Page 1

MELSEC-Q QD73A1 Positioning Module

User's Manual

-QD73A1

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user’s manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) When using a servo amplifier with Servo ON signal, connect the signal to the module. When using

a servo amplifier whose control cannot be stopped through Servo ON signal, satisfy the following.

• Analog voltage must be 0V (motor stop) to power off the programmable controller.

(2) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(3) OPR (Original Point Return) is controlled by two kinds of data: OPR direction and OPR speed.

Deceleration starts when the near-point dog turns on. If an incorrect OPR direction is set, motion

control may continue without deceleration. To prevent machine damage caused by this, configure

an interlock circuit external to the programmable controller.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signal as an output signal from the CPU module to the intelligent

function module. Doing so may cause malfunction of the programmable controller system.

1

Page 4

CAUTION

● Do not install the connection cables for external I/O signals and for the drive unit together with the

main circuit lines, power cables, or load circuit lines of a device other than the programmable

controller.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise, surges, and induction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the user’s

manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

● To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Securely connect the drive unit connector and external device connector to the connector on the

module. Poor contact may cause incorrect input or output.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in damage to the product.

2

Page 5

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

CAUTION

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

● Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when the terminal screw comes

loose, resulting in failure.

● Tighten the connector screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, fire, or

malfunction.

● Connectors for external devices must be crimped with the tool specified by the manufacturer or must

be correctly soldered.

Incomplete connections may cause short circuit, fire, or malfunction.

● Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

3

Page 6

[Startup and Maintenance Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the connector screws. Failure to do so may result in electric shock.

CAUTION

● Do not disassemble or modify the module.

Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit may cause malfunction.

● Before testing operation, set a low speed value for the speed limit parameter so that the operation can

be stopped immediately upon occurrence of a hazardous condition.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

[Precaution during operation]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

[Disposal Precaution]

CAUTION

● When disposing of this product, treat it as industrial waste.

4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

5

Page 8

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi MELSEC-Q series programmable controllers.

This manual describes the operating procedure, system configuration, parameter settings, functions, programming,

and troubleshooting of the QD73A1 positioning module (hereafter abbreviated as QD73A1).

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-Q series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to an actual system, ensure the applicability and

confirm that it will not cause system control problems.

Relevant module: QD73A1

● Unless otherwise specified, this manual describes the program examples in which the I/O numbers of X/Y10 to X/Y2F are

assigned for the QD73A1.

For I/O number assignment, refer to the following manuals.

QnUCPU Users Manual (Function Explanation, Program Fundamentals)

Qn(H)/QnPH/QnPRHCPU User's Manual (Function Explanation, Program Fundamentals)

● Operating procedures are explained using GX Works2. When using GX Developer, refer to the following.

Page 275, Appendix 4

6

Page 9

COMPLIANCE WITH EMC AND LOW VOLTAGE

DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated

into other machinery or equipment, certain measures may be necessary. Please refer to one of the following

manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage

Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to Page 64, Section 4.6.1.

7

Page 10

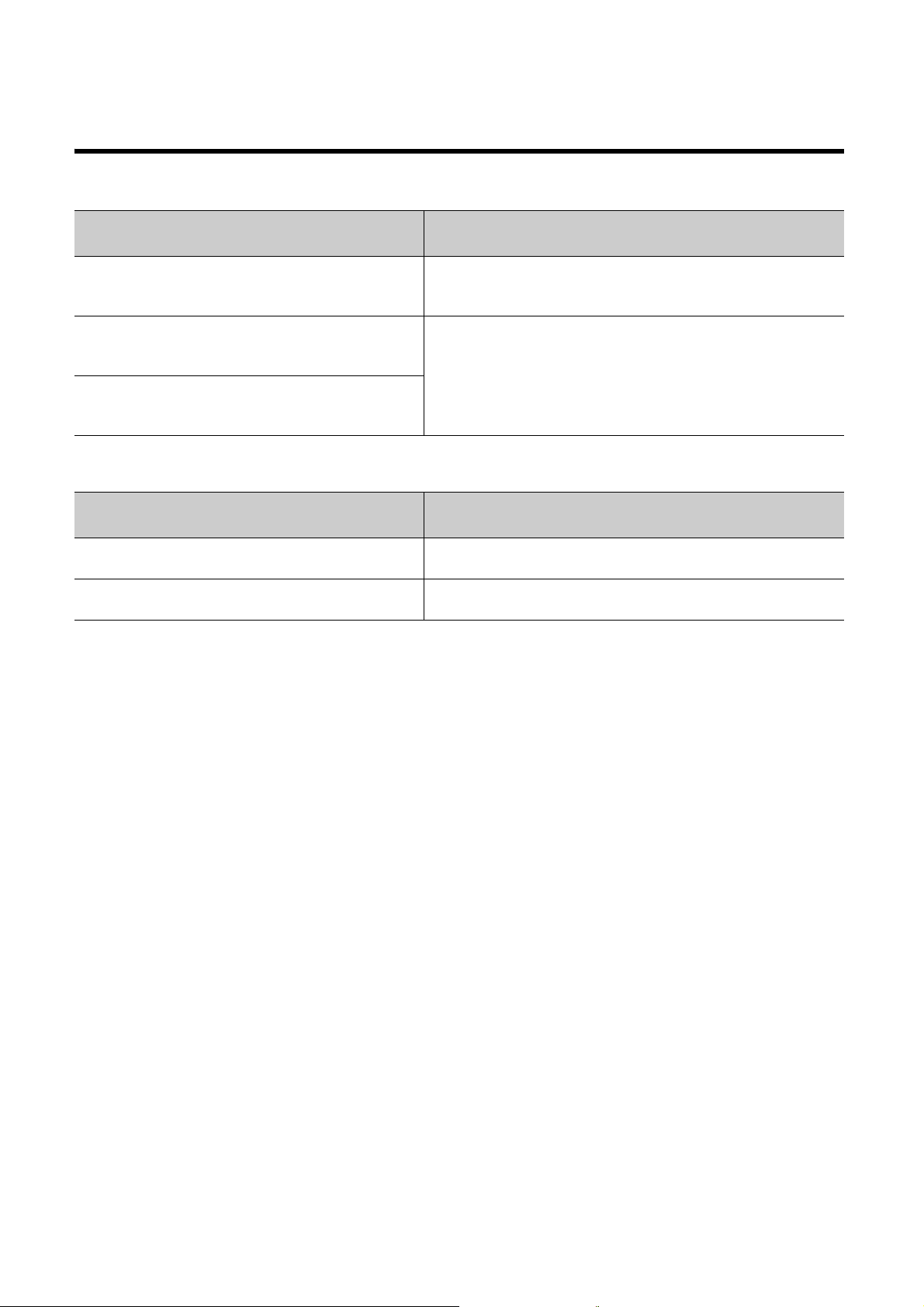

RELEVANT MANUALS

(3) CPU module user's manual

Manual name

<manual number (model code)>

QCPU User's Manual (Hardware Design, Maintenance and

Inspection)

<SH-080483ENG, 13JR73>

QnUCPU Users Manual (Function Explanation, Program

Fundamentals)

<SH-080807ENG, 13JZ27>

Qn(H)/QnPH/QnPRHCPU User's Manual (Function

Explanation, Program Fundamentals)

<SH-080808ENG, 13JZ28>

(4) Operating manual

Manual name

<manual number (model code)>

GX Works2 Version1 Operating Manual (Common)

<SH-080779ENG, 13JU63>

GX Developer Version 8 Operating Manual

<SH-080373E, 13JU41>

Description

Specifications of the hardware (CPU modules, power supply modules,

base units, extension cables, and memory cards), system maintenance

and inspection, troubleshooting, and error codes

Functions, methods, and devices for programming

Description

System configuration, parameter settings, and online operations (common

to Simple project and Structured project) of GX Works2

Operating methods of GX Developer, such as programming, printing,

monitoring, and debugging

8

Page 11

Memo

9

Page 12

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CHAPTER 1 OVERVIEW 17

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.2 Signal Transmission Between the QD73A1 and Others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

CHAPTER 2 SYSTEM CONFIGURATION 21

2.1 Applicable Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 How to Check the Function Version and Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

CHAPTER 3 SPECIFICATIONS 25

3.1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Number of Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.3 List of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.4 I/O Signals from/to the CPU Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.4.1 I/O signal list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.2 Details of input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.3 Details of output signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5 Specifications of I/O Interfaces with External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.5.1 Electrical specifications of I/O signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.5.2 Signal layout for external device connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5.3 List of I/O signal details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.5.4 I/O interface internal circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.6 Memory Configuration and Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.7 List of Buffer Memory Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

CHAPTER 4 SETTINGS AND PROCEDURE BEFORE OPERATION 54

4.1 Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.2 Settings and Procedure Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.3 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4 LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.5 Zero/gain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

4.6 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.6.1 Wiring precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.6.2 Precautions when connecting an encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.6.3 External device connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10

Page 13

CHAPTER 5 DATA USED FOR POSITIONING 73

5.1 Types of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5.2 Positioning Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.3 OPR Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.4 Positioning Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

5.5 Monitor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

5.6 Control Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

CHAPTER 6 VARIOUS SETTINGS 99

6.1 Adding a Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

6.2 Switch Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

6.2.1 Rotation direction setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.2.2 Accumulated pulse setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.2.3 Multiplication setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.2.4 OPR direction setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.2.5 OPR method setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.2.6 Encoder I/F setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.2.7 Analog voltage resolution setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.2.8 Feedback pulse addition/subtraction setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.2.9 Deviation counter clear setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.3 Parameter Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

6.4 Positioning Data Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.5 Auto Refresh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

CHAPTER 7 PROGRAMMING 111

7.1 Precautions on Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

7.2 Programs for Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

7.3 When Using the Module in a Standard System Configuration . . . . . . . . . . . . . . . . . . . . . . . .115

7.3.1 Parameter setting program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7.3.2 OPR program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.3.3 Major positioning control program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

7.3.4 Fixed-feed operation program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.3.5 JOG operation program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.3.6 Control change program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

7.3.7 Stop program during positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

7.4 When Using the Module in a Remote I/O Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

7.4.1 Parameter setting program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7.4.2 OPR program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

7.4.3 Major positioning control program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

7.4.4 Fixed-feed operation program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

7.4.5 JOG operation program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

7.4.6 Control change program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

7.4.7 Stop program during positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

11

Page 14

CHAPTER 8 OPR CONTROL 178

8.1 Overview of OPR Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

8.2 Near-point Dog Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

8.3 Count Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

8.4 Operation Timing and Processing Time of OPR Control . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

8.5 OPR Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

CHAPTER 9 MAJOR POSITIONING CONTROL 185

9.1 Overview of Major Positioning Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

9.2 Data Required for Major Positioning Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

9.3 Relation Between Each Control and Positioning Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

9.4 Specifying a Positioning Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

9.5 Checking the Current Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

9.6 Details of Major Positioning Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

9.6.1 Position control mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

9.6.2 Speed-position control switch mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

9.7 Operation Timing and Processing Time of Major Positioning Control . . . . . . . . . . . . . . . . . .199

CHAPTER 10 JOG OPERATION 200

10.1 Operation of JOG Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

10.2 Operation Timing and Processing Time of JOG Operation . . . . . . . . . . . . . . . . . . . . . . . . . .206

10.3 Data Setting for JOG Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

CHAPTER 11 CONTROL SUB FUNCTIONS 208

11.1 Electronic Gear Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

11.2 Speed Limit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

11.3 Stroke Limit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

11.4 Upper Limit Switch (FLS)/Lower Limit Switch (RLS) Function . . . . . . . . . . . . . . . . . . . . . . . .215

11.5 Current Value Change Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

11.6 Speed Change Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

11.7 Deviation Counter Clear Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

11.8 In-position Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

11.9 Accumulated Pulse Error Detection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

11.9.1 Measuring and saving the reference value in the flash ROM . . . . . . . . . . . . . . . . . . . . . . . 225

11.9.2 Setting the accumulated pulse error detection function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

CHAPTER 12 STOPPING AND RESTARTING CONTROL 230

12.1 Stopping Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

12.2 Restarting the Speed-position Control Switch Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

CHAPTER 13 COMMON FUNCTIONS 236

13.1 Module Status Monitor Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

12

Page 15

13.2 Error History Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

13.3 Module Error Collection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .239

13.4 Error Clear Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240

CHAPTER 14 TROUBLESHOOTING 241

14.1 Checking an Error on GX Works2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

14.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

14.2.1 Troubleshooting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

14.2.2 When the motor does not stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

14.2.3 When positioning cannot be executed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

14.2.4 When a positioning error occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

14.2.5 When the positioning speed is different from the specified speed. . . . . . . . . . . . . . . . . . . . 248

14.2.6 When operation stops abnormally during positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

14.2.7 OPR error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

14.3 Details of Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

14.3.1 Types of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

14.3.2 Storage of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

14.3.3 Error reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

14.3.4 Error code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

APPENDICES 263

Appendix 1 Functions Added or Changed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

Appendix 1.1 Functions added . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Appendix 1.2 Functions changed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Appendix 2 Connection Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .264

Appendix 2.1 Example of connection with a servo amplifier manufactured by Mitsubishi Electric

Corporation

Appendix 2.2 Example of connection with a servo amplifier manufactured by YASKAWA Electric

Corporation

Appendix 3 Comparison of the QD73A1 and the AD70/A1SD70. . . . . . . . . . . . . . . . . . . . . . . . . . .267

Appendix 4 When Using GX Developer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .275

Appendix 4.1 Operation of GX Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Appendix 5 Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

Appendix 6 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

INDEX 282

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

13

Page 16

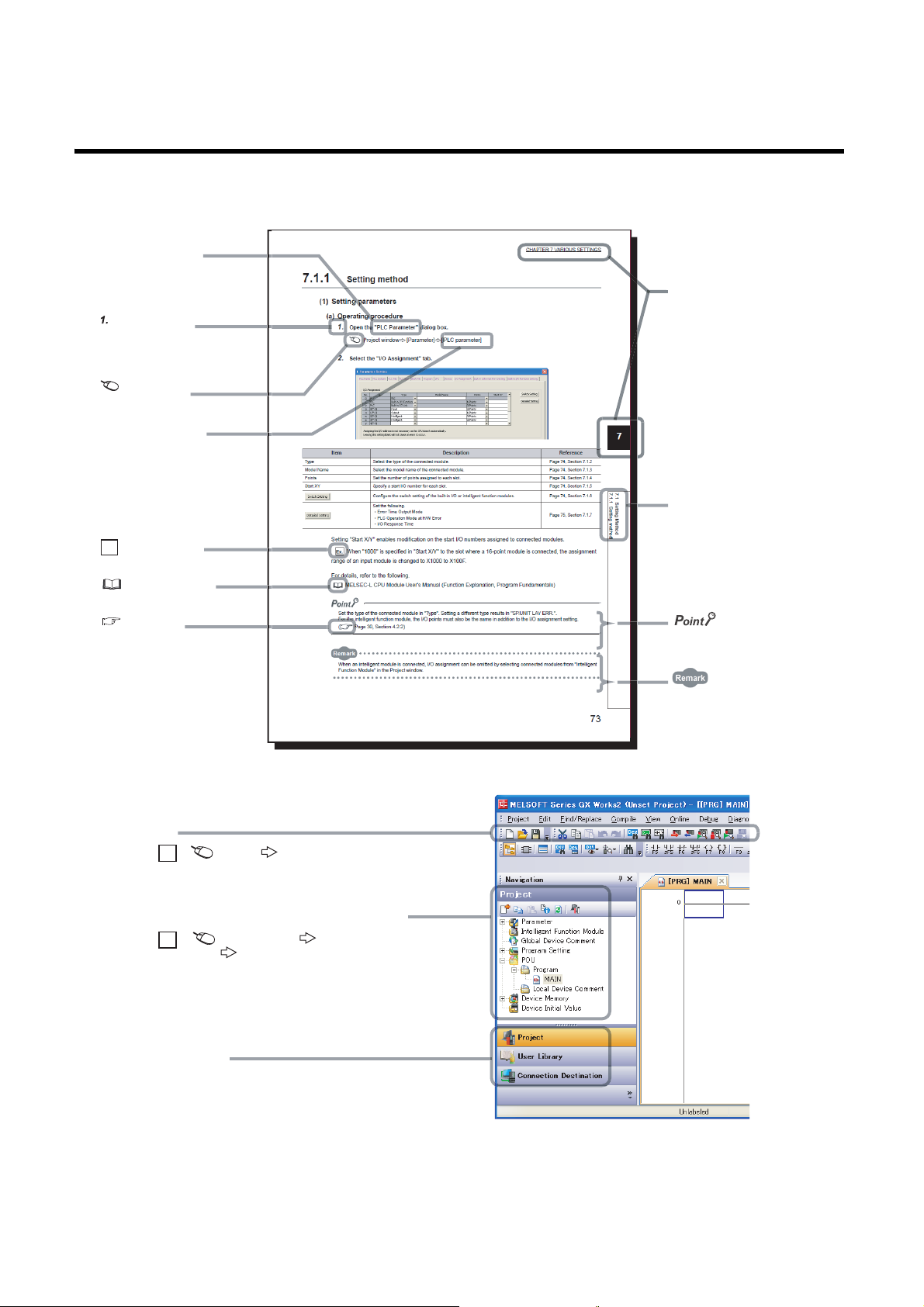

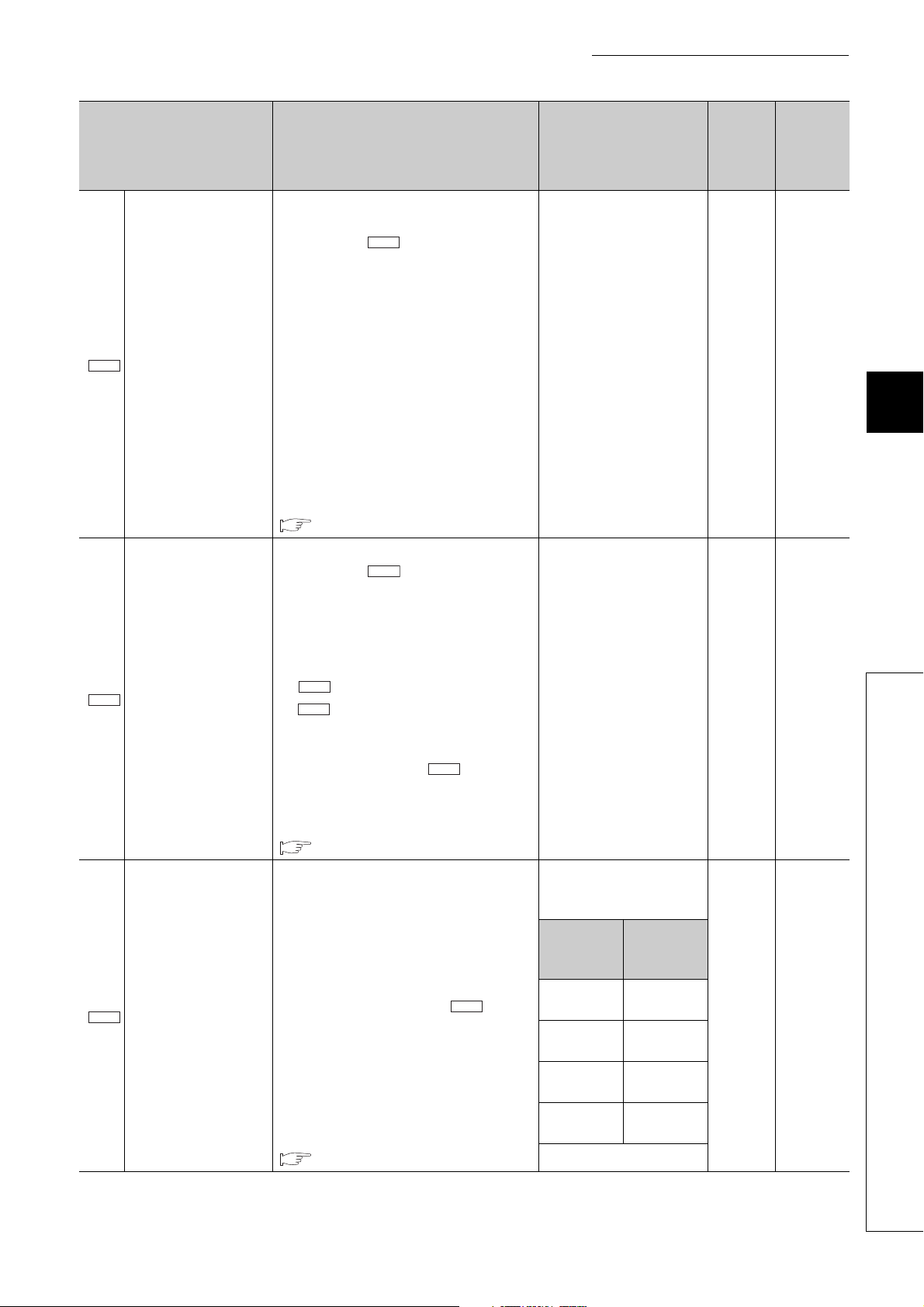

MANUAL PAGE ORGANIZATION

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

"" is used for

screen names and items.

The chapter of

shows operating

procedures.

the current page is shown.

shows mouse

operations.

[ ] is used for items

in the menu bar and

the project window.

Ex.

shows setting or

operating examples.

shows reference

manuals.

shows

reference pages.

*1

*1 The mouse operation example is provided below.

The section of

the current page is shown.

shows notes that

requires attention.

shows useful

information.

14

Page 17

The following symbols are used to represent buffer memory areas in this manual. Serial numbers fit in "*".

Pr.*

Da.*

Md.*

Cd.*

Symbol Description

Symbol indicating positioning parameter and OPR parameter item

Symbol indicating positioning data item

Symbol indicating monitor data item

Symbol indicating control data item

15

Page 18

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

QD73A1 The abbreviation for the QD73A1 positioning module

QCPU Another term for the MELSEC-Q series CPU module

Redundant CPU A generic term for the Q12PRHCPU and Q25PRHCPU

External input The abbreviation for input from connectors for external devices

External output The abbreviation for output to connectors for external devices

Programming tool Generic term for GX Works2 and GX Developer

GX Works2

GX Developer

Buffer memory

For terms related to positioning, refer to the following.

Page 278, Appendix 5

The product name of the software package for the MELSEC programmable

controllers

The memory of an intelligent function module used to store data (such as setting

values and monitored values) for communication with a CPU module

PACKING LIST

The product package contains the following.

Model Product Quantity

QD73A1 QD73A1 positioning module 1

QD73A1-U-HW Before Using the Product 1

16

Page 19

CHAPTER 1 OVERVIEW

Electronic

gear

Deviation

counter

D/A

converter

Multiplication

Servo

amplifier

Setting

data

Sequence

program

Command

pulses

Interface

CPU module

Parameter data

Positioning data

OPR parameters

Data writing/reading

Positioning module QD73A1

Analog

voltage

Speed

command

Drive unit Servomotor

Feedback pulses

Feedback pulses

*1

*2

M

PLG

*1

Current

value

Feedback pulses from the pulse generator (PLG) may be input to the QD73A1

via the drive unit

*1

or directly*2 depending on the servomotor to be used.

Check which method applies in the manual for the servomotor or drive unit to

be used.

Feedback pulse

addition/

subtraction setting

CHAPTER 1 OVERVIEW

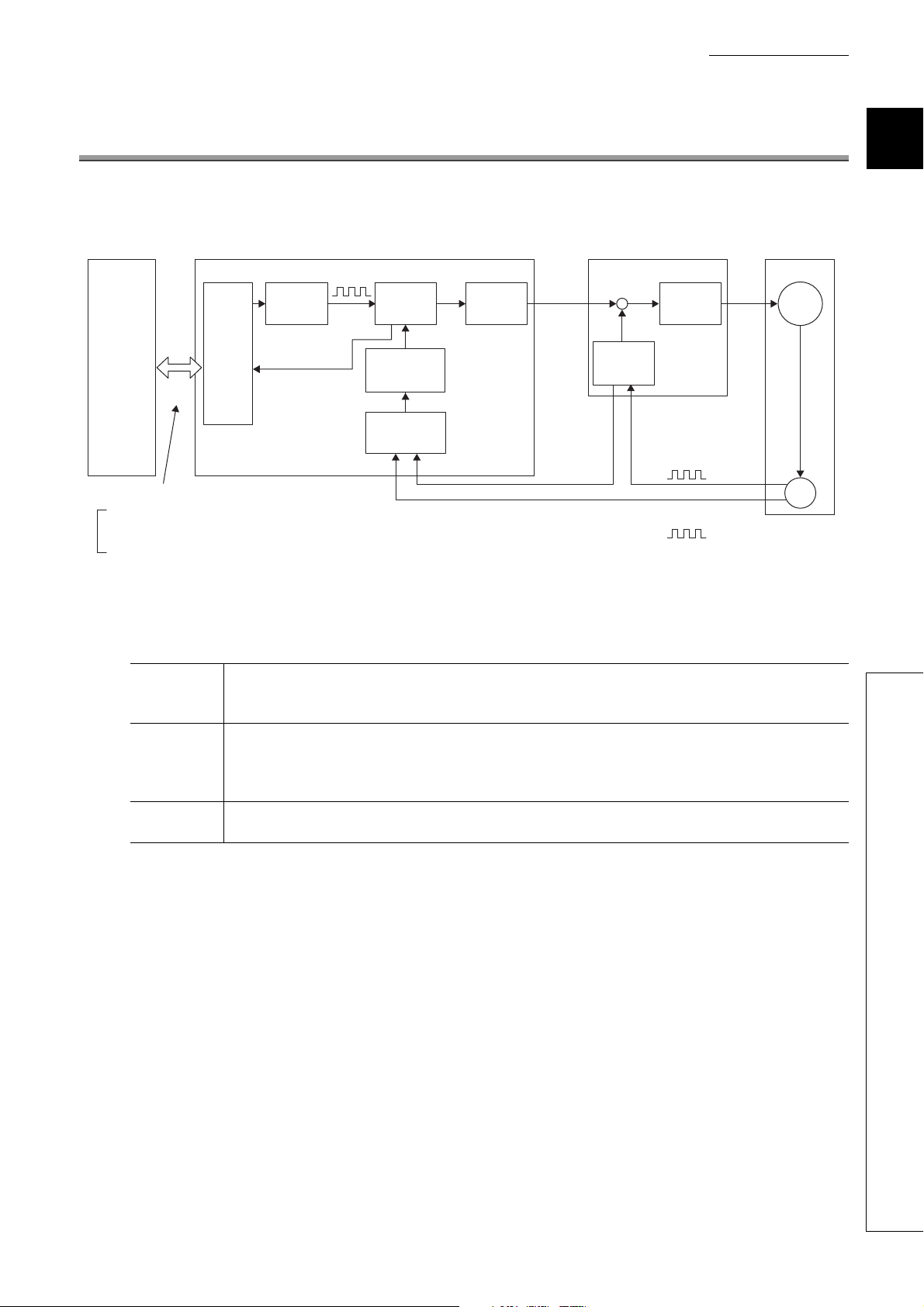

The QD73A1 possesses a deviation counter and D/A converter inside as in the following figure.

1

A system with the QD73A1 operates as follows.

Once a command pulse train for positioning is output, pulses are accumulated in the deviation counter. The

Start

Operation

Stop

integrated value of pulses (accumulated pulses) is converted into DC analog voltage by a D/A converter, then

turns into a speed command to a servomotor. The speed command from a drive unit starts servomotor rotation.

Once the servomotor starts rotating, feedback pulses that are proportional to the number of rotations are

generated by a pulse generator (PLG) attached to the servomotor. The generated feedback pulses are

subtracted from the accumulated pulses in the deviation counter. The deviation counter continues to rotate the

servomotor, maintaining a constant amount of accumulated pulse.

Once the command pulse output from the QD73A1 stops, the accumulated pulses in the deviation counter

decrease, so does the speed. When there is no more accumulated pulse, the servomotor stops.

The rotation speed of a servomotor is proportional to command pulse frequency, while the rotation degree of the

servomotor is proportional to the output command pulse amount. By setting feed per pulse beforehand, analog voltage

that is proportional to the number of pulses in a pulse train is output, and a workpiece can be moved to the set position.

Note that pulse frequency defines the rotation speed of the servomotor (feedrate).

17

Page 20

1.1 Features

(1) Analog output type that possesses a deviation counter and D/A converter

inside

This module converts command pulse for positioning into analog voltage inside, then outputs a speed command

to a servo amplifier.

(2) Compatible with analog input servo amplifiers

A servo amplifier does not require an extra module to convert pulse input into analog voltage; a standard servo

amplifier can be used.

(3) Servomotor control using a high-resolution encoder

This module handles up to 1Mpulse/s of pulse input from an encoder. Servomotor control that uses high-speed

input pulse signals from a high-resolution encoder improves the accuracy of positioning.

(4) Four types of positioning method

The following control can be executed.

• Position control mode: positioning control and two-phase trapezoidal positioning control

• Speed-position control switch mode: speed-position control switchover and speed control

(5) Zero/gain adjustment through a sequence program

Zero/gain adjustment can be performed through a sequence program. Therefore, the adjustment can be

performed without using a switch or checking a LED, saving man-hour.

(Note that zero/gain adjustment can also be performed using switches on the front of the QD73A1.)

(6) Easy setting with GX works2

Sequence programming is reduced since initial settings and the auto refresh setting can be configured on the

screen. In addition, the setting status and operating status of the module can be checked easily.

18

Page 21

CHAPTER 1 OVERVIEW

Y2D

X11

X12

Y20

X20

X13

Y21 to Y23

X21 to X23

X14

X15

Y2C

Y24, Y25

Y26

Y27

X18

Y28

X19

Y29

X1A

Y2A

X16

X17

X1C

X1D

X1E, X1F

X1B

X10

X24

Y1A

X2A

Y1B

X2B

Y1C

X2C

X2D

Interface with

the CPU

module

External

interface

External

control

signals

PLG

Drive unit

PLC READY signal

QD73A1 READY signal

OPR request signal

OPR start signal

OPR start complete signal

OPR complete signal

Positioning start signal

Positioning start complete signal

BUSY signal

Positioning complete signal

Speed-position switching enable signal

JOG start signal

Speed-position mode restart signal

Stop signal

Error detection signal

Error reset signal

Overflow signal

Overflow reset signal

Underflow signal

Underflow reset signal

In-position signal

Excessive error signal

Near-point dog signal

External stop signal

Upper limit signal/Lower limit signal

Servo READY signal

WDT error, H/W error signal

Synchronization flag

Zero/gain adjustment data

writing request signal

Zero/gain adjustment data

writing complete flag

Zero/gain adjustment change request signal

Zero/gain adjustment change complete flag

Set value change request signal

Set value change complete flag

Operating status of the speed-position

control switch mode

Stop signal (STOP)

Near-point dog signal (DOG)

Upper limit signal (FLS)

Lower limit signal (RLS)

Speed-position switching command signal

(CHANGE)

Phase-Z pulse (Zero signal)

Phase-A pulse

Phase-B pulse

Servo READY signal (READY)

Servo ON signal (SVON)

CPU module

QD73A1

Analog voltage

Data writing/reading

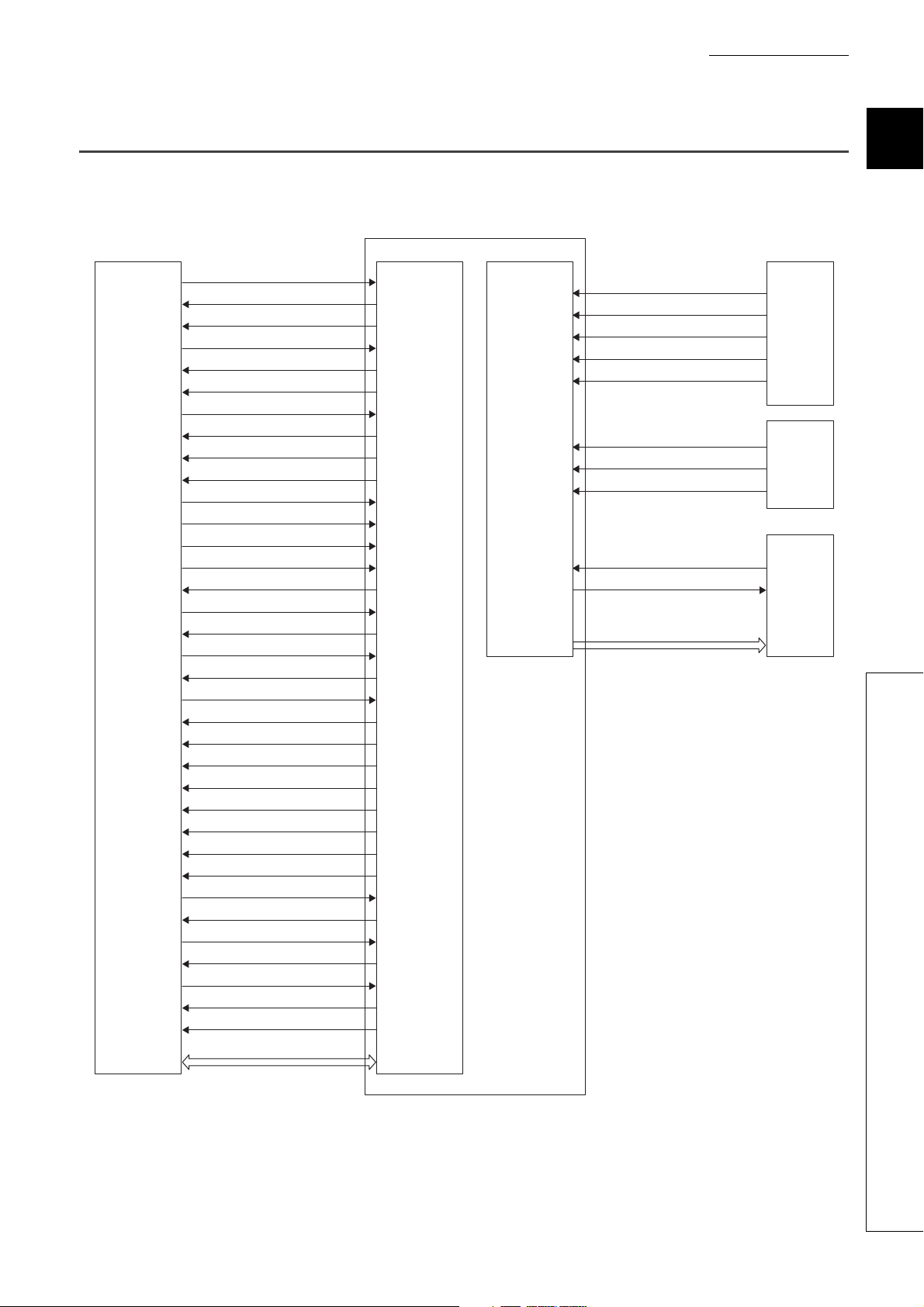

1.2 Signal Transmission Between the QD73A1 and Others

The following figure shows signal transmission between the QD73A1 and a CPU module, and a drive unit.

19

1

1.2 Signal Transmission Between the QD73A1 and Others

Page 22

(1) Between the CPU module and the QD73A1

The CPU module and the QD73A1 transmit control signals and data to each other through the base unit.

Transmitted item Description Reference

Control signal

Data

Signals that indicate the QD73A1's status or

are related to commands are transmitted.

Data is written to or read from the buffer

memory in the QD73A1 by application

instructions of the CPU module.

Page 30, Section 3.4

Page 73, CHAPTER 5

(2) Between the drive unit and the QD73A1

Control signals are transmitted between the drive unit and the QD73A1, and speed commands (analog voltage)

are output from the QD73A1 to the drive unit.

For details, refer to the following.

Page 40, Section 3.5

20

Page 23

CHAPTER 2 SYSTEM CONFIGURATION

CHAPTER 2 SYSTEM CONFIGURATION

This chapter describes the system configuration of the QD73A1.

2.1 Applicable Systems

This section describes applicable systems.

(1) Applicable modules and base units, and number of mountable modules

For the applicable CPU modules and base units, and the number of mountable modules, refer to the user’s

manual for the CPU module used.

Note the following when mounting modules with the CPU module.

• The power supply capacity may become insufficient depending on the combination with other modules or the

number of mounted modules.

Select the power supply capacity according to the modules to be used.

If the power supply capacity is insufficient, change the combination of the modules.

• Mount the modules within the number of I/O points range of the CPU module.

Modules can be mounted on any slot within the number of available slots.

(a) When mounted on MELSECNET/H remote I/O station

For an applicable MELSECNET/H remote I/O station and base units, and the number of mountable modules,

refer to the Q Corresponding MELSECNET/H Network System Reference Manual (Remote I/O network).

2

2.1 Applicable Systems

(2) Multiple CPU system

The function version of the first released QD73A1 is B, and the module supports multiple CPU systems.

When using the QD73A1 in a multiple CPU system, refer to the following.

QCPU User's Manual (Multiple CPU System)

(a) Intelligent function module parameters

Write intelligent function module parameters to only the control CPU of the QD73A1.

(3) Online module change

The QD73A1 does not support online module change.

21

Page 24

(4) Applicable software packages

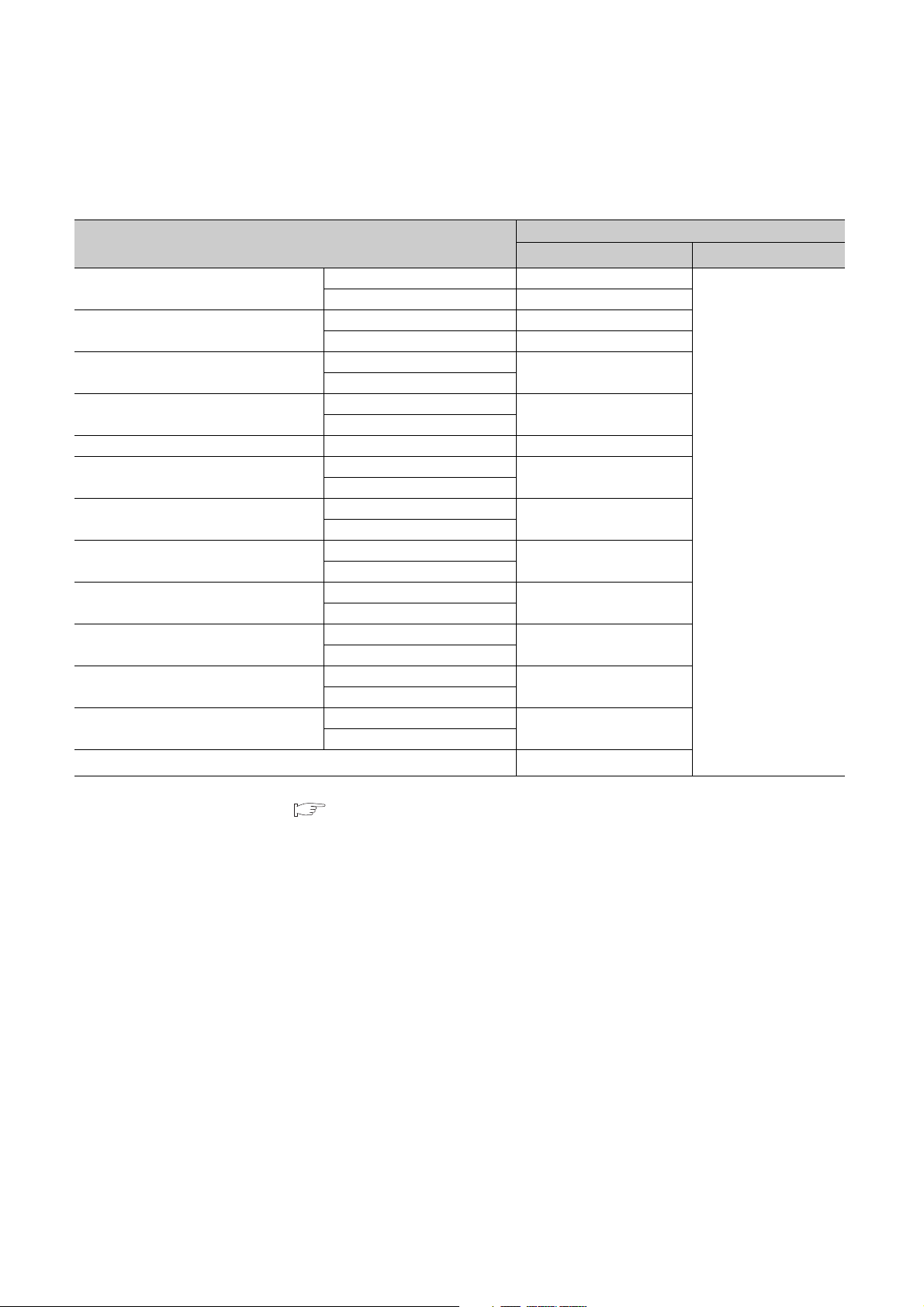

The following table lists systems that use the QD73A1 and applicable software packages.

A programming tool is required to use the QD73A1.

Item

GX Developer

Q00J/Q00/Q01CPU

Q02/Q02H/Q06H/Q12H/Q25HCPU

Q02PH/Q06PHCPU

Q12PH/Q25PHCPU

Q12PRH/Q25PRHCPU Redundant system Version 8.45X or later

Q00UJ/Q00U/Q01UCPU

Q02U/Q03UD/Q04UDH/Q06UDHCPU

Q10UDH/Q20UDHCPU

Q13UDH/Q26UDHCPU

Q03UDE/Q04UDEH/Q06UDEH/Q13UDEH/Q26

UDEHCPU

Q10UDEH/Q20UDEHCPU

CPU modules other than the above

When mounted on a MELSECNET/H remote I/O station Version 6 or later

Single CPU system Version 7 or later

Multiple CPU system Version 8 or later

Single CPU system Version 4 or later

Multiple CPU system Version 6 or later

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Version 8.68W or later

Version 7.10L or later

Version 8.76E or later

Version 8.48A or later

Version 8.76E or later

Version 8.62Q or later

Version 8.68W or later

Version 8.76E or later

*1

N/A

Software version

GX Works2

Refer to the GX Works2

Version 1 Operating Manual

(Common).

*1 When using GX Developer, configure the initial settings and auto refresh settings with the sequence program.

PROGRAMMING ( Page 111, CHAPTER 7)

22

Page 25

CHAPTER 2 SYSTEM CONFIGURATION

14041000000000-B

Relevant regulation standards

Function version

Serial number (first five digits)

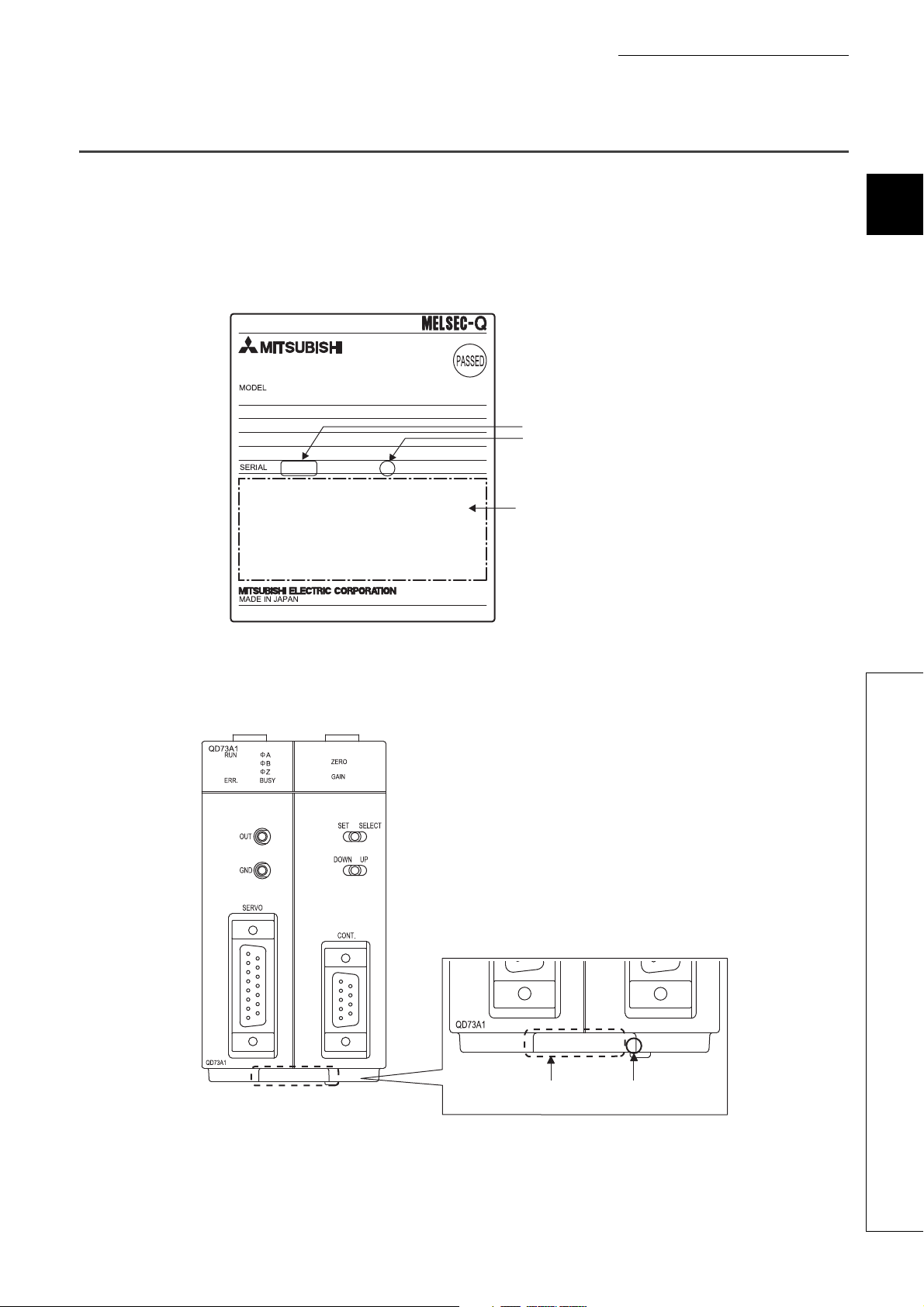

2.2 How to Check the Function Version and Serial Number

The function version and serial number of the QD73A1 can be checked on the rating plate, front part of the module, or

system monitor of the programming tool.

(1) Checking on the rating plate

The rating plate is on the side of the QD73A1.

2

(2) Checking on the front part (bottom part) of the module

The function version and serial number on the rating plate are also shown on the front part (bottom part) of the

module.

140410000000000-B

Serial No. Function version

2.2 How to Check the Function Version and Serial Number

23

Page 26

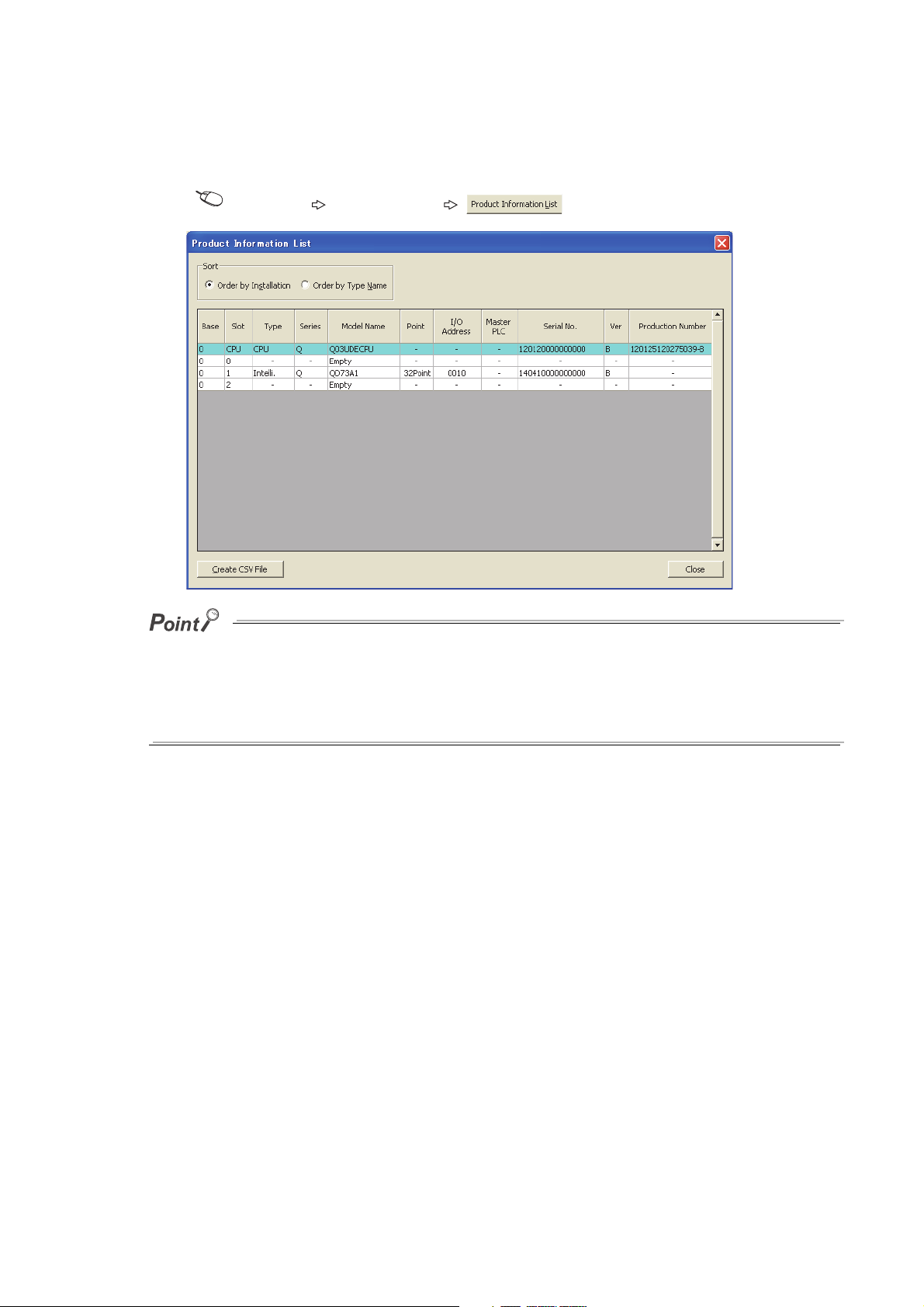

(3) Checking on the system monitor

The function version and serial number can be checked on the "Product Information List" window.

[Diagnostics] [System Monitor...] button

● The serial number displayed on the product information list of a programming tool may differ from that on the rating plate

and on the front part of the module.

• The serial number on the rating plate and front part of the module indicates the management information of the

product.

• The serial number displayed on the product information list of a programming tool indicates the function

information of the product. The function information of the product is updated when a new function is added.

24

Page 27

CHAPTER 3 SPECIFICATIONS

CHAPTER 3 SPECIFICATIONS

This chapter describes performance specifications, I/O signals from/to the CPU module, and buffer memory

specifications of the QD73A1.

For general specifications of the QD73A1, refer to the following.

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

3.1 Performance Specifications

The following table lists performance specifications of the QD73A1.

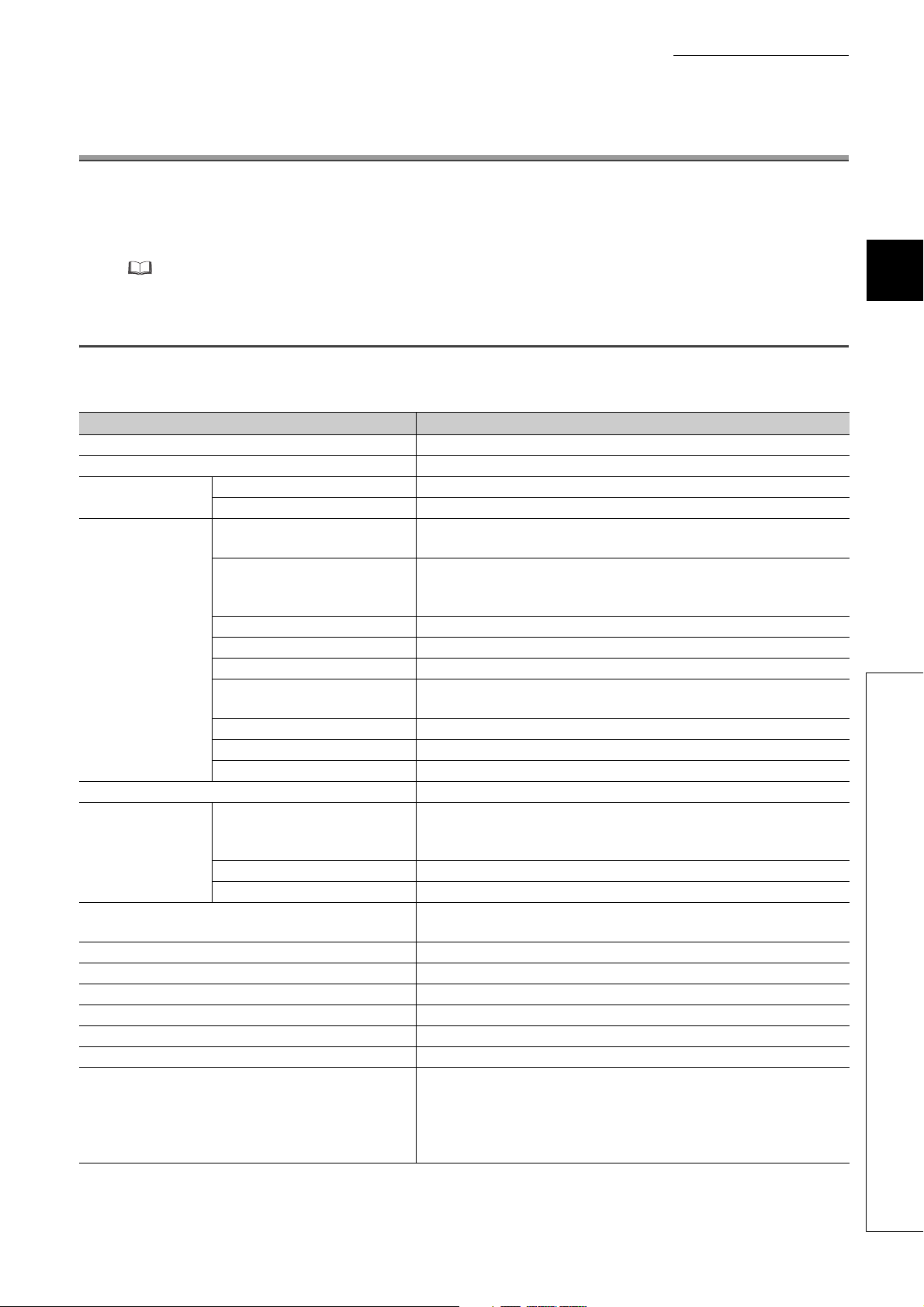

Item Specifications

Number of occupied I/O points 48 points (I/O assignment: empty 16 points and intelligent 32 points)

Number of control axes 1 axis

Positioning data

Positioning

Speed command output 0 to ±10VDC (Adjustable to set in the range of ±5 to ±10VDC)

Positioning feedback

pulse input

OPR control

JOG operation JOG operation can be started by inputting a JOG start signal.

M function None

Internal current consumption (5VDC) 0.52A

External supply voltage/current terminal block No external power supply

External dimensions 98(H)mm × 55.2(W)mm × 90(D)mm

Weight 0.20kg

Starting time

(from a start request to analog output start)

Capacity 1 data

Setting method Sequence program

Mode

Position control mode: Selectable from absolute system or incremental

System

Speed-position control switch mode: Incremental system

Position command -2147483648 to 2147483647 (pulse) (signed 32-bit binary)

Speed command 1 to 4000000 (pulse/s)

Acceleration Automatic trapezoidal acceleration/deceleration

Automatic

acceleration/deceleration time

In-position range 1 to 20479 (pulse)

Backlash compensation None

Error correction function None

Pulse frequency

Connectable encoder type Open collector, TTL, or differential output

Multiplication setting The number of input feedback pulses can be multiplied by 4, 2, 1, or 1/2.

An OPR method and OPR direction can be set with the switch setting.

Absolute system: 1.2ms (same for two-phase trapezoidal positioning)

Incremental system: 1.2ms (same for two-phase trapezoidal positioning)

Position control mode

Speed-position control switch mode

system

Acceleration time: 2 to 9999 (ms)

Deceleration time: 2 to 9999 (ms)

Open collector: 200kpulse/s

TTL: 200kpulse/s

Differential output: 1Mpulse/s

With OP address change

JOG operation: 1.2ms

OPR (near-point dog method): 1.2ms

OPR (count method): 1.2ms

3

3.1 Performance Specifications

25

Page 28

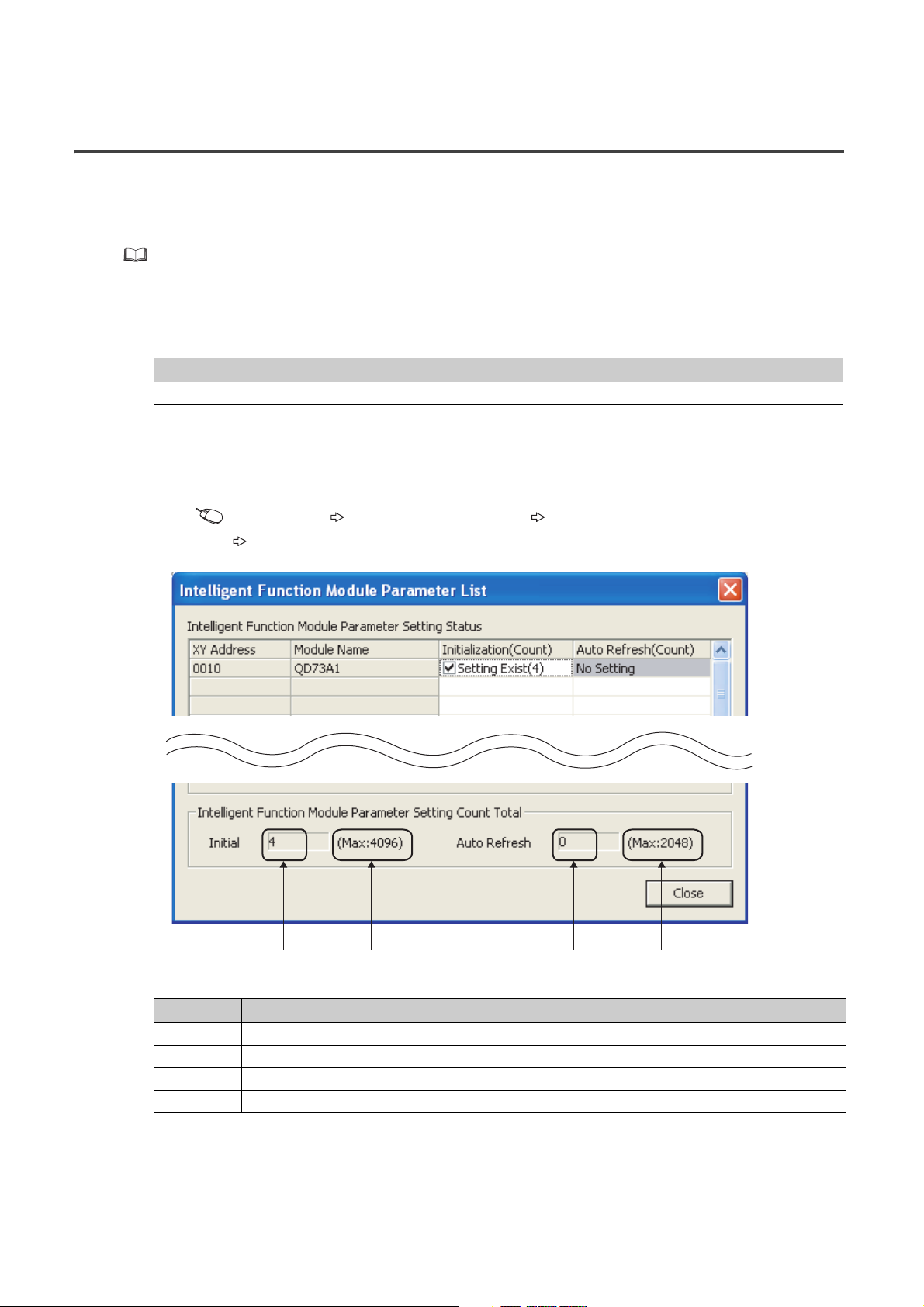

3.2 Number of Parameter Settings

Set initial settings and auto refresh settings of the QD73A1 so that the number of parameters, including those of other

intelligent function modules, does not exceed the number of parameters that can be set in the CPU module.

For the maximum number of parameters that can be set in the CPU module, refer to the following.

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

(1) Number of QD73A1 parameters

For a QD73A1, the following number of parameters can be set.

Initial setting Auto refresh setting

45

(2) Checking method

The maximum number of parameter settings and the number of parameter settings set for the intelligent function

module can be checked on the following.

Project window [Intelligent Function Module] Right-click

[Intelligent Function Module Parameter List...]

26

1) 2) 3) 4)

No. Description

1) The total number of parameters in initial settings checked on the window

2) The maximum number of parameter settings in initial settings

3) The total number of parameters in the auto refresh setting checked on the window

4) The maximum number of parameter settings in the auto refresh setting

Page 29

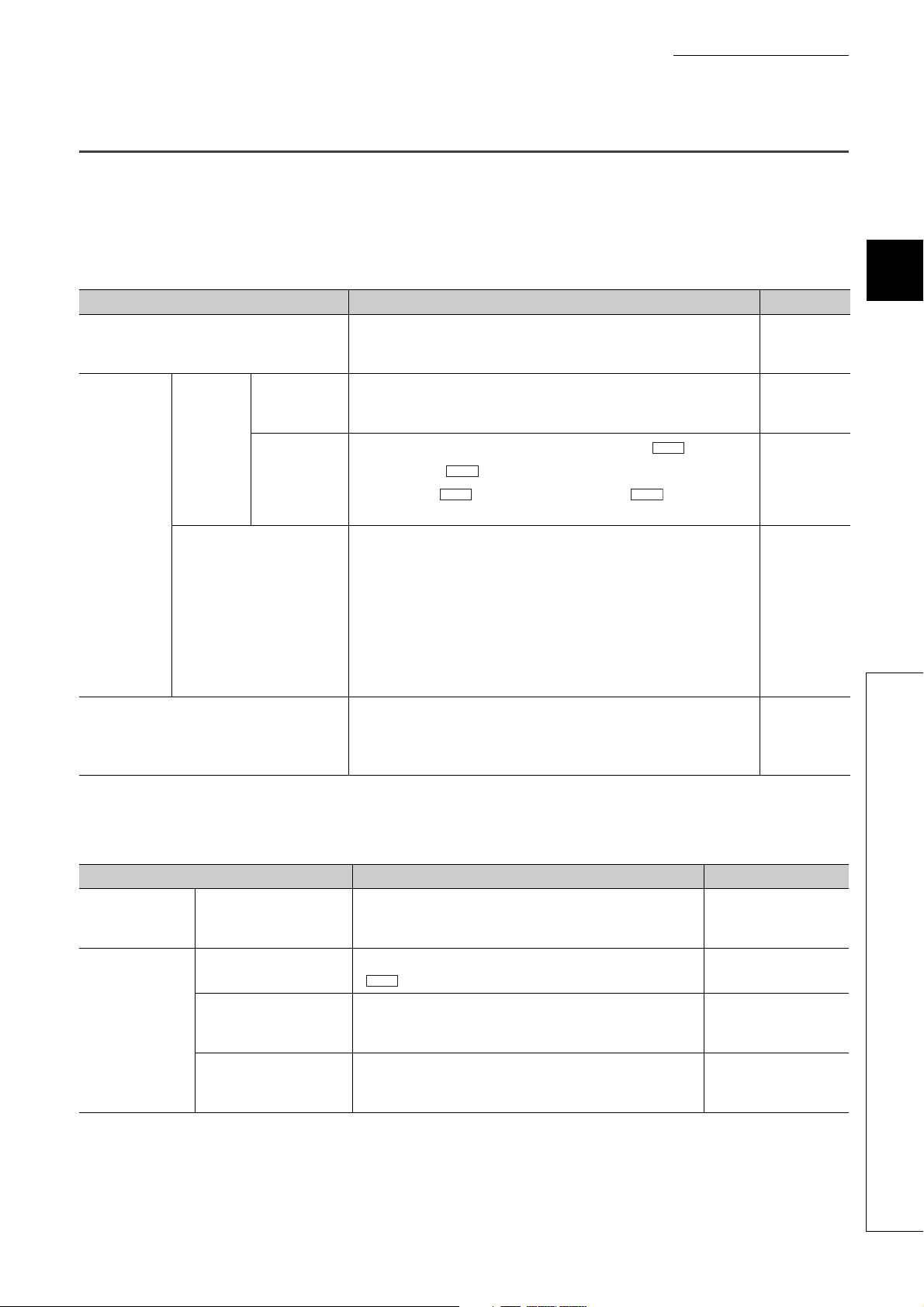

3.3 List of Functions

Da.4

Da.5

Pr.5

This section introduces the functions of the QD73A1.

(1) Main functions

Major positioning functions are as follows.

Item Description Reference

A workpiece is returned to an original point following an OPR start

OPR control

Major

positioning

control

JOG operation

Positioning

control

Position

control

mode

Speed-position control switch

mode

Two-phase

trapezoidal

positioning

control

command, and the current value is corrected as an OP address after the

completion of OPR.

Positioning is executed from the current position to a specified position at

a specified speed.

Positioning is executed to the address specified with " Positioning

address P1" at " Positioning speed V1", then to the address

specified with " Positioning address P2" at " Positioning

speed V2" by one positioning start signal.

Operation starts according to the positioning speed set beforehand by

one positioning start signal, then the operation switches to position

control by Speed-position switching command signal (CHANGE).

If the operation stopped by Stop signal after the input of Speed-position

switching command signal (CHANGE), the positioning can be continued

by requesting a restart.

In addition, the positioning address (movement amount) can be changed

if it is before the input of Speed-position switching command signal

(CHANGE).

Positioning is executed in the specified direction at specified speed while

a JOG operation command is on. Turning on the signal starts operation

at a specified speed and speed control operation can be continued until a

stop signal is input.

Da.3

CHAPTER 3 SPECIFICATIONS

Page 178,

CHAPTER 8

Page 191,

Section 9.6.1

(1)

Da.2

Page 192,

Section 9.6.1

(2)

Page 195,

Section 9.6.2

Page 200,

CHAPTER 10

3

3.3 List of Functions

(2) Sub functions

Sub functions compensate or limit control, or add functions at the execution of major positioning functions.

Functions to

compensate

control

Functions to limit

control

Item Description Reference

Electronic gear function

Speed limit function

Stroke limit function

Upper limit switch

(FLS)/lower limit switch

(RLS) function

This function controls moving distance and speed by

multiplying command pulse output of the QD73A1.

This function limits command speed to the value set in

" Speed limit value".

This function controls operation not to execute positioning

when a command that moves the workpiece outside the

specified stroke limit range is given.

This function decelerates and stops operation according to the

detection on limit switches placed at the upper and lower

stroke limits.

Page 209, Section 11.1

Page 211, Section 11.2

Page 213, Section 11.3

Page 215, Section 11.4

27

Page 30

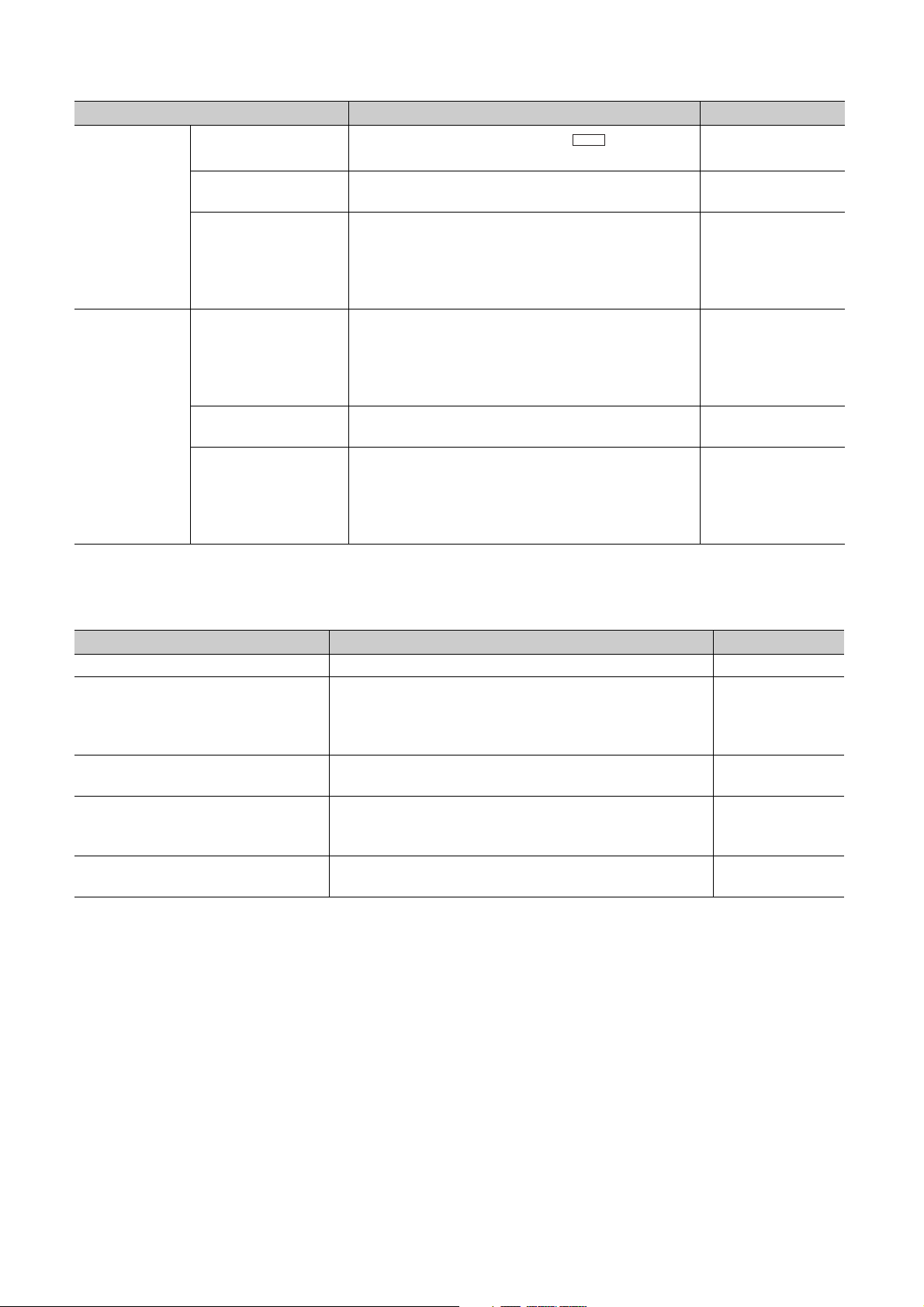

Functions to

change control

details

Other functions

Item Description Reference

Current value change

function

Speed change function

Deviation counter clear

function

In-position function

Multiplication setting

Accumulated pulse error

detection function

This function changes the value set in " Current feed

value" to a specified value.

This function changes speed during major positioning control

or JOG operation.

This function clears the accumulated pulses in the deviation

counter. When the servomotor power was turned off due to an

emergency stop during positioning, clearing the accumulated

pulses in the deviation counter prevents servomotor rotation

at power recovery.

This function turns on In-position signal (X16) while the

accumulated pulse amount in the deviation counter is within

the specified in-position range (1 to 20479pulse). In-position

signal (X16) can be used as the signal right before positioning

completion.

This function multiplies the feedback pulse frequency from the

pulse generator by 4, 2, 1, or 1/2.

This function outputs an alert and immediately stops the

positioning when the accumulated pulses reached the amount

specified by the user before the pulses exceed the amount set

in "Accumulated pulse setting" in the switch setting and an

excessive error occurs.

Md.1

Page 217, Section 11.5

Page 218, Section 11.6

Page 220, Section 11.7

Page 221, Section 11.8

Page 104, Section 6.2.3

Page 223, Section 11.9

(3) Common functions

Common functions can be used regardless of control method when necessary.

Item Description Reference

Zero/gain adjustment This function adjusts analog output voltage. Page 59, Section 4.5

This function monitors the module information, switch setting

Module status monitor function

Error history function

Module error collection function

Error clear function This function allows the user to clear errors on the system monitor.

information, and external I/O signal information. The module's

detailed information can be displayed on the system monitor of GX

Works2.

This function monitors the QD73A1's error history stored in the

buffer memory.

This function reports errors that occurred in the QD73A1 to the CPU

module. The error information is held in the CPU module memory as

a module error history.

Page 236, Section

13.1

Page 238, Section

13.2

Page 239, Section

13.3

Page 240, Section

13.4

28

Page 31

(4) Combination of main function and sub function

: Always used together, : Can be used together, ×: Cannot be used together

Functions to

compensate

control

Item

Functions to limit

control

CHAPTER 3 SPECIFICATIONS

Functions to change

control details

Other functions

3

Electronic gear function

OPR control ×××

Position

Major

positioning

control

JOG operation ××

control

mode

Speed-position control switch

mode

Positioning control × ×

Two-phase

trapezoidal

positioning control

Speed limit function

Stroke limit function

Upper limit switch (FLS)/

Current value change function

lower limit switch (RLS) function

××

××

Speed change function

Deviation counter clear function

In-position function

Multiplication setting

detection function

Accumulated pulse error

3.3 List of Functions

29

Page 32

3.4 I/O Signals from/to the CPU Module

This section describes I/O signals of the QD73A1.

3.4.1 I/O signal list

This section describes I/O signal assignment and use of each signal.

The first half of the I/O assignment is empty 16 points, and the second half is intelligent 32 points. When the module is

mounted on the slot No.0 and 1 of a main base unit, the device No.Xn0 becomes X10. Although, when the slot No.0 is

set as empty 0 point in the I/O assignment setting of GX Works2, the device No.Xn0 becomes X0 (n=0).

Device numbers used in this manual are for the case when the QD73A1 is mounted on the slot No.0 and 1 and when

the slot No.0 is empty 16 points.

(1) Input signal list

Input signal (CPU module QD73A1) Input signal (CPU module QD73A1)

Device No. Signal name Device No. Signal name

X10 WDT error, H/W error signal X20 OPR start complete signal

X11 QD73A1 READY signal X21 Absolute positioning start complete signal

X12 OPR request signal X22 Forward start complete signal

X13 OPR complete signal X23 Reverse start complete signal

X14 BUSY signal X24 Synchronization flag

X15 Positioning complete signal X25

X16 In-position signal X26

X17 Excessive error signal X27

X18 Error detection signal X28

X19 Overflow signal X29

X1A Underflow signal X2A

X1B Servo READY signal X2B Zero/gain adjustment change complete flag

X1C Near-point dog signal X2C Set value change complete flag

X1D External stop signal X2D

X1E Upper limit signal X2E

X1F Lower limit signal X2F

Use prohibited

Zero/gain adjustment data writing complete

flag

Operating status of the speed-position

control switch mode

Use prohibited

30

If a "Use prohibited" area is turned on/off through a sequence program, the QD73A1's function cannot be guaranteed.

Page 33

CHAPTER 3 SPECIFICATIONS

(2) Output signal list

Output signal (CPU module QD73A1) Output signal (CPU module QD73A1)

Device No. Signal name Device No. Signal name

Y10

Y11 Y21 Absolute positioning start signal

Y12 Y22 Forward start signal

Y13 Y23 Reverse start signal

Y14 Y24 Forward JOG start signal

Y15 Y25 Reverse JOG start signal

Y16 Y26 Speed-position mode restart signal

Y17 Y27 Stop signal

Y18 Y28 Error reset signal

Y19 Y29 Overflow reset signal

Y1A

Y1B

Y1C Set value change request signal Y2C Speed-position switching enable signal

Y1D

Y1E Y2E

Y1F Y2F

Use prohibited

Zero/gain adjustment data writing request

signal

Zero/gain adjustment change request

signal

Use prohibited

Y20 OPR start signal

Y2A Underflow reset signal

Y2B Use prohibited

Y2D PLC READY signal

Use prohibited

3

If a "Use prohibited" area is turned on/off through a sequence program, the QD73A1's function cannot be guaranteed.

3.4.1 I/O signal list

3.4 I/O Signals from/to the CPU Module

31

Page 34

3.4.2 Details of input signals

PLC READY signal (Y2D)

QD73A1 READY signal (X11)

OFF

ON

OFF

ON

Executed by the QD73A1

(1) WDT error, H/W error signal (X10)

This signal turns on when a watchdog timer error is detected through the self-diagnostic function of the QD73A1.

In this case, Servo ON signal (SVON) turns off and analog output becomes 0.

(2) QD73A1 READY signal (X11)

When PLC READY signal (Y2D) is turned on through a sequence program, fixed parameters are checked and

this signal turns on.

When PLC READY signal (Y2D) is turned off, this signal turns off.

Use this signal as an interlock in sequence programs.

(3) OPR request signal (X12)

This signal turns on at any of the following timing.

• When the power is turned on

• When the CPU module was reset

• When OPR starts

• When Servo READY signal (READY) turns off while BUSY signal (X14) is on

• When Servo READY signal (READY) turns off while BUSY signal (X14) is off

(only when "0: Clear the deviation counter when the servo ready signal is OFF." is selected for "Deviation

counter clear setting" in the switch setting)

This signal turns off when OPR is completed.

When PLC READY signal (Y2D) is turned on (rising edge), this signal does not turn on.

(4) OPR complete signal (X13)

This signal turns on when OPR is completed.

This signal does not turn on if operation stopped during OPR.

This signal turns off when JOG operation or major positioning control is started.

In the count method, this signal turns off when OPR starts.

This signal turns off when Servo READY signal (READY) turns off (only when "0: Clear the deviation counter

when the servo ready signal is OFF." is selected for "Deviation counter clear setting" in the switch setting)

(5) BUSY signal (X14)

This signal turns on when major positioning control, JOG operation, or OPR starts.

This signal turns off when command pulse output is completed.

If positioning is started while BUSY signal (X14) is on, the error "BUSY signal ON at start" (error code: 81) occurs.

32

Page 35

CHAPTER 3 SPECIFICATIONS

Pr.8

Md.2

Md.1

Excessive error signal (X17)

PLC READY signal (Y2D)

OFF

ON

OFF

ON

Executed by the QD73A1

(6) Positioning complete signal (X15)

This signal turns on when major positioning control is completed (completion of command pulse output).

This signal turns off when the next positioning (major positioning control, OPR, or JOG operation) starts.

If major positioning control was cancelled during its operation, this signal does not turn on.

For the operation in case of cancellation of major positioning control, refer to the following.

Page 230, Section 12.1

(7) In-position signal (X16)

This signal turns on while the accumulated pulse amount in the deviation counter is within the set range of

" In-position range" (1 to

This signal turns off when positioning starts.

Accumulated pulses

±20479) after deceleration started.

In-position set values

3

t

In-position signal

(X16)

Accumulated pulse amount are checked being compared with " In-position range" at the following timing.

ON

OFF

AA

A: In-position range

Pr.8

• When the power is turned on

• When automatic deceleration starts in positioning, and thereafter

• When a JOG start signal was turned off and deceleration starts in JOG operation, and thereafter

• When the near-point dog turned on and deceleration to the creep speed starts in OPR, and thereafter

(8) Excessive error signal (X17)

This signal turns on when accumulated pulse amount exceeds the accumulated pulse setting range.

In this case, the QD73A1's status is as follows.

• Analog output voltage: 0V

• Accumulated pulse: Reset to 0

• Servo ON signal (SVON): OFF

• Actual current value = Current feed value

When PLC READY signal (Y2D) is turned on, this signal turns off.

3.4 I/O Signals from/to the CPU Module

3.4.2 Details of input signals

Even if this signal turns on, Error detection signal (X18) does not turn on.

For the accumulated pulse setting range, refer to the following.

Page 102, Section 6.2.2

33

Page 36

(9) Error detection signal (X18)

Error detection signal (X18)

Error reset signal (Y28)

OFF

ON

OFF

ON

Executed by the QD73A1

Md.1

Overflow signal (X19)

Overflow reset signal (Y29)

OFF

ON

OFF

ON

Executed by the QD73A1

Md.1

Md.1

When a major or minor error occurs, the corresponding error code is stored in the buffer memory, and this signal

turns on.

When Error reset signal (Y28) is turned on, this signal turns off.

(10)Overflow signal (X19)

This signal turns on when " Current feed value" exceeds 2147483647.

When Overflow reset signal (Y29) is turned on, this signal turns off.

In case of an overflow, " Current feed value" changes as follows: 2147483647 -2147483648

(11)Underflow signal (X1A)

This signal turns on when " Current feed value" becomes less than -2147483648.

When Underflow reset signal (Y2A) is turned on, this signal turns off.

Underflow reset signal (Y2A)

In case of an underflow, " Current feed value" changes as follows: -2147483648 2147483647

Md.1

Underflow signal (X1A)

ON

OFF

ON

OFF

Executed by the QD73A1

(12)Servo READY signal (X1B)

This signal indicates the on/off status of Servo READY signal (READY).

(13)Near-point dog signal (X1C)

This signal indicates the on/off status of Near-point dog signal (DOG).

(14)External stop signal (X1D)

This signal indicates the on/off status of Stop signal (STOP).

(15)Upper limit signal (X1E)

(16)Lower limit signal (X1F)

34

This signal indicates the on/off status of Upper limit signal (FLS).

This signal indicates the on/off status of Lower limit signal (RLS).

Page 37

CHAPTER 3 SPECIFICATIONS

(17)OPR start complete signal (X20)

This signal turns on when OPR process starts after OPR start signal (Y20) was turned on.

When OPR start signal (Y20) is turned off after the start of OPR, this signal turns off.

(18)Absolute positioning start complete signal (X21)

This signal turns on when positioning process starts after Absolute positioning start signal (Y21) was turned on.

When Absolute positioning start signal (Y21) is turned off after the start of the positioning, this signal turns off.

(19)Forward start complete signal (X22)

This signal turns on when positioning process starts after Forward start signal (Y22) was turned on.

When Forward start signal (Y22) is turned off after the start of the positioning, this signal turns off.

(20)Reverse start complete signal (X23)

This signal turns on when positioning process starts after Reverse start signal (Y23) was turned on.

When Reverse start signal (Y23) is turned off after the start of the positioning, this signal turns off.

3

(21)Synchronization flag (X24)

This signal turns on when the CPU module becomes accessible to the QD73A1 after the power was turned off

then on, or after the CPU module was reset.

When the module synchronization setting of the CPU module is set to asynchronous, use this signal as an

interlock to access the QD73A1 from a sequence program.

(22)Zero/gain adjustment data writing complete flag (X2A)

This signal turns on when zero/gain adjustment value writing to the QD73A1 is completed after Zero/gain

adjustment data writing request signal (Y1A) was turned on.

When Zero/gain adjustment data writing request signal (Y1A) is turned off, this signal turns off.

ON

Zero/gain adjustment data

writing complete flag (X2A)

Zero/gain adjustment data

writing request signal (Y1A)

Use this signal as an interlock condition to turn on/off Zero/gain adjustment data writing request signal (Y1A)

when writing the zero/gain adjustment value to the QD73A1.

For details on zero/gain adjustment, refer to the following.

Page 59, Section 4.5

OFF

ON

OFF

Executed in a sequence program

Executed by the QD73A1

3.4 I/O Signals from/to the CPU Module

3.4.2 Details of input signals

35

Page 38

(23)Zero/gain adjustment change complete flag (X2B)

Zero/gain adjustment change

complete flag (X2B)

Zero/gain adjustment change

request signal (Y1B)

OFF

ON

OFF

ON

Zero/gain adjustment

specification

Executed in a sequence program

Executed by the QD73A1

Cd.10

This signal turns on when zero adjustment and gain adjustment were switched after Zero/gain adjustment

change request signal (Y1B) was turned on.

When Zero/gain adjustment change request signal (Y1B) is turned off, this signal turns off.

Use this signal as an interlock condition to turn on/off Zero/gain adjustment change request signal (Y1B) when

changing " Zero/gain adjustment specification".

Cd.10

For details on zero/gain adjustment, refer to the following.

Page 59, Section 4.5

(24)Set value change complete flag (X2C)

This signal turns on when the analog output value of zero/gain adjustment was changed after Set value change

request signal (Y1C) was turned on.

When Set value change request signal (Y1C) is turned off, this signal turns off.

ON

Set value change complete flag

(X2C)

Set value change request signal

(Y1C)

OFF

ON

OFF

Executed in a sequence program

Executed by the QD73A1

Use this signal as an interlock condition to turn on/off Set value change request signal (Y1C) when performing

zero/gain adjustment.

For details on zero/gain adjustment, refer to the following.

Page 59, Section 4.5

(25)Operating status of the speed-position control switch mode (X2D)

This signal indicates the operating status in the speed-position control switch mode.

This signal is on during speed control.

This signal is off during position control.

36

Page 39

3.4.3 Details of output signals

Cd.11

(1) Zero/gain adjustment data writing request signal (Y1A)

Turn on this signal to write the zero/gain adjustment value to the QD73A1.

For the on/off timing of this signal, refer to the detail of Zero/gain adjustment data writing complete flag (X2A).

( Page 35, Section 3.4.2 (22))

For details on zero/gain adjustment, refer to the following.

Page 59, Section 4.5

(2) Zero/gain adjustment change request signal (Y1B)

Turn on this signal to change zero adjustment and gain adjustment.

For the on/off timing of this signal, refer to the detail of Zero/gain adjustment change complete flag (X2B).

( Page 36, Section 3.4.2 (23))

For details on zero/gain adjustment, refer to the following.

Page 59, Section 4.5

CHAPTER 3 SPECIFICATIONS

3

(3) Set value change request signal (Y1C)

Turn on/off this signal to increase/decrease the analog output value at zero/gain adjustment.

The analog output is increased/decreased according to the value set in " Zero/gain adjustment value

specification".

For the on/off timing of this signal, refer to the detail of Set value change complete flag (X2C). ( Page 36,

Section 3.4.2 (24))

For details on zero/gain adjustment, refer to the following.

Page 59, Section 4.5

(4) OPR start signal (Y20)

Turn on this signal to start OPR.

(5) Absolute positioning start signal (Y21)

Turn on this signal to start absolute system positioning (position control mode).

(6) Forward start signal (Y22)

Turn on this signal to start positioning in the address increasing direction.

The following table describes the consequence of turning on this signal for each type of positioning (major

positioning control).

3.4 I/O Signals from/to the CPU Module

3.4.3 Details of output signals

Major positioning control Consequence of turning on Forward start signal (Y22)

Positioning control

Position control mode

Speed-position control switch mode Starts in the address increasing direction

Two-phase trapezoidal

positioning control

Starts in the address increasing direction (incremental system)

37

Page 40

(7) Reverse start signal (Y23)

Md.3

Md.4

Turn on this signal to start positioning in the address decreasing direction.

The following table describes the consequence of turning on this signal for each type of positioning (major

positioning control).

Major positioning control Consequence of turning on Reverse start signal (Y23)

Positioning control

Position control mode

Speed-position control switch mode Starts in the address decreasing direction

Two-phase trapezoidal

positioning control

Starts in the address decreasing direction (incremental system)

(8) Forward JOG start signal (Y24)

Turn on this signal to start JOG operation in the address increasing direction.

The JOG operation continues while this signal is on.

The JOG operation decelerates and stops when this signal is turned off.

(9) Reverse JOG start signal (Y25)

Turn on this signal to start JOG operation in the address decreasing direction.

The JOG operation continues while this signal is on.

The JOG operation decelerates and stops when this signal is turned off.

(10)Speed-position mode restart signal (Y26)

Turn on this signal to restart positioning if it stopped due to Stop signal in the speed-position control switch mode.

(11)Stop signal (Y27)

Turn on this signal to decelerate and stop OPR operation, major positioning operation, or JOG operation.

If this signal is turned on during OPR, Error detection signal (X18) turns on.

(12)Error reset signal (Y28)

Turn on this signal to clear the following buffer memory data to 0 when Error detection signal (X18) is on.

• Error code (ERR.1)

• Error code (ERR.2)

When this signal is turned on, Error detection signal (X18) turns off.

(13)Overflow reset signal (Y29)

Turn on this signal to turn off Overflow signal (X19) when it is on.

For the on/off timing of this signal, refer to the detail of Overflow signal (X19). ( Page 34, Section 3.4.2 (10))

38

Page 41

CHAPTER 3 SPECIFICATIONS

(14)Underflow reset signal (Y2A)

Turn on this signal to turn off Underflow signal (X1A) when it is on.