A - 1 A - 1

• SAFETY PRECAUTIONS •

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the user's manual of the CPU module to use.

In this manual, the safety precautions are classified into two levels:"

!

WARNING" and "! CAUTION".

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

Under some circumstances, failure to observe the precautions given under "

!

CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

!

WARNING

!

CAUTION

A - 2 A - 2

When using the MELSEC-Q series serial communication module

When using the MELSEC-Q series serial communication module

[Design Precautions]

!

WARNING

• For the operation status of each station at communication error in each station, refer to the

respective manual for each station.

The communication error may result in an accident due to incorrect output or malfunction.

• When using the notification function, the pager receiver may not be contacted due to the

frequency transmission status from the system setup environment and error on the receiver

side.

To ensure the safety of the programmable controller system, install a call circuit with a lamp

display or buzzer sound.

• When connecting a peripheral with the CPU module or connecting an external device, such as a

personal computer, with an intelligent function module to modify data of a running

programmable controller, configure an interlock circuit in the program to ensure that the entire

system will always operate safely.

For other forms of control (such as program modification or operating status change) of a

running programmable controller, read the relevant manuals carefully and ensure that the

operation is safe before proceeding.

Especially, when a remote programmable controller is controlled by an external device,

immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure.

To prevent this, configure an interlock circuit in the program, and determine corrective actions to

be taken between the external device and CPU module in case of a communication failure.

A - 3 A - 3

When using the MELSEC-Q series serial communication module

[Design Precautions]

!

WARNING

• Do not write any data to the "system area" of the buffer memory in the intelligent function

module.

Also, do not use any "use prohibited" signals as an output signal from the programmable

controller CPU to the intelligent function module.

Doing so may cause malfunction of the programmable controller system.

!

CAUTION

• Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

• When using the module while values, such as buffer memory set values, are registered in the

Flash ROM, do not turn off the power supply for the module loading station nor reset the

programmable controller CPU.

If the power supply for the module loading station is turned off or the programmable controller

CPU is reset while any values are registered, the data contents in the Flash ROM become

inconsistent and as a result the values must be set again in the buffer memory, etc. and

reregistered to the Flash ROM.

Also, this may cause failure and malfunction of the module.

[Installation Precautions]

!

CAUTION

• Use the programmable controller in an environment that meets the general specifications in the

user's manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

• To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the

module with a screw.

• Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• Shut off the external power supply (all phases) used in the system before mounting or removing

a module.

Failure to do so may result in damage to the product.

• Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

A - 4 A - 4

When using the MELSEC-Q series serial communication module

[Wiring Precautions]

!

CAUTION

• When turning on the power and operating the module after installation and wiring are completed,

always attach the terminal cover that comes with the product.

There is a risk of electric shock if the terminal cover is not attached.

• Perform correct pressure-displacement, crimp-contact or soldering for external wire connections

using the tools specified by the manufactures.

Incorrect connection may cause short circuits, fire, or malfunction.

• Attach connectors to the module securely.

• Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

• Before connecting the cables, check the type of interface to be connected.

Connecting or erroneous wiring to the wrong interface may cause failure to the module and

external devices.

• Tighten the terminal screws within the specified torque range.

Undertightening the terminal screws can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• When disconnecting the cable from the module, do not pull the cable by the cable part. For the

cable with connector, hold the connector part of the cable.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable that is still connected to the module may cause malfunction or damage to the

module or cable.

• Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

• A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

A - 5 A - 5

When using the MELSEC-Q series serial communication module

[Starting and Maintenance Precautions]

!

CAUTION

• Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

• Shut off the external power supply (all phases) used in the system before mounting or removing

a module.

Failure to do so may cause the module to fail or malfunction.

• After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit may cause malfunction.

• Do not touch any terminal while power is on.

Doing so may cause malfunction.

• Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may cause the module to fail or malfunction.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• Before handling the module, touch a conducting object such as a grounded metal to discharge

the static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Operation Precautions]

!

CAUTION

• When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent

function module, read relevant manuals carefully and ensure the safety before operation.

Failure to perform correct operations to change data, program, or the status may result in

system malfunction, machine damage, or an accident.

[Disposal Precautions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 6 A - 6

When using the MELSEC-L series serial communication module

When using the MELSEC-L series serial communication module

[Design Precautions]

!

WARNING

• For the operation status of each station at communication error in each station, refer to the

respective manual for each station.

The communication error may result in an accident due to incorrect output or malfunction.

• When connecting a peripheral with the CPU module or connecting an external device, such as a

personal computer, with an intelligent function module to modify data of a running

programmable controller, configure an interlock circuit in the program to ensure that the entire

system will always operate safely.

For other forms of control (such as program modification or operating status change) of a

running programmable controller, read the relevant manuals carefully and ensure that the

operation is safe before proceeding.

Especially, when a remote programmable controller is controlled by an external device,

immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure. To prevent this, configure an interlock circuit in the program, and

determine corrective actions to be taken between the external device and CPU module in case

of a communication failure.

• Do not write any data to the "system area" of the buffer memory in the intelligent function

module.

Also, do not use any "use prohibited" signals as an output signal to an intelligent function

module from the CPU module.

Writing data into the "system area" or outputting a signal for "use prohibited" may cause a

programmable controller system malfunction.

[Design Precautions]

!

CAUTION

• Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Keep a distance of 100mm between them.

Failure to do so may result in malfunction due to noise.

[Installation Precautions]

!

WARNING

• Shut off the external power supply (all phases) used in the system before mounting or removing

a module. Failure to do so may result in electric shock or cause the module to fail or

malfunction.

A - 7 A - 7

When using the MELSEC-L series serial communication module

[Installation Precautions]

!

CAUTION

• Use the programmable controller in an environment that meets the general specifications in the

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection).

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

• To interconnect modules, engage the respective connectors and securely lock the module joint

levers. Incorrect interconnection may cause malfunction, failure, or drop of the module.

• Do not directly touch any conductive parts and electronic components of the module. Doing so

can cause malfunction or failure of the module.

[Wiring Precautions]

!

WARNING

• Shut off the external power supply (all phases) used in the system before wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

• After installation and wiring, attach the included terminal cover to the product before turning it on

for operation. Failure to do so may result in electric shock.

A - 8 A - 8

When using the MELSEC-L series serial communication module

[Wiring Precautions]

!

CAUTION

• Use applicable solderless terminals and tighten them within the specified torque range. If any

spade solderless terminal is used, it may be disconnected when a screw on the terminal block

comes loose, resulting in failure.

• Connectors for external device connection must be crimped or pressed with the tool specified by

the manufacturer, or must be correctly soldered.

Incomplete connections could result in short circuit, fire, or malfunction.

• Connect the connector to the module securely.

• Place the cables in a duct or clamp them.

If not, dangling cables may swing or inadvertently be pulled, resulting in damage to the module

or cables or malfunction due to poor connection.

• Confirm the interface type in advance and connect the cable correctly.

Connecting a cable to a different interface or incorrect wiring will cause failure of the module and

the external device.

• Tighten the terminal block screw within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction. Overtightening can damage the

screw and/or module, resulting in drop, short circuit, fire, or malfunction.

• When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable with connector, hold the connector by hand and pull it out. For the cable

connected to the terminal block, loosen the terminal block screws.

Failure to do so may result in malfunction and damage to the module or cable.

• Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

• A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring. Do not remove the film during wiring. Remove it

for heat dissipation before system operation.

[Startup/Maintenance Precautions]

!

WARNING

• Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

• Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws. Failure to do so may result in electric shock.

A - 9 A - 9

When using the MELSEC-L series serial communication module

[Startup/Maintenance Precautions]

!

CAUTION

• Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a

fire.

• Shut off the external power supply (all phases) used in the system before mounting or removing

a module. Failure to do so may cause the module to fail or malfunction.

• Tighten the terminal block screw within the specified torque range.

Undertightening can cause drop of the component or wire, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• After the first use of the product (module, display unit, and terminal block), the number of

connections/disconnections is limited to 50 times (in accordance with IEC 61131-2). Exceeding

the limit may cause malfunction.

• Before handling the module, touch a conducting object such as a grounded metal to discharge

the static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Operation Precautions]

!

CAUTION

• When controlling a running programmable controller (especially, changing data, program

modification, and operation status change) from an external device such as a personal

computer connected to an intelligent function module, read the relevant user's manual carefully

and ensure the safety before the operation. Incorrect data change, program modification, and

status control may cause malfunction of the system, mechanical damage, or accidents.

• While set values in the buffer memory are being registered to the flash ROM in the module, do

not turn off the power to the module and do not reset the CPU module. Doing so will affect the

flash ROM data, and setting to the buffer memory and registration to the flash ROM need to be

performed again. Also, it may cause failure or malfunction of the module.

[Disposal Precautions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 10 A - 10

• CONDITIONS OF USE FOR THE PRODUCT •

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS,

PRECAUTIONS, OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR

SAFETY MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

y Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

y Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

y Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region. Notwithstanding the above, restrictions Mitsubishi may in its sole

discretion, authorize use of the PRODUCT in one or more of the Prohibited Applications, provided

that the usage of the PRODUCT is limited only for the specific applications agreed to by Mitsubishi

and provided further that no special quality assurance or fail-safe, redundant or other safety features

which exceed the general specifications of the PRODUCTs are required. For details, please contact

the Mitsubishi representative in your region.

A - 11 A - 11

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date

Manual Number Revision

Dec., 1999 SH (NA)-080007-A First edition

Oct., 2000 SH (NA)-080007-B Add the contents of the function version B.

Put WindowsRbase software products together from Mitsubishi

Programmable Controller MELSEC series to Mitsubishi integrated FA

software MELSOFT series.

Standardize the name from software package (GPP function) to product

name (GX Developer).

Correction

Entire manual (change MELSECNET/10H to MELSECNET/H), Contents,

About the Manuals, About the Generic Terms and Abbreviations, Section

1.1, 1.2 POINT, Section 2.1, 2.2.1, 2.2.3, 2.2.5, 2.2.6, 2.3.1, 2.3.2,

Section 3.1.1, 3.2.3, 3.2.4, 3.3.1, 3.3.4, 3.3.5, 3.3.6, 3.4 (entire), Section

4.3, Chapter 9 (entire), Chapter 11 (entire), Section 12.2, 12.3, 12.4

(entire), 12.6 (entire), Section 13.3, 13.4, 13.6 (entire), Section 15.3,

Section 16.2 (entire) to 16.7

Addition

Section 2.4 (9), Section 3.2.3 POINT

Jun., 2001 SH (NA)-080007-C Standardize the name from utility package (QSCU) to product name (GX

Configurator-SC).

Correction

About the Manuals, The Manual's Use and Structure, About the Generic

Terms and Abbreviations, Program example (Section 9.4.1, 9.4.2, 9.4.3,

Section 11.5 (1) (2), Section 16.5, 16.6, 16.7), Section 1.1 (2) (diagram),

1.2, Chapter 3 (entire), Section 4.1 (2), Section 9.1.1 (4) 5), Section

11.3.2 (3), 11.3.3 (3), Section 13.6.1 (diagram)

Addition

Section 3.3.4, 3.3.6 (4), 3.4.5 (4)

Jan., 2003 SH(NA)-080007-D

Additional model

QJ71C24N, QJ71C24N-R2, QJ71C24N-R4

Correction

SAFETY PRECAUTIONS, About the Manuals, The Manual's Use and

Structure, About the Generic Terms and Abbreviations, Section 1.2,

Section 2.2.4 (2) (c), Section 3.3.1, 3.3.5, 3.3.6, 3.4.2, 3.4.3, 3.4.7,

3.4.8 (3), 3.5, Section 6.1, Section 7.1, 7.2, Section 9.1.1 (4), Section

10.4.1 (2) 1), Section 11.2.4 (2), 11.4.3 (a), 11.5, Section 15.1, 15.2,

15.3, 15.4.2, Section 17.1, 17.3, 17.4

Addition

Section 4.4.2 (6), Chapter 16 (entire)

Dec., 2003 SH(NA)-080007-E

Correction

About the Generic Terms and Abbreviations, Section 3.4.6 (4), Section

6.1, 6.3 (1) (b), Section 9.1.1 (4), Section 11.2.4 (2)

Jun., 2004 SH(NA)-080007-F

Correction

About the Generic Terms and Abbreviations, Section 3.3.4 (4), 3.4.3 (6),

3.4.4 (5), Section 8.2 (2), Section 11.3.1, Section 16.2 (1)

A - 12 A - 12

The manual number is given on the bottom left of the back cover.

Print Date

Manual Number Revision

Sep., 2004 SH(NA)-080007-G

Correction

Section 1.2, Section 6.1, Section 9.1.1

Addition

Section 17.8

Feb., 2005 SH(NA)-080007-H

Correction

Section 3.4.2, 3.4.4, Chapter 17 (Simultaneous execution of dedicated

instructions)

Mar., 2006 SH(NA)-080007-I

Correction

SAFETY PRECAUTIONS, Section 6.1, Section 17.1

Jun., 2007 SH(NA)-080007-J

Change of a term

"PLC" was changed to "programmable controller".

Correction

About The Generic Terms and Abbreviations, Section 2.3.1(4), Section

3.4.5, Section 11.4.3, 11.5, Section 12.3, Section 13.4, Section 15.3,

Section 17.2, 17.3, 17.4, 17.5, 17.6, 17.7, 17.8

Aug., 2008 SH(NA)-080007-K

Correction

SAFETY PRECAUTIONS, About The Generic Terms and Abbreviations,

Section 3.1.1, 3.3.3, 3.3.6, 3.3.7, Section 7.1, Section 9.1.2, Section 17.2

to17.4, 17.8

Jun., 2009 SH(NA)-080007-L

Partial correction

About The Generic Terms and Abbreviations, Sections 1.1, 1.2, 3.3.1,

3.3.5, 9.1.2, 9.4.1,Chapter 15, Sections 15.1.2, 15.3, 17.2, 17.3, 17.4,

17.5, 17.6, 17.7, 17.8

Jan., 2010 SH(NA)-080007-M

Additional model

LJ71C24, LJ71C24-R2

Partial correction

SAFETY PRECAUTIONS, INTRODUCTION, Related Manuals, The

Manual's Use and Structure, About The Generic Terms and

Abbreviations, Definitions and Descriptions of Terminology, Section 1.2,

2.3.1, 2.3.2, 3.1.1, 3.1.3, 3.2.4, 3.3.1, 3.3.5, 3.3.6, 3.3.7, 8.3, 9.1.2, 9.4.1,

15.3, 15.4.1, 15.5.1, 16.1.1, 17.2, 17.3, 17.4, 17.7, 17.8

Partial addition

Product application

APPENDIXES

A - 13 A - 13

The manual number is given on the bottom left of the back cover.

Print Date

Manual Number Revision

Nov., 2012 SH(NA)-080007-N

Partial correction

CONTENTS, Generic Terms and Abbreviations, Section 1.1, 1.2, 3.2.3,

3.3.1, 3.3.2, 3.3.3, 3.3.4, 3.3.6, 3.4.2, 3.4.7, 3.4.8, 3.5.2, 4.4.2, 6.3,

Chapter 7, Sections 7.1, 7.2, 7.3, 8.2, 8.4, 8.5, 9.4, 11.2.2, 11.2.3, 11.3.1,

11.3.2, 11.3.3, 11.4.3, 12.4.1, 13.4.1, 14.3.1, 15.3, 16.1.2, 16.2, 16.3,

17.6, 17.7, 17.8, WARRANTY

Partial addition

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Japanese Manual Version SH-080002-S

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 1999 MITSUBISHI ELECTRIC CORPORATION

A - 14 A - 14

INTRODUCTION

Thank you for purchasing the MELSEC-Q/L series programmable controller.

This manual explains the functions and programming required to use the serial communication module.

Before using this product, please read this manual and the related manuals carefully to develop full

familiarity with the functions and performance of the MELSEC-Q/L series programmable controller to handle

the product correctly.

When applying the following program examples to the actual system, make sure to examine the applicability

and confirm that it will not cause system control problems.

Please always forward this manual to the end user.

IMPORTANT

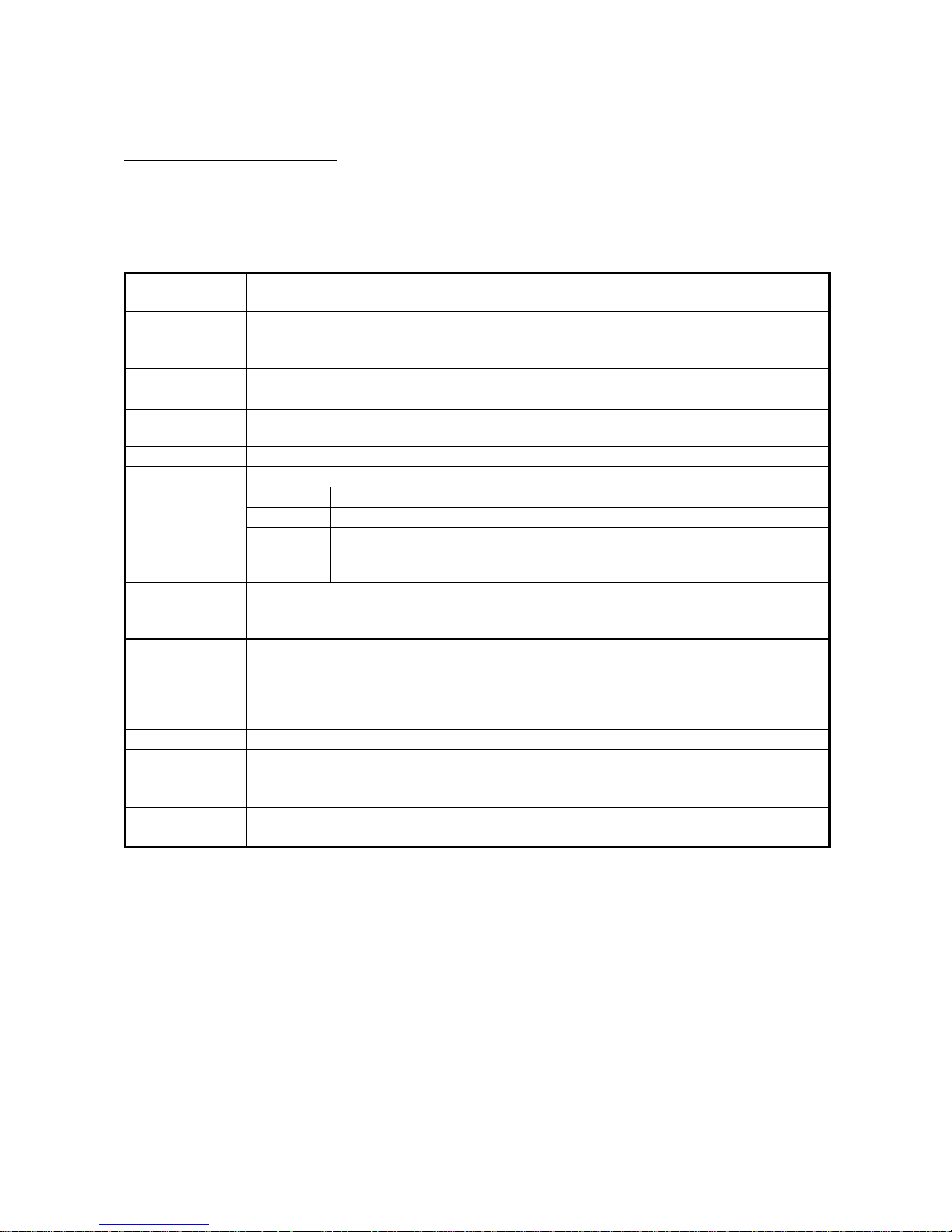

To use LJ71C24 and LJ71C24-R2 serial communication modules

When reading the manual, substitute the contents in the table with the following

descriptions in the explanations.

Description in manual After substitution

Q series C24 L series C24

QCPU LCPU

QCPU station LCPU station

Q/QnACPU Q/L/QnACPU

The specifications of MELSEC-L series and MELSEC-Q series are partially different.

Before using the equipment, please refer to the following to gain familiarity with the

different in specifications.

Appendix 1 Specification Comparisons between the Q Series C24 and L Series C24

REMARKS

• The program examples shown in this manual are the examples in which the

serial communication module is assigned to the I/O No. X/Y00 to X/Y1F

unless otherwise specified.

For the assignment of I/O No., refer to the user's manual (function explanation,

program fundamentals) for the CPU module used.

• This manual explains operations by using GX Configurator-SC.

A - 15 A - 15

CONTENTS

SAFETY PRECAUTIONS..............................................................................................................................A- 1

CONDITIONS OF USE FOR THE PRODUCT .............................................................................................A-10

REVISIONS ....................................................................................................................................................A-11

INTRODUCTION............................................................................................................................................A-14

CONTENTS....................................................................................................................................................A-15

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES ...............................................................A-20

RELEVANT MANUALS .................................................................................................................................A-21

The Manual's Use and Structure ...................................................................................................................A-22

Generic Terms and Abbreviations .................................................................................................................A-24

TERMS ...........................................................................................................................................................A-26

1 OVERVIEW 1- 1 to 1- 6

1.1 Overview.................................................................................................................................................. 1- 1

1.2 Functions Added/Changed for the QJ71C24N (-R2/R4) and QJ71C24 (-R2)...................................... 1- 6

2 USING THE PROGRAMMABLE CONTROLLER CPU MONITORING FUNCTION 2- 1 to 2-29

2.1 Overview.................................................................................................................................................. 2- 1

2.2 About the Programmable Controller CPU Monitoring Function ............................................................ 2- 3

2.2.1 Data registration for using the programmable controller CPU monitoring function ....................... 2- 3

2.2.2 Programmable controller CPU monitoring information ...................................................................2- 3

2.2.3 Timing for programmable controller CPU monitoring ..................................................................... 2- 5

2.2.4 Timings of transmission and notification of monitoring results to the external device ................... 2- 6

2.2.5 Transmission methods of monitoring results and transmission data to the external device.....................2- 9

2.2.6 Execution sequence for using the programmable controller CPU monitoring function ................. 2-20

2.3 Settings for Using the Programmable Controller CPU Monitoring Function......................................... 2-21

2.3.1 System setting items for the programmable controller CPU monitoring function ..........................2-21

2.3.2 How to register and cancel the programmable controller CPU monitoring function ...................... 2-26

2.4 Precautionary Notes for Using the Programmable Controller CPU Monitoring Function..................... 2-28

3 COMMUNICATIONS BY THE MODEM FUNCTION 3- 1 to 3-105

3.1 Overview.................................................................................................................................................. 3- 1

3.1.1 Features............................................................................................................................................ 3- 2

3.1.2 Function list ...................................................................................................................................... 3- 5

3.1.3 Comparisons with related devices ................................................................................................... 3- 6

3.2 System Configuration.............................................................................................................................. 3- 7

3.2.1 System configuration when performing data communication with an external device .................. 3- 7

3.2.2 System configuration when using the notification function ............................................................. 3- 8

3.2.3 System configuration when connecting GX Developer .................................................................. 3- 9

3.2.4 Precautions for system configurations ............................................................................................ 3-10

3.3 Specifications .......................................................................................................................................... 3-12

3.3.1 Transmission specifications ............................................................................................................. 3-12

3.3.2 Specification of connectable modems/TAs (terminal adapters) ..................................................... 3-13

3.3.3 Compatibility with the QCPU remote password function ................................................................ 3-16

3.3.4 Compatibility with the callback function ........................................................................................... 3-22

3.3.5 List of I/O signals for the modem function ....................................................................................... 3-31

3.3.6 Buffer memory .................................................................................................................................. 3-33

3.3.7 Precautions when using the modem function ................................................................................. 3-46

A - 16 A - 16

3.4 Start-up of the Modem Function ............................................................................................................. 3-52

3.4.1 Start-up procedures when communicating data with external devices .......................................... 3-52

3.4.2 Initial settings of the serial communication module......................................................................... 3-55

3.4.3 Register/read/delete of the initialization data .................................................................................. 3-58

3.4.4 Register/read/delete of the data for connection .............................................................................. 3-63

3.4.5 Initialization of modem/TA (terminal adapter) ................................................................................. 3-68

3.4.6 Line connection ................................................................................................................................3-72

3.4.7 Data communication and notification .............................................................................................. 3-78

3.4.8 Line disconnection............................................................................................................................ 3-84

3.5 Sample Programs ................................................................................................................................... 3-87

3.5.1 Sample program for data communication-1 .................................................................................... 3-88

3.5.2 Sample program for data communication-2 .................................................................................... 3-94

3.5.3 Sample program for notification..................................................................................................... 3-103

4 RECEIVING DATA WITH AN INTERRUPT PROGRAM 4- 1 to 4- 6

4.1 Settings for Receiving Data Using an Interrupt Program ...................................................................... 4- 2

4.2 Interrupt Program Startup Timing ........................................................................................................... 4- 2

4.3 Reception Control Method Using an Interrupt Program ........................................................................4- 3

4.4 Programming........................................................................................................................................... 4- 4

4.4.1 Program example ............................................................................................................................. 4- 4

4.4.2 Precautions when receiving data with an interrupt program........................................................... 4- 5

5 CHANGING SEND AND RECEIVE DATA LENGTH UNITS TO BYTE UNITS

(WORD/BYTES UNITS SETTING) 5- 1 to 5- 2

6 CHANGING THE DATA COMMUNICATIONS MONITORING TIMES 6- 1 to 6-13

6.1 No-reception Monitoring Time (timer 0) Setting ..................................................................................... 6- 2

6.2 Response Monitoring Time (timer 1) Setting ......................................................................................... 6- 7

6.3 Transmission Monitoring Time (timer 2) Setting .................................................................................... 6-10

6.4 Message Wait Time Setting.................................................................................................................... 6-13

7 DATA COMMUNICATIONS USING DC CODE TRANSMISSION CONTROL 7- 1 to 7- 8

7.1 Control Contents of DTR/DSR (ER/DR) Signal Control ........................................................................7- 2

7.2 Control Contents of DC Code Control .................................................................................................... 7- 4

7.3 Precautions when Using the Transmission Control Functions .............................................................. 7- 7

8 DATA COMMUNICATIONS USING HALF-DUPLEX COMMUNICATIONS 8- 1 to 8- 8

8.1 Half-duplex Communications.................................................................................................................. 8- 1

8.2 Data Transmission and Reception Timing .............................................................................................8- 2

8.3 Changing the Communication System................................................................................................... 8- 6

8.4 Connector Connections for Half-duplex Communications..................................................................... 8- 7

8.5 Half-duplex Communications Precautions ............................................................................................. 8- 8

A - 17 A - 17

9 CONTENTS AND REGISTRATION OF THE USER FRAMES

FOR DATA COMMUNICATION 9- 1 to 9-22

9.1 User Frame Types and Contents During Communication .................................................................... 9- 1

9.1.1 User frames to be registered and used by the user........................................................................9- 1

9.1.2 Default registration frame (read only) .............................................................................................. 9- 9

9.2 Transmission/Reception Processing Using User Frame Register Data ...............................................9-11

9.3 Precautions when Registering, Reading, Deleting and Using User Frames ........................................ 9-15

9.4 Register/Read/Delete User Frames ....................................................................................................... 9-17

9.4.1 Registering user frames ................................................................................................................... 9-20

9.4.2 Reading user frames ........................................................................................................................ 9-21

9.4.3 Deleting user frames ........................................................................................................................ 9-22

10 ON-DEMAND DATA COMMUNICATIONS USING USER FRAMES 10- 1 to 10- 9

10.1 User Frame Data Communications Function..................................................................................... 10- 1

10.2 User Frame Types and Registration ..................................................................................................10- 2

10.3 User Frame On-Demand Data Transmission and Buffer Memory Used.......................................... 10- 2

10.4 On-Demand Function Control Procedure During User Frame Use ..................................................10- 4

10.4.1 Data communication using the ASCII code ................................................................................ 10- 4

10.4.2 Data communications using the binary code ..............................................................................10- 6

10.5 Example of an On-Demand Data Transmission Program Using User Frames................................ 10- 8

11 DATA COMMUNICATIONS USING USER FRAMES 11- 1 to 11-43

11.1 Overview of Data Communication Procedure.................................................................................... 11- 2

11.2 Data Reception ................................................................................................................................... 11- 3

11.2.1 About reception data .................................................................................................................... 11- 3

11.2.2 Timing for start/completion of data reception ..............................................................................11-10

11.2.3 Receive procedure ....................................................................................................................... 11-14

11.2.4 User frame setting for reception .................................................................................................. 11-15

11.3 Receive Program ................................................................................................................................ 11-21

11.3.1 Sequence program example ....................................................................................................... 11-21

11.3.2 Application example for data reception using a combination that specifies the first frame ....... 11-26

11.3.3 Application example for data reception using a combination that does not specify the

first frame...................................................................................................................................... 11-32

11.4 Data Transmission .............................................................................................................................. 11-34

11.4.1 Send data ..................................................................................................................................... 11-34

11.4.2 Transmission procedure .............................................................................................................. 11-36

11.4.3 Settings for transmission user frames .........................................................................................11-37

11.5 Transmission Program........................................................................................................................ 11-41

12 TRANSPARENT CODES AND ADDITIONAL CODES 12- 1 to 12-20

12.1 Handling the Transparent Code and Additional Code Data ..............................................................12- 1

12.2 Registering Transparent Codes and Additional Codes .....................................................................12- 2

12.3 Handling Transparent Codes and Additional Codes during Non Procedure Protocol Data

Communication ................................................................................................................................... 12- 3

12.4 Example of Data Communication Using the Non Procedure Protocol ............................................. 12- 8

12.4.1 Example of data reception ...........................................................................................................12- 9

12.4.2 Example of data transmission...................................................................................................... 12-11

A - 18 A - 18

12.5 Handling Transparent Codes and Additional Codes During Bidirectional Protocol Data

Communication ................................................................................................................................... 12-13

12.6 Example of Data Communication Using the Bidirectional Protocol ..................................................12-16

12.6.1 Example of data reception ...........................................................................................................12-17

12.6.2 Example of data transmission...................................................................................................... 12-19

13 COMMUNICATING WITH ASCII CODE (ASCII-BIN CONVERSION) 13- 1 to 13-14

13.1 ASCII-BIN Conversion ........................................................................................................................13- 1

13.2 Settings for ASCII-BIN Conversion .................................................................................................... 13- 1

13.3 Performing ASCII-BIN Conversion for Data Communicated via Non Procedure Protocol .............. 13- 2

13.4 Example of Data Communication Using the Non Procedure Protocol ............................................. 13- 4

13.4.1 Example of data reception ...........................................................................................................13- 5

13.4.2 Example of data transmission...................................................................................................... 13- 8

13.5 Performing ASCII-BIN Conversion for Data Communicated via the Bidirectional Protocol .............13-10

13.6 Example of Data Communication Using the Bidirectional Protocol ..................................................13-12

13.6.1 Example of data reception ...........................................................................................................13-13

13.6.2 Example of data transmission...................................................................................................... 13-14

14 DATA COMMUNICATIONS USING EXTERNAL DEVICE AND PROGRAMMABLE

CONTROLLER CPU M : N CONFIGURATION 14- 1 to 14-11

14.1 Data Communications Precautions .................................................................................................... 14- 1

14.2 External Devices Interlock Conditions................................................................................................ 14- 3

14.2.1 Maximum communications time per external device station ...................................................... 14- 3

14.2.2 Message structure when communicating data between external devices................................. 14- 4

14.3 Examples of Procedure for Data Communications with the Programmable Controller CPU .......... 14- 6

14.3.1 Sequential data communications between external devices and the programmable

controller CPU .............................................................................................................................. 14- 6

14.3.2 Data communications between programmable controller CPU and external devices by

designating a master station and slave stations .........................................................................14- 9

15 SWITCHING THE MODE AFTER STARTING 15- 1 to 15-11

15.1 Mode Switching Operation and Contents that can be Changed ....................................................... 15- 2

15.1.1 Settings that can be changed with mode switching .................................................................... 15- 2

15.1.2 Operation for mode switching ...................................................................................................... 15- 2

15.2 Mode Switching Precautions ..............................................................................................................15- 3

15.3 I/O Signals for Handshake with Programmable Controller CPU and Buffer Memory ...................... 15- 5

15.4 Switching the Mode from the Programmable Controller CPU........................................................... 15- 8

15.4.1 Mode switching procedure........................................................................................................... 15- 8

15.4.2 Mode switching sample program................................................................................................. 15- 9

15.5 Switching the Mode from an External Device .................................................................................... 15-10

15.5.1 Mode switching procedure........................................................................................................... 15-10

15.5.2 Mode switching sample program................................................................................................. 15-11

16 USING COMMUNICATION DATA MONITORING FUNCTION 16- 1 to 16-10

16.1 Communication Data Monitoring Function......................................................................................... 16- 1

16.1.1 Overview....................................................................................................................................... 16- 1

16.1.2 Communication data monitoring operation ................................................................................. 16- 2

16.2 Communication Data Monitoring Function Settings .......................................................................... 16- 4

16.3 Communication Data Monitoring Example......................................................................................... 16- 8

A - 19 A - 19

17 DEDICATED INSTRUCTIONS 17- 1 to 17-40

17.1 Dedicated Instruction List and Available Devices .............................................................................. 17- 1

17.2 Z.BUFRCVS ........................................................................................................................................ 17- 3

17.3 ZP.CSET (Programmable Controller CPU Monitoring Register/Cancel) .......................................... 17- 7

17.4 ZP.CSET (Initial Settings)................................................................................................................... 17-16

17.5 G(P).GETE .......................................................................................................................................... 17-21

17.6 G(P).PRR ............................................................................................................................................17-24

17.7 G(P).PUTE ..........................................................................................................................................17-28

17.8 ZP.UINI................................................................................................................................................ 17-32

APPENDIX App.- 1 to App.- 2

Appendix 1 Specification Comparison between the Q Series C24 and L series C24 ...........................App.- 1

INDEX Index- 1 to Index- 3

WARRANTY

A - 20 A - 20

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low

Voltage Directives when incorporated into other machinery or equipment, certain

measures may be necessary.

Please refer to one of the following manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance

with EMC and Low Voltage Directives.

(2) Additional measures

No additional measures are necessary for the compliance of this product with

EMC and Low Voltage Directives.

A - 21 A - 21

RELEVANT MANUALS

The specifications and usage of special functions can be checked in this manual.

In addition, use the following manuals according to their intended use.

Manual name

Manual number

(Model code)

Q Corresponding Serial Communication Module User's Manual (Basic)

Overview of the module, applicable system configuration, specifications, procedures prior to operations,

basic methods for communicating with the external device, maintenance and inspection, and

troubleshooting of the Q series serial communication module. (Sold separately)

SH-080006

(13JL86)

MELSEC-L Serial Communication Module User's Manual (Basic)

Overview of the module, applicable system configuration, specifications, procedures prior to operations,

basic methods for communicating with the external device, maintenance and inspection, and

troubleshooting of the MELSEC-L serial communication module. (Sold separately)

SH-080894ENG

(13JZ40)

MELSEC-Q/L MELSEC Communication Protocol Reference Manual

Information on how the external device reads data from and writes data to the programmable controller

CPU through communication using the MC protocol by utilizing the C24/E71. (Sold separately)

SH-080008

(13JF89)

GX Configurator-SC Version 2 Operating Manual (Protocol FB support function)

Features and usage of the protocol FB support function that supports creation of the data communication

program of the module and how to set parameters. (Sold separately)

SH-080393E

(13JU46)

GX Configurator-SC Version 2 Operating Manual (Pre-defined protocol support function)

The pre-defined protocol support function and usage, and the protocol setting method.

(Sold separately)

SH-080850ENG

(13JU66)

A - 22 A - 22

The Manual's Use and Structure

How to use this manual

This manual describes the use of special functions for the Q series C24

(QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24, QJ71C24-R2), with each

chapter covering a specific function. Please read this manual and use the contents

below as a reference.

(1) To read an overview of special functions

• An overview of the major special functions is described in Chapter 1.

(2) To use the function that monitors errors in the programmable controller CPU

• Chapter 2 describes the programmable controller CPU monitoring function,

which monitors the programmable controller CPU status and devices and

automatically sends status information to the other communicating device

upon occurrence of an error.

For how to register/cancel the programmable controller CPU monitoring

from the external device using the MC protocol, refer to the MELSEC-Q/L

MELSEC Communication Protocol Reference Manual.

(3) To use the data communication function for the exchange of data with an

external device at a remote location

• Chapter 3 describes the specifications, procedures and other items regarding

communication using the modem function in order to exchange of data with an

external device at a remote location.

(4) To use the function for reading received data from the external device using an

interrupt program in order to reduce the scan time

• Chapter 4 describes the programming for execution of a receiving program

only when data from the external device is received.

(5) To use the function for monitoring the data communication time with the external

device

• Chapter 6 describes the function that monitors the data communication time

with the external device, along with the reception-interval time and the

response-reception time for transmission.

(6) To use the transmission control function to control data transmission/reception

with the external device.

• Chapter 7 describes the DTR/DSR control and the DC code function to control

the data communication with the external device.

(7) To use the function for simplifying the data communication program with the

registration data when preregistering the fixed-format section of the

communication message

• Chapters 9 to 11 describe the data transmission/reception function with user

frames in which the fixed-format section of the communication message has

been preregistered.

A - 23 A - 23

(8) To use the function that performs the data communication in ASCII code with

the external device

• Chapter 13 describes the handling of binary code on the programmable

controller CPU and ASCII-BIN conversion function for communicating ASCII

code data for an external device.

(9) To use dedicated instructions

• Chapter 17 describes the dedicated instructions that are used to execute the

functions explained in this manual.

Structure of this manual

This manual describes how to perform the initial settings to execute special

functions by using GX Developer and the utility package for the Q series C24 (GX

Configurator-SC).

For details on the usage of GX Developer and GX Configurator-SC, refer to the Q

Corresponding Serial Communication Module User's Manual (Basic).

A - 24 A - 24

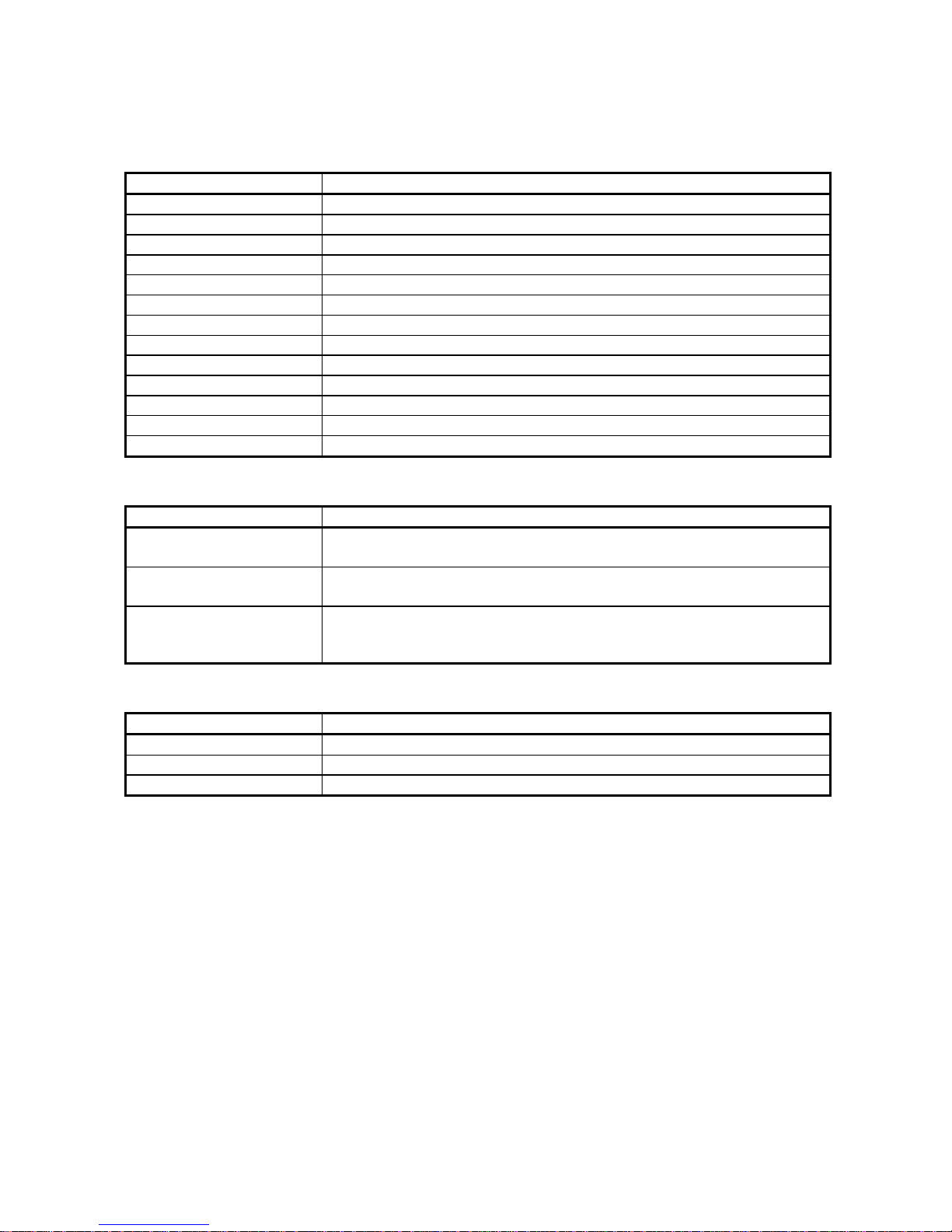

Generic Terms and Abbreviations

In this manual, the following generic terms and abbreviations are used to explain the serial communication

module and data communication devices, unless otherwise specified. Specific names or model names are

provided when it is necessary to explicitly identify the model being discussed.

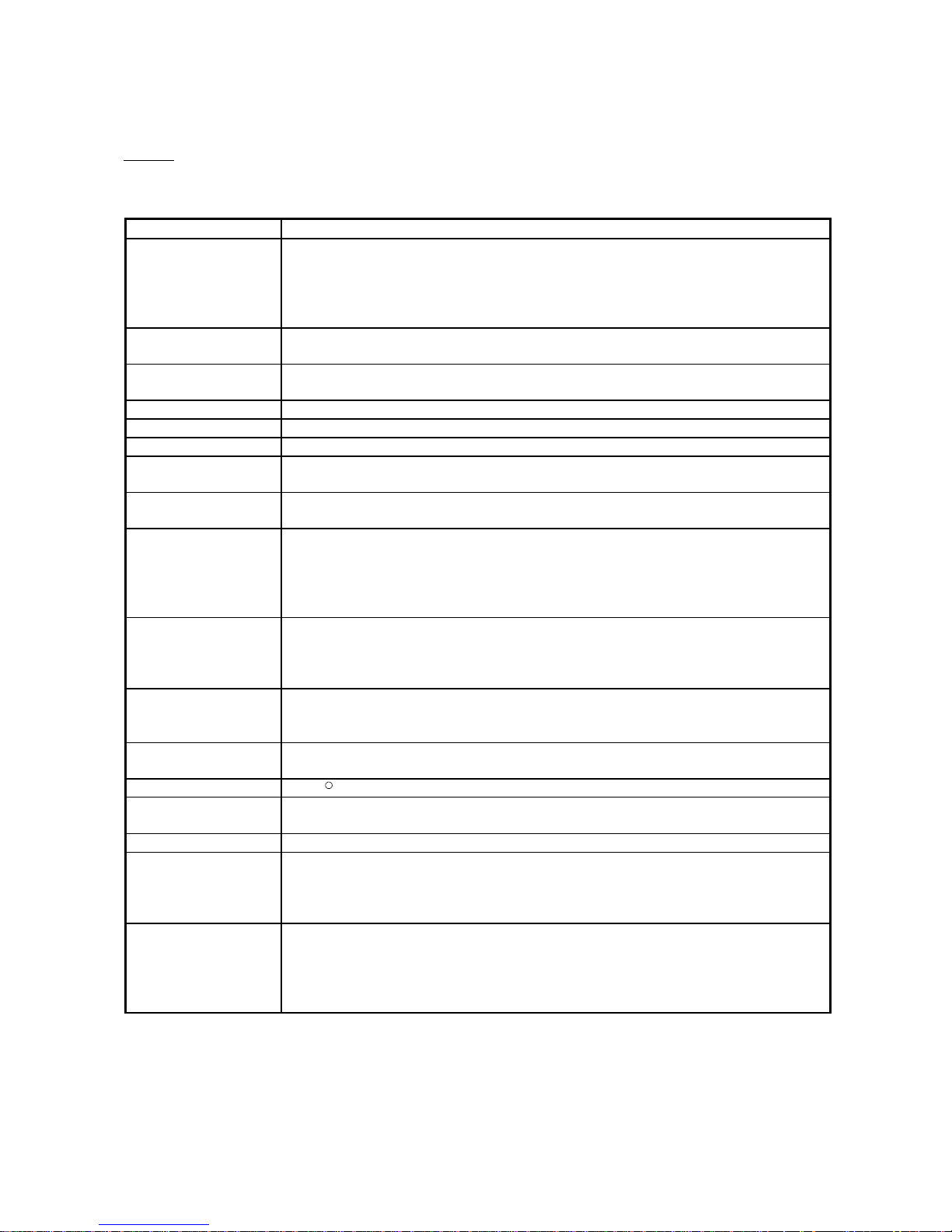

(1) Generic terms and abbreviations for modules

Generic

term/abbreviation

Description

Q series C24 (C24)

Generic term for QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24 and QJ71C24-R2 serial communication

modules.

(Indicated as "C24" in diagrams)

L series C24 Generic term for LJ71C24 and LJ71C24-R2

QC24 Generic term for AJ71QC24, AJ71QC24-R2, AJ71QC24-R4, A1SJ71QC24, and A1SJ71QC24-R2

QC24N

Generic term for AJ71QC24N, AJ71QC24N-R2, AJ71QC24N-R4, A1SJ71QC24N1, A1SJ71QC24N1-R2,

A1SJ71QC24N, and A1SJ71QC24N-R2

QC24(N) Generic term for QC24 and QC24N

Generic term for the modules below.

Q series QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24, QJ71C24-R2

L series LJ71C24, LJ71C24-R2

Serial communication

module

QnA series

AJ71QC24, AJ71QC24-R2, AJ71QC24-R4, A1SJ71QC24, A1SJ71QC24-R2, AJ71QC24N,

AJ71QC24N-R2, AJ71QC24N-R4, A1SJ71QC24N1, A1SJ71QC24N1-R2, A1SJ71QC24N,

A1SJ71QC24N-R2

UC24

A series computer

link module

Generic term for AJ71UC24, A1SJ71UC24-R2, A1SJ71UC24-R4, A1SJ71UC24-PRF, A1SJ71C24-R2,

A1SJ71C24-R4, A1SJ71C24-PRF, A2CCPUC24, and A2CCPUC24-PRF

QCPU

Generic term for Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU,

Q02PHCPU, Q06PHCPU, Q12PHCPU,Q25PHCPU, Q12PRHCPU, Q25PRHCPU, Q00UJCPU, Q00UCPU,

Q01UCPU, Q02UCPU, Q03UDCPU, Q04UDHCPU, Q06UDHCPU, Q10UDHCPU, Q13UDHCPU, Q20UDHCPU,

Q26UDHCPU, Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q10UDEHCPU, Q13UDEHCPU,

Q20UDEHCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

LCPU Generic term for L02CPU, L02CPU-P, L26CPU-BT, and L26CPU-PBT

QnACPU

Generic term for Q2ACPU, Q2ACPU-S1, Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1, Q3ACPU,

Q4ACPU, and Q4ARCPU

Q/QnACPU Generic term for QCPU and QnACPU

Ethernet module

Q series E71 (E71)

Generic term for QJ71E71-100, QJ71E71-B5 and QJ71E71-B2 Ethernet interface modules

(Indicated as "E71" in diagrams)

A - 25 A - 25

(2) Abbreviations for dedicated instructions

Abbreviation Description

BIDIN Abbreviation for G.BIDIN or GP.BIDIN.

BIDOUT Abbreviation for G.BIDOUT or GP.BIDOUT.

BUFRCVS Abbreviation for Z.BUFRCVS.

CPRTCL Abbreviation for G.CPRTCL or GP.CPRTCL

CSET Abbreviation for ZP.CSET.

GETE Abbreviation for G.GETE or GP.GETE.

INPUT Abbreviation for G.INPUT.

ONDEMAND Abbreviation for G.ONDEMAND or GP.ONDEMAND.

OUTPUT Abbreviation for G.OUTPUT or GP.OUTPUT.

PRR Abbreviation for G.PRR or GP.PRR.

PUTE Abbreviation for G.PUTE or GP.PUTE.

SPBUSY Abbreviation for G.SPBUSY or GP.SPBUSY.

UINI Abbreviation for ZP.UINI.

(3) Generic terms and abbreviations for the manuals

Generic term/abbreviation Description

User's Manual (Basic)

Q Corresponding Serial Communication Module User's Manual (Basic)

MELSEC-L Serial Communication Module User's Manual (Basic)

Operating Manual

(Protocol FB support function)

GX Configurator-SC Version 2 Operating Manual (Protocol FB support function)

Operating Manual

(Pre-defined protocol support

function)

GX Configurator-SC Version 2 Operating Manual (Pre-defined protocol support function)

(4) Others

Generic term Description

Data communication function Generic term for MC protocol, pre-defined protocol, nonprocedural protocol, bidirectional protocol

QCPU station Generic term for the programmable controller installed QCPU

LCPU station Generic term for the programmable controller installed LCPU

A - 26 A - 26

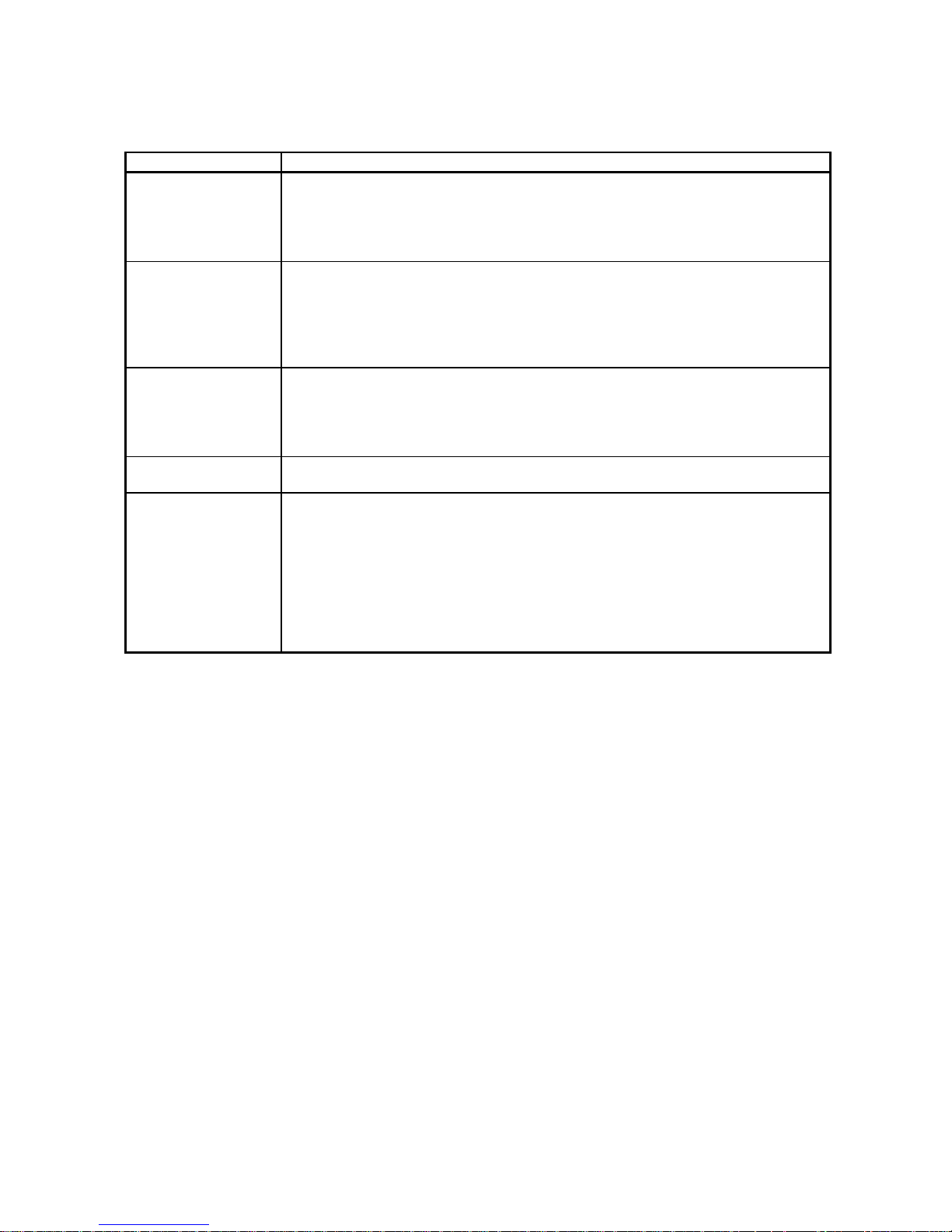

TERMS

The following table lists the definitions and descriptions of terminology used in this manual.

Terminology Description

A compatible 1C frame

(Formats 1 to 4)

One of the message formats for the serial communication modules, which is used to perform ASCII data

communication by MC protocol.

This is the same message format as the one used when communicating using the protocol for the A series

computer link modules. Device memory read/write operations for the QCPU are allowed within the device

range of the AnACPU.

Bidirectional protocol

A communication procedure for the serial communication modules, with which any data communication is

available between the programmable controller CPU and the other device.

Buffer memory

Memory of the intelligent function modules/special function modules, which is used for storing data sent to or

received from the programmable controller CPU (setting values, monitor values, etc.)

Device A memory of the programmable controller CPU used for storing data

GX Configurator-SC Setting and monitoring tool for the serial communication module (MELSOFT product)

GX Developer A programming tool for designing, debugging and maintenance (MELSOFT product)

Independent operation

Operation of each of the two interfaces on the serial communication module when data communication is

performed with other devices using the specified protocols respectively.

Intelligent function module

MELSEC-Q/L series modules with functions other than I/O functions such as A/D and D/A conversion

module

Linked operation

Operation of each of the two interfaces on the serial communication module that are connected to external

devices and linked one another in order to communicate data to/from the external devices.

The two interfaces communicate data using the identical data-communication function (MC protocol

(identical format) or non procedure protocol) and the identical transmission specifications. (Linked operation

using the pre-defined protocol or the bidirectional protocol is not allowed.)

MELSEC communication

protocol

(MC protocol)

A communication procedure for the Q series C24 or the Ethernet interface modules, and a communication

method for accessing a programmable controller CPU from an external device.

(This is called the MC protocol in this manual.)

There are two communication types; one uses ASCII code data and the other uses binary code data.

Message send function

(Printer function)

This function registers character data (messages) to be sent to external devices (mainly printers) to the

serial communication module as a user frame in advance, and sends the registered data for multiple user

frames using the non procedure protocol.

Multidrop connection

A name of the connection when multiple external devices or other C24s are connected on a 1:n or m:n basis

using the serial communication module's RS-422/485 interface.

MX Component Active X

R

control library for serial communication (MELSOFT product)

Non procedure protocol

A communication procedure and one of the data communication functions for communicating any data

between the programmable controller CPU and the other device.

Packet Data string used for communication using pre-defined protocol with external devices

Pre-defined protocol

One of the data communication functions available for the QJ71C24N(-R2/R4) and LJ71C24(-R2). In data

communication between the QJ71C24N(-R2/R4) or LJ71C24(-R2) and an external device, data can be sent

or received by using a protocol for the external device.

This must be set in GX Configurator-SC (Pre-defined protocol support function).

Pre-defined protocol support

function

This function can be used in GX Configurator-SC (Pre-defined protocol support function).

The functional overview of the pre-defined protocol support function is indicated below.

• Protocol setting according to the opposite device

• The writing and reading of protocol setting data to QJ71C24N(-R2/R4) and LJ71C24(-R2) flash ROM

• Debugging support function

A - 27 A - 27

Terminology Description

QnA compatible 2C frame

(Formats 1 to 4)

One of the message formats for the serial communication modules, which is used to perform ASCII data

communication by MC protocol.

This is the same message format as the communication frame using the protocol for the QnA series serial

communication modules.

• QnA compatible 2C frame (Formats 1 to 4): QnA simplified frame (Formats 1 to 4)

QnA compatible 3C frame

(Formats 1 to 4)

QnA compatible 4C frame

(Formats 1 to 4)

One of the message formats for the serial communication modules, which is used to perform ASCII data

communication by MC protocol.

This is the same message format as the communication frame using the protocol for the QnA series serial

communication modules.

• QnA compatible 3C frame (Formats 1 to 4): QnA frame (Formats 1 to 4)

• QnA compatible 4C frame (Formats 1 to 4): QnA extension frame (Formats 1 to 4)

QnA compatible 4C frame

(Format 5)

One of the message formats for the serial communication modules, which is used to perform ASCII data

communication by MC protocol.

This is the same message format as the communication frame using the protocol for the QnA series serial

communication modules.

• QnA compatible 4C frame (Format 5): QnA extension frame (Format 5)

Special function module

MELSEC-QnA/A series modules with functions other than I/O functions such as A/D and D/A conversion

module

User frame

Data name when the fixed format portion of messages to be sent or received between a serial

communication module and an external device is registered in the module and used for sending and

receiving data. (The contents of a user frame data should conform to the specifications of the external

device.)

The data array of the head and tail sections of a message (transmission control code, serial communication

module station No., sum check, fixed data, etc.) to be sent and received is registered in the serial

communication module before use.

User frame is used in MC protocol on-demand functions and data communication functions which use the

non procedure protocol.

A - 28 A - 28

MEMO

1 - 1 1 - 1

1 OVERVIEW

1 OVERVIEW

1.1 Overview

This manual explains special functions of the MELSEC-Q/L series C24.

When applying the following program examples to the actual system, make sure to

examine the applicability and confirm that it will not cause system control problems.

This chapter provides an overview of these special functions. The primary special

functions of the Q series C24 and a functional overview are indicated below.

(1) Monitoring the programmable controller CPU (detailed explanation

in Chapter 2)

(a) The local station programmable controller CPU can be monitored at time

intervals set by the user without a sequence program.

1) The following information can be registered as items to be monitored.

(Monitoring a device for the local station programmable controller CPU)

• A numeric value stored in a word device

• The ON/OFF status of a bit device

(Monitoring the status of the local station programmable controller

CPU)

• Monitoring the status of the local station programmable controller

CPU

2) For the results of the programmable controller CPU monitoring, the

following monitored information can be transmitted/notified.

• Transmission of information on the device to be monitored and status

of the programmable controller CPU (Monitoring information obtained

through combined use of the modem function can also be

transmitted.)

• Notification of notification messages (character string data) registered

for connecting the modem function when using with the modem

function together

3) The user can select one of the following as transmission timing for the

programmable controller CPU monitoring results to the external device.

• Transmission/notification each time the programmable controller CPU

is monitored. (Constant cycle transmission)

• Transmission/notification when the information read from the

programmable controller CPU agrees with conditions set by the user.

(Condition agreement transmission)

(b) The programmable controller CPU monitoring function can be used in

communication using MC protocol or non procedure protocol.

(c) Using the programmable controller CPU monitoring function makes it

possible to do the following:

• Sends device data without using a sequence program

• Simplifies the device monitor procedure

• Sends the programmable controller CPU error information

Q25HCPU

MODE

RUN

ERR.

USER

BAT.

BOOT

RS-232

USB

QJ71C24

CH1. CH2.

RS-232

CH1.

CH.2

SDA

SG

SDB

RS-422

/485

RDA

RDB

(FG)

(FG)

1

2

5

7

3

4

6

Monitoring

device information

CPU error

information

External device

Abnormal d etection

MITSUBISHI

MELSEC

POWER

PULL

Error

occurrence

1

1 - 2 1 - 2

1 OVERVIEW

(2) Communicating with the external device at a remote location via a

modem (detailed explanation in Chapter 3)

1) Connecting a modem or TA (terminal adapter) to the RS-232 interface

facilitates communication via a public line/private line/digital line (ISDN), such

as data communication with a device at a remote location (listed below) and

calling a pager device.

• Data communication using the MC protocol

• Data sending and receiving using the non procedure protocol

• Data communication using the bidirectional protocol

• Programmable controller access using the GX Developer

2) Initialization of a modem or TA, line connection (dialing), and line

disconnection are performed by the programmable controller CPU.

3) When a remote password is set in the QCPU with the GX Developer, the

following access from the external device to QCPU using the Q series C24

modem function can be performed by executing the unlock processing to the

remote password.

• Data communication using MC protocol

• Accessing the programmable controller using the GX Developer

The remote password function is a QCPU function designed to prevent

improper access to the QCPU by users.

The QCPU remote password function can be used by setting a remote

password in the QCPU with GX Developer.

Modem/TA ( 1)

Modem/TA ( 1) External device

Pager receiver

RS-232

Q series C24

1 TA is an abbreviation for Terminal Adapter.

1

1 - 3 1 - 3

1 OVERVIEW

(3) Receiving data with an interrupt program (detailed explanation in

Chapter 4)

1) In data communication between the Q series C24 and the external device,

data can be received using an interrupt program with the following data

communication functions.

• Data reception during communication using the non procedure protocol

• Data reception during communication using the bidirectional protocol

2) Receiving data using an interrupt program expedites data reception by the

programmable controller CPU.

Main program

Interrupt

program executed

Main program

BUFRCVS

SM400

FEND

I

Receive

Q series C24

Interrupt issued

Data

transmission

Programmable

controller CPU

(4) Controlling data communication in accordance with the external

device (detailed explanation in Chapter 7)

1) The Q series C24 controls data communication with the external device by

turning ON/OFF the DTR/DSR signal and sending/receiving the DC code.

2) DTR/DSR signal control

Using the ER (DTR) and DR (DSR) signals, the external device is notified of

whether or not data communication can be performed.

3) DC code control

By sending/receiving the DC1 and DC3 code data, the external device is

notified of whether or not data can be received. By enclosing the user data

with the DC2 and DC4 code data, the external device is notified of the valid

transmission data range.

1 - 4 1 - 4

1 OVERVIEW

(5) Converting binary code data to ASCII code data to communicate

with the external device specification (detailed explanation in

Chapter 13)

1) Binary code data that is processed by the programmable controller CPU can

be converted to ASCII code data for communication.

2) ASCII-BIN conversion is performed by the Q series C24 according to user

settings.

Converts

Buffer memory

1234

H

(12H)(34H)

LH

Head data

34

H

12

H

LH

Does not convert

External

device

Q series C24

33

H

34H 31H 32H

(3)(4)(1)(2)

LH

(6) Sending/receiving data in a message format tailored to the external

device (detailed explanation in Chapters 9 to 11)

1) By preregistering the data arrangement (user frames) of the messages to be

sent and received by the external device, to the Q series C24, the following

data communications can be performed using registered frames.

• MC protocol: Data transmission from the programmable controller CPU to

the external device using the on-demand function

• Non procedure protocol: Data communication between the programmable

controller CPU and the external device

2) For example, multiple first frames and last frames (called user frames) with

the definition shown in the diagram below can be preregistered in the Q

series C24. When sending data to the external device, the data that is

arranged as shown in the diagram below can be sent by designating the

preregistered user frame numbers and arbitrary data. When receiving data

from the external device, by setting the preregistered user frame numbers for

reception at the startup of the Q series C24, the arbitrary data section can be

read to the programmable controller CPU when the message with the

registered content is received.

Arbitrary data

First frame

Last frame

ENQ

Password

Destination

station number

Self-station

number

CR LF

Before sending data, the Q series C24 adds the first frame and last frame

to arbitrary data. When data is received, the arbitrary data section is

stored in the buffer memory as receive data.

3) User frames and various setting values for data communication with the

external device can be preregistered to the Q series C24 flash ROM.

1 - 5 1 - 5

1 OVERVIEW

The following table lists which special functions are available for the main data

communication functions of the Q series C24.

Main data communication functions

Special functions

MC

protocol

Non

procedure

protocol

Bidirectional

protocol

Pre-

defined

protocol

Reference

section

Monitoring of the programmable controller CPU using

the programmable controller CPU monitoring function

Chapter 2

Data communication to a remote location using the

modem function

Chapter 3

Reading received data using an interrupt program

Chapter 4

Changing the unit of the data length for communication

data

Chapter 5

Changing the monitoring time for data communication

Chapter 6

Transmission control for data communication