Page 1

C

MIT

SUBIS

C

HI ELECTRI

MELSEC System Q

Programmable Logic Controllers

User's Manual

(Basic)

Serial Communication Modules

QJ71C24N/-R2/-R4, QJ71C24/-R2

Art. no.: 130031

01 09 2004

SH (NA)-080006

Version H

GX Configurator-SC

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

Page 2

Page 3

• SAFETY PRECAUTIONS •

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the user's manual of the CPU module to use.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to t he circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forw ard it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Instructions]

!

DANGER

•

See manuals of each data link for the operating status of each station when there is a

communication error in the data link.

There is the risk of an accident occurring due to output error or malfunctioning.

•

When using the notification function, the pager receiver may not be contacted due to the frequency

transmission status from the system setup environment and error on the receiver side.

To ensure the safety of the PLC system, install a call circuit with a lamp display or buzzer sound.

•

When performing the control of the PLC in operation (changing data) by connecting a peripheral

devices to the CPU module or personal computer, etc. to the intelligent device module, configure an

interlock circuit in a sequence program so the safety of the overall system is always maintained.

Also when performing other controls of the PLC in operation (changing program and operation

status (status control)), read this manual carefully and confirm if the overall safety is maintained.

Especially, when this control is performed to a remote PLC from an external dev ice, troubles

that have occurred on the PLC side may not be able to immediately be handled if there is a data

communication error.

Define a troubleshooting agreement between external devices and the PLC CPU for data

communication error occurrences, as well as construct an interlock circuit in the sequence program.

•

Do not write data into the "system area" of the buffer memory of intelligent function modules.

Also, do not use any "prohibited to use" signals as an output signal to an int elligent funct ion

module from the PLC CPU.

Writing data into the "system area" or outputting a signal for "prohibited to use" may cause a

PLC system malfunction.

A - 1 A - 1

Page 4

[Design Instructions]

!

CAUTION

•

Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100mm(3.9inch) or more from each other.

Not doing so could result in noise that may cause malfunction.

•

When using the module while values, such as buffer memory set values, are registered in the

Flash ROM, do not turn off the power supply for the module loading station nor reset the PLC

CPU.

If the power supply for the module loading station is turned off or the PLC CPU is reset while any

values are registered, the data contents in the Flash ROM become inconsistent and as a result the

values must be set again in the buffer memory, etc. and reregistered to the Flash ROM.

Also, this may cause failure and malfunction of the module.

[Installation Instructions]

!

CAUTION

•

Use the PLC in an environment that meets the general specifications contained in the user's

manual of the CPU module to use.

Using this PLC in an environment outside the range of the general specificat ions may cause

electric shock, fire, malfunction, and damage to or deterioration of the product.

•

While pressing the installation lever located at the bottom of module, insert the module fixing t ab

into the fixing hole in the base unit until it stops. Then, securely mount t he module with t he fixing

hole as a supporting point.

If the module is not installed properly, it may cause the module to malfunctio n, fail or fall o ff.

Secure the module with screws especially when it is used in an environment where constant

vibrations may occur.

•

Tighten the screws within the range of specified torque.

If the screws are loose, it may cause the module to fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damage to the screw and/or the module,

resulting in fallout, short circuits or malfunction.

•

Switch all phases of the external power supply off when mounting or removing the module.

Not doing so may cause damage to the module.

•

Do not directly touch the conductive area or electronic components of the module.

Doing so may cause malfunction or failure in the module.

A - 2 A - 2

Page 5

[Wiring Instructions]

!

CAUTION

•

When turning on the power and operating the module after installation and wiring are completed,

always attach the terminal cover that comes with the product.

There is a risk of electric shock if the terminal cover is not attached.

•

Perform correct pressure-displacement, crimp-contact or soldering for external wire connections

using the tools specified by the manufactures.

Incorrect connection may cause short circuits, fire, or malfunction.

•

Attach connectors to the module securely.

•

Be sure to fix communication cables or power supply cables leading from the module by placing

them in the duct or clamping them.

Cables not placed in the duct or without clamping may hang or shift, allow ing them to be

accidentally pulled, which may cause a module malfunctio n and cable da mage.

•

Before connecting the cables, check the type o f interface to be connected.

Connecting or erroneous wiring to the wrong interface may cause failure to the module and

external devices.

•

Tighten the terminal screws within the range of specified torque.

If the terminal screws are loose, it may result in short circuits or malfunction.

If the screws are tightened too much, it may cause damage to the screw and/or the module,

resulting in fallout, short circuits or malfunction.

•

When removing the communication cable or power supply cable from the module, do not pull the

cable. When removing the cable with a connector, hold the connector on the side that is

connected to the module.

When removing the cable connected to the terminal block, first loosen the screws on the part

that is connected to the terminal block.

Pulling the cable that is still connected to t he module may cause malfunctio n or damage t o the

module or cable.

•

Be careful not to let foreign matters such as sawdust or wire chips get inside the module.

They may cause fires, failure or malfunction.

•

The top surface of the module is covered with protective film to prevent foreign objects such as

cable offcuts from entering the module when wiring.

Do not remove this film until the wiring is complete.

Before operating the system, be sure to remove the film to provide adequate heat ventilation.

A - 3 A - 3

Page 6

[Startup/Maintenance Instructions]

!

CAUTION

•

Do not disassemble or modify each module.

Doing so could cause failure, malfunction injury or fire.

•

Switch all phases of the external power supply off when mounting or removing the module.

Not doing so may cause failure or malfunction of the module.

•

not

Do

•

Do not touch the connector while the power is on.

•

Switch all phases of the external power supply off when cleaning or retightening ter minal screws

mount/remove the module onto/from base unit more than 50 times (IEC61131-2compliant), after the first use of the product.

Failure to do so may cause the module to malfunction due to poor contact of connector.

Doing so may cause malfunction.

and module installing screws.

Not doing so may cause failure or malfunction of the module.

If the screws are loose, it may cause the module to fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damages to the screws and/or the module,

resulting in the module falling out, short circuits or malfunct ion.

•

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

etc., before touching the module.

Failure to do so may cause a failure or malfunctions of the module.

[Operation Instructions]

!

CAUTION

•

When performing the control of the PLC in operation (especially changing data, program, and

operation status (status control)) by connecting a personal comput er, etc. to the intelligent

function module, read this manual carefully and confirm if the ov erall safety is maintained.

Failure to perform correct operation s to change data, program, or the status may result in

system malfunction, machine damage, or an accident .

[Disposal Instructions]

!

CAUTION

•

When disposing of this product, treat it as industrial waste.

A - 4 A - 4

Page 7

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 1999 SH (NA)-080006-A First Printing

Oct., 2000 SH (NA)-080006-B Add the contents of the function version B.

Correction

Contents, Entire manual (change MELSECNET/10H to MELSECNET/H),

About Manuals, About The Generic Terms and Abbreviations, Product

Configuration, Section 1.2, 1.2(8), 1.3 POINT, Section 2.2, 2.3, 2.5, 2.6,

Section 3.1, 3.6, 3.9, Section 4.2, 4.4.1(2)(a)(Figure), 4.6(1), Chapter

5(all), Section 6.1.1, 6.1.3, 6.1.4, Section 7.1.1, 7.1.2, 7.2.2, Section 8.1,

8.2.1, 8.2.2, 8.3.1, 8.3.2, Section 9.2 to 9.7, Section 10.1.1, 10.2.1,

10.3.8, 10.3.18, Appendix 1.1(2), Appendix 2(all), appendix 3(2),

Appendix 7, appendix 8

Addition

Entire manual (add the explanation on MELSECNET/H remote I/O

station), The Manual's Use and Structure, Section 2.1, Section

3.1(Table), Section 4.4.2( 1)( d), 4.9.2, Sec t ion 8.3.2 POINT, Section

10.2.1 (7164

H

, 7E70H), Appendix 3(1)

Jun., 2001 SH (NA)-080006-C Put Windows® base software product together from Mitsubishi

Programmable Logic Controller MELSEC Series to Mitsubishi integrated

FA Software MELSOFT Series.

Standardize the name from software package (GPP function) to Product

name (GX Developer).

Standardize the name from utility package (QSCU) to Product name (GX

Congifurator-SC).

Feb., 2002 SH (NA)-080006-D

Oct., 2002 SH (NA)-080006-E

Jan., 2003 SH (NA)-080006-F

Correction

Conformation to the EMC Directive and Low Voltage Instruction, About

the Generic Terms and Abbreviations, Product Configuration, Program

Examples (Section 6.1.4, 6.2.3, Section 7.2.3, Section 9.3, 9.5, Appendix-

8), Section 1.2(1)(d), 1.2(4)(b)(Diagram), 1.2(8)(b), 1.3, Section 2.1, 2.3,

2.4, 2.5, 2.7, Section 3.1(Table), 3.2.1(3) , 3.3. 3( 2), 3.4( T able) , 3.9,

Section 4.3, 4.5.2, Section 5.1.5(3), 5.2, Section 6.1.4, Section 8.2, 8.3.2

POINT, 8.4.2, 8.4.9(Table), 8.6.3(Table), 8.6.7(Table), Section 10.1.2(b),

10.3(Table), Appendix 1.1, 2.1, 6, 7, 9

Addition

Section 2.6, Section 8.4.4, 8.6.2(Table), Section 10.2.1(716F

10.2.3(7FE9

H

), 10.3.14, Appendix 3

H,

7FEFH),

Addition

About The Generic Terms and Abbreviations, Section 1.2, Section 2.1,

2.7, Section 4.5.2, Section 8.2.1, 8.2.2, Sec t ion 10.2.1, Appe ndix 1.1, 6

Addition

The Manual’s Use and Structure, About The Generic Terms and

Abbreviations, Sect ion 1.2(1) (4) , Sec t ion 2.1, 2.4, Sec tio n 5.2, Sec ti on

6.1.4, Section 9.8, Appendix 7

Addition model

QJ71C24N, QJ71C24N-R2, QJ71C24N-R4

A - 5 A - 5

Page 8

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Jan., 2003 SH (NA)-080006-F

Addition

SAFETY PRECAUTIONS, About Manuals, About The Generic Terms

and Abbreviations, Product Configuration, Section 1.3, Section 2.1, 2.2,

2.3, 2.5, 2.6, 2.7, Section 3.1, 3.2.1, 3.3.1, 3.6, 3.8, 3.9, Section 4.1, 4.3,

4.4, 4.5, 4.6, 4.7.1, Section 6.1.1, 6.1.2, Section 7.1, 7.2.2, Chapter 8(all),

Section 9.1, 9.6, Section 10.1.2(b), 10.1.3(1), 10.2, Appendix 1, Appendix

2.1, Appendix 3, Appendix 5, Appendix 9

Jun., 2004 SH (NA)-080006-G

Correction

About The Generic Terms and Abbreviations, Product Configuration,

Chapter 2 (all), Section 3.8, Section 4.2.2 (1), Section 5.1.3 POINT,

Section 5.1.4, Chapter 8 (screen change), Section 8.6.10, Section 10.1.1,

Section 10.2

Addition

Appendix 9

Sep., 2004 SH (NA)-080006-H

Correction

Section 1.3, Section 2.5, 2.6, Section 3.5, 3.6, 3.9, Section 4.1, Chapter 8

(screen change), Section 8.6. 9, 8.6. 10, Sec t ion 10. 1, 10.2, Ap pen dix 1.1

Addition

Appendix 9.12

Japanese Manual Version SH-080001-L

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

1999 MITSUBISHI ELECTRIC CORPORATION

A - 6 A - 6

Page 9

INTRODUCTION

Thank you for purchasing the MELSEC-Q series PLC.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Q series PLC you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

CONTENTS (This manual)

SAFETY PRECAUTIONS..............................................................................................................................A- 1

REVISIONS....................................................................................................................................................A- 5

CONTENTS....................................................................................................................................................A- 7

About Manuals ...............................................................................................................................................A-15

Conformation to the EMC Directive and Low Voltage Instruction ................................................................A-15

The Manual’s Use and Structure ...................................................................................................................A-16

About The Generic Terms and Abbreviations...............................................................................................A-19

Definitions and Descriptions of Terminology.................................................................................................A-21

Product Configuration ....................................................................................................................................A-23

1 OVERVIEW 1- 1 to 1-11

1.1 Overview of the Serial Communication Module.....................................................................................1- 1

1.2 Features of the Serial Communication Module......................................................................................1- 2

1.3 About Added/Changed Functions in Function Version B......................................................................1-10

2 SYSTEM CONFIGURATION AND AVAILABLE FUNCTIONS 2- 1 to 2-14

2.1 Applicable Systems.................................................................................................................................2- 1

2.2 Combinations of PLC CPU and External Device, and Available Functions..........................................2- 3

2.3 For Use in Multiple CPU System............................................................................................................2- 6

2.4 For Use with Q00J/Q00/Q01CPU ..........................................................................................................2- 7

2.5 For Use at MELSECNET/H Remote I/O Station....................................................................................2- 8

2.6 Checking the Function Version, Serial No., and Software Version.......................................................2-12

3 SPECIFICATION S 3- 1 to 3-31

3.1 Performance Specifications....................................................................................................................3- 1

3.2 RS-232 Interface Specification...............................................................................................................3- 3

3.2.1 RS-232 connector specifications.....................................................................................................3- 3

3.2.2 RS-232 cable specification ..............................................................................................................3- 5

3.3 RS-422/485 Interface Specifications......................................................................................................3- 6

3.3.1 RS-422/485 terminal block specifications .......................................................................................3- 6

3.3.2 RS-422/485 cable specifications .....................................................................................................3- 7

3.3.3 Precautions when transferring data using RS-422/485 circuit .......................................................3- 8

3.4 Serial Communication Module Function List..........................................................................................3-11

3.5 Dedicated Instruction List........................................................................................................................3-12

3.6 Utility Package (GX Configurator-SC) Function List..............................................................................3-13

3.7 List of GX Devel op e r Se t tin g I tems for S e rial Co mmun i ca ti on M odule s...............................................3-14

3.8 List of Input/Output Signals for the PLC CPU........................................................................................3-15

3.9 List of Applications and Assignments of the Buffer Memory.................................................................3-17

A - 7 A - 7

Page 10

4 SETTINGS AND PROCEDURES PRIOR TO OPERATION 4- 1 to 33

4.1 Handling Precautions..............................................................................................................................4- 1

4.2 Settings and Procedures Prior to Operation .......................................................................................... 4- 2

4.3 Part Names and Functions .....................................................................................................................4- 3

4.4 External Wiring........................................................................................................................................ 4- 5

4.4.1 Connecting the RS-232 interface (full-duplex communications) ....................................................4- 6

4.4.2 Connecting the RS-422/485 interface .............................................................................................4- 8

4.5 Settings for GX Developer......................................................................................................................4-12

4.5.1 I/O assignment settings....................................................................................................................4-12

4.5.2 Switch settings for I/O and intelligent functional module ................................................................4-13

4.5.3 The Intelligent function module interrupt pointer setting.................................................................4-20

4.6 Settings with the Utility Package (GX Configurator-SC)........................................................................ 4-22

4.7 Individual Station Test.............................................................................................................................4-25

4.7.1 ROM/RAM/switch tests....................................................................................................................4-25

4.7.2 Individual station loopback test........................................................................................................4-28

4.8 Loopback Test......................................................................................................................................... 4-30

4.9 Maintenance and Inspection...................................................................................................................4-32

4.9.1 Maintenance and inspection............................................................................................................4-32

4.9.2 When mounting/dismounting the module........................................................................................4-33

5 DATA COMMUNICATION USING THE MELSEC COMMUNICATION PROTOCOL 5- 1 to 5- 6

5.1 Data Communication Functions .............................................................................................................5- 1

5.1.1 Accessing the PLC CPUs using the MC protocol...........................................................................5- 1

5.1.2 Message format and control procedure for data communication...................................................5- 2

5.1.3 PLC CPU setting for performing data communication....................................................................5- 2

5.1.4 Support of multiple CPU system or redundant system...................................................................5- 3

5.1.5 Support for the QCPU remote password function ..........................................................................5- 4

5.2 Utilizing the MX Component...................................................................................................................5- 6

6 DATA COMMUN I CA TI ON USI N G TH E N O N PR OC E DURE P R OTOC O L 6- 1 to 6-31

6.1 Data Reception from the External Device..............................................................................................6- 2

6.1.1 Receiving methods...........................................................................................................................6- 2

6.1.2 The receive area and the received data list ....................................................................................6- 6

6.1.3 Sequence program for data reception.............................................................................................6-11

6.1.4 Receive data clear............................................................................................................................6-14

6.1.5 How to detect reception errors.........................................................................................................6-17

6.1.6 Received data count and receive complete code settings .............................................................6-20

6.2 Sending Data to the External Device .....................................................................................................6-22

6.2.1 Transmission methods.....................................................................................................................6-22

6.2.2 Arrangement and contents of the transmission area and the transmission data...........................6-23

6.2.3 Sequence program for transmission data.......................................................................................6-25

6.2.4 How to detect transmission errors...................................................................................................6-28

6.3 Data Communications Precautions........................................................................................................6-30

A - 8 A - 8

Page 11

7 DATA COMMUNICATION USING THE BIDIRECTIONAL PROTOCOL 7- 1 to 7-28

7.1 Data Reception from the External Device..............................................................................................7- 2

7.1.1 Receiving methods...........................................................................................................................7- 2

7.1.2 Arrangement and contents of the receive area and the receive data............................................7- 4

7.1.3 Sequence program for data reception.............................................................................................7-10

7.1.4 How to detect reception errors.........................................................................................................7-13

7.1.5 Receive data clear............................................................................................................................7-14

7.2 Sending Data to the External Device .....................................................................................................7-15

7.2.1 Transmission methods.....................................................................................................................7-15

7.2.2 Arrangement and contents of the transmission area and the transmission data...........................7-16

7.2.3 Sequence program for data transmission.......................................................................................7-19

7.2.4 How to detect transmission errors...................................................................................................7-22

7.3 Processing when Simultaneous Transmission Performed During Full-Duplex Communications .......7-24

7.3.1 Processing when simultaneous transmissions occur .....................................................................7-24

7.3.2 Communication data processing when simultaneous transmissions occur...................................7-25

7.4 Data Communications Precautions........................................................................................................7-27

8 UTILITY PACKAGE (GX CONFIGURATOR-SC) 8- 1 to 8-51

8.1 Functions Available with Utility Package................................................................................................8- 2

8.2 Installing and Uninstalling Utility Package..............................................................................................8- 3

8.2.1 Usage precautions ...........................................................................................................................8- 3

8.2.2 Operating environment.....................................................................................................................8- 5

8.3 Explanation of Utility Package Operation...............................................................................................8- 6

8.3.1 Operation overview ..........................................................................................................................8- 6

8.3.2 Starting the intelligent function module utility

(displaying the [select parameter setting module] screen)........................................................................8-10

8.3.3 Performing common utility operations.............................................................................................8-13

8.4 System Registration to Flash ROM........................................................................................................8-16

8.4.1 User frame registration.....................................................................................................................8-18

8.4.2 Data for modem initialization registration ........................................................................................8-19

8.4.3 Data for modem connection registration .........................................................................................8-20

8.4.4 Modem function system setting/registration....................................................................................8-21

8.4.5 Transmission control and others system setting.............................................................................8-22

8.4.6 MC protocol system setting..............................................................................................................8-24

8.4.7 Non procedure system setting.........................................................................................................8-25

8.4.8 Bidirectional system setting .............................................................................................................8-26

8.4.9 PLC CPU monitoring system setting...............................................................................................8-27

8.4.10 Transmission user frame No. designation system setting............................................................8-29

8.4.11 Resetting the buffer memory/flash ROM setting values to the default values.............................8-30

8.4.12 Flash ROM write allow/prohibit setting..........................................................................................8-30

8.5 Auto Refresh Setting...............................................................................................................................8-31

8.6 Monitor/Test ............................................................................................................................................8-32

8.6.1 X · Y monitor/test..............................................................................................................................8-33

8.6.2 Modem function monitor/test ...........................................................................................................8-34

8.6.3 Transmission control and others monitor/test.................................................................................8-37

8.6.4 MC protocol monitor......................................................................................................................... 8-39

A - 9 A - 9

Page 12

8.6.5 Non procedure monitor/test .............................................................................................................8-41

8.6.6 Bidirectional monitor.........................................................................................................................8-43

8.6.7 PLC CPU monitoring monitor ..........................................................................................................8-44

8.6.8 Transmission user frame No. designation monitor .........................................................................8-46

8.6.9 Monitor/test others............................................................................................................................8-47

8.6.10 Display LED off and communication error information/error code initialization...........................8-49

8.7 Non Procedure Protocol Receive Data Clear ........................................................................................8-51

9 DEDICATED INSTRUCTIONS 9- 1 to 9-21

9.1 Dedicated Instruction List........................................................................................................................9- 1

9.2 ONDEMAND Instruction .........................................................................................................................9- 2

9.3 OUTPUT Instruction................................................................................................................................9- 5

9.4 INPUT Instruction....................................................................................................................................9- 8

9.5 BIDOUT Instruction.................................................................................................................................9-11

9.6 BIDIN Instruction.....................................................................................................................................9-14

9.7 SPBUSY Instruction................................................................................................................................9-17

9.8 CSET (Receive data clear).....................................................................................................................9-19

10 TROUBLESHOOTING 10- 1 to 10-43

10.1 Checking the Status of the Serial Communication Module...............................................................10- 1

10.1.1 Checking the LED ON status, communications error status, and switch setting status of

the serial communication module................................................................................................10- 1

10.1.2 Initializing error information of the serial communication module...............................................10- 6

10.1.3 Reading the RS-232 control signal status...................................................................................10- 9

10.1.4 Reading the data communication status (Transmission sequence status) ...............................10-10

10.1.5 Reading the switch setting status................................................................................................10-11

10.1.6 How to read the current operation status....................................................................................10-13

10.2 Error Code Tables...............................................................................................................................10-15

10.2.1 Error code table............................................................................................................................10-15

10.2.2 A compatible 1C frame communications error code table..........................................................10-24

10.2.3 Error code list while modem function is used..............................................................................10-25

10.3 Troubleshooting by Symptom.............................................................................................................10-27

10.3.1 Troubleshooting when "RUN" LED is turned OFF......................................................................10-29

10.3.2 Troubl e sho ot in g wh en "R D" LE D doe s not bli n k even th ou gh an e xte r nal dev i ce is

transmitting a message................................................................................................................10-30

10.3.3 Troubleshooting when the Q series C24 does not return a response message even

though an external device transmitted a message and the "RD" LED blinked..........................10-31

10.3.4 Troubleshooting when an external device transmitted a message and "RD" LED blinked,

but the Read Request signal was not turned ON .......................................................................10-32

10.3.5 Troubleshooting when communication error "NAK" generates..................................................10-33

10.3.6 Troubleshooting when communication error "C/N" generates ...................................................10-33

10.3.7 Troubleshooting when communication error "P/S" generates....................................................10-34

10.3.8 Troubleshooting when communication error "PRO." generates.................................................10-35

10.3.9 Troubleshooting when communication error "SIO" generates ...................................................10-36

10.3.10 Troubleshooting when communication error "CH1 ERR.", "CH2 ERR." generate..................10-37

10.3.11 Troubleshooting when communications is intermittently established and lost ........................10-38

10.3.12 Troubleshooting when data that cannot be decoded is transmitted and received ..................10-39

A - 10 A - 10

Page 13

10.3.13 Troubleshooting when it is unclear whether the communication error cause is in

the Q series C24 or an external device ....................................................................................10-40

10.3.14 Troubleshooting when data cannot be communicated via modem..........................................10-41

10.3.15 Troubleshooting when data cannot be communicated with the ISDN sub-address................10-42

10.3.16 Troubleshooting when constant cycle transmission does not operate normally......................10-42

10.3.17 Troubleshooting when condition agreement transmission does not operate normally ...........10-42

10.3.18 Troubleshooting when data cannot be received by an interrupt program ...............................10-42

10.3.19 Troubleshooting when data cannot be written to Flash ROM..................................................10-42

10.3.20 Troubleshooting when the "ERR" LED is lit ..............................................................................10-43

APPENDIX APP.- 1 to APP.-58

Appendix 1 Functional Improvements of the Q Series C24 ...................................................................App.- 1

Appendix 1.1 Comparison of the Functions of Q Series C24/GX Configurator-SC...........................App.- 1

Appendix 1.2 Pr e caut io n s w hen U pda ti ng th e Mo du le fro m Fu n ction Version A to B.......................App.- 5

Appendix 2 QnA/A Series Module...........................................................................................................App.- 6

Appendix 2.1 Functional Comparison with the Q series C24 and the QnA/A Series Modules .........App.- 6

Appendix 2.2 Using Programs Designed for the QC24 (N) and Installing the Q Series C24

into Existing Systems ....................................................................................................App.- 8

Appendix 2.2.1 Using programs designed for the QC24 (N).....................................................App.- 8

Appendix 2.2.2 Installing on existing systems...........................................................................App.- 9

Appendix 2.3 Using Programs Designed for the Computer Link Module and Installing

the Q Series C24 into Existing Systems......................................................................APP.-10

Appendix 2.3.1 Using programs designed for the computer link module..................................App.-10

Appendix 2.3.2 Installing the Q series C24 into existing systems.............................................App.-13

Appendix 3 Processing Time...................................................................................................................App.-14

Appendix 4 ASCII-Code Table.................................................................................................................App.-17

Appendix 5 External Dimensions.............................................................................................................App.-18

Appendix 6 Example of Connection when a Converter is Used.............................................................App.-20

Appendix 7 Communication Support Tool (MX Component) .................................................................App.-23

Appendix 7.1 Overview of MX Component .........................................................................................App.-23

Appendix 7.2 Usage Procedure of MX Component............................................................................App.-26

Appendix 8 Example of Clear Process Program for Receive Data........................................................App.-30

Appendix 9 Program Examples for Using Q Series C24 at MELSECNET/H Remote I/O Station........App.-32

Appendix 9.1 System configuration and program conditions .............................................................App.-32

Appendix 9.2 When accessing buffer memory using sequence program..........................................App.-34

Appendix 9.3 When sending on-demand data....................................................................................App.-35

Appendix 9.4 When receiving data using nonprocedural or bidirectional protocol ............................App.-37

Appendix 9.5 When sending data using nonprocedural or bidirectional protocol..............................App.-39

Appendix 9.6 When clearing received data.........................................................................................App.-41

Appendix 9.7 When sending data using user frames .........................................................................App.-43

Appendix 9.8 When performing initial setting......................................................................................App.-46

Appendix 9.9 When registering user frame.........................................................................................App.-48

Appendix 9.10 When reading user frame............................................................................................App.-50

Appendix 9.11 When deleting user frame...........................................................................................App.-52

Appendix 9.12 When changing the communication protocol and transmission setting.....................App.-54

Appendix 10 Setting Value Recording Sheet..........................................................................................App.-57

INDEX Index- 1 to Index- 2

A - 11 A - 11

Page 14

(Related Manual-1) … Q Corresponding Serial Communication Module User's Manual (Application)

SH-080007-G

1 OVERVIEW

1.1 Overview

1.2 Functions Added/Changed by Function

Version B

2 USING THE PLC CPU MONITORING

FUNCTION

2.1 Overview

2.2 About the PLC CPU Monitoring Function

2.3 Settings for Using the PLC CPU Monitoring

Function

2.4 Precautionary Notes for Using the PLC CPU

Monitoring Function

3 COMMUNICATIONS BY THE MODEM

FUNCTION

3.1 Overview

3.2 System Configuration

3.3 Specifications

3.4 Start-up of the Modem Function

3.5 Sample Programs

4 RECEIVING DATA WITH AN INTERRUPT

PROGRAM

4.1 Settings for Receiving Data Using an Interrupt

Program

4.2 Interrupt Program Startup Timing

4.3 Reception Control Method Using an Interrupt

Program

4.4 Programming

5 CHANGING SEND AND RECEIVE DATA

LENGTH UNITS TO BYTE UNITS

(WORD/BYTES UNITS SETTING)

6 CHANGING THE DATA COMMUNICATIONS

MONITORING TIMES

6.1 No-Reception Monitoring Time (timer 0)

Setting

6.2 Response Monitoring Time (timer 1) Setting

6.3 Transmission Monitoring Time (timer 2)

Setting

6.4 Message Wait Time Setting

7 DATA COMMUNICATIONS USING DC CODE

TRANSMISSION CONTROL

7.1 Control Contents of DTR/DSR (ER/DR)

Signal Control

7.2 Control Contents of DC Code Control

7.3 Precautions when Using the Transmission

Control Functions

8 DATA COMMUNICATIONS USING HALF-

DUPLEX COMMUNICATIONS

8.1 Half-duplex Communications

8.2 Data Transmission and Reception Timing

8.3 Changing the Communication System

8.4 Connector Connections for Half-duplex

Communications

8.5 Half-duplex Communications Precautions

9 CONTENTS AND REGISTRATION OF THE

USER FRAMES FOR DATA COMMUNICATION

9.1 User Frame Types and Contents During

Communication

9.2 Transmission/Reception Processing Using

User Frame Register Data

9.3 Precautions when Registering, Reading,

Deleting and Using User Frames

9.4 Register/Read/Delete User Frames

10 ON-DEMAND DATA COMMUNICATIONS

USING USER FRAMES

10.1 User Frame Data Communications Function

10.2 User Frame Types and Registration

10.3 User Frame On-Demand Data Transmission

and Buffer Memory Used

10.4 On-Demand Function Control Proc ed ur e

During User Frame Use

10.5 Example of an On-Demand Data

Transmission Program Using User Frames

11 DATA COMMUNICATIONS USING USER

FRAMES

11.1 Overview of Data Communication

Procedure

11.2 Data Reception

11.3 Receive Program

11.4 Data Transmission

11.5 Transmission program

12 TRANSPARENT CODES AND ADDITIONAL

CODES

12.1 Handling the Transparent Code and

Additional Code Data

12.2 Registering Transparent Codes and

Additional Codes

12.3 Handling Transparent Codes and Additional

Codes During Non Procedure Protocol Data

Communication

12.4 Example of Data Communication Using the

Non Procedure Protocol

12.5 Handling Transparent Codes and Additional

Codes During Bidirectional Protocol Data

Communication

12.6 Example of Data Communication Using the

Bidirectional Protoc o l

A - 12 A - 12

Page 15

(Related Manual-1) … Q Corresponding Serial Communication Module User's Manual (Application)

SH-080007-G

13 COMMUNICATING WITH ASCII CODE (ASCII-

BIN CONVERSION)

13.1 ASCII-BIN Conversion

13.2 Settings for ASCII-BIN Conversion

13.3 Performing ASCII-BIN Conversion for Data

Communicated via Non Procedure Protocol

13.4 Example of Data Communication Using the

Non Procedure Protocol

13.5 Performing ASCII-BIN Conversion for Data

Communicated Via the Bidirectional Protocol

13.6 Example of Data Communication Using the

Bidirectional Protoc o l

14 DATA COMMUNICATIONS USING EXTERNAL

DEVICE AND PLC CPU M : N

CONFIGURATION

14.1 Data Communications Precautions

14.2 External Devices Interlock Conditions

14.3 Examples of Procedure for Data

Communications with the PLC CPU

15 SWITCHING THE MODE AFTER STARTING

15.1 Mode Switching Operation and Contents

that can be Changed

15.2 Mode Switching Precautions

15.3 I/O Signals for Handshake with PLC CPU

and Buffer Memory

15.4 Switching the Mode from the PLC CPU

15.5 Switching the Mode from an External Device

16 USING COMMUNICATION DATA

MONITORING FUNCTION

16.1 Communication Data Monitoring Function

16.2 Communication Data Monitoring Function

Settings

16.3 Communication Data Monitoring Example

17 DEDICATED INSTRUCTIONS

17.1 Dedicated Instruction List

17.2 BUFRCVS Instruction

17.3 CSET Instruction (PLC CPU Monitoring

Register/Cancel)

17.4 CSET Instruction (Initial Settings)

17.5 GETE Instruction

17.6 PRR Instruction

17.7 PUTE Instruction

17.8 UINI Instruction

A - 13 A - 13

Page 16

(Related Manual-2) … Q Corresponding MELSEC Communication Protocol Reference Manual

SH-080008-F

1 OVERVIEW

1.1 Overview of the MELSEC Communication

Protocol

1.2 Features of the MELSEC Communication

Protocol

2 DATA COMMUNICATION USING THE MELSEC

COMMUNICATION PROTOCOL

2.1 Types and Applications of Data

Communication Frames

2.2 Accessible Range of Each Data

Communication Frames

2.3 How to Read the Control Procedures of the

MC Protocol

2.4 Access Timing of the PLC CPU Side

2.5 Setting Method for Writing to the PLC CPU

during RUN

2.6 Accessing Other Stations

2.7 Precautions on Data Communication

2.8 Time Chart and Communication Time of the

Transmission Sequence of the Serial

Communication Module

2.9 Transmission Time When Accessing Other

Stations Via MELSEC NE T/H, MELSE CNE T/ 10

2.10 Compatibilit y with Multip le CPU Systems

2.11 Compatibility with the Q00CPU, Q01CPU

Serial Communication Function

3 WHEN COMMUNICATING USING THE QnA

COMPATIBLE 3E/3C/4C FRA M ES

3.1 Message Formats

3.2 List of Commands and Functions for the QnA

Compatible 3E/3C/4C Frames

3.3 Device Memory Read/Write

3.4 Buffer Memory Read/Write

3.5 Reading from and Writing to the Buffer

Memory of an Intelligent Function Module

3.6 PLC CPU Status Control

3.7 Drive Memory Defragmentation (for Other

Station QnACPU)

3.8 File Control

3.9 Registering, Deleting and Reading User

Frames: for Serial Communication Modules

3.10 Global Function: for Serial Communication

Modules

3.11 Data Transmission to an External device

(On-Demand Function): for Serial

Communication Modules

3.12 Initializing the Transmission Sequence: for

Serial Communication Modules

3.13 Mode Switching: for Serial Communication

Module

3.14 Turning Off Displayed LEDs and Initializing

Communication Error Information and Error

Code: for Serial Communication Module

3.15 Turning Off the COM.ERR LED: for Ethernet

Modules

3.16 Loopback Test

3.17 Registering or Canceling PLC CPU

Monitoring: for Serial Communication

Modules

3.18 Remote Password Unlock/Lock

4 WHEN COMMUNICATING USING THE QnA

COMPATIBLE 2C FRAMES

4.1 Control Procedures and Message Formats

4.2 Contents of the Data Designation Items

4.3 List of Commands and Functions for QnA

Compatible 2C Frames

4.4 Precautions on the Data Communication

4.5 Example of Data Communication Using QnA

Compatible 2C Frames

5 WHEN COMMUNICATING USING THE A

COMPATIBLE 1C FRAMES

5.1 Control Procedures and Message Formats

5.2 Device Memory Read/Write

5.3 Extension File Register Read and Write

5.4 Reading and Writing in the Buffer Memory of

an Intelligent Function Module

5.5 Loopback Test

6 WHEN COMMUNICATING USING THE A

COMPATIBLE 1E FRAMES

6.1 Message Formats and Control Procedures

6.2 List of Commands and Functions for A

Compatible 1E Frames

6.3 Device Memory Read/Write

6.4 Extension File Register Read and Write

6.5 Reading and Writing in the Buffer Memory of

an Intelligent Function Module

APPENDIX

Appendix-1 Reading and Writing by Designation

of the Device Memory Extension

Appendix 2 Reading from and Writing to the

Buffer Memory

Appendix-3 Processing Time of the PLC CPU

Side While Communicating Using

the MC Protocol

A - 14 A - 14

Page 17

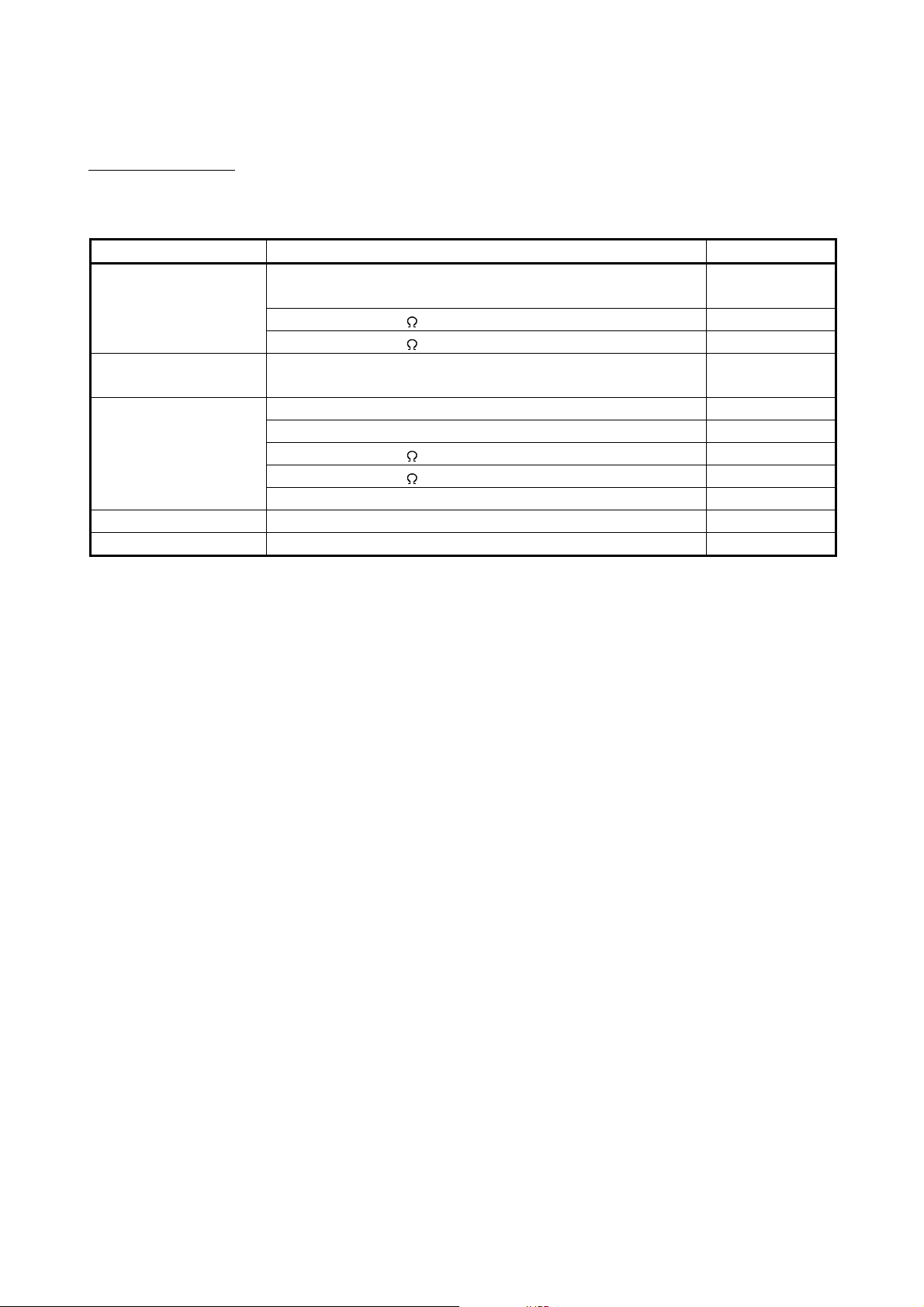

About Manuals

The following table lists the manuals relating to this product. Please order the desired manual(s) as needed.

Related manuals

Manual Name

Q Corresponding Serial Communication Module User's Manual (Application)

This manual explains the specifications and operating procedures for the special module functions, the

settings for use of special functions, and data-communication method for use with external devices.

(sold separately)

Q Corresponding MELSEC Communication Protocol Reference M anual

This manual explains how the external devices read and write PLC CPU data through communication

with the MC protocol using the serial communication module/Ethernet module.

(sold separately)

GX Configurator-SC Version 2 Operating Manual (Protocol FB support function)

This manual explains the function and usage of the protocol FB support function that supports the

creation of the data communication program of the module and set up of each parameter.

(sold separately)

Conformation to the EMC Directive and Low Voltage Instruction

For details on making Mitsubishi PLC conform to the EMC directive and low voltage

instruction when installin g it in your pro duct, ple as e see Cha pter 3, "EM C Dir ec tive

and Low Voltage Instruction" of the User's Manual (Hardware) of the CPU module to

use.

The CE logo is printed on the rating plate on the main body of the PLC that conforms

to the EMC directive and low voltage instruction.

Manual Number

(Model Code)

SH-080007

(13JL87)

SH-080008

(13JF89)

SH-080393E

(13JU46)

By making this product conform to the EMC directive and low voltage instruction, it is

not necessary to make those steps individually.

A - 15 A - 15

Page 18

The Manual's Use and Structure

How to use this manual

In this manual, details of the serial communication modules (QJ71C24N,

QJ71C24N-R2, QJ71C24N-R4, QJ71C24 and QJ71C24-R2) are organized as

shown below, according to their applications.

Please use this manual using the contents below as a reference.

(1) To learn about features, functions and comp onent par ts

(a) To learn about features and functions

(b) To learn about the packed items and system-configured items

(2) To learn about processing requir ed to start up the ser i al

communication module

• Chapter 1 describes the features of the serial communication modules.

• Chapter 3 describes the common specifications and functions of the serial

communication modules.

• The section prior to Chapter 1, "Product Configuration", describes the

parts that are packed along with the serial communication module.

• Parts and components other than those packed with the module must be

prepared separately by the user.

(a) To learn about the startup procedure

• Section 4.2 describes the general procedures prior to starting the

operation of the serial communication module.

(b) To learn about the connection with the external devices

• Section 4.4 describes the connection methods for each type of interface.

(c) To learn about processing required prior to operation of the serial

communication module

• Section 4.5 explains the parameter settings with GX Developer in order to

use the serial communication module.

• Section 4.6 and Chapter 8 describe the settings from GX Configurator-SC

to perform the initial setting of the serial communication module.

To change an initial value, follow the procedure described in Chapter 8.

(d) To check for failure in the serial communication module

• Section 4.7 describes the test of the individual serial communication

module.

(e) To learn how to check for a connection error with the external devices

• Section 4.8 describes how to perform the individual module test and the

loopback test using MC protocol-based communication.

Details of the loopback test command are described in the reference

manual.

A - 16 A - 16

Page 19

(3) To learn about data communication functi ons and d etai l ed

explanations

(a) To learn about the communication functions

• Section 3.4 describes an overview of the serial communication module

functions.

(b) To learn about detailed explanations of the communication functions

• The basic communication methods are described in Chapters 5 to 7.

• Special functions are described in the User's Manual (Application).

(4) To learn about data communication functi ons and programming

(a) To learn how to read data from and written to the PLC CPU

• Data is read from and written to the PLC CPU with a communication

function using the MC protocol.

Details are described in the Reference Manual.

• Appendix 7 describes an overview of the communication support tool (MX

Component) that supports communication using the MC protocol.

(b) To learn how to send and receive data between the PLC CPU and the

external devices

• Data communica ti on be twee n t he PLC CPU an d th e exte r na l de vi ce s is

performed with a communication function using the non procedure

protocol or the bidirectional protocol.

• Chapter 6 explains details of the communication functions and

programming using the non procedure protocol.

• Chapter 7 explains details of the communication functions and

programming using the bidirectional protocol.

(5) To learn how to check for error occurrences and take corr ective

actions

Chapter 10 de scribe s t roub l esho o tin g, how t o che ck for e rr or s, an d de taile d

explanations of error codes.

(6) To learn about functions that have been adde d or chang ed i n

function version B

• Section 1.3 li sts th e fun c ti on s th at have been added or change d a s well as

manuals that provide detailed explanations hereof.

• Appendix 1.1 provides a breakdown of the functions of Q series C24/GX

Configurator-SC by function version/software version.

A - 17 A - 17

Page 20

The structure of this manual

The module's buffer memory stores default values that are used as initial settings

to execute the data send/receive functions in order to communicate with the

external devices.

Data can be sent to or received from the external devices using these default

values. However, it may be necessary to change the default values, depending on

system specifications.

This manual explains how to perform the initial settings in order to use each

function of the utility package available for this module (GX-Configurator-SC).

When changing a default value for sending and receiving data to/from an opposite

device, first see the section describing the applicable function to verify the initial

setting item and setting value you wish to change, then change the default value

as explained in Chapter 8.

A - 18 A - 18

Page 21

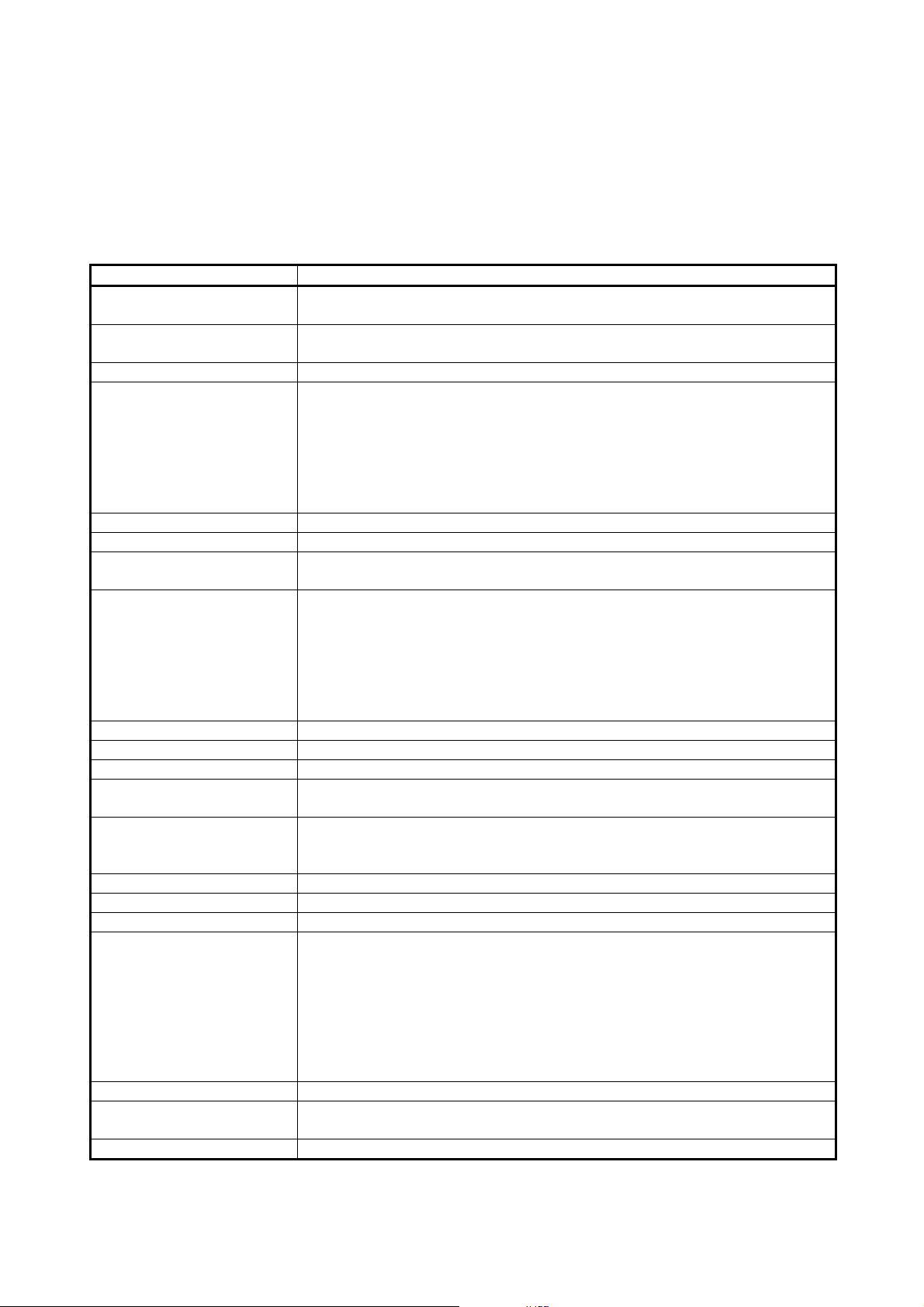

About The Generic Terms and Abbreviations

This manual uses the following generic terms and abbreviations to describe the serial communication

modules, unless otherwise specified.

(1) Generic terms and abbreviati ons of relevant modules

In this manual, the following generic terms and abbreviations are used to indicate

the PLC CPU and other modules used for the data-communication functions of

the serial communication modules. Module model names are provided when

relevant model names are needed to be shown.

Generic term/abbreviation Description of generic term/abbreviation

Abbreviation for QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24 and QJ71C24-R2 type serial

Q series C24 (C24)

QC24 Generic term for AJ71QC24, AJ71QC24-R2, AJ71QC24-R4, A1SJ71QC24, A1SJ71QC24-R2.

QC24N

QC24(N) Generic term for QC24, QC24N.

QCPU Q mode

QCPU station Abbreviation for the PLC with QCPU installed.

QnACPU

Q/QnACPU Generic term for QCPU, QnACPU.

UC24

Computer link module

Serial communication module

communication modules.

(Indicated as "C24" in the diagrams)

Generic term for AJ71QC24N, AJ71QC24N-R2, AJ71QC24N-R4, A1SJ71QC24N, A1SJ71QC24NR2.

Generic term for Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU, Q25HCPU, Q12PHCPU, Q25PHCPU.

Generic term for Q2ACPU, Q2ACPU-S1, Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1,

Q3ACPU, Q4ACPU, Q4 AR C P U .

Generic term for AJ71UC24, A1SJ71UC24-R2, A1SJ71UC24-R4, A1SJ71UC24-PRF,

A1SJ71C24-R2, A1SJ71C24-R4, A1SJ71C24-PRF, A2CCPUC24, A2CCPUC24-PRF.

A series computer link modules.

Generic term for the module below.

AJ71QC24, AJ71QC24-R2, AJ71QC24-R4, A1SJ71QC24, A1SJ71QC24-R2,

QnA series

Q series QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24, QJ71C24-R2

AJ71QC24N, AJ71QC24N-R2, AJ71QC24N-R4, A1SJ71QC24N, A1SJ71QC24NR2.

A - 19 A - 19

Page 22

(2) Other generic terms and abbrevi ati ons

This manual uses the following generic terms and abbreviations to explain the

data-communication devices for the serial communication module. The

names/model names are provided when it is necessary to explicitly identify the

model being discussed.

Generic term/abbreviation Description of generic term/abbreviation

Buffer memory

Computer

Data communication functions Generic term for MC protocol, non procedure protocol, and bidirectional protocol.

GX Configurator-SC

GX Developer Abbreviation for GX Developer (SWnD5C-GPPW-E). (n in the model should be 4 or greater)

I/F Abbreviation for inte r fa ce

Intelligent function module devices

Intelligent function modules

MELSECNET/10 Abbreviation for MELSECNET/10 network system.

MELSECNET/H Abbreviation for MELSECNET/H network system.

MX Component Abbreviation for MX Component (SW0D5C-ACT-E or later).

Operating Manual

(Protocol FB support function)

Opposite devices

(external devices)

Reference Manual Q Corresponding MELSEC Communication Protocol Reference Manual

RS-232 (interface) Abbreviation for interface conforming to RS-232.

RS-422/485 (interface) Abbreviation for interface conforming to RS-422 and RS-485.

Special function modules

Switch setting Generic term for intelligent function module switch setting

User's Manual (Application) or

Application

User's Manual (Basic) or Basic Q Corresponding Serial Communication Module User's Manual (Basic)

Generic term for memory of the intelligent function modules/special function modules used for

storing data sent to or received from the PLC CPU (setting values, monitor values, etc.)

Generic term for one of the external devices with which data can be sent/received using the MC

protocol or the bidirectional protocol.

Abbreviation for GX Configurator-SC (SW0D5C-QSCU-E or later).

• Initial settings for the module, monitoring and testing can be performed without using a sequence

program and without considering I/O signals or buffer memory. (Intelligent function utility)

• Converting sequence programs necessary for data communication processing into FB can

shorten program production man-hours.

In addition, the monitoring and analysis of the transmitted/received data by the communication

network can shorten the system start-up time. (Protocol FB support function)

Generic term for buffer memory of the intelligent function modules used for storing data sent to or

received from the PLC CPU (setting values, monitor values, etc.)

Generic term for the Q series PLC modules that are operated by commands from the PLC CPU

(equivalent to the A series PLC special function modules).

Examples:

• CC-Link interface module

• A/D and D/A conversion modules

• Ethernet interface module

• Serial communication module

GX Configurator-SC Version 2 Operating Manual (Protocol FB support function)

Generic term for computers, indicators, measuring instruments, ID modules, bar code readers,

regulators, other serial communication modules, UC24, etc. that are connected to this serial

communication module for data communication.

Generic term for the A/QnA series PLC modules that are operated by commands from the PLC

CPU (equivalent to the Q series PLC intelligent function modules).

Examples:

• CC-Link interface module

• A/D and D/A conversion modules

• High-speed counter module

• Ethernet interface module

• Computer link module and serial communication module

Q Corresponding Serial Communication Module User's Manual (Application)

A - 20 A - 20

Page 23

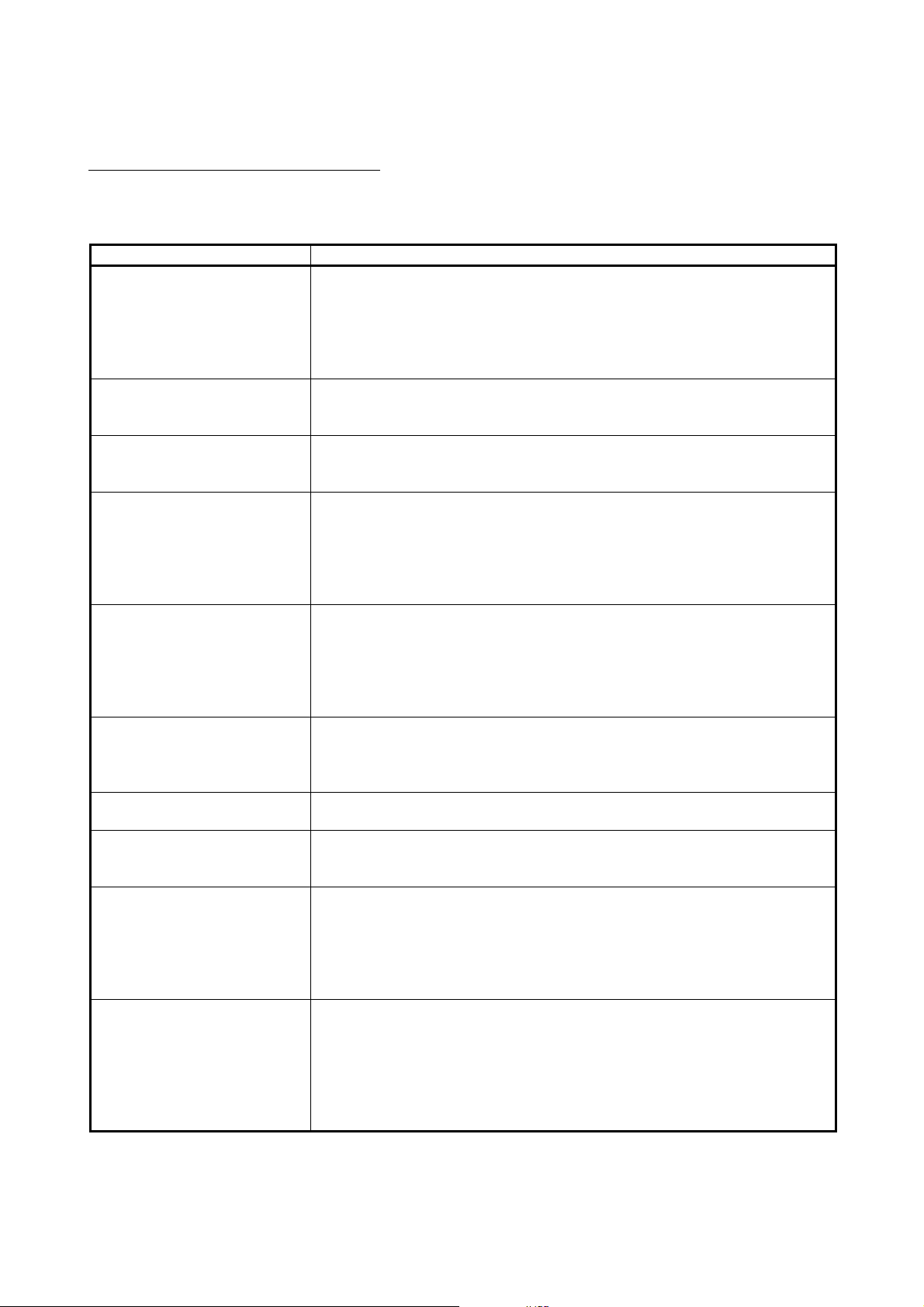

Definitions and Descriptions of Terminology

The following table lists the definitions and descriptions of terminology used in this manual and related

manuals for the Q series serial communication modules.

Terms Description

One of the message formats for the serial communication module for performing communication

using the MC protocol and ASCII code data.

A compatible IC fra me

(Formats 1 to 4)

Bidirectional protocol

Independent operation

Linked operation

MELSEC communication protocol

(MC protocol)

Message send function

(Printer function)

Multidrop connection

Non procedure protocol

QnA compatible 2C frame

(Formats 1 to 4)

QnA compatible 3C frame

(Formats 1 to 4)

QnA compatible 4C frame

(Formats 1 to 4)

This is the same message format as when communicating using the protocol for the A series

computer link modules. Device memory read/write operations for the QCPU are allowed within

the device range of the AnACPU.

For details, see Chapter 5 of the Reference Manual.

A communication procedure for the serial communication modules and one of the data

communication functions for communicating any data between the PLC CPU and an opposite

device. Details are explained in Chapter 7.

A mode of interface operation to communicate data with external devices using a function

specified in each communication protocol setting. Two interfaces of serial communication

modules do not interact.

The operation mode of each of the two interfaces for a serial communication module that are

connected to external devices and linked to one another in order to send/receive data to/from the

external devices.

The two interfaces communicate data using the identical data-communication function (MC

protocol (identical format) or non procedure protocol) and the identical transmission

specifications. (Linked operation using the bidirectional protocol is not allowed.)

A communication procedure for the Q series serial communication modules or the Ethernet

interface modules, and a name of communication method for accessing to the PLC CPU from an

opposite device. (This is called the MC protocol in this manual.)

There are two communication methods; one uses ASCII code data and the other uses binary

code data.

Details are explained in the Reference Manual.

This function registers character data (messages) to be sent to external devices (mainly printers)

in the serial communication module as an user frame in advance, and sends the registered data

for multiple user frames using the non procedure protocol (sent by an instruction from the PLC

CPU).

A name of the connection when multiple external devices or other serial communication modules are

connected in a 1:n or m:n mode using the serial communication module's RS-422/485 interface.

An user's communication procedure and one of the data communication functions for

communicating any data between the PLC CPU and an opposite device. Details are explained in

Chapter 6.

One of the message formats for the serial communication module for performing communication

using the MC protocol and ASCII code data.

This is the same message format as the communication frame using the protocol for the QnA

series serial communication modules.

• QnA compatible 2C frame (Formats 1 to 4): QnA simplified frame (Formats 1 to 4)

Details are explained in Chapter 4 of the Reference Manual.

One of the message formats for the serial communication module for performing communication

using the MC protocol and ASCII code data.

This is the same message format as the communication frame using the protocol for the QnA

series serial communication modules.

• QnA compatible 3C frame (Formats 1 to 4): QnA frame (Formats 1 to 4)

• QnA compatible 4C frame (Formats 1 to 4): QnA extension frame (Formats 1 to 4)

Details are explained in Chapter 3 of the Reference Manual.

A - 21 A - 21

Page 24

Terms Description

QnA compatible 4C frame

User frame

(Format 5)

One of the message formats for the serial communication module for performing communication

using the MC protocol and binary code data.

This is the same message format as the communication frame using the protocol for the QnA

series serial communication modules.

• QnA compatible 4C frame (Format 5): QnA extension frame (Format 5)

Details are explained in Chapter 3 of the Reference Manual.

Data name when the fixed format portion of messages to be sent or received between a serial

communication module and an opposite device is registered in the module and used for sending

and receiving data with the functions listed below. (The contents of an user frame data should

conform to the specifications of the opposite device).

The data array of the head and tail sections of a message (transmission control code, C24 station

number, sum check, fixed data, etc.) to be sent and received is registered in the serial

communication module before use.

• MC protocol on-demand function.

• Data communication function using the non procedure protocol.

Details are explained in Chapter 9 of the User's Manual (Applications).

A - 22 A - 22

Page 25

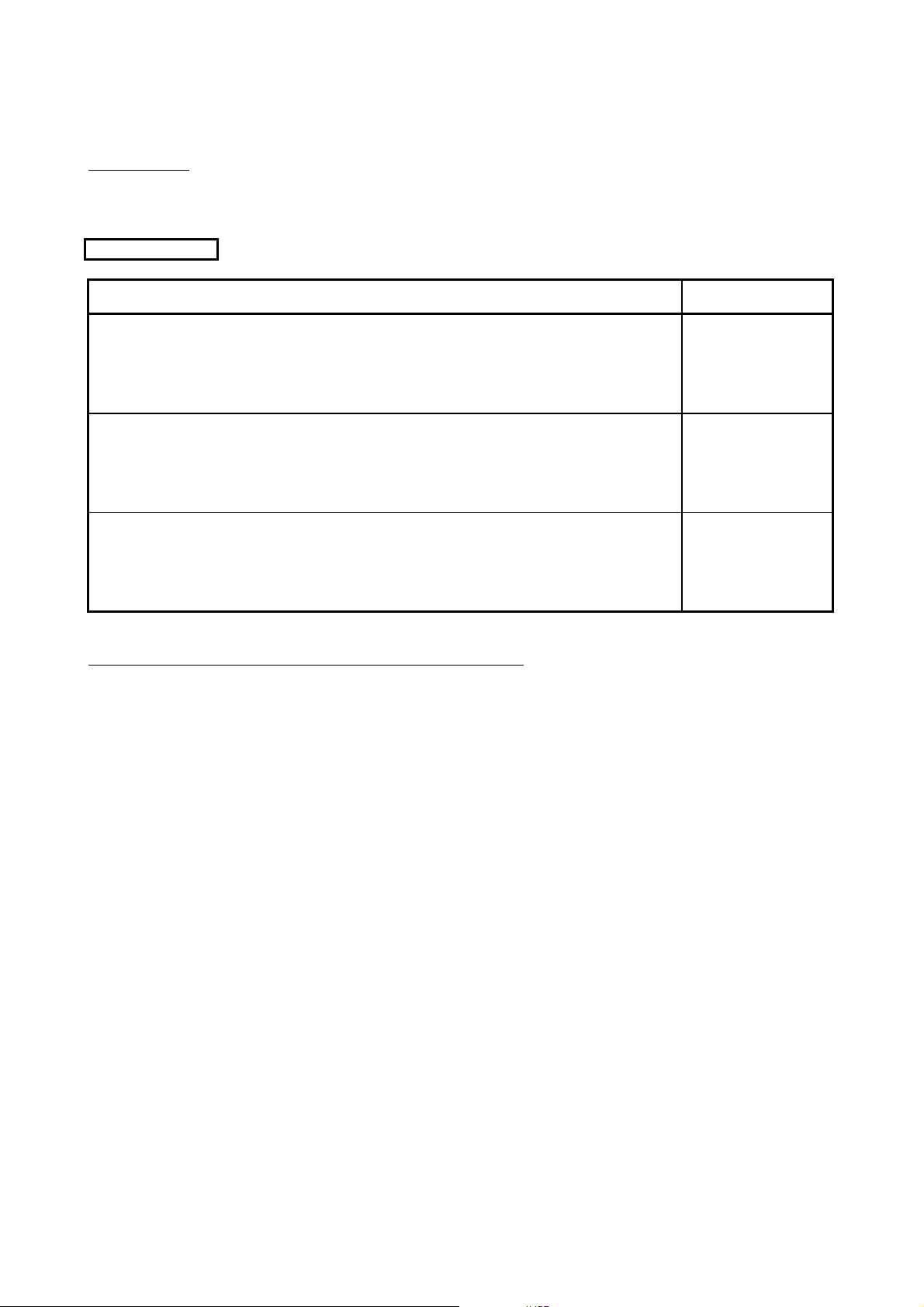

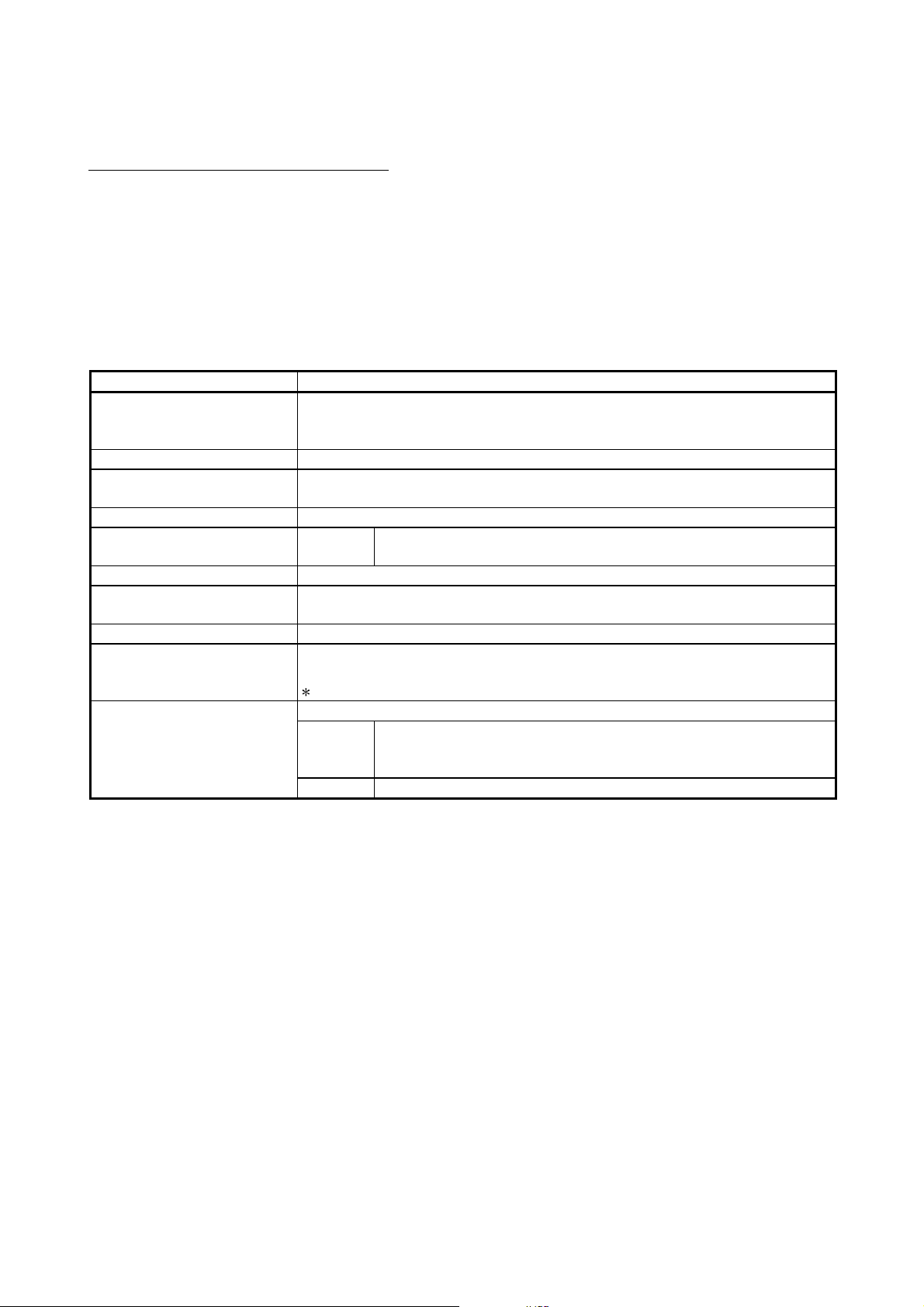

Product Configuration

The following lists the product configuration of the Q series serial communication modules.

Model Item name Quantity

QJ71C24N serial communication module or QJ71C24 seria l

QJ71C24N or QJ71C24

QJ71C24N-R2 or

QJ71C24-R2

QJ71C24N-R4

SW2D5C-QSCU-E GX Configurator-SC Version 2 (1-license product) (CD-ROM) 1

SW2D5C-QSCU-EA GX Configurator-SC Version 2 (Multiple-license product) (CD-ROM ) 1

communication module

Terminal resistor 330 1/4 W (for RS-422 communication)

Terminal resistor 110 1/2 W (for RS-485 communication)

QJ71C24N-R2 serial communication module or QJ71C24-R 2 serial

communication module

QJ71C24N-R4 serial communication module 1

RS-422/485 plug-in connector socket block 2

Terminal resistor 330 1/4 W (for RS-422 communication)

Terminal resistor 110 1/2 W (for RS-485 communication)

Plate terminal (for connecting a braided shield cable) 4

1

2

2

1

4

4

A - 23 A - 23

Page 26

1 OVERVIEW

1 OVERVIEW

MELSEC-Q

1

This manual describes the specifications for the QJ71C24N, QJ71C24N-R2,

QJ71C24N-R4, QJ71C24, QJ71C24-R2 serial communication module (hereinafter

referred to as "Q series C24"), as well as the procedures prior to starting the operation,

maintenance, inspection, data communication methods for use with external devices

and troubleshooting.

When applying the following program examples to the actual system, make sure to

examine the applicability and confirm that it will not cause system control problems.

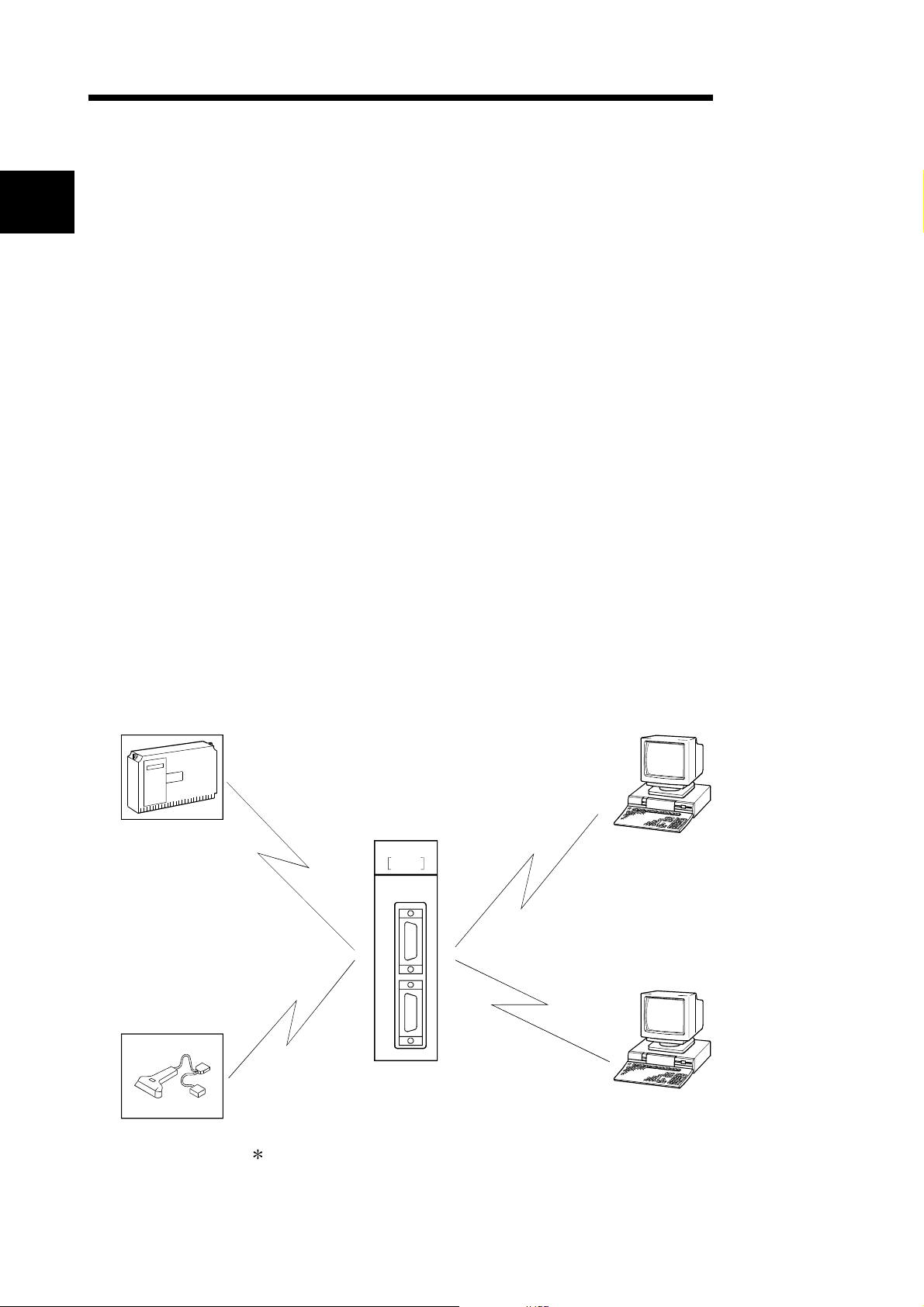

1.1 Overview of the Serial Communi cati on M odule

The Q series C24 is a module that connects the Q series PLC CPU and an external

device using an RS-232 or RS-422/485 line for serial communication, in order to

achieve the data communication described below.

By using a modem/terminal adapter, a public line (analog/digital) can be used for data

communication with a remote location.

• PLC data collection/change from the external devices

(See the MELSEC Communication Protocol Reference Manual.)

• PLC monitoring and control from the external devices (See Chapter 2 of the User's

Manual (Application).)

• Data receiving and sending in any formats that conform to the external device

specifications (See (2) and (3) of Section 1.2.)

• Collection of measured data from a measuring device (See (2) of Section 1.2.)

• Operation of a PLC CPU that is connected to a personal computer (hereinafter

abbreviated as PC) installed with GX Developer (SW4D5C-GPPW-E or later,

hereinafter abbreviated as GX Developer). (See the GX Developer Manual.)

• Collection of measured

data

• Collection of read data

QJ71C24-R2

ERR.

RUN

NEU

NEU

SD

SD

CH.1 CH.2

RD

RD

CH. 1

• PLC data collection/change

• PLC monitoring and control from an

external device

• Data receiving and sending in any

formats that conform to the external

device specifications

• GX Developer

• File writing/reading

• Device monitoring/testing

Being a convenient means of connection among different devices (PCs, display

devices, printers, etc.), the serial communication line is the most widely used

medium on the market today.

1 - 1 1 - 1

Page 27

1 OVERVIEW

1.2 Features of the Serial Communication M odule

MELSEC-Q

The following describes the features of the Q series C24.

(1) Data communication based on the MELSEC communi cation

protocol (hereinafter referred to as the MC protocol )

(Details are explained in the MELSEC Communication Protocol Reference

Manual.)

(a) External devices can read/write the PLC device data and sequence

programs, and can monitor PLC equipment status.

With the exception of the on-demand function described below, the PLC

does not require a sequence program because the PLC sends and receives

data based solely on commands from external devices.

(b) Using the on-demand function, data can be sent from the PLC CPU to the

external devices in each frame format of the MC protocol.

(c) Data communication can be performed using a program at the external

device side that has been created for communicating data with conventional

A/QnA series computer link module/serial communication modules.

(d) If the external devi ce is a PC ru nni ng on e of th e ba si c o pe rat io n sy ste ms

below, it is possible to create a communication program for the external

device without considering the detailed MC protocol (transmission/reception

procedures) using one of the following separately sold communication

support tools.

(Supported basic operation systems)

• Microsoft

• Microsoft

• Microsoft

• Microsoft

• Microsoft

• Microsoft

• Microsoft

Depending on th e ve rsio n o f MX C o mpon en t us ed , different operating

(Separately sold communication support tools)

• MX Component (SW0D5C-ACT-E or later, hereinafter abbreviated as MX

Component)

See Appendix 7 for the overview of MX Component.

®

Windows® 95 Operating Syste m

®

Windows® 98 Operating Syste m

®

Windows NT® Workstation Operating System Version 4.0

®

Windows® Millennium Edition Operating System

®

Windows® 2000 Professional Operating System

®

Windows® XP Professional Operating System

®

Windows® XP Home Edition Ope rat in g Sy ste m

systems are supported.

See the manual of MX Component for the details.

1

1 - 2 1 - 2

Page 28

1 OVERVIEW

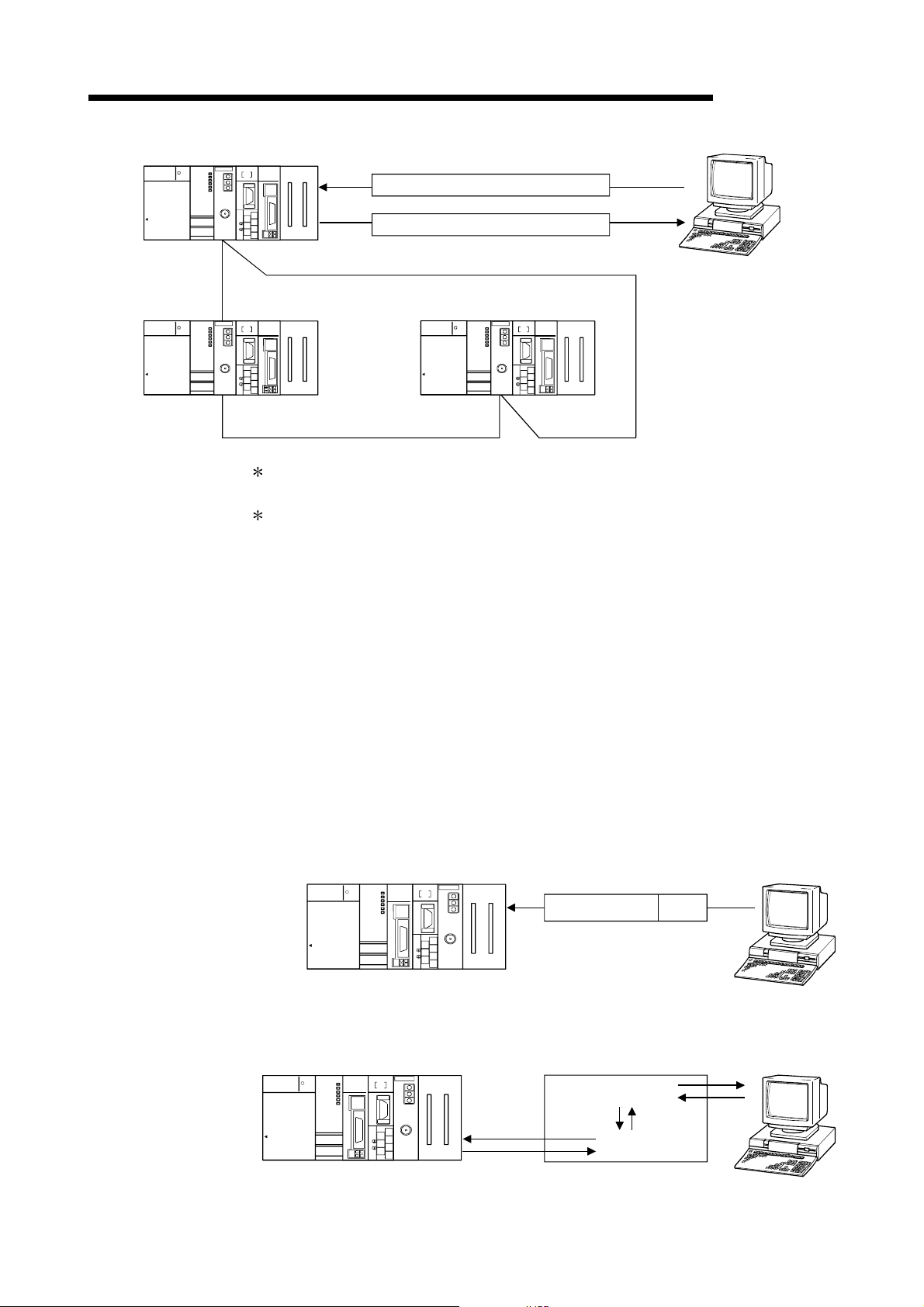

Q25HCPU

MELSEC

POWER

PULL

MITSUBISHI

MELSEC

PULL

MITSUBISHI

USB

RS-232

Q25HCPU

POWER

USB

RS-232

MELSEC-Q

QJ71E71

QJ71C24

RUN

MODE

RUN

ERR.

USER

BAT.

BOOT

MODE

RUN

ERR.

USER

BAT.

BOOT

ERR.

INIT.

COM.ERR

CH1. CH2.

OPEN

SD

RD

CH1.

10BASE-T

RS-232

10BASE

CH.2

SDA

1

SG

2

SDB

(FG)

3

RDA

4

(FG)

5

RDB

+12V

6

12G

RS-422

7

/485

Command

Command request data

MELSECNET/H

(MELSECNET/H mode)

QJ71E71

QJ71C24

CH1. CH2.

RS-232

CH.2

SDA

SG

SDB

(FG)

RDA

(FG)

RDB

RS-422

/485

Q25HCPU

RUN

ERR.

COM.ERR

INIT.

OPEN

RD

SD

10BASE-T

CH1.

10BASE

1

2

3

4

5

6

7

MELSEC

POWER

MODE

RUN

ERR.

USER

BAT.

BOOT

PULL

MITSUBISHI

USB

RS-232

QJ71C24

CH1. CH2.

RS-232

CH.2

SDA

SG

SDB

(FG)

RDA

(FG)

RDB

RS-422

/485

QJ71E71

RUN

ERR.

COM.ERR

INIT.

OPEN

RD

SD

10BASE-T

CH1.

10BASE

1

2

3

4

5

+