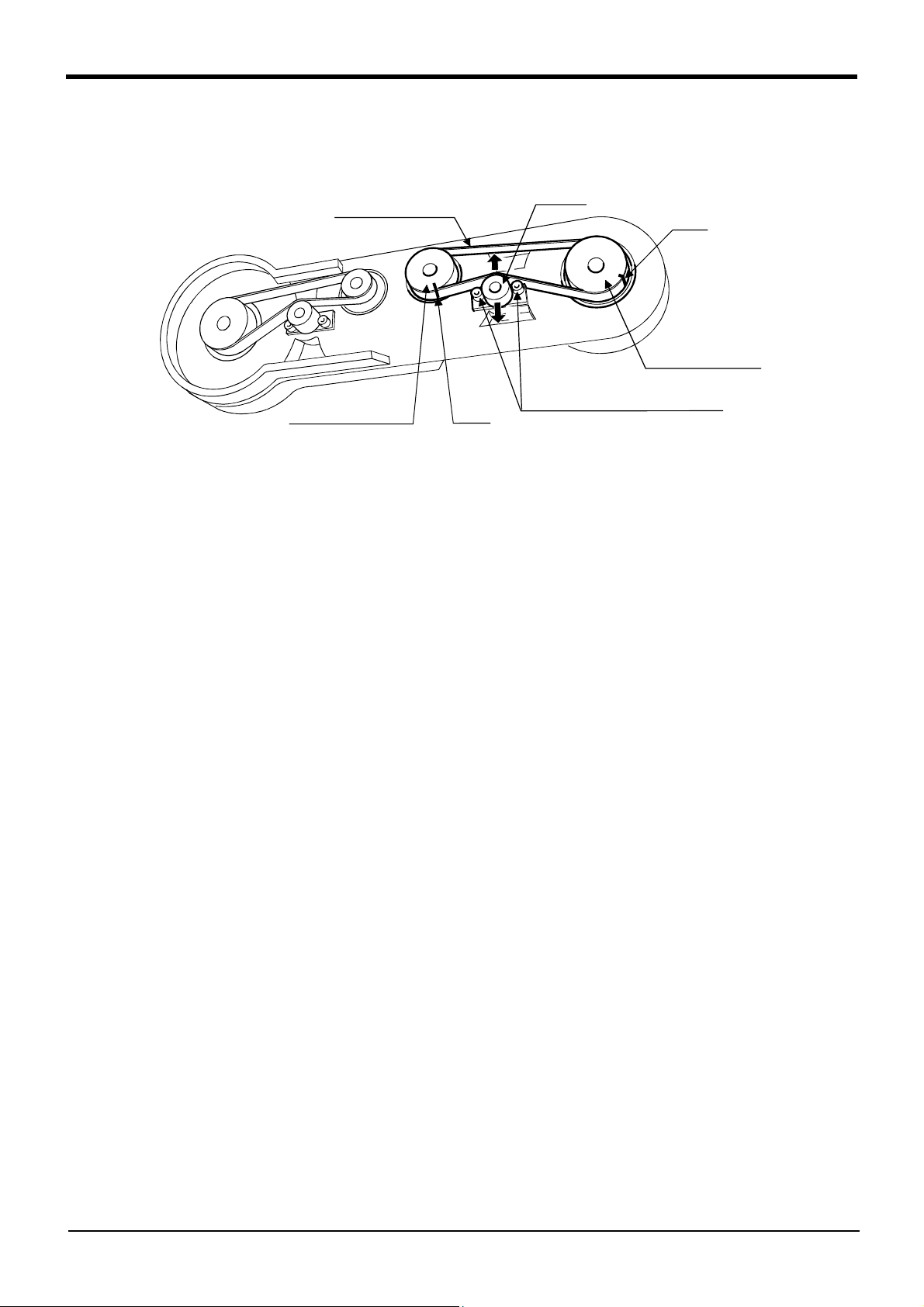

J5 axis

+

+

J6 axis

Fig.2-10 : JOINT jog operation

-

-

J1 axis

J3 axis

-

+

J2 axis

-

+

+

-

J5 axis

+

J6 axis

-

* Each axis moves independently.

The 5-axis type does not have the J4 axis.

-

+

J4 axis

-

J1 axis

6-axis type5-axis type

J3 axis

-

+

J2 axis

-

+

Confirming the operation

2-17

Page 26

2Unpacking to Installation

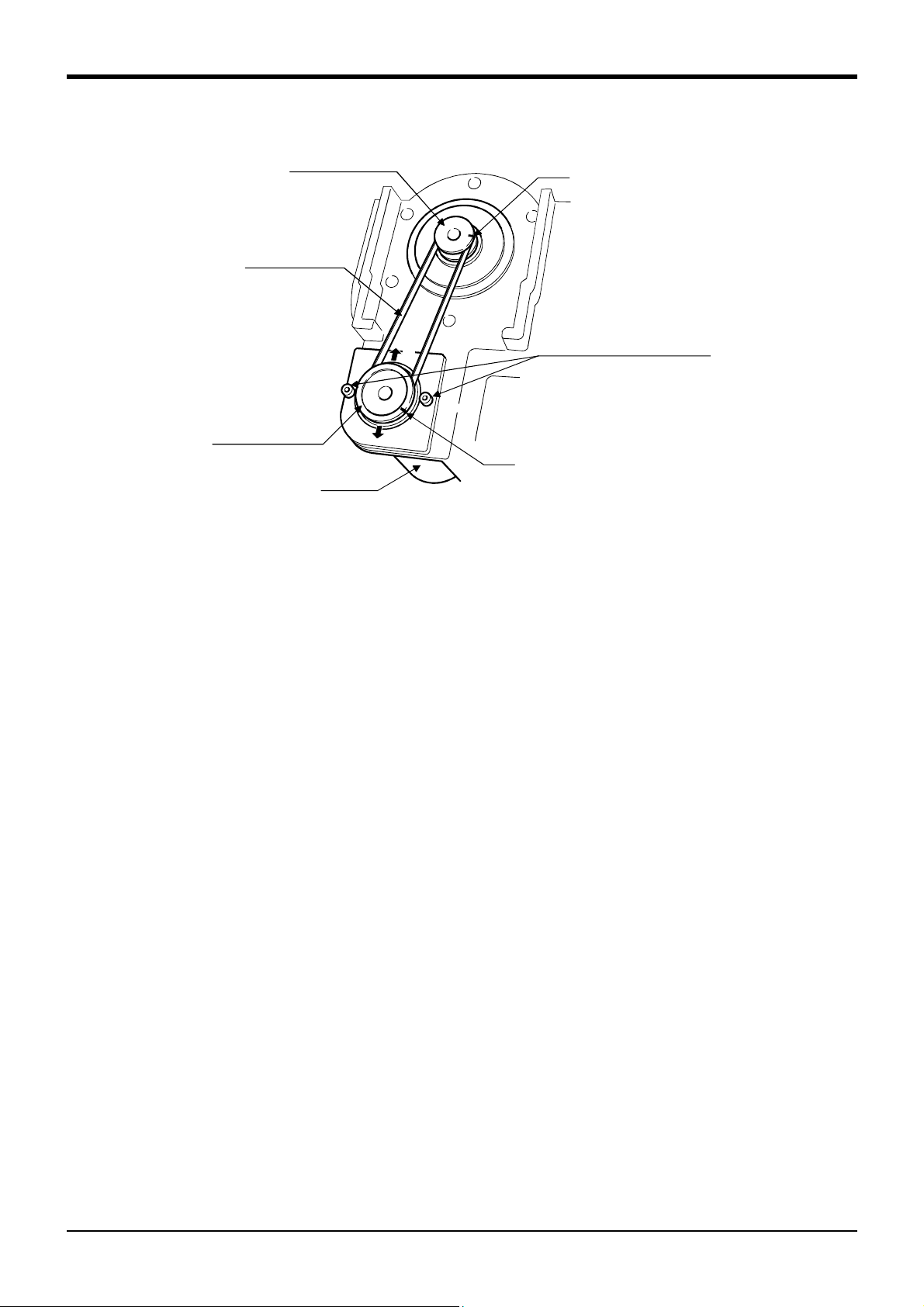

Tool length

-Y

-

+

Control point

-

+

+X

* While maintaining the flange surface posture, the axis moves straight along the base coor-

dinate system.

Also, while maintaining the flange surface position, the flange surface posture changes.

Fig.2-11 : XYZ jog operation

+Z

-Z

5-axis type

+Y

-X

+Z

-

Tool length

+

-

+X

Control point

+

+

-

+Y

+X

-Y

+Z

-Z

6-axis type

-X

+Y

Tool length

+Y

+Z

Control point

+X

* While maintaining the flange surface posture, the axis moves straight along the tool

coordinate system.

Also, while maintaining the flange surface position, the flange surface posture changes.

With the 5-axis type, the axis moves only in the X and Y axis directions of the tool

coordinates.

Fig.2-12 : TOOL jog operation

5-axis type

-X

-Y

+

+Z

Control point

Tool length

-

-Z

+

+

-

+Y

-

+X

6-axis type

2-18

Confirming the operation

Page 27

2Unpacking to Installation

+Z

-

J6

+

-

J5

+

-Y

Control

point

+X

-Z

5-axis type

Tool length

* The axis moves straight along the base coordinate system. At this time, the flange surface

posture is not maintained.

Also, the flange surface posture changes. The flange surface position changes at this time.

Fig.2-13 : 3-axis XYZ jog operation

+Y

-X

Tool length

+

J6

-

J5

-

+

-

+

Control point

-Y

+X

+Z

J4

-Z

6-axis type

-X

+Y

+Z

+Z

Vertical

Tool length

Tool length

Redius

Vertical

Control

point

Arc

+X

-Y

5-axis type

-Z

Redius

Control point

-X

+Y

Arc

-Y

+X

-Z

6-axis type

* The current position is set as the arc centering on the Z axis, and the axis moves along that arc,

expands and contracts in the radius direction, and moves vertically. At this time, for the 6-axis type, the

flange surface posture is maintained. Also, while maintaining the flange surface position, the flange

surface posture changes.

-X

+Y

Fig.2-14 : CYLINDER jog operation

Confirming the operation

2-19

Page 28

2Unpacking to Installation

(1) JOINT jog operation

Select the JOINT jog mode

JOINT LOW

J1 +34.50

J2 +20.00

J3 +80.00

Set the jog speed

JOINT LOW

J1 +34.50

J2 +20.00

J3 +80.00

J1 axis jog operation

STEP

JOINT jog mode

STEP

Set the speed

MOVE

MOVE

+

FORWD-BACKWD

JOINT

+

( )?

+

Press the [MOVE] + [JOINT] keys to select the

JOINT jog mode. "JOINT" will appear at the upper

left of the screen.

Each time the [MOVE] + [+] keys are pressed, the

override will increase in the order of LOW → HIGH →

3 → 5 → 10 → 30 → 50 → 70 → 100%.

When the [MOVE] + [-] keys are pressed, the

override will decrease in the reverse order.

The currently set speed will appear on the upper right

of the screen.

Set the override to 10% here for confirmation work.

STEP

MOVE

+

SPACE

- X

(J1)

-

POR

STEP

MOVE

+

+

+ X

(J1)

' ; ^

STEP

MOVE

+

SPACE

- X

(J1)

-

POR

J1 axis

5-axis type

6-axis type

・ When the [MOVE] + [+X (J1)] keys are pressed, the J1 axis will rotate in the plus direction.

When the [MOVE] + [-X (J1)] keys are pressed, Rotate in the minus direction.

J2 axis jog operation

+

+

- Y

(J2)

MNO

4

&< >

9

+Y

(J2)

-

+

+

- Y

(J2)

MNO

4

-

STEP

MOVE

+

STEP

MOVE

+

+Y

(J2)

&< >

9

STEP

MOVE

STEP

MOVE

STEP

MOVE

J1 axis

+

+

+ X

(J1)

' ; ^

5-axis type

6-axis type

・ When the [MOVE] + [+Y (J2)] keys are pressed, the J2 axis will rotate in the plus direction.

When the [MOVE] + [-Y (J2)] keys are pressed, Rotate in the minus direction.

◆◇ When the robot is in the transportation posture ◇◆◇

The axes may be outside the movement area. Move these axes toward the inner side of the movement area. If

moved outward, an X will appear on the T/B screen, and the robot will not move.

2-20

Confirming the operation

X

Page 29

J3 axis jog operation

STEP

MOVE

+

JKL

3

J3 axis

+

- Z

(J3)

3

+ Z

(J3)

, @\

6-axis type

STEP

MOVE

STEP

MOVE

+

- Z

(J3)

JKL

3

J3 axis

+

+ Z

(J3)

, @\

3

5-axis type

STEP

MOVE

・ When the [MOVE] + [+Z (J3)] keys are pressed, the J3 axis will rotate in the plus direction.

When the [MOVE] + [-Z (J3)] keys are pressed, Rotate in the minus direction.

2Unpacking to Installation

J4, J5 and J6 axis jog

STEP

MOVE

STEP

MOVE

J6 axis

+

+

(J6)

0 ABC

5

- C

+ C

(J6)

-

STU

+

J5

-

axis

+

STEP

MOVE

STEP

MOVE

+

+

- B

(J5)

DEF

1

B

+

(J5)

6VWX

5-axis type

STEP

MOVE

STEP

MOVE

+ C

(J6)

+

5

axis

J6

- C

+

(J6)

0

STU

-

ABC

+

-

J5axis

STEP

MOVE

+

STEP

MOVE

- B

+

(J5)

1

DEF

J

4

axis

+

-

B

+

(J5)

VWX

6

6-axis type

・ When the [MOVE] + [+A (J4)] keys are pressed, the J4 axis will rotate in the plus direction.

When the [MOVE] + [-A (J4)] keys are pressed, Rotate in the minus direction. (6-axis type only)

・ When the [MOVE] + [+B (J5)] keys are pressed, the J5 axis will rotate in the plus direction

When the [MOVE] + [-B (J5)] keys are pressed, Rotate in the minus direction.

・ When the [MOVE] + [+C (J6)] keys are pressed, the J6 axis will rotate in the plus direction

When the [MOVE] + [-C (J6)] keys are pressed, Rotate in the minus direction.

STEP

MOVE

STEP

MOVE

+ A

(J4)

+

7 YZ_

-

(J4)

+

2

A

GHI

◇◆◇ When an X appears on the T/B screen display ◇◆◇

If the robot is moved outside the movement area, an X will appear. In this case, move the axis in the opposite

X

X

direction.

JOINT LOW

XJ1 +160.00

X

In the example on the left, the J1 axis is at the limit of the plus side movement area.

J2 +20.00

J3 +80.00

Confirming the operation

2-21

Page 30

2Unpacking to Installation

X

(2) XYZ jog operation

Select the XYZ jog mode

X,Y,Z

LOW

X +134.50

Y +220.00

Z +280.00

Set the jog speed

X,Y,Z

LOW

X +134.50

Y +220.00

Z +280.00

Moving along the base coordinate system

+

+X

+

(J2)

4

(J1)

- Y

+ X

STEP

MOVE

STEP

MOVE

XYZ jog mode

Set the speed

+

+ Z

(J3)

, @\

8

STEP

MOVE

+Z

MNO

Tool length

+Y

STEP

+

STEP

MOVE

+

MOVE

3

- Z

(J3)

JKL

' ; ^

5-axis type

STEP

MOVE

-Y

+Y

(J2)

9 &< >

MOVE

STEP

MOVE

+X

STEP

+

+Z

SPACE POR

-Z

+

- X

(J1)

XYZ

+

$":

+

FORWD-BACKWD

-X

+Y

Press the [MOVE] + [XYZ] keys to select the XYZ

jog mode. "XYZ" will appear at the upper left of

the screen.

Each time the [MOVE] + [+] keys are pressed, the

override will increase in the order of LOW → HIGH

→ 3 → 5 → 10 → 30 → 50 → 70 → 100%. When

the [MOVE] + [-] keys are pressed, the override

will decrease in the reverse order. The currently

set speed will appear on the upper right of the

screen. Set the override to 10% here for

confirmation work.

+Z

+

+Z

+ Z

(J3)

8 , @\

+

- X

(J1)

SPACE POR

STEP

MOVE

STEP

MOVE

+

- Y

(J2)

4 MNO

STEP

MOVE

Tool length

STEP

MOVE

+X

+

(J1)

+ X

' ; ^

STEP

MOVE

+

STEP

MOVE

- Z

(J3)

3 JKL

+Y

+

+Y

(J2)

9 &< >

+X

-Y

-Z

6-axis type

※ The direction of the frange will not change

-

+Y

・ When the [MOVE] + [+X (J1)] keys are pressed, the robot will move along the X axis plus direction.

When the [MOVE] + [-X (J1)] keys are pressed, Move along the minus direction.

・ When the [MOVE] + [+Y (J2)] keys are pressed, the robot will move along the Y axis plus direction.

When the [MOVE] + [-Y (J2)] keys are pressed, Move along the minus direction.

・ When the [MOVE] + [+Z (J3)] keys are pressed, the robot will move along the Z axis plus direction.

When the [MOVE] + [-Z (J3)] keys are pressed, Move along the minus direction.

◆◇ When the robot is in the transportation posture ◇◆◇

There are directions from which linear movement is not possible from the transportation posture. In this case, an

X will appear on the T/B screen, and the robot will not move. Refer to section "(1) JOINT jog operation" on page

X

20", and move the robot to a position where linear movement is possible, and then carry out XYZ jog.

◆◇ When an X appears on the T/B screen display ◇◆◇

If the robot is moved outside the movement area with any of the axes, an X will appear. In this case, move the axis

in the opposite direction.

XYZ LOW

X

X X +360.00

X

X Y +280.00

X

X Z +170.00

2-22

Confirming the operation

X

X

In the example on the left, further linear movement in the same direction is not possible.

Page 31

Changing the flange surface posture

◇◆◇

◇

+Z

+

- C

(J6)

+Z

ABC

0

-

STEP

MOVE

+

STEP

MOVE

2Unpacking to Installation

+

+ C

(J6)

5 STU

+Z

Control point

(Tool coordinate system)

STEP

+

MOVE

7

+

+Z

STEP

+

MOVE

Tool length

+ A

(J4)

YZ_

-

- A

(J4)

2 GHI

STEP

MOVE

+

STEP

MOVE

+

6 VWX

-

+Y

+ B

(J5)

+

STEP

MOVE

- B

(J5)

DEF

1

STEP

MOVE

+X

+Y

+

+X

+

+ A

(J4)

YZ_

7

+

-

- A

(J4)

2 GHI

Control

point

STEP

MOVE

Tool length

+

+

6-axis type5-axis type

6

* The control point does not change.

・ When the [MOVE] + [+A (J4)] keys are pressed,

6-axis type: The X axis will rotate in the plus direction.

5-axis type: The Z axis will rotate in the plus direction of the tool coordinate system.

When the [MOVE] + [-A (J4)] keys are pressed, Rotate in the minus direction.

・ When the [MOVE] + [+B (J5)] keys are pressed,

6-axis type: The Y axis will rotate in the plus direction.

5-axis type: The Y axis will rotate in the plus direction of the tool coordinate system.

When the [MOVE] + [-B (J5)] keys are pressed, Rotate in the minus direction.

-

(J5)

+Y

+ B

VWX

+X

STEP

MOVE

-Y

+

- B

(J5)

DEF

1

+Y

・ When the [MOVE] + [+C (J6)] keys are pressed,

6-axis type: The Z axis will rotate in the plus direction.

5-axis type: There is no operation.

When the [MOVE] + [-C (J6)] keys are pressed,

6-axis type: Rotate in the minus direction.

5-axis type: There is no operation.

◇◆◇ When alarm No. 5150 occurs ◇◆◇

If alarm No. 5150 (ORIGIN NOT SET) occurs, the origin has not been set correctly. Reconfirm the value input for

the origin data.

Tool length◇◆

The default tool length is 0mm, and the control point is the center of the end axis.

After installing the hand, set the correct tool length in the parameters. Refer to the separate manual "Detailed

Explanation of Functions and Operations" for details.

Confirming the operation

2-23

Page 32

2Unpacking to Installation

(3) TOOL jog operation

Select the TOOL jog mode

TOOL LOW

X +134.50

Y +220.00

Z +280.00

Set the jog speed

TOOL LOW

X +134.50

Y +220.00

Z +280.00

Moving along the tool coordinate system

TOOL jog mode

Set the speed

STEP

MOVE

STEP

+

MOVE

+

+

FORWD-BACKWD

TOOL

=*/

STEP

MOVE

Press the [MOVE] + [TOOL] keys to select the

TOOL jog mode. "TOOL" will appear at the upper

left of the screen.

Each time the [MOVE] + [+] keys are pressed, the

override will increase in the order of LOW → HIGH

→ 3 → 5 → 10 → 30 → 50 → 70 → 100%. When

the [MOVE] + [-] keys are pressed, the override

will decrease in the reverse order. The currently

set speed will appear on the upper right of the

screen. Set the override to 10% here for

confirmation work.

- X

(J1)

+

SPEACE POR

STEP

MOVE

STEP

MOVE

+

+Z

+

- X

(J1)

SPEACE POR

+ Z

(J3)

8

Tool length

, @\

STEP

MOVE

+Y

+X

STEP

MOVE

5-axis type

+

+

3 JKL

+ X

(J1)

' ; ^

- Z

(J3)

STEP

MOVE

+

STEP

MOVE

4

- Y

(J2)

+Z

+

MNO

+ Z

(J3)

8

Tool length

, @\

STEP

MOVE

STEP

MOVE

6-axis type

+Y

- Z

(J3)

+

JKL

3

+

+Y

(J2)

&< >

9

STEP

MOVE

+X

+ X

(J1)

+

' ; ^

* The direction of the frange will not change.

・When the [MOVE] + [+X (J1)] keys are pressed, the robot will move along the X axis plus direction of the tool

coordinate system.

When the [MOVE] + [-X (J1)] keys are pressed, Move along the minus direction.

・When the [MOVE] + [+Y (J2)] keys are pressed, the robot will move along the Y axis plus direction of the tool

coordinate system.

When the [MOVE] + [-Y (J2)] keys are pressed, Move along the minus direction. (6-axis type only)

・When the [MOVE] + [+Z (J3)] keys are pressed, the robot will move along the Z axis plus direction of the tool

coordinate system.

When the [MOVE] + [-Z (J3)] keys are pressed, Move along the minus direction.

◇◆◇ When the robot is in the transportation posture ◇◆◇

There are directions from which linear movement is not possible from the transportation posture. In this case,

an X will appear on the T/B screen, and the robot will not move. Refer to section "(1) JOINT jog operation" on

X

page 20, and move the robot to a position where linear movement is possible, and then carry out TOOL jog.

2-24

Confirming the operation

Page 33

2Unpacking to Installation

◆◇ When an X appears on the T/B screen display ◇◆◇

If the robot is moved outside the movement area with any of the axes, an X will appear. In this case, move the axis

X

X

in the opposite direction.

TOOL LOW

X

X X +360.00

X

X Y +280.00

X

X Z +170.00

In the example on the left, further linear movement in the same direction is not possible.

Changing the flange surface posture

+ C

(J6)

+

STU

+

J6

- B

(J5)

DEF

1

-

STEP

MOVE

+

J5

-

STEP

MOVE

+

+

STEP

MOVE

- C

(J6)

ABC

0

+

6VWX

+ B

(J5)

STEP

MOVE

+Z

+

5-axis type

+

5

0

+ C

(J6)

- C

(J6)

Tool length

STU

-

ABC

STEP

MOVE

+

7

MOVE

-

+Y

+

-

+

+X

+ A

(J4)

YZ_

6-axis type

STEP

STEP

MOVE

+

+

STEP

MOVE

- B

(J5)

DEF

1

+ B

(J5)

6VWX

- A

+

(J4)

2

GHI

STEP

MOVE

+

STEP

MOVE

5

* The control point does not change.

・ When the [MOVE] + [+A (J4)] keys are pressed,

6-axis type: The X axis will rotate in the plus direction of the tool coordinate system.

5-axis type: There is no operation.

When the [MOVE] + [-A (J4)] keys are pressed,

6-axis type: Rotate in the minus direction.

5-axis type: There is no operation.

・ When the [MOVE] + [+B (J5)] keys are pressed,

6-axis type: The Y axis will rotate in the plus direction of the tool coordinate system.

5-axis type: The J5 axis will rotate in the plus direction.

When the [MOVE] + [-B (J5)] keys are pressed, Rotate in the minus direction.

・ When the [MOVE] + [+C (J6)] keys are pressed,

6-axis type: The Z axis will rotate in the plus direction of the tool coordinate system.

5-axis type: The J6 axis will rotate in the plus direction.

When the [MOVE] + [-C (J6)] keys are pressed, Rotate in the minus direction.

◇◆◇ When alarm No. 5150 occurs ◇◆◇

If alarm No. 5150 (ORIGIN NOT SET) occurs, the origin has not been set correctly. Reconfirm the value input for

the origin data.

◇◆◇ Tool length ◇◆◇

The default tool length is 0mm, and the control point is the center of the end axis.

After installing the hand, set the correct tool length in the parameters. Refer to the separate manual "Detailed

Explanation of Functions and Operations" for details.

Confirming the operation

2-25

Page 34

2Unpacking to Installation

X

p

◇◆◇

◇◆◇

(4) 3-axis XYZ jog operation

Select the 3-axis XYZ jog mode

XYZ456 LOW

X +134.50

Y +220.00

Z +280.00

3-axis XYZ jog mode

Set the jog speed

XYZ456 LOW

X +134.50

Y +220.00

Z +280.00

Set the soeed

STEP

MOVE

Moving along the base coordinate system

+Z

+

8

+Z

STEP

MOVE

+

3

5-axis ty

+ Z

(J3)

, @\

Tool length

- Z

(J3)

JKL

+Y

+

STEP

+

MOVE

SPACE POR

-Y

+Y

(J2)

+X

&< >

9

-Z

e

STEP

MOVE

+

STEP

MOVE

- Y

(J2)

4 MNO

+X

+

(J1)

STEP

MOVE

+ X

' ; ^

STEP

MOVE

STEP

MOVE

+

+

FORWD-BACKWD

- X

(J1)

+Y

+

-X

XYZ

$":

XYZ

Press the [MOVE] + [XYZ] keys, and then

press only the [XYZ] key. "XYZ456" will appear

at the upper left of the screen.

$":

Each time the [MOVE] + [+] keys are pressed,

the override will increase in the order of LOW

→ HIGH → 3 → 5 → 10 → 30 → 50 → 70 →

100%. When the [MOVE] + [-] keys are pressed,

the override will decrease in the reverse order.

The currently set speed will appear on the

upper right of the screen. Set the override to

10% here for confirmation work.

+

+Z

+

+ Z

(J3)

8 , @\

Tool length

STEP

MOVE

- Z

(J3)

JKL

3

STEP

MOVE

+Y

+Y

+

(J2)

9 &< >

-Y

+X

6-axis type

+

+Z

- X

(J1)

SPACE POR

-Z

STEP

MOVE

STEP

MOVE

+X

+

+

4

+ X

(J1)

- Y

(J2)

STEP

MOVE

MNO

' ; ^

STEP

MOVE

* The flange position does change.

-

+Y

・ When the [MOVE] + [+X (J1)] keys are pressed, the robot will move along the X axis plus direction.

When the [MOVE] + [-X (J1)] keys are pressed, Move along the minus direction.

・ When the [MOVE] + [+Y (J2)] keys are pressed, the robot will move along the Y axis plus direction.

When the [MOVE] + [-Y (J2)] keys are pressed, Move along the minus direction.

・ When the [MOVE] + [+Z (J3)] keys are pressed, the robot will move along the Z axis plus direction.

When the [MOVE] + [-Z (J3)] keys are pressed, Move along the minus direction.

Jog mode will change when only [XYZ] key is pressed again

When the [MOVE] + [XYZ] keys are pressed and then only the [XYZ] key is pressed, the upper left display will

change in the order of "XYZ" → "XYZ456" → "CYLNDER". Each jog mode can be selected.

◇◆◇ The flange surface end axis posture cannot be maintained with 3-axis XYZ jog. ◇◆◇

With 3-axis XYZ jog, the flange surface end axis posture (orientation) is not maintained when moving linearly in

the X, Y or Z axis direction.

Use XYZ jog to maintain the posture.

2-26

Confirming the operation

Page 35

2Unpacking to Installation

Changing the flange surface

STEP

MOVE

STEP

MOVE

J6 axis

+

+

0 ABC

+ C

(J6)

5 STU

-

- C

(J6)

+

J5

-

axis

+

STEP

MOVE

STEP

MOVE

posture

- B

(J5)

+

1

+

(J5)

+

6VWX

5-axis type

+ C

(J6)

+

5

axis

J6

- C

+

(J6)

0

STU

-

ABC

+

-

J5axis

STEP

MOVE

STEP

MOVE

+

- B

+

(J5)

1

DEF

STEP

J

4

axis

MOVE

+

-

B

+

(J5)

VWX

6

STEP

MOVE

STEP

MOVE

DEF

B

STEP

MOVE

6-axis type

* The flange position changes.

This is the same as the J4, J5 and J6 axis JOINT jog operation.

・ When the [MOVE] + [+A (J4)] keys are pressed, the J4-axis will rotate in the plus direction.

When the [MOVE] + [-A (J4)] keys are pressed, Rotate in the minus direction. (6-axis type only)

・ When the [MOVE] + [+B (J5)] keys are pressed, the J5-axis will rotate in the plus direction.

When the [MOVE] + [-B (J5)] keys are pressed, Rotate in the minus direction.

+ A

(J4)

+

7

-

(J4)

+

2

YZ_

A

GHI

・ When the [MOVE] + [+C (J6)] keys are pressed, the J6-axis will rotate in the plus direction.

When the [MOVE] + [-C (J6)] keys are pressed, Rotate in the minus direction.

Confirming the operation

2-27

Page 36

2Unpacking to Installation

(5)

CYLNDER

jog operation

Select the cylindrical jog mode

CYLNDER LOW

R +134.50

T +220.00

Z +280.00

CYLNDER jog mode

Set the jog speed

CYLNDER LOW

R +134.50

T +220.00

Z +280.00

Set the speed

Moving along an arc centering on the Z axis

Vertical

+

-

Arc

+

+ Z