Mitsubishi QJ71NT11B, QJ71LP21S-25, QJ71LP21-25, QJ71LP21G, QJ71LP21GE Reference Manual

...

Q Corresponding MELSECNET/H

Network System

Reference Manual (PLC to PLC network)

-QJ71LP21

-QJ71LP21-25

-QJ71LP21S-25

-QJ71LP21G

-QJ71LP21GE

-QJ71BR11

-QJ71NT11B

• SAFETY PRECAUTIONS •

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the CPU module user's manual.

In this manual, the safety precautions are classified into to levels: " WARNING" and " CAUTION".

! !

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

!

[Design Precautions]

!

WARNING

• For operating status of each communication failure, refer to this manual. Incorrect output or

malfunction due to a communication failure may result in an accident.

• If a coaxial cable is disconnected, this may destabilize the line, and a network communication

error may occur in multiple stations. Provide an interlock circuit in the sequence program so that

the system will operate safely even if the above error occurs. Failure to do so may result in an

accident due to incorrect output or malfunction.

• When changing data of the running programmable controller from a peripheral connected to the

CPU module or from a personal computer connected to an intelligent function module or special

function module, configure an interlock circuit in the sequence program to ensure that the entire

system will always operate safely.

For program modification and operating status change, read relevant manuals carefully and

ensure the safety before operation.

Especially, in the case of a control from an external device to a remote programmable controller,

immediate action cannot be taken for a problem on the programmable controller due to a

communication failure.

To prevent this, configure an interlock circuit in the sequence program, and determine corrective

actions to be taken between the external device and CPU module in case of a communication

failure.

A - 1 A - 1

[Design Precautions]

!

CAUTION

• Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

[Installation Precautions]

!

CAUTION

• Use the programmable controller in the operating an environment that meets the general

specifications given in the user's manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

• To mount the module, while pressing the module mounting lever located in the lower part of

module, fully insert the module fixing projection(s) into the hole(s) in the base unit press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the

module a screw.

Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• Shut off the external power supply for the system in all phases before mounting or removing the

module. Failure to do so may result in damage to the product.

• Do not directly touch any conductive part of the module.

Doing so can cause malfunction or failure of the module.

A - 2 A - 2

[Wiring Precautions]

!

WARNING

• Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or damage to the product.

!

CAUTION

• Individually ground the FG terminal of the programmable controller with a ground resistance of

100 or less.

Failure to do so may result in electric shock malfunction.

• Check the rated voltage and terminal layout before wiring to the terminal block for the external

power supply, and connect the cable correctly.

Connecting a cable to power supply with a different voltage rating or incorrect wiring may cause

a fire or failure.

• Tighten the terminal screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

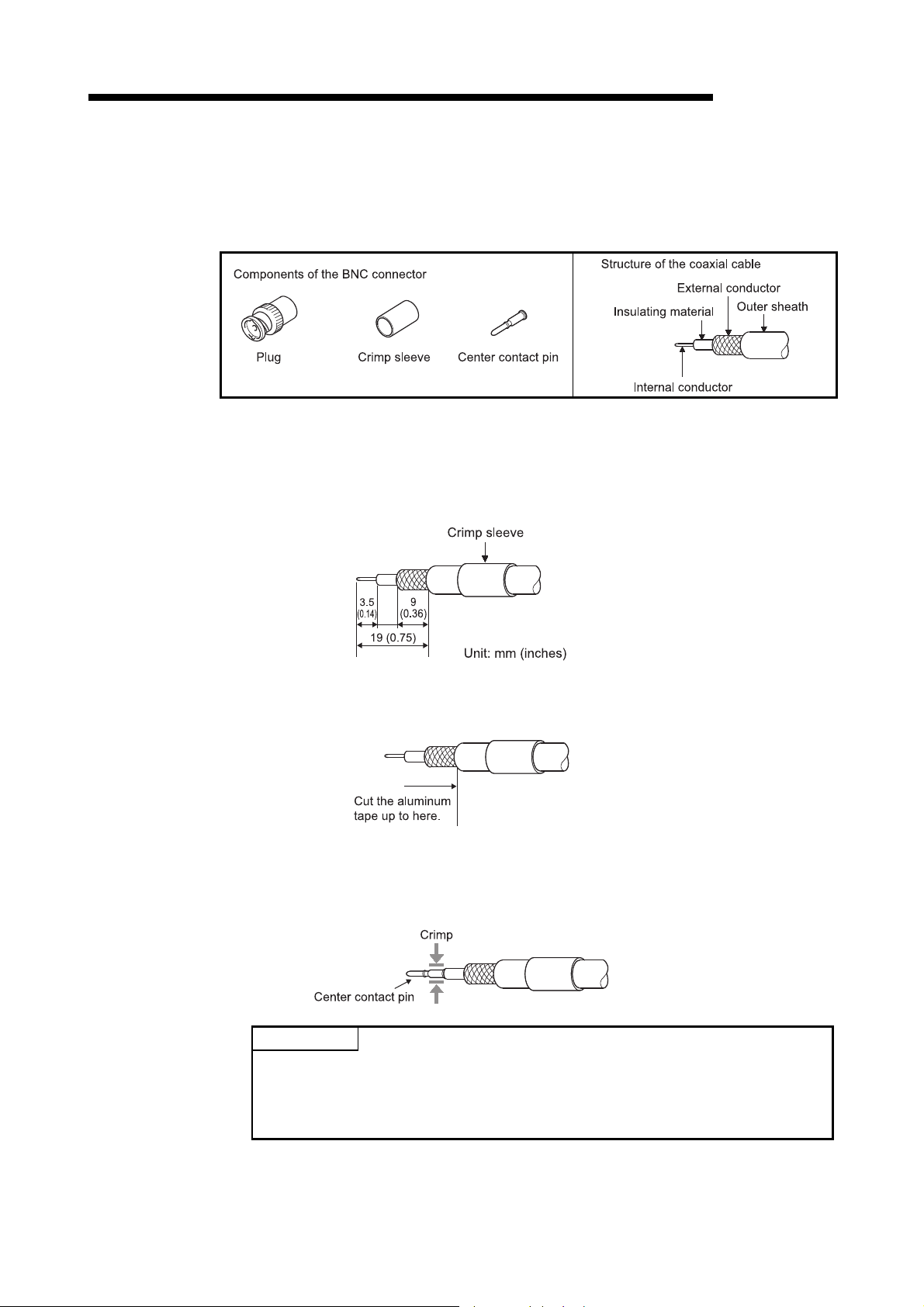

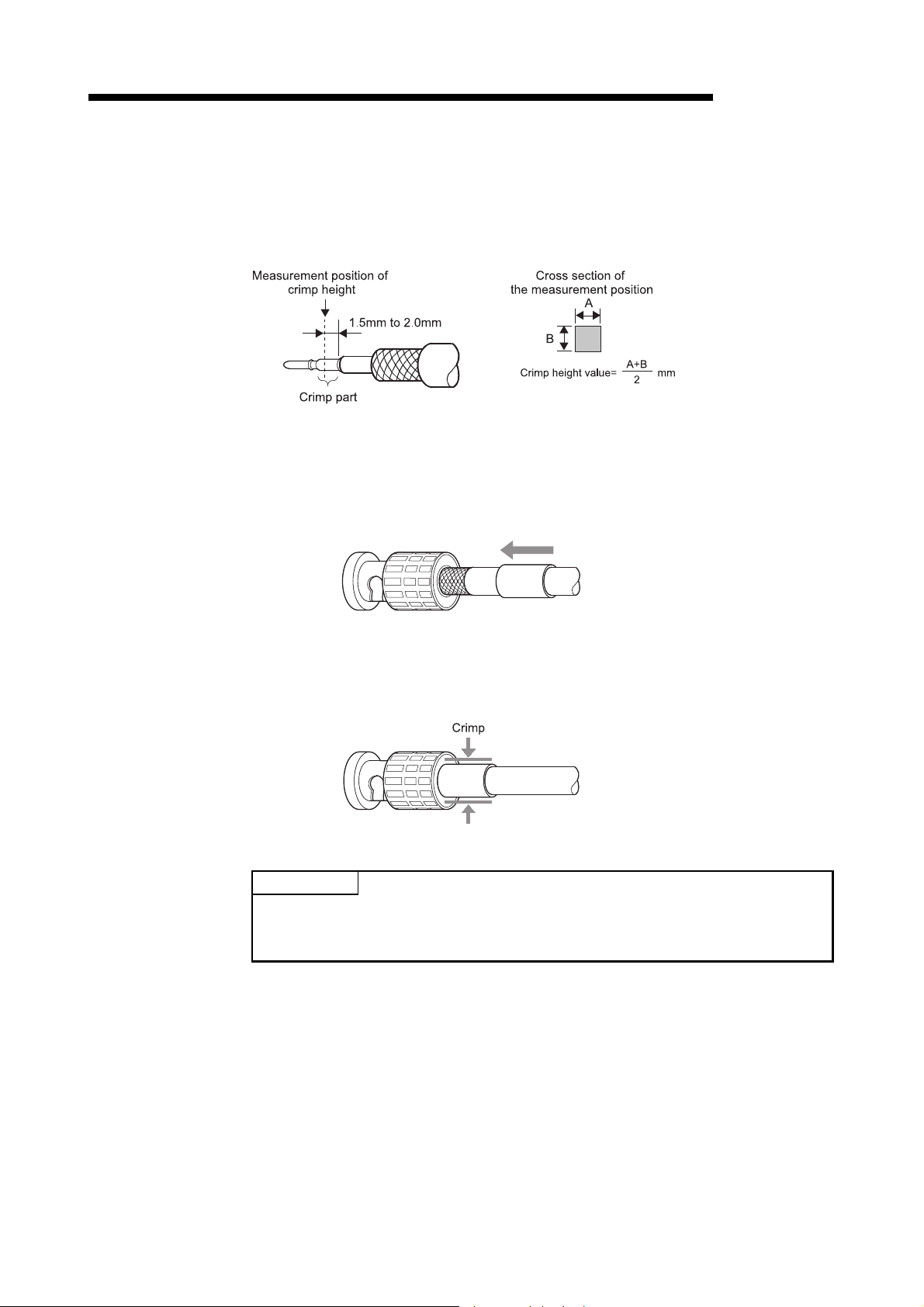

• Properly solder the parts of a soldering-type coaxial cable connector. Incomplete soldering may

result in malfunction.

• Crimp the parts of a crimping-type coaxial cable connector with proper force at a proper position.

Failure to do so may cause drop of the cable or malfunction.

• Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

• A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring.

Do not remove this film during wiring.

Remove it for heat dissipation before system operation.

• Place the cables in a duct or clamp them.

Failure to do so may cause damage of the module or the cables due to accidental pull or

unintentional shifting of the cables, or malfunctions due to poor contact of the cable.

• Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

• When disconnecting the communication and power cables from the module, do not pull the

cable by the cable part. Loosen the screws of connector before disconnecting the cable. When

disconnecting a cable connected to a terminal block, loosen the screws on the terminal block

first before removing the cable.

Failure to do so may result in damage to the module or cable or malfunction due to poor contact.

A - 3 A - 3

[Setup and Maintenance Precautions]

!

CAUTION

• Before performing online operations (especially, program modification, forced output, and

operation status change) for the running CPU module in other station from GX Developer via

MELSECNET/H, read relevant manuals carefully and ensure the safety.

• Do not disassemble or modify the module. Doing so may cause failure, malfunction, injury, or a

fire.

• Use any radio communication device such as a cellular phone or a PHS (Personal Handy-phone

System) more than 25cm (9.85 inches) away in all directions from the programmable controller.

Failure to do so may cause malfunction.

• Shut off the external power supply for the system in all phases before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

• Do not touch any terminals while power is on. Doing so will cause electric shock.

• Shut external power supply for the system before cleaning the module or retightening the

terminal screws or module fixing screws.

Failure to do so may cause the module to fail or malfunction.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• After the firs use of the product, do not mount/remove the module to/from the base unit more

than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

• Before handling the module, touch a grounded metal object to discharge the static electricity

from the human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 4 A - 4

• CONDITIONS OF USE FOR THE PRODUCT •

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 5 A - 5

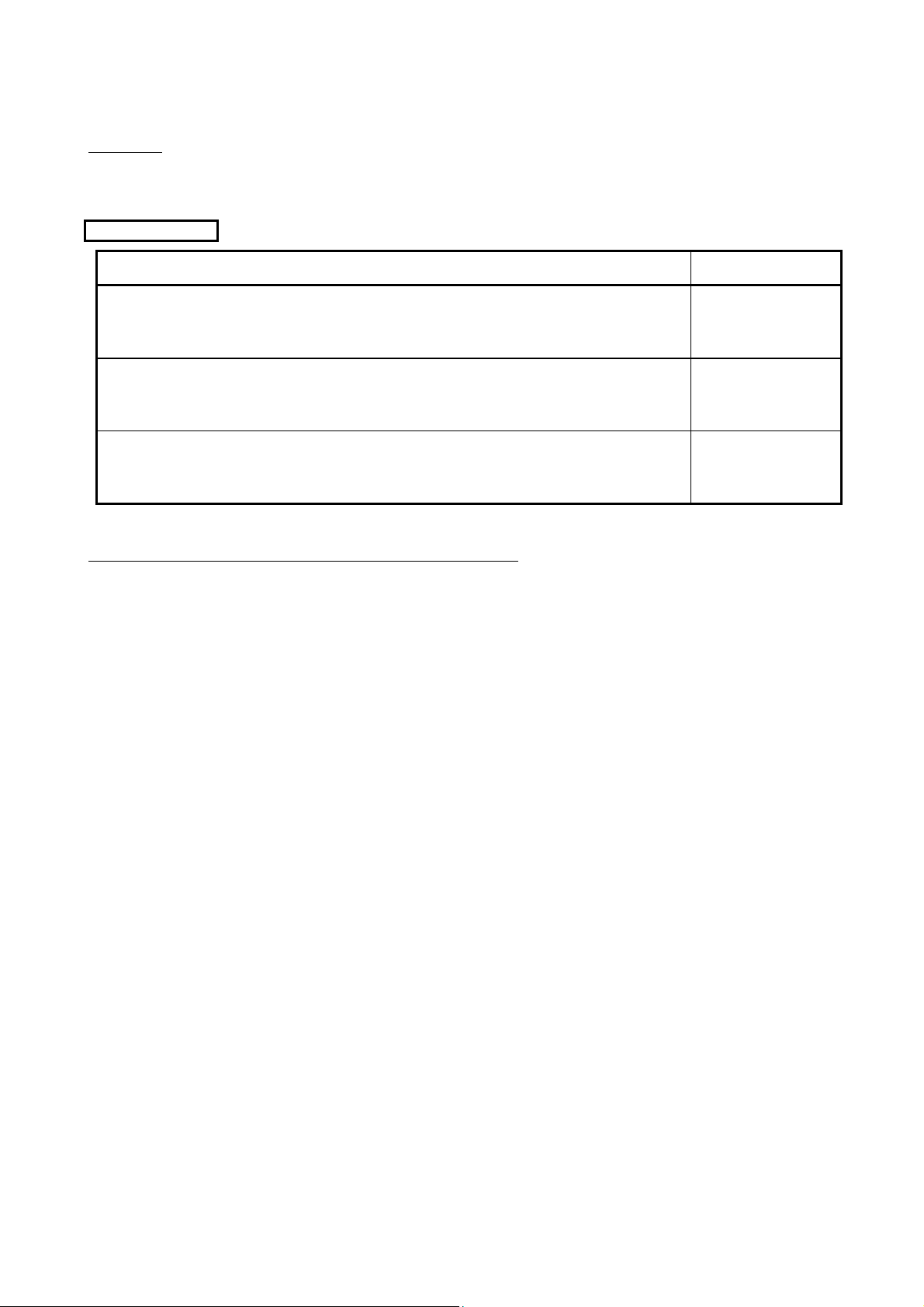

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 1999 SH(NA)-080049-A First printing

Oct., 2000 SH(NA)-080049-B

Correction

Safety Precautions, Contents, About Manuals, About the Generic

Terms and Abbreviations, Chapter 1, Section 1.1, 1.2, Chapter 2,

Section 2.1.3, 2.1.4, 2.2.2, 3.1.1, 3.1.2, 3.2, 3.2.1, 3.2.2, 3.3, 3.3.1,

3.3.2, 3.3.3, 4.1, 4.2, 4.3.1, 4.3.2, 4.5, 4.5.1, 4.5.2, 4.5.3, 4.6.1, 4.6.2,

4.7, 4.7.1, 4.7.2, 4.8, 4.8.1, 4.8.2, 4.8.3, 4.8.4, Chapter 5, Section 5.1,

5.2, 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.5, 5.7, 5.7.1, 5.10, 6.1.2, 6.2, 6.2.1,

6.2.2, 6.2.3, 6.3, Chapter 7, Section 7.2, 7.3.1, 7.4, 7.4.1, 7.4.3, 7.4.5,

7.5, 7.5.3, 7.5.4, 7.5.5, 7.6, 7.7, 7.8, Chapter 8, Section 8.1, 8.1.1, 8.2,

8.2.1, 8.2.2, 8.2.3, 8.2.4, 8.2.5, 8.3, 8.4, Appendix 2.2, 3, 4

Addition

Product Configuration, Section 2.4, 2.5, 2.6, Appendix 1.2, Index

Deletion

Section 2.4

May, 2001 SH(NA)-080049-C

Module addition

QJ71LP21G, QJ71LP21GE

Correction

Safety Precautions, Contents, About the Generic Terms and

Abbreviations, Section 1.1, 1.2, 2.4, 2.13, 2.1.4, 2.2, 2.2.1, 2.3, 3.1.1,

3.1.3, 3.2, 3.2.2, 3.3.2, 3.3.3, 3.3.4, 4.3.2, 4.4.2, 4.5.1, 4.5.2, 4.5.3,

4.6.2, 4.7.1, 4.7.2, Chapter 5, Section 5.1, 5.2.5, 5.2.6, 5.4, 5.6, 5.7.1,

5.7.2, 5.8, 5.9, 6.1.2, 6.2.1, 6.3, Chapter 7, Section 7.2, 7.3, 7.3.1,

7.4.1, 7.4.2, 7.4.5, 7.5, 7.9, 8.1.1, 8.1.4, 8.3, Appendix 2.1

Addition

Section 2.5

Section number changed

Section 2.5 2.6, 2.6 2.7

June, 2002 SH(NA)-080049-D

Module addition

QJ71LP21S-25

Correction

Safety Precautions, Contents, About Manuals, Product Configuration,

Section 1.1, 1.2, 2.2, 3.1.1, 3.2.2, 3.3.2, 4.2, 5.2.1, 5.6, 6.2.1, 6.2.2,

Chapter 7, Section 7.3, 7.3.2, 7.4.5, 8.3, Appendix 3, 4, Index

Apr., 2003 SH(NA)-080049-E

Correction

Safety Precautions, Contents, About Manuals, Section 1.2, 2.1.3, 2.2.2,

2.5, 3.1.1, 3.2.1, 3.2.2, 3.3.1, 3.3.3, Chapter 5, Section 5.2.1, 5.7, 5.7.1,

5.7.2, 5.8, 5.9, 6.1.2, 6.2, 6.4, 7.1, 7.4.2, 7.4.3, 7.4.4, 7.4.5, 7.5, 7.5.4,

7.8, 7.9, 8.1, 8.2, 8.2.1, 8.2.5, 8.3

A - 6 A - 6

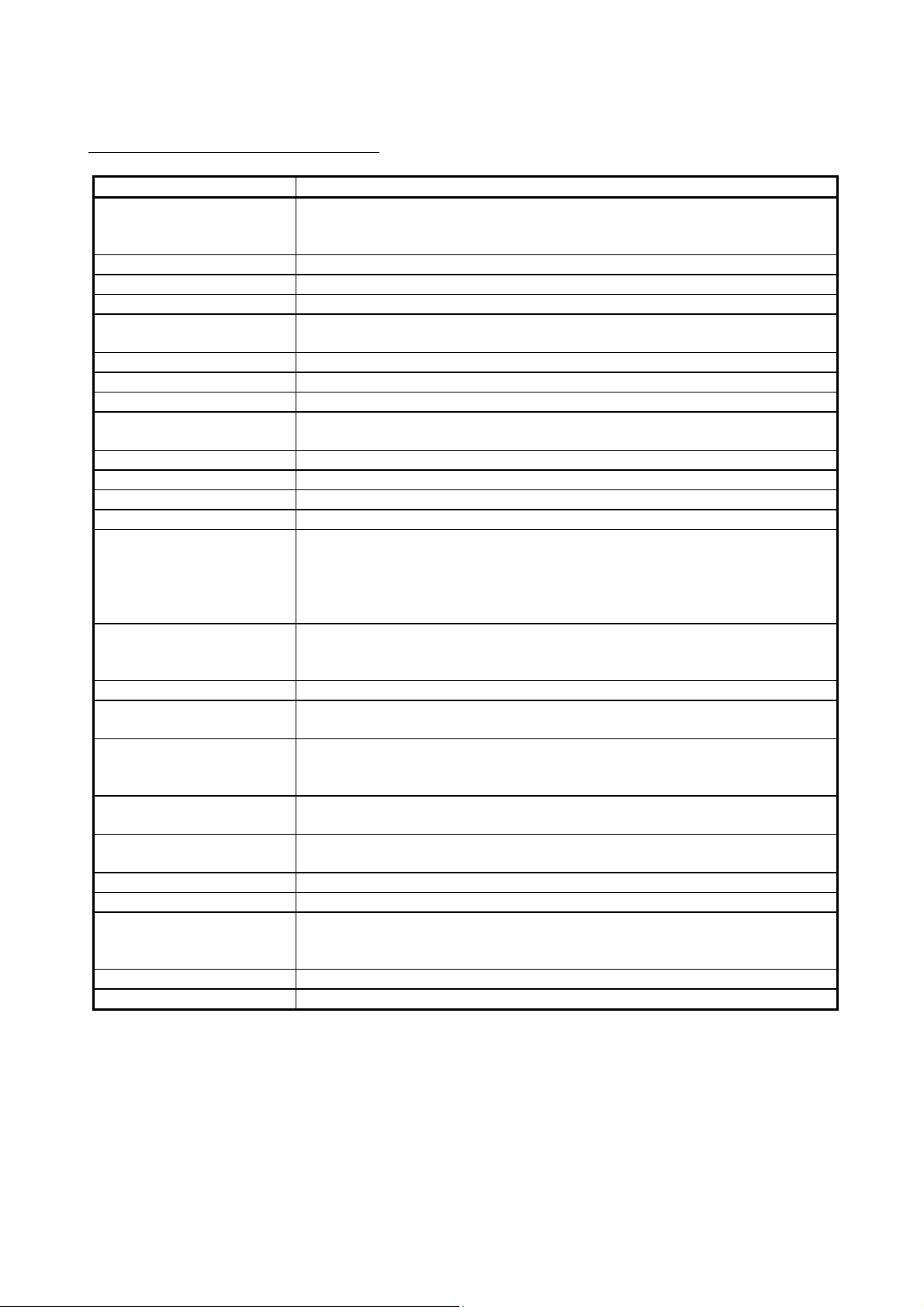

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Jun., 2004 SH(NA)-080049-F · The contents of function version D were added.

· The entire manual was reviewed.

Oct., 2004 SH(NA)-080049-G

Mode addition

MELSECNET/H Extended Mode

Correction

Safety Precautions, Product Configuration, Section 1.1, 1.2, 2.1.2, 2.2,

2.2.2, 2.2.3, 3.1.1, 3.2.1, 3.3.2, 4.2, 4.3.3, 4.6.1, 4.6.2, 4.8.1, Chapter 5,

Section 5.1, 5.4, 6.2.2, 6.2.3, 7.4.5, 7.6, 7.10.2, 8.1, 8.1.1, 8.1.2, 8.1.3,

8.2, 8.2.1, 8.2.7, 8.3, Appendix 1.1, 1.2, 3, 4, 5, INDEX

Addition

Section 8.2.5, 8.2.9, 8.2.10

Section number changed

Section 8.2.5 8.2.6, 8.2.6 8.2.7, 8.2.7

Oct., 2005 SH(NA)-080049-H

Correction

Safety Precautions, Conformation to the EMC Directive and Low

Voltage Instruction, Section 1.1, 1.2, 2.1.2, 2.2, 2.2.1, 2.2.3, 3.1.3,

3.3.2, 4.2, 4.6.1, 4.7.1, 4.7.2, 4.8.1, Chapter 5, Section 5.1, 5.4,

Chapter 6, 7, Section 7.3.1, 7.7, 7.10.2, 8.1.2, 8.1.3, 8.2, 8.2.5, 8.3,

Appendix 1.1, 1.2, 3, 4, 5

Apr., 2006 SH(NA)-080049-I

Correction

Section 2.3, 3.1.2, 4.2, 6.3, 7.4.5, Appendix 4

Oct., 2007 SH(NA)-080049-J

Change of a term

"PLC" was changed to "programmable controller".

Correction

About the Generic Terms and Abbreviations, 1.2, 2.1.3, 2.1.4, 2.2, 2.3,

3.2.1, 3.3.2, 3.3.3, 4.2, 4.5.1, 4.5.2, 4.5.3, 4.6.1, 4.7.1, 4.7.2, Chapter 5,

5.1, 5.6, 5.7, 5.7.1, 5.7.2, 6.1.1, 6.2.2, 6.3, 6.4, 7.2, 7.4.5, 7.5.5, 7.10.2,

8.1, 8.2.1, 8.2.4, 8.3, Appendix 3, 4, 5

8.2.8

Addition

DEFINITIONS OF TERMINOLOGY

Jul., 2008 SH(NA)-080049-K

Correction

SAFETY PRECAUTIONS, Compliance with the EMC and Low Voltage

Directives, About the Generic Terms and Abbreviations, DEFINITIONS

OF TERMINOLOGY, Chapter 1, Section 2.1, 2.2, 3.1.1, 3.1.3, 3.2,

3.3.2 to 3.3.4, 4.2, 4.3.4, 4.6.2, 4.7.1, 4.7.2, Chapter 5, Section 5.1, 5.4,

5.6 to 5.9, 6.1.1, 6.3, Chapter 7, Section 7.2, 7.3, 7.4.1, 7.4.2, 7.4.5,

7.5, 7.5.5, 7.7 to 7.9, 7.10.2, 7.10.5, 7.10.7, 8.1, 8.3, Appendix 1.1, 2.1,

3, 4

A - 7 A - 7

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Jan., 2009 SH(NA)-080049-L

Mode addition

QJ71NT11B

Correction

SAFETY PRECAUTIONS, COMPLIANCE WITH THE EMC AND LOW

VOLTAGE DIRECTIVES, GENERIC TERMS AND ABBREVIATIONS,

PACKING LIST, Section 1.1 to 1.3, 2.1.1, 2.1.2, 2.1.4, 2.2, 2.2.3,

3.1.1 to 3.1.3, 3.2.2, 3.3.2, 3.3.3, 4.1 to 4.3, 4.5, 4.5.1 to 4.5.3, 4.7.1,

4.7.2, 4.8, 4.8.2, Chapter 5, Section 5.1, 5.2.5, 5.4, 5.7.1, 6.1.1, 6.4,

7.1 to 7.3, 7.4.1, 7.4.2, 7.4.5, 7.5.5, 7.9, 7.10.2, 8.2, 8.2.1 to 8.2.4, 8.3,

8.4, Appendix 1.1, 1.2, 3, 4, INDEX

Addition

Section 3.1.4, 3.1.5, 4.2.1 to 4.2.3, 4.6.3, 4.6.4, 5.2.6, 8.2.6,

Appendix 5

Section number changed

Section 4.3.3 4.3.2, 4.3.4 4.3.3, 4.3.5 4.3.4, 5.2.6 5.2.7,

8.2.6 8.2.7, 8.2.7 8.2.8, 8.2.8 8.2.9, 8.2.9 8.2.10,

8.2.10 8.2.11, Appendix 5 6

Aug., 2009 SH(NA)-080049-M

Correction

Section 1.3, 2.2, 2.3, Chapter 8, Appendix 1.2

Addition

Section 8.3.1

Sep., 2010 SH(NA)-080049-N

May, 2012 SH(NA)-080049-O

Section number changed

Section 8.3(4) 8.3.2

Correction

GENERIC TERMS AND ABBREVIATIONS, Section 1.3, 2.2.1, 2.3,

4.2.1, 4.2.2, 4.2.3, 4.3.1, 5.8, 6.4, 7.4.5, 7.5.6, 8.2.4, 8.2.8, 8.2.10,

8.3.2, Appendix 4, 6

Addition

CONDITIONS OF USE FOR THE PRODUCT

Correction

SAFETY PRECAUTIONS, COMPLIANCE WITH THE EMC AND LOW

VOLTAGE DIRECTIVES, GENERIC TERMS AND ABBREVIATIONS,

Section 2.2, 2.3, 3.1.3, 3.1.4, 3.2.2, 3.3.1, 4.2.1, 4.6.2, 5.7, 6.1.1, 6.3,

7.4.5, 7.10.2, 8.3.2, Appendix 3, 6

A - 8 A - 8

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Sep., 2016 SH(NA)-080049-P

Correction

GENERIC TERMS AND ABBREVIATIONS, DEFINITIONS OF

TERMINOLOGY, Section 1.3, 2.1.4, 2.2, 2.3, 3.1.1, 3.1.2, 3.1.4, 3.3.1,

3.3.2, 4.2.1, 4.2.3, 4.3.1, 4.6.3, Chapter 5, Section 5.1, 5.4, 6.1.1, 6.3,

6.4, 7.4.2, 7.4.5, 8.2, Appendix 1.1, 2.1, 3, 4, 5, 6

Nov., 2017 SH(NA)-080049-Q

Correction

Section 7.7

Sep., 2019 SH(NA)-080049-R

Correction

GENERIC TERMS AND ABBREVIATIONS, Section 2.2, 8.1.2,

Appendix 1.2

Addition

Section 8.2.4

Section number changed

Section 8.2.4 to Section 8.2.11 Section 8.2.5 to Section 8.2.12

Japanese Manual Version SH-080026-X

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 1999 MITSUBISHI ELECTRIC CORPORATION

A - 9 A - 9

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC-Q series programmable controller.

Before using the product, please read this manual carefully to develop full familiarity with the functions and

performance of the Q series programmable controller to handle the product correctly.

Please forward a copy of this manual to the end user.

CONTENTS

SAFETY PRECAUTIONS ............................................................................................................................ A- 1

CONDITIONS OF USE FOR THE PRODUCT ........................................................................................... A- 5

REVISIONS .................................................................................................................................................. A- 6

CONTENTS .................................................................................................................................................. A- 10

MANUALS .................................................................................................................................................... A- 15

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES ............................................................. A- 15

GENERIC TERMS AND ABBREVIATIONS ............................................................................................... A- 16

DEFINITIONS OF TERMINOLOGY ............................................................................................................ A- 18

PACKING LIST ............................................................................................................................................ A- 19

1 OVERVIEW 1- 1 to 1-14

1.1 Overview ................................................................................................................................................ 1- 1

1.2 Features ................................................................................................................................................. 1- 4

1.3 Symbols Used in This Manual ............................................................................................................... 1- 14

2 SYSTEM CONFIGURATION 2- 1 to 2-19

2.1 MELSECNET/H Network Configurations .............................................................................................. 2- 1

2.1.1 Single network system .................................................................................................................... 2- 1

2.1.2 Redundant system (Redundant CPU) ............................................................................................ 2- 3

2.1.3 Simple dual-structured system (High Performance model QCPU and Process CPU) ................. 2- 4

2.1.4 Multiple network system (High Performance model QCPU, Process CPU, Redundant CPU,

and Universal model QCPU) .......................................................................................................... 2- 5

2.2 Applicable Systems ................................................................................................................................ 2- 6

2.2.1 Precautions when using link dedicated instructions ....................................................................... 2- 9

2.2.2 Precautions when using network modules in the multiple CPU system ....................................... 2- 11

2.2.3 List of functions for each CPU module ........................................................................................... 2- 17

2.3 Checking Serial Number and Function Version .................................................................................... 2- 18

3 SPECIFICATIONS 3- 1 to 3-52

3.1 Performance Specifications ................................................................................................................... 3- 1

3.1.1 Performance specifications ............................................................................................................. 3- 1

3.1.2 Optical fiber cable specifications..................................................................................................... 3- 5

3.1.3 Coaxial cable specifications ............................................................................................................ 3- 6

3.1.4 Shielded twisted pair cable specifications ...................................................................................... 3- 11

3.1.5 CC-Link Ver. 1.10-compatible cable specifications ........................................................................ 3- 13

3.2 Function Specifications .......................................................................................................................... 3- 14

3.2.1 Cyclic transmission function (periodical communication) .............................................................. 3- 15

3.2.2 RAS function .................................................................................................................................... 3- 18

3.3 Specifications of the Link Data Sending/Receiving Processing Time .................................................. 3- 29

3.3.1 Link data sending/receiving processing ......................................................................................... 3- 29

3.3.2 How to calculate the transmission delay time ................................................................................ 3- 33

A - 10 A - 10

3.3.3 Reducing the link refresh time ........................................................................................................ 3- 47

3.3.4 Reduction of the link scan time ....................................................................................................... 3- 52

3.3.5 Control station shift time .................................................................................................................. 3- 52

4 SETUP AND PROCEDURES BEFORE STARTING THE OPERATION 4- 1 to 4-45

4.1 Procedures Before Starting the Operation ............................................................................................ 4- 1

4.2 Part Names and Settings ....................................................................................................................... 4- 2

4.2.1 QJ71LP21, QJ71LP21-25, QJ71LP21S-25, QJ71LP21G, QJ71LP21GE .................................... 4- 2

4.2.2 QJ71BR11 ....................................................................................................................................... 4- 5

4.2.3 QJ71NT11B ..................................................................................................................................... 4- 7

4.3 Loading and Installation ......................................................................................................................... 4- 8

4.3.1 Handling precautions ...................................................................................................................... 4- 8

4.3.2 Installing and uninstalling the module ............................................................................................. 4- 10

4.3.3 Stopping the CPU module (unintentional output prevention) ........................................................ 4- 11

4.3.4 Checking the input power supply voltage ....................................................................................... 4- 11

4.4 Powering On .......................................................................................................................................... 4- 11

4.4.1 Checking the on status of the POWER LED of the power supply module .................................... 4- 11

4.4.2 Checking the on status of the RUN LED of the network module .................................................. 4- 11

4.5 Standalone Check of the Network Module (Offline Tests) ................................................................... 4- 12

4.5.1 Self-loopback test ............................................................................................................................ 4- 13

4.5.2 Internal self-loopback test ............................................................................................................... 4- 15

4.5.3 Hardware test .................................................................................................................................. 4- 17

4.6 Cable Connection .................................................................................................................................. 4- 19

4.6.1 Optical loop system ......................................................................................................................... 4- 19

4.6.2 Coaxial bus system ......................................................................................................................... 4- 22

4.6.3 Twisted bus system (when using a shielded twisted pair cable) ................................................... 4- 27

4.6.4 Twisted bus system (when using CC-Link Ver. 1.10-compatible cable) ....................................... 4- 29

4.7 Offline Tests from GX Developer .......................................................................................................... 4- 30

4.7.1 Station-to-station test ...................................................................................................................... 4- 30

4.7.2

Forward loop/reverse loop test (optical loop system only) ............................................................ 4- 36

4.8 Network Diagnostics from GX Developer (Online Tests) ..................................................................... 4- 41

4.8.1 Loop test (optical loop system only) ............................................................................................... 4- 42

4.8.2 Setup confirmation test (optical loop, coaxial bus system only) .................................................... 4- 43

4.8.3 Station order check test (optical loop system only) ........................................................................ 4- 44

4.8.4 Communication test......................................................................................................................... 4- 45

5 PARAMETER SETTINGS 5- 1 to 5-42

5.1 Setting the Number of Modules (Network Type) .................................................................................. 5- 7

5.2 Network Settings .................................................................................................................................... 5- 9

5.2.1 Starting I/O No. ................................................................................................................................ 5- 9

5.2.2 Network No. ..................................................................................................................................... 5- 9

5.2.3 Total stations ................................................................................................................................... 5- 10

5.2.4 Group No. ........................................................................................................................................ 5- 10

5.2.5 Mode ................................................................................................................................................ 5- 11

5.2.6 Communication speed setting (twisted bus system only) .............................................................. 5- 12

A - 11 A - 11

5.2.7 Example of parameter settings ....................................................................................................... 5- 13

5.3 Common Parameters (Network Range Assignment Screen) .............................................................. 5- 14

5.3.1 Send range for each station (LB/LW settings) ............................................................................... 5- 14

5.3.2 Send range for each station (LX/LY settings) ................................................................................ 5- 15

5.3.3 Specification of the I/O master station ............................................................................................ 5- 16

5.3.4 Specification of the reserved station ............................................................................................... 5- 16

5.3.5 Pairing setting .................................................................................................................................. 5- 16

5.4 Supplementary Settings ......................................................................................................................... 5- 17

5.5 Control Station Return Setting ............................................................................................................... 5- 20

5.6 Station Inherent Parameters (High Performance model QCPU, Process CPU, Redundant CPU,

and Universal model QCPU) ................................................................................................................. 5- 21

5.7 Refresh Parameters ............................................................................................................................... 5- 25

5.7.1 Concept of the link refreshing ......................................................................................................... 5- 28

5.7.2 How to set the refresh parameters ................................................................................................. 5- 30

5.8 Valid Module During Other Station Access ........................................................................................... 5- 39

5.9 Standby Station Compatible Module (High Performance model QCPU and Process CPU) .............. 5- 40

5.10 Writing Parameters to the CPU ........................................................................................................... 5- 42

6 PROGRAMMING 6- 1 to 6-31

6.1 Programming Precautions ..................................................................................................................... 6- 1

6.1.1 Interlock related signals .................................................................................................................. 6- 1

6.1.2 Program example ............................................................................................................................ 6- 4

6.2 Cyclic Transmission ............................................................................................................................... 6- 5

6.2.1 32-bit data assurance ...................................................................................................................... 6- 5

6.2.2 Station-based block data assurance for cyclic data ....................................................................... 6- 7

6.2.3 Interlock program example ............................................................................................................. 6- 8

6.3 Link Dedicated Instruction List ............................................................................................................... 6- 9

6.4 Using the Link Special Relays (SB)/Link Special Registers (SW) ....................................................... 6- 13

7 APPLICATION FUNCTIONS 7- 1 to 7-160

7.1 Direct Access to the Link Devices ......................................................................................................... 7- 2

7.2 Inter-Link Data Transfer Function (High Performance model QCPU, Process CPU,

Redundant CPU, and Universal model QCPU) .................................................................................... 7- 6

7.3 Low-Speed Cyclic Transmission Function (High Performance model QCPU, Process CPU,

Redundant CPU, and Universal model QCPU) .................................................................................... 7- 9

7.3.1 Send range settings ........................................................................................................................ 7- 10

7.3.2 Send timing ...................................................................................................................................... 7- 11

7.3.3 Startup ............................................................................................................................................. 7- 14

7.4 Transient Transmission Function (Non-Periodical Communication) .................................................... 7- 16

7.4.1 Communication function.................................................................................................................. 7- 17

7.4.2 Routing function ............................................................................................................................... 7- 20

7.4.3 Group function ................................................................................................................................. 7- 27

7.4.4 Message sending function using the logical channel numbers ..................................................... 7- 28

7.4.5 Programming ................................................................................................................................... 7- 30

7.4.5 (1) Data sending/receiving (JP/GP.SEND, JP/GP.RECV) ............................................................ 7- 36

7.4.5 (2) Reading from/writing to word devices of other stations (JP/GP.READ, JP/GP.SREAD,

JP/GP.WRITE, JP/GP.SWRITE) .................................................................................................... 7- 53

A - 12 A - 12

7.4.5 (3) Requesting transient transmission to other stations (J(P)/G(P).REQ) .................................... 7- 72

7.4.5 (4) Reading/writing word devices of other stations (J(P).ZNRD, J(P).ZNWR) .............................. 7- 82

7.4.5 (5) Remote RUN/Remote STOP (Z(P).RRUN, Z(P).RSTOP) ....................................................... 7- 91

7.4.5 (6) Reading and writing clock data of other station CPU modules (Z(P).RTMRD, Z(P).RTMWR)

......................................................................................................................................................... 7- 100

7.4.6 Setting the clock to stations on a network with GX Developer ...................................................... 7- 109

7.5 Starting the Interrupt Sequence Program ............................................................................................. 7- 110

7.5.1 Interrupt setting parameters ............................................................................................................ 7- 111

7.5.2 Interrupts using the RECVS instruction .......................................................................................... 7- 113

7.5.3 Interrupts by the link devices (LB/LW/LX) for cyclic transmission ................................................. 7- 114

7.5.4 Interrupts by the link special device (SB/SW) ................................................................................ 7- 116

7.5.5 Message reception "one scan completion" instruction (Z.RECVS) ............................................... 7- 117

7.5.6 Application example ........................................................................................................................ 7- 121

7.6 Multiplex Transmission Function (Optical Loop System) ..................................................................... 7- 123

7.7 Simple Dual-Structured Network (High Performance model QCPU and Process CPU) .................... 7- 124

7.8 Stopping/Restarting the Cyclic Transmission and Stopping Link Refreshing (Network Test) ............ 7- 129

7.9 Increasing the Number of Send Points by Installing Multiple Modules with the Same Network

(High Performance model QCPU, Process CPU, Redundant CPU, and Universal model QCPU) ... 7- 132

7.10 Configuring a Network with a Redundant System .............................................................................. 7- 134

7.10.1 Outline of the redundant system operation .................................................................................. 7- 134

7.10.2 Precautions for network configuration including a redundant system ......................................... 7- 137

7.10.3 Pairing setting in a redundant system .......................................................................................... 7- 145

7.10.4 Redundant settings in a redundant system ..................................................................................

7.10.5 System switching request to the control system CPU ................................................................. 7- 150

7.10.6 Function for returning to control station in a redundant system .................................................. 7- 152

7.10.7 Data retention time for system switching ...................................................................................... 7- 153

7.10.8 Routing via a redundant system ................................................................................................... 7- 159

7- 149

8 TROUBLESHOOTING 8- 1 to 8-53

8.1 Network Diagnostics (Network Monitor) ................................................................................................ 8- 2

8.1.1 Host information .............................................................................................................................. 8- 5

8.1.2 Other station information ................................................................................................................. 8- 7

8.1.3 Network monitor details ................................................................................................................... 8- 11

8.1.4 Error history monitor ........................................................................................................................ 8- 15

8.2 Troubleshooting ..................................................................................................................................... 8- 18

8.2.1 Items to be checked first ................................................................................................................. 8- 23

8.2.2 Data link failure on the entire system ............................................................................................. 8- 24

8.2.3 Data link failure caused by reset or power-off of each station ....................................................... 8- 24

8.2.4 Cyclic data is 0 caused by reset or power-on of each station ....................................................... 8- 26

8.2.5 Data link failure of a specific station ............................................................................................... 8- 27

8.2.6 Data link failure in MELSECNET/H Extended mode ..................................................................... 8- 27

8.2.7 Data link failure in MELSECNET/H twisted bus system ................................................................ 8- 28

8.2.8 Data link in a redundant system ..................................................................................................... 8- 28

8.2.9 Send/received data failure .............................................................................................................. 8- 29

8.2.10 Link dedicated instruction not complete ....................................................................................... 8- 30

8.2.11 Checking online for reverse optical fiber cable connection ......................................................... 8- 31

8.2.12 When different network types exist in the same network ............................................................ 8- 33

8.3 Error Codes ............................................................................................................................................ 8- 34

8.3.1 How to check error codes ............................................................................................................... 8- 34

A - 13 A - 13

8.3.2 Error code list................................................................................................................................... 8- 39

8.4 H/W Information ..................................................................................................................................... 8- 49

APPENDICES App- 1 to App-42

Appendix 1 Comparison of Network Module Specifications, and Compatibility ................................... App- 1

Appendix 1.1 List of comparison between MELSECNET/H and MELSECNET/H

Extended mode and MELSECNET/10 mode specifications ....................................... App- 1

Appendix 1.2 Upgraded functions of the network module ................................................................. App- 3

Appendix 2 Differences between the AJ71QLP21/AJ71QLP21G/AJ71QBR11, the A1SJ71QLP21/

A1SJ71QBR11, and the QJ71LP21/QJ71LP21-25/QJ71LP21G/ QJ71BR11 ................. App- 4

Appendix 2.1 Differences in LED displays and switch settings ......................................................... App- 4

Appendix 2.2 Precautions when replacing the AJ71QLP21/AJ71QLP21G/AJ71QBR11 and the

A1SJ71QLP21/A1SJ71QBR11 with the QJ71LP21/QJ71LP21-25/ QJ71LP21G/

QJ71BR11 ..................................................................................................................... App- 5

Appendix 3 Link Special Relay (SB) List ................................................................................................ App- 6

Appendix 4 Link Special Register (SW) List ........................................................................................... App- 18

Appendix 5 Screwdriver .......................................................................................................................... App- 37

Appendix 6 External Dimensions ............................................................................................................ App- 38

INDEX Index- 1 to Index- 3

A - 14 A - 14

MANUALS

The following manuals are also relevant to this product.

Order each manual as needed, referring to the following list.

Relevant manuals

Manual name

Q corresponding MELSECNET/H Network System Reference Manual (Remote I/O network)

Specifications, setup and procedures before starting the operation, parameter setting, programming and

troubleshooting of the remote I/O network of the MELSECNET/H network system. (Sold separately)

Type MELSECNET/10 Network system (PLC to PLC network) Reference Manual

System configuration, performance, specifications and programming of MELSECNET/10 network system

(PLC to PLC network). (Sold separately)

For QnA/Q4AR MELSECNET/10 Network System Reference Manual

System configuration, performance, specifications and programming of MELSECNET/10 network system

(PLC to PLC network). (Sold separately)

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi Electric programmable controllers maintain EMC and

Low Voltage Directives when incorporated into other machinery or equipment,

certain measures may be necessary. Please refer to one of the following

manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

Manual number

(Model code)

SH-080124

(13JF96)

IB-66440

(13JE33)

IB-66690

(13JF78)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance

with EMC and Low Voltage Directives.

(2) Additional measures

(a) When using QJ71LP21 and QJ71NT11B

No additional measures are necessary for the compliance of this product

with EMC and Low Voltage Directives.

(b) When using QJ71BR11

To ensure that this product maintains EMC and Low Voltage Directives,

please refer to one of the manuals listed under (1).

A - 15 A - 15

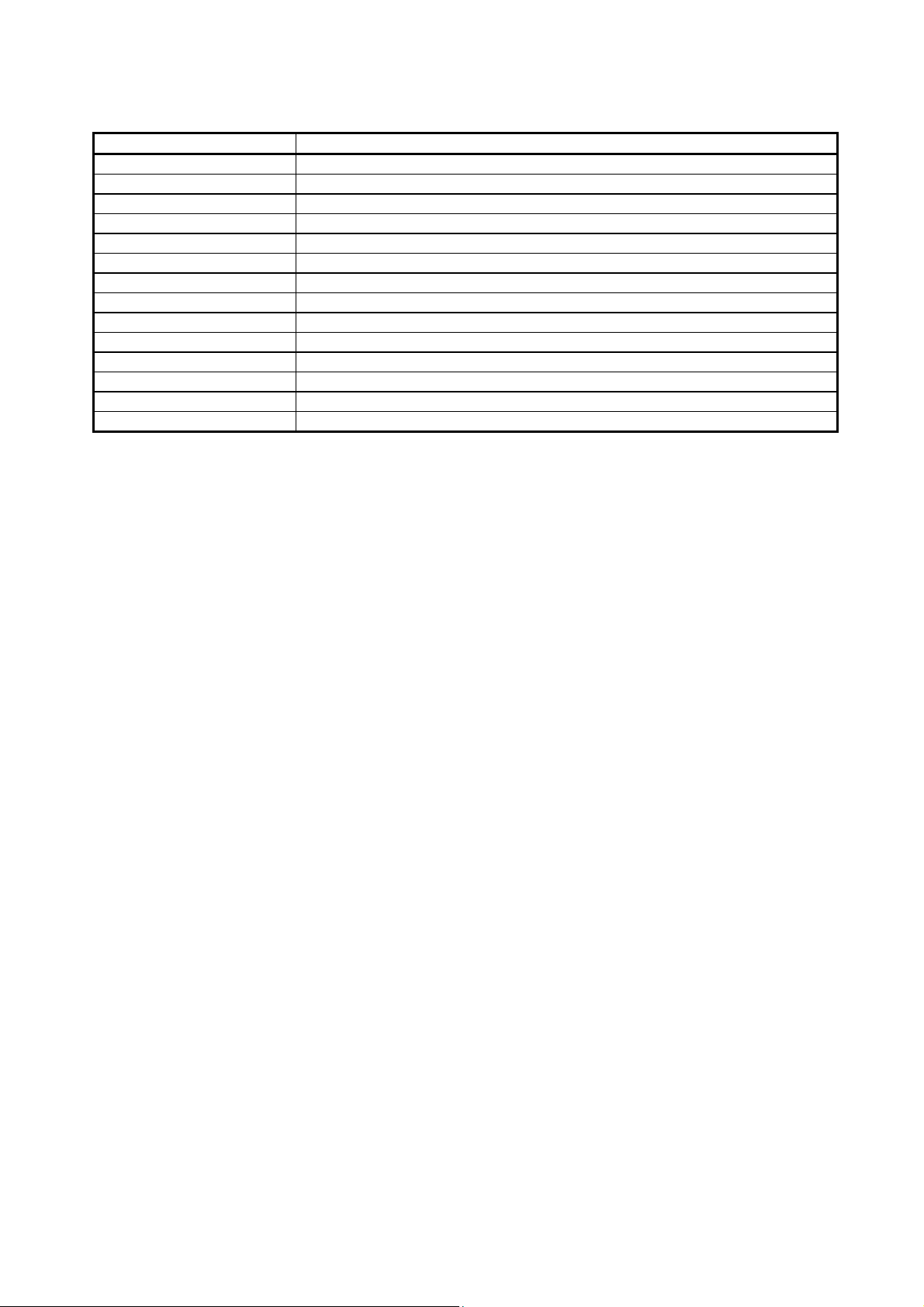

GENERIC TERMS AND ABBREVIATIONS

Generic term/abbreviation Description of generic term/abbreviation

Abbreviation for the QJ71LP21, QJ71LP21-25, QJ71LP21S-25, QJ71LP21G, and QJ71LP21GE

QJ71LP21

QJ71BR11 Abbreviation for the QJ71BR11 MELSECNET/H network module

QJ71NT11B Abbreviation for the QJ71NT11B MELSECNET/H network module

Network modules Generic term for the QJ71LP21, QJ71BR11, and QJ71NT11B

CC-Link IE Controller Network

module

CC-Link IE Field Network module Abbreviation for the QJ71GF11-T2 CC-Link IE Field Network master/local modules

MELSECNET/H Abbreviation for the Q corresponding MELSECNET/H network system

MELSECNET/10 Abbreviation for the AnU and QnA/Q4AR corresponding MELSECNET/10 network system

QCPU

Basic model QCPU Generic term for the Q00JCPU, Q00CPU, and Q01CPU

High Performance model QCPU Generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Process CPU Generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Redundant CPU Generic term for the Q12PRHCPU and Q25PRHCPU

Universal model QCPU

Built-in Ethernet port QCPU

Safety CPU Generic term for the QS001CPU

C Controller module

Control CPU

System A CPU

System B CPU

Control system CPU A CPU module that controls operations in a redundant system

Standby system CPU A CPU module that stands by in case the control system fails in a redundant system

GX Developer

GX Works2 Generic product name for SWnDND-GXW2 and SWnDNC-GXW2 (n: version)

CC-Link Ver. 1.10-compatible cable Abbreviation for the CC-Link Version. 1.10-compatible dedicated cable

MELSECNET/H network modules. However, QJ71LP21, QJ71LP21-25, QJ71LP21S-25,

QJ71LP21G, and QJ71LP21GE are used in this manual to indicate special machine types

Abbreviation for the QJ71GP21-SX and QJ71GP21S-SX CC-Link IE Controller Network modules

Generic term for the Basic model QCPU, High Performance model QCPU, Process CPU,

Redundant CPU, and Universal model QCPU

Generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU, Q03UDVCPU,

Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU, Q06UDVCPU,

Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU, Q13UDVCPU, Q13UDEHCPU,

Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and

Q100UDEHCPU

Generic term for the Q03UDVCPU, Q03UDECPU, Q04UDVCPU, Q04UDEHCPU, Q06UDVCPU,

Q06UDEHCPU, Q10UDEHCPU, Q13UDVCPU, Q13UDEHCPU, Q20UDEHCPU, Q26UDVCPU,

Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

Generic term for the C Controller modules: Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-V,

Q24DHCCPU-V, Q24DHCCPU-VG, Q24DHCCPU-LS, and Q26DHCCPU-LS

A CPU module that controls connected I/O modules and intelligent function modules. In a multiple

CPU system, there are multiple CPU modules and each connected module can be controlled by a

different CPU module.

A CPU module where the system A connector of a tracking cable is connected in a redundant

system

A CPU module where the system B connector of a tracking cable is connected in a redundant

system

Generic product name for SWnD5C-GPPW-E, SWnD5C-GPPW-EA, SWnD5C-GPPW-EV, and

SWnD5C-GPPW-EVA ("n" means version 4 or later.)

"-A" and "-V" mean "volume license product" and "version-upgrade product" respectively.

A - 16 A - 16

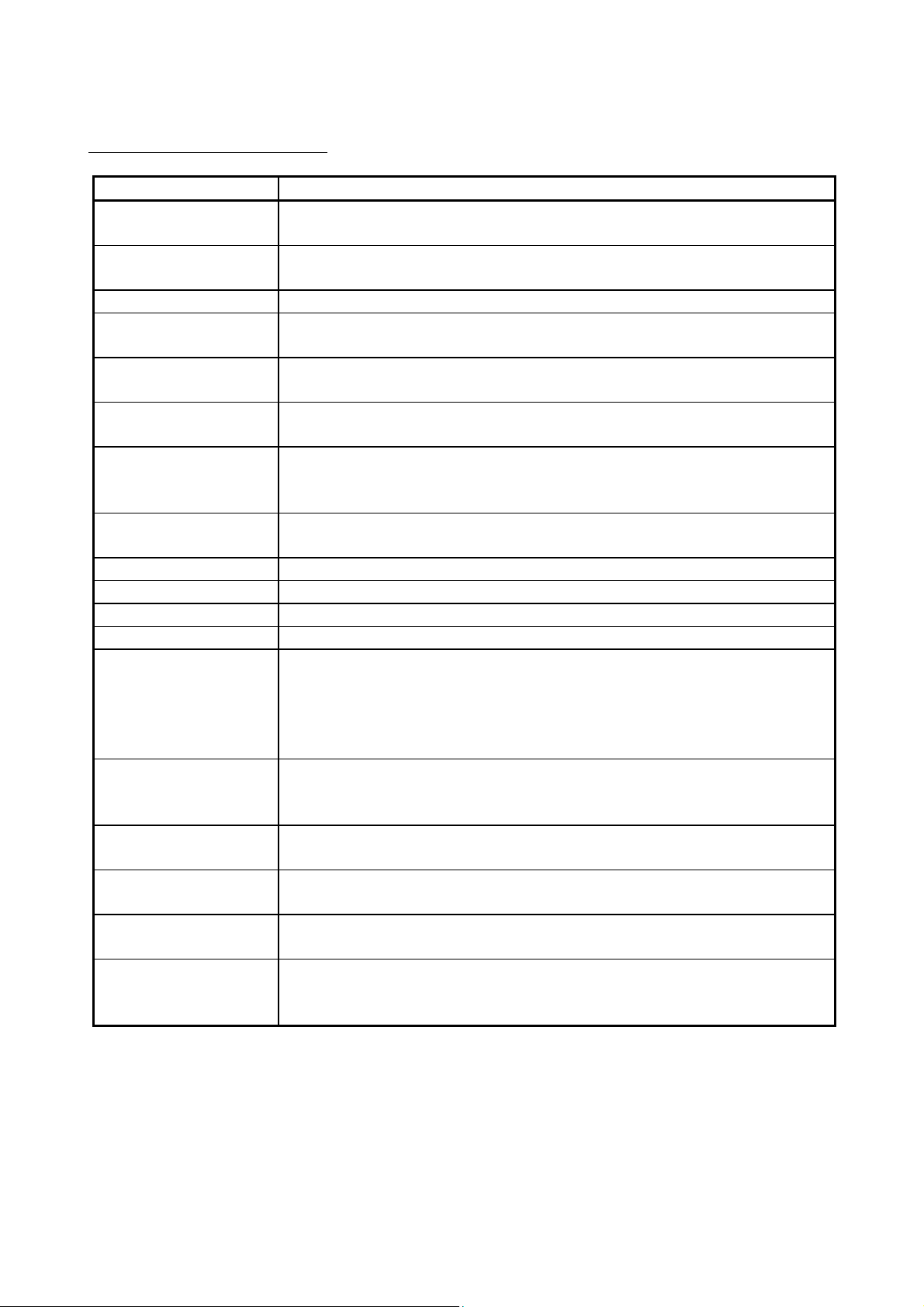

Generic term/abbreviation Description of generic term/abbreviation

SEND Abbreviation for JP.SEND and GP.SEND

RECV Abbreviation for JP.RECV and GP.RECV

READ Abbreviation for JP.READ and GP.READ

SREAD Abbreviation for JP.SREAD and GP.SREAD

WRITE Abbreviation for JP.WRITE and GP.WRITE

SWRITE Abbreviation for JP.SWRITE and GP.SWRITE

REQ Abbreviation for J.REQ, JP.REQ, G.REQ and GP.REQ

ZNRD Abbreviation for J.ZNRD and JP.ZNRD

ZNWR Abbreviation for J.ZNWR and JP.ZNWR

RRUN Abbreviation for Z.RRUN and ZP.RRUN

RSTOP Abbreviation for Z.RSTOP and ZP.RSTOP

RTMRD Abbreviation for Z.RTMRD and ZP.RTMRD

RTMWR Abbreviation for Z.RTMWR and ZP.RTMWR

RECVS Abbreviation for Z.RECVS

A - 17 A - 17

DEFINITIONS OF TERMINOLOGY

Term Description

Cyclic transmission

Transient transmission

Link dedicated instruction Dedicated instruction used for transient transmission.

RAS

Control station

Normal station

Reserved station

Relay station

Reconnection Processing of restarting data link when a faulty station becomes normal.

Disconnection Processing of stopping data link when a data link error occurs.

Device Devices (X, Y, M, D, etc.) that are contained in a CPU module.

Link Device Devices (LB/LW/LX/LY) that are contained in a network module.

Link scan time

Link refresh

Buffer memory

Baton pass

Control station shift time

Group No.

A function by which data are periodically exchanged among stations on the network using

link devices

A function of communication with another station, which is used when requested by a

dedicated instruction or GX Developer

Abbreviation for Reliability, Availability, and Serviceability.

This term is used to express the overall usability of automation systems.

Only one station that controls the network to which it is connected.

Each station's send range for cyclic transmission is assigned to the control station.

Station that performs cyclic transmission according to the range assignment of the control

station.

Station that is not actually connected to the network.

It must be included in the total number of stations in the network, since it is to be connected

in the future.

A station that includes two or more network modules. Data are passed through this station

to stations on other networks.

Time required for data of each station to be sent in order and to make one rotation in the

network.

The link scan time changes depending on the data volume or transient transmission

request.

Link scans are performed "asynchronously" with sequence scans of the CPU module.

Processing of data transfer between link devices of the network module and CPU module

devices.

Link refresh is performed in "END processing" of the sequence scan of the CPU module.

Memory area in an intelligent function module, in which data are temporarily stored.

The network module does not have any buffer memory area that is offered to the user.

A control mechanism in which transmission right (token) is passed around the network for

data transmission.

Time taken from when the control station went down due to a reason such as power-off

until data link is started by the sub-control station.

Number that is assigned for transient transmission to any given stations.

By specifying a group of stations as transient transmission target, data can be sent to the

stations of the same group No.

A - 18 A - 18

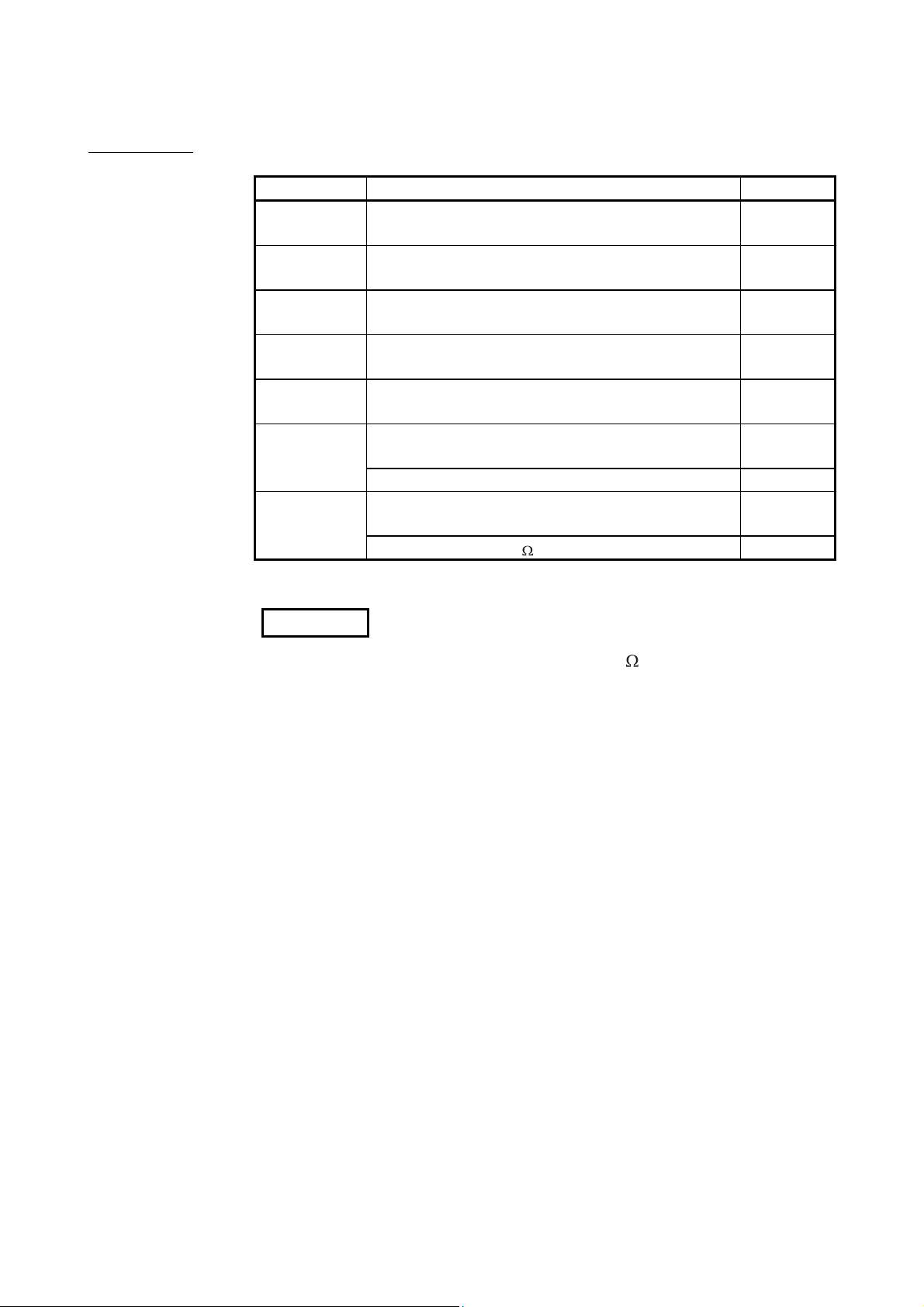

PACKING LIST

Model name Part name Quantity

QJ71LP21*1

QJ71LP21-25

QJ71LP21S-25

QJ71LP21G

QJ71LP21GE

QJ71BR11

QJ71NT11B

QJ71LP21 MELSECNET/H Network Module

(optical loop type)

QJ71LP21-25 MELSECNET/H Network Module

(optical loop type)

QJ71LP21S-25 MELSECNET/H Network Module

(optical loop type, with external power supply function)

QJ71LP21G MELSECNET/H Network Module

(optical loop type)

QJ71LP21GE MELSECNET/H Network Module

(optical loop type)

QJ71BR11 MELSECNET/H Network Module

(coaxial bus type)

F-type connector (A6RCON-F) 1

QJ71NT11B MELSECNET/H Network Module

(twisted bus type)

Terminating resistor 110 , 1/2W (brown, brown, brown) 1

*1: The QJ71LP21 is discontinued in October, 2000.

1

1

1

1

1

1

1

REMARKS

For the coaxial bus system, terminating resistors (75 ) are required in the network

terminal stations.

Terminating resistors are not supplied with the QJ71BR11; they must be purchased

separately.

For a list of the model names and how to use the terminating resistors, refer to

Section 4.6.2.

A - 19 A - 19

1 OVERVIEW

1 OVERVIEW

MELSEC-Q

1

1.1 Overview

The MELSECNET/H network system includes a PLC to PLC network for

communicating between the control station and normal stations, and a remote I/O

network for communicating between the remote master station and remote I/O stations.

This manual is used for configuring PLC to PLC networks on MELSECNET/H network

systems (hereinafter abbreviated as MESECNET/H.)

When configuring a remote I/O network using MELSECNET/H, refer to Q

corresponding MELSECNET/H Network System Reference Manual (Remote I/O

network).

REMARKS

Networks known as MELSECNET/10H are hereinafter abbreviated as

MELSECNET/H.

The PLC to PLC network system of MELSECNET/H provides more functionality,

higher processing speed and more capacity than the conventional PLC to PLC network

system of MELSECNET/10 network system.

In addition, in pursuit of the maximum ease of use of the MELSECNET/10 network

system, the FA system can be networked easily by combining with GX Developer.

The MELSECNET/H system supports the MELSECNET/H and MELSECNET/H

Extended modes (high functionality and high-speed mode) and the MELSECNET/10

mode (functional and performance compatibility mode) to achieve the network

performance improvement and upward compatibility of MELSECNET/10.

Unless otherwise categorized, this is abbreviated as MELSECNET/H for explanatory

purposes in this manual.

1 - 1 1 - 1

1 OVERVIEW

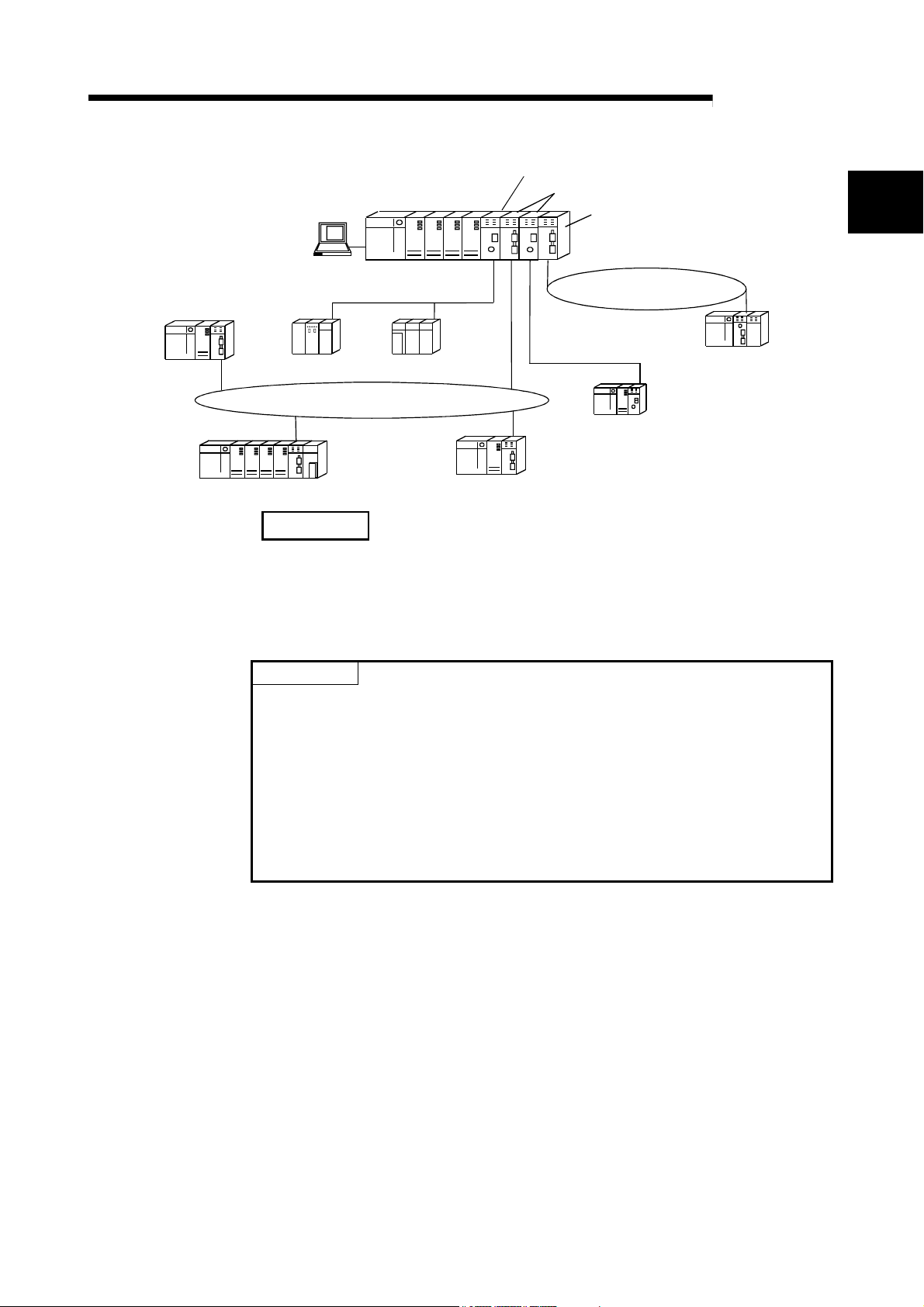

GX Developer

Q25HCPU

MELSEC-Q

Control station (MELSECNET/10 mode)

Control station (MELSECNET/H mode)

Remote master station

1

MELSECNET/10

Q25HCPU Normal station

QnACPU

MELSECNET/H (25Mbps) PLC to PLC network

Q25HCPU

PLC to PLC network

Normal

station

AnUCPU

Normal station

Normal

station

Q25HCPU

REMARKS

MELSECNET/H (25Mbps)

remote I/O network

MELSECNET/H (10Mbps)

PLC to PLC network

Q25HCPU

Normal station

Normal station

Remote I/O

station

This manual is written assuming that MELSECNET/H is used in the MELSECNET/H

or MELSECNET/H Extended mode. Thus, if MELSECNET/H is to be used in the

MELSECNET/10 mode, please refer to the "For QnA/Q4AR MELSECNET/10

Network System Reference Manual".

POINT

(1) Select a QCPU as a programmable controller of the MELSECNET/H for PLC

to PLC network system.

(2) When any of the conventional series QnA, AnU and ACPUs exist in the same

network, select the MELSEC NET/10 mode, which is compatible with the

MELSECNET/10.

(3) Set the control station and normal stations within the same network to the

same network type.

Stations of different network types cannot be used together within the same

network.

1 - 2 1 - 2

1 OVERVIEW

module

QCPU

AnUCPU MELSECNET/10

QnACPU MELSECNET/10

MELSEC-Q

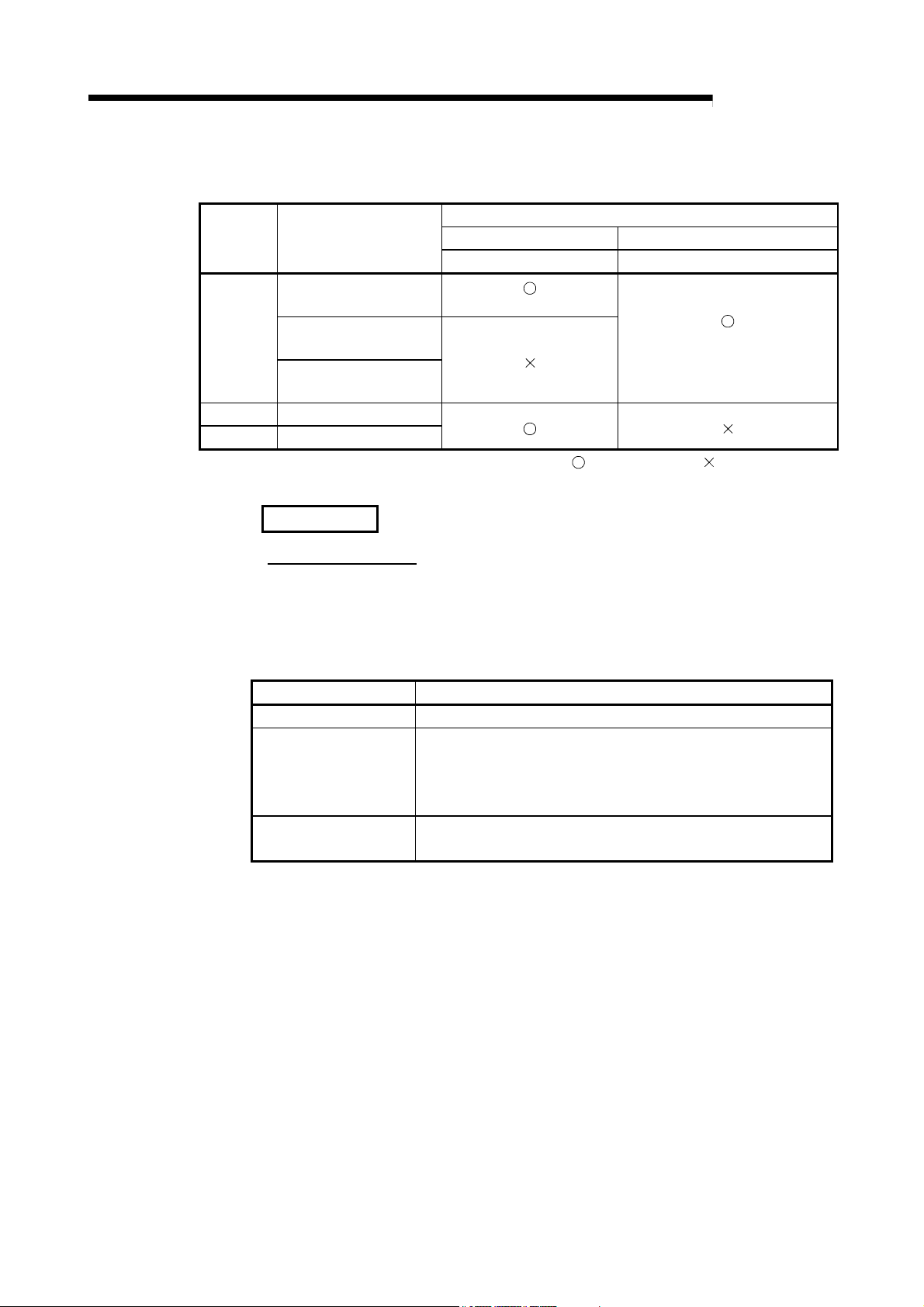

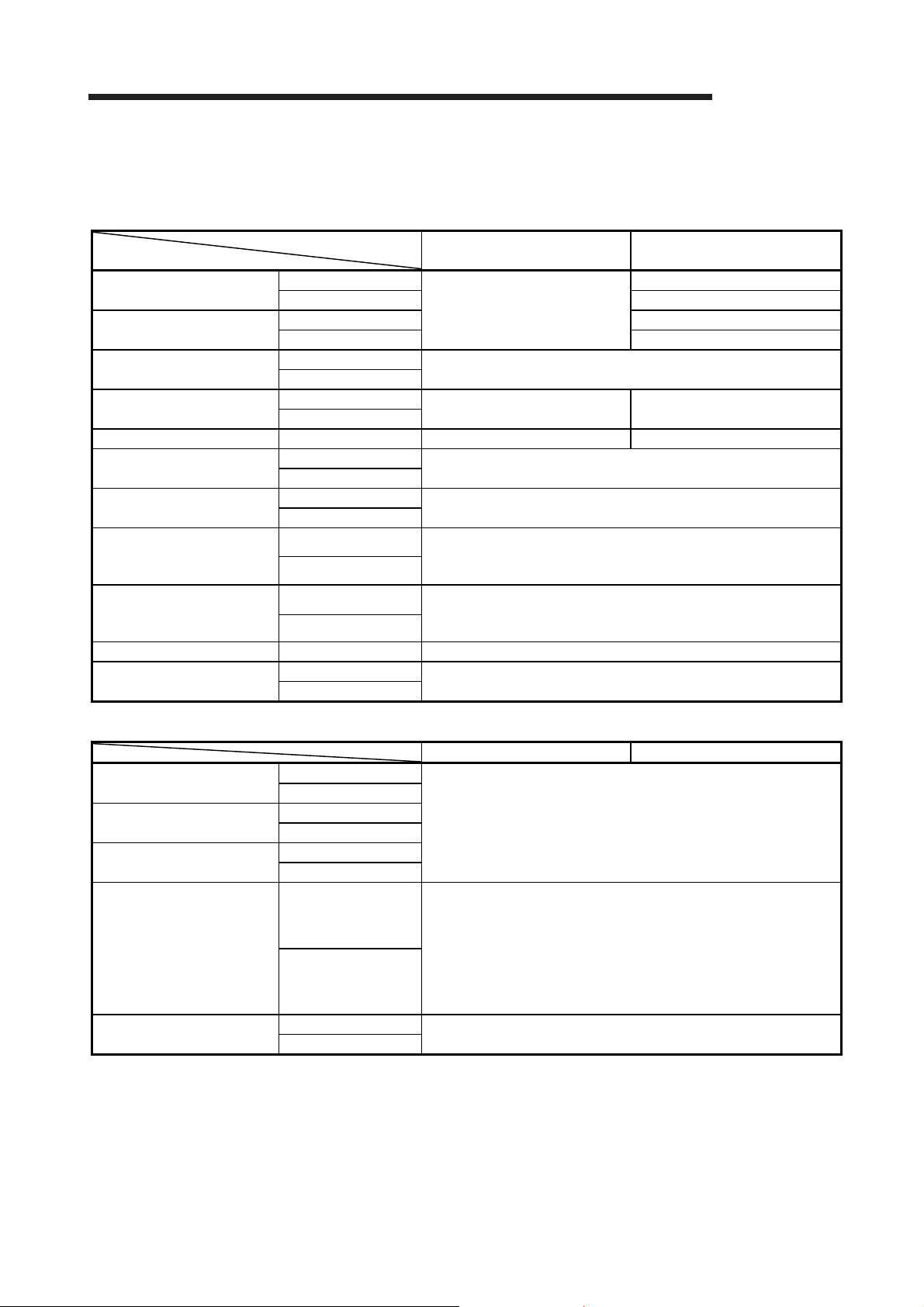

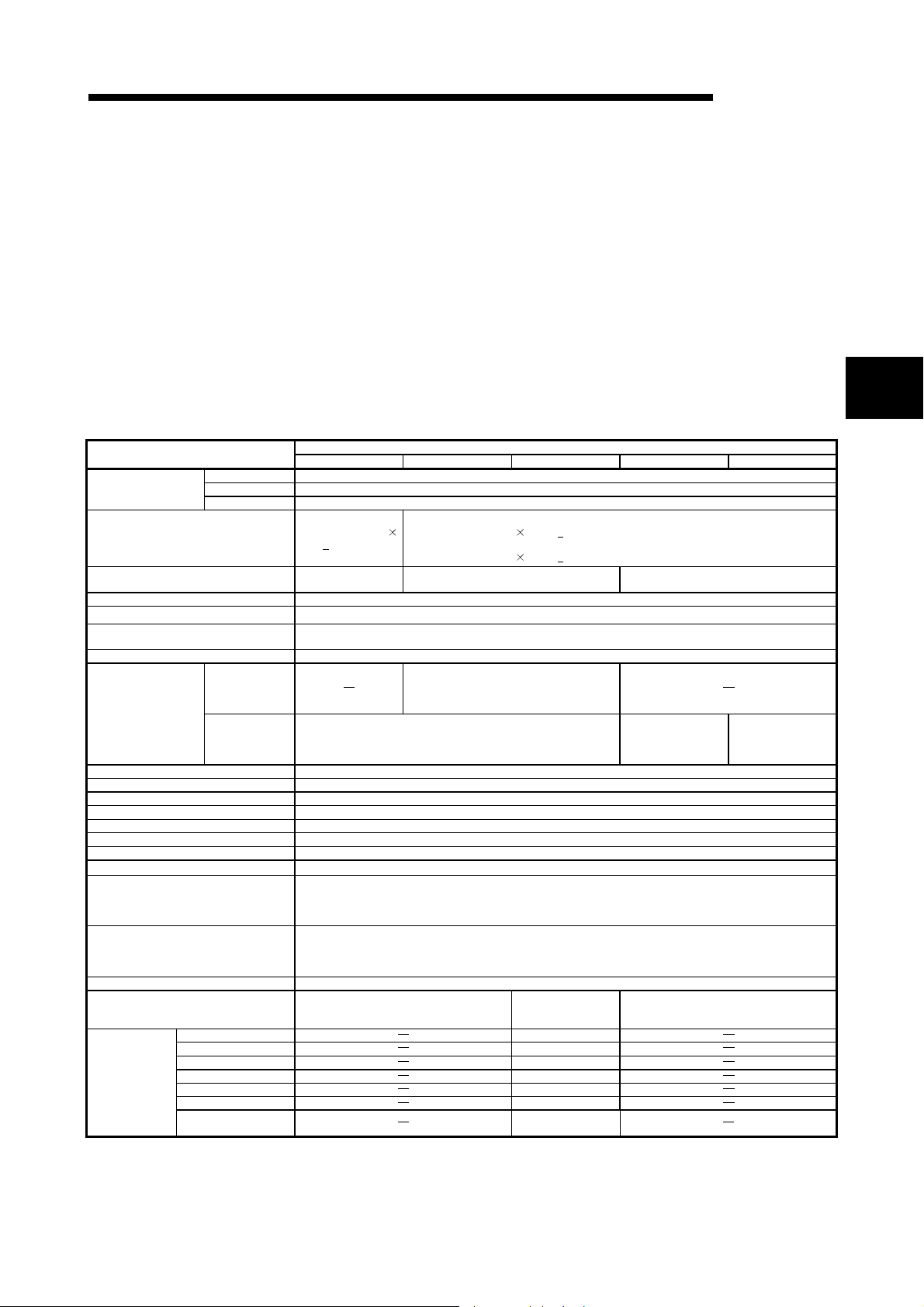

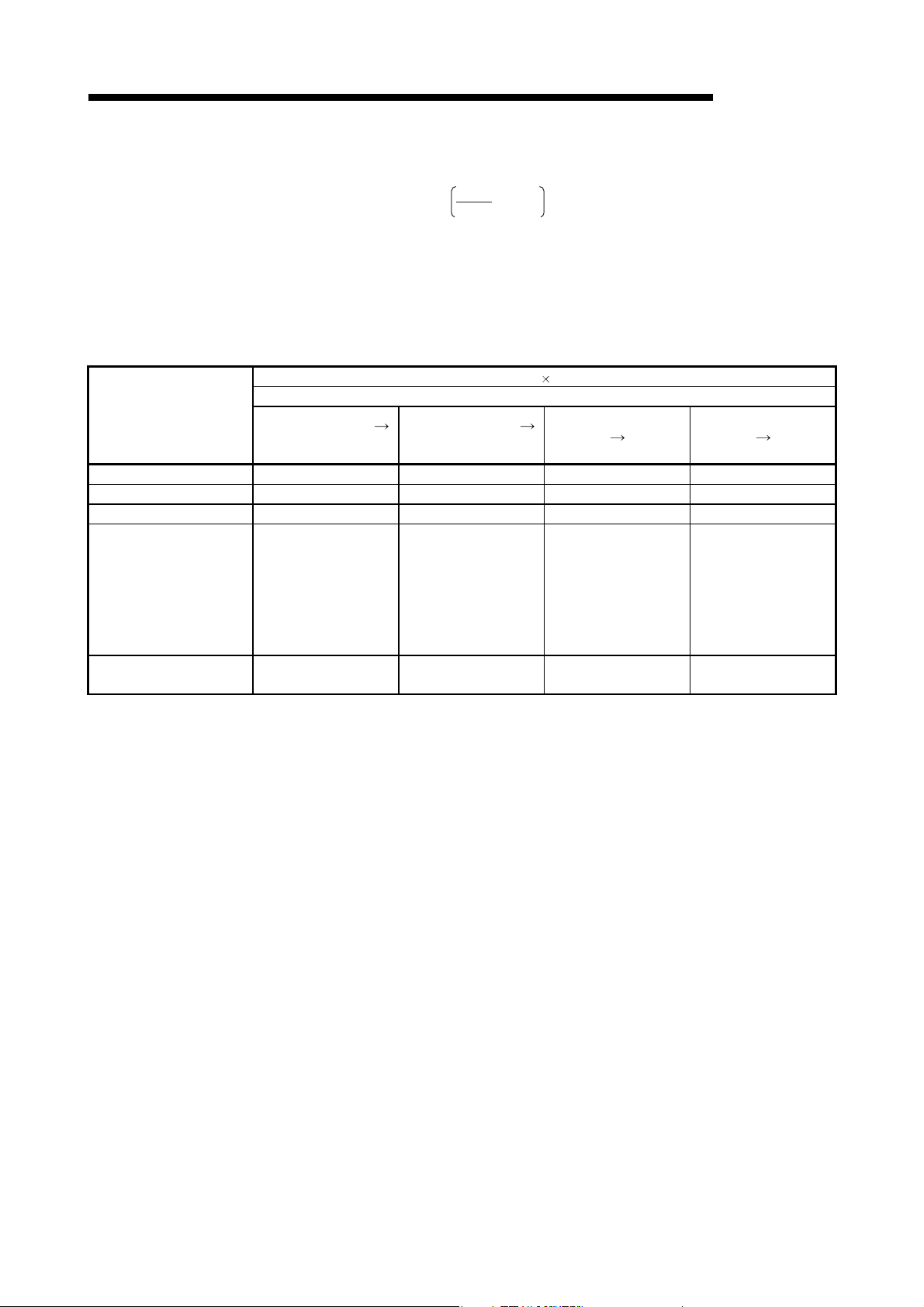

The table below shows the CPU modules that can be combined for use on each

network.

CPU

Type of networks that can

be used with CPU

MELSECNET/H

(10 Mbps)

MELSECNET/H

(25 Mbps)

MELSECNET/H

(Twisted bus)

MELSECNET/10 MELSECNET/H

PLC to PLC network PLC to PLC network

(MESLECNET/10 mode)

Network to be connected

(MESLECNET/H mode,

MELSECNET/H Extended mode)

: Use possible : Use not possible

REMARKS

What is network type?

The network type is a parameter set for specifying the network where the network

module is used.

Set the network type of the network module in the Network parameter of GX

Developer.

There are the following network types.

Network type Description

MELSECNET/H mode Set this mode when all CPUs within the network are QCPUs.

The maximum number of link points per station has been increased

MELSECNET/H Extended

mode

MELSECNET/10 mode

compared with the MELSECNET/H mode.

In excess of 2000 bytes, a maximum of 35840 bytes can be set.

Set this mode when the system uses many link points per station.

This mode is used to operate the network module on a

MELSECNET/10 network where the QnA/AnU exists.

1 - 3 1 - 3

1 OVERVIEW

1.2 Features

The MELSECNET/H is designed to provide higher processing speed, more capacity,

and more functionality while maintaining the connectivity with the MELSECNET/10; it is

easier to use than ever in combination with GX Developer. Furthermore, the

MELSECNET/H has the following features that were not available with the conventional

MELSECNET (II) and MELSECNET/B data link systems.

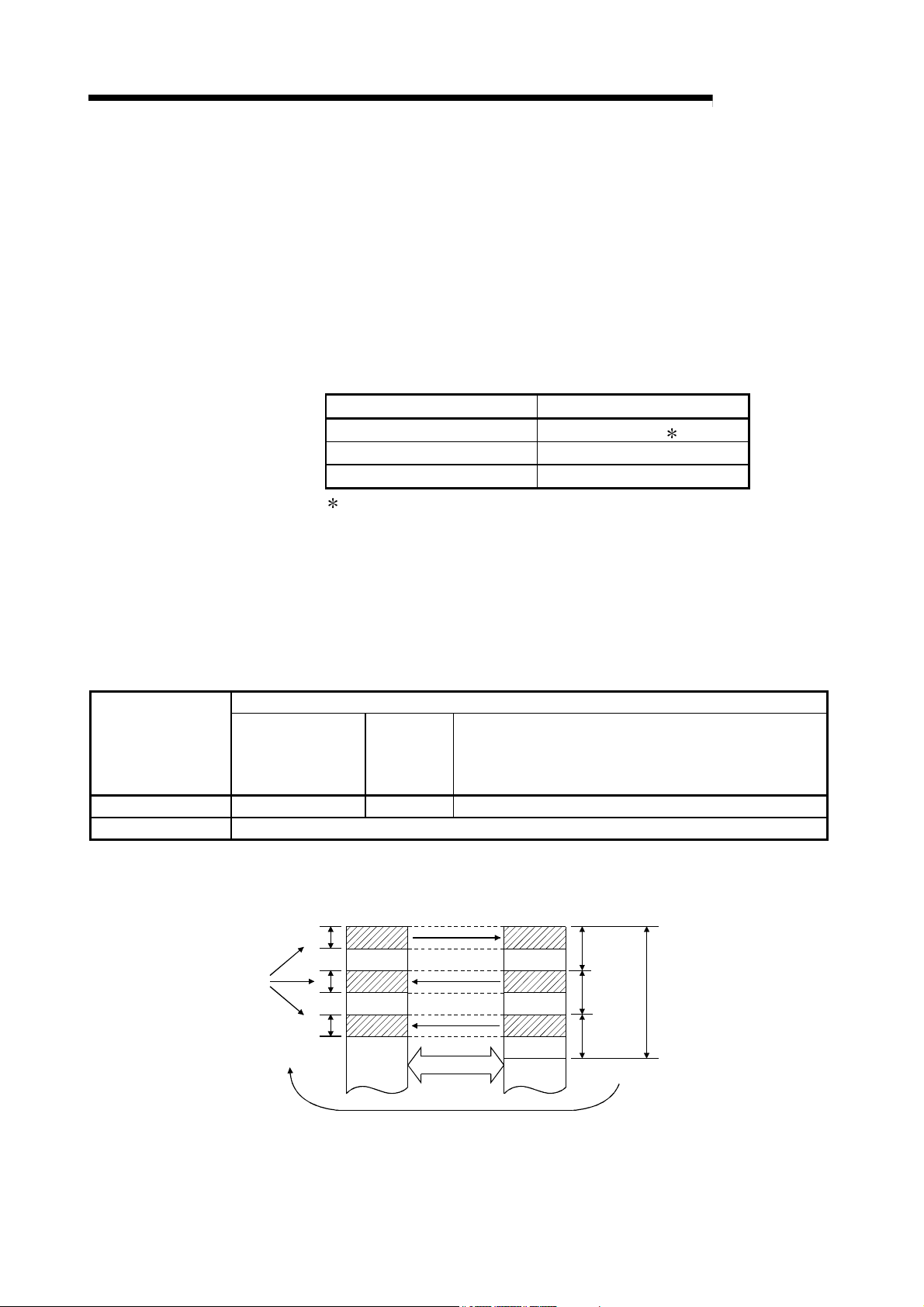

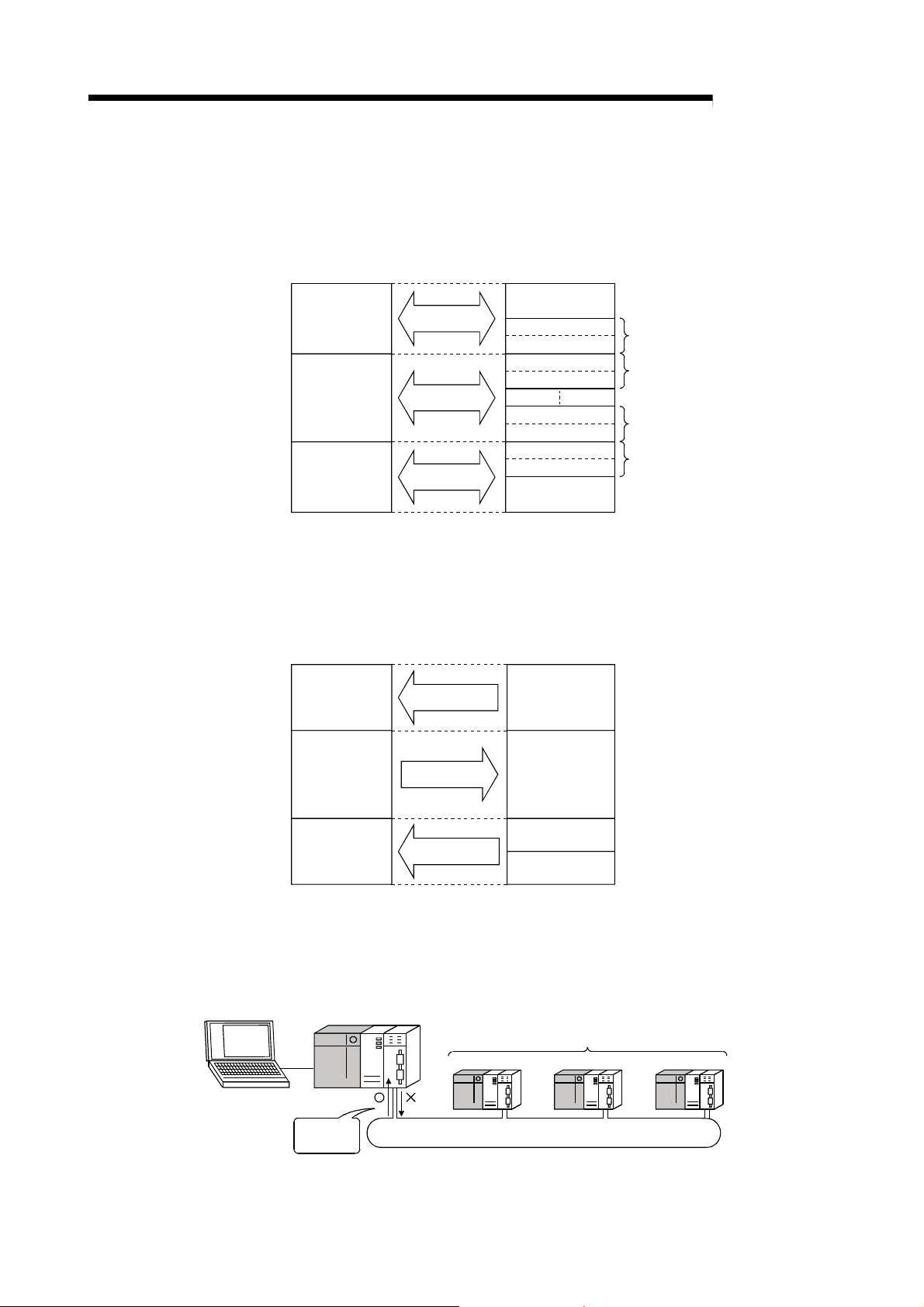

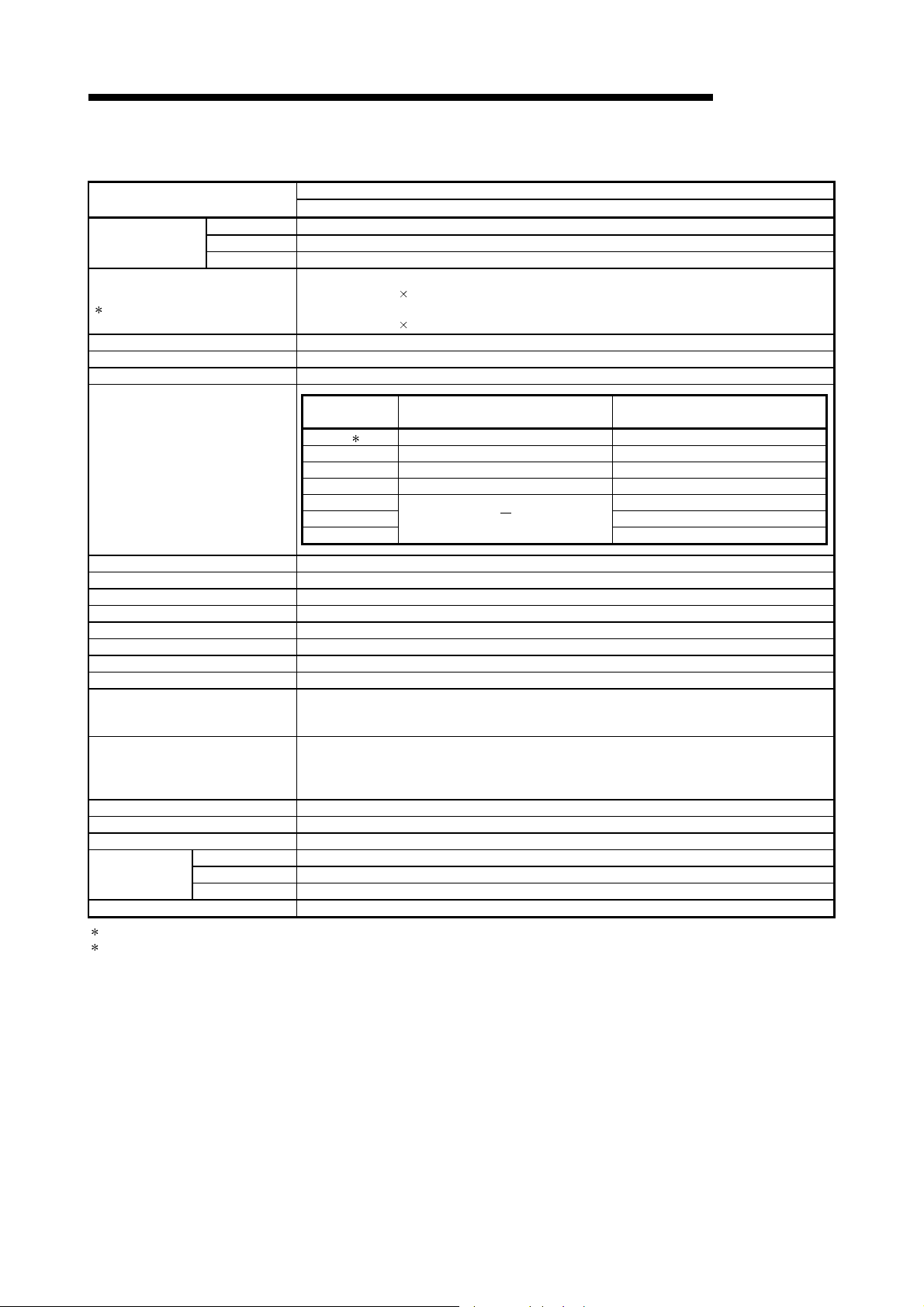

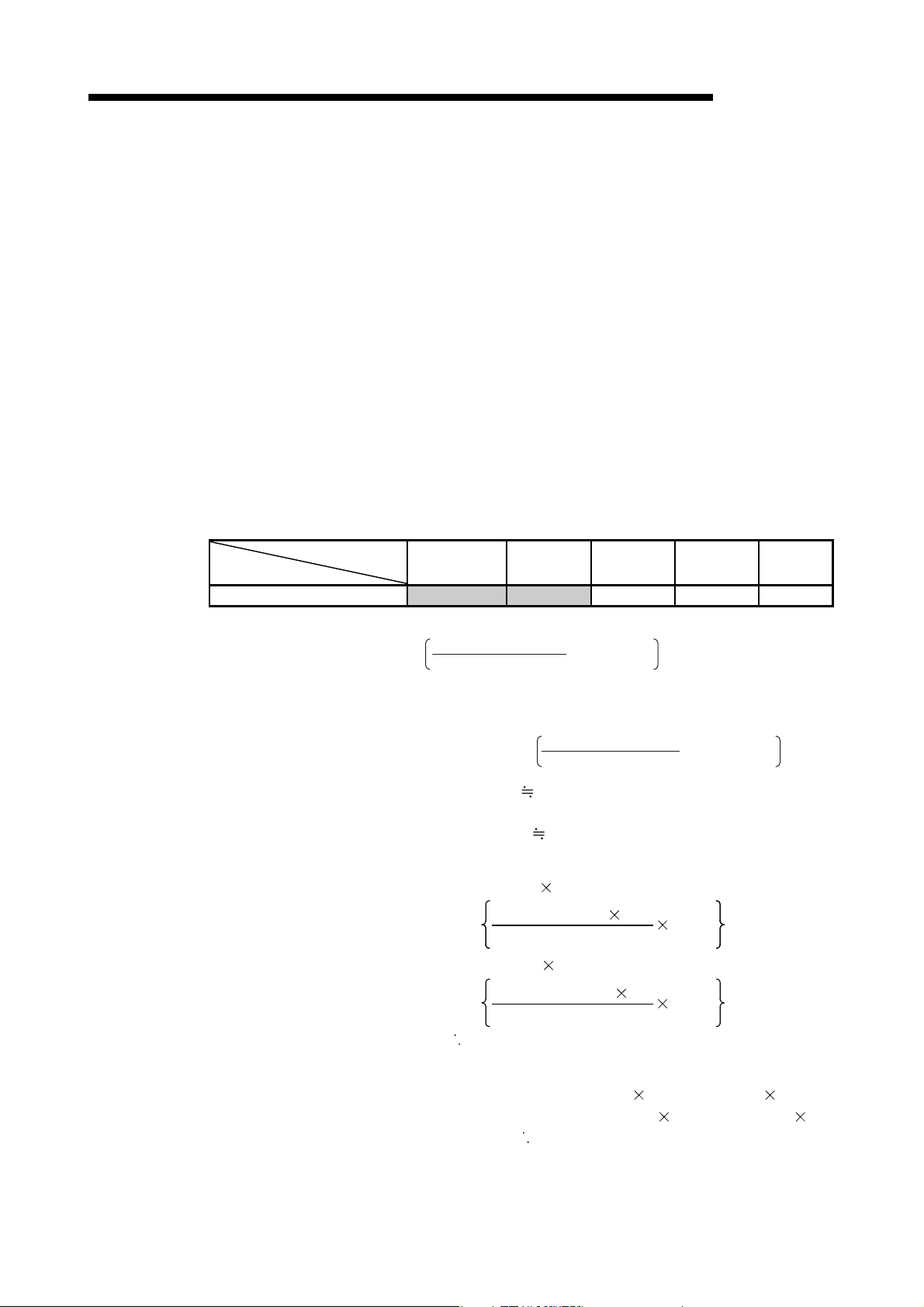

(1) Achievement of a high-speed communication system

(a) The MELSECNET/H enables high-speed communications with 25Mbps

and 10Mbps communication speeds.

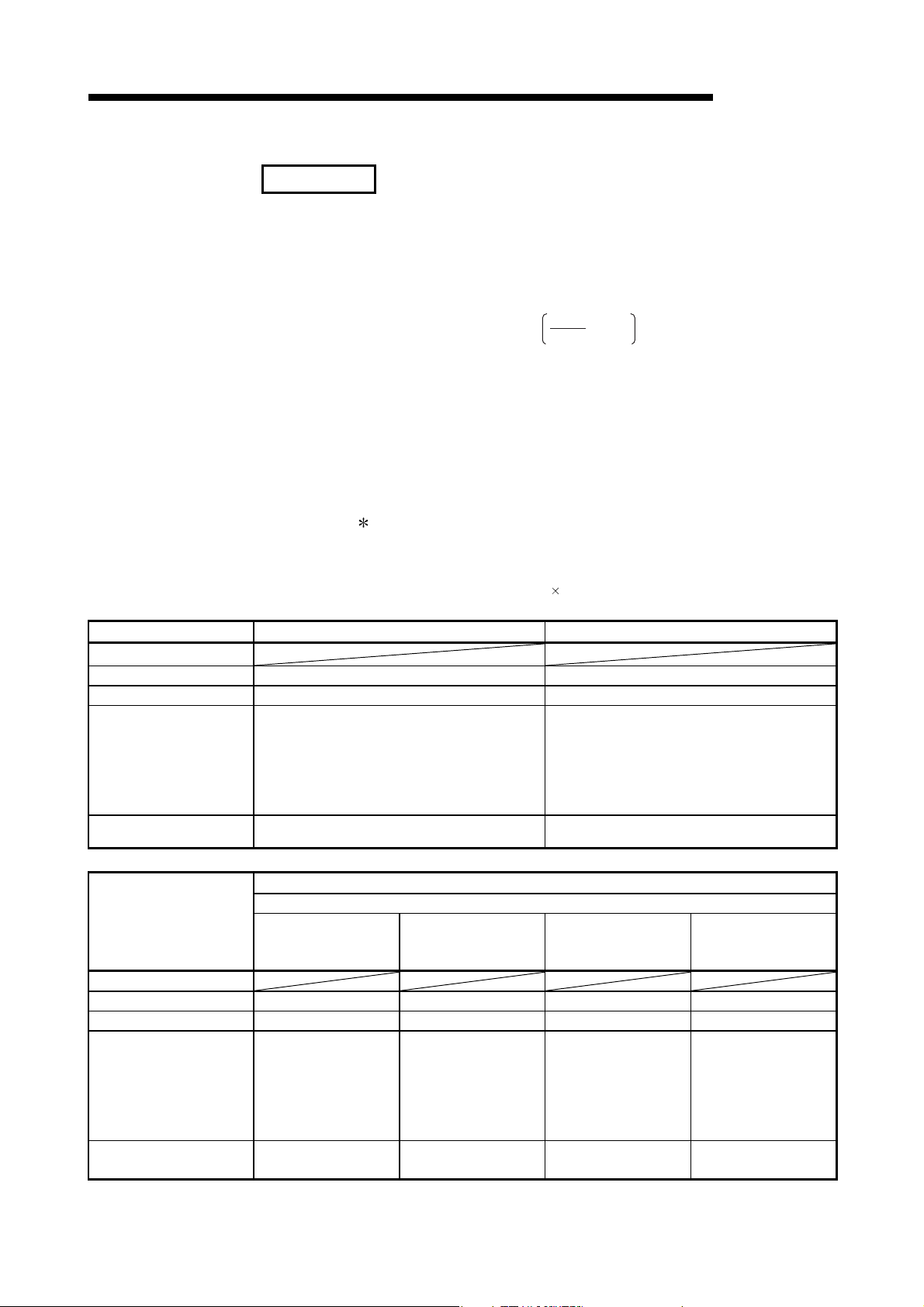

Item

Link device transfer 8 16 64

SB/SW transfer 1 for each

Basic model QCPU

Safety CPU

Refresh range

Communication speeds vary depending on the network system.

Network system Communication speed

Optical loop 10Mbps or 25Mbps 1

Coaxial bus 10Mbps

Twisted bus 156kbps to 10Mbps

1: QJ71LP21-25 and QJ71LP21S-25 only

(b) The link scan time has become even faster through the use of processors

specifically designed for linking.

(c) Refresh parameter area can be subdivided

By subdividing ranges refresh parameter ranges, refreshing of the areas

not used for the sequence program can be eliminated and the refresh time

can be reduced by refreshing only those required. (Refer to Section 5.7

"Refresh Parameters.")

The number of refresh parameter settings per module is shown below.

Number of settings

Q00UJCPU

Q00UCPU

Q01UCPU

Universal model QCPU other than listed in the left column.

High Performance model QCPU

Process CPU

Redundant CPU

Also, because the bus speed between a QCPU and a network module has

been improved, the refresh time has been reduced.

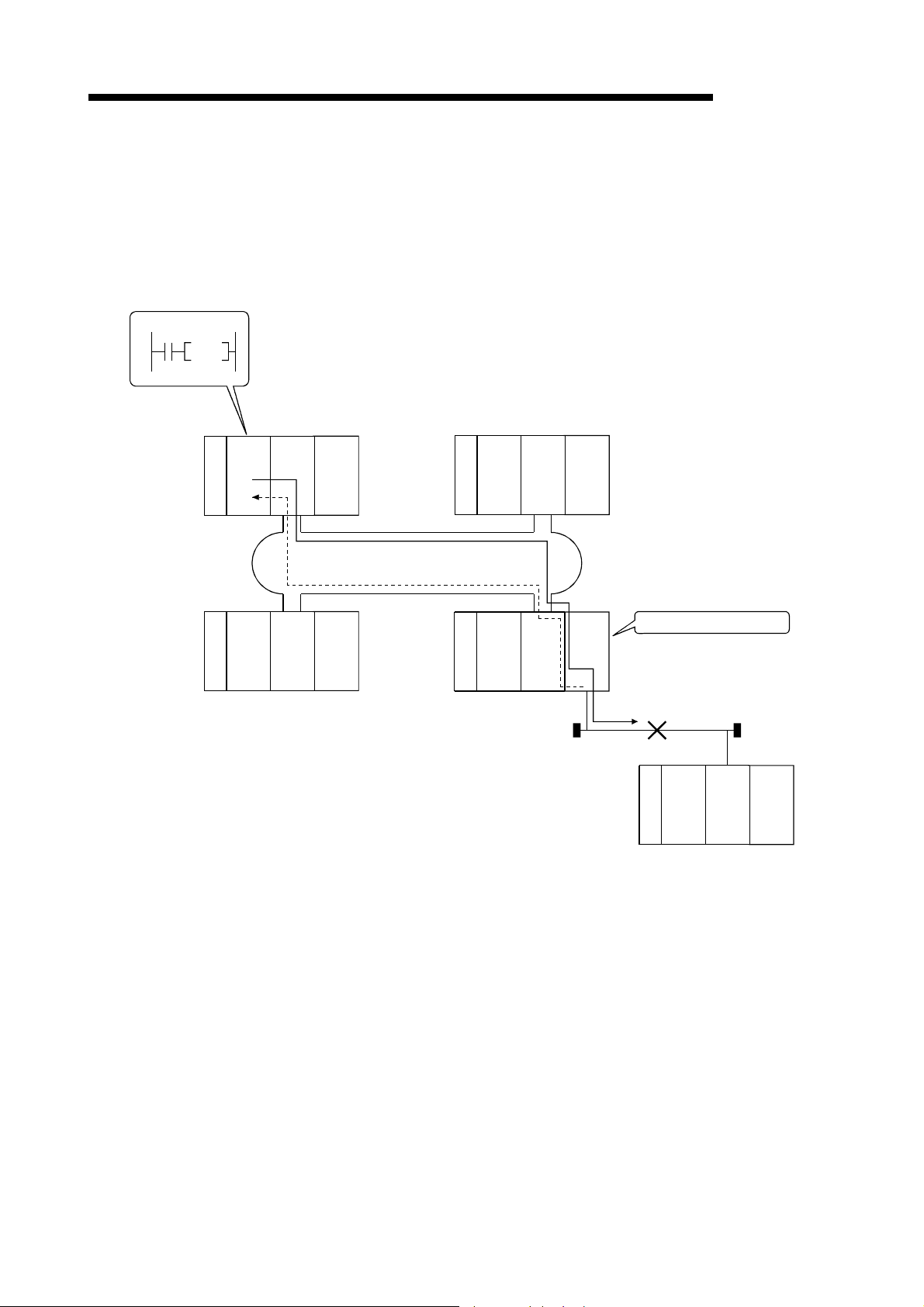

QCPU

device (B)

Network module

link device (LB)

Station

No. 1

(Host)

Station

No. 2

MELSEC-Q

Each station's

total send range

Station

No. 3

High-speed bus

Fragmentation

(d) The optical loop system enables even faster levels of data communication

with multiplex transmission (refer to Multiplex Transmission Function in

section 7.6.)

1 - 4 1 - 4

1 OVERVIEW

MELSEC-Q

(2) Large-scale and flexible system configuration

(a) The link device has a larger capacity: 16384 points for the link relay (LB)

and 16384 points for the link register (LW). (Refer to Section 3.1.1)

(b) The maximum number of link points per station has been increased.

By selecting the network type, the maximum number of link points per

station can be increased.

1) MELSECNET/H Extended mode

By selecting the MELSECNET/H Extended mode as the network type,

the maximum number of link points per station can be set up to 35840

bytes in excess of 2000 bytes.

It is not necessary to install multiple network modules for a single CPU

module to increase the number of transmission points.

2) MELSECNET/H mode

1

By selecting the MELSECNET/H mode as the network type, the

maximum number of link points per station can be set up to 2000 bytes.

Furthermore, by installing multiple network modules with the same

network number for the same CPU module, the link points of "number

of modules

maximum number of link points per station" can be sent.

(High Performance model QCPU, Process CPU, Redundant CPU, and

Universal model QCPU) (Refer to Section 7.9 "Increasing the Number

of Send Points by Installing Multiple Modules Having the Same

Network Number.")

1: The link scan time varies depending on the network type.

Refer to Section 3.3.2 for details.

(c) The commands for transmitting and receiving data with other stations on

the MELSECNET/H network system (SEND, RECV, RECVS, READ,

SREAD, WRITE, SWRITE) enable a maximum of 960 words of data to be

transmitted and received (refer to Programming in section 7.4.5.)

(d) A system can be expanded to contain a maximum of 239 networks. (Refer

to Section 2.1.4, "A Network System Containing Multiple Networks.")

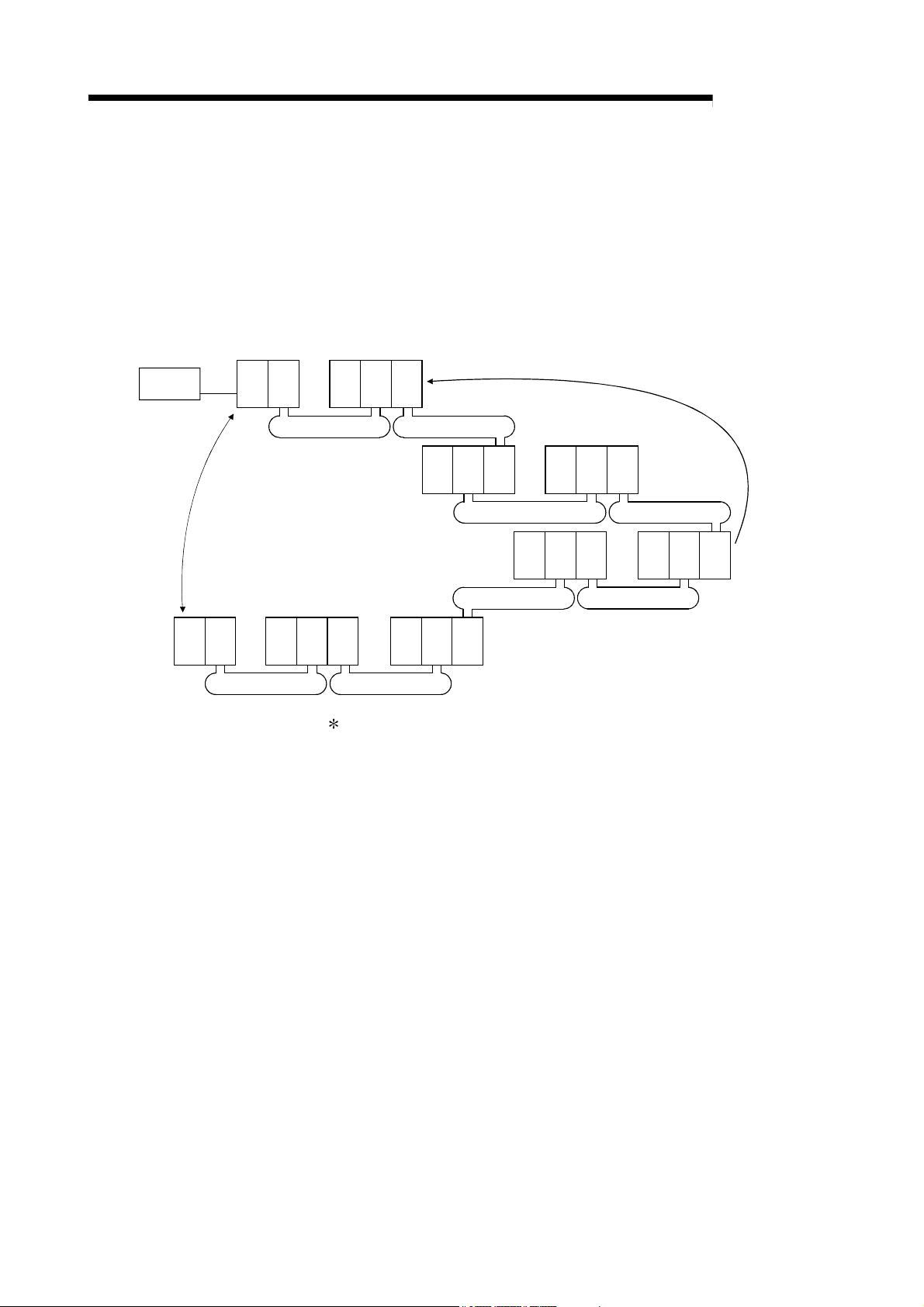

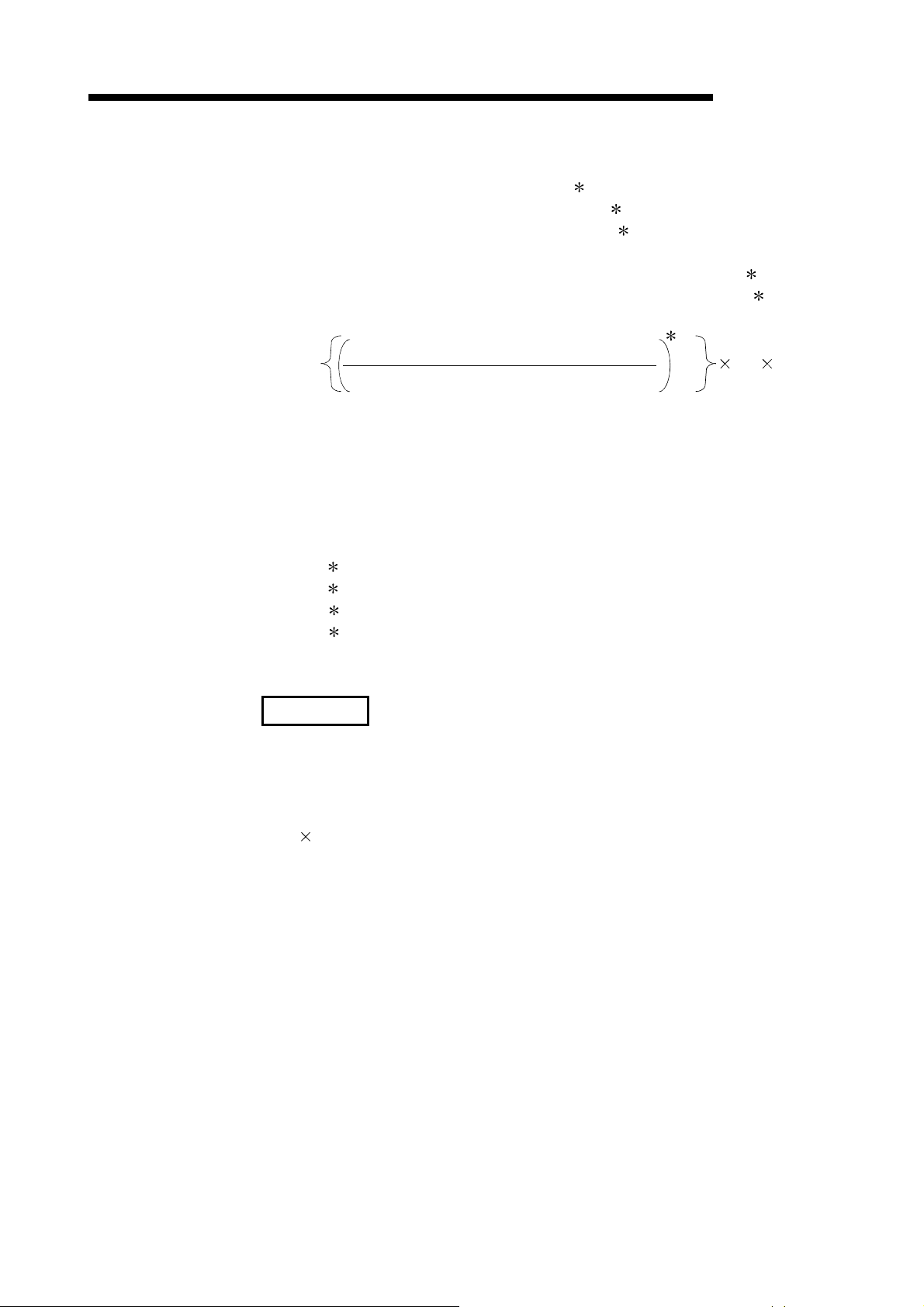

(e) By using the inter-link data transfer function, data (LB/LW) can be transferred

to another network without creating a sequence program. (High Performance

model QCPU, Process CPU, Redundant CPU, and Universal model QCPU)

(Refer to Section 7.2, "Inter-link Data Transfer Function.")

Q25HCPU

Network

module 1

LB LB

0

Network

module 2

1

0

Inter-link data

Q25H

CPU

Network

module

Data of network No. 2

Network No. 1

3FFF

transfer

H

3FFF

Data of network No. 1

Q25H

CPU

H

Network No. 2

Network

module

1 - 5 1 - 5

1 OVERVIEW

GX Developer

Transient transmission

possible.

Q25H

CPU

MELSEC-Q

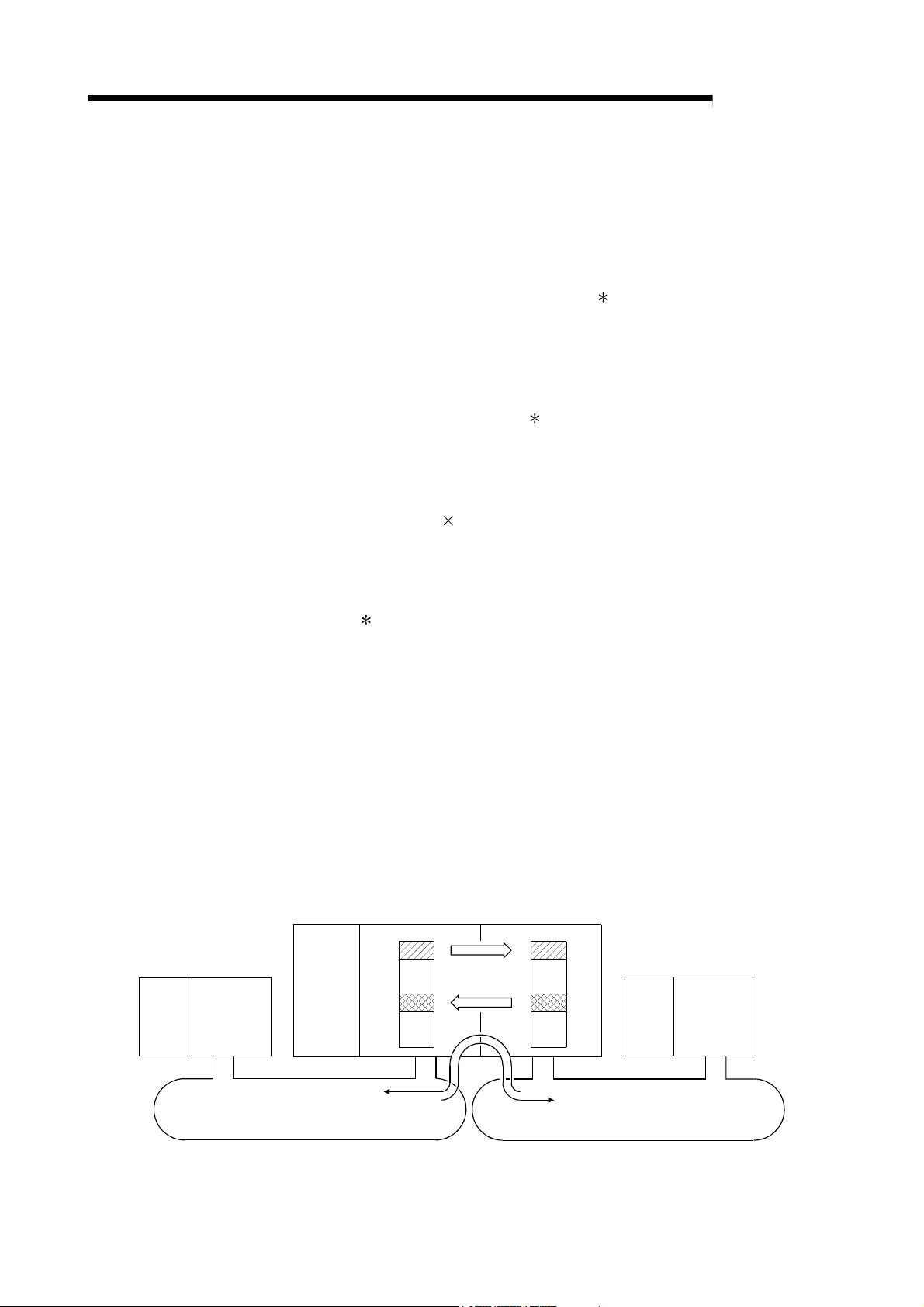

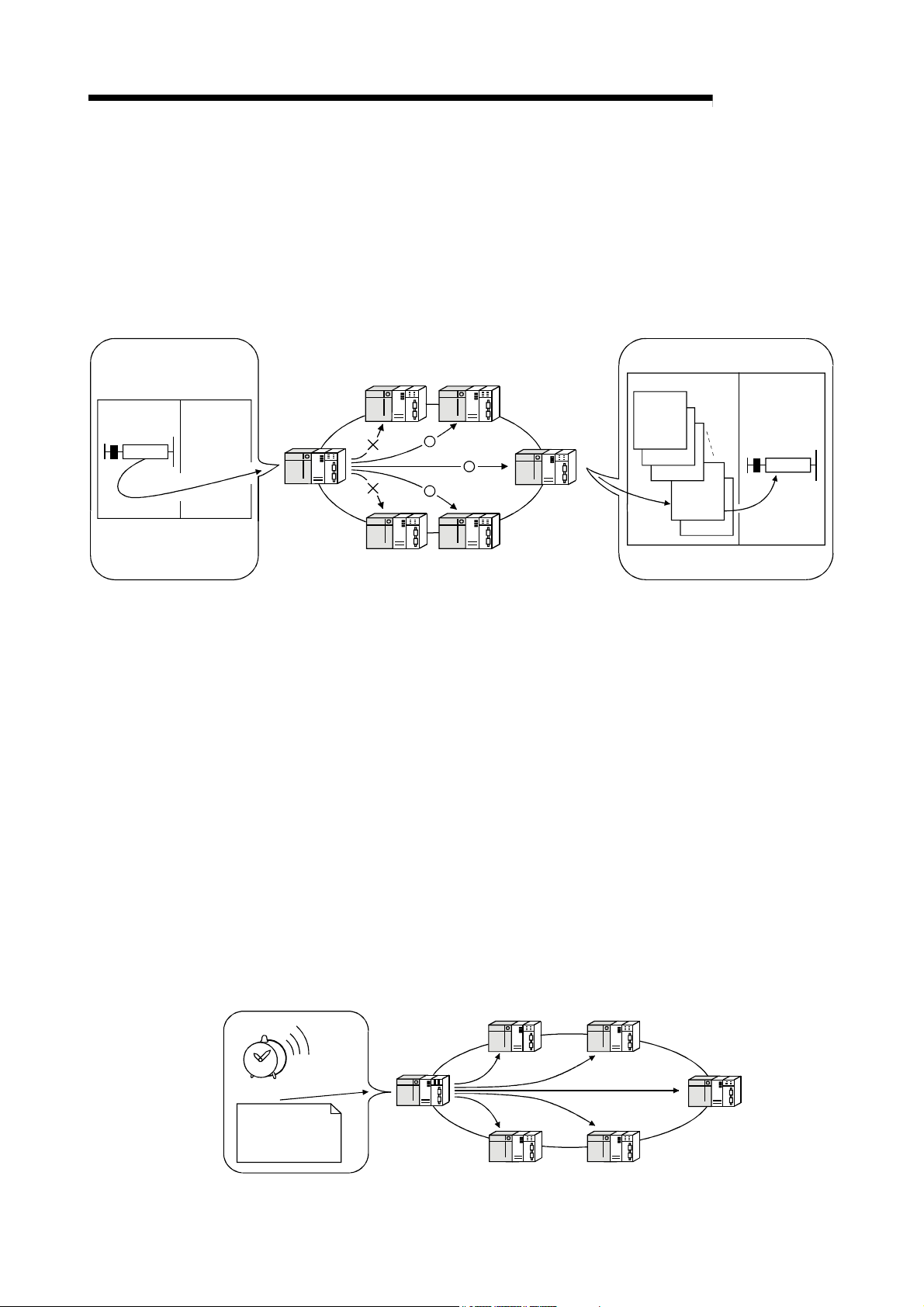

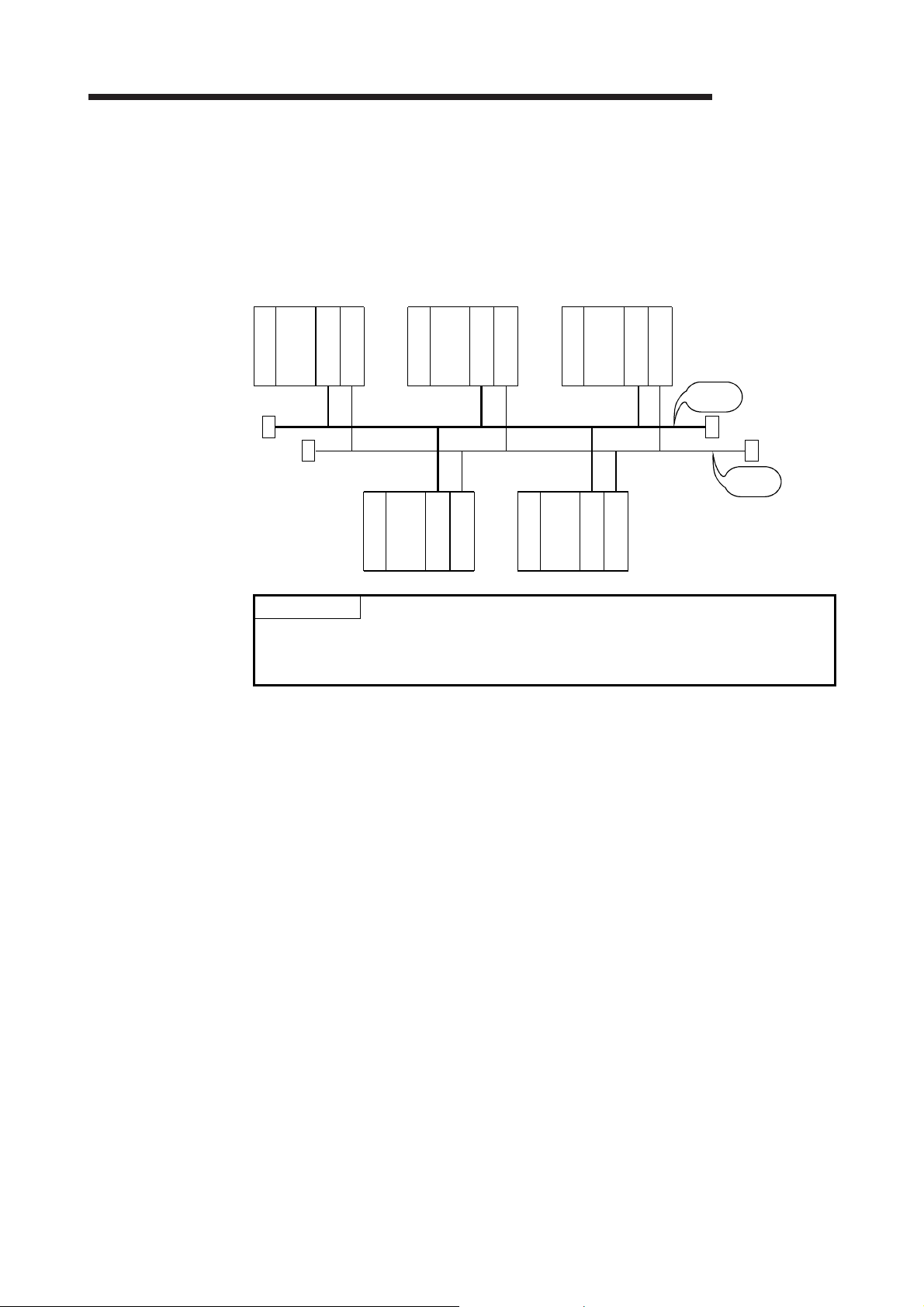

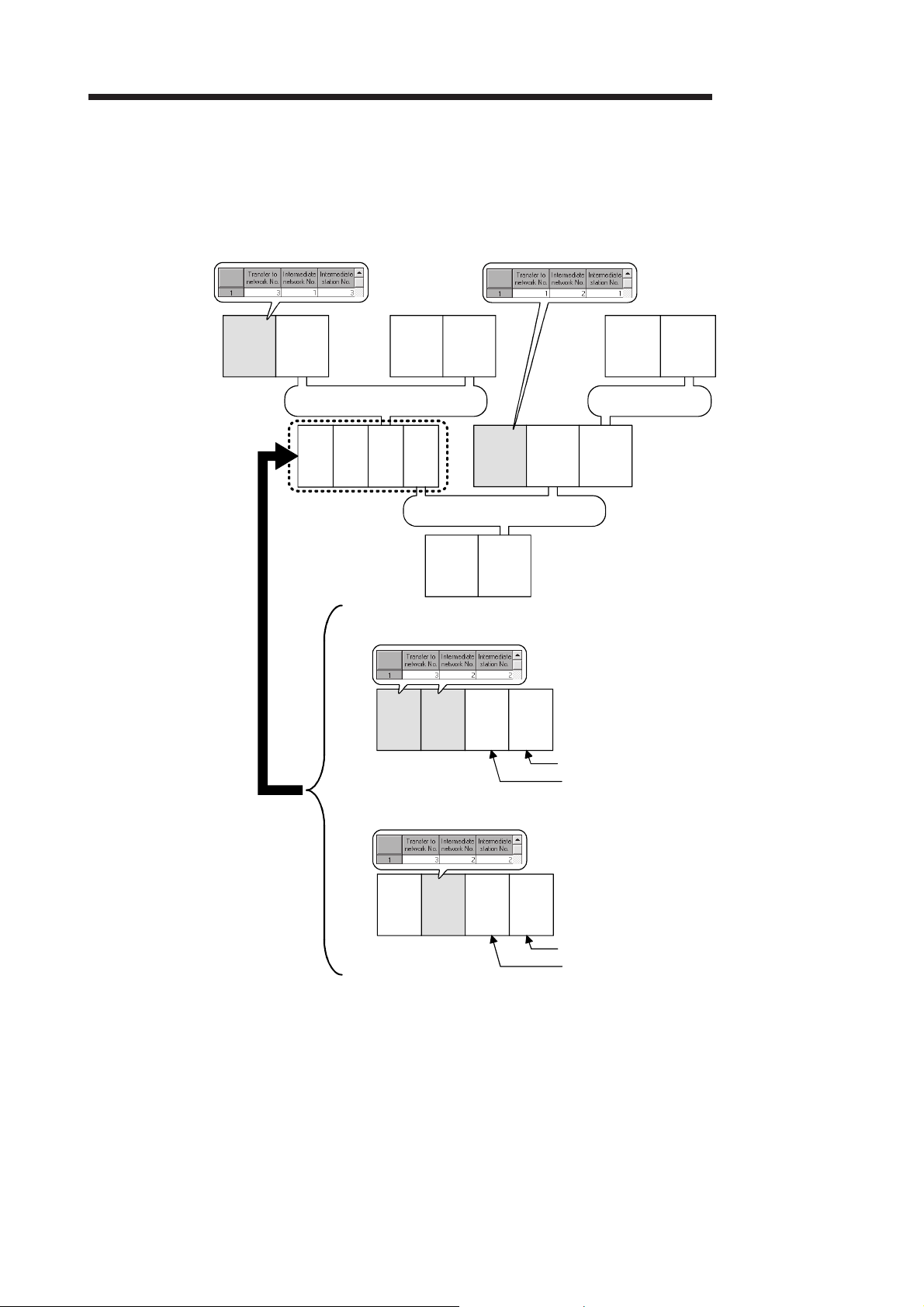

(f) By installing multiple network modules, N:N communication (transient

transmission) with destination stations on eight network systems that use

the programmable controllers as relay stations can be performed using the

routing function.

(Refer to Section 7.4.2, "Routing Function.")

Transient transmission using the routing function can be performed not only

in a system composed of MELSECNET/H networks but also in a system

that contains CC-Link IE Controller Network, CC-Link IE Field Network

and/or MELSECNET/10 networks.

QJ71

LP21

No.1

Q25H

CPU

MELSECNET/H

QJ71

LP21

QJ71

LP21

Request destination

MELSECNET/H

Q25H

QJ71

CPU

LP21

No.3

No.2

QJ71

LP21

Q25H

CPU

Q25H

CPU

QJ71

LP21

QJ71

LP21

QJ71

LP21

QJ71

LP21

MELSECNET/HMELSECNET/H

Q25H

CPU

QJ71

LP21

No.4

QJ71

LP21

Request

source

MELSECNET/ H MELSECNET/H

Q25H

CPU

QJ71

LP21

Q25H

CPU

QJ71

LP21

QJ71

LP21

Q25H

QJ71

LP21

No.7No.8

QJ71

LP21

CPU

MELSECNET/HMELSECNET/H

No.5No.6

: Only the High Performance model QCPU, Process CPU, Redundant

CPU, and Universal model QCPU accept multiple network modules.

(g) The following three types of network systems can be configured

according to applications of each user.

1) Loop system that is more resistant to noise and provides longer distance

in total and between stations. (Up to 30km in total length)

2) Coaxial bus system that allows easier wiring (Up to 500m in total length)

3) Twisted bus system that allows the use of general-purpose cables (Up to

1200m in total length)

(Refer to Section 3.1, "Performance Specifications.")

(h) The following functions facilitate network connection:

1) Any station to be connected in the future can be specified as a reserved

station.

Specifying a station not actually connected as a reserved station

prevents a communication error. (Refer to Section 5.3.4 "Specification of

the reserved station.")

2) It is not necessary to connect stations in order of the station Nos. in the

network. (Refer to Section 4.2 "Part Names and Settings.")

1 - 6 1 - 6

1 OVERVIEW

a

n

i

t

s

e

Network module

e

n

n

a

h

c

n

o

i

t

QCPU

Send

J.SEND

D

(3) Providing various communication services

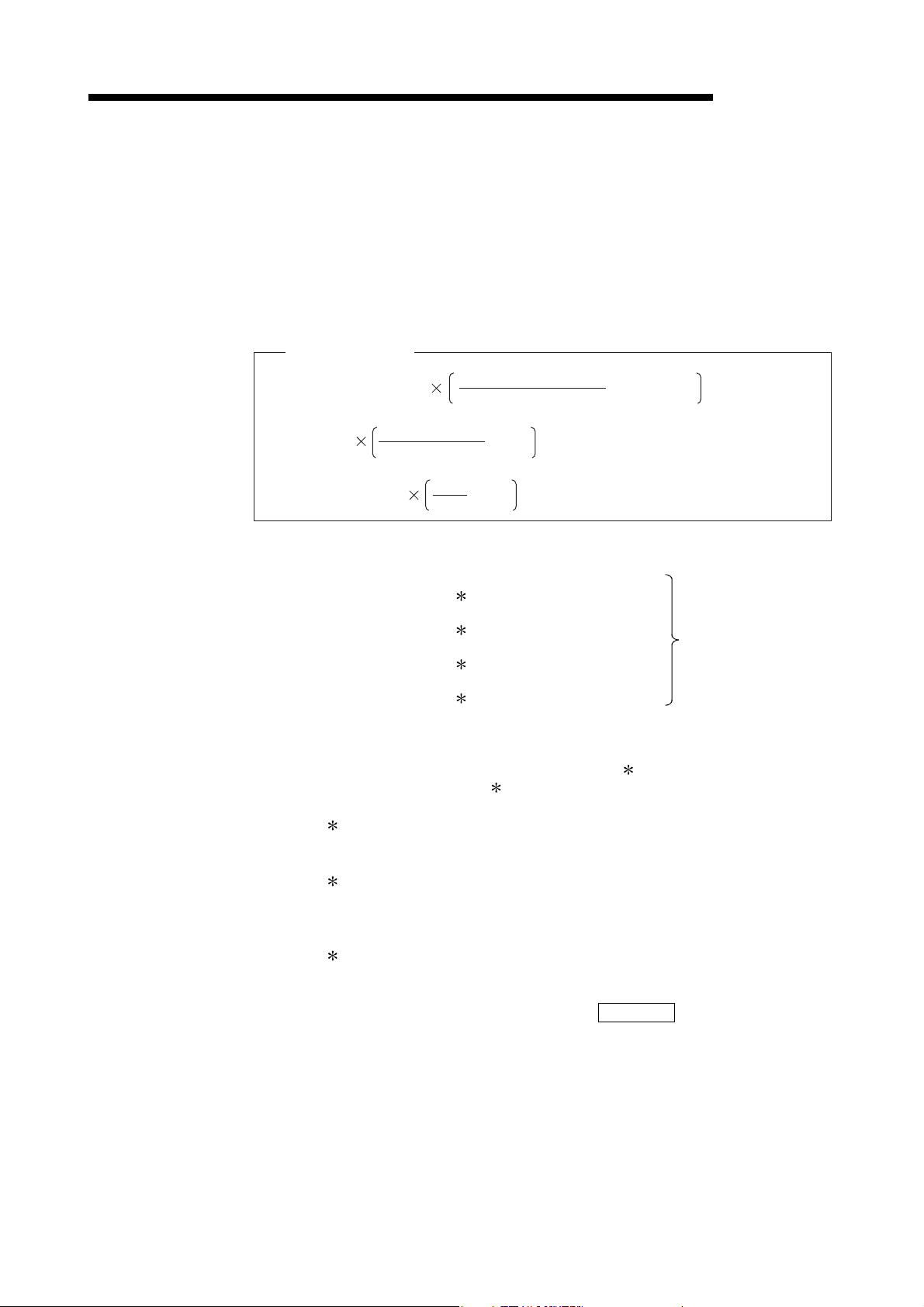

(a) Transient transmission can be performed by designating a channel

number (1 to 64) of the receiving station. This function allows to set

(change) the channel numbers arbitrarily with the sequence programs and

to perform transmission to multiple stations with the same channel number

at one time.

(Refer to Section 7.4.4, "Message sending function using the logical

channel numbers.")

Receiver

channel

unmatched

Sender

9

.

o

N

l

Discard

Discard

Receiver

channel

No. 9

Received

Received

Received

MELSECNET/H

Receiver

channel

No. 9

QCPU

Channel 1

Channel

No.1

No.2

No.3

MELSEC-Q

2

3

7

8

Channel

No.9

No.20

Network module

Receive

J.RECV

Receiver

channel

unmatched

Receiver

channel

No. 9

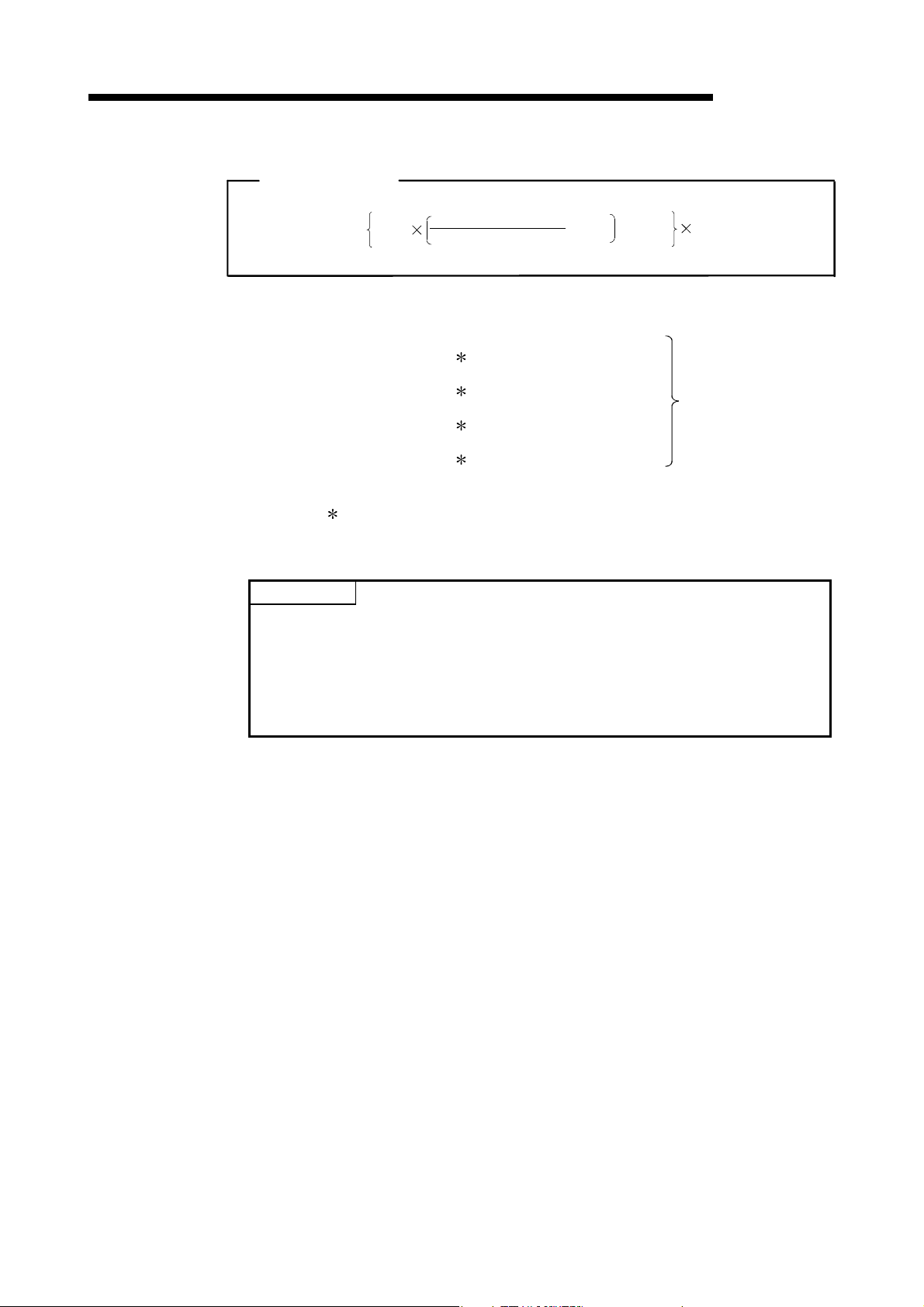

(b) By using the low-speed cyclic transmission function, it is possible to

cyclically send data that does not require high-speed transmission in a

batch mode, separately from the normal cyclic transmission (LB/LW). Highspeed transmission can be achieved by efficiently dividing the data to

transmit into data that requires high-speed transmission, which is sent by

the normal cyclic transmission, and other data that is sent by low-speed

cyclic transmission.

There are three types of transmission method depending on how the

transmission is activated.

1) "Transmission of data for one station in one link scan" (default)

2) "Periodical cycle interval" which transmits in a set time cycle

(hour/minute/second)

3) "System times" which transmits data at the specified timing

(year/month/day/hour/minute/second)

(High Performance model QCPU, Process CPU, Redundant CPU,

and Universal model QCPU)

(Refer to Section 7.3, "Low-Speed Cyclic Transmission Function.")

MELSECNET/H

T

g

i

s

e

d

e

h

t

e

m

i

t

d

e

t

a

n

t

a

n

o

i

s

s

i

m

s

n

a

r

Low-speed cyclic

transmission data

1 - 7 1 - 7

1 OVERVIEW

I50

Interrupt

sequence

program

MELSEC-Q

(c) The interrupt sequence program of the host's CPU module can be started

up using the event issue function. This function reduces the response time

of the system and process real-time data receiving. (Refer to Section 7.5,

"Starting Up the Interrupt Sequence Program.")

CPU module

IRET

MAIN

Normal

sequence

program

END

Conditions

matched

Network module

Condition check

Interrupt condition

parameters

• Relay information

• Register data

• Arrival at a channel

• Network status

MELSECNET/H

Transient transmission

from other station

Cyclic transmission

(4) Enhanced RAS functions (Refer to Section 3.2.2, "RAS function.")

(a) By using the control station switch function, if the control station of the

network is down, a normal station is substituted for the control station,

enabling to continue the network communication.

(b) When a faulty station recovers and can resume normal operation, it

automatically returns to the network to resume the data communication

using the automatic return function.

(c) The automatic return control function allows a failed control station to be

reconnected to the network as a normal station, reducing network downtime.

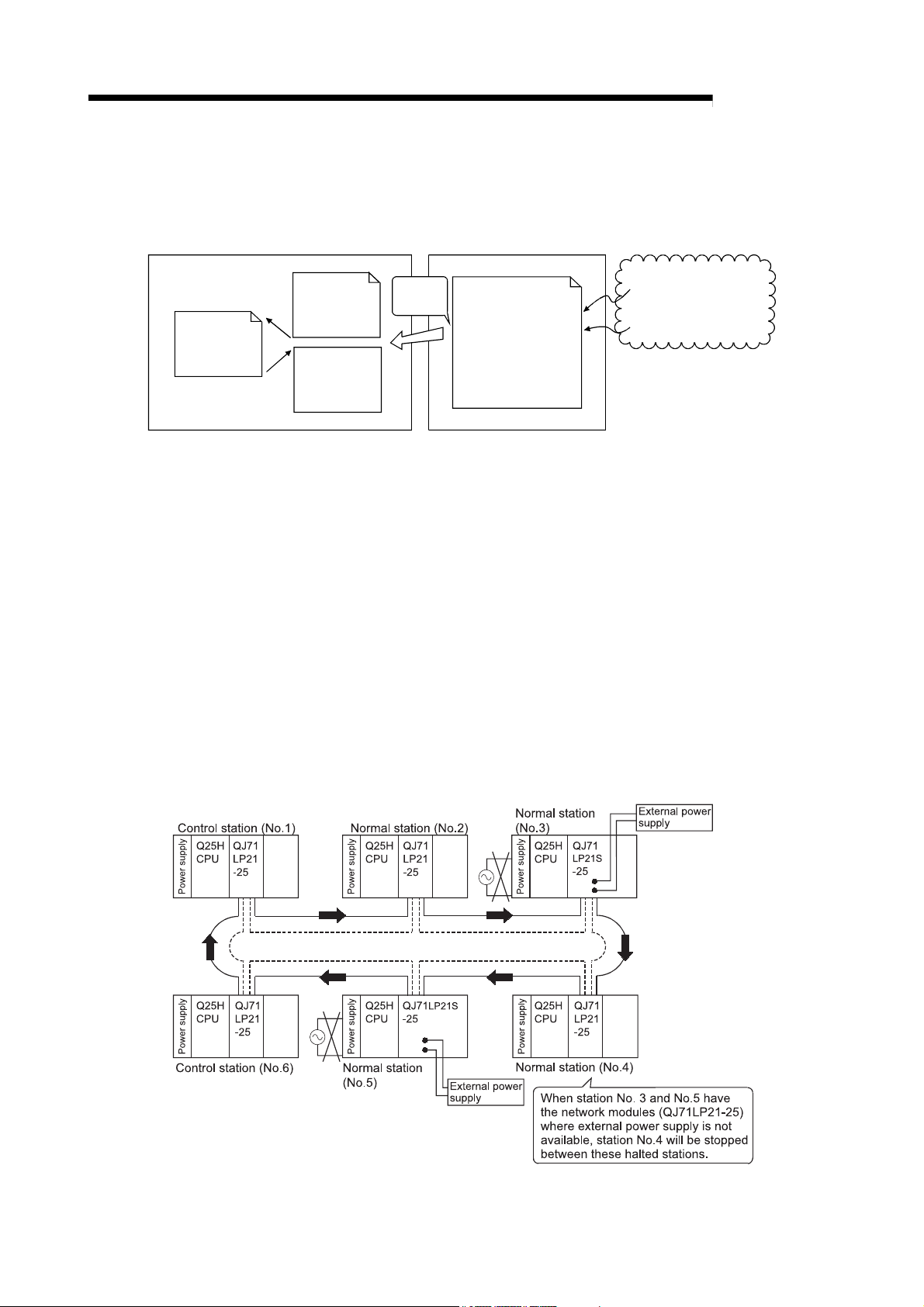

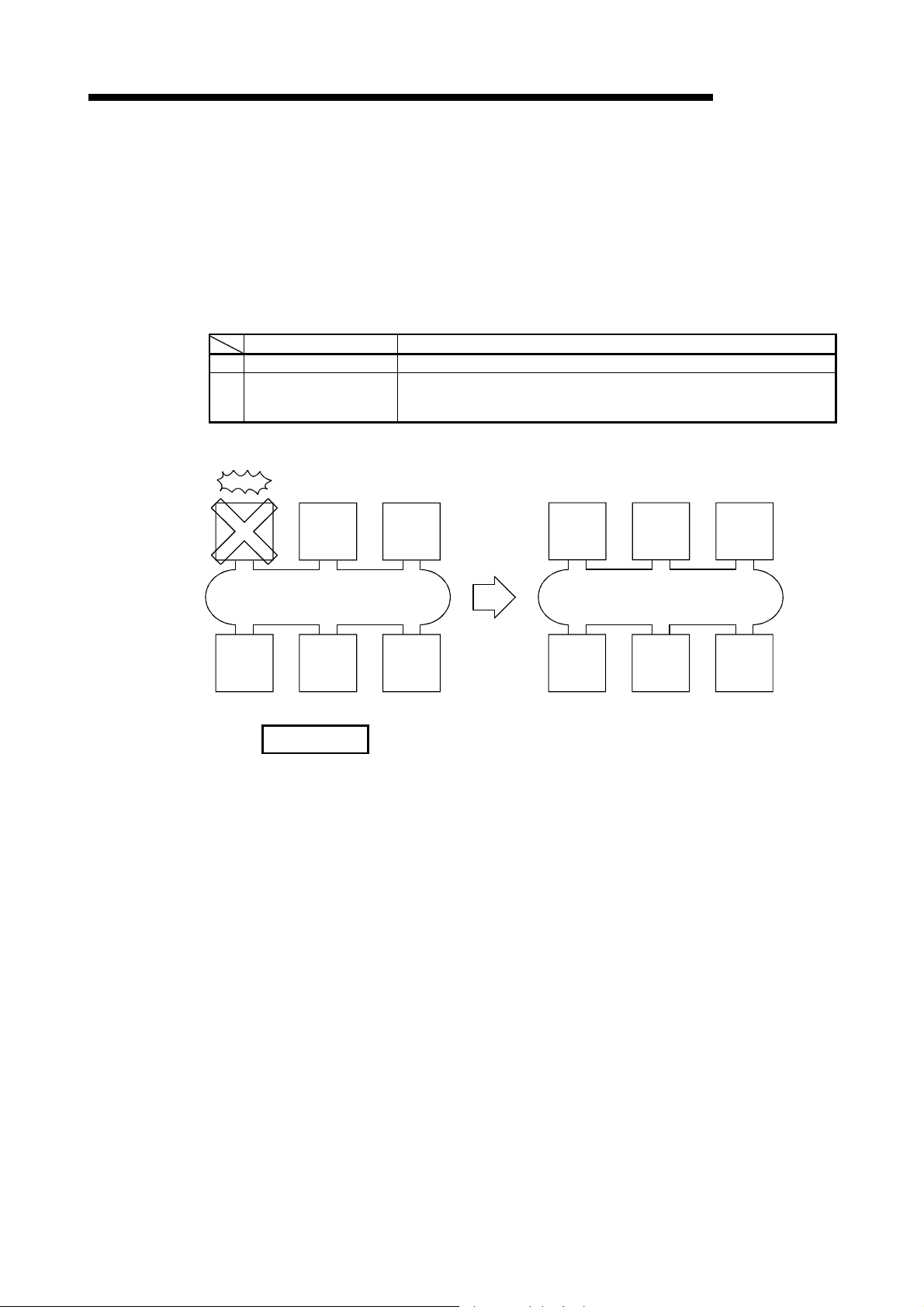

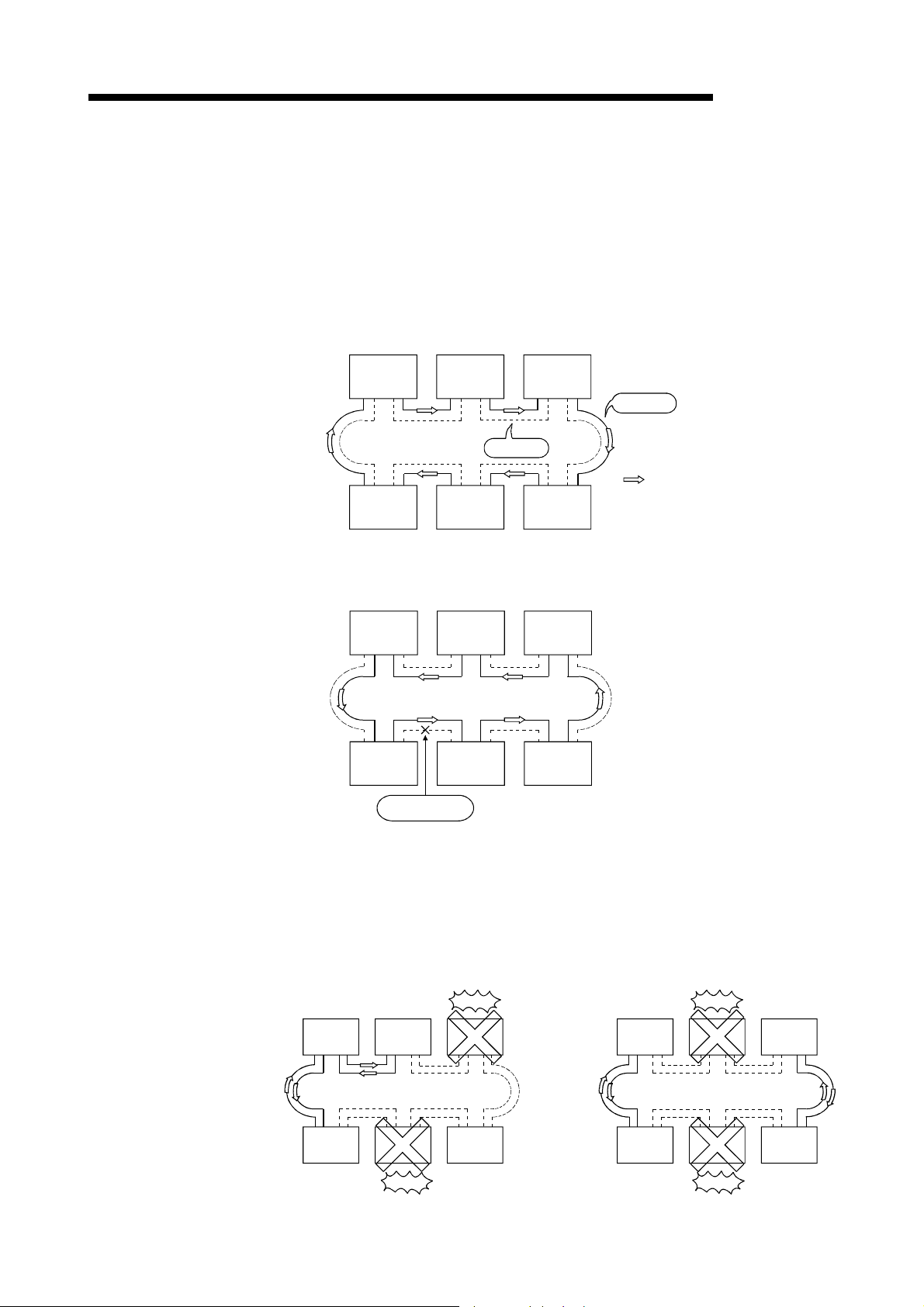

(d) The loopback function (in the optical loop system) isolates a faulty part,

where a fault such as cable disconnection or a station error has occurred,

and enables data communications among operable stations.

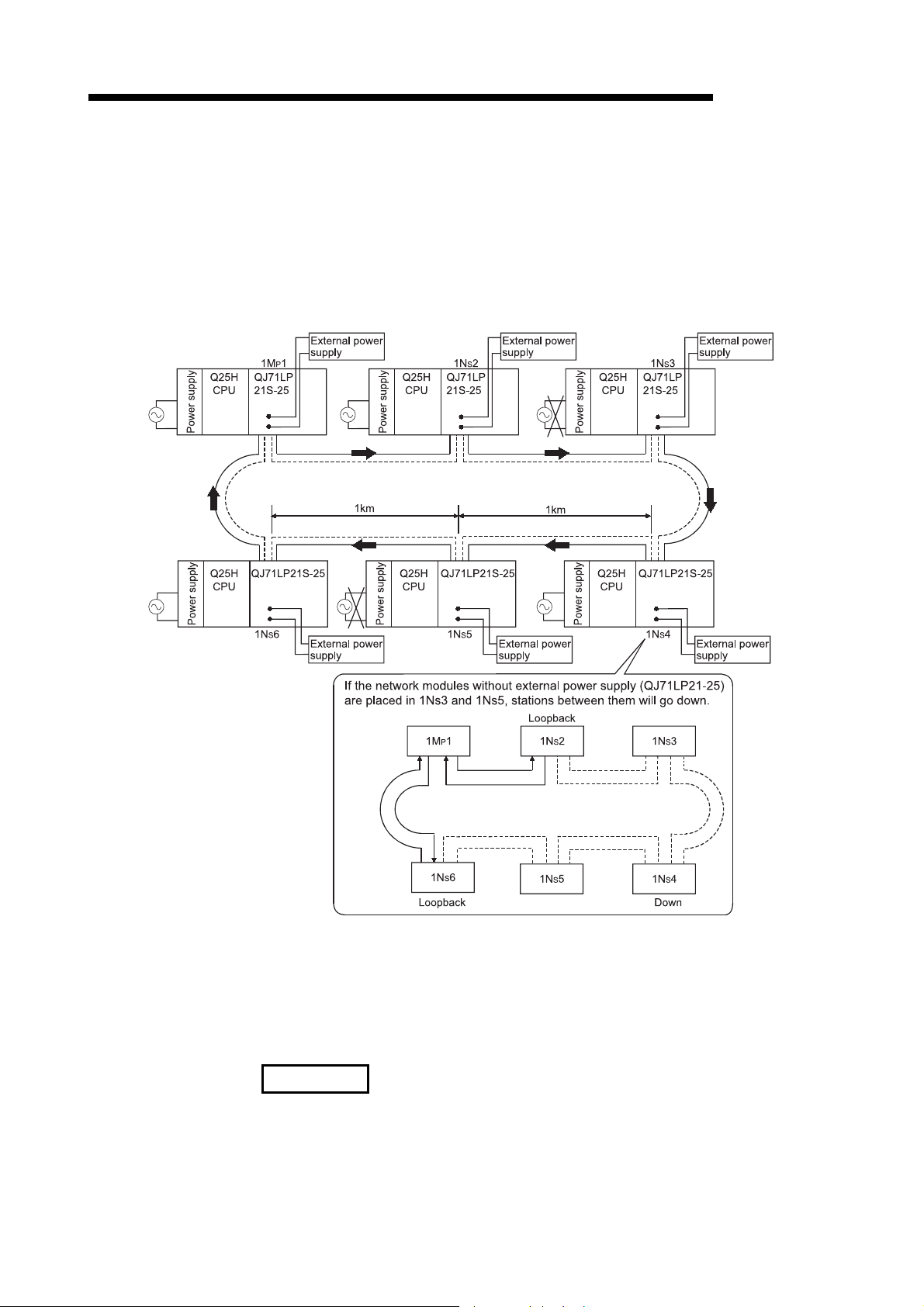

(e) Preventing station failure using external power supply

When two or more stations are faulty and halted in the optical loop system,

stations between these faulty stations can continue the data link.

Because the loop back is prevented, the link scan time will be stabilized.

(The QJ71LP21S-25 is the network module where external power can be

supplied.)

1 - 8 1 - 8

1 OVERVIEW

MELSEC-Q

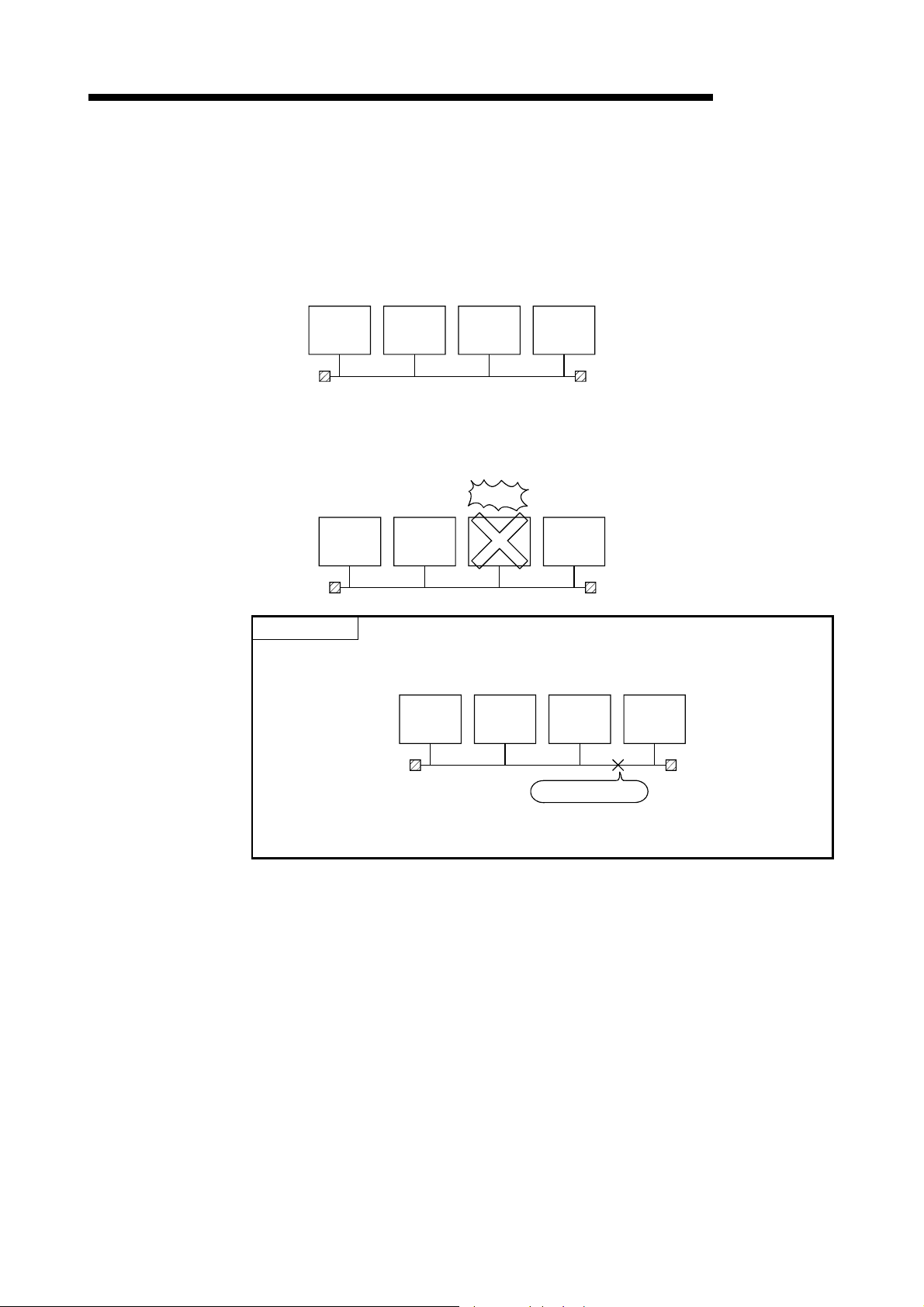

(f) By using the station detach function (coaxial bus system and twisted bus

system), even when some of the connected stations are down due to power

off, etc., the normal communication can be continued among other

operational stations.

(g) W hen an error occurs in a normal network due to disconnection, etc. the

data link can be continued by switching to link data refresh on the standby

network if two network modules, a regular module and a standby module,

are installed for each programmable controller CPU (High Performance

model QCPU and Process CPU)

(h) The network module can continue the transient transmission even if an

error that stops the CPU module while the system is operating occurs.

(i) It is possible to check the time when a transient error occurred.

REMARKS

The following faults make the RAS functions valid.

Break in cable

Power-off of slave station

Network setting error

Fault detectable by self-diagnostics of CPU module

If the network module has become faulty, the RAS functions may not be activated

depending on the fault.

1 - 9 1 - 9

r

1 OVERVIEW

MELSEC-Q

(5) Enhancement and compatibility of the network functions

(a) Because of the 32-bit data assurance, data with double word precision

(32 bits) can be assured without an interlock.

(Refer to Section 6.2.1, "32-bit data assurance.")

CPU module

device W

Network module

LW

Updated part

of refresh A

Updated part

of refresh B

Updated part

of refresh C

Refresh A

Refresh B

Refresh C

Positional data 1 lower

higher

Positional data 2

Positional data 9

Positional data 10

lower

higher

lower

higher

lower

higher

Link refresh in

32-bit units

(b) Through the station-based block data assurance for cyclic data, it is

possible to manipulate multiple word data without interlocks.

(Refer to Section 6.2.2, "Station-based block data assurance for cyclic

data.")

CPU module

device W

Updated part

of refresh A

Refresh A

Network module

LW

Station No. 1

Updated part

of refresh B

Updated part

of refresh C

Refresh B

Refresh C

Station No. 2

(Host)

Station No. 3

Station No. 4

(c) In the network debug mode, the network functions of user programs can

be tested in the online environment without affecting systems being

operated.

(Refer to Section 5.2.5, "Mode.")

Being debuggedGX Develope

Data

receive

possible

LB/LW

Systems being operated

MELSECNET/H

1 - 10 1 - 10

1 OVERVIEW

MELSEC-Q

(d) By using the MELSECNET/10 mode (functional compatibility and

performance compatibility mode), the MELSECNET/H can be used

together with the conventional network modules to easily install a

programmable Controller Network system.

To use the MELSECNET/H in the MELSECNET/10 mode (functional

compatibility and performance compatibility mode), please refer to the "For

QnA/Q4AR MELSECNET/10 Network System Reference Manual".

QnACPU

QCPU QCPU QCPU

MELSECNET/H

QCPU

A2USCPU

MELSECNET/10

(6) Increased ease of network configuration in combination with GX

Developer

(a) The network parameters can easily be set by visualizing pull-down menus,

dialogue boxes, etc.

(b) The settings of network Nos., group numbers and operation modes have

been simplified so that these values can be specified only through software

settings.

(c) On the twisted bus system, the transmission speed setting for the normal

station is not required.

The normal station operates with the transmission speed set to the control

station.

(Refer to Section 5.2.6, "Communication speed setting.")

(Network parameters)

Pull-down menu

Simplified

1 - 11 1 - 11

1 OVERVIEW

MELSEC-Q

(c) Troubleshooting process has been simplified through system monitoring.

(System monitor/error code display)

Displays the latest error code.

Displays error history.

Displays the description and corrective

action of the error code selected in error

history.

(d) After assigning the refresh parameters and inter-link data transfer devices

to a network system in which multiple network modules are installed,

duplicate device settings can easily be checked with [Assignment image

diagram].

1 - 12 1 - 12

1 OVERVIEW

MELSEC-Q

(7) Redundant system configuration

(a) Network modules can be dualized.

A system containing a network module can be dualized (redundant system)

by installing another network module and using redundant CPUs.

In case of an error in the control system CPU or a network module, the

redundant system including double network modules switches the control

system to the standby system, allowing system control and data linking to

be continued on the standby system. (Refer to Section 7.10.1.)

(b) Automatically issuing system switching request to the control system CPU

If failure of a network module mounted to the control system CPU of the

redundant system or a data link error is detected, a system switching

request will be automatically issued to the CPU. (Refer to Section 7.10.5.)

(c) Transient transmission to redundant system is available.

By transient transmission using special link instructions or GX Developer,

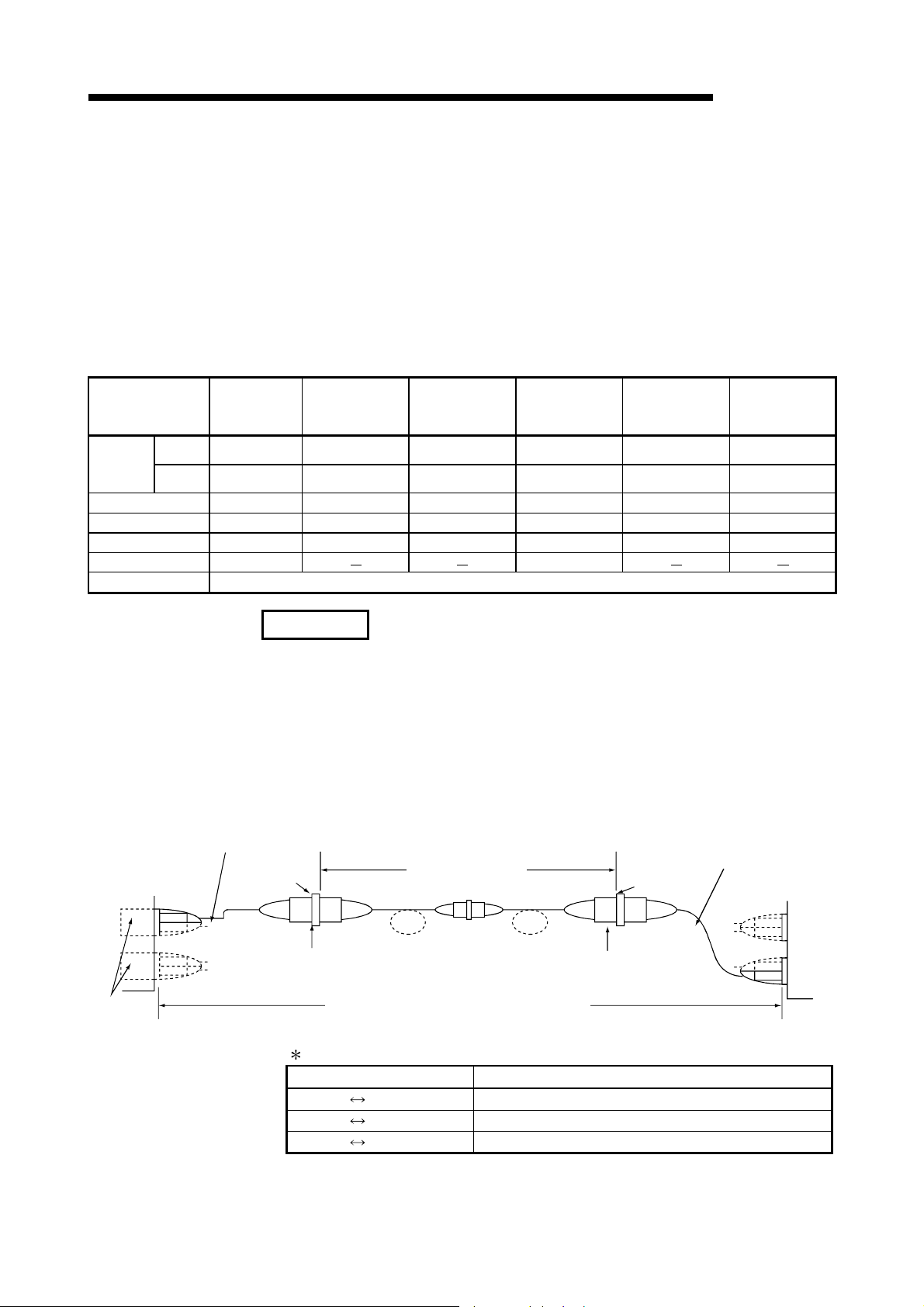

device data can be read from or written to the host system, control/standby