Page 1

C

MIT

SUBIS

C

HI ELECTRI

MELSEC System Q

Programmable Logic Controllers

User's Manual

DeviceNet Master-Slave Module

Art. no.: 139835

01 05 2003

SSH (NA)-080143

Version F

QJ71DN91

GX Configurator-DN

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

Page 2

SAFETY PRECAUTIONS

•

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the User's Manual of the CPU module to use.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

•

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to t he circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forw ard it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[DESIGN PRECAUTIONS]

!

DANGER

If a communications error occurs to a device network, the node in such a communications error

•

will be in a state as follows:

(1) The master node (QJ71DN91) maintains input data which had been received from the slav e

node before the error occurred.

(2) Whether the slave node's output signal is turned off or maintained is determined by the

slave node's specifications or the parameters set at the master node. When using

QJ71DN91 as a slave node, the entered data from master node before the faulty node is

maintained.

By referring to communications states of the slave node, arrange an interlock circuit in a

sequential program and provide safety mechanism externally of the slave node in order the

system to operate safely.

!

CAUTION

Do not bunch the control wires or communication cables with the main circuit or power wires, or

•

install them close to each other.

They should be installed 300 mm (11.8 inch) or more from each other. Not doing so could result

in noise that may cause malfunction.

A - 1 A - 1

Page 3

[INSTALLATION PRECAUTIONS]

!

CAUTION

Use the PLC in an environment that meets the general specifications contained in the CP U

•

User's Manual to use.

Using this PLC in an environment outside the range of the general specific ations may cause

electric shock, fire, malfunction, and damage to or deterioration of the product.

When installing the module, securely insert the module fixing tabs into the mountin g holes of the

•

base module while pressing the installation lever located at the bottom of the module downward.

Improper installation may result in malfunction, breakdown or dropping out of the module.

Securely fix the module with screws if it is subject to vibration during use.

Tighten the screws within the range of specified torque.

•

If the screws are loose, it may cause fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damage to the screw and /or the module,

resulting in fallout, short circuits or malfunction.

Switch all phases of the external power supply off when mounting or removing the module.

•

Not doing so may cause electric shock or damage to the module.

Do not directly touch the conductive area or electric components of the module.

•

Doing so may cause malfunction or failure in the module.

[WIRING PRECAUTIONS]

!

DANGER

Make sure to shut off all the phases of the external power supply before starting installation or

•

wiring. Otherwise, the personnel may be subjected to an electric shock or the product to a

damage.

!

CAUTION

Be careful not to let foreign matters such as sawdust or wire chips get inside the module.

•

These may cause fires, failure or malfunction.

The top surface of the module is covered with protective film to prevent foreign objects such as

•

cable offcuts from entering the module when wiring.

Do not remove this film until the wiring is complete.

Before operating the system, be sure to remove the film to provide adequate heat ventilation.

Be sure to fix cables leading from the module by placing them in the duct or clamping them.

•

Unless the cables are placed with a duct or clamped, the module or cables could be broken by

swinging or moving of the cables or unintentional pulling to cause an operation error result ing

from a contact error.

Do not pull cables by holding them with a hand for removing the cables that are connected to the

•

module. To remove a cable having a connector, hold the connector connected to the module

with a hand. To remove a cable not having a connector, loosen the screws fastening to connect

the module. The cables being pulled while t hey are still connect ed to the module cou ld break the

module or cables, or cause an operation error resulting from a contact error.

A - 2 A - 2

Page 4

[CAUTIONS ON STARTUP AND MAINTENANCE]

!

DANGER

Always turn off all external power supply phases before touching any terminals.

•

Failure to do this may result in malfunction.

Always turn of all external power supply phases before cleaning or tightening the terminal

•

screws.

Failure to do this may result in malfunction.

Do not disassemble or modify any module.

•

This will cause failure, malfu nction, injur ies, or fire.

Always turn off all external power supply phases before mounting or dismounting the module.

•

Failure to do this may result in malfunction or damage to the module.

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

•

etc., before touching the module.

Failure to do so may cause a failure or malfunctions of the module.

[DISPOSAL PRECATION]

!

CAUTION

Dispose of this product as industrial waste.

•

A - 3 A - 3

Page 5

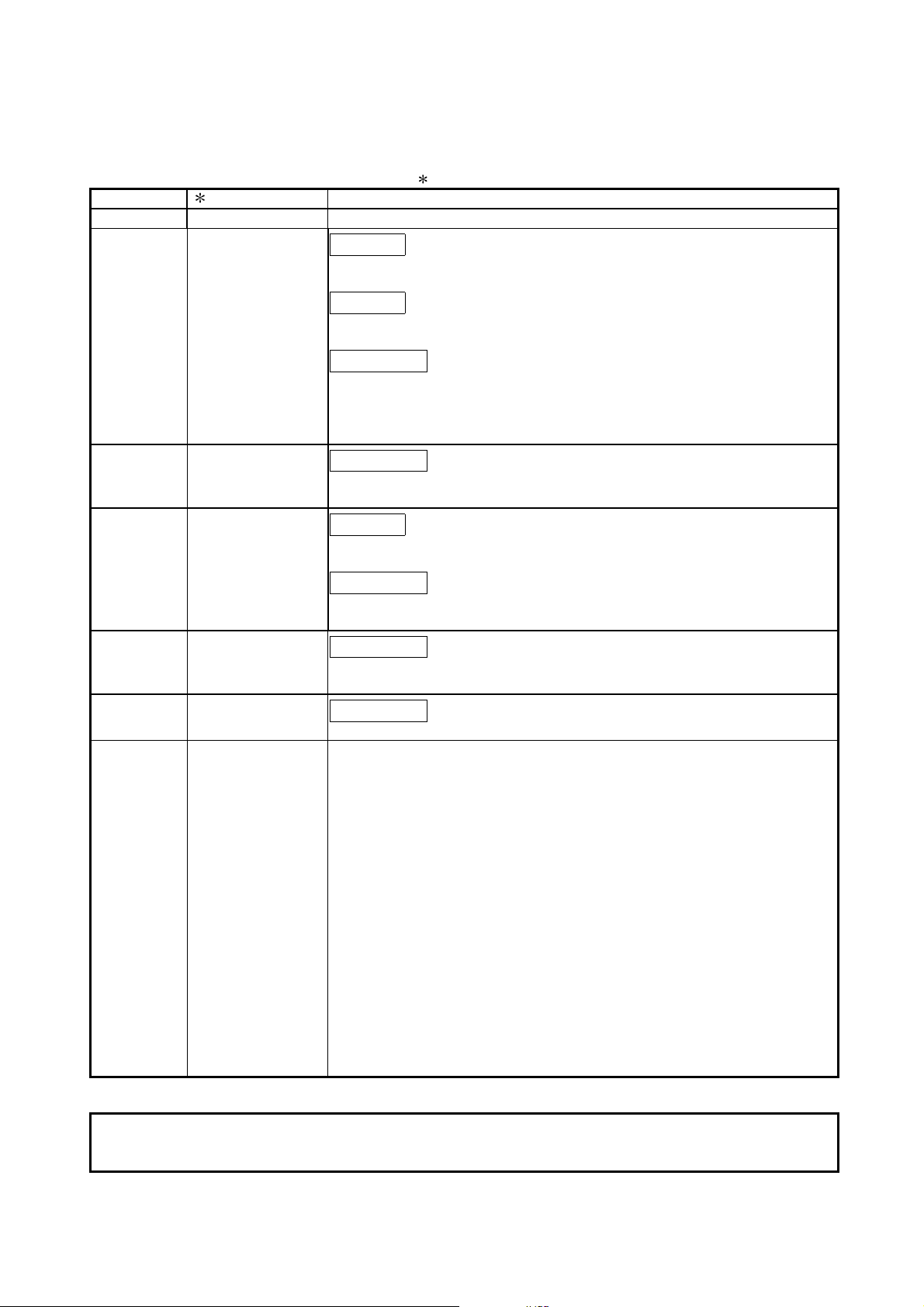

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 2000 SH (NA)-080143-A First Printing

Jun., 2001 SH (NA)-080143-B

Addition

Section 2.3, 2.4

Delete

Section 2.2.1, 2.2.2

Correction

SAFETY PRECAUTIONS, About the Generic Terms and Abbreviations,

Product Configuration, Section 2.2, 2.4, Section 6.2, 6.2.1, 6.2.2, 6.3.3,

6.5

Feb., 2002 SH (NA)-080143-C

Dec., 2002 SH (NA)-080143-D

Feb., 2003 SH (NA)-080143-E

May., 2003 SH (NA)-080143-F

Correction

About the Generic Terms and Abbreviations, Section 2.2, Section 6.2.1,

6.2.2

Addition

Section 2.5

Correction

Section 2.2, Section 3.3.2, 3.4.1, Section 6.1, 6.2.1, 6.3.2, 6.4, 6.5,

Section 9.2.1, 9.2.2

Correction

SAFETY PRECAUTIONS, INTRODUCTION, CONTENTS, Section 6.2.2,

Section 6.3.3, Section 6.4, Section 6.5

Correction

Section 6.3.1

Japanese Manual Version SH-080125-F

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2000 MITSUBISHI ELECTRIC CORPORATION

A - 4 A - 4

Page 6

INTRODUCTION

Thank you for purchasing the MELSEC-Q series PLC.

Before using the equipment. please read this manual carefully to develop full familiarity with the functions

and performance of the Q series PLC you have purchased, so as to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS..............................................................................................................................A- 1

REVISIONS....................................................................................................................................................A- 4

INTRODUCTION............................................................................................................................................A- 5

CONTENTS....................................................................................................................................................A- 5

Conformation to the EMC Directive and Low Voltage Instruction ................................................................A- 8

About the Generic Terms and Abbreviations ................................................................................................A- 8

Product Configuration ....................................................................................................................................A- 9

1 OVERVIEW 1- 1 to 1- 2

1.1 Features ...................................................................................................................................................1- 1

2 SYSTEM CONFIGURATION 2- 1 to 2- 6

2.1 Overall Configuration ...............................................................................................................................2- 1

2.2 Applicable Systems..................................................................................................................................2- 3

2.3 How to Check the Function Version, Serial No. and Software Version .................................................2- 4

2.4 About Use of the QJ71DN91 with the Q00J/Q00/Q01CPU ...................................................................2- 5

2.5 About Additional Function........................................................................................................................2- 6

2.6 Compatible DeviceNet Products from Other Manufacturers..................................................................2- 6

3 SPECIFICATION S 3- 1 to 3- 51

3.1 Performance Specifications..................................................................................................................... 3- 1

3.1.1 Maximum transmitting distance when thick and thin cables coexist...............................................3- 1

3.2 Functions..................................................................................................................................................3- 2

3.2.1 Master function (I/O communication function)..................................................................................3- 2

3.2.2 Master function (Message communication function) .......................................................................3- 8

3.2.3 Slave function (I/O communication function)....................................................................................3-11

3.3 I/O Signals for the PLC CPU ...................................................................................................................3-13

3.3.1 I/O signal list......................................................................................................................................3-13

3.3.2 Details of the I/O signals ...................................................................................................................3-14

3.4 Buffer Memory..........................................................................................................................................3-24

3.4.1 Buffer memory list .............................................................................................................................3-24

3.4.2 Buffer memory details .......................................................................................................................3-26

3.5 Communication Performance..................................................................................................................3-50

3.5.1 Scan time........................................................................................................................................... 3-50

3.5.2 Communication cycle........................................................................................................................3-51

3.5.3 Transmission delays .........................................................................................................................3-51

A - 5 A - 5

Page 7

4 SETUP AND PROCEDURES BEFORE OPERATION 4- 1 to 4- 14

4.1 Setup and Procedures before Operation ................................................................................................4- 1

4.1.1 When using the master function.......................................................................................................4- 1

4.1.2 When using the slave function..........................................................................................................4- 2

4.1.3 When using both the master function and slave function................................................................ 4- 3

4.2 Loading and Installation...........................................................................................................................4- 4

4.2.1 Handling precautions ........................................................................................................................4- 4

4.2.2 Installation environment ....................................................................................................................4- 4

4.3 Component Names and Settings ............................................................................................................4- 5

4.3.1 Meanings of the LED displays..........................................................................................................4- 6

4.3.2 Node number setting switch..............................................................................................................4- 7

4.3.3 Mode switch.......................................................................................................................................4- 7

4.4 Hardware Test..........................................................................................................................................4- 8

4.5 Connecting the Communication Cables to the QJ71DN91....................................................................4- 9

4.6 Communication Test...............................................................................................................................4- 10

4.7 Instructions for Connecting the Network Power Supply ........................................................................4- 11

4.7.1 Network power supply unit installation position...............................................................................4- 11

4.7.2 Calculating network power supply unit installation position and current capacity..........................4- 12

5 PARAMETER SETTINGS 5- 1 to 5- 6

5.1 Description of Parameter Settings...........................................................................................................5- 1

5.1.1 Parameters for the master function ..................................................................................................5- 1

5.1.2 Parameters for the slave function.....................................................................................................5- 2

5.1.3 Common parameters for the master/slave functions.......................................................................5- 2

5.2 Setting Using the Sequence Program.....................................................................................................5- 2

5.3 Setting Using the Auto Configuration Function.......................................................................................5- 3

6 UTILITY PACKAGE (GX Configurator-DN) 6- 1 to 6- 21

6.1 Functions of the Utility Package..............................................................................................................6- 1

6.2 Installing and Uninstalling the Utility Package.........................................................................................6- 2

6.2.1 User precautions ............................................................................................................................... 6- 2

6.2.2 Operating environment...................................................................................................................... 6- 4

6.3 Explanation of Utility Package Operation................................................................................................6- 5

6.3.1 How to perform common utility package operations........................................................................ 6- 5

6.3.2 Overview of operation .......................................................................................................................6- 8

6.3.3 Starting the intelligent function module utility..................................................................................6- 10

6.4 Auto Refresh Settings.............................................................................................................................6- 12

6.5 Monitor/Test ............................................................................................................................................6- 14

6.6 Flash ROM Settings................................................................................................................................6- 20

A - 6 A - 6

Page 8

7 PROGRAMMING WHEN EXECUTING THE MASTER FUNCTION 7- 1 to 7- 12

7.1 Precautions on Programming.................................................................................................................. 7- 1

7.2 System Configuration...............................................................................................................................7- 2

7.3 Setting Parameters ..................................................................................................................................7- 4

7.3.1 Parameter settings using the sequence program............................................................................7- 4

7.3.2 Creating parameters using auto configuration.................................................................................7- 6

7.3.3 Saving parameters in flash ROM......................................................................................................7- 6

7.4 I/O Communication with Slave Nodes.....................................................................................................7- 7

7.5 Performing Message Communication.....................................................................................................7- 8

7.5.1 Example of message communication read......................................................................................7- 8

7.5.2 Example of message communication write......................................................................................7- 9

7.6 Obtaining Error Information ....................................................................................................................7- 10

7.7 Allocating Transmission/Reception Data Storage Devices for Future Expansion................................7- 11

8 PROGRAMMING WHEN EXECUTING THE SLAVE FUNCTION 8- 1 to 8- 4

8.1 System Configuration...............................................................................................................................8- 1

8.2 Setting Parameters Using the Sequence Program.................................................................................8- 2

8.3 I/O Communication with the Master Node ..............................................................................................8- 3

8.4 Obtaining Error Information .....................................................................................................................8- 4

9 TROUBLESHOOTING 9- 1 to 9- 12

9.1 Items to Check When an Error Occurs ...................................................................................................9- 2

9.1.1 Checking the LEDs ...........................................................................................................................9- 2

9.1.2 When communication with all slave nodes cannot be performed (using the master function) ......9- 3

9.1.3 When communication with a specific slave node cannot be performed

(using the master function)................................................................................................................9- 4

9.1.4 When communication with the master node cannot be performed (using the slave function).......9- 5

9.2 Error Codes..............................................................................................................................................9- 6

9.2.1 Communication error codes..............................................................................................................9- 6

9.2.2 Execution error codes of message communication (using the master function only) ....................9- 9

9.3 Verifying the QJ71DN91 Status on the GX Developer System Monitor...............................................9- 11

APPENDIX App- 1 to App- 7

Appendix 1 External Dimension Diagram .................................................................................................App- 1

Appendix 2 Differences between the QJ71DN91 and the AJ71DN91/A1SJ71DN91.............................App- 2

Appendix 3 Parameter Setting Sheet (For the Master Function).............................................................App- 3

Appendix 4 Parameter Setting Sheet (For the Slave Function) ...............................................................App- 4

Appendix 5 List of Communication Parameters of Slave Nodes Manufactured by Various

Manufacturers .........................................................................................................................App- 5

Appendix 6 EDS File of the QJ71DN91 ....................................................................................................App- 6

INDEX Index- 1 to Index- 2

A - 7 A - 7

Page 9

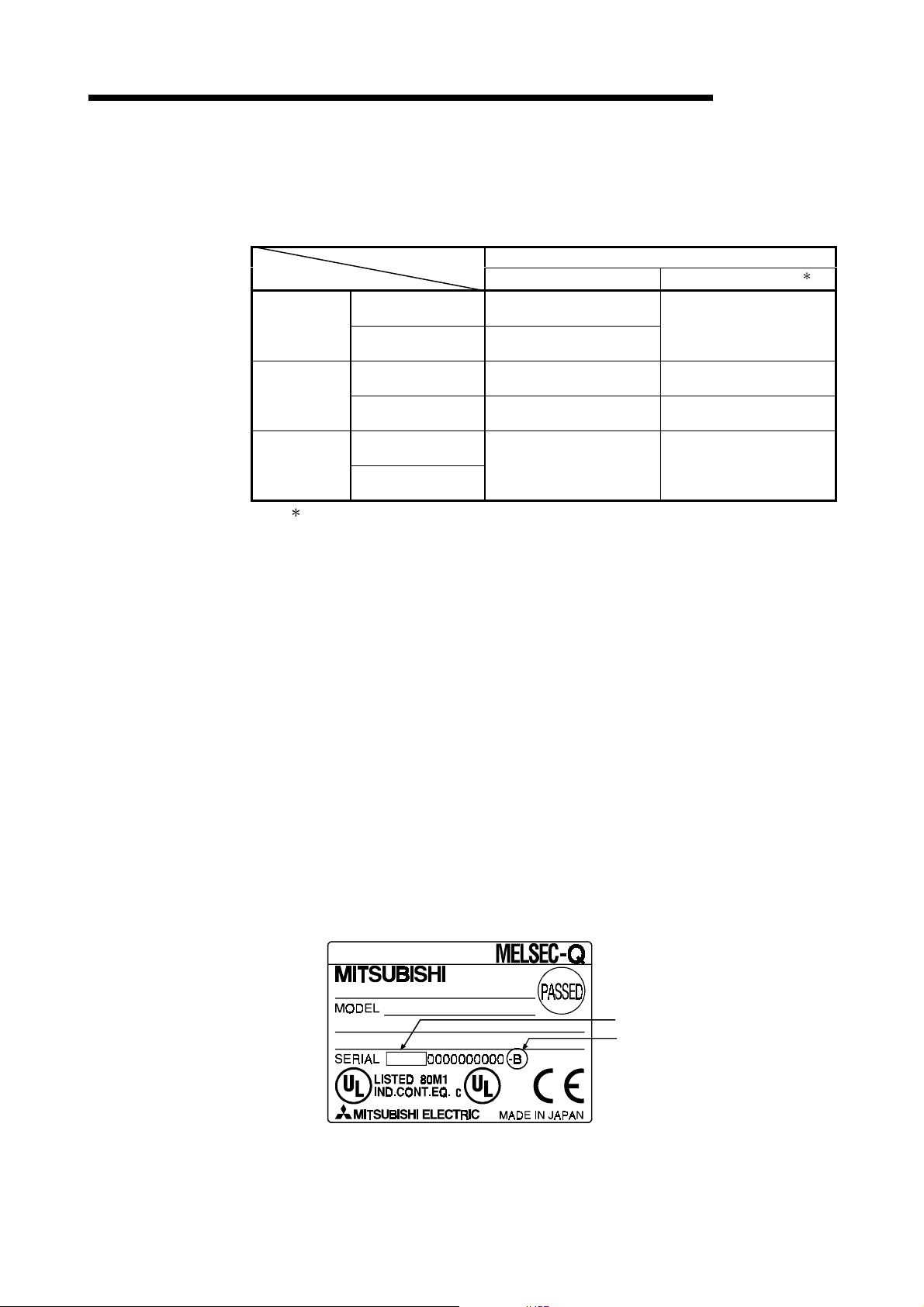

Conformation to the EMC Directive and Low Voltage Instruction

For details on making Mitsubishi PLC conform to the EMC directive and low voltage instruction when

installing it in your product, please see Chapter 3, "EMC Directive and Low Voltage Instruction" of the User's

Manual (Hardware) of the PLC CPU to use.

The CE logo is printed on the rating plate on the main body of the PLC that conforms to the EMC directive

and low voltage instructi on.

BY making this product conform to the EMC directive and low voltage instruc ti on, it is not neces s ary to make

those steps individually.

About the Generic Terms and Abbreviations

Unless otherwise specified, this manual uses the following generic terms and abbreviations to explain

QJ71DN91 DeviceNet Master·S la ve Mo dul e.

Generic Term/Abbreviation Description

Generic product name of the product types SWnD5C-GPPW-E, SWnD5C-GPPW-EA,

GX Developer

QCPU (Q mode)

GX Configurator-DN

QJ71DN91 Abbreviation for QJ71DN91 DeviceNet Master-Slave Module

Personal computer IBM PC/AT® or compatible computer with DOS/V.

SWnD5C-GPPW-EV and SWnD5C-GPPW-EVA.

"n" in the model is 4 or greater.

Generic term for Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU, Q25HCPU, Q12PHCPU, Q25PHCPU

Abbreviation for DeviceNet Master-Slave Module setting/Monitor Tool GX

Configurator-DN (SW1D5C-QDNU-E)

A - 8 A - 8

Page 10

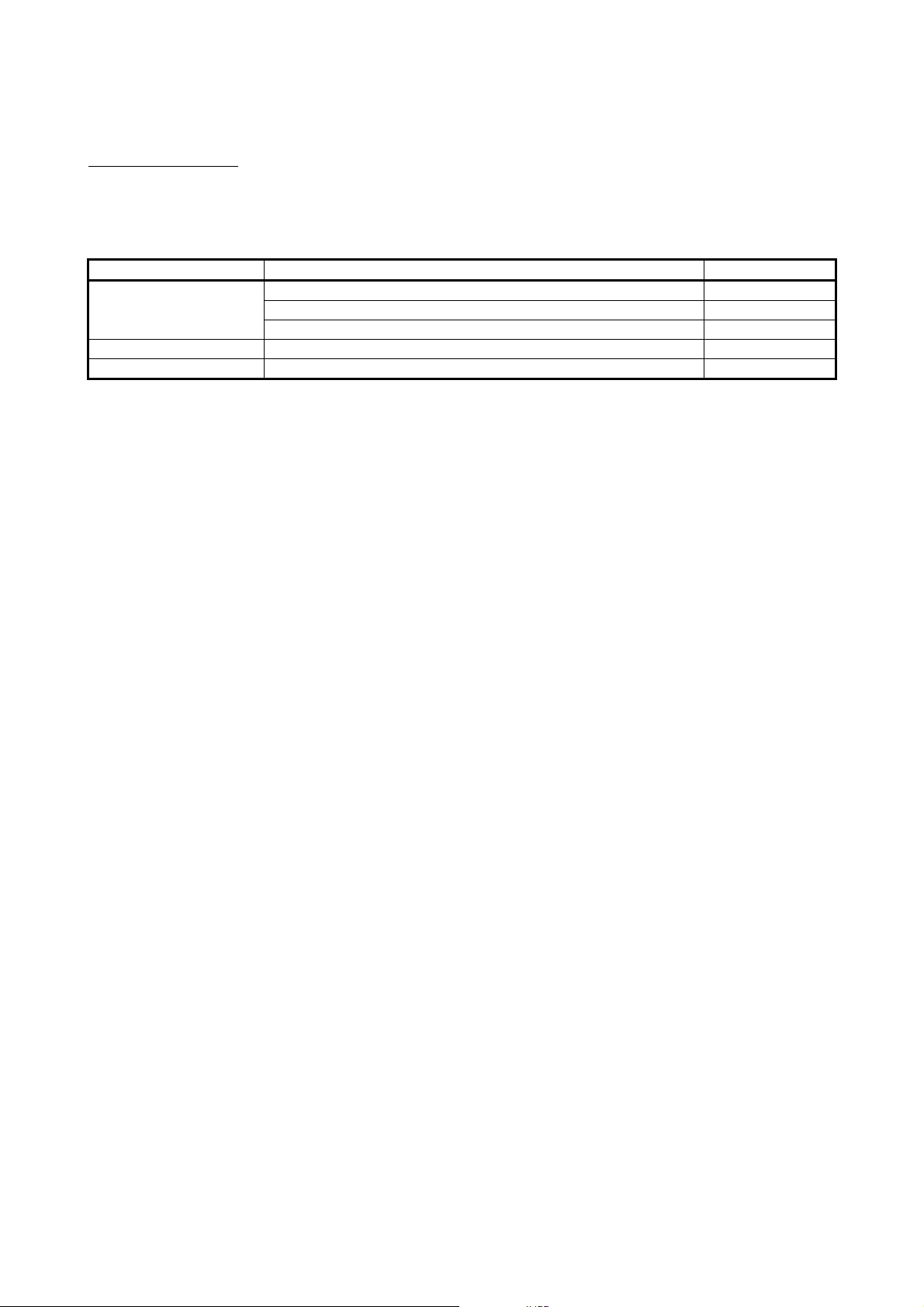

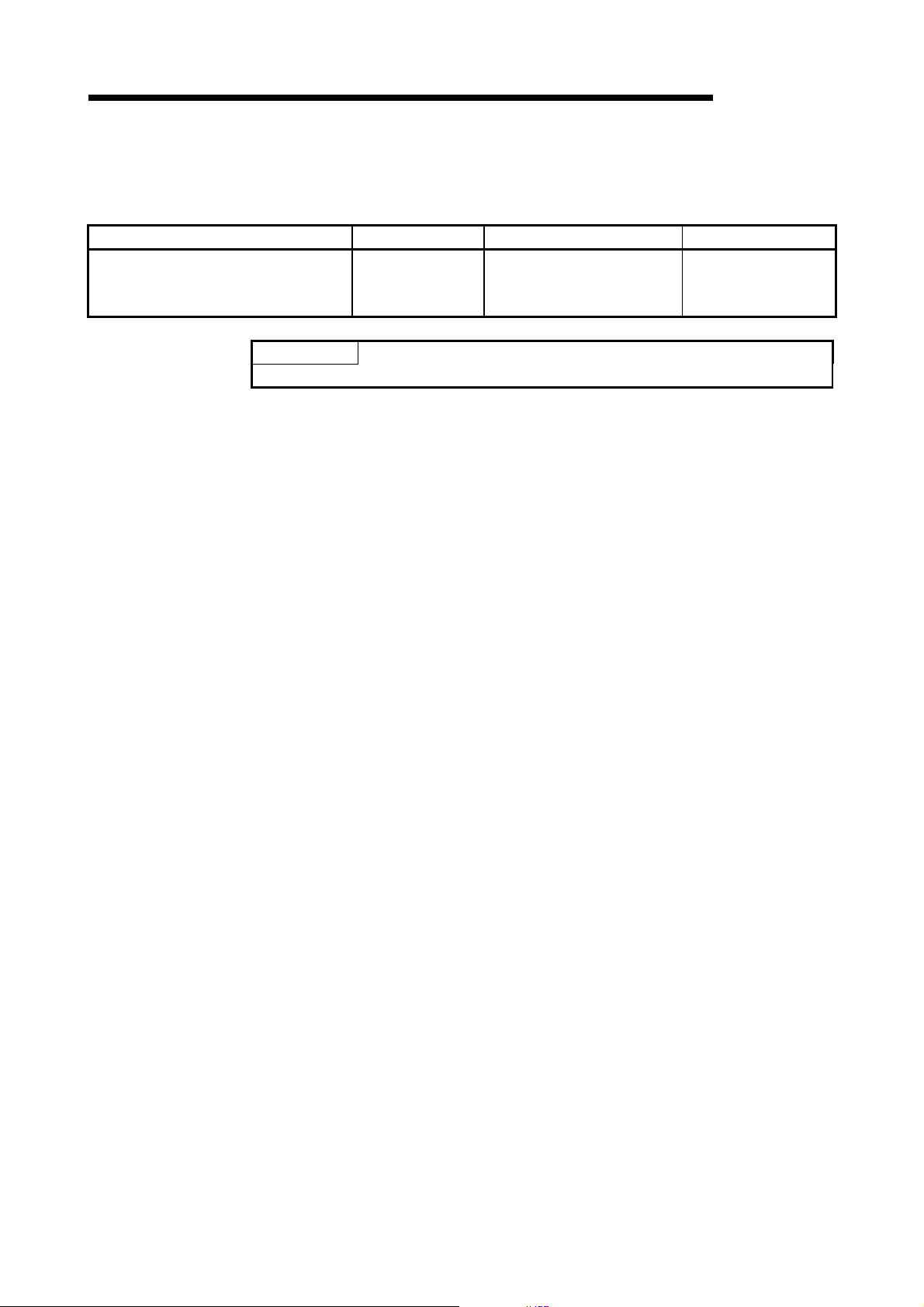

Product Configuration

The following is a list of the components in this product configuration.

Model name Product name Quantity

QJ71DN91 DeviceNet master-slave module

QJ71DN91

Terminal resistor 121Ω, 1/4W

Connector

SW1D5C-QDNU-E GX Configurator-DN Version 1 (1-license product) (CD-ROM) 1

SW1D5C-QDNU-EA GX Configurator-DN Version 1 (Multiple-license product) (CD-ROM) 1

1

2

1

A - 9 A - 9

Page 11

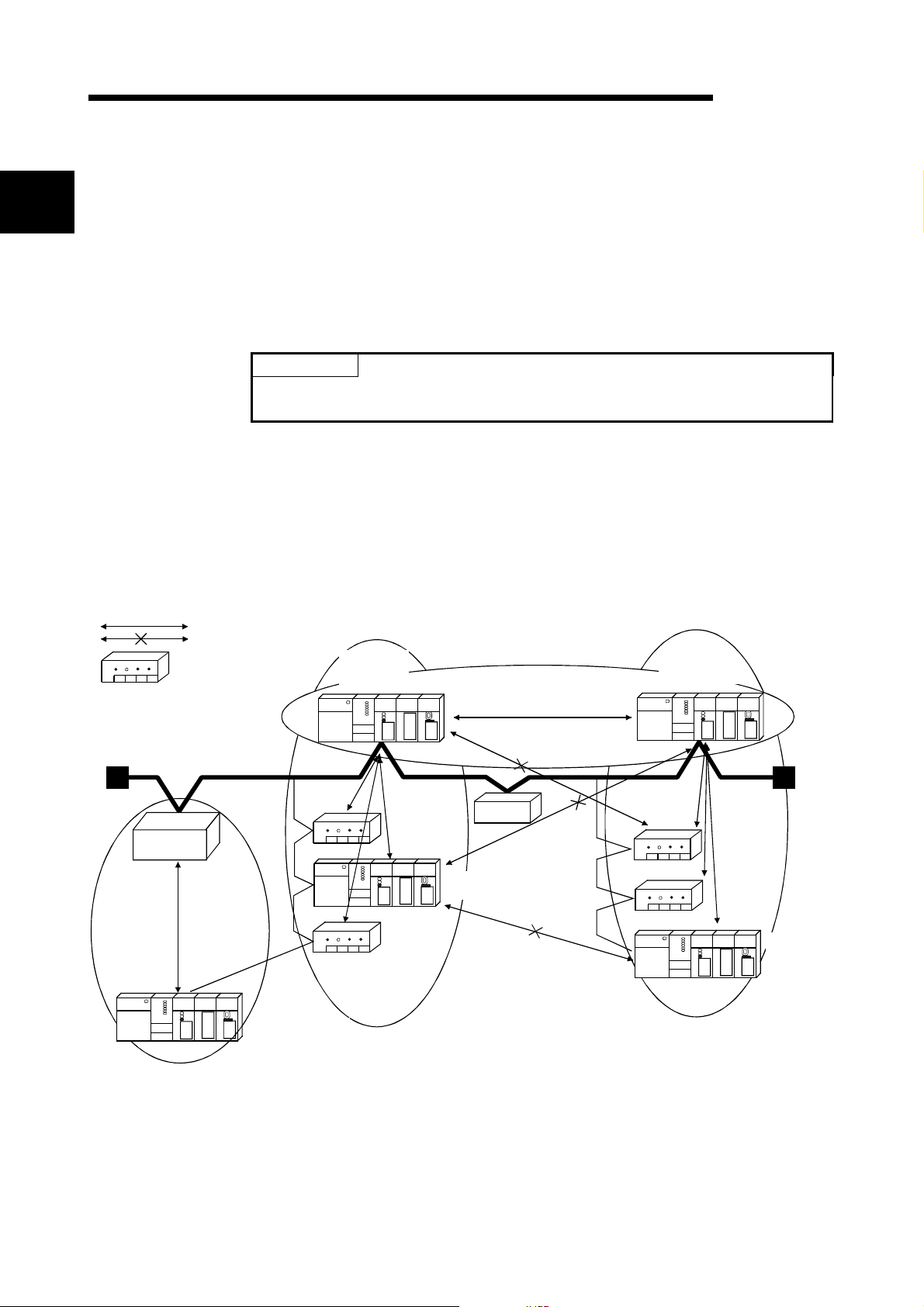

1 OVERVIEW

1 OVERVIEW

MELSEC-Q

1

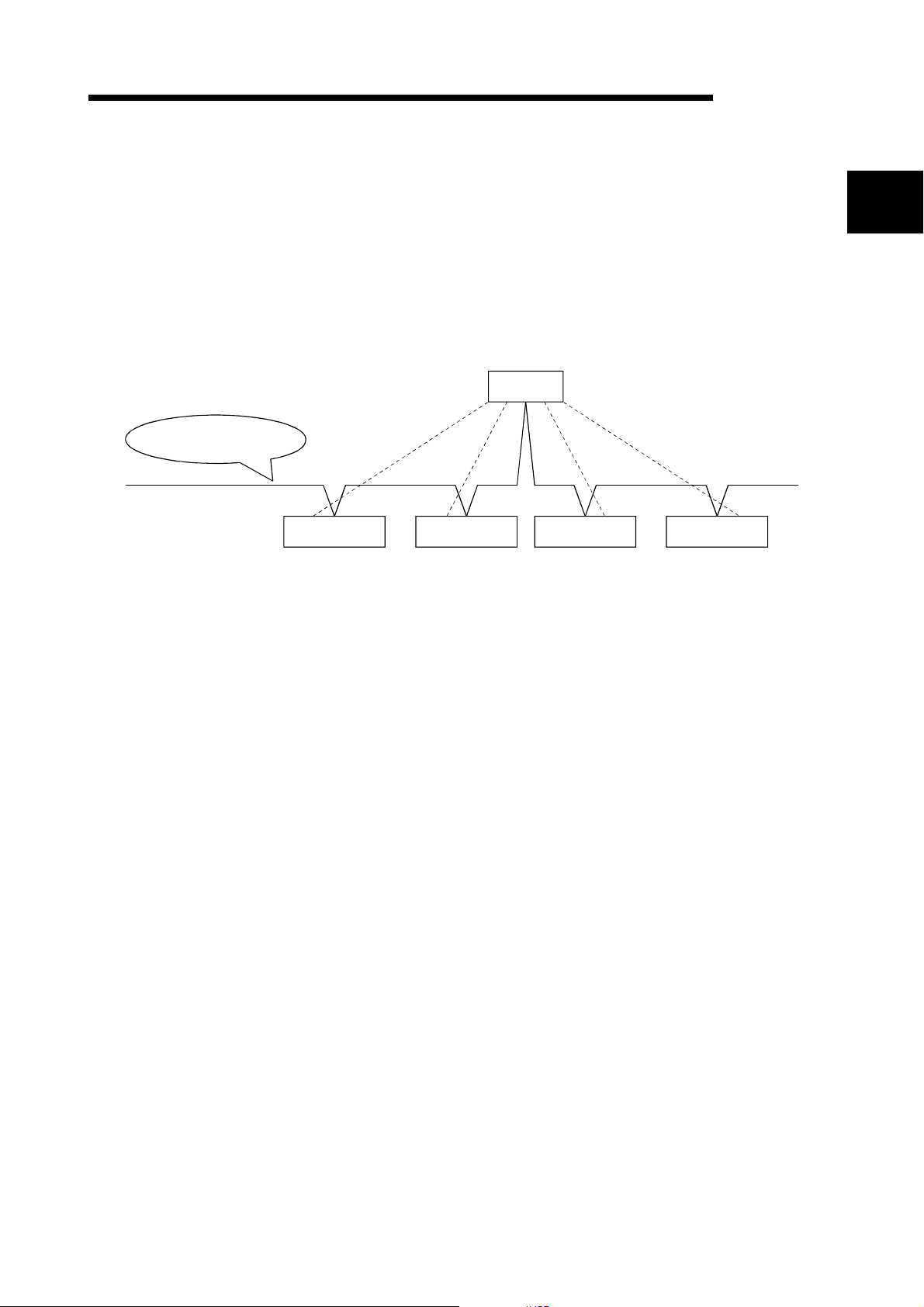

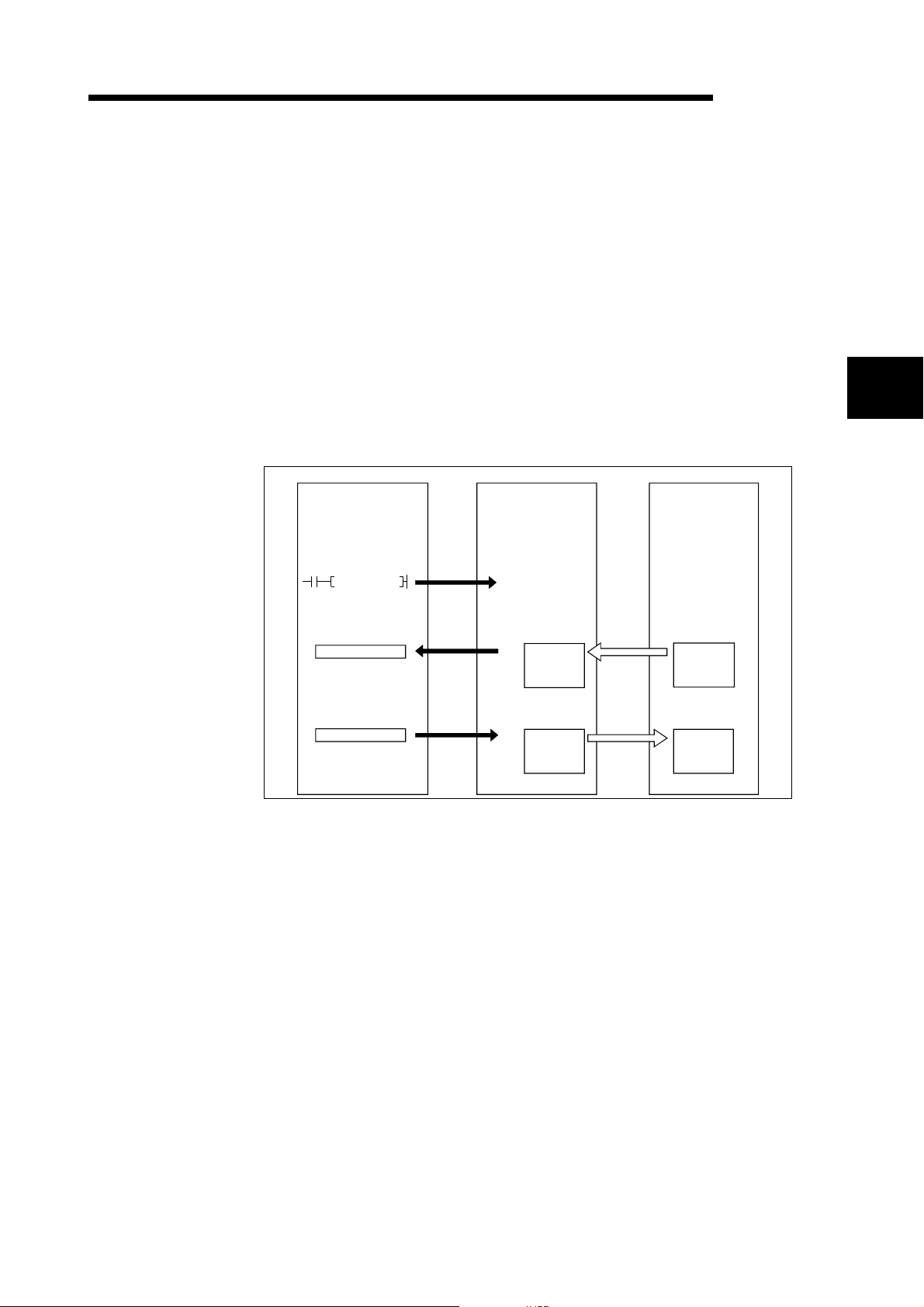

1.1 Features

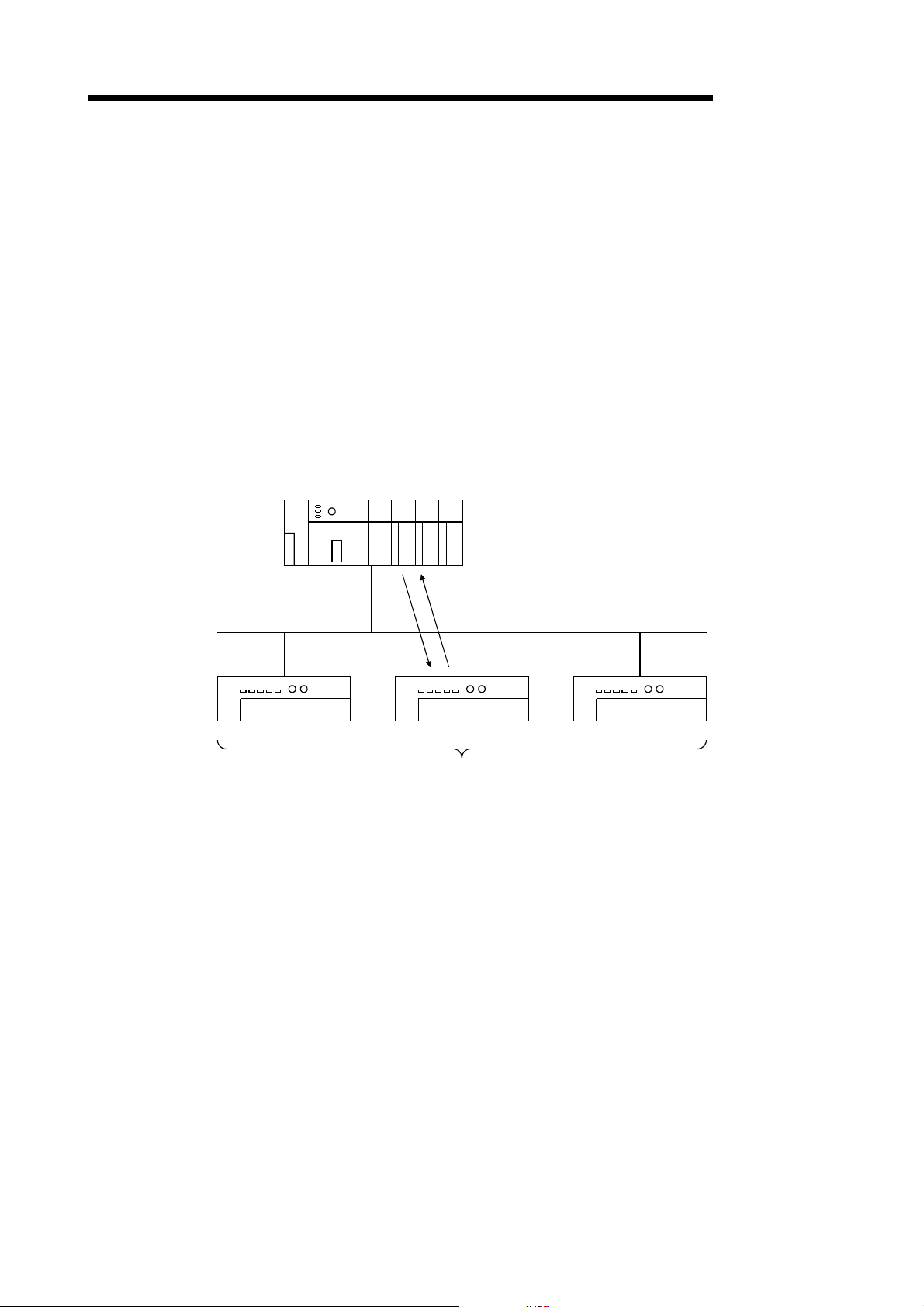

Master station

This manual explains the specifications and name of each component of the

QJ71DN91 DeviceNet master/slave module, which is used in combination with the

MELSEC-Q Series PLC CPU.

Please see Device Ne t Sp e ci ficat io n Ma nu al (Rel ea se 2. 0), Volu mes 1 a nd 2, fo r th e

specifications of DeviceNet.

DeviceNet is a registered trademark of Open DeviceNet Vendor Association, Inc.

This section explains the features of the QJ71DN91.

(1) The module conforms to the DeviceNet Specifications Manual (Release 2.0).

(2) The module can function as a master node, slave node, or master/slave node of

MS

Slave side

I/O communication between the master station and slave sta t i on i s possible.

Communication is not possible.

: DeviceNet slave

POINT

Most of the DeviceNet products on the market are assumed to be compatible.

However, compatibility with the products of other manufacturers is not guaranteed.

DeviceNet.

QJ71DN91

master

(Node No. 5)

M

S

QJ71DN91

master + slave

(Node No. 6)

Master made by

other manufacturer

(Node No. 10)

M

S

(Node No. 2)

S

M

S

(Node No. 4)

S

QJ71DN91 slave

(Node No. 1)

24V power

supply

QJ71DN91 slave

(Node No. 3)

S

M

(Node No. 7)

S

(Node No. 8)

S

QJ71DN91

slave

(Node No. 9)

(3) The paramete rs of QJ71D N91 can be se t by any of th e foll ow in g th re e meth od s:

• Setting the parameters using GX Configurator-DN

• Setting the parameters using the TO instruction of a sequence program

• Setting the parameters using auto configuration

1 - 1 1 - 1

Page 12

1 OVERVIEW

MELSEC-Q

(4) When the module functions as a master node of DeviceNet, I/O communication

and message communication with a DeviceNet slave node are possible.

(5) When the module functions as a master node of DeviceNet, the module can

communicate with a maxi mum of 6 3 slav e node s.

(6) Selection is available from four types of I/O communication methods when this

module functions as a master node in DeviceNet. They are polling, bit strobe,

change-of-state and cyclic which are defined in DeviceNet.

However, only one type o f communi ca ti on met h od ca n be sel e cted fo r each slave

node.

QJ71DN91

1

DeviceNet network

Polling

Bit strobe Cyclic

Slave node 1 Slave node 2 Slave node 3 Slave node 4

Change-of-state

For I/O communication, see Section 3.2.1.

(7) When the module functions as a master node of DeviceNet, an I/O communication

with input of 256 words (4,096 points) and output of 256 words (4,096 points) can

be performed.

(8) When the module functions as a master node of DeviceNet, a message

communication of 240 byte data can be performed at one time.

(9) When the module functions as a slave node of DeviceNet, I/O communication with

input of 64 words (1,024 points) and output of 64 words (1,024 points) can be

performed.

(10) When the module functions as a slave node of DeviceNet, I/O communication can

be performed via polling.

1 - 2 1 - 2

Page 13

2 SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

This chapter explains the system configuration of DeviceNet.

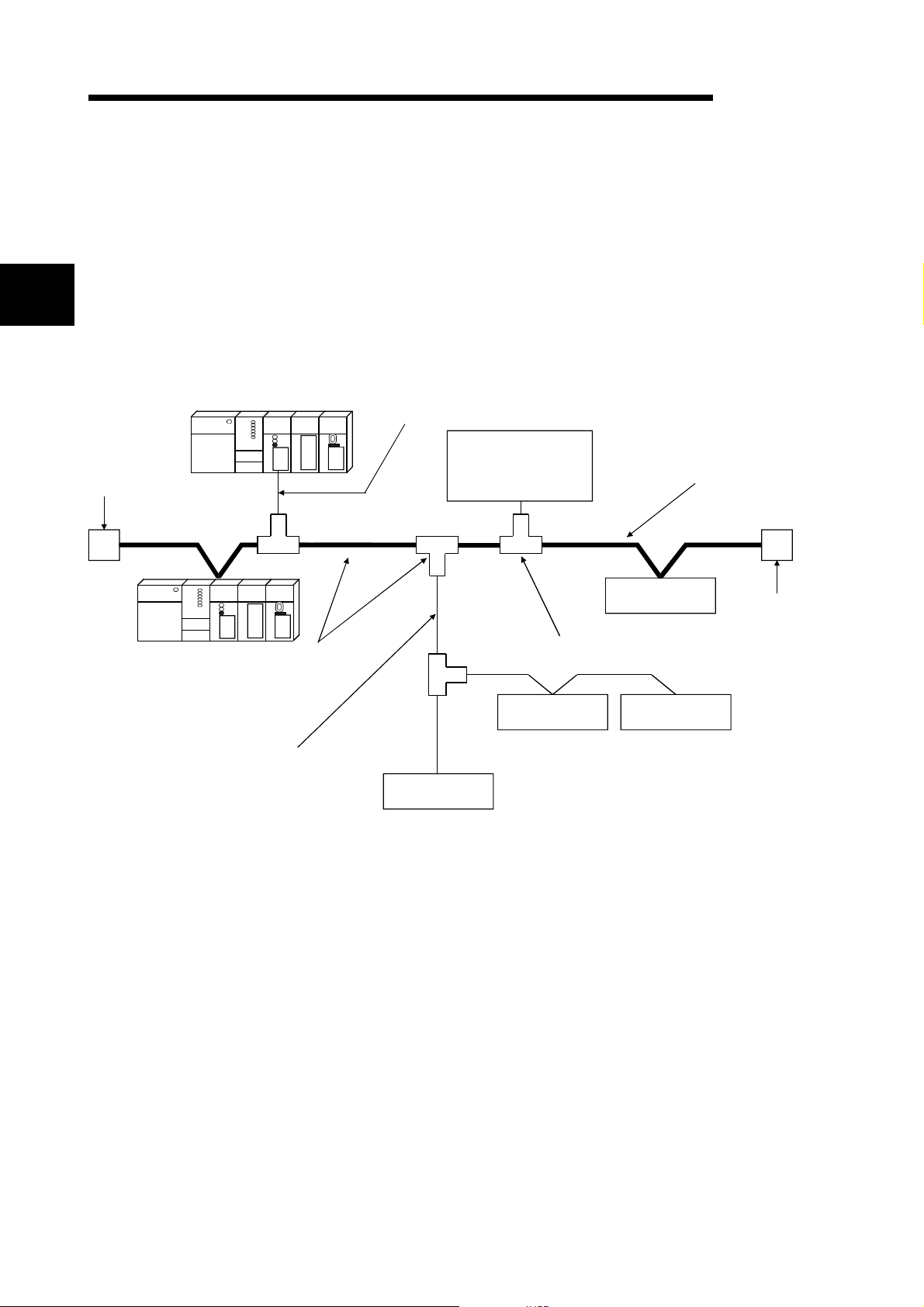

2.1 Overall Configuration

MELSEC-Q

2

Terminal resistor

(121Ω, 1/4W)

Slave node

Master node

A total of 64 modules including a master node, slave nodes and a master/slave node

can be connected.

Each node is connected via a tap from the trunk line or directly to the trunk line.

The following shows an example of a system configuration:

Drop line

Network power-supply

Tap

module (24V DC)

Power supply tap

Slave node Slave node

Trunk line (main line)

Slave node

Terminal resistor

(121Ω, 1/4W)

Drop line (branch line)

1) The QJ71DN91 can be used a s a maste r node , a sl a ve no de or a

2) A combined maximum of 64 master node and slave nodes can be

3) There is no need to connect the master node and slave nodes in the

4) The network cable consists of trunk line (main line) and drop lines

5) It is necessary to connect the network power supply in order to supply

6) Use the terminal resistors included in the package, or they must be

Slave node

master/slave no de .

connected.

order of node number.

(branch lines).

Terminal resistors are required on both sides of the trunk line.

the power supply to the communication circuit in addition to the

operating power supply of each node.

furnished by the user.

2 - 1 2 - 1

Page 14

2 SYSTEM CONFIGURATION

(1) Network specification

The following explains the network specifications of DeviceNet that uses the

QJ71DN91.

(a) Communication speed

The communication speed can be selected from 125kbaud, 250kbaud, or

500kbaud using the mode switch of the QJ71DN91.

The maximum cable length va ri e s depe ndin g on th e co mmunication speed.

See Section 3.1, "Performance Specifications" for details.

(b) Supplying power to the network

The following de scri be s th e met h od o f supp ly ing ne two r k powe r to each

node:

1) Connect a dedicated power supply tap to the trunk-line cable and install

2) The power is supplied from the network power-supply module to each

Remarks

MELSEC-Q

2

the network p owe r -s up ply mod ul e.

node via the network cable.

Inquire to ODVA about the following devices required to construct a DeviceNet

network.

• Network power-supply module

• Power supply tap

• Tap

• Terminal resistor

• Network cable

Contact at ODVA is as follows:

Open DeviceNet Vendor Association, Inc.

Address

20423 State Ro ad 7 - Sui te 499 - B o ca Ra to n, FL 33 49 8 U.S .A.

TEL. +1-954-340-5412

FAX. +1-954-340-5413 or +1-561-477-6621

2 - 2 2 - 2

Page 15

2 SYSTEM CONFIGURATION

2.2 Applicable Systems

This section describes the system configuration for the QJ71DN91.

(1) Applicable module and the nu mber of modules that can be installed

The following are the CPU module in which the QJ71DN91 can be installed and

the number of modules that can be installed.

MELSEC-Q

CPU module

1 See User's Manual (Function Explanation, Program Fundamentals) for the CPU module to use.

Applicable module

Q12PHCPU

Q25PHCPU

Number of modules that

can be installed

Q00JCPU Maximum 16

Q00CPU

Q01CPU

Q02CPU

Q02HCPU

Q06HCPU

Q12HCPU

Q25HCPU

Maximum 24

Maximum 64

Maximum 64

Can be installed in Q mode only

1

(

Remarks

(

)

(

(2) Base unit in which the conversion modul e can be i nstall ed

The QJ71DN91 can be installed in any I/O slot ( 2) of the base unit. However, a

power shortage may occur depending on the combination with other installed

modules and the number of modules used, so always take into consideration the

power supply capa city when installing modules.

2 Limited to the range of the number of I/O points in the CPU module.

(3) Compatibility with a multiple PLC system

First read the QCPU (Q mode) (Function Explanation, Program Fundamentals)

User's Manual if the QJ71DN91 is used with a multiple PLC system.

(a) Compatible QJ71DN91

Use a QJ71DN91 with function version B or higher if using the module in a

multiple PLC system.

1

)

1

)

(b) Intelligent function module parameters

Perform PLC write of the intelligent function module parameters to the

control PLC of the QJ71DN91 only.

2 - 3 2 - 3

Page 16

2 SYSTEM CONFIGURATION

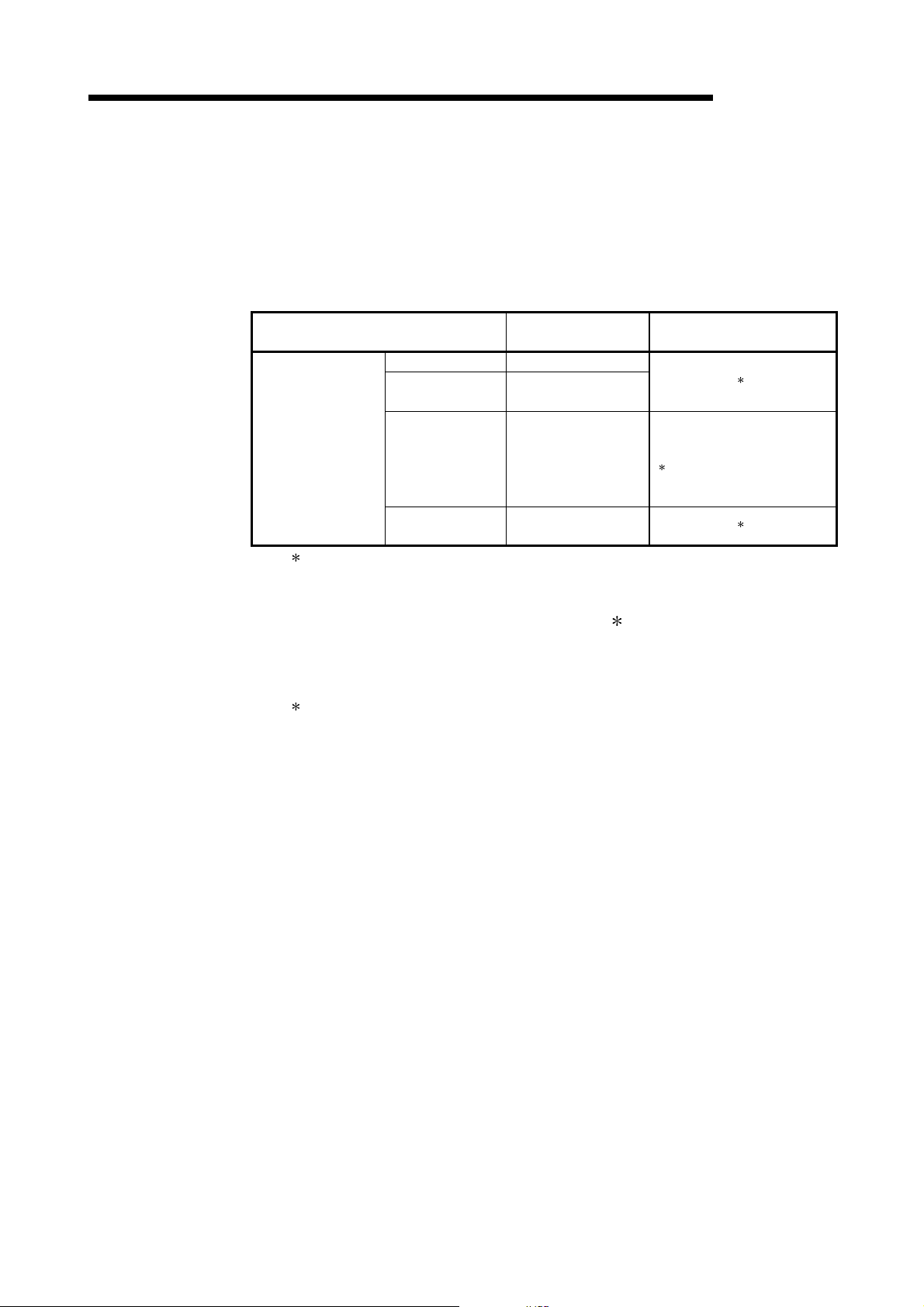

(4) Software packages supported

Correspondence between systems which use QJ71DN91s and software

packages are as shown below.

The GX Developer is necessary when using a QJ71DN91.

GX Developer

Software Version

GX Configurator-DN

MELSEC-Q

2

Q00J/Q00/

Q01CPU

Q02/Q02H/

Q06H/Q12H/

Q25HCPU

Q12PH/

Q25PHCPU

2 Version 1.14Q or earlier is incompatible with Each Node Communi cation Error Status

Single PLC system Version 7 or later

Version 1.10L or later

Multiple PLC system Version 8 or later

Single PLC system Version 4 or later Version 1.00A or later

Multiple PLC system Version 6 or later Version 1.10B or later

Single PLC system

Version 7.10L or later Version 1.13P or later

Multiple PLC system

(addresses 1C0

H

to 1C3H/448 to 451). Use the product of Version 1.15R or later.

(5) Precautions on wiring

In order to avoid the effects of noise, the DeviceNet communication cable, power

cable and signal lines for the I/O module should be installed in such a way that

they are sufficiently away from each other.

(6) Remote operation is not allowed from other DeviceNet node

Each DeviceNet node on DeviceNet cannot read/write/monitor the sequence

program or data of the PLC CPU where the QJ71DN91 is installed.

2.3 How to Check the Function Version, Serial N o. and Softwar e Ver si on

This section describes how to check the function version and serial No. of the

QJ71DN91 and the GX Configurator-DN software version.

(1) How to check the function version and serial No. of the QJ71DN91

(a) To check the version using the "SERIAL column of the rating plate" located

on the side of the module

(b) To check the version using the GX Developer

See Section 9.3 of this manual.

Serial No. (first 5 digits)

Function version

03052

2 - 4 2 - 4

Page 17

2 SYSTEM CONFIGURATION

(2) How to check the GX Configuration-DN software ver si on

The GX Configurator-DN software version can be checked in GX Developer's

"Product information" screen.

[Startup procedure]

GX Developer "Help" Product information

MELSEC-Q

Software version

(In the case of GX Developer Version 7)

2.4 About Use of the QJ71DN91 with the Q00J/Q00/Q01C PU

Here, use of the QJ71DN91 with the Q00J/Q00/Q01CPU is explained.

(1) Number of QJ71DN91 that can be installed when the Q00J/Q00/

Q01CPU is used.

See item 2.2 concerning the number of QJ71DN91 that can be installed when the

Q00J/Q00/Q01CPU is used.

(2) Limitations when using the Q00J/Q00/Q01CPU

When using Q00J/Q00/Q01CPU, use QJ71DN91 which function version is B and

first 5 digits of the serial No. is 03052 or later.

2 - 5 2 - 5

Page 18

2 SYSTEM CONFIGURATION

2.5 About Additional Function

The added func ti on is de scribed below.

Function Serial No. Function Outline Reference Section

Addition of Each Node Communication

H

Error Status (addresses 01C0

/448 to 451)

to 01C3

First five digits of

H

serial No. are

04102 or later

Indicates whether an I/O

communication error has

occurred or not in each node.

POINT

Refer to Se ctio n 2 .3 fo r the w ay to con fi r m th e se ri al No .

2.6 Compatible DeviceNet Products from Other M anu facturers

It is assumed that most of the DeviceNet products on the market are compatible.

However, compatibility with the products of other manufacturers is not guaranteed.

MELSEC-Q

Section 3.4.1 (10)

2 - 6 2 - 6

Page 19

3 SPECIFICATIONS

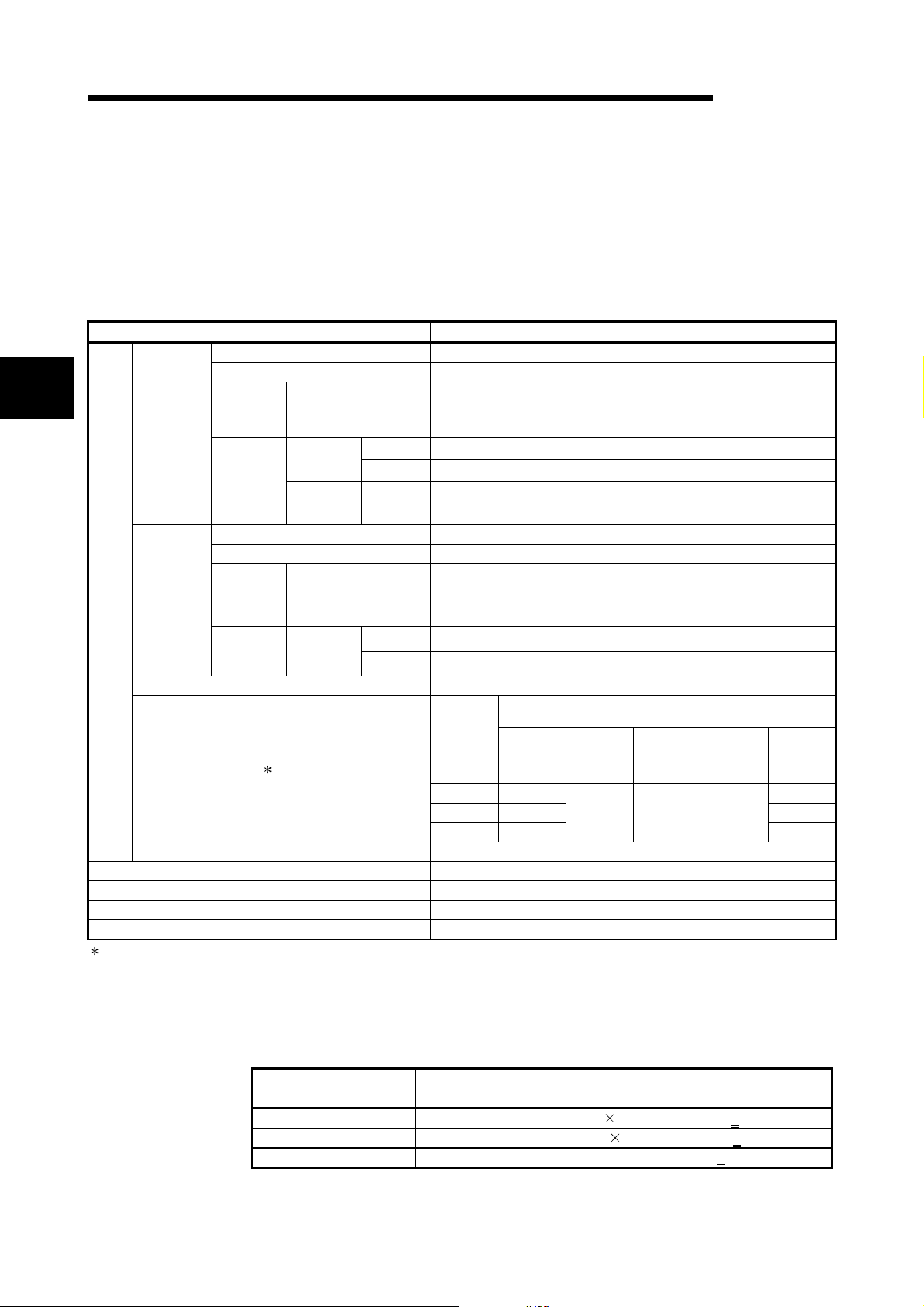

3 SPECIFICATIONS

3.1 Performance Specifications

This section explains the performance specifications for QJ71DN91, I/O signals for

PLC CPU and spe ci fi c atio n s fo r bu ffe r me mory.

See the PLC CPU User's Manual to be used for the general specifications for

QJ71DN91.

Item Specifications

Node type Device net master (Group 2 only client)

Node numbers which can be set 0 to 63

3

When

master

function

When slave

function

Communication specifications

Communications speed One speed can be selected from 125 kbps, 250 kbps and 500kbps.

Maximum cable length

Current consumption required on the network 0.03 A

Number of times to write flash ROM Max. 100000 times

No. of I/O occupied points 32 points (I/O allocation: Intelligent 32 points)

5 V DC internal current consumption 0.17 A

Weight 0.11 kg

: The maximum cable length complies with that in the device net specification (Release 2.0) Volumes 1 and 2.

Number of

connections

that be

created

Amount of

communication data

Node type Device net slaves (Group 2 server)

Setting possible node number 0 to 63

Number of

connections

that can be

created

Amount of

communication data

Message connection 63

I/O connection 63 (polling, bit strobe, change of state, cyclic)

I/O

communication

Message

communication

I/O connection

I/O

communication

Send Max. 4096 points (512 bytes), max. 256 bytes per 1 node

Receive Max. 4096 points (512 bytes), max. 256 bytes per 1 node

Send Max. 240 bytes

Receive Max. 240 bytes

1 (polling)

Send Max. 1024 points (128 bytes)

Receive Max. 1024 points (128 bytes)

Maximum transmitting distance of

Communic

ations

speed

125 kbaud 500 m 156 m

250 kbaud 250 m 78 m

500 kbaud 100 m

Thick

Cables

trunk line

Cables

100 m See 3.1.1 6 m

Thin

Thick and

thin cables

coexist

MELSEC-Q

Length of drop line

Maximum Total

39 m

3.1.1 Maximum transmitting distance w hen thi ck and thin cabl es coexist

The table below lists both the maximum transmitting distance when thick and thin

cables coexist.

Communication speed

125 kbaud Thick cable length + 5 Thin Cable length < 500 m

250 kbaud Thick cable length +2.5 Thin cable length < 250 m

500 kbaud Thick cable length + Thin cable length < 100 m

3 - 1 3 - 1

Maximum transmitting distance of trunk line w hen thick

and thin cables coexist

Page 20

3 SPECIFICATIONS

3.2 Functions

This section explains the functions of the QJ71DN91.

3.2.1 Master function (I/O communication function)

The I/O communication function executes the I/O data communication with each slave

node.

In the I/O communication function, the connection type can be set according to the

specification of the slave node.

There are four connection types: polling, bit strobe, change-of-state, and cyclic. The

connection type can be set with a parameter.

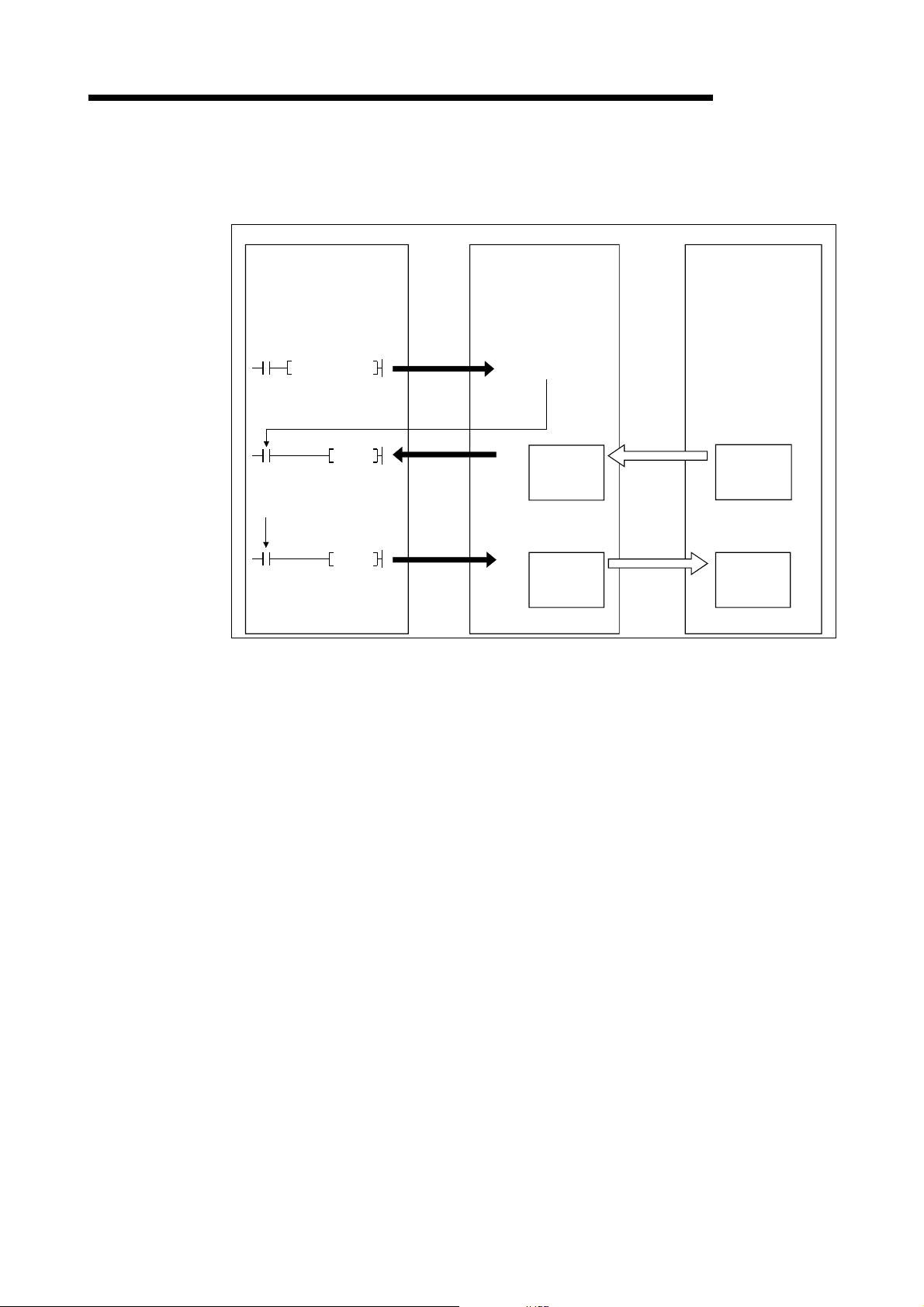

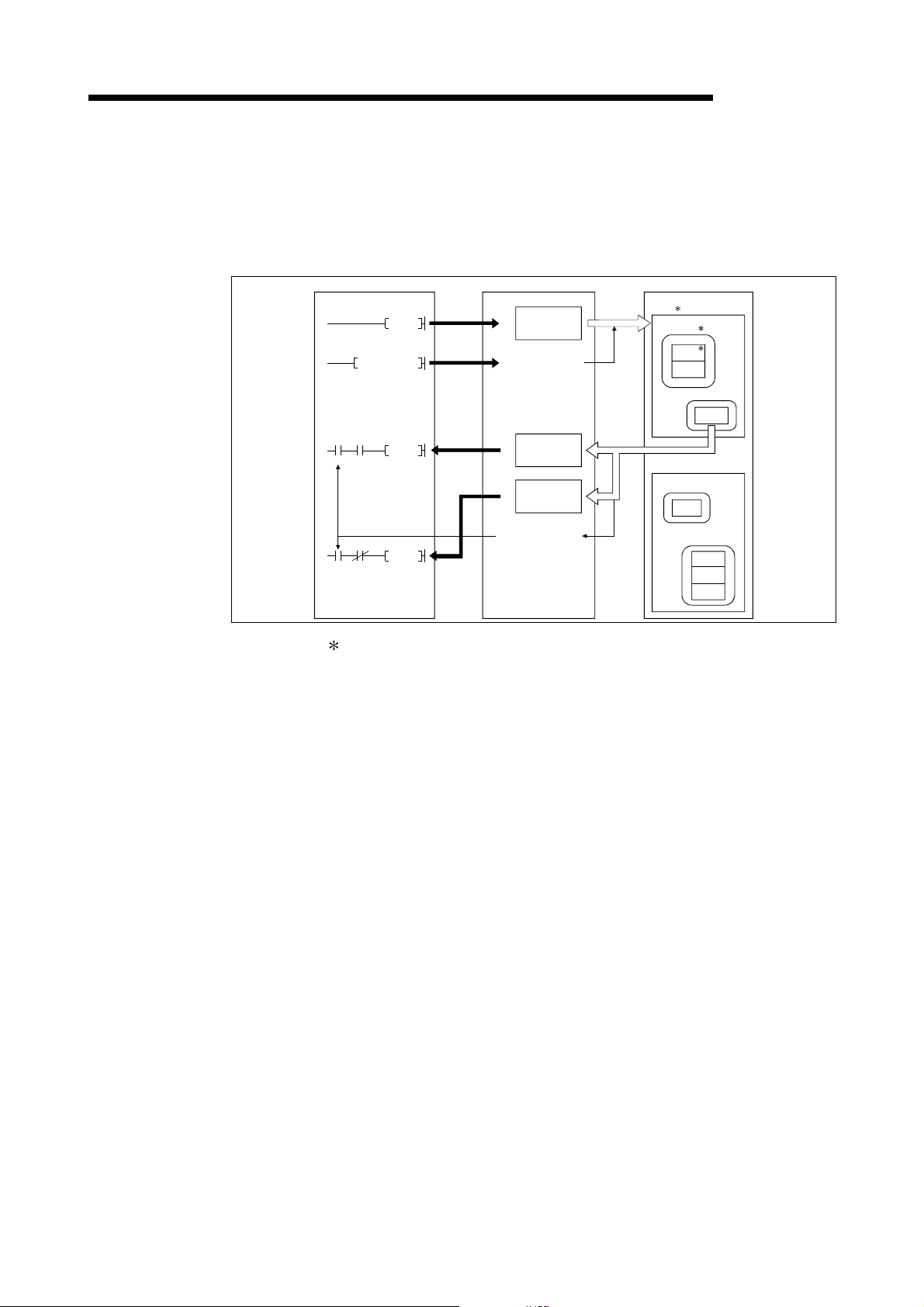

(1) When GX Configurator-DN is used

The following explains the I/O communication function when the GX

Configurator-DN is used.

PLC CPU QJ71DN91 Slave node

MELSEC-Q

3

SET Y11

X

Y

1)

3)

4)

I/O communication

request

0700

H

Master function

receive

data area

07FF

H

0900

H

Master function

transmit

data area

09FF

H

2)

Transmission

5)

Reception

[I/O communication]

1) When the I/O communication request (Y11) is set, the I/O

communication with each slave node starts. It is not ne cessary to set

Y11, however, when the auto communication start is set with a

parameter.

[Reception data]

2) The input status from each slave node is automatically stored in the

"master function reception data" area of the buffer memory in the

QJ71DN91.

3) The input status stored in the "master function reception data" area of

the buffer me mory is loaded onto th e PL C CP U by th e a uto r e fr e sh

setting.

[Transmission data]

4) The ON/OFF information to be sent to the slave node is written into the

"master function transmission data" area of the buffer memory by the

auto refresh setting.

5) The ON/OFF information stored in the "master function transmission

data" area i s aut o mati cal ly sent to a slav e no de .

3 - 2 3 - 2

Page 21

3 SPECIFICATIONS

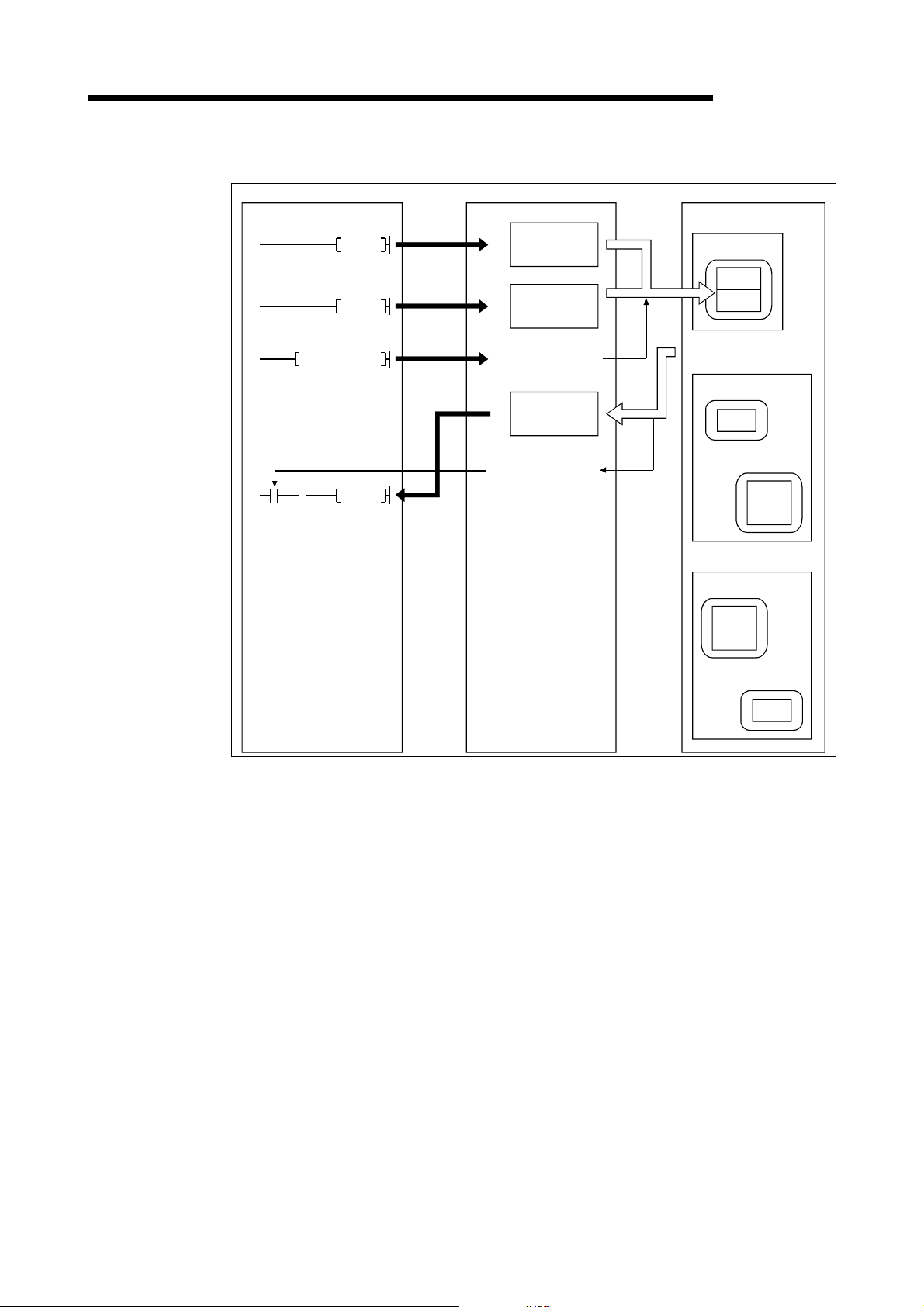

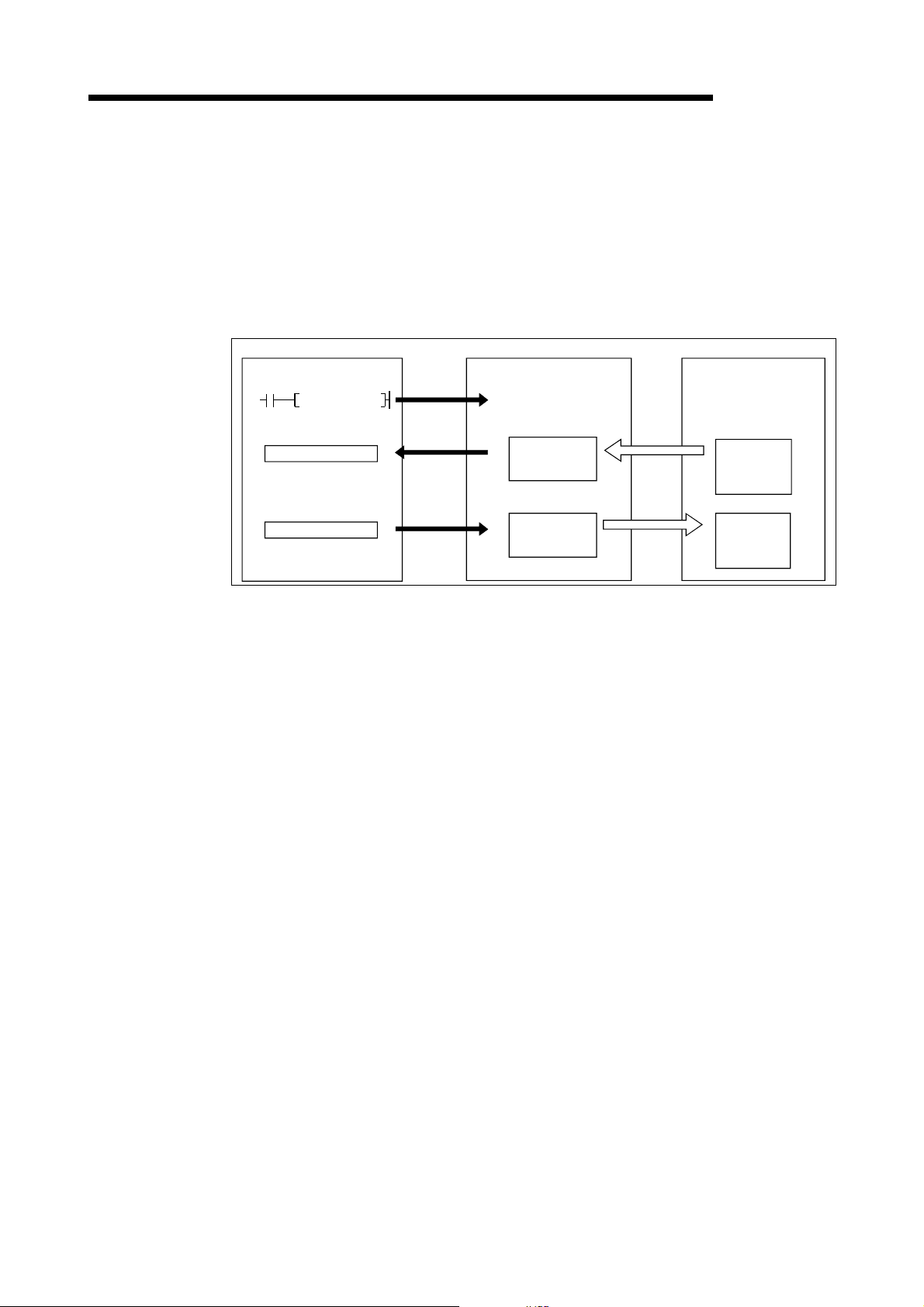

(2) When the sequence program is used

MELSEC-Q

The following explains the I/O communication function when the sequence

program is used.

PLC CPU QJ71DN91 Slave node

SET Y11

FROM

X01

I/O communication

in progress

TO

X01

I/O communicating

[I/O communication]

1) When the I/O communication request (Y11) is set, the I/O

[Reception data]

2) The input status from each slave node is automatically stored in the

3) The input status stored in the "master function receive data" area of the

1)

3)

4)

I/O communication

request

H

0700

Master function

receive

data area

H

07FF

H

0900

Master function

transmit

data area

H

09FF

2)

Transmission

3)

Reception

communication with each slave node starts. It is not ne cessary to set

Y11, however, when the auto communication start is set with a

parameter.

"master function receive data" area of the buffer memory in the

QJ71DN91.

buffer memory is loaded onto the PLC CPU by the FROM instruction of

the sequence program.

[Transmission data]

4) The ON/OFF information to be sent to the slave node is written into the

"master function transmit data" area of the buffer memory by the TO

instruction of the sequence program.

5) The ON/OFF information stored in the "master function transmit data"

area is auto mati cal ly sent to the slave node.

3 - 3 3 - 3

Page 22

3 SPECIFICATIONS

(3) Overview of each connection type

MELSEC-Q

The following explains an overview of each connection type used during the I/O

communication.

(a) Polling

As shown in the following diagram, the communication method by which

the communication with each slave node is repeated, as described from 1)

to 6), is the polling communication. The connection that uses this

communication is the polling connection.

1) The master node tr a ns mit s th e ou tp u t da ta .

2) The slave node transmits input data by setting 1) to trigger.

3) The master node tr a ns mit s th e ou tp u t da ta .

4) The slave node transmits input data by setting 3) to trigger.

5) The master node tr a ns mit s th e ou tp u t da ta .

6) The slave node transmits input data by setting 5) to trigger.

Master node

1)

4)

3)

2)

Slave node

6)

5)

3 - 4 3 - 4

Page 23

3 SPECIFICATIONS

MELSEC-Q

(b) Bit strobe

As shown in the following diagram, the communication method by which

the communication with each slave node is repeated, as described from 1)

to 4), is the bit strobe communication. The connection that uses this

communication is th e bit st robe co nne c ti on .

1) Output information of a maximum of one bit is transmitted

simultaneously to each slave node.

2) The slave node transmits the input data by setting the transmission of

1) to trigger.

3) The slave node transmits the input data by setting the transmission of

1) to trigger.

4) The slave node transmits the input data by setting the transmission of

1) to trigger.

Master node

4)

2)

3)1)

Slave node

3 - 5 3 - 5

Page 24

3 SPECIFICATIONS

MELSEC-Q

(c) Change-of-state

As shown in the following diagram, the communication method that

executes the communication of [1] and [2] as the I/O data changes is the

change-of-state communication, and the connection that uses this

communication is the change-of-state connection.

No data transmission is performed unless the I/O data is changed.

1) When the output data of the master node changes, the data is sent to

the slave node.

2) When the input data of the slave node changes, the data is sent to the

master node.

There is no concept of the network scan in the change-of-state

communication.

Master node

1) 2)

Slave node

3 - 6 3 - 6

Page 25

3 SPECIFICATIONS

MELSEC-Q

(d) Cyclic

As shown in the following diagram, the communication method that

regularly repeats the communication of [1] and [2] is the cyclic

communication, and the connection that uses this communication is the

cyclic connection .

1) The data of the master node is sent to the slave node.

2) The data of the slave node is sent to the master node.

The cycle of the cyclic communication can be specified for each slave

node.

Specify the cycle of the cyclic communication in the following parameter

items:

Transmission cycle from master node: Production inhibit time

Transmission cycle from slave node: Expected packet rate

There is no concept of the network scan in the cyclic communication.

Master node

1) 2)

Slave node

3 - 7 3 - 7

Page 26

3 SPECIFICATIONS

3.2.2 Master function (Message communication function)

The message communication function is used to get and set the attribute data of a

slave node.

(1) Getting attributes

PLC CPU QJ71DN91 Slave node (MAC ID)

0110

TO

SET Y12

FROM

X05

X02

FROM

X05

X02

Message communication

completion

1)

2)

6)

5)

H

Message

communication

command area

H

011F

Message

communication

request

H

0120

Message

communication

result area

H

012F

H

0130

Message

communication

data area

H

01A7

4)

Message

communication

complete

MELSEC-Q

Class

2)

Instance

Attribute

Attribute

Instance

Attribute

3)

Class

Instance

Attribute

Instance

Attribute

Attribute

Attribute

: In DeviceNet, the area used for reading and writing via communication

is specified by the numbers representing the class ID, instance ID, and

attribute ID. For details, refer to the manual of each slave node.

1) The TO instruction of the sequence program sets to get attributes in the

"message communication command" area of the buffer memory.

2) When the message communication request (Y12) is turned ON by the

sequence program, the data, which is set in the "message

communication command" area in the buffer memory, is sent to the

slave node and the message communication starts.

3) When the QJ71DN91 receives data from the slave node, it is processed

as follows:

• The specific data of the slave node that is set in the "message

communication command" area is stored in the "message

communication data" area of the buffer memory.

• The processing result of message communication is stored in the

"message communication result" area of the buffer memory.

4) The message communication is completed when the processing result

is stored in the "message communication result" area of the buffer

memory, and the message communication completion (X02) is

automatically turned ON.

5) Upon normal compl et io n, th e da ta in the sl av e no de , which i s st ore d in

the "message communication data" area of the buffer memory, is

loaded onto the PLC CPU by the FROM instruction of the sequence

program.

6) If the message communication error signal (X05) is turned ON, the

FROM instruction reads the contents of the "message communication

result" area, and the cause of the error is verified.

3 - 8 3 - 8

Page 27

3 SPECIFICATIONS

(2) Setting attributes

MELSEC-Q

PLC CPU QJ71DN91 Slave node (MAC ID)

H

SET Y12

Next

X05

processing

X02

Message

communication

completion

TO

TO

0110

1)

011F

0130

2)

01A7

3)

0120

012F

5)

6)

Message

communication

command area

H

H

Message

communication

data area

H

Message

communication

request

H

Message

communication

result area

H

Message

communication

complete

3)

4)

Class

Instance

Attribute

Attribute

Class

Instance

Attribute

Instance

Class

Attribute

Attribute

Instance

Attribute

Attribute

Instance

Attribute

1) The TO instruction of the sequence program sets to set attributes in the

"message communication command" area of the buffer memory.

2) The TO instruction of the sequence program writes the data to be

written in the "message communication data" area of the buffer

memory.

3) When the message communication request (Y12) is turned ON, the

data, which is stored in the "message communication data" area of the

buffer memory, is written to the slave node in the area specified by the

"message communication command."

4) When the write process is finished, the message communication result

is stored in the "message communication result" area of the buffer

memory.

5) The message communication is completed when the processing result

is stored in the "message communication result" area of the buffer

memory, and the message communication completion (X02) is

automatically turned ON.

6) If the message communication error signal (X05) is turned ON, the

FROM instruction reads the contents of the "message communication

result" area, and the cause of the error is verified.

3 - 9 3 - 9

Page 28

3 SPECIFICATIONS

(3) Reading the communication err or i nformation

MELSEC-Q

PLC CPU QJ71DN91 Slave node (MAC ID)

I/O

Class 1

Instance

Attribute

Attribute

TO

SET Y12

H

1)

2)

0110

011F

Message

communication

command area

H

Message

communication

request

communication

Slave

information

storage area

H

0120

X02

X05

X05

X02

Message communication

completion

The status of each slave station is stored during I/O communication.

FROM

FROM

5)

012F

0130

01A7

3)

4)

Message

communication

result area

H

H

Message

communication

data area

H

Message

communication

complete

1) The TO instruction of the sequence program sets to read the

communication error information in the "message communication

command" area of the buffer memory.

2) When the message communication request (Y12) is turned ON by the

sequence program, the error information of the applicable slave node

that has been accumulated in the QJ71DN91 is read and processed as

follows:

• The error information of the slave node that was set by the "message

communication command" area is stored in the "message

communication data" area of the buffer memory.

• The processing result of the message communication is stored in the

"message communication result" area of the buffer memory.

3) When the processing result is stored in the "message communication

result" area of the buffer memory, the message communication

completion ( X02 ) is au tomat i cal ly turned ON.

4) The communication error information of the slave node, which is stored

in the "message communication data" area of the buffer memory, is

loaded onto the PLC CPU by the FROM instruction of the sequence

program.

5) If the message communication error signal (X05) is turned ON, the

FROM instruction reads the contents of the "message communication

result" area, and the cause of the error is verified.

2)

Instance

Attribute

Attribute

Attribute

Class

Instance

Attribute

Attribute

Attribute

Instance

Attribute

3 - 10 3 - 10

Page 29

3 SPECIFICATIONS

3.2.3 Slave function (I/O communication function)

The I/O communication function executes the communication of the I/O data with the

master node using the polling method.

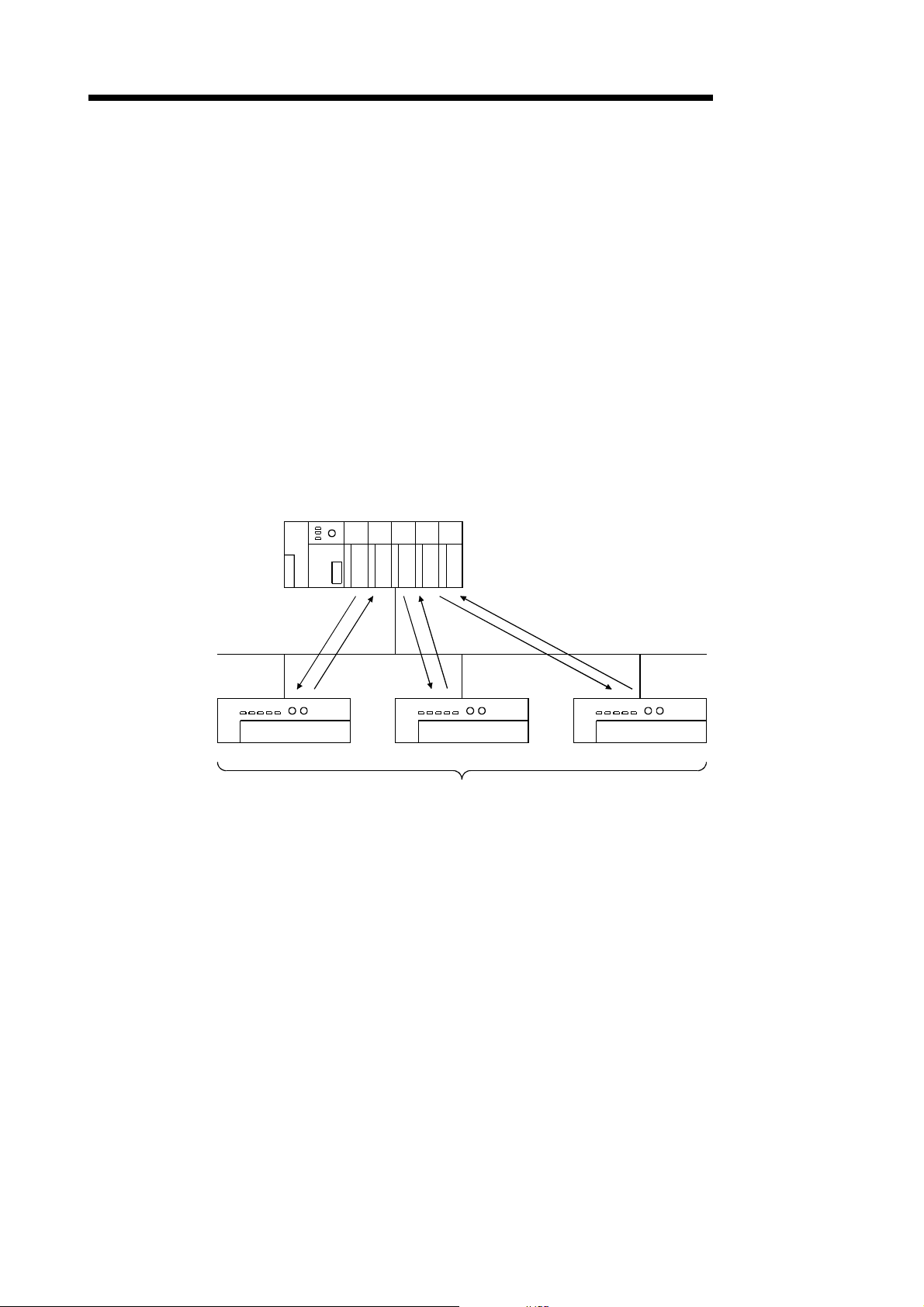

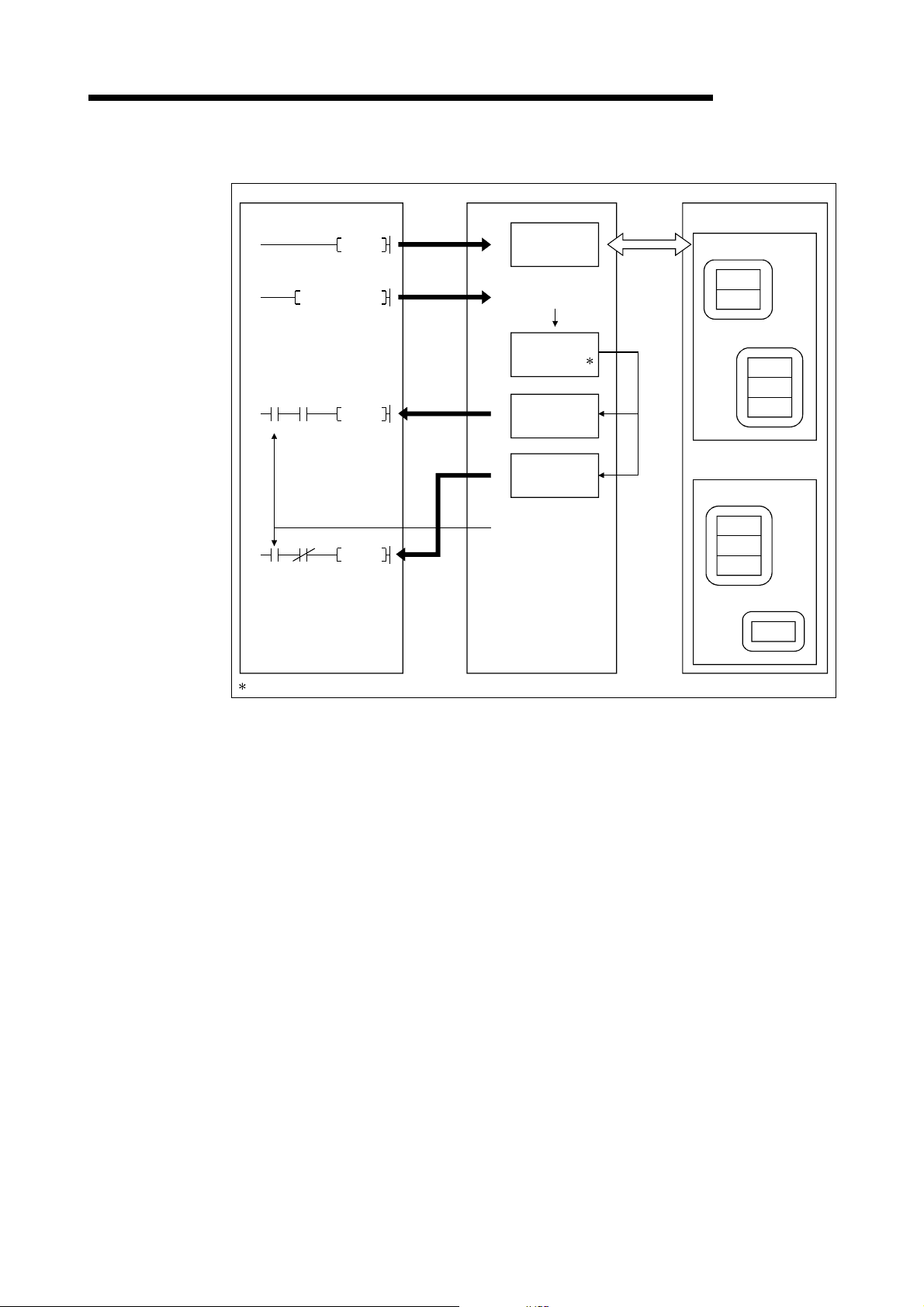

(1) When GX Configurator-DN is used

The following explains the I/O communication function when the GX

Configurator-DN is used.

PLC CPU QJ71DN91 Master node

MELSEC-Q

SET Y11

X

Y

1)

3)

4)

I/O communication

request

H

0B00

Slave function

H

0B3F

H

0C00

Slave function

H

0C3F

receive

data area

transmit

data area

2)

Transmission

5)

Reception

[I/O communication]

1) Communication with the master node starts when the I/O

communication request (Y11) is turned ON.

[Reception data]

2) Transmission data from the master node is automatically stored in the

"slave func ti on re ce ive da ta" ar ea o f th e bu ffe r me mory in the

QJ71DN91.

3) Transmission data from the mater node, which is stored in the "slave

function receive data" area of the buffer memory, is loaded onto the

PLC CPU by the auto refresh setting.

[Transmission data]

4) With the auto refresh setting, the ON/OFF information to be sent to the

master node is written in the "slave function transmit data" area of the

buff er memory.

5) The ON/OFF information, which is stored in the "slave function transmit

data" area of the buffer memory, is automatically sent to the master

node.

3 - 11 3 - 11

Page 30

3 SPECIFICATIONS

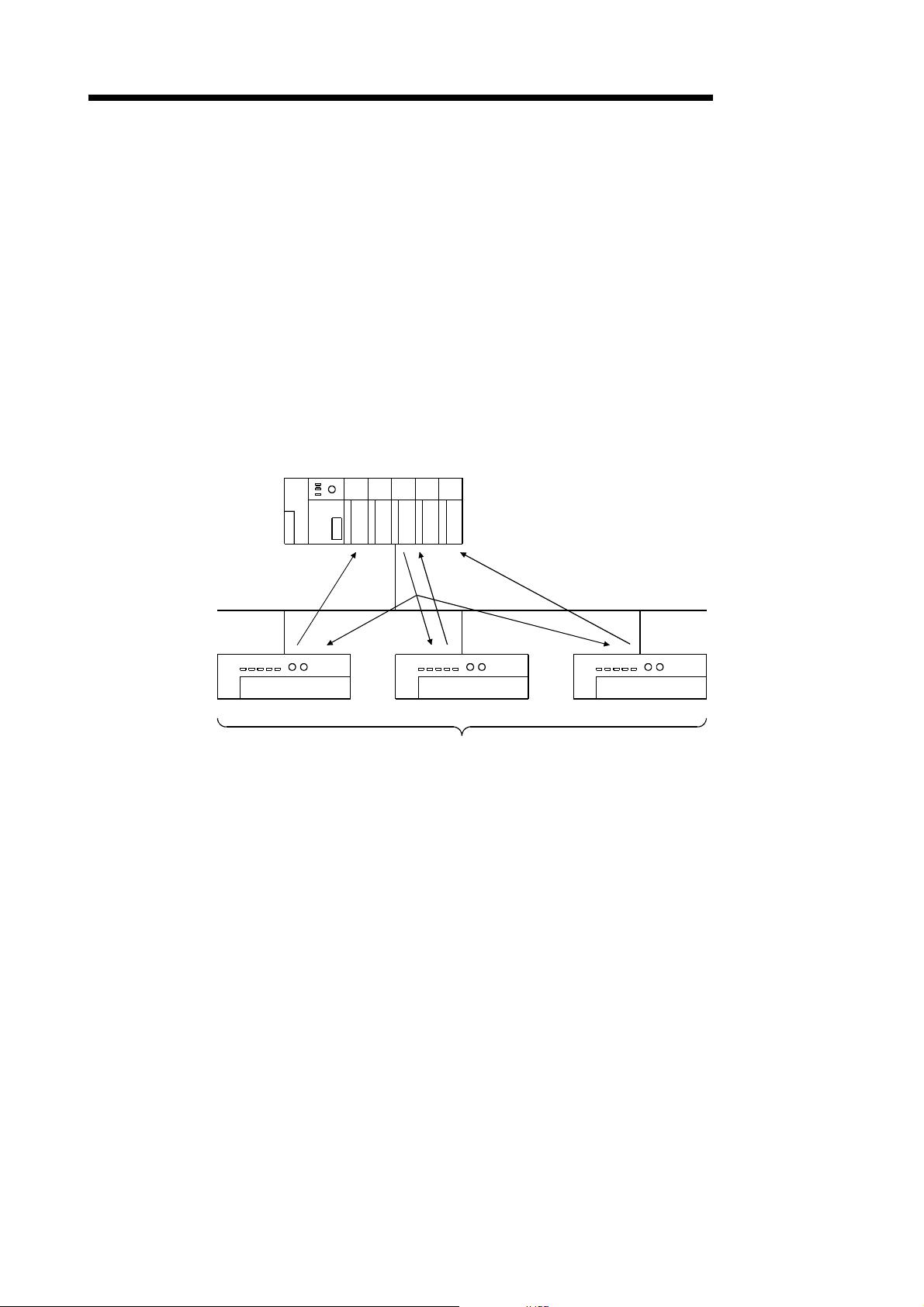

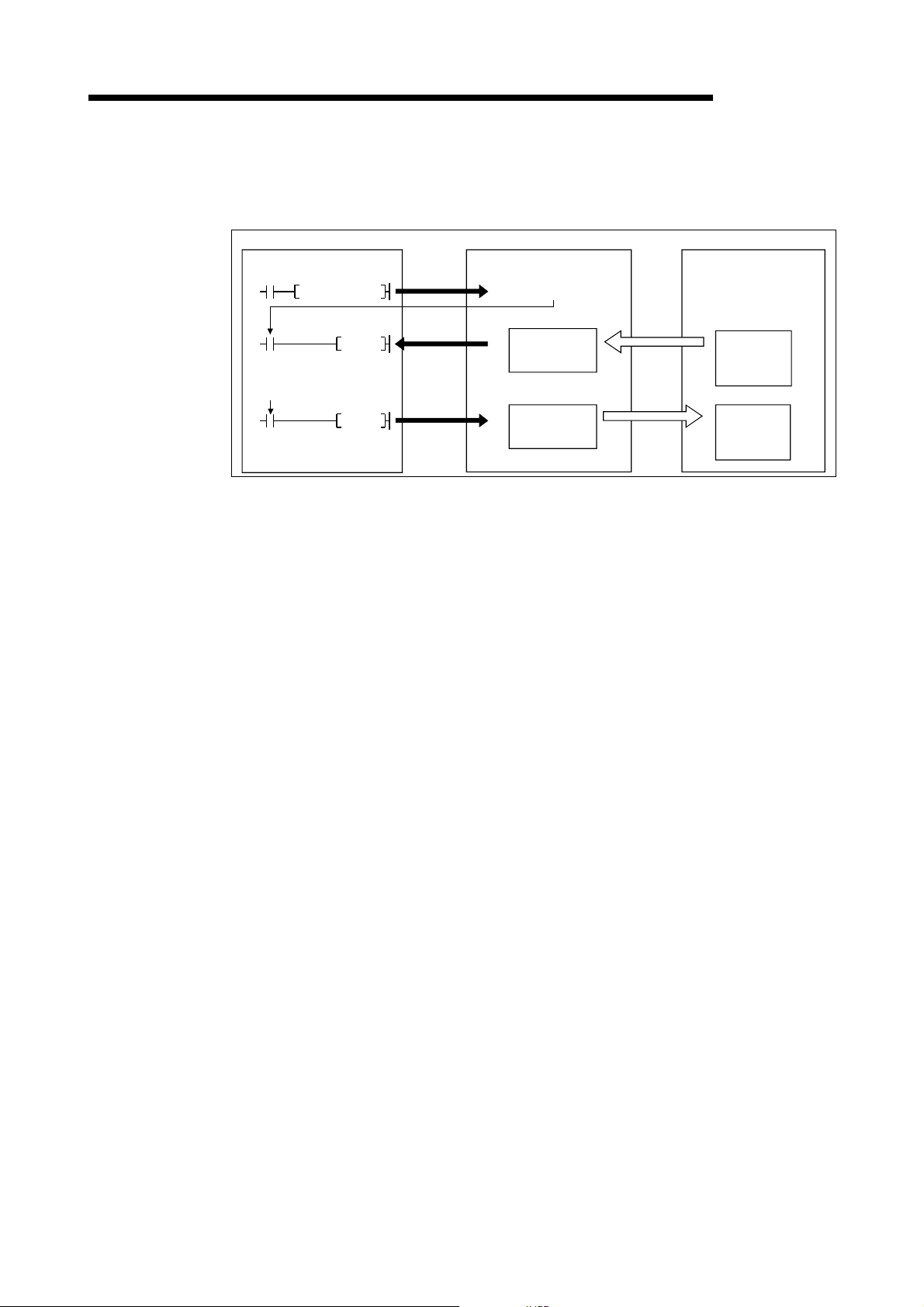

(2) When the sequence program is used

MELSEC-Q

The following explains the I/O communication function when the sequence

program is used.

PLC CPU QJ71DN91 Master node

SET Y11

FROM

X01

I/O communicating

TO

X01

I/O communicating

[I/O communication]

1) Communication with the master node starts when the I/O

communication request (Y11) is turned ON.

[Reception data]

2) Transmission data from the master node is automatically stored in the

"slave func ti on re ce ive da ta" ar ea o f th e bu ffe r me mory in the

QJ71DN91.

3) The transmission data from the master node, which is stored in the

"slave functi on r e ceive da ta" area o f th e bu ffe r memory, is loaded onto

the PLC CPU by the FROM instruction of the sequence program.

1)

3)

4)

I/O communication

request

H

0B00

Slave function

data area

H

0B3F

H

0C00

Slave function

data area

H

0C3F

receive

transmit

2)

Transmission

5)

Reception

[Transmission data]

4) The TO instruction of the sequence program writes the ON/OFF

information to be sent to the master node in the "slave function transmit

data" area of the buffer memory.

5) The ON/OFF information, which is stored in the "slave function transmit

data" area of the buffer memory, is automatically sent to the master

node.

3 - 12 3 - 12

Page 31

3 SPECIFICATIONS

3.3 I/O Signals for the PLC CPU

This section explains the input/output signals for the PLC CPU of the QJ71DN91.

3.3.1 I/O signal list

The I/O signal list fo r the QJ71 DN91 is shown in Ta ble 3 .2.

The I/O numbers (X/Y) and I/O addresses described from this chapter are applicable

when the QJ71DN91 is installed in slot 0 of the basic base module.

MELSEC-Q

Table 3.2 I/O signal list

QJ71DN91 PLC CPU PLC CPU QJ71DN91

Input number Signal name

X00 Watchdog Timer Error Y00

X01 I/O Communicating Y01

X02

X03 Maste r Fun c tion Fo r Error Se t Sig na l —Y03

X04 Slave Down Signal —Y04

X05

X06

X07

X08 Slave Function For Error Set Signal — Y08

X09 Use proh ib ite d — — Y09

X0A H/W Testing

X0B H/W Test Comp le tion

X0C H/W Test Error Detection

X0D Y0D

X0E

X0F Module Ready Y0F

X10 Y10

X11 Y11 I/O Commun icat ion Requ es t

X12 Y12 Message Communication Req u est —

X13

X14 Auto Configuration Executing — Y14 Use prohibite d — —

X15 Au to Co n f ig u r at io n C o mp le t io n — Y15 Auto Conf igur at io n Requ es t —

X16 Y16 Use prohib ite d — —

X17 Y17

X18 Y18

X19 Y19

X1A Y1A

X1B Y1B

X1C Y1C

X1D Y1D

X1E Y1E

X1F

Message Communication

Completion

Message Communication Error

Signal

Saving Parameter To The Flash

ROM

Save Parameter To Flas h ROM

Completion

Use prohibite d — —

Use prohibite d — —

Use prohibite d — —

Usability Usability

Master

function

At the time of the

hardware test

At the time of the

hardware test

At the time of the

hardware test

Slave

function

Output number Signal name

—Y02

—Y05

Y06

Y07

Y0A

Y0B

Y0C

Y0E

Y13

Y1F

Use prohibite d — —

Master Function For Error Reset

Request

Save Parameter To Flas h ROM

Request

Slave Function For Error Reset

Request

Use prohibite d — —

Master

function

Slave

function

—

—

IMPORTANT

The use-prohibited output signals shown in Table 3.2 are accessed by the system

and cannot be accessed by the user. In the event these signals are used (turned

ON/OFF) by the user, normal operations cannot be guaranteed.

3 - 13 3 - 13

Page 32

3 SPECIFICATIONS

W

3.3.2 Details of the I/O signals

The following describes the ON/OFF timings and conditions of the I/O signals.

(1) Watchdog Timer Error: X00

This is turned ON when an error occurs in the QJ71DN91.

OFF: Module normal

ON: Module error

atchdog timer error (X00)

Module ready (X0F)

(2) I/O Communicating: X01, I/O Communication Request: Y11 (w hen

the master function is used)

This signal is used to start the I/O communication of the master function with the

parameters set by the "parameters for the master function" of the buffer memory.

Use this signal while the module ready (X0F) is ON.

MELSEC-Q

(a) When the auto start is not set:

1) Verify that the auto configuration request (Y15) and the save parameter

to flash ROM request (Y17) are OFF.

2) To start the I/O communication, use the sequence program to turn ON

the I/O communication request (Y11).

3) When the I/O communication request (Y11) is turned ON, the

parameter check is executed. If the parameter check is successful, the

I/O communication starts and the I/O Communicating (X01) is turned

ON. If the par a met e r ch e ck fails, the master fun ction for error set sign al

(X03) is turned ON and the ERR. LED is lit. Check the contents of the

error with the "error information for the master function" of the buffer

memory address 1B1

H

.

4) To stop the I/O communication, use the sequence program to turn OFF

the I/O communication request (Y11).

5) I/O communication stops and the I/O communicating (X01) is turned

OFF.

When the parameter check is successful

Module Ready (X0F)

I/O Communication Request (Y11)

I/O Communicating (X01)

Parameter

check

When the parameter check fails

Module Ready (X0F)

I/O Communication Request (Y11)

I/O Communicating

Master Function For Error Set Signal

Parameter

check

3 - 14 3 - 14

Page 33

3 SPECIFICATIONS

MELSEC-Q

(b) When the auto start is set

1) The module re ady ( X0 F) i s tu rn ed ON when th e power is turned ON,

and the parameter check is executed automatically.

2) If the parameter check is successful, the I/O communication starts and

the I/O communicating (X01) is turned ON. If the parameter check fails,

the master function for error set signal (X03) is turned ON and the ERR.

LED is lit. Check the contents of the error with the "master function for

error information" of the buffer memory address 1B1

POINT

To stop the I/O communication, set Y11, then reset after 200 ms or longer.

When the parameter check is successful:

H

.

Module Ready (X0F)

I/O Communicating (X01)

When the parameter check fails:

Module Ready (X0F)

I/O Communicating (X01)

Master Function For Error

Set Signal (X03)

Parameter

check

Parameter

check

3 - 15 3 - 15

Page 34

3 SPECIFICATIONS

(3) I/O Communicating : X01, I/O Communication Request: Y11 (w hen

MELSEC-Q

the slave function is used)

These signals are used to start the I/O communication of the slave function with

the number of I/O points that is set by the "setting area of the number of slave

function reception bytes" and the "setting area of the number of slave function

transmission bytes" of the buffer memory.

Use these signals while the module ready (X0F) is ON.

(a) To start the I/O communication, use the sequence program to turn ON the

I/O communication request (Y11).

(b) When the I/O communication request (Y11) is turned ON, the parameter

check is executed. If the parameter check is successful, the I/O

communication starts and the I/O communicating (X01) is turned ON. If the

parameter check fails, the slave function for error set signal (X08) is turned

ON and the ERR. LED is lit. Check the contents of the error with the "error

information for the slave function" of the buffer memory address 601

H

.

(c) To stop the I/O communication, use the sequence program to turn OFF the

I/O communication request (Y11).

(d) The I/O communication stops and the I/O communicating (X01) is turned

OFF.

When the parameter check is successful:

Module Ready (X0F)

I/O Communication

Request (Y11)

I/O Communicating (X01)

Parameter

check

When the parameter check fails:

Module Ready (X0F)

I/O Communication Request

(Y11)

I/O communicating (X01)

Slave Function For Error Set

Signal (X08)

Parameter

check

3 - 16 3 - 16

Page 35

3 SPECIFICATIONS

(4) Message Communication Completion: X02, M essag e

MELSEC-Q

Communication Error Signal: X05, M essag e C ommuni cation

Request: Y12

These signals are used to execute the message communication. Message

communication can be executed when the "master function communication

status" area of the buffer memory is "in operation (C0

POINT

When making message communication, set the master function parameters.

If the master function parameters have not been set, a message connection is

opened using message group 1.

(a) The procedure for executing the message communication is as follows:

1) Write the message communication data into the "message

communication co mman d" area o f th e bu ffe r me mory.

2) Use the sequence program to turn ON the message communication

request (Y12).

(Set an interv al of 10 0 ms or l on ge r befo r e tu rni ng ON th e messa ge

communication request.)

H

)" or "st op (40H)".

Message Communication

Request (Y12)

Message Communication

Completion (X02)

Message Communication

Error Signal (X05)

FROM/TO

(b) The message communication is completed. The communication result is

written into the "message communication result" area, and the message

communication completion (X02) is turned ON.

(c) Check the message communication result with the message communication

error signal (X05).

(d) After reading the communication data by the FROM instruction, use the

sequence program to turn OFF the message communication request (Y12).

The message communication completion (X02) and the message

communication error signal (X05) are automatically turned OFF.

With an error

No error

Write command

for the message

communication

(TO instruction)

Write data for

the message

communication

(TO instruction)

(During data transmission only)

Read result for

the message

communication

(FROM instruction)

Read data for

the message

communication

(FROM instruction)

(During data reception only)

3 - 17 3 - 17

Page 36

3 SPECIFICATIONS

(5) Master Function For Error Set Signal: X03, Master Function For

MELSEC-Q

Error Reset Request: Y13

These signals are used to indicate an error while executing the master function

and to reset the error code.

(a) When an error occurs via the master function, the error information is stored

in the "error information for the master function" area of the buffer memory

and the master function for error set signal (X03) is turned ON.

The master function for error set signal is automatically turned OFF when

the error cause is removed.

(b) After removing the error cause, use the sequence program to turn ON the

master function for error reset request (Y13), and the error code of the

"error-information for the master function" area is cleared.

Master Function For Error

Reset Request (Y13)

Master Function For Error

Set Signal (X03)

FROM/TO

Read error

information

(FROM instruction)

Error code

clear

(6) Slave Down Signal: X04

This signal indicates whether or not a slave node that is being stopped for

communication exists.

(a) This signal is turned ON when at least one slave node is being stopped

among the slave nodes that are set by the parameters.

OFF: Normal communi ca ti on wit h all no de s

ON: A communication-error node exists.

The slave node that is being sopped can be checked by referring to the

"each node's communication status" area in the addresses 01BC

H

01BF

of the buffer memory.

(b) X04 is automatically turned OFF when communication with the slave node

that is being sto pp ed re sumes.

H

to

3 - 18 3 - 18

Page 37

3 SPECIFICATIONS

(7) Saving Parameter To Flash ROM: X06, Save Parameter To Flash

MELSEC-Q

ROM Completion: X07, Save Parameter To Flash ROM R eq uest:

Y17 (when the master function is used)

These signals are used to save the "parameters for the master function" of the

buffer memory to the flash ROM in the QJ71DN91. Make a request to save

parameters to the flash ROM while the I/O communicating (X01) is OFF.

(a) Set the paramet e rs usi ng th e foll ow in g step s:

1) Write the parameters in the "parameters for the master function" area of

the buffer me mory.

2) Set the parameter save area selection bit.

3) Use the sequence program to turn ON the save parameter to flash

ROM request (Y17).

(b) When the request to save parameters to the flash ROM is accepted, and if the

parameter check is successful, the parameters will be saved and the saving

parameter to the flash ROM (X06) will turn ON. If the parameter check fails,

the master function for error set signal (X03) will tu rn ON and the ERR. LED

will light. Check the contents of the error in the "error information for the

master function" of the buffer memory address 1B1

H

.

(c) When the saving parameters to the flash ROM is completed, the save

parameter to flash ROM completion (X07) signal is automatically turned ON.

Communications with other slave nodes are stopped while the parameter is

being set.

By turning OFF the request to save parameters to the flash ROM, the saving

parameter to the flash ROM complete is automatically turned OFF.

When the parameter check is successful

I/O Communication

Request (Y11)

I/O Communicating (X01)

Save Paramter To Flash

ROM Request (Y 17)

Saving Parameter To

Flash ROM (X06)

Save Parameters To

Flash ROM Comple tio n (X 07)

TO instruction

When the parameter check fails

I/O Communication

Request (Y11)

I/O Communicating (X01)

Parameter

check

Write

parameter

data

Save Parameter To Flash

ROM Request (Y17)

Saving Parame te r To

Flash ROM (X06)

Save Parameter To Flash

ROM Completion (X07)

Master Function For Err or

Set Signal (X03)

TO instruction

Write

parameter

data

Parameter

check

3 - 19 3 - 19

Page 38

3 SPECIFICATIONS

(8) Saving Parameter To Flash ROM: X06, Save Parameter To Flash

MELSEC-Q

POINT

(1) Even if the save parameter to flash ROM request (Y17) is turned ON while the

I/O communicating (X01) is ON, save parameter to flash ROM completion

(X07) is not turned ON. Turn OFF the I/O communication request (Y11), then

after confirming that the I/O communicating (X01) is OFF, turn ON the save

parameter to flash ROM request (Y17) from the OFF state.

(2) Even if the I/O communication request (Y11) is turned ON while the save

parameter to flash ROM request (Y17) is ON, the I/O communicating (X01) is

not turned ON. Turn OFF the save parameter to flash ROM request (Y17), then

turn OFF the I/O communication request (Y11) once and turn it back ON again.

ROM Completion: X07, Save Parameter To Flash ROM R eq uest:

Y17 (when the slave function is used)

These signals are used when saving the "setting area for the number of slave

function input points" and "setting area for the number of slave function output

points" of the buffer memory to the flash ROM in the QJ71DN91. Make a request

to save parameters to the flash ROM while the I/O communicating (X01) is OFF.

(a) Set the paramet e rs usi ng th e foll ow in g step s:

1) Write the parameter in the "setting area of the number of slave function

reception bytes" and the "setting area of the number of slave function

transmission bytes" of the buffer memory.

2) Set the parameter save area selection bit.

3) Use the sequence program to turn ON the save parameter to flash

ROM request (Y17).

(b) When the request to save parameters to the flash ROM is accepted, and if

the number of I/O points check is successful, the number of I/O points

setting will be saved and the save parameter to flash ROM (X06) will turn

ON. If the number of I/O points check fails, the slave function for error set

signal (X08) is turned ON and the ERR. LED is lit. Check the contents of the

error in the "error information for the slave function" of the buffer memory

address 601

(c) When the number of I/O points setting is saved in the flash ROM, the save

parameter to flash ROM completion (X07) is automatically turned ON.

Communication with the master node is stopped while the number of I/O

points setting i s bein g sav ed .

By turning OFF the request to save parameters to the flash ROM, the saving

parameters to the flash ROM complete is automatically turned OFF.

When the parameter check is successful

I/O Communication

Request (Y11)

I/O Communicating (X01)

Save Paramter To Flash

ROM Request (Y17)

Saving Parameter To

Flash ROM (X06)

Save Parameter To Flas h

ROM Completion (X07)

H

.

Parameter

check

Write

TO instruction

parameter

data

3 - 20 3 - 20

Page 39

3 SPECIFICATIONS

I/O Communication

Request (Y11)

I/O Communicating (X01)

Save Parameter To Flash

ROM request (Y17)

Saving Parameter To

Flash ROM (X06)

Save Parameter To Flash

ROM Completion (X07)

Master Function For Error

Set Signal (X03)

TO instruction

MELSEC-Q

When the parameter check fails:

Parameter

check

Write

parameter

data

POINT

(1) Even if the save parameter to flash ROM request (Y17) is turned ON while the

I/O communicating (X01) is ON, save parameter to flash ROM completion

(X07) is not turned ON. Turn OFF the I/O communication request (Y11), then

after confirming that the I/O communicating (X01) is OFF, turn ON the save

parameter to flash ROM request (Y17) again from the OFF state.

(2) Even if the I/O communication request (Y11) is turned ON while the save

parameter to flash ROM request (Y17) is ON, the I/O communicating (X01) is

not turned ON. Turn OFF the save parameter to flash ROM request (Y17), then

turn OFF the I/O communication request (Y11) once and turn it back ON again.

3 - 21 3 - 21

Page 40

3 SPECIFICATIONS

(9) Slave Function For Error Set Signal : X08, Slav e Function For Err or

MELSEC-Q

Reset Request: Y18

These signals notify an error occurrence during execution of the slave function

and are used to reset the error code.

(a) When an error occurs by the slave function, the error information is stored in

the "error information for the slave function" area of the buffer memory, and

the slave function for error set signal (X08) is turned ON.

The slave function for error set signal is automatically turned OFF when the

error cause is removed.

(b) After removing the error cause, use the sequence program to turn ON the

slave function for error reset request (Y18). The error code of the "error

information for the slave function" area will be cleared.

Slave Function For Error Reset

Request (Y18)

Slave Function For Error Set

Signal (X08)

Error code

clear

Read error

FROM instruction

information

(FROM instruction )

(10) H/W Testing: X0A, H/W Test Completion: X0B, H/W Test Error

Detection: X0C

These signals indicate the status when the QJ71DN91 is set to the hardware test

mode (mode 9).

(a) When the mode switch is set to 9 and the power is turned ON, the H/W

testing (X0A) is turned ON.

(b) When the hardware test is completed normally, the H/W test completion

(X0B) signal will be turned ON. If an error occurs, the H/W test completion

(X0B) signal will not be turned ON but the H/W test error detection (X0C) will

be turned ON.

(11) Module Ready: X0F

This signal indicates whether the module is ready to operate.

When the module reaches ready-to-operate status, this signal is turned ON

automatically.

The module ready (X0F) is turned OFF when the watchdog timer error (X00) is

turned ON.

3 - 22 3 - 22

Page 41

3 SPECIFICATIONS

(12) Auto Configuration Executing: X14, Auto Configuration Completion:

MELSEC-Q

X15, Auto Configuration Request: Y 15

These signals are used in order to search the slave nodes that are connected to

the network and create parameters automatically. Execute the auto configuration