MELSEC-Q/L AnyWireASLINK Master Module

User's Manual

-QJ51AW12AL

-LJ51AW12AL

COPYRIGHT

This document is protected by the law of copyright, whereby all rights established therein remain with the company

Mitsubishi Electric Corporation. Reproduction of this document or parts of this document is only permissible within the

limits of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company Mitsubishi Electric Corporation.

PRECAUTIONS REGARDING WARRANTY AND

SPECIFICATIONS

The QJ51AW12AL and LJ51AW12AL were jointly developed and manufactured by Mitsubishi and Anywire

Corporation.

Note that there are some precautions regarding warranty and specifications of this product.

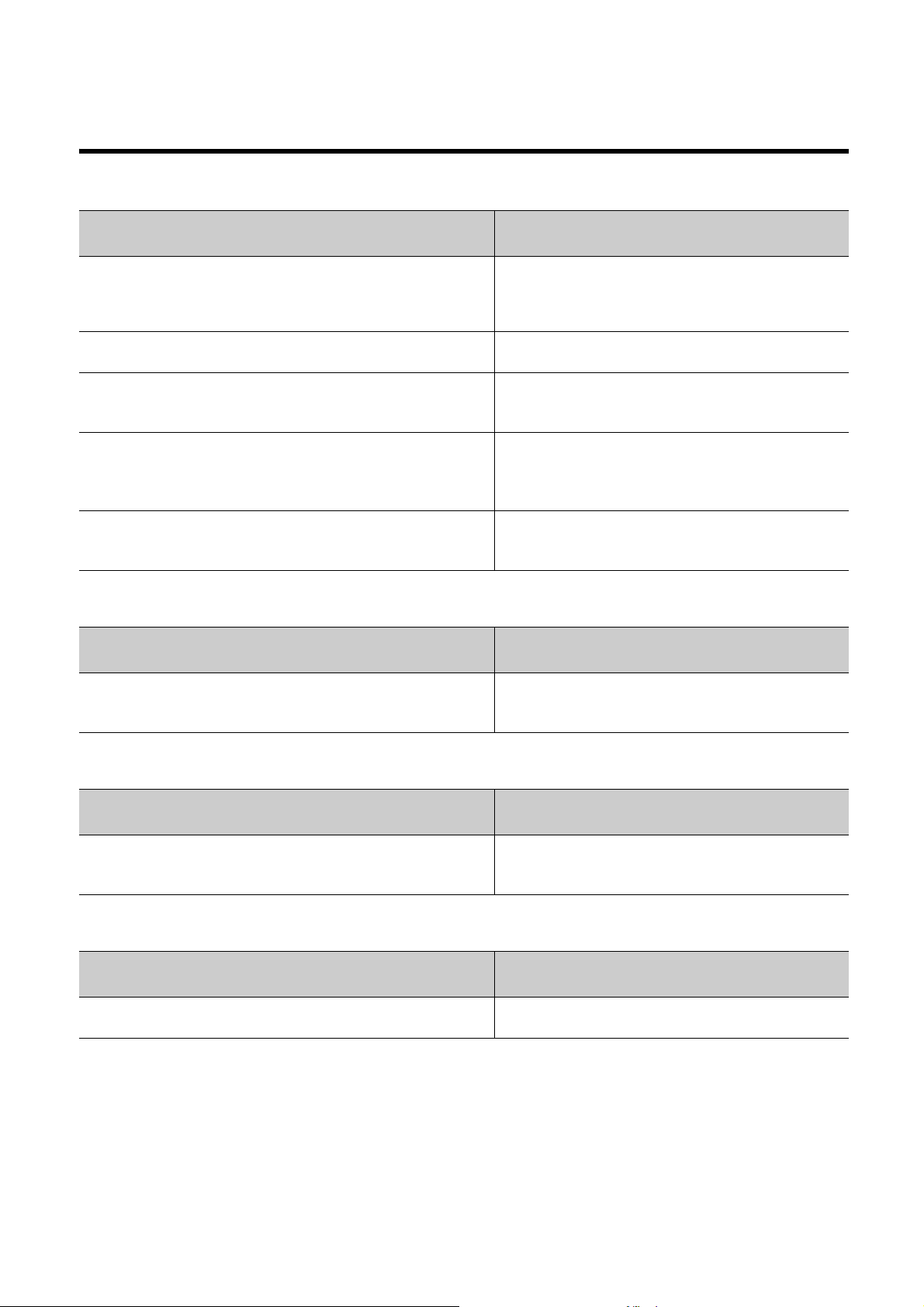

Warranty

Other programmable controller

Item QJ51AW12AL, LJ51AW12AL

Repair term after discontinuation of

production

(e.g. MELSEC-Q series)

1 year 7 years

products

Application of the EMC Directive

Item QJ51AW12AL, LJ51AW12AL

Applicable EMC standard

*1 The master module with a serial number where the sixth digit is "2" or later complies with this standard.

Application of the UL/cUL standards

Item QJ51AW12AL, LJ51AW12AL

Applicable UL standard/cUL standard

*2 The master module with a serial number where the sixth digit is "3" or later complies with this standard.

EN61131-2

*2

UL508

CSA22.2

Other programmable controller

products

(e.g. MELSEC-Q series)

*1

*2

EN61131-2

Other programmable controller

products

(e.g. MELSEC-Q series)

UL508

CSA22.2

1

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

2

Precautions for using the QJ51AW12AL

[Design Precautions]

WARNING

● An AnyWireASLINK system has no control function for ensuring safety.

● When connecting a peripheral with the CPU module or connecting a personal computer with an

intelligent function module to modify data of a running programmable controller, configure an interlock

circuit in the program to ensure that the entire system will always operate safely.

For other forms of control (such as program modification or operating status change) of a running

programmable controller, read the relevant manuals carefully and ensure that the operation is safe

before proceeding.

Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure.

To prevent this, configure an interlock circuit in the program, and determine corrective actions to be

taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the CPU module to the

intelligent function module. Doing so may cause malfunction of the programmable controller system.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them. Failure to do so may result in malfunction due to

noise.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

3

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the user's

manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

● To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect interconnection may cause malfunction, failure, or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module.

Failure to do so may result in damage to the product.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or damage to the product.

4

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less.

Failure to do so may result in electric shock or malfunction.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, fire, or

malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● Do not apply the 24VDC power before wiring the entire AnyWireASLINK system. If the power is

applied before wiring, normal data transmission is not guaranteed.

● Connect a 24VDC external power supply to the device(s) in an AnyWireASLINK system.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

5

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws.

Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the module.

Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause drop of the component or wire, short circuit, or malfunction. Overtightening

can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

6

Precautions for using the LJ51AW12AL

[Design Precautions]

WARNING

● An AnyWireASLINK system has no control function for ensuring safety.

● When connecting a peripheral with the CPU module or connecting a personal computer with an

intelligent function module to modify data of a running programmable controller, configure an interlock

circuit in the program to ensure that the entire system will always operate safely.

For other forms of control (such as program modification or operating status change) of a running

programmable controller, read the relevant manuals carefully and ensure that the operation is safe

before proceeding.

Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure.

To prevent this, configure an interlock circuit in the program, and determine corrective actions to be

taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the CPU module to the

intelligent function module. Doing so may cause malfunction of the programmable controller system.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them. Failure to do so may result in malfunction due to

noise.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

7

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines provided with the CPU module or head module. Failure to do so may result in electric

shock, fire, malfunction, or damage to or deterioration of the product.

● To interconnect modules, engage the respective connectors and securely lock the module joint levers

until they click. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or damage to the product.

8

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less.

Failure to do so may result in electric shock or malfunction.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, fire, or

malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● Do not apply the 24VDC power before wiring the entire AnyWireASLINK system. If the power is

applied before wiring, normal data transmission is not guaranteed.

● Connect a 24VDC external power supply to the device(s) in an AnyWireASLINK system.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

9

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws.

Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the module.

Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause drop of the component or wire, short circuit, or malfunction. Overtightening

can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● After the first use of the product (module and terminal block), do not connect/disconnect the product

more than 50 times (in accordance with IEC 61131-2).

Exceeding the limit may cause malfunction.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

10

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

11

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi MELSEC-Q or -L series programmable controllers.

This manual describes the functions and programming of the QJ51AW12AL AnyWireASLINK master module and

LJ51AW12AL AnyWireASLINK master module.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-Q or -L series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to an actual system, ensure the applicability and

confirm that it will not cause system control problems.

Please make sure that the end users read this manual.

Unless otherwise specified, this manual describes the program examples in which the I/O numbers of X/Y10 to X/Y2F are

assigned for a master module. I/O numbers must be assigned to apply the program examples introduced in this manual to

an actual system.

For I/O number assignment, refer to the following.

User's Manual (Function Explanation, Program Fundamentals) for the CPU module used

COMPLIANCE WITH EMC AND LOW VOLTAGE

DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated

into other machinery or equipment, certain measures may be necessary. Please refer to one of the following

manuals.

• User's manual for the CPU module or head module used

• Safety Guidelines (This manual is included with the CPU module, base unit, or head module.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage

Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to Page 113, Appendix 4.

12

RELEVANT MANUALS

(1) CPU module user's manual

Manual name

<manual number (model code)>

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

<SH-080483ENG, 13JR73>

QnUCPU User's Manual (Function Explanation, Program Fundamentals)

<SH-080807ENG, 13JZ27>

Qn(H)/QnPH/QnPRHCPU User's Manual (Function Explanation, Program

Fundamentals)

<SH-080808ENG, 13JZ28>

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance

and Inspection)

<SH-080890ENG, 13JZ36>

MELSEC-L CPU Module User's Manual (Function Explanation, Program

Fundamentals)

<SH-080889ENG, 13JZ35>

(2) Head module user's manual

Manual name

<manual number (model code)>

MELSEC-L CC-Link IE Field Network Head Module User's Manual

<SH-080919ENG, 13JZ48>

Description

Specifications of the hardware (CPU modules, power supply

modules, base units, batteries, and memory cards), system

maintenance and inspection, and troubleshooting

Functions and devices of the CPU module, and programming

Functions and devices of the CPU module, and programming

Specifications of the CPU modules, power supply modules,

display unit, SD memory cards, and batteries, information on

how to establish a system, maintenance and inspection, and

troubleshooting

Functions and devices of the CPU module, and programming

Description

Specifications, procedures before operation, system

configuration, installation, wiring, settings, and troubleshooting

of the head module

(3) Operating manual

Manual name

<manual number (model code)>

GX Works2 Version 1 Operating Manual (Common)

<SH-080779ENG, 13JU63>

(4) Others

Manual name

<manual number (model code)>

iQ Sensor Solution Reference Manual

<SH-081133ENG, 13JV28>

Description

System configuration, parameter settings, and online

operations of GX Works2, which are common to Simple

projects and Structured projects

Description

Operating methods of iQ Sensor Solution, such as

programming and monitoring

13

CONTENTS

CONTENTS

COPYRIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PRECAUTIONS REGARDING WARRANTY AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CHAPTER 1 FEATURES 20

1.1 AnyWireASLINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHAPTER 2 PART NAMES 23

CHAPTER 3 SPECIFICATIONS 25

3.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.1 Performance list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.2.2 Number of parameters to set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.3 Communication performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.3 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4 List of I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5 List of Buffer Memory Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

CHAPTER 4 PROCEDURES BEFORE OPERATION 35

CHAPTER 5 SYSTEM CONFIGURATION 37

5.1 Overall Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.1 System configuration of the master module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.2 System configuration of AnyWireASLINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.2 Applicable Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.1 QJ51AW12AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.2.2 LJ51AW12AL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.3 Compatible Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

CHAPTER 6 INSTALLATION AND WIRING 43

6.1 Installation Environment and Position of the Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.1 Wiring precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.2.2 Connection of slave modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.2.3 Power supply to the AnyWireASLINK system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.3 Check before Power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

14

6.4 Power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.5 Terminating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CHAPTER 7 VARIOUS SETTINGS 53

7.1 Master Module Operation Mode Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1.1 Master module addition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

7.1.2 Switch setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

7.1.3 Auto refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

7.2 Slave Module Address Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

7.3 Automatic Address Detection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3.1 Performing the automatic address detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.3.2 Interlock program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

7.3.3 Automatic address detection execution timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4 Automatic Reading of the System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

CHAPTER 8 FUNCTIONS 62

8.1 Bit Transmission Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2 Transmission Cable Short Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.3 Disconnected Transmission Cable Location Detection Function . . . . . . . . . . . . . . . . . . . . . . . 63

8.4 Transmission Cable Voltage Drop Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5 Parameter Access Error Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.6 Same ID Used Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.7 Module with No ID Setting Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.8 Reading and Writing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.9 Backup/Restoring Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

CHAPTER 9 PROGRAMMING 75

9.1 Correlations Between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

9.2 System Using the QJ51AW12AL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.2.1 When using a module in the ordinary system configuration. . . . . . . . . . . . . . . . . . . . . . . . . . .76

9.2.2 When connecting a module in a remote I/O station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

9.3 System Using the LJ51AW12AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3.1 When using a module in the ordinary system configuration. . . . . . . . . . . . . . . . . . . . . . . . . . .85

9.3.2 When connecting a module to a head module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

CHAPTER 10 TROUBLESHOOTING 92

10.1 Before Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.2 Check by Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.3 Checking with Module's Detailed Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.4 Checking with Buffer Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.5 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.6 Troubleshooting of the Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.7 Troubleshooting of the Slave Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

15

APPENDICES 101

Appendix 1 Details of I/O Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Appendix 1.1 Input signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Appendix 1.2 Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix 2 Details of Buffer Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix 3 Checking the Serial Number and Function Version . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix 4 EMC and Low Voltage Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix 4.1 Measures to comply with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Appendix 4.2 Requirements for compliance with the Low Voltage Directive . . . . . . . . . . . . . . . . . . 115

Appendix 5 When Using GX Developer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Appendix 5.1 Operating GX Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Appendix 6 Precautions for Creating Program for Slave Module Parameter Access . . . . . . . . . . . 118

Appendix 6.1 Program examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Appendix 7 Functions Added and Modified with Version Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . 123

Appendix 8 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

INDEX 126

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

16

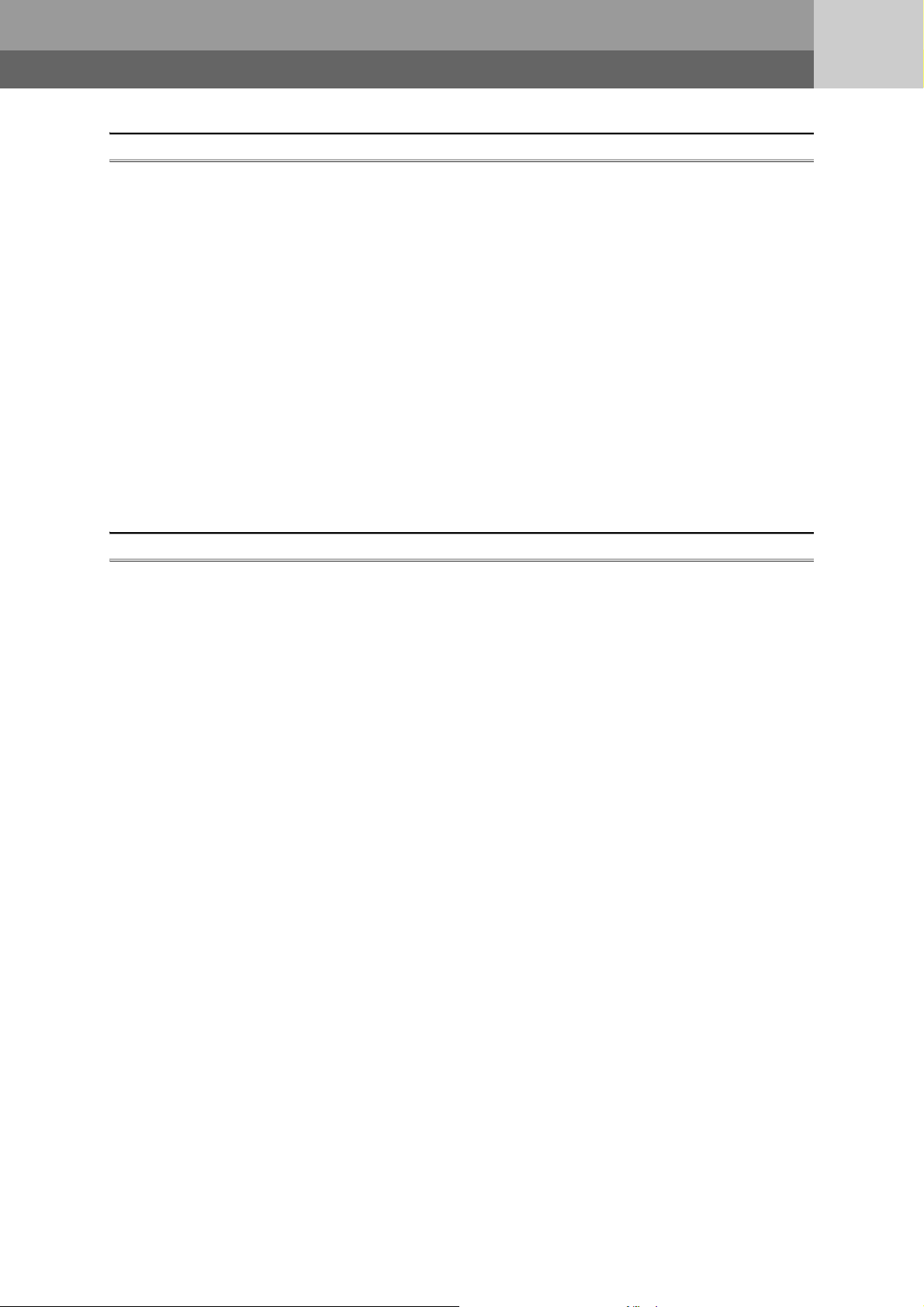

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

*1 The mouse operation example (for GX Works2) is provided below.

Menu bar

Ex.

A window selected in the view selection area is displayed.

Ex.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

In the Project window, expand [Parameter] and

select [PLC Parameter].

[Parameter]

17

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

Address A parameter assigned to a slave module to identify each node on the AnyWireASLINK network

Address writer A hand-held device to read/write parameters (including addresses) from/to a slave module

A system where sensors at the end of a control system are connected to a programmable controller in the most

AnyWireASLINK

AnyWireASLINK bridge module A generic term for the NZ2AW1C2AL and NZ2AW1GFAL

AnyWireASLINK master module A generic term for the RJ51AW12AL, QJ51AW12AL, and LJ51AW12AL

ASLINKAMP A generic term for sensor amplifiers that have an AnyWireASLINK interface

ASLINKER A generic term for I/O devices that have an AnyWireASLINK interface

Buffer memory

CPU module A generic term for the MELSEC-Q and -L series CPU modules

GX Developer

GX Works2

Head module The abbreviation for the LJ72GF15-T2 CC-Link IE Field Network head module

ID

Intelligent function module

Master module A generic term for the QJ51AW12AL and LJ51AW12AL

MELSEC-L series The abbreviation for the Mitsubishi programmable controller MELSEC-L series

MELSEC-Q series The abbreviation for the Mitsubishi programmable controller MELSEC-Q series

Power cable (24V, 0V) A cable that connects a master module to a 24VDC external power supply

Programming tool A generic term for GX Works2 and GX Developer

Slave module A generic term for modules that communicate data with a master module

Terminating unit A waveform shaper

Transmission cable (DP, DN) A signal cable that connects a slave module to a master module

Transmission cycle time A data sampling interval

suitable way.

With this system, a bridge module can detect sensor disconnection and a user can set the I/O operations of a slave

module on a bridge module without using I/O areas of the CPU module.

A memory in an intelligent function module, where data (such as setting values and monitoring values) exchanged

with a CPU module are stored

The product name of the software package for the MELSEC programmable controllers

A parameter to identify whether the module is an input module or output module based on its address

Output slave module ID: Address

Input slave module/I/O combined slave module ID: Address + 200

A MELSEC-Q/L series module that has functions other than input and output, such as an A/D converter module and

D/A converter module

H

18

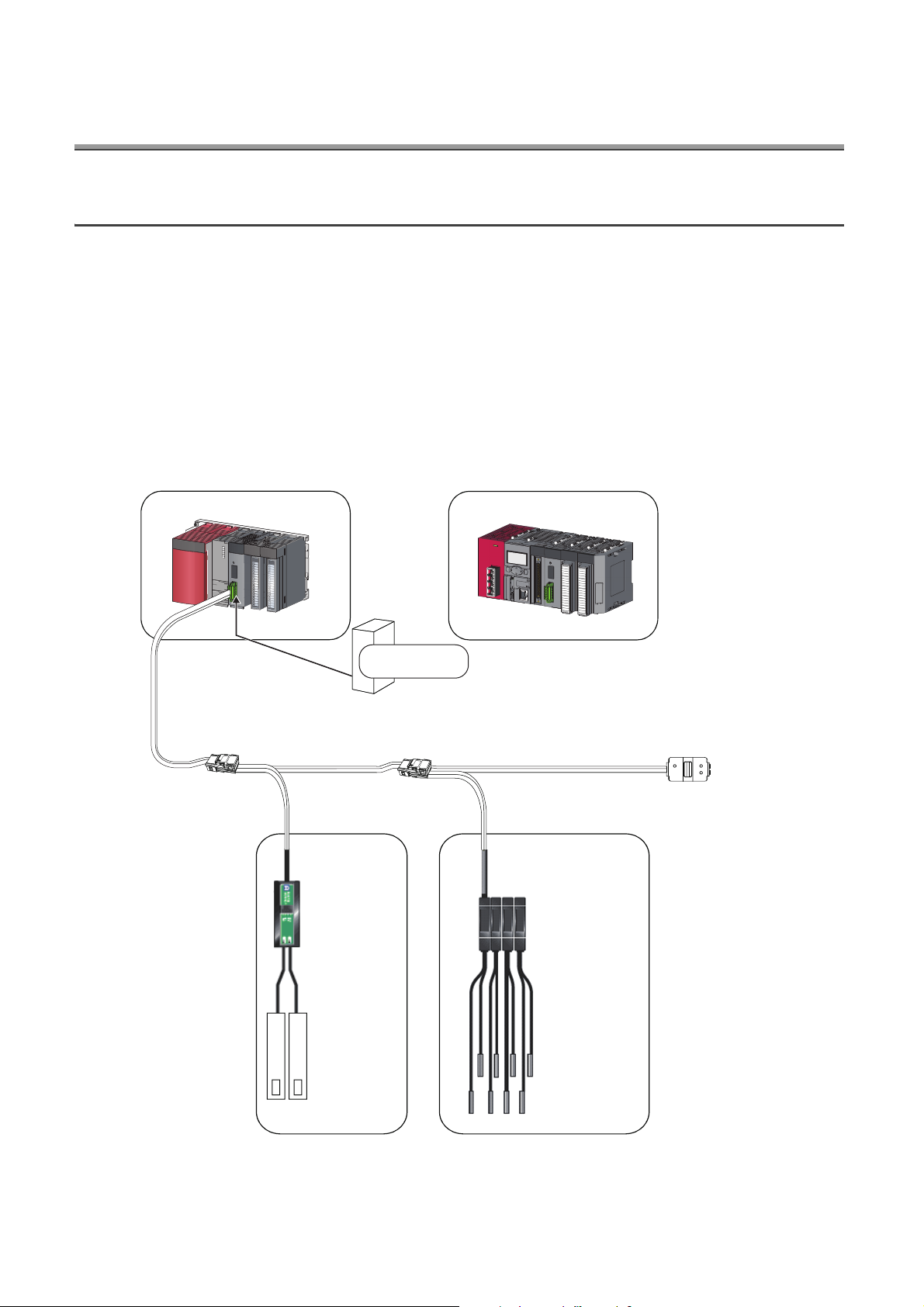

PACKING LIST

QJ51AW12AL Before Using the Product

LJ51AW12AL Before Using the Product

The following items are included in the package of this product. Before use, check that all the items are included.

QJ51AW12AL

LJ51AW12AL

19

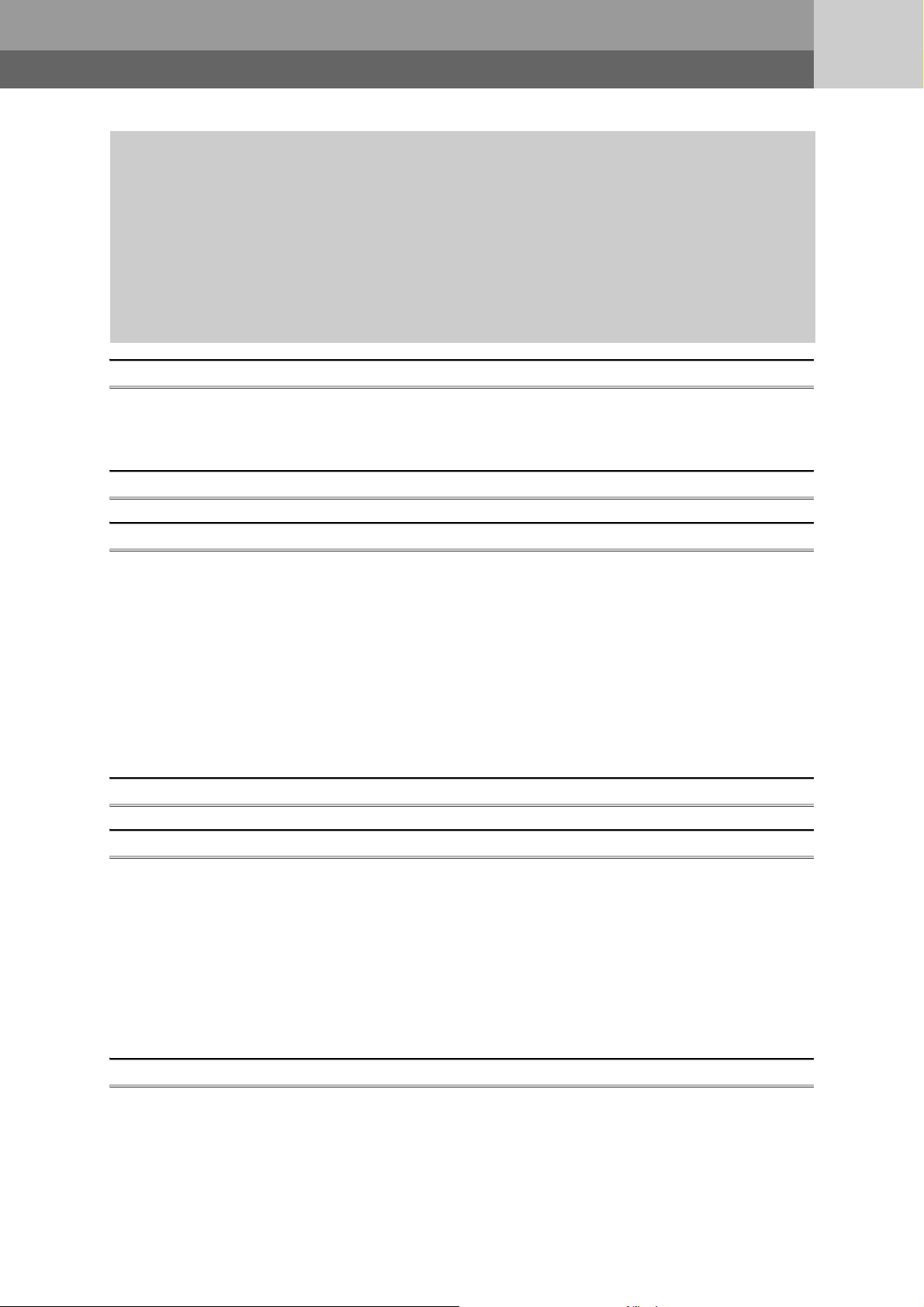

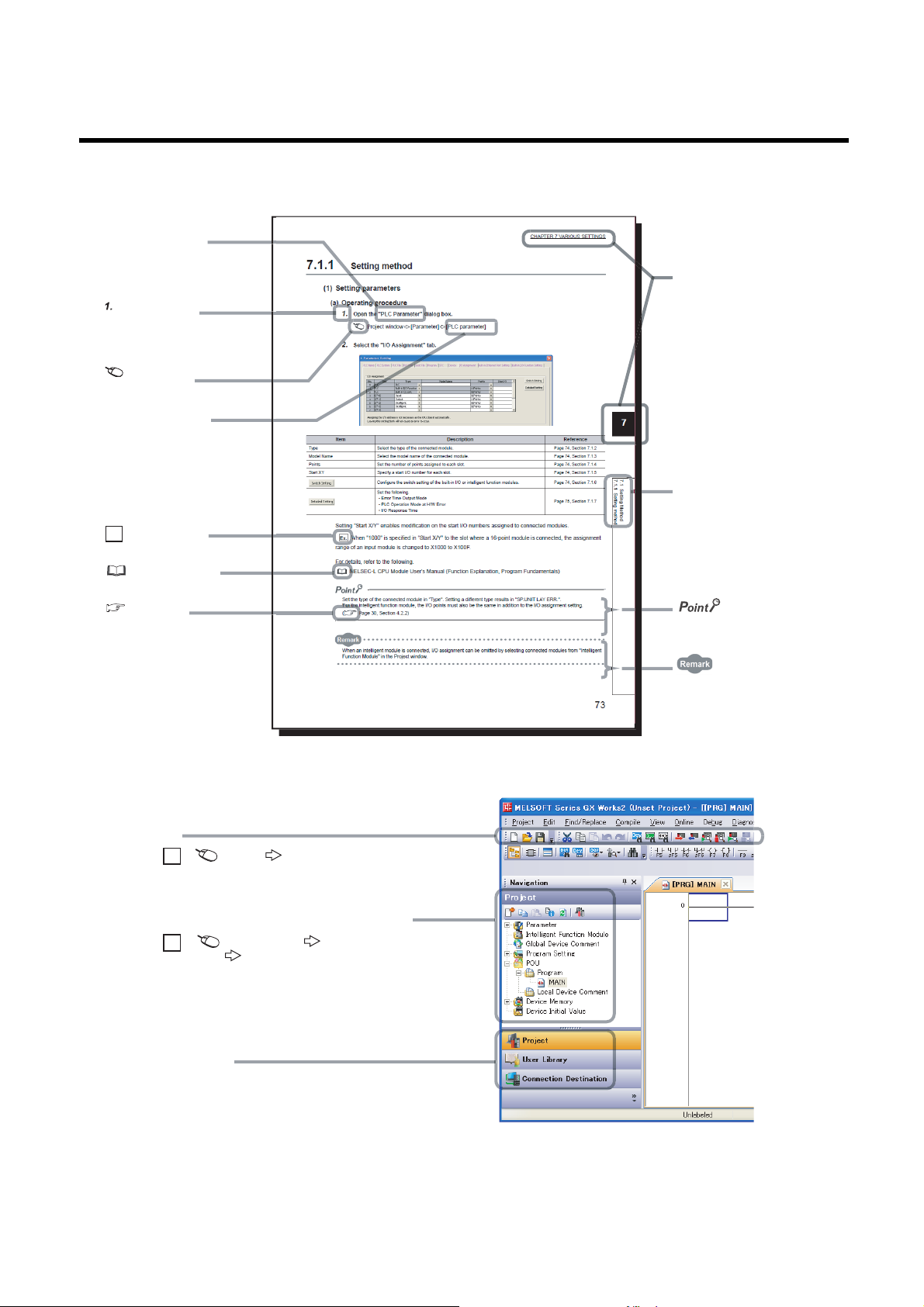

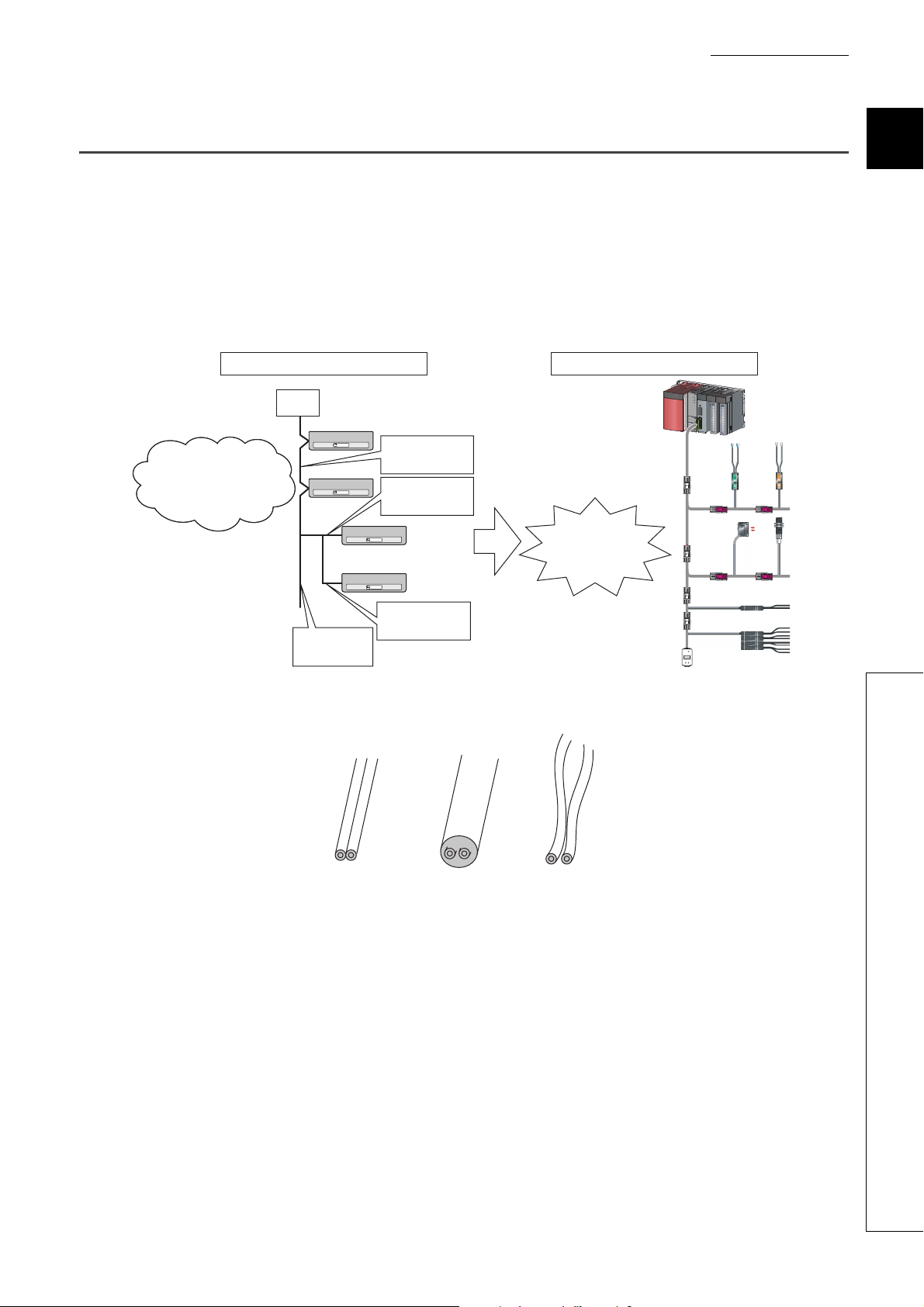

CHAPTER 1 FEATURES

ASLINKER

*1

LJ51AW12AL

ASLINKAMP

*1

24VDC

General-purpose

power supply

QJ51AW12AL

or

Cylinder,

switch, or

others

AnyWireASLINK terminating unit

*1

*

1 Manufactured by Anywire Corporation

Sensor head

1.1 AnyWireASLINK

The AnyWireASLINK is a high-speed and highly reliable system which releases the work site from complicated and

incorrect wiring.

In this network, sensors at the end of a control system are connected to a programmable controller in the optimum

form.

Furthermore, this network enables a mater module to detect sensor disconnection and enables a user to set the

operations of a slave module only using the areas, 32 points occupied, of a master module with the I/O assignment

setting.

The master module, a product of the joint development project with Anywire Corporation, allows the AnyWireASLINK

system to be constructed in a MELSEC-Q or MELSEC-L series programmable controller system.

20

CHAPTER 1 FEATURES

Restricted

station-to-station

distance

Restricted

branch line length

Restricted number

of branches

Restricted main

line length

Standard network

Master

station

AnyWireASLINK

Adding a station to

the existing network is

hard with many

restrictions on wiring.

A station

can be added only

if the total length

is within 200m.

Flat cable

General-purpose

2-wire cable

General-purpose

wire

1.2 Features

This section describes the features of the AnyWireASLINK.

(1) Flexible wiring

The AnyWireASLINK allows flexible connections if the overall cable distance of transmission cables (DP, DN) is

within 200m.

There is no restriction about, for example, the main line length, station-to-station distance, and number of

branches.

1

(2) Single-touch cable connection and disconnection

(3) Space saving

Moreover, because of a little restrictions about cables, cables used for other networks can be used for the

AnyWireASLINK without modification, resulting in reduced wiring man-hours and cable cost.

*1 Before using, check the performance specifications. ( Page 26, Section 3.2.1)

Using a dedicated connector enables cables to be connected and disconnected with a single operation and

eases slave module addition and replacement.

*1 For wiring with the dedicated connectors, contact Anywire Corporation.

The system needs much less space because of a wide selection of small-type slave modules (manufactured by

Anywire Corporation).

*1

*1

1.2 Features

21

(4) RAS improvement

The system start-up time can be reduced by checking whether a slave module is connected or by detecting an ID

setting error.

22

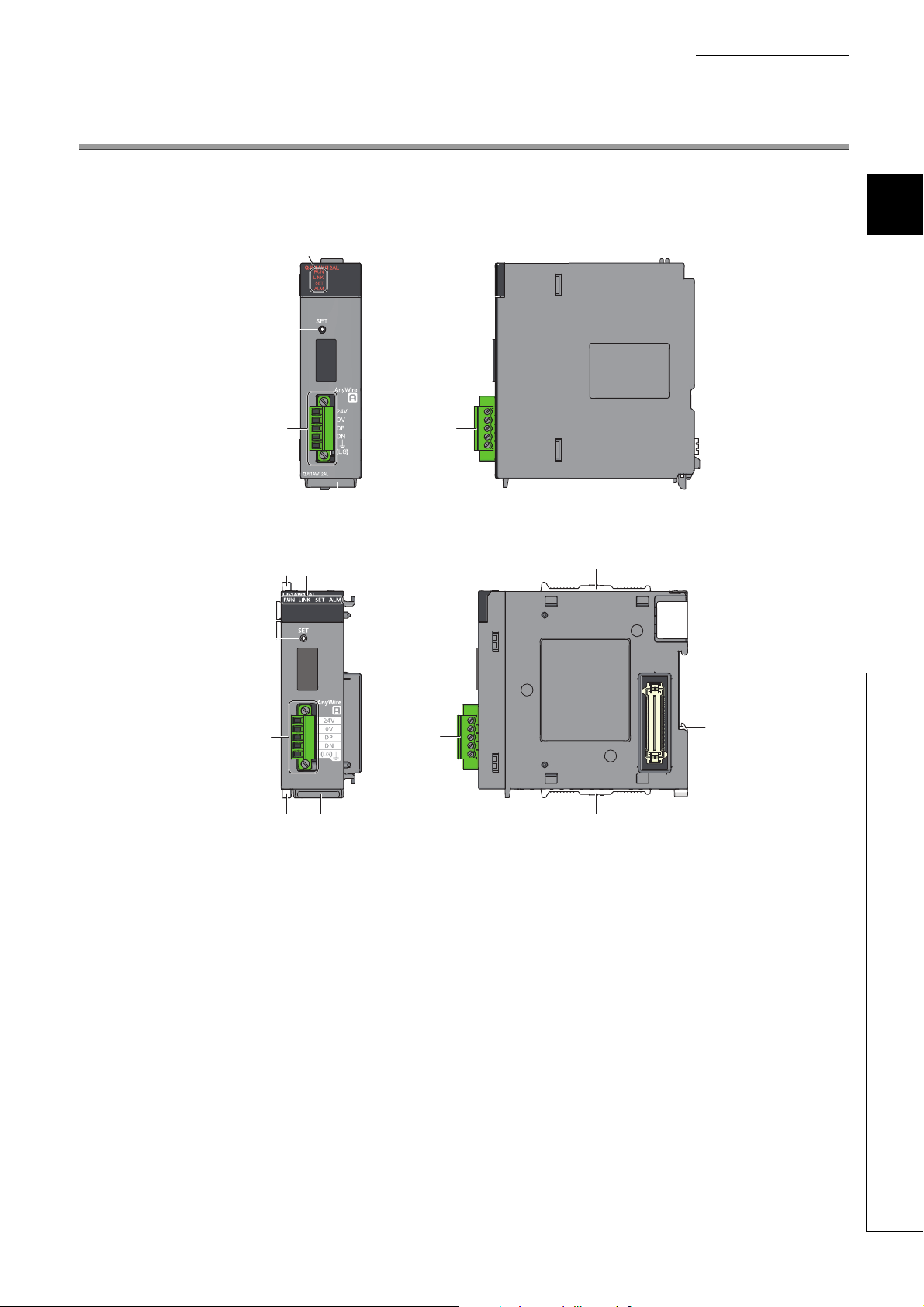

CHAPTER 2 PART NAMES

2)

3)

3)

6)

4)5) 5)

LJ51AW12AL

1)

5)

5)

This chapter describes the part names of the master module.

QJ51AW12AL

1)

2)

3) 3)

CHAPTER 2 PART NAMES

2

4)

23

No. Name Description

The master module status is indicated by the LEDs.

LED name Description

Indicates the operating status of the master module.

RUN LED (green)

LINK LED (green)

1) LED display

SET LED (green)

ALM LED (red)

2) SET switch Switch for automatic detection of the slave module ID (address)

Transmission cable terminal

3)

block

4) Serial number display Displays the serial number printed on the rating plate

5) Module joint lever A lever for connecting modules

6) DIN rail hook A hook for mounting a module to a DIN rail

A terminal block of the AnyWireASLINK

ON: Operating normally

OFF: Master module error, 5VDC power off, or CPU module stop error

Indicates the link status of the master module.

Flashing: Communication is possible.

Off, On: Communication is not possible.

Indicates the address detection status of the master module.

On: Automatic address detection in progress

Flashing: Address write in progress

Off: Before or after automatic address detection

Indicates the alarm status of the master module.

ON: DP/DN disconnection, no response from the slave module

Slow flashing (one-second intervals): DP/DN short

Fast flashing (0.2-second intervals): 24VDC is not being supplied or the

voltage is low.

OFF: Operating normally

24

CHAPTER 3 SPECIFICATIONS

CHAPTER 3 SPECIFICATIONS

This chapter describes the general specifications and performance specifications and lists the functions, I/O signals,

and buffer memory addresses.

3.1 General Specifications

For the general specifications of the master module, refer to the following.

"Safety Guidelines" included with the CPU module, base unit, or head module

3

3.1 General Specifications

25

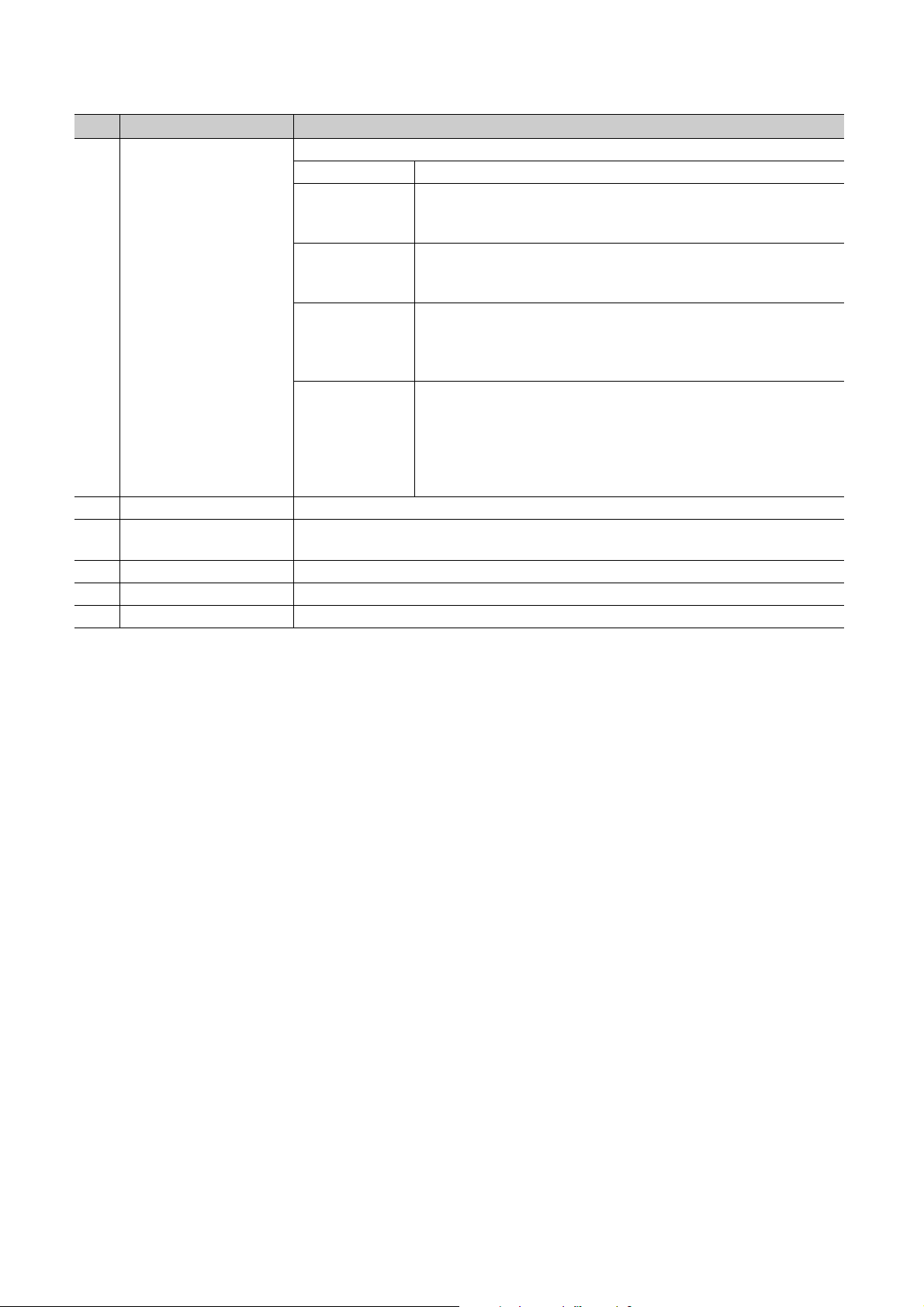

3.2 Performance Specifications

3.2.1 Performance list

The following table lists the performance specifications of the master module.

Item

Transmission clock 27.0kHz

Maximum transmission distance (total

length)

Transmission system DC power supply transmission total frame cyclic system

Connection type Bus topology (multidrop system, T-branch system, tree branch system)

Transmission protocol Dedicated protocol (AnyWireASLINK)

Error control Checksum, double-check system

Number of connected I/O points Up to 512 points (256 input points/256 output points)

Number of connectable slave modules Up to 128 (varies depending on the current consumption of each slave module)

RAS function

Transmission cable (DP, DN)

Power cable (24V, 0V)

Transmission cable supply current

Maximum number of writes to EEPROM Up to 100000 times

Internal current

consumption (5VDC)

Power supply

Number of occupied I/O points 32 points (I/O assignment: intelligent 32 points)

External dimensions 98.0mm (H) 27.4mm (W) 100.0mm (D) 90.0mm (H) 28.5mm (W) 104.5mm (D)

Weight 0.2kg

External power

supply

*1

Disconnected transmission cable location detection function, transmission cable short

• UL-listed general-purpose 2-wire cable (VCTF, VCT 1.25, 0.75, temperature rating

70 or higher)

• UL-listed general-purpose wire (1.25, 0.75, temperature rating 70 or higher)

• Dedicated flat cable (1.25, 0.75, temperature rating 90)

• UL-listed general-purpose 2-wire cable (VCTF, VCT 0.75 to 2.0, temperature

rating 70 or higher)

• UL-listed general-purpose wire (0.75 to 2.0, temperature rating 70 or higher)

• Dedicated flat cable (1.25, 0.75, temperature rating 90)

Voltage: 21.6 to 27.6VDC (24VDC -10% to +15%), ripple voltage 0.5Vp-p or lower

QJ51AW12AL LJ51AW12AL

detection function, transmission cable voltage drop detection function

When using a 1.25 cable: Up to 2A

When using a 0.75 cable: Up to 1.2A

Current consumption: Up to 0.2A

Recommended voltage: 26.4VDC (24VDC + 10%)

Module current consumption: 0.1A

Transmission cable supply current: Up to 2A

Model name

*2

200m

Voltage: 5VDC 5%

*1

26

*1 For the relationship between the total length, the wire diameter of transmission cables (DP, DN), and the transmission

cable supply current, refer to the following. On some slave modules with cables, the wire diameter of module-integrated

transmission cables (DP, DN) may be 0.75or less. However, they can be used without any problem, provided that the

diameter of the transmission cables (DP, DN) meets the requirement below.

Wire diameter of

transmission

cables (DP, DN)

1.25 Up to 2A Up to 1A Up to 0.5A

0.75 Up to 1.2A Up to 0.6A Up to 0.3A

Total length of 50m or

*2

less

Transmission cable supply current

Total length of 50m to

*2

100m

Total length of 100m to

200m

*2

CHAPTER 3 SPECIFICATIONS

*2 For slave modules with integrated transmission cables (DP, DN), the length of the transmission cables (DP, DN) is

included in the total length.

For wiring of 50m or more with 4 wires (DP, DN, 24V, 0V), insert the noise filter for power supply cables between the

power supply and cables. For details, refer to the manual for the AnyWireFILTER (ANF-01) manufactured by Anywire

Corporation.

3

3.2.1 Performance list

3.2 Performance Specifications

27

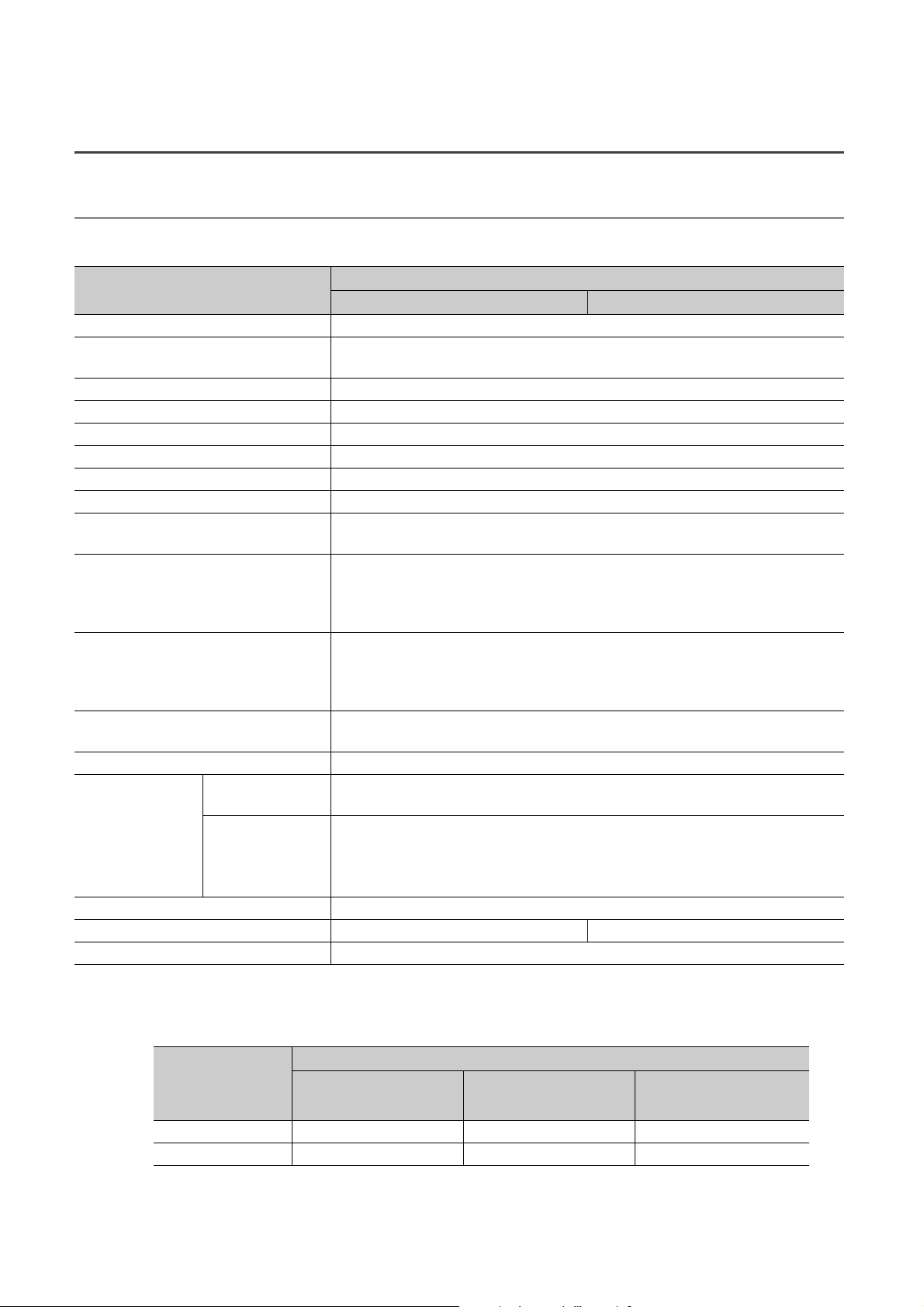

3.2.2 Number of parameters to set

1) 2) 3) 4)

As for the initial settings of a master module and the parameter settings regarding the auto refresh setting, do not set

the number of parameters, including those of other intelligent function modules, greater than the number of parameters

that can be set in a CPU module.

For the maximum number of parameters settable on the CPU module, refer to the following.

User's Manual (Hardware Design, Maintenance and Inspection) for the CPU module used

MELSEC-L CC-Link IE Field Network Head Module User's Manual

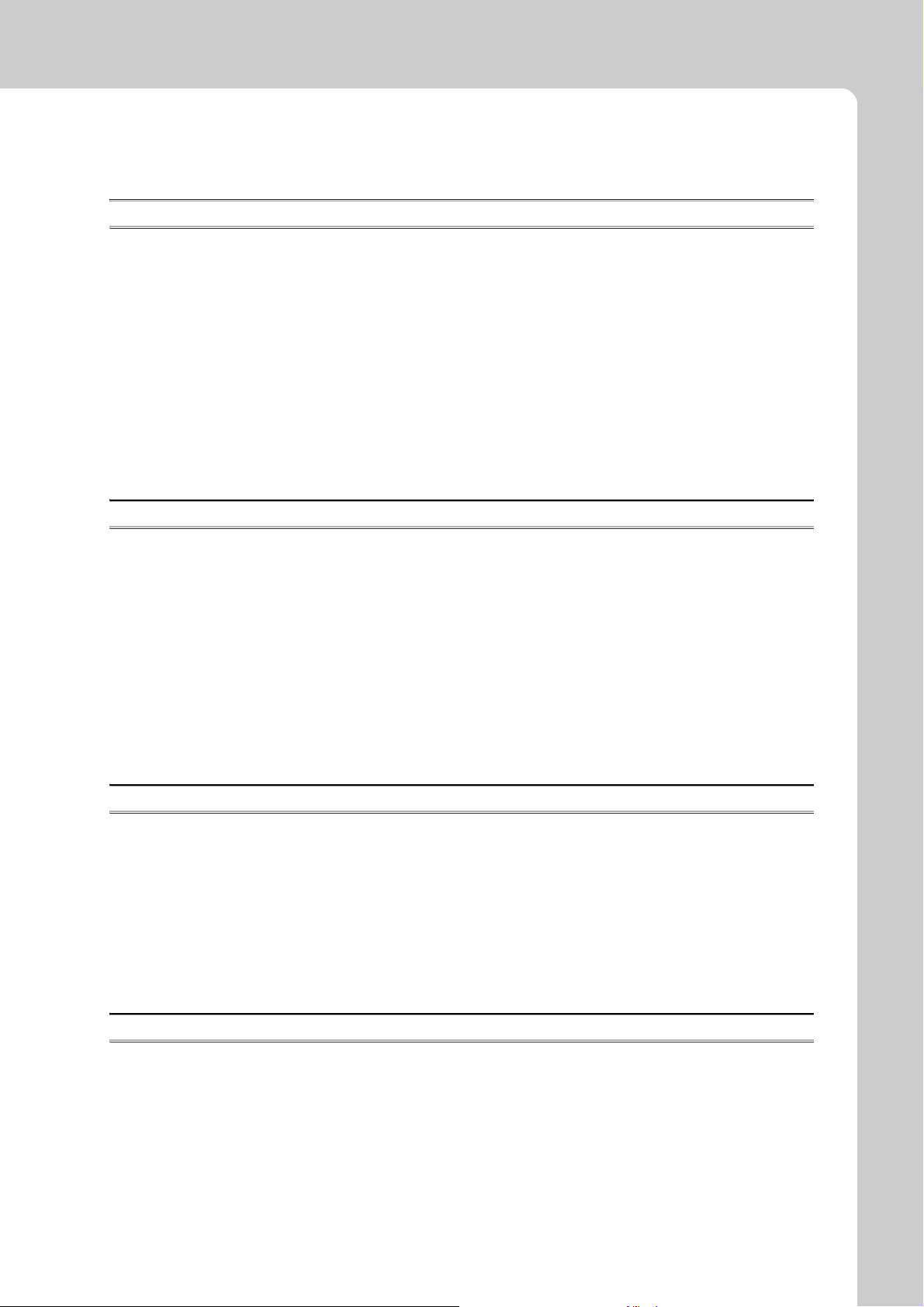

(1) The number of parameters for a master module

The master module allows the following number of parameters per module.

Target module Initial setting Auto refresh setting

QJ51AW12AL 0 (unused) 2 (maximum number of settings)

LJ51AW12AL 0 (unused) 2 (maximum number of settings)

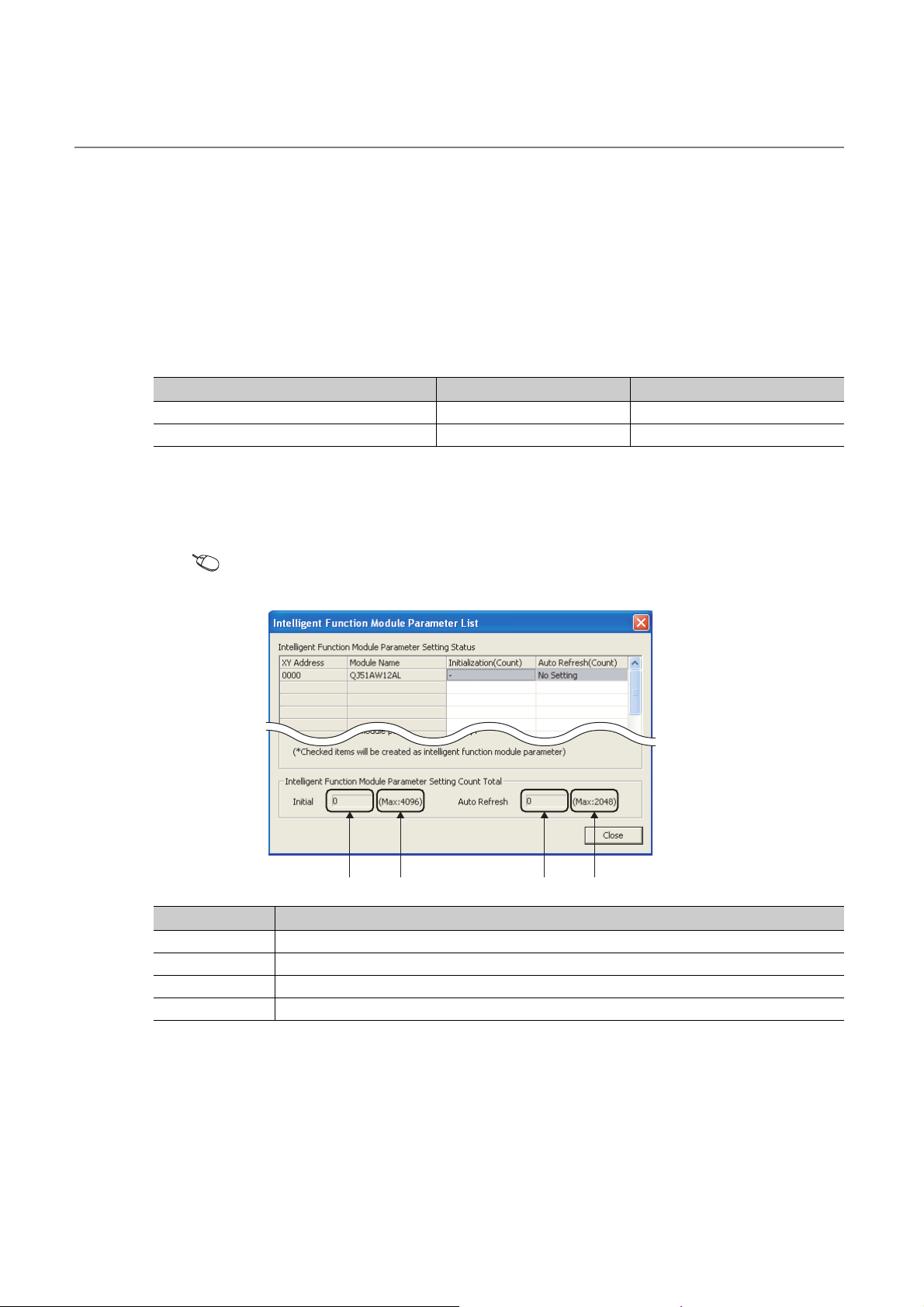

(2) Check method

The number of parameters set in an intelligent function module and the maximum number of parameter settings

can be checked with the following operations:

Project window [Intelligent Function Module] Right click

[Intelligent Function Module Parameter List]

No. Description

1) Total number of initial setting parameters having the checkboxes checked on the window

2) Maximum number of initial parameter settings

3) Total number of auto refresh setting parameters having the checkboxes checked on the window

4) Maximum number of auto refresh setting parameters

28

Loading...

Loading...