Page 1

Type QD75P/QD75D Positioning Module

Mitsubishi Programmable

Logic Controller

QD75P1

QD75P2

QD75P4

QD75D1

QD75D2

QD75D4

Page 2

Page 3

SAFETY INSTRUCTIONS

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable logic controller system, please read the CPU module User's Manual.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to t he circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forw ard it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injur y.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Instructions]

!

DANGER

Provide a safety circuit outside the programmable logic controller so that the entire system will

operate safely even when an external power supply error or PLC fault occurs.

Failure to observe this could lead to accidents for incorrect outputs or malfunctioning.

(1) Configure an emergency stop circuit and interlock circuit such as a positioning upper

limit/lower limit to prevent mechanical damage outside t he PLC.

(2) The machine OPR operation is controlled by the OPR direction and OPR speed data.

Deceleration starts when the near-point dog turns ON. Thus, if the OPR direction is

incorrectly set, deceleration will not start and the machine will continue t o tr avel. Configure

an interlock circuit to prevent mechanical damage outside the PLC.

(3) When the module detects an error, normally deceleration st op or sudden stop w ill take

place according to the parameter stop group settings.

Set the parameters to the positioning system specifications.

Make sure that the OPR parameter and positioning data are within the parameter setting

values.

A - 1

Page 4

[Design Instructions]

!

CAUTION

Do not bundle or adjacently lay the control wire or communication cable with the main circuit or

power wire.

Separate these by 100mm (3.94in.) or more.

Failure to observe this could lead to malfunctioning caused by noise.

[Mounting Instructions]

!

CAUTION

Use the PLC within the general specifications environment giv en in this manual.

Using the PLC outside the general specification range environ ment could lead to electr ic

shocks, fires, malfunctioning, product damage or deterioration.

While pressing the installation lever located at the bottom of module, insert the module fixing

tab into the fixing hole in the base unit until it stops. Then, securely mount the module with the

fixing hole as a supporting point.

Incorrect loading of the module can cause a malfunction, failure or drop.

When using the PLC in the environment of much vibration, tighten the module with a screw.

Tighten the screw in the specified torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to damage to the screw or

module.

Completely turn off the externally supplied power used in the system before mounting or

removing the module.

Not doing so may damage the product.

[Wiring Instructions]

!

DANGER

Always confirm the terminal layout before connecting the wires to the module.

[Startup/Maintenance Instructions]

!

DANGER

Completely turn off the externally supplied power used in the system before cleaning or

tightening the screws.

Failure to turn all phases OFF could lead to electric shocks.

A - 2

Page 5

[Startup/Maintenance Instructions]

!

CAUTION

Never disassemble or modify the module.

Failure to observe this could lead to trouble, malfunctioning, injuries or fires.

Completely turn off the externally supplied power used in the system before installing or

removing the module.

Failure to turn all phases OFF could lead to module trouble or malfunctioning.

Do not mount/remove the module onto/from the base unit more than 50 times (IEC61131-2-

compliant), after the first use of the product. Failure to do so may cause malfunction.

Before starting test operation, set the parameter speed limit value to the slowest value, and

make sure that operation can be stopped immediately if a hazardous state occurs.

Always make sure to touch the grounded metal to discharge the electricity charged in t he body,

etc., before touching the module.

Failure to do so may cause a failure or malfunctions of the module.

[Precautions for use]

!

CAUTION

Note that when the reference axis speed is designated for interpolation operation, the speed of

the partner axis (2nd axis, 3rd axis and 4th axis) may be larger than the set speed (larger than

the speed limit value).

[Disposal Instructions]

!

CAUTION

When disposing of the product, handle it as industrial waste.

A - 3

Page 6

REVISIONS

The manual number is given on the bottom left of the back cov er

Manual Number Revision

Print Date

Dec., 1999 SH (NA)-08005 8-A First edition

Oct., 2000 SH (NA)-080058-B Addition of function version B

(Overall revisions based on the Japanese Manual Version

SH-080047-E)

Jun., 2001 SH (NA)-080058-C The software package names (GPP function software package,

QD75 software package) have been replaced by the product names

(GX Developer, GX Configurator-QP) for standardization.

Partial corrections and additions

CONTENTS, About Manuals, Generic Terms and Abbreviations,

Section 1.4, Section 2.2, Section 2.3, Section 3.2.2 to Section 3.2.4,

Section 3.3.2, Section 3.3.3, Section 3.4.1, Section 3.4.3, Section

3.4.4, Section 4.1.2, Section 4.3, Section 5.1.2, Section 5.1.3, Section

5.2.3, Section 5.2.5, Section 5.6.2, Section 5.7.1, Section 6.2 to

Section 6.4, Section 6.5.3, Section 7.2, Section 8.2.2, Section 8.2.5,

Section 8.2.6, Section 9.1.2, Section 9.2.1, Section 9.2.16, Section

9.2.17, Section 10.3.2, Section 10.6.2, Section 11.2.3, Section 11.3.3,

Section 11.3.4, Section 11.4.3, Section 12.1.1, Section 12.5 to Section

12.7, Section 13.1, Section 13.3, Section 13.4, Section 14.2 to Section

14.7, Section 15.1, Section 15.2, Section 15.4, Appendix 1, Appendix

9.2, Appendix 11, INDEX

.

Apr., 2003 SH (NA)-080058-D

Oct., 2003 SH (NA)-080058-E

Partial corrections and additions

SAFETY INSTRUCTIONS, CONTENTS, Component List,

Section 1.2.3, Section 1.4, Section 2.3, Section 2.4, Section 3.1,

Section 3.2.1, Section 3.2.3, Section 3.2.4, Section 3.4.1, Section

3.4.4, Section 4.1.2, Section 4.3.1, Section 4.3.2, Section 5.1.1,

Section 5.1.7, Section 5.1.8, Section 5.2.1, Section 5.2.4, Section

5.6.2, Section 5.7.1, Section 6.4, Section 6.5.4, Section 6.5.6, Section

8.2.3 to Section 8.2.8, Section 9.2.17, Section 9.2.19, Section 11.2.1,

Section 11.3.1, Section 11.4.1, Section 12.1.1, Section 12.5.1, Section

12.5.2, Section 12.7.3, Section 12.7.5, Section 12.7.9, Section 14.4,

Section 15.2, Appendix 1.1, Appendix 4.1 to Appendix 4.3, Appendix

7.1, Appendix 9.2, Appendix 10 to Appendix 13, INDEX

Partial correcti on s an d ad di t ion s

CONTENTS, Section 1.1.1, Section 1.4, Section 2.2, Section 2.4,

Section 3.2.1, Section 3.2.3, Section 3.2.4, Section 3.3.2, Section

3.4.3, Section 3.4.4, Section 5.1.1, Section 5.1.8, Section 5.7.1,

Section 6.5.3, Section 6.5.6, Section 7.1.2, Section 9.1.2, Section

9.2.3 to Section 9.2.9, Section 11.2.1, Section 11.3.1, Section 11.4.1,

Section 12.2.1, Section 12.7.10, Appendix 9.2, Appendix 12, INDEX

A - 4

Page 7

REVISIONS

Manual Number Revision

Print Date

Feb., 2004 SH (NA)-080058-F

The manual number is given on the bottom left of the back cov er

Partial corrections and additions

CONTENTS, Section 3.4.1, Section 3.4.3, Section 3.4.4,

Section 5.2.1, Section 5.4, Section 5.5, Section 5.6.2, Section 8.2.6,

Section 10.1.2, Section 10.3.3, Section 10.3.5, Section 10.3.7,

Appendix 9.2, Appendix 12

.

Nov., 2004 S H (NA ) -080 05 8 - G

Jun., 2005 SH (NA)-080058-H

Partial correcti on s an d ad di t ion s

SAFETY INSTRUCTIONS, Section 1.4, Section 2.3, Section 2.4,

Section 4.2.1, Section 4.3.1, Section 4.5.1, Section 5.1.7,

Section 5.2.1, Section 5.2.6, Section 5.6.2, Section 6.1,

Section 9.2.19, Section 12.2.1, Section 12.4.4, Section 12.7.4,

Appendix 1.1, Appendix 9.1

Partial correcti on s an d ad di t ion s

Section 5.1.2, Section 9.1.2, Section 9.2.10, Section 9.2.21,

Section 10.3.8, Section 11.4.1, Section 12.5.2, Section 12.7.1,

Section 12.7.6, Section 15.1, Section 15.2

Japanese Manual Version SH-0800047-L

This manual confers no industrial property rights or any rights of any other kind, nor doe s it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems inv olv ing industria l property rights which

may occur as a result of using the contents noted in this manual.

1999 MITSUBISHI ELECTRIC CORPORATION

A - 5

Page 8

INTRODUCTION

Thank you for purchasing the Mitsubishi general-purpose programmable logic controller MELSEC-Q Series.

Always read through this manual, and fully comprehend the functions and performance of the Q Series PLC

before starting use to ensure correct usage of this product.

CONTENTS

SAFETY INSTRUCTIONS.............................................................................................................................A- 1

REVISIONS....................................................................................................................................................A- 4

INTRODUCTION ...........................................................................................................................................A- 6

CONTENTS....................................................................................................................................................A- 6

About Manuals ..............................................................................................................................................A- 13

Using This Manual.........................................................................................................................................A- 13

Conformation to the EMC AND LOW-VOLTAGE DIRECTIVES.................................................................A- 13

Generic Terms and Abbreviations................................................................................................................A- 14

Component List .............................................................................................................................................A- 15

Section 1 Product Specifications and Handling

1. Product Outline 1- 1 to 1- 22

1.1 Positioning control....................................................................................................................................1- 2

1.1.1 Features of QD75..............................................................................................................................1- 2

1.1.2 Purpose and applications of positioning control...............................................................................1- 5

1.1.3 Mechanism of positioning control .....................................................................................................1- 7

1.1.4 Outline design of positioning system................................................................................................1- 9

1.1.5 Communicating signals between QD75 and each module.............................................................1- 12

1.2 Flow of system operation........................................................................................................................1- 15

1.2.1 Flow of all processes........................................................................................................................1- 15

1.2.2 Outline of starting ...................................................................................................... .......................1- 18

1.2.3 Outline of stopping ...........................................................................................................................1- 20

1.2.4 Outline for restarting.........................................................................................................................1- 21

1.3 Restrictions with a system using a stepping motor................................................................................1- 22

1.4 Function additions/modifications according to function version B.........................................................1- 22

2. System Configuration 2- 1 to 2- 6

2.1 General image of system.........................................................................................................................2- 2

2.2 Component list .........................................................................................................................................2- 4

2.3 Applicable system....................................................................................................................................2- 5

2.4 How to check the function version and SERIAL No. .............................................................................2- 6

A - 6

Page 9

3. Specifications and Functions 3- 1 to 3- 24

3.1 Performance specifications......................................................................................................................3- 2

3.2 List of functions .......................................................................................................................................3- 4

3.2.1 QD75 control functions......................................................................................................................3- 4

3.2.2 QD75 main functions......................................................................................................................... 3- 6

3.2.3 QD75 sub functions and common functions ....................................................................................3- 8

3.2.4 Combination of QD75 main functions and sub functions................................................................3- 12

3.3 Specifications of input/output signals with PLC CPU.............................................................................3- 14

3.3.1 List of input/output signals with PLC CPU.......................................................................................3- 14

3.3.2 Details of input signals (QD75

3.3.3 Details of output signals (PLC CPU

3.4 Specifications of input/output interfaces with external devices .............................................................3- 17

3.4.1 Electrical specifications of input/output signals...............................................................................3- 17

3.4.2 Signal layout for external device connection connector..................................................................3- 19

3.4.3 List of input/output signal details......................................................................................................3- 20

3.4.4 Input/output interface internal circuit................................................................................................3- 22

4. Installation, Wiring and Maintenance of the Product 4- 1 to 4- 16

4.1 Outline of installation, wiring and maintenance....................................................................................... 4- 2

4.1.1 Installation, wiring and maintenance procedures.............................................................................4- 2

4.1.2 Names of each part...........................................................................................................................4- 3

4.1.3 Handling precautions ........................................................................................................................4- 5

4.2 Installation ................................................................................................................................................4- 7

4.2.1 Precautions for installation................................................................................................................4- 7

4.3 Wiring........................................................................................................................................................4- 8

4.3.1 Precautions for wiring........................................................................................................................4- 8

4.3.2 Wiring of the differential driver common terminal............................................................................4- 13

4.4 Confirming the installation and wiring.....................................................................................................4- 14

4.4.1 Items to confirm when installation and wiring are completed.........................................................4- 14

4.5 Maintenance............................................................................................................................................4- 15

4.5.1 Precautions for maintenance...........................................................................................................4- 15

4.5.2 Disposal instructions ........................................................................................................................4- 15

PLC CPU) ..................................................................................3- 15

QD75)................................................................................3- 16

5. Data Used for Positioning Control (List of buffer memory addresses) 5- 1 to 5-132

5.1 Types of data............................................................................................................................................5- 2

5.1.1 Parameters and data required for control.........................................................................................5- 2

5.1.2 Setting items for positioning parameters..........................................................................................5- 4

5.1.3 Setting items for OPR parameters....................................................................................................5- 6

5.1.4 Setting items for positioning data......................................................................................................5- 7

5.1.5 Setting items for block start data .....................................................................................................5- 10

5.1.6 Setting items for condition data .......................................................................................................5- 11

5.1.7 Types and roles of monitor data......................................................................................................5- 12

5.1.8 Types and roles of control data .......................................................................................................5- 16

A - 7

Page 10

5.2 List of parameters ...................................................................................................................................5- 20

5.2.1 Basic parameters 1 ..........................................................................................................................5- 20

5.2.2 Basic parameters 2 ..........................................................................................................................5- 26

5.2.3 Detailed parameters 1......................................................................................................................5- 28

5.2.4 Detailed parameters 2......................................................................................................................5- 36

5.2.5 OPR basic parameters.....................................................................................................................5- 46

5.2.6 OPR detailed parameters ................................................................................................................5- 54

5.3 List of positioning data ............................................................................................................................5- 58

5.4 List of block start data .............................................................................................................................5- 74

5.5 List of condition data...............................................................................................................................5- 80

5.6 List of monitor data..................................................................................................................................5- 86

5.6.1 System monitor data ........................................................................................................................5- 86

5.6.2 Axis monitor data..............................................................................................................................5- 96

5.7 List of control data..................................................................................................................................5-110

5.7.1 System control data.........................................................................................................................5-110

5.7.2 Axis control data..............................................................................................................................5-112

6. Sequence Program Used for Positioning Control 6- 1 to 6- 44

6.1 Precautions for creating program............................................................................................................6- 2

6.2 List of devices used..................................................................................................................................6- 5

6.3 Creating a program .................................................................................................................................6- 11

6.3.1 General configuration of program....................................................................................................6- 11

6.3.2 Positioning control operation program.............................................................................................6- 12

6.4 Positioning program examples...............................................................................................................6- 15

6.5 Program details.......................................................................................................................................6- 24

6.5.1 Initialization program ........................................................................................................................6- 24

6.5.2 Start details setting program............................................................................................................6- 25

6.5.3 Start program....................................................................................................................................6- 27

6.5.4 Continuous operation interrupt program..........................................................................................6- 37

6.5.5 Restart program ...............................................................................................................................6- 39

6.5.6 Stop program....................................................................................................................................6- 42

7. Memory Configuration and Data Process 7- 1 to 7- 12

7.1 Configuration and roles of QD75 memory...............................................................................................7- 2

7.1.1 Configuration and roles of QD75 memory........................................................................................7- 2

7.1.2 Buffer memory area configuration ....................................................................................................7- 5

7.2 Data transmission process ......................................................................................................................7- 6

A - 8

Page 11

Section 2 Control Details and Setting

8. OPR Control 8- 1 to 8- 22

8.1 Outline of OPR control.............................................................................................................................8- 2

8.1.1 Two types of OPR control.................................................................................................................8- 2

8.2 Machine OPR...........................................................................................................................................8- 4

8.2.1 Outline of the machine OPR operation.............................................................................................8- 4

8.2.2 Machine OPR method.......................................................................................................................8- 5

8.2.3 OPR method (1): Near-point dog method ........................................................................................8- 6

8.2.4 OPR method (2): Stopper method 1) ...............................................................................................8- 8

8.2.5 OPR method (3): Stopper method 2) ..............................................................................................8- 11

8.2.6 OPR method (4): Stopper method 3) ..............................................................................................8- 14

8.2.7 OPR method (5): Count method 1)..................................................................................................8- 16

8.2.8 OPR method (6): Count method 2)..................................................................................................8- 18

8.3 Fast OPR.................................................................................................................................................8- 20

8.3.1 Outline of the fast OPR operation....................................................................................................8- 20

9. Major Positioning Contro l 9- 1 to 9-114

9.1 Outline of major positioning controls .......................................................................................................9- 2

9.1.1 Data required for major positioning control ......................................................................................9- 4

9.1.2 Operation patterns of major positioning controls .............................................................................9- 5

9.1.3 Designating the positioning address................................................................................................9- 15

9.1.4 Confirming the current value............................................................................................................9- 16

9.1.5 Control unit "degree" handling.........................................................................................................9- 18

9.1.6 Interpolation control..........................................................................................................................9- 21

9.2 Setting the positioning data ...................................................................................................................9- 25

9.2.1 Relation between each control and positioning data ......................................................................9- 25

9.2.2 1-axis linear control ..........................................................................................................................9- 27

9.2.3 2-axis linear interpolation control.....................................................................................................9- 29

9.2.4 3-axis linear interpolation control.....................................................................................................9- 33

9.2.5 4-axis linear interpolation control.....................................................................................................9 -39

9.2.6 1-axis fixed-feed control...................................................................................................................9- 43

9.2.7 2-axis fixed-feed control (interpolation) ...........................................................................................9- 45

9.2.8 3-axis fixed-feed control (interpolation) ...........................................................................................9- 47

9.2.9 4-axis fixed-feed control (interpolation) ..........................................................................................9- 51

9.2.10 2-axis circular interpolation control with sub point designation.....................................................9- 53

9.2.11 2-axis circular interpolation control with center point designation................................................9- 59

9.2.12 1-axis speed control.......................................................................................................................9- 67

9.2.13 2-axis speed control.......................................................................................................................9- 70

9.2.14 3-axis speed control.......................................................................................................................9- 73

9.2.15 4-axis speed control.......................................................................................................................9- 77

9.2.16 Speed-position switching control (INC mode)...............................................................................9- 82

9.2.17 Speed-position switching control (ABS mode)..............................................................................9- 90

9.2.18 Position-speed switching control ...................................................................................................9- 98

9.2.19 Current value changing.................................................................................................................9-105

A - 9

Page 12

9.2.20 NOP instruction .............................................................................................................................9-110

9.2.21 JUMP instruction...........................................................................................................................9-111

9.2.22 LOOP.............................................................................................................................................9-113

9.2.23 LEND .............................................................................................................................................9-114

10. High-Level Positioning Control 10- 1 to 10- 26

10.1 Outline of high-level positioning control...............................................................................................10- 2

10.1.1 Data required for high-level positioning control............................................................................10- 3

10.1.2 " Block start data" and "condition data" configuration.................................................................. 10- 4

10.2 High-level positioning control execution procedure ...........................................................................10- 6

10.3 Setting the block start data..................................................................................................................10- 7

10.3.1 Relation between various controls and block start data ..............................................................10- 7

10.3.2 Block start (normal start) ..............................................................................................................10- 8

10.3.3 Condition start ..............................................................................................................................10- 10

10.3.4 Wait start.......................................................................................................................................10- 11

10.3.5 Simultaneous start ......................................................................................................................10- 12

10.3.6 Repeated start (FOR loop) ..........................................................................................................10- 13

10.3.7 Repeated start (FOR condition) ..................................................................................................10- 14

10.3.8 Restrictions when using the NEXT start......................................................................................10- 15

10.4 Setting the condition data...................................................................................................................10- 16

10.4.1 Relation between various controls and the condition data.........................................................10- 16

10.4.2 Condition data setting examples .................................................................................................10- 19

10.5 Multiple axes simultaneous start control............................................................................................10- 20

10.6 Start program for high-level positioning control .................................................................................10- 23

10.6.1 Starting high-level positioning control..........................................................................................10- 23

10.6.2 Example of a start program for high-level positioning control.....................................................10- 24

11. Manual Control 11- 1 to 11- 36

11.1 Outline of manual control ....................................................................................................................11- 2

11.1.1 Three manual control methods.....................................................................................................11- 2

11.2 JOG operation......................................................................................................................................11- 4

11.2.1 Outline of JOG operation..............................................................................................................11- 4

11.2.2 JOG operation execution procedure ............................................................................................11- 7

11.2.3 Setting the required parameters for JOG operation.....................................................................11- 8

11.2.4 Creating start programs for JOG operation.................................................................................11- 10

11.2.5 JOG operation example...............................................................................................................11- 13

11.3 Inching operation.................................................................................................................................11- 17

11.3.1 Outline of inching operation.........................................................................................................11- 17

11.3.2 Inching operation execution procedure.......................................................................................11- 20

11.3.3 Setting the required parameters for inching operation................................................................11- 21

11.3.4 Creating a program to enable/disable the inching operation......................................................11- 22

11.3.5 Inching operation example...........................................................................................................11- 25

11.4 Manual pulse generator operation......................................................................................................11- 27

11.4.1 Outline of manual pulse generator operation..............................................................................11- 27

11.4.2 Manual pulse generator operation execution procedure............................................................11- 31

11.4.3 Setting the required parameters for manual pulse generator operation ....................................11- 32

A - 10

Page 13

11.4.4 Creating a program to enable/disable the manual pulse generator operation ..........................11- 33

12. Control Sub Functions 12- 1 to 12- 98

12.1 Outline of sub functions .......................................................................................................................12- 2

12.1.1 Outline of sub functions.................................................................................................................12- 2

12.2 Sub functions specifically for machine OPR.......................................................................................12- 4

12.2.1 OPR retry function.........................................................................................................................12- 4

12.2.2 OP shift function ...........................................................................................................................12- 8

12.3 Functions for compensating the control .............................................................................................12- 11

12.3.1 Backlash compensation function.................................................................................................12- 11

12.3.2 Electronic gear function................................................................................................................12- 13

12.3.3 Near pass function .......................................................................................................................12- 18

12.4 Functions to limit the control...............................................................................................................12- 21

12.4.1 Speed limit function......................................................................................................................12- 21

12.4.2 Torque limit function.....................................................................................................................12- 23

12.4.3 Software stroke limit function.......................................................................................................12- 26

12.4.4 Hardware stroke limit function .....................................................................................................12- 32

12.5 Functions to change the control details..............................................................................................12- 34

12.5.1 Speed change function ................................................................................................................12- 34

12.5.2 Override function..........................................................................................................................12- 41

12.5.3 Acceleration/deceleration time change function .........................................................................12- 44

12.5.4 Torque change function ...............................................................................................................12- 48

12.6 Absolute position restoration function ................................................................................................12- 50

12.7 Other functions....................................................................................................................................12- 58

12.7.1 Step function.................................................................................................................................12- 58

12.7.2 Skip function.................................................................................................................................12- 63

12.7.3 M code output function.................................................................................................................12- 66

12.7.4 Teaching function.........................................................................................................................12- 70

12.7.5 Target position change function...................................................................................................12- 77

12.7.6 Command in-position function.....................................................................................................12- 81

12.7.7 Acceleration/deceleration processing function............................................................................12- 84

12.7.8 Pre-reading start function.............................................................................................................12- 87

12.7.9 Deceleration start flag function ....................................................................................................12- 92

12.7.10 Stop command processing for deceleration stop function........................................................12- 96

13. Common Functions 13- 1 to 13- 8

13.1 Outline of common functions...............................................................................................................13- 2

13.2 Parameter initialization function...........................................................................................................13- 3

13.3 Execution data backup function...........................................................................................................13- 5

13.4 External I/O signal logic switching function.........................................................................................13- 7

13.5 External I/O signal monitor function ....................................................................................................13- 8

14. Dedicated instructions 14- 1 to 14- 22

14.1 List of dedicated instructions ...............................................................................................................14- 2

14.2 Interlock during dedicated instruction is executed..............................................................................14- 2

14.3 ABRST1, ABRST2, ABRST3, ABRST4..............................................................................................14- 3

A - 11

Page 14

14.4 PSTRT1, PSTRT2, PSTRT3, PSTRT4...............................................................................................14- 8

14.5 TEACH1, TEACH2, TEACH3, TEACH4............................................................................................14- 12

14.6 PFWRT................................................................................................................................................14- 16

14.7 PINIT ...................................................................................................................................................14- 20

15. Troubleshooting 15- 1 to 15- 38

15.1 Error and warning details.....................................................................................................................15- 2

15.2 List of errors .........................................................................................................................................15- 6

15.3 List of warnings ...................................................................................................................................15- 32

15.4 LED display functions .........................................................................................................................15- 38

Appendices Appendix- 1 to Appendix-108

Appendix 1 Version up of the functions............................................................................................Appendix- 2

Appendix 1.1 Comparison of functions according to function versions.......................................Appendix- 2

Appendix 2 Format sheets................................................................................................................Appendix- 4

Appendix 2.1 Positioning Module operation chart .......................................................................Appendix- 4

Appendix 2.2 Parameter setting value entry table .......................................................................Appendix- 6

Appendix 2.3 Positioning data setting value entry table ............................................................Appendix- 12

Appendix 3 Positioning data (No. 1 to 600) List of buffer memory addresses...............................Appendix- 13

Appendix 4 Connection examples with servo amplifiers manufactured by MITSUBISHI Electric Corporation

.......................................................................................................................................Appendix- 37

Appendix 4.1 Connection example of QD75D

Appendix 4.2 Connection example of QD75D and MR-J2/J2S- A (Differential driver) .....Appendix- 38

Appendix 4.3 Connection example of QD75D

Appendix 5 Connection examples with stepping motors manufactured by ORIENTALMOTOR Co., Ltd.

.......................................................................................................................................Appendix- 40

Appendix 5.1 Connection example of QD75P

Appendix 6 Connection examples with servo amplifiers manufactured by Matsushita Electric Industrial Co.,

Ltd. ................................................................................................................................Appendix- 41

Appendix 6.1 Connection example of QD75D

Appendix 7 Connection examples with servo amplifiers manufactured by SANYO DENKI Co., Ltd.

.......................................................................................................................................Appendix- 42

Appendix 7.1 Connection example of QD75D

Appendix 8 Connection examples with servo amplifiers manufactured by YASKAWA Electric Corporation

.......................................................................................................................................Appendix- 43

Appendix 8.1 Connection example of QD75D

Appendix 9 Comparisons with conventional positioning modules..................................................Appendix- 44

Appendix 9.1 Comparisons with A1SD71S2 model....................................................................Appendix- 44

Appendix 9.2 Comparisons with A1SD75P1-S3/A1SD75P2-S3/ A1SD75P3-S3 models.........Appendix- 45

Appendix 10 MELSEC Explanation of positioning terms................................................................Appendix- 68

Appendix 11 Positioning control troubleshooting............................................................................Appendix- 92

Appendix 12 List of buffer memory addresses.................................................................................Appendix-98

Appendix 13 External dimension drawing......................................................................................Appendix-107

and MR-H A (Differential driver) ...............Appendix- 37

and MR-C A (Differential driver) ...............Appendix- 39

and VEXTA UPD (Open collector)................Appendix- 40

and MINAS-A series (Differential driver)......Appendix- 41

and PYO series (Differential driver)..............Appendix- 42

and Σ- series (Differential driver) .................Appendix- 43

A - 12

Page 15

About Manuals

Related Manu al s

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Manual Name

Type QD75P/QD75D Positioning Module User's Manual

(Hardware)

Describes the performance, specifications, I/O interface, component names, and startup procedure of

the respective positioning modules: QD75P1, QD75P2, QD75P4, QD75D1, QD75D2, and QD75D4.

(The manual is supplied with the module.)

GX Configurator-QP Operating Manual

Describes how to use GX Configurator-QP for the following and other purposes: creating data

(parameters, positioning data, etc.), sending the data to the module, monitoring the positioning

operations, and testing. (The manual is supplied with the software.)

Using This Manual

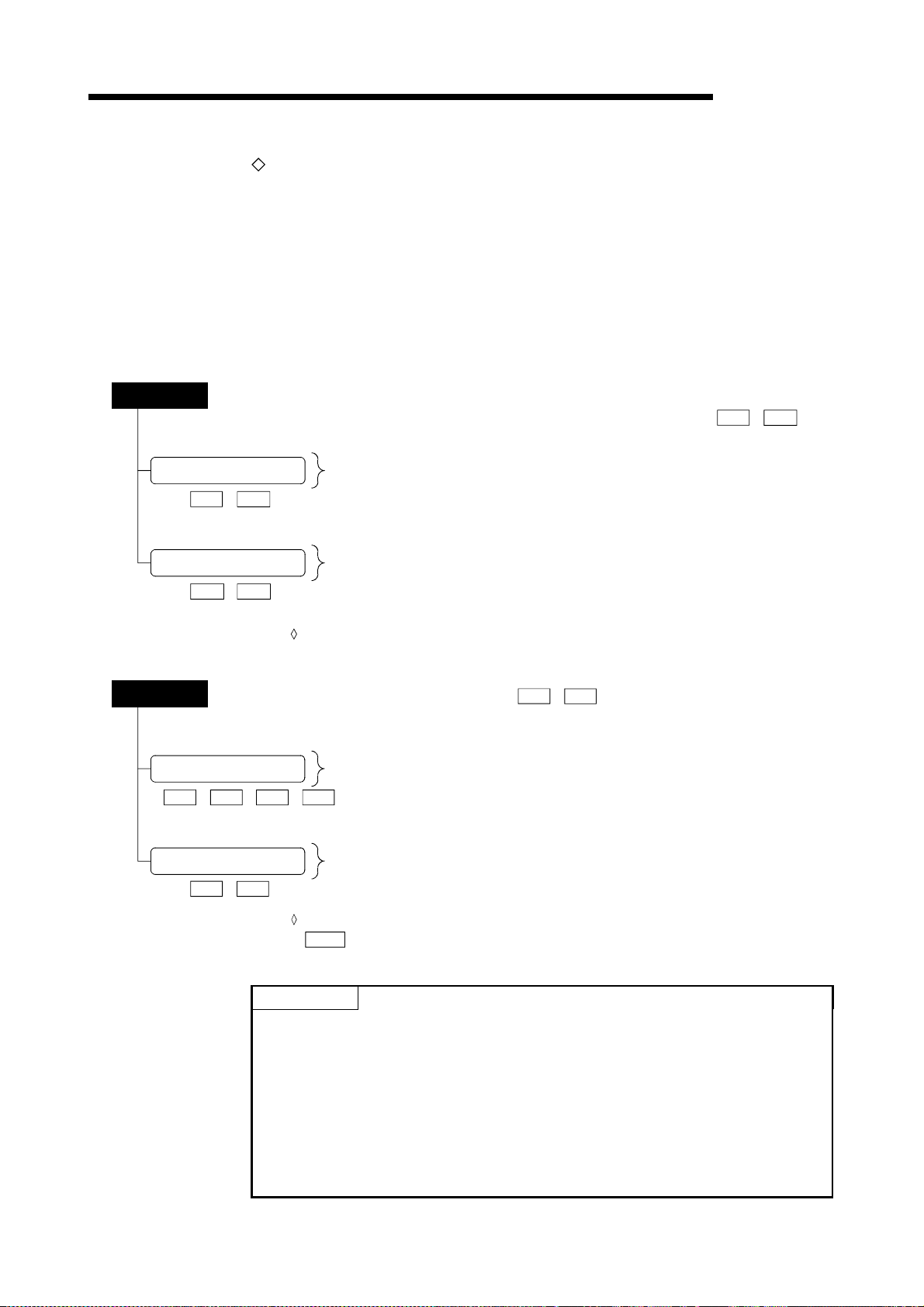

The symbols used in this manual are shown below.

Pr.

Da.

........ Symbol indicating positioning parameter and OPR parameter item.

....... Symbol indicating positioning data, block start data and condition

data item.

Md.

Cd.

....... Symbol indicating m onitor dat a item.

....... Symbol indicating control data item.

Manual Number

(Model Code)

IB-0800063

(13JQ73)

SH-080172

(13JU19)

(A serial No. is inserted in the

mark.)

Representation of numerical values used in this manual.

Buffer memory addresses, error codes and warning codes are represented in

decimal.

X/Y devices are represented in hexadecimal.

Setting data and monitor data are represented in decimal or hexadecimal. Data

ended by "H" are represented in hexadecimal.

(Example) 10.........Decimal

10H......Hexadecimal

Conformation to the EMC AND LOW-VOLTAGE DIRECTIVES

For details on making Mitsubishi PLC conform to the EMC and Low Voltage

Directives when installing it in your product, please refer to Chapter 3, “EMC AND

LOW-VOLTAGE DIRECTIVES” of the using PLC CPU module User’s Manual

(Hardware).

The CE logo is printed on the rating plate on the main body of the PLC that

conforms to the

EMC and Low Voltage Directives

To make this product conform to the

refer to Section 4.3.1 "Precautions for wiring".

A - 13

.

EMC and Low Voltage Directives

, please

Page 16

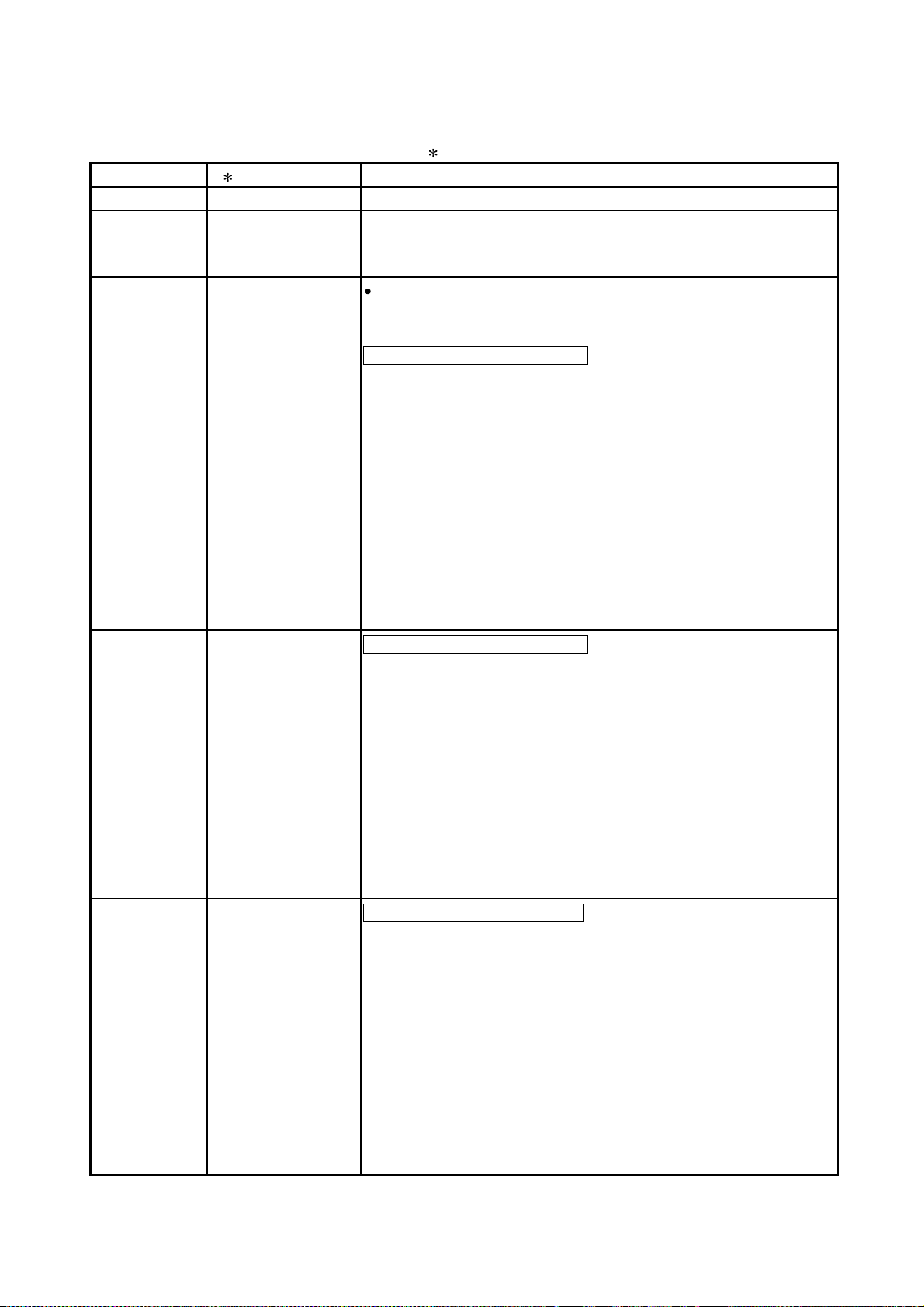

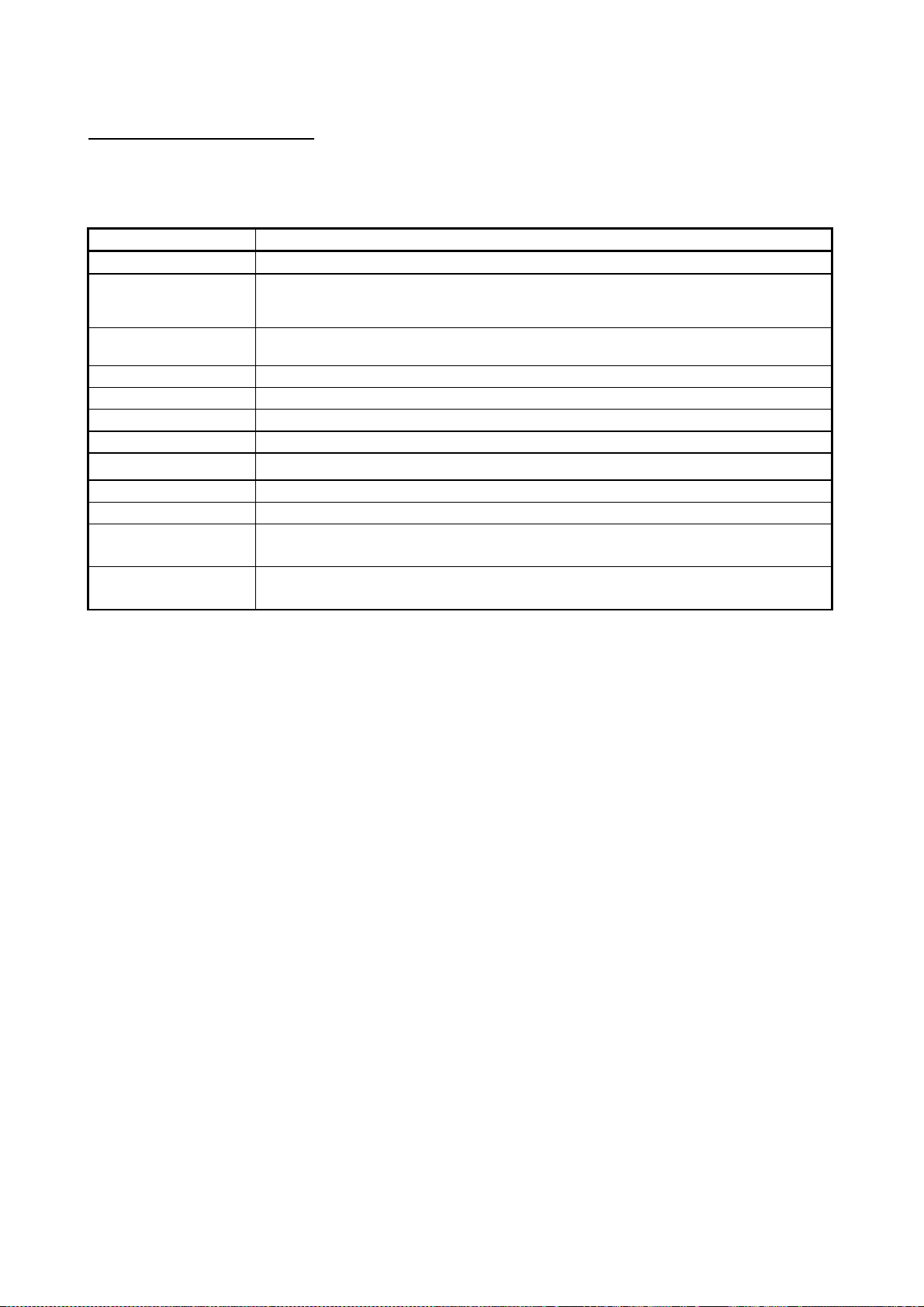

Generic Terms and Abbreviations

Unless specially noted, the following generic terms and abbreviations are used in this

manual.

Generic term/abbreviation Details of generic term/abbreviation

PLC CPU Generic term for PLC CPU on which QD75 can be mounted.

QD75 Generic term for positioning module QD75P1, QD75P2, QD75P4, QD75D 1, QD75D 2, and

QD75D4.

The module type is described to indicate a specifi c modul e.

Peripheral device Generic term for DOS/V personal computer that can run the following "GX D ev eloper" and "GX

Configurator-QP".

GX Configurator-QP Abbreviation for GX Configurator-QP (SW2D5C-QD75P-E or later).

GX Developer Abbreviation for GX Developer (SW4D5C-GPPW-E or later).

Drive unit (servo amplifier) Abbreviation for pulse input compatible drive unit (servo amplifier).

Manual pulse generator Abbreviation for manual pulse generator (prepared by user).

DOS/V personal computer

Personal computer Generic term for DOS/V personal computer.

Workpiece Generic term for moving body such as workpiece and tool, and for v arious control targ ets.

Axis 1, axis 2, axis 3,

axis 4

1-axis, 2-axis, 3-axis,

4-axis

IBM PC/AT

Indicates each axis connected to QD75.

Indicates the number of axes. (Example: 2-ax is = Indicates tw o ax es such as axis 1 and axis 2,

axis 2 and axis 3, and axis 3 and axis 1.)

®

and compatible DOS/V compliant personal computer.

A - 14

Page 17

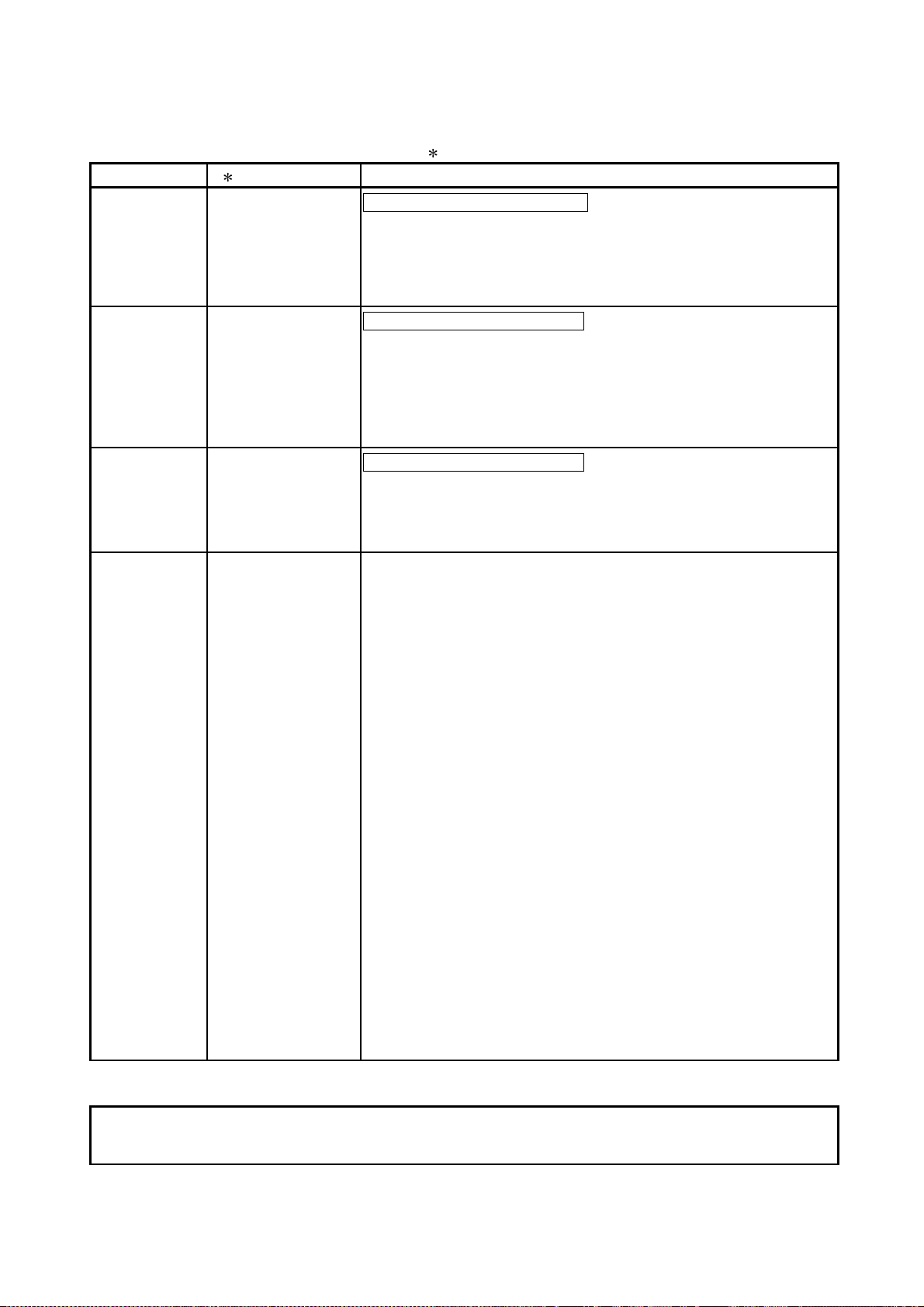

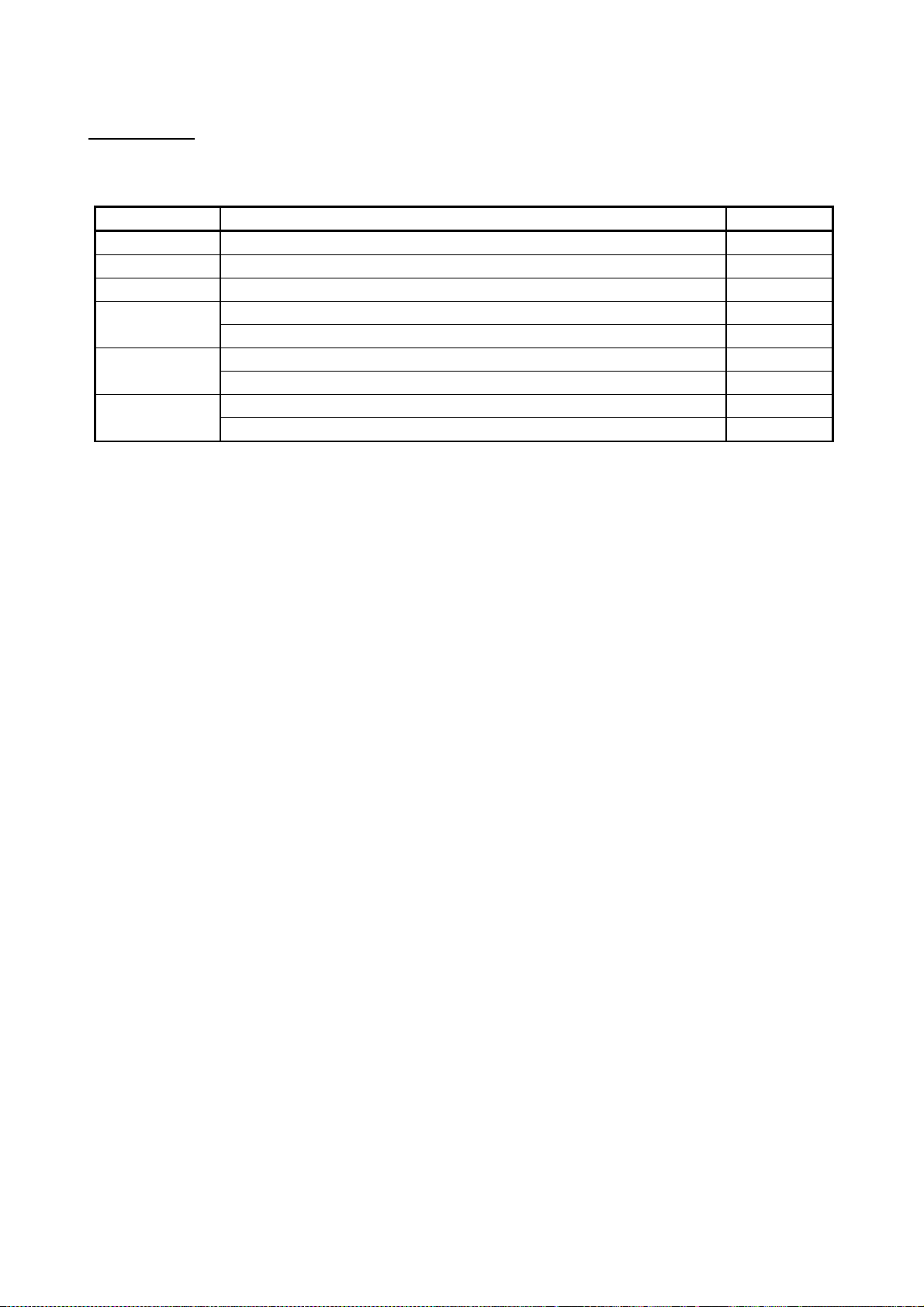

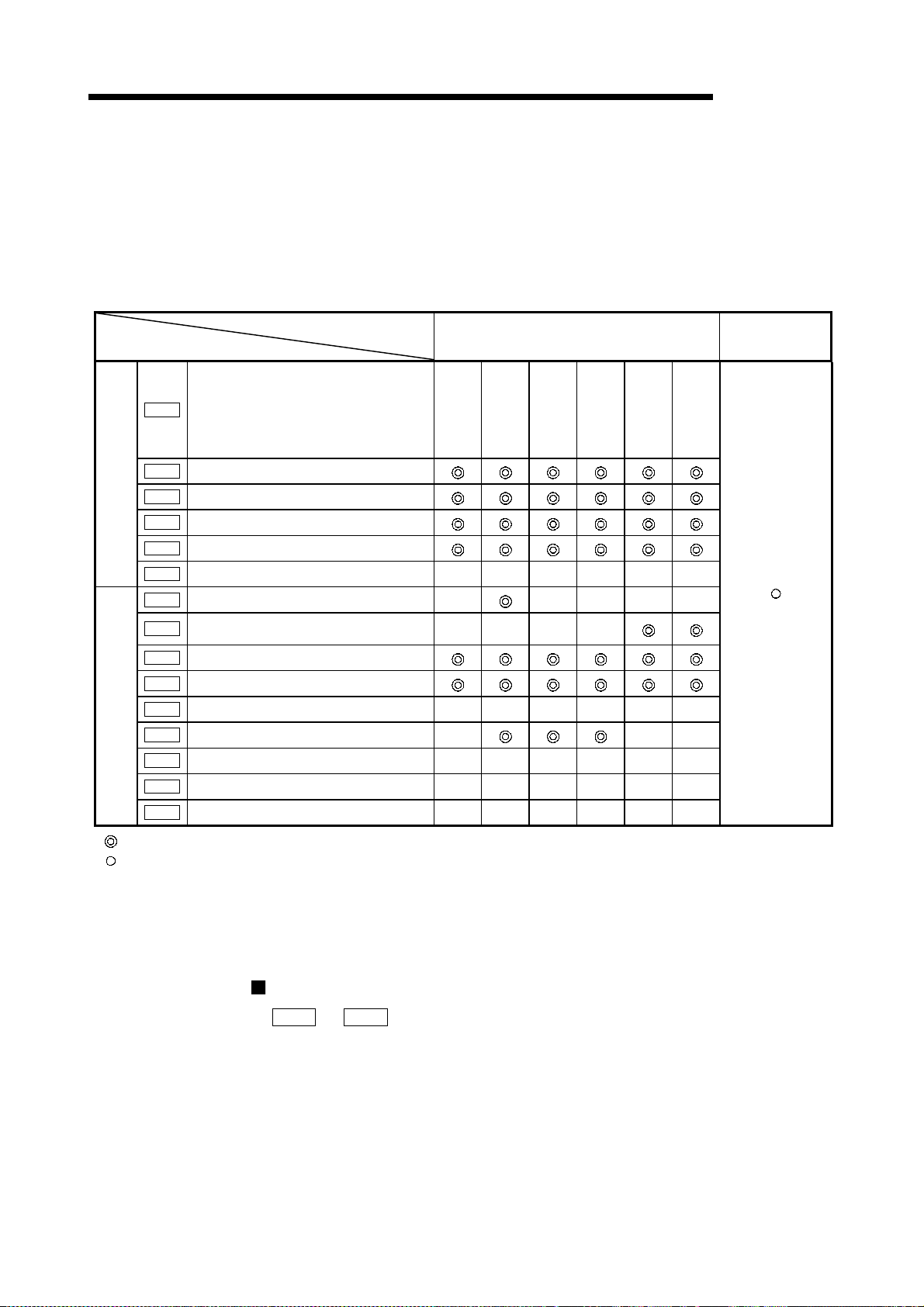

Component List

The table below shows the component included in respective positioning modules:

Module name Description Quantity

QD75P1 QD75P1 Positioning Module(1-axis open collector output system) 1

QD75P2 QD75P2 Positioning Module(2-axes open collector output system) 1

QD75P4 QD75P4 Positioning Module(4-axes open collector output system) 1

QD75D1

QD75D2

QD75D4

QD75D1 Positioning Module(1-axis differential driver output system) 1

Differential driver common terminal 1

QD75D2 Positioning Module(2-axes differential driver output system) 1

Differential driver common terminal 1

QD75D4 Positioning Module(4-axes differential driver output system) 1

Differential driver common terminal 1

A - 15

Page 18

MEMO

A - 16

Page 19

Section 1 Product Specifications and Handling

Section 1 is configured for the following purposes (1) to (5).

(1) To understand the outline of positioning control, and the QD75 specifications

and functions

(2) To carry out actual work such as installation and wiring

(3) To set parameters and data required for positioning control

(4) To create a sequence program required for positioning control

(5) To understand the memory configuration and data transmission process

Section 1

Read Section 2 for details on each control.

Chapter 1 Product outline .............................................................................................. 1- 1 to 1- 22

Chapter 2 System configuration .................................................................................... 2- 1 to 2- 6

Chapter 3 Specifications and Functions........................................................................ 3- 1 to 3- 24

Chapter 4 Installation, Wiring and Maintenance of the Product................................... 4- 1 to 4- 16

Chapter 5 Data Used for Positioning Control................................................................ 5- 1 to 5-132

Chapter 6 Sequence Program Used for Positioning Control........................................ 6- 1 to 6- 44

Chapter 7 Memory Configuration and Data Process.................................................... 7- 1 to 7- 12

Page 20

MEMO

Page 21

Chapter 1 Product Outline

The purpose and outline of positioning control using QD75 are explained in this chapter.

Reading this chapter will help you understand what can be done using the positioning

system and which procedure to use for a specific purpose.

1

By understanding "What can be done", and "Which procedure to use" beforehand, the

positioning system can be structured smoothly.

1.1 Positioning control........................................................................................................1- 2

1.1.1 Features of QD75 ...........................................................................................1- 2

1.1.2 Purpose and applications of positioning control ............................................1- 5

1.1.3 Mechanism of positioning control...................................................................1- 7

1.1.4 Outline design of positioning system .............................................................1- 9

1.1.5 Communicating signals between QD75 and each module ..........................1- 12

1.2 Flow of system operation ............................................................................................1- 15

1.2.1 Flow of all processes .....................................................................................1- 15

1.2.2 Outline of starting...........................................................................................1- 18

1.2.3 Outline of stopping.........................................................................................1- 20

1.2.4 Outline for restarting ......................................................................................1- 21

1.3 Restrictions with a system using a stepping motor....................................................1- 22

1.4 Function additions/modifications according to function version B.............................1- 22

1 - 1

Page 22

1 PRODUCT OUTLINE

1.1 Positioning control

1.1.1 Features of QD75

The features of the QD75 are shown below.

(1) Availability of one, two, and four axis modules

MELSEC-Q

(a) One, two and four axis modules are available for both the open collector

system pulse output (QD75P1, QD75P2, and QD75P4) and differential

driver system pulse output (QD75D1, QD75D2, and QD75D4), comprising

six different models.

A model is determined by the drive unit type and number of axes. (Refer to

Section 2.2.)

(b) For connecting any of the QD75 modules to the base unit, a single slot and

32 dedicated I /O chan nel s a re requ i red .

Within the limit imposed by the maximum number of inputs and outputs

supported by the PLC CPU, up to 64 modules can be used. (Refer to

Section 3.1.)

(2) Wide variety of positioning control functions

(a) A wide variety of positioning control functions essential to any positioning

system are supported: positioning to an arbitrary position, fixed-feed

control, equal-speed control, and so on. (Refer to Section 5.3 and 9.2.)

1) Up to 600 positioning data items, including such information as

positioning addresses, control systems, and operation patterns, can be

prepared for each axis.

Using the prepared positioning data, the positioning control is

performed independently for each axis. (In addition, such controls as

interpolation involving two to four axes and simultaneous startup of

multiple axes are possible.)

2) Independent control of each axis can be achieved in linear control

mode (executable simultaneously over four axes).

Such control can ei th e r be t he in de pe nden t po si tio ni ng con t rol u sing a

single positioning data or the continuous positioning control enabled by

the continuous processing of multiple positioning data.

3) Coordinated control over multiple axes can take the form of either the

linear interpolation through the speed or position control of two to four

axes or the circular interpolation involving two axes.

Such control can ei th e r be t he in de pe nden t po si tio ni ng con t rol u sing a

single positioning data or the continuous positioning control enabled by

the continuous processing of multiple positioning data.

(b) For each positioning data, the user can specify any of the following control

systems: position control, speed control, speed-position switching control,

position-speed switching control, and so on. (Refer to Section 5.3 and 9.2.)

1 - 2

Page 23

1 PRODUCT OUTLINE

MELSEC-Q

(c) Continuous positioning control using multiple positioning data can be

executed in accordance with the operation patterns the user assigned to

the positioning data. (Refer to Section 5.3 and 9.1.2)

Continuous positioning control can be executed over multiple blocks, where

each block consists of multiple positioning data. (Refer to Section 10.3.2.)

(d) OPR control is given additional features (Refer to Section 8.2.)

1) Six different machine OPR methods are provided: near point dog

method (one method), stopper methods (three methods), and count

methods (two methods).

2) OPR retry function facilitates the machine OPR control from an

arbitrary position.

(The machine OP a p remie r re fe ren ce po si t ion fo r positioning cont rol.

The machine is set to the machine OP through one of the machine

OPR methods mentioned in 1) above.)

(e) Two acceleration/deceleration control methods are provided: automatic

trapezoidal acceleration/deceleration and S-pattern

acceleration/deceleration. (Refer to Section 12.7.7.)

(The S-pattern acceleration/deceleration control is disabled if stepping

motors are used. Refer to Section 1.3.)

(3) Quick startup (Refer to Section 3.1.)

A positioning operation starts up quickly taking as little as 6 ms to 7 ms.

When operation using simultaneous start function or interpolation operation is

executed, the axes start without delay.

(Example) Axis 1 and Axis 3 are started by the

simultaneous start function

Axis 2 and Axis 4 are started by the

interpolation operation

: No delay in Axis 1 and

Axis 3 start

: No delay in Axis 2 and

Axis 4 start

(4) Faster pulse output and allowance of longer distance to dr i ve unit

(Refer to Section 3.1.)

The modules with a differential driver (QD75D1, QD75D2, and QD75D4)

incorporate the improvements in pulse output speed and maximum distance to

the drive unit.

• QD75D1/QD75D2/QD75D4: 1 Mpulse/s, 10 m max.

• QD75P1/QD75P 2/QD 75P 4: 20 0 kpu l se/ s, 2 m max.

(5) Easy maintenance

Each QD75 positioning module incorporates the following improvements in

maintainability:

(a) Data such as the positioning data and parameters can be stored on a flash

ROM inside the QD75, eliminating the need of a battery for retaining data.

(Refer to Section 7.1.1.)

(b) Error messages are classified in more detail to facilitate the initial

troubleshooting procedure. (Refer to Section 15.1.)

(c) The module retains 16 error messages and 16 warning messages recently

output, offering more complete error and warning histories.

(Refer to Section 5.6.1.)

1 - 3

Page 24

1 PRODUCT OUTLINE

(6) Support of intelligent function module dedicated instructions

(7) Setups, monitoring, and testing thr oug h GX Configurator-QP

MELSEC-Q

Dedicated instructions such as the absolute position restoration instruction,

positioning start instruction, and teaching instruction are provided.

The use of such dedicated instruction simplifies sequence programs.(Refer to

Chapter 14. )

Using GX Configurator-QP, the user can control the QD75 parameters and

positioning data without having to be conscious of the buffer memory addresses.

Moreover, GX Configurator-QP has a test function which allows the user to check

the wiring before creating a sequence program for positioning control, or test

operation the QD75 using created parameters and positioning data for checking

their integrity.

The control monitor function of GX Configurator-QP allows the user to debug

programs efficiently.

1 - 4

Page 25

1 PRODUCT OUTLINE

)

a

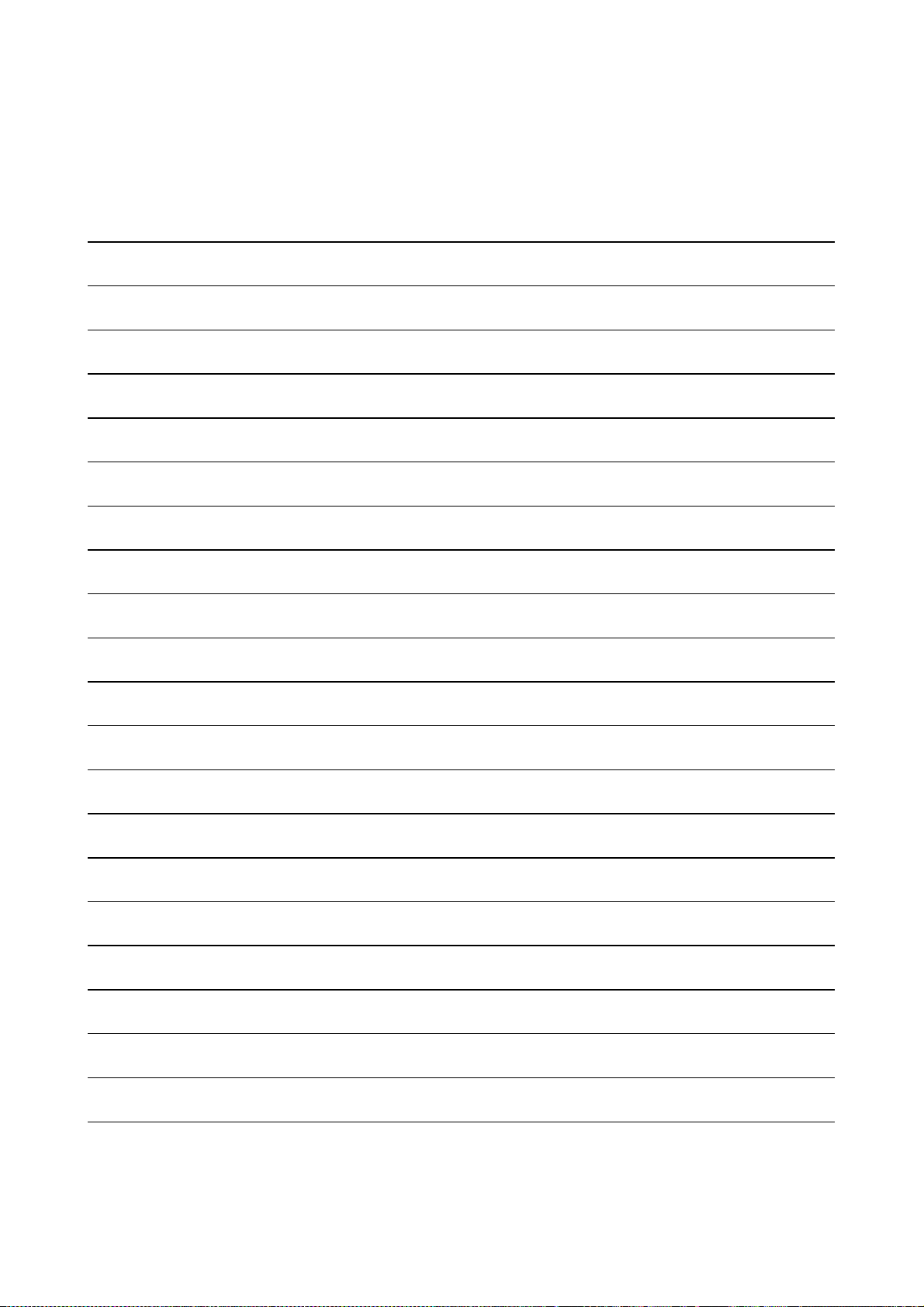

1.1.2 Purpose and applications of positioni ng contr ol

"Positioning" refers to moving a moving body, such as a workpiece or tool (hereinafter,

generically called "workpiece") at a designated speed, and accurately stopping it at the

target position. The main application examples are shown below.

MELSEC-Q

Punch press (X, Y feed positioning

Gear and ball screw

Conveyor control

Servomotor

(with brakes)

Servo amplifier

Teaching unit

AD75TU

Press head

Servo

amplifier

Reduction

gears

Y axis

X axis

servomotor

G

Ball screw

(From QD75)

AD75

Servo

mplifier

Palletizer

Y axis

servomotor

)

X axis

Conveyor

320mm

Y axis

X axis

Gear and rack & pinion

PLC

MELSEC-Q

160mm

Press

punching

12 s

PLC

MELSEC-Q

X axis

Y axis

Position detector

Palletizer

Unloader control

QD75

15m/min

(2000r/min

15m/min

(1875r/min)

QD75

AD75

•

To punch insulation material or leather, etc.,

as the same shape at a high yield, positioning

is carried out with the X axis and Y axis

servos.

•

After positioning the table with the X axis

servo, the press head is positioned with the Y

axis servo, and is then punched with the

press.

•

When the material type or shape changes, the

press head die is changed, and the positioning

pattern is changed.

•

Using the servo for one axis, the palletizer is

positioned at a high accuracy.

•

The amount to lower the palletizer according to

the material thickness is saved.

Compact machining center (ATC magazine positioning)

•

The ATC tool magazine for a compact

machining center is positioned.

•

The relation of the magazine's current value

and target value is calculated, and positioning

is carried out with forward run or reverse run to

achieve the shortest access time.

Servo

amplifier

QD75

AD75

Servomotor

Coupling

Positioning

pin

PLC

MELSEC-Q

Reduction

gears

ATC tool

magazine

Tool

(12 pcs., 20 pcs.)

Rotatio n di r e c t io n

for calling

11, 12, 1, 2 or 3

Current

value

retrieval

position

Rotation direction

for calling 5, 6, 7, 8, 9 or 10

<No. of tools: 12> <No. of tools: 20>

Rotatio n di r e c t io n

for calling

17 to 20, 1 to 5

Rotatio n di r e c t io n

for calling 7 to 16

Current

value

retrieval

position

1 - 5

Page 26

1 PRODUCT OUTLINE

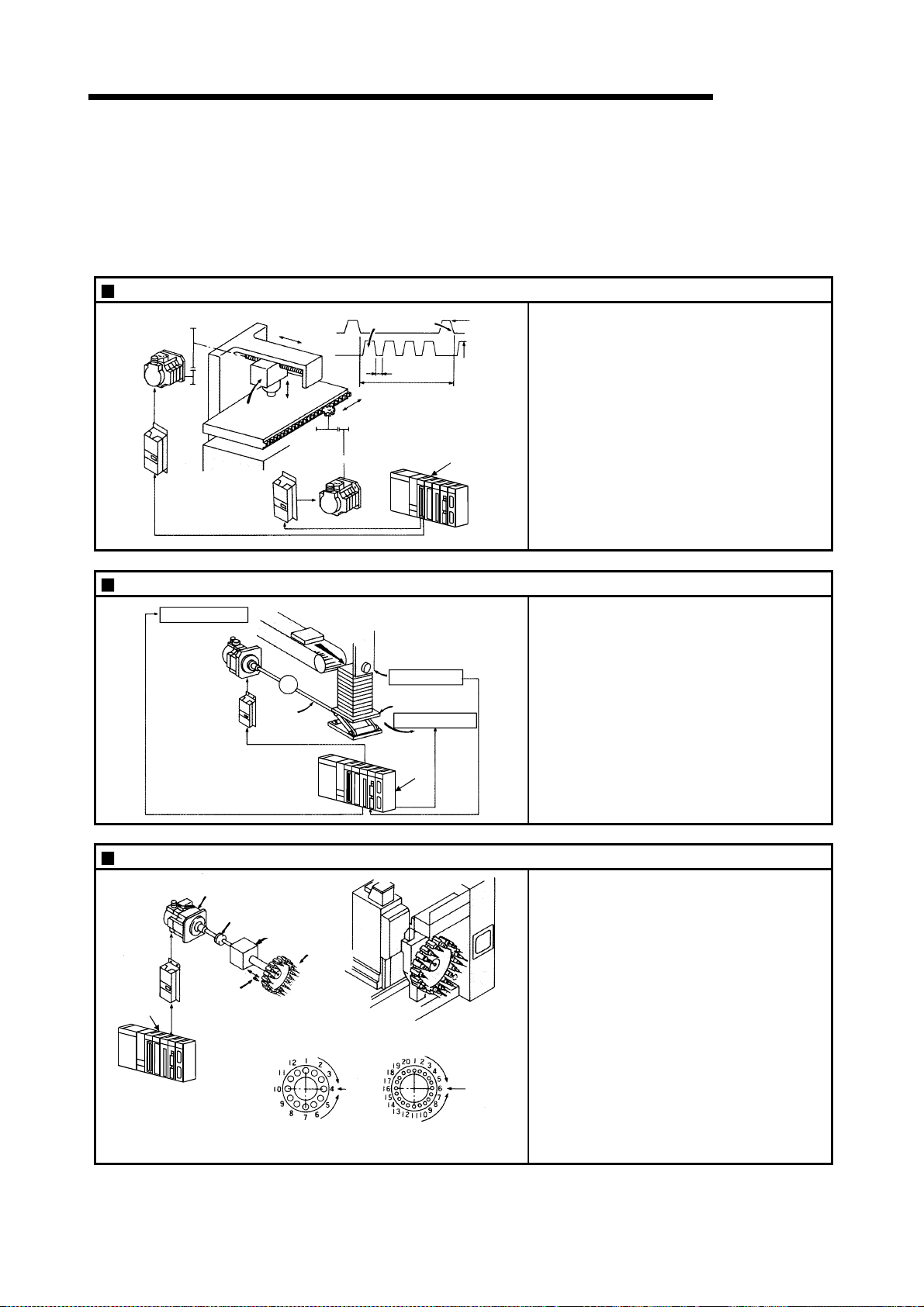

Lifter (Sto rage o f Br au n tub e s on to aging rack)

B conveyor

Lifter C

Counterweight

Reduction

gears

G1

Servomotor

(with brakes)

Index table (High-accuracy indexing of angle)

PLC

MELSEC-Q

conveyor

A conveyor Servo amplifier

Loader

Servomotor

Servo amplifier

Aging rack

G2

Positioni n g modu le

QD75

AD75

QD75

Unloader

Loader/unloader

PLC MELSEC-Q

MELSEC-Q

•

During the aging process of braun tubes,

storage onto the rack is carried out by

positioning with the AC servo.

•

The up/down positioning of the lifter is carried

out with the 1-axis servo, and the horizontal

position of the aging rack is positioned with the

2-axis servo.

•

The index table is positioned at a high accuracy

using the 1-axis servo.

Digital switch

Index table

Worm gears

Inner surface grinder

Servomotor

Inverter

Servo

amplifier

220VAC

60Hz

QD75

PLC

MELSEC-Q

Motor

1M

G

Fix the grinding

stone, feed the

workpiece, and grind.

Operation panel

a

b

c

Workpiece

Grinding stone

a. Total feed

amount (mm)

d

b. Finishing

e

feed amount (mm)

c. Compensation

amount (mm)

Detector

Servomotor

Motor

G

1M

Inverter

Servo

amplifier

d. Rough grind ing speed (mm/s)

e. Fine grindi ng

speed (mm/s)

•

The grinding of the workpiece's inner surface

is controlled with the servo and inverter.

•

The rotation of the workpiece is controlled with

the 1-axis inverter, and the rotation of the

grinding stone is controlled with the 2-axis

inverter. The workpiece is fed and ground with

the 3-axis servo.

1 - 6

Page 27

1 PRODUCT OUTLINE

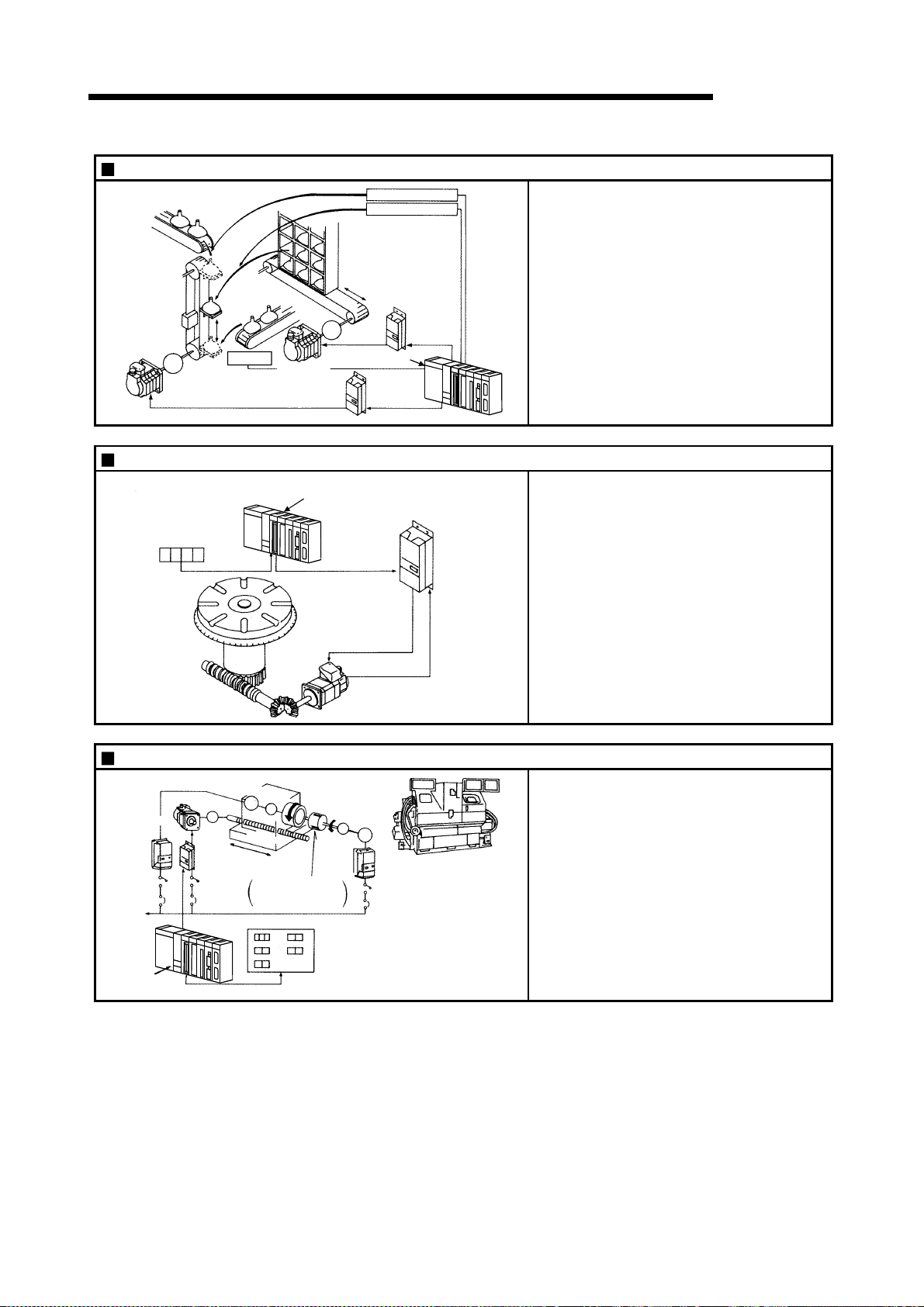

1.1.3 Mechanism of positioning control

Positioning control using the QD75 is carried out with "pulse signals". (The QD75 is a

module that generates pulses). In the positioning system using the QD75, various

software and devices are used for the following roles. The QD75 realizes complicated

positioning control when it reads in various signals, parameters and data and is

controlled with the PLC CPU.

MELSEC-Q

Creates control order and

conditions as a sequence

program.

GX Developer

GX

Configurator

-QP

Sets the parameters and

positioning data for control.

Outputs the start command for

JOG operation, etc., during test

operation with the test mode.

Monitors the positioning operation.

PLC CPU

QD75 positioning

module

Servo

amplifier

Stores t he creat e d program.

The QD75 outputs the start signal and

stop signal following the stored program.

QD75 errors, etc., are detected.

Outputs signals such as the start

signal, stop signal, limit signal and

control changeover signal to the QD75.

External signal

Stores the parameter and data.

Outputs pulses to the servo according to the

instructions from the PLC CPU, GX Configurator-QP,

external signals and manual pulse generator.

Manual pulse

generator

Receives pulse commands from QD75, and

drives the motor.

Outputs the drive unit READY signal and

zero signal to the QD75.

Issues commands by

transmitting pulses.

Motor

Workpiece

1 - 7

Carries out the actual work according to commands

from the servo.

Page 28

1 PRODUCT OUTLINE

A

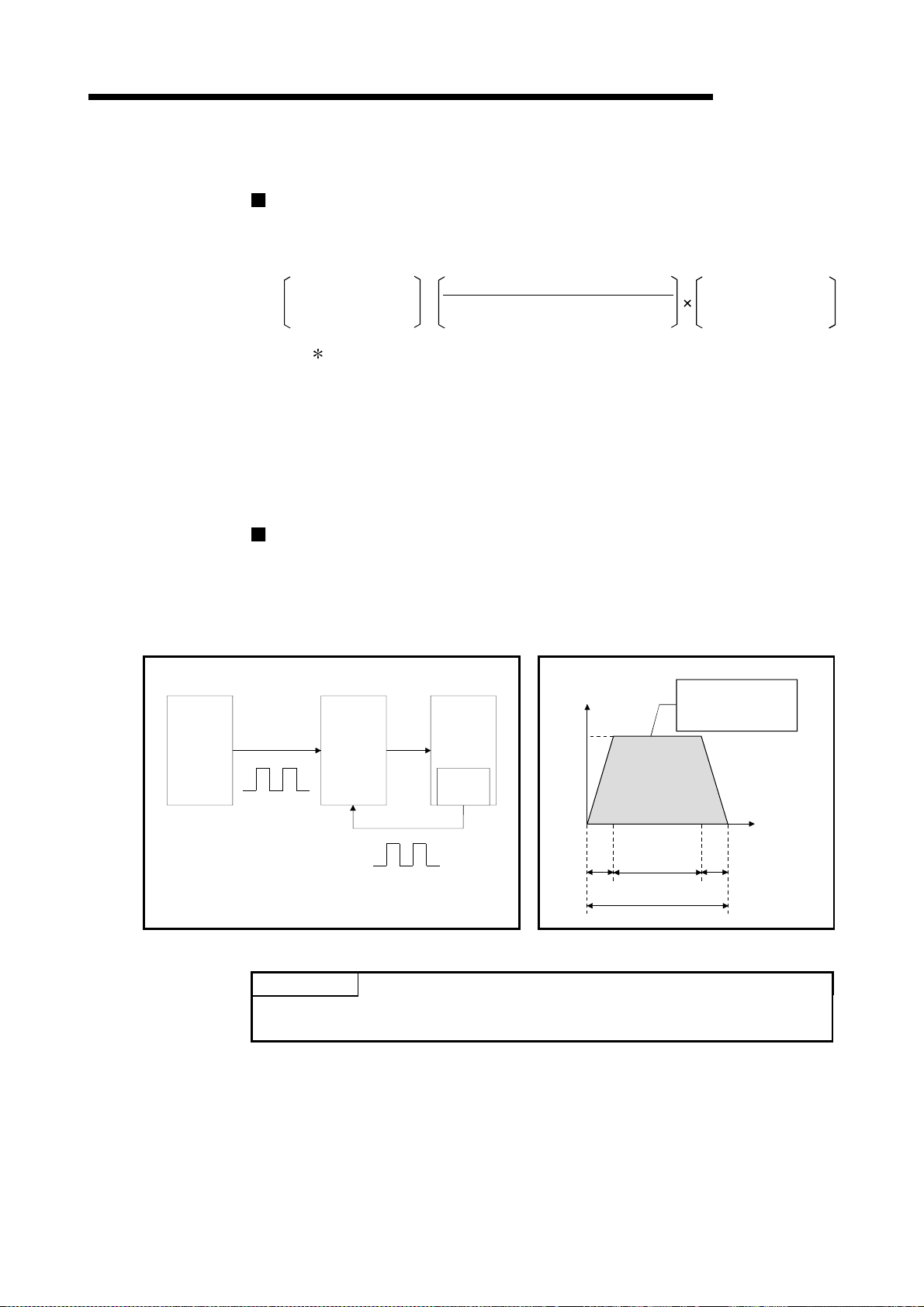

The principle of "position control" and "speed control" operation is shown below.

Position control

The total No. of pulses required to move the designated distance is obtained in the

following manner.

MELSEC-Q

Positioning

module

Total No. of pulses

required to move

designated distance

The No. of pulses required for the motor to rotate once is the "encoder resolution"

described in the motor catalog specification list.

=

Movement amount of machine (load)

side when motor rotates once

Designated distance

No. of pulses

required for motor to

rotate once

When this total No. of pulses is issued from the QD75 to the servo amplifier, control to

move the designated distance can be executed.

The machine side movement amount when one pulse is issued to the servo amplifier is

called the "movement amount per pulse". This value is the min. value for the workpiece

to move, and is also the electrical positioning precision.

Speed control

The "Total No. of pulses" mentioned above is invariably required for controlling the

distance. For positioning or speed control, the speed must be controlled as well.

The speed is determined by the frequency of pulses sent from the QD75 to the drive

unit.

Servo

amplifier

Servo

motor

Detector

(Pulse

encoder)

Pulse frequency

[pps]

This area is the total

No. of commanded

pulses.

Speed = Pulses frequency

Movement amount = No.of pulses

Feedback pulses =

Pulses generated by detector

Fig. 1.1 Relationship between position control and speed control

POINT

The QD75 controls the position with the "total No. of pulses", and the speed with

the "pulse frequency".

Feedback pulses

ta td (s)

0.4 1.2 0.4

Movement amount t = 2

1 - 8

Page 29

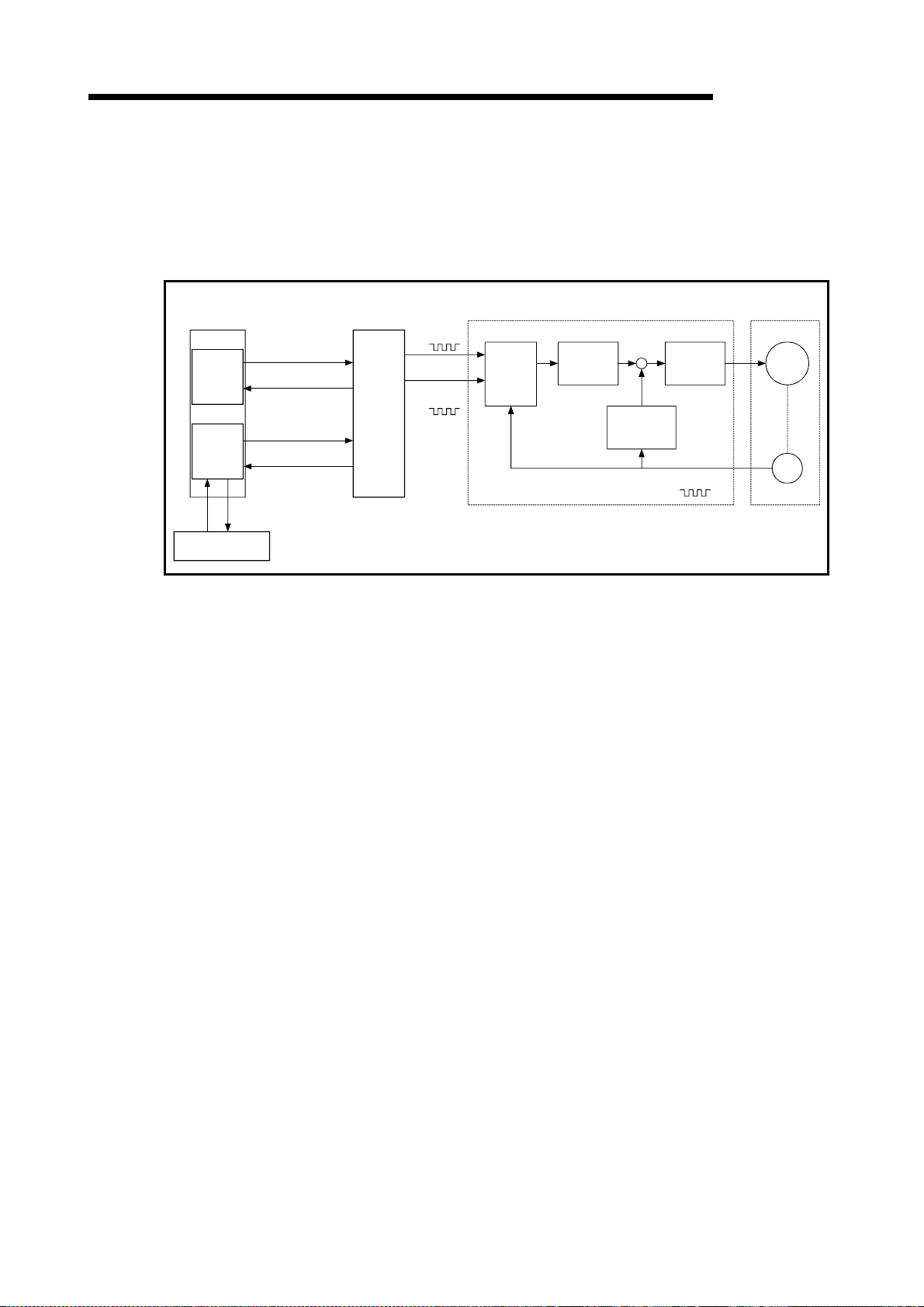

1 PRODUCT OUTLINE

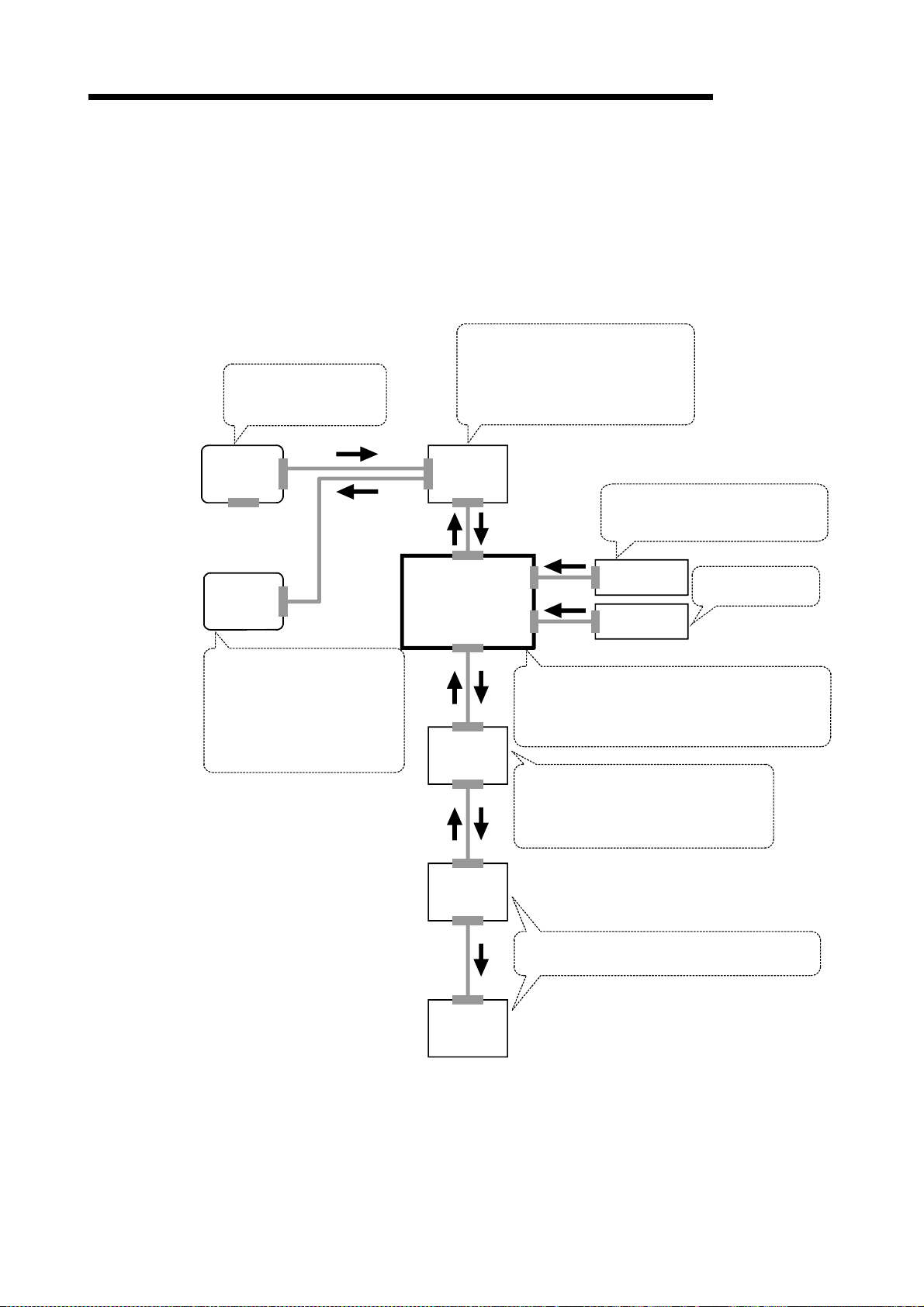

1.1.4 Outline design of positioning system

The outline of the positioning system operation and design, using the QD75, is shown

below.

(1) Positioning system using QD75

MELSEC-Q

PLC CPU

Program

Peripheral

devices

interface

Read, write, etc.

GX Configurator-QP

Fig. 1.2 Outline of the operation of positioning system using QD75

Forward run

pulse train

Reverse run

pulse train

Deviation

counter

Read, write, etc.

Read, write, etc.

Positioning module

QD75

Setting data

(a) Positioning operation by the QD75

1) The QD75 output is a pulse train.

The pulse train output by the QD75 is counted by and stored in the

deviation counter in the drive unit.

The D/A conve rte r out pu ts an an alog DC current pr op o rti on at e t o th e

count maintained by the deviation counter (called "pulse droop"). The

analog DC current serves as the servomotor speed control signal.

2) The motor rotation is controlled by the speed control signal from the

drive unit.

As the motor rotates, the pulse encoder (PLG) attached to the motor

generates feedback pulses, the frequency of which is proportionate to

the rotati on spee d.

The feedback pulses are fed back to the drive unit and decrements the

pulse droop, the pulse count maintained by the deviation counter.

The motor keeps on rotating as the pulse droop is maintained at a

certain level.

3) When the QD75 terminates the output of a pulse train, the motor

decelerates as the pulse droop decreases and stops when the count

drops to zero.

Thus, the motor rotation speed is proportionate to the pulse frequency,

while the overall motor rotation angle is proportionate to the total

number of pulses output by the QD75.

Therefore, when a movement amount per pulse is given, the overall

movement amount can be determined by the number of pulses in the

pulse train.

The pulse frequency, on the other hand, determines the motor rotation

speed (feed speed).

Drive unit

D/A

converter

Speed

command

Interface

Feedback pulse

Servo

amplifier

Servomotor

M

PLG

1 - 9

Page 30

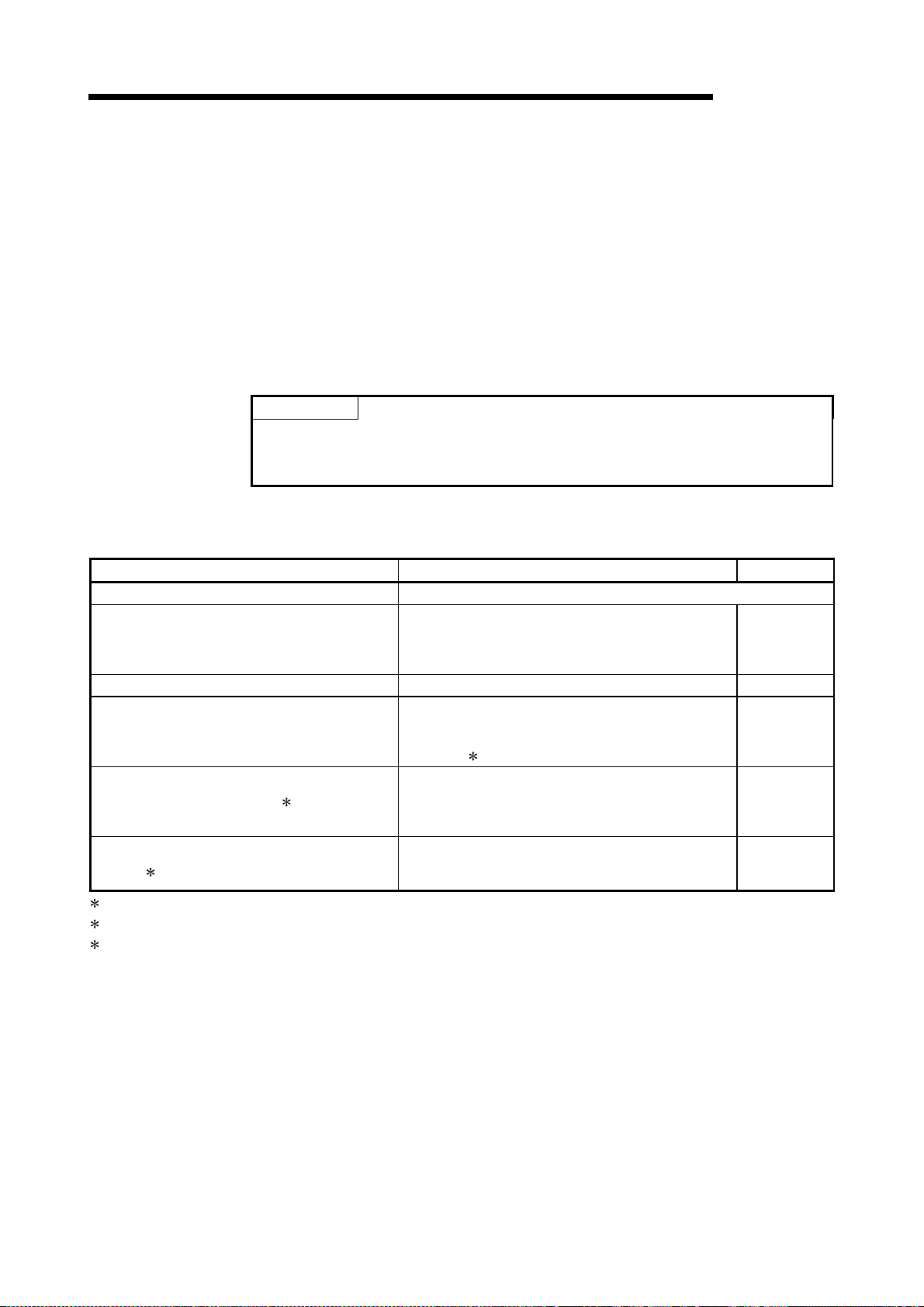

1 PRODUCT OUTLINE

MELSEC-Q

(b) Pulse train output from the QD75

1) As shown in Fig. 1.3, the pulse frequency increases as the motor

accelerates. The pulses are sparse when the motor starts and more

frequent when the motor speed comes close to the target speed.

2) The pulse frequency stab iliz e s when t he mot o r spee d equ al s the targe t

speed.

3) The QD75 decreases the pulse frequency (sparser pulses) to

decelerate the motor before it finally stops the output.

There will be a little difference in timing between the decrease in the

pulse frequency and the actual deceleration and stopping of the motor.

This difference, called "the stop settling time", is required for gaining a

stopping accuracy.

Servomotor

Speed V

Pulse droop

amount

Pulse

distribution

speed

Pulse encoder

(PLG)

Servomotor

Acceleration

Pulse train Rough Dense Rough

Deceleration

Time t

Stop

settling time

Fig. 1.3 QD75 output pulses

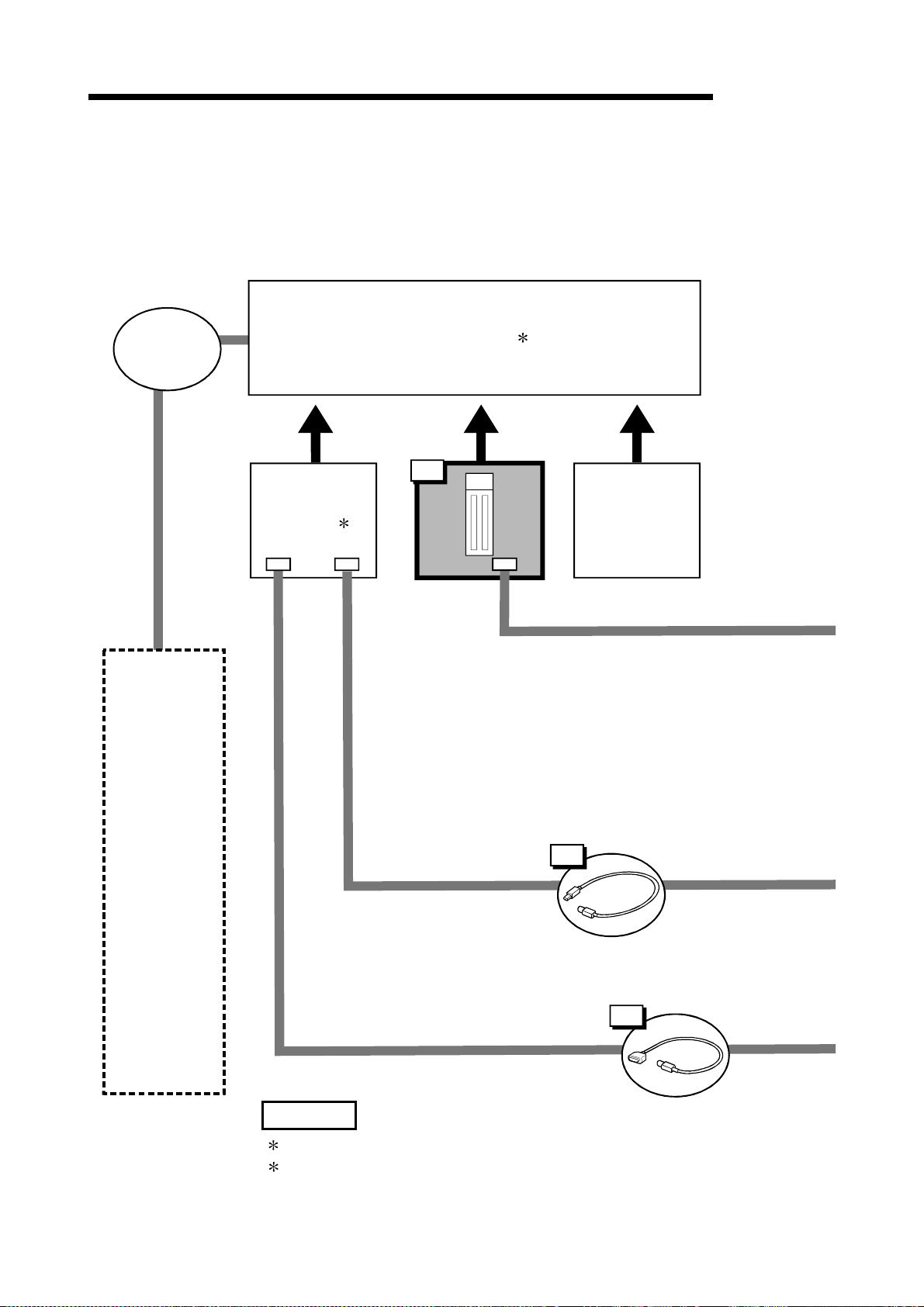

(2) Movement amount and speed in a sy stem using w or m gear s

A : Movement amount per pulse (mm/pulse)

V

Workpiece

Table

P0

Worm gear

L

R

Fig. 1.4 System using worm gears

Vs : Command pulse frequency (pulse/s)

n : Pulse encoder resolution (pulse/rev)

L : Worm gear lead (mm/rev)

R : Deceleration ratio

V : Movable section speed (mm/s)

N : Motor speed (r/min)

K : Position loop gain (1/s)

P

: D ev iation co unter droo p pulse amount

ε

P0 : OP (pulse)

P : Address (pulse)

1 - 10

Page 31

1 PRODUCT OUTLINE

MELSEC-Q

(a) In the system shown in Fig. 1.4, the movement amount per pulse,

command pulse frequency, and the deviation counter droop pulser amount

are determined as follows:

1) Movement amount per pulse

The movement amount per pulse is determined by the worm gear lead,

deceleration ratio, and the pulse encoder resolution.

The movement amount, therefore, is given as follows: (Number of

pulses output) × (Movement amount per pulse).

A =

2) Command pulse frequency

The command pulse frequency is determined by the speed of the

moving part and movement amount per pulse:

Vs =

3) Deviation counter droop pulser amount.

The deviation counter droop pulser amount is determined by the

command pulse frequency and position loop gain.

=

ε

L

R × n

V

A

Vs

K

[mm/pulse]

[pulse/s]

[pulse]

(b) The QD75 allows the user to select from the following four units as the unit

used by positioning commands to any of the axes (1 to 4, if the module

supports four axes): mm, inch, degree, and pulse.

The unit selected for one axis may differ from the unit selected for another

axis.

When such data as the movement amount per pulse,

acceleration/deceleration time, positioning speed, and positioning address

are correctly set in consideration of the chosen unit, the QD75 can calculate