Page 1

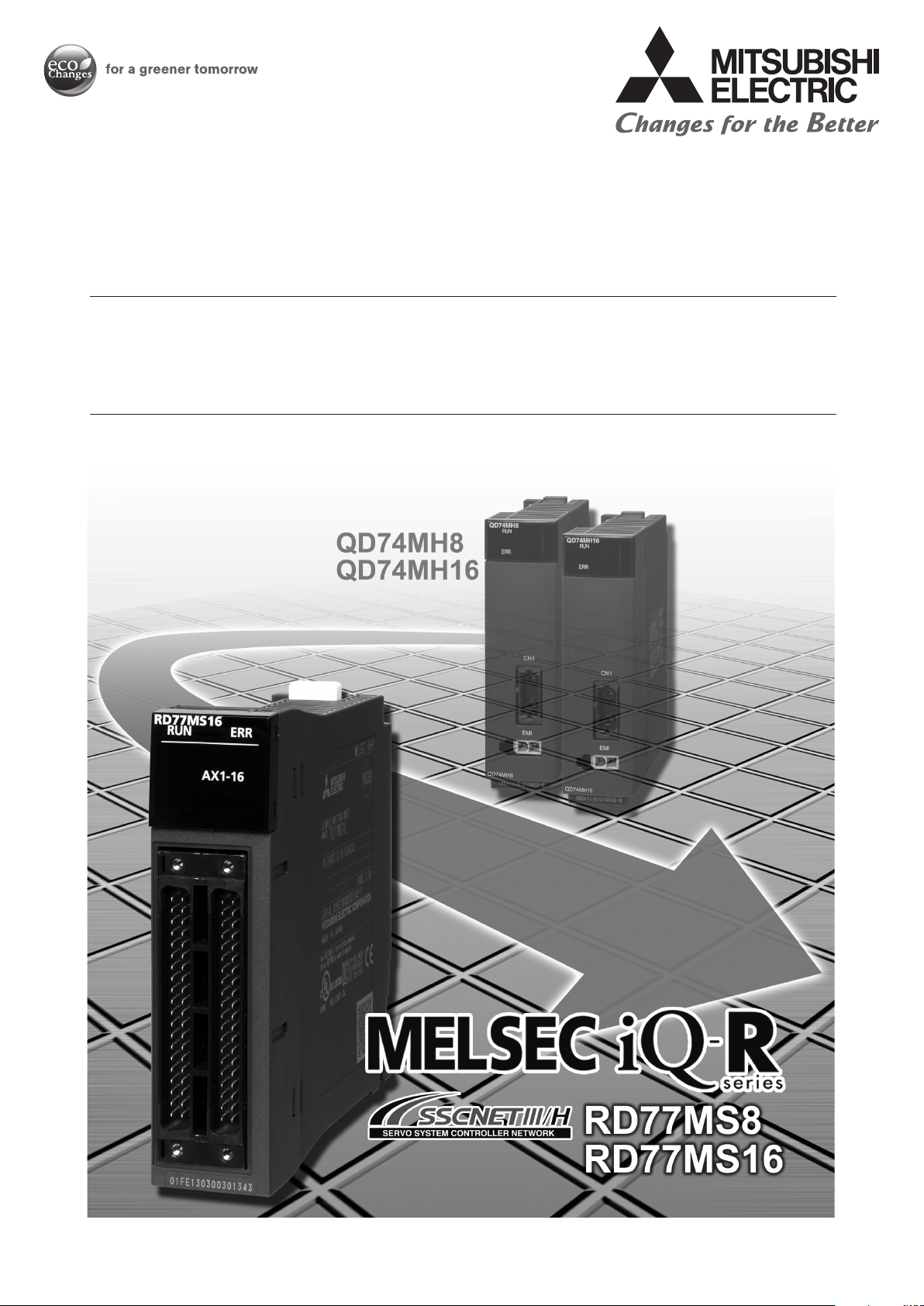

MITSUBISHI ELECTRIC SERVO SYSTEM CONTROLLER

Migration Guide from Positioning Module to

Simple Motion Module [QD74MH ය RD77MS]

Page 2

Page 3

● SAFETY PRECAUTIONS ●

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. Refer to the MELSEC iQ-R

Module Configuration Manual for a description of the PLC system safety precautions.

In this manual, the safety precautions are classified into two levels: “ WARNING” and “ CAUTION”.

Under some circumstances, failure to observe the precautions given under “ CAUTION” may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

A - 1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable

controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be

configured external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and

all outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is

activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a

safety mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe

circuit example, refer to "General Safety Requirements" in the MELSEC iQ-R Module

Configuration Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in

an output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by

a load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure

an external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external

power supply. If the external power supply is turned on first, an accident may occur due to an

incorrect output or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to

the network. Incorrect output or malfunction due to a communication failure may result in an

accident.

● When connecting an external device with a CPU module or intelligent function module to modify

data of a running programmable controller, configure an interlock circuit in the program to ensure

that the entire system will always operate safely. For other forms of control (such as program

modification, parameter change, forced output, or operating status change) of a running

programmable controller, read the relevant manuals carefully and ensure that the operation is

safe before proceeding. Improper operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device,

immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure. To prevent this, configure an interlock circuit in the program, and

determine corrective actions to be taken between the external device and CPU module in case

of a communication failure.

A - 2

Page 5

[Design Precautions]

WARNING

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module

to each module. Doing so may cause malfunction of the programmable controller system. For

the "system area", "write-protect area", and the "use prohibited" signals, refer to the user's

manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a

communication failure of multiple stations. Configure an interlock circuit in the program to

ensure that the entire system will always operate safely even if communications fail. Failure to

do so may result in an accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Configure safety circuits external to the programmable controller to ensure that the entire

system operates safely even when a fault occurs in the external power supply or the

programmable controller. Failure to do so may result in an accident due to an incorrect output or

malfunction.

(1) Machine home position return is controlled by two kinds of data: a home position return

direction and a home position return speed. Deceleration starts when the proximity dog

signal turns on. If an incorrect home position return direction is set, motion control may

continue without deceleration. To prevent machine damage caused by this, configure an

interlock circuit external to the programmable controller.

(2) When the module detects an error, the motion slows down and stops or the motion rapidly

stops, depending on the stop group setting in parameter. Set the parameter to meet the

specifications of a positioning control system. In addition, set the home position return

parameter and positioning data within the specified setting range.

(3) Outputs may remain on or off, or become undefined due to a failure of a component such as

an insulation element and transistor in an output circuit, where the module cannot detect any

error. In a system that the incorrect output could cause a serious accident, configure an

external circuit for monitoring output signals.

● If safety standards (ex., robot safety rules, etc.,) apply to the system using the module, servo

amplifier and servomotor, make sure that the safety standards are satisfied.

● Construct a safety circuit externally of the module or servo amplifier if the abnormal operation of

the module or servo amplifier differs from the safety directive operation in the system.

● Do not remove the SSCNETIII cable while turning on the control circuit power supply of the

module and servo amplifier. Do not see directly the light generated from SSCNETIII connector

of the module or servo amplifier and the end of SSCNETIII cable. When the light gets into eyes,

you may feel something wrong with eyes. (The light source of SSCNETIII complies with class1

defined in JISC6802 or IEC60825-1.)

A - 3

Page 6

[Design Precautions]

WARNING

● Do not install the control lines or communication cables together with the main circuit lines or

power cables. Keep a distance of 100 mm or more between them. Failure to do so may result in

malfunction due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design

circuits so that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the settings are

being written. Doing so will make the data in the flash ROM and SD memory card undefined.

The values need to be set in the buffer memory and written to the flash ROM and SD memory

card again. Doing so also may cause malfunction or failure of the module.

● When changing the operating status of the CPU module from external devices (such as the

remote RUN/STOP functions), select "Do Not Open in Program" for "Opening Method Setting"

in the module parameters. If "Open in Program" is selected, an execution of the remote STOP

function causes the communication line to close. Consequently, the CPU module cannot reopen

the communication line, and external devices cannot execute the remote RUN functions.

A - 4

Page 7

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing

the module. Failure to do so may result in electric shock or cause the module to fail or

malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the

Safety Guidelines included with the base unit. Failure to do so may result in electric shock, fire,

malfunction, or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the

base unit, and push in the module until the hook(s) located at the top snaps into place. Incorrect

interconnection may cause malfunction, failure, or drop of the module.

● To mount a module with no module fixing hook, place the concave part(s) located at the bottom

onto the guide(s) of the base unit, push in the module, and fix it with screw(s). Incorrect

interconnection may cause malfunction, failure, or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the

module with a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

screw, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit

securely. Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is

inserted completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of the CPU module.

After insertion, close the cassette cover and check that the cassette is inserted completely. Poor

contact may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD

memory card, extended SRAM cassette, or connector. Doing so can cause malfunction or

failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on

for operation. Failure to do so may result in electric shock.

A - 5

Page 8

[Wiring Precautions]

● Individually ground the FG and LG terminals of the programmable controller with a ground

resistance of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any

spade solderless terminal is used, it may be disconnected when the terminal screw comes

loose, resulting in failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may

cause fire or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit,

fire, or malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or

power cables. Keep a distance of 100 mm or more between them. Failure to do so may result in

malfunction due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be

pulled, resulting in damage to the module or cables or malfunction due to poor contact. Do not

clamp the extension cables with the jacket stripped. Doing so may change the characteristics of

the cables, resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable

to an incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit, fire, or malfunction. Overtightening

can damage the screw and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the

cable with connector, hold the connector part of the cable. For the cable connected to the

terminal block, loosen the terminal screw. Pulling the cable connected to the module may result

in malfunction or damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter

can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring. Do not remove the film during wiring. Remove it

for heat dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply

to the power supply module in the control panel through a relay terminal block. Wiring and

replacement of a power supply module must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. For wiring, refer to the MELSEC iQ-R

Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the

user's manual for the module used. If not, normal data transmission is not guaranteed.

A - 6

Page 9

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder,

or throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will

cause the battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module

or retightening the terminal screws, connector screws, or module fixing screws. Failure to do so

may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify

data of a running programmable controller, configure an interlock circuit in the program to

ensure that theentire system will always operate safely. For other forms of control (such as

program modification, parameter change, forced output, or operating status change) of a

running programmable controller, read the relevant manuals carefully and ensure that the

operation is safe before proceeding. Improper operation may damage machines or cause

accidents.

● Especially, when a remote programmable controller is controlled by an external device,

immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure. To prevent this, configure an interlock circuit in the program, and

determine corrective actions to be taken between the external device and CPU module in case

of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a

fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25 cm away in all directions from the programmable controller. Failure to do

so may cause malfunction.

A - 7

Page 10

[Startup and Maintenance Precautions]

CAUTION

● Shut off the external power supply (all phases) used in the system before mounting or removing

the module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or

module, resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and

the terminal block to/from the module, and do not insert/remove the extended SRAM cassette

to/from the CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding

the limit may cause malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU

module more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing

so may cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage

the battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any

shock is applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance

personnel with knowledge of protection against electric shock. Lock the control panel so that

only qualified maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge

the static electricity from the human body. Failure to do so may cause the module to fail or

malfunction.

● Before testing the operation, set a low speed value for the speed limit parameter so that the

operation can be stopped immediately upon occurrence of a hazardous condition.

● Confirm and adjust the program and each parameter before operation. Unpredictable

movements may occur depending on the machine.

● When using the absolute position system function, on starting up, and when the module or

absolute position motor has been replaced, always perform a home position return.

● Before starting the operation, confirm the brake function.

● Do not perform a megger test (insulation resistance measurement) during inspection.

● After maintenance and inspections are completed, confirm that the position detection of the

absolute position detection function is correct.

● Lock the control panel and prevent access to those who are not certified to handle or install

electric equipment.

A - 8

Page 11

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent

function module, read relevant manuals carefully and ensure the safety before operation.

Incorrect change or modification may cause system malfunction, damage to the machines, or

accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values

in the buffer memory are being written to the flash ROM in the module. Doing so will make the

data in the flash ROM and SD memory card undefined. The values need to be set in the buffer

memory and written to the flash ROM and SD memory card again. Doing so also may cause

malfunction or failure of the module.

● Note that when the reference axis speed is specified for interpolation operation, the speed of

the partner axis (2nd, 3rd, or 4th axis) may exceed the speed limit value.

● Do not go near the machine during test operations or during operations such as teaching. Doing

so may lead to injuries.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local

regulations. For details on battery regulations in EU member states, refer to the MELSEC iQ-R

Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the

regulated models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a

fumigant used for disinfection and pest control of wood packaging materials, may cause failure

of the product. Prevent the entry of fumigant residues into the product or consider other

methods (such as heat treatment) instead of fumigation. The disinfection and pest control

measures must be applied to unprocessed raw wood.

A - 9

Page 12

REVISIONS

Print Date Manual No. Revision

Sep., 2018 L(NA)03170ENG-A First edition

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2018 MITSUBISHI ELECTRIC CORPORATION

A - 10

Page 13

INTRODUCTION

Please read this manual carefully so that equipment is used to its optimum.

CONTENTS

Safety Precautions ......................................................................................................................................... A- 1

Revisions ···························································································································· A-10

Contents ····························································································································· A-11

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS 1- 1 to 1-14

1.1 Benefits of Migration ········································································································ 1- 1

1.2 Main Target Models for Migration ······················································································· 1- 2

1.3 System Configuration ······································································································ 1- 4

1.3.1 System configuration using QD74MH before migration ····················································· 1- 4

1.3.2 System configuration using RD77MS after migration ························································ 1- 4

1.4 Case Study on Migration ·································································································· 1- 5

1.4.1 Whole system migration (recommended) ······································································· 1- 6

1.4.2 Phased migration ······································································································ 1- 7

1.4.3 Separate repair ········································································································· 1- 8

1.5 Project Diversion ············································································································ 1-10

1.6 Relevant Documents ······································································································· 1-11

1.6.1 Relevant catalogs ····································································································· 1-11

1.6.2 Relevant manuals ····································································································· 1-12

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS 2- 1 to 2- 32

2.1 Table of Components and Software ··················································································· 2- 1

2.1.1 Servo amplifiers and servo motors ················································································ 2- 2

2.1.2 Engineering environment (required) ·············································································· 2- 3

2.2 Differences Between QD74MH and RD77MS ······································································· 2- 4

2.3 Forced Stop Input Cable ·································································································· 2-17

2.4 Project Diversion ············································································································ 2-20

2.4.1 Project diversion procedures by engineering environment ················································· 2-20

2.4.2 List of divertible/not divertible data ················································································· 2-24

A - 11

Page 14

MEMO

A - 12

Page 15

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1

1.1 Benefits of Migration

Migrating from the existing system using QD74MH Positioning modules to a new system using

MELSEC iQ-R series Simple Motion module RD77MS16/RD77MS8 (hereinafter called RD77MS)

is recommended. We also recommend migrating servo amplifiers to the MR-J4 series at the

same time.

Migrating not only allows the system to run for longer periods, but also has the following

advantages.

(1) High functionality of Positioning module (Simple Motion module)

The Simple Motion module achieves further advanced motion control with a wide variety of

motion control functions such as synchronous control, in addition to positioning control.

The replaced model offers various new auxiliary features including cam detection function

and cam auto generation function, helping to reduce programming time further.

Increased productivity from higher functionality of the controller

→

(2) High-speed communication by SSCNETIII/H

Speeding up and improving noise tolerance of servo system network communications are

achieved by optical communication. A long distance cable of 100 m can be also used.

Increased speeds over the entire facility

→

(3) Servo amplifier MR-J4 and servo motor

The MR-J4 series achieves high performance operation with a variety of functions including

one-touch tuning, a 22-bit high resolution encoder (4194304 pulse/rev), and 2.5 kHz speed

frequency response. The product lineup includes multi-axis servo amplifiers that contribute to

energy saving, space saving, and reduced wiring of a machine. The MR-J4 series compatible

rotary servo motor, HG series enables to output high torque at high speed. Linear servo

motors and direct drive motors are also available. Select the motor type according to your

application from our extensive product lineup.

Increase of applications, improved performance, energy saving, downsizing, and reduced

→

wiring of drive systems

(4) Reliable monitoring functions

With our engineering software, the system status is easily monitored just by selecting

monitoring items that your system needs from its wealth of monitoring information.

In addition, operation is checked through waveforms and each device data collected by

digital oscilloscope and GX Logviewer

→ A strong support for troubleshooting

(5) Lower maintenance cost

After 5 years of usage, the products will need maintenance, such as replacement of the whole

circuit board due to the life of components including electrolytic capacitors and memories.

To use the system the longest possible, an early migration to the latest model is

recommended in terms of performance and quality.

Increased equipment longevity

→

1 - 1

Page 16

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

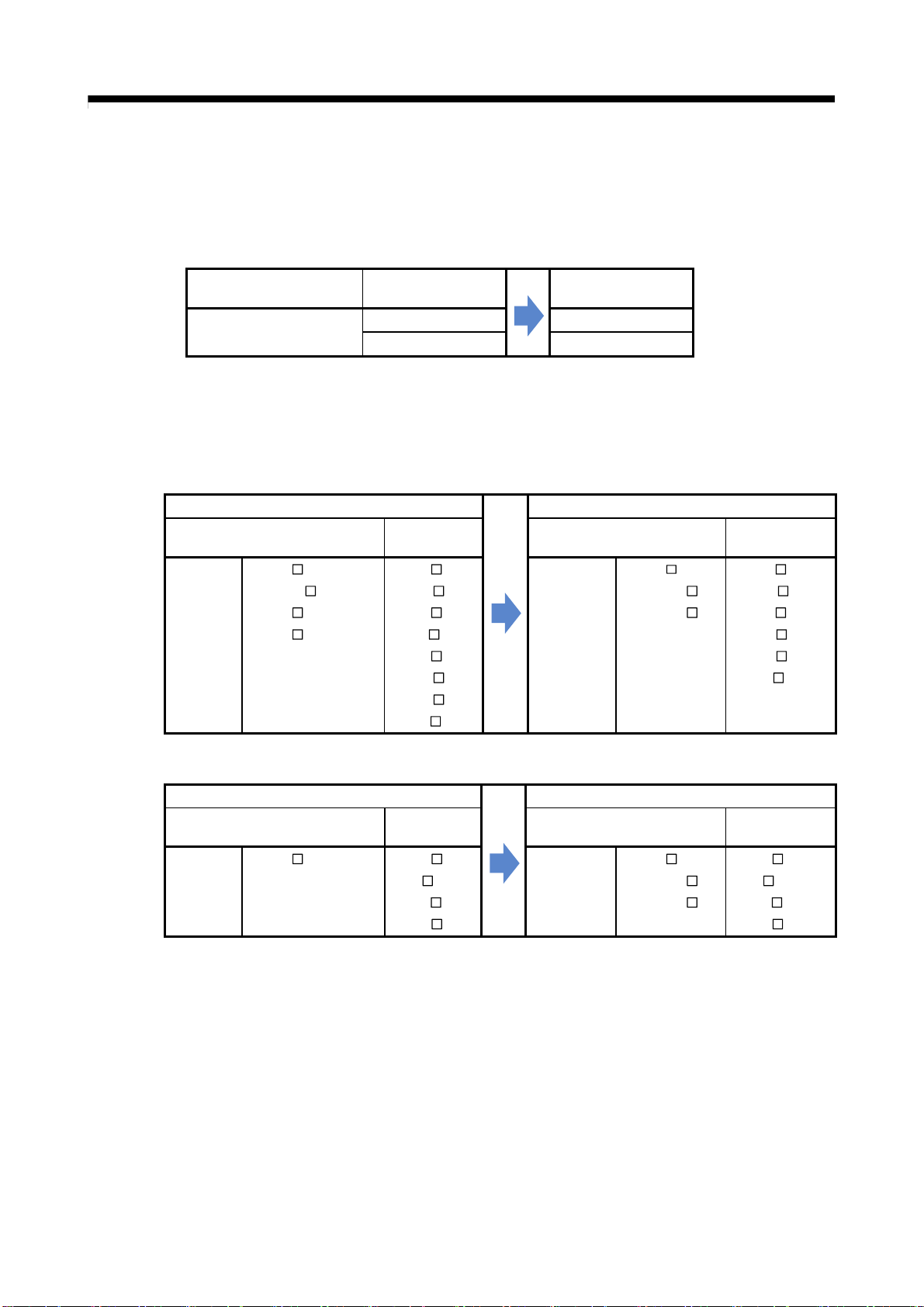

1.2 Main Target Models for Migration

The main target models for replacement described in this section are as follows.

(1) Positioning modules

Product name

SSCNETIII compatible

Positioning module

QD74MH8 RD77MS8

QD74MH16 RD77MS16

Model

before migration

after migration

(2) Servo amplifiers and servo motors

The existing MR-J3 series servo amplifiers can be used in the migrated system with RD77MS,

however, it is strongly recommended to replace them with the MR-J4 series.

(a) Servo amplifiers and rotary servo motors

Before migration from QD74MH

MR-J3

series

Servo amplifier

MR-J3- B

MR-J3W-

MR-J3-

MR-J3- B-RJ006

BS

B

Rotary

servo motor

HF-KP

HF-MP

HF-SP

HF-JP

HC-LP

HC-RP

HC-UP

HA-LP

MR-J4

series

Servo amplifier

(b) Servo amplifiers and linear servo motors

Before migration from QD74MH

Linear

servo motor

LM-F

LM-K2

LM-U2

MR-J4

series

Servo amplifier

MR-J3

series

Servo amplifier

MR-J3- B-RJ004 LM-H2

Model

After migration to RD77MS

servo motor

MR-J4-

MR-J4W2-

MR-J4W3-

After migration to RD77MS

MR-J4-

MR-J4W2- B

MR-J4W3-

B(-RJ)

B(-RJ)

B

B

B

HG-KR

HG-MR

HG-SR

HG-RR

HG-UR

HG-JR

servo motor

LM-H3

LM-F

LM-K2

LM-U2

Rotary

Linear

1 - 2

Page 17

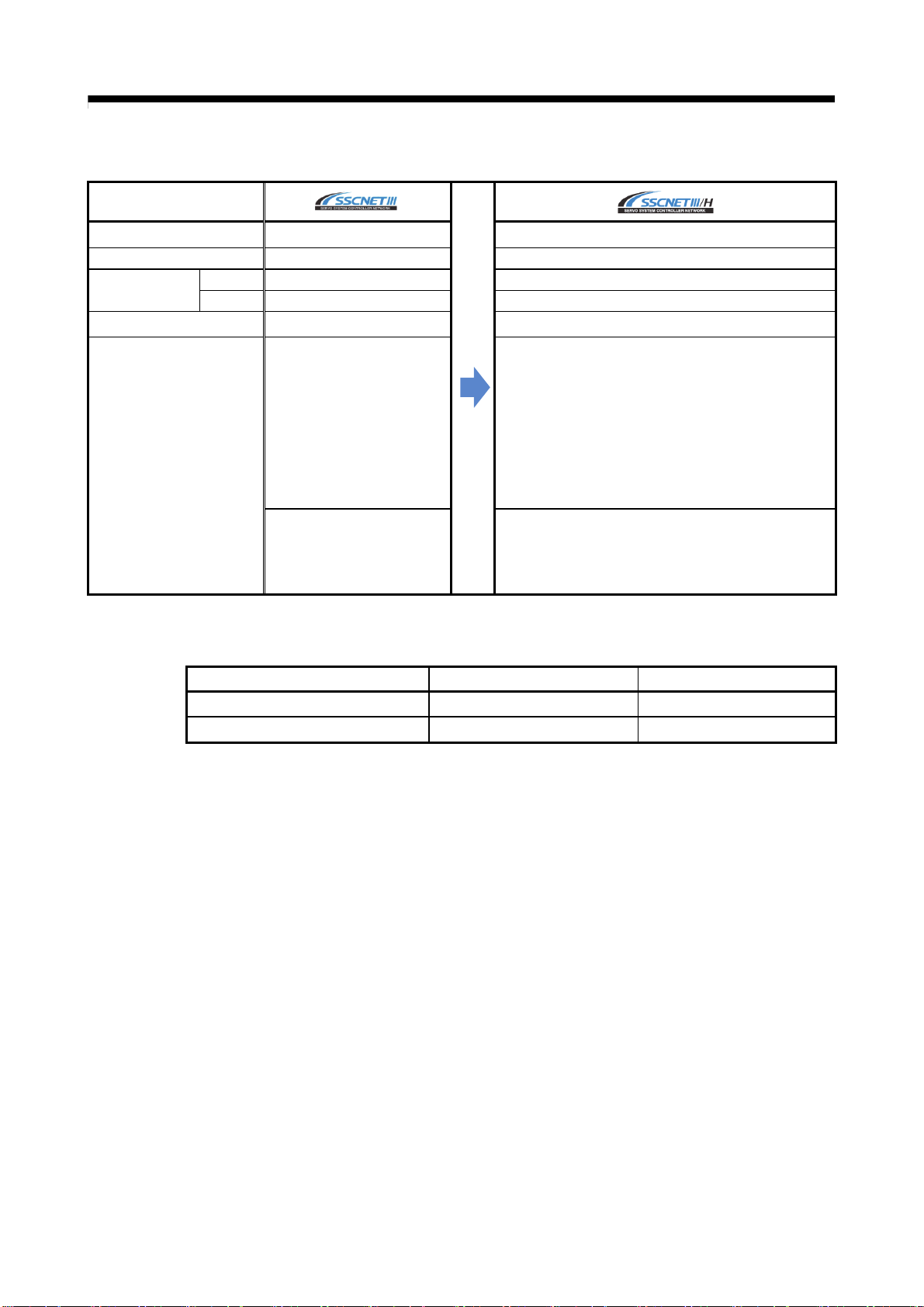

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

Communications medium Optical fiber cable

Communications speed 50 Mbps 150 Mbps

Communications

cycle

Number of control axes

Transmission distance

(3) Servo system network

Item

Send 0.44 ms/0.88 ms 0.222 ms/0.444 ms/0.888 ms

Receive 0.44 ms/0.88 ms 0.222 ms/0.444 ms/0.888 ms

Up to 16 axes/line

[Standard code for inside panel]

Up to 3 m between stations

Maximum overall distance:

48 m (3 m × 16 axes)

[Standard cable for outside panel]

Up to 20 m between stations

Maximum overall distance:

320 m (20 m × 16 axes)

[Long distance cable]

Up to 50 m between stations

Maximum overall distance:

800 m (50 m × 16 axes)

(same as SSCNETIII)

←

(same as SSCNETIII)

←

[Standard code for inside panel and standard cable for

outside panel]

Up to 20 m between stations

Maximum overall distance: 320 m (20 m × 16 axes)

[Long distance cable]

Up to 100 m between stations

Maximum overall distance: 1600 m (100 m × 16 axes)

(4) Engineering environment (required)

Product name Model Version

MELSOFT GX Works3

MELSOFT MR Configurator2

SW1DND-GXW3-E Ver.1.046Y or later

SW1DNC-MRC2-E Ver.1.27D or later

1 - 3

Page 18

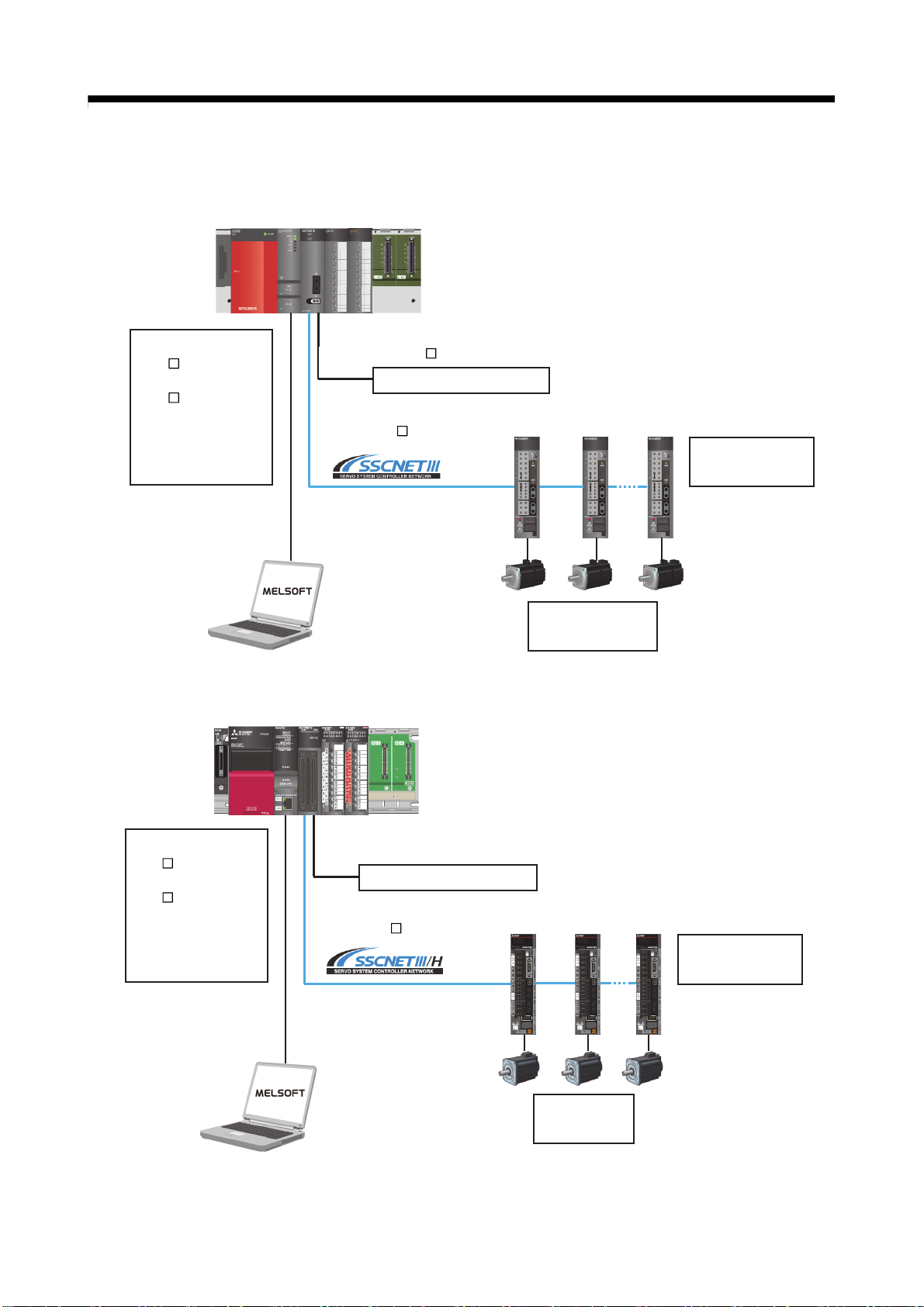

p

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1.3 System Configuration

1.3.1 System configuration using QD74MH before migration

Main base unit

B

Q3

Power supply module

Q6

P

PLC CPU module

Qn(H)CPU

Positioning module

QD74MH

Forced stop input cable

Q170DEMICBL

Forced stop input (24 VDC)

SSCNETIII cable

MR-J3BUS

M(-A/-B)

M

USB communication

cable or RS-232

communication cable

Servo motor

HC/HA/HF series

1.3.2 System configuration using RD77MS after migration

Servo amplifier

MR-J3-B

Main base unit

B

R3

Power supply module

R6

P

PLC CPU module

RnCPU

Simple Motion module

RD77MS

USB communication

cable or Ethernet

communication cable

External in

SSCNETIII cable

MR-J3BUS

(Note-1): Replace the forced stop input cable for the new controller. (Refer to section 1.4.2.)

ut signal cable

Forced stop input (24 VDC)

M(-A/-B)

(Note-1)

Servo amplifier

Servo motor

HG series

MR-J4-B

1 - 4

Page 19

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

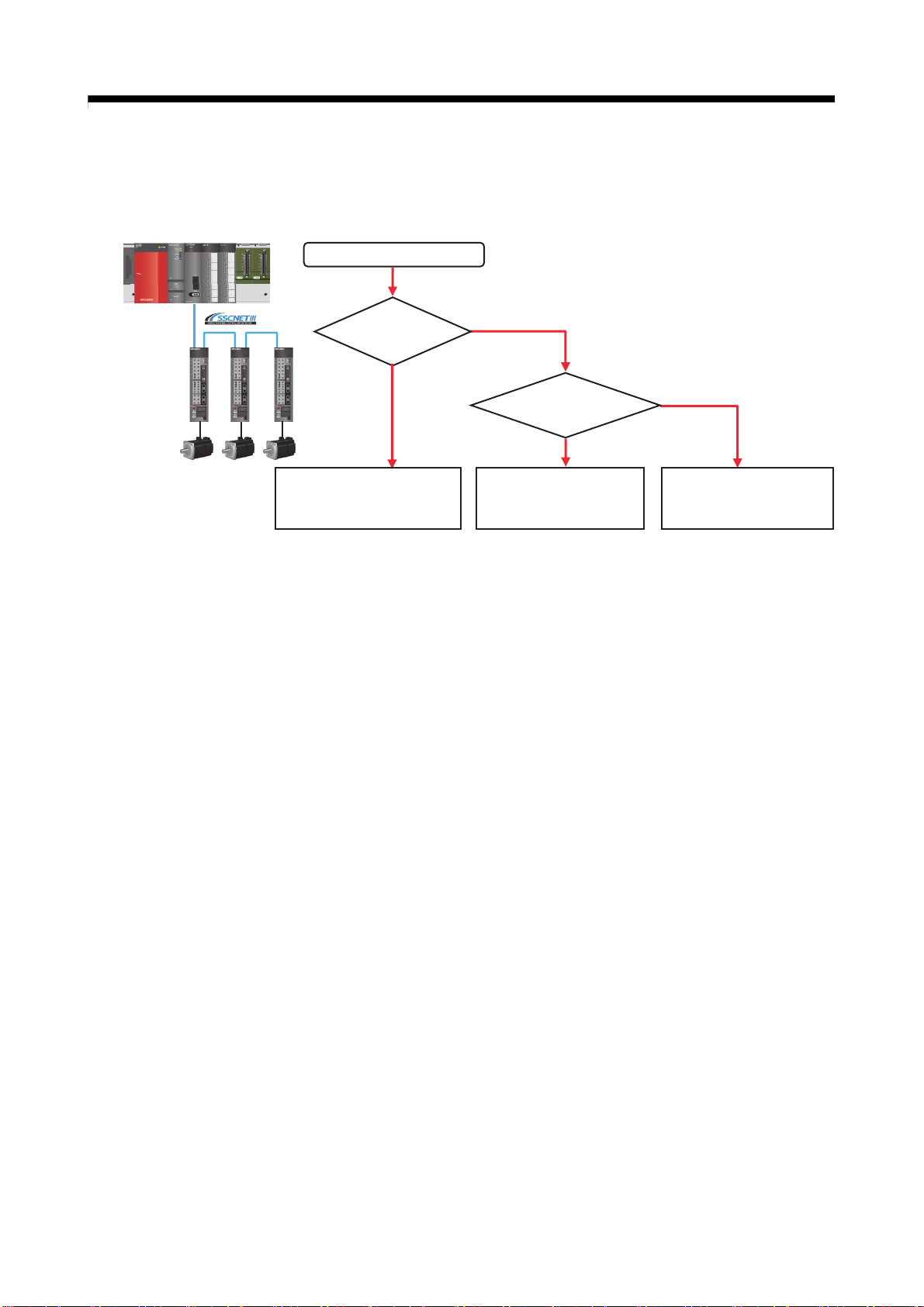

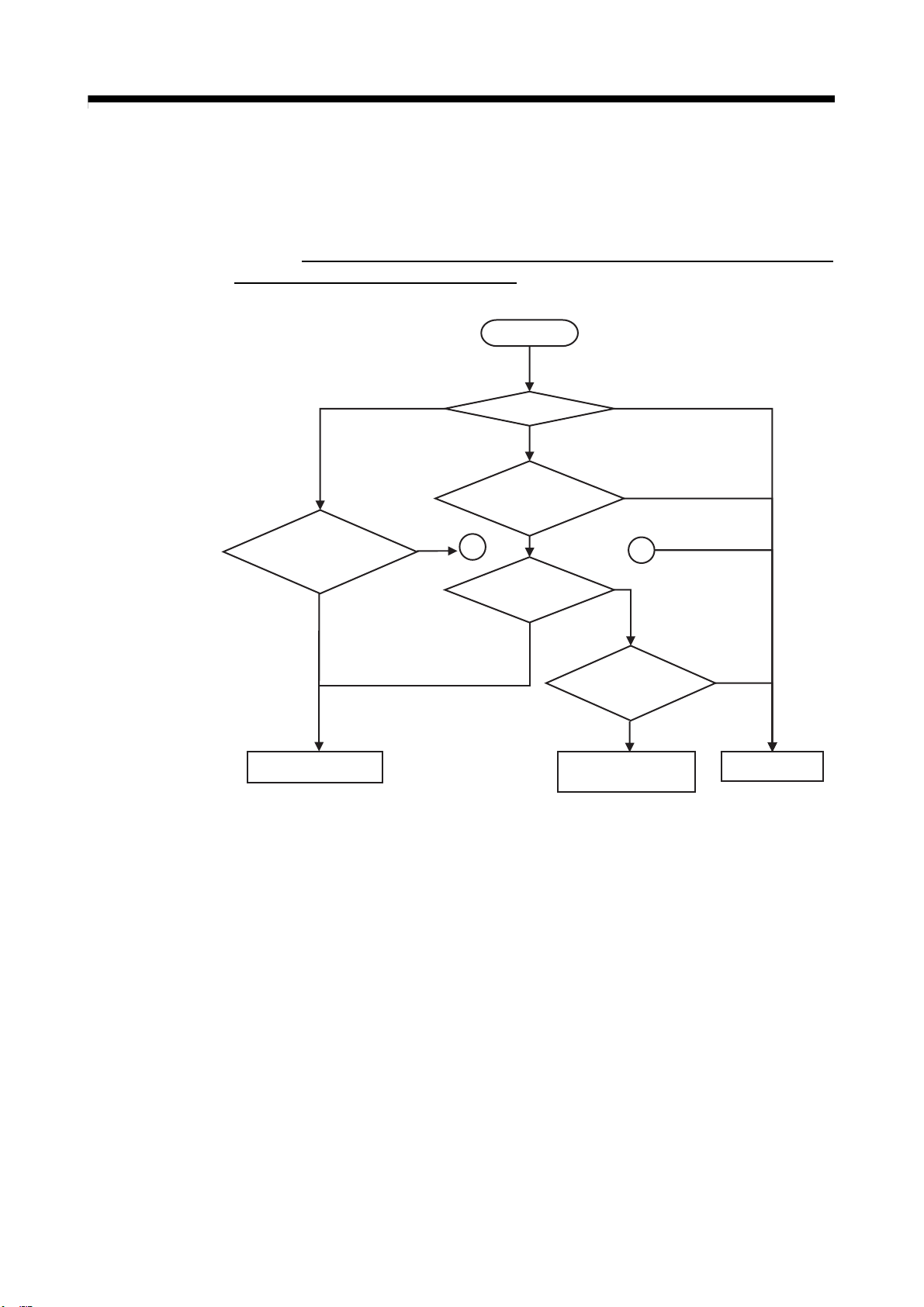

1.4 Case Study on Migration

The following describes a case study for migrating the existing system using QD74MH.

(1) Whole system migration (recommended)

The controller, servo amplifiers, servo motors, and servo system network are replaced

simultaneously. Although a large-scale installation is required, the whole system migration

allows the system to operate for longer periods. (Refer to section 1.4.1.)

(2) Phased migration (When the whole system migration is difficult due to the installation

period and cost.)

The controller is replaced with RD77MS in the first phase, and then the MR-J3-B servo

amplifiers are gradually replaced with MR-J4-B.

(Refer to section 1.4.2.)

(3) Separate repair

This is a replacement method for when the controller, the servo amplifier, or the servo motor

malfunctions.

(Refer to section 1.4.3.)

Consideration of migration

Whole system

migration?

YES

(1) Whole system migration

→ Refer to section 1.4.1.

NO

Phased

migration?

YES

(2) Phased migration

→ Refer to section 1.4.2.

NO

(3) Separate repair

→ Refer to section 1.4.3.

1 - 5

Page 20

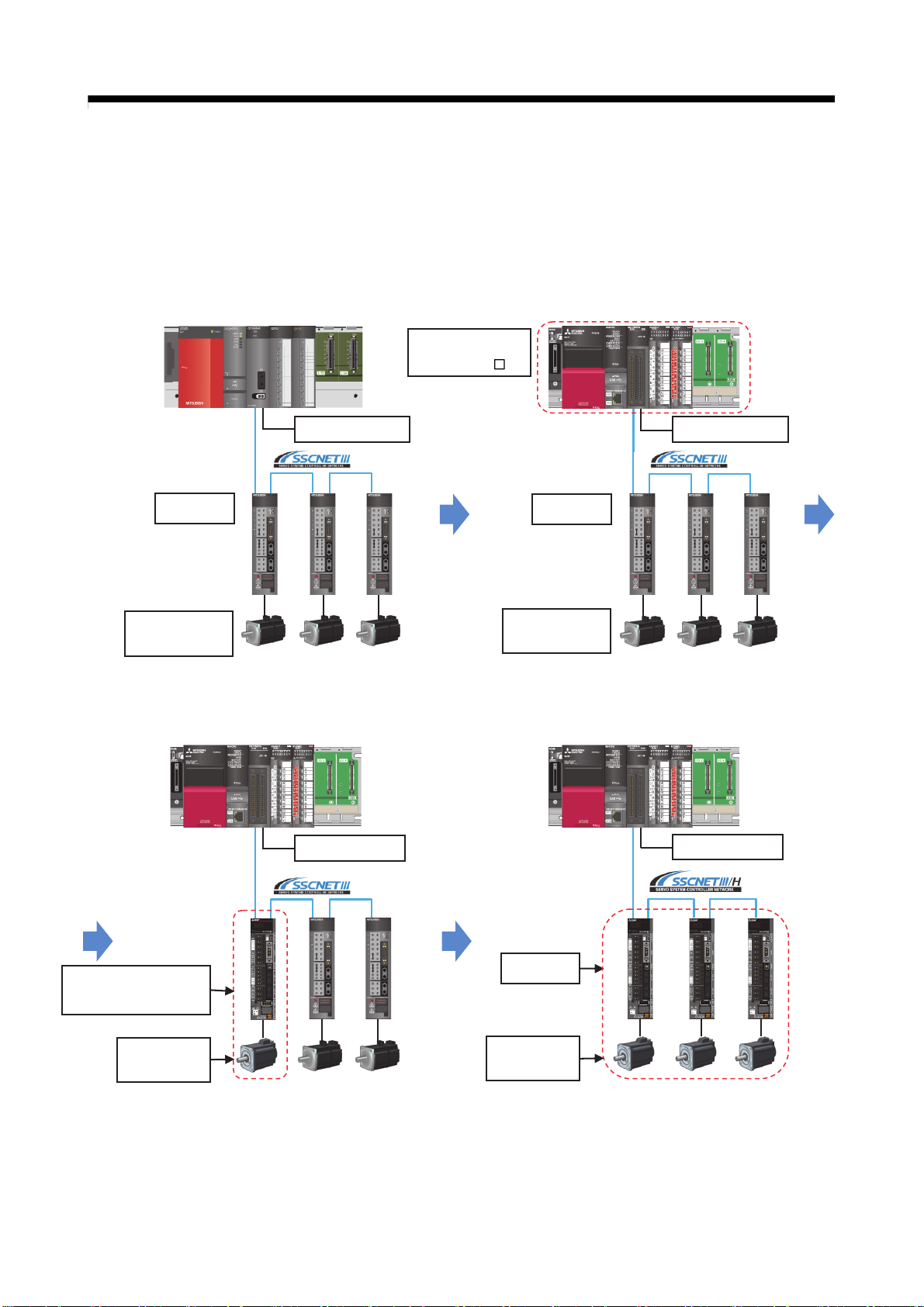

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1.4.1 Whole system migration (recommended)

The following shows the system when the whole system migration takes place.

[Current model]

MR-J3-B

HC/HA/HF

servo motor

[Changes in the system]

Product name Model before migration

Main base unit Q3 B R3 B

PLC CPU module Qn(H)CPU RnCPU

Positioning module QD74MH RD77MS

Servo amplifier MR-J3-B MR-J4-B

Servo motor HC/HA/HF series HG series

Forced stop input cable

QD74MH

Forced stop input Forced stop input

Q170DEMICBL

M

[Model after migration]

MR-J4-B

HG

servo motor

Fabricate the cable with

A6CON connector.

(Refer to section 2.3.)

RD77MS

Model after migration

1 - 6

Page 21

r

r

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1.4.2 Phased migration

The following shows the procedure for the phased migration in which the controller is replaced

with RD77MS in the first phase, and then the MR-J3-B servo amplifiers are gradually replaced

with MR-J4-B in the following phases.

[Current model]

RD77MS

(RnCPU + R3

B)

Replacement - Phase 1]

[

Replacement of the controller

+ forced stop input cable

Forced stop input Forced stop input

MR-J3-B

MR-J3-B

HC/HA/HF

servo motor

HC/HA/HF

servo motor

[Replacement - Phase 2]

Servo amplifier and servo motor

replacement for only one axis

[Replacement - Phase 3]

Servo amplifier and servo motor replacement for all

axes, and servo system network replacement

Forced stop input

MR-J4-B

(J3 compatibility mode)

MR-J4-B

HG

servo moto

HG

servo moto

Forced stop input

(Note): For replacing only the servo amplifier or the servo

motor, refer to “1.4.3 Separate repair”.

(Note): For details of the J3 compatibility mode, refer to

“Transition from MELSERVO-J3/J3W Series to

J4 Series Handbook”.

(Note): When replacing all the servo amplifiers with

MR-J4-B, the operation mode can be switched

from “J3 compatibility mode” to “J4 mode”.

The servo system network is also changed from

SSCNETIII to SSCNETIII/H.

1 - 7

Page 22

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1.4.3 Separate repair

The following shows the procedure for the separate repair.

(1) When the controller has malfunctioned.

Replace only the controller.

MR-J3-B

HC/HA/HF servo motor

(2) When the MR-J3-B servo amplifier has malfunctioned.

Replace only the servo amplifier.

HC/HA/HF servo motor

R3 B

+RnCPU

+RD77MS

(Note):

MR-J3-B can operate with the replaced controller

The existing servo amplifiers and servo motors can

be used with the new controller.

Replacement with MR-J4-B

(J3 compatibility mode)

(Note):

For the compatible servo motors, refer to

“Transition from MELSERVO-J3/J3W

Series to J4 Series Handbook”.

1 - 8

Page 23

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

(3) When the HC/HA/HF servo motor has malfunctioned

Simultaneously replace the servo amplifier and the malfunctioned servo motor.

Replacement with MR-J4-B

(J3 compatibility mode)

Replacement with HG servo motor

1 - 9

Page 24

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1.5 Project Diversion

The following describes about the project diversion for Qn(H)CPU and QD74MH setting software.

(1) PLC CPU projects

Be sure to recreate sequence programs for the migrated system

the buffer memory and the control method differs between QD74MH and RD77MS.

Refer to relevant manuals for details.

(2) Projects of QD74MH setting software (Japanese version only)

Projects in QD74MH setting software are partially divertible.

Refer to "2.4 Project diversion" for the procedure for project diversion.

because the structure of

1 - 10

Page 25

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1.6 Relevant Documents

Refer to the following relevant documents for the replacement.

1.6.1 Relevant catalogs

Servo System Controllers

MELSEC iQ-R/MELSEC iQ-F Series

SERVO AMPLIFIERS & MOTORS

MELSERVO-J4

L(NA)03100

Transition from MELSERVO-J3/J3W Series

to J4 Series Handbook

L(NA)03127

L(NA)03058

1 - 11

Page 26

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

1.6.2 Relevant manuals

MELSEC iQ-R Simple Motion Module User's Manual (Startup)

MELSEC iQ-R Simple Motion Module User's Manual (Application)

MELSEC iQ-R Simple Motion Module User's Manual

(Advanced Synchronous Control)

RD77MS Before Using the Product

MR-J4-_B_(-RJ) SERVO AMPLIFIER INSTRUCTION MANUAL

MR-J4 Servo amplifier Instructions and Cautions for Safe Use of AC Servos

MELSERVO-J4 Servo amplifier INSTRUCTION MANUAL TROUBLE SHOOTING

(1) Simple Motion module

Manual title Manual No.

(2) Servo amplifier

Manual title Manual No.

IB-0300245

IB-0300247

IB-0300249

BCN-B62008-335E

SH-030106

IB-0300175E

SH-030109

MR-J4W2-_B/MR-J4W3-_B/MR-J4W2-0303B6 SERVO AMPLIFIER

INSTRUCTION MANUAL

SH-030105

1 - 12

Page 27

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

MEMO

1 - 13

Page 28

1. OVERVIEW OF MIGRATION FROM QD74MH TO RD77MS

MEMO

1 - 14

Page 29

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

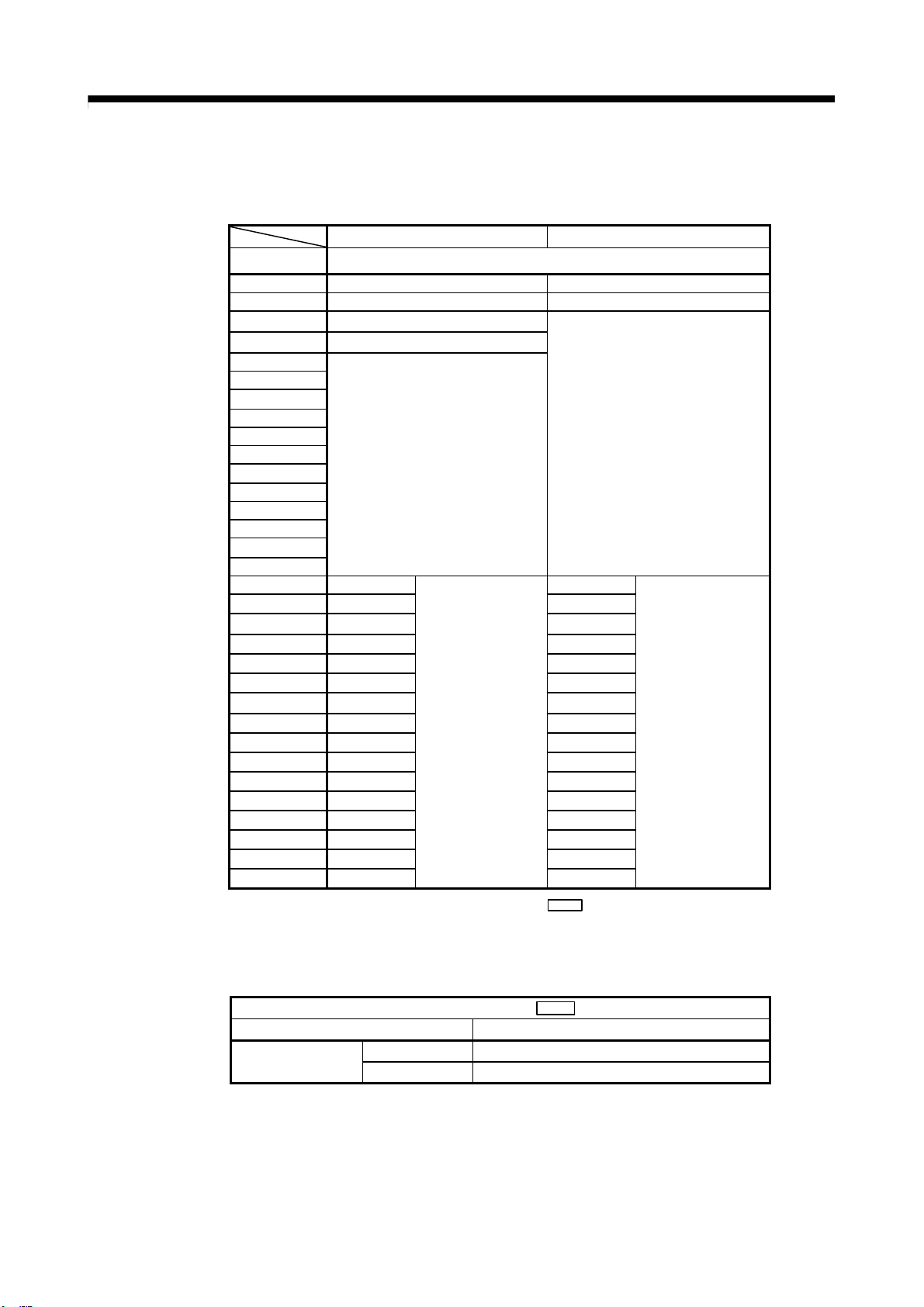

2.1 Table of Components and Software

Prepare Positioning modules, servo amplifiers, and an engineering environment according to the

following tables in this section.

Product name

Positioning module

Forced stop input cable Q170DEMICBL M A6CON1, A6CON2,A6CON4

Connector for forced stop

input cable

SSCNETIII cable

(Note-1): " " indicates the cable length.

(015: 0.15m, 03: 0.3m, 05: 0.5m, 1: 1m, 5: 5m, 10: 10m, 20: 20m, 30: 30m, 40: 40m, 50: 50m)

(Note-2): For a long distance cable of up to 100 m or an ultra-long bending life cable, contact Mitsubishi Electric System &

Service Co., Ltd.

[Sales office] FA PRODUCT DIVISION mail: osb.webmaster@melsc.jp

(Note-1)

QD74MH8

QD74MH16

Q170DEMICON

MR-J3BUS

MR-J3BUS

MR-J3BUS

Model

before migration

M

M-A

(Note-2)

M-B

Model

after migration

[Simple Motion module]

RD77MS8

RD77MS16

←(same as the left)

2

2 - 1

Page 30

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

2.1.1 Servo amplifiers and servo motors

The servo system network is changed from SSCNETIII to SSCNETIII/H.

Select a SSCNETIII/H compatible servo amplifier and a servo motor connectable to the selected

servo amplifier.

(1) Servo amplifiers/Rotary servo motors

Before migration from QD74MH

Rotary

servo motor

HF-KP

HF-MP

HF-SP

HF-JP

HC-LP

HC-RP

HC-UP

HA-LP

MR-J3

series

Servo amplifier

MR-J3- B

MR-J3W-

MR-J3-

MR-J3- B-RJ006

B

BS

MR-J4

series

After migration to RD77MS

Servo amplifier

MR-J4-

MR-J4W2-

MR-J4W3-

B(-RJ)

B

B

Rotary

servo motor

HG-KR

HG-MR

HG-SR

HG-RR

HG-UR

HG-JR

(2) Servo amplifiers/Linear servo motors

Before migration from QD74MH

Linear

servo motor

LM-F

LM-K2

LM-U2

MR-J3

series

Servo amplifier

MR-J3- B-RJ004 LM-H2

After migration to RD77MS

Servo amplifier

MR-J4

series

MR-J4-

MR-J4W2- B

MR-J4W3-

B(-RJ)

B

Linear

servo motor

LM-H3

LM-F

LM-K2

LM-U2

2 - 2

Page 31

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

Communications medium Optical fiber cable

Communications speed 50 Mbps 150 Mbps

Communications

cycle

Number of control axes

Transmission distance

(3) Comparison of servo system network

Item

Send

Receive

0.44 ms/0.88 ms

0.44 ms/0.88 ms

Up to 16 axes/line

[Standard code for inside panel]

Up to 3 m between stations

Maximum overall distance:

48 m (3 m × 16 axes)

[Standard cable for outside panel]

Up to 20 m between stations

Maximum overall distance:

320 m (20 m × 16 axes)

[Long distance cable]

Up to 50 m between stations

Maximum overall distance:

800 m (50 m × 16 axes)

(same as SSCNETIII)

←

0.222ms/0.444ms/0.888ms

0.222ms/0.444ms/0.888ms

(same as SSCNETIII)

←

[Standard code for inside panel and standard cable for

outside panel]

Up to 20 m between stations

Maximum overall distance: 320 m (20 m × 16 axes)

[Long distance cable]

Up to 100 m between stations

Maximum overall distance: 1600 m (100 m × 16 axes)

2.1.2 Engineering environment (required)

The engineering environment that supports RD77MS is as follows.

Product name Model Version

MELSOFT GX Works3 SW1DND-GXW3-E Ver.1.046Y or later

MELSOFT MR Configurator2 SW1DNC-MRC2-E Ver.1.27D or later

2 - 3

Page 32

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

2.2 Differences Between QD74MH and RD77MS

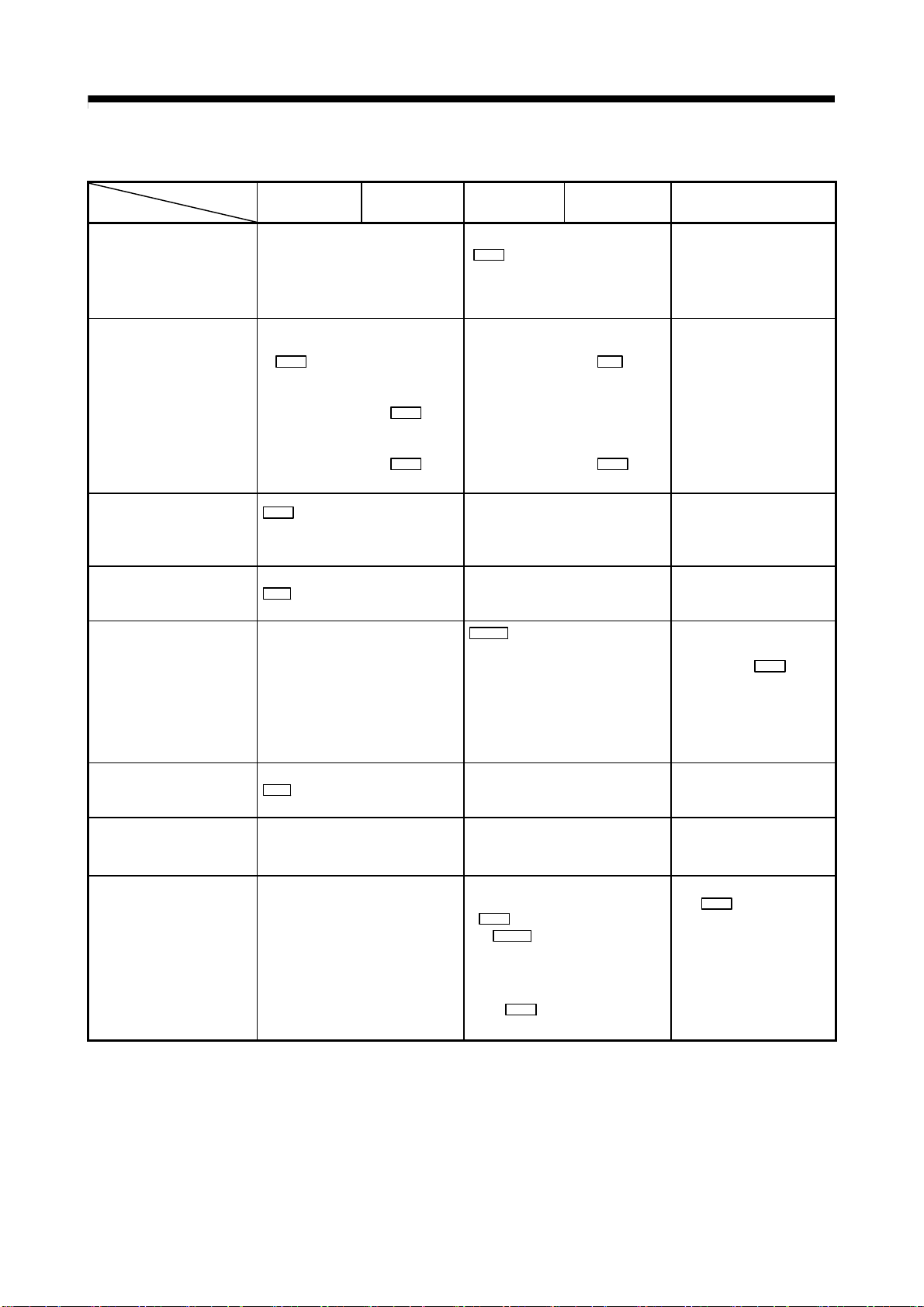

(1) Performance and specifications

►

: An item in which the axis movement will be changed after migration.

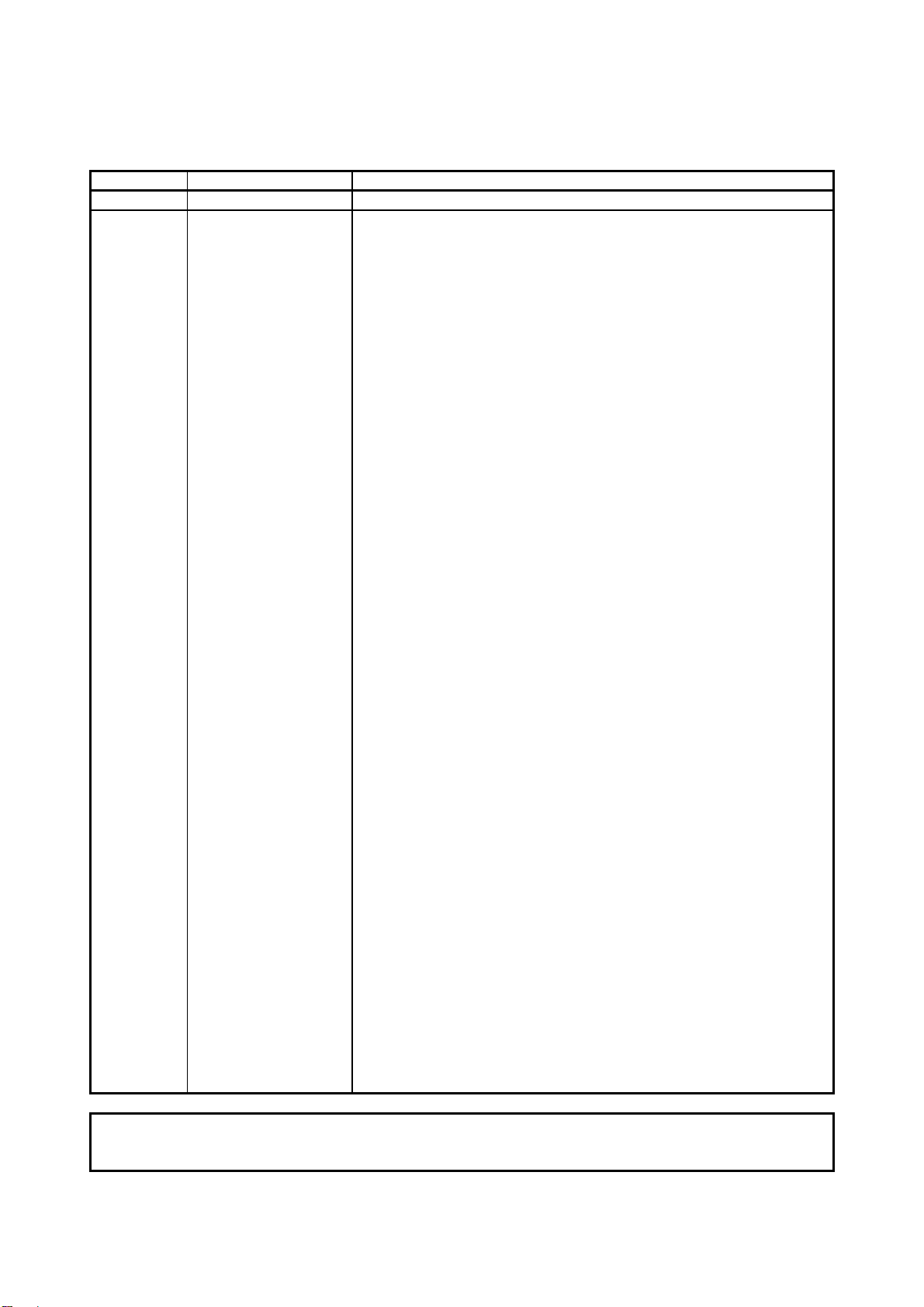

Model

Item

Number of control axes

Operation cycle 0.88ms

QD74MH8 QD74MH16 RD77MS8 RD77MS16 Points for migration

8 16 8 16

♦

0.444ms/0.888ms/1.777ms/

3.555ms

An item that requires a setting change at migration.

−

The default value differs.

►

Pr.96

Set

to “0000H”.

Control

method

Starting time

(1 axis linear

interpolation)

Servo system network SSCNETIII SSCNETIII/H or SSCNETIII

Servo amplifier

Machine home position

return

(Home position return

method)

HP shift function

OP search limit function

Incremental feed operation

Synchronous Not provided Provided −

Trapezoidal

acceleration/

deceleration

S-curve

acceleration/

deceleration

MR-J3-

MR-J3-

Data set method, Stopper type,

Limit switch combined type,

Scale origin signal detection type)

• The speed during HP shift: the

value set in “

• Move for the set amount without

deceleration, even at zero point

signal.

6.0ms

6.5ms

B/MR-J3W- B/

BS/MR-J3W- B-RJ006/

MR-J3-

(Proximity dog method,

Dog cradle type,

B-RJ004

6 types

Pr.56 Creep speed”.

Provided

Provided Provided (Inching operation)

1.46ms (Operation cycle 0.888ms)

1.59ms (Operation cycle 1.777ms)

1.52ms (Operation cycle 3.555ms)

MR-J4-

MR-J4W2-

6 types

(Proximity dog method,

Count method1, Count method2,

Data set method, Scale home

position signal detection method,

Driver home position return method

• The speed during HP shift: Select

the value with either “ Pr.46 HPR

speed” or ”

• Decelerate to a stop at zero point

signal, and then accelerate again to

the specified speed to move for the

set shift distance.

(Note-1)

Pr.47 Creep speed”.

Not provided

B(-RJ)/

B/MR-J4W3- B

)

−

►Select a servo system

network which is

compatible with the

devices to be connected

such as servo amplifiers.

Pr.97 0: SSCNETIII

1: SSCNETIII/H

−

Stopper type, dog cradle

type, and limit switch

combined type are not

available with RD77MS

(Note-2)

.

►

♦ Set ” Pr.56 Speed

designation during HP

shift” to “1” (

Creep speed).

Pr.47

♦ The OP search limit

function is not available

with RD77MS

The operation name has

been changed.

(Note-2)

.

2 - 4

Page 33

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

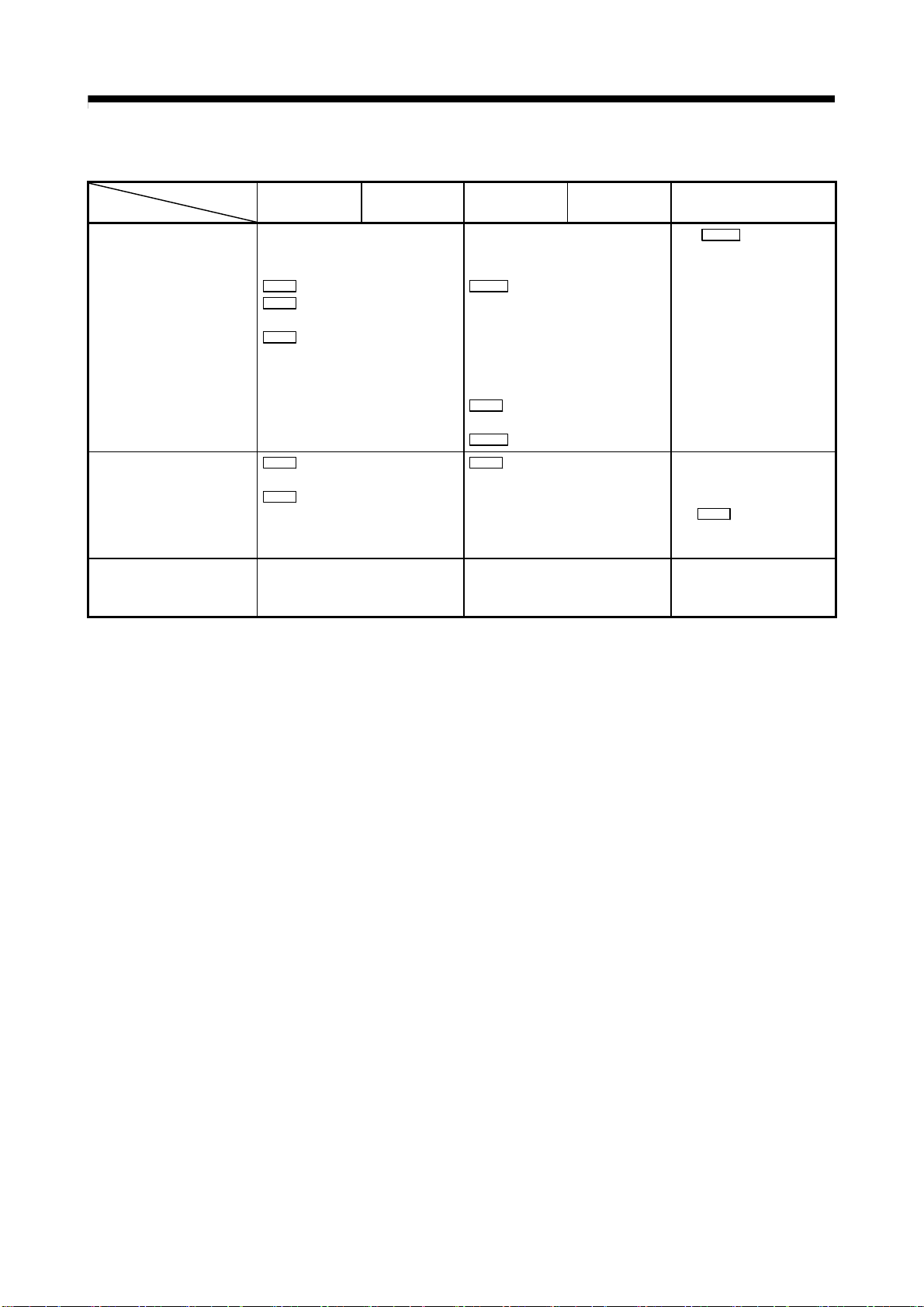

(Continued)

Model

Item

Linear interpolation control Speed: Combined-speed only

Speed limit value

Acceleration/deceleration

control

Sudden-stop control

Forced stop control

Pausing function

Parameter change request

Torque limit function

QD74MH8 QD74MH16 RD77MS8 RD77MS16 Points for migration

Select the command speed with

“

Pr.20 Interpolation speed

designation method”

0: Composite speed

1: Reference axis speed

[Linear interpolation control]

Composite speed:

Pr.26

Linear interpolation speed

limit value

Speed for each axis:

The limits are set with

Pr.10

limit value.

[Manual control]

The limits are set with

Pr.10

limit value.

Pr.16

S-curve

acceleration/deceleration time

[Linear interpolation control]

Speed for each axis:

The limits are set with

limit value.

Speed

[Manual control]

Speed

The limits are set with

speed limit value.

Not provided

constant

Cd.4

Axis sudden stop Not provided

Forced stop is executed by the signal

(Y2) from PLC CPU.

0: Forced stop release

1: Forced stop

Cd.158

Forced stop input

0000H: Forced stop ON (Forced

stop)

0001H: Forced stop OFF (Forced

stop release)

Cd.5

Pausing Not provided

Provided Not provided

Torque limit value: 0.1% unit

Controlled by the motor maximum

torque.

Torque limit value: 0.1% unit

Controlled by the value set in

Pr.17

Torque limit setting value”

“

Cd.101

or “

value”

However, when a home position

Torque output setting

return is being executed, the value

Pr.54

set in “

HPR torque limit value”

is applied.

Pr.8

Pr.31

Speed

JOG

♦ Composite speed cannot

be designated for 4-axis

linear interpolation

(Note-2)

♦ The composite speed

cannot be used for limiting

(Note-2)

speed

.

♦ The S-curve acceleration/

deceleration time

constant is not available

with RD77MS

(Note-2)

.

♦ The sudden-stop control

is not available with

RD77MS

►When the buffer memory

executes the forced stop

control, set “

Forced stop valid/invalid

selection” to “2”.

►Cannot be used with the

forced stop by 24 VDC

external input signal.

(Note-2)

.

Pr.82

♦ The pausing function is

not available with

RD77MS

(Note-2)

.

♦ The parameter change

function is not available

with RD77MS

♦The default value of

►

Pr.17 Torque limit

“

setting value” is

3000[0.1%].

Review the value

according to the motor to

be used.

(Note-2)

.

.

2 - 5

Page 34

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(Continued)

Model

Item

Torque change function

Acceleration/deceleration

time change function

Engineering environment

(Note-1): The home position return set in driver (servo amplifier) is used.

(Note-2): Contact your local sales office for details.

(Note-3): Only Japanese version is available for QD74MH setting software.

QD74MH8 QD74MH16 RD77MS8 RD77MS16 Points for migration

Torque limit value: 0.1% unit

Forward/reverse torque limit

value individual setting

Cd.11 Torque limit request

Cd.12 Forward rotation torque limit

value

Cd.13 Reverse rotation torque limit

value

Torque limit value: 0.1% unit

Forward/reverse torque limit

value same setting/individual setting

Cd.112 Torque change function

switching request

0: Forward/reverse torque

limit value same setting

1: Forward/reverse torque

limit value individual

setting

Cd.22 New torque value/forward

new torque value

Cd.113 New reverse torque value

Cd.18 Acceleration time change

request

Cd.20 Deceleration time change

request

Cd.12 Acceleration/deceleration

time change value during

speed change, enable/

disable

1: Enables modifications to

acceleration/deceleration time

MELSOFT GX Works2

QD74MH setting software

(Note-3)

MELSOFT GX Works3

(Simple Motion Module Setting

Function)

Cd.112 Torque change

Set “

function switching request”

to “1”.

►♦The acceleration/

deceleration time can be

changed by setting

Cd.12 .

−

2 - 6

Page 35

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(2) Exterior dimensions/mass/installation

QD74MH8 QD74MH16

QD74MH16

RUN

ERR.

498

RD77MS8 RD77MS16

RD77MS16

ERRRUN

AX1-16

Exterior

dimensions

[mm]

Mass [kg]

Internal

current

consumption

(5 VDC) [A]

CN1

EMI

QD74MH16

23

90

27.4

498

(Note) The connector for SSCNETIII cable is at the bottom of

the module.

98.0[H]×27.4[W]×90.0[D] 106.0[H]×27.8[W]×110.0[D]

0.15 0.23

0.70 1.0

Top ofpanel or wiring duct

RD77MS

RD77MS4

ERRRUN

3421

AX

AX

30 mm

or more

(Note-1)

Base unit

110

80 mm

or more

27.8

106

Door

70 mm

Panel

119 mm

or more

5mmormore

(Note-2)

5 mm or more

(Note-1): For wiring duct with 50mm or less height. For other cases, 40mm or more.

(Note-2): 20mm (0.79inch) or more when the adjacent module is not removed and the extension cable is connected.

2 - 7

Page 36

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

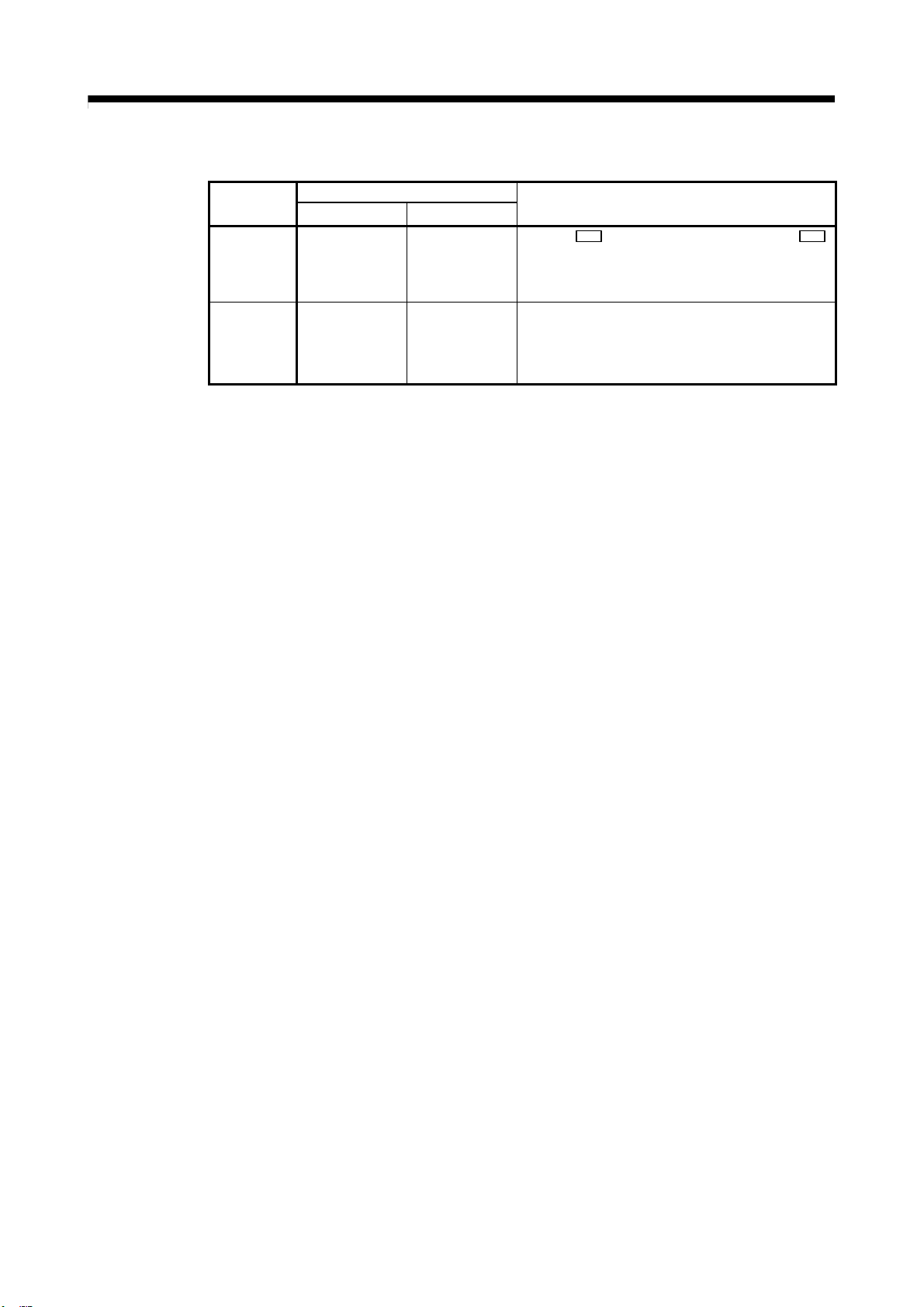

(3) Operation cycle

The operation cycle settings of QD74MH can be imported to RD77MS when the projects of

QD74MH are diverted to RD77MS in MELSOFT GX Works3.

(Refer to section 2.4.1 for details of project diversion.)

However, if the operation cycle is set as default (automatic), the operation cycle will be

changed. Set an operation cycle where necessary by following the table below because the

change in the operation cycle may change program execution timing.

[Control axes and operation cycle at default]

Model

Item

Number of control axes

QD74MH RD77MS

Up to 16 Up to 16

Operation cycle

(default)

[Settable operation cycle]

QD74MH RD77MS

0.88ms

0.88ms

0.444ms

0.888ms

1.777ms

3.555ms

0.444ms/1 to 4 axes

0.888ms/5 to 8 axes

1.777ms/9 to 16 axes

2 - 8

Page 37

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(4) Parameter setting

Review the existing settings and sequence programs for the parameters, monitor

data, control data which do not exist in RD77MS.

Refer to manuals of each module for details.

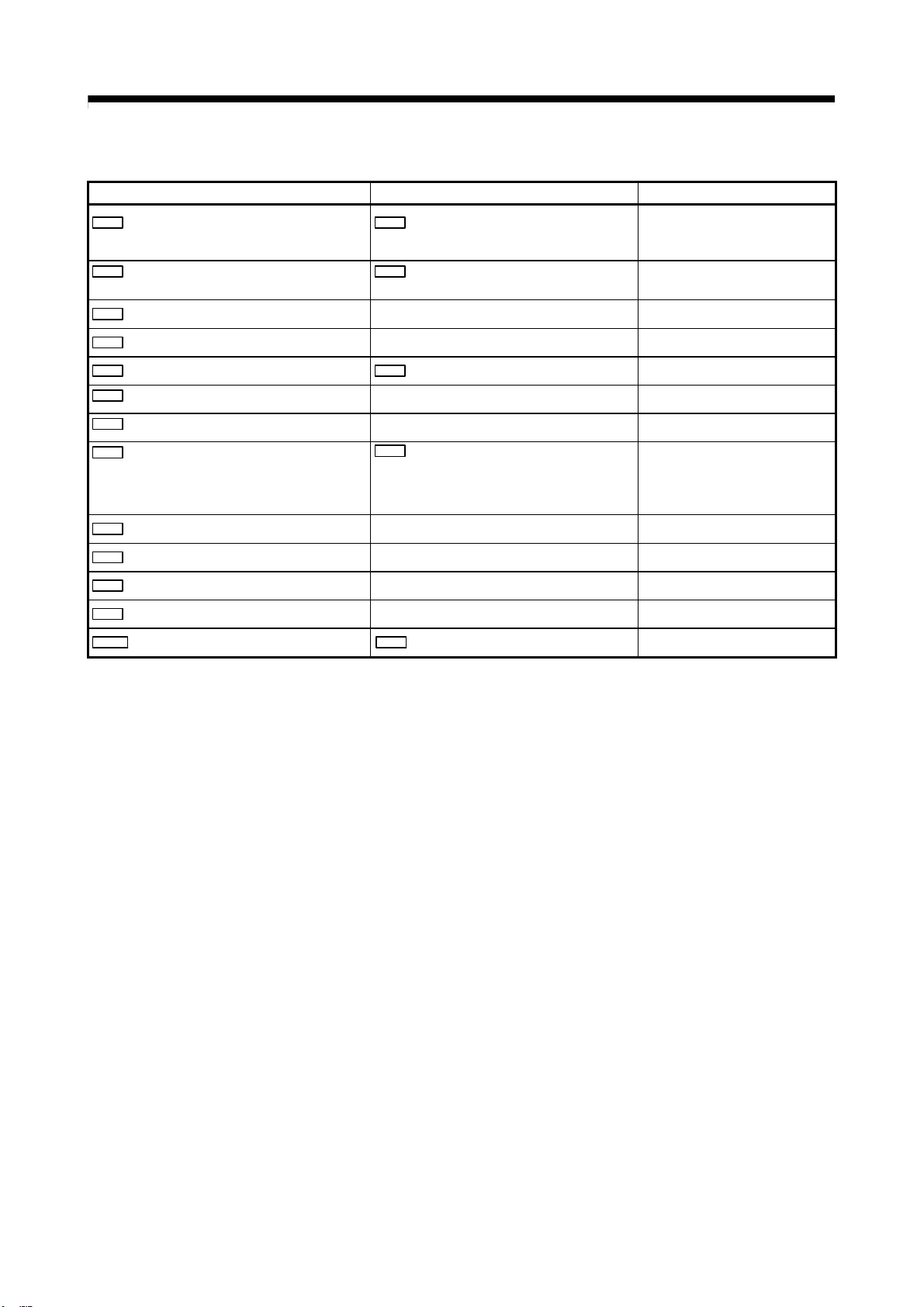

(a) Parameter

QD74MH RD77MS Points for migration

Pr.2

Pr.0

Electronic gear numerator (AP)

1 to 32768

Pr.2

Electronic gear denominator (AL)

1 to 32768

Pr.4

Software stroke limit upper limit value

Number of pulses per rotation (AP)

1 to 200000000

Pr.3

Movement amount per rotation (AL)

1 to 200000000

Pr.12

Software stroke limit upper limit value −

An item that requires a setting change at migration

►

The setting range has been

changed.

Pr.6

Software stroke limit lower limit value

Pr.8

Backlash compensation amount

Pr.10

Speed limit value

1 to 2147 (Unit:×10

Pr.15

Acceleration/deceleration method

6

[PLS/s])

0: Linear acceleration/deceleration

1: S-curve acceleration/deceleration

Pr.16

S-curve acceleration/deceleration time

constant

Pr.17

Sudden stop deceleration time

0 to 20000

Pr.20

Command in-position range

0 to 2147483647

Pr.23

Target position change overrun processing

selection

Pr.25

Interpolation group

Pr.26

Linear interpolation speed limit value

Pr.31

External input signal logic selection

b0: Upper hardware stroke limit

b4: Lower hardware stroke limit

b8: Proximity dog

Pr.50

OPR method

0: Proximity dog

2: Data set

6: Scale origin signal detection

Pr.51

OPR direction

Pr.13

Software stroke limit lower limit value −

Pr.11

Backlash compensation amount −

Set the value multiplied by 10

Pr.8

Speed limit value

1 to 1000000000

Pr.31

JOG speed limit value

►

The setting range has been

changed.

Set the same value as

►

1 to 1000000000

Pr.34

Acceleration/deceleration process

selection

0: Trapezoid acceleration/deceleration process

1: S-curve acceleration/deceleration process

−

Pr.36

Rapid stop deceleration time

►If

1 to 8388608

If “0” is set, change it to “1”.

Pr.16

Command in-position width

►

1 to 2147483647

−

−

−

The layout of signals has been

Pr.22

Input signal logic selection

b0: Lower limit

►

changed.

b1: Upper limit

b6: Proximity dog signal

If “Data set method” or “Scale

Pr.43

HPR method

0: Proximity dog method

6: Data set method

►

origin signal detection method”

are set, change the setting.

7: Scale origin signal detection method

Pr.44

HPR direction −

Pr.8

−

−

“0” is set, change it to “1”.

−

−

−

6 .

.

Pr.52

OP address

Pr.45

HP address −

2 - 9

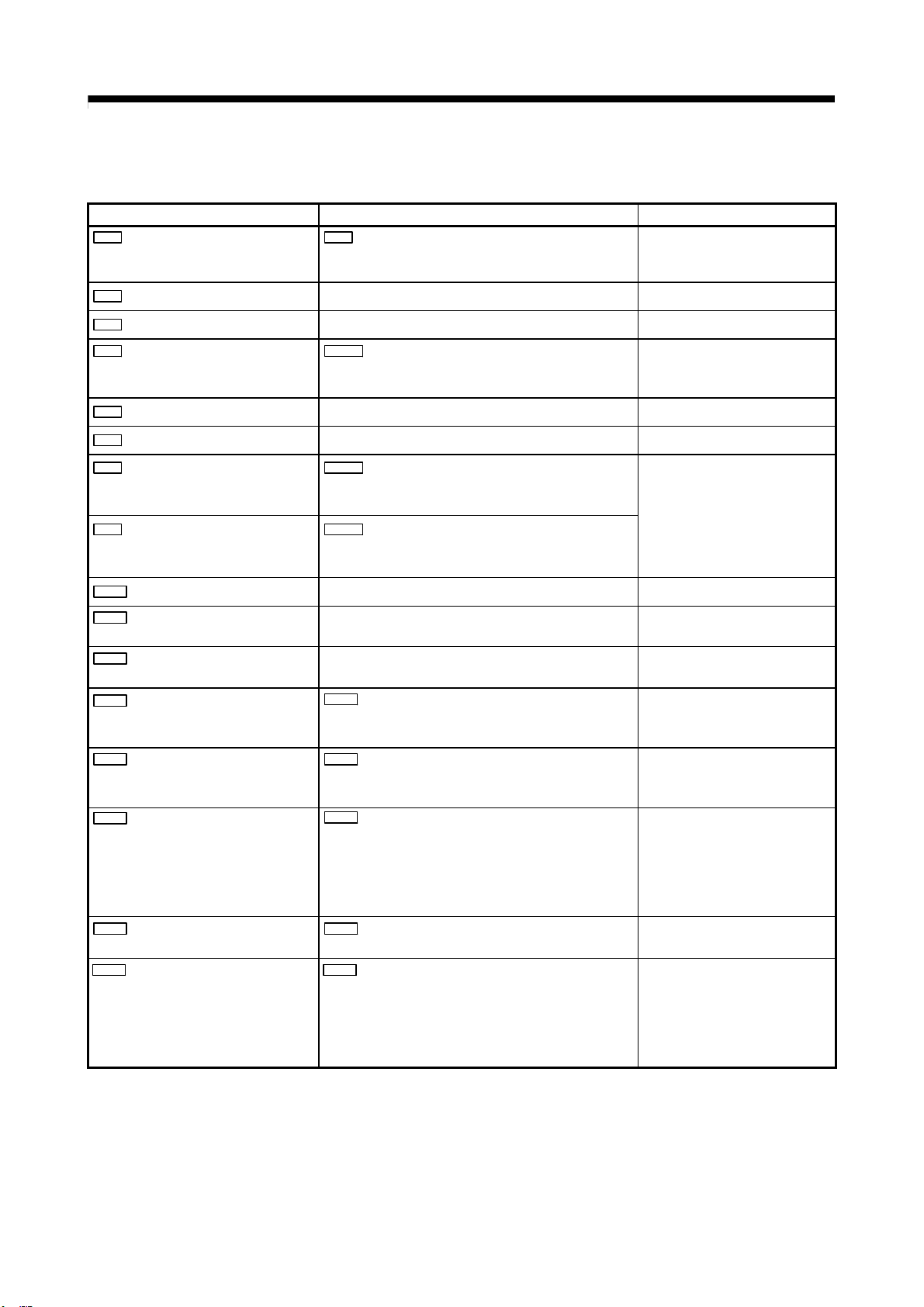

Page 38

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(Continued)

Pr.54

OPR speed

5 to 2147000000

Pr.56

Creep speed

5 to 32767

Pr.58

OPR acceleration time − −

Pr.59

OPR deceleration time − −

QD74MH RD77MS Points for migration

Pr.46

HPR speed

►

1 to 1000000000

Pr.47

Creep speed

1 to 1000000000

The setting range has been

changed.

If the current setting is outside of

the settable range of RD77MS,

review the setting.

Pr.60

OP shift amount

Pr.62

OP search limit

Pr.64

Incremental linear scale setting

Pr.66

Operation setting for incompletion of OPR

0: Not executed

1: Executed

Pr.53

HP shift amount −

− −

− −

Pr.55

Operation setting for incompletion of

HPR

0: Positioning control is not executed

1: Positioning control is executed.

Pr.80

JOG speed − −

Pr.82

JOG operation acceleration time − −

Pr.83

JOG operation deceleration time − −

Pr.84

Incremental feedrate − −

Pr.101

External forced stop selection

Pr.82

Forced stop valid/invalid selection −

−

2 - 10

Page 39

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(b) Monitor data

An item that requires a setting change at migration

QD74MH RD77MS Points for migration

Md.0

Current feed value

Md.2

Feedrate

Md.4

External input signal

b0: Upper hardware stroke limit

b4: Lower hardware stroke limit

b8: Proximity dog

Md.5

Positioning data No. being executed

Md.6

Error code

Md.7

Error details − −

Md.8

Warning code

Md.9

Status 1

b0: OPR request

b1: OPR complete

Md.10

Status 2

b0: Positioning complete

b1: Command in-position

Md.26

Real current value

Md.28

Deviation counter value

Md.31

Motor current

Md.32

Motor rotation speed

Md.34

Regenerative load ratio

Md.35

Effective load torque ratio

Md.36

Peak torque ratio

Md.40

Servo status 1

b0: READY ON

b1: Servo ON

b7: Servo error (Servo alarm)

b12: In-position

b13: Torque limit

b14: Absolute position lost

b15: Servo warning

Md.41

Servo status 2

b0: Zero point pass

b3: Zero speed

Md.100

Axis error status − −

Md.101

Axis warning status − −

Md.102

Number of write accesses to flash ROM

Md.103

Forced stop input status

0: Forced stop

1: Forced stop release

Md.20

Feed current value −

Md.22

Feedrate −

Md.30

External input signal

b0: Lower limit signal

b1: Upper limit signal

b6: Proximity dog signal

Md.44

Positioning data No. being executed −

Md.23

Axis error No. −

Md.24

Axis warning No. −

Md.31

Status

b2 : Command in-position flag

b3 : HPR request flag

b4 : HPR complete flag

b15: Positioning complete

Md.101

Real current value −

Md.102

Deviation counter value −

Md.104

Motor current value −

Md.103

Motor rotation speed −

Md.109

Regenerative load ratio/Optional data

monitor output 1

Md.110

Effective load torque/Optional data

monitor output 2

Md.111

Peak torque ratio/Optional data monitor

output 3

Md.108

Servo status 1

b0: READY ON

b1: Servo ON

b7: Servo alarm

b12: In-position

b13: Torque limit

b14: Absolute position lost

b15: Servo warning

Md.119

Servo status 2

b0 : Zero point pass

b3 : Zero speed

Md.19

Number of write accesses to flash ROM −

Md.50

Forced stop input

0: Forced stop input ON (Forced stop)

1: Forced stop input OFF (Forced stop release)

►

The layout of input signals has

been changed.

Md.31

“

The servo status is 32-bit data

Status” is 16-bit data.

−

−

−

−

2 - 11

Page 40

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(c) Control data

An item that requires a setting change at migration

►

QD74MH RD77MS Points for migration

Cd.0

Axis error reset

0: Not commanded

Cd.5

Axis error reset

1: Axis error is reset.

Only “1: Axis error is reset” is

valid.

1: Commanded

Cd.1

Parameter change request − −

Cd.2

Start method − −

Cd.3

Axis stop

0: Not commanded

1: Commanded

Cd.4

Axis sudden stop − −

Cd.5

Pausing − −

Cd.8

Forward rotation JOG start

0: Stop

1: Start

Cd.9

Reverse rotation JOG start

0: Stop

1: Start

Cd.11

Torque limit request − −

Cd.12

Forward rotation torque limit

value

Cd.13

Reverse rotation torque limit

value

Cd.15

Speed change request

0: Not requested

Cd.180

Axis stop

1: Axis stop requested

Other than 1: Axis stop not requested

Cd.181

Forward run JOG start

1: JOG started

Other than 1: JOG not started

Cd.182

Forward run JOG start

1: JOG started

Other than 1: JOG not started

− −

− −

Cd.15

Speed change request

1: Executes speed change

Only “1: Axis stop requested” is

valid.

Only “1: JOG started” is valid.

Only “1: Change the speed is”

valid.

1: Requested

Cd.16

New speed value

5 to 2147000000

Cd.14

New speed value

0 to 1000000000

If the current setting is outside of

►

the settable range of RD77MS,

review the setting.

Cd.18

Acceleration time change request

0: Not requested

1: Requested

Cd.12

Acceleration/deceleration time change value

during speed change, enable/disable

1: Enables modifications to acceleration/deceleration

time

Other than 1: Disables modifications to acceleration/

Set this data to select whether

►

acceleration/deceleration time is

allowed to be modified or not

when a speed change is

executed.

deceleration time

Cd.19

New acceleration time value

0 to 20000

Cd.20

Deceleration time change request

0: Not requested

1: Requested

Cd.10

New acceleration time value

0 to 8388608

Cd.12

Acceleration/deceleration time change value

during speed change, enable/disable

1: Enables modifications to acceleration/deceleration

time

Other than 1: Disables modifications to acceleration/

The setting range has been

changed.

Set this data to select whether

►

acceleration/deceleration time

is allowed to be modified or not

when a speed change is

executed.

deceleration time

2 - 12

Page 41

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(Continued)

Cd.21

New deceleration time value

0 to 20000

Cd.23

Target position change request

0: Not requested

1: Requested

Cd.24

New target position value

QD74MH RD77MS Points for migration

Cd.11

New deceleration time value

0 to 8388608

Cd.29

Target position change request flag

1: Requests a change in the target position

Cd.27

Target position change value (New address) −

The setting range has been

changed.

Only “1: requests a change in the

target position” is valid.

Cd.28

New current value

Cd.30

Each axis servo OFF

0: Not commanded

1: Commanded

Cd.45

Semi/Fully closed loop switching

request

(When MR-J3-

Cd.46

Gain changing request

B-RJ006 is used)

0: Not requested

1: Requested

Cd.100

Flash ROM write request

0: Not requested

1: Requested

Cd.101

Parameter initialization request

0: Not requested

1: Requested

Cd.9

New current value −

Cd.100

Servo OFF command

0: Servo ON

1: Servo OFF

Valid only during “servo ON for all axes”.

Cd.133

Semi/Fully closed loop switching request

Cd.108

Gain switching command flag

0: Gain switching command OFF

1: Gain switching command ON

Cd.1

Flash ROM write request

1: Requests write access to flash ROM.

Cd.2

Parameter initialization request

1: Requests parameter initialization

−

−

−

−

−

2 - 13

Page 42

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(5) I/O signals

(a) Signal direction: Positioning module (Simple Motion module) → PLC CPU

QD74MH RD77MS

Device No. Signal name

X0 Unit READY

X1 Error detection

X2 Warning detection

X3 Synchronization flag

X4

X5

X6

X7

X8

X9

XA

Unusable

XB

XC

XD

XE

XF

X10 Axis 1

X11 Axis 2 Axis 2

X12 Axis 3 Axis 3

X13 Axis 4 Axis 4

X14 Axis 5 Axis 5

X15 Axis 6 Axis 6

X16 Axis 7 Axis 7

X17 Axis 8 Axis 8

X18 Axis 9 Axis 9

X19 Axis 10 Axis 10

X1A Axis 11 Axis 11

X1B Axis 12 Axis 12

X1C Axis 13 Axis 13

X1D Axis 14 Axis 14

X1E Axis 15 Axis 15

X1F Axis 16 Axis 16

(Note-1): These signals are included in the buffer memory “

(Note-2): There are some devices that will become “Use prohibited” after replacing the existing model

with RD77MS. The device No. with “Use prohibited” are used by system. Therefore, a user

cannot use them. In the case of using them, the operation is not guaranteed.

RD77MS buffer memory “

Buffer memory address Signal name

2417+100n

b9 Axis warning detection

b13 Error detection

(Note-1)

(Note-1)

BUSY

Md.31

RD77MS READY

Synchronization flag

Use prohibited

Axis 1

Md.31

Status” in RD77MS.

Status”

(Note-2)

BUSY

n: Axis No.-1

2 - 14

Page 43

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(b) Signal direction: PLC CPU → Positioning module (Simple Motion module)

QD74MH RD77MS

Device No. Signal name

Y0 PLC READY

Y1 All axis servo ON

Y2 Forced stop input

(Note-1)

Y3

Y4

Y5

Y6

Y7

Y8

Y9

Unusable

YA

YB

YC

YD

YE

YF

Y10 Axis 1

Y11 Axis 2 Axis 2

Y12 Axis 3 Axis 3

Y13 Axis 4 Axis 4

Y14 Axis 5 Axis 5

Y15 Axis 6 Axis 6

Y16 Axis 7 Axis 7

Y17 Axis 8 Axis 8

Y18 Axis 9 Axis 9

Positioning start

Y19 Axis 10 Axis 10

Y1A Axis 11 Axis 11

Y1B Axis 12 Axis 12

Y1C Axis 13 Axis 13

Y1D Axis 14 Axis 14

Y1E Axis 15 Axis 15

Y1F Axis 16 Axis 16

(Note-1): These signals are included in the buffer memory “

(Note-2): There are some devices that will become “Use prohibited” after replacing the existing model

with RD77MS. The device No. with “Use prohibited” are used by system. Therefore, a user

cannot use them. In the case of using them, the operation is not guaranteed.

RD77MS

Buffer memory address Setting value

5945

buffer

memory “

Cd.158

Forced stop input”

Set the forced stop information to the buffer memory.

0: Forced stop ON (Forced stop)

1: Forced stop OFF (Forced stop release)

A value other than "1" is regarded as "0".

Use prohibited

Axis 1

Positioning start

Cd.158

Forced stop input” in RD77MS.

(Note-2)

2 - 15

Page 44

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

(6) Items that need a review or a change following the servo system network change

Items

Electronic

gear

Positioning

data

QD74MH RD77MS

Differences

− −

− −

Change “

Movement amount per rotation” of the basic parameter 1

according to the resolution per the connected servo

motor rotation.

Review the positioing data while taking into account the

differences in resolution per the connected servo motor

rotation and the setting changes in the electronic gear

above.

Change/revision

Pr.2

Number of pulses per rotation” and “

Pr.3

2 - 16

Page 45

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

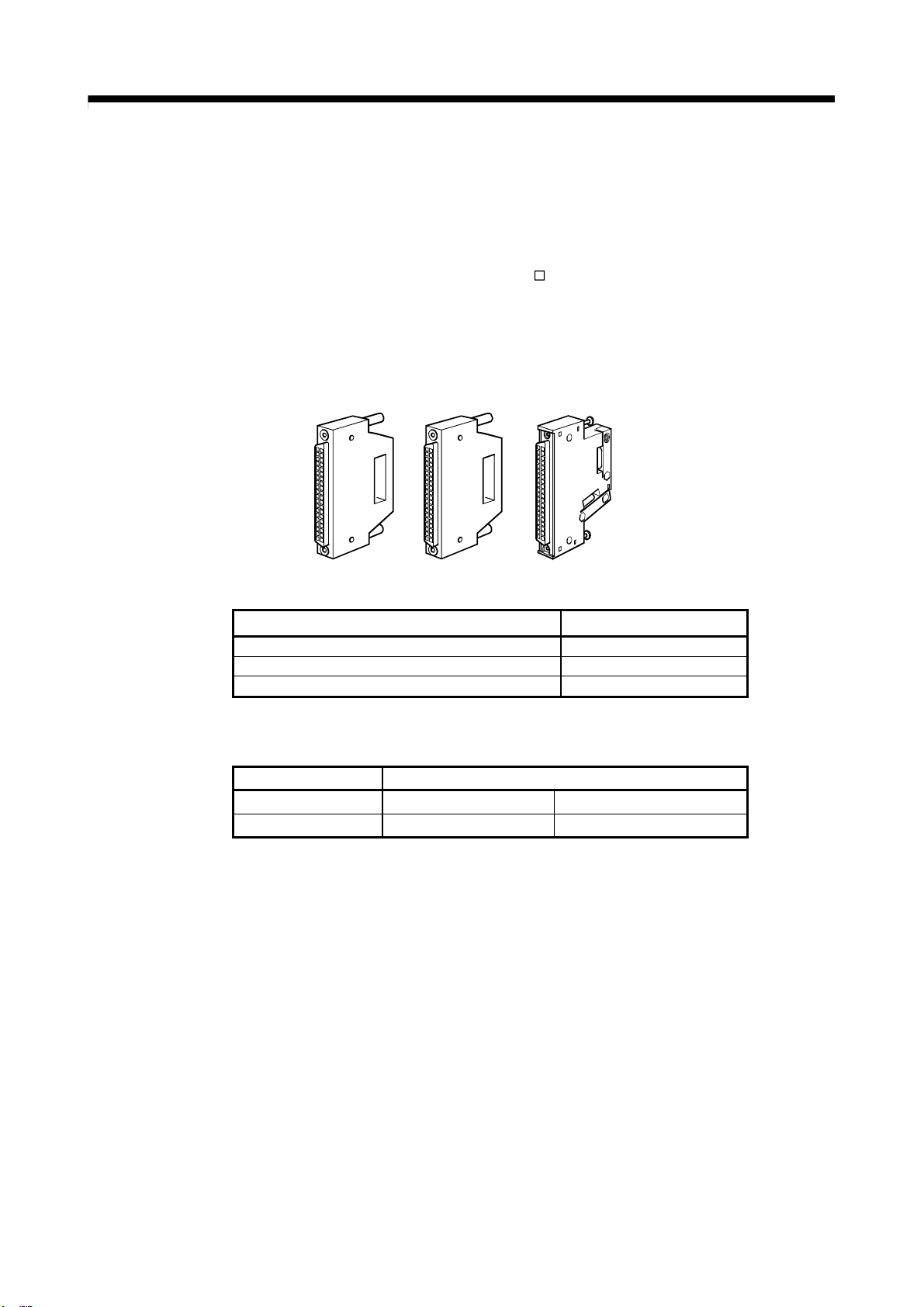

2.3 Forced Stop Input Cable

The forced stop input cable needs to be replaced along with the controller replacement.

(1) Cable replacement (recommended)

The existing forced stop cable (Q170DEMICBL

external input connection connector for RD77MS. To use the forced stop function with

RD77MS, fabricate the cable with the following connectors and cables.

(a) Appearance

A6CON1 A6CON2 A6CON4

M) for QD74MH is not compatible with the

(b) Connector type

Type Model

Soldering type, useable for straight out A6CON1

Crimp-contact type, useable for straight out A6CON2

Soldering type, useable for straight out and diagonal out A6CON4

(c) Specifications of the connector

Part name Specification

Applicable connector A6CON1, A6CON4 A6CON2

Applicable wire size 0.3 mm2 AWG28 to 24

(Note): The external input wiring connector is not included. Please purchase them by customer.

[Specialized tool]

- Pressure-bonding tool for A6CON2 (Fujitsu component LTD.):

Model name: FCN-363T-T005/H

Contact: http://www.fujitsu.com/jp/group/fcl/en/

2 - 17

Page 46

f

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

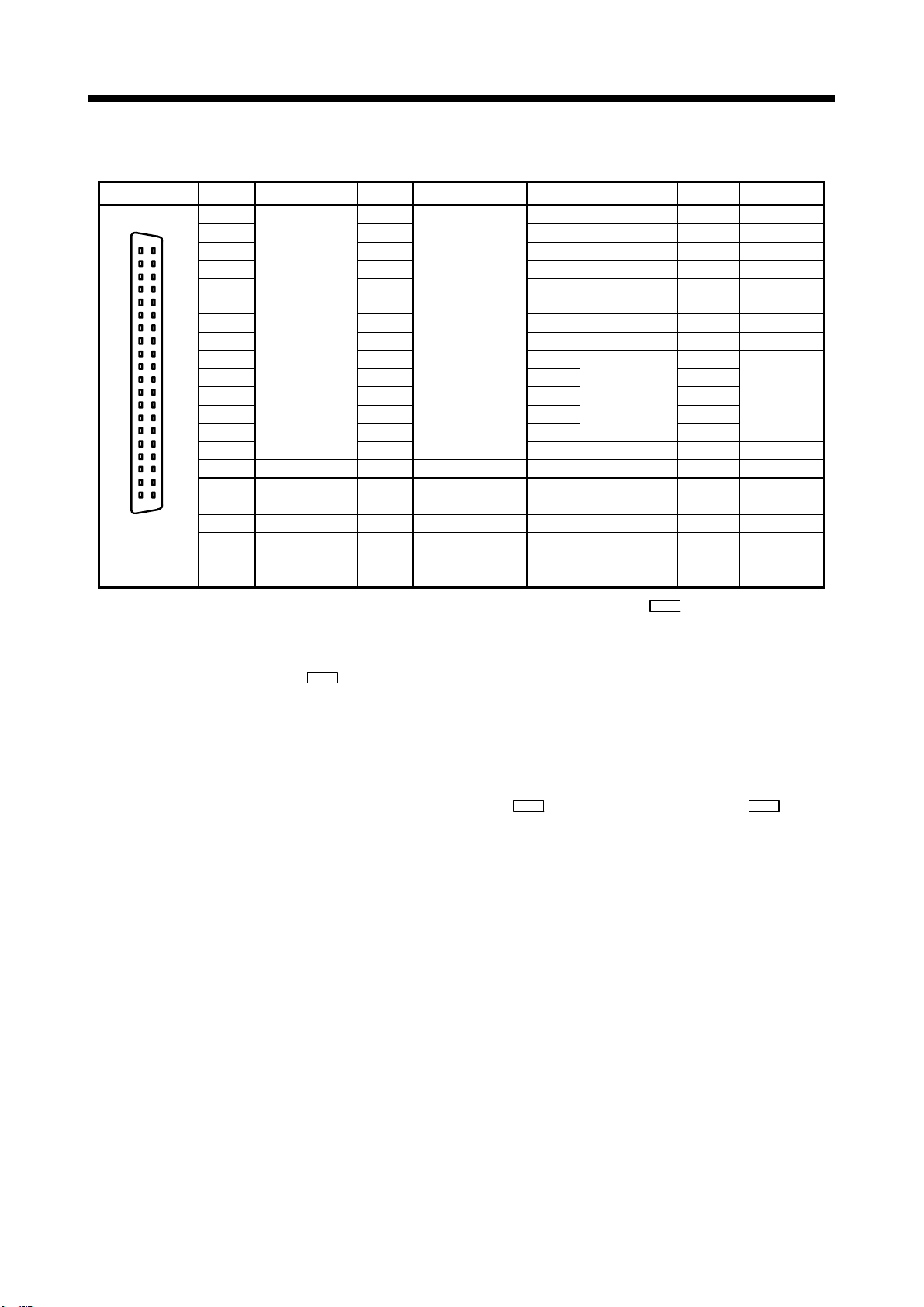

Pin layout

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

Front view o

the module

(Note-1): Input type from manual pulse generator/incremental synchronous encoder is switched in " Pr.89 Manual pulse generator/

Incremental synchronous encoder input type selection". (Only the value specified against the axis 1 is valid.)

• 0: Differential-output type

• 1: Voltage-output/open-collector type (Default value)

(Note-2): Set the signal input form in "

(Note-3): Voltage-output/open-collector type

Connect the A-phase/PLS signal to HA, and the B-phase/SIGN signal to HB.

(Note-4): Differential-output type

Connect the A-phase/PLS signal to HAH, and the A-phase/PLS inverse signal to HAL.

Connect the B-phase/SIGN signal to HBH, and the B-phase/SIGN inverse signal to HBL.

(Note-5): Do not connect to any of the terminal explained as "No connect".

(Note-6): Set the external command signal [DI, FLS, RLS, DOG, STOP] in "

command signal selection" at RD77MS use.

(Note-7): Do not use 1A20, 1A19, 1A(B)15, and 1A(B)14 for other than the power supply of manual pulse generator.

The signal layout for the external input connection connector of RD77MS is shown below.

Pin No. Signal name Pin No. Signal name Pin No. Signal name Pin No. Signal name

2B20

2A20

1B20 HB

2B19 2A19 1B19 HA

A20

2B18 2A18 1B18 HBL

A19

2B17 2A17 1B17 HAL

A18

A17

2B16 2A16 1B16

A16

A15

2B15 2A15 1B15 5V

A14

A13

2B14 2A14 1B14 SG

A12

2B13 2A13 1B13

A11

2B12 2A12 1B12 1A12

A10

A9

2B11 2A11 1B11 1A11

A8

2B10 2A10 1B10 1A10

A7

A6

2B9 2A9 1B9 1A9

A5

2B8 2A8 1B8 EMI.COM 1A8 EMI

A4

2B7 COM 2A7 COM 1B7 COM 1A7 COM

A3

A2

2B6 COM 2A6 COM 1B6 COM 1A6 COM

A1

2B5 SIN20

2B4 SIN19

2B3 SIN18

2B2 SIN17

2B1 SIN16

No connect

(Note-5)

(Note-6)

2A5 SIN15

(Note-6)

2A4 SIN14

(Note-6)

2A3 SIN13

(Note-6)

2A2 SIN12

(Note-6)

2A1 SIN11

Pr.24 Manual pulse generator/Incremental synchronous encoder input selection".

No connect

(Note-5)

(Note-6)

(Note-6)

(Note-6)

(Note-6)

(Note-6)

1B5 SIN10

1B4 SIN9

1B3 SIN8

1B2 SIN7

1B1 SIN6

Pr.80 External input signal selection" and " Pr.95 External

(Note-1, 2, 3)

(Note-1, 2, 3)

(Note-1, 2, 4)

(Note-1, 2, 4)

No connect

(Note-5)

(Note-7)

(Note-7)

No connect

(Note-5)

(Note-6)

(Note-6)

(Note-6)

(Note-6)

(Note-6)

1A20 5V

1A19 5V

1A18 HBH

1A17 HAH

1A16

1A15 5V

1A14 SG

1A13

1A5 SIN5

1A4 SIN4

1A3 SIN3

1A2 SIN2

1A1 SIN1

(Note-7)

(Note-7)

(Note-1, 2, 4)

(Note-1, 2, 4)

No connect

(Note-5)

(Note-7)

(Note-7)

No connect

(Note-5)

(Note-6)

(Note-6)

(Note-6)

(Note-6)

(Note-6)

2 - 18

Page 47

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

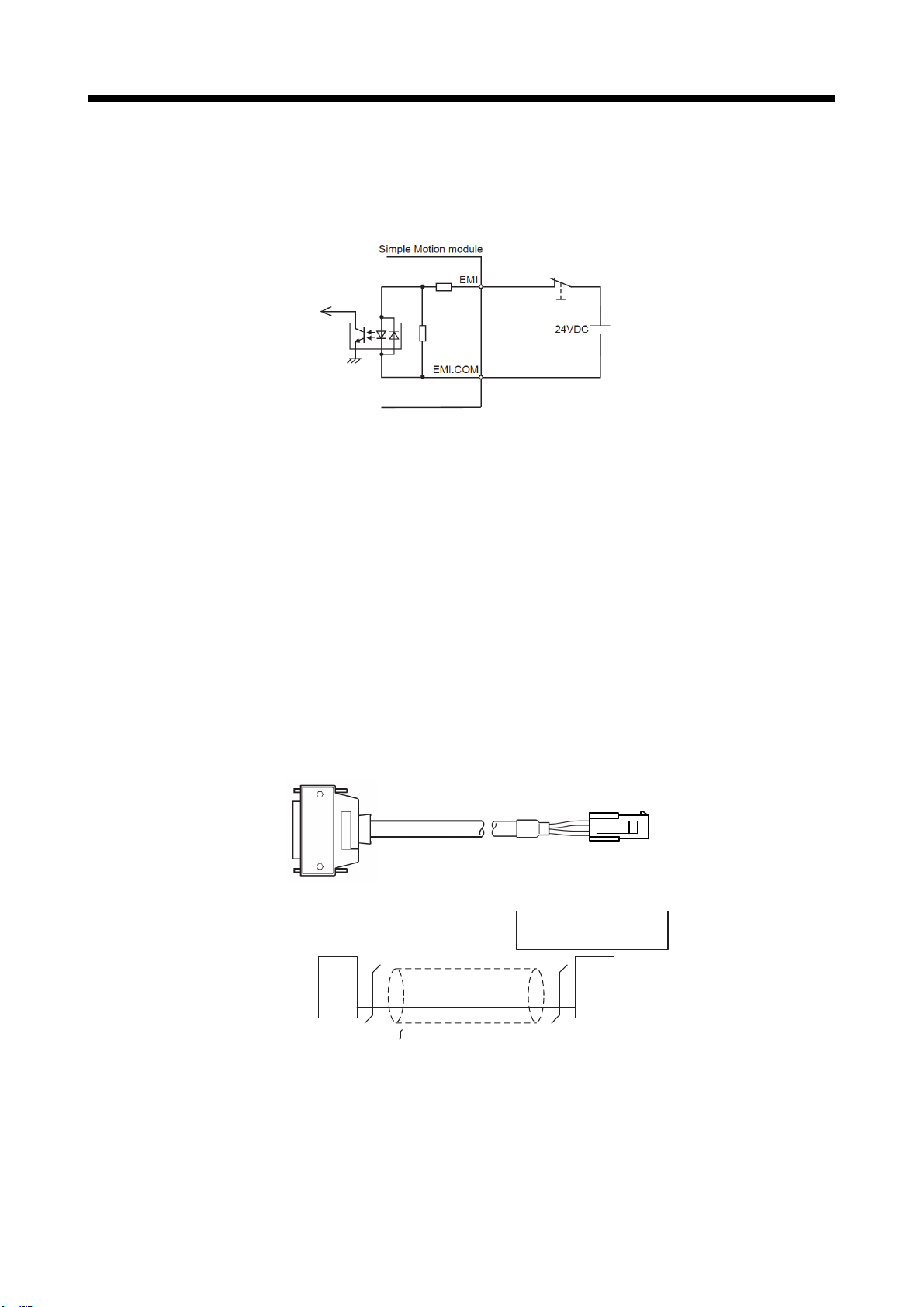

When using the forced stop function, wire the terminals of the Simple Motion module forced

stop input (1A08/1B08) as shown below. As for the 24VDC power supply, the direction of

current can be switched.

(2) Conversion connector

When using the forced stop input cable (Q170DEMICBL

conversion cable with the A6CON connector and the receptacle below.

Use the cable whose wire size is AWG24.

(a) A6CON connector (RD77MS side)

Use the connector in “(1) Cable replacement (recommended)”.

(b) Receptacle (Forced stop input cable side)

Fabricate the receptacle by combining the following housing and terminal.

Housing : 5559-02P-210 (Manufacturer: Molex Incorporated)

Terminal : 5558PBTL (Manufacturer: Molex Incorporated)

RD77MS side

(1A_ _, 1B_ _)

Q170DEMICBL□M side

□

M) for RD77MS, fabricate the

Rec epta cle con nector

EMI.COM

EMI

A6CON

1B8

1A8

・5558 PB TL

・5559 -02 P-21 0

:Twisted pair cable

(N ot e): Use a 24 AWG cable .

(Terminal)

(Hous in g)

2

1

2 - 19

Page 48

2. DETAILS OF MIGRATION FROM QD74MH TO RD77MS

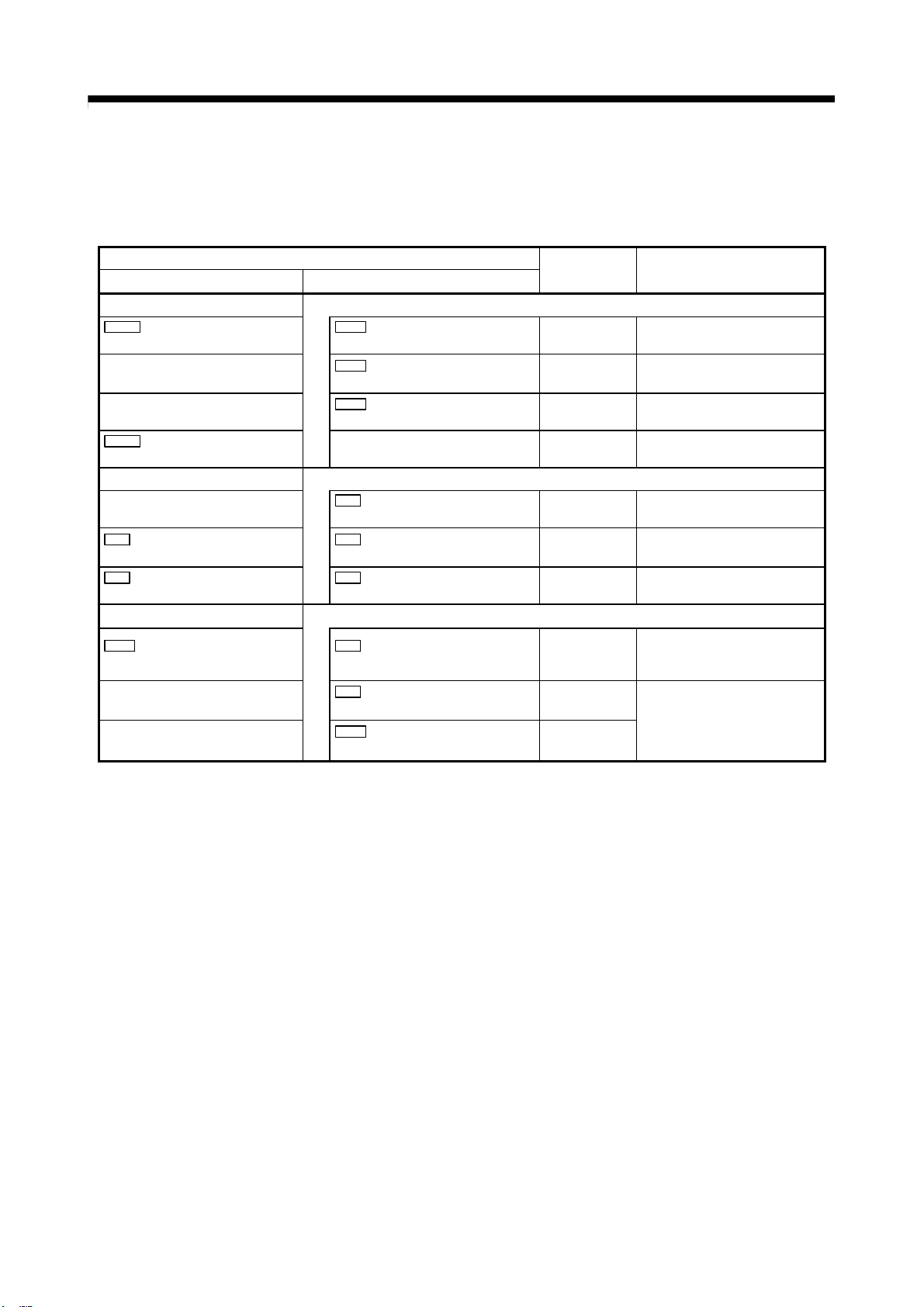

2.4 Project Diversion

2.4.1 Project diversion procedures by engineering environment

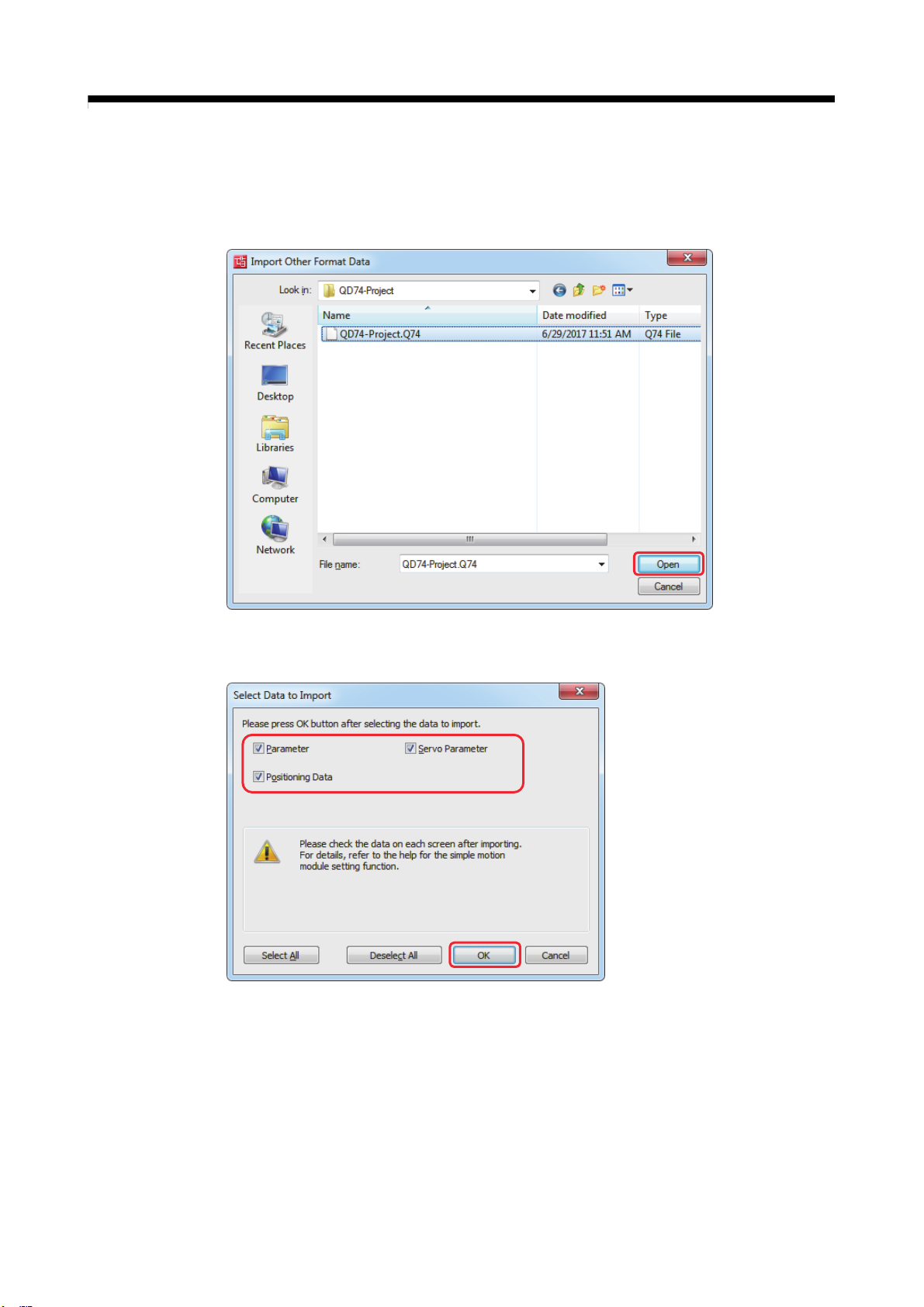

(1) Procedures for diversion of QD74MH setting software data by MELSOFT GX Works3

The following shows the diversion procedure.

1) Start MELSOFT GX Works3.

2) Select “New” in “Project” menu to create a new MELSEC iQ-R series project.