Page 1

Mitsubishi Programmable Controller

Insulation Monitoring Module

User

QE82LG

’

s Manual (Details)

Page 2

IB63564F

Caution

- Installation on excluding the control board

CAUTION

● SAFETY PRECAUTIONS ●

(Read these precautions before using this product.)

This manual contains important instructions for MELSEC-Q series QE82LG.

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product cor rectly .

The precautions given in this manual are concerned with this product only. For the safety precautions of

the programmable controller system, refer to the user’s manual of the CPU module used.

In this manual, the safety precautions are classified into two levels: "DANGER" and "CAUTION".

DANGER

Under some circumstances, failure to observe the precautions given under “ CAUTION” may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Keep this manual in an accessible place for future reference whenever needed, and make sure it is

delivered to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Precautions for Operating Environment and Conditions]

• Do not use this product in the places listed below. Failure to follow the instruction may cause

malfunctions or decrease of product-life.

- Places the Ambient temperature exceeds the range 0 - 55ºC.

- Places the Relative humidity exceeds t he range 5 - 95% or condensation is observ ed.

- Altitude exceeds 2000 m.

- Places exposed to rain or water drop.

- Dust, corrosive gas, saline and oil smoke exist.

- Vibration and impact exceed the specifications.

A - 1

Page 3

[Design Precautions]

Doing so may cause a malfunction to the sequencer system.

Caution

This module can not be used as an Electric Leakage Relay.

Caution

Doing so can cause a malfunction or failure of the module.

Danger

• Do not write data into “System Area” in the buffer memory of the intelligent function module.

Also, do not output (turn ON) the “use prohibited” signal in the output signal sent from the

sequencer CPU to the intelligent function module.

• Do not install the input signal wire together with the main circuit lines or power cables. Keep a

distance of 300 mm or more between them. (Except for the terminal input part) Failure to do so

may result in malfunction due to noise.

•

[Installation Precautions]

• Any person who is involved in the installation and the wiring of this Sequencer should be fully

competent to do the work.

• Use the programmable controller in an environment that meets the general specifications in the

User’s manual of the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

• To mount the module, while pressing the module-mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause a malfunction, failure or a fall of the module.

When using the Sequencer in an environment of frequent vibrations, fix the module with a screw.

• Tighten the screws within the specified torque range.

Fixing-Module screw (arranged by user): M3 x 12mm

Tightening torque of the fixing-module screws 0.36 - 0.48 N•m

When the screw tightening is loose, it causes a fall, short-circuit, and a malfunction.

Over-tightening can damage the screws and the module, and it may cause a fall, short-circuit, or a

malfunction.

• Shut off the external power supply for the system in all phases before mounting or removing the

module. Failure to do so may result in damage to the product.

• Do not touch directly any conductive parts and electronic parts of the module.

A - 2

Page 4

[Wiring Precautions]

Danger

If all phases are not turned off, it may cause an electric shock or product damages.

Caution

• FG terminal must be grounded according to the D-type ground (Type 3) dedicated for sequencer.

CZ-77S , CZ-112S

ZTA600A , ZTA1200A , ZTA2000A

frequency withstand voltage test.

• For installation and wiring works, make sure that the power source is shut off for all outside phases.

Failure to do so may result in electric shock or malfunction.

• When using this product, make sure to use it in combination with Mitsubishi’s zero-phase current

transformer (ZCT). Please not to exceed the ratings of this product for input of zero phase

transformer. For further details, please refer to zero phase transformer manual to maintain the

functionality and the accuracy of this product .

Split-type ZCT

CZ-22S , CZ-30S , CZ-55S

Through-type ZCT

• This module and the zero-phase current tr ansformer are used for less than 600V circuit only. They

are not used with exceeding 600V circuit.

• Do not open the secondary side of the zero-phase current transformer.

• Take care not entering any foreign objects such as chips and wire pieces into the module. It may

cause a fire, failure or a malfunction.

• In order to prevent the module from incoming foreign objects such as wire pieces during wiring

work, a foreign-object preventive label is placed on the module. While a wiring work is performed,

keep the label on the module. Before operating the system, peel off the label for heat release. If the

foreign-object preventive label is not peeled and the system is in use, residual heat inside the

module may reduce the product life.

• The wires to be connected to the module shall be put in a duct or fixed together by clamp. If not, the

loosing and unstable wire or careless stretching results in poor contact of electric wires. That may

cause a breakage of the module or wire or a malfunction.

• Use appropriate size of electric wires. If inappropriate size of electric wire is used, it may cause a

fire due to generated heat. For appropriate size of electric wires, refer to 7.5. 2 How to connect

wires.

• In case using stranded wire, take measures so that the filament should not vary by using a bar

terminal or by processing the point twisted. Use the bar terminal appropriated for the size of electric

wires. If using inappropriate bar terminals, a wire breakage or a contact failure may cause a device

malfunction, failure, a burnout or a fire.

• After wiring, confirm whether there is a wiring forgetting or a faulty wiring. They may cause a

device malfunction, a fire, or an electric shock.

• When removing the wires connected to the module, do not pull wires as holding on their electric

wire portions. Push the buttons on the terminal, and then remov e the w ire.

• If the wires connected to the module are strongly pulled off, it may cause a malfunction or a

breakage to the module or the wire. (Tensile load: 22N or less)

• Ensure the wiring to the module properly, checking the rated voltage and current of the product and

the terminal pin assignment. If the input voltage exceed the rated voltage or the wiring is improper,

it may cause a fire or a breakage.

• Do not exceed the specified voltage when doing an insulation resistance test and a commercial

ZT15B, ZT30B , ZT40B , ZT60B , ZT80B , ZT100B ,

A - 3

Page 5

• Use the product within the ratings specified in this manual. When using it outside the ratings, it not

• Do not touch the live terminal. It may cause a malfunction.

of the connectors. (Check these items under the power failure condition.)

- Places exposed to rain or water drop.

Caution

• Dispose of the product as an industrial waste.

[Start-up Precautions]

Caution

only causes a malfunction or failure but also there is a fear of igniting and damaging by a fire.

• Before operating the product, check that active bare wire and so on does not exist around the

product. If any bare wire exists, stop the operat ion immediately, and take an appropriate action

such as isolation protection.

• Do not disassemble or modify the module. It may cause failure, a malfunction, an injury or a fire.

• Attaching and detaching the module must be performed after the power source is shut off for all

outside phases. If not all phases are shut off, it may cause failure or a malfunction of the module.

[Maintenance Precautions]

Caution

• Cleaning and additional tightening of module-fixing screws must be performed after the input power

source is shut off for all outside phases. If not all phases are shut off, it may cause failure or a

malfunction of the module.

• Use a soft dry cloth to clean off dirt of the module surface.

• Do not let a chemical cloth remain on the surface for an extended period nor wipe the surface with

thinner or benzene.

Check for the following items for using this product properly for long time.

<Daily maintenance>

(1) N o damage on this product (2) No abnormality with LED indicators (3) No abnormal noise,

smell or heat.

<Periodical maintenance> (Once every 6 months to 1 year)

(4) Confirm there is loosing in installation, wire connection to terminal blocks, and the connection

[Storage Precautions]

Caution

• To store this product, turn off the power and remove wires, and put it in a plastic bag.

For long-time storage, avoid the following places. Failure to follow the instruction may cause a

failure and reduced life of the product.

- Places the Ambient temperature exceeds the range -25 to +75ºC.

- Places the Relative humidity exceeds t he range 5 - 95% or condensation is observ ed.

- Dust, corrosive gas, saline and oil smoke exist, and vibration and frequent physical impact

occur.

[Disposal Precautions]

A - 4

Page 6

Printed date

* Manual number

Revision history

9.3

Section 1.1, Section 3.1, Section 4.2, Section 6.1, Section 6.3

7.2,

Back cover

described in this manual.

Revision history

Jan, 2011 IB-63564 First edition

Correction

SAFETY PRECAUTIONS, Section 4.2, Section 8.1, Section 8.3

Sep, 2011 IB-63564-A

Addition

SAFETY PRECAUTIONS, Section 2.1, Section 3.2, Section 7.4, Section

* Manual number is provided at t he bottom of the cov er page.

Aug. 2012 IB-63564-B

Jul. 2013 IB-63564-C

Nov. 2013 IB-63564-D

Jan. 2016 IB63564E

Jul, 2017 IB63564F

Correction

Section 2.3, Section 7.6, Section 9.1

Correction

Section 2.3, Section 7.6, Section 7.7, Section 8.2, Section 9.3

Addition

Correction

Section 4.1, Section 4.2.5, Section 6.1, Section 6.2.2, Section 6.2.3,

Section 6.3.1, Section 6.3.2, Section 6.3.4, Section 6.3.5, Section 6.4.1,

Section 7.6.2, Section 7.6.4, Section 8.2, Section 9.1

Addition

Section 6.1, Section 6.4.3, Appendix 3

Correction

Cover, Back cover

Correction

Compliance with the EMC and Low Voltage Directives,

Section 2.1, Section 3.2, Section 6.2, Section 6.3, Section 6.4, Section

Section 7.5, Section 7.6, Section 8, Section 9.2, Appendix 2, Appendix 3,

This manual does not guarantee to protect or does not give a permission to any industrial property and any related rights.

Also, our company shall not be held any responsible for any issues related to industrial properties due to product usage

2011 MITSUBISHI ELECTRIC CORPORATION

A - 5

Page 7

Table of Content

SAFETY PRECAUTIONS ·········································································································· A-1

Revision history ······················································································································· A-5

Table of content ······················································································································ A-6

Compliance with the EMC and Low Voltage Directives····································································· A-8

Names, abbreviations, terminology ···························································································· A-9

Product configuration ················································································································ A-9

Chapter 1: Overview 1-1

1.1 Features ··························································································································· 1-1

Chapter 2: System Configuration 2-1 - 2-4

2.1 Applicable system ··············································································································· 2-1

2.2 Precautions for system configuration ······················································································· 2-3

2.3 How to check the function version, serial number, and module version ··········································· 2-3

Chapter 3: Specifications 3-1 - 3-2

3.1 General specifications·········································································································· 3-1

3.2 Electrical and mechanical specifications ·················································································· 3-2

Chapter 4: Functions 4-1 - 4-11

4.1 List of functions ·················································································································· 4-1

4.2 Functions in detail ·············································································································· 4-2

Chapter 5: I/O signal to CPU module 5-1 - 5-7

5.1 List of I/O signals ················································································································ 5-1

5.2 Details of I/O signals ············································································································ 5-2

Chapter 6: Buffer memory 6-1 - 6-13

6.1 Buffer memory assignment ··································································································· 6-1

6.2 Configurable sections (Un\G0 to Un\G1100, Un\G2000 to Un\G2100) ··········································· 6-4

6.3 Measurable sections (Un\G1100 to Un\G1999, Un\G2100 to Un\G2999) ······································· 6-6

6.4 Common sections (Un\G3000 to Un\G4999) ··········································································· 6-12

Chapter 7: Setting and procedure for operation 7-1 - 7-24

7.1 Precautions for handling ····································································································· 7-1

7.2 Procedure for operation ······································································································ 7-2

7.3 Name and function of each part ····························································································· 7-3

7.4 Attaching and removing the module ························································································ 7-5

7.5 Connecting wires, wiring ······································································································· 7-7

7.6 Setting from GX Works2 ···································································································· 7-14

7.7 Setting from GX Developer ································································································· 7-20

A - 6

Page 8

Chapter 8: Programming 8-1 - 8-8

8.1 Programming procedure ····································································································· 8-1

8.2 System configuration and usage conditions for sample program ·················································· 8-2

8.3 Sample programming ········································································································· 8-4

Chapter 9: Troubleshooting 9-1 - 9-8

9.1 List of error codes ·············································································································· 9-1

9.2 Troubleshooting ················································································································· 9-4

9.3 Q&A ································································································································· 9-7

Appendix Appendix 1 - 7

Appendix 1: External dimensions ······················································································ Appendix-1

Appendix 2: Optional devices ··························································································· Appendix-2

Appendix 3: Addition or change of functions ······································································· Appendix-7

Index Index 1

A - 7

Page 9

CZ-22S , CZ-30S , CZ-55S

CZ-77S , CZ-112S

ZT15B, ZT30B , ZT40B , ZT60B ,

ZTA600A , ZTA1200A , ZTA2000A

CE marking cable (twisted pair cable )

AWG22 – AWG18 (0.3 – 0.8 mm2)

Max. cable length

50m

Compliance with the EMC and Low Voltage Directives

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage Directives when

incorporating the Mitsubishi program mable controller (EMC and Low Voltage Direc tives compliant)

into other machinery or equipment, refer to QCPU User's Manual (Hardware Des ign, Maintenance

and Inspection).

The CE mark , indicating compliance with the EMC and Low Voltage Directives, is printed on the

rating plate of the programmable controller.

(2) For the product

For the compliance of this pr oduct with the EMC and Low Voltage Directives, refer to Section 7.5

Wiring.

(3) CE marking conformity combination module

This module conforms to CE marking standard in a condition to make combination use with following

zero-phase current transformer (ZCT) and cable.

Split-type ZCT

Through-type ZCT

cable

ZT80B , ZT100B ,

Single wire:

AWG24 – AWG18 (φ0.5 - 1.0mm)

Stranded wire:

A - 8

Page 10

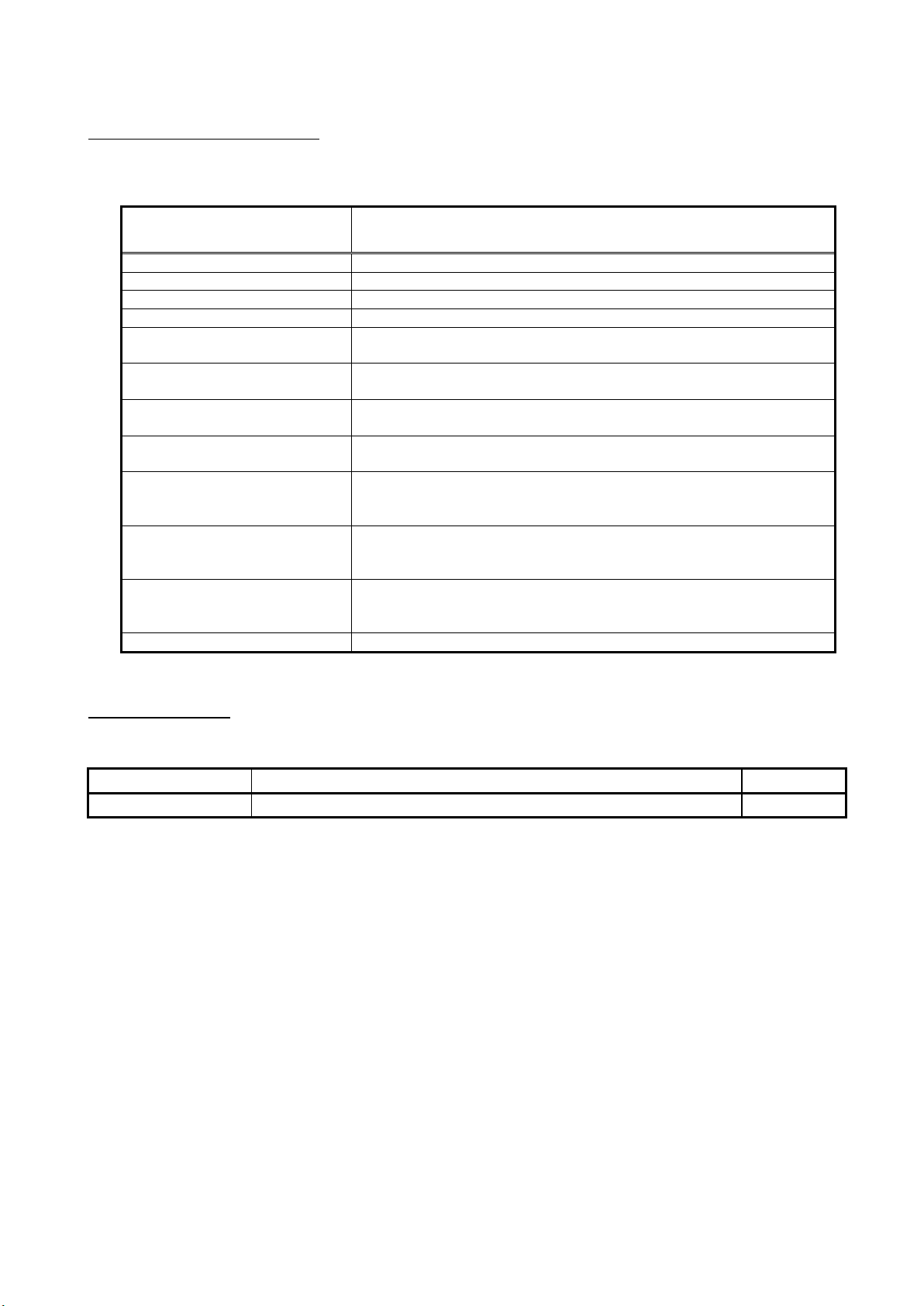

terminology

Io1

Abbreviation for CH1 leak current.

Ior1

Abbreviation for CH1 leak current for resistance.

Io2

Abbreviation for CH2 leak current.

Ior2

Abbreviation for CH2 leak current for resistance.

Collective term for Io1 1-step alarm, Io1 2-step alarm, Ior1 1-step

alarm, and Ior1 2-step alarm.

Collective term for Io2 1-step alarm, Io2 2-step alarm, Ior2 1-step

alarm, and Ior2 2-step alarm.

Collective term for Io1 max. value and its date/time of occurrence, and

Ior1 max. value and its date/time of occurrence.

Collective term for Io2 max. value and its date/time of occurrence, and

Ior2 max. value and its date/time of occurrence.

Collective term for the year of max. value occurrence, month and day

and second and day of the week of max. value occurrence.

Collective term for Io1 1-step alarm occurrence count, Io1 2-step

2-step alarm occurrence count.

Collective term for Io21 1-step alarm occurrence count, Io2 2-step

2-step alarm occurrence count.

ZCT

Abbreviation for zero-phase current transformer

Model name

Product name

Quantity

QE82LG

Insulation monitoring Module

1

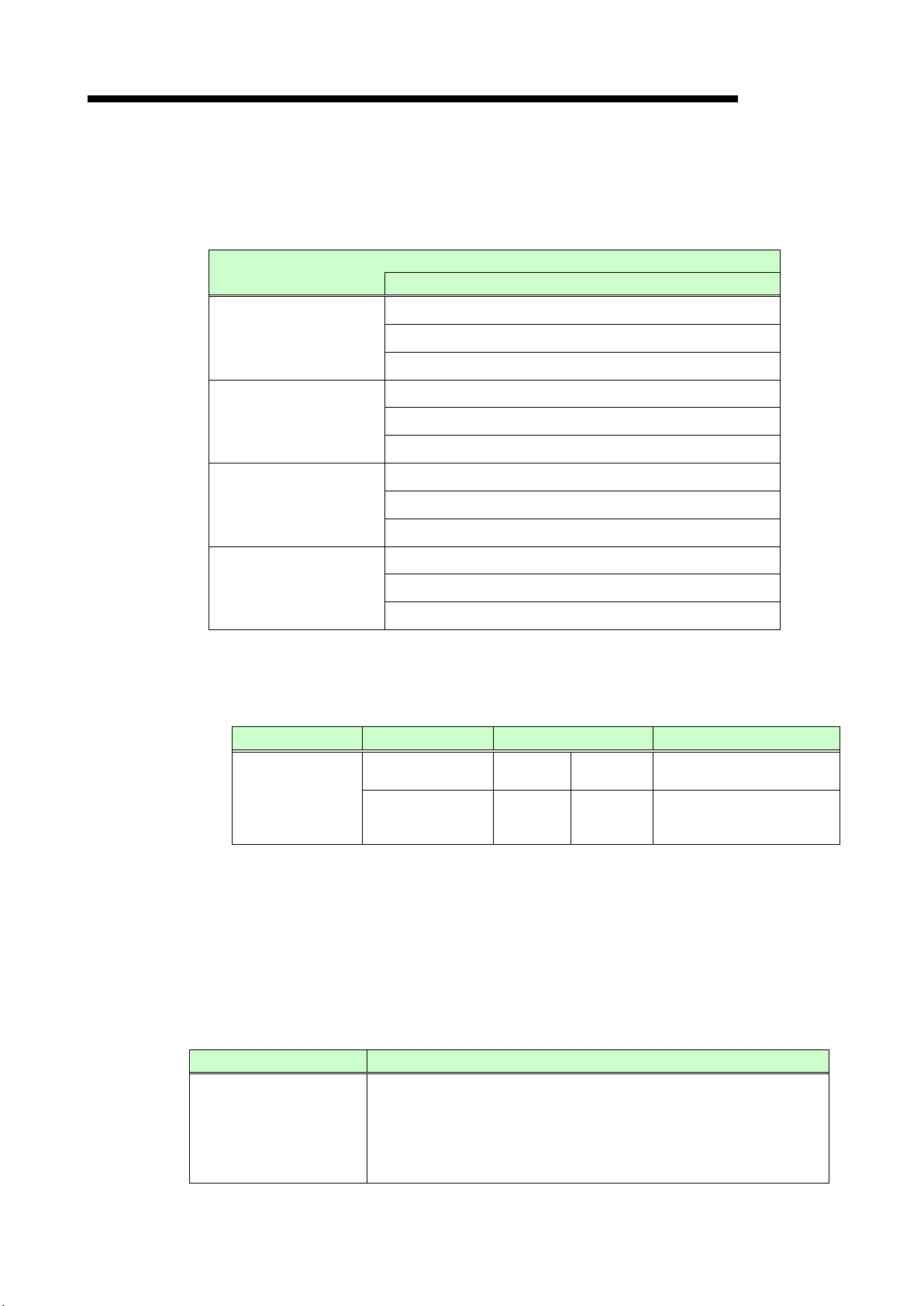

Names, abbreviations, terminology

In this manual, the following names, abbreviations, and terminology are used to explain the insulation

monitoring module, unless otherwise specified.

Names, abbreviations,

CH1 Alarm

CH2 Alarm

CH1 max. value

CH2 max. value

Descriptions of names, abbreviations, terminology

Date/time of occurrence

CH1 Alarm occurrence count

CH2 Alarm occurrence count

Product configuration

The following describes the product configuration.

of max. value occurrence, hour and minute of max. value occurrence,

alarm occurrence count, Ior1 1-step alarm occurrence count, and Ior1

alarm occurrence count, Ior2 1-step alarm occurrence count, and Ior2

A - 9

Page 11

Note

A - 10

Page 12

1 Overview

QE82LG

Chapter 1: Overview

1.1 Features

This manual explains specifications, handling methods, and programming of

Insulation Monitoring Module QE82LG (hereinafter, abbreviated as QE82LG)

supporting MELSEC-Q series.

(1) This enables to measure leak current for safety actions.

By monitoring leak current (Io), risk for electric shock can be detected.

(2) This enables constant monitoring of insulation for equipment.

By monitoring leak curr ent f or res ista nce ( Ior) , det eri orati on of equi pment insulation

can be tracked.

(3) This enables 2-level alarm monitoring during monitoring for each measuring

element.

For each leak current (Io) and leak current for resistance (Ior), 2-level alarm

monitoring can be performed without a sequence.

(4) This enables to measure two circuits, using one device.

At the power source with the same-phase wire system, a single device can

measure two circuits.

(5) This enables to measure sensitive.

By changing setting to high sensitivity mode, this enables to measure from

0.01mA.

1 - 1

Page 13

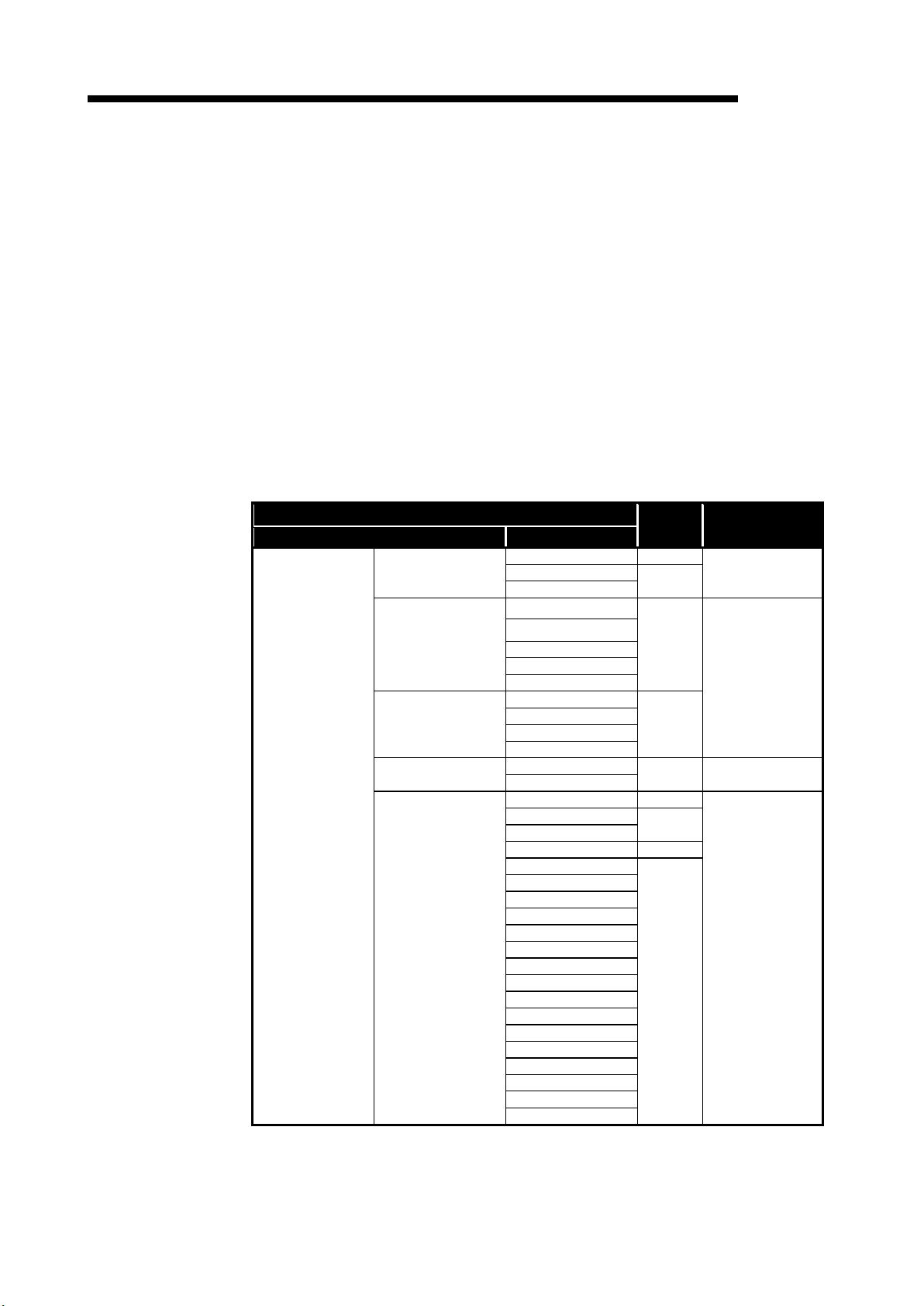

QE82LG

2 System Configuration

Attachable CPU Module

Attachable

Remarks

CPU Type

CPU Model

Q00JCPU

16

Q00CPU

Q01CPU

Q02CPU

Q02HCPU

Q06HCPU

Q12HCPU

Q25HCPU

Q02PHCPU

Q06PHCPU

Q12PHCPU

Q25PHCPU

Q12PRHCPU

Q25PRHCPU

Q00UJCPU

16

Q00UCPU

Q01UCPU

Q02UCPU

36

Q03UDCPU

Q04UDHCPU

Q06UDHCPU

Q10UDHCPU

Q13UDHCPU

Q20UDHCPU

Q26UDHCPU

Q03UDECPU

Q04UDEHCPU

Q06UDEHCPU

Q10UDEHCPU

Q13UDEHCPU

Q20UDEHCPU

Q26UDEHCPU

Q50UDEHCPU

Q100UDEHCPU

Chapter 2: System Configur ati on

2.1 Applicable system

The following describes applicable systems.

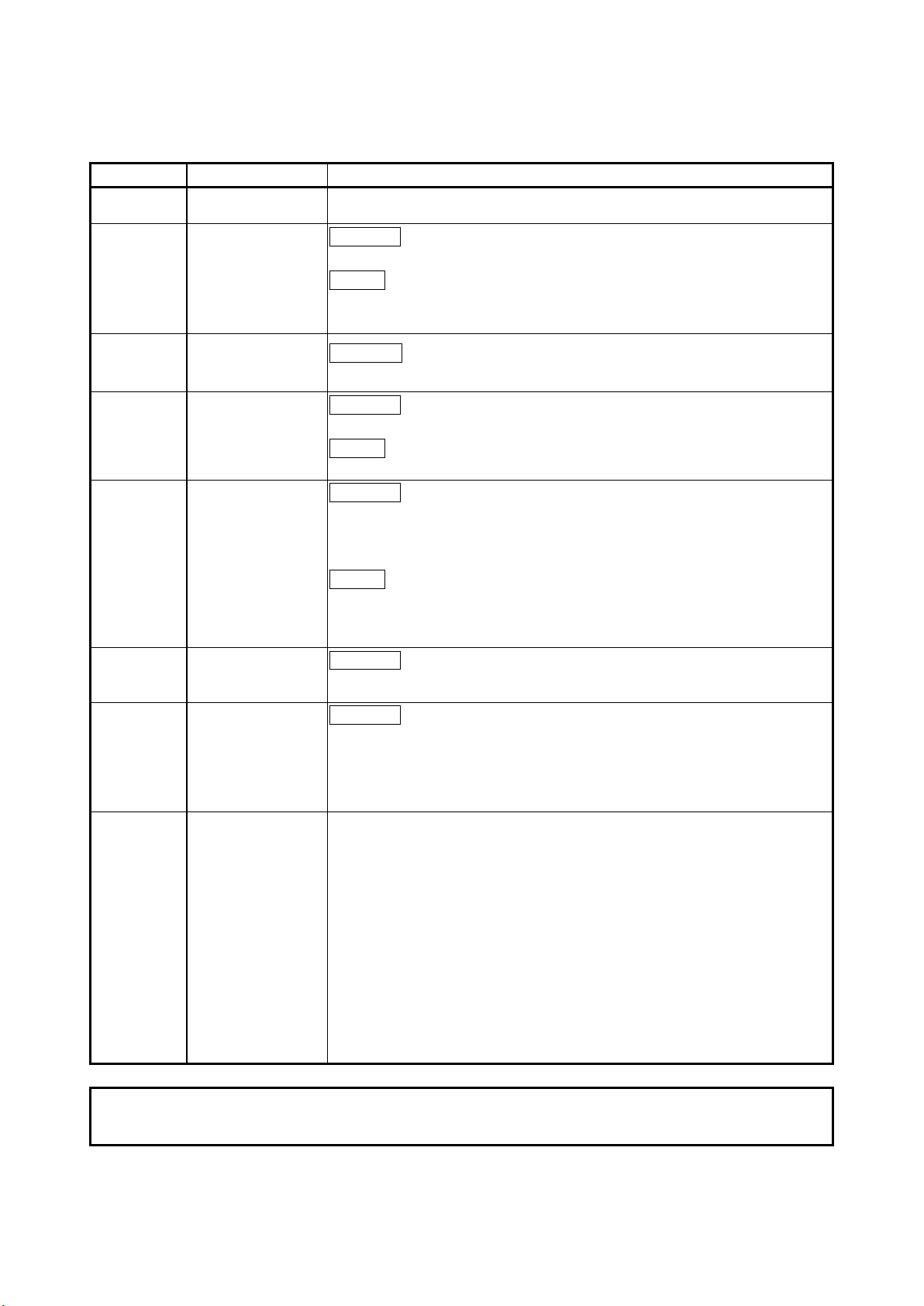

(1) Applicable module and the quantity of attachable pieces

(a)When mounted with CPU module

CPU module to which QE82LG can be attached and the number of attachable

pieces are shown below.

Depending on the combination of the attached module and the number of

attached pieces, lack of power capacity may occur.

When attaching the module, please consider the power capacity.

If the power capacity is insufficien t, reconsid er the com bination of m odules to b e

attached.

Since the number of attachable modu les are limited by the power module which

used, please refer to the notes on the 2.2 precautions for system configuration.

Programmable

controller

CPU

Basic model

QCPU

High performance

model QCPU

Process CPU

Redundant CPU

Universal model

QCPU

quantity.

24

64

64

53

24

64

2 - 1

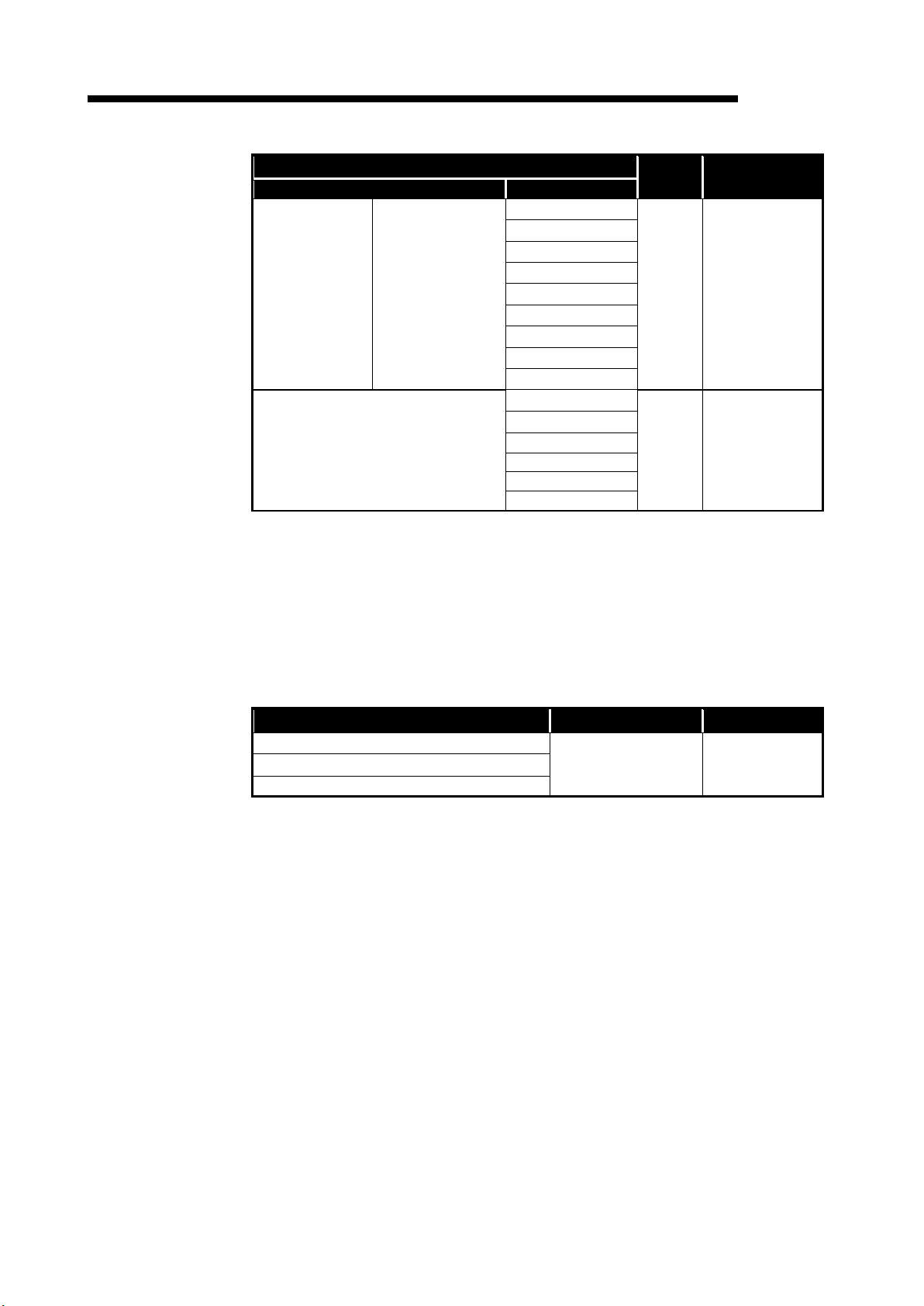

Page 14

QE82LG

2 System Configuration

Attachable CPU Module

Attachable

Remarks

CPU Type

CPU Model

Q03UDVCPU

Q04UDVCPU

Q06UDVCPU

Q13UDVCPU

Q26UDVCPU

Q04UDPVCPU

Q06UDPVCPU

Q13UDPVCPU

Q26UDPVCPU

Q06CCPU-V

Q06CCPU-V-B

Q12DCCPU-V

Q24DHCCPU-LS

Q24DHCCPU-V

Q26DHCCPU-LS

Applicable Network Module

Remarks

QJ72LP25-25

QJ72LP25G

QJ72BR15

quantity.

Programmable

controller

CPU

C Controller module

(b) When mounted with MELSECNET/H remote I/O station

The table belo w shows the network modu les applicable to the QE 82LG and the

number of network modules to be mounted.

Depending on the combination with other modules or the number of mounted

modules, power supply capacity may be insufficient.

Pay attention to the power supp ly capacity before mounting modules, and if the

power supply capacity is insufficient, change the combination of the modules.

High-Speed

Universal model

QCPU

64

64

Number of modules

64

(c) The base unit can be mounted

QE82LG can be installed to any I/O slot of main base unit and extension base unit.

*1 In case of redundant CPU, can be mounted to the extension base unit only.

Mounted to the main base unit is not allowed.

*2 Limited within the range of I/O points for the CPU module.

(2) For multiple CPU system

The function version of the firs t released CT input m odule is C, and the C T input

module supports multiple CPU systems.

When using the CT input module in a multiple CPU system, refer to the following.

*QCPU User’s Manual (Mul tiple CPU system)

2 - 2

Page 15

QE82LG

2 System Configuration

Product name

Model name

Remarks

iQ Platform compatible programmable

controller engineering software

MELSEC sequencer programming software.

“n” in the model name is 4 or larger.

19H101

710G1234

Module version

Serial No.

(3) Applicable software package

QE82LG supported software packages are as follows:

2.2 Precautions for system configuration

(a) Software package for sequencer

GX Works2 SWnDNC-GXW2

GX Developer SWnD5C-GPPW

(1) When attaching it to an expansion base without a power module

If QE82LG is att ached t o an expans ion b ase wit hout a po wer m odule, refer to the

user’s manual of the sequencer CPU to be used in order to select the power

module and expansion cable.

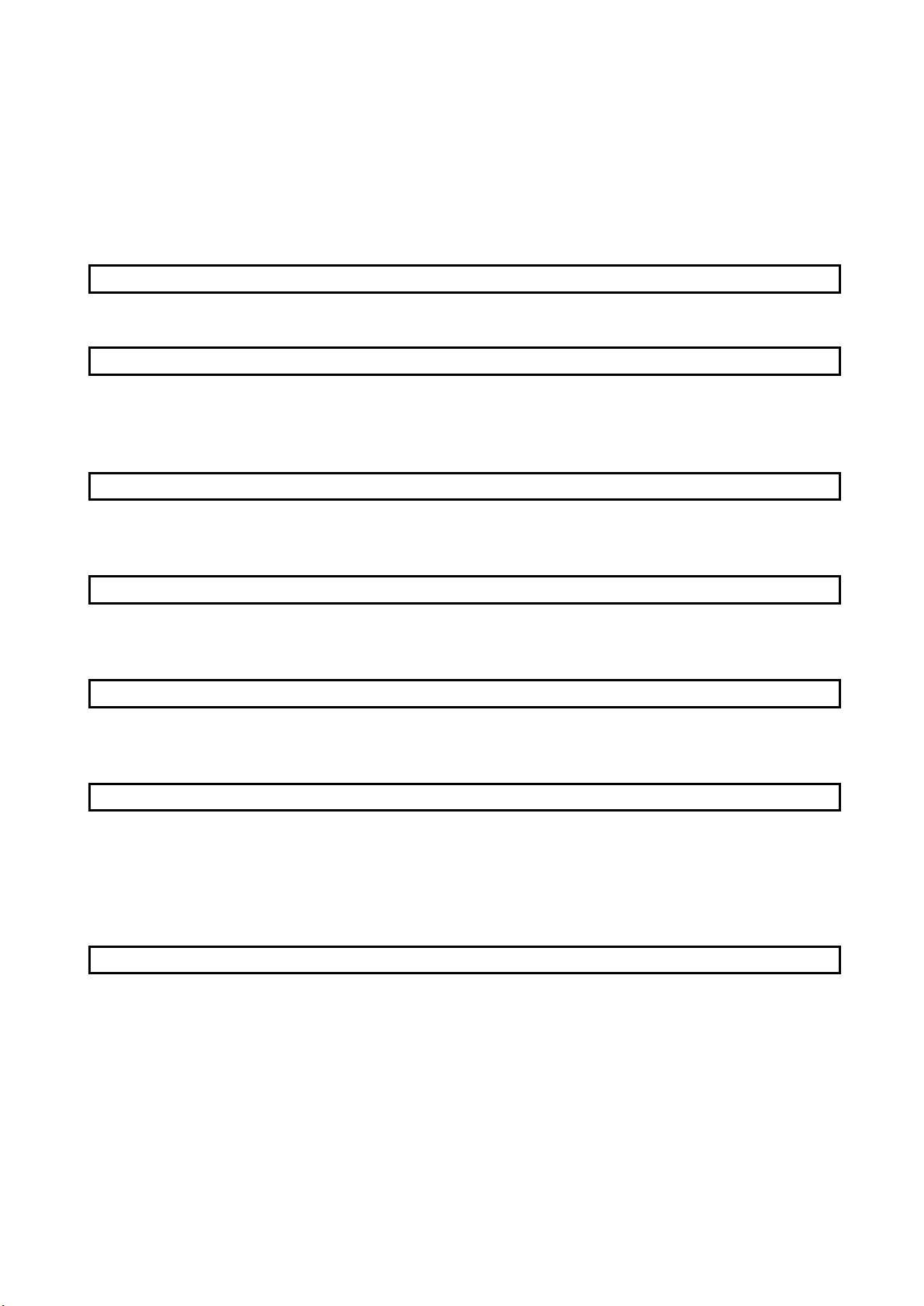

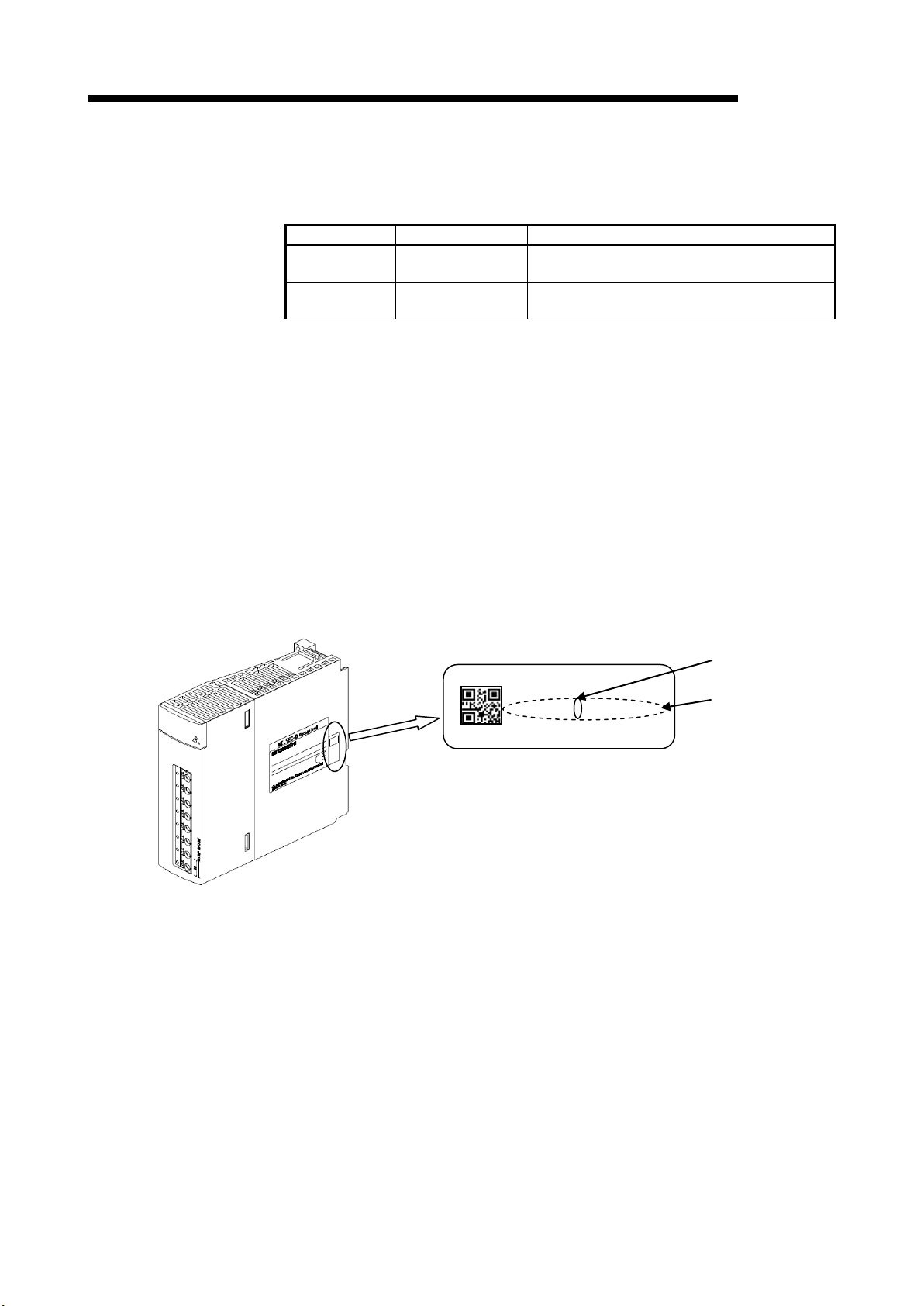

2.3 How to check the function version, serial number, and module version

(1) How to check the serial number and module version

It can be checked with the serial number label (placed on the right side of

QE82LG).

2 - 3

Page 16

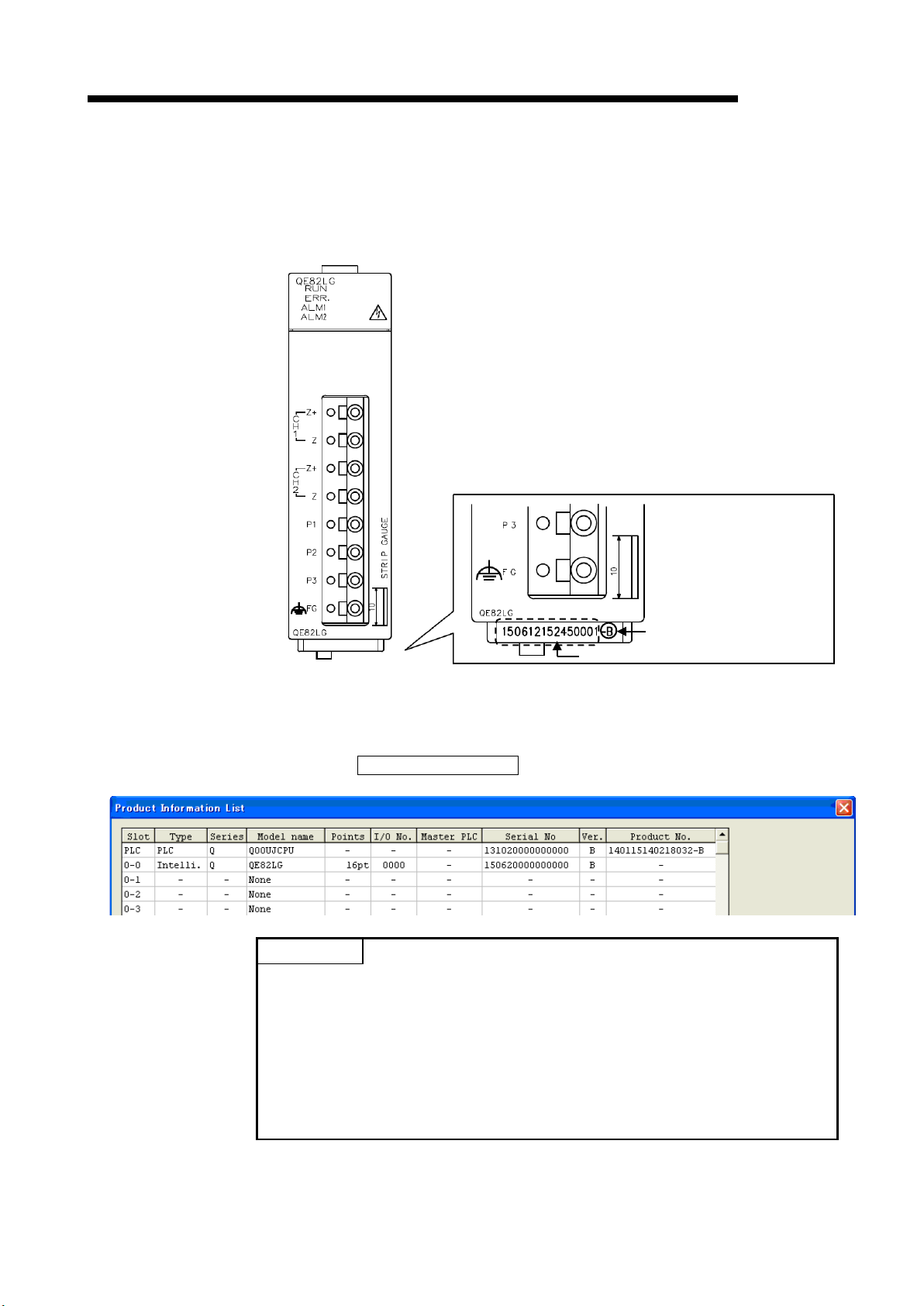

QE82LG

2 System Configuration

The serial number displayed on the Product Information List dialog box of GX

Developer may differ from that on the rating plate and

The function information of the product is updated when a new function is

added.

Serial number

(2) How to check the function version and serial number

(a) Checking on the front of the module.

The serial numbe r an d fu n ction ver sio n on t he r a tin g pl at e i s show n on th e fro nt

(at the bottom) of the module.

Function version

(b) Checking on the System monitor dialog box (Product Information List)

To display the system monitor, select [Diagnostics]

click the Product Information List button of GX Developer.

[System monitor] and

→

Point

on the front of the module.

The serial num ber on the rat ing plate and f ront part of th e module indic ates

・

the management information of the product.

The serial number displa yed o n t he Product Infor mation List dia lo g b ox of G X

・

Developer in di cat e s the fu nct i on information of the product.

2 - 4

Page 17

QE82LG

3 Specifications

Item

Specifications

Phase-wire system

single-phase 2-wire / single-phase 3-wire / three-phase 3-wire

Ratings

Voltage

single-phase

3-wire

110 V , 220 V AC

single-phase

3-wire

110V AC (1 - 2 line, 2 - 3 line) 220 V (1 - 3 line)

Leak current circuit

1 A AC

value of ZCT.)

Frequency

50-60 Hz

Measuring range

Low sensitivity mode : 0-1000mA

High sensitivity mode : 0.00-100.00mA

Resolution

Low sensitivity mode : 1mA

High sensitivity mode : 0.01mA

Allowable tolerance of module

Low sensitivity mode : Leak current

: ±2.5mA

Measurable circuit count

2 circuits*

3

Data update cycle

Leak current : 2 seconds or less

Leak current for resistance : 10 seconds or less

Backup for electric blackout

Nonvolatile memory is used.

Alarm occurrence

count)

I/O occupation

16 points (I/O assignment: intelligence 16 points)

Chapter 3: Specifications

3.1 General specifications

circuit

*1,*

(excluding ZCT)

2

2-wire,

three-phase

(Zero-phase current transformer (ZCT) is used. It indicat es the primar y current

: ±2.5% (10 – 100% range of Ratings)

: ±2.5mA (0 – 10% range of Ratings)

: Leak current for resistance

: ±2.5% (10 – 100% range of Rating s)

: ±2.5mA (0 – 10% range of Ratings)

High sensitivity mode : Leak current

: ±2.5mA

: Leak current for resistance

* 1:110 V, 220V di r e ct con ne ct io n is possible. Abov e 440 V vol t ag e t ran sformer outside (VT) is required.

* 2:In case of m easuring le akage curren t for resis tance, it is possible on single-phase 2-wire, sin gle-phase

3-wire, three-phase 3-wire delta circuit.

* 3:The measurement of two circuits is possible at one module in the same system in the same trans.

(Items: Settings, Max. value and date/time of occurrence,

3 - 1

Page 18

QE82LG

3 Specifications

Item

Specifications

VA

circuit

Each phase 0.1 VA (at 110 V AC), Each phase 0.2 VA (at 220 V AC)

(5 V DC)

0.17 A

Operating temperature

0 – 55°C (Ave rag e daily temperature 35°C or below)

Operating humidity

5 – 95% RH (No condensation)

Storage temperature

-25° – +75°C

Storage humidity

5 – 95% RH (No condensation)

Operating altitude

2000m or below

Installation area

Inside a cont rol panel

Operating environment

No corrosive gas

Conforms to JIS

Constant

acceleration

Half

amplitude

Sweep

time

10 times

vibration

-

1.75 mm

8.4 – 150 Hz

4.9 m/s2

-

Impact resistance

Conforms to JIS B 3502, IEC 61131-2 (147 m/s2, XYZ each direction 3 times)

Over voltage category *1

II

or less

Pollution degree *2

2 or less

Equipment category

Class I

wire)

(Z+, Z terminal)

Single wire

AWG24 – AWG18 (φ0.5 - 1.0mm)

Stranded wire*4

AWG22 – AWG18 (0.3 – 0.8 mm2)

terminal

Single wire

AWG24 – AWG18 (φ0.5 - 1.0mm)

Stranded wire

*4

AWG22 – AWG18 (0.3 – 0.8 mm2)

Tightening torque

Module-fixing screws (M3 screw)

*5

0.36 – 0.48 N・m

Between voltage/leak current input terminals – FG terminal

2210 V AC

5 sec

Between voltage/leak current input terminals – sequencer

power source and GND terminal

2210 V AC

5 sec

Insulation resistance

5 MΩ or more (500 V DC) at locations above

External dimensions

27.4 mm (W) x 98 mm (H) x 90 mm (D), excluding protruding portions

Mass

0.1 kg

Product life expectancy

10 years (used under the average daily temperature 35°C or less)

3.2 Electrical and mechanical specifications

Consumption

Internal current consumption

Vibration resistance

Applicable

wire

(Usable

electric

Voltage

ZCT Input

terminal

Voltage input

B 3502,

IEC 61131-2

*3

Intermittent

vibration

Continuous

Frequency

5 – 8.4 Hz

8.4 – 150 Hz

5 – 8.4 Hz

- 3.5 mm

2

9.8 m/s

-

XYZ

each

direction

-

Commercial frequency

withstand voltage

*1. This indicates the assumed area of electric distribution to which the device is connected, the area

ranging from public distribution to factory machinery. The category II applies to the device

power-supplied from fixed facility. The surge voltage of this product is 2500 V up to the rated voltage of

300 V.

*2. The index indicates the level of conductive substance at the device’s operating environment.

Contamination level 2 m eans only non-conductive sub stance. H owever, occ asional c ondensat ion ma y

lead to temporary conduction.

*3. At the c onnec ti on b etwe en ZCT sec ondary terminal an d th is m odu le termina l (Z +, Z), e ach wire has to

be twisted for usage.

*4. If stranded wire is used, a bar terminal must be used.

Recommended bar terminal: TGV TC-1.25-11T (Made by Nichifu)

*5. The m odule can be fix ed eas ily to t he bas e uni t, using the hook on top of the m odul e. Howe ver, if it is

used under a vibrating environment, we strongly recommend that the module be fixed with screws.

3 - 2

Page 19

4 Functions

Reference

section

and Ior2, and stores

and can measure an

leak current. *1

7.7.2

ddition, you can set 2 steps of alarm values for each

can be used in such way to

the value

to be over the monitoring value

signal is turned

on.

Alarm occurrence

For each alarm monitored element, it counts the

frequency of the alarms, which will be stored in the

Alarm occurrence

Even if the power source reset occurs, the count of

alarm occurrence is retained.

switch enables

into the buffer

existence of voltage and current

Chapter 4: Functions

4.1 List of functions

Functions of QE82LG are provided in Table 4.1-1.

Table 4.1-1 List of functions

QE82LG

No.

1 Measurement

2 Hold max. values

3 Alarm monitoring

Function

It enable measures Io1, Ior1, Io2,

the records into a buffer memory as needed.

It changes a low sensitivity mode (0-1000mA) and high

sensitivity mode (0.00-100.00mA)

For Io1, Ior1, Io2, and Ior2, each maximum va lues and

date of occurrence are stored in the buffer memory as

needed.

Even if the power source reset occurs, maximum values

and date of occurrence are retained.

It can monitor the upper limit for Io1,Ior1,Io2, and Ior2.

In a

monitored element, and they

release cautious alarm and real alarm. When

exceeds and continues

for alarm delay time, a specified input

Descriptions

Section

4.2.1

Section

7.6.2

Section

4.2.2

Section

4.2.3

4

5 Test

count

*1: High sensitivity mode can be used QE82LG whose serial number (upper six digits,

shown on the front (at the bottom) of the module) is 150612 or later.

buffer memory as needed.

It can count up to 9999 times of Alarm occurrence count.

If the count exceeds 9999 times,

count remains 9999 times.

The intelligent function module

pseudo-storage of the specified value

memory, even with non(sensor) input.

Using this module, you can create a sequence, etc.

4 - 1

Section

4.2.4

Section

4.2.5

Page 20

4 Functions

Measured items

Details

Measured items

Mode

Resolution

Measuring range

Low sensitivity

mode

Two

places

Measured items Behavior of this module

or over 66.5 Hz), it becomes 0 mA.

4.2 Functions in detail

4.2.1 Measuring functions

(1) Measured items

Measured items and measured ranges are described as follows:

QE82LG

CH1 leak current

CH1 leak current for

resistance

CH2 leak current

CH2 leak current for

resistance

(2) Resolution of measured data

Resolution of measured data is described as follows:

- Leak current, leak current for resistance

Present value (Un\G1100)

Max. value (Un\G1101)

Date/time of occurrence (Un\G1102 to Un\G1105)

Present value (Un\G1150)

Max. value (Un\G1151)

Date/time of occurrence (Un\G1152 to Un\G1155)

Present value (Un\G2100)

Max. value (Un\G2101)

Date/time of occurrence (Un\G2102 to Un\G2105)

Present value (Un\G2150)

Max. value (Un\G2151)

Date/time of occurrence (Un\G2152 to Un\G2155)

Io1

Ior1

Io2

Ior2

(3) Restrictions for measuring data

- Measurem ent cannot be performed immediatel y after the power loading to the sequencer

system (while Module ready (Xn0) is under the OFF condition).

After checking that Module ready (Xn0) is ON, obtain measuring data.

- Measurement cannot be p er f ormed immediately after operating conditions are s et up to this

module. After checking that Operating conditio n sett ing com pletion f lag (Xn9) bec om es O N,

obtain measuring data.

- Behaviors during operation are as follows:

Io1

Ior1

Io2

Ior2

High sensitivity

mode

When the input cur rent is less tha n 1 mA in low sensi tivity m ode

or 0.01mA in high sensitivity mode, it becomes 0 mA.

When the input current is less than 80 V, it becomes 0 mA.

In the case of abnorm al frequency (when it is less than 44.5 Hz

Integer 1 mA 0-1000mA

decimal

0.01mA

0.00-100.00mA

4 - 2

Page 21

4 Functions

CH1最大値クリア要求(YnA)

CH1最大値クリア完了フラグ(XnA)

ON

OFF

OFF

ON

OFF

OFF

CH1 max. value clear completion flag (XnA)

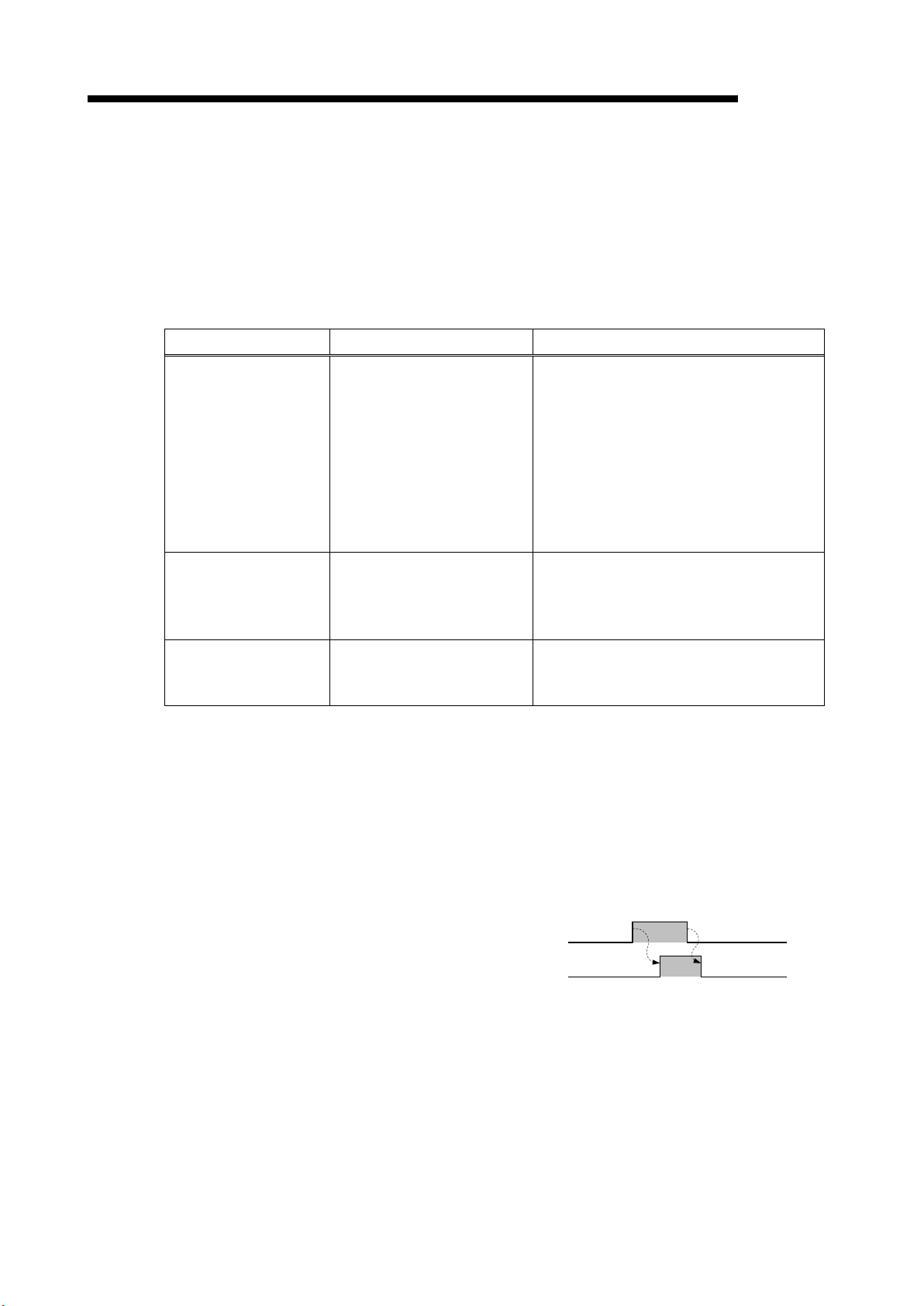

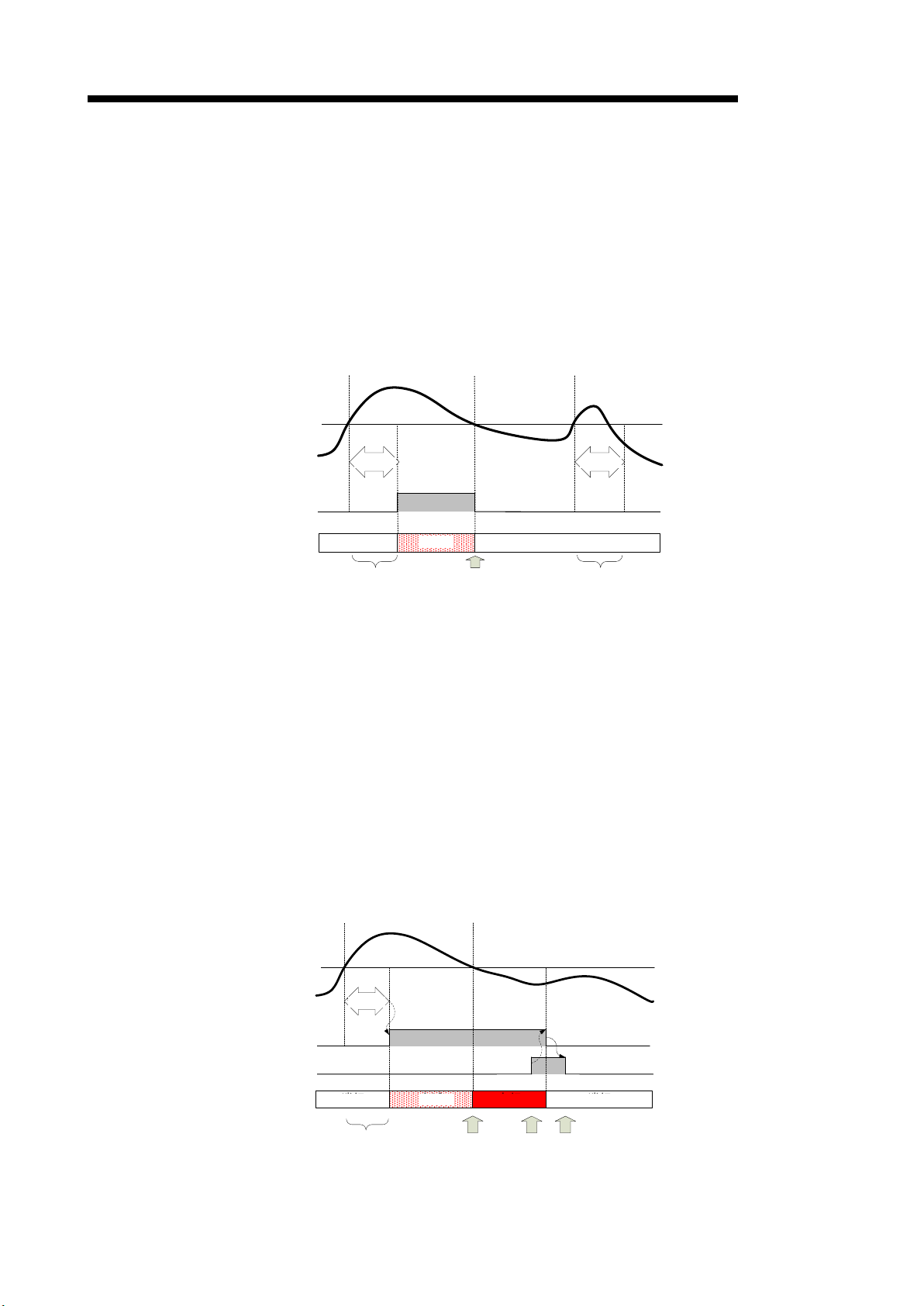

4.2.2 Max. values hold function

It memorizes the m ax. value for each m easured element, and re tains it until the max. value is

cleared.

(1) Max. value memory

1) It memorizes the max. value for the following measured element.

- CH1 leak current

- CH1 leak current for resistance

- CH2 leak current

- CH2 leak current for resistance

2) It mem orizes the date and time of oc cur r ence (year/month/day/hour/minute/second/day of

the week) together with the max. value.

3) The max. value and the date and time of occurrence ar e s tored in t he n on vo lat ile memory,

so that these max. values can be retained even at a power source reset.

(2) How to clear the max. value

1) You can use the I/O signal to clear the max. value.

2) The max. value immediately after clearing will be the present value and the date of

occurrence will be the present date and time.

3) The follow ing data can be cleared up on CH1 max. valu e clear request (YnA). Ho wever,

the following data cannot be cleared individually.

- Io1 max. value (Un\G1101)

- Io1 date and time of occurrence (Un\G1102 to Un\G1105)

- Ior1 max. value (Un\G1151)

- Ior1 date and time of occurrence (Un\G1152 to Un\G1105)

4) The following d ata can be cleared upon CH2 m ax. value clear re quest (YnC). H owever,

the following data cannot be cleared individually.

- Io2 max. value (Un\G2101)

- Io2 date and time and time of occurrence (Un\G2102 to Un\G2105)

- Ior2 max. value (Un\G2151)

- Ior2 date and time of occurrence (Un\G2152 to Un\G2105)

5) The following des cribes how to clear CH 1 max. value. (C H2 max. value follows t he sam e

procedure using CH2 max. value clear request (YnC).)

(i) Check that CH1 max. value clear request (YnA) is OFF.

(ii) Set CH1 max. value clear request (YnA) to ON.

Max. values and dates and times of occurrence of CH1 leak current and CH1 leak

current for resistance are cleared, and then CH1 max. value clear completion flag

(XnA) is turned ON.

(iii) Check that CH1 m ax. value clear completi on fla g (XnA) is ON, and then set CH1 m ax.

value clear request (YnA) to OFF.

QE82LG

CH1 max. value clear request (YnA)

Figure 4.2.2-1 Procedure for clearing max. value

4 - 3

Page 22

4 Functions

Setting item

Setting range

Description

Alarm is released when the present

and the

size.

whether or not the

occurrence condition should be

alarm value after the alarm is released.

Alarm is released when the present

situation continues for alarm delay time.

ON

OFF

OFF

ON

OFF

OFF

動作条件設定完了フラグ

(Xn9

)

動作条件設定要求(

Yn9)

4.2.3 Alarm monitoring function

For monitoring each m easured item, you can set max. 2 points of upper limit alarm to perform

monitoring. During th e alarm monitoring, the module can m onitor the input signal to check for

the occurrence.

(1) Setting the alarm monitoring

1) Setting items and setting range for the alarm monitoring are described below.

Alarm value Low sensitivity mode

QE82LG

The value is for monitoring the target

1 to 1000 (mA)

measured element.

High sensirivity mode

0.01-100.00 (mA)

0: No monitoring

value exceeds alarm value

situation continues for alarm delay time.

Also, in the case of 2-step monitoring,

the 1-step and secondary alarm values

can be configured regardless of their

Alarm reset method 0: Self-retention

1: Auto reset

You can set

alarmretained if the value goes back to the

Alarm delay time 0 to 300 (seconds)

value exceeds the alarm value and the

2) Setting procedures are as follows:

(i) Check that Operating condition setting request (Yn9) is OFF.

(ii) Set ala rm value, a larm reset m ethod, and alarm delay tim e. For the address of buffer

memory corresponding to each measured element, refer to Chapter 6.

(iii) Set Operating condition setting request (Yn9) to ON. Operation starts at each set

value, and then Operating condition setting completion flag (Xn9) is turned OFF.

(iv) Check that O perating cond ition setting c ompletion f lag (Xn9) becom es OFF, and then

set Operating condition setting request (Yn9) to OFF.

Operating condition setting request (Yn9)

Operating condition setting completion flag (Xn9)

Figure 4.2.3-1 Time chart of alarm monitoring setting

3) Each item of the alarm m onitoring is stored in the nonvolatile m emory, so that se t values

can be retained even at a power source reset.

4 - 4

Page 23

4 Functions

CH1漏洩電流一段警報

発生フラグ(Xn1)

OFF

ON

警報マスク時間

ON

OFF

OFF

CH1警報リセット

要求(Yn1)

OFF

警報状態

警報未発生 警報発生 警報リセット自己保持

警報監視値

警報マスク時間

警報

発生

警報未

発生

Io1 primary alarm flag (Xn1)

Alarm

Alarm

occurrence

Self-retention

Alarm

occurrence

Alarm reset

Alarm

non

Alarm

occurrence

Alarm mas k time

Alarm mas k time

Alarm mas k time

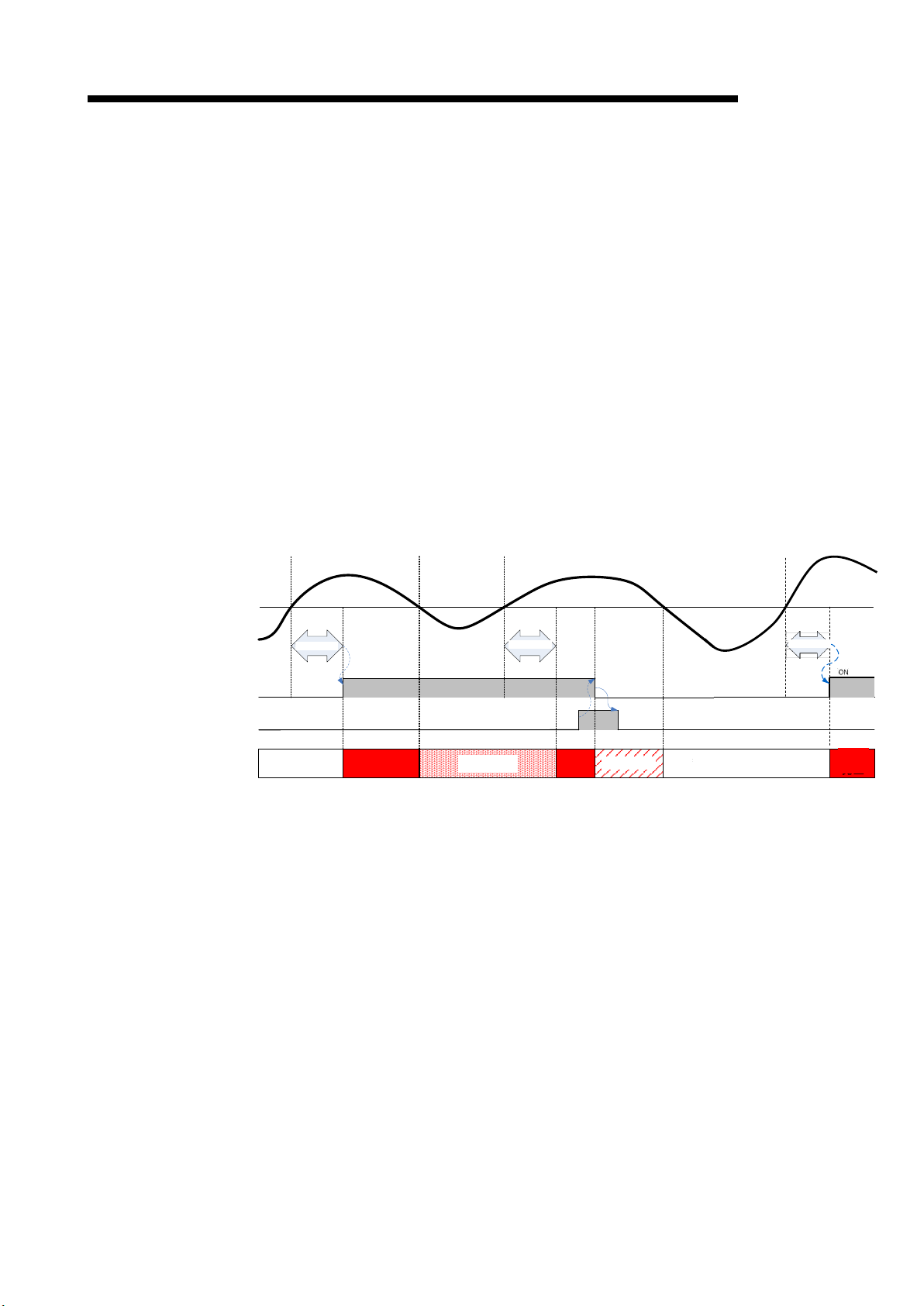

(2) Alarm flag (Xn1 to Xn8) and behavior of ALM1 LED and ALM2 LED

1) There are 4 statuses of alarm for each alarm monitoring element.

(a) Alarm non-occurrence status

(b) Alarm occurrence status

(c) Self-retention status (O n l y w hen the alarm reset method is set to “self-retention”)

(d) Alarm reset status

* In order to st ate the al arm , alar m monitoring must be les s tha n th e v al ue o nce during

Alarm value

Request of CH1 alarm reset (Yn1)

Alarm status

2) Relationship between the alarm status and Alarm flag (Xn1 to Xn8)

(a) Alarm non-occurrence status

(b) Alarm occurrence status

(c) Self-retention status

(d) Alarm reset status

QE82LG

The present value is under alarm value or the prese nt value exceeds alarm value but

the situation continues for less than alarm delay time.

The present value exceeds alarm value and the situation exceeds alarm delay time.

The present value has changed from the alarm oc currence status to be under alarm

value.

Alarm reset request (Yn1, Yn5) is released under the alarm occurrence status, and the

present value is sti ll over alarm value.

the alarm reset state.

non-occurrence

-occurrence

Figure 4.2.3-2 Example of alarm status (alarm reset method = “self-retention”)

Under the alarm non-occurrence status, Alarm flag (Xn1 to Xn8) is OFF.

Under the alarm occurrence status, Alarm flag (Xn1 to Xn8) is ON.

Under the self-retention status, Alarm flag (Xn1 to Xn8) is ON.

Under the alarm reset status, Alarm flag (Xn1 to Xn8) is OFF.

4 - 5

Page 24

4 Functions

QE82LG

3) Behaviors of ALM1 LED and ALM2 LED

(a) The indication of ALM1 LED changes according to status of CH1 Alarm.

Io1 primary alarm flag (Xn1)

Io1 secondary alarm flag (Xn2)

Ior1 primary alarm flag (Xn3)

Ior1 secondary alarm flag (Xn4)

(b) The indication of ALM2 LED changes according to status of CH2 Alarm.

Io2 primary alarm flag (Xn5)

Io2 secondary alarm flag (Xn6)

Ior2 primary alarm flag (Xn7)

Ior2 secondary alarm flag (Xn8)

(c) ALM1 LED and ALM2 LED disp lay the following 3 indications according to the alarm

status of the alarm occurrence flag.

- Flashing

Of the alarm occurrence f lags, one or m ore flags are in the alarm occurrenc e status

or in the alarm reset status (regardless of the status of the remaining alarm

occurrence flags).

- ON

Of the alarm occurrence f lags, one or m ore flags are in the self-retention status and

the remaining flags of alarm occurrence are in the alarm non-occurrence status.

- OFF

Flags of alarm occurrence are all in the alarm non-occurrence status.

4 - 6

Page 25

4 Functions

CH1漏洩電流一段警報

発生フラグ(Xn1)

OFF

ON

警報マスク時間

OFF

警報マスク時間

ALM1 LED

消灯 点滅

消灯

(a)

(b)

(c)

警報監視値

CH

1漏洩電流一段警報

発生フラグ(Xn1)

OFF

ON

警報マスク時間

ON

OFF

OFF

CH1警報リセット要求(Yn1)

OFF

ALM1 LED

消灯

点滅

消灯点灯

(a)

(b)

(c) (d)

警報監視値

Io1 primary alarm flag (Xn1)

OFF

Alarm mas k tim

Alarm mas k time

Flashing

OFF

Alarm mas k time

OFF

Flashing

ON

OFF

QE82LG

(3) Behavior of alarms

1) When the alarm reset m ethod is in the “aut o reset” s etting (Ex ample of Io1 primar y alarm

monitoring):

(a) If the present value Io1 exceeds alarm value and the situation continues for alarm

delay time, Io1 primary alarm flag (Xn1) will be turned ON. At th e same time, ALM1

LED flashes.

(b) If the present value goes below the upper limit, Io1 primar y alarm flag ( Xn1) will be

turned OFF. At this time, ALM1 LED is turned off.

(c) Even if the present value Io1 exceeds alarm value, if the value goes under alarm value

within alarm delay time, Io1 primary alarm flag (Xn1) will remain OFF.

Alarm value

e

Figure 4.2.3-3 Time chart of the secondary alarm (alarm reset method = “auto-reset”)

2) When alarm reset method is set to “self-retention” (Example of Io1 primary alarm

monitoring)

(a) If the present value Io1 exceeds alarm value and the situation continues for alarm

delay time, Io1 primary alarm flag (Xn1) will be turned ON. At th e same time, ALM1

LED flashes.

(b) If the present value Io1 goes below the upper limit, Io1 primary alarm flag (Xn1)

remains ON (self-retention). During the self-retention, ALM1 LED is turned on.

(c) By turning CH1 alarm res et request (Yn1) to ON, Io1 prim ary alarm flag (Xn1) will be

turned OFF. At this time, ALM1 LED is turned off.

(d) Check that Io1 pr im ary al arm flag (Xn1) becomes OFF, an d then s et CH1 alarm reset

request (Yn1) to OFF.

Alarm value

Io1 primary alarm flag (Xn1)

CH1 alarm reset request (Yn1)

Figure 4.2.3-4 Time chart of the secondary alarm (alarm reset method = “self-retention”)

4 - 7

Page 26

4 Functions

QE82LG

3) An example of Io1 primary alarm monitoring is indicated in 1) and 2) above. Other alarm

monitoring will be in accordance with the same behavior.

For the setting items for the buffer m emory that corres ponds to the alarm monitoring and

the I/O signals, refer to Chapters 5 and 6.

(3) How to reset Alarm flag

1) If Alarm flag is ON during the a larm occurrence or the self -retention (in the cas e of the

alarm reset method = “self -retention”), Alarm flag c an be reset (turned OFF) us ing Alarm

reset request.

2) CH1 alarm clear request (Yn1) wi ll clear the followin g data. However, the f ollowing data

cannot be cleared individually.

- Io1 primary alarm flag (Xn1)

- Io1 secondary alarm flag (Xn2)

- Ior1 primary alarm flag (Xn3)

- Ior1 secondary alarm flag (Xn4)

3) The following data can be cleared upon CH2 alarm reset request (Yn5). However, the

following data cannot be cleared individually.

- Io2 primary alarm flag (Xn5)

- Io2 secondary alarm flag (Xn6)

- Ior2 primary alarm flag (Xn7)

- Ior2 secondary alarm flag (Xn8)

4 - 8

Page 27

4 Functions

Io1一段警報発生フラグ

(Xn1)

OFF

ON

警報マスク

時間

ON

OFF

OFF

CH1警報リセット要求

(Yn1)

OFF

ALM1 LED

消灯

点滅 消灯

(b)

(c) (d)

(a)

点滅

(e)

警報マスク

時間

ON

警報監視値

Alarm

mask time

Alarm

mask time

OFF

Flashing

OFF

Flashing

QE82LG

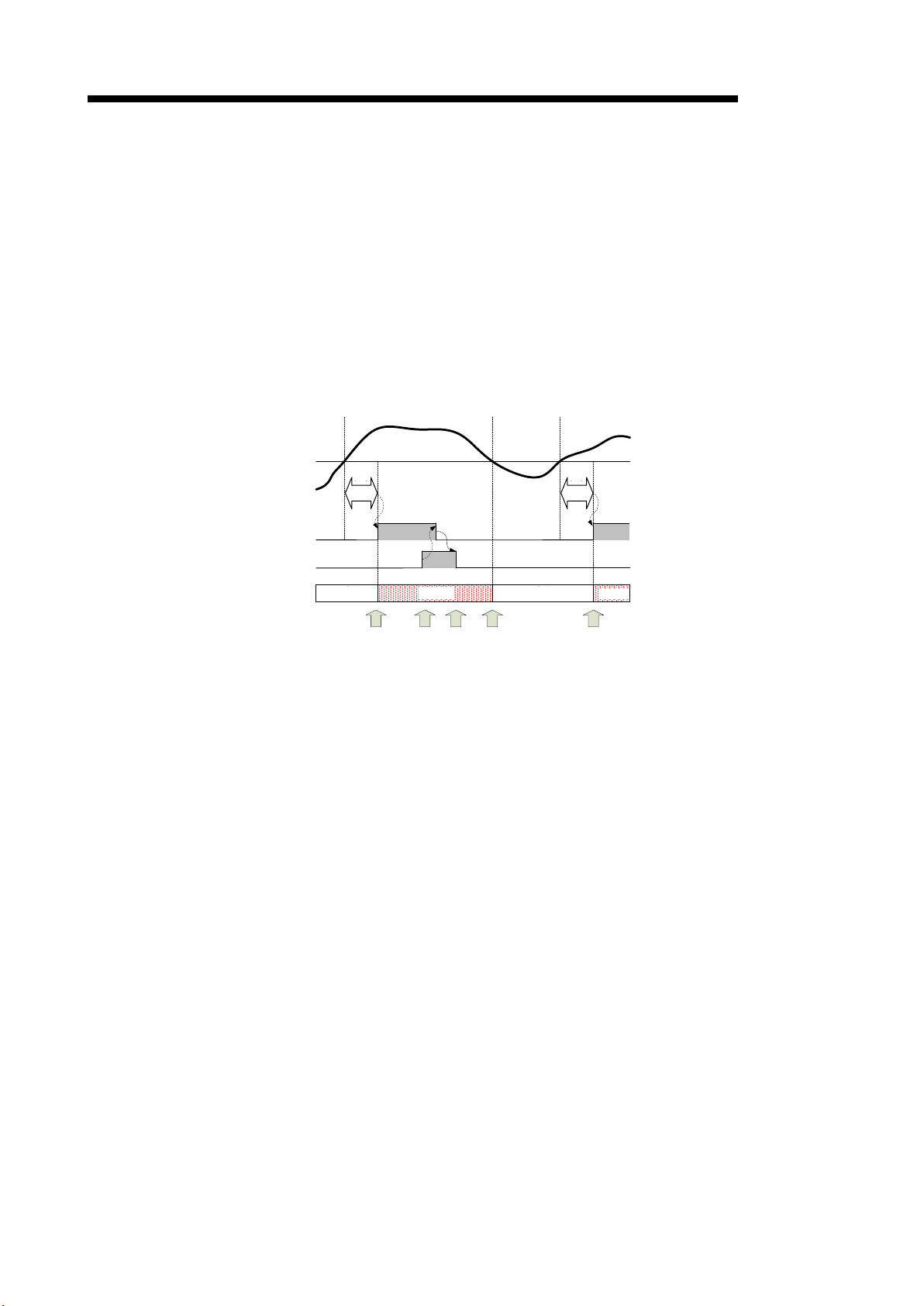

4) How to reset Alarm flag during alarm occurrence (Example of Io1 primary alarm

monitoring)

(a) If the present value Io1 exceeds alarm value, Io1 primary alarm flag (Xn1) will be

turned ON. At the same time, ALM1 LED flashes.

(b) By turning CH1 alarm reset request (Yn1) to ON, Io1 prim ary alarm flag (Xn1) will be

turned OFF. At this time, ALM1 LED will remain flashing (because ALM1 LED is

synchronized with the alarm status, it will not turn off).

(c) Check that Io1 prim ar y alarm f lag (Xn1) becom es O FF, and then set CH1 al arm reset

request (Yn1) to OFF.

(d) If the present value Io1 goes under alarm value, ALM1 LED will be turned off.

(e) After that, if the present value Io1 exceeds alarm value, Io1 primar y alarm flag (Xn1)

will be turned ON again. At the same time, ALM1 LED flashes.

Alarm value

lo1 primary alarm flag (Xn1)

CH1 alarm reset request (Yn1)

5) How to reset Alarm flag during self-retention (in the case the alarm reset method =

“self-retention” only)

Refer to the procedure described in (2) 2).

Figure 4.2.3-5 Procedure for resetting Io1 primary alarm flag

(alarm reset method = “auto-reset”)

4 - 9

Page 28

4 Functions

CH1警報発生回数クリア要求(YnB)

CH1警報発生回数クリア完了フラグ(XnB)

ON

OFF

OFF

ON

OFF

OFF

CH1 alarm occurrence count clear completion flag (XnB)

4.2.4 Alarm occurrence count function

It memorizes the c ount of alarm occurrence f or each alarm monitoring e lement, and retains it

until the count of alarm occurrence is performed.

(1) Memory of Alarm occurrence count

1) It memorizes each alarm occurrence count for the following element.

- Io1 primary alarm

- Io1 secondary alarm

- Ior1 primary alarm

- Ior1 secondary alarm

- Io2 primary alarm

- Io2 secondary alarm

- Ior2 primary alarm

- Ior2 secondary alarm

2) Alarm occ urrence count is stored in the nonvolatile memory, so that it can be retaine d

even at a power source reset.

QE82LG

(2) How to clear Alarm occurrence count

1) You can use I/O signal to clear the count of alarm occurrence.

2) The count of alarm occurrence immediately after the clear will be “0”.

3) The following d ata can b e cleared upon C H1 a larm occ urrenc e co un t clear re ques t (YnB).

However, the following data cannot be cleared individually.

- Io1 primary alarm occurrence count (Un\G1200)

- Io1 secondary alarm occurrence count (Un\G1201)

- Ior1 primary alarm occurrence count (Un\G1250)

- Ior1 secondary alarm occurrence count (Un\G1251)

4) The following dat a can be c leared upon CH2 alar m occur renc e cou nt c lear req ues t (YnD).

However, the following data cannot be cleared individually.

- Io2 primary alarm occurrence count (Un\G2200)

- Io2 secondary alarm occurrence count (Un\G2201)

- Ior2 primary alarm occurrence count (Un\G2250)

- Ior2 secondary alarm occurrence count (Un\G2251)

5) The following describes how to clear CH1 alarm occurrence count. (CH2 alarm

occurrence count follows the same procedure using CH2 alarm occurrence count clear

request (YnD).)

(i) Check that CH1 alarm occurrence count clear request (YnB) is OFF.

(ii) Set CH1 alarm occurrence count clear request (YnB) to ON.

CH1 alarm occurrence count is cleared, and then CH 1 alarm occurrence cou nt clear

completion flag (XnB) is turned ON.

(iii) Check that CH1 alarm occurrenc e count clear completion fla g (XnB) is ON, and then

set CH1 alarm occurrence count clear request (YnB) to OFF.

CH1 alarm occurrence count clear request (YnB)

Figure 4.2.3-6 Procedure for clearing Alarm occurrence count

4 - 10

Page 29

4 Functions

4.2.5 Test function

This function is to output pseudo-fixed value to a buffer memory for debugging sequence

program. The value can be output to the buffer memory without input of voltage and current.

(1) How to use the test function

(2) Content of pseudo-output

QE82LG

1) Using the intelligent function switch sett ings, you can start the test mode to output the

fixed value.

2) For procedure for setting the intelligent function switch, refer to 7.5.2.

3) To finish the tes t mode, the set value is returned by th e intelli gent funct ion switch setting,

and after that, it starts a measuring m ode (low sensitivity mode or high sensitivity mode)

by resetting it.

(It resumes with the previous set value and accumulated electric energy as well as

periodic electric energy.)

For the value to be out put to the buff er memory, refer to Tables 6.1-1 to 6.1-3 in 6.1 Buffer

memory assignment.

(3) Percolations for using the test function

1) Because pseudo-f ixed value is output to the buff er memory, isolate the actual device to

avoid unexpected operation before running the sequence program.

4 - 11

Page 30

5 I/O signal to CPU unit

module)

QE82LG)

Device # Signal name

Device # Signal name

Xn0

Module ready

Yn0

Use prohibited *1

Xn1

Io1 primary alarm flag

Yn1

CH1 alarm reset request

Xn2

Io1 secondary alarm flag

Yn2

Use prohibited *1

Xn3

Ior1 primary alarm flag

Yn3

Use prohibited *1

Xn4

Ior1 secondary alarm flag

Yn4

Use prohibited *1

Xn5

Io2 primary alarm flag

Yn5

CH2 alarm reset request

Xn6

Io2 secondary alarm flag

Yn6

Use prohibited *1

Xn7

Ior2 primary alarm flag

Yn7

Use prohibited *1

Xn8

Ior2 secondary alarm flag

Yn8

Use prohibited *1

flag

XnA

CH1 max. value clear completion flag

YnA

CH1 max. value clear request

completion flag

request

XnC

CH2 max. value clear completion flag

YnC

CH2 max. value clear request

completion flag

request

XnE

Use prohibited *1

YnE

Use prohibited *1

XnF

Error flag

YnF

Error clear request

Chapter 5: I/O signal to CPU module

5.1 List of I/O signals

I/O signals of QE82LG are listed in Table 5.1-1.

The “n” that is us ed i n this and later ch apters (for example: Xn0, Yn0, Un\G0, etc.) refers to th e num ber

that appears at the beginning of QE82LG.

Table 5.1-1 List of I/O signals

Input signal (signal direction from QE82LG to CPU

Output signal(signal direction from CPU module to

QE82LG

Xn9

XnB

XnD

Operating condition setting completion

CH1 alarm occurrence count clear

CH2 alarm occurrence count clear

Yn9 Operating condition setting request

YnB

YnD

CH1 alarm occurrence count clear

CH2 alarm occurrence count clear

Point

*1 These signals cannot be used by the user since they are for system use

only. If these are set to on or off b y the sequence prog ram , the perf orm ance

of the QE82LG cannot be g uaranteed.

5 - 1

Page 31

5 I/O signal to CPU unit

5.2 Details of I/O signals

Detailed explanation about I/O signals of QE82LG is provided as follows:

5.2.1 Input signals

(1) Module ready (Xn0)

(a) When the po wer of CP U module is tur ned on or the CPU module reset is perf orm ed, it w ill

turn ON as soon as the measurement is ready.

(b) Module ready is turned OFF when the i nsulation monitoring module displa ys a hardware

error, and RUN LED is turned off.

(2) Io1 primary alarm flag (Xn1)

(a) When the present value Io1 exceeds Io1 primary alarm value (Un\G1000) and the

situation continues f or Io1 primary alarm delay time (Un\G1002), this sign al (Xn1) turns

ON.

(b) Operations after this s ignal ( X n1) is turned ON will be dif f er ent dep end ing on the s ettin g of

Io1 primary alarm reset method (Un\G1001) below.

[When Io1 primary alarm reset method (Un\G1001) is “self-retention”]

Even if the present value I o1 goes under Io1 prim ary alarm value (Un\G1000), th is signal

(Xn1) remains ON . Then, when CH1 alar m reset reques t (Yn1) is turned to ON, this s igna l

(Xn1) turns OFF.

QE82LG

[When Io1 primary alarm reset method (Un\G1001) is “auto reset”]

If the present value Io1 goes un der Io1 primar y alarm value (Un\G1000), this sig nal (X n1)

turns OFF.

(c) When Io1 pr imary alarm value (Un\G1000) is set to “0 (not m onitoring)”, this signal (Xn1)

is always OFF.

*For the actual behavior of alarm monitoring, refer to 4.2.4.

(3) Io1 secondary alarm flag (Xn2)

The usage procedure is the same as Io1 primary alarm flag (Xn1). Refer to (2).

(4) Ior1 primary alarm flag (Xn3)

The usage procedure is the same as Io1 primary alarm flag (Xn1). Refer to (2).

(5) Ior1 secondary alarm flag (Xn4)

The usage procedure is the same as Io1 primary alarm flag (Xn1). Refer to (2).

5 – 2

Page 32

5 I/O signal to CPU unit

QE82LG

(6) Io2 primary alarm flag (Xn5)

The usage procedure is the same as Io1 primary alarm flag (Xn1). Refer to (2).

(7) Io2 secondary alarm flag (Xn6)

The usage procedure is the same as Io1 primary alarm flag (Xn1). Refer to (2).

(8) Ior2 primary alarm flag (Xn7)

The usage procedure is the same as Io1 primary alarm flag (Xn1). Refer to (2).

(9) Ior2 secondary alarm flag (Xn8)

The usage procedure is the same as Io1 primary alarm flag (Xn1). Refer to (2).

(10) Operating condition setting completion flag (Xn9)

(a) When turning Operating c ondition settin g request (Yn9) to ON and c hanging the f ollowing

settings, this signal (Xn9) turns ON.

- Phase wire system (Un\G0)

- Io1 primary alarm value (Un\G1000)

- Io1 primary alarm reset method (Un\G1001)

- Io1 primary alarm delay time (Un\G1002)

- Io1 secondary alarm value (Un\G1003)

- Io1 secondary alarm reset method (Un\G1004)

- Io1 secondary alarm delay time (Un\G1005)

- Ior1 primary alarm value (Un\G1050)

- Ior1 primary alarm reset method (Un\G1051)

- Ior1 primary alarm delay time (Un\G1052)

- Ior1 secondary alarm value (Un\G1053)

- Ior1 secondary alarm reset method (Un\G1054)

- Ior1 secondary alarm delay time (Un\G1055)

- Io2 primary alarm value (Un\G2000)

- Io2 primary alarm reset method (Un\G2001)

- Io2 primary alarm delay time (Un\G2002)

- Io2 secondary alarm value (Un\G2003)

- Io2 secondary alarm reset method (Un\G2004)

- Io2 secondary alarm delay time (Un\G2005)

- Ior2 primary alarm value (Un\G2050)

- Ior2 primary alarm reset method (Un\G2051)

- Ior2 primary alarm delay time (Un\G2052)

- Ior2 secondary alarm value (Un\G2053)

- Ior2 secondary alarm reset method (Un\G2054)

- Ior2 secondary alarm delay time (Un\G2055)

(b) When Operating condition setting request (Yn9) is OFF, this signal (Xn9) turns OFF.

5 – 3

Page 33

5 I/O signal to CPU unit

QE82LG

(11) CH1 max. value clear completion flag (XnA)

(a) When CH1 max. value clear request (YnA) is turned ON and the following max. value data

are cleared, this signal (XnA) turns ON.

- Io1 max. value (Un\G1101)

- Io1 date/time of occurrence (Un\G1102 to Un\G1105)

- Ior1 max. value (Un\G1151)

- Ior1 date/time of occurrence (Un\G1152 to Un\G1155)

(b) When CH1 max. value clear request (YnA) is turned OFF, this signal (XnA) turns OFF.

(12) CH1 alarm occurrence count clear completion flag (XnB)

(a) When CH1 alarm occurrence count clear request (YnB) is turned ON and the f ollowing

alarm occurrence count data are cleared, this signal (XnB) turns ON.

- Io1 primary alarm occurrence count (Un\G1200)

- Io1 secondary alarm occurrence count (Un\G1201)

- Ior1 primary alarm occurrence count (Un\G1250)

- Ior1 secondary alarm occurrence count (Un\G1251)

(b) When CH1 a larm occurrence count clear req uest (YnB) is turn ed OFF, this signal (XnB)

turns OFF.

(13) CH2 max. value clear completion flag (XnC)

The usage proc edure is the same as C H1 max. value clear com pletion flag (XnA). Refer to

(11).

(14) CH2 alarm occurrence count clear completion flag (XnD)

The usage procedure is the same as CH1 alarm occurrence count clear completion flag (XnB).

Refer to (12).

(15) Error flag (XnF)

(a) If an outside-set-val ue err or oc curs , and if a har dware err or occ urs, this signa l (Xn F) turns

ON.

(b) The description of the error occurred can be checked with latest error code (Un\G3000).

*For description of error codes, refer to section 9.1.

(c) If an outside-set-value error occurs, this signal (XnF) is turned OFF by setting a value

within the range again.

5 – 4

Page 34

5 I/O signal to CPU unit

5.2.2 Output signals

(1) CH1 alarm reset request (Yn1)

(2) CH2 alarm reset request (Yn5)

QE82LG

(a) When resetting the following flags for alarm occurrence, this signal (Yn1) turns ON.

- Io1 primary alarm flag (Xn1)

- Io1 secondary alarm flag (Xn2)

- Ior1 primary alarm flag (Xn3)

- Ior1 secondary alarm flag (Xn4)

(b) When this signal (Yn1) is s witc he d f r om the OF F s tatus to the O N status, above alarm flag

will forcibly be turned OFF regardless of alarm flag status.

(a) When resetting the following flags for alarm occurrence, this signal (Yn5) turns ON.

- Io2 primary alarm flag (Xn5)

- Io2 secondary alarm flag (Xn6)

- Ior2 primary alarm flag (Xn7)

- Ior2 secondary alarm flag (Xn8)

(b) When this signal (Yn5) is switched f r om the O FF st atus to t he O N status, above alarm flag

will forcibly be turned OFF regardless of alarm flag status.

(3) Operating condition setting request (Yn9)

(a) When switching this signal (Yn9) from the OFF status to the ON status, the following

operating conditions will be set.

- Phase wire system (Un\G0)

- Io1 primary alarm value (Un\G1000)

- Io1 primary alarm reset method (Un\G1001)

- Io1 primary alarm delay time (Un\G1002)

- Io1 secondary alarm value (Un\G1003)

- Io1 secondary alarm reset method (Un\G1004)

- Io1 secondary alarm delay time (Un\G1005)

- Ior1 primary alarm value (Un\G1050)

- Ior1 primary alarm reset method (Un\G1051)

- Ior1 primary alarm delay time (Un\G1052)

- Ior1 secondary alarm value (Un\G1053)

- Ior1 secondary alarm reset method (Un\G1054)

- Ior1 secondary alarm delay time (Un\G1055)

- Io2 primary alarm value (Un\G2000)

- Io2 primary alarm reset method (Un\G2001)

- Io2 primary alarm delay time (Un\G2002)

- Io2 secondary alarm value (Un\G2003)

- Io2 secondary alarm reset method (Un\G2004)

- Io2 secondary alarm delay time (Un\G2005)

- Ior2 primary alarm value (Un\G2050)

- Ior2 primary alarm reset method (Un\G2051)

- Ior2 primary alarm delay time (Un\G2052)

- Ior2 secondary alarm value (Un\G2053)

- Ior2 secondary alarm reset method (Un\G2054)

- Ior2 secondary alarm delay time (Un\G2055)

5 – 5

Page 35

5 I/O signal to CPU unit

QE82LG

(b) When the operating con dition s etting is com pleted, Operating cond ition setting c om pletion

flag (Xn9) turns ON.

(c) When this signal (Yn9) is t urned OFF, Operating con dition setting completion fl ag (Xn9)

turns OFF.

(4) CH1 max. value clear request (YnA)

(a) When switching this s ig nal ( YnA) f rom the OFF status to th e O N s tat us , th e following max.

value date will be cleared.

- Io1 max. value (Un\G1101)

- Io1 date/time of occurrence (Un\G1102 to Un\G1105)

- Ior1 max. value (Un\G1151)

- Ior1 date/time of occurrence (Un\G1152 to Un\G1155)

(b) When clear ing the max. da ta above is com pleted, CH1 max. value clear completion fla g

(XnA) turns ON.

(c) When this signal (YnA) is turned OFF, CH1 max. value clear completion flag (XnA) is

turned OFF.

(5) CH1 alarm occurrence count clear request (YnB)

(a) When switching this s ig nal ( YnB) f rom the OFF status to t h e ON status, the follow ing max.

value data will be cleared.

- Io1 primary alarm occurrence count (Un\G1200)

- Io1 secondary alarm occurrence count (Un\G1201)

- Ior1 primary alarm occurrence count (Un\G1250)

- Ior1 secondary alarm occurrence count (Un\G1251)

(b) When clearing the max. data above is completed, CH1 alarm occurrence count clear

completion flag (XnB) turns ON.

(c) When this signal ( YnB) is tur ned OFF, C H1 alarm occurrence cou nt clear com pletion flag

(XnB) turns OFF.

(6) CH2 max. value clear request (YnC)

(a) When switching this s ig nal ( YnC) f r om the O FF st atus to the ON s tat us , the following max.

value data will be cleared.

- Io2 max. value (Un\G2101)

- Io2 date/time of occurrence (Un\G2102 to Un\G2105)

- Ior2 max. value (Un\G2151)

- Ior2 date/time of occurrence (Un\G2152 to Un\G2155)

(b) When clearing the max. data ab ove is completed, CH2 max. value clear completion fla g

(XnC) turns ON.

(c) When this signa l (YnC) is turned OFF , CH2 max. value c lear completion f lag (XnC) turns

OFF.

5 – 6

Page 36

5 I/O signal to CPU unit

QE82LG

(7) CH2 alarm occurrence count clear request (YnD)

(a) When switching this sig na l (YnD) f r om the O FF stat us to the O N s tat us , the following max.

value data will be cleared.

- Io2 primary alarm occurrence count (Un\G2200)

- Io2 secondary alarm occurrence count (Un\G2201)

- Ior2 primary alarm occurrence count (Un\G2250)

- Ior2 secondary alarm occurrence count (Un\G2251)

(b) When clearing the max. data above is completed, CH2 alarm occurrence count clear

completion flag (XnD) turns ON.

(c) When this sign al (YnD) is t urned OFF, CH2 alarm occurrence c ount clear com pletion flag

(XnD) turns OFF.

(8) Error clear request (YnF)

(a) When switching this signal from the OFF status to the ON status while an

outside-set-value error occurs, Error flag (XnF) will be turned OFF and latest error code

(Un\G3000) will be cleared.

(b) At the same time as the clearing error above, the value set in the buffer memory below will

be replaced with the previously set value.

[Values that are to be replaced with the previously set value]

- Phase wire system (Un\G0)

- Io1 primary alarm value (Un\G1000)

- Io1 primary alarm reset method (Un\G1001)

- Io1 primary alarm delay time (Un\G1002)

- Io1 secondary alarm value (Un\G1003)

- Io1 secondary alarm reset method (Un\G1004)

- Io1 secondary alarm delay time (Un\G1005)

- Ior1 primary alarm value (Un\G1050)

- Ior1 primary alarm reset method (Un\G1051)

- Ior1 primary alarm delay time (Un\G1052)

- Ior1 secondary alarm value (Un\G1053)

- Ior1 secondary alarm reset method (Un\G1054)

- Ior1 secondary alarm delay tim e (Un\G1055)

- Io2 primary alarm value (Un\G2000)

- Io2 primary alarm reset method (Un\G2001)

- Io2 primary alarm delay time (Un\G2002)

- Io2 secondary alarm value (Un\G2003)

- Io2 secondary alarm reset method (Un\G2004)

- Io2 secondary alarm delay time (Un\G2005)

- Ior2 primary alarm value (Un\G2050)

- Ior2 primary alarm reset method (Un\G2051)

- Ior2 primary alarm delay time (Un\G2052)

- Ior2 secondary alarm value (Un\G2053)

- Ior2 secondary alarm reset method (Un\G2054)

- Ior2 secondary alarm delay tim e (Un\G2055)

(c) While a hardware error is present (error code: 0000H to 0FFFH), it will not be cleared

even if this signal (YnF) turns ON.

5 – 7

Page 37

6 Buffer memory

QE82LG

Point

Address

(decimal)

Value during the

test mode*4

CH1

CH2

CH1

CH2

0

Pr

Phase wire system

3

R/W

3

1-99

-

System area

- - -

0

Leak current, Leak current for

(x 10n)

primary alarm

value

primary alarm

reset method

primary alarm

delay time

secondary

alarm value

secondary

method

secondary

time

1006-

1049

2006-

2049

primary alarm

value

primary alarm

reset method

primary alarm

delay time

secondary

alarm value

secondary

method

secondary

time

1056-

1100

2056-

2100

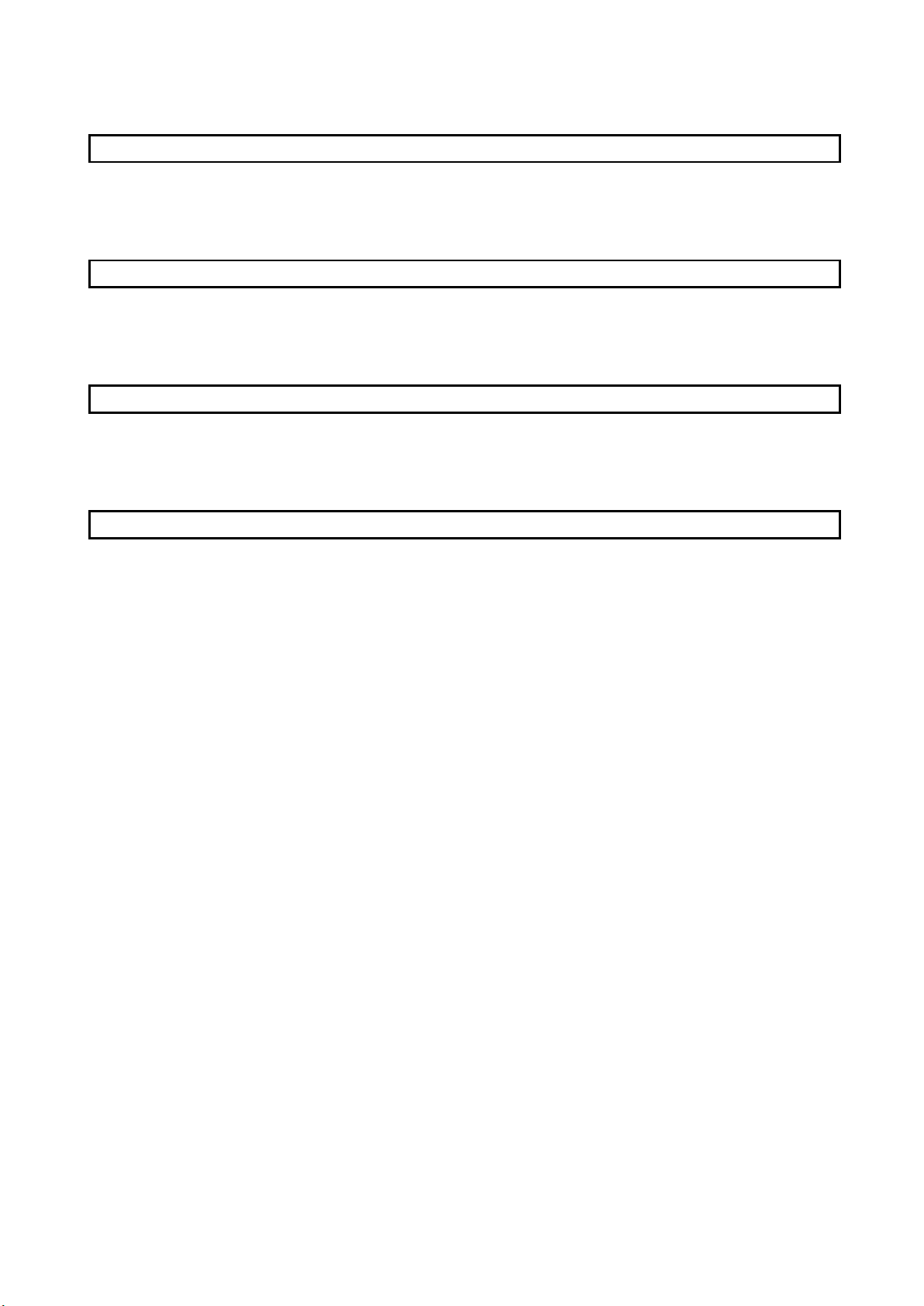

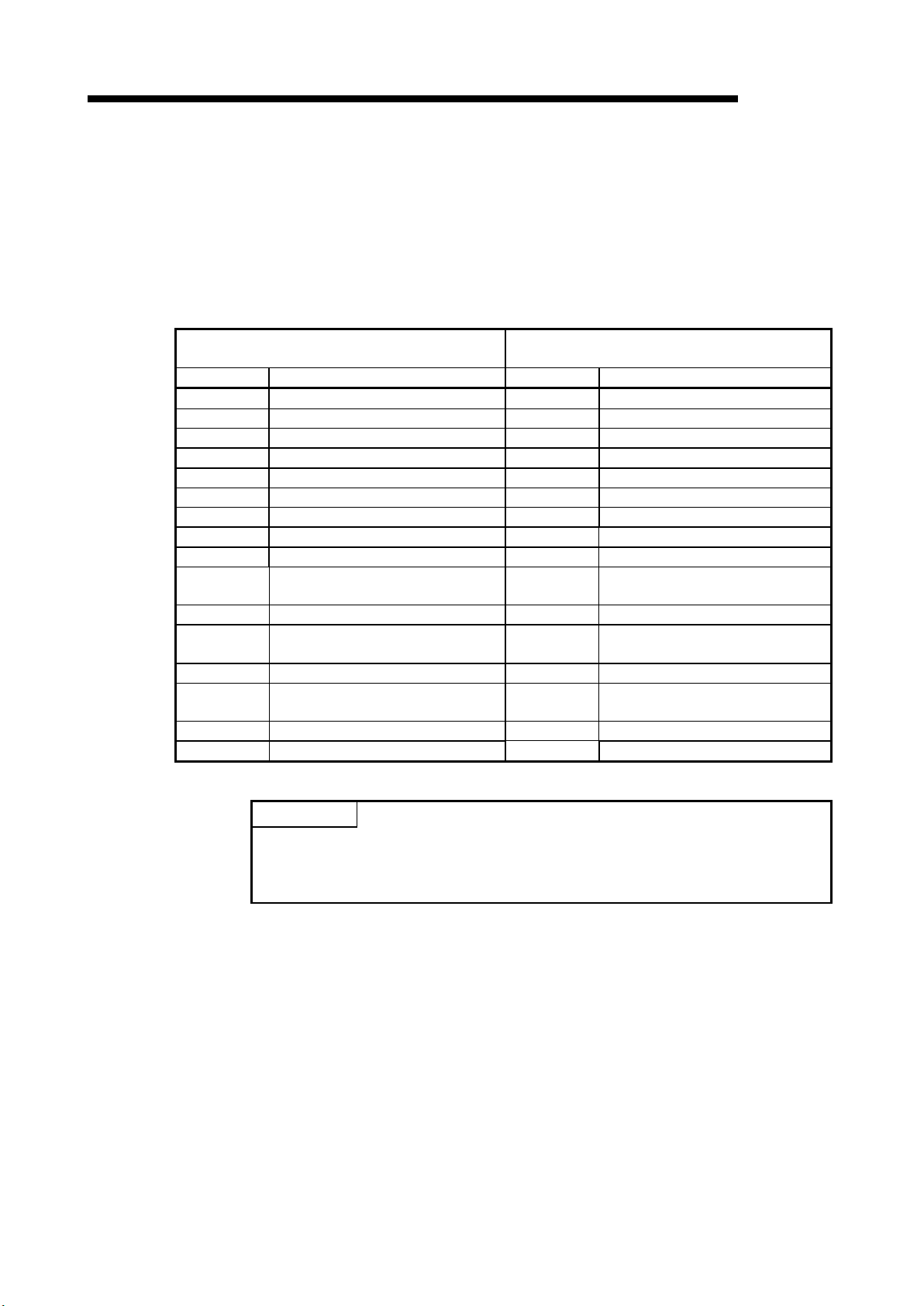

Chapter 6: Buffer memory

6.1 Buffer memory assignment

(1) Configurable sections (Un\G0 to Un\G1100, Un\G2000 to Un\G2100)

Table 6.1-1 Configurable sections (Un\G0 to Un\G1100, Un\G2000 to Un\G2100)

Item

The following describes buffer memory assignment.

Do not write dat a i nto the pr ohib ited area in the buff er memory from s ystem are a

and sequence program. If data are written into these areas, it may cause

malfunction.

Data

type*1

Description

Default

value

R/W*2

Backup

*3

○

Configur-

able

section

100 Md

1000 2000 Pr

1001 2001 Pr

1002 2002 Pr

1003 2003 Pr

1004 2004 Pr

1005 2005 Pr

1050 2050 Pr

1051 2051 Pr

1052 2052 Pr

1053 2053 Pr

1054 2054 Pr

1055 2055 Pr

resistance multiplying factor

Leak

current

alarm reset

alarm delay

- System area - - - - -

Leak

current for

resistance

alarm reset

alarm delay

0 R

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

0 R/W

○

○

○

○

○

○

○

○

○

○

○

○

○

-2

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

*1: Pr indicates setting data, and Md indicates monitoring data.

*2: It indicates readable / writable status from the sequence program.

*3: Even if the power failure is restored, data is held because data is backed up by the nonvolatile memory.

*4: For the procedure for using the test mode, refer to section 4.2.5.

- System area - - - - -

R: Readable

W: Writable

6 – 1

Page 38

6 Buffer memory

QE82LG

Address

(decimal)

Value during the

test mode*4

CH1

CH2

CH1

CH2

1100

2100

Md

Leak

Present value

0 R -

1001

2001

1101

2101

Md

Max. value

0

R

1002

2002

Year of time of

max. value

Month and day

value

Hour and minute

value

Second and day

value

1106-

1149

2106-

2149

System area

1150

2150

Md

Leak

Present value

0 R -

1011

2011

1151

2151

Md

Max. value

0

R

1012

2012

Year of time of

max. value

Month and day

value

Hour and minute

value

Second and day

value

1156-

1199

2156-

2199

System area

Leak

primary alarm

count

secondary alarm

count

1202-

1249

2202-

2249

System area

Leak

primary alarm

count

secondary alarm

count

1252-

1999

2252-

2999

System area

(2) Measurable sections (Un\G1100 to Un\G1999, Un\G2100 to Un\G2999)

Table 6.1-2 Measurable sections (Un\G1100 to Un\G1999, Un\G2100 to Un\G2999)

Item

Data

type*1

Description

Default

value

R/W*2

Backup

*3

Measurable

section

1102 2102 Md

1103 2103 Md

1104 2104 Md

1105 2105 Md

-

1152 2152 Md

1153 2153 Md

1154 2154 Md

1155 2155 Md

-

current

current for

resistance

of time of max.

of time of max.

of the week of

time of max.

of time of max.

of time of max.

of the week of

time of max.

○

0000h R

0000h R

0000h R

0000h R

- - - - -

0000h R

0000h R

0000h R

0000h R

- - - - -

○

○

○

○

○

○

○

○

○

2010h 2020h

0903h 1004h

0102h 0203h

0304h 0405h

2011h 2021h

0102h 0203h

0304h 0405h

0506h 0600h

1200 2200 Md

1201 2201 Md

-

1250 2250 Md

1251 2251 Md

-

current

current for

resistance

occurrence

occurrence

occurrence

occurrence

0 R

0 R

- - - - -

0 R

0 R

- - - - -

○

○

○

○

1021 2021

1022 2022

1031 2031

1032 2032

*1: Pr indicates setting data, and Md indicates monitoring data.

*2: It indicates readable / writable status from the sequence program.

R: Readable

W: Writable

*3: Even if the power failure is restored, data is held because data is backed up by the nonvolatile memory.

*4: For the procedure for using the test mode, refer to section 4.2.5.

6 – 2

Page 39

6 Buffer memory

QE82LG

3000

Md

Latest error code

0000h R -

0001h

3001

Md

Year of time of error

0000h R -

2019h

3002

Md

Month and day of time of error

0000h R -

0910h

3003

Md

Hour and minute of time of error

0000h R -

1112h

3004

Md

Month and day of time of error

0000h R -

1301h

3005-3499

-

System area

- - - - 3500

Md

Measuring mode

0000h R -

0001h

3501-4999

-

System area

- - -

-

(3) Common sections (Un\G3000 to Un\G4999)

Table 6.1-3 Latest error sections (Un\G3000 to Un\G4999)

Item

Common

sections

Address

(decimal)

Data

type*1

Description

Default

value

R/W*2

Backup

*3

Value during the

test mode*4

*1: Pr indicates setting data, and Md indicates monitoring data.

*2: It indicates readable / writable status from the sequence program.

R: Readable

W: Writable

*3: Even if the power failure is restored, data is held because data is backed up by the nonvolatile memory.

*4: For the procedure for using the test mode, refer to section 4.2.5.

6 – 3

Page 40

6 Buffer memory

QE82LG

Setting v alue

Description

1

Single-phase 2-wire

2

Single-phase 3-wire

3

Three-phase 3-wire

Setting ran ge

Description

0