Page 1

MELSEC iQ-R

Motion Module

User's Manual (Network)

-RD78G4

-RD78G8

-RD78G16

-RD78G32

-RD78G64

-RD78GHV

-RD78GHW

Page 2

Page 3

WHEN USING A HUB WITH CC-Link IE TSN

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

The dedicated TSN hub is required when modules on CC-Link IE TSN are configured in a star topology or hubs are

configured in a cascade topology.

Read the following carefully.

MELSEC iQ-R Motion Module User's Manual (Startup)

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. Refer to the MELSEC iQ-R Module Configuration

Manual for a description of the PLC system safety precautions.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

2

Page 5

[Design Precautions]

WARNING

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Failure to do so may result in an

accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Machine homing is controlled by two kinds of data: a homing direction and a homing speed.

Deceleration starts when the proximity dog signal turns on. If an incorrect homing direction is set,

motion control may continue without deceleration. To prevent machine damage caused by this,

configure an interlock circuit external to the programmable controller.

(2) When the module detects an error, the motion slows down and stops or the motion rapidly stops,

depending on the stop group setting in parameter. Set the parameter to meet the specifications of

a positioning control system. In addition, set the homing parameter and positioning data within the

specified setting range.

(3) Outputs may remain on or off, or become undefined due to a failure of a component such as an

insulation element and transistor in an output circuit, where the module cannot detect any error. In

a system that the incorrect output could cause a serious accident, configure an external circuit for

monitoring output signals.

● If safety standards (ex., robot safety rules, etc.,) apply to the system using the module, drive unit and

servomotor, make sure that the safety standards are satisfied.

● Construct a safety circuit externally of the module or drive unit if the abnormal operation of the module

or drive unit differs from the safety directive operation in the system.

3

Page 6

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the settings are being

written. Doing so will make the data in the flash ROM and SD memory card undefined. The values

need to be set in the buffer memory and written to the flash ROM and SD memory card again. Doing

so also may cause malfunction or failure of the module.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

push in the module, and fix it with screw(s). Incorrect interconnection may cause malfunction, failure,

or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette or a battery-less option cassette into the cassette

connector of the CPU module. After insertion, close the cassette cover and check that the cassette is

inserted completely. Poor contact may cause malfunction.

● Do not directly touch any conductive parts of the module, SD memory card, extended SRAM cassette,

battery-less option cassette, or connector. Doing so can cause malfunction or failure of the module.

4

Page 7

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach a blank cover module (RG60) to each empty slot and an included

extension connector protective cover to the unused extension cable connector before powering on the

system for operation. Failure to do so may result in electric shock.

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the cables in a duct or clamp them. If not, dangling cables may swing or inadvertently be pulled,

resulting in malfunction or damage to the modules or cables.

In addition, the weight of the cables may put stress on modules in an environment of strong vibrations

and shocks.

Do not clamp the extension cables with the jacket stripped. Doing so may change the characteristics

of the cables, resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

5

Page 8

[Wiring Precautions]

CAUTION

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for the module used. If not, normal data transmission is not guaranteed.

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25 cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not perform each of the following operations more than 50 times

(IEC 61131-2/JIS B 3502 compliant).

Exceeding the limit may cause malfunction.

• Mounting/removing the module to/from the base unit

• Inserting/removing the extended SRAM cassette or battery-less option cassette to/from the

CPU module

• Mounting/removing the terminal block to/from the module

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette or a batteryless option cassette. Doing so may cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

7

Page 10

[Startup and Maintenance Precautions]

CAUTION

● Before testing the operation, set a low speed value for the speed limit parameter so that the operation

can be stopped immediately upon occurrence of a hazardous condition.

● Confirm and adjust the program and each parameter before operation. Unpredictable movements

may occur depending on the machine.

● When using the absolute position system function, on starting up, and when the module or absolute

position motor has been replaced, always perform a homing.

● Before starting the operation, confirm the brake function.

● Do not perform a megger test (insulation resistance measurement) during inspection.

● After maintenance and inspections are completed, confirm that the position detection of the absolute

position detection function is correct.

● Lock the control panel and prevent access to those who are not certified to handle or install electric

equipment.

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM and SD memory card undefined. The values need to be set in the buffer memory and

written to the flash ROM and SD memory card again. Doing so also may cause malfunction or failure

of the module.

● Note that when the reference axis speed is specified for interpolation operation, the speed of the

partner axis (2nd, 3rd, or 4th axis) may exceed the speed limit value.

● Do not go near the machine during test operations or during operations such as teaching. Doing so

may lead to injuries.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

8

Page 11

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

9

Page 12

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the functions, programming, and troubleshooting of the relevant product listed below.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

RD78G4, RD78G8, RD78G16, RD78G32, RD78G64, RD78GHV, RD78GHW

Symbols used in this manual are shown below.

• [RD78GH]: Symbols indicating that it corresponds to only RD78GH

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated into other

machinery or equipment, certain measures may be necessary. Please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage Directives.

Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

10

Page 13

CONTENTS

WHEN USING A HUB WITH CC-Link IE TSN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FUTURE SUPPORT PLANNED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

CHAPTER 1 FUNCTIONS 17

1.1 Cyclic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Communications using slave labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2 Transient Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Communications using the SLMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connection with MELSOFT products and a GOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Connecting SLMP-compatible devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.4 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

IP filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Remote password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.5 RAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Slave station disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Master station duplication detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

IP address duplication error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Time synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.6 Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Slave station parameter automatic setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CONTENTS

CHAPTER 2 PARAMETER SETTINGS 34

2.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.2 Required Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Station Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Network No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Station No./IP Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3 Basic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Network Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Communication Period Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connection Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Slave Station Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4 Application Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Event Reception from Other Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Module Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.5 "CC-Link IE TSN Configuration" Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Parameter setting of a slave station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connected/Disconnected Module Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Parameter processing of a slave station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Command execution to slave stations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11

Page 14

CHAPTER 3 TROUBLESHOOTING 49

3.1 Checking with LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.2 Checking the Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Module Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.3 Checking the Network Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

CC-Link IE TSN/CC-Link IE Field Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Communication Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.4 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.5 List of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.6 List of Parameter Nos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.7 Event List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

APPENDICES 87

Appendix 1 Buffer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

List of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Details of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix 2 List of Link Special Relay (SB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix 3 List of Link Special Register (SW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Appendix 4 Port No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

INDEX 98

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

12

Page 15

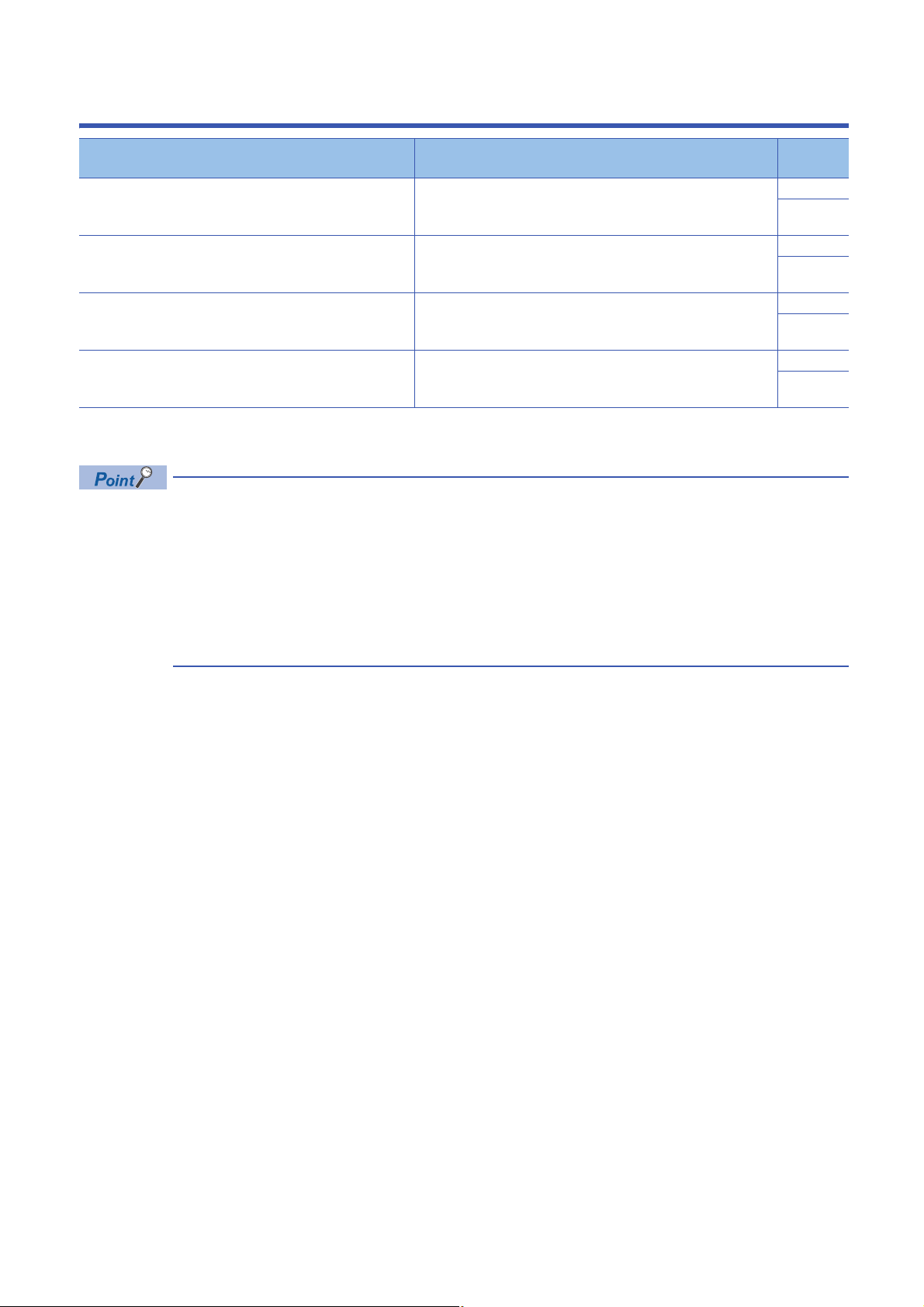

RELEVANT MANUALS

Manual name [manual number] Description Available

form

MELSEC iQ-R Motion Module User's Manual (Network)

[IB-0300426ENG] (This manual)

MELSEC iQ-R Motion Module User's Manual (Startup)

[IB-0300406ENG]

MELSEC iQ-R Motion Module User's Manual (Application)

[IB-0300411ENG]

MELSEC iQ-R Programming Manual (Motion Module Instructions,

Standard Functions/Function Blocks)

[IB-0300431ENG]

For programs, refer to the following.

MELSEC iQ-R Programming Manual (Program Design)

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

Functions, parameter settings, troubleshooting, and buffer memory of

CC-Link IE TSN

Specifications, procedures before operation, system configuration, and

wiring of the Motion module

Functions, I/O signals, variables, labels, programming, and

troubleshooting of the Motion module

Instructions for the Motion module and standard functions/function blocks Print book

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual

PDF

13

Page 16

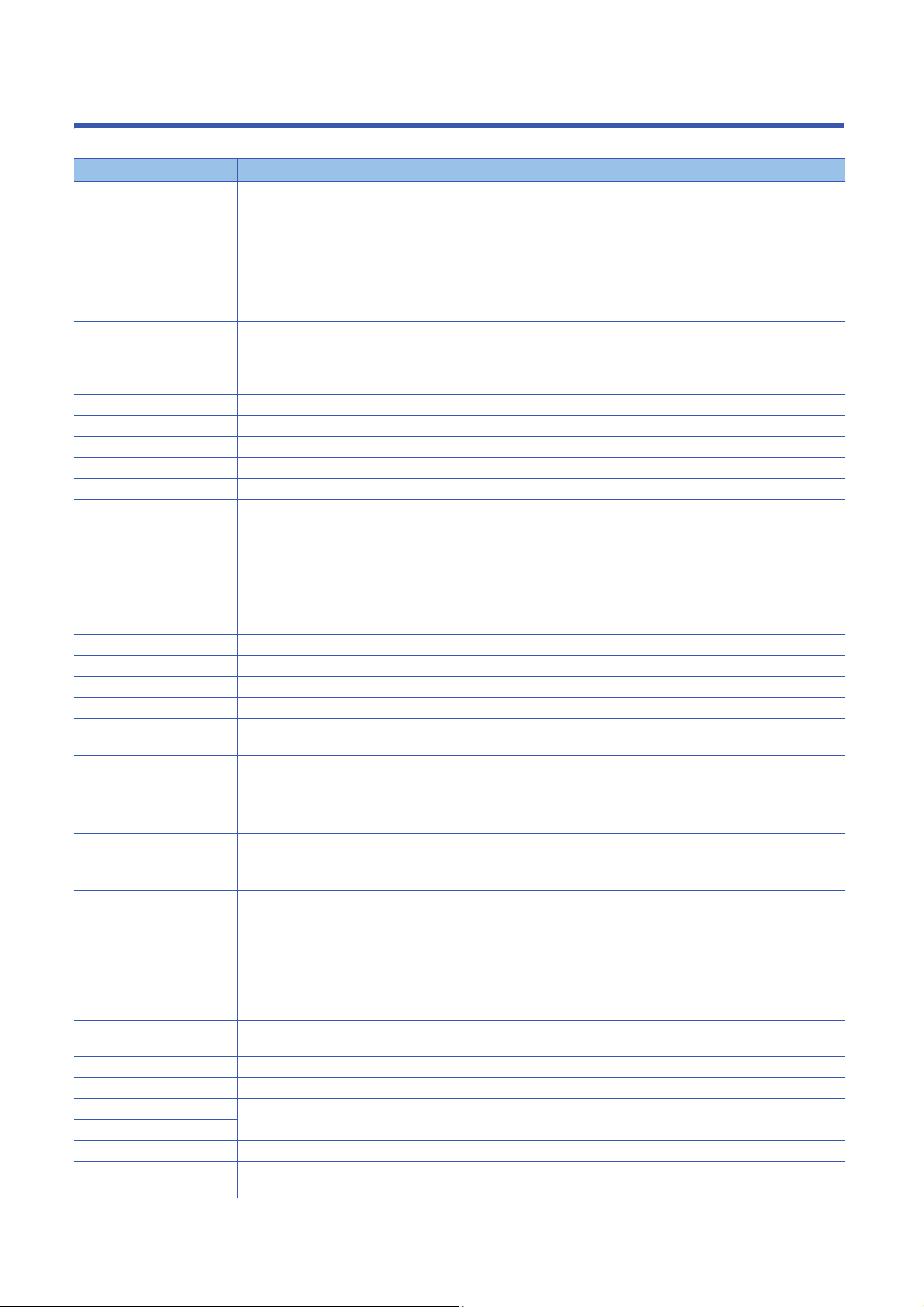

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

Authentication Class A class classified by CC-Link Partner Association (www.cc-link.org) from a function and performance of the

modulecorresponding to CC-Link IE TSN and a switching hub. There are two authentication Classes: A and B, and

authentication Class B for the RD78G(H).

Buffer memory A memory in an intelligent function module, where data (such as setting values and monitoring values) are stored.

CC-Link IE Includes the following network:

Conformance testing Testing performed for communications of a CC-Link or CC-Link IE product to ensure their high reliability.

Control CPU A CPU module that controls connected I/O modules and intelligent function modules. In a multiple CPU system, there are

CPU module The abbreviation for the MELSEC iQ-R series CPU module

Cyclic transmission A function by which data are periodically exchanged among stations on the network using slave labels

Data link A cyclic transmission and a transient transmission

Device Memory in a CPU module. There are two types of devices: a bit device and a word device.

Disconnection A process of stopping data link if a data link error occurs

Engineering tool A generic term for GX Works3 and MR Configurator2

Ethernet device A device supporting IP communication (such as personal computers)

Ethernet-equipped module The following modules when the Ethernet function is used:

General-purpose hub An authentication Class A hub authorized by CC-Link Partner Association

GOT A generic term for Mitsubishi Electric Graphic Operation Terminal GOT1000 and GOT2000 series

Grandmaster A source device or station to synchronize clocks in the time synchronization via PTP

GX Works3 The product name of the software package for the MELSEC programmable controllers

Intelligent function module A module that has functions other than input and output, such as an A/D converter module and D/A converter module

Label A label that represents a device in a given character string

Link scan (link scan time) Time required for all the stations on the network to transmit data. The link scan time depends on data volume and the number

Link device A device in a module on CC-Link IE

Link refresh Automatic data transfer between a link device of the Motion module and a device in a CPU module

Master station A station that controls the entire network. This station can perform cyclic transmission and transient transmission with all

Module label A label that represents one of memory areas (I/O signals and buffer memory areas) specific to each module in a given

Motion module A generic term for the RD78G(H)_

Network module Includes the following modules:

Priority A value that is assigned to devices or stations in a network to determine the grandmaster for time synchronization. The

PTP Precision Time Protocol. A predefined protocol for time synchronization between devices on a network.

RAS An abbreviation for Reliability, Availability, and Serviceability. This term refers to the overall usability of automated equipment.

RD78G Another term for the MELSEC iQ-R series Motion module (compatible with CC-Link IE TSN)

RD78GH

RD78G(H) A generic term for RD78G_, RD78GH_ (high performance version)

Remote station A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic transmission. This

• CC-Link IE TSN

• CC-Link IE Controller Network ( MELSEC iQ-R CC-Link IE Controller Network User's Manual (Application))

• CC-Link IE Field Network ( MELSEC iQ-R CC-Link IE Field Network User's Manual (Application))

For details, refer to the CC-Link Partner Association home page. (www.cc-link.org)

multiple CPU modules and each connected module can be controlled by a different CPU module.

•RJ71EN71

• CPU module

of transient transmission requests.

stations. Only one master station can be used in a network.

character string. For the module used, GX Works3 automatically generates this label, which can be used as a global label.

• Ethernet interface module

• Module on CC-Link IE TSN

• CC-Link IE Controller Network module

• Module on CC-Link IE Field Network

• MELSECNET/H network module

• MELSECNET/10 network module

• RnENCPU (network part)

smaller the value, the higher the priority.

station can perform transient transmission.

14

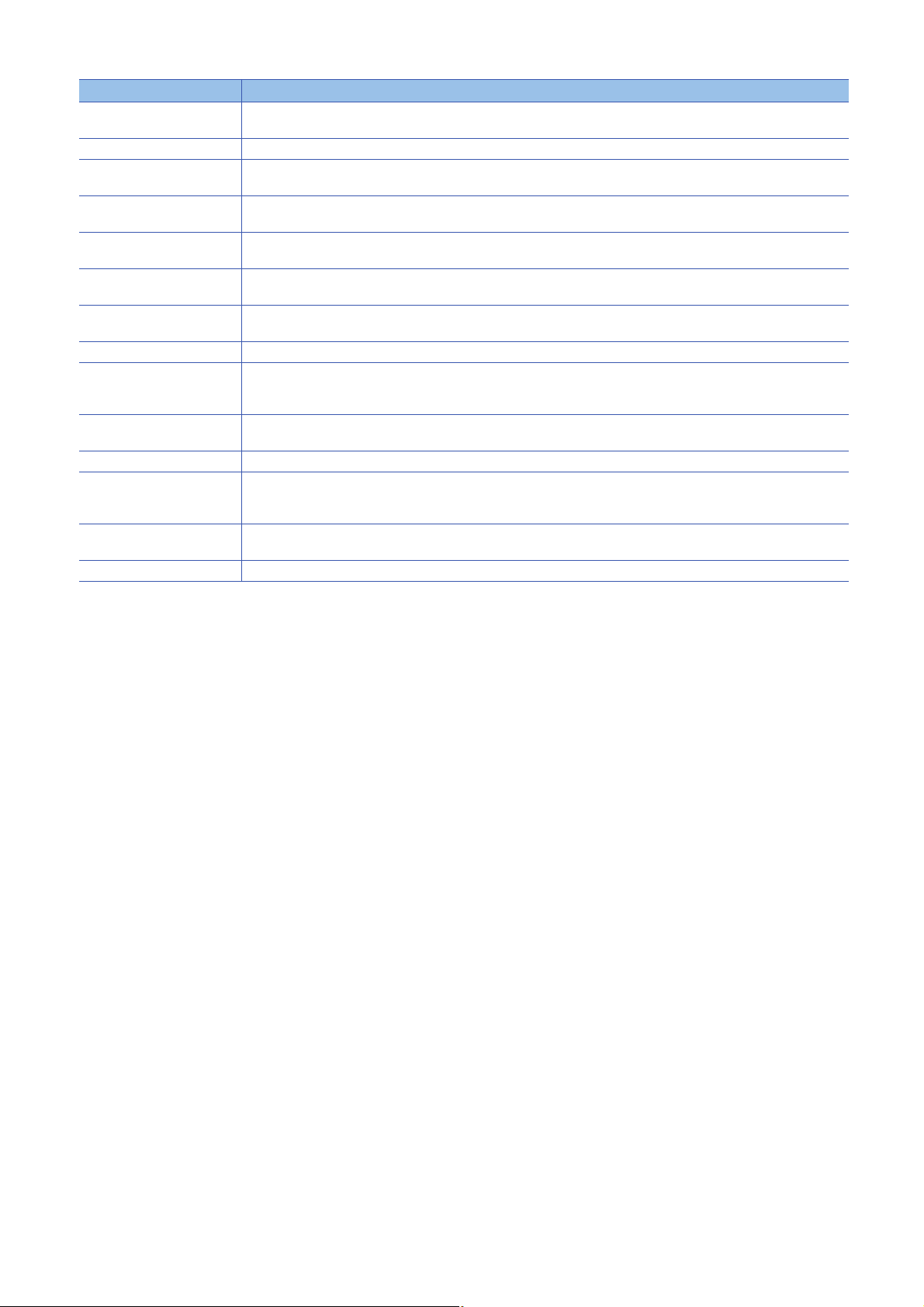

Page 17

Term Description

Reserved address An IP address reserved for special purposes, defined by RFC 6890. This IP address cannot be used when the

programmable controller is connected via the global IP network.

Return A process of restarting data link when a faulty station recovers from an error

Routing A process of selecting paths for communication with other networks. There are two types of routing: dynamic routing that

RWr A remote register of the link device. This refers to word data input from a slave station to the master station. (For some areas

RWw A remote register of the link device. This refers to word data output from the master station to a slave station. (For some

RX Remote input of the link device. This refers to bit data input from a slave station to the master station. (For some areas in a

RY Remote output of the link device. This refers to bit data output from the master station to a slave station. (For some areas in

SB Link special relay. Bit data that indicates the operating status and data link status of a module on CC-Link IE.

Slave station • A generic term for a local station and remote station on CC-Link IE TSN

SLMP A Seamless Message Protocol. This protocol is used to access an SLMP-compatible device or a CPU module connected to

SW Link special register. Word data that indicates the operating status and data link status of a module on CC-Link IE.

Transient transmission A function of data communication unperiodically among nodes (station) on network.

Transient transmission group

No.

TSN hub An authentication Class B hub authorized by CC-Link Partner Association

auto-selects the communication routes, and static routing where communication routes are arbitrarily set.

in a local station, data are input in the opposite direction.)

areas in a local station, data are output in the opposite direction.)

local station, data are input in the opposite direction.)

a local station, data are output in the opposite direction.)

• A generic term for a local station, remote I/O station, remote device station, and intelligent device station on CC-Link IE

Field Network

an SLMP-compatible device from an external device such as a personal computer.

A function used to send message to the target station when requested by a link dedicated instruction or the engineering tool

Communication is available with station on another network via relay station, or gateway.

No. that is assigned for transient transmission to any given stations. By specifying a group of stations as transient

transmission target, data can be sent to the stations of the same group No.

15

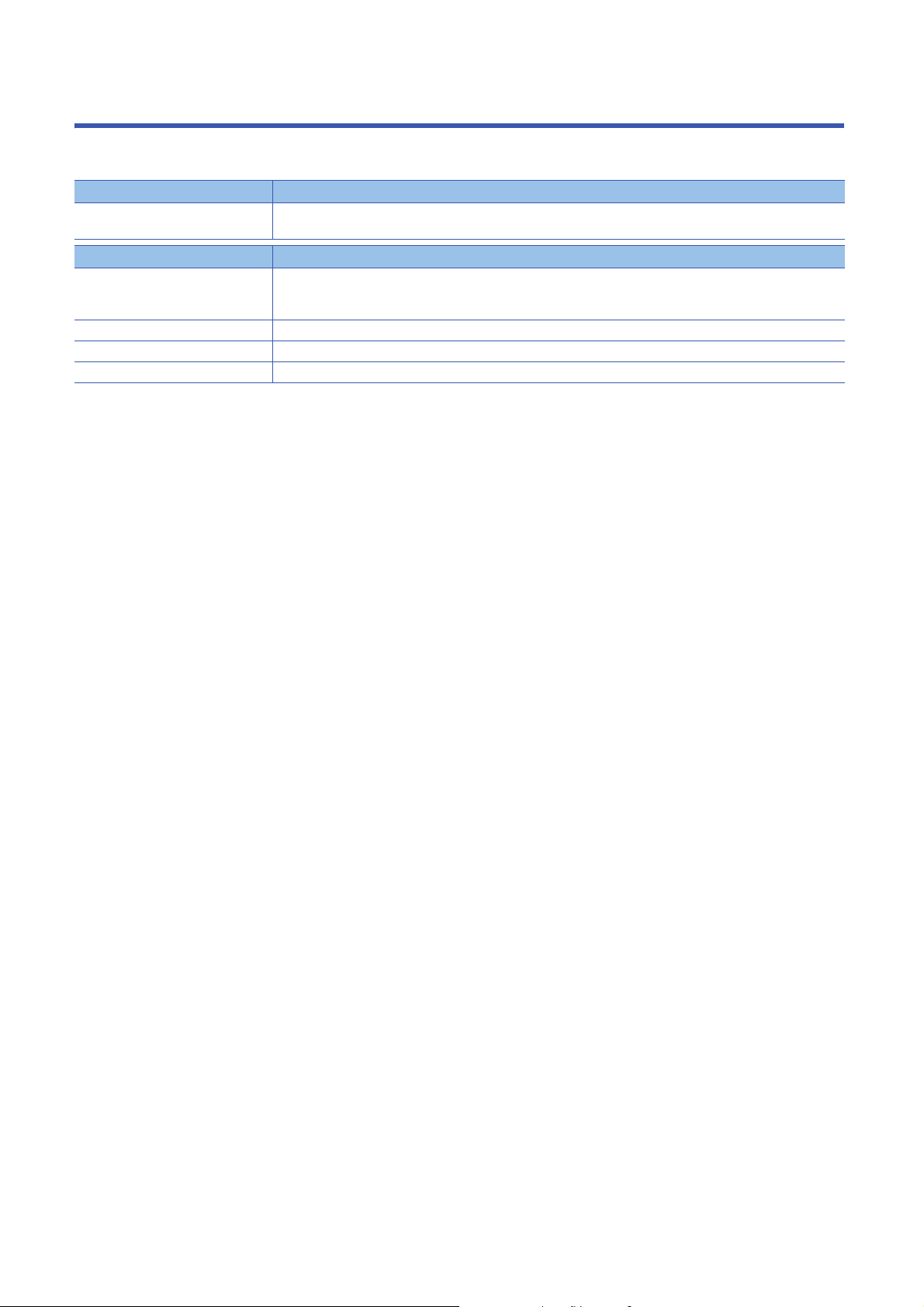

Page 18

FUTURE SUPPORT PLANNED

The following model and functions are mentioned in this manual, but these are planned for a future support.

The information in this page might be changed for improvement without prior notice.

Model Description

RD78GH • RD78GHV

Function Description

Communication period setting Communication period interval setting (Do not set it in units of 1 s)

Station type Local station

Link refresh Refresh setting

Network connected device Standard station

• RD78GHW

[RD78GH]

Minimum communication period 31.25 s

16

Page 19

1 FUNCTIONS

No.1

No.2

No.1

No.2

→No.1

→No.2

→No.1

→No.2

Ô

Ó

RX

RY

RWr

RWw

No.2

No.2

←No.2

←No.2

RWr

RWw

0000H

0003H

No.1

0000H

0003H

←No.1

0000H

0003H

0000H

001FH

0000H

0003H

0000H

001FH

Ò

Õ

No.2No.1No.0

Slave label

Slave label

Slave label

Slave label

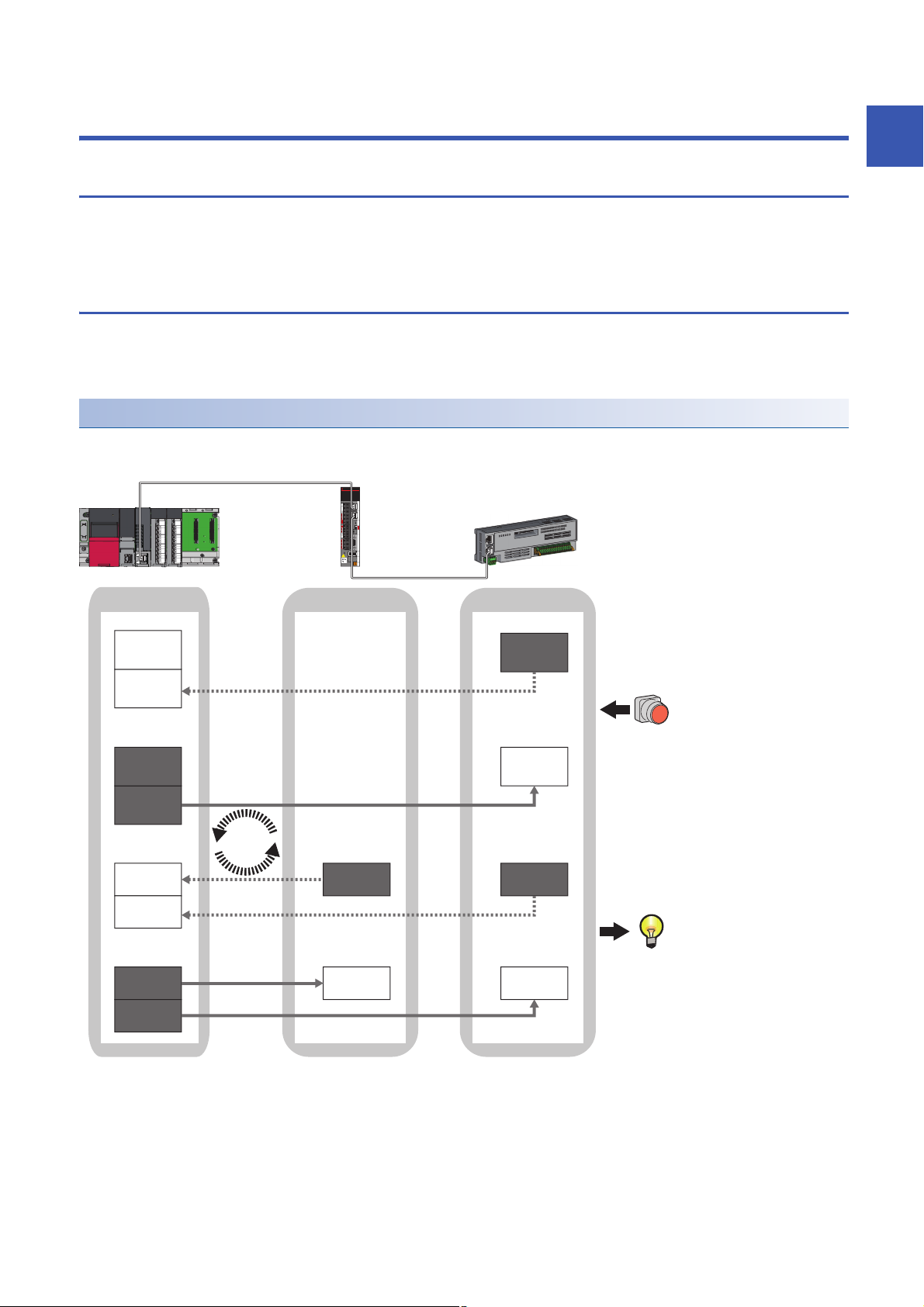

1.1 Cyclic Transmission

This allows data to be periodically exchanged among stations on the same network using slave labels.

• The slave labels can be assigned in "Network Configuration Settings" under "Basic Settings". ( Page 42 "CC-Link IE

TSN Configuration" Window)

Communications using slave labels

This allows I/O data to be exchanged in units of bits and in units of words in the master station and slave station.

Slave labels can be used in the motion control station only.

This function is available for the motion ST program only.

Master station and remote stations

1:1 communications between the master station and each remote station. Remote stations do not communicate with each

other.

1

No.0, No.1, No.2 Station No.0 (master station), Station No.1, Station No.2

No.1, No.2 Send range: to station No.1, Send range: to station No.2

No.1, No.2 Send range: from station No.1, Send range: from station No.2

• Output from the master station

The status data of the slave labels of the master station is stored in the link devices (RY, RWw) of each remote station by cyclic data transfer processing.

The status data of the link devices (RY, RWw) of the remote station are output to the external device.

• Input from the remote station

The status data of the external device is stored in the link devices (RX, RWr) of the remote station.

The status data of the link devices (RX, RWr) of the remote station is stored in the slave labels of the master station by cyclic data transfer processing.

1 FUNCTIONS

1.1 Cyclic Transmission

17

Page 20

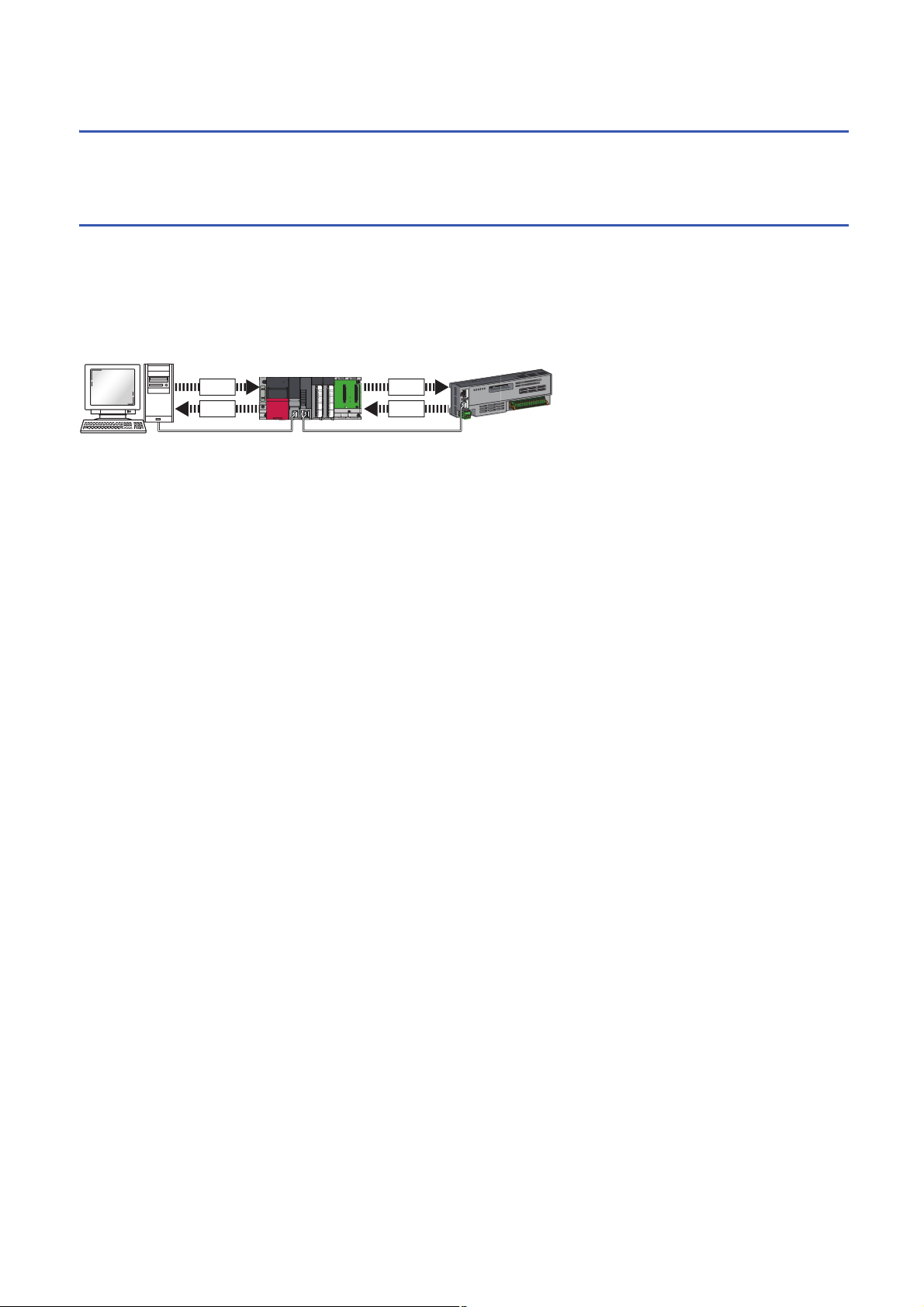

1.2 Transient Transmission

(1)

(6)

(4) (6)

(4)

(3)(2)

(5)

(3)

This uses communications at any timing.

Page 18 Communications using the SLMP

Communications using the SLMP

By SLMP, data is read/written from the external device (1) such as a personal computer or HMI (Human Machine Interface) to

I/O module devices of the master station (2) and (3) and the buffer memory of the remote station.

The Motion module can create, send (4), relay (5), and receive (6) SLMP messages. For details on SLMP, refer to the

following.

SLMP Reference Manual

18

1 FUNCTIONS

1.2 Transient Transmission

Page 21

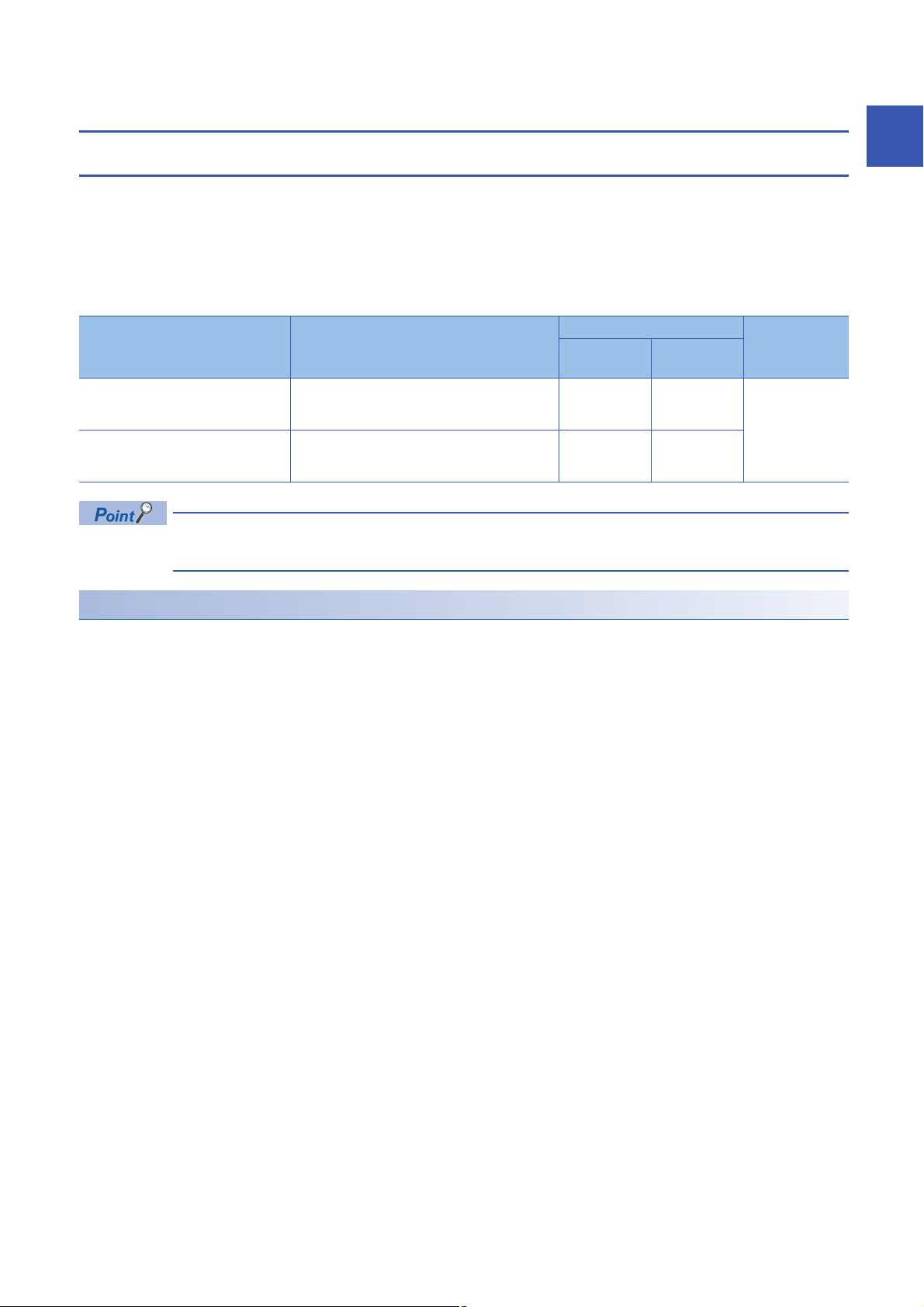

1.3 Ethernet Connection

Connection with MELSOFT products and a GOT

Programming and monitoring of the programmable controller with the engineering tool, and monitoring and testing of the

programmable controller from the GOT is performed via Ethernet. This function enables remote control using Ethernet's long-

distance connectivity and high-speed communications.

The section describes the methods of connecting the Motion module, MELSOFT product (such as engineering tool and MX

Component), and GOT.

: Connection available, : Connection not available

Connection method Purpose Availability Reference

Connection via hub

(Connection by specifying the IP

address)

Connection via hub

(Connection by specifying the network

No. and station No.)

For the procedures to connect the Motion module and GOT, refer to the following.

Manual for the GOT used

MELSOFT

product

To connect multiple MELSOFT products Page 19

To connect multiple MELSOFT products and GOTs

GOT

Connection via hub

1

Connection via hub

■Settings on the Motion module side

Sets the IP address of the Motion module using "Required Settings". ( Page 36 Station No./IP Address Settings)

When connecting by specifying the network No. and station No., set the network No. and station No. in "Required Settings".0

The Motion module can be connected to the MELSOFT product and GOT using the system dedicated connection, so no

settings are required in "Network Configuration Settings" under "Basic Settings".

1 FUNCTIONS

1.3 Ethernet Connection

19

Page 22

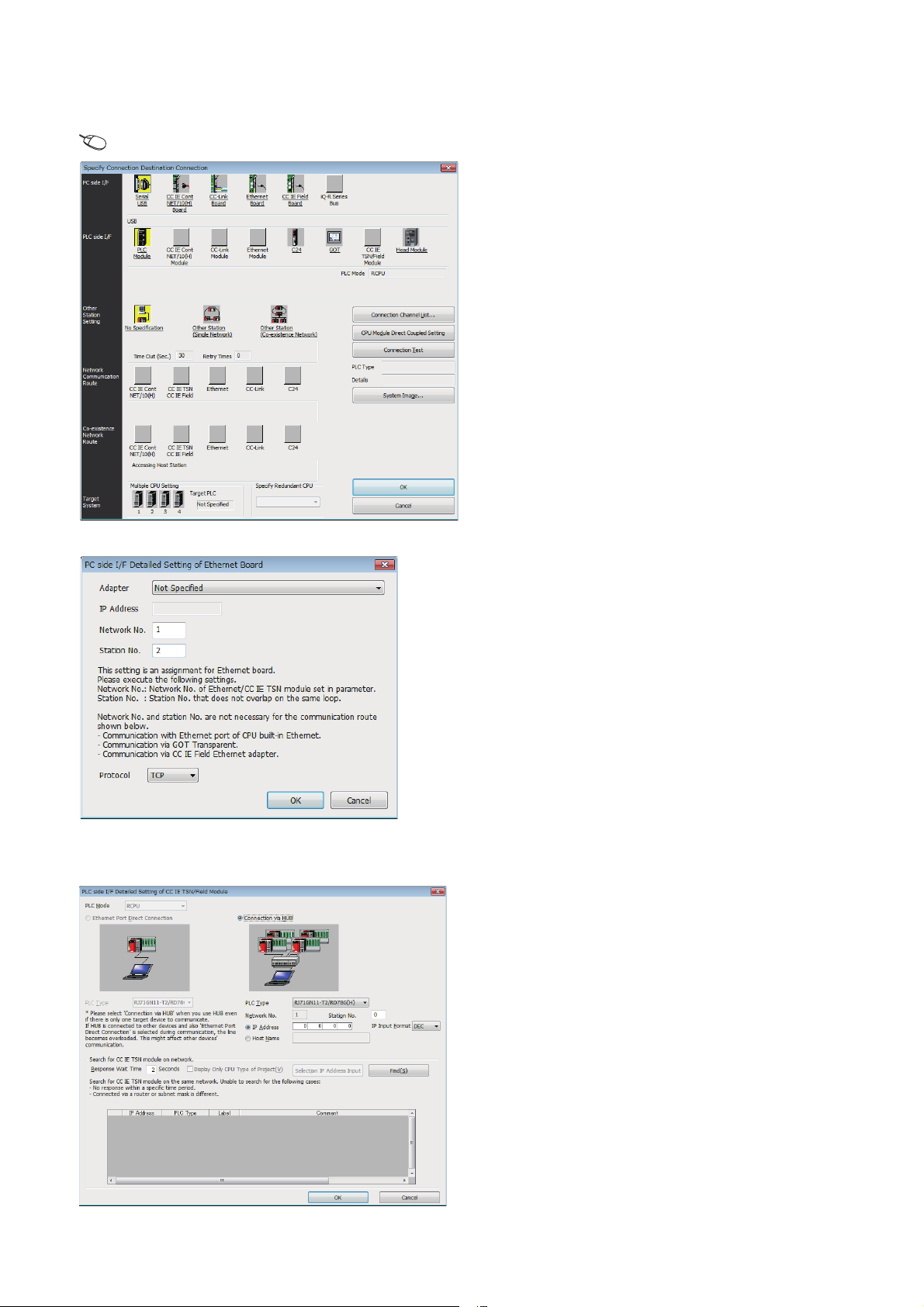

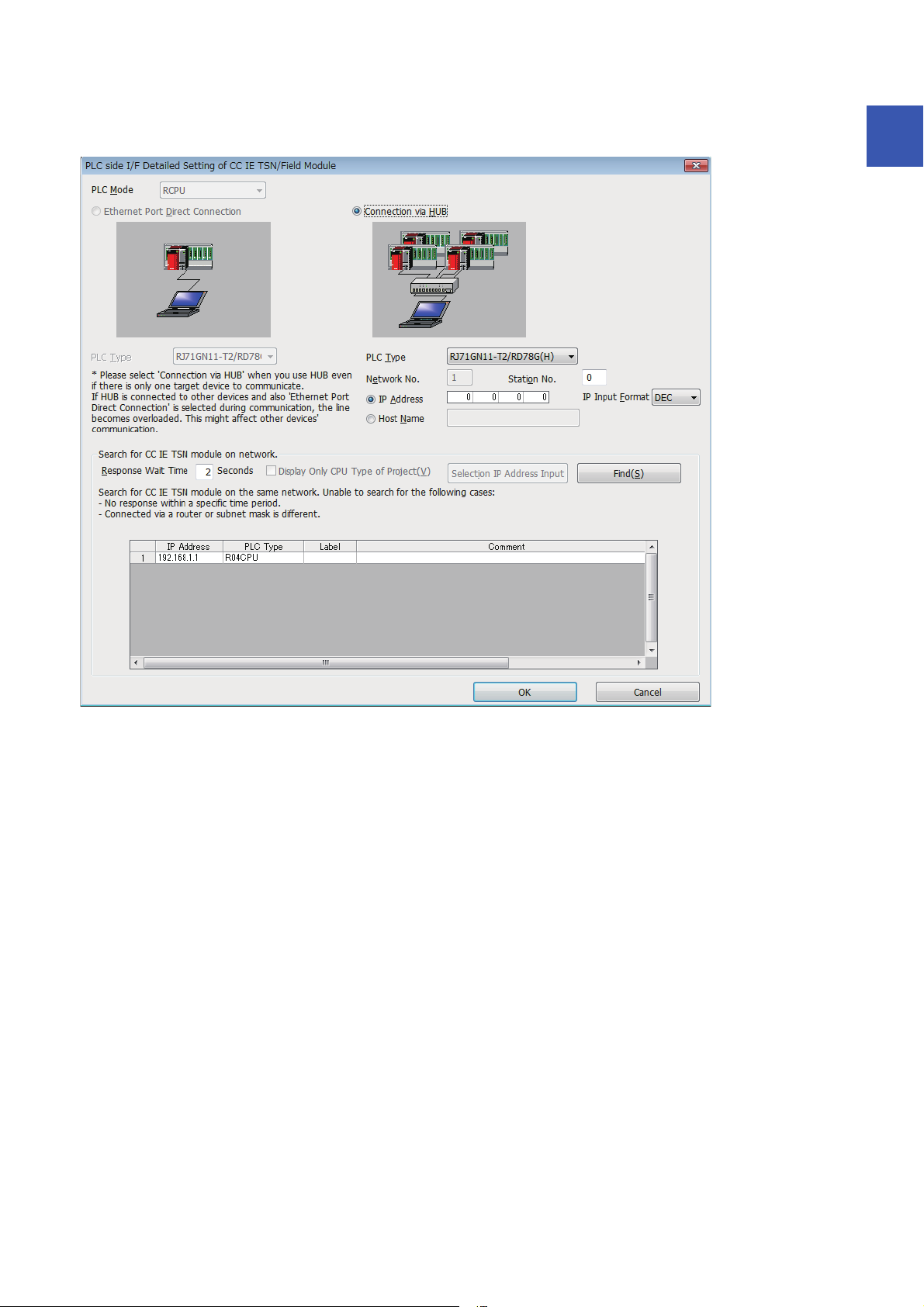

■Settings on the engineering tool side

Set in the "Specify Connection Destination Connection" window.

[Online] [Current Connection Destination]

1. Set "PC side I/F" to "Ethernet Board".

2. Double-click "Ethernet Board", and open the "PC side I/

F Detailed Setting of Ethernet Board" window.

3. Set the network No., station No., and protocol of the

personal computer.

TCP: A connection is established during communication.

Since data is exchanged while checking that the data has

correctly reached the communication destination, the data

reliability can be ensured. Note that the line load is larger

than UDP/IP communications.

UDP: Since a connection is not established during

communication and whether the communication destination

has correctly received the data is not checked, the line load is

lower. Note that the data reliability is lower than TCP/IP

communications.

4. Set the "PLC side I/F" to the module to be connected.

5. Double-click the icon set in step 4, and open the

detailed setting window.

6. Select "Connection via HUB" for the connection method,

and enter the station No. and IP address or host name

for the Motion module.

7. Specify "Other Station Setting" or "Network

Communication Route" if necessary.

20

1 FUNCTIONS

1.3 Ethernet Connection

Page 23

■Searching modules on the network

When connecting with a hub, a list of modules that can be searched for will appear by clicking the [Find] button on the detailed

setting window.

1

Search target modules are as follows.

• The control CPU of the Motion module connected to the same hub as the engineering tool

• The control CPU of the Motion module connected to cascade-connected hub

If the connected Motion module does not appear in the list after searching the modules on the network, check the following

items.

• Search cannot be performed if it is disabled with the IP filter.

• Modules connected via a router cannot be searched.

• If the module is connected via a wireless LAN, IP packet loss can prevent the Ethernet communication from stabilizing, and

may inhibit the module search.

• If there are modules with the same IP address in the list, review the IP address parameter settings for the Motion module.

• If the service processing load of the search-target CPU module is high, it may not be possible to search for the

corresponding module. If the search cannot be performed, increase the response waiting time in the search dialog, and

execute the search again.

1 FUNCTIONS

1.3 Ethernet Connection

21

Page 24

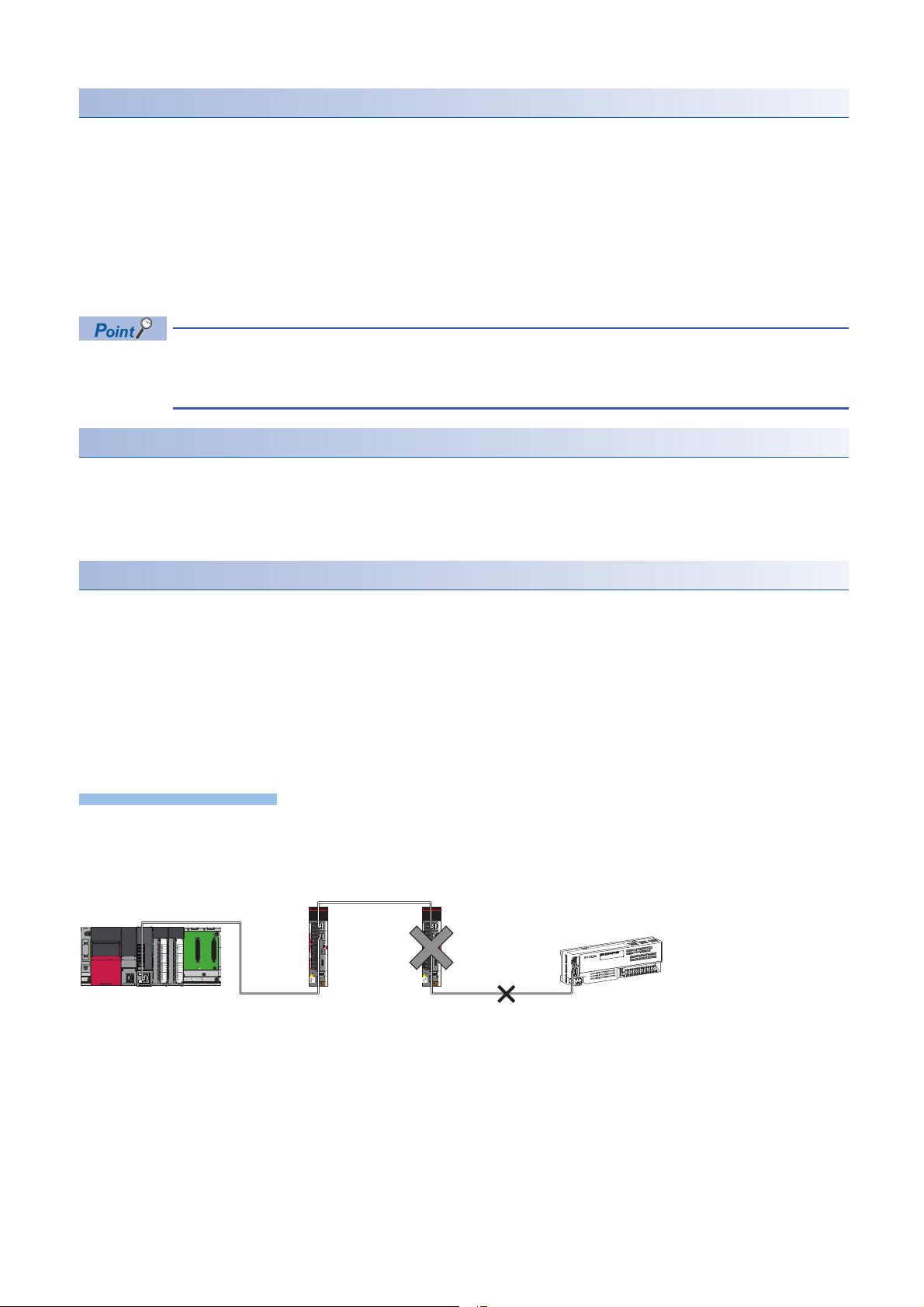

Connecting SLMP-compatible devices

Connect commercially available SLMP-compatible devices. A SLMP-compatible device can be introduced to the CC-Link IE

TSN system, resulting in easier linkage with an upper information network.

For details on SLMP, refer to the following.

SLMP Reference Manual

When the system structure is mixed with an Ethernet device, there are restrictions for the network topology

and connection order of the Ethernet device. (MELSEC iQ-R Motion Module User's Manual (Startup))

22

1 FUNCTIONS

1.3 Ethernet Connection

Page 25

1.4 Security

No.0

HUB

(1) 192.168.1.1

(2) 192.168.1.5

Security for the network environment is structured by restricting access by each communication path that accesses the CPU

module. The following two access restriction methods can be used.

Page 23 IP filter

Page 25 Remote password

IP filter

Identifies the IP address of the access source, and prevents unauthorized access and data links.

By setting the IP address of the access source using the engineering tool, IP packets are allowed or blocked. (Allows or

blocks the IP packets received from the access source. IP packets sent from the own station are ignored.)

Use of this function is recommended when using in an environment connected to a LAN line.

1

When the "Allow" IP address is set to 192.168.1.1 using the IP filter of the master station No.0:

Only the Ethernet device (1) can access the master station, and the Ethernet device (2) cannot access the master station.

This function cannot be used when accessing via a network other than Ethernet or CC-Link IE TSN.

The IP filter is one method of preventing unauthorized access (such as program or data destruction) from an

external device. It does not completely prevent unauthorized access. Incorporate measures other than this

function if the programmable controller system's safety must be maintained against unauthorized access from

an external device. Mitsubishi shall not be held liable for any system problems that may occur from

unauthorized access.

Examples of measures for unauthorized access are given below.

• Install a firewall

1 FUNCTIONS

1.4 Security

23

Page 26

Setting method

Precautions

No.0

No.1: 192.168.1.1 No.2: 192.168.1.2

No.3: 192.168.1.3

1. Set the IP address to be allowed or blocked in the "IP Filter Settings" window of "Security" under "Application Settings".

(Page 41 Security) A warning is displayed in the following cases.

• When blocking the IP address of the slave station set in "Network Configuration Settings" under "Basic Settings" was

attempted

• When the slave station is not set in "Network Configuration Settings" under "Basic Settings", and the "Allow" target IP

address is not set in the "IP Filter Settings" window (because the IP filter is fully blocked)

2. Write the module parameters to the CPU module.

3. The IP filter is enabled when the CPU module power is turned off and on or reset.

Even if the connection was specified in "Network Configuration Settings" under "Basic Settings" or by a

program, access from the external device is either allowed or blocked according to the setting in the "IP Filter

Settings" window.

Setting Target

Allow or block should be set to all IP addresses that connect to the same network. Also, set allow or block to the IP address of

the slave station that is registered in "Network Configuration Settings" under "Basic Settings".

Register the setting details to the master station, and allow or block the IP packets received from the slave station of the

registered IP address.

Operation

Even for the slave station registered in "Network Configuration Settings" under "Basic Settings", a station with an IP address

set as blocked can become a disconnected station. As a result, cyclic transmission and transient transmission are not

performed. Such a station is also displayed as a disconnected station on the "CC-Link IE TSN/CC-Link IE Field Diagnostics"

window. However, Ethernet devices are not displayed on the "CC-Link IE TSN/CC-Link IE Field Diagnostics" window. (

Page 54 CC-Link IE TSN/CC-Link IE Field Diagnostics)

When an IP packet is received from an IP address that is set as blocked, the denial is registered in the event history of the

master station.

( Page 84 Event List)

• Do not set the IP addresses of the master station or slave stations as blocked. When a slave station using line topology is

set as blocked, cyclic and transient transmissions cannot be performed on the slave stations that are connected after the

slave station set as blocked.

When the "Deny" IP address is set to 192.168.1.2 using the IP filter of the master station No.0:

Only the slave station No.1 can access the master station, and the slave station No.2 and slave station No.3 cannot access the master station.

• If there is a proxy server in the LAN line, block the IP address for the proxy server. If the IP address is allowed, it will not be

possible to prevent access from personal computers that access the proxy server.

• To block access from an external device to another station, block access to the connected station (station connected

directly to an external device) by using the IP filter.

24

1 FUNCTIONS

1.4 Security

Page 27

Remote password

Permits or prohibits access from the external device to the CPU module via Motion module. This function can prevent

unauthorized access of the CPU module from a remote location.

The remote password is one method of preventing unauthorized access (such as program or data destruction)

from an external device. It does not completely prevent unauthorized access. Incorporate measures other

than this function if the programmable controller system's safety must be maintained against unauthorized

access from an external device. Mitsubishi shall not be held liable for any system problems that may occur

from unauthorized access.

Examples of measures for unauthorized access are given below.

• Install a firewall

Number of settable modules

Up to eight modules can be set for remote passwords.

When using the multiple CPU system configuration, up to eight modules can be set for each CPU module.

1

1 FUNCTIONS

1.4 Security

25

Page 28

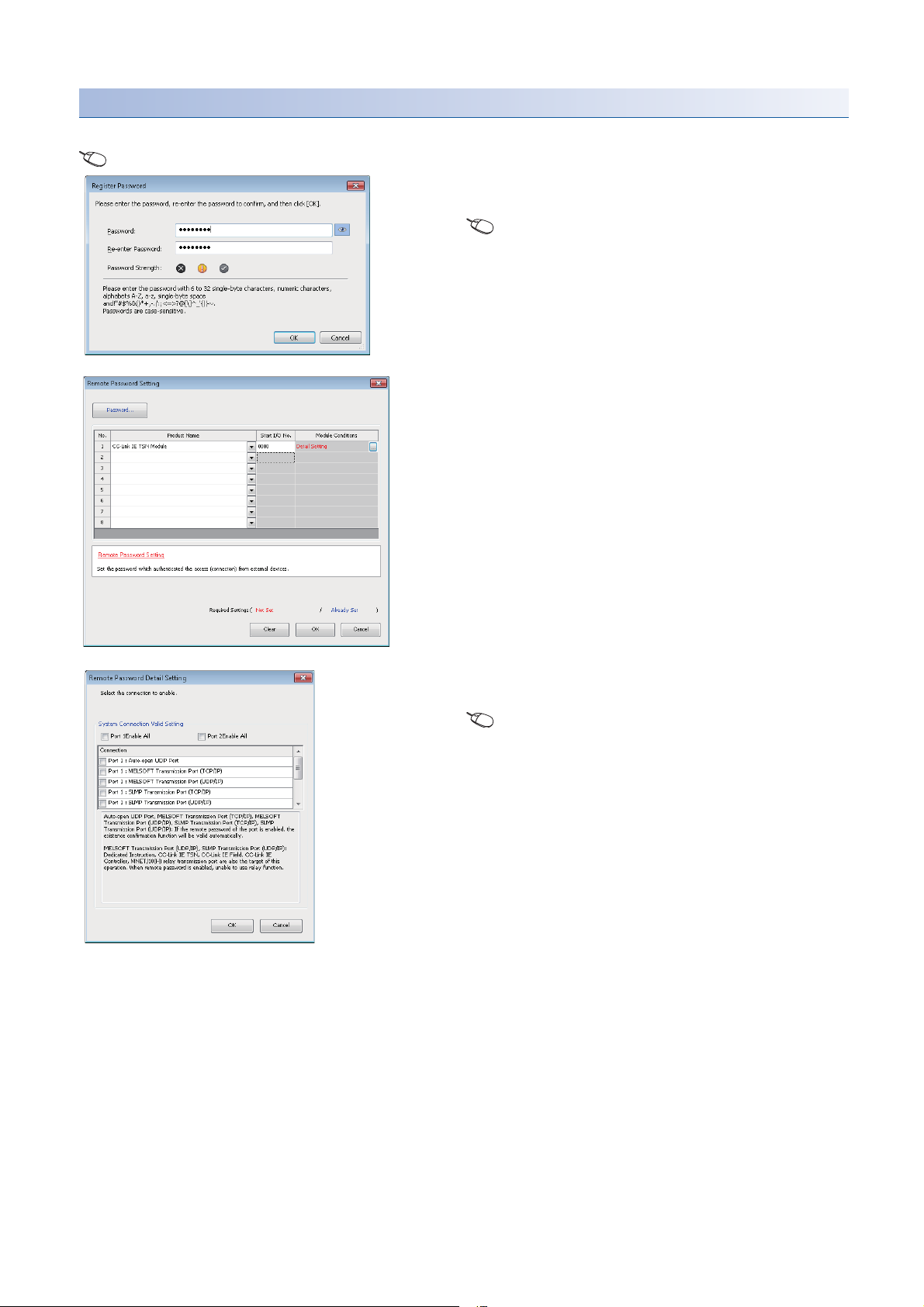

Setting method

Set on the "Remote Password Setting" window.

[Navigation window] [Parameter] [Remote Password]

1. Click the [Password] button, and register the remote

password on the "Register Password" window.

[Password] button

2. Select the module for which the remote password is to

be applied, and set the start I/O No..

3. Set the target connection on the "Remote Password

Detail Setting" window.

"Detail Setting" for the target module

4. Write the remote password to the CPU module.

5. The remote password is enabled when the CPU module

is reset or powered off and on.

■PING

This function uses the Ping command to perform an alive check of external devices whose access is permitted in UDP

communications. Therefore, if external devices do not respond to ping, an alive check error (event code 00906H) occurs.

When this function is used for UDP communications, check if the security setting of external devices (such as a firewall) is set

to respond to ping.

26

1 FUNCTIONS

1.4 Security

Page 29

Access permitted/prohibited processing operation

This section describes the processing for permitting or prohibiting access of the CPU module with remote password by the

external device.

■Access permit processing (Unlock processing)

The external device trying to communicate unlocks the remote password set for the connected Motion module.

If the password is not unlocked, the Motion module to which the external device is connected prohibits access, so an error

occurs in the external device.

The unlocking methods are shown below.

• SLMP dedicated command (Remote Password Unlock)

• Input password from engineering tool

■Access processing

Access to the specified station is possible when the remote password is correctly unlocked. Execute the arbitrary access.

■Access prohibit processing (Lock processing)

When access to the specified station ends, lock the remote password from the external device to disable subsequent access.

The locking methods are shown below.

• SLMP dedicated command (Remote Password Lock)

• Lock with engineering tool (executed automatically)

1

1 FUNCTIONS

1.4 Security

27

Page 30

Precautions

The following section lists the precautions for using remote password.

Ethernet

A

B

C

D

Enable/

Disable

Remote password

check

No remote password

parameter

Remote password

parameter

■Set connection

Set the remote password for the connection used for data communication with an external device that can execute the unlock/

lock processing.

■When remote password is set for UDP/IP connection

• Determine the external device to communicate with and perform data communication. (With UDP/IP, after the remote

password is unlocked, data can be exchanged with devices other than the unlocked external device too. Determine the

communication destination before starting use.)

• Always lock the remote password after data communication is finished. (If the remote password is not locked, the unlocked

state is held until timeout occurs.)

■TCP/IP close processing

If the TCP/IP is closed before the TCP/IP is locked, the CPU module will automatically start the lock processing.

■Remote password valid range

The remote password is valid only for access from the Motion module for which the parameters are set. When using multiple

CPU modules in a multiple CPU system, set a remote password for each CPU module for requiring a remote password.

The remote password is checked when accessing with path A or B.

The remote password is not checked when accessing with path C or D.

28

1 FUNCTIONS

1.4 Security

Page 31

1.5 RAS

No.0 No.1 No.2 No.0

No.0 No.1 No.2 No.0

No.0 No.1 No.0 No.2

This acronym stands for Reliability, Availability, and Serviceability. This function improves overall usability of automated

equipment.

Slave station disconnection

In star topology, the data link of the slave station where the error occurred is stopped, so the data link is connected only with

the normal slave stations. In line topology, the slave station where the error occurred and the stations beyond are

disconnected.

Master station duplication detection

If there are multiple master stations on one network, duplication is detected.

• When multiple master stations are simultaneously powered on, or when multiple master stations are simultaneously

connected, Master station duplication (error code 300FH) is detected in all master stations and cyclic transmission cannot

be performed in all stations. (Transient transmission available)

• If another master station is added to the network during data link, Master station duplication (error code 300FH) is detected

in the added master station and cyclic transmission cannot be performed. (Transient transmission available) Other stations

continue data link.

1

• If two networks are connected during data link, Master station duplication (error code 300FH) is detected in master stations

on both networks and cyclic transmission cannot be performed in all stations. (Transient transmission with IP address

specification is available)

1 FUNCTIONS

1.5 RAS

29

Page 32

IP address duplication error

Precautions

192.163.3.0 192.163.3.1 192.163.3.2 192.163.3.1

192.163.3.0 192.163.3.1 192.163.3.2 192.163.3.1

If one network has stations with the same IP address, duplication is detected.

• If there is already a station with the same IP address when adding a slave station, IP address duplication (error code

2160H) is detected in a station to be added and data link cannot be performed. (Other stations continue data link.)

When the slave station that has already been connected (linked up) with TSN hub is to be added to each TSN HUB, IP

address duplication is not detected in a station to be added. If IP address duplication (error code 1802H) is detected in the

master station, disconnect the relevant slave station from the network. Otherwise, multiple stations with the same IP address

will exist on the same network, possibly leading to transient transmission being sent to an unintended station.

• If the startup processing of cyclic transmission is executed by powering off and on the master station, when a station with

the same IP address is in the network, IP address duplication (error code 3021H) is detected in the master station and data

link cannot be performed.

• During cyclic transmission, IP address duplication is regularly checked in the master station. When there are overlapping IP

addresses, IP address duplication (error code 1802H) is detected in the master station and cyclic transmission cannot be

performed with the relevant slave station. (Other stations continue data link.)

• IP address duplication between an Ethernet device and a CC-Link IE TSN device, and IP address

duplication between Ethernet devices are not detected at cyclic transmission startup of the master station.

• Station No. duplication is not detected.

Methods of recovery from IP address duplication

If IP address duplication is detected in the master station (error codes 1802H, 3021H), change the IP address of the

corresponding station, and power off and on the master station, or reset it.

30

1 FUNCTIONS

1.5 RAS

Page 33

Time synchronization

Precautions

No.0 No.1 No.2

This synchronizes the time of all stations connected to CC-Link IE TSN with the time synchronization source (Motion module

of the master station).

Even if this function is not used, the time of the slave station is always automatically synchronized with the master station.

Setting method

It is set with the buffer memory. ( Page 90 Time synchronization)

If there is no device with a higher priority than the master station, the CPU modules on the same base

synchronize with the time of the Motion module in the master station, which becomes the time synchronization

source.

For the priority verification method and setting method, refer to the manual of the time synchronization device.

1

If "Connection Device Information" of "Basic Settings" is set as "Authentication Class B Only", use a CC-Link

IE TSN-compatible switching hub certified by the CC-Link Partner Association. A slave station connected to

an industrial switching hub that is not compatible with CC-Link IE TSN cannot perform data link.

• If this function is used, the time setting function (SNTP client) of the Ethernet-equipped module cannot be used. (

MELSEC iQ-R Ethernet User's Manual (Application))

• If multiple Motion modules are mounted to a CPU module on the same base, set time synchronization for only one Motion

module. If time synchronization is set for multiple, they are overwritten by the time that is synchronized later.

• When using the multiple CPU system configuration, the CPU module No.1 becomes the time synchronization source.

1 FUNCTIONS

1.5 RAS

31

Page 34

1.6 Others

No.0

GX Works3

No.2

ÒÓ

(A) (A)

No.0

No.2

Ö

Õ

(B)

Ô

SLMP

(A) (B) (A)

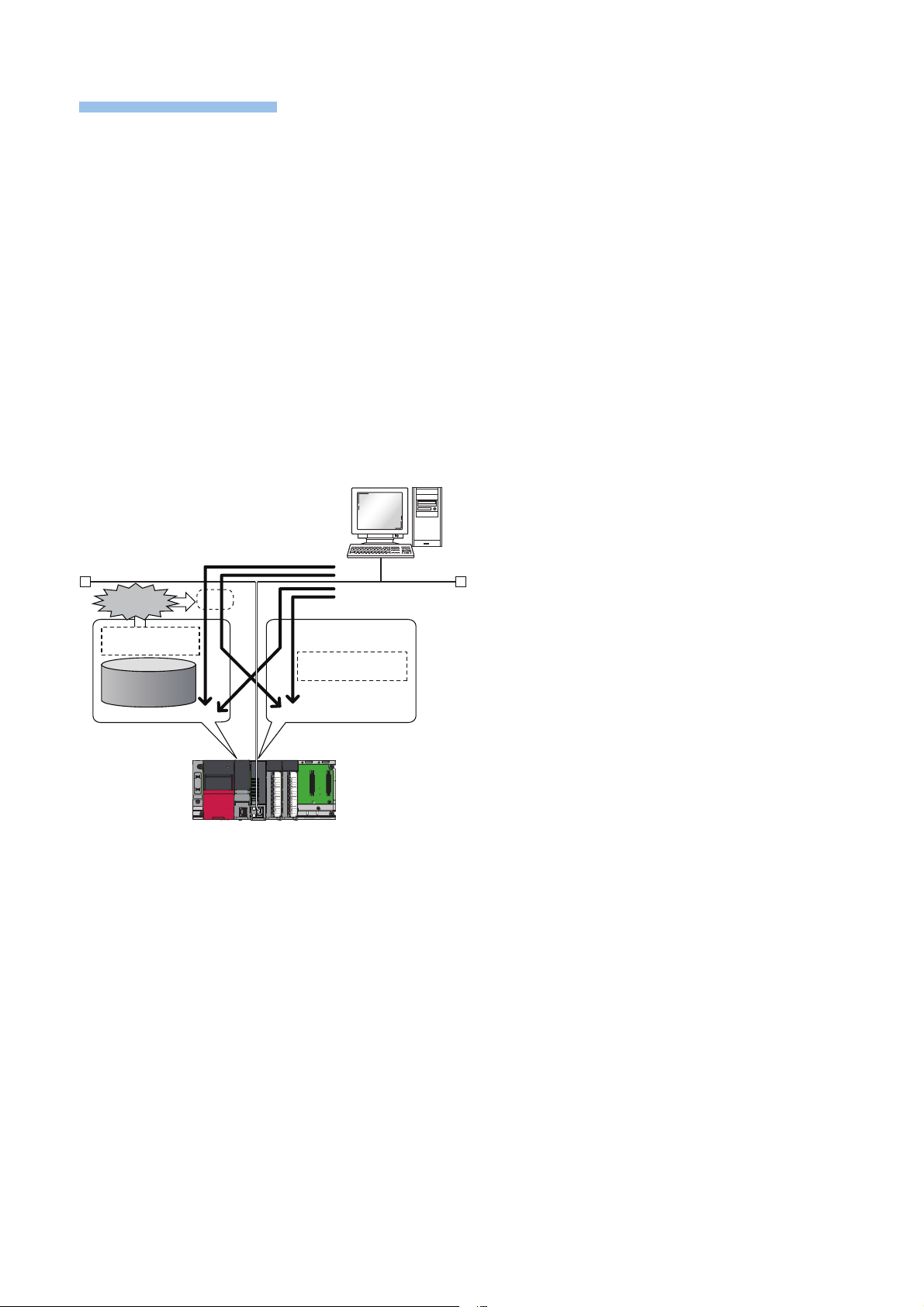

Slave station parameter automatic setting

Parameters of the slave station are saved in the master station, and the parameters will be automatically set when the slave

station is connected/returned.

If parameters are changed on the slave station side, saved parameters on the master station side are automatically updated.

Slave station parameter automatic setting from the master station

1. Parameters of the slave station set using the engineering tool are saved in the memory of the CPU module in the master

station or the SD memory card by writing.

2. When the slave station is connected/returned by power-on, saved parameters are automatically set from the master

station.

Save parameter (A) of the slave station to the CPU module on the master station.

When the slave station is returned/connected, saved parameter (A) is automatically set from the master station to the slave station.

Automatic update of saved parameter

1. If parameters on the slave station side are changed by the engineering tool or SLMP, the parameters of the slave station

that are saved in the memory of the CPU module or the SD memory card are automatically updated.

2. When the module of the slave station has been replaced, updated parameters are automatically set from the master

station by resetting the master station or turning its power off and on.

Parameter (A) of the slave station is changed to (B) by SLMP.

Saved parameter (A) of the CPU module on the master station is automatically updated to parameter (B).

• The master station starts data link with the slave station after parameters of the slave station are

automatically set.

• The slave station parameter automatic setting is also executed for slave stations set as reserved stations.

• The slave station is a CC-Link IE TSN module. (For checking if a module is compatible with automatic

32

1 FUNCTIONS

1.6 Others

update of saved parameter, refer to the manual of the module being used for the slave station.)

Page 35

Setting method

Precautions

Set in the "Parameter of Slave Station" window. ( Page 46 Parameter processing of a slave station)

• A slave station whose slave station parameter automatic setting abnormally ended does not start data link, and 'Execution

result of slave station parameter automatic setting function' (SW0160 to SW0167) turns on. Check 'Detailed execution

result of slave station parameter automatic setting' (SW0194) and the event history and perform corrective actions for

stored error codes.

• Do not disconnect the slave station that is currently executing an automatic update of saved parameters. Update of

parameter may fail.

• Do not turn off the master station that is currently executing an automatic update of saved parameters. Incorrect

parameters are automatically set in the slave station at the next power-on.

• If saved parameters are not in the CPU module when executing an automatic update of saved parameters, an error

response is returned to the relevant slave station.

• Check if the checkbox of "Parameter Automatic Setting" of the slave station is selected in "Network Configuration Settings"

under "Basic Settings".

• Check if the IP address of the slave station in the "Network Configuration settings" under "Basic Settings" matches the

actual IP address of the slave station.

1

1 FUNCTIONS

1.6 Others

33

Page 36

2 PARAMETER SETTINGS

This chapter describes the parameter settings required for communications between the Motion module and other stations.

2.1 Setting Parameters

1. Add the Motion module in the engineering tool.

[Navigation window] [Parameter] [Module Information] Right-click [Add New Module]

2. The required settings, basic settings, and application settings are included in the parameter settings. Select one of the

settings from the tree on the window shown below.

[Navigation window] [Parameter] [Module Information] Target Module [Module parameter (Network)]

3. After setting parameters, click the [Apply] button.

4. Write parameters to the CPU module using the engineering tool.

[Online] [Write to PLC]

5. The settings are reflected by resetting the CPU module or powering off and on the system.

The settings displayed on the required settings, basic settings, and application settings pages (default: ) are

the values that are displayed when the [Restore the Default Settings] button on each window of the

engineering tool is clicked.

34

2 PARAMETER SETTINGS

2.1 Setting Parameters

Page 37

2.2 Required Settings

Set the station type or IP address of the Motion module.

Item Description Reference

Station Type Set the station type of the Motion module. Page 35 Station Type

Network No. Set the network No. of the Motion module. Page 36 Network No.

Station No./IP Address

Settings

Set the IP address of the Motion module. Page 36 Station No./IP Address Settings

2

Station Type

Set the station type of the Motion module.

Item Description Setting range

Station Type The Motion module is used as the master station.

Only one master station can be set in a network.

2 PARAMETER SETTINGS

2.2 Required Settings

35

Page 38

Network No.

Precautions

Set the network No. of the own station of the Motion module.

Item Description Setting range

Network No. Set the network No. of the Motion module. 1 to 239

(Default: 1)

Set a network No. that does not duplicate any other network Nos.

In particular, when using an Ethernet-equipped module (CPU module) at default, the IP address is 192.168.3.39 and the

network No. is the third octet of the IP address, thus 3. Because setting the network No. of the Motion module to 3 causes

duplication, set another network No.

Station No./IP Address Settings

Set the station No. of the own station of the Motion module.

Item Description Setting range

Station No. The station No. of the master station is fixed to 0.

IP Address Set the IP address.

Do not set the following values.

• The third and fourth octets are all 0 or all 1.

• The host address bits are all 0 or all 1

• Reserved address

Subnet Mask Set the subnet mask.

Set the same value for the master station and slave station.

If the subnet mask is empty, the address class (class A, class B, class C) is determined from the

setting of "IP Address", and operation is done with the subnet mask according to the address

class.

The subnet mask for each class is as follows.

• Class A: 255.0.0.0

• Class B: 255.255.0.0

• Class C: 255.255.255.0

The IP address for each class is as follows.

• Class A: 0.x.x.x to 127.x.x.x

• Class B: 128.x.x.x to 191.x.x.x

• Class C: 192.x.x.x to 223.x.x.x

The host address for each class is the 0 section shown below.

• Class A: 255.0.0.0

• Class B: 255.255.0.0

• Class C: 255.255.255.0

Default Gateway Set the default gateway. •Empty

0.0.0.1 to 223.255.255.254

(Default: 192.168.3.253)

•Empty

• 0.0.0.1 to 255.255.255.255

(Default: empty)

• 0.0.0.1 to 223.255.255.254

(Default: empty)

36

2 PARAMETER SETTINGS

2.2 Required Settings

Page 39

2.3 Basic Settings

Set the network configurations, network topology, or other parameters for the Motion module.

2

Item Description Reference

Network Configuration

Settings

Refresh Settings Set link refresh ranges between the devices of the CPU module and the link special

Network Topology Select the network topology type according to the actual network configuration. Page 38 Network Topology

Communication Period Setting Set cycles of the cyclic transmission and transient transmission. Page 38 Communication Period

Connection Device

Information

Slave Station Setting Set items related to the slave station for data link error. Page 39 Slave Station Setting

Set the CC-Link IE configuration. Page 42 "CC-Link IE TSN

Configuration" Window

relay (SB), link special register (SW), and link devices of the Motion module, or

between the module label of the CPU module and the link special relay (SB) and

link special register (SW) of the Motion module.

Setting

Set the authentication Class of connected devices. Page 39 Connection Device

Information

2 PARAMETER SETTINGS

2.3 Basic Settings

37

Page 40

Network Topology

Precautions

Select the network topology type according to the actual network configuration.

Setting is not required and can be left as "Line/Star" (default).

Communication Period Setting

Perform basic cycle setting.

Item Description Setting range

Basic Period

Setting

Multiple Cycle

*3

Setting

Setting in Units of 1s Select whether to set the basic cycle in increments of 1s. • Set

• Not set

(Default: Not set)

Communication Period Interval Setting

(Do Not Set it in Units of 1s)

Communication Period Interval Setting

(Set it in Units of 1s)

System Reservation Time Necessary time for the system to guarantee the

Cyclic Transmission Time Of communication cycle intervals, set the time to be allocated

Transient Transmission Time The value of "Communication Period Interval Setting" minus

Normal-Speed Select the "Normal-Speed" cycle for a basic cycle.

Low-Speed Select the "Low-Speed" cycle for a basic cycle.

*1

Select a communication cycle. • 125.00s

• 250.00s

• 500.00s

• 1000.00s

• 2000.00s

• 4000.00s

(Default: 1000.00s)

Input a communication cycle interval. 125.00s to 4000.00s (in

increments of 1s)

(Default: 1000.00s)

communication cycle interval.

When using an authentication class B/A device with a

communication speed of 100Mbps in the basic cycle, select

200s.

to cyclic transmission.

"Cyclic Transmission Time" and "System Reservation Time" is

displayed.

Secure 14.00s or more.

Setting is not required and can be left as "4".

Setting is not required and can be left as "16".

*2

• 20.00s

• 200.00s