Type QD70

Positioning Module

User’s Manual

(Hardware)

QD70P4

QD70P8

Thank you for buying the Mitsubishi general-purpose programmable

controller MELSEC-Q Series.

Prior to use, please read both this manuals and detailed manual

thoroughly and familiarize yourself with the product.

MODEL QD70P-U-H-JE

MODEL

CODE

13JT42

IB(NA)-0800169-F(0808)MEE

2001 MITSUBISHI ELECTRIC CORPORATION

A

-1

z SAFETY PRECAUTIONS z

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals

introduced in this manual carefully and pay full attention to safety to handle the

product correctly.

These instructions apply only to Mitsubishi equipment. Refer to CPU module

User's Manual for a description of the programmable controller system safety

instructions.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury or

physical damage.

Note that the

CAUTION level may lead to a serious consequence according

to the circumstances.

Always follow the instructions of both levels because they are important to

personal safety.

Please save this manual to make it accessible when required and always forward

it to the end user.

[Installation Precautions]

CAUTION

z Use the programmable controller in an environment that meets the general specifications

contained in CPU module User's Manual to use.

Using this programmable controller in an environment outside the range of the general

specifications could result in electric shock, fire, erroneous operation, and damage to or

deterioration of the product.

z While pressing the installation lever located at the bottom of module, insert the module

fixing tab into the fixing hole in the base unit until it stops. Then, securely mount the

module with the fixing hole as a supporting point.

Incorrect loading of the module can cause a malfunction, failure or drop.

Securely fix the module with screws if it is subject to vibration or shock during use.

Tighten the screw in the specified torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening of screws can cause damages to the screws and/or the module,

resulting in fallout, short circuits, or malfunction.

z Completely turn off the externally supplied power used in the system when mounting or

removing the module.

Not doing so may cause damage to the module.

z Do not directly touch the module's conductive parts or electronic components.

Touching the conductive parts could cause an operation failure or give damage to the

module.

DANGER

CAUTION

A

-2

[Wiring Precautions]

DANGER

z Completely turn off the externally supplied power used in the system when installing or

placing wiring.

Not doing so may cause electric shock or damage to the product.

CAUTION

z Check the layout of the terminals and then properly route the wires to the module.

z Solder connectors for external device properly.

Insufficient soldering may cause malfunction.

z Be sure there are no foreign substances such as sawdust or wiring debris inside the

module. Such debris could cause fires, damage, or erroneous operation.

z The module has an ingress prevention label on its top to prevent foreign matter, such as

wire offcuts, from entering the module during wiring. Do not peel this label during wiring.

Before starting system operation, be sure to peel this label because of heat dissipation.

z Securely connect the connectors for the drive module to the connectors on the module

and firmly tighten the two screws.

z When removing the cable or power supply cable from the module, do not pull the cable.

When removing the cable with a connector, hold the connector on the side that is

connected to the module.

Pulling the cable that is still connected to the module may cause malfunction or damage to

the module or cable.

z The cable used for connecting the QD70 external input/output signal and the drive module

should not be routed near or bundled with the main circuit cable, power cable and/or other

such load-carrying cables other than those for the PLC. These cables should be

separated by at least 100 mm (3.94 in.). They can cause electrical interference, surges

and inductance that can lead to mis-operation.

A

-3

Revisions

* The manual number is noted at the lower left of the back cover.

Print Date *Manual Number Revision

Mar., 2001 IB(NA)-0800169-A First edition

Jun., 2001 IB(NA)-0800169-B

Addition

About Manuals

Partial correction

Section 2.2

Dec., 2001 IB(NA)-0800169-C

Partial correction

Chapter 1, Section 2.1

Jul., 2002 IB(NA)-0800169-D

Partial correction

Chapter 1, Section 2.1

Feb., 2007 IB(NA)-0800169-E

Partial correction

Section 2.2, Chapter 3, Chapter 5

Aug., 2008 IB(NA)-0800169-F

Partial correction

SAFETY PRECAUTIONS, Compliance

with the EMC and Low Voltage Directives,

ABOUT MANUAL, Chapter 1, Chapter 2,

Chapter 3, Chapter 4, Chapter 5,

Chapter 6, Chapter 7

This manual confers no industrial property rights or any rights of any other kind, nor does it

confer any patent licenses. Mitsubishi electric Corporation cannot be held responsible for

any problems involving industrial property rights which may occur as a result of using the

contents noted in this manual.

2001 MITSUBISHI ELECTRIC CORPORATION

A

-4

CONTENTS

1. Overview........................................................................................................1

2. Specifications.................................................................................................2

2.1 Performance Specifications .....................................................................2

2.2 Electrical Specifications ...........................................................................2

3. Handling.........................................................................................................3

3.1 Handling Precautions ...............................................................................4

4. Part Identification Nomenclature ....................................................................5

5. Wiring.............................................................................................................7

5.1 Wiring Precautions ...................................................................................7

5.2 Input/output interface internal circuit.........................................................9

6. Switch setting for intelligent function module................................................10

7. External Dimensions ....................................................................................11

ABOUT MANUAL

The following manual is related to this product.

In necessary, order it by quoting the details in the table below.

Detailed Manual

Manual name

Manual No.

(Model code)

Type QD70 Positioning Module User’s Manual SH-080171

(13JR39)

Compliance with the EMC and Low Voltage Directives

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low

Voltage Directives when incorporating the Mitsubishi programmable

controller (EMC and Low Voltage Directives compliant) into other

machinery or equipment, refer to Chapter 9 "EMC AND LOW VOLTAGE

DIRECTIVES" of the QCPU User's Manual (Hardware Design,

Maintenance and Inspection).

The CE mark, indicating compliance with the EMC and Low Voltage

Directives, is printed on the rating plate of the programmable controller.

(2) For the product

To make this product conform to the EMC directive and low voltage

instruction, please refer to Chapter 5 "Wiring".

1

1. Overview

This manual explains how to handle the Positioning Module, model numbers

QD70P4 and QD70P8 (hereinafter collectively referred to as the QD70).

After unpacking the QD70, please verify that the corresponding product as listed

below is enclosed in the package.

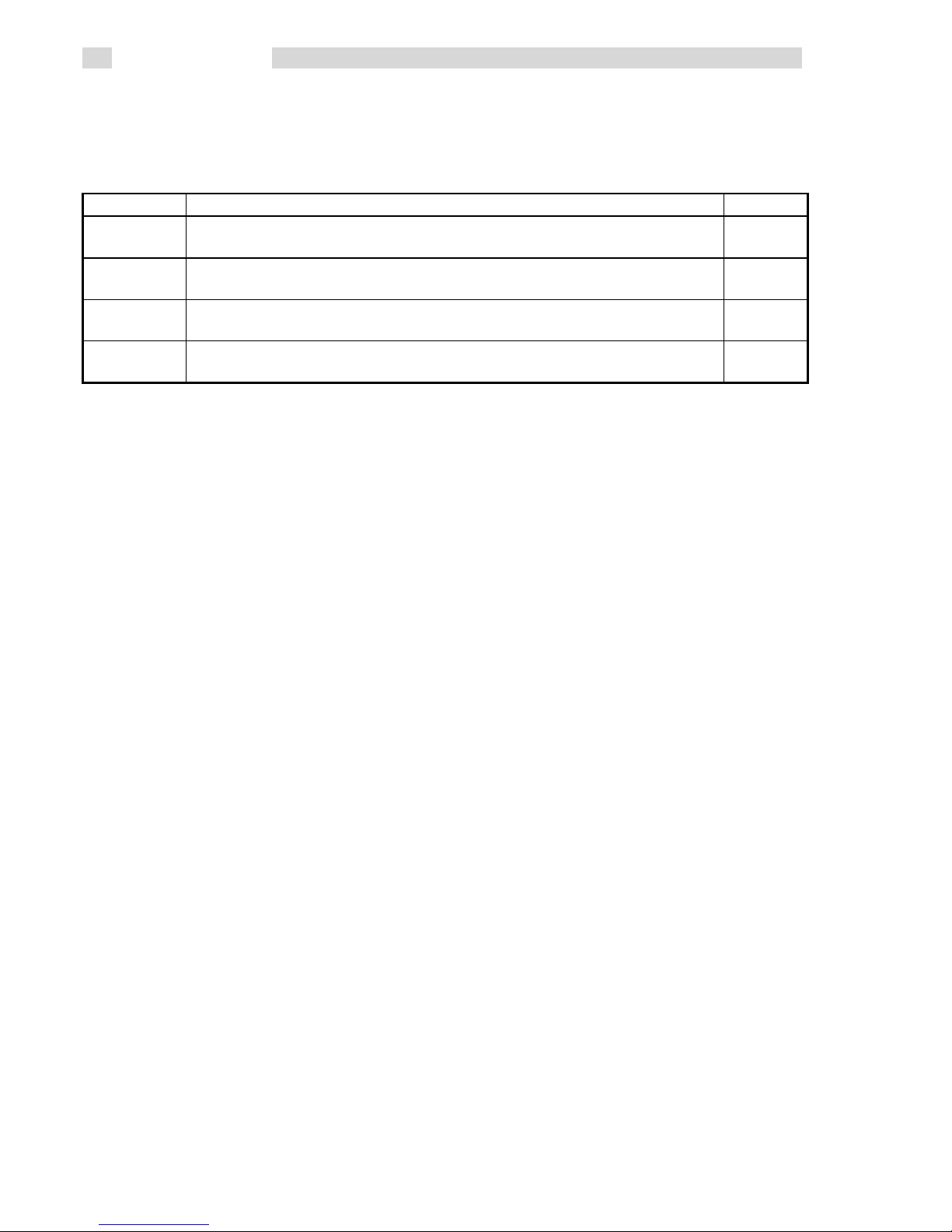

Type Component Quantity

QD70P4

Type QD70P4 Positioning Module (4-axis open-collector output

type)

1

QD70P8

Type QD70P8 Positioning Module (8-axis open-collector output

type)

1

SW1D5CQPTU-E

GX Configurator-PT Version 1 (1-license product) (CD-ROM) 1

SW1D5CQPTU-EA

GX Configurator-PT Version 1 (Multiple-license product) (CD-ROM) 1

The user should arrange for a connector for external wiring since it is not

provided in the package.

* Connector types

A6CON1 (Soldering type, straight out)

A6CON2 (Pressure displacement type, straight out)

A6CON4 (Soldering type, usable for straight out and diagonal out)

* Pressure-displacement tool

Model name: FCN-363T-T005/H

Supplier’s offices :

FUJITSU AMERICA,INC.

250E Caribbean Drive Sunnyvale, CA 94089 U.S.A

Tel: (1-408)745-4900

FUJITSU EUROPE B.V.

Jupiterstaat 13-15, our 2132 Hoofddorp, The Netherland

Tel: (31)23-5560910

FUJITSU EUROPE B.V. Zweiniederlassung Deutschland

Schatzbogen 86 D-81829 Munchen Germany

Tel: (49)89-42742320

FUJITSU EUROPE (UK)

Network House, Morres Drive, Maidenhead, Berkshire, SL6 4FH United

Kingdom

Tel: (44)1628-504600

FUJITSU EUROPE B.V.

127 Chemin Des Bassins, Europarc, Cleteril 94035 Cleterll 94035

France

Tel: (33)145139940

FUJITSU ASIA PACIFIC PTE LIMITED

102E Pasir Panjang Road, #04-01 Citilink Warehouse Complex,

Singapore 118529

Tel: (65)375-8560

FUJITSU HONG KONG CO., LTD.

Suite 913 Ocean Centre, 5 Canton Road, TST, Kowloon, Hong Kong

Tel: (852)2881-8495

Loading...

Loading...