Page 1

MELSEC iQ-R

Motion Module

User's Manual (Startup)

-RD78G4

-RD78G8

-RD78G16

-RD78G32

-RD78G64

-RD78GHV

-RD78GHW

Page 2

Page 3

WHEN USING A HUB WITH CC-Link IE TSN

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

The dedicated TSN hub is required when modules on CC-Link IE TSN are configured in a star topology or hubs are

configured in a cascade connection.

Read the following carefully.

Page 30 Structure of Authentication Class B Devices and Ethernet Devices

Page 40 Hub

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. Refer to the MELSEC iQ-R Module Configuration

Manual for a description of the PLC system safety precautions.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

2

Page 5

[Design Precautions]

WARNING

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Failure to do so may result in an

accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Machine homing is controlled by two kinds of data: a homing direction and a homing speed.

Deceleration starts when the proximity dog signal turns on. If an incorrect homing direction is set,

motion control may continue without deceleration. To prevent machine damage caused by this,

configure an interlock circuit external to the programmable controller.

(2) When the module detects an error, the motion slows down and stops or the motion rapidly stops,

depending on the stop group setting in parameter. Set the parameter to meet the specifications of

a positioning control system. In addition, set the homing parameter and positioning data within the

specified setting range.

(3) Outputs may remain on or off, or become undefined due to a failure of a component such as an

insulation element and transistor in an output circuit, where the module cannot detect any error. In

a system that the incorrect output could cause a serious accident, configure an external circuit for

monitoring output signals.

● If safety standards (ex., robot safety rules, etc.,) apply to the system using the module, drive unit and

servomotor, make sure that the safety standards are satisfied.

● Construct a safety circuit externally of the module or drive unit if the abnormal operation of the module

or drive unit differs from the safety directive operation in the system.

3

Page 6

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the settings are being

written. Doing so will make the data in the flash ROM and SD memory card undefined. The values

need to be set in the buffer memory and written to the flash ROM and SD memory card again. Doing

so also may cause malfunction or failure of the module.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

4

Page 7

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module, and fix it with screw(s). Incorrect interconnection may cause malfunction,

failure, or drop of the module.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette or a battery-less option cassette into the cassette

connector of the CPU module. After insertion, close the cassette cover and check that the cassette is

inserted completely. Poor contact may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, battery-less option cassette, or connector. Doing so can cause

malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach a blank cover module (RG60) to each empty slot and an included

extension connector protective cover to the unused extension cable connector before powering on the

system for operation. Failure to do so may result in electric shock.

5

Page 8

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in malfunction or damage to the module or cables. In addition, the weight of the cables may

put stress on modules in an environment of strong vibrations and shocks. Do not clamp the extension

cables with the jacket stripped. Doing so may change the characteristics of the cables, resulting in

malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in this

manual. If not, normal data transmission is not guaranteed.

6

Page 9

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25 cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

7

Page 10

[Startup and Maintenance Precautions]

CAUTION

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not perform each of the following operations more than 50 times

(IEC 61131-2/JIS B 3502 compliant).

Exceeding the limit may cause malfunction.

• Mounting/removing the module to/from the base unit

• Inserting/removing the extended SRAM cassette or battery-less option cassette to/from the

CPU module

• Mounting/removing the terminal block to/from the module

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette or a batteryless option cassette. Doing so may cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

● Before testing the operation, set a low speed value for the speed limit parameter so that the operation

can be stopped immediately upon occurrence of a hazardous condition.

● Confirm and adjust the program and each parameter before operation. Unpredictable movements

may occur depending on the machine.

● When using the absolute position system function, on starting up, and when the module or absolute

position motor has been replaced, always perform a homing.

● Before starting the operation, confirm the brake function.

● Do not perform a megger test (insulation resistance measurement) during inspection.

● After maintenance and inspections are completed, confirm that the position detection of the absolute

position detection function is correct.

● Lock the control panel and prevent access to those who are not certified to handle or install electric

equipment.

8

Page 11

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM and SD memory card undefined. The values need to be set in the buffer memory and

written to the flash ROM and SD memory card again. Doing so also may cause malfunction or failure

of the module.

● Note that when the reference axis speed is specified for interpolation operation, the speed of the

partner axis (2nd, 3rd, or 4th axis) may exceed the speed limit value.

● Do not go near the machine during test operations or during operations such as teaching. Doing so

may lead to injuries.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

9

Page 12

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the specifications, procedures before operation and wiring of the relevant products listed below. Before

using this product, please read this manual and the relevant manuals carefully and develop familiarity with the functions and

performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

RD78G4, RD78G8, RD78G16, RD78G32, RD78G64, RD78GHV, RD78GHW

Symbols used in this manual are shown below.

• [RD78GH]: Symbols indicating that it corresponds to only RD78GH

• Underlined variables (AxisName

, etc.): Variables defined by users

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated into other

machinery or equipment, certain measures may be necessary. Please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage Directives.

Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

10

Page 13

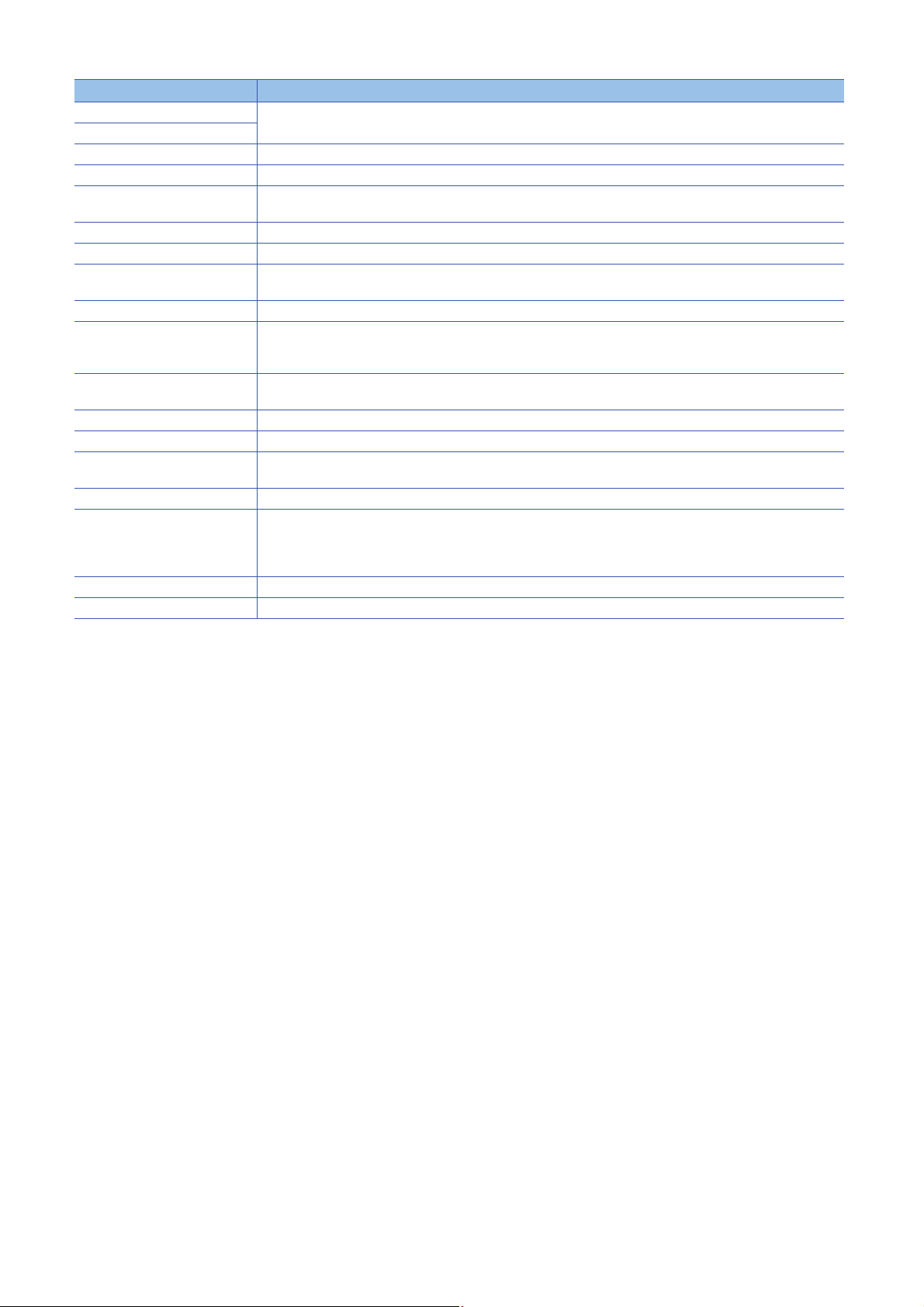

CONTENTS

WHEN USING A HUB WITH CC-Link IE TSN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

FUTURE SUPPORT PLANNED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

CHAPTER 1 PART NAMES 17

1.1 LED Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CHAPTER 2 SPECIFICATIONS 19

2.1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Specifications of Interfaces with External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.3 External Circuit Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHAPTER 3 FUNCTION LIST 23

3.1 Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Motion control 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Motion control 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control/Operation/Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 List of Network Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

CONTENTS

CHAPTER 4 PROCEDURES BEFORE OPERATIONS 27

CHAPTER 5 SYSTEM CONFIGURATION 29

5.1 Structure of Authentication Class B Devices and Ethernet Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 Structure of Authentication Class B/A Devices and Ethernet Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3 Precautions for System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

CHAPTER 6 INSTALLATION AND WIRING 37

6.1 Installation and Removal of SD Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

APPENDICES 41

Appendix 1 Component List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Appendix 2 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Appendix 3 Open Source Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

INDEX 48

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

11

Page 14

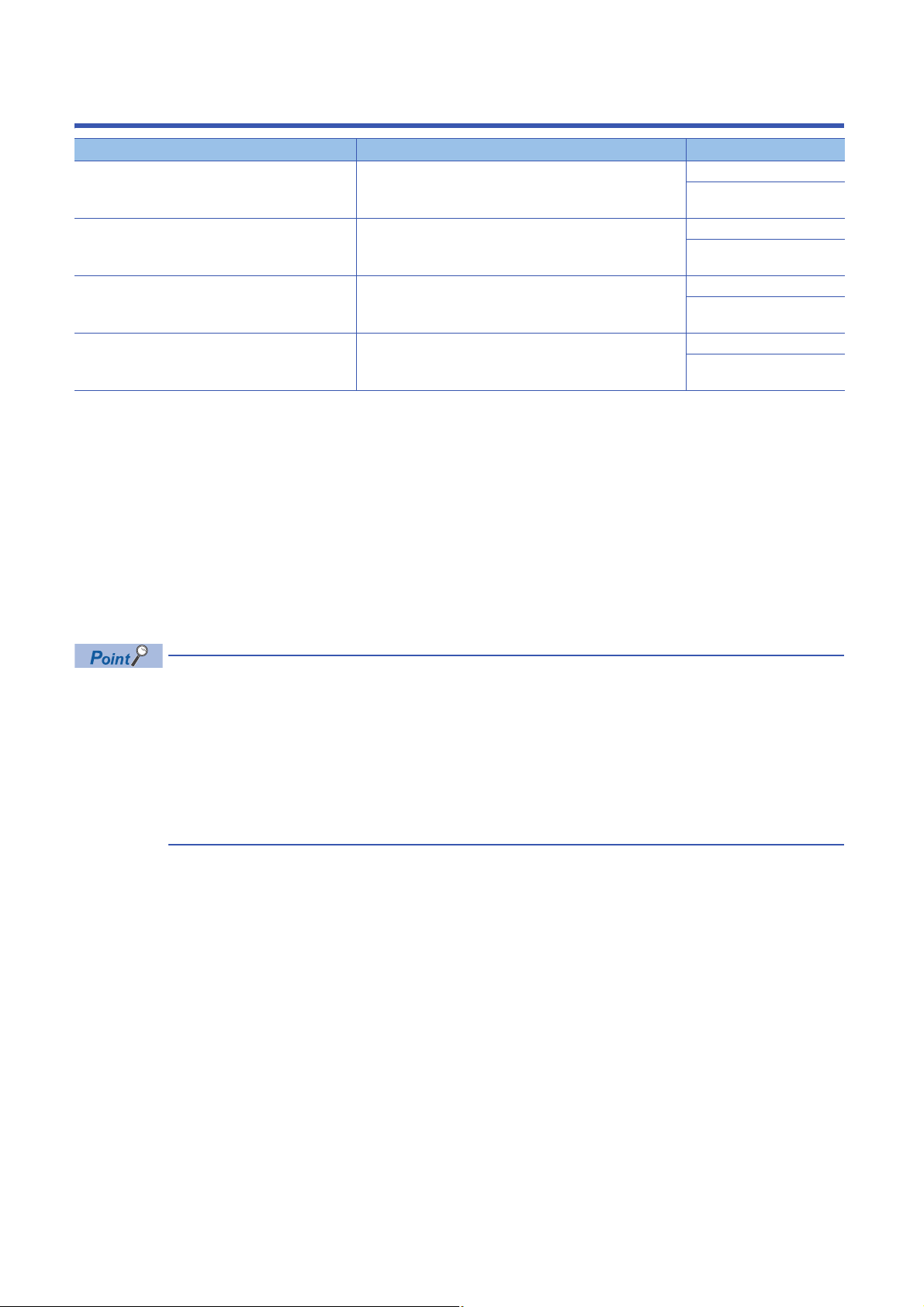

RELEVANT MANUALS

Manual name [manual number] Description Available form

MELSEC iQ-R Motion Module User's Manual (Startup)

[IB-0300406ENG] (This manual)

MELSEC iQ-R Motion Module User's Manual

(Application)

[IB-0300411ENG]

MELSEC iQ-R Motion Module User's Manual (Network)

[IB-0300426ENG]

MELSEC iQ-R Programming Manual (Motion Module

Instructions, Standard Functions/Function Blocks)

[IB-0300431ENG]

This manual does not include detailed information on the followings:

• General specifications

• Available CPU modules and the number of mountable modules

• Installation

For details, refer to the following.

MELSEC iQ-R Module Configuration Manual

For programs, refer to the following.

MELSEC iQ-R Programming Manual (Program Design)

This manual does not include information on the network function blocks. Refer to the following for details on the network

function blocks.

MELSEC iQ-R Ethernet/CC-Link IE Function Block Reference

Specifications, procedures before operation, system configuration,

and wiring of the Motion module

Functions, I/O signals, variables, labels, programming, and

troubleshooting of the Motion module

Functions, parameter settings, troubleshooting, and buffer

memory of CC-Link IE TSN

Instructions for the Motion module and standard functions/function

blocks

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

12

Page 15

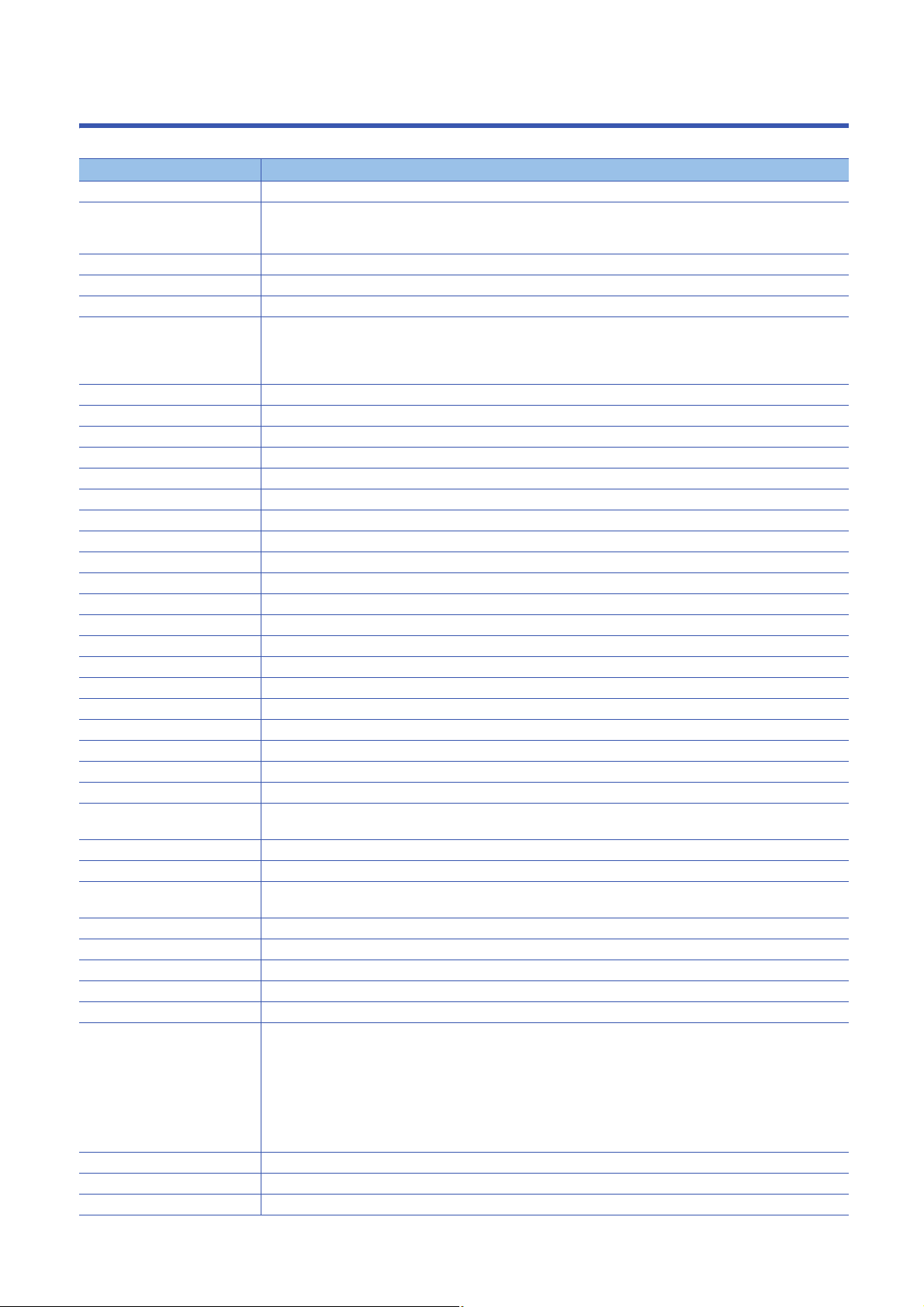

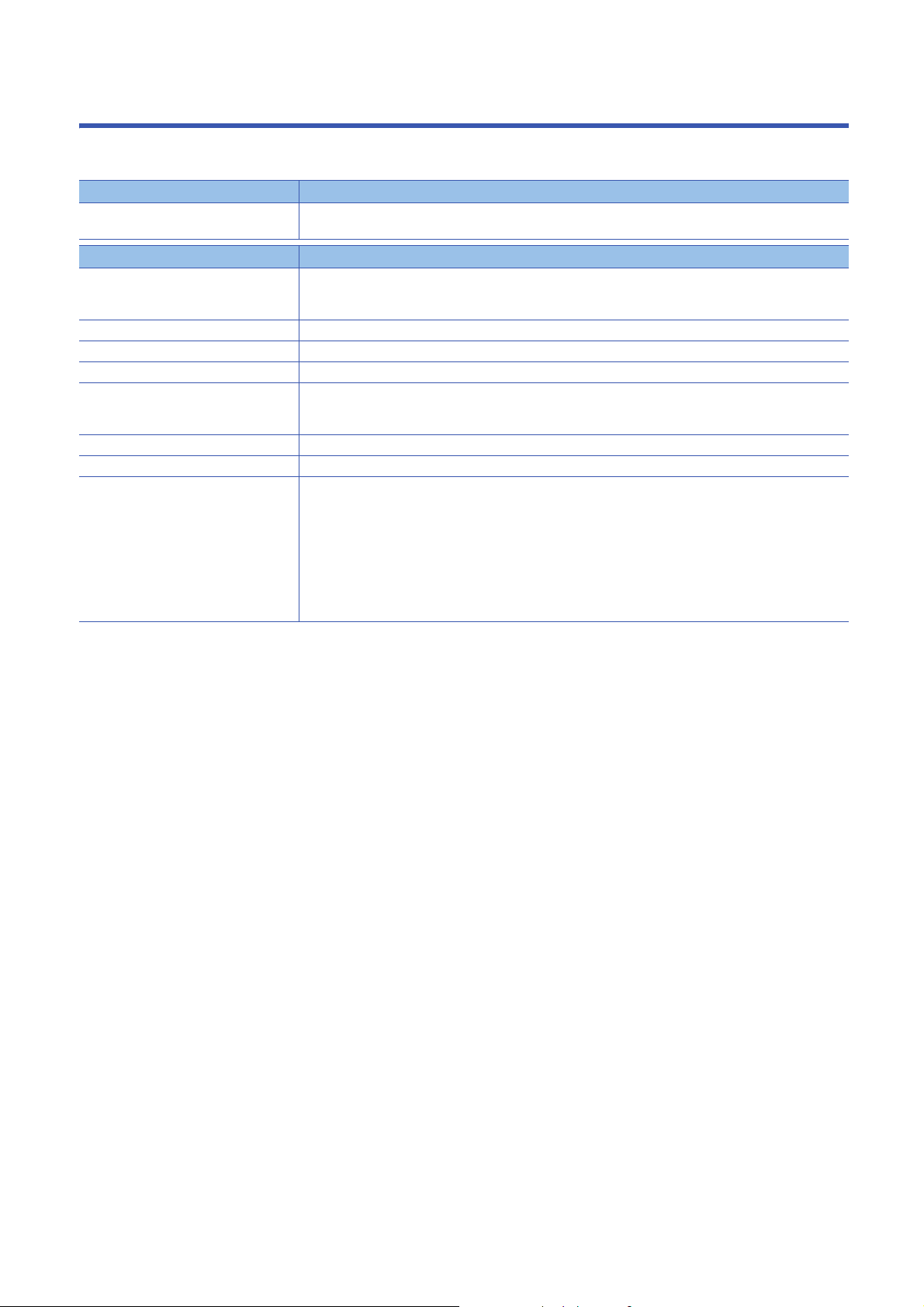

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

Actual position An address that is rounded a position address returned by a slave device. It is affected by a current position change.

Authentication Class A class classified by CC-Link Partner Association (www.cc-link.org) from a function and performance of the module

corresponding to CC-Link IE TSN and a switching hub. There are two authentication Classes: A and B, and

authentication Class B for the RD78G(H).

Axis A target to carry out the motion control

Buffer memory A memory in an intelligent function module, where data (such as setting values and monitoring values) are stored.

Buffer mode A generic term for multiple start

CC-Link IE Includes the following network:

Continuous update Continuously reflecting input values to the control while the ContinuousUpdate input of the motion control FB is TRUE

CPU module The abbreviation for the MELSEC iQ-R series CPU module

Cumulative current position A command position address that is not rounded by a ring counter. It is affected by a current position change.

Cyclic transmission A function by which data are periodically exchanged among stations on the same network using a slave station

Data link Cyclic transmission and transient transmission

Dedicated instruction An instruction for using functions of the module

Device Various memory data in a CPU module. There are devices handled in each bit and in each word.

Disconnection A process of stopping data link if a data link error occurs

Drive unit A generic term for motor drive devices such as a survo amplifier

Engineering tool A generic term for GX Works3, and MR Configurator2

Ethernet device Includes a device supporting IP communication (such as personal computers)

Execute Set TRUE to the Execute input or the Enable input to the motion control FB

General-purpose hub An authentication Class A hub authorized by CC-Link Partner Association

GOT A generic term for Mitsubishi Electric Graphic Operation Terminal GOT1000 and GOT2000 series

GX Works3 The product name of the software package for the MELSEC programmable controllers

Hardware reboot Turning ON the power of the system again or resetting

Intelligent function module A module that has functions other than input and output, such as an A/D converter module and D/A converter module

Label A label that represents a device in a given character string

Link device A device in a module on CC-Link IE

Link refresh Automatic data transfer between a link device of the Motion module and a device in a CPU module

Master station A station that controls the entire network. This station can perform cyclic transmission and transient transmission with all

Motion area A software that performs the motion control in the Motion module

Motion control FB An FB that is related to the motion control. Its name starts with MC_ or MCv_.

Motion FB A motion control FB that takes an axis or an axes group for the argument and changes the axis status or the axes status

Motion management station A station that updates a link device in the Motion module

Motion module A generic term for the RD78G(H)_

MR-J5(W)-G MR-J5-_G_(-RJ)/MR-J5W_-_G type servo amplifier series

Multiple start Executing another motion control FB to the same axis while a motion control FB is executed

Network area A software that performs the network control in the Motion module

Network module Includes the following modules:

Object Various data of a slave device compatible with CANopen

PDO A communication object of CANopen (Process Data Object)

RAS The abbreviation for Reliability, Availability, and Serviceability. This term refers to usability of automated equipment.

• CC-Link IE TSN

• CC-Link IE Controller Network (MELSEC iQ-R CC-Link IE Controller Network User’s Manual (Application)

• CC-Link IE Field Network (MELSEC iQ-R CC-Link IE Field Network User’s Manual (Application)

stations. Only one master station can be used in a network.

by execution

• Ethernet interface module

• Module on CC-Link IE TSN

• CC-Link IE Controller Network module

• Module on CC-Link IE Field Network

• MELSECNET/H network module

• MELSECNET/10 network module

• RnENCPU (network part)

13

Page 16

Ter m Description

RD78G Another term for the MELSEC iQ-R series Motion module (compatible with CC-Link IE TSN)

RD78GH

RD78G(H) A generic term for RD78G_, RD78GH_ (high performance version)

Real axis An axis that is linked with a slave device on network

Remote station A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic transmission. A

transient transmission is available.

Retrigger Starting up the Execute input again while executing an FB to a motion control FB that has the Execute input

Return A process of restarting data link when a station recovers from an error

SB Link special relay

Set position A command position address rounded by the ring counter. It is affected by a current position change.

Slave station • A generic term for a local station, and remote station on CC-Link IE TSN

SLMP A Seamless Message Protocol. This protocol is used to access an SLMP-compatible device or a CPU module connected

Software reboot Resetting only motion area and network area without a hard reboot

Start Executing a motion FB for the first time to an axis or an axes group

SW Link special register

Target position A command position address that is specified in the motion FB

Transient transmission A function of data communication unperiodically among nodes (station) on network.

TSN hub An authentication Class B hub authorized by CC-Link Partner Association

Virtual axis An axis that is not linked with a slave device on network

Bit data that indicates the operating status and data link status of a module on CC Link IE.

• A generic term for a local station, remote I/O station, remote device station, and intelligent device station on CC-Link IE

Field Network

to an SLMP-compatible device from an external device such as a personal computer.

Word data that indicates the operating status and data link status of a module on CC-Link IE.

A function used to send message to the target station when requested by a link dedicated instruction or the engineering

tool

Communication is available with station on another network via relay station, or gateway.

14

Page 17

FUTURE SUPPORT PLANNED

The following functions are mentioned in this manual, but it is planned for a future support.

The information in this page might be changed for improvement without prior notice.

Model Description

RD78GH • RD78GHV

Function Description

Operation cycle Auto refresh link devices of motion syncronization stations

Current position change function Trigger current position change

Override function Overall override function

Touch probe Overall touch probe function

Operation profile data Profile operation

Logging Real-time monitor

File transfer function Access control setting

Motion system software installation Motion software package for the RD78G(H) (including files)

• RD78GHW

[RD78GH]

Minimum operation cycle 31.25 s

Change of current value per cycle

Multidimensional profile

• Boot software binary (for the RD78G)

• Boot software binary (for the RD78GH)

• Basic system software simulator DLL

• Data definition file (axis data, etc.)

• Add-on simulator DLL

• The engineering tool window definition file for add-on

• Boot software binary for network

• Bood software simulator DLL for network

15

Page 18

MEMO

16

Page 19

1 PART NAMES

RD78G RD78GHRD78G RD78GH

(11)

(10)

(1)

(12)

(8)

(9)

(2)

(3)

(4)

(11)

(10)

(1)

(5)

(6)

(7)

(12)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(Uncovered) (Uncovered)

This chapter describes the part names of the Motion module.

1

No. Name Description

(1) RUN LED For details, refer to the following.

(2) ERR LED

(3) PROGRAM RUN LED (P RUN is shown inside the cover)

(4) D LINK LED

(5) SD/RD LED

(6) CARD READY LED (C RDY is shown inside the cover)

(7) CARD ACCESS LED (C ACS is shown inside the cover)

(8) SD memory card access control switch

(9) SD memory card slot

(10) LEDs for CC-Link IE TSN connector L ER LED

LINK LED

(11) Ethernet port Connects to a slave station.

(12) Serial No. marking Shows the serial No. printed on the Motion module.

Page 18 LED Display Specifications

1 PART NAMES

17

Page 20

1.1 LED Display Specifications

This section lists the LED display specifications of the Motion module.

: OFF, : ON, ●: Flashing

Name Description LED display Status

RUN LED Indicates the operating status. RUN LED Operating normally

RUN LED Error, Initializing

ERR LED Indicates the error status. ERR LED Error

ERR LED● 200 ms interval: Error

ERR LED Operating normally

PROGRAM RUN LED Indicates the execution status of built-

in programs.

D LINK LED Indicates the data link status. D LINK LED Data link (cyclic transmission being performed)

SD/RD LED Indicates the data communicating

status.

CARD READY LED Indicates the status of SD memory

card.

CARD ACCESS LED Indicates the access status of SD

memory card.

L ER LED Indicates the port status. L ER LED Abnormal data received

LINK LED Indicates the link status. LINK LED Link-up

PROGRAM RUN LED Executing program

PROGRAM RUN LED Stopping program

D LINK LED● Data link (cyclic transmission stopped)

D LINK LED Data link not performed (disconnection)

SD/RD LED Communicating data

SD/RD LED Not communicating data

CARD READY LED An SD memory card is usable.

CARD READY LED● Preparing

CARD READY LED No SD memory card inserted

CARD ACCESS LED Accessing SD memory card

CARD ACCESS LED Not accessing SD memory card

L ER L ED Normal data received

LINK LED Link-down

500 ms interval: A data link faulty station detected

Error status can be determined by status of the RUN LED and the ERR LED.

RUN LED ERR LED Error status Description

Off On, flashing Major error An error such as hardware failure or memory failure. The module stops operating.

On Flashing Moderate error An error, such as parameter error, which affect module operation. The module stops

operating.

On On Minor error An error such as communication, positioning control, and program error. The module

continues operating.

When multiple errors occur, the error status is displayed in the order of major, moderate, and minor.

18

1 PART NAMES

1.1 LED Display Specifications

Page 21

2 SPECIFICATIONS

2.1 Performance Specifications

This section lists the performance specifications of the RD78G(H).

Item RD78G4 RD78G8 RD78G16 RD78G32 RD78G64 RD78GHV RD78GHW

Number of

controlled

*1

axes

Operation cycle

Interpolation function 1- to 4-axis linear interpolation

Control method PTP (Point To Point) control, path control (linear, and arc can be set), speed control, speed-torque control

Control unit pulse, m, degree, Revolution, inch, arbitrary unit character string

Positioning Positioning range -10000000000.0 Positioning range < 10000000000.0

Flash ROM write count Up to 100,000 times

Number of occupied I/O points 32 points 48 points

Internal current consumption

(5 V DC)

External

dimensions

Real drive axis*24 axes 8 axes 16 axes 32 axes 64 axes 128 axes 256 axes

Virtual drive axis Total 1024 axes

Virtual linked axis

*3

Speed command In position control: 0, +0.0001 to +2500000000.0

Acceleration/

deceleration

process

Acceleration/

deceleration time

Rapid stop

deceleration time

Height 106 mm (4.17 inch)

Width 27.8 mm (1.09 inch) (1 slot width) 56 mm (2.2 inch) (2 slots width)

Depth 110 mm (4.33 inch)

125 to 4 ms 31.25 s / 4axes

2-axis circular interpolation

In speed control: 0, 0.0001 to 2500000000.0

Acceleration/deceleration specification method (acceleration, deceleration, jerk), acceleration/deceleration time constant

method

Acceleration/deceleration specification method

[Unit] U/s

[Range] 0.0000, 0.0001 to 2147483647.0

Acceleration/deceleration time constant method

[Unit] s

[Range] 0.000000, 0.000001 to 8400.0

1.93 A 2.33 A

*4

2

2

Mass 0.26 kg 0.44 kg

*1 Even when an axis (real axis, and virtual axis) does not exist in the system setting, an error does not occur. Since there is no axis to be

controlled, the motion control cannot be carried out. Operation other than the motion control, such as program execution by ST

language is available.

*2 When a multi-axis drive unit and a general output device are used as multiple axes, the number of those axes are counted.

Ex: The 2-axis drive unit is counted as 2 axes.

*3 It depends on the number of controlled axes.

*4 It is restricted by the system memory capacity.

2 SPECIFICATIONS

2.1 Performance Specifications

19

Page 22

2.2 Specifications of Interfaces with External Devices

This section lists the external interfaces.

: Support possible

Interface name RD78G RD78GH Application

CC-Link IE TSN 1 port 2 ports Network connection

SD memory card Restoration of parameters and logs

CC-Link IE TSN

The specifications of the CC-Link IE TSN is shown below.

Item RD77GF4 RD77GF8 RD77GF16 RD77GF32 RD78G64 RD78GHV RD78GHW

Maximum number of link

points per network

Maximum

number of

link points per

station

Communication speed 1 Gbps

Minimum synchronization cycle 125 s

Time synchronization accuracy 1 s

Maximum number of connectable stations

per network

Communication cable Ethernet cable which satisfies standard(Page 40 Wiring products)

Number of cascade connections 1 levels maximum

Maximum number of networks 239

Network topology Line topology, star topology

Transient transmission capacity 1920 bytes maximum

Master

station

*2

RX/RY 16K points each (16384 points, 2K bytes)

RWr/RWw

(including

PDO)

RX/RY 16K points each (16384 points, 2K bytes)

RWr/RWw 8K points each (8192 points, 16K bytes)

8K points each (8192 points, 16K bytes)

64 stations

*3*4

*1

, line + star topology

120 stations

*3*4

*1 TSN hub is required for star topology.

*2 An error will not occur even if there is no station and axis in the network setting.

*3 Even if the station is a multi-axis drive unit device (a device which can control two axes or more), the number of station is counted as one

station when it is recognized as one station. For details, refer to each drive unit instruction manual.

*4 When a slave emulate is carried out, the number of stations is counted according to the connected device setting.

SD memory card

The specifications of the SD memory card is shown below.

Item Specification

Card type SD/SDHC memory card

Card capacity Up to 32G bytes

UHS, UHS-I Unsupported

Number of times of installation/removal Within 500 times

Use the recommended SD memory card listed below.

*1

Model

NZ1MEM-xGBSD Mitsubishi Electric Corporation 2, 4, 8, 16G bytes

*1 The "X" of the model name represents the card capacity.

For commercially available SD memory cards, refer to the following. Before using a commercially available SD memory card,

check that the card does not affect the control of the target system.

www.MitsubishiElectric.co.jp/fa

TECHNICAL BULLETIN No. FA-D-0078

Manufacturer Card capacity

20

2 SPECIFICATIONS

2.2 Specifications of Interfaces with External Devices

Page 23

2.3 External Circuit Design

R61P RD78G(H)RnCPU

X01

X12

X23

X34

X45

X56

7

X78

X89

X910

XA11

XB12

XC13

XD14

XE15

XF

X10

X11

X12

X13

X14

X15

X16

X17

X18

X19

X1A

X1B

X1C

X1D

X1E

X1F

16

17

COM

COM

18

X6

X0

COM

1

2

3

1

2

3

UNIT POWER

CABLE

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

FG

+24V

24G

CC-Link IE

TSN

Remote input

module

Forced stop24 V DC

<Remote input module NZ2GN2B1-32D>

Signal name

Pin

No.

Not insulated

Input terminal block

Module power supply/

FG terminal block

*1

Module power

supply

Forced stop

24 V DC

Forced stop circuit

A wiring example which uses a remote input module (NZ2GN2B1-32D) for the forced stop input is shown below. Set

AxisName

.Pr.ForcedStop_Signal according to the input modules.

2

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

2 SPECIFICATIONS

2.3 External Circuit Design

21

Page 24

It is also possible to use the forced stop signal of the drive unit. Operation status of the emergency stop, drive unit forced stop

and the Motion controller forced stop are as follows.

Item Operation when the

signal is turned on

Emergency stop Servo OFF The power supply of the drive unit is shut off by external circuit, and the servomotor stops.

Drive unit forced

stop

Motion controller

forced stop

Remarks

A stop command from the external circuit to the drive unit is output, and the drive unit stops the servomotor.

A stop command from the remote input module to the drive unit is output, and the drive unit stops the

servomotor.

Shut-off the main circuit power supply of a drive unit when an emergency stop, alarm, servo amplifier forced stop, or remote

input module forced stop occurs. Make sure to use molded-case circuit breakers (MCCB) for input wires of a drive unit power

supply. For details, refer to the drive unit manual.

22

2 SPECIFICATIONS

2.3 External Circuit Design

Page 25

3 FUNCTION LIST

There are restrictions in the function that can be used by the software of the Motion module and the version of engineering

tool. Refer to the following for details.

MELSEC iQ-R Motion Module User's Manual (Application)

3.1 Control Functions

The Motion module has several functions. Refer to the following for details on each function.

MELSEC iQ-R Motion Module User's Manual (Application)

Basic specifications

Functions Details

Axis control function Technical units The position command unit and the velocity command unit used in the motion control can be set.

Since the unit can be specified freely depending on the control target, intuitive programming and

monitoring are available.

Servo ON/OFF This function executes servo ON/OFF of the real axis connected to the Motion module. The servo

ON enables the operation of the real axis.

Follow up In an axis which has the current position (Position actual value) as the slave object, this function

can convert the unit of the current position by the driver unit conversion numerator/denominator

(electronic gear) and reflect in the set position.

Absolute position control Restores the current position of an axis.

Basic functions Operation cycle In the Motion module, operation processing related to the motion control is performed in the fixed

cycle (operation cycle).

Add-on function The Motion module functions can be expanded by installing add-on libraries.

System memory settings Sets the memory size used in the add-on library in the system memory (RAM) and the system

memory (backup RAM).

Software reboot The software reboot (reset the system) is executed by writing the reboot command to the control

command. When "Clear" is specified at the software reboot command, the system restarts and all

data of the system is deleted.

3

3 FUNCTION LIST

3.1 Control Functions

23

Page 26

Motion control 1

Functions Details

Start and stop Start Starts motion control.

Retrigger/continuous update Changes the control of the on-going FB with a retrigger/continuous update.

Multiple start (buffer mode) Multiple motion control FBs execute continuously without stopping by executing the motion FB of

another instance to the axis and the axes group that are executing MCFB.

Stop Stops motion cotrol.

Forced stop Stops axes by the forced stop signal.

Homing Homing request Establishes the start point for carrying out positioning control (home position), and carries out

Driver homing method

Data set homing method

Operation setting for incompletion

of homing

Axis control function Single axis positioning control Executes positioning to the specified position by using address information.

Single axis speed control Executes the speed control for the specified axis with the specified speed.

Single axis manual control Executes the random positioning operation by inputting a signal from an external device.

Multiple axes positioning control Uses address information and executes positioning to the specified position using interpolation

Direct control Velocity control The driver control mode is switched to csv, and the control excluding the position loop is executed.

Torque control The driver control mode is switched to cst, and the control is carried out.

Functions related to

position

Functions related to

speed

Functions related to

torque

Sub functions of

control

Common functions External signal selection Sets I/O signals to be used in various control.

Current position change function Changes the set position to an arbitrary address.

Command in-position Checks the remaining distance to the target position, and turns the command in-position flag to

Software stroke limit An address is set as the movable range. Even if a movement command to the address outside the

Hardware stroke limit Limit switches are set at the upper/lower limit of the physical movable range, and the control is

Acceleration/deceleration

processing function

Speed limit Limits the command speed to a value within the speed limit value setting range when the command

Override function Changes the speed during control.

Torque limit Limits the generated torque to a value within the torque limit value range when the torque

Torque limit value change function Changes the torque limit value during control.

Compensation

function

Command filter Smoothing filter Uses to suppress load-side vibration, such as work-side vibration and base shake.

Input variable change in execution Changes input variables during control.

Touch probe Records (latches) arbitrary data at trigger input signal detection.

Slave emulate Carries out axis control on the real axis without connecting the slave station.

Driver unit

conversion

function

positioning toward that start point. This is used to return a machine system, located at a position

other than the home position when the Motion module requires "homing request" such as when the

power is turned ON or after positioning stop, to the home position.

Selects whether the axis starts or not, when the homing request is TRUE.

The following method is available.

• JOG operation: the machine is moved by only an movement amount.

control.

TRUE.

setting range is issued, the command will not be executed.

stopped by the input of a signal from the limit switch.

Adjusts the acceleration/deceleration of each motion control to the acceleration/deceleration curve

suitable for device.

speed during control exceeds the speed limit value.

generated in the servomotor exceeds the torque limit value.

Converts the cumulative current position to the driver command value and pass it to the target

position (Target Position). Also, it converts the current position of the driver and calculates the

actual position.

24

3 FUNCTION LIST

3.1 Control Functions

Page 27

Motion control 2

Functions Details

Operation profile

data function

Synchronous

control

Operation profile data Opens the profile for the cam and reads/writes the cam.

Cam operation Operates by synchronizing the slave axis with the master axis based on cam table.

Gear operation Sets the speed ratio between the master axis and the slave axis, and starts gear operation.

Addition/subtraction positioning Combines the movement amount of 2 axes and transmits.

Control/Operation/Maintenance

Functions Details

Logging Data logging function Collects the Motion module data at a specified interval based on the logging setting (trigger

Real-time monitor Sets the data collection and monitor the collected data (waveform display) in real time in the status

Application

function

RAS functions Execution time monitor Monitors the operation cycle processing and the normal task execution time.

History data Event history

File control File transfer function Executes file operation based on the specified command.

Module software install When updating or changing to the new software, users have to install the software again.

Event detection When File save setting is set to "Disabled" in the logging setting, only the trigger detection is

Auto logging When inserting an SD memory card, which holds logging setting, into the Motion module, the data

function

Position data

history

condition or data collection condition) written by the engineering tool and save the result to the data

logging file.

where the engineering tool has been connected with the Motion module.

executed without saving files.

logging automatically starts based on the logging setting information on the SD memory card.

Saves the data such as the error detected by the Motion module, the operation executed to the

module, and the event related to the motion control of start and stop as even history.

The position data history of each axis can be monitored by the engineering tool.

3

3 FUNCTION LIST

3.1 Control Functions

25

Page 28

3.2 List of Network Function

The following table lists the functions of CC-Link IE TSN. For details on the functions, refer to the following.

MELSEC iQ-R Motion Module User's Manual (Network)

Cyclic transmission

Data are periodically exchanged among stations on the network using slave label.

Function Description

Communications using slave label Regularly communicates data between the stations on the same network by using the slave label of the

Motion module.

Transient transmission

Uses for communications at arbitrary timing.

Function Description

SLMP communication Reads/writes data from/in the device memory of the self-station or another station CPU module on the

CC-Link IE and the buffer memory of the intelligent function module, via Ethernet from the upper system.

Ethernet connection

This function connects an Ethernet device to a module without interfering with CC-Link IE TSN.

Function Description

Connection with MELSOFT products and

a GOT

Connection with SLMP-compatible Ethernet

devices

Allows programming and monitoring of the CPU module using

the engineering tool, and monitoring and testing of the CPU module from the GOT via Ethernet.

Connects commercially available SLMP-compatible devices.

Security

This function ensures optimal security according to the network environment by restricting access for each communication

path to the CPU module.

Function Description

Remote password Prevents illegal access of the CPU module from a remote location for each function.

IP filter Identifies the IP address of the access source to limit access to the Motion module.

RAS

Function Description

Slave station disconnection In star topology, the data link of the slave station where an error occurred is stopped, and data link

Station type duplication, IP address duplication

detection

Time synchronization Automatically sets the time of the CPU module and the remote device by IEEE1588 or IEEE802.1AS

continues only for slave stations that are operating normally.

Detects master station duplication and IP address duplication.

synchronization.

Others

Function Description

Automatic detection of connected devices (iQSS) Reflects the installation status of network configuration in the network configuration setting of the master

station on engineering tool. At startup of the system, it supports the network configuration setting of the

master station when slave stations are added.

Slave station parameter automatic setting Parameters of the slave station on CC-Link IE TSN set using the engineering tool are written in the data

memory of the CPU module or the SD memory card, and those are automatically set via the master

station when the slave station is returned/replaced by power ON or connected.

Label access to the remote device To slave stations on the network, it allows labels and FBs are used like the proximity module.

Searching CPU modules on the network Searches Ethernet function installed modules that are connected with the same hub as the engineering

tool, and it displays the list of the search result.

26

3 FUNCTION LIST

3.2 List of Network Function

Page 29

4 PROCEDURES BEFORE OPERATIONS

This chapter describes the procedures before operation of RD78G(H).

1. Mounting the module

Mount the Motion module to the main base unit or extension base unit.

For details, refer to the following.

MELSEC iQ-R Module Configuration Manual

2. Wiring

Connect the Motion module to external devices.

3. Adding the module

Add the RD78G(H) to the module map of the project using an engineering tool.

4. Network construction

Set network parameters in "Module Parameter (Network)" of the engineering tool.

• Set the communication cycle setting for Network Configuration Settings.

Set the basic communication cycle according to the number of controlled axes or network device configuration. For a

reference of the cycle, refer to the following manual for operation cycle.

MELSEC iQ-R Motion Module User's Manual (Application)

• Set a slave station for Network Configuration Settings.

The slave station controlled in the Motion module needs to be set in the motion cotrol station. Also, when setting in the

motion control station, set the basic cycle for the communication cycle.

For details, refer to the following.

MELSEC iQ-R Motion Module User's Manual (Network)

5. Module setting (module extended parameter)

Configure the setting related to axis control in "Module Extended Parameter" of the engineering tool.

For details, refer to the following.

MELSEC iQ-R Motion Module User's Manual (Application)

6. Auto refresh setting

Set the link refresh settings in "Basic Settings" of Module Parameter (Network).

For details, refer to the following.

MELSEC iQ-R Motion Module User's Manual (Network)

4

7. Programming

Create programs.

For details, refer to the following.

MELSEC iQ-R Motion Module User’s Manual (Application)

8. Writing parameters

Write the set parameters and programs to the Motion module.

• "Motion Module (internal memory)" or "Motion Module (SD memory card)" can be selected as a storage location for module

extended parameters. The initial setting is "Motion Module (internal memory)". When writing module extended parameters,

specify the same storage location in the writing destination of the engineering tool as "Module extended parameter storage

location setting" in "Module operation setting" of Module Parameter (Motion).

For details, refer to the following.

MELSEC iQ-R Motion Module User's Manual (Application)

4 PROCEDURES BEFORE OPERATIONS

27

Page 30

9. Network diagnostics

Using network diagnostics, check if the cables are connected properly and communication are performed normally with the

parameters.

For details, refer to the following.

MELSEC iQ-R Motion Module User's Manual (Network)

10. Parameter settings in slave devices

Set parameters of the drive unit to use.

For details, refer to each drive unit manual.

11. Test operation

Check that the program is correctly carried out as created

28

4 PROCEDURES BEFORE OPERATIONS

Page 31

5 SYSTEM CONFIGURATION

(5) (1)

(4) (3) (2)

No.0

No.8

No.1

(3)

Ó

Ò

(1)

(2)

No.0 No.1 No.3 No.2

CC-Link IE TSN is configured using Ethernet cables. (Page 40 Ethernet cable)

(1) Motion module

(2) Drive unit

(3) Inverter device

(4) Remote I/O module

(5) Ethernet device

Authentication Class setting

From "Connection Device Information" under "Basic Settings" of the engineering tool, select either of the following items

according to devices to be connected.

Connected device

information

Authentication Class B Only Select this if the system is to be configured without connecting the authentication Class A device.

Mixture of Authentication Class

B/A or Authentication Class A

Only

System configuration Switching hub

TSN hub

• Page 30 Connection with modules on CC-Link IE TSN only

• Page 31 Connection with modules on CC-Link IE TSN and Ethernet devices

Select this if the system is to be configured in the future with the authentication Class A device

connected.

• Page 33 Connection with modules on CC-Link IE TSN and Ethernet devices

(authentication Class

B)

General-purpose hub

(authentication Class

A)

5

When connecting an authentication Class B device and an authentication Class A device, use a general-purpose hub.

(Page 40 Hub)

No.0: Master station of authentication Class B device

Up to eight slave stations of authentication Class B devices can be connected.

General-purpose hub (NZ2EHG-T8(N) or DT135TX)

(1), (2), (3): Ethernet device (such as personal computer, vision sensor, or bar code reader)

Modules can be connected in any order regardless of the station number.

5 SYSTEM CONFIGURATION

29

Page 32

5.1 Structure of Authentication Class B Devices and

No.0 No.2 No.3 No.4

No.5

TSN HUB

TSN HUB

TSN HUB

TSN HUB

Ethernet Devices

System configuration used when "Authentication Class B Only" is selected from "Connection Device Information" under

"Basic Settings" in the engineering tool.

The modules on CC-Link IE TSN and TSN hub are authentication Class B devices.

Connection with modules on CC-Link IE TSN only

■Line topology

The network is configured in line topology. TSN hub is not required.

When an error occurs in a slave station, the stations connected after the faulty station will be disconnected.

■Star topology

The network is configured in star topology via TSN hub. This allows devices to be added easily.

Even when an error occurs in a slave station, data link can be continued with the stations that are operating normally.

■Coexistence of line and star topologies

Line and star topology are mixed.

■Cascade connection

Cascade connection of TSN hub is available up to 1 levels.

30

5 SYSTEM CONFIGURATION

5.1 Structure of Authentication Class B Devices and Ethernet Devices

Page 33

Connection with modules on CC-Link IE TSN and Ethernet devices

No.0 No.1

No.2

(1)

No.0

No.1

No.2

(1)

(2)

(3)

TSN HUB

■Line topology

The network with modules and devices is configured in line topology. TSN hub is not required.

Connect an Ethernet device at the end.

No.0, No.1, No.2: Modules on CC-Link IE TSN (master station, drive unit, remote station)

(1) Ethernet device (such as personal computer)

When an error occurs in a slave station, the stations connected after the faulty station will be disconnected.

■Star topology

Modules or devices are connected in star topology via TSN hub. This allows devices to be added easily.

5

No.0, No.1, No.2: Modules on CC-Link IE TSN (master station, drive unit, remote station)

(1), (2), (3):Ethernet device (such as personal computer, vision sensor or bar code reader)

Even when an error occurs in a slave station, data link can be continued with the stations that are operating normally.

5.1 Structure of Authentication Class B Devices and Ethernet Devices

5 SYSTEM CONFIGURATION

31

Page 34

■Coexistence of line and star topologies

No.0

No.0

No.1

No.2

(1)

(2)

(3)

(1)

(2)

No.2

(1)

TSN HUB

TSN HUB

No.1

Line and star topology can be mixed.

Connect an Ethernet device at the end.

No.0: Master station

No.1: Drive unit

No.2: Remote station

(1), (2), (3) Ethernet device (such as personal computer, vision sensor, or bar code reader)

32

5 SYSTEM CONFIGURATION

5.1 Structure of Authentication Class B Devices and Ethernet Devices

Page 35

5.2 Structure of Authentication Class B/A Devices and

No.0 No.1

No.8

(2)

(1)

No.0

(1)

(2)

(3)

(4)

Ethernet Devices

System configuration used when "Mixture of Authentication Class B/A or Authentication Class A Only" is selected from

"Connection Device Information" under "Basic Settings" of the engineering tool.

The modules on CC-Link IE TSN are an authentication Class B device, and the general-purpose hub is an authentication

Class A device.

Connection with modules on CC-Link IE TSN and Ethernet devices

■Line topology

The network with modules and devices is configured in line topology. A general-purpose hub is not required.

Up to 8 modules on CC-Link IE TSN can be connected to Ethernet port of the master station at the position indicated with (1).

Connect an Ethernet device at the end.

5

No.0: Master station

No.1: Drive unit

No.8: Remote station

(2) Ethernet device (such as personal computer)

When an error occurs in a slave station, the stations connected after the faulty station will be disconnected.

■Star topology

Modules or devices are connected in star topology via a general-purpose hub. This allows devices to be added easily.

No.0: Module on CC-Link IE TSN (Master station)

(1), (2), (3) Ethernet device (such as personal computer, vision sensor, or bar code reader)

(4) General-purpose hub (NZ2EHG-T8(N) or DT135TX)

Even when an error occurs in a slave station, data link can be continued with the stations that are operating normally.

5.2 Structure of Authentication Class B/A Devices and Ethernet Devices

5 SYSTEM CONFIGURATION

33

Page 36

■Coexistence of line and star topologies

No.0

No.0

No.1

No.2

(1)

(2)

(3)

(1)

(4)

(4)

(2)

(3)

No.

No.1

Line and star topology can be mixed.

Connect slave stations of authentication Class B devices without using a general-purpose hub.

Connect an Ethernet device at the end.

When connecting an Ethernet device with a communication speed of 100Mbps to the Motion module, a general-purpose hub

is required.

No.0: Master station

No.1: Drive unit

No.2: Remote station

(1), (2), (3): Ethernet device (such as personal computer, vision sensor, or bar code reader)

(4) General-purpose hub (NZ2EHG-T8(N) or DT135TX)

■Cascade connection

Cascade connection of general-purpose hub is not available.

34

5 SYSTEM CONFIGURATION

5.2 Structure of Authentication Class B/A Devices and Ethernet Devices

Page 37

5.3 Precautions for System Configuration

Devices connected to the same network

Do not connect the devices as described below. Doing so may cause the disconnection of all stations.

• The devices having network types other than CC-Link IE TSN and Ethernet (such as CC-Link IE Controller Network and

CC-Link IE Field Network) are connected to the same network line.

• The modules on CC-Link IE TSN and Ethernet devices (such as personal computers) in various networks are connected to

one switching hub.

Adding 65 or more slave stations

If 64 slave stations are already connected and further slave stations are added, data link will not be performed in the added

65th and subsequent slave stations, but the other stations will continue data link.

Even if the disconnected stations are returned to a system having 65 or more slave stations, the stations may not start data

link.

• Whether 65 or more slave stations are connected can be checked using 'Number of connected modules

over occurrence status' (SB0099). Number of connected modules detected by 'Number of connected

modules over occurrence status' (SB0099) is the total of the slave stations that are currently connected and

the disconnected stations (slave stations that were previously connected).

• The number of stations that were previously connected can be cleared by executing the network map

update of the CC-Link IE TSN/CC-Link IE Field diagnostics. ( MELSEC iQ-R Motion Module User's

Manual (Network))

• A data link error may momentarily occur in all the stations and outputs of the connected slave stations may

turn off since all stations on the network will be reconnected when executing the network map update.

Ensure that the output data is held, if necessary. (Page 36 Output hold when a data link error occurs)

5

Station number of the slave station to be added

Do not duplicate station numbers. Data link may be stopped when the station number is duplicated.

Adding a slave station with no IP address setting

In line topology, do not connect the slave station with no IP address setting at a place other than the end of the line. Data link

may not be performed in the slave stations after the slave station with no IP address setting.

CC-Link IE TSN/CC-Link IE Field diagnostics

If operations such as the following are performed, the actual network configuration and the network map of the CC-Link IE

TSN/CC-Link IE Field diagnostics may be a mismatch.

Network configuration Operation

Star topology • Powering off and on a slave station or switching hub

Line topology • Simultaneously powering off/on multiple stations

• Connecting/disconnecting an Ethernet cable connected to the switching hub

• Disconnecting an Ethernet cable from a slave station and connecting it to another slave station or a switching hub

• Disconnecting more than 9 stations, or half the number of slave stations or more in the system

• Changing the network topology when adding a slave station

• Simultaneously connecting/disconnecting Ethernet cables to/from multiple stations (When a data link faulty station

returns, a data link error will occur in all the stations.)

• Disconnecting more than 9 stations, or half the number of slave stations or more in the system

• Changing the network topology when adding a slave station

5 SYSTEM CONFIGURATION

5.3 Precautions for System Configuration

35

Page 38

The actual network configuration and network map can be matched by executing the network map update of

the CC-Link IE TSN/CC-Link IE Field diagnostics. ( MELSEC iQ-R Motion Module User's Manual

(Network))

A data link error may momentarily occur in all the stations and outputs of the connected slave stations may

turn off since all stations on the network will be reconnected when executing the network map update. Ensure

that the output data is held, if necessary. (Page 36 Output hold when a data link error occurs)

Output hold when a data link error occurs

Setting the following to "Hold" allows holding the outputs when a data link error occurs.

[Navigation window] [Parameter] [Module Information] Target module [Application Settings]

[Supplementary Cyclic Settings] [I/O Maintenance Settings] [Data Link Error Station Setting]

36

5 SYSTEM CONFIGURATION

5.3 Precautions for System Configuration

Page 39

6 INSTALLATION AND WIRING

RD78G RD78GH

CARD READY LED

CARD READY LED

SD memory card

SD memory card

6.1 Installation and Removal of SD Memory Card

This section describes the methods for installation of an SD memory card to the Motion module, and removal.

Installation of SD memory card

• When installing an SD memory card to the Motion module, take note of the SD memory card position, and install using the

following procedure.

1. With the notch facing downwards, insert the SD memory card straight into the slot. After inserting check the SD memory