Mitsubishi QJ71MT91 User Manual

• SAFETY PRECAUTIONS •

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the user's manual of the CPU module to use.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence depending to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Precautions]

!

DANGER

• When controlling a running programmable controller (modifying data) by connecting peripheral

devices to the CPU module or connecting a personal computer to the intelligent function

module, configure an interlocking circuit in a sequence program so that the safety of the overall

system is always maintained. Also, before performing other control operations (program

modifications and operation status modifications (status control)) on the running programmable

controller, be sure to read the manual carefully and thoroughly confirm the safety.

Especially in the above mentioned control operations that are performed from an external device

to a remote programmable controller, any problems on the programmable controller side may

not be dealt with promptly due to a data communication error. In addition to configuring an

interlocking circuit in a sequence program, determine how the system handles data

communication errors, etc. between the devices and the programmable controller CPU.

• Do not write any data in the "system area (Use prohibited)" of the buffer memory of the

intelligent function module. Also, do not output (turn on) the "use prohibited" signal, which is one

of the output signals from the programmable controller CPU to the intelligent function module. If

data is written to the "system area (Use prohibited)" or the "use prohibited" signal is output, there

is a risk that the programmable controller system may malfunction.

A - 1 A - 1

!

CAUTION

• Do not bundle the control wires and the communication cables with the main circuit and the

power wires, and do not install them close to each other. They should be installed at least 100

mm (3.94 in.) away from each other. Failure to do so may generate noise that may cause

malfunctions.

[Installation Precautions]

!

DANGER

• Use the programmable controller in the operating environment that meets the general

specifications described in the user's manual of the CPU Module to use. Using the

programmable controller in any other operating environments may cause electric shocks, fires

or malfunctions, or may damage or degrade the module.

• While pressing the installation lever located at the bottom of the module, insert the module fixing

projection into the fixing hole in the base unit to mount the module.

Incorrect module mounting may cause a malfunction, failure, or drop of the module.

In an environment of frequent vibrations, secure the module with the screw.

• Be sure to tighten the screws using the specified torque. If the screws are loose, it may cause

the module to short-circuit, malfunction or fall off. If the screws are tightened excessively, it may

damage the screws and cause the module to short-circuit, malfunction or fall off.

• Do not directly touch any conductive part or electronic component of the module.

Doing so may cause a malfunction or failure of the module.

!

CAUTION

• Be sure to shut off all phases of the external power supply used by the system before mounting

or removing the module.

Failure to do so may damage the module.

[Wiring Precautions]

!

CAUTION

• Be sure to shut off all phases of the external power supply before installation or wiring.

Failure to do so may result in an electric shock or damage to the product.

• Use crimp-contact, pressure-displacement or soldering to wire the connectors for external

connections properly using the manufacturer-specified tools.

If the connection is incomplete, it may cause the module to short circuit, catch fire, or

malfunction.

A - 2 A - 2

!

CAUTION

• Securely connect the connector to the module.

• Make sure to place the communication and power cables to be connected to the module in a

duct or fasten them using a clamp. If the cables are not placed in a duct or fastened with a

clamp, their positions may be unstable or moved, and they may be pulled inadvertently.

This may damage the module and the cables or cause the module to malfunction because of

faulty cable connections.

• Wire the module correctly after confirming the type of the connected interface. If the cable is

connected to a different interface or wired incorrectly, it may cause a fire or breakdown.

• When disconnecting the communication and power cables from the module, do not pull the

cables by hand. When disconnecting a cable with a connector, hold the connector to the module

by hand and pull it out to remove the cable. If the cable is pulled while being connected to the

module, it may damage the module and/or cable or make cable contact improper, causing a

malfunction.

• Be careful not to let any foreign matter such as wire chips get inside the module.

They may cause fire, as well as breakdowns and malfunctions of the module.

• A protective sheet is pasted on the upper part of the module in order to prevent foreign matter

such as wire chips to get inside the module while wiring.

Do not remove this protective sheet during wiring work. However, be sure to remove the

protective sheet before operating the module to allow heat radiation during operation.

[Setup and Maintenance Precautions]

!

DANGER

• Do not touch the terminals while the power is on. Doing so may cause electric shocks or

malfunctions.

• Before cleaning the module or retightening the module mounting screws, make sure to shut off

all phases of the external power supply used by the system. Failure to do so may cause the

module to electric shocks, breakdown or malfunction. If the screws are loose, it may cause the

module to short-circuit, malfunction or fall off. If the screws are tightened excessively, it may

damage the screws and cause the module to short circuit, malfunction or fall off.

A - 3 A - 3

!

CAUTION

• Before performing online operations (especially, program modification, forced output or

operating status change) by connecting a peripheral device to a running CPU, read the manual

carefully and ensure the safety. Incorrect operation will cause mechanical damage or accidents.

• Never disassemble or modify the module. This may cause breakdowns, malfunctions, injuries or

fire.

• When using a wireless communication device such as a cellular phone, keep a distance of 25cm

(9.85 inch) or more from the programmable controller in all directions. Failure to do so can

cause a malfunction.

• Before mounting/dismounting the module, be sure to shut off all phases of the external power

supply used by the system. Failure to do so may cause module failure or malfunctions.

• Do not install/remove the module to/from the base unit more than 50 times after the first use of

the product. (IEC 61131-2 compliant)

Failure to do so may cause malfunction.

• Always make sure to touch the grounded metal to discharge the electricity charged in the body,

etc., before touching the module.

Failure to do so may cause a failure or malfunctions of the module.

[Operating Precautions]

!

CAUTION

• Please read the manual carefully and confirm the safety thoroughly before performing control

operations (especially, modifications of data, programs and operation status (status control)) of

the programmable controller that is running.

Incorrect modifications of data, programs and operating status may cause system malfunctions,

damages to the machines, or accidents.

[Disposal Precautions]

!

CAUTION

• Dispose of this product as an industrial waste.

A - 4 A - 4

REVISIONS

The manual number is given on the bottom left of the back cover.

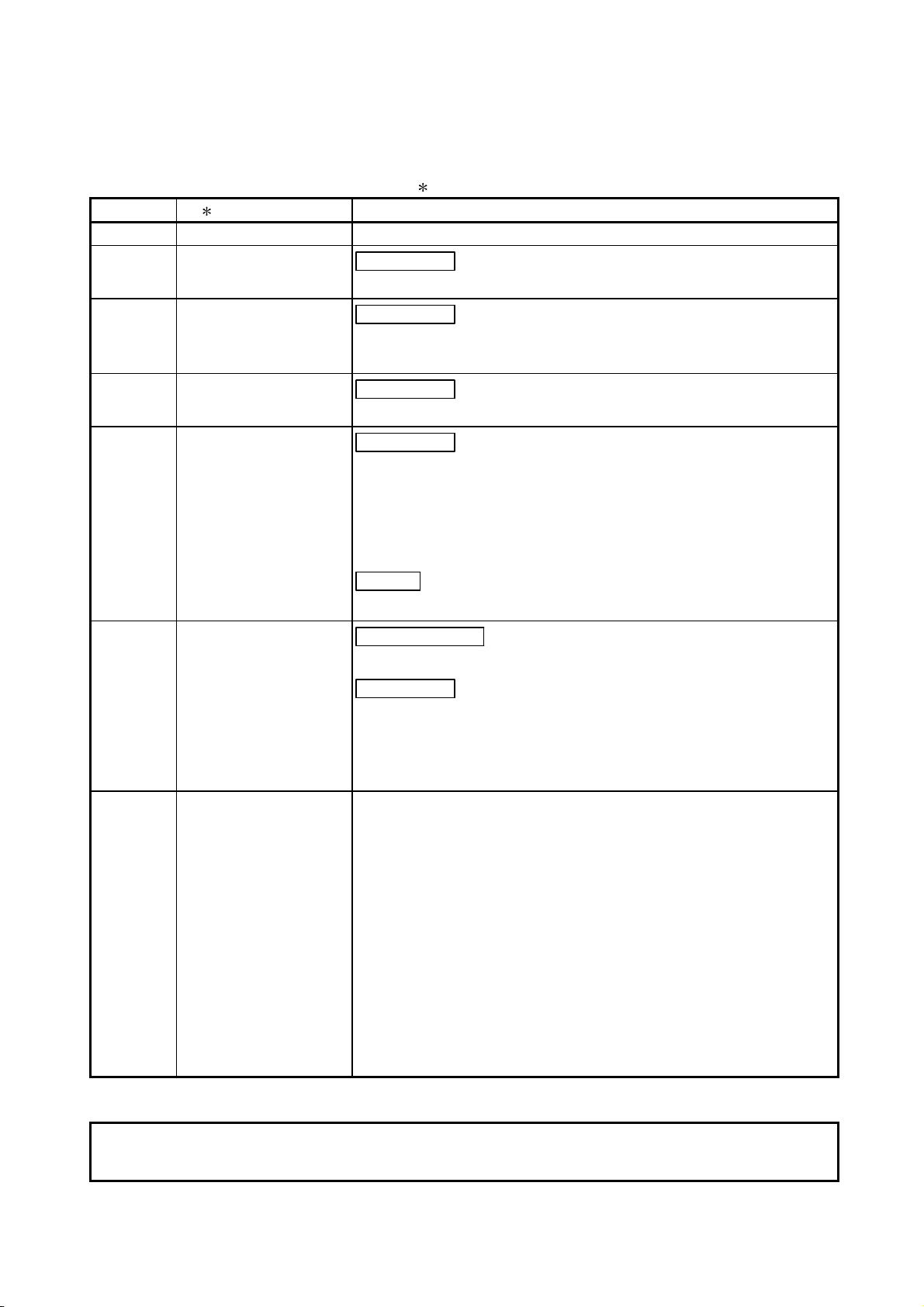

Print Date Manual Number Revision

Jan., 2004 SH (NA) -080446ENG-A First Edition

Mar., 2004 SH (NA) -080446ENG-B

Modifications

Section 7.2.2, 8.3.2, 8.4, 8.6, 8.7, 9.2.2, 11.1, 11.4, 11.5

Nov., 2005 SH (NA) -080446ENG-C

Modifications

Section 4.3.10, 5.2.1, 6.1, 6.2, 6.6, 7.1, 7.3.1, 7.4.1 to 7.4.5, 8.2.2,

8.3.1, 8.3.3, 8.7.2, 9.1, 10.2, 10.3, 11.1, 11.2, 11.3.2, 11.3.3, 11.4

Feb., 2006 SH (NA) -080446ENG-D

Modifications

Section 2.1, 2.4, 10.1

Jan., 2008 SH (NA) -080446ENG-E

Modifications

SAFETY PRECAUTIONS, Conformation to the EMC Directive and

Low Voltage Instruction, About the Generic Terms and

Abbreviations, Section 2.1, 2.5, 3.1, 3.2.1, 5.1, 5.2.1, 5.5, 6.1, 6.4,

6.6, 7.2.2, 7.4.1, 7.4.2, 7.4.4, Chapter 8, Section 9.1.3, 9.3.1, 9.3.2,

9.3.3, 10.2, 10.3, 11.1, 11.2, 11.3.1, 11.3.3, 11.4.1, 11.4.2, 11.5.1

Addition

Section 2.4

May, 2008 SH (NA) -080446ENG-F

Change of a term

"PLC" was changed to "programmable controller".

Modifications

SAFETY PRECAUTIONS, Compliance with the EMC and Low

Voltage Directives, About the Generic Terms and Abbreviations,

Section 2.1, 3.1, 6.1, 6.6, 7.4.2, 8.2.1, 8.3.1, 8.3.3, 8.6, 10.2, 10.3,

11.2, 11.3.3, Appendix 3

Japanese Manual Version SH(NA)-080445-G

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2004 MITSUBISHI ELECTRIC CORPORATION

A - 5 A - 5

INTRODUCTION

Thank you for purchasing the MELSEC-Q series programmable controller.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Q series programmable controller you have purchased, so as to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS..............................................................................................................................A- 1

REVISIONS ....................................................................................................................................................A- 5

INTRODUCTION............................................................................................................................................A- 6

CONTENTS....................................................................................................................................................A- 6

Compliance with the EMC and Low Voltage Directives................................................................................A-10

The Manual's Usage and Structure ...............................................................................................................A-11

About the Generic Terms and Abbreviations ................................................................................................A-13

Meanings and Definitions of Terms ..............................................................................................................A-14

Product Configuration ....................................................................................................................................A-14

1 OVERVIEW 1- 1 to 1- 5

1.1 Features ................................................................................................................................................... 1- 1

2 SYSTEM CONFIGURATION 2- 1 to 2- 9

2.1 Applicable Systems.................................................................................................................................. 2- 1

2.2 Devices Necessary for Network Configuration .......................................................................................2- 4

2.3 System Configuration and Access Range .............................................................................................. 2- 5

2.4 Precautions for System Configuration..................................................................................................... 2- 7

2.5 How to Check the Function Version and Software Version ................................................................... 2- 8

3 SPECIFICATIONS 3- 1 to 3- 9

3.1 Performance Specifications ..................................................................................................................... 3- 1

3.2 I/O Signals for Programmable Controller CPU ....................................................................................... 3- 2

3.2.1 I/O signal list ...................................................................................................................................... 3- 2

3.3 Applications and Assignment of Buffer Memory ..................................................................................... 3- 4

3.3.1 Buffer memory list ............................................................................................................................. 3- 4

4 MODBUS

R

STANDARD FUNCTIONS 4- 1 to 4-20

4.1 MODBUSR Standard Function Support List........................................................................................... 4- 1

4.2 Frame Specifications ............................................................................................................................... 4- 3

4.3 PDU Formats by Functions...................................................................................................................... 4- 4

4.3.1 Read coils (FC: 01) ........................................................................................................................... 4- 6

4.3.2 Read discrete inputs (FC: 02)........................................................................................................... 4- 7

4.3.3 Read holding registers (FC: 03)........................................................................................................ 4- 8

4.3.4 Read input registers (FC: 04) ........................................................................................................... 4- 9

4.3.5 Write single coil (FC: 05)................................................................................................................... 4-10

4.3.6 Write single register (FC: 06) ............................................................................................................ 4-11

4.3.7 Write multiple coils (FC: 15).............................................................................................................. 4-12

4.3.8 Write multiple registers (FC: 16) ....................................................................................................... 4-14

A - 6 A - 6

4.3.9 Read file record (FC: 20) (SC: 06).................................................................................................... 4-15

4.3.10 Write file record (FC: 21) (SC: 06) .................................................................................................. 4-17

4.3.11 Mask write register (FC: 22) ........................................................................................................... 4-19

4.3.12 Read/Write multiple registers (FC: 23) ........................................................................................... 4-20

5 FUNCTIONS 5- 1 to 5-15

5.1 Function List .............................................................................................................................................5- 1

5.2 Master Function ....................................................................................................................................... 5- 3

5.2.1 Automatic communication function................................................................................................... 5- 3

5.2.2 Dedicated instructions ....................................................................................................................... 5- 9

5.3 Slave Function.......................................................................................................................................... 5-10

5.3.1 Automatic response function ............................................................................................................ 5-10

5.3.2 MODBUS

®

device assignment function ........................................................................................... 5-11

5.4 KeepAlive Function .................................................................................................................................. 5-12

5.5 Router Relay Function ............................................................................................................................. 5-14

5.6 GX Developer Connection Function........................................................................................................ 5-15

6 PRE-OPERATIONAL PROCEDURES AND SETTING 6- 1 to 6-19

6.1 Handling Precautions ............................................................................................................................... 6- 1

6.2 Pre-Operational Procedures and Setting ................................................................................................ 6- 2

6.3 Part Names .............................................................................................................................................. 6- 4

6.4 Connection to Ethernet ............................................................................................................................ 6- 6

6.5 Unit Tests ................................................................................................................................................. 6- 8

6.5.1 Hardware test .................................................................................................................................... 6- 8

6.5.2 Self-loopback test .............................................................................................................................. 6- 9

6.6 Intelligent Function Module Switch Setting ............................................................................................. 6-10

6.6.1 Communication starting conditions depending on basic parameter/MODBUS

R

device assignment

parameter starting method setting .................................................................................................... 6-15

7 PARAMETER SETTING 7- 1 to 7-33

7.1 Parameter Settings and Setting Procedure ............................................................................................ 7- 1

7.2 Basic Parameters..................................................................................................................................... 7- 6

7.2.1 Basic parameters details ................................................................................................................... 7- 6

7.2.2 TCP/UDP/IP setting .......................................................................................................................... 7- 8

7.2.3 GX Developer connection information setting.................................................................................. 7-16

7.2.4 MODBUS

®

/TCP setting..................................................................................................................... 7-17

7.3 Automatic Communication Parameters................................................................................................... 7-19

7.3.1 Automatic communication parameters details .................................................................................7-19

7.4 MODBUS

7.4.1 MODBUS

7.4.2 MODBUS

®

Device Assignment Parameters ........................................................................................... 7-23

®

device sizes .................................................................................................................... 7-25

®

device assignment parameters details .......................................................................... 7-26

7.4.3 Default assignment parameters........................................................................................................ 7-29

7.4.4 MODBUS

®

extended file register assignment.................................................................................. 7-31

7.4.5 QJ71MT91 buffer memory assignment ............................................................................................ 7-32

8 UTILITY PACKAGE (GX Configurator-MB) 8- 1 to 8-36

8.1 Functions of the Utility Package .............................................................................................................. 8- 1

A - 7 A - 7

8.2 Installing and Uninstalling the Utility Package ........................................................................................ 8- 2

8.2.1 Handling precautions ........................................................................................................................ 8- 2

8.2.2 Operating environment...................................................................................................................... 8- 4

8.3 Utility Package Operation ........................................................................................................................ 8- 6

8.3.1 Common utility package operations ................................................................................................. 8- 6

8.3.2 Operation overview ........................................................................................................................... 8- 9

8.3.3 Starting the Intelligent function module utility ................................................................................... 8-11

8.4 Initial Setting ............................................................................................................................................. 8-13

8.5 Auto Refresh Setting ................................................................................................................................ 8-15

8.6 Monitor/Test ............................................................................................................................................. 8-17

8.6.1 X/Y Monitor/test ................................................................................................................................. 8-21

8.6.2 Basic/MODBUS

®

device assignment parameter status .................................................................. 8-23

8.6.3 Automatic communication status ...................................................................................................... 8-24

8.6.4 Error log ............................................................................................................................................. 8-26

8.6.5 Communication status....................................................................................................................... 8-27

8.6.6 PING test ...........................................................................................................................................8-29

8.7 Parameter Setting Using GX Configurator-MB ....................................................................................... 8-30

8.7.1 Basic parameters .............................................................................................................................. 8-30

8.7.2 Automatic communication parameters ............................................................................................. 8-33

8.7.3 MODBUS

®

device assignment parameters...................................................................................... 8-35

9 PROGRAMMING 9- 1 to 9-49

9.1 Parameter Setting .................................................................................................................................... 9- 1

9.1.1 Basic parameter setting ....................................................................................................................9- 1

9.1.2 Automatic communication parameter setting ................................................................................... 9- 4

9.1.3 MODBUS

®

device assignment parameter setting ........................................................................... 9- 7

9.2 Program Example for Normal System Configuration.............................................................................. 9-11

9.2.1 System configuration and program conditions ................................................................................. 9-11

9.2.2 Program using utility package........................................................................................................... 9-18

9.2.3 Program without using utility package.............................................................................................. 9-22

9.3 Program Example for Use in MELSECNET/H Remote I/O Network ..................................................... 9-29

9.3.1 System configuration and program conditions ................................................................................. 9-29

9.3.2 Program using utility package........................................................................................................... 9-35

9.3.3 Program without using utility package.............................................................................................. 9-39

10 DEDICATED INSTRUCTIONS 10- 1 to 10-18

10.1 Dedicated Instruction List and Available Devices ............................................................................... 10- 1

10.2 Z(P).MBRW .......................................................................................................................................... 10- 2

10.3 Z(P).MBREQ ........................................................................................................................................10-11

11 TROUBLESHOOTING 11- 1 to 11-48

11.1 Troubleshooting ................................................................................................................................... 11- 1

11.2 Confirming QJ71MT91 Status .............................................................................................................11-10

11.3 Error Codes .......................................................................................................................................... 11-13

11.3.1 Error code storage areas .............................................................................................................. 11-13

11.3.2 Exception code list ........................................................................................................................11-19

11.3.3 Error code list ................................................................................................................................11-21

A - 8 A - 8

11.4 Turning Off the COM.ERR. LED .........................................................................................................11-37

11.4.1 From GX Configurator-MB............................................................................................................ 11-37

11.4.2 Program example for use of sequence program ......................................................................... 11-40

11.5 Conducting PING Test to Check QJ71MT91 Connection .................................................................. 11-41

11.5.1 From GX Configurator-MB............................................................................................................ 11-42

11.5.2 Program example for use of sequence program ......................................................................... 11-46

APPENDICES App- 1 to App- 7

Appendix 1 External Dimensions................................................................................................................App- 1

Appendix 2 Processing Time ......................................................................................................................App- 2

Appendix 3 GX Developer Connection Setup Example ............................................................................App- 5

INDEX Index- 1 to Index- 4

A - 9 A - 9

Compliance with the EMC and Low Voltage Directives

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage

Directives when incorporating the Mitsubishi programmable controller (EMC and

Low Voltage Directives compliant) into other machinery or equipment, refer to

Chapter 9 "EMC AND LOW VOLTAGE DIRECTIVES" of the QCPU User's

Manual (Hardware Design, Maintenance and Inspection).

The CE mark, indicating compliance with the EMC and Low Voltage Directives, is

printed on the rating plate of the programmable controller.

(2) For the product

Note the following when making this product to conform to the EMC and Low

Voltage directives.

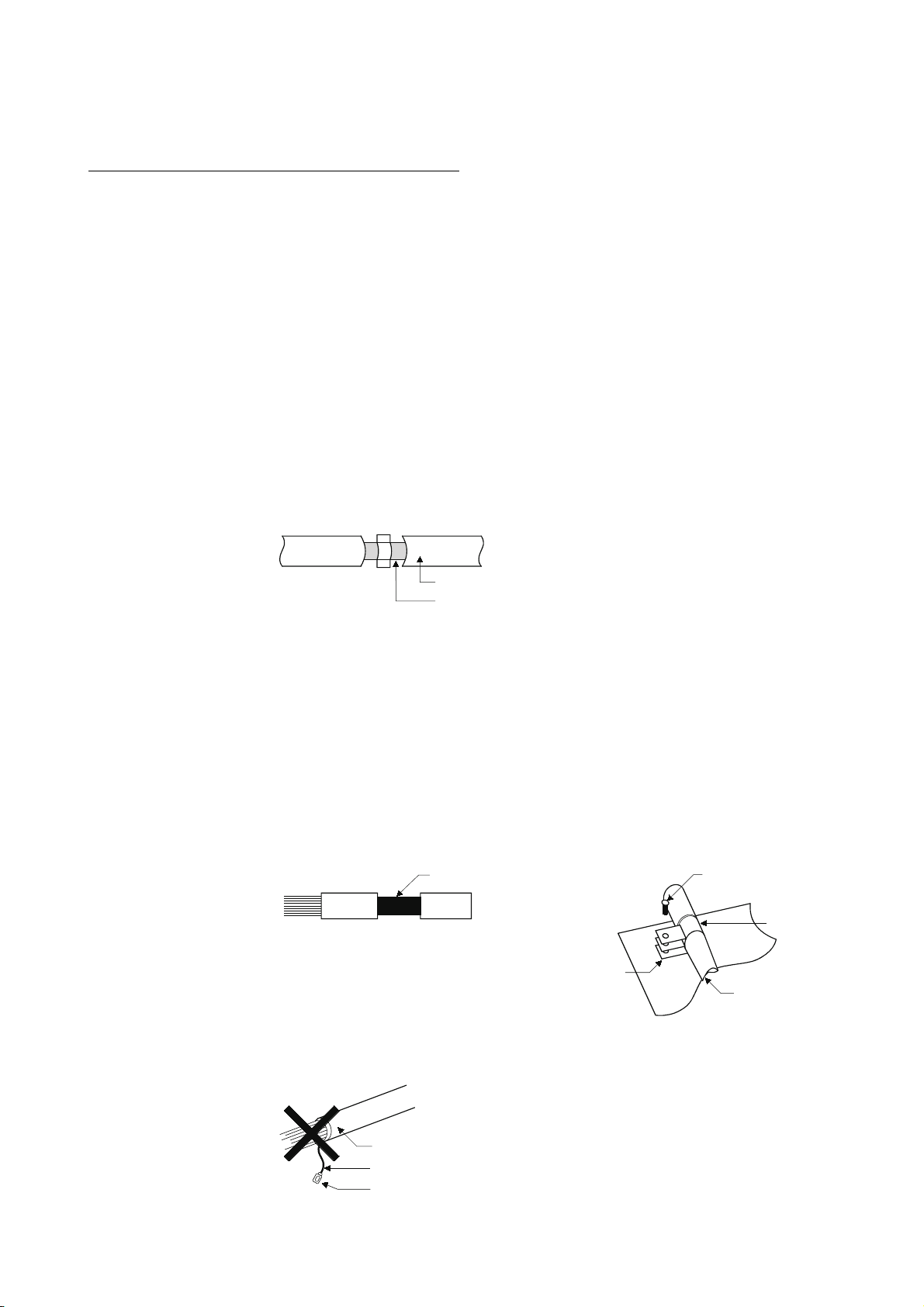

(a) Twisted pair cable

Use shielded twisted pair cables for connecting to the 10BASET/100BASE-TX connectors. For the shielded twisted pair cables, strip a

part of the outer cover and ground the exposed shield section on the widest

contact surface as shown below.

Shielded twisted pair cables

Shield

Refer to (b) for grounding of the shield.

(b) Grounding of shield of shielded cable

1) Ground the shield of the shielded cable as close to the

module as possible to avoid the electromagnetic induction

from ungrounded cables.

2) Take an appropriate measure so that the stripped shield

section can be grounded to the control panel in the largest

area as possible. A clamp may be used as shown below.

In this case, however, mask the contact part when painting

the inner surface of the control panel to allow it to contact

Note) Grounding by soldering a wire onto the shield section of the shielded cable as

shown below is not recommended. The high frequency impedance will increase

and the shield will be ineffective.

with the clamp.

Shield section

Screw

Clamp

Paint mask

Shielded cable

Shielded cable

Wire

Crimp terminal

A - 10 A - 10

The Manual's Usage and Structure

How to use this manual

This manual describes the pre-operation procedure, functions, etc. by use of the

MODBUS

Refer to the corresponding section when you need to know the following:

(1) Features (Chapter 1)

Chapter 1 describes the features of the QJ71MT91.

(2) System configuration (Chapter 2)

(a) Section 2.1 describes the applicable programmable controller CPUs and

compatible software packages.

(b) Section 2.2 describes the devices necessary to configure a network.

(c) Section 2.3 describes the system configurations that use the QJ71MT91 and

the accessible range.

(3) Performance and specifications (Chapter 3)

(a) Section 3.1 provides the performance specifications of the QJ71MT91.

(b) Section 3.2 and 3.3 give the I/O signal and buffer memory lists of the

QJ71MT91.

(4) MODBUSR standard functions supported by the QJ71MT91

(Chapter 4)

(a) Section 4.1 gives a list of MODBUSR standard functions supported by the

QJ71MT91.

(b) Section 4.2 and 4.3 provide the frame specifications of the MODBUS

standard functions supported by the QJ71MT91.

(5) Usable functions (Chapter 5)

Chapter 5 describes the functions of the QJ71MT91.

R

/TCP interface module (QJ71MT91) on a purpose-by-purpose basis.

R

A - 11 A - 11

(6) Settings and procedures necessary to operate the system (Chapter

6)

Chapter 6 describes the pre-operation settings and procedures.

(7) Parameter setting of the QJ71MT91 (Chapter 7)

Chapter 7 describes the parameter setting procedures and parameter details.

(8) Parameter setting from the utility package (Chapter 8)

Chapter 8 describes the utility package operation method.

(9) Parameter setting from sequence programs (Chapter 9)

Chapter 9 describes the I/O signals used for parameter setting, the I/O signal

timing charts, and program examples.

(10) Reading/Writing, etc. of MODBUSR device data with sequence

programs (Chapter 10)

Chapter 10 describes the dedicated instructions designed to perform read/write,

etc. of MODBUS

R

device data with sequence programs.

(11) Error codes and corresponding corrective actions (Chapter 11)

(a) Section 11.1 describes the troubleshooting.

(b) Section 11.2 describes how to check the module condition.

(c) Section 11.3 describes the error code storage location and details.

(d) Section 11.4 describes how to turn OFF the COM.ERR. LED.

(e) Section 11.5 describes the PING test.

About the notation of the numerical values used in this manual

Among the numerical values used in this manual, "H" is placed to the right of the

units place for hexadecimal notation.

(Example) 10 ..... Decimal

10

H ... Hexadecimal

A - 12 A - 12

About the Generic Terms and Abbreviations

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to explain the QJ71MT91 MODBUS

R

/TCP interface module.

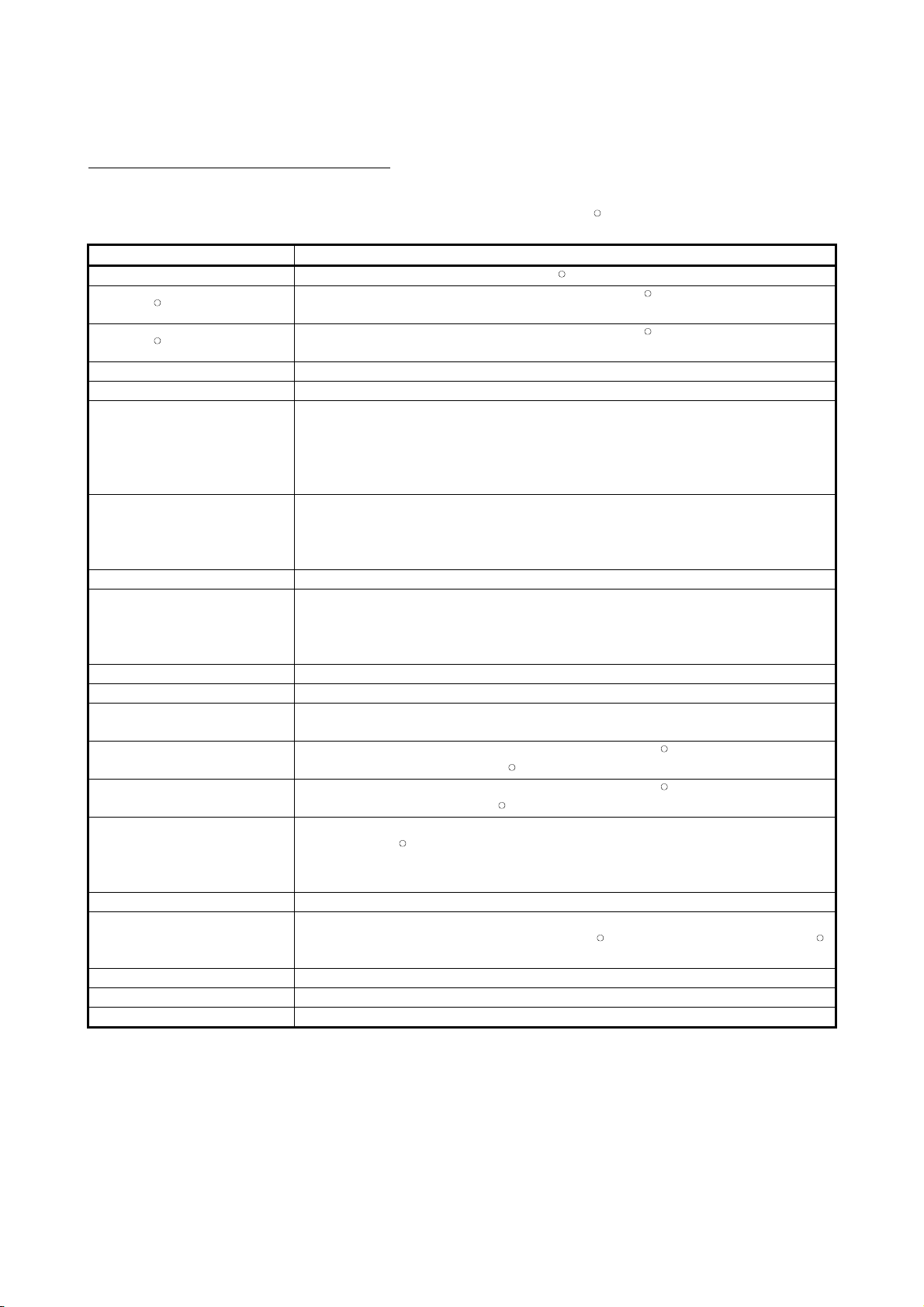

Generic Term/Abbreviation

QJ71MT91 Abbreviation for the QJ71MT91 MODBUSR/TCP interface module.

MODBUSR/TCP

MODBUSRserial protocol

Generic term for the protocol designed to use MODBUS

TCP/IP network.

Generic term for the protocol designed to use MODBUS

serial interface.

FC Abbreviation for the function code.

SC Abbreviation for the sub code.

Generic term for the Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU,

Q06HCPU, Q12HCPU, Q25HCPU, Q02PHCPU, Q06PHCPU, Q02PHCPU,

Programmable controller CPU

Q25PHCPU, Q12PRHCPU, Q25PRHCPU, Q02UCPU, Q03UDCPU, Q04UDHCPU

Q06UDHCPU, Q13UDHCPU, Q26UDHCPU, Q03UDECPU, Q04UDEHCPU,

Q06UDEHCPU, Q13UDEHCPU and Q26UDEHCPU.

Generic product name for SWnD5C-GPPW-E, SWnD5C-GPPW-EA, SWnD5C-

GX Developer

GPPW-EV, and SWnD5C-GPPW-EVA. ("n" means version 4 or later.)

"-A" and "-V" mean "volume license product" and "version-upgrade product"

respectively.

Ethernet module The QJ71E71-100 Ethernet interface module.

A machine-specific address that is also referred to as the MAC (Media Access Control)

Ethernet Address

address. This is used to identify the addresses of external devices over a network.

The Ethernet address of the QJ71MT91 can be verified on the MAC ADD column of

the rating plate.

MELSECNET/H The MELSECNET/H network system.

Master The side from which a request is sent to execute a function.

Slave

Master function

Slave function

Request message

The side where the execution request from the master is processed and its execution

result is sent.

The function that allows communication with the MODBUS

device as the master of MODBUS

The function that allows communication with the MODBUS

device as the slave of MODBUS

The message used to give a function execution request to the slave

In the MODBUS

R

protocol, a function execution request is given from the master to

the slave.

A function execution request cannot be given from the slave to the master.

Response message The message with which the slave returns a function execution result to the master.

Generic term for the communication targets connected for data communication.

Target device

(personal computer, other QJ71MT91 MODBUSR/TCP interface module, MODBUSR

protocol compatible device, etc.)

Personal computer The IBM PC/AT or compatible DOS/V-based personal computer.

MBRW Abbreviation for Z.MBRW or ZP.MBRW.

MBREQ Abbreviation for Z.MBREQ or ZP.MBREQ.

Description

R

/TCP.

R

/TCP.

R

protocol messages on a

R

protocol messages on a

R

/TCP compatible slave

R

/TCP compatible master

A - 13 A - 13

Generic Term/Abbreviation

Windows VistaR

WindowsRXP

Generic term for the following:

Microsoft

R

Windows VistaRHome Basic Operating System,

MicrosoftRWindows VistaRHome Premium Operating System,

MicrosoftRWindows VistaRBusiness Operating System,

MicrosoftRWindows VistaRUltimate Operating System,

Microsoft

R

Windows VistaREnterprise Operating System

Generic term for the following:

MicrosoftRWindowsRXP Professional Operating System,

Microsoft

R

WindowsRXP Home Edition Operating System

Description

Meanings and Definitions of Terms

The following explains the meanings and definitions of the terms used in this manual.

Term

MODBUSRprotocol Communication protocol developed for programmable controller by Schneider Electric SA.

MODBUSRdevice Device used for communication using the MODBUSRprotocol.

Programming system devised to make a contact type sequence compatible with the

Sequence program

programmable controller language as-is. Draw two vertical control buses and describe

contacts, etc. between the buses to perform programming.

Device memory

Memory provided for the programmable controller CPU to record the data handled in

sequence program operation.

Meaning/Definition

Product Configuration

The following indicates the product configuration of the QJ71MT91 MODBUS

Model

QJ71MT91 QJ71MT91 MODBUSR/TCP interface module 1

SW1D5C-QMBU-E GX Configurator-MB Version 1 (1-license product) (CD-ROM) 1

SW1D5C-QMBU-EA GX Configurator-MB Version 1 (Multiple-license product) (CD-ROM) 1

interface module.

Item name

R

/TCP

Quantity

A - 14 A - 14

1 OVERVIEW

MELSEC-Q

1 OVERVIEW

1.1 Features

This manual explains the specifications, functions, programming, troubleshooting, etc.

of the MELSEC-Q series QJ71MT91 MODBUS

R

/TCP interface module (hereafter

abbreviated to the QJ71MT91).

The QJ71MT91 is used to connect the MELSEC-Q series programmable controller to

a MODBUS

R

/TCP network.

MODBUS is a registered trademark of Schneider Electric SA.

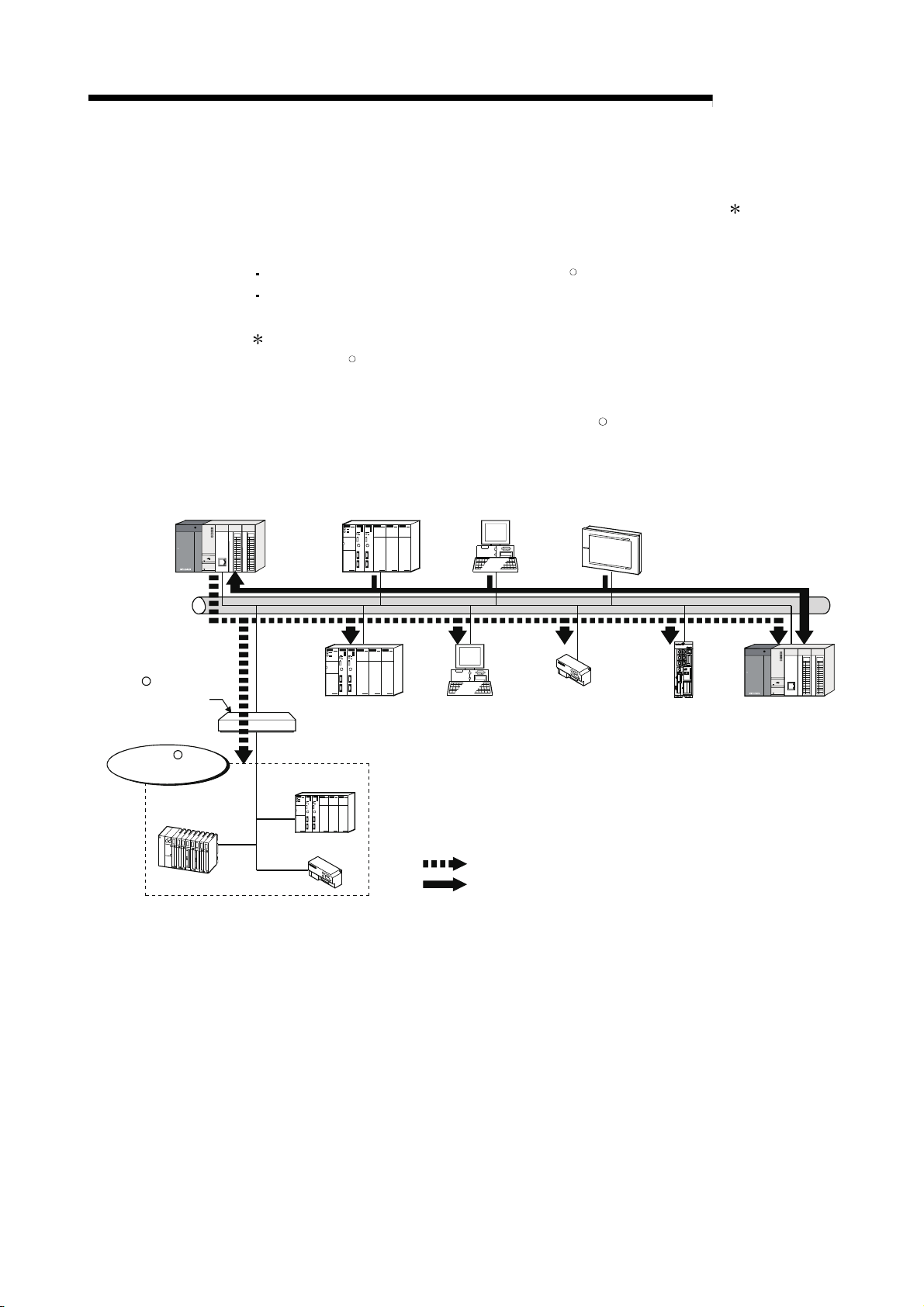

(1) Supporting master function of MODBUSR/TCP communication

The QJ71MT91 supports the master function of MODBUSR/TCP

communication, which is an open network system for factory automation, and it is

compatible with various MODBUS

R

/TCP slave devices (hereafter abbreviated to

the slaves) of other manufactures.

The master function supports the following two functions.

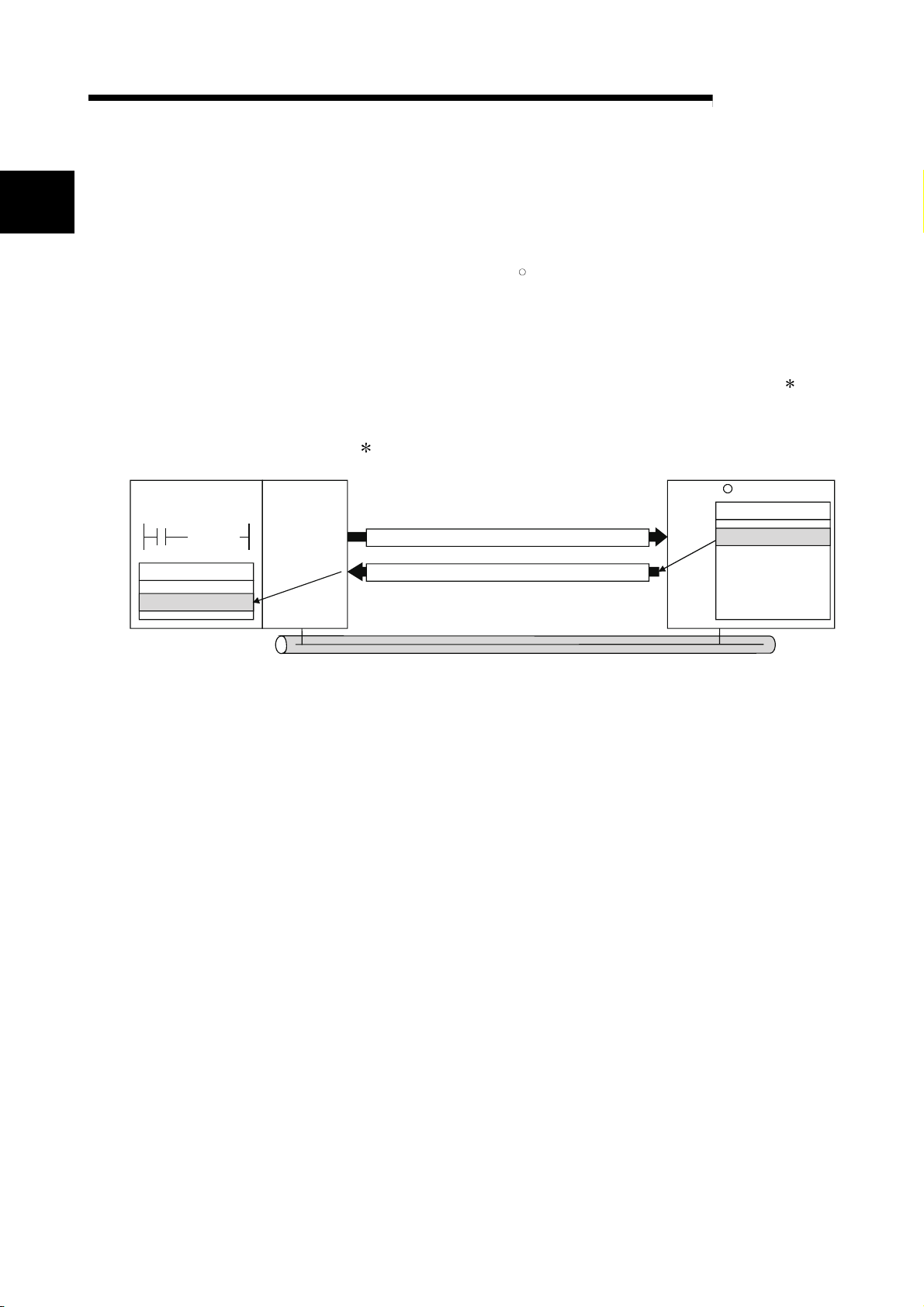

(a) Automatic communication function

By setting the automatic communication parameters, MODBUSR device

data can be automatically read from or written to the slaves at the specified

intervals using the QJ71MT91 buffer memory. (

Data can be transferred between the QJ71MT91 buffer memory and

programmable controller CPU device memory by making the auto refresh

setting with the utility package (GX Configurator-MB) or accessing a

intelligent function module device with a sequence program.

Ethernet

Holding register

1)

MODBUS /TCP slave device

(Third party remote I/O, etc.)

R

1

Programmable

controller CPU

Device memory

Auto refresh

QJ71MT91

MODBUS device read/write request

messages are issued to the slave

repeatedly at specified intervals.

(Master function

Buffer memory

100ms read

250ms read

1000ms read

100ms write

R

)

MODBUS /TCP slave device

(Third party sensor, etc.)

Holding register

MODBUS /TCP slave device

(Third party programmable

controller)

Holding register

R

R

1: The MODBUSR device indicates the device area of the slave where data can be read/written in

response to a request from the master.

1 - 1 1 - 1

1 OVERVIEW

1

Programmable

controller CPU

Command

[Z.MBRW ]

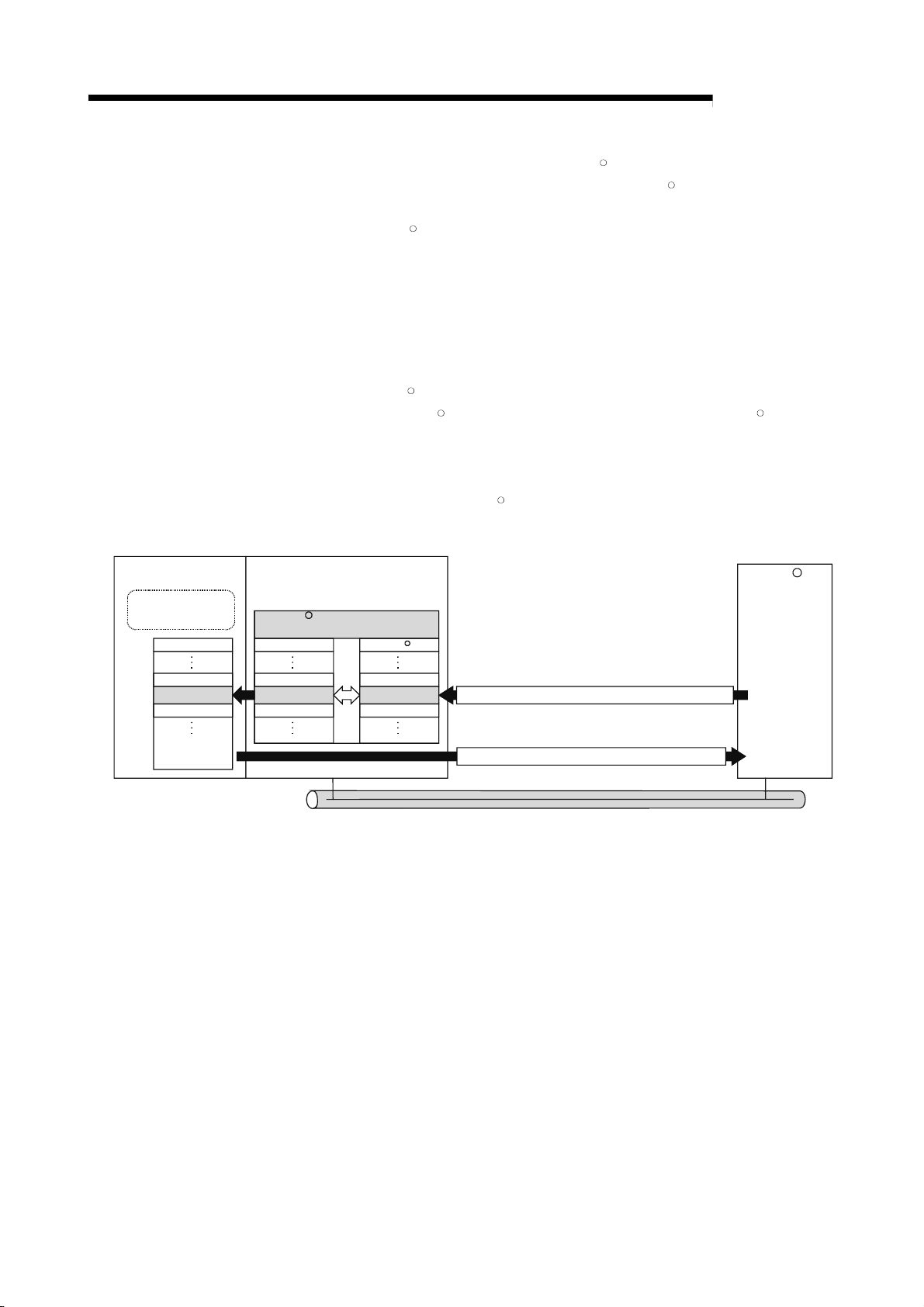

(b) Communication using dedicated instruction

Dedicated instructions can be used to make communication from a

sequence program at any timing.

The QJ71MT91 supports the following two dedicated instructions.

1) MBRW instruction

Reads/writes MODBUSR device data from/to a slave.

This enables slave data to be read out to the programmable controller

CPU device memory or programmable controller CPU data to be

written to the slave.

2) MBREQ instruction

Can issue user-desired request message format (function code 1 +

data unit) to a slave.

1: Refer to Chapter 4 for the function code.

QJ71MT91

(Master function)

Request message (holding register 400500 read request)

MELSEC-Q

MODBUS /TCP slave device

400500

R

Holding register

H

1234

Device memory

H

1234

Response message (holding register 400500 = 1234H)

Ethernet

1 - 2 1 - 2

1 OVERVIEW

Programmable

controller CPU

Sequence program

not needed

Device memory

MELSEC-Q

(2) Supporting slave function of MODBUSR/TCP communication

The QJ71MT91 supports the slave function of MODBUSR/TCP communication,

which is an open network system for factory automation, and it is compatible with

various MODBUS

R

/TCP master devices (hereafter abbreviated to the masters)

of other manufacturers.

The slave function supports the following two functions.

(a) Automatic response function

The QJ71MT91 can automatically respond to a request message received

from the master.

A sequence program for the slave function is not needed.

(b) MODBUSR device assignment function

Using MODBUSRdevice assignment parameters, the MODBUSRdevices

are correlated with the programmable controller CPU device memory.

This enables direct access from the master to the programmable controller

CPU device memory.

Supporting the MODBUS

all device memories of the programmable controller CPU to be assigned.

QJ71MT91(Slave function)

MODBUS

device assignment parameters

R

Device memory

MODBUS device

R

R

devices of large capacity, the QJ71MT91 allows

MODBUS /TCP

master device

R

D300

1234

D299

H

D300 400500

D301 400501

400499

Request message (holding register 400500 read request)

Response message (holding register 400500 = 1234H)

Ethernet

1 - 3 1 - 3

1 OVERVIEW

MELSEC-Q

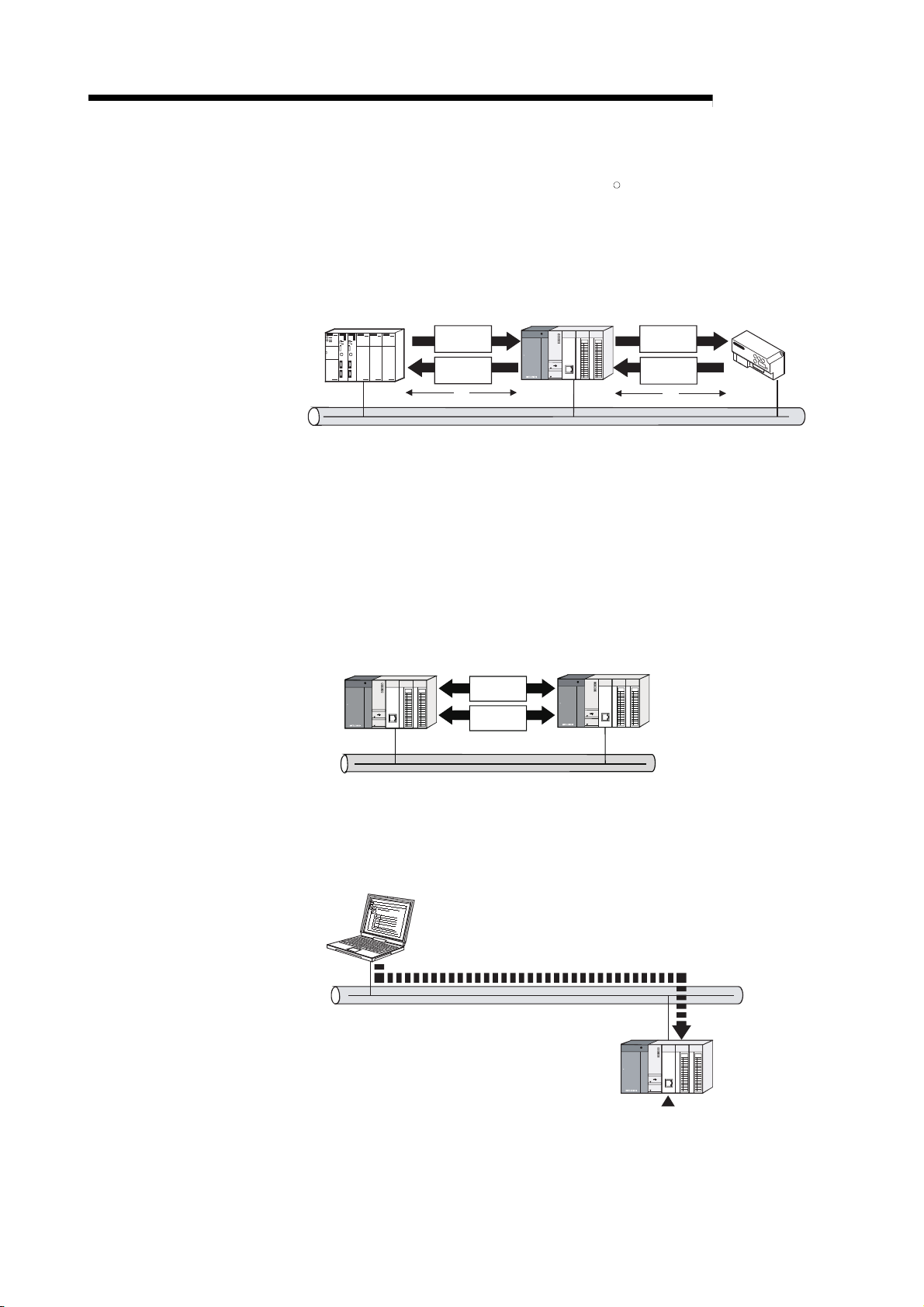

(3) Concurrent operation of master and slave functions

The master and slave functions can be operated concurrently.

This enables flexible construction of a MODBUS

system.

R

/TCP communication-based

(a) Example of communication between QJ71MT91 and third

party devices

Third party

programmable controller

(Master)

Ethernet

Master Slave

Request

message

Response

message

1)

QJ71MT91

(Master/slave function)

Master

Request

message

Response

message

2)

1) In response to a request message from the master, the QJ71MT91

operates as a slave and returns a response message.

2) The QJ71MT91 operates as a master, and issues a request message

to the slave.

Third party remote I/O

(Slave)

Slave

(b) Example of communication between QJ71MT91 and

QJ71MT91

The both functions can be operated bi-directionally between QJ71MT91

and QJ71MT91.

QJ71MT91

(Master/slave function)

Request

message

Response

message

Ethernet

QJ71MT91

(Master/slave function)

(4) Support of GX Developer connection via Ethernet

GX Developer can be connected to Ethernet via the QJ71MT91.

This enables the maintenance of the programmable controller CPU via Ethernet.

GX Developer

Ethernet

QJ71MT91

1 - 4 1 - 4

1 OVERVIEW

MELSEC-Q

(5) Supporting Ethernet functions for more reliability, high speed

communication and flexible system construction

The following Ethernet functions are supported for more reliability, high speed

communication and more flexible system construction.

(a) KeepAlive function

The status of communication with the target device where a TCP

connection has been established can be checked.

When communication is not made for a given period of time between the

QJ71MT91 and the open target device, the QJ71MT91 checks the target

device for existence and cuts off unnecessary TCP connections.

(b) 100 Mbps high-speed communication

Supporting 100BASE-TX, the QJ71MT91 can make 100Mbps high-speed

communication.

(c) Router relay function

Communication can be made with a MODBUSR/TCP device via a router.

(6) Ease of setting with utility package

The optional utility package (GX Configurator-MB) is available.

Though not required, the use of the utility package allows on-screen initial

settings (basic parameters, automatic communication parameters, MODBUS

device assignment parameters) and auto refresh settings, reducing sequence

programs and also facilitating the confirmation of the setting and operating

statuses. (

1: It is recommended to use the utility package with the QJ71MT91.

By making various parameter settings with the utility package,

communication can be made without sequence programs.

1)

R

1 - 5 1 - 5

2 SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

MELSEC-Q

2.1 Applicable Systems

2

CPU type CPU model

Programmable

controller CPU

2 - 1 2 - 1

This chapter explains the system configuration of the QJ71MT91.

This section describes the applicable systems.

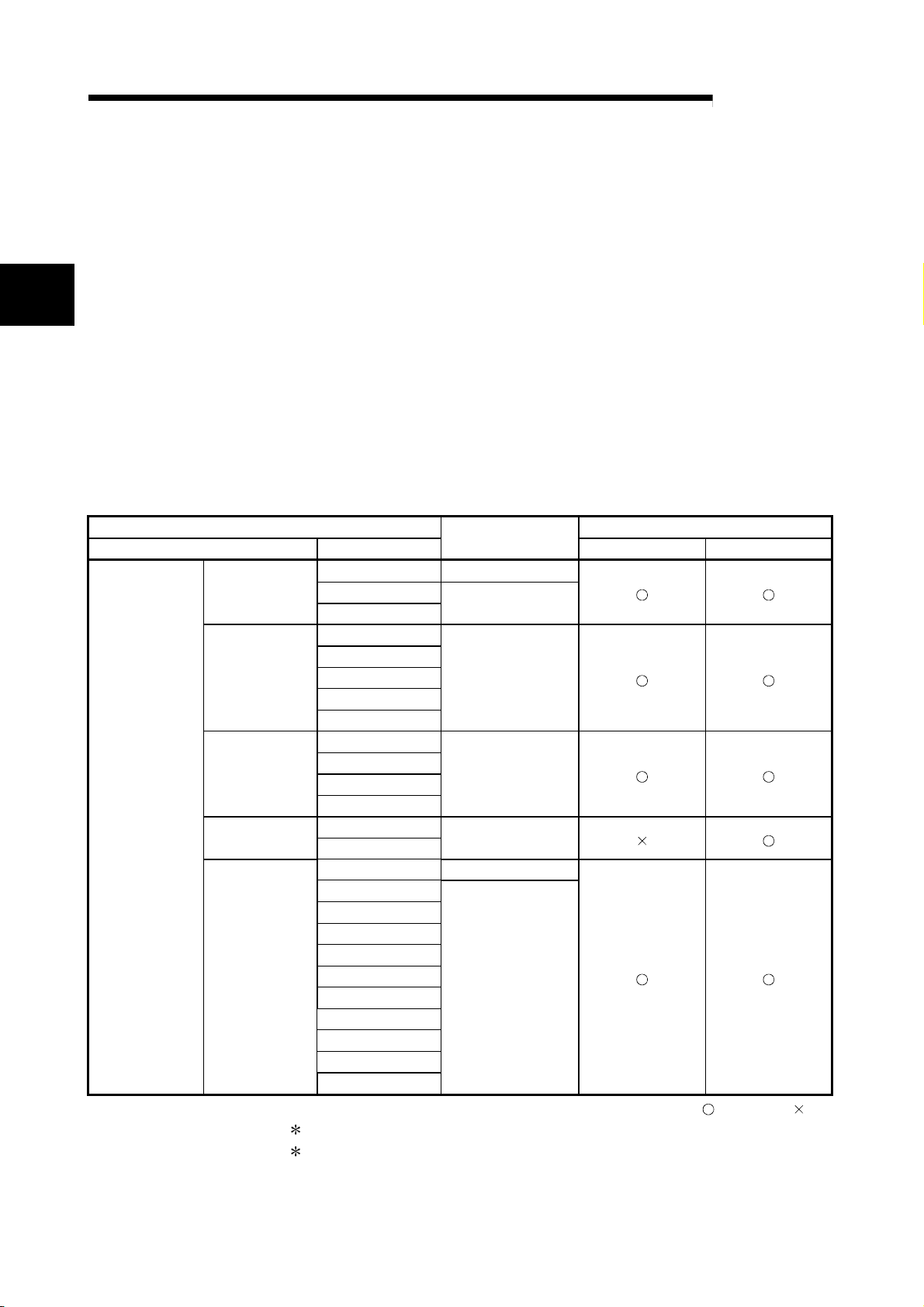

(1) Applicable modules and base units, and No. of modules

(a) When mounted with a CPU module

The table below shows the CPU modules and base units applicable to the

QJ71MT91 and quantities for each CPU model.

Depending on the combination with other modules or the number of

mounted modules, power supply capacity may be insufficient.

Pay attention to the power supply capacity before mounting modules, and if

the power supply capacity is insufficient, change the combination of the

modules.

Applicable CPU module

Basic model

QCPU

High

Performance

model QCPU

Process CPU

Redundant CPU

Universal model

QCPU

Q00JCPU Up to 8

Q00CPU

Q01CPU

Q02CPU

Q02HCPU

Q06HCPU

Q12HCPU

Q25HCPU

Q02PHCPU

Q06PHCPU

Q12PHCPU

Q25PHCPU

Q12PRHCPU

Q25PRHCPU

Q02UCPU Up to 36

Q03UDCPU

Q04UDHCPU

Q06UDHCPU

Q13UDHCPU

Q26UDHCPU

Q03UDECPU

Q04UDEHCPU

Q06UDEHCPU

Q13UDHCPU

Q26UDHCPU

1: Limited within the range of I/O points for the CPU module.

2: Can be installed to any I/O slot of a base unit.

No. of modules

Up to 24

Up to 64

Up to 64

Up to 53

Up to 64

*2

*1

Main base unit Extension base unit

Base unit

(Continued on next page)

: Applicable, : N/A

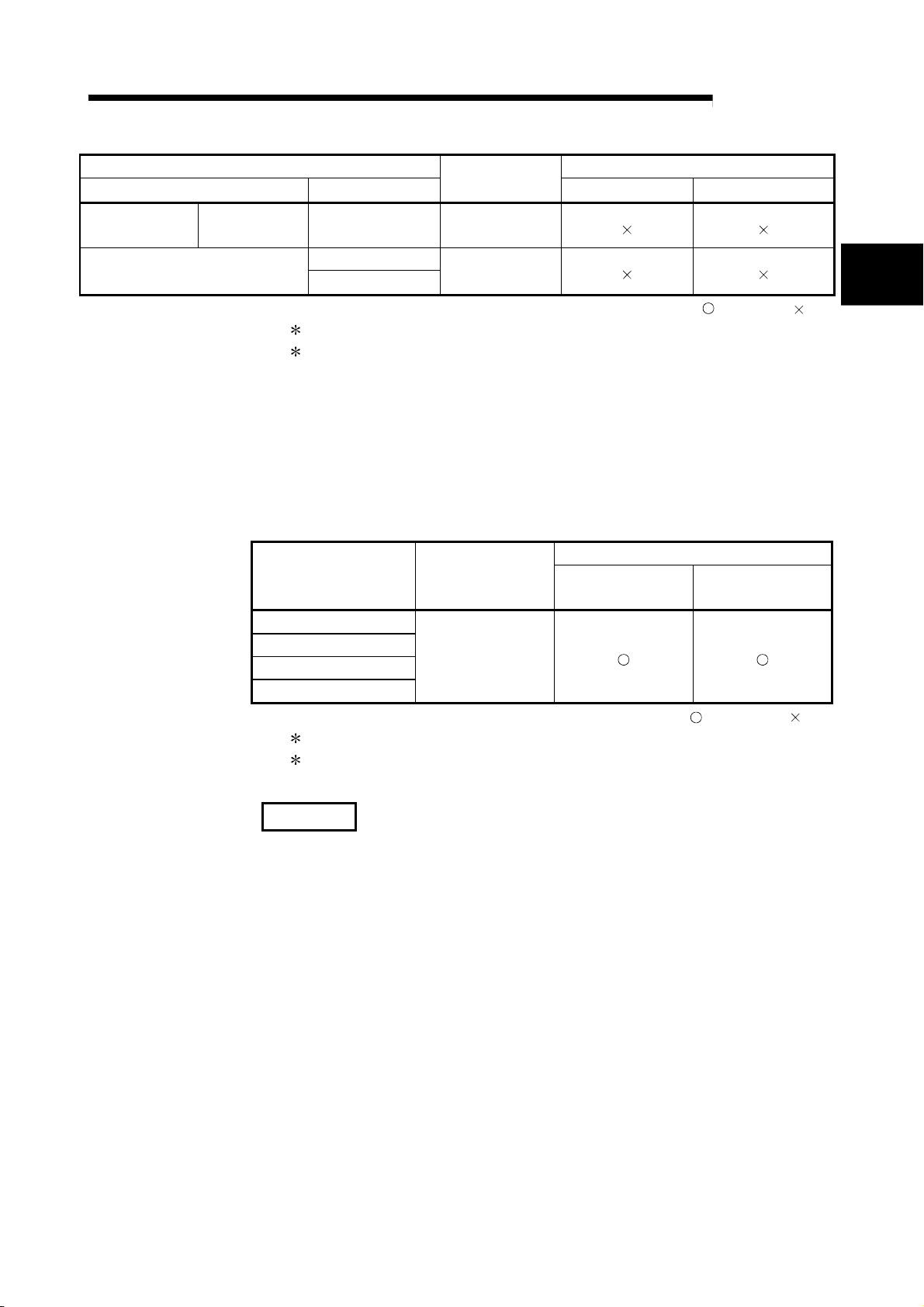

2 SYSTEM CONFIGURATION

Applicable CPU module Base unit*2

CPU type CPU model

Programmable

controller CPU

C Controller module

Safety CPU QS001CPU N/A

Q06CCPU-V

Q06CCPU-V-B

1: Limited within the range of I/O points for the CPU module.

2: Can be installed to any I/O slot of a base unit.

(b) Mounting to a MELSECNET/H remote I/O station

The table below shows the network modules and base units applicable to

the QJ71MT91 and quantities for each network module model.

Depending on the combination with other modules or the number of

mounted modules, power supply capacity may be insufficient.

Pay attention to the power supply capacity before mounting modules, and if

the power supply capacity is insufficient, change the combination of the

Applicable network

module

QJ72LP25-25

QJ72LP25G

QJ72LP25GE

QJ72BR15

modules.

1: Limited within the range of I/O points for the network module.

2: Can be installed to any I/O slot of a base unit.

No. of modules

N/A

No. of modules*1

Up to 64

MELSEC-Q

*1

Main base unit Extension base unit

: Applicable, : N/A

Base unit*2

Main base unit of

remote I/O station

Extension base unit of

remote I/O station

: Applicable, : N/A

2

REMARK

The Basic model or C Controller module QCPU cannot create the MELSECNET/H

remote I/O network.

2 - 2 2 - 2

2 SYSTEM CONFIGURATION

(2) Support of the multiple CPU system

When using the QJ71MT91 in a multiple CPU system, refer to the QCPU User's

Manual (Multiple CPU System) first.

(a) Compatible QJ71MT91

The function version of the first released QJ71MT91 is B, and it supports

multiple CPU systems.

(b) Intelligent function module parameters

Write intelligent function module parameters to only the control CPU of the

QJ71MT91.

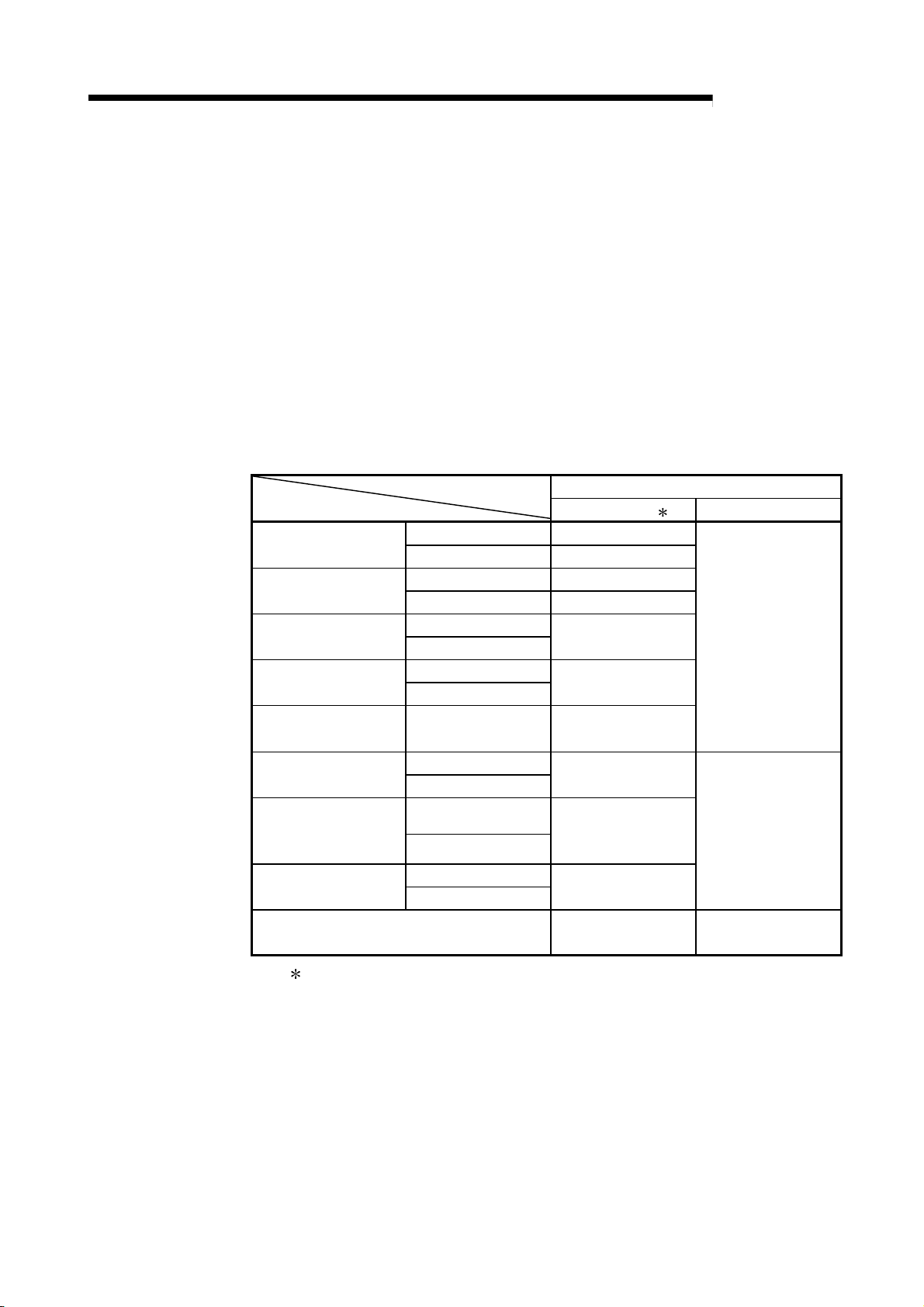

(3) Supported software packages

Relation between the system containing the QJ71MT91 and software package is

shown in the following table.

GX Developer is required to start up the system that uses the QJ71MT91.

Q00J/Q00/Q01CPU

Q12H/Q25HCPU

Q02PH/Q06PHCPU

Q12PH/Q25PHCPU

Software version

GX Developer 1 GX Configurator-MB

Single CPU system Version 7 or later

Multiple CPU system Version 8 or later

Single CPU system Version 4 or later Q02/Q02H/Q06H/

Multiple CPU system Version 6 or later

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Version 8.68W or later

Version 7.10L or later

MELSEC-Q

Version 1.00A or later

Q12PRH/Q25PRHCPU Redundant system Version 8.45X or later

Q13UDH/Q26UDHCPU

Q03UDE/Q04UDEH/

Q06UDEH/Q13UDEH/

Q26UDEHCPU

Q06UDHCPU

When mounted to MELSECNET/H remote I/O

station

1: Refer to Section 2.3 for the accessible range of GX Developer.

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system Q02U/Q03UD/Q04UDH/

Multiple CPU system

Version 8.62Q or later

Version 8.68W or later

Version 8.48A or later

Version 6.01B or later Version 1.00A or later

Version 1.08J or later

2 - 3 2 - 3

2 SYSTEM CONFIGURATION

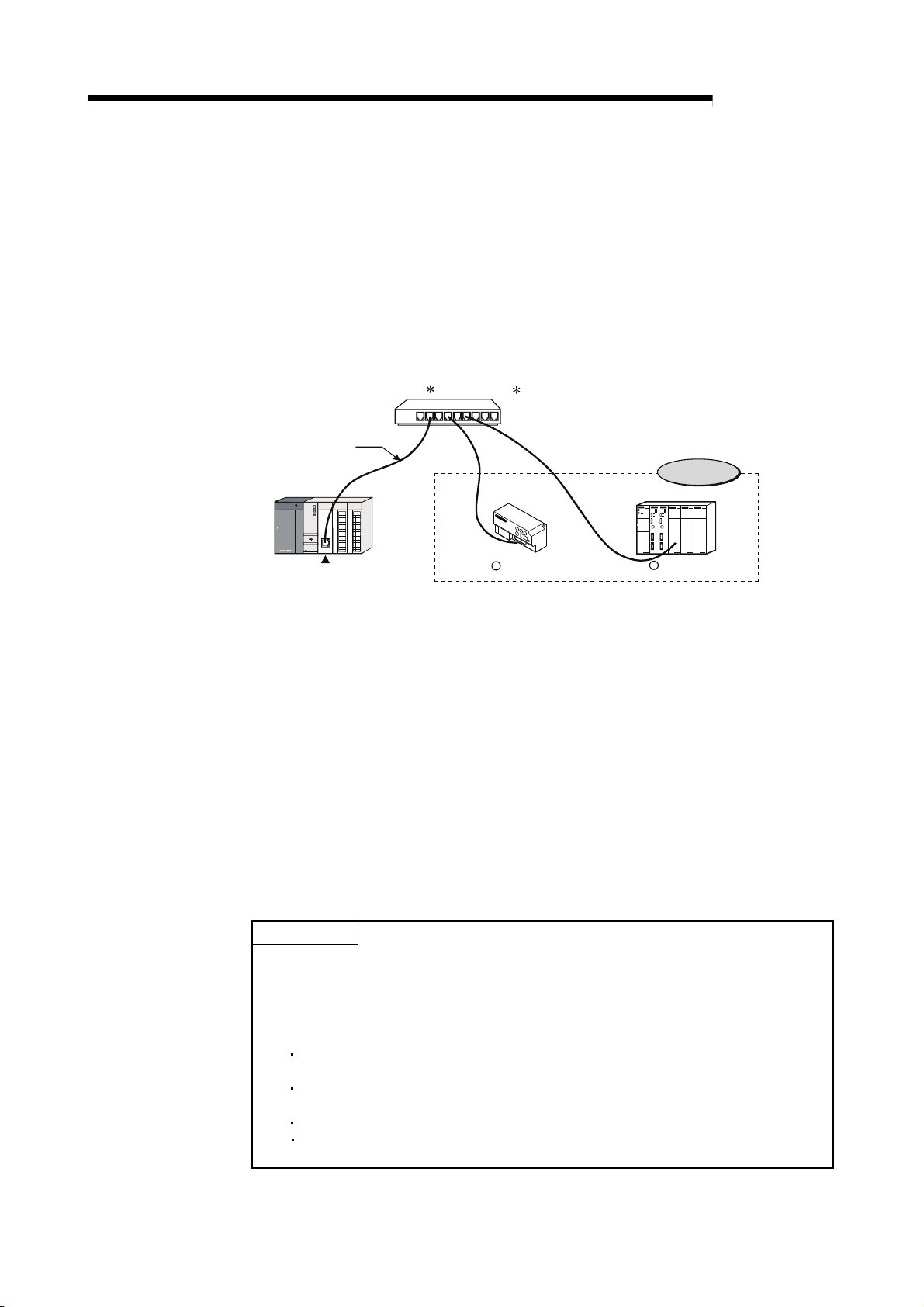

2.2 Devices Necessary for Network Configuration

This section explains the devices that configure a network.

Please note that the network must be installed by qualified networking specialists to

take sufficient safety measures.

The 10BASE-T or 100BASE-TX can be used to connect the QJ71MT91 to a network.

The QJ71MT91 will distinguish between 10BASE-T and 100BASE-TX, and between

the full duplex and half duplex communication mode according to the hub type.

However, for connection with the hub that does not have the auto negotiation function,

set the half duplex communication mode on the hub side.

1)

Hub (

Twisted pair cable

MELSEC-Q

Cascade connection is allowd for up to

*1

two stages when 100BASE-TX is used, or

up to four stages when 10BASE-T is used.

Target device

QJ71MT91

MODBUS /TCP slave device

R

MODBUS /TCP master device

Use the devices that comply with the IEEE802.3 100BASE-TX/10BASE-T Standard.

R

(1) Hub and other equipment

(a) Shielded twisted pair cable

1) For 100BASE-TX

Shielded twisted pair cable (STP cable), Category 5

2) For 10BASE-T

Unshielded twisted pair cable (UTP cable), Category 3 (4, 5)

A straight cable can be used.

(We do not guarantee proper operation if a crossing cable is used for the

100BASE-TX/10BASE-T connection between the QJ71MT91 and the

target device.)

(b) RJ45 jack

(c) Hub for 100Mbps/10Mbps network

POINT

In high-speed communication (100Mbps) by the 100BASE-TX connection, a

communication error may occur under the influence of high frequency noise from

devices other than the programmable controller in the installation environment.

Take the following action on the QJ71MT91 side to prevent the influence of high

frequency noise in the construction of a network system.

(1) Wiring connection

Do not install a twisted pain cable together with the main circuit and power

cables, etc.

Place the twisted pair cable in a duct.

(2) Communication system

Increase the number of communication retries if necessary.

Change the hub used for connection into a 10Mbps hub, and make

communication at a transmission speed of 10Mbps.

2 - 4 2 - 4

2 SYSTEM CONFIGURATION

2.3 System Configuration and Access Range

This section provides the system configurations using the QJ71MT91. ( 1)

The target devices available for communication with the QJ71MT91 are the following

two kinds of devices.

Master/slave device supporting the MODBUSR/TCP protocol

Personal computer running GX Developer

1: Ethernet devices can also be installed on the Ethernet line where the

MODBUS

R

/TCP system exists. (However, communication with the QJ71MT91 is

not available.)

(1) Basic system configuration (MODBUSR/TCP communication)

Third party

QJ71MT91

[Master/slave function]

programmable

controller

[Master]

User application

[Master]

HMI

[Master]

MELSEC-Q

MODBUS /TCP

serial gateway device

R

MODBUS serial

slave device

R

MELSEC-A series

programmable controller

(AJ71UC24-S2)

Third party

programmable

controller

[Slave]

Third party

programmable controller

Remote I/O

User application

[Slave]

Accessible from QJ71MT91 (master function) to each slave

Accessible from each master to QJ71MT91 (slave function)

Remote I/O

[Slave]

CNC

[Slave]

Ethernet

QJ71MT91

[Slave function]

2 - 5 2 - 5

2 SYSTEM CONFIGURATION

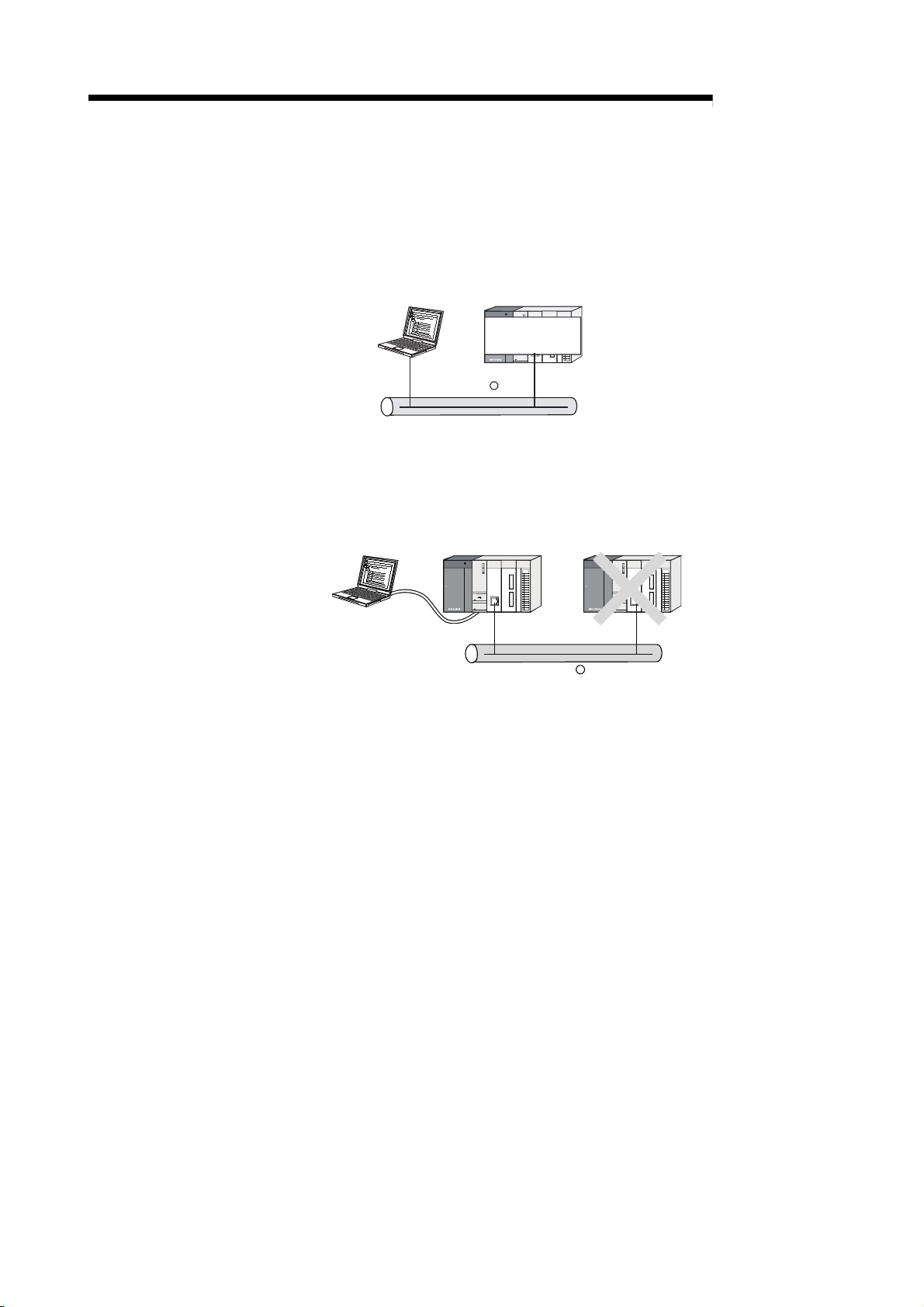

(2) GX Developer connection

(a) Accessible range of GX Developer

Refer to Appendix 3 for the GX Developer connection setup examples.

[Access path via QJ71MT91]

MELSEC-Q

GX Developer

MODBUS /TCP

QJ71MT91

Connected

programmable

controller

R

(b) Precautions for GX Developer connection

When the QJ71MT91 and Ethernet module exist together on the same

Ethernet, access cannot be made between the QJ71MT91 and Ethernet

module.

GX Developer

Ethernet module

Ethernet and MODBUS /TCP mixed network

QJ71MT91

R

2 - 6 2 - 6

2 SYSTEM CONFIGURATION

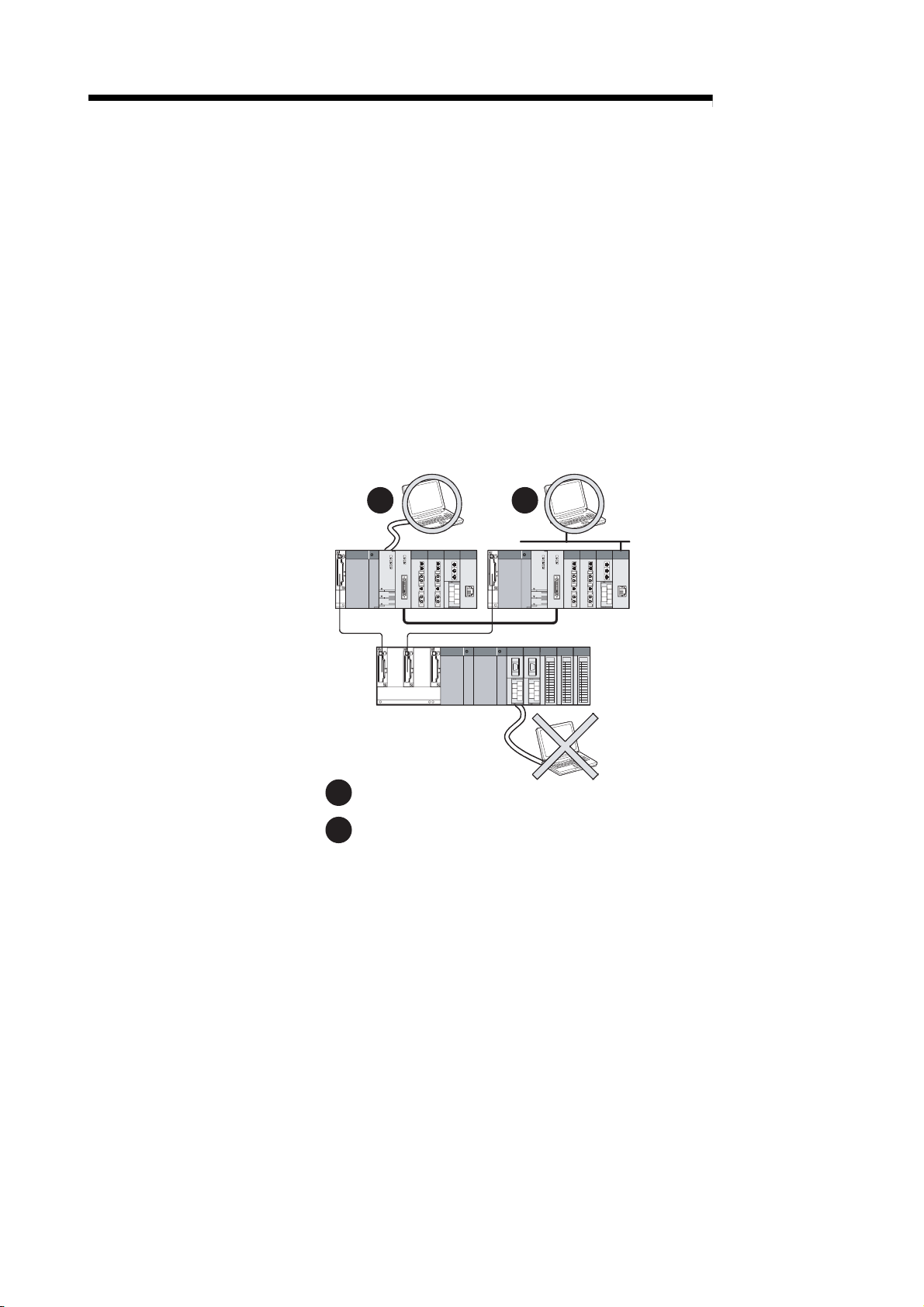

2.4 Precautions for System Configuration

(1) For Use with Q12PRH/Q25PRHCPU

(a) About dedicated instructions

Dedicated instructions cannot be used.

Instead of the MBRW instruction, use the automatic communication

function. (Refer to Section 9.2 and 9.3.)

The MBREQ instruction cannot be used.

(b) GX Configurator-MB

GX Configurator-MB cannot be used when accessing the

Q12PRH/Q25PRHCPU via an intelligent function module on an extension

base unit from GX Developer.

Connect a personal computer with a communication path indicated below.

1 2

MELSEC-Q

Main base unit

Extension base unit

(GX Configurator-MB cannot be used.)

1

Direct connection to the CPU

2

Connection through an intelligent function module on the main base unit

(Through Ethernet module, MELSECNET/H module, or CC-Link module)

2 - 7 2 - 7

2 SYSTEM CONFIGURATION

2.5 How to Check the Function Version and Software Version

Confirm the function version of the QJ71MT91 and the software version of GX

Configurator-MB in the following methods.

(1) Checking the function version of the QJ71MT91

(a) Checking at "the SERIAL field of the rating plate" located on

the side of the module

The serial No. and function version of the module is shown in the SERIAL

field of the rating plate.

MELSEC-Q

MAC ADD.

Serial No.(first5 digits)

Function version

Relevant regulation standards

(b) Checking by GX Developer

The serial No. and function version of the module are displayed on the

"Production Info. List" and "Module's Detailed Information" screen of GX

Developer.

The following explains how to check them on the "Production Info. List"

screen.

(For the case of "Module’s Detailed Information", refer to Section 11.2.)

[Operating procedure]

[Diagnostics]

[System monitor] Product Inf. List

2 - 8 2 - 8

2 SYSTEM CONFIGURATION

[Serial No, Ver, and Product No.]

*1: The Production No. column display is active only when the CPU used is

POINT

The serial No. on the rating plate may be different from the serial No. displayed on

the product information screen of GX Developer.

The serial No. on the rating plate indicates the management information of the

product.

The serial No. displayed on the product information screen of GX Developer

indicates the function information of the product.

The function information of the product is updated when a new function is added.

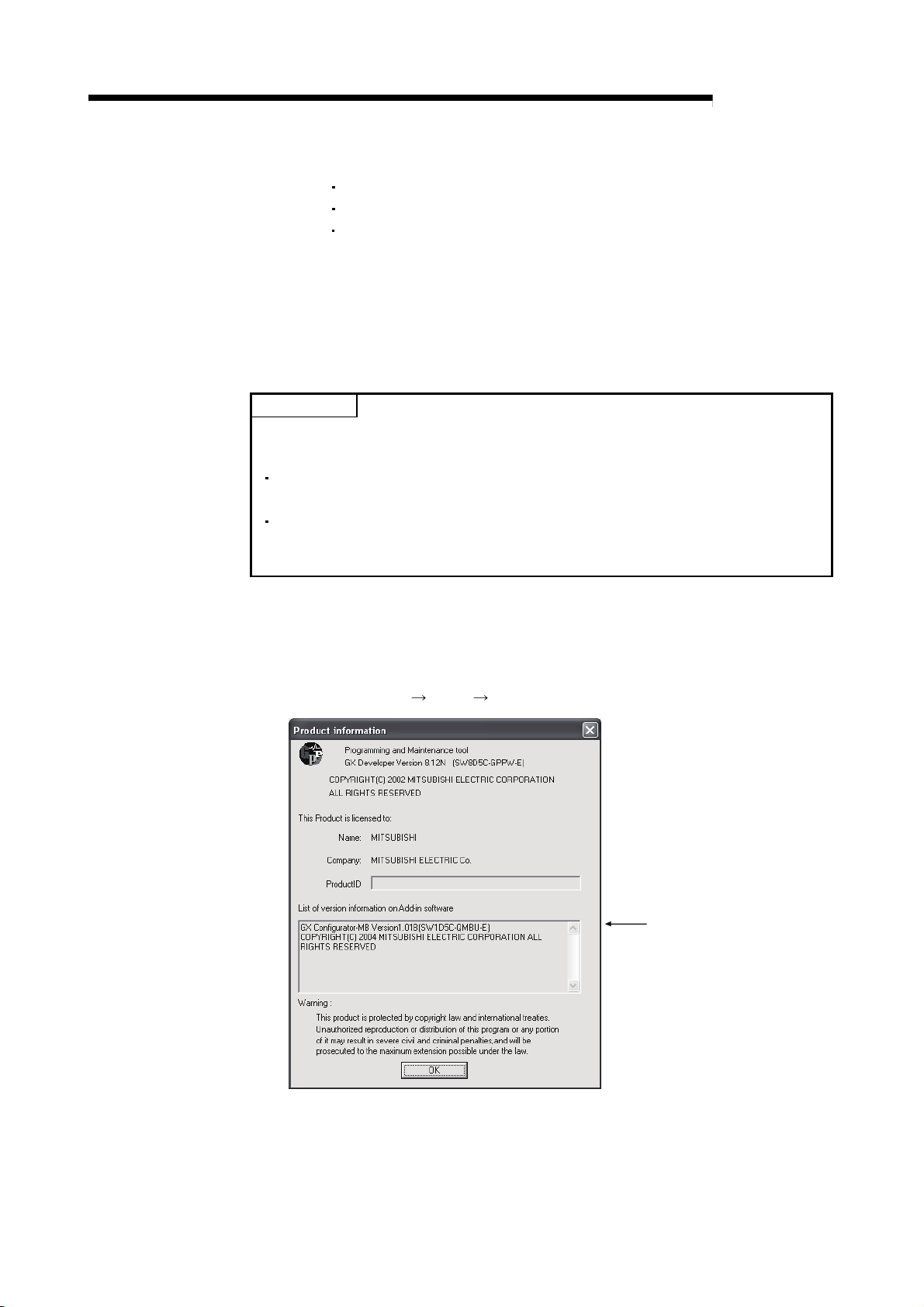

(2) Checking the software version of GX Configurator-MB

The software version of GX Configurator-MB can be checked in GX Developer’s

"Product information" screen.

[Operating procedure]

GX Developer

MELSEC-Q

Serial No. of the module is displayed in the Serial No. column.

Function version of the module is displayed in the Ver. column.

Serial No. printed on the rating plate is displayed in the Production No.

column. *1

Note that, because the QJ71MT91 does not support the production No.

display, "-" is displayed.

a Universal model QCPU.

[Help] [Product information]

Software version

2 - 9 2 - 9

Loading...

Loading...