Page 1

Page 2

Page 3

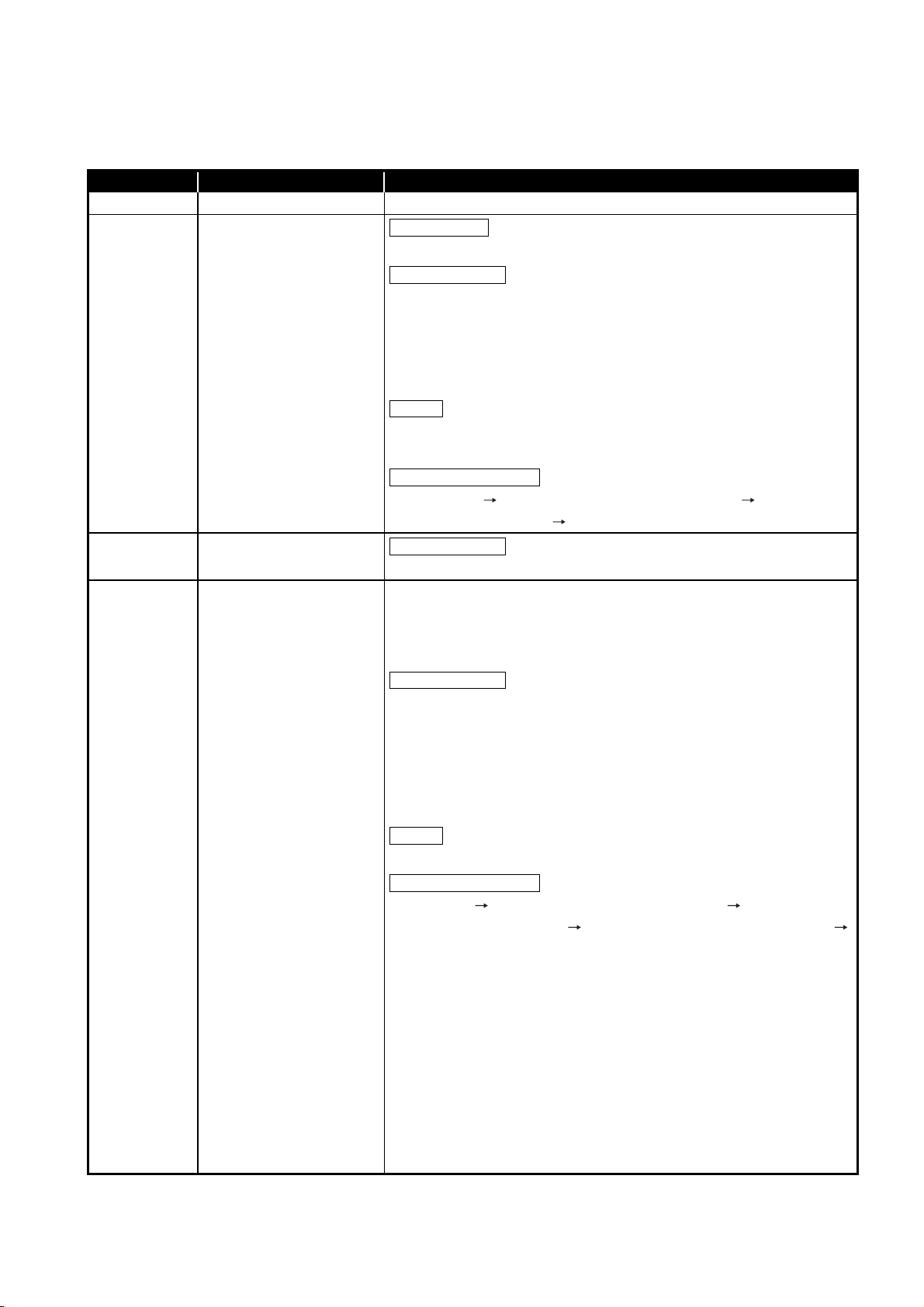

SAFETY PRECAUTIONS

(Read these precautions before using.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product only. For the safety instructions of the

programmable controller system, please read the user's manual of the CPU module used.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

CAUTION

Note that the CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[DESIGN PRECAUTIONS]

DANGER

For each station's operating status in the case of a communication error in the network, refer to this

manual. A malfunction due to a communication error may result in an accident.

To control a running programmable controller (data modification) by connecting GX Developer to a

CPU module or connecting a personal computer to an intelligent function module, create an interlock

circuit on the sequence program so that the entire system will function safely all the time.

Also, before performing any other controls (e.g. program modification, operating status change

(status control)) to the programmable controller, read the manual carefully and ensure the safety.

Especially, in the case of controlling a remotely-located programmable controller from an external

device, a programmable controller side problem could not be resolved immediately due to data

communication failure.

To prevent this, establish corrective procedures for communication failure between the external

device and the programmable controller CPU, as well as creating an interlock circuit on the program.

Laser diodes are used in the optical transceivers of the CC-Link IE controller network.

The class of these laser diodes is Class 1.

A - 1

Page 4

[DESIGN PRECAUTIONS]

CAUTION

Do not install the control lines and/or communication cables together with the main circuit or power

cables, and also do not bring them close to each other.

Keep a distance of 100mm (3.94 inch) or more between them. Failure to do so may cause a

malfunction due to noise.

[INSTALLATION PRECAUTIONS]

CAUTION

Use the programmable controller in the environment conditions given in the general specifications of

the User's Manual for the CPU module used.

Failure to do so may cause an electric shock, fire, malfunction, or damage to or deterioration of the

product.

While pressing the installation lever located at the bottom of the module, insert the module fixing

projection into the fixing hole in the base unit to mount the module.

Incorrect module mounting may cause a malfunction, failure, or drop of the module.

In an environment of frequent vibrations, secure the module with the screw.

The screw must be tightened within the specified torque range.

If the screw is too loose, it may cause a drop, short circuit, or malfunction.

Excessive tightening may damage the screw and/or the module, resulting in a drop, short circuit or

malfunction.

Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the module.

Failure to do so may damage the module.

Do not directly touch any conductive part or electronic component of the module.

Doing so may cause a malfunction or failure of the module.

[WIRING PRECAUTIONS]

DANGER

Be sure to shut off all phases of the external power supply before installation or wiring.

Failure to do so may result in an electric shock or damage to the product.

A - 2

Page 5

[WIRING PRECAUTIONS]

CAUTION

Always ground the FG terminal to the protective ground conductor.

Failure to do so may cause a malfunction.

Verify the rated voltage and pin-out, and connect the external power supply cable properly.

Connecting a power supply with a different voltage rating or faulty wiring may cause a fire or failure.

Terminal screws must be tightened with the specified torque.

If a screw is loose, it may cause a short circuit, fire or malfunction.

Be careful to prevent foreign matter such as dust or wire chips from entering the module.

Failure to do so may cause a fire, failure or malfunction.

Be sure to place the communication cables or power cables in a duct or clamp them.

If not, dangling cables may swing or inadvertently be pulled, resulting in damage to the module or

cables, or malfunctions due to poor cable connection.

When disconnecting a communication cable or a power cable from the module, do not pull the cable

part.

For a cable with connectors, hold the connector by hand and disconnect it from the module.

For a cable connected to a terminal block, loosen the terminal block screws and disconnect the

cable from the module.

Pulling a cable that is still connected to the module may cause a malfunction or damage the module

and/or the cable.

A protective film is attached to the module top to prevent foreign matter such as wire chips from

entering the module during wiring.

Do not remove the film during wiring.

Be sure to remove it for heat dissipation before system operation.

[STARTUP/MAINTENANCE PRECAUTIONS]

CAUTION

When performing online operations (especially, program modification, forced output or operating

status change) by accessing a running CPU on another station from GX Developer via CC-Link IE

controller network, read the manual carefully and ensure the safety.

Improper operation will cause mechanical damage or accidents.

Do not disassemble or remodel each of the modules.

Doing so may cause failure, malfunctions, personal injuries and/or a fire.

A - 3

Page 6

[STARTUP/MAINTENANCE PRECAUTIONS]

CAUTION

When using a wireless communication device such as a mobile phone, keep a distance of 25cm

(9.85 inch) or more from the programmable controller in all directions.

Failure to do so may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the module.

Not doing so may result in a failure or malfunction of the module.

Do not touch terminals during power-on.

Doing so may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the system before cleaning or

retightening the terminal screw or module mounting screw.

Not doing so may result in a failure or malfunction of the module.

If the screw is too loose, it may cause a drop, short circuit or malfunction.

Excessive tightening may cause damage to the screw and/or module, resulting in a drop, short

circuit or malfunction.

Before handling the module, touch a grounded metal object to discharge the static electricity from

the human body.

Not doing so may cause a failure or malfunction of the module.

Do not install/remove the module to/from the base unit more than 50 times after the first use of the

product. (IEC 61131-2 compliant)

Failure to do so may cause malfunction.

[DISPOSAL PRECAUTIONS]

CAUTION

When disposing of this product, treat it as industrial waste.

A - 4

Page 7

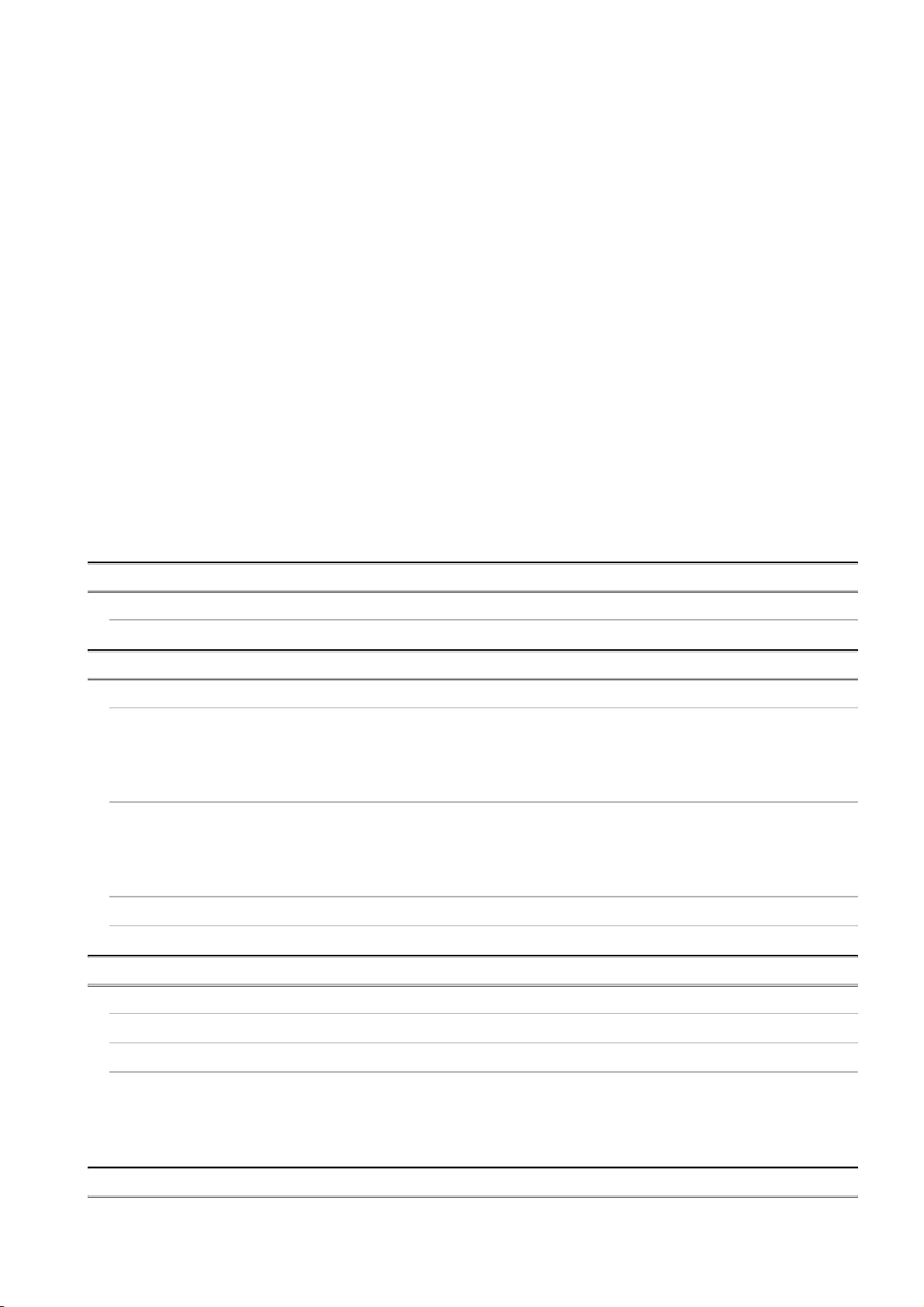

REVISIONS

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

Jan., 2007 SH(NA)-080668ENG-A First edition

Apr., 2007 SH(NA)-080668ENG-B

Nov., 2007 SH(NA)-080668ENG-C

May, 2008 SH(NA)-080668ENG-D The entire manual was reviewed since the existing MELSECNET/G

Model added

QJ71GP21S-SX

Partially revised

SAFETY PRECAUTIONS, Generic Terms and Abbreviations, Definitions of

Terminology, Packing List, Section 1.1, Chapter 2 and 3, Section 4.1.1,

4.1.2, 4.1.4, 4.1.10, 4.2.1, 4.4, 5.1.1, 5.3, 5.4, 5.7.1, 6.2, 6.3.1, 6.3.2, 6.4.1,

6.4.2, 6.5, 6.7, Chapter 7, Section 8.3, 9.1 to 9.8, 10.1, 10.1.5, 10.1.7, 10.2,

10.3, Appendix 1, 2, 4, and 5.

Added

About Manuals, Section 2.2.2, 4.3.7, 4.5, 9.9 to 9.18, 10.1.2, 10.4.12 to

10.4.14, Appendix 3 and 6.2

Change of section No.

Section 2.2 (1) Section 2.2.1, Section 10.1.2 to 10.1.6 Section 10.1.3

to 10.1.7, Appendix 3 to 5 Appendix 4 to 6

Partially revised

Section 1.1, 2.3, 5.6.1, 7.2, 7.3, 8.1.5, 8.2.2, 10.3, 10.4, Appendix 4

network module has been integrated into the CC-Link IE controller network

module.

Descriptions of function version D were added.

Partially revised

SAFETY PRECAUTIONS, About Manuals, Compliance with The EMC and

Low Voltage Directives, How to Read This Manual, Generic Terms and

Abbreviations, Definitions of Terminology, Section 1.1, 2.1, 2.3, 2.4, 3.1,

3.2, 4.1.1, 4.1.2, 4.1.5, 4.1.11, 4.2.1, 4.2.4, 4.3.1, 4.5, 5.1.1, 5.2, 5.4 to 5.6,

5.7.1, 6.1 to 6.5, 6.8, Chapter 7, 8.1.1, 8.1.2, 8.2.1, 8.2.2, 8.3, Chapter 9,

10.1 to 10.4, Appendix 1 to 5

Added

Section 2.1.2, 2.2.3, 3.3, 4.1.8, 4.6, 6.3.3, 6.3.4, 6.6, 7.5, 10.1.8, 10.1.9

Change of section No.

Section 2.1.2 Section 2.1.3, Section 4.1.8 to 4.1.10 Section 4.1.9 to

4.1.11, Section 6.3.3 to 6.3.4 Section 6.3.5 to 6.3.6, Section 6.6 to 6.7

Section 6.7 to 6.8

A - 5

Page 8

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

Oct., 2008 SH(NA)-080668ENG-E

Partially revised

Definitions of Terminology, Section 1.1, 2.3, 3.1, 3.2, 4.1.4, 4.2, 4.2.1, 5.1.1,

6.4.1, 6.4.2, 7.2, 8.3, 9.1, 9.3 to 9.6, 9.11, 9.14 to 9.18, 10.2, Appendix 2, 3,

4.2, 4.3

Added

Section 7.4.2, 9.2.1, 9.2.3, 9.19, 9.20

Change of section No.

Section 7.4 Section 7.4.1, Section 9.2 Section 9.2.2

Japanese Manual Version SH-080649-F

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

2007 MITSUBISHI ELECTRIC CORPORATION

A - 6

Page 9

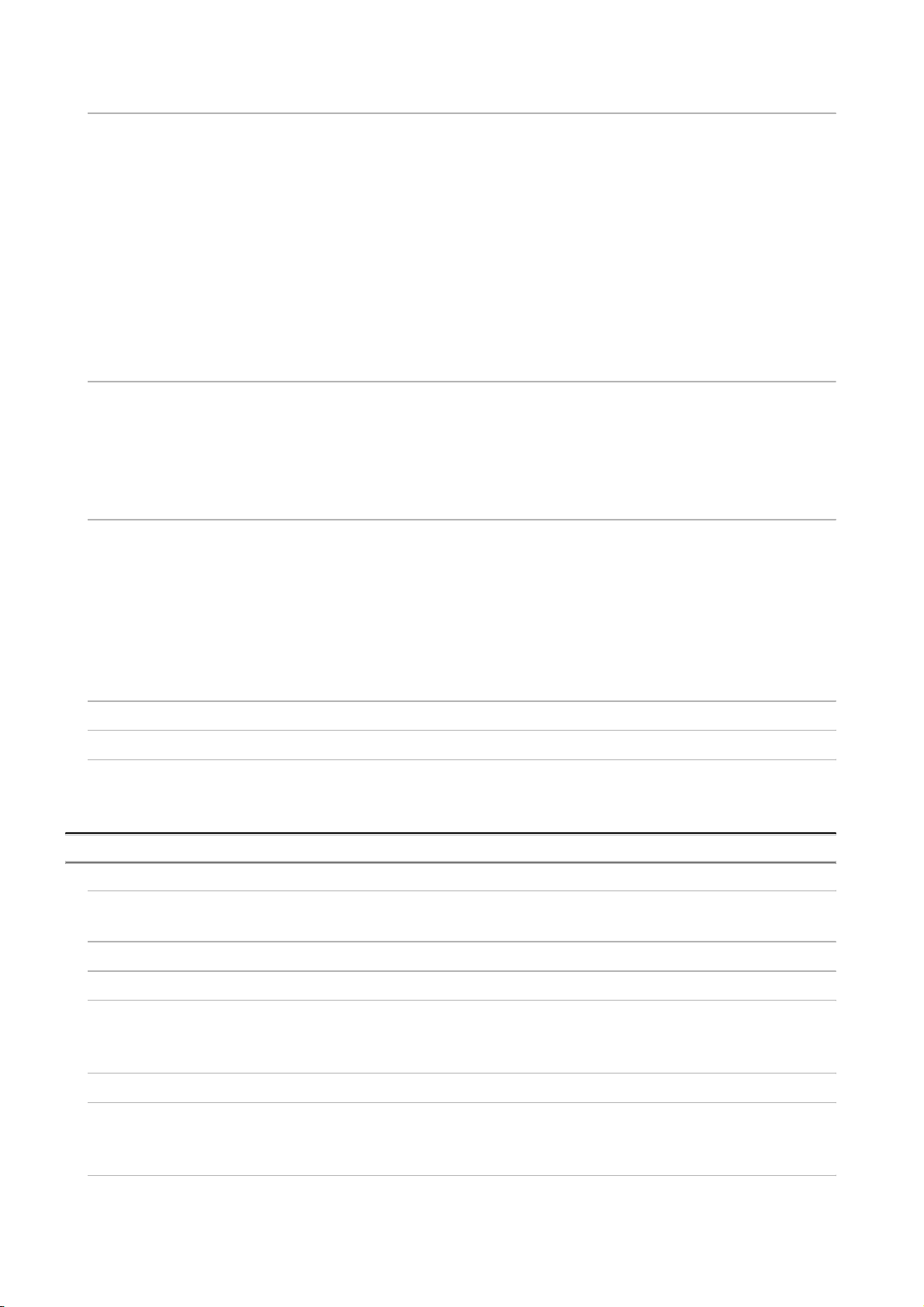

INTRODUCTION

Thank you for choosing the Mitsubishi MELSEC-Q Series of General Purpose Programmable Controllers.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Q series programmable controller you have purchased, so as to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 1

REVISIONS•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••A - 5

INTRODUCTION •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 7

CONTENTS••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 7

ABOUT MANUALS ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 12

Compliance with the EMC and Low Voltage Directives ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 12

HOW TO READ THIS MANUAL ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 13

GENERIC TERMS AND ABBREVIATIONS ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 15

DEFINITIONS OF TERMINOLOGY••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 16

PACKING LIST•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• A - 17

CHAPTER1 OVERVIEW 1 - 1 to 1 - 14

1.1 Features •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1 - 2

CHAPTER2 SYSTEM CONFIGURATION 2 - 1 to 2 - 11

2.1 CC-Link IE Controller Network Configurations •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 1

2.1.1 Single network system ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 1

2.1.2 Redundant system •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 3

2.1.3 Multi-network system ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 4

2.2 Network Components •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 5

2.2.1 Order of optical fiber cables (Optional)••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2 - 5

2.2.2 CC-Link IE controller network interface board ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 6

2.2.3 CC-Link IE controller network communication unit ••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 6

2.3 Applicable Systems••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 7

2.4 Checking the Function Version and Serial No. •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 - 10

CHAPTER3 SPECIFICATIONS 3 - 1 to 3 - 12

3.1 Performance Specifications••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3 - 1

3.2 Function Lists •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3 - 3

3.3 Buffer Memory ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3 - 7

3.3.1 Buffer memory list •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••3 - 7

3.3.2 Transient transmission error log•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3 - 9

3.3.3 Transmission path switching history ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3 - 11

CHAPTER4 FUNCTIONS 4 - 1 to 4 - 64

A - 7

Page 10

4.1 Cyclic Transmission Function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••4 - 1

4.1.1 Communication by LB/LW •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••4 - 3

4.1.2 Communication by LX/LY•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 9

4.1.3 Link refresh ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 12

4.1.4 Direct access to link devices •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 13

4.1.5 Assurance of cyclic data integrity •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 19

4.1.6 Cyclic transmission punctuality assurance ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 23

4.1.7 Constant link scan••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 25

4.1.8 Group cyclic transmission ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 26

4.1.9 Reserved station specification •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 27

4.1.10 Interlink transfer ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 28

4.1.11 Stop/restart of cyclic transmission ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 30

4.2 Transient Transmission Function •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 33

4.2.1 List of dedicated instructions and transient transmission range•••••••••••••••••••••••••••••••••••• 4 - 35

4.2.2 Group function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 40

4.2.3 Routing function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 41

4.2.4 Clock setting from GX Developer •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 42

4.2.5 Changing number of transient transmissions •••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 43

4.3 RAS Functions••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 44

4.3.1 Control station switching function •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 44

4.3.2 Loopback function••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 45

4.3.3 Automatic return function •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 46

4.3.4 Cable fault detection function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 47

4.3.5 Cable insertion error detection function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 47

4.3.6 Detection of duplicated control station or station No. •••••••••••••••••••••••••••••••••••••••••••••••• 4 - 48

4.3.7 External power supply function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 54

4.4 Interrupt Request to CPU Module ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 55

4.5 Station No. Setting by Sequence Program••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 56

4.6 Redundant-CPU-Compatible Function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 58

4.6.1 Overview of redundant system operation••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 58

4.6.2 System switching request to control system CPU •••••••••••••••••••••••••••••••••••••••••••••••••••• 4 - 61

CHAPTER5 PREPARATION AND SETUP 5 - 1 to 5 - 35

5.1 Implementation and Installation •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 1

5.1.1 Handling precautions ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 2

5.2 Pre-operational Procedure •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 3

5.3 Part Names •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 4

5.4 Testing the CC-Link IE controller network module •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5 - 7

5.4.1 Hardware test ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5 - 9

5.4.2 Self-loopback test ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 14

5.5 Wiring ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 19

5.6 Tests for CC-Link IE controller network Startup••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 21

5.6.1 Circuit test •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 22

5.6.2 Station-to-station test ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 26

5.7 Test before CC-Link IE controller network Operation •••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 33

5.7.1 Communication test••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5 - 33

A - 8

Page 11

CHAPTER6 PARAMETER SETTING 6 - 1 to 6 - 66

6.1 Parameter List •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••6 - 1

6.2 Network Setting ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 4

6.3 Network Range Assignment •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 7

6.3.1 LB/LW settings••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 9

6.3.2 LX/LY settings ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 17

6.3.3 Shared group••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 21

6.3.4 Pairing ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 24

6.3.5 Reserved station specification •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 25

6.3.6 Supplementary settings •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 26

6.4 Refresh Parameters •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 28

6.4.1 Refresh parameters••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 28

6.4.2 Change of transfer target CPU-side device •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 37

6.4.3 Default settings •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 46

6.5 Interrupt Settings •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 50

6.6 Redundant settings ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 55

6.7 Interlink Transmission Parameters •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 56

6.8 Routing Parameters •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6 - 61

CHAPTER7 PROCESSING TIME 7 - 1 to 7 - 24

7.1 Link Scan Time •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 7 - 1

7.2 Link Refresh Time ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••7 - 2

7.3 Cyclic Transmission Delay Time ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••7 - 6

7.3.1 Cyclic Transmission Delay Time •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••7 - 6

7.3.2 Transmission delay time calculation example •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••7 - 9

7.4 Dedicated Instruction Transmission Delay Time•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 7 - 13

7.4.1 Link Dedicated Instruction Transmission Delay Time •••••••••••••••••••••••••••••••••••••••••••••••• 7 - 13

7.4.2 CC-Link Dedicated Instruction Transmission Delay Time ••••••••••••••••••••••••••••••••••••••••••• 7 - 18

7.5 Cyclic Data Retention Time for System Switching in Redundant System ••••••••••••••••••••••••••••• 7 - 19

CHAPTER8 PROGRAMMING 8 - 1 to 8 - 57

8.1 Program Example of Single Network System ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 1

8.1.1 System configuration •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••8 - 1

8.1.2 Setting and communication contents••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••8 - 2

8.1.3 Program example of cyclic transmission•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 8

8.1.4 Program example of transient transmission•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 11

8.1.5 Program example of interrupt request••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 16

8.2 Program Example of Multi-network System ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 18

8.2.1 System configuration ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 18

8.2.2 Setting and communication contents•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 19

8.2.3 Program example of cyclic transmission•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 34

8.2.4 Program example of transient transmission•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8 - 34

8.3 Using Link Special Relay (SB) and Link Special Register (SW) ••••••••••••••••••••••••••••••••••••••••• 8 - 37

A - 9

Page 12

CHAPTER9 DEDICATED INSTRUCTIONS 9 - 1 to 9 - 180

9.1 List of Dedicated Instructions and Available Devices •••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 1

9.2 Precautions for Dedicated Instructions ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 3

9.2.1 Precautions for Dedicated Instructions (Common) ••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 3

9.2.2 Precautions for Link Dedicated Instructions••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 5

9.2.3 Precautions for CC-Link Dedicated Instructions••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 9

9.3 JP/GP. READ •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 10

9.4 JP/GP.SREAD••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 21

9.5 JP/GP.WRITE ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 30

9.6 JP/GP.SWRITE ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 44

9.7 J(P)/G(P).REQ (Remote RUN/STOP) •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 53

9.8 J(P)/G(P).REQ (Reading/Writing Clock Data)••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 65

9.9 JP/GP.SEND••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 81

9.10 JP/GP.RECV••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9 - 95

9.11 Z.RECVS ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 103

9.12 J(P).ZNRD•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 109

9.13 J(P).ZNWR ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 118

9.14 Z(P).RRUN ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 127

9.15 Z(P).RSTOP ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 136

9.16 Z(P).RTMRD ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 144

9.17 Z(P).RTMWR •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 153

9.18 Z(P).UINI•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 162

9.19 J(P)/G(P).RIRD•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 167

9.20 J(P)/G(P).RIWT ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9 - 174

CHAPTER10 TROUBLESHOOTING 10 - 1 to 10 - 68

10.1 Troubleshooting Flow •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 1

10.1.1 RUN LED is OFF •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 2

10.1.2 EXT.PW LED is OFF ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 3

10.1.3 MODE LED is OFF or flashing•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 4

10.1.4 D LINK LED is OFF ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 5

10.1.5 D LINK LED is flashing ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 6

10.1.6 Cyclic transmission is disabled ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 7

10.1.7 Transient transmission is disabled ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10 - 9

10.1.8 Data link is disabled in the redundant system ••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 10

10.1.9 Data link is disabled on a station of a Basic model QCPU or safety CPU ••••••••••••••••••••••10 - 13

10.2 Error Code List •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 14

10.3 CC IE Control Network Diagnostics ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 26

10.3.1 Network information display ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 28

10.3.2 Select station network device status display ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 32

10.3.3 Logging•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 34

10.3.4 System monitor •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 37

A - 10

Page 13

10.3.5 Remote operation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 41

10.4 Checking the Error Description with the CC IE Control Network Diagnostics••••••••••••••••••••••••10 - 42

10.4.1 Cable disconnection or line being established••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 43

10.4.2 Cable insertion error •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 45

10.4.3 Monitoring timeout •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 47

10.4.4 Parameter unreceived•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 48

10.4.5 Own station No. is out of range••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 49

10.4.6 Own station is set as reserved station •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 51

10.4.7 Own station No. duplication ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 53

10.4.8 Control station duplication ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 56

10.4.9 Control station duplication and own station No. duplication •••••••••••••••••••••••••••••••••••••••10 - 60

10.4.10 Illegal network No. •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 62

10.4.11 CPU module stop error••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 64

10.4.12 CPU module power stop error •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 66

10.4.13 External power not supplied••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10 - 67

APPENDICES App - 1 to App - 94

Appendix 1 Link Special Relay (SB) List ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 1

Appendix 2 Link Special Register (SW) List •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 16

Appendix 3 Functional Upgrade of CC-Link IE controller network••••••••••••••••••••••••••••••••••••••••••App - 38

Appendix 4 Comparison between CC-Link IE controller network and MELSECNET/H •••••••••••••••• App - 43

Appendix 4.1 Comparison of specifications•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••App - 43

Appendix 4.2 Comparison of function •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 46

Appendix 4.3 Link special relays (SB) and link special registers (SW) •••••••••••••••••••••••••••••••• App - 52

Appendix 4.4 Precautions for system replacement•••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 66

Appendix 4.5 Precautions for program replacement •••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 69

Appendix 5 Parameter Sheet •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 74

Appendix 5.1 Link device assignment sheet•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 79

Appendix 5.2 Quantity setting ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 80

Appendix 5.3 Network range assignment (for control station only) •••••••••••••••••••••••••••••••••••• App - 81

Appendix 5.4 Refresh parameter ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 86

Appendix 5.5 Interrupt setting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••App - 88

Appendix 5.6 Interlink transmission parameter ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••App - 89

Appendix 5.7 Routing parameter •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••App - 91

Appendix 6 External Dimensions••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 92

Appendix 6.1 QJ71GP21-SX ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••App - 92

Appendix 6.2 QJ71GP21S-SX •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• App - 93

INDEX Index - 1 to Index - 2

A - 11

Page 14

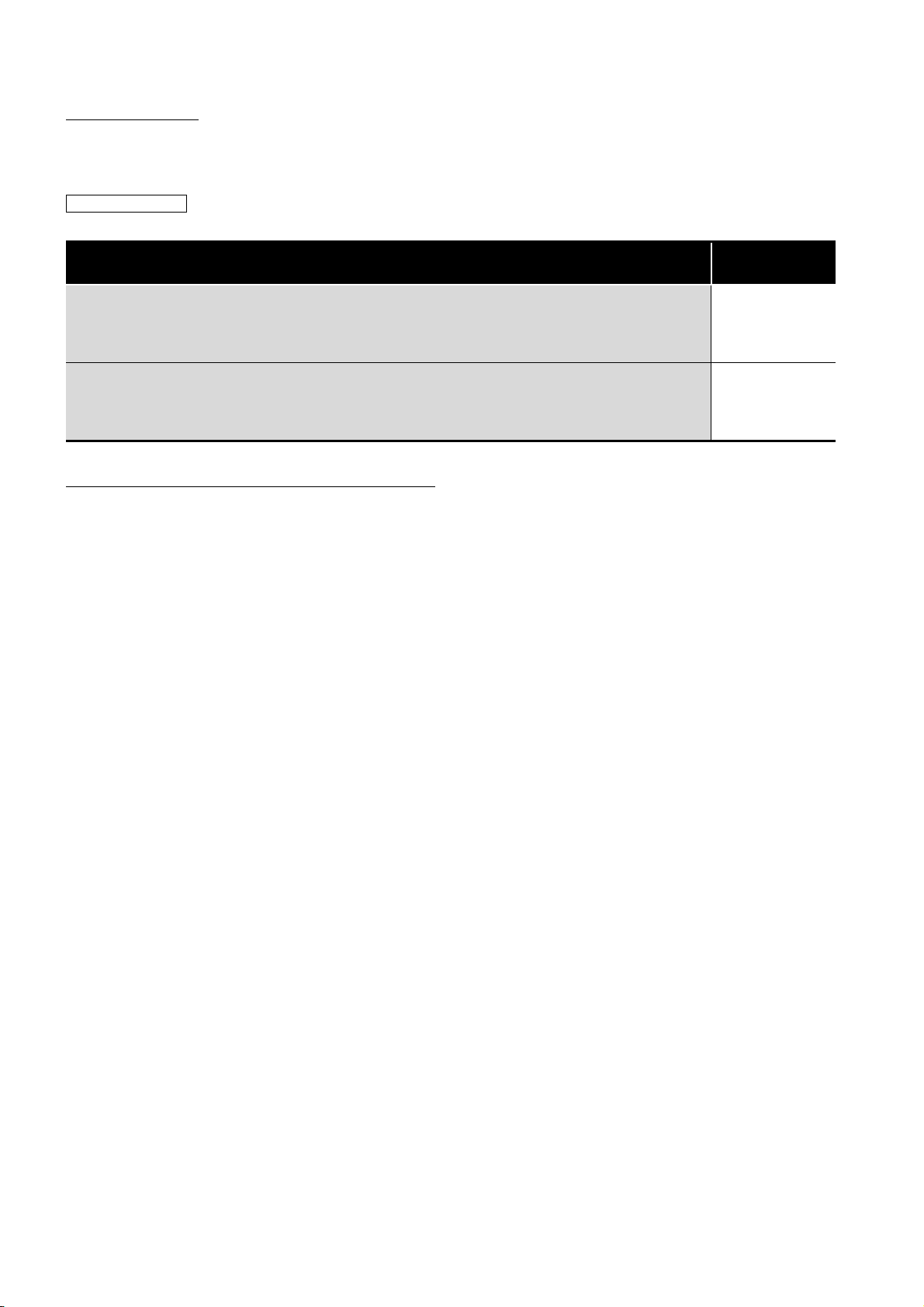

ABOUT MANUALS

Related Manual

The following manual is also related to this product.

Please purchase it if necessary.

Manual Name

CC-Link IE Controller Network Interface Board User's Manual (For SW1DNC-MNETG-B)

Describes the system configurations, specifications, functions, settings and procedure to operation, parameter

setting, programming and troubleshooting of the CC-Link IE controller network interface board.

(Sold separately)

GT15 User's Manual

Describes the GT15 hardware, such as specifications, part names, installation, wiring, and external dimensions,

optional devices, and utilities.

(Sold separately)

Compliance with the EMC and Low Voltage Directives

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage

Directives when incorporating the Mitsubishi programmable controller (EMC and Low

Voltage Directives compliant) into other machinery or equipment, refer to Chapter 9

"EMC AND LOW VOLTAGE DIRECTIVES" of the QCPU User's Manual (Hardware

Design, Maintenance and Inspection).

The CE mark, indicating compliance with the EMC and Low Voltage Directives, is

printed on the rating plate of the programmable controller.

Manual No.

(Model Code)

SH080691ENG

(13JZ02)

SH-080528ENG

(1D7M23)

(2) For the product

No additional measures are necessary for the compliance of this product with the

EMC and Low Voltage Directives.

A - 12

Page 15

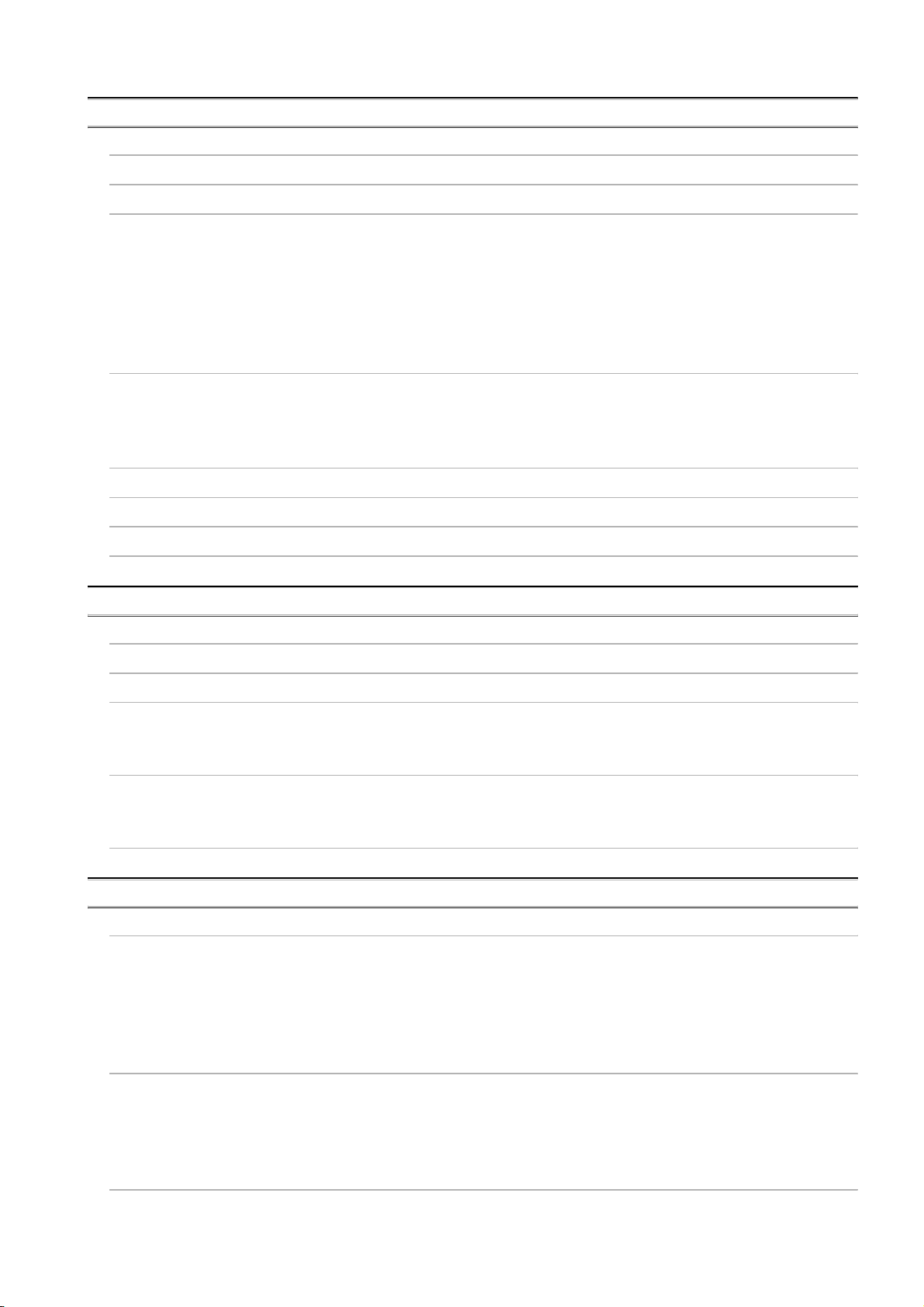

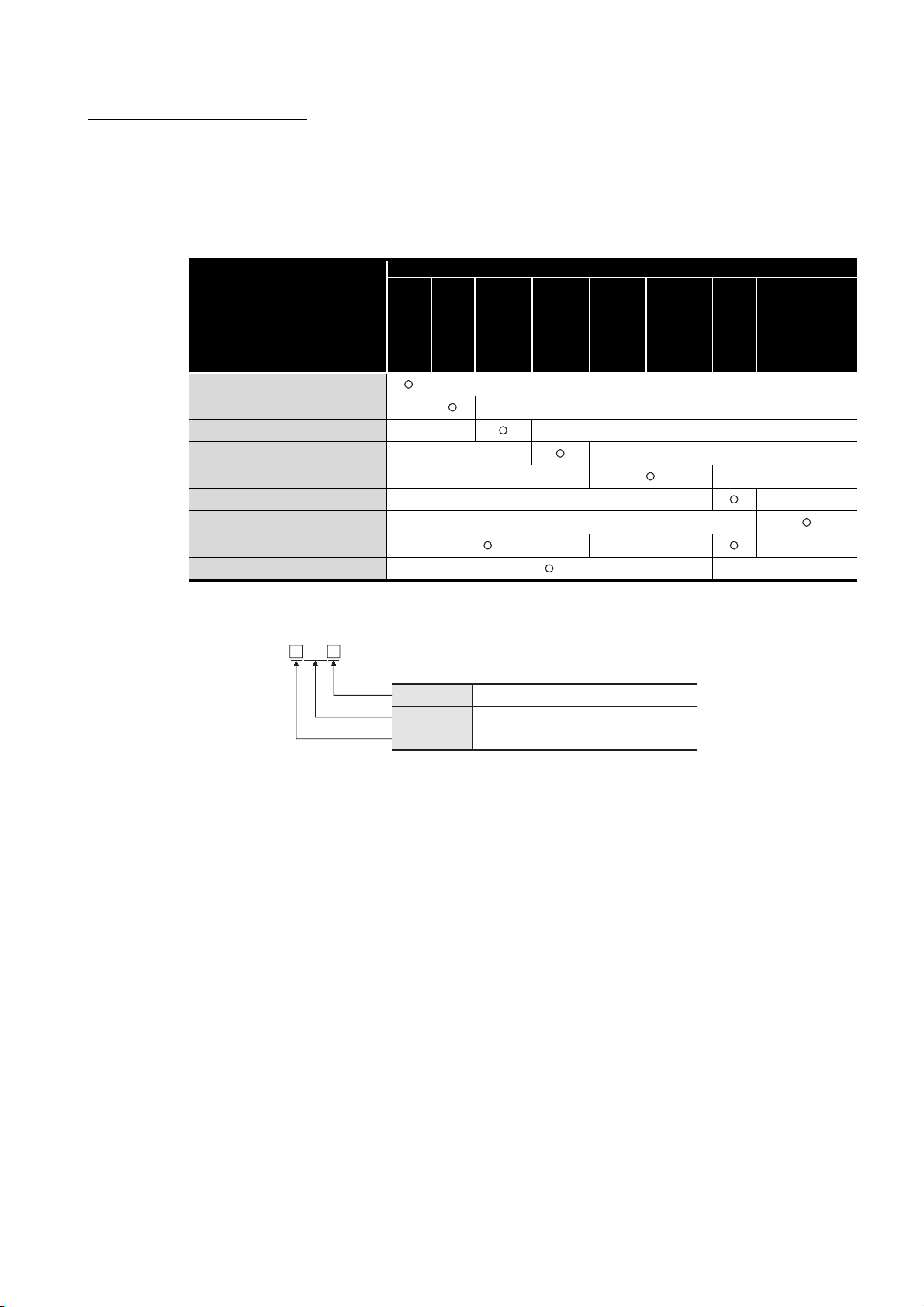

HOW TO READ THIS MANUAL

The following explains generic terms and abbreviations for CPU modules and networking

station type codes that are used in the text, tables, and figures.

(1) Generic terms and abbreviations for CPU modules

Generic terms and abbreviations for

CPU modules

Basic model QCPU —

High Performance model QCPU — —

Process CPU — —

Redundant CPU — —

Universal model QCPU — —

Safety CPU — —

C Controller module —

Other than Universal model QCPU — —

Other than safety CPU —

Q00J

Q00

Q01

Q02

Q02H

Q06H

Q12H

Q25H

Q02PH

Q06PH

Q12PH

Q25PH

Q12PRH

Q25PRH

CPU model

Q02U

Q03UD

Q04UDH

Q06UDH

Q13UDH

Q26UDH

Q03UDE

Q04UDEH

Q06UDEH

Q13UDEH

Q26UDEH

QS001

Q06CCPU-V

Q06CCPU-V-B

(2) Networking station type codes

MP

Station No.

Abbreviation

Network No.

(Example)

• Network No.3, control station, station No.6 • • • 3MP6

• Network No.5, normal station, station No.3 • • • 5N

1 to 120

M

P: Control station, NS: Normal station

1 to 239

S3

A - 13

Page 16

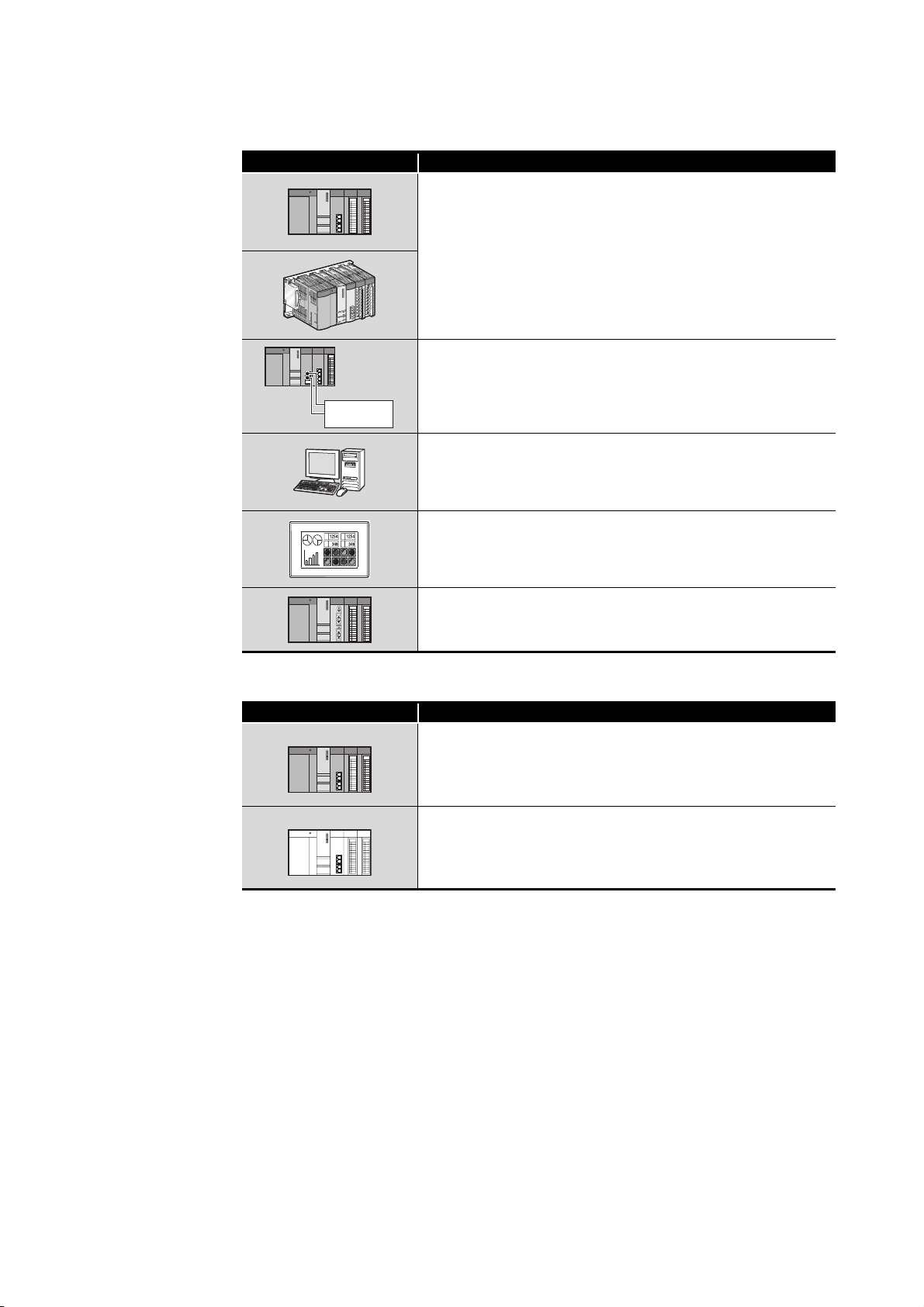

(3) Module illustration

Module illustration Description

External power

supply

CC-Link IE controller network module

CC-Link IE controller network module with external power supply

function

CC-Link IE controller network interface board

CC-Link IE controller network communication unit

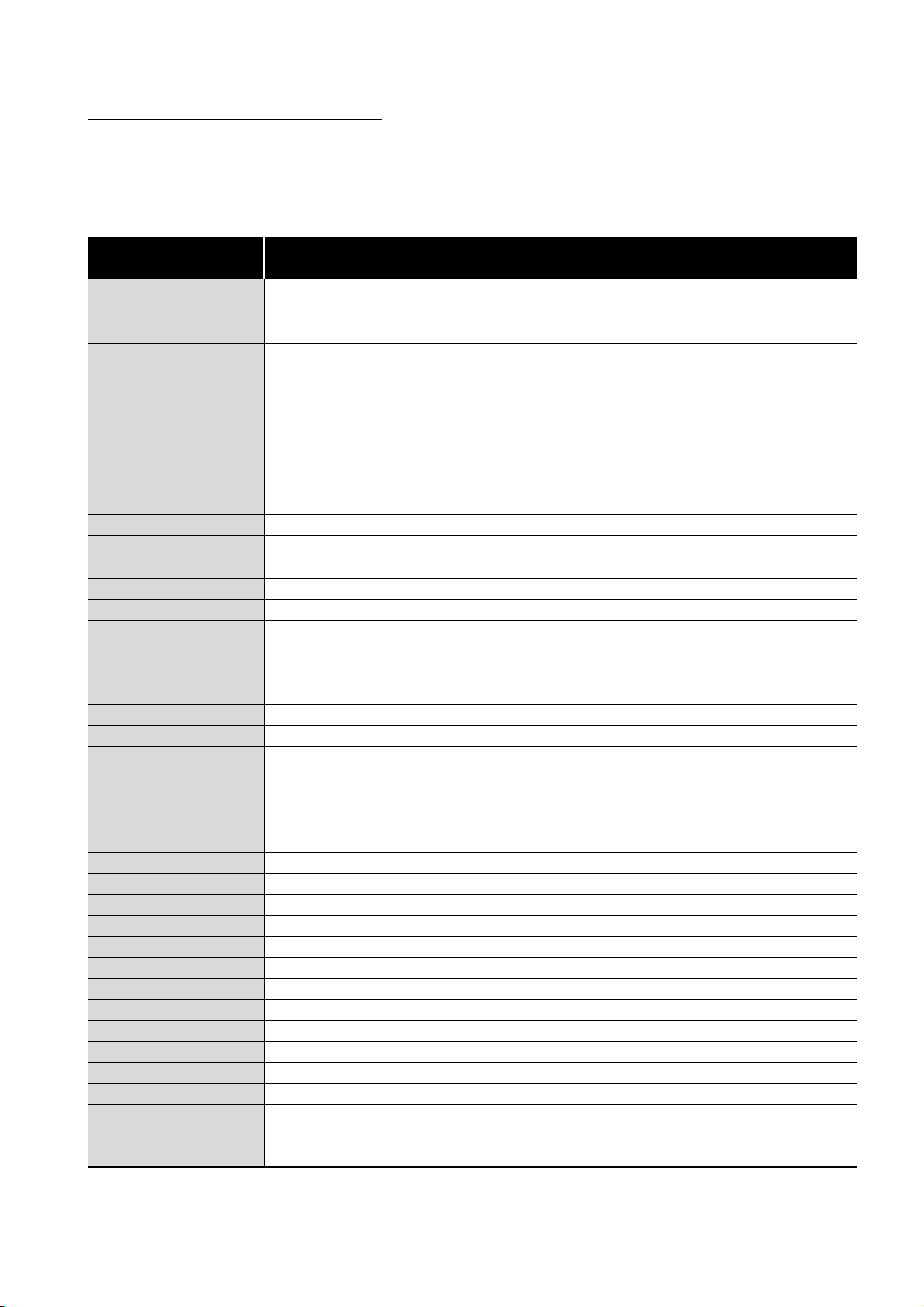

(4) Module status

Module status Description

MELSECNET/H module

Normally operating station

Faulty station (Cyclic transmission is stopped.)

A - 14

Page 17

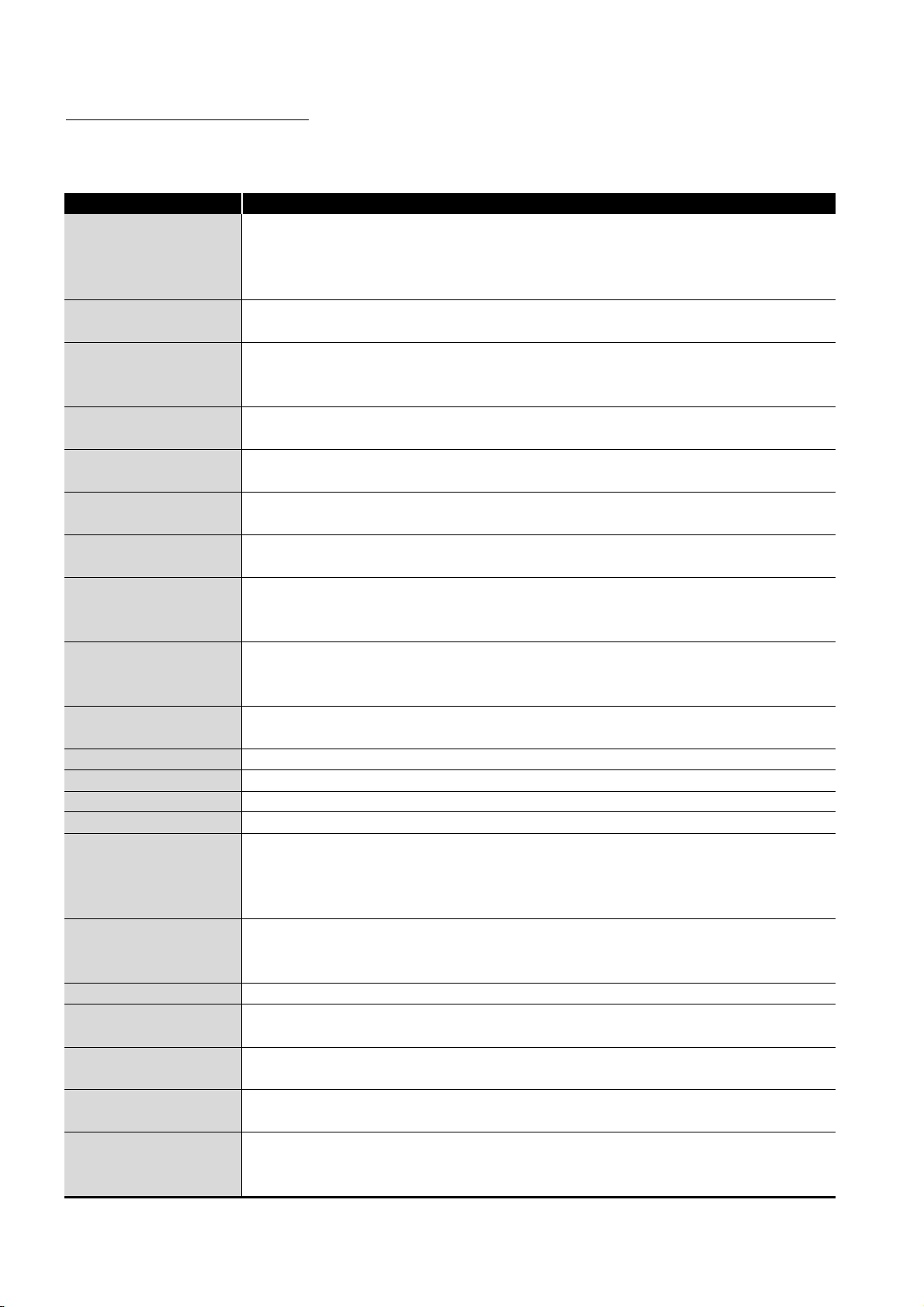

GENERIC TERMS AND ABBREVIATIONS

This manual describes the QJ71GP21-SX or QJ71GP21S-SX CC-Link IE controller

network module using the following generic terms and abbreviations, unless otherwise

specified.

Generic term and

abbreviation

Generic product name for SWnD5C-GPPW-E, SWnD5C-GPPW-EA, SWnD5C-GPPW-EV, and

GX Developer

CC-Link IE controller

network module

CC-Link IE controller

network module with

external power supply

function

CC-Link IE controller

network interface board

MELSECNET/H Abbreviation for the MELSECNET/H network system

MELSECNET/H module

MELSECNET/10 Abbreviation for the MELSECNET/10 network system

Data link Generic term for cyclic transmission and transient transmission

Network module Generic term for the CC-Link IE controller network module and MELSECNET/H module

Basic model QCPU Generic term for the Q00JCPU, Q00CPU, Q01CPU

High Performance model

QCPU

Process CPU Generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU

Redundant CPU Generic term for the Q12PRHCPU, Q25PRHCPU

Universal model QCPU

Safety CPU Generic term for the QS001CPU

C Controller module Generic term for the Q06CCPU-V, Q06CCPU-V-B

READ Abbreviation for JP.READ or GP.READ

SREAD Abbreviation for JP.SREAD or GP.SREAD

WRITE Abbreviation for JP.WRITE or GP.WRITE

SWRITE Abbreviation for JP.SWRITE or GP.SWRITE

REQ Abbreviation for J.REQ, JP.REQ, G.REQ or GP.REQ

SEND Abbreviation for JP.SEND or GP.SEND

RECV Abbreviation for JP.RECV or GP.RECV

RECVS Abbreviation for Z.RECVS

ZNRD Abbreviation for J.ZNRD or JP.ZNRD

ZNWR Abbreviation for J.ZNWR or JP.ZNWR

RRUN Abbreviation for Z.RRUN or ZP.RRUN

RSTOP Abbreviation for Z.RSTOP or ZP.RSTOP

RTMRD Abbreviation for Z.RTMRD or ZP.RTMRD

RTMWR Abbreviation for Z.RTMWR or ZP.RTMWR

UINI Abbreviation for Z.UINI or ZP.UINI

SWnD5C-GPPW-EVA. ("n" means version 4 or later.)

"-A" and "-V" mean "volume license product" and "version-upgrade product" respectively.

Abbreviation for the QJ71GP21-SX or QJ71GP21S-SX CC-Link IE controller network module

Abbreviation for the QJ71GP21S-SX CC-Link IE controller network module

Abbreviation for the Q80BD-J71GP21-SX or Q80BD-J71GP21S-SX CC-Link IE controller

network interface board

Abbreviation for the QJ71LP21, QJ71LP21-25, QJ71LP21S-25, QJ71LP21G, QJ71LP21GE, or

QJ71BR11 MELSECNET/H network module

Generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU and Q25HCPU

Generic term for the Q02UCPU, Q03UDCPU, Q04UDHCPU, Q06UDHCPU, Q13UDHCPU,

Q26UDHCPU, Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q13UDEHCPU and

Q26UDEHCPU

Description

A - 15

Page 18

DEFINITIONS OF TERMINOLOGY

Definitions of the terms used in this manual are explained below.

Term Description

Using the link devices (LB/LW/LX/LY) of the CC-Link IE controller network module, data can be

Cyclic transmission

Transient transmission

Link dedicated instruction

CC-Link dedicated

instruction

RAS

Control station

Normal station

Reserved station

Relay station

Undefined station

Reconnection Processing of restarting data link when a faulty station becomes normal.

Disconnection Processing of stopping data link when a data link error occurs.

Device Devices (X, Y, M, D, etc.) that are contained in a CPU module.

Link device Devices (LB/LW/LX/LY) that are contained in a CC-Link IE controller network module.

Link scan time

Link refresh

Buffer memory Memory area in the CC-Link IE controller network module, in which data are temporarily stored.

Baton pass

Control station switching

time

Shared group No.

Group No.

transferred periodically between stations on the same network.

• LB/LW is used to send data of one station to all stations. (1:N communication)

• LX/LY is used to send data of one station to another station. (1:1 communication)

This function allows communication with another station when a request is made with a

dedicated instruction or from GX Developer.

Dedicated instruction that is used for transient transmission with other programmable

controllers.

Communications can be made with programmable controllers on the same or other networks.

Dedicated instruction that is used for transient transmission with CC-link IE controller network

compatible devices. This allows communication with a station on the same network.

Abbreviation for Reliability, Availability, and Serviceability.

This term is used to express the overall usability of automation systems.

Only one station that controls the network to which it is connected.

Each station's send range for cyclic transmission is assigned to the control station.

Station that performs cyclic transmission according to the range assignment of the control

station.

Station that is not actually connected to the network.

It must be included in the total number of stations in the network, since it is to be connected in

the future.

Station that relays transient transmission data to another network.

Link device data of a network module are transferred to another network module via this station.

Multiple network modules are connected to one programmable controller.

Station to which a station No. is to be set in the sequence program, however, that has presently

no station No. because the UINI instruction has not been executed yet.

Time required for data of each station to be sent in order and to make one rotation in the

network.

The link scan time changes depending on the data volume or transient transmission request.

Link scans are performed "asynchronously" with sequence scans of the CPU module.

Processing of data transfer between link devices of the CC-Link IE controller network module

and CPU module devices.

Link refresh is performed in "END processing" of the sequence scan of the CPU module.

A control mechanism in which transmission right (token) is passed around the network for data

transmission.

Time taken from when the control station went down due to a reason such as power-off until

data link is started by the sub-control station.

Number that is assigned to a station to allow it to share cyclic data with any given stations.

Cyclic data can be shared only with stations of the same group.

Number that is assigned for transient transmission to any given stations.

By specifying a group of stations as transient transmission target, data can be sent to the

stations of the same group No.

A - 16

Page 19

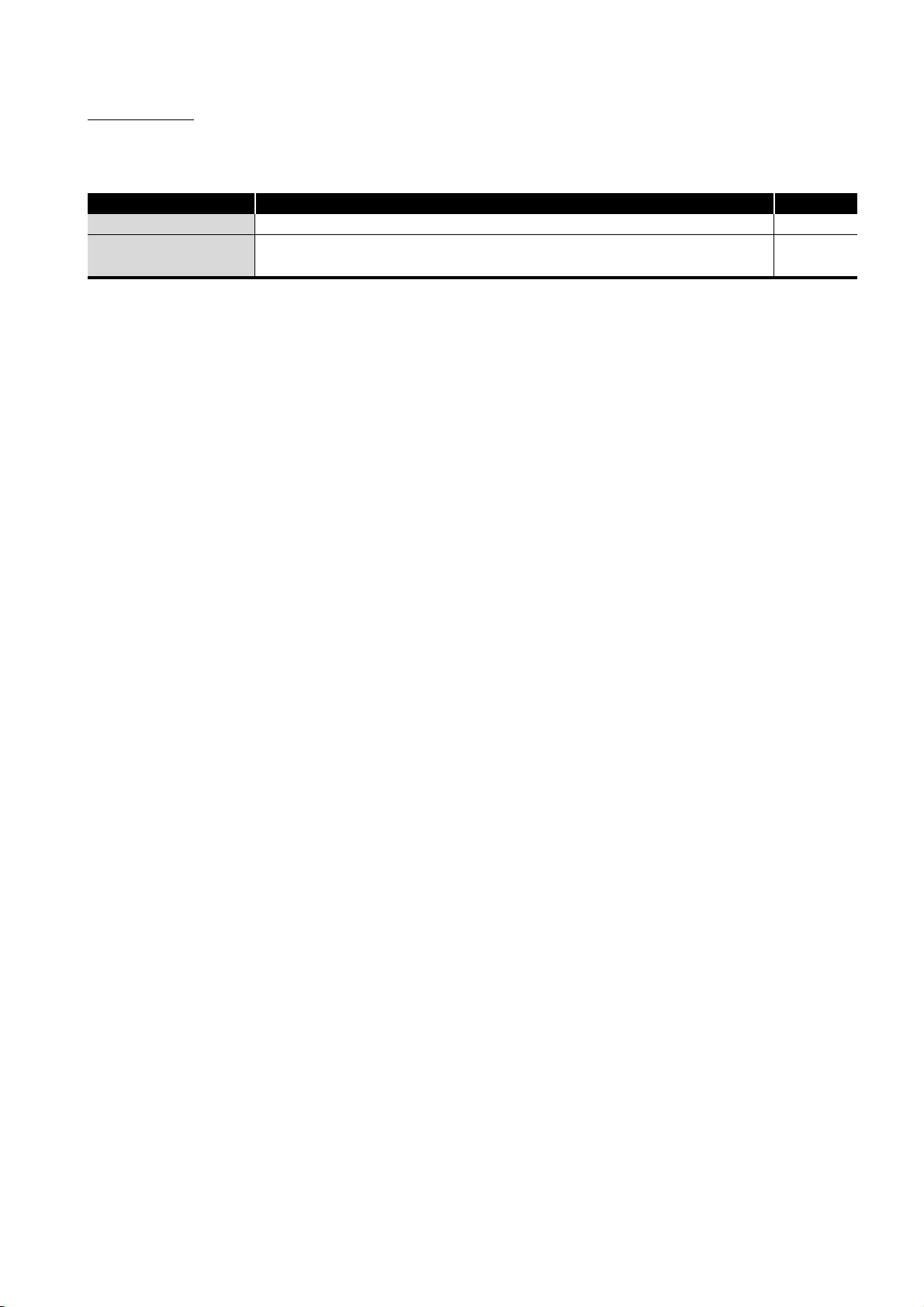

PAC K I NG LIST

The following is included in the package.

Model Product name Quantity

QJ71GP21-SX The QJ71GP21-SX CC-Link IE controller network module 1

QJ71GP21S-SX

The QJ71GP21S-SX CC-Link IE controller network module

(with external power supply function)

1

A - 17

Page 20

1

OVERVIEW

CHAPTER1 OVERVIEW

This manual provides information on the specifications, functions, preoperational

procedure, programming and troubleshooting of the QJ71GP21-SX and QJ71GP21S-SX

CC-Link IE controller network modules (hereinafter referred to as CC-Link IE controller

network module).

When applying a program example introduced in this manual to the actual system, make

sure to examine the applicability and confirm that it will not cause system control

problems.

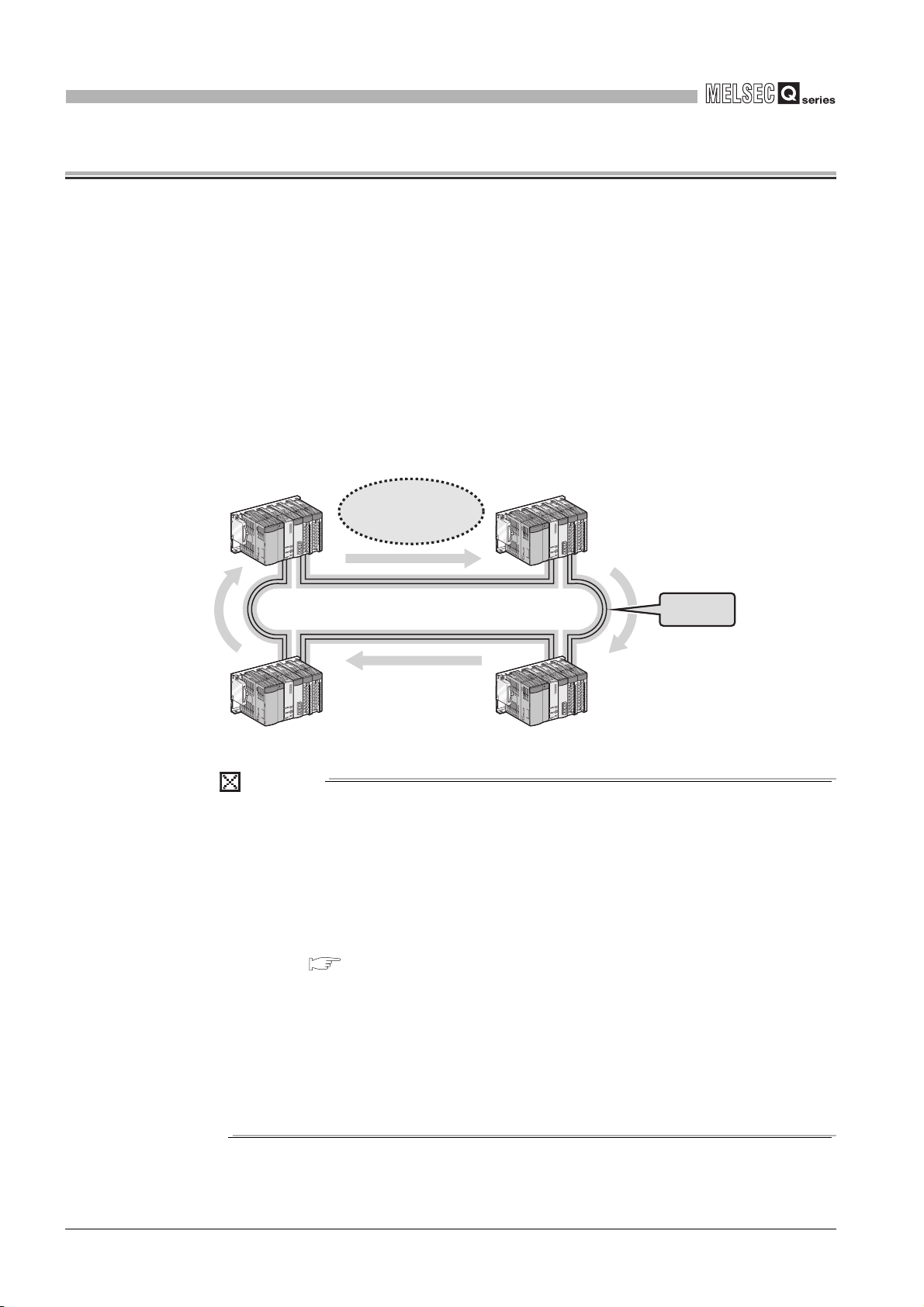

The CC-Link IE controller network module allows connection of MELSEC-Q series

programmable controllers to the CC-Link IE controller network, realizing high-speed and

large-volume data communications between the controllers in the network.

High-speed and

large-volume data

communications

CC-Link IE controller network

Figure 1.1 CC-Link IE controller network

Duplex loop

POINT

(1) The existing MELSECNET/G network module has been integrated into the

CC-Link IE controller network module.

(2) The CC-Link IE controller network is an improved system that has a higher

processing speed and a larger data capacity than the MELSECNET/H

network system (PLC to PLC network).

For comparisons between CC-Link IE controller network and MELSECNET/H,

refer to the following.

Appendix 4 Comparison between CC-Link IE controller network and

MELSECNET/H

(3) One network (of the same network No.) cannot contain both CC-Link IE

controller network and MELSECNET/H modules. (Different networks must be

used.)

• CC-Link IE controller network module: Used for CC-Link IE controller

network

• MELSECNET/H module: Used for MELSECNET/H or MELSECNET/10

1 - 1

Page 21

1

OVERVIEW

1.1 Features

1

This section explains the features of the CC-Link IE controller network module.

LB0

LB7FFF

LW0

LW1FFFF

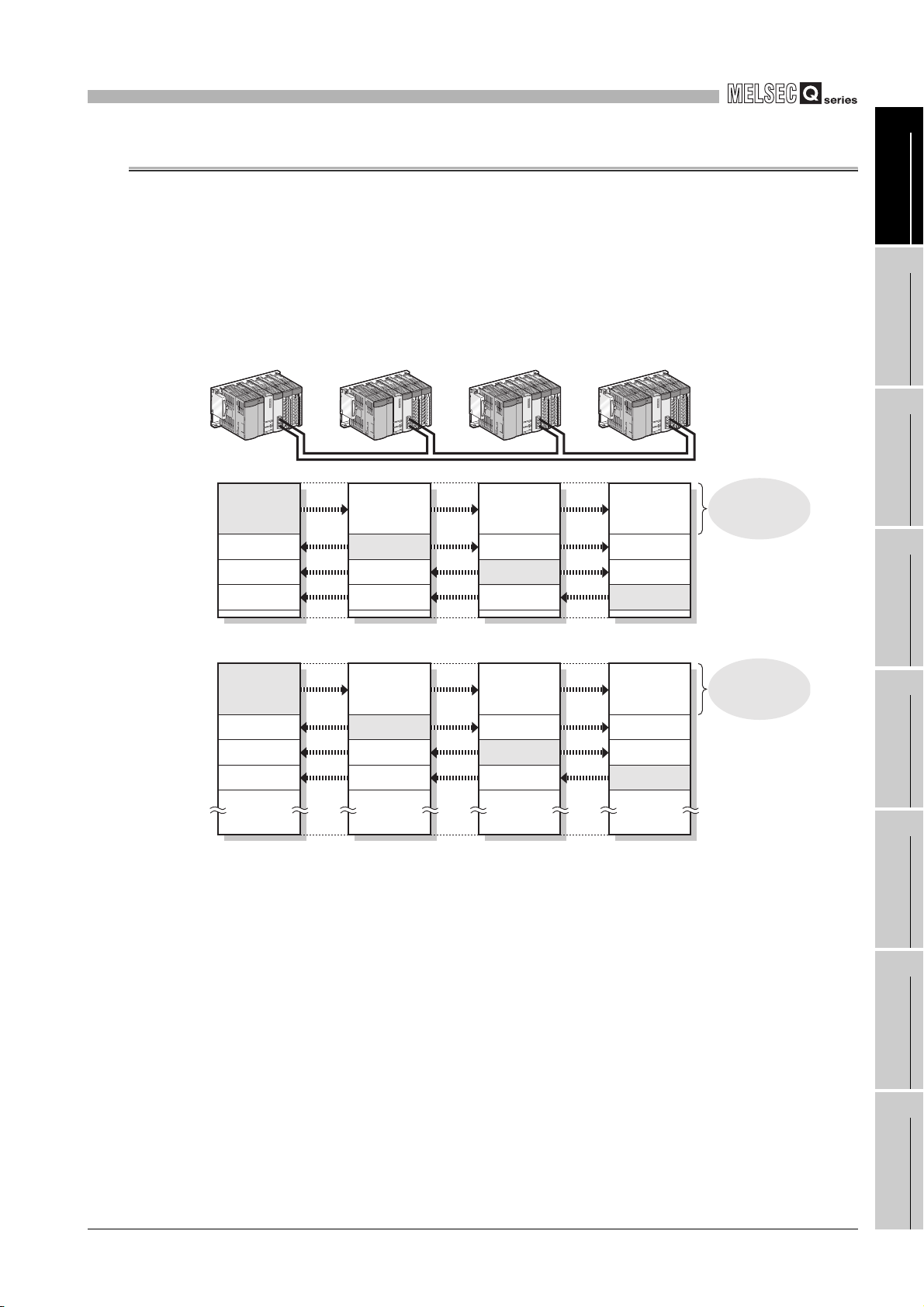

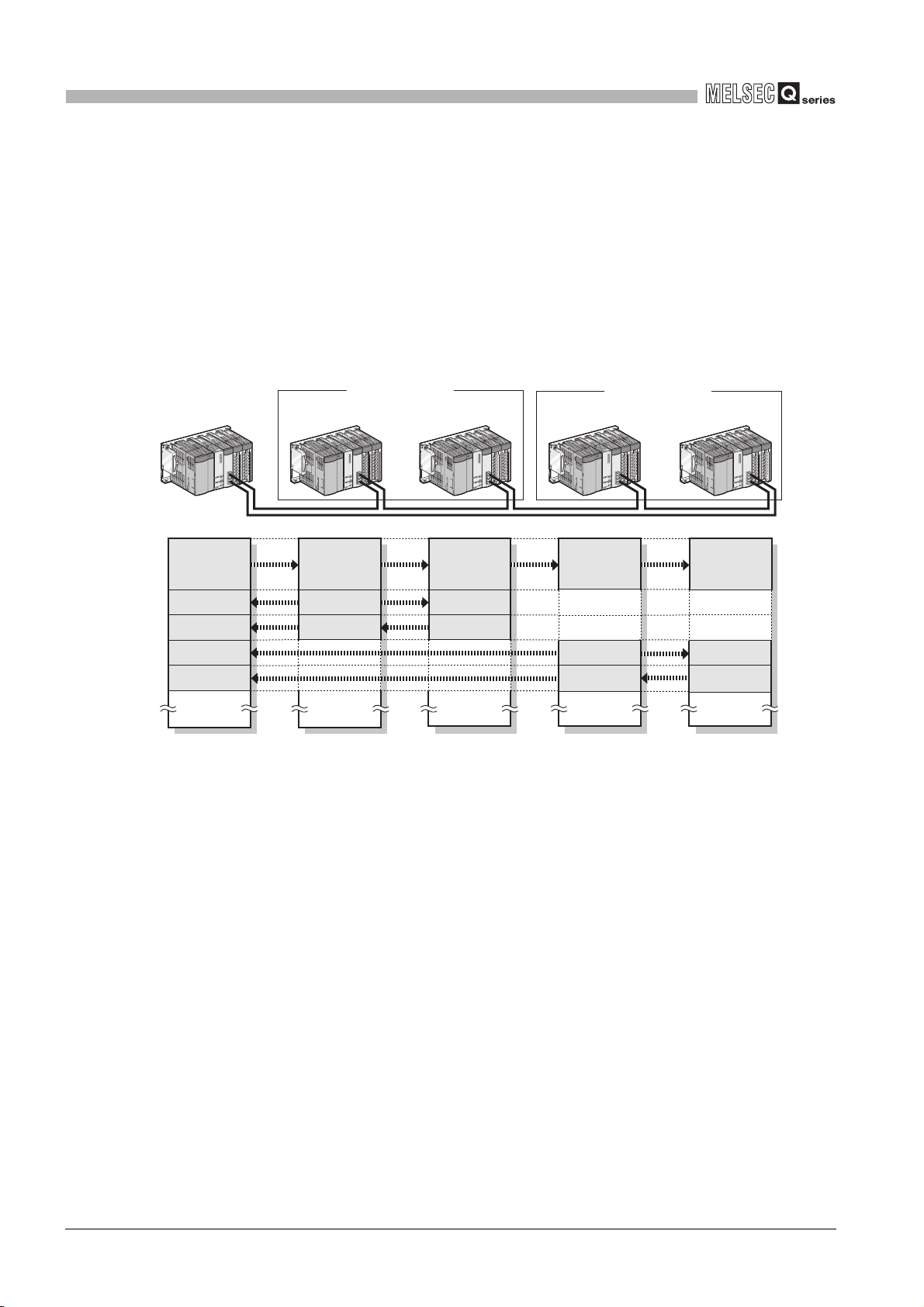

(1) Periodically exchanging large volumes of data (Cyclic transmission)

(a) Using link devices of the CC-Link IE controller network module allows periodical

exchange of large volumes of data between stations on the same network.

Control station

No.1

Link relay (LB)

No.1 send range

No.2

No.3

No.4

Link register (LW)

No.1 send range

No.2

No.3

No.4

Normal station

No.2

No.1 No.1 No.1

No.2 send range

No.3

No.4

No.1 No.1 No.1

No.2 send range

No.3

No.4

Figure 1.2 Cyclic transmission

Normal station

No.3

No.2

No.3 send range

No.4

No.2

No.3 send range

No.4

Normal station

No.4

Up to 16K link

points are available

per station.

No.2

No.3

No.4 send range

Up to 16K link

points are available

per station.

No.2

No.3

No.4 send range

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

FUNCTIONS

5

PREPARATION AND

SETUP

6

1.1 Features

1 - 2

PARAMETER

7

8

SETTING

PROCESSING TIME

PROGRAMMING

Page 22

1

OVERVIEW

(b) Since a large number of modules and link points can be used in one network, a

large-scale network system can be constructed.

Also, when expanding the network, additional stations and send points can be

easily set up.

When control station is

Universal model QCPU

When control station is

other than Universal model QCPU

Link relay (LB)

Link register (LW)

Link input (LX)

Link output (LY)

(c) High-speed data communications are available at the speed of 1Gbps.

120 (Control station:1, Normal station: 119 *1)

64 (Control station: 1, Normal station: 63)*2

Figure 1.3 Number of stations per network

* 1 A Universal model QCPU can be set to station No.1 to 120.

Any other than Universal model QCPUs can be set to station No.1 to 64.

* 2 A Basic model QCPU or safety CPU operates as a normal station. (It cannot be set to a control

station.)

32K points (32768 points, 4KB)*3

128K points (131072 points, 256KB)*3

8K points (8192 points, 1KB)

8K points (8192 points, 1KB)

Figure 1.4 Maximum link points per network

* 3 For a Basic model QCPU or safety CPU, the link relay (LB) is 16K points (16384 points, 2KB) and

the link register (LW) is 16K points (16384 points, 32KB).

Because the link scan time and transmission delay time are short, applications for

production of a short takt time can be built.

(Example) Link scan time in the case where the number of stations in the network

is 32

1 - 3

160

120

80

Link scan time [ms]

40

0

1.1 Features

CC-Link IE controller network (1Gbps)

MELSECNET/H (25Mbps)

MELSECNET/10 (10Mbps)

1 2 4 8 16 32 64 1280

Link points per network [K bytes]

Figure 1.5 High-speed data communications

Approx.

1/14

Approx.

1/30

Page 23

1

OVERVIEW

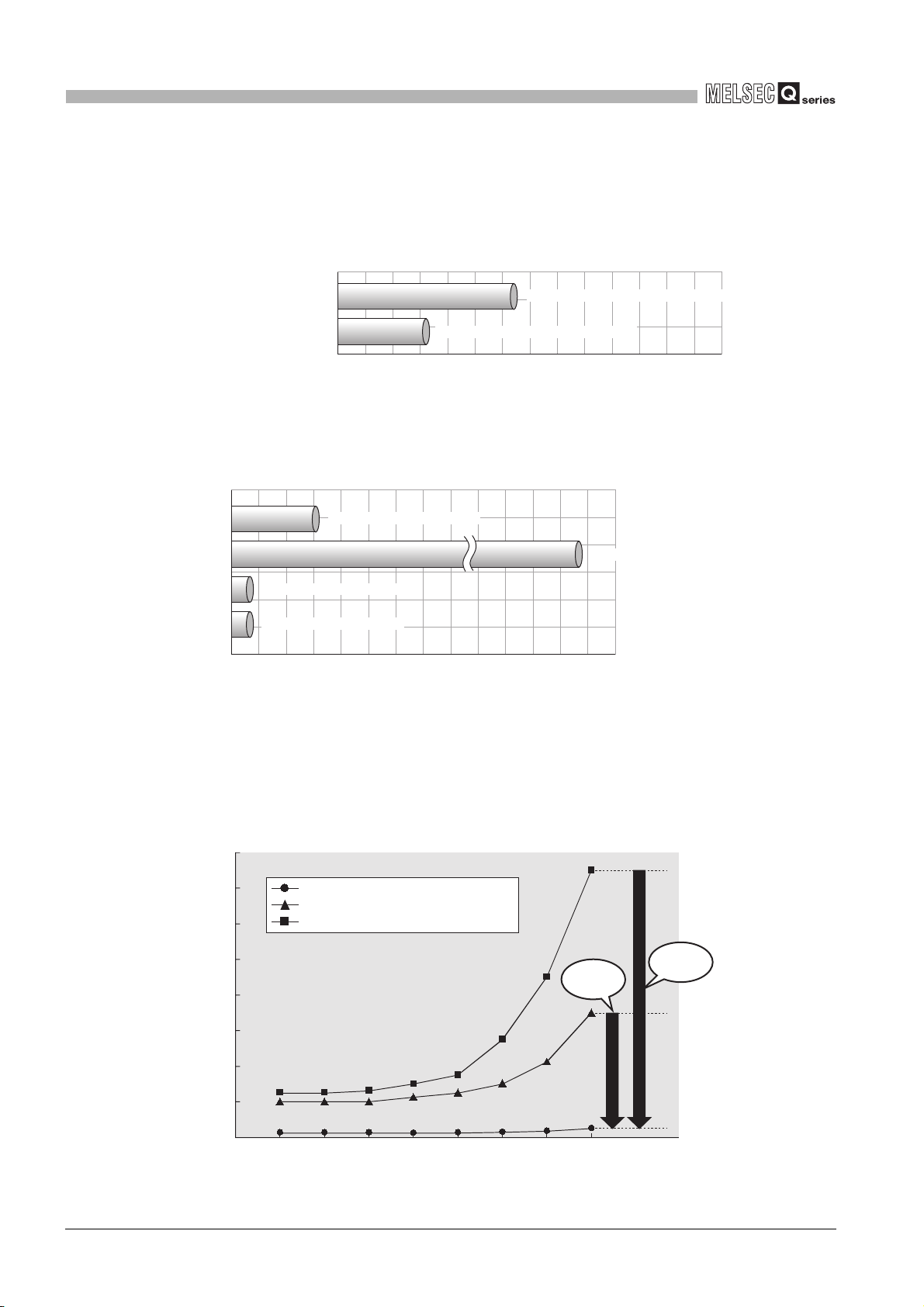

(d) Automatic transfer is available between link devices of the CC-Link IE controller

network module and devices of a CPU module. (Link refresh)

For the Universal model QCPU, the extended link register (W) is useful for

transferring link register (LW) data that exceeds the link register (W) capacity (8K

points).

* 1 Models other than the Universal model QCPU do not have the extended link register (W).

*1

Use a file register instead.

1

OVERVIEW

2

[When using the extended link register as the transfer target CPU-side device]

Universal model QCPU

Extended link register

W0

MOV D0 W8000

MOV W8200 D1

Programming is easy because both

device numbers are hexadecimal.

[When using a file register as the transfer target CPU-side device]

MOV D0 ZR32768

MOV ZR33280 D1

W8000

W1FFFF

High Performance model QCPU

File register

ZR0

ZR32768

ZR33280

CC-Link IE controller

network module

Link register

LW0

LW8000

LW8200W8200

LW1FFFF

Link refresh

CC-Link IE controller

network module

Link register

LW0

LW8000

LW8200

SYSTEM

3

4

5

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

Attention must be paid for programming

because decimal and hexadecimal device

numbers are used.

Figure 1.6 Link refresh

(e) With a sequence program, data can be directly read from or written to CC-Link IE

controller network module's link devices (LB/LW/LX/LY/SB/SW). (Direct access to

link devices)

For the Universal model QCPU, all of the link devices can be specified.

* 2 For models other than the Universal model QCPU, the area of address LB/LW4000 or higher

cannot be specified.

(f) Cyclic transmission punctuality can be ensured even at the time of transient

transmission (Cyclic transmission punctuality assurance).

Applications can be created without the need to consider link scan time

fluctuation.

ZR131071

Link refresh

1.1 Features

LW1FFFF

*2

1 - 4

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

PROCESSING TIME

8

PROGRAMMING

Page 24

1

OVERVIEW

Control station

No.1

(g) Cyclic transmission is available only to any specific stations. (Group cyclic

transmission function)

A Universal model QCPU can share cyclic data with stations in the same shared

group.

This function is useful, for example, when sharing data among all stations that

integrates and controls production lines and not sharing the data with stations that

controls other machines.

Also, receiving cyclic data only from any specific stations can reduce the number

of link refresh points, resulting in a shorter link refresh time.

Shared group No.1 Shared group No.2

Normal station

No.2

Normal station

No.3

Normal station

No.4

Normal station

No.5

Link relay (LB)

LB0

No.1 send range No.1

No.2

No.3

No.4

No.5

LB7FFF

No.1

No.2 send range

No.3

Figure 1.7 Group cyclic transmission

No.1

No.2

No.3 send range

No.4 send range

No.5

No.1

No.4

No.5 send range

1 - 5

1.1 Features

Page 25

1

Word device

read request

OVERVIEW

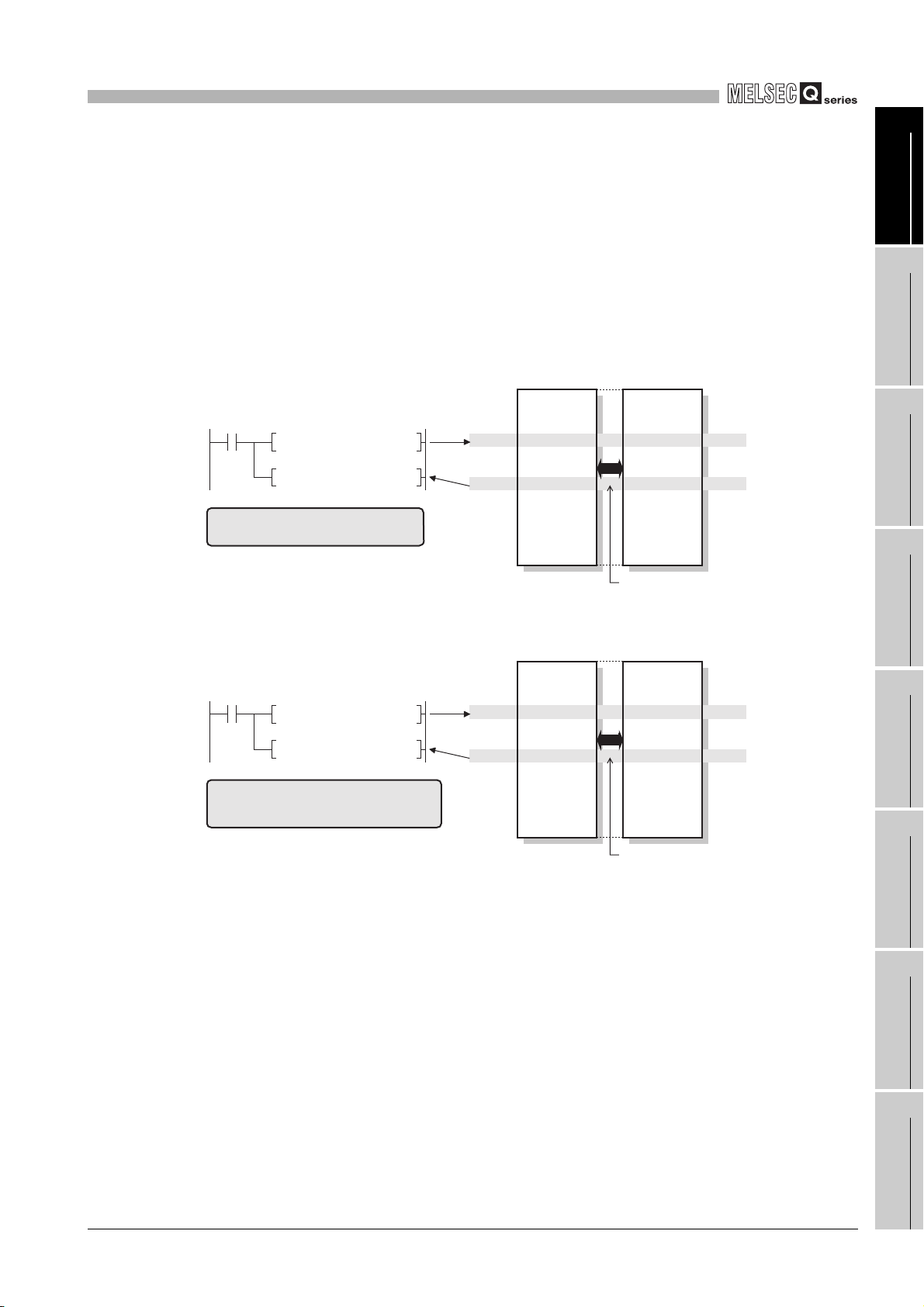

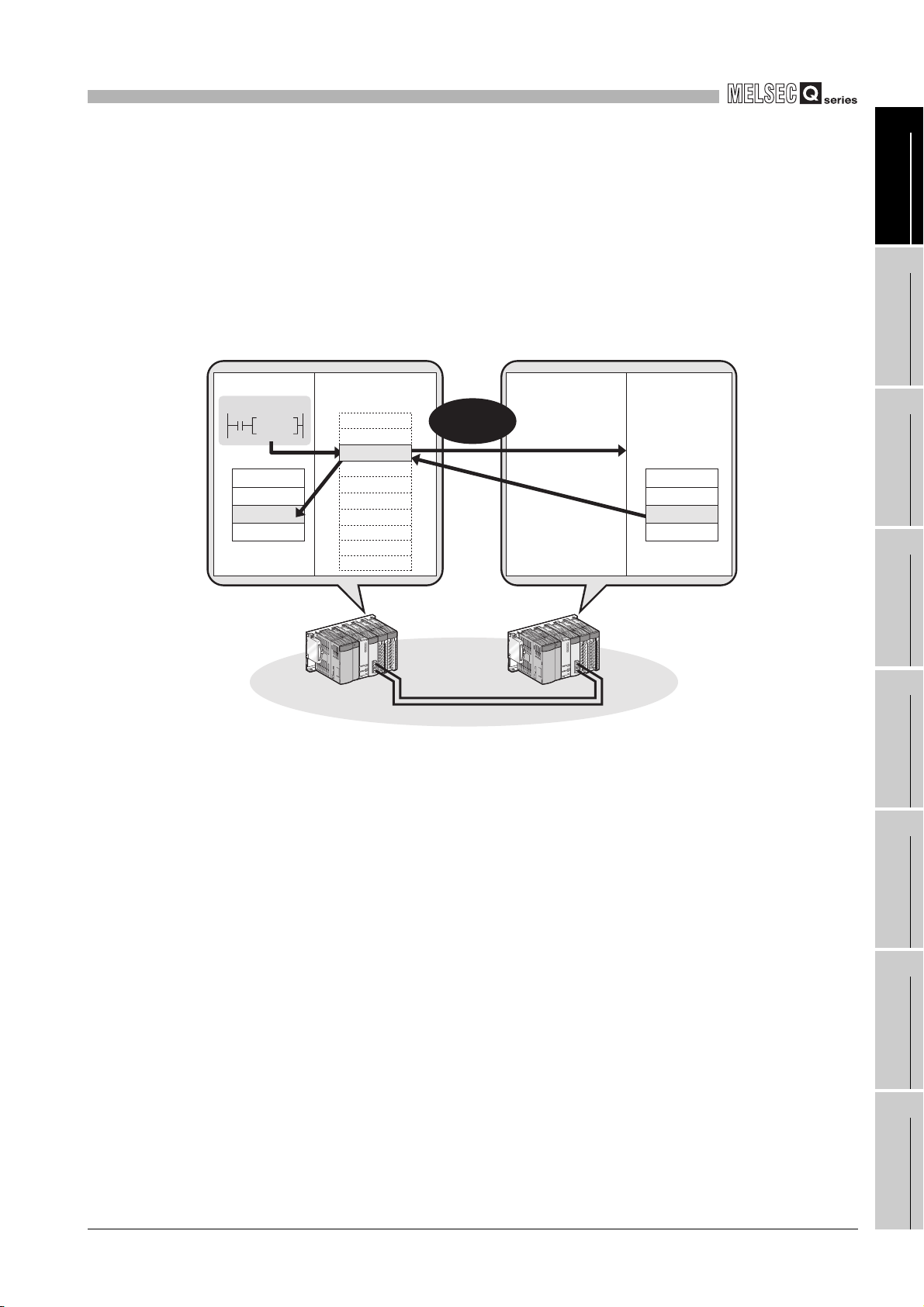

(2) Communications with other stations' programmable controllers and

CPU module CPU moduleCC-Link IE controller

Command

READ

Device

1234

CC-Link IE controller network compatible devices (Transient

transmission)

(a) By using a link dedicated instruction, data can be read from or written to a

programmable controller on another station.

Note that communications with programmable controllers on other networks are

also available.

network module

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

H

Channel 6

Channel 7

Channel 8

Channel 9

Channel 10

Word device

read request

CC-Link IE controller

network module

Device

1234

H

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

Figure 1.8 Communication with a programmable controller on another station by a link dedicated instruction

(b) Large-volume data can be transferred. (READ/SREAD/WRITE/SWRITE

instruction)

One link dedicated instruction execution can read or write data of up to 8192

words from or to a programmable controller on another station.

To specify 961 words or more, use channel 9 or 10 of the own station.

The instructions can be used for sending or receiving a large volume of data

irregularly.

FUNCTIONS

5

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

PROCESSING TIME

8

1.1 Features

PROGRAMMING

1 - 6

Page 26

1

Seamless

access

CC-Link IE

controller network

Reading

/writing data

OVERVIEW

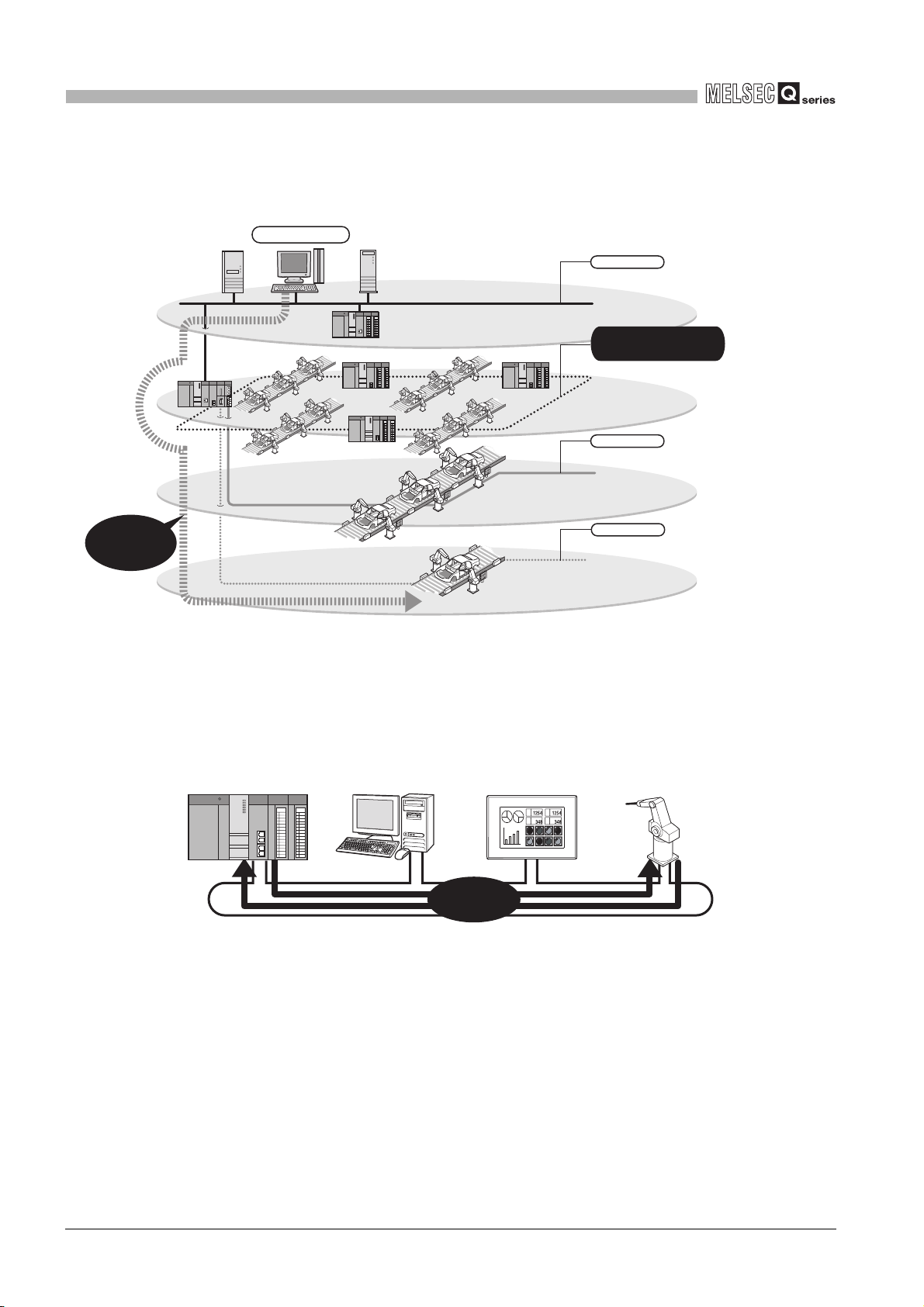

(c) Using GX Developer allows seamless access to the Ethernet, CC-Link IE

controller network, MELSECNET/H, MELSECNET/10, and CC-Link systems.

GX Developer

Ethernet

Intra-factory (Information management)

CC-Link IE

controller network

Inter-line (Production control)

CC-Link

Intra-line (Equipment control)

Seamless

access

Figure 1.9 Seamless access by GX Developer

CC-Link/LT

Individual sensor/actuator (Devices, I/O control)

(d) With a CC-Link dedicated instruction, data can be read from or written to CC-Link

IE controller network compatible devices.

Transient requests can be also received from CC-Link IE controller network

compatible devices.

Control station

No.1

Figure 1.10 Communication with CC-Link IE controller network compatible devices using CC-Link dedicated instructions

Normal station

No.2

Normal station

No.3

Reading

/writing data

Normal station

No.4

1 - 7

1.1 Features

Page 27

1

OVERVIEW

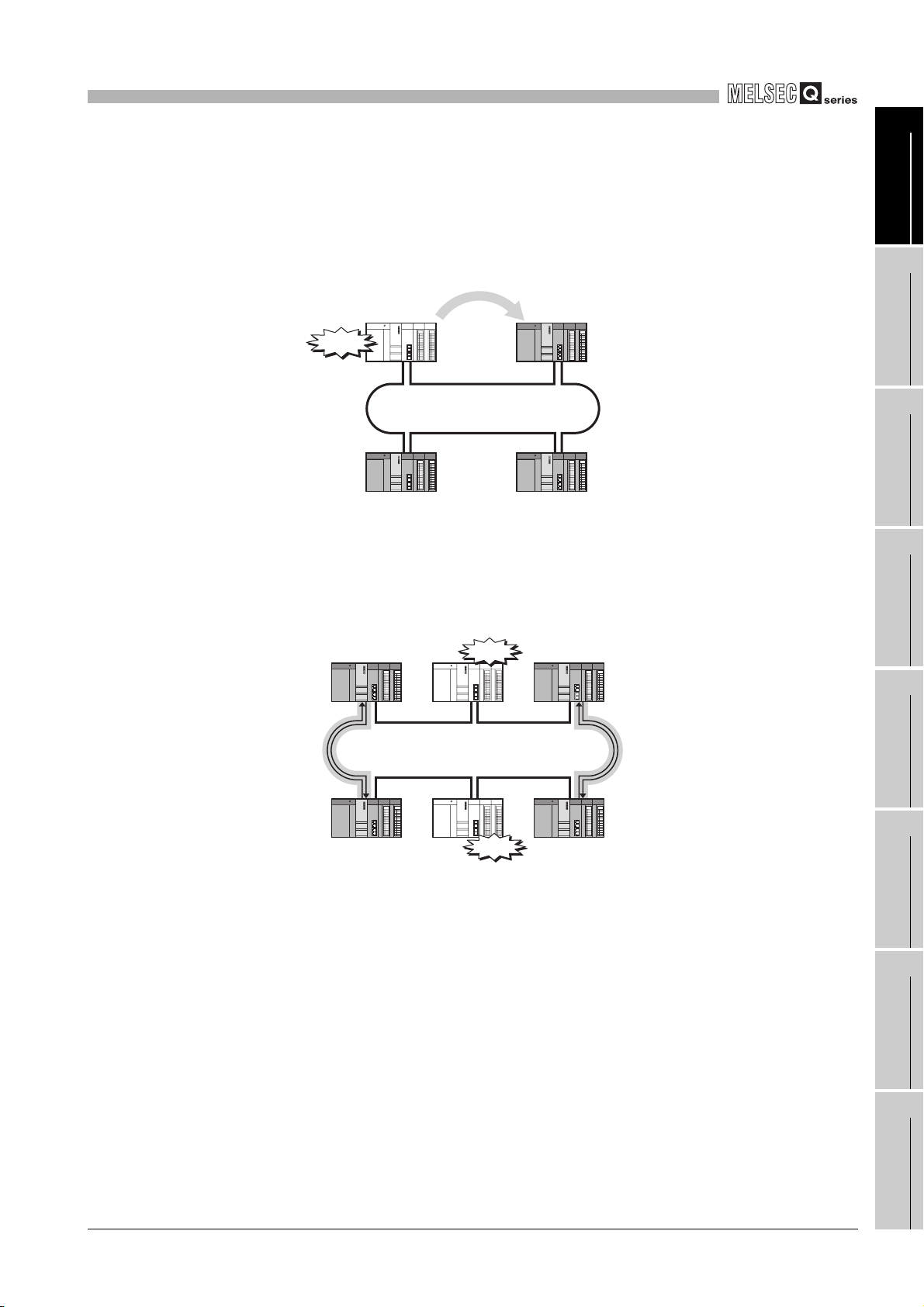

(3) Enriched RAS functions

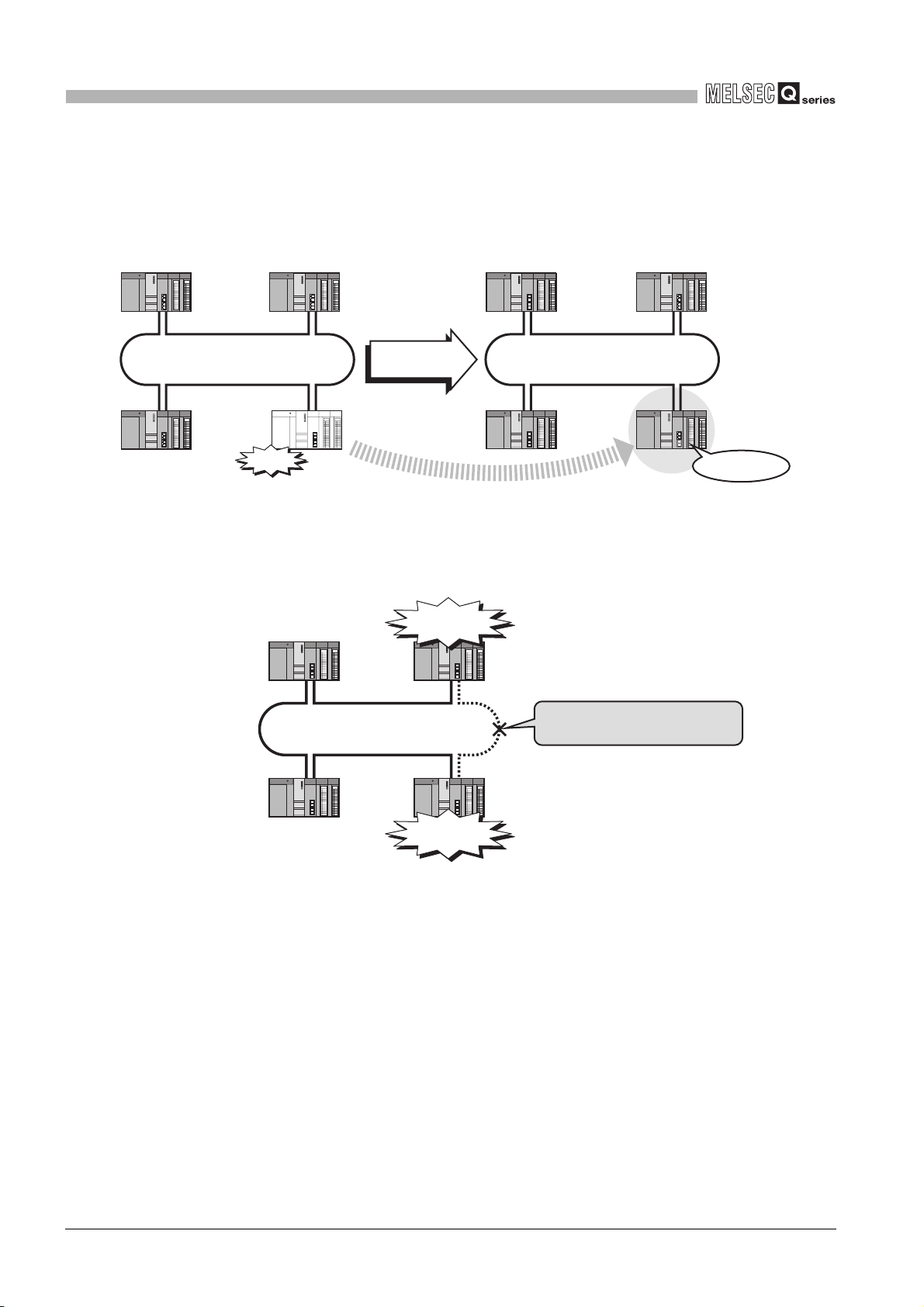

(a) Even if the control station goes down, a normal station (sub-control station) will

take over the control to continue data link. (Control station switching function)

Switching

1

OVERVIEW

2

Control station

Down

Figure 1.11 Control station switching function

No.1

Normal station

No.4

Sub-control station

No.2

Normal station

No.3

(b) Any disconnected cable or faulty station can be isolated from the network, and

data link can be continued among normally operating stations. (Loopback

function)

Control station

No.1

Loopback station

Normal station

No.2

Down

Sub-control station

No.3

Loopback station

SYSTEM

3

4

5

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

Normal station

No.6

Loopback station

Figure 1.12 Loopback function

Down

Normal station

No.5

Normal station

No.4

Loopback station

1.1 Features

1 - 8

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

PROCESSING TIME

8

PROGRAMMING

Page 28

1

OVERVIEW

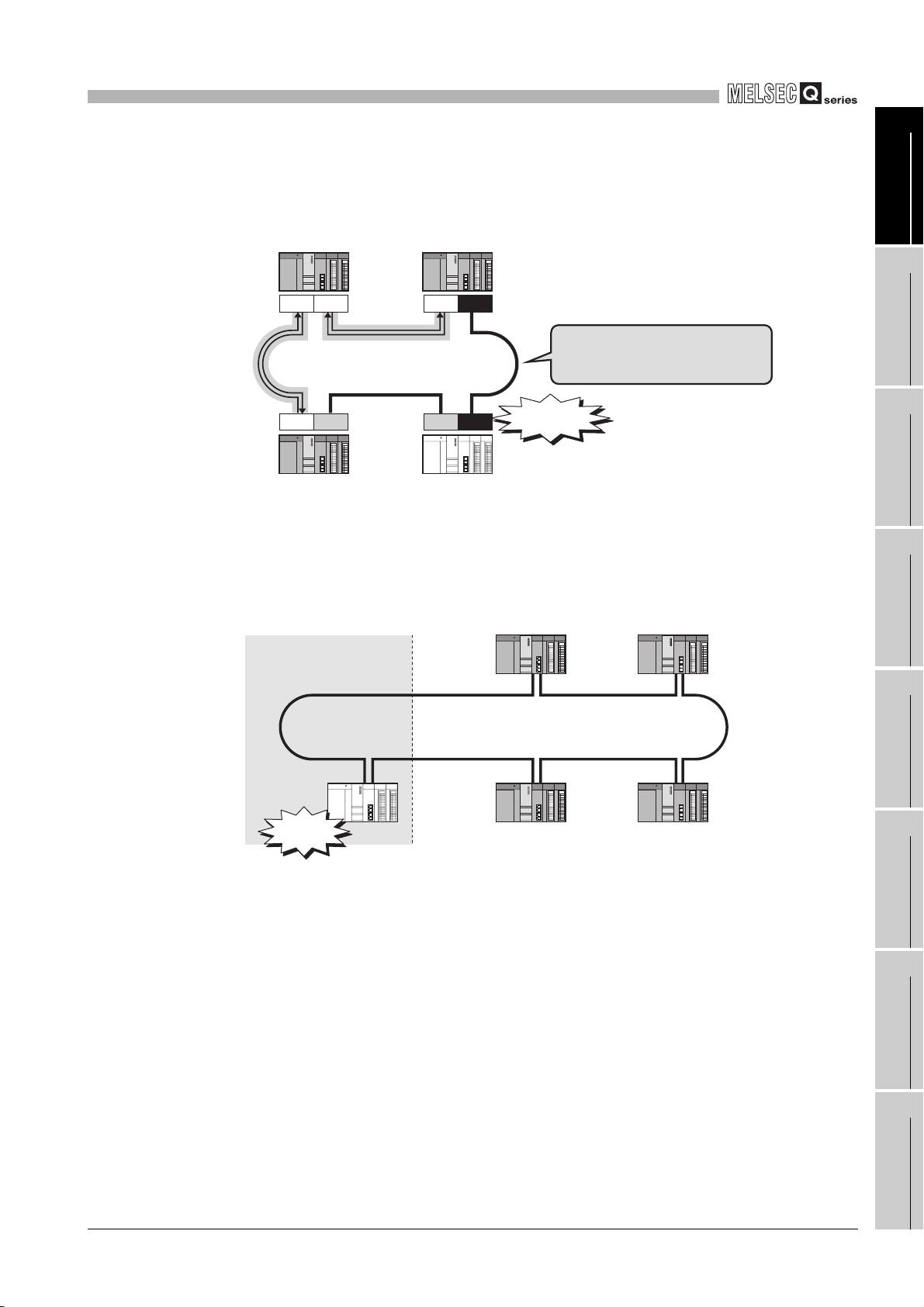

(c) When a station disconnected from a network due to a data link error recovers from

the error, the station is automatically reconnected to the network and restarts data

link. (Automatic return function)

This automatic return does not affect data link.

Control station

No.1

Normal station

No.4

Down

(d) A cable fault can be detected as a cause of a communication error. (Cable fault

Control station

No.1

Normal station

No.2

When recovered

from fault

Normal station

No.3

Figure 1.13 Automatic return function

detection function)

Communication

error

Normal station

No.2

A cable fault is detected as the

cause of the communication error.

Control station

No.1

Normal station

No.4

Normal station

No.2

Normal station

No.3

Reconnected

Normal station

No.4

Normal station

No.3

Communication

error

Figure 1.14 Cable fault detection function

1 - 9

1.1 Features

Page 29

1

OVERVIEW

Control station

No.1

(e) Incorrect cable connection between OUT and IN can be detected as a cause of

loopback or disconnection from the network. (Cable insertion error detection

function)

Normal station

No.2

OUTIN OUTIN

Incorrect cable connection between

OUT and IN is detected as the cause

of the loopback and disconnection.

INOUT OUTIN

Cable

insertion error

1

2

SYSTEM

3

OVERVIEW

CONFIGURATION

Normal station

No.4

Normal station

No.4

Normal station

No.3

Figure 1.15 Cable insertion error detection function

(f) Duplication of the control station or station No. can be detected as a cause of

loopback or disconnection from the network. (Detection of duplicated control

station or station No.)

(Example) When a station is added to a network (Station No. duplication)

Control station

No.1

When a normal

station of a duplicated

No. is added

Normal station

No.4

Station No.

duplicated

Figure 1.16 Detection of duplicated control station or station No.

Stations No.1 to No.4 continues

cyclic transmission.

Normal station

No.2

Normal station

No.3

SPECIFICATIONS

4

FUNCTIONS

5

PREPARATION AND

SETUP

6

1.1 Features

1 - 10

PARAMETER

7

8

SETTING

PROCESSING TIME

PROGRAMMING

Page 30

1

OVERVIEW

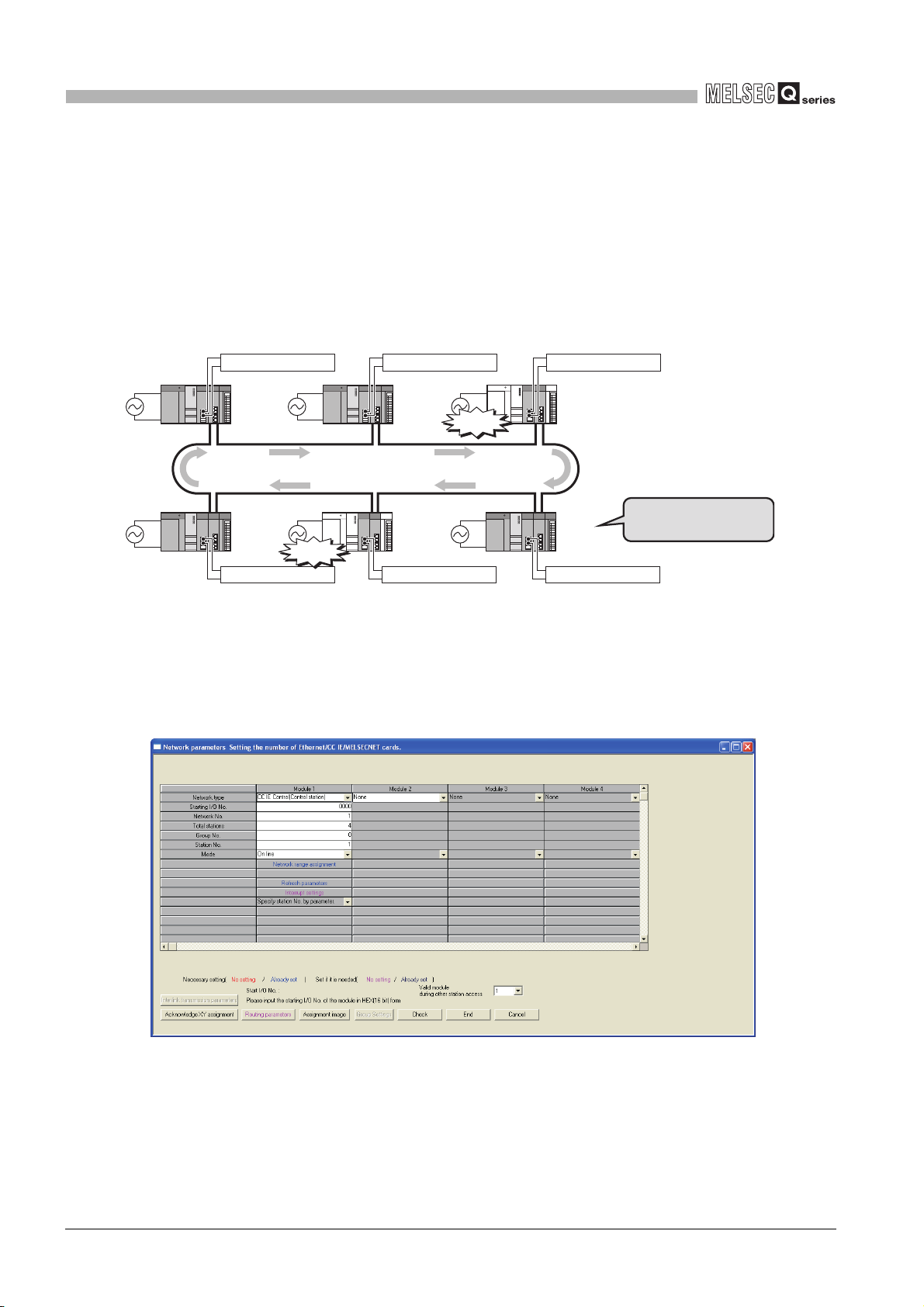

(g) The external power can be directly supplied to the CC-Link IE controller network

module with external power supply function. (External power supply function)

Even if a CPU module power goes down in a network, data link will be continued

among normally operating stations without being disrupted at the power-down

station. (Loopback does not occur.)

Data link is also continued between failed stations when power failure has

occurred on CPU modules on multiple stations.

External power supply

Control

station

No.1

Normal

station

No.6

External power supply External power supply External power supply

Down

Figure 1.17 External power supply function

External power supply External power supply

Normal

station

No.2

Normal

station

No.5

Down

Normal

station

No.3

Normal

station

No.4

Data link is continued

between failed stations.

(4) Simple network parameter setting using GX Developer

Network parameters required for network construction can be easily set up with GX

Developer.

1 - 11

Figure 1.18 Network parameters in GX Developer

1.1 Features

Page 31

1

OVERVIEW

(5) Network diagnostics with GX Developer

The network status or each station's operating status can be checked by the CC IE Control

Network Diagnostics. By using this, even if an error occurs at system startup or during

operation, troubleshooting can be done easily.

OUT-side cable

disconnection

Control station

No.1

Normal station

No.2

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

GX Developer

Normal station

No.4

Figure 1.19 CC IE Control Network Diagnostics in GX Developer

Normal station

No.3

IN-side cable

disconnection

FUNCTIONS

5

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

PROCESSING TIME

8

1.1 Features

PROGRAMMING

1 - 12

Page 32

1

OVERVIEW

(6) Redundant system construction is available. (Compatibility with

redundant CPUs)

(a) System redundancy using CC-Link IE controller network modules can be

designed.

By mounting a CC-Link IE controller network module to each of base units with

redundant CPUs, a redundant system can be configured.

If an error occurs in the control system CPU or CC-Link IE controller network

module, the control and standby systems will be switched each other, and the

standby system will take over the system control and data link.

(b) System switching request can be issued to the control system CPU.

When the CC-Link IE controller network module of the control system CPU

detects a data link error, it can issue a system switching request to the control

CPU.

(c) Transient transmission to a redundant system is executable.

With a link dedicated instruction or from GX Developer, device data can be read

from or written to its own system, control/standby system, system A/B of a

redundant system, and remote RUN/STOP can be controlled.

By specifying the target station's CPU type to Control or Standby system, the

target can be fixed even if a system switching occurs.

CC-Link IE controller

network module

Control

station No.3

CC-Link IE controller network

Control system Standby system

Normal

station No.1

Tracking cable

Figure 1.20 Redundant system

Normal

station No.4

Normal

station No.2

1 - 13

1.1 Features

Page 33

1

OVERVIEW

(7) Common project data can be created for normal stations

GX Developer

For normal

For Universal model QCPUs, the station No. of a normal station (own station) can be

set in the sequence program.

*1

If there are any normal stations that can share the same sequence program and

network parameters (except for station No.), specifying their station numbers in the

sequence program creates common project data for them, allowing easy data

management.

* 1 For modules other than Universal model QCPUs, station No. cannot be set in sequence programs.

Station Nos. must be set with network parameters.

For control

station

stations

Common project data can be created for

normal stations, resulting in easy management.

1

2

SYSTEM

3

OVERVIEW

CONFIGURATION

For control

station

For normal

stations

Station No. setting by

sequence program

Figure 1.21 Creating common project data for normal stations

Station No. setting by

sequence program

For normal

stations

Control

station

No.1

Normal

station

No.6

For normal

stations

Station No. setting by

sequence program

Station No. setting by

sequence program

For normal

stations

Normal

station

No.2

Normal

station

No.5

For normal

stations

Station No. setting by

sequence program

Normal

station

No.3

Normal

station

No.4

SPECIFICATIONS

4

FUNCTIONS

5

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

1.1 Features

PROCESSING TIME

8

PROGRAMMING

1 - 14

Page 34

2

SYSTEM CONFIGURATION

CHAPTER2 SYSTEM CONFIGURATION

This chapter describes system configurations for the CC-Link IE controller network

module.

2.1 CC-Link IE Controller Network Configurations

2.1.1 Single network system

The single network system is a system that consists of a control station and normal

stations, which are connected with optical fiber cables.

CC-Link IE controller

network module

Control station

Station No.1

Figure 2.1 Single network system

* 1 A personal computer equipped with a CC-Link IE controller network interface board can be

connected as a control or normal station of the CC-Link IE controller network.

For details on the CC-Link IE controller network interface board, refer to the following manual.

CC-Link IE controller network interface board User's Manual

* 2 By connecting a CC-Link IE controller network module to a GOT, the GOT can be connected to the

CC-Link IE controller network as a normal station.

For details on the CC-Link IE controller network communication unit, refer to the following manual.

GT15 User's Manual

Normal station

Station No.2

CC-Link IE controller network

interface board

Optical fiber cable

*1

Normal station

Station No.3

CC-Link IE controller network

communication unit

*2

Normal station

Station No.120

POINT

One network (of the same network No.) cannot contain both CC-Link IE controller

network and MELSECNET/H modules. (Different networks must be used.)

• CC-Link IE controller network module: Used for CC-Link IE controller

network

• MELSECNET/H module: Used for MELSECNET/H or MELSECNET/10

2 - 1

2.1 CC-Link IE Controller Network Configurations

2.1.1 Single network system

Page 35

2

SYSTEM CONFIGURATION

(1) When Universal model QCPU is used for control station

Up to 120 stations including one control station and 119 normal stations can be

connected. (One control station is needed for a single network.)

Table 2.1 When Universal model QCPU is used for control station

High Performance

Item

Network type Normal station

Station No. Station No.1 to 64 Station No.1 to 120

*1

*1

*2

Section 4.1.1 (5) Receive range for other stations' data

Section 4.1.2 (5) Receive range for other stations' data

Link device

range

Link relay (LB)

Link register (LW)

Link input (LY)

Link output (LY) LY0 to 1FFF

Link special relay (SB) SB0 to 1FF

Link special register (SW) SW0 to 1FF

* 1 The receive range for other station's data varies depending on the CPU module.

* 2 The receive range for other station's data varies depending on the CPU module.

Basic model QCPU

Safety CPU

LB0 to 3FFF LB0 to 7FFF

LW0 to 3FFF LW0 to 1FFFF

model QCPU

Process CPU

Redundant CPU

LX0 to 1FFF

Universal model

Control station and

normal station

QCPU

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

(2) When other than Universal model QCPU is used for control station

Up to 64 stations including one control station and 63 normal stations can be

connected. (One control station is needed for a single network.)

Table 2.2 When other than Universal model QCPU is used for control station

High Performance

Item

Network type

Station No. Station No.1 to 64

*1

*1

*2

Section 4.1.1 (5) Receive range for other stations' data

Section 4.1.2 (5) Receive range for other stations' data

Link device

range

Link relay (LB)

Link register (LW)

Link input (LY)

Link output (LY) LY0 to 1FFF

Link special relay (SB) SB0 to 1FF

Link special register (SW) SW0 to 1FF

* 1 The receive range for other station's data varies depending on the CPU module.

* 2 The receive range for other station's data varies depending on the CPU module.

* 3 A station with a Basic model QCPU or safety CPU operates as a normal station. (It cannot be set to

a control station.)

Basic model QCPU

Safety CPU

Normal station

LB0 to 3FFF LB0 to 7FFF

LW0 to 3FFF LW0 to 1FFFF

*3

model QCPU

Process CPU

Redundant CPU

Control station and

normal station

LX0 to 1FFF

Universal model

QCPU

Normal station

FUNCTIONS

5

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

PROCESSING TIME

8

2.1 CC-Link IE Controller Network Configurations

2.1.1 Single network system

PROGRAMMING

2 - 2

Page 36

2

SYSTEM CONFIGURATION

2.1.2 Redundant system

A redundant system is a system in which a basic system including a CPU module, a power

supply module, a network module is backed up with the other system.

By mounting a CC-Link IE controller module to each main base unit of a redundant CPU,

two CC-Link IE controller network modules can be used in a redundant system.

For use with redundant CPUs, refer to the following.

Section 4.6 Redundant-CPU-Compatible Function

CC-Link IE controller

network module

Control

station No.3

CC-Link IE controller network

Normal

station No.4

Control system Standby system

Normal

station No.1

Tracking cable

Figure 2.2 Redundant system

Normal

station No.2

2 - 3

2.1 CC-Link IE Controller Network Configurations

2.1.2 Redundant system

Page 37

2

SYSTEM CONFIGURATION

2.1.3 Multi-network system

The multi-network system is a system in which multiple networks are connected by some

relay stations.

Up to 239 networks can be connected.

1

OVERVIEW

2

Control

station

P

1M

Normal station

S

3

1N

CC-Link IE controller

network module

1

CC-Link IE controller network

Network No.1

Control station

P

1

3M

Normal station

S

2

3N

Figure 2.3 Multi-network system

Normal

station

1NS2

MELSECNET/H Network No.3

Control

station

2MP1

Normal station

3NS3

MELSECNET/H

module

MELSECNET/H Network No.2

Normal station

Normal station

3NS4

Normal

station

2NS2

S

2N

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

3

FUNCTIONS

5

Regardless of single or multiple CPU system, one system can contain up to four CC-Link

IE controller network modules (up to four including MELSECNET/H module(s)).

* 1 Depending on the CPU module to be used, there are restrictions on the number of modules that

can be installed to one system.

Section 2.3 Applicable Systems

2nd

1st

3rd

4th

CC-Link IE controller network

network No.1

CC-Link IE controller network

network No.2

Figure 2.4 Number of mountable modules per system

2.1 CC-Link IE Controller Network Configurations

MELSECNET/H

network No.4

MELSECNET/H

network No.3

2.1.3 Multi-network system

*1

2 - 4

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

PROCESSING TIME

8

PROGRAMMING

Page 38

2

SYSTEM CONFIGURATION

2.2 Network Components

The CC-Link IE controller network consists of the following.

2.2.1 Order of optical fiber cables (Optional)

Optical fiber cables with connectors are available from Mitsubishi Electric System &

Service Co., Ltd. (Catalogs of the optical fiber cables are also available.)

In addition, on-site connector polishing, terminal assembly, and fusion splicing is available.

Please consult your local Mitsubishi Electric System & Service representative.

Typ e Model (Manufacturer)

Multi-mode fiber (GI) QG series (Mitsubishi Electric System & Service Co., Ltd.)

POINT

(1) For CC-Link IE controller network modules, 2-core cables are used.

(2) Optical fiber cables used for MELSECNET/H modules or MELSECNET/10

modules cannot be used for CC-Link IE controller network modules.

Table 2.3 Optical fiber cable

Remark

(1) The following types of optical fiber cables are available.

A type: Cable for connection inside control panel

B type: Cable for connection between control panels inside a building

C type: Cable for outdoor connection

D type: Reinforced cable for outdoor connection

There are special cables available for moveable applications and resistance

to heat. Contact your Mitsubishi Electric System & Service for details.

2 - 5

2.2 Network Components

2.2.1 Order of optical fiber cables (Optional)

Page 39

2

SYSTEM CONFIGURATION

2.2.2 CC-Link IE controller network interface board

The CC-Link IE controller network interface boards designed for use in a personal

computer are shown below.

For details on the CC-Link IE controller network interface boards, refer to the following

manual.

CC-Link IE controller network interface board User's Manual

Table 2.4 CC-Link IE controller network interface boards

Model Product name Network type

Q80BD-J71GP21-SX Q80BD-J71GP21-SX CC-Link IE controller network interface board

Q80BD-J71GP21S-SX

2.2.3 CC-Link IE controller network communication unit

Q80BD-J71GP21S-SX CC-Link IE controller network interface board

(with external power supply function)

CC IE Control (Control station)

CC IE Control (Normal station)

1

2

SYSTEM

3

OVERVIEW

CONFIGURATION

The CC-Link IE controller network communication unit used for the GOT is shown below.

For details on the CC-Link IE controller network communication unit, refer to the following

manual.

GT15 User's Manual

Table 2.5 CC-Link IE controller network communication unit

Model Product name Network type

GT15-J71GP23-SX CC-Link IE controller network communication unit CC IE Control (Normal station)

SPECIFICATIONS

4

FUNCTIONS

5

PREPARATION AND

SETUP

6

PARAMETER

SETTING

7

2.2 Network Components

2.2.2 CC-Link IE controller network interface board

PROCESSING TIME

8

PROGRAMMING

2 - 6

Page 40

2

SYSTEM CONFIGURATION

2.3 Applicable Systems

This section describes the applicable systems.

The number of mountable modules represents the maximum number of CC-Link IE

controller network modules that can be used together with MELSECNET/H modules.

(1) Applicable modules and base units, and No. of modules

(a) When mounted with a CPU module

The table below shows the CPU modules and base units applicable to the

CC-Link IE controller network module and quantities for each CPU model.