Mitsubishi Electronics QJ71LP21, QJ71LP21-25, QJ71LP21GE, QJ71LP21S-25, QJ72LP25-25 User Manual

...Page 1

Q Corresponding MELSECNET/H

Network System

Reference Manual (Remote I/O network)

-QJ71LP21

-QJ71LP21-25

-QJ71LP21S-25

-QJ71LP21G

-QJ71LP21GE

-QJ71BR11

-QJ72LP25-25

-QJ72LP25G

-QJ72LP25GE

-QJ72BR15

Page 2

Page 3

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of

the programmable controller system, refer to the user’s manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: "

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under "

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

WARNING" and " CAUTION".

CAUTION" may lead to

!

WARNING

When the network develops a communication error, the station with the communication error will

enter into the following status.

Check the communication status information and configure an interlock circuit in the sequence

program to ensure that the entire system will operate safely. Failure to do so may result in an

accident due to an incorrect output or malfunction.

(1) The remote master station will hold the data from before the communication error.

(2) The remote I/O station turns off all outputs. The output module of the remote I/O station can

clear/hold the output status at the time of error by using the remote I/O module parameters.

As the parameters are set to "clear" by default, the output module turns off the outputs at the

time of error. If it is required to hold the output in order to operate the system safely, set the

parameters to "hold".

A - 1 A - 1

Page 4

[Design Precautions]

!

WARNING

When connecting a peripheral with the programmable controller CPU or connecting a personal

computer with an intelligent function module to modify data of a running programmable

controller, configure an interlock circuit in the sequence program to ensure that the entire

system will always operate safely. For other forms of control (such as program modification or

operating status change) of a running programmable controller, read the relevant manuals

carefully and ensure that the operation is safe before proceeding. Especially, when a remote

programmable controller is controlled by an external device, immediate action cannot be taken if

a problem occurs in the programmable controller due to a communication failure. To prevent

this, configure an interlock circuit in the sequence program, and determine corrective actions to

be taken between the external device and CPU module in case of a communication failure.

If a communication cable is disconnected, the network may be unstable, resulting in a

communication failure of multiple stations. Configure an interlock circuit in the program to ensure

that the entire system will always operate safely even if communications fail. Failure to do so

may result in an accident due to an incorrect output or malfunction.

!

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or

power cables. Keep a distance of 100mm (3.94 in.) or more between them. Failure to do so may

result in malfunction due to noise.

Reset the CPU module or remote I/O module after changing its parameters. Failure to do so

may cause malfunction because the previous parameter settings remain in the module.

[Installation Precautions]

!

CAUTION

Use the programmable controller in an environment that meets the general specifications in the

user’s manual for the CPU module used. Failure to do so may result in electric shock, fire,

malfunction, or damage to or deterioration of the product.

To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place. Incorrect mounting may cause malfunction, failure or drop of the

module. When using the programmable controller in an environment of frequent vibrations, fix

the module with a screw.

Tighten the screws within the specified torque range. Undertightening can cause drop of the

screw, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction

Shut off the external power supply (all phases) used in the system before mounting/removing a

module or connecting/disconnecting a connector. Failure to do so may result in damage to the

product. Modules can be replaced online on a remote I/O station where a remote I/O module

with function version D or later is used. Note that there are restrictions on the modules that can

be replaced online, and each module has its predetermined replacement procedure. For details,

refer to the relevant section in this manual.

A - 2 A - 2

Page 5

[Installation Precautions]

!

CAUTION

Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

!

WARNING

Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or damage to the product.

[Wiring Precautions]

!

CAUTION

Individually ground the FG terminal of the programmable controller with a ground resistance of

100Ω or less.

Failure to do so may result in electric shock or malfunction.

Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may

cause a fire or failure.

Connectors for external devices and coaxial cables must be crimped or pressed with the tool

specified by the manufacturer, or must be correctly soldered. Incomplete connections may

cause short circuit, fire, or malfunction.

Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be

pulled, resulting in damage to the module or cables or malfunction due to poor contact.

Tighten the terminal screws within the specified torque range. Undertightening can cause short

circuit, fire, or malfunction. Overtightening can damage the screw and/or module, resulting in

drop, short circuit, or malfunction.

When disconnecting the cable from the module, do not pull the cable by the cable part. For the

cable with connector, hold the connector part of the cable. For the cable connected to the

terminal block, loosen the terminal screw. Pulling the cable connected to the module may result

in malfunction or damage to the module or cable.

Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter

can cause a fire, failure, or malfunction.

A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

Mitsubishi programmable controllers must be installed in control panels. Connect the main

power supply to the power supply module in the control panel through a relay terminal block.

Wiring and replacement of a power supply module must be performed by qualified maintenance

personnel with knowledge of protection against electric shock. For wiring methods, refer to the

QCPU User's Manual (Hardware Design, Maintenance and Inspection).

A - 3 A - 3

Page 6

[Setup and Maintenance Precautions]

!

WARNING

Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws or module mounting screws.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Setup and Maintenance Precautions]

!

CAUTION

Before performing online operations (especially, program modification, forced output, and

operating status change) for the running CPU module on another station from GX Developer

over the MELSECNET/H network, read relevant manuals carefully and ensure the safety.

Improper operation may damage machines or cause accidents.

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm (9.85 inches) away in all directions from the programmable controller.

Failure to do so may cause malfunction.

Shut off the external power supply (all phases) used in the system before mounting/removing a

module or connecting/disconnecting a connector. Failure to do so may cause the module to fail

or malfunction. Modules can be replaced online in a remote I/O network system where a remote

I/O module with function version D or later is used. Note that there are restrictions on the

modules that can be replaced online, and each module has its predetermined replacement

procedure. For details, refer to the relevant section in this manual.

After the first use of the product, do not mount/remove the module to/from the base unit more

than 50 times (IEC 61131-2 compliant).

Exceeding the limit of 50 times may cause malfunction.

Before handling the module, touch a conducting object such as a grounded metal to discharge

the static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

!

CAUTION

When disposing of this product, treat it as industrial waste.

A - 4 A - 4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 5 A - 5

Page 8

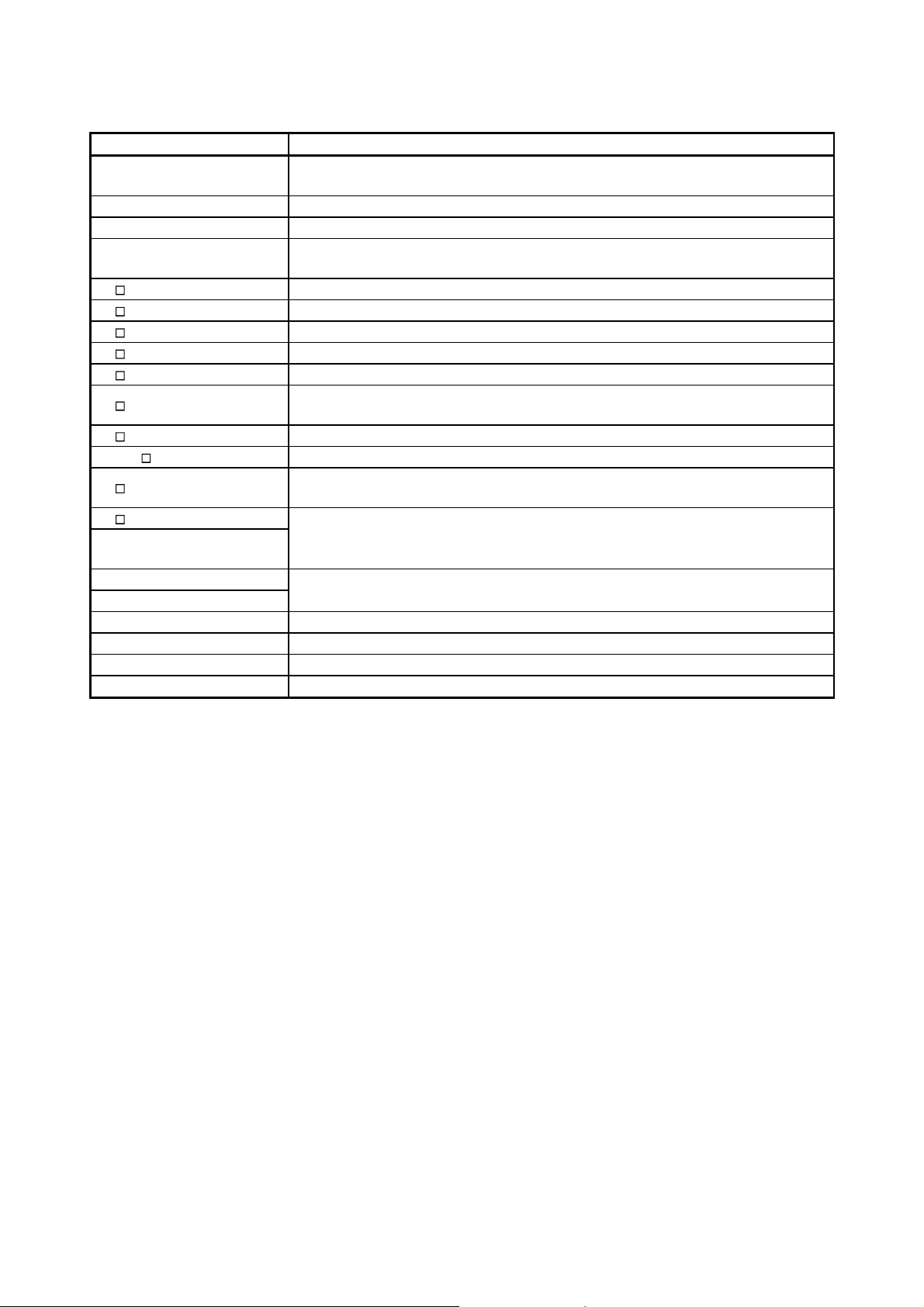

REVISIONS

The manual number is given on the bottom left of the back cover.

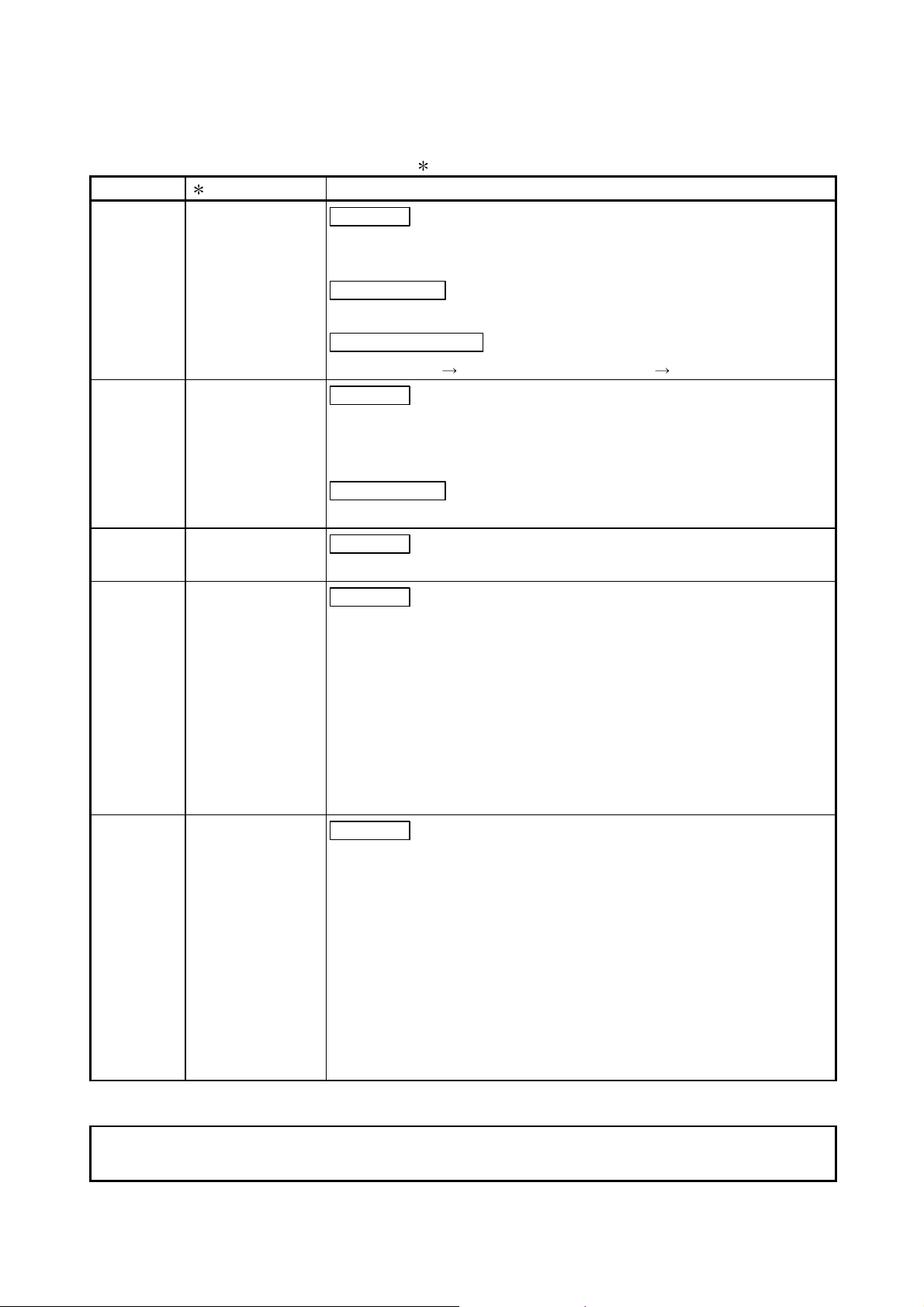

Print Date Manual Number Revision

Oct., 2000 SH (NA) -080124-A First printing

May., 2001 SH (NA) -080124-B

Model addition

QJ71LP21G, QJ72LP25G, QJ71LP21GE, QJ72LP25GE

Correction

Product Components, About The Generic Terms And Abbreviations,

Chapter 1, Section 1.2, 2.4, 3.1.1, 3.1.2, 3.2.1, 3.2.2, 3.3.2, 4.2.1, 4.2.2,

4.8.2, Chapter 5, Section 5.1.5, 5.2.1, 6.1.2, 6.2.1, 6.3, 6.4, 7.1.1, 7.8,

8.1, 8.1.1, 8.1.4, 8.3.1, 8.3.2, Appendix 2, 3, 4, 5, Index

Addition

Section 8.2.6

Apr., 2002 SH (NA) -080124-C

Correction

Section 1.2, 1.3, 2.3.1, 2.3.2, 2.3.3, 2.5, 3.1.1, 3.1.2, 3.2, 3.3.2, 4.2.1,

6.1.1, 6.4, Chapter 7, Section 8.4, Appendix 2, 3

Changed item numbers

Nov., 2002 SH (NA) -080124-D

Apr., 2003 SH (NA) -080124-E

Section 2.3

Addition

Section 2.4, Section 2.4 Section 2.5

Section 7.10

Model addition

QJ71LP21S-25

Correction

SAFETY PRECAUTIONS, CONTENTS,

Generic Terms And Abbreviations, Product Components,

Section 1.1, 1.2, 3.1.1, 3.1.2, 4.1.2, 4.8.1, 4.8.2, 7.1.1, 8.1.4,

Appendix 2, 3

Correction

SAFETY PRECAUTIONS, About Manuals, Section 1.2, 2.1.2, 2.2.2,

2.3.2, 2.5, 3.1.1, 3.1.2, 3.2.2, 3.3.1, Chapter 5, Section 5.1.3, 5.1.5, 6.2,

6.3, 6.4, 6.5, 8.1, 8.2, 8.2.1, 8.2.5, 8.3.1

A - 6 A - 6

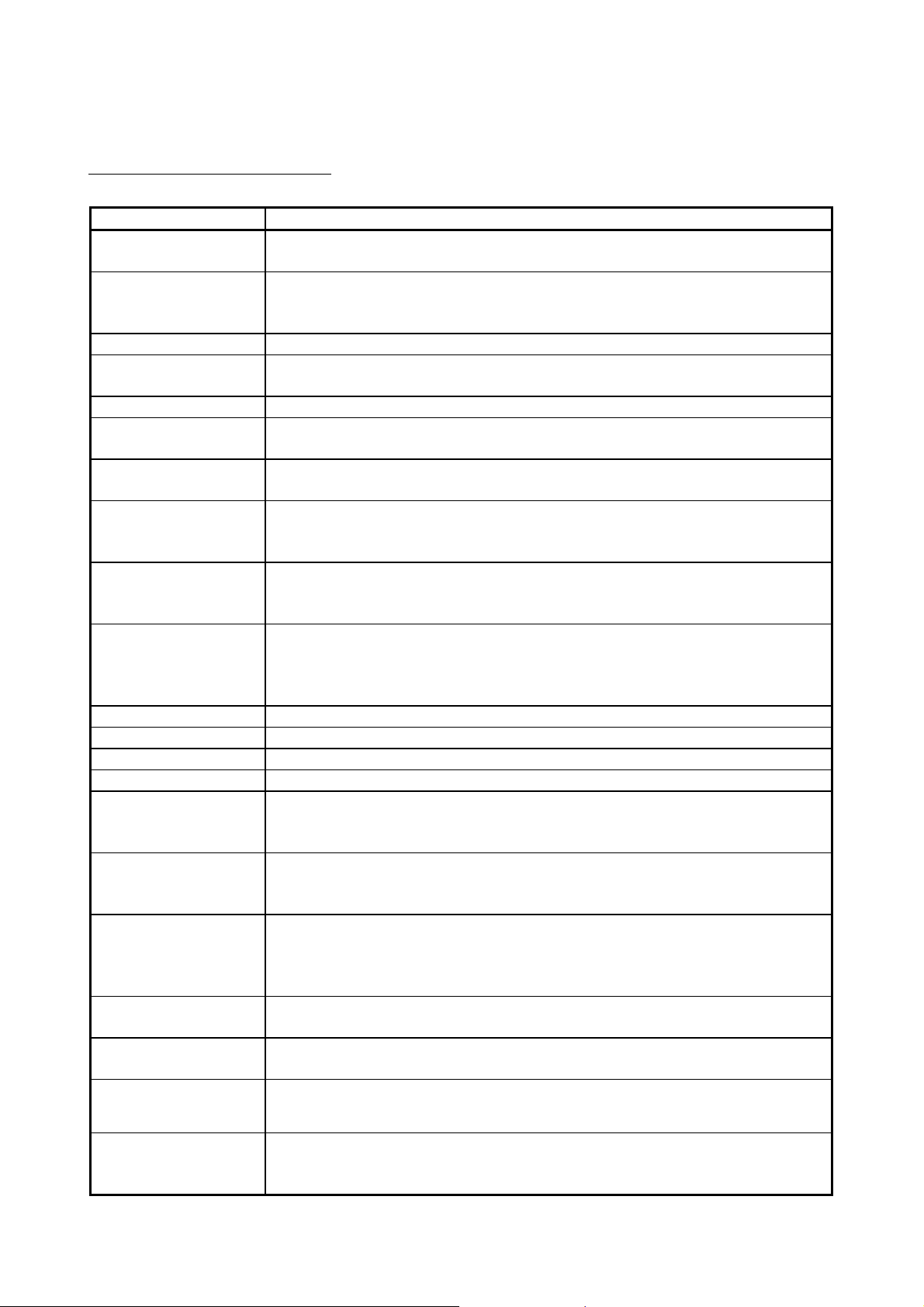

Page 9

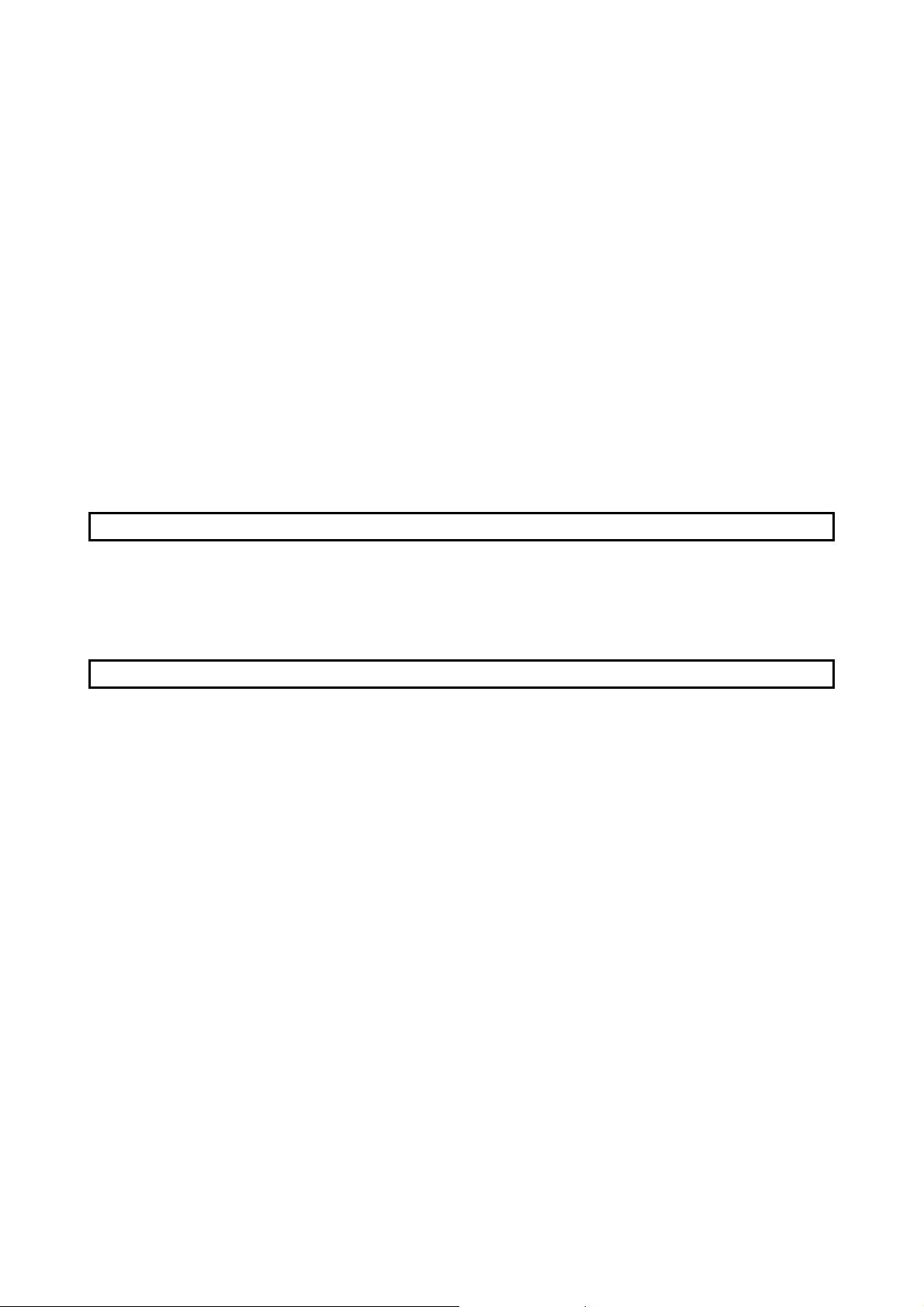

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Jun., 2004 SH (NA) -080124-F

Correction

SAFETY PRECAUTIONS, Manuals, Generic Terms And Abbreviations,

Section 1.2, 2.1.2, 2.2.2, 2.3.2, 2.4.2, 2.5, 3.1.1, 3.1.2, 3.1.3, 3.1.4, 3.2,

3.2.2, 4.2.2, 4.9.1, 4.10, 4.10.1, 4.10.2, 4.10.3, Chapter 5, Section 5.1.1,

5.2, 5.2.1, 6.4, 6.5, Chapter 7, Section 8.1, 8.1.1, 8.1.2, 8.1.3, 8.1.4,

8.2.1, 8.2.3, 8.2.5, 8.2.7, 8.3.1, 8.3.2, Appendix 2, 3

Addition

Section 1.4, 2.4, 2.7, 3.3.3, 3.3.4, 7.11, 7.12, 8.2.7, Appendix 7

Changed section No.

Mar., 2005 SH (NA) -080124-G

Sep., 2005 SH (NA) -080124-H

May, 2006 SH (NA) -080124-I

Sep., 2006 SH (NA) -080124-J

Section 2.4

Correction

Section 2.5, Section 2.5 Section 2.6

Safety Precautions, Conformation to the EMC Directive and Low Voltage

Instruction, Product Configuration, Section 1.1, 1.2, 2.6, 2.7, 3.1.1, 3.1.2,

3.1.4, 3.2.2, 3.3.2, 4.2.1, 4.2.2, 4.3, 4.4, 4.8.1, 4.8.2, 4.9.1, 4.10.1, 5.1.4,

6.1.1, 6.2, 6.2.2, 6.3, 7.4, 8.1, 8.1.2, 8.1.3, 8.2, 8.2.1, 8.3.1, 8.3.2,

Appendix 2, 3, 4, 5, 7

Addition

Section 8.2.8

Correction

Generic Terms And Abbreviations, Section 1.2, Section 2.5, Section 3.2,

3.2.2, 3.3.2, Section 5.1.5, 5.2.1, Section 6.3, 6.5, Section 7.12, Section

8.2, 8.2.5, 8.3.1, 8.3.2, Appendix 3, 4, 5

Correction

Generic Terms And Abbreviations, Section 1.1, Chapter 2, Section 2.2.1,

2.5, 3.1.1, 3.1.4, 4.2.1, 4.2.2, 5.1.3, 5.1.4, 5.1.5, 6.3, 6.4, 7.1.1, 8.1.2,

8.3.2, Appendix 5

Addition

Section 2.5.1, 2.5.2

Correction

Section 2.1.2, 2.2.2, 2.3.2, 2.4.2, 4.2.1, 4.2.2, 8.3.2

A - 7 A - 7

Page 10

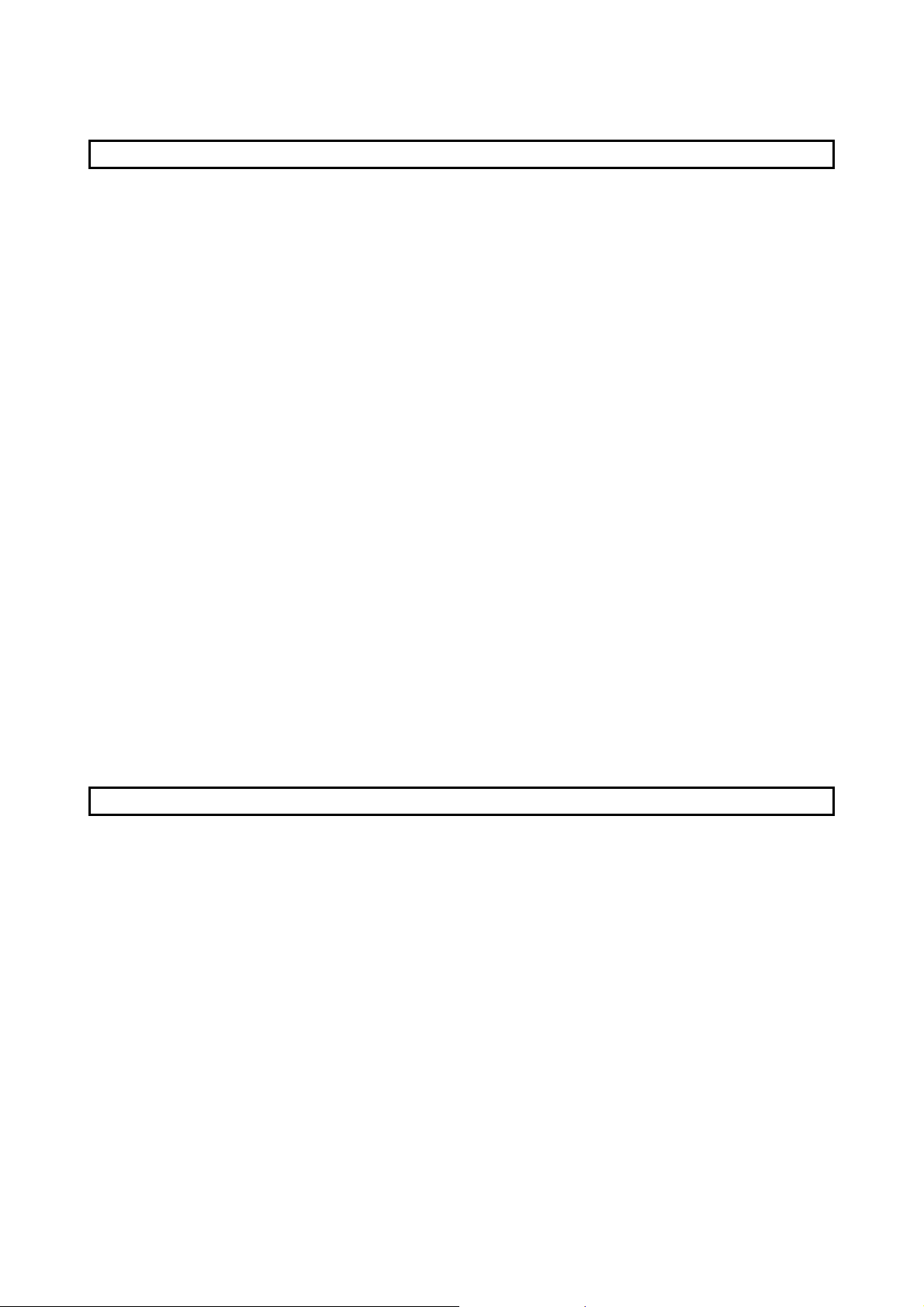

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Nov., 2006 SH (NA) -080124-K

Addition

SAFETY PRECAUTIONS

Correction

Section 2.5.2, 3.2.2, 4.2.1, 4.2.2, 4.3, 4.8.1, 4.8.2, 5.1.5, 8.1.2, 8.2, 8.2.4,

8.3.2, Appendix 2, 3, 5

Sections added

Section 8.2.8, 8.4, 8.5

Changed section No.

Section 8.2.8

Oct., 2007 SH (NA) -080124-L

Addition

Chapter 1, Section 2.1.2, 2.2.2, 2.3.2, 2.4.2, 2.5.1, 2.5.2, 2.7, 3.3.1, 3.3.2,

4.8.2, Chapter 5, Section 5.1.4, 5.1.5, 8.2.1, 8.3.1, Appendix 2, 4, 5

Correction

SAFETY PRECAUTIONS , Generic Terms And Abbreviations, Section

2.2.1, 2.3.1, 2.4.1, 4.2.1, 4.7.1, 4.7.2, 4.7.3, 4.9.1, 5.1.1, 5.1.3, 6.1.1, 6.2,

6.3, 6.5, 6.6, 7.1.1, 7.12, 8.1, Appendix 3

Sections added

DEFINITIONS OF TERMINOLOGY, Section 6.4

Changed section No.

Section 6.4 to 6.5

Feb., 2008 SH (NA)-080124-M

Correction

Generic Terms And Abbreviations, Section 1.2, 2.1.2, 2.2.2, 2.3.2, 2.4.2,

2.5, 3.2.2, 3.3.2, 4.7, 4.8, 4.9.1, 5.1.1, 5.1.4 to 5.1.6, 5.2.1, 6.1.1, 6.5, 6.6,

7.1.1, 7.8, 7.11.4, 8.1, 8.3, 8.4, Appendix 2, 3, 5

Sep., 2008 SH (NA)-080124-N

Correction

SAFETY PRECAUTIONS, Compliance with the EMC and Low Voltage

Directives, Generic Terms And Abbreviations, DEFINITIONS OF

TERMINOLOGY, Chapter1, Section 1.2, 1.3, 2.1.2, 2.1.3, 2.2, 2.2.1,

2.2.3, 2.3, 2.4.2, 2.4.3, 2.5.1, 2.6, 3.1.4, 3.2, 3.3.2, 3.3.4, 4.2.1, 4.2.2, 4.8,

4.9.1, Chapter 5, Section 5.1.3 to 5.1.5, 6.1.2, 6.5, 6.6, Chapter 7, 7.1.1,

7.10, 7.11, 7.11.1, 7.11.3, 7.11.4, Chapter 8, 8.1, 8.2, 8.2.5, 8.2.7, 8.3.1,

8.3.2, Appendix 2 to 6

Section 8.2.9, Section 8.4 Section 8.6

Section 6.5 to 6.6, Appendix 7 Appendix 6

A - 8 A - 8

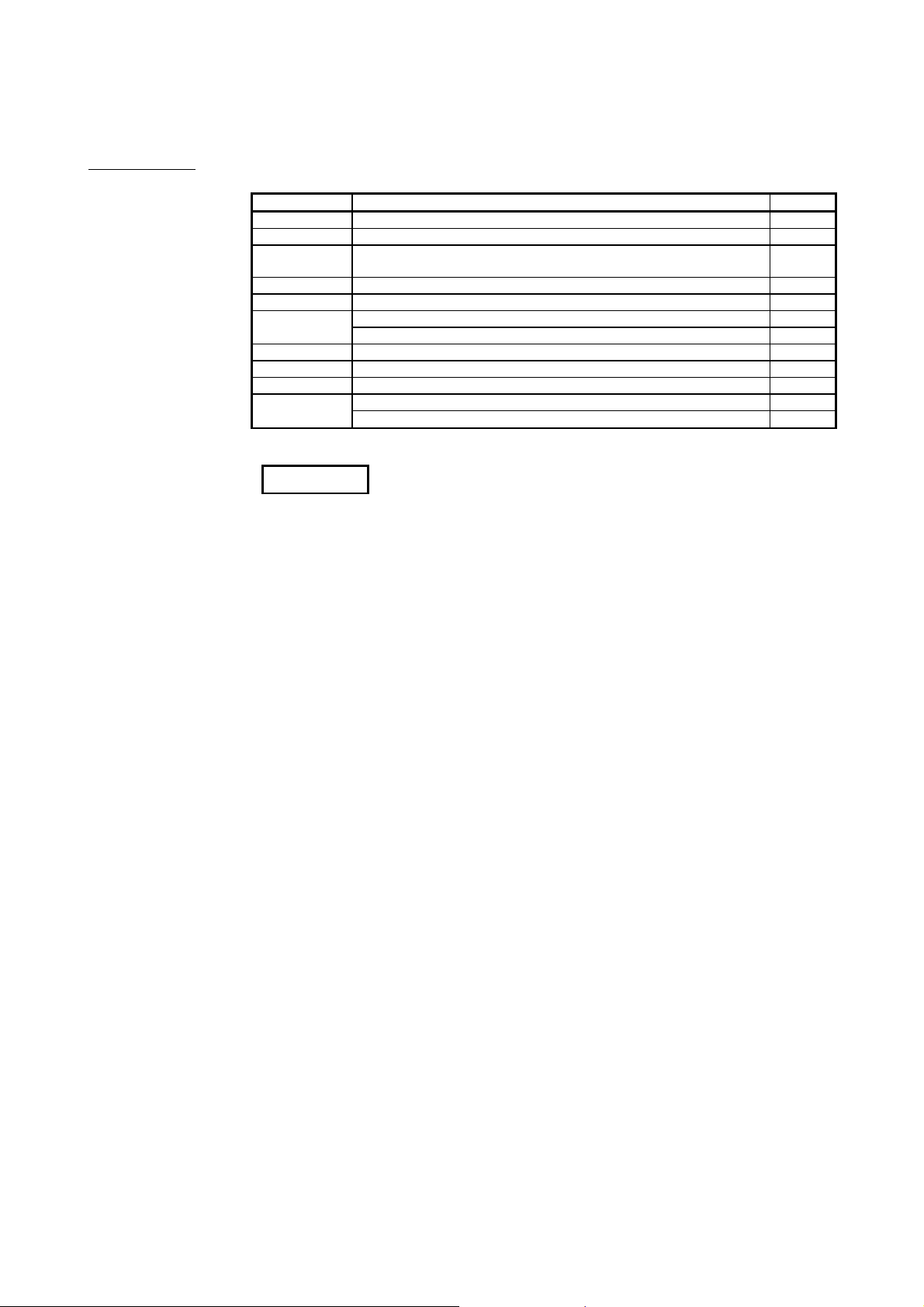

Page 11

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Aug., 2009 SH (NA) -080124-O

Correction

Generic Terms And Abbreviations, Section 1.3, 2.5.1, 2.7, 3.3.2, 6.4.2,

Chapter 8

Sections added

Section 8.3.1

Changed section No.

Sep., 2010 SH (NA) -080124-P

Mar., 2011 SH (NA) -080124-Q

Sep.,2012 SH (NA) -080124-R

Section 8.3.1(4)

Correction

Section 8.3.2, Section 8.3.2 Section 8.3.3

Generic Terms And Abbreviations, Section 1.3, 2.5.1, 2.5.2, 2.7, 3.3.2,

4.2.1, 4.2.2, 4.3, Chapter 5, Section 5.1.5, 5.1.6, 6.1.1, 8.2.9, 8.3.1, 8.3.2,

8.3.3, Appendix 2, 6

Sections added

CONDITIONS OF USE FOR THE PRODUCT

Correction

Section 3.1.4, 3.3.1, 8.3.2, Appendix 5

Correction

SAFETY PRECAUTIONS, COMPLIANCE WITH THE EMC AND LOW

VOLTAGE DIRECTIVES, GENERIC TERMS AND ABBREVIATIONS,

PACKING LIST, Section 1.2, 1.4, 2.1.2, 2.2.2, 2.3.1, 2.3.2, 2.4.1, 2.4.2,

2.5.1, 2.5.2, 2.6, 2.7, 3.1.1, 3.1.2, 3.1.4, 3.2, 3.2.1, 3.2.2, 3.3.1, 3.3.2,

3.3.3, 3.3.4, 4.1, 4.2.1, 4.2.2, 4.3, 4.7, 4.8.1, 4.8.2, 4.9.1, 4.10, 4.10.1,

4.10.2, 4.10.3, Chapter 5, Section 5.1.1, 5.1.2, 5.1.3, 5.1.4, 5.1.5, 5.1.6,

5.2.1, 6.1.1, 6.1.2, 6.5, 6.6, Chapter 7, Section 7.11, 7.11.3, 7.11.4, 7.12,

Chapter 8, Section 8.1, 8.1.1, 8.1.3, 8.2, 8.2.1, 8.2.4, 8.2.5, 8.3, 8.3.1,

8.3.2, 8.3.3, 8.4, 8.6, Appendix 1, 2, 3, 5, 6, INDEX

Jul., 2013 SH (NA) -080124-S

Correction

SAFETY PRECAUTIONS, MANUALS, GENERIC TERMS AND

ABBREVIATIONS, Chapter 1, Section 1.2, 1.3, 2.5.1, 2.5.2, 4.2.1, 4.2.2,

4.7, 4.7.1, 4.7.2, 4.7.3, 4.8.1, 4.10.1, 4.10.2, 4.10.3, 4.10.4, Chapter 5,

Section 5.2.1, 6.1.1, 6.4.1, 6.6, 7.11, 7.12, 8.1.1, 8.1.2, 8.1.3, 8.1.4, 8.2.6,

8.3.1, 8.3.3, Appendix 1, 2, 3, 4, 5

Japanese Manual Version SH-080123-W

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2000 MITSUBISHI ELECTRIC CORPORATION

A - 9 A - 9

Page 12

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC-Q series programmable controllers.

Before using this product, please read this manual carefully and develop familiarity with the functions and

performance of the MELSEC-Q series programmable controller to handle the product correctly.

CONTENTS

SAFETY PRECAUTIONS .............................................................................................................................. A- 1

CONDITIONS OF USE FOR THE PRODUCT ............................................................................................. A- 5

REVISIONS ................................................................................................................................................... A- 6

CONTENTS ................................................................................................................................................... A-10

MANUALS ................................................................................................................................................... A-15

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES ....................................................... A-15

GENERIC TERMS AND ABBREVIATIONS ................................................................................................. A-16

DEFINITIONS OF TERMINOLOGY .............................................................................................................. A-18

PACKING LIST ............................................................................................................................................... A-19

1 OVERVIEW 1- 1 to 1-11

1.1 Overview.................................................................................................................................................. 1- 2

1.2 Features .................................................................................................................................................. 1- 3

1.3 Abbreviations Used in the Text, Tables and Diagrams of This Manual ................................................ 1-10

1.4 Functions Added/Changed with Upgrade to Function Version D.......................................................... 1-11

2 SYSTEM CONFIGURATION 2- 1 to 2-23

2.1 Single Remote I/O Networks .................................................................................................................. 2- 1

2.1.1 Configuration .................................................................................................................................... 2- 1

2.1.2 Setting items ..................................................................................................................................... 2- 2

2.1.3 Available device ranges ................................................................................................................... 2- 3

2.2 Multiple Remote I/O Network (Process CPU) ........................................................................................ 2- 4

2.2.1 Configuration .................................................................................................................................... 2- 4

2.2.2 Setting items ..................................................................................................................................... 2- 5

2.2.3 Available device ranges ................................................................................................................... 2- 6

2.3 Multiplexed Remote I/O Network for Redundant System (Redundant CPU) ....................................... 2- 7

2.3.1 Configuration .................................................................................................................................... 2- 7

2.3.2 Setting items ..................................................................................................................................... 2- 8

2.3.3 Available device ranges ................................................................................................................... 2- 9

2.4 Multiple Remote I/O Network .................................................................................................................. 2-10

2.4.1 Configuration .................................................................................................................................... 2-10

2.4.2 Setting items ..................................................................................................................................... 2-11

2.4.3 Available device ranges ................................................................................................................... 2-12

2.5 Applicable Systems ................................................................................................................................. 2-13

2.5.1 Applicable systems for remote master stations ............................................................................... 2-13

2.5.2 Applicable systems for remote I/O stations ...................................................................................... 2-15

2.6 When Using a Multiple CPU System ...................................................................................................... 2-19

2.7 Checking Function Version and Serial No. ............................................................................................ 2-22

A - 10 A - 10

Page 13

3 SPECIFICATIONS 3- 1 to 3-64

3.1 Performance Specifications .................................................................................................................... 3- 1

3.1.1 Optical loop system performance specifications ............................................................................. 3- 1

3.1.2 Coaxial cable system performance specifications .......................................................................... 3- 3

3.1.3 Optical fiber cable specifications ..................................................................................................... 3- 4

3.1.4 Coaxial cable specifications ............................................................................................................. 3- 5

3.2 Function Specifications ........................................................................................................................... 3-10

3.2.1 Cyclic transmission function (periodic communication) .................................................................. 3-11

(1) Communicating with I/O modules ................................................................................................... 3-11

(2) Communicating with intelligent function modules ........................................................................... 3-12

3.2.2 RAS functions ................................................................................................................................... 3-17

(1) Output reset function for communication errors ............................................................................. 3-17

(2) Hardware error time CPU operation mode setting ......................................................................... 3-17

(3) Automatic return function ................................................................................................................. 3-18

(4) Loopback function (optical loop system) ......................................................................................... 3-19

(5) Station detach function (coaxial bus system) ................................................................................. 3-21

(6) Transient transmission enabled even at CPU module error .......................................................... 3-22

(7) Abnormal detection time .................................................................................................................. 3-23

(8) Diagnostic function .......................................................................................................................... 3-24

(9) Redundant power supply on a remote I/O station .......................................................................... 3-25

(10) Online module change on a remote I/O station ............................................................................ 3-28

3.3 Link Data Send/Receive Processing Time Specifications ..................................................................... 3-34

3.3.1 Link data send/receive processing .................................................................................................. 3-34

3.3.2 Transmission delay time .................................................................................................................. 3-40

3.3.3 Switching time from the multiplexed remote master station to the multiplexed remote

sub-master station in a multiplexed remote I/O network ................................................................ 3-59

3.3.4 Output holding time during system switching in the multiplexed remote I/O network for

redundant system ............................................................................................................................ 3-60

4 SETTING AND PROCEDURE BEFORE OPERATION 4- 1 to 4-37

4.1 Procedure Before Operation ................................................................................................................... 4- 1

4.2 Part Names and Settings ........................................................................................................................ 4- 2

4.2.1 QJ71LP21, QJ71LP21-25, QJ71LP21G, QJ71LP21GE, QJ71BR11 (Remote master station)

......................................................................................................................................................... 4- 2

4.2.2 QJ72LP25-25, QJ72LP25G, QJ72LP25GE, QJ72BR15 ............................................................... 4- 6

4.3 Installing and Uninstalling the Module .................................................................................................... 4-11

4.4 Stopping the CPU (Unintentional Output Prevention) ........................................................................... 4-13

4.5 Checking the Input Power Supply Voltage ............................................................................................. 4-13

4.6 Powering On............................................................................................................................................ 4-13

4.6.1 Checking the on status of the POWER LED of the power supply module .................................... 4-13

4.6.2 Checking the on status of the RUN LED of the network module ................................................... 4-13

4.7 Unit Tests of the Network Module (Offline Test) .................................................................................... 4-14

4.7.1 Self-loopback test ............................................................................................................................. 4-15

4.7.2 Internal self-loopback test ................................................................................................................ 4-17

4.7.3 Hardware test ................................................................................................................................... 4-19

4.8 Cable Connections .................................................................................................................................. 4-21

4.8.1 Optical loop system .......................................................................................................................... 4-21

A - 11 A - 11

Page 14

4.8.2 Coaxial bus system .......................................................................................................................... 4-23

4.9 Offline Tests from GX Developer ........................................................................................................... 4-28

4.9.1 Forward loop/reverse loop test (Remote master station only) ....................................................... 4-28

4.10 Network Diagnostics from GX Developer (Online Tests) .................................................................... 4-32

4.10.1 Loop test (optical loop system only) .............................................................................................. 4-33

4.10.2 Setup confirmation test .................................................................................................................. 4-34

4.10.3 Station order check test (optical loop system only) ...................................................................... 4-35

4.10.4 Communication test ....................................................................................................................... 4-36

5 PARAMETER SETTINGS 5- 1 to 5-38

5.1 Remote Master Station Parameter Setting ............................................................................................ 5- 5

5.1.1 Setting the number of modules (Network type) .............................................................................. 5- 5

5.1.2 Network settings ............................................................................................................................... 5- 6

(1) Starting I/O No. ................................................................................................................................ 5- 6

(2) Network No. ..................................................................................................................................... 5- 6

(3) Total stations .................................................................................................................................... 5- 6

(4) Group No. (Available for multiplexed remote master/sub-master station only) ............................... 5- 7

(5) Mode ................................................................................................................................................ 5- 7

(6) Parameter setting example ............................................................................................................. 5- 8

5.1.3 Common parameter ......................................................................................................................... 5- 9

(1) LX/LY setting .................................................................................................................................... 5- 9

(2) LB/LW setting ................................................................................................................................... 5-12

(3) Reserved station specification ......................................................................................................... 5-13

(4) Remote sub-master station ............................................................................................................. 5-13

5.1.4 Supplementary settings ................................................................................................................... 5-15

5.1.5 Refresh parameters ......................................................................................................................... 5-19

5.1.6 Valid Module During Other Station Access ..................................................................................... 5-31

5.1.7 Redundant settings .......................................................................................................................... 5-32

5.2 Remote I/O Station Parameter Settings ................................................................................................. 5-33

5.2.1 Remote I/O station possible parameter settings ............................................................................. 5-33

6 PROGRAMMING 6- 1 to 6-41

6.1 Programming Precautions ...................................................................................................................... 6- 1

6.1.1 Interlock related signals ................................................................................................................... 6- 1

6.1.2 Program example ............................................................................................................................. 6- 4

6.2 Cyclic Transmission ................................................................................................................................ 6- 7

6.2.1 32-bit data guarantee ....................................................................................................................... 6- 7

6.2.2 Block guarantee of cyclic data per station ....................................................................................... 6- 8

6.3 Communications with I/O Modules ......................................................................................................... 6- 9

6.4 Communications with Intelligent Function Modules ............................................................................... 6-10

6.4.1 Program example when using GX Configurator ............................................................................. 6-11

6.4.2 Program example when not using GX Configurator ....................................................................... 6-15

6.5 Link Dedicated Instruction List ................................................................................................................ 6-18

6.6 Using the Link Special Relays (SB)/ Link Special Registers (SW) ....................................................... 6-23

A - 12 A - 12

Page 15

7 APPLICATION FUNCTIONS 7- 1 to 7-44

7.1 Transient Transmission Function (Non-Periodical Communication) ..................................................... 7- 2

7.1.1 Link Dedicated instruction ................................................................................................................ 7- 3

(1) Reading/writing remote I/O station intelligent function module buffer memory

(Z(P).REMFR/ Z(P).REMTO)........................................................................................................... 7- 3

7.2 Remote I/O Station System Monitor ....................................................................................................... 7- 9

7.3 Device Test for Remote I/O Station ........................................................................................................ 7-10

7.4 Multiplex Transmission Function (Optical Loop System) ...................................................................... 7-12

7.5 Return Sequence Station Number Setting Function.............................................................................. 7-13

7.6 Reserved Station Function ..................................................................................................................... 7-13

7.7 Interrupt Settings ..................................................................................................................................... 7-14

7.8 I/O Assignment Function ........................................................................................................................ 7-15

7.9 Stopping/Restarting the Cyclic Transmission and Stopping Link Refreshing (Network Test) ............. 7-16

7.10 Multiplexed remote master function (Process CPU)............................................................................ 7-17

7.11 Multiplexed remote master function for the redundant system (Redundant CPU) ............................. 7-32

7.11.1 Backup function of master operation on system switching between control system and

standby system ................................................................................................................................ 7-34

7.11.2 Master operation by the station that has started up as the control system.................................. 7-35

7.11.3 System switching request function of control system ................................................................... 7-36

7.11.4 Access function by specifying the control system or standby system ......................................... 7-39

7.12 Remote password ................................................................................................................................. 7-40

8 TROUBLESHOOTING 8- 1 to 8-61

8.1 Network Diagnostics (Network Monitor) ................................................................................................. 8- 2

8.1.1 Host information ............................................................................................................................... 8- 5

8.1.2 Other station information.................................................................................................................. 8- 7

8.1.3 Network monitor details ................................................................................................................... 8- 9

8.1.4 Error history monitor ......................................................................................................................... 8-12

8.2 Troubleshooting ...................................................................................................................................... 8-15

8.2.1 Items checked first ........................................................................................................................... 8-21

8.2.2 Items checked when data link cannot be performed throughout the system ................................ 8-21

8.2.3 Items checked when data link is disabled by resetting or powering off a station .......................... 8-22

8.2.4 Items checked when data link cannot be performed on a certain station ..................................... 8-22

8.2.5 Items checked when an communication data error is detected .................................................... 8-23

8.2.6 Items checked when a link dedicated instruction does not complete ............................................ 8-23

8.2.7 Items checked when multiplexed remote I/O network for redundant system does not operate

normally ........................................................................................................................................... 8-24

8.2.8 Items checked when a minor error (continue error) on a remote I/O station cannot be detected

......................................................................................................................................................... 8-24

8.2.9 Checking incorrect optical fiber cable connection during online .................................................... 8-25

8.3 Error Codes ............................................................................................................................................. 8-28

8.3.1 How to check error codes ................................................................................................................ 8-28

8.3.2 MELSECNET/H error code list ........................................................................................................ 8-34

8.3.3 Error codes detected on remote I/O stations and equivalent to CPU module error codes ........... 8-43

8.4 Canceling a Minor Error (Continue Error) on a Remote I/O Station ...................................................... 8-52

8.4.1 Canceling a specific remote I/O station error .................................................................................. 8-53

8.4.2 Canceling errors of all remote I/O stations ...................................................................................... 8-54

A - 13 A - 13

Page 16

8.5 Procedure for Replacing a Normally Operating Redundant Power Supply Module ............................. 8-59

8.6 H/W Information ...................................................................................................................................... 8-60

APPENDICES App- 1 to App-53

Appendix 1 Precautions for Replacing MELSECNET/10 Remote I/O Network with MELSECNET/H

Remote I/O Network. .............................................................................................................App- 1

Appendix 2 Link Special Relay (SB) .........................................................................................................App- 3

Appendix 3 Link Special Register (SW) .................................................................................................. App-14

Appendix 4 Special Relay (SM) for Remote I/O Stations ....................................................................... App-33

Appendix 5 Special Register (SD) for Remote I/O Module .................................................................... App-36

Appendix 6 External Dimensions ............................................................................................................. App-50

INDEX Index- 1 to Index- 2

A - 14 A - 14

Page 17

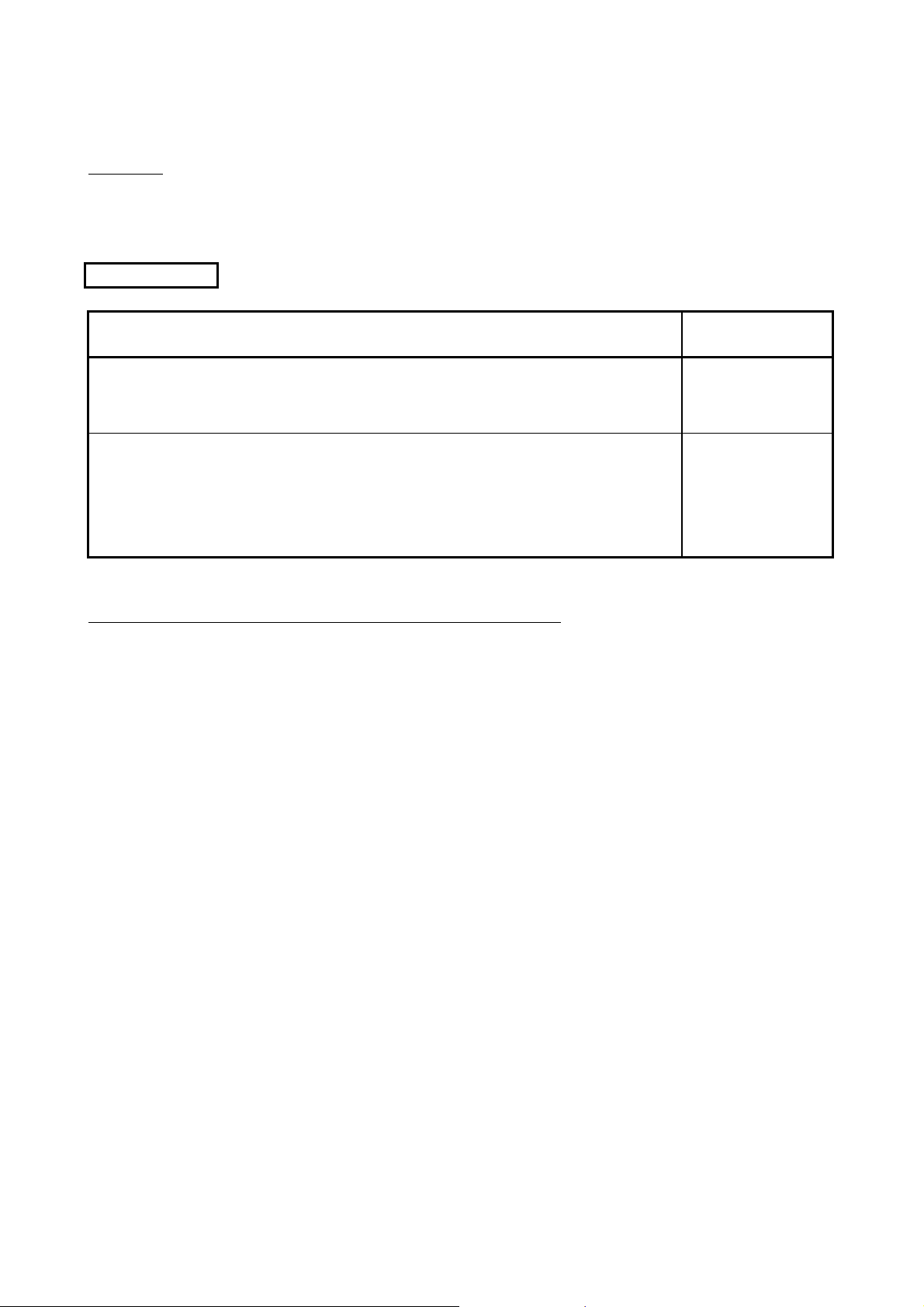

MANUALS

Relevant manuals

The manuals related to this product are listed below.

Order each manual as needed, referring to the following lists.

Manual name

Manual number

(model code)

Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC network)

Specifications, procedures and settings before system operation, parameter setting, programming, and

troubleshooting of a MELSECNET/H network system (PLC to PLC network) (Sold separately)

Q Corresponding MELSECNET/H Remote I/O Module Reference Manual (MELSECNET/10

Mode)

Operating procedures, system configuration, parameter settings, functions, programming, and

troubleshooting of the MELSECNET/H remote I/O module when used in MELSECNET/10 mode.

(Sold separately)

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES

(1) For programmable controller system

To ensure that Mitsubishi programmable controllers maintain EMC and Low

Voltage Directives when incorporated into other machinery or equipment, certain

measures may be necessary. Please refer to one of the following manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance

with EMC and Low Voltage Directives.

(2) For the product

To ensure that this product maintains EMC and Low Voltage Directives, please

refer to one of the manuals listed under (1).

SH-080049

(13JF92)

SH-081164ENG

(13JV30)

A - 15 A - 15

Page 18

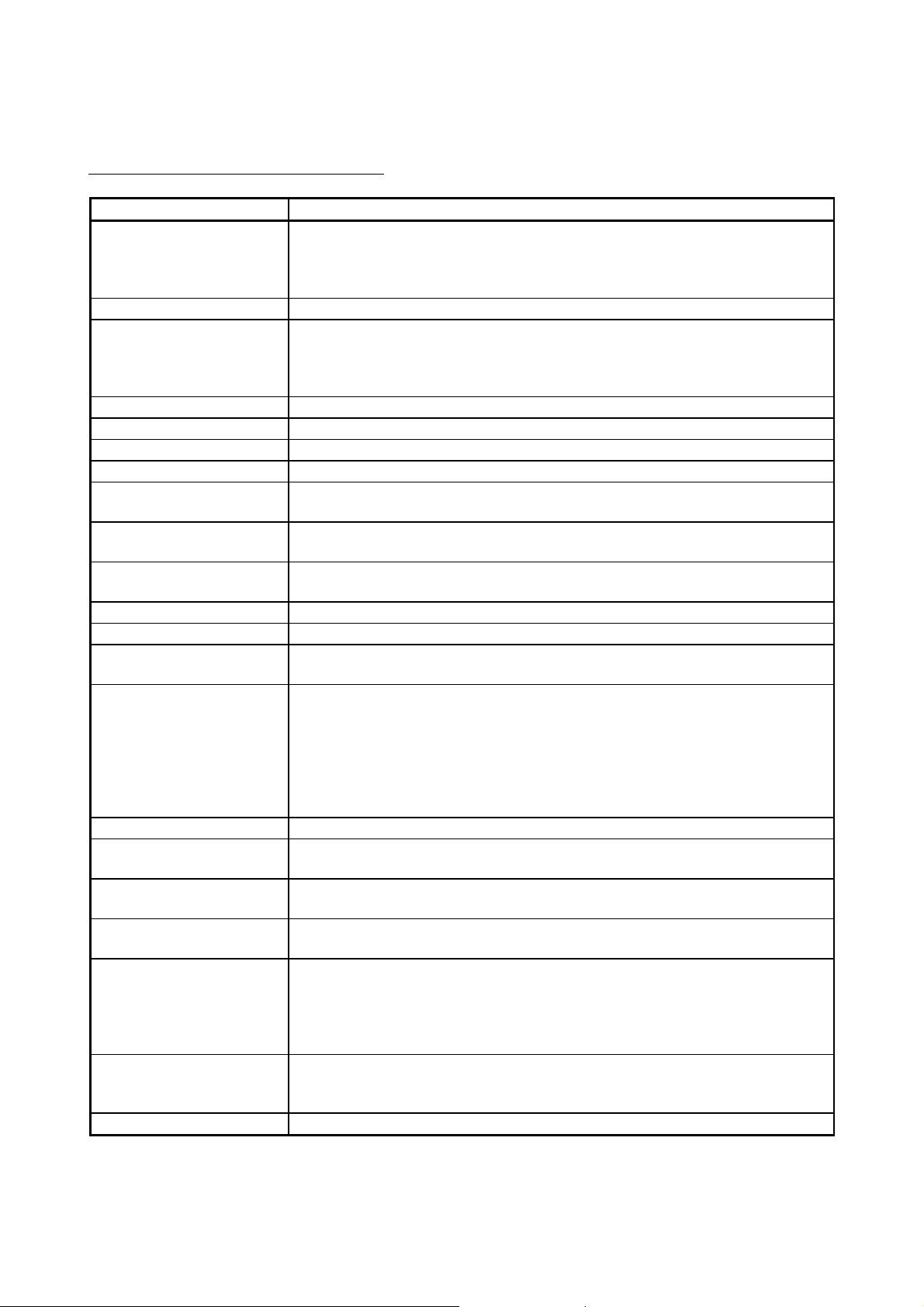

GENERIC TERMS AND ABBREVIATIONS

Generic term/abbreviation Description

The abbreviation for the QJ71LP21, QJ71LP21-25, QJ71LP21S-25, QJ71LP21G,

QJ71LP21

QJ71BR11 The abbreviation for the QJ71BR11 MELSECNET/H network module

QJ72LP25

QJ72BR15 The abbreviation for the QJ72BR15 MELSECNET/H network module

Master module A generic term for the QJ71LP21 and QJ71BR11

Remote I/O module A generic term for the QJ72LP25 and QJ72BR15

Network module A generic term for master module and remote I/O module

Ethernet module

Serial communication module

CC-Link IE Controller Network

module

CC-Link IE Field Network The abbreviation for the QJ71GF11-T2 CC-Link IE Field Network module

MELSECNET/H The abbreviation for the Q series MELSECNET/H network system

MELSECNET/10

QCPU

Basic model QCPU A generic term for the Q00JCPU, Q00CPU, and Q01CPU modules

High Performance model

QCPU

Process CPU

Redundant CPU

Universal model QCPU

Built-in Ethernet port QCPU

Safety CPU A generic term for the QS001CPU

QJ71LP21GE MELSECNET/H network module. However, especially in cases to show

different models, the QJ71LP21, QJ71LP21-25, QJ71LP21S-25, QJ71LP21G and

QJ71LP21GE are printed.

The abbreviation for the QJ72LP25-25, QJ72LP25G, QJ72LP25GE MELSECNET/H

network module

However, especially in cases to show different models, the QJ72LP25-25, QJ72LP25G

and QJ72LP25GE are printed.

The abbreviation for the QJ71E71, QJ71E71-100, QJ71E71-B5, and QJ71E71-B2

Ethernet interface modules

The abbreviation for the QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24, and

QJ71C24-R2 serial communication modules

The abbreviation for the QJ71GP21-SX or QJ71GP21S-SX CC-Link IE Controller

Network module

The abbreviation for the AnU series MELSECNET/10 network system and QnA/Q4AR

series MELSECNET/10 network system

A generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU,

Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU, Q12PRHCPU, Q25PRHCPU,

Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU, Q03UDVCPU,

Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU,

Q13UDVCPU, Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU,

Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

A generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

modules

A generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

modules. (Indicated as QnPHCPU in figures.)

A generic term for the Q12PRHCPU and Q25PRHCPU modules. (Indicated as

QnPRHCPU in figures.)

A generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU,

Q03UDVCPU, Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU,

Q06UDHCPU, Q06UDVCPU, Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU,

Q13UDHCPU, Q13UDVCPU, Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU,

Q26UDHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

A generic term for the Q03UDVCPU, Q03UDECPU, Q04UDVCPU, Q04UDEHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDEHCPU, Q13UDVCPU, Q13UDEHCPU,

Q20UDEHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

A - 16 A - 16

Page 19

Generic term/abbreviation Description

C Controller module

QnACPU A generic term for MELSEC-QnA series CPU modules

ACPU A generic term for MELSEC-A series CPU modules

AnUCPU

Q3 B A generic term for the Q33B, Q35B, Q38B and Q312B main base units.

Q3 SB A generic term for the Q32SB, Q33SB and Q35SB slim type main base units

Q3 RB Another term for the Q38RB main base units for the redundant power supply system

Q5 B A generic term for the Q52B and Q55B extension base units

Q6 B A generic term for the Q63B, Q65B, Q68B and Q612B extension base units

Q6 RB

Q6 WRB Another term for the Q65WRB redundant type extension base units

QA1S6 B A generic term for the QA1S65B and QA1S68B extension base units

Q6 P

Q6 RP

Redundant power supply

module

GX Developer Product name of the software package for the MELSEC programmable controllers

GX Works2

GX Configurator The abbreviation for the GX Configurator software package

REMFR The abbreviation for the Z.REMFR or ZP.REMFR

REMTO The abbreviation for the Z.REMTO or ZP.REMTO

Tracking cable The abbreviation for the QC10TR and QC30TR tracking cables

A generic term for the Q06CCPU-V-H01, Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-V,

and Q24DHCCPU-V type C Controller modules

A generic term for the MELSEC-A series A2UCPU, A2UCPU-S1, A3UCPU, A4UCPU,

A2USCPU, A2USCPU-S1, and A2USHCPU-S1 CPU modules

Another term for the Q68RB extension base units for the redundant power supply

system

A generic term for the Q61P, Q61P-A1, Q61P-A2, Q62P, Q63P, Q64P, and Q64PN

power supply modules

A generic term for the Q61P, Q63RP and Q64RP power supply modules for the

redundant power supply system

A - 17 A - 17

Page 20

DEFINITIONS OF TERMINOLOGY

Term Description

Cyclic transmission

Transient transmission

Link dedicated instruction Dedicated instruction used for transient transmission.

RAS

Remote master station Master station on a remote I/O network

Remote I/O station

MELSECNET/10 mode

MELSECNET/H

(MELSECNET/10 mode)

remote I/O station

Reserved station

Relay station

Reconnection Processing of restarting data link when a faulty station becomes normal.

Disconnection Processing of stopping data link when a data link error occurs.

Device Devices (X, Y, M, D, etc.) that are contained in a CPU module.

Link Device Devices (LB/LW/LX/LY) that are contained in a network module.

Link scan time

Link refresh

I/O refresh

Automatic refresh

Buffer memory

Baton pass

Function by which data communications are performed periodically between a remote master

station and remote I/O stations using link devices (LB/LW/LX/LY) of network modules.

This function allows communication with another station's programmable controller when a

request is made with a link dedicated instruction or from GX Developer.

Communications can be made with programmable controllers on the same or other networks.

The abbreviation for Reliability, Availability, and Serviceability.

This term is used to express the overall usability of automation systems.

Station that performs cyclic transmission according to the range assignment of the remote

master station.

A mode to operate the MELSECNET/H remote I/O module on the MELSECNET/10 remote

I/O network

A remote I/O station where the MELSECNET/H remote I/O module is being operated in

MELSECNET/10 mode

Station that is not actually connected to the network.

It must be included in the total number of stations in the network, since it is to be connected

in the future.

Station that relays transient transmission data to another network.

Link device data of a network module are transferred to another network module via this

station.

Multiple network modules are connected to one programmable controller.

Time required for data of each station to be sent in order and to make one rotation in the

network.

The link scan time changes depending on the data volume or transient transmission request.

On the remote master station, data are transferred between the master module's link devices

and the CPU module's devices. Link refresh means this processing.

Link refresh is performed in "END processing" of the sequence scan of the CPU module.

On a remote I/O station, data are transferred between remote I/O module's link devices and

the following devices. I/O refresh means this processing.

• I/O module's devices

• Intelligent function module’s devices

On a remote I/O station, data are transferred between remote I/O module's link devices and

intelligent function module's devices. Automatic refresh means this processing.

Memory area in an intelligent function module, in which data are temporarily stored.

The network module does not have any buffer memory area that is offered to the user.

A control mechanism in which transmission right (token) is passed around the network for

data transmission.

Number that is assigned for transient transmission to any given stations.

Group No.

By specifying a group of stations as transient transmission target, data can be sent to the

stations of the same group No.

A - 18 A - 18

Page 21

PACKING LIST

Model name Part name Quantity

QJ71LP21 QJ71LP21 MELSECNET/H Network Module (optical loop type) 1

QJ71LP21-25 QJ71LP21-25 MELSECNET/H Network Module (optical loop type) 1

QJ71LP21S-25

QJ71LP21G QJ71LP21G MELSECNET/H Network Module (optical loop type) 1

QJ71LP21GE QJ71LP21GE MELSECNET/H Network Module (optical loop type) 1

QJ71BR11

QJ72LP25-25 QJ72LP25-25 MELSECNET/H Network Module (optical loop type) 1

QJ72LP25G QJ72LP25G MELSECNET/H Network Module (optical loop type) 1

QJ72LP25GE QJ72LP25GE MELSECNET/H Network Module (optical loop type) 1

QJ72BR15

*1: Production of the QJ71LP21 was discontinued in October, 2000.

QJ71LP21S-25 MELSECNET/H Network Module (optical loop type, with

external power supply function)

QJ71BR11 MELSECNET/H Network Module (coaxial bus type) 1

F-type connector (A6RCON-F) 1

QJ72BR15 MELSECNET/H Network Module (coaxial cable bus type) 1

F-type connector (A6RCON-F) 1

REMARKS

For the coaxial bus system, terminating resistors (75 ) are required in the network

terminal stations.

Terminating resistors are not included with the QJ71BR11, QJ72BR15; they must be

purchased separately.

For a list of the model and how to use the terminating resistors, refer to Section

4.8.2.

1

A - 19 A - 19

Page 22

MEMO

A - 20 A - 20

Page 23

1 OVERVIEW

MELSEC-Q

1 OVERVIEW

The MELSECNET/H system includes the following 2 types of networks:

1) PLC to PLC network for communications between a control station and normal

stations

2) Remote I/O network for communications between a remote master station and

remote I/O stations

This is the manual to read when building a remote I/O network for MELSECNET/H

systems (hereinafter referred to as MELSECNET/H). For building a MELSECNET/H

PLC to PLC network, please refer to the Q Corresponding MELSECNET/H Network

System Reference Manual. (PLC to PLC network) (SH-080049)

POINT

The Basic model QCPU and safety CPU cannot configure a remote I/O network in

a MELSECNET/H network system.

REMARKS

(1) The previous network, called MELSECNET/10H is now called MELSECNET/H.

(2) A network module installed on the remote master station is referred to as a

master module.

A network module installed on a remote I/O station is referred to as a remote I/O

module.

1

1 - 1 1 - 1

Page 24

1 OVERVIEW

1.1 Overview

MELSEC-Q

1

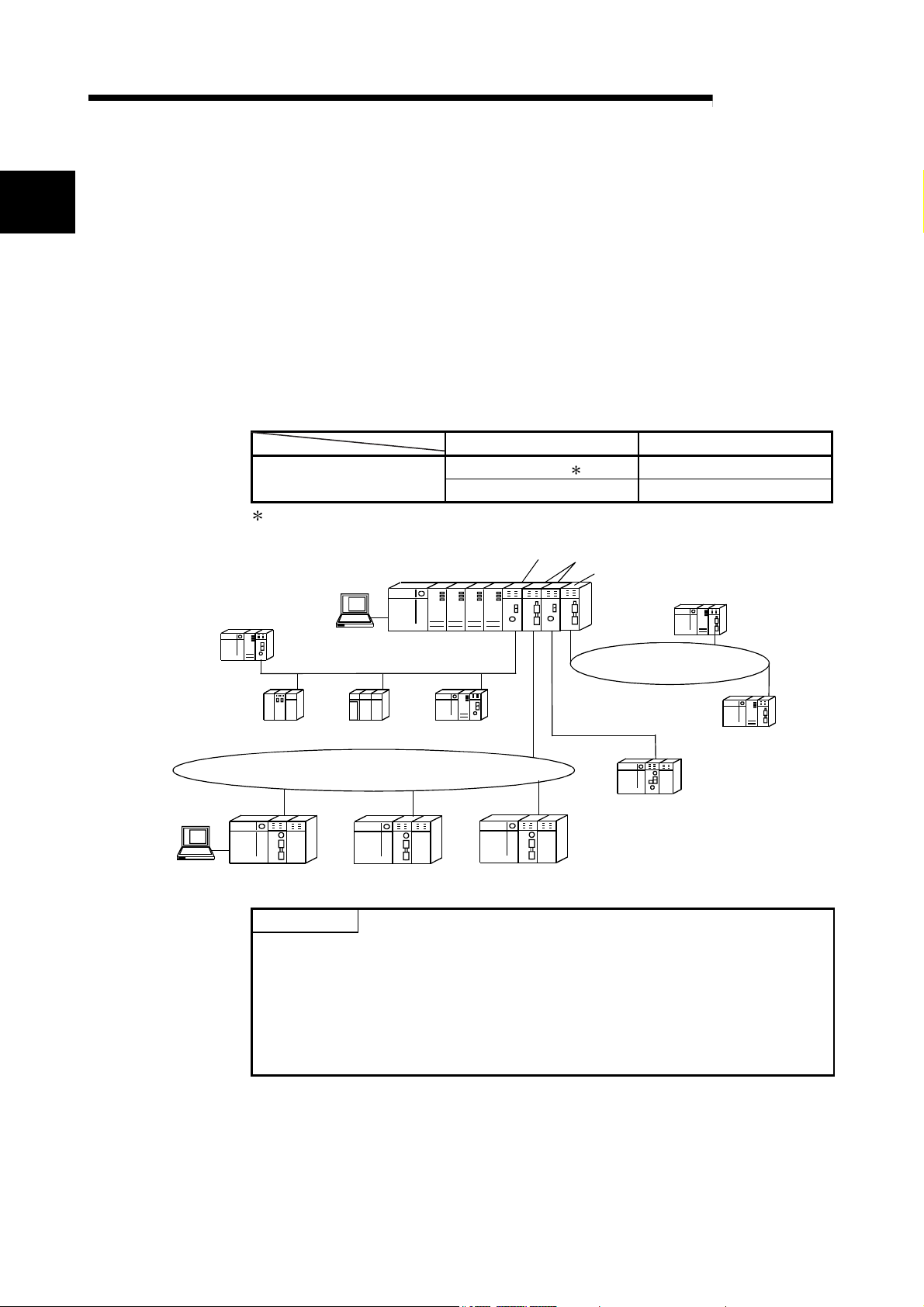

The MELSECNET/H remote I/O network system has more functionality and capacity

than the former network system, MELSECNET/10 network system (hereafter referred

to as MELSECNET/10).

As the MELSECNET/H remote I/O network adopts the same module mounting method

as the usual one (mounting I/O modules and intelligent function modules onto the main

and extension base units), each module mounted on the remote I/O stations can be

handled in the similar way as the basic one.

In addition, the usability of the MELSECNET/10 remote I/O network has been further

enhanced so that networks can be easily configured for factory automation systems.

For the optical loop system in the MELSECNET/H remote I/O network, the

communication speed can be set to 25 Mbps or 10 Mbps.

Network system Communication speed

MELSECNET/H

Optical loop

Optical loop, coaxial bus 10 Mbps

1 25 Mbps

1: QJ71LP21-25, QJ71LP21S-25, and QJ72LP25-25 only

Control station (MELSECNET/10 mode)

QCPU normal station

GX Developer

MELSECNET/H (10Mbps)

PLC to PLC network

QCPU

Remote master station

Control station (MELSECNET/H mode)

QCPU normal station

MELSECNET/H (25Mbps)

PLC to PLC network

GX Developer

QnACPU

normal station

MELSECNET/H (25Mbps) remote I/O network

Remote I/O station Remote I/O station Remote I/O station

POINT

(1) Select QCPUs for MELSECNET/H remote I/O networks.

AnUCPU

normal station

QCPU

normal station

(2) Remote I/O networks and PLC to PLC networks cannot be mixed on the same

MELSECNET/H network. Always build separate networks.

(3) Only MELSECNET/H network modules can be connected to a MELSECNET/H

remote I/O network. Any MELSECNET/10 network modules (AJ72LP25,

A1SJ72QLP25, etc.) are not connectable.

MELSECNET/H (10Mbps)

remote I/O network

QCPU normal station

Remote I/O station

1 - 2 1 - 2

Page 25

1 OVERVIEW

Type of networks

CPU module

QCPU

AnUCPU MELSECNET/10

QnACPU MELSECNET/10

that can be used

MELSECNET/H

(10 Mbps)

MELSECNET/H

(25 Mbps)

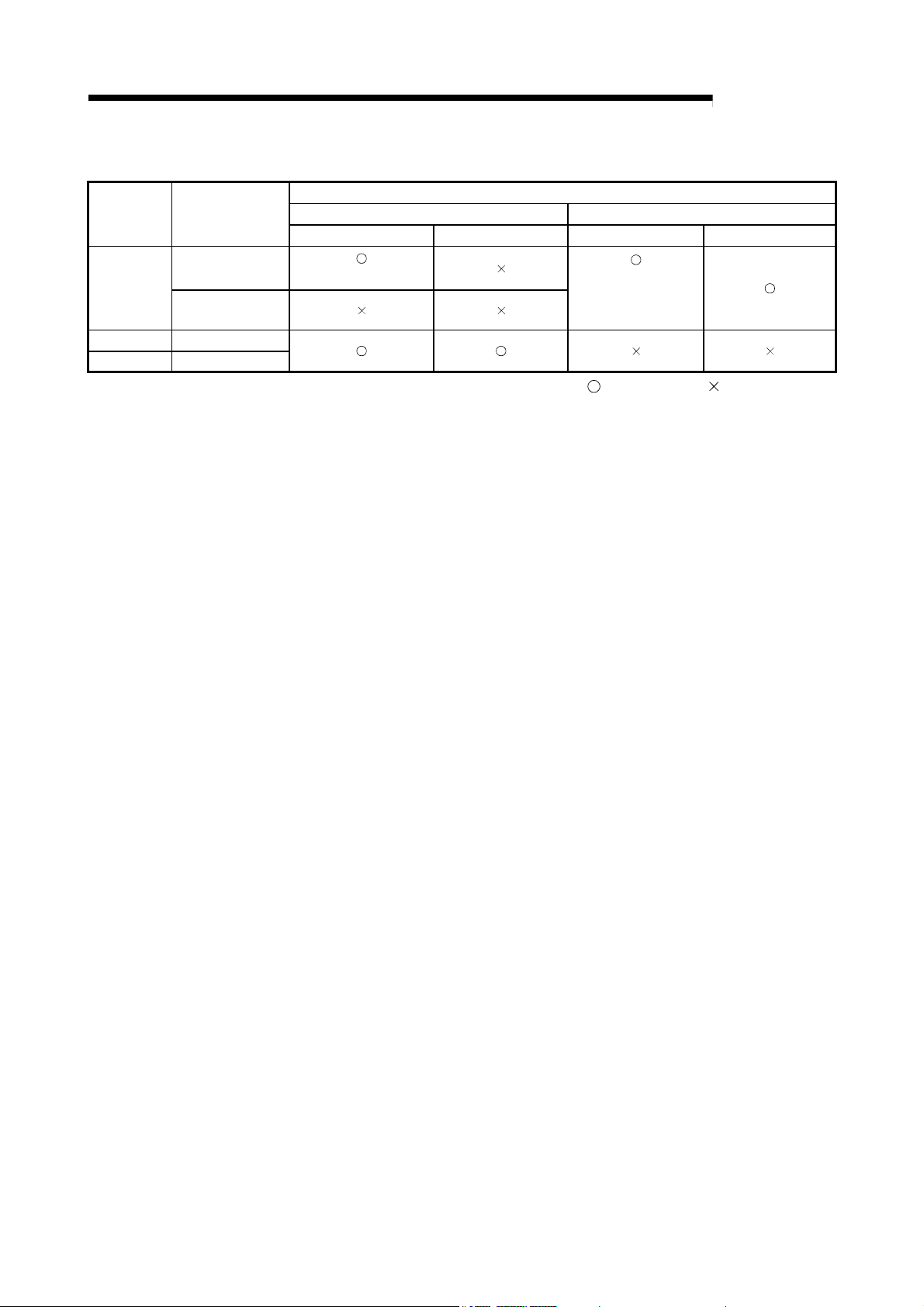

The following table shows the types of networks the CPU modules can be connected to.

with CPU

1.2 Features

The MELSECNET/H remote I/O network has the following features.

(1) Realization of a high-speed communication system

(2) Large-scale and flexible system configuration

MELSEC-Q

Network to be connected

MELSECNET/10 MELSECNET/H

PLC to PLC network Remote I/O network PLC to PLC network Remote I/O network

(MELSECNET/10 mode)

(MESLECNET/H mode,

MELSECNET/H

Extended mode)

: Can be used : Cannot be used

(a) High-speed data communication at 10 Mbps/25 Mbps is possible.

(25Mbps is available for only the optical loop type QJ71LP21-25,

QJ71LP21S-25 and QJ72LP25-25.)

(a) The link device has a larger capacity: 16384 points for the link relay (LB),

16384 points for the link register (LW), and 8192 points for the link inputs

(LX)/link outputs (LY). (Refer to Section 2.1.3, "Available device range

settings.")

(b) A maximum of 4096 I/O points can be set for each remote I/O station.

The link points between a remote master station and a remote I/O station

can be set up to 1600 bytes. The link points of up to 2000 bytes can be set

between a master station and a sub-master station on a multiplexed remote

I/O network.

(c) Either of the following systems can be chosen: the optical loop system

which allows a long station-to-station distance and total distance (up to 30

km (98430 ft.)) and is resistant to noise, or the coaxial bus system

(maximum cable distance of 500 m (1640.5 ft.)) which can be wired easily.

(Refer to Section 3.1, "Performance Specifications.")

1 - 3 1 - 3

Page 26

1 OVERVIEW

MELSEC-Q

(d) The following functions facilitate network connection:

1) Any station to be connected in the future can be specified as a reserved

station.

Specifying a station not actually connected as a reserved station

prevents a communication error. (Refer to Section 5.1.3 "Common

parameter.")

2) It is not necessary to connect stations in order of the station Nos. in the

network. (Refer to Section 4.2.1, 4.2.2.)

(e) The parameters can be written to remote I/O modules using GX Developer

in the same way as to CPU modules.

The parameters of the remote I/O module can be used to change the

detailed settings (response time, error time output mode) for I/O modules

on the remote I/O station, intelligent function module switch settings and I/O

assignments, and remote password settings.

(Refer to Section 5.2 "Remote I/O Station Parameter Settings".)

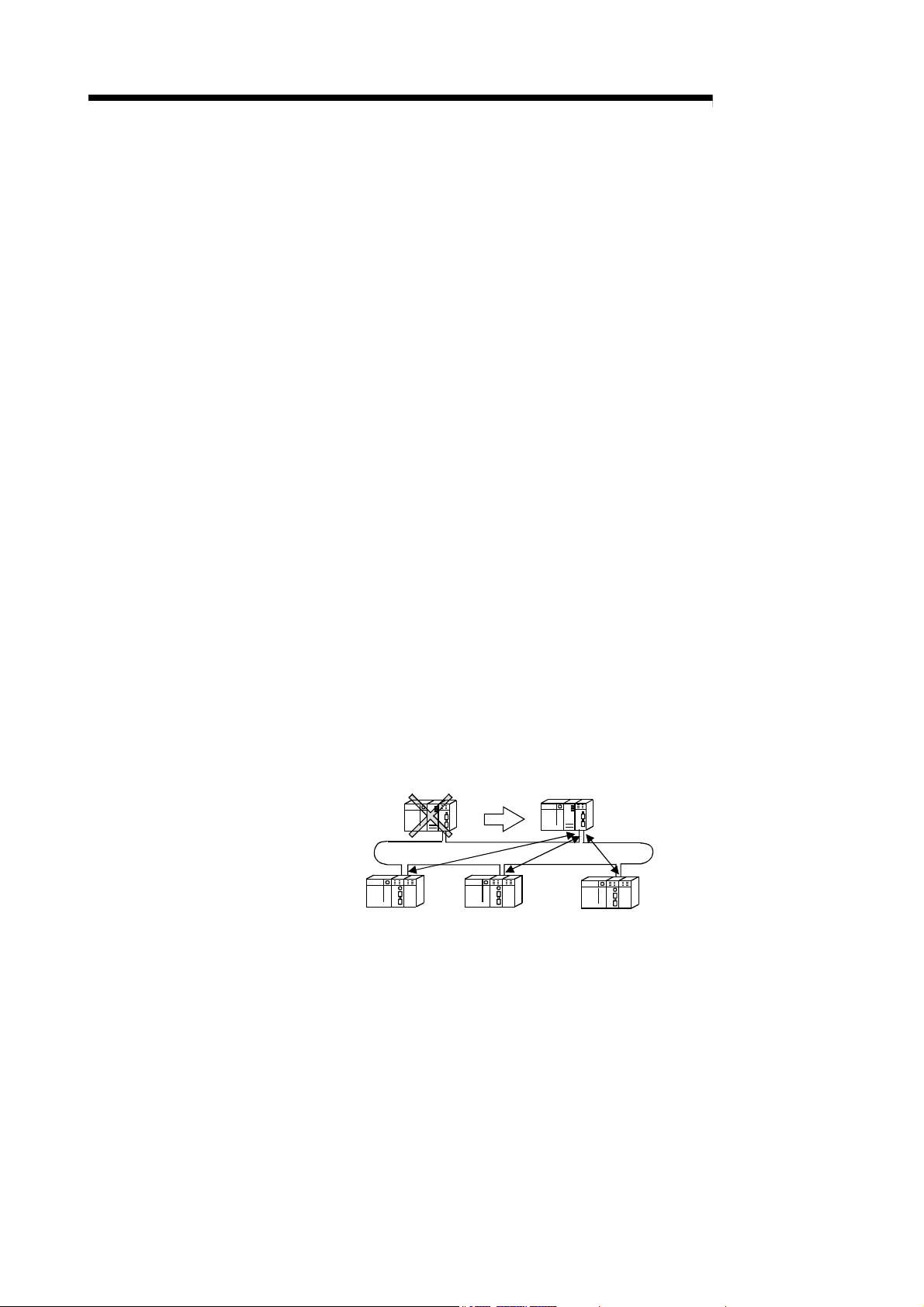

(f) Setting up a master station (DM

) and a sub-master station (DSMR) on the

R

multiplexed remote I/O network allows the sub-master station to take over

the control of remote I/O stations (R) in case of the master station's failure.

(The Process CPU should be used for the multiplexed remote master

station and sub-master station.)

By making a parameter setting, the multiplexed remote sub-master station

can continue the control of the remote I/O stations even if the master

station has recovered to normal and rejoined to the system. (Setting for the

recovered master station to control the remote I/O stations is also

available.)

(Refer to Section 7.10 "Multiplex Remote Master Function (Process CPU)".)

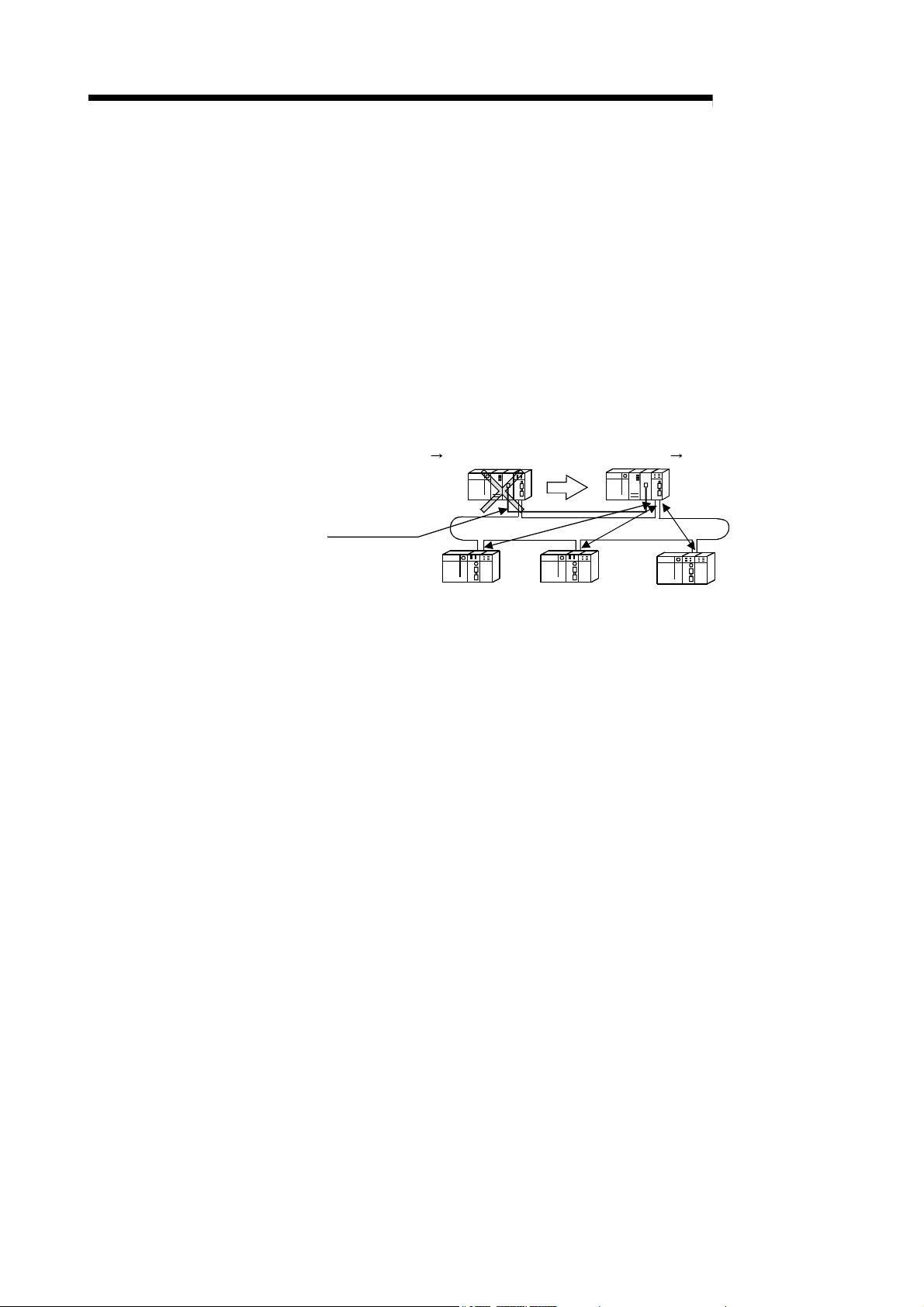

Multiplexed remote

master station (DM

Multiplexed remote

)

sub-master station (DSMR)

R

Remote I/O station (R) Remote I/O station (R) Remote I/O station (R)

1 - 4 1 - 4

Page 27

1 OVERVIEW

MELSEC-Q

(g) The redundant system uses the multiplex remote master function to control

I/O modules and intelligent function modules. (The Redundant CPU should

be used in the redundant system.)

If the multiplexed master station (control system) fails, the multiplex remote

master function will switch the master station from "control system" to

"standby system". At this time, the multiplexed remote sub-master station is

switched from "standby" to "control", continuing the remote I/O control.

The sub-master station (control system) that is controlling the remote I/O

stations will keep its control even if the master station (standby system) has

returned to normal status.

(Refer to Section 7.11 "Multiplex Remote Master Function for Redundant

System (Redundant CPU)".)

Multiplexed remote master station (DMR)

Control system Standby system

Multiplexed remote sub-master station (DSM

Standby system Control system

)

R

Tracking cable

Remote I/O station (R)

Remote I/O station (R)

Remote I/O station (R)

(h) A maximum of 7 extension base units can be connected to the remote I/O

module (eight base units including the main base unit), allowing the

installation of up to 64 modules.

The maximum overall length of extension cables is 13.2m, ensuring a

flexible layout of extension base units.

1 - 5 1 - 5

Page 28

1 OVERVIEW

QCPU Master module

Link register W

Refresh

QCPU Master module

Z.REMTO

(3) Providing versatile communication services

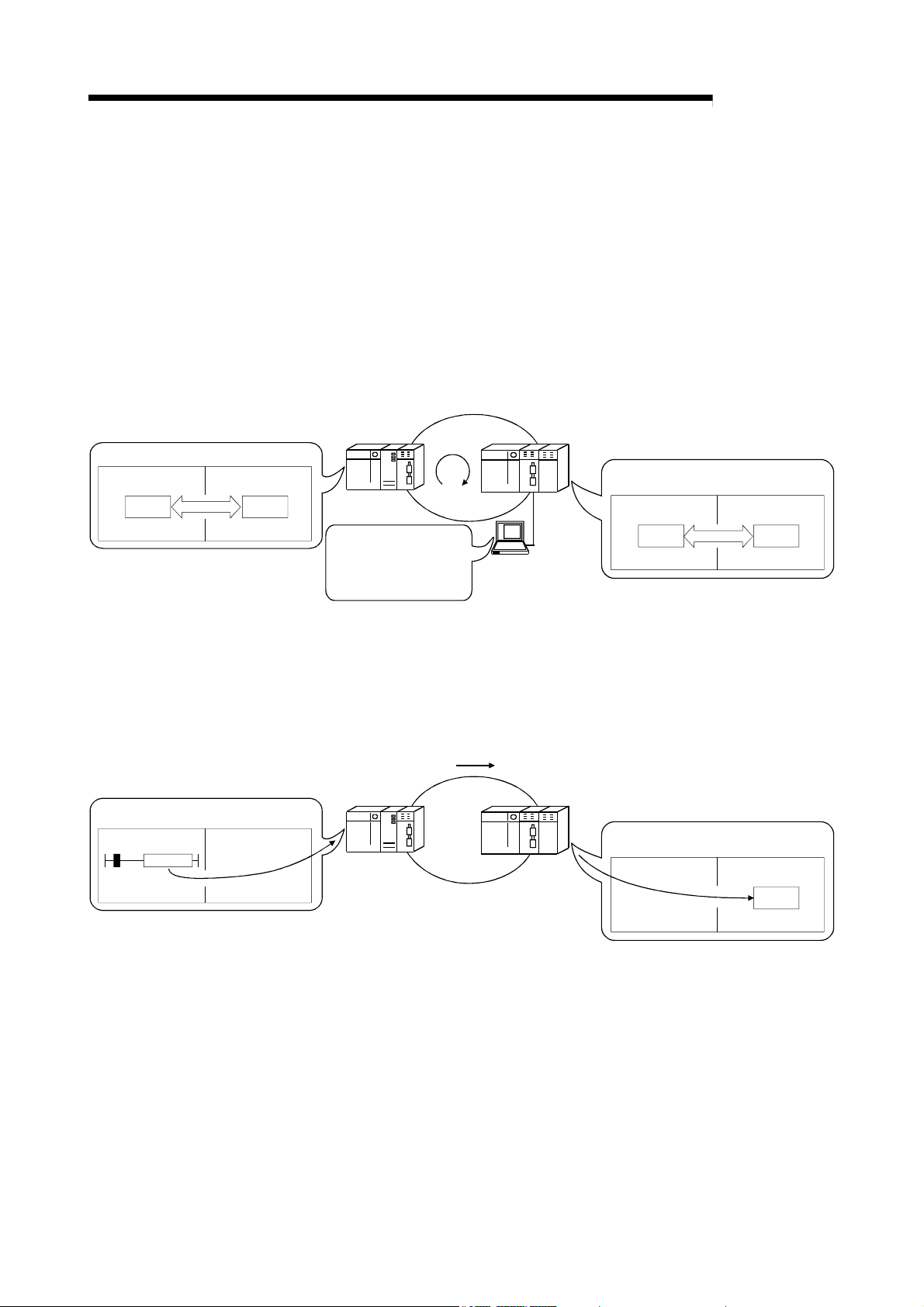

(a) Reading data from and writing data to intelligent function modules mounted

on remote I/O stations are easy.

There are four methods available for reading and writing.

1) Use GX Configurator to make the initial settings and automatic refresh

settings with intelligent function module parameters, and write them

into the remote I/O module in the remote I/O station.

By refreshing the intelligent function module data to the link register W

of the remote I/O module based on the auto refresh settings, the

remote master station can read/write refreshed data by cyclic

transmission.

Remote I/O station

Intelligent function module

GX

Remote I/O station

Intelligent function module

Link register LW

Remote master station

QCPU

Intelligent function

module parameters

• Initial settings

• Automatic refresh

settings

LW

Configurator

2) Link dedicated instructions can be used to directly read from or write to

the buffer memory of the intelligent module.

• REMFR instruction: Reads data from the buffer memory of the

remote I/O station intelligent function module.

• REMTO instruction: Writes data to the buffer memory of the remote

I/O station intelligent function module.

REMTO

Remote master station

QCPU

Remote I/O module

Link register W

Refresh

Remote I/O module

REMTO

MELSEC-Q

Intelligent

function module

Buffer memory

Intelligent

function module

Buffer memory

1 - 6 1 - 6

Page 29

1 OVERVIEW

QCPU Master station

JP.WRITE

QCPU Master station

Link register W Link register LW

Refresh

CPU module Network module

I50

Interrupt

sequence

program

IRET

MELSEC-Q

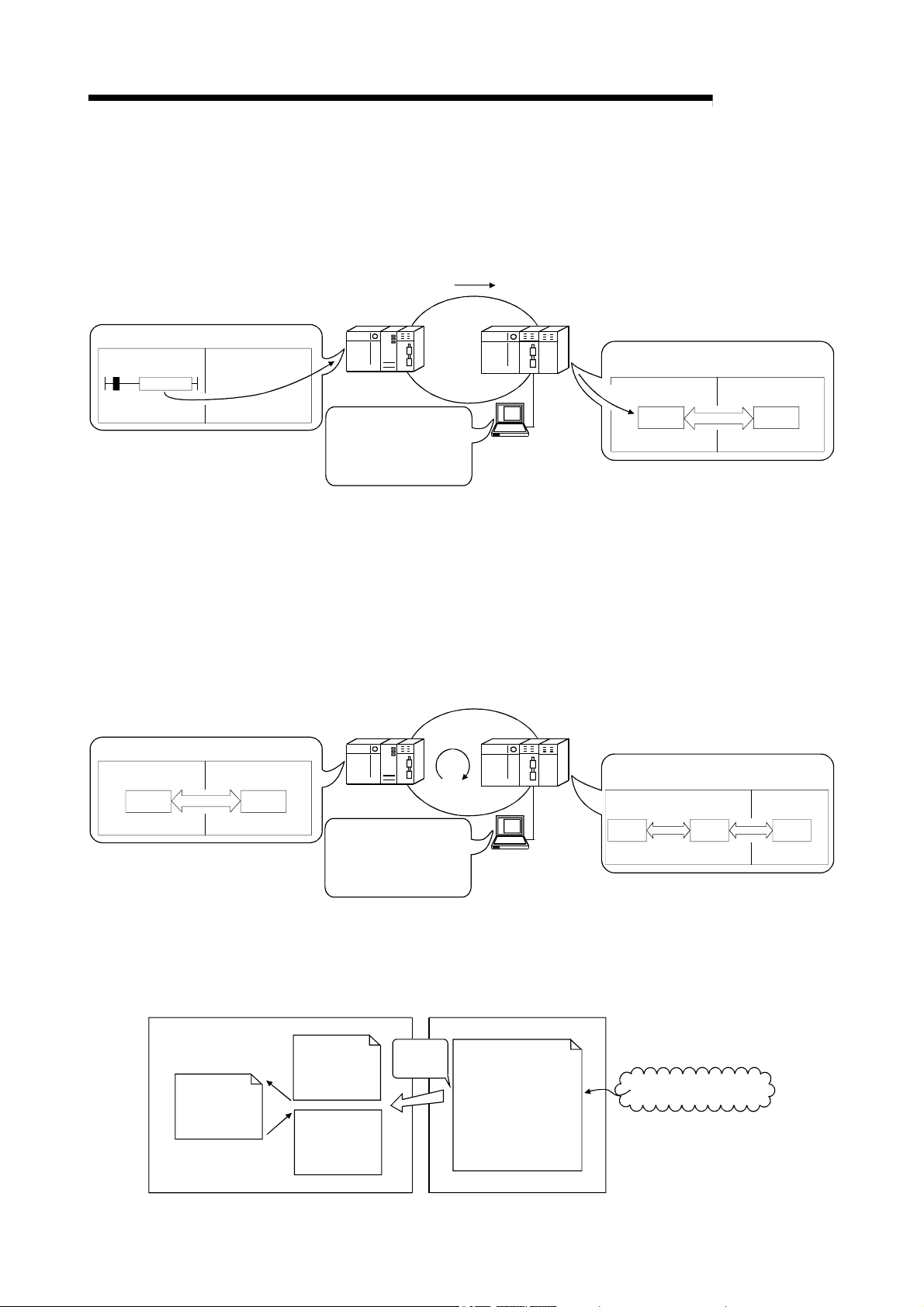

3) By refreshing the intelligent function module data into the remote I/O

module's data register D by the automatic refresh setting of the

intelligent function module parameters, the remote master station can

read/write data from/to the data register D with READ or WRITE

instruction.

WRITE

Remote master station

QCPU

Intelligent function

module parameters

• Initial settings

• Automatic refresh

settings

Configurator

Remote I/O station

Intelligent function module

W

R

GX

Remote I/O module

Data

IT

register D

E

Refresh

Intelligent

function module

memory

4) The automatic refresh setting of the intelligent function parameters

enables the intelligent function module data to be refreshed into the

remote I/O module's data register D. By refreshing the data register D

to the link register W with the parameter of the remote I/O module, the

remote master station can read/write the intelligent function module

data by cyclic transmission.

This method has the advantage that the intelligent function module

parameters created for a QCPU can be applied to the remote I/O

module without making any modifications.

Remote master station

QCPU

Intelligent function

module parameters

• Initial settings

• Automatic refresh

settings

LW

Configurator

Remote I/O station

Intelligent function module

GX

Remote I/O module

Link

register W

Refresh

function module

Data

register D

Refresh

(b) The interrupt sequence program of the host's CPU module can be started

up using the event issue function. This function reduces the response time

of the system and enables real-time data reception.

(Refer to Section 7.7 "Interrupt Settings".)

MELSECNET/H

MAIN

Normal

sequence

program

Conditions

matched

Condition check

Interrupt condition

parameters

• Relay information

• Register data

• Network status

Cyclic transmission

Buffer

Intelligent

Buffer

memory

END

1 - 7 1 - 7

Page 30

1 OVERVIEW

MELSEC-Q

(4) Enhanced RAS functions (Refer to Section 3.2.2 "RAS functions")

(a) When a faulty station recovers and can resume normal operation, it

automatically returns to the network to resume the data communication

using the automatic return function.

(b) By using the loopback function (in the optical loop system), it is possible to

continue data transmission among operational stations by disconnecting

faulty areas such as a part of the network where there is a cable

disconnection, a faulty station, etc.

(c) By using the station detach function (in the coaxial bus system), even when

some of the connected stations are down due to power off, etc., the normal

communication can be continued among other operational stations.

(d) The network module can continue the transient transmission even if an

error, which stops the CPU module, occurs during system operation.

(e) The time of transient error occurrence can be checked.

(f) By mounting 2 power supply modules on a remote I/O station, either of

them can be replaced without powering off the station. (Redundant power

supply on remote I/O station)

The redundant power supply base unit is required for mounting 2 power

supply modules.

(g) When an input module, an output module or an intelligent function module

mounted on a remote I/O station fails, the faulty module can be replaced

without stopping the system operation. (Online module change)

Online module change is executable for the Q series I/O modules and

modules of function version C and later, such as analog-to-digital converter

modules, digital-to-analog converter modules, channel isolated

thermocouple input modules, and temperature control modules.

REMARKS

The following faults make the RAS functions valid.

• Break in cable

• Power-off of slave station

• Network setting error

• Fault detectable by self-diagnostics of CPU module

If the network module has become faulty, the RAS functions may not be activated

depending on the fault.

(5) Control of external connection to remote I/O stations (refer to

Section 7.12)

Setting a remote password for a remote I/O station restricts access from the

outside via an Ethernet interface module or serial communication module.

(Remote password)

1 - 8 1 - 8

Page 31

A

1 OVERVIEW

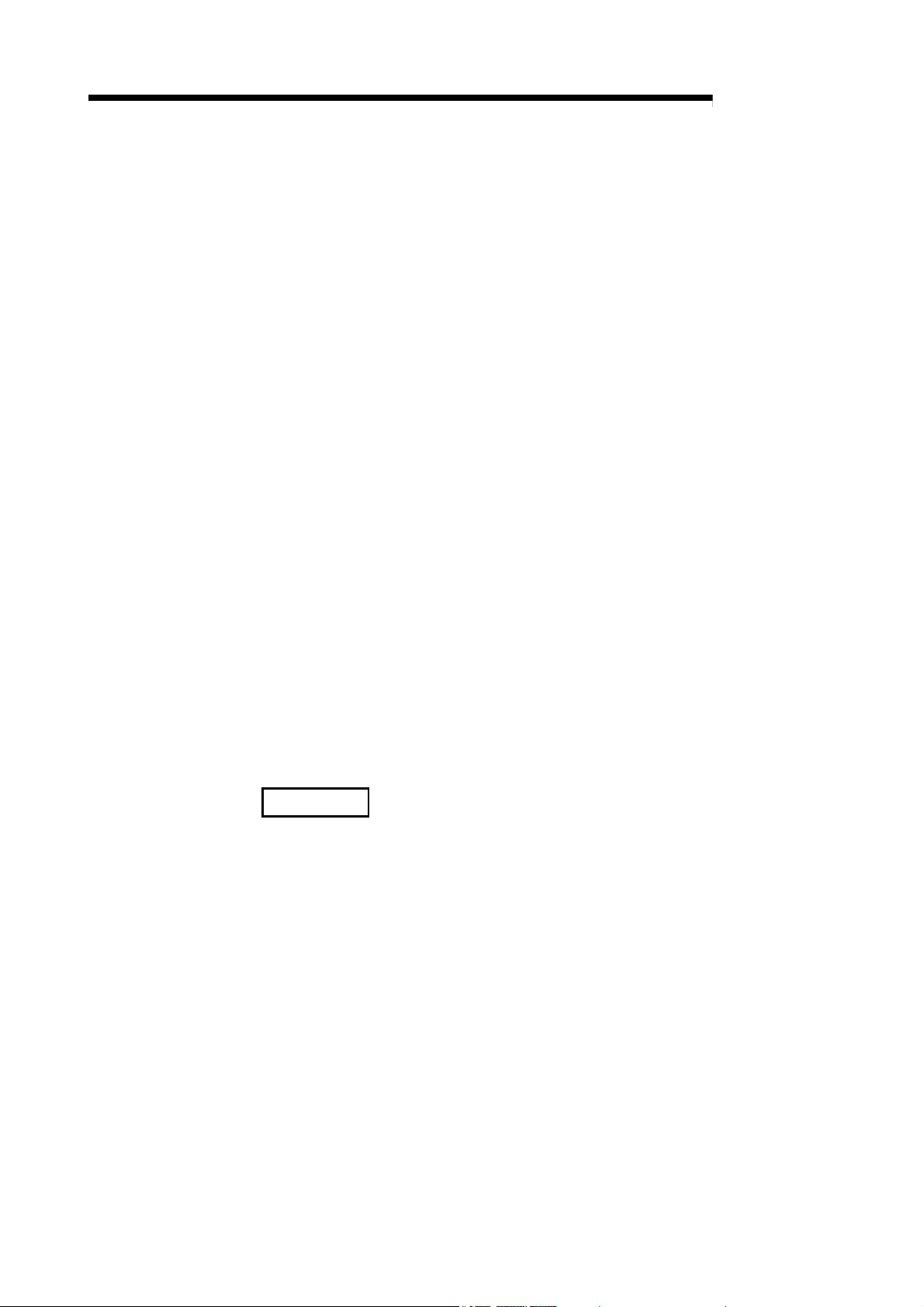

(6) Improved network functions

(a) Intelligent function modules mounted to remote I/O stations can be

diagnosed using the GX Developer system monitor.

Intelligent function modules mounted to remote I/O stations can be

diagnosed using the system monitor of GX Developer, which is connected

to a remote master station or directly connected to a remote I/O station.

MELSEC-Q

Remote I/O station

system monitor

Select

Q64AD

Q64A D

system monitor

GX Developer

Remote I/O station

GX Developer

QCPU

Q64AD

Remote master station

Remote I/O station

GX Developer

When the network seems to be faulty, it can be diagnosed through GX

Developer connected to the remote master station or any remote I/O

station.

(b) If the GX Developer is connected to a remote I/O station, it will not affect the

system operating so user program network function testing can be done online.

It shuts out input (X) from the input module on the remote I/O station and

can turn input (X) on or off using the GX Developer test.

This allows testing of the remote master station input program to be performed.

In addition, it shuts of output (Y) form the remote master station and can

turn remote I/O station output (Y) on and off using the GX Developer test.

This allows testing of the wires for the output module on the remote I/O

station to be performed.

(7) Increased ease of network configuration in combination with GX

Developer

(a) The network parameters can easily be set by visualizing them as pull-down

menus, dialogue boxes, etc.

(b) The settings of network Nos., group numbers and operation modes have

been simplified so that these values can be designated only through

software settings.

(Network parameters)

Pull-down menu

bbreviations

1 - 9 1 - 9

Page 32

)

1 OVERVIEW

1.3 Abbreviations Used in the Text, Tables and Diagrams of This Manual

MELSEC-Q

(1) Abbreviations

Abbreviation Name

MR Remote master station

R Remote I/O station

DMR Multiplexed remote master

DSMR Multiplexed remote sub-master

(2) Marking format

Station number (1 to 64)

Abbreviation

Network No. (1 to 239

[Example]

1) Network No. 3 and remote master station ································· 3M

R

: Station number "0" is not attached to the remote master station.

2) Network No. 5, remote I/O station, station number 3 ··················· 5R3

3) Network No. 7, Multiplexed remote sub-master, station number 4

·················································································· 7DSM

4

R

1 - 10 1 - 10

Page 33

1 OVERVIEW

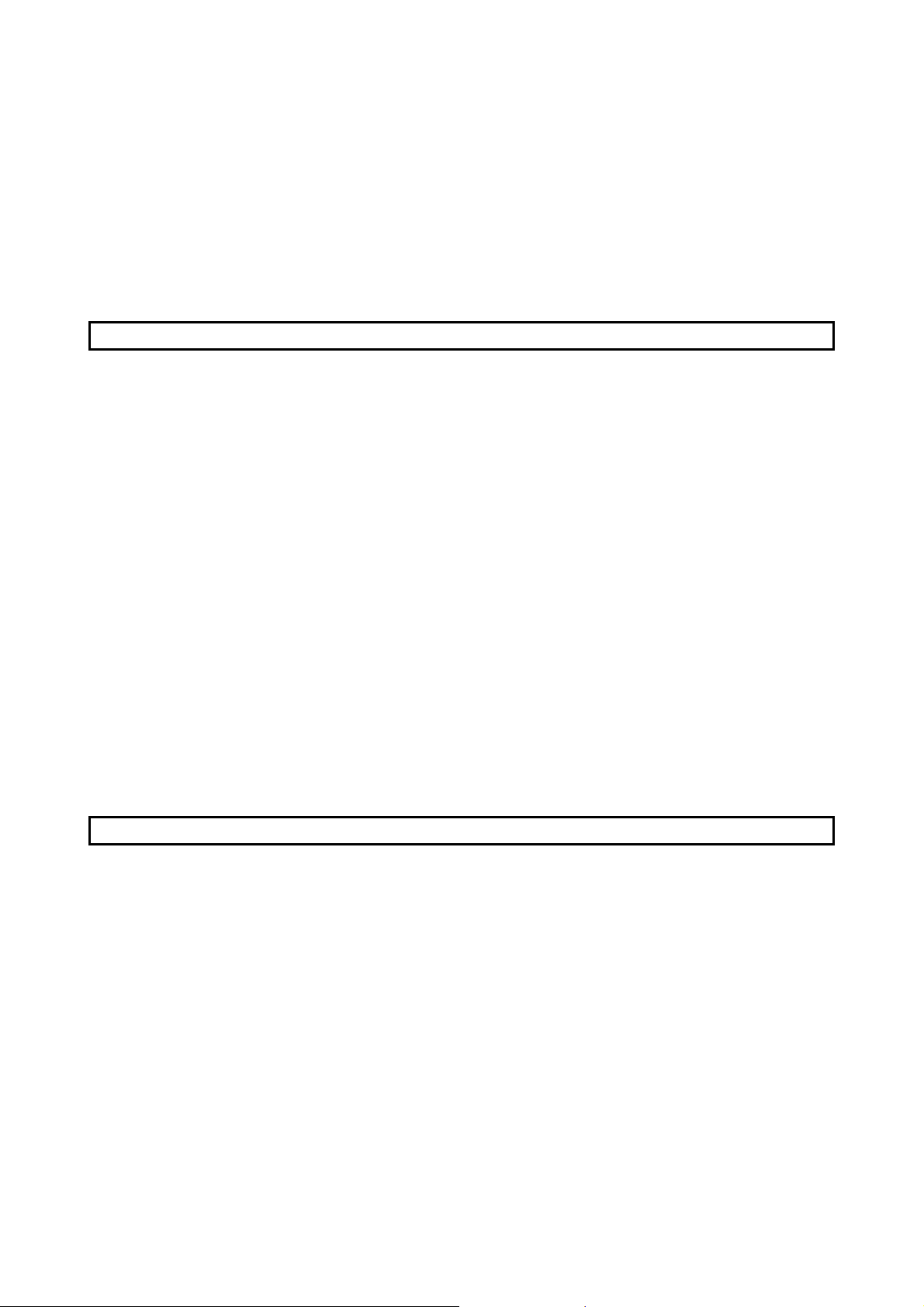

1.4 Functions Added/Changed with Upgrade to Function Version D

The following table lists the additional/altered functions for network modules of function

Function Function version Description Reference

Multiplexed remote I/O

network for redundant

system

Power supply

redundancy on remote

I/O station

Online module change

on remote I/O station

Remote password on

remote I/O station

version D.

Function version D

Function version D

Function version D

Function version D

Allows construction of a multiplexed remote I/O network

that includes the redundant system as the master station.

Allows the construction of the system that includes a

remote I/O station in which 2 power supply modules are

mounted for power supply redundancy.

Allows the faulty I/O module or intelligent function module

on a remote I/O station to be replaced online while the

remote I/O station is running.

Limits the access made from GX Developer via an

Ethernet module or serial communication module

mounted on a remote I/O station, by setting a password.

MELSEC-Q

Section 7.11

Section 3.2.2 (9)

Section 3.2.2

(10)

Section 7.12

1 - 11 1 - 11

Page 34

r

2 SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

MELSEC-Q

This introduces a system comprised of remote I/O networks.