Page 1

CC-Link System Master/Local Module

Mitsubishi Programmable

Logic Controller

QJ61BT11N

Page 2

Page 3

A - 1 A - 1

•

SAFETY PRECAUTIONS •

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly .

The precautions given in this manual are concerned with this product. For the safety precautions of the

programmable controller system, please read the user's manual of the CPU module to use.

In this manual, the safety precautions are ranked as "DANGER" and "CAUTION".

!

DANGER

CAUTION

!

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

Note that the !CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the precautions of both levels because they are important to personal safety .

Please save this manual to make it accessible when required and always forward it to the end user.

[DESIGN PRECAUTION]

!

DANGER

•

See Chapter 5 of this manual for each station's operating status when there is a communication

error in the data link.

•

When performing the control of the PLC in operation (changing data) by connecting a personal

computer, etc. to the intelligent function module or connecting peripheral devices to the CPU

module, configure an interlock circuit in a sequence program so the safety of the overall system

is always maintained.

Before performing other controls of the PLC in operation (changing program and operation

status (status control)), read this manual carefully and confirm if the overall safety is maintained.

Especially, when this control is performed to a remote PC from an external device, troubles t hat

have occurred on the PLC side may not be able to immediately be handled if there is a data

communication error.

Define a troubleshooting agreement between external devices and the PLC CPU for data

communication error occurrences, as well as construct an interlock circuit in the sequence

program.

Page 4

A - 2 A - 2

[DESIGN PRECAUTION]

!

DANGER

•

Do not write data into the "system area" of the buffer memory of intelligent function modules.

Also, do not output the "prohibited to use" signal as the out put signal t o an intelligent function

module from the PLC CPU.

Writing data into the "system area" or outputting a signal for "prohibited to use" may cause

system malfunction in the PLC.

•

To specify the automatic refresh parameter, specify "Y" for the remote output RY refresh device.

If a value other than "Y" (for example, M or L) is specified, the stat us of the dev ice w ill remain as

it was prior to the STOP operation when the CPU is stopped.

See Section 4.4.10 for how to stop the data link.

•

If wire breakage occurs in the CC-Link dedicated cable, the line may become instable, resulting in

a data link communication error at multiple stations. Configure an interlock circuit in a sequence

program to operate the system toward the safety side if a data link communication error occurs at

multiple stations. Failure to do so may result in an accident due to false output or malfunction.

[DESIGN PRECAUTION]

!

CAUTION

•

Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100mm(3.9inch) or more from each other.

Not doing so could result in noise that may cause malfunction.

[INSTALLATION PRECAUTIONS]

!

CAUTION

•

Use the PLC in an environment that meets the general specifications contained in the CPU

user's manual to use.

Using this PLC in an environment outside the range of the general specifications may cause

electric shock, fire, malfunction, and damage to or deterioration of the product.

•

While pressing the installation lever located at the bottom of module, insert the module fixing tab

into the fixing hole in the base unit until it stops. Then, securely mount t he module with the fixing

hole as a supporting point.

Improper installation may result in malfunction, breakdown or dropping out of the module.

Securely fix the module with screws if it is subject to vibration during use.

•

Tighten the screws within the range of specified torque.

If the screws are loose, it may cause fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damage to the screw and/or the module,

resulting in fallout, short circuits or malfunction.

•

Switch all phases of the external power supply off when mounting or removing the module.

Not doing so may cause damage to the module.

•

Do not directly touch the conductive area or electronic components of the module.

Doing so may cause malfunction or failure in the module.

Page 5

A - 3 A - 3

[WIRING PRECAUTIONS]

!

CAUTION

•

When turning on the power and operating the module after installing is completed, always at tach

the terminal cover that comes with the product.

There is a risk of malfunction if the terminal cover is not attached.

•

Tighten the terminal screws within the range of specified torque.

If the terminal screws are loose, it may cause short circuits, or malfunction.

If the terminal screws are tightened too much, it may cause damage to the screw and/or the

module, resulting in fallout, short circuits or malfunction.

•

Be careful not to let foreign matters such as sawdust or wire chips get inside the module.

These may cause fires, failure or malfunction.

•

The top surface of the module is covered with protective film to prevent foreign objects such as

cable offcuts from entering the module when wiring.

Do not remove this film until the w iring is co mplete.

Before operating the system, be sure to remove the film to provide adequate heat v entilation.

•

Use a dedicated cable as specified by the manufacturer for the CC-Link system. If a cable other

than the one specified by the manufacturer is used, the performance of the CC-Link system

cannot be guaranteed. Also, follow the specifications listed in Chapter 3 for the overall cable

distance and the station-to-station cable length. If wiring is done other than as specified,

accurate transmission of data cannot be guaranteed.

•

Be sure to fix communication cables or power supply cables leading from the module by placing

them in the duct or clamping them.

Cables not placed in the duct or without clamping may hang or shift, allowing them to be

accidentally pulled, which may cause a module malfunction and cable damage.

•

When removing the communication cable or power supply cable from the module, do not pull the

cable. When removing the cable with a connector, hold the connector on the side that is

connected to the module.

When removing the cable connected to the terminal block, first loosen the screws on the part

that is connected to the terminal block.

Pulling the cable that is still connected to the module may cause malfunct ion or damage to t he

module or cable.

Page 6

A - 4 A - 4

[STARTING AND MAINTENANCE PRECAUTIONS]

!

CAUTION

•

Do not disassemble or modify each module.

Doing so could cause failure, malfunction, injury or fire.

•

Switch all phases of the external power supply off when mounting or removing the module.

Not doing so may cause failure or malfunction of the module.

•

Do not touch the connector while the power is on.

Doing so may cause malfunction.

•

Switch all phases of the external power supply off when cleaning or retightening terminal screws

and module installation screws.

Not doing so may cause failure or malfunction of the module.

If the screws are loose, it may cause fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damages to the screws and/or the module,

resulting in fallout, short circuits or malfunction.

• Always make sure to touch the grounded metal to discharge the electricity charged in the body, etc.,

before touching the module.

Failure to do so may cause a failure or malfunctions of the module.

[DISPOSAL PRECAUTIONS]

!

CAUTION

•

When disposing of this product, treat it as industrial waste.

Page 7

A - 5 A - 5

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

May, 2003 SH (NA)-080394E-A Firs t editi on

May, 2004 SH (NA)-080394E-B

Addition

Appendix 6

Partial correction

Safety Precautions, Section 2.2.1, Section 2.2.3, Section 2.2.4,

Chapter 4, Section 4.1, Section 4.3.3, Section 4.4.14, Section 7.2.1,

Section 8.2.2, Section 8.3.1, Section 8.3.2, Section 8.4.1, Section 8.4.2,

Section 13.1, Section 13.3, Appendix 3

Japanese Manual Version SH-080395-B

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2003 MITSUBISHI ELECTRIC CORPORATION

Page 8

A - 6 A - 6

INTRODUCTION

Thank you for purchasing the MELSEC-Q series PLC.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Q series PLC you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

CONTENTS

SAFETY PRECAUTIONS..............................................................................................................................A- 1

REVISIONS....................................................................................................................................................A- 5

INTRODUCTION............................................................................................................................................A- 6

Conformation to the EMC Directive and Low Voltage Instruction ................................................................A-13

About the Generic Terms and Abbreviations ................................................................................................A-14

Product Components .....................................................................................................................................A-16

1 OVERVIEW 1- 1 to 1-12

1.1 Overview..................................................................................................................................................1- 1

1.2 Compatibility with CC-Link......................................................................................................................1- 2

1.3 Features ..................................................................................................................................................1- 2

2 SYSTEM CONFIGURATION 2- 1 to 2- 9

2.1 System Configuration..............................................................................................................................2- 1

2.2 Applicable System...................................................................................................................................2- 4

2.2.1 Applicable modules and number of CPUs that can be mounted....................................................2- 4

2.2.2 Notes on the system configuration .................................................................................................. 2- 6

2.2.3 How to check the function version................................................................................................... 2- 8

2.2.4 CC-Link version................................................................................................................................2- 9

3 SPECIFICATIONS 3- 1 to 3- 7

3.1 Performance Specifications....................................................................................................................3- 1

3.1.1 Maximum overall cable distance (for Ver. 1.00)..............................................................................3- 3

3.1.2 Maximum overall cable distance (for Ver. 1.10)..............................................................................3- 5

3.2 CC-Link Dedicated Cable ....................................................................................................................... 3- 6

4 FUNCTIONS 4- 1 to 4-75

4.1 Function List............................................................................................................................................4- 1

4.2 Basic Functions.......................................................................................................................................4- 3

4.2.1 Communication with the remote I/O stations ..................................................................................4- 3

4.2.2 Communication with the remote device stations............................................................................. 4- 5

4.2.3 Communication with the local stations ............................................................................................4-10

4.2.4 Communication with the intelligent device stations......................................................................... 4-16

4.2.5 Parameter setting with GX Developer.............................................................................................4-22

4.2.6 Parameter setting with dedicated instruction ..................................................................................4-23

Page 9

A - 7 A - 7

4.3 Functions for Improving System Reliability............................................................................................4-25

4.3.1 Disconnecting data link faulty stations and continuing the data link with only normal stations

(Slave station cut-off function).........................................................................................................4-25

4.3.2 Automatically reconnecting a disconnected data link faulty station when it returns to normal

(Automatic return function)..............................................................................................................4-26

4.3.3 Continuing the data link when an error occurs in the master station PLC CPU

(Data link status setting when the master station PLC CPU has an error)....................................4-27

4.3.4 Retaining the device status of a data link faulty station

(Setting the status of input data from a data link faulty station).....................................................4-28

4.3.5 Clearing data in case of PLC CPU STOP

(Slave station refresh/compulsory clear setting in case of PLC CPU STOP) ...............................4-29

4.3.6 Continuing the data link even when the master station is faulty

(Standby master function) ...............................................................................................................4-31

4.4 Handy Functions.....................................................................................................................................4-45

4.4.1 Simplifying the initialization procedure registration of remote device stations

(Remote device station initialization procedure registration function) ...........................................4-45

4.4.2 Performing high-speed processing (Event issuance for the interrupt program) ............................ 4-48

4.4.3 Enabling the data link simply by powering on (Automatic CC-Link startup) ..................................4-51

4.4.4 Communicating with intelligent device stations (Remote net mode)..............................................4-53

4.4.5 Speeding up the response from remote I/O stations (Remote I/O net mode) ...............................4-54

4.4.6 Creating a program that contains modules to be added in the future

(Reserved station function) .............................................................................................................4-55

4.4.7 Powering off a station in operation without error detection

(Error invalid station setting function)..............................................................................................4-56

4.4.8 Synchronizing the link scan with the sequence scan (Scan synchronous function)...................... 4-57

4.4.9 Replacing modules without error detection (Temporary error invalid station setting function) .....4-61

4.4.10 Checking operations for each local station (Data link stop/restart) ..............................................4-62

4.4.11 Station number overlap checking function....................................................................................4-63

4.4.12 Multiple PLC system support......................................................................................................... 4-64

4.4.13 Reducing the reserved points of the remote I/O stations (Remote I/O station points setting)....4-65

4.4.14 Increasing the number of cyclic points (Remote net ver.2 mode)................................................4-67

4.5 Transient Transmission Functions .........................................................................................................4-75

4.5.1 Performing transient transmission (Dedicated instructions)...........................................................4-75

5 DATA LINK PROCESSING TIME 5- 1 to 5-45

5.1 Link Scan Time .......................................................................................................................................5- 1

5.2 Transmission Delay Time.......................................................................................................................5- 4

5.2.1 Master station

remote I/O station ...............................................................................................5- 4

5.2.2 Master station

remote device station (Ver. 1 compatible slave station)....................................5- 7

5.2.3 Master station

remote device station (Ver. 2 compatible slave station)....................................5-12

5.2.4 Master station

local station (Ver. 1 compatible slave station) ................................................... 5-20

5.2.5 Master station

local station (Ver. 2 compatible slave station) ................................................... 5-26

5.2.6 Master station

intelligent device station .....................................................................................5-34

5.3 Processing Time for Dedicated Instructions .......................................................................................... 5-35

5.3.1 Master station

local station ......................................................................................................... 5-35

5.3.2 Local stati on

local station............................................................................................................5-38

5.3.3 Master station

intelligent device station .....................................................................................5-39

Page 10

A - 8 A - 8

5.4 Link Refresh Time...................................................................................................................................5-40

5.4.1 Master station/local station ..............................................................................................................5-40

5.5 Station Status at Error Occurrence ........................................................................................................5-44

5.5.1 Status of the master station, standby master station (when the master station is operating)

and remote I/O station at error occurrence.....................................................................................5-44

5.5.2 Status of the remote device station, local station, standby master station

(when the local station is operating) and intelligent device station at error occurrence................5-45

6 PARAMETER SETTINGS 6- 1 to 6-52

6.1 Procedure from Parameter Settings to Data Link Startup.....................................................................6- 1

6.1.1 CPU parameter area and master module parameter memory....................................................... 6- 1

6.1.2 Procedure from parameter settings to data link startup with GX Developer..................................6- 2

6.1.3 Procedure from parameter settings to data link startup with dedicated instruction.......................6- 2

6.2 Parameter Setting Items.........................................................................................................................6- 3

6.3 Example of Parameter Settings with GX Developer (Remote net ver.1 mode)....................................6- 5

6.3.1 Master station network parameter settings.....................................................................................6- 5

6.3.2 Master station automatic refresh parameter settings......................................................................6-10

6.3.3 Local station network parameter settings........................................................................................6-12

6.3.4 Local station automatic refresh parameter settings ........................................................................6-15

6.4 Example of Parameter Settings with GX Developer (Remote net ver.2 mode)....................................6-17

6.4.1 Master station network parameter settings.....................................................................................6-17

6.4.2 Master station automatic refresh parameter settings......................................................................6-22

6.4.3 Local station network parameter settings........................................................................................6-24

6.4.4 Local station automatic refresh parameter settings ........................................................................6-27

6.5 Example of Parameter Settings with GX Developer (Remote net additional mode)............................6-29

6.5.1 Master station network parameter settings.....................................................................................6-29

6.5.2 Master station automatic refresh parameter settings......................................................................6-34

6.5.3 Local station network parameter settings........................................................................................6-37

6.5.4 Local station automatic refresh parameter settings ........................................................................6-40

6.6 Example of Parameter Settings with GX Developer (Remote I/O net mode)....................................... 6-43

6.6.1 Master station network parameter settings.....................................................................................6-43

6.6.2 Master station automatic refresh parameter settings......................................................................6-46

6.7 Example of Parameter Setting with Dedicated Instruction ....................................................................6-48

7 PROCEDURE BEFORE STARTING THE DATA LINK 7- 1 to 7-18

7.1 Procedure Before Starting the Data Link ...............................................................................................7- 1

7.2 Installation ............................................................................................................................................... 7- 3

7.2.1 Handling precautions .......................................................................................................................7- 3

7.2.2 Installation environment ................................................................................................................... 7- 4

7.3 Part Identification Nomenclature and Settings.......................................................................................7- 4

7.4 Checking the Module Status (Hardware Test).......................................................................................7- 7

7.5 Connecting the Modules Using the CC-Link Dedicated Cables............................................................7- 9

7.5.1 Wiring check.....................................................................................................................................7-10

7.6 T-Branch Connection with the CC-Link Dedicated Cable .....................................................................7-11

7.6.1 T-Branch system configuration........................................................................................................7-11

7.6.2 T-Branch communication specifications list ....................................................................................7-12

Page 11

A - 9 A - 9

7.7 Switch Settings........................................................................................................................................7-13

7.7.1 Station number setting .....................................................................................................................7-13

7.7.2 Transmission rate and mode settings .............................................................................................7-14

7.8 Checking the Connection Status (Line Test) ......................................................................................... 7-15

8 PROGRAMMING 8- 1 to 8-40

8.1 Precautions on Programming.................................................................................................................. 8- 1

8.2 I/O Signals for the PLC CPU ...................................................................................................................8- 2

8.2.1 I/O signal list......................................................................................................................................8- 2

8.2.2 Details of the I/O signals ...................................................................................................................8- 4

8.3 Buffer Memory.......................................................................................................................................... 8- 5

8.3.1 Buffer memory list .............................................................................................................................8- 5

8.3.2 Buffer memory details .......................................................................................................................8- 8

8.4 Link Special Relays and Registers (SB/SW) ..........................................................................................8-26

8.4.1 Link special relays (SB).....................................................................................................................8-26

8.4.2 Link special registers (SW)...............................................................................................................8-31

8.5 Mode Selection Method...........................................................................................................................8-40

9 COMMUNICATION BETWEEN THE MASTER STATION AND REMOTE I/O STATIONS 9- 1 to 9-10

9.1 When Remote I/O Net Mode is Used.....................................................................................................9- 1

9.1.1 Configuring a system .......................................................................................................................9- 1

(1) Setting the master station...................................................................................................................9- 2

(2) Setting the remote I/O stations........................................................................................................... 9- 3

9.1.2 Setting the master station parameters ............................................................................................ 9- 4

(1) Setting the network parameters of the master station.......................................................................9- 4

(2) Setting the automatic refresh parameters of the master station ....................................................... 9- 6

9.1.3 Creating a program ..........................................................................................................................9- 7

9.1.4 Performing the data link...................................................................................................................9- 9

(1) Confirming the operation with the LED display..................................................................................9- 9

(2) Confirming the operation with the sequence program.......................................................................9-10

10 COMMUNICATION BETWEEN THE MASTER STATION AND

REMOTE DEVICE STATIONS 10- 1 to 10-57

10.1 When Remote Net Ver. 1 Mode is Used............................................................................................10- 1

10.1.1 Configuring a system ...................................................................................................................10- 1

(1) Setting the master station.................................................................................................................10- 2

(2) Setting the remote device station.....................................................................................................10- 3

10.1.2 Setting the master station parameters ........................................................................................ 10- 4

(1) Setting the network parameters of the master station.....................................................................10- 4

(2) Setting the automatic refresh parameters of the master station ..................................................... 10- 6

10.1.3 Initial setting of the remote device station ................................................................................... 10- 7

(1) Setting the target station number .....................................................................................................10- 7

(2) Setting the regist procedure registration ..........................................................................................10- 7

(3) Validating the remote device station initial settings .........................................................................10-11

10.1.4 Creating a program ......................................................................................................................10-13

Page 12

A - 10 A - 10

10.1.5 Performing the data link...............................................................................................................10-16

(1) Confirming the operation with the LED display................................................................................10-16

(2) Confirming the operation with the sequence program.....................................................................10-17

10.2 When Remote Net Ver. 2 Mode is Used............................................................................................10-18

10.2.1 Configuring a system ...................................................................................................................10-18

(1) Setting the master station.................................................................................................................10-19

(2) Setting the remote device station.....................................................................................................10-20

10.2.2 Setting the master station parameters ........................................................................................10-22

(1) Setting the network parameters of the master station.....................................................................10-22

(2) Setting the automatic refresh parameters of the master station .....................................................10-24

10.2.3 Initial setting of the remote device station ...................................................................................10-25

(1) Setting the target station number .....................................................................................................10-25

(2) Setting the regist procedure registration ..........................................................................................10-25

(3) Validating the remote device station initial settings .........................................................................10-29

10.2.4 Creating a program ......................................................................................................................10-32

10.2.5 Performing the data link...............................................................................................................10-36

(1) Confirming the operation with the LED display................................................................................10-36

(2) Confirming the operation with the sequence program.....................................................................10-37

10.3 When Remote Net Additional Mode is Used .....................................................................................10-38

10.3.1 Configuring a system ...................................................................................................................10-38

(1) Setting the master station.................................................................................................................10-39

(2) Setting the remote device station.....................................................................................................10-40

10.3.2 Setting the master station parameters ........................................................................................10-42

(1) Setting the network parameters of the master station.....................................................................10-42

(2) Setting the automatic refresh parameters of the master station .....................................................10-44

10.3.3 Initial setting of the remote device station ...................................................................................10-45

(1) Setting the target station number .....................................................................................................10-45

(2) Setting the regist procedure registration ..........................................................................................10-45

(3) Validating the remote device station initial settings .........................................................................10-49

10.3.4 Creating a program ......................................................................................................................10-52

10.3.5 Performing the data link...............................................................................................................10-56

(1) Confirming the operation with the LED display................................................................................10-56

(2) Confirming the operation with the sequence program.....................................................................10-57

11 COMMUNICATION BETWEEN THE MASTER STATION AND LOCAL STATIONS 11- 1 to 11-45

11.1 When Remote Net Ver. 1 Mode is Used............................................................................................11- 1

11.1.1 Configuring a system ...................................................................................................................11- 1

(1) Setting the master and local stations ...............................................................................................11- 2

11.1.2 Setting the master station parameters ........................................................................................ 11- 3

(1) Setting the network parameters of the master station.....................................................................11- 3

(2) Setting the automatic refresh parameters of the master station ..................................................... 11- 5

11.1.3 Setting the local station parameters ............................................................................................11- 6

(1) Setting the network parameters of the local station.........................................................................11- 6

(2) Setting the automatic refresh parameters of the local station.........................................................11- 8

11.1.4 Creating a program ......................................................................................................................11- 9

(1) Master station program.....................................................................................................................11-11

(2) Local station program .......................................................................................................................11-11

Page 13

A - 11 A - 11

11.1.5 Performing the data link...............................................................................................................11-12

(1) Confirming the operation with the LED display................................................................................11-12

(2) Confirming the operation with the sequence program.....................................................................11-13

11.2 When Remote Net Ver. 2 Mode is Used............................................................................................11-14

11.2.1 Configuring a system ...................................................................................................................11-14

(1) Setting the master and local stations ...............................................................................................11-15

11.2.2 Setting the master station parameters ........................................................................................11-16

(1) Setting the network parameters of the master station.....................................................................11-16

(2) Setting the automatic refresh parameters of the master station .....................................................11-18

11.2.3 Setting the local station parameters ............................................................................................11-19

(1) Setting the network parameters of the ver.1 compatible local station (station number 1) .............11-19

(2) Setting the automatic refresh parameters of the ver.1 compatible local station

(station number 1).............................................................................................................................11-21

(3) Setting the network parameters of the ver.2 compatible local station (station number 5) .............11-22

(4) Setting the automatic refresh parameters of the ver.2 compatible local station

(station number 5).............................................................................................................................11-24

11.2.4 Creating a program ......................................................................................................................11-25

(1) Master station program.....................................................................................................................11-27

(2) Local station program .......................................................................................................................11-27

11.2.5 Performing the data link...............................................................................................................11-28

(1) Confirming the operation with the LED display................................................................................11-28

(2) Confirming the operation with the sequence program.....................................................................11-29

11.3 When Remote Net Additional Mode is Used .....................................................................................11-30

11.3.1 Configuring a system ...................................................................................................................11-30

(1) Setting the master and local stations ...............................................................................................11-31

11.3.2 Setting the master station parameters ........................................................................................11-32

(1) Setting the network parameters of the master station.....................................................................11-32

(2) Setting the automatic refresh parameters of the master station .....................................................11-34

11.3.3 Setting the local station parameters ............................................................................................11-35

(1) Setting the network parameters of the ver.1 compatible local station (station number 1) .............11-35

(2) Setting the automatic refresh parameters of the ver.1 compatible local station

(station number 1).............................................................................................................................11-37

(3) Setting the network parameters of the ver.2 compatible local station (station number 5) .............11-38

(4) Setting the automatic refresh parameters of the ver.2 compatible local station

(station number 5).............................................................................................................................11-40

11.3.4 Creating a program ......................................................................................................................11-41

(1) Master station program.....................................................................................................................11-43

(2) Local station program .......................................................................................................................11-43

11.3.5 Performing the data link...............................................................................................................11-44

(1) Confirming the operation with the LED display................................................................................11-44

(2) Confirming the operation with the sequence program.....................................................................11-45

12 COMMUNICATION BETWEEN THE MASTER STATION AND INTELLIGENT DEVICE

STATIONS 12- 1 to 12- 2

Page 14

A - 12 A - 12

13 TROUBLESHOOTING 13- 1 to 13-21

13.1 Verification upon Problem Occurrence ..............................................................................................13- 1

13.2 Troubleshooting Procedures When the "ERR." LED of the Master Station is Flashing or

When Normal Data cannot be Sent/Received During Data Link ...................................................... 13- 8

13.3 Error Codes.........................................................................................................................................13-10

13.4 CC-Link Diagnostics Using the GX Developer ..................................................................................13-16

APPENDIX App- 1 to App-46

Appendix 1 External Dimensions Diagram...............................................................................................App- 1

Appendix 2 Dedicated Instruction List ......................................................................................................App- 2

Appendix 2.1 RIRD instruction..............................................................................................................App- 3

Appendix 2.2 RIWT instruction .............................................................................................................App- 8

Appendix 2.3 RIRCV instruction ...........................................................................................................App-13

Appendix 2.4 RISEND instruction.........................................................................................................App-18

Appendix 2.5 RIFR instruction..............................................................................................................App-23

Appendix 2.6 RITO instruction..............................................................................................................App-26

Appendix 2.7 RLPASET instruction......................................................................................................App-29

Appendix 3 Differences Between the New and Previous Models ...........................................................App-40

Appendix 4 Precautions when Changing from AJ61QBT11 to QJ61BT11N..........................................App-41

Appendix 5 Precautions when Changing from QJ61BT11 to QJ61BT11N ............................................App-41

Appendix 6 CPU-dependent Function Availability ...................................................................................App-42

Appendix 7 Parameter Setting Checklist..................................................................................................App-43

Appendix 7.1 Parameter setting checklist ............................................................................................App-43

Appendix 7.2 Station information setting checklist...............................................................................App-44

INDEX Index- 1 to Index- 4

Page 15

A - 13 A - 13

Conformation to the EMC Directive and Low Voltage Instruction

For details on making Mitsubishi PLC conform to the EMC directive and low voltage instruction when

installing it in your product, please see Chapter 3, "EMC Directive and Low Voltage Instruction" of the User's

Manual (Hardware) of the CPU module to use.

The CE logo is printed on the rating plate on the main body of the PLC that conforms to the EMC directive

and low voltage instruction.

To conform this product to the EMC Directive and Low Voltage Directive, refer to the Section of "CC-Link

Modules" in Chapter 3 "EMC Directive and Low Voltage Directive" of the User’s Manual (Hardware) of the

CPU module used.

Page 16

A - 14 A - 14

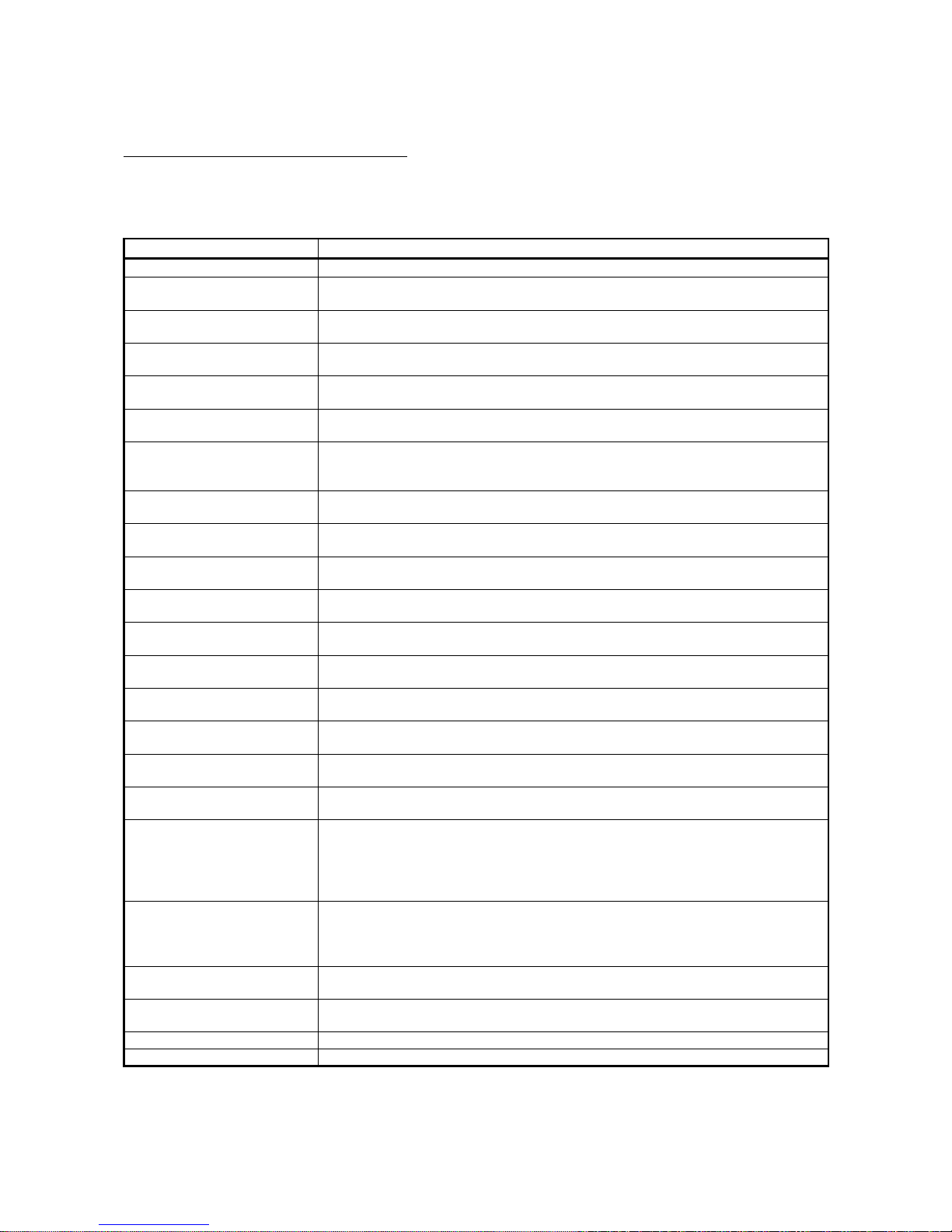

About the Generic Terms and Abbreviations

This manual uses the following generic terms and abbreviations to describe the QJ61BT11N CC-Link

System Master/Local Module, unless otherwise specified.

Generic Term/Abbreviation

Description

QJ61BT11N

Abbreviation for QJ61BT11N CC-Link System Master/Local Module

Cyclic transmission

Transmission method by which to periodically communicate the contents of remote

I/O and remote registers.

Transient transmission

Transmission method with which the counterpart is specified and 1:1 communication

is used at an arbitrary timing.

Master station

Station that controls the data link system.

One master station is required for each system.

Local station

Station having a PLC CPU and the ability to communicate with the master and other

local stations.

Remote I/O station

Remote station that handles bit unit data only. (Performs input and output with

external devices.) (AJ65BTB1-16D, AJ65SBTB1-16D)

Remote device station

Remote station that handles bit unit and word unit data only. (Performs input and

output with external devices, and analog data conversion.)

(AJ65BT-64AD, AJ65BT-64DAV, AJ65BT-64DAI)

Remote station

Generic term for remote I/O station and remote device station.

(Controlled by the master station)

Intelligent device station

Station that can perform transient transmission, such as the AJ65BT-R2 (including

local stations).

Standby master station

Backup station for data link control when the link to the master station is disconnected

due to a PLC CPU or power supply problem.

Slave station

Generic term for remote I/O station, remote device station, local station, intelligent

device station and standby master station.

Master/local module

Generic term for QJ61BT11N, QJ61BT11, AJ61BT11, A1SJ61BT11, AJ61QBT11,

and A1SJ61QBT11

Master module

Generic term for QJ61BT11N, QJ61BT11, AJ61BT11, A1SJ61BT11, AJ61QBT11,

and A1SJ61QBT11 when they are used as master stations.

Local module

Generic term for QJ61BT11N, QJ61BT11, AJ61BT11, A1SJ61BT11, AJ61QBT11,

and A1SJ61QBT11 when they are used as local stations.

Remote module

Generic term for AJ65BTB1-16D, AJ65SBTB1-16D, AJ65BT-64AD, AJ65BT-64DAV,

AJ65BT-64DAI, and A852GOT

Intelligent device module

Module that can perform transient transmission, such as the AJ65BT-R2 (including

local module).

Remote I/O net mode

Dedicated mode for sending and receiving data to and from the remote I/O station at

high speed.

Remote net mode

Mode that can communicate with all stations used for CC-Link (remote I/O station,

remote device station, local station, intelligent device station, and standby master

station)

The remote net mode has three different modes: remote net ver. 1 mode, remote net

ver. 2 mode, and remote net additional mode.

Remote net ver. 1 mode

Mode in which complete compatibility with the conventional module (QJ61BT11) is

achieved.

Select this mode when the number of cyclic points need not be increased or when the

QJ61BT11N is used to replace the conventional module as a maintenance product.

Remote net ver. 2 mode

Select this mode when increasing the number of cyclic points and configuring a new

system.

Remote net additional mode

Select this mode when adding a ver. 2 compatible station to the existing system to

increase the number of cyclic points.

Ver. 1 compatible slave station Slave station compatible with the remote net ver. 1 mode.

Ver. 2 compatible slave station Slave station compatible with the remote net ver. 2 mode.

Page 17

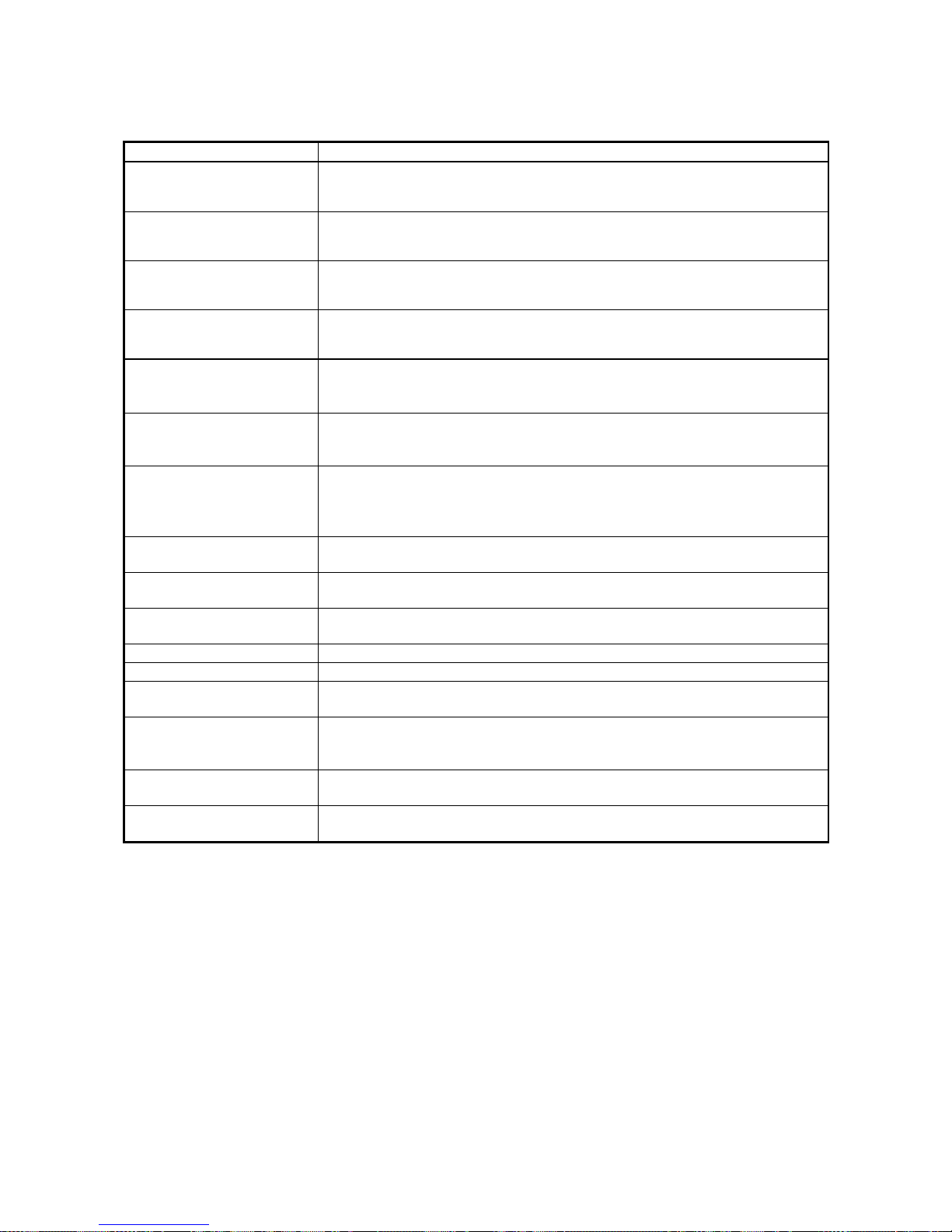

A - 15 A - 15

Generic Term/Abbreviation

Description

SB

Link special relay (for CC-Link)

Bit unit information that indicates the module operating status and data link status of

the master station/local station. (Expressed as SB for convenience)

SW

Link special register (for CC-Link)

16-bit unit information that indicates the module operating status and data link status

of the master station/local station. (Expressed as SW for convenience)

RX

Remote input (for CC-Link)

Information entered in bit units from the remote station to the master station.

(Expressed as RX for convenience)

RY

Remote output (for CC-Link)

Information output in bit units from the master station to the remote station.

(Expressed as RY for convenience)

RWw

Remote register (Write area for CC-Link)

Information output in 16-bit units from the master station to the remote device station.

(Expressed as RWw for convenience)

RWr

Remote register (Read area for CC-Link)

Information entered in 16-bit units from the remote device station to the master

station. (Expressed as RWr for convenience)

ACPU

Generic term for AOJ2HCPU, A1SCPU, A1SHCPU, A1SJCPU-S3, A1SJHCPU,

A2SCPU, A2SHCPU, A2USCPU, A2USCPU-S1, A2USHCPU-S1, A1NCPU,

A2NCPU, A2NCPU-S1, A3NCPU, A2ACPU, A2ACPU-S1, A3ACPU, A2UCPU,

A2UCPU-S1, A3UCPU and A4UCPU

AnUCPU

Generic term for A2USCPU, A2USCPU-S1, A2USHCPU-S1, A2UCPU, A2UCPU-S1,

A3UCPU and A4UCPU

QnACPU

Generic term for Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1, Q2ACPU,

Q2ACPU-S1, Q3ACPU, Q4ACPU and Q4ARCPU

QCPU (Q mode)

Generic term for Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU and Q25HCPU, Q12PHCPU, Q25PHCPU

QCPU (A mode) Generic term for Q02CPU-A, Q02HCPU-A, Q06HCPU-A

QnCPU Generic term for Q00JCPU, Q00CPU, Q01CPU and Q02CPU.

QnHCPU

Generic term for Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU, Q12PHCPU and

Q25PHCPU.

GX Developer

Generic product name of the product types SWnD5C-GPPW-E, SWnD5C-GPPW-EA,

SWnD5C-GPPW-EV and SWnD5C-GPPW-EVA. ("n" in the model name is 4 or

greater)

Intelligent function module

Q series modules other than the CPU module, power supply module and I/O module

that are mounted on the base unit.

Special function module

A series and QnA series modules that are mounted on the base unit, excluding the

CPU module, power supply module and I/O module.

Page 18

A - 16 A - 16

Product Components

The components of the QJ61BT11N are listed below.

Item name Quantity

QJ61BT11N main unit 1

Terminal resistor 110 Ω, 1/2 W (brown-brown-brown)

(used when wiring with the CC-Link dedicated cable or Version 1.10 compatible CC-Link

dedicated cable)

2

Terminal resistor 130 Ω, 1/2 W (brown-orange-brown)

(used when wiring with the CC-Link dedicated high-performance cable)

2

Page 19

1 - 1 1 - 1

MELSEC-Q

1 OVERVIEW

1 OVERVIEW

This manual describes the specifications, parts names and settings of the QJ61BT11N

CC-Link System Master/Local Module (hereinafter referred to as the QJ61BT11N)

which is used with the MELSEC-Q series PLC CPUs.

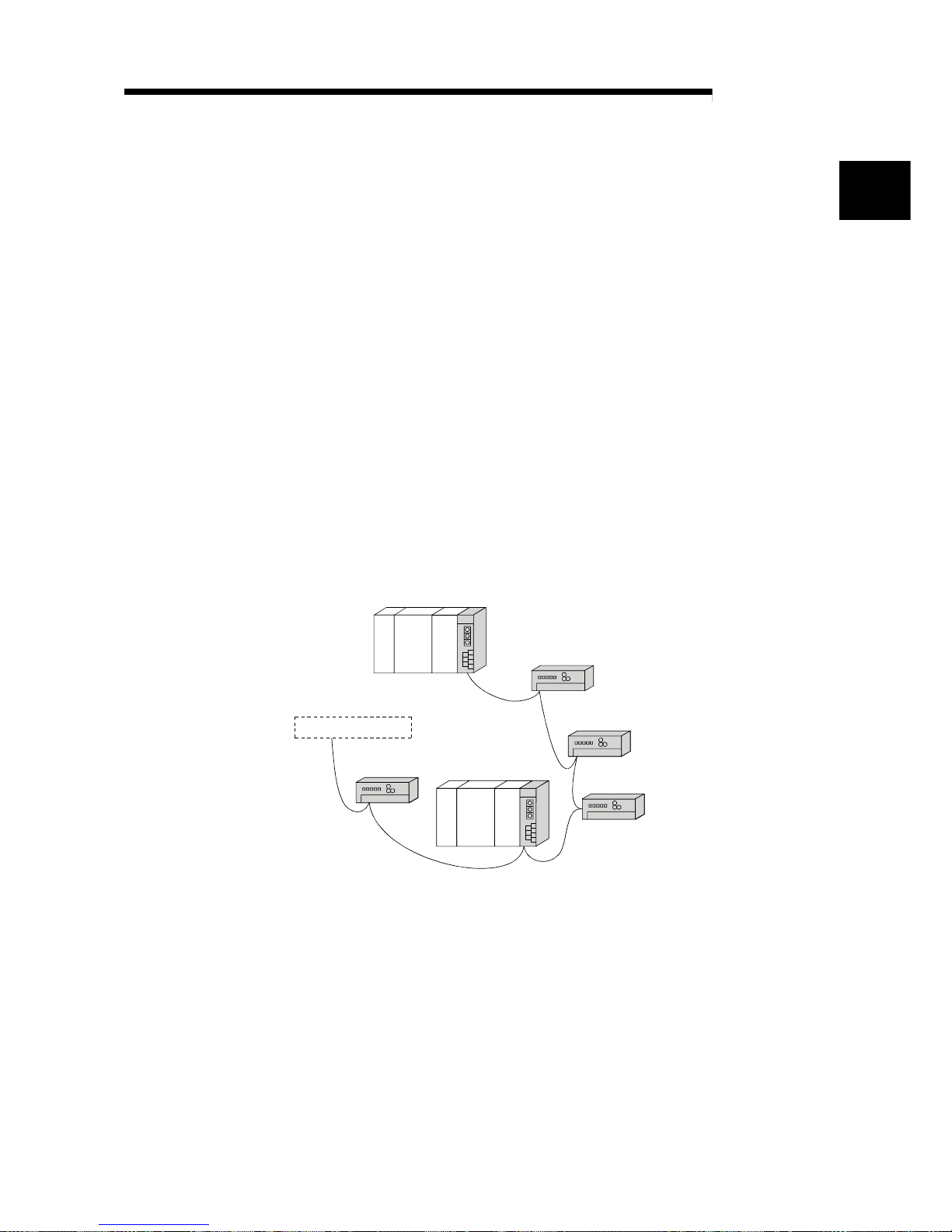

1.1 Overview

The CC-Link system connects distributed modules such as an I/O module, an intelligent

function module, and a special function module using dedicated cables so that these

modules can be controlled by the PLC CPU.

(1) By distributing each module to an equipment device such as a conveyor line and a

machine device, the wiring efficiency of the entire system can be accomplished.

(2) On/off information of input/output and numeric data that are handled by modules

can easily be sent and received at high-speed.

(3) By connecting multiple PLC CPUs, a simple distributed system can be configured.

(4) By connecting various devices made by Mitsubishi's partner manufacturers, the

system can provide flexible solutions to meet a wide range of user needs.

PLC CPU

Master station

Local station

Remote I/O station

Remote device station

Intelligent device s ta tion

Remote I/O station

Device manufactured by one of our

partner manufa ct urers

PLC CPU

Master station

................

The station that controls the data link system.

Remote I/O station

........

The remote station that handles bit unit data only.

Remote device station

....

The remote station that handles bit unit and word unit data

only.

Local station

..................

The station having a PLC CPU and the ability to communicate

with the master and other local stations.

Intelligent device station

..

The station that can perform transient transmission.

1

Page 20

1 - 2 1 - 2

MELSEC-Q

1 OVERVIEW

1.2 Compatibility with CC-Link

This product supports following CC-Link functions and performance.

Cyclic transmission

Increase of cyclic transmission data size

Transient transmission

Less restrictions on the station-to-station cable length

1.3 Features

The features of the CC-Link are described below.

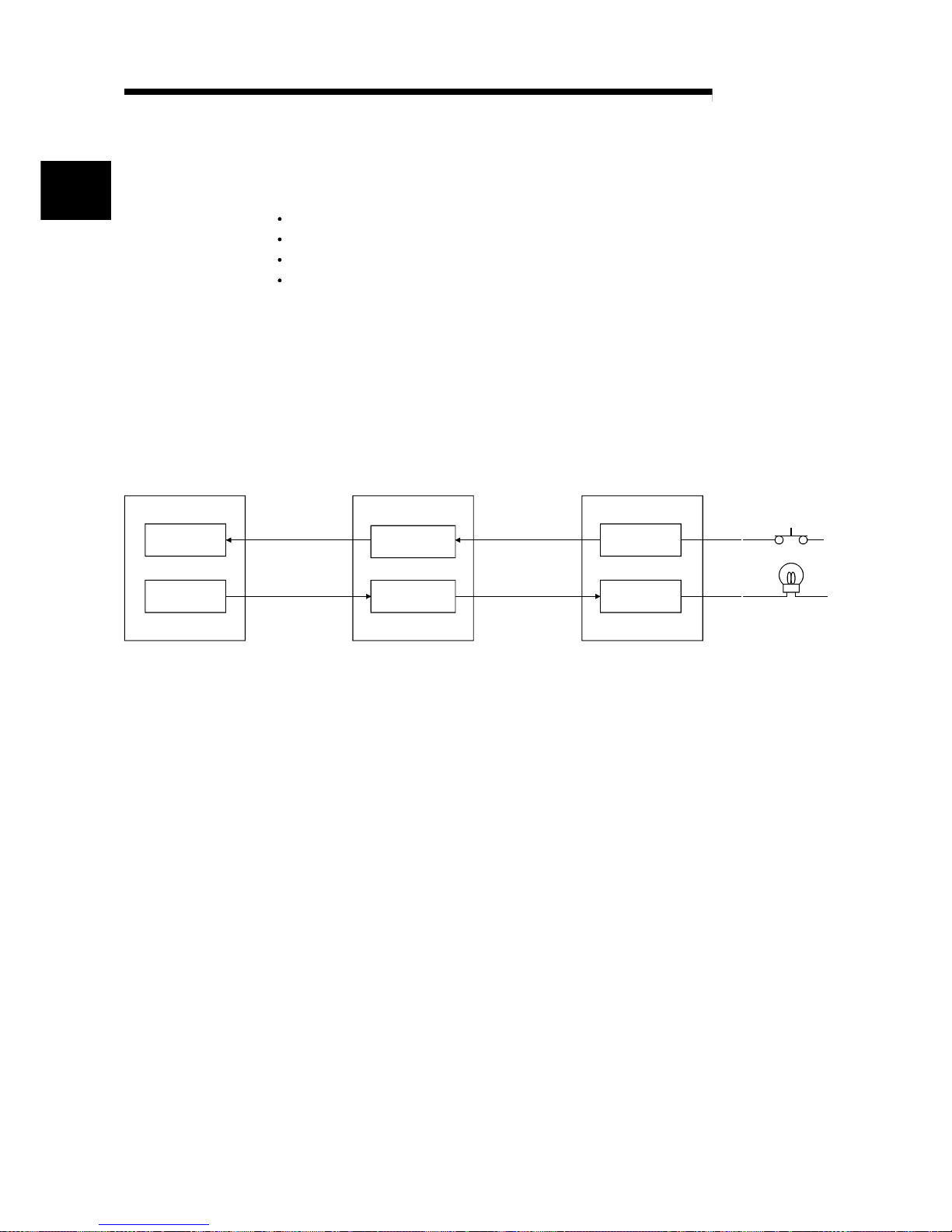

(1) Remote I/O station communication

The ON/OFF status of a switch or indicator lamp is communicated using the

remote input RX and remote output RY (see Section 4.2.1).

Input

Output

Remote input

RX

Remote output

RY

X

Y

Master stationPLC CPU Remote I/O station

Link scan

Link scan

Automatic refresh

Automatic refresh

1

Page 21

1 - 3 1 - 3

MELSEC-Q

1 OVERVIEW

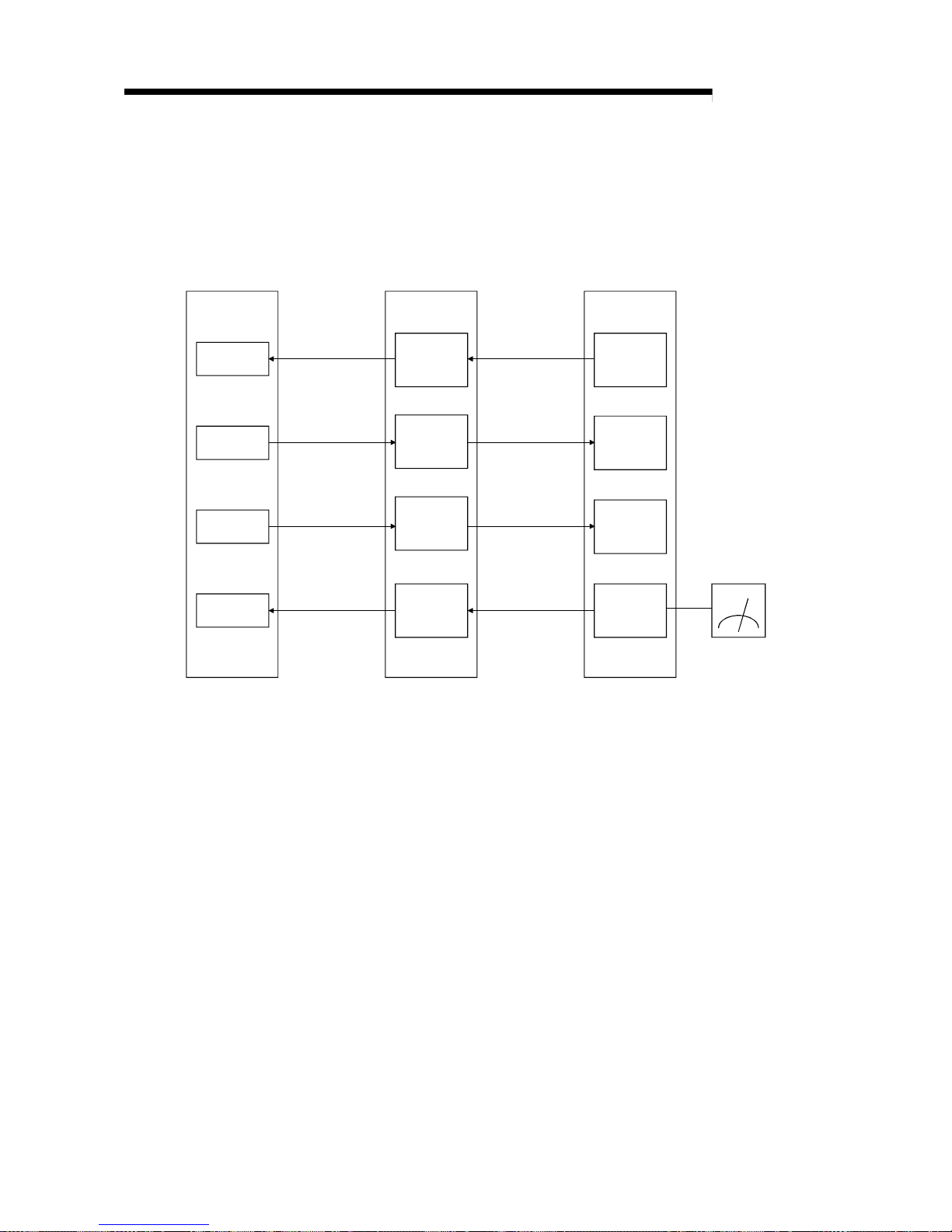

(2) Remote device station communication

Signals for handshaking with the remote device station (initial request, error

occurred flag, etc.) are communicated using the remote input RX and remote

output RY. The setting data to the remote device station are communicated using

remote registers RWw and RWr (see Section 4.2.2).

PLC CPU

X

Y

W

W

Master station

Remote

input

(RX)

Remote

output

(RY)

Remote

register

(RWw)

Remote

register

(RWr)

Automatic refresh

Automatic refresh

Automatic refresh

Automatic refresh

Link scan

Link scan

Link scan

Link scan

Remote device station

Voltmeter

Remote

input

(RX)

Remote

output

(RY)

Remote

register

(RWw)

Remote

register

(RWr)

Page 22

1 - 4 1 - 4

MELSEC-Q

1 OVERVIEW

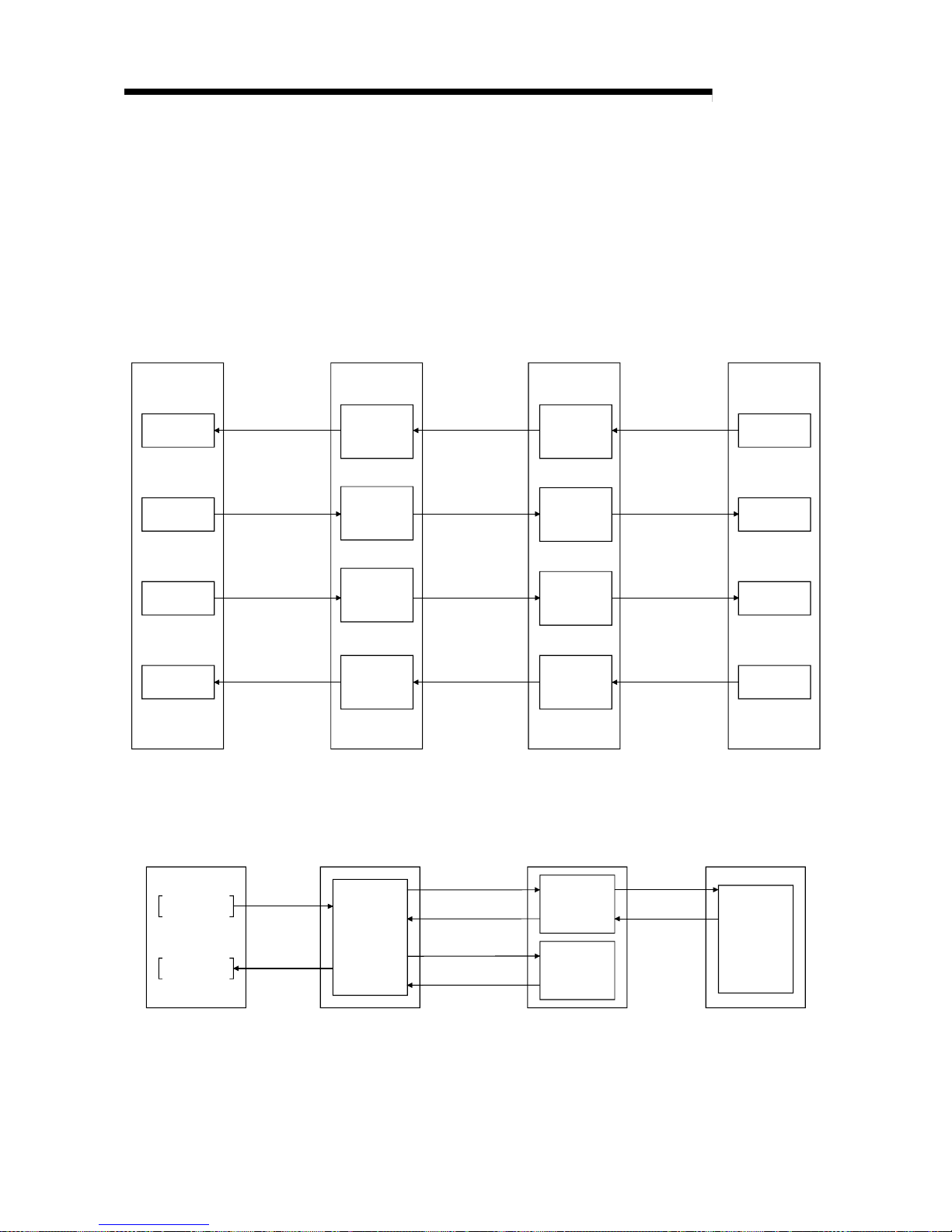

(3) Local station communication

Communication between the master station and the local station uses two types

of transmission methods: cyclic transmission and transient transmission (see

Section 4.2.3).

(a) Cyclic transmission

Data communication between the PLC CPUs can be performed in N:N

mode using bit data (remote input RX and remote output RY) and word data

(remote registers RWw and RWr).

PLC CPU

X

Y

W

W

Master station

X

Y

W

W

Remote

output

(RY)

Remote

input

(RX)

Remote

register

(RWw)

Remote

register

(RWr)

Remote

input

(RX)

Remote

output

(RY)

Remote

register

(RWw)

Remote

register

(RWr)

Automatic refresh

Automatic refresh

Automatic refresh

Automatic refresh

Link scan

Link scan

Link scan

Link scan

Automatic refresh

Automatic refresh

Automatic refresh

Automatic refresh

PLC CPU

Local station

(b) Transient transmission

Read (RIRD) or write (RIWT) operation of the local station buffer memory

and CPU device can be performed at any timing.

Master stationPLC CPU Local station

Transient transmission

PLC CPU

Transient transmission

Transient transmission

Transient transmission

Transient

transmission

area

Transient

transmission

area

Buffer

memory

W

RIWT

RIRD

Page 23

1 - 5 1 - 5

MELSEC-Q

1 OVERVIEW

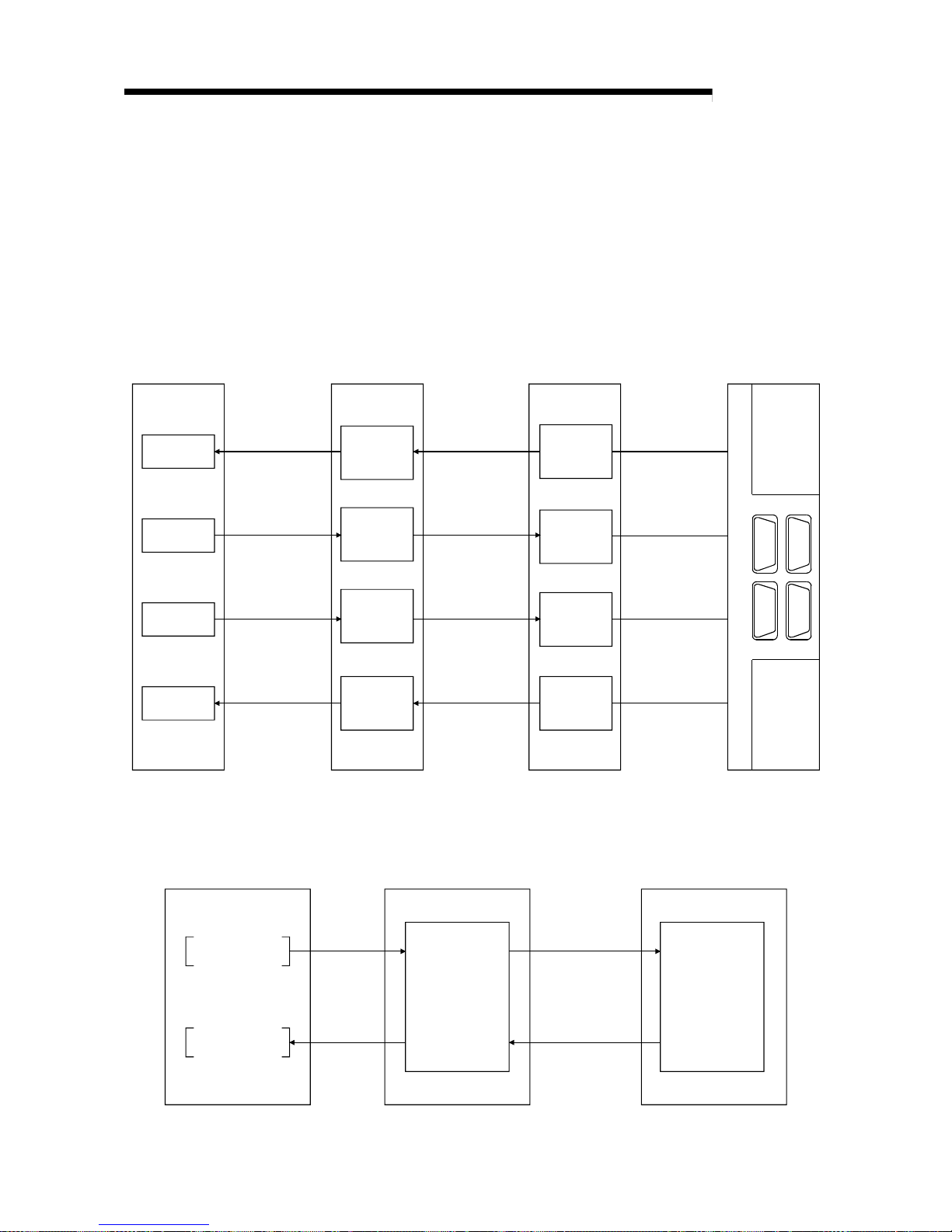

(4) Intelligent device station communication

Communication between the master station and the intelligent device station

uses two types of transmission methods: cyclic transmission and transient

transmission (see Section 4.2.4).

(a) Cyclic transmission

Signals for handshaking with the intelligent device station (positioning start,

positioning complete, etc.) are communicated using the remote input RX and

remote output RY. Numeric data (positioning start number, present feed

value, etc.) is communicated using remote registers RWw and RWr.

PLC CPU

X

Y

W

W

Master station

Remote

output

RY

Remote

input

RX

Remote

register

RWw

Remote

register

RWr

Remote

input

RX

Remote

output

RY

Remote

register

RWw

Remote

register

RWr

Automatic refresh

Automatic refresh

Automatic refresh

Automatic refresh

Link scan

Link scan

Link scan

Link scan

Intelligent device station

Servo amplifier

(b) Transient transmission

Read (RIRD) or written (RIWT) operation of the intelligent device station

buffer memory can be performed at any timing.

Master stationPLC CPU Intelligent device station

Transient transmission

Transient

transmission

area

Transient transmission

RIWT

RIRD

Buffer memory

Page 24

1 - 6 1 - 6

MELSEC-Q

1 OVERVIEW

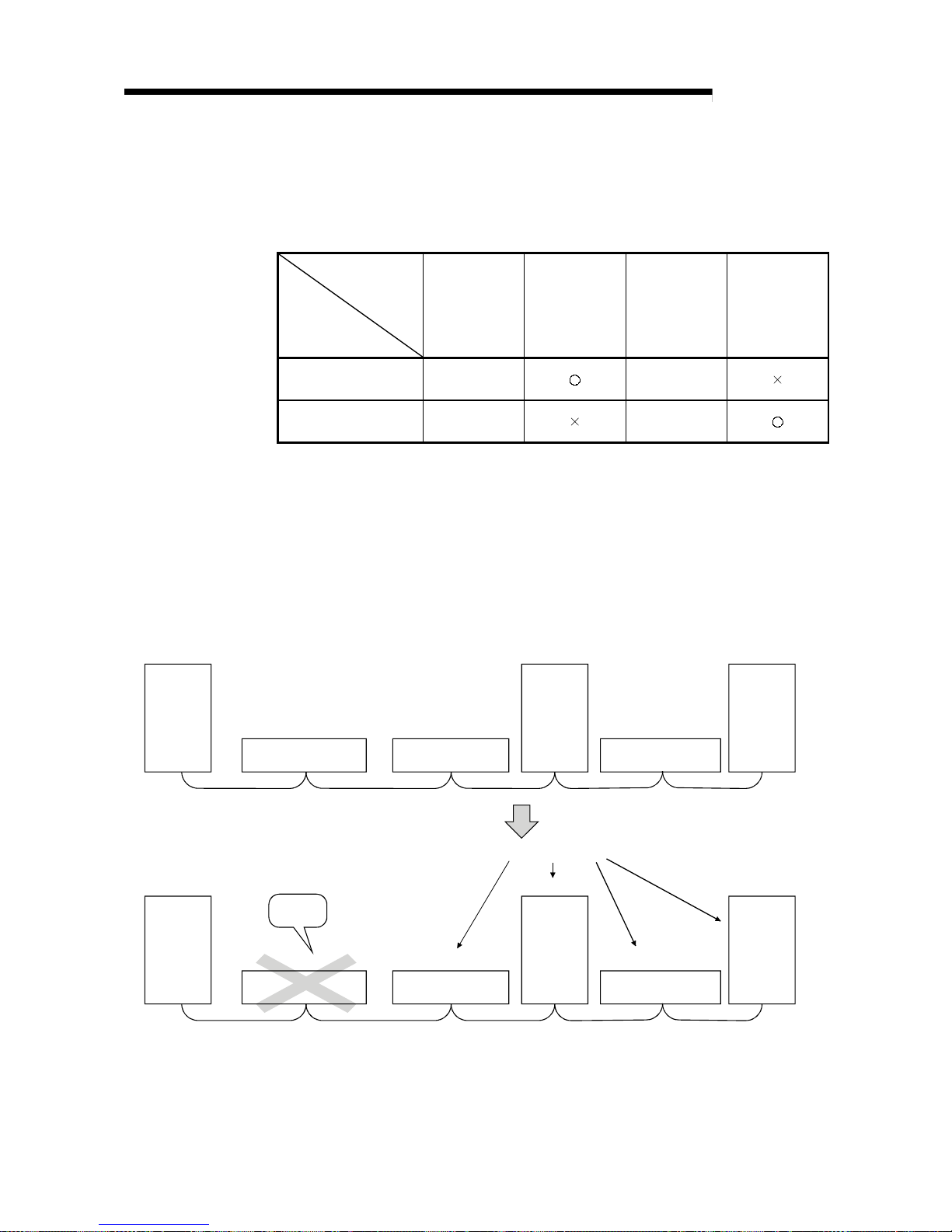

(5) Parameter setting by GX Developer or the dedicated instruction

There are two parameter setting methods; the parameters can either be set by

GX Developer or by using a dedicated instruction (see Sections 2.2.1, 4.2.5 and

4.2.6).

The following table lists the differences between the two setting methods.

Program

requirement for

setting

parameters

Automatic

refresh

Number of

CPUs that can

be mounted

Changing the

parameter

settings while

the PLC CPU is

running

Parameter setting with

GX Developer

Not required

4 modules

Parameter setting with

dedicated instruction

Required

64 modules

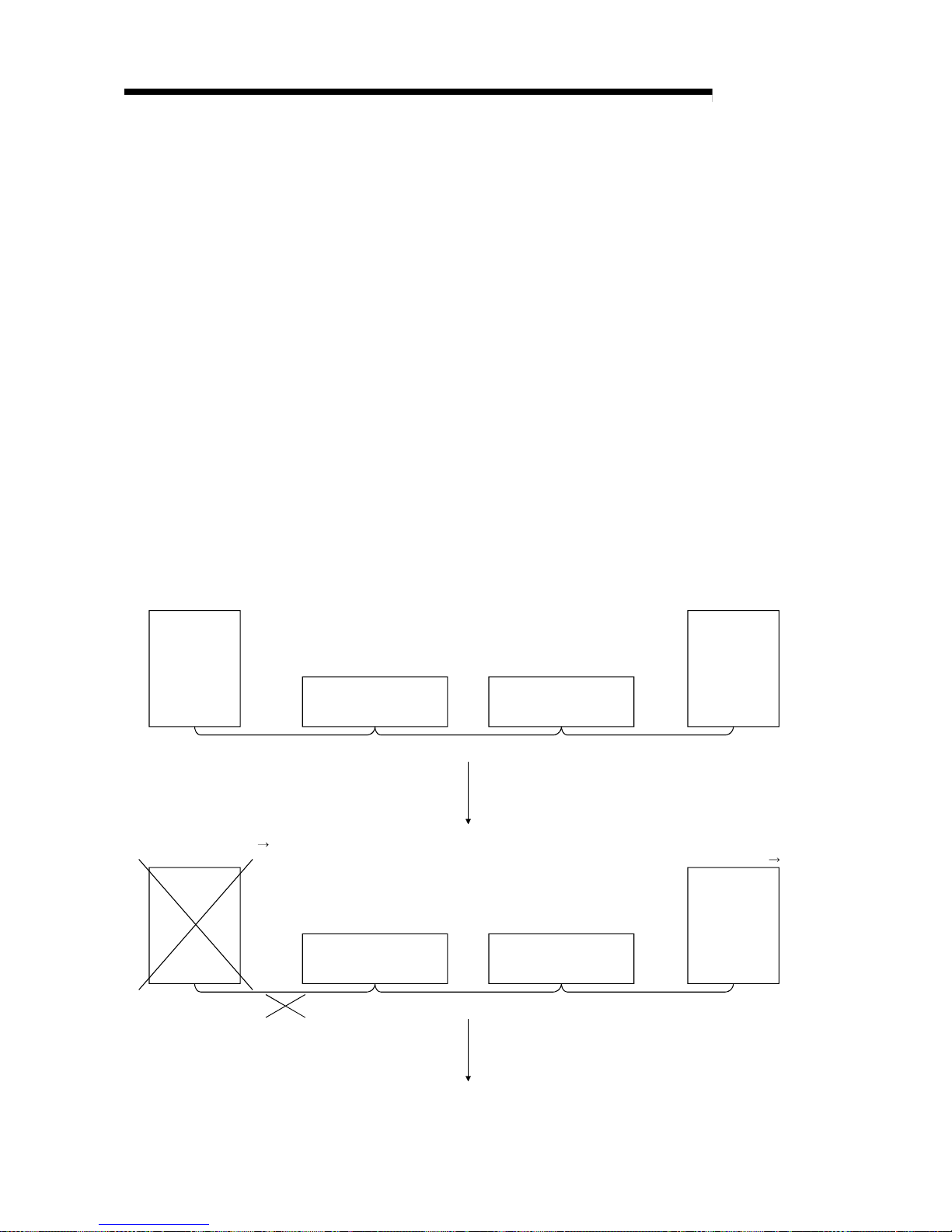

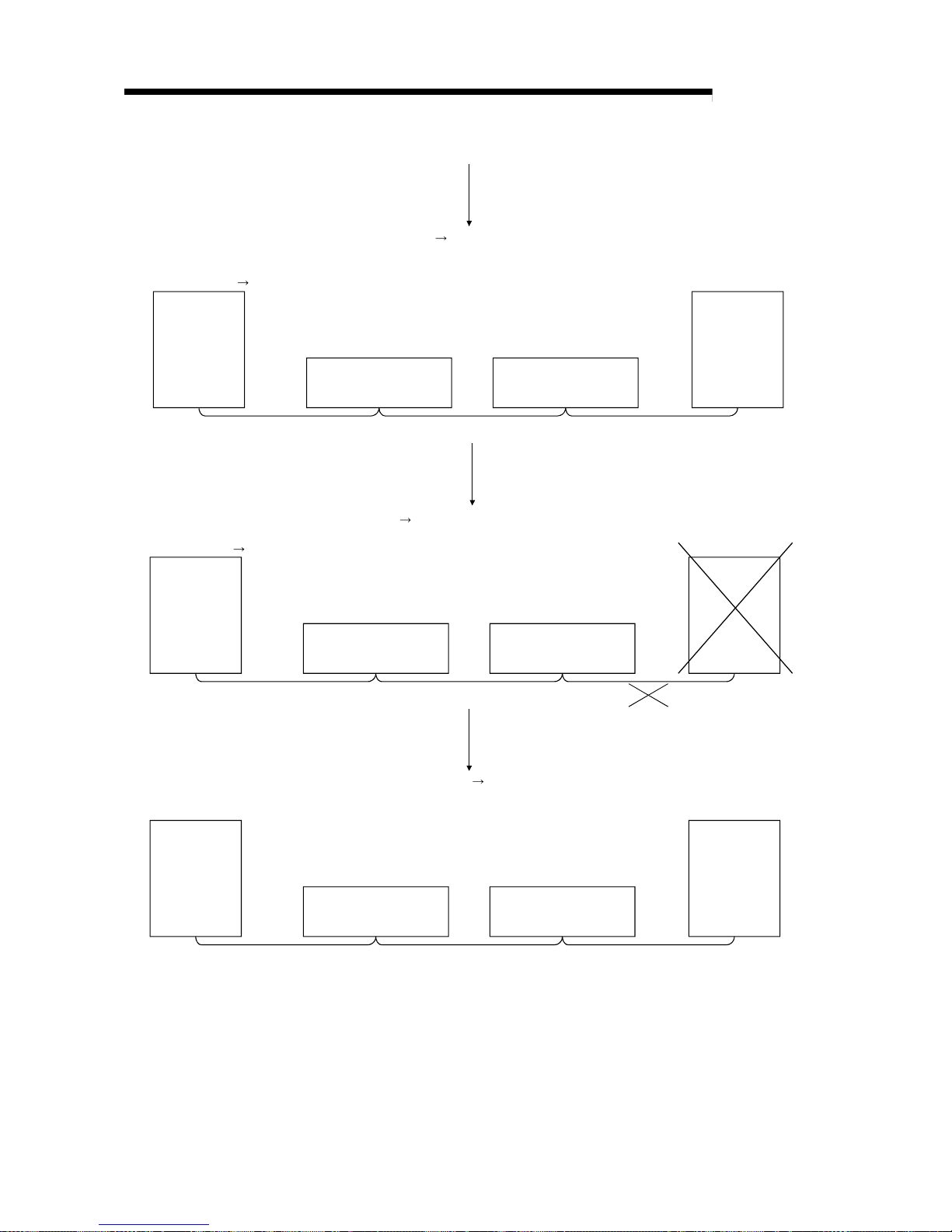

(6) System down prev ention ( Sl av e stati on cut- off function)

Because the system employs the bus connection method, even if a module

system fails due to power off, it will not affect the communication with other

normal modules.

Also, for a module using a 2-piece terminal block, the module can be replaced

during data link. (Replace the module after turning off the module power).

However, if the cable is disconnected, data link to all stations are disabled (see

Section 4.3.1).

Master

station

Remote station

(occupies 2 stations)

Remote station

(occupies 1 station)

Local

station

(occupies

1 station)

Remote station

(occupies 2 stations)

Local

station

(occupies

4 stations)

Station number 1 Station number 3 Station number 5

Station number 4 Station number 7

Master

station

Remote station

(occupies 2 stations)

Remote station

(occupies 1 station)

Local

station

(occupies

1 station)

Remote station

(occupies 2 stations)

Local

station

occupies

4 stations)

Station number 1 Station number 3 Station number 5

Station number 4 Station number 7

Data link continues

Faulty

station

(7) Automatic return function

When a station that has been disconnected from the link due to power off

recovers the normal status, it will join the data link automatically (see Section

4.3.2).

Page 25

1 - 7 1 - 7

MELSEC-Q

1 OVERVIEW

(8) Data link status setting when the master stati on PLC C PU has an

error

The data-link status can be set to either "stop" or "continue" when an error

causing the operation to stop such as "SP. UNIT ERROR" occurs in the PLC

CPU at the master station. With errors enabling the operation to continue such as

"BATTERY ERROR," the data link will continue regardless of the setting (see

Section 4.3.3).

(9) Setting the status of input data from a data link faulty station

The data entered (received) from a data-link faulty station can be cleared or the

previous status immediately before the error can be maintained (see Section

4.3.4).

(10) Standby master function

This function enables the data link to continue working by switching to a standby

master station (backup station for the master station) if a malfunction occurs in

the master station due to a malfunction of the PLC CPU or power supply.

The master station can return to online even during data link control by the

standby master station, and prepares itself for standby master station system

down (see Section 4.3.6).

Data link control by the master station

Master station

Remote device stat ion

Station number 2

Number of occupied stations: 2

Intelligent device station

Station number 4

Number of occupied stations: 1

Standby master station

Station number 1

Number of occupied stations: 1

Data link

control in

progress

Standby

Cyclic communication Cyclic communication Cyclic communication

Remote device stat ion

Station number 2

Number of occupied stations: 2

Intelligent device station

Station number 4

Number of occupied stations: 1

Data link

control in

progress

Cyclic communication Cyclic communication Cyclic communication

To the next page

Standby master station

Station number 1 0

Master station is down Data link control by the standby master station

Master station

Page 26

1 - 8 1 - 8

MELSEC-Q

1 OVERVIEW

Remote device stat ion

Station number 2

Number of occupied stations: 2

Intelligent device station

Station number 4

Number of occupied stations: 1

Standby master station

Data link

control in

progress

Cyclic communication Cyclic communication Cyclic communication

Remote device stat ion

Station number 2

Number of occupied stations: 2

Intelligent device station

Station number 4

Number of occupied stations: 1

Standby master station

Station number 1

Number of occupied stations: 1

Data link

control in

progress

Standby

C

y

clic communication Cyclic communication Cyclic communication

Continued from the previous page

Master station

Problem occurrence in the standby master station Data link control by the master station

Master station

Station number 1 0

Standby master station returns to normal and comes back online

Standby master station prepares itself for master station system down

Remote device stat ion

Station number 2

Number of occupied stations: 2

Intelligent device station

Station number 4

Number of occupied stations: 1

Standby master station

Station number 0

Data link

control in

progress

Standby

Cyclic communication Cyclic communication Cyclic communication

Master station returns to normal and comes back online

Master station prepares itself for standby master station system down

Master station

Station number 0 1

Page 27

1 - 9 1 - 9

MELSEC-Q

1 OVERVIEW

(11) Remote device station initi ali zation procedure registration function

This function performs the initial setting for the remote device station using the

GX Developer, without creating a sequence program (see Section 4.4.1).

(12) Event issuance for the interrupt prog r am

This function issues an event when the conditions set by the GX Developer are

established in order to make the PLC CPU execute the interrupt program (see

Section 4.4.2).

(13) Automatic CC-Link startup

By installing the QJ61BT11N, the CC-Link is started up and all data are refreshed

by simply turning on the power, without creating a sequence program. However,

when the number of connected modules is less than 64, it is necessary to set the

network parameters in order to optimize the link scan time (see Section 4.4.3.).

(14) Selecting a mode according to the sy stem

The CC-Link system has four types of modes according to various systems. (See

sections 4.4.4, 4.4.5 and 4.4.14.)

The overview of the modes is described in the following table.

Mode Connectable Overview

Remote net ver. 1 mode

Mode in which complete compatibility with the

conventional module (QJ61BT11) is achieved.

Select this mode when the number of cyclic points need

not be increased or when the QJ61BT11N is used to

replace the conventional module as a maintenance

product.

Remote net ver. 2 mode

Select this mode when increasing the number of cyclic

points and configuring a new system.

Remote net additional mode

Remote I/O station

Remote device station

Intelligent device station

Local station

Standby master station

Select this mode when adding a ver.2 compatible slave

station to the existing system to increase the number of

cyclic points.

Remote I/O net mode Remote I/O station

Select this mode when the system consists of only the

master station and remote I/O stations.

Since cyclic transmission is made at high speed, the link

scan time can be reduced.

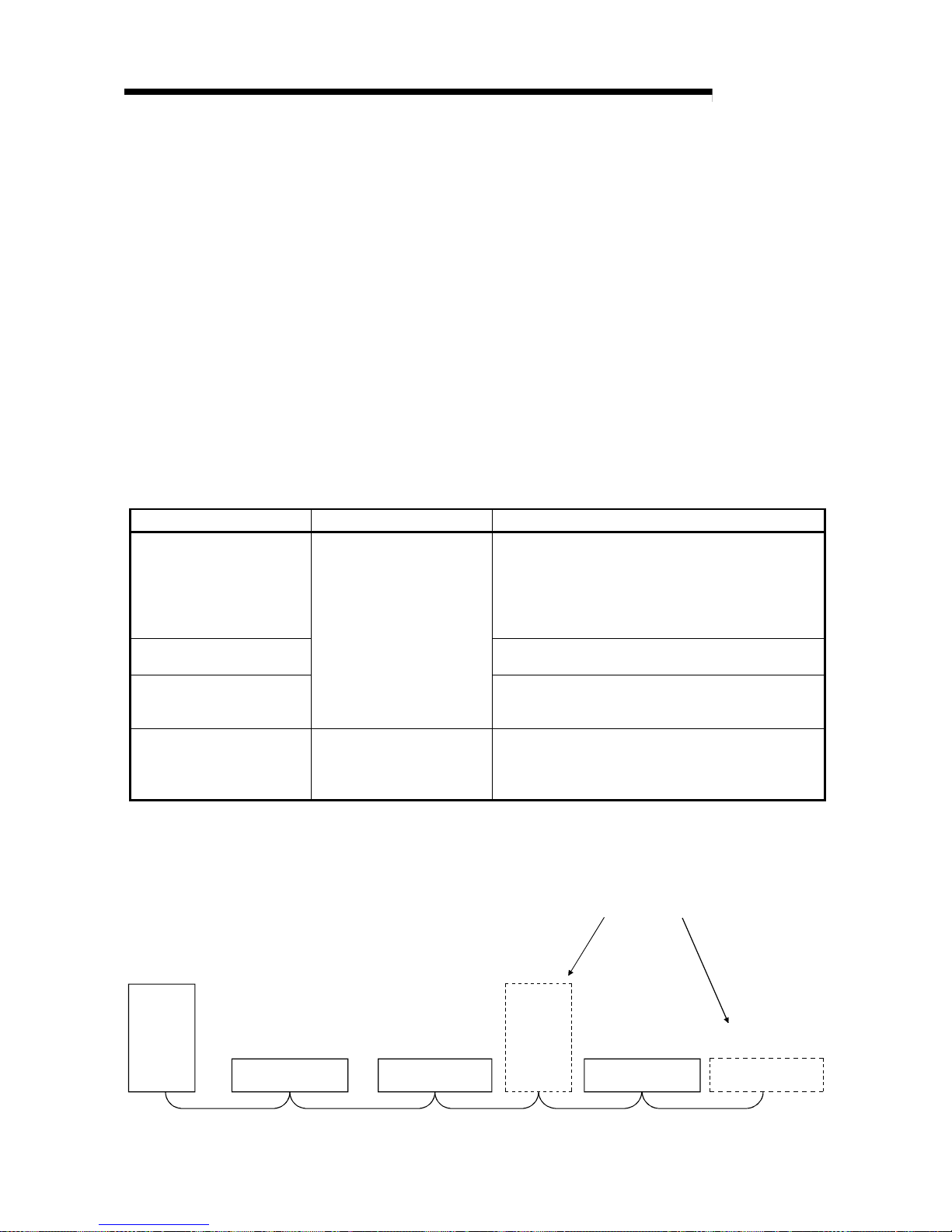

(15) Reserved station function

Stations that are not actually connected (stations to be connected in the future)

will not be treated as faulty stations if they are specified as reserved stations.

The reserved stations can also be set as 0 points. (see Section 4.4.6).

Master

station

Remote station

(occupies 2 stations)

Remote station

(occupies 1 station)

Local

station

(occupies

4 stations)

Remote station

(occupies 2 stations)

Station number 1 Station number 3 Station number 8

(Reserved station)

Station number 4

Remote station

(occupies 1 station)

(Reserved station)

Station number 10

Stations that will be connected in the future

Page 28

1 - 10 1 - 10

MELSEC-Q

1 OVERVIEW

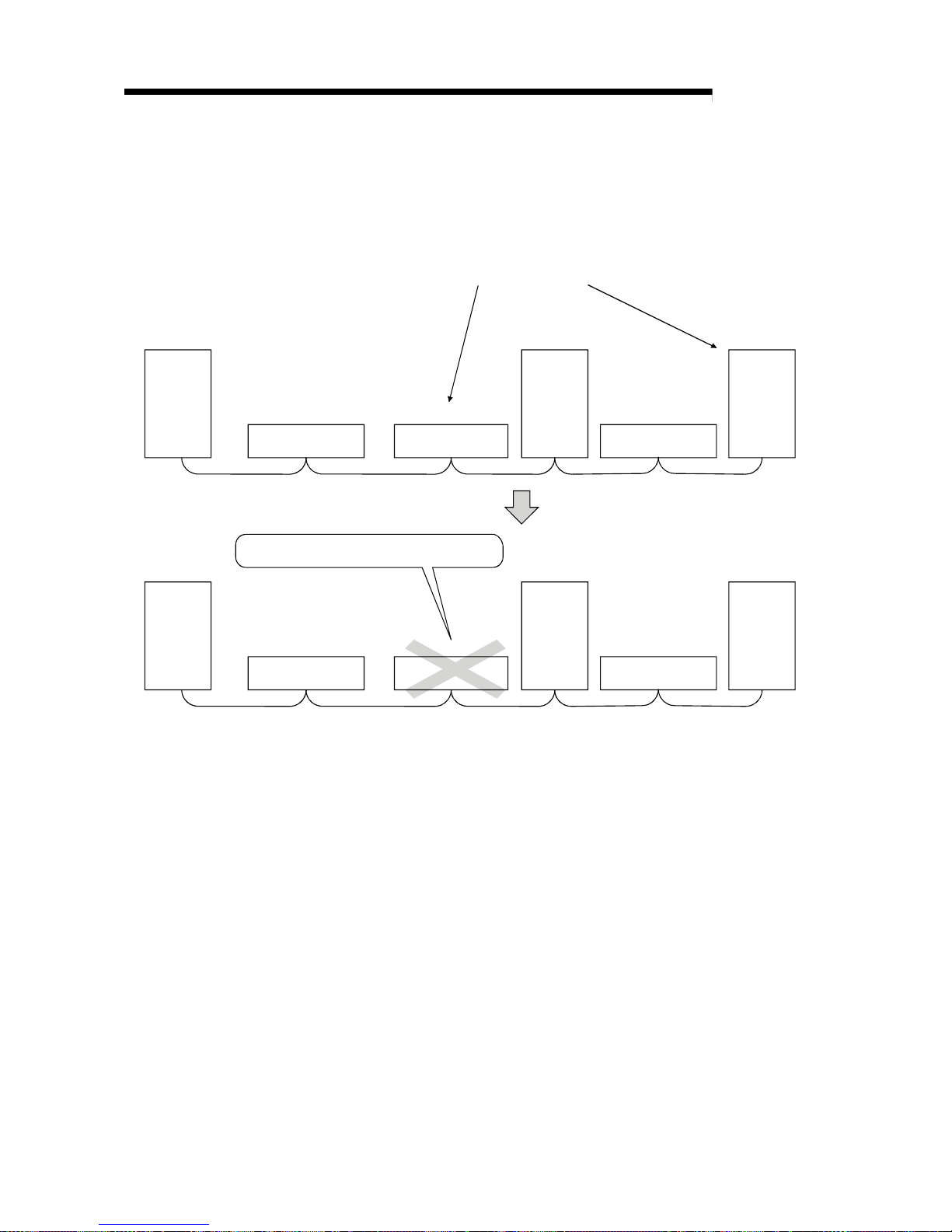

(16) Error invalid station setti ng function

By setting the network parameters, the module that is powered off in the system

configuration will not be treated as a "data link faulty station" by the master

station and local station. However, caution is required since errors are no longer

detected (see Section 4.4.7).

Master

station

Remote station

(occupies 2 stations)

Remote station

(occupies 1 station)

Local

station

(occupies

1 station)

Remote station

(occupies 2 stations)

Local

station

(occupies

4 stations)

Station number 1 Station number 3 Station number 5

Station number 4 Station number 7

Master

station

Remote station

(occupies 2 stations)

Remote station

(occupies 1 station)

Local

station

(occupies

1 station)

Remote station

(occupies 2 stations)

Local

station

(occupies

4 stations)

Station number 1 Station number 3 Station number 5

Station number 4 Station number 7

This station does not become a data link f aul ty station.

Stations to be specified as error invalid stations

(17) Scan synchronous function

This function synchronizes the link scan to the sequence scan (see Section

4.4.8).

(18) Temporary error inv al i d station setti ng function

With this function, the module specified by the GX Developer will not be treated

as a "data link faulty station" by the master or local station while in online. The

module can be replaced without detecting an error in online (see Section 4.4.9).

(19) Data link stop/restart

The data link can be stopped and restarted while it is being used (see Section

4.4.10).

(20) Station number overlap checking function

This function checks the status of the connected stations to see if the number of

occupied stations is overlapping or if there is more than one station with the

station number setting of 0 in the system (see Section 4.4.11).

Page 29

1 - 11 1 - 11

MELSEC-Q

1 OVERVIEW

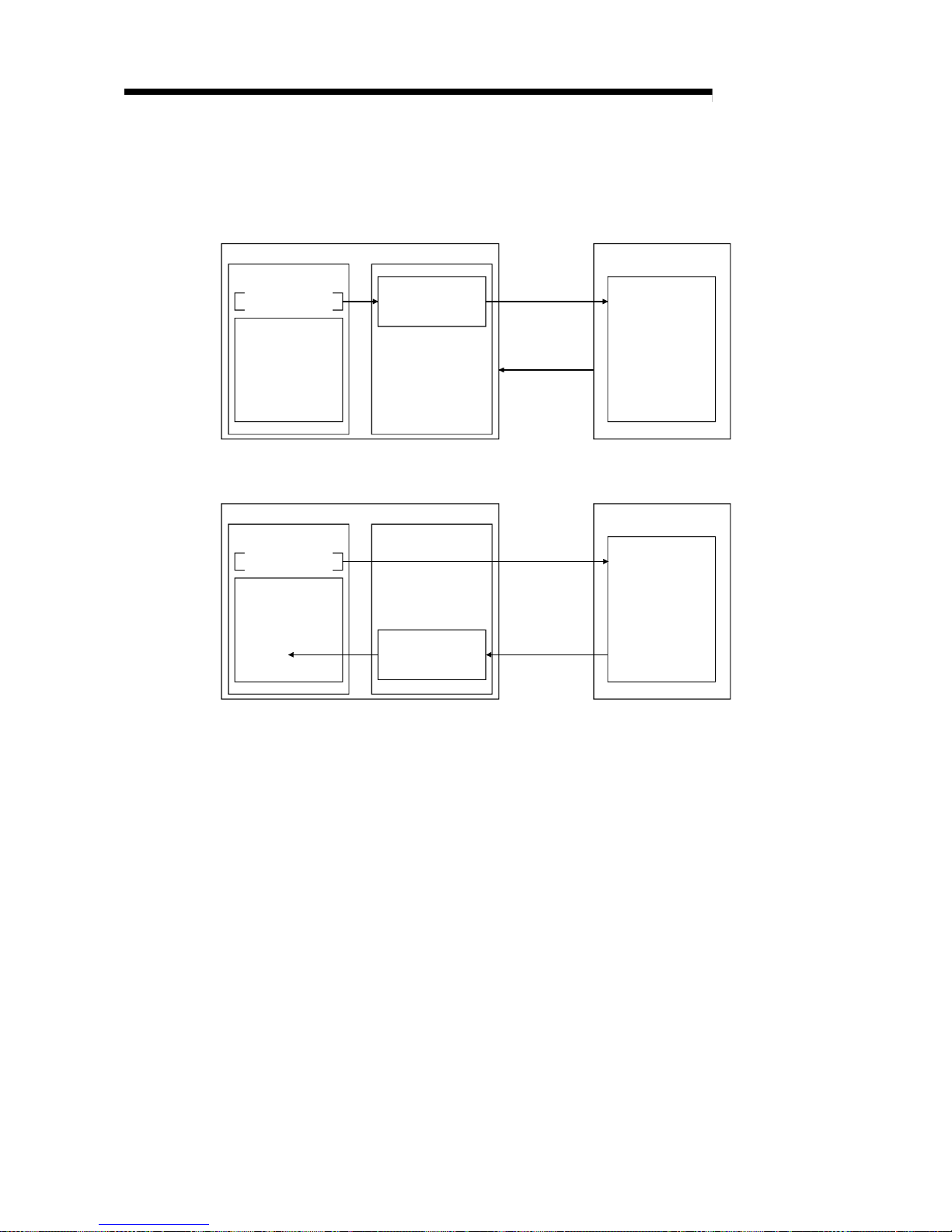

(21) Transient transmission

With this method of transmission, the counterpart is specified and 1:1

communication is performed at an arbitrary timing (see Section 4.5).

Local station

PLC CPU

RIWT

Buffer memory

Device memory

Master module

Send buffer

Master station

Local station

PLC CPU

RIRD

Buffer memory

Device memory

Master module

Send buffer

Master station

Page 30

1 - 12 1 - 12

MELSEC-Q

1 OVERVIEW

(22) Compatibility with conventional module

The QJ61BT11N achieves complete compatibility with the conventional module

(QJ61BT11) in the remote net ver. 1 mode.

Select the remote net ver. 1 mode when the number of cyclic points need not be

increased or when the QJ61BT11N is used to replace the conventional module

as a maintenance product.

(23) Cyclic points increase

Selection of the remote net ver. 2 mode or remote net additional mode allows

RX/RY to be increased to up to 8192 points and RWr/RWw to up to 2048 words

per network by making expanded cyclic setting (single, double, quadruple,

octuple).

Also, RX/RY can be increased to up to 224 points and RWr/RWw to up to 32

words per station. (See Section 4.4.14.)

(24) Remote I/O station points setting

Set the number of I/O points of a remote I/O station.

This setting minimizes CPU device assignment and reduces the reserved points

of remote input RX and remote output RX for remote I/O stations. (See Section

4.4.13.)

(25) Slave station refresh/compulsory clear setti ng in case of PLC CPU

STOP

Set whether output data to the remote, local, intelligent device and standby

master stations will be refreshed or compulsorily cleared when the PLC CPU

comes to STOP. (See Section 4.3.5.)

Page 31

2 - 1 2 - 1

MELSEC-Q

2 SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

The system configuration for the CC-Link is described below.

2.1 System Configuration

(1) Remote net ver. 1 mode

A total of 64 remote I/O stations, remote device stations, local stations, standby

master stations, or intelligent device stations can be connected to a single master

station.

However, the following conditions must all be satisfied.

Condition 1 {(1 a) + (2 b) + (3 c) + (4 d)} ≤ 64

a: Number of modules occupying 1 station

b: Number of modules occupying 2 stations

c: Number of modules occupying 3 stations

d: Number of modules occupying 4 stations

Condition 2 {(16 A) + (54 B) + (88 C)} ≤ 2304

A: Number of remote I/O stations

≤

64

B: Number of remote device stations

≤

42

C: Number of local stations, standby master stations

and intelligent device stations

≤

26

Analog/digital

converter module

AJ65BT-64AD

Remote I/O module

AJ65BTB1-16D

AJ65BTC-32D

Intelligent device station Remote device station Remote I/O station

Maximum 26 Maximum 42 Maximum 64

Terminal resistor (required)

CC-Link dedicated cable

CC-Link dedicated cable

Maximum 26

Total 64

RS-232C

Interface module

AJ65BT-R2

A1SJ61QBT11

AJ61QBT11

Local station

A1SJ61BT11

AJ61BT11

Local station

QJ61BT11

Local station

A1SJ61BT11

AJ61BT11

Master station

T

erminal resistor (required)

A1SJ61QBT11

AJ61QBT11

Master station

QJ61BT11

Master station

1 module for each system

QJ61BT11N

QJ61BT11N

2

Page 32

2 - 2 2 - 2

MELSEC-Q

2 SYSTEM CONFIGURATION

(2) Remote net ver. 2 mode, remote net additional mode

A total of 64 remote I/O stations, remote device stations, local stations, standby

master stations, or intelligent device stations can be connected to a single master

station.

However, the following conditions must all be satisfied.

Condition 1

{(a + a2 + a4 + a8)

+ (b + b2 + b4 + b8)

2

+ (c + c2 + c4 + c8) 3

+ (d + d2 + d4 + d8) 4} ≤ 64

Condition 2

[{(a

32) + (a2 32) + (a4 64) + (a8 128)}

+ {(b

64) + (b2 96) + (b4 192) + (b8 384)}

+ {(c

96) + (c2 160) + (c4 320) + (c8 640)}

+ {(d 128) + (d2 224) + (d4 448) + (d8 896)}] ≤ 8192

Condition 3

[{(a

4) + (a2 8) + (a4 16) + (a8 32)}

+ {(b

8) + (b2 16) + (b4 + 32) + (b8 64)}

+ {(c 12) + (c2 24) + (c4 48) + (c8 96)}

+ {(d 16) + (d2 32) + (d4 64) + (d8 128)}] ≤ 2048

a: The total number of ver.1 compatible slave

stations that occupy 1 station, and ver.2

compatible slave stations that occupy 1 station

which are set to “Single”.